Page 1

358.740160 — 16 in. Bar

358.740180 — 18 in. Bar

22

IMPORT

ANT:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

115892449 Rev. C 2017-06-08

For answers to your questions

about this product, call:

1-888-331-4569

Craftsman Customer Help Line

SASA242PR

Page 2

TABLE OF CONTENTS

Warranty ......................................................... 2

Identification of Symbols ................................. 3

Safety ............................................................. 4

Know Your Product ......................................... 7

Assembly ........................................................ 8

Starting & Stopping ......................................... 9

Working Techniques ..................................... 11

Maintenance ................................................. 15

Troubleshooting Table ................................... 19

Technical Data .............................................. 20

Emissions Statement ..................................... 20

Spanish ......................................................... 22

Parts & Ordering ............................. Back Cover

WARRANTY

CRAFTSMAN LIMITED WARRANTY

FOR TWO YEARS from the date of sale this product is warranted against defects in material or

workmanship.

WITH PROOF OF SALE a defective product will receive free repair. If the product cannot be

repaired it will be replaced free of charge.

For warranty coverage details to obtain free repair, visit the web page:

www.craftsman.com/warranty

This warranty covers ONLY defects in material and workmanship. Warranty coverage

does NOT include:

Expendable items that can wear out from normal use within the warranty period, such as

the chain bar, chain, filters or spark plug.

Product damage resulting from user attempts at product modification or repair or caused by

product accessories.

Repairs necessary because of accident or failure to operate or maintain the product according to

all supplied instructions.

Preventive maintenance, or repairs necessary due to improper fuel mixture, contaminated or stale

fuel.

This warranty is void if this product is ever used while providing commercial services or if rented to

another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

2

Page 3

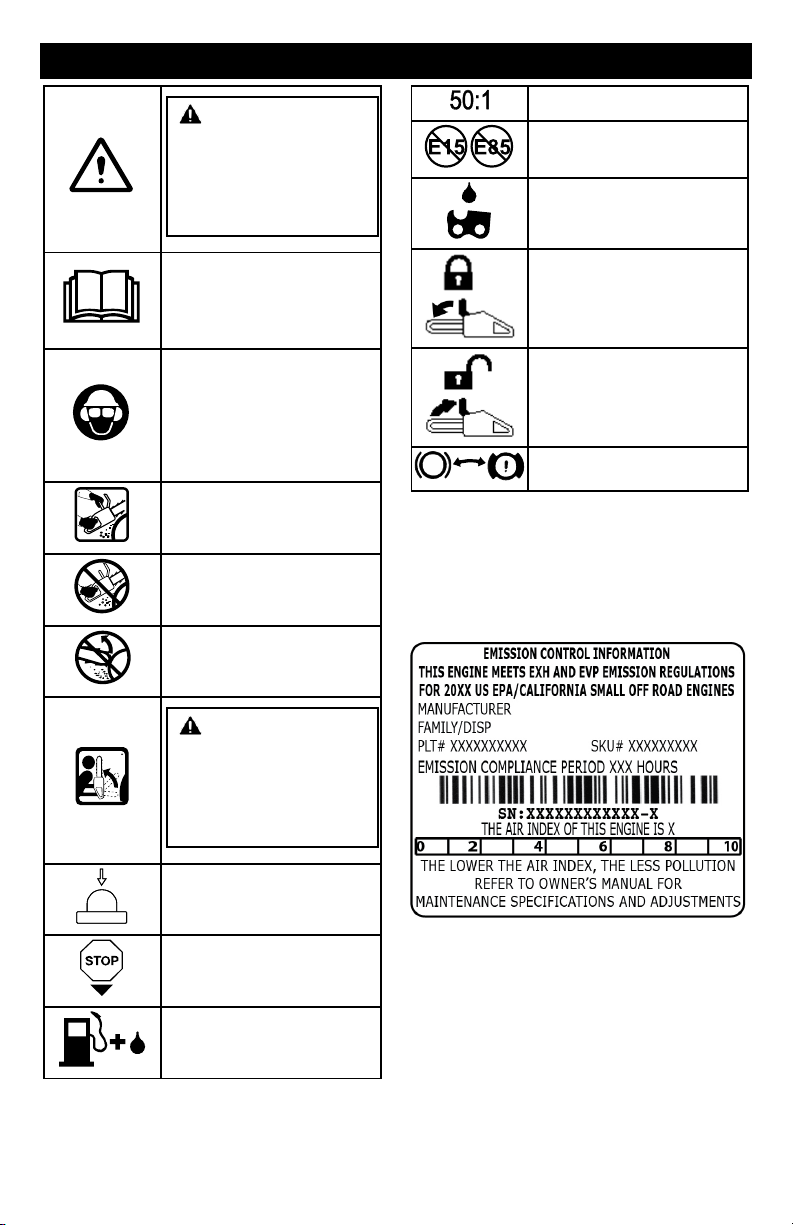

IDENTIFICATION OF SYMBOLS

WARNING:

Chainsaws can be

dangerous! Careless or

improper use can result

in serious or fatal injury

to the operator or

others.

Please read the operator’s

manual carefully and make

sure you understand the

instructions before using the

machine.

Always wear:

Approved protective helmet

Approved hearing

protection

Protective goggles or a

visor

Both of the operator′s hands

must be used to operate the

chainsaw.

Never operate a chainsaw

holding it with one hand only.

Contact of the guide bar tip

with any object must be

avoided.

WARNING: Tip

contact may cause the

guide bar to move

suddenly upward and

backward (so-called

kickback), which may

cause serious injury.

Primer (air purge) bulb.

The engine is stopped by

switching the ignition off using

the stop switch.

Fuel fill.

50:1 gasoline to oil ratio.

Do not use E15 or E85

blended fuels.

Bar and chain oil fill.

Lock chain brake.

Unlock chain brake.

Chain brake unlocked/locked.

XX

Other symbols/decals on the machine refer to

special certification requirements for certain

markets.

The Emissions Compliance Period referred to

on the Emission Compliance label indicates the

number of operating hours for which the engine

has been shown to meet Federal emissions

requirements.

Maintenance, replacement, or repair of the

emission control devices and system may be

performed by any nonroad engine repair

establishment or individual.

3

Page 4

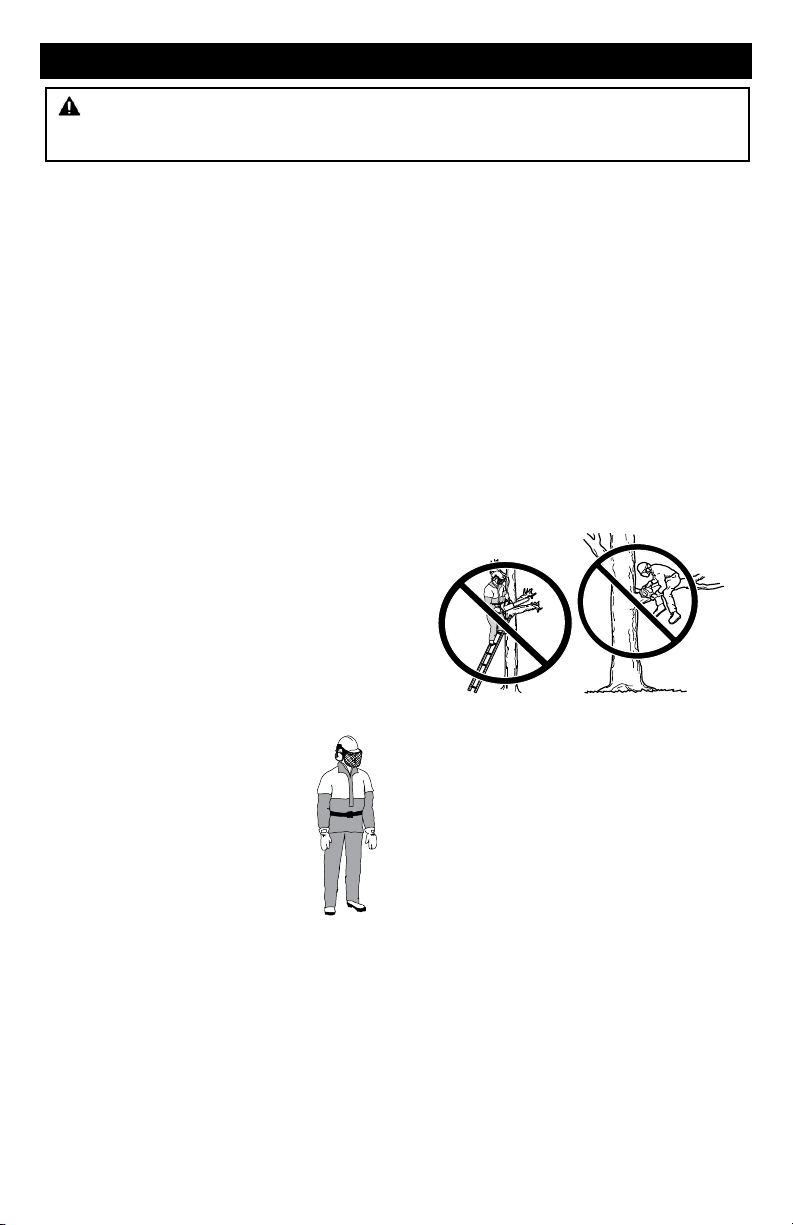

SAFETY

WARNING: Always disconnect spark plug wire and place wire where it cannot

contact spark plug to prevent accidental starting when setting up, transporting, adjusting

or making repairs except carburetor adjustments.

STANDARDS

This saw has been designed in accordance

with:

ANSI B175.1-2012 American National

Standards for Gasoline-Powered Chain Saws Safety Requirements

CSA Z62.1-11 Chain Saws – Occupational

Health and Safety

CSA Z62.3-11 Chain Saw Kickback

Occupational Health and Safety

INTRODUCTION

A chainsaw is a high‐speed wood‐cutting tool.

Special safety precautions must be observed to

reduce the risk of accidents.

Failure to follow all safety rules and precautions

can result in serious injury.

If situations occur which are not covered in this

manual, use care and good judgment. If you

need assistance, contact your authorized

service dealer or call consumer support.

PLANNING AHEAD

Read this manual carefully until you

completely understand and can follow all

safety rules, precautions, and operating

instructions before attempting to use the unit.

Restrict the use of your saw to adult users

who understand and can follow safety rules,

precautions, and operating instructions found

in this manual.

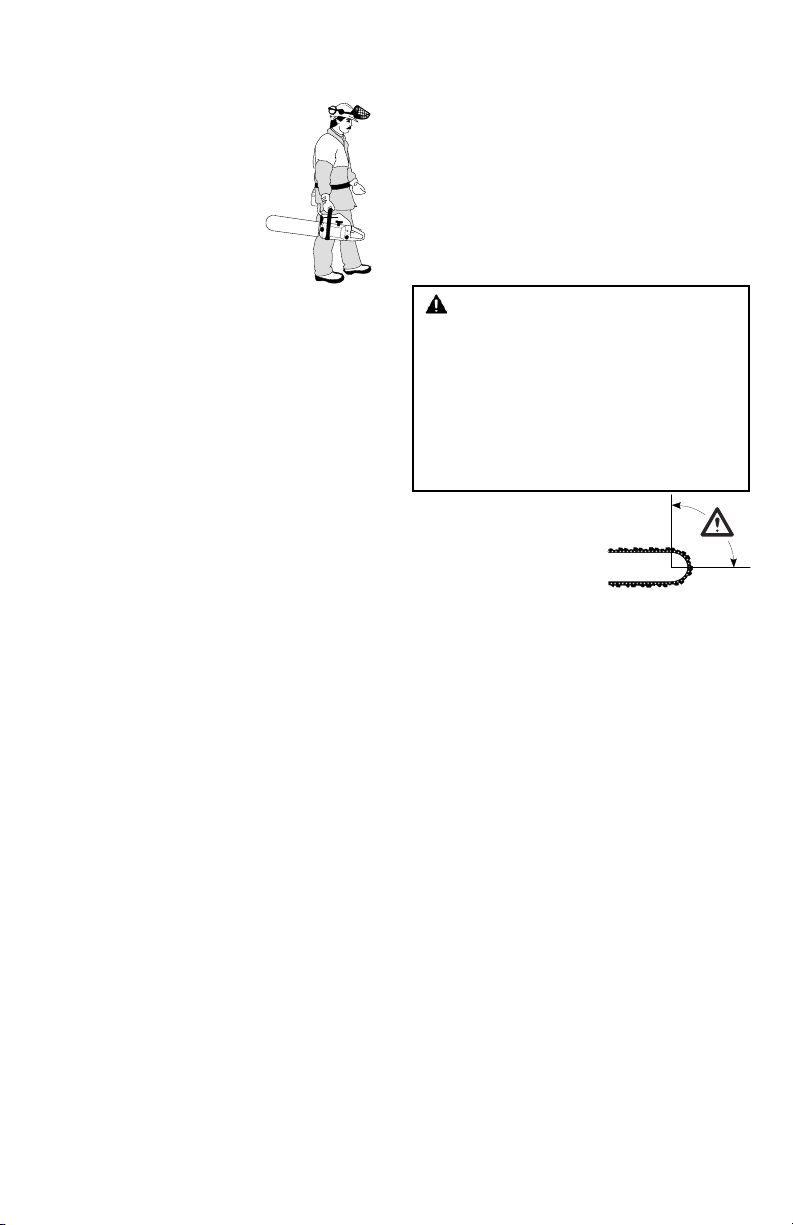

Wear protective gear. Always use

steel‐toed safety footwear with

non‐slip soles; snug‐fitting

clothing; safety chaps; heavy‐

duty, non‐slip gloves; eye

protection such as non‐fogging,

vented goggles or face screen; an

approved safety hard hat; and

sound barriers (ear plugs or

mufflers) to protect your hearing.

Regular users should have

hearing checked regularly as chainsaw noise

can damage hearing. Secure hair above

shoulder length.

Keep all parts of your body away from the

chain when the engine is running.

Keep children, bystanders, and animals a

minimum of 30 feet (10 meters) away from

the work area. Do not allow other people or

animals to be near the chainsaw when

starting or operating the chainsaw.

Do not handle or operate a chainsaw when

you are fatigued, ill, or upset, or if you have

taken alcohol, drugs, or medication. You

must be in good physical condition and

mentally alert. Chainsaw work is strenuous. If

you have any condition that might be

aggravated by strenuous work, check with

your doctor before operating a chainsaw.

Carefully plan your sawing operation in

advance. Do not start cutting until you have a

clear work area, secure footing, and, if you

are felling trees, a planned retreat path.

OPERATING YOUR SAW

Do not operate a chainsaw with one hand.

Serious injury to the operator, helpers,

bystanders or any combination of these

persons may result from one‐handed

operation. A chainsaw is intended for two‐

handed use.

Operate the chainsaw only in a well‐

ventilated outdoor area.

Do not operate saw from a ladder or in a tree.

Make sure the chain will not make contact

with any object while starting the engine.

Never try to start the saw when the guide bar

is in a cut.

Do not put pressure on the saw at the end of

the cut. Applying pressure can cause you to

lose control when the cut is completed.

Stop the engine before setting the saw down.

Do not operate a chainsaw that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace bar,

chain, hand guard, or chain brake

immediately if it becomes damaged, broken

or is otherwise removed.

Exposure to vibrations through prolonged use

of gasoline powered hand tools could cause

blood vessel or nerve damage in the fingers,

hands, and joints of people prone to

circulation disorders or abnormal swellings.

Prolonged use in cold weather has been

linked to blood vessel damage in otherwise

healthy people. If symptoms occur such as

numbness, pain, loss of strength, change in

skin color or texture, or loss of feeling in the

fingers, hands, or joints, discontinue the use

of this tool and seek medical attention. An

4

Page 5

anti-vibration system does not guarantee the

avoidance of these problems. Users who

operate power tools on a continual and

regular basis must monitor closely

their physical condition and the

condition of this tool.

With the engine stopped, hand-

carry the chainsaw with the

muffler away from your body,

and the guide bar and

chain to the rear,

preferably covered with a

scabbard.

MAINTAINING YOUR SAW

Have all chainsaw service performed by a

qualified service dealer with the exception of

the items listed in the maintenance section of

this manual. For example, if improper tools

are used to remove or hold the flywheel when

servicing the clutch, structural damage to the

flywheel can occur and cause the flywheel to

burst.

Make certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to Carburetor Adjustment.

Never modify your saw in any way.

Keep the handles dry, clean, and free of oil or

fuel mixture.

Keep fuel and oil caps, screws, and fasteners

securely tightened.

Use only genuine accessories and

replacement parts as recommended.

Your saw is equipped with a temperature

limiting muffler and spark arresting screen

which meets the requirements of California

Codes 4442 and 4443. All U.S. forest land

and the states of California, Idaho, Maine,

Minnesota, New Jersey, Oregon, and

Washington require by law that many internal

combustion engines to be equipped with a

spark arresting screen. If you operate a

chainsaw in a state or locale where such

regulations exist, you are legally responsible

for maintaining the operating condition of

these parts. Failure to do so is a violation of

the law. Refer to the SERVICE section for

maintenance of the spark arresting screen.

HANDLING FUEL

Do not smoke while handling fuel or while

operating the saw.

Eliminate all sources of sparks or flame in the

areas where fuel is mixed or poured. There

should be no smoking, open flames, or work

that could cause sparks. Allow engine to cool

before refueling.

Always have fire extinguishing tools available

if you should need them.

Mix and pour fuel in an outdoor area on bare

ground; store fuel in a cool, dry, well

ventilated place; and use an approved,

marked container for all fuel purposes. Wipe

up all fuel spills before starting saw.

Move at least 10 feet (3 meters) from fueling

site before starting engine.

Turn the engine off and let saw cool in a non‐

combustible area, not on dry leaves, straw,

paper, etc. Slowly remove fuel cap and refuel

unit.

Store the unit and fuel in an area where fuel

vapors cannot reach sparks or open flames

from water heaters, electric motors or

switches, furnaces, etc.

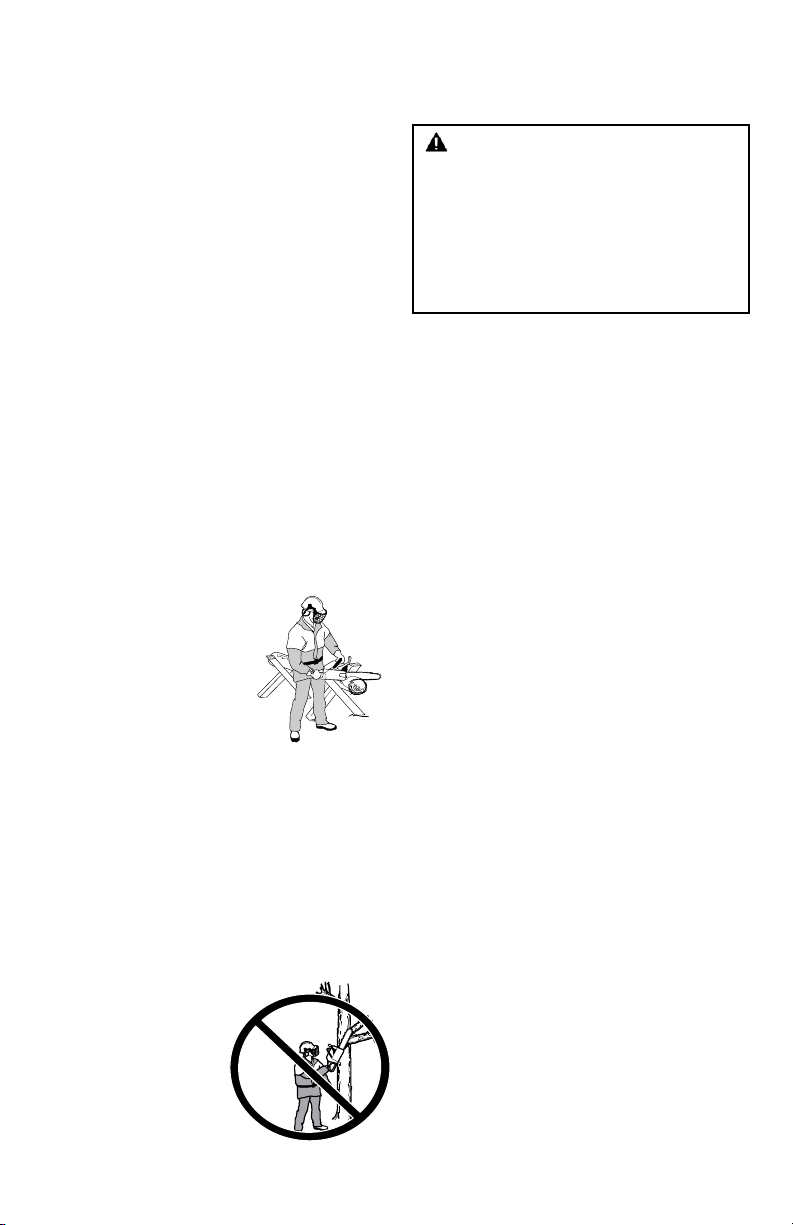

UNDERSTANDING KICKBACK

WARNING: Avoid kickback which

can result in serious injury. Kickback is

the backward, upward or sudden

forward motion of the guide bar

occurring when the saw chain near the

upper tip of the guide bar contacts any

object such as a log or branch, or when

the wood closes in and pinches the saw

chain in the cut. Contacting a foreign

object in the wood can also result in loss

of chainsaw control.

Rotational Kickback

Rotational kickback can

occur when the moving

chain contacts an object

at the upper tip of the

guide bar. This contact can cause the chain to

dig into the object, which stops the chain for an

instant. The result is a lightning fast, reverse

reaction which kicks the guide bar up and back

toward the operator.

Pinch Kickback

Pinch kickback can occur when the wood

closes in and pinches the moving saw chain in

the cut along the top of the guide bar and the

saw chain is suddenly stopped. This sudden

stopping of the chain results in a reversal of the

chain force used to cut wood and causes the

saw to move in the opposite direction of the

chain rotation. The saw is driven straight back

toward the operator.

Pull-In

Pull‐in can occur when the moving chain

contacts a foreign object in the wood in the cut

along the bottom of the guide bar and the saw

chain is suddenly stopped. This sudden

stopping pulls the saw forward and away from

the operator and could easily cause the

operator to lose control of the saw.

REDUCING THE CHANCE OF

KICKBACK

Recognize that kickback can happen. With a

basic understanding of kickback, you can

reduce the element of surprise which

contributes to accidents.

Never let the moving chain contact any object

at the tip of the guide bar.

5

Page 6

Keep the working area free from obstructions

such as other trees, branches, rocks, fences,

stumps, etc. Eliminate or avoid any

obstruction that your saw chain could hit

while you are cutting. When cutting a branch,

do not let the guide bar contact branch or

other objects around it.

Keep your saw chain sharp and properly

tensioned. A loose or dull chain can increase

the chance of kickback occurring. Follow

manufacturer's chain sharpening and

maintenance instructions. Check tension at

regular intervals with the engine stopped,

never with the engine running. Make sure the

bar nuts are securely tightened after

tensioning the chain.

Begin and continue cutting at full speed. If the

chain is moving at a slower speed, there is

greater chance of kickback occurring.

Use wedges made of plastic or wood. Never

use metal to hold the cut open.

Cut one log at a time.

Use extreme caution when re‐entering a

previous cut.

Do not attempt cuts starting with the tip of the

bar (plunge cuts).

Watch for shifting logs or other forces that

could close a cut and pinch or fall into chain.

Do not twist the saw as the bar is withdrawn

from an undercut when bucking.

Use the reduced-kickback guide bar and low-

kickback chain specified for your saw.

MAINTAINING CONTROL

Keep a good, firm grip on

the saw with both hands

when the engine is

running and don't let go.

A firm grip will help you

reduce kickback and

maintain control of the saw.

Keep the fingers of your left hand encircling

and your left thumb under the front

handlebar. Keep your right hand completely

around the rear handle whether you are right

handed or left handed. Keep your left arm

straight with the elbow locked.

Position your left hand on the front handlebar

so it is in a straight line with your right hand

on the rear handle when making bucking

cuts. Never reverse right and left hand

positions for any type of cutting.

Stand with your weight evenly balanced on

both feet.

Stand slightly to the left side of

the saw to keep your body

from being in a direct

line with the cutting

chain.

Do not overreach.

You could be drawn

or thrown off balance

and lose control of

the saw.

Do not cut above shoulder height. It is difficult

to maintain control of saw above shoulder

height.

KICKBACK SAFETY FEATURES

WARNING: The following features

are included on your saw to help reduce

the hazard of kickback; however, such

features will not totally eliminate this

danger. As a chainsaw user, do not rely

only on safety devices. You must follow

all safety precautions, instructions, and

maintenance in this manual to help

avoid kickback and other forces which

can result in serious injury.

Reduced Kickback Guide Bar

The reduced-kickback guide bar is designed

with a small radius tip which reduces the size of

the kickback danger zone on the bar tip. A

reduced-kickback guide bar has been

demonstrated to significantly reduce the

number and seriousness of kickbacks when

tested in accordance with safety requirements

for gasoline powered chainsaws as set by ANSI

B175.1.

Low-Kickback Chain

A low-kickback chain is designed with a

contoured depth gauge and guard link which

deflect kickback force and allow wood to

gradually ride into the cutter. Low-kickback

chain has met kickback performance

requirements when tested on a representative

sample of chainsaws below 3.8 cubic inch

displacement specified in ANSI B175.1.

Front Hand Guard

The front hand guard is designed to reduce the

chance of your left hand contacting the chain if

your hand slips off the front handlebar.

The distance and “in‐line” position of the hands

provided by the front and rear handles work

together to give balance and resistance in

controlling the pivot of the saw back toward the

operator if kickback occurs.

Chain Brake

The chain brake is designed to stop the chain

in the event of kickback.

NOTE: We do not represent and you should not

assume that the chain brake will protect you in

the event of a kickback. Do not rely upon any of

the devices built into your saw. You should use

the saw properly and carefully to avoid

kickback.

Chain brake repairs should only be made by a

Sears or other qualified service dealer.

NOTE: If this saw is to be used for commercial

logging, a chain brake is required and shall not

be removed or otherwise disabled to comply

with Federal OSHA Regulations for

Commercial Logging.

6

Page 7

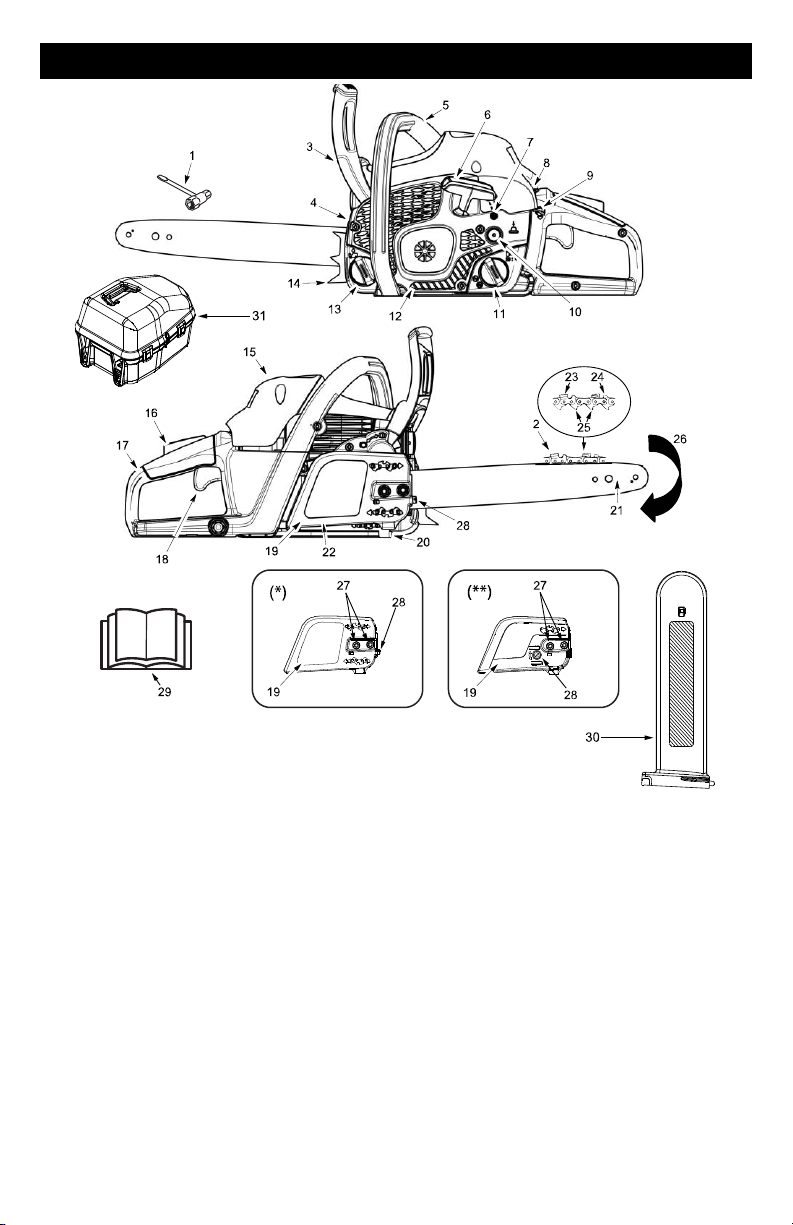

KNOW YOUR PRODUCT

NOTE: The appearance of your product may vary from the item shown.

(*) = Configuration for models equipped with chain tensioning screw located on front. Does not

apply to all models.

(**) = Configuration for models equipped with chain tensioning screw located on side. Does not

apply to all models.

1. Combination tool

2. Chain

3. Front hand guard/chain

brake lever

4. Muffler

5. Front handle

6. Starter rope

7. Idle speed screw

8. ON/STOP switch

9. Choke/fast idle lever

10. Primer (air purge) bulb

11. Fuel mix fill cap

12. Starter housing

13. Bar and chain oil fill cap

14. Bumper spike

15. Cylinder cover

16. Throttle lock-out

17. Rear handle

18. Throttle trigger

19. Clutch cover

20. Chain catcher

21. Guide bar

7

22. Chain brake

23. Cutters

24. Depth gauge

25. Drive links

26. Chain direction of travel

27. Guide bar retaining nuts

28. Chain tensioning screw

29. Manual

30. Scabbard

31. Carrying case

Page 8

The ON/STOP SWITCH (8) is used to stop the

Chain tensioningside adjust models

Chain tensioningfront adjust models

engine.

The THROTTLE TRIGGER (18) controls

engine speed.

The THROTTLE LOCK--OUT (16) must be

pressed before you can squeeze the throttle

trigger. This feature prevents you from

accidentally squeezing the trigger.

The choke and fast idle are set by pulling the

CHOKE/FAST IDLE LEVER (9) out to the full

extent for cold starting or after refueling. The

choke provides additional fuel to the engine

during cold starting.

ASSEMBLY

If received assembled, repeat all steps to

ensure your saw is properly assembled and all

fasteners are secure.

1. Check that the chain brake is in the

unlocked position by pulling the front hand

guard towards the front handle.

2. Loosen and remove the bar nuts and the

clutch cover from the saw.

3. Remove the plastic shipping spacer (A) if

present.

The PRIMER (AIR PURGE) BULB (10)

circulates fuel to the carburetor to provide

quicker starting.

The CHAIN BRAKE (3) is a device designed to

stop the chain if kickback occurs. The chain

brake activates automatically in the event of

kickback. The chain brake activates manually if

the front hand guard is pushed forward. The

chain brake is disengaged by pulling the front

hand guard back toward the front handle as far

as possible.

sprocket. Cutters must face in the direction

of rotation.

7. Check that the drive links of the chain fit

correctly on the drive sprocket and that the

chain is in the groove on the bar.

8. Fit the clutch cover and insert the adjusting

pin in the cut-out in the bar.

9. Tighten the bar nut finger-tight.

10. Tension the chain by turning the chain

tensioning screw clockwise using the

combination tool. The chain is correctly

tensioned when it does not sag from the

underside of the bar, but can still be turned

easily by hand.

4. An adjusting pin and screw is used to adjust

the tension of the chain. It is very important

when assembling the bar that the adjusting

pin located on the adjusting screw aligns

into a hole in the bar. Turning the screw will

move the adjusting pin up and down the

screw. Locate this adjusting pin before you

begin mounting the bar onto the saw. See

following illustration.

5. Turn the adjusting screw by hand

counterclockwise until the adjusting pin is

positioned between the indicator marks (B)

on the clutch cover. This should allow the

adjusting pin to be near the correct position.

6. Slide guide bar with chain on bar bolts until

guide bar stops against clutch drum

11. Hold up the bar tip and tighten the bar nuts

with the combination tool.

When fitting a new chain, the chain tension has

to be checked frequently until the chain is runin. Check the chain tension regularly. A

correctly tensioned chain ensures good cutting

performance and long life.

8

Page 9

HELPFUL TIP

During storage of your fuel

mixture, the oil will

separate from the gasoline.

Shake the fuel can weekly

to insure proper blending of

the gasoline and oil.

STARTING AND STOPPING

PRE-OPERATION INSPECTION

Perform the following steps before every use of

the machine:

Check fuel mixture level

Check bar lubrication

Check chain sharpness

NOTE: Chain sharpening is a complicated task

that requires special tools. We recommend that

you refer chain sharpening to a professional

chain sharpener.

Check chain tension

Inspect and clean the guide bar

Check for damaged parts

Check for loose caps

Check for loose fasteners

Check for loose parts

Check for fuel and oil leaks

NOTE: It is normal for a small amount of oil to

appear under the saw after the engine stops.

Do not confuse this with a leaking oil tank.

FUELING THE ENGINE

WARNING: Be sure to read the fuel

handling information in the safety rules

section of this manual before you begin.

If you do not understand the fuel

handling information do not attempt to

fuel your unit. Seek help from someone

that does understand the information or

call the consumer assistance help line.

WARNING: Remove the fuel cap

slowly when fueling.

This equipment is designed to operate on

unleaded gasoline with a minimum 87 octane

(R+M/2 method), with ethanol blended up to

10% maximum by volume (E-10).

Before operation, gasoline must be mixed with

a good quality full synthetic 2-cycle air-cooled

engine oil designed to be mixed at a ratio of

50:1.

A 50:1 ratio is obtained by mixing 2.6 fluid

ounces of full synthetic oil with 1 gallon of

unleaded gasoline. DO NOT USE automotive

oil or marine oil. These oils will cause engine

damage.

When mixing fuel, follow the instructions printed

on the container. Once the oil is added to the

gasoline, shake the container momentarily to

assure that the fuel is thoroughly mixed.

Fill the fuel tank completely with properly mixed

fuel.

Always read and follow the safety rules relating

to fuel before fueling your unit.

Purchase fuel in quantities that can be used

within 30 days to assure fuel freshness.

CAUTION: Never use unmixed gasoline in your

unit. This will cause permanent engine damage

and void the limited warranty.

CAUTION: Do not use alternate fuels such as

ethanol blends above 10% by volume (E-15, E-

85) or any methanol blended fuel. Use of these

fuels can cause major engine performance

problems and void the limited warranty.

BAR AND CHAIN LUBRICATION

The bar and chain require continuous

lubrication. Lubrication is provided by the

automatic oiler system when the oil tank is kept

filled. Lack of oil will quickly ruin the bar and

chain. Too little oil will cause overheating

shown by smoke coming from the chain and/or

discoloration of the bar. In freezing weather oil

will thicken, making it necessary to thin bar and

chain oil with a small amount (5 to 10%) of #1

diesel fuel or kerosene. Bar and chain oil must

be free flowing for the oil system to pump

enough oil for adequate lubrication.

If bar and chain oil is not available, use a good

grade SAE 30 oil.

Fill the oil tank completely with oil.

CAUTION: Never use waste oil for bar and

chain lubrication.

CAUTION: Always stop the engine before

removing the oil cap.

STARTING POSITION

1. Lay the chainsaw on a

flat surface. The cutting

attachment must not be

in contact with the

ground.

2. Lock the chain brake by

pushing forward on the

handguard.

3. Place your left hand on

the handlebar and your

right hand on the starter rope. Push your

right foot into the rear handle to stabilize the

chainsaw.

4. Follow the starting instructions.

9

Page 10

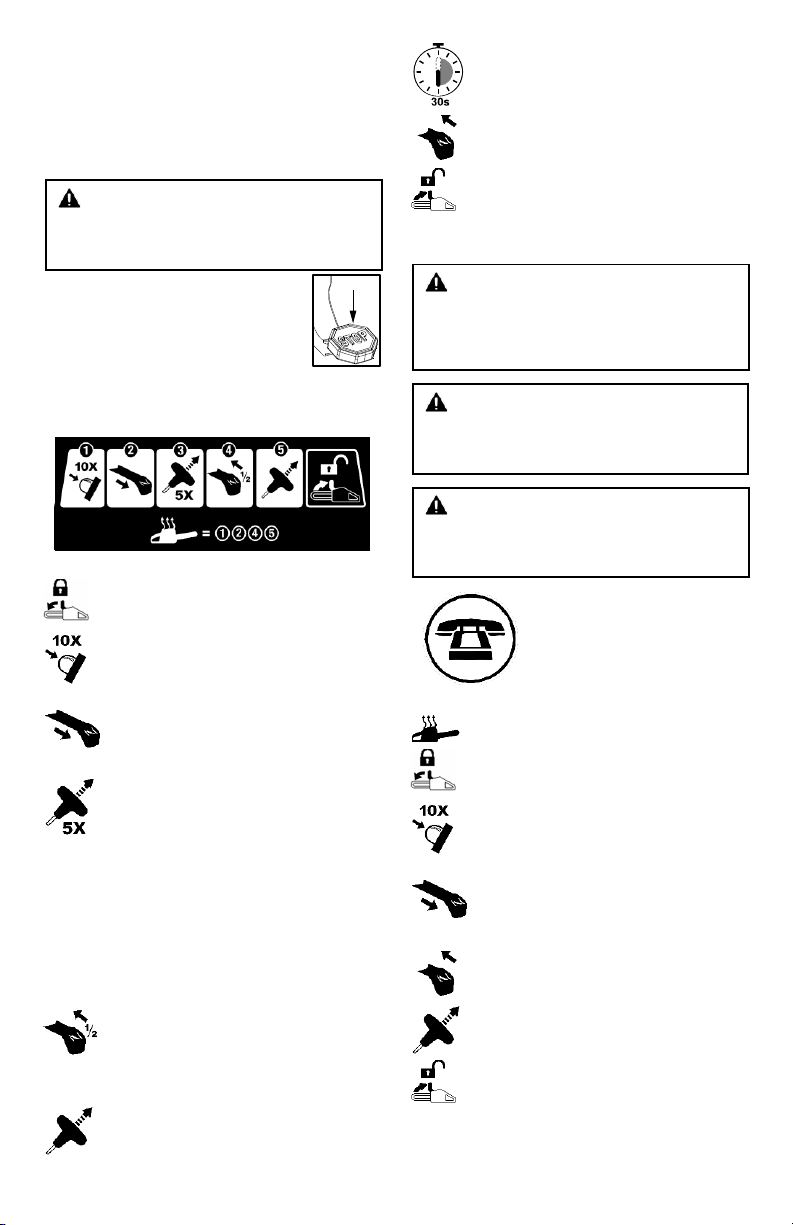

STOPPING THE CHAIN

Before starting, push the front hand

guard toward guide bar to lock chain

brake.

Press the primer (air purge) bulb 10

times until fuel begins to fill the bulb.

The primer (air purge) bulb does not

need to be completely filled.

Pull the blue choke lever to the FULL

CHOKE position. The red ON/STOP

switch will be switched automatically to

the ON position.

Using your right hand, pull the starter

rope until the machine attempts to

start, or a maximum of 5 times.

NOTE: This unit has the SIMPUL+ starting

system. You do not have to pull the starter rope

handle sharply or briskly.

NOTE: If the engine sounds as if it is trying to

start before the fifth pull, stop pulling and

immediately proceed to the next step.

NOTE: Do not attempt to cut material with the

choke/fast idle lever in the FULL CHOKE

position.

Push the blue choke lever to the HALF

CHOKE position.

NOTE: In temperatures above 90°F

(32°C), push the blue choke lever

completely in.

Pull the starter rope sharply with your

right hand until the engine starts.

Allow the engine to run for 30 seconds.

Push the blue choke lever completely

in.

Before accelerating to full throttle, pull

the front hand guard towards the front

handle. The chain brake is now

unlocked. Your chainsaw is now ready

for use.

HELPFUL TIP

If your engine still does not

start after following the

instructions, contact

consumer assistance.

Before starting, push the front hand

guard toward guide bar to lock chain

brake.

Press the primer (air purge) bulb 10

times until fuel begins to fill the bulb.

The primer (air purge) bulb does not

need to be completely filled.

Pull the blue choke lever to the FULL

CHOKE position. The red ON/STOP

switch will be switched automatically to

the ON position.

Push the blue choke lever completely

in.

Pull the starter rope with your right

hand until the engine starts.

Before accelerating to full throttle, pull

the front hand guard towards the front

handle. The chain brake is now

unlocked. Your chainsaw is now ready

for use.

To stop the chain, release the throttle trigger.

The chain will stop moving, but the engine will

continue to run.

Wait until the chain has completely stopped

before setting down the chainsaw or carrying it

to another location.

WARNING: NEVER touch the chain if

it is still moving! Even a very slowly

moving chain can inflict severe cuts to

hands and fingers.

STOPPING THE ENGINE

Press the red stop switch to stop

the engine.

STARTING THE ENGINE

Follow these instructions to start your

chainsaw. Your chainsaw has a starting

reminder decal similar to the one shown below:

Starting A Cold Engine

WARNING: The chain must not move

when the engine runs at idle speed. If

the chain moves at idle speed refer to

CARBURETOR ADJUSTMENT within this

manual.

WARNING: Do not attempt to throw

or drop-start the chainsaw. Doing so will

put the operator at risk of serious injury

due to loss of control of the chainsaw.

WARNING: The muffler is very hot

during and after use. Do not touch the

muffler or allow combustible material

such as dry grass or fuel to do so.

Starting A Warm Engine

10

Page 11

NOTE: If the product does not restart, the

problem could be overheated fuel.

To fix this problem, try the following procedure:

1. Set the product in a cool area away from

direct sunlight.

2. Allow the product to cool for at least 20

minutes.

3. Press primer (air purge) bulb repeatedly for

10-15 seconds.

4. Follow the cold starting procedure.

Repeat this procedure if the problem still exists.

NOTE: Always use fresh seasonal fuel and

shorten operation time during unseasonably

warm weather.

Starting A Flooded Engine

The engine may be flooded with too much fuel

if it has not started after 10 pulls.

Flooded engines can be restarted by pushing

the blue choke lever in completely to the OFF

CHOKE position and then following the warm

engine starting procedure listed above. Ensure

the red ON/STOP switch is in the ON position.

Starting could require pulling the starter rope

handle many times depending on how badly

the unit is flooded. If the engine fails to start,

refer to the TROUBLESHOOTING TABLE or

call the consumer assistance help line.

CHAIN TENSION

It is normal for a new chain to stretch during the

first 15 minutes of operation. You should check

your chain tension each time before you start

the chainsaw. See the chain tensioning

instructions in the ASSEMBLY section.

WARNING: If the saw is operated

with a loose chain, the chain could jump

off the guide bar and result in serious

injury to the operator and/or damage the

chain, making it unusable.

CHECKING THE CHAIN BRAKE

The chain brake must be checked before each

use. The engine must be running when

performing this procedure.

This is the only instance when the saw should

be placed on the ground with the engine

running.

1. Place the saw on firm ground.

2. Grip the rear handle with your right hand

and the front handle with your left hand.

3. Apply full throttle by fully depressing the

throttle trigger.

4. Activate the chain by turning your left wrist

to contact the front hand guard without

releasing your grip around the front handle.

The chain should stop immediately.

CHECKING THE INERTIA ACTIVATING

FUNCTION CONTROL

WARNING: When performing the

following procedure, the engine must be

turned off.

1. Grip the rear handle with your right hand

and the front handle with your left hand.

2. Hold the chainsaw approximately 16-18

inches (40-45 centimeters) above a stump

or other wooden surface.

3. Release your grip on the front handle and

use the weight of the saw to let the tip of the

guide bar fall forward and contact the stump.

When the tip of the bar hits the stump, the

brake should activate as observed by the

front hand guard snapping forward toward

the guide bar.

WORKING TECHNIQUES

PRACTICING YOUR CUTS

Practice cutting a few small logs using the

following techniques to get the “feel” of using

your saw before you begin a major sawing

operation.

Squeeze the throttle trigger and allow the

engine to reach full speed before cutting.

Begin cutting with the saw frame against the

log.

Keep the engine at full speed the entire time

you are cutting.

Allow the chain to cut for you. Exert only light

downward pressure. If you force the cut,

damage to the guide bar, chain, or engine

can result.

Release the throttle trigger as soon as the cut

is completed, allowing the engine to idle. If

you run the saw at full throttle without a

cutting load, unnecessary wear can occur to

the chain, guide bar, and engine. It is

recommended that the engine not be

operated for longer than 30 seconds at full

throttle.

To avoid losing control when cut is complete,

do not put pressure on saw at end of cut.

Stop the engine before setting the saw down

after cutting.

11

Page 12

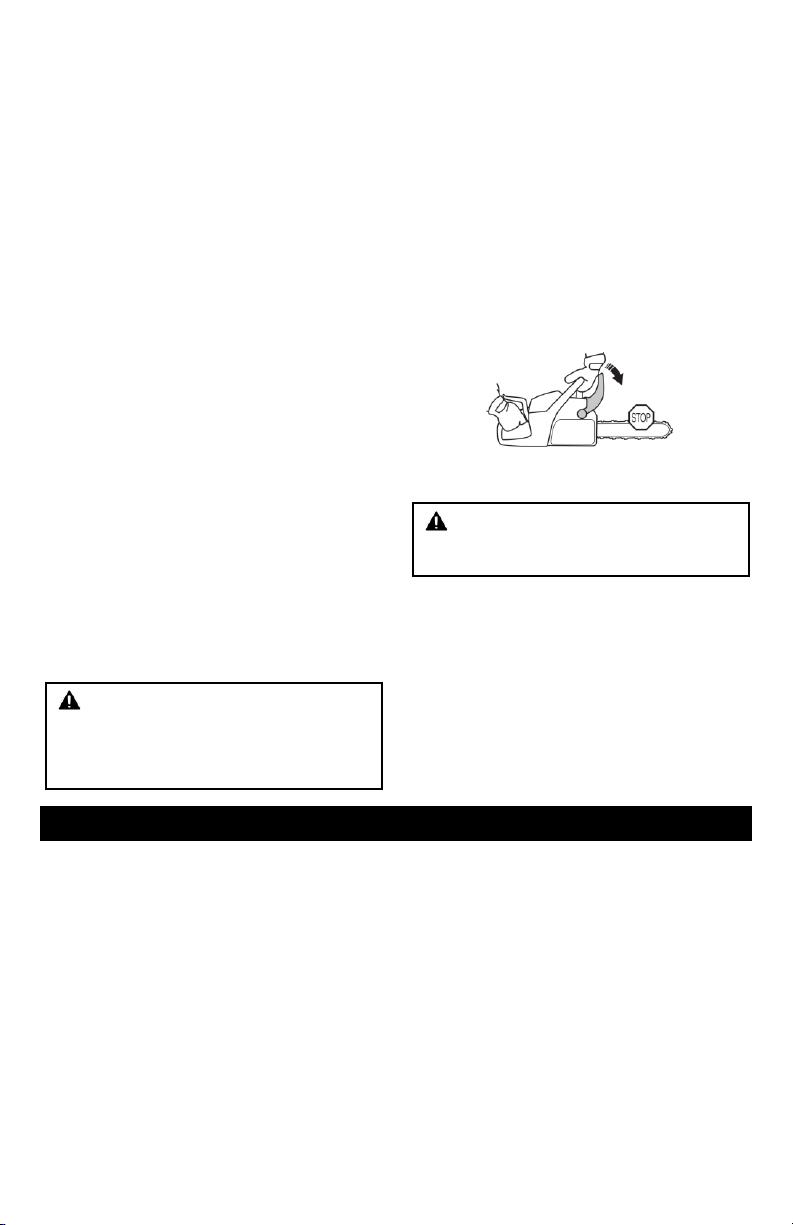

FELLING A TREE

Re trea t path

Retreat path

Danger z one

Da

n

g

e

r

z

o

n

e

D

a

n

g

e

r

z

o

n

e

Felling direction

1

2

1

2

1

3

Planning

WARNING: Check for broken or dead

branches which can fall while cutting

causing serious injury. Do not cut near

buildings or electrical wires if you do not

know the direction of tree fall, nor cut at

night since you will not be able to see

well, nor during bad weather such as

rain, snow, or strong winds, etc. If the

tree makes contact with any utility line,

the utility company should be notified

immediately.

Carefully plan your sawing operation in

advance.

Clear the work area. You need a clear area all

around the tree so you can have secure

footing.

The chainsaw operator should keep on the

uphill side of the terrain as the tree is likely to

roll or slide downhill after it is felled.

Study the natural conditions that can cause the

tree to fall in a particular direction.

Natural conditions that can cause a tree to fall

in a particular direction include:

The wind direction and speed.

The lean of the tree. The lean of a tree might

not be apparent due to uneven or sloping

terrain. Use a plumb or level to determine the

direction of tree lean.

Weight and branches on one side.

Surrounding trees and obstacles.

Look for decay and rot. If the trunk is rotted, it

can snap and fall toward the operator. Check

for broken or dead branches which can fall on

you while cutting.

Make sure there is enough room for the tree to

fall. Maintain a distance of 2-1/2 tree lengths

from the nearest person or other objects.

Engine noise can drown out a warning call.

Using The Notch Method

The notch method is used to fell large trees. A

notch is cut on the side of the tree in the

desired direction of fall. After a felling cut is

made on the opposite side of tree, the tree will

tend to fall into the notch.

NOTE: If the tree has large buttress roots,

remove them before making the notch. If using

saw to remove buttress roots, keep saw chain

from contacting ground to prevent dulling of the

chain.

Make the notch cut by cutting the top of the

notch first. Cut through 1/3 of the diameter of

the tree. Next complete the notch by cutting the

bottom of the notch. Once the notch is cut

remove the notch of wood from the tree.

After removing the wood from the notch, make

the felling cut on the opposite side of the notch.

This is done by making a cut about two inches

(5 cm) higher than the center of the notch. This

will leave enough uncut wood between the

felling cut and the notch to form a hinge. This

hinge will help prevent the tree from falling in

the wrong direction.

Remove dirt, stones, loose bark, nails, staples,

and wire from the tree where cuts are to be

made.

Plan a clear retreat path to the rear and

diagonal to the line of fall. Note the danger

zone (1), retreat path (2), and felling direction

(3) in the following diagram.

NOTE: Before felling cut is complete, use

wedges to open the cut if necessary to

control the direction of fall. To avoid

kickback and chain damage, use wood or

12

Page 13

plastic wedges, but never steel or iron

wedges.

Be alert to signs that the tree is ready to fall:

cracking sounds, widening of the felling cut, or

movement in the upper branches.

As tree starts to fall, stop saw, put it down, and

get away quickly on your planned retreat path.

DO NOT cut down a partially fallen tree with

your saw. Be extremely cautious with partially

fallen trees that may be poorly supported.

When a tree doesn’t fall completely, set the

saw aside and pull down the tree with a cable

winch, block and tackle, or tractor.

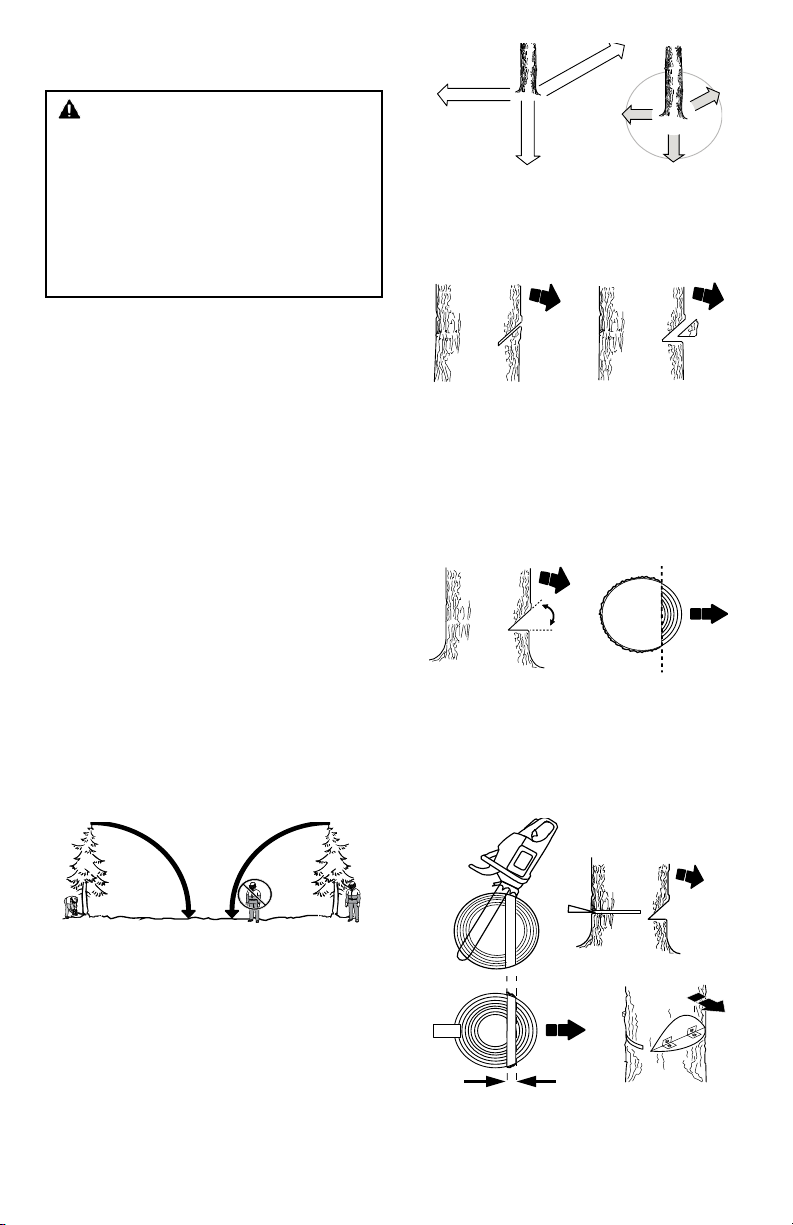

CUTTING A FALLEN TREE (BUCKING)

Bucking is the term used for cutting a fallen tree

to the desired log size.

WARNING: Do not stand on the log

being cut. Any portion can roll causing

loss of footing and control. Do not stand

downhill of the log being cut.

Important Points

Cut only one log at a time.

Cut shattered wood very carefully; sharp

pieces of wood could be flung toward

operator.

Use a sawhorse to cut small logs. Never

allow another person to hold the log while

cutting and never hold the log with your leg or

foot.

Do not cut in an area where logs, limbs, and

roots are tangled such as in a blown down

area. Drag the logs into a clear area before

cutting by pulling out exposed and cleared

logs first.

Make sure the chain will not strike the ground

or any other object during or after cutting.

Types Of Bucking Cuts

Overcutting begins on the top side of the log

with the bottom of the saw against the log.

When overcutting use light downward pressure.

Undercutting involves cutting on the underside

of the log with top of saw against the log. When

undercutting use light upward pressure. Hold

saw firmly and maintain control. The saw will

tend to push back toward you.

WARNING: Never turn saw upside

down to undercut. The saw cannot be

controlled in this position.

Always make your first cut on the compression

side of the log. The compression side of the log

is where the pressure of the log’s weight is

concentrated.

WARNING: If saw becomes pinched

or hung in a log, don’t try to force it out.

You can lose control of the saw resulting

in injury and/or damage to the saw. Stop

the saw, drive a wedge of plastic or

wood into the cut until the saw can be

removed easily. Restart the saw and

carefully reenter the cut. To avoid

kickback and chain damage, do not use

a metal wedge. Do not attempt to restart

your saw when it is pinched or hung in a

log.

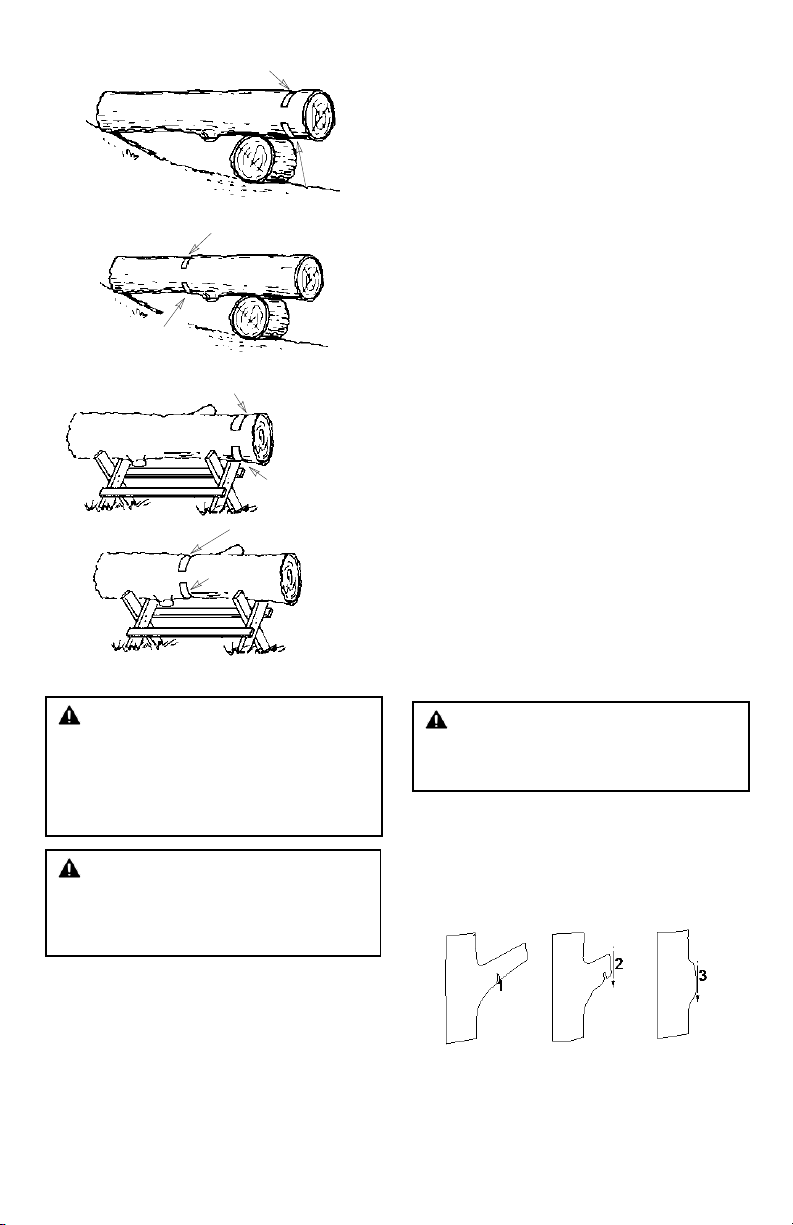

Bucking Without A Support

1. Overcut through 1/3 of the diameter of the

log.

2. Roll the log over and finish with a second

overcut.

NOTE: Watch for logs with a compression side

to prevent the saw from pinching.

Bucking Using A Log Or Support Stand

1. Make the first cut on the compression side

of the log. Your first cut should extend 1/3 of

the diameter of the log.

2. Finish with your second cut.

13

Page 14

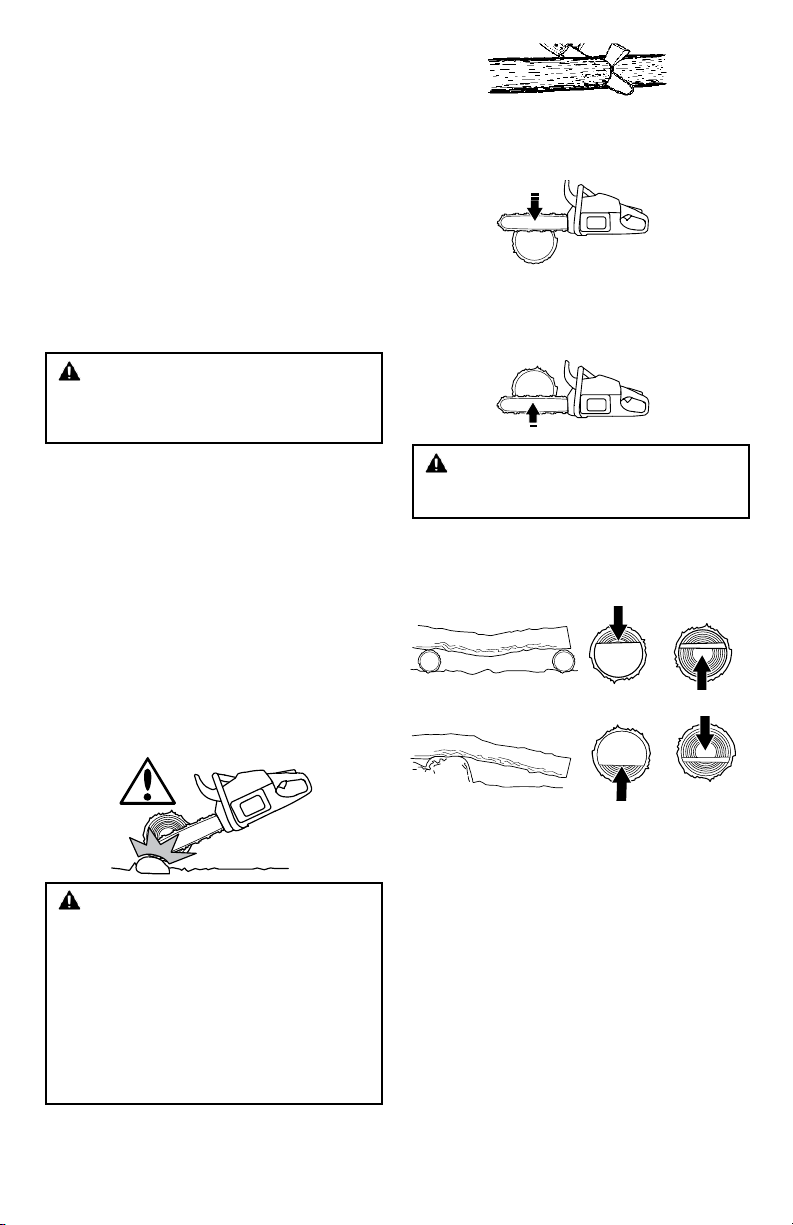

LIMBING AND PRUNING

1

2

1

2

1

2

1

2

WARNING: Be alert for and guard

against kickback. Do not allow the

moving chain to contact any other

branches or objects at the nose of the

guide bar when limbing or pruning.

Allowing such contact can result in

serious injury.

WARNING: Never climb into a tree to

limb or prune. Do not stand on ladders,

platforms, a log, or in any position

which can cause you to lose your

balance or control of the saw.

Important Points

Work slowly, keeping both hands firmly

gripped on the saw. Maintain secure footing

and balance.

Watch out for springpoles. Springpoles are

small size limbs which can catch the saw

chain and whip toward you or pull you off

balance. Use extreme caution when cutting

small size limbs or slender material.

Be alert for springback. Watch out for

branches that are bent or under pressure.

Avoid being struck by the branch or the saw

when the tension in the wood fibers is

released.

Keep a clear work area. Frequently clear

branches out of the way to avoid tripping over

them.

Limbing

Always limb a tree after it is cut down. Only

then can limbing be done safely and properly.

Leave the larger limbs underneath the felled

tree to support the tree as you work.

Start at the base of the felled tree and work

toward the top, cutting branches and limbs.

Remove small limbs with one cut.

Keep the tree between you and the chain. Cut

from the side of the tree opposite the branch

you are cutting.

Remove larger, supporting branches with the

cutting techniques described in BUCKING

WITHOUT A SUPPORT.

Always use an overcut to cut small and freely

hanging limbs. Undercutting could cause limbs

to fall and pinch the saw.

Pruning

WARNING: Limit pruning to limbs

shoulder height or below. Do not cut if

branches are higher than your shoulder.

Get a professional to do the job.

1. Make the first cut one-third of the way

through the bottom of the limb.

2. Make the second cut all the way through

the limb.

3. Make the third overcut leaving a 1 to 2 inch

(2.5 to 5 cm) collar from the trunk of the tree.

14

Page 15

MAINTENANCE

GENERAL RECOMMENDATIONS

WARNING: Disconnect the spark

plug before performing maintenance

except for carburetor adjustments.

The warranty on this unit does not cover items

that have been subjected to operator abuse or

negligence. To receive full value from the

warranty, the operator must maintain the unit

as instructed in this manual. Various

adjustments will need to be made periodically

to properly maintain your unit.

Have all repairs other than the recommended

maintenance described in the instruction

manual performed by a Sears or other qualified

service dealer. It is your responsibility to

maintain and perform general maintenance.

MAINTENANCE SCHEDULE

Daily

Check fuel mixture level

Check bar lubrication

Check chain sharpness

NOTE: Chain sharpening is a complicated task

that requires special tools. We recommend that

you refer chain sharpening to a professional

chain sharpener.

Check chain tension

Inspect and clean the guide bar

Check for damaged parts

Check for loose caps

Check for loose fasteners

Check for loose parts

Check for fuel and oil leaks

Every 5 hours*

Inspect and clean air filter

Inspect and clean chain brake

Inspect and clean guide bar

Every 25 hours*

Inspect and clean spark arresting screen and

muffler

Yearly

Replace spark plug

Replace fuel filter

Replace air filter

* Each hour of operation is approximately 2

tanks of fuel.

CHAIN

WARNING: Improper chain

sharpening techniques and/or depth

gauge maintenance will increase the

chance of kickback which can result in

serious injury.

WARNING: Wear protective gloves

when handling chain. The chain is sharp

and can cut you even when it is not

moving.

Conditions which indicate the need for chain

sharpening:

Reduction in size of wood chips.

The size of the wood chip will decrease as

the chain gets duller until it becomes more

like a powder than a chip. Note that dead or

rotted wood will not produce a good chip.

Saw cuts to one side or at an angle.

Saw has to be forced through the cut.

Tools required:

5/32 inch (4 mm) diameter round file and

filing guide

Flat file

Depth gauge tool

To sharpen chain:

1. Move ON/STOP switch to the STOP

position.

2. Check chain for proper tension. Adjust chain

tension if necessary. See CHAIN TENSION

section.

3. Sharpen cutters.

To sharpen the cutters, position the filing

guide level (90°) so that it rests on the top

edges of the cutter and depth gauge.

NOTE: The chain has both left and right hand

cutters.

Align the 30° filing guide marks parallel with

the bar and to the center of the chain.

15

Page 16

Sharpen cutters on one side of the chain first.

File from the inside of each cutter to the

outside. Then, turn the chain saw around and

repeat the process for the other side of the

chain.

File on the forward stroke only. Use 2 or 3

strokes per cutting edge.

Keep all cutters the same length when filing.

File enough to remove any damage to cutting

edges (side plate and top plate of cutter).

File chain to meet the specifications as

shown.

NOTE: The very top of the depth gauge should

be flat with the front half rounded off with a flat

file.

GUIDE BAR

Conditions which require guide bar

maintenance:

Saw cuts to one side or at an angle.

Saw has to be forced through the cut.

Inadequate supply of oil to bar/chain.

Check the condition of guide bar each time

chain is sharpened. A worn guide bar will

damage the chain and make cutting difficult.

After each use, ensure ON/STOP switch is in

the STOP position, then clean all sawdust from

the guide bar and sprocket hole.

To maintain guide bar:

1. Move ON/STOP switch to STOP.

2. Loosen and remove bar nuts and clutch

cover. Remove bar and chain from saw.

3. Clean the oil holes (A) and bar groove (B).

WARNING: Maintain the proper hook

angle according to the manufacturer’s

specifications for the chain you are

using. Improper hook angle will increase

the chance of kickback which can result

in serious injury.

4. Check and lower depth gauges.

Place gauge tool on cutter.

If the depth gauge is higher than the depth

gauge tool, file it level to the top of the depth

gauge tool.

Maintain rounded front corner of depth gauge

with a flat file.

4. Burring of guide bar rails is a normal

process of rail wear. Remove these burrs

with a flat file.

5. When rail top is uneven, use a flat file to

restore square edges and sides.

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when

excess heating or burring of the rails occurs. If

replacement is necessary, use only the guide

bar specified for your saw in the repair parts list

or on the decal located on the chainsaw.

INSPECT AND CLEAN THE UNIT AND

DECALS

After each use, inspect complete unit for loose

or damaged parts. Clean the unit and decals

using a damp cloth with a mild detergent.

Wipe off unit with a clean dry cloth.

CHECK THE CHAIN BRAKE

See CHAIN BRAKE in the OPERATION

section.

MUFFLER

As the unit is used, carbon deposits build up on

the muffler and spark arresting screen, and

16

Page 17

must be removed to avoid creating a fire

hazard or affecting engine performance.

Replace the spark arresting screen if breaks

occur.

1. Loosen and remove the nut (A) from the

exhaust outlet cover (B).

2. Remove the exhaust outlet cover.

3. Remove the spark arresting screen (C).

Handle the screen carefully to prevent

damage.

4. Clean the spark arresting screen gently with

a wire brush. Replace screen if breaks are

found.

5. Replace any broken or cracked muffler

parts.

6. Reinstall spark arresting screen, exhaust

outlet cover, and nut. Tighten nut securely to

25-35 in-lb.

SPARK PLUG

NOTE: For models sold in Canada, the spark

ignition system complies with the Canadian

standard ICES-002.

1. Loosen the three screws (A) on the cylinder

cover (B).

2. Remove the cylinder cover.

3. Pull off the spark plug boot (C).

4. Remove spark plug (D) from the cylinder

and discard.

5. Install a new spark plug and tighten securely

with a 3/4 inch (19 mm) socket wrench to

15-25 ft-lb. The spark plug gap should be

0.025 inch (0,6 mm).

6. Reinstall the spark plug boot.

7. Reinstall the cylinder cover and the three

screws. Tighten securely to 13-18 in-lb.

FUEL FILTER

To replace fuel filter, drain your unit by running

it dry of fuel. Remove fuel cap and its

connected retainer from tank. Pull filter from

tank and remove from line. Replace and

reassemble.

AIR FILTER

CAUTION: Do not clean filter in gasoline or

other flammable solvent to avoid creating a fire

hazard or producing evaporative emissions.

A dirty air filter decreases the life and

performance of the engine and increases fuel

consumption and exhaust emissions. Always

clean your air filter according to the

maintenance schedule. Clean more frequently

in dusty conditions.

A used air filter can never be completely

cleaned. It is advisable to replace your air filter

with a new one according to the maintenance

schedule.

1. Loosen the three screws (A) on the cylinder

cover (B).

2. Remove the cylinder cover.

3. Remove the air filter cover (C) and air filter

(D).

4. Clean the air filter using hot soapy water.

Rinse with clean cool water. Air dry

completely before reinstalling.

5. Reinstall the air filter and air filter cover.

6. Reinstall the cylinder cover and three

screws. Tighten securely to 13-18 in-lb.

17

Page 18

CARBURETOR ADJUSTMENT

WARNING: The chain will be moving

during most of this procedure. Wear

your protective equipment and observe

all safety precautions. The chain must

not move at idle speed.

Indications for idle speed adjustment:

The carburetor has been carefully set at the

factory. Adjustments may be necessary if you

notice any of the following conditions:

The chain moves at idle. See IDLE SPEED-T

ADJUSTMENT procedure.

The saw will not idle. See IDLE SPEED-T

ADJUSTMENT procedure.

Idle speed-T adjustment:

Allow the engine to idle. If the chain moves, the

idle is too fast. If the engine stalls, the idle is

too slow.

Adjust the speed until the engine runs without

chain movement (idle too fast) or stalling (idle

too slow).

The idle speed screw is located in the area

above the primer (air purge) bulb and is labeled

“T”.

Turn the idle speed screw (T) clockwise to

increase the engine speed.

Turn the idle speed screw (T) counterclockwise

to decrease the engine speed.

STORAGE

WARNING: Stop the engine and

allow it to cool. Secure the unit before

storing or transporting it in a vehicle.

Store the unit and fuel in an area where

fuel vapors cannot reach sparks or open

flames from water heaters, electric

motors, switches, furnaces, etc.

WARNING: Store the unit with all

guards in place. Position so that any

sharp object cannot accidentally cause

injury to passersby. Store the unit out of

reach of children.

Before storing, drain all fuel from the unit.

Start the engine and allow it to run until it

runs completely out of fuel.

Clean the unit before storing. Pay particular

attention to the air intake area, keeping it free

of debris. Use a mild detergent and sponge to

clean the plastic surfaces.

Ensure the machine is cleaned and that a

complete service is carried out before longterm storage.

The guide bar and chain should be covered

with a scabbard when the machine is being

transported or in storage in order to prevent

accidental contact with the sharp chain. Even

a non-moving chain can cause serious cuts

to yourself or others that make contact with

an exposed chain.

CAUTION: It is important to prevent gum

deposits from forming in essential fuel system

parts such as the carburetor, fuel filter, fuel

hose, or fuel tank during storage. Alcohol

blended fuels (called gasohol) or using ethanol

or methanol can attract moisture which leads to

fuel mixture separation and formation of acids

during storage. Acidic gas can damage the

engine.

18

Page 19

CAUSE

REMEDY

1. Ignition switch

off.

See “STARTING” in the STARTING AND STOPPING

section.

2. Engine

flooded.

See “Starting a Flooded Engine”

in

the

OPERATION

section.

3. Fuel tank

empty.

Fill tank with correct fuel

mixture. See “FUELING

THE ENGINE” in the STARTING AND STOPPING

section.

4. Spark plug not

firing.

Install new spark

plug. See “SPARK PLUG” in the

MAINTENANCE section.

5. Fuel not reaching carburetor.

Check for dirty fuel filter;

replace.

Check for kinked or split fuel

line. For r

epair or

replacement, contact a Sears or other qualified

service dealer.

CAUSE

REMEDY

1. Idle speed r equi res adjustment.

See “CARBURETOR ADJUSTMENT” in

the

MAINTENANCE Section.

2. Carburetor requires adjustment.

Contact a Sears or other qualified service dealer.

CAUSE

REMEDY

1. Air filter

dirty.

Clean or replace air

filter.

2. Spark plug

fouled.

Clean or replace plug and

regap.

3. Chain brake

locked.

Unlock chain

brake. See “STARTING POSITION”

in the STARTING AND STOPPING section.

4. Carburetor requires adjustment.

Contact a Sears or other qualified service dealer.

CAUSE

REMEDY

1. Too much oil mixed with gasoline.

Empty fuel tank and refill with correct fuel

mixture.

CAUSE

REMEDY

1. Idle speed r e qu ir es adjustment.

2. Clutch requires

repair.

See “CARBURETOR ADJUSTMENT” in

the

MAINTENANCE Section.

Contact a Sears or other qualified service dealer.

TROUBLESHOOTING

WARNING: Always stop the unit and disconnect the spark plug before performing all

of the recommended remedies below except remedies that require operation of the unit.

TROUBLE: Engine will not start or will run only a few seconds after starting.

TROUBLE: Engine will not idle properly.

TROUBLE: Engine will not accelerate, lacks

TROUBLE: Engine smokes excessively.

TROUBLE: Chain moves at idle

speed.

power,

or dies under a

load.

19

Page 20

TECHNICAL DATA

Model

Guide Bar

Chain

CKA without

chain brake

Part No.

Length (in/cm)

358.740160

586514501

16/40

UC83G 56DL

45°

358.740180

580678801

18/45

UC83G 62DL

45°

Type

In

In (mm)

In (mm) ° ° ° In (mm)

In (mm) : dl

UC83G

0,375

0,050 (1,3)

5/32 (4,0)

85°

30

0

0,025 (0,65)

16 (40) : 56

18 (45) : 62

The computed kickback angle (CKA) listed on your saw and listed in the CKA table below

represents angle of kickback your bar and chain combinations will have when tested in accordance

with CSA (Canadian Standards Association) and ANSI standards. When purchasing replacement

bar and chain, considerations should be given to the lower CKA values. Lower CKA values

represent safer angles to the user, higher values indicate more angle and higher kick energies.

Computed angles represented indicate total energy and angle associated without activation of the

chain brake during kickback. Activated angle represents chain stopping time relative to activation

angle of chain break and resulting kick angle of saw. In all cases lower CKA values represent a

safer operating environment for the user.

The following guide bar and chain combinations meet kickback requirements of CSA Standards

Z62.1, Z62.3, & ANSI B175.1 when used on saws listed in this manual. Use of bar and chain

combinations other than those listed is not recommended and may not meet the CKA requirements

per standard.

EMISSION CONTROL WARRANTY STATEMENT

IMPORTANT: This product is compliant with U.S. EPA Phase 3 regulations for exhaust and

evaporative emissions. To ensure EPA Phase 3 compliance, we recommend using only genuine

replacement parts. Use of non-compliant replacement parts is a violation of federal law.

YOUR WARRANTY RIGHTS AND OBLIGATIONS: The U.S. Environmental Protection Agency,

California Air Resources Board, Environment Canada and Sears Brands Management

Corporation, U.S.A. (Sears) are pleased to explain the emissions control system warranty on your

year 2017 and later off-road engine. In California, all small off-road engines must be designed, built,

and equipped to meet the State’s stringent anti-smog standards. Sears must warrant the emission

control system on your small off-road engine for the periods of time listed below provided there has

been no abuse, neglect, or improper maintenance of your small off-road engine.

Your emission control system includes parts such as the carburetor, the ignition system and the fuel

tank, line, and cap. Where a warrantable condition exists, Sears will repair your small off-road

engine at no cost to you. Expenses covered under warranty include diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE: If any emissions related part on your engine (as

listed under Emissions Control Warranty Parts List) is defective or a defect in the materials or

workmanship of the engine causes the failure of such an emission related part, the part will be

repaired or replaced by Sears.

OWNER’S WARRANTY RESPONSIBILITIES: As the small off-road engine owner, you are

responsible for the performance of the required maintenance listed in your instruction manual.

Sears recommends that you retain all receipts covering maintenance on your small off-road engine,

but Sears cannot deny warranty solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance. As the small off-road engine owner, you should be

aware that Sears may deny you warranty coverage if your small off-road engine or a part of it has

failed due to abuse, neglect, improper maintenance, unapproved modifications, or the use of parts

not made or approved by the original equipment manufacturer. You are responsible for presenting

your small off-road engine to a Sears authorized repair center as soon as a problem exists.

Warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If

you have any questions regarding your warranty rights and responsibilities, you should contact your

nearest authorized service center.

Call Sears at 1-888-331-4569 or send e-mail correspondence to emissions@husqvarnagroup.com.

20

Page 21

WARRANTY COMMENCEMENT DATE: The warranty period begins on the date the small off-road

engine is purchased.

LENGTH OF COVERAGE: This warranty shall be for a period of two years from the initial date of

purchase, or until the end of the product warranty (whichever is longer).

WHAT IS COVERED: REPAIR OR REPLACEMENT OF PARTS. Repair or replacement of any

warranted part will be performed at no charge to the owner at an approved Sears servicing center.

If you have any questions regarding your warranty rights and responsibilities, you should contact

your nearest authorized service center.

Call Sears at 1-888-331-4569 or send e-mail correspondence to emissions@husqvarnagroup.com.

WARRANTY PERIOD: Any warranted part which is not scheduled for replacement as required

maintenance, or which is scheduled only for regular inspection to the effect of “repair or replace as

necessary” shall be warranted for 2 years. Any warranted part which is scheduled for replacement

as required maintenance shall be warranted for the period of time up to the first scheduled

replacement point for that part.

DIAGNOSIS: The owner shall not be charged for diagnostic labor which leads to the determination

that a warranted part is defective if the diagnostic work is performed at an approved Sears

servicing center.

CONSEQUENTIAL DAMAGES: Sears may be liable for damages to other engine components

caused by the failure of a warranted part still under warranty.

WHAT IS NOT COVERED: All failures caused by abuse, neglect, or improper maintenance are not

covered.

ADD-ON OR MODIFIED PARTS: The use of add-on or modified parts can be grounds for

disallowing a warranty claim. Sears is not liable to cover failures of warranted parts caused by the

use of add-on or modified parts.

HOW TO FILE A CLAIM: If you have any questions regarding your warranty rights and

responsibilities, you should contact your nearest authorized service center.

Call Sears at 1-888-331-4569 or send e-mail correspondence to emissions@husqvarnagroup.com.

WHERE TO GET WARRANTY SERVICE: Warranty services or repairs shall be provided at all

Sears service centers. Call Sears at 1-888-331-4569 or send e-mail correspondence to

emissions@husqvarnagroup.com.

MAINTENANCE, REPLACEMENT AND REPAIR OF EMISSION RELATED PARTS: Any Sears

approved replacement part used in the performance of any warranty maintenance or repair on

emission related parts will be provided without charge to the owner if the part is under warranty.

EMISSION CONTROL WARRANTY PARTS LIST: Carburetor, air filter (covered up to maintenance

schedule), ignition system: spark plug (covered up to maintenance schedule), ignition module,

muffler including catalyst (if equipped), fuel tank, line, and cap.

MAINTENANCE STATEMENT: The owner is responsible for the performance of all required

maintenance as defined in the instruction manual.

This engine is certified to be emissions compliant for the following use: 50 hours

21

Page 22

TABLA DE MATERIAS

Garantía ....................................................... 22

Identificación de símbolos ............................. 23

Seguridad ..................................................... 24

Aprenda su producto .................................... 28

Armado ......................................................... 29

Arranque y parada ........................................ 30

Técnicas de trabajo ...................................... 33

Mantenimiento............................................... 36

Solución de problemas .................................. 41

Datos técnicos............................................... 42

Declaración de garantía de control de

emisiones ...................................................... 42

Repuestos y encargos ................ Contraportada

GARANTÍA

GARANTÍA LIMITADA DE CRAFTSMAN

POR DOS AÑOS a partir de la fecha de la compra, este producto está garantizado contra cualquier

defecto de material o mano de obra.

CON LA PRUEBA DE VENTA producto defectuoso recibirán una reparación gratuita. Si el producto

no puede ser reparado será reemplazado de forma gratuita.

Para detalles de la cobertura de garantía para obtenir la reparación gratuita, visite la página web:

www.craftsman.com/warranty

Esta garantía SOLO cubre defectos de material y mano de obra. La cobertura de la garantía NO

incluye:

Piezas desechables que pueden sufrir desgaste debido al uso normal dentro del período de

garantía, incluidas, entre otras, la barra guía, la cadena, los filtros o la bujía.

Daños provocados por los intentos del usuario de modificar o reparar el producto o debido a los

accesorios del producto.

Reparaciones debidas a un accidente o a no utilizar o mantener el producto de acuerdo a todas

las instrucciones proporcionadas.

Mantenimiento preventivo o reparaciones debidas al uso de un tipo incorrecto de combustible,

una mezcla incorrecta de combustible o combustible contaminado o con impurezas.

Esta garantía se anulará si el producto se utiliza para ofrecer servicios comerciales o si se alquila a

otra persona.

Esta garantía otorga derechos legales específicos y puede que algunos varíen de un estado a otro.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

22

Page 23

IDENTIFICACIÓN DE SÍMBOLOS

ADVERTENCIA:

¡Las motosierras

pueden ser

peligrosas! Un uso

descuidado o

inadecuado puede

causar daños graves

o mortales al

operador o a otras

personas.

Lea atentamente el manual

de instrucciones y

asegúrese de que entiende

las instrucciones antes de

utilizar la máquina.

Siempre use:

Casco de protección

aprobado

Protección para los

oídos aprobada

Gafas de protección o un

visor

El operador debe usar

ambas manos para

manejar la motosierra.

Nunca opere una

motosierra sujetándola con

una sola mano.

Debe evitar que la punta

de la espada entre en

contacto con cualquier

objeto.

XX

ADVERTENCIA:

El contacto con la

punta puede causar

que la espada se

mueva hacia arriba y

hacia atrás

repentinamente (lo

que se conoce como

reculada), lo que

puede provocar

daños graves.

Bulbo cebador

(bomba de combustible).

El motor se detiene al

desactivar la ignición con

el interruptor de parada.

Abastecimiento de

combustible.

Relación gasolina a aceite

de 50:1.

No use combustibles

mezclados E15 o E85.

Abastecimiento de aceite

de la espada y cadena.

Bloqueo del freno de

cadena.

Desbloqueo del freno de

cadena.

Freno de cadena

desbloqueado/bloqueado.

Otros símbolos/etiquetas en la máquina se

refieren a requisitos de certificación especiales

para ciertos mercados.

El Período de cumplimiento de emisiones al

que se hace referencia en la etiqueta de

Cumplimiento de emisiones indica la cantidad

de horas de funcionamiento en la que se ha

demostrado que el motor cumple los requisitos

de emisiones federales.

El mantenimiento, reemplazo o reparación de

los dispositivos y sistemas de control de

emisiones sistema puede ser realizado por

cualquier establecimiento o persona de

reparaciones de motores para uso fuera de

carretera.

23

Page 24

SEGURIDAD

ADVERTENCIA: Siempre desconecte

el cable de la bujía y coloque el cable en

algún lugar en el que no pueda estar en

contacto con la bujía para evitar el

arranque accidental durante la

configuración, el transporte, los ajustes

o las reparaciones, salvo los ajustes en

el carburador.

ESTÁNDARES

Esta sierra se diseñó de acuerdo a:

ANSI B175.1-2012 Estándares Nacionales

Estadounidenses para Motosierras a Gasolina Requisitos de seguridad

CSA Z62.1-11 Motosierras - Seguridad y Salud

Ocupacional

CSA Z62.3-11 Seguridad y Salud Ocupacional

de Reculada de Motosierras

INTRODUCCIÓN

Una motosierra es una herramienta de corte de

madera de alta velocidad. Se deben tener

precauciones especiales de seguridad para

reducir el riesgo de accidentes.

Si no se siguen todas las normas y

precauciones

de seguridad, se pueden producir daños

graves.

Si se producen situaciones que no están

cubiertas en este manual, tenga cuidado y

buen juicio. Si necesita ayuda, póngase en

contacto con su taller de servicio autorizado o

llame al centro de asistencia al consumidor.

PLANIFICACIÓN PARA EL FUTURO

Lea este manual cuidadosamente hasta que

entienda completamente todas las normas de

seguridad, las precauciones y las

instrucciones de funcionamiento y pueda

seguirlas antes de utilizar la unidad.

Limite el uso de la sierra a usuarios adultos

que entiendan y puedan seguir las normas

de seguridad, precauciones e instrucciones

de funcionamiento de este manual.

Use equipo de protección.

Siempre use calzado de

seguridad con punta de acero y

suela antideslizante, ropa

ajustada, pantalones de

seguridad, guantes

antideslizantes reforzados,

protección ocular como gafas

de seguridad o pantalla facial

antiempañamiento y con

ventilación, un casco seguridad

aprobado y barreras de sonido

(tapones de oídos o silenciadores) para

proteger su sistema auditivo. Los usuarios

regulares deben tener revisiones médicas de

su sistema auditivo con regularidad, ya que

el ruido de la motosierra puede dañar la

audición. Asegure su cabello sobre el nivel

de los hombros.

Mantenga todas las partes de su cuerpo lejos

de la cadena cuando el motor está en

marcha.

Mantenga a los niños, las personas y los

animales un mínimo de 10 metros

(30 pies) de distancia del área de trabajo. No

permita que otras personas o animales estén

cerca de la motosierra durante el arranque o

el funcionamiento de esta.

No maneje ni opere una motosierra si está

cansado, enfermo o molesto, o si ha

consumido alcohol, drogas o medicamentos.

Debe estar en buena condición física y

mentalmente alerta. Trabajar con una

motosierra es agotador. Si tiene alguna

enfermedad que pueda ser agravada por el

trabajo arduo, consulte con su médico antes

de usar una motosierra.

Planifique cuidadosamente la operación de

sierra de antemano. No comience el corte

hasta que tenga un área de trabajo limpia,

segura, y, si está cortando árboles, una

retirada planificada.

FUNCIONAMIENTO DE LA SIERRA

No opere la motosierra con una sola mano.

Usar la motosierra con una mano puede

causar daño graves al operador, sus

ayudantes, transeúntes o cualquier

combinación de estas personas. Las

motosierras deben usarse con dos manos.

Haga funcionar la motosierra solo en lugares

bien ventilados y al aire libre.

No opere la sierra desde una escalera o un

árbol.

Asegúrese de que la cadena no entrará en

contacto con algún objeto mientras arranca el

motor. Nunca intente arrancar la sierra

cuando la espada guía está en un corte.

No ejerza presión sobre la sierra al final del

corte. Aplicar presión puede provocar que

pierda el control al terminar el corte.

Detenga el motor antes de dejar la sierra.

No utilice una motosierra que esté dañada,

mal ajustada, montada de forma incompleta

e insegura. Siempre reemplace la espada, la

protección para la mano o el freno de cadena

de inmediato si se dañan, rompen o se

retiran por algún otro motivo.

24

Page 25

La exposición a las vibraciones a través uso

prolongado de herramientas de mano a

gasolina puede causar daños a los vasos

sanguíneos o los nervios de los dedos, las

manos y las articulaciones

de las personas propensas a o trastornos de

la circulación y a las hinchazones anormales.

El uso prolongado en condiciones de clima

frío se ha relacionado con daños en los

vasos sanguíneos en personas por lo demás

sanas. Si se presentan síntomas como

adormecimiento, dolor, pérdida de la fuerza,

cambio en el color o la textura de la piel o

pérdida de la sensibilidad en los dedos, las

manos, o en las articulaciones, suspenda el

uso de esta herramienta y busque atención

médica. Un sistema de antivibración no

garantiza la prevención de estos problemas.

Los usuarios que utilizan herramientas

motorizadas en forma

continua y regular deben

vigilar de cerca su

condición física y el estado

de las herramientas.

Con el motor parado,

transporte la motosierra

con el silenciador lejos de

su cuerpo, y la espada y

cadena guía hacia atrás,

preferiblemente con una

cubierta.

MANTENIMIENTO DE LA SIERRA

Asegúrese de que todo el mantenimiento a la

motosierra sea realizado por un proveedor de

servicios calificado, salvo para los artículos

que se indican en la sección de

mantenimiento de este manual. Por ejemplo,

si se utilizan herramientas inapropiadas para

retirar o sostener el volante al realizar

mantenimiento al embrague, pueden

producirse daños estructurales al volante

y causar que este reviente.

Asegúrese de que la cadena de sierra deje

de moverse al soltar el gatillo del acelerador.

Para la corrección, consulte la sección Ajuste

del carburador.

Nunca modifique su sierra de ninguna forma.

Mantenga los mangos secos, limpios y libres

de aceite o de mezcla de combustible.

Mantenga las tapas de combustible y aceite,

los tornillos y las fijaciones bien apretadas.

Utilice solo accesorios y piezas de repuesto

auténticos, como se recomienda.

La sierra está equipada con un silenciador

limitador de temperatura y una pantalla anti

chispas que cumplen con los requisitos de

los Códigos California 4442 y 4443. Todos

los terrenos forestales y en los estados de

California, Idaho, Maine, Minnesota, Nueva

Jersey, Oregon y Washington exigen por ley

que muchos los motores de combustión

interna estén equipados con pantallas anti

chispas. Si está operando una motosierra en

un estado o localidad donde existan tales

reglamentos, es su responsabilidad legal

mantener las condiciones de funcionamiento

de estos componentes.

El no hacerlo es una violación de la ley.

Consulte la sección SERVICIO para obtener