CRAIN 625 Instruction Manual

CRAIN CUTTER CO., INC.

1155 WRIGLEY WAY, MILPITAS, CA 95035-5426

TEL: 408-946-6100 FAX: 408-946-4268

Printed by:HF

FORM F1625-0910

Made in

INSTRUCTION

MANUAL

FOR

America

This Crain tool is guaranteed to be free of defects

due to faulty materials or workmanship for a period

of 6 months.

During this period, any parts of tools found defective

subject to the guarantee will be replaced at no charge.

Returns should be sent freight PREPAID, in assembled

condition and with a copy of the Bill of Sale (proof of

purchase) to CRAIN CUTTER COMPANY, Milpitas,

CA 95035. New tools or loaners will not be given for

those pending warranty repairs.

No claims shall exceed in amount the suggested sales

price of the product. No other guarantee, oral or written, is expressed or implied.

REPLACEMENT PARTS AND

ORDERING INFORMATION

•

T

h

i

n

k

S

a

f

e

t

y

•

W

e

a

r

E

y

e

P

r

o

t

e

c

t

i

o

n

CRAIN

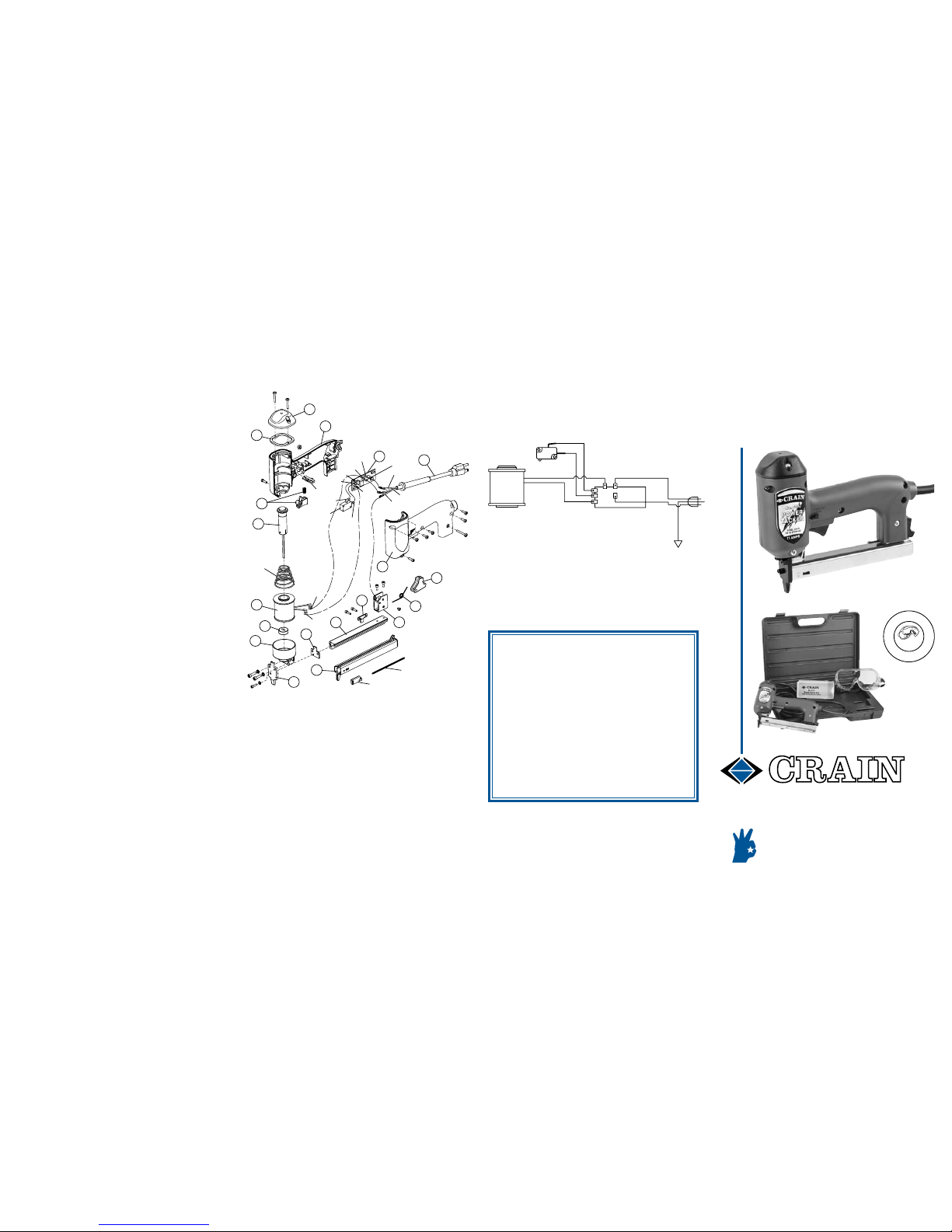

No. 625 POWER TACKER

1625-01 Front Guide

& Screws

1625-02 Front Cover

1625-03 Aluminum Channel

& Screw

1625-04 Rear Bracket

& Screws

1625-05 Aluminum Cap

& Screws

1625-06 Torsion Spring

1625-07 Magazine

1625-08 Handle Set

& Screws

1625-10 Stop & Screws

1625-15 Retaining Ring

& Screws

1625-17 Trigger & Spring

1625-19 Coil Housing

& Screws

1625-20 Release Button

1625-22 Driver Assembly

1625-23 Control Board

1625-34 Bumper

1625-38 Staple Coil

1625-41 Carrying Case

1625-42 Power Cord

1615-C Driver Spring

1615-I Micro Switch

1615-J Trigger Lock

1615-S Staple Pusher

1615-T Pusher Spring

WIRING DIAGRAM

TO SW1

TO SW2

BLACK

COIL WIRE 1

WHITE

AC OUTLET

GREEN

GROUND

1625-23

CONTROL BOARD

1615-I

MIRCO SWITCH

1625-38

STAPLE COIL

COIL WIRE 2

01

02

03

04

05

06

07

08

08

10

15

17

19

34

20

1615-J

22

23

42

1615-I

ACH

ACG

L1

L2

SW1

To L1

To L2

1615-S

1615-T

SW2

BLK To ACH

WHT To ACG

GREEN To GRD

To SW1

TO SW2

38

1615-C

IMPORTANT SAFETY

INSTRUCTIONS

GENERAL SAFETY RULES

WARNING! Read and understand all instructions.

Failure to follow all instructions listed below may result

in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of ammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you

to lose control.

Electrical Safety

Grounded tools must be plugged into an outlet

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way.

Do not use any adaptor plugs. Check with a qualied electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should

electrically malfunction or break down, grounding

provides a l ow resistance path to carry electricity

away from the user.

Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electric shock if your body is

grounded.

Don’t expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord to carry

the tool or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Da maged

cords increase the risk of electric shock.

When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W.” These

For proper operation, please take time to carefully

read all the instructions and rules for safe operation

in this booklet.

SAFETY GLASSES:

Always wear safety glasses when using this tool, especially when loading staples or clearing jams.

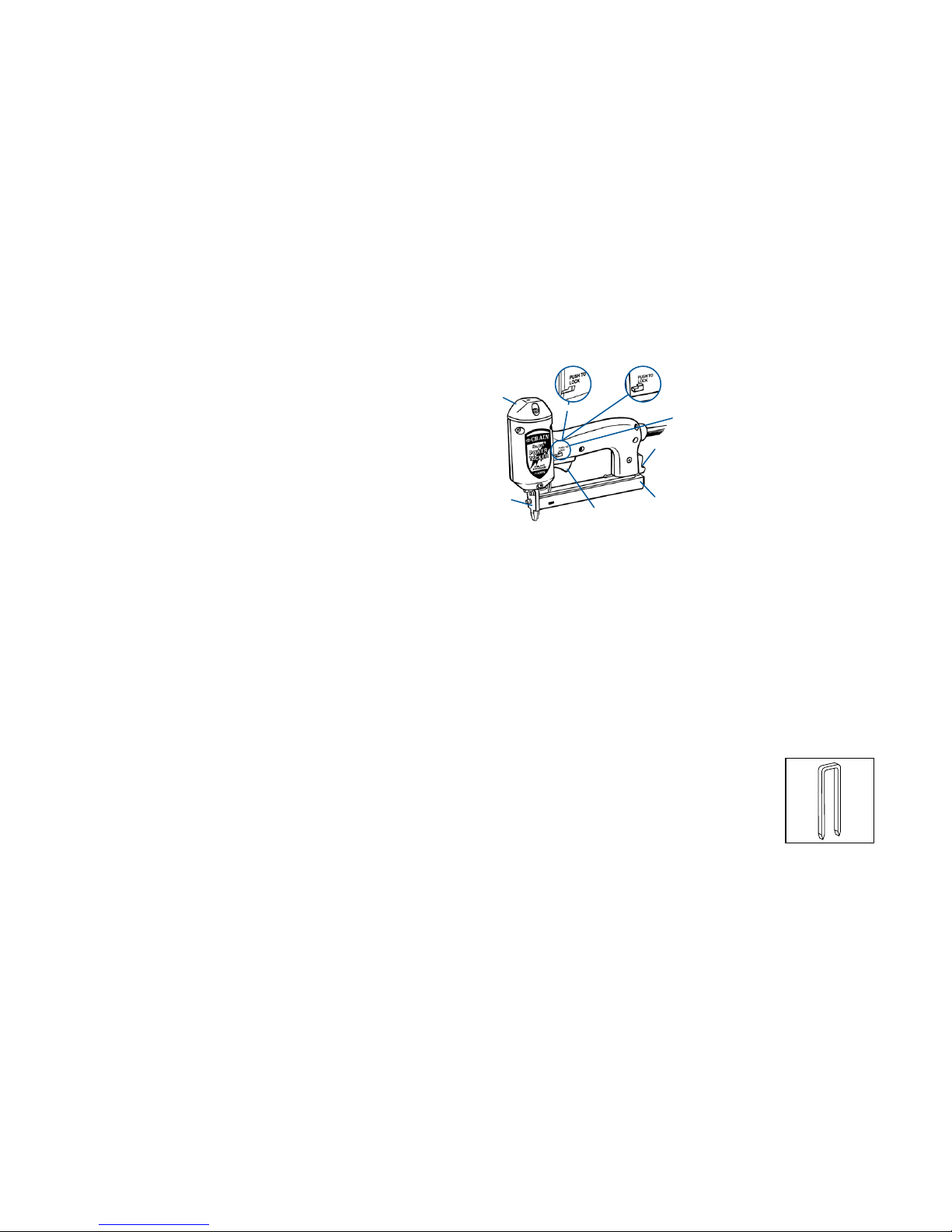

SAFETY SWITCH:

This tool is designed with a safety lock to prevent accidental firing. Depress the lock (Figure 1) whenever

you need to plug in the tacker, load staples, clear a

jam, or you need to leave the tacker unattended.

PREVENT ACCIDENTS:

NEVER point the tacker at another person. Unplug the

tool when you are walking from room to room.

TRIGGER:

See figure 1. With each pull of the trigger (located under

the handgrip), the tacker completes one cycle and fires

one staple. Make sure your finger is not on the trigger

when plugging in, or loading staples. Do NOT point the

nose of the tacker at anyone! Place the nose directly

onto the material being fastened.

ON/OFF TRIGGER SAFETY LOCK:

This tacker is equipped with a sliding on/off safety

lock, located above th e trigger at the front of the

hand grip, which is used to prevent accidental firing. Be sure the safety lock is depressed on the side

marked “PUSH TO LOCK” (figure 1) when plugging

the tacker in, loading staples, or whenever the tacker

is not in use.

TO LOAD STAPLES:

1. Make sure the tacker is unplugged and the safety

lock is depressed as shown in figure 1 above.

2. Turn the tacker upside-down, push the magazine

release button, and slide the magazine assembly

backward, fully open.

3. Insert a brick of staples into the channel, with the

staple points facing up.

4. Close magazine assembly until it locks in place.

TO OPERATE:

1. Use safety glasses!

2. Plug into a 115 volt/15 amp outlet.

3. Push the safety lock so that it is not depressed on

the side marked “PUSH TO LOCK” (figure 1).

4. Hold the nose of the tacker firmly against the mate-

MAINTENANCE INSTRUCTIONS

1. To clear a jam, depress the safety lock, and unplug the tacker. Turn the tacker upside-down and

depress the magazine release button to unlock.

Slide the magazine assembly back to expose the

channel in the nose. Remove the cause of the jam.

Close the magazine.

2. Use a clean cloth to remove dirt from the tacker.

Avoid using solvents when cleaning plastic parts.

3. DO NOT lubricate. The tacker does not require oil

or grease to operate.

4. In the event of a malfunction, DO NOT attempt to

repair the tacker yourself. Tool service must be

performed by qualified repair personnel.

5.

CAUTION: DO NOT alter, attach special fixtures

to, or “redesign” parts of the tacker. DO NOT fire

without staples, as this may cause damage to the

tacker.

STAPLE SELECTION:

The No. 625 Power Tacker uses standard Crain No.

619D Shur-Fast Staples, Duo Fast No. 5415 or No.

5418 electric tacker staples (or generics).

CRAIN NO. 619D 9/16"

LENGTH DIVERGENT

CAP

MAGAZINE

RELEASE

BUTTON

MAGAZINE

DEPRESSED NOT DEPRESSED

FIGURE 1

TRIGGER

NOSE

cords are rated for outdoor use and reduce the risk

of electric shock.

Personal Safety

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the inuence of

drugs, alcohol, or medication. A moment of inatten-

tion while operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

Avoid accidental starting. Be sure switch is off

before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch on

invites accidents.

Remove adjusting keys or switches before turning

the tool on. A wrench or a key that is left attached to a

rotating part of the tool may result in personal injury.

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables better

control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable and

may lead to loss of control.

Do not force tool. Use the correct tool for your application. The correct tool will do the job better and

safer at the rate for which it is designed.

Do not use tool if switch does not turn it on or off.

Any tool that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power source before

making any adjustments, changing accessories,

or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Store idle tools out of reach of children and other

untrained persons. Tools are dangerous in the hands

of untrained users.

Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools, with sharp

cutting edges are less likely to bind and are easier

to control.

Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that

may affect the tool’s operation. If damaged, have

the tool serviced before using. Many accidents are

caused by poorly maintained tools.

Use only accessories that are recommended by

the manufacturer for your model. Accessories that

may be suitable for one tool, may become hazardous

when used on another tool.

SERVICE

Tool service must be performed only by qualied

repair personnel. Service or maintenance performed

by unqualified personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance

section of this manual. Use of unauthorized parts or

failure to follow Maintenance Instructions may create

a risk of electric shock or injury.

ADDITIONAL SAFETY RULES:

Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may

contact hidden wiring or its own cord. Contact with

a “live” wire will make exposed metal parts of the tool

“live” and shock the operator.

OPERATING INSTRUCTIONS

rial to be fastened, and place the palm of your other

hand firmly on the cap, holding the tacker down.

5. Squeeze trigger to fire.

6. Avoid using long extensio n cords, as th ey will

noticeably reduce the tool’s drive strength. If you

must, use heavy- duty 3-wire cords with these

minimum wire sizes:

25' = 16 gauge wire

50' = 14 gauge wire

LOCKED UNLOCKED

SAFETY

LOCK

Loading...

Loading...