Craftsman C950524302A Owner’s Manual

8 _ JR8

owner's

manual

Model

C950524302A

9.5 H.P. 27 inch

DUAL STAGE

SNOW BLOWER

CAUTION:

You must read and

understand this owner's

manual before operating

unit.

Serial No.

401357 SEARS CANADA INC., TORONTO, ONTARIO M5B 2B8 PrintedinU.S.A.

RULES FOR SAFE OPERATION

GeneralInformation

Thisinstructionbookiswrittenfura personwithsomemechanicalability.

Ukemostsen_icebooks,notallthestepsaredescribod.Stepsonhowto

loosenortightenfastenersarestepsanyonecanfollowwithsome

mechanicalability.Readandfollowtheseinstructionsbeforeyouusethe

unit.

Knowyourproduct:Ifyouunderstandtheunitandhowtheunit

operates,youwillgetthebestperformance.Asyoureadthismanual,

comparetheillustrationstotheunit.LearntheIocaUonandthefunctionof

thecontrols.Tohelppreventanaccident,followtheoperatinginstructions

andthesafetyrules.Keepthismanualforfuturereference.

IMPORTANT:Manyunitsarenotassembledandaresoldincartons.Itis

theresponsibilityoftheownertomakesuretheassemblyinstructionsin

thismanualareexactlyfollowed.Otherunitsarepurchasedinan

assembledcondflion.Onassembledunits,itistheresponsibilityofthe

ownertomakesuretheunitiscorrectlyassembled.Theownermust

carefullychecktheunitaccordingtotheinstructionsinthismanualbefore

itisfirstused.

Thismanualcon_nssafetyinformationtomakeyou

awareofthehazardsanddsksassociatedwithsnow

throwers,andhowtoavoidthem.Thesnowthrowerisdesignedand

intendedforremovalofsnow,andshouldnotbeusedforanyother

purpose.It isimportantthatyoureadandunderstandthese

instructions,andanyoneoperatingtheequipmentreadand

understandthoseinstructions.

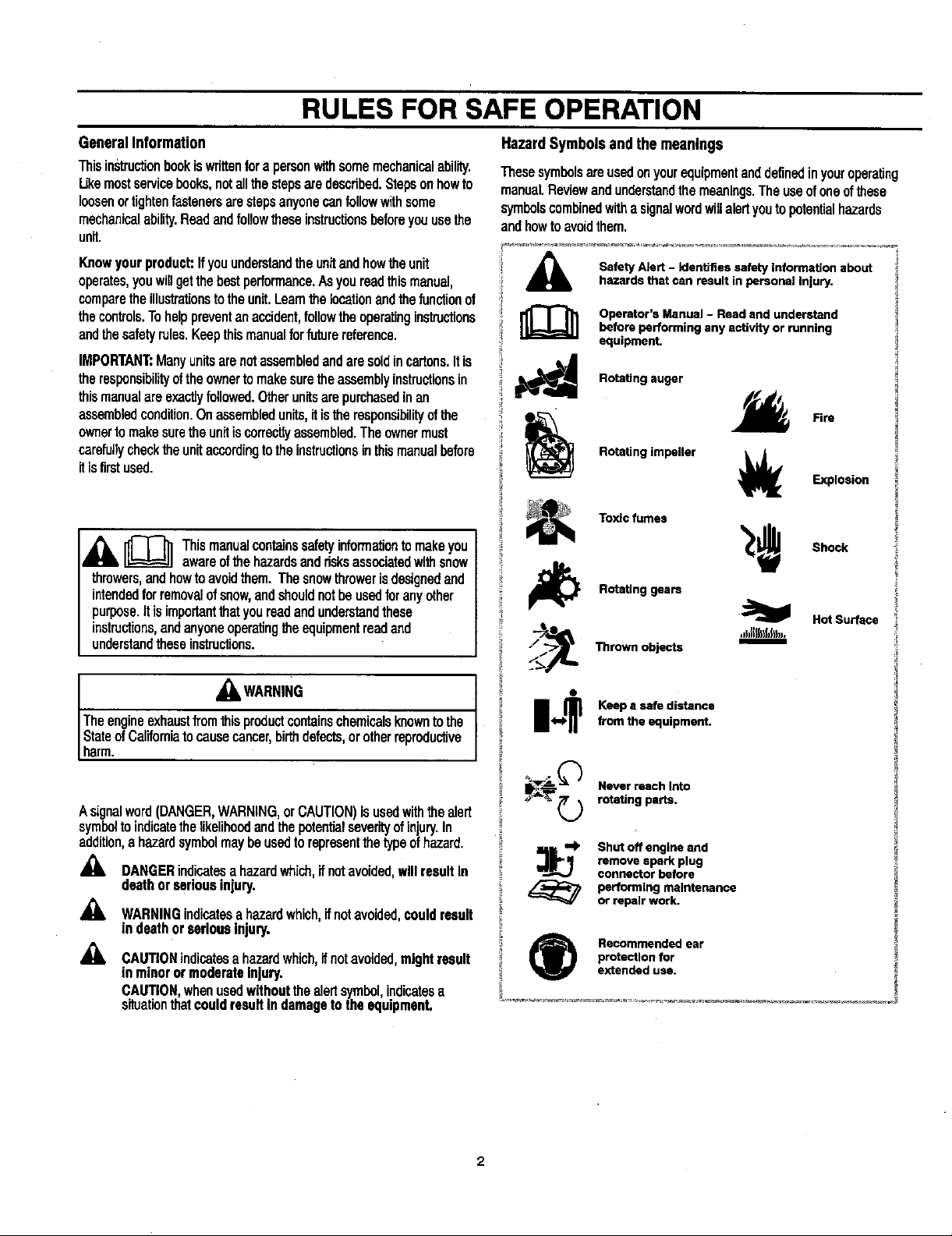

HazardSymbolsand themeanings

Thesesymbolsareusedonyourequipmentanddefinedinyouroperating

manual.Reviewandunderstandthemeanings.Theuseofoneofthese

symbolscombinedwithasignalwordwillalertyoutopotentialhazards

andhowtoavoidthem.

A

_ Thrown objects

Safety Alert - Identifies safety Information about

hazards that can result in personal Injury.

Operator's Manual - Read and understand

before performing any activity or running

equipment.

Rotating auger

Fire

Rotating impeller

Explosion

Toxlcfumes

Shock

Rotating gears

.J}=l[ll,fJS,..

Elm

Hot Surface

Theengineexhaustfromthisproductcontainschemicalsknowntothe

StateofCaliforniatocausecancer,birthdefects,orotherreproductive

_,WARNING I

harm.

Asignalword(DANGER,WARNING,or CAUTION)isusedwiththealert

symboltoindicatethelikelihoedandthepotentialseverityofinjury.In

addition,ahazardsymbolmaybeusedtorepresentthetypeofhazard.

_k DANGERindicatesahazardwhich,ifnotavoided,willresultIn

deathorseriousinjury.

WARNINGindicatesahazardwhich,ifnotavoided,couldresult

indeathorseriousinjury.

CAUTIONindicatesahazardwhich,ifnotavoided,mightresult

inminorormoderateInjury.

CAUTION,whenusedwithoutthealertsymbol,indicatesa

situationthatcouldresultindamagetotheequipmenL

o

I<,,1,_ eep a safe distancefrom the equipment.

Never reach Into

rotating parts.

_]j_=$' Shot off engine and

(_ Recommended ear

remove spark plug

connector before

performing maintenance

or repair work.

protection for

extended use.

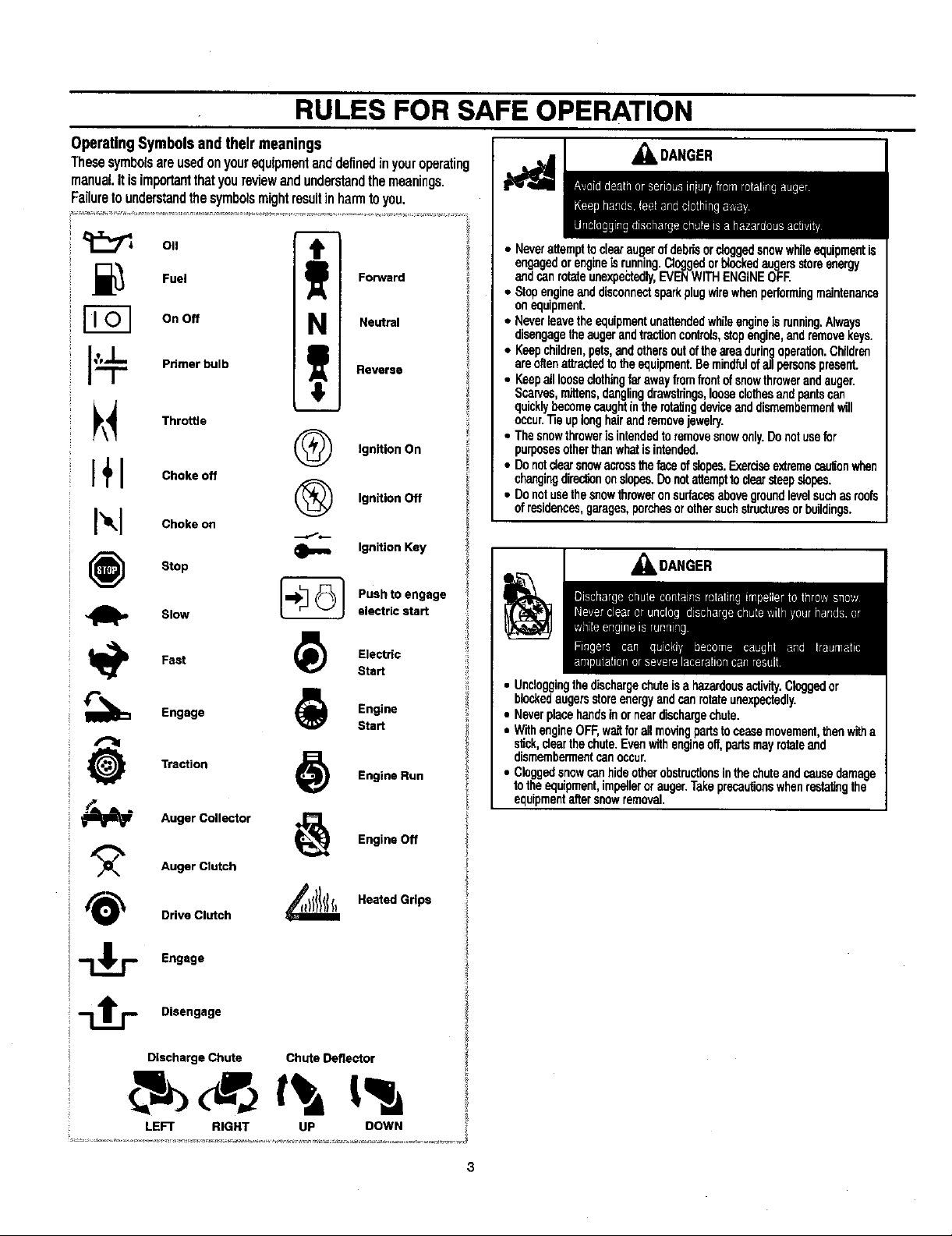

RULES FOR SAFE OPERATION

OperatingSymbols andtheir meanings

Thesesymbolsareusedonyourequipmentanddefinedinyouroperating

manual It is importantthatyoureviewandunderstandthemeanings.

Failuretounderstandthesymbolsmightresultinharmtoyou.

I_ _IL DANGER

011 T

._ Fuel -- Forward

On Off N Neutral

__. Palmerbulb Reverse

_\_ Throttle

(_ IgnitionOn

I+1 Cho.o,

IgnitionOff

I'_lt_I Chokeon

IgnitionKey

(_ Stop

Slow electricstart

lb Fast _) Electric

I_ Engage _ Engine

Traction _) Engine Run

Pushto engage

Start

Start

• Neverattempttoclearaugerofdebrisordoggedsnowwhileequipmentis

engagedorengineisrunning.Cloggedorbfsckedaugersstoreenergy

andcanrotateunexpe_:tedly,EVENWITHENGINEOFR

• Stopengineanddisconnectsparkplugwirewhenperformingmaintenance

onequipment.

• Neverleavetheequipmentunattendedwhileengineisrunning.Always

disengagetheaugerandtractioncontrols,stopengine,andremovekeys.

• Keepchildren,pets,andothersoutoftheareaduringoperation.Childrefl

areoftenattractedtotheequipment.Bemindfulofallparsonspresent.

• Keepalllooseclothingfarawayfromfrontofsnowthrowerandauger.

Scarves,mittens,danglingdrawstrings,looseclothesandpantscan

quicklybecomecaughtintherefutingdevicaanddismembermentwill

occur."fieuplonghairandremovejewelry.

• Thesnowthrowerisintendedtoremovesnowonly.Donotusefur

purposesothertheewhatisintended.

• Donotdearsnowaumssthefaceofslopes.Exerdseextremecan_onwhen

changingdirectiononslopes.Donotattempttodearsteepslopes.

• Donotusethesnowthroweronsurfasesabovegroundlevelsuchasroofs

ofresidences,garages,porchesorothersuchstructuresorbuildings.

,_k DANGER

• Uncloggingthedischargechuteisa hazardousactivity.Cloggedor

blockedaugersstoreenergyandcanrotateunexpectedly.

• Neverplacehandsinorneardischargechute.

• WithengineOFF,waitforallmovingpartstoceasemovement,thenwitha

stick,deerthechute.Evenwithengineoff,partsmayrotateand

dismembermentcanoccur.

• Cloggedsnowcanhideotherobstructionsinthechuteandcausedamage

totheequipment,impellerorauger.Takeprecautionswhenrestatingthe

equipmentaftersnowremoval.

"_ Auger Collector _ Engine Off

Auger Clutch

Drive Clutch _ Heated Grips

Engage

Disengage

Discharge Chute Chute Deflector

LEFT RIGHT UP DOWN

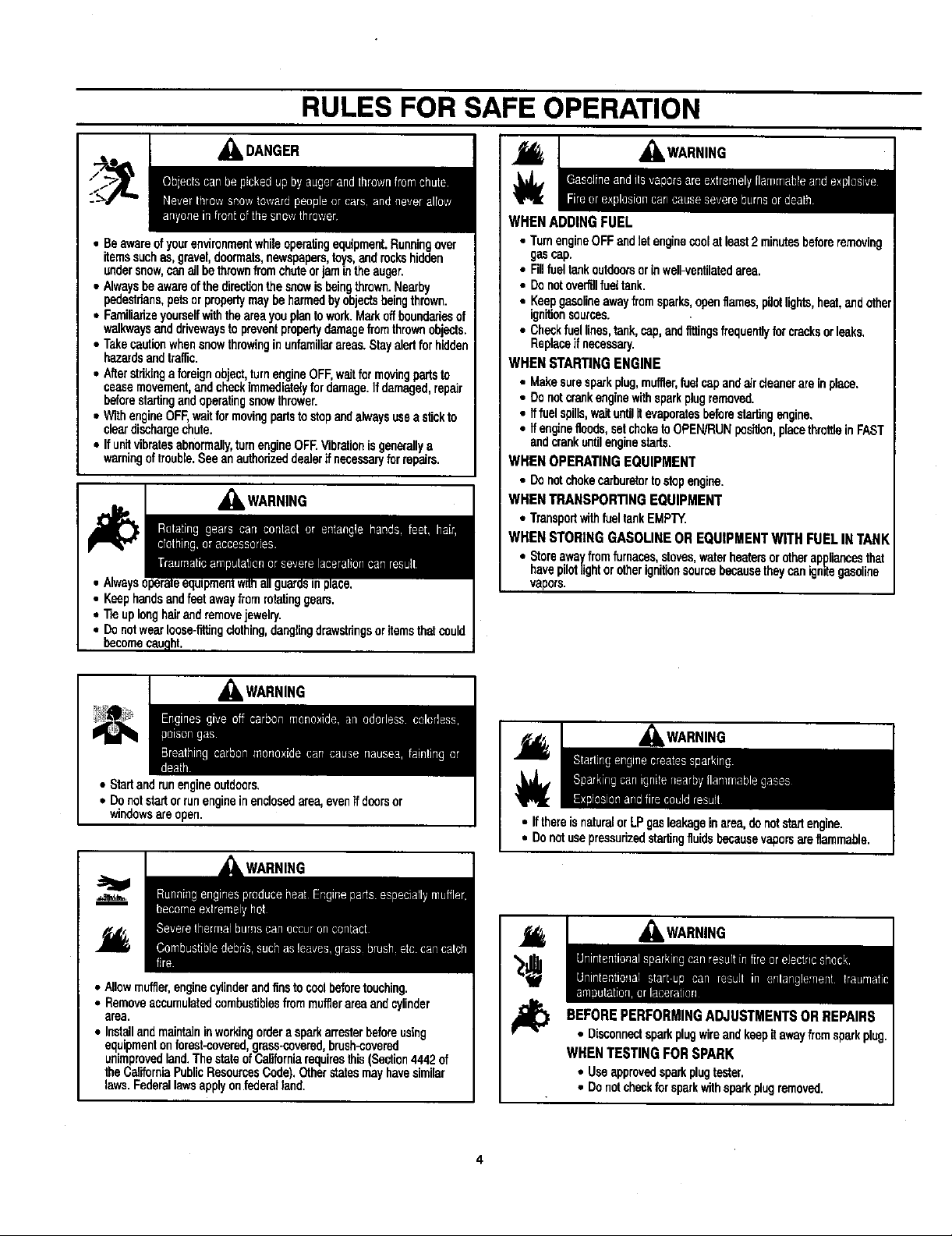

RULES FOR SAFE OPERATION

_kDANGER

• Beawareofyourenvironmentwhileoperatingequipment.Runningover

itemssuchas graveldoormats,newspapers,toys,androckshidden

undersnow,canallbethrownfromchuteoram ntheauger.

• Alwaysbeawareofthedirectionthesnowisbeingthrown.Nearby

pedestrians,petsorpropertymaybeharmedbyobjectsbeingthrown.

• Famitiaitzeyearsalfwiththeareayooptantowork.Markoffbo_ed_es of

walkwaysanddrivewaystopreventpropertydamagefromthrownobjects.

• Takecautionwhensnowthrowinginunfamiliarareas.Stayalertforhidden

hazardsandtraffic.

• Afterstrikinga foreignobject,turnengineOFF,waitformovingpartsto

ceasemovement,andcheckimmedietalyfordamage.Ifdamaged,repair

beforestartingandoperatingsnowthrower.

• WithengineOFF,waitformovingpartstostopandalwaysuseastickto

cleardischargechute.

• Ifunitvibratesabnormally,turnengineOFF.Vibrationisgenerallya

warningoftrouble.Seeanauthodzeddealerif necessaryforrepairs.

,_WARNING

AWARNING

WHENADDING FUEL

• TurnengineOFF andletenginecoolatleast2minutesbeforeremoving

gascap.

•Fm fualtankoutdoorsorInweU-ventilatadarea.

• Donotoverfillfuel tank.

• Keepgasolineawayfromsparks,openflames,pilotlights,heat,andnthe

ignitionsources.

• Checkfuellines,tank,cap,andfittingsfrequentlyforcracksorleaks.

Replaceifnecessary.

WHENSTARTINGENGINE

• Makesuresparkplug,muffler,fuelcapandaircteanerarein place.

• Donotcrankenginewithsparkplugremoved.

• If fuelspills,waituntilit evaporatesbeforestartingengine,

• Ifenginefloods,setchoketoOPEN/RUNpea'_on,ptacethrottleinFAST

andcrankuntilenginestarts.

WHENOPERATING EQUIPMENT

• Donotchokecarburetortostopengine.

WRENTRANSPORTINGEQUIPMENT

• TransportwithfueltankEMPTY.

WHENSTORING GASOLINE OR EQUIPMENTWITH FUEL INTANK

• Storeawayfromfurnaces,stoves,waterheatersorotherappliancesthat

havepilotlightorotherignitionsourcebecausetheycanignitegasoline

vapors.

,_k WARNING

• Startandr_nangineoutdoors.

• Donotstartorrunengineinenclosedarea,evenif doorsor

windowsareopen.

WARNING

• Allowmuffler,enginecylinderandfinstocoolbeforetouching.

• Removeaccumulatedcombustiblesfrommufflerareaandcylinder

area.

• Installandmaintaininworkingordera sparkarresterbeforeusing

equipraenton forest-coveredgmss-oovered,brush-covered

unimprovedland.ThestateofCaliforniarequiresthis(Section4442of

theCaliforniaPublicResourcesCode).Otherstatesmayhavesimilar

laws.Federallawsapplyonfederalland.

• Donntusepressudzedstartingfluidsbecassev_orsareflammable.

WARNING

BEFOREPERFORMINGADJUSTMENTSOR REPAIRS

• DiSConnectsparkplugwireandkeepitawayfromsparkplug.

WHENTESTING FORSPARK

• Useapprovedsparkplugtester.

• Donotcheckforsparkwithsparkplugremoved.

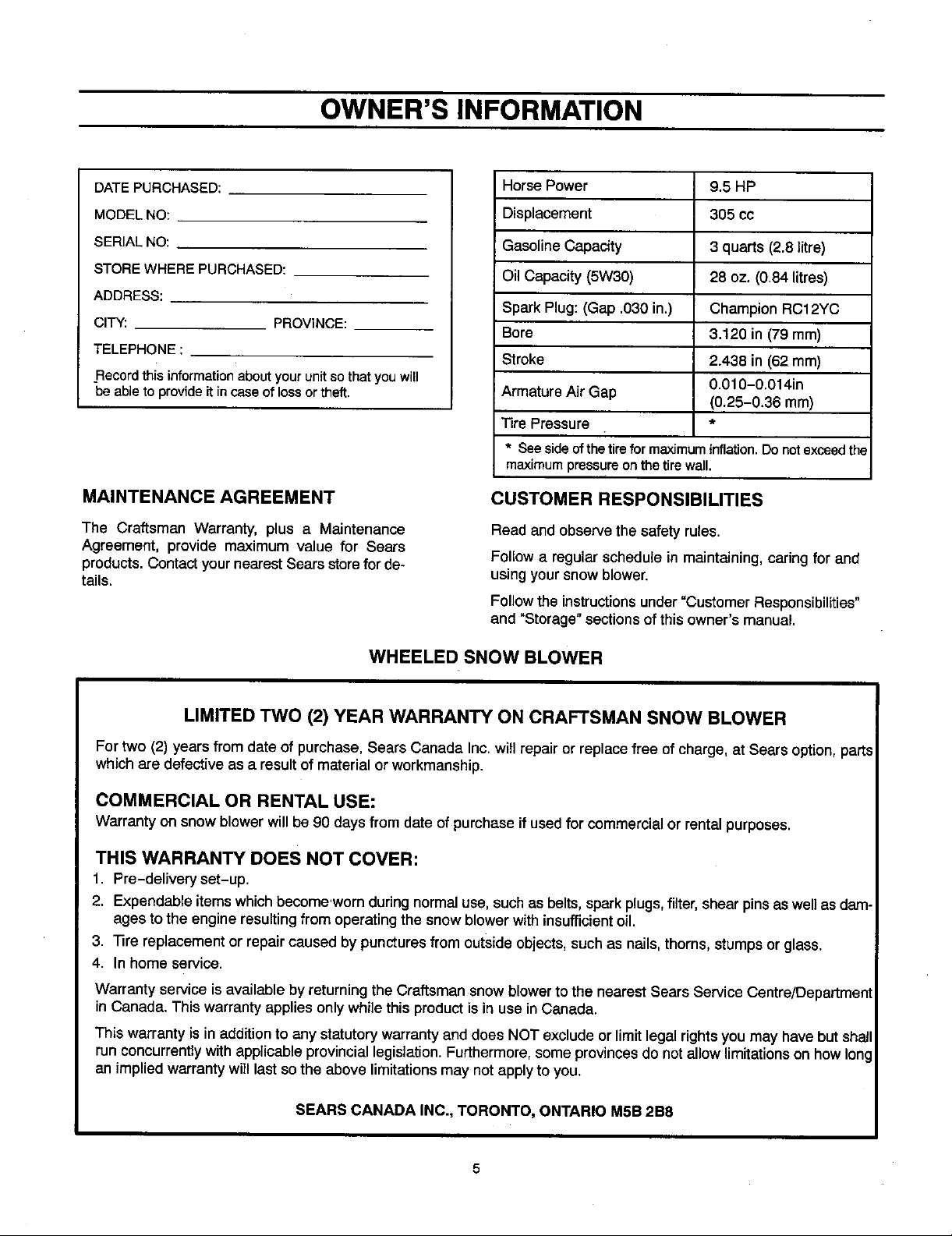

OWNER'S INFORMATION

DATE PURCHASED:

MODEL NO:

SERIAL NO:

STORE WHERE PURCHASED:

ADDRESS:

CITY: PROVINCE:

TELEPHONE :

Record this information about your unit so that you will

be able to provide it incase of loss or theft.

MAINTENANCE AGREEMENT

The Craftsman Warranty, plus a Maintenance

Agreement, provide maximum value for Sears

products. Contact your nearest Sears store for de-

tails.

Horse Power 9.5 HP

Displacement 305 cc

Gasoline Capacity 3 quarts (2.8 litre)

Oil Capacity (5W30) 28 oz. (0.84 litres)

Spark Plug: (Gap .030 in.) Champion RC12YC

Bore 3.120 in (79 mm)

Stroke 2.438 in (62 mm)

0.010-0.014in

Armature Air Gap (0.25-0.36 mm)

Tire Pressure *

• Seesideofthetire for maximuminflation.Donotexceedthe

maximumpressureonthe tirewall.

CUSTOMER RESPONSIBILITIES

Read and observethe safetyrules.

Follow a regular schedule in maintaining, caring for and

using your snow blower.

Follow the instructions under "Customer Responsibilities"

and "Storage" sections of this owner's manual.

WHEELED SNOW BLOWER

LIMITED TWO (2) YEAR WARRANTY ON CRAFTSMAN SNOW BLOWER

For two (2) years from date of purchase, Sears Canada Inc,willrepair or replace free of charge, at Sears option, parts

whichare defectiveas a resultof material or workmanship,

COMMERCIAL OR RENTAL USE:

Warranty on snow blowerwillbe 90 days from date of purchase if usedfor commercial or rental purposes.

THIS WARRANTY DOES NOT COVER:

1. Pre-delivery set-up.

2. Expendable itemswhichbecome'worn duringnormal use, suchas belts,spark plugs,filter,shear pinsas well as dam-

ages tothe engine resultingfrom operating the snow blower withinsufficient oil.

3. Tire replacement or repair caused by puncturesfrom outside objects, such as nails,thorns, stumpsor glass.

4. Inhome service.

Warranty service is available by returningthe Craftsman snow blower to the nearest Sears Service Centre/Department

in Canada. This warranty applies only while this product is in use in Canada.

This warranty is in addition to any statutory warranty and does NOT exclude or limit legal rights you may have but shall

run concurrently with applicable provincial legislation. Furthermore, some provinces do not allow limitations on how Iorl

an implied warranty will last so the above limitations may not apply to you.

SEARS CANADA INC., TORONTO, ONTARIO M5B 2B8

TABLE OF CONTENTS

HAZARD SYMBOLS AND THE MEANINGS .......... 2

OPERATING SYMBOLS AND THEIR MEANINGS ..... 3

OWNER'S INFORMATION .......................... 5

ASSEMBLY ....................................... 7

TOOLS REQUIRED FOR ASSEMBLY .............. 7

CONTENTS OF SHIPPING CARTON .............. 7

PARTS BAGS CONTENTS: ....................... 7

UNPACKING .................................... 8

UPPER HANDLE AND CRANK ASSEMBLY ......... 9

CHECK THE CABLES ............................ 9

HOW TO SET THE LENGTH OF THE CABLES ..... 9

SPEED SELECT LEVER ........................ 10

SNOW CHUTE ASSEMBLY ...................... 11

HOW TO USE THE CLEAN-OUT TOOL ........... 18

OPERATING TIPS .............................. 19

SERVICE RECOMMENDATIONS ................... 20

CUSTOMER RESPONSIBILITIES .................. 21

SNOW BLOWER ............................... 21

LUBRICATION AT STORAGE .................... 21

LUBRICATION - EVERY 10HOURS .............. 21

LUBRICATION - EVERY 25 HOURS .............. 22

ENGINE ....................................... 23

ADJUSTMENT/REPAIR ........................... 24

AUGER HOUSING HEIGHT ADJUSTMENT ....... 24

TO ADJUST SCRAPER BAR ..................... 24

TO ADJUST SKID HEIGHT ...................... 24

HEADLIGHT ASSEMBLY ........................ 11

OPERATION ..................................... 12

OPERATING CONTROLS ....................... 12

SNOW BLOWER OPERATION ................... 13

WHEEL LOCK OUT PIN ......................... 14

BEFORE STARTING ENGINE .................... 15

CHECK THE OIL ............................... 15

FILL GAS ...................................... 15

BEFORE STOPPING THE ENGINE ............... 16

TO STOP ENGINE .............................. 16

TO START ENGINE ............................. 16

FROZEN STARTER ............................. 18

HOW TO CLEAR A CLOGGED DISCHARGE CHUTE . 18

HOW TO REMOVE THE SNOW HOOD ........... 25

BELT ADJUSTMENT ............................ 26

HOW TO REPLACE THE BELTS ................. 27

BELT GUIDE ADJUSTMENT ..................... 30

HOW TO CHECK AND ADJUST THE CABLES .... 30

AUGER DRIVE CABLE ADJUSTMENT ............ 30

TRACTION DRIVE CABLE ADJUSTMENT ......... 31

HOW TO ADJUST OR REPLACE

THE FRICTION WHEEL ....................... 32

AUGER SHEAR BOLT REPLACEMENT ........... 35

STORAGE ....................................... 36

TROUBLE SHOOTING CHART ..................... 37

REPAIR PARTS .................................. 38

ORDER REPAIR PARTS ........................... 68

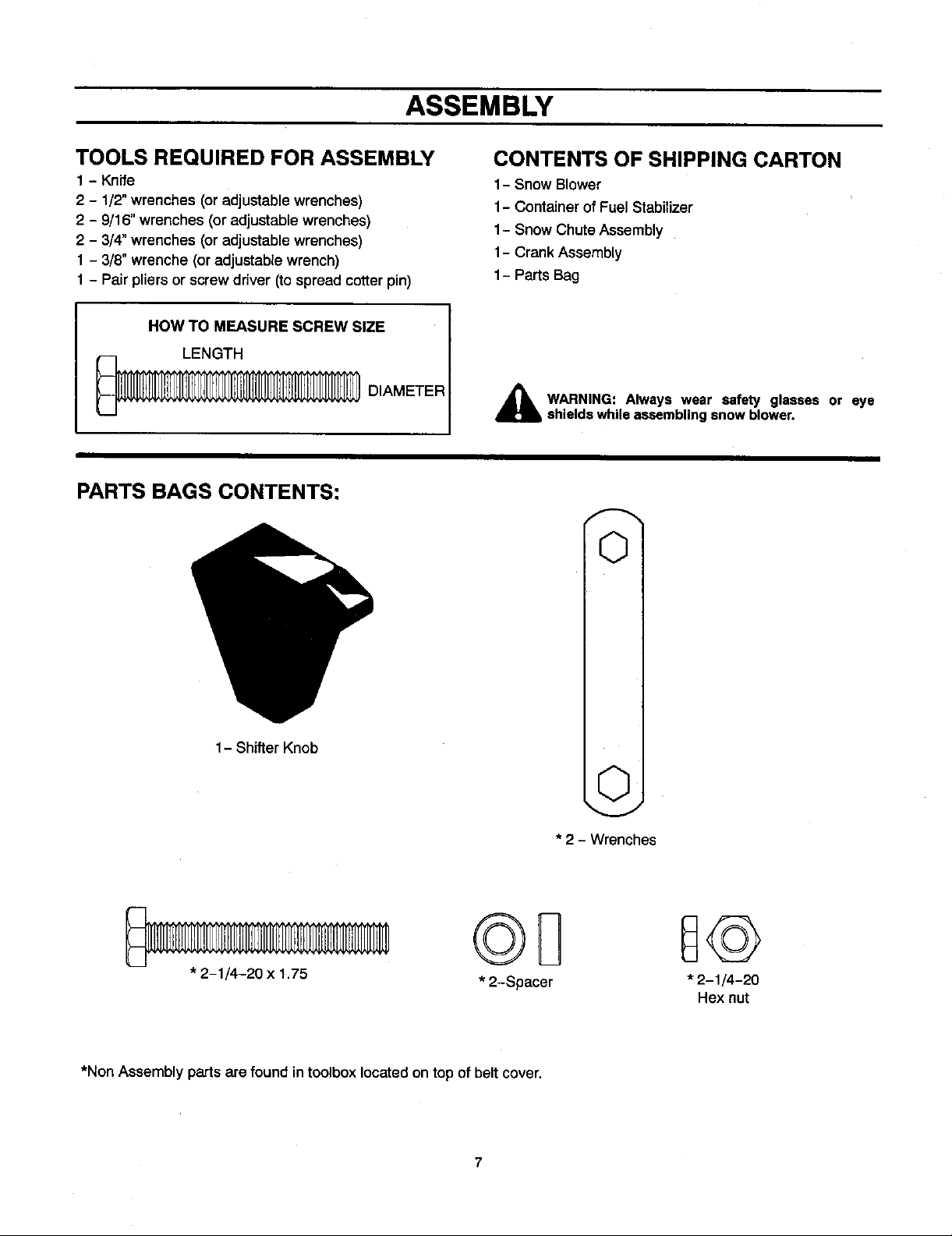

ASSEMBLY

TOOLS REQUIRED FOR ASSEMBLY

1 - Knife

2 - 1/2"wrenches (or adjustable wrenches)

2 - 9/16" wrenches (or adjustable wrenches)

2 - 3/4"wrenches (or adjustable wrenches)

1 - 3/8" wrenche (or adjustable wrench)

1 - Pair pliers or screw driver (tospread cotter pin)

HOW TO MEASURE SCREW SIZE

_ DIAMETER

PARTS BAGS CONTENTS:

CONTENTS OF SHIPPING CARTON

1- Snow Slower

1- Container of Fuel Stabilizer

1- Snow Chute Assembly

1- CrankAssembly

1- Parts Bag

_hb WARNING: Always wear safety glasses or

shields while assembling snow blower.

OI

eye

1- Shifter Knob

©@

* 2-1/4-20 x 1.75

*Non Assembly parts are found in toolbox located on top of belt cover.

* 2-Spacer

7

OI

* 2 - Wrenches

* 2-1/4-20

Hex nut

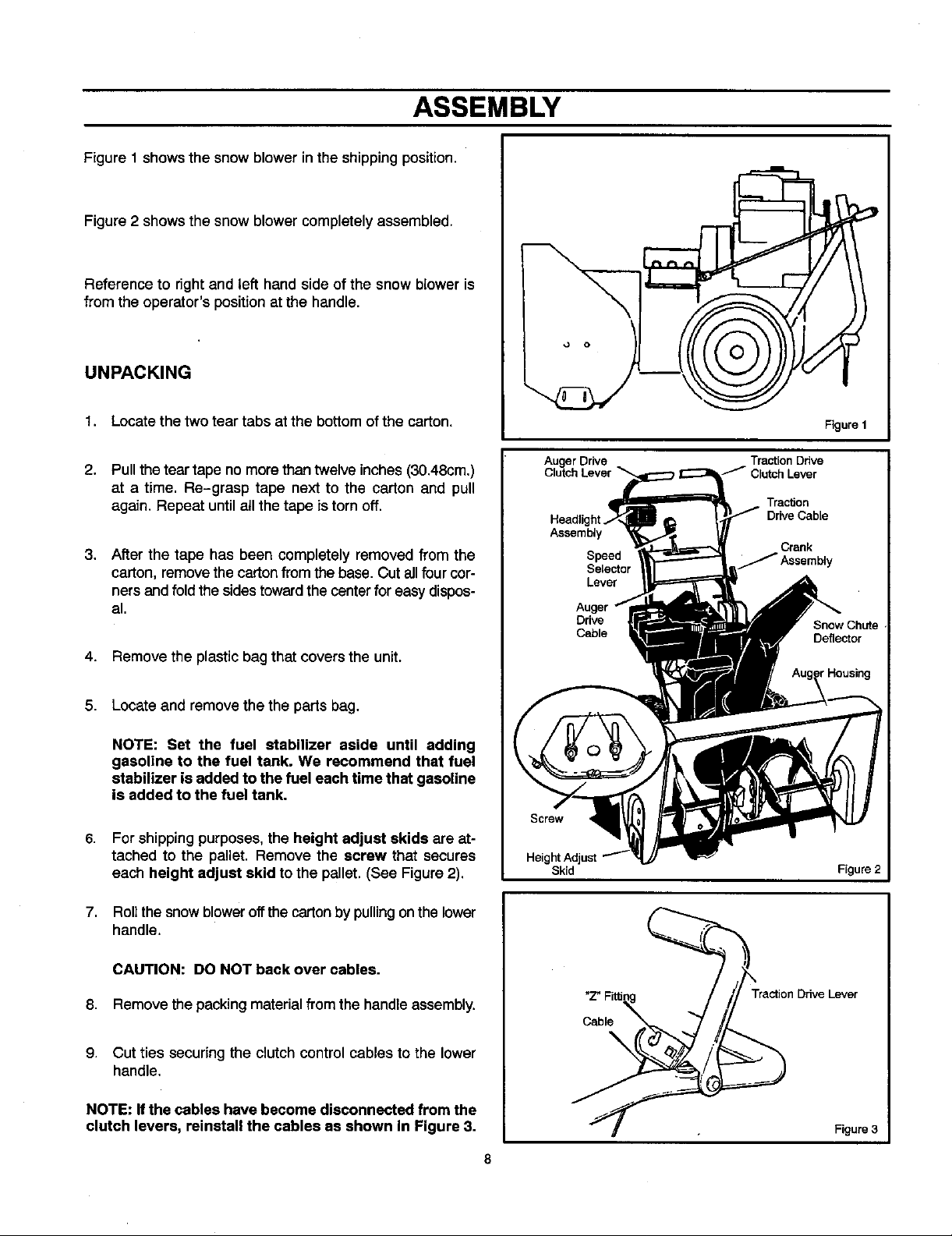

ASSEMBLY

Figure 1shows the snow blower in the shipping position.

Figure 2 shows the snow blower completely assembled.

Reference to right and left hand side of the snow blower is

from the operator's position at the handle.

UNPACKING

1. Locate the two tear tabs at the bottom of the carton.

2. Pull the tear tape no more than twelve inches (30.48cm.)

at a time, Re-grasp tape next to the carton and pull

again. Repeat until atl the tape is torn off.

3. After the tape has been completely removed from the

carton, remove the carton from the base. Cut all four cor-

ners and fold the sides toward the center for easy dispos-

al.

4. Remove the plastic bag that covers the unit.

5. Locateand remove the the parts bag.

NOTE: Set the fuel stabilizer aside until adding

gasoline to the fuel tank. We recommend that fuel

stabilizer is added to the fuel each time that gasoline

is added to the fuel tank.

6.

For shipping purposes,the height adjust skids are at-

tached to the pallet. Remove the screw that secures

each height adjust skid to the pallet. (See Figure 2).

AugerDr_e

Clutch Lever

Assembly

Drive

Cable

Screw

Height Adjust

Skid

Speed

Selector

Lever

Figure 1

TractionDdve

Figure 2

7,

Roll the snow blower off the carton by pulling on the lower

handle.

CAUTION: DO NOT back over cables.

8. Remove the packing material fromthe handle assembly.

9. Cut ties securing the clutch control cables to the lower

handle.

NOTE: If the cables have become disconnected from the

clutch levers, reinstall the cables as shown in Figure 3.

Cable

Figure 3

8

ASSEMBLY

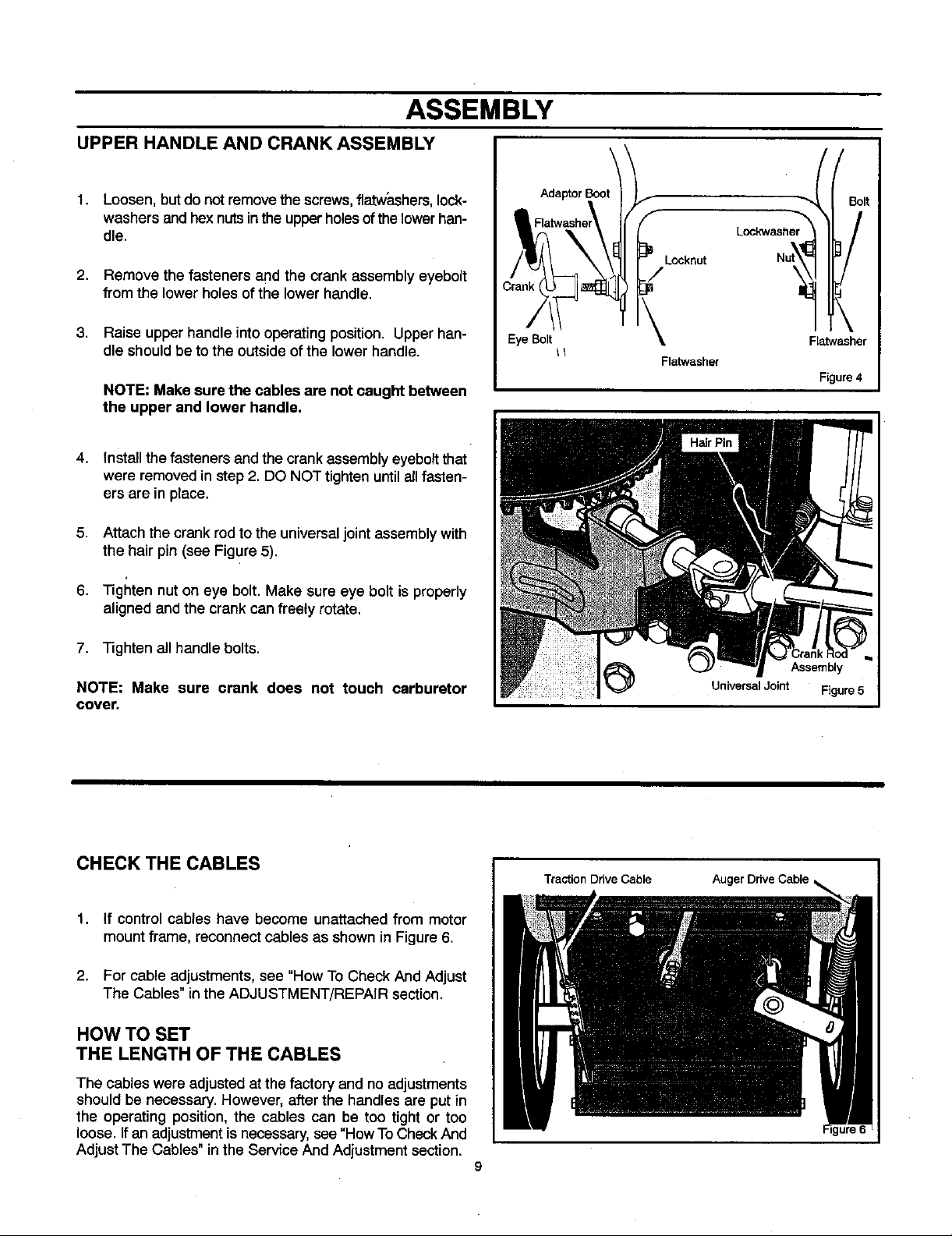

UPPER HANDLE AND CRANK ASSEMBLY

1,

Loosen, but do not remove the screws, flatw'ashers, lock-

washers and hex nuts in the upper holes of the lowerhan-

dle.

2*

Remove the fasteners and the crank assembly eyebolt

from the lower holes of the lower handle.

Bolt

Lockwasher

Locknut

3. Raise upper handle into operating position. Upper han- EyeBolt

die should be to the outside of the lower handle. _

NOTE: Make sure the cables are not caught between

the upper and lower handle,

4. Install the fasteners and thecrank assembly eyebalt that

were removed in step 2. DO NOT tighten until allfasten-

ers are in place.

5. Attach the crank rod to the universal joint assembly with

the hair pin (see Figure 5).

6. Tighten nut on eye bolt. Make sure eye bolt is properly

aligned and the crank can freely rotate.

7. Tighten all handle bolts.

NOTE: Make sure crank does not touch carburetor

cover.

Flatwasher

Flatwasher

Figure 4

Assembly

Universal Joint Figure 5

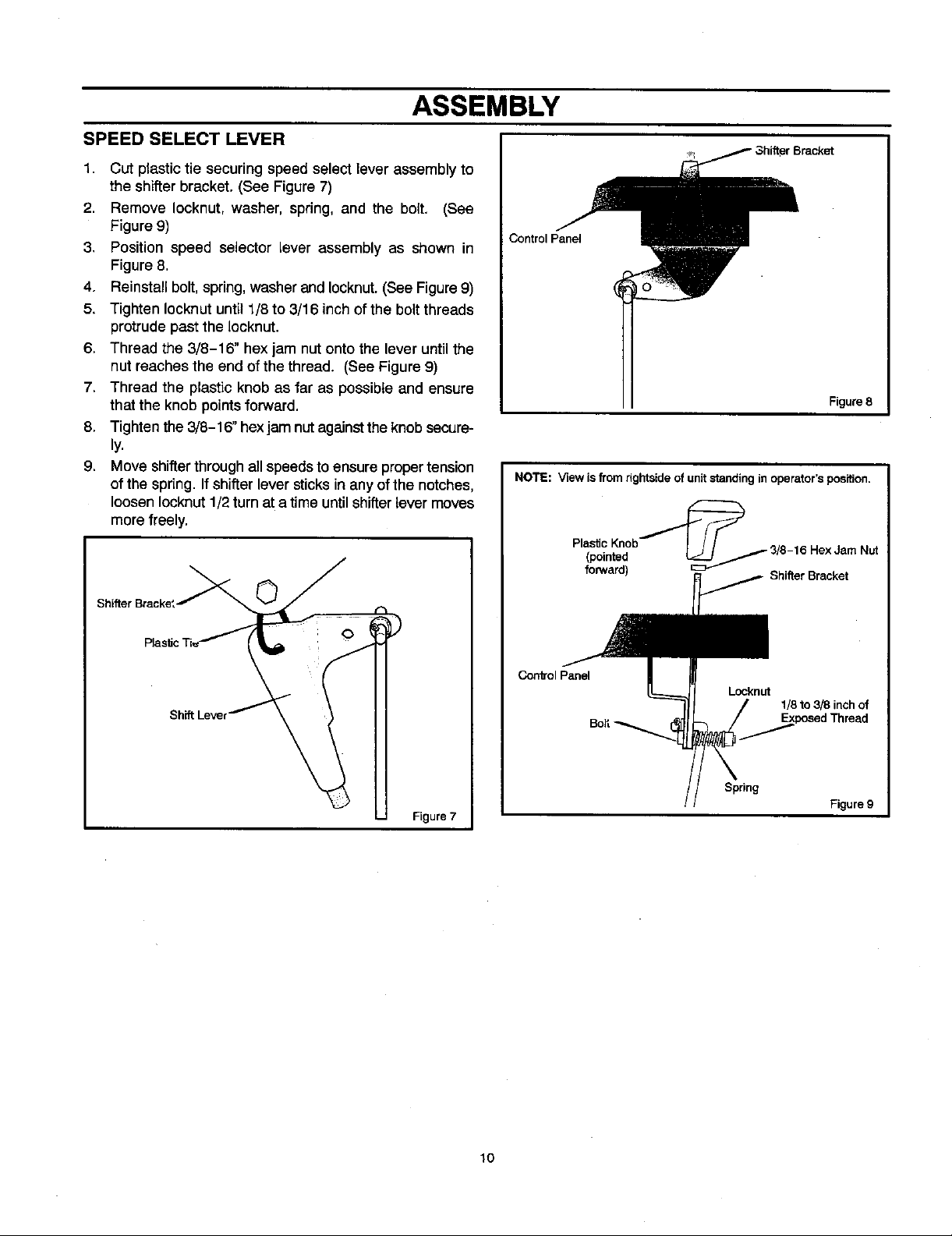

CHECKTHECABLES

1. If controlcables have become unattached from motor

mount frame, reconnect cables as shown in Figure 6.

2. For cable adjustments, see "How To Check And Adjust

The Cables" inthe ADJUSTMENT/REPAIR section.

HOW TO SET

THE LENGTH OF THE CABLES

The cables were adjusted at the factory and no adjustments

should be necessary. However, after the handles are put in

the operating position, the cables can be too tight or too

loose. If an adjustment is necessary, see "How To Check And

Adjust The Cables" inthe Service And Adjustment section.

Traction Drive Cable

9

Auger Drive Cable

ASSEMBLY

SPEED SELECT LEVER

1. Cut plastic tie securing speed select lever assembly to

the shifter bracket. (See Figure 7)

2. Remove Iocknut, washer, spring, and the bolt, (See

Figure 9)

3, Position speed selector lever assembly as shown in

Figure 8.

4, Reinstall bolt,spring, washer and Iocknut. (See Figure 9)

5. Tighten Iocknut until 1/8 to 3/16 inch of the bolt threads

protrude past the locknut.

6. Thread the 3/8-16" hex jam nut onto the lever until the

nut reaches the end of the thread. (See Figure 9)

7. Thread the plastic knob as far as possible and ensure

that the knob points forward.

8. Tighten the 3/8-16" hex jam nutagainst the knob secure-

ly.

9. Move shifter through all speeds to ensure proper tension

of the spdng. Ifshifter lever sticks in any of the notches,

loosen Iocknut 1/2 turn at a time until shifter lever moves

more freely.

Control Panel

Figure 8

NOTE: View is from rightside of unit standing in operator's position.

Plastic Kn°b_c:_._..,,,,,_ 38__ 16 HexJ

(pointed / - am Nut

forward) Shifter Bracket

Shifter Bracke',_

ConlrolPanel

Locknut

1/8 to 3/8 inchof

Spring

Figure g

Figure 7

lO

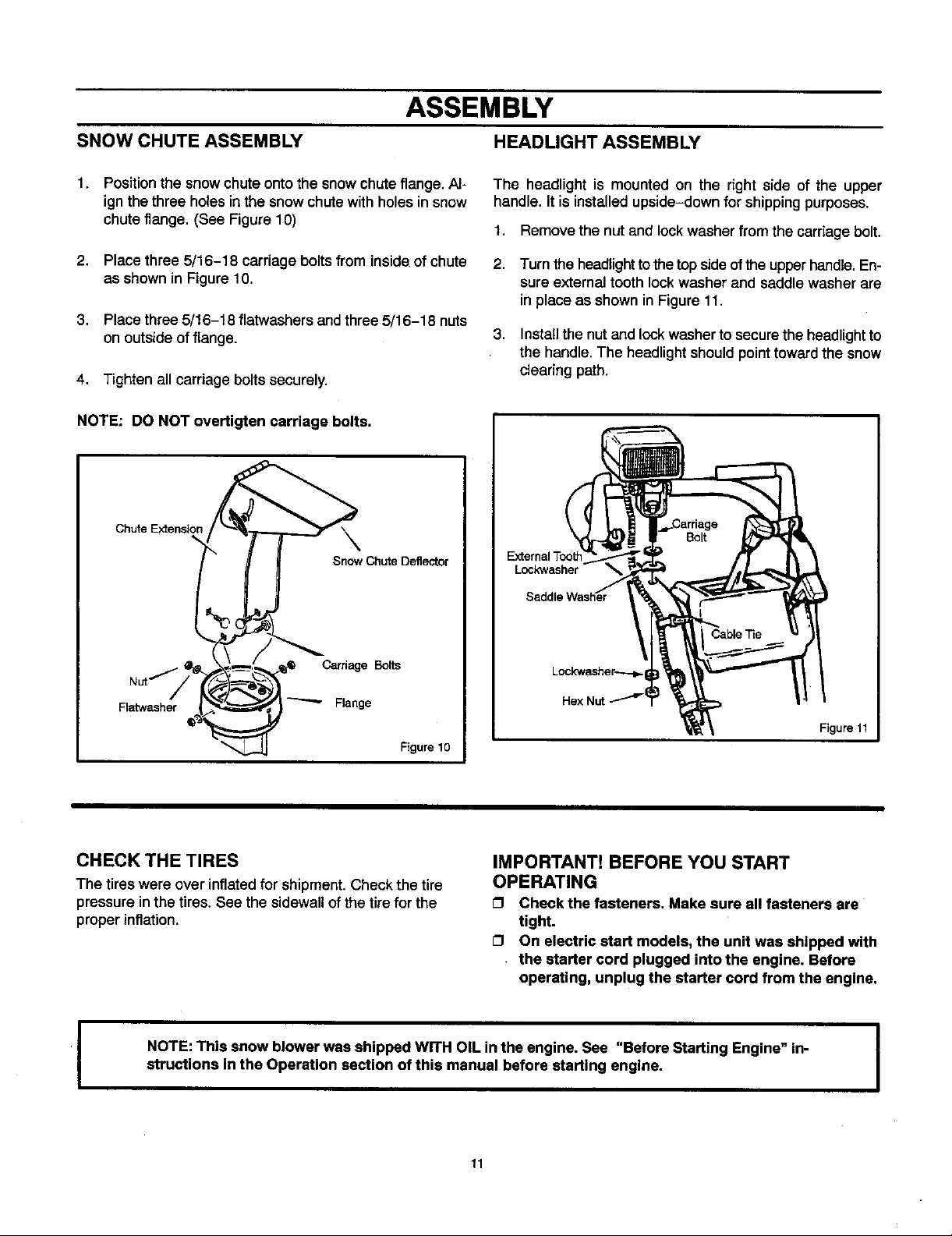

ASSEMBLY

SNOW CHUTE ASSEMBLY

1. Position the snowchute onto the snow chuteflange. Al-

ign the three holes inthe snow chute with holes in snow

chute flange. (See Figure 10)

2. Place three 5/16-18 carriage bolts from inside of chute

as shown in Figure 10.

3. Place three 5/16-18 flatwashers and three5/16-18 nuts

on outside of flange.

4. Tightenall carriage bolts securely.

NOTE: DO NOT overtigten carriage bolts.

Chute Extension

\

Snow Chu_Defle_or

HEADLIGHT ASSEMBLY

The headlight is mounted on the right side of the upper

handle. It is installed upside-down for shipping purposes.

1, Remove the nut and lockwasherfrom the carriagebolt.

2. Turn the headlight to the top side of the upper handle. En-

sure external tooth lock washer and saddle washer are

in place as shown in Figure 11.

3. Installthe nut and lockwasher to secure the headlight to

the handle. The headlight should point toward the snow

clearing path.

ExternalTool

Lockwasher

Nut/

Carriage Bolts

Flatwasher Flange

Figure 10

CHECK THE TIRES

The tires were over inflated for shipment. Check the tire

pressure in the tires. See the sidewall of the tire for the

proper inflation.

NOTE: This snow blower was shipped WITH OIL in the engine. See "Before Starting Engine" in-

structions in the Operation section of this manual before starting engine.

Lockwasher---_

Figure 11

IMPORTANT! BEFORE YOU START

OPERATING

O Check the fasteners. Make sure all fasteners are

tight.

GI On electric start models, the unit was shipped with

the starter cord plugged into the engine. Before

operating, unplug the starter cord from the engine.

11

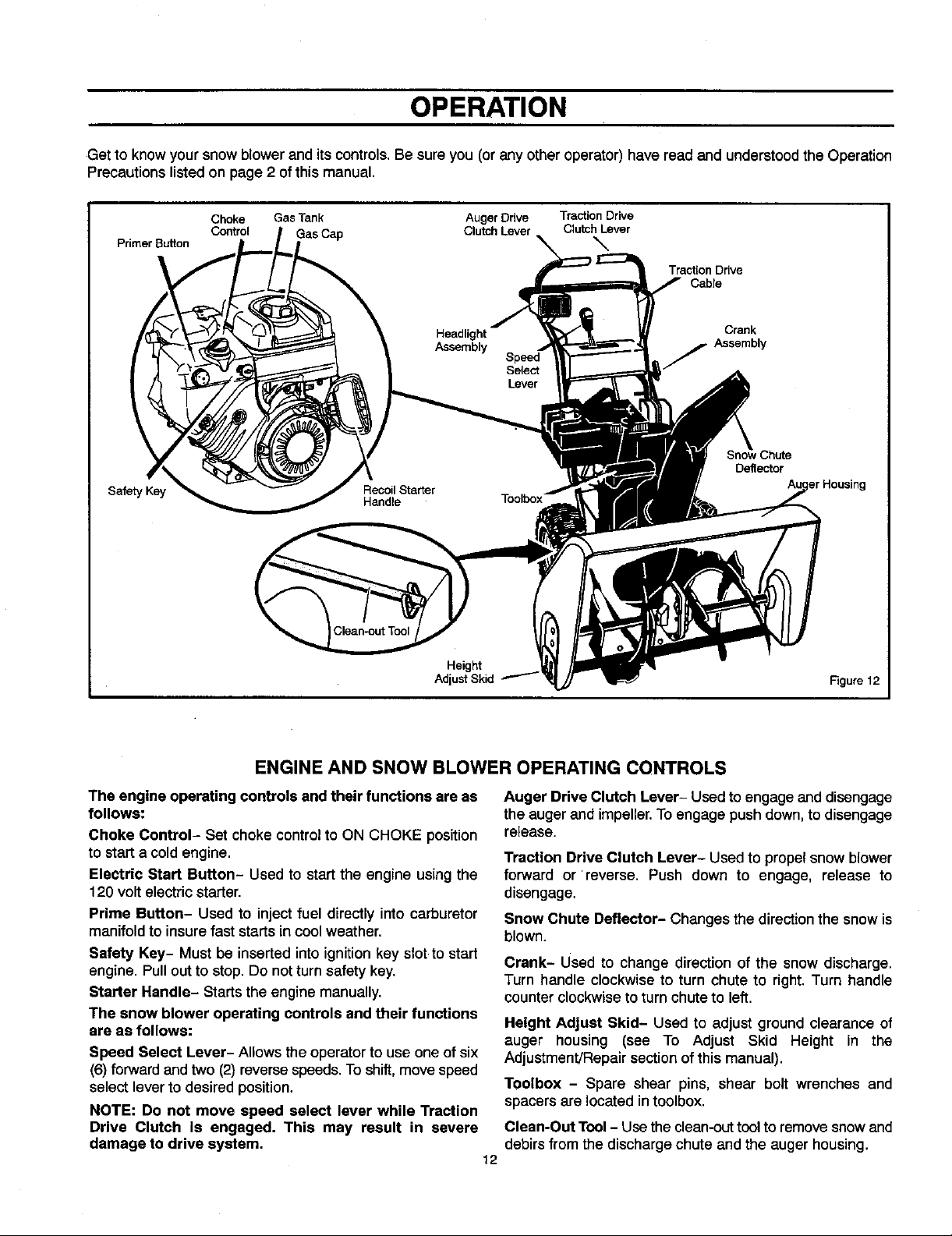

OPERATION

Get to know your snow blower and its controls. Be sure you (or any other operator) have read and understood the Operation

Precautions listed on page 2 of this manual.

Choke Gas Tank Auger Drive Traction Drive

Primer Button

Safety Key

Control Clutch Lever Clutch Lever

\

Traction Drive

Cable

Crank

Assembly

Deflector

Height

Adjust Skid Figure 12

ENGINE AND SNOW BLOWER OPERATING CONTROLS

The engine operating controls and their functions are as

follows:

Choke Control- Set choke control to ON CHOKE position

to starta cold engine.

Electric Start Button- Used to start the engine usingthe

120 volt electricstarter.

Prime Button- Used to injectfuel directly into carburetor

manifoldto insure fast startsin cool weather.

Safety Key- Must be inserted into ignitionkey slot to start

engine. Pullout to stop.Do notturnsafety key.

Starter Handle- Starts the engine manually.

The snow blower operating controls and their functions

are as follows:

Speed Select Lever- Allowsthe operator to use one of six

(6) forwardand two (2) reversespeeds.To shift,movespeed

select lever todesired position.

NOTE: Do not move speed select lever while Traction

Drive Clutch Is engaged. This may result in severe

damage to drive system.

Auger Drive Clutch Lever- Used to engage and disengage

the augerand impeller.To engage pushdown,to disengage

release.

Traction Drive Clutch Lever- Used to propelsnow blower

forward or reverse. Push down to engage, release to

disengage.

Snow Chute Deflector- Changes the direction the snow is

blown.

Crank- Used to change direction of the snow discharge.

Turn handle clockwise to turn chute to right. Turn handle

counter clockwise to turn chute to left.

Height Adjust Skid- Used to adjust ground clearance of

auger housing (see To Adjust Skid Height in the

Adjustment/Repair sectionofthis manual).

Toolbox - Spare shear pins, shear bolt wrenches and

spacers are located in toolbox.

Clean-Out Tool - Use the clean-out tool to remove snowand

debirsfrom the dischargechute and the auger housing.

12

OPERATION

The operation of any snow blower can result in foreign objects being thrown into the eyes,which can

result in severe eye damage. Always wear safety glasses or eye shields before beginning snow blower

Operation. We recommend standard safety glasses or Wide Vision Safety Mask for over spectacles.

SNOW BLOWER OPERATION

The most effective use of the snowblower willbe established

by experience, taking into consideration the terrain, wind

conditions and building location which will determine the

direction of the discharge chute.

NOTE: Do not blow snow towards a building as hidden

objects could be blown with sufficient force to cause

damage.

1. Start the engine as described insection "ToStart Engine"

(see Figure 14).

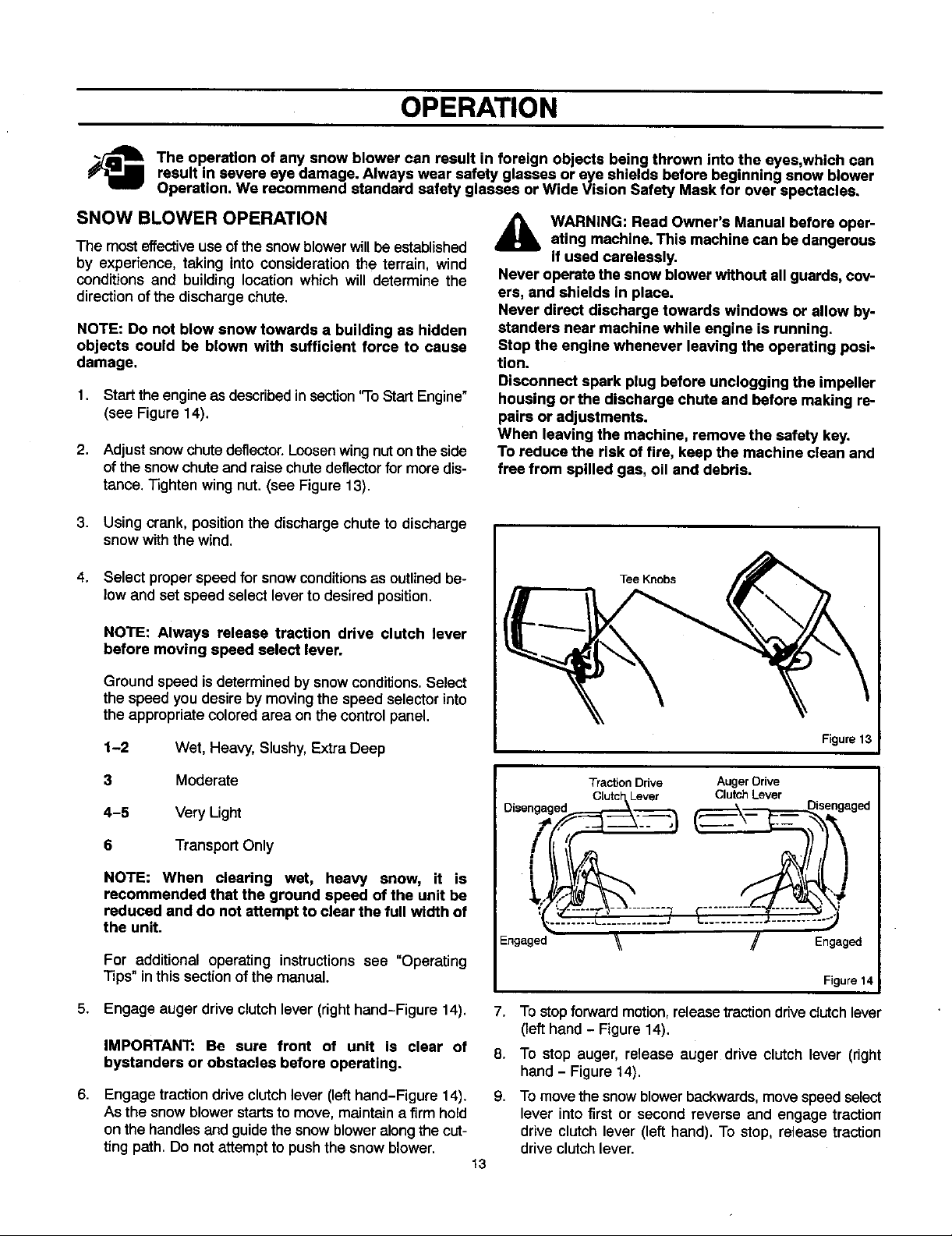

2. Adjust snow chute deflector. Loosen wing nut on the side

of the snow chute and raise chute deflector for more dis-

tance. Tighten wing nut. (see Figure 13).

3,

Using crank, position the discharge chute to discharge

snow with the wind.

_[b ARNING: Read Owner's Manual before oper-

ating machine.This machine can be dangerous

if used carelessly.

Never operate the snow blower without all guards, cov-

ers, and shields in place.

Never direct discharge towards windows or allow by-

standers near machine while engine is running.

Stop the engine whenever leaving the operating posi-

tion.

Disconnect spark plug before unclogging the impeller

housing or the discharge chute and before making re-

pairs or adjustments.

When leaving the machine, remove the safety key.

To reduce the risk of fire, keep the machine clean and

free from spilled gas, oil and debris.

4.

Select proper speed for snow conditionsas outlined be-

low and set speed select lever to desired position.

NOTE: Always release traction drive clutch lever

before moving speed select lever.

Ground speed is determined by snowconditions. Select

the speed you desire by moving the speed selector into

the appropriate colored area on the control panel.

1-2 Wet, Heavy, Slushy, Extra Deep

3 Moderate

4-5 Very Light

6 Transport Only

NOTE: When clearing wet, heavy snow, it is

recommended that the ground speed of the unit be

reduced and do not attempt to clear the full width of

the unit.

For additional operating instructions see "Operating

Tips" in this sectionof the manual.

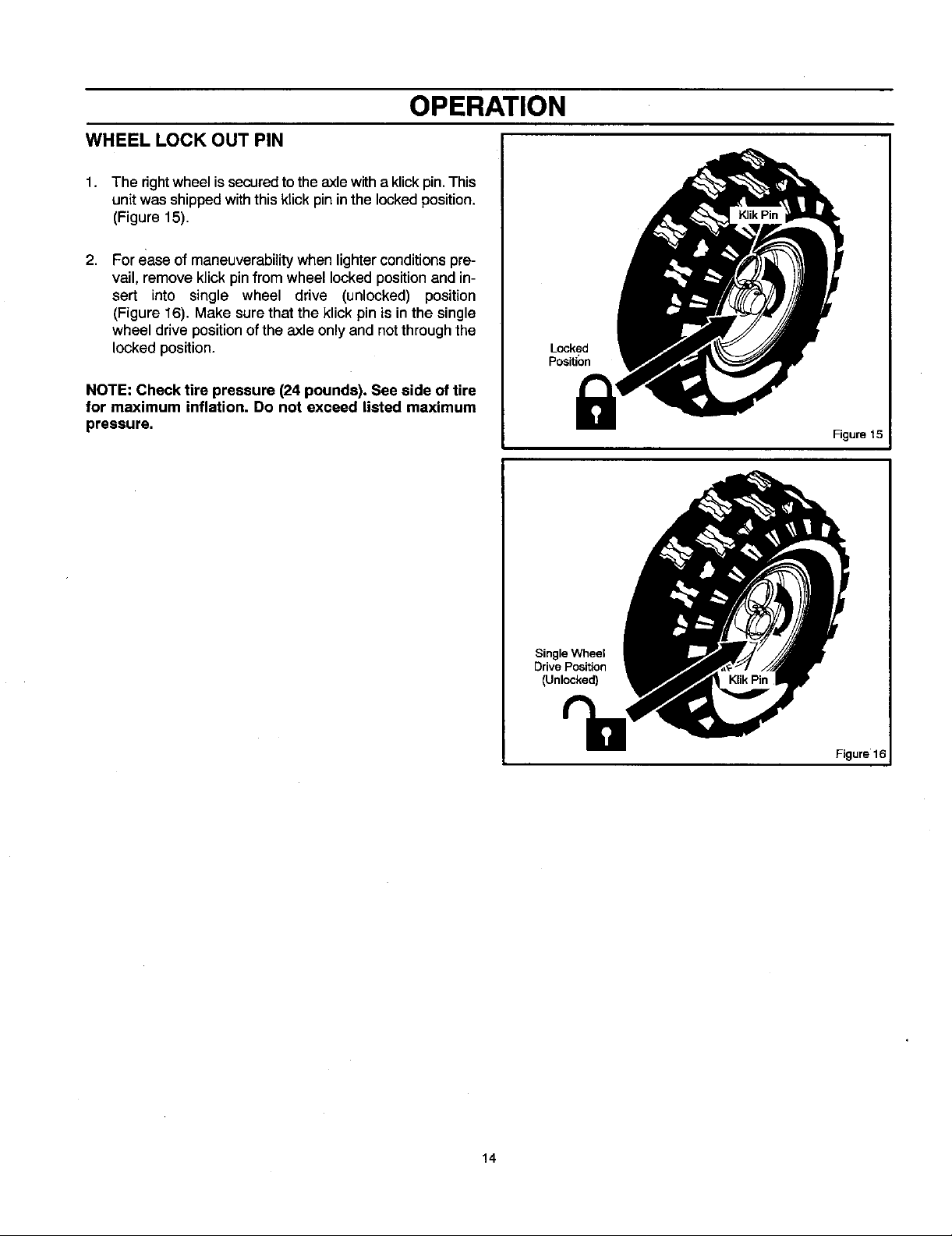

5. Engage auger drive clutch lever (right hand-Figure 14).

IMPORTANT: Be sure front of unit is clear of

bystanders or obstacles before operating.

6,

Engage tractiondrive clutch lever (left hand-Figure 14).

As the snow blower starts to move, maintain a firm hold

on the handles andguide the snow blower along the cut-

ting path. Do not attempt to push the snow blower.

Tee Knobs

Figure 13

Traction Drive Auger Drive

Disengaged C'l 'ch [e_ r_ ---'--'-_ Clu_h Lever

Engaged _ / Engaged

Figure 14

7. To stop forwardmotion, release tractiondrive dutch lever

(left hand - Figure 14).

8. To stop auger, release auger drive clutch lever (right

hand - Figure 14).

9. To move thesnow blower backwards, move speed select

lever into first or second reverse and engage traction

drive clutch lever (left hand). To stop, release traction

drive clutch lever.

13

g_

OPERATION

WHEEL LOCK OUT PIN

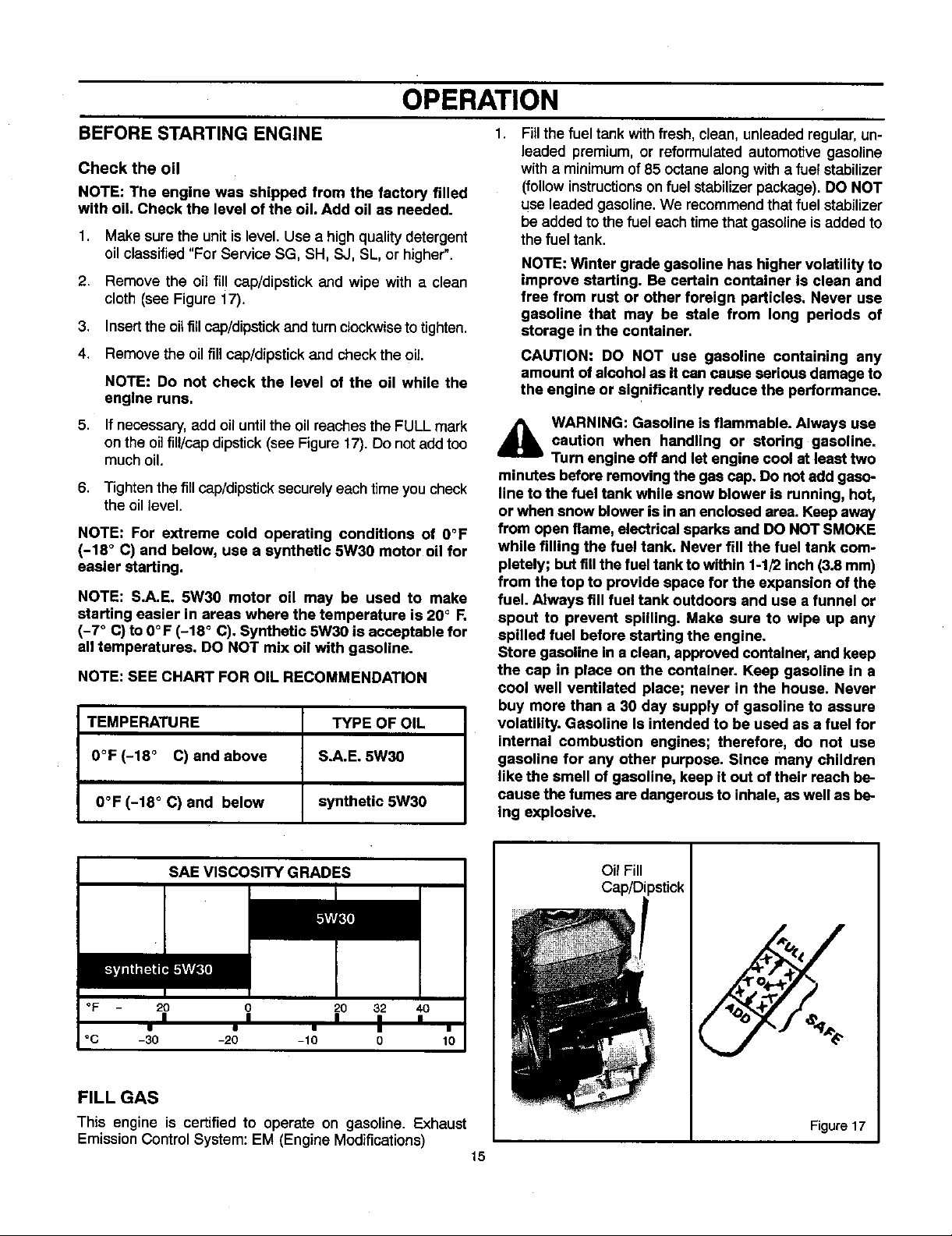

1. The rightwheel issecuredtothe axle witha klick pin. This

unit was shipped with this klick pin in the locked position.

(Figure 15).

2, For ease of maneuverability when lighter conditions pre-

vail, remove klick pin from wheel locked position and in-

sert into single wheel drive (unlocked) position

(Figure 16). Make sure that the klick pin is in the single

wheel drive position of the axle only and not through the

locked position.

NOTE: Check tire pressure (24 pounds). See side of tire

for maximum inflation. Do not exceed listed maximum

pressure.

Locked

Positic)n

Figure 15

Single Wheel

Drive Position

(Unlocked)

Figure 16

14

OPERATION

BEFORE STARTING ENGINE 1.

Check the oil

NOTE: The engine was shipped from the factory filled

with oil. Check the level of the oil. Add oil as needed.

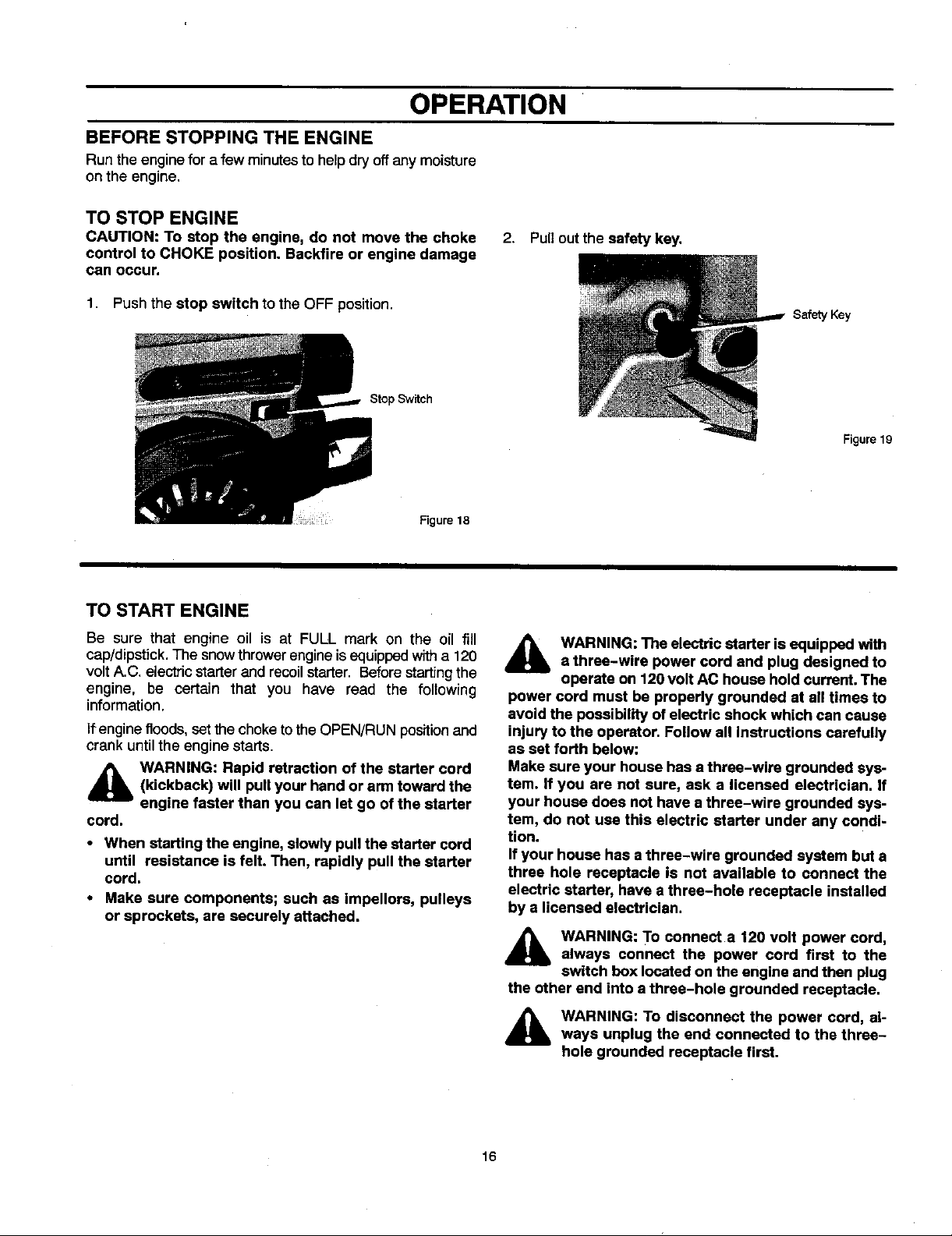

1. Make surethe unitislevel. Use a high quality detergent

oil classified "For Service SG, SH, SJ, SL, or higher".

2. Remove the oil fill cap/dipstick and wipe with a clean

cloth (see Figure 17).

3. Insert the oil fill cap/dipstick and turn clockwiseto tighten.

4. Remove the oil fill cap/dipstick and check the oil

NOTE: Do not check the level of the oil while the

engine runs.

5. If necessary, add oiluntilthe oilreaches the FULL mark

on the oil fill/cap dipstick (see Figure 17). Do not add too

much oil.

6. Tighten the fill cap/dipstick securelyeach time youcheck

the oil level.

NOTE: For extreme cold operating conditions of O°F

(-18 ° C) and below, use a synthetic 5W30 motor oil for

easier starting.

NOTE: S.A.E. 5W30 motor oil may be used to make

starting easier in areas where the temperature is 20 ° F.

(-7 ° C) to 0°F (-18 ° C). Synthetic 5W30 is acceptable for

all temperatures. DO NOT mix oil with gasoline.

NOTE: SEE CHART FOR OIL RECOMMENDATION

TEMPERATURE TYPE OF OIL

0°F (-18 ° C) and above S.A.E. 5W30

0°F (-18 ° C) and below synthetic 5W30

Fillthe fuel tank withfresh, clean, unleaded regular, un-

leaded premium, or reformulated automotive gasoline

with a minimum of 85 octane along with a fuel stabilizer

(follow instructions on fuel stabilizer package). DO NOT

use leaded gasoline. We recommend that fuel stabilizer

be added to the fuel each time that gasoline is added to

the fuel tank.

NOTE: Winter grade gasoline has higher volatility to

improve starting. Be certain container is clean and

free from rust or other foreign particles. Never use

gasoline that may be stale from long periods of

storage in the container.

CAUTION: DO NOT use gasoline containing any

amount ofalcohol as it can cause serious damage to

the engine or significantly reduce the performance.

,_ WARNING: Gasoline is flammable. Always use

minutes before removing the gas cap. Do not add gaso-

line to the fuel tank while snow blower is running, hot,

or when snow blower is in an enclosed area.Keep away

from open flame, electrical sparks and DO NOTSMOKE

while filling the fuel tank. Never fill the fuel tank com-

pletely; butfill the fuel tankto within 1-1/2 inch (3.8 mm)

from the top to provide space for the expansion of the

fuel. Always fill fuel tank outdoors and use a funnel or

spout to prevent spilling. Make sure to wipe up any

spilled fuel before starting the engine.

Store gasoline in a clean, approved container, and keep

the cap in place on the container. Keep gasoline in a

cool well ventilated place; never in the house. Never

buy more than a 30 day supply of gasoline to assure

volatility. Gasoline Is intended to be used as a fuel for

internal combustion engines; therefore, do not use

gasoline for any other purpose. Since many children

like the smell of gasoline, keep it out of their reach be-

cause the fumes are dangerous to inhale, as wellas be-

ing explosive.

caution when handling or storing gasoline.

Turn engine off and let engine cool at least two

SAE VISCOSITY GRADES

°F 20 O 20 32 40

°C -30 -20 -10 0 10

FILL GAS

This engine is certified 1o operate on gasoline, Exhaust

EmissionControl System: EM (Engine Modifications)

n n n , ,

• • • i i

OilFill

%

Figure 17

15

OPERATION

BEFORE STOPPING THE ENGINE

Runthe enginefor a few minutes to helpdry offanymoisture

on the engine.

TO STOP ENGINE

CAUTION: To stop the engine, do not move the choke

control to CHOKE position. Backfire or engine damage

can occur.

2. Pull out the safety key.

1. Push the stop switch to the OFF position.

Stop Switch

Figure 18

TO START ENGINE

Be sure that engine oil is at FULL mark on the oil fill

cap/dipstick. The snow thrower engine is equipped witha 120

volt A.C. electric starter and recoil starter. Before starting the

engine, be certain that you have read the following

information.

If engine floods, setthe choke tothe OPEN/RUN position and

crank until the engine starts.

_lb WARNING: Rapid retraction of the starter cord

cord.

• When starting the engine, slowly pull the starter cord

• Make sure components; such as Impellers, pulleys

(kickback) will pull your hand or arm toward the

engine faster than you can let go of the starter

until resistance is felt. Then, rapidly pull the starter

cord.

or sprockets, are securely attached.

Saf_y Key

Figure 19

,_lb WARNING: The electric starter is equipped with

power cord must be properly grounded at all times to

avoid the possibility of electric shock which can cause

injury to the operator. Follow all instructions carefully

as set forth below:

Make sure your house has athree-wire grounded sys-

tem. If you are not sure, ask a licensed electrician. If

your house does not have a three-wire grounded sys-

tem, do not use this electric starter under any condi-

tion.

If your house has a three-wire grounded system but a

three hole receptacle is not available to connect the

electric starter, have a three-hole receptacle installed

by a licensed electrician.

a three-wire power cord and plug designed to

operate on120 volt AC house hold current. The

_lb WARNING: T° connect a 120 volt power cord,

the other end into a three-hole grounded receptacle.

_lb WARNING: To disconnect the power cord, al-

16

always connect the power cord first to the

switch box located on the engine and then plug

ways unplug the end connected to the three-

hole grounded receptacle first.

Primer

OPERATION

Choke Knob

Safety Key

Stop Switch

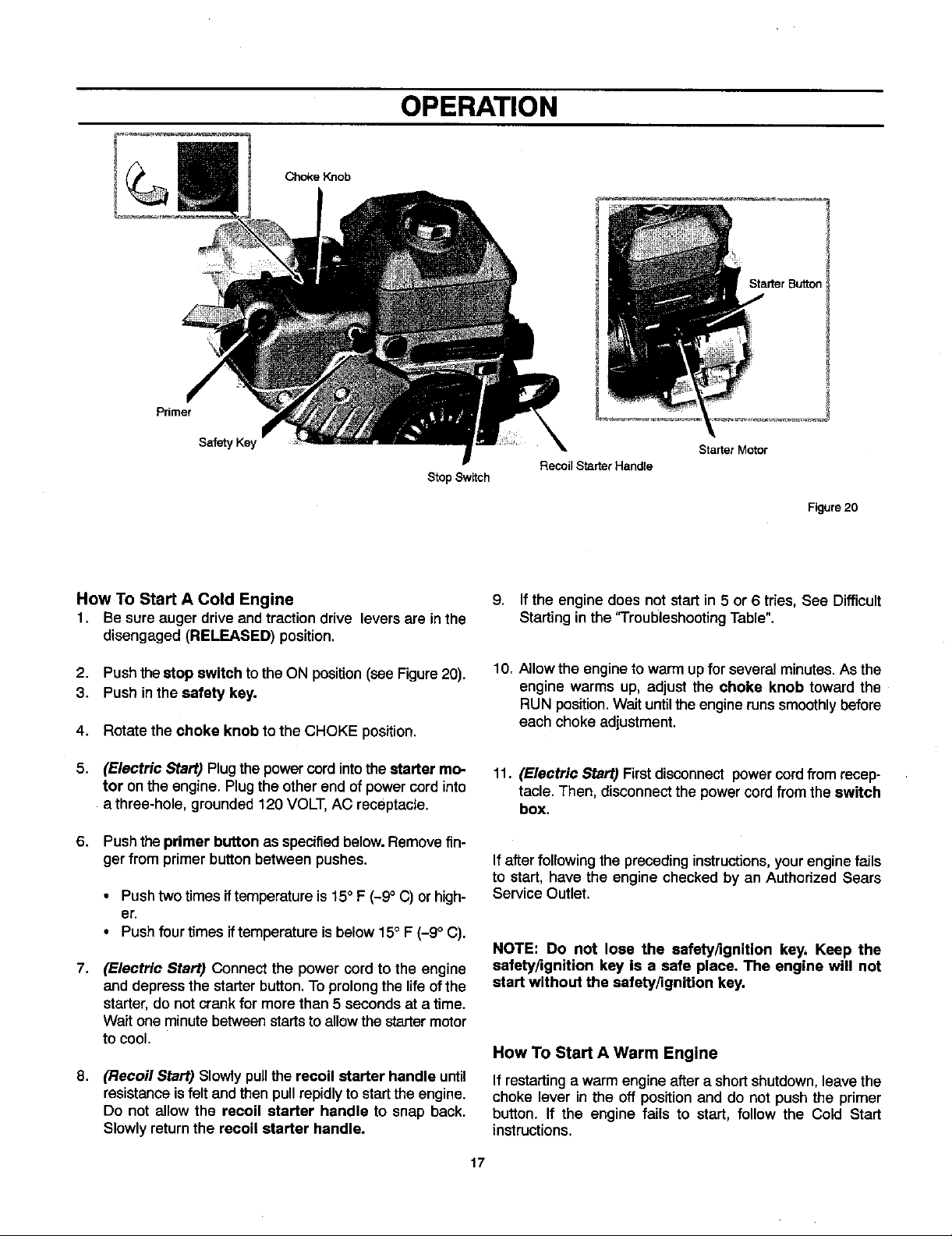

How To Start A Cold Engine

1. Be sure auger driveand traction drive loversare inthe

disengaged (RELEASED) position,

2. Push thestop switch tothe ON position(seeFigure20).

3. Push inthe safety key.

4. Rotate the choke knob tothe CHOKE position.

5. (Electric Start) Plug the power cord intothe starter mo-

tor on the engine. Plugthe other end of powercord into

a three-hole, grounded120 VOLT, AC receptacle.

6. Push theprimer button as specifiedbelow.Removefin-

ger from primer buttonbetween pushes.

• Push two times iftemperature is 15° F (-9° C) or high-

er.

• Push four times iftemperature is below 15° F (-9 ° C).

7,

(Electric Start) Connect the power cord to the engine

and depress the starterbutton. To prolongthe lifeof the

starter,do not crank for more than 5 seconds at a time.

Wait one minutebetweenstarts to allow the startermotor

to cool.

8,

(Recoil Start) Slowlypull the recoil starter handle until

resistanceis felt and then pullrepidlyto startthe engine.

Do not allow the recoil starter handle to snap back.

Slowlyreturnthe recoil starter handle.

Starter Motor

Recoil Starter Handle

Figure 20

9. If the engine does not start in 5 or 6 tries, See Difficult

Starting in the 'q'roubleshooting Table".

10. Allowthe engineto warm upfor several minutes. As the

engine warms up, adjust the choke knob toward the

RUN position. Wait until the engine runs smoothly before

each choke adjustment.

11. (Electric Start) First disconnectpower cordfrom recep-

tacle. Then, disconnectthe powercordfrom the switch

box.

If after following the preceding instructions,your engine fails

to start, have the engine checked by an Authorized Sears

Service Outlet.

NOTE: Do not lose the safety/ignition key, Keep the

safety/ignition key is a safe place. The engine will not

start without the safety/ignition key.

How To Start A Warm Engine

If restarting a warmengine after a shortshutdown,leave the

choke lever in the off position and do not push the primer

button. If the engine fails to start, follow the Cold Start

instructions.

17

OPERATION

FROZEN STARTER

Ifthe starter is frozen and willnot turn engine:

1 Pull as muchrope out ofthe starteras possible.

2. Release the starter handle and let itsnap back against

the starter. Repeat until the engine starts.

Warm engines will cause condensation in cold weather, To

help prevent possible freeze-up of recoil starter and engine

controls, proceed as follows after each snow removal job.

1. With engine off, allow engine to cool for severalminutes.

2. Pull starter rope very slowly until resistance is felt, then

stop. Allow the starter rope to recoil. Repeat three times.

3. With the engine not running, wipe all snow and moisture

from the carburetor cover in area of control levers. Also

move choke knob and starter handle several times.

,_ WARNING: Never run engine indoors or in en-

AND DEADLY GAS. Keep hands, feet, hair and loose

clothing away from any moving parts on engine and

snow thrower.

• Engine parts, especially the muffler, become ex-

• Never allow children to operate the snow thrower.

• Keep the area of operation clear of all persons, partic-

• Never leave the snow blower unattended while the

IMPORTANT: After each use of the snow blower, stop the

engine, remove the safety/ignition key, remove all

accumulated snow from the snow blower and wipe

clean. Store the snow blower in a protected area.

NOTE: Never cover snow blower while engine and

exhaust area ere still warm.

closed, poorly ventilated areas. Engine exhaust

contains CARBON MONOXIDE, AN ODORLESS

tremely hot. Severe thermal burns can occur on con-

tact. Allow the engine to cool before touching.

Never allow adults to operate the snow blower with-

out proper instruction.

ularly small children and pets.

engine Is running. Anyone opersting the engine or

equipment must carefully read and understand the

operating instructions.

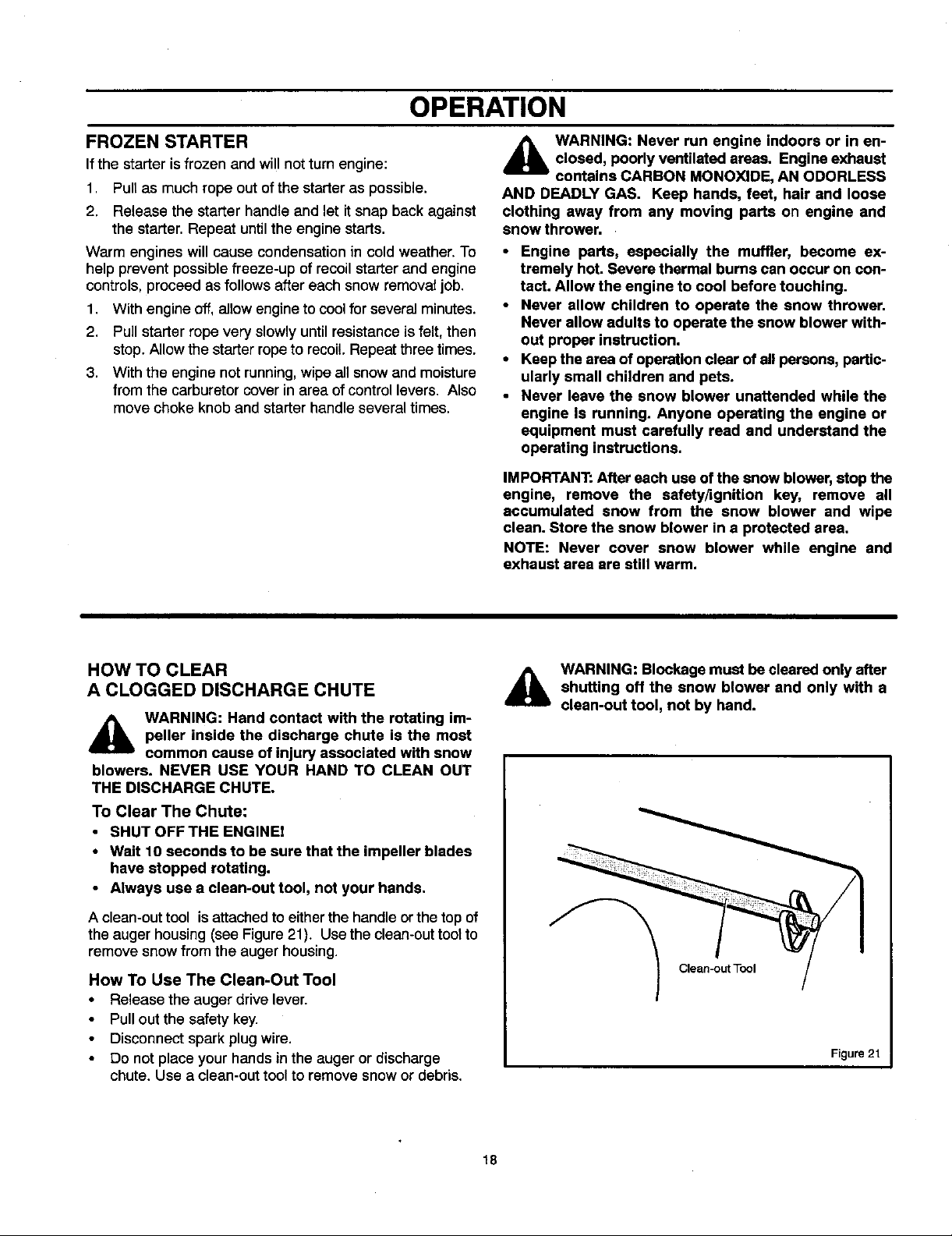

HOW TO CLEAR

A CLOGGED DISCHARGE CHUTE

_k WARNING: Hand contact with the rotating im-

blowers. NEVER USE YOUR HAND TO CLEAN OUT

THE DISCHARGE CHUTE.

To Clear The Chute:

• SHUT OFF THE ENGINEI

• Wait 10 seconds to be sure that the impeller blades

• Always use a clean-out tool, not your hands.

A clean-out tool is attached to either the handle or the top of

the auger housing (see Figure 21). Use the clean-out toot to

remove snow from the auger housing.

How To Use The Clean-Out Tool

• Release the auger drive lever.

• Pull out the safety key.

peller inside the discharge chute is the most

common cause of injury associated with snow

have stopped rotating.

Disconnectspark plug wire.

Do notplace your hands inthe auger or discharge

chute. Use a clean-outtoolto removesnow or debris.

A

WARNING: Blockage must be cleared only after

shutting off the snow blower and only with a

clean-out tool, not by hand.

Clean-out Tool

Figure 21

18

OPERATING TIPS

OPERATION

1. Most efficient snowblowingis accomplished when snow 6.

is removed immediately after it falls.

2. For complete snow removal, slightly overlap each swath

previously taken. 7.

3. Snow should be discharged downwind whenever pos-

sible. 8.

4. For normal usage, set the skids one-eighth inch (3 mm)

below the scraper bar. For extremely hard-packed snow

surfaces, the skids may be adjusted upward to insure

cleaning efficiency.

5. On gravel or crushed rock surfaces, the skids should be

set at 1-1/4 inch (32mm) below the scraper bar (see To

Adjust Skid Height, in the Adjustment/Repair section in

this manual). Rocks and gravel must not be picked up

and thrown by the machine.

After the snowblowing jobhas been completed, allow the

engine to idle far a few minutes, to melt snow and ice ac-

cumulated on the engine.

Clean the snowthrower thoroughly after each use.

Remove ice and snow accumulation and all debris from

the entire snow thrower, and flush with water ('ifpossible)

to remove all salt orother chemicals. Wipe snow thrower

dry.

9.

Before starting snow blower, always inspect augers and

impeller for ice accumulation and/or debris, which could

result in snow blower damage.

10.

Check oil level before every start. Make sure the oil is at

the FULL mark on the oil fill cap/dipstick.

19

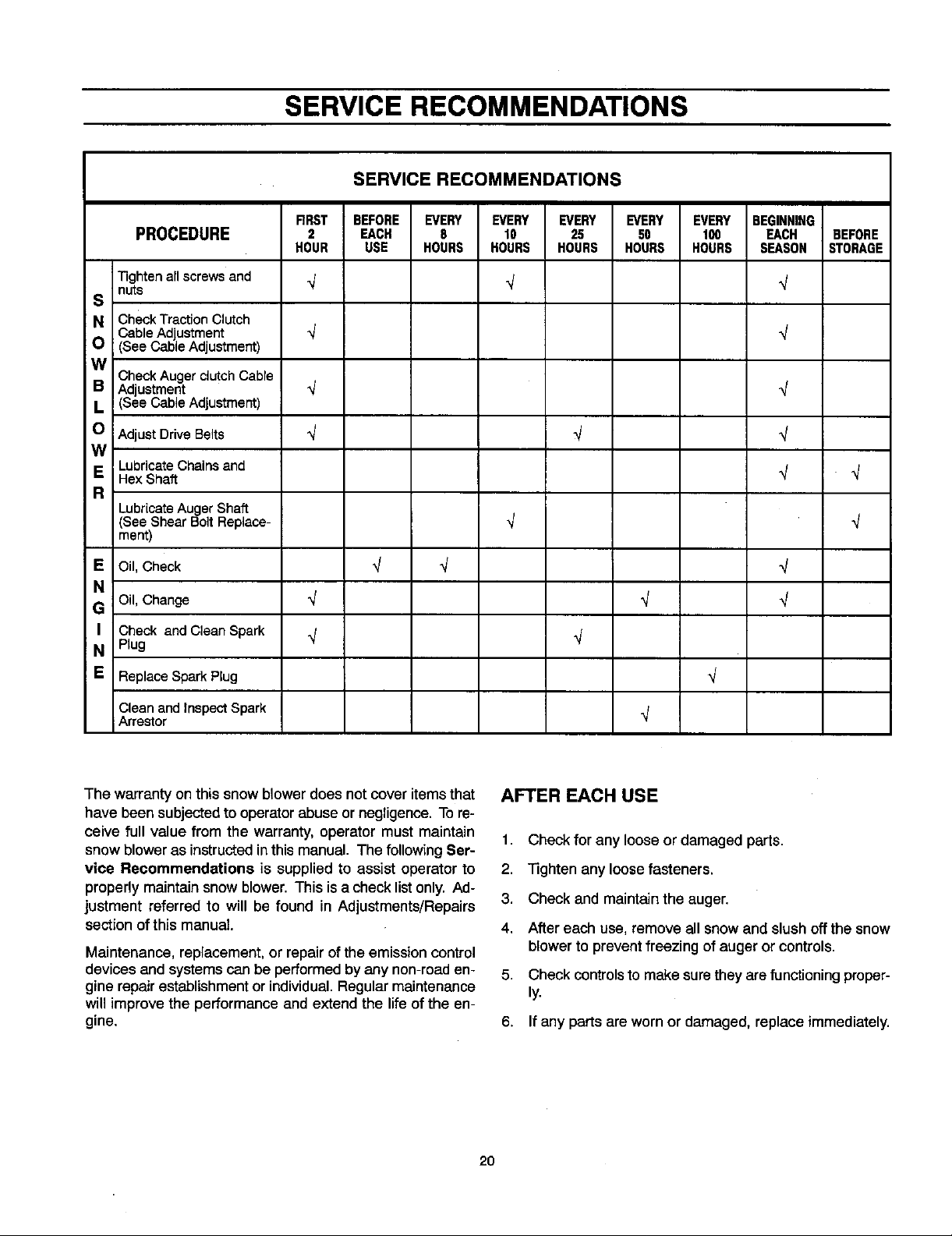

SERVICE RECOMMENDATIONS

SERVICE RECOMMENDATIONS

PROCEDURE 2 EACH 8 10 25 50 t00 EACH BEFORE

RRST BEFORE EVERY EVERY EVERY EVERY EVERY BEGINNING

HOUR USE HOURS HOURS HOURS HOURS HOURS SEASON STORAGE

Tightenallscrewsand _/ _/ _/

S nuts

N Check TractionClutch

CableAd ustment _/ _/

O (SeeCabeAd ustment)

;_l CheckAuger clutchCable

Adustment "_

(SeeCabe Adustmerrt)

O AdjustDriveBelts _ _ _/

W

E LubricateChainsand

HexShaft "J "_

R

LubricateAuger Shaft

(SeeShear BoltReplace-

ment)

E Oil, Check _J

N

G Oil,Change "_

I Check and Clean Spark

N Plug

q

.j

,/

,/

,J

E Replace Spark Plug

Clean and Inspect Spark

Arrestor

The warranty on this snow blower does not cover items that

have been subjected to operator abuse or negligence. Tore-

ceive full value from the warranty, operator must maintain

snow blower as instructed in this manual. The following Ser-

vice Recommendations is supplied to assist operator to

properly maintain snow blower. This is a check listonly. Ad-

justment referred to will be found in Adjustments/Repairs

section of this manual.

Maintenance, replacement, or repair of the emission control

devices and systems can be performed by any non-road en-

gine repair establishment or individual. Regular maintenance

will improve the performance and extend the life of the en-

gine.

,J

q

AFTER EACH USE

1. Check for any loose or damaged parts.

2. "]]ghten any loose fasteners.

3. Check and maintain the auger.

4. After each use, remove all snow and slush off the snow

blower to prevent freezing of auger or controls.

5. Check controls to make sure they arefunctioning proper-

ly.

6. If any parts are worn or damaged, replace immediately.

20

CUSTOMER RESPONSIBILITIES

Some adjustments will need to be made periodically to

properly maintain your snow blower.

All adjustments in ADJUSTMENTS/REPAIRS section of this

manual should be checked at least once each season.

SNOW BLOWER

The following adjustment should be performed more than

once each season.

Auger and Traction Drive Belts should be adjustedafterthe

first 2to 4 hours of use, again about mid-season andtwice

each seasonthereafter(See ToAdjustBeltsparagraphinthe

Adjustment/Repair section).

AS REQUIRED

Auger Gear Box

The auger gear box is lubricatedat thefactory and shouldnot

require additional lubrication.

If for some reason the lubdcantshould leak out, orif the auger

gear box has been serviced, add Lubriplate GR132 Grease

or equivalent. Maximum 3-1/4 ounces, (92grams) should be

used.

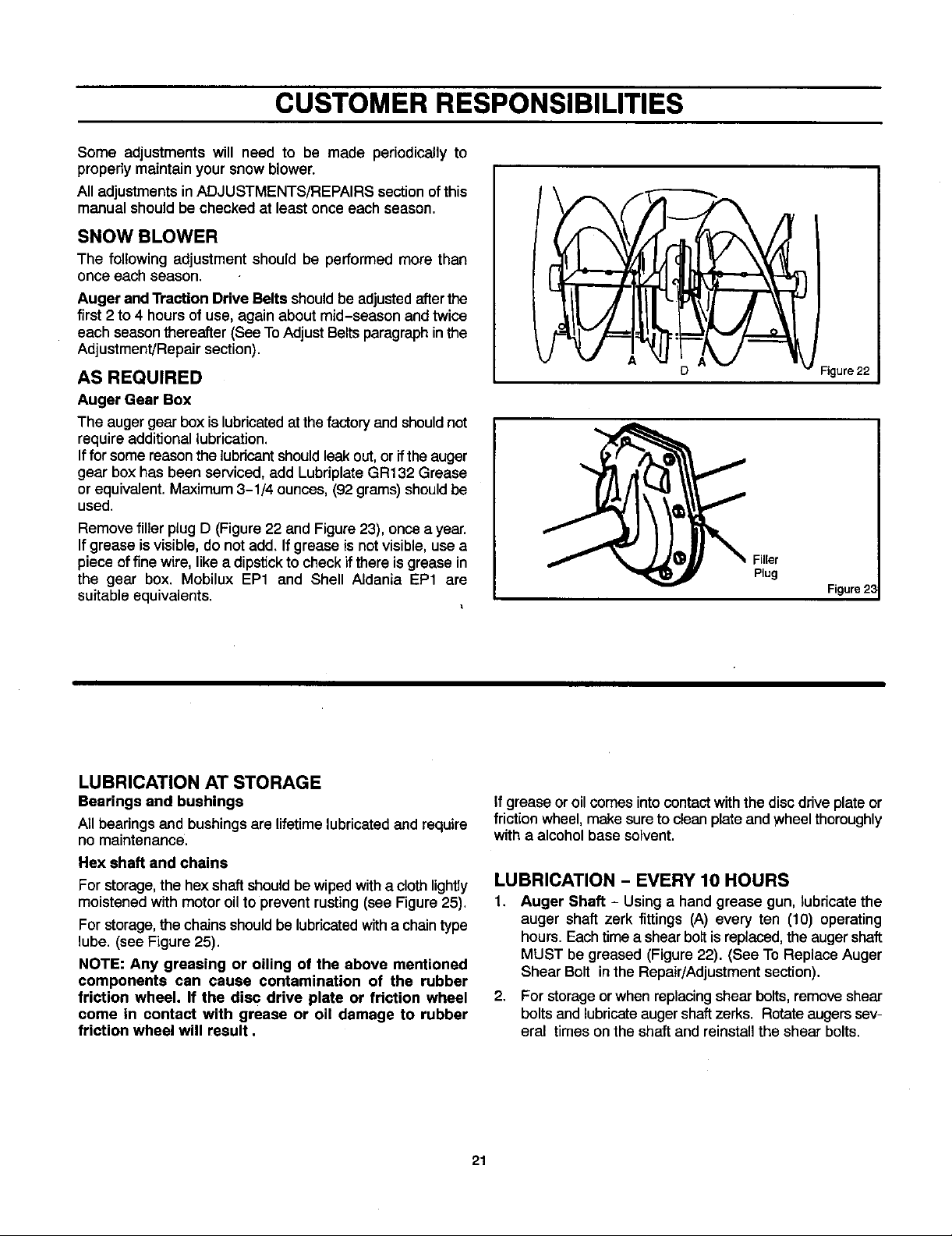

Remove filler plug D (Figure 22 and Figure 23), once a year.

If grease is visible, do not add. If grease isnot visible, use a

piece of fine wire, like a dipstick to check if there is grease in

the gear box. Mobilux EP1 and Shell Aldania EP1 are

suitable equivalents.

D Figure 22

_ FiUer

Plug

Figure 23

LUBRICATION AT STORAGE

Bearings and bushings

All bearingsand bushingsare lifetimelubricatedand require

no maintenance.

Hex shaft and chains

For storage, the hex shaft shouldbe wipedwitha cloth lightly

moistened with motor oil to prevent rusting (see Figure 25),

For storage, the chains should be lubricatedwith a chain type

lube. (see Figure 25).

NOTE: Any greasing or oiling of the above mentioned

components can cause contamination of the rubber

friction wheel. If the disc drive plate or friction wheel

come in contact with grease or oil damage to rubber

friction wheel will result.

if grease oroil comesintocontactwith the disc drive plate or

friction wheel, make sure to clean plate and wheelthoroughly

with a alcohol base solvent.

LUBRICATION - EVERY 10 HOURS

1. Auger Shaft - Using a hand grease gun, lubricate the

auger shaft zerk fittings (A) every ten (10) operating

hours.Each timea shearboltisreplaced,the auger shaft

MUST be greased (Figure22). (See To Replace Auger

Shear Bolt inthe Repair/Adjustmentsection).

2. For storage orwhen replacing shear bolts,remove shear

bolts and lubricate auger shaft zerks. Rotate augers sev-

eral times on the shaft and reinstall the shear bolts.

21

Loading...

Loading...