Craftsman 944609900 Owner’s Manual

SEARS

OWNER'S

MANUAL

MODEL NO.

944.609900

CRRFTSMU

Caution:

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

20.0 HP

ELECTRIC START

46" MOWER

AUTOMATIC

GARDEN TRACTOR

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

Sears Canada, Inc., Toronto, Ontario M5B 2B8

Safe Operation Practices for Ride-On Mowers

IMP_)RTANT: THIS CU']-FING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING

OBJECTS. FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS

INJURY OR DEATH.

I. GENERAL OPERATION

Read, understand, and follow all instructions in the manual

and on the machine before starting.

Only allow responsible adults, who are familiar with the

instructions, to operate the machine.

• Clear the area of ob acts such as recks, toys, wire, etc.,

which could be picked up and thrown by the bade.

• Be sure the areais clear ofotherpeople before mowing. Stop

machine if anyone enters the area.

Never carry passengers.

Donot mow in reverse unless absolutely necessary. Always

look down and behind before and while backing.

Be aware of the mower discharge direction and do not point

it at anyone. Do not operate the mower without either the

entire grass catcher or the guard in place.

Slow down before turning.

Never leave a runningmachine unattended. Always turn off

blades, set parking brake, stop engine, and remove keys

before dismounting.

Tum off blades when not mowing.

Stop engine before removing grass catcher or unclogging

chute,

Mow only in daylight or good artificial light.

Do not operate the machine while under the influence of

alcohol or drugs.

Watch fortrafficwhen operating near or crossing roadways.

• Use extra care when loading or unloading the machine into

a trailer or truck.

II. SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tipover

accidents, which can result in severe injury or death. All slopes

require extra caution. If you cannot back upthe slope or ifyoufeel

uneasy on it, do not mow it.

DO:

Mow up and down slopes, not across.

Remove obstacles such as recks, tree limbs, etc.

Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine. Tall grass can hide obstacles.

• Use slow speed. Choose a low gear so that you willnot have

to stop or shift while on the slope.

Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

Usa extra care with grass catchers or other attachments.

These can change the stability of the machine.

Keep all movement on the slopes slowand gradual. Do not

make sudden changes in speed or direction.

Avoid starting orstopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

DO NOT:

Do not turnon slopes unless necessary, end then, turnslowly

and gradually downhill, ifpossible.

Do not mow near drop-offs, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or it an edge caves in.

Do not mow on wet grass. Reduced traction could cause

sliding•

• Do not try to stabilize the machine by puttingyourfoot on the

ground.

Do not use grass catcher on steep slopes.

SAFETY RULES A

IlL CHILDREN

Tragic accidentscan occur if the operatoris not alert to the

presenceofchildren.Childrenareoftenattracted tothemachine

andthemowingactivity. Neverassumethat childrenwillremain

whereyoulastsawthem.

• Kaspchildranoutofthemowingarea andunderthewatchful

careof anotherresponsibleadult.

Be alertand tum machineofti| childrenenterthearea.

Beforeand when backing,lookbehind and downforsmall

children.

Never carrychildren. They may fall off and be seriously

injuredorintederewithsafemachineoperation.

• Neverallowchildrentooperatethe machine.

Use extra care when approachingblind comers, shrubs,

trees,or otherobjectsthatmay obscurevision.

IV. SERVICE

• Usaextracareinhandlinggasolineandotherfuels.Theyare

flammableand vaporsare explosive.

Useonlyanapprovedcontainer.

Never remove gas cap or add fuel with the engine

running. Allowenginetocoolbeforerefueling.Do not

smoke.

Neverrefuelthe machineindoors.

Neverstorethemachineorfuel containerinsidewhere

thereisan openflame, suchasa water heater.

• Neverruna machineinsidea closedarea.

• Keepnutsandbolts,especiallybladeattachmentbolts,tight

and keepequipmentingoodcondition.

Never tamper with safety devices. Check their proper

operationregularly.

Keepmachinefree ofgrass,leaves,orotherdebrisbuild-up.

Clean oil or fuel spillage. Allow machineto cool before

storing.

Stop and inspectthe equipmentif you strike an object.

Repair,if necessary,beforerestarting.

Nevermakeadjustmentsor repairswiththeenginerunning.

• Grasscatchercomponentsaresubecttowear,damage,and

deterioration,which could expose movng parts or a ow

objectsto be thrown. Frequentlycheckcomponentsand

replacewithmanufacturer'srecommendedparts,whennec-

essary.

• Mowerbladesare sharpandcan cut. Wrapthe blade(s)or

weargloves,and usa extracautionwhenservicingthem.

Check brake operationfrequently. Adjustand serviceas

required.

Look for this symbol to point out impor-

tant safety precautions. It means

CAUTIONI!! BECOME ALERT!

CONGRATULATIONS on your purchase of a Sears

Tractor. It has been designed, engineered and manufac-

tured to give you the best possible dependability and

pedormance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service Centre/Department We have competent, well-

trained technicians and the proper toolsto service or repair

this tractor.

Please read and retain this manual. The instructionswill

enable you to assemble and maintain your tractor properly.

Always observe the "SAFETY RULES",

MODEL

NUMBER 944.609900

SERIAL

NUMBER

DATEOFPURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

PRODUCT SPECIFICATIONS

HORSEPOWER: 20.0

GASOLINECAPACITY 3.5 GALLONS

ANDTYPE: UNLEADED REGULAR

iOIL TYPE (API-SF/SG/SH): SAE t0W30 (above 32°F'/

SAE 5W-30 (below 32°F)

OILCAPACITY: W/FILTER: 4.2 PINTS

W/O FILTER: 3.7 PINTS

SPARK PLUG: CHAMPION RC12YC

3AP: .030")

VALVE CLEARANCE: NOT ADJUSTABLE

GROUND SPEED (MPH): FORWARD: 0- 5,8

REVERSE: 0-2.1

TIRE PRESSURE: FRONT: 14 PSI

REAR: 10 PSI

CHARGINGSYSTEM: t 5 AMPS @ 3600 RPM

BATTERY: AMP/HR: 35

MIN. CCA: 280

CASE SIZE: U1R

BLADEBOLT TORQUE: 27-35 FT. LBS.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available onthis prod-

uct. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regularschedule inmaintaining, cadngfor and

using your tractor.

• Followthe instructions under"Customer Responsibili-

ties" and =Storage" sections ofthis owner's manual.

WARNING: This tractor is equipped with an internal

combustionengine and shouldnot be used onor near any

unimproved forest-covered, brush-covered or grass-cov-

ered land unless the engine's exhaust system is equipped

witha spark arrester meeting applicable local or state laws

(ifany). If a spark arrestar is used, it shouldbe maintained

in effective working order by the operator.

A spark arrester for the muffler is available through your

nearest SearsAuthorized Service Centre/Depadment (See

REPAIR PARTS section of this manual).

3

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ...................................... 3

CUSTOMER RESPONSIBILITIES ..................... 3, 16-19

WARRANTY .................................................................. 4

ASSEMBLY .......................................................... ,.... 6-9

OPERATION ........................................................... 10-15

MAINTENANCE SCHEDULE ...................................... 16

SERVICE AND ADJUSTMENTS ............................ 20-26

STORAGE ................................................................... 27

TROUBLESHOOTING ............................................ 28-29

REPAIR PARTS - TRACTOR ................................. 32-49

REPAIR PARTS - ENGINE .................................... 50-57

PARTS ORDERING/SERVICE ................ BACK COVER

LIMITED TWO (2) YEAR WARRANTY ON CRAFTSMAN TRACTOR (RIDING EQUIPMENT)

For two (2) years from date of purchase Sears Canada, Inc. will repairor replace at Sears option free of charge parts which are

defective as a result of matedal or workmanship.

FULL ONE (1) YEAR WARRANTY ON BAI-I'ERY

For one (t) year from date of purchase, if any battery included with this riding equipment proves defective in matedal or

workmanship and our testing determines the battery will not hold a charge, Sears will replace the battery at no charge.

COMMERCIAL OR RENTAL USE

Warranty on Riding Equipment used for commercial or rental purposes is limitedto ninety (90) days.

This Warranty does NOT cover:

1. Pre-delivery set-up.

2. Tire replacement or repair caused by punctures from outside objects (such as nails, thorns, stumps, or glass).

3. Expendable items which become worn dudng normal use, such as blades, spark plug, air cleaners and belts.

4. Repairs necessary because of operator abuse or negligence, including damaged jackshaft or mandrel and the

failure to operate and maintain the equipment according to the instructions contained In the Owner's Manual.

5. In Home service.

Warranty service is available by returning the Craftsman Riding Equipment to the nearest Sears Service Centre/Department in

Canada. This warranty applies onlywhile this product is in use inCanada.

This warranty is in addition to any statutory warranty and does not exclude or limit legal dghts you may have but shall run

concurrentlywith applicable provincial legislation. Furthermore, some provinces do NOT allow limitationon how long an implied

warranty will last sothe above limitationsmay not apply to you.

SEARS CANADA, INC., TORONTO, ONTARIO M5B 2B8

4

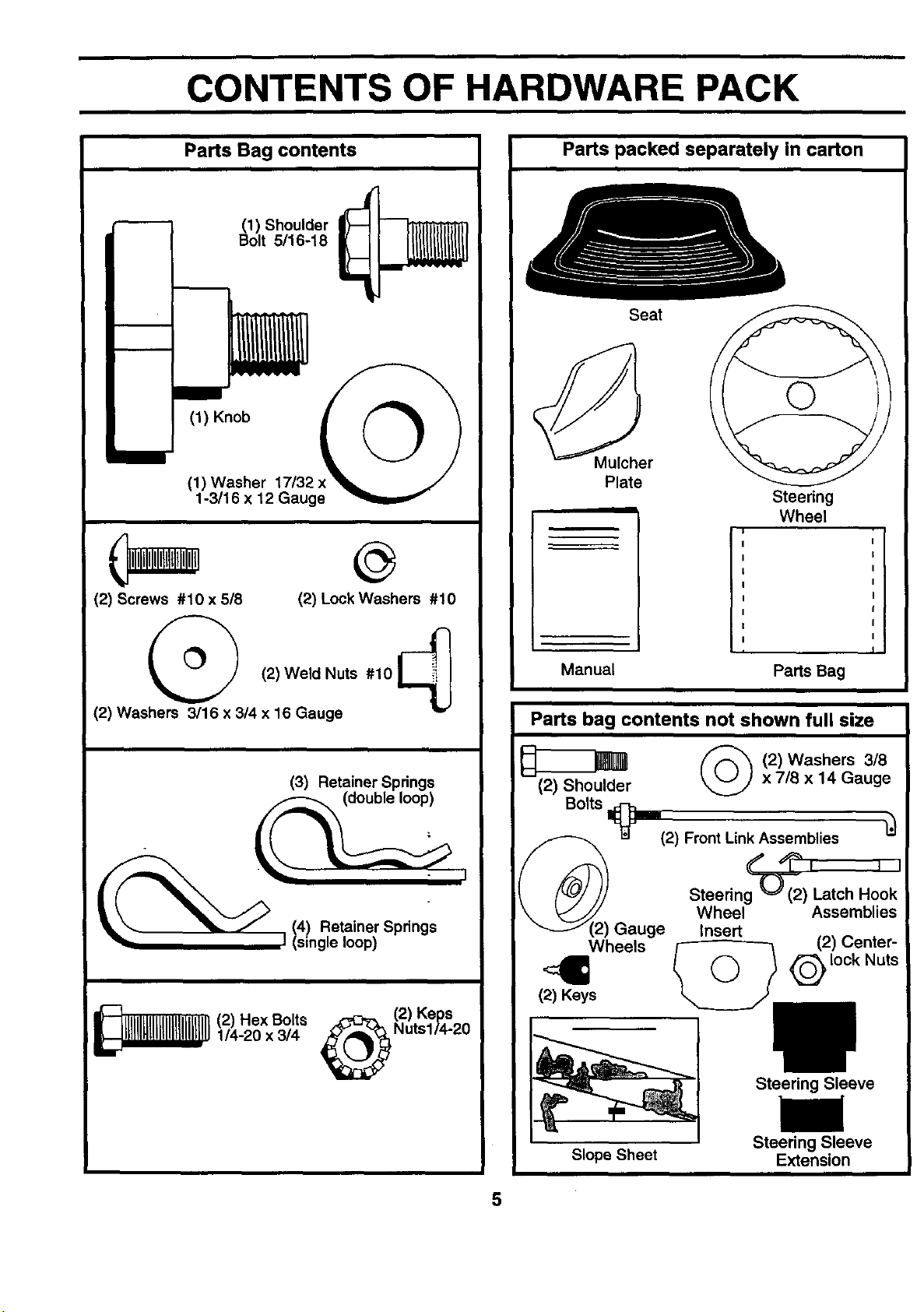

CONTENTS OF HARDWARE PACK

Parts Bag contents

(1) Shoulder

Bolt 5/16-18

m

(1) Knob

©

(1) Washer 17/32

1-3/16 x 12 Gauge

(2) Screws #10 x 518 (2) Lock Washers #10

Parts packed separately in carton

Seat

Mulcher

Plate

Steering

Wheel

(2)Weld Nuts #10_

(2) Washers 3/16 x 3/4 x 16 Gauge

(3) Retainer Springs

_ _ J 14) Retainer Springs

I (single loop)

1/4-20 x 3/4 Nuts114-20

_(2) Hex Bolts _(2) Keps

I

Manual Parts Bag

Parts bag contents not shown full size

_ (2)Washers 3/8

(2) Shoulder _ x 7/8 x 14 Gauge

Bolts

_J (2) Front Link Assemblies

¢" L_% ii

Steering'-O--((2) Latch Hook

Wheel Assemblies

Gauge Insert

Wheels /-----------3 (2) Center-

,4= @,ookNuts

(2) Keys

Steering Sleeve

Slope Sheet

Steering Sleeve

Extension

5

ASSEMBLY

Your new tractor has been assembled at the factory with exception of those parts left unassembled for shipping purposes.

To ensgre safe and proper operation of your tractor all parts and hardware you assemble must be tightened securely. Use

the correct tools as necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(2) 7/16" wrenches (1) Tire pressure gauge

(1) 9/16" wrench (1) Utility knife

(1) 1/2" wrench (1) 3/4" socket w/drive ratchet

(1) Pliers (1) PhillipsScrewddver

When right or left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

TO REMOVE TRACTOR FROM CARTON

I_1 _/STEEr'NGWHEEL

STEERING

WHEEL ----.........,,_ JABS

_..___F._ INSERT

_,._--.--- HEX BOLT

_ LOCK WASHER

@_ TEERING

WHEEL

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton (See page 5).

• Cut, from top to bottom, along lineson allfour corners

of carton, and lay panels flat.

• Remove mower and packing materials.

• Check for any additional loose parts or cartons and

remove.

BEFORE ROLLING TRACTOR OFF SKID

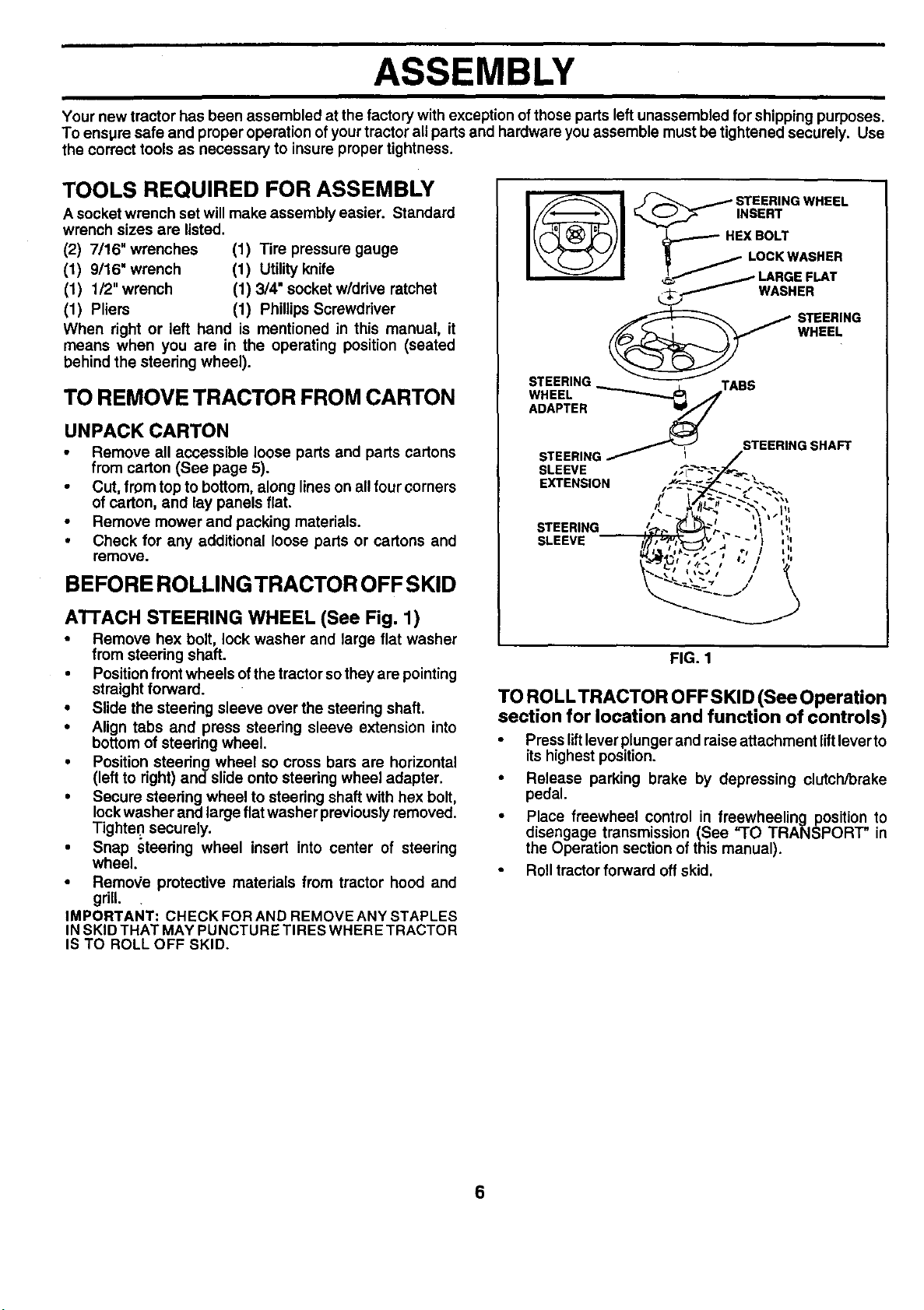

ATTACH STEERING WHEEL (See Fig. 1)

• Remove hex bolt, lock washer and large flat washer

from steering shaft.

• Positionfront wheels of thetractor sothey are pointing

straight forward.

• Slide the steering sleeve over the steering shaft.

• Align tabs and press steering sleeve extension into

bottom of steering wheel.

• Position steering wheel so cross bars are horizontal

(left to right) and slide onto steering wheel adapter.

• Secure steering wheel to steering shaft with hex bolt,

lockwasher and large flatwasher previouslyremoved.

Tighten securely.

• Snap steedng wheel insert into center of steering

wheel.

• RemoVe protective materials from tractor hood and

grill.

IMPORTANT: CHECKFORAND REMOVEANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE TRACTOR

IS TO ROLL OFF SKID.

ADAPTER _

STEERING _- I

SLEEVE

EXTENSION

STEERING

SLEEVE

FIG. 1

TO ROLLTRACTOR OFF SKID (See Operation

section for location and function of controls)

• Press lift leverplunger and raise attachment lift lever to

its highest position.

• Release parking brake by depressing clutch/brake

pedal.

• Place freewheel control in freewheelingposition to

disengage transmission (See "TO TRANSPORT" in

the Operation section of this manual).

Roll tractor forward off skid.

STEERING SHAFT

%\*1

6

ASSEMBLY

HOW TO SET UP YOUR TRACTOR

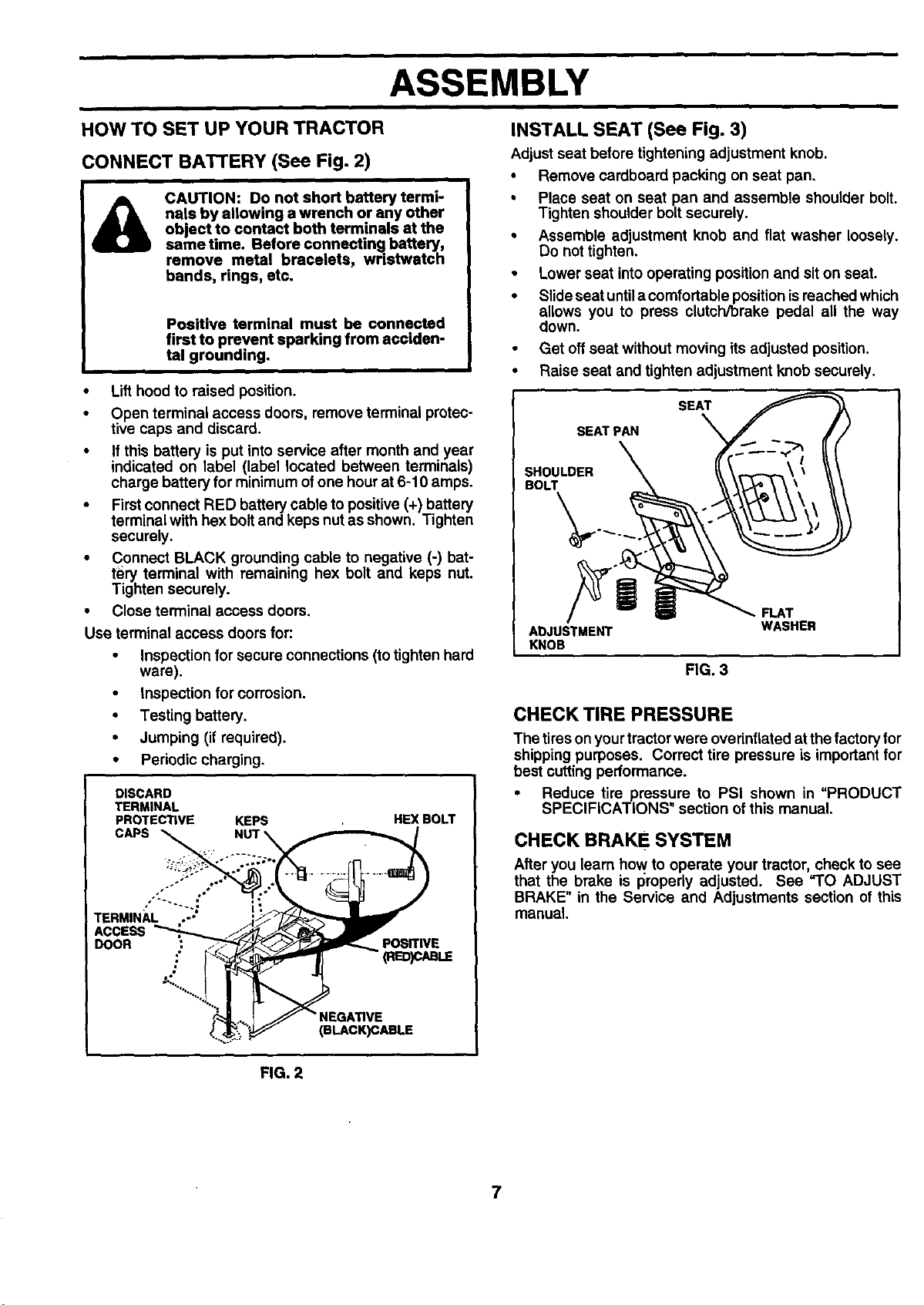

CONNECT BATTERY (See Fig. 2)

CAUTION: Do not short battery termi-

nals by allowing a wrench or any other

object to contact both terminals at the

same time. Before connecting battery,

remove metal bracelets, wristwatch

bands, rings, etc.

Positive terminal must be connected

first to prevent sparking from acciden-

tal grounding.

• Lift hood to raised position.

• Open terminal access doors, remove terminal protec-

tive caps and discard.

• If this battery is put into service after month and year

indicated on label (label located between terminals)

charge battery for minimum ofone hour at 6-10 amps.

• First connect RED battery cable to positive (+) battery

terminal with hex bolt and keps nutas shown. Tighten

securely,

• Connect BLACK grounding cable to negative (-) bat-

tery terminal with remaining hex bolt and keps nut.

Tighten securely.

• Close terminal access doors.

Use terminal access doors for:

• Inspection for secure connections (to tighten hard

ware).

• Inspection for corrosion.

• Testing battery.

• Jumping (if required).

• Periodic charging.

DISCARD

TERMINAL

PROTECTIVE KEPS HEX BOLT

...._,,:y , o"

TERM,N;,i.:J i

ACCESS

DOOR .: _ _'F_.mm_ posrrlvs

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment knob.

• Remove cardboard packing on seat pan.

• Place seat on seat pan and assemble shoulder bolt.

Tighten shoulder bolt securely.

• Assemble adjustment knob and flat washer Ioossty.

Do not tighten.

• Lower seat into operating position and sit on seat.

• Slide seat untila comfortable positionis reached which

allows you to press clutch/brake pedal all the way

down.

• Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment knob securely.

SEAT

SEATPAN

SHOULDER

BOLT

. FLAT

ADJUSTMENT

KNOB

FIG. 3

WASHER

CHECK TIRE PRESSURE

The tires on yourtractor were ovefinflated at the factoryfor

shipping purposes. Correct tire pressure is important for

best cutting performance.

• Reduce tire pressure to PSI shown in "PRODUCT

SPECIFICATIONS" section of this manual.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adjusted. See "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual.

2'_'%"-..., j

. GATIVE

FIG. 2

7

ASSEMBLY

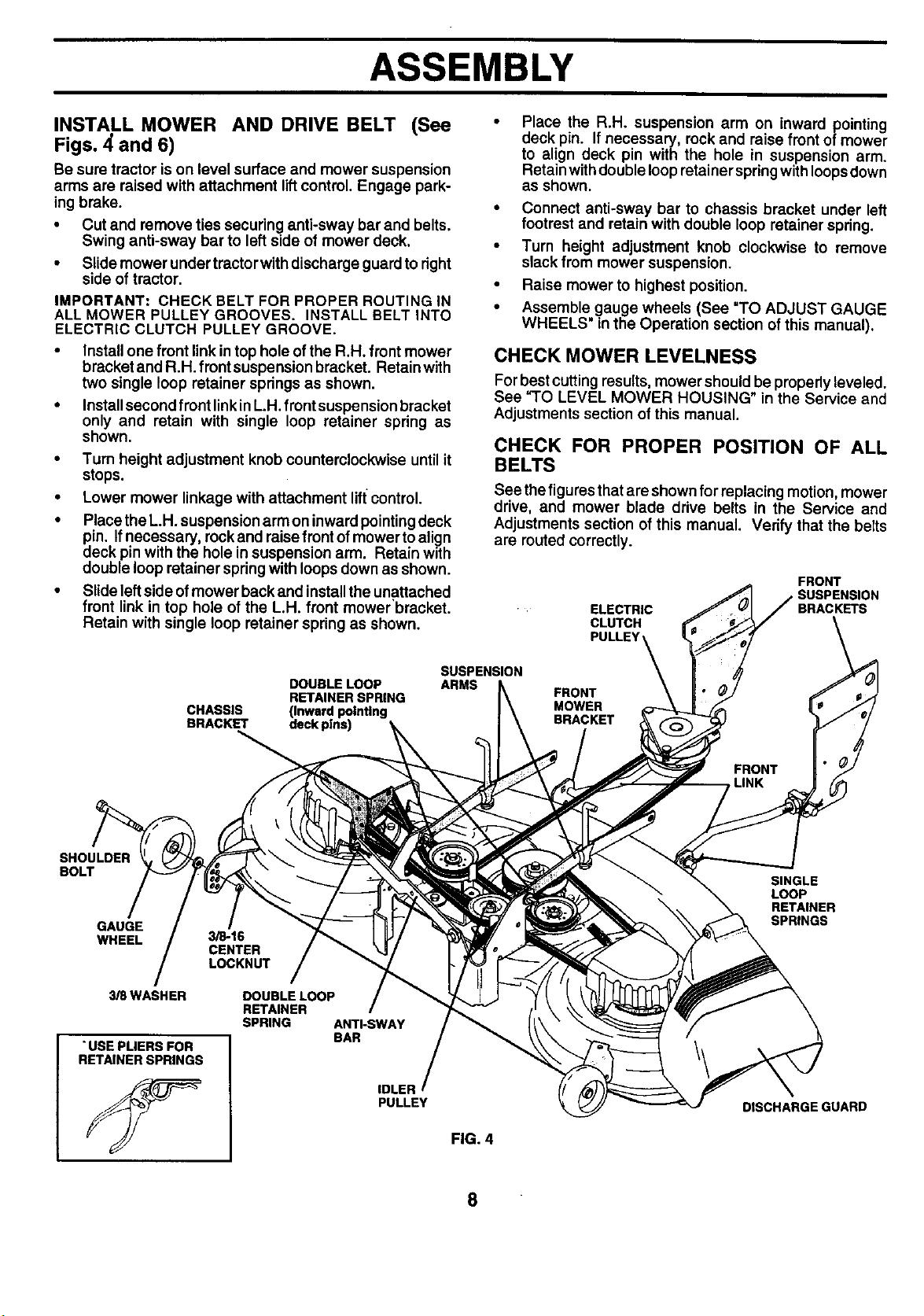

INSTALL MOWER AND DRIVE BELT (See

Figs. 4 and 6)

Be sure tractor ison level surface and mower suspension

arms are raised with attachment liftcontrol. Engage park-

ing brake.

• Cut and remove ties securing anti-sway bar and belts.

Swing anti-sway bar to left side of mower deck.

• Slide mower undertractorwith discharge guard to right

side of tractor.

IMPORTANT: CHECK BELT FOR PROPER ROUTING IN

ALL MOWER PULLEY GROOVES. INSTALL BELT INTO

ELECTRIC CLUTCH PULLEY GROOVE.

• Install one front linkin top hole ofthe R.H. front mower

bracket and R.H. front suspension bracket. Retain with

two single loop retainer springs as shown.

• Installsecond front linkinL.H. front suspension bracket

only and retain with single loop retainer spring as

shown.

• Turn height adjustment knob counterclockwise until it

stops.

• Lower mower linkage with attachment liftcontrol.

• Place the L.H.suspension arm on inward pointingdeck

pin. Ifnecessary, rockand raise front of mower to align

deck pin with the hole insuspension arm. Retain with

double loop retainer spring with loops down as shown.

• Slide leftside of mower back and installthe unattached

front link in top hole of the LH. front mower'bracket.

Retain with single loop retainer spring as shown.

Place the R.H. suspension arm on inward pointing

deck pin. If necessary, rock and raise front of mower

to align deck pin with the hole in suspension arm.

Retainwithdouble loop retainer springwithloopsdown

as shown.

• Connect anti-sway bar to chassis bracket under left

footrest and retain with double loop retainer spring.

• Turn height adjustment knob clockwise to remove

slack from mower suspension.

• Raise mower to highest position.

• Assemble.gauge wheels (See "TO ADJUST GAUGE

WHEELS in the Operation section of this manual).

CHECK MOWER LEVELNESS

For best cutting results, mower shouldbe properly leveled.

See "TO LEVEL MOWER HOUSING" in the Service and

Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See thefigures that are shownfor replacing motion, mower

drive, and mower blade drive belts in the Service and

Adjustments section of this manual. Verify that the belts

are routed correctly.

FRONT

ELECTRIC

CLUTCH

PULLEY'

SUSPENSION

BRACKETS

SHOULDER

BOLT

GAUGE

WHEEL

3_WASHER

"USE PLIERS FOR

RETAINERSPRINGS

DOUBLE LOOP

RETAINER SPRING

CHASSIS (Inward pointing

BRACKET deck plns)

3/8-16

CENTER

LOCKNUT

DOUBLELOOP

RETAINER

SPRING ANTI-SWAY

BAR

IDLER

PULLEY

SUSPENSION

ARMS

FRONT

MOWER

BRACKET

SINGLE

LOOP

RETAINER

SPRINGS

DISCHARGE GUARD

FIG. 4

8

ASSEMBLY

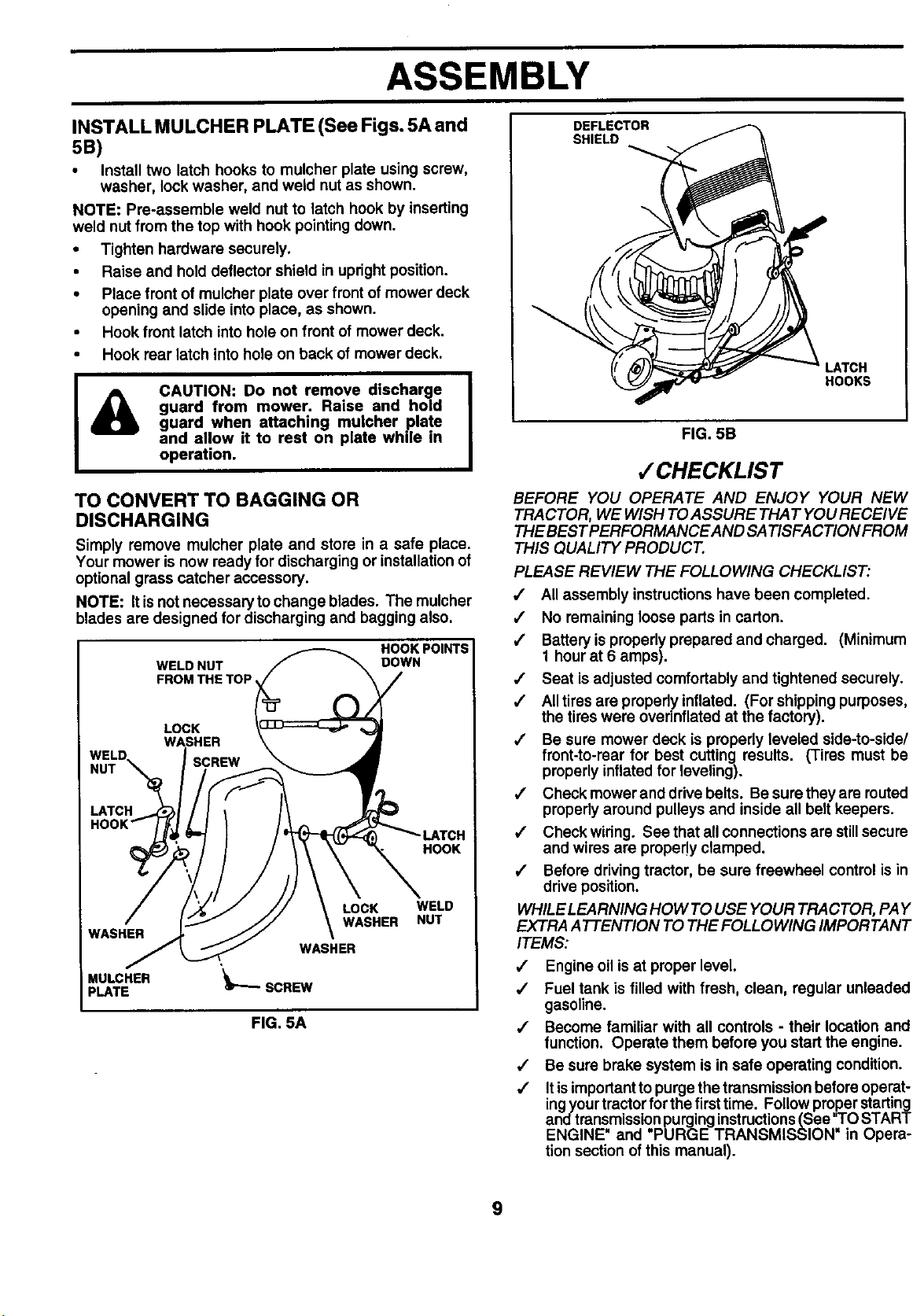

INSTALL MULCHER PLATE (See Figs. 5A and

5B)

• Install two latch hooks to mulcher plate using screw,

washer, lock washer, and weld nut as shown.

NOTE: Pre-assemble weld nut to latch hook by inserting

weld nut from the top with hook pointing down.

• Tighten hardware securely.

• Raise and hold deflector shield in upright position.

• Place front of mulcher plate over front of mower deck

opening and slide into place, as shown.

• Hook front latch intohole on front of mower deck.

• Hook rear latch into hole on back of mower deck.

CAUTION: Do not remove discharge

&

TO CONVERT TO BAGGING OR

DISCHARGING

Simply remove mulcher plate and store in a safe place.

Your mower is now ready for discharging or installation of

optional grass catcher accessory.

NOTE: It isnot necessaryto change blades. The mulcher

blades are designed for discharging and bagging also.

LATCH

WASHER

MULCHER

PLATE

guard from mower. Raise and hold

guard when. attaching mulcher p.late.

and allow it to rest on plate while m

operation.

HOOK POINTS

WELD NUT

FROM THE TOP

LOCK

WASHER

ISCREW

WASHER

'_'_SCREW

FIG. 5A

DOWN

LOCK

WASHER

HOOK

WELD

NUT

DEFLECTOR

SHIELD

LATCH

HOOKS

FIG. 5B

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TO ASSURE THAT YOU RECEIVE

THE BEST PERFORMANCE AND SATISFA CTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

/ All assembly instructions have been completed.

/ No remaining loose parts in carton.

,,1 Battery is properly prepared and charged. (Minimum

1 hour at 6 amps).

,/ Seat is adjusted comfortably and tightened securely.

,/ Alltires are properly inflated. (For shipping purposes,

the tires were ovednflated at the factory).

/ Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results. (Tires must be

properly inflated for leveling).

,/ Check mower and drive belts. Be surethey are routed

properly around pulleys and inside all belt keepers.

,/ Check wiring. See that allconnections are stillsecure

and wires are properly clamped.

,/ Before drivingtractor, be sure freewheel control is in

drive position.

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

/ Engine oil isat proper level.

,/ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

/ Become familiar with all controls - their location and

function. Operate them before you start the engine.

,/ Be sure brake system is in safe operating condition.

,/ Itis importantto purge the transmission before operat-

ingyour tractorfor the firsttime. Followproper starting

and transmissionpurginginstructions(See"TO START

ENGINE' and "PURGE TRANSMISSION" in Opera-

tionsection of this manual).

9

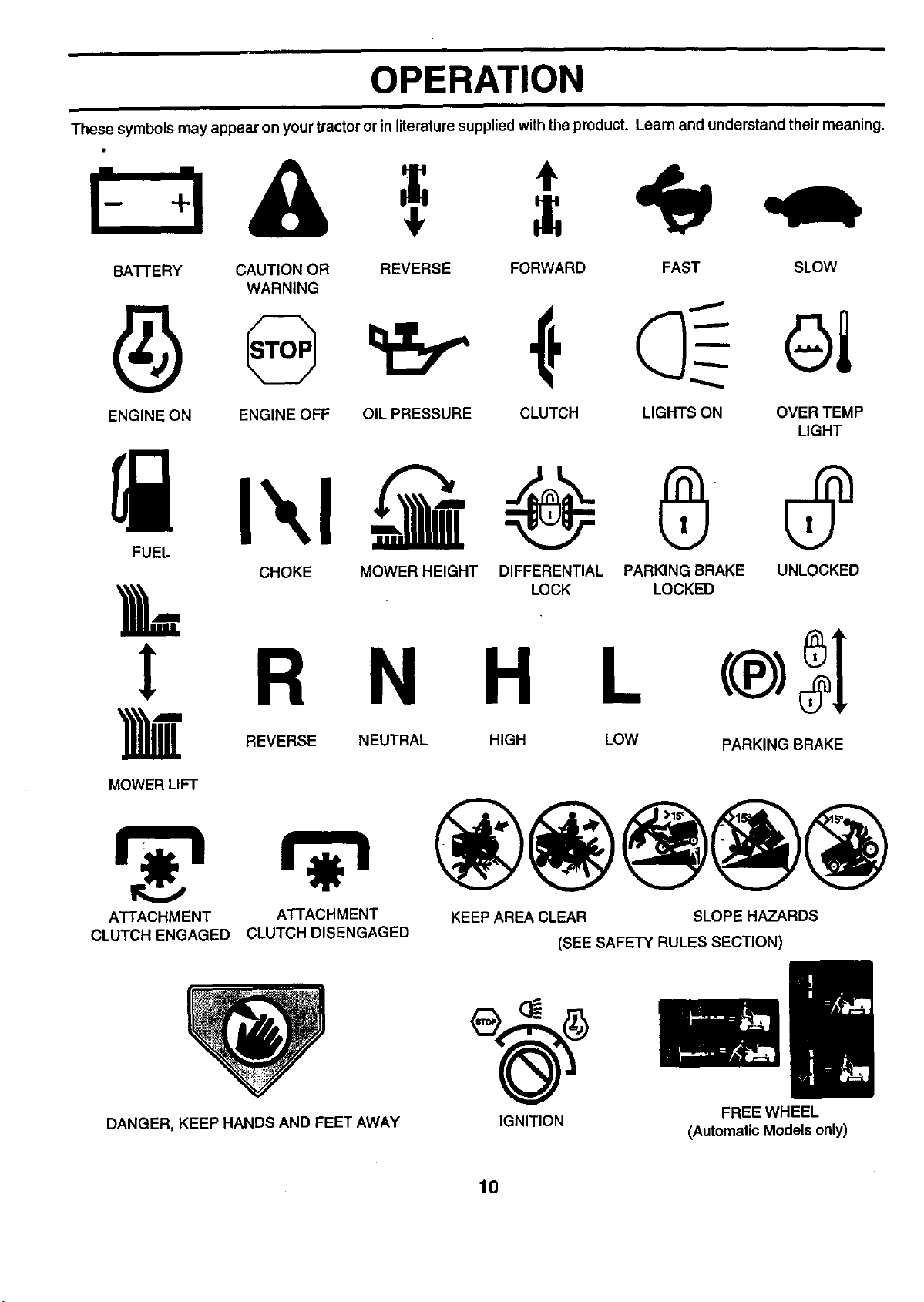

OPERATION

These symbols may appear on your tractor or in literaturesupplied withthe product. Learn and understand their meaning.

BATTERY CAUTION OR REVERSE FORWARD FAST SLOW

WARNING

ENGINE ON ENGINE OFF OIL PRESSURE CLUTCH

FUEL

CHOKE MOWER HEIGHT DIFFERENTIAL PARKING BRAKE UNLOCKED

LOCK LOCKED

! R N H L

_1_ REVERSE NEUTRAL HIGH LOW

MOWER LIFT

LIGHTS ON OVER TEMP

LIGHT

PARKING BRAKE

ATTACHMENT

CLUTCH ENGAGED

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT KEEP AREA CLEAR SLOPE HAZARDS

CLUTCH DISENGAGED (SEE SAFETY RULES SECTION)

IGNITION

10

FREEWHEEL

(Automatic Models only)

OPERATION

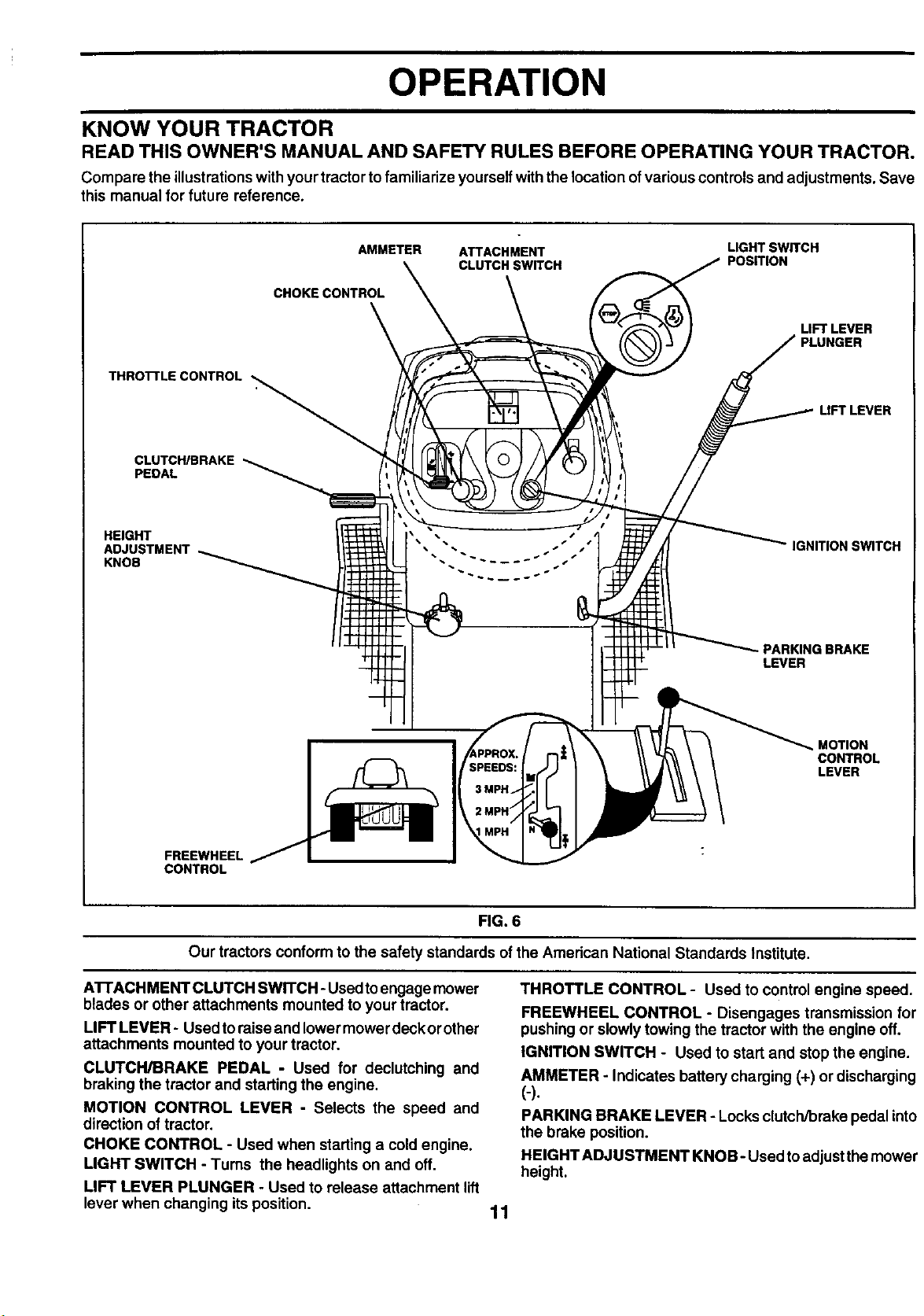

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR.

Compare the illustrationswith your tractorto familiarize yourselfwith the location of variouscontrols and adjustments. Save

this manual for future reference.

THROI-I'LECONTROL

CLUTCH/BRAKE

PEDAL

HEIGHT

ADJUSTMENT

KNOB

AMMETER ATTACHMENT LIGHT SWITCH

CLUTCH SWITCH POSITION

CHOKE CONTROL

LIFT LEVER

PLUNGER

LIFT LEVER

IGNITION SWITCH

- PARKING BRAKE

LEVER

FREEWHEEL

CONTROL

Our tractors conform to the safety standards of the American National Standards Institute.

A'B'ACHMENT CLUTCH SWITCH -Used toengage mower

blades or other attachments mounted to your tractor.

LIFT LEVER - Used to raise and lower mower deck or other

attachments mounted to your tractor.

CLUTCH/BRAKE PEDAL - Used for declutching and

braking the tractor and starting the engine.

MOTION CONTROL LEVER - Selects the speed and

direction of tractor.

CHOKE CONTROL - Used when starting a cold engine.

LIGHT SWITCH - Turns the headlights on end off.

LIFT LEVER PLUNGER - Used to release attachment lift

lever when changing its position.

MOTION

CONTROL

LEVER

FIG. 6

THROTTLE CONTROL - Used to control engine speed.

FREEWHEEL CONTROL - Disengages transmission for

pushing or slowly towing the tractor with the engine off.

IGNITION SWITCH - Used to start and stop the engine.

AMMETER - Indicates battery charging (+) or discharging

(-).

PARKING BRAKE LEVER - Locks clutch/brake pedal into

the brake position.

HEIGHT ADJUSTMENT KNOB- Used toadjust the mower

height.

11

OPERATION

in severe eye damage. Always wear safety glasses or eye shields while operating your tractor

I The operation of any tractor can result in foreign objects thrown into the eyes, which can result I

or performing any adjustments or repairs. We recommend a wide vision safety mask over

spectacles or standard safety glasses.

I

HOW TO USE YOUR TRACTOR

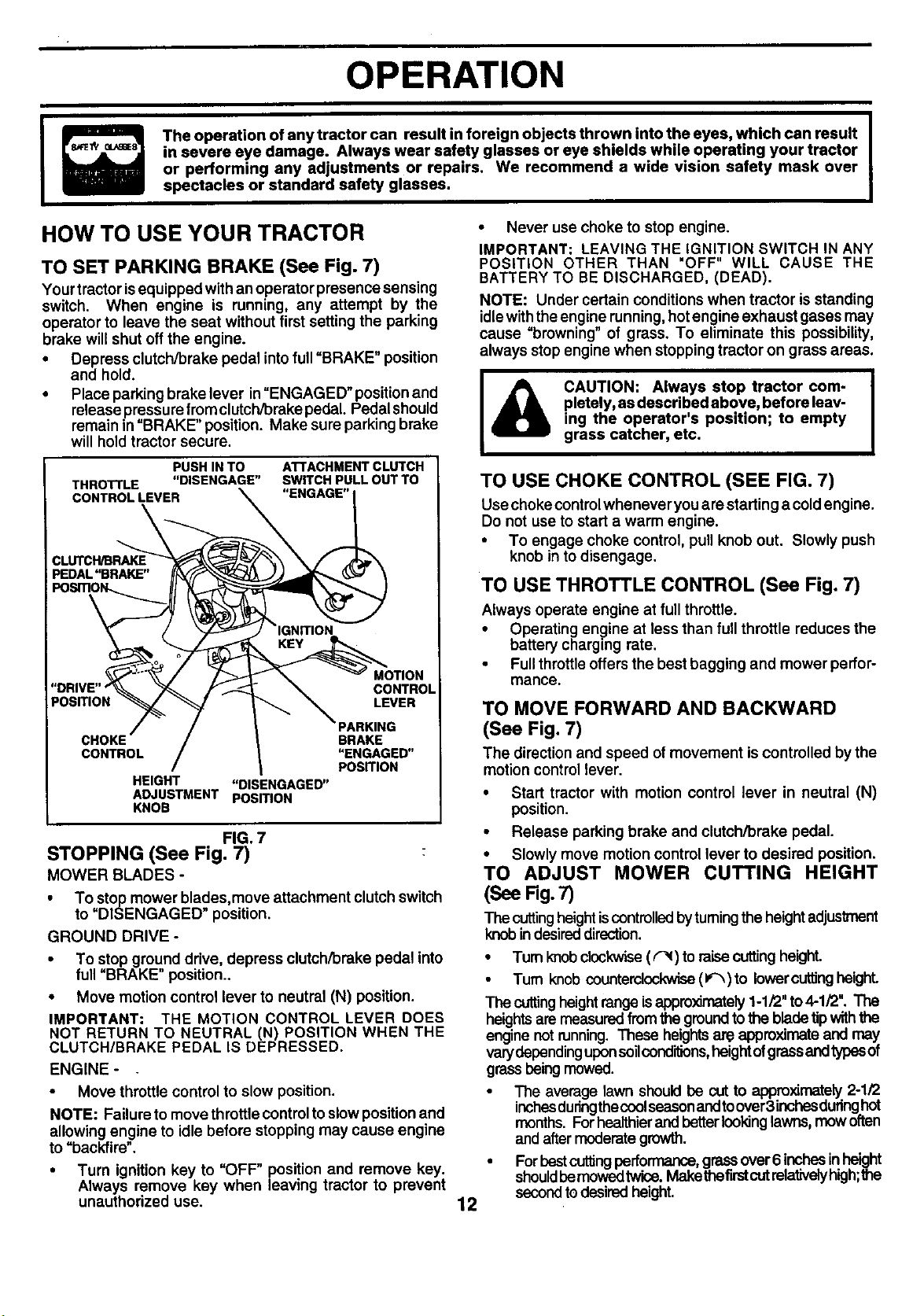

TO SET PARKING BRAKE (See Fig. 7)

Yourtractor isequipped with an operator presence sensing

switch. When engine is running, any attempt by the

operator to leave the seat without first setting the parking

brake will shut off the engine.

• Depress clutch/brake pedal intofull =BRAKE" position

and hold.

• Place parkingbrake lever in=ENGAGED" positionand

release pressurefromclutch/brake pedal. Pedal should

remain in =BRAKE" position. Make sure parking brake

will hold tractor secure,

PUSHINTO

THROTrLE "DISENGAGE"

CONTROLLEVER

ATTACHMENT CLUTCH

SWITCH PULL OUT TO

"ENGAGE"

\

PosmoN LEVER

CHOKE BRAKE

CONTROL "ENGAGED"

HEIGHT "DISENGAGED"

ADJUSTMENT POSITION

KNOB

FIG. 7

STOPPING (See Fig. 7)

MOWER BLADES -

• To stop mower blades,move attachment clutchswitch

to "DISENGAGED" position.

GROUND DRIVE -

• To stop ground drive, depress clutch/brake pedal into

full=BRAKE" position..

• Move motion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

ENGINE -

• Move throttle control to slow position.

NOTE: Failure to move throttle controlto slow positionand

allowing engine to idle before stopping may cause engine

to =backfire".

• Turn ignition key to =OFF" position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

CONTROL

PosmoN

• Never use choketo stop engine.

IMPORTANT: LEAVING THE IGNITION SWITCH IN ANY

POSITION OTHER THAN "OFF" WILL CAUSE THE

BATTERY TO BE DISCHARGED, (DEAD).

NOTE: Under certain conditions when tractor is standing

idlewiththe engine running,hotengineexhaust gases may

cause =browning" of grass. To eliminate this possibility,

always stopengine when stopping tractor on grass areas.

CAUTION: Always stop tractor com- |

pletely, as described above, before leav-

&

TO USE CHOKE CONTROL (SEE FIG. 7)

Use chokecontrolwhenever you are starting a cold engine.

Do not use to start a warm engine.

• To engage choke control, pull knob out. Slowly push

knob in to disengage.

TO USE THROTTLE CONTROL (See Fig. 7)

Always operate engine at full throttle.

• Operating engine at lessthan fullthrottle reduces the

battery charging rate.

• Fullthrottle offersthe best bagging and mower perfor-

mance.

TO MOVE FORWARD AND BACKWARD

(See Fig. 7)

The direction and speed of movement iscontrolled bythe

motion control lever.

• Start tractor with motion control lever in neutral (N)

position.

• Release parking brake and clutch/brake pedal.

• Slowly move motion control lever to desired position.

TO ADJUST MOWER CUTTING HEIGHT

ing the operator's position; to empty

grass catcher, etc.

(See Rg. 7)

The cuttingheightiscontrolledbytumingthe heightadjustment

knobin desireddirection.

• Turnknobclockwise(r'_) to raisecuttingheight.

Turn knob counterclockwise(1_) to lower cuttingheight.

The cuttingheight range isappro)dmately1-1/2" to4-1/2". The

heights are measuredfrom the ground to the blade tipwith

engine not running. These heights are approximate and may

varydependingupon soil conditions,height of grass andtypesof

grass beingmowed.

• The average lawn shouldbe cutto approximately2-1/2

inchesduringthecoolseasonandtoover3inchesduringhot

months. Forhealthierand betterlookinglawns, mow often

and aftermoderategrowth.

• ForbestcutlJngperformance,grassover6 inchesin height

shouldbemowedtwice.Makethefirstcutrelativelyhigh;the

12

secondto desiredheight.

!

I

OPERATION

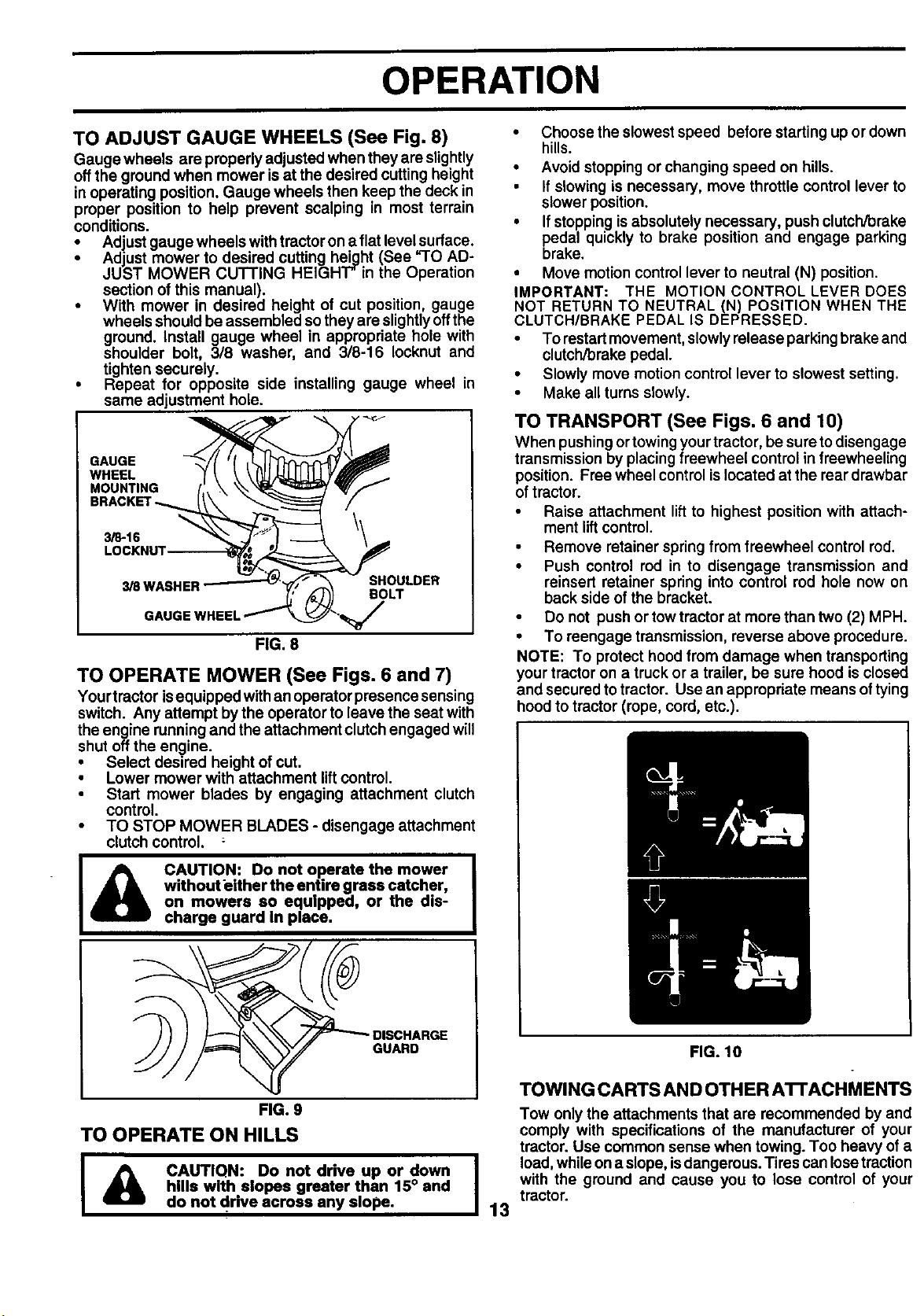

TO ADJUST GAUGE WHEELS (See Fig. 8)

Gauge wheels are properly adjusted when they are slightly

offthe ground when mower is at the desired cutting height

in operating position. Gauge wheels then keep the deck in

proper position to help prevent scalping in most terrain

conditions.

• Adjust gauge wheels withtractor ona flat level surface.

• Adjust mower to desired cutting height (See =TO AD-

JUST MOWER CUTTING HEIGHT"in the Operation

section of this manual).

• With mower in desired height of cut position, gauge

wheels should be assembled so they are slightlyoff the

ground. Install gauge wheel in appropdate hole with

shoulder bolt, 3/8 washer, and 3/8-16 Iocknut and

tighten securely.

• Repeat for opposite side installing gauge wheel in

same adjustment hole.

GAUGE

WHEEL

MOUNTING

3/8-16

LOCKNU1

SHOULDER

BOLT

FIG. 8

TO OPERATE MOWER (See Figs. 6 and 7)

Yourtractor isequipped withan operator presence sensing

switch. Any attempt by the operator to leave the seat with

the engine running and the attachment clutchengaged will

shut offthe engine.

• Select desired height of cut.

• Lower mower with attachment liftcontrol.

• Start mower blades by engaging attachment clutch

control.

• TO STOP MOWER BLADES -disengage attachment

clutchcontrol. :

• Choose the slowestspeed before starting up or down

hills.

• Avoid stopping or changing speed on hills.

• If slowing is necessary, move throttle control lever to

slower position.

• Ifstopping isabsolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

• Move motioncontrol lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

• To restartmovement, slowlyrelease parkingbrakeand

clutch/brake pedal.

• Slowly move motion control lever to slowest setting.

• Make all turns slowly.

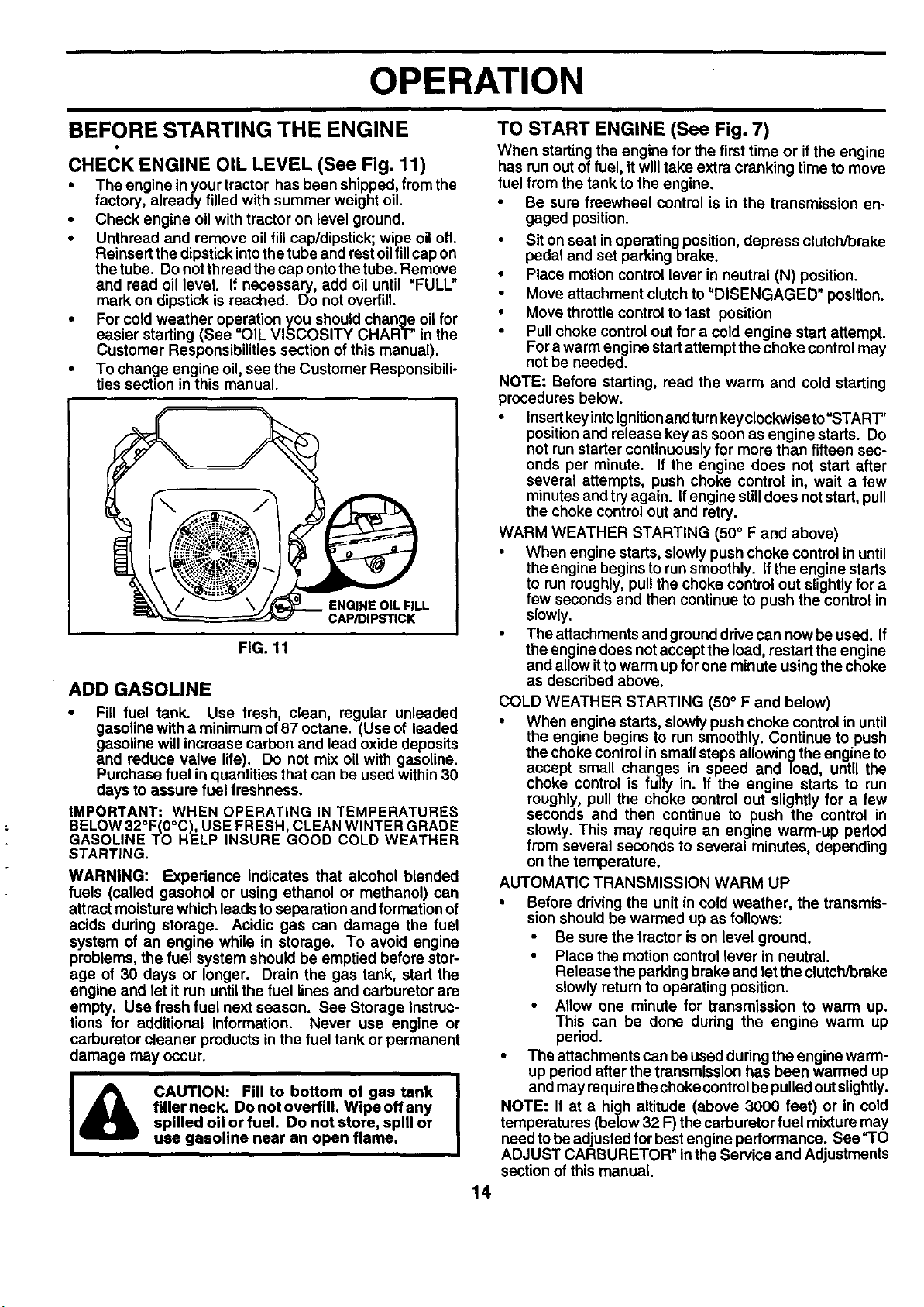

TO TRANSPORT (See Figs. 6 and 10)

When pushing ortowingyour tractor, be sure to disengage

transmission by placing freewheel control in freewheeling

position. Free wheel controlislocated at the roar drewbar

of tractor.

Raise attachment liftto highest position with attach-

ment lift control.

• Remove retainer spring from freewheel control rod.

• Push control rod in to disengage transmission and

reinsert retainer spring into control rod hole now on

back side of the bracket.

Do not push or tow tractorat more than two (2) MPH.

• To reengage transmission, reverse above procedure.

NOTE: To protect hood from damage when transporting

your tractor on a truckor a trailer, be sure hood is closed

and secured to tractor. Use an appropriate means oftying

hood to tractor (rope, cord, etc.).

CAUTION: Do not operate the mower

withouteither the entire grass catcher,

on mowers so equipped, or the dis-

charge guard in place.

GUARD

FIG. 9

TO OPERATE ON HILLS

I & CAUTIQN: Donotdriveupordown I

hills with elopes greater than 15° and

do not drive across any slope. 13

FIG. 10

TOWING CARTS AND OTHER ATrACHMENTS

Tow only the attachments that are recommended by and

comply with specifications of the manufacturer of your

tractor. Use common sense when towing. Too heavy of a

load,while ona slope, is dangerous. Tires can losetraction

with the ground and cause you to lose control of your

tractor.

OPERATION

BEFORE STARTING THE ENGINE

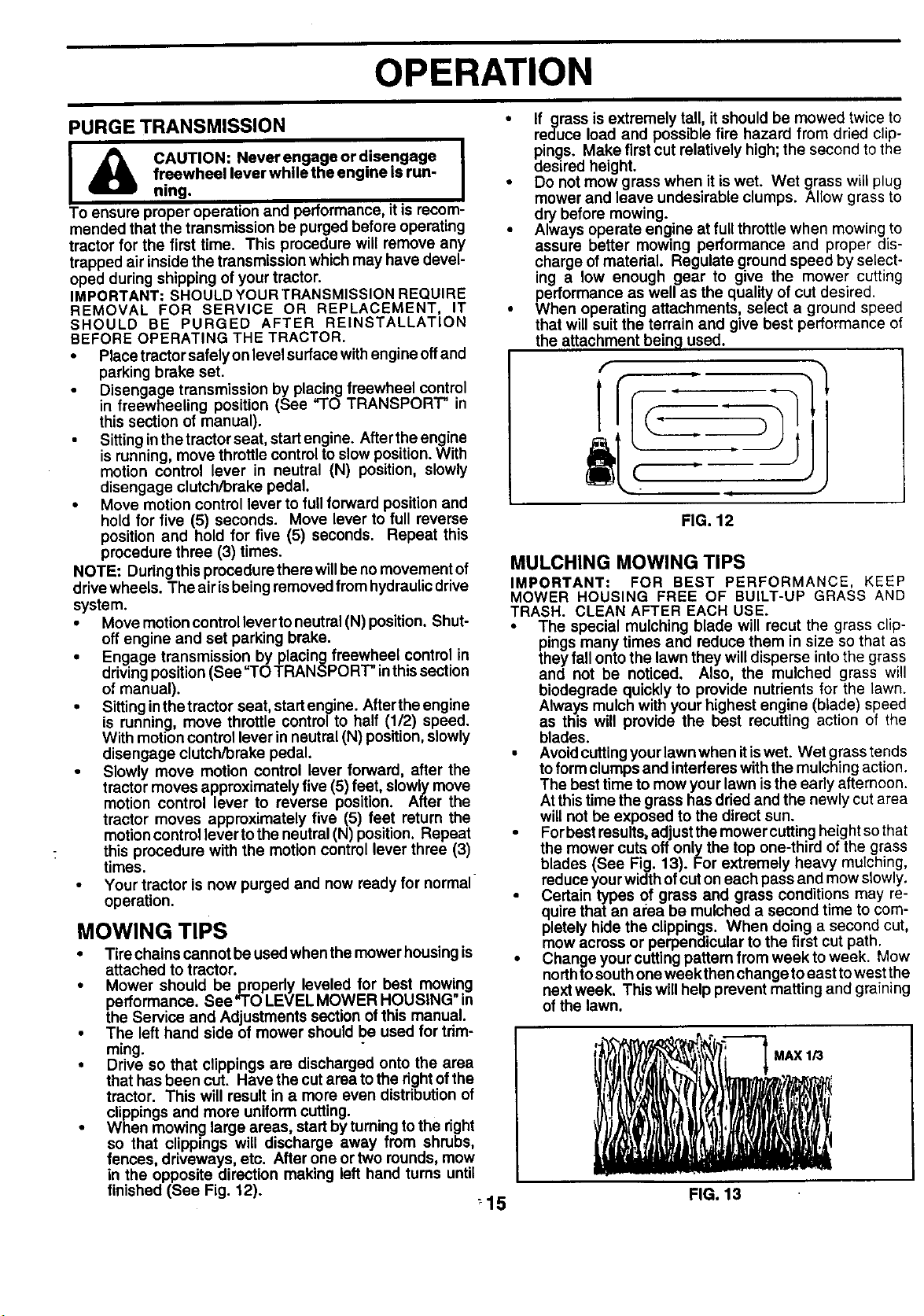

CHECK ENGINE OIL LEVEL (See Fig. 11)

• The engine in your tractor has been shipped, fromthe

factory, already filled with summer weight oil.

• Check engine oilwith tractor on level ground.

• Unthread and remove oil flUcap/dipstick; wipe oil off.

Reinsert the dipstick intothe tube end rest oilfill capon

the tube. Do notthread the cap ontothe tube. Remove

and read oil level. If necessary, add oil until "FULL"

mark on dipstick is reached. Do not overfill.

• For cold weather operation you should change oil for

easier starting (See "OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manual).

• To change engine oil, see the Customer Responsibili-

ties section in this manual.

ENGINE OIL FILL

CAP/DIPSTICK

FIG. 11

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded

gasoline with a minimum of 87 octane. (Use of leaded

gasoline will increase carbon and lead oxide deposits

and reduce valve life). Do not mix oil with gasoline.

Purchase fuel inquantities that can be used within 30

days to assure fuel freshness.

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F(0°C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads toseparation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage Instruc-

tions for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

filler neck. Do not overfill, Wipe off any

I& CAUTION: Fill to bottom of gas tank I

spilled oil or fuel. Do not store, spill or

use gasoline near an open flame.

TO START ENGINE (See Fig. 7)

When starting the engine for the first time or if the engine

has run out of fuel, itwilltake extra cranking time to move

fuel from the tank to the engine,

Be sure freewheel control is in the transmission en-

gaged position.

• Sit on seat in operating position, depress clutch/brake

pedal and set parking brake.

• Place motion control lever inneutral (N) position.

• Move attachment clutch to'DISENGAGED" position.

• Move throttlecontrol to fast position

• Pullchoke control out for a cold engine start attempt.

Fora warm engine startattemptthe choke controlmay

not be needed.

NOTE: Before starting, read the warm and cold starting

procedures below.

• Insertkeyintoignitionandturnkeyclockwise to=START,,

position and release key as soon asengine starts. Do

not run starter continuouslyfor more than fifteen sec-

onds per minute. If the engine does not start after

several attempts, push choke control in, wait a few

minutes and try again. If engine stilldoes notstart, pull

the choke controlout and retry.

WARM WEATHER STARTING (50° F and above)

• When engine starts, slowlypush choke control in until

the engine begins to runsmoothly. Ifthe engine starts

to run roughly, pullthe choke control out slightly for a

few seconds and then continue to push the control in

slowly.

• The attachments and grounddrive can now be used. If

the engine does notaccept the load, restart the engine

and allow ittowarm up forone minute usingthe choke

as described above.

COLD WEATHER STARTING (50° F and below)

• When engine starts, slowlypush choke control in until

the engine begins to run smoothly. Continue to push

the choke control in small steps allowing the engine to

accept small changes in speed and load, until the

choke control is fully in. If the engine starts to run

roughly, pull the choke control out slightly for a few

seconds and then continue to push the control in

slowly. This may require an engine warm-up period

from several seconds to several minutes, depending

on the temperature.

AUTOMATIC TRANSMISSION WARM UP

• Before driving the unit in cold weather, the transmis-

sion should be warmed up as follows:

• Be sure the tractor is on level ground.

• Place the motion control lever in neutral.

Release the parkingbrake and let the clutch/brake

slowly return to operating position.

• Allow one minute for transmission to warm up.

This can be done dudng the engine warm up

period.

• The attachments can be usedduring the engine warm-

i

I

up pedod after the transmission has been warmed up

and may requirethe choke controlbe pulledout slightly.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need tobe adjustedfor bestengine performance. See "TO

ADJUST CARBURETOR" inthe Service and Adjustments

section of this manual.

14

OPERATION

PURGE TRANSMISSION •

CAUTION: Never engage or disengage [

AI freewheel lever while the engine is run- I

I ning. I

To ensure proper operation and performance, it is recom-

mended that the transmission be purged before operating

tractor for the first time. This procedure will remove any

trapped air inside the transmission which may have devel-

oped during shipping of your tractor.

IMPORTANT: SHOULDYOURTRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT

SHOULD BE PURGED AFTER REINSTALLATION

BEFORE OPERATING THE TRACTOR.

• Place tractorsafely onlevelsurface withengine offand

parking brake set.

Disengage transmission by placing freewheel control

in freewheeling position (See "TO TRANSPORT" in

this section of manual).

Sitting inthe tractor seat, start engine. After the engine

isrunning, move throttle controlto slow position. With

motion control lever in neutral (N) position, slowly

disengage clutch/brake pedal.

• Move motion control lever to full forward position and

hold for five (5) seconds. Move lever to full reverse

position and hold for five (5) seconds. Repeat this

procedure three (3) times.

NOTE: Duringthis procedure there willbeno movement of

drivewheels. The air is being removed fromhydraulicdrive

system.

• Move motioncontrolleverto neutral (N) position. Shut-

off engine and set parking brake.

• Engage transmission by placing freewheel control in

drivingposition(See "TO TRANSPORT" inthis section

of manual).

• Sittinginthe tractor seat, startengine. Afterthe engine

is running, move throttle control to half (1/2) speed.

With motion control lever in neutral (N) position, slowly

disengage clutch/brake pedal.

• Slowly move motion control lever forward, after the

tractor moves approximately five (5)feet, slowly move

motion control lever to reverse position. After the

tractor moves approximately five(5) feet return the

motioncontrollever to the neutral (N) position. Repeat

this procedure with the motion control lever three (3)

times.

• Your tractor is now purged and now ready for normal

operation.

MOWING TIPS

• Tire chains cannot be used when the mower housingis

attached to tractor.

• Mower should be properly leveled for best mowing

performance. See "TO LEVEL MOWER HOUSING" in

the Service and Adjustments section ofthis manual.

• The left hand side of mower should be used for trim-

ming.

• Drive so that clippings are discharged onto the area

that has been cut. Have the cut area to the rightof the

tractor. This will result in a more even distribution of

clippingsand more uniform cutting.

• When mowinp large areas, start by turning to the right

so that clippings will discharge away from shrubs,

fences driveways, etc. After one or two rounds, mow

in the opposite direction making left hand tums unt

finished (See Fig. 12).

:15

If grass is extremely tall, it should be mowed twice to

reduce load and possible fire hazard from dried clip-

pings. Make first cut relatively high;the second tothe

desired height.

Do not mow grass when it iswet. Wet grass will plug

mower and leave undesirable clumps. Allow grass to

dry before mowing.

Always operate eng.ineat full throttle when mowing to

assure better mowing performance and proper dis-

charge of material. Regulate ground speed by select-

ing a low enough gear to give the mower cutting

_ehrformance as well as the quality of cut desired.

en operating attachments, select a ground speed

that will suitthe terrain and give best performance of

the attachment bein 9 used.

FIG. 12

MULCHING MOWING TIPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH. CLEAN AFTER EACH USE.

• The special mulching blade will recut the grass clip-

pings many times and reduce them in size so that as

they fall onto the lawn they will disperse intothe grass

and not be noticed. Also, the mulched grass will

biodegrade quickly to provide nutrients for the lawn.

Always mulch with your highest engine (blade) speed

as this will provide the best recutting action of the

blades.

• Avoidcuttingyour lawn when itiswet. Wet grass tends

toform clumps and interferes with the mulchingaction.

The best time to mow your lawn isthe early afternoon.

Atthis time the grass has driedand the newly cut area

will not be exposed to the direct sun.

• For bestresults, adjust the mowercuttingheight so that

the mower cuts off only the top one-third of the grass

blades (See Fig. 13). For extremely heavy muIching,

reduceyour widthof cuton each pass and mow slowly.

• Certain types of grass and grass conditions may re-

quire that an area be mulched a second time to com-

pletely hide the clippings. When doing a second cut,

mow across or perpendicular to the first cut path.

• Change your cutting pattern from week to week. Mow

northtosouth one weekthen change toeast to west the

nextweek. This will help prevent matting and graining

of the lawn.

FIG. 13

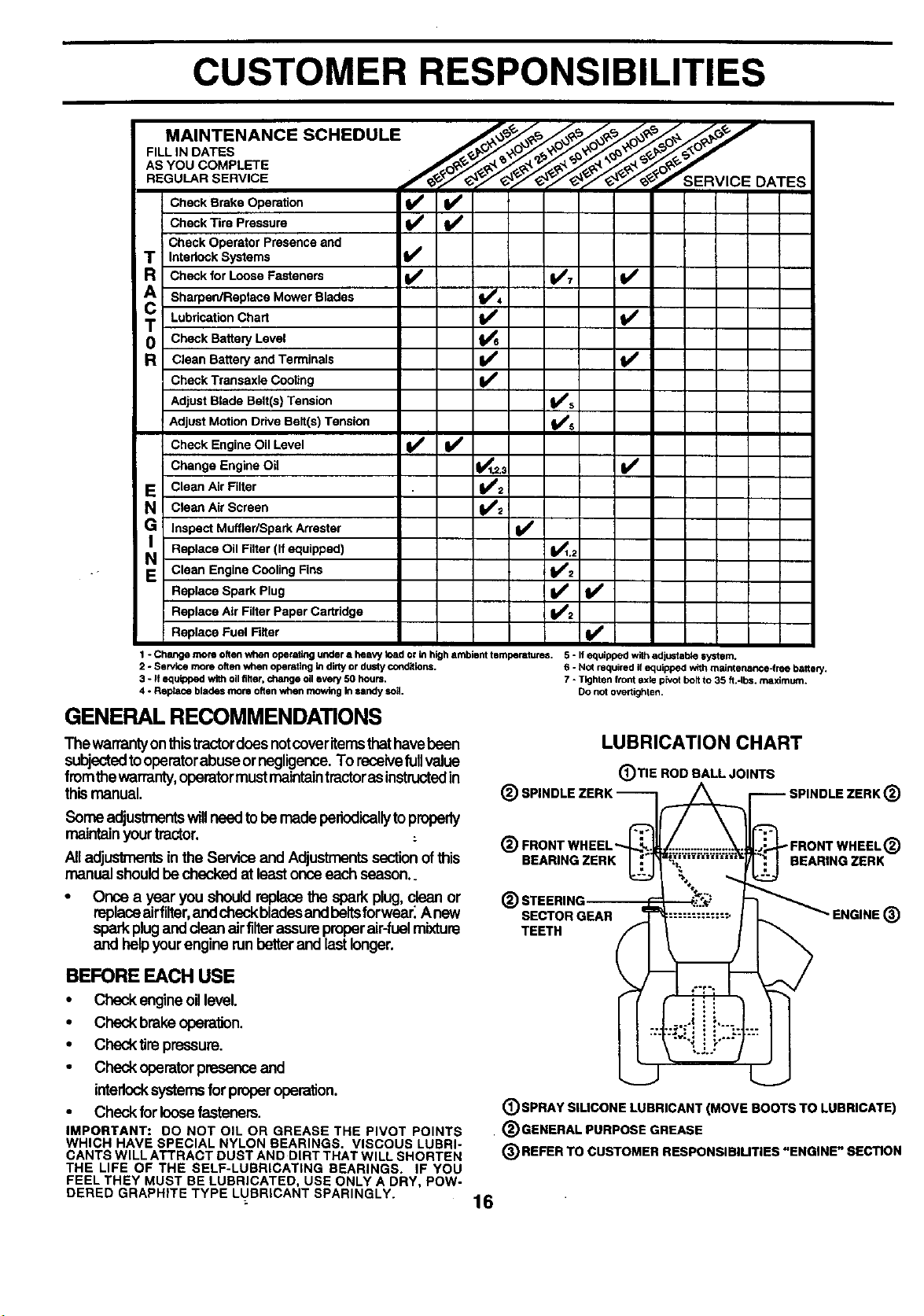

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE ,*_ _ _. ,_,_ ,_'_ c,_

AS YOU COMPLETE ,_.'_ _,'_._,'_._O_-_

REGULARSERVICE _'/_/¢_'/_/¢t_//_-//_"_/T/_'-_**'S ERVICE

cC:::: BTir:; rOsP:ur_:'°n _

Check Operator Presence and

T Intedock Systems

R Check for Loose Fasteners I_ 1_7

A SharperdReplece Mower Blades II,/'=

0 Check Battery Level

ic Lu.deat,onC.a. ,/

R Clean Battery and Terminals

Check Transaxle Cocting

Adjust Blade Belt(s) Tension tfs

Adjust Motion Drive Belt(s) Tension k/s

Check Engine Oil Level if V'

I Change Engine Oil _,2.3 If

E Clean Air Filter VP2

N Clean Air Screen V'2

DATES

Inspect Muffler/Spark Arrester If

N Replace Oil Filter (If equipped) 11_1,;

Clean Engine Cooling Fins 11_'2

Replace Spark Plug _2 I#1

Replace Air Filter Paper Cadddge

Replace Fuel Filter ¥1

1 -Chartgemomoftenwhenoperafingunderaheavytoadorinhighambienttemperatures. 5-1fequippedwfihadjustablesyotem.

2 - Service more often when operatingin dirtyor dustycor_ifions. 6 -Not required if equipped withmaintenance-free battery.

3 - If equipped withoilfilter, change oil every50 hours. 7 - Tighten front Bxle pk_otholt to 35 fi.-Ibs, maximum.

4 - Reptace blades mote oftenwhen mowing Insandy soil. Do not overtighlen.

GENERAL RECOMMENDATIONS

The warranty onthistractordoes notcover itemsthathavebeen

subjectedto operatorabuse ornegligence. To receivefullvalue

fromthe warranty,operatormust maintaintractor asinstructedin

this manual.

Some adjustmentswillneed tobe madeperiodicallytoproperly

maintainyourtractor.

Alladjustmentsinthe Serviceand Adjustmentssectionofthis

manualshouldbechecked at leastonce eachseason..

Once a year you shouldreplacethe sparkplug, clean or

replaceairfilter,andcheckbladesandbeltsforwear_Anew

sparkplug anddean airfilterassureproperair-fuelmixture

and helpyour enginerunbetterand lastlonger.

BEFORE EACH USE

• Checkengineoillevel.

• Check brakeoperation.

• Checktire pressure.

• Checkoperatorpresenceand

interlocksystemsfor properoperation.

• Checkfor loosefasteners.

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI-

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS. IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW-

DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

LUBRICATION CHART

(_)TIE ROD BALL JOINTS

_) SPINDLE ZEI (_

@ ®

BEARING ZERK BEARING ZERK

® STEERING

SECTOR GEAR "ENGINE ®

TEETH

(_)SPRAY SILICONE LUBRICANT (MOVE BOOTS TO LUBRICATE)

• (_GENERAL PURPOSE GREASE

(_REFER TO CUSTOMER RESPONSIBILITIES "ENGINE" SECTION

16

CUSTOMER RESPONSIBILITIES

TRACTOR

Always observe safety rules when performing any mainte-

nance.

BRAKE OPERATION

Iftractor requires more than six (6) feet stopping distance

at highspeed in highest gear, then brake must beadjusted.

(See "TO ADJUST BRAKE" in the Service and Adjust-

ments section of this manual).

TIRES

• Maintain proper air pressure in all tires (See =PROD-

UCT SPECIFICATIONS" section of this manual).

• Keeptires free of gasoline, oil,or insectcontrol chemi-

cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM

Be sure operator presence and interlock systems are

working properly. If your tractor does not function as

described, repair the problem immediately.

• The engine should not start unless the clutch/brake

pedal isfully depressed and attachement clutchcontrol

is in the disengaged position.

• When the engine is running, any attempt bythe opera-

tor to leave the seat without first setting the parking

brake should shut off the engine.

• When the engine is runningand the attachment clutch

is engaged, any attempt by the operator to leave the

seat should shut off the engine.

• The attachment clutch shouldnever operete unlessthe

operator is inthe seat.

TRAILING EDGE UP STAR MANDREL

BLADE

HOLE

FLAT WASHEI_

i LOCK

WASHER

HEX BOLT

(GRADE 8)*

*A GRADE 8 HEAT TREATED BOLT CAN BE

IDENTIFIEDBY SIX LINES ON THE BOLT HEAD.

FIG. 14

TO SHARPEN BLADE (See Fig. 15)

NOTE: We donot recommend sharpening blade- butifyou

do, be sure the blade is balanced.

Care should be taken to keep the blade balanced. An

unbalanced blade willcause excessive vibrationand even-

tual damage to mower and engine.

• The blade can be sharpened with a file or on a gdnding

wheel. Do not attempt to sharpen while on the mower.

• To check blade balance, you will need a 5/8" diameter

steelbolt, pin, oracone balancer. (When usingacone

balancer, follow the instructions supplied with bal-

ancer).

NOTE: Do notuse a nail for balancing blade. The lobes of

the center hole may appear to be centered, but are not.

• Slide bladeon to an unthreaded portionofthe steelbolt

or pinand hold the boltor pin parallel with the ground.

If blade is balanced, it should remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

ASSEMBLY

BLADE CARE

For best results mower blades must be kept sharp. Re-

place bent or damaged blades.

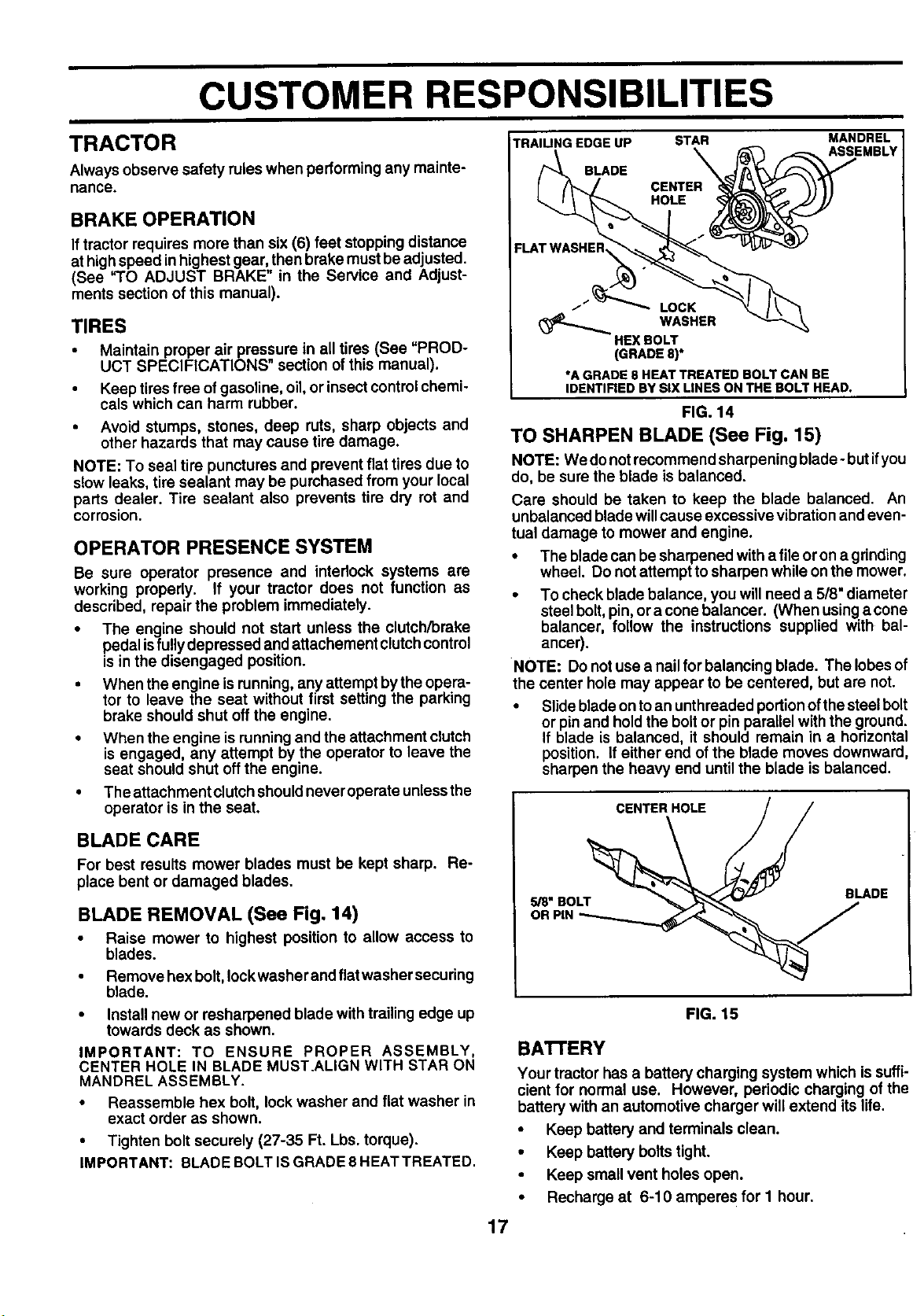

BLADE REMOVAL (See Fig. 14)

• Raise mower to highest position to allow access to

blades.

• Remove hex bolt,lockwasher and flatwasher securing

blade.

• Install new or resharpened blade with trailing edge up

towards deck as shown.

IMPORTANT: TO ENSURE PROPER ASSEMBLY,

CENTER HOLE IN BLADE MUST.ALIGN WITH STAR ON

MANDREL ASSEMBLY.

• Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

• Tighten bolt securely (27-35 Ft. Lbs. torque).

IMPORTANT: BLADE BOLT ISGRADE 8 HEAT TREATED.

FIG. 15

BATrERY

Your tractor has a battery charging system which is suffi-

cient for normal use. However, periodic charging of the

battery with an automotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

Keep small vent holes open.

Recharge at 6-10 ampere s for I hour.

17

CUSTOMER RESPONSIBILITIES

NOTE: The original equipment battery on your tractor is

maintenance free. Do not attempt toopen or remove caps

or covers. Adding or checking level of electrolyte is not

necessary.

TO CLEAN BATI'ERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to "leak" power.

• Remove terminal guard.

• Disconnect BLACK battery cable first then RED bat-

tery cable and remove battery from tractor.

• Rinse the battery with plain water and dry.

TRANSAXLE COOLING

The fan and cooling fins of transmission should be kept

clean to assure proper cooling.

Do notattempt to clean fan or transmission while engine is

running or while the transmission is hot. To prevent

possibledamage to seals, no not use high pressure water

or steam to clean transaxle.

• Inspect coolingfan to be surefan blades are intactand

clean.

• Inspect cooling fins for dirt, grass clippings and other

materials. To prevent damage to seals, do not usa

compressed air or high pressure sprayer to clean

cooling fins.

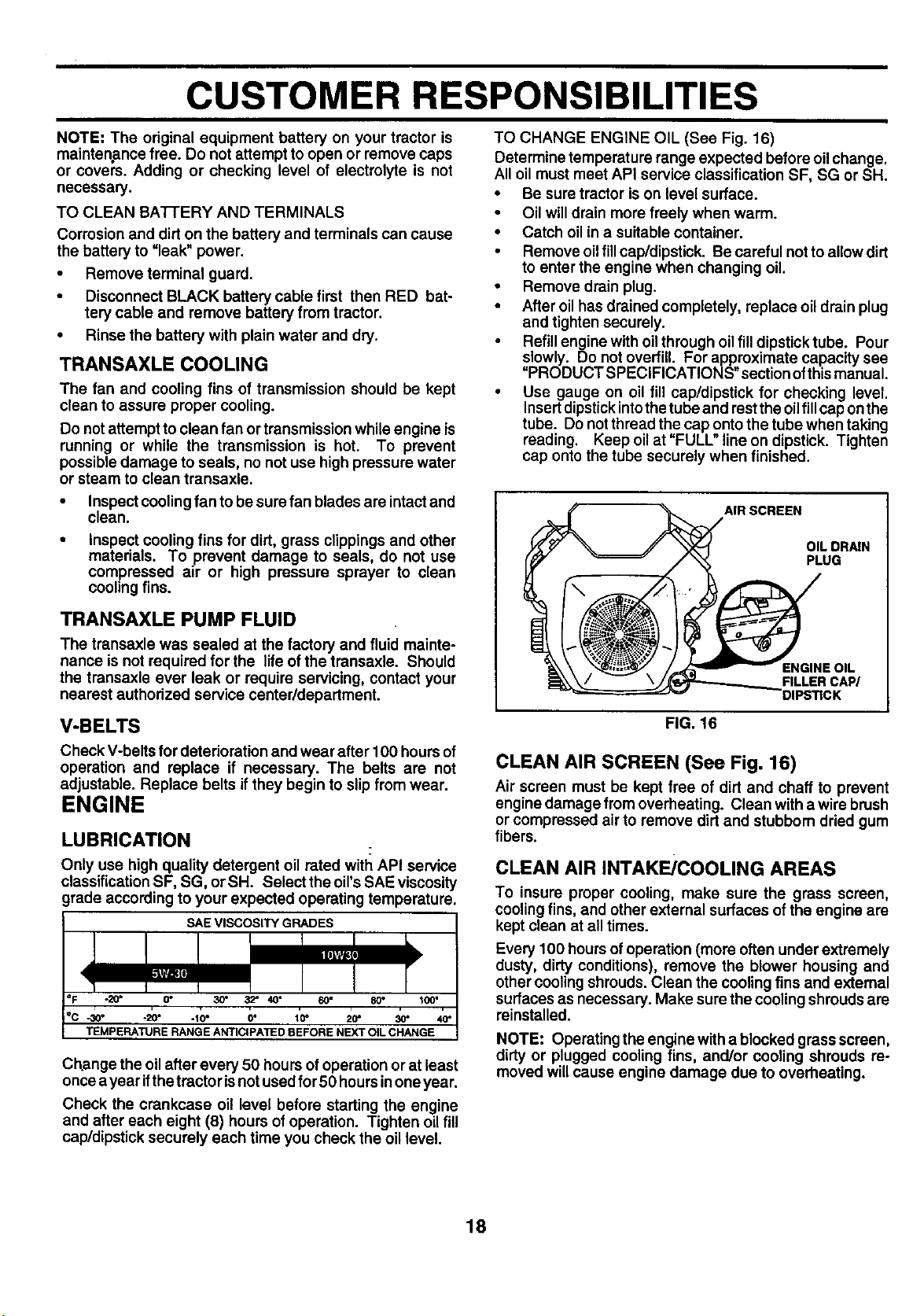

TO CHANGE ENGINE OIL (See Fig. 16)

Determine temperature range expected before oil change.

All oil must meet API service classification SF, SG or SH.

• Be sure tractor is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

• Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine when changing oil.

• Remove drain plug.

• After oil has drained completely, replace oil drain plug

and tighten securely.

Refill engine with oil through oil fill dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

"PRODUCT SPECIFICATIONS" section ofthis manual.

• Use gauge on oil fill cap/dipstick for checking level.

Insert dipstick into the tube and rest the oil fill cap on the

tube. Do not thread the cap onto the tube when taking

reading. Keep oil at "FULL" line on dipstick. Tighten

cap onto the tube securely when finished.

AIR SCREEN

OIL DRAIN

PLUG

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory and fluid mainte-

nance is notrequired for the life of the transaxle. Should

the transaxle ever leak or require servicing, contact your

nearest authorized service center/department.

V-BELTS

Check V-belts for deterioration and wear after 100 hoursof

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin to slip from wear.

ENGINE

LUBRICATION

Only use high quality detergent oil rated with API service

classification SF, SG, or SH. Select the oirs SAE viscosity

grade according to your expected operating temperature.

SAE VISCOSITY GRADES

-20"

-30" -20" *10" 0_ 10" 20" 30'

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

Change the oil after every 50 hours of operationor at least

once ayear ifthetractor is not usedfor 50 hours inone year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level.

ENGINE OIL

FILLER CAP/

FIG. 16

CLEAN AIR SCREEN (See Fig. 16)

Air screen must be kept free of dirt and chaff to prevent

engine damage from overheating. Clean with a wire brush

or compressed air to remove dirt and stubborn dried gum

fibers.

CLEAN AIR INTAKE/COOLING AREAS

To insure proper cooling, make sure the grass screen,

coolingfins, and other external surfaces of the engine are

kept clean at all times.

Every 100 hours of operation (more often underextremely

dusty, dirty conditions), remove the blower housing and

other cooling shrouds. Clean the cooling fins and external

surfaces as necessary. Make sure the cooling shroudsare

reinstalled.

NOTE: Operating the engine with a blocked grass screen,

dirty or plugged cooling fins, and/or cooling shrouds ra-

moved willcause engine damage due to overheating.

18

Loading...

Loading...