Craftsman 944.609150 Owner's Manual

SEARS

OWNER'S

MANUAL

MODEL NO.

944.609150

Caution:

Read and follow

all Safety Rules

and Instruct,ons

Before Operating

Thts Equ,pment

(R;IFTZMrlNo

15.5 HP

ELECTRIC START

36" MOWER

AUTOMATIC

LAWN TRACTOR

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

Sears Canada, Inc., Toronto, Ontario M5B 2B8

SAFETY RULES &

Safe Operation Practices for Ride-On Mowers

IMPORTANT: THIS CU'I-I'ING MACHINE IS CAPABLE

OBJECTS. FAILURE TO OBSERVE THE FOLLOWING

INJURY OR DEATH.

I. GENERAL OPERATION

• Read, understand, and follow all instructions in the manual

and on the machine before starting.

Only allow responsible adults, who are familiar with the

instructions, to operate the machine.

• Clear the area of ob ects such as rocks, toys, wire, etc.,

which could be p cked up and thrown by the b ads.

Be sure the area isclear ofotherpeople before mowing. Stop

machine if anyone enters the area.

• Never carry passengers.

• Do not mow inreverse unless absolutely necessary. Always

look down and behind before and while backing.

• Be aware ofthe mower discharge direction and do not point

it at anyone. Do not operate the mower without either the

entire grass catcher or the guard in place.

• Slow down before tuming.

• Never leave a running machine unattended. Always turn off

blades, set parking brake, stop engine, and remove keys

before dismounting,

• Turn off blades when not mowing.

Stop engine before removing grass catcher or unclogging

chute.

• Mow only in daylight or good adificial light.

• Do not operate the machine while under the influence of

alcohol or drugs.

• Watch for traffic when operating near or crossing roadways.

• Use extra care when loading or unloading the machine into

a trailer or truck.

II. SLOPE OPERATION

Slopesare ama orfactor related to loss-of-control andtipover

accidentswhichcan resultinsevereinjuryor death. Allslopes

requiraextracaution.Ifyoucannotbackuptheslopeor fyoufee

uneasyonit, do notmowit.

DO:

• Mow up add down slopes, not across.

• Remove obstacles such as rocks tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could

overturn the machine. Taftgrass can hide obstacles.

Use slow speed. Choose a low gear so that you willnot have

to stop,o_sh_ while on the slope.

• Follow the manufacturer's recommendations for wheel

weights or counterweights to improve stability.

• Use extra bare with grass catchers or other attachments.

These cab Change the stability ofthe machine.

Keep all movement on the slopes slowand gradual, Do not

make sudden changes in speed or direction.

• Avoid starting or stopping on a slope. If tires lose traction,

disengage the blades and proceed slowly straight down the

slope.

DO NOT:

• Donotturnonslopasunlessnecessary, andthen, tumslowly

and gradually downhill, if possible,

• Do not mow near drop-ode, ditches, or embankments. The

mower could suddenly turn over if a wheel is over the edge

of a cliff or ditch, or if an edge caves in.

Do not mow on wet grass. Reduced traction could cause

sliding.

Do not tryto stabilize the machine by puttingyour foot on the

ground.

• Do not use grass catcher on steep slopes.

OF AMPUTA.TING HANDS AND FEET AND THROWING

SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS

IlL CHILDREN

Tragic accidents can occur if the operator is not alert to the

presenceofchildren,Childrenareoftenattractedtothemachine

and themowing activity. Neverassumethatchildrenwillremain

whereyoulast sawthem,

• Keepchildrenoutofthe mowingareaandunderthewatchful

careof another responsibleadult.

• Bealert andturn machineoffif childrenenterthearea.

Beforeand whenbacking,lookbehindand downfor small

children.

Never carrychildren. They may tall off and be seriously

injuredor interferewithsafe machineoperation.

• Neverallowchildrento operatethe machine.

• Use extra care when approaching blindcorners,shrubs,

trees,or otherobjectsthatmay obscurevision.

IV. SERVICE

• Use extra carein handling gasoline and other fuels. They are

flammable and vapors are explosive.

Use only an approved container.

Never remove gas cap or add fuel with the engine

running. Allow engine to eool before refueling. Do not

smoke.

Never refuel the machine indoors.

Never store the machine or fuel container inside where

there is an open flame, such as a water heater.

Never run a machine inside a closed area.

• Keep nutsand bolts, especially blade attachment botts, tight

and keep equipment in good condition.

Never tamper with safety devices. Check their proper

operation regulady,

• Keep machine free of grass, leaves, or other debds build-up.

Clean oil or fuel spillage. Allow machine to cool before

storing,

• Stop and inspect the equipment if you stdke an object.

Repair, if necessary, before mstading.

• Never make adjustments or repairs with the engine running.

• Grass catcher components ara sub ect towear, damage, and

deterioration, which could expose moving pads or allow

objects to be thrown. Frequently check components and

replace with manufacturer's recommended pads, when nec-

essary.

• * Mower blades are sharp and can cut. Wrap the blade(s) or

wear gloves, and use extra caution when servicing them.

• Check brake operation frequently. Adjust and service as

required.

i I I

Look for this symbol to point out impor-

tant safety precautions. It means

CAUTIONll! BECOME ALERTI!! YOUR

SAFETY IS INVOLVED,

i

{

CAUTION: Always disconnect spark

plug wire and place wire where it cannot

contact spark plug in order to prevent

acc dental starting when setting up,

transporting, adjusting or making

repairs,

2

CONGRATULATIONS on your purchase of a Sears

Tractor. It has been designed, en_.ineered and manufac-

tured to give you the best possible dependability and

performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service Center/Department. We have competent, wel!-

trained technicians and the propertools to service or repair

this tractor.

Please read and retain this manual. The instructionswill

enable youtoassemble and maintain your tractor properly.

Always observe the =SAFETY RULES".

MODEL

NUMBER 944.609150

SERIAL

NUMBER

DATE OF PURCHASE

THE MODELAND SERIAL NUMBERSWlLL BE FOUND

ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement isavailable on this prod-

uct. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

Follow aregular schedule inmaintaining, caringfor and using

your tractor.

• Follow the instructions under =Customer Responsibilities"

and "Storage" sections of this owner's manual.

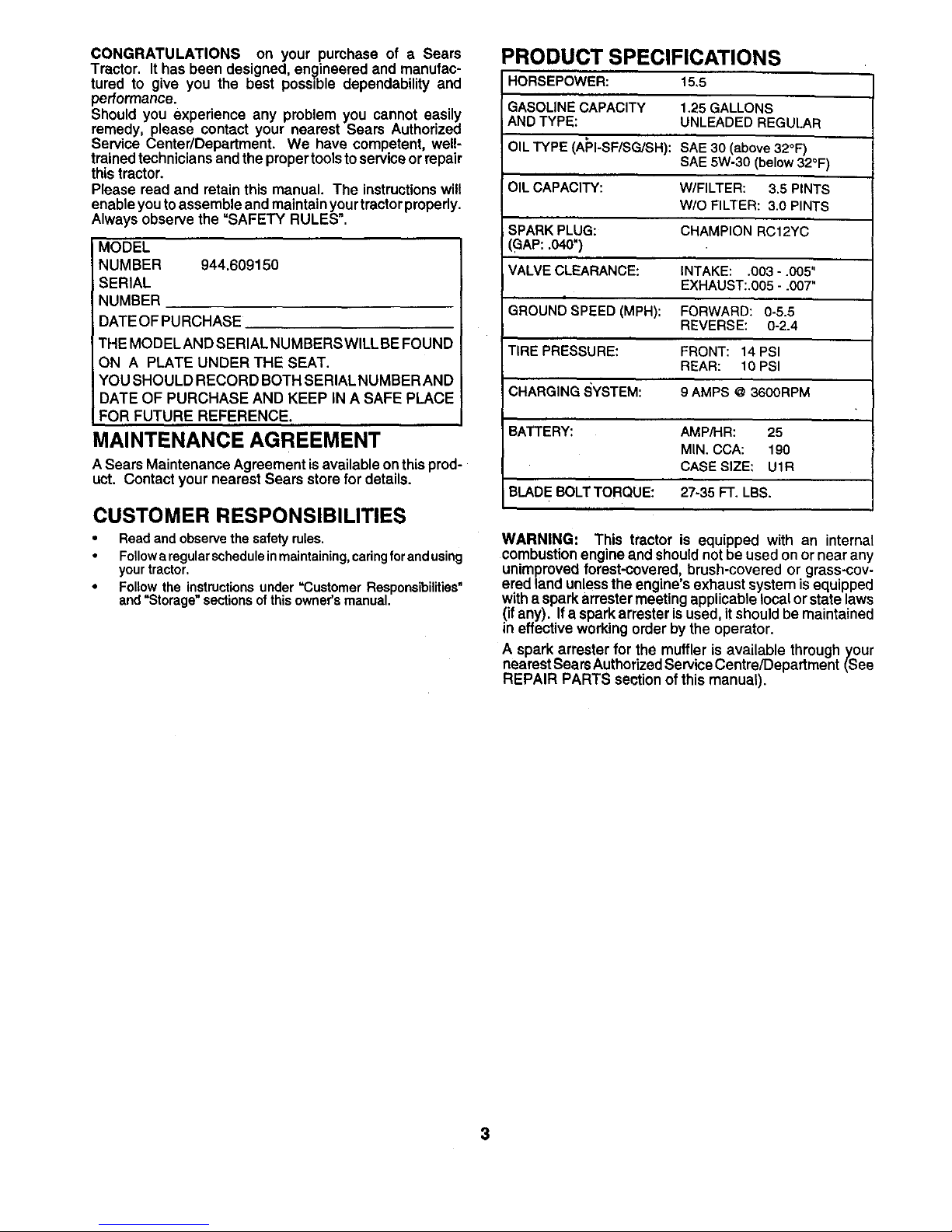

PRODUCT SPECIFICATIONS

HORSEPOWER: 15.5

GASOLINE CAPACITY 1.25 GALLONS

AND TYPE: UNLEADED REGULAR

b

OIL TYPE (API-SF/SG/SH): SAE 30 (above 32°F)

SAE5W-30 (below32°F)

OIL CAPACITY: W/FILTER: 3.5 PINTS

W/O FILTER: 3.0 PINTS

SPARKPLUG: CHAMPION RC12YC

(GAP:.040")

VALVE CLEARANCE:

, i

GROUND SPEED (MPH):

TIRE PRESSURE:

CHARGING SYSTEM:

INTAKE: .003 - .005"

EXHAUST:.005 - .007"

FORWARD: 0-5.5

REVERSE: 0-2.4

FRONT: 14 PSI

REAR: 10 PSI

9 AMPS @ 3600RPM

BATTERY: AMP/HR: 25

MIN. CCA: 190

CASE SIZE: U1R

BLADE BOLT TORQUE: 27-35 FT, LSS.

WARNING: This tractor is equipped with an internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov-

ered land unless the engine's exhaust system is equipped

with a spark arrester meeting applicable local or state laws

(ifany). If a spark arrester is used, it should be maintained

in effective working order by the operator.

A spark arrester for the muffler is available through your

nearest Sears Authorized Service Centre/Department (See

REPAIR PARTS section of this manual).

3

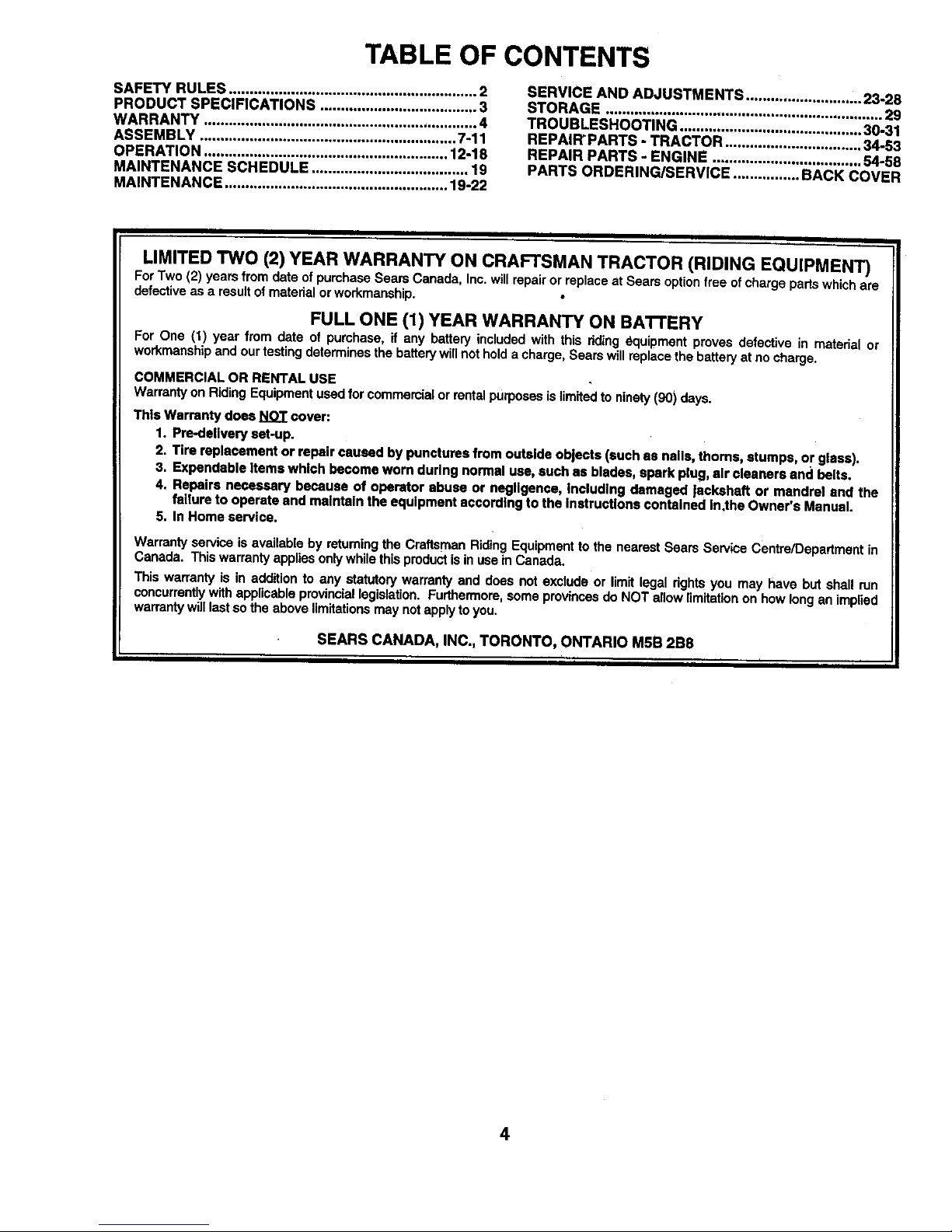

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ...................................... 3

WARRANTY .................................................................. 4

ASSEMB LY .............................................................. 7-11

OPERATION ........................................................... 12-18

MAINTENANCE SCHEDULE ...................................... 19

MAINTENANCE ...................................................... 19-22

SERVICE AND ADJUSTMENTS ............................ 23-28

STORAGE ................................................................... 29

TROUBLESHOOTING ............................................ 30-31

REPAIR'PARTS - TRACTOR ................................. 34-53

REPAIR PARTS - ENGINE .................................... 54-58

PARTS ORDERING/SERVICE ................ BACK COVER

I I

LIMITED TWO (2) YEAR WARRANTY ON CRAFTSMAN TRACTOR (RIDING EQUIPMENT)

ForTwo (2) yearsfromdate of purchaseSearsCanada,Inc.willrepairorreplaceat Sears optionfree ofchargepartswhichare

defectiveasa resultofmaterialorworkmanship.

FULL ONE (1) YEAR WARRANTY ON BATrERY

For One (1) year from date of pumhase,if any battery includedwith this dding _quipment provesdefectivein materialor

workmanshipand ourtestingdeterminesthe batterywillnotholda charge,Searswillreplacethebatteryat nocharge.

COMMERCIAL OR RENTAL USE

Warrantyon RidingEquipmentusedfor commercialor rentalpurposesislimitedtoninety (90) days.

This Warranty does NOT cover:

1. Pre-dellveryset-up.

2. Tire replacement or repair caused by punctures from outside objects (such as nails, thoms, stumps, or glass).

3. Expendable Items which becomeworn during normal use, such as blades, spark plug,air cleaners and belts.

4. Repairs necessary because of operator abuse or negligence, Including damaged lackshaft or mandrel end the

failure to operate and maintain the equipment accordingto the Instructions contained In.the Owner's Manual.

5. In Home service.

Warranty serviceis evailabioby returning the CraftsmanR_ing Equipment tothe nearest SearsServiceCentre/Departmentin

Canada. Thiswarrantyappliesonlywhilethisproductisin useIn Canada.

Thiswarrantyis in additionto any statutorywarranty and does not excludeor limitlegal dghtsyou may have but shall run

concurrentlywithapplicable provirmiallegislation.Furthermore,someprovincesdo NOT e{!owlimitationon how longan impend

warrantywilllastso the abovelimitationsmaynotapplytoyou.

SEARS CANADA, INC., TORONTO, ONTARIO MsB 2B8

I I I I

4

I i

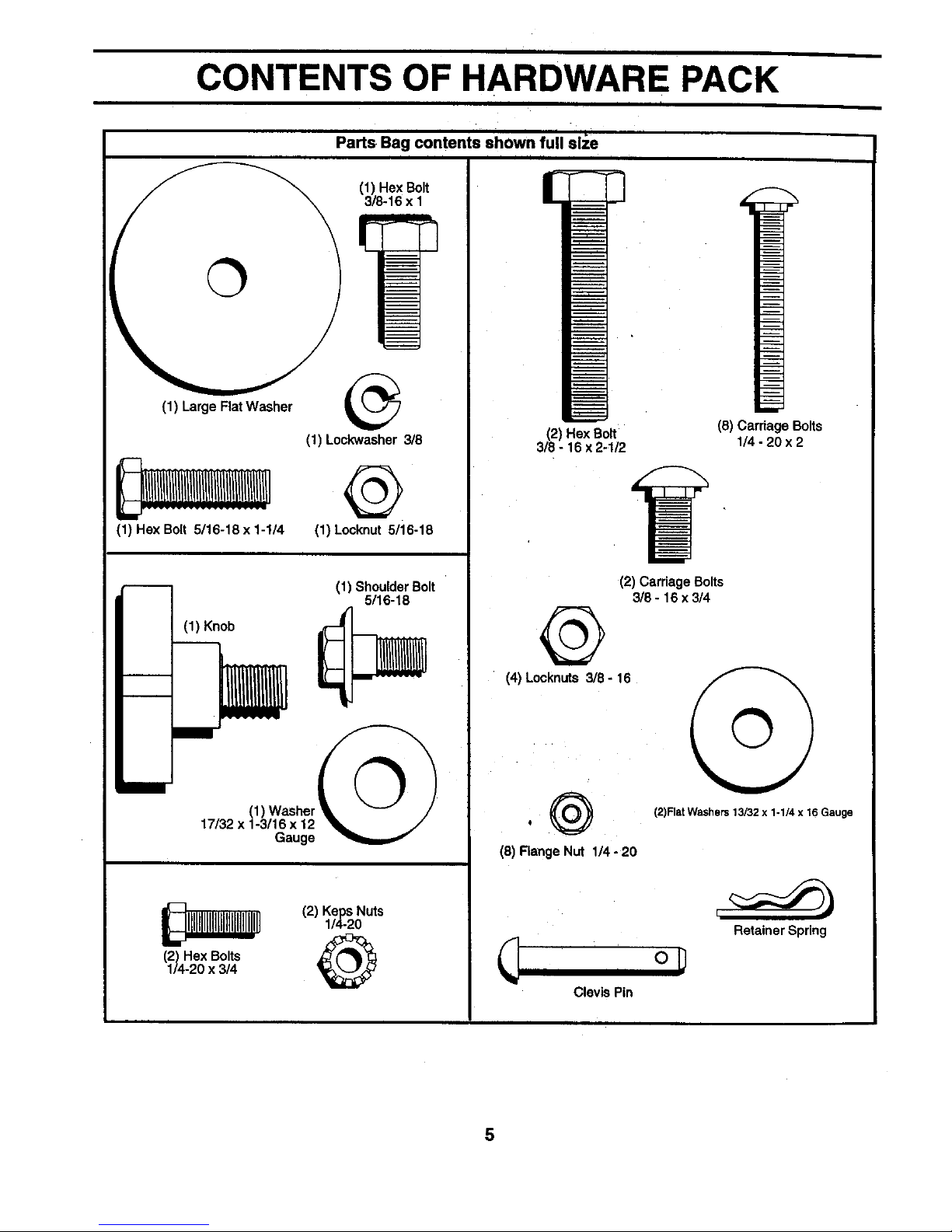

CONTENTS OF HARDWARE PACK

i II

i i i

Parts Bag contents shown full slie

I

(1) Large FlatWasher

(1) HexBolt

3/8-16 x 1

i

(1) Lockwasher_8

F---

ram"

(1) Hex Bolt 5/16-18 x 1-1/4

@

(1) Locknut 5/16-18

(1) ShoulderBolt

5/16-18

(1) Knob -_

l

(1) Washer I

17/32 x 1-3/16 x 12

Gauge

I_ (2) Keps Nuts

1/4-20

(2) Hex Bolts _%

1/4-20 x 314

m

n air

i..

(2) Hex Boff (8) Carriage Bolts

3/8 - 16 x 2-1/2 1/4 - 20 x 2

!

(2) CardageBolts

_8 - 16x 3/4

(4) Locknuts _8 - 16

@

(2)FlatWashers 13/32 x 1-1/4 x 16 Gauge

(8) FlangeNut 1/4- 20

I

Clevis Pin

op

Retainer Spring

5

i i i i i i i i

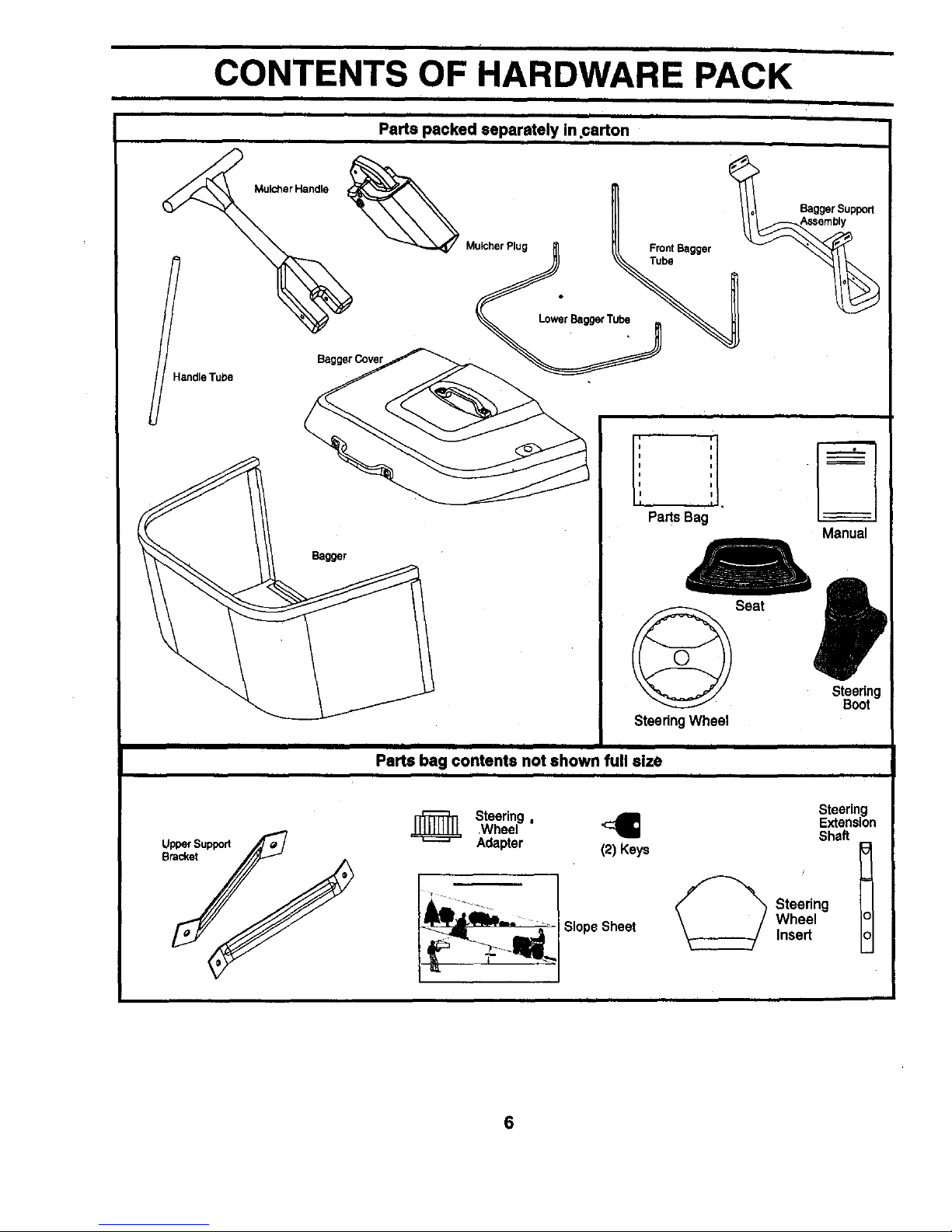

CONTENTS OF HARDWARE PACK

I i i i I I

I I i i iiii i i i I i i i

, , Parts packe d separately in.carton , ,

MulcherHandle

FrontBagger

Tube

eTube

_/BaggerSupport

Bag_r

i i i

L : -

PartsBag

Manual

PI

Steering

Boot

SteeringWheel

I I I II II I I I

Parts bag contents not shown full size

i i i i i

j_ Steering ,

Wheel <:_

Adapter (2) Keys

SlopeSheet

i

Steering

Extension

Shaft

Steering t

Wheel

Insert

6

ASSEMBLY

i i

Your new tractor has been assembled at the factory with exception of those parts left unasSembled for shipping purposes.

To ensure safe and proper operation of your tractor, all partsand hardware you assemble must be tightened securely. Use

the correct tools as necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(2) 9/16" wrenches (1) 3/8" socket with drive ratchet

(2) 7/16" wrenches Utility knife

(2) 1/2" wrenches Tire pressure gauge

When right and left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton (See page 5&6).

• Cut, from top to bottom, along lines on allfour comers

of carton, and lay panels flat.

• Check for any additional loose parts or cartons and

remove.

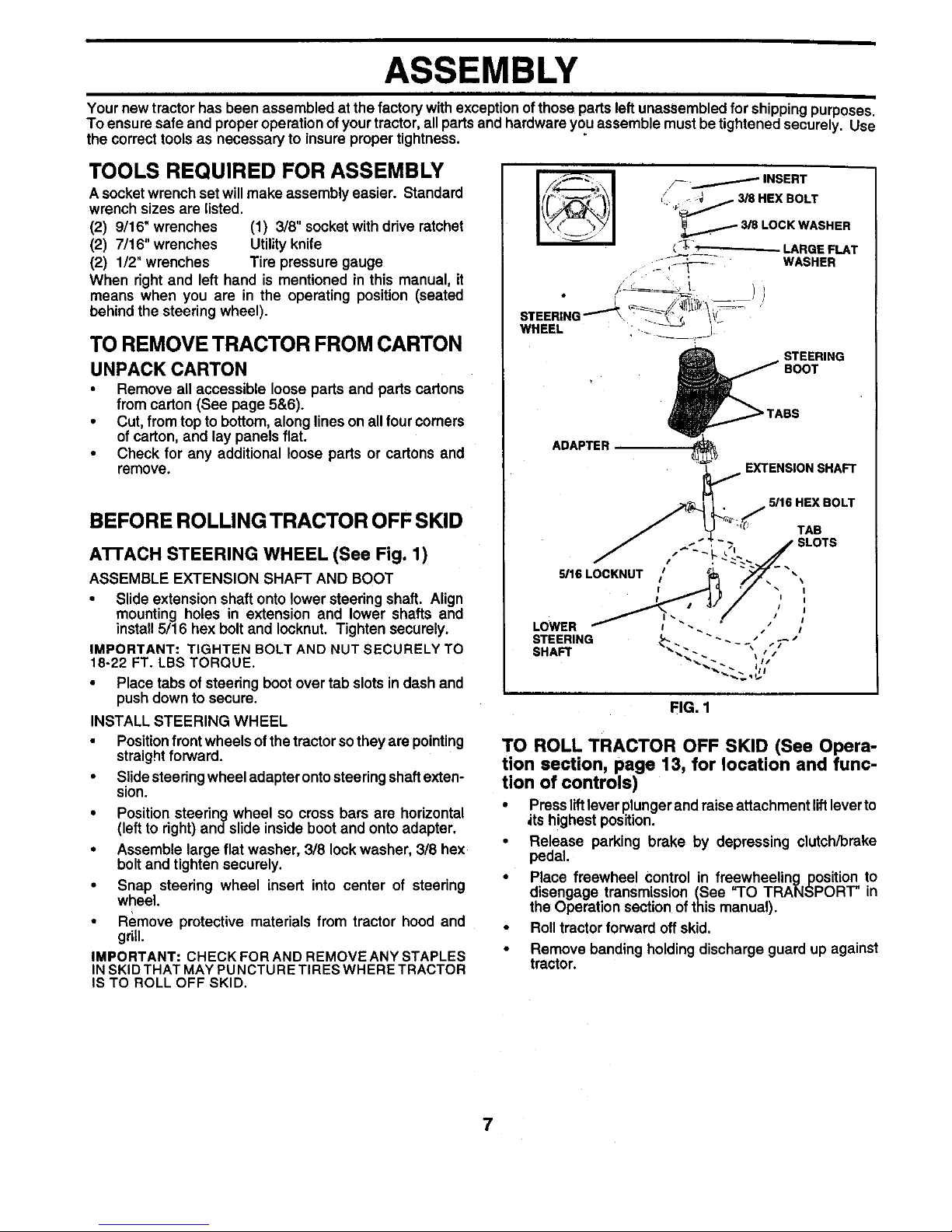

BEFORE ROLLING TRACTOR OFF SKID

A'FrACH STEERING WHEEL (See Fig. 1)

ASSEMBLE EXTENSION SHAFT AND BOOT

• Slide extension shaft onto lower steering shaft. Align

mounting holes in extension and lower shafts and

install 5/16 hex bolt and Iocknut. Tighten securely.

IMPORTANT: TIGHTEN BOLT AND NUT SECURELY TO

18-22 FT. LBS TORQUE.

• Place tabs of steering boot over tab slots in dash and

push down to secure.

INSTALL STEERING WHEEL

• Positionfront wheels of thetractor so they are pointing

straight forward.

• Slidesteeringwheeladapterontosteering shaftexten-

sion.

• Position steering wheel so cross bars are horizontal

(left to right) and slide inside boot and onto adapter.

• Assemble large flat washer, 3/8 lock washer, 318 hex

bolt and tighten securely,

• Snap steering wheel insert into center of steering

wheel.

• Remove protective materials from tractor hood and

grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE TRACTOR

IS TO ROLL OFF SKID.

F/INSERT

=_,,,_ - _. 3/8 HEX BOLT

_.._ 5/8 LOCK WASHER

(_ _ -- LARGE FLAT

"---- WASHER

STEERING _- \, ._, \\_

WHEEL , -_ _ J

STEERING

ADAPTER

FIG. 1

TO ROLL TRACTOR OFF SKID (See Opera-

tion section, page 13, for location and func-

tion of controls)

• Press liftlever plunger and raise attachment liftlever to

,itshighest position.

• Release parking brake by depressing clutch/brake

pedal.

• Place freewheel control in freewheelingposition to

disengage transmission (See 90 TRANSPORT" in

the Operation section of this manual).

• Roll tractor forward off skid.

• Remove banding holding discharge guard up against

tractor.

7

ii

ASSEMBLY

I

HOWTO SET UPYOUR TRACTOR

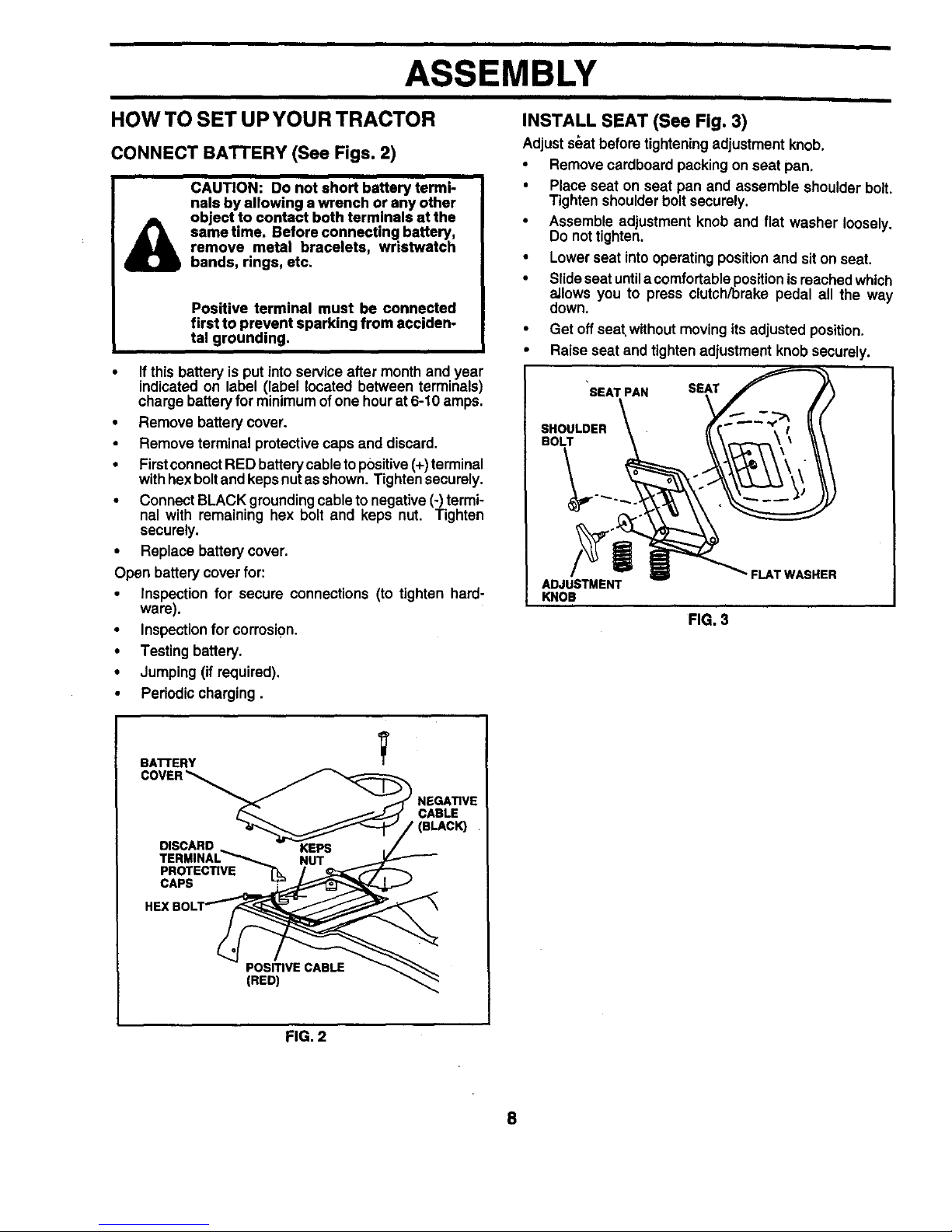

CONNECT BATTERY (See Figs. 2)

CAUTION: Do not short battery termi-

nals by allowing a wrench or any other

object to contact both terminals at the

same time, Before connecting battery,

remove metal bracelets, wristwatch

bands, rings, etc.

Positive terminal must be connected

first to prevent sparking from acciden-

tal grounding.

• Ifthis battery is put into service after month and year

indicated on label (label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

• Remove battery cover.

• Remove terminal protective caps and discard.

• Firstconnect RED battery cable topositive (+)terminal

with hexboltand keps nut as shown. Tighten securely.

• Connect BLACK grounding cable to negative (-) termi-

nal with remaining hex bolt and keps nut. Tighten

securely.

• Replace battery cover.

Open battery cover for:

• Inspection for secure connections (to tighten hard-

ware).

• Inspection forcorrosi0n.

• Testing battery.

• Jumping (if required).

• Periodic charging.

INSTALL SEAT (SeeFig. 3)

Adjust s_at before tightening adjustment knob.

• Remove cardboard packing on seat pan.

• Place seat on seat pan and assemble shoulder bolt.

Tighten shoulder bolt securely.

• Assemble adjustment knob and flat washer loosely.

Do not tighten.

• Lower seat into operating position and sit on seat.

• Slideseat untila comfortable positionis reached which

allows you to press clutch/brake pedal all the way

down.

• Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment knob securely.

'SEAT PAN SEAT

SHOULDER

BOLT

ADJUSTMENT

KNOB

FIG. 3

- FLAT WASHER

BATrERY

V

DISCARD

TERMINAL_

PROTEC_VE TU.

CAPS "I"

NUT

CABLE

(BLAC_

PosmvE CABLE

(RED)

FIG. 2

8

ASSEMBLY

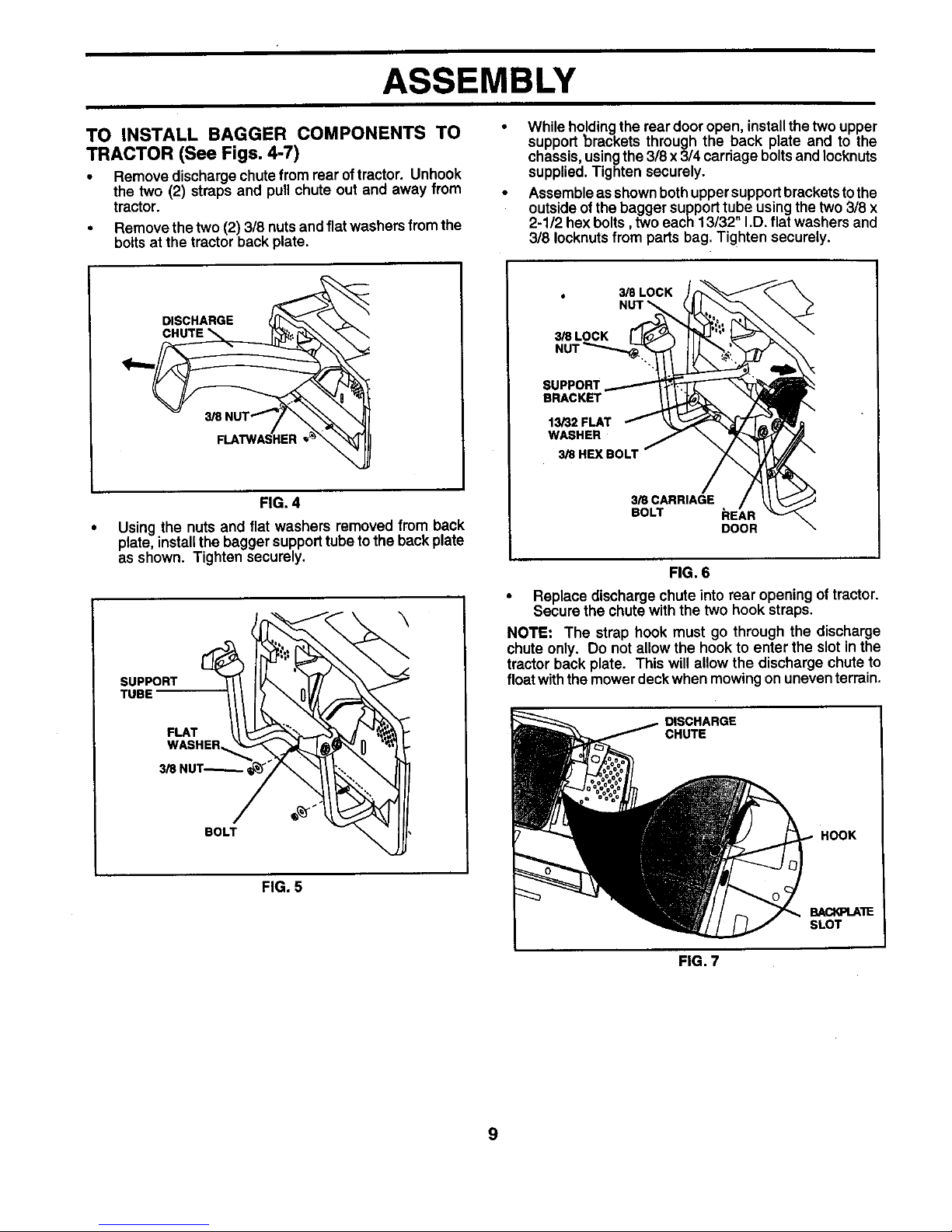

TO INSTALL BAGGER COMPONENTS TO

TRACTOR (See Figs. 4-7)

• Remove discharge chute from rear of tractor. Unhook

the two (2) straps and pull chute out and away from

tractor.

• Remove the two (2) 3/8 nuts and flat washers from the

bolts at the tractor back plate.

While holdingthe rear door open, install the two upper

support brackets through the back plate and to the

chassis, using the 3/8 x 3/4 carriage bolts and Iocknuts

supplied. Tighten securely.

Assemble as shown both upper support brackets to the

outside of the bagger support tube using the two 3/8 x

2-112 hex bolts, two each 13/32" I.D. flat washers and

3/8 Iocknuts from parts bag. Tighten securely.

DISCHARGE

FIG. 4

Using the nuts and flat washers removed from back

plate, installthe bagger supporttube to the back plate

as shown. Tighten securely.

\

SUPPORT

TUBE

FLAT

WASHER

BOLT

FIG. 5

3/8 LOCK

3/8L

SUPPORT

BRACKET

13/32 FLAT

WASHER

3/8HEXBOLT

3/SCARRIAGE

BOLT hEAR

DOOR

FIG. 6

• Replace discharge chute into rear opening of tractor.

Secure the chute with the two hook straps.

NOTE: The strap hook must go through the discharge

chute only. Do not allow the hook to enter the slot in the

tractor back plate. This will allow the discharge chute to

float with the mower deck when mowing on uneven terrain.

DISCHARGE

CHUTE

HOOK

BACKPLAIE

SLOT

FIG. 7

9

ASSEMBLY

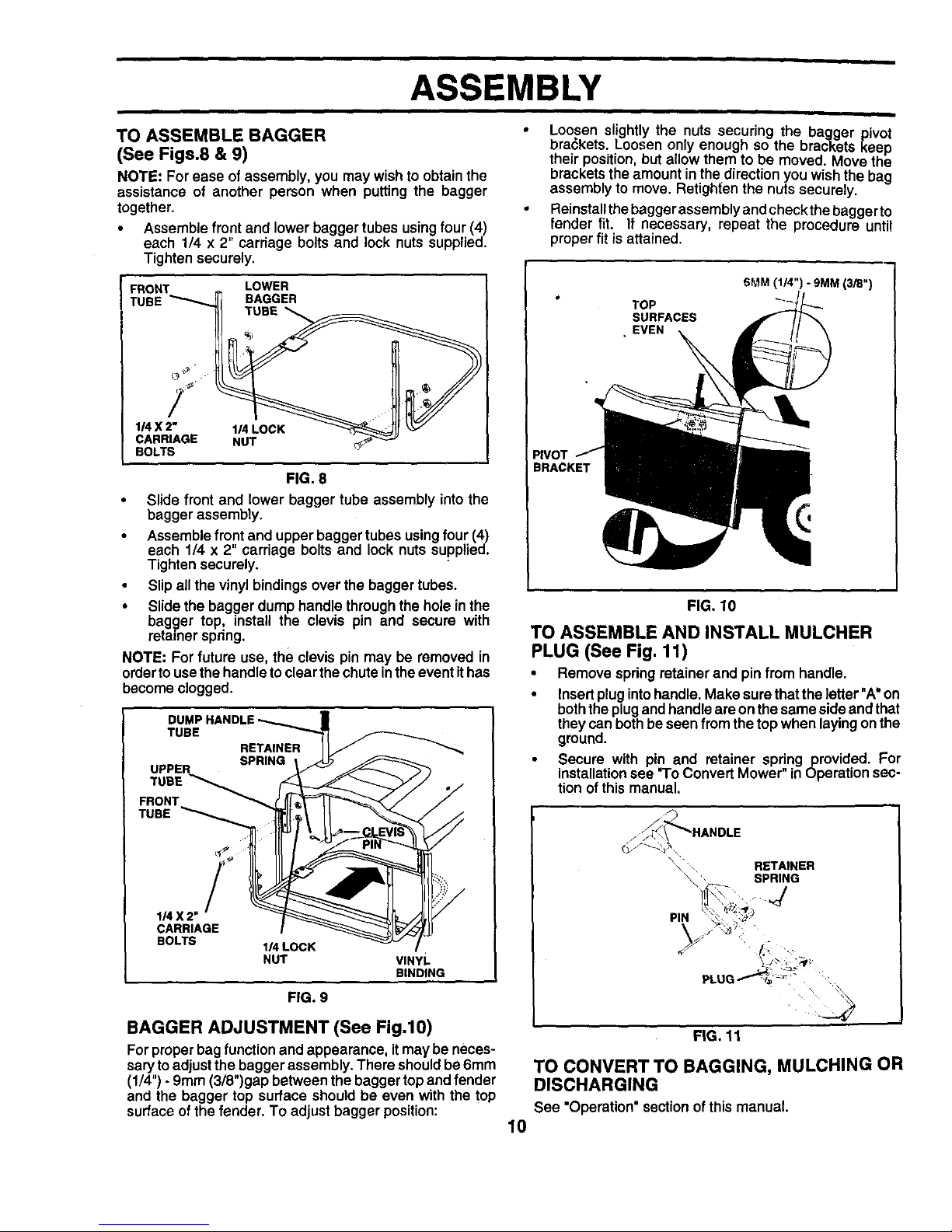

TO ASSEMBLE BAGGER

(See Figs.8 & 9)

NOTE: For ease of assembly, you may wish to obtain the

assistance of another person when putting the bagger

together.

• Assemble front and lower bagger tubes using four (4)

each 1/4 x 2" carriage bolts and lock nuts supplied.

Tighten securely.

FRONT LOWER

TUBE BAGGER

TUBE

1/4 X 2" 1/4 LOCK

CARRIAGE NUT

BOLTS

FIG. 8

• Slide front and lower bagger tube assembly into the

bagger assembly.

• Assemble front and upper bagger tubes using four (4)

each 1/4 x 2" carriage bolts and lock nuts supplied.

Tighten securely.

• Slip all the vinyl bindings over the bagger tubes.

• Slide the bagger dump handle through the hole in the

bagger top_ install the clevis pin and secure with

retainer spnng.

NOTE: For future use, the clevis pin may be removed in

order to use the handle toclear the chute inthe event ithas

become clogged.

TUBE

TUBE

RETAINER

1_X2 _

CARRIAGE

BOLTS

1_ LOCK

NUT

FIG. 9

VINYL

BINDING

Loosen slightly the nuts securing the bagger pivot

brackets. Loosen only enough so the brackets keep

their position, but allow them to be moved. Move the

brackets the amount in the direction you wish the bag

assembly to move. Retigh{en the nuts securely.

Reinstall the bagger assembly and check the baggerto

fender fit. If necessary, repeat the procedure until

proper fit is attained.

TOP

SURFACES

• EVEN

SMM (114")- 9MM (3/8")

PIVOT

BRACKET

FIG. 10

TO ASSEMBLE AND INSTALL MULCHER

PLUG (See Fig. 11)

• Remove spring retainer and pin from handle.

• Insert plug into handle. Make surethat the letter"A' on

boththe plug and handle are on the same side and that

they can both be seen fromthe top when laying on the

ground.

• Secure with pin and retainer spring provided. For

installationsee "ToConvert Mower" in Operation sec-

tion of this manual.

\ _ RETAINER

_ SPRING

'4

BAGGER ADJUSTMENT (See Fig.10)

For proper bag functionand appearance, it may be neces-

sary to adjust the bagger assembly. There should be 6ram

(1/4") - 9ram (3/8")gap between the bagger top and fender

and the bagger top surface should be even with the top

surface of the fender. To adjust bagger position:

10

FIG. 11

TO CONVERT TO BAGGING, MULCHING OR

DISCHARGING

See "Operation" section of this manual.

ASSEMBLY

I I

/ CHECKLIST

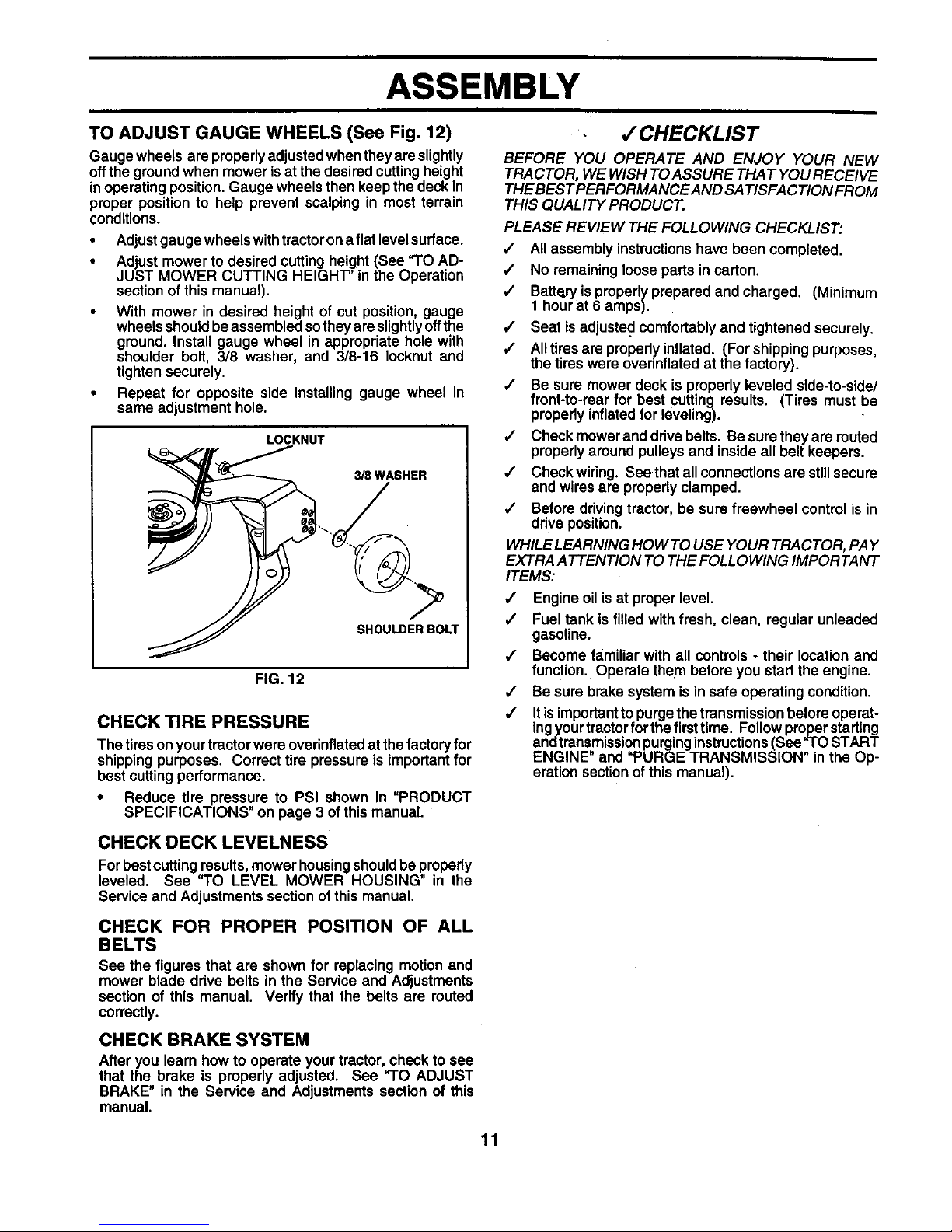

TO ADJUST GAUGE WHEELS (See Fig. 12)

Gauge wheels are properly adjustedwhen they are slightly

off the ground when mower is at the desired cutting height

inoperating position. Gauge wheels then keep the deck in

proper position to help prevent scalping in most terrain

conditions.

• Adjust gauge wheels withtractor on a flat level surface.

• Adjust mower to desired cutting height (See "TO AD-

JUST MOWER CUTTING HEIGHT' in the Operation

section of this manual).

• With mower in desired height of cut position, gauge

wheels should be assembled so they are slightly off the

ground. Install gauge wheel in appropriate hole with

shoulder bolt, 3/8 washer, and 3/8-16 Iocknut and

tighten securely.

• Repeat for opposite side installing gauge wheel in

same adjustment hole.

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TOASSURE THAT YOU RECEIVE

THE BEST PERFORMANCE AND SATISFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

,/ All assembly instructionshave been completed.

/ No remaining loose parts in carton.

,/ Batteryis properly prepared and charged. (Minimum

1 hour at 6 amps).

•/ Seat is adjusted comfortably and tightened securely.

/ Alltires are propedy inflated. (For shipping purposes,

the tires were ovednflated at the factory).

,/ Be sure mower deck is properly leveled side-to-side/

front-to-rear for best cutting results. (Tires must be

properly inflated for leveling).

LOCKNUT / Check mower and drive belts. Be sure they are routed

o__ properly around pulleys and inside all belt keepers.

3/8 WASHER /

/

/

/

SHOULDER BOLT

Check wiring. See that all connections are still secure

and wires are properly clamped.

Before driving tractor, be sure freewheel control is in

drive position.

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

FIG. 12

CHECK TIRE PRESSURE

The tires on yourtractor were overinflated at the factory for

shipping purposes. Correct tire pressure is important for

best cutting performance.

• Reduce tire pressure to PSI shown in =PRODUCT

SPECIFICATIONS" on page 3 of this manual.

,,I

,/

Engine oil is at proper level.

Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

Become familiar with all controls - their location and

function. Operate them before you start the engine.

Be sure brake system is in safe operating condition.

Itis Important to purge the transmission before operat-

ingyour tractor for the firsttime. Follow proper starting

andtransmission purging instructions(See"TO START

ENGINE" and =PURGE TRANSMISSION" in the Op-

eration section of this manual).

CHECK DECK LEVELNESS

For bestcutting results,mower housingshould be properly

leveled. See "TO LEVEL MOWER HOUSING" in the

Service and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

see the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adjusted. See "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual.

11

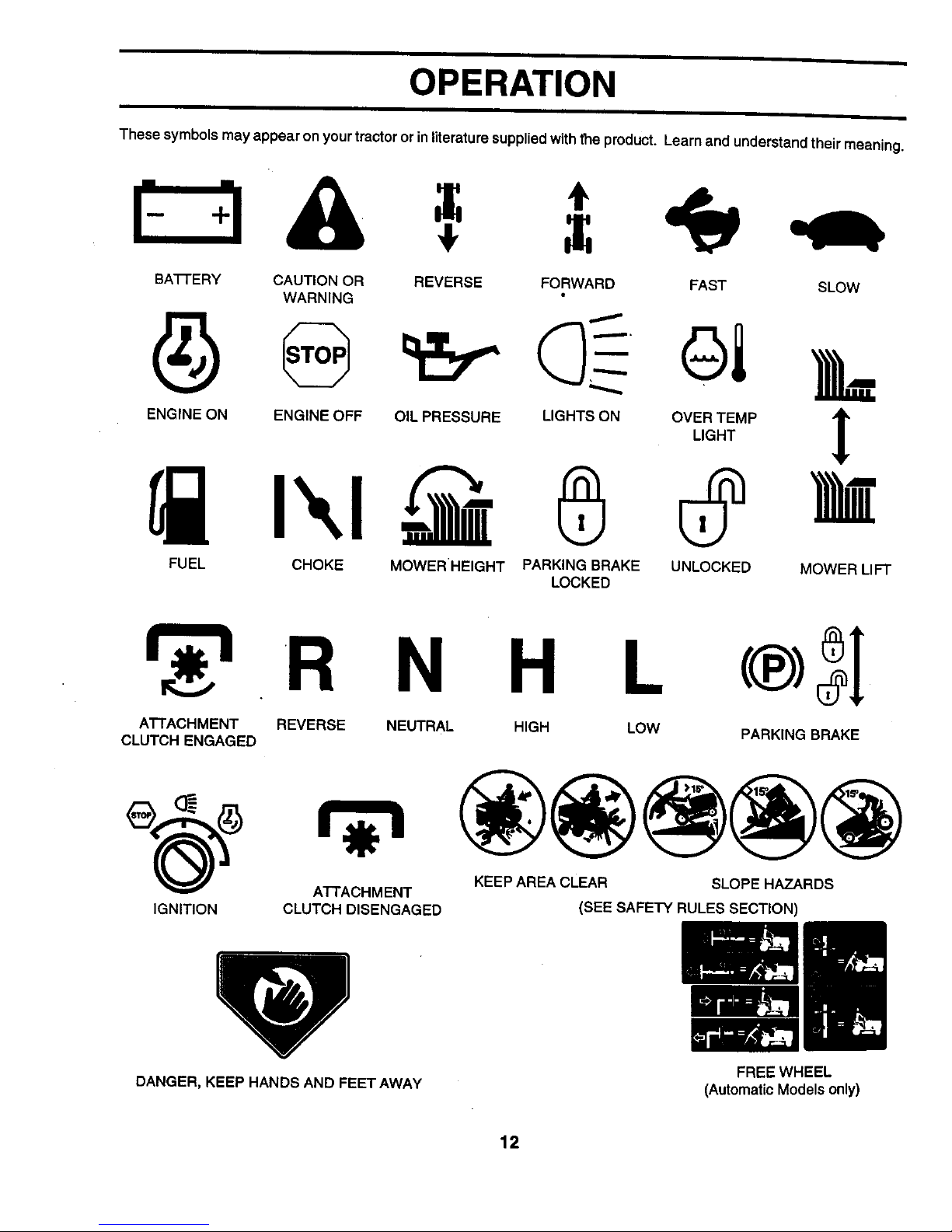

OPERATION

These symbols may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

BA'I-I'ERY CAUTION OR REVERSE FORWARD FAST SLOW

WARNING

ENGINE ON ENGINE OFF OIL PRESSURE LIGHTS ON OVER TEMP "_

LIGHT

L

FUEL CHOKE MOWERHEIGHT PARKING BRAKE UNLOCKED

LOCKED

MOWER LIFT

N H L

ATTACHMENT REVERSE NEUTRAL HIGH LOW

CLUTCH ENGAGED

IGNITION

A'N'ACHM ENT

CLUTCH DISENGAGED

PARKING BRAKE

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULES SECTION)

DANGER, KEEP HANDS AND FEET AWAY

FREE WHEEL

(Automatic Models only)

12

i i

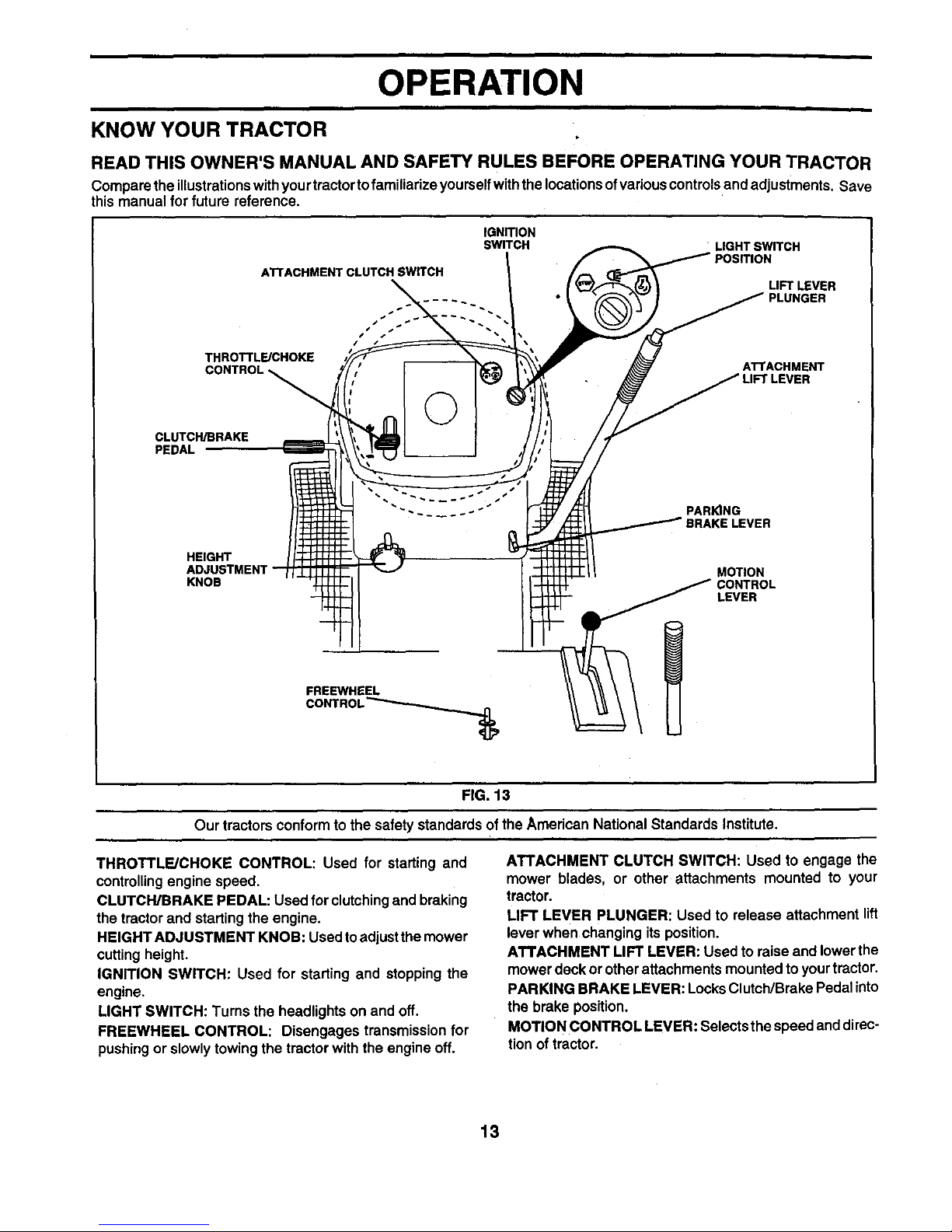

OPERATION

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrationswith yourtractorto familiarize yourself withthe locations ofvarious controls and adjustments. Save

this manual for future reference.

IGNITION

SWITCH

ATTACHMENT CLUTCH SWITCH

THROTTLE/CHOKE

LIGHT SWITCH

LIFT LEVER

PLUNGER

ATTACHMENT

CLUTCH/BRAKE

PEDAL

©

PARKING

E LEVER

HEIGHT

ADJUSTMENT

KNOB

MOTION

CONTROL

LEVER

FREEWHEEL

FIG. 13

Our tractors conform to the safety standards of the American National Standards Institute.

THROTTLE/CHOKE CONTROL: Used for starting and

controllingengine speed.

CLUTCWBRAKE PEDAL: Used for clutchingand braking

the tractor and starting the engine.

HEIGHT ADJUSTMENT KNOB: Used toadjust the mower

cutting height.

IGNITION SWITCH: Used for starting and stopping the

engine.

LIGHT SWITCH: Turns the headlights on and off.

FREEWHEEL CONTROL: Disengages transmission for

pushing or slowly towing the tractor with the engine off.

ATTACHMENT CLUTCH SWITCH: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIFT LEVER PLUNGER: Used to release attachment lift

lever when changing its position.

ATTACHMENT LIFT LEVER: Used to raise and lower the

mower deck or other attachments mounted to your tractor.

PARKING BRAKE LEVER: Locks Clutch/Brake Pedal into

the brake position.

MOTION CONTROL LEVER: Selects the speed and direc-

tion of tractor.

13

i

OPERATION

i

The operation of any tractor can result if=foreign objects thrown into the eyes, which

can result In severe eye damage. Always wear safety glasses or eye shields while

operating your tractor or performing any adjustments or repairs. We recommend a

wide vision safety mask over spectacles or standard safety glasses.

HOW TO USE YOUR TRACTOR

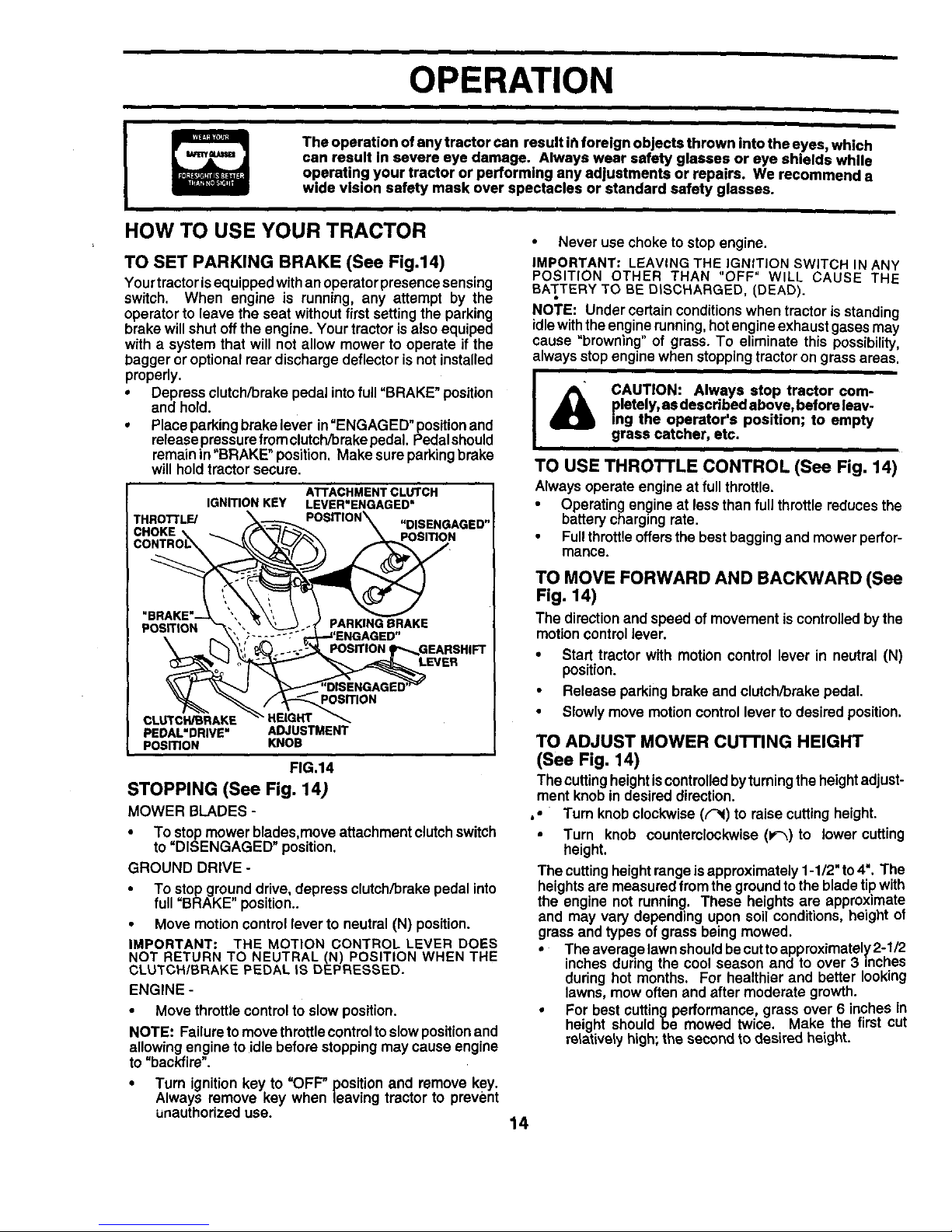

TO SET PARKING BRAKE (See Fig.14)

Yourtractor isequipped with an operator presence sensing

switch. When engine is running, any attempt by the

operator to leave the seat without first setting the parking

brake willshut offthe engine. Your tractor is also equiped

with a system that will not allow mower to operate if the

bagger or optional rear discharge deflector is not installed

properly.

• Depress clutch/brake pedal into full=BRAKE" position

and hold.

• Place perking brake lever in"ENGAG ED" positionand

release pressure from clutch/brake pedal. Pedalshoukf

remain in "BRAKE" position. Make sure parking brake

will hold tractor secure.

THROTrLE/

FIG.14

STOPPING (See Fig, 14)

MOWER BLADES -

• To stop mower blades,move attachment clutch switch

to "DISENGAGED" position,

GROUND DRIVE -

• To stop ground drive, depress clutch/brake pedal into

full =BRAKE" position..

• Move motion control lever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

ENGINE -

• Move throttle control to slow position.

NOTE: Failure to move throttle controltoslow positionand

allowing engine to idle before stopping may cause engine

to "backfire".

• Turn ignition key to =OFF" position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

• Never use choke to stop engine.

IMPORTANT: LEAVING THE IGNITION SWITCH IN ANY

POSITION OTHER THAN "OFF" WILL CAUSE THE

BATTERY TO BE DISCHARGED, (DEAD).

NOTE: Under certain conditions when tractor is standing

idle with the engine running, hot engine exhaust gases may

cause "browning" of grass. To eliminate this possibility,

always stop engine when stopping tractor on grass areas.

LOU_SE CAUTION: Always stop tractor com-

pletely, as described above, before leav-

ing the operator's position; to empty

grass catcher, etc.

THROTTLE CONTROL (See Fig. 14)

Always operate engine at full throttle.

• Operating engine at lessthan full throttle reduces the

battery charging rate.

• Full throttle offers the best bagging and mower perfor-

mance.

TO MOVE FORWARD AND BACKWARD (See

Fig. 14)

The directionand speedofmovementis controlledbythe

motioncontrollever.

• Start tractor with motion control lever in neutral (N)

position.

• Release parking brake and clutch/brake pedal.

• Slowly move motion control lever to desired position.

TO ADJUST MOWER cu'rrlNG HEIGHT

(See Fig. 14)

The cuttingheight is controlled byturning the height adjust-

ment knob in desired direction.

,. Turn knob clockwise (F,i) to raise cutting height.

• Turn knob counterclockwise (P-_) to lower cutting

height.

The cuttingheight range is approximately 1-1/2" to4". The

heights are measured from the ground to the bladetip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average lawn shoukf becut to approximately 2-1/2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

• For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

14

OPERATION

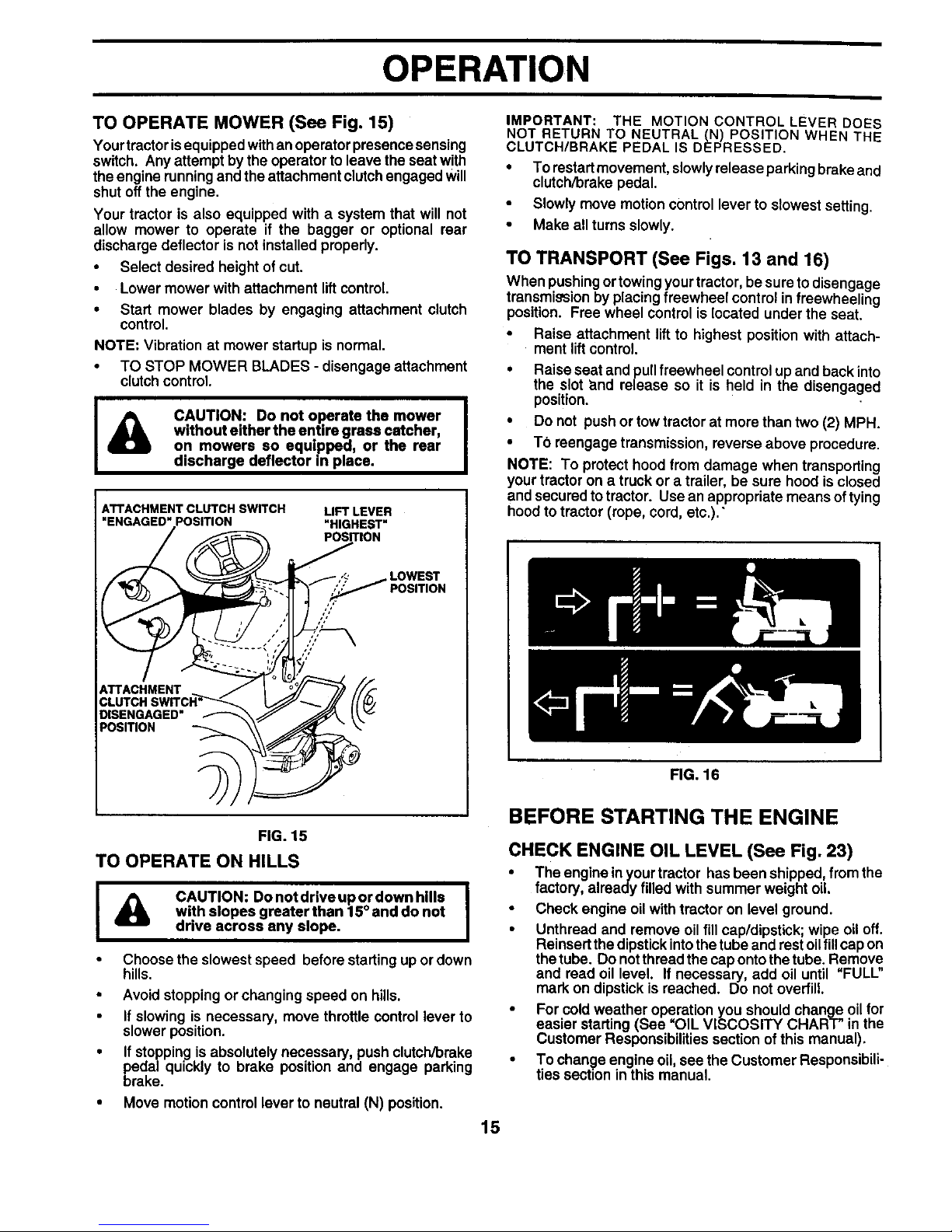

TO OPERATE MOWER (See Fig. 15)

Yourtractor isequipped with an operator presence sensing

switch. Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged will

shut off the engine.

Your tractor is also equipped with a system that will not

allow mower to operate if the bagger or optional rear

discharge deflector is not installed properly.

• Select desired height of cut.

• Lower mower with attachment lift control.

• Start mower blades by engaging attachment clutch

control.

NOTE: Vibration at mower startup is normal.

• TO STOP MOWER BLADES - disengage attachment

clutch control.

I

CAUTION: Do not operate the mower I

without either the entire grass catcher,

I

on mowers so equipped, or the rear

discharge deflector in place.

LIFT LEVER

"HIGHEST"

PosmoN

LOWEST

7/

ATTACHMENT

DISENGAGED"

POSITION

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

• To restart movement, slowlyrelease parking brake and

clutch/brake pedal.

• Slowly move motion control lever to slowest setting.

• Make all turns slowly.

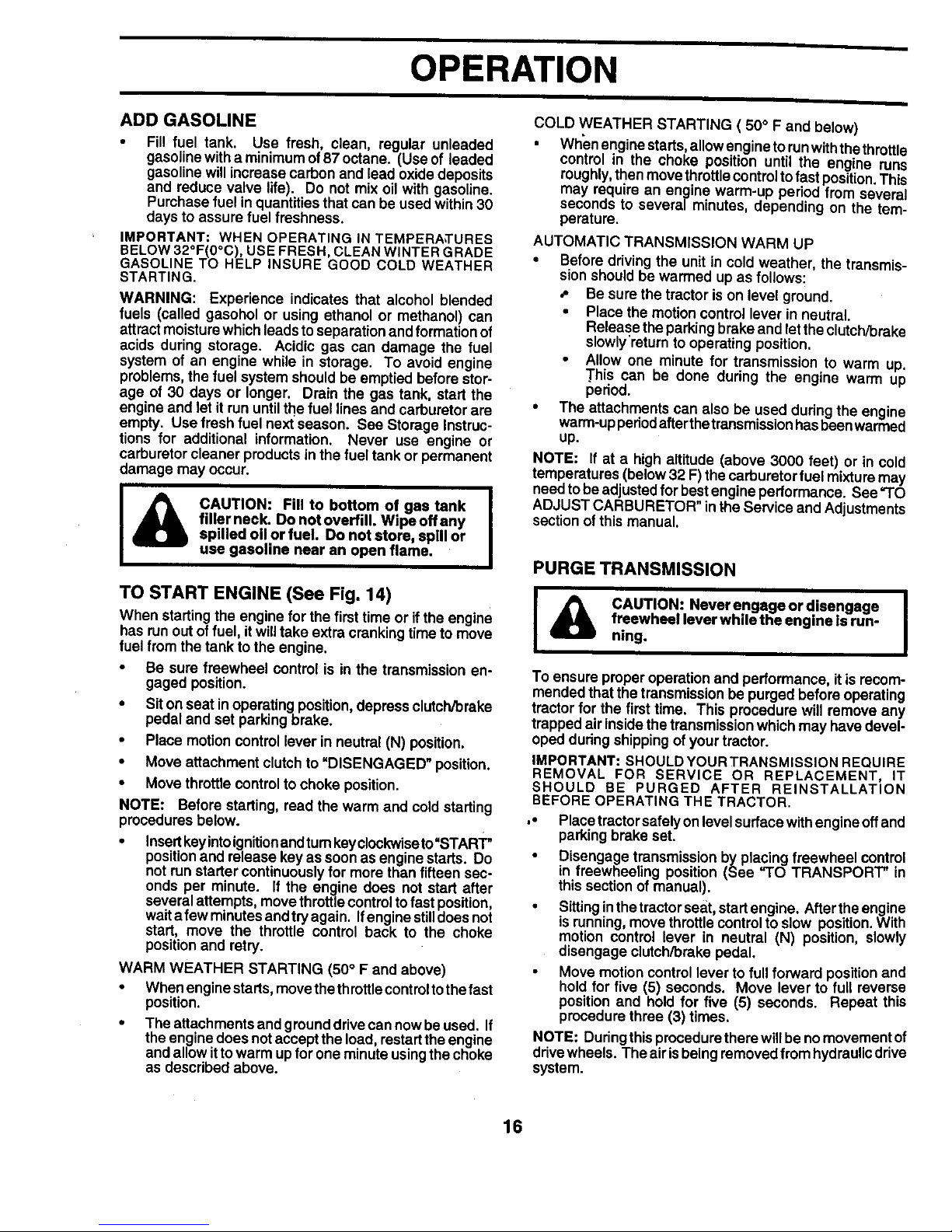

TO TRANSPORT (See Figs. 13 and 16)

When pushingortowing your tractor, be sure to disengage

transmission by placing freewheel control in freewheeling

position. Free wheel control is located under the seat.

• Raise attachment liftto highest position with attach-

ment liftcontrol.

• Raise seat and pull freewheel control up and back into

the slot and release so it is held in the disengaged

position.

• Do not push or tow tractor at more than two (2) MPH.

• TO reengage transmission, reverse above procedure.

NOTE: To protect hood from damage when transporting

your tractor on a truck or a trailer, be sure hood is closed

and secured to tractor. Use an appropriate means oftying

hood to tractor (rope, cord, etc.)."

FIG. 16

FIG. 15

TO OPERATE ON HILLS

I _, CAUTION: Donotdriveupordownhllls I

with slopes greater than 15° and do not

drive across any slope.

• Choose the slowest speed before starting up or down

hills.

• Avoid stopping or changing speed on hills.

• If slowing is necessary, move throttle control lever to

slower position.

• If stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake.

• Move motion control lever to neutral (N) position.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 23)

• The engine in your tractor has been shipped, from the

factory, already filled with summer weight oil.

• Check engine oil with tractor on level ground.

• Unthread and remove oil fill cap/dipstick; wipe oil off.

Reinsert the dipstick intothe tube and rest oilfill cap on

the tube. Do not thread the cap onto the tube. Remove

and read oil level. If necessary, add oil until "FULL"

mark on dipstick is reached. Do not overfill.

• For cold weather operation you should change oil for

easier starting (See OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manual).

• To change engine oil, see the Customer Responsibili-

ties section in this manual.

15

OPERATION

ADD GASOLINE

• Fil! fuel tank. Use fresh, clean, regular unleaded

gasoline with a minimum of87 octane. (Use of leaded

gasoline will increase carbon and lead oxide deposits

and reduce valve life). Do not mix oil with gasoline.

Purchase fuel in quantities that can be used within 30

days to assure fuel freshness.

IMPORTANT: WHEN OPERATING IN TEMPERA,TURES

BELOW 32°F(0°C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

WARNING: Experience indicates that alcohol blended

fuels (called gasohol or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage Instruc-

tions for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

CAUTION: Fill to bottom of gas tank

filler neck. Do not overfill. Wipe off any

spilled oil or fuel. Do not store, spill or

use gasoline near an open flame.

TO START ENGINE (See Fig. 14)

When starting the engine for the first time or if the engine

has runout of fuel, itwilltake extra cranking time to move

fuel from the tank to the engine.

• Be sure freewheel control is in the transmission en-

gaged position.

• Siton seat inoperating position, depress clutch/brake

pedal and set parking brake.

• Place motion control lever in neutral (N) position.

• Move attachment clutch to =DISENGAGED" position.

• Move throttle control to choke position.

NOTE: Before starting, read the warm and cold starting

procedures below.

• Insertkeyinto ignitionandtum keyclockwiseto "START"

positionand release key as soon as engine starts. Do

not run starter continuously for more than fifteen sec-

onds per minute. If the engine does not start after

several attempts, move throttle control tofast position,

wait a few minutes and try again. Ifengine stilldoes not

start, move the throttle control back to the choke

position and retry.

WARM WEATHER STARTING (50 ° F and above)

• When engine starts, move the throttle controlto the fast

position.

• The attachments and ground drivecan now be used. If

the engine does not accept the load, restart the engine

and allow itto warm up for one minute using the choke

as described above.

COLD WEATHER STARTING ( 50° F and below)

• When enginestarts, allow engine to runwith the throttle

control in the choke position until the engine runs

roughly,then movethrottle controlto fast position.This

may require an engine warm-up period from several

seconds to several minutes, depending on the tem-

perature.

AUTOMATIC TRANSMISSION WARM UP

• Before driving the unit in cold weather, the transmis-

sion should be warmed up as follows:

•- Be sure the tractor is on level ground.

• Place the motion control lever in neutral.

Release the parking brake and let the clutch/brake

slowly'return to operating position.

• Allow one minute for transmission to warm up.

This can be done during the engine warm up

period.

• The attachments can also be used during the engine

warm-up pedod after thetransmission has been warmed

up.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for best engine performance. See "TO

ADJUST CARBURETOR" in the Service and Adjustments

section of this manual.

PURGE TRANSMISSION

I _ CAUTION: Neverengageordisengage

freewheel lever while the engine is run-

ning.

To ensure proper operation and performance, it is recom-

mended that the transmission be purged before operating

tractor for the first time. This procedure will remove any

trapped air inside the transmission which may have devel-

oped dudng shipping ofyour tractor.

IMPORTANT: SHOULD YOURTRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT

SHOULD BE PURGED AFTER REINSTALLATION

BEFORE OPERATING THE TRACTOR.

," Place tractorsafely on level surface with engine offand

parking brake set.

• Disengage transmission by placing freewheel control

in freewheeling position (See "TO TRANSPORT" in

this section of manual).

• Sitting inthe tractorseat start engine. After the engine

is running, move throttlecontrolto slow position.With

motion control lever in neutral (N) position, slowly

disengage clutch/brake pedal.

• Move motion control lever to full forward position and

hold for five (5) seconds. Move lever to full reverse

position and hold for five (5) seconds. Repeat this

procedure three (3) times.

NOTE: During this procedure there willbe no movement of

drivewheels. The air isbeing removed from hydraulicdrive

system.

16

I

OPERATION

• Move motioncontrollever toneutral (N) position. Shut-

off engine and set parking brake.

• Engage transmission by placing freewheel control in

driving position (See "TO TRANSPORT" inthis section

of manual).

• Sittinginthetractor seat, startengine. Afterthe engine

is running, move throttle control to half (1/2) speed.

With motioncontrol lever in neutral (N) position, slowly

disengage clutch/brake pedal.

• Slowly move motion control lever forward, after the

tractor moves approximately five (5) feet, slowly move

motion control lever to reverse position. After the

tractor moves approximately five (5) feet retum the

motion control lever tothe neutral(N) position. Repeat

this procedure with the motion control lever three (3)

times.

Your tractor is now purged and now ready for normal

operation.

MOWING TIPS

• Tire chains cannot be used when the mower housing

is attached to tractor.

• Mower should be properly leveled for best mowing

performance. See "TO LEVEL MOWER HOUSING" in

the Service and Adjustments section ofthis manual.

• The left hand side of mower should be used for trim-

ming.

• If grass is extremely tall, it should be mowed twice to

reduce load and possible fire hazard from dded clip-

pings. Make first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet grass will plug

mower and leave undesirable clumps. Allow grass to

dry before mowing.

• Always operate engine at fullthrottle when mowing to

assure better mowing performance and proper dis-

charge of material. Regulate ground speed by select-

ing a low enough gear to give the mower cutting

performance as well as the quality of cut desired.

• When operating attachments, select a ground speed

that will suit the terrain and give best performance of

the attachment being used.

MULCHING MOWING TIPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH. CLEAN AFTER EACH USE,

The special mulching blade will recut the grass clip-

pings many times and reduce them in size so that as

they fall ontothe lawn they will disperse into the grass

and not be noticed. Also,. the mulched grass will

biodegrade quickly to provide nutrients for the lawn.

Always mulch with your highest engine (blade) speed

as this will provide the best recutting action of the

blades.

• Avoid cuttingyourlawn when it is wet. Wet grass tends

to form clumps and interferes with the mulching action.

The best time to mow your lawn is the early afternoon.

At this time the grass has dried and the newly cut area

will not be exposed to the direct sun.

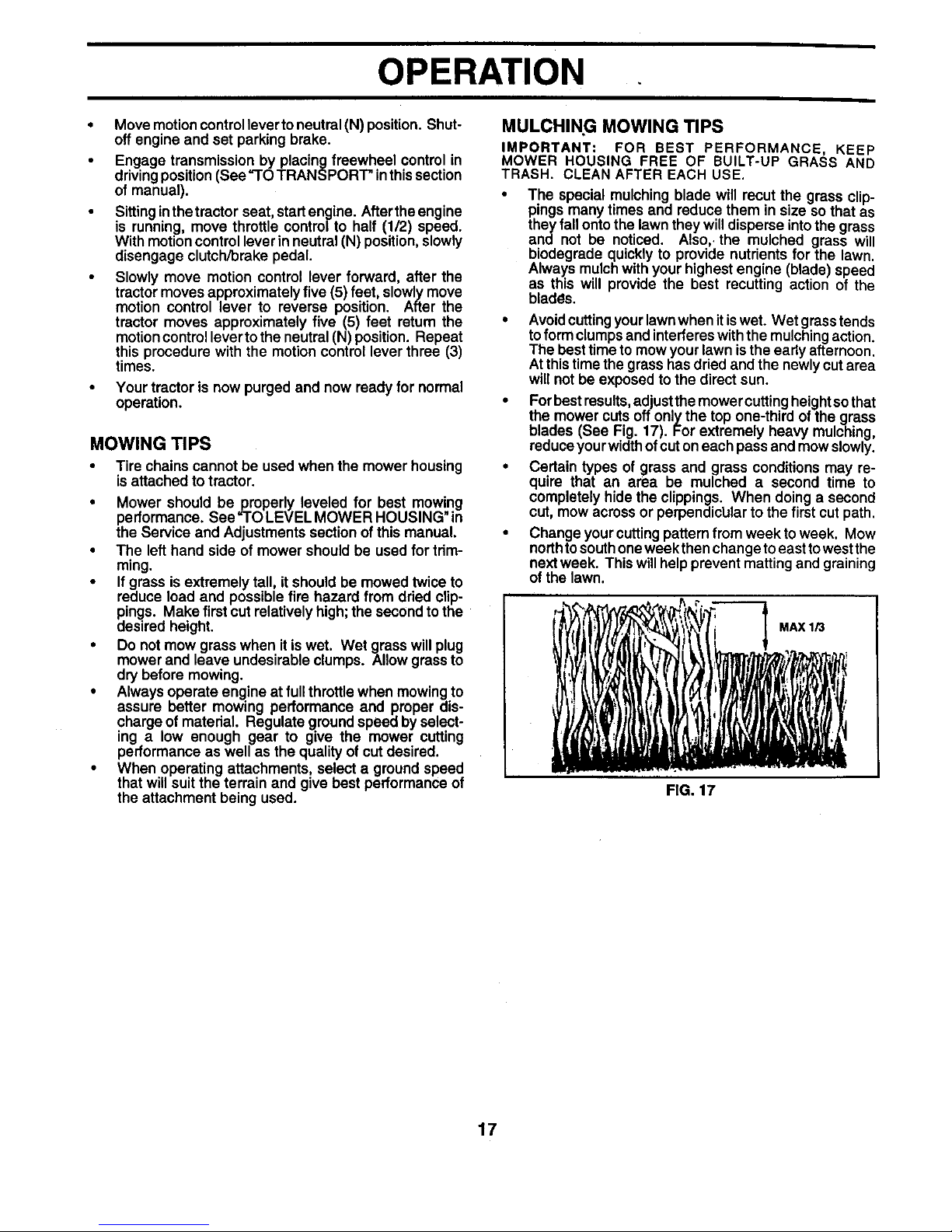

• For best results, adjust the mower cutting height so that

the mower cuts off only the top one-third of the grass

blades (See Fig. 17). For extremely heavy mulching,

reduce your width of cut on each pass and mow slowly.

• Certain types of grass and grass conditions may re-

quire that an area be mulched a second time to

completely hide the clippings. When doing a second

cut, mow across or perpendiclJlar to the first cut path.

• Change your cutting pattern from weekto week. Mow

north to south one weekthen change to east to west the

next week. This will help prevent matting and graining

of the lawn.

MAX 1/3

FIG. 17

17

OPERATION

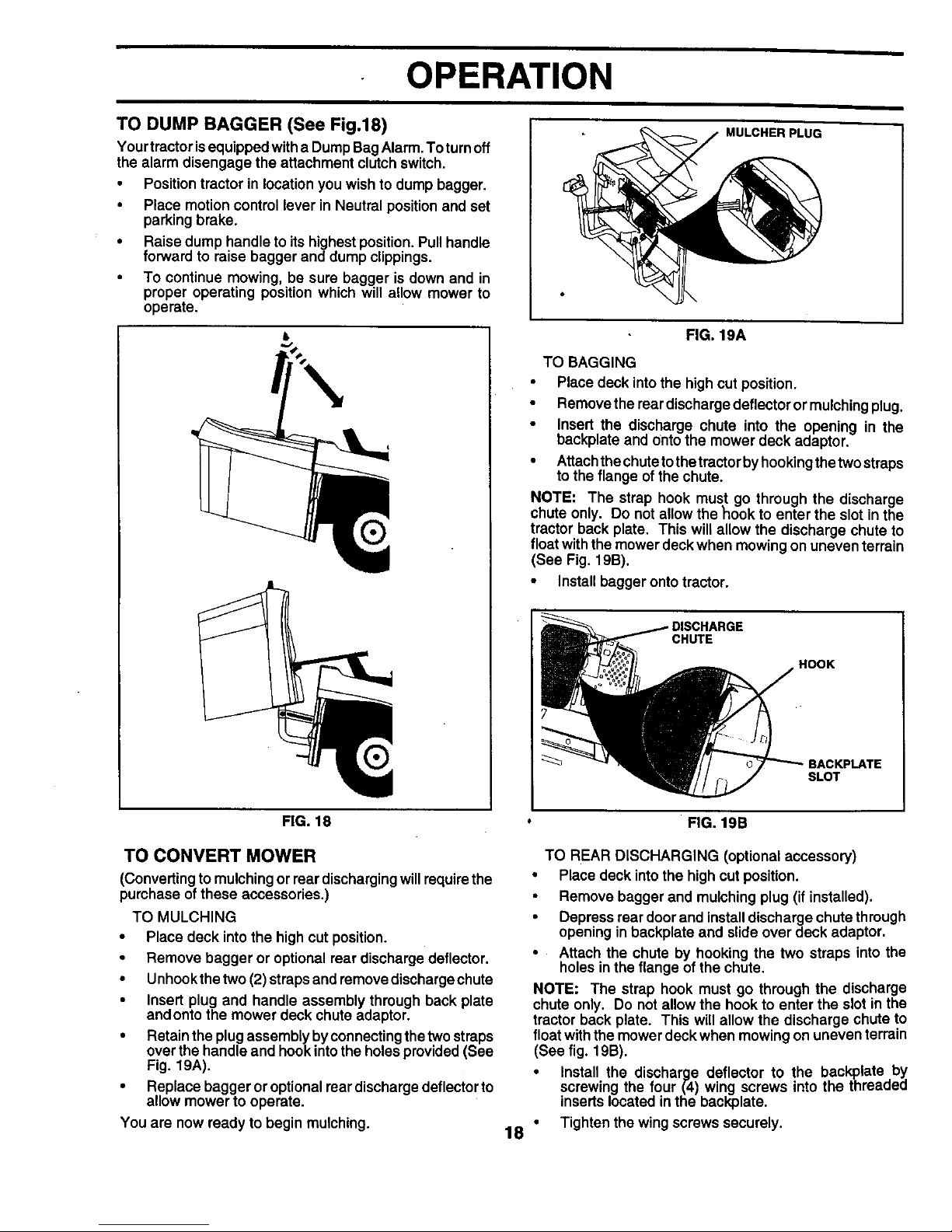

MULCHER PLUG

TO DUMP BAGGER (See Fig.18)

Yourtractor is equipped witha Dump Bag Alarm, To turnoff

the alarm disengage the attachment clutch switch.

• Positiontractor in location you wish to dump bagger.

• Place motion control lever in Neutral position and set

parking brake.

• Raise dump handle to its highest position. Pull handle

forward to raise bagger and dump clippings.

• To continue mowing, be sure bagger is down and in

proper operating position which will allow mower to

operate.

FIG. 19A

TO BAGGING

• Place deck intothe high cut position.

• Remove the rear discharge deflector or mulching plug.

• Insert the discharge chute into the opening in the

backplate and ontothe mower deck adaptor.

• Attachthe chuteto thetractor by hooking the twostraps

to the flange of the chute.

NOTE: The strap hook must go through the discharge

chute only. Do not allow the hook to enter the slot in the

tractor back plate. This will allow the discharge chute to

float with the mower deck when mowing on uneven terrain

(See Fig. 19B).

• Install bagger onto tractor.

CHUTE

HOOK

SLOT

FIG. 18

TO CONVERT MOWER

(Converting to mulching or rear discharging will require the

purchase of these accessories.)

TO MULCHING

• Place deck into the high cut position.

• Remove bagger or optional rear discharge deflector.

• Unhook the two (2) straps and remove discharge chute

• Insert plug and handle assembly through back plate

and onto the mower deck chute adaptor.

• Retain the plug assembly byconnecting the two straps

over the handle and hook into the holes provided (See

Fig. 19A).

• Replace bagger or optional rear discharge deflector to

allow mower to operate.

You are now ready to begin mulching.

FIG. 19B

TO REAR DISCHARGING (optional accessory)

• Place deck intothe high cut position.

• Remove bagger and mulching plug (if installed).

• Depress rear door and install discharge chute through

opening in backplate and slide over deck adaptor.

• Attach the chute by hooking the two straps into the

holes in the flange of the chute.

NOTE: The strap hook must go through the discharge

chute only. Do not allow the hook to enter the slot inthe

tractor back plate. This will allow the discharge chute to

float with the mower deck when mowing on uneven terrain

(See fig. 19B).

• Install the discharge deflector to the backplate by

screwing the four (4) wing screws into the threaded

inserts located in the back,plate.

18 " Tighten the wing screws securely.

Loading...

Loading...