Page 1

Operator's Manual

II:RRFTSHRN'I

10 mm (3/8 in.) CORDLESS DRILL-DRIVER

Variable Speed / Reversible

Stock Nos.

_22535 - 9.6 Volt

22536 - 12 Volt

Model Nos.

973.225350 - 9.6 Volt

973.225360- 12 Volt

Save this manual for

future reference

CAUTION: Read and followall

Safety Rules and OperatingInstructions

beforefirst use of this product.

Customer Help Line: 1-877-369-8665

Sold by: Sears Canada Inc., Toronto M5B 2B8

Visit the Craftsman web page: www.sears.com/craftsman

972000*963

2-02

• Safety

• Features

• Operation

• Maintenance

• Parts List

Page 2

• Table Of Contents .......................................................................................................................................................... 2

• Warranty......................................................................................................................................................................... 2

• Introduction..................................................................................................................................................................... 3

• Gsnerai Safety Rules, SpecificSafety Rules, And Symbols ..................................................................................... 3-6

• ProductSpecifications.................................................................................................................................................... 7

• Features ..................................................................................................................................................................... 7-8

• Operation.................................................................................................................................................................. 8-13

• Maintenance................................................................................................................................................................. 14

• Acceasodas.................................................................................................................................................................. 14

• ExplodedView And Repair Parts list .......................................................................................................................... 15

• PartsOrdering/Service ............................................................................................................................................... 16

FULL TWO YEAR WARRANTY ON CRAFTSMAN TOOL

IfthisCRRFTSMIIMtool failsto to operate withintwo yearsfromthe date of purchase,return it to the nearestSears

Canada Inc. ("Sears') storeand "Sears"willrepair It,free of charge.

Ifthistool is used for commercialor rentalpurposes,thiswarranty appliesfor only90 daysfrom the date of purchase.

Thiswarranty is inadditionto any statutorywarranty.

Sears Canada Inc., Toronto MSB 2B8

Look for this symbol to point out imporlant safety precautions. It means attentionlll Your safety is

involved.

A WARNING:

The operation ofanypowertool_ resultinforeignobjectsbeingthrown into youreyes, which can

resultinsevere eye damage. Before beginningpower tool operation,always wear safetygogglesor

safetyglasses withside shieldsand a fullface shieldwhen needed. We recommendWide Vision

Safety Mask for useover eyeglasses orstandard safetyglasseswith side shields,availableat Seam

RetailStores.Alwayswear eye protectionwhichis markedto complywithANSI Z87.1.

"SAFETY AND INTERNATIONAL SYMBOLS

Thisoperator'smanual describes safetyand internationalsymbolsand piotographsthat may appear on thisproduct.

Read the operator'smanualfor completesafety,assembly, operatingand maintenance,and repairinformation.

@

MEANING

Do notexposeto rainor usein damp locations.

2

Page 3

Yourdrill-driverhasmanyfeaturesformakingyourdrilling

operationsmorepleasantandenjoyable.Safety,

performanceand dependabilityhavebeen giventop

pnorityinthe design of thisdrill-drivermaking iteasy to

maintainand operate.

,_ CAUTION: Carefully readthrough thisentire

operator'smanual before usingyournewdrill-driver.

Pay closeattentiontothe SpecificSafety Rules/

Symbols,WarningsandCautions. ifyou useyour

drill-driverproberlyand onlyfor it'sintendeduse, you

willenjoyyears ofsafe, reliableservice.

A WARNING: Read and understand all Irmtructlino.

Failureto followall instructionslistedbelow, may

resultinelectdoshock,fire and/orseriouspersonal

injury.

SAVE THESE INSTRUCTIONS

Work Area

• Keep your work area clean and well lB.Cluttered

benchesand dark areas inviteaccidents.

Do not operate power tools In m(ploalve atmo-

spheres, such as In the presence of flammable

liquids, gases, or dust. Powertools createsparks

whichmay ignitethe dustor fumes.

• Keep bystanders, children, and visllora away while

operating a power tool. Distractionscan cause you

to lose control.

Elect dcal Safety

• Do not abu_sethe cord. Never use the cord to carry

the charger. Keep cord away from he_, o11,shaft)

edges, or moving parts. Replace damaged cords

Immodlatoly. Damaged cordsmay createa fire,

• A battery operated tool wRh Integral hattorles or a

separate battery pack must be recharged only wlh

the specified cherger for the battery. A chargerthat

may be suitablefor one type ofbatterymay create a

riskoffire when usedwith anotherbattery.Use battery

onlywithcharger listed.

MODEL BATFERYPACKCHARGINGASSEMBLY

973.225350 1323401 1425001

973.225360 139.3402 1425002

Use hattery operated tool only with spuclflcally

designated battery peck. Use of any otherbatteries

may creme a riskoffire. Use onlywithbatterypack

listed.

Personal Safety

• Stay alert, welch whst you are doing and use

common eanM when oparetlng a power tool. Do

not use tool while Urad or under the Influence of

drugs, alcohol, or medication. A moment ofinatten-

tionwhileoperatingpowertools may result inserious

personalinjury.

• Dress properly. Do not wear loose clothing or

jewelry. Confaln long hair. Keep your heW,clothing,

and gloves away from moving pads. Looseclothes,

jewelry,or longhaircanbe caughtin movingparts.

• Avoidaccidental starting. Be sum switch Is In the

licked or off paaltion before InserUng battery

pack. Carryingtoolswithyour fingeronthe switchor

insertingthebattery packintoa tool withthe switchon,

invitesaccidents.

• Remove adjusting keys ormnchse beforatum-

Ing the tool on.A wrenchor a keythat is Isf_attached

to a rotatingpartof the toolmay resultinpersonal

injury.

• Donot overreach. Keep proper footing and hal-

=nee st all tlmea. Properfootingand balanceenables

better controlof thetool in unexpectedsituations,Do

net useon a ladderor unstablesupport,

• Use safety equlpmcoL Always wear aye protection.

Dustmask, nonskidsafetyshoes,hardhat, or hearing

protectionmustbe usedfor appropriateconditions.

Page 4

Tool Use and Care

• Use clamps or other practical way to secure end

support the workploce to a stable platform. Holding

the workby handor againstyour bodyisunstableand

may leadto lossof control.

• Do not fome tool. Use the corract tool for your

applicction. The correcttoolwill dothejob betterand

safer at the rateforwhich it isdesigned.

• Do not use tool if switch does not turn It on or off.

A tool that cannotbe controlledwiththe sw_chis

dangerousand mustbe repaired.

• Discomte_ hettec/pack fromtoolor plaestlw w_lctt

In the lockedor off poallicnbalers nwldngeny edJust-

merits,changingam or storklgthetcoL Such

pr_ver_ve safetymeasuresreduceriskofsta_ngthe_col

a_er_l_.

• Store Idle tools out of reach of children and other

unlrained persons. Too|sare dangerousinthe hands

of untrainedusers.

• When battery pack is not in use, keep It away from

other metal objects like: paper clips, coins, keys,

nails, screws, or other roll metal objects that can

make a connection from one terminal to another.

Shortingthe batteryterminatstogethermay cause

sparks,bums, ora fire.

• Maintain tools wIth oars. Keep cutting tools sharp

and olsun. Propedymaintainedtools, withsharp

cuttingedgesare less likelytobindand are easier to

control.

• Checkfor mlesitgnmontor bindingof moving pads,

brealmgeof pads, andany other condItion that may

affect the toors operation, ffdamaged, have the tool

se_lced before using. Manyaccidentsarecaused by

poodymaintainedtools,

• Use only eccosserles that are recommended by

the manufacturer for your model. Accessoriesthat

may be suitablefor one tool, may createa nckof injury

when used onanothertool.

Service

• Tool =mvlce must be performed only byqualified

repair personnel. Serviceor malntananco performed

by unqualifiedpersonnelcould resultin a nsk of injury.

• When servicing a tool, use only Identicat replace-

merit parts. Follow Instructions In the Maintenance

section of this manual. Use of unauthonzedpartsor

failureto followMaintenance Instructionsmaycreatea

riskofshockor iniury,

Hold tool by Insulated gripping surfaces when performing an operation where the cutting tool may contact hidden

wiring. Contactwith a *live" wire willmake exposed metal partsofthe tool"live"and shockthe operator.

AddlUonal Rules For Safe Opera.on

• Know your power tool. Read operetoYs manual

carefully. Learn Its applications end limitations, as

well asthe specific potential hazards related to

this tool. Followingthisrulewillreducethe riskof

electricshock,fire, or sedous injury.

• Make anre your extsuston cord ISIn gnod condllon.

When using an ex'tansicn cord, he =are to use one

heavy enough to eany the cuwent your product will

draw. Awlro gags size (A.W.G.) of at Isast 16 Is

recommended for an extenalon cord 100 fact or

In length.A corda(coedlng 100feet Isnot recom-

mended. If In doubt, usethe next heavlar gage. The

smaller the gage number, the he=wlarthe cord, An

undemizedcordwill cause a dropin linevolt=qgeresult-

inginlossof power andoverheating,

Important Rules for Battery Tools

• Bsttery tools do not heveto he plugged Into an

eta€ideal outlet; therefore, they am always In

operating condItion. Be aware of possible hazards

when not using your battery tool or when chang-

Ing sccesserlos. Followingthis rulewi11reducethe

dskofsled:rioshock, fire, or seriouspersonal injury.

• Do not place battery tools or their bsttorlse near

fire or heat. This will reduce the riskof explosionand

possible injury.

_L WARNING: Batteriesvent hydrogengas and can

explodeinthe presence of a seurca ofignition, such

as a pilotlight.To reducethe riskof seriouspersonal

injury,never use any cordless productinthe pres-

ence ofopenf_me. An explodedbattery canpropel

debrisand chemicals.Ifexposed, flushwithwater

immediately.

Do not charge bsttow tool In u damp orwet

location. Followingthis rulewillreducethe risk of

electricshock.

For best results, your battery tool should be

charged In s location where the temperature Is

mare then 50°F but less than IOOOF.Do not store

outside or In vehicles.

• Under extreme usage or temperature condItions,

battery Isekugumey occur. If Itqukl comes In

contact with your skin, wseh Immediately with

seep and water, then noutrallz= with lemon juice

or vinegar. If liquid gets Into your eyes, flush them

with olean water for at least 10 minutes, then seek

Immedlatu medical attenilon. Followingthisrule will

reducethe risk of seriouspersonal injury,

4

Page 5

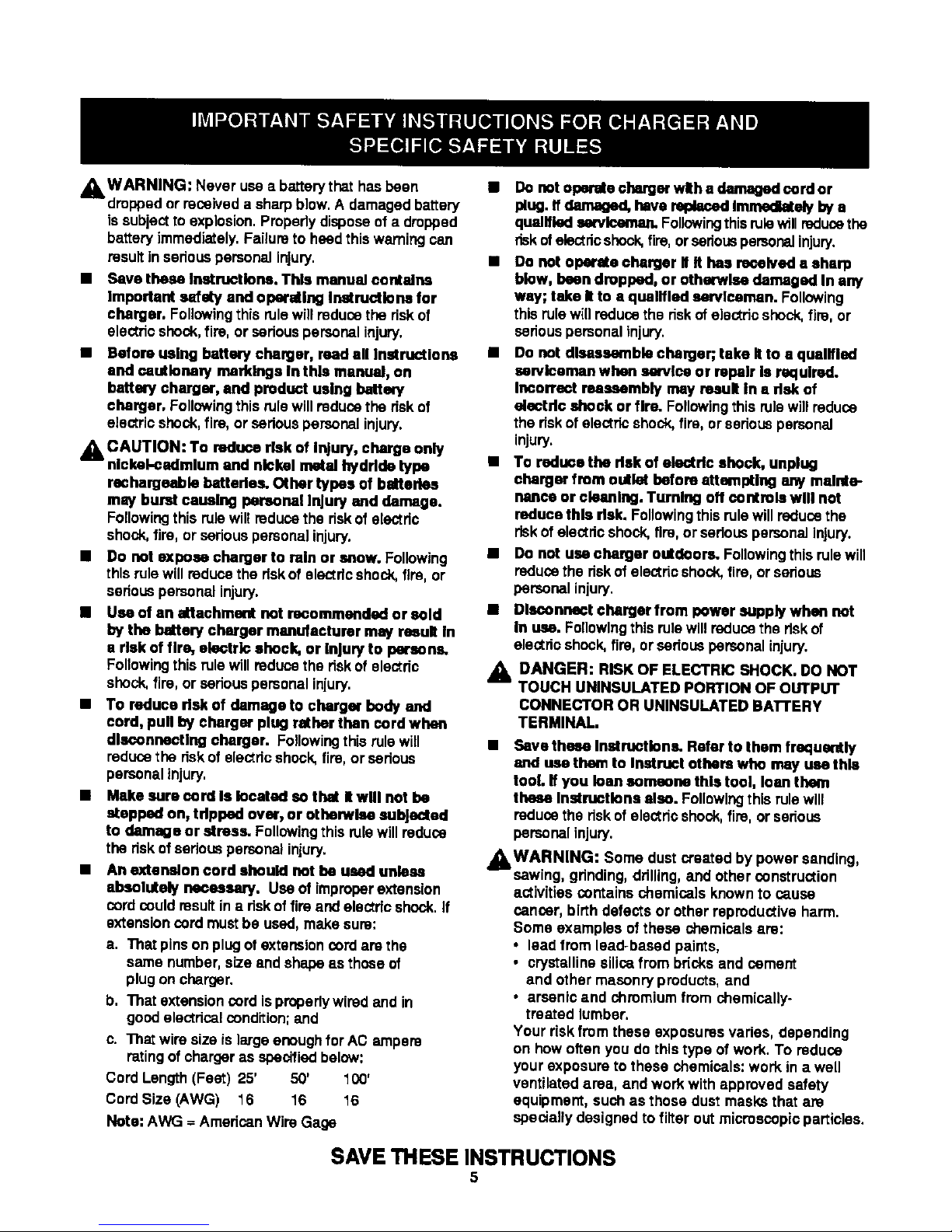

_kWARNING: Never use a batterythat hasbeen

dropped orreceived a sharpblow. A damaged battery

is subjectto explosion.Properlydisposeof a dropped

battery immediately.Failureto heed this warningcan

resultinsedous personal Injury.

• Save these Instructions. This manual contains

Important safety and operating Instructicns for

charger. Followingthis rulewill reducethe riskof

electricshock,fire, orserious personalinjury.

• Before using battery charger, reed all Instructions

and cautlonon/markings In this manual, on

hatteoy charger, and product using balttary

charger. Following this rule willreducethe riskof

electricshock,fire, or serious personal injury.

_k CAUTION: To reduce risk of Injury, charge only

nickel-cadmium and nickel metal bydrlde type

rashargnsble hattedes. Other types of batteries

may burst causing personal Injury and damage.

Followingthis rulewill reducethe dsk of electric

shock,firs, or serious personalinjury.

Do not expose charger to rain or snow. Following

this rulewill reduce the riskof electricshock,fire, or

serious personal injury.

Use of an attachment not recommended or sold

by the battery charger manufacturer may result In

s risk of fire, electric shack, or Injury to persons.

Followingthis rulewill reducethe riskof electric

shock,fire, or seriouspersonalinjury.

To reduce risk of damage to charger body and

cord, pull by charger plug rather than cord whan

disconnecting charger. Followingthis rulewill

reducethe riskof electricshock, fire, or serious

personalinjury.

Make sure cord Is located sothat It will not ha

stepped on, tdpped over, or othenvlse subjected

to damage or stress. Followingthis rule will reduce

the risk ofseriouspersonalinjury.

An extension cord should not he used unless

absolutely necessary. Use of improperextension

cordcould resultin a riskoffire and electricshock.If

extensioncord mustbe used, make sure:

a. That pinson plugof extensioncordam the

same number,size and shape as those of

plug on charger.

b. That extensioncordisproperlywired and in

good electricalcondition;and

c. That wire size is large enough for AC ampere

ratingof chargeras specifiedbelow:

Cord Length(Feet) 25' 50' 100'

Cord Size (AWG) 16 16 16

Note: AWG = AmericanWire Gage

• Do notoperatechargarwlthadamagndcordor

plug. If damaged, have raglanndImmediately by a

qualIfied serviceman.Followingthisrulewill reducethe

riskofelectricshock,fire, orserious personalinjury.

• Do not operate charger If It has received a sharp

blow, been dropped, or othen_lse damaged In any

way; take It to a qualIfied serviceman. Following

this rulewill reducethe riskof electricshock,fire, or

sedous personalinjury.

• Do not disassemble charger; take Itto e qualified

serviceman whan service or repair is required.

Incorrect reeseembly may result In a dak of

electric shock or fire. Followingthis rulewill reduce

the riskof electric shock,fire, orseriouspersonal

injury.

• To reduce the risk of eluctdc shack, unplug

charger from outlet before attempting any malnte-

nanns or cleaning. Turning off controls will not

reduce this dsk. Followingthis rule will reducethe

riskofelectdc shock,fire, or seriouspersonalinjury.

• Do not use charger outdoors. Followingthis rule will

reducethe riskof electric shock,fire,or serious

personalinjury.

• Disconnect chargerfrom power supply when not

In use. Followingthisrule will reducethe riskof

electricshock, fire, or serious personalinjury.

A DANGER: RISK OF ELECTRIC SHOCK. DO NOT

TOUCH UNINSULATED PORTION OF OUTPUT

CONNECTOR OR UNINSULATED BATFERY

TERMINAL.

• Save these Instructicne. Refer to them frequently

and use them to Instruct others who may use this

tool. If you loan someone this tool, loan them

these Instructions also. Followingthisrule will

reducethe riskof electricshock,fire,or serious

personal injury.

_.WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activitiescontains chemicals knownto cause

cancer, bl_h defects or other reproductive harm.

Some examples ofthese chemicalsare:

• lead from lead-based paints,

• crystallinesilica from bricks and cement

and other masonry products, and

• arsenic and chromiumfrom chemically-

treated lumber.

Your riskfrom these exposuresvaries, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

SAVE THESE INSTRUCTIONS

5

Page 6

Important:Someofthefollowingsymbolsmaybeusedonyourtool.Pleasestudythemandlearntheirmeaning.Proper

interpretationofthesesymbolswillnllowyouto operatethe tool betterand safer,

SYMBOL _ DESIGNATION/EXPLANATION

V Volts Voltage

A Amperes Currem

Hz Hertz Frequency(cyclesper second)

rain Minutes Time

"_ AlternatingCurrent Type or a characteristicof current

--= DirectCurrent Type or a charaoteristloof current

no No LoadSpeed Rotationalspeed,at no load

•../rain Revolutionsor ReciprocationPer Minute Revolutions,strokes,

surfacespeed, orbitsetc, per minute

Safety Symbol Indicatesdanger,warningor caution.

Alert

It rreans a_entlonlll Your safety is

involved,

The purpose of safety symbols Is to attract your nttention to poselbio dangers. The safely symbols, and

the explanations with them, deserve your careful attenilon and understanding. The safety warnings do

not by themselves eliminate any danger. The Instructions or warnings they give are not substitutes for

proper accident prevention measures.

SYMBOL

&

,&

A

&

NOTE:

MEANING

SAFETY ALERT SYMBOL:

Indicatesdanger,warning,orcaution.Maybe usedinconjunction withothersymbolsorpictogrephs.

DANGER: Failure to obey a safetywarningwill resuitinsedous injuryto yourselforto others,

Alwaysfollowthe safety precautionsto reducethe riskoffire,electrioshockand personal injury.

WARNING: Failureto obey a selety warning can resultin serious injurytoyourseffotto others,

Alwaysfollowthe safety precautionsto reducathe riskof fire,eleotdcshockand personal injury.

CAUTION: Failure to obey a safetywarningmay resultinpropertydamage or personalinjuryto

yourselforto others,Alwaysfollowthe safetyprecautionsto reducethe riskoffire,electricshock

and personalinjury.

Advisesyou of informationorinstructionsvitalto the operationor maintenanceof the equipment.

6

Page 7

DRILL-DRIVER

Chuck

Motor

Switch

No LoadSpeed

Clutch

MaximumTorque

CHARGING ASSEMBLY

Rating

ChargingVoltage

Charge Rate

BATTERY PACK

973.225350

10 mm (3/8 in.Keyless)

DC Motor9.6 Volt

Vadable Speed

O-7OORPM

24 Positions

90 in,/lbs

1425001

"_20V, 60 Hz, AC only

9.6 Volt

3-6 Hours

1323401

973.225360

10 mm (3/8 in.) Keyless

DC Motor 12 Volt

Vadable Speed

0-600

24 Positions

"_00in._bs

1425002

"_20V, 60 Hz, AG oNy

12 Volt

3-6 Hours

1323402

KNOW YOUR DRILL-DRIVER

F_zLIl'eI.

Beforeattemptingto use your drill-driver,familiarize

yourselfwith all operatingfeatures and safety

requirements.

KEYLESS CHUCK

Yourddll-ddverhasa keylesschuckthat allowsyouto hand

tightenor releaseddnbit inthe chuck jaws,

SWITCH

To tum yourddll-ddverON, depressthe switchtdggen

Release switchtdggsrto turnyour ddll-ddverOFF,

SWITCH LOCK

The switchtdgger can be locked inthe OFF position.This

feature helps reducethe possibilityofaccidentalstarting

when not in use,

VARIABLE SPEED

Your drillhas a variablespeed switch thatdelivemhigher

speed with increasedtdggerpressure.Speed is controlled

bytheamountof switchtdggerdepression.

FORWARDIREVERSE SELECTOR

(DIRECTION OF ROTATION SELECTOR)

Yourdrill-driverhas a forward/h_erse selector located

abovethe switchtdgger,

WRIST STRAP

See F_ure I.

Awriststrap isprovidedto mduosthe chancesof dropping

yourdrill-driver.Plaosone handthroughthe wriststrap

when carryingtool.

BIT STORAGE

When not in use,bits providedwith yourdrill-drivercartbe

placedin the storagearea locatedon the bottomofthe

motorhousing,

LEVEL

To keepdd]l bit leveldudng ddllingoperations,a level is

locatedonthe back of the motor housing.

_, WARNING: Do notallowfamiliaritywithyourdri!l-

driverto make youc_reless. Rememberthst a

careless fractionof a secondissufficientto inflict

severe iniury,

A WAFINING: If any partsare missing,donotoperate

yourddll-ddveruntilthe missingpartsare replaced.

Failureto do sooould resultinpossibleserious

personalinjury,

7

Page 8

TOROUE

ADJUSTMENT

KEYLESS I_NG

CHUCK

SWITCH

TRIGGER

SCREWDRIVER

BITS

BAI"rERY

PACK

WRIST

STRAP

BATTERYPACKSHOWN

INCHARGINGSTAND

REDUGHT

(LED)

CHARQ[NG

STAND

CHARGER

DIRECTION

OF ROTATION

SELECTOR

(FORWARD

REVERSE)

LEVEL BATTERY PACK

STOOGE

8

Fig. 1

The batterypackforyourtoolhasbeen shippedIn a low

chargeconditionto prevent possibleproblems.Therefore,

youshouldchargeit overnightpriorto use.

Note: Batterieswill notreachfull charge the first time they

are charged.Allowseveralcycles(drillingfollowed by

recharging]for themto becomefullycharged.

CHARGING BATrERY PACK

See F-_ure I.

• Chargebatterypack only withthe chargingassembly

provided.

• Make sure power supply Is normal household

voltage, 120volts, 60 Hz, AC only.

• Connectchargarto power supply.

• Place batterypack in chargingstand.Alignraisedrib

on batterypackwithgroovein charging stand.

See F_ure I.

• Pressdown on batterypackto be sum contacts on

batterypack engagepropadywith contacts incharging

stand.

• Thecharge indicaZorlight(LED), Iocad_edonthe

charging stand, willlightup red and glowwhenthe

chargerisproperlyconnected to power supply.This

lightindicatesthe chargeris operatingproperly.Itwill

remainon untilbatterypackisremovedfrom charging

standor chargerisdisoonneotedfrompowersupply,

The tightonlyglowswhile batterypack is charging.

• Note: ffchargerdoes not chargebatterypack, ratum

batterypack and charging essembly to your nearest

Sears RepairCenter for electricalcheck.

• Afternormalusage,3 hoursorlessofchargingtimeis

requiredtofullyrechargebatterypack.Note: it battery

packis cornplstely discharged,6 hoursor longerof

chargingtime is requiredto fullyrechargebatterypack.

• Thebatterypack willbecome slightlywarmtothe

touchwhilecharging.Thisisnormaland does not

indicatea problem.

• Do not place charger inan area of extreme heat or

cold. it willworkbestat normal roomtemperature.

• Whenbatteriesbecomefully charged,unplugcharger

from power supplyand remove thebatterypack.

IMPORTANT INFORMATION FOR RECHARGING

HOT BATTERIES

When usingyour drill-drivercontinuously,the batteries in

yourbatterypackwillbecome hot,You shouldlet a hot

batterypackcool down for approximately30 minutes

before attemptingto recharge,

Note: This situationonlyoccurswhen continuous useof

yourdrillcausesthebatteriesto become hat. itdoes net

occurundernormaldmumstances,Refarto "CHARGING

BA'I'rERY PACK" for normalrechargingof batteries,ffthe

chargerdoesnotchargeyourbatterypack undernormal

dmumstances,returnboththe batterypack andchargerto

your nearest Searsrepairranter for electrioaicheck.

Page 9

WARNING:Alwayswearsafetygogglesorsafety

glasses withside shieldswhen operatingtools.

Failuretodo so could resultin objectsbeingthrown

Into your eyes, resultinginpossibleseriousinjury.

SWITCH

See _gure 2.

To turnyour ddllON, depressthe switchtdgger.To turn it

OFF, release the switchtdgger.

VARIABLE SPEED

This tool has a vadable speed switchthat delivers higher

speedand torquewith increasedtdggerpressure. Speed is

controlledbythe amount of switchtdgger depression,

Note: Youmighthear a whistlingor dngingnoisefrom the

switchduring use, Do notbe concerned,this isa normal

part of the switchfunction,

TO INSTALL BATrERY PACK

• Lockswitchtriggeronyour drill by placingthe direction

of rotationselector in centerposition.Sea F7#u/e4.

• Place battery peck inyour ddU.Align raisedrib on

batterypackwith grooveinsideddlL Sac F/gura3.

t

BATI'ERY

PACK

DEPRESSLATCHESTO

RELEASEBATTERYPACK

LATCHES

Fig. 3

• Make sure the latcheson each side ofyourbattery

packsnap in place and batterypack issecured indrill

beforebeginningoperation.

CAUTION: When placingbatterypack inyour drill,

be sure raisedfibon battery pack alignswithgroove

Insideddll and latchessnap Imoplace pmpedy.

Improperassemblyof batterypack canc_use

damageto intemat components.

TO REMOVE BA'R'ERY PACK

• Lockswitch triggeron your drillbyplacingthe direction

ofrotationselector insenter position. Sae r"Tgu/e4.

• Locatelatcheson end of batterypackand depress to

release batterypack from yourddll. See F_jure 3.

• Remove batterypack from yourdrill.

Page 10

SWITCHLOCK

See Figure 4.

The switchtriggercan be lockedinthe OFF position.This

feature can be used to prevent the possibilityofaccidental

startingwhen not in use. To lockswitchtdgger, push the

directionof rotationselector(Forward/ReverseSelector)

to the centerposition.

SELECTORWITH

CENTERLOCKPosfrlON

FORWARD

A WARNING: Batterytoolsare always in operating

condition.Therefore, switchshouldalways be locked

when not in useor carrying at your side,

REVERSIBLE

KEYLESSCHUCK

See R'gum 5.

Yourdrillhas e keylesschuck Asthe came implies,youcan

handtightenorreleasedrillbitsinthechuckjaws.Graspand

hold the collar of the chuck withone hand.Rotate the chuck

bodywith your other hand.The arrowsonthe chuck

indicatewhichdirection to rotatethe chuckbodyinorderto

LOCK (tighten)or UNLOCK (release)the drillbit.

UNLOCK CHUCK

CHUCK (RELEASE) COLLAR

TRIGGER

Fig. 4 (TIGHTEN)

WARNING: Donot holdchuckbedywith one hand

and usepower of the drillto tighten chuck jaws on

drillbit,Chuckbodycouldslipinyour hand oryour

handcould slipand come in contact with rotatingdrill

bit.This could cause an accidentresultinginserious

persona]injury.

See Figure 4.

This tool hasthe feature of being reversible.The direction

ofrotationiscontrolled by a selector locatedabove the

switchtrigger. With the drillheld in normaloperating

position,the directionof rotationselector should be

positionedto the leftof the switeh for drilling.The drilling

directionis reversedwhen the selector isto the rightof

the switch. When the selector Isin centerposition,the

switchtrigger is locked.

_lh CAUTION: To prevent gear damage, always allow

chuck to come to a complete stopbefore changing

the directionof rotation.

To stop, release switchtrigger and allowthe chuckto come

to a completestop.

10

Page 11

INSTALLING BITS

See Figure 6.

• Lockthe switchtrigger by placingthediractionof

rotationselector incenter position. See Figure#.

• Openor dose chuck _ws to a pointwhere the open-

ingis slightlylargerthan the bit size you intendto use.

Also, raisethefront ofyour drillslightlyto keepthe bit

from falling outofthe chuckjaws.

• Insertdrillbit straightinto chuckthe fulllengthof the

jaws as shownin Figure 6.

• Tightenthe chuck jaws on drillbit.

UNLOCK CHUCK

CHUCK (RELEASE) COU,.AR

DRILLBiT

LOCK

(TIGHTEN) CHUCK

BODY

RIGHT Fig. 6

• To tightenthe chuckjaws on ddll bit;graspand hold

the collarof the chuckwithone hand,while rotating

the chuckbody with yourother hand.

Note: Rotate the chuckbodyIn the directionof the

arrowmarked LOCK to tightenchuck jaws.

• Do not usea wrench to tightenor loosenthechuck

jaws.

_k WARNING: Make sureto insertdrillbit straightinto

chuck jaws. Do not Insert drillbit intochuckjaws st

an anglethen tighten, as showninFigure 7. This

couldcause drillbitto be thrown fromddll,resulting

in possible serious personalinjury ordamage tothe

chuck.

REMOVING BITS

See F_gure6.

• Lockthe switchtriggerby placingthe directionof

rotationselectorin center position.Sae FTqum4,

• Loosenthe chuck jawsfrom ddllbit.

• Toloosen:grasp and held the collar ofthechuck with

one hand,whilerotatingchuckbodywith yourother

hand. Note; Rotate chuck bodyin the directionofthe

arrowmarked UNLOCK to loosenchuckjaws.

• Do not use a wrenchto tightenor loosenthe chuck

j_WS.

• Removedrillbitfrom chuckJaws.

ADJUSTABLE TORQUE CLUTCH

Your ddll isequipped with an adjustable torque clutchfor

driving different types of screws into different matedals.

The propersetting dependson the type of matahaland the

size of screwyou are using.

TO ADJUST TORQUE

• Identify the twentyfour torqueindicatorsettingslocated

onthe frontofyourdrill.See Fi#/Jre8,

• Rotateadjustingringtothe desiredsetting.

• 1 - 4 Fordrivingsmallscrews.

5 - 8 Fordrivingscrewsintosoft

material.

• 9-12 Fordrivingscrews intosoft and hard

materials.

• 13- 16 Fordrivingscrewsin hard wood.

• 17- 20 For drivinglarge scmws.

• 21 - 4k,1 For heavy drilling.

TODECREASE

TORQUE ADJUSTING

RING

TOINCREASE

TORQUE

Fig.8

WRONG

Fig. 7

11

Page 12

BITSTORAGE

See Fioure9.

When not in use, bitsprovidedwithyourdrillcanbe

placed inthe storage area locatedon the bottomofyour

drillas shown infigure 9.

DRILLING

See Figure I f.

SCREWDRIVERBITS

BIT

STORAGEAREA

Fig. 9

A WARNING: Alwayswear safety gogglesor safety

glasseswithside shieldswhen operatingtools.

Failureto do so couldresultin objectsbeing thrown

intoyour eyes, resultingin possibleserious injury.

LEVEL

See Figure fO.

A convenient feature providedwith yourdrillis a level. It

is recessedin the motor housingon backof your drill. It

canbe usedto keepddllbit level duringdrillingopera-

tions,

REARVIEWOFDRILL

Fig. 11

When drillinghardsmoothsurfaces use a centerpunchto

mark desired holelocation. Thiswill preventthe drill bit

from slippingoff(:enterasthe holeis started. However,

the lowspeed feature allowsstartingholes withoutcenter

punchingif desired, To accomplishthis, simplyoperate

your drillat a lowspeed untilthe hole is started.

The materialto be drilledshouldbe secured ina vise or

withdamps to keep it fromturning as the drillbit rotates,

Holdtool firmly and place the bit at the pointto be drilled.

Depressthe switchtrigger to start tool.

Move the ddl]bit Intothe workplecoapplyingonlyenough

pressureto keep the bitcutting,Do notfores orapply side

pressuretoelongate a hole.

LEVEL

Fig. 10

_, WARNING: Be preparedfor bindingor bit

breakthrough.When these situationsoccur,drillhas

a tendency to graband kickopposite to the direction

ofrotationand could cause lossof oontrol when

breakingthroughmaterial. If notprepared, this loss

of control can resultin possibleseriousinjury.

When diflllngmetals,use a light oil on the drillbitto keep

Itfrom overheating. The oilwillprolongthe lifeof the bit

and increasethe drillingaction.

ff the bitjams inworkpiece or ifthe drillstalls, release

switchtrigger Immediately.Removethe bit from the

workpiecaand determinethe reason for jamming.

12

Page 13

CHUCKREMOVAL

See Figures 12, 13, and 14.

The chuck mustbe removedinorder to use some

accessories.To remove:

• Lockthe switchtrigger by placing the directionof

rotationselectorIn centerposition.See _gura 4.

• Inserta 5/16 In. orlargerhex key Intothe chuckof your

dnlland tightenthechuck jaws securely.

• Tap the hex key sharply with a mallet in a clockwise

direction.See fTgure 1_ This will loosenthe screw in

the chuck for easy removal.

MAILEr

CHUCK

JAWS

KEYLESS

CHUCK

HB( KEY Fig, 12

• Open chuck jawsand remove hex key. Removethe

chuck screwby tuming it ina clockwisedirection.

See Figure f3.

Note: The screw has left hand threads.

SCREWDRIVER

• Ir_ert hex key in chuck andtightenchuck jaws se-

curely.Tap sharplywitha mallet ina counterclockwise

direction.This will loosenchuckon the spindle.Itcan

now be unscrewedby hand. See Figure 1#.

Fig. 14

TO RETIGHTEN A LOOSE CHUCK

The chuck may become loose on spindleand developa

wobble.Periodicallycheck chuck screw for tightness.

To tighten, follow these steps:

• Lockthe switchtdggerby placingthe directionof

rotation selector in centerposition.See F/gum 4.

• Open the chuck jaws.

• Insert hex key intochuck and tightenchuck jaws

securely. Tap hex keysharplywitha mallet in a

clockwisedirection.This willtighten chuck onthe

spindle.

• Open thechuck jaws and remove hexkey.

• _ghten the chuckscrew.

Note: The chuck screw hasleft handthreads.

Fig. 13

13

Page 14

WARNING: When sewlclng, use only Identical

Craltsman replacement parts. Use ofany other

pan maycreatea hazard orcauseproductdamage.

Avoidusingsolventswhen c_eaningplasticparts. Most

plasticsare susceptibleto damage from varioustypesof

commercialsolventsand may be damaged by theiruse.

Use clean c_othsto remove dirt, dust,oil, grease, etc.

A WARNING: Do not at any timelet brake fluids,

gasoline,petroleum-basedproducts,penetratingoils,

etc. come incontact with plasticparts. They contain

chemicalsthat can damage,weaken or destroy

plastic.

Do not abuse powertools. Abusivepracticescan

damage tool as well as workplece.

Only the partsshownon parts list,page 15, are Intended

to be repaired or replacedbythe customer.Allotherparts

shouldbe replacedat a Sears Service Center.

WARNING: Donot attemptto modifythis tool or

create accessoriesnot recommendedfor use with

thistool,Any such alterationor modificationis

misuse and could resultin a hazardouscondition

leading topossibleseriouspersonalinjury.

BATFERIES

Your ddlrs batterypack isequippedwith nickel-cadmium

rechargeeblebatteries. Lengthofservicefrom each

charging willdepend onthe type of work youare doing.

The battehes in thistoolhave been designedto provide

maximumtroublefree life.However, likeall batteries,they

willeventuallywear out, Do not disassemblebatterypack

and attempt to replacethe batteries, Handlingofthese

batteries, espaciaily whenwearing ringsand jewelry,

could resultin a serious bum.

To obtainthe longestpossiblebatterylife, we suggestthe

following:

• Storeand chargeyourbatteries in a cool area.

Temperaturesabove orbelownormal room

temperaturewillshortenbatterylife.

• Neverstora batteries in a dischargedcondition.

Rechargethem immediatelyafter they are

discharged.

• All batteriesgraduallylosetheircharge. The higher

thetemperature the quickerthey losetheir charge, ff

you storeyourtoolfor longperiodsof time without

using it, rechargethe bettedasevery monthortwo.

Thispracticewill pro!ongbattery life.

I FOR A COMPLETE SELECTION OF1

ACCESSORIES FOR THIS AND OTHER[

CRAFTSMAN POWER AND BENCH TOOLS,[

VISff YOUR NEAREST SEARS RETAIL STORE.)

14

Page 15

CRAFTSMAN 10 mm (3/8 In.) CORDLESS DRILL-DRIVER

MODEL NOS, 973.225350 / 973.225360

Them_de_numberw___bef_und_nap_ateatta_hedt_them_t_rh_using_A_waysmenti_nthem_de_number J

inallcorrespondenceregardingyour10 mm (3/8 In.) CORDLESS DRILL-DRIVER orwhen ordedngrepair

parts,

SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS

2

4

Key Part

No. Number

1 616478-003

2 6903326

3 1323401

1323402

4 1425001

1425002

972000-963

PARTS LIST

Descdpltlon Quart,

Screw (Special)...................................................................... 1

Chuck(Item No._ 75188) ...................................................... 1

BatteryPack (Model973.225350) ......................................... 1

BatteryPack (Model973.225360) ......................................... 1

Charging Assembly(Model973,225350) ............................... 1

ChargingAssembly(Model 973.225360) ............................... 1

Operator'sManual

15

Page 16

Operator's Manual

STOCK NOS. 922535 / 222536

MODEL NOS. 973.225350 / 973.225360

Sears service is available at or through

your Sears Retail Store

or Catalogue Sales Office,

How to order repair parts

SERVICE AND REPAIR PARTS

CALL 1-800-665-4455 *

Keep this number handyshould you requirea

service call or need to order repairparts.

Ifordedng parts, make sure you have the name, make and

modelno, ofthe merchandise andthe name and number

ofthe partyou wish to order,

Whenorderingrepairpartsalways give:

1. The PartNumber

2. The PartDescription

3. The Model Numbers:

973.225350 / 973,225360

4. The nameofthe item:

10 mm (3/8 in.) CordlessDrill-Driver

* If calling locally, please use one of the following numbers:

Regina - 566-5124 Montreal - 333-5740

Toronto - 744-4900 Halifax - 454-2444

Kitchener - 894-7590 Ottawa - 738-4440

Vancouver - 420-8211

WE SERVICE WHAT WE SELL.

WE MAKE THIS PLEDGE BECAUSE OUR CONCERN FOR OUR CUSTOMERS DOES NOT END WITH

THE SALE. TO HONOR OUR PLEDGE, WE HAVE DEVELOPED A TOP-NOTCH SERVICE PROGRAM

STAFFED BY HIGHLY TRAINED SPECIALISTS. THEIR KNOWLEDGE OF OUR NEW PRODUCTS IS

CONSTANTLY UPGRADED. THEY USE ONLY PARTS SPECIFICALLY DESIGNED FOR YOUR FINE

SEARS PRODUCTS.

Sold by: SEARS CANADA INC., TORONTO MSB 2B8

Loading...

Loading...