Page 1

Owner’s Manual

5.5 Horsepower

2400 PSI

2.2 GPM

PRESSURE WASHER

• Safety Guidelines

• Assembly

• Operation

• Maintenance

• Storage

• Troubleshooting

• Repair Parts

Model No.

919.672240

CAUTION: Read the Safety Guidelines

and All Instructions Carefully Before

Operating.

Sold by Sears Canada, Inc. Toronto, Ont. M5B 2B8

D25083 Rev. 0 12/6/01

Page 2

2- ENG

D25083

FULL ONE YEAR WARRANTY ON PRESSURE WASHERS

If this pressure washer fails due to a defect in material or workmanship within

one year from the date of purchase, RETURN IT TO THE NEAREST SEARS

SERVICE CENTER THROUGHOUT CANADA AND SEARS WILL REPAIR IT,

FREE OF CHARGE.

If this pressure washer is used for commercial or rental purposes, the warranty will apply for ninety days (90) from the date of purchase.

This Craftsman pressure washer warranty gives you specific legal rights and

you may have other rights which vary from province to province.

Sears Canada, Inc., Toronto, Ont. M5B 2B8

TABLE OF CONTENTS

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SPECIFICATION CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SAFETY GUIDELINES- DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . .3

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . .3-7

BOX CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-17

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-21

REPAIR PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-38

HOW TO ORDER REPAIR PARTS . . . . . . . . . . . . . . . . . . . .Back Cover

WARRANTY

Page 3

3- ENG

D25083

used without the

safety alert symbol

indicates a potentially hazardous situation which, if not avoided, may

result

in property damage.

indicates a poten-

tially hazardous sit-

uation which, if not avoided, could

result in death or serious injury.

This product may not be equipped with a spark arresting muffler. If

the product is not equipped and will be used around flammable

materials, or on land covered with materials such as agricultural crops, forest,

brush, grass, or other similar items, then an approved spark arrester must be

installed and is legally required in the state of California. It is a violation of

California statutes section 130050 and/or sections 4442 and 4443 of the

California Public Resources Code, unless the engine is equipped with a spark

arrester, as defined in section 4442, and maintained in effective working order.

Spark arrester are also required on some U.S. Forest Service land and may also

be legally required under other statutes and ordinances.

Engine exhaust contains chemicals known, in certain quantities, to cause cancer,

birth defects or other reproductive harm.

Read Operator’s Manual. Do not operate equipment until you have

read Operator’s Manual for Safety

, Assembly, Operation, and

Maintenance Instructions

.

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read and understand the manual and pay attention to

these symbols.

10/2/97

SAFETY GUIDELINES - DEFINITIONS

indicates an immi-

nently hazardous

situation which, if not avoided, will

result in death or serious injury.

indicates a potentially hazardous situa-

tion which, if not avoided, may

result

in minor or moderate injury

.

SPECIFICATION CHART

Model No. 919-672240

Pressure Washer

Pressure 2400 PSI

Flow Rate 2.2 GPM

Cleaning Units (PSI x GPM) 5280

Engine

RPM 3600

Rated Horsepower 5.5

Spark Plug Gap .030” (0.76mm)

Gasoline Capacity .29 gallons (1.1 liters)

Oil .58 quarts ( .55 liters) capacity SAE 30 weight

Page 4

4- ENG

D25083

HAZARD

HOW TO PREVENT ITWHAT CAN HAPPEN

RISK TO BREATHING

RISK OF EXPLOSION OR FIRE

• Use of acids, toxic or corrosive chemi-

cals, poisons, insecticides, or any kind of

flammable solvent with this product

could result in serious injury or death.

• Some cleaning fluids contain substances

which could cause injury to skin, eyes, or

lungs.

• Spilled gasoline and it’s vapors can become ignited from cigarette sparks,

electrical arcing, exhaust gases, and hot

engine components such as the muffler.

• Heat will expand fuel in the tank which

could result in spillage and possible fire

explosion.

• Operating the pressure washer in an explosive environment could result in a

fire.

• Materials placed against or near the

pressure washer can interfere with its

proper ventilation features causing overheating and possible ignition of the

materials.

• Muffler exhaust heat can damage painted surfaces, melt any material sensitive

to heat (such as siding, plastic, rubber,

or vinyl), and damage live plants.

• Improperly stored fuel could lead to accidental ignition. Fuel improperly

secured could get into the hands of children or other unqualified persons.

• Do not spray flammable liquids

• Shut off engine and allow it to cool

before adding fuel to the tank.

• Use care in filling tank to avoid spilling

fuel. Move pressure washer away from

fueling area before starting engine.

• Keep maximum fuel level ½” below top

of tank to allow for expansion.

• Always keep pressure washer a minimum of four feet away from surfaces

(such as houses, automobiles, or live

plants) that could be damaged from

muffler exhaust heat.

• Store fuel in an OSHA approved container, in a secure location away from

work area.

• Operate and fuel equipment in well ventilated areas free from obstructions.

Equip areas with fire extinguishers suitable for gasoline fires.

• Never operate pressure washer in an

area containing dry brush or weeds.

HAZARD

HOW TO PREVENT ITWHAT CAN HAPPEN

• Operate pressure washer in a well ventilated area. Avoid enclosed areas such

as garages, basements ,etc.

• Never operate unit in a location occupied by humans or animals.

• Use only cleaning fluids specifically recommended for high pressure washers.

Follow manufacturers recommendations.Do not use chlorine bleach or any

other corrosive compound

• Breathing exhaust fumes will cause serious injury or death.

IMPORTANT SAFETY INSTRUCTIONS

Page 5

5- ENG

D25083

RISK OF UNSAFE OPERATION

• If proper starting procedure is not followed, engine can kickback causing

serious hand and arm injury.

HAZARD

HOW TO PREVENT ITWHAT CAN HAPPEN

• Become familiar with the operation and

controls of the pressure washer.

• Keep operating area clear of all persons,

pets, and obstacles.

• Do not operate the product when

fatigued or under the influence of alcohol or drugs. Stay alert at all times.

• Never defeat the safety features of this

product.

• Do not operate machine with missing,

broken, or unauthorized parts.

• Never leave wand unattended while unit

is running.

• If engine does not start after two

pulls, squeeze trigger of gun to

relieve pump pressure. Pull starter

cord slowly until resistance is felt.

Then pull cord rapidly to avoid kickback and prevent hand or arm injury.

• Unsafe operation of your pressure

washer could lead to serious injury or

death to you or others.

• The spray gun/wand is a powerful cleaning tool that could look like a toy to a

child.

• Keep children away from the pressure

washer at all times.

• Reactive force of spray will cause

gun/wand to move, and could cause the

operator to slip or fall, or misdirect the

spray. Improper control of gun/wand can

result in injuries to self and others.

• Do not overreach or stand on an unstable support. Grip gun/wand firmly with

both hands. Expect the gun to kick

when triggered.

RISK OF ELECTRICAL SHOCK

• Spray directed at electrical outlets or

switches, or objects connected to an

electrical circuit, could result in a fatal

electrical shock.

• Unplug any electrically operated product

before attempting to clean it. Direct

spray away from electric outlets and

switches.

HAZARD

HOW TO PREVENT ITWHAT CAN HAPPEN

Page 6

6- ENG

D25083

HOW TO PREVENT ITWHAT CAN HAPPEN

RISK TO FLUID INJECTION

• Your washer operates at fluid pressures

and velocities high enough to penetrate

human and animal flesh, which could

result in amputation or other serious

injury. Leaks caused by loose fittings or

worn or damaged hoses can result in

injection injuries. DO NOT TREAT FLUID

INJECTION AS A SIMPLE CUT! See a

physician immediately!

• Never place hands in front of nozzle.

• Direct spray away from self and others.

• Make sure hose and fittings are tightened and in good condition. Never

hold onto the hose or fittings during operation.

• Do not allow hose to contact muffler.

• Never attach or remove wand or hose

fittings while system is pressurized.

• Use only hose and high pressure

accessories rated for pressure higher

than your pressure washer's p.s.i.

HAZARD

• Relieve system pressure before attempting maintenance or disassembly

of equipment.

• To relieve system pressure, shut off

engine, turn off water supply, and pull

gun trigger until water stops flowing.

HOW TO PREVENT ITWHAT CAN HAPPEN

HAZARD

RISK OF CHEMICAL BURN

• Use of acids, toxic or corrosive chemicals, poisons, insecticides, or any kind

of flammable solvent with this product

could result in serious injury or death.

• Do not use acids, gasoline, kerosene, or

any other flammable materials in this

product. Use only household detergents, cleaners and degreasers recommended for use in pressure washers.

• Wear protective clothing to protect eyes

and skin from contact with sprayed

materials.

• Do not use chlorine bleach or any other

corrosive compound.

Page 7

7- ENG

D25083

HOW TO PREVENT ITWHAT CAN HAPPEN

HAZARD

RISK OF HOT SURFACES

• Contact with hot surfaces, such as

engines exhaust components, could

result in serious burn.

• During operation, touch only the control

surfaces of the pressure washer. Keep

children away from the pressure washer

at all times. They may not be able to

recognize the hazards of this product.

HOW TO PREVENT ITWHAT CAN HAPPEN

HAZARD

• Fuel or oil can leak or spill and could

result in fire or breathing hazard, serious

injury or death can result. Fuel or oil

leaks will damage carpet, paint or other

surfaces in vehicles or trailers.

• If pressure washer is equipped with a

fuel shut-off valve, turn the valve to the

off position before transporting to avoid

fuel leaks. If pressure washer is not

equipped with a fuel shut-off valve, drain

the fuel from tank before transporting.

Only transport fuel in an OSHA

approved container. Always place pressure washer on a protective mat when

transporting to protect against damage

to vehicle from leaks. Remove pressure

washer from vehicle immediately upon

arrival at your destination.

RISK OF INJURY AND PROPERTY

DAMAGE WHEN TRANSPORTING

OR STORING

The powerful spray from your pressure washer is capable of caus-

ing damage to surfaces such as wood, glass, automobile paint, auto

striping and trim, and delicate objects such as flowers and shrubs. Before spraying,

check the item to be cleaned to assure yourself that it is strong enough to resist

damage from the force of the spray. Avoid the use of the concentrated spray stream

except for very strong surfaces like concrete and steel.

Operating without flow of water will result in equipment damage. Operating the pressure washer with water supply shutoff will void your warranty. You should never run

this pressure washer for more than 2 minutes without pulling the trigger to allow cool

water to enter the pump and the heated (recirculated) water to exit.

Page 8

8- ENG

D25083

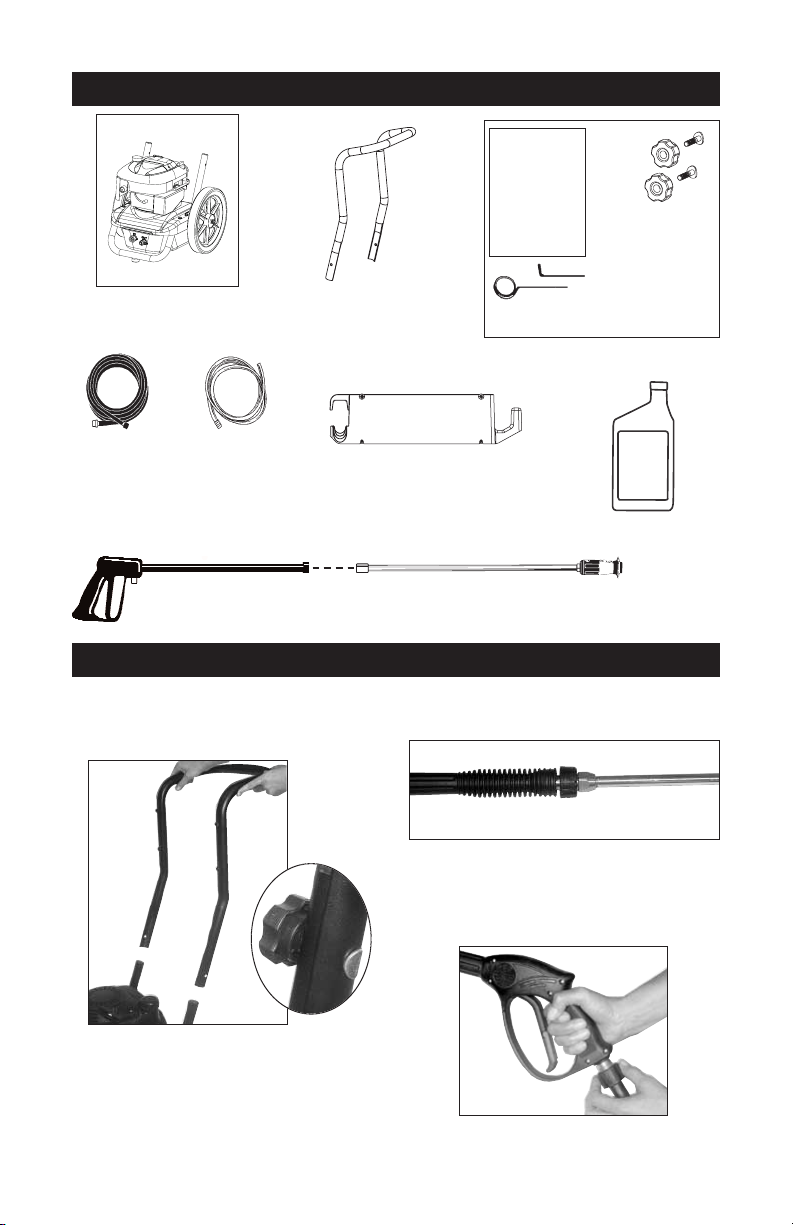

2. Connect wand to gun. Tighten

securely.

3. Attach high pressure hose to gun.

Tighten securely.

ASSEMBLY

1. Place handle assembly onto

frame and connect handle to

frame.

BOX CONTENTS

Handle

Part No. D22316

Bagged Parts

Nozzle Cleaning

Kit

English/

French

Operator’s

Manual

Engine Frame and

Wheel Assembly

High Pressure

Hose

Part No. D22166

Chemical Hose

Part No. H140

Engine Oil

Spray Gun

Part No. 17780

Multi-Reg Wand

Part No. 16395

Accessories Panel Part No. D25081

with Screws Part No. D22901

Knobs

Part No.

16471

Saddle

Bolts Part

No. D23196

Allen Wrench Part No. 16797

Cleaning Tool Part No. NCT001

Page 9

9- ENG

D25083

5. To Assemble Accessories Panel

a. Remove top screws on han-

dle assembly.

b. Loosen bottom screws on

handle assembly.

c. Place grooves in accessories

panel assembly onto screws

and slide panel assembly

into place.

d. Place screws (removed earli-

er) into the top holes and

secure accessories panel

assembly to handles. Do

not overtighten.

Loosen

Screws

Remove

Page 10

10- ENG

D25083

PRESSURE WASHER

High Pressure Pump (located

inside the shroud): Increases the

pressure of the water supply.

Engine: Drives the high pressure

pump.

High Pressure Hose: Carries the

pressurized water from the pump to

the gun and wand.

Spray Gun: Connects with wand to

control water flow rate, direction, and

pressure.

Multi-Reg Wand: Has a spray nozzle

which adjust from a pencil stream (0°)

to a wide angle fan spray (40°). The

spray can be adjusted by twisting the

nozzle clockwise and/or counterclockwise. Also, the high and low

pressure settings can be controlled

by moving the nozzle in and out. See

Operation section.

ENGINE

Choke Control: Opens and closes

the choke valve in carburetor.

Throttle Control Lever: Controls

engine speed.

Starter Grip: Pulling starter grip

operates recoil starter to crank

engine.

Fuel Valve Lever: Opens and closes

connection between fuel tank and

carburetor.

Chemical Hose: Allows cleaners or

cleaning solvents to be mixed with

the pressurized water stream. See

How To Siphon Chemicals/Cleaning

Solvents in Operation section of this

manual.

OPERATION

Know Your Pressure Washer

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with

the location of various controls and adjustments. Save this manual for future

reference.

High

Pressure

Pump

Engine

High

Pressure

Hose

Spray

Gun

Multi-Reg

Wand

Chemical

Hose

Hand

Grip

Air Filter

Fuel Valve

Lever

Choke

Control

Throttle

Control

Page 11

11- ENG

D25083

TO ADJUST PRESSURE

The pressure setting is preset at the

factory to achieve optimum pressure

and cleaning. If you need to lower the

pressure, it can be accomplished by

these methods.

1. Back away from the surface to be

cleaned. The further away you

are, the less the pressure will be

on the surface to be cleaned.

2. Reduce the speed of the gasoline engine (RPM). Slow the

engine down and the water pressure will go down with it.

DO NOT attempt to

increase pump

pressure. A higher pressure setting than the factory set pressure

may damage pump.

HOW TO USE

IMPORTANT: Read and understand

how to use the pressure washer

before operating.

TO USE WAND

Your pressure washer is equipped

with a multi-reg wand with both high

and low pressure settings. The high

pressure setting is for cleaning and

rinsing, the low pressure setting is for

applying chemicals or cleaning solutions to surfaces.

Risk of injection or

injury to person. Do

not direct discharge stream toward

persons, unprotected skin, eyes, or

towards any pets or animals.

Serious injury can occur.

For high pressure operation, pull back

the nozzle of the multi-reg wand as

shown.

PRESSURE WASHER

TERMINOLOGY

NOTE: Become familiar with this ter-

minology before operating.

PSI: Pounds per Square Inch. The

unit of measure for water pressure.

Also used for air pressure, hydraulic

pressure, etc.

GPM: Gallons Per Minute. The unit

of measure for the flow rate of water

through the pressure washer.

CU: Cleaning Units. GPM multiplied

by PSI.

Bypass Mode: In Bypass Mode, the

pump is recirculating water because

the trigger of the spray gun is not

pulled. If unit is left in bypass mode

for more than two (2) minutes, the

water temperature will rise to a dangerous level and damage internal

components of the pump.Any damage to pump due to these causes will

not be covered under warranty.

DO NOT allow your

unit to operate in

bypass mode for more than two

minutes at any time. Overheating

of pump can cause damage to

pump.

Thermal Relief Valve: In an effort to

prevent damage, pumps are

equipped with a thermal relief valve.

This valve will open when the temperature inside the pump rises too high.

This valve will then release a gush of

water in an effort to lower the temperature inside the pump.

Immediately after this occurs, the

valve will close.

Chemical Injection: Feeds cleaning

agents into the pump to mix with the

pressurized water and help in cleaning.

Water Supply: All pressure washers

must have a source of water. The

minimum requirements for a water

supply are 20 PSI and 5 gallons per

minute.

Page 12

12- ENG

D25083

The nozzle at the end of the multi-reg

wand can be rotated to change the

high pressure spray pattern from a

narrow jet to a 40º fan shape, as

shown. Markings have been placed

on the nozzle to help you select the

spray pattern.

For low pressure operation, extend

the nozzle of the multi-reg wand as

shown.

40º fan spray

narrow jet stream

TO SIPHON

CHEMICALS/CLEANING

SOLVENTS

Siphoning chemicals or cleaning solvents is a low pressure operation.

NOTE: Use only soaps and chemicals designed for pressure washer

use. Do not use bleach.

1. Press chemical hose onto

barbed fitting located near high

pressure hose connection of

pump as shown.

2. Place other end of chemical hose

with filter on it into container

holding chemical/cleaning solution.

3. Set multi-reg nozzle to low pressure setting, see How To Use

Wand paragraph in this section.

4. After use of chemical, siphon

clean water through chemical

hose to rinse it and pump clean.

Chemicals which remain in pump

can damage it. Damage to pump

due to chemicals will not be covered under warranty.

NOTE: Chemicals and soap will not

siphon when wand is in the high

pressure setting.

Barb fitting

TO SHUT DOWN

IMPORTANT: Read and understand

how to shut down the pressure

washer before operating.

1. If you have siphoned chemicals,

siphon a bucket of clean water

through the chemical hose.

NOTE: Failure to do so will

cause damage to the pump.

2. Turn engine off by placing the

throttle control in the OFF

position.

NOTE: NEVER turn the water off

with the engine running.

3. Turn the fuel valve to the OFF

position if engine will not be

restarted soon.

4. Turn water source off.

5. Pull trigger on spray gun to

relieve any water pressure in

hose or spray gun.

6. See Storage section in this manual for proper storage procedures.

Page 13

13- ENG

D25083

3. Verify the filter screen is in water

inlet of pump, as shown.

4. Connect high pressure hose to

pump outlet.

5. Connect water source to pump

inlet.

NOTE: Water source must provide

a minimum of 5 gallons per minute

at 20 p.s.i.

6. If you are applying a chemical or

cleaning solution, See How To

Siphon Chemicals/Cleaning

Solvents in Operation section of

this manual.

7. Turn water source on.

NOTE: Make sure water supply is

turned on.

Water

Source

High

Pressure

Hose

Filter Screen

BEFORE STARTING

Read and understand all Important

Safety Instructions in the front of

this manual and the following

Cautions and Warnings before

starting the pressure washer.

• Never fill fuel tank completely.

Fill tank to 1/2" below bottom

of filler neck to provide space

for fuel expansion. Wipe any

fuel spillage from engine and

equipment before starting

engine.

• Never fill fuel tank indoors.

Never fill fuel tank when engine

is running or hot. Do not

smoke when filling fuel tank.

• Never run engine indoors or in

enclosed, poorly ventilated

areas. Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

• Never turn water supply off

while pressure washer engine

is running or damage to pump

will result.

• DO NOT use hot water, use

cold water only.

• DO NOT stop spraying water

for more than two minutes at a

time.

1. Add fresh high quality unleaded

gasoline with a pump octane rating of 86 or higher. Do not overfill. Wipe up spilled fuel before

starting the engine.

2. Remove filler cap/dipstick and

add engine oil (supplied) to

engine. NOTE: There will be a

slight amount of oil in the engine

from factory testing. Always

check oil level before each startup.

Filler cap/dipstick

Page 14

14- ENG

D25083

If the engine does

not start after two

pulls, pull the trigger to relieve the

pressure.

11. If the choke was used to start

the engine, move the choke lever

to the OFF position.

12. Depress trigger on gun to start

water flow. Release trigger to

stop water flow.

13. Adjust nozzle spray for the task

being performed. See How To

Use Wand instructions in this

section.

DO NOT let hoses

come in contact

with very hot engine muffler during

or immediately after use of your

pressure washer.

MAINTENANCE

WHEN PERFORMING MAINTENANCE, YOU MAY BE

EXPOSED TO HOT SURFACES, WATER PRESSURE, MOVING PARTS, OR FIRE RESULTING IN DEATH. BEFORE PERFORMING ANY

MAINTENANCE OR REPAIR, DISCONNECT SPARK PLUG WIRE, LET

ENGINE COOL AND RELEASE ALL WATER PRESSURE. THE ENGINE CONTAINS FLAMMABLE FUEL. DO NOT SMOKE OR WORK NEAR OPEN

FLAMES WHILE PERFORMING MAINTENANCE.

To ensure efficient operation and longer life of your pressure washer, a routine

maintenance schedule should be prepared and followed. If the pressure washer

is used in unusual conditions, such as high-temperatures or dusty conditions,

more frequent maintenance checks will be required.

8. Turn fuel valve to the ON position, 1/4 turn counterclockwise.

9. Move the choke control lever to

the CHOKE ON position and

the throttle control to the FAST

position. NOTE: No choke is

needed to start a warm engine.

10. Pull starter grip slowly until you

feel resistance, then pull briskly.

Return starter grip gently. Pull

rope with a rapid full arm stroke.

Let rope rewind slowly. Repeat if

necessary.

Fuel Valve Knob

Choke

Control

Throttle

Control

Page 15

15- ENG

D25083

4. If the oil level is low, fill to the

edge of the oil filler hole with the

SAE 10W-30 oil.

NOTE: Other viscosities shown in the

chart may be used when the average

temperature in your area is within the

recommended range.

CUSTOMER RESPONSIBILITIES TABLE

MAINTENANCE TASK

PRESSURE WASHER

ENGINE

check/clean inlet screen

check high pressure hose

check soap and chemical

hose and filter

check gun and wand for leaks

check oil level

change oil

check air filter

clean/replace spark plug

prepare for storage

Before

each use

Every 25

hours or

yearly

Every 50

hours or

yearly

Every 100

hours or

yearly

Prepare unit for storage if it is to remain idle for longer

than 30 days

X

X

X

X

X

X

X

X

ENGINE

To Check Oil

1. Shut down engine and place on a

level surface.

2. Remove filler cap/dipstick and

wipe it clean.

3. Insert and remove the filler

cap/dipstick without screwing it

into the filler neck. Check the oil

level shown on the dipstick.

Filler cap/dipstick

Oil Filler

Cap/Dipstick

Upper Limit

Lower Limit

SAE Viscosity Grades

**

*

Synthetic 5W-30, 10W-30

-20 0 20 40 60 80 100

F

-30 -20 -10 0 10 20 30 40

C

STARTING TEMPERATURES RANGE

ANTICIPATED BEFORE NEXT OIL CHANGE

32

Page 16

16- ENG

D25083

Air Cleaner

A dirty air cleaner will restrict air flow

to the carburetor and cause poor

engine performance. Inspect the filter

each time the engine is operated.

Clean the filter more frequently if the

engine is operated in very dust areas.

NOTICE: Operating the engine without a filter, will allow dirt to enter the

engine, causing rapid engine wear.

This type of damage is not covered

under the warranty.

Inspect

1. Press the latch tabs on the top of

the air cleaner cover and remove

the cover. Check the filter to be

sure it is clean and in good condition.

2. Reinstall the filter and air cleaner

cover.

Cleaning

1. Tap the filter several times on a

hard surface to remove dirt or

blow compressed air [not

exceeding 30 psi (207kPa, 1.2

kg/cm

2

] through the filter from the

clean side that faces the engine.

Never try to brush off dirt.

Brushing will force dirt into the

fibers.

2. Wipe dirt from the air cleaner

body and cover using a moist

rag. Be careful to prevent dirt

from entering the air duct that

leads to the carburetor.

To Change Oil

Drain the engine oil when the engine

is warm. Warm oil drains quickly and

completely.

1. Turn the fuel valve to the OFF

position, 1/4 turn clockwise.

2. Place a suitable container next

the engine to catch the used oil.

3. Remove filler cap/dipstick and

drain the oil into the container by

tipping the engine toward the oil

filler neck.

NOTE: Please dispose of used motor

oil in a manner that is compatible with

the environment. It is recommended

to take used oil in a sealed container

to your local recycling center or service station for reclamation. Do not

throw it in the trash or pour it on the

ground or down a drain.

4. With the engine in a level position, fill to the upper limit mark on

the dipstick with SAE 10W-30 oil.

Engine oil capacity is 0.58 quart

(.055 liter). NOTE: Other viscosities shown in the chart in the “To

Check Oil” paragraph may be

used.

5. Replace the oil filler cap/dipstick

securely.

Oil Filler

Cap/Dipstick

Upper Limit

Lower Limit

Oil Filler Neck

Air Cleaner Body

Filter

Air

Cleaner

Cover

Latch

Tabs

Lower

Tabs

Air Duct

Page 17

17- ENG

D25083

5. Remove the nozzle from the end

of the wand with the 2mm allen

wrench provided as shown.

6. Clean the nozzle using the nozzle

cleaner provided or a straightened paper clip. Insert into the

nozzle end and work back and

forth until obstruction is removed.

7. Direct water supply into nozzle

end to backflush loosened particles for 30 seconds.

8. Reconnect spark plug wire.

9. Reassemble the nozzle to the

wand. Tighten securely to prevent leaks.

10. Reconnect wand to gun and turn

on water supply.

11. Start pressure washer and place

wand into high pressure setting

to test.

WAND

If the nozzle becomes clogged with

foreign materials, such as dirt, excessive pressure may develop. If the

nozzle becomes partially clogged or

restricted, the pump pressure will pulsate. Clean the nozzle immediately

using the nozzle kit supplied and the

following instructions:

1. Shut off the pressure washer and

turn off the water supply.

2. Disconnect spark plug wire.

3. Pull trigger on gun handle to

relieve any water pressure.

4. Disconnect the wand from the

gun.

Clean and Replace Spark Plug

Change the spark plug every 100

hours of operation or once each year,

whichever comes first. This will help

your engine to start easier and run

better.

Resistor

.030” (0.76 MM)

Wire Gauge

PUMP

This screen filter should be checked

periodically and cleaned if necessary.

1. Remove filter by grasping end

and removing it from water inlet

of pump as shown.

2. Clean filter by flushing it with

water on both sides.

3. Install filter into water inlet of

pump

Filter Screen

Page 18

18- ENG

D25083

ENGINE

IMPORTANT: It is important to prevent

gum deposits from forming in essential

fuel system parts such as the carburetor, fuel filter, hose or tank during storage. Also, experience indicates that alcohol-blended fuels (called gasohol or

using ethanol or methanol) can attract

moisture which leads to separation

and formation of acids during storage.

Acidic gas can damage the fuel system of an engine while in storage. To

avoid engine problems, the fuel system should be emptied before storage

of 30 days or longer. Never use engine

or carburetor cleaner products in the

fuel tank or permanent damage may

occur.

Engine Preparation

• First add a fuel stabilizer to the

fuel tank.

• Run pressure washer for a full 5

minutes to allow fuel stabilizer to

enter the fuel system.

While preparing the

engine make sure

water supply is turned on and flowing to the unit. NEVER run unit

without water supply running

through pump. Failure to do so will

cause pump damage.

• Next shut off engine and discon-

nect the water supply.

• Disconnect the spark plug wire

and remove the spark plug.

• Add one teaspoon of oil through

the spark plug hole.

• Place rag over spark plug hole

and pull the recoil a few times to

lubricate the combustion chamber.

• Replace the spark plug, but do

not connect the spark plug wire.

PUMP

It is recommended that you follow

these steps to protect the internal

seals of the pressure washer when

storing the unit for an extended

period and WHEN FREEZING TEMPERATURES ARE EXPECTED.

NOTE: If storing the unit for more

than 30 days RV antifreeze or windshield washer fluid needs to be run

through the pump. This helps prevent damage within the pump head.

RV antifreeze or windshield washer

fluid is not only added for winterizing, but for proper lubrication

regardless of temperature or environment. Storing the pump less than

30 days does not require the RV

antifreeze or windshield washer

fluid.

1. Obtain a funnel, six ounces of RV

antifreeze or windshield washer

fluid, and approximately 12 inches

of garden hose with a male hose

connector attached to one end.

Use only RV

antifreeze. Any

other antifreeze is corrosive and can

damage pump.

2. Disconnect spark plug wire.

3. Disconnect high pressure hose

from pump and from spray gun.

4. Connect 12 inch length of hose to

water inlet of pump.

5. Add RV antifreeze or windshield

washer fluid to hose as shown.

STORAGE

Page 19

19- ENG

D25083

6. Pull engine starter rope slowly

several times until antifreeze or

windshield washer fluid comes

out of high pressure hose connection of pump.

7. Remove short hose from water

inlet of pump.

8. Install spark plug into spark plug

hole and tighten securely, then

reconnect spark plug wire.

9. Drain all water from high pressure

hose, coil it, and store it in cradle

of the pressure washer handle.

10. Drain all water from spray gun

and wand by holding spray gun in

a vertical position with nozzle end

pointing down and squeezing

trigger. Store in gun/hose holder.

11. Store chemical hose, high pressure hose, spray gun, and wand

so they are protected from damage, such as being run over.

TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

CORRECTION

Engine will not

start

1. No fuel.

2. Pressure builds up after

two pulls on the recoil

starter or after initial use.

3. Not choked.

4. Spark plug wire not

attached.

5. Choke lever in the

"Choke" position on a

"hot" engine or an engine

that has been exposed to

thermal heat for a long

period of time.

6. Fuel valve closed

1. Add Fuel.

2. Squeeze gun trigger to

relieve pressure.

3. Choke engine, place

engine in the choke position.

4. Attach spark plug wire.

5. Move choke to the "No

Choke" position.

6. Move the fuel valve knob

to the "Open" position.

No or low

pressure

(initial use)

1. Wand not in high pressure.

1. See How to Use Wand

paragraph in the

Operation Section.

2. Low water supply.

2. Water supply must be at

least 5 GPM @ 20 PSI.

3. Leak at high pressure

hose.

3. Repair leak. Apply sealant

tape if necessary.

4. Nozzle obstructed.

4. Clean nozzle with paper

clip or nozzle cleaning

tool, pour water into nozzle end to flush out obstruction.

5. Water filter screen

clogged.

5. Remove and clean filter.

Page 20

20- ENG

D25083

6. Air in hose.

6. Turn off the engine, then

the water source.

Disconnect the water

source from the pump

inlet and turn the water

source on to remove all air

from the hose. When there

is a steady stream of

water present, turn water

source off. Reconnect

water source to pump inlet

and turn on water source.

Squeeze trigger to remove

remaining air.

7. Choke lever in the

"Choke" position.

8. Throttle control lever is

not in the "Fast" position.

9. High pressure hose is too

long.

7. Move choke to the "No

Choke" position.

8. Move throttle control lever

to the "Fast" position.

9. Use high pressure hose

under 100 feet.

PROBLEM

CAUSE

CORRECTION

No or low

pressure

(initial use)

(continued)

6. Chemical build up in

chemical injector.

Will not draw

chemicals

1. Wand not in low

pressure.

2. Chemical filter clogged.

3. Chemical screen not in

chemical

4. Chemical too thick

5. Pressure hose is too long

2. Clean filter.

3. Insure end of chemical

hose is fully submerged

into chemical.

4. Dilute chemical. Chemical

should be the same consistency as water.

5. Lengthen water supply

hose instead of pressure

hose.

6. Have parts cleaned or

replaced by AWSC.

1. See How to Use Wand

paragraph in the

Operation Section.

Page 21

21- ENG

D25083

PROBLEM

CAUSE

CORRECTION

No or low

pressure (after

period of normal use.)

Water leaking

at gun/wand

connection

Water leaking

at pump

1. Worn seal or packing.

2. Worn or obstructed

valves.

3. Worn unloader piston.

1. Worn or broken o-ring.

2. Loose hose connection.

1. Loose connections.

2. Piston packings worn.

3. Worn or broken o-rings.

4. Pump head or tubes damaged from freezing.

1. Have replaced by AWSC.

2. Have replaced by AWSC.

3. Have replaced by AWSC.

1. Check and replace.

2. Tighten.

1. Tighten.

2. Have replaced by AWSC.

3. Have replaced by AWSC.

4. Have replaced by AWSC.

Page 22

39- ENG

D25083

NOTES

Page 23

D25079

HOW TO ORDER

REPAIR PARTS

Model No.

919.672240

Sold by Sears Canada, Inc. Toronto, Ont. M5B 2B8

SERVICE

5.5 Horsepower

2400 PSI

2.2 GPM

PRESSURE WASHER

SERVICE AND REPAIR PARTS

CALL 1-800-665-4455*

Keep this number handy should you

require a service call or need to order

repair parts.

If ordering parts make sure you have the

name, make and model no. of the merchandise and the name and number of

the part you wish to order.

* If calling locally, please use one of the following numbers:

Regina - 566-5124 Montreal - 333-5740

Toronto - 744-4900 Halifax - 454-2444

Kitchener - 894-7590 Ottawa - 738-4440

Vancouver - 420-8211

WHEN ORDERING REPAIR PARTS,

ALWAYS GIVE THE FOLLOWING

INFORMATION:

• PART NUMBER

• PART DESCRIPTION

• MODEL NUMBER

• NAME OF ITEM

All parts listed may be ordered from any Sears

Service Center and most Sears stores.

If the parts you need are not stocked locally,

your order will be electronically transmitted to a

Sears Repair Parts Distribution Center for handling.

Page 24

Guide de l’utilisateur

LAVEUSE À PRESSION

5,5 chevaux

2 400 lb/po

2

2,2 gal./min

• Mesures de sécurité

• Assemblage

• Utilisation

• Entretien

• Entreposage

• Dépannage

• Pièces de rechange

Modèle nº

919.672240

IMPORTANT : Lisez attentivement les

directives de sécurité et toutes les

instructions avant d’utiliser l’appareil.

Vendu par Sears Canada, Inc. Toronto, Ont. M5B 2B8

D25083 Rév. 0 12/6/01

Page 25

2- FR

D25083

TABLE DES MATIÈRES

GARANTIE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

TABLEAU DES SPÉCIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

MESURES DE SÉCURITÉ – DÉFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . .3

MESURES DE SÉCURITÉ IMPORTANTES . . . . . . . . . . . . . . . . . . . . . . . .3-7

CONTENU DE LA BOÎTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ASSEMBLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-17

ENTREPOSAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

GUIDE DE DÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-21

PIÈCES DE RECHANGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22-38

COMMANDE DES PIÈCES DE RECHANGE . . . . . . . . . . . .Couverture arrière

GARANTIE COMPLÈTE DE UN AN SUR LES LAVEUSES À PRESSION

Si cette laveuse à pression arrête de fonctionner à cause d’un défaut de fabrication ou

de main-d’œuvre dans une période d’un an à compter de la date d’achat,

RETOURNEZ-LA AU CENTRE DE SERVICE APRÈS-VENTE SEARS LE PLUS PROCHE

AU CANADA ET SEARS LA RÉPARERA SANS FRAIS.

Si cette laveuse à pression est utilisée à des fins commerciales ou comme appareil de

location, la garantie ne s’applique que pour une période de quatre-vingt-dix (90) jours à

compter de la date d’achat.

Cette garantie sur la laveuse à pression de Craftsman vous donne des droits

particuliers. Il se peut que vous ayez d’autres droits qui varient d’une province à l’autre.

Sears Canada, Inc., Toronto, Ont. M5B 2B8

GARANTIE

Page 26

3- FR

D25083

N° de modèle 919.672240

Laveuse à pression

Pression 2 400 lb/po

2

Débit 2,2 gal./min

Unités de nettoyage (gal./min x lb/po

2

) 5 280

Moteur

Tr./min 3 600

Puissance nominale en chevaux 5,5

Écartement de la bougie d’allumage 0,030 po (0,76 mm)

Capacité du réservoir à carburant 0,29 gallon (1,1 litre)

Capacité d’huile : 0,58 pinte (0,55 litre) SAE 30

TABLEAU DES SPÉCIFICATIONS

MESURES DE SÉCURITÉ - DÉFINITIONS

Indique un danger

imminent qui, s'il n'est

pas évité, causera de graves blessures

ou la mort.

Indique la

possibilité

d’un danger qui, s’il n’est pas évité,

pourrait causer de graves blessures

ou la mort.

Ce guide contient des renseignements importants que vous deviez bien saisir. Cette information

porte sur VOTRE SÉCURITÉ et sur LA PRÉVENTION DE PROBLÈMES D’ÉQUIPEMENT. Afin

de vous aider à identifier cette information, nous avons utilisé les symboles ci-dessous. Veuillez

lire attentivement ce guide en portant une attention particulière à ces sections.

Indique la

possibilité d'un

danger qui, s'il n'est pas évité,

peut causer des blessures mineures ou

moyennes.

Sans le symbole d’alerte.

Indique la possibilité d’un

danger qui, s’il n’est pas évité,

peut causer

des dommages à la propriété.

Lisez le Guide de l’utilisateur. Ne tentez pas d’utiliser cet

appareil avant d’avoir lu les directives sur la sécurité

,

l’assemblage, l’utilisation et l’entretien de ce Guide de l’utilisateur.

Il se peut que ce produit ne soit pas équipé d’un silencieux à

pare-étincelles. Si le produit n’en est pas équipé, et s’il est

utilisé près de matériaux inflammables ou sur de la terre couverte de produits agricoles,

forêts, broussailles, gazon ou autres articles semblables, un pare-étincelles approuvé doit

être posé, et est exigé par la loi en Californie. Selon la section 130050 de la loi de la

Californie, et les sections 4442 et 4443 du Code sur les ressources publiques de la

Californie, ce produit ne peut pas être utilisé en Californie, à moins que le moteur ne soit

équipé d’un pare-étincelles, tel que décrit dans la section 4442, et à moins que l’appareil

ne soit maintenu en bon état de fonctionnement. Des pare-étincelles sont également

requis sur certaines terres forestières des États-Unis et peuvent être exigés légalement

sous certains autres lois et arrêtés.

Les gaz d’échappement du moteur contiennent des produits chimiques qui, dans

certaines quantités, peuvent causer le cancer, les anomalies congénitales ou d’autres

maux de reproduction.

Page 27

4- FR

D25083

PRÉVENTION

RISQUE

RISQUE PAR INHALATION

RISQUE DE FEUX OU D'EXPLOSION

• L'utilisation d'acides, de produits chimiques

toxiques ou corrosifs, de poisons, d'insecticides ou

de toute sorte de solvant inflammable dans ce

produit pourrait provoquer des blessures graves ou

la mort.

•

Certains nettoyeurs liquides contiennent des

substances pouvant causer des lésions à la peau,

aux yeux et aux poumons.

• La chaleur peut causer l'expansion de l'essence

dans le réservoir pouvant aboutir à un déversement

et provoquer un feu ou une explosion.

• Le fait d'utiliser la laveuse à pression dans un milieu

explosif peut aboutir à un feu.

• Des matières placées contre ou à proximité de la

laveuse à pression peuvent nuire à une ventilation

adéquate provoquant ainsi une surchauffe et un

risque d'inflammation de ces matières.

• La chaleur des gaz d'échappement du silencieux

peut endommager les surfaces peintes, faire fondre

des matériaux sensibles à la chaleur (tels que le

revêtement d'extérieur, le plastique, le caoutchouc

et le vinyle) et endommager les plantes.

• Un entreposage inapproprié du carburant peut

causer une inflammation accidentelle. Le carburant

qui n'est pas rangé de façon sécuritaire peut

tomber entre les mains d'un enfant ou autres

personnes non compétentes.

• Ne pas vaporiser des liquides inflammables.

• Couper le moteur et le laisser refroidir avant

d'ajouter de l'essence au réservoir.

• Prendre des précautions lors du remplissage du

réservoir pour éviter le déversement de l'essence.

Placer la laveuse à pression loin du lieu de

remplissage avant de démarrer le moteur.

• Maintenir le niveau maximal d'essence à environ

½ po (13 mm) du haut du réservoir afin de permettre

l'expansion de l'essence.

• Toujours garder la laveuse à pression à une distance

minimum de quatre pieds (1,2 m) des surfaces qui

pourraient être endommagées par les gaz

d'échappement du silencieux (telles que les

maisons, automobiles ou plantes).

• Placer le carburant dans un contenant approuvé par

l'OSHA et le ranger dans un lieu sûr, loin de l'aire de

travail.

• Faire le plein et utiliser l'équipement dans un endroit

bien aéré et libre de toutes obstructions. Équiper

ces lieux d'extincteurs appropriés pour combattre

les feux comprenant de l'essence.

• Ne jamais faire fonctionner la laveuse à pression

dans un endroit comprenant des herbes ou buissons

secs.

• Utiliser la laveuse à pression dans un endroit bien

aéré. Éviter les endroits clos tels que les garages,

sous-sols, etc.

• Ne jamais utiliser l'appareil dans un endroit occupé

par d'autres personnes ou des animaux.

• N'utiliser que des liquides de nettoyage

recommandés pour des laveuses à pression. Suivre

les recommandations du fabricant. Ne pas utiliser

d'eau de Javel ou tout autre produit corrosif.

•

L'inhalation des émanations à l'échappement peut

causer de graves blessures ou la mort.

MESURES DE SÉCURITÉ IMPORTANTES

• L'essence répandue par déversement et les vapeurs

qui en émanent risquent de s'enflammer en

présence d'étincelles provenant d'une cigarette

allumée, d'un arc électrique, de gaz d'échappement

et de pièces chaudes du moteur, telles que le

silencieux.

PRÉVENTION

RISQUE

Page 28

5- FR

D25083

RISQUE D'UNE

UTILISATION NON

SÉCURITAIRE

• Si la procédure de démarrage appropriée n'est

pas suivie, le moteur peut provoquer des contrecoups et causer des blessures graves aux mains

ou aux bras.

• S'habituer au fonctionnement et aux commandes de

la laveuse à pression.

• Garder toutes les personnes non autorisées, les

animaux domestiques et les obstacles loin de l'aire

de vaporisation.

• Ne pas utiliser l'appareil lorsque vous êtes fatigué

ou sous l'effet de boissons alcooliques ou de

drogues. Restez alerte à tout moment.

• Ne jamais contourner un dispositif de sécurité de

cet appareil.

• Ne jamais utiliser un appareil auquel il manque des

pièces, qui comprend des pièces brisées ou non

autorisées par le fabricant.

• Ne jamais s'éloigner de la lance lorsque

l'appareil est en marche.

•

Si le moteur ne démarre pas après deux essais,

appuyer sur la détente du pistolet afin de dégager

la pression de la pompe. Tirer lentement sur le

cordon de démarrage jusqu'à ce qu'on sente une

résistance. Tirer ensuite rapidement sur le cordon

pour éviter les contre-coups et les blessures aux

mains ou aux bras.

• Une utilisation de la laveuse à pression qui n'est pas

conforme aux mesures de sécurité peut causer de

graves blessures ou la mort de l'utilisateur ou

d'autres personnes.

• Le pistolet/la lance de vaporisation est un outil de

nettoyage puissant qui peut ressembler à un jouet

aux yeux d'un enfant.

• Garder les enfants éloignés de la laveuse à pression

à tout moment.

• La force de rétroaction du jet fait déplacer le

pistolet/la lance et peut faire tomber l'utilisateur ou

provoquer un changement de direction du jet. Une

mauvaise maîtrise du pistolet/lance peut causer des

blessures à l'utilisateur ou à d'autres personnes.

• Ne pas trop éloigner le pistolet du corps et ne pas

se tenir sur une surface instable. Saisir le

pistolet/lance fermement avec les deux mains.

S'attendre à ressentir un contre-coup lors du

déclenchement.

RISQUE DE CHOCS

É

LECTRIQUES

• Une vaporisation dirigée vers des prises de courant,

des interrupteurs ou des objets branchés sur un

circuit électrique peut causer des chocs électriques

mortels.

• Débrancher tout appareil électrique avant de tenter

de le nettoyer. Diriger le jet de vaporisation loin de

toutes prises de courant et interrupteurs.

PRÉVENTION

RISQUE

PRÉVENTION

RISQUE

Page 29

6- FR

D25083

RISQUE D'INJECTION

D'UN FLUIDE

• La laveuse à pression fonctionne à une pression et à

une vitesse suffisamment élevées pour faire pénétrer

le fluide dans la peau de personnes ou d'animaux et

causer des blessures graves ou la nécessité d'une

amputation. Une fuite causée par des raccords

relâchés ou usés ou par un boyau endommagé peut

aboutir à une blessure par injection. NE PAS

TRAITER L'INJECTION D'UN FLUIDE COMME UNE

SIMPLE COUPURE ! Consulter immédiatement un

médecin !

• Ne jamais placer la main devant la buse.

• Diriger le jet de vaporisation loin de soi et d'autrui.

• S'assurer que le boyau et les raccords sont bien

serrés et en bon état. Ne jamais se cramponner au

boyau ou aux raccords lors de l'utilisation de

l'appareil.

• Éviter tout contact du boyau avec le silencieux.

• Ne jamais mettre ni enlever les raccords de la lance

ou du boyau lorsque l'appareil est pressurisé.

• N'utiliser qu'un boyau et des accessoires à haute

pression classés pour un service nominal plus élevé

que la puissance nominale (lb/po

2

) de l'appareil.

• Libérer la pression avant de tenter d'entretenir

l'appareil ou de démonter l'équipement.

RISQUE DE BRÛLURES

CHIMIQUES

• L'utilisation d'acides, de produits chimiques

toxiques ou corrosifs, de poisons, d'insecticides ou

de toute sorte de solvant inflammable dans ce

produit pourrait provoquer des blessures graves ou

la mort.

• Ne pas utiliser d'acides, d'essence, de kérosène ou

toute autre matière inflammable avec cet appareil.

N'employer que des détergents, nettoyeurs ou

dégraisseurs d'entretien ménager qui sont

recommandés pour une utilisation avec une laveuse

à pression.

• Porter un équipement et des vêtements de

protection pour se protéger les yeux et la peau

contre tout contact avec des matières vaporisées.

• Ne pas utiliser de l'eau de Javel ou tout autre

produit corrosif.

PRÉVENTION

RISQUE

PRÉVENTION

RISQUE

• Pour dégager la pression de l’appareil, couper le

moteur, couper l’alimentation d’eau et enfoncer la

détente jusqu’à ce que l’eau arrête de s’écouler.

Page 30

7- FR

D25083

RISQUE DE

SURFACES

CHAUDES

• Le contact avec les surfaces chaudes, telles que les

pièces d'échappement du moteur, peut provoquer

des brûlures graves.

• Durant le fonctionnement de l'appareil, ne toucher

qu'aux surfaces de commande de la laveuse à

pression. Garder les enfants loin de la laveuse à

pression en tout temps. Les enfants ne sont pas

nécessairement capables de reconnaître les dangers

que comporte cet appareil.

• Des fuites ou des déversements de carburant ou

d'huile peuvent se produire et entraîner des risques

d'incendie ou des problèmes aux voies respiratoires,

des blessures graves ou la mort. Des fuites de

carburant ou d'huile endommagent les tapis, la

peinture et d'autres surfaces dans les véhicules et les

remorques.

• Si la laveuse à pression est munie d'une soupape

d'arrêt, tourner la soupape à la position fermée avant

le transport pour éviter tout risque de fuite. Si

l'appareil n'est pas muni d'une soupape d'arrêt,

vidanger le carburant du réservoir avant le transport.

Ne transporter le carburant que dans des contenants

approuvés par l'OSHA. Pour le transport, toujours

placer la laveuse à pression sur un tapis protecteur

pour éviter l'endommagement du véhicule par des

fuites. Retirer la laveuse à pression du véhicule

immédiatement à l'arrivée.

RISQUE DE BLESSURES ET DE

DOMMAGES À LA PROPRIÉTÉ

PENDANT LE TRANSPORT OU

L'ENTREPOSAGE

Le puissant jet de la laveuse à pression est capable

d'endommager les surfaces fragiles telles que le bois, le verre, la

peinture d'automobiles, les garnitures d'auto ainsi que les objets délicats tels que

les fleurs et arbustes. Avant de vaporiser, vérifiez l'objet à nettoyer afin de vous

assurer qu'il est assez robuste pour résister à la puissance du jet sans subir de

dommages. Évitez d'utiliser le jet à débit concentré sauf pour des surfaces très

résistantes telles que le béton ou l'acier.

Le fait de faire fonctionner l'appareil sans alimentation d'eau endommage l'appareil.

L'utilisation de l'appareil sans alimentation d'eau annule la garantie. Vous ne devez

jamais faire fonctionner l'appareil plus de deux (2) minutes sans appuyer sur la

détente du pistolet afin de permettre à l'eau fraîche d'entrer dans la pompe et à

l'eau chauffée (recirculée) d'en sortir.

PRÉVENTION

RISQUE

PRÉVENTION

RISQUE

MISE EN GARDE

Page 31

8- FR

D25083

2. Attachez la lance au pistolet et bien

serrer.

3. Attachez le boyau à haute pression au

pistolet et bien serrer.

ASSEMBLAGE

1. Placez l’ensemble de poignée sur le

châssis et attachez la poignée au

châssis.

CONTENU DE LA BOÎTE

Poignée

n

o

de pièce D22316

Pièces dans un sac

Trousse de nettoyage

de la buse

Boutons de selle

n

o

de pièce

D23196

Guide de

l'utilisateur

en anglais et

français

Ensemble de châssis

de moteur avec roues

Boyau à haute

pression

node pièce

D22166

Boyau de

produit chimique

n

o

de pièce H140

Huile à moteur

Pistolet de vaporisation

n

o

de pièce 17780

Lance à réglages multiples

n

o

de pièce 16395

Tableau d'accessoires

n

o

de pièce D25081

avec vis - n

o

de pièce D22901

Boutons

n

o

de

pièce

16471

Clé Allen - no de pièce 16767

Outil de nettoyage - node pièce NCT001

Page 32

9- FR

D25083

4. Assemblage du tableau

d’accessoires:

a. Retirez les vis supérieures de

l'ensemble de poignée.

b. Desserrez les vis inférieures de

l'ensemble de poignée

.

c. Positionnez les rainures du

tableau d'accessoires sur les vis

et mettez le tableau en place.

d. Insérez les vis (retirées plus tôt)

dans les trous supérieures et

fixez le tableau d'accessoires

sur les poignées. Ne pas trop

serrer.

Desserer

Vis

Retirer

Page 33

10- FR

D25083

MOTEUR

Commande d'étrangleur : Ouvre et ferme la

soupape de l'étrangleur dans le carburateur.

Levier de commande des gaz : Commande la

vitesse du moteur.

Poignée du démarreur : Tirer sur la poignée

du démarreur fait fonctionner le lanceur à

rappel pour démarrer le moteur.

Levier de la soupape de carburant : Ouvre et

ferme la connexion entre le réservoir de

carburant et le carburateur.

UTILISATION

Familiarisez-vous avec votre laveuse à pression

LISEZ CE GUIDE DE L’UTILISATEUR ET TOUTES LES MESURES DE SÉCURITÉ AVANT

D’UTILISER CET APPAREIL. Comparez les illustrations avec votre appareil afin de vous

familiariser avec l’emplacement des commandes et des réglages. Conservez ce guide

pour les références futures.

Pompe à

haute

pression

Moteur

Boyau à

haute

pression

Pistolet de

vaporisation

Lance à réglages

multiples

Boyau de

produit

chimique

Poignée du

démarreur

Filtre à air

Levier de la

soupape de

carburant

Commande

d'étrangleur

Bouchon de remplissage d’huile

Commande

des gaz

LAVEUSE À PRESSION

Pompe à haute pression (située à l’intérieur

du bouclier) : Augmente la pression de la

source d’eau.

Moteur : Entraîne la pompe à haute pression.

Boyau à haute pression : Achemine l'eau

pressurisée de la pompe jusqu'au pistolet ou à

la lance.

Pistolet de vaporisation : S'attache à la lance

pour régler le débit d'eau, la direction et la

pression.

Lance à réglages multiples : Comporte une

buse de vaporisation réglable d'un jet de

l'épaisseur d'un crayon (0°) jusqu'à un jet en

éventail à angle large (40°). Le réglage de la

vaporisation est effectué en tournant la buse

dans le sens des aiguilles d'une montre ou

dans le sens contraire. De plus, le réglage de

haute ou de basse pression s'effectue en tirant

la buse vers l'intérieur ou en la poussant vers

l'extérieur. Voir la section sur l'utilisation.

Boyau de produit chimique : Ce boyau

permet de mélanger un produit de nettoyage

ou un solvant avec le jet d’eau pressurisé. Voir

le paragraphe intitulé « Siphonnage de produits

chimiques/solvants de nettoyage » dans la

section sur l’utilisation de ce guide.

Page 34

11- FR

D25083

RÉGLAGE DE LA PRESSION

La pression est préréglée à l'usine afin

d'obtenir une pression ainsi qu'un nettoyage

optimums. La pression peut être diminuée de

deux façons différentes.

1. Éloignez-vous de la surface à nettoyer.

Plus vous êtes éloigné, moins sera la

pression sur la surface à nettoyer.

2. Réduisez la vitesse du moteur à essence

(tr/min). Lorsque la vitesse du moteur est

réduite, la pression d'eau est diminuée

aussi.

NE tentez PAS

d'augmenter la

pression de la pompe. Une pression plus

élevée que celle réglée à l'usine peut

endommager la pompe.

UTILISATION

IMPORTANT :

Lisez attentivement la

section sur l’utilisation de la laveuse à

pression avant d’utiliser l’appareil.

UTILISATION DE LA LANCE

Votre laveuse à pression est équipée d'une

lance à réglages multiples avec positions de

haute et de basse pression. La position de

haute pression est utilisée pour le nettoyage et

le rinçage et la position de basse pression est

utilisée pour l'application de produits

chimiques ou de solutions de nettoyage sur

une surface.

Risque

d’injection d’un

liquide ou de blessures corporelles. Ne

dirigez jamais le jet de sortie vers une

personne, vers la peau nue, vers les yeux

ou vers les animaux. Cela peut causer des

blessures graves.

Pour la vaporisation à haute pression, tirez vers

l'arrière la buse de la lance à réglages

multiples, tel qu'illustré.

TERMINOLOGIE DES LAVEUSES À

PRESSION

REMARQUE : Familiarisez-vous avec cette

terminologie avant d’utiliser l’appareil.

lb/po

2

: livres par pouce carré. Une unité de

mesure de pression d'eau. Également utilisé

pour la pression d'air, la pression hydraulique,

etc.

GPM : gallons par minute. L'unité de mesure

du débit d'eau à travers la laveuse à pression.

CU : Unités de nettoyage. gal./min x lb/po2.

Mode de dérivation : En mode de dérivation,

la pompe recircule simplement l’eau car la

détente du pistolet de vaporisation n’est pas

tirée. Si l’appareil demeure en mode de

dérivation pendant plus de deux (2) minutes, la

température de l’eau augmentera jusqu’à un

niveau dangereux et endommagera des

composantes internes de la pompe. Les

dommages à la pompe causés par une telle

situation ne sont pas couverts par la garantie.

NE faites PAS

fonctionner votre

appareil en mode de dérivation pendant

plus de deux minutes à la fois. Toute

surchauffe de la pompe entraînera des

dommages à la pompe.

Soupape de décharge thermique : Afin

d'empêcher des dommages, les pompes sont

équipées d'une soupape de décharge

thermique. Cette soupape s'ouvrira lorsque la

température à l'intérieur de la pompe devient

trop élevée. Elle dégagera alors un jet d'eau

afin d'abaisser la température à l'intérieur de la

pompe et se refermera toute suite après.

Injection d'un produit chimique : Alimente

un produit de nettoyage à la pompe afin de le

mélanger à l'eau pressurisée pour améliorer la

puissance de nettoyage.

Source d'eau : Tous les appareils de lavage

sous pression ont besoin d'une source d'eau.

Les exigences minimums pour la source d'eau

sont de 20 lb/po

2

et de 5 gallons (19 litres) à la

minute.

MISE EN GARDE

MISE EN GARDE

Page 35

12- FR

D25083

D25083

SIPHONNAGE DE PRODUITS

CHIMIQUES/SOLVANTS DE NETTOYAGE

Siphonner des produits chimiques/solvants de

nettoyage est une fonction à basse pression.

REMARQUE : Utilisez seulement des savons

ou des produits chimiques qui sont conçus

spécialement pour une laveuse à pression. Ne

pas utiliser de l'eau de Javel.

1. Poussez le boyau de produit chimique

dans le raccord cannelé, près du point de

connexion du boyau à haute pression de

la pompe, tel qu'illustré.

2. Placez l'autre extrémité du boyau de

produit chimique (l'extrémité avec le filtre)

dans le contenant avec le produit

chimique/solution de nettoyage.

3. Réglez la buse à réglages multiples à la

position de basse pression. Voir le

paragraphe intitulé « Utilisation de la

lance » de cette section.

4. Suite à l'utilisation d'un produit chimique,

siphonnez de l'eau propre à travers le

boyau pour rincer le boyau et la pompe.

Des produits chimiques qui restent dans

la pompe peuvent l'endommager. Les

dommages de la pompe qui sont causés

par des produits chimiques ne seront pas

couverts par la garantie.

REMARQUE :

Les produits chimiques et

savons ne peuvent pas être siphonnés

lorsque la lance est réglée à la position de

haute pression.

Raccord

cannelé

ARRÊT DE LA LAVEUSE À PRESSION

IMPORTANT : Lisez attentivement comment

arrêter la laveuse à pression avant de

l’utiliser.

1. Si vous avez utilisé des produits

chimiques, siphonnez un seau d'eau

propre à travers le boyau de produit

chimique. REMARQUE : Si vous

n'exécutez pas cette étape, la pompe

sera endommagée.

2.

Arrêtez le moteur en plaçant la

commande des gaz à la position d’arrêt

« OFF ».

REMARQUE : NE fermez JAMAIS le robinet

d'eau lorsque le moteur tourne.

3.

Placez la soupape de carburant à la

position d’arrêt « OFF » si vous n’avez

pas l’intention de redémarrer le moteur

bientôt.

4.

Fermez le robinet de la source d'eau.

5.

Appuyez sur la détente du pistolet de

vaporisation pour dégager toute pression

d'eau dans le boyau ou dans le pistolet.

6.

Consultez la section sur l'entreposage de

ce guide pour connaître les procédures

d'entreposage appropriées.

jet en éventail de 40°

jet mince

La buse à l'extrémité de la lance à réglages

multiples peut être tournée pour changer le jet

de vaporisation à haute pression d'un jet mince

jusqu'à un jet en éventail de 40°, tel qu'illustré.

Les marques sur la buse vous aideront à

choisir le type de jet désiré.

Pour la vaporisation à basse pression, poussez

la buse de la lance à réglages multiples vers

l'avant, tel qu'illustré.

Page 36

13- FR

D25083

D25083

3. Assurez-vous que l'écran filtrant est dans

l'orifice d'entrée d'eau de la pompe, tel

qu'illustré.

4.

Attachez le boyau à haute pression à la

sortie de la pompe.

5.

Branchez la source d'eau à l'orifice

d'entrée de la pompe.

REMARQUE : La source d'eau doit fournir

un minimum de 5 gallons par minute à 20

lb/po2.

6. Si vous appliquez un produit chimique ou

une solution de nettoyage, consultez le

paragraphe intitulé « Siphonnage de

produits chimiques/solvants de

nettoyage » de la section sur l'utilisation

de ce guide.

7.

Ouvrez le robinet de la source d'eau.

REMARQUE : Assurez-vous que le robinet

de la source d'eau est ouvert.

Source

d’eau

Boyau à

haute

pression

Écran filtrant

AVANT LE DÉMARRAGE

Lisez attentivement toute la section

intitulée « Mesures de sécurité

importantes » au début de ce guide, ainsi

que les mises en garde et avertissements

suivants, avant de démarrer la laveuse à

pression.

•

Ne jamais remplir le réservoir à

carburant

jusqu'au bout. Remplissez-le

jusqu'à ½ po en dessous du bas du

culot de remplissage afin de permettre

l'expansion du carburant. Essuyez tout

carburant versé sur le moteur ou sur

l'appareil avant de démarrer le moteur.

•

Ne remplissez jamais le réservoir à

carburant à l'intérieur ni lorsque le

moteur est en marche. Ne jamais

fumer en remplissant le réservoir à

carburant.

•

Ne mettez jamais le moteur en marche

à l’intérieur ou dans un espace fermé

sans aération adéquate. Les gaz

déchappement du moteur contiennent

du monoxide de carbone, un gaz

inodore et mortel.

• Ne fermez jamais le robinet de la

source d'eau lorsque le moteur de

l'appareil de lavage sous pression est

en marche puisque cela risque

d'endommager la pompe.

• N'utilisez PAS d'eau chaude. Utilisez

seulement de l'eau froide.

• N’arrêtez PAS de vaporiser pendant

plus de deux minutes à la fois.

1. Ajouter de l’essence pure, sans plomb,

de haute qualité et ayant un indice

d’octane de 86 ou plus. Ne pas trop

remplir. Essuyez l’essence déversée

avant de démarrer le moteur.

2. Retirez le bouchon de remplissage/jauge

d’huile et ajoutez de l’huile à moteur

(fournie) au moteur. REMARQUE : Une

petite quantité d’huile a été versée dans

le moteur pour effectuer les essais à

l’usine. Vérifiez toujours le niveau d’huile

avant le démarrage.

Bouchon de remplissage/jauge d’huile

MISE EN GARDE

Page 37

14- FR

D25083

D25083

cordon en effectuant un mouvement rapide

et complet du bras. Laissez le cordon

s’enrouler lentement. Répétez au besoin.

Si le moteur ne

démarre pas après deux essais, appuyez sur la

détente afin de dégager la pression.

11. Si vous avez utilisé la commande

d’étrangleur lors du démarrage, replacez le

levier d’étrangleur à la position d’arrêt

« OFF ».

12. Appuyez sur la détente du pistolet pour

commencer la vaporisation d'eau. Relâchez

la détente pour l'arrêter.

13. Réglez le jet de vaporisation de la buse

pour correspondre à la tâche à effectuer.

Consultez les directives intitulées

« Utilisation de la lance » de cette section.

NE laissez PAS

les boyaux entrer en contact avec le silencieux

du moteur qui est extrêmement chaud, lors de

l’utilisation de la laveuse à pression ou tout de

suite après.

ENTRETIEN

LORS DE L'ENTRETIEN, VOUS POUVEZ ÊTRE EXPOSÉ À DES

SURFACES CHAUDES, DE L'EAU SOUS PRESSION, DES PIÈCES

MOBILES OU DES FLAMMES QUI PEUVENT PROVOQUER LA MORT. AVANT

D'EFFECTUER TOUT ENTRETIEN OU TOUTE RÉPARATION, DÉBRANCHEZ LE FIL

DE LA BOUGIE D'ALLUMAGE, LAISSEZ LE MOTEUR REFROIDIR ET DÉGAGEZ

L'EAU SOUS PRESSION. LE MOTEUR CONTIENT DU CARBURANT INFLAMMABLE.

NE PAS FUMER OU TRAVAILLER PRÈS DES FLAMMES NUES LORSQUE VOUS

EFFECTUEZ L'ENTRETIEN.

Afin d'assurer le bon fonctionnement et une durée de vie prolongée de votre laveuse à

pression, vous devez préparer et suivre un calendrier d'entretien régulier. Si votre laveuse

à pression est utilisée dans un environnement défavorable, tel qu'à des températures

élevées ou des conditions poussiéreuses, les vérifications d'entretien doivent être

exécutées plus souvent.

8. Placez la soupape de carburant à la

position de marche « ON » en tournant un

quart de tour dans le sens inverse des

aiguilles d’une montre.

9. Placez le levier de commande d’étrangleur

à la position « CHOKE ON »

et la commande des gaz à la position

rapide « FAST »

REMARQUE : L’étrangleur n’est pas

nécessaire pour démarrer un moteur chaud.

10. Tirez lentement la prise du démarreur

jusqu’à ce que vous sentiez une résistance

et tirez brusquement ensuite. Relâchez

doucement la prise du démarreur. Tirez le

Bouton de la

soupape de

carburant

Commande

d'étrangleur

Commande

des gaz

Page 38

4. Si le niveau d’huile est bas, ajoutez

de l’huile SAE 10W-30 jusqu’au

rebord du trou de remplissage

d’huile.

REMARQUE : Une huile d’une autre

viscosité que celle indiquée dans le

tableau peut être utilisée lorsque la

température moyenne de votre région

est dans les limites recommandées.

15- FR

D25083

TABLEAU DES RESPONSABILITÉS DU CLIENT

TACHE D’ENTRETIEN

LAVEUSE À PRESSION

MOTEUR

Avant

chaque

utilisation

Toutes les 25

heures ou

annuellement

Toutes les 50

heures ou

annuellement

Toutes les 100

heures ou

annuellement

X

X

X

X

X

X

X

X

MOTEUR

Vérification du niveau d’huile

1. Coupez le moteur et placez-le sur

une surface de niveau.

2. Retirez le bouchon de

remplissage/jauge d’huile et

essuyez-le.

3. Insérez et retirez le bouchon de

remplissage/jauge d’huile sans le

visser sur le culot de remplissage.

Vérifiez le niveau d’huile indiqué sur la

jauge d’huile.

Bouchon de remplissage/jauge d’huile

Bouchon de vidange d’huile

Bouchon de

remplissage/jauge d’huile

Limite supérieure

Limite inférieure

Vérification/nettoyage de l’écran

filtrant de l’arrivée d’eau

Vérification du boyau à haute pression

Vérification du boyau de savon/produit

chimique et du filtre

Vérification du pistolet et de la lance pour

déceler des fuites

Vérification du niveau d’huile

Changement de l’huile moteur

Vérification du filtre à air

Préparation pour l’entreposage

Préparer l’appareil pour l’entreposage s’il ne sera pas

utilisé pendant 30 jours ou plus.

Nettoyage/remplacement de la bougie d’allumage

Degré de viscosité SAE

**

*

5W-30, 10W-30 synthétique

-20 0 20 40 60 80 100

F

-30 -20 -10 0 10 20 30 40

C

GAMME DE TEMPÉRATURES ANTICIPÉES LORS DES

DÉMARRAGES AVANT LA PROCHAINE VIDANGE D'HUILE

32

Page 39

16-FR

Filtre à air

Un filtre à air sale réduira le débit d’air au

carburateur et entraînera un rendement

médiocre du moteur. Inspectez le filtre après

chaque utilisation. Nettoyez le filtre plus

souvent si le moteur est utilisé dans un lieu

très poussiéreux.

REMARQUE : Si vous faites tourner le moteur

sans le filtre, les saletés entreront dans le

moteur et entraîneront une usure prématurée

du moteur. Les dommages de ce genre ne sont

pas couverts par la garantie.

Inspection

1. Poussez sur les pattes de verrouillage sur

le haut du couvercle du filtre à air et

retirez le couvercle. Inspectez le filtre

pour vous assurer qu’il est propre et en

bon état.

2. Remettez en place le filtre et le couvercle

du filtre à air.

Nettoyage

1. Tapez le filtre sur une surface dure à

plusieurs reprises pour libérer la saleté ou

soufflez de l’air comprimé [ne dépassant

pas 30 lb/po2(207 kPa, 1,2 kg/cm2)] à

travers le filtre, à partir de la surface

propre qui fait face vers le moteur.

N’essayez jamais de brosser la saleté

puisque cela fait pénétrer la saleté dans

les fibres.

2. Essuyez la saleté du corps du filtre à air

et du couvercle à l’aide d’un chiffon

humide. Faites attention afin d’empêcher

la saleté d’entrer dans la conduite d’air

menant au carburateur.

Changement de l’huile

Vidangez l’huile à moteur lorsque le moteur

est chaud. L’huile se vidange plus rapidement

et complètement lorsqu’elle est chaude.

1. Placez la soupape de carburant à la

position d’arrêt « OFF » en tournant un

quart de tour dans le sens des aiguilles

d’une montre.

2. Placez un récipient approprié à côté du

moteur pour attraper l’huile usée.

3. Retirez le bouchon de remplissage/jauge

d’huile et vidangez l’huile dans le

récipient en inclinant le moteur vers le

culot de remplissage d’huile.

REMARQUE : Veuillez disposer de l’huile usée

d’une manière écologique. Nous vous

recommandons de mettre l’huile usée dans un

contenant scellé et de l’apporter à un centre

de recyclage local ou à une station service