Page 1

I:RnFTXHaN°

MODEL NUMBER 917.258692 OWNER'SMANUAL

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

CAUTION: Read and follow all safety rules and instructions before operating this equipment.

l't]IIl'll

II

FOR CONSUMER ASSISTANCE HOT LINE, CALLTHiS TOLL FREE NUMBER: 1-800-659+5917

Page 2

SAFETY RULES

Safe Operation Practices for Ride-On Mowers

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS tNJURY OR DEATH

I. GENERAL OPERATION

, Read, understand, and followall instructionsinthe manual

end on the machine before starling,

, On_yagow responsibleadults, who are familiar wIth the

tnstructlons, toop_rala the machine.

= Clear the area of objects such as rocks, toys,wire, eta,

whichcouldbe pickedupand lhrawnbytheblade

• Beaura Ihearea tsclear ofother peopfebefore mewing Stop

machine if anyone enters the area

• Never carry p=_ssengers

• Do not mowin reverseunless absolutely necessary Always

fook down andbehind belore and while backing

• Be aware of themower discharge direction and do not point

tt at anyone, Do notoperate the mower withouteither the

entire grass catcheror theguard in place

• Slow down before turning

• Never leavea running machine unattended. Always tam off

blades, set parking brake, slop engine, and remove keys

before dismounting

• Turn oft blades when not mowing.

• Stop engine belore removinggrass catcher or unclogging

chute.

• Mow onlyIsdaylightorgood artMclalilght

• Do not operate the machine while under the Inlluenca el

etcohot or drugs

• Welch forIrafiio whenoperating nearor crossing roadways.

• Use exlra care when {ceding or unloading themachine Into

a traitor or truck,

IL SLOPE OPERATION

Slopes are a major factor related to Ices-of-control and

t_poveraccidents, which can resull in severe Injunyor death.

All slopes require extra caulion. I{you cannot back up the

siope or if you feel uneasy on it, do not mow It.

DO:

• Mow up and down slopes, not across

• Remove obstectessuch as rocks, tree limbs, etc.

Watch for holes, ruts, or bumps. Uneven terrain could

ovedum the machine Tatl grass can hide obetacfas

, Useslow speed, Choose a low gearsothat youwtilnothave

lo slop or shift while on the slope

, Follow the manufacturer's recommendallons Ior wheel

weights orcounterWeightsto Improve stability?

• Usa extra care with grass catchersor other attachments,

These can change the stabilityof the maoMns

• Keep allmovementonthe slopes slow and gradual Donot

make sudden changes inspeed or d_rectfen

• Avoid starting or slopping on e slope. If tires lose traction,

disengagethe blades ano proceed slowly straightdown Ihe

slope

DO NOT:

• Donotturnonslopasuniessnecessary, andthen, tumslowly

and graduallydownhill,{tposslble

. Do not mow near drop=oh's,ditches, or embankments. The

mower couldsuddenly turn over tf a wheatIsover the edge

of a clilfor ditch, or if anedge caves in_

• Do not mow on wet grass., Reduced Iractton could cause

sliding

• Dosol try tostabilizethe machine by puttingyourtoot on the

ground°

• Do not usa grass catcheron sleep slopes

IlL CHILDREN

Tragic accidents can occur ifthe operator is not alert to the

presence of children Children are often attracted to the

machine and lhe mowing activity, Never assume that

children will remain where you last saw them.

° Keepchtidrenou!of the mowing area andunder the watchful

careofanotherresponsibleadult

• Be Bled and Iura mschlne off ifchildren enter the area

• Before and whenbacking, look behind and down for small

children

• Never carFy children. They may fall oil and be seriously

Injuredor intedere with satemachine operation

• Never aItow chltdren to operate the machine,

• Use extra care when approaching bl_ndcomers, shrubs,

trees, or other objectsthat may obscure vision,

IV. SERVICE

• Use extracarein hand)(nggasottneandotherfusts_ Theyare

gammable and vapors are expIoslve

Use onlyan approvedcontainer,

Never remove gas cap or add fuel with the engine

running Allow engine to cool belore refue!ing. Do not

smoke,

Never refuelthe machine indoors

Neverstorethemachine or fuelcontainer Insidewhere

thera Isan open game, such as awater heater

• Never runa machine inside a closedarea,

." Keep nutsand boltm especially blade attachmentbolts, tight

and keep equipment ingood condition

• Never tamper wllh safety devices Check Ihek proper

operation regularly

• Keepmachine free o!grass leaves, or other debris build-up

Csan o or luel spillage Allow machine to cool beg'ore

storing,

Slop and inspect the equipmenl ityou strike an obJecl.

Repair, I!necessary, before resladlng_

• Never make adjustmentsor repairs withtheengine running

• Grasscalchercomponenls are subject towear, damage,and

deterioration, which could expose moving parts or allow

ob acts Io be thrown, Frequenllycheck components and

rapace w lh manufacturer srecommended pads, when nec-

essary

• Mower bladesare sharpand can cuL Wrap the blade(s) or

weargloves, anduse extra caution when servicing them-

. Check brake operation frequently, Adjust and service as

required.

H= ==H, ,H,= , ,H , , ,

i_ Look for thls symbol to point out im-

_b wire and plaeewire where tt cannot contect

portant safety precautions. It means

CAUTIONH| BECOME ALERTIII YOUR

SAFETY IS INVOLVED.

, H, ,, ,,,

CAUTION: Always disconnect spark plug

spark plug In order to prevent accidental

starting when setting up, transporting,

adjusting or making repairs.

A WARNING

The engine exhaust from this product con-

tams cnemtcats Known to the State of uad!or-

nla to cause cancer, birth defects, or other

reproductive harm.

Page 3

CONGRATULATIONS on your purchase of a Sears

Tractor It has been designed, engineered and manufac-

tured to give you the best possible dependability and

pedormance,

Shoufd you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service CentedDepartment, We have competent, well-

trained lechnlctans and the proper toots to service or repair

thts tractor,

Please read and retain th{s manual The instructions wilt

enable you to assemble and maintain your tractor propefly

Always observe the "SAFETY RULES".

MODEL

NUMBER 917258692

SERIAL

NUMBER

DATEOFPURCHASE

THE MODELAND SER1ALNUMBERSW[LL BE FOUND

ON A PLATE UNDER THE SEAT.

iYOU SHOULD RECORD BOTH SERfALNUMBERAND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement Is available on this prod-

uct Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the satety rules

. Followa regufarschedulein ma[nlaintng, caring for and

using your tractor.

, Foliow the Instructions under "Customer Responsibili-

{ice" and "Storage" sections of this owner's manual

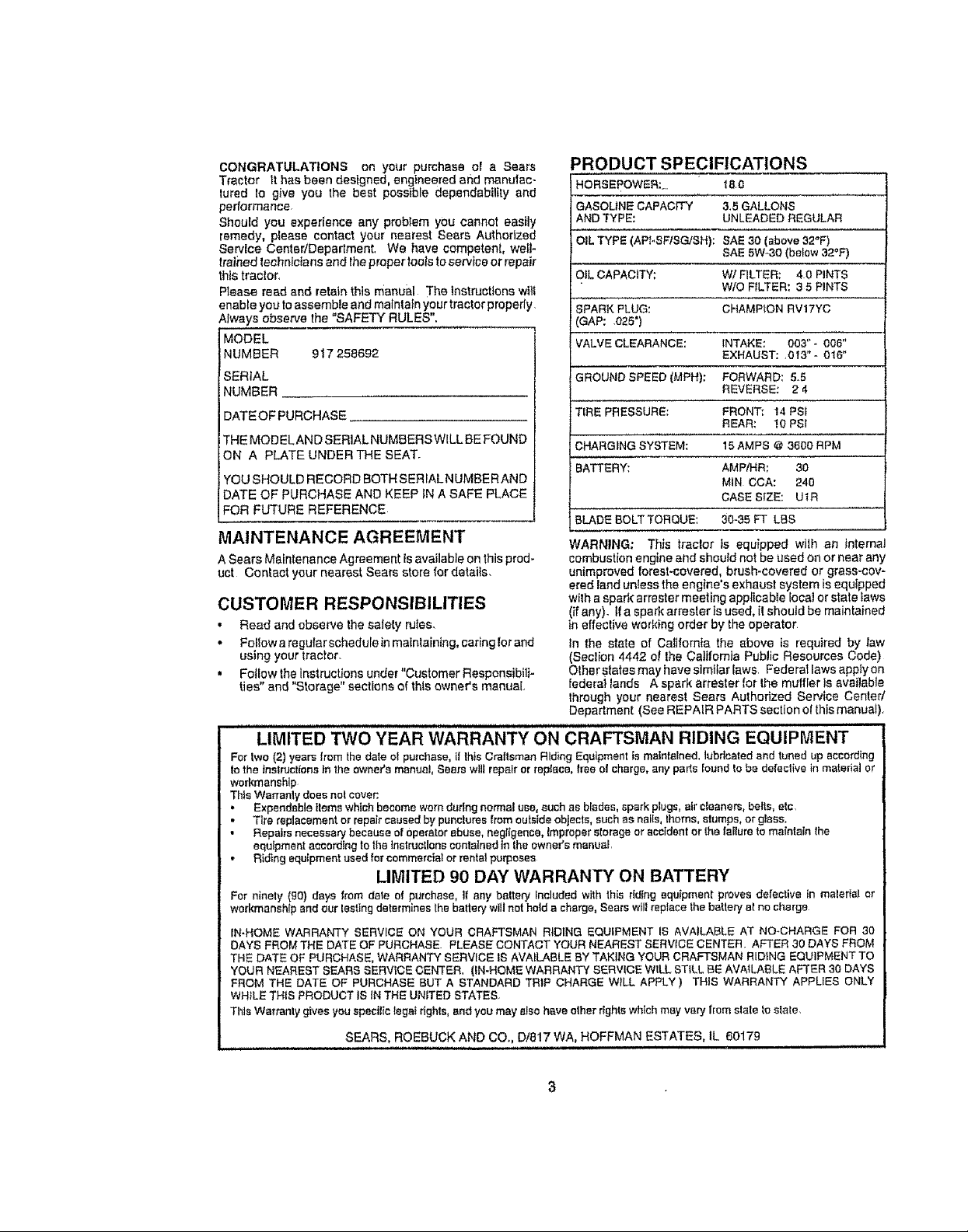

PRODUCT SPECIFICATIONS

HORSEPOWER:.. t8 0

GASOLtNE CAPACITY 3.5 GALLONS

AND TYPE; UNLEADED REGULAR

OIL TYPE (API.,SP/SG/SH): SAE 3.0(above 32°F)

OIL CAPACITY: WI FILTER: 40 PINTS

IPARK PLUG: CHAMPION RV17YC

3AP: ,025")

VALVE CLEARANCE: iNTAKE: 003" - 006"

GROUND SPEED (MPH): FORWARD; 5,5

TIRE PRESSURE; FRONTt 14 PSI

CHARGING SYSTEM: 15AMPS @ 3600 RPM

BATTERY: AMPtHR; 30

BLADE BOLT TORQUE: 30-35 FT LBS

WARNING: This traclor is equipped with an Internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov-

ered land unless the engine's exhaust system is equipped

wIIh a spark arrestor meeting applicable local or state taws

(if any). t!a spark arresler is used. it should be maintained

in effective working order by the operator

In the state of California the above is required by taw

(Seclion 4442 of Ihe California Public Resources Code)

Olher states may have simifar Iaws, Federal laws apply on

federal lands A spark arrestor for the muffler Is available

through your nearest Sears Aulhorized Service Center/

Department (See REPAIR PARTS section o¿this manua0,

SAE 5W-30 (below 32°F)

W/O FILTER: 3 5 PINTS

EXHAUST: .013_'- 0"f6"

REVERSE: 2 4

REAR: 10 PSI

MIN CCA: 240

CASE SIZE: U'IR

LIMITED TWO YEAR WARRANTY ONCRAFTSMAN RIDING EQUIPMENT

For two (2) years (rumthe date el purchase, if Ibis Craftsman Riding Equipment ismatnlalned_lubdeated and tuned up according

to the instructions tnthe owner's manua!, Searswll! repairor replace, tree ol charge,any parts foundtobe defeclive in material or

workmanship

Thts Warranly does nol cover:.

• Expendable Itemswhich become warnduring normal use, such as blades, spark plugs,aircleaners, belts, elc,

Tire replacement or repaircaused by panclures trsmoutalde objects, suchae nails, Ihoms, stamps, or glass.

• Repairs necessary because of Operatorabuse, negffgence,Improper storage oraccident orthe failuretomaintain the

equipment according to theInstructionscontainedin lhe owner'smanuaL

• Riding equipment used for commercial or rentalpurposes

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety (gO) days from dale of purchase, 1Iany baltary Included with this ddtng equipment provesdefective [n maleflal or

workmanshipand our testing determines thebatte_ will not holds cha_ge,Sears will replace the be{toryat no charge

IN-HOME WARRANTY SERVICE ON YOUR CRAFTSMAN RIDING EQUIPMENT IS AVAILABLE AT NO-CHARGE FOR 30

DAYS FROM THE DATE OF PURCHASE. PLEASE CONTACT YOUR NEAREST SERVICE CENTER AFTER 30 DAYS FROM

THE DATE OF PURCHASE, WARRANTY SERVICE IS AVAILABLE BY TAKING YOUR CRAFTSMAN RIDING EQUIPMENT TO

YOUR NEAREST SEARS SERVICE CENTER, {IN-HOME WARRANTY SERVICE WILL STILL BE AVAILABLE AFTER 30 DAYS

FROM THE DATE OF PURCHASE BUT A STANDARD TRIP CHARGE WILL APPLY ) THIS WARRANTY APPLIES ONLY

WHILE THIS PRODUCT IS IN THE UNITED STATES

This Warranty gives you specitic legaf dghts, end you may also have other rights which may vary from s|ale to state,

SEARS, ROEBUCK AND CO., D/817 WA, HOFFMAN ESTATES, IL 60179

Page 4

,lU_l,i ii , i,iin ii I I roll ilu ,i I ,

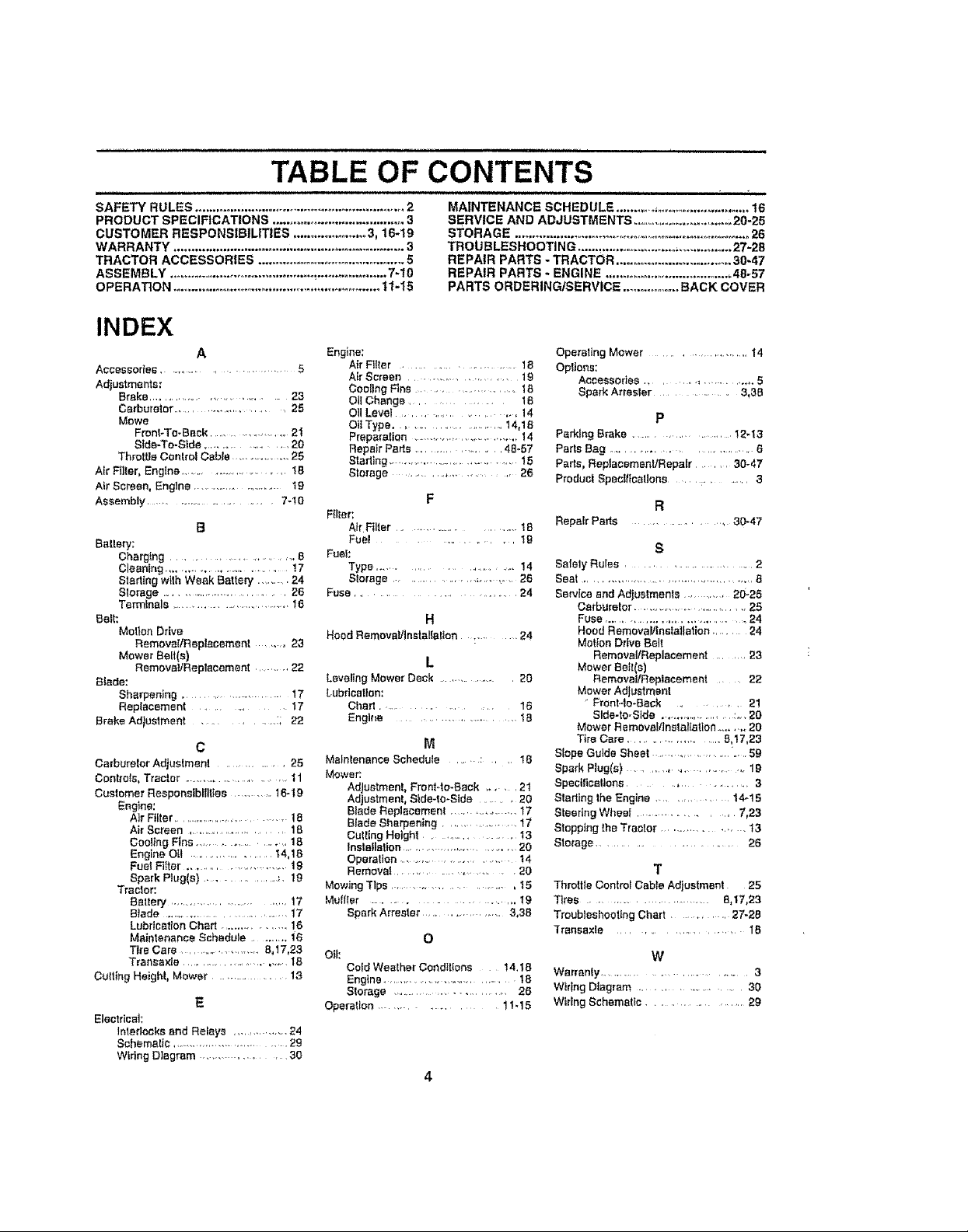

TABLE OF CONTENTS

SAFETY RULES ............................................................. 2

PRODUCT SPECIFICATIONS ...................................... 3

CUSTOMER RESPONSIBILITIES ...................... 3, 16-19

WARRANTY .................................................................. 3

TRACTOR ACCESSORIES ............................................ 5

ASSEMBLY .......................................... _.................... 7-I0

OPERATION ............................................................ t1-t5

INDEX

A

Accessodes .......................... 5

Adjustments:

Brake ............................. 23

Carburetor .......................... , 25

Mows

Front-To-Back ................... 21

Slde-To-Stde ....................... 20

Throttle Control Cable............... 25

Air Filter, Engine............................ 1B

AirScreen, Engine ...................... 19

Assembly .................................... 7-10

B

Battery;

Charging ........................... B

Cleaning ......................... 17

Stedlng wtth Weak Battery ......... 24

S{orage ................................. 26

Terminals .............................. !6

Belt:

Motion Drive

Remover/Replacement ..... 23

Mower Belt(s)

RemovaVReptacement .......... 22

Btade:

Sharpening ........................ 17

Replacement ..................... 17

Brake Adtustment .............. :; 22

C

Carburetor Adjustment ................... 25

Controls, Tractor ............................... 11

Customer RespensiblIil{es ........ 16-19

Englne:

A]r Filter ................................ t8

Air Screen ......................... 1B

CostingFins ................ .18

Engine Oi! ................... 14,18

Fuel Filter ............................. 19

Spark Plug(s) .............. _. t9

Tractor:

Battery .............................. 17

Blade ............................ 17

LubricationChart ................. 16

Maintenance Schedule ........ 16

Tire Care ........................ 8,17,23

Transaxle ............................. 18

Cutting Heighl, Mower ................ 13

E

Electrical;

Interlocks and Relays ............... 24

Schematic ........................... 29

Wtdng Diagram ............... 30

Engine:

Air Filter .................... 18

Air Screen ..................... 19

CoolingFins.......................18

OilChange ............ 1B

O11Level ..... ............... ,., 14

OilType ......................... 14,18

Preparation .............................. 14

Repair Parts ................... 48-57

Starting ......................................15

Storage ........ _.............. 26

F_IIer;

AirFilter ............................18

Fuel .............. 10

Fue!:

Type ................................ !4

Slorage ..................................... 26

Fuse.................... 24

Hoed Removab'tnstallalton ............ 24

LevelingMower Deck ............... 20

Lubrication:

Chart. ........................ 16

Englt_e ......................... I8

Malnlenance Schedule ....... : , , t0

Mower:

Adjustment, Front4o-Back ...... 21

Adjustment, Side-to-Side ......20

Blade Replacemenl ...................17

Blade Sharpening ...................17

Culling Height . 13

Installation.............................20

Operation ...............................14

Remover ............,........20

Mowing Tips......................... 15

MuIller ......................... ,. t9

Spark Arrestor ....................... 3,38

Oil:

Cold Weather Conditions t4,t8

Engine................................... 18

Storage ............................. 26

Operation ........................ 11,15

i,iii,Ul i

MAINTENANCE SCHEDULE ........... ,........................... t6

SERVICE AND ADJUSTMENTS ...............................;20-25

STORAGE ...................................................................... 26

TROUBLESHOOTING ............................... .,............... 27-2B

REPAIR PARTS - TRACTOR ................................. 30-47

REPAIR PARTS- ENGINE .................................... 48-57

PARTS ORDERINGISERVICE ................. BACK COVER

Operating Mower ........................ 14

Options:

Accessories .... _., ..............5

Spark Arresler ........... 3,38

P

PerkingBrake ...................... !2-'_3

Parts Bag .............................. 6

Parts, Reptaoemenl/Repafr ....... 30-47

Product Spectlicaflona .............. 3

F

Repair Pads ..................., 30-47

R

S

Safety Rules ......................2

Seat ............................................8

Service andAdjustments......... 20-25

Carburetor...............................25

H

L

M

Fuse ................................... 24

Hood Removal/insIallation ...... 24

MotionDriveBall

RemovalfReplacement .......23

Mower Bait(s)

RemovallReptacemeet .... 22

Mower Adjustment

" Front-,lo-Back ................ 2!

Side-to-Side . ......................:o..20

Mower Remova!/lnstatiatlen ........,. 20

Tire Care ......................8,17,23

Slope Guide Sheet ..................."_.5g

Spark Plug(e) .......................... 1g

Speciticellens ............................. 3

Starting the Engine .............. 14,-15

Steering Wheel ................. 7,23

Stopping the Tractor ....................t3

Storage ................................... 26

T

ThrottleControlCableAdjustment 25

Tires............................8,17_23

Troubleshooilng Chart ...........27-28

O

Transaxle ......................... IB

W

Warranly .....................................3

Wiring Diagram ................. 30

WiringSchematic.................... 29

Page 5

ACCESSORIES AND ATTACHMENTS

Theseaccessories and attachments were available throughmostSoars retail Outletsand s.etrice centers when thetractor waspurchased

Most Seers storescan orderthese items for you whenyou providethe model number of yourtractor

ENGINE

SPARKPLUG GASCAN

ENGINEOIL FUELSTABILIZER AIR FILTER

MAINTENANCE

BLADES BELTS

%

PERFORMANCE

Sears offoma widevariety o| attachments that fityourtractor Manyofihesearelistedbelowwtthbdefexplenat_onselhowlhcycanhelp

you This list was current atthe lime of publication: however, itmay change infuture years- more attachments may be added,changes

may be made in these attachments,orsomemay no longerbe available orfityour model Contact your nearest Sears store for the

accessories and attachments that are available for yourtractor.

Most of these attachmentsdo not raqutre addil_onalhitches orconversionkits (those that do are tndJceled}and are designedtar easy

attaching and detaching

AERATOR promotes deep rootgro_;th to_"a healthy lawn Ta-

pered 2.5-Inch steel spikesmounted on tO-inch diameter d_ses

punclure hates in soil at close tnierva(sto Iet moisture soak In

Steel weight tray for Increased penetration.

BAGGER lets you collect grass olipp_ngs and Ieaves tar a

healthier, nearer looking Iawn, Two permene× containers hold

30-gaUonplasftc begs

BUMPER protects hent end oftractor Item damage

CARTS make hauling easy Variety of sizes available, ptus

eccessodos such as side panel kits, tool caddy, cart Coyote

prolective mat and doily,

CORING AERATOR takessme(}plugs oat ofso_lto atIewmois-

ture end nutrients to reach grass roots_ 36-tnoh swa_ 24

hardened stee! coringtips 150 Ib capacity weighttray.,

EASY OIL DRAIN VALVE makes oil changeseasier, fester

FRONT NOSE ROLLER canterstnfrontof mowerdeck to reduce

chancesof "scalping" on uneven terrain

GANG HITCH letsyou tow2or3 pull-behind attachments elonce,

such es sweepers, dethalchere, aerators (not for usawl_hrollers,

cartsorother heavy agachments}

GAUGE WHEELS on both sides of the mower deck reduce

chances el"scalping" on uneven terrain Formower decksnct so

equipped

MULCH RAKFJDETHATCHER loosens soiland flipsthatch and

matted leaves toIawn surface foreasypickup, Twenty springt{ne

teeth UsefuIto prepare bareareas forseeding, Available for {rent

or rear mounting. HIGH PERFORMANCE REEL.ACTION

SPRING TINE IJETHATCHER covers 36-1richwide path and

tosses Ihatch Into largo hopper Mounts behind tractor,

MULCHING CLOSE-OUT PLATE KIT once installed tots you

mulch, discharge or bag clippings (bagger optional) without

changingb!ades. For modelsnotequipped as 3-in.I Convertible

mowers See "MOWER" tn the Repair Parts section of this

manuel.

RAMP TOPS AND FEET let you feed end unload frecter from e

pickup Iruck Use with 2x 8 or 2 x 10lumber

ROLLER for smoother [awe audace. 36-Inch wide, 18*tnch

dtemetorwator-tight drum holdsup to3901bs,olwaight, Rounded

edges prevent harm to tud Adustable scraper automatically

ccans drum,

SNOW BLADEfor snowremovalonly. 14*inchhigh. ,_B_inchwfde

blade clears42-1nchpathwhen angledleft orright. Raises, towers

w_thside_ever Adjustable skids; replaceable,reversible scraper

bar (Use withtirechatns and wheel weights and/or reardrawber

weight)

SNOWTHROWER hes40-fnch swath, Drum-type auger handles

powdery and weVheavy snow Mounts easily with simple pin

arrangement Discharge chute adjusts tram tractor seat. 6-inch

diameter spout dlschargos snow 10 to50 feet Uft controlled at

tractor seat. (Use with chafns end wheel weights and/er rea_'

drawbar weight )

SPRAYERS use 12-volt DC etectrlcmotor thai connectsto Ihe

tractor battery or other 12-vei! source. Includes booms far

automaticspraying and hand heid wand tot spotspraying Wand

has ad ustable spray pattern. For applyingherbicides, tnsecti-

cdee, fang cdes and liquid fertilizers

SPREADERISEEDERS make seeding,fertilizing,end weedkill-

Ing easy. Broadcast spreaders are also uselulfor granular de,-

leers and sand

SWEEPERS let you collect grass clippingsand reaves

TILLER has 5hp engineand36-tnclrswath to prepareseed beds,

cultivate end compost garden residue Tiller has itsown built-In

tiltand depthcent rotsystem anddoes NOTrequire asleeve hitch.

Fitsany lawn yardorgardentractor, Simply bookup tothe Irsctor

drawbar end go_ Optional accesser}as convert unit for

dethatching, aerating, hilling without tools

TIRE CHAINS are heavy duty; closelyspaced extra-large cross

Elnksgive smooth ride. outsl_ndlngt_'action

TRACTOR CA_ hoe heavy duly vinyl fabric over tubularsteel

frame, ASSpta,,Uctop;ctear plastic windshieldoilers360degree

vls{billty Hinged metaldoomswith catch. Keeps operator warm

and dry Remove v_nytsides end windshields tar use as sun

protector in summer, Optional accessories include: tinted/

temperedsolidsafetyglass windshieldwilh hand opereled wiper;,

12-volt ember cautionIIght for mounting oncab top

VACS forpoweflul collection el heavy grass clippings andleaves.

Optional wand attachment to pick up debris in herd-to-reach

places VACICH1PPER Includes a chtppeFshredder

WEIGHT BRACKET for drawber lorsnow removal apptlcatlons.

Uses (t} 55 Ib: weight

WHEEL WEIGHTS for rear wheeIs provlde needed traction for

snow removsIordozing heavy materials

Page 6

I..L_ Ul,U, nil

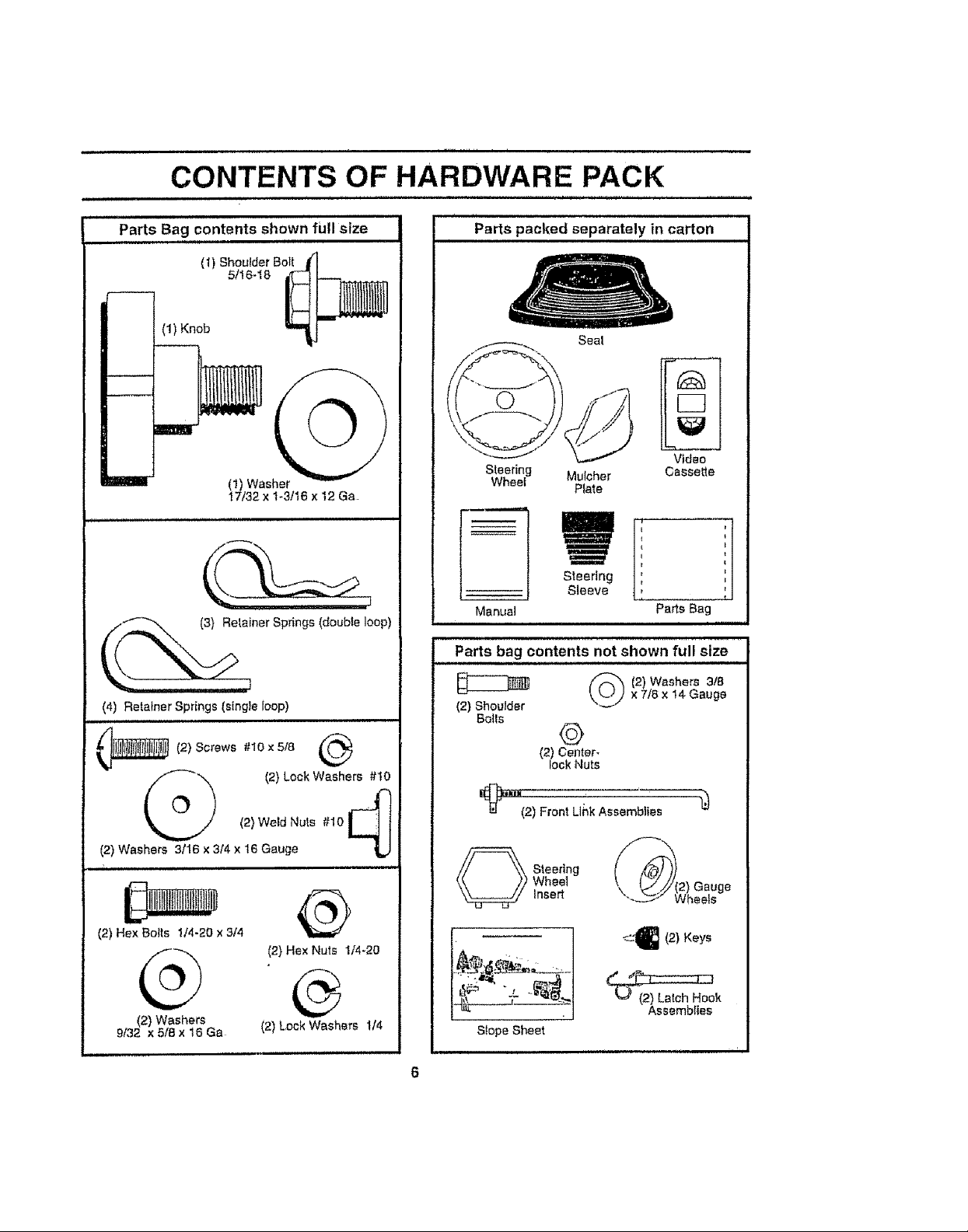

CONTENTS OF HARDWARE PACK

Parts Bag contents shown full size

(1) Shoulder BoTI

5/I6-18

tr

Parts packed separately in carton

(1) Knob

(I) Washer

17/32 x 1-3/16 x 12 Ga

ner Springs (double loop)

(4) Retainer Springs (single loop)

_ (2) Screws #10 x 518

Seat

Vldeo

Steering

Wheel

n

Manual

Parts bag contents not shown full size

(2) Shoulder

Bolls

Mulcher Cassette

Plate

f t

t I

t =

t

Steering

Sleeve

t i

t I

Pa_s Bag

x 7/8 x t4 Gauge

(2) Washers 3t8

4#

(2) Center-

lock Nuts

(2) Weld Nuts #10

(2) Washers 3116 x 3/4 x 16 Gauge

, ,,,i,,

(2) Hex Bolts 1/4-20 x 314

G

(2) Washers

9/32 x 5/8 x t6 Ga

(2) Lock Washers #1[_

®

(2) Hex Nuts !/4-20

®

(2) Lock Washers 1/4

[(_""(2) Front Link Assemblies

_ teering

Wheel

insert

_-<-'_ (2) Keys

Assemblies

S{ope Sheet

Page 7

_LIJI II '" II I I . .

ASSEMBLY

................... illl, i, L ,iJ,

Your new trac or has been assembled at the factory with exception of those parts teft unassembled for shipping purposes.

To ensure safe and proper operation of your tractor aII parts and hardware you assemble must be ttgittened securely Use

the correct tools as necessary to insure proper tightness

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set wtil make assembly easier Slandard

wrench sizes are tlsted.

(2) 7/t6" wrenches Ptlers

(1) 9/16" wrench Tire pressure gauge

(1) 3/4" Socket w/drive ratchet Phfflips Screwdriver

Utility knife

When fight or left hand is mentioned in this manual, tt

means when you are in the operating position (seated

behind the steering wheel)

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

Remove all accessible loose parts and parts cartons

from carton (See page 6).

• Cut from top tobottom, along lines on at[ four corners

of carton, and lay panels fat.

- Remove mowerand packing materials

• Check for any additional loose parts or cartons and

remove

_" WHEEL

__j.... STEERING

STEERING

WHEEL _ G

AO,_PTEn_t, SHAFT

STEERING ,;;_ -_'

SLEEVE----....._" ('(i D_, - _ -. _'__'

l t ,t I /

t I i/ I

FIG, 1

STEERINGWHEEL

HEX LOCKNUT

FLATWAS.ER

STEERIN

BEFORE ROLLING TRACTOR OFF SKID

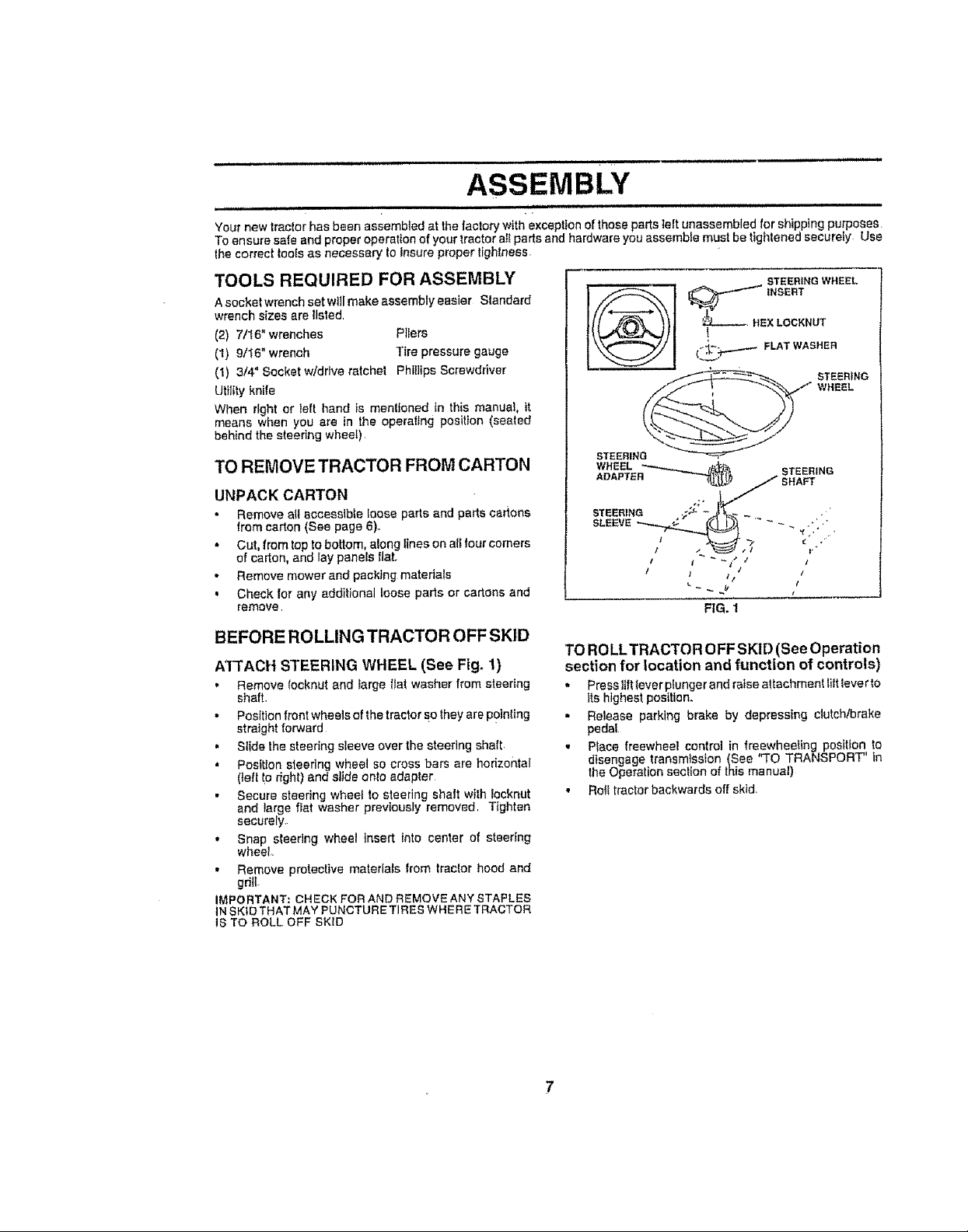

ATTACH STEERING WHEEL (See Fig. 1)

• Remove {ocknut and farge flat washer from steering

shaft-

. Position front wheels of the tractor Sothey are Pointing

straight forward

• Slide the steering sleeve over the steering shaft

• Position steering wheel so cross bars are horizontal

(left !o right) and slide onto adapter

• Secure steering wheel to steering shalt wlth Iocknut

and _arge flat washer previously removed. Tighten

securely,

• Snap steering wheel insert into center of steering

wheel,

• Remove protective materials from traclor hood and

gdlL

IMPORTANT; CHECK FOR AND REMOVE ANY STAPLES

iN SK1DTHATMAY PUNCTURETIRES WHERE TRACTOR

IS TO ROLL OFF SKID

TO RO LLTRACTOR OFF SKID (See Operation

section for location and function of controls)

• Press liftleverplungerandraise attachment littlever to

Itshighestposition.

• Release parking brake by depressing clutehtbrake

pedal,

, Ptacefreewheel controlin freewheeling position to

disengage transmission(See "TO TRANSPORT" In

the Operationsection of thismanual)

• Rolltractor backwards off skid

Page 8

, ,,,,,,,

ASSEMBLY

HOW TO SET UP YOUR TRACTOR

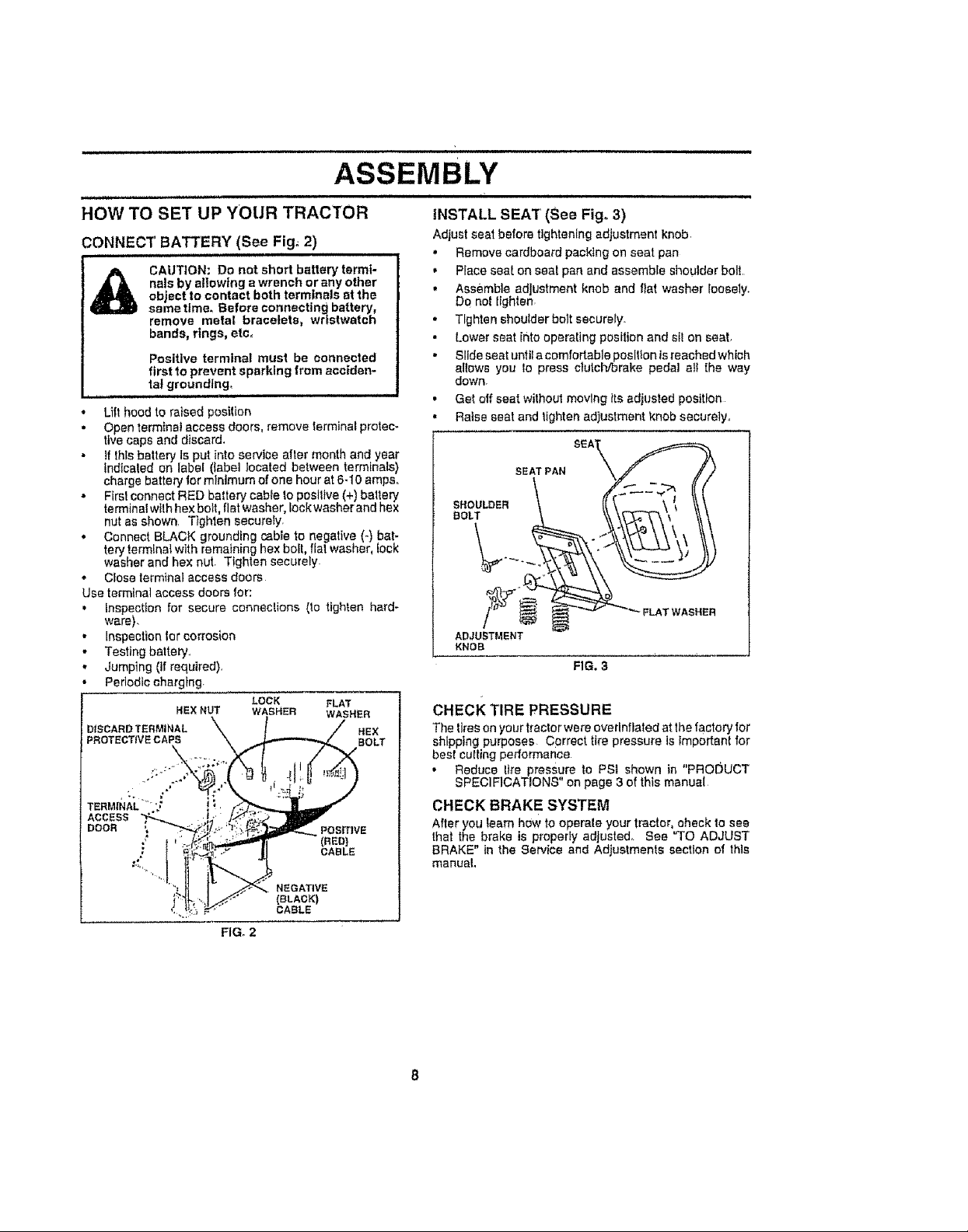

CONNECT BATTERY (See Fig, 2)

• Lift hood to raised position

• Open terminal access doors, remove terminal protec-

tive caps and discard.

• tf lhls battery Is put into service after month and year

indicated an label (label located between terminals)

charge battery for minimum of one hour at 6-10 ampso

,, First connect RED baltery cable to positive (+) battery

terrain alwlth hex bolt, tier washer, lock washBr and hex

nut as shown. Tighten securely.

, Connect BLACK grounding cable te negative (-) bat-

tery terminal with remaining hex bolt, flat washer, lock

washer and hex nut. Tighten securely

,, Close lerminat access doors

Use terminal access doors for:

, Inspection for secure conneclions (Io tighten hard-

ware),

• InspectionIor corrosion

• Testing battery.,

• Jumping (if required),

Periodic charging.

HEX NUT WASHER WASHER

DISCARD TERMINAL NEX

PROTECTIVE CAPS BOLT

TERMfNAL - r {1 _

ACCESS

DOOR

LOCK FLAT

NEGATIVE

(BLACK)

CABLE

FIG. 2

POSEWE

(REDt

CABLE

INSTALL SEAT (See Fig. 3)

Adjust seal before tightening adjustment knob.

• Remove cardboard packtng on seat pan

• Place seal on sea! pan and assemble shoulder bolt.

• Assemble adjustment knob and flat washer loosely.

DO notlighten,

. Tighten shoulderbott securely.

• Lower seat into operating position and sil on seat.

• Slide seat unlif a comfortable position is reached which

allows you lo press clutch/brake pedal all the way

down.

• Get off seat without moving its adjusted position

• Raise seat and tighten ad)ustment knob securely..

SEAT PAN

SHOULDER

BOLT

FLAT WASHER

ADJUSTMENT

KNOB

FIG. 3

CHECK TIRE PRESSURE

The tires an your tractor were overlnflated at the factory for

shipping purposes Cprrect tire pressure is important for

best cutting performance

• Reduce tire pressure to PSI shown in "PRODUCT

SPECIFICATIONS" on page 3 of this manual

CHECK BRAKE SYSTEM

After you learn h_w to operate your tractor, check to see

thai the brake is properly adjusted° See "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual.

Page 9

,Li

ASSEMBLY

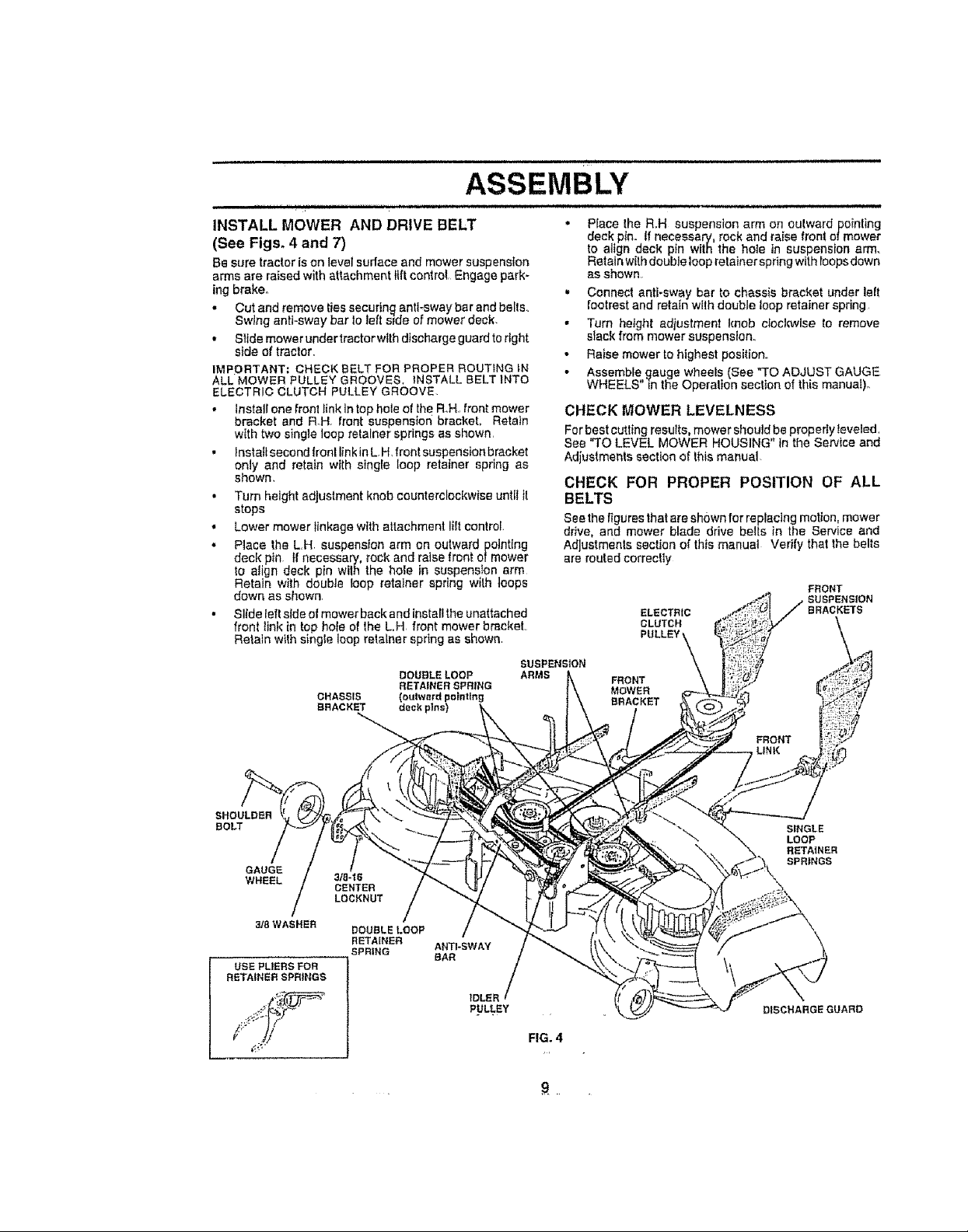

INSTALL MOWER AND DRIVE BELT

(See Figs. 4 and 7)

Be sure tractor is on level sudace and mower suspension

arms are raised with attachment lift control Engage park-

ing brake.

. Cut and remove ties securin_ anti-sway bar and belts,,

Swing anti-sway bar Io left side of mower deck-

. Slide mowerundertractorwtth dlschargeguardto right

side of tractor,

IMPORTANT= CHECK BELT FOR PROPER ROUTING iN

ALL MOWER :PULLEY GROOVES. INSTALL BELT INTO

ELECTRIC CLUTCH PULLEY GROOVE.

• Install one front link in top hole of the Roll., front mower

bracket and R_H. front suspensior_ bracket, Retain

with two single loop relalner springs as shown,

• _nstall second fronl linkin L.H. front suspension bracket

only and retain with single loop retainer spdng as

shown,

• Turn height adjustment knob counterclockwise untf! it

stops

• Lower mower Iinkage with altachment lilt control

• Place the L.H. suspension arm on outward pointing

deck pin. tf necessary, rock and raise front of mower

to align deck pin wilh the hole in suspension arm

Retain with double loop retainer spring wilh loops

down as shown,

• Slide left side of mower back and instatt the unattached

front link in top hote of the LH front mower bracket

Retaln wtlh single loop retainer spring as shown

DOUBLELOOP

CHASSIS (oulwardpoi_lng

BRACKST deckpln_

RETAINER SPRING

. Place the R.H suspension arm on oulward pointing

deck pin. if necessary, rock and raise front of mower

to atign deck ptn with the hole in suspension arm.

Relain with double loop retainer spring with roopsdown

as shown

* Connect anti-sway bar to chassis bracket under lett

footrest and retain w[Ih double loop retainer spring

. Turn height adiustment knob clocl_._lse to remove

slack from mower suspension,

. Raise mower to highest position.,

. Assemble gauge wheels (See "TO ADJUST GAUGE

WHEELS" in the Operalion section of this manual)°

CHECK MOWER LEVELNESS

For best cutting results, mower should be propedyleveled,

See "TO LEVEL MOWER HOUSING" in the Service and

Adjustments section of this manual

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion, mower

drive, and mower blade drive belts in the Service and

AdJustmenls section of this manual Verify that the belts

are routed correctiy

ELECTRIC

CLUTCH

PULLEY

SUSPENSION

ARMS

FRONT

MOWER

BRACKET

FRONT

SUSPENSION

BRACKETS

SHOULDER

BOLT

GAUGE

WHEEL

3/8 WASHER

USE PLIERS FOR

RETAINER SPRINGS

3f@-'tS

CENTER

LOCKNUT

DOUBLE LOOP

RETAINER

SPRING

ANTI*SWAY

BAR

IDLER

PULLEY

FIG. 4

• ,9.

SINGLE

LOOP

DISCHARGEGUARO

Page 10

ASSEMBLY

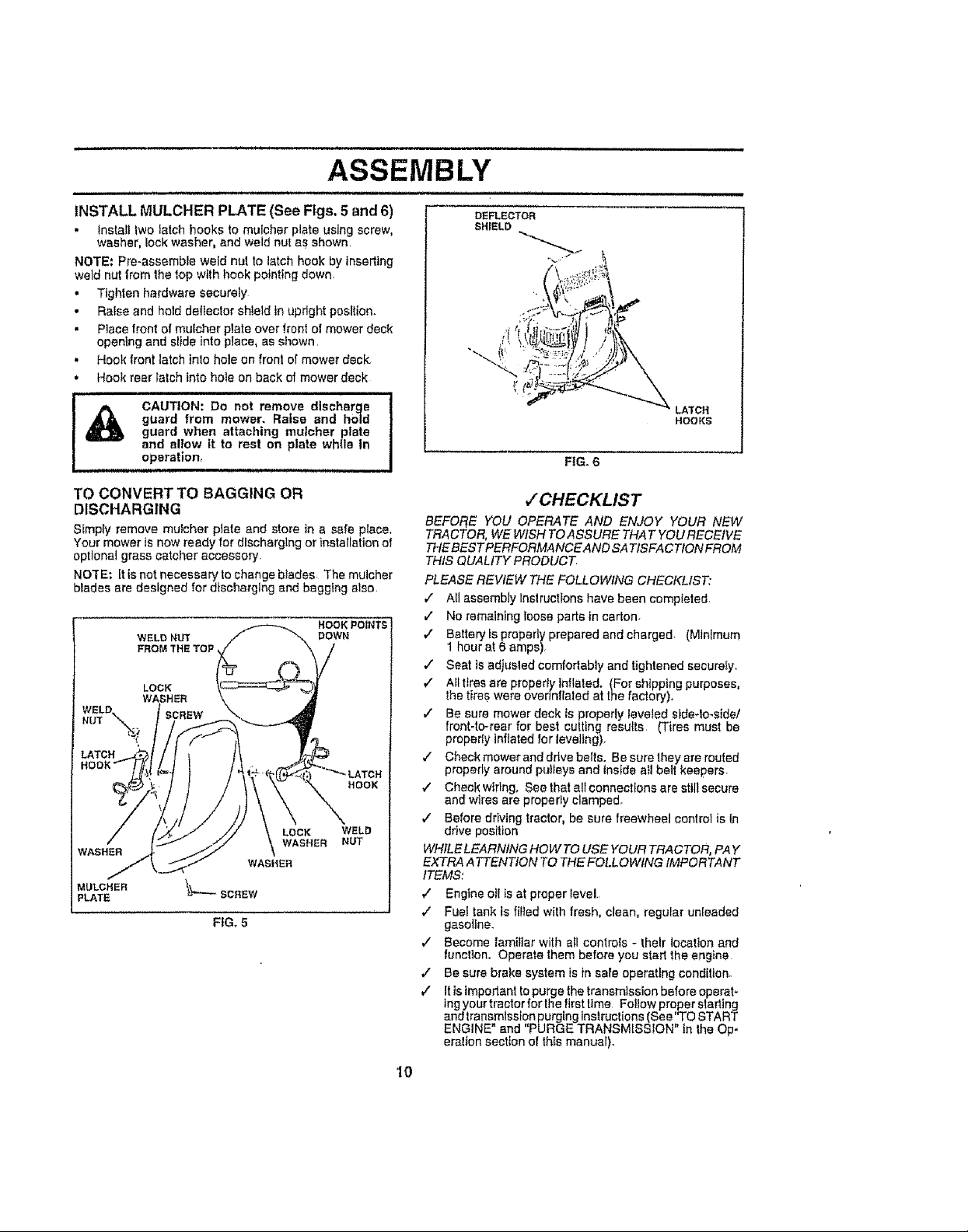

INSTALL MULCHER PLATE (See Figs, 5 and 6)

, Install two latch hooks to mulcher plate using screw,

washer, lock washer, and weld nut as shown.

NOTE: Pro-assemble weld nul to latch hook by inserting

weld nut from the top with hook pointing down.

• Tighten hardware securely

• Raise and hold detteclor shield in upright position.

,, Place front of mulcher plate over front of mower deck

opening and slide into place, as shown.

• Hook front latch into hole on front of mower deck.

,, Hook rear latch into hole on back of mower deck

guard from mower, Raise and hold

CAUTION: De not remove discharge

guard when attaching mutcher plate

and allow it to rest on plate while In

operation,

,w lull i,ll iii

TO CONVERT TO BAGGING OR

DISCHARGING

Sfmpiy remove mulcher ptateand store in a safe place,

Your mower is now ready for discharging orinstallationof

optionat grass catcher accessory,

NOTE: Itisnot necessary tochangeblades The muleher

blades are designed for discharging and bagging also,

HOOK

LOCK WELD

WASHER

MULCHER _'_""--SCREW

PLATE

FiG. 5

WASHER NUT

WASHER

DEFLECTOR

EHrELD

LATCH

HOOKS

FIGo6

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TO ASSURE THAT YOU RECEfVE

THE BEST PERFORMANCE AND SATISFACTION FROM

THIS QUA LtTY PRODUCT

PLEASE REVIEW THE FOLLOWING CHECKLIST:

•/ Aft assembly Inslructions have been completed

,/ No remaining _oosa parts in carton.

,," Battery is properly prepared and charged. (Minimum

1 hour at 6 amps)

,/ Seat is adiusled comfortably and tightened securely.

,." AII tires are property inflated. (For shipping purposes,

the tires were overfnflaled at the factory),

,/ Be sure mower deck is properly leveled slde-lo.side/

front-to-rear for best culling results (Tires must be

properiy inflated for leve]tng)_

/ Check mower and dflve belts. Be sure they are routed

properly around pulleys and inside all belt keepers.

,/ Check wiring, See that alfconnectfons are still secure

and wiles are property clamped.

_" Before driving tractor, be sure freewheel control is in

drNe position

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA A TTENTfON TO THE FOLLOWING IMPORTANT

ITEMS:

,/ Engine oil is at proper level..

,/ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

v" Become familiar with afl controls - their location and

function. Operate them before you start the engine

,I Be sure brake system is in sate operating cond{tton.

,f" It is importanl topurge the transmission before operat-

ing your tractor for lSe first time Foltow proper slaritng

and transmission purging instructions (Sea'TO START

ENGINE" and 'PURGE TRANSMISSION" {n the Op-

eralton section of this manual).

10

Page 11

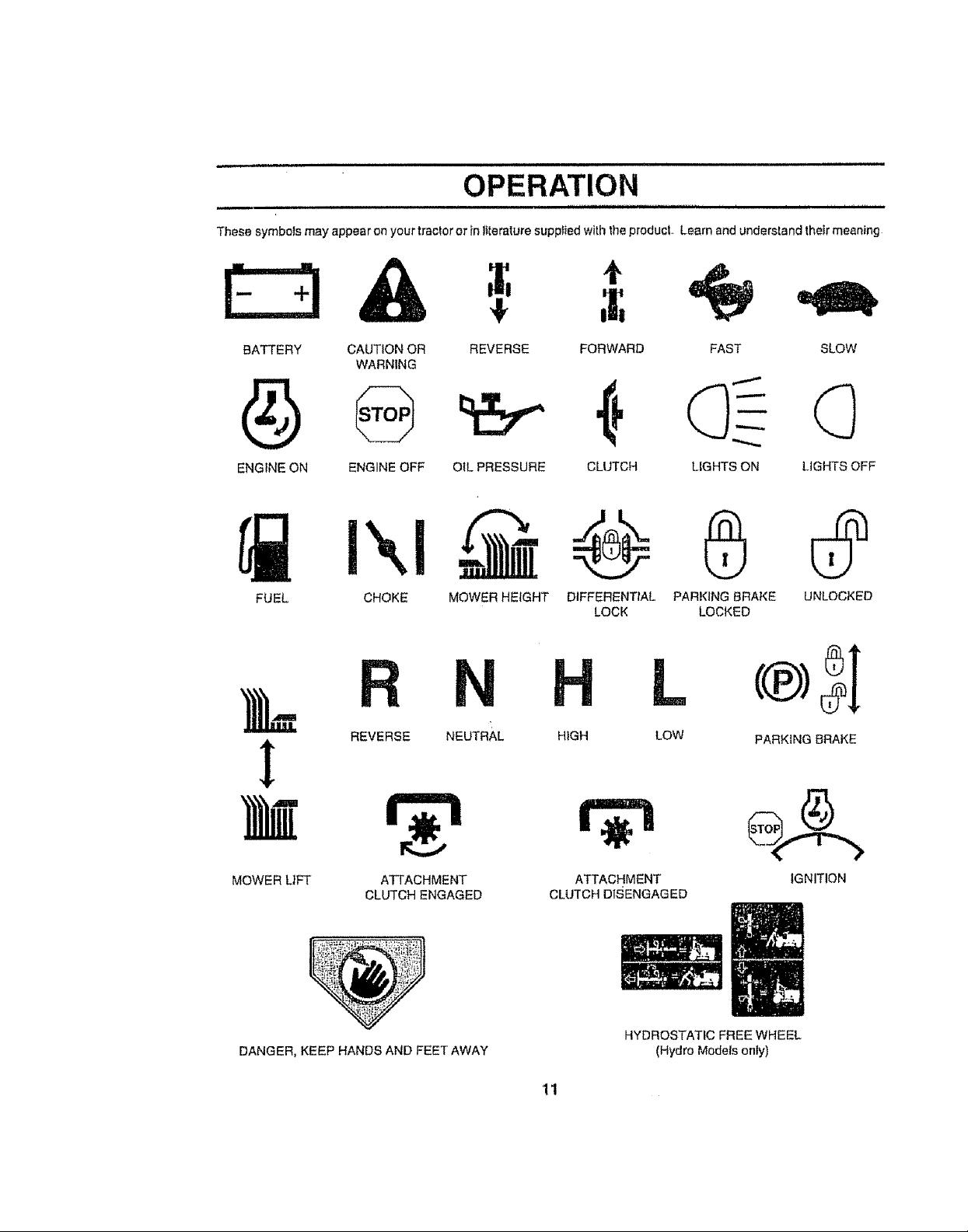

OPERATION

These symbols may appear on your tractor or in ]ttera_ure supplied with the producL Learn end understand their meaning

41,

BATTERY CAUTION OR

WARNING

ENGINE ON ENGINE OFF

FUEL CHOKE MOWER HEIGHT DIFFERENTIAL

REVERSE

OIL PRESSURE CLUTCH

FORWARD FAST SLOW

N

REVERSE NEUTRAL HIGH

LOCK

LIGHTS ON LIGHTS OFF

0

PARKING BRAKE UNLOCKED

LOCKED

L

LOW PARKING BRAKE

MOWER L|FT ATTACHMENT

CLUTCH ENGAGED

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH DfSENGAGED

HYDROSTATIC FREE WHEEL

11

IGNITION

(Hydro Models only)

Page 12

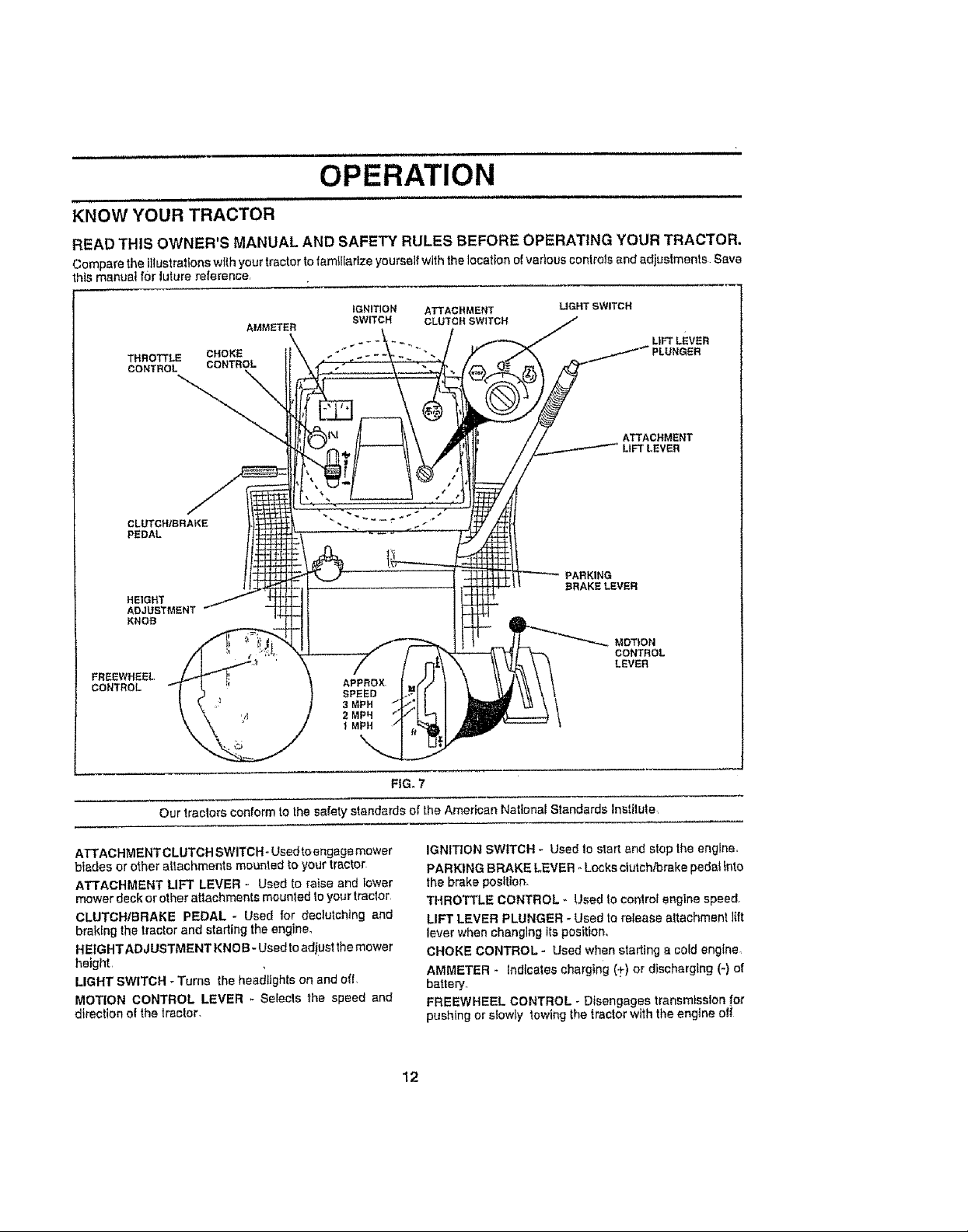

,1111 i iiiiii i iii

OPERATION

i iii

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR.

Compare the illustrations with your tractor to familiarize yourself with the location o! various controls and adjustments Save

his manual for luture reference

THRO_LE CHOKE

CONTROL CONTROL

CLUTCH/BRAKE

PEDAL

HEIGHT

ADJUSTMENT

KNOB

FREEWHEEL,

CONTROL

AMMEI'ER

IGNITION ATTACHMENT

SWITCH CLUTCH SW_TCH

UGHT SWITCH

PARKING

BRAKELEVER

MOTION

CONTROL

LEVER

LtFT LEVER

PLUNGER

ATTACHMENT

Our tractors conform to the safety standards of the American Nettena_ Standards lnstitule_

ATTACHMENTC LUTCH SWITCH _Used to engage mower

biades or other attachments mounted to your tractor

ATTACHMENT LIFT LEVER - Used to raise and lower

mower deck or other attachments mounted to your tractor,

CLUTCHIBRAKE PEDAL - Used for declutching and

bretdng the tractor and starting the engine_

HEIGHT ADJUSTMENT KNOB - Used to adjust the mower

height,

LIGHT SWITCH - Turns the headlights on end off,

MOTION CONTROL LEVER _ Selects the speed and

direction ot the tractor,

FIG. 7

IGNITION SWITCH - Used !o slert and stop the engine,

PARKING BRAKE LEVER -Locks clutch!brake pedaf _nto

the brake position,

THROTTLE CONTROL - Used to conlrol engine speed,

LIFT LEVER PLUNGER - Used to reIease attachment lift

lever when changing Its posftfon,

CHOKE CONTROL - Used when starting a cold engine.

AMMETER - indicates charging (+) or discharging (-) of

battery

FREEWHEEL CONTROL - Disengages transmission !or

pushing or slowly towing the tractor with the engine off

12

Page 13

OPERATION

, , = =,,, ,

The operation of any tractor can result in foreign objects thrown Into the eyes, which can

result in severe eye damage. Always wear safety glasses or eye shields while operating

your tractor or performing any adjustments or repairs. We recommend a wlde v=ston safety

mask over the spectacles or standard safety glasses.

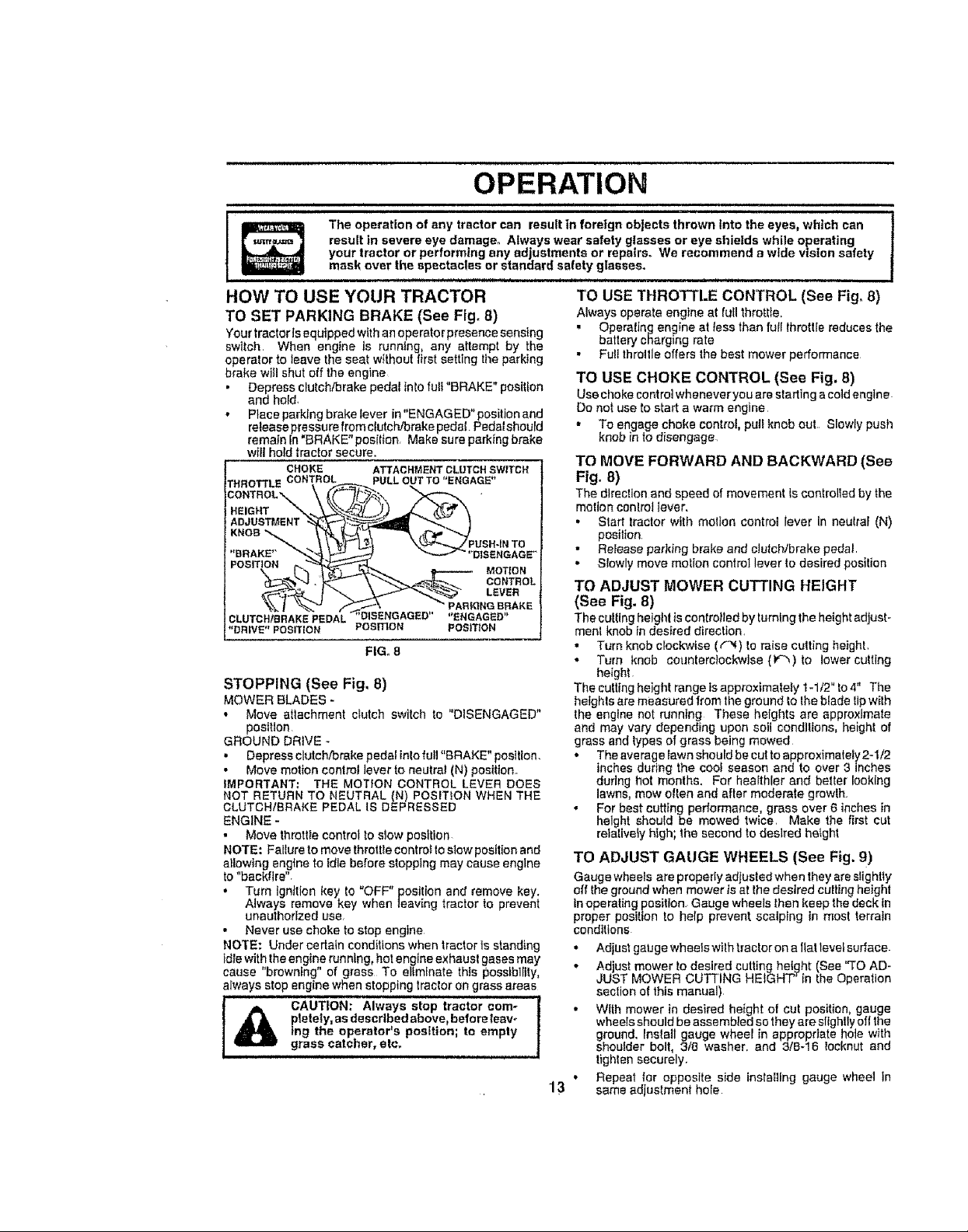

HOW TO USE YOUR TRACTOR TO USE THROTTLE CONTROL (See Fig. 8)

TO SET PARKING BRAKE (See Fig, 8) Always operate engine at(uilthrottle.

Your tractorls equipped with an operatorpresencesensing • OperalJng engine at less than full lhrott[e reduces the

switch. When engine Is running, any attempt by the

operator to leave the seal without lirst setting the parking • Full throttle offers the best mower performance

brake wtfl shut off the engine TO USE CHOKE CONTROL (See Fig, 8)

• Depress clutch/brake pedal Inlo fu]! "BRAKE" position

and hold. Use choke control whenever you are starting acold engine

• Place parking brake lever in "ENGAGED" position and Do not use to start a warm engine

reteasepr_ssurefromctutchYorake pedal Pedalshould • To engage choke control, put_ knob out Slowly push

remain [n BRAKE position. Make sure parking brake knob in to disengage

w_tlhold tractor secure.

THROTTLECONTROL PULLOUTTO *'ENGAGE*' Fig. 8)

CHOKE ATTACHMENTBLOTCHSWITCH

DISENGAGE"

MOTION

CONTROL TO ADJUST MOWER CUTTING HEIGHT

LEVER

PAe_NGBRAKE (See Fig. 8)

CLUTCHIBRAKE PEDAL "_;"DISENGAGED"

"DRIVE" POSmON POSITiON

FIG,. 8

STOPPING (See Fig. 8)

MOWER BLADES =

• Move attachment c_utch switch to "DISENGAGED"

position

GROUND DRIVE -

,, Depress clutch/brake pedal inlo full "BRAKE" position.

Move motion control lever to neutral (N) position.

IMPORTANT; THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED

ENGINE -

• Move throttie control to slow position

NOTE: Failure to move throtlle control toslow position and

allowing engine to idle before stopping may cause engine

to "backfire".

• Turn ignition key to "OFF" position and remove key,

Always remove key when leaving tractor to prevent

unauthorized use

• Never use choke to stop engine

NOTE: Under certain condiltonswhen traclorls standing

Idle with the engine running, hot englne exhaust gases may

cause "browning" of grass To eliminate this possibility,

always stop engine when stopping traelor on grass areas

ptetely,asdescribedabove, before leav-

I_ AUTION: Always stop tractor corn- l

ing the operator's position; to empty

grass catcher, etc.

"ENGAGED'_ The culling heighl is controlled by turning the height adjust-

POSITION meni knob tn desired direction.

13 same adjustment hole

battery charging rate

TO MOVE FORWARD AND BACKWARD (See

The direction and speed of movement is controlled by the

motion conlrol lever.

• Start tractor with molten control lever In neulrai (N)

position.

• Release parking brake and cJutchJbrake pedal

• Slowly move motion control lever to desired position

• Turn knob clockwise (,"_) to raise cutting height.

• Turn knob counterclockwise {K"_)to lower culling

height

The cutting height range is approximately 1-1/2" to 4" The

heights are measured from the ground to Ihe blade tipwilh

the engine not running These heights are approximate

and may vary depending upon salt conditions, height of

grass and types of grass being mowed

• The average fawn should be cur to approximately 2d/2

inches during the cool season and to over 3 inches

during hot months, For hea!thler and better looking

lawns, mow olten and after moderate growlh..

• For best cutting performance, grass over 6 inci_es in

height should be mowed twice. Make the first cut

relatively htgh; the second to desired height

TO ADJUST GAUGE WHEELS (See Fig, 9)

Gauge wheels are properly adtusted when they are slightly

off the ground when mower ts at the desired cutting height

in operating position. Gauge wheels then keep the deck in

proper position to help prevent scalping in most terrain

conditions

• Adjust gauge wheelswilh tractor on a tlattevef surface

• Ad ust mower to desired cutting hei_ht (See "TO AD-

JUST MOWER CUTT NG HE GHT' in the Operation

section of this manuel)

• With mower in desired height of cut position, gauge

wheels should be assembled so they are slighliy off the

ground, Inslall gauge wheel in appropriate hole with

shoufder boll, 318 washer, and 3lB-16 !ocknut and

tighten securely.

• Repeat far opposite side installing gauge wheel in

!

Page 14

OPERATION

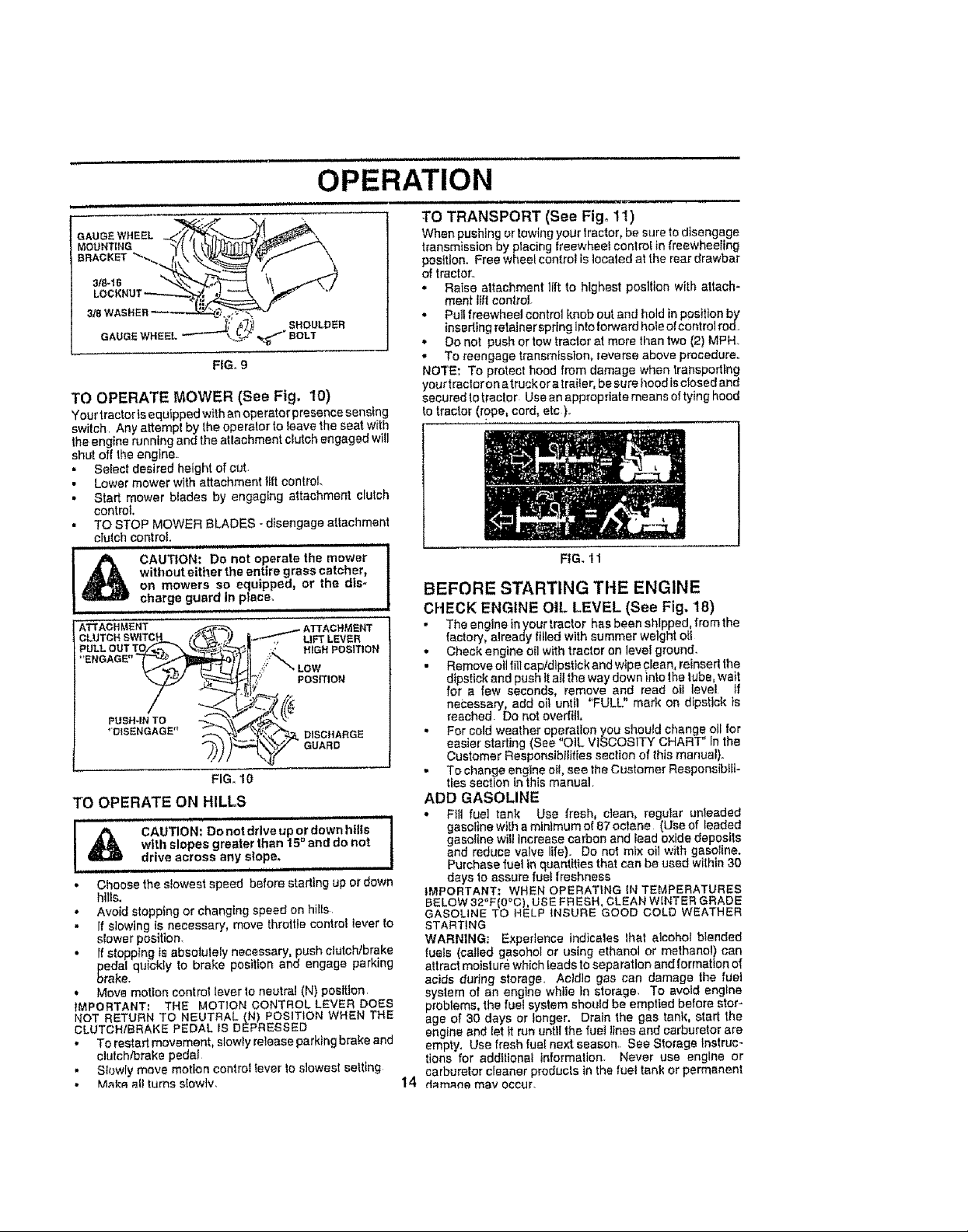

GAUGE WHEEL

MOUNTING

BBACKE'T_

3t8-16

3/8 WASHER

GAUGEWF _"_'BOLT

FIG, g

TO OPERATE MOWER (See Fig. 10)

',(ourtractor is equipped with an operator presence sensing

switch Any attempt by the operator to leave the seat wilh

the engine running and the attachment clutch engaged will

shut off the engine

• Selecl desired height of cut.

• Lower mower with attachment itft control.

• Start mower blades by engaging attachment clutch

control.

• TO STOP MOWER BLADES - disengage atlachment

clutch control.

t& AUTION: Do not operate the mower

ii, H,,, IIIIMI

without either the entire grass catcher,

on mowers so equipped, or the dis-

charge guard in place,

i ii

FIG. 10

TO OPERATE ON HILLS

i ,mHi ,Ul i H •

with slopes greater lhan 15° and do not

OA T,O.:Oonotd.vo pe.downhi.s

drive across any slope.

• Choose the slowest speed before starting up or down

hills,

• Avoid stopping or changing speed on hil{s

• If slowing {s necessary', move throttte control lever to

slower position.

• rfstopp ng s absolufeiy necessary push clutch/brake

pedal quickly to brake position and engage parking

brake.

• Move motion control lever lo neutral (N) position,

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTOHIBRAKE PEDAL IS DEPRESSED

• To restart movement, slowly release parking brake and

clutch/brake pedal

• Slowly move motion control tever lo slowest setting

• Make all turns sIowlv.

SHOULDER

TO TRANSPORT (See Fig. 11)

When pushing or towing your tractor, be sure todisengage

transmission by placing freewheel control _nfreewheeling

position. Free wheel control is located al the rear drawbar

of tractor.

• Raise attachment lift to highest posllion with attach-

ment tilt control-

. Pull freewheel control knob out and hold in position by

inserting retainersprlng into forward hole ofcontrol rod

. Do not push or tow tractor at more than two (2) MPH

• To reengage transmission, reverse above procedure.

NOTE: To protect hood from damage when transpodlng

your traclcron atruck or a traiter, be sure hood is closed and

secured totraclor Use an appropriate means oftying hood

to tractor (rope, cord, etc).

FiG. 11

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 18)

• The englneinyour tractor has been shipped, fromthe

factory, already filled with summer weight oil

• Check engine otl with tractor on level ground.

• Remove oit tiltcap/dipstick and wipe clean reinsed the

dipstick and push IIall the way down into the tube, wait

for a few seconds, remove and read oil ievei if

necessary, add oil until "FULL" mark on dipstick is

reached Do notoverfHl.

• For cold weather operation you should change oll for

easier starting (See "OIL VISCOSITY CHART" In the

Customer Responsibilities section of this manuat).

• To change engine oil see the Customer ReeponsibLli-

ties section in this manual

ADD GASOLINE

• Fill fuel tank Use fresh clean regular unleaded

gasoline with a minimum of 87 octane {Use of leaded

gasoline wilt increase carbon and fead oxide deposits

I

i

and reduce valve life). Do not mix oil with gasoline.

Purchase fuel in quantities that can be used within 30

days lo assure fuel freshness

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32"F(0°C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP _NSURE GOOD COLD WEATHER

STARTING

WARNING; Experience indicales that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which Ieads to separation and formation o_

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuet lines and carburetor are

empty, Use fresh fuel next season. See Storage Instruc-

tions for additional Information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

14 damana may occur.

Page 15

ii

OPERATION

filler neck, Do not overfill Wipe off any

[_ CAUTION: Fill to bottom of gas tank |

TO START ENGINE (See Fig. 8)

When starting the engine for the first time or if the engine

has run out of fuel, It will take extra cranking lime to move

fuel from the tank to the engine.

• Be sure freewheel control is ]n the lransmlsston an.-

" Sit on seat in operating position, depress clutch/brake

• Place motion control lever in neutral IN) postlten

° Move altachment clutch to "DISENGAGED" posillon

, Move throttle conlrol to fast position

• Pull choke control out for a cold engine slad attempt

NOte: Before starting, read the warm and cold starting

procedures below

• Insert keyinlo ignition and turn keydockwise to"START"

the choke control out and retry

WARM WEATHER STARTING (50° F and above)

• When engine starts, slowly push choke centrotln until

slowly

• The attachmenls and ground drive can now be used if

the engine does not accept the toad, restart the engine

and allow ttto warm up for one minute using the choke

COLD WEATHER STARTING (50° F and betow)

• When engine slarts, slowly push choke conlral inunlit

the engine begins le run smoothly Continue to push

the choke conlrol in small steps allowing the engine to

choke control is fully In. If Ihe engine starts to run

from several seconds to several minutes, depending

on the temperature.

HYDROSTATIC TRANSMLSSION WARM UP

• Before driving the unit fn cold weather, the transmis-

• The attachments can be used during the engine warm-

and may require the choke control be pulled out sfigh_ly.

spilled oi! or fuel. Do not store, spill or

use gasoline near an open flame,

gaged position.

pedal and set parking brake

For awarm engine start atlempl lhe choke csntro! may

net be needed_

position and release key as soon as engine slarts Do

not run starter continuously for more than fifteen sec-

onds per minute If Ihe engine does nat start after

several attempts, push choke control in, wait a few

minutes and lry again tf engine slilldoes notstart, putl

the engine begins to run smoothly. Ifthe engine slarts

to run roughly, pu]t the choke control out slightly for a

few seconds and then continue to push the control in

as described above

accept small changes in speed and load, until the

roughly pull the choke control out stlghlly for a few

seconds and then continue to push the centre n

slowly. This may require an engine warm-up period

sion should be warmed up as lellows;

• Be sure the tractor is on level ground.

• Place the motion control lever in neutral.

Release the parking brake and let Ihe clutch/brake

slowly retum to operating position,

,, Allow one minute for transmission to warm up_

This can be done during the engine warm up

period.

up period after the transmission has been warmed up

=

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need Io be adjusted for best engine performance. Sea"TO

ADJUST CARBURETOR" in _he Service and Adjustments

I

section of this manual

PURGE TRANSMISSION

_ CAUTION: Neverengageordisengage !

To ensure proper operation and performance, It is recom-

mended thai the lransmlsston be purged before operating

tractor for the firsl time This procedure witl remove any

trapped air Inside the lransmtssion which may have devel-

oped during shipping of your tractor

IMPORTANT: SHOULD YOUR TRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT

SHOULD BE PURGED AFTER REINSTALLATION

BEFORE OPERATING THE TRACTOR.

• Plasetractor safely on levetsurface with engine off and

,, D_sengage lransmtsslon by placing freewheel control

° Sittinginthelractorseat, startenglne Alterlheeng[ne

• Move motion control lever to full forward position and

NOTE: During thisprocedure lhere witJbe no movement of

drive wheels. The air Is being removed from hydraulic drive

system

• Move metlon control lever to neutral (N) position.. Shut-

• Engage transmission by placing freewheel control in

• Sitting in the tractor seat. start engine. After theengine

• Slowly move motion control lever forward, alter the

, Your_lractor is now purged and now ready for normal

freewheel lever while the engine is run_

nlng,

parking brake set

in freewheeling position (See TO TRANSPORT" in

this section of manual)

[s running, move throttle control Eoslow position. With

motion controt lever in neutral IN) position, slowly

disengage clutch/brake pedal.

hold for five (5) seconds. Move lever to furl reverse

posilion and hold tor five (5) seconds_ Repeat this

procedure three (3) times

elf engine and set parktng brake

driving posilien (See "TO TRANSPORT" in thissection

of manual)

is running move throttle centre/to half (1/2) speed.

With motion control lever in neutrat IN) position, s owly

disengage c_utchibrake pedal

lractcr moves approximately five (5) feet, slowly move

motion control lever to reverse position_ After the

trB,ctor moves approximately l[ve (5) feet return the

motion control lever to the neutral IN) position. Repeat

this procedure with the motion control lever lhree {3)

times.

operation

15

Page 16

OPERATION

i J,

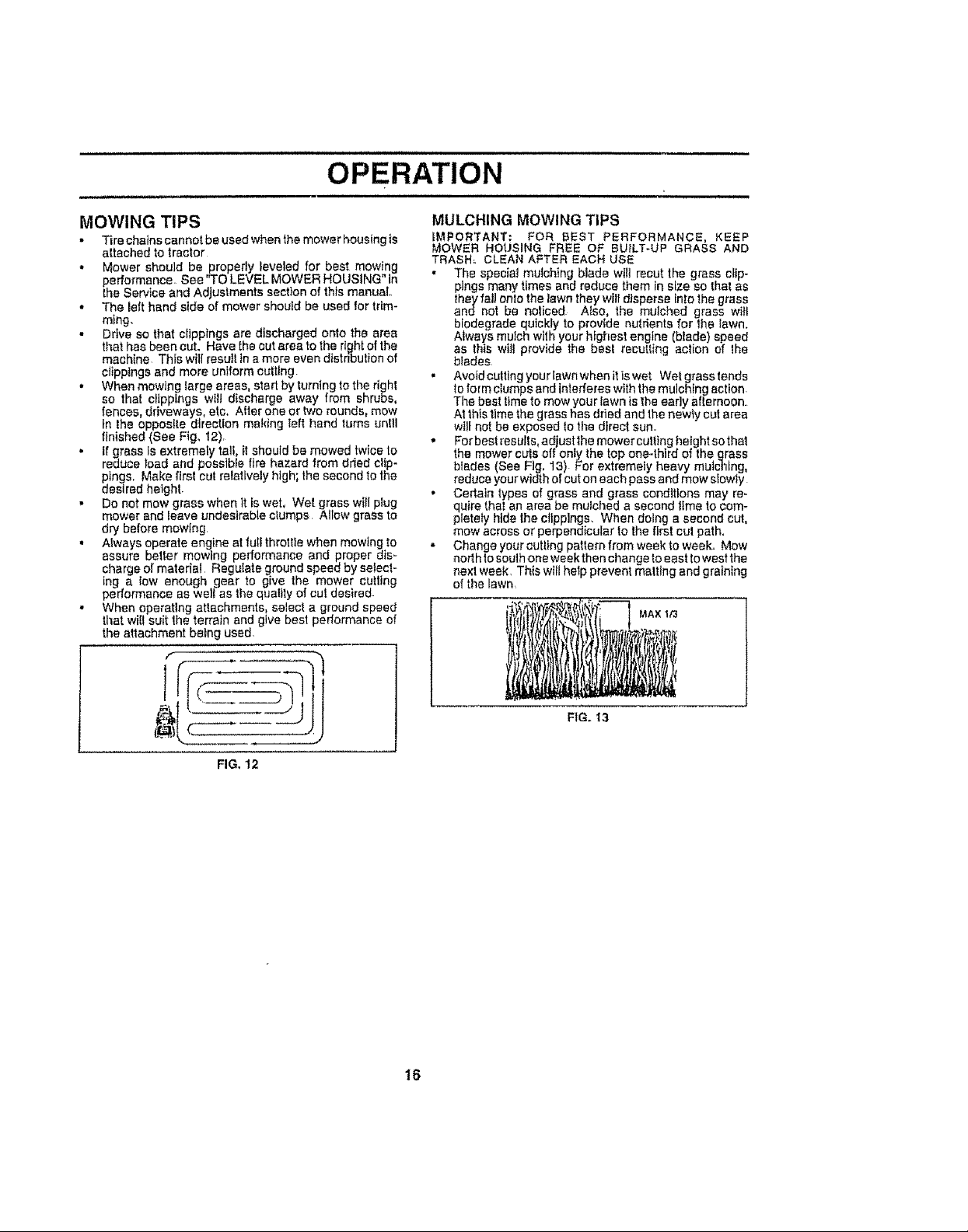

MOWING TIPS

• Tire chains cannot be used when the mower housing is

attached to tractor

° Mower should be properly teveled for best mowing

performance° See "TO LEVEL MOWER HOUSING" in

the Service and Adjustments section of this manual,,

• The left hand side of mower should be used for trLm-

ming,

• Drive so that clippings are discharged onto the area

that has been out. Have the cut area to the right of the

machine, This wit{ resuIt in a more even distribution of

clippings and more uniform cutting

• When mowing large areas, stad by turning to the right

so that clippings will discharge away from shrubs,

fences, driveways, etc, After one or two rounds, mow

in Ihe opposite direction making left hand turns until

ffnished (See Fig, 12),

• if grass _sextremely tall, it should be mowed twice to

reduce toad and posstbfe fire hazard from tided clip-

pings, Make first cut relatively high; the second to the

deslredheight.

• Do not mow grass when It is wet, Wet grass will plug

mower and leave undesirable clumps Allow grass to

dry before mowing

• Atways operate engine at full throttle when mowing to

assure better mowing performance end proper dis-

charge of matedal Regulate ground speed by select-

ing a low enough gear to give the mower cutting

performance as wel! as the quality of cut desired

• When operating attachments, select a ground speed

that witl suit tile terrain and give best performance of

the attachment being used,

MULCHING MOWING TIPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH_ CLEAN AFTER EACH USE

• The special mutching blade will recur the grass clip-

pings many times and reduce them in size so that as

they fall onto the lawn they"will disperse into the grass

and not be noliced Also, the mulched grass will

blodegrade quickly to provide nutrients for lhe lawn.

Always mulch with your h_ghest engine (blade) speed

as this will provide the best recurring action of lhe

blades

= Avoidcultlngyourlawnwhenitiswet Welgrasslends

to term clumps and interferes with themulching action

The best time to mow your lawn is 1haearly aflemoon.

At this tlme the grass has dried and the newIy cut area

wt!f not be exposed to the direct sun.,

', For best resuIls, adjust the mower cutting height so that

the mower cute off only the top one..thlrd of the grass

bfedes (See Fig. 13) For extremely heavy mutcHng,

reduce your width of cut on each pass and mow slowly

• Certain types of grass and grass conditions may re-

quire thal an area be mutehed a second time to com-

pletely hide the clippings. When doing a second cut,

mow across or perpendicular to the first cul path.

= Changeyourcuttingpatternfromweektoweek. Mew

nedh to soulh one weekthen change to east towest the

next week, This will help prevent malting and graining

ofthelawn,

FIG, 12

FIG. 13

16

Page 17

CUSTOMER RESPONSIBILITIES

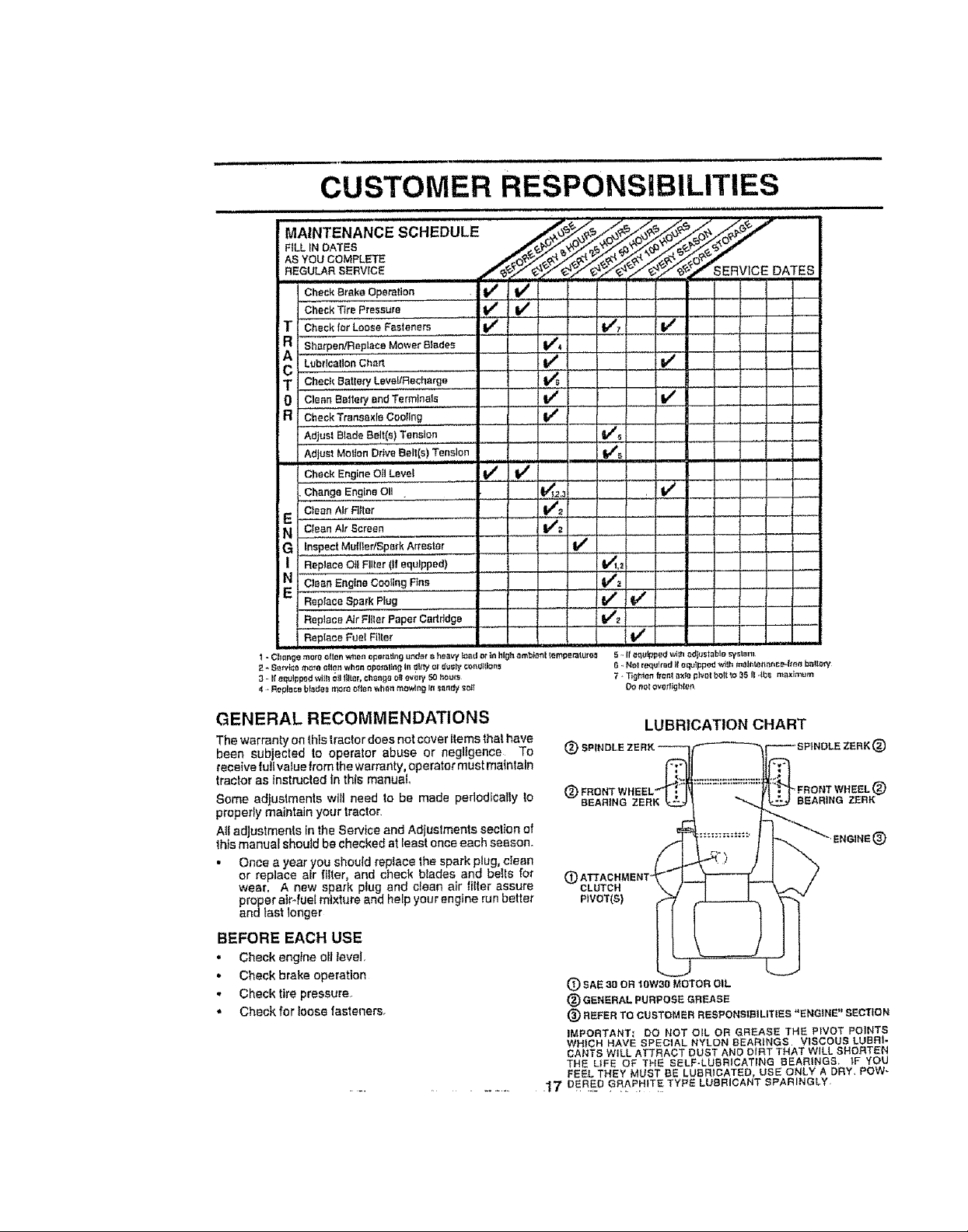

MAINTENANCE SCHEDULE ___oo_n_J

AS YOUCOMPLETE f__-_'_9,_._._O?'_ti '"

" CheckBrake Operation . . If V' ........

CheckT_rePressure I,/ V' ....

1"JChec,forLoo,oF.eteners V" V', V'

LUb,iCa"oec.e_" V' I," [

_Sh_rpen!ReptaceMowerBlades I#"*,_ J

T iiChecF!BatteryLeve,_echarge I/_

0 '.CleenBstre_.,RedTerm!._._!e' ' ' V' ........ i --

a i CheckTrensaxle,€ooilng ,, If .............. i

Adjust B{adeBelt{e}Tension V'#_ ..... {

k_lustMotionD,_veee,(s)Te_e_on V'e '

CheckEngineOilLeve_ V _' I_ : ,

Change EngineOil _2.,_ . !if ,

Clean Air Screen ......

i InspectMultt_dSperkAttester _ .............

_ReptaceOil Filter(if equipped) I_l,z .....

ReplaceSparkFI,g V' V' : "

RepiacFgeIRepi_eeAirFiilerFitlerPaperCartridge ....., V'_t V _ .........]

GENERAL RECOMMENDATIONS

The warranty on this _ractor does not cover items that have

been subjected to operator abuse or negligence To (])sPl_

receive lullvalue from the warranty, ope rater must maintain

tractor as instrucled {nth{s manual

Some adjustments wilt need to be made perlodfcatly to

properly maintain your tractor.

AII adjustments in the Service and Adjuslments section of

this manual should be checked at least once each season.

• Once a year you should replace the spark plug, cfean

or replace air filter, and check blades and belts for _("f')CLUTCH

wear. A new spark plug and clean air tilter assure

proper elf-fuel mixture and help your engine run better PWOT(S)

and tast longer

BEFORE EACH USE

• Check engine oil level,

• Checkbrake operation

. Checktire pressure.

• Checkfor teose fasteners,

(_) SAE 30 OR '_swe0 MOTOR OIL

(_ GENERAL PURPOSE GREASE

® REFER TO CUSTOMER RESPONSIBILITIES "ENGINE" SECTION

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS VISCOUS LUBRi-

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS, IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW-

17 DERED GFLAPHITE TYPE LUBRICANT SPARINGLY

LUBRICATION CHART

®

FRONT WHEEL (_

BEARING ZERK BEARING ZERK

®

Page 18

CUSTOMER RESPONSIBILITIES

TRACTOR

Always observe safety rules when performing any mainte-

nance.

BRAKE OPERATION

II tractor requires more than six (6) feet stopping distance

at htgh speed in h_ghest gear, then brake must be adjusted,

(See "TO ADJUST BRAKE" in 1he Service and Adjust-

merits section of this manual)

TIRES

,, Malntatnproper air pressure in all tires (See "PROD-

UCT SPECIFICATIONS on page 3 of this manua!)

• Keep tires free of gasoline, o11,or insect control cheml-

cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seal tire punctures and prevent fiat tires due to

s_ow leaks, tire sealant may be purchased from your tocal

parts dealer Tire sealant atso prevents tire dry rot and

corrosion.

BLADE CARE

For best results mower blades must be kept sharp. Re-

place bent or damaged blades.

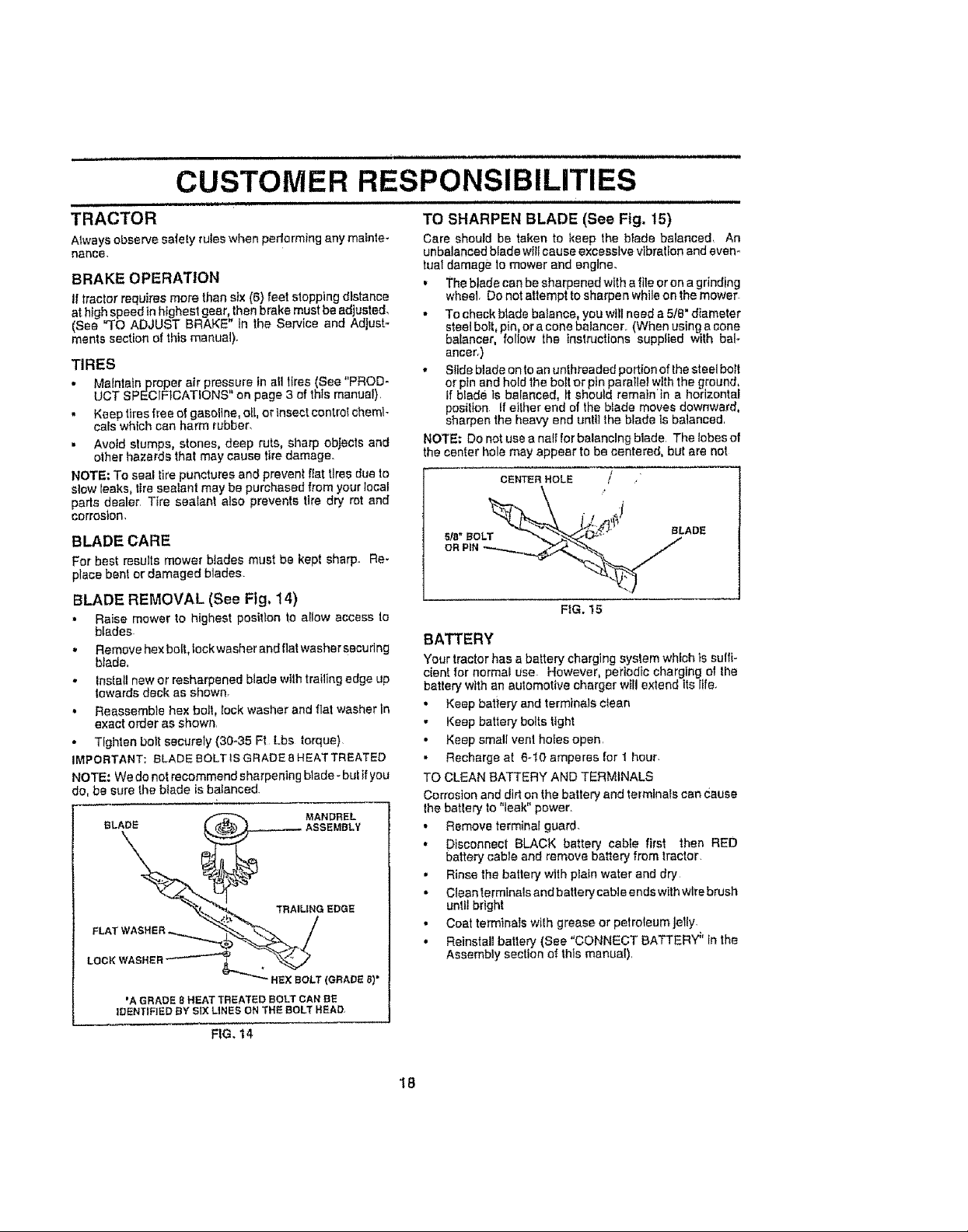

BLADE REMOVAL (See Fig, 14)

• Raise mower to highest posilton to allow access to

bIades

• Remove hex boff, lockwasher and flat washer securing

blade.

• install new or resharpened blade with trailing edge up

towards deck as shown.

• Reassemble hex boll, lock washer and flat washer in

exact order as shown

• Tighten bott securely (30-35 Ft Lbs torque}

IMPORTANT: BLADE BOLT IS GRADE 8HEAT TREATED

NOTE: We do not recommend sharpening blade- but ifyou

do, be sure the blade is balanced

BLADe

LOCK WASHER

'A GRADe 8 HEAT TReATeD BOLT CAN BE

IDENTiFieD BY SIX L|NES ON THE BOLT HEAD.

FIG. 14

MANDREL

TRAILING EDGE

HeX BOLT (GRADe 8}*

TO SHARPEN BLADE (See Fig. 15)

Care should be taken to keep the blade balanced, An

unbalanced blade wlifcause excessive vibration and even-

tual damage to mower and engine.

• The blade can be sharpen?d with afile or on a grinding

wheel Do not attempt to snarpen while on the mower

. To check blade balance, you will need a 5/B" diameter

steel bolt, pin or a cone balancer (When using a cone

balancer, follow the instructions supplied with ba-

ancer,)

• Slide blade on toan unthreaded portion of lhe steel bolt

or pin and hold the bolt or pin parallel with the ground,

If blade ts balanced, It should remain tn a ho_:izontel

posilion if ellher end of the btade moves downward,

sharpen the heavy end unlit the blade is balanced

NOTE; Do not use a neff for balancing blade The lobes of

he center hole may appear to be centered, but are not

CENTER HOLE ' / ,"

s,." LADe

FIG. 15

BATTERY

Your tractor has a battery charging system which is sulfi-

cient for normal use However, periodic charging of the

battery with an automotive charger will extend its life,

• Keep battery and terminals ctean

• Keep battery bolts tight

• Keep smallvent holesopen

• Recharge at 6-I0 amperes for 1 hour

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can c_ause

lhe battery to "leak" power.

• Remove terminal guard.

• Disconnect BLACK battery cable first then RED

battery cable and remove battery from tractor

• Rinse the battery with plain water and dry

• Clean terminals and batterycable endswith wire brush

until bright

• Coat terminals wilh grease or petroleum Jelly

• Reinstall battery (See "CONNECT BATTERY _'in the

Assembly section Of this manual)

18

Page 19

CUSTOMER RESPONSIBILITIES

V-BELTS

Check V-be!Is for delerIorat}on and wear after 100 hours of

operation and replace tf necessary. The belts are not

adjustable, Replace belts if they begin to slip from wear

TRANSAXLE COOLING

The fan and cooling fins of transmission should be kept

clean to assure proper cooling

Do not atlempt to clean fan or transmission while engine is

running or while the transmission is hot,

• Inspect coating fan to be sure fan biades are intact and

clean

• Inspect coo_ing tins for dirt, grass clippings and other

materials To prevent damage to seals, do not use

compressed air or high pressure sprayer to clean

cooling fins.

TRANSAXLE PUMP FLUID

The transaxiewas sealed at the factory and fluid mainte-

nancetsnotrequlredfor the lifeofthetransaxle,Shouldthe

trensaxle ever[oakorrequire servicing_contactyour near_

eatauthorized service center/department

ENGINE

LUBRICATION

Only use high quality detergent oi! rated with APt service

classification SF, SG or SH. Select the oil's SAE viscosity

grade according to your expected operating temperature.

_C,3,,. O" .2'_1" -_C," b* 10_ _1}" 30* 40_

TE,MPERATURE RANGE ANT_C_PA"fEO aEFOR_ NEXT OIL CHANGE

NOTE: Although mu_ti-viscosiiy oils (5W30, 10W30 efc

improve starting In cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F, Check your engine oil level more frequently to avoid

possible engine damage from running low on oil

Change the of! after every 50 hours of operation or at least

once a year tfthe tractor isnot used for50 hours In one yea r

Check the crankcase oil tevel before starting the engine

and after each eight (8) hours of operation, Tighten oil fil_

capldtpstick securely each time you check the oll [eve[

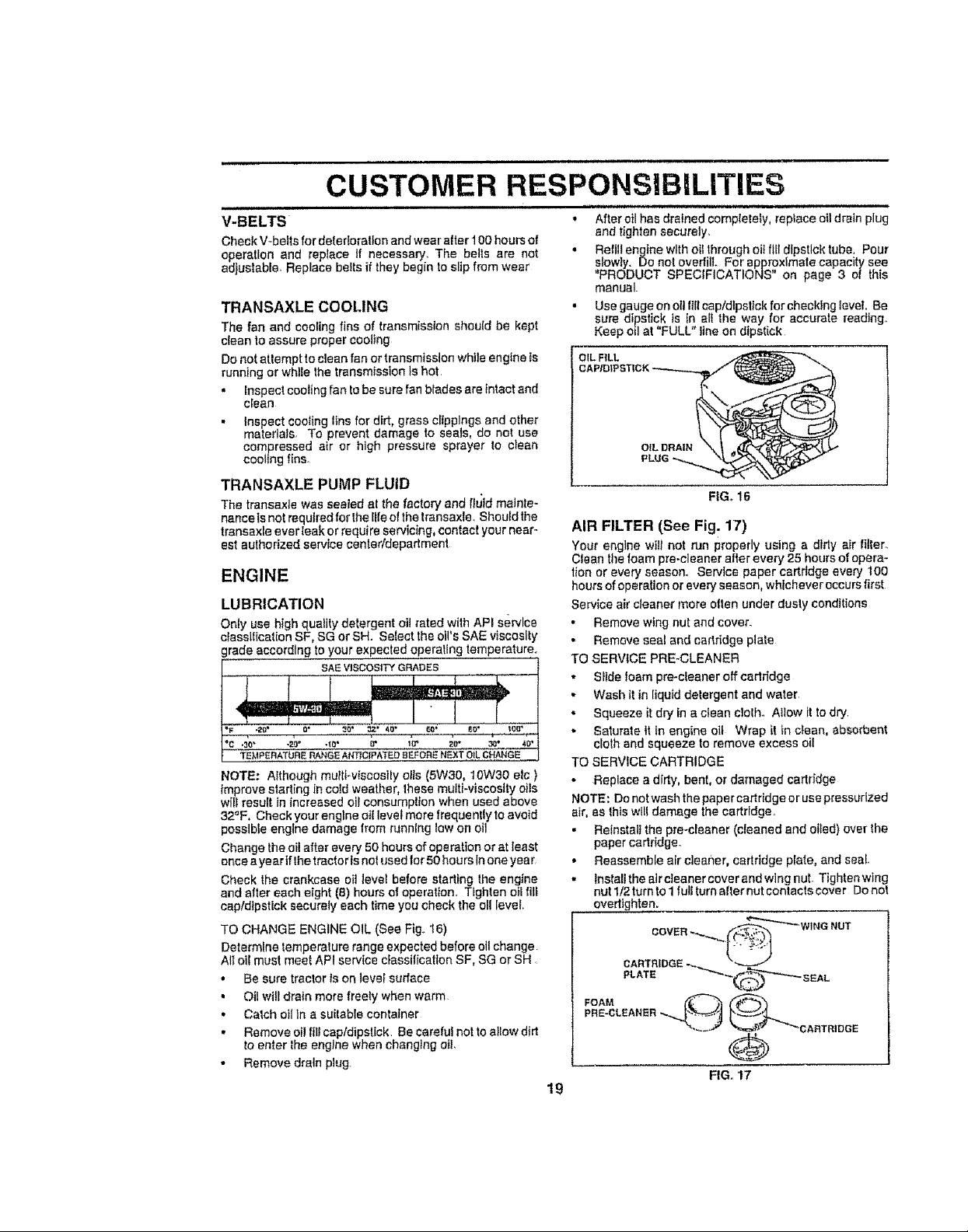

TO CHANGE ENGINE OIL (See Fig. 16)

Determine temperalure range expected before oil change

All ell must meet API service classification SF, SG or SH

• Be sure tractor is on level surface

• Oil will drain more freety when warm,

• Catch oil in a suitabEe container

• Remove eil fill capldipstick. Be careful not toallow dirt

to enter the engine when changing oil

Remove drain plug.

SAlE VISCOSITY GRADES

,,,,,, ,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,_

• After oil has drained completely, reptace oil drain plug

and tighten securely.

• Refill engine with oil through eft fill dipstick tube, Pour

slowly. Do not overfill. For approximate capacity see

"PRODUCT SPECIFICATIONS" on page 3 oi this

manual.

• Use gauge on oil fillcep/dlpsllck for checking level, Be

sure dipstick is In all the way for accurate reading,

Keep oil at "FULL" line on dipstick

OIL FILL

OIL DRAIN

FIG. 16

AIR FILTER (See Fig. 17)

Your engine wilt not run properly using a dtdy air fitter_

Clean the foam pro-cleaner after every 25 hours of opera-

tion or every season. Service paper cartridge every 100

hours of operation or every season, whichever occurs first

Service air cleaner more often under dusty conditions

• Remove wing nut and cover.

• Remove seal and cartridge plate

TO SERVtCE PRE-CLEANER

• Slide loam pro-cleaner off cartridge

• Wash it in liquid detergent and water,

• Squeeze it dry in a clean clolho Mow it to dry

• Saturate it In engine o11 Wrap it in clean, absorbent

cloth and squeeze to remove excess oil

TO SERVICE CARTRIDGE

• Replace a dirty, bent, or damaged cartrfdge

NOTE: Do not wash the paper cartridge or use pressurized

air, as thts will damage the cartridge,

. Reinstall the pre*cleaner (cleaned and oiled) over the

paper cartridge.

• Reassemble air cleaner, cartridge plate, and seal.

• Installtheaircteanercoverandwingnut Tightenwing

nut 1/2 turn to I full turnafter nut contacts cove r Do not

overttghten.

COVER-,_, .,.-_'-'_'_'- WING

SEAL

PRE-CLEANER".-._ ""CARTRIDGE

0

19

FIG. 17

NUT

Page 20

.................... , ill ill,i ,,,I,II I I I IIIlllllllllllllllll I Illl,.utl

CUSTOMER RESPONSIBILITIES

i,, .... ,, ............... i i,,,,

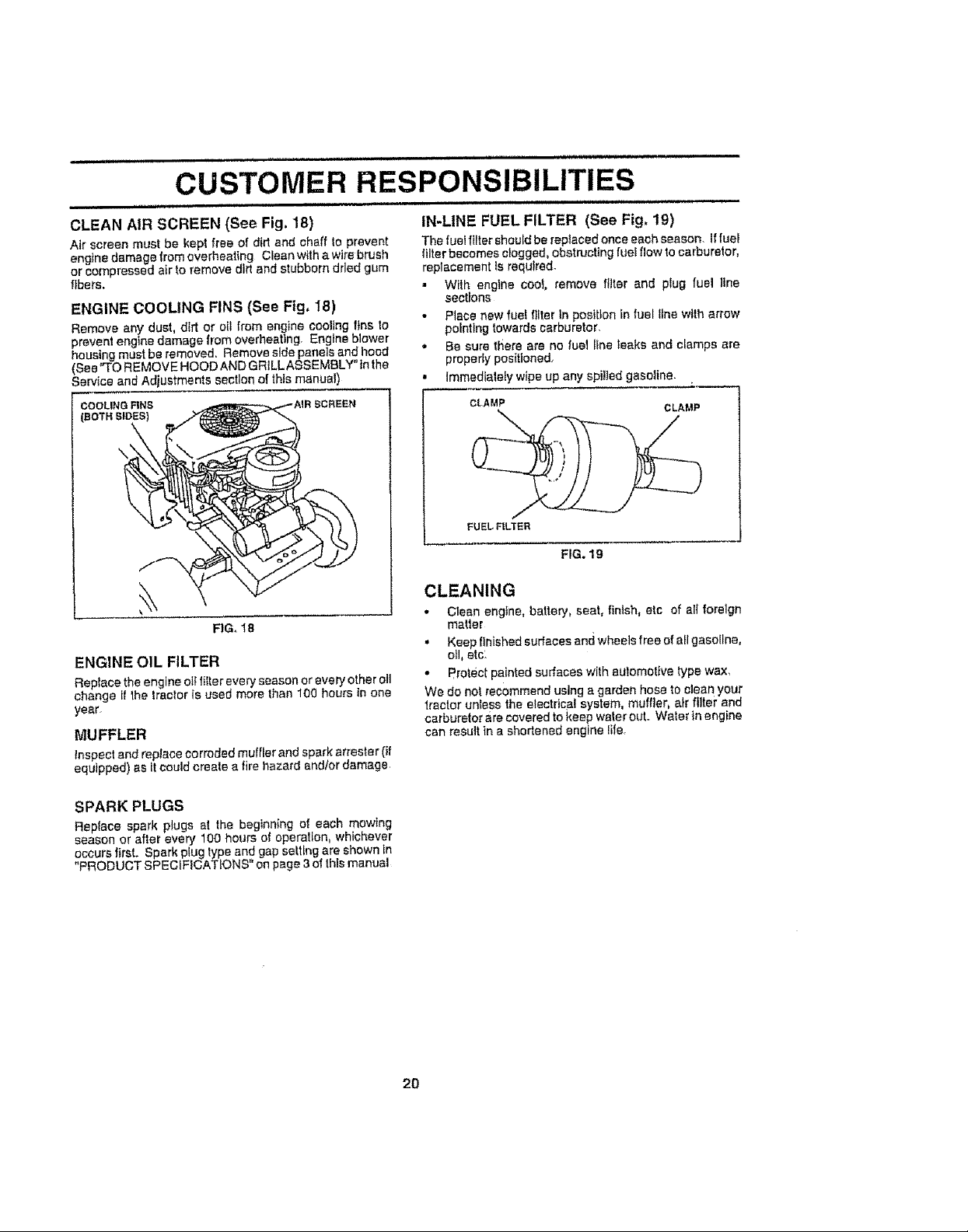

CLEAN AIR SCREEN (See Fig. 18)

Air screen must be kept free of did and chaff to prevent

engine damage from overheating Clean with a wire brush

or compressed air to remove dirt and stubborn dried gum

fibers.

ENGINE COOLING FINS (See Fig, I8)

Remove any dust, dirt or oil from engine coolingfinsto

prevent engine damage from overheating, Engine blower

housing mustbe removed, Remove side panels andhood

(See"TO REMOVEHOOD ANDGRILLASSEMBLY tnthe

_erviceend Adjustments section ofthismanual)

IN-LINE FUEL FILTER (See Fig, 19)

The fuel filter should be replaced once each season. If fuel

filter becomes clogged, obstructing fuel flow to carburetor,

replacement ts requlrsd.

• With engine cool, remove filter and plug fuel line

sections

• Place new fuel filter In position in fuel line with arrow

pointing towards carburetor.

• Be sure there are no fuel line leaks and clamps ere

properly positioned.

Immediately wipe up any spilled gasoline.

CLAMP

CLAMP

\

FIG,, 18

ENGINE OIL FILTER

Replacetheengine otttilter everyseason orevery otheroil

change if the lractor is used more than 100 hours tn one

year_

MUFFLER

inspectand replacecorroded muffler and sparkarrestor (if

equipped) as l( could create a fire hazard andtor damage

SPARK PLUGS

Replace spark plugs at the beginning of each mowing

season or after every 100 hours of operation, whichever

occurs first. Spark plug type and gap salting are shown in

"PRODUCT SPECIFICATIONS" on page 3of this manual

FUELF1LTER

FfG, 19

CLEANING

• Clean engfne, battery, seat, finish, etc of all foreign

metier

. Keep finished surfaces and wheels free of all gasoline,

otl, etc.

- Protect painted surfaces with automotive type wax,

We do not recommend using a garden hose to clea n your

1rector unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Wafer in engine

can result in a shortened engine life

2O

Page 21

i ill,,iu,,i i i .....

SERVICE AND,ADJUSTMENTS

CAUTION: BEFORE PERFORMING ANY SERVICE OR ADJUSTMENTS:

Depress clutch/brake pedal fully and set parking brake°

Place motion control lever in neutral iN) positlono

Place attachment clutch in "DISENGAGED" position,

Turn ignition key "OFF" and remove key.

Make sure the blades and all moving parts have completely stopped°

Disconnect spark plug wire from spark plug and place wire where it cannot come in contact

with piug.

TRACTOR

TO REMOVE MOWER (See Fig. 20)

• Place attachment ciutch in "DISENGAGED" position

• Turn height adjustment knob to lowest setting

- Lower mower to its Iowesf position

• Remove retainer spring holding anl}-swaybar to chas-

sis bracket and disengage anti-swaybar from brackeL

• Remove retainer springs from suspension arms at

deck and disengage arms from deck

• Raise attachment lift to Its highest position:

• Remove two retainer springs from each front link and

remove iinks.,

• Sitde mower forward and remove bett from eieclric

clutch pulley

• Slide mower out from under right side of traclor,

iMPORTANT; iF AN ATTACHMENT OTHER THAN THE

MOWER DECK IS TO BE MOUNTED ON THE TRACTOR,

REMOVE THE FRONT LINKS

TO INSTALL MOWER

Farrow procedure described in "iNSTALL MOWER AND

DRIVE BELT' in the Assembly section of this manual

ADJUSTMENT

NUTS UFT FRONT

i

LINKS SUSPENSION

TO LEVEL MOWER HOUSING

Adjust the mower white tractor isparked on level ground or

driveway. Make sure tires are property inflated (Sea

"PRODUCT S PECIF1CATtONS" o npage 3 of this manual).

Iftires are over or undertnflated, you wll! not properly adjust

your mower

SIDE-TO-SIDE ADJUSTMENT (See Figs, 21 and 22)

• Raise mower to its highest position.

• At the midpoint of both sides ol mower, measure heigltt

from bottom edge of mower to ground Distance"A"on

both sides of mower should be the same or within 1/4"

of each other,

• If adjustment is necessary, make adjustment on one

side of mower only.

• To raise one side of mower, tighten liftlink adjustment

nul on 1hal side

• To lower one side of mower, toosen lilt link adjustmenl

nul on lhal side,,

NOTE: Each full turn of adjustment nut wltl change mower

height about 1/8"

• Recheck measurements after adjusting,

CHASSIS

RETAINER

SPRING

ANTi-SWAY

BAR RETAINER

SPRINGS

RRACNET

FIG. 20

RETAINER

BRACKET

FRONT

SUSPENSION

BRACKET

MOWER

Page 22

iii, i, IIIIHIIlll ii

SERVICE AND ADJUSTMENTS

BOTTOM EDGE

OF MOWER TO

GROUND

BOTTOM EDGE

OF MOWER TO

GROUND

FIG. 21

_(_ SUSPENSIONARM

. /

LIFT LiNK ADJUSTMENT NUT

FIG_ 22

FRONT-TO-SACK ADJUSTMENT (See Figs 23 and 24)

IMPORTANT: DECK MUST BE LEVEL SIDE÷TO-S_DE _F

THE FOLLOWING FRONT-TO-BACK ADJUSTMENT IS

NECESSARY, BE SURE TO ADJUST BOTH FRONTLINK8

EQUALLY SO MOWER WILL STAY LEVEL SIDE-TO-

SIDE,

To obtain the best cutting results, the mower housing

should be adjusted so that the front is approximately 118"to

1/2" lower than the rear when the mower is in its highest

position,

Check adjuslment on right side of tractor Measure dis-

tance "D" directly in front and behind the mandrel at boltom

edge of mower housing as shown

• Before making any necessary adjustments, check that

both fron! links are equalin tenglh Both links should be

approximately 10-3/8",

• tf links are not equal in length, adjust one link to same

Ieng[h as other link,

• To lower front of mower loosen nut "E" on both front

links an equal number of turns

• When distance "D" is 1/8" to 1/2" lower at front than

rear, tighten nuts "F" against trunnion on both front

links.

• To raise front of mower, loosen nut"F" from trunnion on

both front links. Tighten nut "E" on both front links an

equal number ol turns

• When distance "D" is 1/8" to 1/2" lower at front than •

rear, tighten nut"F" against trunnionon both front links.

Recheck side-to-side adjustment.

:,_,,,% t _ =,_ MANDREL

BOTHFRONTLINKSMUSTBE EQUALINLENGTH

NUT "E"

NUl

FIG. 24

TO REPLACE MOWER DRIVE BELT

MOWER DRIVE BELT REMOVAL (See Fig, 25)

, Park!rector on a level surface Engage parking brake.

• Remove four screws from L,H mandrel cover and

remove cover,

• Roll beIt over the top of L H, mandrel pui_ey,

• Remove belt from electric clutch pulley.

• Remove belt from tdter pulleys,

Remove any dirt or grass clippings which may have

accumulated around mandrels and entire upper deck

surface,

• Check primary idler arm and two idlers to see that they

rotate freely,

• Be sure spdng ts securely hooked to primary idler arm

and bolt in mower housing,

MOWER DRIVE BELT INSTALLATION (See Fig, 25)

• Install be{t in both idlers, Make sure belt. is in both belt

keepers at the idlers as shown

• Install new belt onto electric cFutch puItey,

• Roll belt into upper groove ol LH mandrel pulley

. Carefully check bell routing making sure belt ls in the

grooves correctly and inside belt keepers

Reassemble LH. mandrel cover

ELECTRIC

CLUTCH

PULLEY

FIG, 23

22 FIG. 25

Page 23

SERVICE AND ADJUSTMENTS

TO REPLACE MOWER BLADE DRIVE BELT

(See Fig. 26)

Park the tractor on level surface Engage parking brake

• Remove mower drive belt (See "TO REPLACE MOWER

DRIVE BELT" in this section ofthls manual)

• Remove mower (See "TO REMOVE MOWER" in this

section of this manual)

• Remove four screws from R H mandrel cover and

remove cover Unhook spring from bop on mower

housing

• Carefully roll belt oIf R H mandrel putley

• Remove beft from center mandrel pulley, idler pulley,

and L.Ho mandrel pulley

Remove any dirt or grass which may have accumu-

lated around mandrels and entire upper deck surface

• Check secondary idler arm and Idler to sea that they

rotate freety

• Be sure spring is hooked in secondary idler arm and

sway-bar bracket.

• Install new belt in lower groove of LH mandrel pulley,

fdter pulley, and cenler mandrel pu/tey as shown

• Rollbelt over R H mandrel pulley Make sure belt isln

all grooves properly

• Reconnect spring to bolt in mower housing and rein-

stall R H mandrel cover

• Reinstall mower to lractor (See "iNSTALL MOWER

AND DRWE BELT" in the Assembly section of this

manual)

• Reassemble mower drive belt (See "TO REPLACE

MOWER DRIVE BELT" in this section o! thismanual

LH. BLADE CENTER

MANDREL DRIVE9ELT MANDREL

MOWER

tDLER

ROTOR CLUTCHF.LATE

NYLON_SL_ _eRAKE

LOCKNUT(3) PLATE

FIG. 27

TO ADJUST BRAKE (See Fig. 28)

Your tractor is equipped with an adjustable brake system

which is mounted on the side of the transaxle

if _ractor requires more than six (6) feet stopping distance

at high speed in htghesl gear, then brake must be adjusted

• Depress c]ulchibraka pedal and engage parking brake.

• Measure d{stance between brake operating arm and

nut "A" on brake rod

• II distance is other than 1-3/4% loosen jam nut andturn

nut "A" until distance becomes !-3/4" Retlghten iam

nut against nut "A".

• Roadtest tractor forproper stopping distance as stated

above, Rsadjusl if necessary. If stopping distance is

stil! greater than six (6) leel tn highest gear, further

maintenance is necessary Contact your nearest au-

thorized service center/department

WITH PARKING BRAKE "ENGAGED"

HUT "A'"-_._.__, JAM NUT

R H,

MANDREL

COVER

SFR|NG

SWAY-eAR

BRACKET

FIG. 26

SCREW

TO ADJUST ATTACHMENT CLUTCH (See

Fig, 27)

The eiectflc ctutch should provide years of service The

clutch has a built-in brake that stops the pultey within 5

seconds Eventually, the tntemat brake wilt wear which

may cause the mower btades to not engage, or, to not stop

as required Adjustments should be made by your nearest

authorized service center/department

• Make sure attachment clutch andignttton switches are

in "OFF" positron.

• Ad ust the three nylon Iocknuls unlit space between

clutch plate and rotor measures O12" at all three slot

tocalions cut in the side of brake plate.

NOTE; After installing a new electric clutch, run tractor at

full throttle and engage and disengage electric clutch 10

cycles to wear In clutch plate

-77_;__ OPERATING

DONOTTOUCHTHt5 NUT. IF FURTHER;BRAKeADJUST-

MENT|S NECESSARYCONTACTYOURNEARESTAUTHO-

R|ZEDSERVICECENTER!DEPARTMENT

F|Go 28

TO REPLACE MOTION DRIVE BELT

(See Fig. 29)