Page 1

HOW

DO

M

TO

ORE

WITH

YOUR

11

2926

OVER

Bench

100

OPERATIONS

A

CRAFTSMAN

Saw

DESCRIBED

AND

HANDBOOK

IllUSTRATED

Page 2

BwA-Ji,

~

A~IIN'

FOR SAWING

Use

the

correct

Just

a few

are shown here.

FOR CUTTING

Use

the universal jig

ing

of

.workpiece.

VARIOUS

blade

of the various blades

Also

see page 8.

TRUE

for exact

FOR CUTTING EXA

TAPERS

Use

the

adjustable

tap

MATERIALS

for

the material

and

DADO TENONS

positioning and hold-

CT

MEASUREMENT

er jig.

and

their

the

job.

purposes

FO

R GROOVES, RABBETS, CHAMFERS

Use a

dado

set

or

FOR EDGE

MOLDING,

TONGUE-ANDAND

DECORATING

Use

either

the

...

the

iliary,

with an

hold-down

single-

assortment

homemade

attachment

an adjustable

GROOVE

or

fence)

da<;lo.

CUTTING

JOINTS

triple-cutter mol

of

cutters. You also need

(to

attach

and/or

the

universal jig.

to

ding

an

head

aux

-

FOR SANDING

AND/OR

Use a sanding wheet

discs

cemented

BEVEL

to

its two faces .

EDGES

ANGLES

...

FOR ACCURATE, EASIER CROSSCUTTING

U

se a hold-down

large w

orkpieces,

of

the

table

on

equip

extensions.

your

miter

your

saw

gauge .

with

..

one

and.

Or

for

both

AT

with

TRUE

two

different

MITER

grit

Page 3

REVISED

INDEX

1969

GENERAL

Descriptive

Saw

ACCESSORIES

HAVE

Pertinent

increasing

accessories.

PROPER

PROCEDURES

General

actions

an

SELECTION

STANDARD

Ripping.

Work,

Miter

Extension -Stops

Blocks.

MAKING

Bevel

Ripping.

SPECIAL

Making

End

Curves -Coves -Bawls;

a

Miter

THE

The

Handling -Regularly

Grooves -Wide

and

Rabbets -Rounding

Square

MOLDING

OPERATIONS

Molding

Straight

Circular

and

Ornamental

-

Coves

Power

30

DIFFERENT

Completely

for

joints.

FASTENERS

G

tuing,

TABLES

INFORMATION

Data -Selection

and

Motor.

.............

circular

Resewing,

Gage,

Cuts -Miter

Cuts;

DADO

Tools -Adjustments -Work

Stopped

Stock.

Raised

Saw.

making

YOU

facts

about

and

safer-operation

OPERATING

................

information

and

handling

saw.

OF

SAW

SAW

Narrow

ANGLE

SAW

Center

Board -Cutting

Set-Up -Patterns

Edges -Strip

and

.••

nailing,

....•.•.......•••.....

OPERATIONS.

Work,

Crosscutting,

Auxiliary

CUTS

OPERATION

Cuts,

Cutting

Rabbets

SAWS.

Grooves -Gains

Grooves -Tenons-

AND

SANDING

.•...•..•••••.•

Curved

Panels -Dowels

Work -Spiral

and

Sanding

WOOD

illustrated

thirty

different

...•.•...•.....•

bolting,

of

SHOULD

,

•.....•..

work

about

proper

of

work

pieces

BLADES

Lang

and

Table

and

Clearance

•.......•

Cuts -Taper

.•.••

Edge

Cuts,

-

Using

Tenons.

_.

_

.i

.••..••

Spaced

and

Tapering

-

Moldings

Work -Tenons

-

Turnings

with

JOINTS

instructions

woad

screwing.

..•.

-

..

Page

4-5

6-7

9-11

13-17

18-20

21-23

24-29

29-31

32

12

3

8

The

Bench

An

Illustrated

of

Operation

for the

SET-UP - ACCESSORIES - PROPER

HOME

SHOP

ALL

STANDARD

SAWING

DADO

MOLDING

SANDING

...

Saw

Manual

CRAFTSMAN

OWNER

AND

SPECIAL

OPERATIONS.

OPERATIONS

OPERATIONS

OPERATIONS

TABLES

HANDLING

Catalog

-<

~.~

A

MIDWEST

No.

9-2926

A

TECHNICAL

215

CRAFTSMAN

PUBLICATION

Form

No.

B71

123208 A 000

HANDBOOK

ILLUSTRATIONS

Copyrighted

SEARS.

ROEBUCK

1969

and CO.

Printed

in

U.S.A.

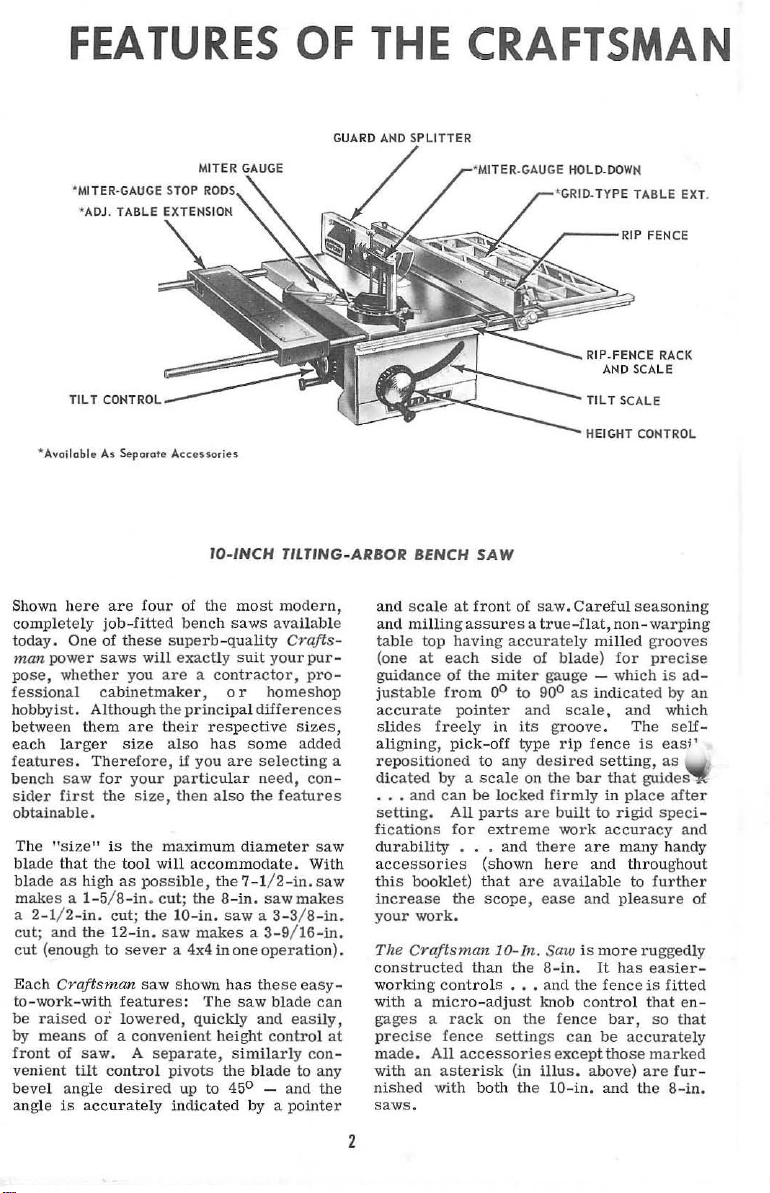

Page 4

FEATURES

OF

THE

CRAFTSMAN

'M

TIL T

'A"oilable

Shown

here

compl

ete

y.

power

whe

ional

etween

lar

ch

saw

first

"size"

that

as

s a

2-1/2-i

; and

(enough to

Craftsman

work-with

raised

eans

of

angle

is

ly

One

tilt

toda

man

pose,

f

ess

hobbyist.

b

each

features.

ben

sider

obtainable.

The

blade

blade

make

a

cut

cut

Each

tobe

by m

front

venient

bevel

angle

ITER

-GAUGE

SlOP

CONTROL

As

of

saws

ther

cabinetmaker

Although

them

ger

Therefore,

for your

the size, then

the

high

1-5/8-in. cut;

n.

the 12-in.

or

of a convenient

saw. A separate,

accurately

Separ

are

job

-fi

these

you

are

size

is

the

tool

as

cut;

sever

feature

lower

control

desired

ate

four of the

tted

will

the

will

possible,

the IO-in.

saw

.--

Accessories

bench

superb-quality

exactly

are a contractor,

, 0 r

principal

their

also

if

you

particular

maximum

accommodate.

the 8-i

saw

makes a 3-9

a 4x4

shown

s:

The

ed,

quickly

pivots

up to 45

indicated

IO-/NCH

TILTING-ARBOR

most

modern,

saws

available

Crafts-

suit

your

pur

pro-

homeshop

differences

respective

has

are sel

also the

the7-1/2-in.saw

saw a 3-3/8-in.

in

one

has

height

similarly con-

the

some

need,

features

diamet

n.

saw

operation).

the

saw

blade

and

control

blade to

0

-

by a

sizes,

added

ecting

con

er

With

makes

/ 16-in.

se

easy

easily,

and

pointer

-

a

-

saw

-

can

at

any

the

r'MllrB',G,'U';'

BENCH

and

scale

and

table

(one

guidance

ju

stab

accurate

slides freely

aligning,

repo

dicated

•••

setting. All

fications

durability

acc

this booklet)

increase

your

The

constructed

working

with a

gages a rack

preci

mad

with

nished

saws.

at

milling

assures a true-nat,

top

having

at

eac

of

the

le

from

pointer

pick-off

sitioned

by a sca

and

can

for

•••

essories

the

work.

Craftsman

contro

micro-adjust

se

fence

e.

All

accessories except those

an

asterisk

with both

r-"',RII',TYPE

SAW

front

of

accurate

h side

of

miter

00 to 900 as

and

in

its

type

to

any

le

on

be

lock

ed

parts

are

extreme

and

(shown

that

are

scope,

lO-ln.

than

the 8-in.

ls •

..

on

the

settings can

(in

the

HOLD.

DOWN

~--RIP

RIP.FENCE RACK

AND

TILT SCALE

HEIGHT

saw.

Careful

non-warping

ly

mill

blade)

gauge -which

groove.

desired

the

firm

built

there

here

ava

ease

Saw

and

knob

fence

illu

la-in.

for

indicated

scale,

rip

fence

setting,

bar

that

ly

in

to

rigid

work

accuracy

are

many

and

ilable

and

ple

is

more

It

has

the

fence

control that en-

bar,

be

s.

above)

and

TABLE

FENCE

SCALE

COHTROL

seasoni

ed

grooves

precise

is

by

and

which

The

is

easi'

as

guides

place

speci

handy

throu

gho

to

further

asure

ruggedly

easier

is

fitted

so

accurate

marked

are

the 8-in.

EXT.

ad-

an

seU

after

and

that

fur-

ng

-

-

ut

of

-

ly

2

Page 5

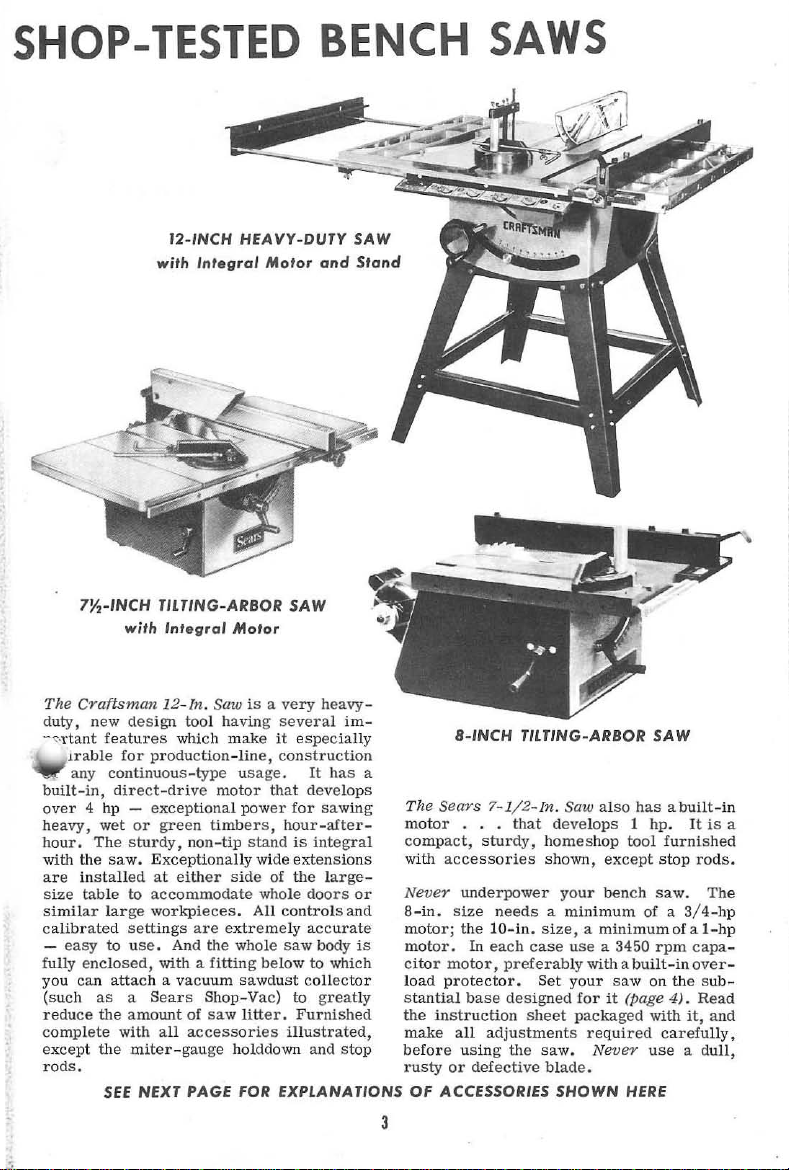

SHOP-TESTED

BENCH

SAWS

12-1NCH

with

7j1,-lNCH

The

Craftsman

duty, new

--;-'1'tant

uable

any

built-in,

over

4 hp -

heavy,

wet

hour.

The

with

the

are

installed

size

table

similar

TILTING-ARBOR

with

Integral

12-1n.

design

featur

es

for

production

continuous-type usage.

direct-drive

exceptional

or

green

sturdy,

saw.

Exceptionally

at

to

accommodate

large

workpieces.

calibrated settings

-

easy

to

use.

f

ully enclosed,

you

can

(such

reduce

complete

except

rods.

attach a vacuum

as a Sears

the

the

SEE

And

with a

amo

unt

with a

ll

miter-gauge

NEXT

HEAVY-DUTY

'nfegral

Motor

Saw

tool

which

is a very

having

make

-lin

motor

e,

power

timbers,

non-tip

stand

wide

either

side

whole

All

are

extremely accurate

the

whole

fitting

below

sawdust

Shop-Vac)

of

saw

litter.

accessories

holddown

PAGE

FOR

SAW

Motor

and

Stand

SAW

heavy

several im-

it

especially

construction

It

has

that

develops

for

sawing

hour-after-

is

integral

extensions

of

the

large-

doors

controls

saw

to

illustrated,

EXPLANATIONS

or

and

body

to which

collector

greatly

Furnished

and

stop

is

-

a

8-/NCH

The

Sears

motor

compact,

with

accessories

Never

8-in.

size

motor;

motor.

citor

motor,

load

protector.

stantial

the

instruction

make all

before

rusty

or

OF

ACCESSORIES SHOWN HERE

TIlTING

7-1/2-In.

. . .

that

sturdy,

underpower

needs a minimum

the

10-in.

In

each

case

preferab

base

designed

sheet

adjustments

using

the

defective

3

-ARBOR

Saw al

develops 1 hp.

homeshop

shown,

your

size, a minimumofal-hp

use

ly with a

Set

your

for

packaged

required

saw.

blade.

so

except

bench

a 3450

saw

it

(page

Never

tool

built-in

SAW

has a built-in

It

furnishe

stop

rods.

saw.

of a 3/4-hp

rpm

capa

over

on

the

sub

4).

Read

with

it,

carefully,

use a dull,

is

The

and

a

d

-

-

-

Page 6

BENCH

SAW

ACCESSORIES

IMPROVE

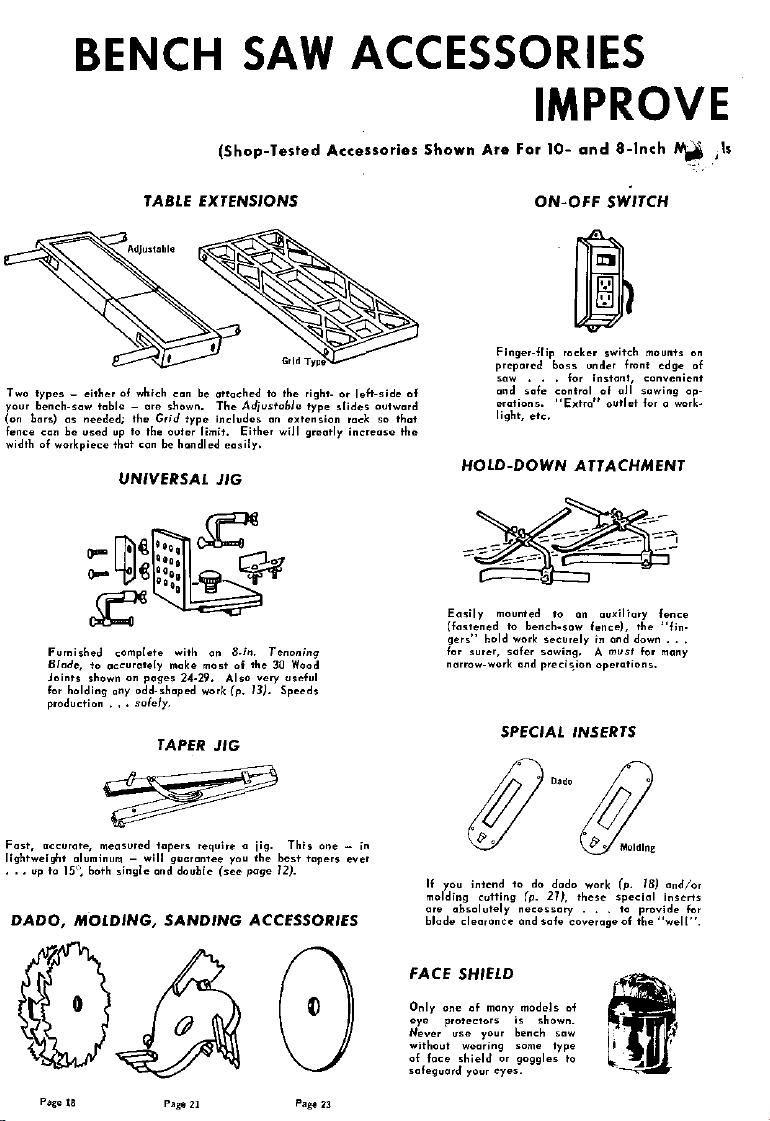

Two

types _ either

your

bench-saw

(on bors)

fence

..

width

of

as

needed;

cn

be

used

workpiece

Furnished

Blade,

Joints

shown on

~or

holding

production.

TABLE

01

which

table -ore

the

up

to

the

that

can be handle.!

UNIVERSAL

complete

to

(I<:cu'ole[y make

poges

any

odd-shaped

, ,

safely.

EXTENSIONS

can

be

shown.

Grid

type

outer

with on

24·29.

TAPER

(Shop-Tested

attached

to

The

Adjustable

includes

Either

easily,

on

limit.

JIG

8.in.

of

Also

the

13).

very

Tenoning

most

work (p.

JIG

the

extension

will

30

Wood

useful

Speeds

Accessories

right_ Or

left-side

type

slides

rock so

g.eotly

increase

outward

thot

the

Shown

01

Easily

(fastened

gers"

for

narrow_work

Are

For

10-

ON-Off

Finger.Hip

prepored

boss

saw

•••

ond

safe

erations.

light,

etc.

HOLD-DOWN

mounted

to

to

bench_sow

hold

work

surer,

securely

safer

sowing. A must

and

preci~ion

SPECIAL INSERTS

and

a-Inch

SWITCH

rocker

switch

under

front

for

instont,

control

of

"Extra"

011

outlet

ATTACHMENT

an

auxiliary

fence),

the

in

and

down

operations.

~

mounts

edge

convenient

sowing

for

(I

work.

fence

"fin-

..•

for many

op-

j

15

on

of

Fast,

"ccurate,

lightweight

...

up

to

DADO,

Page

measured

aluminum - will

15",

both

single

MOLDING,

18

topers

require a jig.

guarantee

and

double

SANDING

Page

21

you

the

best

(see

page

12).

ACCESSORIES

This

Page 23

One _ in

tapers

ever

If you

molding

are

blade

fACE

Only

one

eye

protectors

Never

without

of

face

safeguard

intend

cuttillg

absolutely

clearollce

SHIElD

of

many

use

your

wearing

shield

your

or

eyes.

to

do

(p.

necessary

and

safe

models

is

shown.

bench

some

goggles

dado

21

type

saw

work (p.

J.

these

..

coverage

of

to

special

, to

of

18)

provide

the

"welr",

and/or

illserts

for

Page 7

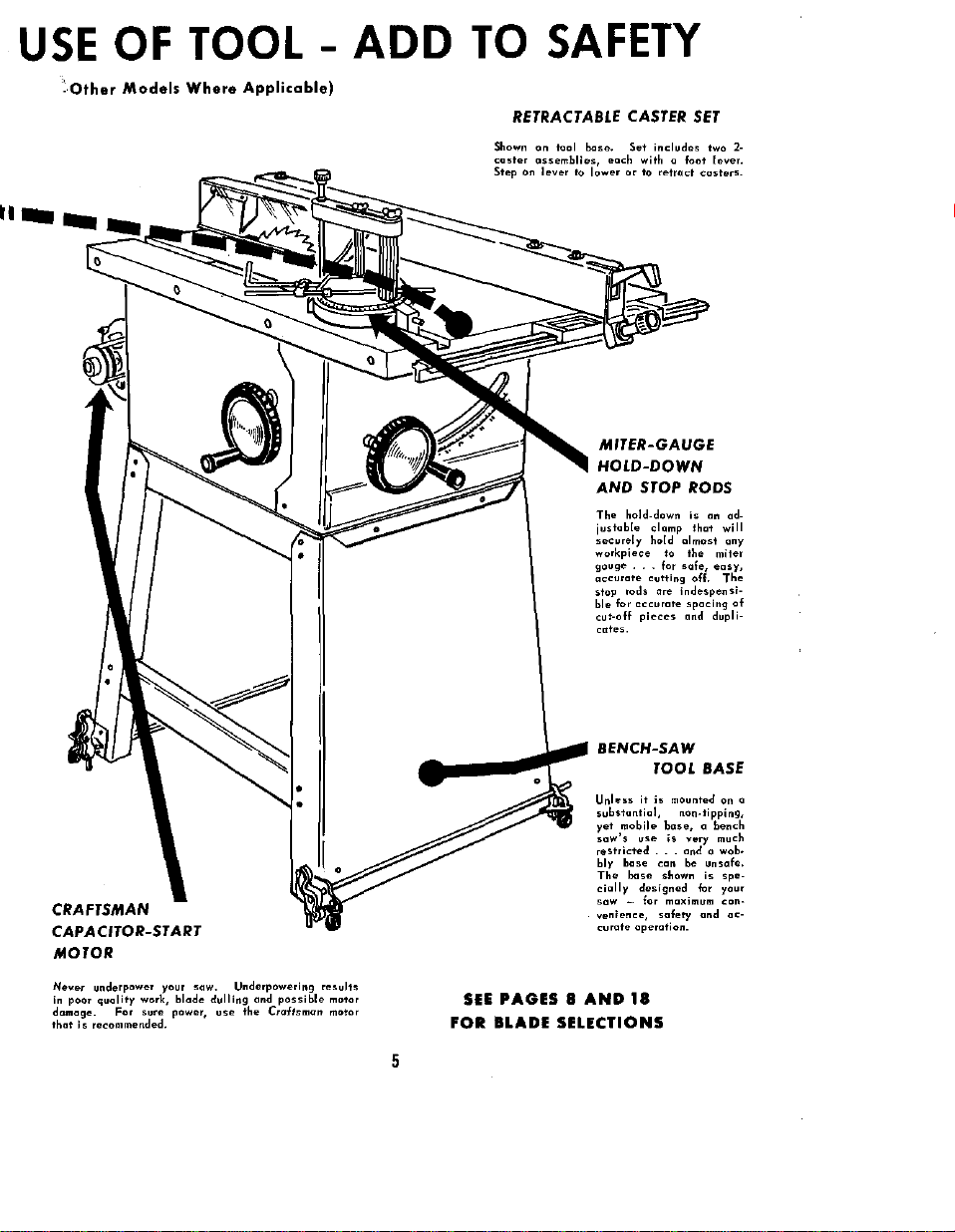

USE

.,Other

OF

TOOL

Models Where Applicable)

ADD

TO

SAFETY

RETRACTABLE CASTER

Shown

On

tool

(lssemblies,

lever

to

base.

lower

coster

Step

On

Set

each

or

AND

The

hold_dawn

justable

securely

workpiece

gouge

...

accurate

stop

tocls are

ble

for

cut-off

cotes.

SET

includes

retract

foot

two

costers.

with"

to

STOP RODS

is

on

clomp

that

hold

almost

to

the

for

sale,

cutting

off.

indespensi-

accurate

spacing

pieces

and

lever.

ad.

will

ony

miter

easy,

The

dupli.

2-

of

CRAFTSMAN

CAPACITOR-START

MOTOR

Nev"r

in

poor

damage.

the,

underpower

quality

is

recommended.

For

work,

sure

),our

blade

powe"

saw.

dulling

Underpowering

oml

use

the

possible

Craffsman

.esulfs

motor

motor

BENCH-SAW

TOOL BASE

Unl""s

it

is

mobile

use

bose

base

designed

operation.

18

mounted on "

non_tipping,

base,

is

very

...

and"

can

be

shown

maximum

safety

a bench

much

wob.

unsafe.

is

spe-

for

your

can·

and

aC-

SEE

PAGES 8 AND

FOR

BLADE

substontinl,

yel

sow's

restricted

bly

The

cially

saw _ for

venience,

curate

SELECTIONS

5

Page 8

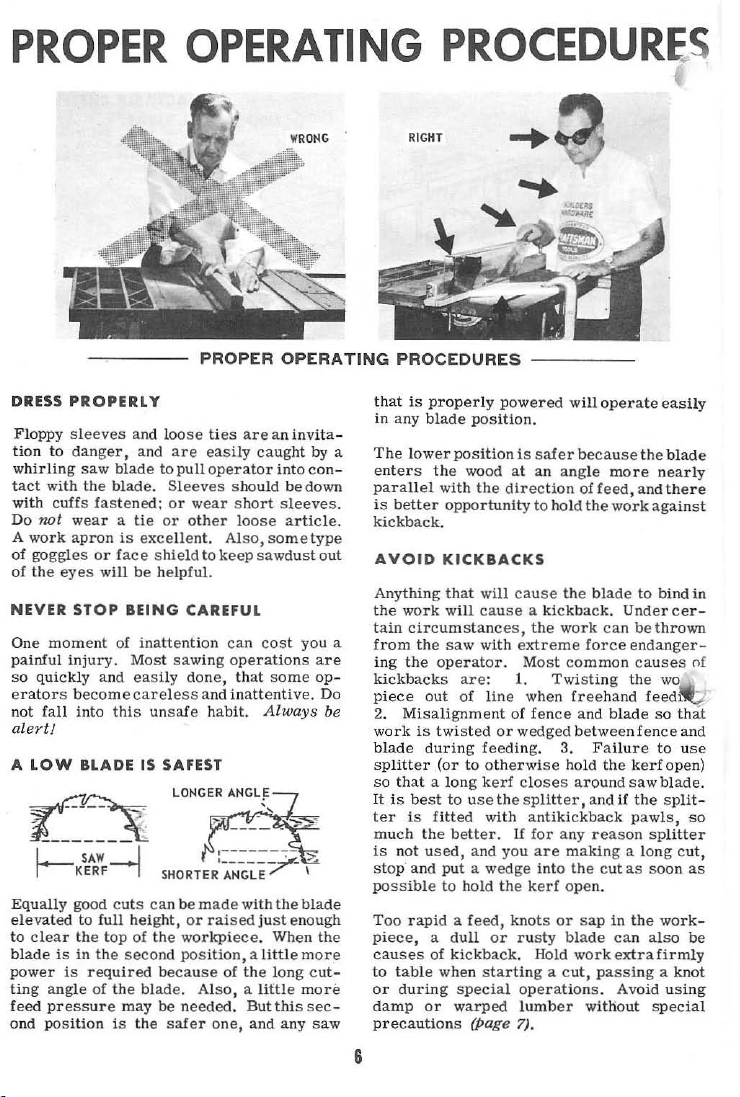

PROPER

OPERATING

PROCEDURES

DRESS

PROPERLY

Floppy

sleeves

tion

to

with

cuffs

work

goggles

the

eyes

moment

injury.

quickly

fall

danger,

wear a tie

apron

STOP

become

whirling

tact

with

Do twt

A

of

of

NEVER

One

painful

so

erators

not

alert!

A

LOW

~

1-

r-KERF

Equally

elevated

to

clear

bl

ade

is

power

is

ting

angle

feed

pressure

position

ond

and

and

saw

blade

the

faste

or

will

and

inlo

BLADE

to

blade. Sleeves

ned;

is

excelle

face shie

be helpful.

BEING

of

inattention

Most

easily

careless

this

unsafe

IS SAFEST

SAW-1

good

cuts can be

to

full

height,

the

top

of

the

of

second

the

may

is

the

the

because

blade.

be

in

required

RIGHT

PROPER

loose

ties

are

easily

pull

operator

or

wear

or

other

nt. Al

ld to

keep

CAREFUL

sawing

done,

and

habit.

LONGdR

~. ------~

,-

SHORTER'~NGLET

made

or

rai

workpiece

position, a little

Also, a liftle

needed.

safer

one,

OPERATING

are

an

invita

caught

by a

into

bedown

sleeves

article.

sawdust

cost

you a

some

Always

--:-

con

out

are

op-

Do

be

;;>-

should

short

loose

so,sometype

can

operations

that

inattentive.

ANGL~E,

----

\

with

the

just

enough

. When

the long

But

this

and

any

blade

the

more

cut-

more

sec

saw

s ed

of

that

in

The

-

enters

parallel

.

is

kickback.

AVOID

Anything th

the

tain

from

ing

kickbacks

piece

2.

work

blade

splitter

so

It

is

ter

much

is

stop· and

possible

Too

piece, a dull

causes

to

or

-

damp

precautions

PROCEDURES

is

properly

any

blade

lower

position

the

with

better

opportunity

KICKBACKS

at

work

will

circumstances,

the

saw

the

operator.

are:

out

of

Misalignment

is

twisted

during

(or

that

a l

ong

best

to

is

fitted

the

better. U for

not

used,

put a wedge

to

rapid a feed,

of

kickback.

tab

le when

during

special operations.

or

warped

...

powered

position.

is

wood

to

use

and

hold

(page 7).

safer

at

an

direction

to

the

extreme

Most

1.

when

of

fence

wedged

closes

splitter,

antikickback

you

are

into

the

kerf

knots

rusty

Hold

lumber

angle

hold

the

work

common

Twisting

3.

hold

any

making a long

open

or

blade

the

will cause

cause a kickback.

with

line

or

feeding.

otherwise

kerf

the

with

or

starting a cut,

will

operate

because

of

feed,

the

blade

force

freehand

and

between

Failure

around

and

reason

the

cut

.

sap

workextrafirmly

passing a knot

witliout

more

work

Undercer

can

endangerthe

blade

the

saw

if

as

tn

can

Avoid

easily

the

nearly

and

against

to

bind

be

thrown

causes

wo

feedr

so that

fence

to

kerf

blade.

the

split

pawls,

splitter

soon

the

work

also

special

blade

there

open)

using

in

-

nf

and

use

-

so

cut,

as

-

be

6

Page 9

contrivance

supported

supp

NO

STRAIGHT

EDGE

N°'fI

~

\;!

,

orted

blade

AVOID

when

be

sure

end

of

the

end

free

the

cut

AWKWARD

to

work,

to

fall

is

complete.

HAND

place

it

against

leaving

away

from

POSITIONS

the

the

un-

the

Warped

cause

table

permits

ing

process.

will

slide

tendency

KEEP

Always

between

ti

ng

your

the

safe

hand to

available

'."'ur

palm.

ur

hand

a

outer

steady,

and

anchor

and

kickba

ck,

or

against

binding

on

to bind

HANDS

be

certain

the

blad

hand into

slde,make

push

work

is

equal

For

for

fingers over

and

tuck

it

against

crooked

especially

fence

or

Always

table

the

CLEAR

that

e and

it

through,

to

added

the

push

the

thumb

wor

kpi

in a manner

twisting

make

and

along

saw

blade.

OF

there

the

fen

this

position. To

a

rule·notlo

the

maximum

safety,

through,

the

fence

in

end

of

eces

can

if

placed

during

fence

THE

is

ample

ce,

unless

to

behind

the

that

BLADE

before

use

the

width

when using

hook

keep

the

certain

workpiece.

also

on

the

that

feed-

work

without

room

get-

be

on

your

space

of

the

hand

palm

When

crosscutting,

even

for

cutting

backs

type

groove,

left

behind

hand

push

h

gauge

SUPPORT

and

are

of

hand

gauge

to

gauge

is

as

involves

stand

used,

straight

especially

operation.

at

on

workpiece

at

hold

work

and

keep

possible.

WORK

use

cuts.

more

likely

If

the

left

center

agai

work

it

AGAINST

the

Freehand

risk

to

using

side

with

of

gauge.

nst

to

the

as close

miter

gauge,

cross-

because

occur

in

the

left-hand

of

blade.

Place

thumb

hooked

Use

gauge,

and

saw.

If

to

center

WOBBLING

kick-

this

this

to

right

of

If

work

used,

around

from

you

is too n

use a push

the

behind

walk

around

YES~

.

~..

NEVER

When us

BIND

ing a miter-gauge

saw

to

J " I

.

arrow

and

finish

the

:.

FREE

for

stic

k (Page 9),

pull

the

saw.

\-

END

hand to

the

cut.

OF

stop

work

Hold

WORK

rod

use

GVARI)

be

safely

or walk

through

work

or

sim

AND

as

ilar

SPLITT

Never

saw

to

few

that

out

TWO

Dontt

of

Dontt

feet

hazard,

shou

7

ER

WHENEveR

advance

without

keep

minutes

will

danger

OBVIOUS

reach

free

let

might

ld

not

an

first

it

from

to

allow

work

of

being

up

to

wood -

floor

become

slip.

especially

be

allowed

f>QSSIBLE

unwieldy

providing a good

being

arrange

upset

DON'TS

saw

until

Sawdus

upset.

some

to

slide

or

blade

blade

littered

t is a

after

to

accumulate.

workpiece

kicked

to

being

to

support

It

takes

but

safe

support

on

table

with-

back

grab a piece

has

stoppe

so

that

definite

damp,

the

a

.

d.

your

fire

and

Page 10

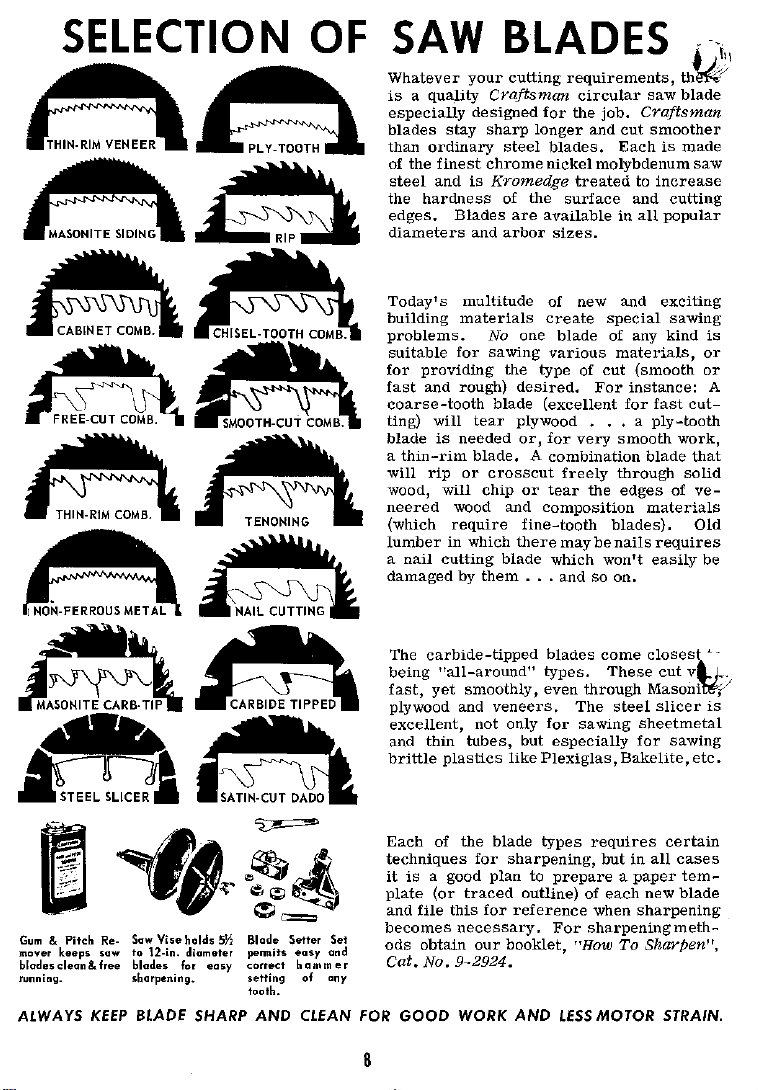

SELECTION

OF

SAW

Whatever

is a quality

especially

blades

than

of

steel

the

edges.

diameters

ordinary

the

finest

and

hardness

your

designed

stay

is

Blades

and

BLADES

cutting

the

are

for

longer

available

requirements,

circular

the

job.

and

blades,

nickel

molybdenum

treated

surface

sizes.

cut

Each

and

in

Craftsman

sharp

steel

chrome

Kromedge

of

arbor

-'("

th~

saw

blade

Craftsman

smoother

is

made

saw

to

increase

cutting

all

popular

Gum & Pitch

moVer

keeps

blades

<:Ieon

running.

ALWAYS

Re- Saw Vise holds

sow

to

12-in.

& free blades for

sharpening.

KEEP

BLADE

5J1

diameter

easy

SHARP

Blade Setter Set

permits

easy

correct

setting

tooth.

AND

ond

hammer

of

any

CLEAN FOR

Today's

building

problems.

suitable

for

fast

multitude

materials

for

providing

and

rough)

coarse-tooth

ting) will

blade

is

a

will

wood,

neered

(which

lumber

a

damaged

The

being

fast,

needed

thin-rim

rip

or

will

wood

require

in which

nail

cutting

by

carbide-tipped

"all-around"

yet

smoothly,

plywood and

excellent,

and

thin

brittle

plastics

Each

of

the

techniques

it

is

a good

plate

(or

file

obtain

No.

traced

this

necessary.

9-2924.

WORK

and

becomes

ods

Cat.

GOOD

of

new

No

sawing

blade

tear

one

the

type of

desired.

plywood

or J for

create

(excellent

special

blade

of

various

cut

For

•.• a ply-tooth

very

blade. A combination

crosscut

chip

blade

them

veneers,

not

tubes,

blade

for

plan

for

our

freely

or

tear

and

composition

fine-tooth

there

may

which

...

and

blades

types.

even

only

for

but

especially

like

Plexiglas,

types

sharpening,

to

prepare a paper

outline) of

reference

For

booklet,

AND

"How

LESS

the

blades).

be

nails

won't

so

on.

come

These

through

The

steel

sawing

requires

but

each

when

sharpening

MOTOR

and

exciting

sawing

any

kind

materials,

(smooth

instance:

for

fast

smooth

work,

blade

through

edges

of

materials

requires

easily

closes~'

cut

Masoni

slicer

sheetmetal

for

sawing

Bakelite,

certain

in

all

cases

new

sharpening

meth-

To

Sharpen",

STRAIN.

is

or

or

A

cut-

that

solid

veOld

be

v .

'/

is

etc,

tem-

blade

8

Page 11

STANDARD

SAW

OPERATIONS

IMPORTANT:

for

the

sake

",-,liNG

~ping

It

as

at

work

a

contact

make

will

vide a

even

auxiliary

serve

cut-out

iary

is

the

operations.

to

saw

is

kerf

to do

is

generally

a guide to

the

correct

is

reasonably

solid

not

straight

if

as

guide

warped,

use

of

the

splitter

spring

blade.

not

used,

just

so.

is

the

pushed

with

contact

wobble

this

means

straightedge

a guide.

near

board

turn

saw

should

closed

If,

as

of

clarity

sawing

done

position

width

along

straight

the

fence.

with

during

edge to go

center)

to

the

gua:rd

always

Wood

behind

for

stop

and

soon

as

We

have omitted

...

but

of wood with

with

the

help

and

maintain

for

the

cut.

the

fence,

edge to

Also,

the

the

operation.

against

temporary

board

If

a

molding

is

used,

the

fence.

hollow

side

is

recommended;

be

cut

with

the

reason,

insert

the

saw

cut

any

the

the

grain.

of

the

the

Because

it

must

sliding

work

that

thefence,

the

work

fence

an

auxil-

workpiece

up.

in

ripping

grain

and

bind

the

splitter

in

long

enough

fence

work

have

must

Proof an

(with

tends

saw guard and splitter

the

it

Best

blade

to

fingers

thumb

operators

pull

piece

pulling

and

front.

from

that

the

table

the

HANDLING

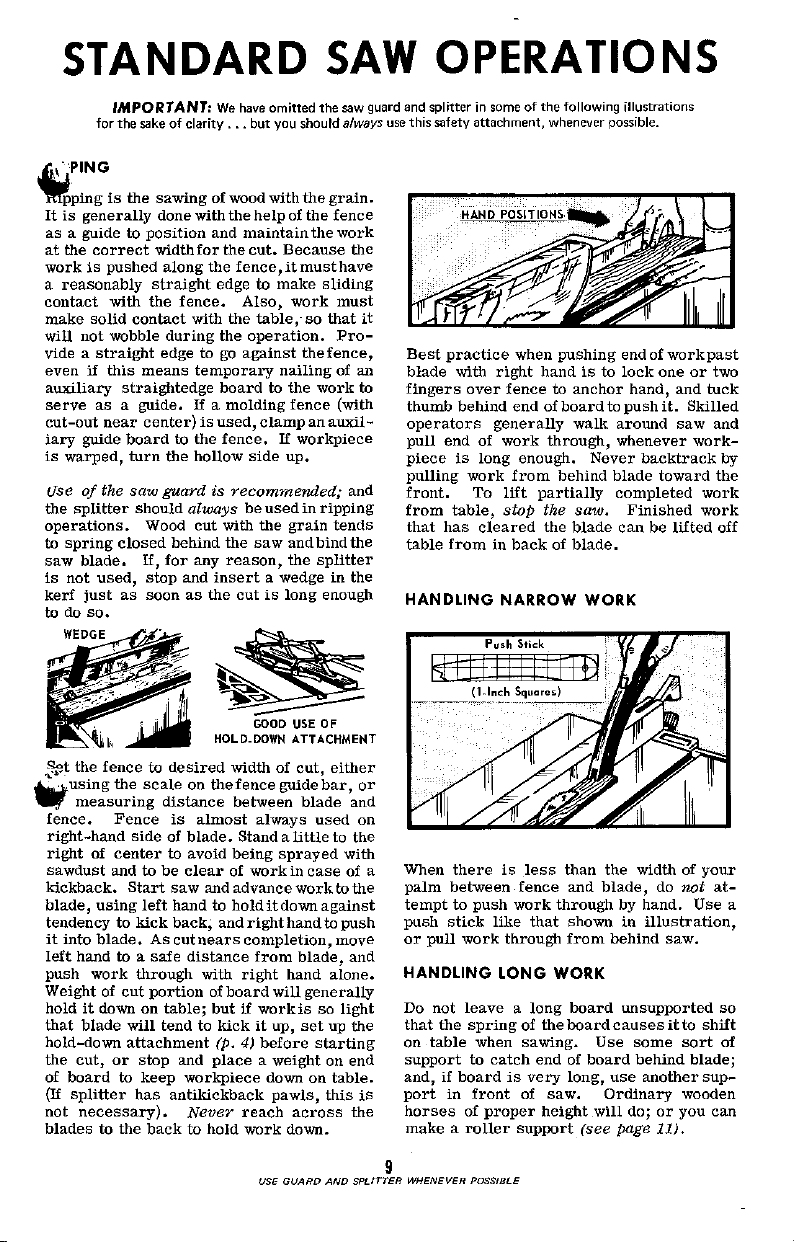

you should always use this safety attachment, whenever possible.

make

table, -so

nailing

to

clamp

If

used

the

a wedge

is

in

some

practice

with

right

over

behind

generally

end

of

is

long enough.

work

To

table,

has

cleared

from

in

of

the

when

pushing

hand

fence

to

end

of

board

work

through,

from

behind

lift

partially

stop

the

the

back

of

NARROW

following illustrations

is

to

anchor

to

walk

Never

saw.

blade

blade.

WORK

end of

workpast

lock

one

hand,

push

it.

around

whenever

backtrack

blade

toward

completed

Finished

can

be

lifted

or

and

Skilled

saw

work-

work

work

two

tuck

and

by

the

off

.~t

the

~using

,.,.

measuring

fence.

right-hand

right

of

sawdust

kickback.

blade,

using

tendency

it

into

blade.

left

hand to a

push

work

Weight of

hold

it

that

blade

hold-down

the

cut,

board

of

(If

splitter

not

necessary).

blades

fence

the

scale

Fence

side

center

and

to

Start

left

to

kick

through

cut

down on

will tend to

attachment

or

stop

to

keep

has

to

the

back

to

desired

on

distance

is

almost

of

blade.

to avoid

be

clear

saw

and

hand to

back;

As

cut

nears

safe

distance

with

portion

table;

and

workpiece

antikickback

Never

to hold

~

GOOD

USE

cut,

blade

little

sprayed

in

case

work

it

down

hand

blade,

hand

will

generally

up,

set

down on

pawls,

across

down.

GUARD

OF

either

bar,

and

used

on

to

the

with

of a

to

the

against

to

push

move

and

alone.

so

light

up

the

starting

on end

table.

this

the

AND

SPLITTER

or

is

HOLD.DOWN ATTACHMENT

width of

the

fence. guide

between

always

Stand a

being

of

work

advance

hold

and

right

completion,

from

right

of

board

but

if

workis

kick

it

(p.

4)

before

place a weight

reach

work

USE

When

there

palm

between·fence

tempt

to

push

stick

or

pull

work

HANDLING

Do

not

that

the

on

table

support

and,

if

board

port

in

horses

make a roller

9

WHENEVER POSSIBLE

is

less

push

work

like

that

through

LONG

leave a long

spring

of

catch

is

proper

support

the

sawing.

end

very

of

saw.

height

when

to

front

of

than

the

and

blade,

through

WORK

shown

from

board

board

Use

of

board

long,

will

by

behind

causes

use

Ordinary

(see page 11).

width of

do

1Wt

hand.

in

unsupported

do;

Use

illustration,

saw.

it

to

some

sort

behind

blade;

another

wooden

or

you

your

at-

a

so

shift

of

sup-

can

Page 12

RESAWING

Resawing

thinner

sawed

pas

Boards

plet

saw

When

quired,

about

the

kerf

ond

the

are

it

will

Position

Then

same

the

kickback

push

back

If

the

cuts

resawing

is

ones. Narrow

in one

ses,

one

up

ely

resawed

will

handle

two

cuts

these

1/ 2

inch

board.

will

close

cut,

with

kerf

closes,

no lon

ger

cut

into th

the

turn

the

face

is

seco

nd cut. Hold

...

stick,

side

of

board

from

the

or

the

of which will

ready made).

the

pass;

along

to

4-3/4

boards

from

shou

at

If

the

and bind

danger

parallel

em

fence

board

sti

ll

and

by

saw.

is

too wide,

opposite

board

track

ripping

of

thick

boards

hut

wide

ones

each

edge of the

in.

an

8-in

wide

. saw;

on

up to

opposite

ld

be

the

made

approximate cent

first

cut

the

of

kickback. Also,

the

two

sides

to the

to

spoil

their

and

make

end

(or

aga

inst

the

board

finish

pulling

securely

each cut

work

make

edges,

on a

band

nicely

in

boards

can

require

can be

the

6-1

/ 4

edges

to

is

too

deep.

saw

on

of

blade

appearance.

the

first

end (so

fence) to

by

through

two

maximum

then

saw

(the

the cuts al

into

be

retwo

board.

com-

lO-in.

in.

wide.

ar e

re-

overlap

er

the

the sec-

the

cut

...

and

cut.

that the

make

agai

nst

using

from

finish

blade

the

the

placed

cutting.

to guide

is

held

contact

a

miter-gauge

If

the left

hand

of

with

gauge

free

if

hand

reversed.

a

Ordinarily J the

groove with the s

work

table

Howe

not strike the

right-hand

permit

NORMAL

grain.

long way J

across

Therefore,

the

in

position

with

-hand

is

used

the

gauge and

into

to

assist

groove

MITER

is

so

in

front

ver,

make

reversing

CROSSCUTTING

As

planks

the

the

work

the

gauge

hold-down,

gro

to hold

the

blade.

as

is

used,

GAUGE

gauge

lide

wide

that

of saw,

certain

blade

table

groove

the

are

cut

long

edge

table

the

miter

to

the

saw,

by

keeping it

(preferably

ove

the

to

push

The

required.

the

hand

REVERSED

is

placed

in

front.

it

completely

reverse

that

- on

gauge.

top

p.

is

work

your

some

is

with

of

5).

used,

the

the

work

when

cross-

gauge

is

and

the

firmly

by us

the

in

contact

the

work

right

hand is

If

the

poSitions

in

the

When

covers

the

gauge.

gauge

saws

too clo

grain

used

work

ing

left

and

right-

are

table

the

will

the

se

is

in

to

CROSSCUTTING

Crosscutting is

the

sawing

of wood

across

10

Square

gauge

bl

ade).

of

the

the

cut

to

pre

held

again

to

bind

st

crosscutting

set

at

zero

The splitter

saw

guard

slowly and hold

vent

kickback

workpieces

table

when

the

blade

and

is

done with

(at a

right

is

not

is

will

needed,

recomm

work

or

firmly

chatter.

sometimes vibra

crosscutting.

dull

the teeth.)

the

angle

ended.

This

miter

to

but

Start

to

table

(Loose

tends

the

use

ly

te

Page 13

HANDLING

Work

)\

·ct

e

you s hould

of

the

USING MITER-GAUGE EXTENSION

To

prevent

rosscutting

c

gauge

gauge hold-down

s

imply a long-eno

bolted

electric

further

USE

OF

Cr

osscutting

that

to

push, and

boards

table

extension

to

the

tape

preve

STOPS

LARGE

WORK

PIECES

hangs

over

the

cut, str

or for

fit

yo

ur

extensions

AND

HOLD

a long

board

it,

you

together

(p.

ugh,

miter-gauge

stuck

along

nt Slippin

& CLEARANCE BLOCKS

Duplicate

table

aight.

crosscutting

saw

with

(p.

4).

DOWN

from

should

also

with

5J.

The

straightedge

face. A strip

the

board

g.

Cut-Off

side(s)

For

ripping

long

one

or

twisting

use a miter-

the

miter-

extensio

board,

face

PariS

is

ones

both

while

n is

of

will

Crosscutting

When

it

ce

is

being

the pie

remaining),

can

be

used

the

miter

the

the

gauge

piece

piece

hold

bind

kickback.

USING

FENCE

The

clearance

so

that

against

operation

contact

the

noted,

it

the

begins.

with

blade.

the

duplicated

Duplicate

desired

cut

the

fence

for a stop.

or

being

to

AND

block

can

be

miter

the

If

the

block

at

any

Remaining

to

establish

off (ins

and a clearance

Nev

miter-gauge

cut

off,

the

blade

A

CLEARANCE

is

clamped

used

to

gauge,

before

This

block

work

when

position

and

fence

lat

er

date.

the

tead

of

er

use a stop

extension

as

and

locate

must

work

of

the

set

Parts

length

the

this

result

to

the

the

the

not

is

fence

-up

of

piece

block

on

to

would

in

a

BLOCK

fence

work

sawing

make

fed

to

is

can

be

USING

THE

MITER-GAUGE

To

reduce

o

ne

m

iter

s

hort

stop

set to

s

ame.

If

the

is

no

te

nsion

be

screwed

s

erve

against

various

identical length, a stop

gauge

is used. When

enough, the

rod

attachment

position

each

workpieces

stop

rod,

(as

then

preceding).

or

clamped

as a stop.

the

stop

length

workpieces

fastened

the

handiest

(p.

5).

stop

This

workpiece

are

too

long,

use a miter-gauge

A wood

to

workpiece

position

the

it

USE

Each

to

STOP ROD

all

to

pieces

to

use

is

rod

can

exactly

or

if

there

block

extension

is held

for

cutti

GUARD

AND

to

the

are

the

be

the

excan

to

ng.

SPLITTER

11

WHENEVER

USING

Another

to

the

front

OPPOSite

A

HOMEMADE

ROLLER

SUPPORT

FOR

RIPPING

LONG

WORK

PIECES

POSSIBI.E

A

method

corner

the

miter

WOOD

is

to

of

gauge_

STOP BLOCK

clamp a piece

the

table

on

of wood

the

side

Page 14

BEVEL

MAKING

CUTS

ANGLE CUTS

TAPER RIPPING

B

evels

from

10 to

saw

arbor

blade

rippin

table

use

the

miter-

MITER

Miter

the

of

the r e

Unle

creep

is

into the

of

the

blade. To eliminate

(and

tilt

ed

g and cross

remains level.

the fe n

ce;

miter-

gauge hold-down.

CUTS

s ar e

crosscuts

workpiece.

quired

ss

th e

work

while ma

saw

teeth,

gauge extensi

45°

blade).

are

much

cutting

when

gauge -preferably

angle

or

on (pa

bevel

at

The

to

make

is

very

king a miter

blade,

the

taper

creep,

ge

miter-gauge hold-down.

are

cut

by

Operation

the same as standard

oper

When b

an

miter

tightly held

and

of

11)

togeth

tilting the

s with

ations,

as

evel rippi

crosscutting, use

angle to the edge

the

is due to the s

a hollow -ground

with

gauge

is set at

cut.

,

cut.

it

This creep

use a miter-

er

with the

will

the

the

ng,

the

et

12

JIG

SAW

WORK-

TAPER

FIRST SIDE

arms

the

ready

fence

touches corner

and

the

cut one

Befor

op

to

TO BE : f

Ripped tapers

(pa

ge

4) .

pe r

in

all

te

until the

at

er des

to

so

work

e c

the

ow

i-

1<

~

on

sides,

for

First,

foot.

the

illustration.

one side,

rmining the

the

12-inch

ired.

cut

the

that

inner

toge

ther

If

a s

quare

adjacent

utting the

jig to

the

J-

•

•

I t

I

l4

<\:

taper

shown

be

poSi

when us ing th e fo

TAPER

CAlCUlATION

TAPERPERFOOT

After dete

the

jig

tap

cut.

en

all

CUT

are

cut

determin

This

instead

multiply

rmula.

W

Ii·

with an

e the

is

easily figu

If

by 12

T

AHa

adjusta

the

taper

of

on

instead

CAlCUlATION

24" I I

I'

W_ X 6

_ - L

distance

first

of

side

twice

tapers alr

TOUCHING

FENCE

'-1

-x

="""'24><

taper per

between the

mark

Lock

taper.

edge

work,

past

the

piece

in

the same manner.

remaining side or sides,

the

WORK

SAW

-~=

6

foo

is

the

the

jig.

Position

of saw blade

then slide

blad

e to

is

being tapered,

previous se

eady cut.

ble

amount

red,

is to

two

of

" 63/

t, open

two

sa

me t .J

It

is no

just

the

make

tting

TWICE

CALCU.

LATED

TAPER

SECOND

SIDE

jig

of

as

op-

6

,,,

f

.}

the

jig

Page 15

SPECIAL

HANDLING

It

is

often

on an

odd

the

fence

very

ard,

as

guide

table

faces

s,

the

rev

ers

TTING

- s

useful

illustrated,

str

grooves.

of

and similar

are

by

is

bo

the

the

the

dowe ls

boards

head

(by

CU

ODD-SHAPED

necessary

hap

ed

board that

or

miter

for

jobs

ip

at

bottom

the

boards

cOWltersunk

fixture

can

ing

bolts)

T!WE

STRAIGHT

SAW

WORK

to

make

a s

traight

cannot

this

stock.

r

eceive

EDGES

be gu

kind.

made.

for

upside

gauge. A cut-off

of

is

easily

a good sliding

Matching V -groov

are

useful

round

to

be

turned

for

freehand use

cut

ided

board

The

Make

fit

es

holding

If

both

the

bolt

down

.

OPERATIONS

guide

so

it

will

contact

board,

with

but not

fence

so

as

the

cut.

two

aux

ragged

and

If

edge

to

ili

trued

more

of

workpieces, then

edges.

from

guide.

CUTTING

trim

ary

board,

in

in

cut-off

Position

off

of

the

board

along

true,

straight

A

board

ilarly

trimmed

straight

be

trimed

auxiliary

PATTERN

the

top

the

approx.

slide

guide

edges can

to

have

than

3/4 in.

use a thicker

board

of

the

to

1/4in.

cut-off

make

be

sim

paralle

must

the

workpieces.

two

a

l

Wh

en

reversed,

board

can

One s

uch

joi

nti

ng.

gether in

1

/2 in. of

at

one side.

or

more thick.

f'

be

use

i s

Lock

the

cut

the

ragged

Clamp an

as

not

ed

used

for

for

trimming veneer

both

pieces

-off

board

edge

aux

to the f

ence.

above, the

other

operations.

of

veneer

with approx.

of

each exposed

ili

ary

guide, 1 in.

Position

cut-off

for

to

t.hi s

-

13

Odd-shaped,

c

ut

with

fence

sired

make

must

edge

outer

flu

If

to

be

gether,

a

piec

the

guid

shape,

firm

have a curv

so that the

faces

sh.

a wooden

the

workpiece.

us ed to hold

and

material

e.

MATCHING

If

it

is

work

(top

already

the

between

the pa

desired

(bo

piece),

described,

blad

each

ttern

ttom

e by the

straight-sided pieces

aid

of a pattern

e. The

contact

that cannot

.

but

of

patt

is

very

EDGES

pie

use

edge

pattern

should

with the

ed

rabb

blade

the

blad

ern

is used,

The

workpiece

useful

OF

to

hav

ce)

larger

the

pattern

but set

amount

of

the

be

et

at

will

e a nd

cut-off

when

be

nailed

OffSET

e a

the guide

of

second

and

auxiliary

can

be

any

thick

enough to

guide. The

bottom

of

recess

guide

nail

it

board

can also

and

pattern

pattern

to

the

WORK

seco

nd

piece

than

the

saw

ing

out

offset

desired

pie

can

de-

guide

outer

and

the

will

lightly

to-

is

work-

pattern

set

-up

over

ce

and

be

be

of

of

Page 16

MAKING

CENTER

(fjjJ

-

If

a l

ong slot

is to be cut,

boa

rd

the

cut.

to

the

front

end

at

one

of

board

back

of board slowly down ov

until

blade

table.

end

of

lifting board

down on

Always c la

table

in

of

side

or

on

table

cuts

Push

desired

through

it

top

front

board

in

back

against

through

or

pull

cut,

from

CUTS

the cent

is

nece

of

the

mp some

of

against

of the

board

then

table.

ssary

saw

the bl

the

and

stop

er

of a

to

blade

type

ade,

to hold t

kickback.

saw.

Place

stop,

then

er

board

until

blade

the

saw

board

drop

the

to

start

of a stop

Stand

front

lower

the

blade

is flat

is

before

he

on

at

You

can

This

is

(at

approx.

end.

Clamp

end bears

front

edge

the

fence.

MAKING

easily

make

it

CUTS

to

a wood

the

the

to

simply a length

a 450 angle)

against

of blade,

END

of

and s

table

work

keep

spring

wood,

lotted

so the

just

work

hold

-in.

miter

cut

at

O!'~

SlO!~\;"",

behind

~

against

MAKING

Edge

cutting,

ful support

peci

ally

secure

it

bottom

erabl

tru

an aux

sufficient

two-thirds

y, always use

SAW

DESIGN

EDGE

CUTS

like

of

the

e of

high,

ili

ary

height

CUTS APPROX .

W'

APART

FOR

A

resawing,

workpiec

guide to

to

of

a ho

HOMEMADE

requires

e.

thin

boards. Always

the

support

the

work

ld-in, as

This

fence

at l

. Al

so, pref

shown.

HOLD-IN

care-

is

to give

east

es-

the

End cuts

becau

se

tom

does

with the

are best

but

cuts

fence.

Note

high,

and th

left

hand

CUTTING A RABBET

-

A

rabbet

angles,

piece

edge. First mark

are

more difficult

the small

not

table.

made wit

can

away

requires

to

remove a corner

portion

give a firm

Specialendcuts,Uketenons,

h a

universal jig

be

made

the

using an

auxiliary

stick

the

blad

two

saw

that

at a push

from

than

edge

of board at

sliding con

(page

auxilia

fence

cuts

size

is

at

the

is used to

e.

from

the

cut

bot-

tact

I

quite

keep

r ight

work

of the

s

-

14

Page 17

FIRST SETTING FIRST

rabbet

on one end of

s

etting the

the

touch

make

first.

to m

CUTTING

blade

the

center

the

Then reset

ake

the

required

so

that

of

cut

into the

second

CURVES

saw

the

the

the

cut.

Though intended fo r s

bench

saw

can

the

not

exceeding

One

pattern

other

for

an

ed. These

tu

re

desired.

the

same

pattern

d co

ntact when

length

;!X

fu

nly be used when

on

e edge

the

cut

patter

match

be guided

only one

point

be

1/2-in.

for a co

ncave

a convex (outside) c

are

made

The

concave

as

the

can

be any length

acting

the

to a

concave curve

n (a s

by

the

pattern

of

contact.)

CUT

the

work

blade

top

of

mark

flat

side

saw

in similar

trai

ght

used

to

cut

curvature

(inside)

to

the

degree

pattern

workpiece.

as

workpiece

trai

ght

as

WORK

,.w

·SECOND

as

a guide

heights .

the

teeth

for the

cut

of

the

board

manner

line

work

slow curves

per

curve,

urv

e is

need-

of c

urva-

must

The

that

will give

a guide; and

alre

ady

that

edge

could

there

would be

CUT

for

Set

just

and

only

foot.

and

be

con-

can

has

will

not

,

with

the

with

the

work

in con

slowly.

for

shaping

set

-up

and

CUTTING

Coves

are

the

work

light

cuts

full

depth

ses, the

u

rounded

To

make

two

identical

neously

rounds

of s

duce

the

ends

off squarely.

to

produce

Last,

halve each

uarter

q

outSide,

center

of

tact

the

the

the

axis.

with

convex

other

blade

If

procedure

COVES

rounded

at

an

angel

grooves

of about

is

reached.

most

popular

table corners.

TWO

TURNED

HAt

VES

four

rounded

boards

turned

on a

uitable

m to

lengt h.

desired

Now

the

desired

piece

roundS, cu

for

the four

curve exactl

Rig a hold-in

the

pattern. Feed

pattern

edg

e of

are

the same.

made

to

the saw

1/8

in. at a

Cove c

being the

DIVIDE IN

ONE

TW~

FINISHED

corners,

which can

lathe

to

produce

After

length

s

cove

inside

to

end up with four

rved

ins

ide

table edges.

y in

to

is

to be

the

work,

by

f

blade,

time

uts

have many

making

f1fY

'~

COVE

CUT

start

be simulta-

two half

turning,

by

c

utting

cut

eachpiece

curvature.

as

well

line

keep

work

used

the

eed

ing

taking

until

HALF

with

rethe

of

as

A

CONCAVE

Set

the

work.

blade

Clamp

CUT

to

the

barely

concave

A

CONVEX

project

pattern

through

to

the

fence

CUT

the

To

cove cut,

width.

of wood and

rosspie

c

15

first

Then

secure these

ces,

to

take

make an

decide

on

two

the

straightedge strips

together

oblong

frame

depth

by

having

and

two

Page 18

the

two

inner

lel

and

the

blade

actly

frame

touc h

of

setting.

alo

strip.

guide

exactly

desired

the blade. Whirl

ng the

width of

so

its

the

depth of

over

es

the

Draw a pencil

inner

This

line

must

be

edges

of

the

same

the

height above

the

blade

and

tips

of

the

blade

edge

of

gives

set.

the

long

distance

cove.

the

desired

turn

front

by hand

line on

the

left-hand

the

angle

strips

Position

table

cove.

it

until

and

at

paral-

apart

is

Place

it

rear

teeth

to check

the

table

frame

which

as

the

ex-

just

the

CUTTING

BOWLS

Use a straightedge

this

to

tab

le

is

parallel

from

is

on a

when

to

project

and

to blade

at a time

cove

at left

line

work

make

is

finished

the

along

edge

enough

work

blade

bl

ade

1/8

in.,

slowly

1/8

in.

until

board

of

to

the

blade

with

is

placed

above

first

and

.

as

blade

so

pencil

so

that

the

exact center

against

table

cut

by

the

guide.

continue

aguide.

that

the

line

centerline

guide. Set

no

more

feeding

Raise

making

Clamp

inner

and

of

than

work

blade

cuts

far

of

the

Bowl-like

manner

of any

to

The

nearly

is

form a "V"

these

is

the

cut.

an

Take

one

FOR

CUTTING

as a cove

boWl

the

width,

smaller

semicircular.

used,

two

in

back

positioned

blade

If

a

arm

to

1/8-in.

complete

ROUND

cuts can

will

square

hold a

SQUARE

be

cut.

cut

will

for

anyone size

blade

s will

boards clamped

will

serve

of

the

blade

against the

be at the

workpiece

pivot

cuts

at a time,

turn

for

WORK

made

in much

However,

be

in fixed

of

make

If

a

round

to

as

a guide.

so

that.

m,

th e

center

ofthe

at center

is

of

revolving work

each

cut

until

..

~

-

\

FOR SQUARE

MITERS

BO,6.RD

TURNED

OVER

the

the

proportion

saw

blade

cuts

workpiece

the

table

Arrang

when

top

center

desir

used,

rig

workpiec

finished.

•

WORK

same

depth

.

mor

e

to

e

wor

k

of

ed

up

e.

,<>~--

The

fini s hed cove will not be p

Actual s

shown in the

cove

stock.

by

saw

hapes for variou

round

first

cuts.

illustr

with sandpaper

Tim

e can be saved

cutting out a "V"

ation.

erfectl

s guide angl

If

desired,

wrapped

in

making coves

with

two

y round.

es

are

work

on

round

bevel

FIRST END

The

ordinary

boa

rd

45°. To

board, turn

calUlot be

miter

to 450 in

allowed

jOints will be

son,

cabinet

miter-gauge

16

SECOND

s is

(squar e)

cut

cut

the o

the boa

turn

gauge to the opposite sid e and r e

the

opposite

to c

reep

out

joint

hold-down

mit

with

ed

of s

s ar e be s t

er f

the mite r gauge s

PPO

site

rd

ups i

de

ups

ide down, move the

dire

ction.

(p

age 11), th e

quar

e.

or a miter

or

jOining two

end of the same

clown. U

If

resultin

For

thi s

made

using

END

et

boar

set

work

rea

board

at

d

it

is

g

-

the

.

Page 19

RESULTS

•

~

CRffPI

A

¥p

CUTTING TENONS

CHEEK

A

2-

When

first,

accurately.

and the

SHO

There

(or edge)

the

tion

side

around

moving

.it

rately, but

.

dl!'

ubject

width

~~~

'

d

c\~

('II

~

\ EDGE CUT CHEEK

SIDED

TEN

cutting

using a stop

two

edge

ULDER CUT

are

three

cuts. The

work

to a

the

jig

so

away

from

and

cut

the

jig. This

to

the

.

~

II

1/

the

position

the

two

CHE

of

making

jig

(p

. 4)

Then

cheek,

tenon

of

the

'\ \

shoulder

these

cheek

EK

CUT

is

to

and

cheek

turn

the

without

the

tenon ac-

will

workpiece

clamp

on

HOULDER5

ON A 4 -SIDED TENON

tenons,

Then

block

make

cuts

.

methods

universal

as

to

cut

the

jig.

the

the

width of

accuracy

make

to

simplest

Qutthe

other

centers

cuts

cuts

cuts

cheek

posi-

the

work

be

ACCURATE CENTERING;

Accurate

a

backing

of

saw

however, is

the

Accurately

be

collar

blades

a

tenon

ing

table

the

width

block. This

the

desired

kerf.

Accurate

workpiece

cut

jig

centered,

by

using

between. Exact

can

be

can

be

the

work

groove, after

.

tenons

tenon

now

subject

width.

two

equal

obtained

accurately

in

the

jig

plus

centering

exact

carefully

ACCURAT

can

be

should

the

to

the

width

size

spacing

with

paper

center

to

slide

E WIDTH

cut

by

be

the

width

of

the

tenon,

accuracy

tenons

blades

with a

between

discs;

ed

by

clamp-

it

along

positioning

using

width

of

the

can

the

and

the

of

A

HOMEMAD

USE

GUARD

AND

E

MITER

SPLITTER

17

BOARD

A

simple

mitered

time

Guide

miter-gauge

square

plus

then

WHENEVER

strips

, with

strips

cut

1/4 in. to

miter

POSSIBLE

miter

board

is

should

miter

desired

the

for

jig.

be

gauge

are

saw

the

underneath

grooves. Workpieces

to

the

allow

cut

in

shown.

cut

at

set

to

over-all

kerfs,

the

slide

should

The

at

length

and

same

450•

in

are

two

the

be

Page 20

HOW

A

Typical

SATIN-CUT

A

DADO

Head

THE

HEAD WORKS

Set

DADO

, I

&

HEAVY-DUTY

'

,;'

"

~

...

HEAD

NEW

ADJUSTABLE

The

Dado

Head