Craftsman 944.609760 Owner's Manual

SF.ARS

OWNER'S

MANUAL

MODEL NO,

944.609760

Caution:

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

£RAFTSMAN°

16.0 HP

ELECTRIC START

42" MOWER

6 SPEED TRANSAXLE

LAWN TRACTOR

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

£Z 3

Sears Canada, Inc., Toronto, Ontario M5B 2B8

SAFETY RULES

, Safe Operation Practices for Ride-On Mowers

IMPORTANT: THIS CU'I-I'ING MACHINE IS cAPABLE OF AMPUTATING HANDS AND FEET AND THROWING

OBJECTS. FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS

INJURY OR DEATH.

I. GENERAL OPERATION

• Read, understand, and follow all instructionsin the manual

and on the machine before starting.

Only allow responsible adults, who are familiar with the

instructions,to operate the machine.

Clear the area of ob ects such as rocks, toys, wire, etc,,

which could be p cked up and thrown by the bade.

Be surethe area isclear of other peoplebefore mowing.Stop

machine ifanyone enters the area.

• Never carry passengers.

Do not mow in reverse unless absolutely necessary. Always

lookdown and behind before and while backing.

Be aware ofthe mower discharge directionand do not point

it at anyone. Do n_,,operate the mower wi_houLeither the

entire grass catcher or the guard inplace.

Slow down before turning.

Never leave a runningmachine unattended. Always turn off

blades, set parking brake, stop engine, and remove keys

before dismounting.

Turn off blades when not mowing.

Stop engine before removing grass catcher or unclogging

chute.

Mow only indaylight orgood artificial light.

Do not operate the machine while under the influence of

alcoholor drugs.

Watch fortraffic when operating near orcrossingroadways.

• Use extra care when loadingor unloading the machine into

a trailer or truck.

II. SLOPE OPERATION

Slopes are ama or factor related to loss-of-control and tipover

accidents, which can result in severe inury or death. All slopes

requ re extra caut on. fyou cannot back upthe slope orifyou feet

uneasy on it, do not mow it.

DO:

Mow up and down slopes, not across.

Remove obstacles such as rocks, tree limbs, etc.

Watch for holes, ruts, or bumps. Uneven terrain could

overtum the machine. Tall grass can hide obstacles.

• Use slow speed. Choose a low gear so thatyou willnot have

to stop or shift while on the slope.

Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

Use extra care with grass catchers or other attachments.

These can change the stability of the machine.

Keep all movement on the slopes slowand gradual. Do not

make sudden changes inspeed or direction.

Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straightdownthe

slope.

" -Do NOTi

Donot turnonslopes unless necessary, andthen, turnslowly

and gradually downhill, if possible.

Do notmow near drop-offs, ditches, orembankments. The

mower could suddenly turn over if a wheel is over the edge

ofa cliffor ditch, or if an edge caves in.

Do not mow on wet grass. Reduced traction could cause

sliding.

Do not tryto stabilizethe machine byputtingyour feet onthe

ground.

IlL CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence ofchildren. Children are oftenattracted tothe machine

and the mowingactivity. Neverassume that children willremain

where you last saw them.

Keep childrenout ofthe mowing area and under the watchful

care of another responsible adult.

Be alert and turn machine off if children enter the area.

• Before and when backing, look behind and down for small

children.

Never carry children. They may fall off and be seriously

injured or interfere with safe machine operation,

Never allow children to operate the machine.

Use extra care when approaching blind comers, shrubs,

trees, or other objects that may obscure vision.

IV. SERVICE

Use extra care inhandlinggasoline and other fuels. They are

flammable and vapors are explosive,

Use only an approved container.

Never remove gas cap or add fuel with the engine

running. Allow engine to cool before refueling. Do not

smoke.

Never refuel themachine indoors.

Never store the machine or fuel container inside where

there is an open flame, such as a water heater.

Never run a machine inside a closed area.

• Keep nutsand bolts,especially blade attachment bolts,tight

and keep equipment in good condition.

Never tamper with safety devices. Check their proper

operation regularly.

Keep machine free of grass, leaves, orother debds build-up.

Clean oil or fuel spillage. Allow machine to cool before

stodng.

Stop and inspect the equipment if you strike an object.

Repair, if necessary, before restarting.

• Never make adjustments or repairswith the engine running.

Grass catcher componentsare sub ect to wear, damage, and

detedoration, which cou d expose mov ng pads or aow

objects to be thrown. Frequently check components and

replace withmanufacturer'srecommended parts, when nec-

essary.

Mewer blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when servicing them.

Check brake operation frequently. Adjust and service as

required.

Look for this symbol to point out impor- I

tant safety precautions. It means

CAUTION!!I BECOMEALERTIH YOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark

plug wire and place wire where it cannot

contact spark plug in order to prevent

accidental starting when setting up,

transporting, adjusting or making

repairs.

Do not use grass catcher on steep slopes.

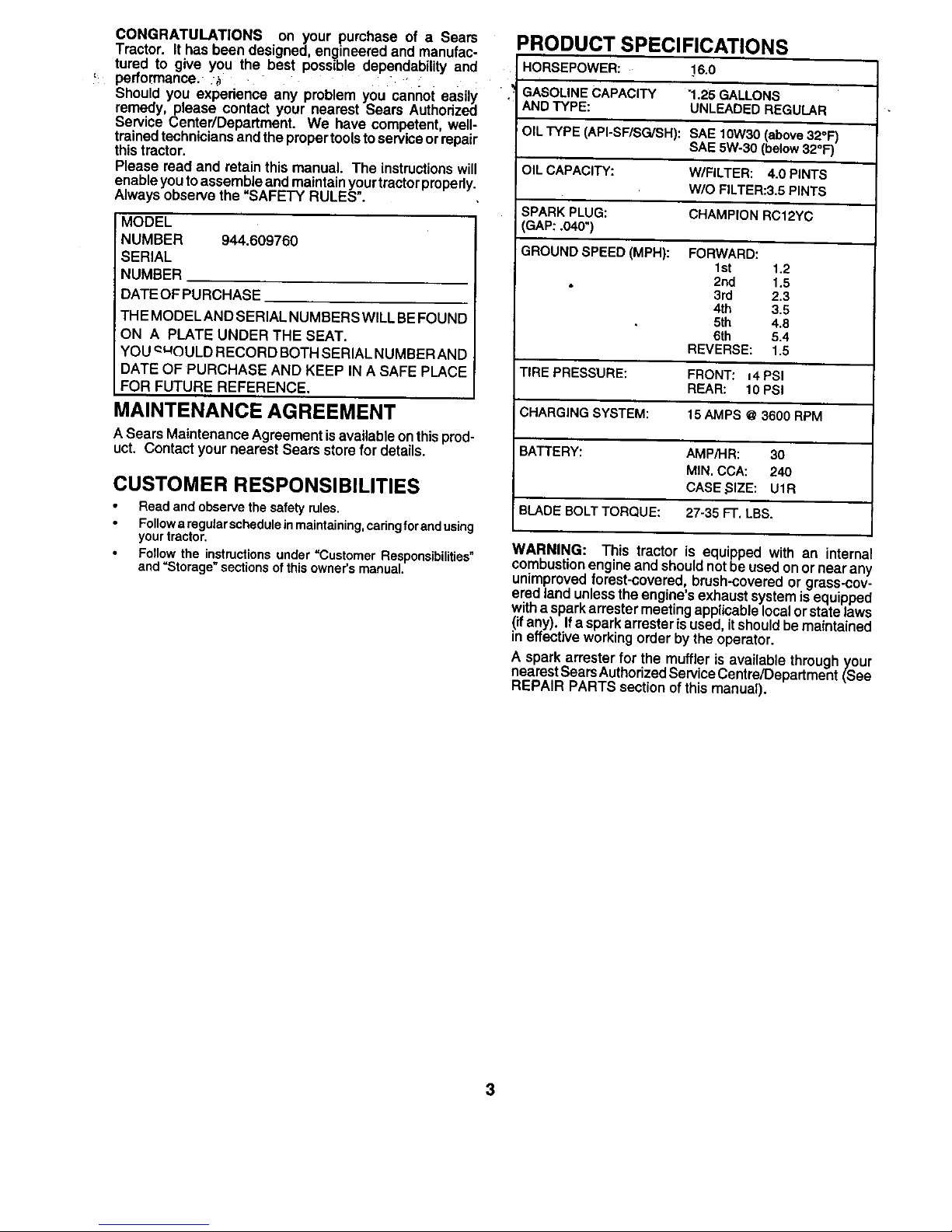

CONGRATULATIONS on your purchase of a Sears

Tractor. It has been designed, engineered and manufac-

tured to give you the best possible dependability and

_ performance. _ . " . .

Should you expedence any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service CentedDepartment. We have competent, well-

trained technicians and the proper tools toservice or repair

this tractor.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your tractor properly.

Always observe the "SAFETY RULES".

MODEL

NUMBER 944.609760

SERIAL

NUMBER

DATEOF PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE FOUND

ON A PLATE UNDER THE SEAT.

YOU _OULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available onthisprod-

uct. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

Readandobservethesafetyrules.

Fellowaregularscheduleinmaintaining,caringforandusing

yourtractor.

• FoTIowthe instructionsunder"Customer Responsibilities"

and=Storage"sectionsofthisowner'smanual.

PRODUCT SPECIFICATIONS

HORSEPOWER: 16.0

GASOLINECAPACITY 1.25 GALLONS

ANDTYPE: UNLEADEDREGULAR

OIL TYPE (API-SF/SG/SH): SAE 10W30 (above 32°F)

SAE 5W-30 (below 32°F)

OIL CAPACITY: W/FILTER: 4.0 PINTS

W/O FILTER:3.5 PINTS

SPARK PLUG: CHAMPION RC12YC

GAP: .040")

GROUND SPEED (MPH): FORWARD:

1st 1.2

2rid 1.5

3rd 2.3

4th 3.5

5th 4.8

6th 5.4

REVERSE: 1.5

TIRE PRESSURE: FRONT: 14PSI

REAR: 10PSi

CHARGING SYSTEM: 15 AMPS @3600 RPM

BATTERY: AMPiHR: 30

MIN. CCA: 240

CASE _SIZE: U1R

i

BLADE BOLT TORQUE: 27-35 FT. LBS.

WARNING: This tractor Is equipped with an internal

combustionengine and shouldnotbe used onor near any

unimprovedforest-covered, brush-coveredor grass-cov-

ered land unlessthe engine's exhaust system is equipped

with a sparkarrester meetingapplicable localor state laws

(ifany). Ifa spark arrester isused,it shouldbe maintained

in effectiveworking order by the operator.

A spark arrester for the muffler is available throughyour

nearestSearsAuthorizedService Centre/Department (See

REPAIR PARTS section of this manual).

3

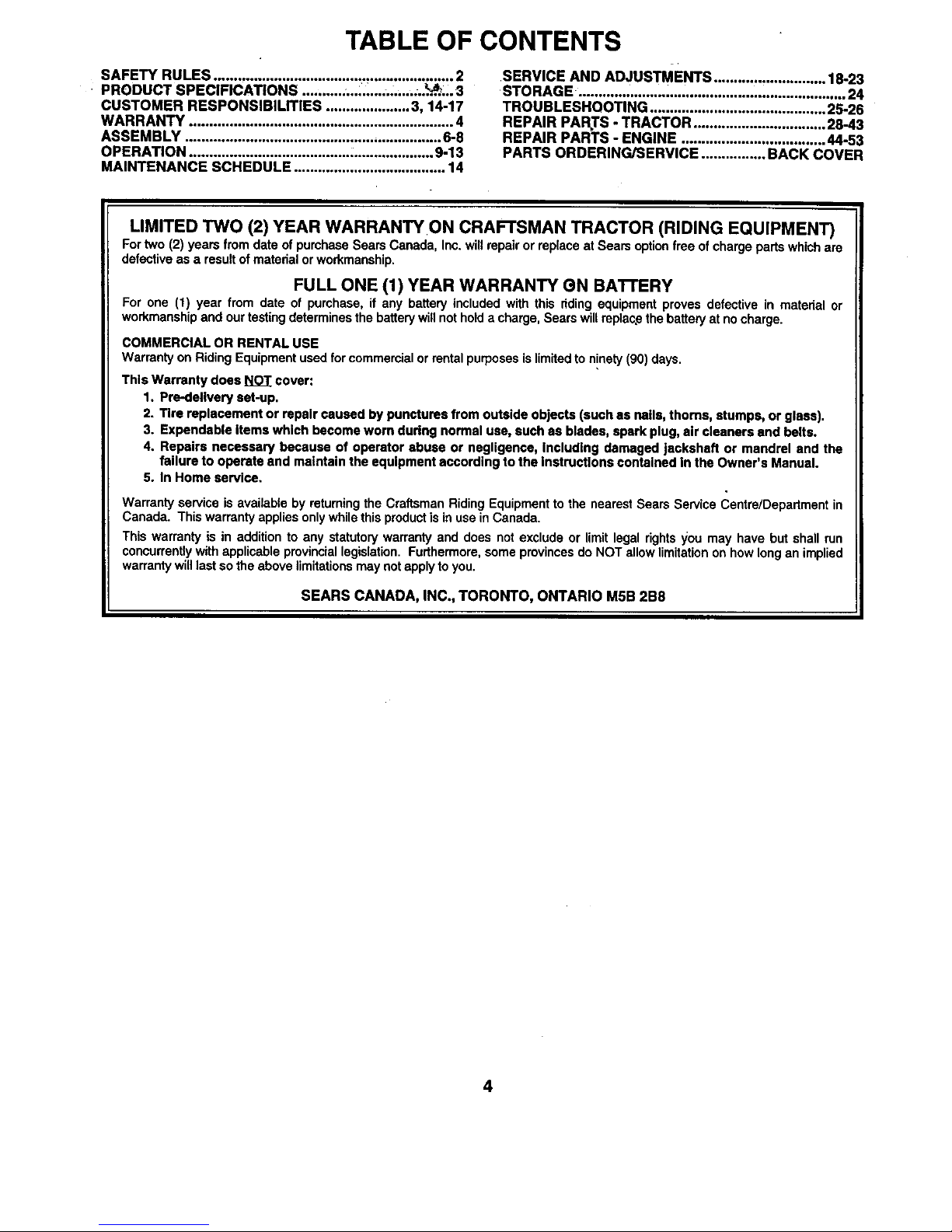

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

• PRODUCT SPECIFICATIONS .......... :..._,....... ,...:...._#J_'.3

CUSTOMER RESPONSIBILITIES ..................... 3, 14-17

WARRANTY .................................................................. 4

ASSEMBLY ................................................................ 6-8

OPERATION ........................................ ..................... 9-13

MAINTENANCE SCHEDULE ...................................... 14

SERVICE AND ADJUSTMENTS ............................ 18-23

STORAGE ...................... ............................................. 24

TROUBLESHOOTING ............................................ 25-26

REPAIR PARTS - TRACTOR ................................. 28-43

REPAIR PARTS - ENGINE .................................... 44-53

PARTS ORDERING/SERVICE ................ BACK COVER

LIMITED TWO (2) YEAR WARRANTY ON CRAFTSMAN TRACTOR (RIDING EQUIPMENT)

For two (2) years from date of purchase Sears Canada, Inc. will repair or replace at Sears optionfree of charge parts which are

defective as a result ofmaterial orworkmanship.

FULL ONE (1) YEAR WARRANTY GN BA'I-rERY

For one (1) year from date of purchase, if any battery included with this riding equipment proves defective in materiel or

workmanship and our testing determines the batterywill nothold a charge, Sears will replac,ethe battery at no charge.

COMMERCIAL OR RENTAL USE

Warranty on Riding Equipment used for commemiel or rental purposesis limitedton!nety (90) days.

This Warranty does NOT cover:

1. Pre-dellvery set-up.

2. Tire replacement or repair caused by punctures from outside objects (such as nails, thorns, stumps, or glass).

3. Expendable items which become worn dudng normal use, such as blades, spark plug, air cleaners and belts.

4. Repairs necessary because of operator abuse or negligence, Including damaged jaoksheft or mandrel end the

failure to operate and maintain the equipment according to the Instructions contained In the Owner's Manual.

5. In Home service.

Warranty service is available by returningthe Craftsman Riding Equipmentto the nearest Sears Service Centre/Department in

Canada. This warranty applies onlywhile this productis inuse inCanada.

This warranty is in addition to any statutory warranty and does not exclude or limit legal rights you may have but shall run

concurrentlywith applicable provinciallegislation. Furthermore, some provinces do NOT ellow limitationon how long an implied

warranty will lastso the above limitationsmay not apply to you.

SEARS CANADA, INC., TORONTO, ONTARIO M5B 2B8

4

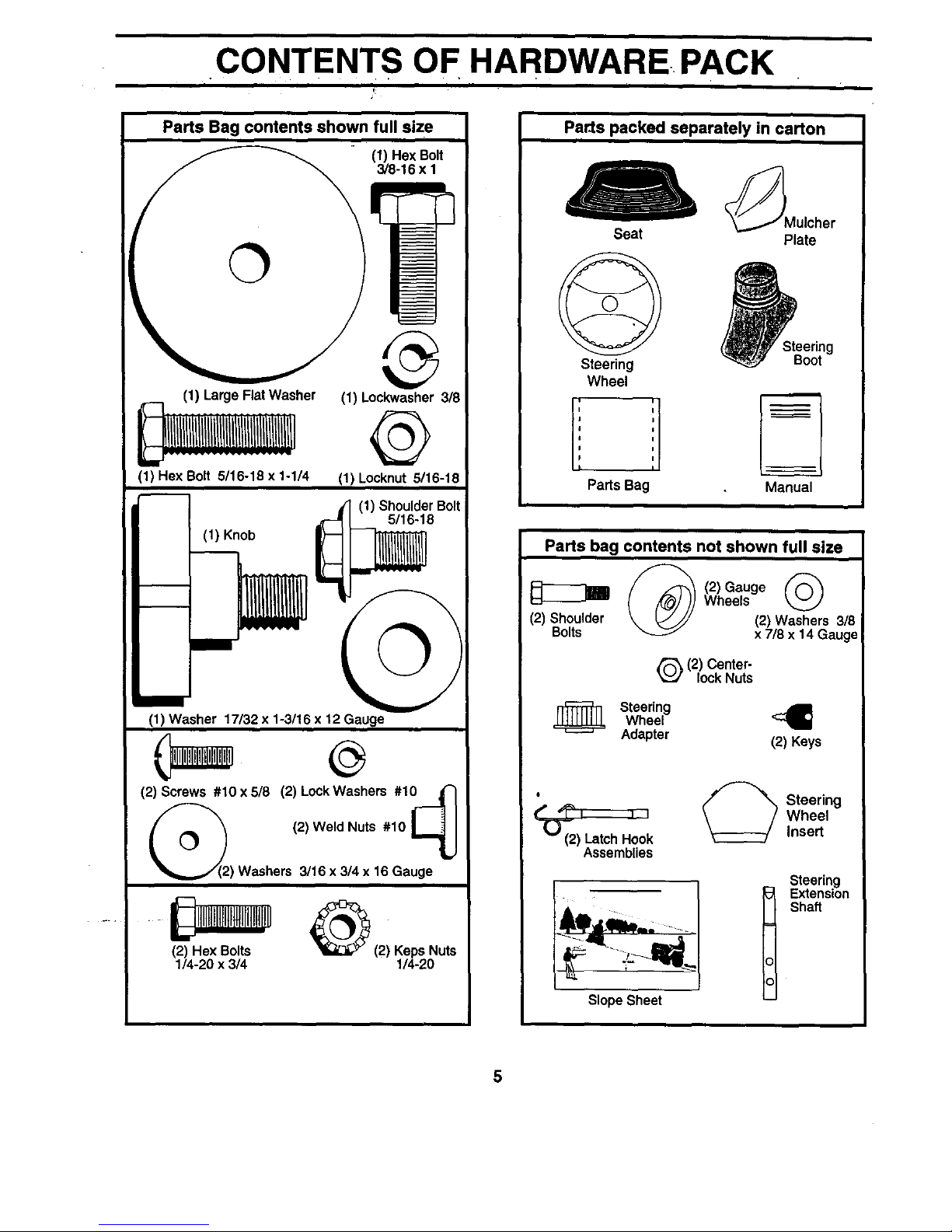

CONTENTS OF HARDWARE-. PACK

T

Parts Bag contents shown full size

(1) Hex Bolt

3/8-16 x 1

O

(1) Large Flat Washer

(1) Hex Bolt 5/16-18 x 1-1/4

(1) Knob

(1) Lockwasher 3/8

@

11)Locknut 6/16-18

(1) ShoulderBolt

5/16-18

©

R

(1) Washer 17132x 1-3/16 x 12 Gauge

(2) Screws #10 x5/8 (2) LockWashers #101 _

_2_we,d.uts.10I--_

c-31

"_...,,J(2) Washers 3/16 x 3/4 x 18 Gauge

(2) Hex Bolts Nuts

1/4-20 x 3/4 1/4-20

Parts packed separately in carton

_Mulcher

Seat Plate

Steering

Wheel

i i

;teering

Boot

Pa_s Bag Manual

Parts bag contents not shown full size

_ _2_Gauge

Wheels

(2) Shoulder (2) Washers 3/8

Bolts x 7/8 x 14 Gauge

Q(2) Center-

lockNuts

Steering

Wheel

Adapter (2) Keys

° Steering

W.ee,

(2) LatchHook Insert

Assemblies

SlopeSheet

Steering

Extension

Shaft

5

, ASSEMBLY

Your new tractorhas been assembled at the factory with exception ofthose parts left unassembled for shippingpurposes.

To ensure safe and properoperation ofyourtractor, all partsand hardware youassemble mustbe tightened securely. Use

the correct tools as necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench setwill make assemblyeasier. Standard

• wrench sizes are listed.

(1) Phillipsscrewdriver Utility knife

(2) 7/16" wrenches Tire pressure gauge

(2) 1/2" wrenches (1) 3/4" socket with drive ratchet

(1) 9/16" wrenche

When right and left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton (See page 6).

• Cut, from topto bottom, along lines on allfour comers

of carton, and lay panels flat.

• Check for any additional loose parts or cartons and

remove.

BEFORE ROLLING TRACTOR OFF SKID

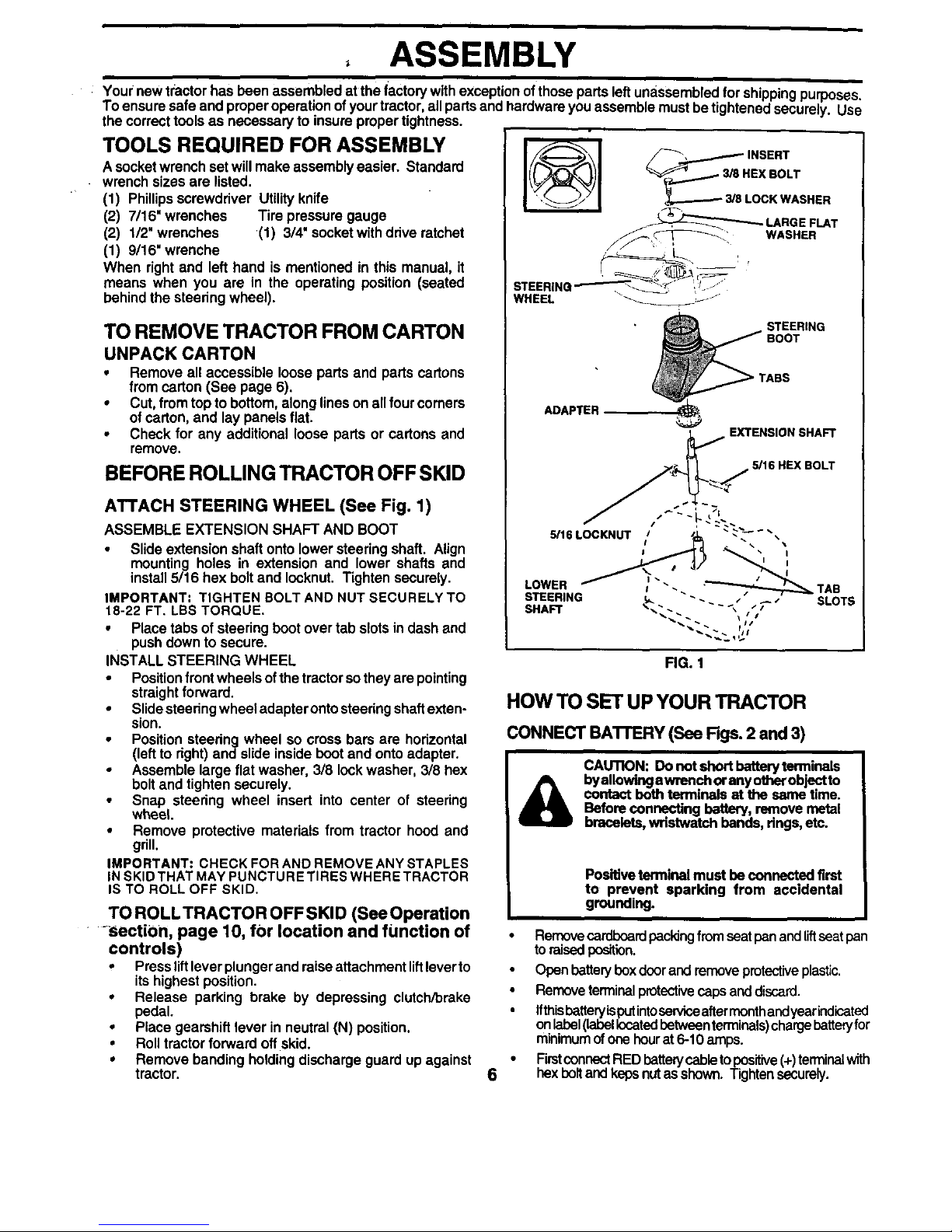

ATTACH STEERING WHEEL (See Fig. 1)

ASSEMBLE EXTENSION SHAFT AND BOOT

• Slide extension shaft onto lowersteedng shaft. Align

mounting holes in extension and lower shafts and

install5116 hex boltand Iocknut. Tighten securely.

IMPORTANT: TIGHTEN BOLT AND NUT SECURELY TO

18-22 FT. LBS TORQUE.

• Place tabs of steering boot over tab slotsin dash and

pushdown to secure.

INSTALL STEERING WHEEL

• Positionfront wheels ofthe tractor so theyare pointing

straightforward.

• Slide steeringwheel adapterontosteering shaftexten-

sion.

• Position steedng wheel so cross bars are horizontal

(leftto right)and slide insideboot and onto adapter.

• Assemble large flat washer, 3/8 lockwasher, 3/8 hex

bolt and tighten securely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective materials from tractor hood and

grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

INSKIDTHAT MAY PUNCTURE TIRES WHERE TRACTOR

IS TO ROLL OFF SKID.

TO ROLLTRACTOR OFFSKID (SeeOperation

-section, page 10, for location and function of

controls)

• Press liftlever plunger and raise attachment liftlever to

its highest position.

• Release parking brake by depressing clutch/brake

pedal.

• Place gearshiftlever in neutral (N) position.

• Roll tractor forward off skid.

• Remove banding holdingdischarge guard up against

tractor.

INSERT

EX BOLT

LOCK WASHER

LARGE FLAT

_ \_ WASHER

STEERINQ.--------_-_ _- ,j •

WHEEL _JJ

__ STEERING

BOOT

TASS

ADAPTER _

EXTENSION SHAFT

5/16 HEX BOLT

FIG. 1

HOW TO SET UP YOUR TRACTOR

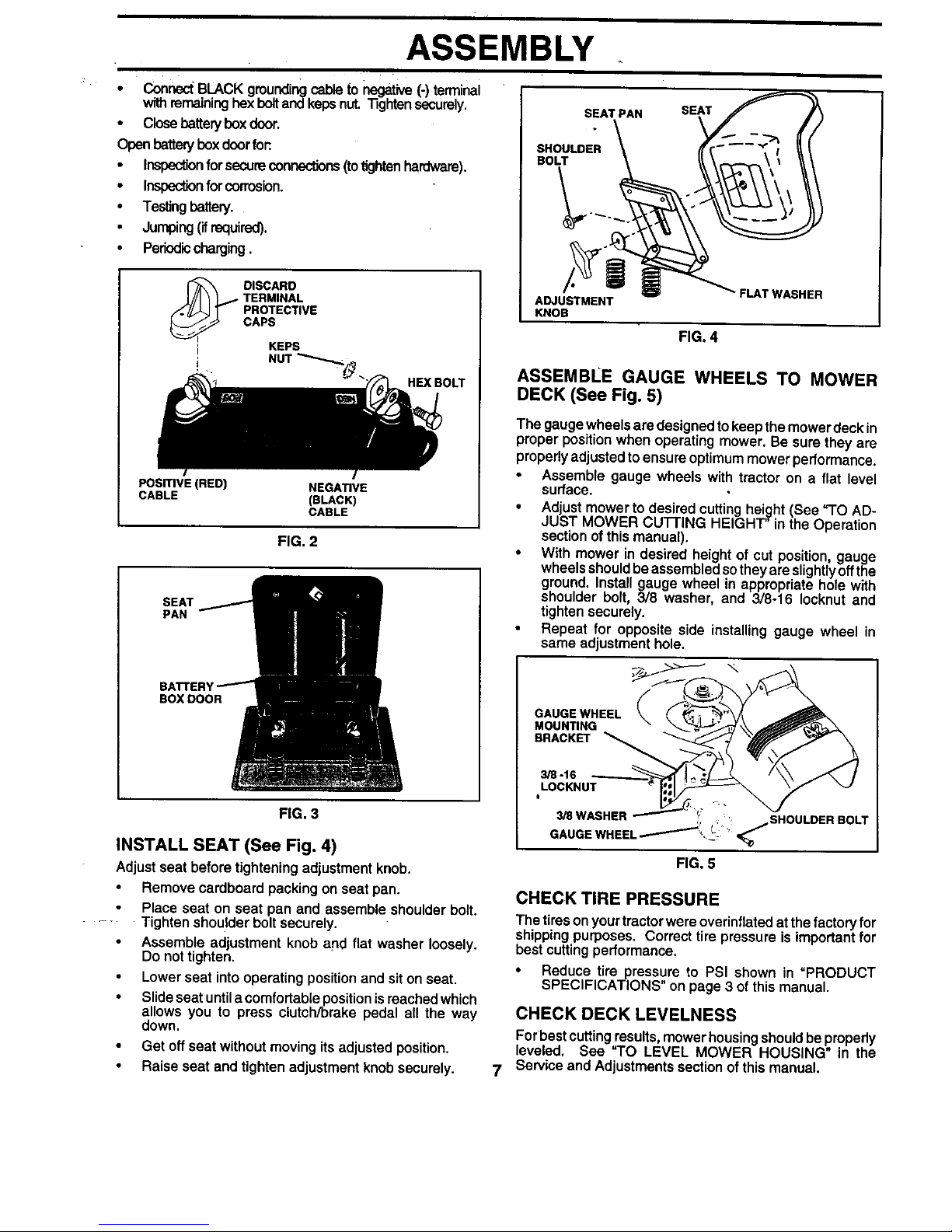

CONNECTBA'FrERY (See Rgs. 2 and3)

CAUTION: Do not short batteryterminals

byallowingawrench orany otherobjectto

contact both terminals at the same time.

Beforeconnecting battery, remove metal

bracelets,wristwatch bends, rings,etc.

6

Positiveterminal must be connected first

to prevent sparking from accidental

grounding.

• Removecardboard packingfromseat pan andliftseat pan

toraisedposition.

• Open bettery boxdoor and removeprotectiveplastic.

• Removeterminalprotectivecapsanddiscard.

• Ifthisbetteryisputintoserviceaftermonthandyearindicated

onlabel(labellocatedbetweenterminals)chargebatteryfor

minimumofonehourat 6-10arnps.

• FirstconnectREDbetterycabletoposiUve(+)terminalwith

hexbolt and keps nutas shown. Tightensecurely.

i

ASSEMBLY

• connect BLACKgroundingcableto negative(-) terminal

withremaininghexboltandkeps nut. _ghten securely.

• Closebatteryboxdoor.

Open battery boxdoorfor:

• Inspection forsecureconnections(totightenhardware).

• Inspection forcorrosion.

• TesUngbattery.

• Jumping (ifrequired).

• Periodiccharging.

_ ISCARD

TERMINAL

PROTECTIVE

CAPS

KEPS

i

HEX BOLT

POSITIVE (RED) NEGATIVE

CABLE (BLACK)

CABLE

FIG, 2

SEAT

PAN

BOX DOOR

FIG. 3

iNSTALL SEAT (See Fig. 4)

Adjust seat before tightening adjustment knob.

• Remove cardboard packing on seat pan.

Place seat on seat pan and assemble shoulder bo_t,

Tighten shoulder bolt securely.

Assemble adjustment knob and flat washer loosely.

Do not tighten.

Lower seat intooperating positionand sit onseat,

• Slide seat untila comfortableposition isreached which

allows you to press clutch/brake pedal all the way

down.

Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment knob securely.

SEAT PAN SEAT

SHOULDER

BOLT

ADJUSTMENT

KNOB

FIG. 4

• FLAT WASHER

ASSEMBLE GAUGE WHEELS TO MOWER

DECK (See Fig. 5)

The gaugewheels are designed tokeep themower deck in

proper position when operating mower. Be sure they are

properlyadjusted toensure optimummowerperformance.

• Assemble gauge wheels with tractor on a flat level

surface.

• Adjust mowerto desired cuttinghei,,ght(See %0 AD-

JUST MOWER CU]-FING HEIGHT' in the Operation

sectionof thismanual).

• With mower in desired height of cut position, gauge

wheels shouldbe assembledsotheyare slightlyoffthe

ground. Install gauge wheel in appropriate hole with

shoulder bolt, 3/8 washer, and 3/8-16 Iocknut and

tighten securely.

• Repeat for opposite side installing gauge wheel in

same adjustmenthole.

GAUGE WHEEL

MOUNTING

BRACKET

7

3/8-16

LOCKNUT

I

3/S WASHER

ISHOULDER BOLT

GAU EWNEEL :

FIG. 5

CHECK TIRE PRESSURE

The tireson your tractorwere overinflated atthe factoryfor

shipping purposes. Correct tire pressure is importantfor

best cutting performance,

• Reduce tire pressure to PSi shown in "PRODUCT

SPECIFICATIONS on page 3 of this manual.

CHECK DECK LEVELNESS

Forbest cuttingresults, mowerhousingshould beproperly

leveled. See "TO LEVEL MOWER HOUSING" in the

Service and Adjustmentssection ofthis manual.

ASSEMBLY

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for rep!acing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to Operate your tractor,check to see

that the brake is propedy adjusted. See "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual.

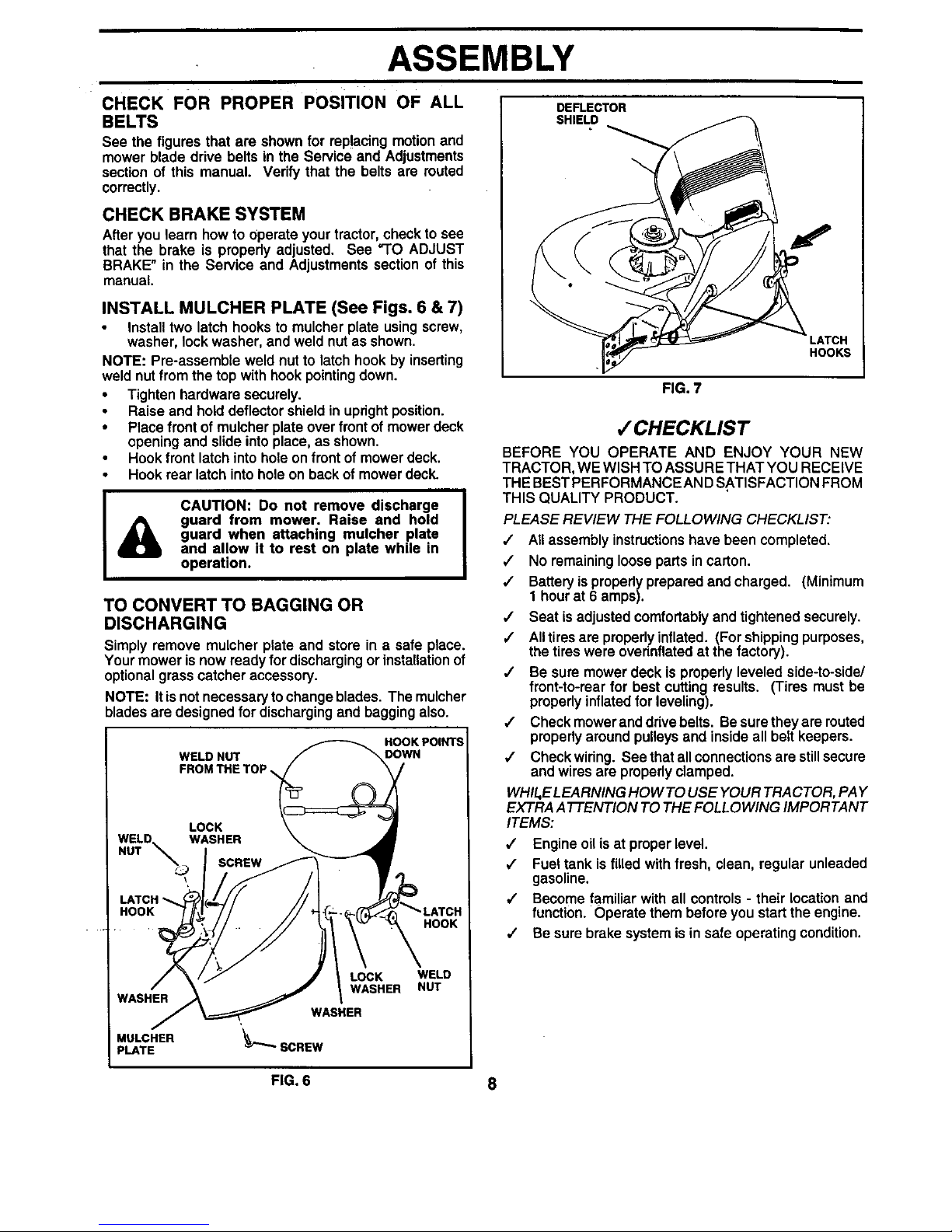

INSTALL MULCHER PLATE (See Figs. 6 & 7)

Install two latch hooks to mulcher plate using screw,

washer, lock washer, and weld nut as shown.

NOTE: Pre-assemble weld nut to latch hook by inserting

weld nutfrom the top withhook pointingdown.

• Tighten hardware securely.

• Raise and hold deflector shield in upright position.

• Place front of mulcher plate over frontof mower deck

opening and slide into place, as shown.

• Hook front latch into hole on front of mower deck.

• Hook rear latch into hole on back of mower deck.

A

CAUTION: Do not remove discharge

guard from mower. Raise and hold

guard when attaching mulcher plate

and allow it to rest on plate while in

operation.

TO CONVERT TO BAGGING OR

DISCHARGING

Simply remove mulcher plate and store in a safe place.

Your mower is now ready for discharging or installationof

optional grass catcher accessory.

NOTE: It is not necessaryto change blades. The mulcher

blades are designed for discharging and bagging also.

HOOK POINTS

WELD NUT DOWN

LOCK

WELD. WASHER

NUT _

'.23' SCREW

\

LATCH

HOOK

HOOK

WASHER

MULCHER

PLATE

LOCK WELD

WASHER NUT

DEFLECTOR

SHIELD

FIG. 7

LATCH

HOOKS

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TO ASSURE THAT YOU RECEIVE

THE BESTPERFORMANCE AN DSATISFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

,/ All assembly instructionshave been completed.

,/ No remaining loose partsin carton.

,/ Batteryis propedy prepared and charged. (Minimum

1 hourat 6 amps).

,/ Seat isadjusted comfortably andtightened securely.

,/ Alltiresare propedy inflated. (For shippingpurposes,

the tires were overinflatedat the factory).

•/ Be sure mower deck is properlyleveled side-to-side/

front-to-rear for best cutting results. (Tires must be

properly inflated for leveling).

/ Check mower anddrivebelts. Besure they are routed

properlyaround pulleys and inside all belt keepers.

/ Check wiring. See thatall connections are stillsecure

and wires are properlyclamped.

WI-tlt,ELEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

,/ Engine oil isat proper level.

,/ Fuel tank isfilled with fresh, clean, regular unleaded

gasoline.

,,/ Become familiar withall controls - their location and

function. Operate them before you startthe engine.

,/ Be sure brake system is in safe operating condition.

FIG. 6 8

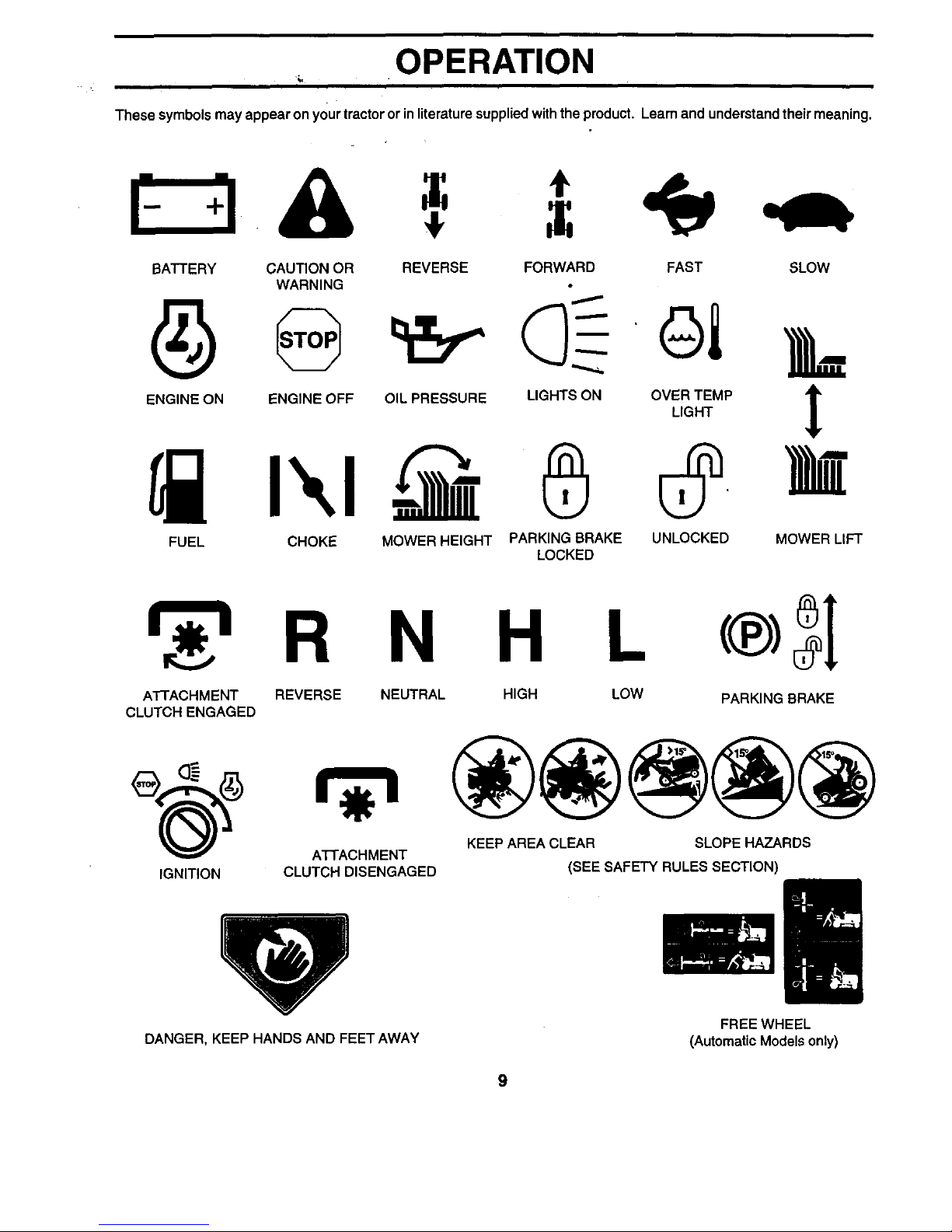

OPERATION

These symbolsmay appear on yourtractor or in literaturesuppliedwiththe product. Learn and understandtheir meaning.

BATTERY CAUTION OR REVERSE FORWARD FAST SLOW

WARNING

ENG,NEONENG,NEOFFO,LPRESSUREL.G._SONOV_,_E#PI

FUEL CHOKE MOWER HEIGHT PARKING BRAKE UNLOCKED MOWER LIFT

LOCKED

H L

ATTACHMENT REVERSE NEUTRAL HIGH LOW

CLUTCH ENGAGED

IGNITION

AI-I'ACHMENT

CLUTCH DISENGAGED

PARKING BRAKE

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION)

DANGER, KEEP HANDS AND FEET AWAY

FREE WHEEL

(Automatic Models only)

9

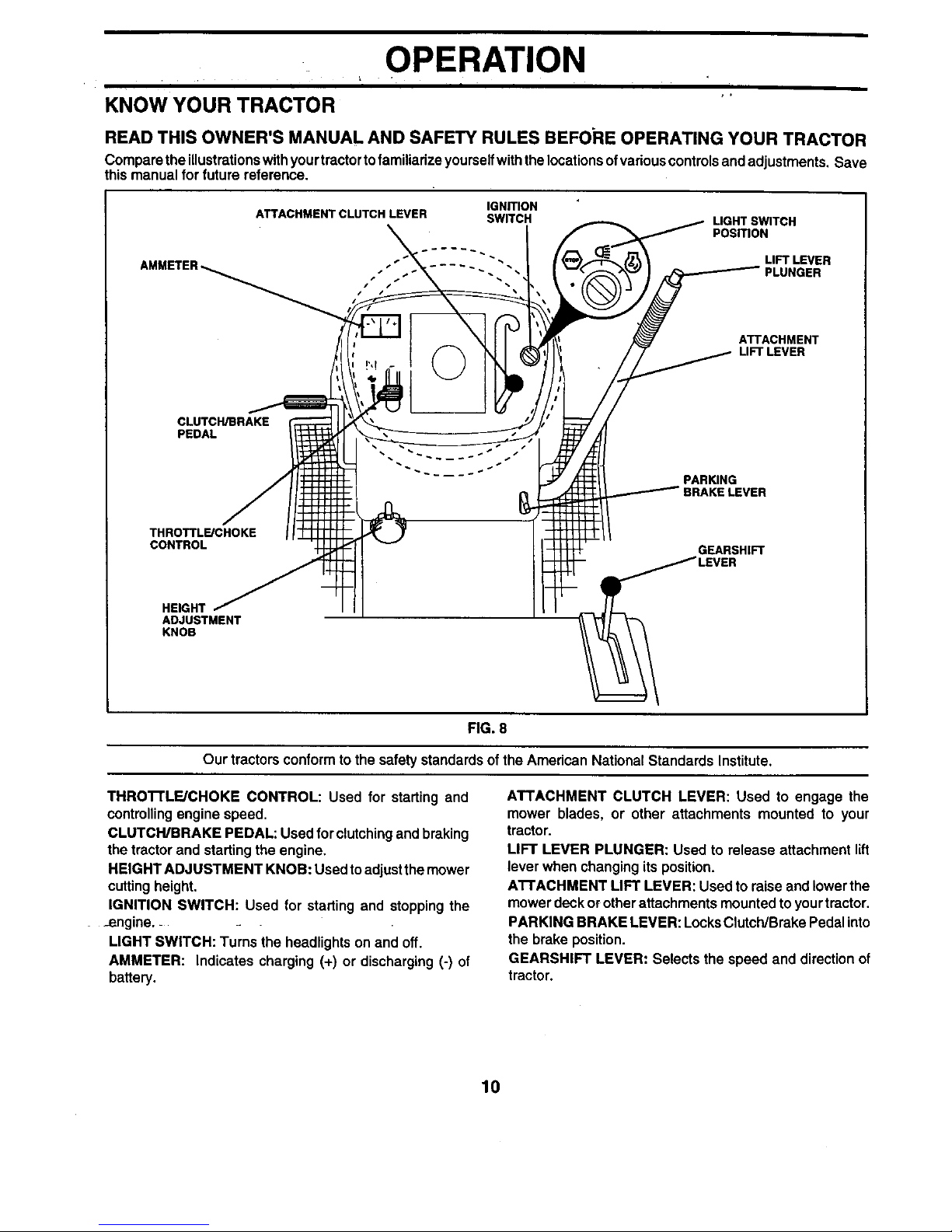

KNOW YOUR TRACTOR

OPERATION

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrationswithyourtractortofamiliarizeyourselfwiththe locationsof variouscontrolsandadjustments, Save

this manual forfuture reference.

ATTACHMENT CLUTCH LEVER

IGNmON

SWITCH

LIGHTSWITCH

PosmoN

©

ATTACHMENT

LIFT LEVER

CLUTCH/BRAKE

PEDAL

PARffiNG

BRAKELEVER

THROTTL_CHOKE

CONTROL

GEARSHIFT

HEIGHT

ADJUSTMENT

KNOB

FIG. 8

Our tractors conform to the safety standardsof the American National Standards Institute.

THROI-rLFJCHOKE CONTROL: Used for starting and

controllingengine speed.

CLUTCWBRAKE PEDAL: Used for clutchingand braking

the tractorand starting the engine.

HEIGHT ADJUSTMENT KNOB: Used to adjustthe mower

cuttingheight.

IGNITION SWITCH: Used for starting and stopping the

_engine._

LIGHT SWITCH: Turns the headlights on and off.

AMMETER: Indicates charging (+) or discharging (-) of

battery.

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIFT LEVER PLUNGER: Used to release attachment lift

lever when changingits position.

AI-I'ACHMENT LIFT LEVER: Used to raiseand lowerthe

mower deckor other attachments mounted toyour tractor.

PARKING BRAKE LEVER: LocksClutch/Brake Pedalinto

the brake position.

GEARSHIFT LEVER: Selects the speed and directionof

tractor.

10

OPERATION

The operationof anytractor can result in foreign objectsthrown intothe eyes, which can

resultin severeeye damage. Always wear safetyglasses or eye shields while operating

your tractor or performinganyadjustments or repairs. We recommenda wide vision

safety maskover spectacles or standard safetyglasses.

HOW TO USE YOUR TRACTOR

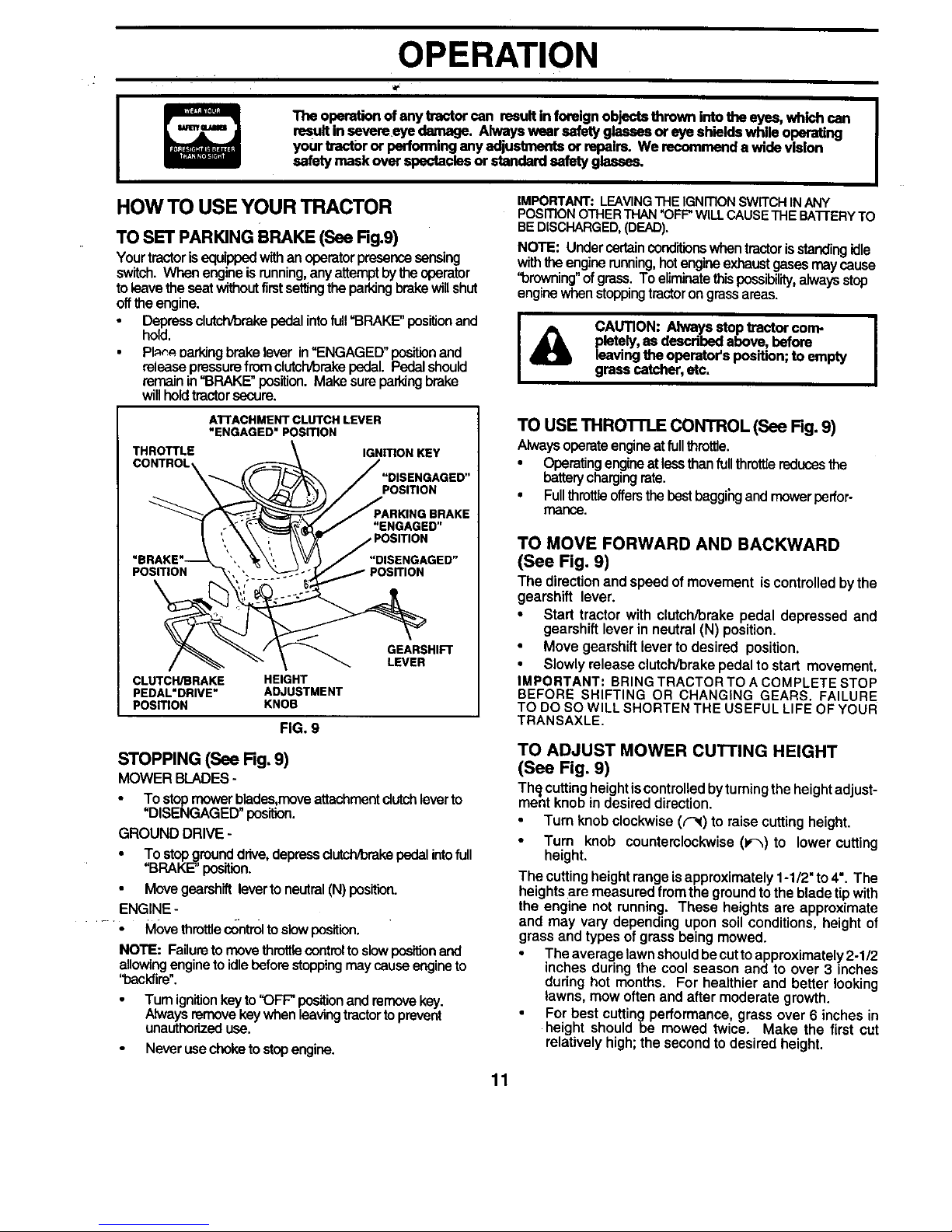

TO SET PARKING BRAKE (See Rg.9)

Yourtractorisequippedwithan operatorpresence sensing

switch.When engineisrunning,any attemptbythe operator

toleavetheseat withoutfirstsettingthe parkingbrakewillshut

offthe engine.

• Depressclutch/brakepedalintofull"BRAKE"positionand

hold.

• PI_. oarkingbrakelever in"ENGAGED" positionand

releasepressurefrom clutch/brekepedal. Pedalshould

remainin"BRAKE" position. Make sureparldngbrake

willholdtractorsecure.

ATTACHMENT CLUTCH LEVER

"ENGAGED" POSITION

THROTTLE IGNITIONKEY

CONTROL

POSITION

POSITION

"ENGAGED"

"DISENGAGED"

POSITION

CLUTCH/BRAKE HEIGHT

PEDAL'DRIVE" ADJUSTMENT

POSITION KNOB

FIG. 9

GEARSHIFT

LEVER

STOPPING (See Fig, 9)

MOWER BLADES-

To stopmowerblades,moveattachmentdutch leverto

"DISENGAGED" position.

GROUND DRIVE -

• To stepgrounddrive,depressdutch/brakepedalintofull

"BRAKE" position.

Move gearshift lever to neutral (N) position.

ENGINE -

.... • Movethrottle controltoslowposition.

NOTE: Failuretomove throttlecontroltoslowposition and

allowingengineto idlebeforestoppingmay causeengineto

"backfire".

Turnignitionkey to"OFF position and removekey.

Alwaysremovekeywhen leavingtractorto prevent

unauthorizeduse.

Never use choketo stepengine.

IMPORTANT:LEAVINGTHEIGNmONSWITCHINANY

PosmoN OTHERTHAN"OFF"WILLCAUSETHEBA'I-rERYTO

BEDISCHARGED,(DEAD).

NOTE: Under certainconditionswhen tractor is standing idle

with the enginerunning,hot engine exhaust gases may cause

"browning"of grass. To eliminate this possibility,always stop

engine when stopping tractorongrass areas.

J_ CAUTION: Always stoptractor com- I

pletely,as described above, before

leavingthe operator's position;to empty

grass catcher, etc.

TO USE THROI'TLE CONTROL (See Rg. 9)

Alwaysoperateengineatfullthrottle.

• Operating engineat lessthan full throttlereducesthe

batterychargingrate.

• Fullthrottle offersthebestbaggihg andmower perfor-

mar'Ice.

TO MOVE FORWARD AND BACKWARD

(See Fig. 9)

The directionand speed of movement iscontrolledbythe

gearshift lever.

• Start tractor with clutch/brake pedal depressed and

gearshift lever in neutral (N) position,

• Move gearshift lever to desired position.

• Slowly release clutch/brake pedalto start movement.

IMPORTANT: BRING TRACTOR TO A COMPLETE STOP

BEFORE SHIFTING OR CHANGING GEARS, FAILURE

TO DO SOWILL SHORTEN THE USEFUL LIFE OF YOUR

TRANSAXLE.

TO ADJUST MOWER CUTTING HEIGHT

(See Fig. 9)

Th_ cuttingheightiscontrolledby turningthe heightadjust-

ment knob in desired direction.

Turn knobclockwise (('_) to raise cuttingheight.

• Turn knob counterclockwise(1,-_) to lower cutting

height.

The cuttingheightrange isapproximately1-1/2" to4". The

heightsare measured from the groundtothe bladetip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions,height of

grass and types of grass beingmowed.

The average lawnshouldbecutto approximately2-1/2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

For best cuttingperformance, grass over 6 inches in

height shouldbe mowed twice. Make the first cut

relatively high; the second to desired height.

11

OPERATION

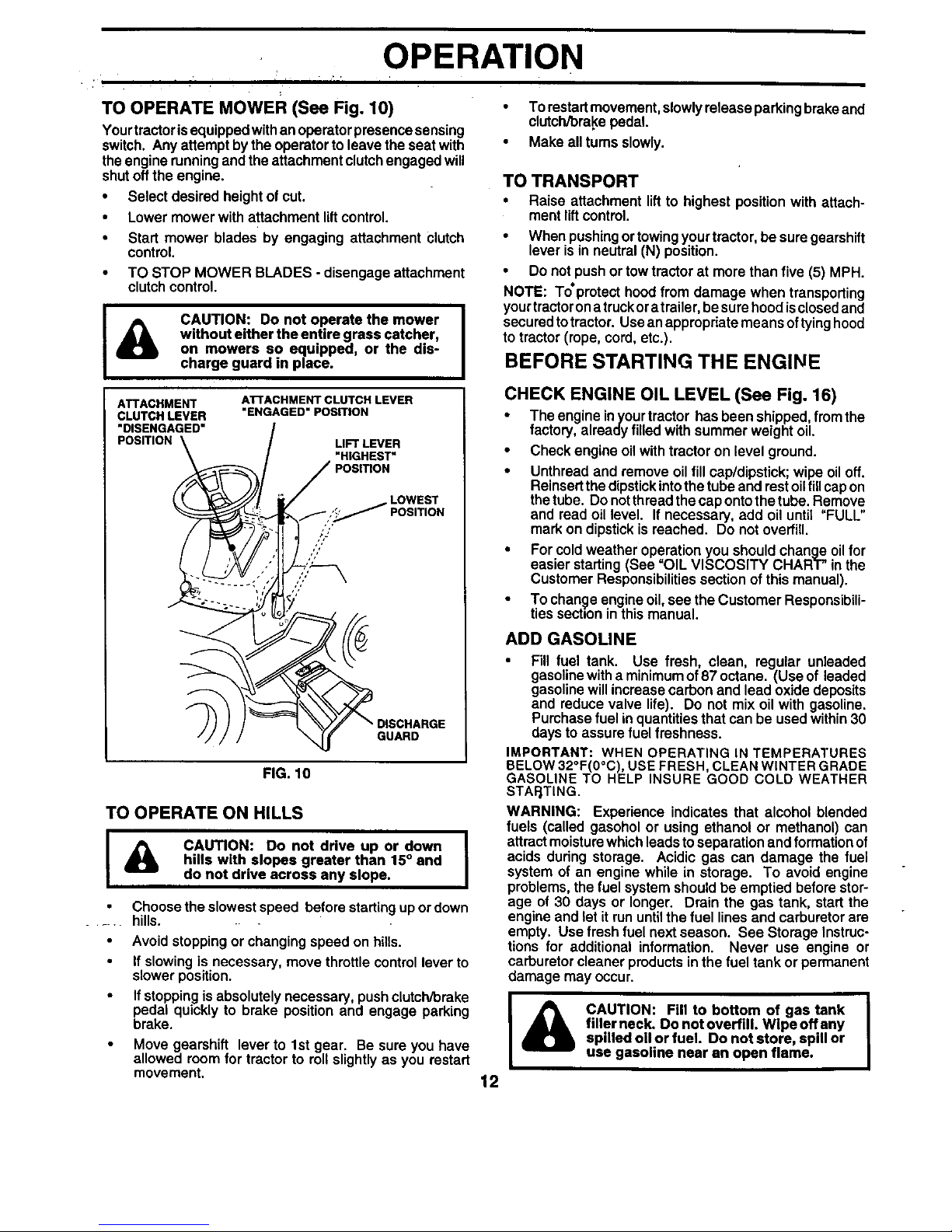

TO OPERATE MOWER (See Fig. 10)

Yourtractor isequippedwithan operatorpresencesensing

switch. Any attempt by the operator to leave the seat with

theengine runningand the attachment clutchengaged will

shut offthe engine.

• Select desired height of cut.

• Lower mower with attachment liftcontrol.

• Start mower blades by engaging attachment Clutch

control.

• TO STOP MOWER BLADES - disengage attachment

clutch control.

&

CAUTION: Do not operate the mower

without either the entire grass catcher,

on mowers so equipped, or the dis-

charge guard in place.

ATTACHMENT

CLUTCH LEVER

"DISENGAGED"

POSITION

ATTACHMENT CLUTCH LEVER

"ENGAGED" POSITION

LIFT LEVER

"HIGHEST"

POSITION

LOWEST

POSITION

/,'

,J

GUARD

FIG. 10

TO OPERATE ON HILLS

I & CAUTION: Do not drive up or down I

hills with slopes greater than 15° and

do not drive across any slops.

Choose the slowest speed before startingupor down

hills.

Avoid stopping or changing speed on hills.

If slowing is necessary, move throttle controllever to

slower position.

If stoppingis absolutely necessary, pushclutch/brake

pedal quickly to brake position and engage parking

brake.

Move gearshift lever to 1st gear. Be sure you have

allowed room for tractor to rollslightly as you restart

movement.

• To restartmovement, slowlyrelease parkingbrake and

clutch/brake pedal.

• Make allturns slowly.

TO TRANSPORT

• Raise attachment lift to highest position with attach-

ment liftcontrol.

• When pushing ortowingyour tractor, be sure gearshift

lever isin neutral (N) position.

• Do not push or tow tractor at more than five (5) MPH.

NOTE: To'protect hood from damage when transporting

yourtractoron atruckora trailer,be sure hoodisclosed and

securedto tractor. Useanappropriate means oftyinghood

to tractor (rope, cord, etc.).

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 16)

The engine inyourtractor hasbeen shipped, from the

factory, already filled withsummer weight oil.

Check engine oilwith tractoron level ground.

Unthread and remove oilfill cap/dipstick; wipe oil off.

Reinsertthe dipstickintothe tubeand restoilfill capon

thetube. Do notthread the cap onto thetube. Remove

and read oil level. If necessary, add oil until "FULL"

mark on dipstick is reached. Do not overfill.

For cold weather operation you should change oil for

easier starting (See "OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manual).

To change engine oil, see the Customer Responsibili-

ties section in this manual.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded

gasolinewitha minimumof87 octane. (Use of leaded

gasoline will increasecarbon and lead oxide deposits

and reduce valve life). Do not mix oil with gasoline.

Purchase fuel inquantities that can be used within30

days to assurefuel freshness.

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW32°F(0°C), USE FRESH, CLEANWINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STAFJTING.

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisturewhichleads toseparation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine and let it rununtilthe fuel lines and carburetorare

empty. Use fresh fuel nextseason. See Storage Instruc-

tions for additional information. Never use engine or

carburetorcleaner productsin the fuel tank or permanent

damage may occur.

I

CAUTION: Fill to bottom of gas tank

filler neck. Do not overfill. Wipe off any

spilled oil or fuel. Do not store, spill or

use gasoline near an open flame.

12

OPERATION

TO START ENGINE (See Fig. 9) •

When startingthe engine for the firsttime or ifthe engine

has runout of fuel, it will take extra crankingtime to move

fuel from the tank to the engine. •

• Sit on seat inoperating position,depress clutch/brake

pedal and set parking brake.

• Place gear shiftlever in neutral (N) position. •

• Move attachment clutchto =DISENGAGED" position.

• Move throttle control to choke position.

NOTE: Before starting, read the warm and cold starting

procedures below. •

• Insert keyinto ignition and turn keyclockwiseto "START"

position and release key as soon as engine starts. Do

not run starter continuously for more than fifteen sec-

onds per minute, if the engine does "lot start after

several attempts, move throttle control to fast position,

wait afew minutes andtry again. If engine stilldoes not

start, move the throttle control back to the choke

position and retry.

WARM WEATHER STARTING (50° F and above)

• When engine starts, move the throttle controltothe fast

position.

• The attachments and ground drive can nowbe used. If

the engine does not accept the load, restart the engine

and allow itto warm up for one minute using the choke

as described above.

COLD WEATHER STARTING ( 50° F and below)

• When engine starts, allowengine to runwith thethrottle

control in the choke position until the engine runs

roughly, then movethrottle control tofast position. This

may require an engine warm-up period from several

seconds to several minutes, depending on the tem-

perature.

• The attachments can also be used during the engine

warm-up period.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See "TO

ADJUST CARBURETOR" in the Service and Adjustments

section of this manual.

MOWINGTIPS

Tire chains cannot be used when the mower housing

is attached to tractor.

• Mower should be properly leveled for best mowing

performance. See "TO LEVEL MOWER HOUSING" in

the Service and Adjustments section of this manual.

The left hand side of mower should be used for trim-

ming.

Drive so that clipPings are discharged onto the area

that has been cut. Have the cut area to the right of the

machine. This will result in a more even distnbution of

clippings and more uniform cutting.

• When mowing large areas, start by turning to the right

so that clippings will discharge away from shrubs,

fences, driveways, etc. After one or two rounds, mow

in the opposite direction making left hand turns until

finished (See Fig. 11 ).

If grass is extremely tall, itshould be mowed twice to

reduce Ipad and possible fire hazard from dried clip-

pings. Make first cut relatively high the second to the

des red he ght.

Do not mow grass when it is wet. Wet grass will plug

mower and leave undesirable clumps. Allow grass to

dry before mowing.

Always operate engine atfull throttle when mowing to

assure better mowing performance and proper dis-

charge of material. Regulate ground speed by select-

ing a low enough gear to give the mower cutting

performance as well as the quality of cutdesired.

Wheh operating attachments, select a ground speed

that will suit the terrain and give best performance of the

attachment bei0g used.

FIG. 11 "

MULCHING MOWING TIPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH. CLEAN AFTER EACH USE.

• The special mulching blade will recut the grass clip-

pings many times and reduce them in size so that as

they fall onto the lawn they will disperse into the grass

and not be noticed. Also, the mulched grass will

biodegrade quickly to provide nutrients for the lawn.

Always mulch with your highest engine (blade) speed

as this will provide the best recutting action of the

blades.

• Avoidcuttingyour lawnwhen itiswet. Wet grasstends

to form clumpsand interfereswiththe mulchingaction.

The besttimeto mowyourlawn isthe early afternoon.

At thistime the grasshas dried and thenewly cut area

will not be exposedto the directsun.

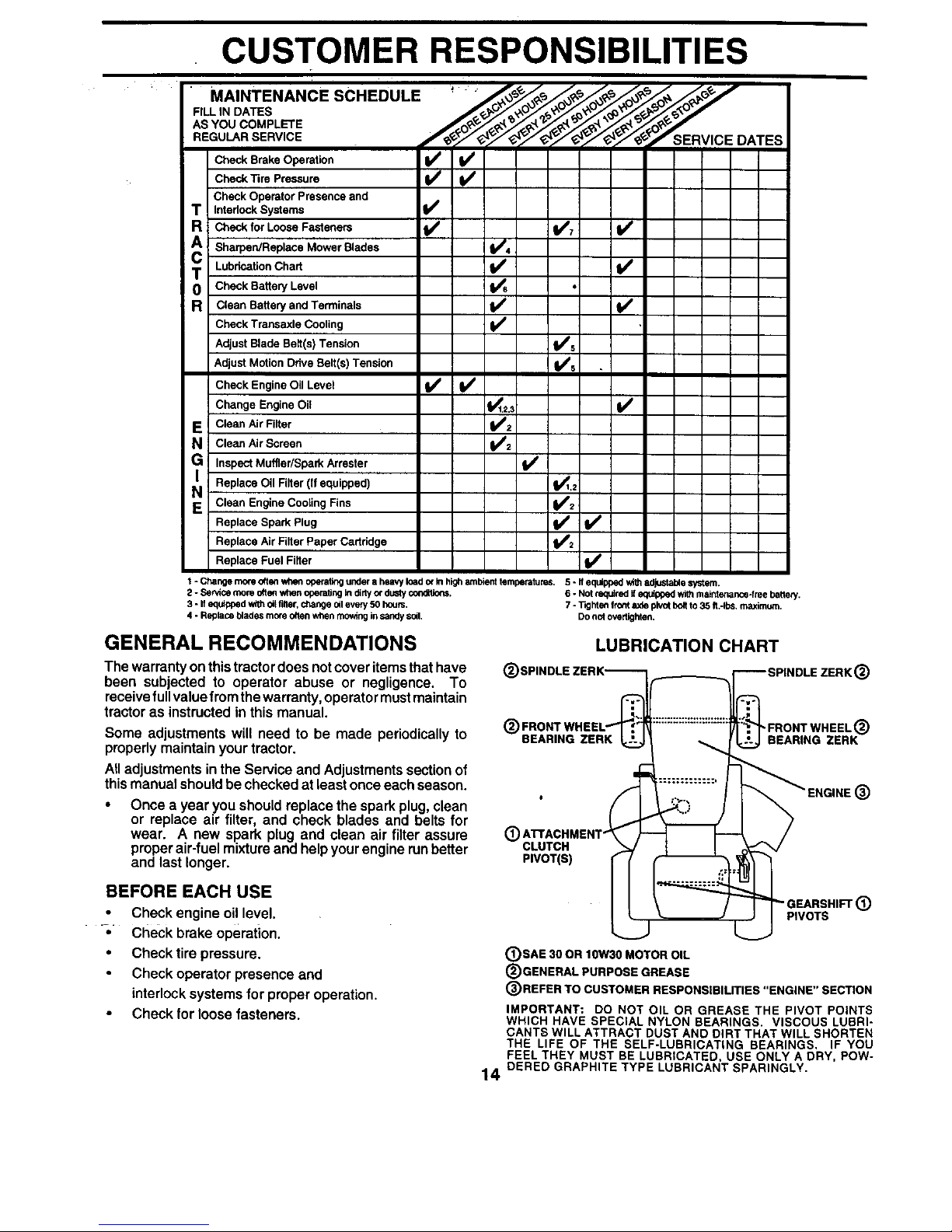

• For bestresults,adjustthe mowercuttingheightsothat

the mower cutsoffonly the top one-third of the grass

_lades (See Fig. 12). For extremely heavy mulching

reduce your width of cuton each pass and mow slowly.

• Certain types of grass and grass conditions may re-

quire that an area be mulched a second time to com-

pletely hide the clippings. When doing a second cut,

mow across or perpendicular to the first cut path.

• Change your cutting pattern from weekto week. Mow

north to south one week then change to eastto west the

next week. This will help prevent matting and graining

of the lawn.

13 FIG. 12

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE _ " '_,_ ",/_,_s/_ _/_,_/_ _//_"_

AS YOU COMPLETE _v _,_ _ _'/_'_'_q'_'_'_'_'_'_,_""

REGU 'RSERV,CE

:::c:Bg:;o::::,on

Check Operator Presence and

T Interlock Systems

R Check for Loose Fasteners l_ V/7 V _

A Sharpen/Replace Mower Blades i4

t Lubrication Chart V'

0 Check Battery Level

R Clean Battery and Terminals !_

Check Transaxle Cooling I_

Adjust Blade Belt(s) Tension I_s

Adjust Motion Drive Belt(s) Tension V's

Check Engine Oil Level V' If

Change Engine Oil _2.3 V P

E Clean Air Filter _:

N Clean Air Screen

i/

G Inspect Muffler/Spark Arraster

N Replace Oil Filter (If equipped) 11_1.2

Clean Engine Cooling Fins V'2

Replace Spark Plug _V'2 V_

Replace Air Filter Paper Cartddge

Replace Fuel Filter ll_

1* Change more ottetl wheneperating under a heaw loador_ hi_nP,mbienttemperatures. 5 -If equipped v/_thedjustable syslam.

2 - Se_ce more otlan when operatingIn dirtyor dusty cond_ons. 6 -Not requiredifequippedwithmaintenance-freebattery,

S - If eputpped w#h oltfiner,ot_angedil eveP/50 hours. 7 -"l-_htenfm_t axle pivotbditto 35 ft,-Ibs, maximum.

4 - Replace blades more o(ten whenmowinginsandy soil, Donot overUghten,

GENERAL RECOMMENDATIONS

LUBRICATION CHART

The warrantyon thistractordoes notcoveritems that have @

been subjected to operator abuse or negligence. To

receivefull value fromthe warranty, operatormustmaintain

tractor as instructed in this manual.

@

Some adjustments will need to be made periodically to

properly maintain your tractor.

Alladjustments in the Service and Adjustmentssection of

thismanual should be checked at leastonce each season.

BEARING ZERK

Once a year you should replace the sparkplug, clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure (_)

properair-fuel mixture and helpyour engine runbetter CLUTCH

and last longer. PIVOT(S)

@

'FRONT WHEEL@

BEARING ZERK

®

BEFORE EACH USE

Check engine oil level.

-;, Check brake operation.

• Check tire pressure.

Check operator presence and

interlock systems for properoperation.

Check forloose fasteners.

IEARSHIFT@

PIVOTS

(_)SAE 30 OR lOW30 MOTOR OIL

@GENERAL PURPOSE GREASE

@REFER TO CUSTOMER RESPONSIBILITIES "ENGINE" SECTION

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI-

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS. IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW-

14 DERED GRAPHITE TYPE LUBRICANT SPARINGLY.

CUSTOMER RESPONSIBILITIES

TRACTOR

Always observe safety ruleswhen performing any mainte-

nance.

BRAKE OPERATION

Iftractor requires morethan six (6)feet stoppingdistance

at highspeed inhighestgear, then brake mustbe adjusted.

(See "TO ADJUST BRAKE" in the Service and Adjust-

ments section of this manual).

TIRES

• Maintain proper air pressure in all tires (See =PROD-

UCT SPECIFICATIONS" section of this manual).

• Keep tiresfree of gasoline,oil, or insectcontrolchemi-

cals which can harm rubber.

Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE; To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM

Be sure operator presence and interlock systems are

working properly. If your tractor does not function as

described, repairthe problem immediately.

• The engine should not start unless the clutch/brake

pedalisfully depressedand attachementclutchcontrol

isin the disengaged position.

• When theengine is running,any attemptbythe opera-

tor to leave the seat without first settingthe parking

brake shouldshut offthe engine.

• When the engine isrunning and the attachmentclutch

is engaged, any attempt by the operatorto leave the

seat should shut off the engine.

• The attachment clutchshouldneveroperate unlessthe

operator is in the seat.

BLADE CARE

For best results mower blades must be kept sharp. Re-

place bent or damaged blades.

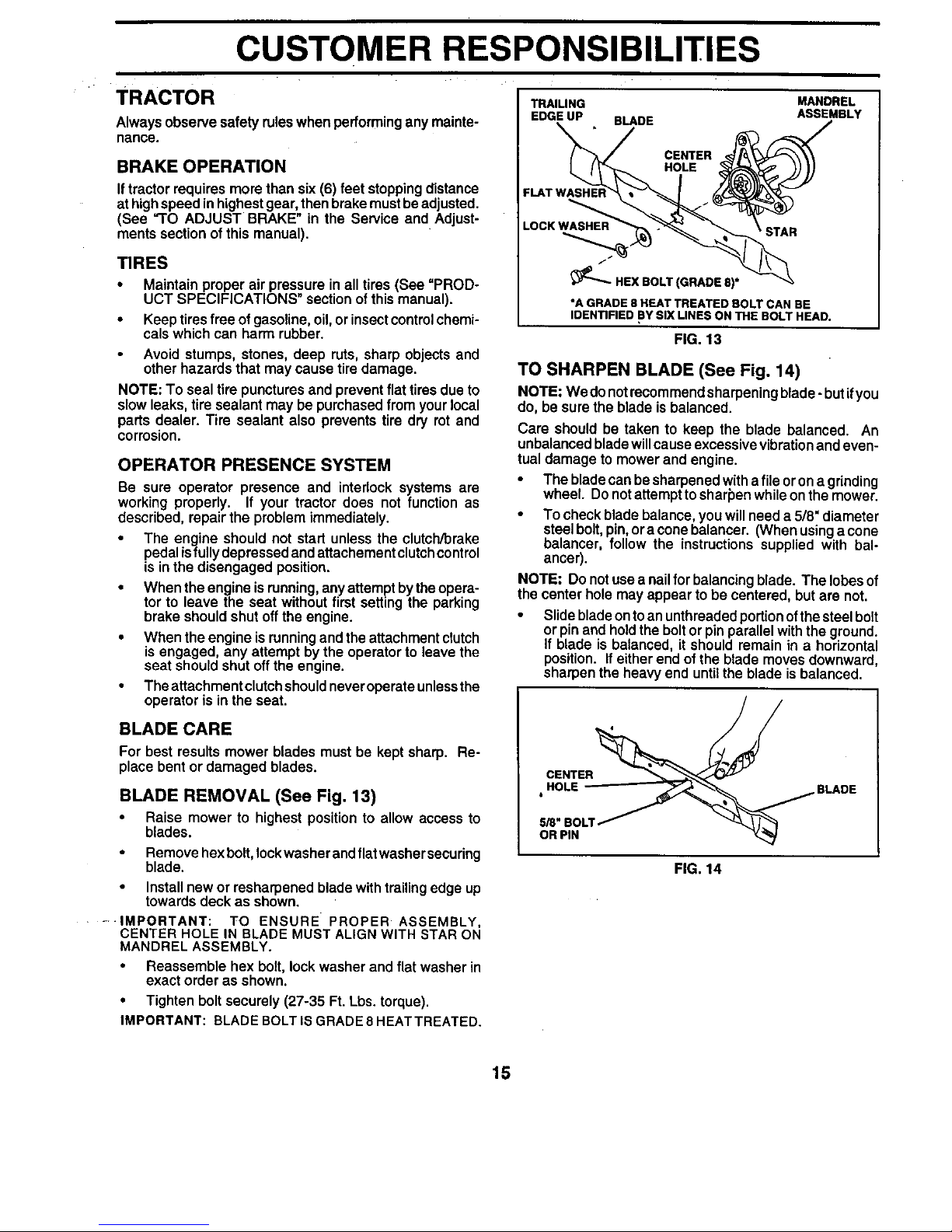

BLADE REMOVAL (See Fig. 13)

• Raise mower to highest positionto allow access to

blades.

• Remove hexbolt, lockwasherandflat washer secudng

blade.

• Install new or resharpened blade with trailing edge up

towards deck as shown.

---IMPORTANT: TO ENSURE PROPER ASSEMBLY,

CENTER HOLE IN BLADE MUST ALIGN WITH STAR ON

MANDREL ASSEMBLY.

• Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

• Tighten bolt securely (27-35 Ft. Lbs. torque).

IMPORTANT: BLADE BOLTIS GRADE8 HEATTREATED.

TRAILING

EDGE UP

\

FLAT WASHEF

BLADE

CENTER

HOLE

MANDREL

ASSEMBLY

LOCK WASHER

_'.- HEX BOLT (GRADE 8)*

*A GRADE 8 HEAT TREATED BOLT CAN BE

IDENTIFIED BY SiX LINES ON THE BOLT HEAD

FIG. 13

TO SHARPEN BLADE (See Fig. 14)

NOTE: We do notrecommend sharpeningblade - butifyou

do, be sure the blade is balanced.

Care should be taken to keep the blade balanced. An

unbalanced blade will cause excessive vibration and even-

tual damage to mower and engine.

• The blade can be sharpened with a file or on agdnding

wheel. Do not attempt to sharpen while on the mower.

• To check blade balance, you will need a 5/8" diameter

steel bolt, pin, ora cone balancer. (When using a cone

balancer, follow the instructions supplied with bal-

ancer).

NOTE: Do not use a nail for balancing blade. The lobes of

the center hole may appear to be centered, but are not.

• Slide blade on to an unthreaded portion of the steel bolt

or pin and hold the bolt or pin parallel with the ground.

If blade is balanced, it should remain in a horizontal

position. Ifeither end of the blade moves downward,

sharpen the heavy end until the blade is balanced.

CENTER '_

OR PIN

FIG. 14

15

CUSTOMER RESPONSIBILITIES

BATrERY

Your tractor has a battery chargingsystem which issuffi-

cient for normal use. However, period!c charging of the

battery with an automotive charger willextend its life.

• Keep battery and terminals clean.

• Keep battery boltstight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

TO CLEAN BA'I-IERY AND TERMINALS

Corrosionand dirton the battery and terminals can cause

the battery to "leak" power.

• Open battery box door.

• Disconnect BLACK battery cable first then RED bat-

tery cable and remove batteryfrom tractor.

Rinse the battery withplain water and dry.

Clean terminals and batterycable ends withwire brush

until bright.

• Coat terminals with grease or petroleum jelly.

• Reinstall battery (See "CONNECT BATI'ERY" in the

Assembly sectionof this manual).

• Catch oil ina suitable container.

• Remove oilfillcap/dipstick. Be careful nottoallow dirt

to enter the engine whenchanging oil.

• Remove drain plug.

• After oilhas drained completely, replace oildrain plug

and tightensecurely.

Refill engine with oil throughoil filldipsticktube. Pour

slowly. Do not overfill For approximate capacity see

"PRODUCT SPECIFICATIONS" sectionofthismanual.

• Use gauge on oil fill cap/dipstick for checking level.

Insertdipstickintothetube and resttheoilfillcaponthe

tube. Do notthread the cap onto the tube when taking

reading. Keep oil at "FULL" line ondipstick. Tighten

cap onto the tube securely when finished.

AIR CLEANER

,WING NUT

V-BELTS

Check V-belts fordeterioration and wear after 100hoursof

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin to slip from wear.

TRANSAXLE COOLING

Keep trensaxle free from build-up of dirtand chaff which

can restrictcooling. PAPER CARTRIDGE

3LEANER

BASE

ENGINE

CAP/DIPSTICK

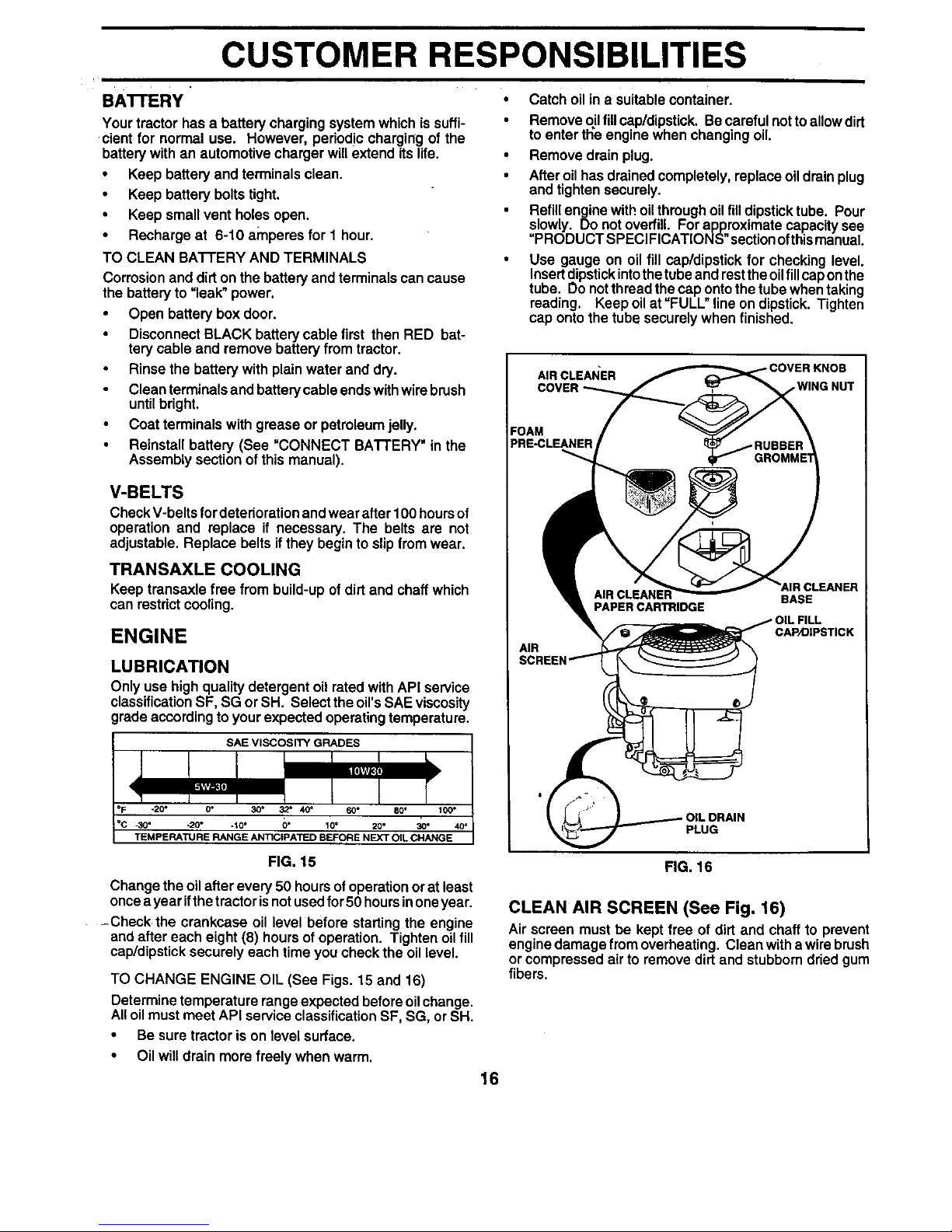

LUBRICATION

Only use high quality detergent oil ratedwith API service

classificationSF, SG or SH. Select the oil'sSAE viscosity

grade according toyour expected operatingtemperature.

SAE VISCOSITY GRADES

-20* 0 ° 30* 32 ° 40 _ 60" 80 °

-30" -20 ° -I0 ° O" 10 ° 20 ° 30 ° 40 °

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

FIG° 15

PLUG

Change the oil after every 50 hours ofoperation or at least

once ayear if the tractor is not used for 50 hours in one year.

--Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oilfill

cap/dipstick securely each time you check the oil level.

TO CHANGE ENGINE OIL (See Figs. 15 and 16)

Determine temperature range expected before oil change.

All oil must meet API service classificationSF, SG, or SH.

• Be sure tractor is on level surface.

• Oil will drain more freely when warm.

FIG. 16

CLEAN AIR SCREEN (See Fig. 16)

Air screen must be kept free of dirt and chaff to prevent

engine damage from overheating. Clean witha wire brush

or compressed air to remove dirt and stubborndriedgum

fibers.

16

CUSTOMER RESPONSIBILITIES

AIR FILTER (See Fig. 16) MUFFLER

Your engine will not run properly using a dirty air filter.

Clean the foam pre-cleaner after every 25 hours ofopera-

tion or every season. Service paper cartridge every 100

hoursofoperationor every season,whichever occursfirst.

Service aircleaner more often under dustyconditions.

Remove knob and cover.

• Remove wing nut and air cleaner from base.

TO SERVICE PRE-CLEANER

Slide foam pre-cleaner off cartridge.

Wash it in liquid detergent and water.

Squeeze it dry in a clean cloth. Allow it to dry.

• Saturate it in engine oil. Wrap it in clean, absorbent

cloth and squeeze to remove excess oil.

TO SERVICE CARTRIDGE

• Replace a dirty, bent, or damaged cartridge.

NOTE: Do not wash the paper cartridge or use pressurized

air, as this will damage the cartridge.

• Reinstall the pre-cleaner (cleaned and oiled) over the

paper cartridge.

Reassemble air cleaner, wing nut, cover and tighten

knob securely.

CLEAN AIR INTAKE/COOLING AREAS

To insure proper cooling, make sure the grass screen,

coolingfins, and other external surfaces ofthe engine are

kept clean at all times.

Every 100 hours of operation (more often under extremely

dusty, dirty conditions), remove the blower housing and

othercooling shrouds. Clean the coolingfins and external

surfacesas necessary. Make surethe coolingshroudsare

reinstalled.

NOTE: Operetingthe enginewitha blockedgrass screen,

dirty or plugged cooling fins, and/or cooling shrouds re-

moved willcause engine damage due to overheating.

Inspect and replace corroded muffler and spark arrester (if

equipped) as itcouldcreate a fire hazard and/or damage.

SPARKPLUGS

Replace spark plugs at the beginning of each mowing

season or after every 100 hours ofuse, whichevercomes

first. Spark plugtype and gap setting isshown in"PROD-

UCT SPECIFICATIONS" section of this manual.

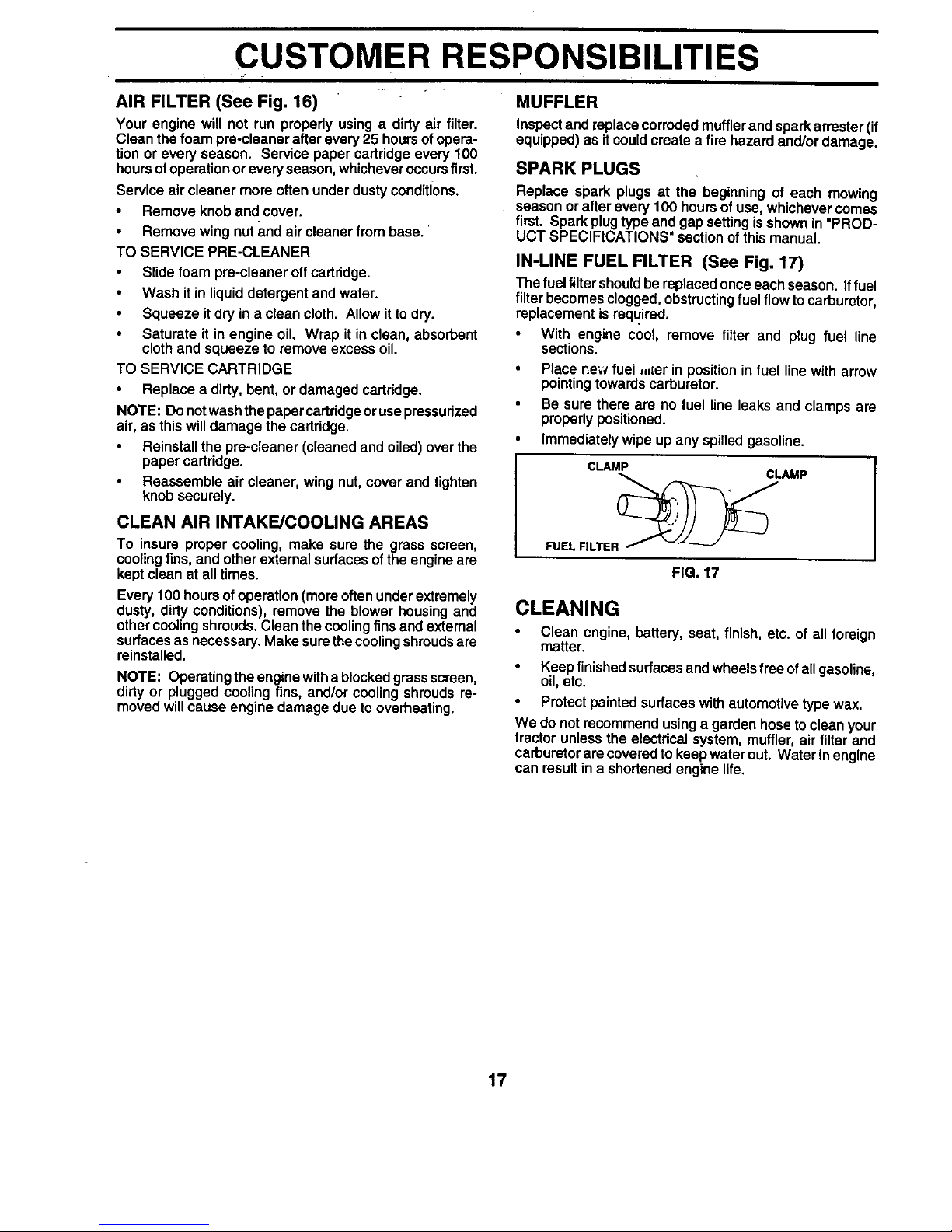

IN-LINE FUEL FILTER (See Fig, 17)

The fuel filtershouldbe replaced onceeach season. Iffuel

filter becomesclogged, obstructingfuel flow tocarburetor,

replacement is required.

With engine cool, remove filter and plug fuel line

sections.

Place new fuel ,,,{er in position in fuel line with arrow

pointingtowards carburetor.

Be sure there are no fuel line leaks and clamps are

properly positioned.

Immediately wipe up any spilledgasoline.

CLAMP

FUEL RLTER _AMP

FIG. 17

CLEANING

• Clean engine, battery, seat, finish, etc. of all foreign

matter.

• Keep finished surfacesand wheels free ofall gasoline,

oil, etc.

• Protect painted surfaces with automotivetype wax.

We do not recommend using a garden hose toclean your

tractor unless the electrical system, muffler, air filter and

carburetor are coveredto keep water out. Water inengine

can resultin a shortenedengine life.

17

Loading...

Loading...