Page 1

CertainTeed

Installation Guide

Vinyl and Polymer Siding

Page 2

CertainTeed Vinyl Siding Installation Guide

Top Ten Tips for Installing Vinyl Siding

Scan for our latest Vinyl

and Polymer Siding

Installation video.

CertainTeed provides quality vinyl siding and accessories that are

backed by one of the industry’s best warranties. However, even

the best products fall short of expectations if they are not installed

properly. Following these ten recommendations—the basics of a

professional installation—can help ensure a quality installation that

fullls homeowners’ expectations and reduces call backs.

1. Install all siding and accessories over a smooth, at surface.

Always install siding over a rigid sheathing, and never install it

over open studs.

2. Vinyl siding is not a watertight material. Install a weather-resistant

barrier, like CertainTeed CertaWrap and ash around all windows

and doors before installing vinyl siding and trim.

3. There are three recommended ways to cut vinyl siding:

For rip cuts, score the panel with a knife or vinyl blade and bend

the panel back and forth. Use aviator snips or shears to t panels

around windows and doors. For cross cuts, use a circular saw with

a plywood blade in the reverse position.

4. Always leave room for expansion and contraction into receiving

channels like outside cornerposts, inside cornerposts, and

J-channel. If the temperature is above 40°, leave 1/4"; if the

temperature is below 40°, leave 3/8".

5. When installing horizontal vinyl siding panels 12' 6" in length or

shorter, overlap the factory notches 1" to 1-1/4" (depending on the

temperature).

6. Always nail in the center of the nail slots: 16" on center for siding;

8" to 12" for accessories.

7. DO NOT NAIL TIGHT! Always leave 1/8" to 1/16" between the nail

head and the wall surface to allow for movement when the panel

expands and contracts.

8. Hang vertical accessories from the top of the top nail slot.

If the accessory is longer than 12', hang it from the top two

nail slots.

9. Lap away from the highest trafc pattern, typically the front of the

house. Keep laps at least 3' apart from course to course, and

install three courses between laps above each other.

10. Finish the last piece of siding into utility trim or dual utility trim.

1

Page 3

CertainTeed Vinyl Siding Installation Guide

Become a CertainTeed

Master Craftsman

The CertainTeed Master Craftsman program is your opportunity to earn valuable rewards while maintaining a leg up

on your competition. These rewards are not available to everyone, just to those who have successfully passed the

Master Craftsman Education and Development test.

As a Master Craftsman, you are entitled to:

• Receive a personalized Certificate of Completion that

you can use to promote your professional services.

• Be listed as a Master Craftsman on our contractor

locator website, where potential customers can find

you. The listing will include your name, company

name, phone number, e-mail address, and a link

to your website if you have one.

• Have access to the Master Craftsman website,

which includes Building Solutions® program

information, industry news and information,

and product and installation updates.

2

For more information about the CertainTeed Master

Craftsman program, call

800-233-8990

or log on to

www.certainteed.com/

mastercraftsman

Page 4

Important Information

CertainTeed Vinyl Siding Installation Guide

Warranties

These instructions describe and illustrate the steps

involved in installing CertainTeed siding, trim, and

accessories. Their purpose is to provide detailed

information and how-to tips that will simplify the

installation process. CertainTeed shall not accept any

liability or responsibility under its written warranty for

failure caused by application that does not meet the

requirements for proper installation. These requirements

are outlined throughout this book. Any deviations from

these requirements should be addressed and approved

in writing by CertainTeed Corporation.

In rare instances, intense sunlight reflected from glass

on vinyl siding may create heat buildup and cause the

siding to distort. To help minimize the effects of heat

buildup from reflected sun, the homeowner may take

one or more of the following measures:

• Install a screen in the window causing the problem.

• Install an awning over the window to break the line

of light reflection.

• Use shrubbery to protect the area of siding

from reflections.

For more information on the potential damaging effects

of concentrated solar reflection, visit the VSI website

at http://www.vinylsiding.org/aboutsiding/cleanmain/

solarandheat/index.asp

Building codes and regulations vary throughout

the country. Be sure to check with your local

code official or governing body for the building

requirements in your area.

New OSHA Fall Protection

Compliance Directives

STD 03-11-002 Compliance Guidance for Residential

Construction was issued on Dec. 6, 2010 and went

into effect June 16, 2011. For more information visit

www.OSHA.gov or consult your local State OSHA plan.

Lead Renovations

Many houses and apartments built before 1978 have

paint that contains high levels of lead (called lead-based

paint). Lead from paint, chips, and dust can pose

serious health hazards if not taken care of properly.

You can find out about safety measures for lead-based

paint by calling 1-800-424-LEAD. Ask for the brochure

“Reducing Lead Hazards When Remodeling Your

Home.” That brochure explains what to do before,

during, and after renovations.

Important Fire Safety Information

Exterior vinyl building materials require little

maintenance for many years. Nevertheless, common

sense dictates that builders and suppliers of vinyl

products store, handle and install vinyl materials in a

manner that avoids damage to the product and/or

the structure. Owners and installers should take a few

simple steps to protect vinyl building materials from fire:

• To Home and Building Owners: Rigid vinyl siding

is made from organic materials and will melt or

burn when exposed to a significant source of

flame or heat. Building owners, occupants and

outside maintenance personnel should always take

normal precautions to keep sources of fire, such as

barbecues, and combustible materials, such as dry

leaves, mulch and trash, away from vinyl siding.

• To the Building Trades, Specifiers, Professionals

and Do-It-Yourself Installers: When rigid vinyl siding

is exposed to significant heat or flame, the vinyl will

soften, sag, melt or burn, and may thereby expose

material underneath. Care must be exercised when

selecting underlayment materials because many

underlayment materials are made from organic

materials that are combustible. You should ascertain

the fire properties of underlayment materials prior to

installation. All building materials should be installed

in accordance with local, state and federal building

codes and fire regulations.

This manual shows the basic guidelines for installation. It is based on ASTM (American Society for Testing and Materials) D4756, the standard

practice for installation of vinyl siding and soffit. Additionally, we recommend that local building codes be reviewed.

3

Page 5

CertainTeed Vinyl Siding Installation Guide

TABLE OF CONTENTS

Top Ten Tips for Installing Vinyl Siding ......................... 1

Become a CertainTeed Master Craftsman ................... 2

Important Information .................................................3

SECTION 1 — Introduction ..................................... 6

SECTION 2 — Siding Overview

Home Exterior Terms ..................................................7

Features of Polymer Shake Siding ..............................8

Polymer Shake and Shingle Siding Styles ...................9

Traditional Vinyl Siding Terms .................................... 10

Vinyl Siding Styles ..................................................... 11

Insulated Siding Styles .............................................. 12

SECTION 3 — Vinyl Soffit and Ventilation

Features of Vinyl Soffit ..............................................13

SECTION 4 — Accessories and Tools

Corner Systems ........................................................14

Lineals ...................................................................... 16

Decorative Trim ......................................................... 16

J-Channels ............................................................... 17

Functional Trim .........................................................18

Starter Strips ............................................................18

Soffit Trim .................................................................20

Equipment and Tools ................................................21

Transporting and Storing

Vinyl Siding and Polymer Shakes ........................... 22

Special Tools ............................................................23

SECTION 5 — Estimating

Siding ....................................................................... 24

Measuring ................................................................26

Estimating Form .......................................................27

Nail Spacing and Product

Expansion and Contraction ...................................35

Installing Accessories ...............................................37

Outside Cornerposts ................................................38

Extra Wide Cornerposts ...........................................40

Inside Cornerposts ...................................................41

Federal Corners ........................................................ 42

Inside Federal Corners .............................................. 42

Bay Window Corners ................................................43

Decorative Trim Options around

Windows and Doors ............................................. 44

Window Flashing ......................................................45

Window and Door Trim ............................................. 46

Snap-on Lineals .......................................................47

Lineal Starter Application for Windows

and Door Surrounds .............................................49

Lineal Application around Windows ..........................50

Lineals over Horizontal Siding ...................................53

Capping a Lineal Used as a Rake .............................53

Corner Blocks ..........................................................54

5" Square Header with Endcaps over

3-1/2" Lineals Sides and Bottoms ........................55

Creating End Caps for 5" Lineals ..............................56

Slip Joints for Lineal Corners ....................................57

Crown Molding Treatment Options ...........................58

Crown Molding and Cap for 3/4"

Pocket J-Channel ................................................. 59

Crown Molding with 3-1/2" Lineal Surround ..............59

Crown Molding with Cap for 5" Header Lineal ...........60

Band Board ..............................................................62

Blind Miter ................................................................64

Lineal Frieze Board ...................................................64

Finishing with Cornice Molding and Receiver ............65

SECTION 6 — Preparing for Horizontal Siding

Preparing Wall Surfaces ............................................28

CertaWrap™ Weather-Resistant Barrier .....................29

Nailing, Stapling and Other Fastening Methods.........33

4

Installing J-Channel as Gable End Trim ..................... 66

Using Lineals as Gable Trim ...................................... 67

Restoration Millwork Trim .......................................... 68

Page 6

CertainTeed Vinyl Siding Installation Guide

SECTION 7 — Installing Horizontal Siding

Top Ten Tips for Installing Vinyl Siding ....................... 70

Cutting Panels .......................................................... 71

Overlapping Panels ................................................... 71

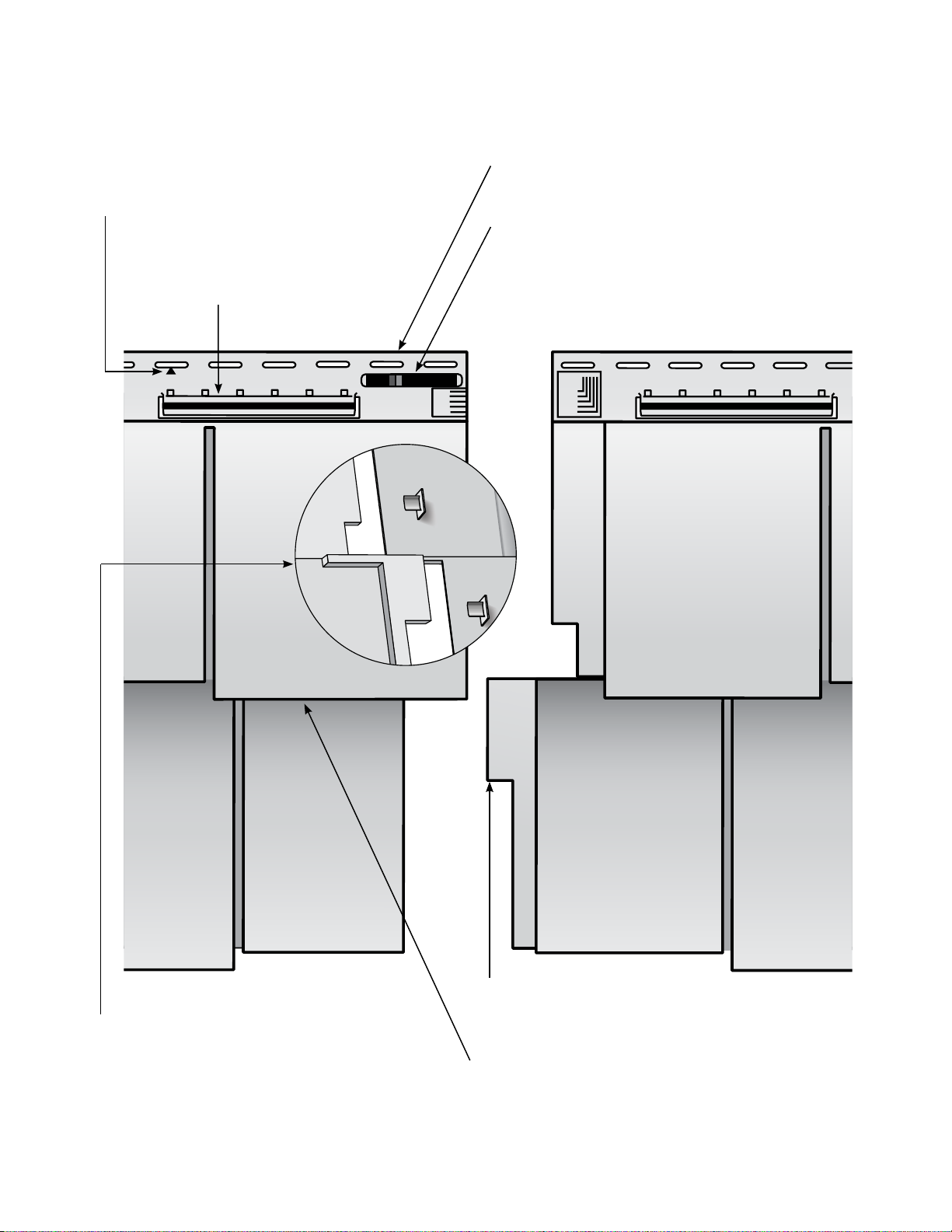

STUDfinder™ Installation System for 12' Panels ........72

STUDfinder™ Installation System

for Oversized Panels ............................................. 73

Preparing Wall Surfaces ............................................74

Completion ............................................................... 78

Shutter Installation .................................................... 79

SECTION 8 — Installing Vertical Siding

(including Board & Batten)

Preparing Wall Surfaces ............................................80

Cornerposts .............................................................81

Top and Bottom J-Channel .......................................81

J-Channel at Gable Ends .......................................... 82

Wall Panels ...............................................................83

Cedar Impressions Inside Cornerpost ..................... 108

Cedar Impressions Bay Window Cornerposts .........109

Half-Round Shingles ............................................... 110

Half-Round Shingles in Gable Ends ........................113

Cedar Impressions on a Steep Rake .......................116

Cedar Impressions on Non-vertical Walls ................116

Starting Cedar Impressions with Lineals

over Horizontal Siding ......................................... 117

Starting Cedar Impressions

over Horizontal Siding ......................................... 118

Application of Half-Round Shingle under Soffit ........119

Special Effects with Cedar Impressions ..................120

Replacing a Damaged Cedar Impressions

Panel with the Repair Kit ..................................... 121

Replacing a Damaged Cedar Impressions Panel ....124

Northwoods S7" and S9" Shakes .......................... 125

CedarBoards Insulated Siding ................................127

Band Board ............................................................133

Gable End Panels ..................................................... 84

SECTION 9 — Porch Ceilings, Soffit, Fascia

Requirements for Proper Soffit Ventilation .................85

Porch Ceilings ..........................................................86

Soffit .........................................................................88

Triple 3-1/3 Solid and InvisiVent Soffit

and Perimeter Soffit .............................................. 91

Vinyl Fascia...............................................................92

SECTION 10 — Installing Specific

CertainTeed Products

Cedar Impressions Shingles and Shakes ..................94

D7 Straight Edge Perfection Shingles .......................95

T5 Straight Edge Perfection Shingles ....................... 97

D9 Staggered Rough-Split Shakes ........................100

D7 Straight Edge Rough-Split Shakes ....................102

D7 Staggered Perfection Shingles ..........................104

Cornice Cap with Cedar Impressions

Mitered Cornerpost ............................................106

SECTION 11 — Special Situations

Trimming Curved Openings ....................................135

Frieze Board ...........................................................136

Decorative Sunbursts .............................................136

SECTION 12 — Repair

Replacing a Damaged Siding Panel ........................ 139

Replacing a Damaged Outside Cornerpost ............. 139

Repairing Buckled Siding at the Joist ...................... 140

SECTION 13 — Miscellaneous

Cleaning Vinyl Siding ..............................................141

Siding Over Asbestos .............................................142

Historic Restoration ................................................142

Lead Renovations ................................................... 143

For More Information ..............................................143

Index ......................................................................144

Glossary .................................................................146

5

Page 7

CertainTeed Vinyl Siding Installation Guide

Section 1 — Introduction

Introduction

Plan your work, then work your plan.

That’s the key to success with any project, and it’s doubly true

when it comes to installing vinyl siding, soffit, trim and accessories.

If you use the right materials and the right tools in the right order,

you’ll complete remodeling and new home installations in less

time, with less effort, and with far greater satisfaction.

Since you’re using CertainTeed products, you’ve already taken

the first step toward success. CertainTeed sidings, soffit, trim

and accessories provide premium quality, rugged durability and

outstanding appearance. Quite simply, they’re made to look

great—on the day they’re installed and for years after.

The second ingredient of success —using the proper tools,

techniques and procedures—is covered in this book. As you’ll see

by scanning the table of contents, this book guides you through

every step of the installation process, from estimating materials to

attaching mailboxes and shutters. Every major installation project

is covered: horizontal; vertical, including Board & Batten; soffit

and fascia; porch ceilings; and decorative trim. Where various

approaches to a particular installation procedure are possible,

the book presents practical alternatives. To make the instructions

as detailed and complete as possible, hundreds of illustrations

accompany the text.

As you’re reading—and while you’re working—keep in mind the

most important rule of thumb for successful vinyl siding installation:

allow for movement. All vinyl siding, soffit and accessories

used in exterior applications must be able to move freely as they

expand and contract with temperature changes. You’ll see this

point emphasized again and again throughout this book; you’ll also

learn various techniques for measuring, fitting and nailing that will

allow this unobstructed movement. These are perhaps the most

important lessons in this booklet.

NOTE: No instruction book can anticipate all the questions

that might arise during a siding or soffit installation.

Recognizing this, we’ve focused on the tools and techniques

used to complete typical installations. Where appropriate,

we’ve also included alternative approaches for specific

installation steps. If you encounter a unique installation

problem not covered in this book, we suggest you contact

your building materials distributor or call our Sales Support

Group at 1-800-233-8990.

6

Page 8

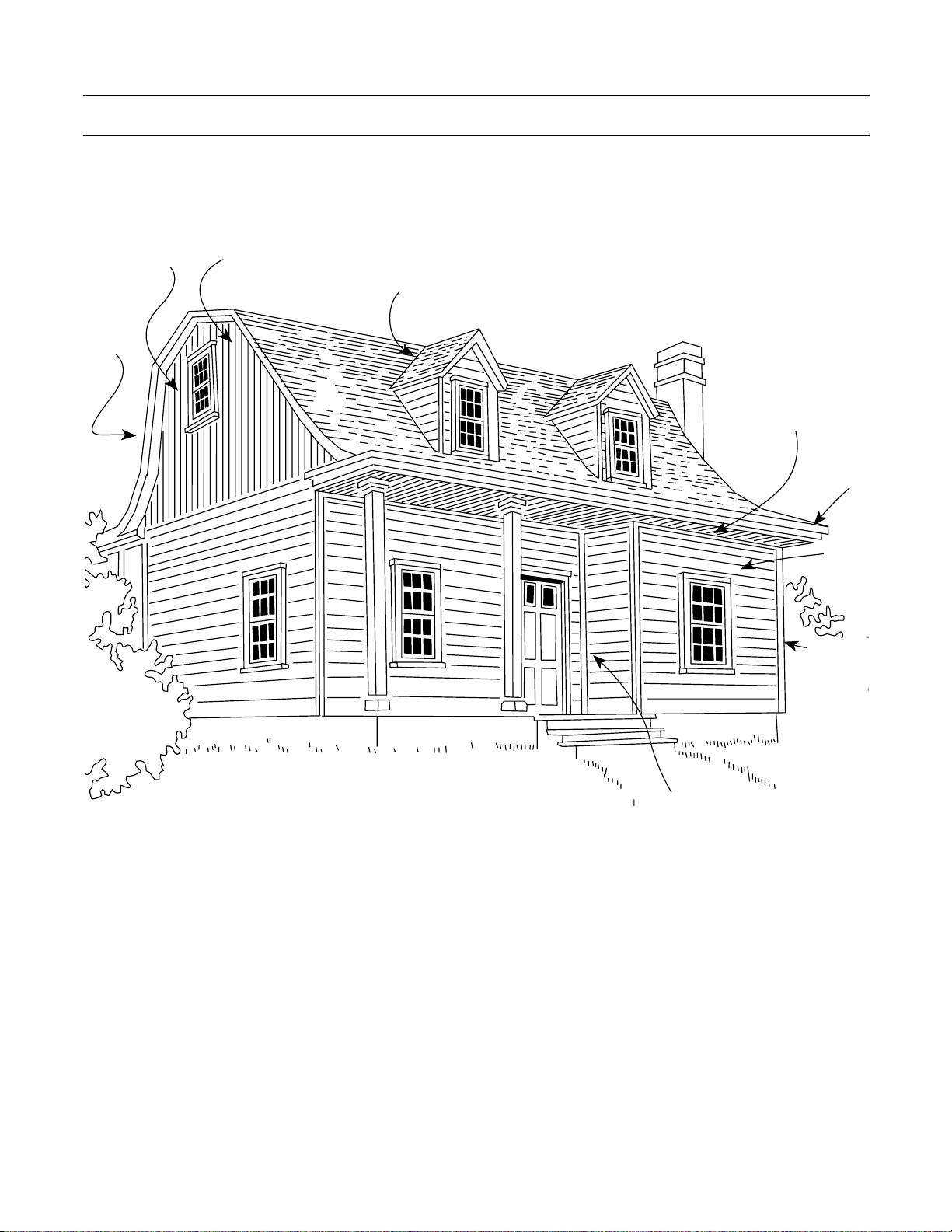

SECTION 2 — Siding Overview

Home Exterior Terms

CertainTeed Vinyl Siding Installation Guide

Vertical Siding

Rake

Gable

Dormer

Soffit

Fascia

Siding

Outside

cornerpost

Inside

cornerpost

7

Page 9

CertainTeed Vinyl Siding Installation Guide

Features of Polymer Shake Siding

QuickReferenceTM Nail Mark Indicators

• Industry exclusive easy-to-use nailing guide

• No measuring needed for correct panel nailing

Extra Long Top Locking Tabs

• Create an easier locking panel

A

0 30 65 100 130 160

100°F

130°F

QuickReferenceTM Panel Cut Indicators

• Improves speed and ease of installation

Patented PanelThermometer

• Displays panel temperature!

• Easy-to-use temperature gauge

• The brightest cell indicates panel temperature

• Increases installation accuracy, decreases call backs

0°F

30°F

65°F

100°F

130°F

0°F

30°F

65°F

TM

Oversized Perimeter

Side Locking Tabs

• Helps create seamless appearance

• Allow for fast and easy panel engagement

• Offer greater tab strength and less breakage

• Extended lead-in allows for ease of installaton

8

Straight-Up Installation

• Notched side laps allow you to push in and straight-up to

lock the panel securely — just like traditional vinyl siding!

Deep Panel Projection

• Created distictive shadow lines and shingle definition

• Perfection and Half-Round Shingles: 3/4" projection

• Rough-Split Shakes: 1" projection

Page 10

CertainTeed Vinyl Siding Installation Guide

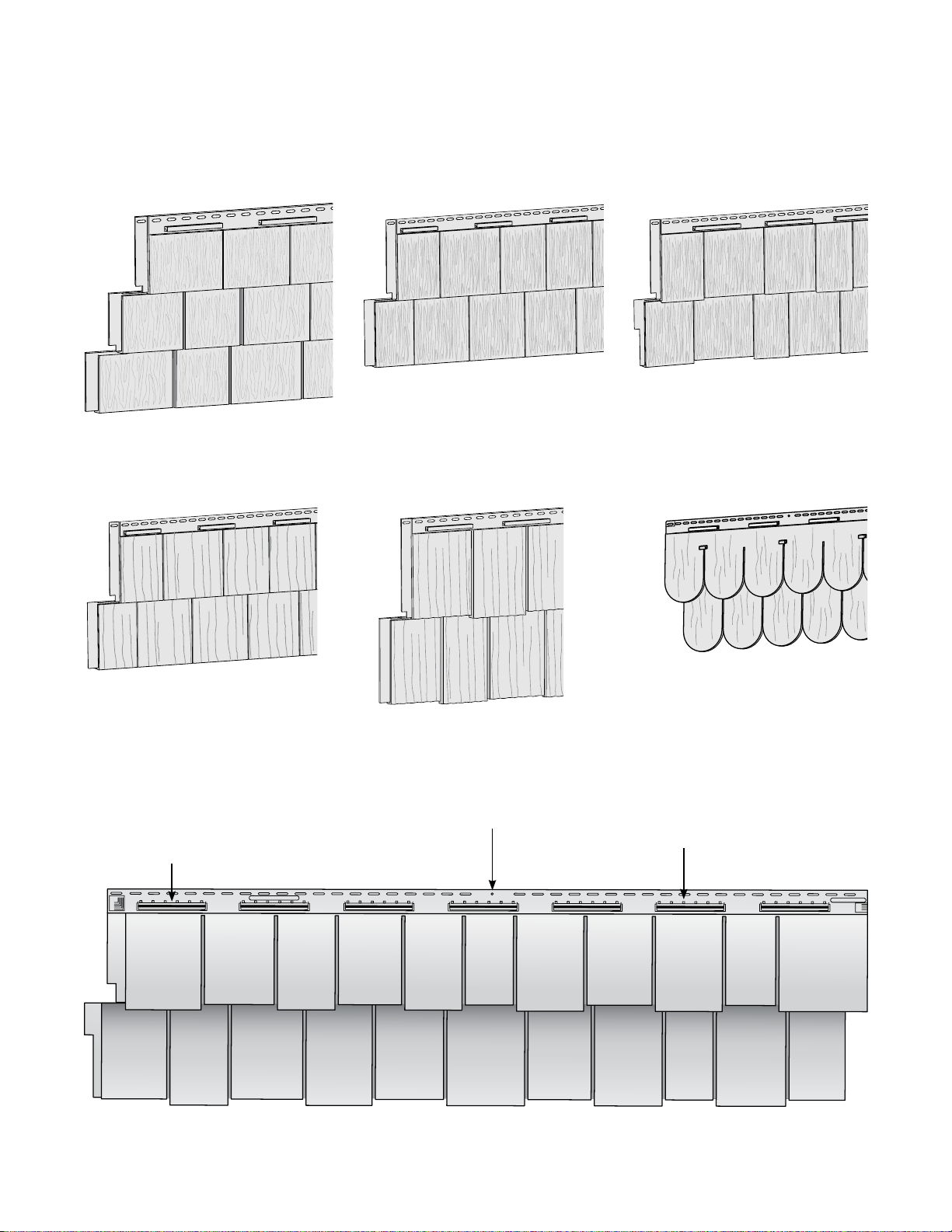

Polymer Shake and Shingle Siding Styles

Triple 5" Straight

Edge Perfection Shingles

Double 7" Straight

Edge Rough-Split Shakes

Double 7" Straight

Edge Perfection Shingles

Double 9" Staggered

Rough-Split Shakes

Double 7" Staggered

Perfection Shingles

Double 6-1/4"

Half-Round Shingles

Exclusive Positive Lock

• Self-supporting, friction lock

• No need to hold panel while nailing

• Lead-in guide ensures engagement

• Allows for band board shrinkage

Center Pin Hole

Allows for even expansion

and contraction of the panel.

Reinforced Ribs on Nail Slots

and Lock Tabs

• Provide improved lock strength

and holding power

9

Page 11

CertainTeed Vinyl Siding Installation Guide

5"

5"

3"

3"

3"

7/16"

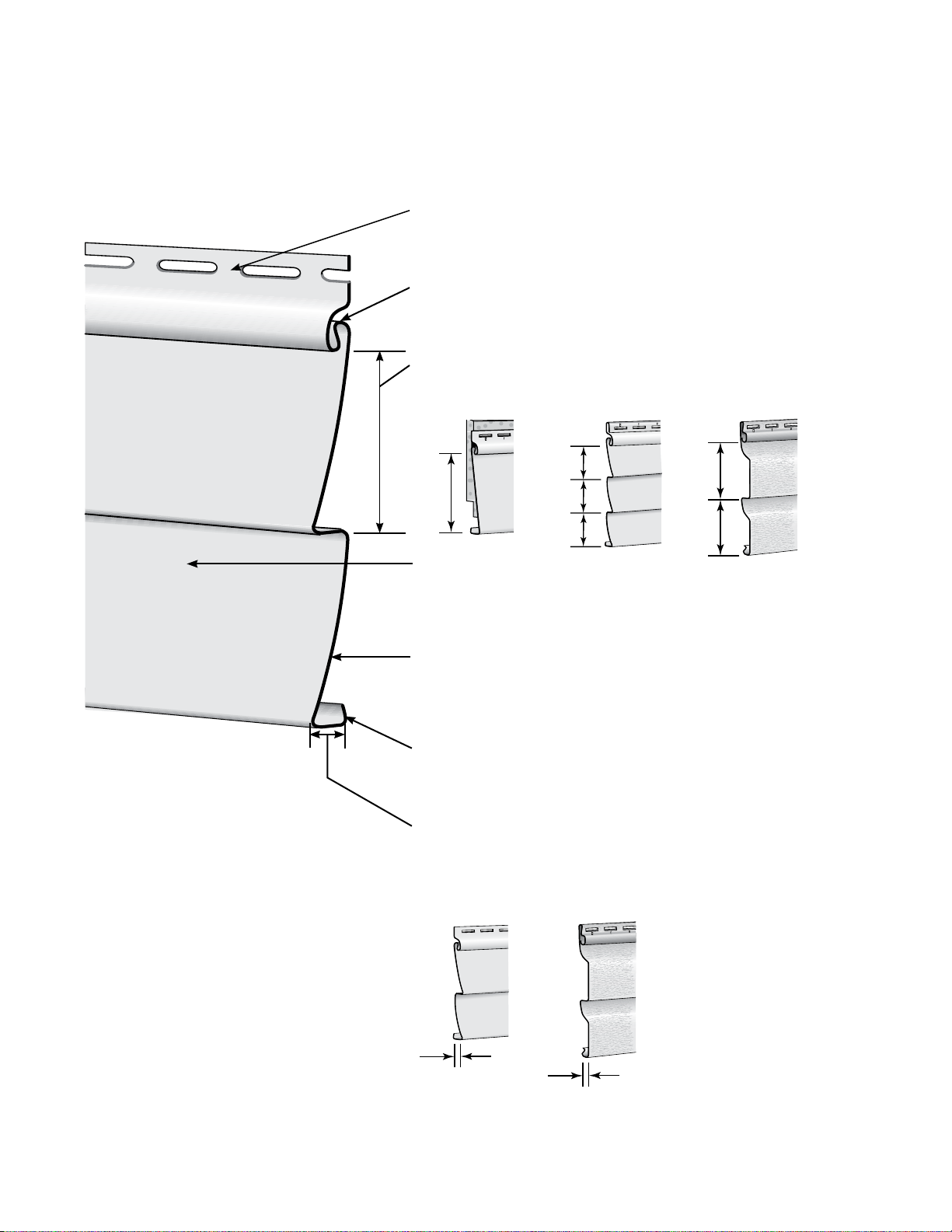

Traditional Vinyl Siding Terms

Profile

The contour or outline of a siding panel as viewed from the side.

Nail flange

Flat area along top of panel with slots for nailing; slots

allow for expansion and contraction.

Lock

Molded area just under nailing flange into which butt

leg/locking leg of next panel above is secured.

Exposure

The width of the exposed face of each panel of siding;

also referred to as reveal.

7"

Texture

Visual and tactile characteristics of the siding panel;

designed to recreate the authentic look of natural wood

grain, stucco, smooth painted clapboard, etc.

Panel Thickness

An important element of siding quality. Thicker panels are

more durable, stand up to impacts and high winds, and

look straighter on the wall.

Butt leg/locking leg

The bottom part of a siding profile that connects or locks

into the panel below.

Panel projection

Common to products with multiple faces (i.e. Double 4 or Triple 3).

It is the dimension required for the proper selection of receiving

channels (e.g., J-channels and corner pieces).

3/4"

10

Page 12

i

i

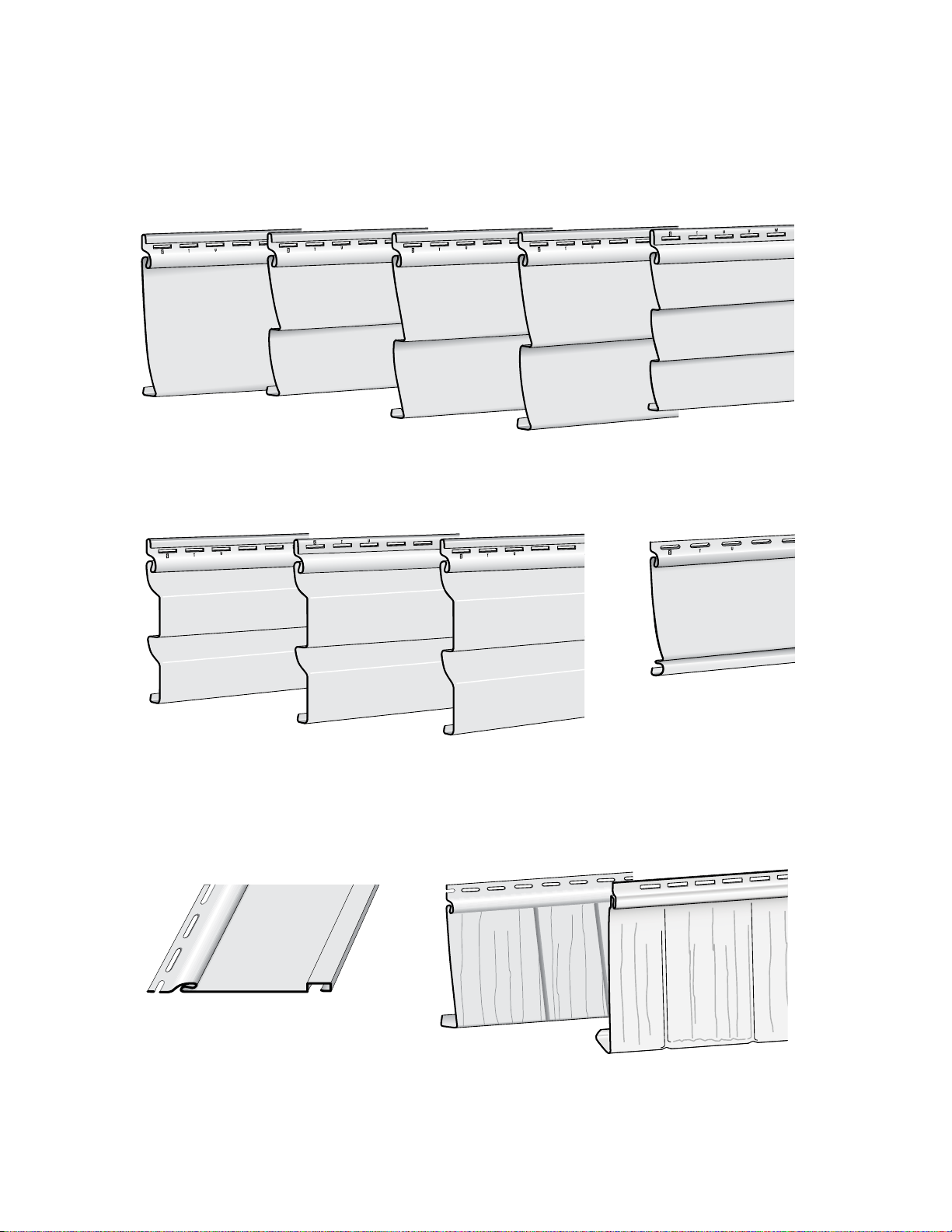

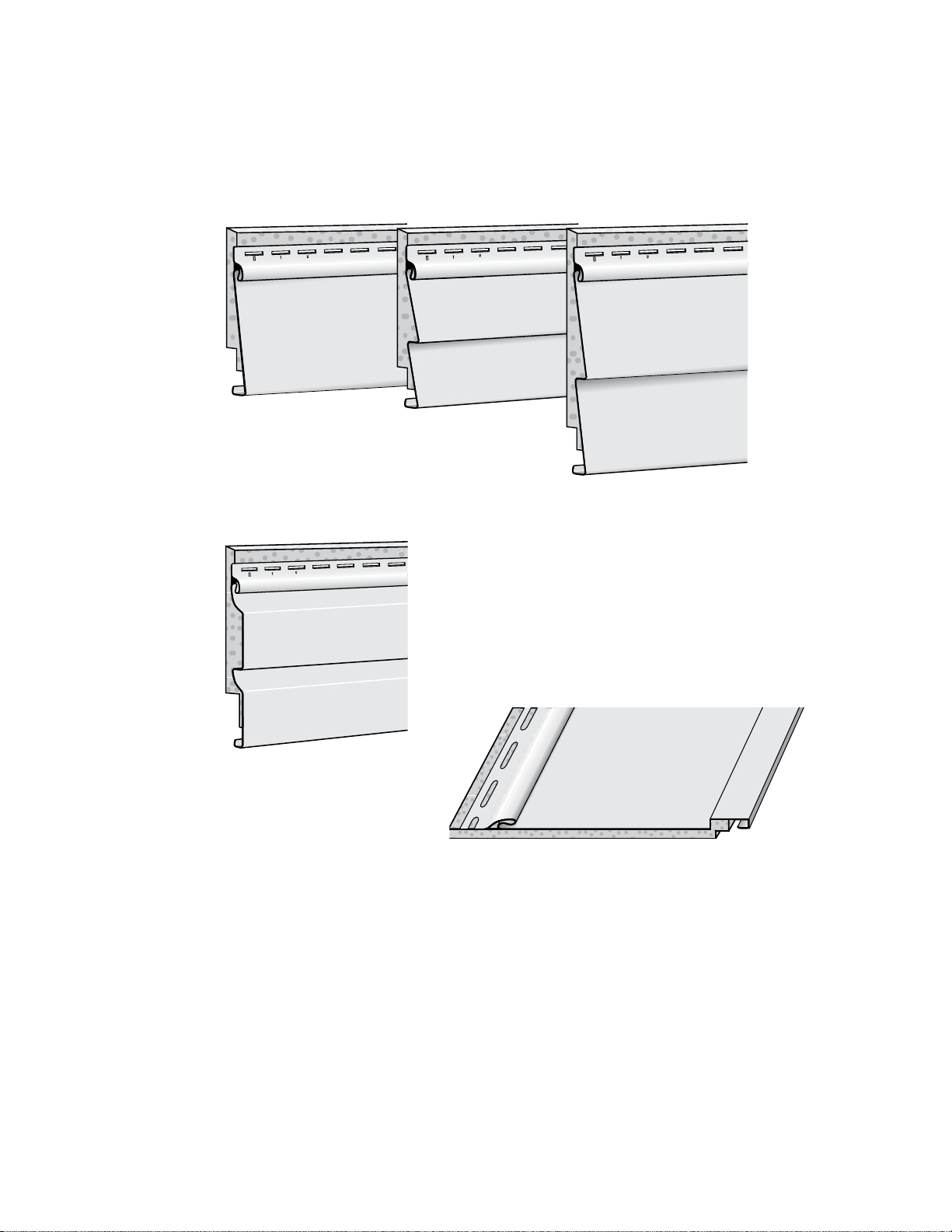

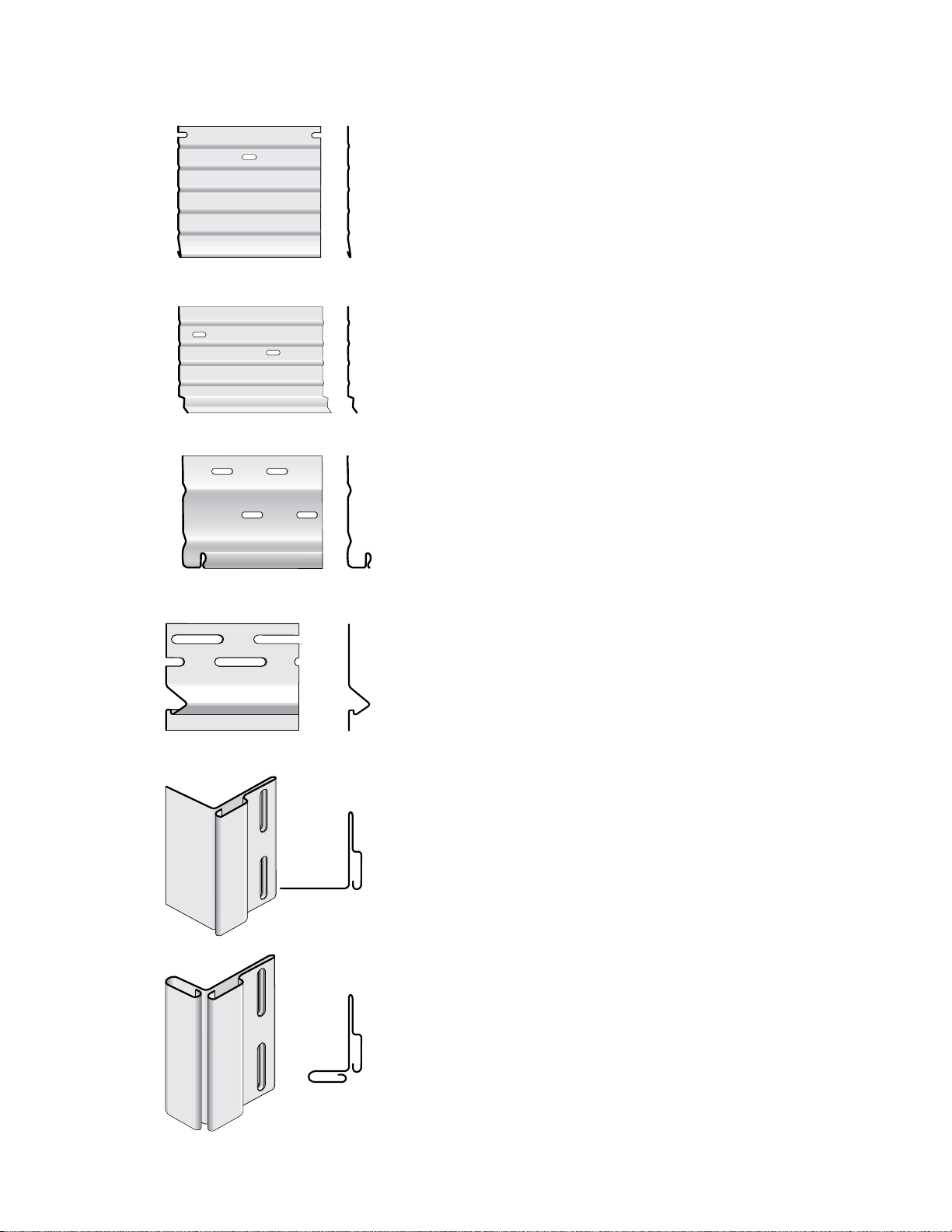

Vinyl Siding Styles

CertainTeed Vinyl Siding Installation Guide

Single 8"

Clapboard

Double 4"

Dutchlap

Double 4"

Clapboard

f

D

f

D

Double 4-1/2"

Clapboard

f

i

D

Double 4-1/2"

Dutchlap

i

i

f

D

D

Double 5"

Dutchlap

i

Double 5"

Clapboard

i

f

f

D

Triple 3"

Clapboard

i

f

D

Single 6-1/2"

Beaded

f

D

Single 8" Vertical

Board & Batten

Single 7" Straight

Edge Rough-Split

Shakes

Single 9" Staggered

Rough-Split Shakes

11

Page 13

CertainTeed Vinyl Siding Installation Guide

Insulated Siding Styles

Single 7"

Clapboard

Double 4.5"

Dutchlap

Double 4"

Clapboard

i

f

D

n

i

f

D

D

Double 6"

Clapboard

i

f

i

f

D

Single 12" Vertical

Board and Batten

12

Page 14

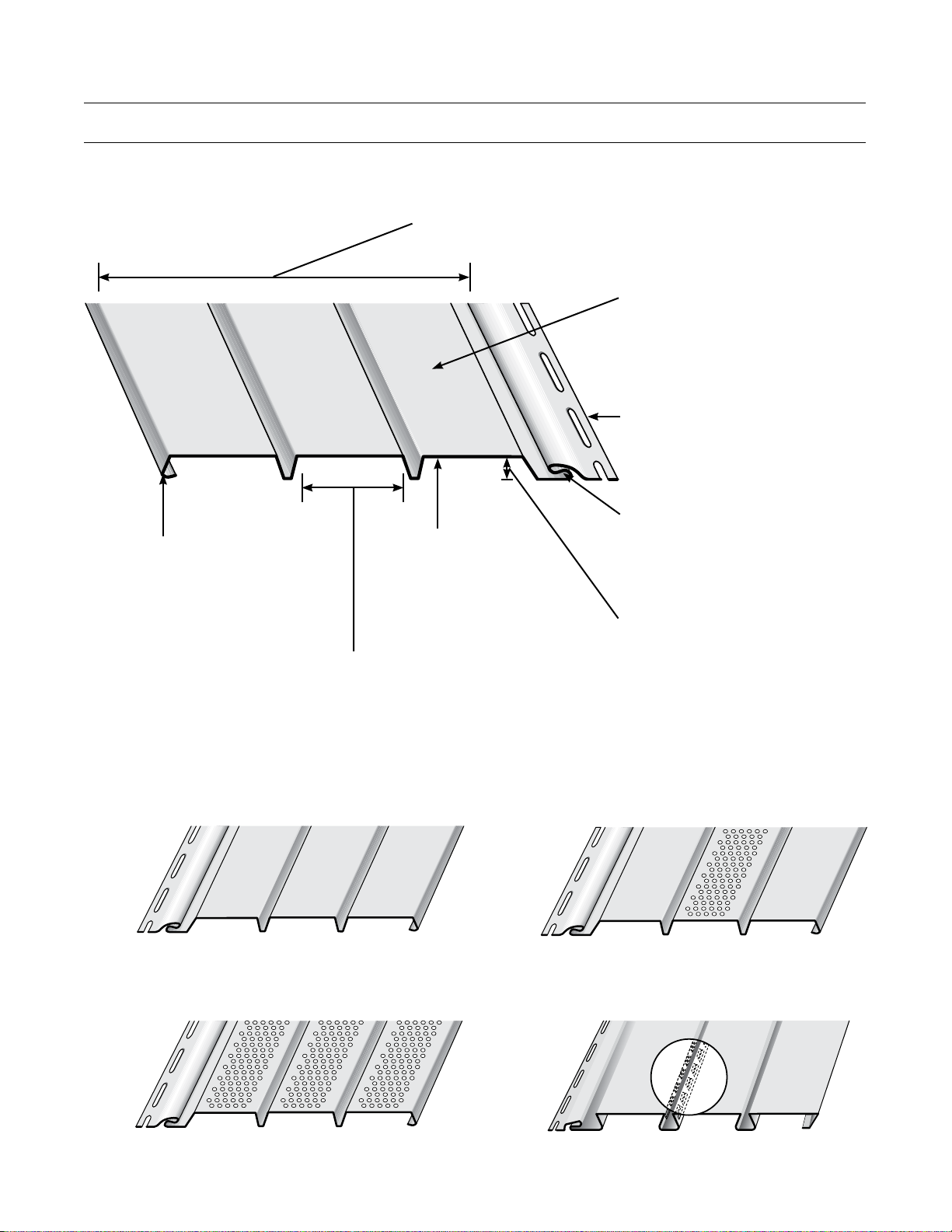

SECTION 3 — Vinyl Soffit and Ventilation

Features of Vinyl Soffit

Profile

The contour or outline of a soffit panel as viewed from the side.

Texture

Visual and tactile characteristics of

the soffit panel; designed to recreate

the authentic look of natural wood

grain, stucco, smooth, etc.

Nailing Flange

Flat area along top of panel with

slots for nailing; slots allow for

expansion and contraction.

CertainTeed Vinyl Siding Installation Guide

Butt Leg / Locking Leg

Molded area at bottom of

panel that is snapped into lock

on adjacent panel for secure

connection.

Solid Soffit

Panel Thickness

An important element

of soffit quality. Thicker

panels are more

durable and are less

prone to sagging.

Exposure

The width of the exposed

face of each panel of soffit;

also referred to as reveal.

Lock

Molded area just under nailing

flange into which butt leg/locking leg

of adjacent panel is secured.

Panel Projection

Common to products with

multiple faces (i.e. Triple 3). It is

the dimension required for the

proper selection of receiving

channels (e.g., J-channels and

corner pieces).

Center Vented Soffit

Fully Vented Soffit

Invisibly Vented Soffit

13

Page 15

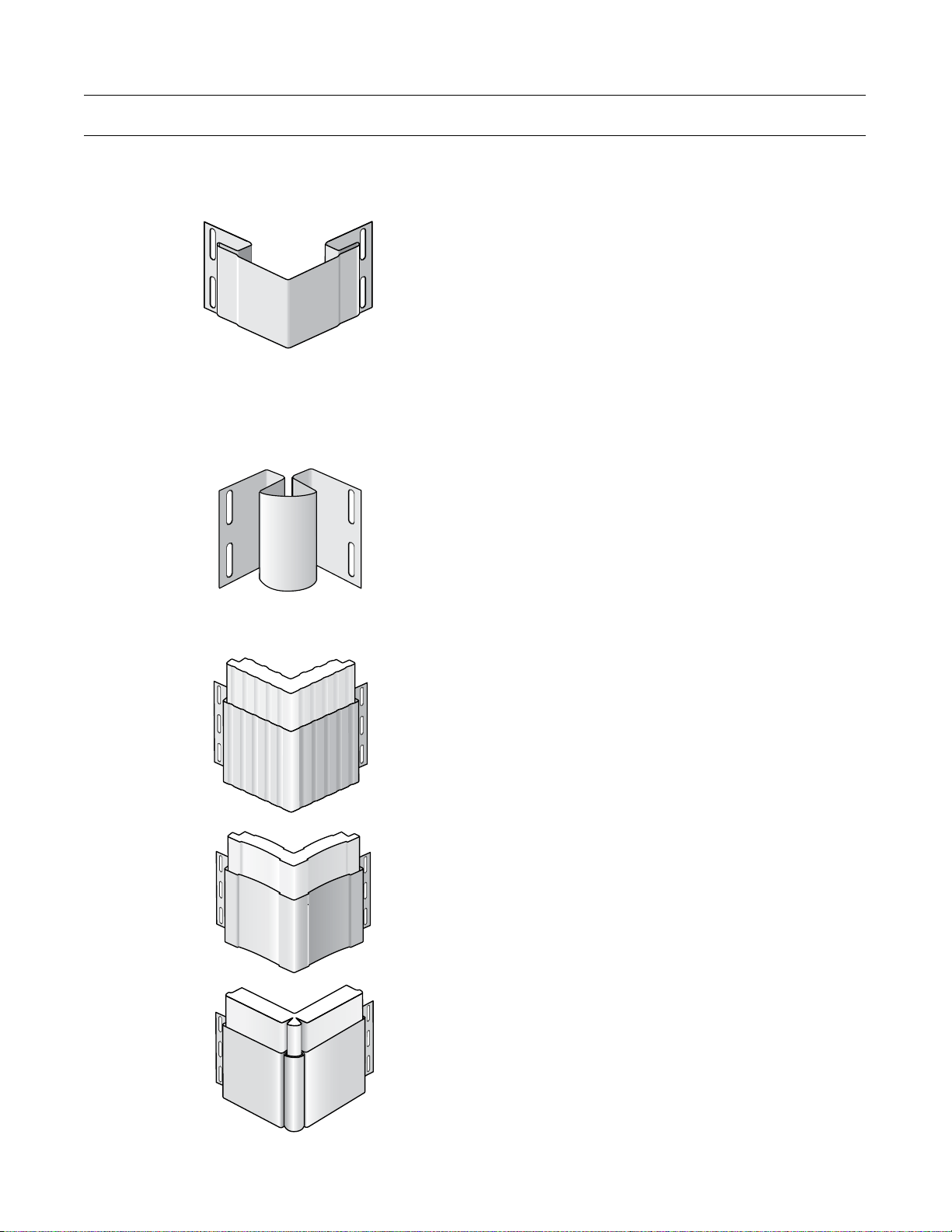

CertainTeed Vinyl Siding Installation Guide

SECTION 4 — Accessories and Tools

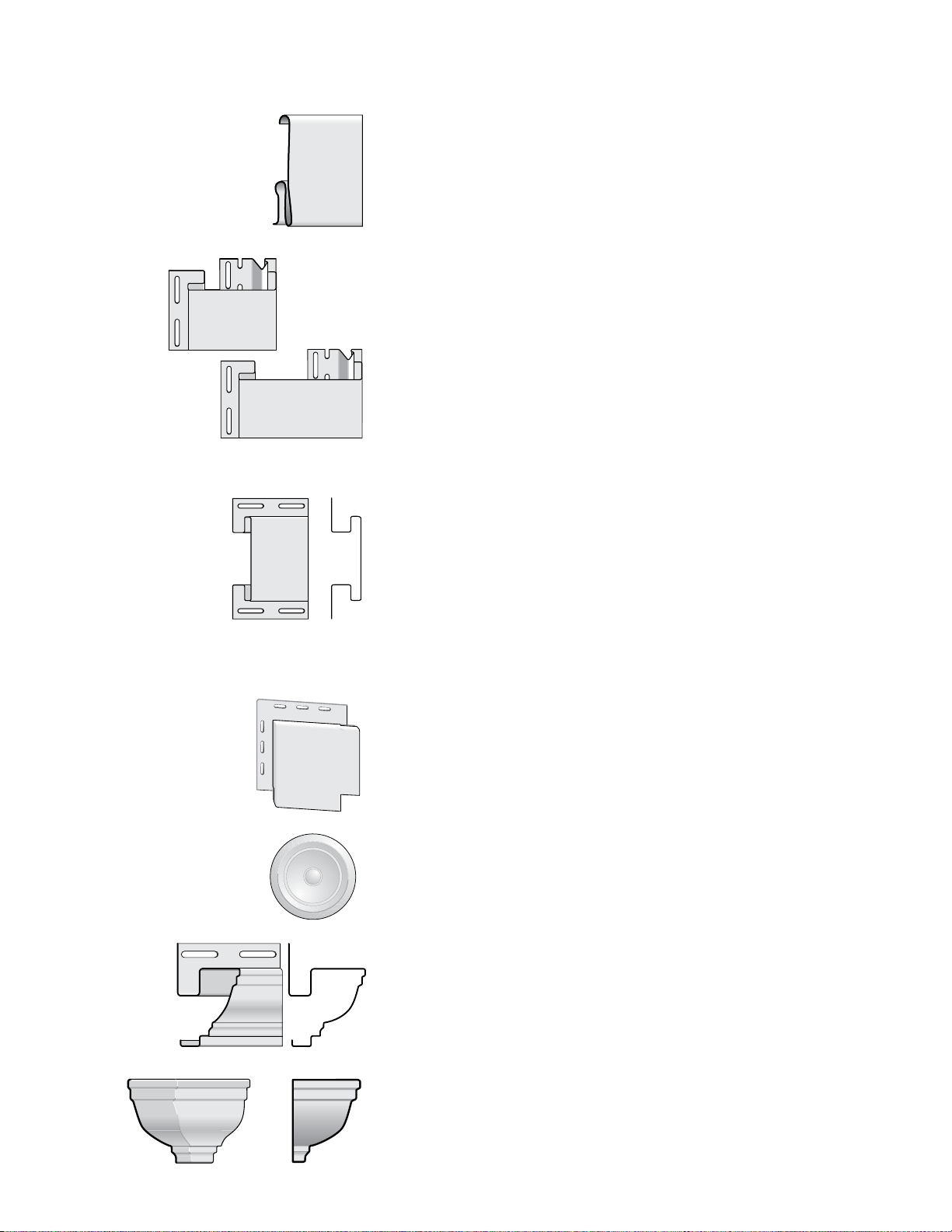

Corner Systems

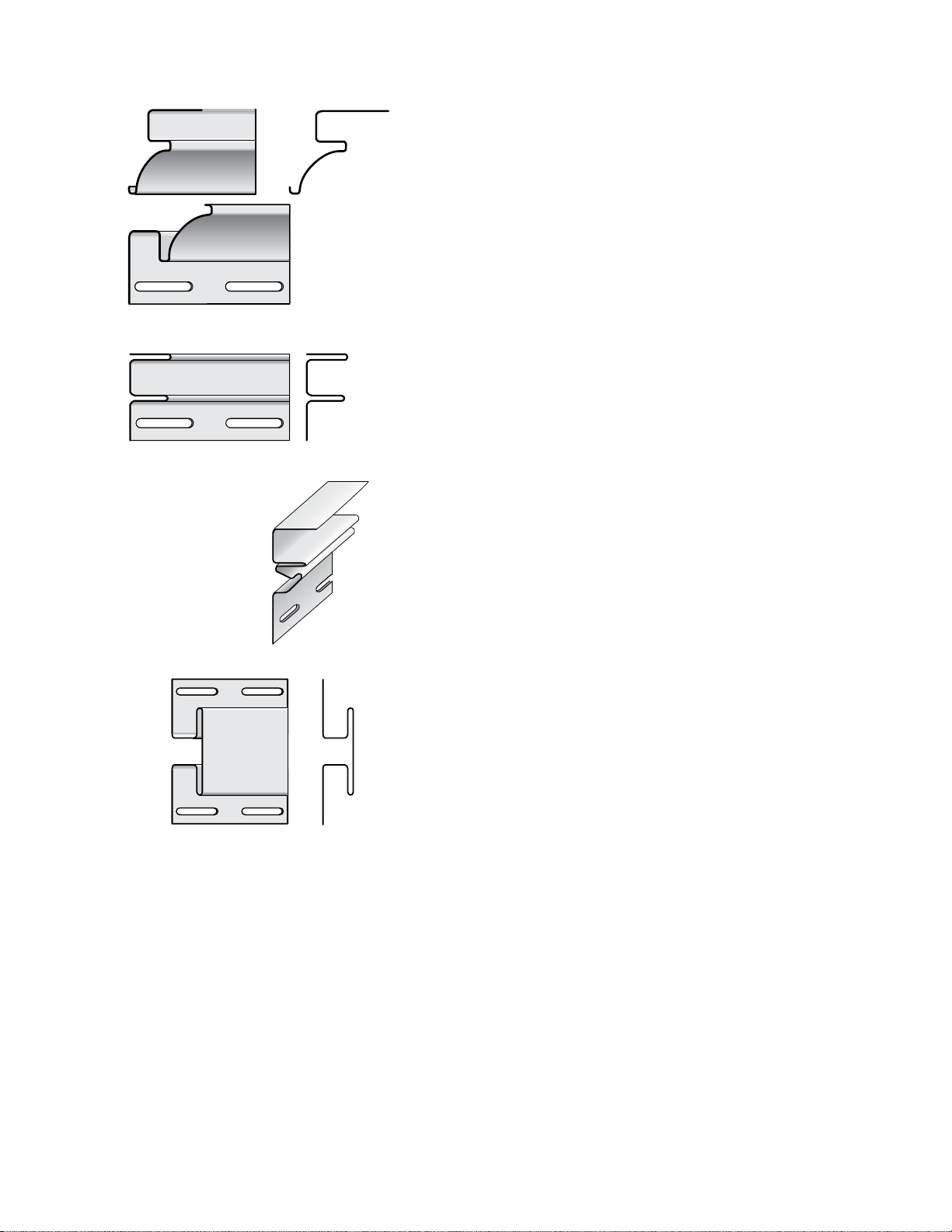

Outside cornerposts

3/4" Outside cornerpost—woodgrain and matte.

Use with all sidings except Cedar Impressions D9 Rough-Split

Shakes, Northwoods S9 Rough-Split Shakes and CedarBoards.

1" Outside cornerpost—woodgrain.

Use with Cedar Impressions D9 Rough-Split Shakes and

Northwoods Shakes.

1-1/4" Outside cornerpost with foam insert—woodgrain.

Use with Cedar Impressions Rough-Split Shakes,

Northwoods Shakes and CedarBoards.

Inside cornerposts

3/4" Inside cornerpost—matte.

Use where siding meets at inside corners; provides a finished look.

1-1/4" Inside cornerpost—matte.

Use with Cedar Impressions Rough-Split Shakes,

Northwoods Shakes and CedarBoards.

Fluted SuperCorner—matte

3/4" Fluted corner design with foam backing.

Traditional SuperCorner™—matte

3/4" and 1-1/4" Wide decorative traditional corner treatment with

foam backing. The 1-1/4" is used with Cedar Impressions RoughSplit Shakes, Northwoods Shakes, and CedarBoards.

14

Beaded SuperCorner™—matte

Wide decorative beaded corner treatment with foam backing.

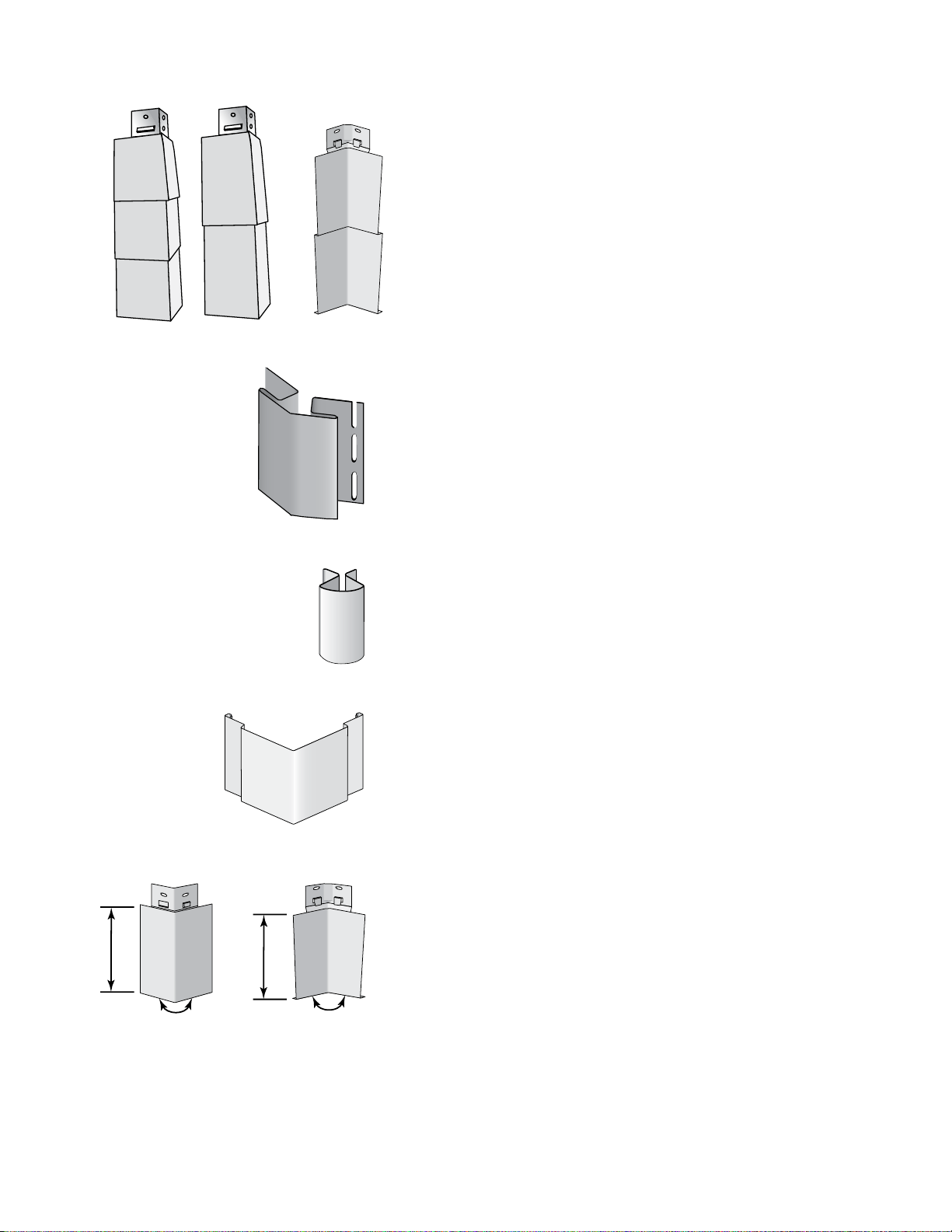

Page 16

CertainTeed Vinyl Siding Installation Guide

Corner Systems (continued)

Mitered cornerposts

Outside and inside corner treatment for use with

Cedar Impressions.

Bay window cornerpost—matte

Adapts to odd angles of bay windows.

7" 7"

47.5°

Quarter round insert—matte

Installed with a Corner Starter and lineals as a decorative

corner treatment.

5" Corner cap—matte

Used to create corner systems.

Cedar Impressions S7" bay window inside

and outside cornerposts

Use with Cedar Impressions D7" Straight Edge Perfection Shingles

only to adapt to the odd angles of a bay window.

42.5°

15

Page 17

CertainTeed Vinyl Siding Installation Guide

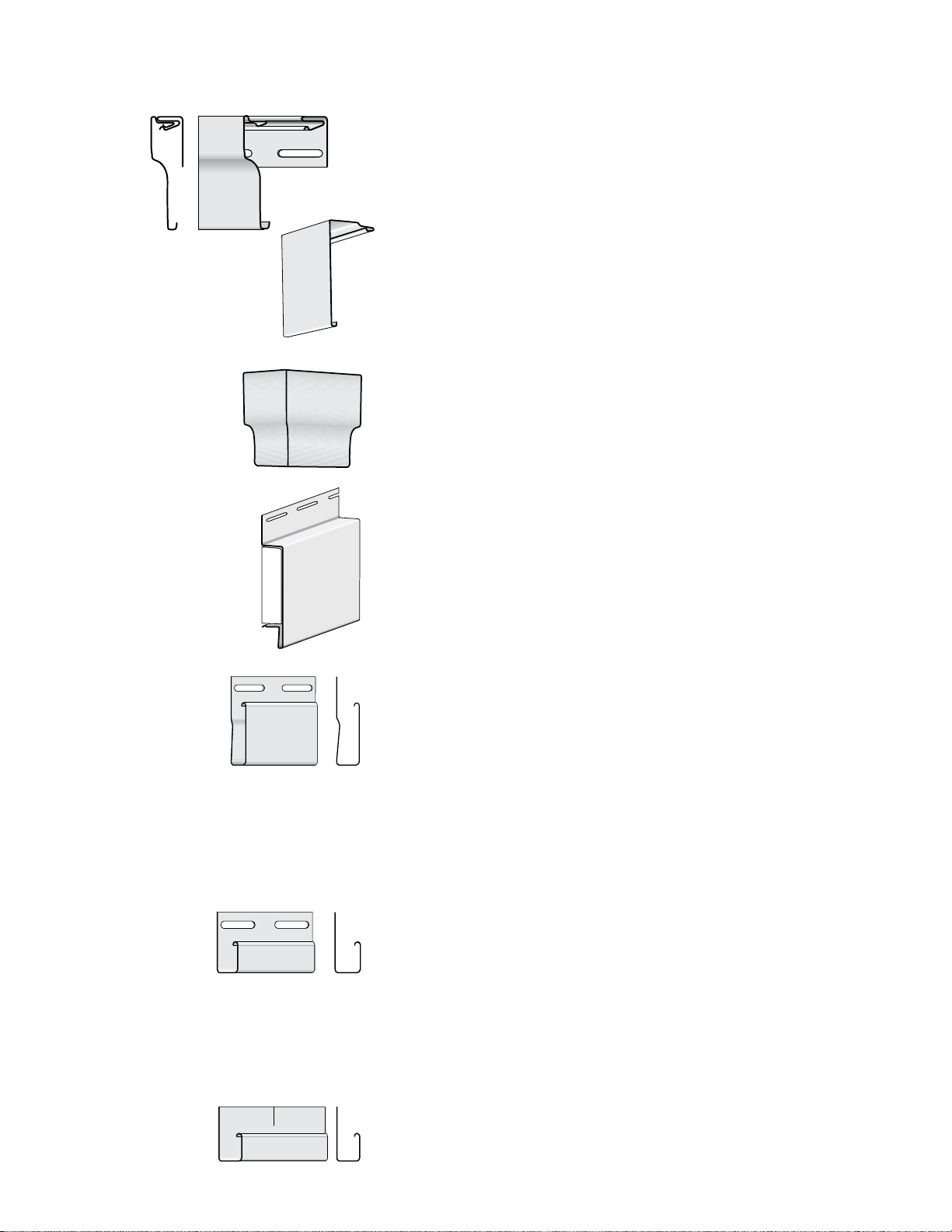

Lineals

3-1/2" Snap-on lineal

Use with J-channel.

3-1/2" Lineal

5" Lineal

3-1/2" Lineal with foam insert

For use with a New Construction Window and Door Starter around

windows and doors as a casing. Two lineals can be used to create

a corner system when installed with a corner starter and corner

insert. The 3/4" channel receives siding panels. Lineals with foam

inserts are available for use with insulated siding.

3-1/2" Double channel lineal

5" Double channel lineal

For use with horizontal or vertical siding transitions. Exposure

matches 3-1/2" window and door surround lineals.

Decorative Trim

Corner block

Used with 3-1/2" lineals to finish corners around windows

and doors.

Rosette

Attaches to Corner Block as a decorative treatment.

Crown molding

16

Used in conjunction with 5" lineals to create a custom molded

window or door header. Can also be used with 3-1/2" lineals and

3/4" pocket J-channels. Crown has a 2-1/4" top exposed edge.

Crown molding cap

Caps the ends of a crown molding with minimal cutting.

NOTE: Shown already cut in half—one piece makes

a left and right-end cap.

Page 18

CertainTeed Vinyl Siding Installation Guide

Decorative Trim (continued)

Cornice molding

Finish board

Held in place by the F-channel or Cornice Molding Receiver, this

accessory hides the installation of the topmost siding panels.

With the help of a nail slot punch, topmost siding panels can be

installed with nails every time. Can also be used under windows.

Cornice molding receiver

Installed under eaves to hold the Cornice Molding or Finish Board

in place. Does not receive soffit panels.

Cornice molding cornerpost cap

Used to cap Cornice Molding over Mitered Cornerposts.

Band board

7-1/4" foam backed, decorative trim used with Cedar Impressions

Rough-Split Shakes, Northwoods Rough Split Shake, and

CedarBoards.

2-1/2" Window and door casing

A 2-1/2" wide-face J-channel that accentuates windows and

doors. Designed to accommodate new construction window

flanges and fit snugly against window and door frames.

This accessory is also ideal for gable trim applications.

J-Channels

J-Channel

3/8" J-channel

1/2" J-channel

3/4" J-channel

1" J-channel

1-1/4" J-channel

Universal siding and soffit receiving channel for use around

utility openings, under eaves, etc.

3/4" Flexible J-Channel

Specialized 3/4" siding receiving trim; particularly useful

around curved windows and ventilation treatments.

17

Page 19

CertainTeed Vinyl Siding Installation Guide

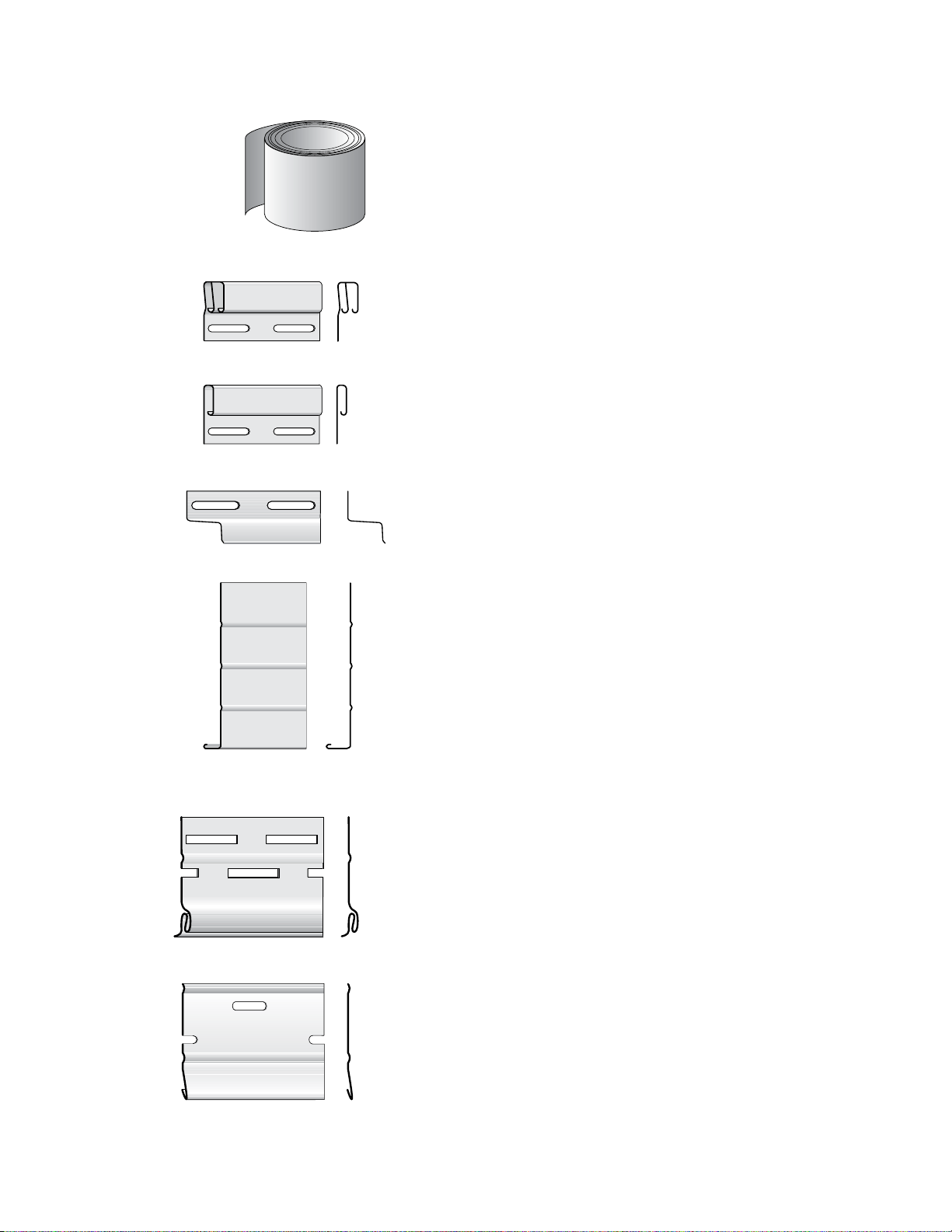

Functional Trim

Aluminum trim coil

24"-wide PVC-coated aluminum.

Dual undersill trim

Secures trimmed siding panels under windows and eaves

regardless of the profile or where in the panel face the panel

has been trimmed.

Undersill trim

Cedar Impressions undersill trim

Helps secure trimmed siding panels under windows and eaves.

Drip cap

Acts as a flash over windows and doors.

Vinyl fascia

Installed with F-channel and undersill trim to provide a virtually

maintenance-free fascia board.

Starter Strips

2-1/4" Vinyl starter strip

Secures the first course of siding to the home.

For use with all sidings except Monogram® 46, Monogram® 46L,

Monogram® 46XL, CedarBoards, CedarBoards XL, and

Cedar Impressions®.

18

2-1/2" Metal starter strip

For use with all sidings except CedarBoards and

Cedar Impressions.

Page 20

CertainTeed Vinyl Siding Installation Guide

Starter Strips (continued)

5" Metal starter strip

Designed to be used on remodeling jobs to help level the first

course and span areas that cannot be nailed. For use with all

sidings except CedarBoards and Cedar Impressions.

4" Metal shingle starter strip

4" metal starter to be used with Cedar Impressions.

Starter strip for Insulated Siding

Vinyl starter strip that accommodates 1-1/4" thickness

of insulated siding.

New construction window and door starter

Butts up against protruding window and door jambs and

overhangs for installation of 3-1/2" and 5" lineals.

Remodeling window and door starter

Holds 3-1/2" and 5" lineals in place around window and door

openings. Used in re-siding applications where existing casings

have not been removed.

Corner starter strip

Secures 3-1/2" and 5" lineals and quarter round insert

to create a 4-piece corner.

19

Page 21

CertainTeed Vinyl Siding Installation Guide

Soffit Trim

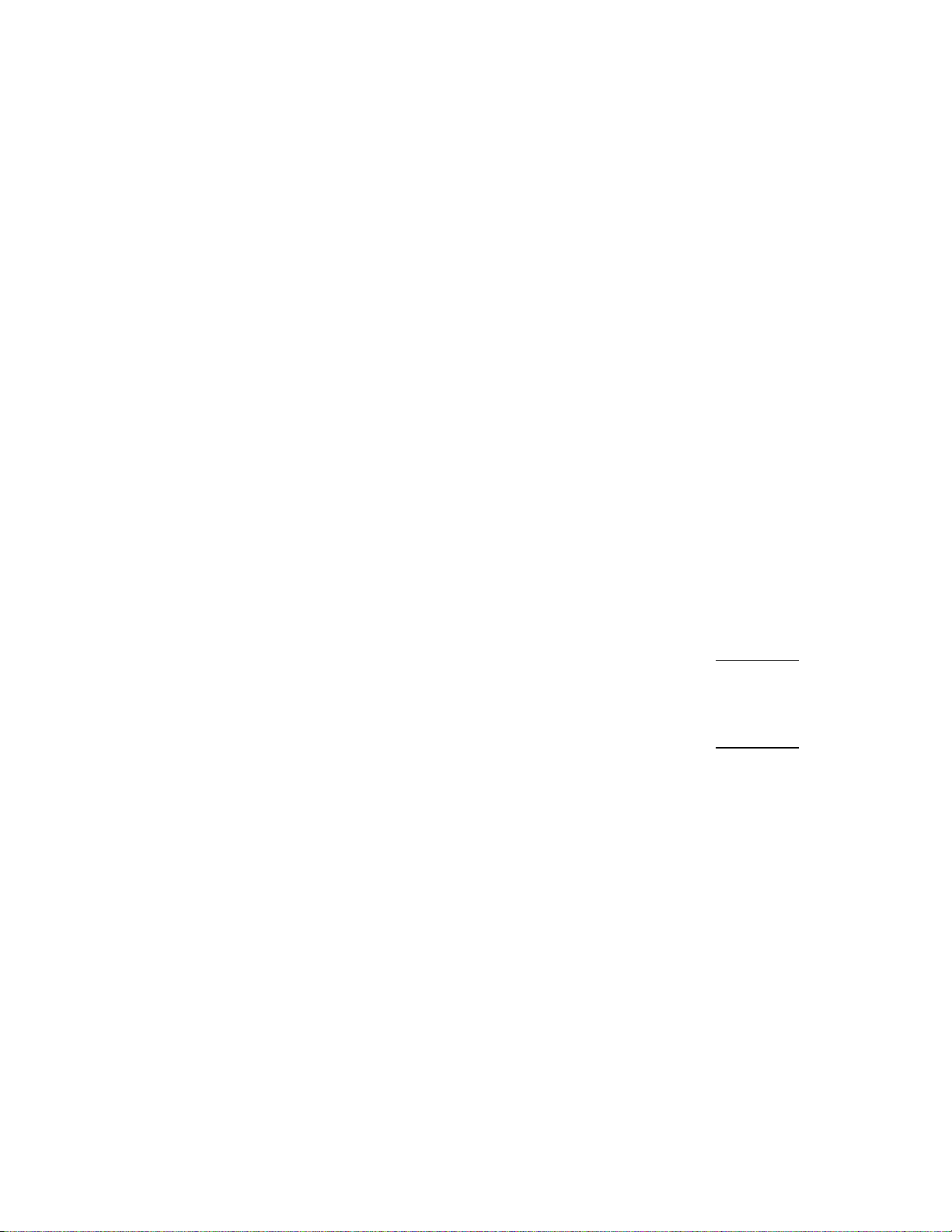

Soffit cove trim

A decorative soffit receiver featuring a 9/16" receiving pocket.

This profile can also be used as an inside cornerpost. Will not

work for all profiles.

5/8" and 3/4" F-Channel

Receives soffit panels.

Deluxe F-Channel

Receives soffit panels and cornice molding or finish board.

3/8" H-Bar

1/2" H-Bar

3/4" H-Bar

Joins soffit panels. Particularly useful on porch ceilings and

hip roof applications.

20

Page 22

CertainTeed Vinyl Siding Installation Guide

Equipment and Tools

Fasteners

Use only corrosion-resistant nails (aluminum, stainless or

galvanized roofing.) Nails should have a minimum head diameter of

5/16". CertainTeed recommends the use of stainless steel nails or

other corrosion-resistant fasteners, when installing siding in coastal

areas. Be sure to check with your local code official or governing

body for the building requirements in your area. Staples should be

a minimum of 16 gauge.

If screws are used, use non-corrosive, self-tapping, pan head or

washer head screws or oval head with countersunk washer screws

with at least 5/16" diameter head, 1/8" (3mm) diameter shaft, and

at least 1-1/8" (29mm) long.

To determine the length of nail required, measure the thickness of

the sheathing material. Then add at least 3/4" to allow the nail to

penetrate the solid wood substrate (studs or existing wood siding).

For more secure fastening, add 1" to sheathing thickness. The

minimum nail size should be 1-1/2".

Example: If you’re applying siding over 1/2" sheathing, use a nail

at least 1-1/2" long (1/2" sheathing + 3/4" stud penetration +

nailing hem thickness + minimum 1/16" between nailing hem

and fastener head).

To determine the quantity of nails required, complete the following:

Total square feet of siding required:

(If using aluminum nails) x .005

(If using galvanized roofing nails) x .01

Pounds of nails required: =

For nailing instructions, see page 33 to 34.

Tools required

Hammer Tin snips Tape measure Square

Chalk line Level Utility knife Shears

Power circular saw with sharp, fine-tooth plywood blade mounted

in reverse direction. (Irwin® Tools Vinyl siding blade is not

reversed—tooth design is symmetric 60º.)

21

Page 23

CertainTeed Vinyl Siding Installation Guide

Ladders and Scaffolds

NOTE: If you will be using an extension ladder during

installation, be sure to cushion the upper side rails to help

prevent damage to installed siding.

Cutting table

Portable brake

Essential for bending aluminum trim coil to fit around fascia boards,

window sills, window and door casings, etc.

Please refer to the brake manufacturer’s instructions for metal

bending techniques.

Transporting and Storing Vinyl Siding

and Polymer Shakes

CertainTeed’s standard shipment method incorporates palletizing

and stretch wrapping all products.

• The pallet is a double-faced, reversible, Grade M, SPEQ®certified pallet constructed of quality materials that meet

NWPCA Uniform Voluntary Standards (Sec. 5.1, Table 1).

• Customer racking should be at least 46" deep x 157" long

to accommodate CertainTeed pallets.

• Do not store pallets by more than three units high.

• Vinyl and polymer siding should be stored indoors and away

from direct sources of heat and sunlight. Storing products

outside may result in damage.

• Cedar Impressions polymer shakes must be stored vertically.

If you are transporting vinyl siding to a job site, make certain to

keep cartons flat and supported along their entire length.

At the job site, take the following precautions when storing panels:

• Store on a flat surface and support the entire length of

the carton.

• Keep cartons dry.

• Store away from areas where falling objects or other

construction activity may cause damage.

22

• Do not store in any location where temperatures may exceed

130° F (e.g., on black top pavement during unusually hot

weather, under dark tarps or plastic wraps without air

circulation, or in unventilated storage trailers).

Page 24

CertainTeed Vinyl Siding Installation Guide

Cut off and

discard

Cut off and

discard

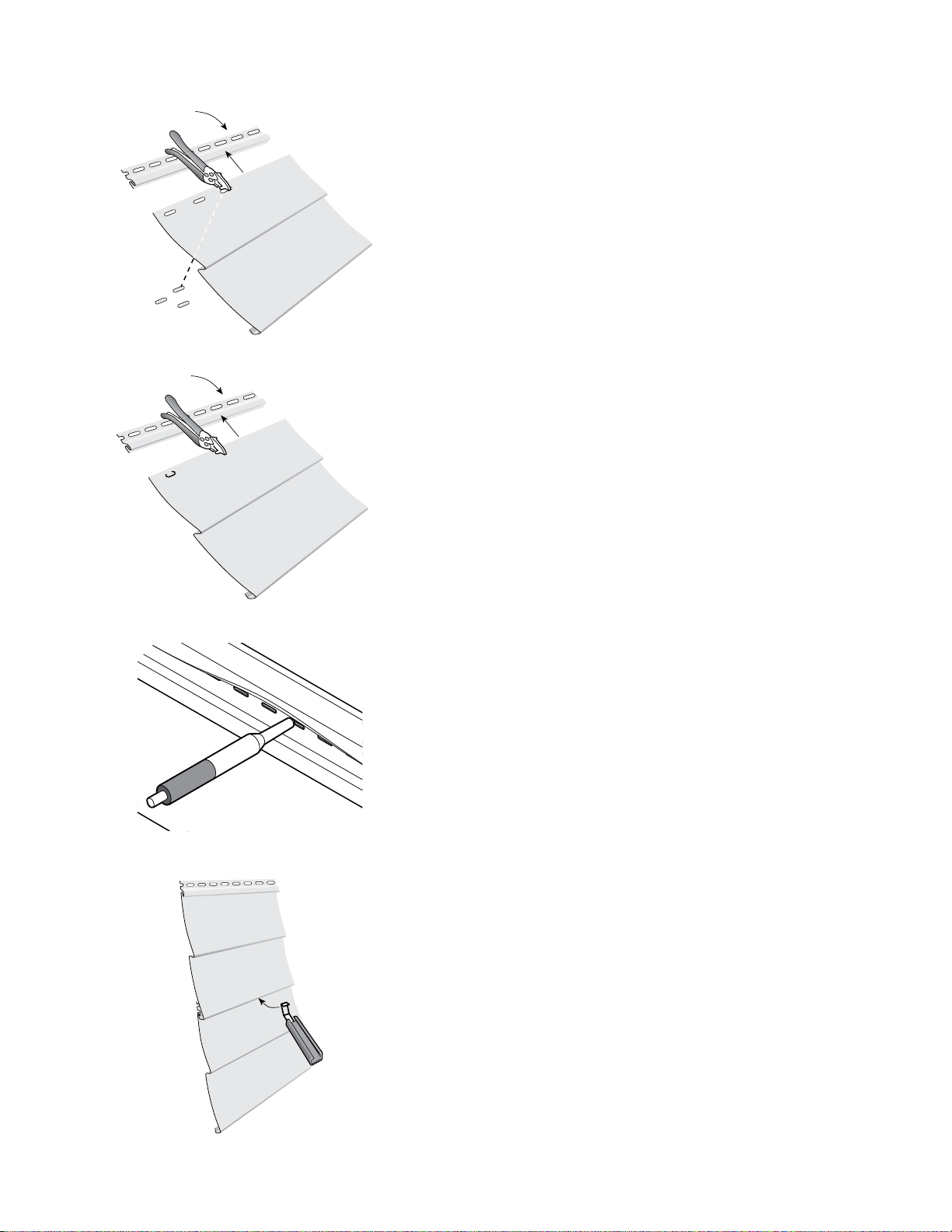

Special Tools

Nail slot punch (CertainTeed Item # 57997)

Punches elongated holes to allow nailing the cut edge of a panel.

Also used to enlarge an existing hole to allow proper nailing.

Snaplock punch (CertainTeed Item # 57995 or 57996)

Punches tabs in the cut edge of a panel used as a finishing

course at the top of a wall or underneath a window. The tabs

lock into undersill trim. For best results, we recommend using

item 57995 Snaplock Punch, which is designed specifically

for vinyl applications.

Trim nail punch

Punches trim nail holes into soffit, fascia, and other finishing trim

without denting or marring the material. Available from Malco

Products, Granger, ProSidingTools.com

Zip tool (CertainTeed Item # 57998 or 57999)

Locks and unlocks panels.

23

Page 25

CertainTeed Vinyl Siding Installation Guide

Section 5 — Estimating

Siding

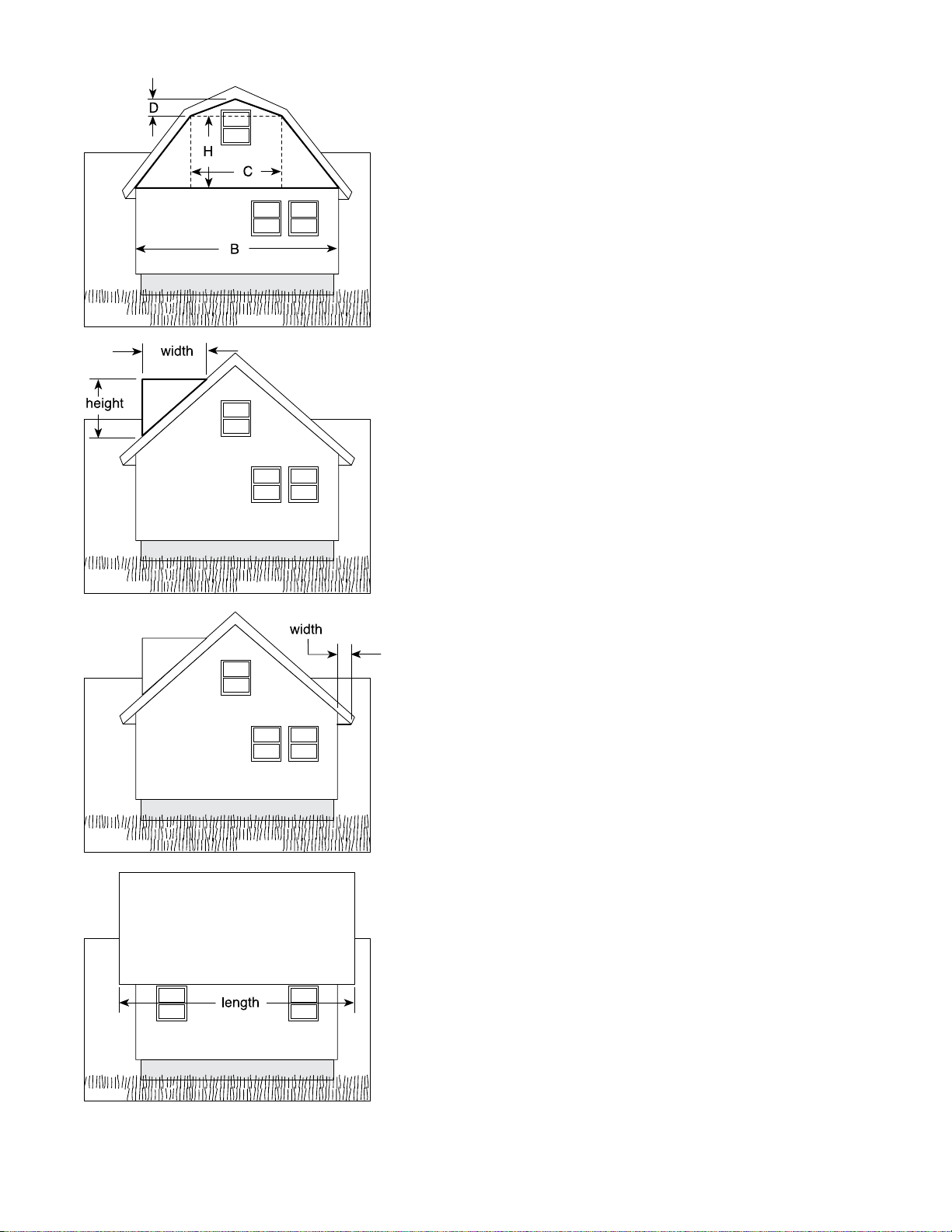

Use the illustrations and formulas below and enter totals on

the estimating form on page 27. These formulas apply for both

horizontal and vertical installations.

NOTE: When estimating for a large project, you may want to

add a waste allowance of 10 percent to the totals for siding,

soffit and accessories.

Rectangular wall surfaces

Measure height (excluding gables). Measure width

(including doors and windows).

_____________ x _____________ = _____________

(height) (width) (surface area)

Repeat for remaining walls.

Triangular gable end surfaces

Measure height at center (add 1' to allow for waste).

Measure width and divide by half.

_____________ x _____________ = _____________

(height) (1/2 width) (surface area)

Repeat for remaining gables.

NOTE: Lower pitch roofs will produce more waste

than higher pitch roofs.

24

Page 26

CertainTeed Vinyl Siding Installation Guide

Upper wall of gambrel house

Divide the upper wall of a gambrel house as shown in the

illustration. Then use the following formulas:

1/2 (B + C) x H = ____________

1/2 C x D = ____________

Add these figures to get total area: ____________

Repeat for remaining gambrel surfaces.

Dormer sides

Measure height of dormer (add 1' to allow for waste).

Use the following formula:

_____________ x _____________ = ____________________

(1/2 height) (1/2 width) (surface area, 1 side)

____________________ x 2 = _________________________

(surface area, 1 side) (total dormer surface area)

Repeat for all dormers.

Soffit

Measure width of eave to be covered. Measure length of eave.

_____________ x _____________ = _____________

(width) (length) (surface area)

Repeat for remaining eaves.

Porch Ceiling

Measure length of porch area to be covered. Measure width

of porch.

_____________ x _____________ = _____________

(length) (width) (surface area)

25

Page 27

CertainTeed Vinyl Siding Installation Guide

Measuring

Before ordering accessories, you also have to determine the width

of the J-channel into which you will fit the vinyl siding. To do this,

you must first determine which of two methods you will use to

apply sheathings or underlayments. This is covered in more detail

under “Sheathings.”

NOTE: Refer to product catalog for product accessory

recommendations and availability.

Starter strip: Measure along base of building.

J-channel: For siding installations, measure around doors

and windows, under eaves, at rake edges of gables where

dormer meets roofline, and anywhere else required to provide

a finished appearance.

For soffit, measure along wall under eave and along fascia board.

For porch ceilings, measure along perimeter of the porch area.

F-channel: For soffit, measure along wall under eve.

For porch ceilings, measure along perimeter

of the porch area.

3-1/2" and 5" Lineals: For casing, measure along perimeter of

doors and windows. For gables, measure at rake edges of gables

where dormer meets roof line.

Undersill trim: Measure above and below windows and above

doors and top course of siding below soffit.

Soffit H-bar: Measure diagonals at all eave corners.

Outside cornerpost: Measure length of outside corners.

Inside cornerpost: Measure length of inside corners.

NOTE: If you plan to use J-channel instead of inside cornerposts, remember to double this measurement and add the

total to your entry for J-channel.

Dual undersill trim: Measure along top of wall where siding

will meet eaves.

26

Page 28

Estimating Form

CertainTeed Vinyl Siding Installation Guide

Siding

Soffit

Porch ceiling

Accessories

Receiving channel

Walls sq feet

Gable ends sq feet

Dormer sides sq feet

Upper gambrel walls sq feet

Total wall surface area sq feet (A)

Large areas not to be covered:

(garage doors/sliding glass doors) sq feet

x .50

Uncovered area sq feet (B)

Subtract B from A for

Total net surface area sq feet

sq feet

sq feet

Starter strip lineal feet

Window & door lineal starter lineal feet

Four piece corner starter lineal feet

Utility trim lineal feet

J-channel lineal feet

2-1/2" window & door casing lineal feet

Flexible J-channel lineal feet

F-channel: 5/8" or 3/4" lineal feet

Deluxe F-channel lineal feet

3-1/2" or 5" lineals lineal feet

New construction window starter lineal feet

Dual undersill trim lineal feet

Outside corner

Inside corners

Nails

Outside cornerpost lineal feet

Fluted SuperCorner lineal feet

Traditional SuperCorner lineal feet

Beaded SuperCorner lineal feet

Cedar Impressions/

CedarBoards cornerpost lineal feet

Four piece corner system lineal feet

Inside cornerpost lineal feet

J-channel lineal feet

Soffit cove trim lineal feet

H-Bar lineal feet

Corner Blocks pairs

Rosettes pairs

Cornice molding receiver lineal feet

Cornice molding lineal feet

Width of accessory recess opening: (circle one) 1/2" 3/4" 1-1/4"

Pounds required (1-1/2" minimum)

27

Page 29

CertainTeed Vinyl Siding Installation Guide

SECTION 6 — Preparing for Horizontal Siding

Preparing Wall Surfaces

Sheathings

In new construction, apply sheathing first, then nail accessories

over it.

The application method you choose determines the width of the

recess opening required. For example, use:

• 1/2" opening when applying accessories over sheathing and

installing siding with a panel projection of 1/2" or less.

• 3/4" opening when applying accessories over sheathing and

installing siding with a panel projection of 3/4" or less.

• 1-1/4" opening when applying accessories first and using

sheathing that’s less than 3/4" thick for sidings with a panel

projection of 1/2" or less. For sidings with a panel projection of

5/8" or 3/4", use a sheathing that is 1/2" thick or less.

New construction

Make sure all studs are straight and true. Correct any

bowed studs.

NOTE: Vinyl siding must be applied over a rigid sheathing that

provides a smooth, flat surface or an underlayment (such as

wood, wood composition, rigid foam or fiber sheathing) that is

no more than 1" thick. Vinyl siding cannot be applied directly

to studs. See the instructions on page 29 for installation over

continuous insulation systems thicker than 1".

If you’re planning to use a conventional house wrap or building

felt, apply according to the manufacturer’s recommendations.

In all cases, however, install the products so they are secured

firmly to the substrate so that they provide a smooth, even

surface for the final siding installation. Make sure sheathing is

fastened securely to studs.

Vinyl siding is an exterior cladding; it is not a complete weather

resistant barrier. Before applying siding, make certain the substrate

is watertight. In order to be protected from precipitation, the

substrate may need to be properly flashed around areas such as

windows, doors, other openings and corners so as to shed water

to the exterior. See page 45 for proper flashing around windows.

The siding alone is not meant to be a watertight barrier.

28

Vinyl siding cannot be installed on a radius wall.

Page 30

CertainTeed Vinyl Siding Installation Guide

Continuous foam insulation systems (SIPs)

Continuous foam insulation systems (e.g. rigid insulation,

structural insulation products) thicker than 1" create a condition

where CertainTeed vinyl siding and polymer shakes cannot be

properly attached to the existing framing members, steel studs,

or structural sheathing.

The easiest way to meet the fastening requirements for

CertainTeed siding is to install 3/4" structural sheathing (such as

OSB or plywood) over the continuous foam insulation. However,

the wall assembly must be designed in such a way that the

structural fastening surface that is re-established on the exterior

of the insulating products is sufficient to meet the requirements

of ICC-ES Evaluation Report ESR-1066 for vinyl siding or ICC-ES

Evaluation Report ESR-3085 for polymer shakes.

CertainTeed does not provide instructions for wall design or

assembly that specifically relates to the fastening requirements

for re-establishing a structural fastening surface for CertainTeed

vinyl and polymer siding. However, FastenMaster® provides

two documents to assist in successfully re-establishing a

structural fastening system on the exterior of a continuous foam

insulation system:

32"

• Technical Evaluation Report (TER No. 1009-01): Use of

FastenMaster HeadLok™ Fasteners to Attach Cladding and/or

Furring to Wood Framing through Foam Sheathing

• Technical Bulletin: Attaching Exterior Wall Covering Assemblies

with Foam Sheathing to Steel Wall Framing

The Fasten Master reports must be used in combination with

ICC-ES Evaluation Report ESR-1066 for vinyl siding or ICC-ES

Evaluation Report ESR-3085 for polymer shakes to determine

attachment requirements. In addition, all the installation methods

included in this manual must be met.

Fastening CertaWrap™ Weather

8"

16"

32"

8"

Resistant Barrier

To secure the Weather-Resistant Barrier, use the

appropriate recommended fasteners and fastening

schedule for your application.

Wood-based sheathing

When attaching CertaWrap Weather-Resistant Barrier on woodbase sheathing, such as 7/16" OSB or 15/32" plywood, apply

plastic-capped staples or plastic-capped nails every 32" vertically

and horizontally.

Open-stud construction or non-structural sheathing

When attaching CertaWrap Weather-Resistant Barrier on open

studs or non-structural sheathing, apply plastic-capped staples or

plastic-capped nails long enough to penetrate the stud a minimum

of 5/8" every 32" vertically and horizontally.

29

Page 31

CertainTeed Vinyl Siding Installation Guide

Steel framing

12"

(min.)

flap

When installing CertaWrap Weather-Resistant Barrier over steel

framing, use screws with minimum 1" diameter washers every

32" vertically and horizontally.

STUDfinder™ installation instructions

1. The STUDfinder Installation System combines precisely

engineered fastening locations with graphics that help ensure

quick, accurate, and secure installation. Install CertaWrap

horizontally to exterior walls prior to the application of exterior

cladding. Vertically position the CertaWrap roll at the corner of

the structure with the printed side out.

2. Locate the first stud and verify that it is plumb. Align the first

stud with the nearest vertical STUDfinder line, allowing for a

minimum 12" flap to wrap the corner for attachment to the

adjoining wall. Extend the bottom edge of the CertaWrap

2"–4" over the sill plate. Apply plastic-capped staples or

plastic-capped nails every 32" vertically along the first stud

to secure the Weather-Resistant Barrier into position.

3. Unroll the CertaWrap along the exterior wall. Wrap CertaWrap

completely around the building, covering window and door

openings, plates, sills and corners.

4. To secure the Weather-Resistant Barrier, use the fasteners

and fastening schedule that is appropriate for your application.

The STUDfinder marks will quickly guide you to your desired

fastening location without the need for chalk lines. Each letter

is spaced 1.6" apart, and each series spans 16". To achieve

32" spacing between fasteners, first locate the letter that the

first row of fasteners covers. The second repeat of that letter

is at 32".

5. Pull the CertaWrap snug and fasten it to the studs or sheathing

and to the top and bottom plates.

6. When starting a new roll in the middle of a wall, overlap vertical

and horizontal laps in the field a minimum of 6". When starting

a new roll at an inside or outside corner, overlap vertical and

horizontal seams a minimum of 12". All vertical and horizontal

seams are to be installed in a weatherboard fashion. Lap

CertaWrap over all existing flashings (e.g. z-flashing, roof-towall flashing, drip cap).

30

7. Flash or tape all vertical and horizontal seams and penetrations.

Page 32

CertainTeed Vinyl Siding Installation Guide

Drop-in foam backer boards

Some drop-in foam backers can restrict the movement of vinyl

siding. Therefore, CertainTeed vinyl siding may not be applied

over any drop-in foam backer other than a contoured drop-in

foam backer designed specifically for each profile.

IMPORTANT: CertainTeed will not accept any responsibility

or liability in the event the drop-in foam backer restricts the

movement of the vinyl. The use, fit, and performance of the

siding backer board is the responsibility of the installer and the

backer board manufacturer.

NOTE: Contoured drop-in foam backer boards are not a

substitute for rigid foam sheathing.

Home improvement projects

You can prepare your current siding surface to receive vinyl siding

in one of three ways:

Strip off old siding and level the wall. If felt paper covers the wall,

you have two alternatives: either strip it off completely or staple

or nail it to create a smooth surface. If there is no solid sheathing

under the old siding, you must apply it as described in the

instructions for New Construction.

Apply rigid sheathing to existing siding to provide a smooth

surface. Nail securely to old siding. Nail evenly to bridge low spots.

NOTE: Failure to establish a smooth, solid surface constitutes

misapplication under the terms of the warranty.

Apply vertical furring to old siding to straighten noticeable surface

unevenness. (See “Tips for applying wood furring.”) Then apply

rigid sheathing, following the instructions presented under New

Construction.

NOTE: For information on installing siding over asbestos and

for historic applications, see page 142.

Tips for applying wood furring

If you are working on an older home with noticeably uneven walls,

you must correct this condition before proceeding. If not corrected

during preparation, this uneven surface will produce a wavy

appearance in siding applied over it.

For best results, space horizontal furring strips 12" on center.

Do not exceed 16". To correct an uneven wall, use furring strips

(and wood shims if necessary) to eliminate low spots.

NOTE: You must apply rigid sheathing over furring.

31

Page 33

CertainTeed Vinyl Siding Installation Guide

undersill trim

sill

J-channel

siding

siding

J-channel

sill

When covering over masonry or bricks, it’s better to use 1" x 3"

furring. For best thermal performance, install a minimum

of 1/4" foam over furring strips.

Furring strip/foam shim

Furring and/or foam is also used below eaves and windowsills to

maintain correct slope angles when siding panels must be cut to

a narrower dimension to fit.

Similarly, when panels are cut to fit over doors or windows, furring

and/or foam is used to establish the correct slope angle.

furring strip/foam shim

foam

sheathing

16"

stucco

1" x 3" furring

masonry

fastener for

attaching

furring

Applying over stucco or masonry

When applying vinyl siding over stucco or masonry, you first

have to be sure you’re working on an even surface. To create

that surface, you may have to knock down high spots where

furring strips will be applied. Use caution when chipping off these

spots—you don’t want to crack or damage the remaining stucco

or masonry.

Apply 1" x 3" furring over the stucco or masonry using poweractuated fasteners or other appropriate masonry fasteners.

Stucco will not hold fasteners tightly, so be sure nails or screws

are anchored securely to studs. Furring strips should be spaced

16" on center.

Applying rigid foam sheathing to furring

Install sheathing according to manufacturer’s instructions.

Do not apply siding directly to furring strips. For best thermal

performance, install a minimum of 1/4" foam over furring strips.

32

Page 34

sheathing

or substrate

center nail in slots

CertainTeed Vinyl Siding Installation Guide

Applying over steel studs

Pre-planning is the key when installing vinyl siding and accessories

over steel studs. Pre-planning includes the selection of siding style

and the types of accessories. Pre-planning proper stud placement

will eliminate many of the problems that could surface once the

job has been started, such as at corners, windows, and

transitional areas.

Follow the same guidelines as in a wood surface—except for the

type of fasteners used. Wall sheathing must be installed over the

studs. This will provide a straighter, smoother and more rigid wall

surface and help prevent studs from twisting. Siding must be

secured into metal studs if the substrate is not a nailable surface

such as exterior dry wall, gypsum board, etc.

The application of vinyl siding, soffits and accessories over steel

stud framing rather than typical wood framing is straightforward.

The main difference is the use of screws to hang components

that make up a completed siding job.

Use noncorrosive, self-tapping screws with at least 5/16" diameter

head, 1/8" diameter shaft, and at least 1-1/8" long.

center nail in slots

upper edge

of topmost

nailing slot

Although the fastening method for steel studs differs from wood

construction, all other procedures still apply, including fastening in

the center of the nail slot and not overtightening the fasteners.

Nailing, Stapling and Other

Fastening Methods

If you want to ensure a quality vinyl siding installation, focus your

attention on nailing techniques. Unfortunately, a lot of installers

don’t. They feel nailing is a routine task, something everyone

knows how to do. But that’s not the case. At CertainTeed, we

analyzed reported installation problems, and we found that

more than half of them can be traced back to improper

nailing. So if you want to save yourself lost time and frustration,

carefully observe the following guidelines when installing

accessories, siding panels, soffit, or porch ceilings.

Lock the panel and begin nailing at the center of the panel,

working toward the ends. This helps maintain a level line.

With horizontal accessories and panels, position the nails in the

center of the elongated nailing slots to allow for expansion and

contraction. Never nail through the panel surface.

Note: See pages 35-36 for general

fastening guidelines

With vertical accessories and panels, position the first nail at the

upper edge of the topmost nailing slot. This allows a panel to

hang from the nail. Position the remaining nails in the center

of the nailing slots. Allow for 1/3 of the total expansion at the top

and 2/3 of the total expansion at the bottom.

33

Page 35

CertainTeed Vinyl Siding Installation Guide

Too Tight

Up to 1/8"

Too Loose

Center staples in slots

Correct

NOTE: Do not nail too tightly. To permit expansion and

contraction, panels should hang freely from nails. This allows

the panels to move as the temperature changes. Drive the

nails until there is between 1/8" to 1/16" of space between

the nail head and the nailing flange.

Drive the nails straight in. Do not angle nails.

Per the ASTM specification for vinyl siding installation (D4756),

proper nail penetration is at least 3/4". In most cases, that

requires anchoring to studs.

Fastener spacing

Fasteners are typically spaced a maximum of 16" apart. In new

construction, fasten to studs on 16" centers. Do not skip studs.

Some vinyl siding may be used in 24" on center construction in

areas without special wind-load requirements (fasteners spaced a

maximum of 24" apart). Check with your local building code official

for special requirements and ICC-ES Evaluation Report ESR-1066

for specific wind-load requirements.

Other fastening techniques:

Manual nailing is the most common way of fastening vinyl

siding to a wall. That’s because it offers greater control, making

it easier to learn how to fasten panels securely, but not tightly.

You also can use power screwdrivers or pneumatic staplers/

nailers to attach vinyl siding to a wall, but you must take the time

to develop the proper skills. If you choose to use one of these

alternate techniques, follow all the recommendations above for nail

positioning and spacing and the recommendations for substrate

preparation on pages 28 to 32 for horizontal applications and

page 80 for vertical, including Board & Batten. In addition, be sure

to observe the following guidelines:

34

Power screwdrivers

Use noncorrosive, self-tapping truss head screws. Screws must

have at least 5/16" diameter head and 1/8" diameter shaft. Screws

must be at least 1-1/8" long. If underlayment is less than 3/4"

thick and is not considered a nailable surface (for example, foam

or exterior grade gypsum), be sure screws are long enough to

penetrate at least 3/4" into wood studs or substrate, 1/8" through

a steel stud. Be sure screws are centered in the nail slot. Leave

1/16" to 1/8" space between the screw head and the panel

nailing flange.

Pneumatic staplers/nailers

Use corrosion-resistant fasteners only. Fasteners must be centered

in the nail slot, no more than 16" on center.

NOTE: Some power staplers/nailers use an attachment that

helps position the fastener in the nail slot. If your unit does

not have that feature, you must carefully position the fastener

by sight.

Page 36

CertainTeed Vinyl Siding Installation Guide

Fasteners must penetrate a nailable surface at least 3/4".

Be sure to leave up to 1/16" between the fastener and the

panel nailing flange. If you’re using a power stapler, drive the

staple perpendicular to the nailing slot with one leg of the staple

centered in the slot and the other leg above the panel.

NOTE: Check with local building codes to verify fastener

requirements for your area.

Nail Spacing and Product Expansion

and Contraction

It’s normal for vinyl building products to expand and contract with

temperature changes. To ensure a successful siding installation,

you must allow for this movement during application.

See the following charts for more information.

1/4" to 3/8"

Product

Category

Horizontal Lap

Siding (12' 6")

Horizontal Lap

Siding (16')

Horizontal Lap

Siding (20')

Horizontal Lap

Siding (25')

*Depends on profile, fastener and geographic area.

Max. Nail

Spacing Gaps to Accessories Overlap

16"–24"* 1/4" 3/8" 1-1/4" 1"

16"–24"* 3/8" 1/2" 1-1/2" 1-1/4"

16"–24"* 3/8" 1/2" 1-1/2" 1-1/4"

16"–24"* 3/8" 1/2" 1-1/2" 1-1/4"

40°F

or Greater

Less

than

40° F

40° F

or Greater

Less

than

40° F

35

Page 37

CertainTeed Vinyl Siding Installation Guide

1/4" to 3/16"

Product

Category

Product

Category

top most

nail at the

top of the

top most

full nail slot

Max. Nail

Spacing Gaps to Accessories

Vertical Siding 12"

center

remaining

nails in

the slot

3/8" to 1/2"

Hang off of top nail slot (see page 80 for more details).

Max. Nail

Spacing Gaps to Accessories Overlap

40°F

or Greater

Less

than

40° F

40°F

or Greater

40°F

or Greater

3/16" top

3/8" bottom

Less

than

40° F

Less

than

40° F

1/4" top

1/2" bottom

Notes Specific

to Product

Fasten

Cedar Impressions

at Delta

1/4" 3/8"

Indicators

Northwoods 16" 1/4" 3/8"

CedarBoards 16" 1/4" 3/8"

CedarBoards XL 16" 3/8" 1/2"

Use Temp.

Marks/

Gauge

Use Temp.

Marks

1-1/2"

Butt Foam

1-1/4" to

1-3/4"

Use Temp.

Marks/

Gauge

Use Temp.

Marks

1-1/2"

Butt

Foam

1-1/2"

Butt

Foam

All panels must

be center pinned

(see page 95 for

more details)

All panels must

be center pinned

(see page 125 for

more details)

36

Page 38

sheathing

housewrap

CertainTeed Vinyl Siding Installation Guide

Installing Accessories

Snapping a chalk line

To ensure proper installation, you must establish a straight

reference line to guide the positioning of the starter strip and the

first course of siding.

starter

strip

metal

flashing

foundation

If the house is reasonably level, find the lowest point of the old

siding (or sheathing if working on new construction). Partially drive

a nail at one corner, starter height minus 1/4" above the lowest

corner. Attach chalk line. Go to other corner and pull the chalk line

taut. Stretch the chalk line from this nail to the opposite corner

of the house. Make sure the line is level, using a line level or 4'

(minimum) level. Snap chalk line and repeat the procedure around

the entire house.

A water level, a long clear plastic tube 90% filled with water, is

useful in marking level points around the house and on opposite

sides of openings such as doors. Water will always seek a level

state, ensuring the markings will always be at the same level.

NOTE: If after establishing a chalk line you find that your

starter strip will be positioned below an easily nailed surface,

you may have to apply a nailable base.

If you have added sheathing, you may want to bend trim coil to

act as flashing and help prevent entry of insects. Bend the coil in

a “Z” shape so the top edge of the coil is on the chalk line and the

bottom edge extends down over the foundation. (See illustration.)

NOTE: The general guidelines for cutting and nailing vinyl

panels and for allowing for expansion and contraction also

apply to vinyl accessory items.

6-1/2"

for wide

corners

& lineals

4" for

standard

corners

8" to 10"

Installing the starter strip

Position the starter strip with the top edge on the chalk line and

the ends 6-1/2" away from the outside and inside corners

(when using lineal systems or wide corners), 4" if using standard

one-piece corners. Nail to wall following previously mentioned

nailing instructions. When hollows occur in the wall surface,

shim out the starter strip to avoid a wavy appearance in the

finished siding job. Nail every 8" to 10".

As you add starter strip sections, be sure to leave 1/4" space

between them for expansion.

Sometimes—especially at sills above garage doors, porches or

brick surfaces where the siding has been cut lengthwise —you

may find it easier to use a combination of utility trim and J-channel

as a starter strip to secure a panel.

If you are concerned that the house is not level, measure down

from the soffit at one corner of the house to the top of the

foundation and subtract the width of the starter strip minus 1/4".

Mark the wall, then transfer the measurement to the other corner

of the wall. Snap a chalk line in between the corners at the marks.

37

Page 39

CertainTeed Vinyl Siding Installation Guide

1/4"

3/4"

Top of topmost

nail, center

remaining nails

flashing

nail every 8" to 10"

Outside Cornerposts

Flash the corners of the home by bending a 20"-wide piece of

aluminum trim coil 90° so you have two 10" legs. Cover the entire

length of the corner, lapping the upper pieces over the lower

pieces. (Self-adhering flashing may be substituted for trim coil.

Follow the manufacturer’s installation instructions and observe local

building code requirements.)

For cornerposts 12' long or less

Position the outside cornerpost so that the top of the post is

1/4" from the underside of the eave. Extend the bottom of the

cornerpost 3/4" below the starter strip.

Before nailing, make sure the post is straight and true. Hang the

cornerpost by first positioning a nail at the top of the topmost

nail slot. Position all remaining nails in the center of nail slots a

maximum of every 8" to 10". Leave 1/8" to 1/16" between the nail

head and the cornerpost to allow the cornerpost to move during

normal expansion and contraction. (DO NOT NAIL TIGHT.) Follow

this nailing pattern on both nail flanges of each post.

NOTE: CedarBoards corners install similar to standard

outside cornerposts.

3/8"

3/4"

Top of two top

nail slots, center

remaining nails

flashing

For cornerposts longer than 12' long

Position the outside cornerpost so that the top of the post is

3/8" from the underside of the eave. Extend the bottom of the

cornerpost 3/4" below the starter strip.

Before nailing, make sure the post is straight and true. Hang the

cornerpost by first positioning a nail at the top of the two top nail

slots slot. Position all remaining nails in the center of nail slots a

maximum of every 8" to 10". Leave 1/8" to 1/16" between the nail

head and the cornerpost to allow the cornerpost to move during

normal expansion and contraction. (DO NOT NAIL TIGHT.) Follow

this nailing pattern on both nail flanges of each post.

NOTE: When installing any hanging cornerpost longer than

12', position the fasteners at the top of the top two nail

slots on each side of the corner.

Transitioning from masonry to stucco

Position the bottom of the cornerpost 3/4" below the starter strip.

If the corner is less than 12', leave 3/8" from masonry/flashing to

allow for expansion. If the corner is greater than 12', leave 5/8"

from masonry/flashing for expansion.

38

Page 40

CertainTeed Vinyl Siding Installation Guide

NOTE: If the transition material allows, the bottom 3/4" of the

channels may be removed from the outside cornerpost so

that the face of the corner may be positioned lower and more

in line with the bottom of the siding. This method creates

a transition with more pleasing aesthetics. The outside

cornerpost face must still maintain 3/8" or 5/8" clearance

from obstructions.

If posts must be spliced for high walls, you have two options:

Option 1

1/4"

1"

1 pc. outside

corner piece

flashing behind

finished corner

assembly

Cut 1" off the nailing flanges and back so just the face of the

outside cornerpost remains. Then lap 3/4" of the upper post

over the lower post, allowing 1/4" gap for expansion. This

method will provide an obvious joint between the two posts,

but will allow water to flow over the joint, reducing the chance

of water infiltration.

When the bottom edge of a cornerpost terminates into a porch,

deck, brick, stone ledge, or roof line, etc., allow 3/8" for every

10' of corner when the ambient temperature is above 40°F;

1/2" for every 10' of corner when the ambient temperature is

40°F or below.

NOTE: It is acceptable to reverse lap outside corners as long

as the corners are properly flashed and water can drain from

the bottom of the cornerpost.

Option 2

Cut a 6" length of cornerpost and trim the nail flange, receiving

channel, and sides until you have just a 90° bend of vinyl. Using

PVC primer and PVC cement, glue the bent piece to the inside

of the upper post and lower post. Butt the two posts together.

Nail the entire assembly as one post with all nails in the lower

post centered in the nail slots.

Also see additional instructions covering installation of four-piece

cornerposts (page 40).

butted splice joint

splice backer (hidden)

cornerpost

splice

backer

PVC adhesive

on backside of

cornerposts

PVC primer

and PVC

cement must

be used

39

Page 41

CertainTeed Vinyl Siding Installation Guide

7/8"

Capping an outside cornerpost

One method of capping an outside cornerpost is to cut a piece

of J-channel twice as long as the width of the corner-post face.

Mark a 90° angle from the center and cut out this area. Then cut

7/8" away from each end, except for the nailing flange. Bend the

J-channel in the center and nail it to the outside of the corner of

the house. Then insert the cornerpost into the J-channel.

Another alternative is to trim the nail flange, receiving channel, and

sides from the bottom 1" of the cornerpost. Notch 1" at the 90°

bend, fold the bottom 1" of the cornerpost face, and fasten these

“flaps” with a pop rivet.

Extra Wide Corner Posts

(Four-Piece Corner System)

Extra-wide cornerposts give you a distinctive, easy-to-install

method of finishing outside corners. Each cornerpost consists

of four parts: corner starter, two lineals, and a quarter-round

snap-in insert.

long leg insert

Lineals are available in two board styles: 5" smooth and

3-1/2" smooth.

The installation procedure is identical for all lineals and inserts.

To install this four-part accessory, follow these steps:

Before you begin, make sure the corners are flashed properly.

Measure the vertical span, and allow 1/4" from the underside of

the eave if the post is 12' or shorter and 3/8" from the underside

if the post is longer than 12'. Extend the cornerpost 3/4" below

the bottom of the starter strip. Cut all four pieces using a power

circular saw.

Hang a starter strip. Position the starter strip, leaving 1/4"

allowance for expansion at the top and 3/8" at the bottom.

Position the first nail at the uppermost edge of top nail slot

(shown). Nail loosely. Working from the top down, position the

remaining nails every 8" to 10", with the nails centered in the slots.

Attach the side lineals. Lock the first lineal into the starter strip.

Nail it to the sheathing, following the procedure described above.

Repeat the process for the other lineal.

Snap in the quarter-round corner insert. Working from the bottom

up, begin by inserting the longer leg of the insert into the nail flange

side of the starter strip first; then snap in the shorter leg. Lightly

press along the length of the insert as you snap it into place.

40

NOTE: For a more secure installation, use a pop rivet to

attach the molding insert to a side lineal. The rivet should be

positioned at the top of the cornerpost.

Page 42

1/4" to 3/8"

hang from top

nail, center

remaining nails

8" to 10"

3/4"

CertainTeed Vinyl Siding Installation Guide

Inside Cornerposts

There are three options for trimming inside corners: Standard

3/4" inside cornerpost, single J-channel, and two J-channels.

To flash the inside corner, bend a 20"-wide piece of aluminum

coil stock 90° so you have two 10" legs. Insert the flashing into

the corner. If you use more than one piece of flashing, overlap

the upper pieces of the flashing over the lower pieces.

To install inside cornerpost, hang the post from the top of the eave.

The bottom should extend 3/4" below the starter strip. Remove

the bottom 3/4" of the nailing flange so it does not show below

the siding. Set the post straight and true. Position the top nail in

the top of the nailing slot. All other nails should be in the center

of the nail slots

solid nailable

substrate

(scrap aluminum coil, for example)

corner flashing

inside cornerpost splice

standard 3/4"

inside corner post

two J-channels

single J-channel

If you have to splice the inside cornerpost, cut 1" off all but the

outer face of the lower post. Lap 3/4" of the upper post over the

lower post, leaving 1/4" for expansion.

If you are using two pieces of J-channel instead of inside

cornerpost, flash the corner with a 10" x 10" “L” corner fabricated

from aluminum coil stock or any weather-resistant barrier. Hang

the J-channel from the top of the eave. The bottom should extend

3/4” below the starter strip. Remove the bottom 3/4" of the nailing

flange so that it will not show below the siding. Use the same

positioning and nailing guidelines as inside cornerpost.

To create a narrower corner, you can also use a single length

of J-channel and flashing. First, install the siding on one wall.

Then place the J-channel lightly against the siding and nail it to

the substrate on the adjacent wall. Follow the same positioning

and nailing guidelines as inside cornerposts.

41

Page 43

CertainTeed Vinyl Siding Installation Guide

“L” shaped

flashing

Federal Corners

To create a federal-style corner, flash the corner with aluminum trim

coil or other flashing materials. Hang a new construction starter

strip. Position the top nail in the top of the nailing slot. All other

nails should be centered in the slots spaced 8" to 10" apart.

Position and secure the 3-1/2" lineal.