Page 1

Operator's Manual

®

LAWN TRACTOR

17.5 HR*42" Mower

Electric Start

6 Speed Transaxle

Model No.

917.28903

n the USA.,

o EspaSol, p. 33

This product has a low emission engine which operates

differently from previously built engines. Before you start the

engine, read and understand this Owner's Manual.

IMPORTANT:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website.www searscom/craftsman 'As raled by lhe engine manufaclurer

For answers to your questions about

this product, Call:

t=800-659=5917

Sears Craftsman Help Line

5 am - 5 pro, Mon - Sat

Page 2

Warranty ........................................................... 2

Safety Rules .........................................................3

Product Specifications ....................................6

AssemblylPre-Operation ............................. 8

Operation ...................................................... 1t

Maintenance Schedule ...................................t7

CRAFTSMAN LIMITED WARRANTY

TWO YEARS ON TRACTOR

When operated and maintained according to all supplied instructions, if this tractor fails

due to a defect in material or workmanship within two years from the date or purchase,

call 1-800-4-MY-HOME® to arrange for free repair.

During the first year of purchase, there will be no charge for warranty service in your home..

For your convenience, in-home warranty service will still be available after the first year

of purchase, but a trip charge will apply. This charge will be waived if you transport the

tractor to an authorized Craftsman drop-off location. For the nearest authorized location,

call 1-800-4-MY-HOME®.

90 DAYS ON BATTERY

For ninety (90) days from date of purchase, if the battery included with this tractor is

defective in material or workmanship (our testing proves it will not hold a charge), it will be

replaced free of charge in your home..

This warranty covers ONLY defects in material and workmanship, Sears will NOT pay for:

. Expendable items that become worn during normal use, including but not limited to

blades, spark plugs, air cleaners, belts, and oil filters.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails,

thorns, stumps, or glass.

• Tire or wheel replacement or repair resulting from normal wear, accident, or improper

operation or maintenance°

. Repairs necessary because of operator abuse, including but not limited to damage

caused by towing objects beyond the capability of the tractor, impacting objects that

bend the flame or crankshaft, or over-speeding the engine..

• Repairs necessary because of operator negligence, including but not limited to, electrical

and mechanical damage caused by improper storage, failure to use the proper grade

and amount of engine oil, failure to keep the deck clear of flammable debris, or failure

to maintain the equipment according to the instructions contained in the operator's

manual.

• Engine (fuel system) cleaning or repairs caused by fueldetermined to be contaminated or

oxidized (stale). In general, fuel should be used within 30 days of its purchase date°

• Normal deterioration and wear of the exterior finishes, or product label replacement,.

Maintenance .....................................................17

Service and Adjustments .......................... 22

Storage .............................................................27

Troubleshooting ..............................................28

Sears Service ....................................Back Cover

All tractor and battery warranty coverage is void if this product is ever used for

commercial or rental purposes.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

2

Page 3

DANGER: This cutting machine is capable of amputating hands and feetand throwing

objects, Failure to observe the following safety instructions could result in serious

injury or death,

_,WARNING: Inorderto prevent accidental

starting when setting up, transporting, ad-

justing ormaking repairs, always disconnect

spark plug wire and ptace wire where it cannot

contact spark plug.

_,WARNING: Do not coast down a hilt in

neutral, you may lose control of the tractor..

_WARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor Use common sense when towing.

Operate only at the lowest possible speed

when on a slope. Too heavy of a load, while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor_

_WARNING: Engine exhaust, some of its

constituents, and certain vehicle components

contain or emit chemicals known to the State

of California to cause cancer and birth defects

or other reproductive harm,

_WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and birth defects

or other reproductive harm Wash hands

after handling.

I. GENERAL OPERATION

. Read, understand, and follow all instruc-

tions on the machine and in the manual

before starting.

. Do not put hands or feet near rotating

parts or under the machine.. Keep clear

of the discharge opening at all times..

• Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

• Clear the area of objects such as rocks,

toys, wire, etc., which could be picked up

and thrown by the blades.

• Be sure the area is clear of bystanders

before operating.. Stop machine if anyone

enters the area

, Never carry passengers_

. Do not mow in reverse unless absolutely

necessary, Always look down and behind

before and while backing.

. Never direct discharged material toward

anyone, Avoid discharging material

against a wall or obstruction. Material may

ricochet back toward the operator. Stop the

blades when crossing gravel surfaces_

• Do not operate machine without the entire

grass catcher, discharge guard, or other

safety devices in place and working,

• Slow down before turning.,

. Never leave a running machine unat-

tended. Always turn off blades, set park-

ing brake, stop engine, and remove keys

before dismounting.

• Disengage blades when not mowing. Shut

off engine and wait for all parts to come

to a complete stop before cleaning the

machine, removing the grass catcher, or

unclogging the discharge guard,

° Operate machine only in daylight or good

artificial light,

• Do not operate the machine while under

the influence of alcohol or drugs,

• Watch for traffic when operating near or

crossing roadways,,

• Use extra care when loading or unloading

the machine into a trailer or truck.

. Always weareye protection when operat-

ing machine

. Data indicates that operators, age 60

years and above, are involved in a large

percentage of riding mower-related inju-

ries, These operators should evaluate

their ability to operate the riding mower

safely enough to protect themselves and

others from serious injury.

• Follow the manufacturer's recommen-

dation for wheel weights or counter-

weights,

• Keep machine free of grass, leaves or

other debris build-up which can touch hot

exhaust t engine parts and burn. Do not

allow the mower deck to plow leaves or

other debris which can cause build-up to

occur. Clean any oil or fuel spillage before

operating or storing the machine,, Allow

machine to cool before storage,

Page 4

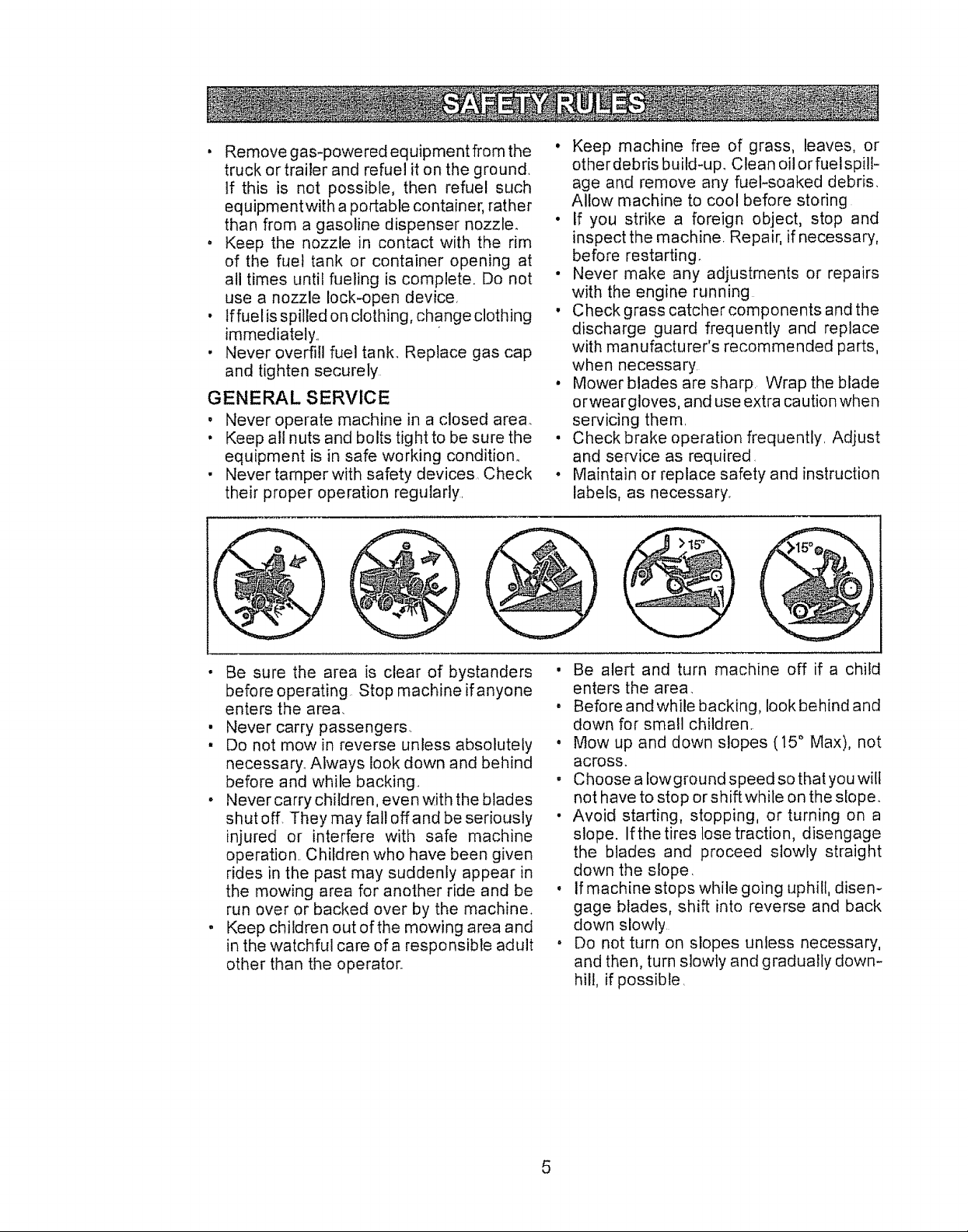

II. SLOPE OPERATION

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death° Operation

on all slopes requires extra caution. If you

cannot back up the slope or if you feel uneasy

on it, do not mow it.

• Mow up and down slopes, not across

. Watch for holes, ruts, bumps, rocks, or

otherhidden objects. Uneven terrain could

overturn the machine. Tail grass can hide

obstacles.

• Choose a low ground speed so that you

wilt not have to stop or shift while on the

slope.

• Do not mow on wet grass, Tires may lose

traction.

Always keep the machine in gear when

going down slopes. Do not shift to neutral

and coast downhill..

• Avoid starting, stopping, or turning on a

slope. If the tires lose traction, disengage

the blades and proceed slowly straight

down the slope

• Keep all movementon the s!opes s!owand

gradual. Do not make sudden changes

in speed or direction, which could cause

the machine to roll over.

• Use extra care while operating machine

with grass catchers or other attachments;

they can affect the stability of the machine.

Do no use on steep slopes.

• Do not try to stabilize the machine by

putting your foot on the ground°

• Do not mow near drop-offs, ditches, or

embankments.. The machine could sud-

denly roll over if a wheel is over the edge

or if the edge caves ino

ii!, CHILDREN

Tragic accidents can occur if the operator

is not alert to the presence of children°

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them..

• Keep children outofthe mowing area and

in the watchful care of a responsible adult

other than the operator.

• Be alert and turn machine off if a child

enters the area.

. Beforeandwhile backing, Iookbehind and

down for small children.

, Nevercarrychildren,evenwiththeblades

shut off They may fall off and be seriously

injured or interfere with safe machine

operation, Children who have been given

rides in the past may suddenly appear in

the mowing area for another ride and be run

over or backed over by the machine.

. Never allow chifdren to operate the ma-

chine

o Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may block your view of a child

IV, TOWING

. Tow only with a machine that has a hitch

designed for towing. Do not attach towed

equipment except at the hitch point.

• Follow the manufacturer's recommenda-

tion for weight limits for towed equipment

and towing on slopes.

• Never allow children or others in or on

towed equipment,

• On slopes, the weightofthe towed equip-

ment may cause loss of traction and loss

of control,

• Travel slowly and allow extra distance to

stop

V. SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, use extreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

° Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

• Use only approved gasoline container..

• Never remove gas cap or add fuel with

the engine running. Allow engine to cool

before refueling.

, Never fuel the machine indoors..

• Never store the machine or fuel container

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances.

° Never fill containers inside a vehicle or

on a truck or trailer bed with plastic liner..

Always place containers on the ground

away from your vehicle when filling.

4

Page 5

• Removegas-poweredequipmentfromthe

truck or trailer and refuel it on the ground.

If this is not possible, then refuel such

equipment with a portable container, rather

than from a gasoline dispenser nozzle.

, Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times until fueling is complete.. Do not

use a nozzle lock-open device,

• lffuel is spilled on clothing, change clothing

immediately..

• Never overfill fuel tank. Replace gas cap

and tighten securely

GENERAL SERVICE

o Never operate machine in a closed area_

, Keep all nuts and bolts tight to be sure the

equipment is in safe working condition,

• Never tamper with safety devices, Check

their proper operation regularly,

• Keep machine free of grass, leaves, or

otherdebris build-up. Clean oil orfuelspill-

age and remove any fuel-soaked debris,

Allow machine to cool before storing

• If you strike a foreign object, stop and

inspect the machine. Repair, if necessary,

before restarting.

• Never make any adjustments or repairs

with the engine running

• Check grass catcher components and the

discharge guard frequently and replace

with manufacturer's recommended parts,

when necessary.

• Mower blades are sharp. Wrap the blade

orwear gloves, and use extra caution when

servicing them.

• Check brake operation frequently. Adjust

and service as required.

• Maintain or replace safety and instruction

labels, as necessary.

• Be sure the area is clear of bystanders

before operating Stop machine if anyone

enters the area.

• Never carry passengers..

• Do not mow in reverse unless absolutely

necessary. Always look down and behind

before and while backing,.

, Nevercarrychildren, even with the btades

shut off. They may fail offand be seriously

injured or interfere with safe machine

operation. Children who have been given

rides in the past may suddenly appear in

the mowing area for another ride and be

run over or backed over by the machine.

• Keep children outofthe mowing area and

in the watchful care of a responsible adult

other than the operator.

. Be alert and turn machine off if a child

enters the area.

, Before andwhile backing, Iookbehind and

down for small children,

. Mow up and down slopes (15 ° Max), not

across.

, Choose alowgroundspeedsothatyouwill

not have to stop or shift while on the slope.

• Avoid starting, stopping, or turning on a

slope. If the tires lose traction, disengage

the blades and proceed slowly straight

down the slope,

• If machine stops while going uphill, disen-

gage blades, shift into reverse and back

down slowly

o Do not turn on slopes unless necessary,

and then, turn slowly and gradually down-

hill, if possible,

5

Page 6

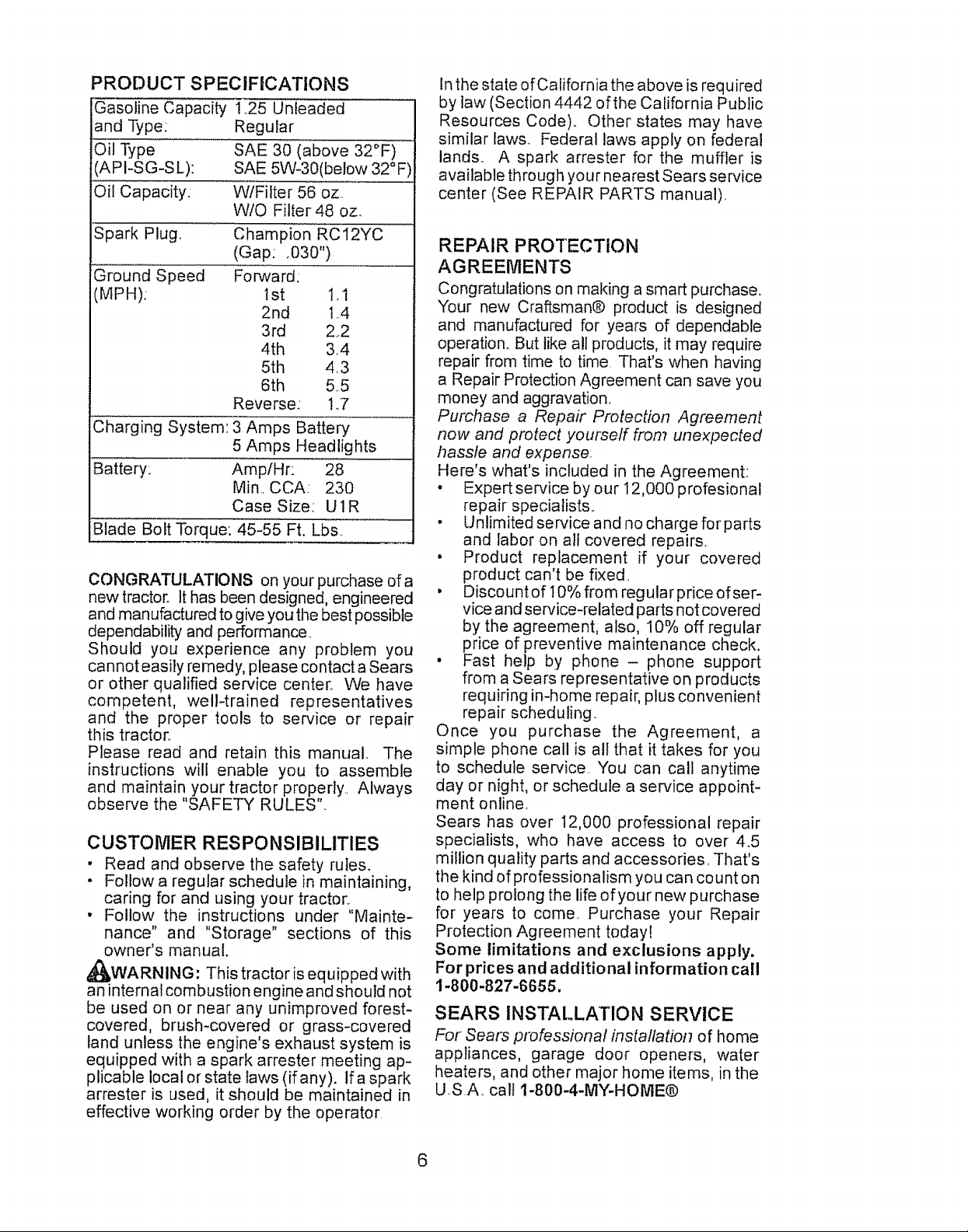

PRODUCT SPECiFiCATIONS

Gasoline Capacity !25 Unleaded

and Type: Regular

Oil Type SAE 30 (above 32°F)

API-SG-SL): SAE 5W-30(below 32°F

Oil Capacity: W/Filter 56 oz..

WtO Filter 48 oz.

Spark Plug. Champion RC12YC

(Gap: ,030")

Ground Speed

(MPH):

Charging System: 3 Amps Battery

Battery: AmpiHr: 28

Blade Bolt Torque: 45-55 Ft. Lbs..

CONGRATULATIONS on your purchase of a

new tractor° It has been designed, engineered

and manufactured to give you the best possible

dependability and performance,

Should you experience any problem you

cannot easily remedy, please contact a Sears

or other qualified service center,, We have

competent, well-trained representatives

and the proper tools to service or repair

this tractor°

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly.. Always

observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

. Read and observe the safety rules.

. Follow a regular schedule in maintaining,

caring for and using your tractor,

• Follow the instructions under "Mainte-

nance" and "Storage" sections of this

owner's manual.

_IbWARNING: This tractor is equipped with

an internal combustion engine and should not

be used on or near any unimproved forest-

covered, brush-covered or grass-covered

land unless the engine's exhaust system is

equipped with a spark arrester meeting ap-

plicable local or state laws (if any). If a spark

arrester is used, it should be maintained in

effective working order by the operator.

Forward:

t st 1.1

2nd 1..4

3rd 22

4th 3,4

5th 4,3

6th 5.5

Reverse: 1,7

5 Amps Headlights

Min.. CCA: 230

Case Size: U 1R

In the state of California the above is required

by law (Section 4442 of the California Public

Resources Code),. Other states may have

similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is

availablethrough your nearest Sears service

center (See REPAIR PARTS manual).

REPAIR PROTECTION

AGREEMENTS

Congratulations on making a smart purchase.

Your new Craftsman® product is designed

and manufactured for years of dependable

operation,. But like all products, it may require

repair from time to time That's when having

a Repair Protection Agreement can save you

money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourseff from unexpected

hassle and expense

Here's what's included in the Agreement:

• Expert service by our 12,000 profesional

repair specialists,.

. Unlimited service and no charge forparts

and labor on all covered repairs,

, Product replacement if your covered

product can't be fixed.

' Discount of I0% from regular price of ser-

vice and service-related parts not covered

by the agreement, also, 10% off regular

price of preventive maintenance check.

• Fast help by phone - phone support

from a Sears representative on products

requiring in-home repair, plus convenient

repair scheduling.

Once you purchase the Agreement, a

simple phone call is all that it takes for you

to schedule service. You can call anytime

day or night, or schedule a service appoint-

ment online.

Sears has over I2,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories, That's

the kind of professionalism you can count on

to help prolong the life of your new purchase

for years to come.. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information call

1-800-827-6655.

SEARS INSTALLATION SERVlCE

For Sears professional insta!lation of home

appliances, garage door openers, water

heaters, and other major home items, in the

USA. call t-80O-4-MY.HOr_E®

6

Page 7

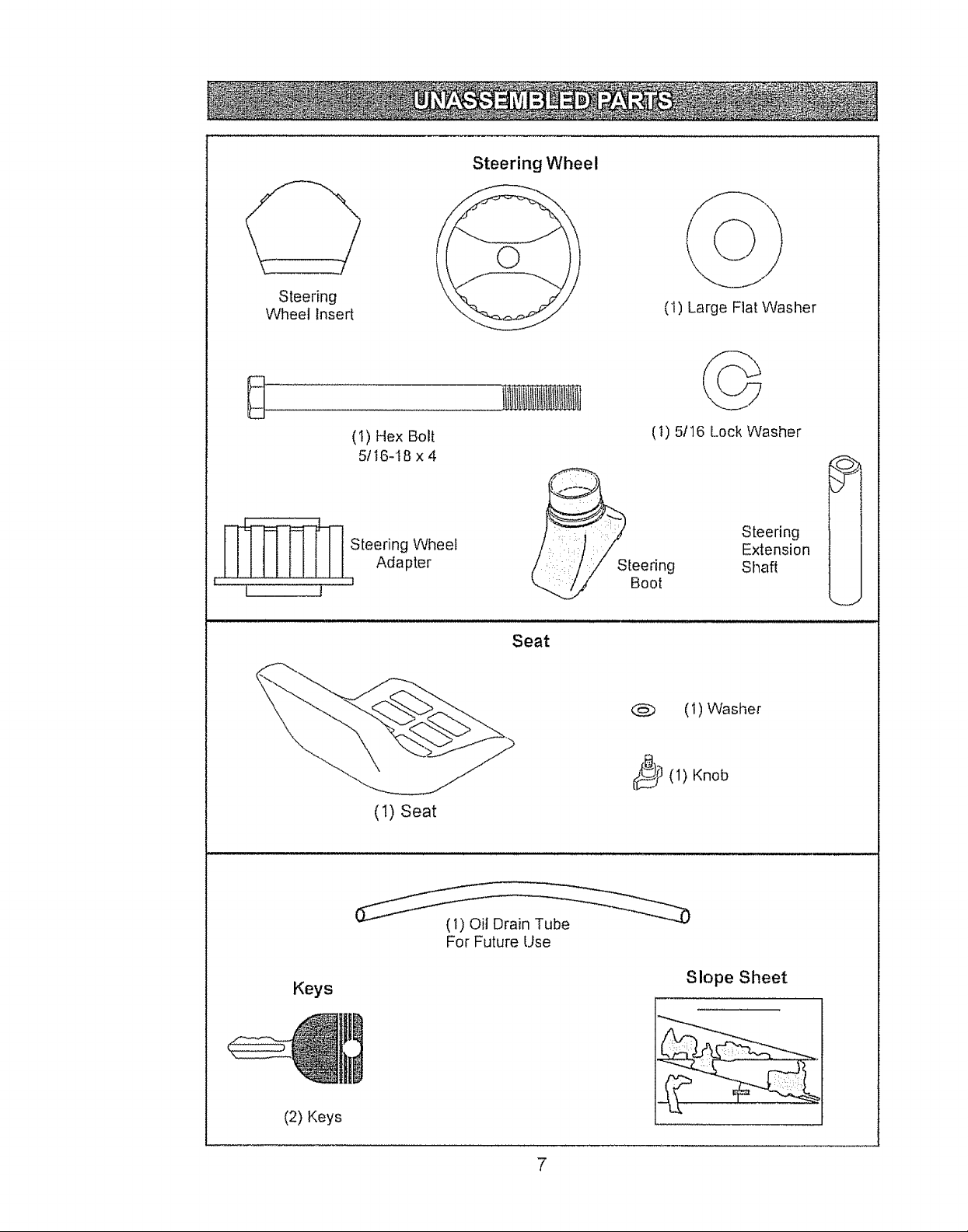

fb

Steering Wheel

Steering

Wheel Insert

(I) Hex Bolt

5116-18 x 4

__-'_ Steering Wheel

t!t1!f1111, Adapter

I t

Seat

(1) Large Flat Washer

O

(1) 5/16 Lock Washer

Steering

Boot

(1) Washer

Steering

Extension

Sllafi

Keys

(2) Keys

_(1) Knob

(I) Seat

(1) Oil Drain Tube

For Future Use

Slope Sheet

7

Page 8

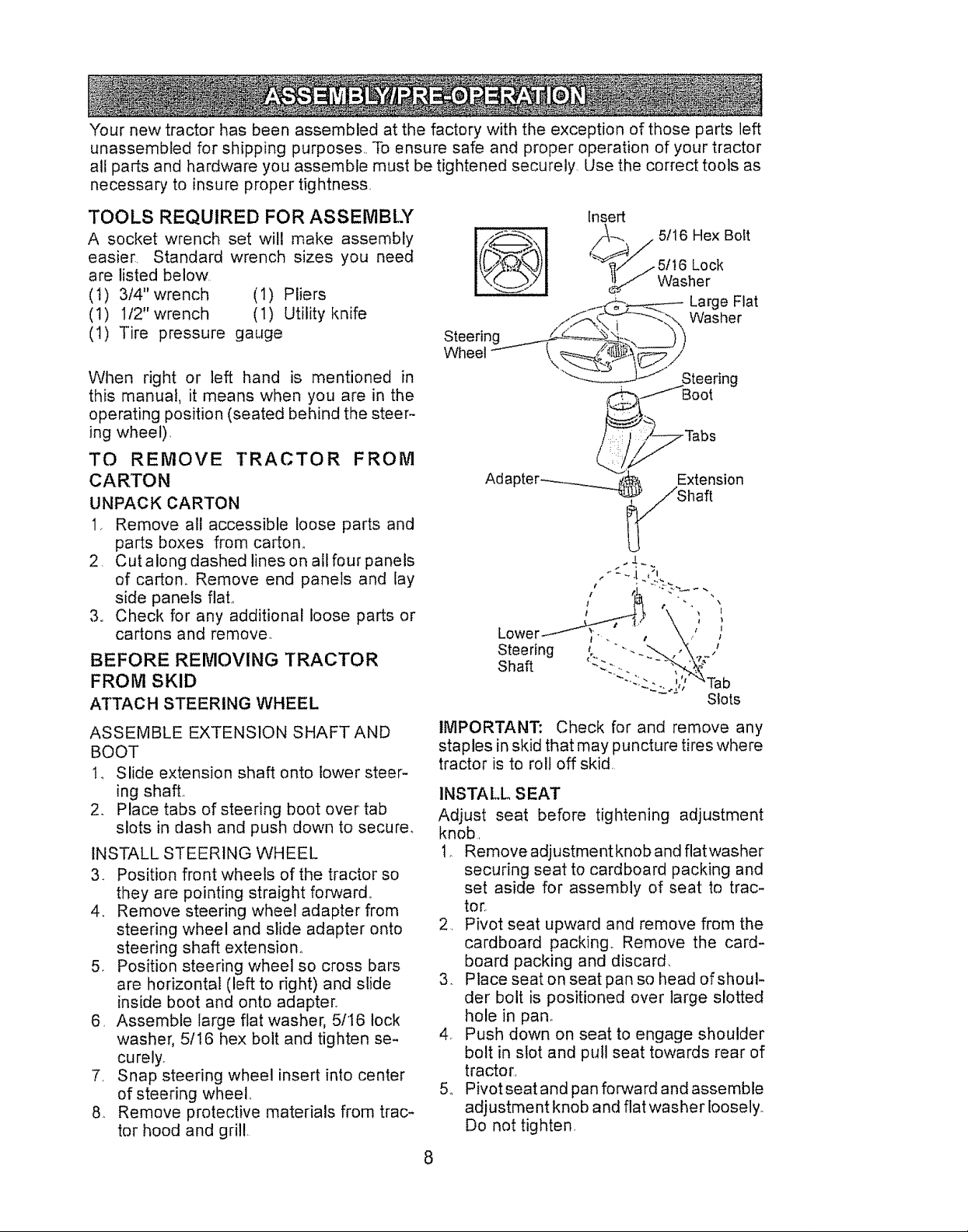

Your new tractor has been assembled at the factory with the exception of those parts left

unassembled for shipping purposes,, To ensure safe and proper operation of your tractor

all parts and hardware you assemble must be tightened securely Use the correct tools as

necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier, Standard wrench sizes you need

are listed below,

(I) 3/4"wrench (1) Pliers

(1) 1/2"wrench (1) Utility knife

(1) Tire pressure gauge

When right or left hand is mentioned in

this manual, it means when you are in the

operating position (seated behind the steer-

ing wheel),

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

1, Remove all accessible loose parts and

parts boxes from carton°

2, Cut along dashed lines on all four panels

of carton.. Remove end panels and lay

side panels flat,,

3,, Check for any additional loose parts or

cartons and remove,

BEFORE REMOVING TRACTOR

FROM SKID

ATTACH STEERING WHEEL

ASSEMBLE EXTENSION SHAFT AND

BOOT

t. Slide extension shaft onto lower steer-

ing shaft.

2. Place tabs of steering boot over tab

slots in dash and push down to secure,

INSTALL STEERING WHEEL

3. Position front wheels of the tractor so

they are pointing straight forward,,

4. Remove steering wheel adapter from

steering wheel and slide adapter onto

steering shaft extension.

5, Position steering wheel so cross bars

are horizontal (left to right) and slide

inside boot and onto adapter,

6, Assemble large flat washer, 5t16 lock

washer, 5t16 hex bolt and tighten se-

curely.

7, Snap steering wheel insert into center

of steering wheel,

8. Remove protective materials from trac-

tor hood and grill,

Insert

.K ,,*-!_ _-----_ \

Steering

Wheel

IMPORTANT: Check for and remove any

staples in skid that may puncture tires where

tractor is to roll off skid,

INSTALL SEAT

Adjust seat before tightening adjustment

knob,

t_ Removeadjustmentknoband flatwasher

securing seat to cardboard packing and

set aside for assembly of seat to trac-

tor.

2, Pivot seat upward and remove from the

cardboard packing,, Remove the card-

board packing and discard,

3. Place seat on seatpan so head ofshoul-

der bolt is positioned over large slotted

hole in pan°

4, Push down on seat to engage shoulder

bolt in slot and pull seat towards rear of

tractor,

5_ Pivotseatand pan forward and assemble

adjustment knob and flat washer Ioosely_

Do not tighten,

/_-.,., 5116 Hex Bolt

Washer

. /16 Lock

Large Flat

Washer

8

Page 9

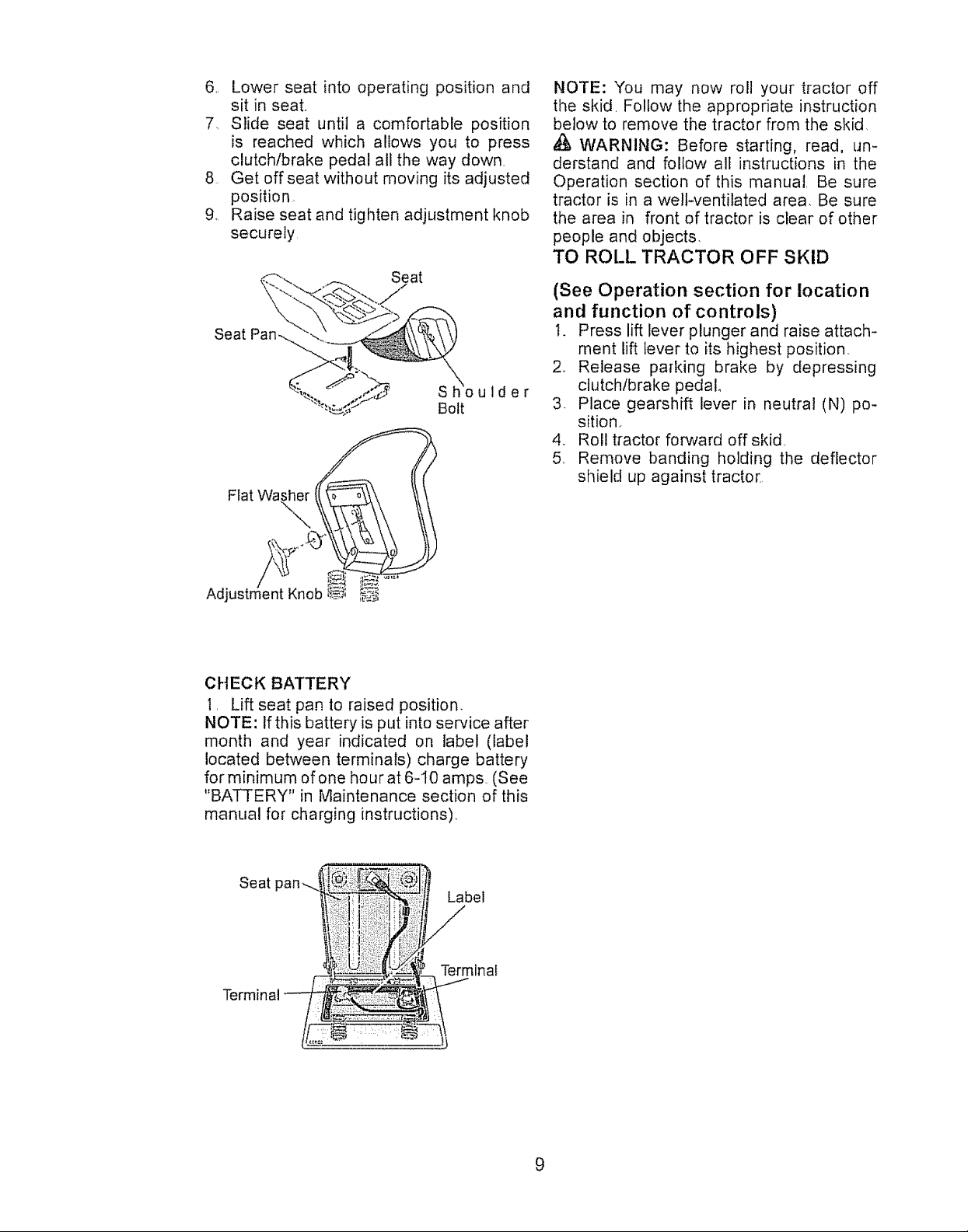

6. Lower seat into operating position and

sit in seat.

7, Slide seat until a comfortable position

is reached which allows you to press

clutchlbrake pedal all the way down.

8. Get off seat without moving its adjusted

position.

9.. Raise seat and tighten adjustment knob

securely

d"-,-. _ Seat

Seat Pa ....

'"a, 4_' S h o

"_X"',-..,,_"M" _nl_

ulder

Flat Wa_..h_

NOTE: You may now roll your tractor off

the skid. Follow the appropriate instruction

below to remove the tractor from the skid

,_ WARNING: Before starting, read, un-

derstand and follow all instructions in the

Operation section of this manual. Be sure

tractor is in a well-ventilated area. Be sure

the area in front of tractor is clear of other

people and objects.

TO ROLL TRACTOR OFF SKID

(See Operation section for location

and function of controls)

I. Press lift lever plunger and raise attach-

ment lift lever to its highest position.

2_ Release pa[king brake by depressing

clutchlbrake pedal°

3. Place gearshift lever in neutral (N) po-

sition.

4. Roll tractor forward off skid.

5. Remove banding holding the deflector

shield up against tractor.

Adjl Knob

CHECK BATTERY

I, Lift seat pan to raised position.

NOTE: tfthis battery is put into service after

month and year indicated on label (label

located between terminals) charge battery

for minimum of one hour at 6-t0 amps, (See

"BATTERY" in Maintenance section of this

manual for charging instructions).

Seat

Label

Terminal

9

Page 10

CHECK TIRE PRESSURE

The tires on your tractorwere overinflated at

the factory for shipping purposes Correct

tire pressure is important for best cutting

performance.

. Reduce tire pressure to PSI shown on

tires_

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

CHECK FOR PROPER POSITION

OF ALL BELTS

See the figures that are shown for replac-

ing motion and mower blade drive belts in

the Service and Adjustments section of this

manual° Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,

check to see that the brake is operating

properly. See "TO CHECK BRAKE" in the

Service and Adjustments section of this

manual°

_"CHECKLIS T

Before you operate and enjoy your new

tractor, we wish to assure that you receive

the best performance and satisfaction from

this Quality Product..

Please review the following checklist:

v/All assembly instructions have been corn-

pleted.

•/'No remaining loose parts in carton,,

v/Battery is properly prepared and

charged.

•/'Seat is adjusted comfortably and

tightened securely

•,/All tires are properly inflated (For ship-

ping purposes, the tires were overinflated

at the factory)

V/Be sure mower deck is properly leveled

side4o-side/front-to-rear for best cutting

results. (Tires must be properly inflated

for leveling)_

'v/Check mower and drive belts Be sure

they are routed properly around pulleys

and inside all belt keepers.

v/Check wiring. See that all connections

are still secure and wires are properly

clamped.

While learning how to use your tractor, pay

extra attention to the following important

items:

v/Engine oil is at proper level.

•/'Fuel tank is filled with fresh, clean, regular

unleaded gasoline

v/Become familiar with all controls - their

location and function. Operatethem before

you start the engine_

.i/Be sure brake system is in safe operating

condition..

V/Be sure Operator Presence System and

Reverse Operation System (ROS) are

working properly (See the Operation and

Maintenance sections in this manual)_

10

Page 11

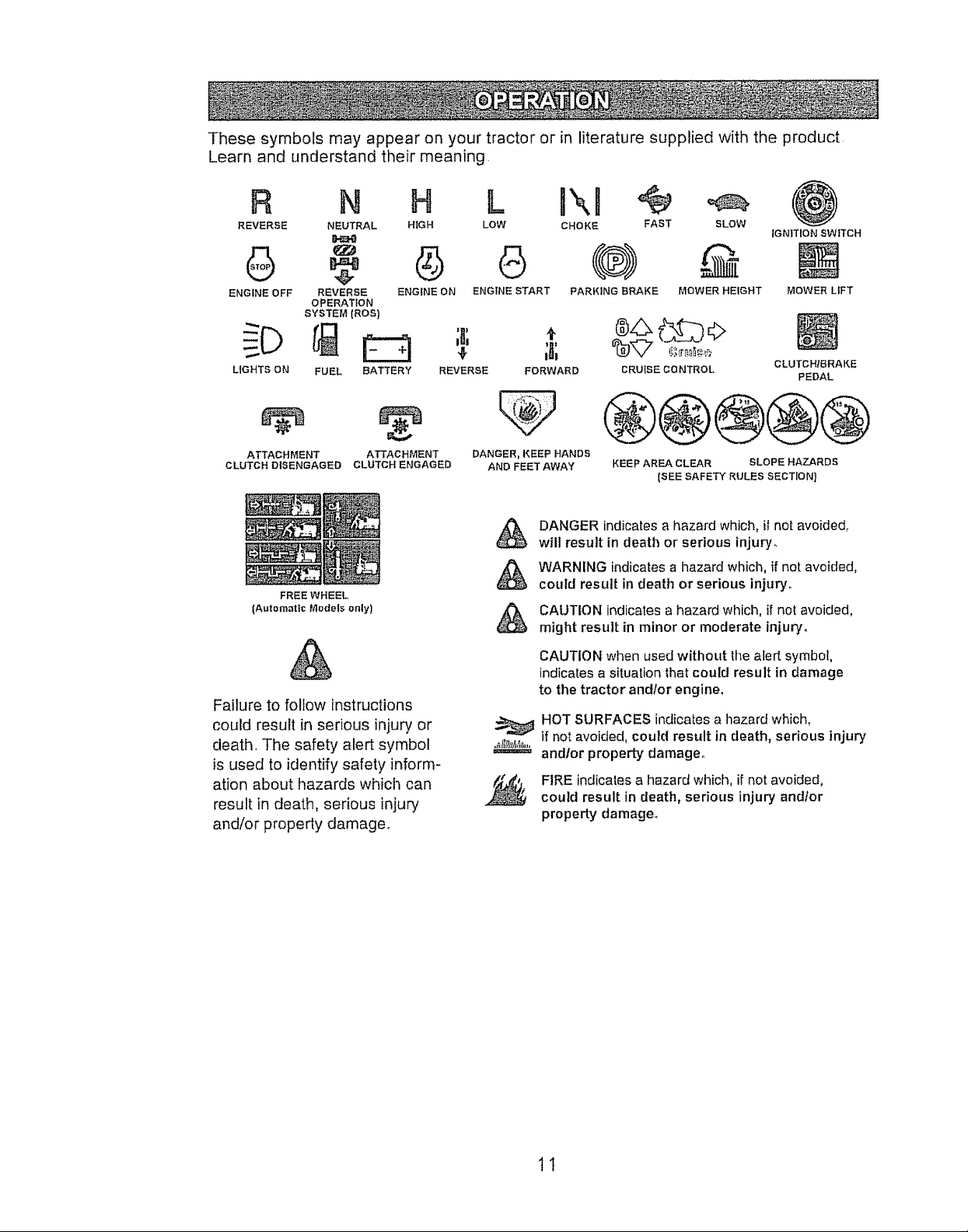

These symbols may appear on your tractor or in literature supplied with the product

Learn and understand their meaning,

R H L IXR @ @

REVERSE HIGH LOW CHOKE FAST SLOW

ENGINE OFF REVERSE ENGINE ON ENGINE START PARKING BRAKE MOWER HEIGHT

N

NEUTRAL

OPERATION

SYSTEM{ROS)

IGNITION SWITCH

MOWER LIFT

@

LIGHTS ON FUEL, BATTERY REVERSE FORWARD CRUISE CONTROL CLUTCHtBRAKE

PEDAL

®@@@@

ATTACHMENT ATTACHMENT DANGER, KEEP HANDS

CLUTCH DISENGAGED CLUTCH ENGAGED AND FEET AWAY

DANGER indicates a hazard which, if not avoided_

will result in death or' serious injury.

WARNING indicates a hazard which, if not avoided

FREE WHEEL

{Automatic Models only I

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided

might result in minor or moderate injury.

KEEP AREA CLEAR SLOPE HAZARDS

[SEE SAFETY RULES SECTION)

Failure to follow instructions

could result in serious injury or

death, The safety alert symbol

is used to identify safety inform-

ation about hazards which can

result in death, serious injury

and/or property damage.

CAUTION when used without the alert symbol,

indicates a situation that could result in damage

to the tractor andlor engine.

HOT SURFACES indicates a hazard which,

if not avoided, could result in death, serious injury

and/or property damage.

FIRE indicates a hazard which, if not avoided,

could result in death, serious injury and/or

property damage°

1!

Page 12

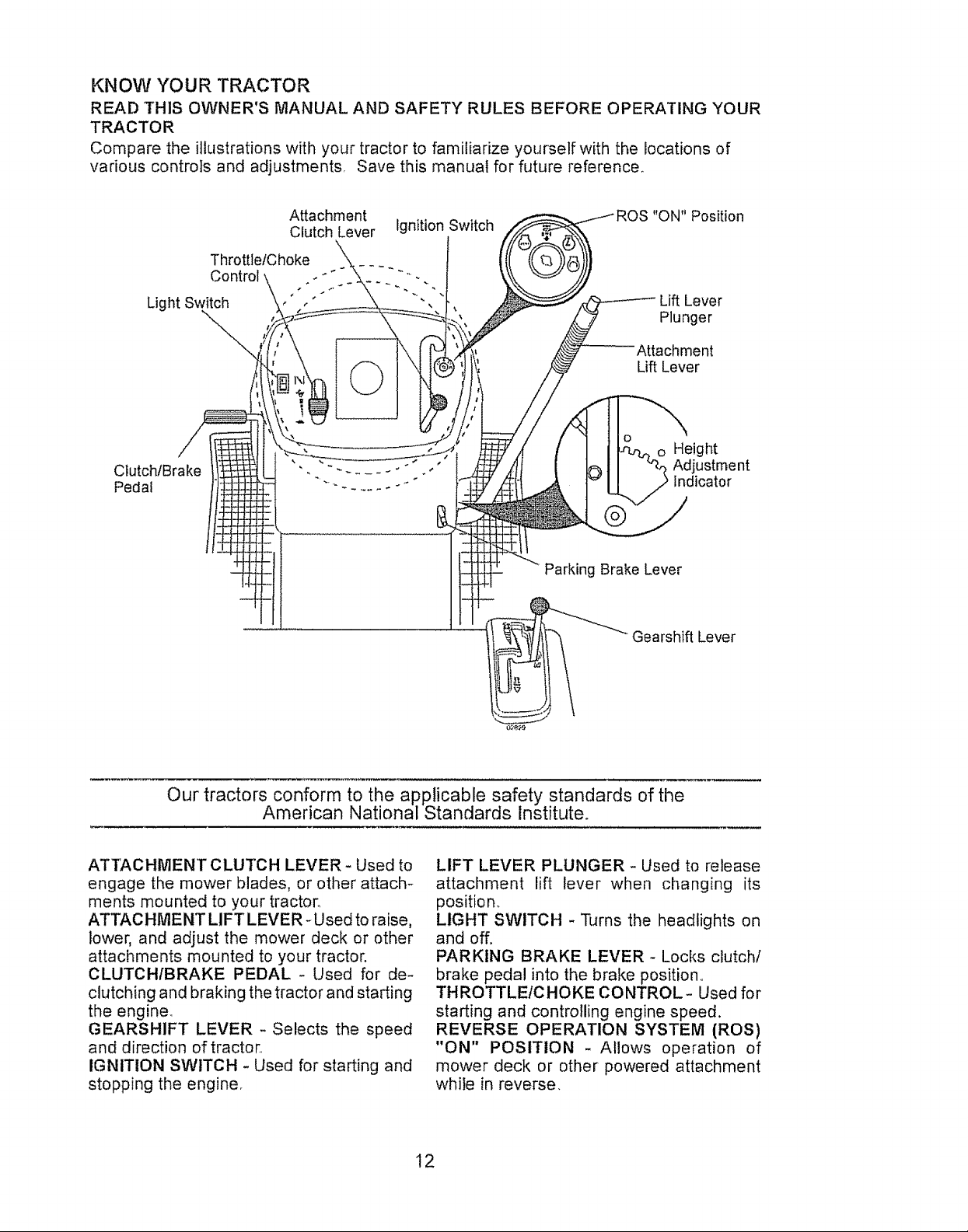

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

TRACTOR

Compare the illustrations with your tractor to familiarize yourself with the locations of

various controls and adjustments, Save this manual for future reference°

Light Switch

Clutch/Brake

Pedal

Attachment

Clutch Lever Ignition Switch

ThrottlelChoke X- - _.

Control .. -" \_.___ "" -

-.\

"ON" Position

Lift Lever

Plunger

Attachment

Lift Lever

o Height

Adjustment

Indicator

Parking Brake Lever

Gearshift Lever

Our tractors conform to the applicable safety standards of the

American National Standards Institute°

ATTACHMENT CLUTCH LEVER - Used to

engage the mower blades, or other attach-

ments mounted to your tractor.

ATTACHMENT LIFT LEVER _Used to raise,

lower, and adjust the mower deck or other

attachments mounted to your tractor.

CLUTCH/BRAKE PEDAL - Used for de-

clutching and braking the tractor and starting

the engine.,

GEARSHIFT LEVER - Selects the speed

and direction of tractor.,

IGNITION SWITCH - Used for starting and

stopping the engine.

0,2#_'9

LIFT LEVER PLUNGER - Used to release

attachment lift lever when changing its

position,,

LIGHT SWITCH - Turns the headlights on

and off.

PARKING BRAKE LEVER - Locks clutch/

brake pedal into the brake positiom

THROTTLE/CHOKE CONTROL- Used for

starting and controlling engine speed.

REVERSE OPERATION SYSTEM (ROS)

"ON" POSITION -Allows operation of

mower deck or other powered attachment

while in reverse.

12

Page 13

The operation of any tractor can result in foreign objects thrown into

the eyes, which can result in severe eye damage, Always wear safety

glasses or eye shields while operating your tractor or performing any

adjustments or repairs, We recommend a wide vision safety mask over

spectacles or standard safety glasses,

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE

Your tractor is equipped with an operator

presence sensing switch. When engine is

running, any attempt bythe operator to leave

the seat without first setting the parking brake

will shut off the engine°

I. Depress clutch/brake pedal all the way

down and hold.

2, Pull parking brake lever Lip and release

pressure from clutch!brake pedal. Pedal

should remain in brake position. Make

sure parking brake will hold tractor se-

cure.

Throttle/ Attachment Clutch Lever

Choke Position

Control \\ Key

laged"

"Brake" Position

Position

Clutch/Brake

Pedal

STOPPING

MOWER BLADES-

. To stop mower blades, move attachment

clutch lever to disengaged position,

GROUND DRIVE-

• To stop ground drive, depress clutch/brake

pedal all the way down..

• Move gearshift lever to neutral (N) po-

sition_

"Disengaged" Lever

Position

Parking Brake

"Engaged"

Position

Gearshift

ENGINE -

• Move throttle control between halfand full

speed (fast) position,

NOTE: Failure to move throttle control

between half and full speed (fast) posi-

tion, before stopping, may cause engine to

"backfire",

. Turn ignition key to"STOP" position and re-

move key. Always remove key when leav-

ing tractor to prevent unauthorized use

. Never use choke to stop engine°

IMPORTANT: Leaving the ignition switch in

any position other than "STOP" will cause

the battery to discharge and go dead,

NOTE: Undercertain conditions when tractor

is standing idle with the engine running, hot

engine exhaust gases may cause "brown-

ing" of grass, To eliminate this possibility,

always stop engine when stopping tractor

on grass areas,

_CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position,

TO USE THROTTLE CONTROL

Always operate engine at full speed (fast).

• Operating engine at less than full speed

(fast) reduces engine's operating effi-

ciency

• Full speed (fast) offers the best mower

performance

TO MOVE FORWARD AND BACKWARD

The direction and speed of movement is

controlled by the gearshift lever_

1. Start tractor with clutch/brake pedal

depressed and gearshift lever in neutral

(N) position.

2 Move gearshift lever to desired po-

sition.

3., Slowly release clutchtbrake pedal to start

movemenL

IMPORTANT: Bring tractor to a complete

stop before shifting or changing gears.

Failure to do so will shorten the useful life

of your transaxle,

TO ADJUST MOWER CUTTING HEIGHT

The position of the attachment lift lever

determines the cutting height.

. Grasp lift lever.

• Press plungerwith thumb and move lever

to desired position.

The cutting height range is approximately

1-1/2 to 4" The heights are measured from

the ground to the blade tip with the engine

not running These heights are approximate

and may vary depending upon soil condi-

tions, height of grass and types of grass

being mowed,

13

Page 14

• The average lawn should be cut to ap-

proximately 2-I/2 inches during the cool

season and to over 3 inches during hot

months. For healthier and better looking

lawns, mow often and after moderate

growth..

. For best cutting performance, grass over

6 inches in height should be mowed twice

Make the first cut relatively high; the sec-

ond to desired height.

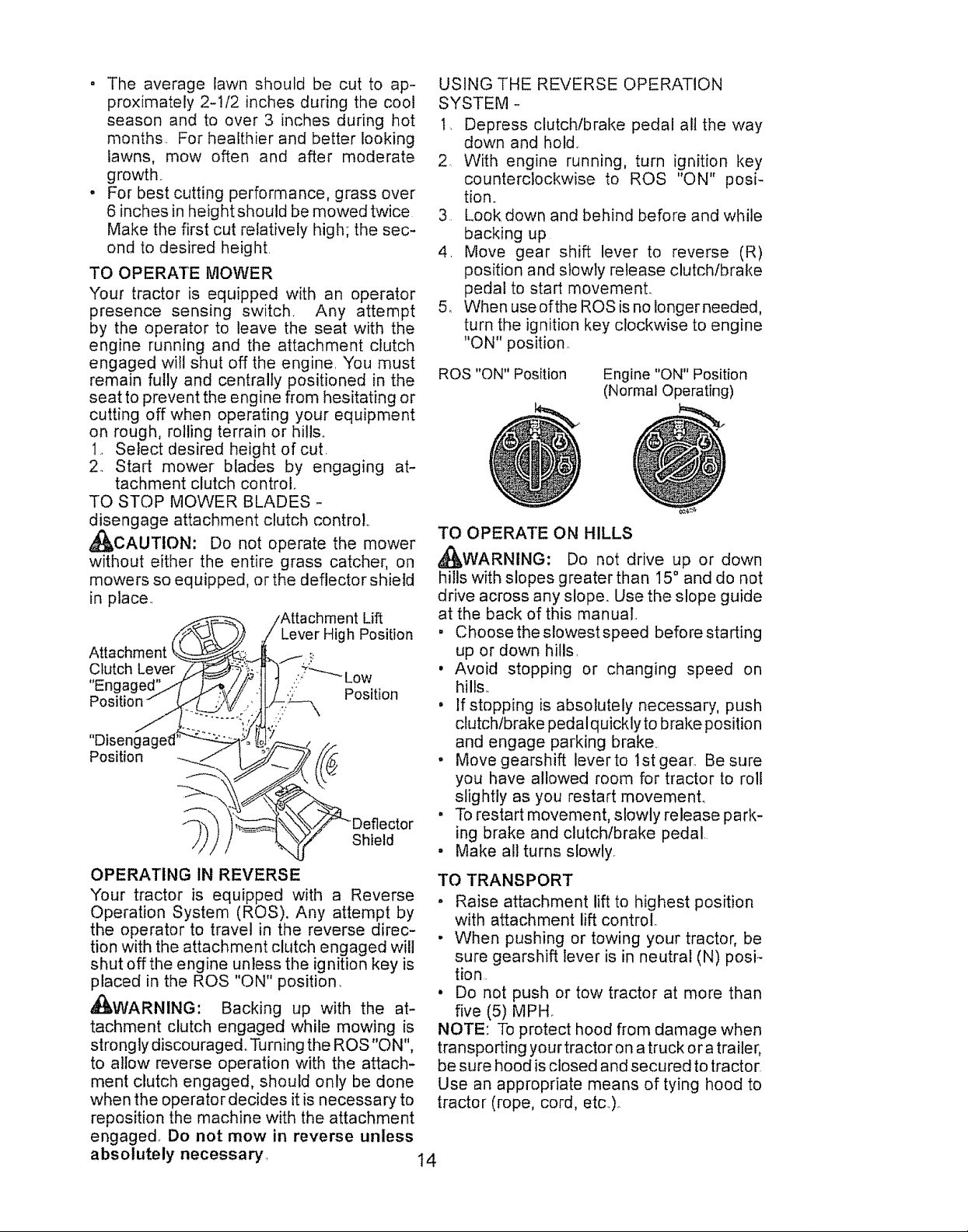

TO OPERATE MOWER

"four tractor is equipped with an operator

presence sensing switch. Any attempt

by the operator to leave the seat with the

engine running and the attachment clutch

engaged will shut off the engine. You must

remain fully and centrally positioned in the

seat to prevent the engine from hesitating or

cutting off when operating your equipment

on rough, rolling terrain or hills_

1. Select desired height of cut.

2. Start mower blades by engaging at-

tachment clutch control_

TO STOP MOWER BLADES -

disengage attachment clutch control..

,_CAUTION: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, or the deflector shield

in place.,

t Lift

Lever High Position

Attachment

Clutch Lever

"Engaged

"Disen,

Position _

Shield

OPERATING IN REVERSE

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator to travel in the reverse direc-

tion with the attachment clutch engaged will

shut offthe engine unless the ignition key is

placed in the ROS "ON" position.

,_WARNING: Backing up with the at-

tachment clutch engaged while mowing is

strong ly discouraged,. Turn ing the ROS "ON",

to allow reverse operation with the attach-

ment clutch engaged, should only be done

when the operator decides it is necessary to

reposition the machine with the attachment

engaged. Do not mow in reverse unless

absolutely necessary.

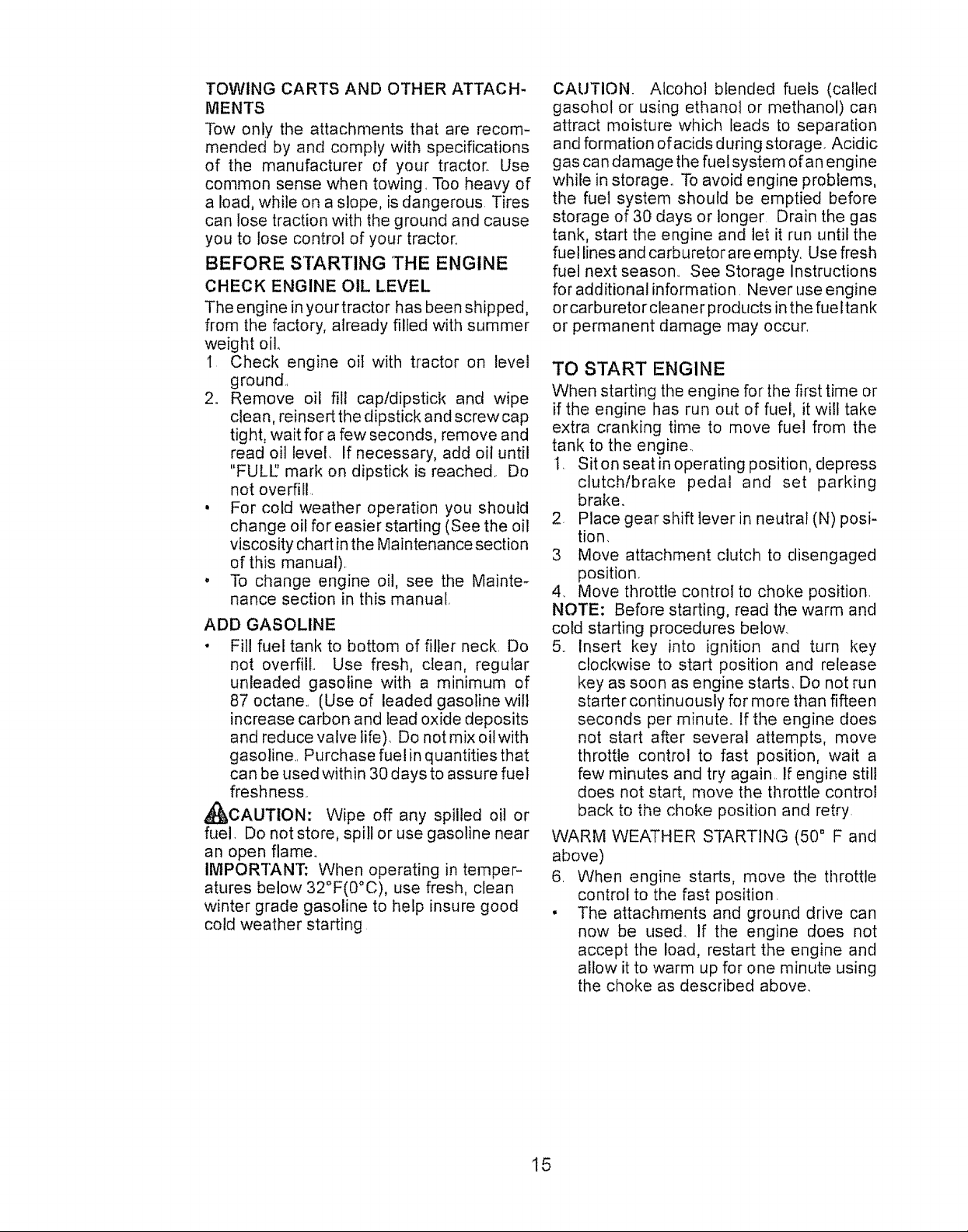

USING THE REVERSE OPERATION

SYSTEM -

1. Depress clutchtbrake pedal alt the way

down and hold.

2, With engine running, turn ignition key

counterclockwise to ROS "ON" posi-

tion..

3 Look down and behind before and wMle

backing up

4. Move gear shift lever to reverse (R)

position and slowly release clutchfbrake

pedal to start movement.

5_ When use ofthe ROS is no longer needed,

turn the ignition key clockwise to engine

"ON" position.

ROS "ON" Position

TO OPERATE ON HILLS

_!_WARNING: Do not drive up or down

hills with slopes greater than 15° and do not

drive across any slope. Use the slope guide

at the back of this manual.

• Choosetheslowestspeed before starting

up or down hills.

, Avoid stopping or changing speed on

hills.

, If stopping is absolutely necessary, push

clutch/brake pedal quickly to brake position

and engage parking brake.

. Move gearshift lever to 1st gear. Be sure

you have allowed room for tractor to roll

slightly as you restart movement.

. To restart movement, slowly release park-

ing brake and clutch/brake pedal.

o Make all turns slowly.

TO TRANSPORT

. Raise attachment lift to highest position

with attachment lift control..

• When pushing or towing your tractor, be

sure gearshift lever is in neutral (N) posF

tion..

. Do not push or tow tractor at more than

five (5) MPH

NOTE: To protect hood from darnage when

transporting yourtractor on atruck ora trailer,

be sure hood is closed and secured to tractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.)°

Engine "ON" Position

(Normal Operating)

14

Page 15

TOWING CARTS AND OTHER ATTACH-

MENTS

Tow only the attachments that are recom-

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when towing. Too heavy of

a load, while on a slope, is dangerous Tires

can lose traction with the ground and cause

you to lose control of your tractor.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine inyour tractor has been shipped,

from the factory, already filled with summer

weight oil.

t Check engine oil with tractor on level

ground.,

2o Remove oil fill captdipstick and wipe

clean, reinsert the dipstick and screw cap

tight, wait for a few seconds, remove and

read oil level. If necessary, add oil until

"FULL' mark on dipstick is reached.. Do

not overfill.

• For cold weather operation you should

change oil for easier starting (See the oil

viscosity chart in the Maintenance section

of this manual).

, To change engine oil, see the Mainte-

nance section in this manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do

not overfill.. Use fresh, clean, regular

unleaded gasoline with a minimum of

87 octane.. (Use of leaded gasoline will

increase carbon and lead oxide deposits

and reduce valve life). Do not mix oilwith

gasoline. Purchase fuel in quantities that

can be used within 30 days to assure fuel

freshness_

_CAUTION: Wipe off any spilled oil or

fuel. Do not store, spill or use gasoline near

an open flame.

IMPORTANT: When operating in temper-

atures below 32°F(0°C), use fresh, clean

winter grade gasoline to help insure good

cold weather starting

CAUTION. Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation

and formation of acids during storage.. Acidic

gas can damage the fuel system of an engine

while in storage. To avoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer Drain the gas

tank, start the engine and let it run until the

fuel lines and carburetor are empty. Use fresh

fuel next season.. See Storage Instructions

for additional information. Never use engine

or carburetor cleaner products in the fueltank

or permanent damage rnay occur,

TO START ENGINE

When starting the engine for the first time or

if the engine has run out of fuel, it will take

extra cranking time to move fuel from the

tank to the engine..

I. Siton seat in operating position, depress

clutch/brake pedal and set parking

brake.

2 Place gearshift lever in neutral (N) posi-

tion,

3 Move attachment clutch to disengaged

position.

4. Move throttle controi to choke position.

NOTE: Before starting, read the warm and

cold starting procedures below.

5. Insert key into ignition and turn key

clockwise to start position and release

key as soon as engine starts, Do not run

starter continuously for more than fifteen

seconds per minute. If the engine does

not start after several attempts, move

throttle control to fast position, wait a

few minutes and try again. If engine still

does not start, move the throttle control

back to the choke position and retry.

WARM WEATHER STARTING (50 ° F and

above)

6. When engine starts, move the throttle

control to the fast position.

• The attachments and ground drive can

now be used If the engine does not

accept the load, restart the engine and

allow it to warm up for one minute using

the choke as described above_

15

Page 16

COLD WEATHER STARTING ( 50 ° F and

below)

6, When engine starts, leave throttle control

in choke position until engine warms up

and begins to run roughly, Once rough

running begins, immediately move the

throttle controlto the fast position_ Engine

warm-up may take from several seconds

to several minutes (the colder the tem-

perature, the longer the warm-up),

o The attachments can also be used during

the engine warm-up period,

NOTE: If at a high altitude (above 3000

feet) or in cold temperatures (below 32 F)

the carburetor fuel mixture may need to be

adjusted for best engine performance (see

"TOADJUSTCARBURETOR"in the Service

and Adjustments section of this manual)°

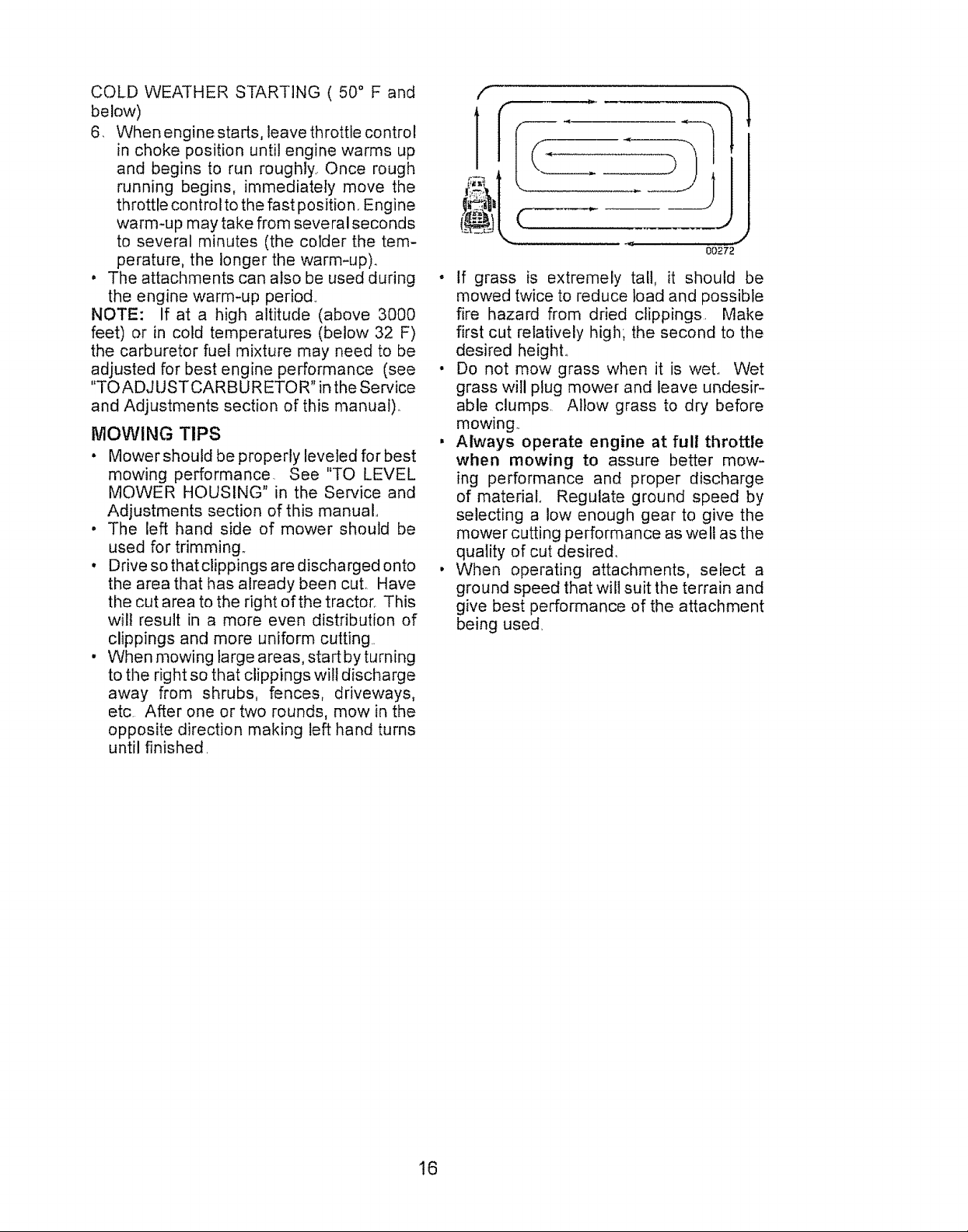

MOWING TIPS

• Mowershoutd be properly leveled forbest

mowing performance See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual

o The left hand side of mower should be

used for trimming.

• Drive so thatclippings are discharged onto

the area that has already been cut, Have

the cut area to the right of the tractor. This

will result in a more even distribution of

clippings and more uniform cutting

. When mowing large areas, start by turning

to the right so that clippings will discharge

away from shrubs, fences, driveways,

etc After one or two rounds, mow in the

opposite direction making left hand turns

until finished.

................

00272

• If grass is extremely tall, it should be

mowed twice to reduce toad and possible

fire hazard from dried clippings. Make

first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet

grass will plug mower and leave undesir-

able clumps. Allow grass to dry before

mowing..

, Always operate engine at full throttle

when mowing to assure better mow-

ing performance and proper discharge

of material Regulate ground speed by

selecting a low enough gear to give the

mower cutting performance as well as the

quaIity of cut desired.

, When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

16

Page 17

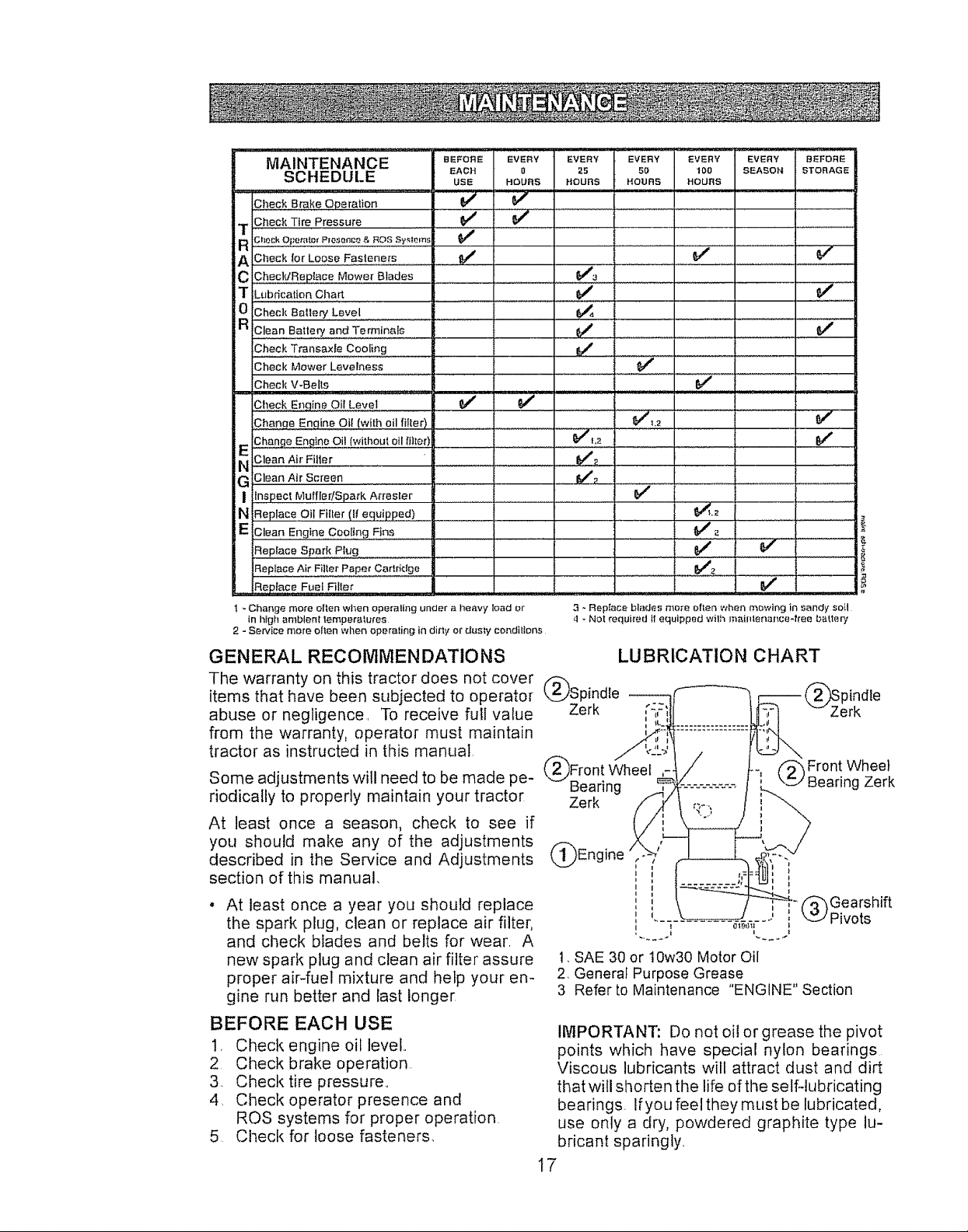

MAINTENANCE eEFo.E EVE.Y EVE.Y EVE.'r EVERY EVERY SEFO.E

SCHEDULE EACH . =5 50 loo SEASO. STO.AGE

Cl_eckBrakeOperation _ _

USE HOURS HOU}3S HOURS HOUriS

TCheckTireProsoure...................................... .................

A Check lor Loose Fasteners _ _

C ChecldReplace Mower Blades

T LubdcatioR Chart _

0 Check BaHery Level

R C,ean Battery and Termina,e ...... ,/ .......... "_ ................... ......_

Check 7_nsax!e Coo!i!'_g i_ ............ _ :

Check Mower Levelness

Check V-Belts

Cl)eck_E_;_ine Oil Level _ 6f

C,h,ange Engine Oil (with oil filter) _ii_ ........

Change En,g!ne 0i! (Without oil filter 6/'h2 , _ .

E Clean Air Filter .................

G Clean Air Screen ...................................................

| Inspect MuffledSpark Arresler _#'

N Replace OH Filler (l! eguip#ed)

E Clean Engine €00 ng F:{]s ....... _" _ , , _

Replace SPa[.!_....P!ug _ , _

Replace Air Filter Paper Cartridge ................. 6_1'_....................... €,

,R....eplaceFuel Filler 6/ _

! - Change more ellen when operating under a heavy Send or

tn high ambien! temperatures

2 - Service more oiten when operating in dirty or dusty condiHons

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover

items that have been subjected to operator

abuse or negligence, To receive full value

from the warranty, operator must maintain

tractor as instructed in this manual.

Some adjustments will need to be made pe-

riodically to properly maintain your tractor

At least once a season, check to see if

you should make any of the adjustments

described in the Service and Adjustments

section of this manual.

H '1 II!11_1 I '_l'/'J'" "1

3 _RepIace blades more often when mowing in sandy soil

4 -Not requbed if equipped wilh maildenance-free baltery

LUBRICATION CHART

Spindle

Zerk ,,

(_Front Wheel ,-

Bearing

Zerk

(_Engine

Zerk

Front Wheel

&

£

g Zerk

At least once a year you should replace

the spark plug, clean or replace air filter,

and check blades and belts for wear, A

new spark plug and clean air filter assure

proper air-fuel mixture and help your en-

gine run better and last longer

BEFORE EACH USE

1, Check engine oil level.,

2 Check brake operation

3, Check tire pressure,,

4, Check operator presence and

ROS systems for proper operation

5 Check for loose fasteners,

1, SAE 30 or 10w30 Motor Oil

2, General Purpose Grease

3 Refer to Maintenance "ENGINE" Section

IMPORTANT: Do not oil or grease the pivot

points which have special nylon bearings

Viscous lubricants will attract dust and dirt

that will shorten the life of the self-lubricating

bearings, Ifyou feel they must be lubricated,

use only a dry, powdered graphite type lu-

bricant sparingly,,

17

Page 18

TRACTOR

Alwaysobservesafetyruleswhenperforming

anymaintenance

BRAKEOPERATION

Iftractor requiresmorethanfive(5)feetto

stopat highestspeedin highestgearon a

level,dry concreteorpavedsurface,then

brakemustbecheckedandadjusted,(See

"TO CHECK BRAKE"in the Serviceand

Adjustmentssectionof thismanual)°

TIRES

. Maintainproper air pressurein all tires

(Seesides oftirefor properPSI)..

• Keeptires free of gasoline,oil, or insect

controlchemicalswhichcanharmrubber.

• Avoid stumps,stones,deep ruts,sharp

objectsandotherhazardsthatmaycause

tiredamage,,

NOTE:To sealtire puncturesandprevent

flattiresdueto slowleaks,tiresealantmay

bepurchasedfromyour localpartsdealer,

Tire sealantalso preventstire dry rotand

corrosion°

OPERATORPRESENCESYSTEMAND

REVERSEOPERATIONSYSTEM(ROS)

Be sure operator presence and reverse

operationsystemsareworkingproperly.If

yourtractordoesnotfunctionasdescribed,

repairthe problemimmediately_

• The engine shouldnotstart unlessthe

brake pedal is fully depressed,and the

attachmentclutchcontrolisin thedisen-

gagedposition.

CHECK OPERATOR PRESENCE

SYSTEM

• Whentheengineisrunning,anyattempt

bytheoperatorto leavetheseatwithout

firstsettingtheparkingbrakeshouldshut

offtheengine.

. Whenthe engineis runningandtheat.-

tachmentclutchisengaged,anyattempt

bythe operatorto leavetheseatshould

shutofftheengine

• Theattachmentclutchshouldneveroper-

ateunlesstheoperatoris inthe seat,

CHECK REVERSEOPERATION(ROS)

SYSTEM

. Whentheengineisrunningwiththeignition

switchintheengine"ON"positionandthe

attachmentclutchisengaged,anyattempt

bythe operatorto gointoreverseshould

shutofftheengine

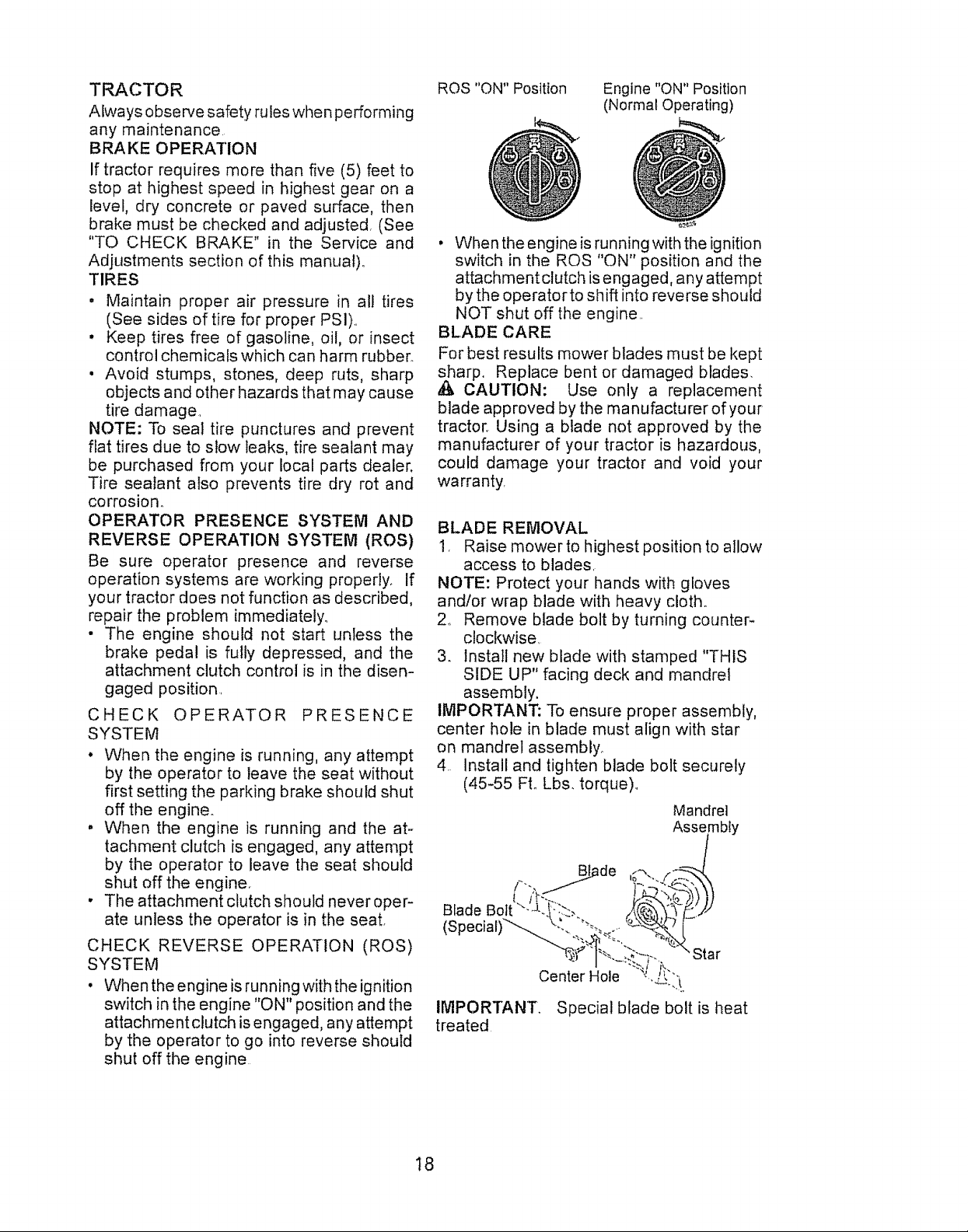

ROS "ON" Position

. When the engine is running with the ignition

switch in the ROS "ON" position and the

attachment clutch is engaged, any attempt

by the operator to shift into reverse should

NOT shut off the engine,

BLADE CARE

For best results mower blades must be kept

arp, Replace bent or damaged blades,

CAUTION: Use only a replacement

blade approved by the manufacturer of your

tractor, Using a blade not approved by the

manufacturer of your tractor is hazardous,

could damage your tractor and void your

warranty,

BLADE REMOVAL

!. Raise mower to highest position to allow

access to blades

NOTE: Protect your hands with gloves

and/or wrap blade with heavy cloth.

2, Remove blade bolt by turning counter-

clockwise

3. Install new blade with stamped "THIS

SIDE UP" facing deck and mandrel

assembly.

IMPORTANT: To ensure proper assembly,

center hole in blade must align with star

on mandrel assembly_

4. Install and tighten blade bolt securely

(45-55 Ft. Lbs. torque),,

Center Hole /_,".,

IMPORTANT. Special blade bolt is heat

treated

Engine "ON" Position

(Normal Operating)

Mandrel

Assembly

t8

Page 19

BATTERY

Your tractor has a battery charging system

which is sufficient for normal use. However,

periodic charging of the battery with an au-

tomotive charger will extend its life.

, Keep battery and terminals clean,,

, Keep battery bolts tight.

• Keep small vent holes open,

, Recharge at 6-10 amperes for 1 hour.

NOTE: The original equipment battery on

your tractor is maintenance free,, Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and termi-

nals can cause the battery to "leak" power,

I. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor:,

2, Rinse the battery with plain water and

dry,,

3., Clean terminals and battery cable ends

with wire brush until bright,,

4. Coat terminals with grease or petroleum

jelly,,

5. Reinstall battery (See "REPLACING

BATTERY" in the SERVICE AND AD-

JUSTMENTS section of this manual).

TRANSAXLE COOLING

Keep transaxle free from build-up of dirt and

chaff which can restrict cooling,

Check V-belts for deterioration and wear after

100 hours of operation and replace if neces-

sary. The belts are not adjustable, Replace

belts if they begin to slip from wear_

ENGINE

LUBRICATION

Only use high quality detergent oil rated with

API service classification SG-SL. Select the

oil's SAE viscosity grade according to your

expected operating temperature.

[ SAtvtscosrrvGnAOr_.S

_-2,J.. o 3o ._-_ _u _ . _,_

NOTE: Although multi-viscosity oils (5W30,

10W30 etco) improve starting in cold weather,

the oils wi!l result in increased oil consumption

when used above 32°F. Check yourengine

oil level more frequently to avoid possible

engine damage from running low on oil..

Change the oil after every 50 hours of opera-

tion or at least once a year if the tractor is

not used for 50 hours in one year. 19

Check the crankcase oil level before starting

the engine and after each eight (8) hours of

operation, Tighten oil fill captdipstick se-

curely each time you check the oil level,

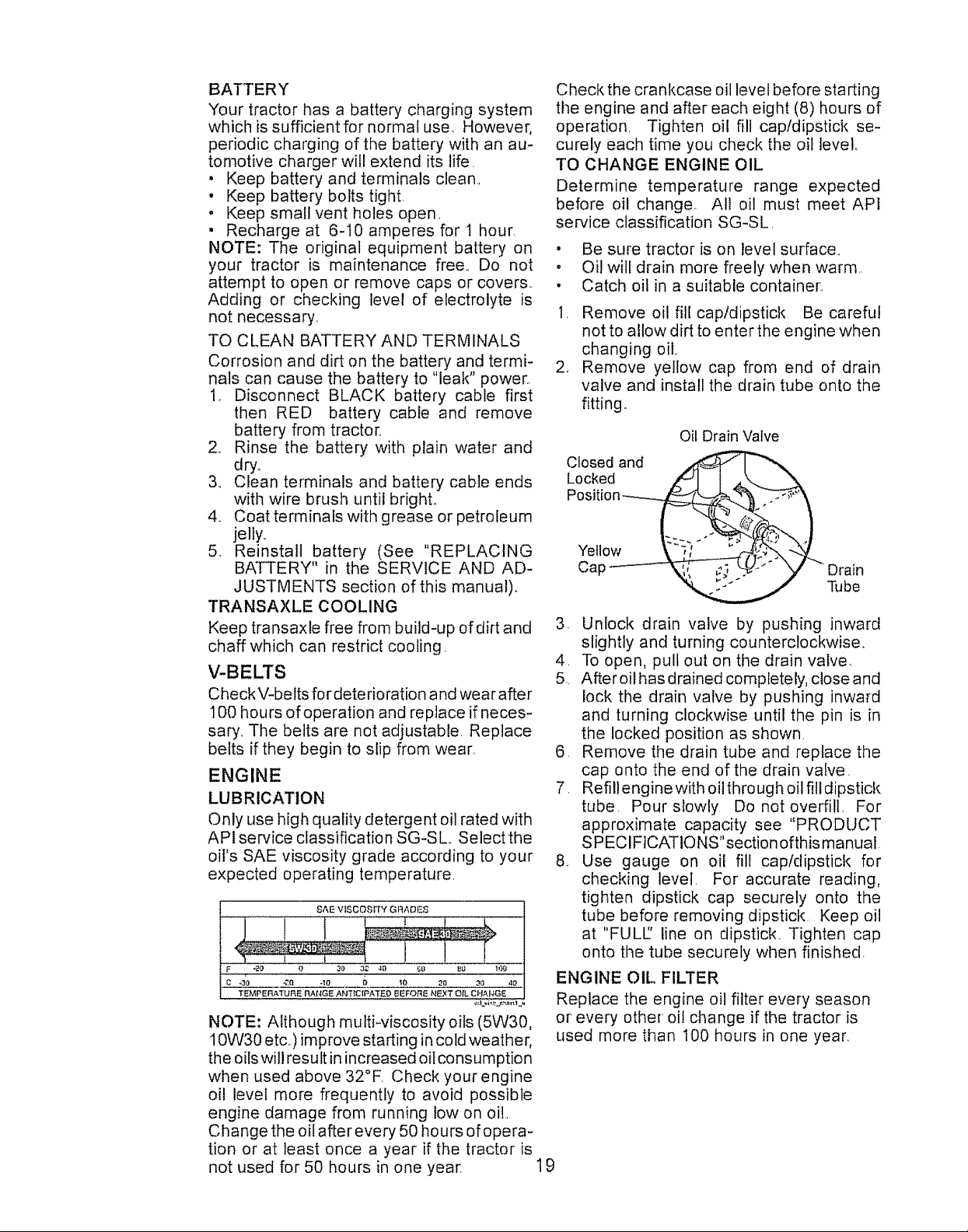

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change° All oil must meet API

service classification SG-SL.

Be sure tractor is on level surface,,

o

Oil will drain more freely when warm,_

e

Catch oil in a suitable container,,

1,

Remove oil fill capldipstick Be careful

not to allow dirt to enter the engine when

changing oil.,

2_

Remove yellow cap from end of drain

valve and install the drain tube onto the

fitting.

Oil Drain "Valve

Closed and

Locked

Posil

Yellow

_Drain

Cap

Tube

3. Unlock drain valve by pushing inward

slightly and turning counterclockwise.

4. To open, pull out on the drain valve.

5. After oil has drained completely, close and

lock the drain valve by pushing inward

and turning clockwise until the pin is in

the locked position as shown.

6, Remove the drain tube and replace the

cap onto the end of the drain valve.

7. Refill engine with oil through oil fill dipstick

tube, Pour slowly Do not overfill_ For

approximate capacity see "PRODUCT

S PEClFtCATIONS"section ofthismanual

8 Use gauge on oil fill capfclipstick for

checking level, For accurate reading,

tighten dipstick cap securely onto the

tube before removing dipstick Keep oil

at "FULE' line on dipstick, Tighten cap

onto the tube securely when finished,

ENGINE OIL. FILTER

Replace the engine oil filter every season

or' every other' oil change if the tractor is

used more than 100 hours in one year_

Page 20

IN-LINE FUEL FILTER

The fuel filtershould be replaced once each

season° If fuel filter becomes clogged, ob-

structing fuel flow to carburetor, replacement

is required

1.. With engine cool, remove fiiter and plug

fuel line sections.

2. Place new fuel filter in position in fuel line

with arrow pointing towards carburetor.

3, Be sure there are no fuel line leaks and

clamps are properly positioned..

4. Immediately wipe up any spilled gasoline,

CLEANING

• Clean engine, battery, seat, finish, etc of

all foreign matter..

• Keep finished surfaces and wheels free

of all gasoline, oil, etc

• Protect painted surfaces with automotive

type wax.

We do not recommend using a garden hose

or pressure washer to clean your tractor

unless the engine and transmission are

covered to keep water out, Water in engine

or transmission will shorten the useful life of

your tractor, Use compressed air or a leaf

blower to remove grass, leaves and trash

from tractor and mower.

I Filter

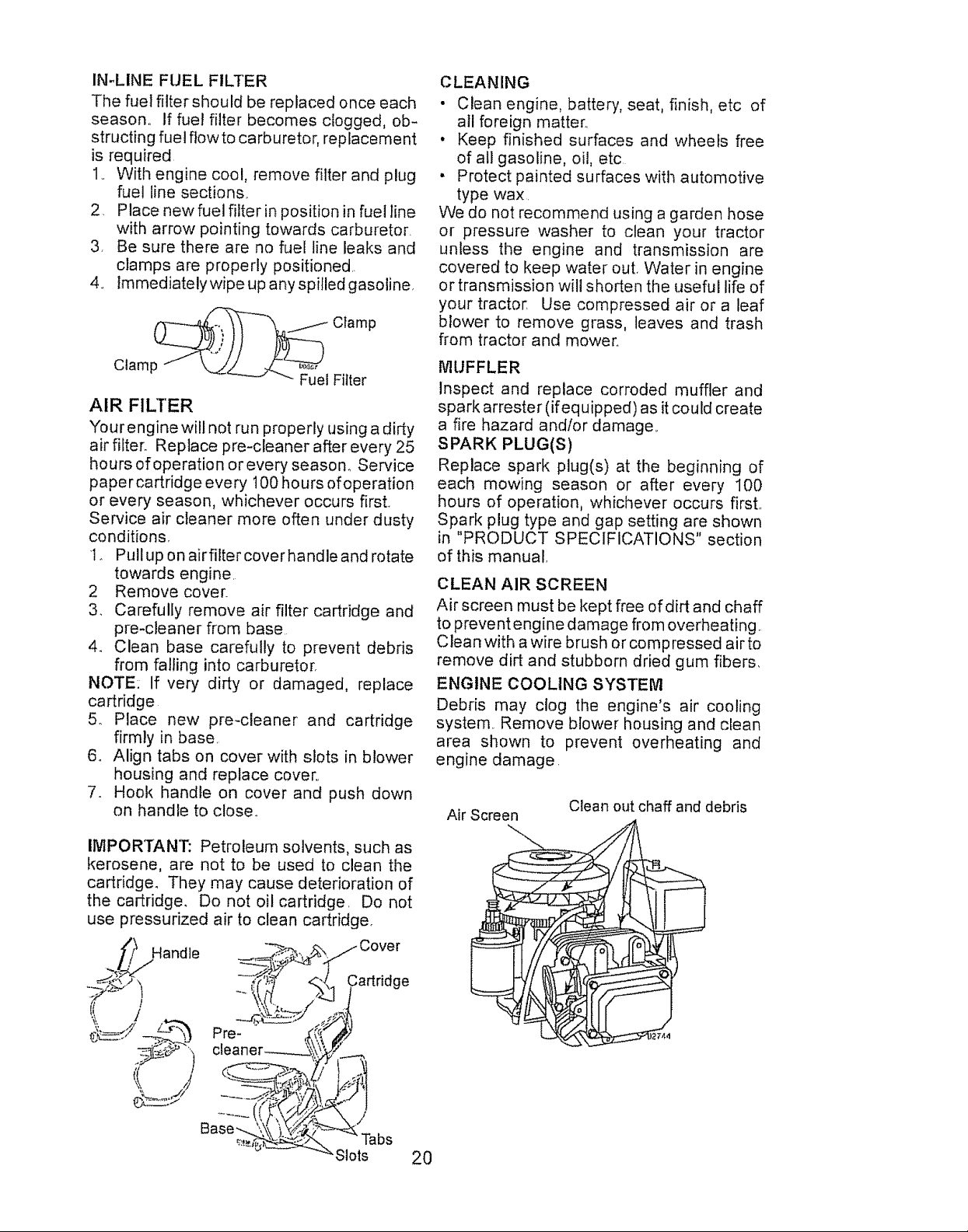

AIR FILTER

Yourengine will not run properly using a dirty

air filter° Replace pre-cleaner after every 25

hours of operation or every season. Service

papercartridge every 100 hours of operation

or every season, whichever occurs first.

Service air cleaner more often under dusty

conditions,

1. Pull up on airfilter cover handle and rotate

towards engine.

2 Remove cover.

3. Carefully remove air filter cartridge and

pre-cleaner from base.

4. Clean base carefully to prevent debris

from falling into carburetor.

NOTE: If very dirty or damaged, replace

cartridge

5. Place new pre-cleaner and cartridge

firmly in base.

6. Align tabs on cover with slots in blower

housing and replace cover..

7. Hook handle on cover and push down

on handle to close.

MUFFLER

Inspect and replace corroded muffler and

spark arrester (if equipped) as itcould create

a fire hazard and/or damage..

SPARK PLUG(S)

Replace spark plug(s) at the beginning of

each mowing season or after every I00

hours of operation, whichever occurs first°

Spark plug type and gap setting are shown

in "PRODUCT SPECIFICATIONS" section

of this manual,

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff

to prevent engine damage from overheating.

Clean with a wire brush or compressed air to

remove dirt and stubborn dried gum fibers,

ENGINE COOLING SYSTEM

Debris may clog the engine's air cooling

system, Remove blower housing and clean

area shown to prevent overheating and

engine damage.

Air Screen

Clean out chaff and debris

IMPORTANT: Petroleum solvents, such as

kerosene, are not to be used to clean the

cartridge. They may cause deterioration of

the cartridge, Do not oil cartridge. Do not

use pressurized air to clean cartridge.

_ Handle

ii, /

Slots 20

Page 21

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY

SERVICE OR ADJUSTMENTS:

1., Depress clutch/brake pedal fully and set parking brake.

2.. Place gearshift lever in neutral (N) position

3,. Place attachment clutch in "DISENGAGED" position.

4, Turn ignition key to "STOP" and remove key,.

5_ Make sure the blades and all moving parts have completely stopped

6. Disconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plugo

TRACTOR

TO REMOVE MOWER

Mower will be easier to remove from the

right side of tractor,

1. Place attachment clutch in "DISEN-

GAGED" position.

2.. Move attachment lift lever forward to

lower mower to its lowest position.

3, Roll belt off engine pulley

4. Remove small retainer spring, and re-

move clutch spring off pulley bolt,

5. Remove large retainer spring, slide col-

lar off and push housing guide out of

brackeL

6 Disconnect anti-sway bar from chassis

bracket by removing retainer spring

7. Disconnect suspension arms from rear

deck brackets by removing retainer

springs_

8 Disconnect front links from deck by re-

moving retainer springs..

9. Raise lift leverto raise suspension arms.

Slide mower out from under tractor

IMPORTANT: If an attachment other than the

mower deck is to be mounted on the tractor,

remove the front links and hook the clutch

spring into square hole in frame.

TO INSTALL MOWER

I. Raise attachment lift lever to its highest

position,

2, Slide mower under tractor with deflector

shield to right side of tractor,

3, Lower lift lever to its lowest position,

4, Connect front links to mower deck and

secure with retainer springs,

5, Connect suspension arms to rear deck

brackets and secure with retainer

springs,

6. Connect anti-sway barto chassis bracket

and secure with retainer spring.

7 Push clutch cable housing guide into

bracket, slide collar onto guide and secure

with large retainer spring.

8_ Place flat washer and clutch spring on

idler pulley bolt and secure with small

retainer spring.,

9, Install belt onto engine pulley

Small Retainer Spring

Clutch Spring

Retainer S

Anti-Sway Bar

Housing

Guide

Large Retainer Spring

Small Retainer Spring

Clutch S

Bracket

Front Link

Retainer Springs

Both Sides)

Deflector Shield

21

Page 22

TO LEVEL MOWER HOUSING

Adjust the mower while tractor is parked on

level ground or driveway. Make sure tires are

properly inflated (See side of tire for proper

PSI). If tires are over or underinflated, you

will not properly adjust your mower.

SIDE-TO-SIDE ADJUSTMENT

. Raise mower to its highest position.

. At the midpoint of both sides of mower,

measure height from bottom edge of

mower to ground.. Distance %" on both

sides of mower should be the same or

within 1t4" of each other,.

• If adjustment is necessary, make adjust-

ment on one side of mower only.

. To raise one side of mower, tighten lift link

adjustment nut on that side..

• To lower one side of mower, loosen lift link

adjustment nut on that side_

NOTE: Each fullturnofadjustmentnutwill

change mower height about !18".

. Recheck measurements after adjusting.

FRONT-TO-BACK ADJUSTMENT

Bottom edge Bottom edge of

of mower to ___. _ @Qw,er to ground

0 o,n0

AT L2L "7,T-A

• To raise front of mower, loosen nut"F" from

trunnion on both front links, Tighten nut

"E" on both front links an equal number

of turns.. The two front links must remain

equal in length.

. When distance "D" is 118" to 1/2" lower

at front than rear, tighten nut "F" against

trunnion on both front links.

, Recheck side-to-side adjustment

°_\', l oo!

_"{_ \ __- Mandrel

Both Fronl nks Should be ual in Length

)

/

Nut "E"

_L_ Suspension Arm

...... o__

A /

Lift Link

Adjustment Nut ------'- .....

IMPORTANT: Deck must be level side-to

side. Ifthe following front-to-back adjustment

is necessary, be sure to adjust both front

links equally so mower will stay level side-

to-sideo

To obtain the best cutting results, the mower

housing should be adjusted so thatthe front is

approximately t18" to 112" lower than the rear

when the mower is in its highest position,.

Check adjustment on right side of tractor.

Measure distance "D" directly in front and

behind the mandrel at bottom edge of mower

housing as shown.

• Before making any necessary adjust-

ments, check that both front links are equal

in length.

• If links are not equal in length, adjust one

link to same length as other linko

• To lower front of mower loosen nut "E"

on both front links an equal number of

turns_

• When distance "D" is II8" to 1/2" lower

at front than rear, tighten nuts "F" against

trunnion on both front links. 22

Fron

kinks ...... "

Page 23

TO REPLACE MOWER BLADE DRIVE

BELT

The mower blade drive belt may be replaced

without tools, Park the tractor on level sur-

face. Engage parking brake.

BELT REMOVAL-

1. Remove mower from tractor (See "TO

REMOVE MOWER" in this section of

manual).

2. Work belt off both mandrel pulleys and

idler pulleys.

3o Pull belt away from mower°

BELT INSTALLATION -

1 Work belt around both mandrel pulleys

and idler pulleys

2. Make sure belt is in all pulley grooves

and inside all belt guides..

3_ Install mower (See "To Install Mower" in

this section of this manual)°

Mandrel

Idler Pulleys

Mandrel

Pulley

TO REPLACE MOTION DRIVE BELT

Park the tractor on level surface. Engage

parking brake For assistance, there is a

belt installation guide decal on bottom side

of left footrest.

BELT REMOVAL -

1, Remove mower (See "TO REMOVE

MOWER" in this section of manual).

NOTE: Observe entire motion drive belt and

position of all belt guides and keepers.

2, Remove belt from stationary idler and

clutching idler°

3, Remove belt downward from around

engine pulley,

4, Pull belt slack toward rear of tractor,

Remove belt upwards from transaxle

pulley by deflecting belt keepers.

5, Remove belt from center span keeper

and pull belt away from tractor,

BELT INSTALLATION -

1. Carefully work new belt down between

transaxle belt keepers and onto the input

pulley.

2. Slide belt into the center span keeper..

3, Pull belt toward front of tractor and roll

around the top groove of engine pulley,.

4. Install belt through stationary idler and

clutching idler.

5, Make sure belt is in all pulley grooves

and inside all belt guides and keepers.

6. Install mower (See "TO INSTALL MOW-

ER" in this section of manual),.

TO CHECK BRAKE

If tractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dry concrete or paved surface, then

brake must be serviced.

You may also check brake by:

1. Park tractor on a level, dry concrete or

paved surface, depress clutch/brake

pedal all the way down and engage

parking brake.

2. Place gear shift lever in neutral position.

The rear wheels must lock and skid when

you try to manually push the tractor forward.

tf the rear wheels rotate, then the brake

needs to be serviced. Contact a Sears or

other qualified service center.

Engine

Clutching

Stationary Idler

Transaxle

Pulle'

Center

Keeper

23

Page 24

TRANSAXLE GEAR SHIFT [.EVER NEU-

TRAL ADJUSTMENT

The transaxle should be in neutral when the

gear shift lever is in neutral (N) (lock gate)

position, The adjustment is preset at the

factory; however, if adjustment is needed,

proceed as follows:

1. Make sure transaxle is in neutral (N).

NOTE: When the tractor rear wheels move

freely, the transaxle is in neutral.

2_ Loosen adjustment bolt in front of the

right rear wheel.

3o Position the gearshift lever in the neutral

(N) position..

4. Tighten adjustment bolt securely..

NOTE: If additional clearance is needed to

get to adjustment bolt, move mower deck

height to the Lowest position.

Neutral Lock Gate

Gearshift_Lever _

TO REMOVE WHEEL FOR REPAIRS

'1. Block up axle securely,

2. Remove axle cover, retaining ring and

washers to allow wheel removal (rear

wheels have a square key - Do not

lose)..

3. Repair tire and reassemble,

NOTE: On rear wheels only. align

grooves in rear wheel hub and axle_ Insert

square key.

4.. Replace washers and snap retaining

ring securely in axle groove

5. Replace axle cover..

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, purchase and

use tire sealant from Sears. Tire sealant

also prevents tire dry rot and corrosion,.

Washers

Retaining

AxleRing \

TO ADJUST STEERING WHEEL ALIGN-

MENT

If steering wheel crossbars are not horizontal

(left to right) when wheels are positioned

straight forward, remove steering wheel

and reassemble with crossbars horizontal.

Tighten securely.

FRONT WHEEL TOE-INICAMBER

The front wheel toe-in and camber are not

adjustable on your tractor.. If damage has

occurred to affect the front wheel toe-in or

camber, contact a Sears or other qualified

service center.

Square Key

(Rear Wheel Only)

TO START ENGINE WITH A WEAK

BATTERY

_,WARNING: Lead-acid batteries gene rate

explosive gases. Keep sparks, flame and

smoking materials away from batteries,.

Always wear eye protection when around

batteries_

If your battery is too weak to start the engine, it

should be recharged.. (See "BATTERY" in the

MAINTENANCE section of this manual)°

if "jumper cables" are used for emergency

starting, follow this procedure:

IMPORTANT: Yourtractor is equipped with

a 12volt system The other vehicle must also

be a 12 volt system. Do not use your tractor

battery to start other vehicles,

TO ATTACH JUMPER CABLES -

I. Connect one end ofthe RED cable to the

POSITIVE (+)terminal of each battery(A-

B), taking care not to short against tractor

chassis.

2 Connect one end of the BLACK cable

to the NEGATIVE (-) terminal (C) of fully

charged battery.

3. Connect the other end of the BLACK

cable (D) to good chassis ground, away

from fuel tank and battery

24

Page 25

TO REMOVE CABLES, REVERSE

ORDER -

1. BLACK cable first from chassis and

then from the fully charged battery..

2, RED cable last from both batteries.

Weak or Dead Fully Charged

Battery Battery

REPLACING BATTERY

_,WARNING: Do not Short battery termi-

nals by allowing a wrench or any other object

to contact both terminals at the same time.

Before connecting battery, remove metal

bracelets, wristwatch bands, rings, etc.

Positive terminal must be connected first to

prevent sparking from accidental ground-

lng.

I.. Lift seat pan to raised position..

2 Disconnect BLACK battery cable first

then RED battery cable and carefully

remove battery from tractor..

3 Install new battery with terminals in same

position as old battery.

4 First connect RED battery cable to posi-

tive (+) terminal with hex bolt and keps

nut as shown. Tighten securely. Slide

terminal cover over terminal

5. Connect BLACK grounding cable to

negative (-) terminal with remaining hex

bolt and keps nut, Tighten securely.

3. Replace bulb in holder and push bulb

17older securely back into the hole in the

backside of the grill.

4. Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause your

tractor to run poorly, stop running, or prevent

it from starting

• Check wiring. See electrical wiring dia-

gram in the Repair Parts section

TO REPLACE FUSE

Replace with 20 amp automotive-type plug-

in fuse. The fuse holder' is located behind

the dash_

TO REMOVE HOOD AND GRILL AS-

SEMBLY

1 Raise hood.

2 Unsnap headlight wire connector

3 Stand in front of tractor. Grasp hood at

sides, tilt toward engine and lift off of

tractor

4 When replacing hood, be sure to recon-

nect the headlight wire connector.

\ Hood

i "\ /\

/ _', /_". Headlight Wire

/ .. " .// .--..'. Connector

. , t

Seat _an--__...__1_ _.,IR

_, _::i::::lfLabel

I

Ci!,:_..............

/_!

Terminal

Posi

(Red)

Cable Negative (Black)

TO REPLACE HEADLIGHT BULB

t_ Raise hood

2. Pull bulb holder out of the hole in the

backside of the grill°

IC.. Keps

Hex

Bolt

Cable

ENGINE

Maintenance, repair, or replacement of the

emission control devices and systems, which

are being done atthe customers expense, may

be performed by any non-road engine repair

establishment or individual. Warranty repairs

must be performed by an authorized engine

manufacturer's service outlet,

TO ADJUST THROTTLE CONTROL

CABLE

The throttle control has been preset at the

factory and adjustment should not be neces-_

sary. Check adjustment as described below

before loosening cable,. If adjustment is

necessary, proceed as follows:

I With engine not running, move throttle

control lever from slowto choke position

Slowly move lever from choke to fast

position

25

Page 26

2 Check that holes 'F," in governor control

lever and hole in governor plate line-

up if holes 'A" are not aligned, loosen

clamp screwand move throttle cable until

holes are aligned. Tighten clamp screw

securelyr

Governor Control Lever Governor

Control Plate

t

Holes .... ..-i.. :,-T--- /m_t -, -T

A _ ,, _ _ _1 Throttle

[ ';_,; ulamp _UIJIL,_j Cahla

t J .....

..... _) Screw

TO ADJUST CARBURETOR

NOTE: The carburetor on this engine is

tow emission° It is equipped with an idle

fuel adjusting needle with a limiter cap,

which allows some adjustment within the

limits allowed by the cap. Do not attempt

to remove the limiter cap,. The limiter cap

cannot be removed without breaking the

adjusting needle.

The carburetor has been preset at the fac-

tory and adjustment should not be neces-

saryo However, minor adjustment may be

required to compensate for differences in

fuel, temperature, altitude or load. If the

carburetor does need adjustment, proceed

as follows.

In general, turning idle mixture valve in

(clockwise) decreases the supply of fuel to

the engine giving a leaner fuellair mixture.

Turning the idle mixture valve out (counter-

clockwise) increases the supply of fue! to the

engine giving a richer fuellair mixture°

IMPORTANT: Damage to the needle valve

and the seat in carburetor may result if screw

is turned in too tight.

PRELIMINARY SETTING -

1.. Air cleaner assembly must be assembled

to the carburetorwhen making carburetor

adjustments,

2_ Be sure the throttle control cable is ad-

justed properly (see above).

FINAL SETTING -

t. Start engine and allow to warm for five

minutes, Make final adjustments with

engine running and shift/motion control

lever in neutral (N) position_

2. Move throttle control lever to slow posi-

tion. With finger, rotate and hold throttle

lever against idle speed screw,. Turn idle

speed screw to attain 1750 RPM

3. While still holding throttle lever against

idle speed screw, turn idle mixture

valve full travel clockwise then counter-

clockwise until engine runs rough. Turn

valve to a point midway between those

two positions. Release throttle level

ACCELERATION TEST -

4 Move throttle control lever from slow

to fast position If engine hesitates or

dies, turn idle mixture valve out (coun-

terclockwise) It8 turn. Repeat test and

continue to adjust, if necessary, until

engine accelerates smoothly_

High speed stop is factory adjusted, Do not

adjust - damage may resulL

IMPORTANT: Nevertamperwith the engine

governor, which is factory set for proper

engine speed. Overspeeding the engine

above the factory high speed setting can be

dangerous. If you think the engine-governed

high speed needs adjusting, contact a Sears

or other qualified service center, which has

proper equipment and experience to make

any necessary adjustments

Idle Speed [- Throttle

Screw--_

d

Idle i

With Lirniter

26

Page 27

Immediately prepare your tractor for storage

at the end of the season or if the tractor will

not be used for 30 days or more°

_WARNING: Never store the tractor with

gasoline in the tank inside a building where

fumes may reach an open flame or spark.

Allow the engine to cool before storing in

any enclosure,

TRACTOR

Remove mower from tractor for winter

storage_ When mower is to be stored for a

period of time, clean it thoroughly, remove

all dirt, grease, leaves, etc, Store in a clean,

dry area,

1. Clean entire tractor (See "CLEANING"

in the Maintenance section of this

manual).

2. inspect and replace belts, if necessary

(See belt replacement instructions in the

Service and Adjustments section of this

manual).

3. Lubricate as shown in the Maintenance

section of this manual

4. Be sure that all nuts, bolts and screws

are securely fastened. Inspect moving

parts for damage, breakage and wear.

Replace if necessary

5, Touch up all rusted or chipped paint

surfaces; sand lightly before painting.

BATTERY

• Fully charge the battery for storage..

• After a period of time in storage, battery

may require recharging,

° To help prevent corrosion and power

leakage during long periods of storage,

battery cables should be.. disconnected

and battery cleaned thoroughly (see "TO

CLEAN BATTERY AND TERMINALS"

in the Maintenance section of this man-

ual) _.

• After cleaning, leave cables disconnected

and place cables where they cannot come

in contact with battery terminals

• If battery is removed from tractor for

storage, do not store battery directly on