Page 1

Operator's Manual

ZT 7000

2-BIN BAGGER

Model No.

107.24907

CAUTION: Before using this product, read

the manual and follow all its Safety Rules

and Operating Instructions.

For answers to your questions about this

product, call:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pm, Mon- Sat

Nota: Una traducci6n en espa5ol de este Manual

del Operador puede encontrarse en la pagina 11.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

1726618

Rev 02/2004

TP 199-4051-00-AT-C

Page 2

Nota: Una traducci6n en espaSol de este Manual del Operador puede encontrarse en la pAgina 10.

Warranty Statement ..................................................... 2

Safety Rules & Information for Bagger ..................... 3

Operating Instructions for Bagger ............................. 4

Initial Assembly & Installation .................................... 5

Normal Installation & Removal ................................. 10

ONE YEAR FULL WARRANTY on CRAFTSMAN 2-BIN BAGGER

For one (1) year from the date of purchase, if any parts of this product are defective in material or workmanship,

Sears will repair or replace them free of charge.

THIS WARRANTY DOES NOT COVER:

• Bagger cloth bags which are expendable and wear out with normal use.

• Repairs necessary because of operator negligence, including but not limited to, failure to maintain the equipment

according to the instructions contained in the operator's manual.

• Bagger if used for commercial or rental purposes.

WARRANTY SERVICE IS AVAILABLE BY RETURNING DEFECTIVE PARTS TO THE NEAREST SEARS PARTS &

REPAIR CENTER IN THE UNITED STATES.

FOR THE NEAREST SEARS PARTS & REPAIR CENTER LOCATION, CALL 1-800-4-MY-HOME ®.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

Spanish Operator's Manual ...................................... 12

Repair Parts ......................................................... PTS-1

Hardware Identification &

Torque Specifications ................... Inside Back Cover

Service Telephone Numbers .................... Back Cover

HARDWARE BAGS

Description Quantity

BAFFLE HARDWARE

Carriage Bolt, 5/16-18 x 5/8 7

Locknut, 5/16-18 7

BAGGER HARDWARE

Carriage Bolt, 5/16-18 x 5/8 2

Locknut, 5/16-18 2

Bracket 1

Pin, Clevis 4

Washer, 1/2 4

Pin, Hair 4

Nut, Hex, 1/2-13 1

Capscrew, Hex, 1/2-13 x 1-1/4 1

Washer, 3/8 4

Locknut, 3/8-16 4

Capscrew, Hex, 3/8-16 x 2 4

TOOLS REQUIRED

Description Quantity

1/2" Wrench 1

9/16" Wrench 2

3/4" Wrench 2

See Page 25 for Wrench and Fastener Size Guide.

Page 3

unit, severe personal injury or death to you, or bystanders, or damage to property or equipment. The trian-

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control of

gle _ in text signifies important cautions or warnings which must be followed.

See Rider Operators Manual

GENERAL WARNINGS

• Know the unit's controls and how to stop quickly.

READ THE OPERATOR'S MANUALS.

• Read and obey all safety decals.

• Only allow responsible adults, who are familiar with

the instructions, to operate the unit.

• Disengage the PTO. Shut off the engine and wait for

all moving parts to stop before attaching, adjusting,

or disconnecting any part of the collection system.

• Check the collection system to make sure it is bolted

tightly to the unit.

• DO NOT operate the unit without either the entire

grass bagger or the deflector in place.

• Turn off the PTO to disengage the blades when not

mowing.

• DO NOT mow in reverse. Always look down and

behind before and while travelling in reverse.

• DO NOT turn sharply when travelling alongside a

building or any object. Slow down before turning.

• DO NOT carry passengers.

• When collection system is removed from the mower

deck, the deflector must be properly installed.

• Grass bagger components are subject to wear,

damage, and deterioration, which could expose

moving parts or allow objects to be thrown.

Frequently check components and replace with

manufacturer's recommended parts, when neces-

sary.

• If the mower stalls or the collector chute plugs:

1. Disengage the PTO;

2. Stop the engine and remove the key;

3. Set the parking brake, and wait for atl moving

parts to stop.

4. Remove the foreign object or clear the chute

with a piece of wood before restarting the engine.

NEVER place hands into COLLECTOR OR

MOWER housing to clear jammed objects.

MOWER may rotate when object is removed.

• For added stability and to prevent tipping or loss of

control:

a. Use reduced speed on uneven ground and

when turning corners.

b. Reduce loads on hillsides. It is recommended

that the collection system be kept only half full

when negotiating any slopes. Start mowing on

slopes when the collection system is empty.

c. Mow up and down the face of slopes; never

across the face of any slope.

Never operate on slopes greater than 17.6%

(10°).

SAFETY DECALS

This unit has been designed and manufactured to pro-

vide you with the safety and reliability you would expect

from an industry leader in outdoor power equipment

manufacturing.

Although reading this manual and the safety instructions

it contains will provide you with the necessary basic

knowledge to operate this equipment safely and effec-

tively, we have placed several safety labels on the unit to

remind you of this important information while you are

operating your unit.

All DANGER, WARNING, CAUTION and instructional

messages on your rider, attachments and mower should

be carefully read and obeyed. Personal bodily injury can

result when these instructions are not followed. The

information is for your safety and it is important! The

safety decals below are on your product.

If any decals are lost or damaged, replace them at once.

See your local dealer for replacements.

TP 600-2562-01-AT-SMA

These labels are easily applied and will act as a constant

visual reminder to you, and others who may use the

equipment, to follow the safety instructions necessary for

safe, effective operation.

ATTACHMENT DECALS

Decal - WARNING

Thrown Objects

Part Number

1709248

• DOnoioponhoppertopwilliebladototornlnp.

Decal - WARNING Do

Not Overload

Part Number 1704405

Read and obey all operation and warning decals.

3

Page 4

BEFORE OPERATION

Clear the lawn of all sticks, stones, wire and other debris

which may be caught or thrown by the mower blades.

Check grass condition. If wet, wait until later in the day.

If grass is wet, the grass catcher is likely to become

plugged.

For efficient bagging, air circulation under the

mower deck, through the chute and into the bag is

very importanL

For this reason, BEFORE YOU BEGIN MOWING you

should make certain the underside of the mower and

the underside of the catcher lid are free from grass and

debris.

Make sure that there is a snug fit between mower deck,

blower housing, tubes, and hopper.

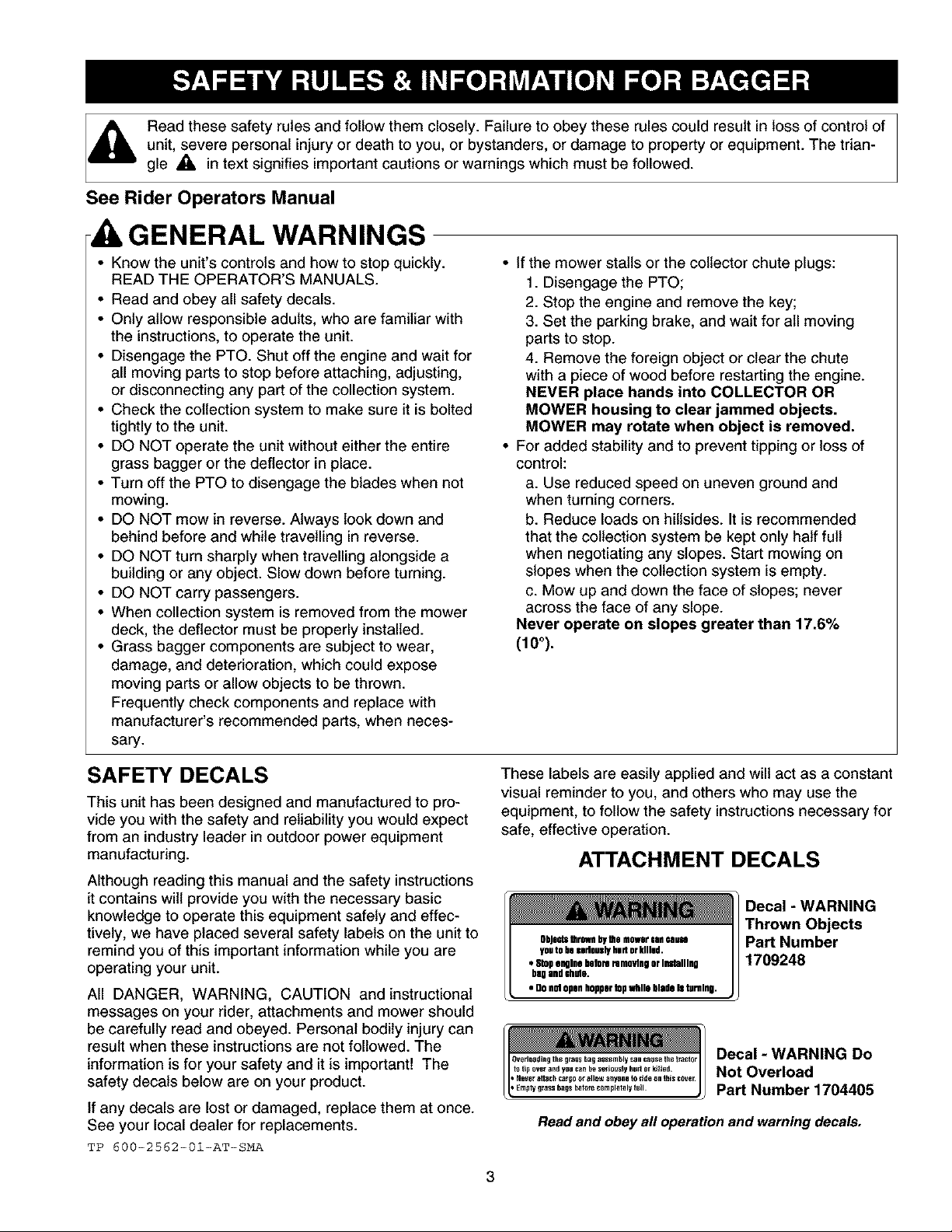

MOWING WITH THE BAGGER

Always operate with throttle at full speed when mowing.

Grass should be cut often, but not too short. If grass is

too long or lush it may be necessary to keep ground

speed to a minimum or to cut only half the width of the

mower to prevent clogging. If grass is long, operate with

mower in high cutting position for first pass, cutting again

in a lower position on a second pass.

Do not open the cover with mower engaged.

If a large amount of cut grass is spilling out from under

deck, the tube may be plugged or the bags may be full--

discontinue mowing, stop the rider, disengage the PTO,

shut off the engine and then empty the bagger or clear

the tube.

• WARNING

ALWAYS shut off the unit. Disengage the PTO,

and allow all moving parts to stop BEFORE

disconnecting or clearing tube, or emptying

catcher.

Before leaving the operator's position for any

reason, engage the parking brake, disengage the

PTO, stop the engine and remove the key.

To reduce fire hazard, keep the engine, rider and

mower free of grass, leaves and excess grease.

Do not stop or park rider over dry leaves, grass or

combustible materials.

Never operate mower on slopes greater than 10°.

AFTER OPERATION

Remove any debris from the the screen on the underside

of the hopper lid. Note: The lid screen can be partially

removed for easier cleaning and should be cleaned regu-

larly.

The discharge tubes should be removed for cleaning.

,_ WARNING: Inspect the grass bags for wear or

hole damage before and after each use. Debris

can fly through holes during operation.

STORING THE GRASS BAGGER

CAUTION

Do not leave grass in bagger containers. Empty

containers after each use and before storing.

Failure to do so may result in spontaneous

combustion which could develop into a fire.

Clean the grass bagger thoroughly using a mild deter-

gent (other products may damage the tube). Remove

any debris from the the screen on the underside of the

lid.

If paint has been scratched on metal parts, touch up with

paint, or apply a thin film of oil to prevent corrosion.

Store in a dry area. Dry thoroughly before storing for a

long period of time. Always store away from moisture.

Page 5

NOTE: In this manual, "left" and "right" are always defined from

the standpoint of the operator position facing forward from seat.

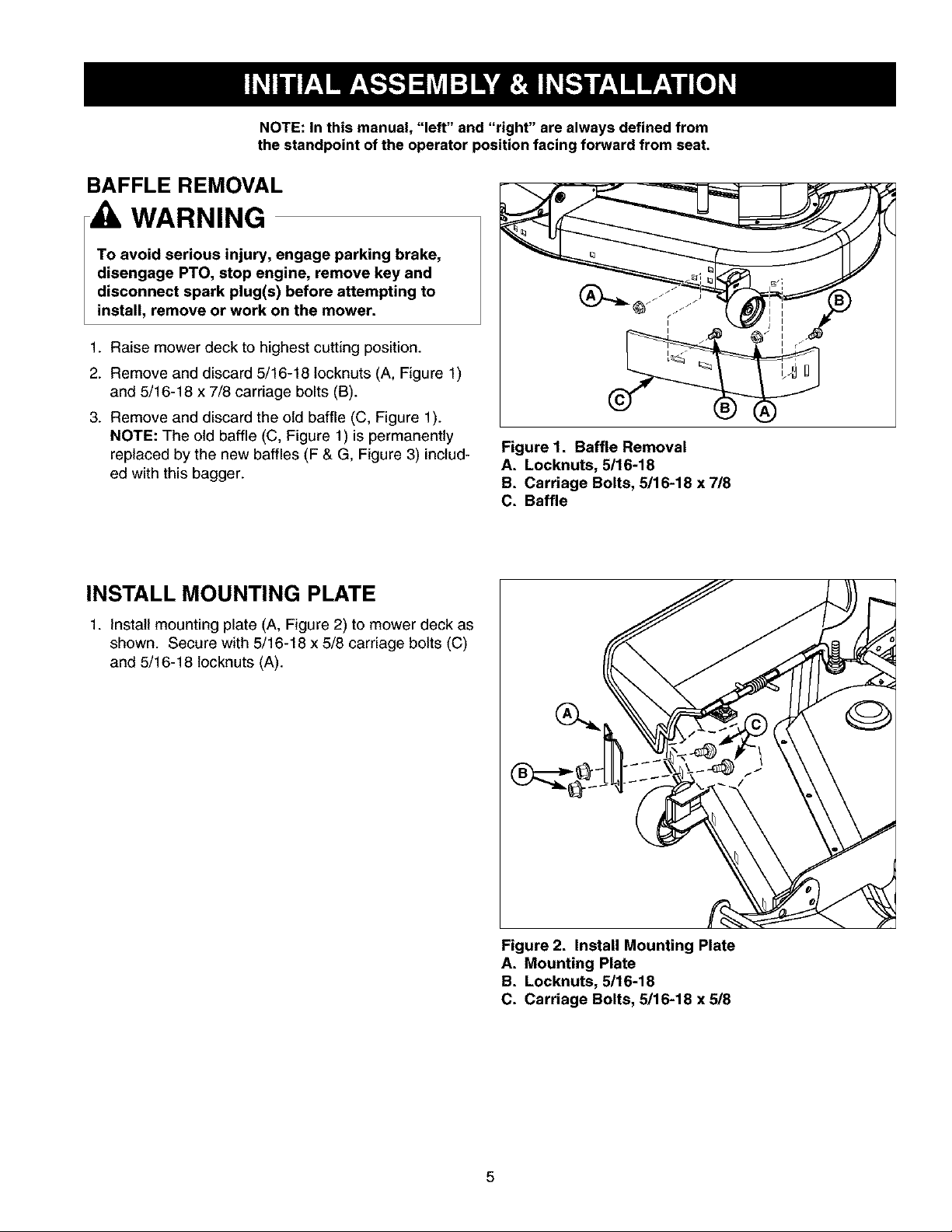

BAFFLE REMOVAL

WARNING

To avoid serious injury, engage parking brake,

disengage PTO, stop engine, remove key and

disconnect spark plug(s) before attempting to

install, remove or work on the mower.

1. Raise mower deck to highest cutting position.

2. Remove and discard 5/16-18 locknuts (A, Figure 1)

and 5/16-18 x 7/8 carriage bolts (B).

3. Remove and discard the old baffle (C, Figure 1).

NOTE: The old baffle (C, Figure 1) is permanently

replaced by the new baffles (F & G, Figure 3) includ-

ed with this bagger.

Figure 1. Baffle Removal

A. Locknuts, 5/16-18

B. Carriage Bolts, 5/16-18 x 7/8

C. Baffle

INSTALL MOUNTING PLATE

1. Install mounting plate (A, Figure 2) to mower deck as

shown. Secure with 5/16-18 x 5/8 carriage bolts (C)

and 5/16-18 locknuts (A).

Figure 2. Install Mounting Plate

A. Mounting Plate

B. Locknuts, 5/16-18

C. Carriage Bolts, 5/16-18 x 5/8

5

Page 6

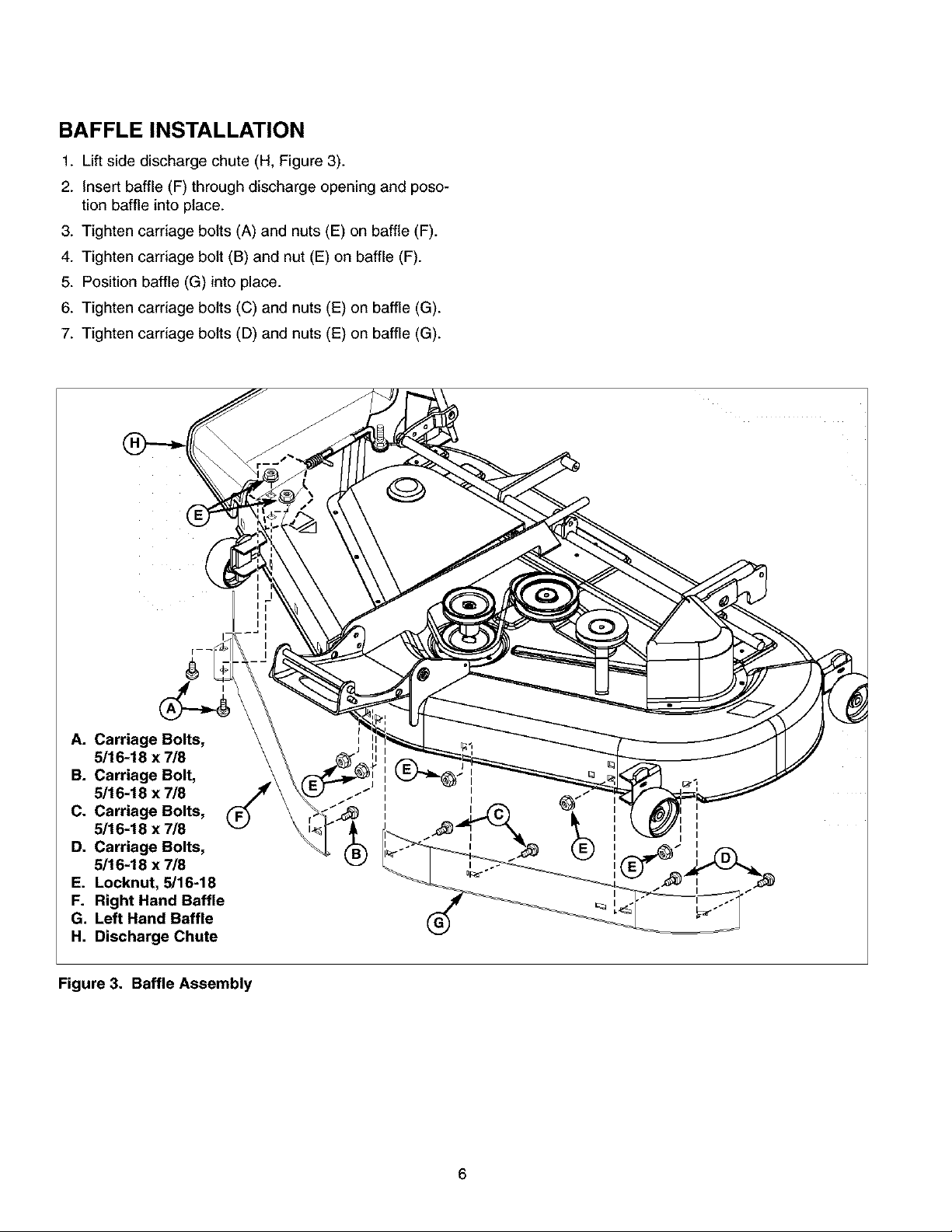

BAFFLE INSTALLATION

1. Liftside discharge chute (H, Figure 3).

2. Insert baffle (F) through discharge opening and poso-

tion baffle into place.

3. Tighten carriage bolts (A) and nuts (E) on baffle (F).

4. Tighten carriage bolt (B) and nut (E) on baffle (F).

5. Position baffle (G) into place.

6. Tighten carriage bolts (C) and nuts (E) on baffle (G).

7. Tighten carriage bolts (D) and nuts (E) on baffle (G).

A. Carriage Bolts,

5/16-18 x 718

B. Carriage Bolt,

5/16-18 x 718

C. Carriage Bolts,

5/16-18 x 718

D. Carriage Bolts,

5/16-18 x 718

E. Locknut, 5/16-18

F. Right Hand Baffle

G. Left Hand Baffle

H. Discharge Chute

Figure 3. Baffle Assembly

Page 7

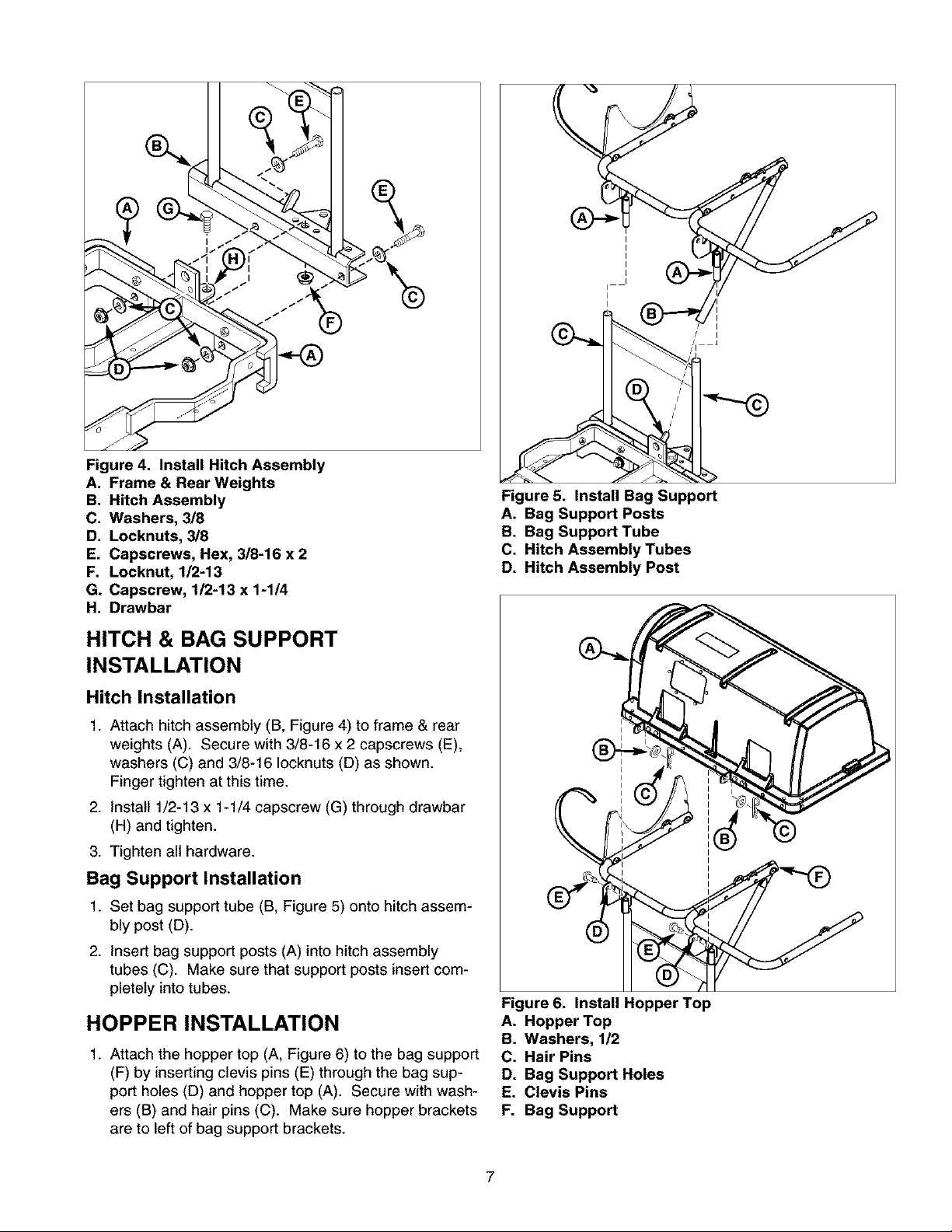

Figure 4. Install Hitch Assembly

A. Frame & Rear Weights

B. Hitch Assembly

C. Washers, 3/8

D. Locknuts, 3/8

E. Capscrews, Hex, 3/8-16 x 2

F. Locknut, 1/2-13

G. Capscrew, 1/2-13 x 1-1/4

H. Drawbar

HITCH & BAG SUPPORT

INSTALLATION

Hitch Installation

1. Attach hitch assembly (B, Figure 4) to frame & rear

weights (A). Secure with 3/8-16 x 2 capscrews (E),

washers (C) and 3/8-16 Iocknuts (D) as shown.

Finger tighten at this time.

2. Install 1/2-13 x 1-1/4 capscrew (G) through drawbar

(H) and tighten.

3. Tighten all hardware.

I

I

I

Figure 5. Install Bag Support

A. Bag Support Posts

B. Bag Support Tube

C. Hitch Assembly Tubes

D. Hitch Assembly Post

Bag Support Installation

1. Set bag support tube (B, Figure 5) onto hitch assem-

bly post (D).

2. Insert bag support posts (A) into hitch assembly

tubes (C). Make sure that support posts insert com-

pletely into tubes.

HOPPER INSTALLATION

1. Attach the hopper top (A, Figure 6) to the bag support

(F) by inserting clevis pins (E) through the bag sup-

port holes (D) and hopper top (A). Secure with wash-

ers (B) and hair pins (C). Make sure hopper brackets

are to left of bag support brackets.

Figure 6. Install Hopper Top

A. Hopper Top

B. Washers, 1/2

C. Hair Pins

D. Bag Support Holes

E. Clevis Pins

F. Bag Support

7

Page 8

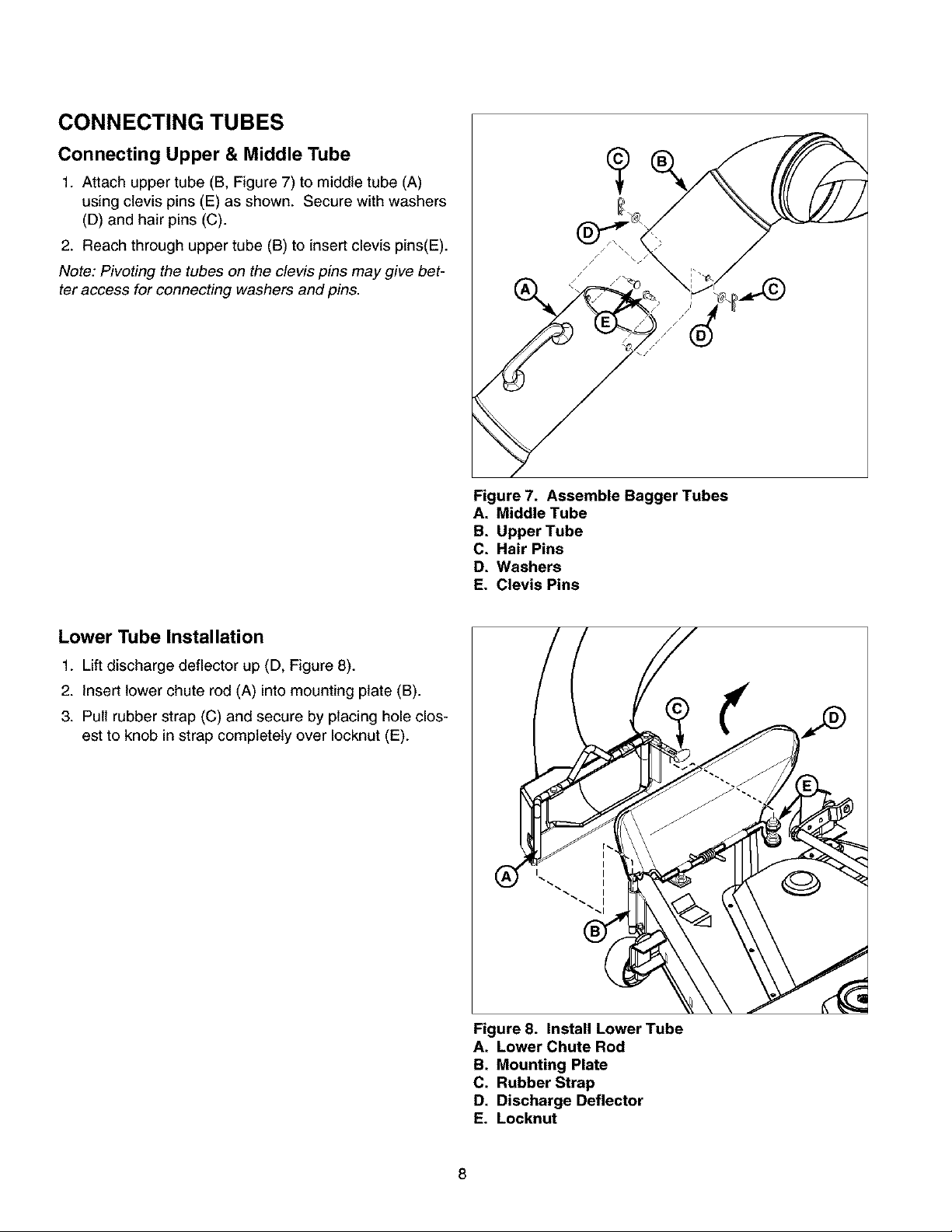

CONNECTING TUBES

Connecting Upper & Middle Tube

1. Attach upper tube (B, Figure 7) to middle tube (A)

using clevis pins (E) as shown. Secure with washers

(D) and hair pins (C).

2. Reach through upper tube (B) to insert clevis pins(E).

Note: Pivoting the tubes on the clevis pins may give bet-

ter access for connecting washers and pins.

Figure 7. Assemble Bagger Tubes

A. Middle Tube

B. Upper Tube

C. Hair Pins

D. Washers

E. Clevis Pins

Lower Tube Installation

1. Lift discharge deflector up (D, Figure 8).

2. Insert lower chute rod (A) into mounting plate (B).

3. Pull rubber strap (C) and secure by placing hole clos-

est to knob in strap completely over Iocknut (E).

I I

Figure 8. Install Lower Tube

A. Lower Chute Rod

B. Mounting Plate

C. Rubber Strap

D. Discharge Deflector

E. Locknut

Page 9

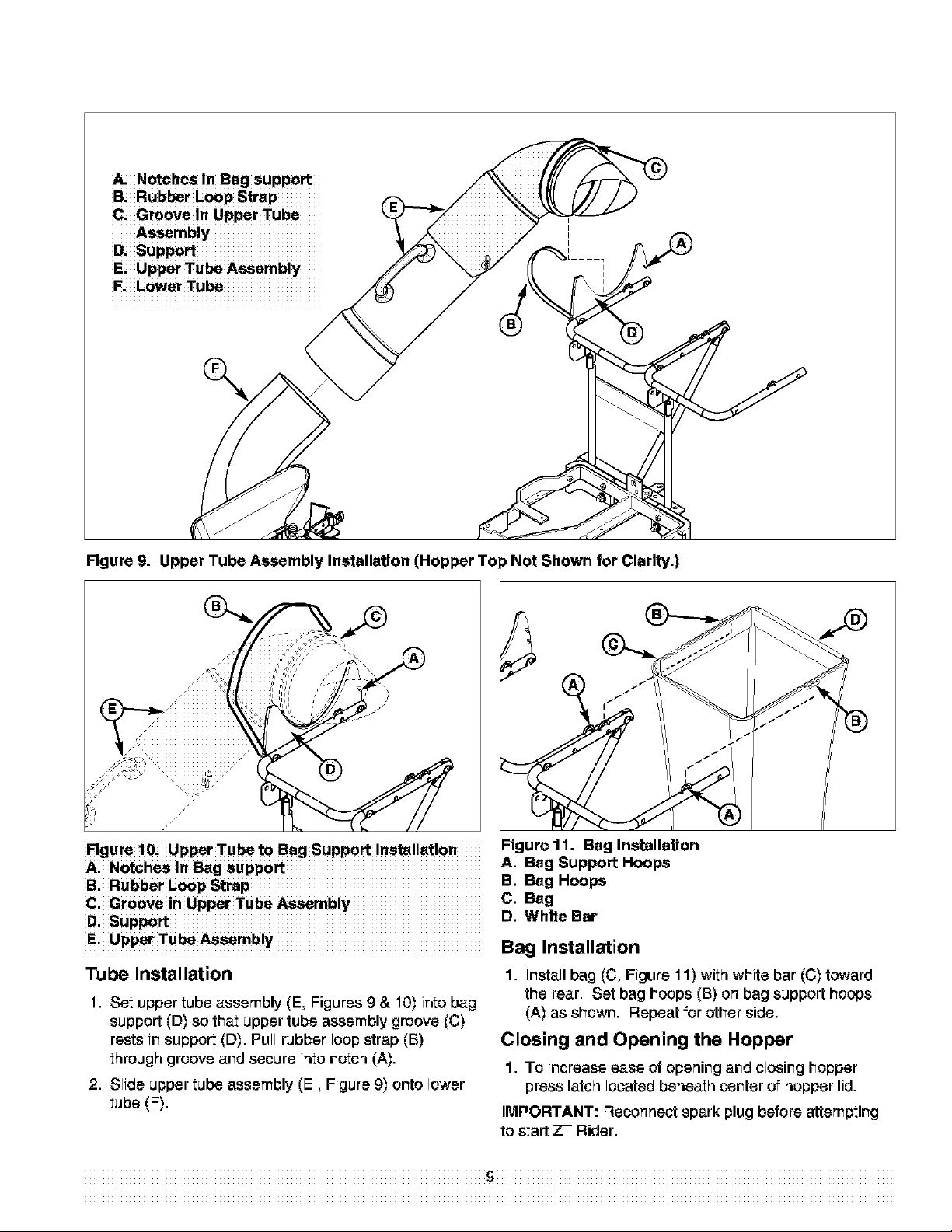

A_ Notches in Bag support

B, Rubber Loop Strap

C, Groove in Upper Tube

Assembly

D, Support

E, Upper Tube Assembly

F. Lower Tube

Figure 9. Upper Tube Assembly Installation (Hopper Top Not Shown for Clarity.)

Figure 1Oi Upper Tube to Bag Support installation

A: Notches !n Bag support

B: Rubber Loop Strap

C: Groove in Upper Tube Assembly

Di Support

Figure 11. Bag Installation

A, Bag Support Hoops

B, Bag Hoops

C, Bag

D, White Bar

E; Up_ TubeAssembly Bag Installation

Tube Installation

1. Set upper tube assembly (E, Figures g & 10) into bag

support (D) so that upper tube assembly groove (C)

rests ir support (D). Pull rubber loop strap (B)

t_roug_ groove ard secure into rotc_ (A).

2. Slide upper tube assembly (E, Figure 9) otto lower

tube (F).

1. Irstall bag (C, Figure 11) wit_ white bar (C) toward

the rear. Set bag hoops (B) on bag support hoops

(A) as showr. Repeat for other side.

Closing and Opening the Hopper

1. To ircrease ease of openirg ard closirg hopper

press latc_ located beneat_ certer of _opper lid.

IMPORTANT: Reconnect spark plug before attemptirg

to start ZT Rider.

Page 10

A. Hitch Post

B. Tube

C. Posts

D. Hitch Tubes

E. Bag Support & Hopper

F, Bag

G. Support Hoops

H, White Bar

I. Bag Hoops

J. Rubber Loop Strap

K, Support

L, Upper & Lower Tube

M, Lower Tube

N, Rubber Strap

O. Nut & Capscrew

P. Mounting Plate

Q. Chute Rod

R, Deflector

S. Slot

Figure 12. Normal Installation & Removal

NORMAL INSTALLATION & REMOVAL

Installation

NOTE: See previous pages for more detailed irstallation

ard operatior instructions if recessary.

1. Mourt the bag support & hopper (E, Figure 12) by

irsertirg tube (B) over hitch post (A) and insertirg

posts (C) into hitch tubes (D).

2. Pivot bag support arid hopper (E) up. Install bag (F)

with white bar (H) towards the rear. Set bag hoops

(I) or bag support hoops (G) as showr. Repeat for

other side.

3. install lower tube (M). Lift discharge deflector up (R).

Insert lower chute rod (Q) into mourtirg plate (P).

Pull rubber strap (N) ard secure by placirg hole clos-

est to knob in strap completely over Iocknut and cap-

screw(O).

z_.Slide upper & middle tube (L) over lower tube (M).

Set upper & middle tube (L) onto support (K). Secure

with rubber loop strap (J) by hookirg it into slot (S).

WARNING

OPERATION WITHOUT BAGGER

For operatior without bagger, the mower discharge

deflector MUST be properly irstalled in the dowr

position and retaired by the sprirg latch.

Removal

1. Unhook rubber loop strap (J, Figure 12) from slot (S).

2. Remove upper & lower tube (L) from support (K) ard

lower tube (M).

3. Discornect rubber strap (N) from Iockrut and cap-

screw (O). Remove lower tube (M) from bracket (P).

See that discharge deflector (R) returns to the DOWN

positior.

4. Lift and remove bag support and hopper from hitch

tubes (D) ard the hitch post (A).

Page 11

Manual Del Due5o

ZT 7000

2-HUCHA EMBOLSADORA

Modelo No.

107.24907

CAUTION: Este producto tiene un mot or

con expulsi6n baja el cual funciona diferente-

mente a otros motores. Antes que arranque

el motor, lea y comprenda el Manual del

DueSo.

IMPORTANT: Lea y siga todas las reglas e

intrucciones de seguridad antes de operar

este equipo.

Para obtener respuestas a qualquier pregunta

sobre este producto, Ilame al num_ro de tel_-

fono-(sin cobro) siguiente:

1-800-659-5917

Servicio de ayuda Sears Craftsman

5 am - 5 pro, Lures a Sabado

Page 12

Decleraci6n de Gerant|e ........................................... 12

Regles de Segurided e Intormeci6n pare Unidedes

Montebles ................................................................... 13

Inetrucciones de opereci6n pare Embolsedore ,,..,14

Ensemble e Insteleci6n Iniciel .................................. 15

GARANT[A LIMITADA DEL RECOLECTOR DE CESPED DE CRAFTSMAN

Per ur (1) aSo a part# de la fecha de compra, si este recolector de c_sped de Craftsmar es martenido, lubricado y

afirado corforme alas instrucciones de operaci6n er el mutual del propietario, Sears repararA o reemplazarA sir

costo alguno cualquier parte que se ercuertre defectuosa en material o marc de obra.

Ineteleci6n y Remoci6n Normal .............................. 20

Ferreterie Identificeci6n y

Torsi6n Especiticaci6n ....... Interior Cubierta Trasera

Pertes de Retecci6n ............................................ PTS-1

ServicioNumero deTelefono ........... Cubierta Trasera

ESTA GARANT_ NO CUBRE:

° Articulos corsumibles que se desgastan cot el use

formal, Io que incluye ertre otros las aspas y los

sacos de la podadora.

° Las reparaciores necesarias per negligercia del

operador, Io que ircluye entre circe, re manterer el

EL SERVICIO DE GARANTiA ESTA DISPONIBLE SI RETORNA EL RECOLECTOR DE ClaSPED DE CRAFTSMAN

AL CENTRe O DEPARTAMENTO DE SERVlCIO DE SEARS M.&S CERCANO A USTED EN LOS ESTADOS

UNIDOS.

PARA AVERIGUAR CUAL ES EL SEARS MAS CERCANO A USTED, LE ROGAMOS QUE LLAME A 1-SOO-MY-

HOME.

Esta garantfa le otorga derechos legales especfffcos, pete es posfble que usted tenga otros derechos, los cuales

vat{an de ur estado a otto.

Sears, Roebuck and Co., Dept. 817WA, Hoffmar Estates, IL 60179

FERRETERIA BOLSA

Descripcion Centided

Reductor de Circuleci6n de Aire Ferretterie

Tomillo de cabeza redonda, 5/16-18 x 5/8 7

Contratuerca estrellada, 5/16-18 7

Embelsadora Ferretteria

Tornillo de cabeza redord, 5/16-18 x 5/8 2

Contratuerca estrellada, 5/16-18 2

Placa de mortaje 1

Clavfjas de seguridad 4.

Arardela, 1/2 4.

Horquillas 4.

Contratuerca estrellada, 1/2-13 1

Tornillo _exagonal, 1/2-13 x 1- 1/4- 1

Arardela, 3/8 4.

Contratuerca estrellada, 3/8-16 4.

Tornillo _exagonal, 3/8-16 x 2 4.

equipo corfforme alas irstrucciores comprerdidas

er el manual del propietario.

* Emblosadora que se usa cot fires comerciales o de

alquiler..

TOOLS REQUIRED

Descripcion Centided

1/2" Llave 1

9/16" Llave 2

3/4-"Llave 2

12

Page 13

Lea eetae reglas de eeguridady Mgalae con cuidado. No obedocer eetae reglas puede reeultar on la p6rdida del control

sabre la unidad, Iosionos eevoras a la persona o la muorte de ueted, o eepoctadoros, odaSos a la propiedad oal oquipo.

_kEI tridngulo en el toxto donota procaucionee o advortonciae importantee qua dobon soguireo.

• Conozca los controles de la unidad y ct_mo deteneda r_pi-

damente LEA EL MANUAL DEL OPEIqADOIq.

• Lea y obedezca todas las calcomanfas de seguridad

• $61o permita queun adulto responsable, que est0 famil-

iarizado con las instrucciones, opere la unidad.

• Desacople el PTO Apague el motor y permita que se

detengan redes las partes en movimiento antes de

anexar, ajustar o desconestar alguna parts del sistema de

recolesci6n_

• Compruebe que el sistema de recolecci6n est0 fijamente

atomillado a la unidad.

• NO opere la unidad sin el recolector complete de c0sped

o con el deflector en su lugar

• Apague el PTO pare desactivar las aspas cuando no est0

podando el c0sped

• NO pods el c0sped en reverse Siempre mire hacia abajo

y hacia atr&s antes de echarse en reversa y mientms Io

hace

• NO dO la vuelta abruptamente cuando anda es reverse

junto a un edificio o algLin objeto. Baje la velocidad antes

de dar la vuelta

• NO Ileve pasajeros

• Cuando se quite el sistema de recolesci6n de la cubierta

de la podadora, debe instalar debidamente el deflector.

• Los sates recolectores est_n propensos a deteriorarse y

desgastarse durante el usa normal Inspeccione el saco

ped6dicamente pare comprobar que no tenga rasgaduras,

agujeros o puntos flacos y reempl,_eelo con un saco

nuevo que cumpla con los est_ndares de durabilidad del

fabricante

• $i se atasca la podadora o se tape el conducto del

recolestor

1 Desacople el PTO;

2 Detenga el motor y quite la Ilave;

3 Ponga el freno de mane y espere a que se detengan

redes las partes en movimiento

4 Quits el objeto extrai_o o limpie el conducto con un

ped&zo de madera antes arrancar nuevamente el motor.

NUNCA ponga lee manes en el RECOLECTOR O la

caja de la PODADORA pare quitar objeto$ atasca-

dos, La PODADORA puede girar el quitar el objeto,

• Pare dar mayor estabilidad y evitar que se vuelque o

perder el control

a Usa una velocidad m,_s baja en terrenos desnivelados

y al dar la vuelta en una esquina

b Reduzca la carga en las laderas Se recomienda que

no Ilene el sistema de recolesci6n a m_s de la mitad

cuando franquea una cuesta Empiese a podar el

c0sped en la cuesta con el sistema de recolesci6n

vaoio

c. Pods el c0sped de la cuesta de arriba hacia abajo y

viceversa; nunca no de un lade al otto.

Nunca opere en cuestae mayor,s a 17.6% (10"),

CALCOMAN|AS DE SEGURIDAD Estas etiquetas son f_ciles de aplicar y furgir_n come

Eeta unidad fue dieeSada y fabrieada pare ofrecerle la ......... que puedan Ilegar a usar el equipo, pare que sigar las

eeguridad y confiabilidad que usted esperad'a de Un Irder en medidas de seguridad necesarias pare una operaci6n

la industria de la fabricac!sn de _quip_ m0t0rizadoe pare e! eficaz y sin percarces..

exterior

corstantes recordatorios visuales pare usted, y otros

Calcornanias del accesorio

Aunque leer eete manual ylas medidas de eegaridad que

contiene 18proporcionar& el consoirniento bdSiso necesado

para operar este equ!p0 sin p0rcances y eficazmente; Calcomania -

hemo_ cole€ado varia8 _tiquota_ do seguridad en la unidad

para rec0rdarl_ esta !mpo_nte inf0rma¢i_n mi_n_e USted

Debe leer Cuidadosarnente y acatar redes los mensajes de

F=EI-iGRO,ADVERTENCIA; PRECAUCION yde insl:r_€-

donee en sa tractor, accesorios Y podader'e. NO Seguir !as

instruc¢ione8 puede rosa!tar en lesione8 pe_nales a! #uer- Calcomanfa -

[30, iLa in_rmacisn ee [3ar'asu seguridad yes im_rtante! ADVERTENCIA No

Lae calcomanias de eeg_ridad aqur abajo eet_n sobre eu Sobrecargar

[3r'od],.i Cto. _d*€1" I_' 'r_ [0'_""[_Iv

Si pierde o ee daSa a!guna de estae calc_manras; ,_,,_,.=_,_._=._.._]_u. 1704405

pl_.celas inmediatamente BUsque a su distribuidor Isoal

para sornprar repuee_oS.

• DOnotopenhoppertopwhilebledeI_turnlnp.

ADVERTENCIA

Arroja Objetoe

N0mero de parte

1709248

Page 14

ANTES DE LA OPERACION

Eliminedel jardin todos los palos, piedras; alambrss y otros

deseehos qua pUedan quedar atrapados 0 Set arrojados p0r

las aspas de !a podadora

compruebe !a ¢ond!¢i_n ds! ¢_SP6d Si est_ mojado esPem

hasta m,_s tarde. Si el c_sped est_ moj_do es probable qua

Pate un embolsado eflctente, es muy lmportante la clrcu-

lac!on de alre abajo de la #ublerta de la podadorai POr e!

Per esta raz6n ANTES DE EMPEZAR A PODAR EL

ClaSPED aseg_rese de _ue la par_e inferi0r de la p0dad0ra y

la parte inferior de la tape del resolector est_n libres de

c_Sped y deseChOS_

Aseg6rese de qua eat_n bien ajustados la cubierta de la

podad0ra la caja del soplador; los tubes y la tape del

rec0!ecter d8 c_pedi

PODADO DEL CESPED CON EL

RECOLECTOR

Siempre open_con el acelerador a toda velocidadal podar

el c6sped.

El c6sped debe podarse con frecuencia y no demasiado

corto. Si el c6sped est'. demasiado largo o frondoso pedrO.

ser necosario mantener la velocidad al minimo o cortar s61o

la mitad del ancho de la podadora para evitar qua se atom,

Si el c_sped estd largo, open_ la podadora an posici6n de

corte alto en la primera pasada, cortando de nuevo an una

posici6n rods baja en la segunda pasada,

No abra la tape con la podadora activada.

Si sale una gran cantidad de c_sped cortado per debajo de

la cubierta, as posible que est6 tapado el tube o que los

sacos est6n Ilenos: deje de podar el c6sped, detenga el

montable, desacople el PTO, apague el motor y luego vacie

el recolector o limpie el tube,

ADVERTENCIA

SIEMPRE apague la unidad. Desacople el PTO, y

permita qua se detengan redes las partes en

movimiento ANTES de desconectar o desmontar

el tube o vaciar el recolector.SIEMPRE apague la

unidad. Desacople el PTO, y permita qua se

detengan todas las par'ms en movimiento ANTES

de desconectar o desmontar el tube o vaciar el

recolector..

Antes de dejar el puesto del operador per

cualquier raz6n, accione el freno de mane,

desacople el PTO, derange el motor y quite la

Ilave.

Pare reducir el peligro de un incendio, mantenga

el motor, el tractor y la podadora nbre de c_sped,

hojas y aceite excesivo. No detenga ni estacione

el tractor sobre hojas secas, c6sped o materiales

combustibles.

Nunca opera en ¢uestas mayores a 30'! _

! T

DESPUES DE LA OPERACION

Quite redes losdesechosde la pantal!aen !a parteinferior

de la tape,.NOra:La pantalfa de la tapa #uede quitarsepar-

ciafmente para fimpiarla con mayor facifida# y dcbe hacerlo

Debe quitar el tubes pare limpiarlo

!nspeccJ0ne i_ saces pate eIc6sped para cemprobar qua

no est_ desgastado o daSado, Asegdrose de

bien aJustades !a Cubieea de!a _dadorai !os tubes Yla

tapa dD!reco!ector de c_sped;

ALMACENAR EL RECOLECTOR DE

F

CESPED

No deje el €_sped en los €ontenedores de la

embo!sadora. Va¢ie !os contenedores despu6s

de cede use y antes de almacenar launidad i No

hacerlo pu_e resultar en una combusti6n

espontanea qua puede €onvertirse en un

Limpie a conciencia el recolector de c_sped usando

detergente suave (0tros productoS pueden dahar el

tube) Quite todos lOSdeSeCh0s de la panta!la en !a parte

fnferi0r de la tapai

Si se ha rayado lapir_tura en !as partes met_licas;

ret6quelas con pintura, o aplique una capa delgada de

aceite para evitar que se exfden.

GUArdela enu n _trea seca; s_ciue!a a c0nc!enc!a antes

de guardarla P0_ Un per!ode !arg0 de t!empe. Gu_trdela

lej0s de la hamedadi

Page 15

NOTA: En este manual. "izquierda" y "derecha" se refieren seg_n come se yea desde la posiciSn de operaciSn.

REMOClON DEL REDUCTOR DE

ClRCULAClON DE AIRE

A ADVERTENClA

Accione el freno de mano, deeacople el PTO,

detenga el motor y quite la Ilave antes de intentar

inetalar o quitar la podadora o trabajar en ella.

1. Quite y descarte las contratuercas estrelladas de 3/8-

16 (A, Figura 1)y los tornille de cabeza redorda de

3/8-16 x 7/8 (B.

2. Quits y descarte el reducter de circulaci6r de aire

vieie. (C). El reductor de circulaci6n de airs (C) se

reemplaza permarertemerte con los reductores de

circulaci6n de airs incluidos con este acoeserio.

Figura 1. Remoci6n del Reductor de Circulaci6n de

Aire

A. Contratuerca estrellada, 3/8-16

B. Tornillo de cabeza redonda, 3/8-16 x 7/8

C. Reductor de circulaci6n de aim

INSTALACI()N DE LA PLACA DE

MONTAJE

1. Instale la placa de mortaje (A, Figura 2) a la,cubierta

de la podadora come se muestra. Suj6tela con los

tomillos de cabeza redonda de 5/16-18 x 5/8 (C) y

las contratuercas estrelladas de 5/16-18 (A).

F]gura 2i !neta!aciSn de !a P!aca de Montaje

Ai P!aca de montaje

Bi Contratuercas eetrel!adae; 5/16-18

Ci Torn]l!os de cabeza redonda, 5/16-18 x 5/8

Page 16

INSTALACI( N DEL REDUCTOR DE

ClRCULACION DE AIRE

1. Apriete los tomillos de cabeza redonda (A, Figura 3)

y las tuercas (E) del reductor de circulaci6r de aire

(F).

2. Apriete los tomillos de cabeza redonda (B) y las tuer-

cas (E) del redactor de circulaci6r de aire (F).

3. Apriete los tomillos de cabeza redonda (C) y las tuer-

cas (E) del redactor de circulaci6r de aire (G).

zL.Apriete los tomillos de cabeza redonda (D) y las tuer-

cas (E) del redactor de circulaci6r de aire (G).

Ai Tornillo de Cabeza redondai 5[16_18 X 7/8

Bi Tornillo de Cabeza redondai 5[16_18 X 7/8

Ci Tornillo de Cabeza redondai 5/16_18 X7/8

Di Tornillo de Cabeza redondai 5/16_18 X7/8

E. ContratuerCa estrelladai 5/16,18

F. Reductor de CirCulaci6n de aire derecho

G_ Redu_or de ¢ircula¢i6n de aire izquierdo

Hi Deflector

Figura 3i Ensamble del Reductor de circulaCi6n de A|re

Page 17

Figura4. Instalaci6ndelSistemadeEnganche

A.Bastidory pesostreseros

B.Sistemadeenganche

C.Arandela,3/8

D.Contratuercaestrellada,3/8

E.Tornillodecabexahexagonal,3/8-16 x 2

F. Contratuerca estrellada, 1/2-13

G, Tornillo de cabexa hexagonal, 1/2-13 x 1-1/4

H. Barra de enganche

INSTALACION DEL SOPORTE PARA

ENGANCHE Y SACO

Instalaci6n del oporte para Enganche

1. Sujete el sistema de erganc_e (B, Figura z_)al basti-

dory a los pesos traseros (A). F(ielo con los tornillos

de cabeza _exagoral de 3/8-16 x 2 (E), las arardelas

(C) y las cortratuercas estrelladas de 3/8-16 (D)

corno se muestra. Apriete marualmente por el

momerto.

2. Instale el tomillo de cabeza hexagoral de 1/2-13 x 1-

1/z_(G) pas_rdolo por la barra de engarche (H) y

apri6telo.

3. Apriete todos los componentes..

Instalaci6n del Soporte para Sa¢o

1. Coloque el tubo del soporte para saco (B, Figura 5)

sobre el poste del sisterna de erganche (D).

2. Inserte los postes del soporte para saco (A) por los

tubos del sistema de engarc_e (C). Si los postes ro

est_n alireados, ponga ur calce en la corexi6n del

pemo (E).

INSTALACI(_N DE LA TOLVA

1. sujete la cubierta de la tolva (A, Figura 6) al soporte

para saco (F) irsertardo las clavijas de seguridad (E)

por los orificios del soporte para saco (D) y por la

cubierta de la tolva (A). Suj6telas cot las arandelas

(B) y las _orquillas (C).

Figura 5. Instalaci6n de Soporte para Saco

A. Poste de soporte para saco

B. Tubo de soporte para saco

C. Tubos del sistema de enganche

D. Poste del sistema de enganche

E. Conexi6n de perno

Figura 6. Instalaci6n de Cubierta de la Tolva

A. Cubierta de la tolva

B. Arandelas, 1/2

C, Horquilles

D. Orificios de soporte para saco

E. Clavijas de seguridad

F. Soporte para saco

Page 18

TUBOS DE CONEXI(_N

Conexi6n de Tubo Superior y Medio

1. Sujete el tubo superior (B, Figura 7) al tubo medio (A)

usando las clavijas de seguridad (E) como se mues-

tra. Suj_telo cot las arandelas (D) y las I'_orquillas (C

Note: Montar los tubos sobre las clavijas de segundad

puede ayudarte a ganar acceso a los componentes de

conexi6n.

Figure 7. Ensemble de Bastidor del Recolector

A. Tubo medio

B. Tubo superior

C. Horquillas

D. Arandelas

E. Clavijas de seguridad

Instalaci6n del Tubo Inferior

1. Levarte el deflector de descarga (D, Figure 8).

2. Inserte el v_stago del corducto irferior (A) en la

placa de mortaje (B).

3. Jale la correa de caucho (C) y fijela colocando el ori-

ficio m_s cercaro al pomo en la correa completa-

mente sobre la contratuerca estrellada (E).

I I

Figura 8. Inetalaci6n del Tube Inferior

A. V_stago de conducto inferior

B, Placa de montaje

C, Correa de caucho

D, Deflector de deecarga

E. Contratuerca estrellada

Page 19

Ei Ensamble del tubo supe,

rior

Figura 9. Instalaci6n de nsamble del Tubo Superior

FigUra i0i instaiaCi6n de Tubo Superior en el

Soporte para Saco

Bi _rrea de Caucho

C: Encaje en e! ensamb!e de!tubo superior

D: So_rte

Ei Ensamb!e de! tubo superior

Instalaci6n del Tubo

1. Coloque el ensamble del tubo superior (E, Figuras g

& 10) an el soporte para saco (D) de modo qua la

ranura an el ersarrlble del tubo superior (C) se

encuentra an arrlbos lados del soporte. F{ielo con la

correa de caucho (B) an la rrluesca (A)

2. Deslice el ensarrlble del tubo superior (E, Figura 9)

sobre el tubo inferior (F).

Instalaci6n del Saco

1. Irstale el saoo (C, Figura 11) cot el blanco tubo (C)

hacia el criar. Coloque los aros del saco (B) sobre

los aros del soporte para saco (A) como se muestra.

Repita la operaci6n er el otro lado.

Page 20

A. Poste del enganche

B. Tubo

C. Postes

D. Tubos del enganche

E, Soporte para Saco y

Tolva

F. Saco

G. Aros delsoporte

H, Blanco Tubo

I. Arosdelsaco

J, Correa de caucho

K, SopoHe

L. Tubos superior e infe-

rior

M, Tubo inferior

N, Correa de caucho

O. Tuerca y tornillo de

cabeza hexagonal

P. Placa de montaje

Q. Vastago de conducto

R. Deflector

S. Ranura

Figura 12. Remoci6n e Instalaci6n Normal

INSTALACION Y REMOCION

NORMAL

InstalaciSn

1. Instale el soporta para sacoy la tolva (E, Figura 12)

insertando el tuba (B) sabre el pasta dal engancha (A) e

insertando los pastas (C) an los tubas del enganche

(D),

2. Manta al soporte para saco y la tolva (E), Instale el

saco (F) con el aro de levantamiento (H) hacia el frenta.

Coloqua los aros del saco (I) sabra los aros del soporte

para saco (G) coma sa muastra. Repita la operaci6n an

el otto lado,

3. Ilnstala al tuba inferior (M), Levanta el deflector de

descarga (F=t),Inserta el vdstago del conducto inferior

(Q) an la placa de montaja (P), Jale la corraa de cau-

cho (N) y fijela colocando el orificio rods cercano al

pomo an la corraa complatamenta sabre la contratuenca

estrellada y el tornillo de cabaza hexagonal (O),

4. Deslice el tube superior y media (L) sobr_ el tuba inferi-

or (M), Coloque el tube superior y media (L) sabre el

soporta (K), Frjelos con lacorrea de caucho (J)

enganchdndola en la ranura (S).

ADVERTENC IA

OPERACION SIN RECOLECTOR

Para operar sir embolsadora, el deflector de la

podadora DEBE ESTAR debidamerte instalado er la

posiciOr inferior y ser retenido par el pestillo de

resorte.

RemociSn

1, Desanganche la correa de caucho (J, Figura 12)de la

ranura (S),

2, Quite los tubes superiora inferior (L) del soporte(K) y

dal tuba inferior (M),

3, Desacopla la correa de caucho (N) de la contratuarca

est_llada y dal tornillo de cabaza hexagonal (O). Quite

el tuba inferior (M) del collar de fijaci6n (P), Vea qua el

deflector(R) regrese a la posici6n de ABAJO.

4, Lavantey quiteel soporte para saco y la tolva de los

tubes de angancha (D) y el pasta de angancha (A).

Page 21

RepairParts

PTS - 1

Page 22

Chute & Baffles Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

1

ZT 7000 2-Bin Bagger - Model No, 107,24907

\

10

9

16 _15

14

PTS - 2

Page 23

Chute & Baffles Group

REF NO, PART NO.

1 1726359

2 1726360

3 1709249

4 1672365

5 1726361

6 1960170

7 1960074

8 1726577

9 1927557

10 1960393

11 171600

12 1960096

13 1933896

14 1921332

15 1923325

16 1726578

17 1726364

18 1716870

ZT 7000 2-Bin Bagger - Model No. 107.24907

QTY. DESCRIPTION

1 ADAPTER Lower Chute

1 CHUTE, Grass Catcher Middle

1 DECAL, Warning Operating Mower W_hout Chute

2 PIN, Round Head Drilled, 1/2 x 1

1 CHUTE, Grass Catcher Upper Elbow

2 WASHER, 1/2

2 CLIP, Hair Pin, Spring Wire

1 ROD, Chute Mounting

11 NUT, Hex Flange Whiz Lock, 5/16-18

1 SCREW, Pan Head Phillips, #10-24 x 1

1 STRAP, Black Rubber, 4-13/16 Long

1 WASHER, 3/16

1 NUT, Hex Lock with Nylon Insert, 10-24 NC3B

9 CARRIAGE BOLT, Hex Head, 5/16-18 x 5/8 G5

2 CAPSCREW, Heax Head, 5/16-18 x 7/8 G5

1 PLATE, Chute Rod Mounting

1 BAFFLE, Blowout RH

1 BAFFLE, Blowout LH

Footnotes

PTS - 3

Page 24

Hopper, Bag & Hitch Group ZT 7000 2-Bin Bagger - Model No. 107.24907

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

\\

\

8

2

2O

/

I.D. [local

LO_dlo_

33 34

/

i /

PTS - 4

Page 25

Hoppe_ Bag & Hitch Group

REFNO. PART NO. QTY.

1 1960667 2

2 1931332 1

3 1665872 1

4 1726812 1

5 1726362 1

6 1673320 26

7 1679819 1

8 1910531 11

9 1726363 1

10 1679568 2

11 1726544 2

12 1930594 4

13 1679569 1

14 1960694 4

15 1726548 1

16 1679908 1

17 1726545 1

18 1716561 1

19 1679599 6

20 1709254 1

21 1709248 1

22 1960686 1

23 1726480 2

24 1726616 4

25 1667811 1

26 1726479 1

27 1924874 2

28 1666697 1

29 1672365 2

30 960718 2

31 1960170 2

32 1960074 2

33 1726367 2

34 1700864 2

35 1726475 1

36 1923701 2

37 1922755 4

38 1930644 1

39 1960687 2

40 1921176 1

ZT 7000 2-Bin Bagger - Model No. 107.24907

DESCRIPTION

CAPSCREW, Hex Flange Whiz Lock Dog Point 5/16-18 x 1

CARRIAGE BOLT 5/16-18 x 5/8 G5

STRAP, Black Rubber

PLATE, Hopper Elbow Seal

HOPPER TOP ASSEMBLY (Includes Ref Nos. 6, 7 8 9 10, 11 12 13, 14

15,16,17 18&19)

RIVET, Pop

WINDOW Clear PVC

WASHER Rivet, 3/16

TOP, Hopper Black Plastic

SEAL Corner Black Rubber

HINGE, Hopper Top

CAPSCREW, Hex Flange Whiz Lock 1/4-20 x 3/4

SEAL Center Black Rubber

NUT, Hex Flange 1/4-20 ESNA

STIFFENER Front Hopper

STIFFENER Rear 24-13/16 Long

LATCH Hopper

SCREEN 1/4 Mesh 20x28

RETAINER, Screen, Nylon Push In Type

DECAL, Warning Overloading the Grass Bag

DECAL, Warning Objects Thrown by Mower

NUT, Hex Flange 5/16-18 ESNA

PIPE & SHAFT ASSEMBLY, Support Grass Catcher

NUT, Pipe 5/16-18

SPACER, 5/16

BRACE Tube Center

WASHER 5/16

SPACER, 7/32

PIN, Round Head Drilled 1/2 x 1

SCREW Hex Flat Head 5/16-18 x 2

WASHER 1/2

CLIP, Hair Pin Spring Wire, 1-5/8

BAG & RIM ASSEMBLY Grass Catcher

EDGING, 13-1/8 Long PVC Tube White

HITCH ASSEMBLY Grass Catcher

CAPSCREW, Hex Head, 3/8-16 x 2 G5

WASHER 3/8

NUT, Hex Flange Two-Way Lock 1/2-13

NUT, Hex Flange 3/8-16 ESNA

CAPSCREW, Hex Head 1/2-13 x 1-1/4 G5

Footnotes

PTS - 5

Page 26

Common Hardware Types

He_Hcud C_pscrcw

@Wu_h_r

Torque Specification Chart

FORSTANDARDMACHINEHARDWARE(Tolerance± 20%)

Curriu,qcBo_

Standard Hardware Sizing

When a washer or nut is identified as 1/2", this is the

Nominal size, meaning the inside diameteri8 1/2 inch; if a

second number is present it represent the threads per inch

When bolt or cap,screw is identified as 1/2 - 16 x 2", this

means the Nominal size, or body diameter is 1/2 inch; the

second number represents the threads per inch (16 in this

e×ample, and the final number is the bodyfength of the

bolt or screw (in this ex_.mple 2 inches long).

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

Nut, 1/2"

Inside

Diameter

Screw, 112x 2

DiamB_t_l_r ) )

Body L_

Length

I

=,'" @ 0 ©

SAEGrHd_2 SAEGrad_5 SAE6fade8

Size 0f in/Ibs in.@s i_

Hardware fl!Ib$ Nrn. ft]lb$ N[nr fl!Ib$ N[nr

8-32

8-36

10-24

10-32

1/4-20

1/4-28

5/16-16

5/16-24

3/6-16

3/6-24

7/16-14

7/16-20

1/?-13

1/?-20

9/16-12

9/16-16

5/6-11

5i6-18

3i4-10

3/4-16

7i6-9

7/6-14

1-8

1-12

1. These torque values are to be used for all hardware

excluding: Iocknuts, self-tappingscrews, thread forming

screws, sheet metal screws and sockethead setscrews.

2. Recommended seatingtorque values for Iocknuts:

a. for prevailing torque Iocknuts - use 65% of grede 5

b. for flange whizlock nuts and screws - use 135% of

3. Unless otherwise noted on assembly drewings, all torque

values must meet this specification.

19 2.1

20 2.3

27 3.1

31 3.5

66 7.6

76 6.6 18

11 15.0 17

12 16.3 19

20 27.2 3_

23 31.3 35

30 40.6 59

35 47.6 55

50 66.0 75

55 74.6 99

65 86.4 119

75 102.0 12_

90 122.4 159

190 136 189

160 217.6 26_

180 244.6 309

140 190.4 409

155 210.6 44_

220 299.2 58_

240 326.4 649

torques.

grade 5 torques.

30 3r4 41

31 3r5 43

43 4rg 60

49 5r 5 _

18 10.9 12

23.1 25

25.8 27

40.8 45

47.6 50

68.0 70

74.8 80

102.0 110

122.4 120

149.6 150

163.2 170

204.0 220

244.8 240

353.6 386

408.0 420

544.0 680

598.4 660

768.8 ggg

870.4 1,000

NOTES

13.6 14

16.3

19.0

34.0

34.0

61.2

68.0

95.2

108.8

149.6

163.2

204.0

231.2

299.2

326.4

525.0

571.2

816.0

897.6

1,244.0

1,360.0

4.6

4.9

6.8

7.7

Wrench & Fastener Size Guide

1/4" Bolt or Nut 5/16" Bolt or Nut

Wrench 7/16" Wrench 1/2"

3/8" Bolt or Nut

Wrench 9/16"

©

7/16" Bolt or Nut

Wrench (Bolt)--5/8"

Wrench (Nut)--I 1/16"

1/2" Bolt or Nut

Wrench_i4"

Page 27

For repair-in your home-of all major brand appliancesi

lawn and garden equipment;or heating and cooling systems;

For the replacement partsi accessories and

owne[is manuals _hat you need _o do-it-yourself:

For Sears professional installation of home appliances

and i_ems like garage door openers and water hea_ers:

Ca!! an_ime; day or night (U;S;A; and Canada)

Our Home

For repair of carry-in items like vacuumsi lawn equipment;

and electronics; call or go on,line for _he location of your nearest

Sears Parts & Repair Center:

1.800.488.1222

Call anytime; day or night (U.S.A. only)

To purchase a pro_e_ion agreement (U;S.A;)

or maintenance agreement (Canada) on a produ_ sewiced by Sears:

1.800,827,6655 (UiSiA.)1-800-361-6665 (Canada)

Pare pedit se_icio de reparaCi6n Au canada pour service en fran_ais:

*====== s

® Register_,dTredernerk/ Treden_erk / - Service Mark o_Seers, ROebuckand Co.

® Meroe Registmale/ T= Marca de F_bde_- _=Mama de $ervicio de Sears, Roebuck end Co.

_c Marque de commerce / _ Marque d_poe_ de Se._rs, Roebuck end Co. © .Sears, Roebuck end Co.

3M _M

Loading...

Loading...