Craftsman 944527700 Owner’s Manual

OWNER'S

MANUAL

MODEL NO.

944.527700

®

Caution:

Read and follow

all Safety Rules

and instructions

Before Operating

This Equipment

Sears Canada, Inc., Toronto, Ontario MSB 2B8

P

TWO-STAGE

R- ROPELLE

THROWER

• Assembly

• Operation

• Maintenance

• Service and Adjustments

• Repair Parts

&

Safe Operation Practices for Walk=Behind Snow Throwers

This snow thrower is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury.

Look for this symbol to point out im-

portant safety precautions, it means

CAUTION!!! BECOMEALERT!!! YOUR

SAFETY iS iNVOLVED.

WARNING: Always disconnect spark

plug wire and place it where it cannot

contact plug in order to prevent acci=

dental starting when setting up, trans=

porting, adjusting or making repairs.

iMPORTANT

WARNING: Snow throwers have ex=

posed rotating parts, which can cause

terial thrown from the discharge chute.

severe injury from contact, or from ma-

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

parts become extremely hot during

CAUTION: Muffler and other engine

operation and remain hot after engine

WARNING: This snow thrower is for

use on sidewalks, driveways and other

be exercised while using on sloping

surfaces. Do not use snow thrower on

ground level surfaces. Caution should

surfaces above ground level such as

roofs of residences, garages, porches

or other such structures or buildings.

Training

1, Read, understand and follow all instructions on the

machine and in the manual(s) before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

3, Keep the area of operation clear of all persons, par-

ticularly small children.

4, Exercise caution to avoid slipping orfalling, especially

when operating the snow thrower in reverse.

Preparation

1, Thoroughly inspect the area where the equipment is

to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting the engine (motor).

3, Do notoperatethe equipment without wearing adequate

winter garments. Avoid loose fitting clothing that can

get caught in moving parts. Wear footwear that will

improve footing on slippery surfaces.

4, Handle fuel with care; it is highly flammable

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot en-

gine.

(c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

(d) Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers onthe ground, away from your vehicle,

before filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than

from a gasoline dispenser nozzle.

_ has stopped. To avoid severe burns on

(f) Keep the nozzle in contact with the rim of the fuel

(g) Replace gasoline cap securely and wipe up spilled

(h) If fuel is spilled on clothing, change clothing im-

5,

Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

6,

Adjust the collector housing height to clear gravel or

crushed rock surface.

7,

Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by manufacturer).

8,

Always wear safety glasses or eye shields during op-

eration or while performing an adjustment or repair to

protect eyes from foreign objects that may be thrown

from the machine.

contact, stay away from these areas.

WARNING: Engine exhaust, some of

components contain or emit chemi=

cals known to the State of California

its constituents, and certain vehicle

to cause cancer and birth defects or

other reproductive harm.

tank or container opening at all times, until refu-

eling is complete. Do not use a nozzle lock-open

device.

fuel.

mediately.

Operation

1, Do not put hands or feet near or under rotating parts,

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or cross-

ing gravel drives, walks, or roads, Stay alert for hidden

hazards or traffic.

3, After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, disconnect the

cord on electric motors, thoroughly inspect the snow

thrower for any damage, and repair the damage before

restarting and operating the snow thrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5, Stop the engine (motor) whenever you leave the oper-

ating position, before unclogging the collector/impeller

housing or discharge chute, and when making any

repairs, adjustments or inspections,

6. Whencleaning,repairingor inspectingthe snow

thrower,stoptheengineandmakecertainthecol-

lector/impellerandall movingpartshavestopped.

Disconnectthesparkplugwireandkeepthewireaway

fromtheplugtopreventsomeonefromaccidentally

startingtheengine.

7. Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthesnowthrowerinor

outofthebuilding.Opentheoutsidedoors;exhaust

fumesaredangerous.

8. Exerciseextremecautionwhenoperatingonslopes.

9. Neveroperatethesnowthrowerwithoutproperguards,

andothersafetyprotectivedevicesinplaceandwork-

ing.

10.Neverdirectthedischargetowardpeopleor areas

wherepropertydamagecanoccur.Keepchildrenand

othersaway.

11.Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofasta rate.

12.Neveroperatethemachineathightransportspeeds

onslipperysurfaces.Lookbehindandusecarewhen

operatinginreverse.

13.Disengagepowertothecollector/impellerwhensnow

throweristransportedornotinuse.

14.Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofthesnowthrower(suchaswheel

weights,counterweights,orcabs).

15.Neveroperatethesnowthrowerwithoutgoodvisibility

orlight.Alwaysbesureofyourfooting,andkeepa

firmholdonthehandles.Walk;neverrun.

16.Nevertoucha hotengineormuffler.

Clearing a Clogged Discharge Chute

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snow throwers. Never use your hand to clean out the dis-

charge chute. To clear the chute:

1. SHUTTHE ENGINE OFF!

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean-out tool, not your hands.

Maintenance and Storage

1. Check shear bolts and other bolts at frequent intervals

for proper tightness to be sure the equipment is in safe

working condition.

2. Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present

such as hot water heaters, space heaters, or clothes

dryers. Allow the engine to cool before storing in any

enclosure.

3, Always refer to operator's manual for important details

if the snow thrower is to be stored for an extended

period,

4, Maintain or replace safety and instruction labels, as

necessary,

5, Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller,

TABLE OF CONTENTS

SAFETY RULES ........................................................ 2-3

PRODUCT SPECiFICATiONS ...................................... 4

CUSTOMER RESPONSIBILITIES ................................ 4

WARRANTY .................................................................. 4

ASSEMBLY / PRE-OPERATION ............................... 6-8

OPERATION ............................................................ 9=14

MAINTENANCE ..................................................... 15-16

MAINTENANCE SCHEDULE ..................................... 15

SERVICE AND ADJUSTMENTS ........................... 17=19

STORAGE ................................................................... 19

TROUBLESHOOTING ................................................ 20

REPAIR PARTS ..................................................... 22-38

SEARS SERVICE ................................... BACK COVER

LIMITED TWO (2) YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For two (2) years from date of purchase Sears Canada, Inc. will repair or replace, at Sears option, free of charge

parts which are defective as a result of material or workmanship,

COMMERCIAL OR RENTAL USE:

Warranty on Snow Thrower will be 90 days from date of purchase if used for commercial or rental purposes,

This Warranty does NOT cover:

1. Pre=delivery set=up.

2. Expendable items which become worn during normal use, such as belts, spark plugs, air cleaners,

and shear pins, as well damage to the engine resulting from operating snow thrower with insufficient oil.

3. Repairs necessary because of operator abuse or negligence, including the failure to operate and main=

tain the equipment according to the instructions contained in the Owner's Manual.

4. Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps or glass.

Warranty service is available by returning the Craftsman Snow Thrower to the nearest Sears Service Centre/Depart-

ment in Canada. This warranty applies only while this product is in use in Canada.

This warranty is in addition to any statutory warranty and does NOT exclude or limit legal rights you may have but

shalll run concurrently with applicable provincial legislation. Furthermore, some provinces do not allow limitations

on how long an implied warranty will last, so the above limitations may not apply to you,

Sears Canada, inc., Toronto, Ontario M5B 2B8

CONGRATULATIONS on your purchase of a new snow

thrower. It has been designed, engineered and manufac-

tured to give best possible dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears service centre/

department. We have competent, well-trained technicians

and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your snow thrower

properly. Always observe the "SAFETY RULES",

SERIAL NUMBER:

DATE OFPURCHASE:

THE MODELAND SERIAL NUMBERSWILL BE FOUND

ON ADECALATTACH EDTOTHE REAR OFTHE SNOW

THROWER HOUSING.

YOUSHOULDRECORDBOTHSERIALNUMBERAND

DATE OF PURCHASE AND KEEPIN A SAFE PLACE

FOR FUTURE REFERENCE.

PRODUCT SPECiFiCATiONS

Gasoline Capacity 4.0 Quarts (4,54 Liters)

and Type: Unleaded Regular only

Oil Type SAE 5W-30 or 10W-30

(APl SG-SL): (0°F to +40°F / -18°C to +5°C)

Synthetic SAE 5W-30 or 10W-30

(below 0°F / -18°C)

Oil Capacity: 28 Ounces (0,8 Liters)

Spark Plug: Champion RC12YC

Gap: 0,030" (0,762 mm)

CUSTOMER RESPONSIBiLiTiES

• Read and observe the safety rules,

• Follow a regular schedule in maintaining, caring for

and using your snow thrower,

• Follow the instructions under "Maintenance" and "Stor-

age" sections of this owner's manual,

PARTS PACKED SEPARATELY I CARTON

(1) POWER

(1) DISCHARGE CHUTE

EXTRA SHEAR DOLTS AND NUTS

CORD

(1) FUEL STABiLiZER PACKET

(2) SAFETY iGNiTiON KEYS

(1) AUGER CONTROL ROD

1111111

(1) TRACTION DRIVE CONTROL ROD

©

(1) MULTi=

WRENCH

(2) SHEAR BOLTS 1/4=20 x %3/4

ROTATOR HEAD MOUNTING

(1) WASHER 3/8 (1) LOCKNUT 3/8

(1) LOCKNUT

5/16=18

(1) CARRIAGE

BOLT 5/16=18 x 5/8

(2) SPACERS (2) LOCKNUTS

1/4=20

CHUTE DEFLECTOR REMOTE CONTROL

(1) LOCKNUT (1) NYLON

1/4-20 WASHER

(3) RETAINER

SPRINGS

{1) SHOULDER

BOLT 1/4=20

(1)

AS / RE-O ERATION

Read these instructions and this manual in its entirety

before you attempt to assemble or operate your new

snow thrower. Reading the entire manual will familiar=

ize you with the unit, which will assist you inassembly,

operation and maintenance of the product.

Your new snow thrower has been assembled at the factory

with the exception of those parts left unassembled for ship-

ping purposes. All parts such as nuts, washers, bolts, etc.,

necessary to complete the assembly have been placed in

the parts bag. To ensure safe and proper operation of your

snow thrower, all parts and hardware you assemble must

be tightened securely. Use the correct tools as necessary

to ensure proper tightness.

REMOVE SNOW THROWER FROM CARTON

1. Remove all accessible loose parts and parts boxes

from carton.

2. Cut down all four corners of carton and lay panels flat.

3. Remove the two (2) screws securing the auger housing

to the pallet.

4. Remove all packing materials except plastic tie holding

speed control rod to lower handle.

5. Remove the two (2) plastic ties securing the upper

handle to the pallet.

6. Remove snow thrower from carton and check carton

thoroughly for additional loose parts.

INSTALL SPEED CONTROL ROD (See Figs. 1 and 2)

1. Remove plastic tie securing rod to lower handle.

2. insert rod into speed control bracket and secure with

retainer spring.

SPEED

CONTROL

ROD //

PLASTIC TIE

UPPER

HANDLE

/ /

/ /

i

HANDLE

KNOB

LOWER

HANDLE

J

HOW TO SET UP YOUR SNOW THROWER

TOOL BOX (See Fig, 10)

A toolbox is provided on your snow thrower. The toolbox is

located on top of the belt cover. Store the extra shear bolts,

nuts and multi-wrench provided inparts bag in the toolbox.

NOTE: The multi-wrench may be used for assembly of the

chute rotator head tosnow thrower and making adjustments

to the skid plates.

UNFOLD UPPER HANDLE

1. Raise upper handle tothe operating position and tighten

handle knobs securely.

FIG. 1

SPEED CONTROL ROD

RETAINER

SPRING

SPEED SPEED

CONTROL CONTROL

BRACKET LEVER

FIG. 2

AS / RE-O ERATION

INSTALL TRACTION DRIVE CONTROL ROD

(See Figs. 3 and 4)

The traction drive control rod has the long loop on the end

of the spring as shown.

1. Slide rubber sleeve up rod and hook end ofspring into

pivot bracket with loop opening down as shown.

2. With top end of rod positioned under left side of control

panel, push rod down and insert top end of rodinto hole

in drive control bracket. Secure with retainer spring.

LOOP

OPENING

DOWN

INSTALL AUGER CONTROL ROD (See Figs. 5 and 6)

The auger control rod has the short loop on the end of the

spring as shown.

1. Slide rubber sleeve up rod and hook end ofspring into

control arm with loop opening up as shown.

2. With top end of rod positioned under right side of

control panel, push down on rod and insert end of rod

into hole in auger control bracket. Secure with retainer

spring.

AUGER

ROD

RUBBER

SLEEVE

CONTROL

ARM

CONTROL

BRACKET

FIG. 3

FIG, 4

RETAINER

SPRING

FIG. 5

AUGER CONTROL ROD AUGER

CONTROL

RETAINER LEVER

SPRING \

CONTROL

BRACKET

FIG. 6

AS BLY / RE-O ERATION

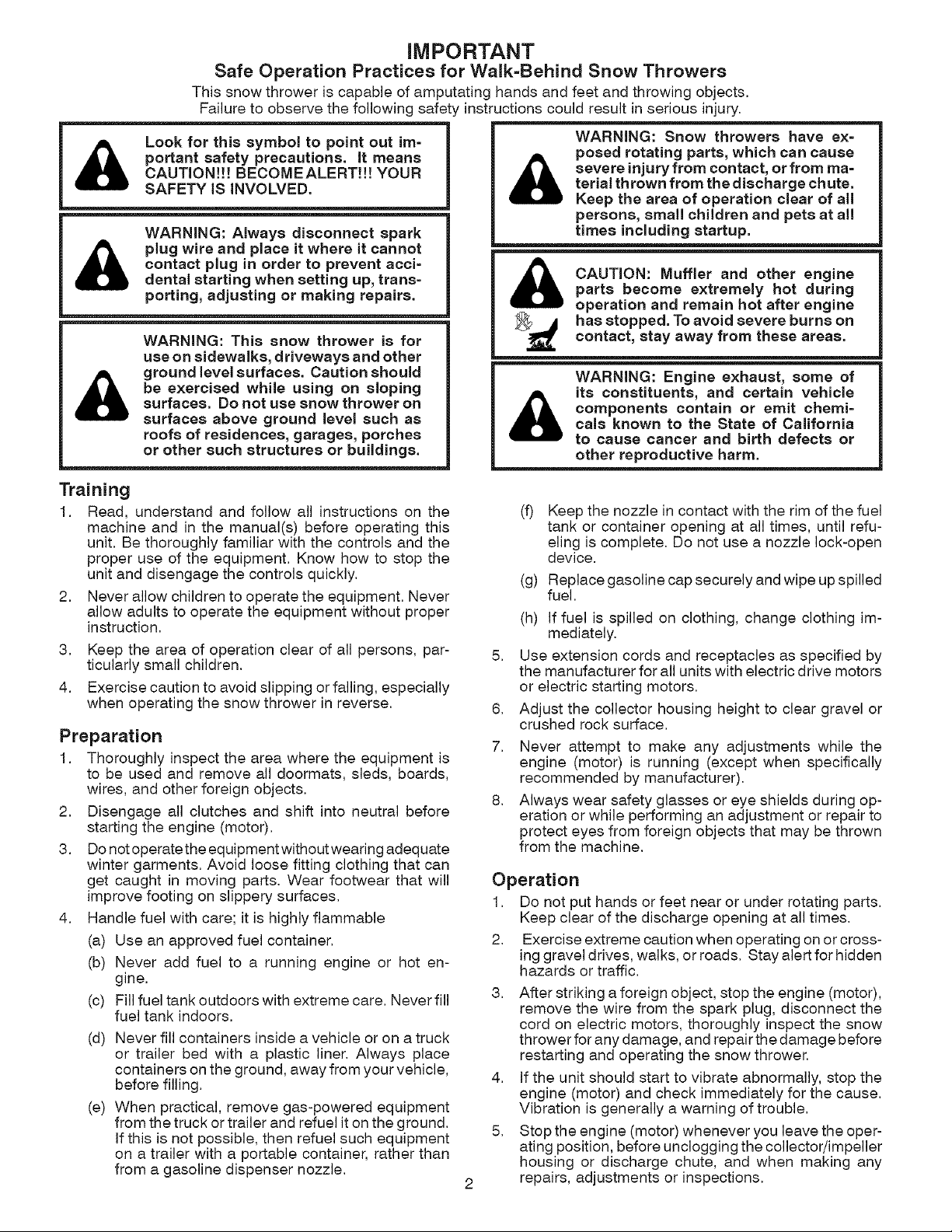

iNSTALL DISCHARGE CHUTE / CHUTE ROTATER

HEAD (See Fig. 7)

NOTE: The multi-wrench provided in your parts bag may

be used to install the chute rotater head,

1, Place discharge chute assembly on top of chute base

with discharge opening toward front of snow thrower,

2, Position chute rotater head overchute bracket, Ifneces-

sary, rotatechute assembly toalign square and pin onun-

derside of chute rotater head with holes inchute bracket,

3, With chute rotater head and chute bracket aligned,

position chute rotater head on pin and threaded stud

of mounting bracket,

4, Install 3/8 washer and Iocknut on threaded stud and

tighten securely,

CHUTE

ROTATER

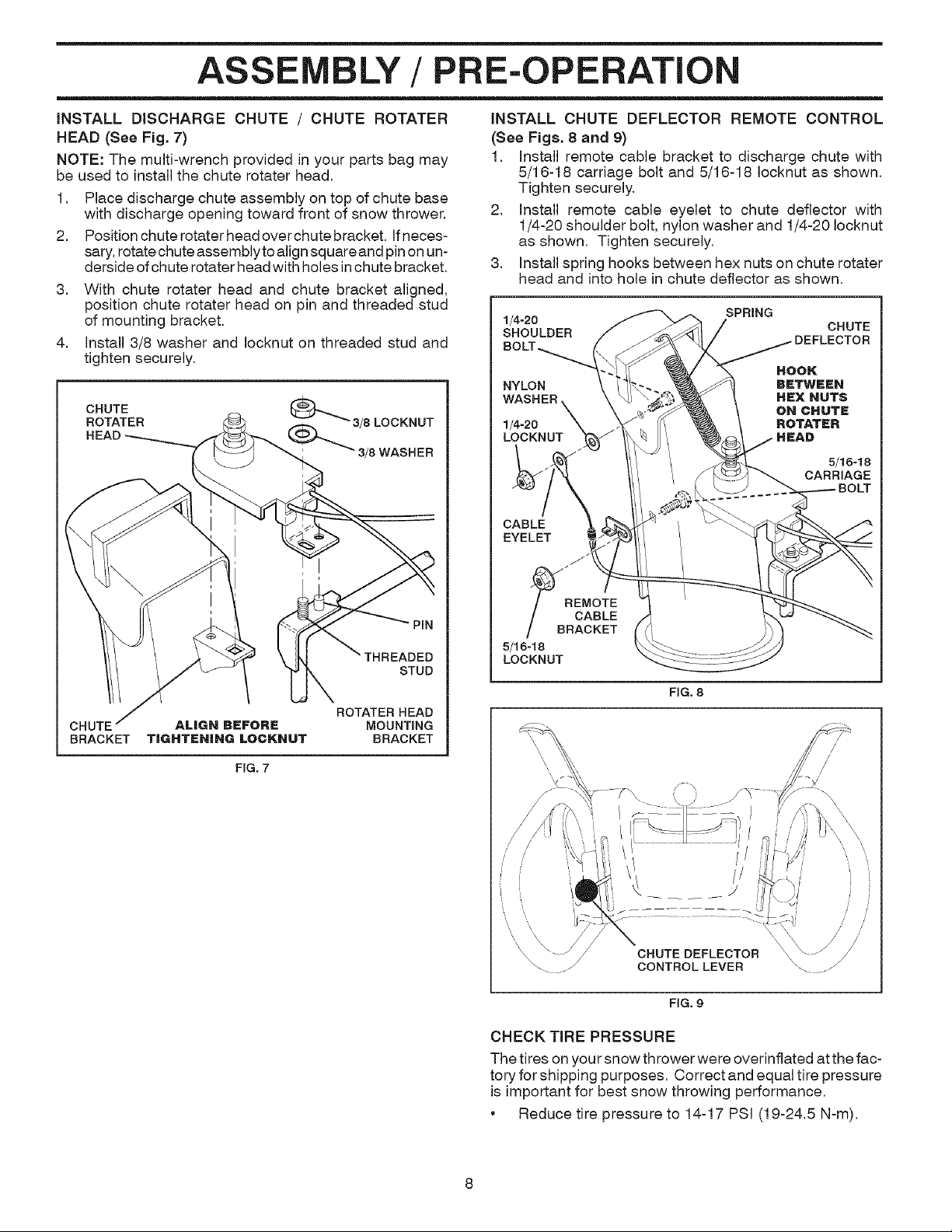

iNSTALL CHUTE DEFLECTOR REMOTE CONTROL

(See Figs. 8 and 9)

1, Install remote cable bracket to discharge chute with

5/16-18 carriage bolt and 5/16-18 Iocknut as shown,

Tighten securely,

2, Install remote cable eyelet to chute deflector with

1/4-20 shoulder bolt, nylon washer and 1/4-20 Iocknut

as shown, Tighten securely,

3, Install spring hooks between hex nuts on chute rotater

head and into hole in chute deflector as shown,

1/4-20 CHUTE

SHOULDER

NYLON BETWEEN

WASHER HEX NUTS

1/4-20 ROTATER

LOCKNUT

CABLE

EYELET

SPRING

HOOK

ON CHUTE

5/16- ! 8

CARRIAGE

BOLT

FIG. 7

PIN

STUD

ROTATER HEAD

MOUNTING

BRACKET

_B _EMOTE

CABLE

RACKET

5/16-18

LOCKNUT

FiG. 8

// //

CHUTE DEFLECTOR

CONTROL LEVER

FIG. 9

CHECK TiRE PRESSURE

The tires on your snow thrower were overinflated at the fac-

tory for shipping purposes. Correct and equal tire pressure

is important for best snow throwing performance,

• Reduce tire pressure to 14-17 PSi (19-24,5 N-m),

OPERATION

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUALAND ALL SAFETY RULES BEFORE OPERATING YOUR SNOWTHROWER. Compare

the illustrations with your snow thrower to familiarize yourself with the location of various controls and adjustments, Save

this manual for future reference,

These symbols may appear on your snow thrower or in literature supplied with the product. Learn and understand

their meaning,

I\1

DANGER ENGINE FAST SLOW CHOKE PRIMER

OR WARNING ON

FUEL OIL FORWARD REVERSE

IGNITION KEY.

INSERT TO START

AND RUN,

PULL OUT TO STOP.

ENGINE

OFF

R

READ AND FOLLOW ALL SAFETY INFORMATION

AND INSTRUCTIONS BEFORE USE OF THIS PRODUCT.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

\ J

SNOW

DISCHARGE

DISENGAGED

ENGAGED

_J

TRACTION

DRIVE CONTROL

O ERATION

GASOLINE ELECTRIC AUGER DISCHARGE CHUTE CONTROL LEVER

CHOKE DEFLECTOR CONTROL

CON- LEVER

TROL

SAFETY

IGNITION

KEY

NOTE: ITEMS ABOVE

ARE SHOWN IN

THEIR TYPICAL

LOCATION ON THE

ENGINE. ACTUAL

LOCATION MAY VARY

WITH THE ENGINE

ON YOUR UNIT.

ON / OFF

SWITCH

CLEAN-OUT TOOL i

\

START BUTTON CONTROL

CHUTE

LEVER DRIVE SPEED DEFLECTOR REMOTE

RECOIL X CONTROL LEVER CONTROL LEVER

STARTER

HANDLE

CHUTE DRIVE

\

'TRACTION

_HTURN

TRIGGER

LIGHT

HANDLE

KNOB

TOOLBOX

CONTROL

FIG. 10

MEETS A,N,S,I, SAFETY REQUIREMENTS

Our snow throwers conform to the standards of the American National Standards Institute,

Toolbox = used to store spare shear bolts, Iocknuts and

wrench,

Safety ignition key - must be inserted for the engine to

start and run, Remove when snow thrower is not in use,

Electric start button - used for starting the engine,

Recoil (auxiliary) starter handle- used forstarting engine,

Primer - pumps additional fuel from the carburetor to the

cylinder for use when starting a cold engine,

Choke Control - used for starting a cold engine,

ON / OFF switch =used to STOP the engine,

Freewheel control - disengages transmission for pushing

the snowthrower with the engine off,

LH and RH turn triggers - used to steer the snow thrower,

Drive speed control lever - used to select forward or

reverse motion and speed of snow thrower,

Traction drive control lever- used to engage power-pro-

pelled forward or reverse motion of snow thrower,

Auger control lever - used to engage auger motion

(throw snow),

Discharge chute control lever - used to change the

direction the snow is thrown,

Deflector remote control lever - used to change the

distance the snow is thrown,

Skid plate - used to adjust height of scraper barfrom ground,

10

Drift cutter - used to cut through deep snowdrifts,

DRIFT CUTTER

PLATE

OPERATION

The operation of any snow thrower can result

in foreign objects thrown into the eyes, which

can result insevere eyedamage. Always wear

safety glasses or eye shields while operating

your snow thrower or performing any adjust-

ments or repairs. We recommend standard safety glasses

or a wide vision safety mask worn over spectacles.

HOW TO USE YOUR SNOW THROWER

Know how to operate all controls before adding fuel or

attempting to start the engine.

STOPPING

TRACTION DRIVE

• Release traction drive control lever to stop the forward

or reverse movement of the snow thrower.

AUGER

• Release the auger control lever to stop throwing snow.

ENGINE

1. Move ON / OFF switch to "OFF" position.

2. Remove (do not turn) safety ignition key to prevent

unauthorized use.

NOTE: Never use choke to stop engine.

TO USE THROTTLE CONTROL (See Fig. 11)

The throttle control islocated on the engine. Always operate

the snow thrower with the engine at full throttle. Full throttle

offers the best snow thrower performance.

TO CONTROL SNOW DISCHARGE (See Fig. 13)

WARNING: Snow throwers have ex-

posed rotating parts, which can cause

terial thrown from the discharge chute.

severe injuryfrom contact, or from ma-

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

WARNING: If the discharge chute or au-

and wait for all moving parts to stop. Use

get become clogged, shut-off engine

the clean=out tool, NOT YOUR HANDS,

to unclog the chute and/or auger.

The DIRECTION inwhich snow isto be thrown iscontrolled

by the discharge chute control lever.

• Tochangethe discharge chute position, press downward

on discharge chute control lever and move lever left

or right until chute is in desired position. Be sure lever

springs back and locks into desired position.

The DISTANCE that snow is thrown is controlled by the

position of the chute deflector. Set the deflector low to

throw snow a short distance; set the deflector higher to

throw snow farther.

Press downward on chute deflector control lever and

move lever forward to lower the deflector and decrease

the distance. Move lever back to raise the deflector

and increase the distance. Be sure lever springs back

and locks into desired position.

(, )

SLOW FAST

FIG, 11

TO USE CHOKE CONTROL (See Fig. 12)

The choke control is located on the engine. Use the choke

control whenever you are starting a cold engine. Do not

use to start a warm engine.

• To engage choke, turn knob counterclockwise. Slowly

turn knob clockwise to disengage.

(

DISCHARGECHUTE

CONTROLLEVER

CHUTE DEFLECTOR

REMOTE CONTROLLEVER

FIG, 13

TO THROW SNOW (See Fig. 14)

The auger rotation is controlled by the auger control lever

located on the right side handle.

• Squeeze auger control lever to handle to engage the

auger and throw snow.

• Release the auger control lever to stop throwing snow.

OFF I\lFULL

FIG. 12 1 1 FIG. 14

OPERATION

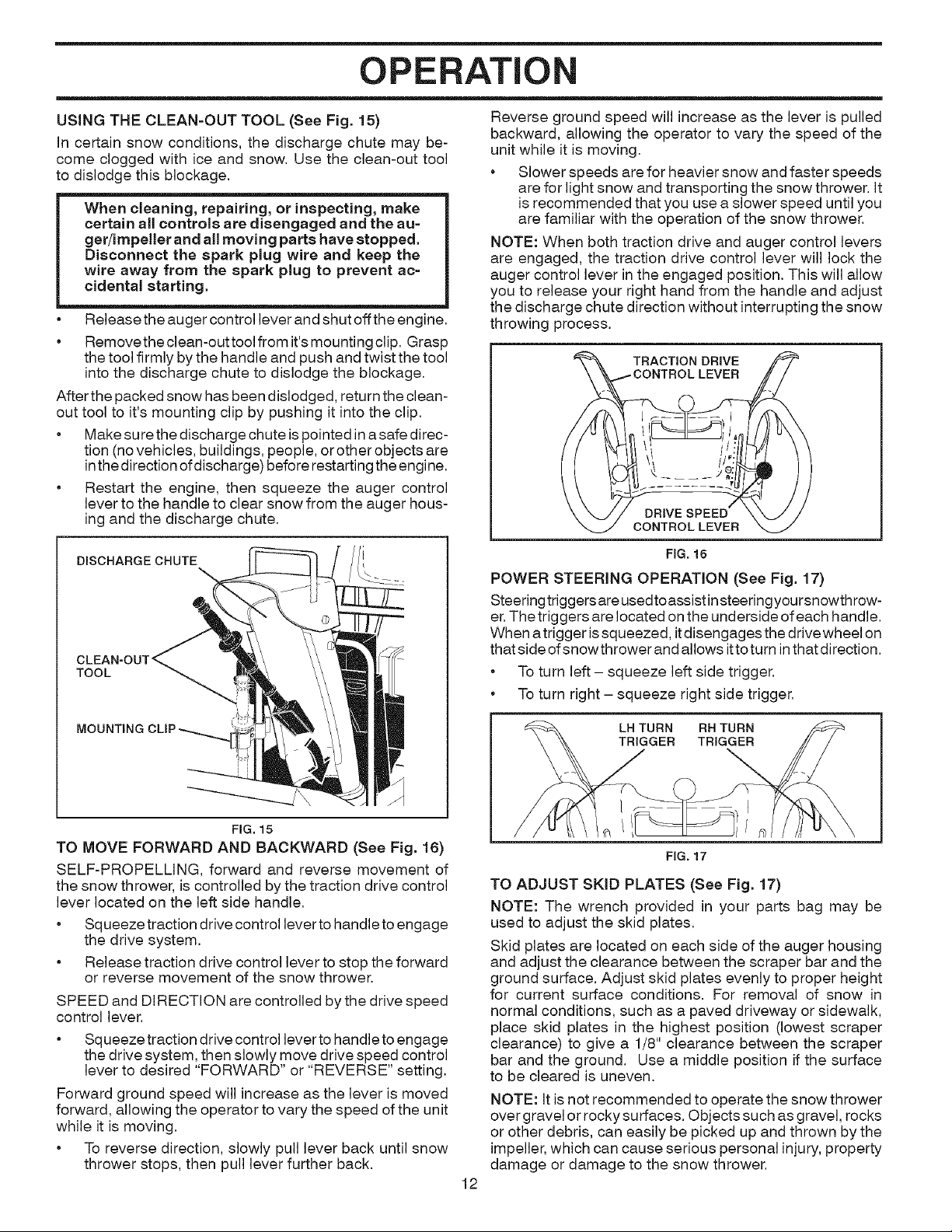

USING THE CLEAN-OUT TOOL (See Fig. 15)

in certain snow conditions, the discharge chute may be-

come clogged with ice and snow. Use the clean-out tool

to dislodge this blockage.

When cleaning, repairing, or inspecting, make

certain all controls are disengaged and the au=

get/impeller and all moving parts have stopped.

Disconnect the spark plug wire and keep the

wire away from the spark plug to prevent ac-

cidental starting.

Release the auger control lever and shut offthe engine.

• Removethe clean-out tool from it'smounting clip. Grasp

the tool firmly bythe handle and push and twist the tool

into the discharge chute to dislodge the blockage.

After the packed snow has been dislodged, return the clean-

out tool to it's mounting clip by pushing it into the clip.

. Make surethe discharge chute is pointed in asafe direc-

tion (no vehicles, buildings, people, orother objects are

inthe direction ofdischarge) before restarting the engine.

• Restart the engine, then squeeze the auger control

lever to the handle to clear snow from the auger hous-

ing and the discharge chute.

DISCHARGECHUTE

TOOL

Reverse ground speed will increase as the lever is pulled

backward, allowing the operator to vary the speed of the

unit while it is moving.

• Slower speeds are for heavier snow and faster speeds

are for light snow and transporting the snow thrower. It

is recommended that you use a slower speed until you

are familiar with the operation of the snow thrower.

NOTE: When both traction drive and auger control levers

are engaged, the traction drive control lever will lock the

auger control lever in the engaged position. This will allow

you to release your right hand from the handle and adjust

the discharge chute direction without interrupting the snow

throwing process.

TRACTION DRIVE

l

DRIVE SPEED

CONTROLLEVER

POWER STEERING OPERATION (See Fig. 17)

Steering triggers are usedtoassist insteering yoursnowthrow-

er.The triggers are located on the underside of each handle.

When atrigger is squeezed, itdisengages the drive wheel on

that side of snowthrower and allows ittoturn inthat direction,

• To turn left- squeeze left side trigger,

• To turn right - squeeze right side trigger,

LEVER

1

FIG. 16

MOUNTING

FIG, 15

TO MOVE FORWARD AND BACKWARD (See Fig. 16)

SELF-PROPELLING, forward and reverse movement of

the snow thrower, is controlled by the traction drive control

lever located on the left side handle.

• Squeeze traction drive control lever to handle toengage

the drive system,

• Release traction drive control lever to stop the forward

or reverse movement of the snow thrower,

SPEED and DIRECTION are controlled by the drive speed

control lever.

• Squeeze traction drive control lever to handle toengage

the drive system, then slowly move drive speed control

lever to desired "FORWARD" or "REVERSE" setting,

Forward ground speed will increase as the lever is moved

forward, allowing the operator to vary the speed of the unit

while it is moving,

• To reverse direction, slowly pull lever back until snow

thrower stops, then pull lever further back,

TURN

FIG. 17

TO ADJUST SKiD PLATES (See Fig. 17)

NOTE: The wrench provided in your parts bag may be

used to adjust the skid plates.

Skid plates are located on each side of the auger housing

and adjust the clearance between the scraper bar and the

ground surface. Adjust skid plates evenly to proper height

for current surface conditions. For removal of snow in

normal conditions, such as a paved driveway or sidewalk,

place skid plates in the highest position (lowest scraper

clearance) to give a 1/8" clearance between the scraper

bar and the ground. Use a middle position if the surface

to be cleared is uneven.

NOTE: Itis not recommended to operate the snow thrower

over gravel or rocky surfaces. Objects such as gravel, rocks

or other debris, can easily be picked up and thrown by the

impeller, which can cause serious personal injury, property

damage or damage to the snow thrower.

12

Loading...

Loading...