Page 1

OWNER’S

MANUAL

MODEL NO.

987.889000

CRAFTSMAM

A Caution;

Read and Follow

All Safety Rules

and Instructions

Before Operating

This Equipment.

8 HORSEPOWER 33-INCH MOWER

Assembly

Operation

Customer Responsibilities

Service and Adjustments

Repair Parts

Sears, Roebuck and Co., Hoffman Estates, Illinois 60179 U.S.A.

FORM 1905122 (3/98)

Page 2

SAFETY RULES

A

CAUTION: ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT

AA CANNOT CONTACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SET- Ak

TING UP, TRANSPORTING, ADJUSTING OR MAKING REPAIRS. **

IMPORTANT

Safe Operation Practices for Walk-Behind Mowers

This cutting machine is capable of amputating hands and feet and throwing objects. Fail

ure to observe the following safety instructions could result in serious injury or death.

8. Do not operate the mower without proper guards,

WARNING:

The engine exhaust from this product

contains chemicais known to the State of

California to cause cancer, birth defects, or

other reproductive harm.

I. GENERAL OPERATION

1. Read, understand, and follow alt instructions on the

machine and in the manuals. Be thoroughly familiar

with the controls and the proper use of the mower

before starting.

2.

Do not put hands or feet near or under rotating parts.

Keep clear of the mower blade and discharge open

ing at all times.

plates, grass catcher or other safety protective de

vices in place.

9. Refer to provided instructions for proper operation

and installation of accessories. Only use acces

sories approved by Sears, Roebuck and Co.

10. Stop the blade when crossing gravel drives, walks,

or roads.

11. Stop the engine and disconnect the spark plug wire

from the spark plug whenever you leave the unit, be

fore cleaning the mower or unclogging the chute.

A

FI

3.

Only allow responsible individuals, who are familiar

with the instructions, to operate the mower.

4.

Clear the area of objects such as rocks, toys, wire,

bones, sticks, etc., which could be picked up and

thrown by the blade.

5.

Be sure the area is clear of other people before

mowing. Stop mower if anyone enters the area.

Keep bystanders at least 25 feet away from the area

of operation.

6.

Do not operate the mower when barefoot or wearing

open sandals. Always wear substantial foot wear.

7.

Do not pull mower backwards unless absolutely nec

essary. Look down and behind before and while

moving backwards.

12. Shut the engine off, wait until the blade comes to a

complete stop, and disconnect the spark plug wire

before installing or removing the mulcher cover or

the optional grass catcher. Make certain that the

grass catcher is securely attached before operating

the mower. Empty the grass catcher after each use-

decomposing debris could generate enough heat to

catch fire.

13. Mow in daylight or good artificial light.

14. Do not operate the mower while under the influence

of alcohol or daigs.

15. Never operate mower in wet grass. Always be sure of

your footing; keep a firm hold on the handle and walk;

never run.

16. Disengage the Wheel Drive Lever on self-propelled

models before starting the engine.

17. If the unit should start to vibrate abnormally, stop the

engine and disconnect the spark plug wire. Then

check immediately for the cause. Vibration is gener

ally a warning of trouble.

A

LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS. IT MEANS-ATTENTION!!! BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

Page 3

SAFETY RULES

18. Always wear safety goggles or safety glasses with

side shields when operating mower.

19. Watch for traffic when operating near, or when cross

ing roadways.

20. Never attempt to carry children or other passengers

on the mower. They could fall off and be seriously in

jured, or they could interfere with the safe operation

of the mower.

21. Check the operation of the Operator Presence Con

trol before each use. See the Customer Responsibili

ties Section of this manual for instructions. If the

mower blades rotate longer than three seconds after

the Operator Presence Control is released, the sys

tem is not working properly. Immediately contact

your local Sears Service Center/Department for in

structions. Do not use the mower until the mecha

nism is repaired.

22. The mower is equipped with a safety discharge

chute, comes with a special mulcher cover and offers

an optional grass catcher. The safety discharge

chute must be working properly at all times. Never

attempt to disconnect or othenwise cause this dis

charge chute to cease working. If used, mulcher

cover or grass catcher attachment must be installed

properly and function correctly. Do not use your

equipment othenwise.

23. Never run the engine in an enclosed area. Engine ex

haust contains carbon monoxide, a deadly gas that is

odorless, colorless, and tasteless. Always run the en

gine outdoors and make sure there is adequate

ventilation.

II. SLOPE OPERATION

Slopes are a major factor related to slip and fall acci

dents which can result in severe injury. All slopes

require extra caution. If you feel uneasy on a slope,

do not mow it.

DO:

Mow across the face of slopes; never up and down.

Exercise extreme caution when changing direction on

slopes. Avoid slopes greater than 150.

Remove objects such as rocks, tree limbs, etc.

Watch for holes, ruts, or bumps. Tall grass can hide

obstacles. .

DO NOT:

Do not mow near drop-offs, ditches, or embankments.

The operator could loose footing or balance.

Do not mow excessively steep slopes.

Do not mow on wet grass. Reduced footing could

cause slipping.

III. CHILDREN

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often at

tracted to the mower and to the mowing activity.

Never assume that children will remain where you

iast saw them.

1. Keep children out of the mowing area and under the

watchful care of a responsible adult.

2. Be alert and turn mower off if children enter the area.

3. Before and while moving backwards, look behind

and down for small children.

4. Never allow children to operate the mower.

5. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

IV. SERVICE

1. Use extra care in handling gasoline and other fuels.

They are flammable and their vapors are explosive.

a) Use only an approved container.

b) Never remove gas cap or add fuel when the en

gine is running. Allow engine to cool before refu

eling. Do not smoke.

c) Never refuel the machine indoors.

d) Never store the machine or fuel container inside

where there is an open flame, such as a water

heater, etc.

e) Move mower away from any gasoline fumes be

fore starting the engine.

2. Never run an engine inside a closed area.

3. Never make adjustments or repairs with the engine

running. Disconnect the spark plug wire and keep

the wire away from the plug to prevent accidental

starting.

4. Keep all nuts and bolts, especially the blade attach

ment bolts, tight and keep equipment in good condi

tion.

5. Never tamper with safety devices. Check their opera

tion regularly. .

Page 4

SAFETY RULES

6. Keep mower free of grass, leaves or other debris

build-up. Clean up oil or fuel spillage. Allow mower to

cool before storing.

7. After striking an object, stop the engine and discon

nect the spark plug wire. Inspect the mower and re

pair, if necessary, before restarting.

8. Never attempt to make mower cutting height adjust

ments whiie the engine is running.

9. Grass catcher components are subject to wear, dam

age and deterioration, which could expose moving

parts or allow objects to be thrown. Frequently check

components and replace with Sears recommended

parts, when necessary.

10. Mower blades are sharp and can cut. Wrap the blade

or wear gloves, and use extra caution when servicing

them.

PI

11. Do not change the engine governor setting or over

speed the engine.

12. Do not touch engine parts which may be hot from

operation. Allow parts to cool completely before in

specting, cleaning or repairing the mower.

13. To access the underside of the mower, tip the mower

rearward. Do not tip the mower forward or on either

of its sides, uniess specifically advised to do so in

this manuai.

14. Maintain or replace safety and instructional decals.

Refer to the Repair Parts Section for replacement

decal information.

Page 5

CONGRATULATIONS on your purchase of a Craftsman

33-lndi Mower. It has been designed, engineered and

manufactured to give you the best possibie dependability

and performance.

Should you experience any problems you cannot easily

remedy, please contact your nearest Seam Service

Center/Department. We have competent, well-trained

technicians and the proper tools to service or repair this

machine.

Please read and retain this manual. The instructions will

help you assemble and maintain your machine properiy.

Always observe the “SAFETY RULES.”

MODEL NUMBER: 987.889000

SERIAL

NUMBER:

_____________________________________

DATE OF

PURCHASE:___________________________________

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON A DECAL LOCATED RIGHT SIDE OF

THE MOWER DECK.

YOU SHOULD RECORD BOTH THE SERIAL NUM

BER AND DATE OF PURCHASE AND KEEP IN A

SAFE PLACE FOR FUTURE REFERENCE.

PRODUCT SPECIFICATIONS

HORSEPOWER:

DISPLACEMENT:

8 HP

19.43 CU. IN.

FUEL CAPACITY: 3 Quarts

SPARK PLUG (GAP .030-in.):

Champion RJ-17LM

or equivalent

IGNITION

■ Electronic

NET ENGINE WEIGHT 57 LBS.'

' in Canada, replace spark plug with a resistor plug.

WARNING: This machine is equipped with an internal

combustion engine and should not be used on or near

any unimproved forest-covered, brush-covered or

grass-covered land unless the engine’s exhaust system

is equipped with a spark arrester meeting applicable lo

cal or state taws (if any). If a spark arrester is used, it

should be maintained in effective working order by the

operator.

In the state of California the above is required by law

(Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply

on federal lands. This engine is not equipped with a

spark arrestor for the muffler. A spark arrester for the

muffler is available through your nearest Sears autho

rized service center. See the REPAIR PARTS section of

this manual.

MAINTENANCE AGREEMENT

A Sears maintenance agreement is avaiiable on this

product. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

□ Read and observe the safety rules.

□ Follow a regular schedule in maintaining, caring for

and using this product.

□ Follow the instmctlons under "CUSTOMER

RESPONSIBILITIES” and “STORAGE" sections of

this manual.

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN® POWER MOWER

For two years from date of purchase, when this Craftsman® Lawn Mower is maintained, lubricated, and tuned up according to the

operating and maintenance instructions in the owner’s manual, Sears will repair free of charge any defect in material or workmanship.

If this Craftsman® Lawn Mower is used for commercial or rental purposes, this warranty applies for only 90 days from the date of

purchase.

THIS WARRANTY DOES NOT COVER:

• Expendable items which become worn during normal use, such as rotary mower blades, blade adapters, belts, air cleaners and

sparlLDlug.

• Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to maintain the equipment

according to the instructions contained in the owner’s manual.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN® MOWER TO THE NEAREST SEARS SERVICE CENTER/ DE

PARTMENT IN THE UNITED STATES. THIS WARRANTY APPLIES ONLY WHILE THIS PRODUCT IS IN USE IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

One year warranty on the following: #38700, #38607. #38712. #38720, #38721, #38725 -

Page 6

TABLE OF CONTENTS

ACCESSORIES AND ATTACHMENTS.

INDEX

Accessories and Attachments

Adjustments:

B

Blade:

,.7

.15

.25

. .8

32

32

..........

2

C OQ

.0|

....

5

c

............

7

............

8

...

13

.5,23

Features/Controls ......................

Fuel Storage

Fuel Type..................................

Gear Select Lever ........

Handlebar;

14

Assembly...............................

.....

SERVICE AND ADJUSTMENTS....

^TnRAOF ...............................

TROUBLESHOOTING

DECALS

...................................

REPAIR PARTS - MOWER......................................

REPAIR PARTS - ENGINE

PARTS ORDERING/SERVICE

F

__ _

13

.......................

G

H

.17, 34

___

17

... .14

.........

.....................

.................

Recoil Stert Rope

Repair Parts

Responsibilities, Customer .. .5, 23

Safety Decals

Safety Rules

Service and Adjustments

Spark Plug........................................26

Specifications

Starting/Stopping Engine....................19

9

Storage

............. .

..............

..............

.....................................36

.

.....................................37

.....................................46

...

.............

Back Cover

R

.............................

.....................................

S

..................................

......................................

....................

.....................................

...........................................

26

34

35

16

37

36

2

26

5

34

Controls:

Customer Responsibilities:

Decals

Engine:

Oil

.26

. 14

. 15

. 16

. 14

. 13

. 15

.25

.32

i-25

.23

.26

.36

. .25

. .24

. .24

. .13

. .16

. .26

. .34

L

Lubrication:

Engine

.....

...........................

Mower

.................................

M

Maintenance:

Agreement ...........................

Schedule

Mowing Tips

Mulching Cover

Off-Season Storage..................

Oil ..........................................

Operation

Operator Presence Control

Options

Parts List

Product Specifications ....

...........................

............................

.......................

0

................................

..................................

P

...............................

.17, 23

........

..........

........

.........21

. .15, 18

.........34

..17, 23

........

.........13

...........

,. .21-27

.

...........

23

23

T

Troubleshooting

Unpacking..........................................8

5

................................

U

W

Warranty

Wheel Drive Control ...........................15

13

7

4

...........................................

OPERATOR’S POSITION

All references in this Manual

to LEFT and RIGHT sides of

thè mower are given from the

operator’s position behind the

handlebars (unless specified

: otherwise).

35

5

Page 7

ACCESSORIES AND ATTACHMENTS

These accessories and attachments were available when the mower was purchased. They are also available at most

Sears retail outlets, catalog and service centers. Most Sears stores can order repair parts for you when you provide

the model number of your unit.

ENGINE

Spark Plug

MOWER

Grass Catcher

Gas Can

Belt

Fuel Stabilizer

Blade

Motor Oil

Page 8

©

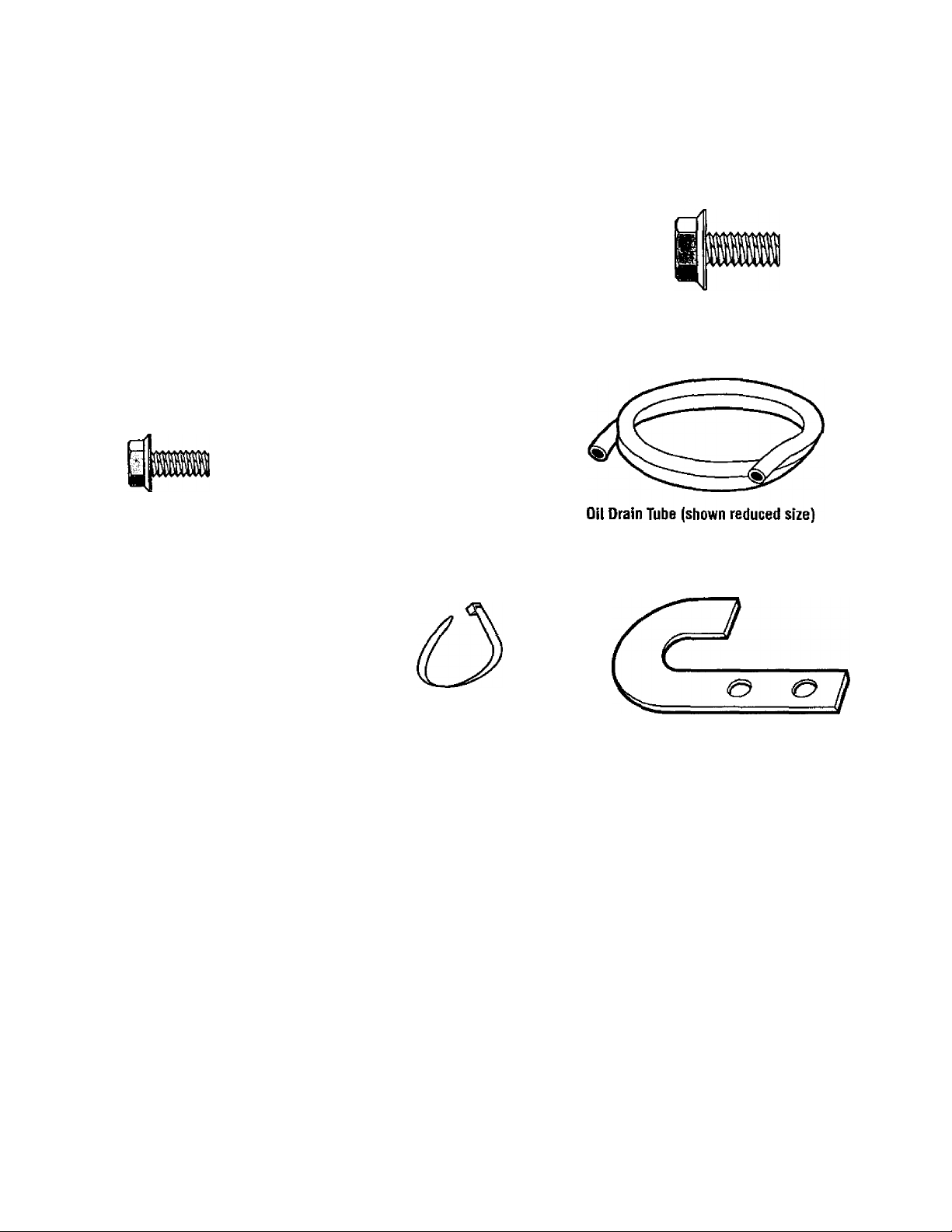

CONTENTS OF HARDWARE PACK

Parts Bag Contents

Flat Washer,

5/16”

Qty;4

Hex Flange Lock Screw,

1/4”-20 X1/2"

Qty:2

PI

Shift Link - Gear Select Lever

{shown reduced size)

Qty:1

Cotter Pin,

3/32" X 5/8”

Qty:6

Hex Flange Lock Nut,

1/4-20”

Qty:2

Plastic Cable Tie

(shown reduced size)

Qty:1

Hex Flange Lock Screw,

5/16”-18 X 3/4”

Qty:2

Qty: 1

Shift Rod Mounting Plate

(shown reduced size)

Qtytl

Page 9

ASSEMBLY

Read these instructions in their en

tirety before you attempt to assem

ble or operate your new equipment.

Your new equipment has been as

sembled at the factory with the ex-

Toots Needed For Assembly:

(1)7/16’ Wrench

(1) 3/8“ Wrench

(2) 1/2“ Wrenches

(1) Needle-nose Pliers

(1) Wire Cutter Pliers

(1) Tire-Gauge

(1) Scissors or Pen Knife

UNPACKING

INSTRUCTIONS

• Inspect your machine immediate

ly. Be sure neither the carton nor

contents have been damaged. If

you find or have reason to sus

pect damage, contact your near

est Sears Service Center/Department for assistance.

• Cut plastic banding with scissors.

Open box flaps and remove any

packing material from around the

machine. Remove any staples

securing bottom of carton to wood

pallet. Lift off carton. Cut metal

straps securing unit to base.

Leave unit on base of pallet dur

ing assembly steps (to safely re

move unit from base, wait until

you have completed assembly

steps 1-2). Before disposing of

the carton or any of the packing

materials, be sure to check them

thoroughly for any small parts.

• Cut plastic tie straps holding three

long control rods to handlebars.

Also remove any packaging

around the handlebars.

• Perform the assembly on a clean,

level surface. If you need to

move the machine, be careful not

to severely bend any of the con

trol cables on the equipment.

ception of those parts left unassem

bled for shipping purposes. To en

sure safe and proper operation of .

your machine, all parts and hard

ware you install or adjust must be

ASSEMBLY STEPS

Before starting any assembly

steps, disconnect the engine

spark plug wire from the spark

plug.

STEP1: Attach Handlebars

• If applicable, cut and remove any

plastic ties holding wheel drive rod

(F, Figure 2-5) to left handlebar and

blade drive rod (C, Figure 2-5) to

right handlebar. Put rods aside.

• Handlebars (A, Rgure 2-2) are

shipped partially assembled with two

screws (Y, Rgure 2-2) loosely instEjIed. It may be necessary to

loosen screws (Y) further to allow the

handlebars to clear the engine air

cleaner.

• Rotate handlebars over engine

and position as shown in Figure 2-2.

Be careful that the handlebars clear

the unit while unfolding. Also, put

end of control rod (E, Figures 2-3

and 2-5) into cut-out (W, Figures

2-2 and 2-3) in back of frame while

rotating handlebars into position.

• Install two 5/16“-18 X 3/4" hex

flange screws (B, Figure 2-2).

• Tighten all four screws (B and Y).

• Secure the engine throttle cable

to the left handlebar with a cable tie

from the hardware bag. Clip off any

excess tie length.

tightened according to the assem

bly instructions. Use the correct

tools as necessary to ensure proper

tightness. .

Figure 2-2: Attach handlebars.

Page 10

STEP 2: Attach Control Rods

WARNING

The control rods are adjusted

at the factory and should not

require additional adjustment

during assembly. After as

sembling unit, control rod ad

justment should be checked

(and re-adjusted, if neces

sary) according to information

in “Customer Responsibili

ties” Section. Severe person

al injury or property

damage could result from

not following this

instruction.

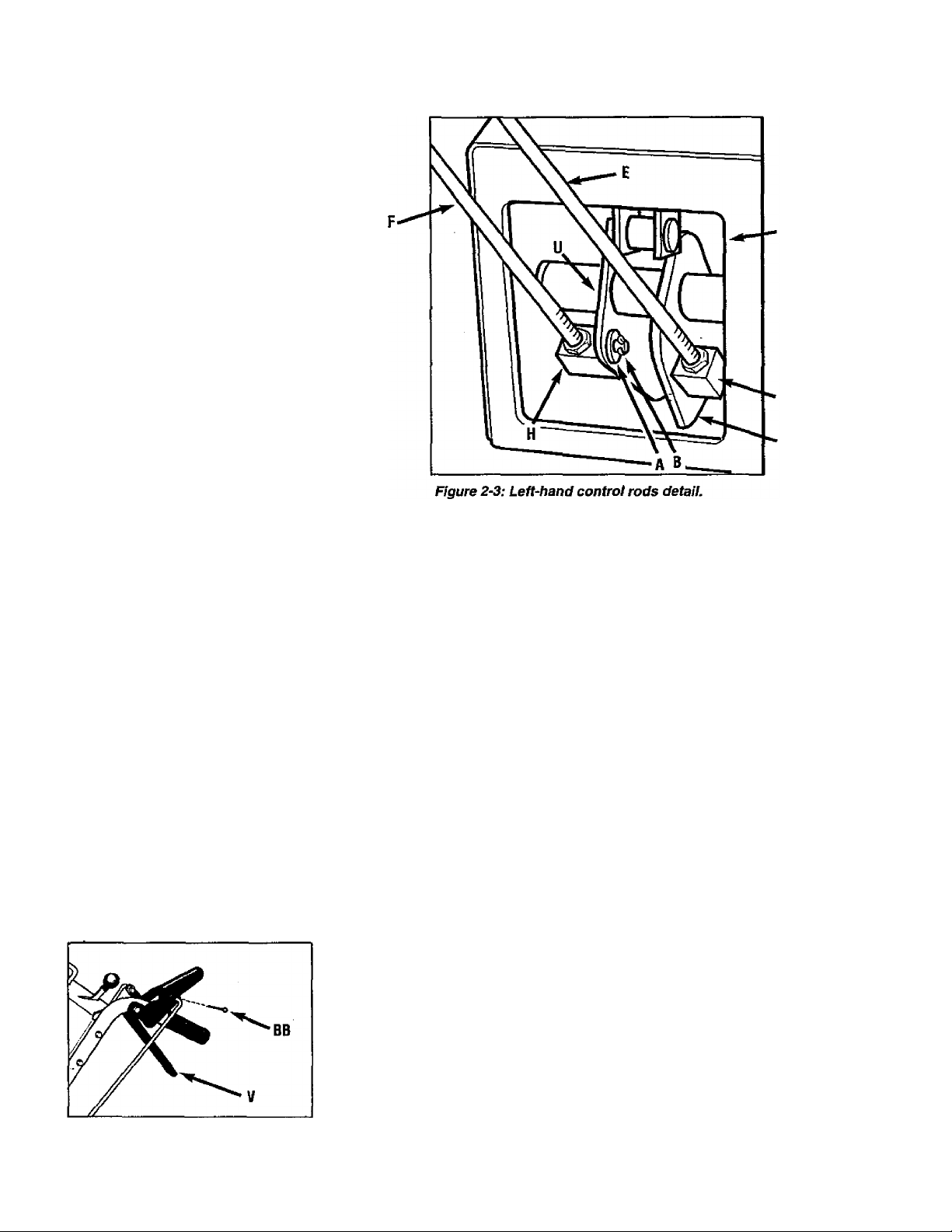

A. Attach Wheel Drive Control

Rod

• Locate the wheel drive control

rod (F, Figures 2-3 & 2-5) that you

removed from the left handlebar in

Step 1. This rod has a swivel block

(H, Figure 2-3) on one end.

• At left side of engine frame,

insert swivel block (H, Figures 2-3

& 2-5) on wheel drive control rod

into wheel drive control arm (U,

Figure 2-3).

• Add one 5/16” washer (A. Figure

2-3). Secure with cotter pin (B,

Figure 2-3). Bend ends of cotter

pin to secure.

• At upper end of control rod,

secure angled end to Wheel Drive

Control lever (V, Figure 2-4), using

a cotter pin (BB). Bend ends of

cotter pin to secure.

Figure 2~4: Attach wheel drive con

trol rod to lever.

ASSEMBLY

B. Attach Operator Presence

Control Rod:

• Locate control rod (E, Figures.

2-3 & 2-5) attached at upper end

to Operator Presence Control (W,

Figure 2-5).

• At bottom of control rod, insert

swivel block (G, Figures 2-3 &

2-5) into control arm {T, Figure

2-3).

• Add one 5/16” washer and se

cure with cotter pin. Bend ends of

cotter pin to secure.

C. Attach Blade Drive Control

Rod:

• Locate the blade drive control

rod (C, Figure 2-5) that you re

moved in Step 1. Insert one end of

control rod into blade drive bracket

(D, Figure 2-5). Add one 5/16”

washer and secure with cotter pin

(CC). Bend ends of cotter pin to

secure.

• Insert upper end of rod into bot

tom end of Blade Drive Control

lever (J). Add one 5/16” washer

and secure with cotter pin (AA).

Bend ends of cotter pin to secure.

• W

D. Attach and Adjust Gear Select

Lever:

• To remove unit from shipping

crate, hold down Operator Pres

ence Control lever (W, Figure 2-5)

which releases the wheel brake.

• Using the edge of a piece of flat

wood (such as a ruler), remove

the vinyl grip (B, Figure 2-6) from

the gear select lever (I). Place the

wood edge against the edge of the

grip and slowly pull off the grip.

• Insert nylon bushing (Z, Figure

2-6) up into console (L).

• Slide spring and washers (J)

down onto gear select lever.

• Insert gear select lever (I) up

through nylon bushing (Z) in han

dlebar console (L, Figure 2-6).

Guide pin (K) on gear select lever

into groove in shift quadrant (EE).

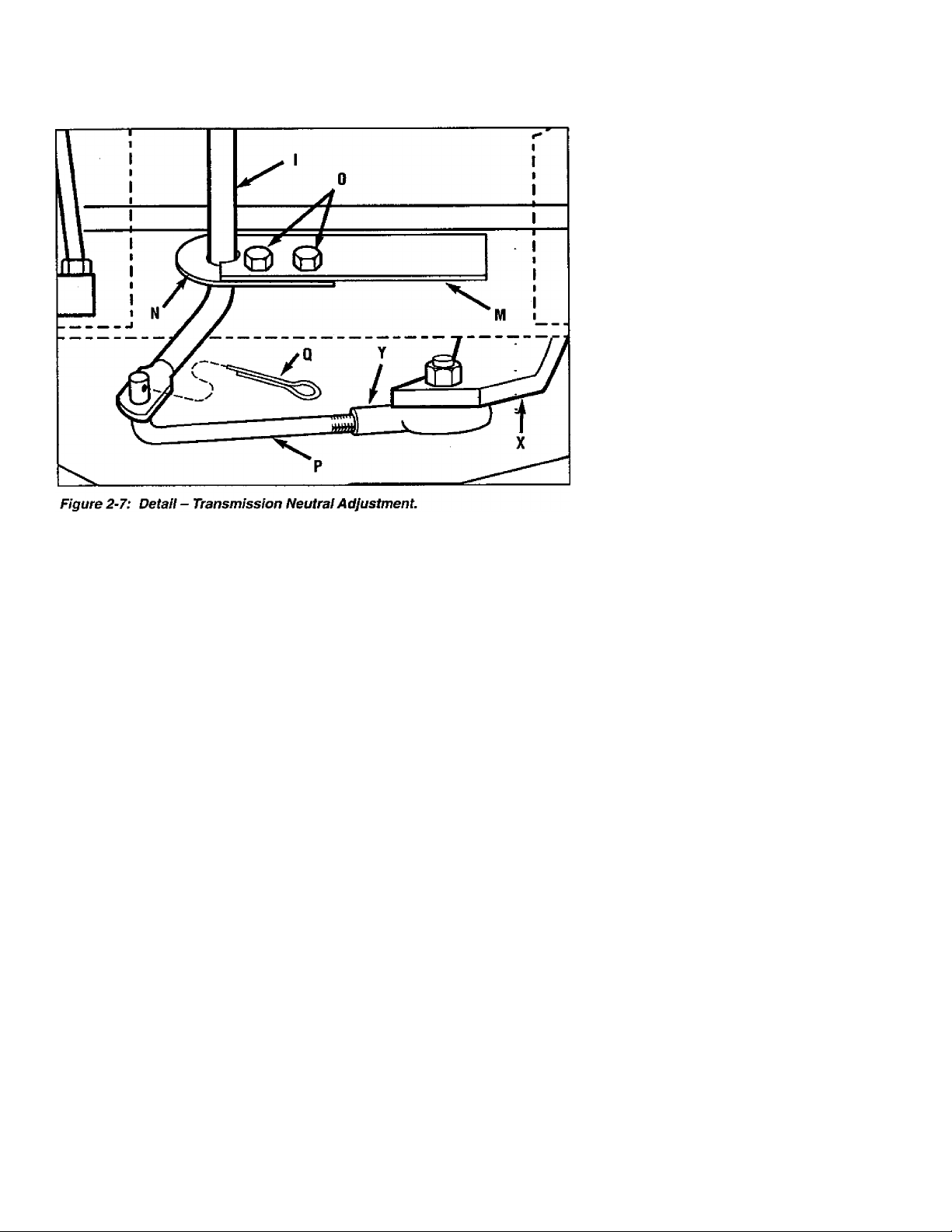

• Hold lower part of gear select

(ever (I) against bracket (M, Figure

2-7). Position retaining plate (N)

from parts bag in place as shown

in Figure 2-7 (plate below brack

et). Secure plate with two 1/4”-20

X 1/2” long screws (O) and 1/4”-20

locknuts.

• Slide grip (B, Figure 2-6) back

onto upper end of gear select

lever (I).

10

Page 11

ASSEMBLY

• Rotate gear select lever (I, Rgures 2-6 & 2-7) clockwise until pin

(K) on gear select rod stops in the

neutral position detent on the shift

pattern quadrant (Figure 2-6).

• Thread shift link (P, Figure 2-7)

partially into ball-joint (Y).

• Move shift arm (X, Figure 2-7)

from side to side as necessary into

each transmission gear detent un

til transmission is in neutrai.

NOTE: Moving shift arm (X) all

the way to the left, and then one

notch back to the right, should put

transmission into neutral. When ~

transmission is in neutral, unit will

move freely when pushed while

holding the Operator Presence

Control iever (W, Figure 2-5)

down. If transmission is NOT in

neutral, there will be a slight drag

on the wheels when pushing unit.

EE

• When shift arm (X) is in neutral

position, rotate shift link (P) toward

end of gear select lever rod (I).

Adjust length of shift link (P) as

necessary to fit into hole in bottom

of gear select lever (I).

NOTE: Pin (K) on Gear Select

Lever (I) must be held in the neu

tral position detent on the shift

quadrant (see Figure 2-6) while

shift link (P, Figure 2-7) is

adjusted. .

I

Pin (K) must be in this detent

when transmission neutrai is

adjusted.

Figure 2-6: Detail - Gear Select Lever in Neutral (N) position.

11

Page 12

• Insert hooked end of shift link (P,

Figure 2-7) into hole in bottom end

of gear select lever (I) and secure

with cotter pin (Q). Bend ends of

cotter pin. NOTE: It may be nec

essary to lift gear select lever (I) to

install shift link (P).

* Hold down Operator Presence

Control lever (W, Figure 2-5) and

push unit forward and backward.

The wheels should move freely. If

not, adjust length of shift link {P,

Figure 2-7) as necessary.

E. Test Wheel Brake:

Put the Gear Select Lever in in

neutral (N), release all of the con

trol levers, and try to push the unit

forward and backward. The

wheels should not turn. If they do

turn, an adjustment is necessary.

DO NOT OPERATE THE UNIT

UNTIL THE WHEEL BRAKE

MECHANISM HAS BEEN

ADJUSTED AND IS WORKING

PROPERLY. See "Wheel Brake

Adjustment’ in “Customer Respon

sibilities.”

ASSEMBLY

WARNING

Do not use the mower if the

wheels continue to turn after

releasing the Operator Pres

ence Control and the Wheel

Drive Control. Severe per

sonal injury or property dam

age could result if this in

struction is not followed.

WARNING

The control rods are adjusted

at the factory and should not

require additional adjustment

during assembly. After

assembling unit, control rod

adjustment should be

checked {and re-adjusted, if

necessary) according to

information in “Customer Re

sponsibilities” Section. Se

vere personal injury or prop

erty damage could result from

not following this

instruction.

STEP 3: Check Tire Pressure

• Use a tire gauge to check №e air

pressure in the rear tires. The air

pressure should be between 15-20

PSI (20 PSI maximum).

• Keep both tires equally inflated

to help prevent machine from

pulling to one side.

STEP 4: After Assembling and

Before Using Unit

• Read this entire Owner’s Manual

for proper safety, operation and

maintenance information.

• Make sure spark plug wire is

connected to spark plug before

starting unit.

IMPORTANT: MOTOR OIL MUST

BE ADDED TO THE ENGINE

CRANKCASE BEFORE START

ING THE ENGINE. OIL FILLING

INSTRUCTIONS ARE COVERED

IN THE “OPERATION” SECTION.

CAUTION

Unit is shipped without oil in

engine crankcase. DO NOT

start engine until oil has been

added. Severe engine dam

age will result if this instruc

tion is not followed. See “Op

eration” Section ot this man

ual for oil filling procedure.

12

Page 13

OPERATION

KNOW YOUR EQUIPMENT

READ THIS OWNER’S MANUAL AND ALL SAFETY RULES BEFORE OPERATING YOUR EQUIPMENT. Know the

location and function of all features and controls on the equipment. Save this manual for future reference.

MEETS ANSI B71.1 -1996

SAFETY STANDARD

This machine meets voluntary

safety standard B71.1 - 1996,

which is sponsored by the Outdoor

Power Equipment Institute, Inc.,

and is published by the American

National Standards Institute, Inc,

Operating Symbols

Various symbols are used on the

mower to indicate control settings

(your model may not have all of the

symbols). These symbols are

shown below with a description of

their meaning.

V

FAST SLOW

s 6

ENGINE

STOP

ENGAGE DISENGAGE

ENGINE

START

9

N

CHOKE

S

ENGINE

RUN

IP

IMPORTANT: The mower is

equipped with a blade-brake-clutch

control system which is designed

to stop the mower blades within

three (3) seconds after release of

the Operator Presence Control.

This system will stop the blades

but not the engine. Therefore, you

can disengage the blade drive at

anytime without having to stop and

restart the engine. This feature is

particularly useful when you need

to cross gravel drives or rough ter

rain and you do not want the spin

ning blades to strike stones or hid

den obstacles.

LOCATION AND USE OF

CONTROLS

Operator Presence Control

This lever (A, Figure 3-1) regu

lates the operation of the rear

wheel brake and the separate

Blade Drive Control.

To engage the Operator Pres

ence Control, press and hold the

lever against the handlebar grip.

Engaging the lever releases the

brake on the rear wheels (allows

wheels to turn). The engaged po

sition also permits the separate

Blade Drive Control to lock In its

engaged position (allows the mow

er blades to turn).

Releasing the lever (disengaged

position) applies the rear wheel

brake and quickly stops the

wheels. Releasing the lever will

also disengage the Blade Drive

WARNING

The blade-brake-clutch con

trol system should stop the

mower blades within three (3)

seconds after release of the

Operator Presence Control. If

the blades do not stop within

three'(3) seconds, put the En

gine Throttle Control in the

STOP position. Disconnect

the spark plug wire and do not

operate the mower until the

blade-brake-clutch control

system has been repaired!

Control, which will apply a brake

that stops the blades within three

(3)seconds.

Always disengage the Operator

Presence Control before starting

the engine. Always engage this

control before engaging the sepa

rate blade drive or wheel drive

controls. ■

A-OPERATOR

PRESENCE CONTROL

Disengaged

Engaged

Figure 3~1

13

Page 14

OPERATION

Blade Drive Control

Use this lever (B, Figure 3-2) to

engage drive to the mower blades.

To engage the blades, first en

gage the Operator Presence Con

trol (A, Figure 3-2). Then, push the

spring-loaded Blade Drive Control

lever (B) forward until it stays in the

engaged position.

To stop the blades, release the

Operator Presence Control (A).

Doing so will disengage the Blade

Drive Control (B) and automatically

apply the brake that stops the

blades.

. When starting the engine, the

Blade Drive Control should be dis

engaged (released). This helps to

ensure that the blades will not start

turning when the engine starts.

NOTE: Pushing the Blade Drive

Control fonward will engage the

blades even though the Operator

Presence Control is not engaged.

However, this procedure is NOT

RECOMMENDED as you must

maintain constant pressure on the

lever (releasing lever disengages

blades). Always engage the Oper

ator Presence Control before en

gaging the Blade Drive Control.

Gear Select Lever

This lever (C, Figure 3-3) is used

to select any of three forward

ground speeds (1 - Slow, 2 - Medi

um and 3 - Fast), N (Neutral) and

R (Reverse). The gear shift pattern

is shown in Figure 3-4.

To avoid damaging the trans

mission, do not shift gears when

the mower is moving. Select for

ward ground speeds according to

mowing conditions and terrain (use

slower speeds in high grass or on

rough terrain).

For fonward travel, move the

lever into one of the three num

bered settings. To select reverse,

shift to neutral and then puli up on

the lever. Turn the lever to the R

(reverse) position and release the

lever.

Put the lever in N (neutral) to

manually push the mower and

when the mower is not in use.

LIFT FOR

REVERSE

Figure 3-4; Shift pattern on console.

14

Page 15

OPERATION

Wheel Drive Control

Use this lever {D, Figure 3-5) to

engage and disengage drive to the

wheels.

To engage the wheels, first select

a fonward or reverse gear with the

Gear Select Lever and press the

Operator Presence Control (A, Fig

ure 3-5) against the handlebar

grip. Then, squeeze the Wheel

Drive Control lever (D) up against

the handlebar grip. The ground

speed can be varied in any gear by

increasing (to go faster) or de

creasing (to go slower) pressure

on the lever. To avoid sudden ac

celeration, slowly squeeze the

lever when first engaging the

wheels.

Release the Wheel Drive Control

to disengage the wheels. The

Cutting Height Control Lever

This lever (E, Figure 3-6) is used

to adjust the mower cutting height.

The cutting height can be adjusted

from 1 to 4 inches.

Turn the lever clockwise to raise

the cutting height or counterclock

wise to lower the cutting height. A

decal and pointer (not illustrated)

wheels will gradually slow to a

stop. NOTE; To stop the wheels

quickly, release the Operator Pres

ence Control along with the Wheel

Drive Control.

When starting the engine, the

Wheel Drive Control should be dis

engaged (released). This helps to

ensure that the wheels will not start

turning when the engine starts.

CAUTION

Do not engage the Wheel

Drive Control without first en

gaging the Operator Presence

Control. Doing so could re

sult in wear or damage to the

wheel brake mechanism.

on the right side of the mower deck

show the cutting height settings

ranging from A (highest) to G (low

est). Note that the actual cutting

heights will vary according to soil

conditions.

A ~ OPERATOR

PRESENCE CONTROL

Disengage

Engage

Engage

)isengage

/”

D-WHEEL

DRIVE CONTROL

Figure 3-5

Mulcher Cover

To use the mulching feature, in

sert the mulcher cover (Figure 3-7)

securely in the right side of the

deck beneath the discharge chute.

Insert the front tab of the cover

into the mower front support brack

et (AA, Figure 3-7). Then push the

cover into place by sliding the

cover rearward, making sure that

the slot (BB) in the cover is com

pletely engaged in the rear edge of

the deck opening.

Remove the mulcher cover if you

want to do side-discharge mowing.

The mulcher cover is

pre-installed at the factory.

NOTE: The mulcher cover is

designed to keep the discharge

chute raised up while you mow.

When the cover is removed, the

discharge chute lowers.

DANGER

Before installing or re

moving mulching cover,

stop engine, wait for parts

to stop moving, and dis

connect spark plug wire.

15

Figure 3-7

Page 16

OPERATION

Engine Thrnttle Control

This lever (F, Figure 3-8) is used

to adjust engine speeds and to

stop the engine. Always run en

gine at fast speed setting for best

mower performance. The throttle

settings are shown to the right.

Kl

CHOKE - Use when

starting a cold engine.

FAST - Use during mower

operation.

SLOW - Use when idling

engine.

STOP - Stops engine.

s

BEFORE OPERATING

Pre-Operation

Checklist

Perform the following checks before each use of your

machine;

□ Review; “Safety” and “Operation” sections of manual.

□ Check for loose or missing hardware. Tighten or replace

before starting engine.

□ Check the engine oil level. Refer to “Customer Respon

sibilities” section for instructions.

□ Check the fuel level in the fuel tank (refer to next page

for instructions).

□ Check all levers for freedom of movement. Do not start

engine if any lever does not function correctly.

■B>

Figure 3-8

Engine Recoil Starter

The engine recoil starter (H, Fig

ure 3'9) is used to "pull-start" the

engine. Do not pull the recoil

starter until you have read the Oper

ation Section.

□ Adjust the blade cutting height (refer to this Section for

instructions).

□ Inspect the area to be mowed and remove any debris.

□ Check that all guards and shields are in place and prop

erly secured.

□ Check the installation of the mulcher cover in the right

side deck opening. Remove the mulcher cover if you

want to side discharge the grass.

□ Check air pressure in rear tires at first use and every 25

operating hours. Maintain 15-20 PSI (maximum 20 PSI)

in each tire. Keep tires inflated equally or mower may

pull to one side.

□ Attach the spark plug wire to the spark plug.

Figure 3-9

16

Page 17

BEFORE STARTING ENGINE

OPERATION

Add Motor Oil

• Only use high quality detergent

oil rated with API service classifica

tion SR SG or SH. Select the oil's

SAE viscosity grade according to

your expected operating tempera

ture. Above 320R use SAE 30;

below 320R use 5W30.

NOTE; Although multi-viscosity oils

(5W30, .10W30 etc.) improve start

ing in cold weather, these oils will

result in increased oil consumption

when used above 320R Check

engine oil more frequently to avoid

possible engine damage from run

ning low on oil.

• Be sure that engine is level. Re

move dipstick (A, Figure 3-10).

• Fill with recommended oil to be

tween “Full” and “Add” marks on

dipstick (approximately 32 oz.).

Pour slowly and do not overfill.

While pouring, stop frequently, re

insert dipstick until it is seated

completely, remove and check oil

level. (Wipe dipstick each time be

fore re-inserting.) Replace dipstick

securely.

• Check oil before each use. Add if

needed.

• Change oil after the first 2 operat

ing hours and every 25 operating

hours thereafter (more often in ex

tremely dusty or dirty conditions).

Fill Fuel Tank

• stop engine and allow it to cool

for three minutes before removing

fuel fill cap (B, Figure 3-10). Do

not check fuel level or add fuel

while indoors.

• Clean area around fuel fill cap

and remove fill cap. Fill gas tank

with clean, fresh unleaded gaso

line. Do not mix oil with gasoline.

• Using a funnel or spout, fill tank

to 1/2 inches below bottom of fuel

tank filler neck to prevent spills and

to allow for fuel expansion.

WARNING: Experience indicates

that alcohol blended fuels (gasohol

or using ethanol or methanol) can

attract m'oisture which leads to

separation and formation of acids

during storage. Acidic gas can

damage the fuel system of an en

gine while in storage. To avoid

problems, the fuel system should

be emptied before storage for 30

days or longer. Drain the gas tank,

start the engine and let it run until

the fuel lines and carburetor are

empty. Use fresh fuel next season.

See STORAGE instructions for ad

ditional information. Never use en

gine or carburetor cleaner products

in the fuel tank or permanent dam

age may occur.

DANGER

Gasoline is highly flammable and its vapors are explosive. Read and fol

low these precautions to help avoid severe personal injury or property

damage.

• Do not remove gas cap or add gasoline if engfne is running or still hot

from operation. Allow engine to cool at least three minutes before

refueling.

• Keep open flame, matches, sparks, or smoking materials away from fuel

tank and fuel container.

• Do not fill fuel tank indoors. After filling, wipe up any spills and move

machine away from gasoline fumes before starting engine. Securely re

place the caps on the fuel tank and fuel container.

• Do not fill fuel tank completely. Fill tank to 1/2” below bottom of filler

neck to provide space for fuel expansion.

• Store gasoline in an approved fuel container and in a well-ventilated area.

Store it safely out of the reach of children.

• Do not store gasoline where vapors may reach an open spark or flame, or

where ignition sources (such as hot water heaters, space heaters, furnaces,

clothes dryers, stoves, electric motors, etc.) are present.

Figure 3-10

• Install fill cap securely and wipe

up any spilled gasoline.

17

Page 18

OPERATION

Ad|ust Mowet Cutting Height

The cutting height can be adjust

ed from 1 to 4 inches by rotating

the Cutting Height Control lever (A,

Figure 3-11).

Choose cutting heights accord

ing to grass conditions and terrain.

In heavy or tail grass, it is usually

better to make the first cut at a

higher setting and then make a

second cut at the desired setting.

When mowing in rough terrain, a

higher setting is recommended as

it will minimize the chances of the

blade striking the ground or hidden

obstructions.

1. Release all mower controls

before adjusting cutting height

2. Turn Cutting Height Control

lever clockwise to raise cutting

height or counterclockwise to lower

cutting height. A decal and pointer

(not illustrated) on the right side of

the mower deck show cutting

height settings ranging from A

(highest) to G (lowest). Note that

actual cutting heights will vary

according to the grass and soil

conditions.

CAUTION

To avoid personal injury, do

not adjust cutting height

while wheels or blades are

turning. Release all handle

bar controls and wait for all

motion to stop before adjust

ing cutting height.

Test Blade*Brake*Glutch

Control System

The mower is equipped with a

blade-brake-clutch which is de

signed to stop the mower blades

within three (3) seconds after re

lease of the Operator Presence

Control or the Blade Drive Control.

Never tamper with, or attempt to

defeat the purpose of this safety

device.

The-control system is a mechanicat device which is subject to wear.

Therefore, test the operation of the

blade-brake-clutch control system

before each use of the mower. Re

fer to “Blade Brake Control Tesf at

the end of this Section.

Select Mulching or Side-Discharge Mowing

Your combination mower allows

you to select either mulching or

side-discharging of the grass clip

pings. To use the mulching fea

ture, insert the mulcher cover.

Remove the cover if side dis

charge mowing is desired. Refer

to “Mulching Cover” on Page 15

for installation instructions.

Figure 3-12: Mulcher cover.

■ M

MOVING THE MOWER

WITHOUT ENGINE POWER

DANGER

Before installing or removing

mulching cover, stop engine,

wait tor parts to stop moving,

and disconnect spark plug

wire.

Figure 3-11: Cutting Height Control

lever.

The mower can be manually

pushed or pulled by putting the

Gear Select Lever (C, Figure 3-13)

in N (neutral) and pressing and

holding the Operator Presence

Control (A, Figure 3-13) down

against the handlebar grip.

To stop the wheels at anytime,

release the Operator Presence

Control.

18

Page 19

STARTING AND STOPPING THE ENGINE

DANGER

Do not operate engine In an enclosed area. Engine exhaust contains

carbon monoxide, a deadly gas that is odorless, colorless and tasteless.

Always run engine outdoors and make sure there is adequate

ventilation.

C-Gear Select Lever

OPERATION

To Stop the Engine

1. Release all mower controls to

stop wheels or mower blade.

2. Move throttle control down to

slow (turtle) position. (Whenever

possible, gradually reduce engine

speed before stopping engine.)

3. Move Throttle Control all the

way down to stop position.

WARNING

To avoid injury:

• Keep hands and feet clear

of mower blades or other ro

tating parts.

• Look behind you to be sure

there are no obstacles before

pulling recoil starter rope.

To Start the Engine

1. Move mower to a level area.

2. Release all controls on mower

to prevent wheels or mower blades

from rotating when engine starts.

3. Move Engine Throttle Control

(E, Figure 3-13) fully upward to

choke setting to start a cold engine

or to fast (rabbit) setting to start a

warm engine.

4. To start engine using recoil

starter. -

A. Stand on left side (as viewed

from behind handlebars) of ma

chine. Be sure your feet are

safely away from the underside

of the mower deck and all mow

er controls are released. Place

one foot on top of tire.

B. Grasp rope handle (G, Figure

3-13) and pull slowly until rope

pulls slightly harder. Let rope

rewind slowly. Then pull rope

with a rapid, full arm stroke. Let

rope return slowly. If engine fails

to start after three pulls, repeat

instructions starting with Step 2

(try setting throttle at fast setting).

C. When engine starts, operate in

fast throttle setting (move throt

tle from choke setting to fast

setting).

Figure 3-14: Engine recoii starter.

ENGAGING THE RLADES

DANGER

To avoid injury from rotating

biades, keep face, hands and

feet ciear of mower biades at

ali times.

To Engage the Blades

1. Start engine as described in “To

Start the Engine” instructions. Put

engine throttle in fast speed

setting.

2. Press and hold Operator Pres

ence Control (A, Figure 3-13)

against handlebar grip.

3. Slowly push Blade Drive Control

(B, Figure 3-13) fully fon/vard until it

stays in the engaged position. The

blades are now rotating.

To Stop the Blades

To stop the blades, release the

Operator Presence Control.

19

Page 20

OPERATION

TO ENGAGE THE WHEELS

CAUTION

• To avoid damaging the

transmissio'n, do not shift

gears whiie in motion.

• To avoid damaging the

wheel brake mechanism, do

not engage the Wheel Drive

Control without first engaging

the Operator Presence

Control.

WARNING

Before engaging the Wheel

Drive Lever for the very first

time, check that the neutrai

(N) position on the Gear Se

lect Lever is properly adjust

ed. See “Neutral Adjust

ment” in “Service and

Adjustments” Section for the

procedure to follow.

Failure to follow this instruc

tion could result in personal

injury or property damage.

1. Start engine as described in

“To Start the Engine” instructions.

2. FOR FORWARD TRAVEL:

A. Press and hold Operator Pres

ence Control (A, Figure 3-13)

against handlebar grip.

B. Put the Gear Select Lever (C,

Figure 3-13) into one of the

numbered settings (1 - Slow, 2 Medium and 3 - Fast). When

first practicing with the mower,

put lever in No. 1 setting. Se

lect forward speeds according

to mowing conditions and ter

rain. Use slower speeds on

rough terrain or when grass is

heavy or thick. The fonvard

speed can be increased on

smooth terrain or if the grass

cover is light. Allow the wheels

to stop completely before shift-

^ ing from one forward speed into

■ another.

C. To start the wheels, slowly

squeeze the Wheel Drive Con

trol (D, Figure 3-13). The hard

er you squeeze, the faster the

wheels will turn. To avoid sud

den acceleration, slowly

squeeze the lever.

D. TO STOP THE WHEELS:

• To stop drive power to the

wheels, release the Wheel

Drive Control. The wheels will

gradually slow to a stop.

• To quickly stop the wheels, re

lease both the Wheel Drive

Control and the Operator Pres

ence Control.

WARNING

To avoid Injury or property

damage:

• Look behind mower before

and during reverse operation.

• Stop the mower blades be

fore operating in reverse.

3. FOR REVERSE TRAVEL:

A. Stop the mower blades and

wheels by releasing the Opera

tor Presence Control (A, Figure

3-13).

B. Press and hold Operator Pres

ence Control against handlebar

grip.

C. Put the Gear Select Lever (C,

Figure 3-13) in R (reverse) set

ting by first moving lever to N

(neutral). Then pull lever up,

turn it to R position, and release

lever.

D. To start the wheels, slowly=

squeeze Wheel Drive Control

(D, Figure 3-13). To avoid sud

den acceleration, slowly

squeeze the lever.

E. TO STOP THE WHEELS:

• To stop drive power to the

wheels, release the Wheel

Drive Control. The wheels will

gradually slow to a stop.

• To quickly stop the wheels, re

lease both the Wheel Drive

Control and the Operator Pres

ence Control.

• Return the Gear Select Lever

to the N (neutral) position when

you have completed reverse op

eration. Allow the wheels to

stop completely before shifting

from R (reverse) into a forward

speed.

MAKING TURNS

The mower turns easily by push

ing the handlebars in the opposite

direction that you want to turn. The

differential mechanism inside the

transaxle will allow the inside turn

ing wheel to stop or slow down

while the outside turning wheel is

powered by the drive system.

Reduce the wheel speed before

turning the mower. For tight turns,

disengage the Wheel Drive Control

and manually push the mower

through the turn (if needed, put the

Gear Select Lever in neutral so the

wheels turn freely).

20

Page 21

OPERATION

MOWING TIPS AND HINTS

WARNING

To avoid injury or property damage:

• Before mowing, thoroughly inspect area where mower is to be used

and remove all stones, slicks, wires, bones, nails and other foreign

objects.

• Disengage mower blades before crossing gravel drives, roads, or side

walks to prevent blades from throwing stones or other hazardous

objects.

Mow When Lawn Is Dry

For best results, avoid cutting

grass when it is wet. Wet grass

tends to form clumps which inter

fere with the cutting action. The

best time to mow is in the late af

ternoon or early evening when the

grass is usually dry.

Cut Top 1/3 of

Grass Blades

Cutting more than 1/3 of grass

length may cause the grass to be

come excessively dry. In tall

grass, it may be necessary to mow

at a higher setting and then mow

again at the desired height.

NOTE: The cutting height is criti

cal to achieving a well-groomed

lawn. You should experiment with

various settings to find that “just

right” cutting height.

Vary Cutting Pattern

Vary the cutting pattern from

week to week to help prevent mat

ting of the grass. One week, mow

from north to south, the next week

mow from east to west.: Overlap

several inches when mowing to

obtain an even appearance.

_

1

Mowing on Slopes

Do not mow excessively steep

slopes (see WARNING statement

below). Slow down and exercise

extreme caution when changing di

rection on slopes. Before mowing

on slopes, check the engine oil lev

el and make sure that the level is at

the FULL mark. Maintaining a

FULL oil level is particularly im

portant when operating on slopes

as oil can be drained away from vi

tal engine parts.

WARNING

To avoid injury or property

damage:

• Maximum safe operating

angle is 15°.

• Exceeding maximum safe

operating angle may cause

tipping or loss of footing.

• Do not mow wet slopes.

• Mow across slopes, not up

and down.

• Exercise extreme caution

when changing direction on

slopes.

21

Mulching Leaves

• The mower can also be used to

mow leaves in the fall. The leaf

particles filter down into the lawn

and provide added fertilizer.

• The leaves must be dry in order

to be mulched.

• Use a slower ground speed if the

leaves are not mulched into fine

particles.

• If you mulch oak leaves (which

add acid to the soil), add lime to

the lawn in the spring to reduce the

acidity of the soil.

Keep Mower Blades Sharp

For best mower performance,

keep the blades sharp. A dull blade

will tear, bruise and split the ends

of grass.

Clean Mower Frequently

Clean the underside of the mower

deck frequently to remove grass

build-up.

Precision Trimming

For precision trimming, use the

slowest gear and inch the mower

along by “feathering” the Wheel

Drive Control lever. Or, disengage

the wheel drive by releasing the

Wheel Drive Control so that you

can manually maneuver the mower

(if needed, put the Gear Select

Lever in neutral so that the wheels

turn freely).

Mowing Ditches

If you have to mow ditches, stop

the engine and adjust the cutting

height to its highest setting. Mow

in the direction of the ditch. Mow

both sides of the ditch first, and

then mow the bottom. When

mowing ditches, watch out for

cans, bottles, or other debris.

Page 22

OPERATION

BUDE BRAKE CONTROL TEST

When the Operator Presence

Control is released during opera

tion of the mower, the engine does

not stop, but the blades should

stop within three (3) seconds. The

following test provides a visual test

of whether the Blade Brake Control

System is functioning. Perform

this test before each use of the

mower.

WARNING

To avoid personal injury or

property damage, make sure

that the mower is on grass,

and that the test area is clear

of foreign objects and by

standers before you begin the

Blade Brake Control Test.

It the Operator Presence Con

trol or the Blade Drive Control

are not adjusted correctly, the

blades may continue to rotate

after release of the Operator

Presence Control. If the

blades do not stop within

three (3) seconds of release

of the Operator Presence Con

trol, move the Engine Throttle

Control to the STOP position,

disconnect the spark plug

wire, and move the wire away

from the spark plug. Do not

operate the mower until the

Blade Brake Control System

f .TJ

has been repaired.

Failure to do this could result

in personal injury or property

damage.

1. Park mower on a portion of

lawn which has not been recently

mowed. ■

2. Set the cutting height so the

mower cuts 1/3 of the grass height.

3. Start the engine.

4. Press the Operator Presence

Control down against the handle

bar grip and push the Blade Drive

Control fully fonward until it stays in

the engaged position.

5. Put the Gear Select Lever in

the No. 1 setting.

6. " Engage the wheels with the

Wheel Drive Control and drive the

mower for several feet. Then re

lease the Operator Presence Con

trol.

A. Look at the lawn just mowed.

The lawn should be cut up to

the point where the Operator

Presence Control was released.

B. Press the Operator Presence

Control against the handlebar

grip but DO NOT re-engage the

Blade Drive Control. Drive the

mower fonward for several more

feet. Release the Operator

Presence Control and look at

the lawn. The grass should

NOT have been cut. This indi

cates that the Operator Pres-

■ ence Control has disengaged

the blade drive and stopped the

blades.

7. If the mower cuts the grass in

Step 6-B, the Operator Presence

Control is NOT disengaging the

blade drive. Immediately stop

the engine, disconnect the

sparkplug wire, and move the

wire away from the spark plug.

8. Do not use the mower until the

Blade Brake Control System has

been inspected, adjusted or re

paired by a Sears Service Center.

Page 23

CUSTOMER RESPONSIBILITIES

Maintenance Chart

INTERVAL* ITEM SERVICE

Each use

-

1 St 2 hours

25 hours

-

50 hours

Annually or 100 hours Air Filter Element***

Monthly

Mower Blade As Required

Loose or Missing Hardware

Belts Check

Engine Oil Level Check

Controls Check for Proper Operation

Mulching Cover

Engine Oil

Engine Oil"**

Foam Air Filter*** Clean

Mower Blade(s) :

Control Linkages and Pivots

Engine Oil

Blade Drive Belt Adjust

Engine Cooling Fins Clean

Grease Fittings** Grease

Spark Plug

Linkages Adjust

Belts

Tighten or Replace -

Check for Proper Cover Installation

Change

Change

Sharpen and Balance

Lube with Light Oil

Change

Adjust Tension

Replace

Clean/Replace, Re-gap

Check/Replace, Adjust

Annually or 50 hours

Front Wheel Bearings

*lnterval describes rtinning time.

**A hand-type grease gun Is recommended when greasing your

unit. High-pressure type grease guns could cause damage to

iittings/seals.

Lubrication Chart

ITEM

Engine Crankcase

Front Wheel Bearings

Control Linkages/Pivots

* A hand-type grease gun is recommended.

INTERVAL

First 2 hours

25 hours (more often in

dusty conditions)

50 hours

25 hours

Grease

***Clean more often under dusty conditions or when airborne de

bris Is present. Replace air cleaner parts, if very dirty.

****Change more often under dusty conditions.

LUBRICATION

LUBRICATION TYPE

Change Oil

Change Oil

(Lubrication Intervals Vary

with Operating Conditions

and Type of Oil Used)

Oil and grease the mower

according to the recommen

dations listed in the Lubrica

tion Chart.

• Stop engine, wait for all

parts to stop moving, and

disconnect spark plug

wire before performing

any lubrication proce

dures.

Grease (1-3 Strokes)

Light Oil (A few drops)

• The transmission has been

factory sealed and requires

no lubrication, if a leak

should develop, contact your

local Sears Service Center.

23

Page 24

CUSTOMER RESPONSIBILITIES

GENERAL RECOMIVIENDATIONS

The warranty on this equipment

does not cover items that have

been subjected to operator abuse

or negligence. To receive full val

ue from the warranty, the operator

must maintain the equipment as

instructed in this manual.

Some adjustments will need to be

made periodically to property

maintain your equipment.

All adjustments in the Service and

Adjustments section of this manu

al should be checked.at least

once each season.

Keep the air filters clean and

change the spark plug once a

year. A clean air filter system and

a new spark plug will help your

engine run better and last longer.

Before Each Use

• Check engine oil level.

• Check all hardware for

tightness.

• Check that all guards and

shields are in place and properly

secured.

MOTOR OIL

• Only use high quality detergent

oil rated with API sen/ice classifi

cation SF, SG or SH. Select the

oil’s SAE viscosity grade accord

ing to your expected operating

temperature. Above 32op, use

SAE 30; below 320F, use 5W30.

NOTE: Although multi-viscosity

oils (5W30,10W30 etc.) improve

starting in cold weather, these oils

will result in increased oil con

sumption when used above 320R

Check engine oil more frequently

to avoid possible engine damage

from running low on oil.

Checking Oil Level

Engine oil level must be between

"ADD" and "FULL" marks on dip

stick at all times. Check before

each use and every 5 operating

hours.

1. Park machine on level ground.

2. Stop engine, wait for parts to

stop moving, and disconnect

spark piug wire. : '

3. Clean area around dipstick (Z,

Figure 5-1) to prevent dirt from en

tering oil fill hole.

4. Remove dipstick. Oil level must

be between “ADD” and “FULL”

marks. Do not exceed “PULL”

mark on dipstick.

5. To add oil, pour slowly into dip

stick opening. While adding,

check oil level frequently by se

curely replacing dipstick and re

moving to read oil level. Wipe dip

stick clean each time oil level is

checked.

6. After filling to “FULL” mark, se

curely replace dipstick.

Changing Oil

Change oil after the first 2 operat

ing hours and every 25 operating

hours thereafter. Change oil while

engine is still warm from recent

operation. Warm oil flows more

freely and carries away more

impurities.

1. Stop engine, wait for parts to

stop moving, and disconnect

spark piug wire.

2. Remove dipstick (Z, Rgure 5-1).

3. Remove protective cap (A, Fig

ure 5-2) to expose oil drain port

(B).

4. Push oil drain hose (D) (includ

ed in hardware bag with unit) onto

oil drain port. Route other end of

hose to an appropriate oil collec

tion receptacle.

5. Twist oil drain fixture (C) to the

open position. Pull out. Drain oil

completely.

6. Push in and twist oil drain fixture

to the closed position. Remove

drain hose. Replace protective cap

(A).

7. Refill engine with fresh oil and

securely replace dipstick.

NOTE: Please dispose of all waste

materials in an ecologically re

sponsible manner. Use proper

waste material storage containers.

24

Hgure 5-1

ENGINE CLEANING

• Stop engine, wait for parts to

stop moving, disconnect spark

plug wire, and allow engine to

coot before inspecting or clean

ing engine.

• Daily or more often, before run

ning engine, remove grass and

chaff from recoil finger guard or

rotating screen to prevent engine

damage caused by overheating.

Also keep cooling vanes, governor

linkage, springs and controls free

of debris.

• Daily or more often, before run

ning engine, clean muffler area

(be sure muffler is cool) to remove

all grass and combustible debris.

If engine is equipped with a spark

arrestor screen, remove assembly

every 50 hours for cleaning and

■ inspection. Replace if damaged.

Page 25

CUSTOMER RESPONSIBILITIES

AIR CLEANER SERVICE

Improper air cleaner maintenance

can cause engine damage.

SERVICE SCHEDULE:

Foam Filter (A, Fig. 5-3): Wash

and re-oil every 3 months or every

25 operating hours. Clean and re

oil daily if used in extremely dusty

conditions.

Paper or Foam/Screen Filters

(B, Fig. 5-3): DO NOT ATTEMPT

TO CLEAN OR OIL FILTER.

Replace once a year or every 100

operating hours, more often if used

in extremely dusty conditions.

DO NOT RUN ENGINE WITHOUT

COMPLETE AIR CLEANER IN

STALLED ON ENGINE.

A. To Service Foam Air Filter (A, Figure 5-3)

1. Wash in water and detergent

solution and squeeze (don’t twist)

until all dirt is removed.

2. Rinse thoroughly in clear water.

3. Wrap in a clean cloth and

squeeze (don't twist) until com

pletely dry.

4. Saturate with engine oil and

squeeze (don’t twist) to distribute

oil and remove excess oil.

A. To Remove and Install Filters

(Figure 5-3)

1. stop engine, wait for parts to

stop moving, and disconnect

spark piug wire.

2. Remove wing nuts and cover.

3. Slide Filter (A) off Filter (B).

4. Inspect filter(s) for discoloration

or dirt accumulation. If either is

present, service as described in

Service Schedule above.

5. Remove nuts and Filter (B). Dis

card Filter (B) and nuts (if service

is necessary).

Figure 5-3

7. Install new Filter (B) and new

nuts. Tighten nuts finger tight and

then turn one (1) more complete

turn.

8. Slide foam filter over paper

filter.

9. Install cover and wing nuts.

Tighten wing nuts.

TIPPING MOWER FOR SERVICE

When servicing the underside of

the mower for any reason, the

mower should only be tipped

backward on its rear wheels (and

securely propped up to prevent it

from falling). Tipping the mower

forward or to either side could re

sult in damage to engine.

WARNING

Before servicing underside of

mower, stop engine, wait for

all parts to stop moving, and

disconnect spark piug wire.

Faiiure to foliow this instruc

tion could resuit in personal

injury or property damage.

TIP: Before tipping mower, install a

small plastic sandwich style bag

under the gas cap and tighten se

curely. This will virtually eliminate

any fuel weepage from the cap.

Be sure-to remove the plastic bag

before re-using mower.

CLEANING UNDERSIDE OF MOWER DECK

Frequently check, and clean if

necessary, the underside of the

mower deck. Grass build-up in

this area can affect the cutting

performance. Before inspecting or

cleaning, make sure that the en

gine is shut off and the spark plug

wire is disconnected from the

spark plug.

WARNING

Mower blades are sharp.

When working near blades,

wear heavy leather gloves or

wrap blades in thick rags to

protect yourself from the

sharp edges.

inspection/Cleaning ol Mower Deck

1. Stop engirte, wait for aii parts

to stop moving, and disconnect

spark piug wire. .

2. Tip mower on rear wheels by

following instructions “Tipping

Mower For Sen/ice” on this page.

3. Use a plastic or metal scraper

to remove grass build-up from

deck or blades, if needed, spray

with a garden hose.

6. Clean inside of cover and body

thoroughly.

25

Page 26

SERVICE AND ADJUSTMENTS

SPARKPLUG

Inspect the spark plug (Figure 5-4)

after every 100 hours of operation.

Be sure the gap is set at .030". Do

not reuse plug if it is severely worn

or damaged.

Best results are obtained with a

new plug. See engine owner’s

manual to determine proper re

placement plug. Use of incorrect

plug can cause engine damage.

NOTE; Do not clean spark plug in

machines which use abrasive grit.

Clean spark plug by scraping or

wire brushing, or washing with a

commercial solvent. '

CARBURETOR

The carburetor is adjusted at the

factory. It should not need to be

reset. If black exhaust is noted,

check the air cleaner first. An

over-rich mixture is usually caused

by a poorly serviced or clogged air

cleaner element, not an improperly

adjusted carburetor. If readjust

ment is necessary, contact your

Sears Service Center.

BELT COVER REMOVAL

The belt cover must be removed

to perform several maintenance

procedures.

To Remove Belt Cover ,

1. stop engine, wait for all parts

to stop moving, and disconnect

spark plug wire.

2. Remove four screws (R, Figure

5-5) and remove cover.

To Reinstall Belt Cover

1. Position belt cover in place.

2. Secure with four screws re

moved earlier.

WARKING

Do not operate unit without

belt cover instalied. Failure

to follow this instruction

could result in personal injury

or property damage.

Figure 5-5; Belt cover removal.

BUDE SPINDLE BELT REPLACEMENT

Follow this procedure to remove

and replace the blade spindle

drive belt (remove blade drive belt

first; see “Blade Drive Belt

Replacemenf).

1. Stop engine, wait for all parts

to stop moving and disconnect

sparkplug wire.

2. Remove belt cover (see “Belt

Cover Removal”).

3. Align sight holes (O, Figure

5-6) in pulley with spindle housingto-mower deck mounting bolts (L).

4. Loosen screw (J) and rotate

arm (K) to the rear,

5. Loosen four mounting bolts (L)

securing spindle housing (beneath

mower deck) to mower deck.

6. Slide spindle housing (with pul

ley attached) toward center.

7. Replace belt (N) with new belt.

IMPORTANT: Set blades perpen

dicular (90°) to each other.

8. Rotate arm (K) to move spindle

housing and apply tension to belt.

Belt cogs and pulley grooves must

mesh together. When applying

moderate finger tension (8-12

ibs.), belt should deflect approxi

mately 1/2” (12.7 mm) at (P), mid

point of deck. -

9. Tighten bolts (L) to 15 ft.-lbs.

(20.3 Nm). Tighten screw (J).

10. Blades must not contact deck.

Check and readjust as needed.

11. Reinstall blade drive belt and

belt cover (removed earlier).

26

Page 27

SERVICE AND ADJUSTMENTS

BUDE DRIVE BELT

REPLACEMENT

Follow this procedure to remove

and replace the blade drive belt.

An assistant will be needed.

To Remove Belt

1. stop engine, wait for aii parts

to stop moving, and disconnect

spark piug wire.

2. Disengage blade drive control

(Figure 5-7) by releasing all con

trols on the mower.

3. Remove belt cover (see “Belt

Cover Removal”).

4. Loosen belt guides (B and C,

Figure 5-8).

5. Move flap bracket (N, Figure

5-8) out of the way by loosening

two screws (M).

6. Remove belt (A, Figure 5-8)

from around sheaves.

To Install Belt

1. Route belt (A, Figure 5-8)

around sheaves as shown.

2. Have an assistant hold down

Operator Presence Control and

then push the Blade Drive Control

fonward until it latches in place

(Figure 5-7).

3. With the Blade Drive Control

lever engaged, adjust and tighten

belt guide (B) to 1/32 -1/16“ away

from tensioned belt. (Be sure that

belt does not contact belt guide

when belt is under tension.) Se

cure belt guide (C) rotated into po

sition as shown in Figure 5-8.

4. Disengage Blade Drive Control.

5. Re-tighten two screws (M, Fig

ure 5-8) that secure flap bracket

(N).

6. Reinstall belt cover securely.

Figure 5-7: Blade Drive Control.

BLADE BRAKE REPLACEMENT

Follow this procedure to install a

new blade brake.

To Remove Blade Brake

1. Stop engine, wait for ail parts

to stop moving, and disconnect

spark piug wire.

2. Remove belt cover as described

in “Belt Cover Removal” instruc

tions.

3. Remove hardware (G, Figure

5-8) securing blade brake (H).

4. Remove old brake (H) from idler

arm (I).

To Install Brake

1. Position new brake (H) in place

on idler arm (I).

2. Center brake in sheave groove

and secure brake (H) with hard

ware (G) removed earlier.

3. Reinstall belt cover securely.

4. Test operation of blade brake

(see “Blade Brake Control Test" on

Page 22).

27

Page 28

SERVICE AND ADJUSTMENTS

BUDE DRIVE BELT ADJUSTMENT

If the blade drive belt is slipping

due to lack of belt tension, follow

the steps below.

1. Stop engine, wait for all parts

to stop moving, and disconnect

sparkplug wire.

2. Remove belt cover as described

in “Belt Cover Removal" instruc

tions.

3. With mower on ievel ground,

adjust blade cutting height at

about 3" {measure frgm ground to

flat portion of blade)..

4. With the Blade Drive Control

(Figure 5-7) in the disengaged

position, set a gap of 1/8" between

the spring (F. Figure 5-9) and flat

washer (E) by adjusting the nut

(D).

5. Reinstall the belt cover,

securely.

6. Test the operation of the blade

brake (see “Blade Brake Control

Test”).

7. If the drive belt slips during op

eration, it may be necessary to re

locate idler (J, Figure 5-9) in the

slot provided in the mounting

bracket. With the engine

stopped and the sparkplug

wire disconnected, loosen the

hardware on the idler (J) and slide

it forward to take up slack in the

belt.

8. Engage the blade drive and

measure the distance (X, Figure

5-8) between the centers of pul

leys (K) and (L). The distance

should be 5-1/2 to 5-5/8". After

obtaining the correct dimension,

reinstall the belt cover securely

and test the operation of the blade

brake.

Adjust idler in direction

of arrow to tighten

blade drive belt

1/8"

Figure 5-9: Blade drive adjustment.

28

Page 29

SERVICE AND ADJUSTMENTS

BLADE DRIVE CONTROL LEVER

ADJUSTMENT

Make the following adjustment if

the Blade Drive Control Lever re

leases during operation..

1. Stop engine, wait for all parts

to stop moving, and disconnect

spark plug wire.

2. Engage the Operator Presence

Control and the Blade Drive Con

trol. Without releasing the controls,

look inside the cutout at the rear of

the frame and make sure the Op

erator Presence Control latches (A

and B, Fig. 5-10) are fully engaged

at point (C). If they are not fully en

gaged, improper operation or pre

mature wear could result. To ad

just, loosen hex nut (D) and short

en length of control rod (E). To