Craftsman C944.526460 Owner's Manual

I

Sears

I

,

owner s

manual

MODEL NO.

C944.526460

CAUTION:

Read RULES for

Safe OPERATION

and INSTRUCTIONS

Carefully

CRAFTSMAN

22", 7 H.P. SNOW THROWER

• Assembly

• Operating

• Maintenance

• Repair Parts

IMPORTANT

RULES FOR SAFE OPERATION

TRAINING

1. Read the operating and service instruction manual

carefully. Be thoroughly familiar with the controls

and the proper use of the equipment. Know how to

stop the unit and disengage the controls quickly.

2. Never allow children to operate the equipment.

Never allow adults to operate the equipment with-

out proper instruction.

3. Keep the area of operation clear of all persons,

particularly small children and pets.

4. Exercise caution to avoid slipping or falling, espec-

ially when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment

is to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting the engine.

3. Do not operate the equipment without wearing

adequate winter outer garments. Wear footwear

which will improve footing on slippery surfaces. Do

not wear long scarfs or loose fitting clothing which

may become entangled in machinery.

4. Handle fuel with care; it is highly flammable.

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

(d) Replace gasoline cap securely and wipe up

spilled fuel.

5. Use a grounded three-wire plug-in for all units

equipped with electric starting motors.

6. Adjust the impeller housing height to clear gravel

or crushed rock surface.

7. Never attempt to make any adjustments while the

engine is running (except where specifically recom-

mended by manufacturer).

8. Let engine and machine adjust to outdoor tempera-

tures before starting to clear snow.

OPERATION

1. Do not put hands or feet near or under rotating

parts. Keep clear of the discharge opening at all

times.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert

for hidden hazards or traffic. Do not carry pass-

engers.

3. After striking a foreign Object, stop the engine,

remove the wire from the spark plug, thoroughly

inspect the snow thrower for any damage, and .re-

pair the damage before restarting and operating

the snow thrower.

4. If t:le unit should 'start to vibrate abnormally, stop

the engine and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine whenever you leave the operating

position, before unclogging the impeller housing

or discharge guide, and when making any repairs,

adjustments, or inspections.

6. Take all possible precautions when leaving the

unit: shift into neutral, disengage the drive (prim-

ary) clutch, shut off the engine, and remove the

key.

7. When cleaning, repairing, or inspecting, make

certain the impeller and all moving parts have

stopped. Disconnect the spark plug wire, and keep

the wire away from the plug to prevent accidental

starti ng. Disconnect the cord on electric starter

motor.

8. Do not run the engine indoors, except when start-

ing the engine and for transporting the snow

thrower in or out of the building. Open the outside

doors; exhaust fumes are dangerous.

9. Do not clear snow across the face of slopes.

Exercise extreme caution when changing direction

on slopes. Do not attempt to clear steep slopes.

10. Never operate the snow thrower without proper

guards, plates, or other safety protective devices

in place.

11. Never operate the snow thrower near glass en-

closures, automobiles, window wells, drop ofts, etc.

without proper adjustment of the snow discharge

angle. Keep children and pets away.

12. Do not overload the machine capacity by attempt-

ing to clear snow at too fast a rate.

13. Never operate the machine at high transport

speeds on slippery surfaces. Use care when

backing.

14. Never direct discharge at bystanders or allow

anyone in front of the unit.

15. Disengage power to the impeller when snow

thrower is transported or not in use.

16. Use only attachments and accessories approved

by the manufacturer of snow thrower (such as

electric starter kits, cabs, etc.).

17. Never operate the snow thrower without g.ood vis-

ibility or light. Always be sure of your footing, and

keep a firm hold on the handles. Walk; never run.

MAINTENANCE AND STORAGE

1. Check shear bolts, engine mounting bolts, etc. at

frequent intervals for proper tightnes~ .to be sure

the equipment is in safe working conditIOn.

2. Never store the machine with fuel in the fuel tank

inside a building where open flame or spar~s a:e

present. Allow the engine to cool before storing In

any enclosure.

3. Always refer to owner's manual in.structions for

important details if the snow throwerISto be stored

for an extended period.

4. Run the machine a few minutes after throwing snow

to prevent freeze up of the impeller.

craftsman quality snow removal equipment

For one year from purchase date, Simpsons-Sears will replace, Free of Charge,

any part or parts including the engine, found, upon examination to be defective

under normal use and service, by reason of defects in material and workman-

ship. The warranty is void if the unit has been the subject of misuse.

A modern low cost maintenance agreement is available on this product, to

extend the guarantee. Contact your nearest Simpsons-Sears Store.

Compliance with radio interference regulations certified, replace spark plug

with resistor spark plug only.

DEFLECTOR

IMPEllERClUT\

LEFT HANDLE

J

~

~. PRIMARY CLUTCH

/

SKID

GUARANTEE 3

ASSEMBLY 5

OPERATING 7

MAINTENANCE 12

SERVICE CHECK LIST 13

REPAIR PARTS 14

ENGINE REPAIR PARTS 18

For shipping purposes, the handles and operating

controls of your snow thrower have not been assembled

to the unit. The carton of parts, in which this owner's

manual was found, contains all components and hard-

ware necessary to complete the assembly.

NOTE: The terms Left Hand (L.H.) and Right Hand

(R.H). refer to your left and right hands when you

stand in the operator's position behind the unit.

ATTENTION: FOR EASIER ASSEMBLY, TILT SNOW

THROWER FORWARD SO THAT IT RESTS ON SAFETY

BAR AS SHOWN (FIG. 2).

HANDLE ASSEMBLY

1. Slide lower two holes of R.H. handle over weld

screws on R.H. side of snow thrower chassis (Fig.

3). Assemble formed washer to upper weld screw,

and secure handle with two

3fs

-16 flange nuts.

Tighten finger tight only.

2. Assemble L.H. handle to snow thrower in same

manner.

~ RIGHT HANDLE

~.:y /

CHASSIS

r'

0

FORMED WASHER

!

~I

~~~~f*

c'

rn~

\ "'"· -J

\ WELD SCREWS

@

FLANGE NUTS

3. Assemble handle plate to handles (Fig. 4), using

four 5/16-18 x 1

¥.i

carriage bolts and four 5/16-18

flange nuts. Tighten securely.

4. Tighten four

3fs

-16 flange nuts securely against

lower end of both handles (Fig. 3).

FIG. 4

SHIFT CONTROL ROD ASSEMBLY (Fig. 5 to 8)

1. Assemble one

3fs

-16 flange nut (A) to end of shift

control rod having the longest threaded portion.

Flange of nut must face toward threaded end of

shift control rod as shown (Fig. 5 and 6). Thread

the nut the full length of the threads.

TRANSMISSION CONTROL BRACKET

(C)

'Z' SLOT

HANDLE PLATE

LOCATING PIN

SHIFT CONTROL ROD

SHIFT CONTROL ROD________ A

TRANSMISSION CONTROL BKT. /

TRANSMISSION ~..... ~~

SHIFT~~.

/

~~\

~

~

\\.

FIG. 6

2. Position other end of shift control rod up through

slot in top of handle plate, so that locating pin on

rod engages the "Z" slot in handle plate (Fig. 5).

Swing transmission control bracket upwards (Fig.

6), and insert lower end of shift control rod into

hole in transmission control bracket (Fig. 5 and 6).

3. Assemble one

3fs

-16 flange nut (B), with flange up,

to lower end of shift control rod (Fig. 6). Do not

tighten nut.

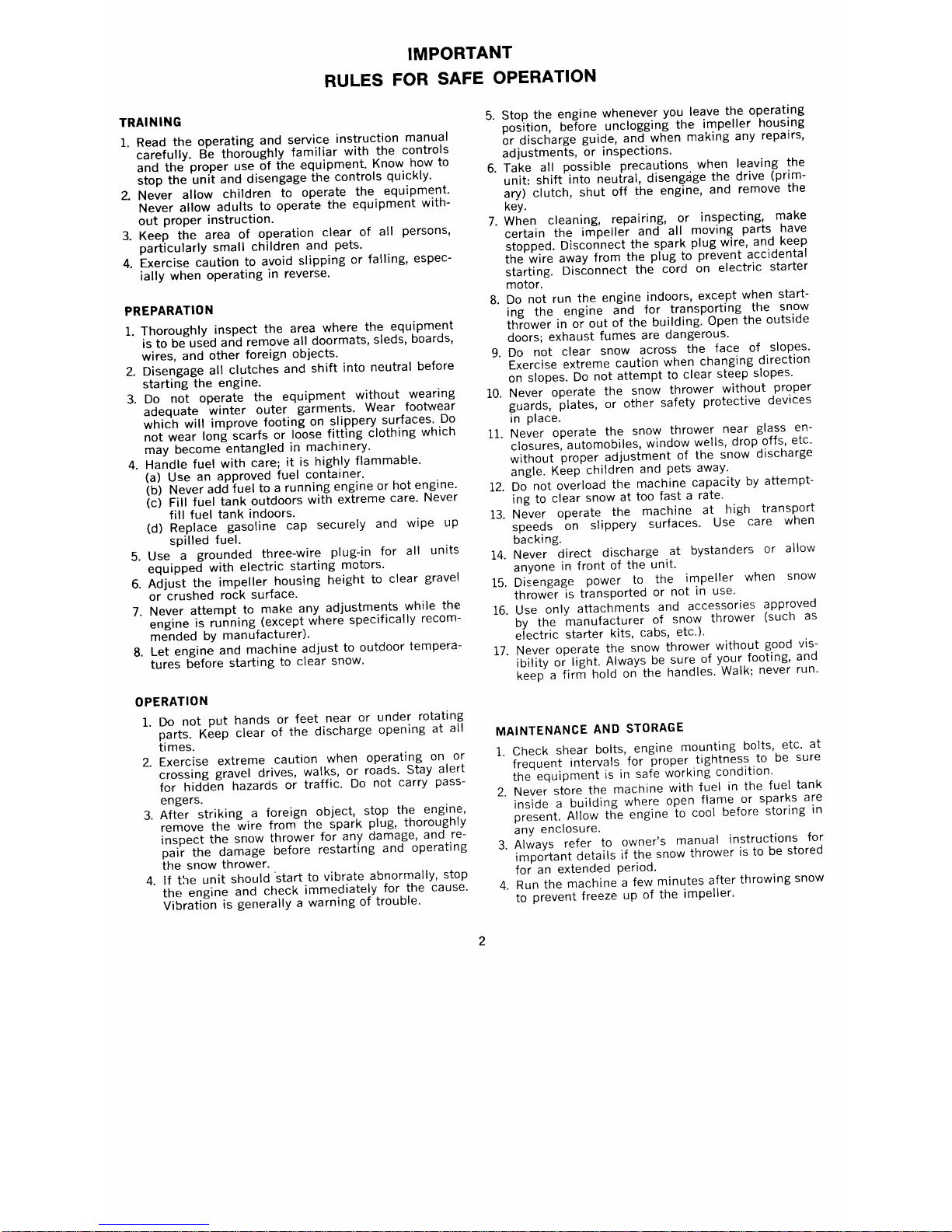

4. IMPORTANT: Position transmission shift lever in

neutral position (Fig. 7), approximately in the centre

of slot in rear cover. Rotate wheels of unit; wheels

should turn freely if neutral has been obtained. Shift

lever may have to be moved up or down slightly

from centre of slot in order to obtain neutral.

TRANSMISSION BOLTS (4)

;J2~==li

Q;:;

~;'~;E::~Bi~IFT":ER

L

TRANSMISSION CONTROL

BRACKET

SElF TAPPING SCREWS

5. Place shift control rod in neutral position (centre

of

"l"

slot at handle plate) (Fig. 8). Holding shift

control rod in this position, thread lower

3fB

-16 flange

nut (B) (Fig. 6) up to transmission control bracket.

Tighten upper flange nut (A) down onto top of

transmission control bracket.

Be sure locating pin is not cocked in

"l"

slot of

handle plate (Fig. 8). Pin should be perpendicular

to face of handle plate.

CAUTION: Do not tighten nut and bolt securing

transmission control bracket to transmission shift

lever (Fig. 6). These parts must pivot freely.

6. IMPORTANT: Be sure transmission stays in neutral

when shift rod locating pin is moved through entire

neutral range at handle plate as shown in Fig. 8.

Wheels of unit should turn freely through entire

neutral range. If they do not, make one of the fol-

lowing adjustments:

If transmission stays in "Forward" drive inside the

neutral range, adjust flange nuts at lower end of

shift rod (Fig. 5 and 6):

(a) Loosen upper flange nut (A).

(b) Tighten lower flange nut (B) up against trans-

mission control bracket one or two turns. This

will, in effect, shorten the shift control rod.

(c) Tighten upper flange nut down onto transmis-

sion control bracket, and check again that trans-

mission remains in neutral through entire

neutral range.

If transmission stays in reverse within the neutral

range, adjust flange nuts on lower shift control

rod:

(a) Loosen lower flange nut (B).

(b) Tighten upper flange nut (A) down against

transmission control bracket one or two turns.

This will, in effect, lengthen the shift control

rod.

(c) Tighten lower flange nut up against transmis-

sion control bracket, and check again that

transmission remains in neutral through entire

neutral position.

7. Attach spring to locating pin on shift control rod,

and to hole in bottom of handle plate (Fig. 8).

8. Assemble one

3/B

-16 jam nut (C) (Fig. 5) all the way

onto threads at top of shift control rod. Screw

control knob onto shift control rod until tight, and

tighten jam nut (C) securely against knob.

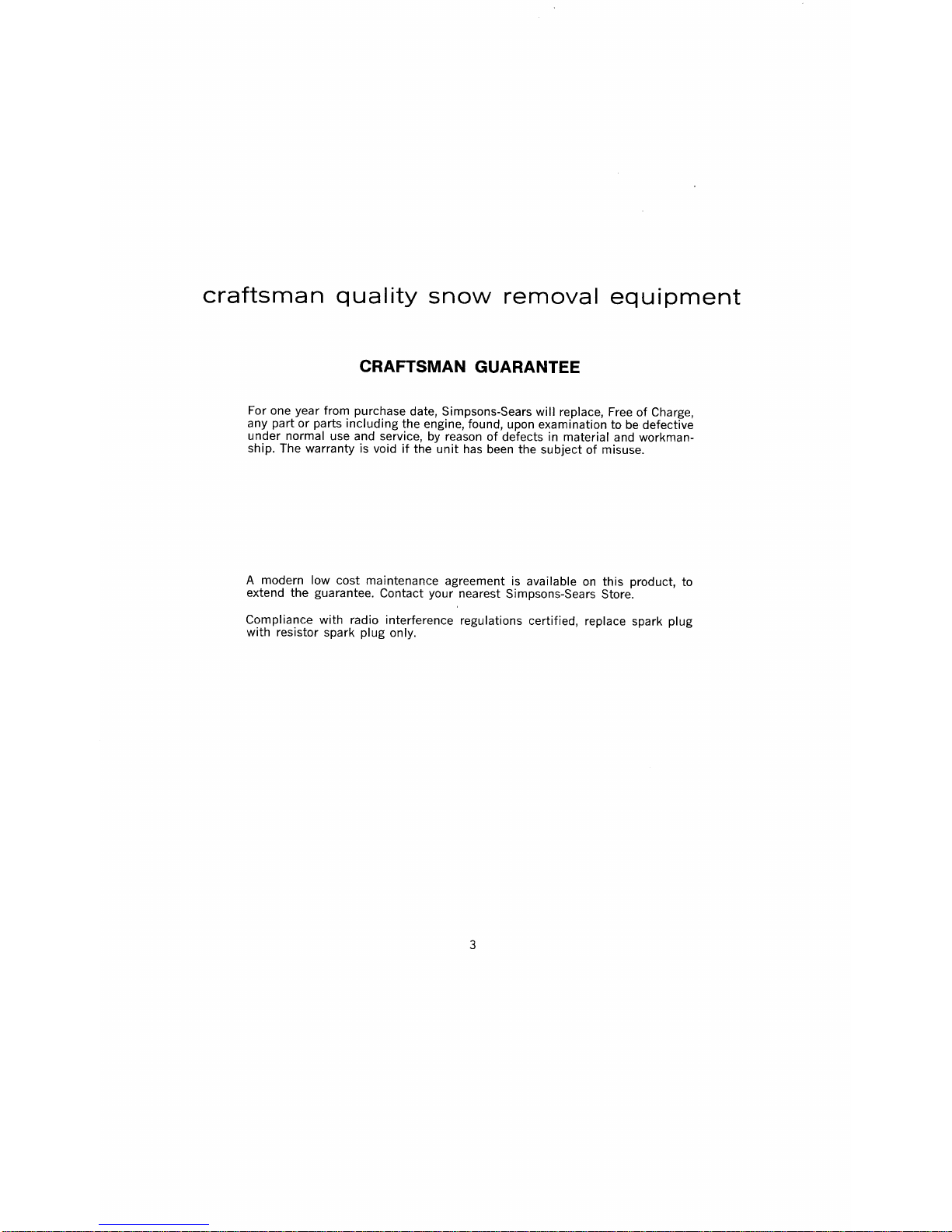

CHUTE CONTROL ROD ASSEMBLY (Fig. 9 and 10)

1. Slide lower adjusting bracket onto chute control

rod. NOTE: adjusting bracket must be angled toward

the sprocket on chute control rod as shown (Fig. 9).

EYE BOLT

/1

ADJUSTING BKT.

1 ~ / .

1 ~~~

\

/

~ ~

I rn

I

ffi

CHUTE CONTROL ROD L.H.HANDLE

FIG. 9

2. Slide eye bolt onto chute control rod, and slide

rubber bushing onto shank of eye bolt.

3. Assemble eye bolt to outside of L.H. handle, and

secure with one

1/4

-20 lock nut

(0).

Do not tighten

nut.

4. Assemble lower adjusting bracket to lower support

bracket using two 5/16-18 x%carriage bolts (E)

and two 5/16-18 flange nuts (F) (Fig. 10).

SPROCKE~Y

,)1\

SUPPORT BKT. ". ~

FIG. 10

5. Raise the lower adjusting bracket into position

SO

that sprocket on chute control rod engages holes

in flange at base of chute assembly, and tighten

two 5/16-18 flange nuts (F).

6. Tighten

1/4

-20 locknut (D) on eye bolt (Fig. 9), being

careful to position eye bolt perpendicular to chute

control rod.

7. Assemble rubber grip to end of chute control rod

(Fig. 9).

CHECKING CHUTE OPERATION (Fig. 10)

If sprocket teeth tend to jam in holes in flange at

base of chute assembly, lower the sprocket slightly by

loosening the two 5/16-18 flange nuts (F) and lowering

the lower adjusting bracket.

If sprocket teeth skip across holes in flange, raise the

sprocket by loosening two nuts (F) and raising the

lower adjusting bracket slightly. Tighten nuts (F)

securely.

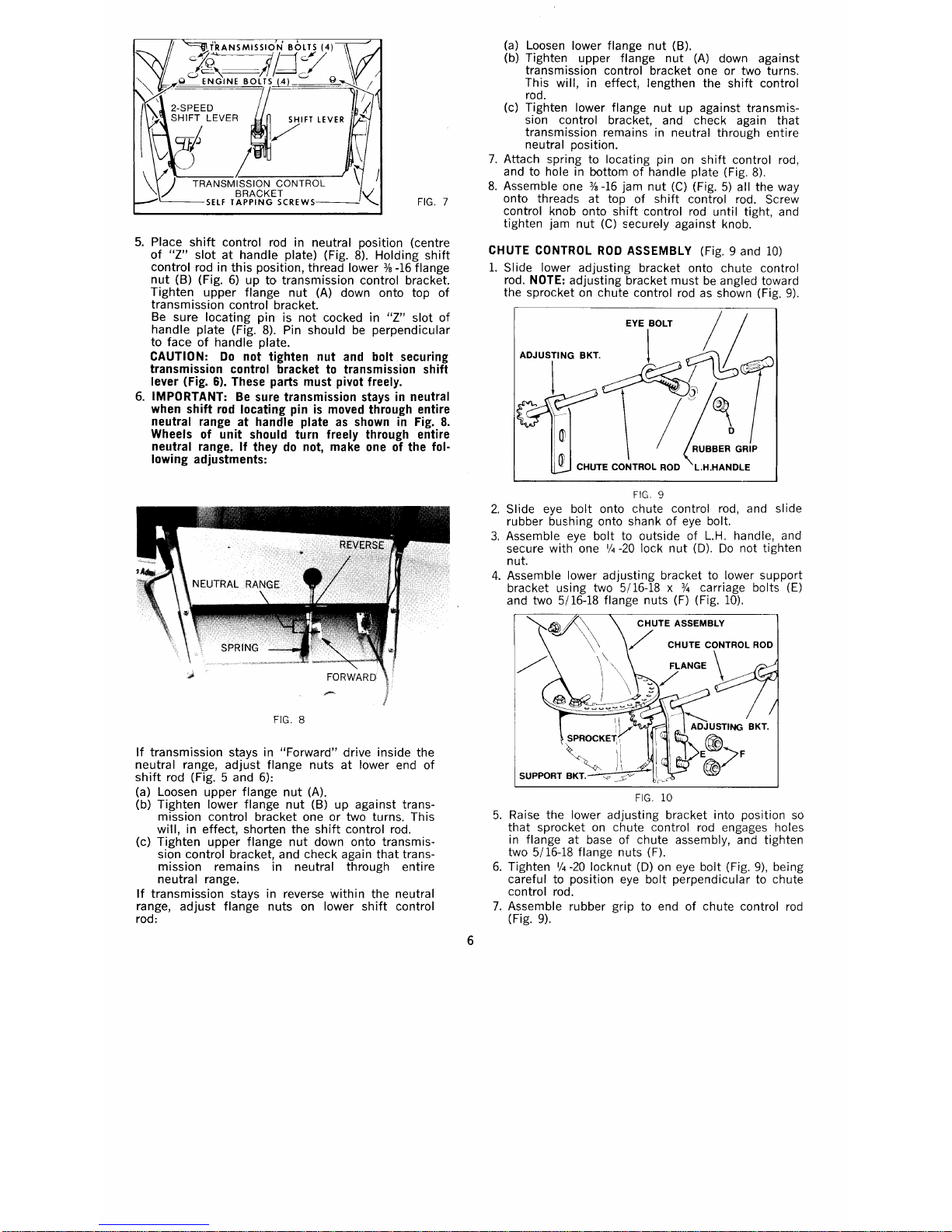

INTERLOCK WIRING HARNESS ASSEMBLY (Fig. 11)

IMPORTANT: For the protection of yourself and others,

your snow thrower is equipped with a safety interlock

system which allows operation of the unit only from

the operator's position. To complete the assembly of

the interlock system, connect safety wire on R.H.

handle to wire at base of engine as shown (Fig. 11).

CAUTION: If these wires are left disconnected, your

unit will not operate.

THROTTLE CONTROL ASSEMBLY (Fig. 12)

1. As~emble throttle control to back of handle plate

uSing two#10-16 x

112

self-tap screws

(0)

as shown'

tighten securely. '

2. Press plastic knob firmly onto throttle control lever

(Fig. 12).

2-SPEED SHIFT LEVER

The 2-SPEED SH IFT LEVER (Fig. 7) provides 2 speed

ranges which are selected with lever at rear of chassis.

The high speed (H I) is to be used for norma I snow re-

moval and low speed (LO) is desirable for use when

extremely heavy work is required. Move lever to the

left for "H I" and to the right for "LO". Select "H I" or

"LO" speed prior to shifting control rod to "FORWARD"

or "REVERSE" drive. It may be necessary to move

snow thrower forward or backward slightly to align

cogs in transmission so that shift lever can be com-

pletely engaged in "HI" or "LO" position.

Before attempting to use your snow thrower, read

carefully all the operating instructions below and be

sure you understand the function of all controls. Read

again the "Rules for Safe Operation" at the front of

this manual.

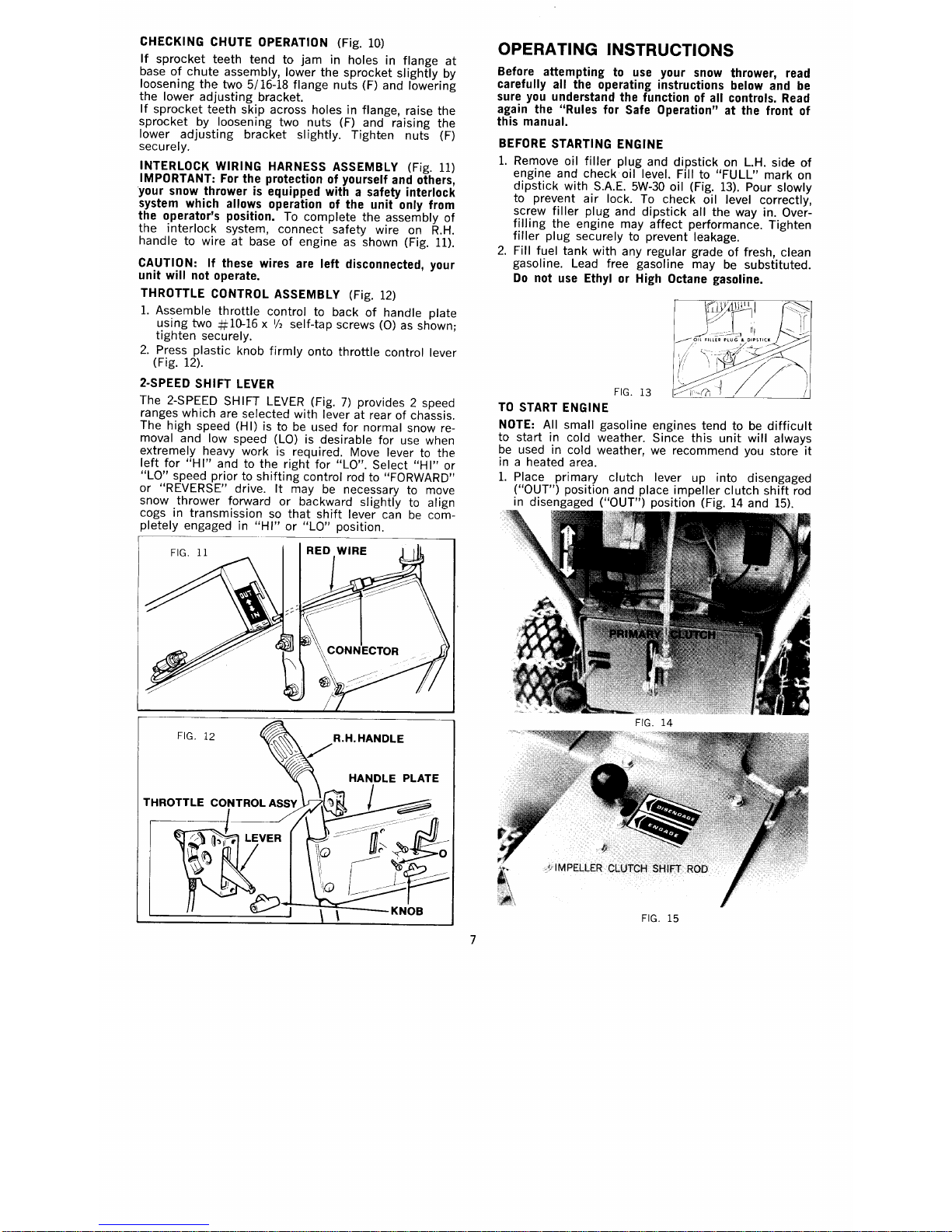

BEFORE STARTING ENGINE

1. Remove oil filler plug and dipstick on L.H. side of

engine and check oil level. Fill to "FULL" mark on

dipstick with S.A.E. 5W-30 oil (Fig. 13). Pour slowly

to prevent air lock. To check oil level correctly,

screw filler plug and dipstick all the way in. Over-

filling the engine may affect performance. Tighten

filler plug secur:ely to prevent leakage.

2. Fill fuel tank with any regular grade of fresh, clean

gasoline. Lead free gasoline may be substituted.

Do not use Ethyl or High Octane gasoline.

J

~.'\ll'lill

_rT

---------:::l1

_____..... Oll Flll' ....R PlU .." • O.IPST ..'.~'. .

/' ;Y'

/_ _ -"l

, ; .'=:i2J;Y' '.

o

'~/?

~"'.//-

/

FIG. 13

TO START ENGINE

NOTE: All small gasoline engines tend to be difficult

to start in cold weather. Since this unit will always

be used in cold weather, we recommend you store it

in a heated area.

1. Place primary clutch lever up into disengaged

("OUT") position and place impeller clutch shift rod

in disengaged ("OUT") position (Fig. 14 and 15).

2. Move shift control rod to "NEUTRAL" position in

"Z" slot of handle plate (Fig. 16).

3. Move throttle control down to "FAST'" position (Fig.

16).

4. Turn choke lever to "FULL" choke position (Fig. 17).

Turn ignition switch located on engine shroud to

"ON" position (Fig. 17).

5. IF TEMPERATURE IS BELOW loaF: Depress primer

button on carburetor (Fig. 17), 2 or 3 times.

Step #5 may be omitted if temperature is above loaF.

6. Pull engine over rapidly with starter rope.

7. As engine warms up, slowly return choke lever to

"OFF" position (Fig. 17).

TO STOP ENGINE

Move throttle control up to "STOP" position (Fig. 16).

OPERATING YOUR SNOW THROWER

1. Before starting engine, be sure primary clutch lever

is up in disengaged ("OUT") position (Fig. 14), im-

peller clutch shift rod is in ("OUT") position (Fig.

15), and shift control rod is in neutral position (Fig.

16).

2. Assume operating position behind unit, and start

engine. Using throttle control, adjust to moderate

speed.

3. Squeeze safety lever up into operating position

against R.H. handle with right hand, and maintain

hold on lever and R.H. handle. (Fig. 16).

4. Move primary clutch lever down into engaged ("IN")

position (Fig. 14).

IMPORTANT: The safety interlock system on this unit

will automatically stop the engine when the primary

clutch is engaged unless the safety lever on the R.H.

handle is maintained in closed position (Fig. 16).

5. To obtain forward motion of snow thrower move

2-speed shift lever into "La" position (Fig. 7). With

left hand, move shift control rod down into "For-

ward" position - bottom of "Z" slot in handle plate.

To stop forward motion: Move shift control rod back

up into "Neutral" position - centre of "Z" slot in

handle plate (Fig. 16).

6. To obtain reverse motion: With left hand, move shift

control rod up into "Reverse" position and hold in

that position (Fig. 16). NOTE: Return spring (Fig. 8)

behind handle plate will automatically return shift

rod to "neutral" position when shift control rod is

released from "reverse" position.

7. To obtain impeller operation: IMPORTANT: Be sure

front of unit is clear of bystanders or obstacles

before operating impeller.

(a) Before leaving operating position to engage im-

peller clutch lever, move primary clutch lever

up into disengaged ("OUT") position (Fig. 14).

IMPORTANT: The engine will always stop if the oper-

ator attempts to leave the operating position and

releases the safety lever without first disengaging the

primary clutch.

(b) Move impeller clutch shift rod on R.H. side of

unit to engaged ("IN") position (Fig. 15).

(c) Return to operating position (behind handles),

and squeeze safety lever on R.H. handle. Now

move primary clutch lever down slowly into en-

gaged ("IN") position (Fig. 14). The impeller is

now operating and ready to throw snow.

8. TO DISENGAGE IMPELLER DRIVE:

(a) Before leaving operating position, disengage

primary clutch lever ("OUT" position) (Fig. 14).

(b) Move impeller shift rod to "OUT" position (Fig.

15). Impeller is now disengaged.

9. Operaticn of discharge chute and deflector: (Fig.

18). The direction of snow discharge from the chute

can be varied 180°, from left to right. To discharge

snow to your left, turn chute control rod handle

clockwise. Rotate handle anti-clockwise to obtain

snow discharge to your right. The distance the snow

will be thrown can be adjusted by tilting the de-

flector up or down (Fig. 18).

Loading...

Loading...