Craftsman 987.799600 Owner's Manual

IMPORTANT

MANUAL

DO NOT THROW AWAY

SEARS

OWNER'S

MANUAL

MODEL NO.

987.799600

A Caution:

Read and Follow

All Safety Rules

and

Instructions

Before Operating

This

Equipment.

SIEARS

[RAFTSMAN™

5 Horsepower

CHIPPER/VAC

Safety

Assembly

Operation

Customer Responsibilities

Repair Parts

SEARS, ROEBUCK AND CO., HOFFMAN ESTATES, IL 60179 U.S.A.

FORM 1769199 (12/93)

II.

•

Limited Warranty

For One Year from date of purchase, when this ChipperlVac is maintained, lubricated, and tuned up

according to the operating and maintenance instructions

in

the Owner's Manual, Sears will repair free of

charge any defect

in

material or workmanship.

This warranty excludes the collection bag, spark plug, air cleaner, and chipper blade which are

expendable parts and become worn during normal use.

If

this ChipperlVac is used for commercial or rental purposes, this warranty applies for only 30 days from

the date of purchase.

WARRANTY SERVICE

IS

AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT

IN

THE UNITED STATES. This warranty applies only while this product is

in

useinthe United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

SEARS, ROEBUCK AND CO.,

D/817WA - HOFFMAN ESTATES,

IL

60179

WARNINGTOCALIFORNIA

OWNERS

AND

OTHER

POWER

EQUIPMENT

OPERATORS

Under

California

law,

and

under

the

lawsofseveral

other

states,

you

are

not

permiUedtooperateaninternal

combustion

engine

using

hydrocarbon

fuelsonany

forest

covered,

brush

covered,orgrass

covered

land,oron

land

covered

with

grain,

hay,orother

flammable

agricultural

crop,

withoutanengine

spark

arresterincontinuous

effective

working

order.

The

engineonyour

power

equipment

like

most

outdoor

power

equipment,isan

internal

combustion

engine

that

burns

gasoline,ahydrocarbon

fuel.

Therefore,

your

power

equipment

mustbeequipped

withaspark

arrester

muffler

in

continuous

effective

working

order.

The

spark

arrester

mustbeaUachedtothe

engine

exhaust

systeminsuchamanner

that

flamesorheat

from

the

system

will

not

ignite

flammable

material.

Failureofthe

owner/operatorofthe

equipment

to

comply

with

this

regulationisa

misdemeanor

under

California

law,

and

may

alsobea

violationofother

state

and/or

federal

regulations,

laws,

ordinances,orcodes.

Contact

your

local

fire

marshalorforest

service

for

specific

information

about

what

regulations

applyinyour

area.

NOTE:

This

ChipperNacisnot

equipped

withaspark

arresteronits

mufflerasstandard

equipment.

You

must

provide

the

spark

arrester.Aspark

arrester

for

the

mufflerisavailable

through

your

Sears

Service

Center.

TO

PREVENT

PERSONAL

INJURYORPROPERTY

DAMAGE

•

Cutting

blades

begintorotate

when

engine

starts

and

slow

down

gradually

after

the

engineisshut

off.

Do

not

allow

handsorany

other

partofthe

bodyorclothing

inside

the

vacuum

inlet,

chipper

chute,

discharge

opening,

blower

deflector,ornear

any

moving

part

.

•

Before

inspection,

cleaning,orservicing

machine,

shut

off

engine,

disconnect

spark

plug

wire,

and

make

sure

that

all

moving

parts

have

cometoa

complete

stop.

This machine meets voluntary safety standard

B71.6-1990, which

is

sponsored by the Outdoor

Power Equipment Institute, Inc., and is published

by the American Standards Institute, Inc.

TableofContents

Model/Serial Number & Specifications 2

Safety 3-5

Training 3

Preparation 3

Operation 4

Customer Responsibilities and Storage 5

Safety Decals 5

Accessories 6

Unpacking the ChipperlVac 6

Assembly 7-9

Operation 10-22

Features and Controls 10

Engine Operation

11

General Operation 12

Vacuuming and Chipping Operation 13

Materials to Avoid 13

Walk-Behind Vacuuming 14-15

Vacuum Hose Operation 16-18

Blower Operation 19-20

Chipper Operation 20-21

Clearing Jams and Clogs

21

Removing and Installing Shredder Screen 22

Customer Responsibilities 23-30

Important Service Message

23

Service Recommendations 23-24

Check and Change Engine Oil 23

Service the Air Cleaner 24

Clean the Cooling System 24

Inspect Engine Spark Arrester 24

Service the Spark Plug 24

Carburetor and Ignition System Information 25

Lubrication 25

Check Bolts and Nuts for Tightness 25

Replace the Chipper Cutting Blade 25-27

Torque Specifications 27

Off-Season Storage 28

Troubleshooting 29-30

Decals

31

Parts List 32-35

Index

36

A

LOOK FOR THIS SYMBOL TO POINT

OUT IMPORTANT SAFETY

PRECAUTIONS. IT MEANS ATTENTION!!! BECOME ALERT!!!

YOUR SAFETY IS INVOLVED.

1

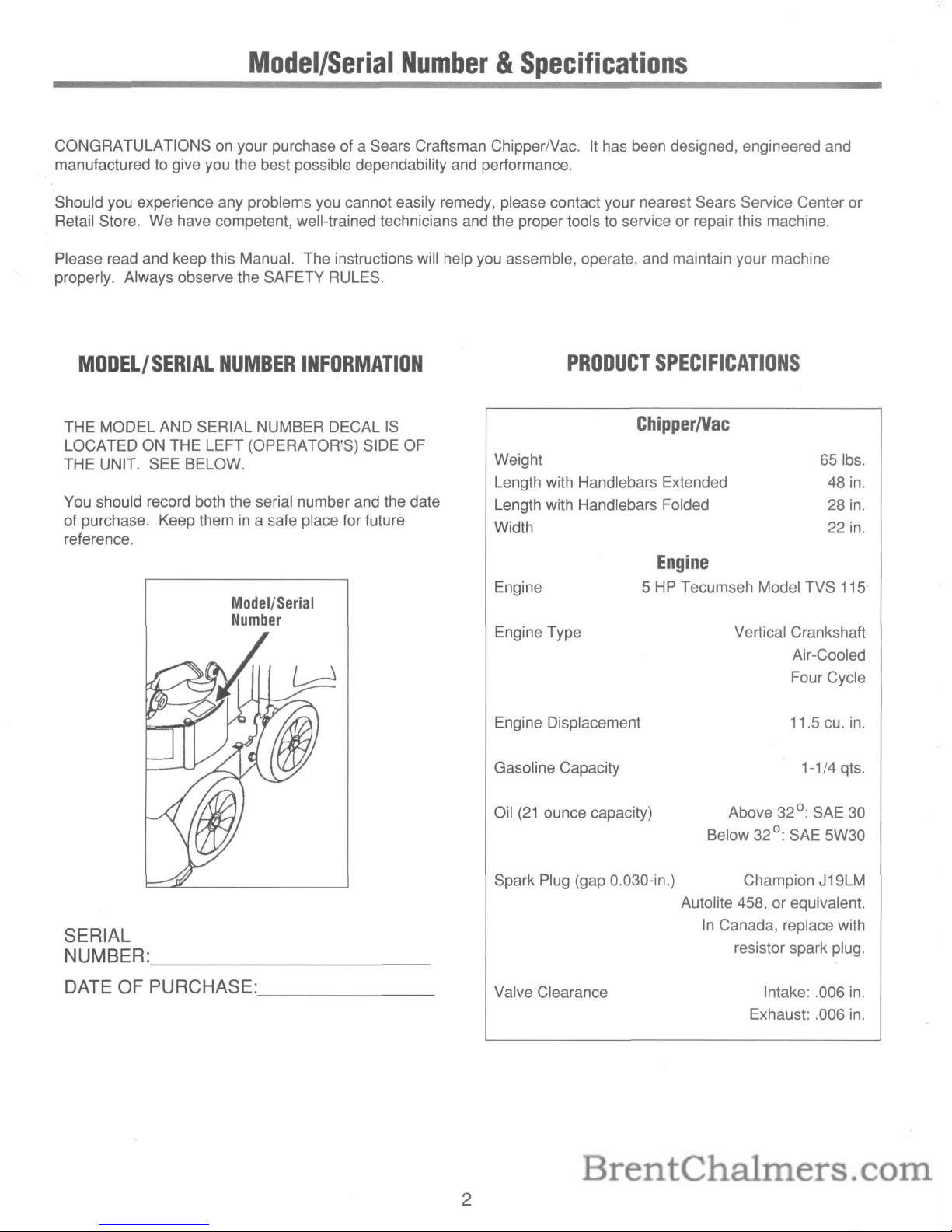

Model/Serial

Number&Specifications

CONGRATULATIONSonyour purchase of a Sears Craftsman ChipperlVac.Ithas been designed, engineered and

manufactured to give you the best possible dependability and performance.

Should you experience any problems you cannot easily remedy, please contact your nearest Sears Service Center or

Retail Store. We have competent, well-trained technicians and the proper tools to service or repair this machine.

Please read and keep this Manual. The instructions will help you assemble, operate, and maintain your machine

properly. Always observe the SAFETY RULES.

MODELl

SERIAL

NUMBER

INFORMATION

PRODUCT

SPECIFICATIONS

THE MODEL AND SERIAL NUMBER DECAL

IS

LOCATED ON THE LEFT (OPERATOR'S) SIDE OF

THE UNIT. SEE BELOW.

You should record both the serial number and the date

of purchase. Keep them

in

a safe place for future

reference.

ChipperNac

Weight

Length with Handlebars Extended

Length with Handlebars Folded

Width

651bs.

48 in.

28 in.

22 in.

Spark Plug (gap 0.030-in.) Champion J19LM

Autolite 458, or equivalent.

In

Canada, replace with

resistor spark plug.

Oil

(21

ounce capacity)

Model/Serial

Number

SERIAL

NUMBER: _

DATE OF PURCHASE: _

2

Engine

Engine Type

Engine Displacement

Gasoline Capacity

Valve Clearance

Engine

5

HP

Tecumseh Model TVS 115'

Vertical Crankshaft

Air-Cooled

Four Cycle

11.5 cu. in.

1-1/4qts.

Above

32°:

SAE 30

Below

32°:

SAE 5W30

Intake: .006 in.

Exhaust: .006

in.

Safety

Please read and follow all of the safety instructionsinthis Safety Section. Failure to comply can resultinserious

personal injury or property damage.

If

you have questions, or are not completely sure about any of the information

found here or elsewhere

in

this Manual, please call your local Sears Service Center for assistance before you operate

your equipment.

DANGER

Cutting

blades

begintorotate

when

the

engine

starts

and

slow

down

gradually

after

the

engineisshut

off.

Do

not

allow

handsorany

other

partofthe

body

or

clothing

inside

the

vacuum

inlet,

chipper

chute,

discharge

opening,

blower

deflector,ornear

any

moving

part.

A

LOOK FOR THIS SYMBOL TO

POINT OUT IMPORTANT SAFETY

PRECAUTIONS. IT MEANS ATTENTION!!! BECOME

ALERT!!! YOUR SAFETY IS

INVOLVED!!!

TRAINING

1. Read this Owner's Manual and

the separate Engine Owner's Manual

carefully before operating this

equipment. Be thoroughly familiar

with the controls and the proper use

of this equipment.

2.

Never allow children or untrained

adults to operate this equipment.

3. Keep the area of operation clear

of all persons, particularly small

children, and pets. Keep bystanders

at least 25 feet away from the area

of operation.

4. Familiarize yourself with all of the

safety and operating decals

on

this

equipment and on any of its

attachments or accessories.

PREPARATION

1. Always wear approved safety

goggles (provided) when operating

this equipment. The operation of any

powered machine can result

in

foreign objects being thrown by highspeed rotating parts.

2.

Do not wear loose-fitting clothing

or jewelry that can get drawn into the

vacuum inlet or chipper chute, or that

can get caught by moving parts.

3.

Do

not operate this equipment

unless the collection bag or blower

deflector is installed.

4. Do not process material through

chipper chute when equipment

is

on

uneven ground.

5.

Do

not run engineinan

enclosed

area. Engine exhaust contains

carbon monoxide gas, a deadly

poison that

is

odorless, colorless, and

tasteless.

Do

not operate this

equipment near buildings, windows,

or air conditioners.

6.

Do

not allow hands or any other

part of the body or clothing inside the

vacuum inlet, chipper chute,

discharge opening, blower deflector,

or near any moving part. Cutting

blades begin to rotate when engine

starts and slow down gradually after

engine

is

shut off.

5.

Before starting engine, check that

all screws, nuts, bolts, and other

fasteners are properly secured.

Replace any damaged or unreadable

warning and operating decals.

6. Wear work gloves, sturdy

footwear, and hearing protection

when operating this equipment.

7.

Use extra care when handling

gasoline and other fuels. Gasoline

and its vapors are highly flammable

and explosive. To help prevent a fire

or explosion:

a.

Useanapproved fuel container.

3

7.

Before inspecting or servicing any

part of the equipment, stop the

engine and make sure that all

moving parts have come to a

complete stop. Disconnect the spark

plug wire and secure it away from the

spark plug. Be aware that rotating

blades slow down gradually after

engine

is

shut off.

8.

Do

not operate this equipment if

you are under the influence of alcohol, medication, or when tired or ill.

b. Never add fuel to a running or a

hot engine.

c. Keep matches, smoking

materials, open flames, and sparks

away from the fuel tank and fuel

container.

d. Fill the fuel tank outdoors and

with extreme care. Never fill fuel

tank indoors.

e. Replace the caps

on

the fuel

tank and fuel container and clean

up spilled fuel before starting

engine. Gas cap shall never be

removed or fuel added while

engine

is

running.

1.

Leave 1/2 inch air space at top of

fuel tank to

aliON

for expansion of

fuel.

OPERATION

1. Before starting this equipment,

make certain that the chipper chute,

vacuum inlet, discharge opening,

and blower deflector are empty.

Disconnect spark plug wire before

making these checks.

2.

Never carry passengersonthis

equipment. They could fall off and

be seriously injured, or they could

interfere with safe operation.

3.

Do

not allow hands or any other

part of the body or clothing inside the

vacuum inlet, chipper chute,

discharge opening, blower deflector,

or near any moving part.

4. Before vacuuming, inspect the

area where the equipment is to be

used and remove all metal, bottles,

cans, or other foreign objects.

5.

Do not vacuum any burning or

smoldering materials such as cigars,

cigarettes, ashes, or cinders.

6.

When vacuuming or chipping,

be

extremely careful that pieces of

metal, rocks, bottles, cans, or other

foreign objects are not inclUded.

7.

Do

not use vacuum or blower

on

areas that have been recently

treated with fertilizers, pesticides, or

herbicides. Follow chemical

manufacturer's safety instructions

regarding contact with treated areas.

8.

Do

not vacuum flammable liquids

such as gasoline, kerosene, diesel

fuel, paint thinner, etc.

9.Ifequipment strikes any foreign

object or starts making an unusual

noise or vibration, immediately shut

off engine and allow all

mOVing

parts

to come to a complete stop.

Disconnect the spark plug wire and

secure

it

away from the spark plug.

Then take the following steps:

a.

Inspect for damage.

Safety

g.

Do

not store the machine or fuel

container where there

isanopen

flame or spark, or where ignition

sources such as hot water and space

heaters, furnaces, clothes dryers,

stoves, or electric motors are present.

b. Replace or repair any damaged

parts.

c. Check for and tighten any loose

parts.

10.

If

equipment jams or becomes

clogged, immediately shut off the

engine and allow all moving parts to

come to a complete stop. Disconnect

the spark plug wire and secure

it

away from the spark plug. Use only a

wooden stick

to

clear away debris.

11. Before adding or changing any

attachments or before switching

between vacuum and blower operation stop the engine and allow all

moving parts

to

come to a complete

stop. Disconnect the spark plug wire

and secure it away from the spark

plug.

12. Keep all guards, covers, and

shields

in

place andingood working

condition.

13. Always stand clear of discharge

area when operating equipment with

blower deflector installed. Material

exits at a high speed from the blower

deflector.

14.

Do

not operate the chipper with

the blower deflector installed.

15.

Do

not operate the chipper if the

chipper chute flap

is

damaged or

missing.

16. Keep your face and body safely

away from the chipper chute. When

chipping, stand

on

either side of

chute and keep arms perpendicular

(at a

90°

angle)tochute inlet.

17.

Do

not overreach when feeding

material into the chipper chute. Keep

proper balance and footing at all

times.

18. Check collection bag frequently

for deterioration or wear and replace

worn bags. Use only original-

equipment replacement bags.

4

Bags manufactured by others could

present a safety hazard.

19. Before removing and installing

collection bag, stop the engine and

allow all moving parts to come to a

complete stop. Disconnect the spark

plug wire and secure it away from

the spark plug.

20. Empty the collection bag after

each use. Decomposing debris

could generate enough heat to catch

fire.

21. Exercise extreme caution on

slopes and avoid excessively steep

slopes.

22. Never operate this equipment

on

a slippery surface.

23. Look behind and use care when

operating

in

reverse.

24.

Do

not allow any part of the

engine, especially around the cooling

fins and muffler to become clogged

with leaves, oil, grease, or any other

combustible material.

25. Watch for traffic when operating

near, or when crossing roadways.

26. Never leave the equipment

unattended when the engine

is

running. Stop the engine, disconnect

spark plug wire, and secure it away

from the spark plug before leaving

the equipment.

27. Use only attachments and

accessories that are approved for

use with this equipment.

28. Operate equipment only

in

daylight oringood artificial light.

29.

Do

not tamper with the engine

governor settings. The governor

controls the maximum safe operating

speed and protects the engine and

all moving parts from damage

caused by excessive speed.

Request help at the nearest Sears

service location if a problem exists.

30. This equipmentisprovided with

a safety interlock system which

prevents the engine from starting

unless the collection bag or blower

deflector

is

installed. The system

is

Safety

also designed to shut off the engine

if the operator attempts to remove

the collection bag or blower deflector

while the engine

is

running. Never

attempt to disconnect or otherwise

defeat the purpose of this system. If

the interlock fails to operate properly,

shut off the engine and do not

operate this equipment until the

system

is

repaired andisfunctioning

properly.

CUSTOMER

RESPONSIBILITIES

AND

STORAGE

1. When equipmentisstopped for

servicing, inspection, storage, or to

change

an

attachment or accessory,

make sure the spark plug wire

is

disconnected from the spark plug.

Allow the engine to cool before

making any inspections,

adjustments, etc.

2. Maintain equipment and all

attachments and accessories

in

safe

working condition.

3.

Never perform any maintenance

while engine

is

running or when

spark plug wire

is

connected to spark

plug, except where specifically

instructed to do so.

4. Never store this equipment with

fuel

in

the fuel tank inside a building

where fumes may reach

an

open

flame or spark, or where ignition

sources are present such

as

hot

SAFETY

DECALS

Make certain that all safety decals on

this equipment are kept clean and

in

good condition. The decals are

shown on Page

31

of this Manual.

water and space heaters, furnaces,

clothes dryers, stoves, electric

motors, etc.

5.

Allow engine to cool before

storing

in

any enclosure.

6.

Store gasolineina cool, wellventilated area, safely away from any

spark- or flame-producing

equipment. Store gasoline

in

an

approved container, safely out of the

reach of children.

7.

Use only original equipment

replacement parts. Parts

manufactured by others could

present a safety hazard even though

they may fit

on

this equipment.

5

8.

Store this equipment where

children will not have access.

Always disconnect the spark plug

wire from the spark plug to prevent

accidental starting.

9.

Check collection bag frequently

for deterioration or wear and replace

worn bags. Use only original

equipment replacement bags. Bags

manufactured by others could

present a safety hazard.

10. Refer to the Engine Owner's

Manual and to "Off Season Storage"

in

this Manual for important storage

instructions

if

equipmentisto

be

stored foranextended period.

Accessories

VACUUM

HOSE

The optional vacuum hose attachment allows you to

extend the reach of the machine by 10 feet to easily

reach in, around, under and behind bushes, shrubs,

trees, fences, lawn furniture, etc. This attachment is

available at your Sears Service Center or Sears Retail

store. If you purchased a vacuum hose with the

ChipperNac, you will find it packaged

in

a separate

carton.

Instructions for installation and use of the vacuum hose

are presented

in

this Manual. See "Vacuum Hose

Operation" on Page 16.

Engine

Accessories

Optional vacuum hose

and

baffle plate.

(Stock No. 71-85689)

Engine accessories such as gas cans, engine oil, and replacement spark plugs are also available at your local Sears

Service Center and most Sears Retail stores.

Unpacking

the

Vacuum/Blower/Chipper

UNPACKING

INSTRUCTIONS

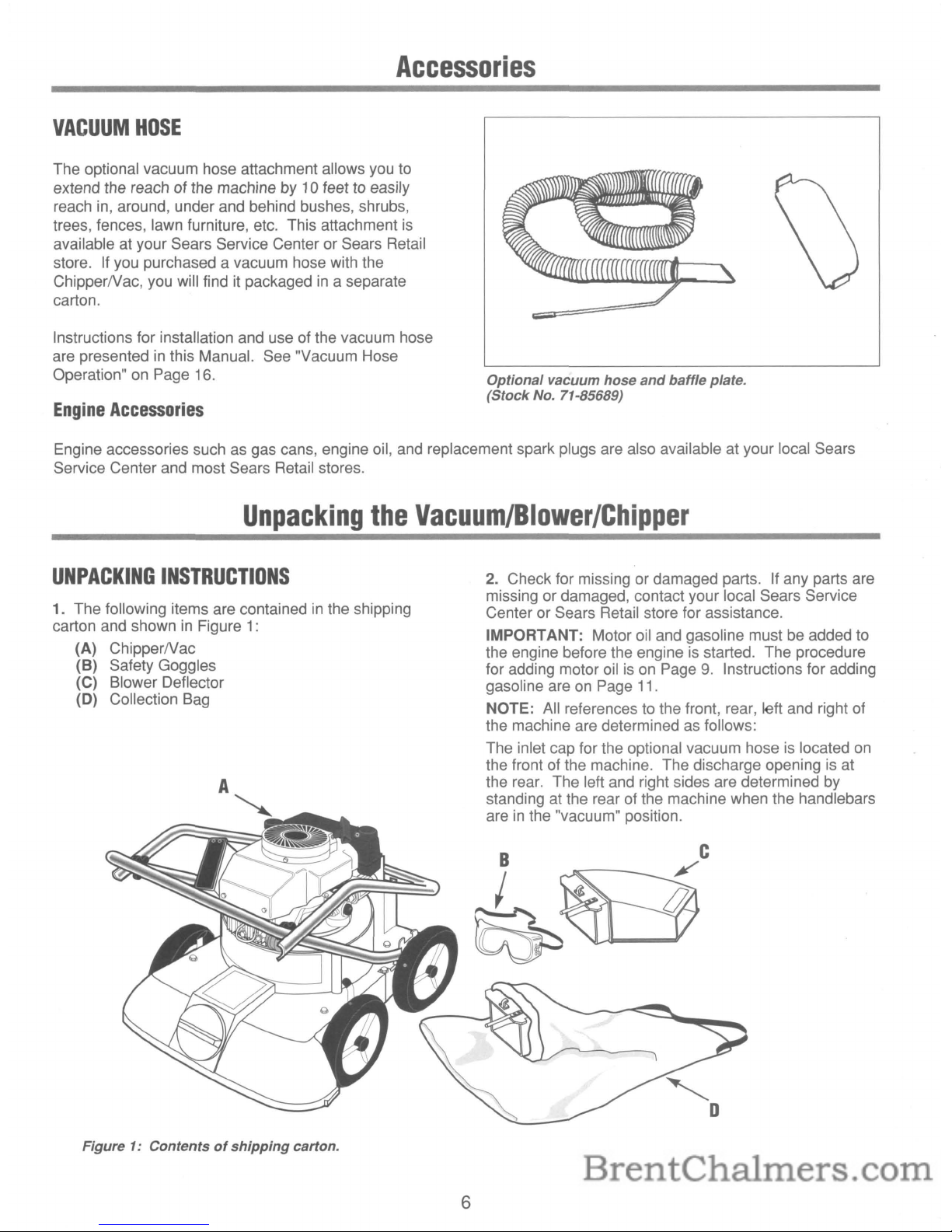

1. The following items are containedinthe shipping

carton and shown

in

Figure 1:

(A) ChipperNac

(B) Safety Goggles

(C) Blower Deflector

(0)

Collection Bag

Figure 1: Contentsofshipping

carton.

6

2. Check for missing or damaged parts. If any parts are

missing or damaged, contact your local Sears Service

Center or Sears Retail store for assistance.

IMPORTANT: Motor oil and gasoline must be added to

the engine before the engine is started. The procedure

for adding motor oil is on Page

9.

Instructions for adding

gasoline are

on

Page 11.

NOTE: All references to the front, rear, left and right of

the machine are determined as follows:

The inlet cap for the optional vacuum hose is located

on

the front of the machine. The discharge opening is at

the rear. The left and right sides are determined by

standing at the rear of the machine when the handlebars

are

in

the "vacuum" position.

B

I

~

Assembly

ASSEMBLY

FOR

WALK-BEHIND

VACUUMING

Your machine has been partially assembled at the

factory. The remaining assembly steps, which are

described below, should be done on a clean, level

surface.

This assembly procedure readies the machine for use for

walk-behind vacuuming. Instructions for converting the

machine for other uses begin on Page 16. Remember to

add oil to the engine before starting the machine. See

"Add Oil to Engine" on Page

9.

CAUTION

To

prevent

personal

injuryorproperty

damage,donot

connect

the

spark

plugorstart

the

engine

until

all

assembly

steps

are

complete

and

you

have

read

and

understood

the

safety

and

operating

instructions

in

this

Manual.

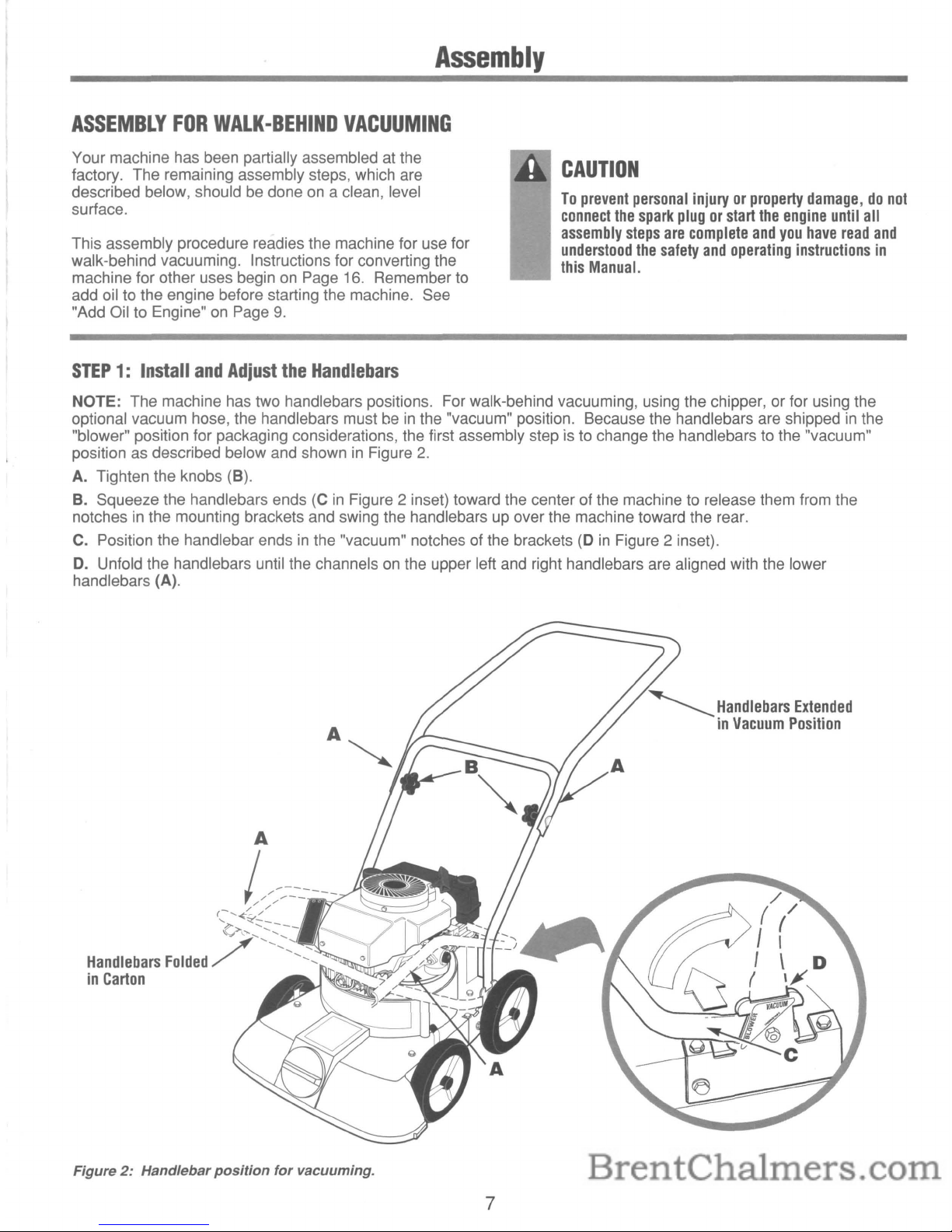

STEP1:Install

and

Adjust

the

Handlebars

NOTE: The machine has two handlebars positions. For walk-behind vacuuming, using the chipper, or for using the

optional vacuum hose, the handlebars must

beinthe "vacuum" position. Because the handlebars are shippedinthe

"blower" position for packaging considerations, the first assembly step is to change the handlebars to the "vacuum"

position as described below and shown

in

Figure

2.

A. Tighten the knobs (B).

B. Squeeze the handlebars ends

(CinFigure 2 inset) toward the center of the machine to release them from the

notches

in

the mounting brackets and swing the handlebars up over the machine toward the rear.

C. Position the handlebar ends

in

the "vacuum" notches of the brackets(0in

Figure 2 inset).

O.

Unfold the handlebars until the channels on the upper left and right handlebars are aligned with the lower

handlebars (A).

~

Handlebars

Extended

in

Vacuum

Position

Figure2:Handlebar

position

for

vacuuming.

7

Assembly

STEP2:InstallorRemove

Collection

Bag

For walk-behind vacuuming, install the collection bag as

described below. To empty the bag or to convert the

machine for use with the blower deflector, remove the

collection bag

as

describedinStep

B.

DANGER

•

Before

installing/removing

the

collection

bag,

stop

the

engine

and

make

sure

that

all

moving

parts

have

cometoa

complete

stop.

Disconnect

the

spark

plug

wire

and

secureitaway

from

the

spark

plug.

•

Check

the

collection

bag

frequently

for

deterioration

and

wear

and

replace

worn

bags.

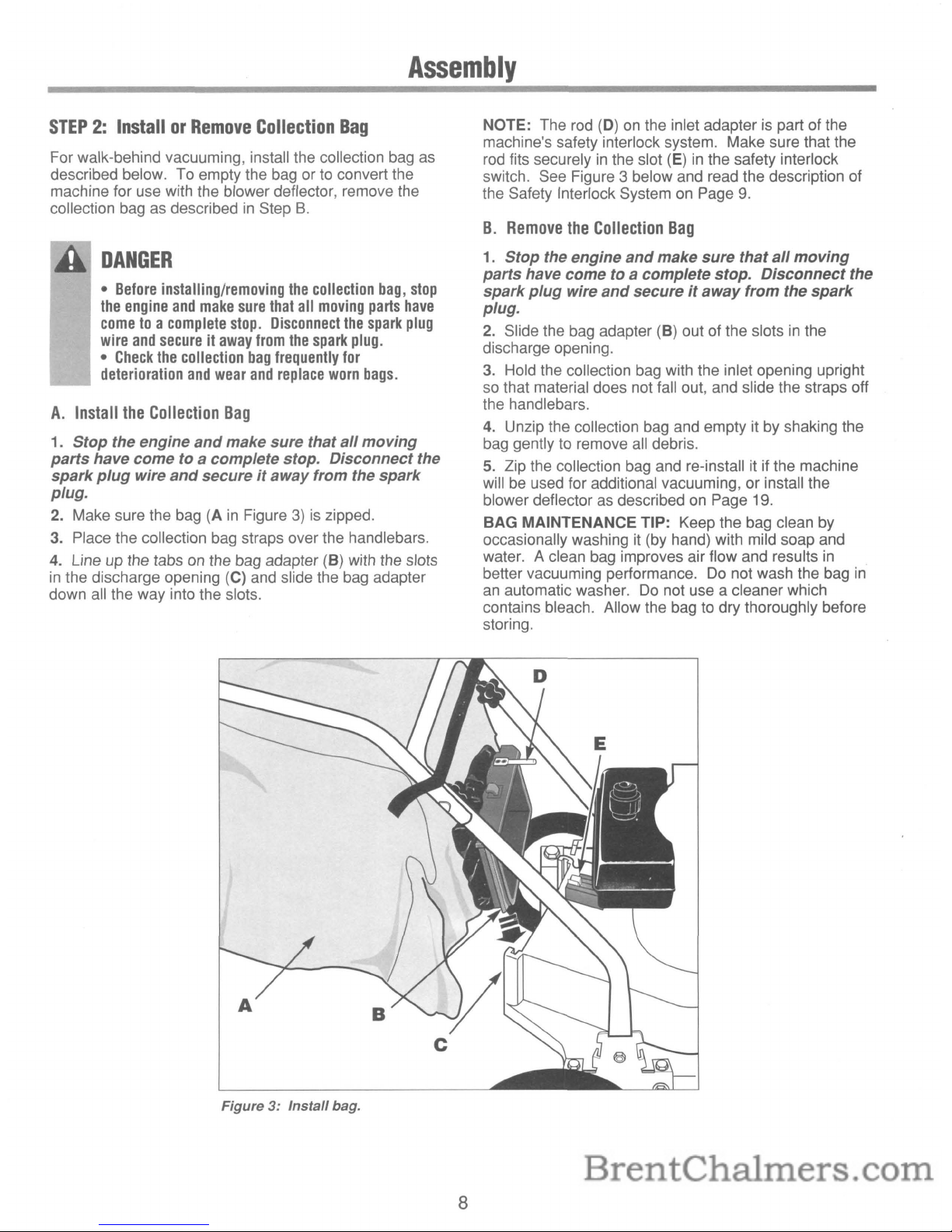

A.

Install

the

Collection

Bag

1.

Stop the engine

and

make sure that

all

moving

parts

have come to a complete stop. Disconnectthe

spark

plug

wire

and

secureitaway from the spark

plug.

2.

Make sure the bag (AinFigure3)is

zipped.

3.

Place the collection bag straps over the handlebars.

4.

Line up the tabs on the bag adapter (B) with the slots

in

the discharge opening (C) and slide the bag adapter

down all the way into the slots.

NOTE: The rod (0) on the inlet adapter

is

part of the

machine's safety interlock system. Make sure that the

rod fits securely

in

the slot (E)inthe safety interlock

switch. See Figure 3 below and read the description of

the Safety Interlock System on Page

9.

B.

Remove

the

Collection

Bag

1.

Stop the engine

and

make sure that

all

moving

parts

have come to a complete stop. Disconnect the

spark

plug

wire

and

secureitaway from the

spark

plug.

2.

Slide the bag adapter (B) out of the slotsinthe

discharge opening.

3.

Hold the collection bag with the inlet opening upright

so that material does not fall out, and slide the straps off

the handlebars.

4.

Unzip the collection bag and empty it by shaking the

bag gently to remove all debris.

5.

Zip the collection bag and re-install itifthe machine

will

be

used for additional vacuuming, or install the

blower deflector as described on Page 19.

BAG MAINTENANCE TIP: Keep the bag clean by

occasionally washing it (by hand) with mild soap and

water. A clean bag improves air flow and results

in

better vacuuming performance. Do not wash the bag

in

an

automatic washer.

Do

not use a cleaner which

contains bleach. Allow the bag to dry thoroughly before

storing.

Figure3:Install

bag.

8

Assembly

Safety

Interlock

System

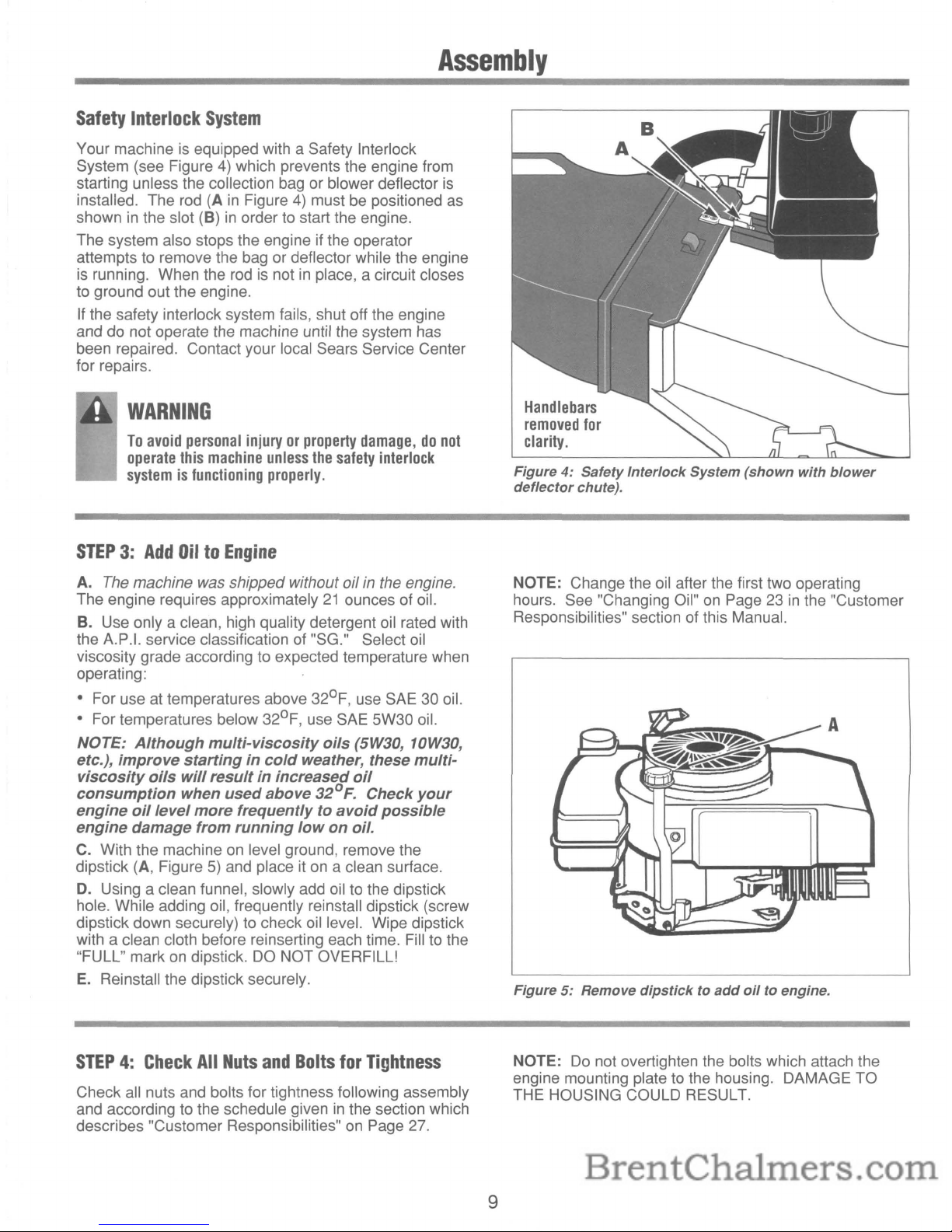

Your machineisequipped with a Safety Interlock

System (see Figure

4)

which prevents the engine from

starting unless the collection bag or blower deflector

is

installed. The rod (AinFigure4)must be positioned

as

showninthe slot (B)inorder to start the engine.

The system also stops the engine

if

the operator

attempts to remove the bag or deflector while the engine

is running. When the rod

is

notinplace, a circuit closes

to ground out the engine.

If the safety interlock system fails, shut off the engine

and do not operate the machine until the system has

been repaired. Contact your local Sears Service Center

for repairs.

WARNING

To

avoid

personal

injuryorproperty

damage,donot

operate

this

machine

unless

the

safety

interlock

systemisfunctioning

properly.

STEP3:Add

OiltoEngine

A.

The machine was shipped without oil in the engine.

The engine requires approximately21ounces of oil.

B. Use only a clean, high quality detergent oil rated with

the

A.P.1.

service classification of "SG." Select oil

viscosity grade according to expected temperature when

operating:

• For use at temperatures above 32

0

F,

use SAE30oil.

• For temperatures below 32

0

F,

use SAE 5W30 oil.

NOTE:

Although

multi-viscosity

oils

(5W30, 10W30,

etc.),

improve

startingincold

weather, these

multi-

viscosity

oils

will

resultinincreased

oil

consumption

when

used

above 320F.

Check

your

engine

oil

level

more

frequentlytoavoid

possible

engine

damage from

running

lowonoil.

C.

With the machine on level ground, remove the

dipstick (A, Figure

5)

and place it on a clean surface.

D.

Using a clean funnel, slowly add oil to the dipstick

hole. While adding oil, frequently reinstall dipstick (screw

dipstick down securely) to check oil level. Wipe dipstick

with a clean cloth before reinserting each time. Fill to the

"FULL" mark on dipstick.

DO

NOT OVERFILL!

E.

Reinstall the dipstick securely.

STEP4:Check

All

Nuts

and

Bolts

for

Tightness

Check all nuts and bolts for tightness following assembly

and according to the schedule given

in

the section which

describes "Customer Responsibilities"

on

Page 27.

9

Handlebars

removed

for

clarity.

Figure4:Safety

Interlock

System

(shown

with

blower

deflector

chute).

NOTE: Change the oil after the first two operating

hours. See "Changing Oil"

on

Page 23inthe "Customer

Responsibilities" section of this Manual.

Figure5:Remove

dipsticktoadd

oil

to engine.

NOTE:

Do

not overtighten the bolts which attach the

engine mounting plate to the housing. DAMAGE TO

THE HOUSING COULD RESULT.

Operation

FEATURES

AND

CONTROLS

Figure 6 identifies the following key features and controls

on

your machine:

(A) Collection Bag

(8)

Engine Control Lever

(C) Engine Primer

(0)

Air Cleaner

(E) Chipper Chute

(F)

FuelTank

(G) Recoil Starter Rope

(H) Blower Deflector

(I) Safety Interlock Rod

(J) Vacuum Hose (optional)

(K) Baffle Plate (used with optional vacuum hose)

(L) Vacuum Inlet Cap

(M) Spark Plug

(N) Vacuum Height Adjustment Lever

DANGER

Rotating

Cutting

Blades

Will

Cause

Serious

Personallnjuryl

Do

not

allow

handsorany

partofthe

bodyorclothing

inside

the

vacuum

inlet,

chipper

chute,

discharge

opening,orblower

deflector

opening

when

the

engineisrunning.

Before

inspectingorservicing

any

partofthe

machine,

stop

the

engine

and

make

sure

that

all

moving

parts

have

cometoa

complete

stop.

Disconnect

the

spark

plug

wire

and

secureitaway

from

the

spark

plug.

NOTE: The Shredder Screen is not showninFigure

6.

Informationonremoving and installing the Shredder

Screen

is

foundonPage 22.

Figure 6: Features

and

Controls.

10

Loading...

Loading...