Page 1

S _ARS

Owners

manual

Model

C950524312A

11.5 H.P, 30 inch

DUAL STAG

SNOW BLOWER

CAUTION:

You must read and

understand this owner's

manual before operating

unit.

Serial No.

401428 SEARS CANADA INC., TORONTO, ONTARIO M5B 2B8 PrintedinU.S.A.

Page 2

RULES FOR SAFE OPERATION

GeneralInformation

Thisinstructionbookiswrittenfora personwithsomemechanicalability.

Ukemostservicebooks,notallthestepsaredescribed.Stepsonhowto

loosenortightenfastenersarestepsanyonecanfollowwithsome

mechanicalability.Readandfollowtheseinstructionsbeforeyouusethe

unit.

Knowyourproduct:Ifyouunderstandtheunitandhowtheunit

operates,youwillgetthebestperformance.Asyoureadthismanual,

comparethe illustrationstotheunit.Leamthe locationandthefunctionof

thecontrols.Tohetppreventanaccident,fellowtheoperafinginstructions

andthesafetyrules.Keepthismanualforfuturereference.

IMPORTANT:Manyunitsarenotassembledandaresoldincartons.Itis

theresponsibilityoftheownertomakesuretheassemblyinstructionsin

thismanualareexactlyfollowed.Otherunitsarepurchasedinan

assembledcondition.Onassembledunits,itistheresponsibilityefthe

ownertomakesuretheunitiscorrectlyassembled.Theownermust

carefullychecktheunitaccordingtotheinstrustionsinthismanualbefore

itisfirstused.

,_1_ Thismanualcontainssafetyinformationtomakeyou

awareofthehazardsanddsksassociatedwithsnow

throwers,andhowtoavoidthem. Thesnowthrowerisdesignedand

intendedforremovalofsnow,andshouldnot beusedforanyother

purpose,it isimportantthatyoureadandunderstandthese

instructions,andanyoneoperatingtheequipmentreadand

understandtheseinstructions.

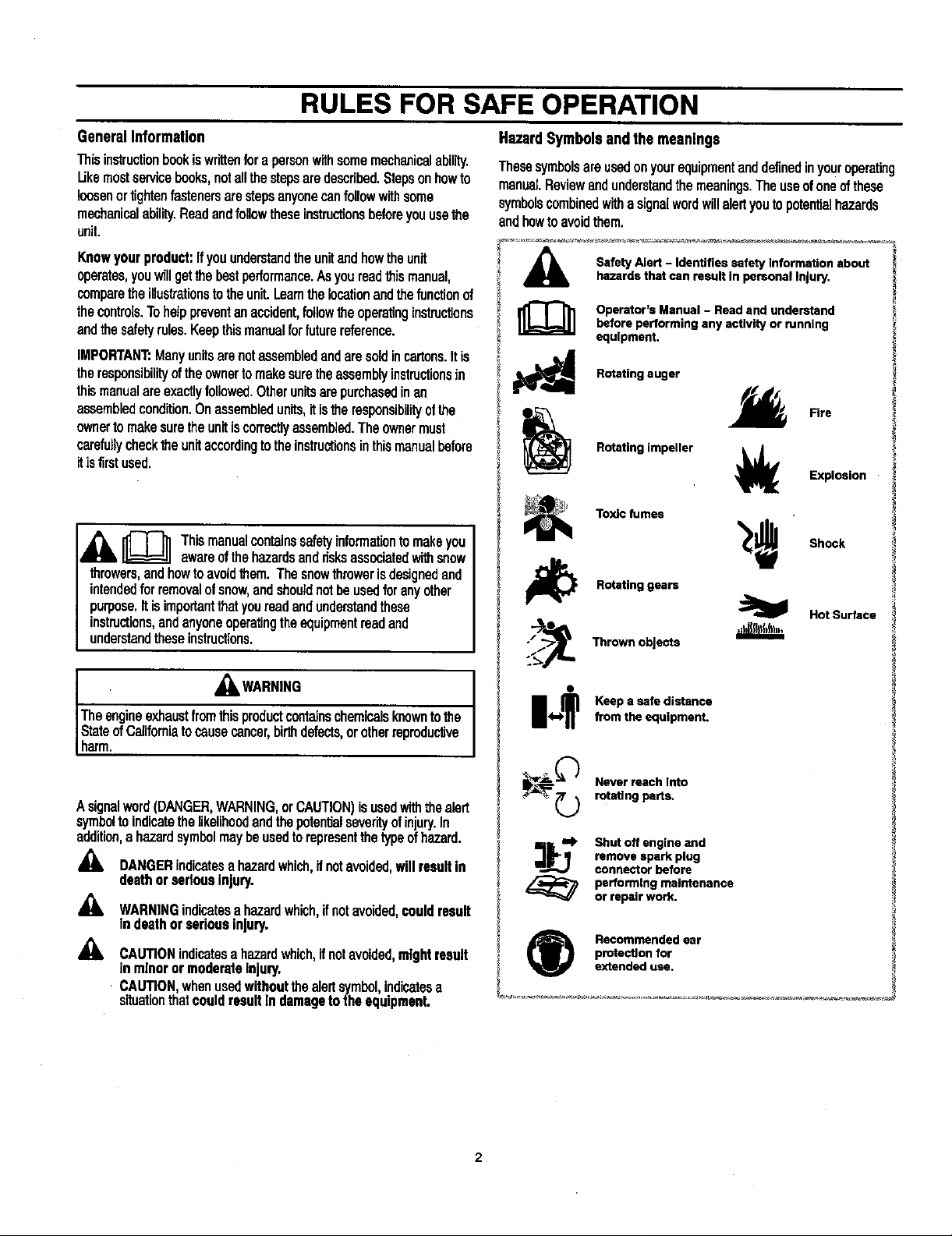

HazardSymbolsend themeanings

ThesesymbolsareusedonyourequipmentanddefinedinYouroperating

manual.Reviewandunderstandthemeanings.Theuseofoneofthese

symbolscombinedwithasignalwordwillalertyoutopotentialhazards

andhowtoavoidthem.

,_ Safety Alert - Identifies safety Information about

_]]] perator's Manual - Read and understand

_ RutaUng auger

li_ Rotating gears

/_ Thrown objects

hazards that can result in personal Injury,

before performing any activity or running

equipment.

Fire

Rotating impeller _ Explosion

Toxic fumes

Shock

HotSu_ace

• ,_WARNING

Theengineexhaustfromthisproductcontainschemicalsknowntothe

StateofCaliforniatocausecancer,birthdefects,orotherrepmducUve

harm.

A signalword(DANGER,WARNING,orCAUTION)isusedwiththealert

symboltoindicatethelikelihoodandthe potentialseverityofinjury.In

addition,a hazardsymbolmaybeusedtorepresentthetypeofhazard.

,_ DANGERindicatesahazardwhich,ifnotavoided,willresultin

deathorseriousInjury.

_1= WARNINGindicatesahazardwhich,ifnotavoided,couldresult

indeathorseriousInjury.

_. CAUTIONindicatesa hazardwhich,ifnotavoided,mightresult

in minoror moderateinjury.

CAUTION,whenusedwithoutthealertsymbolindicatesa

sifuatonthatcouldresultIn damagetothe equipment,

14._? Keep a safe distancefrom the equlpmenL

_ ever reach Into

:_mt. Shot off engine and

(_ Recommended ear

rotating parts,

remove spark plug

connector before

pertormlng maintenance

or repair work.

protection for

extended use.

2

Page 3

RULES FOR SAFE OPERATION

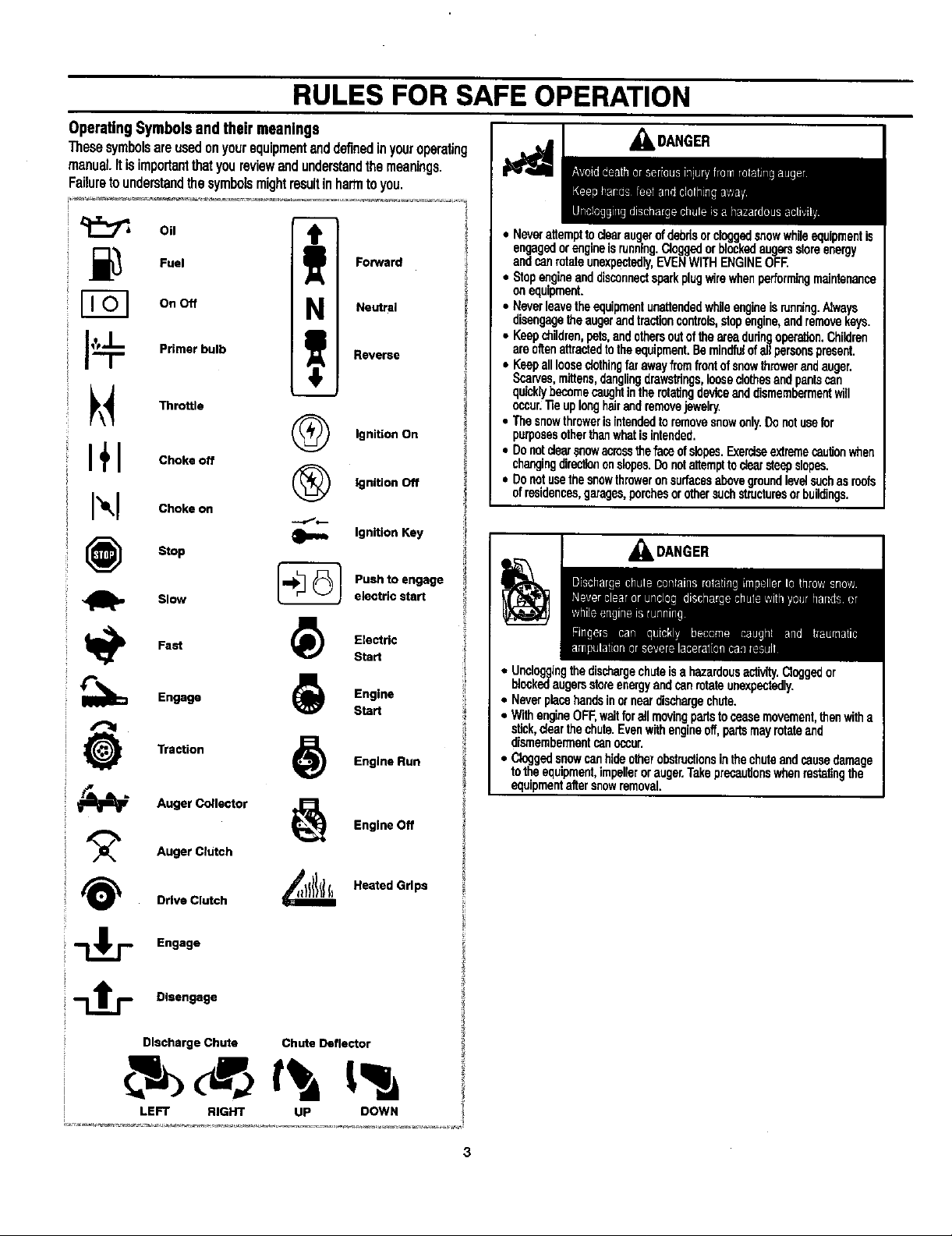

OperatingSymbolsandtheirmeanings

These symbolsare usedonyourequipmentenddefinedinyouroperating

manuel. Itisimportantthat youreviewandunderstandthe meanings.

Failureto understandthe symbolsmightresultinharmto you.

_kDANGER

Oil

_,_ Fuel

On Off

J_ Primerbulb

_\_ Throttle

I+1 Ch.oo

Ch.on

Stop

Slow

Fast _) Electric

Engage (_ Engine

Traction _) Engine Run

Forward

N Neutral

Reverse

(_ Ignition On

(_ Ignition Off

Ignition Key

-_ Pushto engage

electric start

Start

Start

• NeverattempttodearaugerofdebdsorcloggedsnowwhJeequipmentis

engagedorengineis running.Cloggedorblockedaugersstoreenergy

andcanrotateunexpectedly,EVENWITHENGINEOFf

• Stopengineanddisconnectsparkplugwirewhenperformingmaintenance

onequipment.

• Neverleavetheequipmentunattendedwhileengineisrunning.Nways

disengagetheaugerendtractioncontrols,stopengine,andremovekeys.

• Keepchildren,pets,andothersoutoftheareadudngoperation.Children

areo_enattractedtotheequipment.Beminclfutofallparsonspresent.

• Keepalllooseclothingfarawayfromfrontofsnowthrowerendauger.

Scarves,mittens,danglingdrawstdngslooseclothesandpantscan

qucklybecomecaughtintherotatingdeviceanddismembermentwill

occur."fieuplonghairendremovejewelry.

• Thesnowthrowerisintendedtoremovesnowonly.Donotusefor

purposesotherthenwhatisintended.

• Donotclearsnowacmssthefaceofslopes.Exerciseextremecautionwhen

changingdirectiononslopes.Donotattempttoclearsteepslopes.

• Donotusethesnowthroweronsurfacesabovegroundlevelsuchasreefs

ofresidences,garages,perchesorothersuchstructuresorbuildings.

_DANGER

• Uncloggingthedischargechuteisa hazardousactivity.Cloggedor

blockedaugersstoreenergyendcanrotateunexpectedly.

• Neverplacehandsinorneardischargechute.

• WithengineOFF,waitforallmovingpartstoceasemovement,thenwitha

stick,clearthechute.Evenwithengineoff,partsmayrotateend

dismembermentcanoccur.

• Cloggedsnowcanhideotherobstructionsinthechuteandcausedamage

totheequipment,impellerorauger.Takeprecautionswhenrestatingthe

equipmentaltersnowremoval.

Auger Collector _ Engine Off

_/_ Auger Clutch

Drive Clutch _ Heated Grips

Engage

_-_ Disengage

Discharge Chute Chute Deflector

LEFT RIGHT UP DOWN

Page 4

RULES FOR SAFE OPERATION

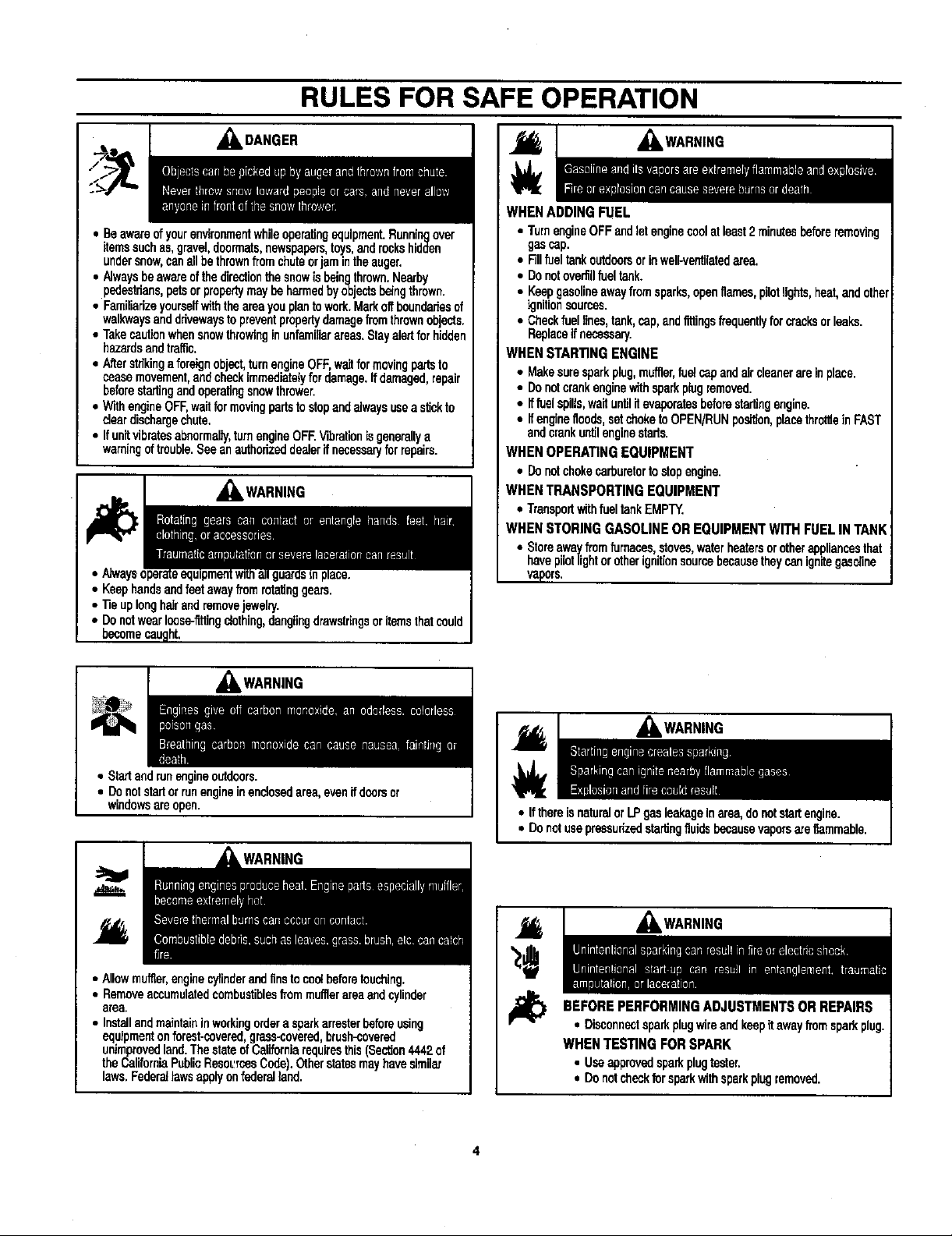

_I=DANGER

• Beawareofyourenvironmentwhileoperatingequipment.Runningover

itemssuchas,gravel,doormats,newspapars,toys,androckshidden

undersnow,canallbethrownfromchuteorjamintheauger.

• Alwaysbeawareofthedirectionthe snowisbeingthrown.Nearby

pedestrians,petsorpropertymaybeharmedbyobjectsbeingthrown.

• Familiarizeyourselfwiththeareayouplantowork.Markoffbeundadasof

walkwaysanddrivewaystopreventpropertydamagefromthrownobjects.

• Takecautionwhensnowthrowinginunfamiliarareas.Stayalertforhidden

hazardsandtraffic.

• Afterstdkinga foreignobject,turnengineOFF,w_ formovingpartsto

ceasemovement,andcheckimmediatelyfordamage.If damaged,repair

beforestartingandoperatingsnowthrower.

• W'dhengineOFF,waitformovingpadsto stopandalwaysuseastickto

cleardischargechute.

• Ifunitvibratesaboormally,turnengineOFRVibrationisgenerallya

warningoftrouble.Seaanauthorizeddealerifnecessaryfor repairs.

• Keephandsandfeetawayfromrataitnggears.

• "fieuplonghairandremovejewelry.

• Donotwearloose-fitting_thing, danglingdrawstringsoritemsthatcould

becomecaught.

,_WARNING

WHENADDINGFUEL

• TurnengineOFFandletenginecoolatleast2minutesbeforeremoving

gascap.

• RIIfueltankoutdoorsorinweli-ventilatadarea.

• Donotoverfillfueltank.

• Keepgasolineawayfromsparks,openflames,pilotlights,heat,andother

k3nitionsources.

• Checkfuellines,tank,cap,andfittingsfrequentlyfor cracksorleaks.

Replaceifnecessary.

WHENSTARTINGENGINE

• Makesuresparkplug,muffler,fuelcapandaircleanerareinplace.

• Donotcrankenginewithsparkplugremoved.

• fffuelspills,waituntilit evaporatesbeforestartingengine.

• ifenginefloods,setchoketoOPEN/RUNpostiion,placethrottleinFAST

andcrankunfitenginestarts.

WHENOPERATINGEQUIPMENT

• Donotchokecarburetorto stopengine.

WHENTRANSPORTINGEQUIPMENT

• TransportwithfueltankEMPTY.

WHENSTORING GASOLINEOR EQUIPMENTWITH FUELIN TANK

• Storeawayfromfurnaces,stoves,waterheatersorotherap_liancasthat

havepilotlightorotherignitionsourcebecausetheycanignitegasaline

vapors,

• Startandrunengineoutdoors.

• Donotstartorrunengineinenclosedarea,evenifdoomsor

windowsareopen.

WARNING

• Allowmuffler,enginecylinderandfinstocoo_beforetouching.

• Removeaccumulatedcombustiblesfrommufflerareaandcylinder

area.

• Installandmaintaininworkingorderasparkarresterbeforeusing

equipmentonforest-cavered,grass-cavered,brush-cavared

unimprovedland.ThestateofCaliforniarequiresthisSection4442of

theCaliforniaPublicResourcesCede. Otherstatesmayhavesimilar

laws.Federalewsapplyonfederalland.

_I=WARNING

• IfthereisnaturalorLPgasleakageInarea,donotstartengine.

• Donutuseprassodzedstaringfluidsbecausevaporsareflammable.

&WARN,NG

BEFORE PERFORMINGADJUSTMENTSOR REPAIRS

• Disconnectsparkplugwireandkeepitawayfromsparkplug.

WHENTESTINGFOR SPARK

• Useapprovedsparkplugtester.

• Donotcheckfor sparkwithsparkplugremoved.

Page 5

OWNER'S INFORMATION

DATE PURCHASED:

MODEL NO:

SERIAL NO:

STORE WHERE PURCHASED:

ADDRESS:

CITY: PROVINCE:

TELEPHONE :

_Recordthis information about your unit so that you will

be able to provide it in case of loss or theft.

MAINTENANCE AGREEMENT

The Craftsman Warranty, plus a Maintenance

Agreement, provide maximum value for Sears

products. Contact your nearest Sears storefor de-

tails.

Horse Power 11.5 HP

Displacement 305 cc

Gasoline Capacity

Oil Capacity (5W30)

Spark Plug: (Gap .030 in.)

Bore

Stroke

Armature Air Gap

IT ire Pressure

* Seeside ofthe tirefor maximuminflation.Do

maximumpressureonthetire wall.

3 quarts (2.8 litre)

28 oz. (0.82 litres)

Champion RC12YC

3.120 in (79 mm)

2.438 in (62 mm)

0.010-0.014in

(0.25-0.36 mm)

notexceed the

CUSTOMER RESPONSIBILITIES

Read and observethe safety rules.

Follow a regular schedule in maintaining, caring for and

using your snow blower.

Follow the instructions under "Customer Responsibilities"

and "Storage" sections of this owner's manual.

WHEELED SNOW BLOWER

LIMITED TWO (2)YEAR WARRANTY ON CRAFTSMAN SNOW BLOWER

Fortwo (2) yearsfrom date of purchase, Sears Canada Inc. willrepair orreplacefree of charge,at Sears option, parts

which are defective as a resultof materialor workmanship.

COMMERCIAL OR RENTAL USE:

Warranty on snowblower willbe 90 daysfrom date of purchase if usedfor commercialor rentalpurposes.

THIS WARRANTY DOES NOT COVER:

1. Pre-delivery set-up.

2. Expendable itemswhichbecomeworn duringnormaluse, such as belts, sparkplugs,filter,shear pinsas well asdam-

ages to the engineresultingfrom operatingthe snowblower withinsufficientoil.

3. Tire replacement or repaircaused by puncturesfrom outsideobjects,such as nails,thorns,stumpsor glass.

4. In homeservice.

Warranty service isavailable by returning the Craftsman snow blower to the nearest Sears Service Centre/Department

in Canada. This warranty applies only while this product is in use in Canada.

This warranty isin addition to any statutorywarranty and does NOT exclude or limit legal rights you may have but shall

run concurrently with applicable provincial legislation. Furthermore, some provinces do not allow limitations on how Ion

an implied warranty will last so the above limitations may not apply to you.

SEARS CANADA INC., TORONTO, ONTARIO M5B 2B8

5

Page 6

TABLE OF CONTENTS

HAZARD SYMBOLS AND THE MEANINGS .......... 2

OPERATING SYMBOLS AND THEIR MEANINGS ..... 3

OWNER'S INFORMATION .......................... 5

ASSEMBLY ....................................... 7

TOOLS REQUIRED FOR ASSEMBLY .............. 7

CONTENTS OF SHIPPING CARTON .............. 7

PARTS BAGS CONTENTS: ....................... 7

UNPACKING .................................... 8

UPPER HANDLE AND CRANK ASSEMBLY ......... 9

CHECK THE CABLES ............................ 9

HOW TO SET THE LENGTH OF THE CABLES ..... 9

SPEED SELECT LEVER ........................ 10

SNOW CHUTE ASSEMBLY ...................... 11

OPERATION ..................................... 12

OPERATING CONTROLS ....................... 12

SNOW BLOWER OPERATION ................... 13

WHEEL LOCK OUT PIN ......................... 14

BEFORE STARTING ENGINE .................... 15

CHECK THE OIL ............................... 15

FILL GAS ...................................... 15

BEFORE STOPPING THE ENGINE ............... 16

OPERATING TIPS .............................. 19

SERVICE RECOMMENDATIONS ................... 20

CUSTOMER RESPONSIBILITIES .................. 21

SNOW BLOWER ............................... 21

LUBRICATION AT STORAGE .................... 21

LUBRICATION - EVERY 10HOURS .............. 21

LUBRICATION - EVERY 25 HOURS .............. 22

ENGINE ....................................... 23

ADJUSTMENT/REPAIR ........................... 24

AUGER HOUSING HEIGHT ADJUSTMENT ....... 24

TO ADJUST SCRAPER BAR ..................... 24

TO ADJUST SKID HEIGHT ...................... 24

HOW TO REMOVE THE SNOW HOOD ........... 25

BELTADJUSTMENT ............................ 26

HOW TO REPLACE THE BELTS ................. 27

BELTGUIDE ADJUSTMENT ..................... 30

HOW TO CHECK AND ADJUST THE CABLES .... 30

AUGER DRIVE CABLE ADJUSTMENT ............ 30

TRACTION DRIVE CABLE ADJUSTMENT ......... 31

HOW TO ADJUST OR REPLACE

THE FRICTION WHEEL ....................... 32

TO STOP ENGINE .............................. 16

TO START ENGINE ............................

FROZEN STARTER ............................

HOW TO CLEAR A CLOGGED DISCHARGE CHUTE

HOW TO USE THE CLEAN-OUT TOOL ..........

.16

.18

.18

.18

AUGER SHEAR BOLT REPLACEMENT ........... 35

STORAGE ....................................... 36

TROUBLE SHOOTING CHART ..................... 37

REPAIR PARTS .................................. 38

ORDER REPAIR PARTS ........................... 67

Page 7

ASSEMBLY

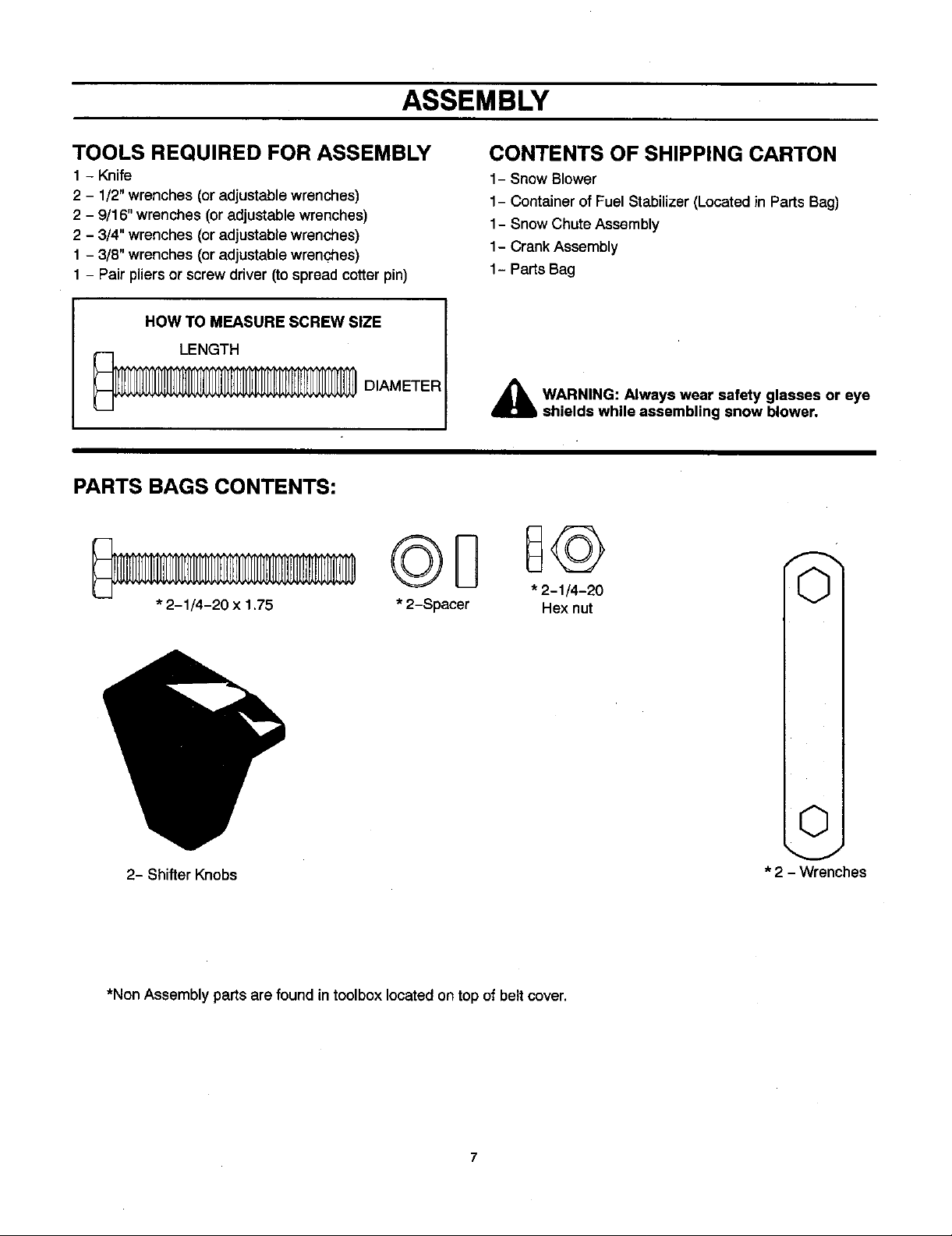

TOOLS REQUIRED FOR ASSEMBLY

1 - Knife

2 - 1/2" wrenches (or adjustable wrenches)

2 - 9/16" wrenches (or adjustable wrenches)

2 - 3/4" wrenches (or adjustable wrenches)

1 - 3/8" wrenches (or adjustable wrenches)

1 - Pair pliers or screw driver (to spread cotter pin)

HOW TO MEASURE SCREW SIZE

LENGTH

_ DIAMETER

PARTS BAGS CONTENTS:

* 2-1/4-20 x 1.75

"2-Spacer * 2H-Jx/4n"u20 O

CONTENTS OF SHIPPING CARTON

1- Snow Blower

1- Container of Fuel Stabilizer (Located in Parts Bag)

1- Snow Chute Assembly

1- Crank Assembly

1- Parts Bag

_b WARNING: Always wear safety glasses or eye

shields while assembling snow blower.

2- Shifter Knobs

*Non Assembly parts are found intoolbox locatedon top of belt cover.

7

©

* 2 - Wrenches

Page 8

ASSEMBLY

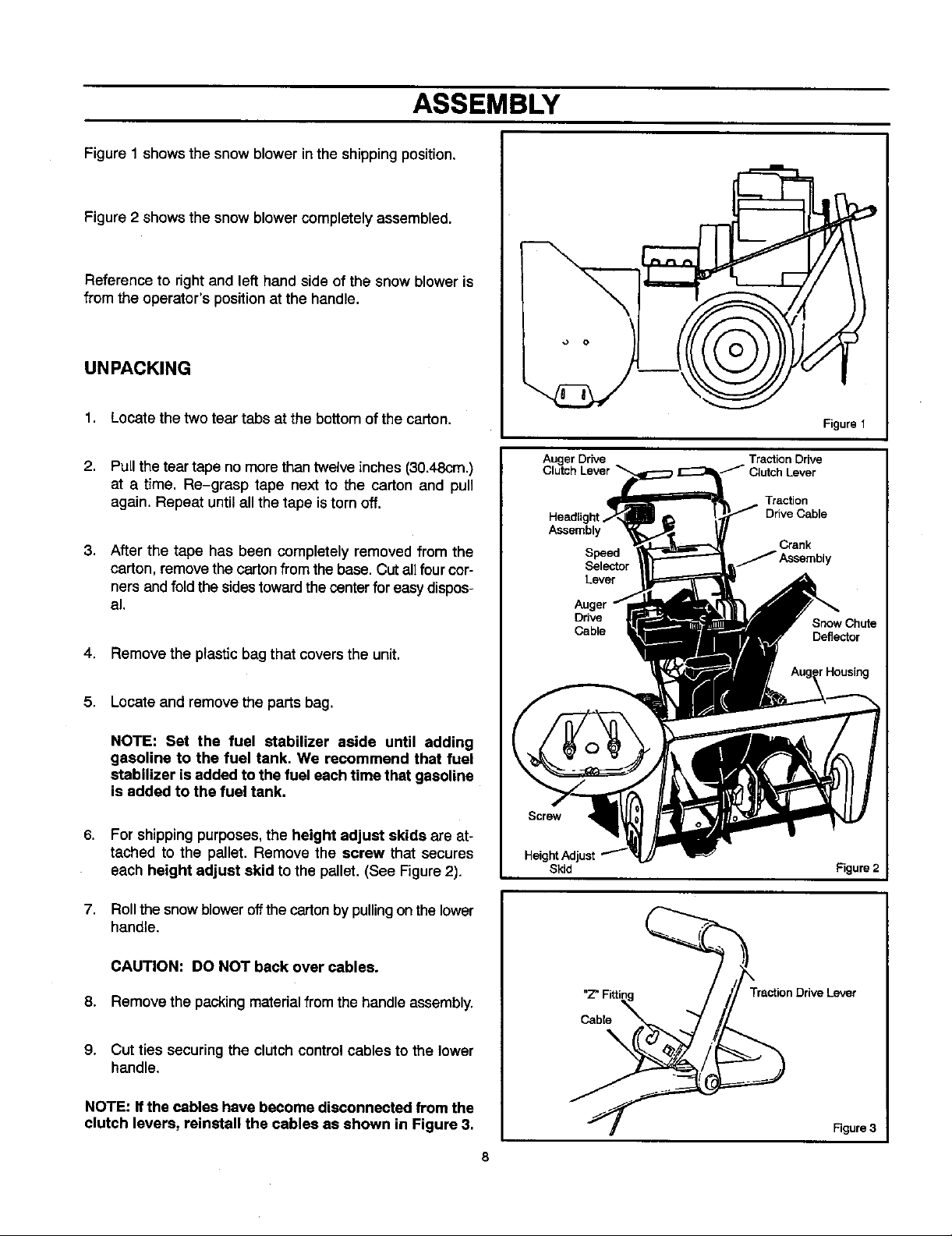

Figure 1 shows the snow blower in the shippingposition.

Figure 2 shows the snow blower completely assembled.

Reference to right and left hand side of the snow blower is

from the operator's position at the handle.

UNPACKING

1. Locate the twotear tabs at the bottomofthe carton,

2. Pull the tear tape no more than twelve inches (30.48cm.)

at a time. Re-grasp tape next to the carton and pull

again. Repeat until all the tape is torn off.

3. After the tape has been completely removed from the

carton, remove thecarton from the base. Cut all four cor-

ners andfold the sidestoward the center for easy dispos-

al.

4. Remove the plastic bag that covers the unit.

5. Locate and remove the parts bag.

NOTE: Set the fuel stabilizer aside until adding

gasoline to the fuel tank. We recommend that fuel

stabilizer isadded to the fuel each time that gasoline

is added to the fuel tank.

6. For shipping purposes, the height adjust skids are at-

tached to the pallet. Remove the screw that secures

each height adjust skid to the pallet. (See Figure2).

7. Roll the snow blower off the carton by pulling onthe lower

handle.

Auger Drive Traction Drive

Clutch Lever

Traction

Drive Cable

Assembly

Speed J Assembly

Selector

Lever

Auger

Drive

Cable

Screw

Skid

Crank

Snow Chute

Deflector

_rHousing

Figure 2

CAUTION: DO NOT back over cables.

8. Remove the packing materialfrom the handleassembly.

9. Cut ties securing the clutch control cables to the lower

handle.

NOTE: Ifthe cables have become disconnected from the

clutch levers, reinstall the cables as shown in Figure 3.

Traction Drive Lever

Cable

\

Figure 3

Page 9

ASSEMBLY

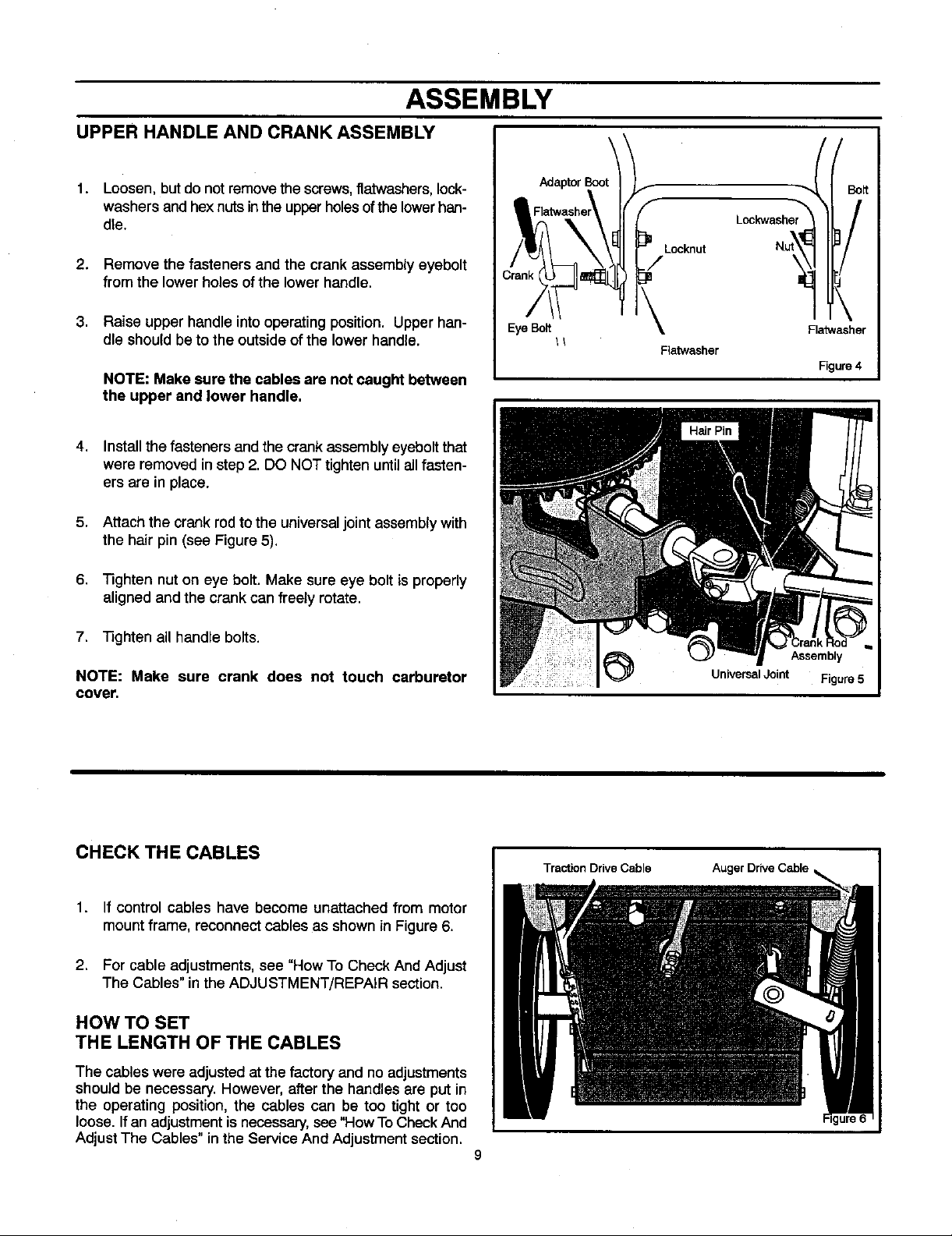

UPPER HANDLE AND CRANKASSEMBLY

1. Loosen, but do not remove the screws, flatwashers, lock-

washers and hex nuts inthe upperholes ofthe lower han-

dle.

2. Remove the fasteners and the crank assembly eyebolt

from the lower holes of the lower handle.

3. Raise upper handle into operating position. Upper han-

dle should beto the outside of the lower handle.

NOTE: Make sure the cables are not caught between

the upper and lower handle.

4. Install the fasteners and the crank assembly eyebolt that

were removed instep 2.DO NOT tighten until all fasten-

ers are in place.

5. Attach the crank rod to the universal joint assembly with

the hair pin (see Figure 5).

Adaptor Boot!

_ Flatwashe_

Eye Bolt

f

F

D,

Locknut

Fiatwasher

[/

\ Bo_

Lockwasher_

!

\

\

Flatwasher

Figure 4

6. Tighten nut on eye bolt. Make sure eye bolt is properly

aligned and the crank can freely rotate.

7. Tighten all handle bolts.

NOTE: Make sure crank does not touch carburetor

cover.

CHECKTHECABLES

1. If control cables have become unattached from motor

mount frame, reconnect cables as shown in Figure 6.

2. For cable adjustments, see "How To Check And Adjust

The Cables" in the ADJUSTMENT/REPAIR section.

HOW TO SET

THE LENGTH OF THE CABLES

Traction DriveCable

Assembly

Universal Joint Figure 5

Auger Drive Cable

The cables were adjusted atthe factory and no adjustments

should be necessary. However, after the handles are put in

the operating position, the cables can be too tight or too

loose. Ifan adjustment is necessary, see "How To Check And

Adjust The Cables" in the Service And Adjustment section.

9

Page 10

ASSEMBLY

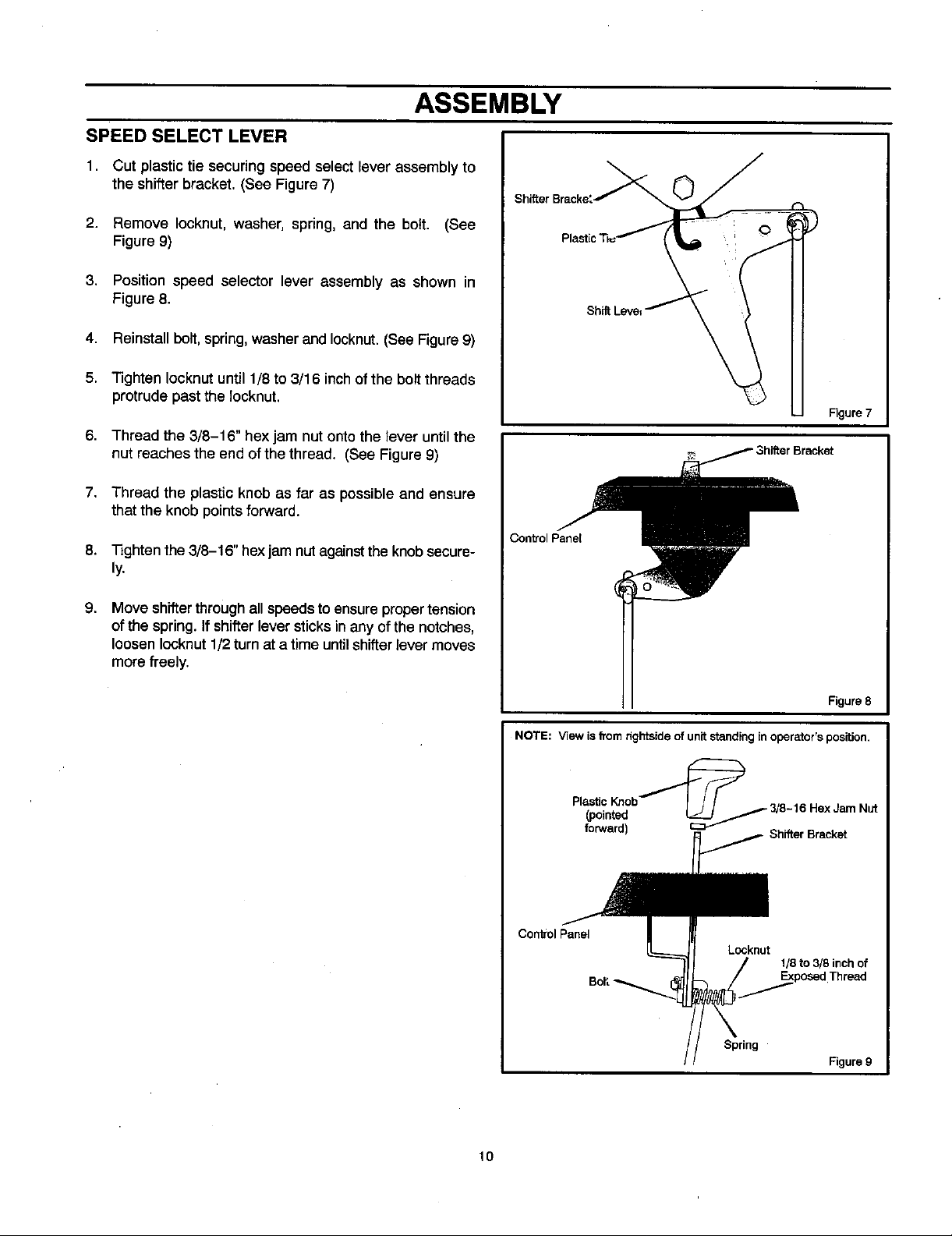

SPEED SELECT LEVER

1, Cut plastic tie securing speed select lever assembly to

the shifterbracket. (See Figure 7)

2. Remove Iocknut, washer, spring, and the bolt. (See

Figure 9)

3. Position speed selector lever assembly as shown in

Figure 8.

4. Reinstall bolt, spring, washer and Iocknut. (See Figure 9)

5. Tighten Iocknut until 1/8 to 3/16 inch of the bolt threads

protrude past the locknut.

6. Thread the 3/8-16" hex jam nut onto the lever until the

nut reaches the end ofthe thread. (See Figure 9)

7. Thread the plastic knob as far as possible and ensure

that the knob points forward.

8. Tighten the 3/8-16" hex jam nut against the knob secure-

ly.

Shifter Bracke_

Figure7

Control Panel

9,

Move shifterthroughall speedsto ensure propertension

of the spring. If shifter lever sticks in any of the notches,

loosen Iocknut 1/2turn at a time until shifter lever moves

more freely.

Figure 8

NOTE: View is trorn rightside of unit standing inoperator's position.

Plastic Knob"_,_-'_ 3"8 6" "

(pointed (.J--_// / -1 Hex,Jam Nut

forward) _ Shifter Bracket

Control Panel

Lccknut

1/8 to 3/8 inch of

Spring

Figure 9

lO

Page 11

ASSEMBLY

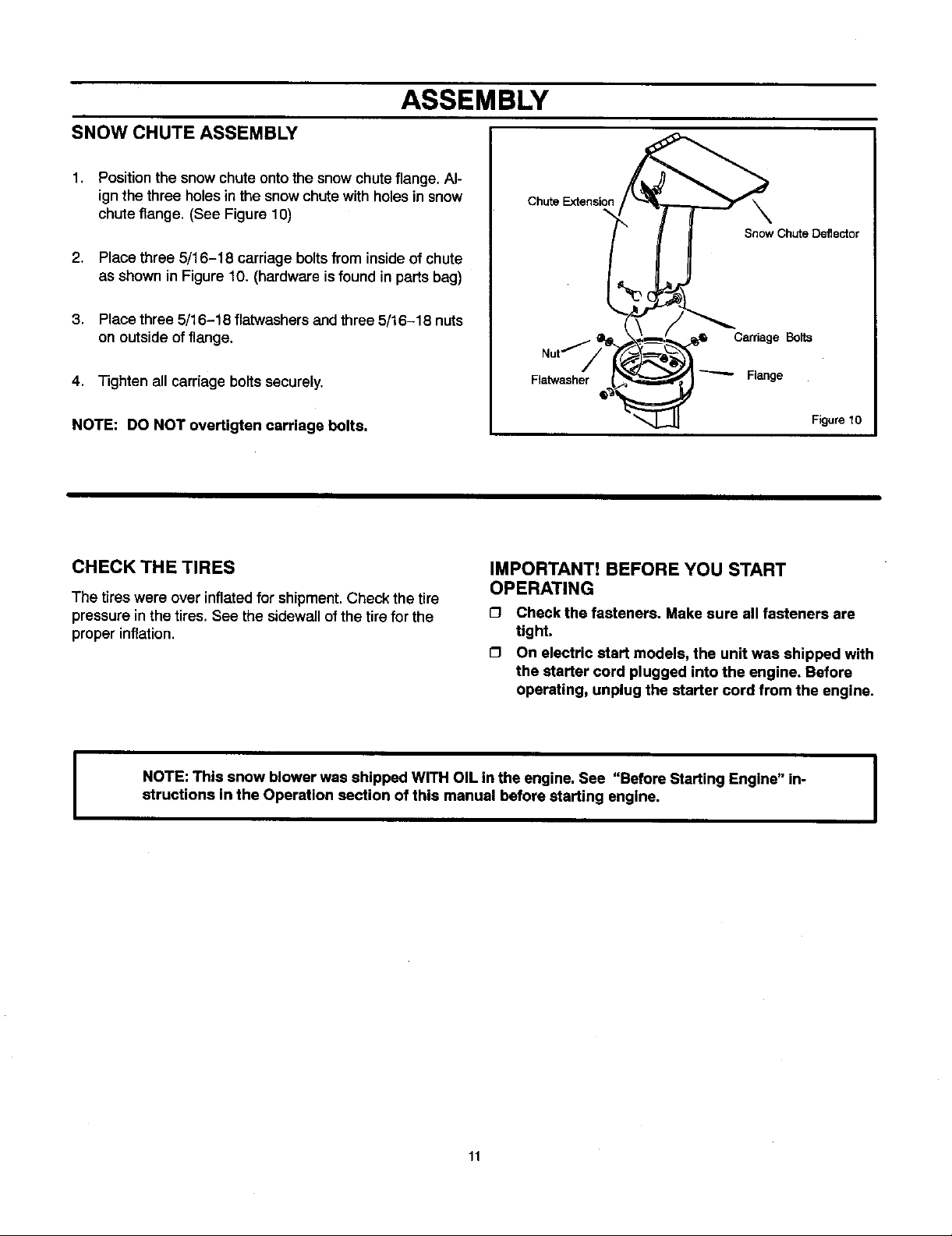

SNOW CHUTE ASSEMBLY

1. Positionthe snow chute ontothe snow chuteflange, Al-

ignthe three holesinthe snow chutewith holesin snow

chuteflange. (See Figure 10)

2, Place three 5/16-18 carriage boltsfrom insideof chute

as shown in Figure10. (hardware isfound in partsbag)

3. Place three 5/16-18 flatwashers and three5/16-18 nuts

on outside offlange.

Chute Extension

\

Snow Chute Deflector

Carriage Bolts

4. Tighten all carriage boltssecurely.

NOTE: DO NOT overtigten carriage bolts.

CHECK THE TIRES

The tires were over inflatedfor shipment.Check the tire

pressure in the tires. See the sidewall of the tire for the

proper inflation.

NOTE: This snow blower was shipped WITH OIL in the engine. See "Before Starting Engine" in-

structions In the Operation section of this manual before starting engine.

Flatwasher

IMPORTANT! BEFORE YOU START

OPERATING

Check the fasteners. Make sure all fasteners are

tight.

O On electric start models, the unit was shipped with

the starter cord plugged into the engine. Before

operating, unplug the starter cord from the engine.

"-"'- Flange

Figure 10

I

11

Page 12

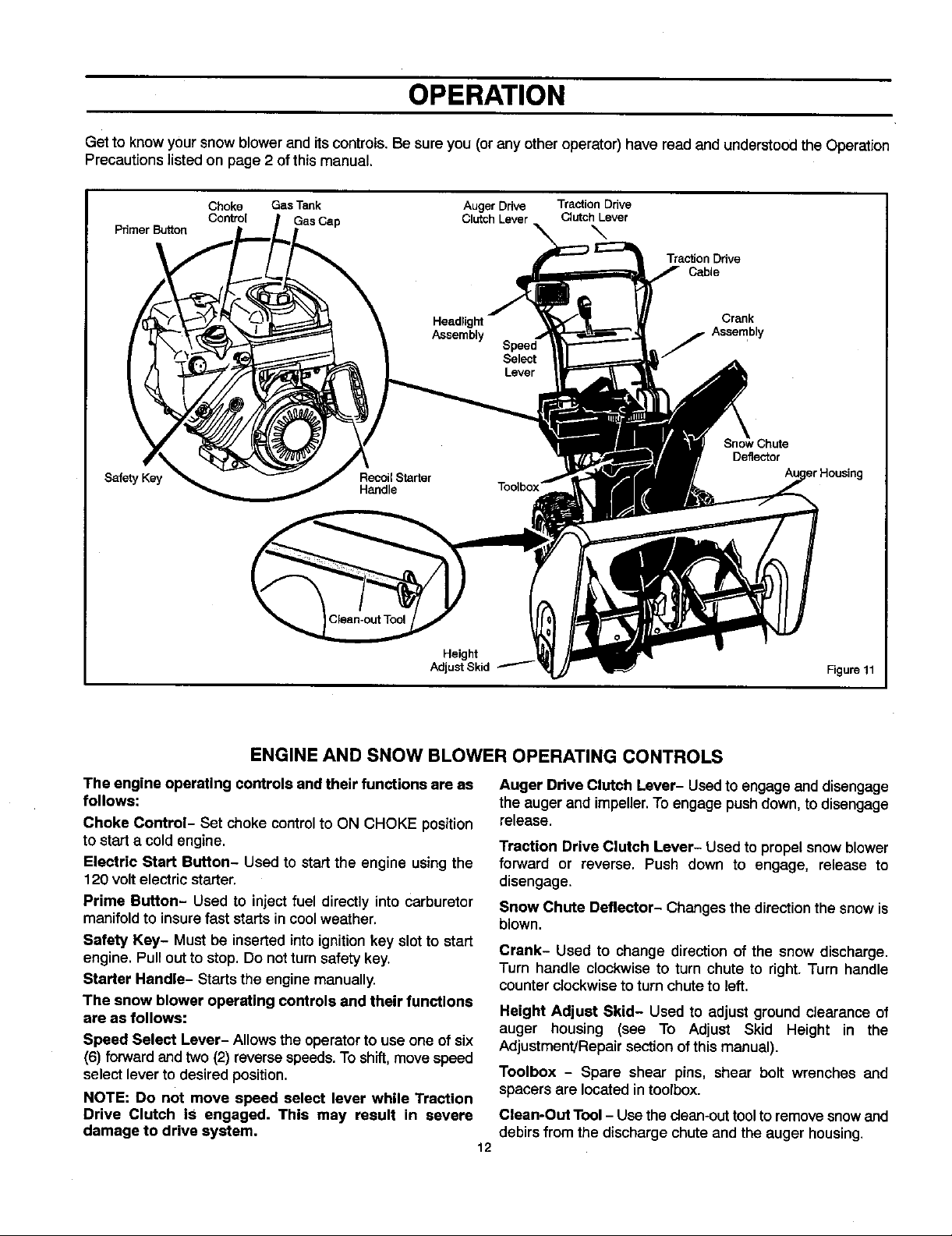

OPERATION

Get to know your snow blower and its controls. Be sureyou (or any other operator) have read and understoodthe Operation

Precautions listed on page 2 of this manual.

Choke Gas Tank Auger Drive Traction Drive

Primer Button

Safety Key

Control Clutch Lever Clutch Lever

\

Traction Ddve

Cable

Crank

Assembly

Deflector

Height

Adjust Skid Figure 11

ENGINE AND SNOW BLOWER OPERATING CONTROLS

The engine operating controls and their functions are as

follows:

Choke Control- Set choke controlto ON CHOKE position

to starta coldengine.

Electric Start Button- Used to startthe engine usingthe

120 voltelectric starter.

Prime Button- Used to inject fuel directly into carburetor

manifoldto insurefast starts incoolweather.

Safety Key- Must be inserted intoignitionkey slot to start

engine. Pull outto stop. Do notturnsafety key.

Starter Handle- Startsthe engine manually.

The snow blower operating controls and their functions

are as follows:

Speed Select Lever- Allows the operatorto use one ofsix

(6) forward and two(2) reversespeeds.To shift,movespeed

select lever to desired position.

NOTE: Do not move speed select lever while Traction

Drive Clutch is engaged. This may result in severe

damage to drive system.

Auger Drive Clutch Lever- Used to engage and disengage

the augerand impeller.Toengage pushdown, to disengage

release.

Traction Drive Clutch Lever- Used to propel snow blower

forward or reverse. Push down to engage, release to

disengage.

Snow Chute Deflector- Changes the direction the snow is

blown.

Crank- Used to change direction of the snow discharge.

Turn handle clockwise to turn chute to right. Turn handle

counter clockwise to turn chute to left.

Height Adjust Skid- Used to adjust ground clearance of

auger housing (see To Adjust Skid Height in the

Adjustment/Repairsectionofthis manual).

Toolbox - Spare shear pins, shear bolt wrenches and

spacers are located intoolbox.

Clean-Out Tool - Use the clean-outtoolto removesnowand

debirs from the discharge chuteand the auger housing.

12

Page 13

OPERATION

The operation of any snow blower can result in foreign objects being thrown into the eyes,which canresult in severe eye damage. Always wear safety glasses or eye shields before beginning snow blower

Operation. We recommend standard safety glasses or Wide Vision Safety Mask for over spectacles.

SNOW BLOWER OPERATION

The most effective use of the snowblower willbe established

by experience, taking into consideration the terrain, wind

conditions and building location which will determine the

direction of the discharge chute.

NOTE: Do not blow snow towards a building as hidden

objects could be blown with sufficient force to cause

damage.

1. Start theengine as described in section"To Start Engine"

(see Figure 13).

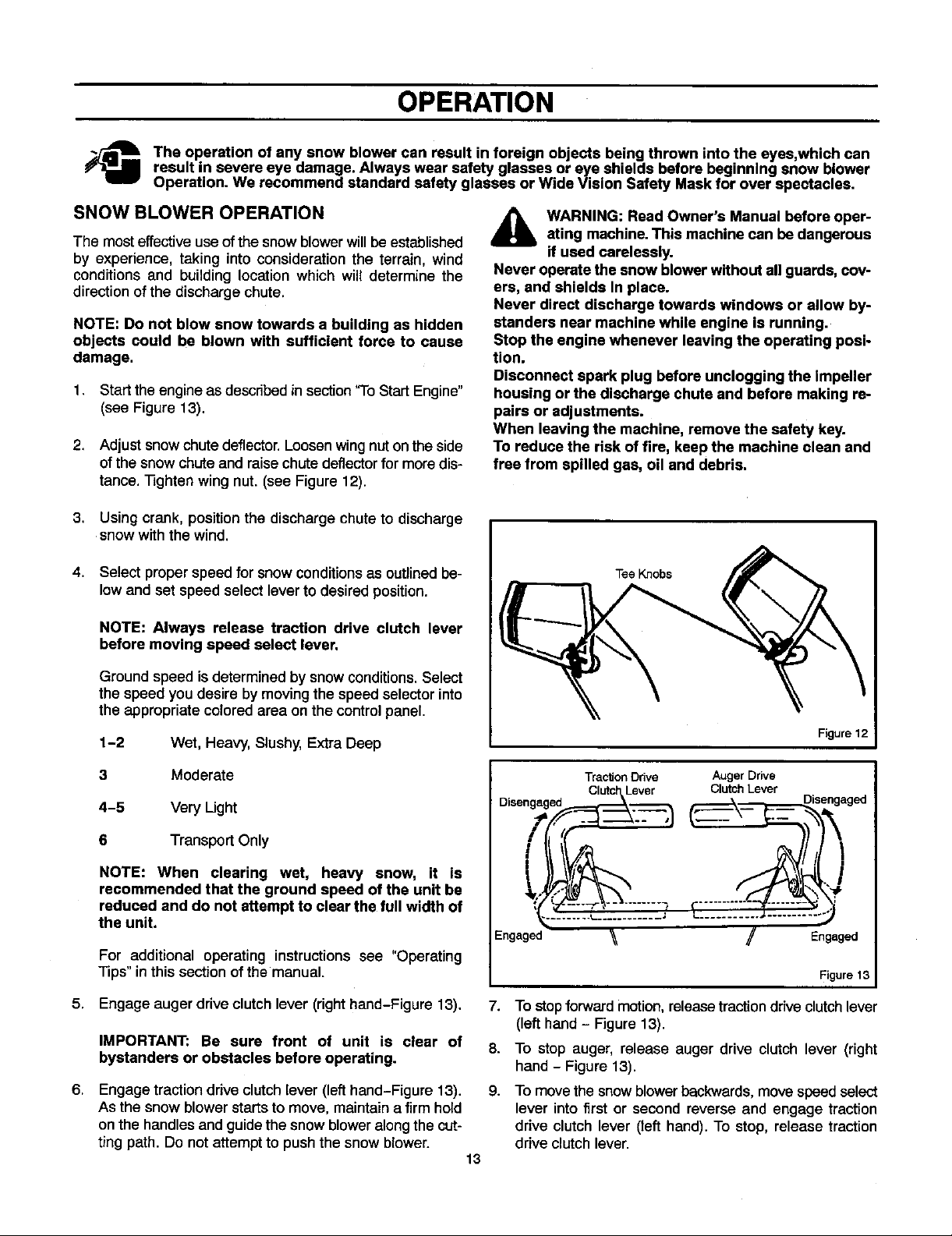

2. Adjust snowchute deflector. Loosen wingnut on the side

of the snow chute and raise chute deflector for more dis-

tance. Tighten wing nut. (see Figure 12).

3.

Using crank, position the discharge chute to discharge

snow with the wind.

,_ WARNING: Read Owner's Manual before oper-

ating machine.This machine can be dangerous

if used carelessly.

Never operate the snow blowerwithout all guards, cov-

ers, and shields In place.

Never direct discharge towards windows or allow by-

standers near machine while engine is running.

Stop the engine whenever leaving the operating posi-

tion.

Disconnect spark plug before unclogging the impeller

housing or the discharge chute and before making re-

pairs or adjustments.

When leaving the machine, remove the safety key.

To reduce the risk of fire, keep the machine clean and

free from spilled gas, oil and debris.

4.

Select proper speed for snow conditions as outlinedbe-

low and set speed select lever to desiredposition.

NOTE: Always release traction drive clutch lever

before moving speed select lever.

Ground speed is determined by snow conditions. Select

the speed you desire by moving the speed selector into

the appropriate colored area on the control panel.

1-2 Wet, Heavy, Slushy, Extra Deep

3 Moderate

4-5 Very Ught

6 Transport Only

NOTE: When clearing wet, heavy snow, it is

recommended that the ground speed of the unit be

reduced and do not attempt to clear the full width of

the unit.

For additional operating instructions see "Operating

Tips" in this section of the manual.

5. Engage auger drive clutch lever (right hand-Figure 13).

IMPORTANT: Be sure front of unit is clear of

bystanders or obstacles before operating.

6,

Engage tractiondrive clutch lever (lefthand-Figure 13).

As the snow blower starts to move, maintain a firm hold

on the handles and guide the snow blower alongthe cut-

ting path. Do not attempt to push the snow blower.

Tee Knobs

Figure 12

Traction Ddve Auger Drive

ged

Disengaged_ .._._ ClutchLever is_l_ a

Engaged '_ J Engaged

Figure 13

7. To stop forwardmotion, releasetraction drive clutch lever

(lefthand - Figure 13).

8. To stop auger, release auger drive clutch lever (right

hand - Figure 13).

g. To movethe snowblower backwards, movespeed select

lever into first or second reverse and engage traction

drive clutch lever (left hand). To stop, release traction

drive clutch lever.

13

Page 14

OPERATION

WHEEL LOCK OUT PIN

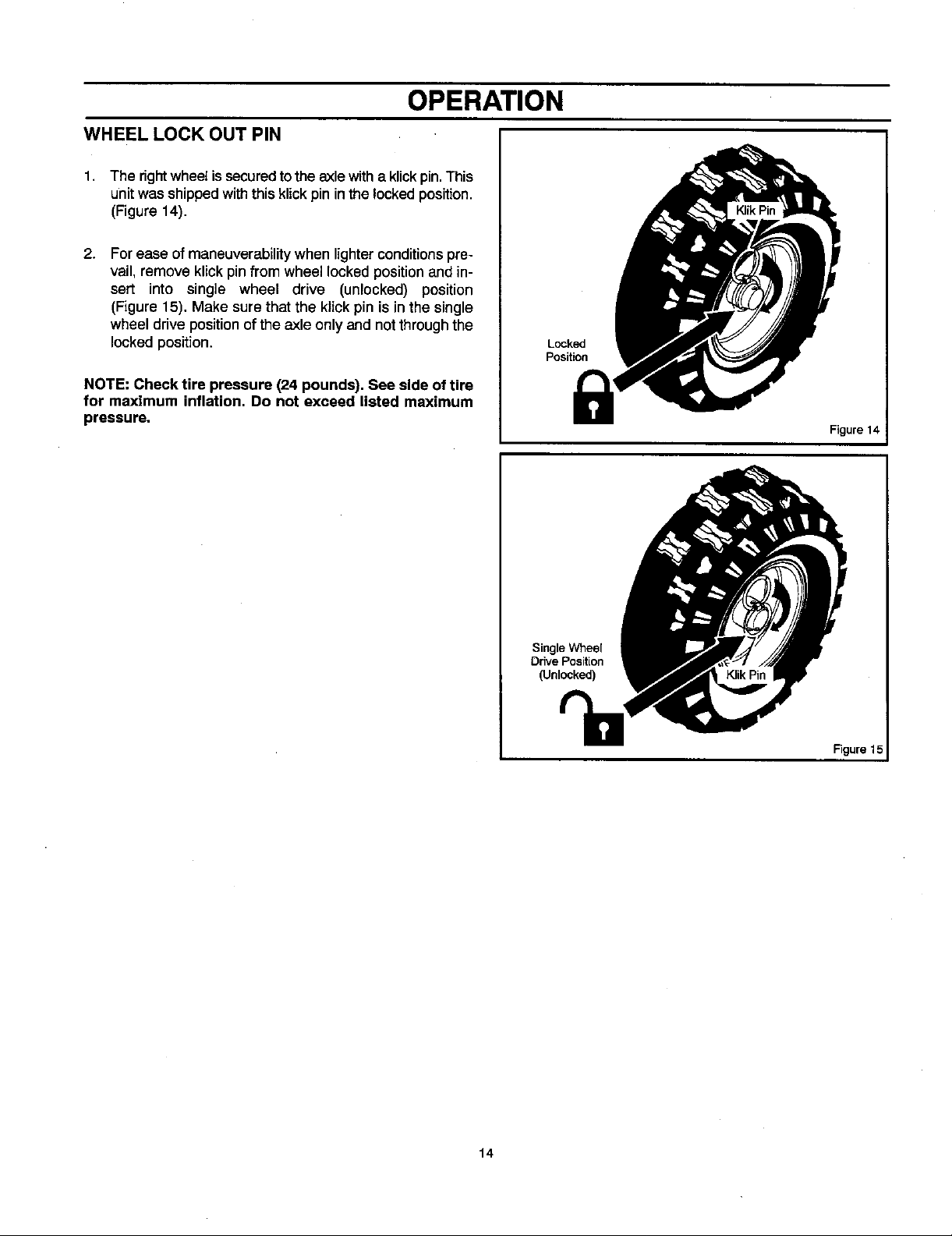

1. The rightwheel issecured to the axle witha klickpin.This

unit was shipped with this klick pin in the locked position.

(Figure 14).

2. For ease of maneuverability when lighter conditions pre-

vail, remove klick pin from wheel locked position and in-

sen into single wheel drive (unlocked) position

(Figure 15). Make sure that the klick pin is in the single

wheel drive position of the axle only and not through the

locked position.

NOTE: Check tire pressure (24 pounds). See side of tire

for maximum inflation, Do not exceed listed maximum

pressure.

Locked

Position

Figure 14

Single Wheel

Drive Position

(Unlocked)

Figure 15

14

Page 15

OPERATION

BEFORE STARTING ENGINE 1.

Check the oil

NOTE: The engine was shipped from the factory filled

with oil. Check the level of the oil Add oil as needed.

1,

Make sure the unit islevel. Use a high quality detergent

oil classified "For Service SG, SH, SJ, SL, or higher".

2,

Remove the oil fill cap/dipstick and wipe with a clean

cloth (see Figure 16).

3. Insert the oilfillcap/dipstick and turn clockwise to tighten.

4. Remove the oil fill cap/dipstick and check the oil

NOTE: Do not check the level of the oil while the

engine runs.

5. If necessary, add oiluntil the oil reaches the FULL mark

on the oil fill/capdipstick (see Figure 16). Do not add too

much oil.

6. Tighten the fill cap/dipstick securelyeach time you check

the oil level.

NOTE: For extreme cold operating conditions of 0°F

(-18 ° C) and below, use a synthetic 5W30 motor oil for

easier starting.

NOTE: S.A.E. 5W30 motor oil may be used to make

starting easier in areas where the temperature is 20 ° F.

(-7 ° C) to O°F (-18 ° C). Synthetic 5W30 is acceptable for

all temperatures. DO NOT mix oil with gasoline,

NOTE: SEE CHART FOR OIL RECOMMENDATION

TEMPERATURE TYPE OF OIL

0°F (-18 ° C) and above S.A.E. 5W30

0°F (-18 ° C) and below synthetic 5W30

Fillthefuel tank withfresh, clean, unleadedregular, un-

leaded premium, or reformulated automotive gasoline

with a minimum of 85 octane along with a fuel stabilizer

(follow instructions onfuel stabilizer package). DO NOT

use leaded gasoline. We recommend that fuel stabilizer

be added to the fuel each time that gasoline is added to

the fuel tank.

NOTE: Winter grade gasoline has higher volatility to

improve starting. Be certain container is clean and

free from rust or other foreign particles. Never use

gasoline that may be stale from long periods of

storage in the container.

CAUTION: DO NOT use gasoline containing any

amount of alcohol as it can cause sedous damage to

the engine or significantly reduce the performance.

_k ARNING: Gasoline isflammable. Always use

minutes before removingthe gas cap. Do not add gaso-

line to the fuel tank while snow blower is running, hot,

or when snow blower is in an enclosed area. Keep away

from open flame, electrical sparks and DO NOT SMOKE

while filling the fuel tank. Never fill the fuel tank com-

pletely; but fill the fueltank to within 1-1/2 inch (3.8 mm)

from the top to provide space for the expansion of the

fuel. Always fill fuel tank outdoors and use a funnel or

spout to prevent spilling, Make sure to wipe up any

spilled fuel before starting the engine.

Store gasoline ina clean, approved container, and keep

the cap in place on the container. Keep gasoline in a

cool well ventilated place; never in the house. Never

buy more than a 30 day supply of gasoline to assure

volatility. Gasoline Is intended to be used as a fuel for

internal combustion engines; therefore, do not use

gasoline for any other purpose. Since many children

like the smell of gasoline, keep it out of their reach be-

cause the fumes are dangerous to inhale, as well as be-

ing explosive.

caution when handling or storing gasoline.

Turn engine off and let engine cool at least two

SAE VISCOSITY GRADES

=,- WJ JBJ

°F 20 0 20 32 40

°C -30 -20 -10 0 10

FILL GAS

This engine is certified to operate on gasoline. Exhaust

Emission Control System: EM (Engine Modifications)

I I I • •

• i ¶ • •

Oil Fill

Cap/Dipstick

%

Figure 16

15

Page 16

OPERATION

BEFORE STOPPING THE ENGINE

Run the engine fora few minutes to help dry off any moisture

on the engine.

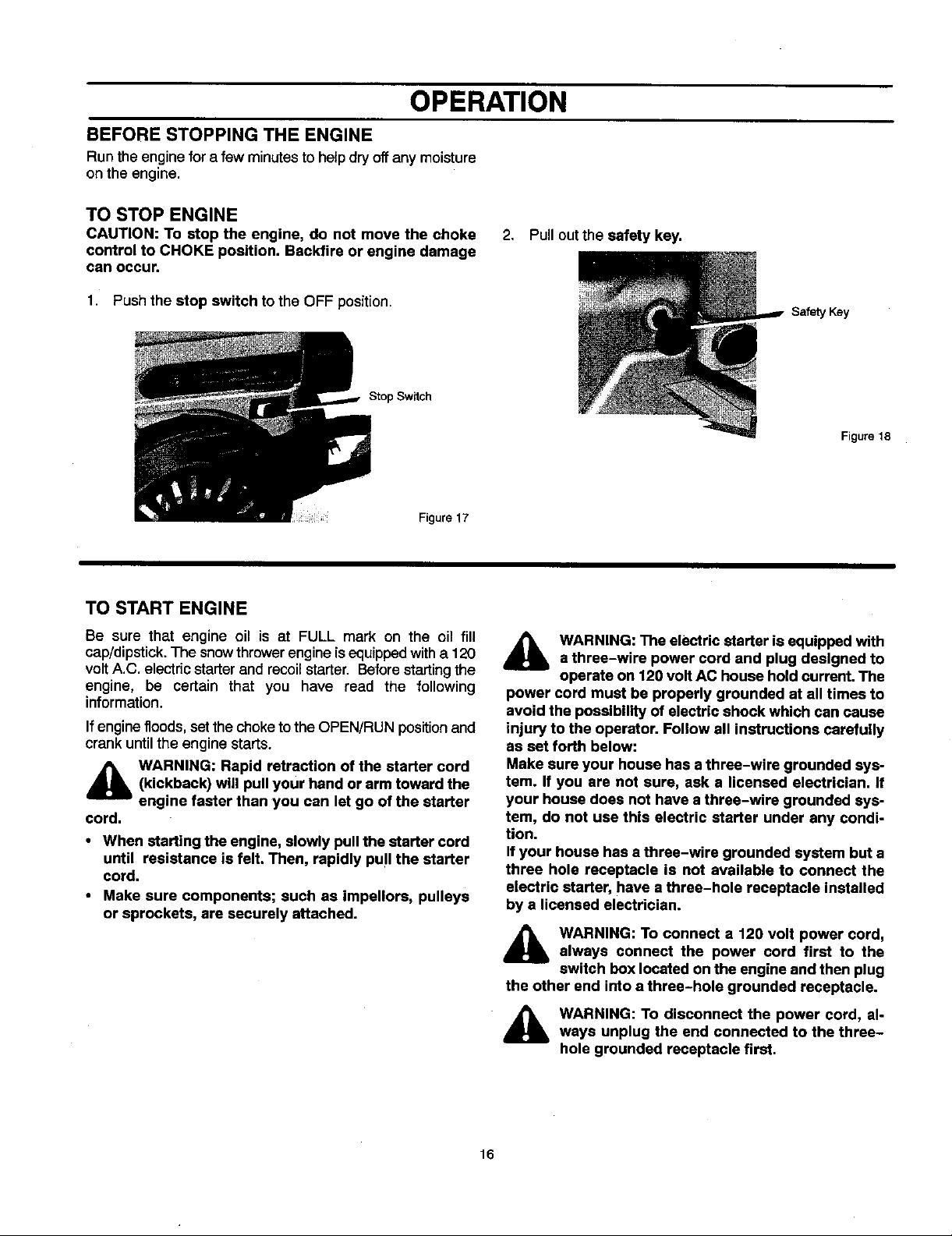

TO STOP ENGINE

CAUTION: To stop the engine, do not move the choke

control to CHOKE position. Backfire or engine damage

can occur.

2. Pull out the safety key.

1. Push the stop switch to the OFF position.

Stop Switch

Figure 17

TO START ENGINE

Be sure that engine oil is at FULL mark on the oil fill

cap/dipstick. The snowthrower engine is equipped with a 120

volt A.C. electric starter and recoil starter. Before starting the

engine, be certain that you have read the following

information.

If engine floods, set the choke to the OPEN/RUN position and

crank until the engine starts.

_lb WARNING: Rapid retraction of the starter cord(kickback) will pull your hand or arm toward the

engine faster than you can let go of the starter

cord.

• When starting the engine, slowly pull the starter cord

until resistance is felt. Then rapidly pull the starter

cord.

• Make sure components; such as impellore, pulleys

or sprockets, are securely attached.

Safety Key

Figure 18

_lb WARNING: The electric starter is equipped with

power cord must be properly grounded at all times to

avoid the possibility of electric shock which can cause

injury to the operator. Follow all instructions carefully

as set forth below:

Make sure your house has a three-wire grounded sys-

tem. If you ere not sure, ask • licensed electrician. If

your house does not have a three-wire grounded sys-

tem, do not use this electric starter under any condi-

tion.

If your house has a three-wire grounded system but a

three hole receptacle is not available to connect the

electric starter, have a three-hole receptacle installed

by a licensed electrician.

a three-wire power cord and plug designed to

operate on 120 volt AC house hold current. The

_IL WARNING: To connect a 120 volt power cord,

the other end into a three-hole grounded receptacle.

16

always connect the power cord first to the

switch box located on the engine and then plug

WARNING: To disconnect the power cord, al-

ways unplug the end connected to the three-

hole grounded receptacle first.

Page 17

Primer

OPERATION

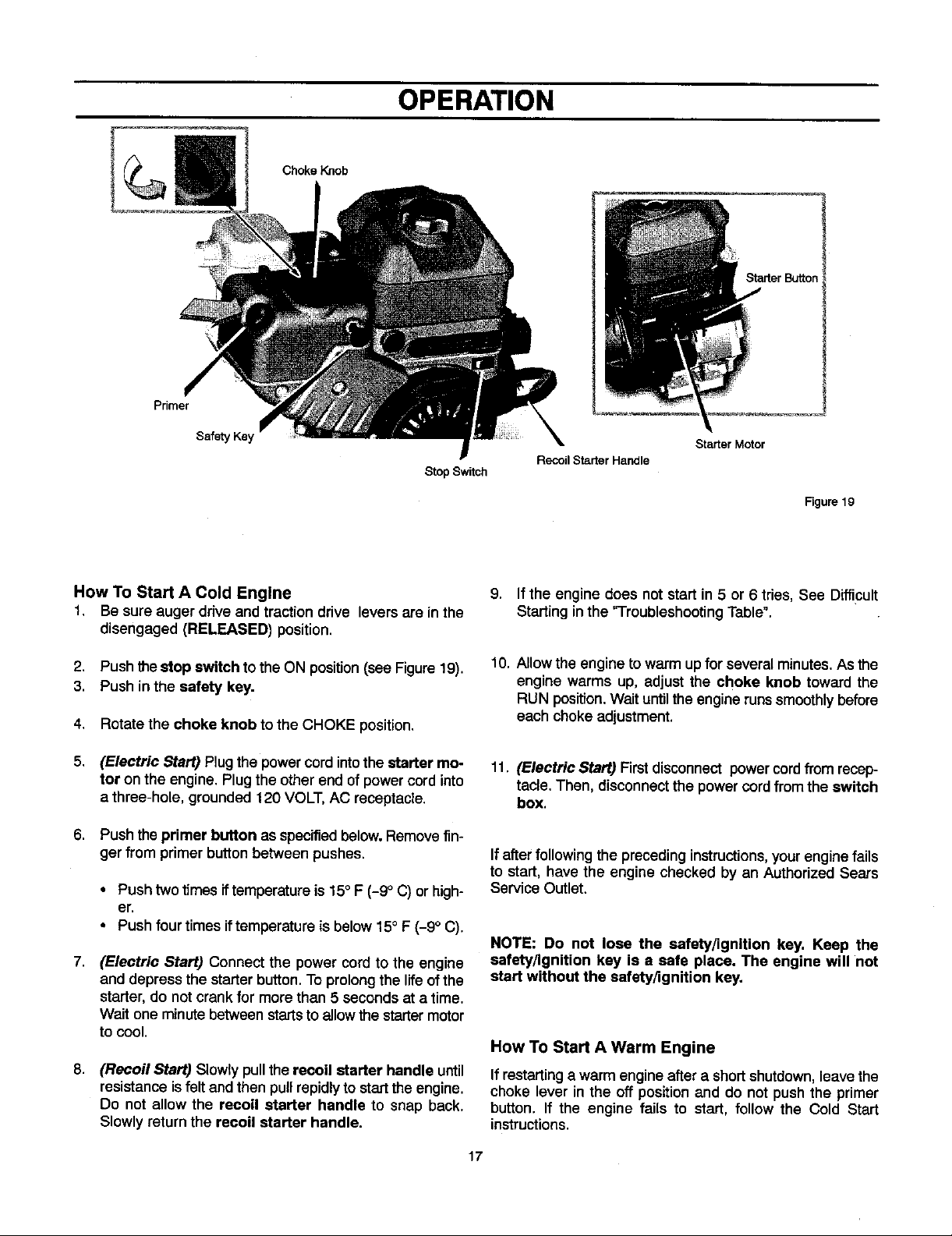

Choke Knob

Safety Key

Stop Switch

How To Start A Cold Engine

1, Be sure auger drive and tractiondrive levers are in the

disengaged (RELEASED) position.

2. Push thestop switch to the ON position (seeFigure 19).

3. Push in the safety key.

4. Rotate the choke knob to the CHOKE position.

5. (Electric Start) Plug the power cord intothe starter mo-

tor on the engine. Plug the otherend of power cord into

a three-hole, grounded 120 VOLT, AC receptacle.

6. Push theprimer button asspecifiedbelow. Remove fin-

ger from primer button between pushes.

• Push two times iftemperutureis 15° F (-9 ° (3)or high-

er.

• Push fourtimes iftemperature is below 15° F (-9° C).

7,

(Electric Start) Connect the power cord to the engine

and depress the starterbutton. To prolongthe lifeof the

starter,do not crankfor more than 5 seconds at a time.

Wait one minute between startsto allowthestartermotor

to cool.

8.

(Recoil Start) Slowlypull therecoil starter handle until

resistanceisfelt andthen pullrepidlyto startthe engine.

Do not allow the recoil starter handle to snap back.

Slowlyreturn the recoil starter handle.

Starter Motor

Recoil Starter Handle

Figure 19

9. If the engine does not start in 5 or 6 tries, See Difficult

Starting inthe 'Troubleshooting Table".

10. Allow the engine to warm up for several minutes. As the

engine warms up, adjust the choke knob toward the

RUN position. Walt untilthe engine runs smoothly before

each choke adjustment.

11. (Electric Start) First disconnect power cordfrom recep-

tacle. Then, disconnectthe powercord from the switch

box.

If after following the preceding instructions,your engine fails

to start, have the engine checked by an Authorized Sears

Service Outlet.

NOTE: Do not lose the safety/ignition key. Keep the

safety/ignition key is a safe place. The engine will not

start without the safety/ignition key.

How To Start A Warm Engine

Ifrestarting a warm engine aftera shortshutdown,leave the

choke lever in the off positionand do not push the primer

button. If the engine fails to start, follow the Cold Start

instructions.

17

Page 18

OPERATION

FROZEN STARTER

If the starter is frozen and will not turn engine:

1. Pull as much rope out of the starter as possible.

2. Release the starter handle and let it snap back against

the starter. Repeat until the engine starts.

Warm engines will cause condensation in cold weather. To

help prevent possible freeze-up of recoil starter and engine

controls, proceed as follows after each snow removal job.

1. With engine off, allow engine to cool for several minutes.

2. Pull starter rope very slowly until resistance is felt, then

stop. Allow the starter rope to recoil. Repeat three times.

3. With the engine not running, wipe all snow and moisture

from the carburetor cover in area of control levers. Also

move choke knob and starter handle several times.

,_ WARNING: Never run engine indoors or In en-

AND DEADLY GAS. Keep hands, feet, hair and loose

clothing away from any moving parts on engine and

snow thrower.

• Engine parts, especially the muffler, become ex-

• Never allow children to operate the snow thrower.

• Keep the area of operation clear of all persons, partic-

• Never leave the snow blower unattended while the

IMPORTANT: After each use of the snow blower, stop the

engine, remove the safety/ignition key, remove all

accumulated snow from the snow blower and wipe

clean. Store the snow blower in a protected area.

NOTE: Never cover snow blower while engine and

exhaust area are still warm.

closed, poorly ventilated areas. Engine exhaust

contains CARBON MONOXIDE, AN ODORLESS

tremely hot. Severe thermal burns can occur on con-

tact. Allow the engine to cool before touching.

Never allow adults to operate the snow blower with-

out proper instruction,

ularly small children and pets.

engine is running. Anyone operating the engine or

equipment must carefully read and understand the

operating instructions.

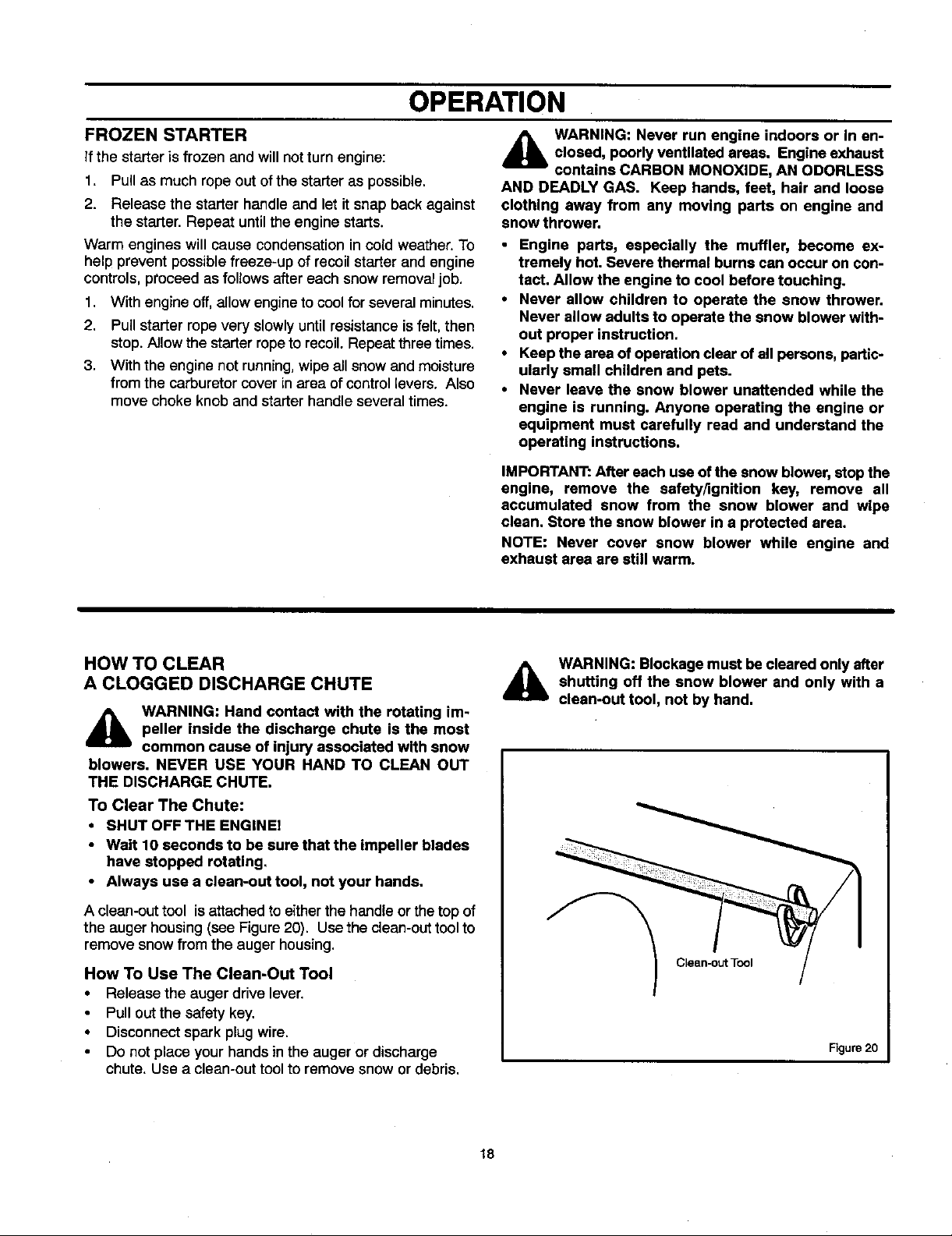

HOW TO CLEAR

A CLOGGED DISCHARGE CHUTE

4_b WARNING: Hand contact with the rotating im-

blowers. NEVER USE YOUR HAND TO CLEAN OUT

THE DISCHARGE CHUTE.

To Clear The Chute:

• SHUT OFF THE ENGINE!

• Wait 10 seconds to be sure that the impeller blades

• Always use a clean-out tool, not your hands.

A clean-out tool isattached toeither the handle or the top of

the auger housing (see Figure 20). Use the clean-out tool to

remove snow from the auger housing.

How To Use The Clean-Out Tool

• Release the auger drive lever.

• Disconnect spark plug wire.

peller inside the discharge chute is the most

common cause of injury associated with snow

have stopped rotating.

Pullcut the safety key.

Do not place your handsin the auger or discharge

chute. Use a clean-out tool to remove snowor debris.

WARNING: Blockage must be cleared only after

,a,

shutting off the snow blower and only with a

clean-out tool, not by hand.

/_ Clean-out Tool

Figure 20

18

Page 19

OPERATION

OPERATING TIPS

1,

Most efficient snowblowingis accomplished when snow

isremoved immediately after it falls.

2.

For complete snow removal, slightly overlap each swath

previously taken.

3.

Snow should be discharged downwind whenever pos-

sible. 8.

4.

For normal usage, set the skids one-eighth inch (3 mm)

below the scraper bar, For extremely hard-packed snow

surfaces, the skids may be adjusted upward to insure

cleaning efficiency.

5.

On gravel or crushed rock surfaces, the skids should be

set at 1-1/4 inch (32 mm) below the scraper bar (see To

Adjust Skid Height, in the Adjustment/Repair section in

this manual). Rocks and gravel must not be picked up

and thrown by the machine.

6,

After the snowblowingjob has been completed, allow the

engine to idle for a few minutes, to melt snow and ice ac-

cumulated on the engine.

7.

Clean the snow thrower thoroughly after each use.

Remove ice and snow accumulation and all debris from

the entire snow thrower, and flush with water Ofpossible)

to remove all salt or other chemicals. Wipe snowthrower

dry.

9,

Before starting snow blower, always inspectaugers and

impeller for ice accumulation and/or debris, which could

result in snow blower damage.

10.

Check oil level before every start. Make sure the oil isat

the FULL mark on the oil fill cap/dipstick.

19

Page 20

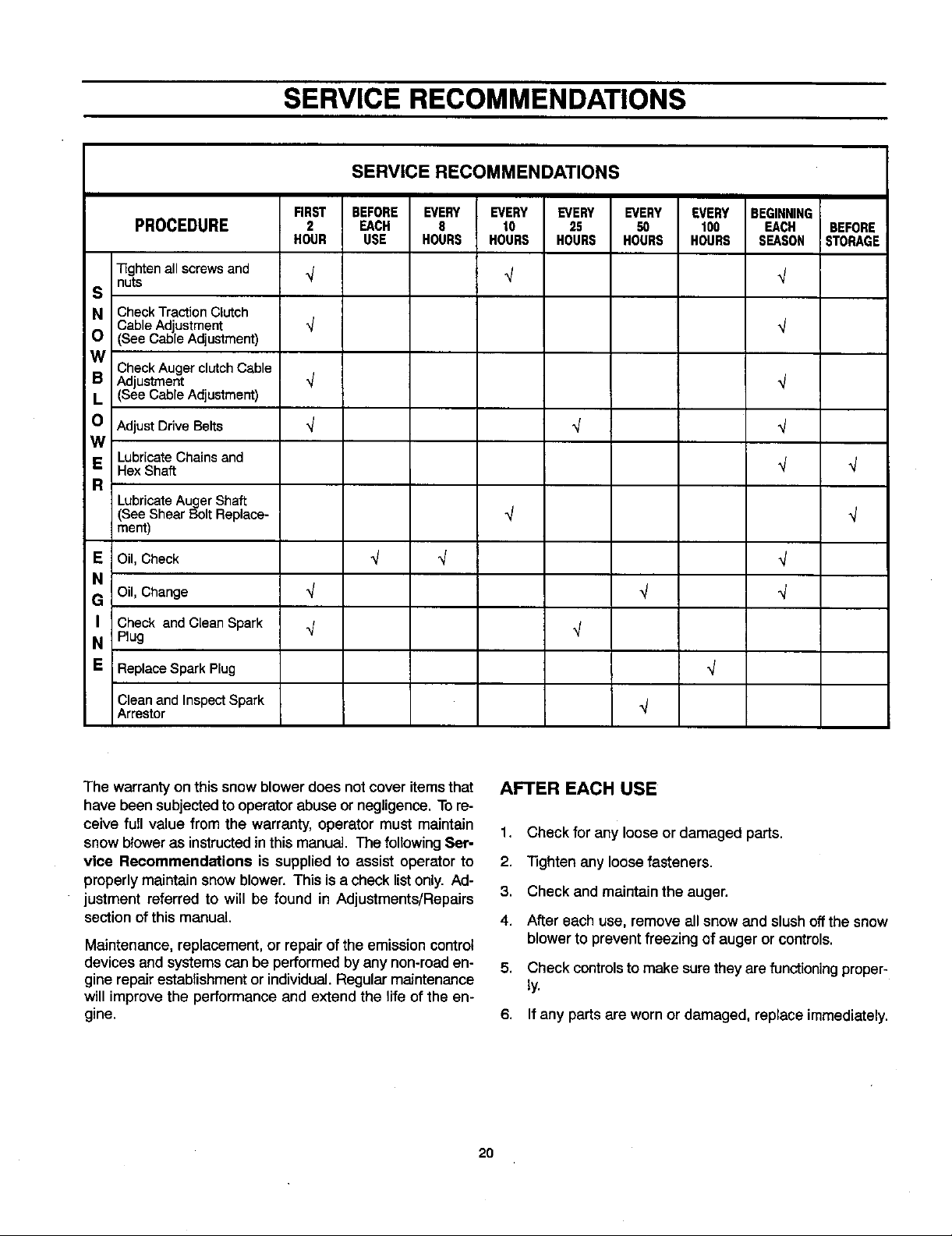

SERVICE RECOMMENDATIONS

SERVICE RECOMMENDATIONS

PROCEDURE

]]ghtenallscrewsand

nuts

S

Check Traction Clutch

N

Cable Ad ustment

O

See Cab e Ad ustment)

W

Check Auger clutch Cable

B

\d ustment

See Cab e Ad ustment)

L

O

Adjust Drive Belts

W

Lubricate Chains and

E

Hex Shaft

R

Lubricate Auger Shaft

See Shear Bolt Replace-

ment)

E

Oil, Check

N

Oil, Change

G

I

Check and Clean Spark

Plug

N

E

iReplace Spark Plug .j

FIRST BEFORE EVERY EVERY EVERY EVERY EVERY BEGINNING

2 EACH 8 10 25 50 100 EACH BEFORE

HOUR USE HOURS HOURS HOURS HOURS HOURS SEASON STORAGE

q

q

q

q

q

q

q

q

Clean and InspectSpark

Arrestor

The warranty on thissnow blower does not cover itemsthat

have been subjected to operator abuse or negligence. Tore-

ceive full value from the warranty, operator must maintain

snow blower as instructed inthis manual. The following Ser-

vice Recommendations is supplied to assist operator to

properlymaintain snow blower. This is a check list only. Ad-

justment referred to will be found in Adjustments/Repairs

section of this manual.

Maintenance, replacement, or repair of the emission control

devices and systems can be performed by any non-road en-

gine repair establishment or individual. Regular maintenance

will improve the performance and extend the life of the en-

gine.

AFTER EACH USE

1. Check for any loose or damaged parts.

2. "lighten any loose fasteners.

3. Check and maintain the auger.

4. After each use, remove all snow and slush offthe snow

blower to prevent freezing of auger or controls.

5. Check controls to make sure they arefunctioningproper-

ly.

6. If any parts are worn or damaged, replace immediately.

2O

Page 21

CUSTOMER RESPONSIBILITIES

Some adjustments will need to be made periodically to

properly maintain your snow blower.

All adjustments in ADJUSTMENTS/REPAIRS section of this

manual should be checked at least once each season.

SNOW BLOWER

The following adjustment should be performed more than

once each season.

Auger and Traction Drive Belts shouldbe adjustedafterthe

first2 to 4 hoursof use, again about mid-season and twice

each season thereafter(See ToAdjustBeltsparagraphinthe

Adjustment/Repairsestion).

AS REQUIRED

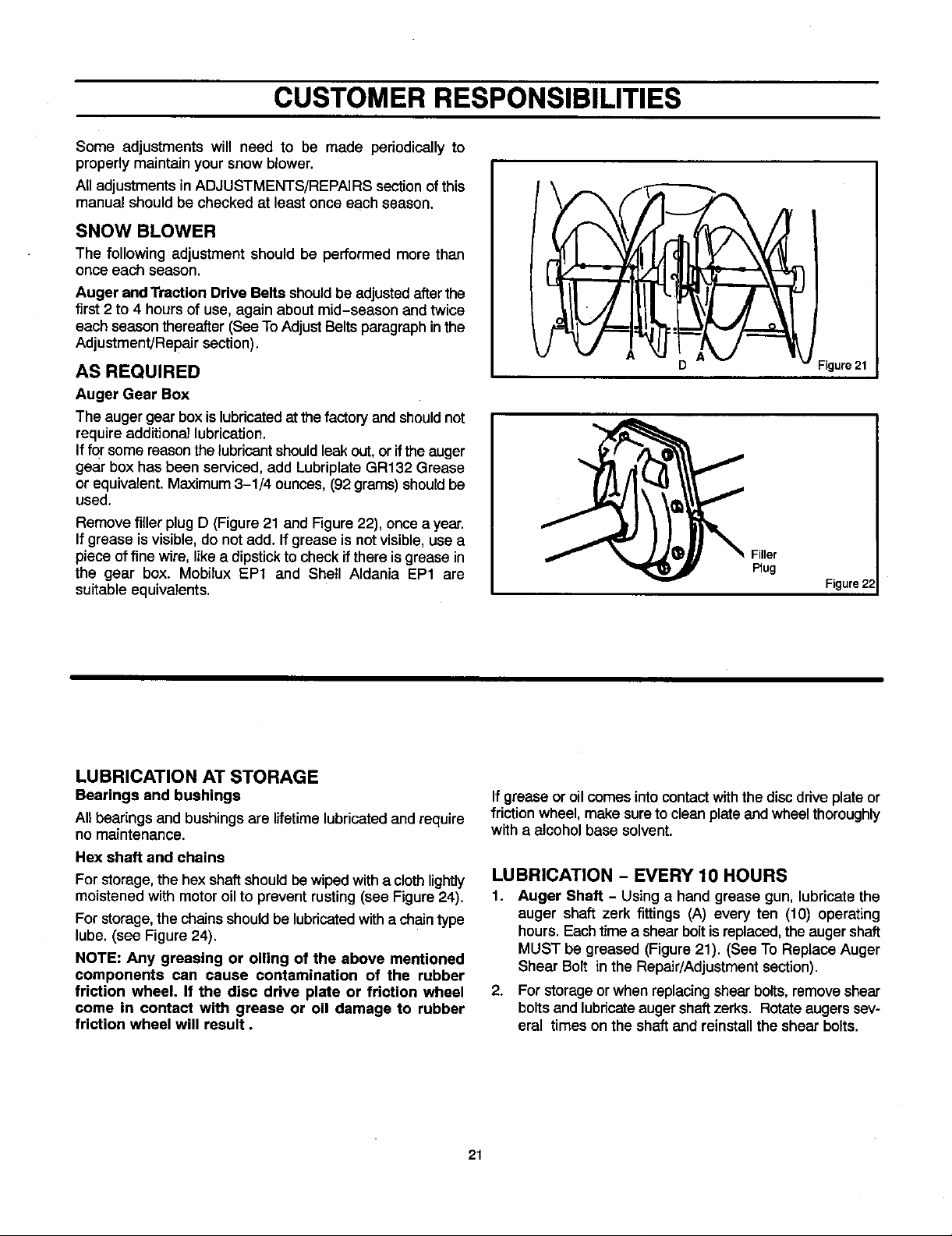

Auger Gear Box

The auger gear box islubricated atthe factory and shouldnot

require additional lubrication.

If fQrsome reason the lubricant should leak out, or ifthe auger

gear box has been serviced, add Lubriplate GR132 Grease

or equivalent. Maximum 3-1/4 ounces, (92 grams) should be

used.

Remove filler plug D (Figure 21 and Figure 22), once a year.

If grease is visible, do not add. If grease is not visible, use a

piece of fine wire, like a dipstick tocheck if there is grease in

the gear box. Mobilux EP1 and Shell Aldania EP1 are

suitable equivalents.

Filler

Plug

Figure 22

LUBRICATION AT STORAGE

Bearings and bushings

All bearings and bushingsare lifetimelubricatedand require

no maintenance.

Hex shaft and chains

For storage, the hex shaftshouldbe wiped witha clothlightly

moistened with motor oil to prevent rusting (see Figure 24).

For storage, the chains should be lubricated witha chain type

lube. (see Figure 24).

NOTE: Any greasing or oiling of the above mentioned

components can cause contamination of the rubber

friction wheel. If the disc drive plate or friction wheel

come in contact with grease or oil damage to rubber

friction wheel will result.

If grease or oil comes into contact withthe disc drive plate or

friction wheel, make sure to clean plate and wheel thoroughly

with a alcohol base solvent.

LUBRICATION - EVERY 10 HOURS

1. Auger Shaft - Usinga hand grease gun, lubricatethe

auger shaft zerk fittings (A) every ten (10) operating

hours. Each time a shear bolt is replaced, the auger shaft

MUST be greased (Figure 21). (See To Replace Auger

Shear Bolt in the Repair/Adjustment section).

2. For storageor when replacing shear bolts, removeshear

bolts and lubricate auger shaft zerks. Rotate augers sev-

eral times on the shaft and reinstall the shear bolts.

21

Page 22

CUSTOMER RESPONSIBILITIES

LUBRICATION - EVERY 25 HOURS

Chute Rotation Gear

Lubricatethe chute rotation gear withautomotivetype oil,

(see Figure 23).

Figure 22

Chains

1. Position speed selector lever infirst (1) forward gear.

2. Stand the snow blower up on the auger housing end.

NOTE: When the crank case if filled with oil, do not

leave the snow blower standing up on the auger

housing for an extended period of time,

3. Remove the bottom panel.

4. Lubricate the chains witha chain type lubricant.

5. Wipe the hexshaft and sprockets with5W30 motoroil,

NOTE: Clean all excess grease or oil found on the

rubber friction wheel or the disc drive plate.

CAUTION: Do not allow grease or oil to contact the

rubber friction wheel or the disc drive plate,

6. Installthe bottom panel,

22

contact with grease or oil

ge to rubber friction wheel

will result,

If grease or oilcome in contact with

the disc drive plate orfriction wheel,

make sure to cJeanthe plate and

wheel thoroughlywith a alcohol base

solvent.

t in

"!

Figure 24

Page 23

CUSTOMER RESPONSIBILITIES

ENGINE

POWER RATINGS

The power ratingsfor an individualengine model are initially

developed by starting with SAE (Society of Automotive

Engineers) code J1940 (Small Engine Power & Torque

Rating Procedure) (Revision 2002-05). Given both the wide

array of products on which our engines are placed, and the

variety of environmental issues applicable to operating the

equipment, it may be thatthe engine you have purchased will

not develop the rated horsepower when used in a piece of

power equipment (actual "on-site" power). This difference is

due to a variety of factors including, but not limited to, the

following: differences in altitude, temperature, barometric

pressure, humidity, fuel, engine lubrication, maximum

governed engine speed, individual engine to engine

variability, design of the particular piece of power equipment,

the manner in which the engine is operated, engine run-in to

reduce friction and clean out of combustion chambers,

adjustments to the valves and carburetor, and other factors.

The power ratings may also be adjusted based on

comparisons to other similar engines utilized in similar

applications, and will therefore not necessarily match the

values derived using the foregoing codes.

TEMPERATURE TYPE OF OIL

0°F (-18 ° C) and above S.A.E. 5W30

0°F (-18 ° C) and below synthetic 5W30

SAE VISCOSITY GRADES

°F 20 0 20 32 40

°C -30 -20 -10 0 10

II I II s s

i l • l l

Oil Fill Cap/Dipstick _ _ b

F 'LL

Check Crankcase Oil Level before starting engine andafter

each 8 hours of continuous use (see Figure 25). Add the

recommendedmotoroil as required.

NOTE: Overfilling the engine can affect performance.

Tighten the oil fill cap securely to prevent leakage.

Change Oil every 50 hoursofoperation or at least once a

year, even ifthe snow blower is notused forfiftyhours_ Use

a clean, highqualitydetergentoil. Fillthe crankcase to FULL

line on dipstick(see Figure25). Be sure originalcontaineris

marked: A.P.I. service"SF" or higher.Do notuseSAE10W40

oil (as it may notprovideproper lubrication).See Chart for oil

recommendations.

To Drain Oil - Positionsnow blower sothatthe oildrain plug

is lowest point on engine. When the engine is warm, remove

oil drain plug and oil fill cap and drain oil into a suitable

container (Figure 26).

Replace oil drain plug andtighten securely. Refill crank case

with the recommended motor oil.

NOTE: OII level must be at FULL mark. -,uC=*ure

Oil Fillcap/Dipstick

Figure 26

25

23

Page 24

ADJUSTMENT/REPAIR

_lb WARNING: Always turn unit off, remove igni-

AUGER HOUSING HEIGHT ADJUSTMENT

TO ADJUST SCRAPER BAR

After considerable use, the metal scraper bar will have a

definite wear pattern. The scraper bar in conjunction with the

skids should always be adjusted to allow one-eighth of an

inch (3 mm) between the scraper bar and the sidewalk or

area to be cleaned.

To adjust the scraper bar, proceed as follows:

1. Position the snow blower on a levelsurface.

2. Loosen the carriagebolts and nuts securing the scraper

3. Adjust the scraper bar to the proper position. Tighten the

4. For extended operation, the scraper bar may be re-

TO ADJUST SKID HEIGHT

This snow blower is equipped with two height adjust skids,

secured to the outside of the auger housing. These elevate

the front of the snow blower.

When removing snow from a hard surface area such as a

paved driveway or walk, adjust the skids upto bring the front

of the snow blower down.

When removing snow from rock or uneven construction,

raise the front of the snow blower by moving the skids down.

This will help to prevent rocks and other debris from being

picked up and thrown by the augers.

tion key and disconnect the spark plugwire be-

fore making any repairs or adjustments.

bar to the auger housing.

carriage bolts and nuts, insuring that the scraper bar is

parallel with the working surface.

versed. If the scraper bar must be replaced because of

wear, remove the carriage bolts and nuts and install a

new scraper bar.

To adjust skids, proceed as follows:

1. Place a block(equalto heightfrom grounddesired) un-

der scraper bar near butnot under skid.

2. Loosen skid mounting nuts (Figure 27) and push the skid

down until it touches the ground. Retightsn mounting

nuts.

3. Set skid on other side at same height.

NOTE: Make sure that snow blower is sat at same height

on both sides.

,_ WARNING: Be certain to maintain proper

debris, if struck by the impeller, may be thrown with

sufficient force to cause personal injury, property dam-

age or damage to the snow blower.

ground clearance for your particular area to be

cleared. Objects such as gravel, rocks or other

Height Adjust Skid

Skid MountingNuts

Figure 27

24

Page 25

ADJUSTMENT/REPAIR

HOW TO REMOVE THE SNOW HOOD

To access the sparkplug, the snow hoodmustbe removed

as follows:

1. Remove the chokecontrol knob (see Figure 28).

2. Remove the safety key.

3. Remove the mounting screws (see Figure 29).

4. Slowlyremovethe snowhood.Make surethatthe prim-

er button hose and the ignition wire are not discon-

nected.

5. The spark plug can now be accessed.

6. To installthe snow hood, firstmake surethat the primer

buttonhose andthe ignitionwire are connected.

7. Mountthe snow hoodto the engineand secure withthe

mountingscrews (see Figure29).

8. Connect the chokecontrol knobwith the'choke shaft on

the carburetor (seeFigure 30 and Figure 31). Make sure

the choke control knob is properly installed, if the choke

control knob is not installed correctly, the choke will not

operate.

Mounting Screws

Snow Hood

Spark

Plug

Hose

Figure 29

Choke Control Knob

9. In_allthe safety key.

Choke Control

Knob

Choke Shaft Figure 30

Figure 28

Carburetor Figure 31

25

Page 26

ADJ USTMENT/REPAIR

BELT ADJUSTMENT

Traction Drive Belt

The tractiondrive belt has constant springpressure anddoes

not require an adjustment. Ifthe traction drive belt is slipping,

replace the belt. See "How To Replace The Belts" in the

Maintenance section.

Auger Drive Belt

If your snowthrower will not discharge snow, check the

control cable adjustment. If it is correct, then check the

condition of the auger drive belt. If it is damaged or loose,

replace it (see Belt Replacement in this section of the

manual),

1. Disconnect spark plug wire.

2. Remove screw from belt cover. Remove belt cover

(see Figure 32).

3. Loosen nut on auger idler pulley and move auger idler

pulley towards belt about 1/8 inch (3 mm) (see

Figure 36).

4. Tighten nut.

5. Have someone engage auger drive clutch. Check ten-

sion on belt (opposite idler pulley). Belt should deflect

about 1/2 inch (12.5 mm) with moderate pressure

Figure 33). Youmay have to move idler pulley more than

once to obtain the correct tension.

Auger

Drive

( -_'J_- p_ Engine

k.j; o Po,ey

.....3. ;,\ 1/2 inch

Idler"-"w"V _w_ _'_f" _'A Deflection

Pulley /A/_ ;A

6. Reinstall belt cover.

7. Whenever belts are adjusted orreplaced, the cables will

need to be adjusted. (See Cable Adjustment in this sec-

tion of the manual).

8. Attach the spark plug wire.

Engaged _

Pulley

\-÷-/--,m.r

Figure 33

26

Page 27

HOW TO REPLACE THE BELTS

ADJUSTM ENT/RI=PAIR

The drive belts are of special constructionand must be

replaced with original factory replacement belts available

from your nearest authorized service center.

Some steps require the assistance of a second person.

How To Remove the Auger Drive Belt

Ifthe augerdrive belt isdamaged, the snowthrower willnot

discharge snow. Replace the damaged belt as follows.

1. Disconnect the spark plug wire.

2. Loosen the bolts on each side of the bottom panel (see

Figure 34).

3. Remove the bottom panel.

4. Remove screw from belt cover. Remove the belt cover

(see Figure 32).

5. Loosen the belt guide. Pullthe belt guide away from the

auger drive pulley (see Figure 36),

6. Pull the idler pulley away from the auger drive belt and

slip the auger drive belt off of the idler pulley.

7. Remove the auger drive belt from theengine pulley. To

remove the auger drive belt, the engine pulley may

have to be partially rotated,

8. Remove the top four bolts that hold together the auger

housing and the motor box. Loosen the.bottom two

bolts, The auger housing and the motor box can now

be split apart for removal of the belt (see Figure 35).

9. Remove the old auger drive belt from the auger drive

pulley. Replace the auger drive belt with an original

factory replacement belt available from an authorized

service center (see Figure 36).

16. Install the belt cover. Tighten screw (See Figure 32).

17. Check theadjustmentofthe cables.See "How To Check

And Adjust The Cables" inthe Maintenancesection,

18. Installthe bottom panel (see Figure 34).

19. Tightenthe bolts on each side of the bottom panel.

20. Connect the sparkplug wire.

Bolt

Bottom Panel

Auger Housing

Figure 34

10. Install the new auger drive belt onto the auger drive

pulley.

NOTE: To assemble the auger housing to the mo-

tor box, have someone hold the auger clutch lever

in the ENGAGED position. This will move the idler

arm and pulley enough to allow the auger drive

pulley to move back into position,

11. Assemble theauger housing to the motor box with the

four bolts thatwere removedin step 8, Tightenthe bot-

tom two bolts.

12. Install the auger drive belt onto the engine pulley.

13. Slip the auger drive belt underthe idler pulley.

14. Adjust theauger drive belt. See "HowToAdjust The Au-

ger Drive Belt" inthe Maintenancesection.

15. Adjust the belt guide. See "How To Adjust The Belt

Guide" inthe Maintenance section,

27

Motor Box

Bolts

Auger

Housing

Figure 35

Page 28

Swing PlateAxle Rod

ADJUSTMENT/REPAIR

Belt Guide

Auger Drive Pulley

Auger Drive Belt

Traction Drive Spring

Traction DriveBelt

Traction Drive Pulley

Engine Pulley

Figure 36

28

Page 29

ADJ USTM ENT/R EPAIR

How To Remove the Traction Drive Belt

If the snow throwerwillnot move forward, checkthe traction

drive belt for wear or damage. If the traction drive belt isworn

11. Install andadjust the auger drive belt. See =HowToRe-

moveThe Auger Drive Belt"inthe Maintenance section.

or damaged, replace the belt as follows.

1. Disconnect the spark plug wire.

12. Adjust the belt guide. See "How To Adjust The Belt

Guide" in the Maintenance section.

2. Remove the auger drive belt. See "How To RemoveThe

Auger Drive Belt" in the Maintenance section.

13. Install the bottom panel (see Figure 34).

3. Remove the e-ring from one end of the swing plate 14. Tighten the bolts on each side ofthe bottom panel.

axle rod. Remove the swing plate axle rod to allow the

the swingplate to pivotforward (see Figure36). 15. Installthe belt cover. Tighten screw (see Figure32),

4.

Remove the traction drive spring.

5.

Remove the old traction drive belt from the traction

16. Check the adjustment ofthe cables. See "How To Check

And Adjust The Cables" inthe Maintenance section.

drive pulley and from the engine pulley. Replace the

traction drive belt withan originalfactory replacement

17. Connect the spark plug wire.

belt available from an authorized servicecenter.

6.

Install the new traction drive belt onto the traction

drive pulley and ontoengine pulley.

7,

Make sure the traction drive idler pulley is properly

aligned withthe traction drive belt.

t

8. Attach the traction drive spring.

9. Installthe swing plate axle rod and secure withthe e-

ring removed earlier.

10. The bottom ofthe swing plate must be positionedbe-

tween the alignment tabs. Make surethe swing plate

is properlysecured (seeFigure 37).

NOTE: If the drive will not engage after the traction

drive belt has been replaced, then check to make

sure that the swing plate is positioned between the

alignment tabs.

29

I

AJignment Tabs

Figure 37

Page 30

BELT GUIDE ADJUSTMENT

1. Remove spark plug wire.

ADJUSTMENT/REPAIR

2. Have someone engage auger drive.

3. Measure the distance between the belt guide and belt.

The distance should be 1/8 inch (3.175 mm) for guide.

See Figure 38.

4, If adjustment is necessary, loosen belt guide mounting

bolt. Move belt guide to the correct position. Tighten

mounting bolt.

5. Reinstall belt cover.

6. Reconnect spark plug wire.

HOW TO CHECK AND ADJUST THE CABLES

Tl_e cables are adjusted at the factory and no adjustment

should be necessary, tf the cables have become stretched

or are sagging adjustment will be necessary.

Whenever belts are adjusted or replaced, the cables will

need to be adjusted.

To check for correct adjustment, unhook "Z" fitting at

clutch lever (see Figure 39).

_- -'_O// BeltGuide

i

Figure 38

"Z"Fitting Control lever

forwardposition

(justcontacting

plastic bumper)

when checking

cable length.

must be in full

1. Move clutch lever to the full forward position (just con-

tacting plastic bumper). Holding cable tight, note posi-

tion of fitting to hole in clutch lever,

2. The center ofthe "Z" fitting should be between the centre

and top of the hole in the clutch lever. Adjust either the

auger drive cable or the traction drive cable as follows.

Auger Drive Cable Adjustment

_k WARNING: Drain the gasoline outdoors, away

1,

2,

3,

from fire or flame.

Remove the gas from the gas tank. Stand the snow

thrower up on the front end of the auger housing.

Push cable through spring to expose the threaded por-

tion of the cable (see Figure 40).

Hold square end of threaded portion with pliers and ad-

just locknutin or out until correct adjustment is reached.

Pull cable back through spring and connect cable.

30

Square

End

Plastic

Bumper

Figure 39

x,,

Cable

Spring

o

Locknut

Figure 40

Page 31

Traction Drive Cable Adjustment

ADJUSTMENT/REPAIR

_lb ARNING: Drain the gasoline outdoors, away

1. Remove the gas from the gas tank. Stand the snow

2. Loosenthe bolts on each side ofthe bottom panel (see

3. Remove the bottom panel.

4. Disconnect the "Z" fitting from the drive lever (see

5. Slide the cable boot offthe cable adjustment bracket

6. Push the bottom of the traction drive cable throughthe

7. Remove the "Z" hook from the cable adjustment

from fire or flame.

thrower up on the front end of the auger housing.

Figure 41).

Figure 39),

(see Figure 42).

cable adjustment bracket untilthe"Z" hook can bere-

moved.

bracket. Move the "Z '° hook down to the next adjust-

ment hole.

8. Pullthe traction drive cable upthroughthe cable ad-

justment bracket.

9, Putthe cable boot overthe cable adjustment bracket.

10, Install the "Z" hook to the traction drive lever (see

Figure39).

11. To check the adjustment, depress the drive lever and

check the length of the drive spring (see Figure 43). In

correct adjustment, the length of the drive spring is

minimum 3 inches (76 mm.)

maximum 3-3/8 inches (85 mm.),

12. Install the bottom panel (see Figure 41).

13. "nghtenthe bolts oneach side ofthe bottom panel.

31

Page 32

ADJUSTMENT/REPAIR

HOW TO ADJUST OR REPLACE

THE FRICTION WHEEL

How To Check The Friction Wheel

If the snow thrower willnot move forward, checkthe traction

drive belt, the traction drive cable orthe friction wheel. If the

friction wheel is worn or damaged, it must be replaced. See

"How To Replace the Friction Wheel" in this section. If the

friction wheel is not worn or damaged, check as follows.

1. Remove the gas from the gas tank. Stand the snow

thrower up on the front end of the auger housing (see

Figure 44).

_Jll= WARNING: Drain the gasoline outdoors, away

2. Disconnect the spark plug wire.

3. Loosen the bolts oneach side ofthe bottom panel (see

4. Remove the bottom panel.

from fire or flame.

Figure44).

5. Tightenthe jam nut.

6. Installthe bottom panel (see Figure 44).

7. Tighten the bolts on each side of the bottom panel,

Bolt

II

5. Position the shift speed lever in the lowest forward

speed.

6.

Note the position ofthe friction wheel (see Figure 45).

The correctdistance "A" from the rightside ofthe fric-

tion wheel to the outside ofthe motorbox is as follows:

Tire Size Distance "A"

12 and 13 inch 4-1/8" (10.5 cm.)

16 inch 4-5/16" (10.95 cm.)

Ifthe friction wheel isnot inthe correct position,adjust

as follows.

How To Adjust The Friction Wheel

1,

Position the shift speed lever in the lowest forward

speed.

2,

Loosen hex jam nut on speed select rod. Remove ball

joint from shifter bracket (see Figure46).

3.

Move the friction wheel against tothe correctposition

(see Figure 45).

Figure 45

Rod

\

Adap_r

4.

Turn the adaptor untilthe ball joint is aligned withthe

mounting hole in the shifter rod (see Figure 46). When

aligned, attach the ball joint to the shifter rod.

er Rod _1

Figure 46

32

Page 33

ADJUSTMENT/REPAIR

How To Replace The Friction Wheel

Ifthe friction wheelisworn or damaged, the snowthrower will

not move forward. The friction wheel must be replaced as

follows.

1. Remove the gas from the gas tank. Stand the snow

thrower up on the front end of the auger housing (4),

(see Figure 44).

_lb ARNING: Drain the gasoline outdoors, away

from fire or flame.

2. Disconnect the spark plug wire.

3. Remove the fasteners that secure the left wheal. Re-

move the left wheel from the axle (see Figure 47)

4. Loosen the bolts on each side of the bottom panel.

5. Remove the bottom panel.

Axle Bort

8,

Remove the fourbolts that holdthe bearings on each

side of the hex shaft (see Figure49).

9.

Remove the hex shaft and bearings.

NOTE: Take special note of the position of the

washers on the hex shaft.

_dJ

Panel

Bolt

Wheel Figure 47

6. Remove the fastenersthat securethe drive sprocket to

the axle (see Figure48).

7. Remove the right wheel, axle, and drive sprocket.

t

49

33

Page 34

ADJUSTMENT/REPAIR

10. Remove thethree fasteners that holdthe friction wheel

to the hub (see Figure 50).

11. Remove the friction wheel from the hub. Slip the fric-

tion wheel offthe hex shaft.

12. Assemble the new friction wheel onto hub withthe fas-

teners removed earlier.

Fasteners

Hex Shaft

Friction

Hub Wheel

\

Washer

\

Washer

15.

Installthe right wheel, axle, and drive sprocket withthe

_.,._ Washer

fasteners removed earlier. Install the chain onto the

drive sprocket (see Figure48).

Figure 51

16.

Check the adjustment of the friction wheel. See "HowTo

Fasteners

Figure 50

Adjust The Friction Wheel" in this section.

17.

Make sure the friction wheel and the disc drive plate are

free from grease or oil.

13. Install the hex shaft and bearings with the four bolts re-

18. Install the bottom panel (see Figure 47).

moved earlier (see Figure51).

19. _ghtan the bolts on each side ofthe bottom panel.

Make sure the washers are properly installed in the

original position. Also, make sure the two washers

are properly aligned with the actuator arms.

20. Installthe left wheel to the axle with the fasteners re-

moved earlier.

14. Make sure the hex shaft turnsfreely. 21. Connect the spark plug wire.

34

Page 35

ADJUSTMENT/REPAIR

AUGER SHEAR BOLT REPLACEMENT

The augers are secured to the auger shaftwith specialbolts

that are designed to break if an object becomes lodged inthe

auger housing. Use of a harderbolt will reduce the protection

provided by the shear bolt. To replace a broken shear bolt,

proceed as follows:

_lb WARNING: To insure safety and performance

levels, only original replacement shear bolts

should be used.

1. Stop engine, disengage all controls, disconnect the

spark plug lead wire, and insure all moving parts have

stopped.

2. Lubricate the auger shaft zerk fittings (see Lubrication

Points in the Maintenance section of this manual).

3,

Align the holein theauger with the holein the auger shaft.

Install new shear bolt, spacer and Iocknut found in the

toolbox located on the belt cover (See Figure 52). "l]ght-

en with the shear boltwrench.

NOTE: For the operator's convlence, the shear bolt

wrenches are located in the toolbox.

NOTE: The spacer fits into the larger hole in the auger

tube.

Shear Bolt Wrench

Shear Pin _

LF _ Spacer

Locknut

Figure 52

SPARK PLUG ADJUSTMENT (SEE FIGURE 53)

NOTICE: This spark ignition system meets all 6.

requirements of the Canadian Interference-Causing

Equipment Regulations.

Check thespark plug everytwenty-five (25) hours.Replace

the spark plug if the electrodesare pittedor burned, if the

porcelain is cracked, or every 100 hoursof use.

1. Clean spark plug and reset gap periodically.

2. Clean area around spark plug base before removal, to

prevent dirt from entering engine.

3. Replace spark plug if electrodes are pitted or burned or

if porcelain is cracked.

4,

Clean sparkplug by carefully scrapingelectrodes (donot

sandblast or use wire brush).

5.

Be sure spark plug is cleanand free of foreign material.

Check electrodes gap with a wire feeler gauge and reset

gap to 0.030" (0.76 mm) if necessary. Ifa new spark plug

is needed, refer to Engine Repair Parts section of this

manual for proper replacement spark plug.

35

Before installing spark plug, coat threads lightly with

graphite grease to insure easy removal.

7.

"nghten plug firmly into engine. If torque wrench is avail-

able, torque plug to 18-23 ft-lbs.

Figure 53

Page 36

STORAGE

OFF SEASON STORAGE

_lb ARNING: Never store engine with fuel in tank

flame, spark or pilot light as on a furnace, water heater,

clothes dryer, etc.

Handle gasoline carefully. It is highly flammable and

careless use could result Inserious fire damageto your

person and/or property.

Drain fuel into approved containers outdoors, away

from open flame.

If the snow blower is to be stored for thirty (30) days or more

at the end of the snow season, the following steps are

recommended to prepare your snow blower for storage.

NOTE: Gasoline must be removed or treated to prevent

gum deposits from forming in the tank, filter, hose, and

carburetor during storage.

1,

4_lb WARNING" Drain gasoline outdoors, away fromfire or flame.

indoors or in enclosed, poorly ventilated enclo-

sures, where fuel fumes may reach an open

To remove gasoline, run engine until tank is empty and

engine stops.Then drain remaining gasoline from carbu-

retor by pressing upward on bowl drain located on the

bottom of carburetor (see Figure 54).

4. Thoroughly clean the snow blower.

5. Lubricate all lubricationpoints (see Lubrication, see Cus-

tomer Responsibilities).

5. Insure that all nuts, bolts, and screws are securely fas-

tened. Inspect all visible moving parts for damage,

breakage, and wear. Replace if necessary.

7. Touch up all rusted orchipped paint surfaces; sand lightly

before painting.

8. Cover the bare metal parts of the blower housing auger,

and the impeller with rust preventative.

9. If possible, store your snow blower indoors and cover it

to give protection from dust and dirt.

10. Store ina clean and dry area, but NOT near a stove, fur-

nace orwater heater which uses apilot light or any device

that can create aspark.

11. If the machine must be stored outdoors, block up the

snow blower and insure the entire machine is off the

ground. Cover the snow blower with a heavy tarpaulin.

If you do not want to remove gasoline use the fuel stabilizer

supplied with unit. Add fuel stabilizer (follow instructions on

fuel stabilizer package) to any gasoline left in the tank to

minimize gum deposits and acids. If the tank is almost empty,

mix stabilizer with fresh gasoline in a separate container and

add some to the tank. ALWAYS FOLLOW INSTRUCTIONS

ON STABILIZER CONTAINER. THEN RUN ENGINE AT

LEAST 10 MINUTES AFTER STABILIZER IS ADDED TO

ALLOW MIXTURE TO REACH CARBURETOR. STORE

SNOW BLOWER IN SAFE PLACE.

2. You can help keep your engine ingood operating condi-

tion by changing oil before storage.

3. Remove the spark plugand pour about 15 ml (1/2 oz) of

engine oil into the cylinder. Replace the spark plug and

crank slowly to distribute the oil.

Bowl Drain

Figure 54

36

Page 37

TROUBLE SHOOTING CHART

PROBLEM LOOK FOR REMEDY

Difficult starting Defective spark plug. Replace defectivespark ptug.

Engine runs erratically Blocked fuel line. Clean fuel line.

Emptygas tank. Check fuel supply,

Stale gasoline. Addfresh gasolinewithfuel stabilizer.

Water or dirtin fuel system. Remove carburetorbowlto drainfuel tank. Refill

withfresh fuel. CAUTION: Do not remove

carburetor bowl when the engine is hot.

' Engine stalls Unit running on CHOKE. Set choke leverto RUN position.

Loss of power Gas cap vent hole is plugged. Remove ice and snowfrom cap. Be surevent

Excessive vibration Loose parts or damaged impeller, Stop engine immediatelyand removespark plug

Unit fails to propel Drive belt loose or damaged. Replace drive belt. Refer to Drive Belt

itself Replacement inAdjustments/Repairs sectionof

hole isclear.

wire. Tighten all bolts and make all necessary

repairs. If vibration continues, have the unit

serviced by a competent repairman.

this manual.

Incorrectadjustmentoftractiondrive Adjust tractiondrive cable. Refer to Cable

cable. Adjustment inAdjustments/Repairs sectionof

Worn or damaged frictiondisc. Replace friction disc. Refer to Friction Wheel

Unit fails to discharge Auger drive belt looseor damaged. Replace oradjustauger drivebelt, Refer to Drive

snow Belt Replacement and Drive Belt Adjustment in

Auger controlcable notadjusted Adjust auger controlcable. Refer to Cable

correctly. Adjustment inAdjustments/Repairs sectionof

Broken shear bolt. Replace shear bolt. Refer to Auger Shear Bolt

Discharge chuteclogged. Stop engine immediatelyand disconnect spark

Foreign object lodged in auger. Stop engineimmediatelyand disconnectspark

this manual.

Replacement inAdjustments/Repairs sectionof

this manual.

Adjuetments/Repairs sectionofthis manual,

this manual.

Replacement inAdjustments/Repairs sectionof

this manual.

plugwire. Refer to the first Warning in Snow

blower Operation inOperation sectionof this

manual. Clean dischargechuteand inside of

auger housing.

plug wire. Refer to the third Warning in Snow

blower Operation in Operation sectionof this

manual. Remove object from auger.

Identifying Your Snow blower

Your new Snow blower has two (2) identifying numbers: (1) unitmodel number: (2) unit serial number. The two preceding

numbers are required to insure that the proper replacement parts are obtained when required, if you have any questions

concerning parts, service, or technical data, contact your nearest Sears Service Department.

For complete warranty information refer to the warranty in the Owner's Information section of this manual.

37

Page 38

CRAFTSMAN 30" SNOW BLOWER C950524312A REPAIRPARTS

CRAFTSMAN 30" CHASSE NEIGE C950524312A PIECESDERECHANGE

ENGINE / MOTEUR

25-2

5

25-3

25-2

\

\

28

16

\

I

17

\

12

20/

22

24 14 J

/ 15

25-1

4

25-4

6

/

11

18

8

/

\

/

9

Ref. Drive Page

3

Ref. Auger Housing Page

38

Page 39

CRAFTSMAN 30" SNOW BLOWER C950524312A REPAIRPARTS

CRAFTSMAN 30" CHASSE NEIGE C950524312A PIECESDERECHANGE

ENGINE / MOTEUR

Key No.

NO8ur le Part No,