Page 1

INSTRUCTION MANUAL | GUIDE D’UTILISATION | MANUAL DE INSTRUCTIONES

4” RESTORER

4” RESTAURADOR

PONCEUSE 4”

CMXEQWX3232

IF YOU HAVE QUESTIONS OR COMMENTS, CONTACT US.

POUR TOUTE QUESTION OU TOUT COMMENTAIRE, NOUS CONTACTER.

SI TIENE DUDAS O COMENTARIOS, CONTÁCTENOS.

1-888-331-4569 WWW.CRAFTSMAN.COM

Page 2

TABLE OF CONTENTS

DEFINITONS: SAFETY ALERT SYMBOLS AND WORDS

GENERAL SAFETY WARNINGS

EYE, EAR & LUNG PROTECTION

ELECTRICAL SAFETY

POWER TOOL SAFETY

GENERAL SAFETY RULES

WORK AREA

ELECTRICAL SAFETY

PERSONAL SAFETY

POWERS TOOL USE AND CARE

SERVICE

SPECIFIC SAFETY RULES

GUIDELINES FOR EXTENSION CORDS

SYMBOLS

ASSEMBLY AND OPERATING

CHANGING SANDING SLEEVE ON ROLLER

VARIABLE SPEED CONTROL

ON/OFF TRIGGER SWITCH

LOCK-ON BUTTON

SANDING

CLEANING THE TOOL

MAINTENANCE

EXPLODED VIEW

PARTS LIST

WARRANTY

2

Page 3

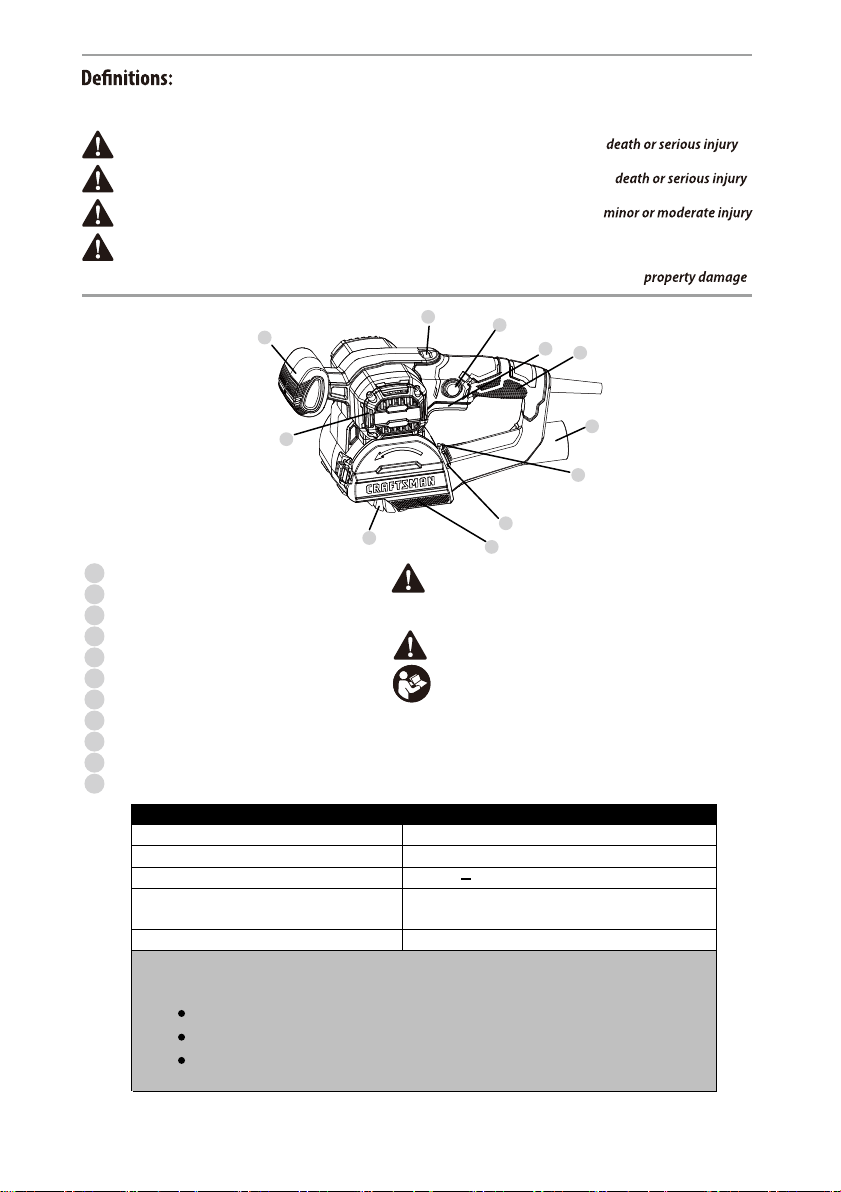

This instruction manual uses the following safety alert symbols and words to alert you to hazardous situations and your risk

of personal injury or property damage.

Safety Alert Symbols and Words

DANGER: Indicates a n imminently hazardous situation wh ich, if not avoided, will result in .

WARNING: Indicates a potentially hazardous situation w hich, if not avoided, could resul t in .

CAUTION: Indicates a potentially hazardous situation w hich, if not avoided, may result in .

(Used without word) Indicates a safety related message.

NOTICE: Indicates a practice not related to personal i njury which, if not avoided, may result in .

1

Variable speed control

2

Lock-on button

3

ON/OFF trigger switch

4

Main handle

5

Dust port

6

Roller end cover hasp

7

Roller end cover clamp

8

Roller end cover

9

Roller

10

Air vents

11

handle

Rating: 120 V, 60 Hz AC

Amperes: 4 A

Speed: 1,000 3,200 RPM (no load)

Sanding roller size: 2 13/16" (72mm) diameter

Weight: 4 lb. 8 oz. (2.0 kg)

Need Assistance?

Call our toll free customer support line:1-888-331-4569

1

11

10

9

Components

WARNING: Read all s afety warnings and all

instructions. Fail ure to follow the warnings and

instructions may re sult in electric shock, fire and/or

WARNING: Never mod ify the product or any part of it.

WARNING: To reduce the risk of injury, read the

If you have any questions or comments about this or

any product, call CRAFTSMAN toll free at:

1-888-331-4569.

PRODUCT SPECIFICATIONS

4" (100mm) wide

Technical questions

Replacement parts

Parts missing from package

3

2

3

4

5

6

7

8

Page 4

WARNING:

manual and follow all Safety Rules and Operating Instructions. The important

precautions, safeguards and instructions appearing in this manual are not

meant to cover all possible situations. It must be understood that common

sense and caution are factors which cannot be built into the product.

!

GENERAL SAFETY WARNINGS

Before using this tool or any of its accessories, read this

This instruction manual includes the following:

General Safety Rules

Specific Safety Rules and Symbols

Functional Description

Assembly

Operation

Maintenance

Accessories

EYE, EAR & LUNG PROTECTION

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CAN/CSA

STANDARD Z94.3 or ANSI SAFETY STANDARD Z87.1

FLYING DEBRIS can cause permanent eye damage. Prescription

eyeglasses ARE NOT a replacement for proper eye protection.

WARNING:

broken during the operation of a power tool.

!

WARNING: Use hearing protection, particularly during extended

periods of operation of the tool, or if the operation is noisy.

Non-compliant eyewear can cause serious injury if

!

SAVE THESE INSTRUCTIONS FOR REFERENCE

4

Page 5

GENERAL SAFETY WARNINGS

ELECTRICAL SAFETY

WEAR A DUST MASK THAT IS DESIGNED TO BE USED WHEN

OPERATING A POWER TOOL IN A DUSTY ENVIRONMENT.

WARNING:

!

drilling, and other construction activities may contain chemicals that are

known to cause cancer, birth defects, or other genetic abnormalities. These

chemicals include:

Lead from lead-based paints

Crystalline

products

Arsenic and chromium from chemically treated lumber

The level of risk from exposure to these chemicals varies, according to how

often this type of work is performed. In order to reduce exposure to these

chemicals, work in a well-ventilated area, and use approved safety

equipment, such as a dust mask that is specifically designed to filte

microscopic particles.

WARNING:

tool, use proper circuit protection.

This tool is wired at the factory for 120 V AC operation. It must be

connected to a 120 V AC, 15 A circuit that is protected by a time-delayed

fuse or circuit breaker. To avoid shock or fire, replace power cord

immediately if it is worn, cut or damaged in any way.

Dust that is created by power sanding, sawing, grinding,

silica from bricks, cement, and ot

To avoid electrical hazards, fire hazards or damage to the

her masonry

r out

SAVE THESE INSTRUCTIONS FOR REFERENCE

5

Page 6

follow the warnings and instructions may result

in electric shock, fire and/or serious injury.

Save all warnings and instructions for future

reference.

WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

create sparks which may ignite the dust or

fumes.

Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

ELECTRICAL SAFETY

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs and

matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or

grounded

ranges and refrigerators. There is an

increased risk of electric shock if your body is

earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep the cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangl

shock.

!

WARNING:

warnings and instructions. Failure to

surfaces such as pipes, radiators,

ed cords increase the risk of electric

POWER TOOL SAFETY

Read all safety

tools

SAVE THESE INSTRUCTIONS FOR REFERENCE

When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of a ground f ault

circuit interrupter (GFCI) reduces the risk of

electric shock.

PERSONAL SAFETY

Stay al

common sense when operating a power tool.

Do not use a power tool while you are tired

or under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used fo

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attach

may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

ert, watch what you are doing and use

r appropriate

ed to a rotating part of the power tool

6

Page 7

Personal safety

If devices are provided for the connection of

dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

POWER TOOL USE AND CARE

Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it wa

Do not use the power tool

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the

Store idle power tools out of the reach of

chi

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation. I

damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

Keep

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

ldren and do not allow persons unfamiliar

cutting tools sharp and clean. Properly

s designed.

power tool accidentally.

POWER TOOL SAFETY

if the switch does

Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the

work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Hold power tool by insulated grippi

surfaces, because the abrasive sleeve may

contact its own cord. Cutting a "live" wire may

make exposed metal parts of the tool "live" and

could give the operator an electric shock.

SERVICE

Have your power tool serviced by a qualifie

repair person using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

f

ng

d

SAVE THESE INSTRUCTIONS FOR REFERENCE

7

Page 8

Do not plug in the Restorer

until you have read and understand this

Instruction Manual. Learn the tool’s

applications and limitations, as well as the

specific potential hazards related to this tool.

Following this rule will reduce the risk of electric

shock, fire, or serious injury.

Always wear eye protection. Any power

tool can throw foreign objects into your

eyes and cause permanent eye damage.

ALWAYS wear safety g

comply with CAN/CSA Standard Z94.3 or ANSI

safety standard Z87.1. Everyday glasses have

only impact resistant lenses. They ARE NOT

safety glasses.

!

WARNING: Glasses or goggles not in

compliance with ANSI Z87.1 could cause

serious inj

!

when sanding or stripping paint.

!

protection when using this tool, particularly

during extended periods of operation.

!

the power source before changing the roller,

sanding cylinder, accessory and when

cleaning the tool.

!

WARNING: FIRE HAZARD:

Never us

atmosphere or combustible materials. If the

sandpaper hits a nail or any ferrous metal, a

spark could cause an explosion of fire.

!

WARNING: FIRE HAZARD:

Collected sanding dust from sanding

coatings such as polyur

etc. can self-ignite. To reduce the risk, clear

dust frequently from the sanding drum area and

from the surrounding work area. Str

the cleaning instructions in the Owner’ s Manual

and coating manufacturer’s instructions.

ury when they break.

WARNING: Always use a dust mask

WARNING: Always use hearing

WARNING: Always unplug the tool from

e this tool near explosive

SPECIFIC SAFETY RULES

oggles (not glasses) that

ethane, linseed oil

ictly follow

!

WARNING:

and a dust mask when using compressed air

to remove sanding dust from the tool.

!

WARNING: Make sure the roller has

come to a full stop before taking your hands

off the tool. If the roller is still moving, the tool

may move erratically and either damag

workpiece or cause injury to the user.

Always place the Restorer on its “ nose”

(balanced between the front handle and the

roller housing) when the tool is turned OFF and

when storing the tool. This will prevent

inadvertent loss of control if the tool is

accidentally turned ON. It will also avoid the

roller from developi

stored for long periods of time with weight

the roller.

Always use two hands when operating the

Restorer. One hand should be used on the front

handle and the other hand should be placed on

the rear handle to operate the switches. Using

both hands will provide better control over the

tool.

Do not wear gloves, neckties or loose clothing.

Secure the workpiece. Use clamps or a vise to

hold the wo

using yo

ur hand and it frees both hands to

operate the tool.

Do not use this tool on material too small to be

securely held.

Make sure there are no nails or foreign objects

in the part of the workpiece to be sanded or

cleaned.

Always keep hands out of the path of the roller.

Avoid awkward hand positions where a sudden

slip could cause your hand to move into the path

of the roller.

Always use safety goggles

e the

ng a flat spot if the tool is

on

rk when practical. It is safer than

SAVE THESE INSTRUCTIONS FOR REFERENCE

8

Page 9

9

GUIDELINES FOR EXTENSION CORDS

!

(

(

(

(

!

Make sure your extension cord is the proper

size. When using an extension cord, be sure to

use one heavy enough to carry the current the

tool will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power

and overheating. The table at right shows the

correct size to use according to cord length and

nameplate ampere rating. If in doubt, use the

next heavier gauge. The sma

number the heavier

the cord.

ller the gauge

Be sure your extension cord is properly

wired and in good condition. Always replace a

damaged extension cord or have it repaired by a

qualified electrician before using it. Protect your

extension cord from sharp objects, excessive

heat and damp or wet areas.

Use a separate electrical circuit for your

power tools. This circuit must not be less than

14 ga

uge wire and should be protected with

either a 15A time delay fuse

or circuit breaker.

Before connecting the power tool to the power

source, make sure the switch is in the OFF

position and the power source is the same as

indicated on the nameplate. Running at lower

voltage will damage the motor.

WARNING: Repair or replace damaged

or worn extension cords immediately.

Select the appropriate exte

nsion cord gauge

and length using the chart at right.

When operating a power tool outdoors, u

se

an outdoor extension cord marked “W -A” or

hese cords are rated for outdoor use and

T

“W”.

reduce the risk of electric shock.

WARNING: Keep the extension cord

clear of the working area. Position the cord

so it will not get caught on the workpiece,

tools or any other obstructions while you are

working with the power tool.

MINIMUM GAUGE (AWG) EXTENSION

CORDS (120 V use only)

Ampere rating Total length in feet

More

than

Not

more

than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Applicable

7.5 m

25')

15 m

50')

30 m

100')

45 m

150')

SAVE THESE INSTRUCTIONS FOR REFERENCE

Page 10

This symbol designates that this tool Conforms

t

t

b

3042597

V

A

Hz

W

kW

L

kg

H

Newtons per square

centimeter

Pa

OPM

Min

S

Three-phase alternating

current

Three-phase alternating

current with neutral

Alternating or direct

current

Splash-proof

construction

Protective grounding at

Class I tools

Revolutions or

minute

Wear your safety

glasses

SYMBOLS

WARNING:

!

these symbols and learn their meaning. Proper interpretation of these symbols will

allow for more efficient and safer operation of this tool.

Some of the following symbols may appear on the Restorer. Study

Volts

Amperes

Hertz

Watts

Kilowatts

Microfarads

Liters

Kilograms

Hours

N/cm2

Pascals

Oscillations per minute

Minutes

Seconds

or a.c.

Alternating current

Direct current

JD2679U

o UL Std. 60745-1, 60745-2-4 and is Certified

o CAN/CSA Std.C22.2 No. 60745-1, 60745-2-4

y ETL Testing Laboratories, Inc.

No load speed

Class II construction

Watertight construction

grounding terminal,

reciprocations per

Diameter

Off position

Directional arrow

Warning symbol

Wear a dust mask

Wear hearing protection

Fire hazard

Read all instructions

Page 11

CHANGING SANDING SLEEVE ON ROLLER

!

WARNING: Remove the plug from the

power source before installing or removing a

sanding roller.

1. Lift the two roller end cover hasps (1) away

from the main housing (2) (Fig. 1).

2

1

3

2. Release the RIGHT hasp from the roller

end cover (3).

3. Pull the cover out from the main housing

and flip it toward the front of the tool using

the LEFT hasp as a hinge (Fig

ASSEMBLY AND OPERATING

1

Fig. 1

2).

4. Slide the roller (4) off the roller shaft (5).

5. Remove the old sanding sleeve and slide

the new sanding sleeve (6) onto the roller

(4) (Fig. 3).

NOTE: Rotate the roller sleeve counterclockwise as you slide the roller sleeve fully

onto the roller. Make sure it is centered on

the roller and is not overhanging one end

of the roller.

Fig. 2

6. Slide the roller onto the roller shaft

NOTE: The roller can only be installed one

. When properly installed, the

way

directional arrow (7) on the end of the roller

will be visible.

7. Reinstall the roller end cover and fasten it

in place with the two roller end cover

hasps.

CAUTION: Make sure the roller end cover

is properly seated onto the main housing

and the hasps snap into place.

VARIABLE SPEED CONTROL

The variable sp

change the speed at which the roller will rotate

(Fig. 5). Rotate the speed c ontrol to the LEFT

(#1) for slowest speed and to the right (MAX) for

the fastest speed.

NOTE: See "SANDING" section of this manual

for recommended speeds.

Fig. 3

Fig. 4

eed control (1) can be rotated to

11

6

4

7

(Fig. 4).

Page 12

ON/OFF TRIGGER SWITCH

The ON/OFF trigger switch (1) is a single

function switch (Fig. 6). To turn the tool ON,

squeeze the trigger. To turn the tool OFF,

release the trigger.

LOCK-ON BUTTON

The lock-on button (2) is used to lock the

ON/OFF trigger switch in the ON position

(Fig. 7). Locking the trigger switch in the ON

position will reduce hand fatigue when operating

the tool for extended perio

1. To lock the trigger switch i

position, squeeze the trigger (1) to turn the

tool ON.

2. While squeezing the trigger, press the lockon button (2) into the handle.

3. While holding the lock-on button into the

handle, release the trigger. At this point,

the tool will remain running.

ASSEMBLY AND OPERATING

1

Fig. 5

Fig.

1

6

ds of time.

n the ON

4. To release the lock-on button to turn the

tool OFF, squeeze and then release the

trigg

er. The trigger switch will then turn

OFF.

!

WARNING:

depressed by cycling the ON/OFF switch

several times or by depressing and releasing

the switch several times before plugging in your

restorer. Damage to your tool or personal injury

may result.

!

WARNING

Fig. 7

Be sure the lock button is not

2

1

12

Page 13

13

ASSEMBLY AND OPERATING

!

!

! ! !

SANDING

This tool can be used to sand rough material or

to remove paint, varnish or other finishes.

WARNING: Always use safety glasses,

dust mask and hearing protection when

operating this tool. Failure to wear these

protective devices may cause serious

injuries.

WARNING: Never use this tool near

flammable materials. A spark from sanding

hidden fasteners could ignite flammable

rials.

mate

WARNING: An unsecured workpiece

could be thrown toward the operator causing

injury.

WARNING: Clamp or otherwise secure

your workpiece to prevent it from moving under

the Restorer while being sanded.

WARNING: Always use two hands to

operate this tool. One hand should be on the

front handle and the other on the rear

handle. Failure to use two hands may cause

the tool to be

cause serious injury to the operator.

Do NOT cover the cooli

will cause the tool to overheat and damage the

tool.

Before starting any sanding project, you should

practice sanding on a scrap workpiece similar to

the item to be sanded. This will allow you to get

the "feel" of the tool and also establish the grit of

the sanding sleeve and

the type of material being sanded.

In general, removing heavier finishes and when

sanding rough surface

sleeve and slower tool speeds are

recommended. Slower speeds will reduce the

heat created while sanding and reduce the

tendency of the sanding sleeve to become

clogged. For sanding smoother surfaces without

finishes, finer sanding sleeves and higher

speeds are recommended.

difficult to control and possibly

ng vents in the tool. This

tool speed to best suit

s, a coarser sanding

tool

To begin sanding, install the appropriate

sanding sleeve, set the tool speed and squeeze

the trigger switch to turn the tool ON.

NOTE: The sa

contact with the workpiece until it has reached

its operating speed.

Once the tool has reached its operating speed,

hold onto the tool with both hands and carefully

bring the sanding sleeve into

workpiece.

NOTE: When the sanding sleeve contacts the

workpiece, the tool will tend to be pulled forward

away from you. Make sure you have a firm grip

on the tool with both hands.

NOT FORCE THE RESTORER. The weight

DO

of the Restorer usually provides adequate

pressure. Let the Restorer and the sandpaper

do the work. Applying added pressure will slow

the motor, increase the wear on t

sleeve and greatly reduce the tool speed. Motor

damage may occur if excessive downward

pressure is applied. It will also create an inferior

finish on sanded work. Any finish or resin on

wood will soften from the frictional heat, c

the sanding sleeve to become clogged very

quickly. Do not sand in one spot as the sanding

sleeve will remove too much material, making

the surface uneven.

When sanding wood, always move the Restorer

forward and backward with the grain (Fig. 8).

Sanding across the grain will not leave a smooth

surface.

nding sleeve should NOT be in

contact with the

he sanding

ausing

Fig. 8

Page 14

SANDING

Always keep the tool "moving" when the sanding

sleeve is in contact with the workpiece. This is

particularly important when sanding wood or

other soft materials. Failure to keep the tool

"moving" will result in gouges in the workpiece.

Do not allow sanding dust to accumulate in the

tool. Stop and clean out all loose sanding dust

at regular intervals to prevent unnecessary

buildup that

and to guard against overheating. Refer to

"CLEANING THE TOOL" f or details.

Always place the Restorer on its “nose”

(balanced between the front handle and the

roller housing) when the tool is turned OFF and

when storing the tool (Fig. 9). This will prevent

inadvertent loss of control if the tool is

accidentally turned ON. It will also prevent the

roller from developing a flat spot if the tool is

stored for long periods of time w

will cause the tool to be ineffi

ASSEMBLY AND OPERATING

cient

ith weight on

Fig. 9

CLEANING THE TOOL

It is important to keep the tool as clean as

possible to reduce the risk of fire and to produc e

the best possible sanding results.

!

WARNING: Always remove the plug

from the power source before removing the

sanding roller and before cleaning the tool.

!

WARNING: Always wear safety goggles

and a dust mask when using compressed air

to remove sanding dust from the tool.

!

WARNING:

brake fluids, gasoline, petroleum-based

products, penetrating oils, etc. to come in

contact with plastic parts. They contain

chemicals that can damage, weaken or

destroy plastic.

1. Unlatch the roller end cover (Fig. 1).

2. Remove the roller from the tool.

3. Remove the

4. Use compressed air to blow all the loose

sanding dust from the:

NOTE: If compressed air is not available, use a

soft DRY long bristled brush to remove the

sanding dust.

Use a clean, dry cloth to remove sanding dust

from the other tool components.

NOTE: Do NOT use any solvents or water on

the cloth.

Do not at any time allow

sanding sleeve from the roller.

roller housing,

roller end cover.

slots in the roller, and

dust chute in the back of the rear

handle.

14

Page 15

15

MAINTENANCE

!

! ! !

GENERAL

WARNING: When servicing, use only

identical replacement parts. Use of any other

replacement parts may create a hazard or

cause product damage.

DO NOT use solvents when cleaning plastic

parts. Most plastics are susceptible to damage

from various types of commercial solvents and

may be damaged by their use. Use a clean cloth

to remove dirt, dust, oil, grease, etc.

WARNING: Do not at any time allow

brake fluids, gasoline, petroleum-based

products, penetrating oils, etc. to come in

contact with plastic parts. They contain

chemicals that can damage, weaken or

destroy plastic.

DO NOT abuse power tools. Abusive practices

can damage the tool as well as the workpiece.

WARNING: DO NOT attempt to modify

tools or create accessories not

recommended. Any such alteration or

modification is misuse and could result in a

hazardous condition leading to possible

serious injury. It will also void the warranty.

It has been found that electric tools are

subjected to accelerated wear and possible

premature failure when they are used on

fiberglass boats and automotive parts,

wallboard, spackling compounds or plaster. The

chips and grindings from these materials are

highly abrasive to electric tool parts such as

bearings, brushes, commutators, etc.

Consequently, it is not recommended that this

tool be used for extended work on any

fiberglass material, wallboard, spackling

compounds or plaster. During any use on these

materials it is extremely important that the tool is

cleaned frequently by blowing the dust out of the

tool with an air jet. See "CLEANING THE TOOL"

section of this manual for details.

WARNING: Always wear safety goggles

or safety glasses with side shields during all

sanding operations. It is critical that you also

wear safety goggles or safety glasses with

side shields and a dust mask while blowing

dust out of the Restorer with an air jet.

Failure to take these safety precautions

could result in permanent eye or lung

damage.

LUBRICATION

All of the bearings in this restorer are lubricated

with a sufficient amount of high grade lubricant

for the life of the unit under normal conditions.

Therefore, no further lubrication is required.

Page 16

EXPLODED VIEW

16

Page 17

17

Key #

Part #

Part Name

Quantity

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

PARTS LIST

!

!

WARNING:

other parts may create a safety hazard or cause damage to the Restorer.

WARNING: To assure SAFETY and RELIABILITY of repairs, maintenance and accessories, the

use of any accessory not recommended for use with this tool could be hazardous. Recommended

accessories for use with your tool are available

you need assistance regarding accessories, please call the toll-free helpline at 1-888-331-4569.

Any attempt to repair or replace electrical parts on this Restorer may create a safety hazard unless

repairs are performed by a qualified technician. For more information, call the toll-free helpline, at

1-888-331-4569.

Always order by PART NUMBER, not by key number.

When servicing, use only original equipment replacement parts. The use of any

from your local dealer or authorized service center. If

1190030064

3140010054

4030010099

2030050002

1061260011

1130010270

3011300003

4030010106

3140070029

3150010116

1010310001

2040080048

2040040116

3160090120

4030010096

4010010054

2040080049

2030170007

4010010084

2040310051

2040040117

4130010020

6300010003

2030160168

4020010031

2040310052

4100020010

4030010179

2030020269

2030030316

3160090121

4010010042

3150050097

Cord & Plug

Cord Sleeve

Tapping Screw ST3.9X14

Strain Relief

Switch

Circuit board

Housing

Tapping Screw ST3.9X19

Non-slip mat

Fan

Rotor

Transmission gear

Gear shaft

Gear cover

Tapping Screw ST3.9X12

Bearing6000 2RS

Output gear

Bearing Washer

Bearing6002 2RS

Wheel coupling sleeve

Output shaft

Elastic

cylindrical pin

Roller

Anti-reverse platen

Tapping Screw M3X10

Quick coupling sleeve

Spring washer Φ14

Tapping Screw ST3.9X10

Bearing Washer

Sand ring baffle

Rear cover

Bearing696

Guide vane

1

1

2

1

1

1

1

12

2

1

1

1

1

1

5

2

1

1

2

1

1

1

1

1

2

2

1

8

2

2

1

2

1

Page 18

18

PARTS LIST

Key #

Part #

Part Name

Quantity

34

35

36

37

38

39

40

41

42

1020310001

4010010053

4030010120

2030030281

4030010020

1230010146

2030070053

3160050013

1250010002

Stator

Bearing607 2RS

Tapping Screw ST3.9X60

Hasp

Tapping Screw ST2.9X6

Carbon Brush

Brush Holder

Motor cover

Terminal block

1

1

2

2

4

2

2

1

1

CRAFTSMAN will repair, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase. This warranty does not

cover part failure due to normal wear or tool abuse. For further detail of warranty

THREE YEAR LIMITED WARRANTY

coverage and warranty repair information, visit www.craftsman.com

or call 1-888-331-4569. This warranty does not apply to accessories or damage

caused where repairs have been mad

e or attempted by others. This warranty

gives you specific legal rights and you may have other rights which vary in

certain states or provinces.

In addition to the warranty, CRAFTSMAN tools are covered by our:

1 YEAR FREE SERVICE: CRAFTSMAN will maintain the tool and replace worn

parts caused by normal use, for free, any time during the first year after

purchase.

90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with

the performan

ce of your CRAFTSMAN Power Tool, Laser, or Nailer for any

reason, you can return it within 90 days from the date of purchase with a receipt

for a full refund – no questions asked.

To register your tool for warranty service, visit our website at

www.craftsman.com.

LATIN AMERICA: This warranty does not apply to products sold in Latin

America. For products sold in Latin America, see country specific warranty

informa

tion contained in the packaging, call the local company or see website for

warranty information.

CRAFTSMAN

®

is a registered trademark of Stanley Black & Decker, Inc., used under license.

©2019 CRAFTSMAN.

Product Manufactured by: Jinding Group Co.,Ltd.

LICENSEE NAME: Wellington Corp LLC.

LICENSEE ADDRESS: 1510 Ridge Rd Vienna, OH 44473.

U.S. & Canada Only.

Rev 1.0 04/03/2019

Loading...

Loading...