Page 1

Operator's Manual

II:RRFTSMRN I

3 HORSEPOWER

REAR TINE TILLER

Model No: 987.293190

CAUTION:

Before using this tiller, read

this manual and follow all its

Safety Rules and Operating

Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit the Craftsman web page: www.sears.com/craftsman

• Safety Rules

• Assembly

• Operation

• Maintenance

• Parts

Page 2

SAFETY RULES

_ CAUTION" ALWAYS DISCONNECT SPARK PLUG WIRE AND PLACE WIRE WHERE IT

CANNOT CONTACT SPARK PLUG TO PREVENT ACCIDENTAL STARTING WHEN SET-

TING UP, TRANSPORTING, ADJUSTING OR MAKING REPAIRS.

I

TRAINING

%, Read ,this Owner's Manual and

any other literature you may receive

carefully before operating this equip-

ment. Be completely familiar with

the controls and the proper use of

this equipment. Know how to stop

the unit and disengage the controls

quickly.

2. Never allow children or untrained

adults to operate this equipment.

3. 'Keep the area of operation clear

of'all persons, particularly small chiL-

dren and pets. Keep bystanders at

least 25 feet from area of operation.

4. Keep in mind that the operator or

user is responsible for accidents or

hazards occurring to other people,

their property, and themselves.

5. Familiarize yourself with all of the

safety and operating decals on this

equipment and on any of its attach-

ments or accessories.

6. Do not run engine in an enclosed

area. Engine exhaust contains car-

bon monoxide gas, a deadly poison

that is odorless, colorless, and taste-

less. Do not operate this equipment

near buildings, windows, or air

6onditioners.

7. Do not allow hands or any other

part of the body or clothing near the

rotating tines or

near any other

moving part. The

tines begin to ro-

tate backward

.once the engine

starts and the

Forward Clutch

Bail is engaged.

8. Before inspecting or servicing any

part of the equipment, shut off the

engine, wait for all moving parts to

come to a complete stop, disconnect

the spark plug wire from the spark

plug and move wire away from the

spark plug.

9. Do not operate this equipment if

you are under the influence of alco-

hol, medication, or when tired or ill.

PREPARATION

1. Thoroughly inspect the area

where the tiller will be used. Re-

move foreign objects before tilling.

2. Make sure that all control levers

are released and both wheels are in

Wheel Drive position before starting

the engine.

3. Do not operate the tiller without

wearing suitable clothing. Avoid

loose garments or jewelry that could

get caught in moving parts of the

tiller or its engine.

4. Do not operate the tiller when you

are barefoot, in sandals, sneakers or

other light footwear. Wear protective

footwear that grips well on slippery

surfaces.

5. Do not till near underground elec-

tric cables, telephone lines, pipes, or

hoses. Contact your telephone or

utility to verify locations of under-

ground cables or lines.

6. Handle gasoline with care; it is

highly flammable and has explosive

vapors. Take the following precau-

tions:

a. Use an approved gas container.

b. Gas caps shall never be re-

moved or fuel added with en-

gine running. Engine shall be

allowed to cool before refueling.

Operators shall notsmoke.

c. Keep matches, cigarettes,

cigars, pipes, open flames, or

sparks away from the fuel tank

and fuel container.

d. Fill fuel tank outdoors using ex-

treme caution. Never add fuel

indoors. Use a funnel or spout

to prevent spillage.

e. Replace all fuel tank and con-

tainer caps securely.

f. If fuel is spilled, do not attempt

to start the engine, but move

the machine away from the area

of spillage and avoid creating

any source of ignition until fuel

vapors have dissipated.

7. Never attempt to make any ad-

ustments while the engine is running

or the spark pug w re is connected,

except when so instructed.

OPERATION

1. Never operate the tiller unless

safety guards or other protective de-

vices are in place.

2. Never operate the tiller without

good visibility or light.

3.' Never operate the tiller if you are'

fatigued, or under the influence of al-

cohol, drugs or medication.

4. Use tiller attachments and acces-

sories when recommended. Use only

attachments and accessories

approved by the manufacturer.

5. Operators shall net tamper with

the engine-governor settings on the

machine; the governor controls the

maximum safe operating speed and

protects the engine and all moving

parts from damage caused by over-

speed. Authorized service shall be

sought if a problem exists.

6. To load or unload the tiller from a

vehicle, see instructions in the "Oper-

ation" section.

7. Keep children and pets away.

8. Clear the area of bystanders

before tilling.

9. Do not run the engine in an en-

closed area. Engine exhaust con-

tains carbon monoxide gas, a deadly

poison that is odorless, colorless,

and tasteless.

10. Start the engine carefully accord-

ing to instructions and with feet well

away from the tines.

11. Never pick up or carry a machine

while the engine is running.

12. Never use the tiller at high

ground speeds on hard or slippery

surfaces.

13. Never operate the tiller under

engine power if the wheels are in the

FREEWHEEL position. In FREE-

WHEEL, the wheels will not hold the

tiller back and the revolving tines

could propel the tiller rapidly

!_ LOOK FOR THIS SYMBOL TO POINT OUT IMPORTANT SAFETY PRECAUTIONS.

IT MEANS- ATTENTION!!f BECOME ALERT!!! YOUR SAFETY IS INVOLVED.

© Sears, Roebuck and Co.

2

Page 3

SAFETY RULES

backward, possibly causing loss of

control. Always engage the wheels

with the Wheel Drive Pins in WHEEL

DRIVE position before starting en-

_ne or engaging tines with Forward

Ibtch Bail.

14. Look behind and exercise cau-

tion when backing up.

15. The tiller could unexpectedly

bounce upward or jump backward

and be propelled toward you if the

tines strike or catch very hard-

packed soil, sod, frozen ground, or

any buried obstacle such as large

stones or roots. If in doubt about till-

ing conditions, use the following pre-

cautions to assist you in maintaining

tiller control:

a. Walk behind and on either side

of the tiller, using one hand on

the handlebar. Relax your arm,

but use a secure hand grip.

b. Use a deep depth regulator

setting.

c. Use.slower engine speeds.

d. Clear the tilling area of big

stones, roots and other debris.

e. Avoid putting downward pres-

sure on the handlebar. If nec-

essary, apply slight upward

pressure to prevent the tines

from digging too deeply.

f. In an emergency, stop tines and

wheels by releasing the

Forward Clutch Bail. Do not at-

tempt to restrain the tiller.

16. Do not overload the machine ca-

pacity by trying to till too deeply at

too fast a rate.

17. Do not operate tiller on a slope

too steep for safety, On slopes, slow

down and be sure you have good

footing, Don't let the tiller "freewheel"

down slopes.

18. Do not touch engine parts that

may be hot from operation (muffler,

fins, etc.). Make certain all parts have

cooled down before inspecting, clean-

ing or repairing.

19. Remember--To stop the tines

and wheels, release the Forward

Clutch Bail.

20. Do not put hands or feet near or

under rotating parts.

21. Use extreme caution when on or

crossing gravel driveways, walks or

roads. Be alert for hidden hazards

or traffic. Do not carry passengers.

22. If you hit a foreign object, stop

the engine, let all moving parts come

to a complete stop, disconnect spark

plug wire, move wire away from the

spark plug, and inspect for damage.

Repair damage before restarting.

23. Exercise caution to avoid slip-

ping or falling.

24, If abnormal tiller vibration oc-

curs, stop engine immediately, dis-

connect the spark plug wire and

move wire away from spark plu_.

Check for the cause. Carefully re-

spect for any damage. Fix the prob-

lem before using the tiller again.

Vibration is generally a warning sign

of trouble.

25. Stop the engine, disconnect the

spark plug wire and move wire away

from spark plug after leaving the op-

erating position, before unclogging

tines, or before making repairs, ad-

justments or inspections.

26. Take all possible precautions be-

fore leaving the machine unattended.

Make sure that all control levers are

released, stop engine, and disconnect

spark plug wire and move wire away

from plug to prevent accidental start-

ing. Be sure both wheels are in the

Wheel Drive position.

27. Before cleaning, repairing or in-

specting, stop the engine, let all

moving parts stop, and disconnect

spark plug wire and move wire away

from spark plug to prevent accidental

starting.

28. The flap on the tine hood must

be down when operating tiller.

MAINTENANCE& STORAGE

1. Never perform maintenance

when engine is running or spark plug

wire is connected except when

specifically directed to do so.

2. Keep tiller, attachments and ac-

cessories in safe working condition.

3. Check all nuts, bolts, and screws

frequently for proper tightness.

Always verify your equipment is in

safe working condition.

4. Never store the machine with fuel

in the fuel tank inside a building

where fumes may reach an open

flame or spark, or where ignition

sources are present (such as hot wa-

ter and space heaters, furnaces,

clothes dryers, etc.).

5. Let the engine cool down before

storing it in an enclosure.

6. To reduce chance of a fire hazard,

keep grass, leaves, grease offengine.

7. Store gasoline in a cool, well-ven-

tilated area, safely away from any

spark- or flame-producing equip-

ment. Store gasoline in an approved

container, safely out of the reach of

children.

e. Refer to the Maintenance section

in this Manual for storage information

if your tiller is to be stored for an ex-

tended period.

9. If the fuel tank has to be drained,

do so outdoors.

10. Follow manufacturer's recom-

mendations for safe loading, unload-

ing, transport, and storage of

machine.

TOAVOIDINJURY:

• READOWNER'SMANUAL.

• KNOW LOCATION AND

FUNCTION OF ALL CON-

TROLS,

• KEEPALLSAFETYDEVICES

AND SHIELDS IN PLACE

ANDWORKING.

• NEVERALLOW CHILDREN

ORUNINSTRUCTEDADULTS

TO OPERATETILLER.

• SHUT OFF ENGINE AND

DISCONNECTSPARKPLUG

WIRE BEFORE UNCLOG-

GING TINES OR MAKING

REPAIRS.

• KEEPBYSTANDERSAWAY

FROMMACHINE,

• KEEPAWAYFROM ROTAT-

INGPARTS.

• USE EXTREME CAUTION

WHEN REVERSING OR

PULLINGTHEMACHINETO-

WARDSYOU.

WARNING:

The engine exhaust from this

product contains chemicals

knownto the Stateof California

to cause cancer, birth defects,

orotherreproductiveharm.

3

Page 4

CONGRATULATIONSonyourpurchaseofaSears

Craftsmantiller.Ithasbeendesigned,engineeredand

manufacturedtogiveyouthebestpossibledependability

andperformance.

Shouldyouexperienceanyproblemsyoucannoteasily

remedy,pleasecontactyournearestSearsService

Center/Department.Wehavecompetent,well-trained

technJciansandthepropertoolstoserviceorrepairthis

machine.

Pleaseread and retain this manual. The instructions will

help you assemble and maintain your machine properly.

Always observe the "SAFETY RULES."

MODEL NUMBER: 987.293190

SERIAL

NUMBER:

DATE OF

PURCHASE:

THE MODELAND SERIAL NUMBERS WILL BE

"FOUND ON A DECAL LOCATED ON THE TRANS-

MISSION OF YOUR MACHINE.

YOU SHOULD RECORD BOTH THE SERIAL NUM-

BER AND DATE OF PURCHASE AND KEEP tN A

SAFE PLACE FOR FUTURE REFERENCE.

MAINTENANCEAGREEMENT

A Sears maintenance agreement is available on this

pr'oduct. Contact your nearest Sears store for details.

CUSTOMERRESPONSIBILITIES

[3 Read and observe the safety rules.

[3 Follow a regular schedule in ma_intaining, caring for

and using this product.

(3 Fellow the instructions under "CUSTOMER

RESPONSIBILITIES" and "STORAGE" sections of

this manual.

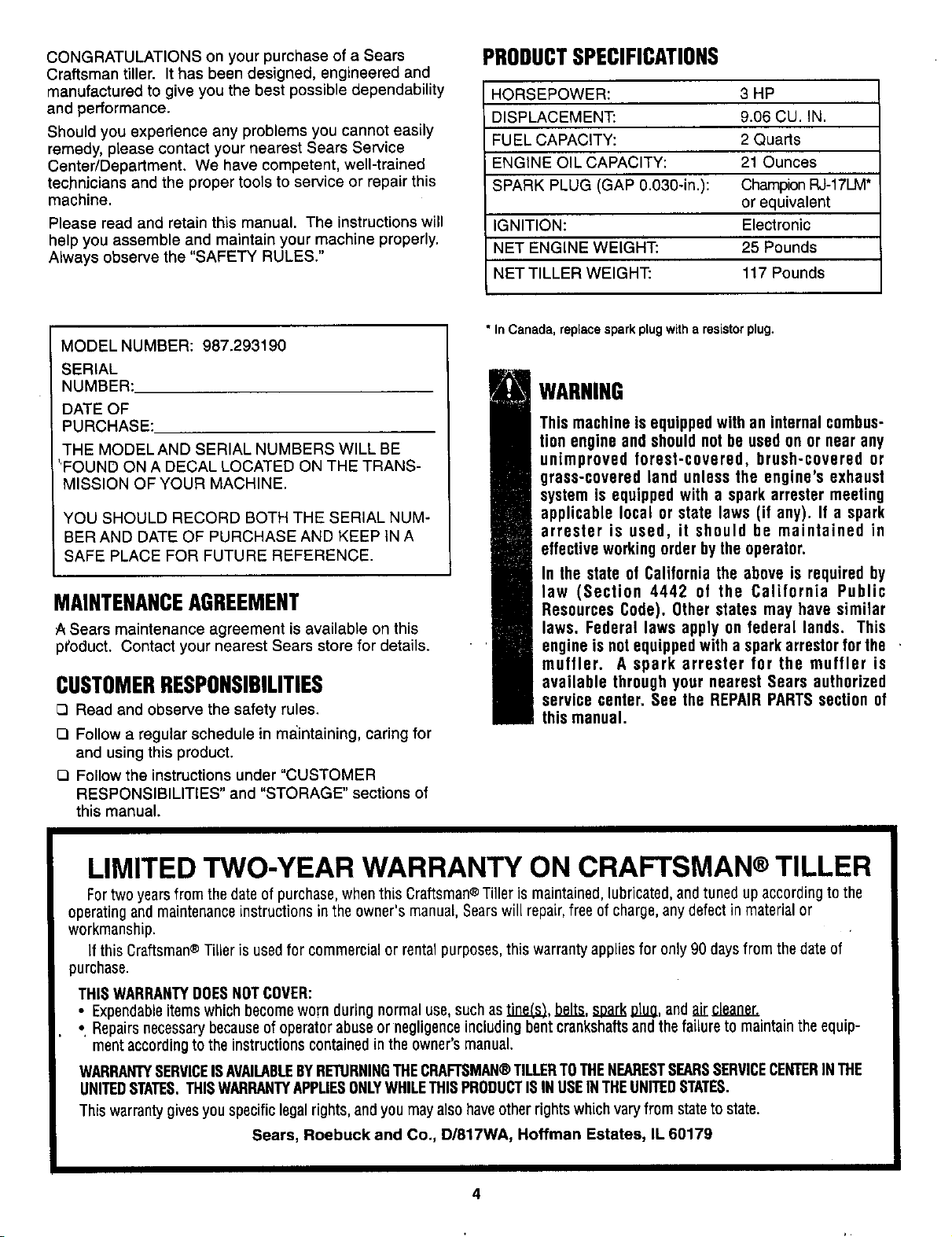

PRODUCTSPECIFICATIONS

HORSEPOWER: 3 HP

DISPLACEMENT: 9.06 CU. IN.

FUEL CAPACITY: 2 Quarts

ENGINE OIL CAPACITY: 21 Ounces

;PARK PLUG (GAP 0.030-in.): Champion RJ-17LM*

or equivalent

IGNITION: Electronic

NET ENGINE WEIGHT: 25 Pounds

NET TILLER WEIGHT: 117 Pounds

• In Canada, replace spark plug with a resistor plug.

WARNING

This machine is equipped with an internal combus-

tion engine and should not be used on or near any

unimproved forest-covered, brush-covered or

grass-covered land unless the engine's exhaust

system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark

arrester is used, it should he maintained in

effective working order by the operator.

In the state of California the above is required by

law (Section 4442 of the California Public

Resources Code). Other states may have similar

laws. Federal laws apply on federal lands. This

engine is not equipped with a spark arrestor for the .

muffler, Asparkarrester for the muffler is

available through your nearest Sears authorized

service center. See the REPAIR PARTS section of

this manual.

LIMITED TWO-YEAR WARRANTY ON CRAFTSMAN® TILLER

Fortwo yearsfrom the date of purchase,whenthis Craftsman®Tiller is maintained,lubricated, and tuned up according to the

operating and maintenanceinstructions in the owner's manual, Searswill repair,free of charge, anydefect in material or

workmanship.

if this Craftsman®Tiller is usedfor commercial or rental purposes, this warranty applies for only 90 days from the date of

purchase.

THIS WARRANTYDOESNOTCOVER:

• Expendableitemswhichbecome worn duringnormaluse, suchastJQP,._,belts,sDarkP_Lu.g,and aircleaner.

• Repairsnecessarybecauseofoperatorabuseor negligenceincludingbentcrankshaftsand the failure to maintaintheequip-

mentaccording to the instructionscontainedinthe owner'smanual.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHECRAFTSMAN®TILLERTOTHENEARESTSEARSSERVICECENTERINTHE

UNITEDSTATES,THISWARRANTYAPPLIESONLYWHILETHISPRODUCTISINUSEINTHEUNITEDSTATES.

This warranty givesyou specific legalrights, andyou mayalso haveother rightswhichvary from state to state.

Sears, Roebuck and Co., D/817WA, Hoffman Estates, IL 60179

Page 5

•TABLE OF CONTENTS

SAFETY RULES ................................................... 2

PRODUCT SPECIFICATIONS .............................. 4

WARRANTY .......................................................... 4

ACCESSORIES .................................................... 6

CONTENTS OF HARDWARE PACKAGE ............ 7

ASSEMBLY ........................................................... 8

OPERATION ....................................................... 11

CUSTOMER RESPONSIBILITIES ..................... 20

INDEX

A

Accessories .................. 6

Air Cleaner Maintenance ....... 23

Anti-Reverse Stake ........... 13

Assembly .................... 8

B

Break-In Operation ........... 16

Belt Tension Adjustment ....... 25

Belt Removal and Replacement . 25

C

Carburetor .................. 23

Checking/Adding Engine Oil .... 21

Checking/Adding Transmission Oil 21

Checking/Adjusting Belt Tension. 25

Checking for Oil Leaks ......... 23

Changing Engine Oil .......... 21

Changing Transmission Oil ..... 22

Cleaning .................... 23

Cooling System Maintenance... 23

Controls .................... 11

Cultivating .................. 18

D

Decals ..................... 30

Depth Regulator Lever ........ 13

E

Engine:

Air Filter .................. 23

Carburetor ................ 23

Choke Lever .............. 14

Cooling System ............ 23

Fuel Tank ................. 15

Oil, Checking/Adding ........ 21

Operation ................. 16

Part_ .................... 40

Recoil Start Rope .......... 14

Spark Plug ................ 23

Speed ................... 14

Starting Engine ............ 16

Stopping Engine ........... 16

Storage .................. 28

Throttle Lever ............. 14

Features/Controls ............ 11

Forward Clutch Bail ........ 12, 26

Forward Clutch Cable (Install) .... 9

Forward Clutch Cable (Replace) .26

Forward Travel ............ 12, 17

Guiding the Tiller ............. 16

Handlebar Height Adjustment ...13

Hardware .............. 7,10, 24

Leaks, Oil ................... 23

Loading and Unloading Tiller .... 19

Location of Controls ........... 11

Lubrication .................. 20

Maintenance Schedule ........ 20

Maintenance Agreement ........ 4

Model/Serial Number ........... 4

Motor Oil, Adding .......... 15, 21

Motor Oil, Changing ........... 21

Oil ...................... 15

Off-Season Storage ........... 28

Operation ................ 11,17

Parts List ................... 31

Preparation ................. 14

Pre-Start Checklist ............ 14

Product Specifications .......... 4

Rearward Travel ............. 17

Recoil Starter Rope ........... 14

Repair Parts ................. 31

SERVICE AND ADJUSTMENTS ........................ 24

STORAGE ........................................................... 28

TROUBLESHOOTING ........................................ 29

DECALS .............................................................. 30

REPAIR PARTS - TILLER .................................. 31

REPAIR PARTS - ENGINE ................................. 40

PARTS ORDERING/SERVICE ........... Back Cover

F

G

II

Safety Rules ................. 2

Safety Decals ............... 30

Seedbed Preparation .......... 18

Service Recommendation

Checktist ................. 20

Slopes ..................... 19

Spark Plug .................. 23

Starter Rope ................ 14

Storage .................... 28

S

T

"Filler Parts ................. ,_31

Tilling ...................... 17

Tilling Depths ................ 16

"line Cleaning ................ 19

Tine Removal ................ 24

Transmission Gear Oil...10, 21, 22

Troubleshooting .............. 29

Turning Around .............. 17

M

U

Unpacking ................... 8

Untangling Tines ............. 19

W

Warranty .................... 4

0

P

R

Wheel Drive Pins ............. 11

RIGHT

SIDE

FORWARr SIDE

OPERATOR'S POSITION

All references to LEFT and

RIGHT sides of the tiller are

given from the operator's posi-

tion behind the handlebars (un-

less specified otherwise).

Page 6

ACCESSORIES

These accessories were available when the tiller was purchased. They are available at most Sears retail

outlets, catalog and service centers. Most Sears stores can order repair parts for you when you provide the

model number of your tiller.

ACCESSORIES

SparkPlug

Figure 1-1

4,

GasCan Motor 0il

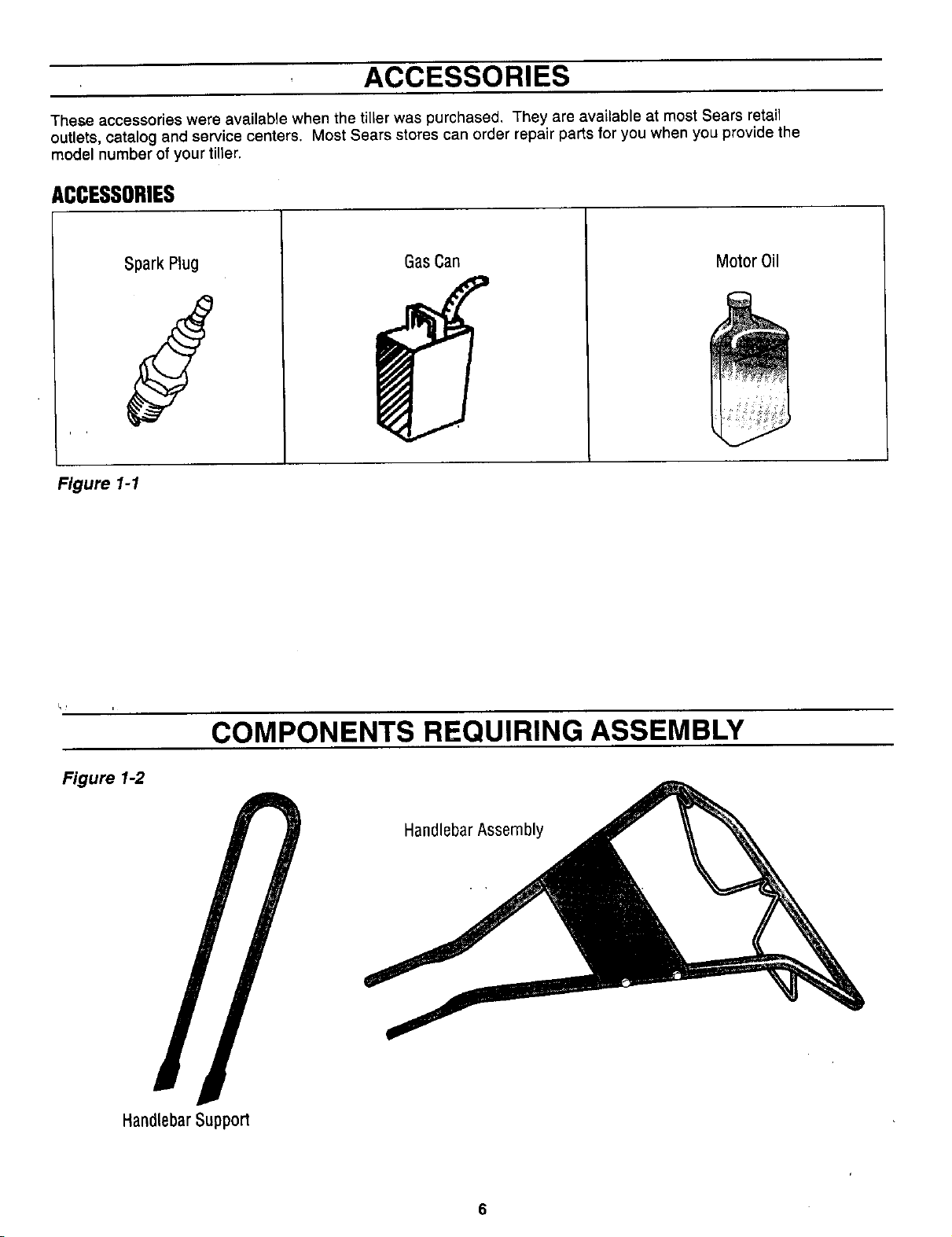

Figure 1-2

HandlebarSupport

COMPONENTS REQUIRING ASSEMBLY

HandlebarAssembly

6

Page 7

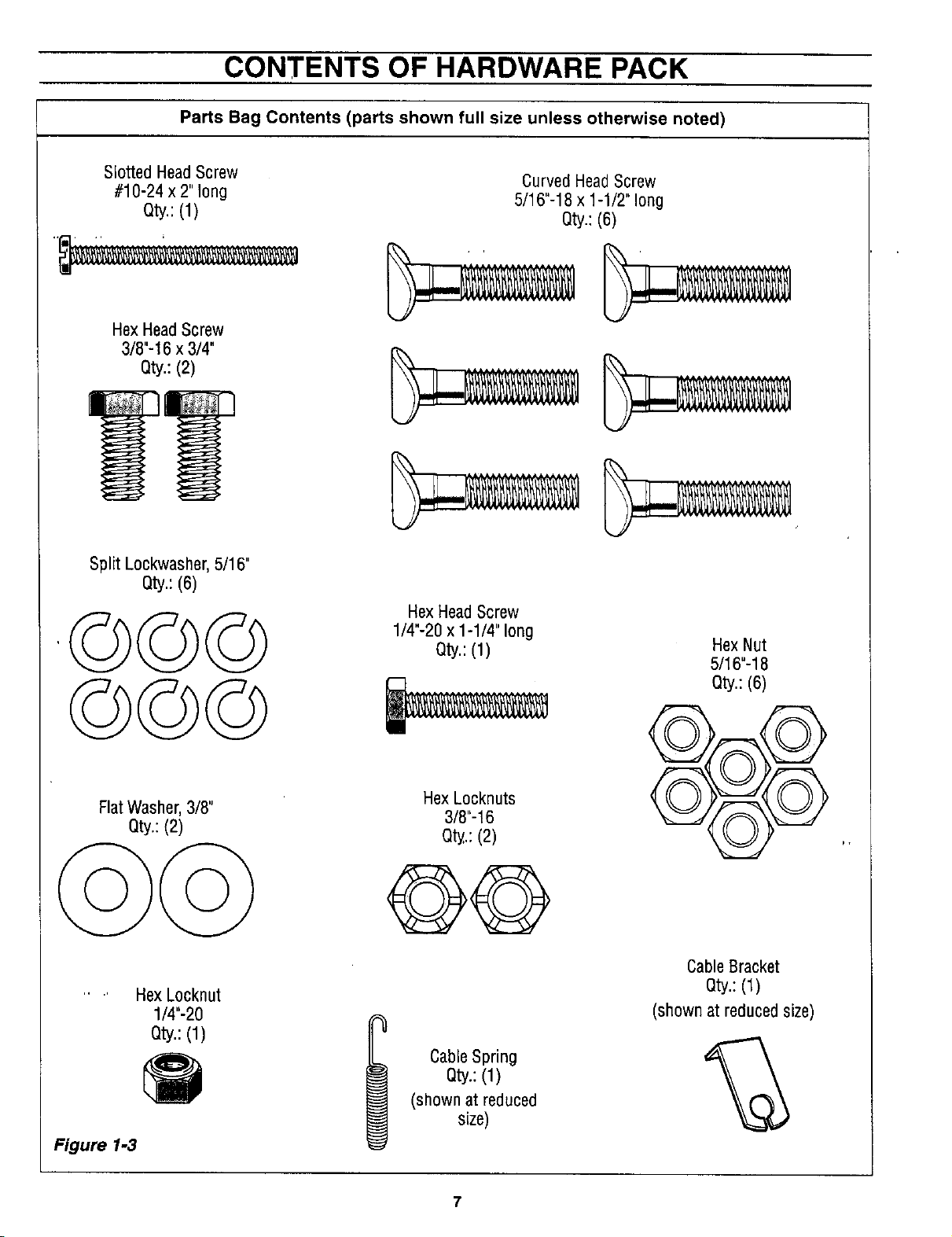

CONTENTS OF HARDWARE PACK

Parts Bag Contents (parts shown full size unless otherwise noted)

Slotted HeadScrew

#10-24 x 2" long

Qty.:(1)

Hex HeadScrew

3/8"-16x 3/4"

Qty.:(2)

Split Lockwasher,5/16"

Qty.:(6)

.©©©

5/16"-18x 1-1/2"long

HexHeadScrew

1/4"-20x 1-1/4" long

Qty.:(1)

CurvedHeadScrew

Qty.:(6)

HexNut

5/16"-18

Qty.:(6)

©©©

FlatWasher,3/8"

Qty.:(2)

.... Hex Locknut

1/4"-20

Qty.:(1)

Figure 1-3

HexLocknuts

3/8"-16

Qty.:(2)

©©

CableSpring

Qty.:(1)

(shownat reduced

size)

CableBracket

Qty.:(1)

(shownat reducedsize)

%

Page 8

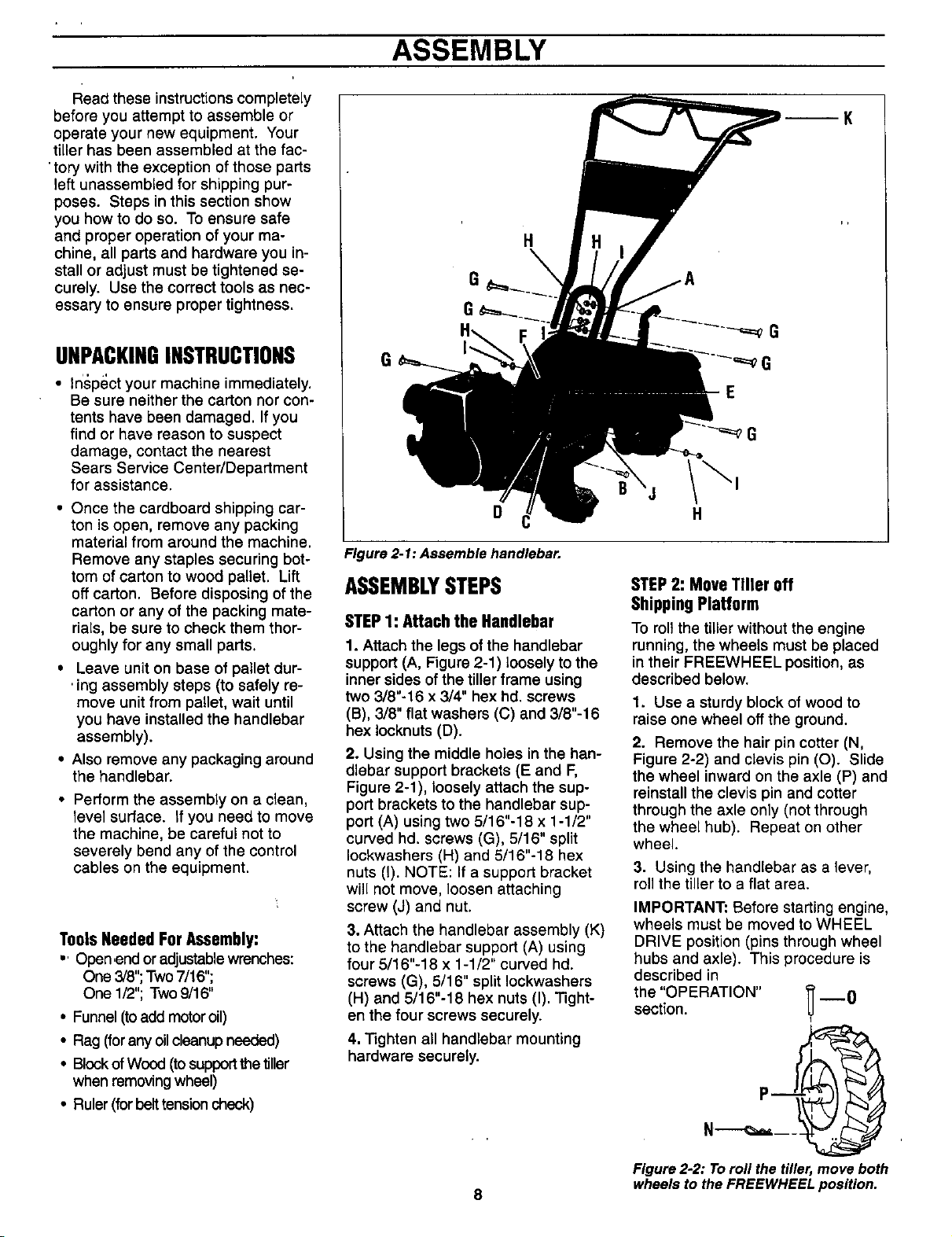

Read these instructions completely

before you attempt to assemble or

operate your new equipment. Your

tiller has been assembled at the fac-

tory with the exception of those parts

left unassembled for shipping pur-

poses. Steps in this section show

you how to do so. To ensure safe

and proper operation of your ma-

chine, all parts and hardware you in-

stall or adjust must be tightened se-

curely. Use the correct tools as nec-

essary to ensure proper tightness.

UNPACKINGINSTRUCTIONS

• Inspect your machine immediately.

Be sure neither the carton nor con-

tents have been damaged. If you

find or have reason to suspect

damage, contact the nearest

Sears Service Center/Department

for assistance.

• Once the cardboard shipping car-

ton is open, remove any packing

material from around the machine.

Remove any staples securing bot-

tom of carton to wood pallet. Lift

off carton. Before disposing of the

carton or any of the packing mate-

rials, be sure to check them thor-

oughly for any small parts.

• Leave unit on base of pallet dur-

.ing assembly steps (to safely re-

move unit from pallet, wait until

you have installed the handlebar

assembly).

• Also remove any packaging around

the handlebar.

• Perform the assembly on a clean,

level surface. If you need to move

the machine, be careful not to

severely bend any of the control

cables on the equipment.

Tools Needed For Assembly:

• Open,end oradjustable wrenches:

One 3/8";Two 7/16";

One 1/2"; Two9/16"

• Funnel (toadd motor oil)

• Rag (forany oil cleanup needed)

• Blockof Wood (to support Me tiller

when removing wheel)

• Ruler (for belttension check)

ASSEMBLY

H

G

D

Figure 2-1: Assemble handlebar.

ASSEMBLYSTEPS

STEP1:Attach the Handlebar

1. Attach the legs of the handlebar

support (A, Figure 2-1) loosely to the

inner sides of the tiller frame using

two 3/8"-16 x 3/4" hex hd. screws

(B), 3/8" flat washers (C) and 3/8"-16

hex Iocknuts (D).

2. Using the middle holes in the han-

dlebar support brackets (E and F,

Figure 2-1), loosely attach the sup-

port brackets to the handlebar sup-

port (A) using two 5/16"-18 x 1-1/2"

curved hd. screws (G), 5/16" split

Iockwashers (H) and 5/16"-18 hex

nuts (I). NOTE: If a support bracket

will not move, loosen attaching

screw (J) and nut.

3. Attach the handlebar assembly (K)

to the handlebar support (A) using

four 5/16"-18 x 1-1/2" curved hd.

screws (G), 5/16" split Iockwashers

(H) and 5/16"-18 hex nuts (I). Tight-

en the four screws securely.

4. Tighten all handlebar mounting

hardware securely.

B

STEP2: MoveTiller off

ShippingPlatform

To roll the tiller without the engine

running, the wheels must be placed

in their FREEWHEEL position, as

described below.

1. Use a sturdy block of wood to

raise one wheel off the ground.

2. Remove the hair pin cotter (N,

Figure 2-2) and clevis pin (O). Slide

the wheel inward on the axle (P) and

reinstall the clevis pin and cotter

through the axle only (not through

the wheel hub). Repeat on other

wheel.

3. Using the handlebar as a lever,

roll the tiller to a flat area.

IMPORTANT: Before starting engine,

wheels must be moved to WHEEL

DRIVE position (pins through wheel

hubs and axle). This procedure is

described in

the "OPERATION" _ --0

section.

U

I

N ,

Figure22: Toroll the tiller,move both

8

wheels to theFREEWHEEL position.

Page 9

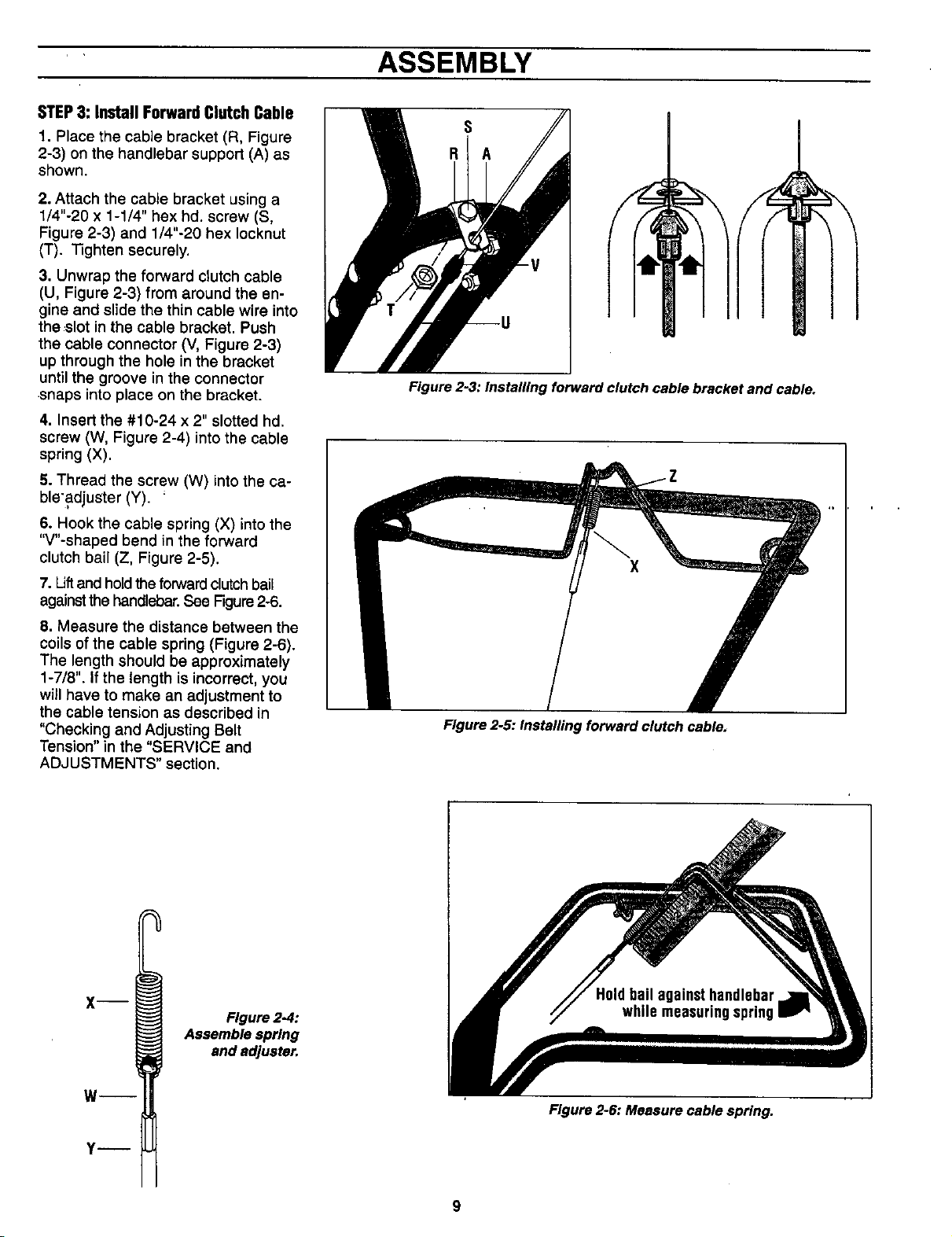

STEP3: Install Forward Clutch Cable

1. Place the cable bracket (R, Figure

2-3) on the handlebar support (A) as

shown.

2. Attach the cable bracket using a

1/4"-20 x 1-1/4" hex hd. screw (S,

Figure 2-3) and 1/4"-20 hex Iocknut

(T). _ghten securely.

3. Unwrap the forward clutch cable

(U, Figure 2-3) from around the en-

gine and slide the thin cable wire into

the .slot in the cable bracket. Push

the cable connector (V, Figure 2-3)

up through the hole in the bracket

until the groove in the connector

snaps into place on the bracket.

4. Insert the #10-24 x 2" slotted hd.

screw (W, Figure 2-4) into the cable

spring (X).

5. Thread the screw (W) into the ca-

ble'adjuster (Y). '

6. Hook the cable spring (X) into the

"V"-shaped bend in the forward

clutch bail (Z, Figure 2-5).

7. Uftand hold the forward clutch bail

against the handlebar.See Figure 2-6.

8. Measure the distance between the

coils of the cable spring (Figure 2-6).

The length should be approximately

1-7/8". If the length is incorrect, you

will have to make an adjustment to

the cable tension as described in

"Checking and Adjusting Belt

Tension" in the "SERVICE and

ADJUSTMENTS" section.

ASSEMBLY

Figure 2-3: Installing forward clutch cable bracket and cable.

Figure 2-5: Installing forward clutch cable.

Figure 2-4:

Assemble spring

and adjuster.

Figure 2-6: Measure cable spring.

9

Page 10

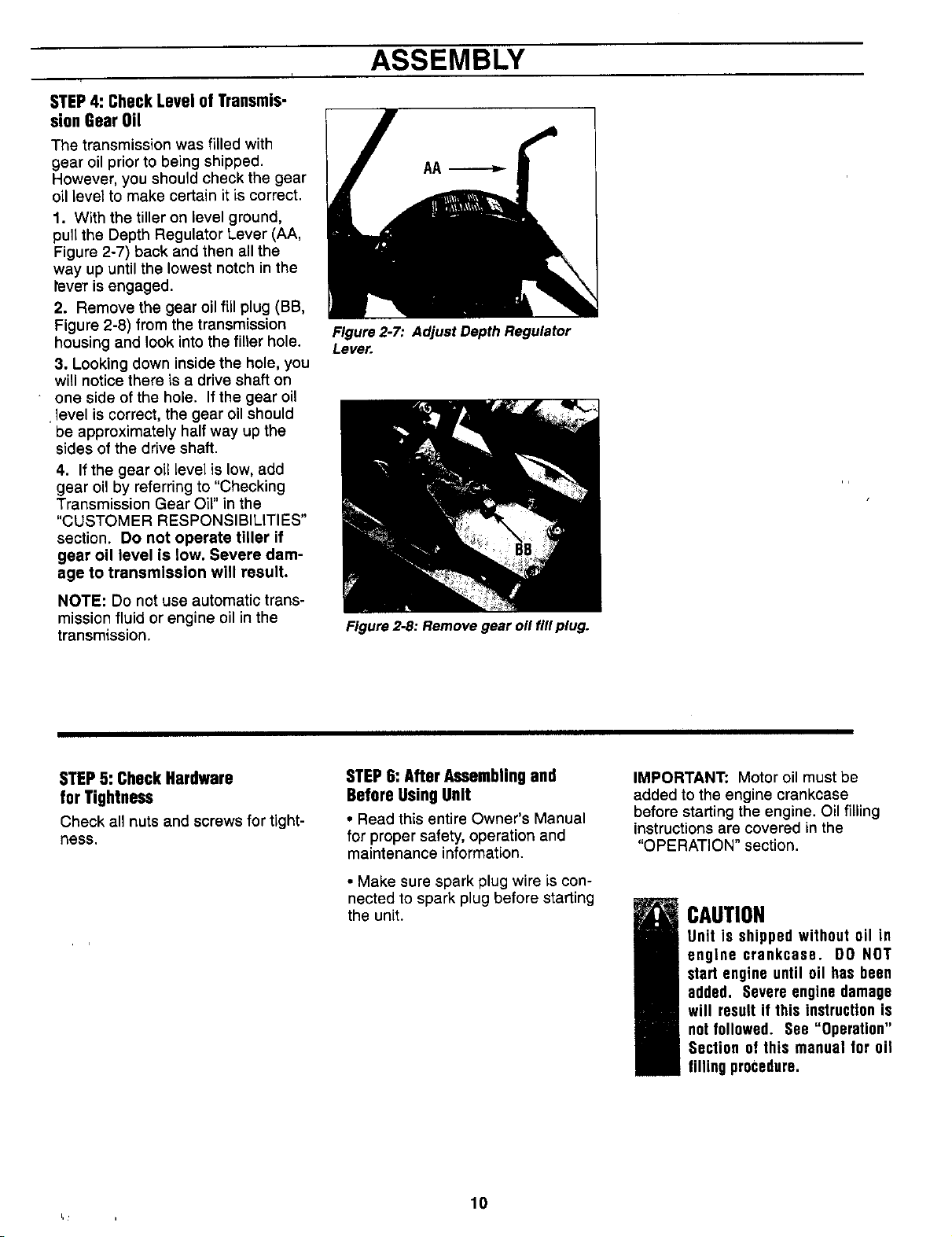

STEP4: CheckLevelof Transmis-

sionGearOil

The transmission was filled with

gear oil prior to being shipped.

However, you should check the gear

oil level to make certain it is correct.

1. With the tiller on level ground,

pull the Depth Regulator Lever (AA,

Figure 2-7) back and then all the

way up until the lowest notch in the

fever is engaged.

2. Remove the gear oil fill plug (BB,

Figure 2-8) from the transmission

housing and look into the filler hole.

3. Looking down inside the hole, you

will notice there is a drive shaft on

one side of the hole. If the gear oil

.level is correct, the gear oil should

be approximately half way up the

sides of the drive shaft.

4. Ifthe gear oil level is low, add

gear oil by referring to "Checking

Transmission Gear Oil" in the

"CUSTOMER RESPONSIBILITIES"

section. Do not operate tiller if

gear oil level is low. Severe dam-

age to transmission will result.

NOTE: Do not use automatic trans-

mission fluid or engine oil in the

transmission.

ASSEMBLY

AA

Figure 2-7: Adjust Depth Regulator

Lever.

Figure 2-8: Remove gear oll fill plug.

STEP5: CheckHardware

forTightness

Check all nuts and screws for tight-

ness.

STEP 6: After Assembling and

Before Using Unit

• Read this entire Owner's Manual

for proper safety, operation and

maintenance information.

• Make sure spark plug wire is con-

nected to spark plug before starting

the unit.

10

IMPORTANT: Motor oil must be

added to the engine crankcase

before starting the engine. Oil filling

instructions are covered inthe

"OPERATION" section.

CAUTION

Unit is shipped without oil in

engine crankcase. DO NOT

start engine until oil has been

added. Severeengine damage

will result if this instructionis

not followed. See "Operation"

Section of this manual for oil

filling procedure.

Page 11

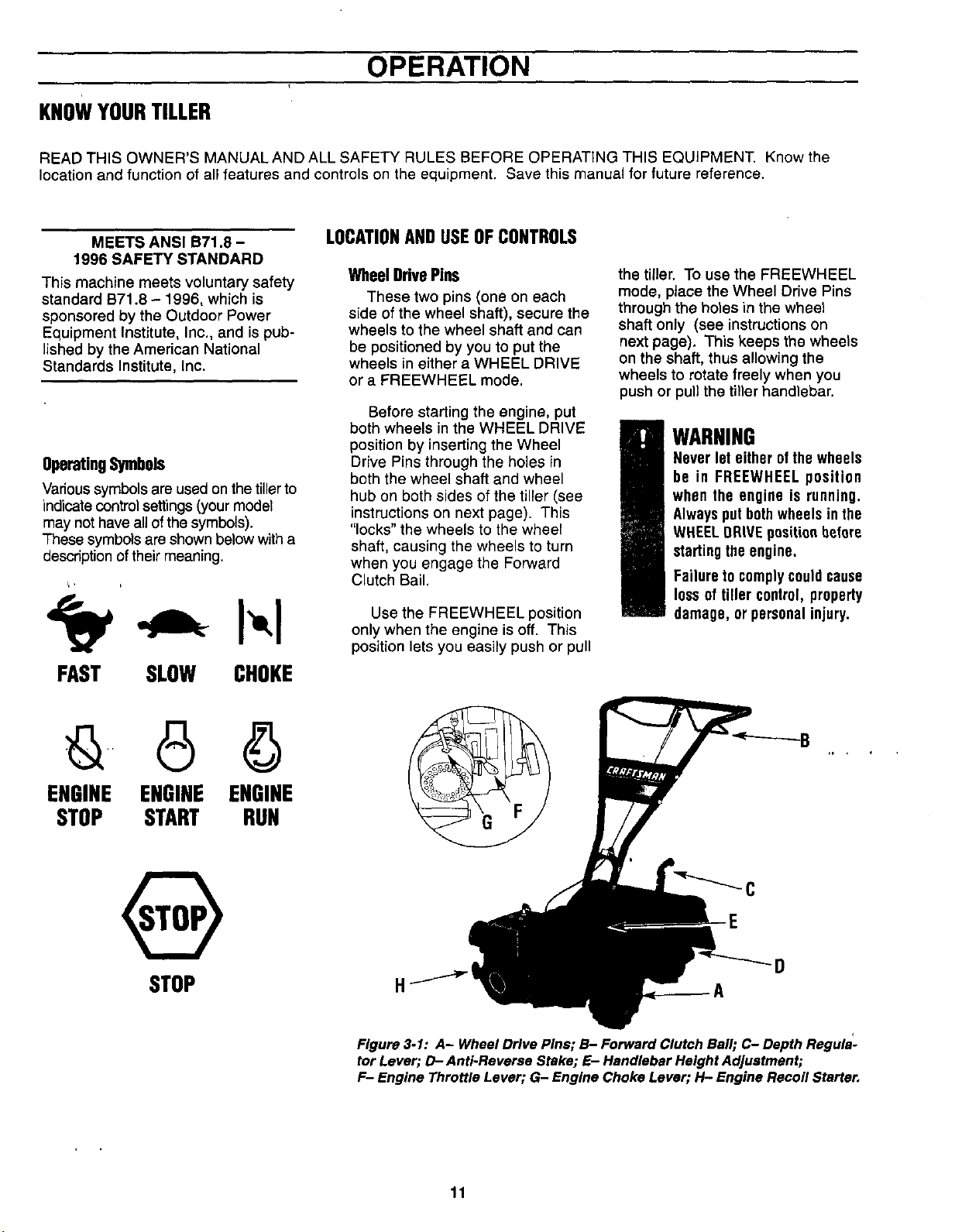

OPERATION

KNOWYOURTILLER

READ THIS OWNER'S MANUAL AND ALL SAFETY RULES BEFORE OPERATING THIS EQUIPMENT. Know the

location and function of all features and controls on the equipment. Save this manual for future reference.

MEETS ANSI B71.8 -

1996 SAFETY STANDARD

This machine meets voluntary safety

standard B71.8- 1996, which is

sponsored by the Outdoor Power

Equipment Institute, Inc., and is pub-

lished by the American National

Standards Institute, Inc.

OperatingSymbols

Various symbols are used on thetillerto

indicate control settings(your model

may not have allof the symbols).

These symbols are shown below with a

description of their meaning.

I,, b

FAST SLOW CHOKE

LOCATIONANDUSEOFCONTROLS

WheelDrivePins

These two pins (one on each

side of the wheel shaft), secure the

wheels to the wheel shaft and can

be positioned by you to put the

wheels in either a WHEEL DRIVE

or a FREEWHEEL mode.

Before starting the engine, put

both wheels in the WHEEL DRIVE

position by inserting the Wheel

Drive Pins through the holes in

both the wheel shaft and wheel

hub on both sides of the tiller (see

instructions on next page). This

"locks" the wheels to the wheel

shaft, causing the wheels to turn

when you engage the Forward

Clutch Bail,

Use the FREEWHEEL position

only when the engine is off. This

position lets you easily push or pull

the tiller. To use the FREEWHEEL

mode, place the Wheel Drive Pins

through the holes in the wheel

shaft only (see instructions on

next page), This keeps the wheels

on the shaft, thus allowing the

wheels to rotate freely when you

push or pull the tiller handlebar.

WARNING

Never let either of the wheels

be in FREEWHEEL position

when the engine is running.

Alwaysput bothwheelsin the

WHEELORIVEpositionbefore

startingthe engine,

Failureto complycouldcause

loss of tiller control, property

damage, or personalinjury.

ENGINE ENGINE ENGINE

STOP START RUN

STOP

E

Figure 3-1: A- Wheel Drive Pins; B- Forward Clutch Bail; C- Depth Regula'-

tor Lever; D- Anti-Reverse Stake; E- Handlebar Height Adjustment;

F- Engine Throttle Lever; G- Engine Choke Lever; H- Engine Recoil Starter.

11

Page 12

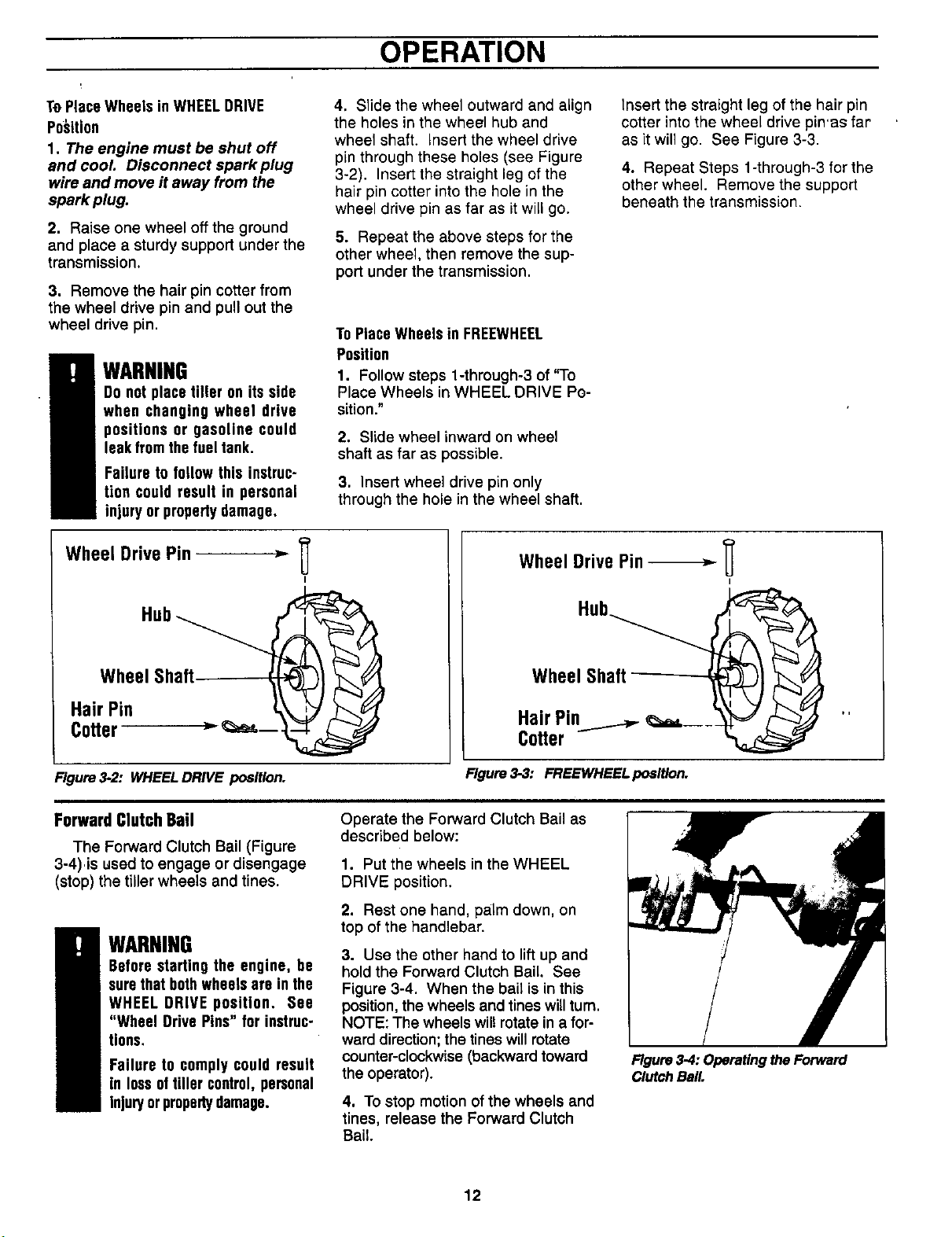

OPERATION

ToPlaceWheels in WHEELDRIVE

PoSition

1, The engine must be shut off

and cool. Disconnect spark plug

wire and move it away from the

spark plug.

2. Raise one wheel off the ground

and place a sturdy support under the

transmission.

3. Remove the hair pin cotter from

the wheel drive pin and pull out the

wheel drive pin.

WARNING

Do not place tiller on its side

when changing wheel drive

positions or gasoline could

leak fromthe fuel tank.

Failure to follow this instruc-

tion could result in personal

injury or propertydamage,

4. Slide the wheel outward and align

the holes in the wheel hub and

wheel shaft, insert the wheel drive

pin through these holes (see Figure

3-2). Insert the straight leg of the

hair pin cotter into the hole in the

wheel drive pin as far as it will go.

5. Repeat the above steps for the

other wheel, then remove the sup-

port under the transmission.

To PlaceWheels in FREEWHEEL

Position

1. Follow steps 1-through-3 of "To

Place Wheels in WHEEL DRIVE Po-

sition."

2. Slide wheel inward on wheel

shaft as far as possible.

3. Insert wheel drive pin only

through the hole in the wheel shaft.

Insert the straight leg of the hair pin

cotter into the wheel drive pin'as far

as it will go. See Figure 3-3.

4. Repeat Steps 1-through-3 for the

other wheel. Remove the support

beneath the transmission.

Wheel DrivePin -.

Hub_

w,oo,

Hair Pin k_. _ .L"_-..(¢'_

Cotter = _,aL_ _

Figure3-2: WHEELDRIVE position.

ForwardClutchBail

The Forward Clutch Bail (Figure

3-4) is used to engage or disengage

(stop) the tiller wheels and tines.

WARNING

Before starting the engine, be

surethat bothwheelsare in the

WHEEL DRIVE position. Bee

"Wheel Drive Pins" for instruc-

tions.

Failure to comply could result

in lossoftiller control,personal

In]uryorpropertydamage.

Operate the Forward Clutch Bail as

described below:

1. Put the wheels in the WHEEL

DRIVE position.

2. Rest one hand, palm down, on

top of the handlebar.

3. Use the other hand to lift up and

hold the Forward Clutch Bail. See

Figure 3-4. When the bail is in this

position, the wheels and tines will turn.

NOTE: The wheels will rotate in a for-

ward direction; the tines will rotate

counter-clockwise (backward toward

the operator).

4. To stop motion of the wheels and

tines, release the Forward Clutch

Bail.

WheelDrivePin_

I

WheelShaft

Nub__@

Hair Pin ._......_._=.__

Cotter --

Rgura 3-3: FREEWHEEL poslUon.

Rgura 3.4: Operating the Forward

Clutch Ball.

12

Page 13

OPERATION

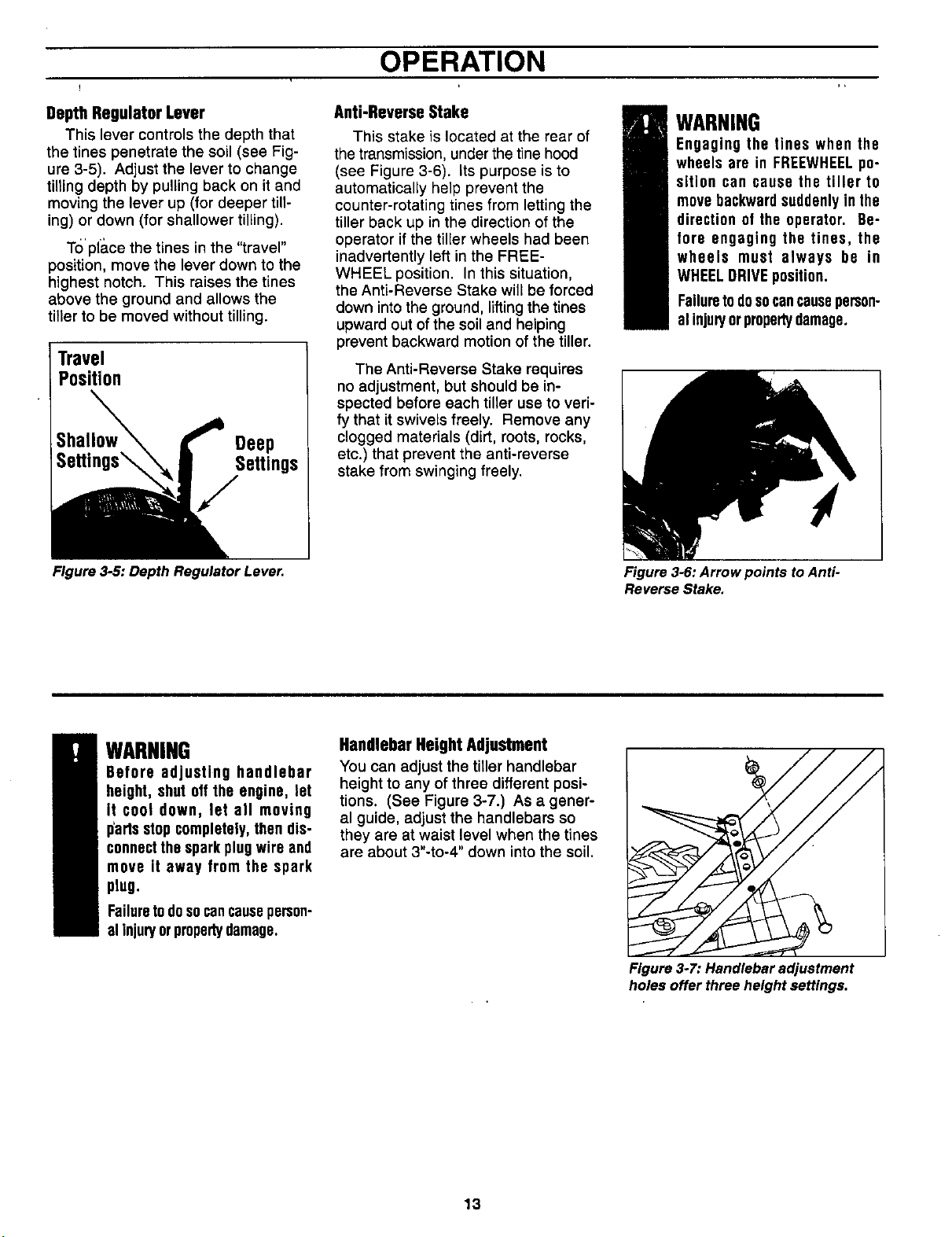

DepthRegulatorLever

This lever controls the depth that

the tines penetrate the soil (see Fig-

ure 3-5). Adjust the lever to change

tilling depth by pulling back on it and

moving the lever up (for deeper till-

ing) or down (for shallower tilling).

To'place the tines inthe "travel"

position, move the lever down to the

highest notch. This raises the tines

above the ground and allows the

tiller to be moved without tilling.

Travel

Position

Deep

Settings_

Settings

Anti-Reverse Stake

This stake is located at the rear of

the transmission, under the tine hood

(see Figure 3-6). Its purpose is to

automatically help prevent the

counter-rotating tines from letting the

tiller back up in the direction of the

operator if the tiller wheels had been

inadvertently left in the FREE-

WHEEL position. In this situation,

the Anti-Reverse Stake will be forced

down into the ground, lifting the tines

upward out of the soil and helping

prevent backward motion of the tiller.

The Anti-Reverse Stake requires

no adjustment, but should be in-

spected before each tiller use to veri-

fy that it swivels freely. Remove any

clogged materials (dirt, roots, rocks,

etc.) that prevent the anti-reverse

stake from swinging freely.

WARNING

Engaging the tines when the

wheels are in FREEWHEELpo-

sition can cause the tiller to

movebackwardsuddenlyin the

direction of the operator. Be-

fore engaging the tines, the

wheels must always be in

WHEELDRIVEposition.

Failuretodosocancauseperson-

alinjuryorpropertydamage.

Figure 3-5: Depth Regulator Lever. Figure 3-6: Arrow points to Anti-

Reverse Stake.

WARNING

Before adjusting handlebar

height, shut off the engine, let

it cool down, let all moving

p'artsstopcompletely,then dis-

connectthesparkplugwire and

move it away from the spark

plug.

Failuretodosocancauseperson-

alinjuryorpropertydamage.

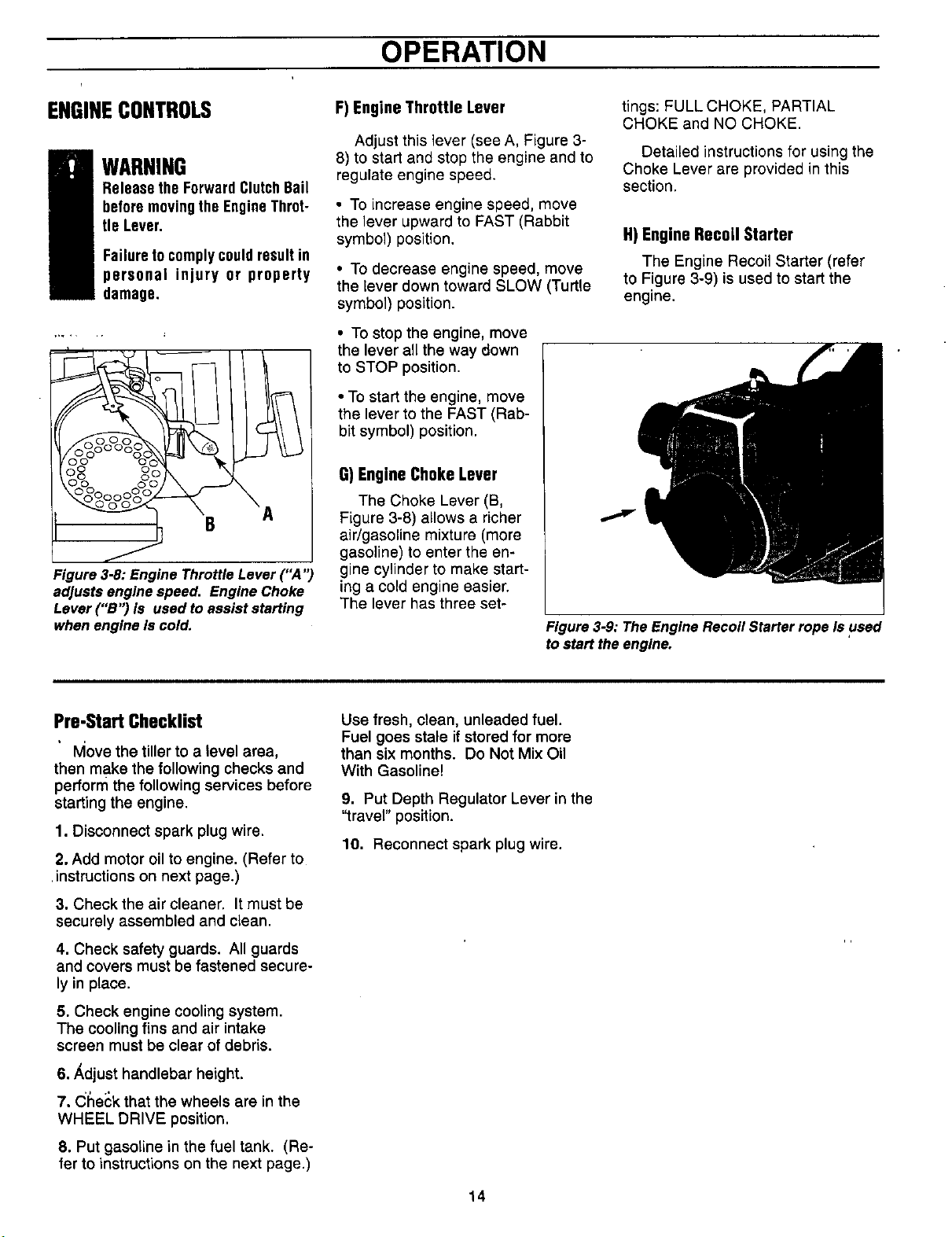

Handlebar HeightAdjustment

You can adjust the tiller handlebar

height to any of three different posi-

tions. (See Figure 3-7.) As a gener-

al guide, adjust the handlebars so

they are at waist level when the tines

are about 3"-to-4" down into the soil.

Figure 3°7: Handlebar adjustment

holes offer three height settings.

13

Page 14

OPERATION

ENGINECONTROLS

WARNING

Releasethe ForwardClutchBail

beforemovingthe EngineThrot-

tle Lever.

Failureto complycouldresultin

personal injury or property

damage.

Figure 3-8: Engine Throttle Lever ("A")

adjusts engine speed. Engine Choke

Lever ("B") Is used to assist starting

when engine is cold.

F) Engine Throttle Lever

Adjust this lever (see A, Figure 3-

8) to start and stop the engine and to

regulate engine speed.

• To increase engine speed, move

the lever upward to FAST (Rabbit

symbol) position.

• To decrease engine speed, move

the lever down toward SLOW (Turtle

symbol) position.

• To stop the engine, move

the lever all the way down

to STOP position.

• To start the engine, move

the lever to the FAST (Rab-

bit symbol) position.

G)EngineChokeLever

The Choke Lever (B,

Figure 3-8) allows a richer

air/gasoline mixture (more

gasoline) to enter the en-

gine cylinder to make start-

ing a cold engine easier.

The lever has three set-

Figure 3-9: The Engine Recoil Starter rope Is used

to start the engine.

tings: FULL CHOKE, PARTIAL

CHOKE and NO CHOKE.

Detailed instructions for using the

Choke Lever are provided in this

section.

H)EngineRecoil Starter

The Engine Recoil Starter (refer

to Figure 3-9) is used to start the

engine.

Pre-StartChecklist

Move the tiller to a level area,

then make the following checks and

perform the following services before

starting the engine.

1. Disconnect spark plug wire.

2. Add motor oil to engine. (Refer to

.instructions on next page.)

3, Check the air cleaner. It must be

securely assembled and clean.

4. Check safety guards. All guards

and covers must be fastened secure-

ly in place.

5. Check engine cooling system.

The cooling fins and air intake

screen must be clear of debris.

6. ,_djust handlebar height.

7. €lleck that the wheels are in the

WHEEL DRIVE position.

8. Put gasoline in the fuel tank. (Re-

fer to instructions on the next page.)

Use fresh, clean, unleaded fuel.

Fuel goes stale if stored for more

than six months. Do Not Mix Oil

With Gasoline!

9. Put Depth Regulator Lever in the

"travel" position.

10. Reconnect spark plug wire.

14

Page 15

BEFORESTARTINGENGINE

OPERATION

Engine Lubrication

The tiller is shipped without oil in the

engine. Permanent engine damage

will result if the engine is run without

oil.

1. Only use high quality detergent oil

WithAPI service classification SF,

SG, SH, or SH/CD. Above 32OF,use

SAE 30; below 32OF,use 5W30. DO

NOT USE SAE 10W40 OIL.

NOTE: Although multi-viscosity oils

(5W30, 10W30, etc.) improve start-

ing in cold weather, these oils will re-

sult in increased oil consumption

when used above 32OF. Check en-

gine oil more frequently to avoid pos-

sible engine damage from running

low on oil.

colder_ 32OF...._. warmer

5W30 SAE 30

2. With the tiller on level ground, pull

the Depth Regulator Lever (Figure 3-

5) back and then all the way up until

the lowest notch in the lever is

engaged. The tines must be in con-

4. Securely replace the oil fill plug.

• Check the oil level before each use

and after every five operating

hours. See Page 21.

• Change the oil after the first two op-

erating hours and every 10 operat-

ing hours thereafter. Change the oil

more often if the machine is operat-

ed in extremely dusty or dirty condi-

tions. See Page 21.

Figure 3-10: Add motor oll to the en-

gine using the oil fill hole.

tact with the ground-- move the anti-

reverse stake back out of the way to

allow the tines to rest on the ground.

3. Unscrew the engine oil fill plug

(D, Figure 3-10). Using a clean fun-

nel, slowly add oil until the oil level

reaches the overflow point in the oil

fill tube. ALWAYS MAINTAIN THE

OIL LEVEL AT THE OVERFLOW

POINT.

Fill Fuel Tank

The engine must be off and cool be-

fore removing the fuel fill cap (Figure

3-11).

Clean area around fuel fill cap and

then remove fill cap. Fill gas tank

with clean, fresh unleaded gasoline.

Do not mix oil with gasoline.

Using a funnel or spout, fill tank to

within 1/2" below the bottom of the

fuel tank filler neck to prevent spills

and to allow for fuel expansion.

install the fill cap securely and wipe

up any spilled gasoline.

Fuel Fill Cap

IMPORTANT: Experience indicates

that alcohol-blended fuels (gasohol or

usingethanol or methanol) can attract

moisturewhich leads to separation

and formation of acids during storage.

Acidic gas can damage the fuel sys-

tem of an engine while in storage. To

avoid problems, the fuel system

should be emptied before storage for

30 days or longer. Drain the gas

DANGER

Gasoline is highly flammable and its vapors are explosive. Follow these

safetypracticesto preventinjury fromfire or explosion:

• Neverfill tank if engine is runningor hotfrom use. Letengineand muffler

cooldownbefore refueling.

• Donotpermitopenflames, sparks,matchesorsmokinginfueling area.

• Fill fuel tank outdoorsin a well-ventilated area. Wipe up anyfuel spills

andmovetiller awayfrom fumesbefore startingthe engine.

• Useonlyan approvedfuel containerand lockit safely awayfrom children.

• Storefuel andthetiller in a well-ventilated area. Donot storefuel ortiller

where fuel vaporsmay reachan openflame or spark,or an ignitionsource

(a hotwaterheater,furnace, clothesdryer,electric motor,or the like).

• Letenginecool betore storing.

tank, start the engine and let it run un-

til the fuel lines and carburetor are

empty. Use fresh fuel next season.

See STORAGE instructions for addi-

tional information. Never use engine

or carburetor cleaner products in the

fuel tank or permanent damage may

occur.

Figure 3.11: Fill the fuel tank.

15

Page 16

OPERATION

Stopping the Engine

1. Release the Forward Clutch Bail

to stop the wheels and tines from

turning.

2. Move Engine Throttle Lever to

STOP position to stop the engine.

Startingthe Engine

1. Do not engage (hold) the Forward

Clutch Bail against the handlebar

when starting engine.

2. Both wheels must be in the

WHEEL DRIVE position (see Figure

3-2).

3; Mov_ the Choke Lever to the

FULL CHOKE position (move lever

in direction of arrowhead located on

lever). NOTE: If restarting a warm

engine after a short shutdown, move

Choke Lever to NO CHOKE position.

4. Move the Engine Throttle Lever

fully up to fast (Rabbit) position

which is used for starting.

5:_Place your left hand on the gaso-

line tank (to avoid hot surfaces) to

stabilize the tiller when starting.

6. Use your right hand to slowly pull

the recoil starter rope (Figure 3-12)

untilyou feel resistance. Let it

rewind. Then rapidly pull the starter

rope outward. (First check for any

obstaclesbehindyou.) Repeat until

the engine starts.

WARNING

Always place both wheels in

the WHEELORIVEpositionbe-

fore startingthe engine.

Never have the wheels in the

FREEWHEELpositionwhenthe

engine is running. When the

wheels are in FREEWHEEL,

theydo nothold backthetiller,

and the tines could propel the

tiller backwardrapidly.

Failure to complycould result

in serious personal injury or

propertydamage.

7. Once the engine is running, gradu-

ally move the Choke Lever to the NO

CHOKE position. If engine falters,

move Choke Lever to 1/2 Choke until

engine runs smoothly, then to NO

CHOKE position.

NOTE: If engine fails to start after

three pulls, move Choke Lever to NO

CHOKE position and pull starter rope

again.

NOTE: If engine fires, but does not

continue to run, move Choke Lever to

FULL CHOKE and repeat steps 4, 5

and 6 until engine starts.

8. Move the Engine ThrottleLever to

the positionthat provides the desired

engine speed.

Figure 3-12: Pull Recoil Start Rope

out rapidly to start engine.

DANGER

Do not run engine indoors.En-

gine exhaust contains carbon

monoxide,o deadlygasthat is

colorless, odorless and

tasteless. "

Failure to follow this instruc-

tion couldresult inseriousper-

sonal injury or properly

damage.

Guiding the Tiller

When tilling, relax and let the tiller

move along at its own speed. Do

not push the tiller to make it move

Figure3.13: TIIIIngWlthJustOne

Hand Is recommended.

faster. Do not push down on the

handlebars to make the tines dig

more deeply.

Walk beside the tiller on the un-

tilled side. Use one hand, yet keep a

firm hand grip on the handlebar

(while keeping your arm loose) to

guide the tiller. Walking alongside

keeps you from disturbing the newly

tilled soil and replanting any weed

seeds which the tines might have

brought up to the surface. It is also

easier to control the tiller in hard or

rocky soil if you walk beside it guid-

ing it with one hand (instead of walk-

ing behind the tiller, controlling it with

two hands).

16

TillingDepths

This is a CRT (counter-rotating tine)

tiller. As the wheels pull forward, the

tines rotate backward. This creates

an "uppercut" tine action which digs

deeply, uprooting soil and weeds.

Don't overload the engine, but dig as

deeply as possible on each pass.

On later passes, the wheels may

tend to spin in the soft dirt. Help

them along by liftingslightly on the

handlebar. (Using just one hand,

palm upward, works most easily.)

When cultivating between rows,

use a shallow Depth Regulator Lever

setting. This will get rid of in-row

weeds, but prevent the tines from

digging deeply enough to damage

plant roots.

Page 17

OPERATION

Moving the Tiller Forward

IMPORTANT: Before you begin till-

ing, move the tiller to a safe, level

area and practice maneuvering

without actually tilling. Keep the

Depth Regulator Lever in the "travel"

position.

After you become familiar with the

handling of your tiller,you can move

it into the garden and begin tilling.

WARNING

Do not push downon the han-

dlebars to try to make the tiller

till more deeply. This prevents

the wheels from controlling

tiller speed and can allow the

tines to rapidlypropelthe tiller

backward,whichcouldresult in

loss of control, property dam-

age, or personal injury.

1. Put the wheels in the WHEEL

DRIVE position (wheel pins must be

through the wheel hubs and the axle

holes).

2. Move the Depth Regulator Lever

to the desired position. Check that

the Anti-Reverse Stake swivels freely

back and forth- remove any clogged

material on or around the stake.

3. Start the engine.

4. For forward motion of the wheels

and tines, lift and hold the Forward

Clutch Bail against the handlebars.

The wheels and tines will rotate as

long as the bail is held in this posi-

tion.

5. As the tiller moves forward, let the

wheels pull the tiller along. Do not

push the tiller to make it go faster.

Allow the tiller to move along at its

own speed.

6. To stop the wheels and tines, re-

lease the Forward'Clutch Bail. The

engine wLIIcontinue to run until

stopped by moving the Engine Throt-

tle Lever to the STOP position.

Moving the Tiller Rearward

The tiller weighs only 117 pounds,

so it is quite easily maneuvered rear-

ward for _ distances by using the

following procedure:

1. Release the Forward Clutch Bail.

2. 131tthe handlebar slightly upward

until the tLnes are out of the soil.

3. Swing the handlebar to the left so

the right wheel takes a "step" toward

the rear.

4. Now move the handlebar to the

right so the left wheel takes a step

backward.

5. Repeat to "walk" your tiller rear-

ward. If longer distances need to be

covered in reverse, shut off the en-

gine, then move the wheel pins so

the wheels are in FREEWHEEL.

Turningthe Tiller Around

Practice turning your tiller in an

open, level area until you feel com-

fortable with the procedure.

1. As you near the end of a row, lift

the handlebar so the tines clear the

ground. Refer to Figure 3-14.

2. As you come out of a row, swing

the handlebars to the side, pivoting

the tiller 180°, so you can line up

with the next row. See Figure 3-15.

3. As the tiller enters the next row,

lower the handlebar slowly until the

tines start to till.

Tilling in the Garden

The following pages provide

suggestions for using the tiller in the

garden. You can design your garden

layout to obtain the most beneficial

use from your tiller.

Figure 3-14: Exiting a row in the garden.

Figure 3-15: Lining up the tiller to enter the next row.

17

Page 18

OPERATION

SeedbedPreparation

Pdor to planting, be sure the soil

is as loose and finely textured as

possible. About two or three weeks

before planting, till the garden two or

three times. Then, till once more

before planting.

When preparing the soil, till a

fresh path on each pass rather than

overlapping. This gives the wheels

maximum traction on undisturbed

soil. See Figure 3-15. Dig as deeply

as possible on each pass without

overloading the engine. Later pass-

es can be overlapped. After going

up and down the rows in one direc-

tion, make a second pass at a right

angle across your earlier rows, See

Figure 3-16. In very hard ground,

additional passes may be needed.

Don't till when the soil is too wet.

This produces large clumps which

later dry out and become hard. If the

soil compresses easily into a ball, it

is still too wet to be tilled.

Cultivating

When planning your garden, keep

in mind that the tiller has a tilling

width of approximately 14". Allow at

least this width between rows in your

garden-- plus additional width for

plant growth. Take into account that

bushy plants like beans and toma-

toes need more width.

When cultivating, use a shallow

Depth Regulator Lever setting. Do

not cultivate deeper than 1"-or-2".

Shallow cultivating keeps weed

growth to a minimum and doesn't

damage plant roots.

For best results, begin cultivating

as soon as seedlings appear, and

then cultivate as often as once a

week. The day after a light rain is an

excellent time to cultivate, as long as

the plants are dry. Avoid working in

the garden when plants are wet.

Diseases, blight, and rust can be

easily spread among wet plants with

your hands, clothing or even the

tiller.

AvoidMakingFootprints

When tilling, always try to walk

alongside the tiller on the side that is

yet to be tilled. This prevents re-

planting weed seeds and leaves a

nicer appearance.

Figure 3-15: Initial tilling pattern.

°1

l

i= • • •

Figure 3-16: Second tilling pattern.

18

_d

Page 19

OPERATION

Preventing Tines From

BecomingTangled

...When tilling, you may find that the

tines.become tangled with material

(tall vegetation, long grass, tough

vines, etc.).

WARNING

Before removing any debris

fromthe tines, stopthe engine,

allow it to cool, disconnectthe

spark plug wire and move it

awayfrom thesparkplug.

Failure to do so could result in

personal injury or property

damage.

Tohelppreventtangling:

1. While tilling, swing the handle-

bars from side-to-side about 6"-to-

12". This "fishtailing" action will often

dislodge any debris.

2. Always use the deepest Depth

Regulator Lever setting possible

(without making the tiller jump or

buck upward).

3. "1311under cover crops and crop

residues while they are still green.

'4. Shred or chop up any tall, tough,

or stringy organic matter before till-

ing it into the soil.

5. You may have to mow or cut veg-

etation before power composting.

6. If the tines are heavily tangled,

stop the engine and disconnect the

spark plug wire. Then, cut away any

debris.

Tilligg.,onSlopes

Plant your garden preferably on

flat ground, but certainly on no more

than a moderate slope. Do not oper-

ate the tiller on a slope that is too

steep for safe operation.

Plant garden rows vertically on a

slope (up and down the slope). This

lets you use the entire area for a

seedbed and leaves enough room

between the rows for cultivation.

You lose these benefits if you garden

on areas styled like terraces.

WARNING

Do not operatethe tiller ona

slopetoo steep for safe oper-

ation, Till slowlyand be sure

thatyou have goodfooting.

Failure to doso couldresult

in personalinjuryor property

damage.

If you put enough organic material

intothe soil to improve its water-

holding capabilities, you should not

have a problem with soil erosion.

NOTE: On a slope, the oil level in

the tiller engine slants toward the

downhill side of the engine. Some

internal parts may not get enough

oil. To prevent this, make sure that

the engine oil level is full to the point

of overflowing from the oil check

tube before starting to till. Also

check the oil level every thirty min-

utes while you're tilling on a slope.

Tiller LoadingandUnloading

• Shut the tiller engine off before

loading or unloading. Let engine

cool, disconnect spark plug wire and

prevent wire from touching the plug.

• The tiller is too heavy (over 115

Ibs.) to be safely lifted by one per-

son. If you do lift the tiller, two or

more people should share the load.

• We recommend that you use stur-

dy ramps and that you manually roll

the tiller into or out of the vehicle

(tiller engine must be off). This re-

quires the assistance of another.

• Ramps should be strong enough

to support the tiller and those moving

it. The ramps shouLd provide good

traction and have side rails to guide

the tiller up and down; they should

have a locking device to secure

them to the vehicle bed.

• The operator and handlers should

wear sturdy footwear that grips well.

• Position the vehicle so the ramp

angle is as flat as possible. Turn the

vehicle engine off and apply the ve-

hicle parking brake.

CAUTION

Loadingand unloadingatiller

into or from a vehicle is po-

tentially hazardous. We.do,

notrecommendthatyoudoso

unless absolutely necessary

because this could result in

personal injury or property

damage.

If loading or unloading must

be undertaken, use the fol-

lowing guidelines to assist

you,

• When going UP ramps, stand in

the normal operating position and

push the tiller ahead of you. Position

a person at each wheel to help.

• When going DOWN ramps, care-

fully walk backward down the ramps

with the tiller following you. Position

a person at each wheel to control the

speed of the tiller.

• Have wood blocks handy to place

on the downhill sides of the wheels if

you need to stop the tiller from rolling

down the ramps. Use the blocks to

temporarily keep the tiller in place on

the ramps while you get a firmer grip

on the handlebars, etc. Also use

blocks to keep the wheels in place

after tying down the tiller.

• After positioning the tiller in the

vehicle, be sure both wheels are en-

gaged in the WHEEL DRIVE position

to prevent the tiller from moving.

Then securely tie down the tiller.

19

Page 20

CUSTOMER RESPONSIBILITIES

REQUIREDMAINTENANCESCHEDULE

Before Every Every Every As

REQUIREDMAINTENANCE Each 10 30 50 Noted

Use Hours Hours Hours

Tiller Lubrication

CheckEngine0ilLevel"EngineLubrication" • 1

ChangingEngine0il • 2

CheckingTransmissionGear0il Level • 4

Air cleaner Maintenance • 5

EngineCooling System Maintenance

Spark Plug Maintenance

TightenTillerHardware • 3

CheckTinesfor Wear •

Checking/Adjusting BeltTension • 3

CheckAnti-Reverse Stake

NOTEt - Checkfrequentlyduringfirst 2 hoursofnewoperation;thereafterevery5 hours.

NOTE2- Changeafter2 initialoperatinghours;thereafterevery10hours.

NOTE3- Checkafter2initialoperatinghours;thereafterevery10hours.

NOTE4 - Checkafter2 initialoperatinghours;thereafterevery30hours.

NOTE5 - Replacemoreoftenif usedinextremelydustyor dirtyconditions

grease to the wheel shaft. This

makes future wheel removal easy.

2. Depth RegulatorLever "

Clean and grease the back, front

and sides (refer to "2", Figure 4-1 ).

3. HandlebarSupportBolls

Oil the threads on both handlebar

support bolts ("3", Figure 4-1).

4. Tine Shaft

Remove the tine holder assemblies

and clean any rust or burrs from the

shaft ("4", Figure 4-1) with a fine

sandpaper. Liberally apply grease to

the tine shaft.

5. Shifting Mechanism

Carefully oil all pivot points on the

shifting mechanism ("5", Figure 4-2),

NOTE: When you oil the pivot points

on the shifting mechanism, be sure

that you do not get any oil on either

the belt or the pulleys. Otherwise,

the belt could slip and would be un-

able to transfer engine power to the

transmission.

GENERALRECOMMENDATIONS Tiller Lubrication

The Warranty on this machine does

not cover items that have been sub-

jected to operator abuse or negli-

gence. To receive full value from the

warranty, the operator must maintain

the machine as instructed inthismanual.

Some adjustments will need to be

made periodically to properly main-

tain your machine.

Keep the air filters clean and change

the spark plug annually. A clean air

filter system and new spark plug help

the engine run better and last longer.

Refer to Figure 4-1 and Figure 4-2 for

lubrication points on your tiller.

Use common lubricating oil (#30

weight motor oil is acceptable) at the

oil points. Use a good quality grease

(preferably with a metal lubricant ad-

ditive) at the grease points.

1. Wheel Shaft

Remove the wheels and use a clean

rag to wipe off old grease from the

wheel shaft ("1", Figure 4-1). Inspect

the shaft and use fine sandpaper to

remove any rust or burrs. Apply new

Regular,Maintenance

Because the tiller is operated in the

garden, frequently under hot and

dirty conditions, regular maintenance

is very important to ensure that you

are getting proper performance from

your tiller. There are several mainte-

nance procedures that will hetp keep

your tiller in good operating condition:

• ,. Change engine oil regularly.

• 'Lubricate the controls when needed.

• Keep the correct tension on the

forward drive belt.

• Replace the engine air cleaner

element when dirty.

• Keep engine cooling fins clean. Figure 4-1: Tiller lubricaUon points.

Figure 4-2: Lubrication points on

shifting mechanism,

2

2O

Page 21

CUSTOMER RESPONSIBILITIES

EngineLubrication

Only use high quality detergent oil

with API service classification SF,

SG, SH, or SH/CD. Above 32OF,use

SAE 30; below 32OF,use 5W30. DO

NOT USE SAE 10W40 OIL.

NOTE: Although multi-viscosity oils

(5W30, 10W30, etc.) improve start-

ing in cold weather, these oils will re-

suit in increased oil consumption

when used above 32OF. Check en-

gine oil more frequently to avoid pos-

sible engine damage from running

low on oil.

colder-,ll-----...-- 32OF_ warmer

"_ ' 5W30 = SAE 30

!_

C'

WARNING

Stop the engine, allow it to

cool, disconnectthe spark plug

wire and prevent it from touch-

ing the spark plug before

changingthe engineoil. Donot

touch any engine parts which

may behot.

Failure to do so could result in

personal injury or property

damage.

CheckingEngineOil Level:

1. Move the tiller to a level area.

2. Pull the Depth Regulator Lever all

the way up until it is in the bottom

notch. The tines must be in contact

with the ground-- move the anti-re-

verse stake back if necessary.

3. Unscrew the oil fill plug from right

side of engine (see Figure 4-3).

4. If the oil level is correct, the level

will crest at the top of, or begin to

flow from, the oil fill tube. Reinstall

the oil fill plug.

5. If the level of the oil was below

the very top of the fill tube, oil must

be added as follows.

4. Place a drain pan with a minimum

capacity of 1-quart beneath the drain

plug.

5. Use a 3/8" open end wrench to re-

move the drain plug (see arrow in

Figure 4-4). Put it aside. Let all of

the old engine oil drain completely

intothe drain pan.

6. Reinstall the drain plug securely.

7. Remove the wood board from be-

neath the wheel.

8. Refill the engine with the correct

type and weight engine oil. Above

32°F, use SAE30 oil; below 32OF,

use SAE 5W30 oil. Do not use SAE

10W40 oil.

9. Check the oil level to be sure it is

correct before starting the engine.

,p ,

0il Fill

Jj

Figure4-3: Off Fill Plug location.

• Check the engine oil level frequent-

ly during the first two hours of en-

'gine break-in operation.

• Check the engine oil level before

starting the engine. When operat-

ing the tiller, stop the engine and

check oil level every 5 operating

hours. Keep oil level at the over-

flow point in the oil fill hole.

o Change the oil after the first two op-

erating hours and every 10 operat-

ing hours thereafter. Change the oil

more often if the machine is operat-

ed in extremely dusty or dirty condi-

tions. See Page 21.

AddingEngineOil:

1. Insert a clean funnel into the oil

fill hole.

2. Above 32°F, use SAE30 oil; be-

low 32Ol, use SAE 5W30 oil. Do not

use SAE 10W40 oil

3. Slowly pour oil into the funnel.

Check the oil level frequently while

pouring. (Remove the funnel when

checking.) When the oil just begins

to overflow, the level is correct.

4. Replace the oil fillplug securely.

Changing Engine Oil

1. Start engine and let it warm up,

Then turn the engine off.

2. There are two engine oil drain

plugs on either side of the engine

base. Use whichever one is most

conveniently located for you.

3. Place a 2"x 4" wood board under

the wheel opposite the drain plug

you'll be removing.

ain Plug

Figure 4-4: Draining engine oil.

21

Page 22

CUSTOMER RESPONSIBILITIES

CheckingandTopping-Off

TransmissionGearOil

Checking Transmission Gear Oil:

'1. Move the tiller to a level area.

2. Pull the Depth Regulator Lever

up.

3, Unscrew ihe filler/check plug

from the top of the transmission (it

is located just behind the belt cover).

4. Use a flashlight to look down into

the filler/check plug hole. See Fig-

ure 4-5. Note the drive shaft on

one side of the hole. If the gear oil

level is correct, it should be halfway

up the sides of the drive shaft. If

topping off is needed, follow the

instructions below.

Figure 4-5: Checking the transmis-

sion gear oil level

ToppingoffTransmission

GearOil

,1. Complete steps 1-through-3 de-

scribed in "Checking Transmission

Gear Oil."

2. Insert a funnel into the

filler/check plug hole.

NOTE: When adding only a few

ounces of gear oil, use API rated

GL-4 or GL-5 transmission gear oil

with a viscosity of SAE 140, SAE

85W-140, or SAE 80W-90. When

adding a complete refill of new

gear oil after having drained the

transmission, refill only with

SAE 140 or SAE 85W-140 with

an API of GL-4.

NOTE: Do not use automatic

transmission fluid or engine oil in

the transmission.

Figure 4-6: Gear oil fill hole.

3. Slowly pour clean gear oil into

the transmission. Frequently

check the level so as not to overfill

the transmission. See Figure 4-6.

4. When gear oil level is correct,

reinstall filler/check plug securely.

ChangingTransmissionOil

The transmission gear oil does

not have to be changed unless you

know that it has been contaminat-

ed by foreign materials such as

sand, dirt, or metal particles. Of

course, any internal repairs on the

transmission would also require

that the gear oil be drained and

changed.

1, Drain gasoline from the fuel

tank or run the engine until the fuel

tank is empty.

2. Drain the oil from the engine.

3. Remove the four screws secur-

ing the transmission cover to the

front part of the transmission. Lift

the cover and gasket off the trans-

mission. See Figure 4-7.

4. Remove the left wheel.

5. Lower the left axle down into a

drain pan and slowly tilt the tiller to

the left so the gear oil drains from

the top of the transmission into the

drain pan. See Figure 4-8.

6. Once gear oil has drained, tilt

tiller upright and reinstall wheel.

7. Reinstall the transmission cover

using a new cover gasket.

8. Add new gear oil--see specifi-

cations in NOTE at left.

9. Add engine oil to the engine.

DANGER

Gasolineis highlyflammable

and its vapors are explosive.

Follow these safety practices

to prevent persona[ injury or

propertydamage from fire or

explosion.

• Allow the engine and muf-

fler to cool for at least two

minutes before draining the

tiller's gasolinetank.

• Do not allow openflames,

sparks, matches or smoking

in the area.

• Wipe away spills and push

tiller awayfrom spilledfuel.

• Use only an approvedfuel

container and store it safely

out of the reach of children.

• Do not store gasolinein an

area where its vapors could

reachanopenflame or spark,

or where ignition sourcesare

present (such as hot water

and space heaters, furnaces,

clothes dryers, stoves, elec-

tric motors,etc.)

Figure 4.7: Remove four screws to

remove transmission cover.

Figure 4-8: Draining the gear oil.

i,

22

Page 23

CUSTOMER RESPONSIBILITIES

CheckingforOilLeaks

Regularly check your tiller for oil

leaks from the engine and the

transmission. Slight seepage is no

cause for major concern. How-

ever, if your tiller is losing a lot of

oil, do not use it until it's repaired.

Inspect the area where you park

your tiller for stains on the floor

which would indicate a leak. If you

find a leak, first tighten any bolts or

screws which may have loosened

up.

If you are unsure how much oil

has been lost from the tiller, check

the oil levels before operation.

Also, when operating your tiller,

frequently check the oil levels to be

sure that engine oil and transmis-

sion gear oil levels don't become

too low for safe operation.

If you have further problems

with oil leaks, contact your Sears

Service Center for assistance.

Air Cleaner Maintenance

Your tiller's engine is equipped

with a replaceable dry paper filter.

Replace this filter every 30 operat-

ing hours or at least once a year,

and even more frequently under

dusty or dirty operating conditions.

Do not attempt to clean this fil-

ter. Simply replace it when dirty.

To Remove Paper Air Filter:

1. Loosen the two screws that se-

cure the air cleaner cover to the

base of the air cleaner.

2. Slightly turn the cover counter-

clockwise. Remove the cover and

the paper air filter.

To Change the Paper Air Filter:

1. Thoroughly clean the base of

the air cleaner and the inside of

the air cleaner cover.

2. Place the new paper filter inthe

cover.

3. Place the cover (with filter in-

side it) on the base of the air

cleaner. Align the two screw holes

in the cover with the two screws in

the base of the air cleaner. Refer

to Figure 4-9.

4. Turn the cover slightly clock-

wise and tighten the two screws.

o o _<

oo o _----_Air Filter

Figure 4-9: EngineAir Filter.

EngineCoolingSystem

Maintenance

Frequently inspect the engine

cooling fins, shrouds, and throttle

linkage for a build-up of dirt, dried

weeds, grease, etc.

Always keep these areas free

from debris to keep air currents

flowing freely. See arrows in Fig-

ure 4-10. :

Figure 4-10: Keep these areas free

of debris.

Engine Ignition System

Maintenance

Your tiller's engine has a de-

pendable, maintenance-free elec-

tronic ignition system. The system

has no condenser or points. This

means you do not have to tune up

the engine. The only ignition sys-

tem maintenance required is peri-

odic changing of the spark plug.

(See the following spark plug in-

structions.)

SparkPlugMaintenance

Check the spark plug at the be-

ginning or the end of each season,

or every 30 operating hours.

Clean the area around the spark

plug hole before removing the

spark plug.

1. Stop the engine, and wait for all

moving parts to stop completely.

2. Disconnect the spark plug wire

from the spark plug.

3. Use a 13/16" spark plug socket

to remove the spark plug. The

plug may be cleaned (do not sand-

blast or wire-brush it), and the gap

set at .030" or a new spark plug

may be used instead.

4. Install a new plug if the old

plug's electrodes are pitted or

burned or if the porcelain is

cracked. For replacement use

Champion RJ-17LM only.

NOTE: A resistor spark plug must

be used for replacement.

Carburetor Adjustments

Your carburetor has been pre-

set for best tiller performance. If

your carburetor may need adjust-

ment, contact your nearest Sears

Service Center.

23

Page 24

SERVICE AND ADJUSTMENTS

WARNING

Stop the engine, allow it to

cool, disconnectthe spark plug

wire and prevent it from touch-

ing the spark plug beforetight-

ening any bolts, screws, or

nuts.

Failure to do so couldresult in

personal injury or property

damage.

TighteningTillerHardware

After the first two hours of tiller oper-

ation, check all fasteners (nuts,

bolts, screws, pins, etc.) and tighten

any that may have loosened. After

this initial check, check those same

fasteners after every ten hours of

tiller operation.

Most of the fasteners on your tiller

are in plain view. However, the fol-

lowing ones are not readily visible.

Be sure to check them for tightness

as well.

1. Rear End Cap Bolts- These

three bolts are located at the rear

end of the tiller transmission. They

secure the rear cap and the anti-re-

verse stake. Lift up the hood flap to

view this hardware.

2. Transmission Housing Cover

Bolts- These four bolts are located

on the top of the rear end of the tiller

transmission. You see them when

you liftthe hood flap.

Tines

As you use your tiller, the tines

will gradually wear. They will be--

come shorter, narrower and pointed,

decreasing their ability to till effeC-

tively. Check the tines for wear sev-

eral times a season, and replace

badly worn tines to restore the tiller's

effectiveness.

NOTE: You must first remove the

tiller hood before removing either a

single tine holder or individualtines.

Remove the two screws at the front

of the hood and the two screws at

the rear of the hood and liftoff the

hood. Be sure to replace the hood

securely after changing tines or tine

holders.

Rgure 4-11

WARNING

This is a CRT (counter-rotating

tine) tiller and its tines mustbe

mountedin the directionshown

in Figure4-11. It mountedwith

curves in the opposite direc-

tion, tiller will dig poorly and

be more likely to run back-

wards.

Failure to comply could result

in personal injury or property

damage.

RemovingandInstalling

Tine Assemblies

WARNING

Stop the engine, allow it to

cool, disconnectthe sparkplug

wire and prevent it fromtouch-

ing the spark plug before re-

moving or installing a tine or a

tine assembly.

Failure to comply could result

in personal injury or property

damage.

1. Use a 9/16" socket, 6" extension,

a ratchet, and a 9/16" box end

wrench to loosen the nut (A, Figure

4-11) and screw (B) that secure the

tine holder to the tine shaft.

2. Use a rubber mallet to tap the

tine holder loose. Slide the tine as-

sembly oft the tine shaft.

c

aJ

3. Repeat Steps 1 and 2 above to

remove the other tine assembly.

4. Installing the tine assembly is

simply the reverse of its removal.

First be sure to remove any rust, un-

even spots or burrs from the tine

shaft using fine sandpaper. Then

grease the tine shaft before rein-

stalling the tine assemblies. Be sure

all the cutting edges face so they will

enter the soilfirst when the tiller is

moving forward-this means the cut-

ting edge on the top of each tine faces

toward the operator position.Tighten

the hardware very securely.

RemovingandInstalling

IndividualTines

1. Use two 9/16" box end wrenches

to remove the two screws (C, Figure

4-11) and nuts (D) that secure the

tine to its tine holder.