Page 1

Operator’s Manual

22 Inch Walk-Behind

String Trimmer

Model No. CMXGCAQ108493

CAUTION: Before using this product,

read this manual and follow all safety

rules and operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com

• SAFETY

• UNPACKING

• ASSEMBLY

• OPERATION

• MAINTENANCE

Page 2

TABLE OF CONTENTS

!

!!!

Safety Instructions ................ Page 3

Assembly . . . . . . . . . . . . . . . . . . . . . . . Page 7

Operation. . . . . . . . . . . . . . . . . . . . . . Page 10

Maintenance ................... Page 18

PRODUCT SPECIFICATIONS MODEL NUMBER

Engine: Kohler XT6.75, 149CC

Engine Speed: 3600 RPM

Cutting Width: 22 inches

Cutting Height: 5 Heights 1.5 - 3.5”

Cutting Speed: 3800 RPM

Cutting Line: .155” dia. (4mm) x 19” length

Wheel Size: 14” x 1.75” width

Frame: 14 Gauge Steel

Trimmer Ball: 4” dia., 4” heat treated cutting blade

Drive Belt: V-Belt, 3L440

Dimensions: 50.4” L x 21.5” W x 38.3” H

Shipping Weight: 67 Lbs.

Off-Season Storage . . . . . . . . . . . . . . . Page 21

Troubleshooting ................. Page 22

Under License .................. Page 32

Model Number

Serial Number

Date of Purchase

Record the model number, serial number,

and date of purchase above.

Denitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations

and your risk of personal injury or property damage.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

(Used without word) Indicates a safety related message.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may result in property damage.

READ AND UNDERSTAND INSTRUCTION MANUAL: To reduce the risk of injury, user and all

bystanders must read and understand instruction manual before using this product.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

2

Page 3

SAFETY INSTRUCTIONS

!

!

!

!

WARNING

This symbol points out important safety instructions

which, if not followed, could endanger the personal

safety and/or property of yourself and others. Read and

follow all instructions in this manual before attempting

to operate this string trimmer. Failure to comply with

these instructions may result in personal injury. When

you see this symbol, HEED ITS WARNING!

WARNING

CALIFORNIA PROPOSITION 65

Engine Exhaust, some of its constituents, and certain

vehicle components contain or emit chemicals known to

State of California to cause cancer and birth defects or

other reproductive harm.

GENERAL OPERATION

a. Read this operator’s manual carefully in its entirety before

attempting to assemble this string trimmer. Read, understand,

and follow all instructions on the string trimmer and in the

manuals before operation. Keep this manual in a safe place for

future and regular reference and for ordering replacement parts.

b. Be completely familiar with the controls and the proper use of

this string trimmer before operating it.

c. This string trimmer is a precision piece of power equipment, not

a plaything. Therefore, exercise extreme caution at all times.

This string trimmer has been designed to perform one job: to

mow grass. Do not use it for any other purpose.

d. Never allow children under 14 years of age to operate this string

trimmer. Children 14 and over should read and understand the

instructions and safe operation practices in this manual and on

the string trimmer and should be trained and supervised by an

adult.

e. Only responsible individuals who are familiar with these rules of

safe operation should be allowed to use this string trimmer.

f. Thoroughly inspect the area where the equipment is to be used.

Remove all stones, sticks, wire, bones, toys and other foreign

objects, which could be tripped over or picked up and thrown

by the trimmer line. Thrown objects can cause serious personal

injury.

g. Plan your trimming operation to avoid discharge of material

toward roads, sidewalks, bystanders and the like. Also, avoid

discharging material against a wall or obstruction, which may

cause discharged material to ricochet back toward the operator.

h. To help avoid trimmer line contact or a thrown object injury, stay

in operator zone behind handles and keep children, bystanders,

helpers and pets at least 75 feet from trimmer while it is in

operation. Stop the string trimmer if anyone enters area.

i. Always wear safety glasses or safety goggles during operation

and while performing an adjustment or repair to protect your

eyes. Thrown objects which ricochet can cause serious injury to

the eyes.

j. Wear sturdy, rough-soled work shoes and close-tting slacks and

DANGER

This string trimmer was built to be operated according to

the safe operation practices in this manual. As with any

type of power equipment, carelessness or error on the

part of the operator can result in serious injury. This ma-

chine is capable of amputating ngers, hands, toes and

feet and throwing debris. Failure to observe the following

safety instructions could result in serious injury or death.

WARNING

Your Responsibility—Restrict the use of this power machine

to persons who read, understand and follow the warnings

and instructions in this manual and on the string trimmer.

SAVE THESE INSTRUCTIONS!

shirts. Shirts and pants that cover the arms and legs and steeltoed shoes are recommended. Never operate this string trimmer

in bare feet, sandals, slippery or light-weight (e.g. canvas) shoes.

k. Do not put hands or feet near rotating parts or under the cutting

deck. Contact with cutting line can amputate ngers, hands,

toes and feet.

l. A missing or damaged discharge cover can cause cutting line

contact or thrown object injuries.

m. Many injuries occur as a result of the trimmer being pulled

over the foot during a fall caused by slipping or tripping. Do

not hold on to the trimmer if you are falling: release the handle

immediately.

n. Never pull the trimmer back toward you while you are walking.

If you must back the trimmer away from a wall or obstruction,

rst look down and behind to avoid tripping and then follow

these steps:

1. Step back from trimmer to fully extend your arms forward.

2. Be sure you are well balanced with sure footing.

3. Pull the trimmer back slowly, no more than half way toward

you.

4. Repeat these steps as needed.

o. Do not operate the trimmer while under the inuence of alcohol

or drugs.

p. The safety control bar is a safety device. Never attempt to bypass

its operation. Doing so makes the safety device inoperative

and may result in personal injury through contact with the

cutting line. The safety control bar must operate easily in both

directions and automatically return to the disengaged position

when released.

q. Never operate the trimmer in wet grass. Always be sure of your

footing. A slip and fall can cause serious personal injury. If you

feel you are losing your footing, release the safety control bar

immediately and the cutting line will stop rotating within three

seconds.

r. Operate only in daylight or good articial light. Walk, never run.

s. Release the safety control bar when crossing gravel drives, walks

or roads.

3

Page 4

SAFETY INSTRUCTIONS

t. If the equipment should start to vibrate abnormally, stop the engine

and check immediately for the cause. Vibration is generally a

warning of trouble.

u. Shut the engine off and wait until the blade comes to a complete

stop before removing the grass catcher or unclogging the chute.

The cutting blade continues to rotate for a few seconds after the

blade control is released. Never place any part of the body in the

blade area until you are sure the blade has stopped rotating.

v. Never operate the string trimmer without proper shield, discharge

cover, grass catcher, blade control handle or other safety protective

devices in place and working. Never operate string trimmer with

damaged safety devices. Failure to do so can result in personal

injury.

w. Mufer and engine become hot and can cause a burn. Do not

touch.

x. Never attempt to make a wheel or cutting height adjustment while

the engine is running.

y. Only use parts and accessories made for this string trimmer by

the manufacturer as listed in the Parts pages of this Operator’s

Manual. Failure to do so can result in personal injury.

z. When starting engine, pull cord slowly until resistance is felt, then

pull rapidly. Rapid retraction of starter cord (kickback) will pull

hand and arm toward engine faster than you can let go. Broken

bones, fractures, bruises or sprains could result.

aa. If situations occur which are not covered in this manual, use care

and good judgement.

SLOPE OPERATION

Slopes are a major factor related to slip and fall accidents, which can

result in severe injury. Operation on slopes requires extra caution.

The string trimmer is heavy and can speed up when going downhill.

Be prepared to maintain control of the string trimmer. If you feel

uneasy on a slope, do not mow it. For your safety, use the slope

gauge included as part of this manual to measure slopes before

operating this string trimmer on a sloped or hilly area. If the slope is

greater than 15 degrees, do not mow it.

Do:

a. Operate across the face of slopes; never up and down to avoid loss

of control.

b. Exercise extreme caution when changing direction on slopes; turn

uphill not down.

c. Watch for holes, ruts, rocks, hidden objects, or bumps which can

cause you to slip or trip. Tall grass can hide obstacles.

d. Always be sure of your footing. A slip and fall can cause serious

personal injury. If you feel you are losing your balance, release

the safety control bar immediately and the cutting line will stop

rotating within three (3) seconds.

Do Not:

a. Do not trim near drop-offs, ditches or embankments, because you

could lose your footing or balance.

b. Do not trim slopes greater than 15 degrees as shown on the slope

guide.

c. Do not trim on wet grass. Unstable footing could cause slipping.

CHILDREN

Tragic accidents can occur if the operator is not alert to the presence

of children. Children are often attracted to the string trimmer and

the trimming activity. They do not understand the dangers. Never

assume that children will remain where you last saw them.

a. Keep children out of the trimming area and under watchful care of

a responsible adult other than the operator.

b. Be alert and turn string trimmer off if a child enters the area.

c. Before and while moving backwards, look behind and down for

small children.

d. Use extreme care when approaching blind corners, doorways,

shrubs, trees, or other objects that may obscure your vision of a

child who may run into the string trimmer.

e. Keep children away from hot or running engines. They can suffer

burns from a hot mufer.

f. Never allow children under 14 years of age to operate the string

trimmer. Children 14 and over should read and understand the

instructions and safe operation practices in this manual and on the

string trimmer and be trained and supervised by an adult.

SERVICE

Safe Handling of Gasoline:

To avoid personal injury or property damage use extreme care in

handling gasoline. Gasoline is extremely ammable and the vapors are

explosive. Serious personal injury can occur when gasoline is spilled

on yourself or your clothes which can ignite. Wash your skin and

change clothes immediately.

a. Use only an approved gasoline container.

b. Never ll containers inside a vehicle or on a truck or trailer bed

with a plastic liner. Always place containers on the ground away

from your vehicle before lling.

c. Remove gas-powered equipment from the truck or trailer and

refuel it on the ground. If this is not possible, then refuel such

equipment on a trailer with a portable container, rather than from

a gasoline dispenser nozzle.

d. Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do not use

a nozzle lock-open device.

e. Extinguish all cigarettes, cigars, pipes and other sources of

ignition.

f. Never fuel the string trimmer indoors because ammable vapors

will accumulate in the area.

g. Never remove gas cap or add fuel while engine is hot or running.

Allow engine to cool at least two minutes before refueling.

h. Never over-ll fuel tank. To allow for expansion of the fuel, do not

ll above the bottom of the fuel tank neck.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine and equipment. Move

the string trimmer to another area. Wait 5 minutes before starting

engine.

4

Page 5

SAFETY INSTRUCTIONS

!

Never store the string trimmer or fuel container near an open ame,

spark or pilot light as on a water heater, space heater, furnace,

clothes dryer or other gas appliances.

a. To reduce re hazard, keep string trimmer free of grass, leaves, or

other debris build-up. Clean up oil or fuel spillage and remove any

fuel-soaked debris.

b. Allow string trimmer to cool at least 5 minutes before storing.

General Service:

a. Never run an engine indoors or in a poorly ventilated area. Engine

exhaust contains carbon monoxide, an odorless and deadly gas.

b. Before cleaning, repairing, or inspecting, make certain the blade

and all moving parts have stopped. Disconnect the spark plug wire

and ground against the engine to prevent unintended starting.

c. Check the blade and engine mounting bolts at frequent intervals

for proper tightness. Also, visually inspect blade for damage (e.g.,

bent, cracked, worn). Replace blade with the original equipment

manufacturer’s (O.E.M.) blade only, listed in the Parts pages of

this manual. Use of parts which do not meet the original equip-

ment specications may lead to improper performance and

compromise safety!

d. String trimmer blades are sharp and can cut. Wrap the blade or

wear gloves, and use extra caution when servicing them.

e. Keep all nuts, bolts, and screws tight to be sure the equipment is

in safe working condition.

f. Never tamper with safety devices. Check their proper operation

regularly.

g. After striking a foreign object, stop the engine, disconnect the

spark plug wire and ground against the engine. Thoroughly

inspect the string trimmer for any damage. Repair the damage

before starting and operating the string trimmer.

h. Never attempt to make a wheel or cutting height adjustment while

the engine is running.

i. Grass catcher components, discharge cover, and trail shield are

subject to wear and damage which could expose moving parts or

allow objects to be thrown. For safety protection, frequently check

components and replace immediately with original equipment

manufacturer’s (O.E.M.) parts only, listed in the Parts pages of this

manual. Use of parts which do not meet the original equipment

specications may lead to improper performance and compromise

safety!

j. Do not change the engine’s governor setting or over-speed the

engine. The governor controls the maximum safe operating speed

of the engine.

k. Check fuel line, tank, cap, and ttings frequently for cracks or

leaks. Replace if necessary.

l. Do not crank engine with spark plug removed.

m. Maintain or replace safety and instruction labels, as necessary.

n. Observe proper disposal laws and regulations. Improper disposal

of uids and materials can harm the environment.

o. According to the Consumer Products Safety Commission (CPSC)

and the U.S. Environmental Protection Agency (EPA), this product

has an Average Useful Life of seven (7) years, or 140 hours of

operation. At the end of the Average Useful Life have the string

trimmer inspected annually by a Sears or other qualied service

dealer to ensure that all mechanical and safety systems are working properly and not worn excessively. Failure to do so can result

in accidents, injuries or death.

DO NOT MODIFY ENGINE

To avoid serious injury or death, do not modify engine in any way.

Tampering with the governor setting can lead to a runaway engine

and cause it to operate at unsafe speeds. Never tamper with factory

setting of engine governor.

NOTICE REGARDING EMISSIONS

Engines which are certied to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment) are

certied to operate on regular unleaded gasoline, and may include

the following emission control systems: Engine Modication (EM),

Oxidizing Catalyst (OC), Secondary Air Injection (SAI) and Three Way

Catalyst (TWC) if so equipped.

SPARK ARRESTOR

WARNING

This machine is equipped with an internal combustion

engine and should not be used on or near any unimproved

forest-covered, brush covered or grass-covered land unless

the engine’s exhaust system is equipped with a spark arrestor meeting applicable local or state laws (if any).

If a spark arrestor is used, it should be maintained in effective

working order by the operator. In the State of California the above

is required by law (Section 4442 of the California Public Resources

Code). Other states may have similar laws. Federal laws apply on

federal lands. A spark arrestor for the mufer is available through

your nearest Sears Parts and Repair Service Center.

5

Page 6

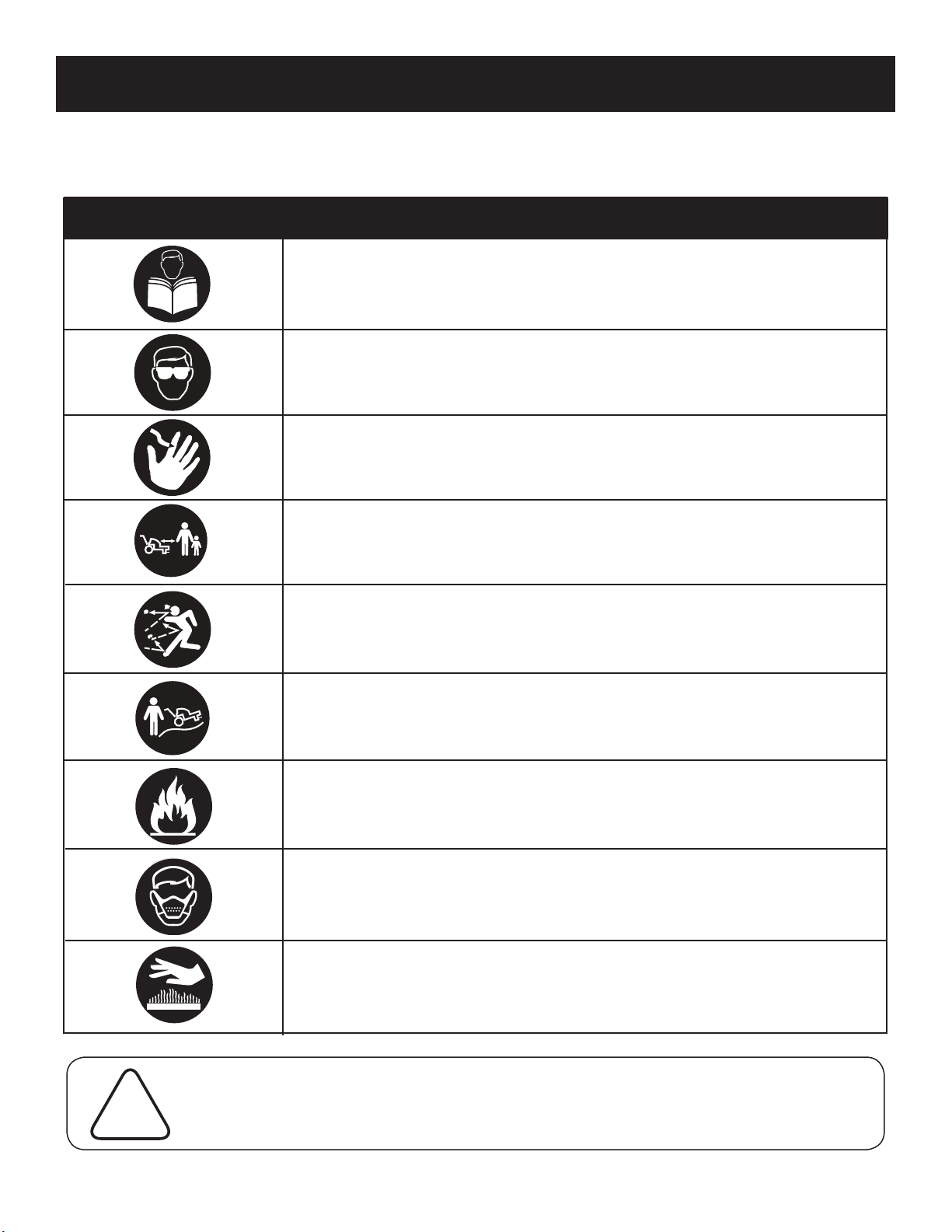

SAFETY INSTRUCTIONS

!

SAFETY SYMBOLS

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all

instructions on the string trimmer before attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate.

DANGER —WEAR EYE PROTECTION

To reduce the risk of eye injury, wear protective eye ware, goggles or glasses.

DANGER —SHARP CUTTING LINE

To reduce the risk of injury, keep hands and feet away. Do not operate unless the

discharge cover is in its proper place. If damaged, replace immediately.

DANGER — DO NOT OPERATE NEAR OTHER PEOPLE

The string trimmer may eject objects at high speed. Use caution when operating around

children, pets and other adults.

DANGER — MAY EJECT ITEMS AT HIGH SPEED

The string trimmer may eject objects at high speed. Use caution when operating around

children, pets and other adults.

DANGER — USE CAUTION ON SLOPES

The string trimmer is heavy and can speed up when going downhill. To avoid loss of

control, operate across slopes, not up and down. When turning, turn uphill, not down. Do

not operate on slopes greater than 15°.

DANGER — GASOLINE IS FLAMMABLE

Allow the engine to cool at least ve minutes before refueling. Never smoke, use matches

or lighters in the immediate vicinity of the string trimmer.

DANGER — CARBON MONOXIDE

Carbon Monoxide from engine exhaust is a deadly poisonous, odorless and colorless gas.

Never run the engine in an enclosed space or poorly ventilated area. Carbon Monoxide

can render a person unconscious in a matter of minutes.

DANGER — HOT SURFACES

Engine parts, especially the mufer and other exhaust components, can become

extremely hot during operation. Use caution to avoid severe burns. Allow the engine to

cool down before performing any maintenance.

WARNING: Your Responsibility—Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this manual and on the string trimmer.

SAVE THESE INSTRUCTIONS!

6

Page 7

ASSEMBLY

IMPORTANT: This unit is shipped without gasoline or oil in

the engine. Be certain to ll engine with gasoline and oil

as instructed in the Operation section of the Engine Manual

before starting or running your string trimmer.

List of tools needed for assembly:

• 13mm wrench

• (2) 10mm wrenches

OPENING CARTON

1. Cut each corner of the carton vertically from top to

bottom.

2. Remove all loose parts.

3. Remove loose packing material.

REMOVING UNIT FROM CARTON

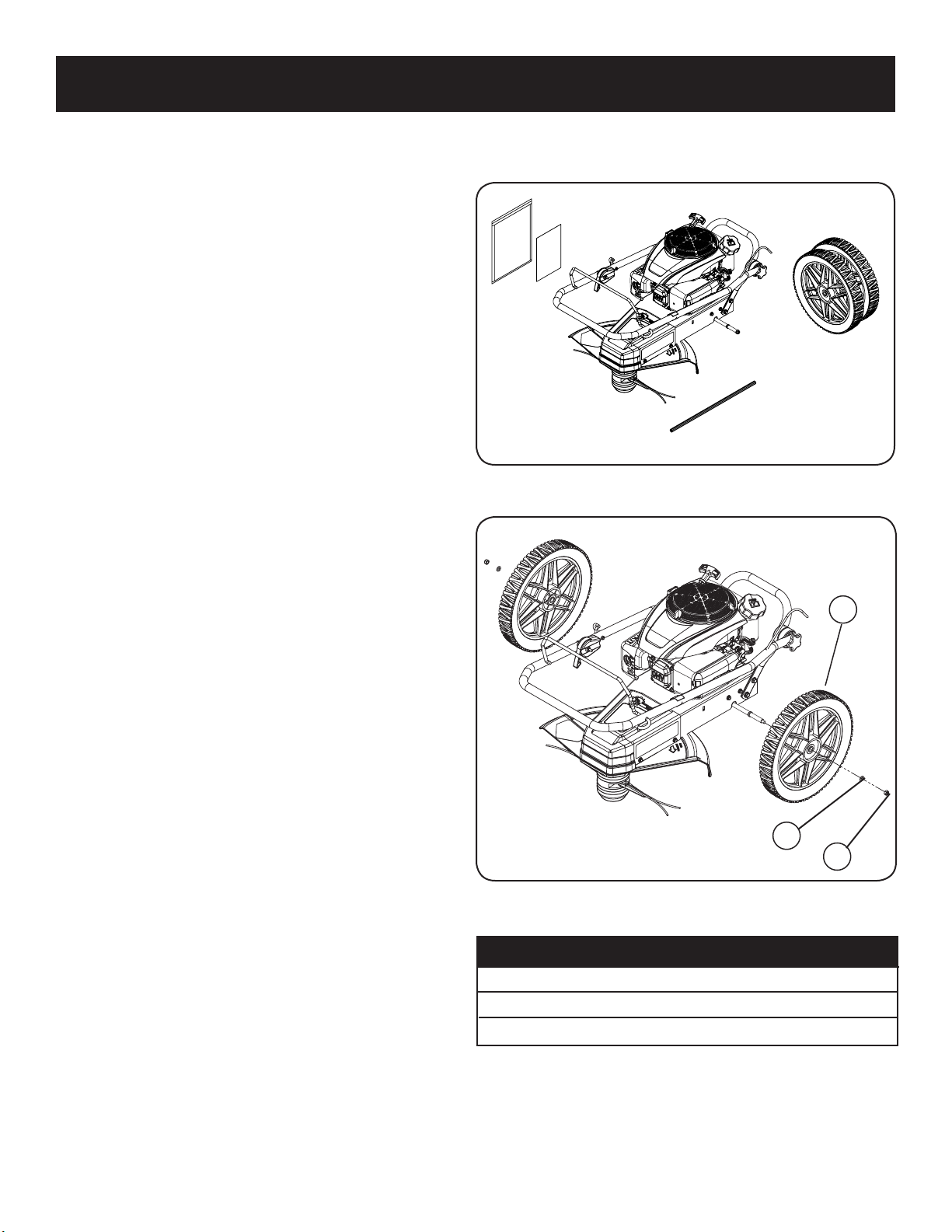

1. Remove wheels, manuals and extra trimming line from

box (see Figure 1). With assistance, lift the trimmer

out of box and set on a level surface.

2. Attach wheels to the trimmer axle using nuts and

washers (see gure 2).

Figure 1

1

2

3

Figure 2

Item # Part # Description Qty.

1 101094 Trimmer Wheel Assembly 2

2 100130 Flat Washer, M8 2

3 100128 Hex Nut, Nylock, M8 x 1.25mm, G8.8 2

7

Page 8

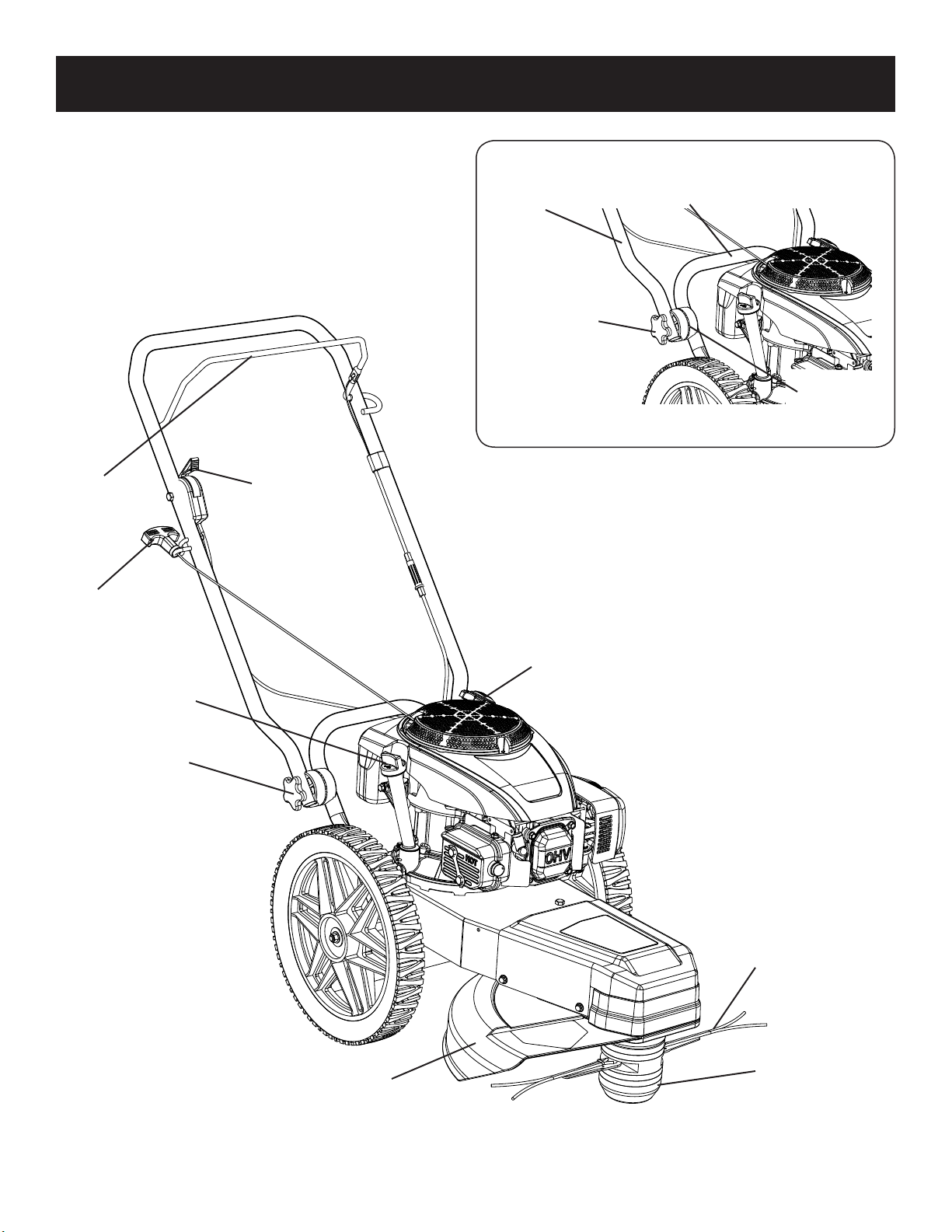

4. Flip upper handlebar up to the operating position.

Loosen both adjustment knobs (see Figure 3) and

align the upper handlebar both sides to a comfortable

operating position. Tighten the adjustment knobs

securely. It is important to nd a handlebar height

that allows the cutting head to hover just above the

ground and remain balanced so you do not have to

push down or pull up on the handlebar.

ASSEMBLY

UPPER

HANDLEBAR

ADJUSTMENT

LOWER

HANDLEBAR

KNOB

NOTCHES IN

ALIGNMENT

SAFETY

CONTROL

BAR

RECOIL

STARTER

HANDLEBAR

ADJUSTMENT

THROTTLE

Figure 3

GASOLINE FUEL

FILL

OIL FILL

CUTTING HEAD

GUARD

CUTTING CORD

CUTTING

HEAD

String trimmer Components

8

Page 9

ASSEMBLY

!

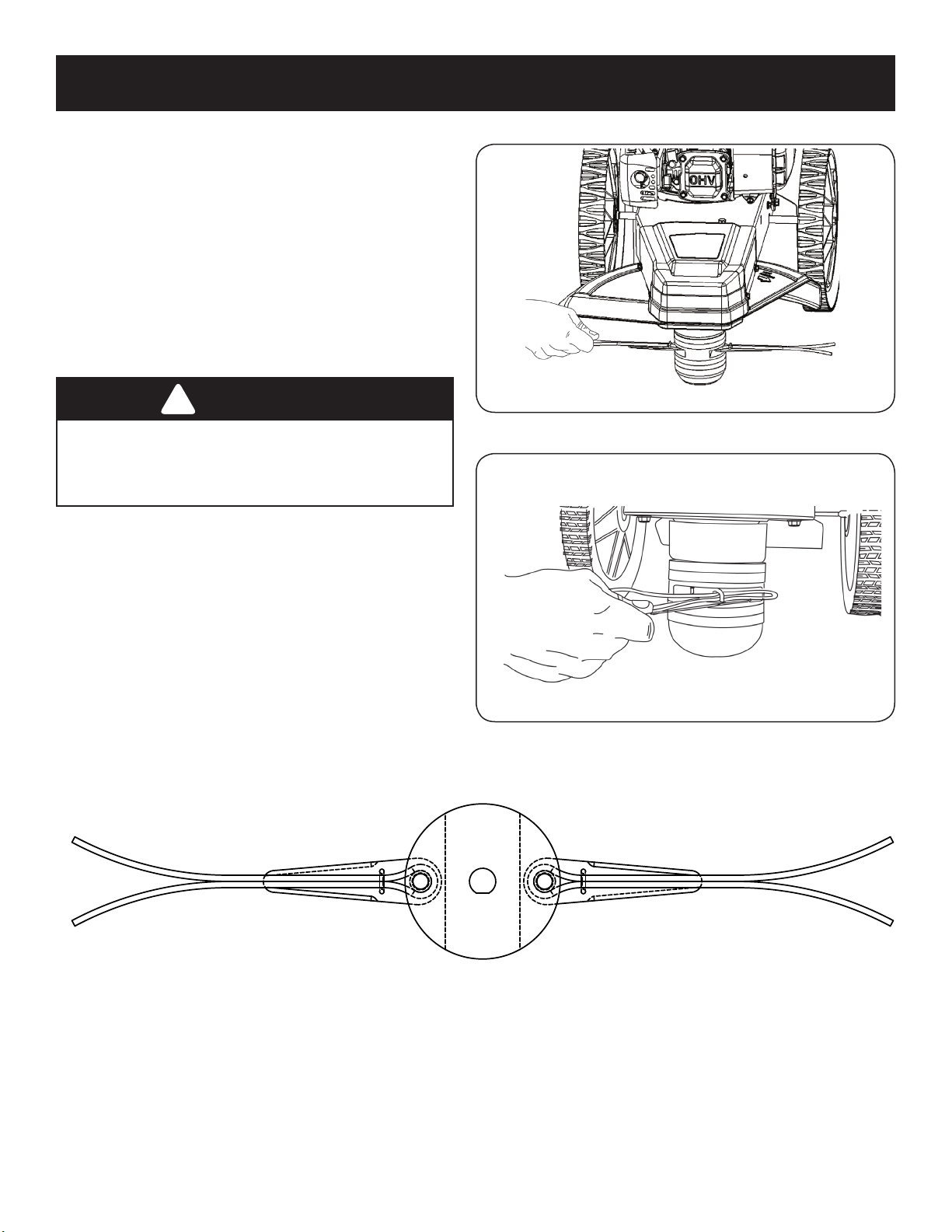

INSTALLING THE CUTTING LINE

There are two installation points on the line plate. Each

point is 180 degrees apart. Always install two lines,

one opposite the other of the same length and weight

(diameter).

1. Insert the end of the cord into the side openings in the

line plate (see Figure 4).

2. Push the cord through until the end comes out the

center hole in the line plate. Adjust the cord ends so

the tips are of equal length.

3. Pull the cord under the loop and push the loop up into

the line plate groove above them (see Figure 5) and

then pull the cord ends tight.

CAUTION

If the tips of the cutting cords are not of equal length,

it can cause unbalance of the cutting head and will

result in increased vibration and potential damage

to the cutting head.

Figure 6 illustrates the proper cord installation on the

line plate. It shows the line plate from a top view. The

cord ends should be of equal length and the same length

on each side. There are two installation points on the line

plate. Each point is 180 degrees apart. Always install

two cords, one opposite the other of the same length and

weight (diameter).

Figure 4

Figure 6

9

Figure 5

Page 10

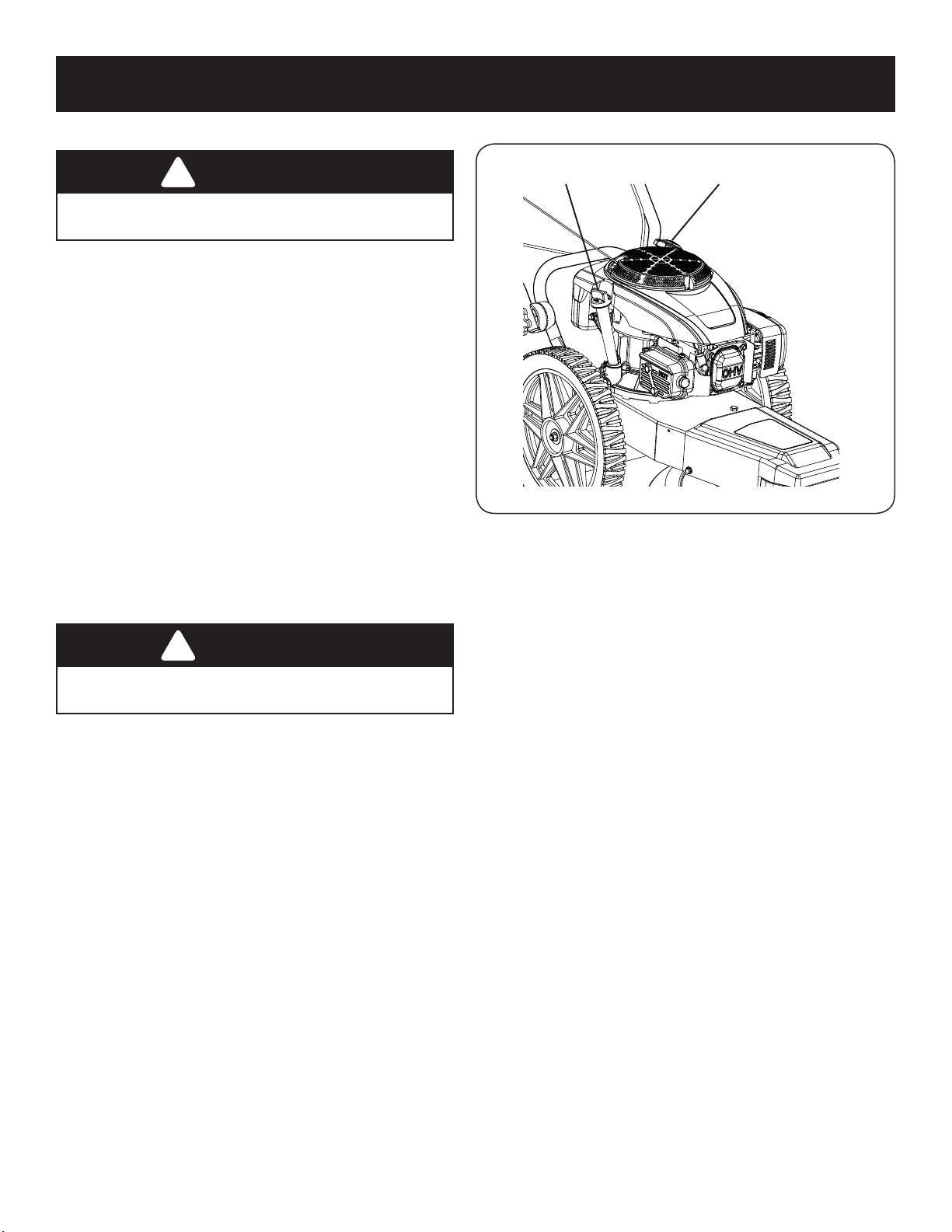

FILLING WITH OIL AND GASOLINE

!

!

OPERATION

WARNING

ADD OIL BEFORE STARTING THE ENGINE

The string trimmer is shipped without uids installed.

Keep the caps on the fuel and oil lls until you are ready

to pour either gasoline or oil into the correct ll. Requires

approximately 15 - 22 ounces of SAE 30 engine oil.

Please refer to your Engine Owner’s Manual for detailed

information on oil quantity and cold temperature oil

specications.

1. Place the string trimmer on a level surface and initially

add 1/2 of the SAE 30 high detergent oil into the oil ll

(see Figure 7) and wait one (1) minute for the oil to

settle.

2. Check the dipstick and continue adding a few ounces

of oil at a time, rechecking the dipstick until the oil

reaches the ll mark. Be careful not to overll.

3. Fill the fuel tank with fresh, unleaded gas (min. 85

Octane), to 1/4” from the top of the ll neck to allow

for expansion. Be careful not to overll and reinstall

the cap before starting the engine.

OIL FILL

FUEL FILL

Figure 7

WARNING

ALWAYS FILL THE TANK WITH ENGINE OFF AND COOL.

ALWAYS CHECK THE OIL LEVEL BEFORE OPERATING.

Allow the engine to cool for at least two minutes before

removing the fuel cap.

Before performing any adjustments to the cutting head,

cutting cords or any other procedure or inspection, stop

the engine, wait ve minutes to allow parts to cool.

Disconnect the spark plug wire, keeping it away from the

spark plug. Contact with internal rotating parts will cause

serious personal injury. Never put hands, face, feet,

or clothing under the string trimmer deck or discharge

opening at any time.

10

Page 11

OPERATION

!

CAUTION

CHECK THE ENGINE OIL LEVEL Check fuel level.

Remove any debris from around the underside of the string

trimmer.

Manual Starting

1. Push the throttle control lever on the right side of the

handlebar (see Figure 8) all the way forward (choke

position).

2. Grasp the recoil starter and slowly pull until you feel

resistance. Let the cord retract a little bit and then

pull the cord rapidly to start the engine. One or two

pulls usually starts the string trimmer. Do not engage the

safety bar until after the engine has started.

3. Once the engine is started, move the throttle lever to

the RUN or IDLE position.

If the engine fails to start after several pulls of the recoil

starter, allow the motor to cool down. Check the cause of

hard starting; see the Troubleshooting Guide (page 22).

THROTTLE

CONTROL

RECOIL

STARTER

Stopping the Engine

1. Move the throttle control lever (see Figure 8) all

the way back past the SLOW position to the STOP

position.

Engaging the Cutting Head

1. Bring the safety bar toward you and grip it together

with the handlebar. Cutting cords rotate until you

release the safety bar.

Note: Before using your cutting head for the rst time or

after you have installed a new belt, engage the safety bar

10 times and hold it for 3 seconds each time.

Stopping the Lines from Spinning

1. Release the safety bar from the handlebar. The cutting

head will stop spinning while the engine continues to

run.

Figure 8

11

Page 12

OPERATION

!

!

SETTING THE CUTTING HEIGHT

CAUTION

BEFORE PERFORMING ANY ADJUSTMENT, MAINTENANCE

PROCEDURE OR INSPECTION, STOP THE ENGINE, WAIT FIVE

(5) MINUTES TO ALLOW PARTS TO COOL AND DISCONNECT

THE SPARK PLUG WIRE, KEEPING IT AWAY FROM THE

SPARK PLUG.

Setting the cutting height is easy. Cutting heights range in

10mm (0.4 in).

WARNING

RUNNING THE CUTTING HEAD WITH CORDS OF UNEQUAL

LENGTH OR A CORD INSTALLED AT OTHER THAN 180

DEGREES APART CAN CAUSE EXCESSIVE VIBRATION AND

MAY DAMAGE THE STRING TRIMMER.

Installing the trimming line

After you install cutting cord, and before trimming, engage

the cutting head with the engine running to spin the new

cord for a few seconds so they pull tight and are set.

1. Insert the ends of the cord into the side opening in the

line plate (see Figure 10).

2. Push the cord through until the ends come out the

center opening in the line plate. Adjust the cord ends so

they are even.

3. Pull the ends of the cord under the loop and push the

loop up into the line cord ends plate groove above them

(see Figure 11) and then pull the ends tight.

3.5”

3.1”

2.7”

2.3”

1.9”

Figure 9

Figure 10

Figure 11

12

Page 13

OPERATION

CUTTING CORD RECOMMENDATIONS

Cutting cord is available in Blue (175 mil) and Green

(155 mil). Because conditions and vegetation vary

so much, you should experiment with cord weights

(diameters) to discover what works best for your

particular mowing and trimming situations.

Here are a few things to keep in mind:

• If the cutting cord is purchased in rolls, cut to 25”

lengths.

• Cord life depends on trimming conditions. Replace

cords when they become broken or frayed.

• The smallest diameter cord combined with the

fastest engine speed provides the best grass trimming

performance. The 175 mil cord is recommended for

thicker growth such as bramble, thistle, and ragweed.

• Ease the ends of the cord into heavy growth and move

slowly through thick growth. If there are woody weeds

in the material you are cutting, the cutting cords may

wrap around the stalks they cannot cut, and pull away

from the cutting head.

• Installing two (2) cords, 180 degrees apart, of equal

length and weight on the line plate, is the best method

for optimal trimming performance.

• When replacing cords, do it one at a time and use the

old cord to mark the position for the new cord that you

are replacing.

• If the cord breaks off ush at the line plate, use needle

nose pliers to pull out the old cord.

• Storing the cord in a plastic bag with a damp sponge

or cloth will help keep it pliable. You can also soak

your cutting cord in a bucket of room temperature

water for a few days before use to make it more

pliable.

• UV light can degrade cord, store out of direct sunlight.

DO NOT USE DIFFERENT WEIGHT CORDS ON THE CUTTING

HEAD AT THE SAME TIME. THIS CAN CAUSE EXCESSIVE

VIBRATION AND MAY DAMAGE THE STRING TRIMMER.

13

Page 14

OPERATION

CUTTING HEAD

Allow the front end of the string trimmer to rest lightly on

the cutting head as you are trimming. The cutting head

should glide on the ground as you maneuver the string

trimmer. To achieve the best and smoothest cut, do not lift

up on the handlebar while operating your string trimmer.

Lifting the handlebar will force weight down on the cutting

head. This uses more energy, slows the cutting, and

produces an unsatisfactory cut. Ideally, the cutting head

should lightly rest on the ground while the wheels balance

most of the weight of the string trimmer.

Replacing the Cutting Head or Line Plate

Tools and Supplies Needed:

• Phillips head screwdriver with at least a 6” shank

• Gloves

Cutting Head Disassembly

1. Align the hole in the anti-wrap canister with the hole

in the internal housing at the location shown (see

Figure 12).

2. Insert a Phillips head screwdriver into the hole in the

anti-wrap canister and the hole in the internal housing.

3. Rotate the cutting head assembly until the screw driver

slides into a hole in the shaft, locking it into place.

4. Looking down at the top of the frame, turn the cutting

head clockwise until it unscrews completely from the

bearing housing.

ROTATE

CLOCKWISE

Figure 12

SCREWDRIVER

CUTTING

HEAD

NOTE: If the cutting head continues to turn, but does

not come off, check to be sure that you locked the

screwdriver into the shaft. If the cutting head will not

turn by hand a 9/16” socket wrench can be used on the

bolt (inside the bottom of the cutting head) to loosen it.

You may need to clean grass or debris out of the recess

rst.

5. Slide the line plate and spacers off the shaft.

14

Page 15

CUTTING HEAD COMPONENTS

!

!

OPERATION

CAUTION

Improper installation can cause damage to the cutting

head bearings. Follow directions carefully to protect the

string trimmer from damage.

Assemble components in the order shown (see gure 13.)

1. Place the spacer and bearing cover (with the lip facing up)

onto the shaft (Figure 13).

2. Align the ats at the center of the plates with the at on the

shaft and slide the line plate onto the shaft. Ensure they

are facing top side up as shown.

3. Place the cutting head bolt so it is sitting in the hex cavity

at the bottom of the cutting head.

4. Looking down at the top of the frame, hold the bolt

head in place with your nger and turn the cutting head

counterclockwise to start the bolt into the shaft.

5. Insert the screwdriver as shown in Figure 12 and tighten

the assembly securely by turning the cutting head

counterclockwise when looking down on the top of the

frame.

NOTE: When nished there should be no gaps between

any of the components.

BEARING

COVER

SPACER

LINE

PLATE

WARNING

Always make sure you remove the screwdriver from the

head assembly when nished. Failure to remove the

screwdriver could cause injury when the head assembly is

engaged.

CUTTING

HEAD

BOLT

Figure 13

15

Page 16

OPERATION

!

OPERATING ENVIRONMENT

WARNING

The cutting head can easily throw debris at great velocity,

which could cause personal injury or property damage. Do

not run the string trimmer over loose gravel or mulch

with the cutting head spinning.

• The string trimmer discharges cut material to the right.

• Always try to cut and trim with the uncut tall grass or

weeds on the left.

• Always check your work area before trimming and

remove any debris that might tangle or damage the string

trimmer.

• If you do run into debris and the cutting head becomes

tangled, turn off the engine and disconnect the spark

plug wire before attempting to untangle the string

trimmer.

• For the neatest appearance, do your trimming rst,

discharging clippings away from borders and shrubs,

then do your mowing.

• Many owners like to mow easy, open areas with their

regular riding or walk behind string trimmer and nish

trimming all the odd and hard-to-reach spots with the

string trimmer.

Heavy Growth Trimming Recommendations

• Take your time in heavy growth.

• Be sure to keep uncut material to your left, maintaining

a clear discharge area to your right.

• If the string trimmer cannot do it all in one pass, overlap

half of the cutting swath.

• If the grass is very thick and heavy, try raising the cutting

head off the ground a few inches by pushing down on

the handlebar. Cut the material at this height, and then

make a second pass with the cutting head close to the

ground.

• Ease the string trimmer into denser growth. If the

material is too tough or woody to cut, the cutting cords

will wrap around it, wear down, or even break off.

• Sometimes the growth is so heavy, you cannot mow it in

rows. Use a forward and back “vacuum cleaner” motion

in these cases.

16

Page 17

OPERATION

!

OPERATING ENVIRONMENT

Wet Environments

You can use the string trimmer in damp and wet conditions,

after a rain, or in the early morning dew without clogging

or stalling. You can mow wet areas such as ditches and

around ponds.

Note: NEVER mow in the rain. Water on the spark plug may

cause the engine to stall.

Dry Environments

When trimming and mowing in very dry conditions, be

extra cautious of cut grass, chaff, weeds, seeds, etc.,

accumulating on the

engine, especially around the recoil-starter housing and

engine cooling ns. Please see the Engine Owner’s Manual

for more

detailed information on cleaning the air intake, air lter,

and cooling system on the engine.

WARNING

Frequently remove debris from the recoil guard on top of

the engine and the cooling ns on the front of the engine to

prevent overheating and engine damage.

Slopes

You can trim and mow on slopes up to 20 degrees.

Continuous use on slopes steeper than 20 degrees may

deprive the engine of adequate lubrication, and damage

components.

Windrows

The string trimmer cutting cords cut tall grass in one pass,

so you can collect clippings and leaves for mulch without

raking. The string trimmer ejects cut material to its right

side, so you can use it like a lawn broom to make cleanup

easy and to create windrows.

Firebreaks

Use your cutting head as a labor saving tool to cut material

when creating rebreaks.

Garden Clean-Up

The string trimmer is perfect for cutting down dead

perennials, annuals, and wildowers, saving you hours

of hand pruning and deadheading. You can also re-cut

downed material a second time to create mulch for garden

beds.

17

Page 18

MAINTENANCE

!

WARNING

BEFORE PERFORMING ANY MAINTENANCE PROCEDURE

STOP THE ENGINE, WAIT FIVE (5) MINUTES TO ALLOW ALL

PARTS TO COOL. Disconnect the spark plug wire, keeping it

away from the spark plug.

Regular maintenance is the way to ensure the best

performance and long life of your string trimmer. Please

refer to this manual and the engine manufacturer’s owner’s

manual for maintenance procedures.

Maintenance Checklist

Maintenance Before Every Every

Procedure Each Use 25 Hours of Use 100 Hours of Use

Check engine oil level X

Clean engine exterior, cooling ns and X

remove debris. Cleaning the engine top

during use is critical for proper air ow.

Check general equipment condition X

including nuts, bolts, welds, etc.

Replace broken or frayed cutting cords X

Check cutting head and line plate X

for excessive wear

Check the belt for stretching The rst time X

Adjust the drive cable if necessary after 2 hours of use

Lubricate throttle cable and X

cutting head control cable with SAE 30 oil

Change the engine oil The rst time X

after 5 hours of use

Replace the engine air lter cartridge X

and foam pre-lter if equipped.

Replace spark plug X

18

Page 19

MAINTENANCE

CHANGING THE ENGINE OIL

Tools and Supplies needed:

• SAE 30 HD Oil (refer to your Engine Owner’s Manual

for quantity required)

• Suitable container for used oil

• Cleaning Rags

• Wooden pallet or workbench

NOTE: Drain the oil when the engine is warm. Warm oil

drains quickly and completely.

1. For convenience, place the string trimmer up on a

wooden pallet or workbench.

2. Remove the oil cap/dipstick and position a suitable oil

receptacle beside the oil ll tube.

3. Make sure to securely tighten the gas ll cap.

4. Using the handle of the string trimmer, tip the string

trimmer to drain the oil out through the oil ller tube into

a suitable receptacle. (see Figure 14).

NOTE: Be sure to use environmentally safe disposal

procedures in the disposing of the used oil.

5. Rell the engine using SAE 30 HD oil to the level

indicated on the dipstick.

ADJUSTING THE BELT TENSION THROUGH THE CUTTING

HEAD CONTROL CABLE

Before adjusting the cutting head belt tension cable, check

that the belt is properly installed. Also make sure the cable

is attached to the bail bar. The belt will stretch a little when

new, then more over time. If the cutting head does not

spin with the safety bar engaged, adjust the cutting head

control cable to put more tension on it. The adjuster is

located on the control cable itself.

1. Locate the cutting head cable along the left handlebar.

There is an in-line adjuster to change the tension on the

cable (see Figure 15).

2. You can take the slack out of the cable by holding the

hex at sections of the in-line adjuster and rotating the

body of the in-line adjuster in the counterclockwise

direction as you look down on the cable. If the cable

is too tight, you can loosen the cable by twisting the

adjuster in the clockwise direction.

3. If the in-line adjuster is adjusted all the way out and

more adjustment is needed then the belt needs to be

replaced.

OIL CAP

DIPSTICK

Figure 14

CUTTING

HEAD

CONTROL

CABLE

Figure 15

19

Page 20

MAINTENANCE

REPLACING THE BELT

Tools needed:

• 10mm Wrench

• 13mm Wrench

1. Tip the string trimmer back just far enough to access

the underside and support the handlebars.

2. Unscrew cutting head cap and remove cutting head

plates from spindle.

3. Remove the four debris guard bolts and at washers

with a 10mm wrench. Remove the cutting head guard

(see Figure 16).

4. Loosen the belt guide locknut using a 10mm wrench

(see Figure 17) and rotate the guide out of the way.

5. Remove the two locknuts from the idler link using

a 13mm wrench so the idler link, idler pulleys and

spacers can be removed from the string trimmer.

6. Remove the belt from around the engine and head

assembly pulleys.

7. Install a new drive belt around the engine and head

assembly pulleys.

8. Install the small spacer and at idler pulley (see

Figure 18). Make sure you place the belt correctly

between the idler pulley, bracket tab, and guide pin.

9. Install the small spacer and v-groove idler pulley.

Position the idler link over the idlers and secure with

the two locknuts using a 13mm wrench (Figure 17).

10. Rotate the belt guide into position and tighten the

locknut with a 10mm wrench.

11. Position the cutting head guard and secure with the

four bolts and at washers using the 10mm wrench.

12. Install the cutting head and tip the cutting head

down on the head assembly.

13. After installing the new belt, be sure to adjust the

tension properly by adjusting the in-line adjuster

all the way in (refer to page 19). Proper tension will

extend the life of the belt.

CUTTING

HEAD

GUARD

BELT

Figure 16

IDLER

LINK

ENGINE

PULLEY

Figure 17

BOLTS AND

WASHERS

CUTTING

CORD

LOCK NUTS

BELT

GUIDE

Note: Before using your string trimmer for the rst

time or after you have installed a new belt, engage the

safety bar 10 times and hold it for 3 seconds each

time. This is required to wear in the belt to ensure the

best grip for trimming.

20

BRACKET

TAB

BELT

GUIDE

PIN

IDLER

PULLEY

Figure 18

Page 21

MAINTENANCE

!

Replacing the Wheels

Tool needed:

• 13mm Wrench

1. Block and stabilize the string trimmer so that the

wheels are off the ground.

2. Loosen and remove the locknut (see Figure 19).

3. Slide the wheel off the axle.

4. Reverse the steps to install the new wheel.

LOCKNUT

Figure 19

OFF SEASON STORAGE

WARNING

Never store lawn string trimmer with fuel in tank indoors

or in poorly ventilated areas where fuel fumes may reach

an open ame, spark, or pilot light as on a furnace, water

heater, clothes dryer, or gas appliance.

Preparing The Engine

For engines stored over 30 days:

• To prevent gum from forming in fuel system or on carburetor

parts, run engine until it stops from lack of fuel or add a

gasoline additive to the gas in the tank. If you use a gas

additive, run the engine for several minutes to circulate the

additive through the carburetor.

• An oil change is not required but if you desire to change the

oil then change while the engine is warm.

• Clean engine of surface debris.

Preparing The Lawn String trimmer

• Clean and lubricate string trimmer thoroughly as described

in the lubrication instructions.

• Do not use a pressure washer or garden hose to clean your

unit.

• Coat string trimmer’s cutting blade with chassis grease to

prevent rusting.

• Refer to Preparing the Engine for correct engine storage

instructions.

• Store string trimmer in a dry, clean area. Do not store next to

corrosive materials, such as fertilizer.

When storing any type of power equipment in a poorly

ventilated or metal storage shed, care should be taken to

rust-proof the equipment. Using a light oil or silicone, coat

the equipment, especially cables and all moving parts of your

lawn string trimmer before storage.

21

Page 22

TROUBLESHOOTING

!

WARNING

BEFORE PERFORMING ANY MAINTENANCE PROCEDURE

STOP THE ENGINE, WAIT FIVE (5) MINUTES TO ALLOW ALL

PARTS TO COOL. Disconnect the spark plug wire, keeping it

away from the spark plug.

PROBLEM SOLUTION

Recoil will not pull out or is difcult to pull. • Check the engine oil level, the engine may be seized.

(Refer to the engine Owner’s Manual) • There may be an oil compression lock in the cylinder. Take

out the spark plug; hold a rag over the spark plug hole and

pull the recoil cord several times to blow out any oil in the

cylinder. Wipe off the spark plug and reinstall it.

• The recoil may be broken or jammed. Try to turn the engine

pulley by hand, with the spark plug wire off. If it turns,

the recoil is broken or jammed. Visit our web site at www.

dirtyhandtools.com or call 1-877-487-8275 for assistance.

The engine will not start manually. • Check that the throttle is in the most forward position (or

RUN position when the engine is warm). Check the throttle

cable and make sure that it is attached to the engine and is

moving freely.

• Check for proper attachment of the spark plug wire.

• Check that the engine has the right amount of clean oil. If

the oil is dirty, change it following the procedure on page

17.

• Use only fresh, clean, unleaded gas. If the gas is old,

change it. Use a fuel stabilizer if you keep gas longer than

one month.

• Check the fuel lter (if equipped) to see if it is clear. Place

a can under the fuel lter and remove the fuel line from the

engine side of the lter. If gas ows freely, it is OK.

• Check that the air lter is clean. If it is dirty, change it

following the procedure in the engine Owner’s Manual.

• Make sure that the spark plug is clean. If the spark plug is

dirty or cracked, change it. If it is oily, leave it out, hold a

rag over the spark plug hole and pull the recoil cord several

times to blow out any oil in the cylinder, then wipe off the

spark plug and reinsert it.

• If the engine still will not start, visit our web site at www.

dirtyhandtools.com or call 1-877-487-8275 for assistance.

22

Page 23

TROUBLESHOOTING

PROBLEM SOLUTION

Engine smokes. • Check the oil level and adjust as needed.

• You may be operating the trimmer on too great an incline.

• Check the air lter and clean or replace if needed.

• You may be using the wrong oil - too light for the

temperature. Refer to your engine Owner’s Manual for

detailed information.

• Clean the engine cooling ns and the carburetor housing if

they are dirty.

• If the engine still smokes, visit our web site at www.

dirtyhandtools.com or call 1-877-487-8275 for assistance.

Engine lacks power or isn’t running smooth. • Check the throttle travel. The throttle lever should be in the

most forward position (or RUN position when the engine is

warm).

• Check for debris (hay seed, etc.) clogging the air lter intake

and clean out as required.

• The engine’s blower housing, throttle linkage, and cooling

ns should be free of debris. Clean them following the

instructions in the engine Owner’s Manual.

• Check that the air lter is clean. If it is dirty, change it

following the procedure in the engine Owner’s Manual.

• Remove the spark plug wire and dry the connection with a

clean rag.

• The spark plug may be dirty or cracked, change it. If it’s oily,

leave it out, hold a rag over the spark plug hole and pull the

recoil cord several times to blow out any oil in the cylinder,

then wipe off the spark plug and reinsert it.

• You should be using fresh, clean, unleaded gas. If it is old,

change it. Use a fuel stabilizer if you keep gas longer than

one month.

• Check that the engine has the right amount of clean oil. If it

is dirty, change it following the procedure on page 19.

• If your engine still lacks power, visit our web site at www.

dirtyhandtools.com or call 1-877-487-8275 for assistance.

Cutting head won’t spin or lacks power. • Check for proper alignment of the v-belt. Check it against

Figure 18 in the “Replacing the Belt” section on page 20.

• The belt may be worn or frayed; if so, replace it.

• If the cutting head still will not spin, follow the procedure

for “Adjusting the Belt Tension through the Cutting head

Control Cable” on page 19.

• If none of the above helps, visit our web site at www.

dirtyhandtools.com or call 1-877-487-8275 for assistance.

23

Page 24

TROUBLESHOOTING

PROBLEM SOLUTION

Cutting head keeps spinning or spins • Check for proper alignment of the v-belt. Check it against

when you release the safety bar. Figure 18 in the “Replacing the Belt” section on page 20.

• If the cutting head keeps spinning when you release the

safety bar, see “Adjusting the Belt Tension through the

Cutting Head Control Cable” on page 19.

• If none of the above helps, visit our web site at www.

dirtyhandtools.com or call 1-877-487-8275 for assistance.

Cutting cords are breaking. • The cords may be too dry. Store cords in a plastic bag with a

damp sponge or cloth to make them less prone to breaking

or soak them in a bucket of water for a few days.

• You may be trying to do too much too fast. Ease into the

material you are cutting; let the cord tips do the work. Take

small bites of tall or tough vegetation. Cut half a swath at a

time, keeping the cut area to the discharge or right side of

the cutting head. Go over tall material twice, the rst time

with the cutting head tilted up and back; the second time

with the cutting head on the ground.

• Make sure that you are not hitting the cords against a stone

or a chain-link fence. The cords won’t last as long against

obstacles as in the open. Work on controlling the cutting

pattern. With practice, you’ll learn to cut closer to obstacles

without hitting them.

`

Cutting cords are pulling out. • You may be moving too fast into tough, woody growth. In

doing so, the cords may wrap on stalks and pull out. Check

the operating tips in the section above on breaking cords.

• Make sure that you are not trying to cut material too heavy

for the cord. The design of your cutting head is to cut green

material up to about the thickness of a pencil.

• If none of the above helps, visit our web site at www.

dirtyhandtools.com or call 1-877-487-8275 for assistance.

The cutting head is wearing too quickly. • You may be pushing the cutting head down into the ground.

The string trimmer works best with a light touch, with the

cutting head resting easily on the ground.

• You may be hitting the cutting head against rocks, concrete

driveways or other hard obstacles. Try approaching them

slowly, and from different directions, to avoid unnecessary

wear.

• If none of the above helps, visit our web site at www.

dirtyhandtools.com or call 1-877-487-8275 for assistance.

24

Page 25

3

14

2

15

1

13

HANDLEBAR ASSEMBLY

11

Item # Part # Description Qty.

1 100128 Hex Nut, Nylock, M8 x 1.25, G8.8 1

2 100130 Flat Washer, M8 1

3 100837 Hex Bolt, M8 x 1.25 x 60mm, G8.8 1

4 101156 Lower Handlebar 1

5 101157 Upper Handlebar 1

6 102902 Handlebar Jaw Adjuster, Left 2

7 102903 Handlebar Jaw Adjuster, Right 2

8 101160 Spring .720 OD x .063 2

9 101161 Handlebar Adjuster Handle 2

10 101162 Carriage Bolt, M8 x 1.25 x 80mm 2

11 101165 Bail Bar 1

12 101166 Belt Engagement Cable Assembly 1

13 101164 Throttle Cable Assembly 1

14 101752 Pull Cord Guide 1

15 101494 Hex Nut, Nylock M6 x 1.0, G8.8 1

12

5

4

8

6

9

7

10

25

Page 26

ENGINE ASSEMBLY

9

6 3

30 13

23

1

24

22

21

37

19

18

32

10 8

28

4

11

17

25

26

36

31

14

29 15

2

34

7

33

5

27

12

35

16 20

SEE CUTTING HEAD

ASSEMBLY

PAGE 28

26

Page 27

ENGINE ASSEMBLY

Item # Part # Description Qty.

1 101138 Frame Plate 1

2 101151 Debris Guard 1

3 101148 Belt Guide 1

4 100125 Hex Bolt, M8 x 1.25 x 20mm, G8.8 4

5 101300 Hex Bolt, 5/16-18 x 3”, G5 1

6 100126 Hex Bolt, M8 x 1.25 x 30mm, G8.8 1

7 101140 Engine Belt Pulley 1

8 101146 Idler Stand Off 1

9 101136 Engine, Kohler XT6.5, 49ST 1

10 101145 Spring 1

11 101150 Safety Guard 1

12 101050 Cutting Head Assembly 1

13 101049 Nose Cover 1

14 100128 Hex Nut, Nylock, M8 x 1.25, G8.8 1

15 101494 Hex Nut, Nylock, M6 x 1.0, G8.8 3

16 101491 Hex Bolt, 3/8-16 x 1.5, G5 3

17 101492 Hex Bolt, M6 x 1.0 x 14, G8.8 1 4

18 101493 Hex Bolt, M8 x 1.25 x 20, G8.8 4

19 101536 Hex Bolt, M6 x 1.0 x 20, G8.8 1

20 100611 Lock Washer, 3/8 4

21 100127 Lock Washer, M8 9

22 100202 Lock Washer, M6 4

23 100579 Hex Nut, M8 x 1.25 9

24 100198 Hex Nut, M6 x 1.0, G8.8 4

25 100077 Flat Washer, 1/2” 2

26 100130 Flat Washer, M8 2

27 107456 V-Belt, 3L X 44” 1

28 101137 Tension Pulley Bracket 1

29 101227 Engine Belt Guide 1

30 101225 DHT Decal 1

31 101052 Danger Decal 1

32 101054 Safety Decal 1

33 101144 Idler Pulley Flat 1

34 101143 Idler Pulley V 1

35 101810 Pulley Bottom Bracket 1

36 101147 Spacer, Idler Pulley 2

37 108747 Debris Guard Bar 1

27

Page 28

AXLE/WHEEL ASSEMBLY

Item # Part # Description Qty.

1 101152 Axle 1

2 101094 Wheel Assembly 2

3 100128 Hex Nut, Nylock, M8 x 1.25, G8.8 2

CUTTING HEAD ASSEMBLY

1

2

3

12

14

10

15

16

2

11

1

17

9

3

7

8

5

6

Item # Part # Description Qty.

1 101149 Hexagon Spindle 1

2 101041 Spindle Rod 1

3 101043 Bearing Cover 1

4 101042 End Cap 1

5 101037 Blade Slot 1

6 101038 Spacer 4

7 101036 Blade 2

8 101044 String 2

9 101039 Blade Pin 2

10 101045 Bearing 2

11 101040 Spindle Spacer 1

12 100085 Hex Bolt, M6 x 1.0 x 20mm, G8.8 1

13 100126 Hex Bolt, M8 x 1.25 x 30mm, G8.8 1

14 100202 Lock Washer, M6 1

15 100445 Fender Washer, M6 1

16 101141 Belt Pulley 1

17 101827 Retaining Ring, Internal, 40mm 1

13

4

28

Page 29

NOTES

29

Page 30

NOTES

30

Page 31

NOTES

31

Page 32

CRAFTSMAN®

is a registered trademark of Stanley Black & Decker, Inc., used under license.

© 2018 CRAFTSMAN

All rights reserved.

Product Manufactured by:

Frictionless World

1100 W 120th Ave. Suite 600

Westminster, Colorado 80234

U.S. & Canada Only

Loading...

Loading...