Page 1

Instruction Manual

32cc/1.9 cu.in. 2-Cycle

GASOLINE BRUSHWACKER ®

Model No.

0944.512561

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Franqais

WARNING:

Read and follow all Safety Rules and Operating

Instructions before first use of this product.

For answers to your questions about this product:

Call 7 am-7 pm, Mon.-Sat., or 10 am-7 pm, Sun.

1-800-235-5878 _.o._ listed are Central Time)

Sears Canada, Inc., Toronto, Ontario M5B 2B8

530163724 4/23/03

Page 2

Warranty Statement 2 Storage 20

Safety Rules 2 Troubleshooting Table 21

Assembly 5 Emissions Statement 22

Operation 9 Parts List 24

Maintenance 18 French 26

Service & Adjustments 19 Parts and Ordering BackCover

LIMITED TWO (2_ YEAR WARRANTY ON CRAFTSMAN ® GAS POWERED

WEEDWACKER _ LINE TRIMMER

For two (2) years from the date of purchase, Sears Canada, ]nc., will repair or

replace free of charge at Sears option parts which are defective as a result of

material or workmanship.

COMMERCIAL OR RENTAL USE:

Warranty on Gas Weedwacker will be 90 days from the date of purchase if used

for commercial or rental purposes.This warranty does not cover:

1. Spark plugs, filter, line, spool, starter rope, and blade.

2. Damages to the motor of the unit when operated without the proper fuel

mixture (see manual).

Warranty service is available by returning the Weedwacker to the nearest Sears Ser-

vice Centre/Department in Canada. This warranty applies only while this product is in

use in Canada.

This warranty is in addition to any statutory warranty and does not exclude or limit

legal rights you may have but shall run concurrently with applicable provincial

legislation. Furthermore, some provinces do NOT allow limitations on how long an

implied warranty will last, so the above limitations may not apply to you.

Sears Canada, Inc., Toronto, Ontario M5B 2B8

_WARNING: When using gar-

dening appliances, basic safety pre-

cautions must always be followed to

reduce the risk of fire and serious

injury. Read and follow all instructions.

DANGER: This power tool can

be dang.erous! This unit can cause se-

rious InjurY including amputation or

blindness to the operator and others.

The warnings and safety instructions

in this manual must be followed to pro-

vide reasonable safety and efficiency

in using the unit. The operator is re-

sponsible for following the warnings

and instructions in this manual and on

the unit. Read the entire instruction

manual before assembling and using

the unit! Restrict the use of this unit to

persons who read, understand, and

follow the warnings and instructions in

this manual and on the unit. Never al-

low children to operate this unit.

INSTRUCTION SAFETY INFORMATION

MANUAL ON THE UNIT

DANGER: Blade can thrust vio-

lently away from material it does not

cut. Blade thrust can cause amputa-

tion of arms or legs.

_I_WARNING: Blade/trimmer line

can throw ob ects violently. You and

others can be b nded or njured. Wear

safety glasses and leg protection.

2

Page 3

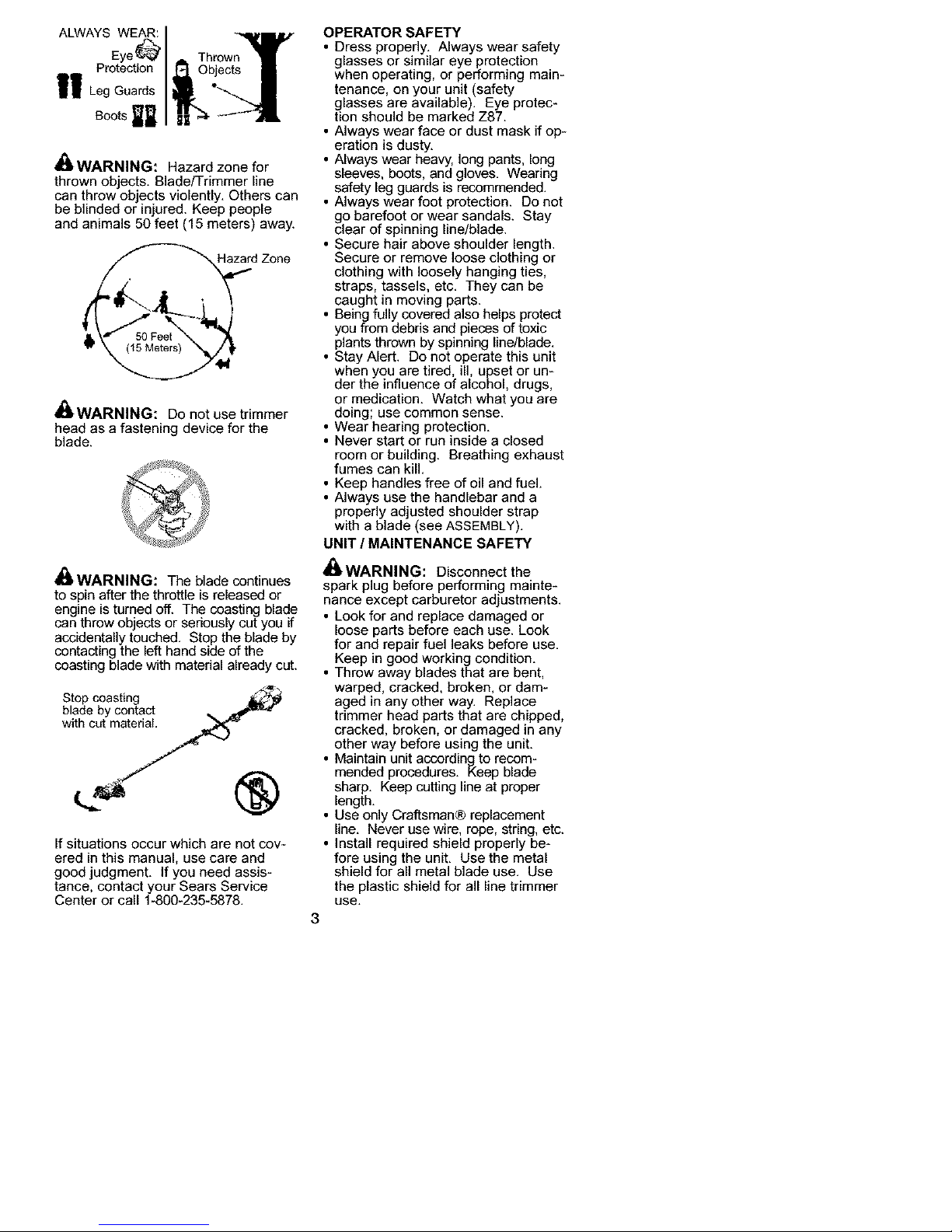

ALWAYSWEAR:I _,9_l.r

Eye_I_ Thrown_r

ProtectionIr;"l Objectsm

11 LegGuards_-°_..!

Boots -/ lL

_I_WARNING: Hazard zone for

thrown objects. Blade/Trimmer line

can throw ob ects violently. Others can

be b nded or nured. Keep peop e

and animals 50 feet (15 meters) away.

d Zone

_l_ WARNING: Do not use trimmer

head as a fastening device for the

blade.

_I_WARNING: The blade continues

to spin after the throttle is released or

engine is turned off. The coasting blade

can throw objects or seriously cut you if

accidentally touched, Stop the blade by

contacting the left hand side of the

coasting blade with material already cut.

Stop coasting _

blade by contact _,_ ,e_m'_l

with cut material

If situations occur which are not cov-

ered in this manual, use care and

good judgment. If you need assis-

tance, contact your Sears Service

Center or call 1-800-235-5878.

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection

when operating, or performing main-

tenance, on your unit (safety

glasses are available). Eye protec-

tion should be marked Z87.

• Always wear face or dust mask if op-

eration is dusty.

• Always wear heavy, long pants, long

sleeves, boots, and gloves. Wearing

safety leg guards is recommended.

• Always wear foot protection. Do not

go barefoot or wear sandals. Stay

clear of spinning line/blade.

• Secure hair above shoulder length.

Secure or remove loose clothing or

clothing with loosely hanging ties,

straps, tassels, etc. They can be

caught in moving parts.

• Being fully covered also helps protect

you from debris and pieces of toxic

plants thrown by spinning line/blade.

• Stay Alert. Do not operate this unit

when you are tired, ill, upset or un-

der the influence of alcohol, drugs,

or medication. Watch what you are

doing; use common sense.

• Wear hearing protection.

• Never start or run inside a closed

room or building. Breathing exhaust

fumes can kill.

• Keep handles free ofoil and fuel.

• Always use the handlebar and a

properly adjusted shoulder strap

with a blade (see ASSEMBLY).

UNIT / MAINTENANCE SAFETY

_I_i,WARNING: Disconnect the

spark plug before performing mainte-

nance except carburetor adjustments.

• Look for and replace damaged or

loose parts before each use. Look

for and repair fuel leaks before use.

Keep in good working condition.

• Throw away blades that are bent.

warped, cracked, broken, or dam-

aged in any other way. Replace

trimmer head parts that are chipped,

cracked, broken, or damaged in any

other way before using the unit.

• Maintain unit according to recom-

mended procedures. Keep blade

sharp. Keep cutting line at proper

length.

• Use only Craftsman® replacement

line. Never use wire, rope, string, etc.

• Install required shield properly be-

fore using the unit. Use the metal

shield for all metal blade use. Use

the plastic shield for all line trimmer

use.

3

Page 4

,_ WARNING: Only use brushcut-

ter attachments that provide a metal

shield with proboscis nose.

se

° Use only specified blade or trimmer

head; make sure it is properly

installed and securely fastened.

° Make sure unit is assembled cor-

rectly as shown in this manual.

° Never start engine with clutch

shroud removed. The clutch can fly

off and cause serious injury.

* Be sure blade or trimmer head stops

turning when engine idles.

* Make carburetor adjustments with

lower end supported to prevent

blade or trimmer line from contacting

any object. Hold unit by hand; do

not use the shoulder strap for sup-

port.

* Keep others away when making car-

buretor adjustments.

* Use only recommended Craftsman

accessories and replacement parts.

* Have all maintenance and service

not explained in this manual per-

formed by a Sears Service Center.

FUEL SAFETY

* Mix and pour fuel outdoors.

* Keep away from sparks or flames.

* Use a container approved for fuel.

* Do not smoke or allow smoking near

fuel or the unit.

* Avoid spilling fuel or oil. Wipe up all

fuel spills.

, Move at least 10 feet (3 meters)

away from fueling site before start-

ing engine.

, Stop engine and allow to cool before

removing fuel cap.

, Always store gasoline in a container

approved for flammable liquids.

CUTTING SAFETY

£*.

all.WARNING: Inspect the area to

be cut before each use. Remove ob-

jects (rocks, broken glass, nails, wire,

etc.) which can be thrown or become

entangled in the blade or trimmer line.

* Keep others including children, ani-

mals, bystanders, and helpers at

least 50 feet (15 meters) away. Stop

engine immediately if you are ap-

proached.

• Always keep engine on the right

hand side of your body.

• Hold the unit firmly with both hands.

• Keep firm footing and balance. Do

not overreach or use from unstable

surfaces such as ladders, trees,

steep slopes, rooftops, etc.

• Keep blade/trimmer head (or other

optional attachment) below waist

level and away from all parts of your

body. Do not raise engine above

your waist.

• Keep all parts of your body away

from muffler and spinning line/blade

(or other optional attachment).

• Keep engine below waist level. A

hot muffler can cause serious burns.

• Cut only from your left to your right.

Cutting on right side of the shield will

throw debris away from the operator.

• Use only in daylight or good artificial

light.

• Use only for jobs explained in this

manual (or manuals for optional at-

tachments).

TRANSPORTING AND STORAGE

• Allow engine to cool before storing

or transporting in vehicle.

• Empty the fuel tank before storing or

transporting the unit. Use up fuel left

in the carburetor by starting the en-

gine and letting it run until it stops.

• Store unit and fuel in area where fuel

vapors cannot reach sparks or open

flames from water heaters, electric

motors or switches, furnaces, etc.

• Store unit so the blade or line limiter

blade cannot accidentally cause inju-

ry. The unit can be hung by the tube.

• Store unit out of reach of children.

SAFETY NOTICE: Exposure to vibra-

tions through prolonged use of gaso-

line powered hand tools could cause

blood vessel or nerve damage in the

fingers, hands, and joints of people

prone to circulation disorders or ab-

normal swellings. Prolonged use in

cold weather has been linked to blood

vessel damage in otherwise healthy

people. If symptoms occur such as

numbness, pain, loss of strength,

change in skin color or texture, or loss

of feeling in the fingers, hands, or

joints, discontinue the use of this tool

and seek medical attention. An anti-

vibration system does not guarantee

the avoidance of these problems. Us-

ers who operate power tools on a con-

tinual and regular basis must monitor

closely their physical condition and

the condition of this tool.

4

Page 5

SPECIAL NOTICE: This unit is not

equipped with a temperature limiting

muffler and spark arresting screen

which meets the requirements of Cali-

fornia Codes 4442 and 4443. All U.S.

forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey,

Oregon, and Washington require by law

that many internal combustion engines

CARTON CONTENTS

be equipped with a spark arrestor

screen. If you operate in a locale where

such regulations exist, you are legally

responsible for installing and maintain-

ing the operating condition of these

parts. Failure to do so is a violation of

the law. If a spark arresting screen is

required in your area, contact your

Sears Service Centre for the correct kit.

Check carton contents against the fol-

lowing list.

Model C944.512561

Powerhead

Brushcutter attachment

Blade shield screws (4)

Cupped washer

Large nut for installing blades

Hex wrench

Metal shield

Plastic shield

Shoulder strap with warning

4-point weed blade

Trimmer head (assembled on unit)

Handlebar (assembled on unit)

Wing nut (screwed onto shield)

Container of oil

Examine parts for damage. Do not

use damaged parts.

NOTE: If you need assistance or find

parts missing or damaged, call

1-800-235-5878.

It is normal for the fuel filter to rattle in

the empty fuel tank.

Finding fuel or oil residue on muffler is

normal due to carburetor adjustments

and testing done by the manufacturer.

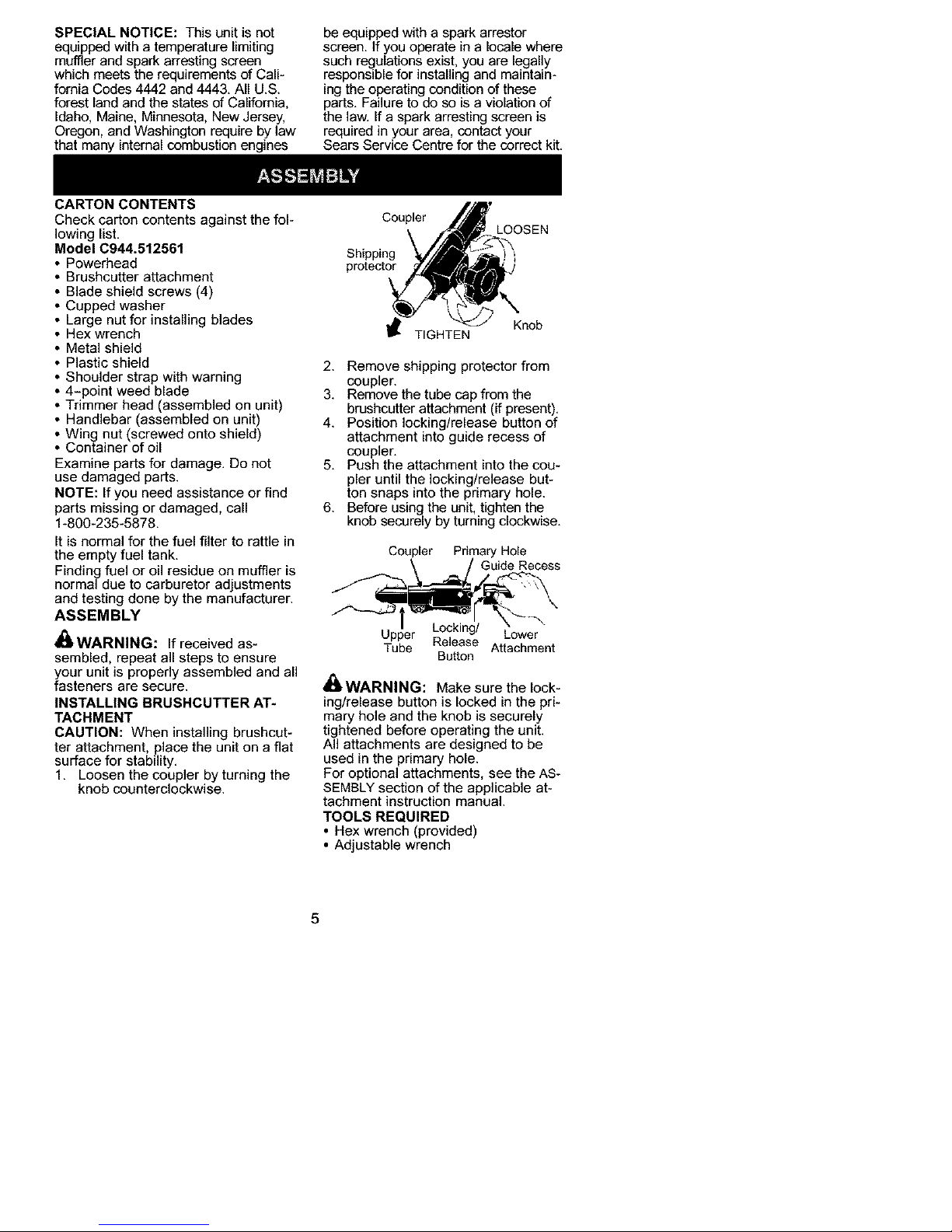

ASSEMBLY

_ WARNING: If received as-

sembled, repeat all steps to ensure

your unit is properly assembled and all

fasteners are secure.

INSTALLING BRUSHCUTTER AT-

TACHMENT

CAUTION: When installing brushcut-

ter attachment, place the unit on a flat

surface for stability.

1. Loosen the coupler by turning the

knob counterclockwise.

Coupler

LOOSEN

Shipping

protector

Knob

TIGHTEN

2. Remove shipping protector from

coupler.

3. Remove the tube cap from the

brushcutter attachment (if present).

4. Position locking/release button of

attachment into guide recess of

coupler.

5. Push the attachment into the cou-

pler until the locking/release but-

ton snaps into the primary hole.

6. Before using the unit, tighten the

knob securely by turning clockwise.

Cot_ F i/rr_rYidHOl_ecess

UTPuPberRelease AtL°(_emrent

Button

_1_WARNING: Make sure the lock-

ing/release button is locked in the pri-

mary hole and the knob is securely

tightened before operating the unit.

All attachments are designed to be

used in the primary hole.

For optional attachments, see the AS-

SEMBLY section of the applicable at-

tachment instruction manual.

TOOLS REQUIRED

• Hex wrench (provided)

• Adjustable wrench

5

Page 6

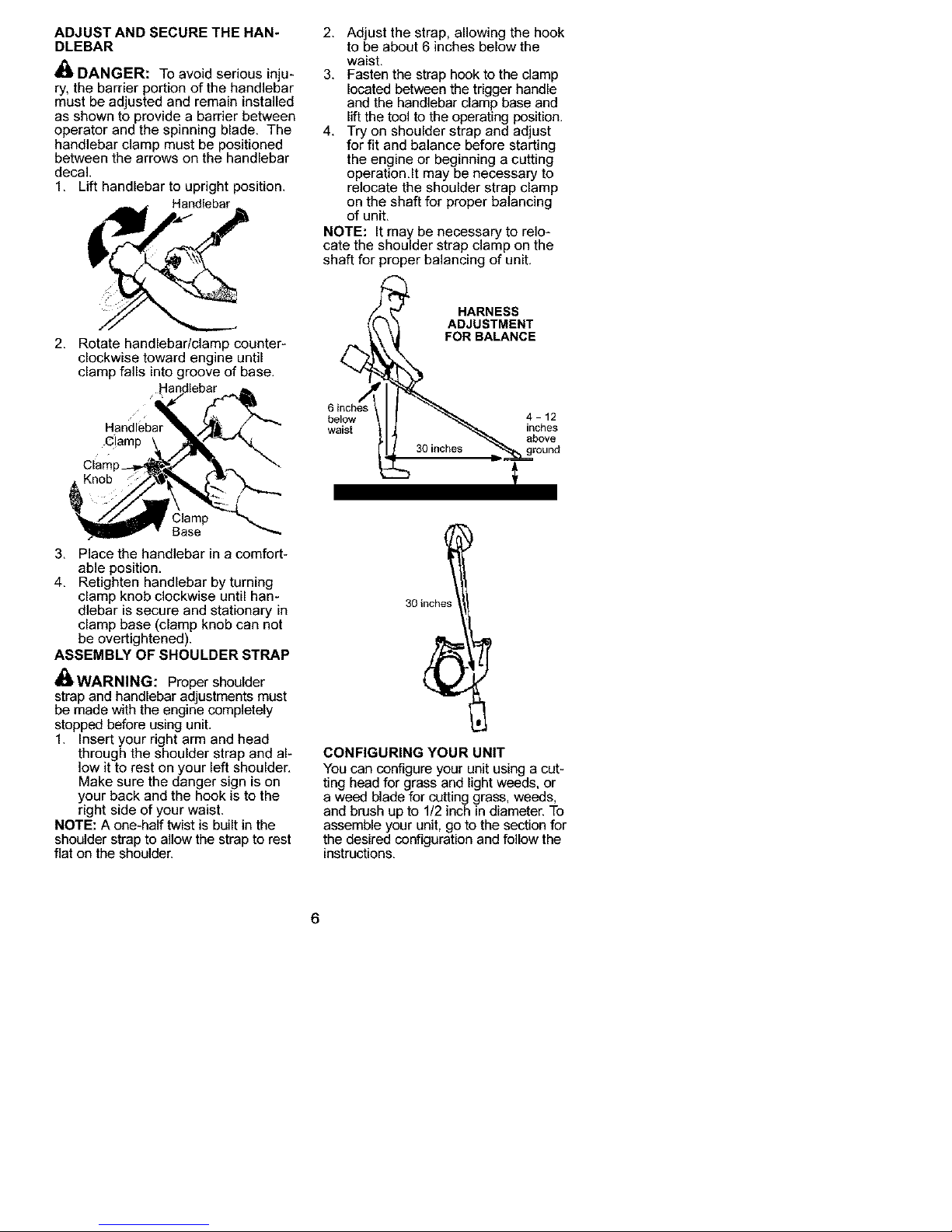

ADJUST AND SECURE THE HAN*

DLEBAR

_1_DANGER: To avoid serious inju-

ry, the barrier portion of the handlebar

must be adjusted and remain installed

as shown to provide a barrier between

operator and the spinning blade. The

handlebar clamp must be positioned

between the arrows on the handlebar

decal.

1. Lift handlebar to upright position.

Handlebar

2. Adjust the strap, allowing the hook

to be about 6 inches below the

waist.

3. Fasten the strap hook to the clamp

located between the trigger handle

and the handlebar clamp base and

lift the tool to the operating position.

4. Try on shoulder strap and adjust

for fit and balance before starting

the engine or beginning a cutting

operation.It may be necessary to

relocate the shoulder strap clamp

on the shaft for proper balancing

of unit.

NOTE: It may be necessary to relo-

cate the shoulder strap clamp on the

shaft for proper balancing of unit.

2. Rotate handlebar/clamp counter-

clockwise toward engine until

clamp falls into groove of base.

Clamp

Base

3. Place the handlebar in a comfort*

able position.

4. Retighten handlebar byturning

clamp knob clockwise until han-

dlebar is secure and stationary in

clamp base (clamp knob can not

be overtightened).

ASSEMBLY OF SHOULDER STRAP

_1_WARNING: Proper shoulder

strap and handlebar ad ustments must

be made w th the eng ne compete y

stopped before using unit.

1. Insert your right arm and head

through the shoulder strap and al-

low it to rest on your left shoulder.

Make sure the danger sign is on

your back and the hook is to the

right side of your waist.

NOTE: A one-half twist is built in the

shoulder strap to allow the strap to rest

flat on the shoulder.

HARNESS

ADJUSTMENT

FOR BALANCE

6 inches

below

waist

4-12

inches

above

30 inches

CONFIGURING YOUR UNIT

You can configure your unit using a cut*

ting head for grass and light weeds, or

a weed blade for cutting grass, weeds,

and brush up to 1/2 inch in diameter. To

assemble your unit, go to the section for

the desired configuration and follow the

instructions.

6

Page 7

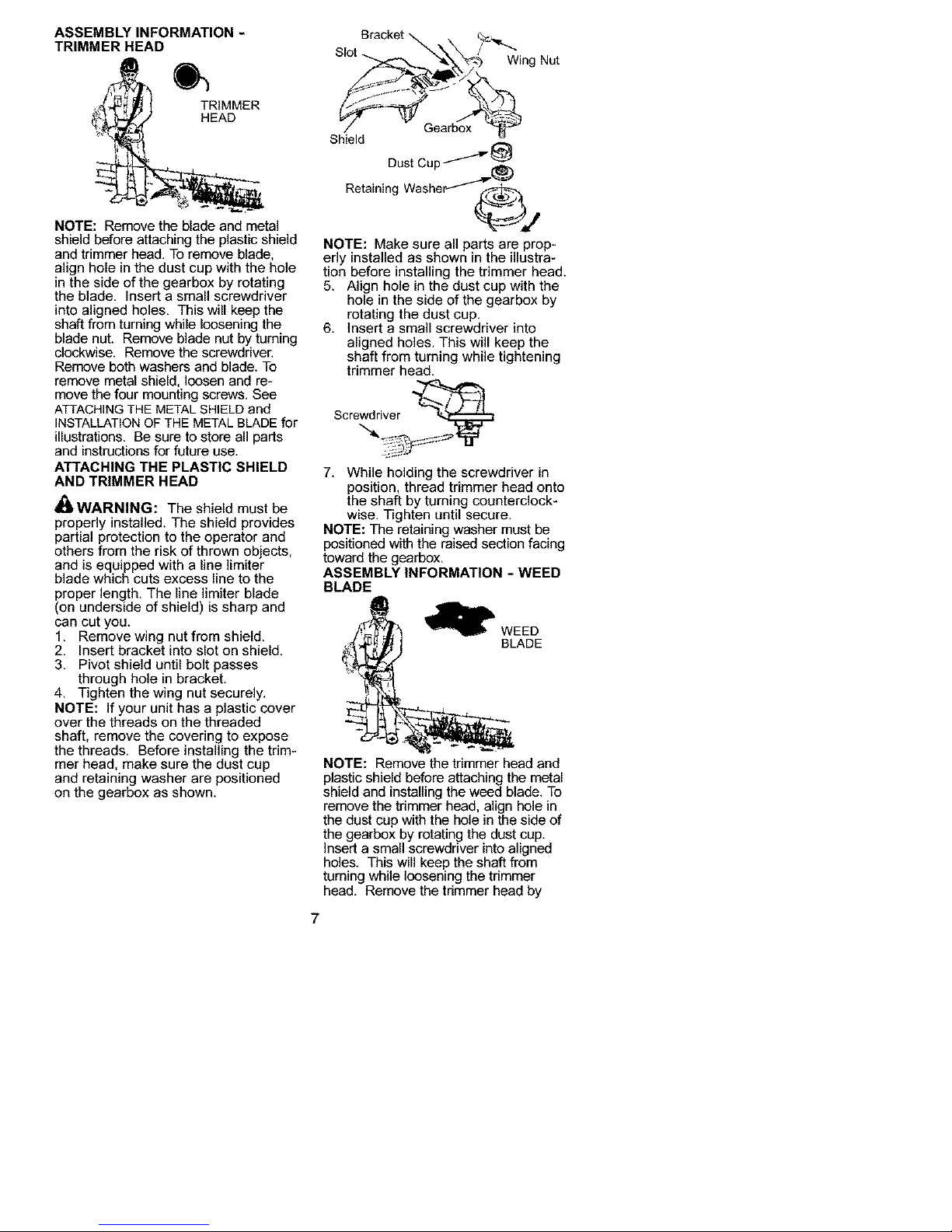

ASSEMBLY INFORMATION -

TRIMMER HEAD

TRIMMER

HEAD

NOTE: Remove the blade and metal

shield before attaching the plastic shield

and trimmer head. To remove blade,

align hole in the dust cup with the hole

in the side of the gearbox by rotating

the blade. Insert a small screwdriver

into aligned holes. This will keep the

shaft from turning while loosening the

blade nut. Remove blade nut by turning

clockwise. Remove the screwdriver.

Remove both washers and blade. To

remove metal shield, loosen and re-

move the four mounting screws. See

ATTACHINGTHE METALSHIELDand

INSTALLATIONOF THE METAL BLADEfor

illustrations. Be sure to store all parts

and instructions for future use.

ATTACHING THE PLASTIC SHIELD

AND TRIMMER HEAD

_WARNING: The shield must be

properly installed. The shield provides

partial protection to the operator and

others from the risk of thrown objects,

and is equipped with a line ]imiter

blade which cuts excess line to the

Droper length. The line limiter blade

on underside of shield) is sharp and

can cut you.

1. Remove wing nut from shield.

2. Insert bracket into slot on shield.

3. Pivot shield until bolt passes

through hole in bracket.

4. Tighten the wing nut securely.

NOTE: If your unit has a plastic cover

over the threads on the threaded

shaft, remove the covering to expose

the threads. Before installing the trim-

mer head, make sure the dust cup

and retaining washer are positioned

on the gearbox as shown.

Bracket Q

Shield

DustCup _" _

Retaining Washer-_

NOTE: Make sure all parts are prop-

erly installed as shown in the illustra-

tion before installing the trimmer head.

5. Align hole in the dust cup with the

hole in the side of the gearbox by

rotating the dust cup,

6. Insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while tightening

trimmer head.

Sore _,

7. While holding the screwdriver in

position, thread trimmer head onto

the shaft by turning counterclock-

wise. Tighten until secure.

NOTE: The retaining washer must be

positioned with the raised section facing

toward the gearbox.

ASSEMBLY INFORMATION - WEED

BLADE

E

NOTE: Remove the trimmer head and

plastic shield before attaching the metal

shield and installing the weed blade. To

remove the trimmer head, align hole in

the dust cup with the hole in the side of

the gearbox by rotating the dust cup.

Insert a small screwdriver into aligned

holes. This will keep the shaft from

turning while loosening the trimmer

head. Remove the trimmer head by

7

Page 8

turning clockwise. Remove the screw-

driver. To remove the plastic shield,

loosen and remove wing nut. Pivot

shield to release bracket from slot. See

INSTALLATIONOF THE CUTTINGHEAD

and ATTACHINGTHE PLASTIC SHIELDfor

illustrations. Be sure to store all parts

and instructions for future use. Never

use the trimmer head with the metal

blade installed.

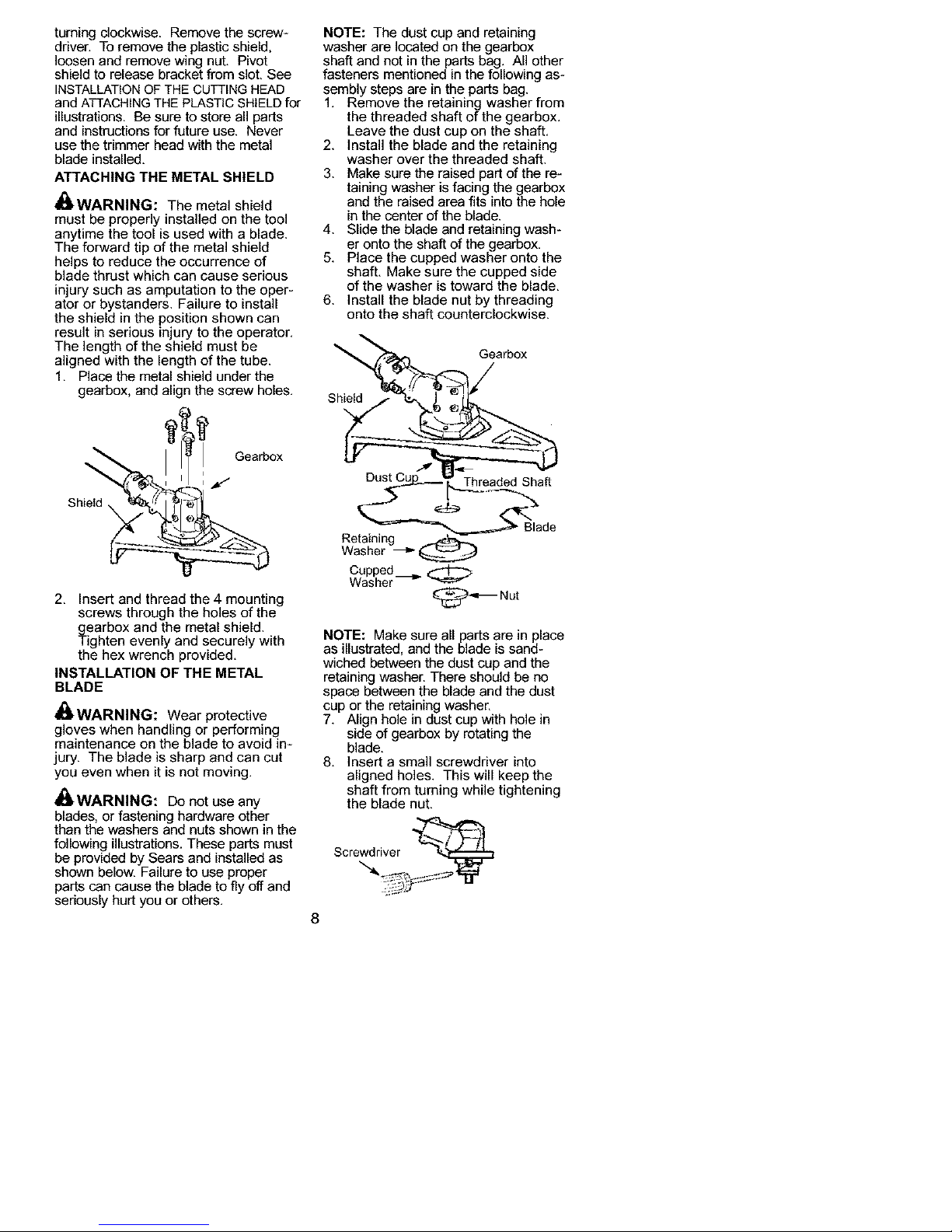

ATTACHING THE METAL SHIELD

_I_i,WARNING: The metal shield

must be properly installed on the tool

anytime the tool is used with a blade.

The forward tip of the metal shield

helps to reduce the occurrence of

blade thrust which can cause serious

injury such as amputation to the oper-

ator or bystanders. Failure to install

the shield in the position shown can

result in serious injury to the operator.

The length of the shield must be

aligned with the length of the tube.

1. Place the metal shield under the

gearbox, and align the screw holes.

If

Gearbox

' _-

Shield

2. Insert and thread the 4 mounting

screws through the holes of the

grearbox and the metal shield.

ighten evenly and securely with

the hex wrench provided.

INSTALLATION OF THE METAL

BLADE

_ WARNING: Wear protective

gloves when handling or performing

maintenance on the blade to avoid in-

jury. The blade is sharp and can cut

you even when it is not moving.

_WARNING: Do not use any

blades, or fastening hardware other

than the washers and nuts shown in the

following illustrations. These parts must

be provided by Sears and installed as

shown below. Failure to use proper

parts can cause the blade to fly off and

seriously hurt you or others.

NOTE: The dust cup and retaining

washer are located on the gearbox

shaft and not in the parts bag. All other

fasteners mentioned in the following as-

sembly steps are in the parts bag.

1. Remove the retaining washer from

the threaded shaft of the gearbox.

Leave the dust cup on the shaft.

2. Install the blade and the retaining

washer over the threaded shaft.

3. Make sure the raised part of the re-

taining washer is facing the gearbox

and the raised area fits into the hole

in the center of the blade.

4. Slide the blade and retaining wash-

er onto the shaft of the gearbox.

5. Place the cupped washer onto the

shaft. Make sure the cupped side

of the washer is toward the blade.

6. Install the blade nut by threading

onto the shaft counterclockwise.

Gearbox

Shield

Threaded Shaft

Retaining

Washer

Cupped

Washer -_

_-_Nut

NOTE: Make sure all parts are in place

as illustrated, and the blade is sand-

wiched between the dust cup and the

retaining washer. There should be no

space between the blade and the dust

cup or the retaining washer.

7. Align hole in dust cup with hole in

side of gearbox by rotating the

blade.

8. insert a small screwdriver into

aligned holes. This will keep the

shaft from turning while tightening

the blade nut.

8

Page 9

9. Tighten blade nut firmly with a

wrench while holding screwdriver

in position.

10. Remove the screwdriver.

11. Turn blade by hand. If the blade

binds against the shield, or appears

to be uneven, the blade is not cen-

tered, and you must reinstall.

NOTE: To remove blade, insert screw-

driver into aligned holes. Unthread the

nut and remove parts. Be sure to store

parts and instructions for future use.

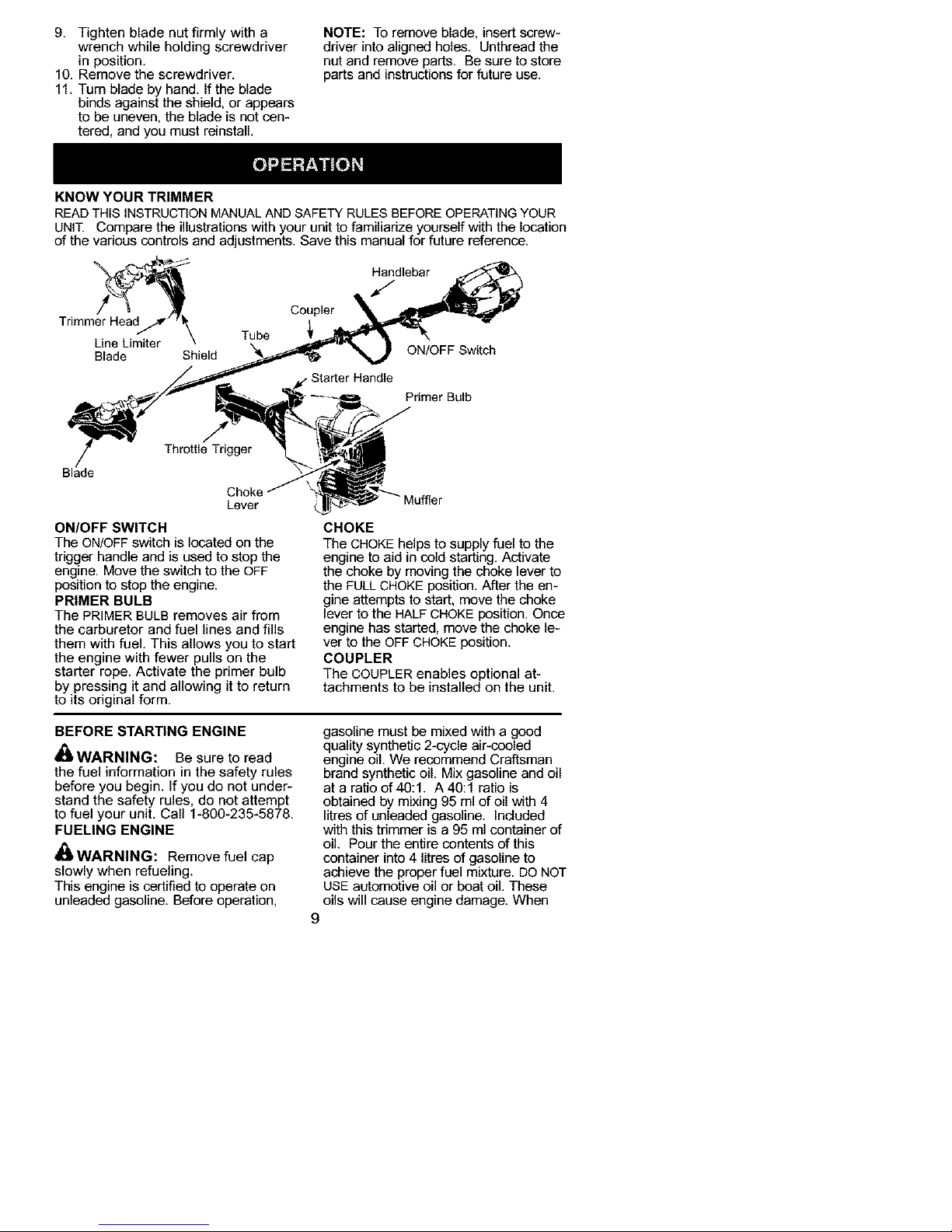

KNOW YOUR TRIMMER

READTHIS INSTRUCTIONMANUALANDSAFETYRULES BEFOREOPERATINGYOUR

UNIT. Compare the illustrations with your unit to familiarize yourself with the location

of the various controls and adjustments. Save this manual for future reference.

_-_ Handlebar

Coupler

Trim

Line Limiter \ Tube

Blade Shield ON/OFF Switch

Primer Bulb

Blade

Lever

ON/OFF SWITCH

The ON/OFF switch is located on the

trigger handle and is used to stop the

engine. Move the switch to the OFF

position to stop the engine.

PRIMER BULB

The PRIMER BULB removes air from

the carburetor and fuel lines and fills

them with fuel. This allows you to start

the engine with fewer pulls on the

starter rope. Activate the primer bulb

by pressing it and allowing it to return

to its original form.

er

CHOKE

The CHOKEhelps to supply fuel to the

engine to aid in cold starting. Activate

the choke by moving the choke lever to

the FULL CHOKE position. After the en-

gine attempts to start, move the choke

lever to the HALF CHOKE position. Once

engine has started, move the choke le-

ver to the OFF CHOKEposition.

COUPLER

The COUPLER enables optional at-

tachments to be installed on the unit.

BEFORE STARTING ENGINE

_1_WARNING: Be sure to read

the fuel information in the safety rules

before you begin, If you do not under-

stand the safety rules, do not attempt

to fuel your unit, Call 1-800-235-5878,

FUELING ENGINE

_WARNING: Remove fuel cap

slowly when refueling,

This engine is certified to operate on

unleaded gasoline, Before operation,

gasoline must be mixed with a good

quality synthetic 2-cycle air-cooled

engine oil. We recommend Craftsman

brand synthetic oil. Mix gasoline and oil

at a ratio of 40:1. A 40:1 ratio is

obtained by mixing 95 ml of oil with 4

litres of unleaded gasoline. Included

with this trimmer is a 95 ml container of

oil. Pour the entire contents of this

container into4 litres of gasoline to

achieve the proper fuel mixture. DO NOT

USEautomotive oil or boat oil. These

oils will cause engine damage. When

9

Page 10

mixingfuel,followinstructionsprintedon

container.

Onceoilisaddedtogasoline,shake

containermomentarilytoassurethatthe

fuelisthoroughlymixed.Alwaysread

andfollowthesafetyrulesrelatingto

fuelbeforefuelingyourunit.

IMPORTANT

Experienceindicatesthatalcohol

blendedfuels(calledgasoholorusing

ethanolormethanol)canattractmois-

turewhichleadstoseparationand

formationofacidsduringstorage.

Acidicgascandamagethefuelsys-

temofanenginewhileinstorage.

Toavoidengineproblems,emptythe

fuelsystembeforestoragefor30days

orlonger.Drainthegastank,startthe

engineandletitrununtilthefuellines

andcarburetorareempty.Usefresh

fuelnextseason.

Neveruseengineorcarburetorclean-

erproductsinthefueltankorperma-

nentdamagemayoccur.

SeetheSTORAGEsectionforaddition-

alinformation.

HOW TO STOP YOUR UNIT

• To stop the engine, move the

ONIOFF switch to the OFF position.

• If engine does not stop, move choke

lever to FULL CHOKE position.

;witch

HOW TO START YOUR UNIT

_ WARNING: The trimmer head

will turn while starting the engine.

Avoid any contact with the muffler. A

hot muffler can cause serious burns.

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

Starting Position

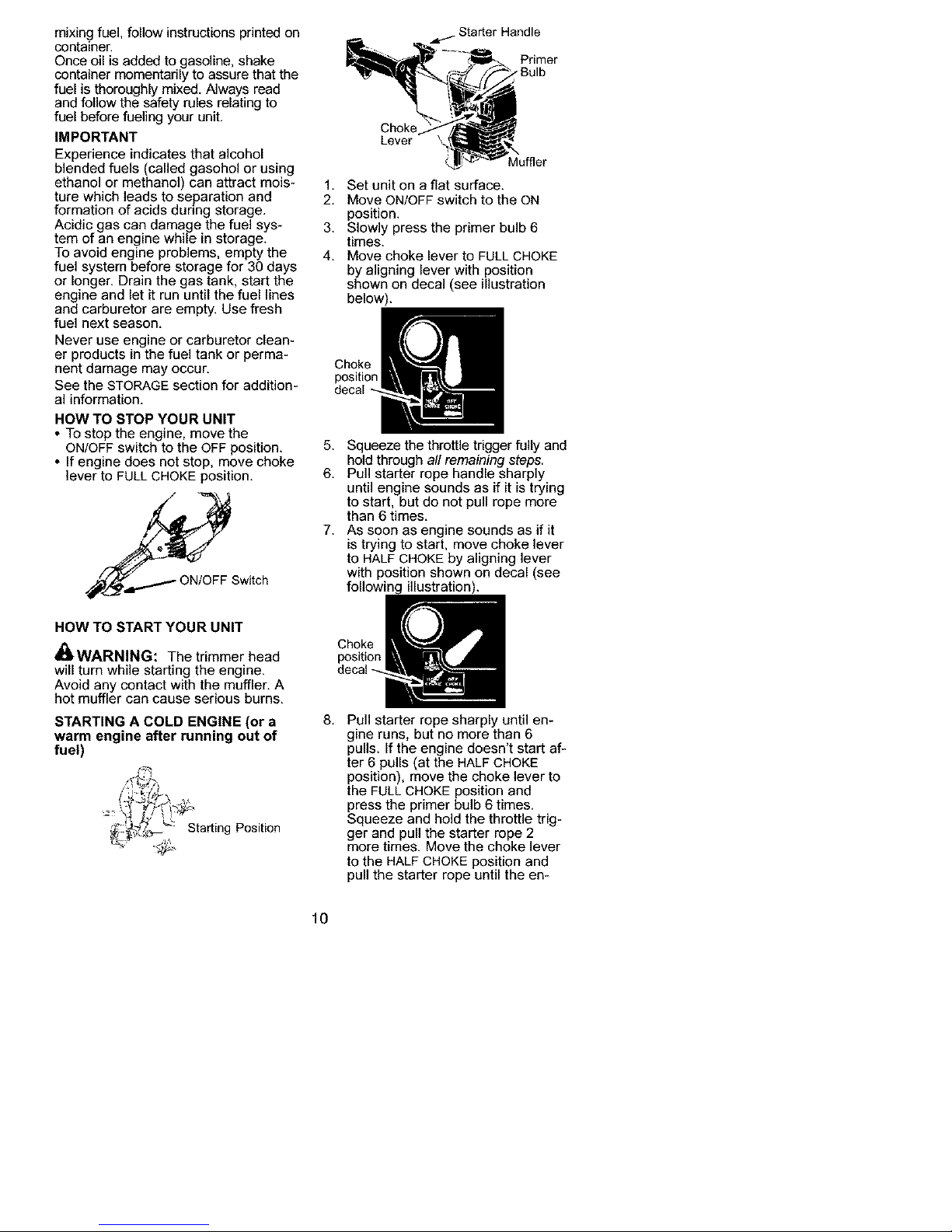

Starter Handle

Primer

-"Bulb

Choke

Lever

Muffler

1. Set unit on a flat surface.

2. Move ON/OFF switch to the ON

position.

3. Slowly press the primer bulb 6

times.

4. Move choke lever to FULL CHOKE

by aligning lever with position

shown on decal (see illustration

below).

Choke

position

decal

5. Squeeze the throttle trigger fully and

hold through all remaining steps.

6. Pull starter rope handle sharply

until engine sounds as if it is trying

to start, but do not pull rope more

than 6 times.

7. As soon as engine sounds as if it

is trying to start, move choke lever

to HALF CHOKE by aligning lever

with position shown on decal (see

illustration).

Choke

position

8.

Pull starter rope sharply until en-

gine runs, but no more than 6

pulls. If the engine doesn't start af-

ter 6 pulls (at the HALF CHOKE

position), move the choke lever to

the FULL CHOKE position and

press the primer bulb 6 times.

Squeeze and hold the throttle trig-

ger and pull the starter rope 2

more times. Move the choke lever

to the HALF CHOKE position and

pull the starter rope until the en-

10

Page 11

g,

gine runs, but no more than 6

pulls. If the engine doesn't start,

repeat procedure 2 additional

times. NOTE: If engine still doesn't

start, it is probably flooded. Proceed

to STARTINGA FLOODED ENGINE.

Once the engine starts, allow it to

run 10 seconds, then move the

choke lever to OFF CHOKE by

aligning lever with position shown

on decal (see illustration below).

Allow the unit to run for 30 more

seconds at OFF CHOKE before re-

leasing the throttle trigger. NOTE:

If engine dies with the choke lever

in the OFF CHOKE position, move

the choke lever to the HALF

CHOKE position and pull the rope

until engine runs, but no more

than 6 pulls.

Choke

position

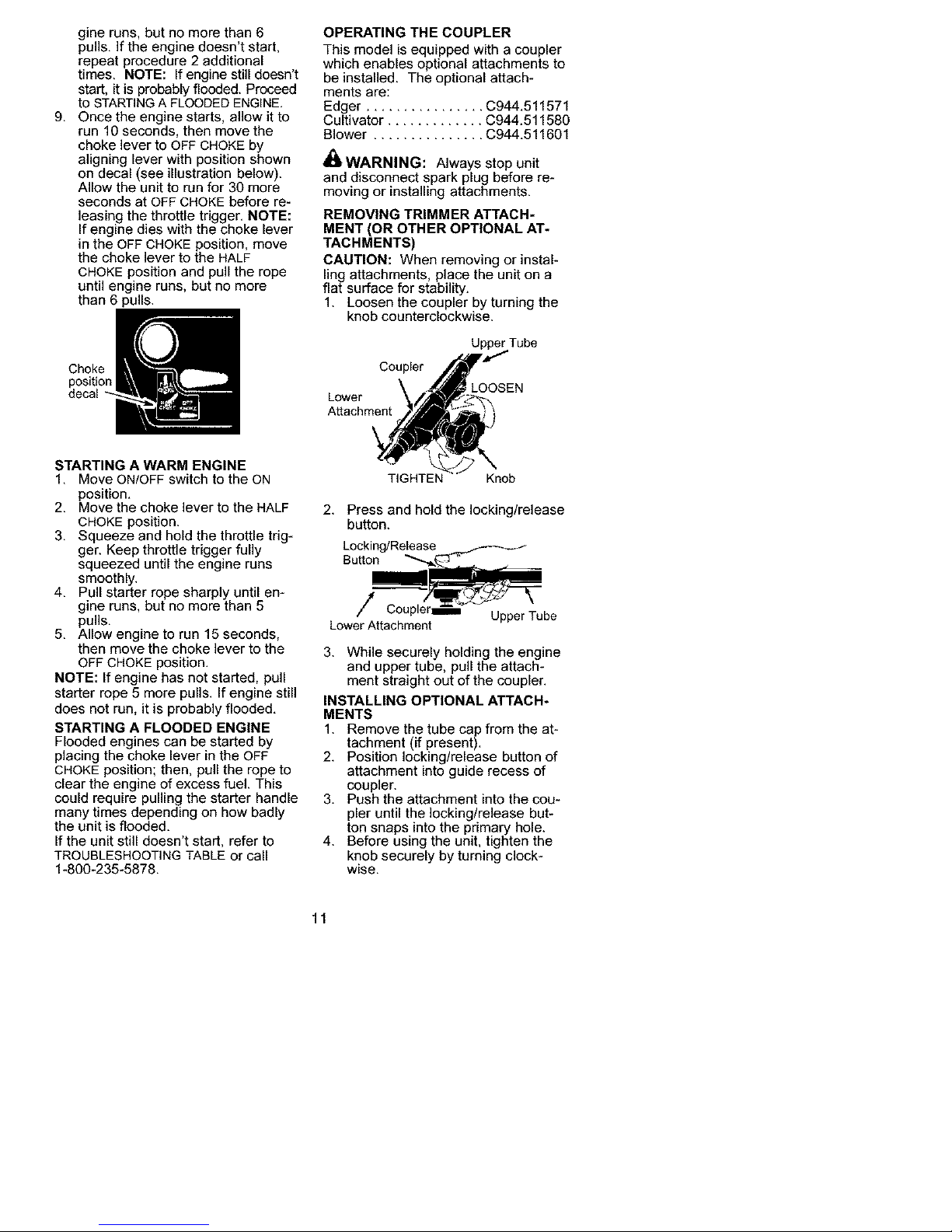

OPERATING THE COUPLER

This model is equipped with a coupler

which enables optional attachments to

be installed. The optional attach-

ments are:

Edger ................ C944.511571

Cultivator ............. C944.511580

Blower ............... C944.511601

_I_WARNING: Always stop unit

and disconnect spark plug before re-

moving or installing attachments.

REMOVING TRIMMER ATTACH-

MENT (OR OTHER OPTIONAL AT*

TACHMENTS)

CAUTION: When removing or instal-

ling attachments, place the unit on a

flat surface for stability.

1. Loosen the coupler by turning the

knob counterclockwise.

UpperTube

Coupler

Lower

Attachment

STARTING A WARM ENGINE

1. Move ON/OFF switch to the ON

position.

2. Move the choke lever to the HALF

CHOKE position.

3. Squeeze and hold the throttle trig-

ger. Keep throttle trigger fully

squeezed until the engine runs

smoothly.

4. Pull starter rope sharply until en-

gine runs, but no more than 5

pulls.

5. Allow engine to run 15 seconds,

then move the choke lever to the

OFF CHOKE position.

NOTE: If engine has not started, pull

starter rope 5 more pulls. If engine still

does not run, it is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by

placing the choke lever in the OFF

CHOKE position; then, pull the rope to

clear the engine of excess fuel. This

could require pulling the starter handle

many times depending on how badly

the unit is flooded.

If the unit still doesn't start, refer to

TROUBLESHOOTING TABLE or call

1-800-235-5878.

TIGHTEN Knob

2. Press and hold the locking/release

button.

Locking/Release

Button

/

LowerAttachment

UpperTube

3. While securely holding the engine

and upper tube, pull the attach-

ment straight out of the coupler.

INSTALLING OPTIONAL ATTACH-

MENTS

1. Remove the tube cap from the at-

tachment (if present).

2. Position locking/release button of

attachment into guide recess of

coupler.

3. Push the attachment into the cou-

pler until the locking/release but-

ton snaps into the primary hole.

4. Before using the unit, tighten the

knob securely by turning clock-

wise.

11

Page 12

Coupler Primary Hole

Upper Locking/ Attachment

Tube Release

Button

_1_WARNING: Make sure the lock-

ing/release button is locked in the pri-

mary hole and the knob is securely

tightened before operating the unit.

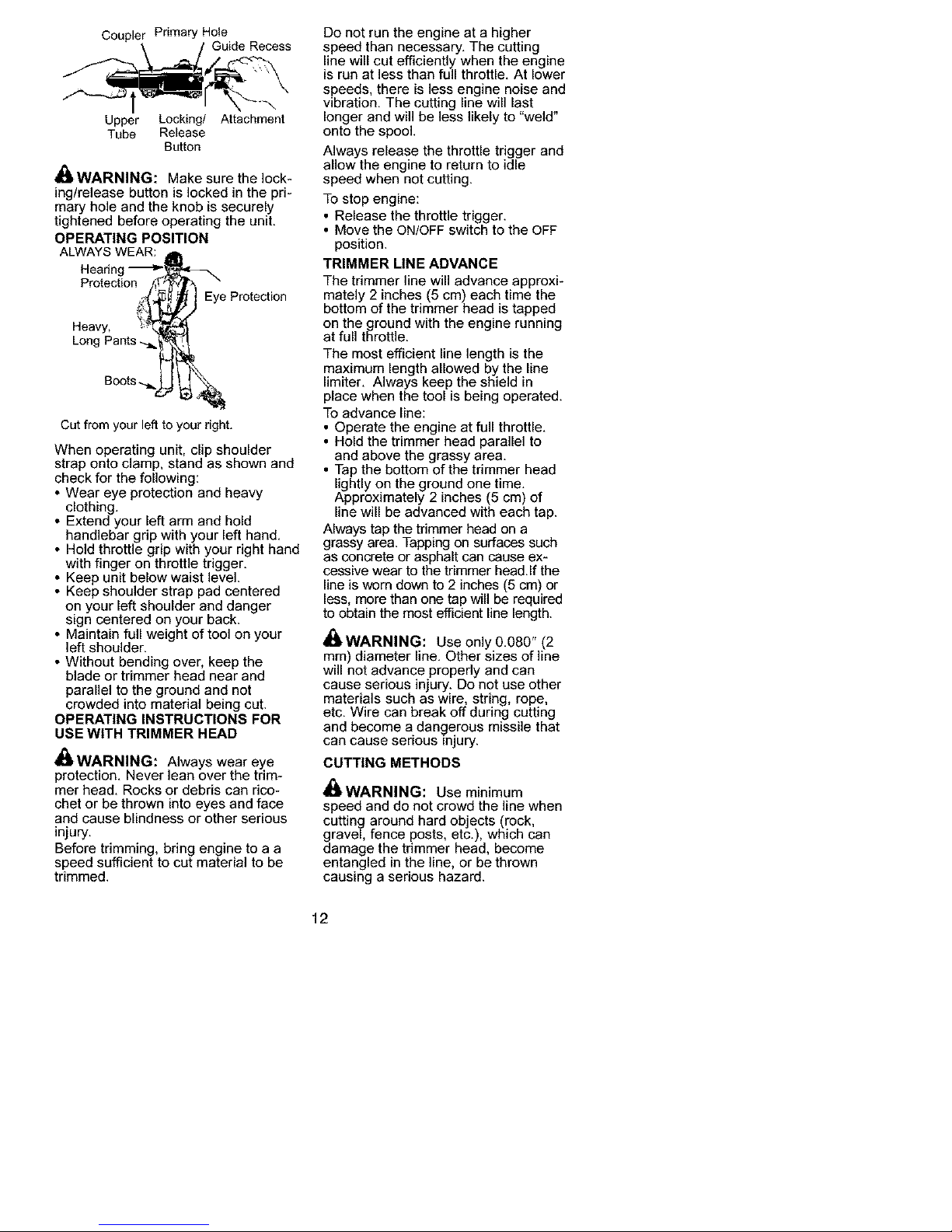

OPERATING POSITION

ALWAYSWEAR: _1

Hearing -_P',_'L,r_-,_

Protection __

,_ _ Eye Protection

Heavy, :_[ _'/

Long Pants _

Boots-.._ _ _ _

Cut from your left to your right.

When operating unit, clip shoulder

strap onto clamp, stand as shown and

check for the following:

• Wear eye protection and heavy

clothing.

• Extend your left arm and hold

handlebar grip with your left hand.

• Hold throttle grip with your right hand

with finger on throttle trigger.

• Keep unit below waist level.

• Keep shoulder strap pad centered

on your left shoulder and danger

sign centered on your back.

• Maintain full weight of tool on your

left shoulder.

• Without bending over, keep the

blade or trimmer head near and

parallel to the ground and not

crowded into material being cut.

OPERATING INSTRUCTIONS FOR

USE WITH TRIMMER HEAD

DWARNING: Always wear eye

protection. Never lean over the trim-

mer head. Rocks or debris can rico-

chet or be thrown into eyes and face

and cause blindness or other serious

injury.

Before trimming, bring engine to a a

speed sufficient to cut material to be

trimmed.

Do not run the engine at a higher

speed than necessary. The cutting

line will cut efficiently when the engine

is run at less than full throttle. At lower

speeds, there is less engine noise and

vibration. The cutting line will last

longer and will be less likely to "weld"

onto the spool.

Always release the throttle trigger and

allow the engine to return to idle

speed when not cutting.

To stop engine:

• Release the throttle trigger.

• Move the ON/OFF switch to the OFF

position.

TRIMMER LINE ADVANCE

The trimmer line will advance approxi-

mately 2 inches (5 cm) each time the

bottom of the trimmer head is tapped

on the ground with the engine running

at full throttle.

The most efficient line length is the

maximum length allowed by the line

limiter. Always keep the shield in

place when the tool is being operated.

To advance line:

• Operate the engine at full throttle.

• Hold the trimmer head parallel to

and above the grassy area.

• Tap the bottom of the trimmer head

lightly on the ground one time.

Approximately 2 inches (5 cm) of

line will be advanced with each tap.

Always tap the trimmer head on a

grassy area. Tapping on surfaces such

as concrete or asphalt can cause ex-

cessive wear to the trimmer head.If the

line is worn down to 2 inches (5 cm) or

less, more than one tap will be required

to obtain the most efficient line length.

_WARNING: Use only 0.080" (2

ram) diameter line. Other sizes of line

will not advance properly and can

cause serious injury. Do not use other

materials such as wire, string, rope,

etc. Wire can break off during cutting

and become a dangerous missile that

can cause senous =njury.

CUTTING METHODS

_I_WARNING: Use minimum

speed and do not crowd the line when

cutting around hard objects (rock,

gravel, fence posts, etc.), which can

damage the trimmer head, become

entangled in the line, or be thrown

causing a serious hazard.

12

Page 13

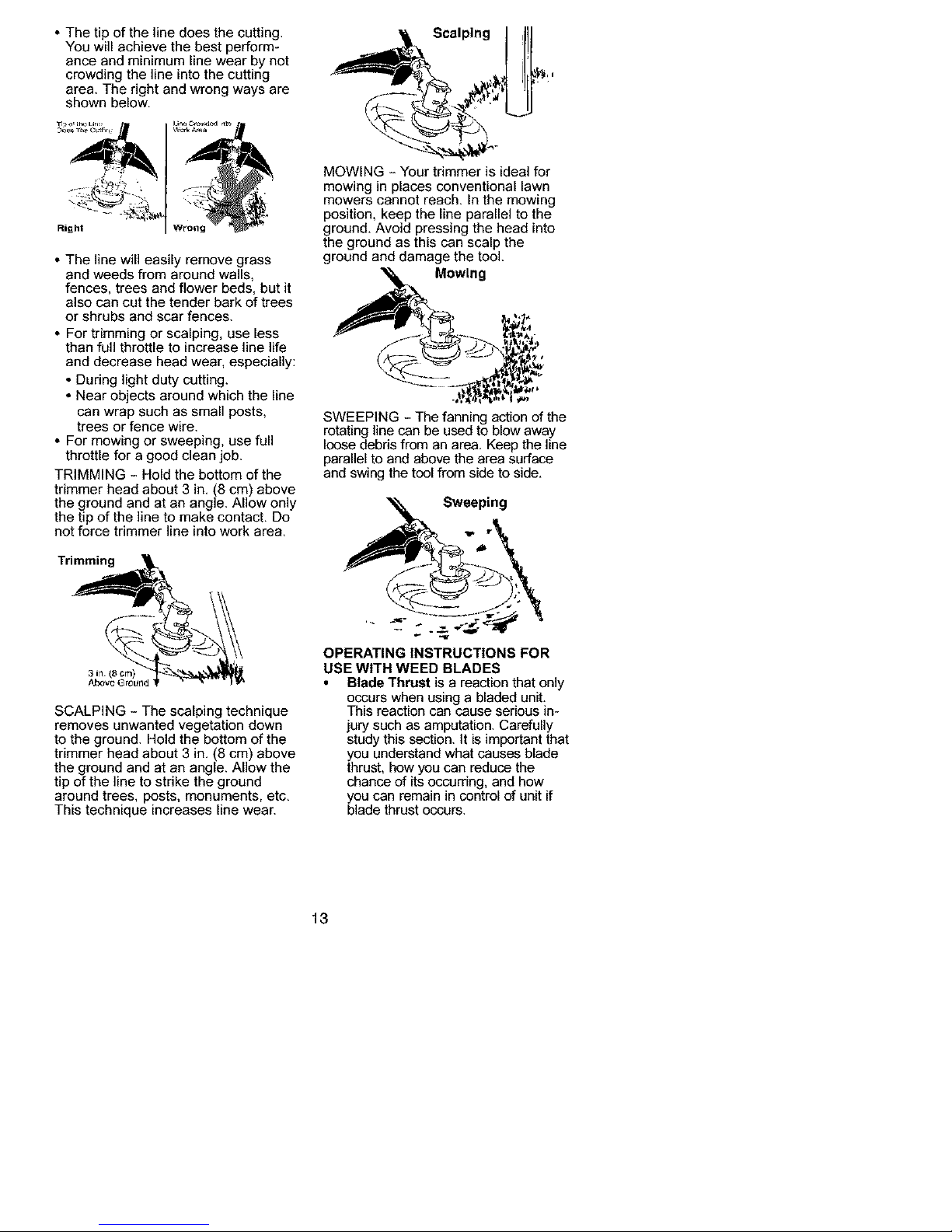

• The tip of the line does the cutting.

You will achieve the best perform-

ance and minimum line wear by not

crowding the line into the cutting

area. The right and wrong ways are

shown below.

Right

• The line will easily remove grass

and weeds from around walls,

fences, trees and flower beds, but it

also can cut the tender bark of trees

or shrubs and scar fences.

• For trimming or scalping, use less

than full throttle to increase line life

and decrease head wear, especially:

• During light duty cutting.

• Near objects around which the line

can wrap such as small posts,

trees or fence wire.

• For mowing or sweeping, use full

throttle for a good clean job.

TRIMMING - Hold the bottom of the

trimmer head about 3 in. (8 cm) above

the ground and at an angle. Allow only

the tip of the line to make contact. Do

not force trimmer line into work area.

Trimming

SCALPING - The scalping technique

removes unwanted vegetation down

to the ground. Hold the bottom of the

trimmer head about 3 in. (8 cm) above

the ground and at an angle. Allow the

tip of the line to strike the ground

around trees, posts, monuments, etc.

This technique increases line wear.

Scalping

MOWING - Your trimmer is ideal for

mowing in places conventional lawn

mowers cannot reach. In the mowing

position, keep the line parallel to the

ground. Avoid pressing the head into

the ground as this can scalp the

ground and damage the tool.

Mowing

SWEEPING - The fanning action of the

rotating line can be used to blow away

loose debris from an area. Keep the line

parallel to and above the area surface

and swing the tool from side to side.

"_ Sweeping

_'8 r

OPERATING INSTRUCTIONS FOR

USE WITH WEED BLADES

Blade Thrust is a reaction that only

occurs when using a bladed unit.

This reaction can cause serious in-

jury such as amputation. Carefully

study this section. It is important that

you understand what causes blade

thrust, how you can reduce the

chance of its occurring, and how

you can remain in control of unitif

blade thrustoccurs.

13

Page 14

WHAT CAUSES BLADE

THRUST - Blade Thrust can oc-

cur when the spinning blade con-

tacts an object that it does not cut.

This contact causes the blade to

stop for an instant and then sud-

denly move or "thrust" away from

the object that was hit. The "thrust-

ing" reaction can be violent

enough to cause the operator to

be propelled in any direction and

lose control of the unit. The uncon-

trolled unit can cause serious in-

jury if the blade contacts the op-

erator or others.

WHEN BLADE THRUST OC-

CURS - Blade Thrust can occur

without warning if the blade snags,

stalls, or binds. This is more likely

to occur in areas where it is diffi-

cult to see the material being cut.

By using the unit properly, the oc-

currence of blade thrust will be re-

duced and the operator will be

less likely to lose control.

Cut only grass, weeds, and woody

brush up to 1/2 inch in diameter

with the weed blade. Do not let the

blade contact material it cannot

cut such as stumps, rocks, fences,

metal, etc., or clusters of hard,

woody brush having a diameter

greater than 1/2 inch.

Keep the blade sharp. A dull blade

is more likely to snag and thrust.

Cut only at full throttle. The blade

will have maximum cutting power

and is less likely to bind or stall.

Feed the blade deliberately and

not too rapidly. The blade can

thrust away if it is fed too rapidly.

Cut only from your left to your

right. Cutting on right side of the

shield will throw debris away from

the operator.

Use the shoulder strap and keep a

firm grip on the unit with both

hands. A properly adjusted shoul-

der strap will support the weight of

the unit, freeing your arms and

hands to control and guide the

cutting motion.

Keep feet comfortably spread

apart and braced for a possible

sudden, rapid thrust of unit. Do not

overreach. Keep firm footing and

balance.

Keep blade below waist level; it will

be easier to maintain control of unit.

Do not raise the engine above

your waist as the blade can come

dangerously close to your body.

Do not swing unit with such force

that you are in danger of losing your

balance.

Bring the engine to cutting speed be-

fore entering the material to be cut.if

the blade does not turn when you

squeeze the throttle trigger, make sure

tube is fully inserted into the engine.

Always release the throttle trigger and

allow engine to return to idle speed

when not cutting. The blade should

not turn while the engine is running at

idle. If the blade turns at idle, do not

use your unit. Refer to the CARBURE-

TOR ADJUSTMENT section or contact

your Sears Service Center.

Maintain good firm footing while

using the unit. Do this by planting

feet firmly in a comfortable apart

position.

Cut while swinging the upper part

of your body from left to right.

As you move forward to the next

area to cut, be sure to maintain

your balance and footing.

RECOMMENDED CUTTING POSITION

_ o'clock

Cut using the 2 _;

o'clock to 4 o'clock

position of the 4 o'clock

blade

_I_t,WARNING: The operator or oth-

ers must not try to clear away cut mate-

rial with the engine running or the blade

turning to avoid serious injury. Stop en-

gine and blade before removing materi-

als wrapped around blade or tube.

14

Page 15

_1_WARNING: For each optional

attachment used. read entire instruc-

tion manual before use and follow all

warnings and instructions in manual

and on attachment.

_WARNING: Ensure handlebar

remains installed on upper tube (en-

gine end of unit) at all times.

t Handlebar

EDGER SAFETY

_WARNING: Inspect the area to

be edged before each use. Remove

objects (rocks, broken glass, nails,

wire, etc.) which can be thrown by the

blade or can wrap around the shaft.

• Blade rotates momentarily after the

trigger is released. The blade can

seriously cut you or others.

• Allow blade to stop before removing

it from the cut.

Bladerotatas Allow bladetostop

deforeramovingit

afterthe fromthe cut.

• Throw away blades that are bent,

warped, cracked, broken or dam-

aged in any other way. Replace

parts that are cracked, chipped, or

damaged before using the unit.

• Do not attempt to remove cut material

nor hold material to be cut when the

engine is running or when cutting

blade is moving.

• Always keep the wheel and depth ad-

justing skid in contact with the ground.

• Always push the unit slowly over the

ground. Stay alert for uneven side-

walks, holes in the terrain, large

roots, etc.

• Always use the handlebar when us-

ing edger attachment.

BLOWER/VACUUM SAFETY

_I_WARNING: Inspect area before

starting unit. Remove all debris and

hard objects such as rocks, glass,

wire, etc. that can ricochet, be thrown,

or otherwise cause injury or damage

during operation.

• Do not set unit on any surface except

a clean, hard area while engine is

running. Debris such as gravel, sand,

dust, grass, etc., could be picked up

by the air intake and thrown out

through discharge opening, damaging

unit, property, or causing serious injury

to bystanders or operator.

• Never place objects inside the blow-

er tubes, vacuum tubes or blower

outlet. Always direct the blowing de-

bris away from people, animals,

glass, and solid objects such as

trees, automobiles, walls, etc. The

force of air can cause rocks, dirt, or

sticks to be thrown or to ricochet

which can hurt people or animals,

break glass, or cause other damage.

• Never run unit without the proper

equipment attached. When using

your unit as a blower, always install

blower tubes.

• Check air intake opening, blower

tubes or vacuum tubes frequently,

always with engine stopped and

spark plug disconnected. Keep

vents and discharge tubes free of

debris which can accumulate and

restrict proper air flow.

• Never place any object in air intake

opening as this could restrict proper

air flow and cause damage to the unit.

• Never use for spreading chemicals,

fertilizers, or other substances which

may contain toxic materials.To avoid

spreading fire, do not use near leaf or

brush fires, fireplaces, barbecue pits,

ashtrays, etc.

CULTIVATOR SAFETY

_WARNING: Rotating tines can

cause serious injury. Keep away from

rotating tines. Stop the engine and

disconnect the spark plug before un-

clogging tines or making repairs.

15

Page 16

4_WARNING: Inspect the area to

be cultivated before starting the unit.

Remove all debris and hard and sharp

objects such as rocks, vines, branch-

es, rope, string, etc.

• Avoid heavy contact with solid objects

that might stop the tines. If heavy

contact occurs, stop the engine and

inspect the unit for damage.

• Never operate the cultivator without

the tine cover in place and properly

secured.

• Keep the tines and guard clear of

debris.

• After striking a foreign object, stop

the engine, disconnect the spark

plug and inspect the cultivator for

damage. Repair before restarting.

• Disconnect attachment from the drive

engine before cleaning the tines with

a hose and water to remove any

build-up. Oil the tines to prevent rust.

• Always wear gloves when servicing

or cleaning the tines. The tines be-

come very sharp from use.

• Do not run unit at high speed unless

cultivating.

HEDGE TRIMMER SAFETY

,,&

_1_DANGER: RISK OF CUT; KEEP

HANDS AWAY FROM BLADE - Blade

moves momentarily after the trigger is

released. Do not attempt to clear away

cut material when the blade is in mo-

tion. Make sure the switch is in the OFF

position, the spark plugwire is diScon-

nected, and the bladehas stopped

moving before removing ammed mate-

rial from the cutting blade. Do not grab

or hold the unit by the cutting blade.

Blades move Allow blades to stop

momentarily before removing

after the them from the cut.

t ggeria

_ released, /" ._

_l_ WARNING: Inspect the area be-

fore starting the unit. Remove all de-

bris and hard objects such as rocks,

glass, wire, etc. that can ricochet, be

thrown, or otherwise cause injury or

damage during operation.

• Do not use a cutting blade that is

bent, warped, cracked, broken or

damaged in any other way. Have

worn or damaged parts replaced by

your Sears Service Center.

• Always keep unit in front of your

body. Keep all parts ofyour body

away from the cutting blade.

• Keep the cutting blade and air vents

clear of debris.

POLE PRUNER SAFETY

_I_WARNING: The reciprocating

blade/rotating chain can cause severe

injury. Inspect the unit before use. Do

not operate unit with a bent, cracked

or dull blade or dull chain. Keep away

from the blade/chain.

_I_WARNING: The reciprocating

blade/rotating chain is sharp. Do not

touch. To prevent serious injury, al-

ways stop engine and ensure blade/

chain has stopped moving, disconnect

spark plug, and wear gloves when

changing or handling the blade or

chain.

_I_WARNING: Acoasting blade/

rotating chain can cause injury while it

continues to move after the engine is

stopped. Maintain proper control of

the unit until the blade/chain has com-

Fletely stopped moving. Keep hands,

ace and feet at a distance from all

moving parts. Do not attempt to touch

or stop the blade or chain when it is

moving.

4_WARNING: Falling objects can

cause severe head injury. Wear head

protection when operating this unit

with a pole pruner attachment.

16

Page 17

_ WARNING: To prevent serious

injury, do not use more than one boom

extension with a pole pruner attach-

ment.

_ WARNING: Keep the pruner

away from power lines or electrical

wires.

• Onty use for pruning _imbs or

branches up to 4 inches in diameter.

• Do not operate the unit faster than

the speed needed to prune. Do not

run the unit at high speed when not

pruning.

• Always stop the unit when work is

delayed or when walking from one

cutting location to another.

• if you strike or become entangled

with a foreign object, stop the engine

immediately and check for damage.

Have any damage repaired by a

Sears Service Center before at-

tempting further operations. Discard

blades that are bent, warped,

cracked or broken.

• Stop the unit immediately if you feel

excessive vibration. Vibration is a

sign of trouble. Inspect thoroughly

for loose nuts, bolts or damage be-

fore continuing. Contact Sears Ser-

vice for repair or replacement of af-

fected parts as necessary.

SNOW THROWER SAFETY

_WARNING: Keep hands and

feet away from the rotor when starting

or running the engine. Never attempt

to clear the rotor with the engine/motor

running. Stop engine and disconnect

spark plug before unclogging snow or

debris from discharge chute or when

adjusting vanes.

_WARNING: Never lean over dis-

charge chute. Rocks or debris could

be thrown into the eyes and face and

cause serious injury or blindness.

_WARNING: Inspect the area

where the unit is to be used. Remove

objects that could be thrown or dam-

age the unit. Some objects may be

hidden b}( fallen snow - be alert for

the possibility.

• Direct material discharge away from

glass enclosureS, automobiles, etc.

• Do not run engine at high speed

while not removing snow.

• Be attentive when using the snow-

thrower, and stay alert for holes in the

terrain and other hidden hazards.

• Make sure the rotor will spin freely

before attaching the snowthrower to

the powerhead.

• If the rotor will not rotate freely due

to frozen ice, thaw the unit before

thoroughly before attempting to op-

erate under power.

• Keep the rotor clear of debris.

• Do not throw snow near other

people. The snow thrower could

propel small objects at high speed

causing injury.

• After striking a foreign object, stop

the engine, disconnect spark plug

and inspect the snowthrower for

damage and repair if necessary be-

fore restarting unit.

• Never operate the snowthrower near

glass enclosures, automobiles and

trucks.

• Never attempt to use the snow-

thrower on a roof.

• Never operate the snowthrower near

window wells, dropoffs, etc.

• Never discharge snow onto public

roads or near moving traffic.

• Clear snow from slopes by going up

and down; never across. Use cau-

tion when changing directions. Nev-

er clear snow from steep slopes.

• Let snowthrower run for a few min-

utes after clearing snow so moving

parts do not freeze.

• Look behind and use care when

backing up. Exercise caution to

avoid slipping or falling, especially

when operating in reverse.

• Know how to stop quickly,

17

Page 18

MAINTENANCE SCHEDULE

WARNING: Disconnect the spark plug before performing maintenance

except for carburetor adjustments.

CARE & MAINTENANCE TASK WHEN TO PERFORM

Check for loose fasteners and parts Before each use

Check for damaged or worn parts Before each use

Inspect and clean unit and labels After each use

Clean air filter Every 5 hours of operation

Replace spark plug Yearly

_ENERAL RECOMMENDATIONS

The warranty on this unit does not

cover items that have been sub ected

to operator abuse or neg gence. To

receive full value from the warranty,

the operator must maintain unit as

instructed in this manual. Various ad-

justments will need to be made peri-

odically to properly maintain your unit.

CHECK FOR LOOSE

:LEAN AIR FILTER

A dirty air filter decreases engine per-

formance and increases fuel con-

sumption and harmful emissions. Al-

ways clean after every 5 hours of

operation.

1. Clean the cover and the area

around it to keep dirt from falling

into the carburetor chamber when

the cover is removed.

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

Housing Screws

o

• Assist Handle Screw

• Debris Shield

CHECK FOR DAMAGED OR

WORN PARTS

2. Remove parts by pressing button

to release air filter cover.

NOTE: To avoid creating a fire hazard

or producing harmful evaporative

emissions, do not clean filter in gaso-

line or other flammable solvent.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Add a few drops of oil to the filter;

Contact Sears Service Center for re-

placement of damaged or worn parts.

• ON/OFF Switch - Ensure ON/OFF

switch functions properly by moving

the switch to the OFF position. Make

sure engine stops; then restart en-

gine and continue.

• Fuel Tank - Discontinue use of unit

if fuel tank shows signs of damage

or leaks.

• Debris Shield - Discontinue use of

unit if debris shield is damaged.

INSPECT AND CLEAN UNIT AND LA-

BELS

• After each use, inspect complete

unit for loose or damaged parts.

Clean the unit and labels using a

damp cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

squeeze the filter to distribute oil.

6. Replace parts.

• Air Filter

Button ¢_ _ ._:,

_;_'_ . " Air Filter

. Cover

REPLACE SPARK PLUG

Replace the spark plug each year to

ensure the engine starts easier and

runs better. Set spark plug gap at

0.025 inch. Ignition timing is fixed and

nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder

and discard.

3. Replace with Champion RCJ-6Y

spark plug and tighten securely

with a 3/4 inch socket wrench.

4. Reinstall the spark plug boot.

18

Page 19

REPLACING THE LINE

1. Move ON/OFF switch to the ON

position.

2. Disconnect the spark plug wire.

3. Remove spool by firmly pulling on

tap button.

4. Clean entire surface of hub and

spool.

5. Replace with a pre-wound spool, or

cut two lengths of 12-1/2 feet of

0.080" (2 mm) diameter

Craftsman® brand line.

I_ WARNING: Never use wire,

rope, string, etc., which can break off

and become a dangerous missile.

6. Insert ends of the lines about 1/2

inch (1 cm) into the small holes on

the inside of spool.

U" Ji>_ No es

V, t! _<:P_I

J 'J' l

Line exit holes Line in Notch

\

Line in Notch

7. Wind the line evenly and tightly

onto the spool. Wind in the direc-

tion of the arrows found on the

spool.

8. Push the lines into the notches,

leaving 3 to 5 inches (7 - 12 cm)

unwound.

9. insert the lines into the the exit

holes in the hub as shown in the

illustration.

10. Align the notches with the line exit

holes.

11. Push spool into hub until it snaps

into place.

12. Pull the lines extending outside of

the hub to release the lines from

the notches.

BLADE REPLACEMENT

Refer to the ASSEMBLY section for

blade replacement instructions and

illustrations.

CARBURETOR ADJUSTMENT

I_ WARNING: Keep others away

when making idle speed adjustments.

The trimmer head, blade or any op-

tional attachment will be spinning dur-

ing most of this procedure. Wear your

protective equipment and observe all

safety precautions. After making ad-

justments, the trimmer head, blade or

any optional attachment must not

move/spin at idle speed.

The carburetor has been carefully set

at the factory. Adjustments may be

necessary if you notice any of the fol-

lowing conditions:

• Engine will net idle when the throttle is

released.

• The trimmer head, blade or optional

attachment moves/spins at idle.

Make adjustments with the unit sup-

ported so the cutting attachment is off

the ground and will not make contact

with any object. Hold the unit by hand

while running and making adjust-

ments. Keep all parts of your body

away from the cutting attachment and

muffler.

Idle Speed Adjustment

Allow engine to idle. Ad ust speed until

engine runs without trimmer head,

blade or optional attachment moving

or spinning (idle too fast) or stalling

(idle speed too slow).

• Turn idle speed screw clockwise to

increase enqine speed if engine

stalls or dies.

• Turn idle speed screw

counterclockwise to decrease

engine speed if trimmer head, blade

or optional attachment moves or

spins at idle.

_ WARNING: Recheck the idle

speed after each adjustment. The

trimmer head, blade or optional at-

tachment must not move or spin at

idle speed to avoid serious injury to

the operator or others.

19

Page 20

Air Filtere___ "

Cover

Idle Spe

Screw

If you require further assistance or are

unsure about performing this proce-

dure, contact your Sears Service Cen-

ter or call our customer assistance

help line at 1-800-235-5878.

_ WARNING: Perform the follow-

ing steps after each use:

• Allow engine to cool before storing

or transporting.

• Store unit and fuel in a well venti-

lated area where fuel vapors cannot

reach sparks or open flames from

water heaters, electric motors or

switches, furnaces, etc.

• Store unit with all guards in place.

Position unit so that any sharp ob-

ect cannot accidentally cause injury.

• Store un t and fue we out of the

reach of children.

SEASONAL STORAGE

Prepare unit for storage at end of sea-

son or if it will not be used for 30 days

or more.

If your unit is to be stored for a period

of time:

• Clean the entire unit before lengthy

storage.

Store in a clean dry area.

Lightly oil external metal surfaces.

FUEL SYSTEM

Under FUELING ENGINE in the OPERA-

TION section of this manual, see mes-

sage labeled IMPORTANT regarding

the use of gasohol in your engine.

Fuel stabilizer is an acceptable alter-

native in minimizing the formation of

fuel gum deposits during storage. Add

stabilizer to the gasoline in the fuel

tank or fuel storage container. Follow

the mix instructions found on stabilizer

container. Run engine at least 5 min-

utes after adding stabilizer.

Craftsman 40:1, 2-cycle engine oil (air

cooled) is already blended with fuel

stabilizer. ]f you do not use this Sears

oil, you can add a fuel stabilizer to

your fuel tank.

ENGINE

• Remove spark plug and pour 1 tea-

spoon of 40:1, 2-cycle engine oil (air

cooled) through the spark plug

opening. Slowly pull the starter rope

8 to 10 times to distribute oil.

• Replace spark plug with new one of

recommended type and heat range.

• Clean air filter.

• Check entire unit for loose screws,

nuts, and bolts. Replace any dam-

aged, broken, or worn parts.

• At the beginning of the next season,

use only fresh fuel having the proper

gasoline to oil ratio.

OTHER

• Do not store gasoline from one sea-

son to another.

• Replace your gasoline can if it starts

to rust.

20

Page 21

TROUBLESHOOTING TABLE

WARNING: Always stop unit and disconnect spark plug before perform-

ing all of the recommended remedies below except remedies that require

operation of the unit.

TROUBLE

Engine will not

start.

Engine will

not idle

properly.

Engine will not

accelerate,

Jacks power,

or dies under

a load.

Engine

smokes

_=xcessively.

Engine runs

hot.

CAUSE

1. ON/OFF switch in

OFF position.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor,

6. Carburetor requires

adjustment.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. Air filter dirty.

2. Spark plug fouled,

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compression low.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1, Fuel mixture incorrect.

2, Spark plug incorrect,

3, Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

REMEDY

1, Move ON/OFF switch to ON.

2, See "Starting a Flooded Engine" in

Operation Section.

3, Fill tank with correct fuel mixture.

4, install new spark plug.

5, Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6, Contact Sears Service (see back cover).

1, See "Carburetor Adjustment" in

Service and Adjustments Section.

2, Contact Sears Service (see back cover).

3, Contact Sears Service (see back cover).

1. Clean or replace air filter.

2. Clean or replace plug

and regap,

3. Contact Sears Service (see back cover)

4. Contact Sears Service (see back cover)

5. Contact Sears Service (see back cover)

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact Sears Service (see back cover)

1. See "Fueling Engine" in Operation

section.

2. Replace with correct spark plug.

3. Contact Sears Service (see back cover)

4. Contact Sears Service (see back cover)

21

Page 22

YOUR WARRANTY RIGHTS AND

OBLIGATIONS: The U. S. Environ-

mental Protection Agency/Environ-

ment Canada and Sears Canada.

Inc., are pleased to explain the emis-

sions control system warranty on your

year 2002-2004 small off-road engine.

Sears Canada must warrant the emis-

sion control system on your small off-

road engine for the periods of time listed

below provided there has been no

abuse, neglect, or improper mainte-

nance of your small off-road engine.

Your emission control system includes

parts such as the carburetor and the

ignition system. Where a warrantable

condition exists. Sears Canada will re-

pair your small off-road engine at no

cost to you. Expenses covered under

warranty include diagnosis, parts and

labor. MANUFACTURER S WARRAN-

TY COVERAGE: If any emissions re-

lated part on your engine (as listed un-

der Emissions Control Warranty Parts

List) is defective or a defect in the mate-

rials or workmanship of the engine

causes the failure of such an emission

related part, the part will be repaired or

replaced by Sears Canada. OWNER'S

WARRANTY RESPONSIBILITIES: As

the small off-road engine owner, you

are responsible for the performance of

the required maintenance listed in your

instruction manual. Sears Canada rec-

ommends that you retain all receipts

covering maintenance on your small

off-road engine, but Sears Canada

cannot deny warranty solely for the lack

of receipts or for your failure to ensure

the performance of all scheduled main-

tenance. As the small off-road engine

owner, you should be aware that Sears

Canada may deny you warranty cover-

age if your small off-road engine or a

part of it has failed due to abuse, ne-

glect, improper maintenance, unap-

proved modifications, or the use of parts

not made or approved by the original

equipment manufacturer. You are re-

sponsible for presenting your small off-

road engine to a Sears Canada autho-

rized repair center as soon as a

problem exists. Warranty repairs should

be completed in a reasonable amount

of time, not to exceed 30 days. If you

have any questions regarding your war-

ranty rights and responsibilities, you

should contact your nearest authorized

service center or call Sears Canada at

1-800-665-4455. WARRANTY COM-

MENCEMENT DATE: The warranty pe-

riod begins on the date the small off-

road engine is purchased. LENGTH

OF COVERAGE: This warranty shall be

for a period of two years from the initial

date of purchase. WHAT IS COV-

ERED: REPAIR OR REPLACEMENT

OF PARTS. Repair or replacement of

any warranted part will be performed at

no charge to the owner at an approved

Sears Canada servicing center. If you

have any questions regarding your war-

rarity rights and responsibilities, you

should contact your nearest authorized

service center or call Sears Canada at

1-800-665-4455. WARRANTY PE-

RIOD: Any warranted part which is not

scheduled for replacement as required

maintenance, or which is scheduled

only for regular inspection to the effect

of "repair or replace as necessary" shall

be warranted for 2 years. Any war-

ranted part which is scheduled for re-

placement as required maintenance

shall be warranted for the period of time

up to the first scheduled replacement

point for that part. DIAGNOSIS: The

owner shall not be charged for diagnos-

tic labor which leads to the determina-

tion that a warranted part is defective if

the diagnostic work is performed at an

approved Sears Canada servicing cen-

ter. CONSEQUENTIAL DAMAGES:

Sears Canada may be liable for dam-

ages to other engine components

caused by the failure of a warranted

part still under warranty. WHAT IS NOT

COVERED: All failures caused by

abuse, neglect, or improper mainte-

nance are not covered. ADD-ON OR

MODIFIED PARTS: The use of add-on

or modified parts can be grounds for

disallowing a warranty claim. Sears

Canada is not liable to cover failures of

warranted parts caused by the use of

add-on or modified parts. HOW TO

FILE A CLAIM: If you have any ques-

tions regarding your warranty rights and

responsibilities, you should contact your

nearest authorized service center or call

Sears Canada at 1-800-665-4455.

WHERE TO GET WARRANTY SER-

VICE: Warranty services or repairs shall

be provided at all Sears Canada service

centers. Call 1-800-665-4455. MAIN-

TENANCE, REPLACEMENT AND RE-

PAIR OF EMISSION RELATED

PARTS: Any Sears Canada approved

22

Page 23

replacementpartusedin the pertor-

mance of any warranty maintenance or

repair on emission related parts will be

provided without charge to the owner if

the part is under warranty. EMISSION

CONTROL WARRANTY PARTS LIST:

Carburetor, 19nition System: Spark Plu9

(covered up to maintenance schedule),

Ignition Module. MAINTENANCE

STATEMENT: The owner is responsible

for the performance of all required main-

tenance as defined in the instruction

manual.

The information on the product label indicates which standard your engine is certified.

Example: (Year) EPA Phase 1 or Phase 2 and/or CALIFORNIA,

This engine is certified to be emissions compliant for the following use:

[] Moderate (50 hours)

[] Intermediate (125 hours)

[] Extended (300 hours)

23

Page 24

Garantie 26

R_gles de S6curit6 26

Montage 30

Fonctionnement 34

Entretien 44

R6parations et R6glages 45

Rangement 47

Tableau de D6pannage 48

Garantie de lutte an missions 49

Commande de pieces Page arri_re

GARANTIE LIMITEE DE DEUX (2) ANS SUR LE WEEDWACKER CRAFTSMAN

.,&.ESSENCE

Durante une p6riode de deux (2) an _ compter de la date d'achat, Sears Canada

Inc., _ sa discretion, r6parera ou remplacera gratuitement les pieces qui sont s6-

fectueuses, suite _ route d6fectuosit6 de mat6riaux ou de fabrication.

UTiLISATION COMMERCIALE OU POUR LOCATION:

La garantie couvrant le Weedwacker sera de 90 jours _ compter de la date d'a-

chat si I'appareil est utilis6 _ des fins commerciales ou de location.

Cette garantie ne couvre pas ce qui suit:

t. Bougies, ffltre, fil de coupe, bobine, courde du d6marreur et lame.

2. Les dommages au moteur de I'apparefl si le bon melange d'essence et d'huile

n'a pas 6t6 utilise (voir le manuel).

Un service sous garantie peut _tre obtenu en retournant le Weedwacker au Centre

de Service Sears le plus proche au Canada. Cette garantie ne s'applique que pen-

dant que appareil est utilis6au Canada.

Cette garantie vient s'ajouter _ toute garantie statutaire et n'exclut nice limite pas

]es droits juridiques que vous pourriez avoir, mais sera applicable en conjonction

avec toute Ioi provinciale en vigueur. De plus, certaines provinces ne permettent

PAS ]es restrictions quant _ la dur6e de la garantie implicite et les restrictions ce-

dessus pourraient done ne pas s'appliquer _ vous.

Sears Canada Inc., Toronto, Ontario M5B 2B8

_ AVERTISSEMENT: Lorsque

vous employez n'importe que] appareil

de ardinage, il faudra toujours respecter

des pr6caut ons fondamenta esde s6-

curit6 afin de r6duire le risque d'incendie

et de biessures graves. Lisez et obser-

vez toutes les instructions.

DANGER: Cet outil motoris6 peut

6tre dangereux ! II peut causer des

blessures graves dont I'amputation ou

la c6cit6 _ I'utilisateur ou _ des tiers.

Les instructions et avertissements de

ce manuel doivent etre respect6s pour

assurer une s6curit6 et une efficacit6

raisonnables Iors de I'utilisation de

I'outil. L'utilisateur a la responsabilit6

de respecter les avertissements qui se

trouvent dans ce manuel et sur I'outil !

R6server I'usage de cet outil aux per-

sonnes qui lisent, comprennent et re-

spectent les avertissements et instruc-

tions qui se trouvent dans ce manuel

et sur I'outil. Ne jamais laisser d'en-

fants utiliser cet outiL

Y /

MANUEL iNFORMATION DE

D'INSTRUCTIONS SECURITE SUR

L'APPAREIL

A

41_ DANGER: Bien respecter tous

les avertissements et toutes les

instructions. Tout d6faut de le faire

peut entrai'ner des blessures graves.

26

Page 25

AVERTISSEMENT: La lame/ill

de coupe peut se projeter violement

hors de mat6riaux qu'elle ne coupe

pas. Cette projection peut causer I'am-

putation de bras ou jambes.

TOUJOURS PORTEZ:

Lunettes _Qr!_

de s6curite

Jambieres

BottJnes

_1_AVERTISSEMENT: Zone de

danger des objet projet6s. Le ill de

coupe ou la lame peuvent projeter vio-

lemment les objets. Vous risquez

d'aveugler ou de blesser des person-

nes tiers. Ne laissez ni personnes ni

animaux s'approcher _ moins de 15

metres.

Zone de

Danger

_1_AVERTISSEMENT: N'utilisez

pas la t6te de coupe pour attacher la

lame.

AVERTISSEMENT: La lame

continue _ tourner apres avoir rel_ch6

I'acc61erateur ou arrete le moteur. La

lame en rotation peut projeter des objets

ou vous couper gravement si touchez.

Arr6tez la lame en touchant la matiere

coup6e avec le c6t6 droite de la lame

en rotation.

Arr6tez la lame

qui fait roue Iibre

en la mettant en

contact avec du

mat_riau coup&

®

Si vous vous trouvez dans des situa-

tions non descrites dans ce manuel,

soyez prudents et utilisez votre bon

sens. Si vous avez besoin d'aide, met-

tez-vous en rapport avec votre Centre

de Service Sears ou avec le t61ephone

1-800-235-5878.

SF:CURITF: DE L'UTILISATEUR

• Equipez-vous bien. Quand vous uti-

]isez ou entretenez votre appareil,

portez toujours des lunettes de secu-

rit6 ou une protection des yeux simik

aire (lunettes de securit6 dispo-

nibles). La protection des yeux

devriez marqu6e Z87.

• Pour les travaux poussiereux, portez

toujours un masque.

• Portez toujoursdes pantalons longs

et 6pals, des manches Iongues, des

bottes et des gants. On recommande

I'utilisation de jambieres.

Tou ours protection de pleds d usure.

Ne trava ez pas p eds nus et ne

portez pas de sandales. Tenez-

vous _ 1'6cart le ill/lame qui tourne.

• Attachez-vous les cheveux pour

qu'ils ne d6passent pas les 6paules.

Attachez ou enlevez tousles vete-

merits amples et les bijoux ou les

vetements qui ont des attaches, des

bretelles, des pompons, etc. qui pen-

dent. IIs peuvent se prendre dans

les pieces mobiles.

• Si vous etes bien couvert(e), cela

vous aidera _ vous proteger contre

les debris et brins de plantes toxk

ques qui sont projet6s par le ill/lame

qui tourne.

• Soyez vigilant(e). N'utilisez pas I'ap-

pareil quand vous 6tes fatigue, mal-

ade ou sous influence de I'alcool,

des drogues ou des m6dicaments.

Portez attention _ ce vous faites et

faites preuve de bon sens.

• Portez un protecteur de I'oufe.

• Ne mettez pas I'appareil en marche

ni laissez pas tourner le moteur dans

un endroit ferm& Respirer la vapeur

d'essence peut vous tuer.

• Conservez les poignee libres d'huile

et de carburant.

27

Page 26

• Utilisez toujours le poignee-guidon

et la bandouliere correctement pc-

see sur repaule en vous servant

d'une lame. Voir MONTAGE.

S¢:CURIT¢: DE L'APPAREIL ET

DANS LE ENTRETIEN

,_ AVERTISSEMENT: Debranchez

toujours la bougie quand vous faites le

maintien, sauf les reglages du carbura-

teur.

• Inspectez rappareil et changez les

pieces endommagees ou branlantes

avant chaque utilisation de I'appareiL

Reparez toute fuite de carburant

avant d'utiliser I'appareiL Tenez I'ap-

pareil toujours en bon etat de fonc-

tionnement.

• Jetez toute lame tordue, deformee,

craquelee, brisee ou autrement en-

dommagee. Remplacez les pieces

de la tete de coupe qui sont 6bre-

chees, craquelees, cassees ou en-

dommagees de n'importe quelle

autre fa?on avant de faire demarrer

le moteur.

• Entretenez rappareil selon les me-

thodes recommandees. Conservez

]a lame affilee. Conservez le fil de

coupe _ la bonne Iongueur.

• N'utilisez que le fil de coupe de

marque Craftsman®. Ne utilisez pas

jamais de broche, de corde, de fi-

celle, etc.

• Installez-bien la protecteur requise

avant d'utiliser I'appareiL Utilisez le

protecteur en metal Iors de toute uti-

lisation de la lame en metal. Utilisez

le protecteur en plastique lots de

toute utilisation du tete de coupe.

_ AVERTISSEMENT: N'utilisez

que les accessoire du coupe-brous-

saille qui possedent un protecteur de

metal avec une nez saillant.

Nes saillant

• Utilisez la tete de coupe ou la lame

specifiee. Assurez-vous qu'elle est

bien installee et que toutes les

pieces sont bien serrees.

• Assurez-vous que I'appareil est cor-

rectement monte selon ce manuel.

• Ne demarrez jamais le moteur sans

le carter de protection de I'embray-

age. Des pieces pourraient ce separ*

er et blesser grievement quelqu'un.

• Assurez-vous que la lame ou la tete

de coupe ne tournent plus Iorsque le

moteur est au point mort.

• Entreprenez les reglages du carbura-

teur, en 6vitant que la lame ou le fil de

coupe ne touche quelqu'objet que ce

soit. Tenez rappareil _ la main et n'uti-

lisez pas la bretelle.

• Tenez toute autre personne eloignee

pendant que vous faites le reglage

au carburateur.