Page 1

Operator’s Manual

Model No. C950-52301-0

Dual Stage Snowthrower, 11.5 TP, 24 Inch

CAUTION: Before using this product, read the manual

and follow all its Safety Rules and Operating Instructions.

Sears Canada Inc., Toronto, Ontario M5B 2C3

Visit our Craftsman website: www.sears.ca/craftsman

80006828

Revision -

Page 2

Thank you for purchasing this quality-built CRAFTSMAN snowthrower. We’re pleased that you’ve placed your condence

in the CRAFTSMAN brand. When operated and maintained according to the instructions in this manual, your CRAFTSMAN

product will provide many years of dependable service.

This manual contains safety information to make you aware of the hazards and risks associated with snowthrowers and

how to avoid them. This snowthrower is designed and intended only for snow throwing and is not intended for any other

purpose. It is important that you read and understand these instructions throroughly before attempting to start or operate

this equipment. This snowthrower requires nal assembly before use. Refer to the Assembly section for instructions

on nal assembly procedures. Follow the instructions completely. Save these instructions for future reference.

Snowthrower:

Model Number ______________________________

Revision _____

Serial Number ______________________________

Engine:

Model Number

______________________________

Revision

_____

Serial Number ______________________________

Date Purchased: ______________________________

Store Where Purchased: ______________________________

City: ______________________________

Province: ______________________________

Telephone: ______________________________

NOTICE: Record this information about your snowthrower so that you will be able to provide it in case of loss or theft.

2

Page 3

Table of Contents

Operator Safety ............................................................................. 4

Hazard Symbols and Meanings ................................................. 4

Control Symbols on Equipment ................................................. 4

Safety Alert Symbols and Signal Words .................................... 5

Safety Decals ............................................................................ 9

Features and Controls .................................................................. 10

Snowthrower Controls ............................................................... 10

Engine Controls ......................................................................... 11

Operation ....................................................................................... 12

Before Operating Snowthrower ................................................. 12

Safety System Tests .................................................................. 12

Operate the Snowthrower .......................................................... 12

Stop the Snowthrower ............................................................... 13

Easy-TurnTM Traction Control ...................................................... 13

Check the Oil (Before Starting Engine) ...................................... 14

Fuel Recommendations ............................................................ 14

High Altitude .............................................................................. 14

Adding Fuel ............................................................................... 15

Start the Engine ......................................................................... 15

Stop the Engine ......................................................................... 16

Clear a Clogged Discharge Chute ............................................. 17

Operating Tips ........................................................................... 17

Maintenance ................................................................................. 18

Maintenance Chart .................................................................... 18

Emissions Control Statement .................................................... 18

Engine Maintenance ................................................................. 18

Skid Shoe Height Adjustment .................................................... 19

Auger Control Cable Adjustment ............................................... 20

Auger Shear Bolt Replacement ................................................. 21

Check the Tires ......................................................................... 21

O-Season Storage................................................................... 22

Troubleshooting ............................................................................ 23

Warranties ...................................................................................... 25

Specifications ................................................................................ 28

en

3

Page 4

Operator Safety

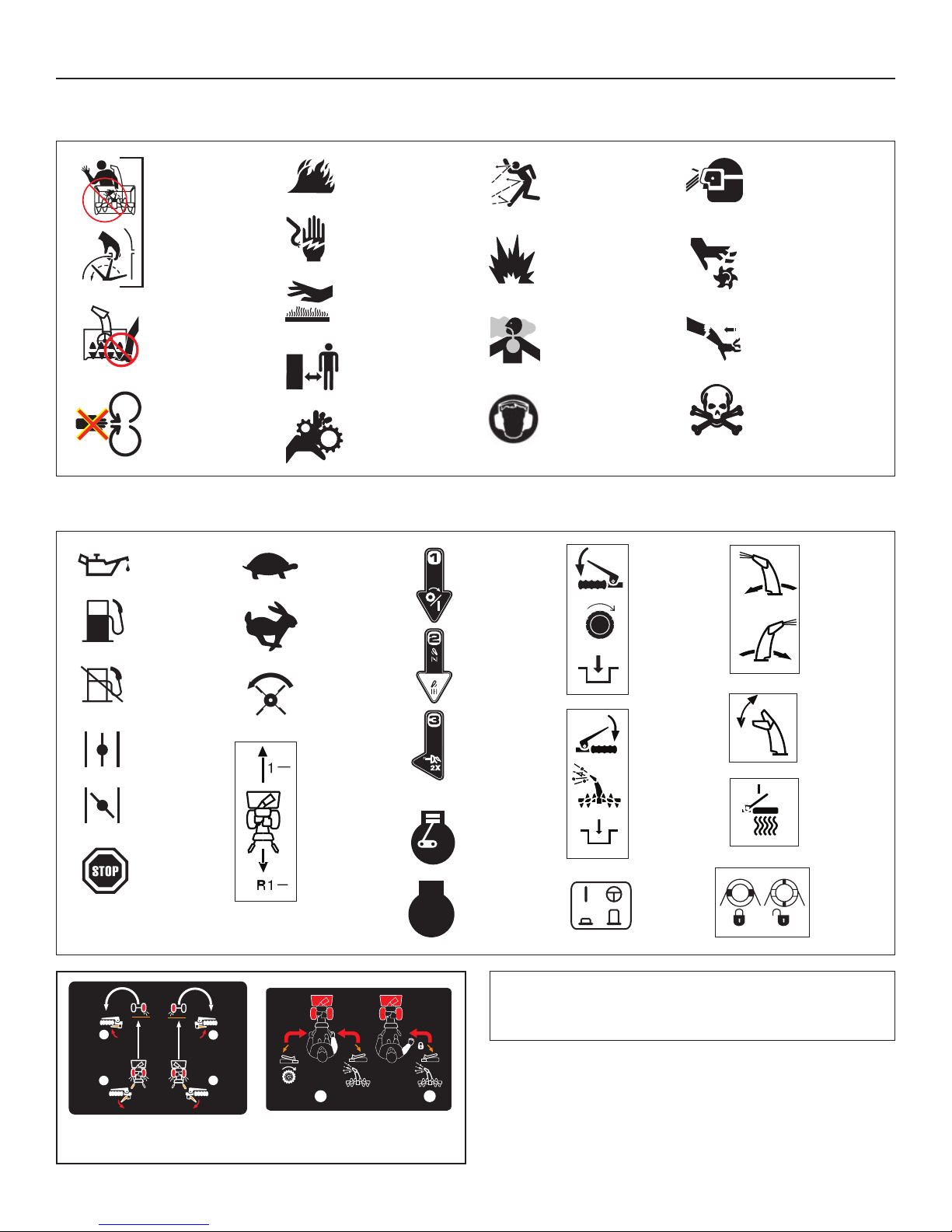

Hazard Symbols and Meanings

Rotating

Impeller

Rotating

Auger

Rotating

Parts

Control Symbols on Equipment

Oil

Fuel

Fuel

Shuto

Choke

O

Choke

On

Stop

Slow

Fast

Auger

Clutch

Forward

Neutral

Reverse

Fire

Shock

Hot

Surface

Safe

Distance

Rotating

Gears

STOP

Engine

On-O

ChokeRun

Engine

Primer

Engine

Run

Engine

Stop

Thrown

Objects

Explosion

Toxic

Fumes

Ear

Protection

Traction

Control

Auger

Control

Electric

Start

Eye

Protection

Moving

Parts

Kickback

Hazardous

Chemical

Discharge

Chute

Chute

Deector

Heated

Hand

Grips

Wheel

Lock

2

1

Easy-Turn™

Traction Control

2

1

1

Free-Hand™ Control

4

NOTE: Not all control symbols shown on this page will appear

on your snowthrower. See Features and Controls section for

the applicable symbols.

2

Page 5

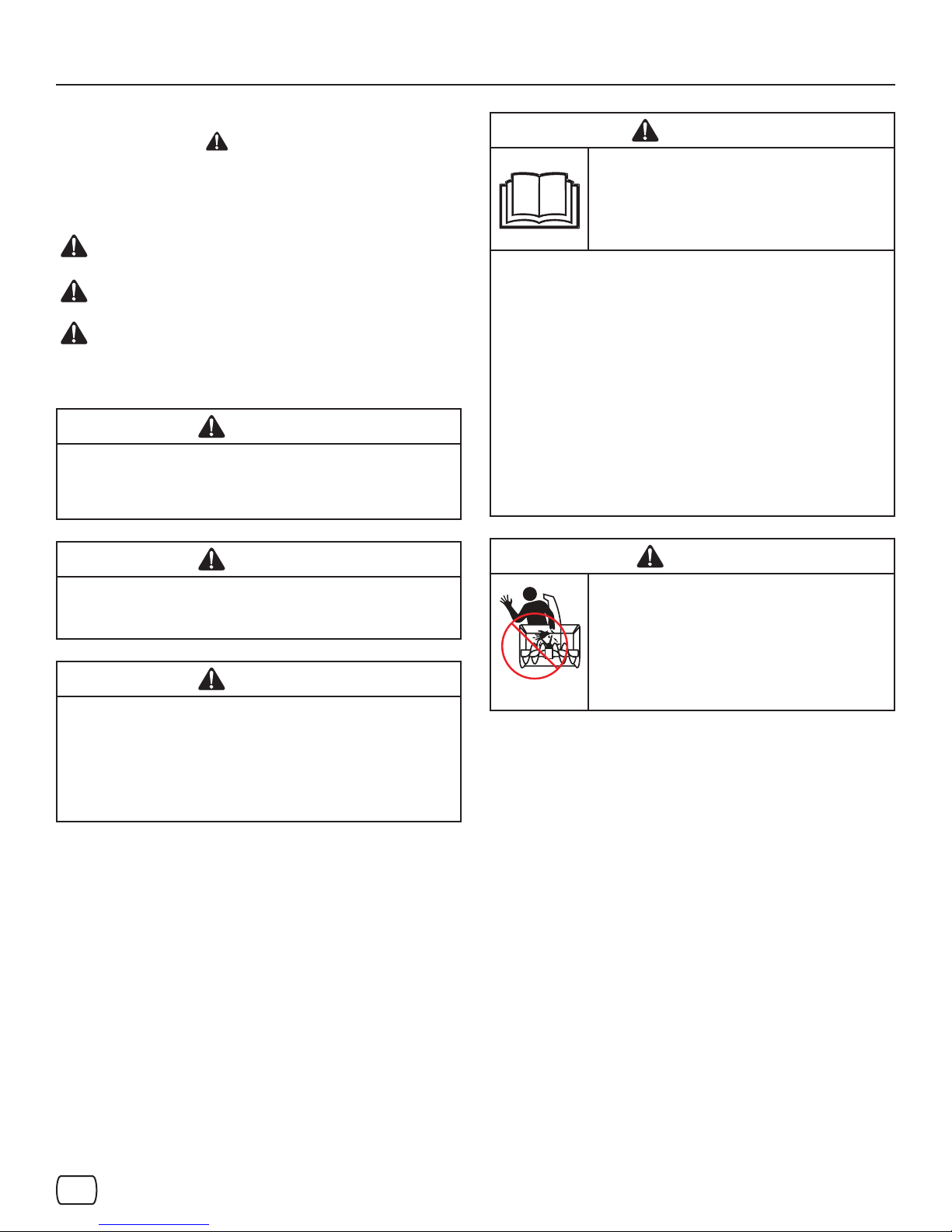

Operator Safety

Safety Alert Symbol and Signal Words

The safety alert symbol and signal word (DANGER,

WARNING, CAUTION, or NOTICE) is used to indicate the

likelihood and potential severity of personal injury and/or damage

to the product. In addition, a hazard symbol may be used to

represent the type of hazard.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, could

result in minor or moderate injury.

NOTICE indicates a situation that could result in

damage to the product.

WARNING

Certain components in this product and its related accessories

contain chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm. Wash hands

after handling.

WARNING

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects,

or other reproductive harm.

WARNING

• Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snowthrowers.

• This snowthrower is capable of amputating hands and feet,

and throwing objects. Read and observe all the safety instructions in this manual. Failure to do so could result in death or

serious injury.

WARNING

Read, understand, and follow all the

instructions on the snowthrower and in the

operator’s manual before operating this unit.

Failure to observe the safet y instructions in this

manual could result in death or serious injury.

• Be thoroughly familiar with the controls and the proper use of

the snowthrower.

• Make sure you are properly trained before operating the

snowthrower.

• Know how to stop the unit and disengage the controls quickly.

• Never allow anyone to operate the snowthrower without

proper instruction.

• Always follow the instructions in the operator’s manual, if the

snowthrower will be stored for an extended period.

• Maintain or replace safety and instruction labels as neces-

sary.

• Never attempt to make major repairs on the snowthrower un-

less you have been properly trained. Improper servicing of the

snowthrower can result in hazardous operation, equipment

damage, and voiding of the product warranty.

DANGER

Discharge chute contains rotating impeller

to throw snow. Never clear or unclog the

discharge chute with your hands. Fingers can

quickly become caught in the impeller. Always

use a clean-out tool.

Failure to observe these safety instructions

will result in traumatic amputation or severe

laceration.

en

5

Page 6

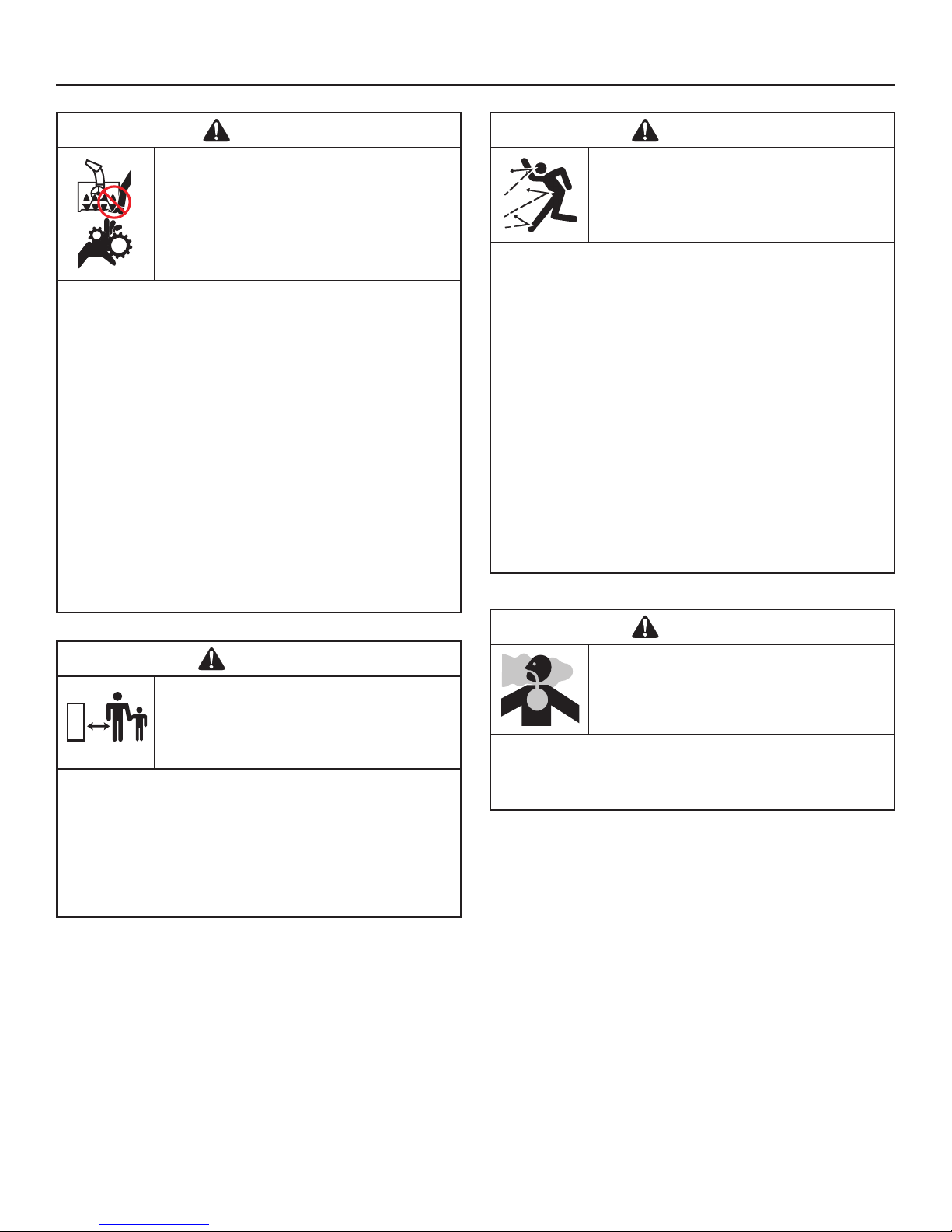

Operator Safety

DANGER

Keep hands, feet, and clothing away from

rotating parts. Rotating parts can contact

or entangle hands, feet, hair, clothing, or

accessories.

Failure to observe these safety instructions

will result in traumatic amputation or severe

laceration.

• Whenever cleaning, repairing, or inspecting the snowthrower,

make sure the engine is OFF, spark plug wire is disconnected,

and all moving parts have stopped.

• Do not put hands or feet near or under rotating parts. Keep

clear of the discharge opening at all times.

• Never operate the snowthrower without proper guards, and

other safety devices in place and working.

• Never leave the snowthrower unattended while engine is run-

ning. Always disengage the auger and traction controls, stop

engine, and remove keys.

• Keep all loose clothing away from the front of the snowthrower

and auger. Scarves, mittens, dangling drawstrings, loose

clothes, and pants can quickly become caught in the rotating

device and amputation will occur. Tie up long hair and remove

jewelry.

• Run the machine a few minutes after discharging snow to pre-

vent freeze-up of the collector/impeller.

• Disengage power to the collector/impeller when snowthrower

is transported or not in use.

WARNING

Objects can be picked up by auger and thrown

from chute. Never discharge snow toward

bystanders or allow anyone in front of the

snowthrower. Failure to observe these safety

instructions will result in death or serious injury.

• Always wear safety glasses or eye shields during operation,

and while performing an adjustment or repair.

• Always be aware of the direction the snow is being thrown.

Nearby pedestrians, pets, or property may be harmed by objects being thrown.

• Be aware of your environment while operating the

snowthrower. Don’t run over items such as gravel, doormats,

newspapers, toys, and rocks hidden under snow, as they can

all be thrown from the chute or jam in the auger.

• Use extreme caution when operating on or crossing gravel

drives, walks, or roads.

• Adjust the collector housing height to clear gravel or crushed

rock surface.

• Never operate the snowthrower near glass enclosures, automobiles, window wells, drop-os, and the like without proper

adjustment of the discharge chute angle.

• Familiarize yourself with the area in which you plan to operate

the snowthrower. Mark o boundaries of walkways and drive-

ways.

WARNING

Tragic accidents can occur if the operator is

not alert to the presence of children. Children

are often attracted to the unit and the operating

activity. Never assume the children will remain

where you last saw them.

• Keep children out of the area during operation. Children are

often attracted to the equipment. Be mindful of all persons

present.

• Be alert and turn unit o if children enter the area.

• Never allow children to operate the unit.

• Use extra care when approaching blind corners, shrubs,

trees, or other objects that may obscure vision. Children may

be present.

WARNING

Engines give o carbon monoxide, an

odorless, colorless, poison gas. Breathing

carbon monoxide can cause nausea, fainting,

or death.

• Start and run engine outdoors.

• Do not run the engine in an enclosed area, even if doors or

windows are open.

6

Page 7

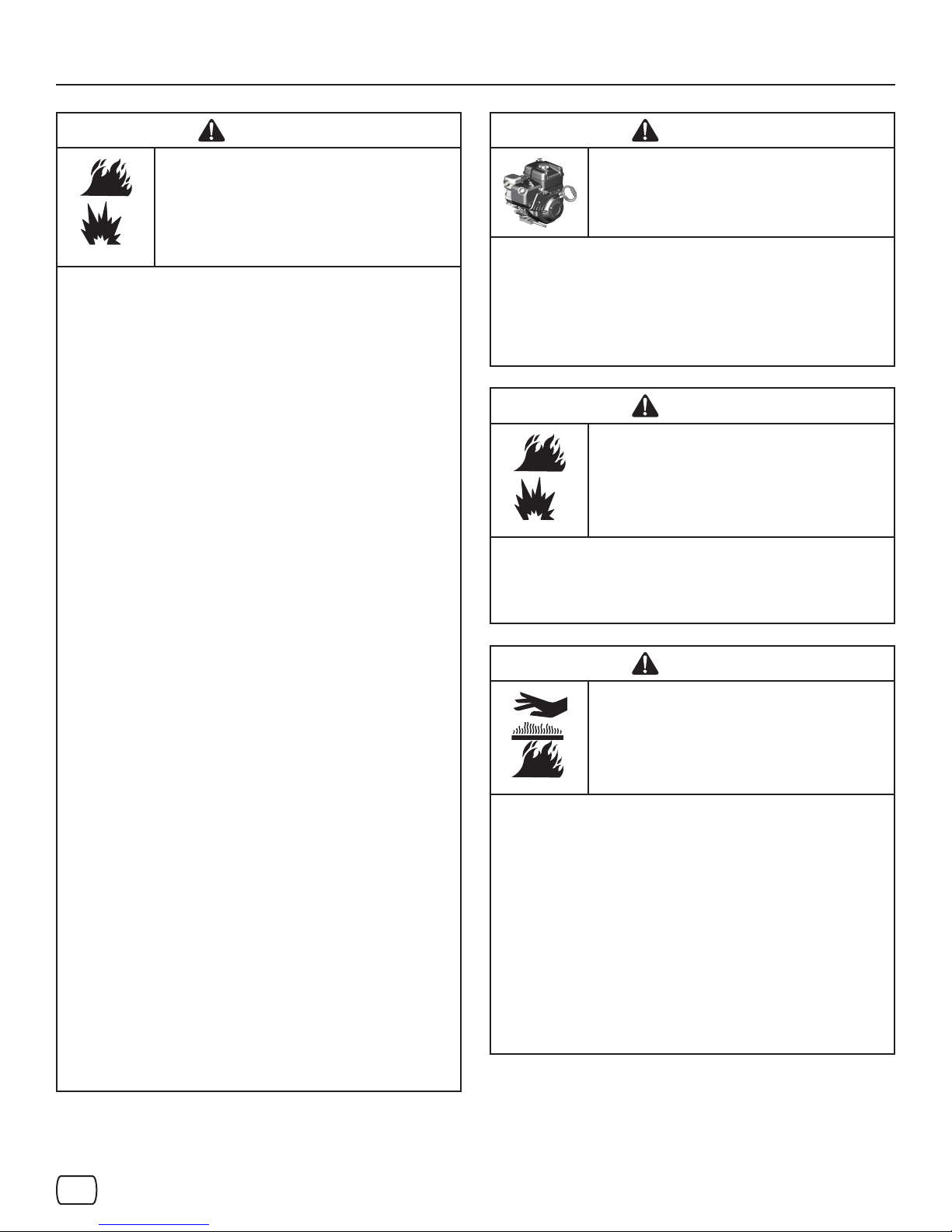

Operator Safety

WARNING

Fuel and its vapors are extremely ammable

and explosive. Always handle fuel with

extreme care.

Failure to observe these safety instructions can

cause a re or explosion which will result in

severe burns or death.

WHEN ADDING FUEL

• Turn o engine and let cool at least 2 minutes before removing

the fuel cap and adding fuel.

• Fill fuel tank outdoors or in a well ventilated area.

• Do not overll the fuel tank. To allow for the expansion of gasoline, do not ll above the bottom of the fuel tank neck.

• Keep fuel away from sparks, open ames, pilot lights, heat,

and other ignition sources.

• Check fuel lines, cap, and ttings frequently for cracks or

leaks. Replace if necessary.

• Use an approved fuel container.

• If fuel spills, wait until it evaporates before starting engine.

WHEN STARTING ENGINE

• Ensure that spark plug, muer, fuel cap, and air cleaner (if

equipped) are in place and secured.

• Do not crank the engine with the spark plug removed.

• If fuel is spilled, do not attempt to start the engine, but move

the snowthrower away from the area of the spill, and avoid

creating any source of ignition, until the fuel vapors have dissipated.

• Do not over-prime the engine. Follow the engine starting instructions in this manual.

• If the engine oods, set choke (if equipped) to OPEN/RUN position, move throttle (if equipped) to FAST position and crank

until engine starts.

WHEN OPERATING EQUIPMENT

• Do not tip the snowthrower at an angle which causes the fuel

to spill.

• Do not choke the carburetor to stop the engine.

• Never run the engine with the air cleaner assembly (if

equipped) or the air lter (if equipped) removed.

WHEN CHANGING OIL

• If you drain the oil from the top oil ll tube, the fuel tank must

be empty or fuel can leak out and result in a re or explosion.

WHEN TRANSPORTING EQUIPMENT

• Transport with fuel tank EMPTY, or with fuel shut-o valve

OFF.

WHEN STORING GASOLINE OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters, or other appliances that have pilot light or other ignition source because

they can ignite fuel vapors.

WARNING

Safe operation of the snowthrower requires the

proper care and maintenance of the engine.

• Disengage all clutches and shift into neutral before starting the

engine may cause personal injury.

• Let the engine adjust to outdoor temperatures before starting

to clear snow.

• Use a grounded three-wire plug for all snowthrowers equipped

with electric drive motors or electric starting motors.

WARNING

Starting engine creates sparking.

Sparking can ignite nearby ammable gases.

Explosion and re could result.

• If there is natural or LP gas leakage in area, do not start

engine.

• Do not use pressurized starting uids because vapors are

ammable.

WARNING

Running the engine produces heat. Engine

parts, especially muer, become extremely

hot.

Failure to observe these safety instructions

could result in severe thermal burns on

contact.

• Never touch a hot engine or muer. Allow muer, engine cylinder, and ns to cool before touching.

• Remove debris from muer area and cylinder area.

• Install and maintain in working order a spark arrester before

using equipment on forest-covered, grass-covered, or brushcovered unimproved land.

• It is a violation of California Public Resource Code, Section 4442, to use or operate the engine on any forest-covered,

brush-covered, or grass-covered land unless the exhaust sys-

tem is equipped with a spark arrester, as dened in Section

4442, maintained in eective working order. Other states or

federal jurisdictions may have similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain a

spark arrester designed for the exhaust system installed on

this engine.

en

7

Page 8

Operator Safety

WARNING

This snowthrower must be properly maintained

to ensure safe operation and performance.

Failure to observe the safety instructions in this

manual could result in death or serious injury.

• When performing any maintenance or repairs on the

snowthrower, shut OFF the engine, disconnect spark plug

wire, and keep the wire away from the plug to prevent someone from accidently starting the engine.

• Check shear bolts and other hardware at frequent intervals for

proper tightness.

• Keep nuts and bolts tight and keep snowthrower in good con-

dition.

• Never tamper with safety devices. Check their proper opera-

tion regularly and make necessary repairs if they are not functioning properly.

• Components are subject to wear, damage, and deteriora-

tion. Frequently check components and replace with recommended parts, when necessary.

• Check control operation frequently. Adjust and service as re-

quired.

• Use only factory authorized replacement parts, or like, parts

when making repairs.

• Always comply with factory specications on all settings and

adjustments.

• Use only factory authorized, or like, attachments and acces-

sories such as wheel weights, counterweights, or cabs.

• Never attempt to make any adjustments while the engine is

running (except when specically recommended by the fac-

tory).

WARNING

This snowthrower is only as safe as the

operator. If it is misused, or not properly

maintained, it can be dangerous. Remember

you are responsible for your safety and those

around you.

• Keep the area of operation clear of all persons, particularly

small children and pets.

• Thoroughly inspect the area where the snowthrower will be

used and remove all doormats, sleds, boards, wires, and

other foreign objects.

• Do not operate the snowthrower without wearing adequate

winter clothing.

• Wear footwear that will improve footing on slippery surfaces.

• Use caution to avoid slipping or falling especially when operat-

ing the snowthrower in reverse.

• Never operate the snowthrower without good visibility or light.

Always be sure of your footing, and keep a rm hold on the

handles.

• Do not clear snow across the face of slopes. Use extreme

caution when changing direction on slopes. Do not attempt to

clear steep slopes.

• Do not overload the machine capacity by attempting to clear

snow too quickly.

• Never operate the snowthrower at high transport speeds on

slippery surfaces. Look behind the snowthrower and use care

when operating in reverse.

• Do not use the snowthrower on surfaces above ground level

such as roofs of residences, garages, porches, or other such

structures or buildings.

• Operators should evaluate their ability to operate the

snowthrower safely enough to protect themselves and others

from injury.

• The snowthrower is intended to remove snow only. Do not use

the snowthrower for any other purpose.

• Do not carry passengers.

• After striking a foreign object, shut OFF the engine, discon-

nect the cord on electric motors, thoroughly inspect the

snowthrower for any damage, and repair the damage before

restarting and operating the snowthrower.

• If the snowthrower vibrates abnormally, shut OFF the engine.

Vibration is generally a warning of trouble. See an authorized

dealer if necessary for repairs.

• For models equipped with electric starting motors, disconnect

the power cord after the engine starts.

8

Page 9

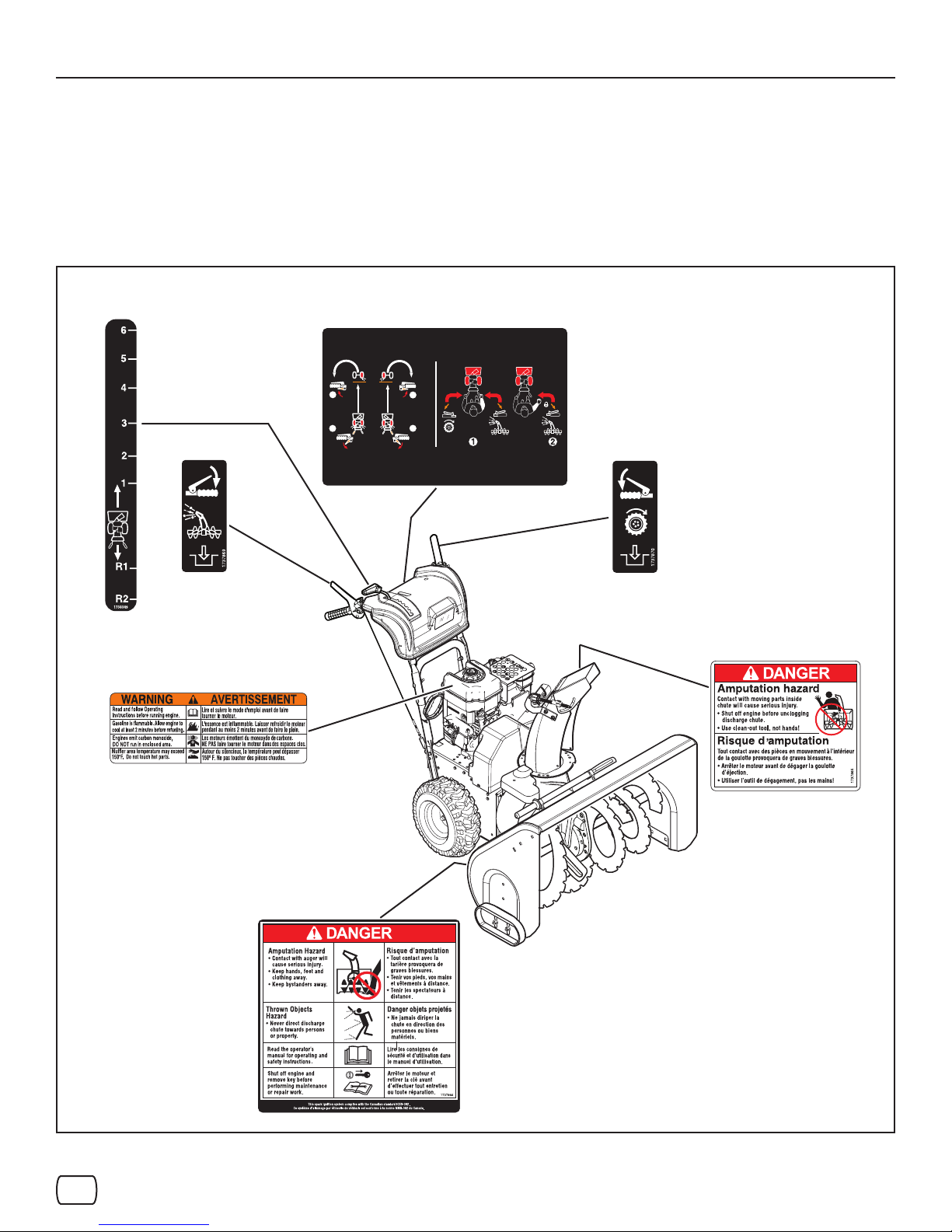

Safety Decals

Operator Safety

Before operating your snowthrower, read the safety decals

installed on your snowthrower. The cautions and warnings

are for your safety. To avoid a personal injury or damage to

your snowthrower, understand and follow all the safety decals.

Part No. 1754679

Main Dash Decal

Part No. 1751582

Shift Decal

Part No. 1737869

Auger Control Decal

2

1

2

1

If any safety decals become worn or damaged and cannot

be read, order replacement decals from your local dealer.

1754679

Part No. 1737870

Traction Control Decal

Part No. 278297

Engine Decal

Product ID Number &

Serial Number Decal

(Rear of Motor Box)

Figure 1

en

Part No. 1737865

Chute Danger Decal

Part No. 1737866

Auger Danger Decal

9

Page 10

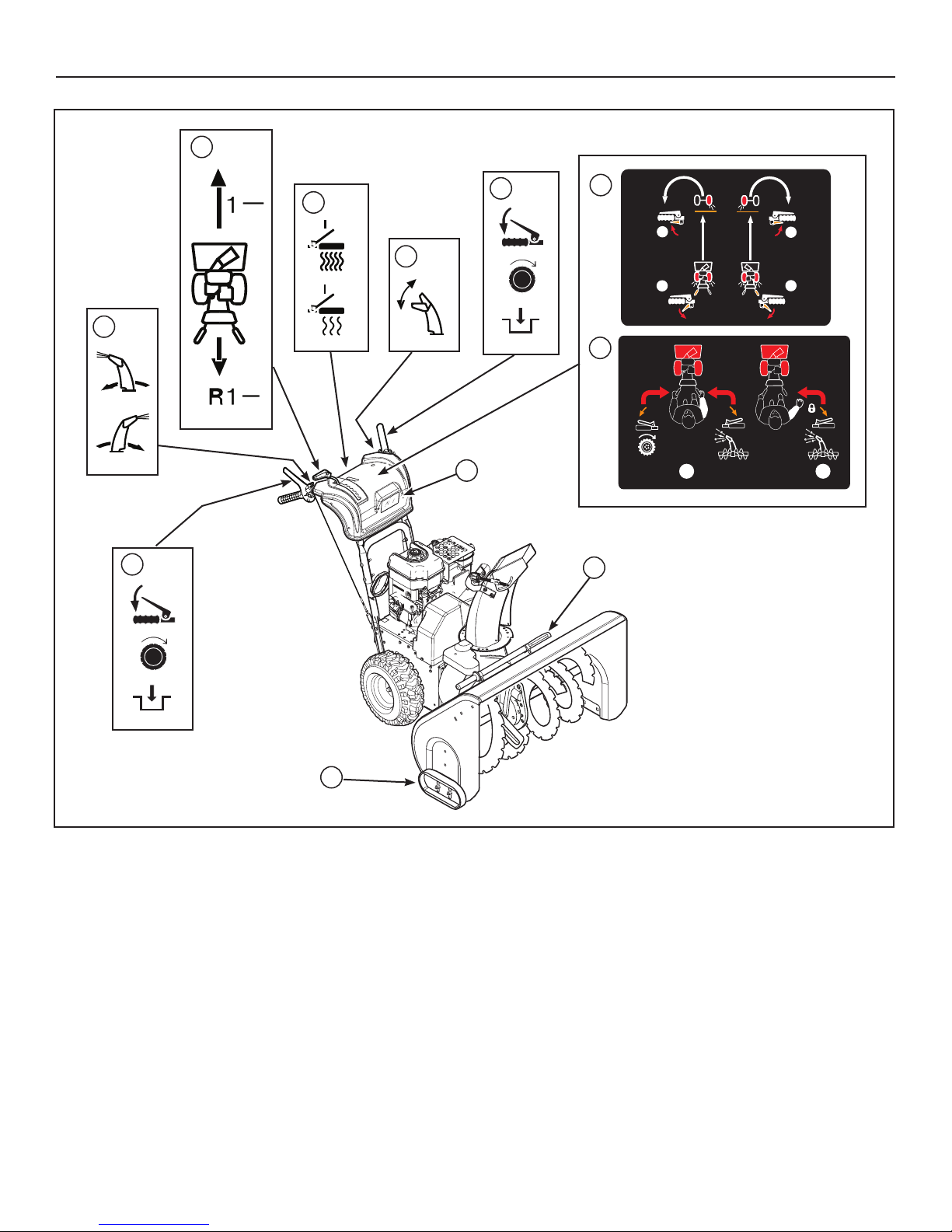

Features and Controls

A

G

E

K

2

2

D

1

1

C

F

J

B

H

1

2

Figure 2

SNOWTHROWER CONTROLS

A. Speed Select Lever — Allows the operator to select forward

and reverse speeds (see Figure 2). To shift, move speed se lect lever to desired position.

NOTICE: Do not move speed select lever while Traction

Control is engaged. This may result in severe damage

to the drive system.

B. Auger Control Lever — Used to engage and disengage the

auger and impeller. To engage push down, to disengage re-

lease.

C. Chute Rotation Switch — Used to rotate the discharge

chute to the left or right.

D. Deector Control Switch — Used to control the angle of the

chute deector (up or down).

10

I

E. Easy-TurnTM Traction Control — When engaged, allows the

operator to release one drive wheel, but allows the other

wheel to continue driving for easy turning.

F. Free-HandTM Control — After engaging the traction control

(left hand) and auger control (right hand), allows the operator

to release the auger control lever to use the other controls.

G. Traction Control Lever — Used to propel snowthrower for-

ward or reverse. Push down to engage, release to disengage.

See also, “Free-Hand Control”.

H. Clean-Out Tool — Used to remove snow and debris from the

discharge chute and the auger housing.

I. Skid Shoes — Used to adjust the ground clearance of the

auger housing.

Page 11

Features and Controls

G

F

B

A

C

E

D

H

STOP

Figure 3

SNOWTHROWER CONTROLS (Continued)

J. Headlight — Used to operate the snowthrower in poor light-

ing conditions.

K. Grip Warmer Switch — Used to warm the hand grips

(On/O).

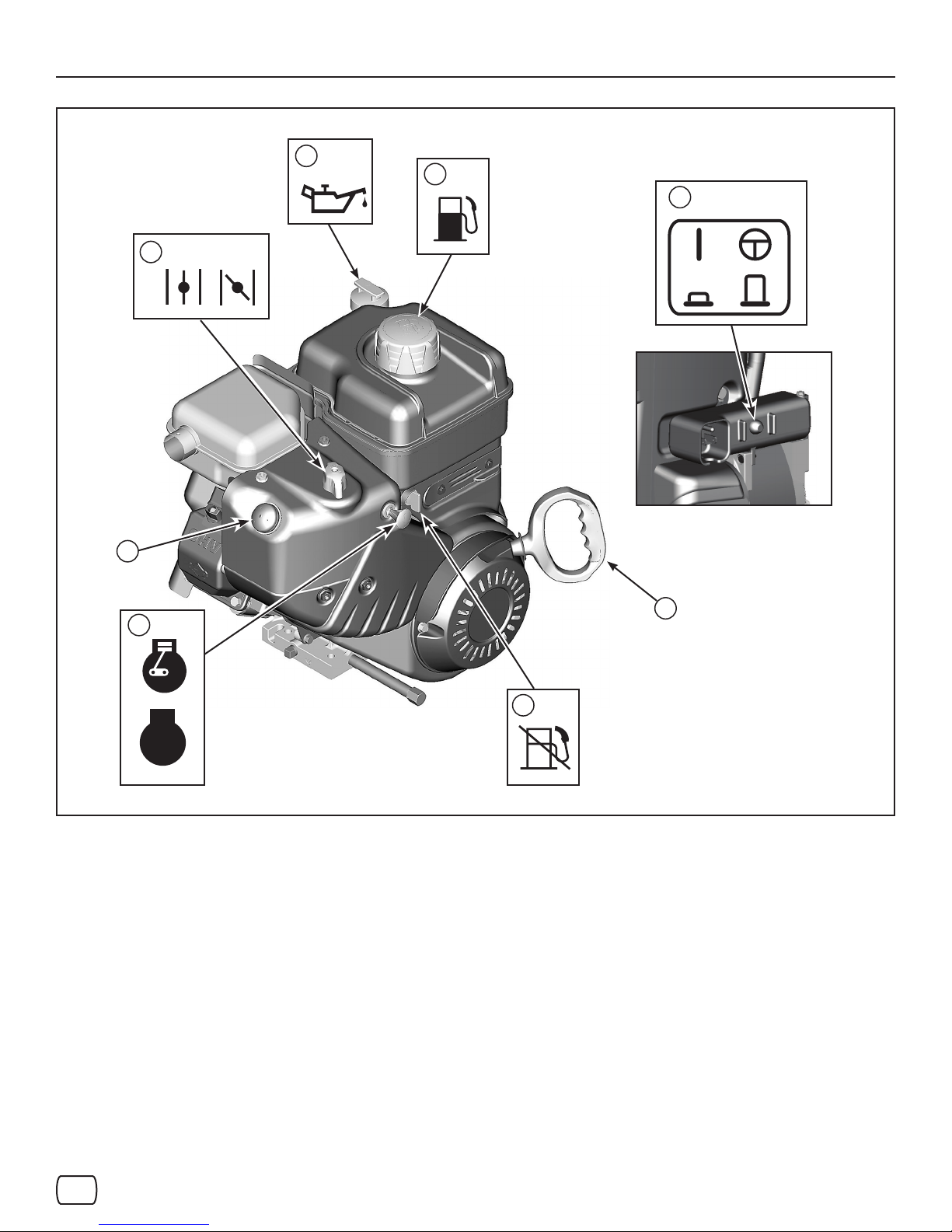

ENGINE CONTROLS

A. Choke Control Knob — Used to start a cold engine (see

Figure 3).

B. Electric Start Button — Used to start the engine using the

electric starter.

C. Primer Button — Used to inject fuel directly into the carbure tor manifold to ensure fast starts in cool weather.

D. Safety Key — Must be inserted to start engine. Pull out to

stop. Do not turn safety key.

E. Starter Cord Handle — Used to start the engine manually.

F. Fuel Tank and Cap — Fill the fuel tank to approximately

1-1/2 in. (38 mm) below the top of the neck to allow for fuel

expansion.

G. Oil Fill Cap (Extended Dipstick)

H. Fuel Shut-O Valve (if equipped) — Used to turn the fuel

supply o for out-of-season storage.

en

11

Page 12

Operation

BEFORE OPERATING SNOWTHROWER

Check the fasteners. Make sure all fasteners are tight.

Read this Operator’s Manual and Operator Safety before

operating your snowthrower. Compare the illustrations with

your snowthrower to familiarize yourself with the location of

various controls and adjustments. Save this manual for future reference.

WARNING: The operation of any snowthrower can result in foreign objects being thrown into the eyes, which

can result in severe eye damage. Always wear safety glasses or eye shields before beginning snowthrower

operation. We recommend standard safety glasses or Wide Vision Safety Mask over spectacles.

SAFETY SYSTEM TESTS

WARNING

Amputation Hazard

This snowthrower is equipped with several mechanical

safety systems designed to keep the operator safe while

using the unit. Check the operation of these systems

regularly using the safety system tests listed. If the unit

fails to operate as described, DO NOT operate it. See your

authorized dealer for service immediately.

Test 1 – Auger/Impeller Control

With the engine running:

• Press down on the auger control lever. (The auger/impeller

should rotate.)

• Release the auger control lever. (The auger/impeller should

stop within 5 seconds.)

Test 2 – Traction Drive Control

With the engine running and speed control in 1st gear:

• Press down on the traction control lever. (The unit should

move forward.)

• Release the traction control lever. (The unit should stop.)

Test 3 - Free Hand Control

With the engine running:

• Engage the auger and traction control levers, then release

the auger control lever. (Both controls should remain

engaged.)

• Next, release the traction control lever. (Both controls should

release.)

OPERATE THE SNOWTHROWER

CAUTION: Operation with a Snow Cab. Wind may

blow exhaust gasses back towards the operator. If

you notice the smell of exhaust, change direction of

operation.

NOTICE: Do not throw snow toward a building as hidden objects

could be thrown with sucient force to cause damage.

1. Start the engine. See Start the Engine in this section.

2. Press the chute rotation switch (C, Figure 2) to rotate the dis-

charge chute left or right.

NOTE: This snowthrower was shipped WITH OIL in the engine.

See “Before Starting Engine” instructions in the Operation

section of this manual before starting engine.

NOTICE: Before operating, make sure the area in front of the

snowthrower is clear of bystanders or obstacles.

3. Press the deector control switch (D) to control the angle of

the chute deector.

4. Fully press and hold the auger control lever (B) to engage

the auger rotation. Releasing the auger control lever will

disengage the auger - unless the Free-Hand™ control is activated.

5. Fully press and hold the traction/Free-Hand™ control lever

(G) to engage the traction drive and begin moving the snowthrower. To disengage the traction drive, completely release

the lever.

6. When BOTH levers are pressed, the Free-Hand™ control is

activated. This allows you to release the auger control lever to

use the other controls. The auger will continue to run until the

traction/Free-Hand™ control lever is released.

NOTE: Always release the traction control lever before moving

the speed select lever.

7. Use the speed select lever (A) to select the forward drive

speed. Set the speed select lever to one of the following positions as determined by snow conditions:

1-2 Wet, Heavy, Slushy, Extra Deep

3 Moderate

4-5 Very Light

6 Transport

NOTE: When clearing wet, heavy, snow, it is recommended that

the ground speed of the unit be reduced, maintained full throttle

and do not attempt to clear the full width of the unit.

8. Press the grip warmer switch (K) to heat the hand grips.

9. To stop moving forward, release the traction control lever (G).

10. To move the snowthrower backwards, move the speed select

lever into either rst or second reverse position and engage

the traction control lever.

12

Page 13

STOP THE SNOWTHROWER

1. Release the traction control lever (C, Figure 2).

2. Pull out the safety key (D, Figure 3).

3. Keep the safety key out of the reach of children.

Operation

2

2

WARNING: Never run engine indoors or in

an enclosed, poor ventilated area. Engine

exhaust contains CARBON MONOXIDE, an

ODORLESS and DEADLY GAS.

• Keep hands, feet, hair, and loose clothing

away from any moving parts on engine and

snowthrower.

• Temperature of muer and nearby areas can

exceed 150°F (66°C). Avoid these areas.

• DO NOT allow children or young teenagers to

operate or be near snowthrower while it is

operating.

WARNING: Read Operator’s Manual before

operating machine. This machine can be

dangerous if used carelessly.

• Never operate the snowthrower without all

guards, covers, shields in place.

• Never direct discharge towards windows or

allow bystanders near machine while engine is

running.

• Stop the engine whenever leaving the operating

position.

• Disconnect spark plug before unclogging the

impeller housing or the discharge chute and

before making repairs or adjustments.

• When leaving the machine, remove the safety key.

To reduce the risk of re, keep the machine clean

and free from spilled gas, oil, and debris.

1

Figure 4

1

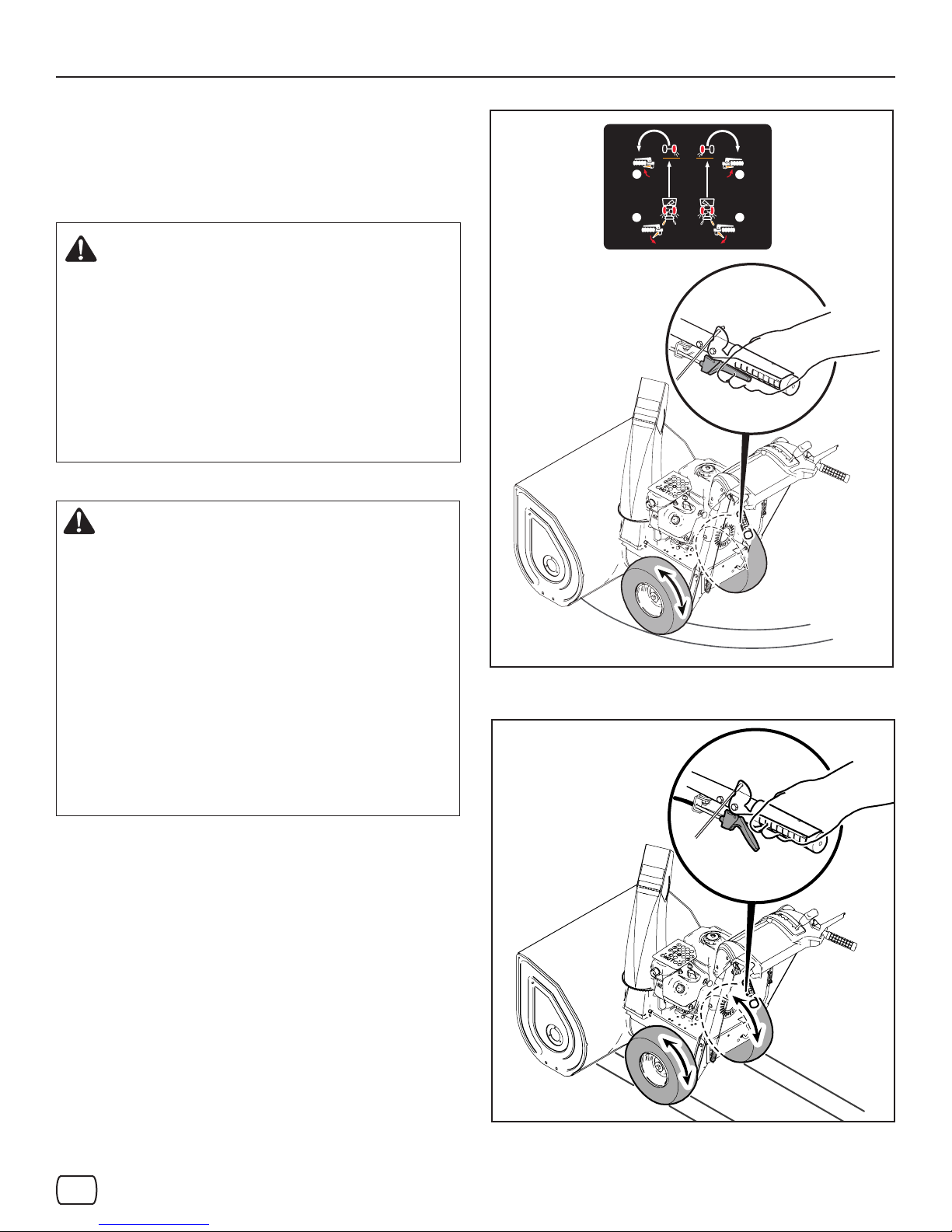

EASY-TURNTM TRACTION CONTROL

For easy turning when using the snowthrower, squeeze the EasyTurn™ lever.

Engaging the Easy-Turn™ lever releases the left or right traction

wheel, but allows the opposite wheel to continue driving. Figure 4

shows the left Easy-Turn lever engaged.

Releasing the Easy-Turn™ lever automatically engages both

drive wheels for full traction (see Figure 5).

NOTE: The Easy-TurnTM will be more dicult to activate under a

heavy load. Activate the lever before beginning a turn.

en

Figure 5

13

Page 14

Operation

CHECK THE OIL (BEFORE STARTING ENGINE)

NOTE: The engine was shipped from the factory lled with oil.

Check the level of the oil. Add oil as needed.

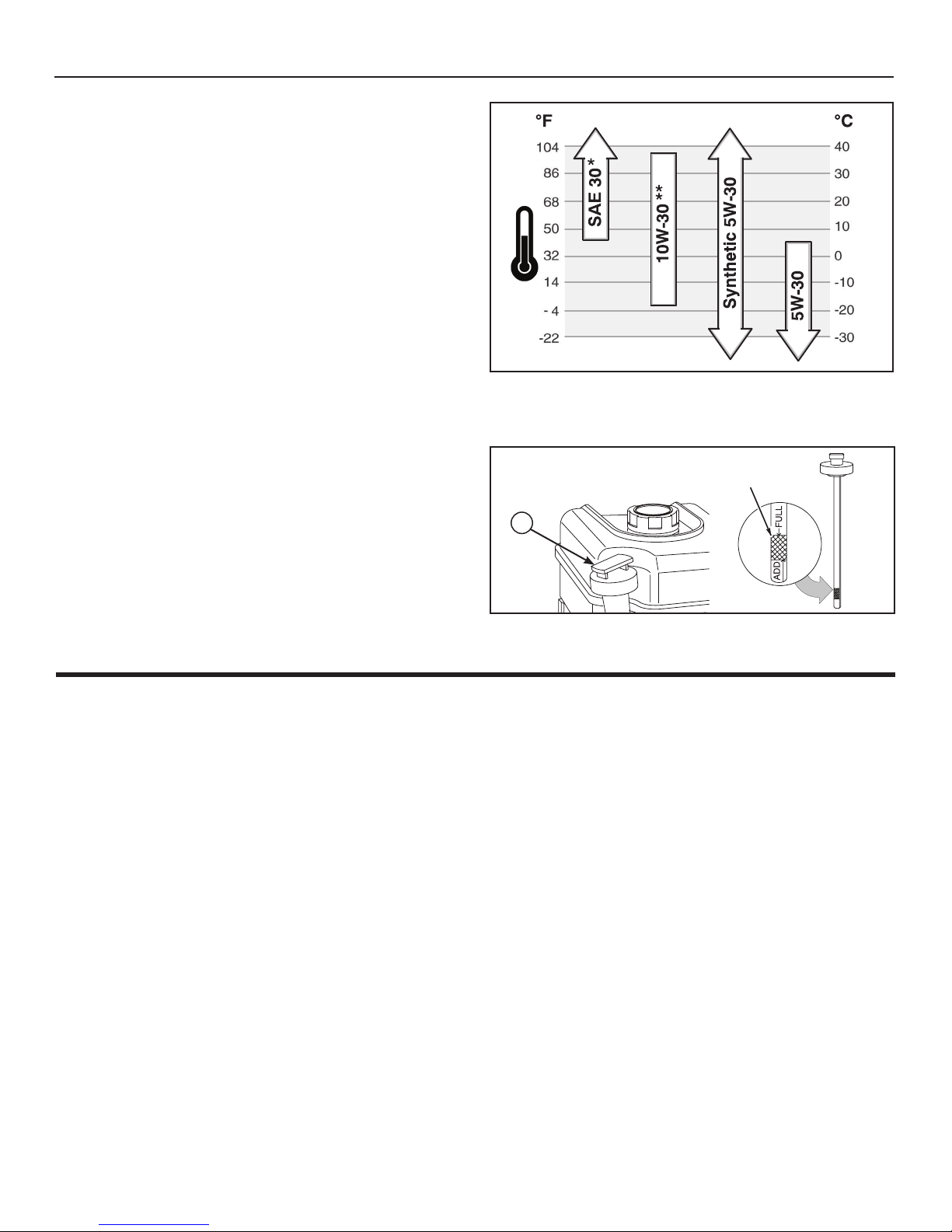

1. Make sure the unit is level. Use a high quality detergent oil

classied “For Service SF, SH, SJ, SL, or higher”.

2. Remove the oil ll cap/dipstick (A, Figure 6) and wipe with a

clean cloth.

3. Insert the oil ll cap/dipstick and turn clockwise to tighten.

4. Remove the oil ll cap/dipstick and check the oil.

NOTE: Do not check the level of the oil while the engine runs.

5. If necessary, add oil until the oil reaches the FULL mark

on the oil ll cap/dipstick. Do not add too much oil.

6. Tighten the oil ll cap/dipstick securely each time you check

the oil level.

NOTE: For extreme cold operating conditions of 0°F (-18°C)

and below, use a synthetic 5W30 motor oil for easier starting.

NOTE: S.A.E. 5W30 motor oil may be used to make starting

easier in areas where the temperature is 20°F (-7°C) to 0°F

(-18°C). Synthetic 5W30 is acceptable for all temperatures.

DO NOT mix oil with gasoline. See Chart for oil recommendations.

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W-30 may cause increased oil con-

sumption. Check oil level more frequently.

FULL

A

FUEL RECOMMENDATIONS

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON). High altitude

use, see below.

• Gasoline with up to 10% ethanol (gasohol) is acceptable.

CAUTION: Do not use unapproved gasolines, such as E15 and

E85. Do not mix oil in gasoline or modify the engine to run on

alternate fuels. Use of unapproved fuels will damage the engine

components and void the engine warranty.

To protect the fuel system from gum formation, mix a fuel stabilizer into the fuel. See Storage. All fuel is not the same. If starting or performance problems occur, change fuel providers or

change brands. This engine is certied to operate on gasoline.

The emissions control system for this engine is EM (Engine

Modications).

Figure 6

HIGH ALTITUDE

At altitudes over 5,000 feet (1524 meters), a minimum 85 octane/85 AKI (89 RON) gasoline is acceptable. To remain emissions compliant, high altitude adjustment is required. Operation

without this adjustment will cause decreased performance, increased fuel consumption, and increased emissions. See an

authorized Briggs & Stratton Dealer for high altitude adjustment

information.

Operation of the engine at altitudes below 2,500 feet (762 meters) with high altitude adjustment is not recommended.

14

Page 15

Operation

ADDING FUEL

WARNING

Fuel and its vapors are extremely ammable

and explosive.

Fire or explosion can cause severe burns or

death.

When Adding Fuel

• Turn engine o and let engine cool at least 2 minutes

before removing the fuel cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overll fuel tank. To allow for expansion of the fuel,

do not ll above the bottom of the fuel tank neck.

• Keep fuel away from sparks, open ames, pilot lights,

heat, and other ignition sources.

• Check fuel lines, tank, cap, and ttings frequently for

cracks or leaks. Replace if necessary.

• If fuel spills, wait until it evaporates before starting engine.

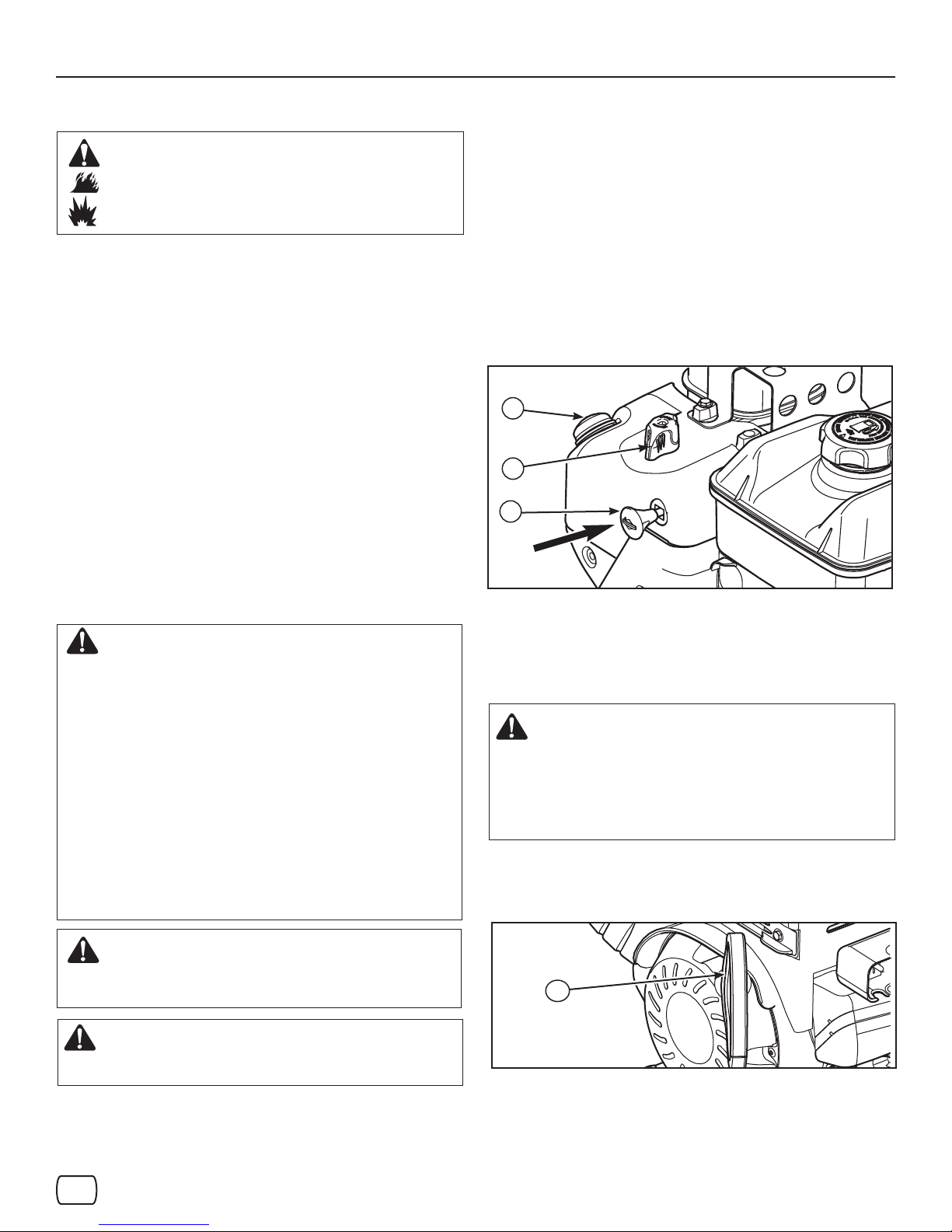

START THE ENGINE

Be sure that engine oil is at FULL mark on the oil ll cap/dipstick. The

snowthrower engine is equipped with an A.C. electric starter and recoil

starter. Before starting the engine, be certain that you have read the following information.

If engine oods, set the choke to the OPEN/RUN position and crank

until the engine starts.

Start the engine as follows:

1. Check the oil level. See Check the Oil section.

2. Make sure equipment drive controls are disengaged.

3. Insert the safety key (A, Figure 7) into the safety key slot

and push fully in to the RUN position.

4. Turn the choke control knob (B) to the CHOKE position.

NOTE: Do not use the choke to start a warm engine.

5. Push the primer button (C) two times.

NOTE: Do not use the primer to start a warm engine.

NOTE: Ensure that electric extension cord is removed from the

power receptacle.

C

B

A

Figure 7

WARNING: The electric starter is equipped with a

three−wire power cord and plug designed to operate

on AC house hold current. The power cord must be

properly grounded at all times to avoid the possibility

of electric shock which can cause injury to the

operator. Follow all instructions carefully as set forth:

Make sure your house has a three−wire grounded

system.

If you are not sure, ask a licensed electrician. If your

house does not have a three−wire grounded system,

do not use this electric starter under any condition.

If your house has a three−wire grounded system but

a three-hole receptacle is not available to connect the

electric starter, have a three−hole receptacle installed

by a licensed electrician.

WARNING: To connect power cord, always

connect the power cord rst to the switch box

located on the engine and then plug the other end

into a three−hole grounded receptacle.

WARNING: To disconnect the power cord,

always unplug the end connected to the three−

hole grounded receptacle rst.

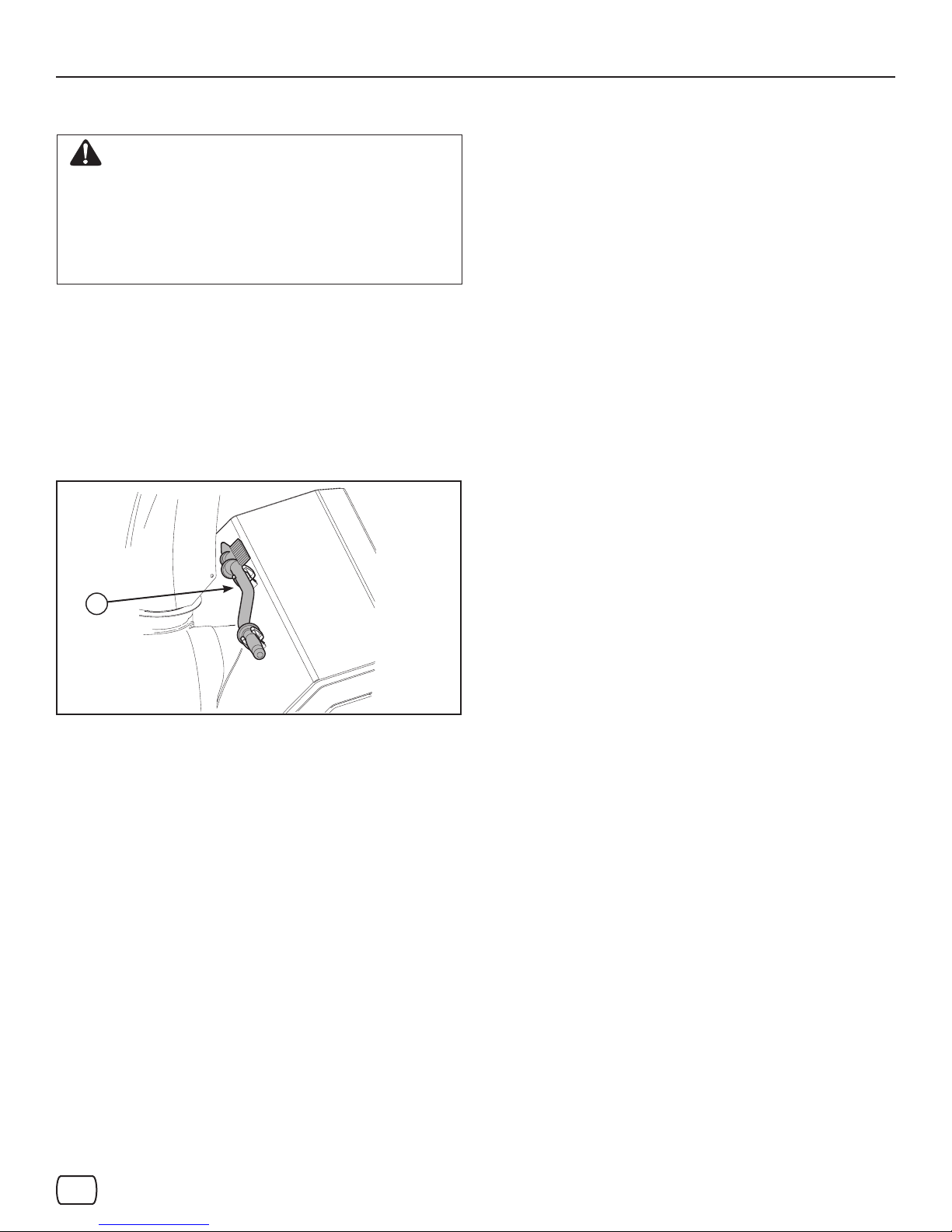

6. Rewind Start: Firmly hold the starter cord handle (A, Figure 8).

Pull the starter cord handle slowly until resistance is felt, then pull

rapidly.

WARNING: Rapid retraction of the starter cord

(kickback) will pull your hand and arm toward

the engine faster than you can let go. Broken

bones, fractures, bruises, or sprains could result.

When starting engine, pull the starter cord slowly

until resistance is felt and then pull rapidly to avoid

kickback.

NOTE: If the engine does not start after three attempts, see

an authorized dealer.

A

Figure 8

en

en

15

Page 16

Operation

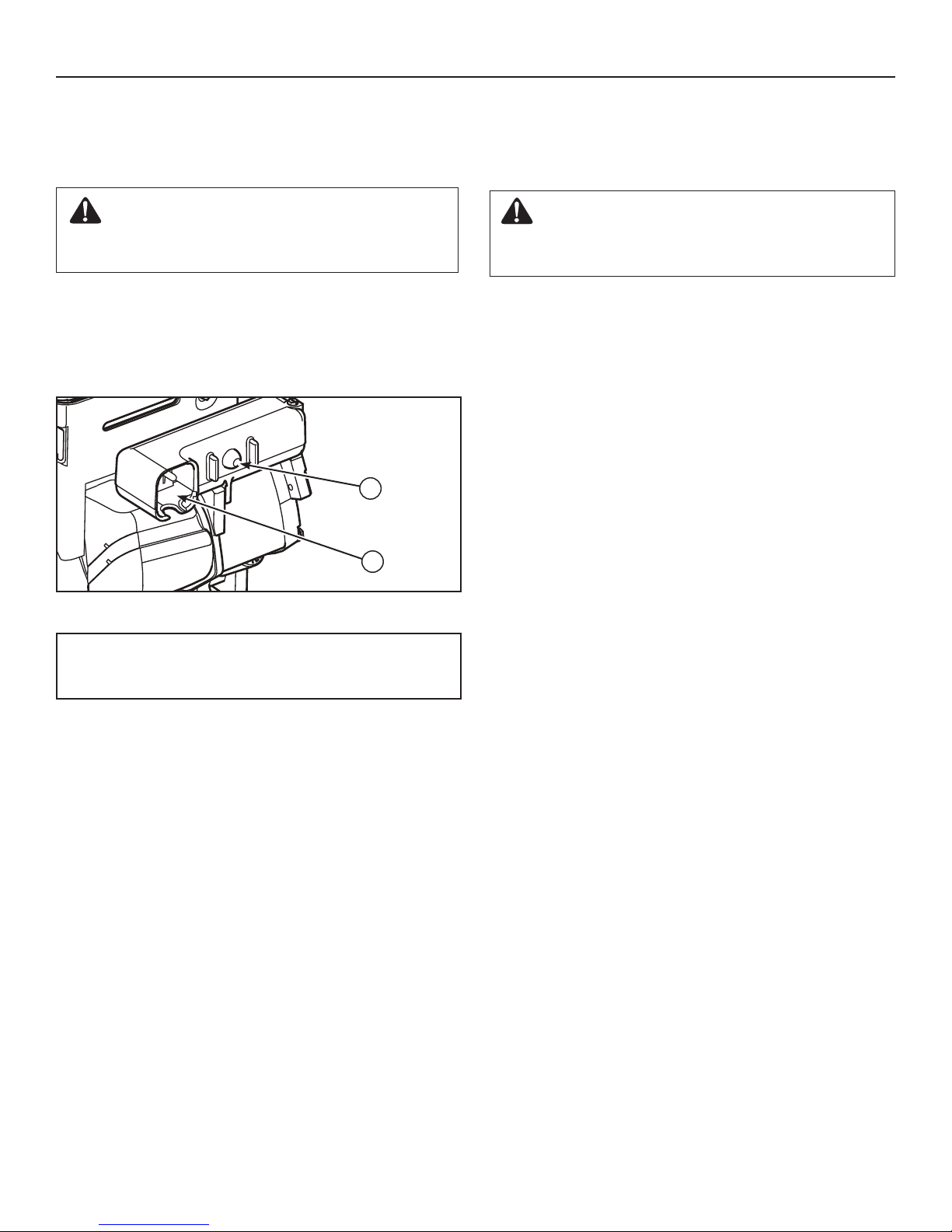

7. Electric Start: First connect the extension cord to the

power cord receptacle and then into a wall receptacle. If additional extension cord is required, make sure it is three-wire.

WARNING: If the extension cord is damaged,

it must be replaced by the manufacturer (or its

service agent) or a similarly qualied person

to avoid a hazard.

8. Electric Start: Depress the starter push button (A, Figure 9).

After you start the engine, rst disconnect the extension cord

from the wall receptacle and then from the power cord receptacle (B).

A

B

STOP THE ENGINE

Before stopping the engine for a few minutes to help dry o

any moisture on the engine.

WARNING: Gasoline and vapors are extremely

ammable and explosive. Fire or explosion can

cause severe burns or death. DO NOT choke

the carburetor to stop the engine.

1. Remove the safety key (A, Figure 7).

2. Keep the safety key out of the reach of children.

NOTE: Do not lose the safety key. Keep the safety key in a

safe place. The engine will not start without the safety/ignition key.

Figure 9

IMPORTANT: To extend the life of the starter, use

short starting cycles (ve seconds maximum). Wait

one minute between starting cycles.

NOTE: If the engine does not start after three attempts, see

an authorized dealer.

16

Page 17

Operation

CLEAR A CLOGGED DISCHARGE CHUTE

WARNING: Hand contact with the rotating

impeller inside the discharge

chute is the most common cause of injury

associated with snowthrowers. Never clear or

unclog discharge chute with your hands, or while

engine is running. Fingers can quickly become

caught and traumatic amputation or severe

laceration can result.

• SHUT OFF THE ENGINE!

• Wait 10 seconds to be sure that the impeller blades

have stopped rotating.

• Always use a clean-out tool, not your hands.

A clean-out tool (A, Figure 10) is attached to either the handle or

the top of the auger housing. Use the clean-out tool to remove

snow from the auger housing.

A

OPERATING TIPS

1. Most ecient snowthrowing is accomplished when snow

is removed immediately after it falls.

2. For complete snow removal, slightly overlap each swath previously taken.

3. Snow should be discharged downwind whenever possible.

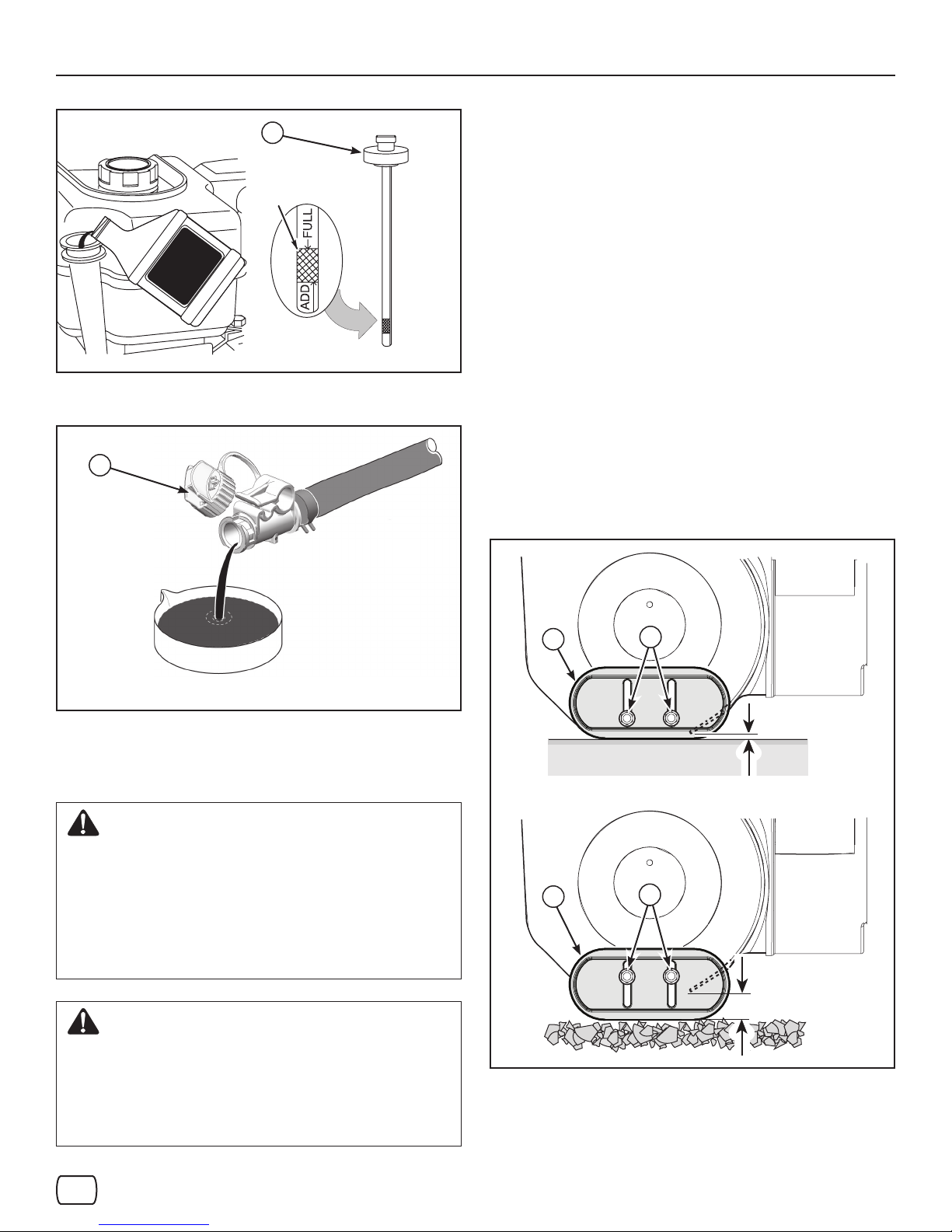

4. For normal usage, set the skids 1/8 inch (3 mm) below the

scraper bar. For extremely hard-packed snow surfaces,

the skids may be adjusted upward to ensure cleaning ef-

ciency.

5. On gravel or crushed rock surfaces, the skids should be

set at 1-1/4 inch (32 mm) below the scraper bar (see “Adjust Skid Height” in the Maintenance section of this manual). Rocks and gravel must not be picked up and thrown

by the machine.

6. After the snowthrowing job has been completed, allow the

engine to idle for a few minutes, to melt snow and ice accumulated on the engine.

7. Clean the snowthrower thoroughly after each use.

8. Remove ice and snow accumulation and all debris from

the entire snowthrower, and ush with water (if possible)

to remove all salt or other chemicals. Wipe snowthrower

dry.

9. Before starting snowthrower, always inspect augers and

impeller for ice accumulation and/or debris, which could

result in snowthrower damage.

10. Check oil level before every start. Make sure the oil is at

the FULL mark on the oil ll cap/dipstick.

Figure 10

en

17

Page 18

Maintenance

MAINTENANCE CHART

SNOWTHROWER

After Each Use

Remove the snow and slush o snowthrower to prevent

freezing of controls

Every 8 Hours or Daily

Perform snowthrower safety tests

Every 25 Hours or Annually *

Check tire pressure

Check snowthrower for loose hardware

See Dealer Annually to

Lubricate control levers and linkages

Lubricate deector hinge

Lubricate deector motor (if equipped)

Lubricate chute rotation gear (if equipped)

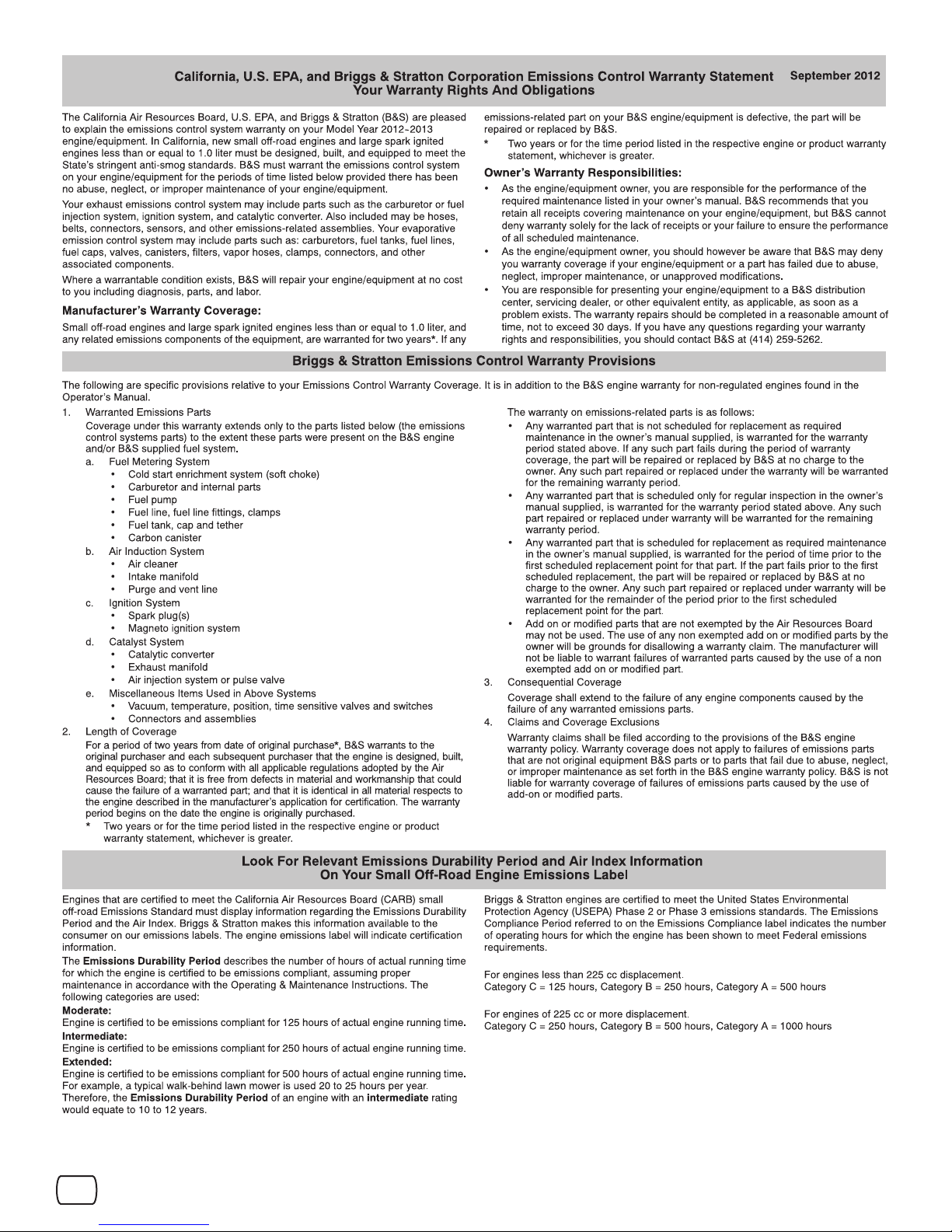

EMISSIONS CONTROL STATEMENT

Maintenance, replacement, or repair of the emissions control

devices and systems may be performed by any non-road engine repair establishment or individual. However, to obtain “no

charge” emissions control service, the work must be performed

by a factory authorized dealer. See the Emissions Warranty.

ENGINE

First 5 Hours

Change engine oil

Every 8 Hours or Daily

Check engine oil level

Every 50 Hours or Annually *

Change engine oil

Check muer and muer guard.

See Dealer Annually to

Replace spark plug

Check valve clearance

* Not required unless there are problems with engine

performance.

Drain Oil – Position snowthrower so that the oil drain plug (A,

Figure 12) is lowest point on engine. When the engine is warm,

remove oil drain plug and oil ll cap and drain oil into a suitable

container.

Replace oil drain plug and tighten securely. Rell crankcase

with the recommended motor oil.

ENGINE MAINTENANCE

Check Crankcase Oil Level - Before starting engine and after

each 8 hours of continuous use. Add the recommended motor

oil as required.

NOTE: Over lling the engine can aect performance. Tighten

the oil ll cap securely to prevent leakage.

Change Oil - Every 50 hours of operation or at least once a

year, even if the snowthrower is not used for fty hours. Use

a clean, high quality detergent oil. Fill the crankcase to FULL

line on dipstick (A, Figure 11). Be sure original container is

marked: A.P.I. service “SF” or higher. Do not use SAE10W40

oil (as it may not provide proper lubrication). See Chart for oil

recommendations.

* Below 40°F (4°C) the use of SAE 30 will result in hard starting.

** Above 80°F (27°C) the use of 10W-30 may cause increased oil con-

sumption. Check oil level more frequently.

18

Page 19

A

Full

Figure 11

A

Maintenance

This snowthrower is equipped with two height adjust skids,

secured to the outside of the auger housing. These elevate the

front of the snowthrower.

When removing snow from a hard surface area such as a paved

driveway or walk, adjust the skids up to bring the front of the

snowthrower down.

When removing snow from rock or uneven construction, raise

the front of the snowthrower by moving the skids down. This will

help to prevent rocks and other debris from being picked up and

thrown by the augers.

1. Determine how much clearance you want between the scraper

bar at the bottom of the auger housing and the ground. If

clearing a gravel surface, enough ground clearance is needed

to prevent the unit from picking up rocks.

2. Place a block equal to the desired ground clearance under the

scraper bar.

3. Loosen the skid shoe mounting nuts (A, Figure 13) and push

the skid shoe (B) down until it touches the ground. Re-tighten

mounting nuts.

4. Set the skid shoe on the other side at the same height.

Figure 12

SKID SHOE HEIGHT ADJUSTMENT

DANGER: Amputation Hazard

The discharge chute contains a rotating impeller to

throw snow. Fingers can quickly become caught and

traumatic amputation or severe laceration will result.

Hand contact with the rotating impeller inside the

discharge chute is the most common cause of injury

associated with snowthrowers.

Turn the engine OFF, wait for all moving parts to

stop, and remove the engine key before performing

any maintenance or repairs.

WARNING: Thrown Objects Hazard

Objects such as gravel, rocks, or other debris, if

struck by the impeller, may be thrown with sucient

force to cause personal injury, property damage, or

damage to the snowthrower.

Be sure to set the skid shoes at the proper height

to maintain ground clearance for the type of surface

being cleared.

B

A

1/8” - 3/16″

(3 mm - 5 mm)

B

A

1″

(2,5 cm)

Figure 13

en

19

Page 20

Maintenance

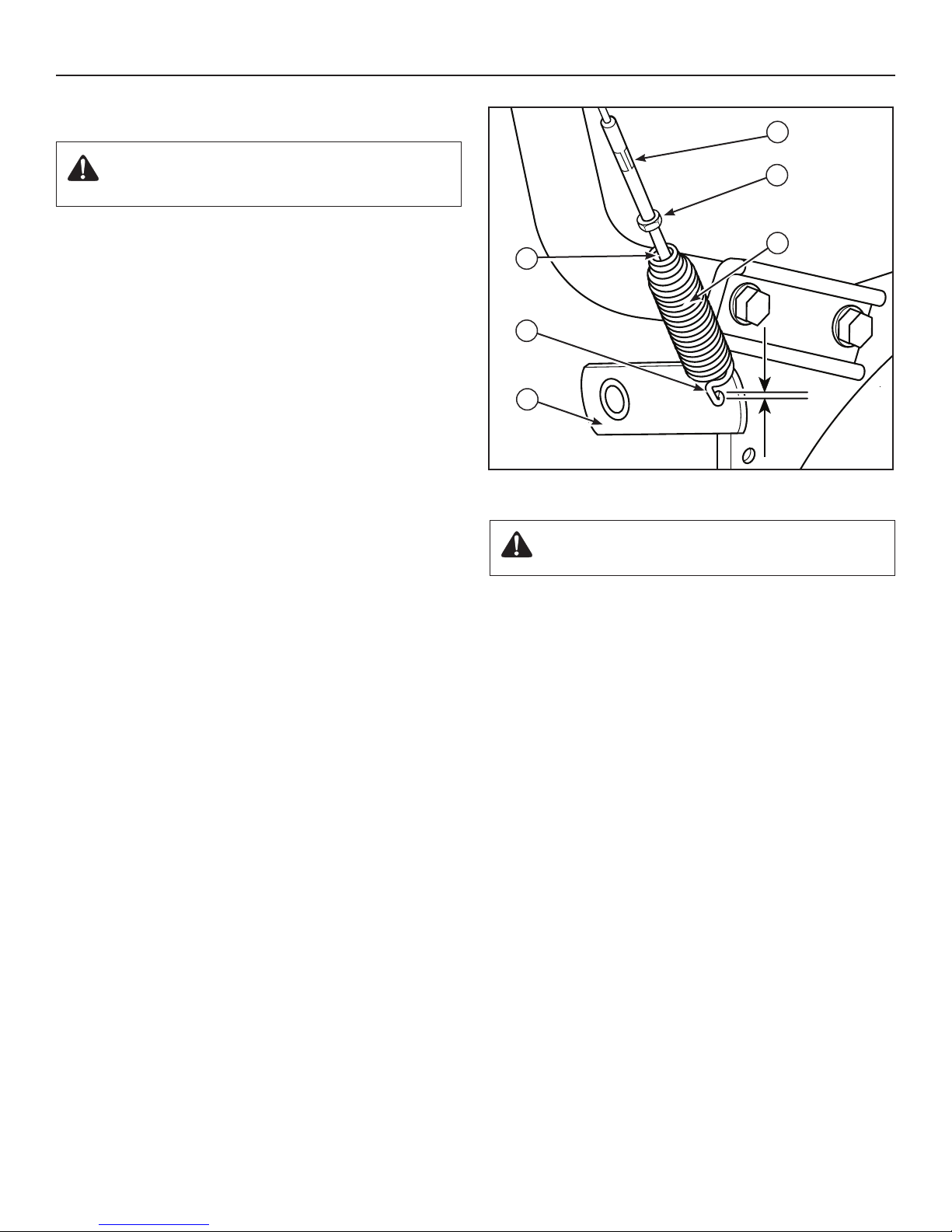

AUGER CONTROL CABLE ADJUSTMENT

WARNING: Do not over-tighten, as this may lift the

lever and cause the auger drive to be engaged

without depressing the auger drive control.

1. With the auger control lever released, the hook (A, Figure 14)

should barely touch the lever (B) without raising it. There can

be a maximum of 1/32 in. (0.8 mm) clearance.

2. To adjust, loosen the nut (C) by holding the adjusting ats (D)

and turning the nut. Then, turn the adjusting ats and hold

the adjustment screw (E). The adjustment screw is a phillips

screw and the head can be held or turned by inserting a

screwdriver through the spring (F).

3. Hold the adjusting ats and tighten the nut.

4. Start the engine and check the auger. The auger must not be

engaged unless the auger control lever is depressed.

5. With the engine running, fully depress the auger drive control

lever. The auger should engage and run normally.

D

C

F

E

A

1/32”

B

Figure 14

(0.8mm)

WARNING: The auger must stop within 5 seconds.

If it does not, see an authorized dealer.

6. Release the auger control lever.

7. If the auger does not operate properly, stop the engine and

recheck the auger control cable adjustment.

8. If the drive linkage is properly adjusted, the tension of the

auger drive belt may require an adjustment. See an authorized

dealer.

20

Page 21

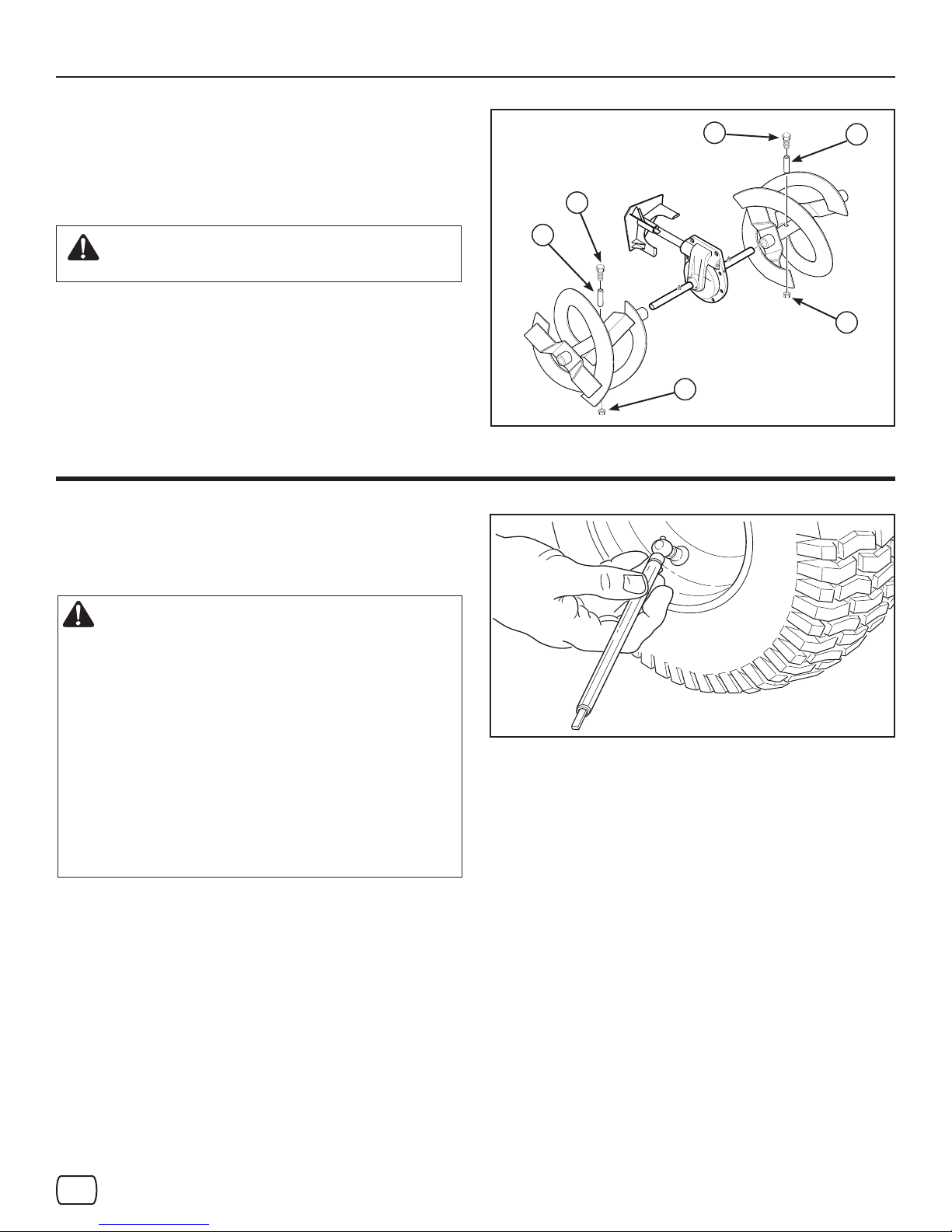

AUGER SHEAR BOLT REPLACEMENT

The augers are secured to the auger shaft with special bolts that

are designed to break if an object becomes lodged in the auger

housing. Use of a harder bolt will reduce the protection provided

by the shear bolt.

Maintenance

A

A

B

WARNING: To ensure safety and performance

levels, only original replacement shear bolts

should be used.

1. Stop the engine, disengage all controls, disconnect the spark

plug lead wire, and make sure all moving parts have stopped.

2. Align the hole in the auger with the hole in the auger shaft. In-

stall new shear bolt (A, Figure 15), spacer (B) and locknut (C)

found in the parts bag or toolbox located on the belt cover.

NOTE: The spacer ts into the larger hole in the auger tube.

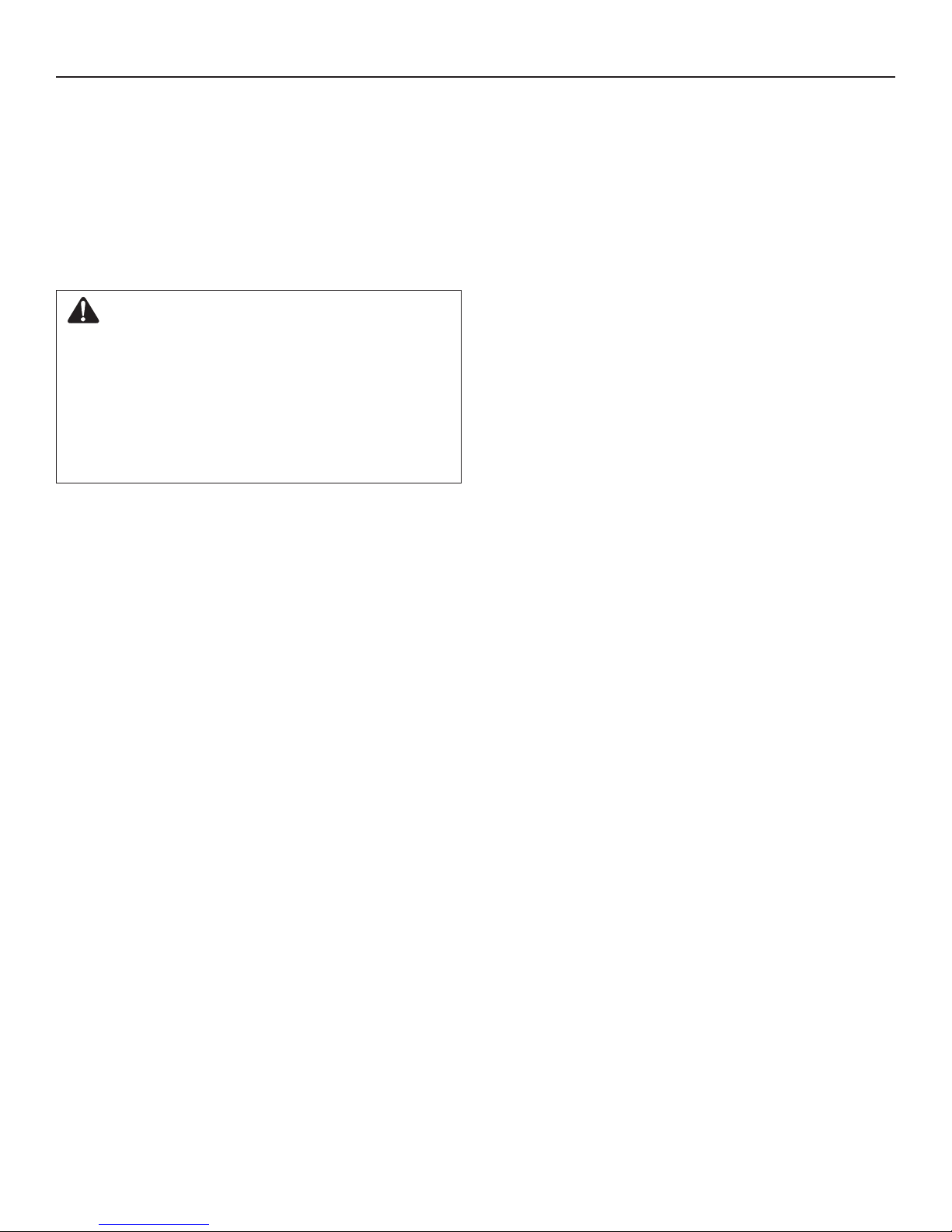

CHECK THE TIRES

Check tires for damage. Check the air pressure in the tires with an

accurate gauge (see Figure 16).

CAUTION: Avoid Injury! Explosive separation of

tire and rim parts is possible when they are ser-

viced incorrectly.

• Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

• Do not inate the tires above the maximum

pressure.

• Do not weld or heat a wheel and tire assembly.

Heat can cause an increase in air pressure

resulting in an explosion. Welding can

structurally weaken or deform the wheel.

• Do not stand in front or over the tire assembly

when inating. Use appropriate tool that allows

you to stand to one side.

B

C

C

Figure 15

Figure 16

NOTICE: Check side of tire for maximum tire pressure. DO

NOT exceed maximum.

en

21

Page 22

Maintenance

OFF-SEASON STORAGE

If the unit will be stored for thirty (30) days or more at the end of

the season, the following steps are recommended to prepare it

for storage. Always refer to the operator’s manual for important

details if the unit is to be stored for an extended period.

NOTE: Fuel must be removed or treated to prevent gum

deposits from forming in the tank, lter, hose, and carburetor

during storage.

DANGER: Fire and Explosion Hazard

Gasoline is highly ammable and its vapors

are explosive. Fumes may travel to a distant

ignition source and an explosion and/or re

may result.

Handle gasoline carefully. Never store the unit,

with fuel in the tank, indoors or in a poorly

ventilated enclosure where fuel fumes could

reach an open ame, spark, pilot light, such as

a furnace, water heater, or clothes dryer.

• Thoroughly clean the unit.

• Lubricate all lubrication points (see authorized dealer).

• Make sure all nuts, bolts, and screws are securely fastened.

Inspect all visible moving parts for damage, breakage, and

wear. Replace if necessary.

• Touch up all rusted or chipped paint surfaces; sand lightly

before painting.

• Cover the bare metal parts of the snowthrower housing

auger, and the impeller with rust preventative.

• If possible, store your unit indoors and cover it to give

protection from dust and dirt.

• If the machine must be stored outdoors, cover with a heavy

tarpaulin.

To Return to Service:

• Fill the fuel tank with a fresh fuel.

• Make sure all fasteners are tight.

• Make sure all guards, shields, and covers are in place.

22

Page 23

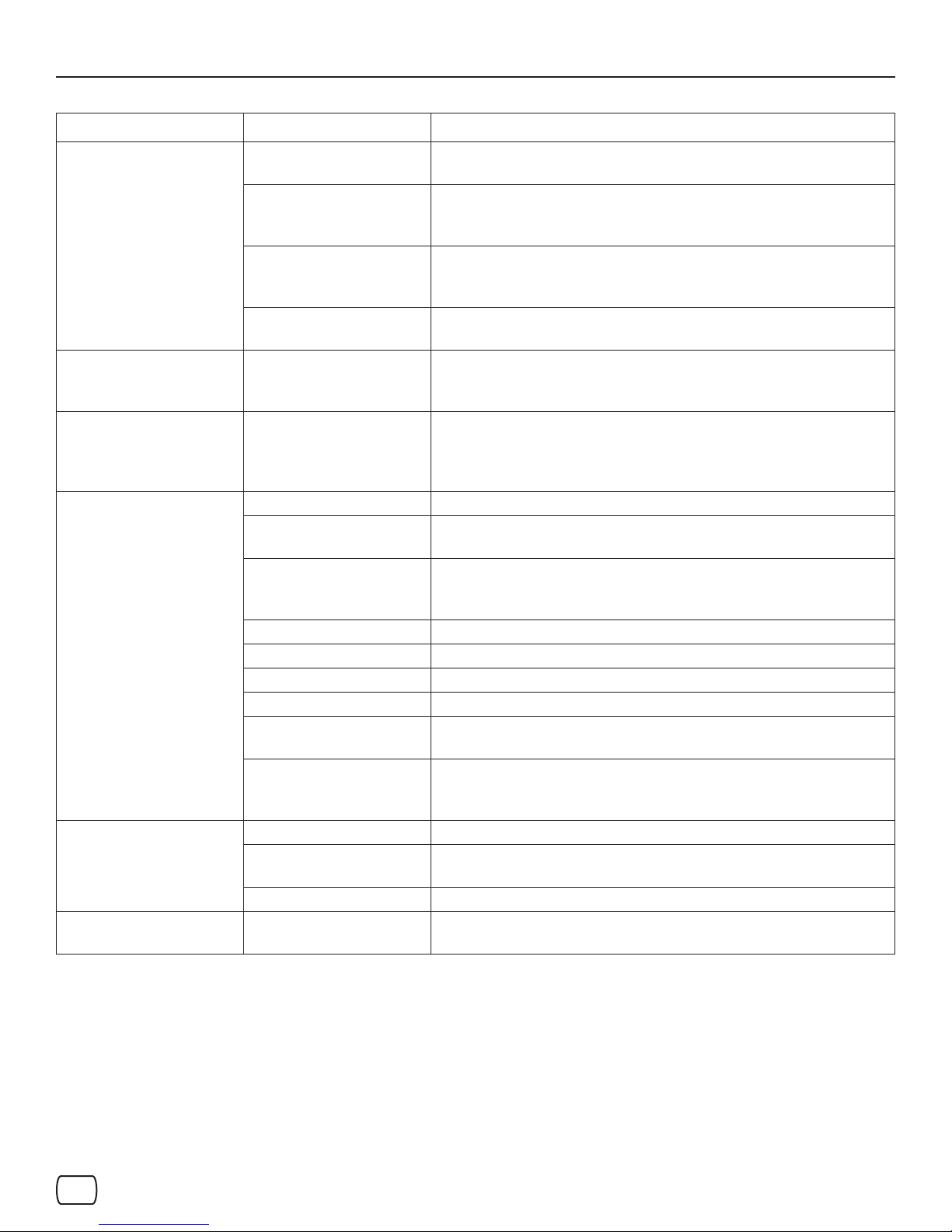

PROBLEM LOOK FOR REMEDY

Auger does not stop

within 5 seconds after

right control lever is

released.

Discharge chute or

deector does not work

(electric).

Discharge chute or

deector does not work

(remote-manual).

Engine fails to start. Key is o. Push key in to the ON position.

Engine starts hard or

runs poorly.

Excessive vibration. Loose parts or damaged

Free-Hand™ control is

ACTIVE.

Free-Hand™ control is

not working correctly (fails

Safety Test 3).

Auger control cable out of

adjustment (fails Safety

Test 1).

Auger belt guide out of

adjustment.

Electrical failure. See authorized dealer.

Discharge chute

or deector out of

adjustment or needs

lubrication.

Failure to prime a cold

engine.

Fuel shut-o valve is

CLOSED position (if

equipped).

Out of fuel. Fill fuel tank.

Choke OFF - cold engine. Turn choke ON, set throttle to FAST.

Engine ooded. Turn choke to OFF; try starting.

No spark. See authorized dealer.

Water in fuel, or old fuel. Drain tank. (Dispose of fuel at an authorized hazardous waste

Cord not plugged in or

malfunctions (Electric

Start models).

Fuel mixture too rich. Move choke to OFF position.

Spark plug faulty, fouled,

or gapped incorrectly.

Fuel cap vent is blocked. Clear vent.

impeller/auger.

Release both auger control and traction/Free-Hand™ control

levers to stop auger.

See authorized dealer.

Adjust auger control cable. Refer to “Auger Control Cable

Adjustment” in the Maintenance section of this manual. Make

sure auger control passes Safety Test 1.

See authorized dealer.

See authorized dealer.

Press primer button twice and start.

Turn valve to OPEN position.

facility.) Fill with fresh fuel.

Plug in cord or replace defective cord.

See authorized dealer.

Stop engine immediately. See authorized dealer.

Troubleshooting

en

23

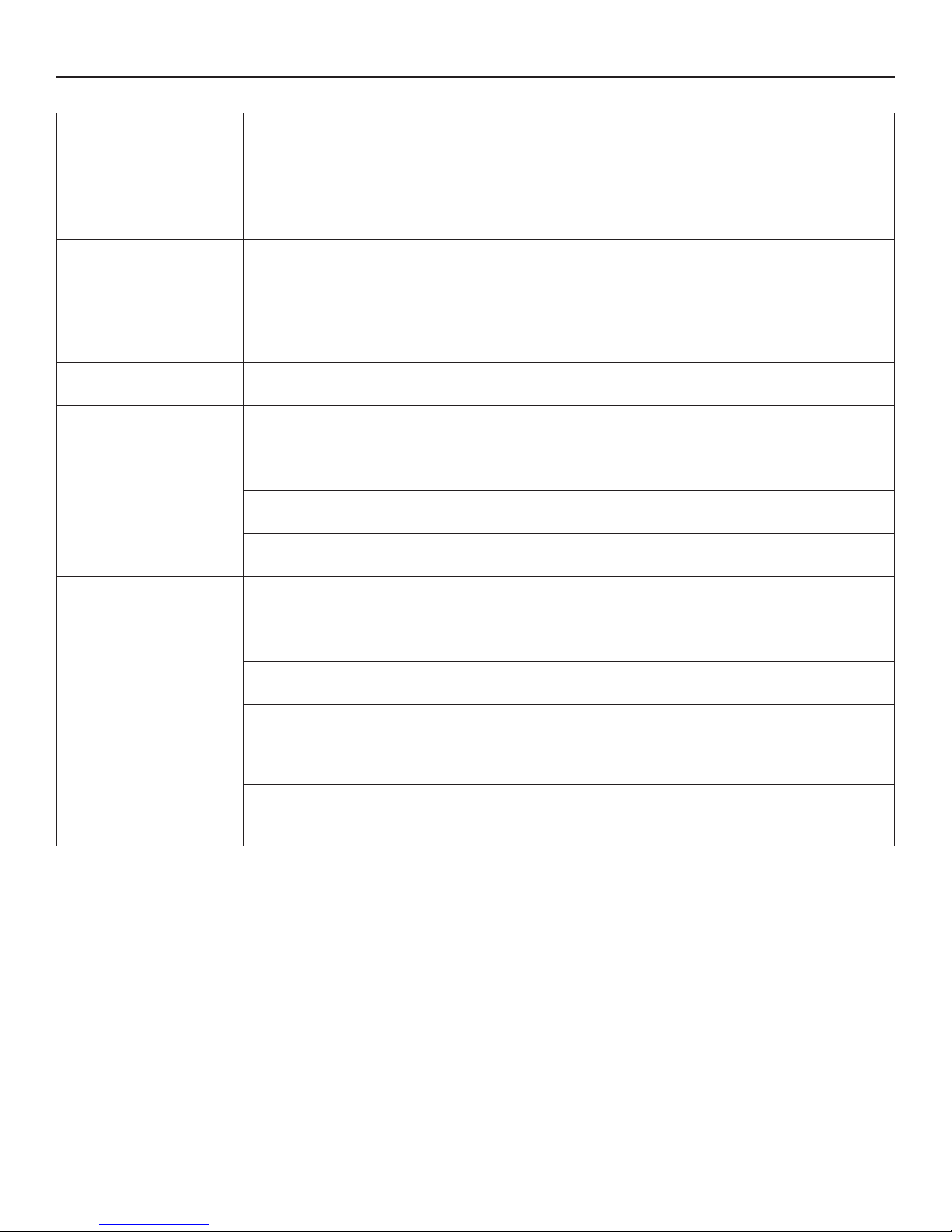

Page 24

Troubleshooting

PROBLEM LOOK FOR REMEDY

Snowthrower forward

and reverse motion

does not stop when

traction control lever is

released.

Snowthrower veers to

one side.

Scraper bar does not

clean hard surface.

Snowthrower fails to

move at slow speeds.

Snowthrower fails

to move forward or

reverse at any speed.

Unit fails to discharge

snow.

Traction control out of

adjustment (fails Safety

Test 2).

Tire pressure not equal. Check tire pressure.

One wheel is set in freewheeling mode. (Traction

lock pin is in the OUTER

hole.) Models with wheel

pins or locks.

Skid shoes improperly

adjusted.

Traction control out of

adjustment.

Drive belt loose or

damaged.

Traction control out of

adjustment.

Worn or damaged friction

disc.

Auger control cable out of

adjustment.

Auger drive belt loose or

damaged.

Broken shear bolt. Replace shear bolt. Refer to “Auger Shear Bolt Replacement” in

Discharge chute clogged

with snow.

Foreign object lodged in

auger.

See authorized dealer.

Make sure the left traction lock pin is in the INNER holes (to

engage the traction drive).

Adjust skid shoes as needed.

Move speed select lever one speed faster. If that doesn’t work, see

authorized dealer.

See authorized dealer.

See authorized dealer.

See authorized dealer.

Adjust auger control cable. Refer to “Auger Control Cable

Adjustment” in the Maintenance section of this manual.

See authorized dealer.

the Maintenance section of this manual.

Stop engine immediately. Always use the clean-out tool to clear a

clogged discharge chute, not your hands. Clean discharge chute

and inside of auger housing. Refer to “Warnings” in Operator

Safety section.

Stop engine immediately. Always use the clean-out tool to clear a

clogged chute, not your hands. Remove object from auger. Refer

to “Warnings” in Operator Safety section.

24

Page 25

Warranties

Craftsman Limited Warranty

General: Craftsman products are warranted to be free from defects in materials or workmanship for a specic time period as set-out below (the “Warranty Period”). Warranties extend to the original purchaser of a Craftsman product only.

Purchases made through an online auction or through any website other than www.sears.ca are excluded. The relevant

Warranty Period commences on the original date of purchase. Within this period, Sears Canada, Inc. will, at its sole op-

tion, repair or replace any products or components which fail in normal use. Such repairs or replacement will be made at no

charge to the customer for parts or labor, provided that the customer shall be responsible for any transportation cost.

Exclusions: This warranty does not cover failures due to normal wear, abuse, misuse, neglect (including but not limited to

the use of stale fuel, dirt, abrasives, moisture, rust, corrosion, or any adverse reaction due to improper storage or use habits), improper maintenance or failure to follow maintenance guidelines and/or instructions, failure to operate the product in

accordance with the owner’s manual or any additional instructions or information provided at the time of purchase or in subsequent communications with the original purchaser, accident or unauthorized alterations or repairs made or attempted by

others. Also excluded from warranty coverage – except as provided below - are the following: maintenance, adjustments,

components subject to wear including but not limited to: cosmetic components, belts, blades, blade adapters, bulbs, tires,

lters, guide bars, lubricants, seats, grips, recoil assemblies, saw chains and bars, trimmer lines and spools, spark plugs,

starter ropers and tines, and discoloration resulting from ultraviolet light. Any product missing the model and/or serial num-

ber identication label will be disqualied from coverage under this warranty.

Repairs: Repairs have a 90 day warranty. If the defective product is still within the Warranty Period, then the new warranty

is 90 days from the date of repair or to the end of the original Warranty Period, whichever period is longer.

Disclaimers: THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES, WHETHER ORAL OR WRITTEN (OTHER THAN AS STATED HEREIN), AND WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING BUT NOT LIMITED TO ANY. THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, WHICH MAY VARY FROM PROVINCE TO PROVINCE.

IN NO EVENT SHALL SEARS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE OR INABILITY TO USE THE PRODUCT OR FROM DEFECTS

IN THE PRODUCT. THE EXCLUSIONS IN THIS PARAGRAPH SHALL NOT APPLY IN JURISDICATIONS WHERE APPLICABLE LAW DOES NOT ALLOW FOR THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES. IN

SUCH JURISDICTIONS, THIS PARAGRAPH SHALL NOT APPLY, BUT THE REMAINING PROVISIONS OF THIS DOCUMENT SHALL REMAIN VALID.

Sears retains the exclusive right to repair or replace the product or oer a full refund of the purchase price at its sole discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

Customer Responsibilities: In additional to complying with all suggested maintenance guidelines and instructions, customers’ obligations shall include but shall not be limited to: operating the product in accordance with the owner’s manual

or any additional instructions or information provided at the time of purchase or in subsequent communications to the purchaser from time to time, exhibit reasonable care in the use, operation, maintenance, general upkeep and storage of the

product. Failure to comply with these requirements will void any applicable warranty.

List of Applicable Warranty Periods: The following list contains the applicable Warranty Period for your Craftsman prod-

uct and is based on a combination of the type of product or component and the intended and actual use of the product or

component:

1. 90 days: Craftsman products intended for use or actually used for commercial, institutional, professional or income-

producing purposes.

2. 2 years: Craftsman riding lawn mowers, yard and garden tractors, walk behind mowers, tillers, brush cutters, snow

blowers, handheld blowers, backpack blowers, hedge trimmers and electrical products for noncommercial, nonprofes-

sional, non-institutional, or non-income-producing use, except for those components which are part of engine systems

manufactured by third party engine manufacturers for which the purchase has received an separate warranty with

product information supplied at the time of purchase.

en

25

Page 26

Warranties

3. 1 year: Craftsman power cutters, stump grinders, pole pruners, gas chain saws, electric chain saws, trimmer attach-

ments, baggers and pole saws for noncommercial, nonprofessional, non-institutional, or non-income-producing use.

4. 90 days: All defective batteries, which will be replaced during this 90-day Warranty Period.

5. 60 days: Additional Warranty Period of 60 days will apply to adjustments and worn products or components BUT

DOES NOT INCLUDE WEAR OR ADJUSTMENTS for products used for commercial, institutional, professional or in-

come-producing purposes. Wear items include but are not limited to: belts, blades, tires, spark plugs, air lters,

chains, shear bolts, skid plates, scraper bars, drift cutters, ropes, tines, collection bags and pulleys.

As the Warranty Period runs from the date of purchase and NOT from the date that a product is delivered, opened, assembled or rst used, please ensure during this time period that your product or component has been assembled and tested for

correction operation regardless of when you intend to actually use it. Claims made after the Warranty Period has expired

will not be honored.

Proof of Purchase/Documentation: Warranty coverage is conditioned upon the original purchaser furnishing Sears Canada or its authorized third party service provider if applicable, with the original sales receipt or other adequate written proof

of the original purchase date and identication of the product. In the event that the original purchaser is unable to provide

a company of the original sales receipt, Sears Canada Inc. reserves the right to determine in its sole discretion what other

written proof of the original purchase date and identication of the product is acceptable.

Revision: 03/13/2009

Maintenance Agreement

The Craftsman Warranty plus a Maintenance Agreement, provide maximum value for Sears products. Contact your nearest

Sears store for details.

26

Page 27

en

27

Page 28

Specications

ENGINE:

Brand Briggs & Stratton®

Model Series Professional Series

Gross Torque 11.5 T.P. @ 3060 rpm

Type 4-Cycle - OHV

Displacement 15.26 cu in. (250 cc)

Starting System Recoil, 110V Electric w/Cord

Alternator 9 Amp Reg

Spark Plug Gap 0.030 in. (0,76 mm)

Oil Capacity 20 oz (0,59 liters)

Engine Oil Mineral 5W30

Fuel Tank Volume Nylon 3.2 qts (3,0 liters)

Ignition System This spark ignition system complies

with Canadian standard ICES-002.

AUGER/IMPELLER:

Clearing Width 24.0 in. (61 cm)

Intake Height 19.75 in. (50,2 cm)

Auger/Impeller Diameter 12.0 in. (30,5 cm)

Number of Impeller Blades 3

TM

CHUTE:

Chute Deector Electric

Chute Rotation Electric 200°

DRIVE SYSTEM:

Drive Type Friction Disc - PRO Easy-Turn

Drive Speeds 6 Forward Speeds, 2 Reverse

Tire Size 16 x 4.8 in. (41 x 12 cm)

Tire Ination See the sidewall of the tire for proper ination.

TM

Power Rating

The gross power rating for individual gasoline engine models is labeled in accordance with SAE (Society of Automotive Engi-

neers) code J1940 Small Engine Power & Torque Rating Procedure, and is rated in accordance with SAE J1995. Torque values

are derived at 2600 RPM for those engines with “rpm” called out on the label and 3060 RPM for all others; horsepower values are

derived at 3600 RPM. The gross power curves can be viewed at www.BRIGGSandSTRATTON.COM. Net power values are taken

with exhaust and air cleaner installed whereas gross power values are collected without these attachments. Actual gross engine

power will be higher than net engine power and is aected by, among other things, ambient operating conditions and engine-to-

engine variability. Given the wide array of products on which engines are placed, the gasoline engine may not develop the rated

gross power when used in a given piece of power equipment. This dierence is due to a variety of factors including, but not limited

to, the variety of engine components (air cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations,

ambient operating conditions (temperature, humidity, altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations, Briggs & Stratton may substitute an engine of higher rated power for this engine.

28

Page 29

Repair Parts

PTS - 1

Page 30

Handles & Controls Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 2

Page 31

Handles & Controls Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

CAPSCREW, Hex Head, 3/8-16 x 2, GR5 0010 1923701SM 1

SPRING, 1/2 Dia. x 3/4 0050 50786MA 1

WASHER, 3/8 x 13/16 OD 0060 1918266SM 1

NUT, Hex Lock, ESNA Light, 3/8-16 0070 1919439SM 1

LEVER, Clutch, LH 0080 1739782AYP 1

SPEED LEVER ASSEMBLY 0100 1736836YP 1

CAPSCREW, Hex Head, 1/4-20 x 1-3/4, GR5 0120 1921962SM 6

BRACKET, Controls 0130 1737684YP 1

ROD, Speed Select 0140 1737331YP 1

NUT, Hex Flange Whiz Lock Small, 5/16-18 0150 1931277SM 3

NUT, Hex, 5/16-24 0170 2820263SM 2

BALL JOINT, Quick Release 0190 1739290YP 1

WIRING HARNESS 0230 1752981YP 1

* FUSE, Mini, 10 Amp 0230-10 ----- 1

HARNESS, Heated Hand Grip, ON/OFF 0233 1752164YP 1

NUT, Hex Nylock Flange, 1/4-20 0235 5025391SM 3

NUT, Hex Lock, ESNA Light, 1/4-20 0300 1920397SM 4

BRACKET, Light 0320 1753046YP 2

SCREW, Torx, 1/4-20 x 5/8 0325 880845YP 2

CONTROL PANEL ASSEMBLY 0330 1753269BTYP 1

SCREW, Pan Head Torx, Taptite, 1/4-20 x 3/4 0340 1960556SM 4

BOLT, Shoulder, Hex Washer Head, 1/4 x 1-9/32 0360 1750554YP 2

BOLT, Carriage, 5/16-18 x 3/4 0370 340720MA 3

SUPPORT, Dash 0390 1739500AYP 1

CABLE, Steering Control 0395 1737510YP 2

CABLE, Auger Drive 0400 1737544YP 1

LEVER, Clutch, RH 0410 1739783AYP 1

NUT, Hex Lock, Nylon Insert, 10-24 0420 1933896SM 2

HAND GRIP, Heated 1" Dia. x 5-1/4 Lg 0430 1738124YP 2

SCREW, 1/8-20 x 1/8 0435 703044 4

SPACER, Stepped 0440 1736542YP 2

SCREW, #10C x 1-1/2 0445 7073145YP 2

SPACER, 17/64 ID x 3/8 OD x 11/32 Lg 0450 1678392SM 2

BRACE, Shift 0460 1737552YP 1

HANDLE, Upper, Right 0470 1737531AYP 1

HANDLE, Upper, Left 0480 1737532AYP 1

BOLT, Carriage, Locking, 5/16-18 x 2-1/4 0490 1750299YP 2

HANDLE, Lower 0500 1737274AYP 1

KNOB, Wing, 5/16-18 0510 7035744YP 4

WASHER, Locking, Internal Teeth, 5/16 0515 7090391SM 4

LIGHT, Halogen 0520 762343MA 1

BOLT, Carriage, 5/16-18 x 3/4, G5 0530 1737687YP 4

NUT, Hex KEPS, Conical Washer, 5/16-18 0535 1960684SM 4

Footnotes

Note* See your local hardware store for replacement bulbs and fuses.

PTS - 3

Page 32

Handles & Controls Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 4

Page 33

Handles & Controls Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

CABLE, Traction Drive 0560 1737511YP 1

BRACKET, Pivot, Free Hand 0590 1733505ASM 1

SPACER, Powdered Metal 0600 1733095SM 1

ROD & SPRING ASSEMBLY 0610 1736363YP 1

SPRING, Compression, 017/32 ID x 2-1/4 Lg 0630 2108360SM 1

BRACKET, Mounting, Dash, R.H. 0640 1739663AYP 1

ROD, Hold Down, 5/32 Dia., 5-5/8 Lg 0650 1736360YP 1

CABLE TIE, 7" 0670 7012080SM 5

KNOB, Slot Speed 0680 1733192SM 1

WASHER, 1/4 x 5/8 OD 0700 1921319SM 6

TIE, Self Locking 0720 1737275YP 1

SCREW, Round Head Phillips, #10-24 x 3/4 0750 1960589SM 1

NUT, Hex Lock, Nylon, #10C 0760 7091290SM 1

SCREW, Hex Washer Head, Taptite, 1/4-20 x 3/4 0780 1925592SM 1

BOLT, Carriage, 5/16-18 x 1-3/4, G5 0790 1931338SM 1

BOLT, Carriage, Short Neck, 1/4-20 x 3/4, G5 0930 7091530SM 1

SWITCH, Heated Hand Grip 0970 1752242YP 1

BRACKET, HHG Switch 0980 1739861AYP 1

POD, Chute Rotation, RH 1010 1739483AYP 1

POD, Deflector Control, LH 1020 1739484AYP 1

SCREW, Pan Head Torx, Taptite, 1/4-20 x 3/4 1030 1960556SM 5

BRACKET, Dash Mounting, LH 1080 1739664AYP 1

Footnotes

Note* See your local hardware store for replacement bulbs and fuses.

PTS - 5

Page 34

Engine & Frame Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 6

Page 35

Engine & Frame Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

* ENGINE, 11.5TP Briggs & Stratton (Engine Model: 15C114-0153-F8) 0010 15C114-0153-F8 1

CAP, Fuel 0010-10 792647 1

GUARD, Muffler (Incl. Ref. No. 0010-30) 0010-20 797003 1

SCREW, Tapping, Hex Washer Head 0010-30 810214 3

CORD, Electric 0020 6219MA 1

CAPSCREW, Hex Head, Trilobular, 3/8-16 x 1-1/4 0050 75246GS 4

PULLEY ASSEMBLY 0080 1737509YP 1

LOCKWASHER, Spring 5/16 0100 703116 1

CAPSCREW, Hex Head, 5/16-24 x 1-3/4, G8 0110 1750393YP 1

KEY, Parallel 0115 2157427SM 1

V-BELT, Multi Speed 0120 1737220YP 1

PULLEY ASSEMBLY 0125 1733968YP 1

BELT, Auger, V4L 38.10 MF 05-10B 0130 585416MA 1

STOP, Belt 0140 1737377YP 1

NUT, Hex KEPS, Conical Washer, 5/16-18 0170 1960684SM 1

BOLT, Carriage, 5/16-18 x 1 G5 0171 1931335SM 1

WASHER, 1/4 x 1-1/4 x 1/16 0176 1960151SM 1

SPACER, Powdered Metal 0177 1733095SM 1

BELLCRANK 0178 1737329YP 1

BRACKET, Lower 0179 1737328AYP 1

BRACKET, Support, Auger Idler 0180 1737297YP 1

BRACKET, Guide Wheel 0190 1737347AYP 1

CAPSCREW, Hex Head, 1/4-20 x 1-1/2 G5 0191 1922837SM 1

SPOOL CABLE, Auger Control 0192 579860MA 1

NUT, Lock, Serrated, 1/4-20 0193 192432GS 2

IDLER, Plastic, Ball Bearing 0200 1502120MA 1

NUT, Hex Jam, 3/8-16 0210 1960251SM 1

BOLT, Carriage, 3/8-16 x 1-1/4 0220 585781MA 1

WASHER, Thrust 0225 1670971SM 1

IDLER, Auger 0230 1737296YP 1

WASHER, 1/2” Flat 0250 1960027SM 2

BRACKET & HUB ASSEMBLY, Spring 0260 1733451SM 1

PIN, Hair 0270 0031X6MA 2

PIN, Clevis 0280 1736381YP 1

PANEL, Bottom 0290 1737221AYP 1

SCREW, Hex Washer Head Taptite, 1/4-20 x 5/8 0300 1927429SM 7

SPRING, Torsional 0310 1737350YP 1

FRAME BOX 0320 1737106ZYP 1

PLATE, Engine Mount 0330 1754138ZYP 1

SCREW, Hex Washer Head Taptite, 5/16-18 x 3/4 0350 1664847SM 19

COVER, Belt 0360 1750551YP 1

SCREW, Hex Washer Head, SEMS, Taptite, 1/4-20 x 3/4 0370 1751355YP 2

COTTER PIN, 1/4" Self Locking 0420 7023590SM 1

Footnotes

Note* To verify your specific engine model, please reference the ID Tag located on your engine. See your local Briggs &

Stratton distributor for parts and service.

PTS - 7

Page 36

Auger Drive Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 8

Page 37

Auger Drive Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

GEAR CASE ASSEMBLY 0070 704363 1

KEY, Square, 3/16 x 3/4 0080 2001022MA 1

IMPELLER 0090 1739094AYP 1

HUB, Impeller 0100 1739073YP 1

SCREW, Hex Washer Head, Taptite, 5/16-18 x 5/8 0110 1930601SM 3

SET SCREW, Socket Head, 5/16-18 x 1/2 0130 7090848SM 3

PULLEY 0150 1501211MA 1

CAPSCREW, Hex Head, 1/4-20 x 1-3/4 0160 9524MA 2

NUT, Hex Center Lock, 1/4-20 0170 73826MA 2

SPACER, Sleeve, 1/4 x 1/2 0190 3943MA 2

AUGER, LH, 24" (Includes Ref. No. 0220-40) 0220 1738299BTYP 1

AUGER, RH, 24" (Includes Ref. No. 0220-40) 0230 1738300BTYP 1

FITTING, Grease 0220-40 10104MA 1

KIT, Shear Bolt (Includes Ref. Nos. 0160, 0170 & 0190) -- 1501216MA 1

Footnotes

PTS - 9

Page 38

Auger Housing Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 10

Page 39

Auger Housing Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

HOUSING, Auger, 24" 0010 1687773YP 1

CLAMP 0020 1736620YP 2

SCREW, Truss Head Torx, #10-24 x 3/8 0030 1960569SM 2

NUT, Nylock, 10 x 24 0040 15X146MA 2

BRUSH, Cleanout 0060 1736094YP 1

BEARING, Auger Shaft 0070 53757MA 2

CAPSCREW, Hex Washer Head, Taptite, 5/16-18 x 3/4 0080 1664847SM 4

BOLT, Carriage, Short Neck, 3/8-16 x 1-1/4, GR5 0090 7091790YP 4

NUT, Hex Flange, 3/8-16 0100 7091619SM 4

NUT, Hex Flange, Serrated Lock, 5/16-18 0110 710026MA 7

SKID, Height Adjust 0150 1750222YP 2

BLADE, Scraper, 24" 0160 1738335AYP 1

RETAINER, Ball Bearing 0170 1756809YP 1

BEARING, Ball 0180 1705897SM 1

CAPSCREW, Hex Head, 5/16-18 x 5/8 0190 001X45MA 3

PLUG, Panel 0200 760040MA 2

BOLT, Carriage, 5/16-18 x 5/8, G5 0210 7090799SM 4

DRIFT CUTTER 0220 1733102ASM 2

BOLT, Carriage, 5/16-18 x 3/4 0230 340720MA 2

NUT, Wing, 5/16-18 0240 711604MA 2

Footnotes

PTS - 11

Page 40

Traction Drive Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 12

Page 41

Traction Drive Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

* TRANSMISSION, General Transmission H2 0200 1733972YP 1

BRACKET 0210 1737267AYP 2

CAPSCREW, Hex Head, 3/8C x 2-3/4 GR5 0220 7091557SM 4

NUT, Hex Jam, 3/8-16 0230 1960251SM 4

ROD, Speed Select 0240 1737330YP 1

COTTER PIN, 1/4" Self Locking 0250 7023590SM 2

TUBE, Support 0260 1737310YP 1

GEAR, Drive 0300 1737311YP 2

AXLE 0310 1737309YP 2

NUT, Hex Flange, Whiz Lock Large, 3/8-16 0320 1928352SM 4

RETAINER, Bearing 0330 1736396YP 2

BEARING, Ball 0340 53263MA 2

RING, Retaining 0350 1737742YP 2

RETAINER, Bolt 3/8" 0355 7013847YP 4

SCREW, Hex Washer Head Taptite, 5/16-18 X 3/4 0420 1664847SM 4

BOLT, Carriage, FH GR 5, 3/8-16 x 3/4 0430 1737686YP 4

WASHER, Flat, 3/8 0450 703184 2

Footnotes

Note* See Transmission Assembly Group for detailed service parts.

PTS - 13

Page 42

Transmission SERVICE PARTS - General Transmission H2

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 14

Page 43

Transmission SERVICE PARTS - General Transmission H2

PART NO. DESCRIPTIONREF NO QTY.

TRANSMISSION, Complete General Transmission H2 0200 1733972YP 1

SPRING, Traction, 8.75 Inches 0200-1 1739646YP 2

SCREW, 5 X 25 0200-2 1739645YP 1

WASHER, 5.3 X 15 X 1.2.ipt 0200-3 1739641YP 1

LEVER 0200-4 1739642YP 1

CAM, Control 0200-5 1739644YP 1

SPRING, Variator 0200-6 1739640YP 1

SHIFT ARM 0200-7 1739625YP 1

PULLEY ASSEMBLY 0200-8 1739624YP 1

SCREW, M8x20 left 0200-9 1739622YP 1

WASHER, 25 X 35 X 1.5 0200-10 1739636YP 1

BEARING, 6005 2RS 0200-11 1739639YP 1

GEAR 0200-12 1739648YP 2

RETAINER 0200-13 1739647YP 2

WASHER, 0.8 X 27 X 3 0200-14 1739623YP 1

SCREW, 4 X 16 0200-15 1739643YP 4

NUT 0200-16 1739626YP 2

BOLT, Allen-Head, CHC M5 X 1.2 0200-17 1739629YP 2

PIN 0200-18 1739632YP 2

WASHER, Starlock 0200-19 1739634YP 4

CRAFTSMAN 24" C950-52301-0

Footnotes

PTS - 15

Page 44

Wheels & Tires Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 16

Page 45

Wheels & Tires Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

WHEEL & TIRE ASSEMBLY, 4.80-8, LH (Includes Ref. 0010-20) 0010 1754243YP 1

WHEEL & TIRE ASSEMBLY, 4.80-8, RH (Includes Ref. 0010-20) 0020 1754245YP 1

VALVE STEM & CAP 0010-20 2172353SM 1

BOLT, Hex, 1/4-20 x 1-3/4, G5 0060 577015MA 2

NUT, Hex, Nylock, 1/4-20 0070 15X145MA 2

Footnotes

PTS - 17

Page 46

Decals Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 18

Page 47

Decals Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

DECAL, Danger Chute, FR/ENG 0040 1737865YP 1

DECAL, Danger Foot, FR/ENG 0050 1737866YP 1

DECAL, Auger Control Symbols 0060 1737869YP 1

DECAL, Traction Control Symbols 0070 1737870YP 1

DECAL, Handle Operation 0080 1754679YP 1

DECAL, Gear Shift 0095 1751582YP 1

DECAL, Do Not Shift 0330 1755585YP 1

DECAL, 1150/24 0340 704353 1

DECAL, Craftsman, Rear Stripe 0350 1750853YP 1

DECAL, Hood Stripe 0360 1750850YP 1

Footnotes

PTS - 19

Page 48

Discharge Chute Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

CRAFTSMAN 24" C950-52301-0

PTS - 20

Page 49

Discharge Chute Group

PART NO. DESCRIPTIONREF NO QTY.

CRAFTSMAN 24" C950-52301-0

PINION 0010 1728967SM 1

SCREW, Torx Button Head, M5 x .8 x 14 0030 1739621YP 3

WASHER, Flat, 1/4 0035 7091552SM 3

SCREW, Hex Washer Head, Taptite, 1/4-20 x 3/4 0040 1925592SM 1

COVER, Electric Chute Rotation 0050 1737455YP 1

RETAINER, Spout 0060 7011938SM 3

SCREW, Hex Washer Head, Plastite, 10-14 x 5/8 0070 1960001SM 6

SWITCH, Chute Rotation 0090 1737378YP 1

DECAL, Hinge 0150 1733601SM 2

CHUTE 0160 1738045ZYP 1

MOTOR, Spout Rotator 0200 1739309YP 1

GEAR 0230 1737465AYP 1

ADAPTER, Chute Ring 0240 1737411YP 1