Page 1

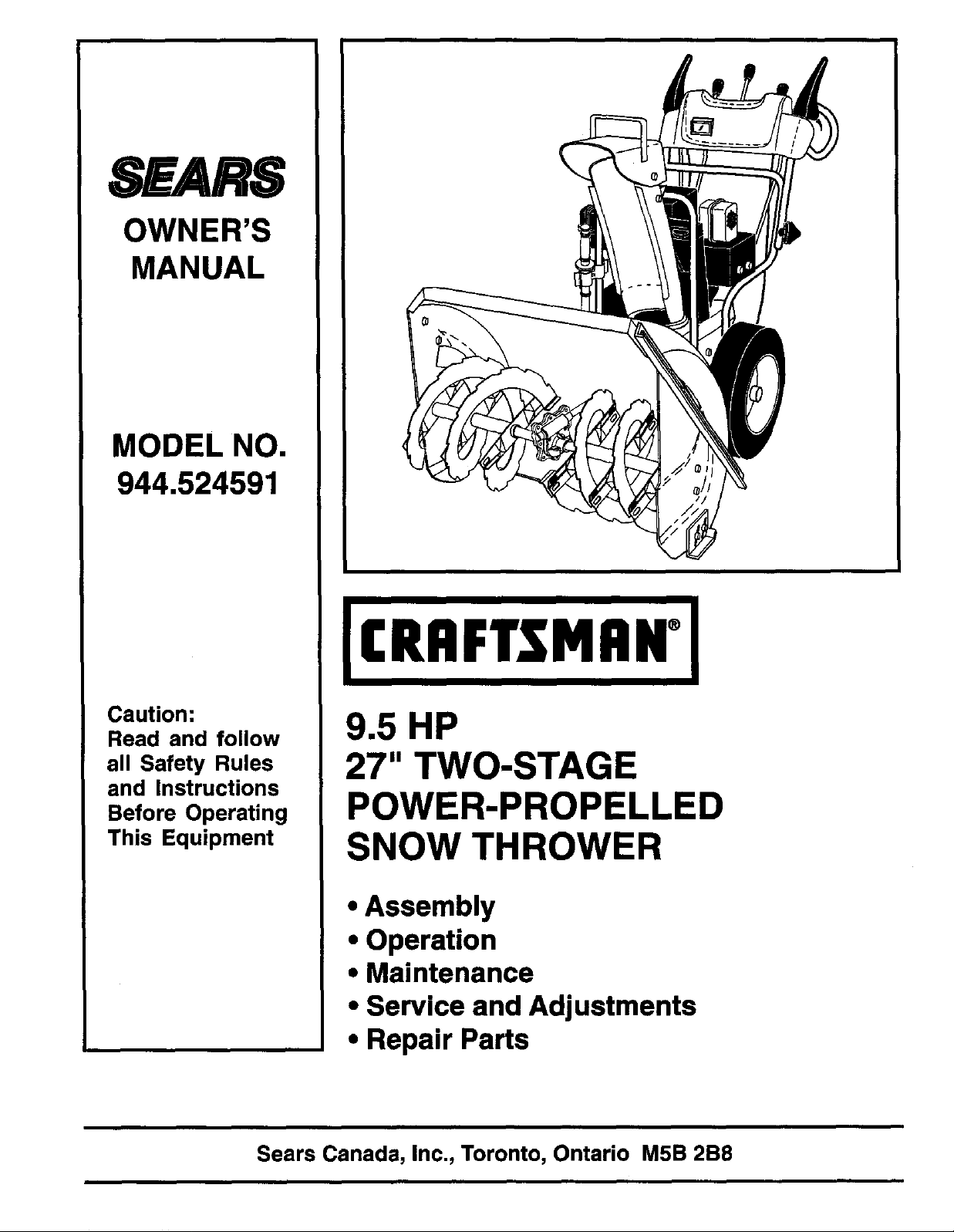

SEARS

OWNER'S

MANUAL

MODEL NO.

944.524591

Caution:

Read and follow

all Safety Rules

and Instructions

Before Operating

This Equipment

ICRIIFT.TMIIN°[

9.5 HP

27" TWO-STAGE

POWER-PROPELLED

SNOW THROWER

• Assembly

• Operation

• Maintenance

• Service and Adjustments

• Repair Parts

Sears Canada, Inc., Toronto, Ontario M5B 2B8

Page 2

IMPORTANT

Safe Operation Practices for Walk-Behind Snow Throwers

This snow thrower is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructionscould result in serious injury.

Look for this symbol to point out im-

portant safety precautions. It means

&

&

Training

1. Read, understand and follow all instructions on the

machine and in the manual(s) before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

3. Keep the area of operation clear of all persons, par-

ticularly small children.

4. Exercise caution to avoid slipping or falling, especially

when operating the snow thrower in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is

to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting the engine (motor).

3. Donot operate the equipment without wearing adequate

winter garments. Avoid loose fitting clothing that can

get caught in moving parts. Wear footwear that will

improve footing on slippery surfaces.

4. Handle fuel with care; it is highly flammable

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot en-

(c) Fill fuel tank outdoors with extreme care. Never fill

(d) Never fill containers inside avehicie or on atruck or

(e) When practical, remove gas-powered equipment

CAUTION!H BECOMEALERT!H YOUR

SAFETY IS INVOLVED.

WARNING: Always disconnect spark

plug wire and place it where it cannot

contact plug in order to prevent acci-

dental starting when setting up, trans-

porting, adjusting or making repairs.

WARNING: This snow thrower is for

use on sidewalks, driveways and other

ground level surfaces. Caution should

be exercised while using on sloping

surfaces. Do not use snow thrower on

surfaces above ground level such as

roofs of residences, garages, porches

or other such structures or buildings.

gine.

fuel tank indoors.

trailer bed with a plastic liner. Always place contain-

ers on the ground, away from your vehicle, before

filling.

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than

from a gasoline dispenser nozzle.

WARNING: Snow throwers have ex-

posed rotating parts, which can cause

severe injury from contact, or from ma-

&

&

terial thrown from the discharge chute.

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

CAUTION: Muffler and other engine

parts become extremely hot during

operation and remain hot after engine

has stopped. To avoid severe burns on

contact, stay away from these areas.

WARNING: Engine exhaust, some of

its constituents, and certain vehicle

components contain or emit chemi-

cals known to the State of California

to cause cancer and birth defects or

other reproductive harm.

(f) Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times, until refuel-

ing is complete. Do not use a nozzle lock-open

device.

(g) Replace gasoline cap securely and wipe upspilled

fuel.

(h) If fuel is spilled on clothing, change clothing im-

mediately.

5,

Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

6.

Adjust the collector housing height to clear gravel or

crushed rock surface.

7.

Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by manufacturer).

8.

Always wear safety glasses or eye shields during op-

eration or while performing an adjustment or repair to

protect eyes from foreign objects that may be thrown

from the machine.

Operation

1. Do not put hands or feet near or under rotating pads.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on orcross-

inggravel drives, walks, orroads. Stay alert for hidden

hazards or traffic.

3. After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, disconnect the

cord on electric motors, thoroughly inspect the snow

thrower for any damage, and repair the damage before

restarting andoperating the snow thrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the oper-

ating position, before unclogging the collector/impeller

housing or discharge chute, and when making any

2

repairs, adjustments or inspections.

Page 3

6. Whencleaning,repairingor inspectingthe snow

thrower,stoptheengineandmakecertainthecollector/

impellerandallmovingpartshavestopped.Disconnect

thesparkplugwireandkeepthewireawayfromthe

plug.topreventsomeonefromaccidentallystartingthe

engine.

7. Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthesnowthrowerinor

outofthebuilding.Opentheoutsidedoors;exhaust

fumesaredangerous.

8. Exerciseextremecautionwhenoperatingonslopes.

9. Neveroperatethesnowthrowerwithoutproperguards,

andothersafetyprotectivedevicesinplaceandwork-

ing.

10.Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.Keepchildrenand

othersaway.

11.Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

12.Neveroperatethemachineathightransportspeeds

onslipperysurfaces.Lookbehindandusecarewhen

operatinginreverse.

13.Disengagepowertothecollector/impellerwhensnow

throweristransportedornotinuse.

14.Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofthesnowthrower(suchaswheel

weights,counterweights,orcabs).

15.Neveroperatethesnowthrowerwithoutgoodvisibility

orlight.Alwaysbesureofyourfooting,andkeepa

firmholdonthehandles.Walk;neverrun.

16.Nevertouchahotengineormuffler.

Clearing a Clogged Discharge Chute

Hand contactwith the rotating impeller insidethe discharge

chute is the most common cause of injury associated with

snow throwers. Never use your hand to clean out the dis-

charge chute. To clear the chute:

1. SHUT THE ENGINE OFF!

2. Wait 10 seconds to be sure the impetler blades have

stopped rotating.

3. Always use a clean-out tool, not your hands.

Maintenance and Storage

1. Check shear bolts and other bolts at frequent intervals

for proper tightness to be sure the equipment is in safe

working condition.

2. Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present

such as hot water heaters, space heaters, or clothes

dryers. Allow the engine to cool before storing in any

enclosure.

3. Always refer to operator's manual for important details

if the snow thrower is to be stored for an extended

period.

4. Maintain or replace safety and instruction labels, as

necessary.

5. Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller.

TABLE OF CONTENTS

SAFETY RULES ........................................................ 2-3

PRODUCT SPECIFICATIONS ...................................... 4

CUSTOMER RESPONSIBILITIES ................................ 4

WARRANTY .................................................................. 4

ASSEMBLY / PRE-OPERATION ............................... 6-8

OPERATION ............................................................ 9-15

MAINTENANCE ..................................................... 15-16

MAINTENANCE SCHEDULE ..................................... 15

SERVICE AND ADJUSTMENTS ........................... 17-19

STORAGE ................................................................... 19

TROUBLESHOOTING ................................................ 20

REPAIR PARTS ..................................................... 22-38

SEARS SERVICE ................................... BACK COVER

3

Page 4

LIMITED TWO (2) YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

For two (2) years from date of purchase Sears Canada, Inc. will repair or replace, at Sears option, free of charge

parts which are defective as a result of material or workmanship.

COMMERCIAL OR RENTAL USE:

Warranty on Snow Thrower will be 90 days from date of purchase if used for commercial or rental purposes.

This Warranty does NOT cover:

1. Pre-delivery set-up.

2. Expendable items which become worn during normal use such as belts, spark plugs air cleaners,

and shear pine, as we damage to the engine resu ting from operating snow thrower with insufficient oil.

3. Repairs necessary because of operator abuse or negligence, including the failure to operate and main-

tain the equipment according to the instructions contained in the Owner's Manual.

4. Tire replacement or repair caused bypunctures from outside objecta, such as nails,thorns, stumps or glass.

Warranty service isavailable by returning the Craftsman Snow Throwerto the nearest Sears Service Centre/Department

in Canada. This warranty applies only while this product is in use in Canada.

This warranty is in addition to any statutory warranty and does NOT exclude or limit legal rights you may have but

shalll run concurrently with applicable provincial legislation. Furthermore, some provinces do not allow limitations

on how long an implied warranty will last, so the above limitations may not apply to you.

Sears Canada, Inc., Toronto, Ontario MSB 2B8

CONGRATULATIONS on your purchase of a new snow

thrower. It has been designed, engineered and manufactured

to give best possible dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears service centre/

department. We have competent, well-trained technicians

and the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your snow thrower

properly. Always observe the "SAFETY RULES".

SERIAL NUMBER:

DATE OF PURCHASE:

THE MODELAND SERIAL NUMBERSWtLLBE FOUND

ON A D ECALA'I-I'ACH EDTO THE REAR OFTH ESNOW

THROWER HOUSING.

YOU SHOULD RECORD BOTH SERIAL NUMBERAND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

PRODUCT SPECIFICATIONS

Gasoline Capacity 4,54 Liters

and Type: Unleaded Regular only

Oil Type SAE 5W-30 or 10W-30

(API SG-SL): (0°F to +40°F/-18°C to +5°C)

Synthetic SAE 5W-30 or 10W-30

(below 0°F / -18°C)

Oil Capacity: 0,8 Liters

Spark Plug: Champion RC12YC

Gap: 0,072 mm

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

' and using your snow thrower.

• Follow the instructions under"Maintenance" and "Stor-

age" sections of this owner's manual.

4

Page 5

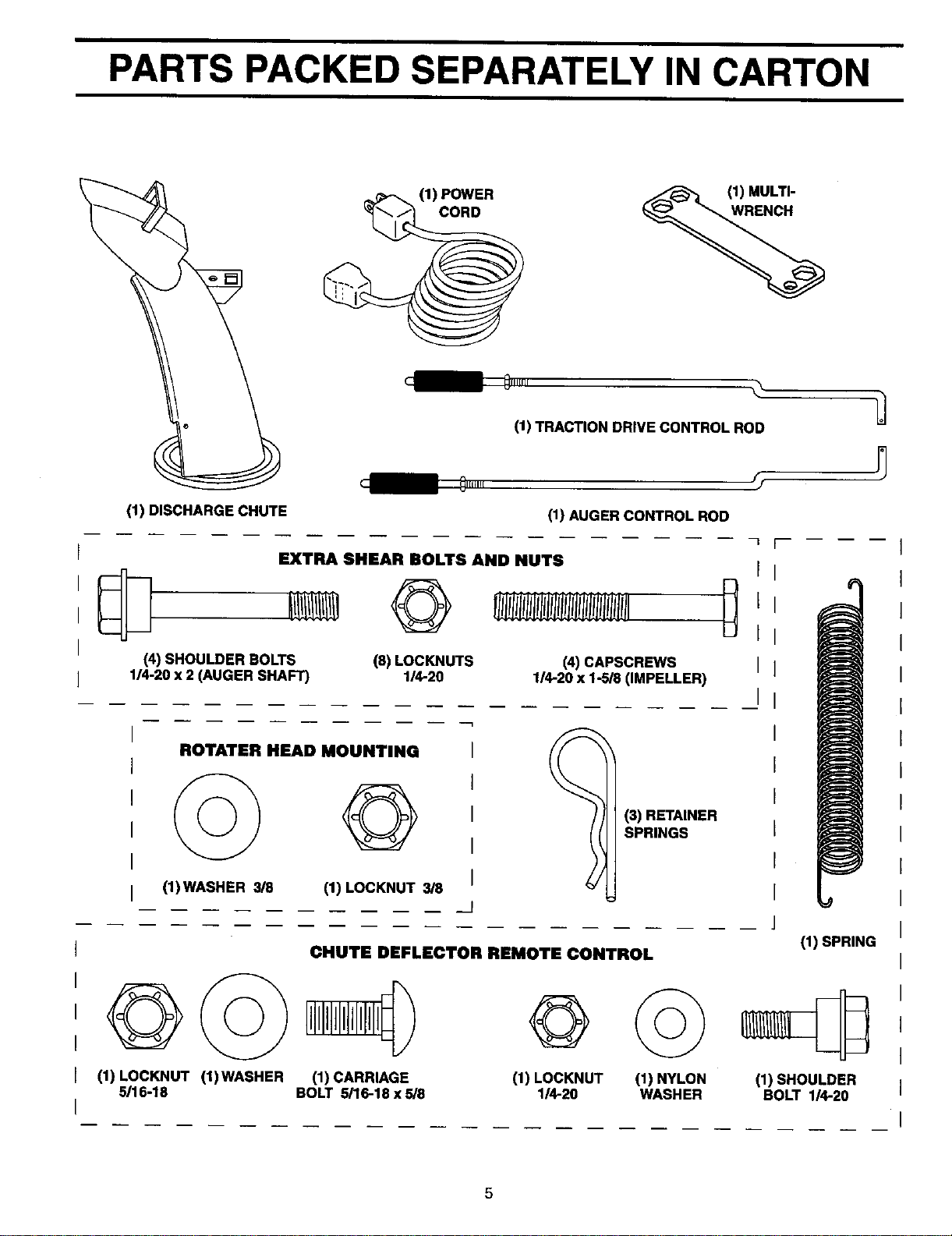

PARTS PACKED SEPARATELY IN CARTON

(1) DISCHARGE CHUTE

(1) POWER

(1) TRACTION DRIVE CONTROL ROD

EXTRA SHEAR BOLTS AND NUTS

(1) MULTI-

WRENCH

0

(1) AUGER CONTROL ROD

7

I

L

I

(4) SHOULDER BOLTS

1/4-20 x 2 (AUGER SHAFT)

ROTATER HEAD MOUNTING

(1)WASHER 3/8

(1) LOCKNUT (1)WASHER

5116-18

(8) LOCKNUTS

1/4-20

(4) CAPSCREWS

1/4-20x 1-5/8 (IMPELLER)

©

(1) LOCKNUT 3/8

_J

CHUTE DEFLECTOR REMOTE CONTROL

(1) CARRIAGE

BOLT 5/16-18 x 5/8

(1) LOCKNUT (1) NYLON (1) SHOULDER

1/4-20 WASHER BOLT 1/4-20

I

I

(3) RETAINER

SPRINGS

]

(1) SPRING

5

Page 6

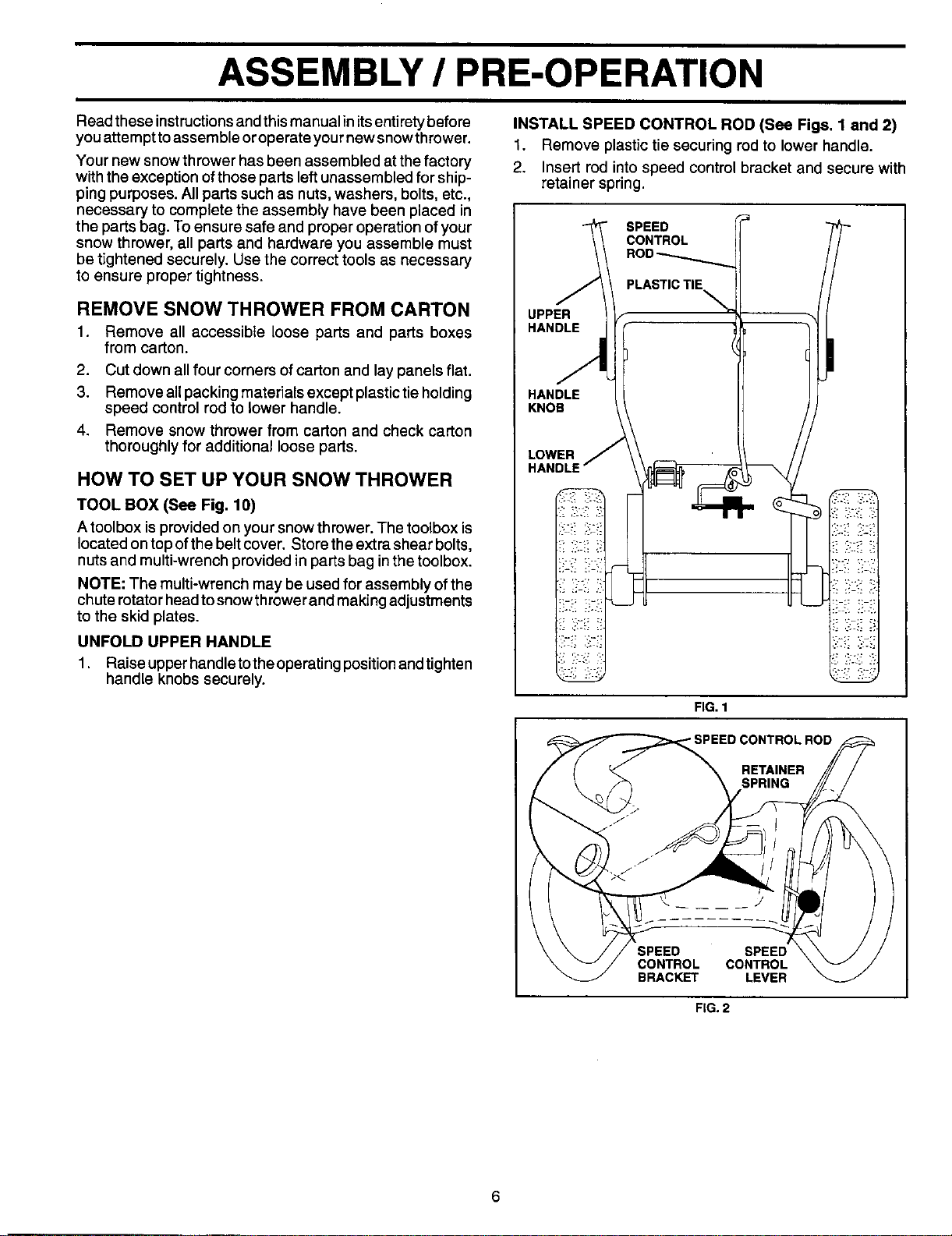

ASSEMBLY / PRE-OPERATION

Read these instructions and this manual in its entirety before

you attempt to assemble or operate your new snow thrower.

Your new snow thrower has been assembled at the factory

with the exception of those parts left unassembled for ship-

ping purposes. All parts such as nuts, washers, bolts, etc.,

necessary to complete the assembly have been placed in

the parts bag. To ensure safe and proper operation of your

snow thrower, all parts and hardware you assemble must

be tightened securely. Use the correct tools as necessary

to ensure proper tightness.

REMOVE SNOW THROWER FROM CARTON

1. Remove all accessible loose parts and parts boxes

from carton.

2. Cut down all four corners of carton and lay panels flat.

3. Remove all packing materials except plastic tie holding

speed control rod to lower handle.

4. Remove snow thrower from carton and check carton

thoroughly for additional loose parts.

HOW TO SET UP YOUR SNOW THROWER

TOOL BOX (See Fig. 10)

Atoolbox is provided on your snow thrower. The toolbox is

located on top ofthe belt cover, Store the extra shear bolts,

nutsand multi-wrench provided in parts bag inthe toolbox.

NOTE: The multi-wrench may be used for assembly of the

chute rotator headtosnow thrower and making adjustments

to the skid plates.

UNFOLD UPPER HANDLE

1. Raise upper handle tothe operating position and tighten

handle knobs securely.

INSTALL SPEED CONTROL ROD (See Figs. 1 and 2)

1. Remove plastic tie securing rod to lower handle.

2. Insert rod into speed control bracket and secure with

retainer spring.

SPEED

CONTROL

UPPER

HANDLE

HANDLE

KNOB

LOWER

FIG. 1

SPEED SPEED

CONTROL CONTROL

BRACKET LEVER

FIG. 2

6

Page 7

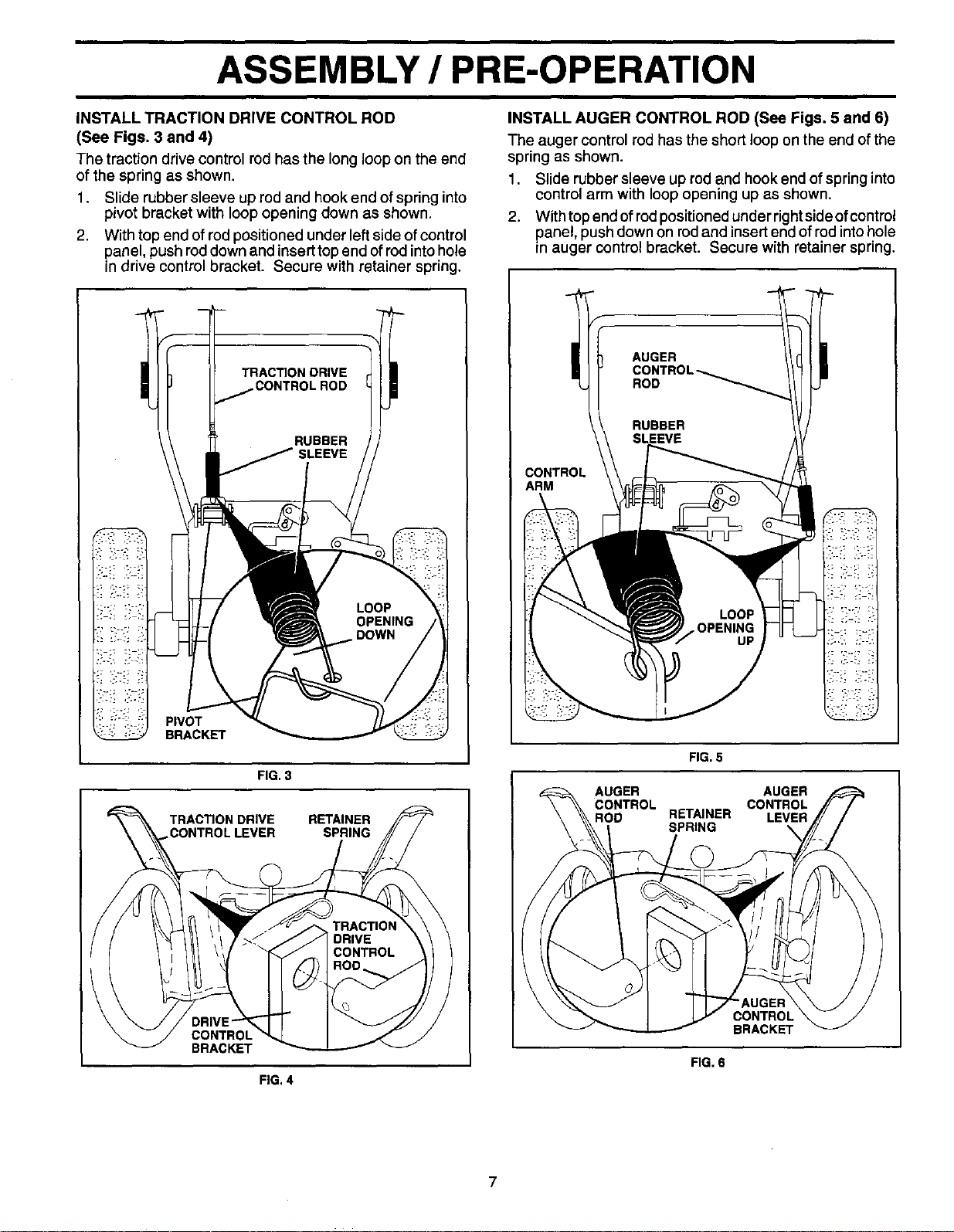

ASSEMBLY / PRE-OPERATION

INSTALL TRACTION DRIVE CONTROL ROD

(See Figs. 3 and 4)

The traction drive control rod has the long loop on the end

of the spring as shown.

1. Slide rubber sleeve up rod and hook end of spring into

pivot bracket with loop opening down as shown,

2. With top end of rod positioned under left side of control

panel, push rod down and insert top end of rod into hole

in drive control bracket. Secure with retainer spring.

TRACTION DRIVE

ROD

INSTALL AUGER CONTROL ROD (See Figs. 5 and 6)

The auger control rod has the short loop on the end of the

springas shown.

1. Slide rubber sleeve up rod and hookend ofspring into

controlarm with loop opening up as shown.

2. With topend ofrod positioned under rightside ofcontrol

panel, push down on rodand insertend of rod intohole

in auger control bracket. Secure with retainer spring.

AUGER

CONTROL

ARM

I

PIVOT

BRACKET

FIG. 3

TRACTION DRIVE RETAINER

CONTROL LEVER

CONTROL

BRACKET

FIG,4

FIG. 5

AUGER

CONTROL

RETAINER LEVER

SPRING \

CONTROL

BRACKET

FIG. 6

7

Page 8

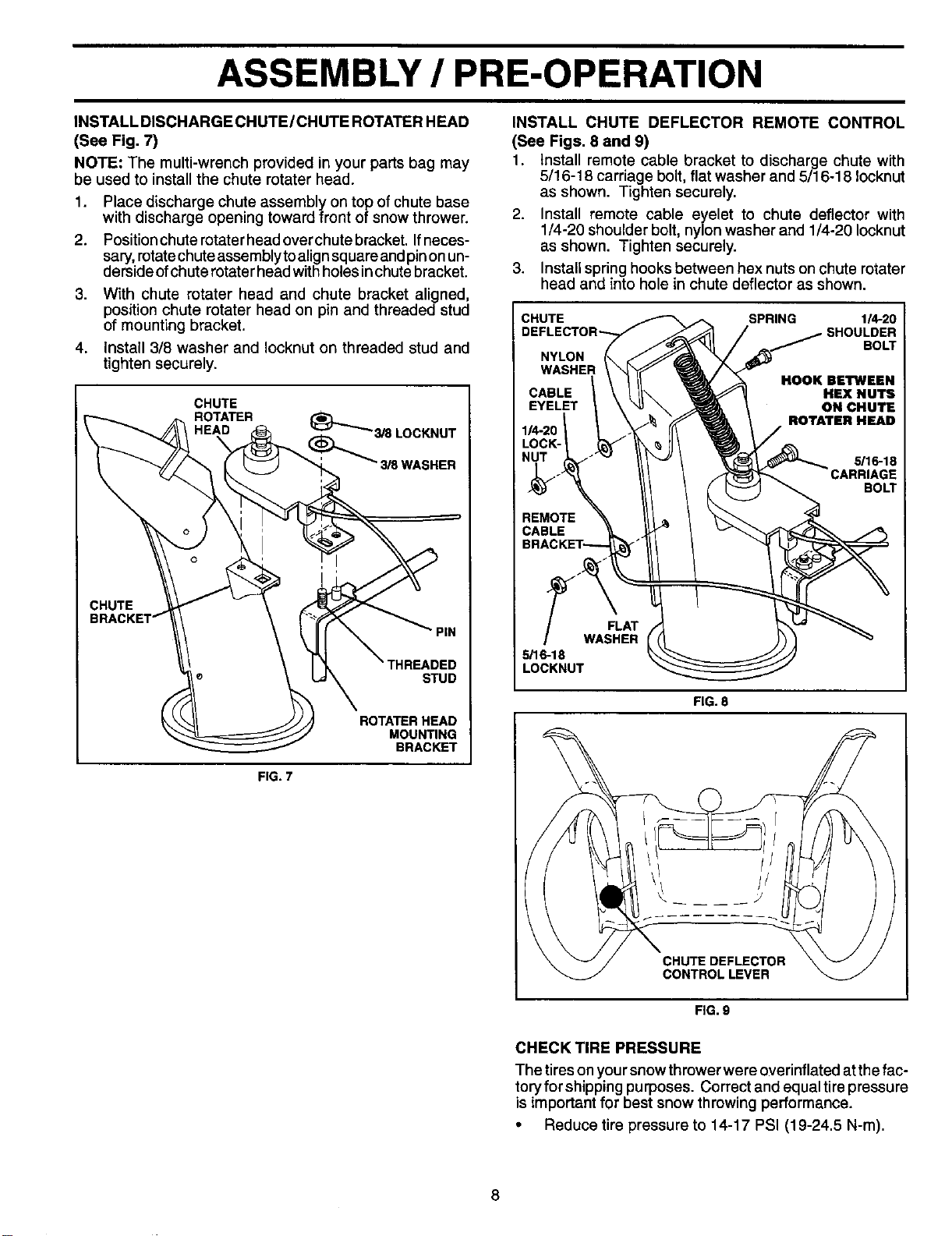

ASSEMBLY / PRE-OPERATION

INSTALL DISCHARGE CHUTE/CHUTE ROTATER HEAD

(See Fig. 7)

NOTE: The multi-wrench provided in your parts bag may

be used to install the chute rotater head.

1. Place discharge chute assembly on top of chute base

with discharge opening toward front of snow thrower.

2. Positionchuterotaterheadoverchutebracket. Ifneces-

sary, rotate chute assembly to align square and pin onun-

derside of chute rotater head with holes in chute bracket.

3. With chute rotater head and chute bracket aligned,

position chute rotater head on pin and threaded stud

of mounting bracket.

4. Install 3/8 washer and Iocknut on threaded stud and

tighten securely.

CHUTE

ROTATER

INSTALL CHUTE DEFLECTOR REMOTE CONTROL

(See Figs. 8 and 9)

1. Install remote cable bracket to discharge chute with

5/16-18 carriage bolt, flat washer and 5/16-18 Iocknut

as shown. Tighten securely.

2. Install remote cable eyelet to chute deflector with

1/4-20 shoulder bolt, nylonwasher and 1/4-20 Iocknut

as shown. Tighten securely.

3. Install spring hooks between hex nutson chute rotater

head and into hole in chute deflector as shown.

CHUTE

NYLON

WASHER

CABLE HEX NUTS

EYELET ON CHUTE

REMOTE

CABLE

SPRING 1/4-20

SHOULDER

BOLT

HOOK BETWEEN

ROTATER HEAD

_1_18

CARRIAGE

BOLT

FIG. 7

PIN

STUD

ROTATER HEAD

MOUNTING

BRACKET

FLAT

WASHER

5/1_18

LOCKNUT

FIG. 8

CHUTE DEFLECTOR

CONTROL LEVER

FIG. 9

CHECK TIRE PRESSURE

The tires on your snow thrower were overinflated at the fac-

tory for shipping purposes. Correct and equal tire pressure

is important for best snow throwing performance.

• Reduce tire pressure to 14-17 PSI (19-24.5 N-m).

8

Page 9

OPERATION

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUALAND ALL SAFETY RULES BEFORE OPERATING YOUR SNOW THROWER. Compare

the illustrations with your snow thrower to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

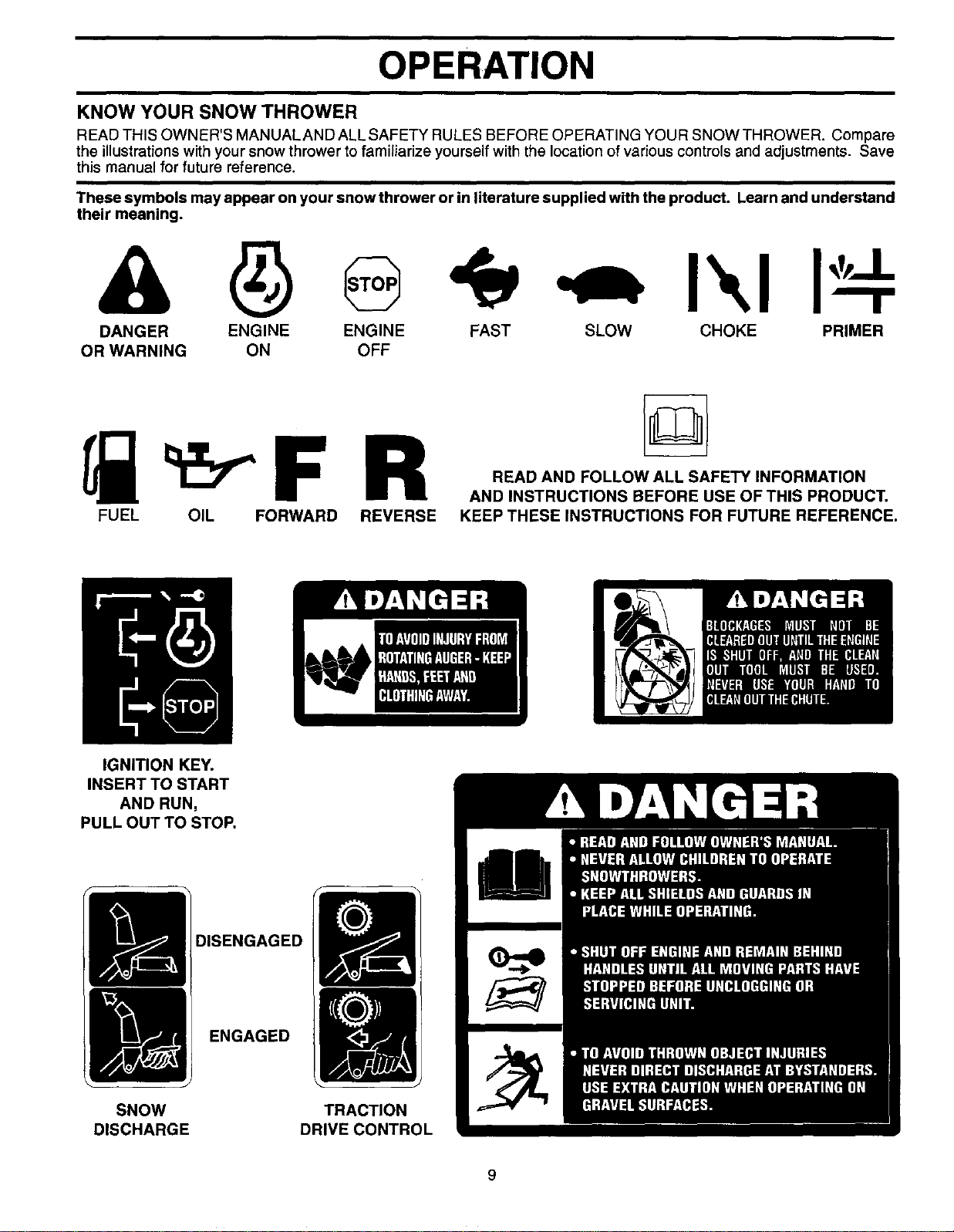

These symbols may appear on your snow thrower or in literature supplied with the product. Learn and understand

their meaning.

DANGER ENGINE SLOW CHOKE PRIMER

OR WARNING ON

FUEL OIL FORWARD REVERSE

IGNITION KEY.

INSERT TO START

AND RUN,

PULL OUT TO STOP.

ENGINE FAST

OFF

READ AND FOLLOW ALL SAFETY INFORMATION

AND INSTRUCTIONS BEFORE USE OF THIS PRODUCT.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

SNOW

DISCHARGE

DISENGAGED

ENGAGED

TRACTION

DRIVECONTROL

9

Page 10

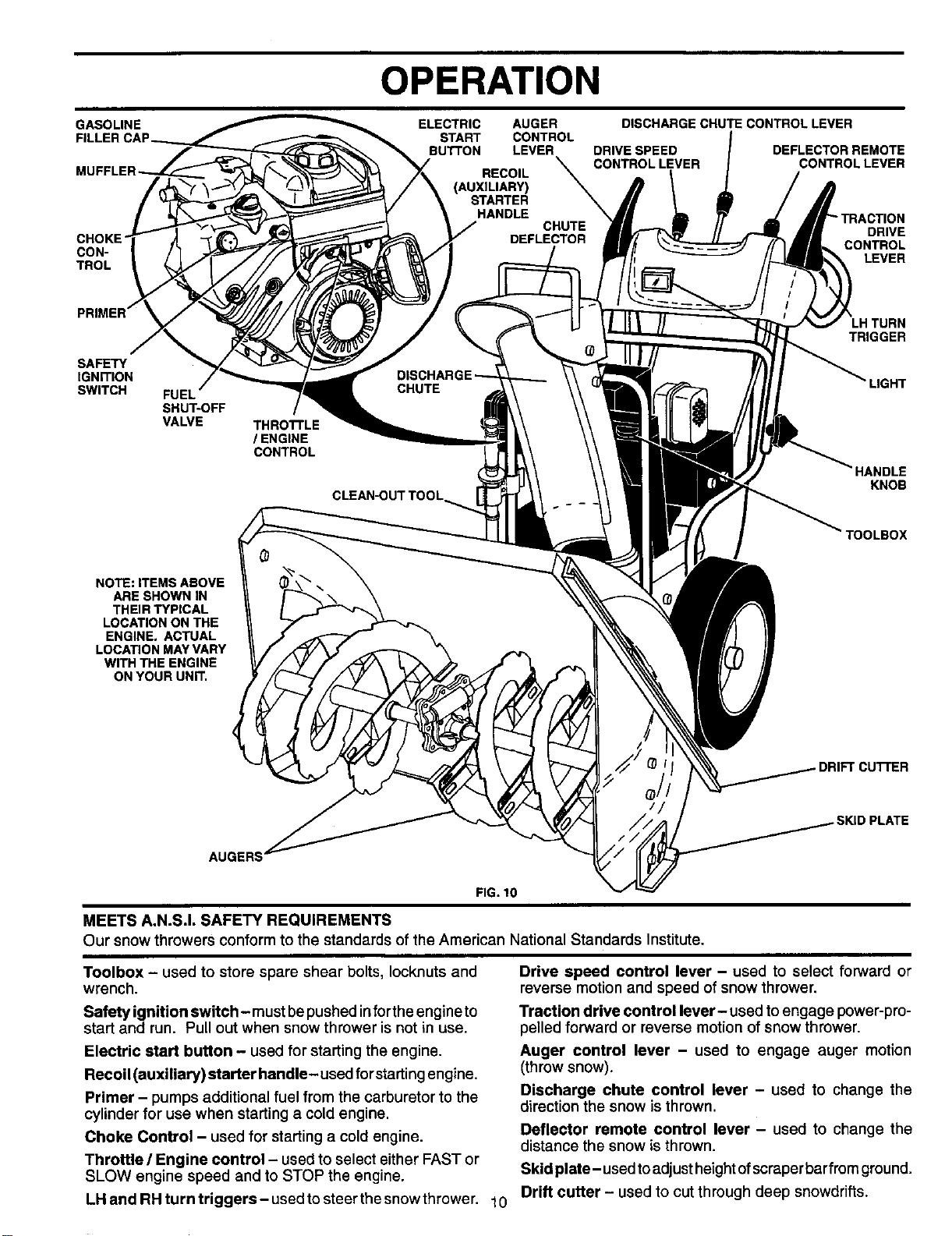

OPERATION

GASOLINE ELECTRIC AUGER

FILLER I START CONTROL

CHOKE"

CON-

TROL

PRIMER"

SAFETY

IGNWION

SWITCH FUEL

SHUT-OFF

VALVE

THROTTLE

/ ENGINE

CONTROL

BUTTON LEVER

(AUXILIARY)

STARTER

CHUTE

RECOIL

HANDLE

CHUTE

DEFLECTOR

DISCHARGE CHUTE CONTROL LEVER

DRIVE SPEED DEFLECTOR REMOTE

CONTROL LEVER CONTROL LEVER

DRIVE

CONTROL

LEVER

LHTURN

TRIGGER

GHT

KNOB

TOOLBOX

NOTE: ITEMS ABOVE

ARE SHOWN IN

THEIR TYPICAL

LOCATIONON THE

ENGINE. ACTUAL

LOCATIONMAYVARY

WITH THE ENGINE

ON YOUR UNIT,

FIG. 10

MEETS A.N.S.I. SAFETY REQUIREMENTS

Our snow throwers conform to the standards of the American National Standards Institute.

Toolbox - used to store spare shear bolts, Iocknuts and

wrench.

Safety ignition switch- must bepushed inforthe engineto

start and run. Pull out when snow thrower is not in use.

Electric start button - used for starting the engine.

Recoil (auxiliary) starter handle- usedforstarting engine.

Primer - pumps additional fuel from the carburetor to the

cylinder for use when starting a cold engine.

Choke Control - used for starting a cold engine.

Throttle / Engine control - used to select either FAST or

SLOW engine speed and to STOP the engine.

LH and RH turn triggers- used to steer the snow thrower. 10

Drive speed control lever - used to select forward or

reverse motion and speed of snow thrower,

Traction drive control lever- used toengage power-pro-

pelled forward or reverse motion of snow thrower.

Auger control lever - used to engage auger motion

(throw snow).

Discharge chute control lever - used to change the

direction the snow isthrown.

Deflector remote control lever - used to change the

distance the snow is thrown.

Skid plate - used to adjust height ofscraper barfrom ground.

Drift cutter - used to cut through deep snowdrifts.

Page 11

OPERATION

The operation of any snow thrower can result

in foreign objects thrown into the eyes, which

can result in severe eye clamage. Always wear

safety glasses or eye shields while operating

your snow thrower or performing any adjust-

ments or repairs. We recommend standard safety glasses

or a wide vision safety mask worn over spectacles.

HOW TO USE YOUR SNOW THROWER

Know how to operate all controls before adding fuel or

attempting to start the engine.

STOPPING

TRACTION DRIVE

• Release traction drive control lever to stop the forward

or reverse movement of the snow thrower.

AUGER

• Release the auger control lever to stop throwing snow.

ENGINE

1. Move throttle control to "STOP" position.

2. Pull safety ignition switch out to prevent unauthorized

use.

NOTE: Never use choke to stop engine.

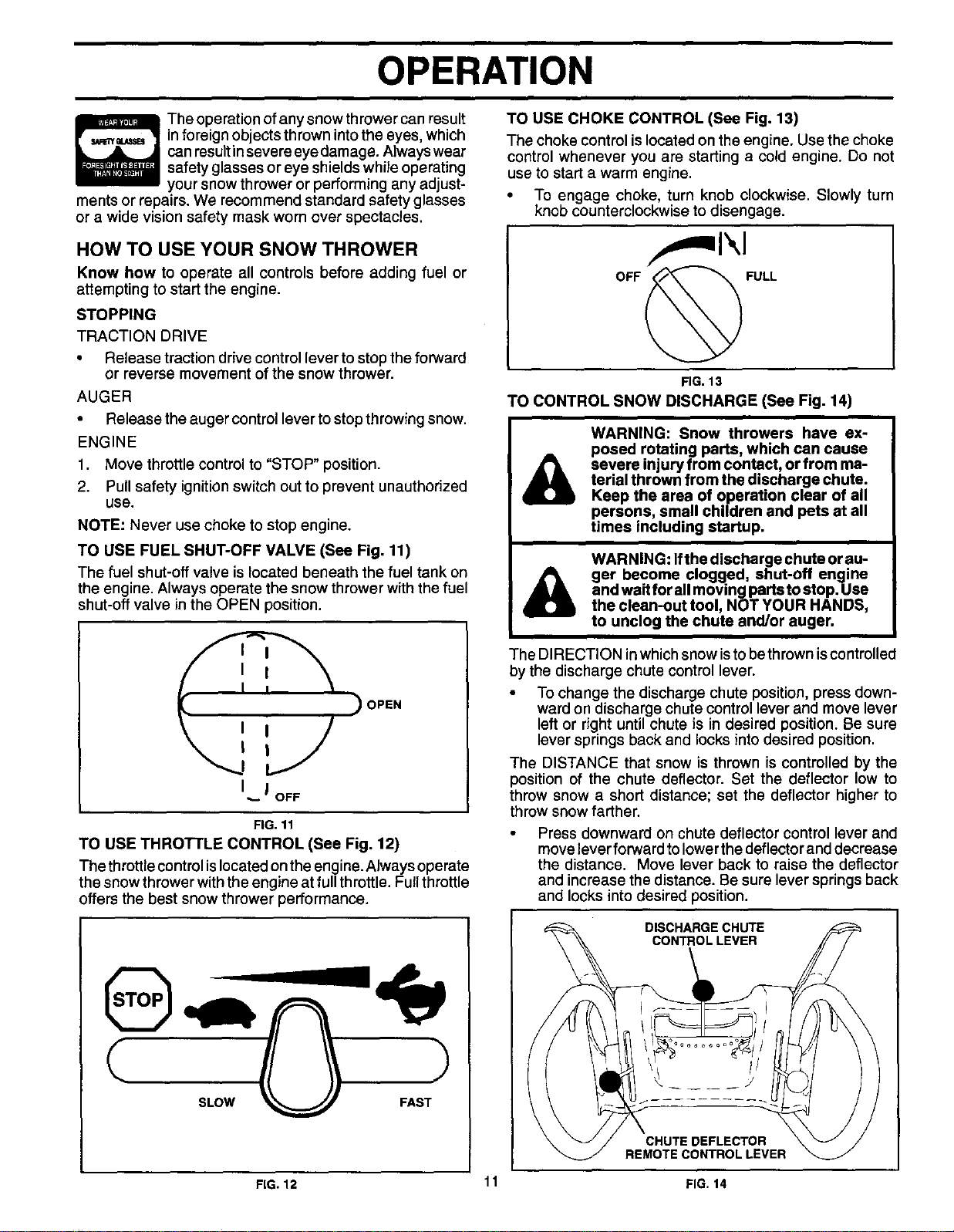

TO USE FUEL SHUT-OFF VALVE (See Fig. 11)

The fuel shut-off valve is located beneath the fuel tank on

the engine. Always operate the snow thrower with the fuel

shut-off valve in the OPEN position.

TO USE CHOKE CONTROL (See Fig. 13)

The choke control is located on the engine. Use the choke

control whenever you are starting a cold engine. 0o not

use to start a warm engine.

• To engage choke, turn knob clockwise. Slowly turn

knob counterclockwise to disengage.

/,.ml\l

OFF (_ FULL

FIG.13

TO CONTROL SNOW DISCHARGE (See Fig. 14)

WARNING: Snow throwers have ex-

posed rotating parts, which can cause

severe injury from contact, orfrom ma-

terial thrown from the discharge chute.

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

WARNING: Ifthe discharge chuta orau-

and wait for all moving parts to stop. Use

ger become clogged, shut-off engine

the clean-out tool, NOT YOUR HANDS,

to unclog the chute and/or auger.

I i

! I

I j

OFF

FIG. 11

TO USE THROTTLE CONTROL (See Fig. 12)

The throttlecontrolislocatedonthe engine. Always operate

the snow thrower with the engine at full throttle. Full throttle

offers the best snow thrower performance.

_ OPEN

C "=bt )

The DIRECTION in which snow isto bethtown is controlled

by the discharge chute control lever.

• To change the discharge chute position, press down-

ward on discharge chute control lever and move lever

left or right until chute is in desired position. Be sure

lever springs back and locks into desired position.

The DISTANCE that snow is thrown is controlled by the

position of the chute deflector. Set the deflector low to

throw snow a short distance; set the deflector higher to

throw snow farther.

Press downward on chute deflector control lever and

move lever forward to lower the deflector and decrease

the distance. Move lever back to raise the deflector

and increase the distance. Be sure lever springs back

and locks into desired position.

DISCHARGE CHUTE

CONTROLLEVER

SLOW _ FAST

FIG. 12 11 FIG. 14

CHUTE DEFLECTOR

REMOTE CONTROL LEVER

Page 12

OPERATION

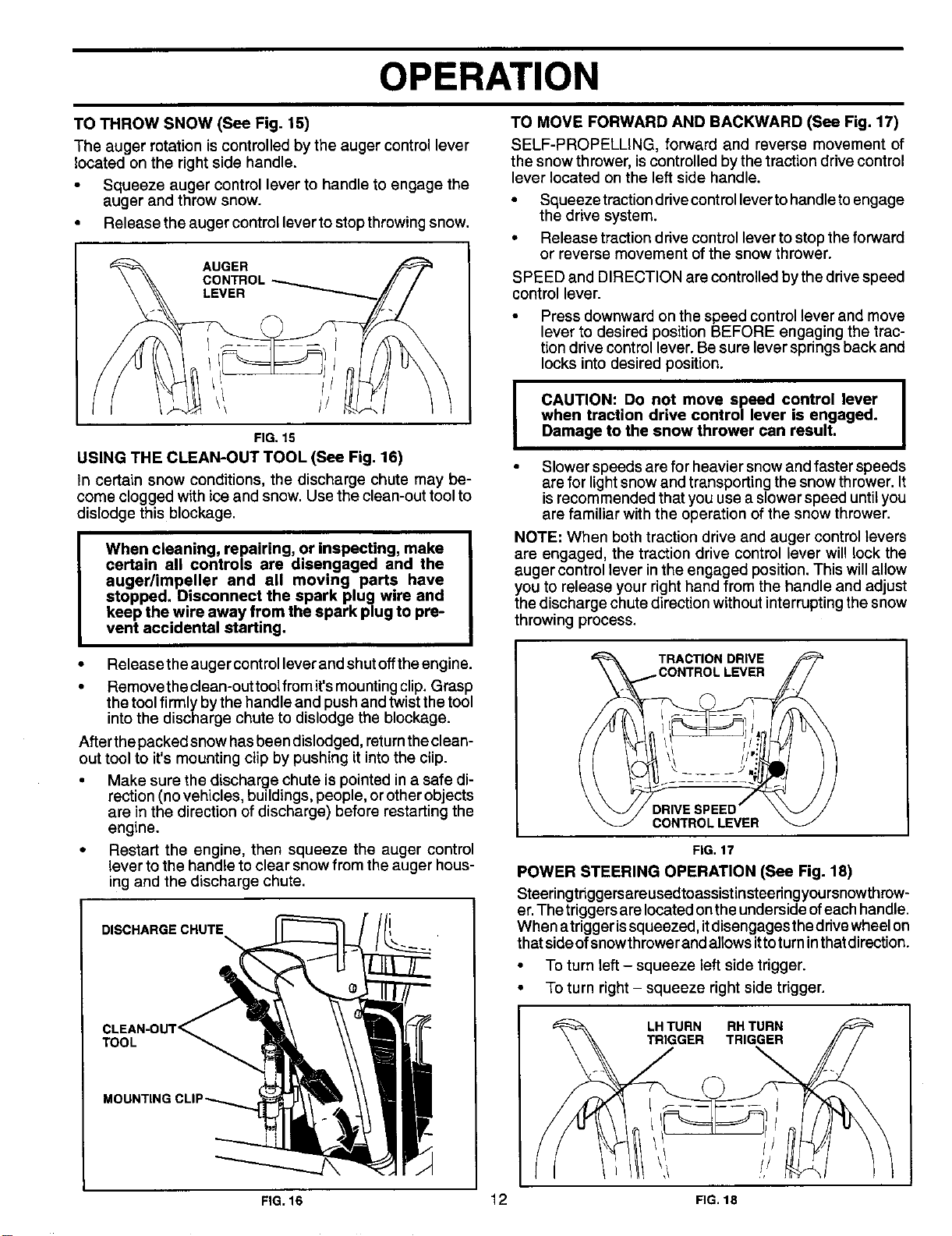

TO THROW SNOW (See Fig. 15)

The auger rotation is controlled by the auger control lever

located on the right side handle•

• Squeeze auger control lever to handle to engage the

auger and throw snow.

• Release the auger controllever to stopthrowing snow.

AUGER

CONTROL

LEVER

FIG. 15

USING THE CLEAN-OUT TOOL (See Fig. 16)

In certain snow conditions, the discharge chute may be-

come clogged with ice and snow. Use the clean-out tool to

dislodge this blockage.

When cleaning, repairing, or inspecting, make

certain all controls are disengaged and the

auger/impeller and all moving parts have

stopped. Disconnect the spark plug wire and

keep the wire away from the spark plug to pre-

vent accidental starting.

TO MOVE FORWARD AND BACKWARD (See Fig. 17)

SELF-PROPELLING, forward and reverse movement of

the snow thrower, is controlled by the traction drive control

lever located on the left side handle.

• Squeeze tractiondrive control lever to handle to engage

the drive system.

• Release traction drive control lever to stop theforward

or reverse movement of the snow thrower•

SPEED and DIRECTION are controlled by the drive speed

control lever.

Press downward on the speed control lever and move

lever to desired position BEFORE engaging the trac-

tion drive control lever. Be sure lever springs back and

locks into desired position.

CAUTION: Do not move speed control lever |

when traction drive control lever is engaged.

Damage to the snow thrower can result.

• Slower speeds are for heavier snow and faster speeds

are for lightsnow and transporting the snowthrower. It

isrecommended that you use a slower speed untilyou

are familiar with the operation of the snow thrower.

NOTE: When both traction drive and auger control tevers

are engaged, the traction drive control lever will lock the

auger control lever in the engaged position.This will allow

you to release your right hand from the handle and adjust

thedischarge chute direction withoutinterruptingthe snow

throwing process.

I

I

• Release the auger control lever and shut offthe engine.

• Remove the clean-out toot from it's mounting clip. Grasp

the tool firrnlyby the handle and push and twist the tool

into the discharge chute to dislodge the blockage.

After the packed snow has been dislodged, return the clean-

out tool to it's mounting clip by pushing it into the clip.

• Make sure the discharge chute is pointed in a safe di-

rection (no vehicles, buildings, people, or other objects

are in the direction of discharge) before restarting the

engine.

• Restart the engine, then squeeze the auger control

lever to the handle to clear snow from the auger hous-

ing and the discharge chute.

DISCHARGE CHUTE

CLEAN-OUT_

TOOL

MOUNTING

TRACTION DRIVE F/_

CONTROL LEVER

FIG. 17

POWER STEERING OPERATION (See Fig. 18)

Steeringtriggersareusedtoassistinsteeringyoursnowthmw-

er. The triggersare located onthe undemide of each handle.

When atrigger issqueezed, itdisengages the ddvewheel on

thatsideof snowthrowerand allowsittoturn inthatdirection.

• To turn left- squeeze left side trigger.

• To turn right- squeeze right side trigger•

LH TURN RH TURN

TRIGGER TRIGGER

\

FIG. 16 12 FIG. 18

Page 13

OPERATION

TO ADJUST SKID PLATES (See Fig. 19)

NOTE: The wrench provided inyour parts bag may be used

to adjust the skid plates.

Skid plates are located on each side of the auger housing

and adjust the clearance between the scraper bar and the

ground surface. Adjust skid plates evenly to proper height

for current surface conditions. For removal of snow in

normal conditions, such as a paved driveway or sidewalk,

place skid plates in the highest position (lowest scraper

clearance) to give a 5 mm clearance between the scraper

bar and the ground. Use a middle position if the surface

to be cleared is uneven.

NOTE: It is not recommended to operate the snow thrower

over gravel or rocky surfaces. Objects such as gravel, rocks

or other debris, can easily be picked up and thrown by the

impeller, which can cause serious personal injury, property

damage or damage to the snow thrower.

• If snow thrower must be operated over gravel surface,

use extra caution and be sure skid plates are adjusted

to lowest (highest scraper clearance) position.

1. Shut off engine and wait for all moving parts to stop.

2. Adjust skid plates by loosening the rear 1/2" hex nut

only, then moving skid plate to desired position. Be sure

both plates are adjusted evenly. Tighten securely.

(LOW GROUND

CLEARANCE)

I

t

I

I

LOW POSITION (HIGH GROUND CLEARANCE)

I

FIG. 19

HOUSING

1/2" HEX NUT

SCRAPER BAR

The scraper bar is not adjustable, but is reversible. After

considerable use it may become worn. When it has worn

almost to the edge of the housing, it can be reversed,

providing additional service before requiring replacement.

Replace a damaged or worn scraper bar.

TO USE DRIFT CUTTERS (See Fig. 20)

Use the drift cuttersto cut through deep snowdrifts that are

higher than the front of the snow thrower.

• Loosen upper adjustment nut enough to allow drift

cutter to be raised to highest position and tighten nut

securely. Repeat for opposite side of snow thrower.

• When not using drift cutters, loosen adjustment nut,

lower to storage position and tighten nut securely.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 21)

The engine on your snow thrower has been shipped, from

the factory, already filled with oil.

1. Check engine oil with snow thrower on level ground.

2. Remove oil fill cap/dipstick and wipe clean, reinsert

the dipstick and screw tight, wait for a few seconds,

remove and read oil level. If necessary, add oil until

"FULL" mark on dipstick is reached. Do not overfill.

• To change engine oil, see "TO CHANGE ENGINE OIL"

in the Maintenance section of this manual.

ADD GASOLINE (See Fig. 21)

• Fill fuel tank to bottom of tank filler neck. Do not over-

fill. Use fresh, clean, regular unleaded gasoline with

a minimum of87 octane. Do not mix oilwith gasoline.

Purchase fuel inquantities that can be used within 30

days to assure fuel freshness.

fuel. Do not store, spill or use gasoline

WARNING: Wipe off any spilled oil or

near an open flame.

CAUTION: Alcohol blended fuels (called gas-

ohol or using ethanol or methanol) can attract

moisture which leads to separation and for-

mation of acids during storage. Acidic gas can

damage the fuel system of an engine while in

storage. To avoid engine problems, the fuel

system should be emptied before storage of

30 days or longer. Empty the gas tank, start

the engine and let it run until the fuel lines and

carburetor are empty. Use fresh fuel next eea-

son. See Storage Instructions for additional

information. Never use engine or carburetor

cleaner products in the fuel tank or permanent

damage may occur.

CHOKE ENGINE OIL GASOLINE

CONTROL FILL CAP / DIPSTICK FILLER CAP

FUEL SHUT-

STARTER

BU'I-rON

AUGER

HOUSING

PRIMER

DRIFT

CuI-rER

ADJUST-

MENT NUT

FIG. 20 13 FIG. 21

SAFETY

IGNITION

SWITCH

NOTE: ALL ITEMS ARE SHOWN IN THEIR TYPICAL LOCATION,

ACTUAL LOCATION MAY VARY WITH ENGINE ON YOUR UNIT.

RECOIL

STARTER

HANDLE

THRO'n'LE

Page 14

OPERATION

TO START ENGINE WARM START - RECOIL STARTER

• Be sure fuel shut-off valve is in the OPEN position.

Your snow thrower engine is equipped with both a 120 Volt

A.C. etectdc starter and a recoil starter. The electric starter

is equipped with a three-wire power cord and plug and is

designed to operate on 120 Volt A.C. household current.

• Be sure your house is a 120 Volt A.C. three-wire

grounded system. If you are uncertain, consult a

licensed electrician.

WARNING: Do not use the electric

starter if your house is not a 120 Volt

A.C. three-wire grounded system. Se-

rious personal injury or damage to your

snow thrower could result.

COLD START - ELECTRIC STARTER

1. Push safety ignition switch in,

2. Place threttle control in FAST position.

3. Rotate choke control to FULL position.

4. Connect the power cord to the engine.

5. Plug the other end of the power cord into a three-hole

grounded 120 Volt A.C. receptacle.

NOTE: Do not use primer when starting engine with the

electric starter.

6. Push starter button until engine starts.

IMPORTANT: Do not crank engine more than five con-

tinuous seconds between each time you try to start. Wait

5 to 10 seconds between each attempt.

7. When the engine starts, release the starter button and

slowly move the choke control to the OFF position.

8. Disconnect the power cord from the receptacle first,

then from the engine.

Allow the engine to warm up for a few minutes. Engine will

not develop full power until ithas reached normal operating

temperature.

WARM START - ELECTRIC STARTER

Follow the steps above, keeping the choke control in the

OFF position.

COLD START - RECOIL STARTER

1. Push safety ignition switch in.

2. Place throttle control in FAST position.

3. Rotate choke control to FULL position.

4. Push the primer four (4) times if the temperature is

below 15°F/-10°C, or two (2) times if temperature is

between 15°and 50°F/-10°C and 10°C, Iftemperature

is above 50°F/10°C, pnming is not necessary.

NOTE: Overpriming maycause flooding, preventing the en-

gine from starting. Ifyou do flood the engine, wait a few min-

utes before attempting to start and DO NOT push the primer.

5. Pull recoil starter handle quickly. Do not allow starter

rope to snap back.

6. When the engine starts, releasethe recoilstarter handle

and slowly move the choke control to the OFF position.

Allow the engine to warm up for a few minutes. Engine will

not develop full power until ithas reached normal operating

temperature.

Follow the steps above, keeping the choke in the OFF

position. DO NOT push the primer.

BEFORE STOPPING

Run the engine for a few minutes to help dry off any mois-

ture on the engine.

Toavoid possible freeze- up ofthe starter, proceed as follows:

ELECTRIC STARTER

1. Connect the power cord to the engine.

2. Plug the other end of the power cord into a three-hole

grounded 120 Volt A.C. receptacle.

3. While the engine is running, push starter button and

spin the starter for several seconds.

NOTE: The unusual sound made while starter is spinning

will not harm the engine or starter.

4. Disconnect the power cord from the receptacle first,

then from the engine.

RECOIL STARTER

1. While the engine is running, pull the recoil starter handle

with rapid, full arm strokes three or four times.

NOTE: The unusual sound made while pulling the recoil

starter handle will not harm the engine or starter.

IF RECOIL STARTER HAS FROZEN

If the recoil starter has frozen and will not turn the engine,

proceed as follows:

1. Grasp the recoil starter handle and slowly pull as much

rope out of the starter as possible.

2. Release the recoil starter handle and let it snap back

against the starter.

If the engine still fails to start, repeat the above steps or

use the electric starter.

SNOW THROWING TIPS

• Always operate the snow thrower with the engine at

full throttle. Full throttle offers the best performance,

• Goslowerindeep, freezingorheavywetsnow. Usethe

drive speed control, NOT the throttle, to adjust speed.

• It is easier and more efficient to remove snow imme-

diately after itfalls.

• The best time to remove snow isthe early morning. At

this time the snow is usually dry and has not been ex-

posed to the direct sun and warming temperatures,

• Slightly overlap each successive path to ensure all

snow will be removed.

• Throw snow downwind whenever possible.

• Adjust the skid plates to proper height for current snow

conditions. See "TO ADJUST SKID PLATES" in this

section of this manual.

• For extremely heavy snow, reduce the width of snow

removal byoverlapping previous path and moving slowly.

• Keep engine clean and clear of snow during use. This

will help air flow and extend engine life.

• After snow-threwing is completed, allow engine to runfor

a few minutes to melt snow and ice off the engine.

• Clean the entire snow thrower thoroughly after each

14

use and wipe dry so it is ready for next use.

Page 15

I & WARNING: Do not operate snow thrower if weather conditions impair visibility. Throwing snow I

during a heavy, windy snowstorm can blind you and be hazardous to the safe operation of the

snow thrower.

MAINTENANCE

MAINTENANCE SCHEDULE

AS YOU COMPLETE

REGU RSERV,CE

Check for Loose Fasteners I_

Clean / Inspect Snow Thrower If

Check / Replace V-Belts

Lubrication Chart

R

Check Engine Oil Level

Change Engine Oil

Inspect Muffler

Check / Replace Spark Plug

Empty Fuel Tank

GENERAL RECOMMENDATIONS

Thewarranty on this snowthrower does not cover itemsthat

have been subjected to operator abuse or negligence. To

receive full value from the warranty, operator must maintain

snow thrower as instructed in this manual. Some adjust-

ments will need to be made periodically to properly maintain

your snow thrower.

At least once a season, check to see if you should make

any of the adjustments described in the Service and Ad-

justments section of this manual.

• At least once a year, you should replace the spark plug

and check belts for wear. A new spark plug will help

your engine run better and last longer.

• Follow the maintenance schedule in this manual.

NOTE: Use only Original Equipment Manufacturer (OEM)

parts to service this unit. Failure to do so can cause the unit

to malfunction and pose a risk of injury to the operator.

v'

v'

i/

LUBRICATION CHART

(!) SAE 5!/t/-30 Motor Oil

(_) See "ENGINE" in

Maintenance section

(_) General

Purpose

Grease

_) Engine oil

v'

v'

BEFORE EACH USE

1. Check engine oil level

2. Check for loose fasteners.

3. Checkcontrols to be surethey are functioningproperly.

LUBRICATION

Keep your snow thrower well lubricated

(See "LUBRICATION CHART").

SNOW THROWER

Always observe the safety rules when performing any

maintenance.

TIRES

• Maintain proper air pressure in bothtires (See "PROD-

UCT SPECIFICATIONS section in this manual),

Pivot

points

(_ Auger

grease fittings

• Keep tires free of gasoline and oil, which can harm

rubber.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

15 corrosion.

Page 16

MAINTENANCE

V-BELTS TO CHANGE ENGINE OIL

Check V-belts for deterioration and wear after every 50

hours of operation and replace if necessary. The belts

are not adjustable. Replace belts if they begin to stip from

wear. (See "TO REMOVE BELT COVER" in the Service

and Adjustments section of this manual).

The V-belts on you rsnow thrower are of special construction

and should be replaced by original equipment manufacturer

(OEM) belts available from your nearest dealer. Using other

than OEM belts can cause personal injury or damage to

the snow thrower.

AUGER GEAR CASE

The gear case was filled with lubricant to the proper

level at the factory. The only time the lubricant needs

attention is if service has been performed on the gear

case.

• If lubricant is required, use only Ronex ED #1 grease.

TRACTION DRIVE SYSTEM

DO NOT lubricate the drive components insidethe snow

thrower. The sprockets, hex shafts, drive disc and friction

wheel require no lubrication. The bearings and bushings

are lifetime lubricated and require no maintenance.

CAUTION: Any lubricatin_ of the above compo-

nents can cause contamination of the friction

wheel and damage to the drive system of your

snow thrower.

ENGINE

LUBRICATION

Use only high quality detergent oil rated with API service

classification SG-SL. Select the oil's SAE viscosity grade

according to your expected operating temperature,

SAE VISCOSITY GRADES

<

I"F -20 0 30 32 40

= |

"c -3o -20 -lo 6 lo

TEMPERATURE RANGE ANTICIPATED

BEFORE NEXT OIL CHANGE

NOTE: Although multi-viecosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosityoils

will result in increased oil consumption when used above

32°F/0°C. Check your engine oil level more frequently to

avoid possible engine damage from running low on oil.

Change the oil after every 25 hours of operation or at least

once a year ifthe snow thrower is not used for 25 hours

in one year.

Checkthe crankcase oillevel before startingthe engine and

after each five (5) hours of continuous use. Tighten oil fill

cap / dipstick securely each time you check the oil level.

Determine temperature range anticipated before next oil

change. All oil must meetAPI service classification SG-SL.

• Be sure snow thrower is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

NOTE: The left side wheel may be removed from snow

thrower for easier access to the oil drain plug and place-

ment of a suitable container. The unit tilted, resting on the

frame with the left wheel removed, will help drain any oil

trapped inside the engine. (See "TO REMOVE WHEELS"

in the Service and Adjustments section of this manual).

1. Disconnect spark plug wire from spark plug and place

wire where it cannot come in contact with plug.

2. Clean area around drain plug.

3. Remove drain plug and drain oil in a suitable container.

4. Install drain plug and tighten securely.

5. Wipe off any spilled oil from snow thrower and engine.

6. Install left wheel (if removed for draining oil). Be sure to

install klick pin into proper hole in wheel axle (See "TO

REMOVE WHEELS" in the Service and Adjustments

section of this manual).

7. Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine.

8. Refill engine with oil through oil dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

"PRODUCTSPECIFICATIONS" section of this manual.

9. Use gauge on oil fill cap/dipstick for checking level. Be

sure dipstick cap is tightened securely for accurate

reading. Keep oil at "FULL" line on dipstick.

10. Wipe off any spilled oil

MUFFLER

Inspect and replace corroded muffler as it could create a

fire hazard and/or damage.

SPARK PLUG

Replace spark plug at the beginning of each season or after

every 100 hours ofoperation, whichever occurs first. Spark

plug type and gap setting are shown in the "PRODUCT

SPECIFICATIONS" section of this manual.

CLEANING

IMPORTANT: For best performance, keep snow thrower

housing free of any dirt or trash. Clean the outside of your

snow thrower after each use.

I WARNING: Disconnectsparkplugwire I

Keep finished surfacest%vheels free of gasoline, oil, etc.

We do not recommend using a garden hose to clean

your snowthrower unless the electrical system, muffler

and carburetor are covered to keep water out. Water

in engine can result in shortened engine life.

from spark plug and place wire where it

cannot come in contact with plug.

16

Page 17

SERVICE AND ADJUSTMENTS

WARNING: To avoid serious injury, before

performing any service or adjustments:

1. Be sure throttle is in STOP position.

2. Pull safety ignition switch out.

&

SNOW THROWER

TO ADJUST SNOW THROWER HEIGHT

See "TO ADJUST SKID PLATES" and "SCRAPER BAR"

in the Operation section of this manual.

CHUTE DEFLECTOR

The chute deflector, attached to the top of the discharge

chute, is provided to direct discharging snow away from

the operator. If the deflector becomes damaged, it should

be replaced.

I w+..o+o+o,.ou.n,I

3. Make sure the augers and all moving

parts have completely stopped.

4. Disconnect spark plug wire from

spark plug and place wire where it

cannot come in contact with plug.

never operate your snow thrower with

the deflector removed or damaged.

1. Disengage all controls and move throttle control to

STOP position. Wait for all moving parts to stop,

2. Disconnect spark plug wire from spark plug and place

wire where it cannot come in contact with plug.

3. Align holes in impeller hub with holes in impeller shaft

and install two (2) new 1/4-20 x 1-5/8" capscrew/shear

bolts. Install 1/4-20 Iocknuts and tighten securely.

CAUTION: Do not substitute. Use only original

equipment capscrew/shear bolts as supplied

I

with your snow thrower.

4.

Connect spark plug wire to spark plug.

;0%.°+

• To change directionand/ordistance snow isdischarged,

see "TO CONTROL SNOW DISCHARGE" in the Op-

eration section of this manual.

SHEAR BOLTS (See Fig. 22)

AUGER SHEAR BOLTS

Both right and left-hand augers are secured to the auger

shaft with a shoulder/shear bolt and hex nut, Should afor-

eign object or ice become lodged in the augers, the shear

bolts are designed to break, preventing damage to any

other components. If one or both augers do not turn when

auger control lever is engaged, check to see if one or both

of the bolts have sheared, To replace the shear bolts:

1. Disengage all controls and move throttle control to

STOP position• Wait for all moving parts to stop.

2. Disconnect spark plug wire from spark plug and place

wire where it cannot come in contact with plug.

3. Align hole in auger hub with hole in auger shaft and

install a new 1/4-20 x 2" shoulder/shear bolt. Install

1/4-20 lock nut and tighten securely.

CAUTION: Do not substitute. Use only original |

equipment shear bolts as supplied with your

snow thrower.

I

4. Connect spark plug wire to spark plug.

IMPELLER SHEAR BOLTS

The impeller is secured to the impeller shaft with two (2)

capscrew/shear bolts and hex nuts. Should a foreign object

or ice become lodged in the impeller, the capscrews are

designed to break, preventing damage to any other com-

ponents. If impeller does not turn when auger control lever

is engaged, check to see if the capscrews have sheared.

To replace the capscrew/shear bolts:

FIG. 22

TO REMOVE BELT COVER (See Fig. 23)

1. Remove the two (2) screws securing belt cover to

frame.

2. Remove belt cover.

• Replace belt cover by installing cover and screws and

tighten securely.

I

I

SCREWS

FIG.23

17

Page 18

SERVICE AND ADJUSTMENTS

TO REPLACE BELTS (See Fig. 24)

The auger and traction drive belts are not adjustable. If the

belts are damaged or begin to slip from wear, they should

be replaced. It is recommended that the belt(s) be replaced

by a Sears service centre/department.

NOTE: It is recommended that both the auger and traction

drive belt be replaced at the same time.

The V-belts onyoursnowthrowerare ofspecial construction

and should be replaced by originalequipment manufacturer

(OEM) belts available from your nearest Sears service

centre/department. Using otherthan OEM belts can cause

_ersonal injury or damage to the snow thrower.

WARNING: Belt replacement requires

separation of the snow thrower. While

separating the auger housing from the

frame assembly, it is important that an

assistant stand in the operating position

and hold the snow thrower handles. Se-

rious personal injury and/or damage to

the unit could occur if the snowthrower

should fall during the belt changing

process.

FRAME AUGER

ASSEMBLY HOUSING

HINT: Insert a 3/8" drive ratchet (in the "ON" position) into

the square hole in idler arm and rotate ratchet clockwise

to relieve tension.

8. With tension relieved on idler, installnew traction drive

belt around pulleys and inside belt keepers.

9. Place auger belt around and inside the groove of auger

pulley only.

10. While your assistant slowly raises handles to rejoin

the auger housing and frame assembly, pull up on the

auger belt and squeeze sides together above pulley

so belt is fully seated in groove of pulley.

11. Bring snow thrower completely together and check

carefully for proper routing of belts. If auger belt has

become dislodged from the pulley (by catching the idler

arm bracket while bringing snow thrower together),

separate the snow thrower and repeat step 10. Belt

must be fully seated in pulley groove when bringing

the snow thrower together.

12. Install the two (2) hex bolts and lock washers and

tighten securely.

13. INSTALL ENGtNE PULLEY- Place belt in pulleygroove

and slide pulley on crankshaft. Install flat washer,

Iockwasher and bolt and tighten securely (41-47 N-m

torque). Make sure belt is inside belt keeper.

14. INSTALL BELT COVER and two (2) screws. Tighten

securely.

15. INSTALL DISCHARGE CHUTE - See "INSTALL DIS-

CHARGE CHUTE / CHUTE ROTATER HEAD" in the

Assembly / Pre-Operation section of this manual.

1.

REMOVE GASOLINE FROM FUELTANK- Draingaso-

line from fuel tank into a suitable container, outdoors,

away from fire or flame. Wipe up any spilled gasoline.

2.

REMOVE DISCHARGE CHUTE - Loosen Iocknut

securing chute rotator head to mounting bracket only

enough to allow chute rotator head to be raised and

discharge chute to be removed from snow thrower.

.

REMOVE BELT COVER - See "TO REMOVE BELT

COVER" in this section of this manual.

4.

REMOVE ENGINE PULLEY- Remove bolt, Iockwasher

and flat washer securing pulley to engine crankshaft.

Remove outside (auger) pulley only from crankshaft.

5.

SEPARATE SNOW THROWER - With your assistant

standing in the operating position holding the handles,

remove the two (2) bolts and lock washers holding

auger housing and frame together.

have your assistant carefully lower the

WARNING: As the last bolt is removed,

handles down to the ground,

.

REMOVE AUGER BELT from around pulley.

7.

RELIEVE TENSION ON TRACTION DRIVE BELT

IDLER and remove traction drive belt from around

pulleys.

HOLE

18 FIG.24

Page 19

TOREMOVEWHEELS(SeeFig.25)

• Remove the klik pin and remove wheel from axle.

IMPORTANT: When installing wheel, be sure to use the

axle hole closest to the end of the shaft - do not use the

hole in the wheel hub (if equipped). Inner hole in axle and

hole in wheel hubare notused foryour model snow thrower.

KLIK PIN (INSTALL

IN OUTER HOLE

OF AXLE ONLY)

FIG. 25

OUTER HOLE

AXLE

WHEEL HUB

STORAGE

NOTE: To seal punctures or prevent flat tires due to slow

leaks, tire sealant may be purchased from your local parts

dealer. Tire sealant also prevents tire dry rot and corrosion.

ENGINE

CARBURETOR

Your carburetor is not adjustable. Engine performance

should not be affected at altitudes up to 2,134 meters. If

your engine does not operate properly due to suspected

carburetor problems, take your snow thrower to a Sears

service centre/department.

ENGINE SPEED

Never tamper withthe engine governor, which isfactory set

for proper engine speed. Overspeeding the engine above

the factory high speed setting can be dangerous and will

void the warranty. If you think the engine-governed high

speed needs adjusting, contact a Sears service centre/de-

partment, which has the proper equipment and experience

to make any necessary adjustments.

Immediately prepare your snow thrower for storage at the

end of the season or if the unit will not be used for 30 days

or more.

WARNING: Never store the snow

thrower with gasoline inthe tank inside

a building where fumes may reach an

&

open flame, spark or pilot light as on a

furnace, water heater, clothes dryer or

gas appliance. Allow the engine to cool

before storing in any enclosure.

SNOW THROWER

When snow thrower is to be stored for a period of time,

clean it thoroughly, remove all dirt, grease, leaves, etc.

Store in a clean, dry area.

1. Clean entire snow thrower (See "CLEANING" in the

Maintenance section of this manual).

2.

Inspect and replace belts, if necessary (See TO RE-

PLACE BELTS" inthe Service and Adjustments section

of this manual).

3.

Lubricate as shown in the Maintenance section of this

manual.

4.

Be surethat all nuts, bolts, screws, and pins are securely

fastened. Inspect moving parts for damage, breakage

and wear. Replace if necessary.

5.

Touch up al! rusted or chipped paint surfaces; sand

lightly before painting.

ENGINE

FUEL SYSTEM

IMPORTANT: It isimportant to prevent gum deposits from

forming in essential fuel system parts such as carburetor,

fuel hose, or tank duringstorage. Also,alcohol blended fuels

(called gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system of

an engine while in storage.

• Empty the fuel tank by starting the engine and letting

it run until the fuel lines and carburetor are empty.

• Never use engine or carburetor cleaner products in the

fuel tank or permanent damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in min-

imizing the formation of fuel gum deposits during storage.

Add stabilizer to gasoline infuel tank or storage container.

Always follow the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding stabilizer to

allow the stabilizer to reach the carburetor. Do not empty

the gas tank and carburetor if using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace with clean en-

gine oil. (See "ENGINE" in the Maintenance section of

this manual).

CYLINDER

1.

Remove spark plug.

2.

Pour approximately one ounce (30 ml) of oil through

spark plug hole into cylinder.

,

Pull recoil starter handle slowly a few times to distribute

oil.

4.

Replace with new spark plug.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• if possible, store your snow thrower indoorsand cover

it to protect it from dust and dirt.

• Cover yoursnowthrower witha suitableprotectivecover

thatdoes not retain moisture. Do not use plastic. Ptastic

cannotbreathe, whichallowscondensation toform and

will cause your snow thrower to rust.

IMPORTANT: Never cover snow thrower while engine/

exhaust area is still warm.

19

Page 20

TROUBLESHOOTING

See appropriate section in manual unless directed to a Sears service centre/department.

PROBLEM CAUSE CORRECTION

Does not start 1. 1. Turn fuel shut-off valve to OPEN position.

Fuel shut-off valve (if so

equipped) in OFF position.

2. Safety ignition switch OUT.

3. Out of fuel.

4. Throttle in STOP position.

5. Choke in OFF position.

6. Primer not depressed.

7. Engine is flooded.

8. Spark plug wire is

disconnected.

9. Bad spark plug.

10. Stale fuel.

11. Water in fuel.

2. Push safety ignition switch IN.

3. Fitl fuel tank with fresh, clean gasoline.

4. Move throttle to FAST position.

5. Move to FULL position.

6. Prime as instructed in the Operation section of this manual.

7. Wait a few minutes before restarting, DO NOT prime.

8. Connect wire to spark plug.

9. Replace spark plug.

10. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

11. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

Loss of power

Engine idles or

runs roughly

Excessive 1. Loose parts or damaged 1. Tighten all fasteners. Replace damaged parts. If vibration

vibration augers or impeller, remains, contact a Sears service centre/department.

Recoil starter 1. Frozen recoil starter. 1. See "IF RECOIL STARTER HAS FROZEN"

is hard to pull in the Operation section of this manual.

Loss of traction 1. Drive belt is worn. 1. Check/replace drive belt.

drive / slowing 2. Drive belt is off of pulley. 2. Check / reinstall drive belt.

of drive speed 3. Friction drive wheel is worn. 3. Contact a Sears service centre/department.

Loss of snow 1. Auger belt is off of pulley. 1. Check / reinstall auger belt.

discharge or 2. Auger belt is worn, 2. Check / replace auger belt.

slowing of 3. Clogged discharge chute. 3. Clean snow chute.

snow discharge 4. Augers / impeller jammed. 4. Remove debris or foreign object from augers / impeller.

1. Spark plug wire loose.

2. Throwing too much snow.

3. Fuel tank cap is covered

with ice or snow.

4. Dirty or clogged muffler.

1. Choke is in FULL position.

2. Blockage in fuel line.

3. Stale fuel.

4. Water in fuel.

5. Carburetor is in need of

adjustment or overhaul.

1. Reconnect spark plug wire.

2. Reduce speed and width of swath.

3. Remove ice and snow on and around fuel tank cap.

4. Clean or replace muffler.

1. Move choke to OFF position.

2. Clean fuel line.

3. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

4. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

5. Contact a Sears service centre/department.

2O

Page 21

SERVICE NOTES

21

Page 22

REPAIR PARTS SNOW THROWER - - MODEL NUMBER 944.524591

AUGER HOUSING / IMPELLER ASSEMBLY

48

_.51

32

34

37

44 27

56

45

5O

41

40

15

20

21

10

52

24

55

27

55 24

17

52

20

23

21

29

23

31

21

30

22

Page 23

REPAIR PARTS SNOW THROWER

AUGER HOUSING I IMPELLER ASSEMBLY

KEY PART

NO. NO. DESCRIPTION

4 191079 Pulley, Impeller

5 188909 Bearing Assembly, Flange

6 155377 Nut, Hex Flange 5/16-18

7 180355 Bolt, Flat Head, Carriage 5/16-18 x 5/8

8 72250505 Bolt, Carriage 5/16-18

9 178820 Nut, Cage 3/8-16

10 178826X615 Housing, Auger

11 178690X479 Bar, Scraper

12 178675X008 Bracket, Corner Discharge

13 175322 Base, Discharge Chute

14 19111507 Washer, Flat

15 10040500 Washer, Lock 5/16

16 74950512 Screw, HexHead 5/16-18x3/4

17 155595 Fitting, Grease

18 179582 Screw, Hex Head 5/16 x 1

19 73800400 Nut, Hex Lock 1/4-20

20 73800500 Nut, Hex Lock 5/16-18

21 155415 Washer, Fiat 5/16

22 178777X479 Skid Plate, RH

23 179246 Washer, Nylon, Friction

24 72270506 Bolt, Carriage 5/16-18 x 3/4

25 185600 Bolt, Shoulder 1/4-20

26 174658 Bearing, Auger

27 174697 Washer, Thrust, 1"

28 192090 Bolt, Shear

29 174762X479 Skid Plate, LH

30 198991X479 Auger Assembly, RH

31 198990X479 AugerAssembly, LH

32 174699 O-Ring

33 174700 Bushing, Flange 3/4

34 174681 Washer, Thrust 3/4

35 174684 Bearing, Thrust 3/4

36 174660 Shaft, Impeller

37 174683 Washer, Thrust 5/8

38 174686 Bushing, Flange 5/8

39 150078 Screw, HexHead 5/16-18x3/4

40 86447 Plug, Case

41 174688 Housing, Gearbox, RH

42 174698 Seal, Oil

43 174701 Bushing, Flange, 1"

44 189282 Key, Square 1/4 x1/4 x 7/8

45 174659 Gear, Worm

46 174657 Shaft, Auger

47 174687 Housing, Gearbox, LH

48 175321X479 ImpellerAssembly

49 74780426 Screw, Hex Head 1/4-20 x 1-5/8

50 175311 Gasket, Gearbox

51 7836M Pin, Roll 3/16 x 1-1/8

52 181160X479 Bar, Drift Cutter

54 53847 Washer, Flat 1/4

55 188243 Kit, Shear (Contains 6 each of Key Numbers 19 and 28)

56 180684 Multi-Wrench

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your unit and void your warranty.

23

- - MODEL NUMBER 944.524591

Page 24

REPAIR PARTS SNOW THROWER - - MODEL NUMBER 944.524591

CONTROL PANEL / DISCHARGE CHUTE

19

2

22

\

\

\

\

\

\

i\

23 \ \

3

',\

\

31

\\

25

30

20

29

27

\

4

6

7

18

9

10

11

12

14

:1

3

13

15

8

Page 25

REPAIR PARTS SNOW THROWER - - MODEL NUMBER 944.524591

CONTROL PANEL / DISCHARGE CHUTE

KEY PART

NO. NO. DESCRIPTION

1 183334

2 17501010

3 178674

4 73800600

5 19131316

6 178659

7 178638X479

8 71210616

9 184505

10 179829

11 179246

12 73800400

13 72250505

14 73800500

15 178628X615

16 178633X615

17 179145

18 128415

19 183333

20 72270506

21 155415

22 74041024

23 188303

25 155377

26 198875

27 169675

28 180445

29 187716

30 192710

31 192199

Knob, Lever

Screw #10-24 x 5/8

Control Assembly, Deflector

Nut, Lock 3/8-16

Washer, Flat 3/8

Control Assembly, Chute Rotater

Support, Pivot

Screw, Hex Head

Spring, Deflector

Bolt, Shoulder

Washer, Friction, Nylon

Nut, Lock 1/4-20

Bolt, Carriage 5/16-18

Nut, Lock 5/16-18

Chute Assembly

Deflector Assembly

Seal, Deflector

Rivet, Blind

Knob, Speed Control Lever

Bolt, Carriage 5/16-18 x 3/4

Washer, Flat

Screw #10-24 x 1-1/2

Control Assembly, Power Steedng

Nut, Lock 5/!6-18

Lever Assembly, Speed Control

Retainer, Hairpin

Rod, Upper, Speed Control

Rod, Lower, Speed Control

Clamp, Mounting, Clean-Out Tool

Tool, Clean-Out

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your unit and void your warranty.

25

Page 26

REPAIR PARTS

HANDLES

SNOW THROWER - - MODEL NUMBER 944.524591

7 28

6

4

36

5

4

9 '\

1

5

46

34

15

15 11

17

J

22

j_

30

17 16

J

f

/

\

/

J

.1

27

\

\

\

,2o\

24

25 \

I

I

I

I

I

I

27

J

L

I

\

29 40

39

41 "-../

26

Page 27

REPAIR PARTS

HANDLES

KEY PART

NO. NO.

SNOW THROWER - - MODEL NUMBER 944.524591

DESCRIPTION

1 178675X479

2 178648X479

3 179439

4 178888

5 169675

6 180402

7 178652

8 196333X008

9 196334X008

10 196619X479

11 74780524

12 74780528

13 178646X479

14 178696X479

15 73800500

16 19131316

17 178899

18 184594

19 193081

20 180428

21 73350500

22 72120618

23 178643X479

24 180447

25 180926

26 178669

27 71210616

28 175331

29 193072

30 182906

31 175262

32 184471

33 196335X008

34 183518

35 68038

36 178831

37 193885

38 178666

39 178668

40 180964

41 178890

42 196336X008

43 196337

44 196338

45 700279

46 179246

Lever, Auger Control, RH

Lever, Traction Drive Control, LH

Nut, Cage 1/4-20

Bushing, Flange

Retainer, Hairpin

Screw, Hex Head 1/4-20 x 3/4

Rod, Interlock

Arm, Impeller Rod

Arm, Traction Rod

Panel, Control

Screw, Hex Head 5/16-18 x 1-1/2

Screw, Hex Head 5/16-18 x 1-3/4

Handle Tube, LH

Handle Tube, RH

Nut, Lock 5/16-18

Washer, Flat 3/8

Knob, Handle

Rod, Auger Control

Rod, Traction Control

End, Control Rod

Nut, Hex, Jam 5/16-18

Bolt, Carriage 3/8-16 x 2-1/4

Handle Tube, Lower

Sleeve, Spring

Spring, Traction Drive

Spring, Auger Control

Screw, Hex Head 3/8-16 x 1

Bushing, Pivot Lever

Screw, Headlight Ground Wire to Blower Housing

Console, Panel

Screw, Hex Head, Tapping #10-24 x 1-1/4

Screw, Hex Head, Tapping #10-24 x 1/2

Latch, Interlock

Bolt, Shoulder

Nut, Lock 1/4-20

Spring, Torsion, Lever

Spring, Interlock

Headlight, Halogen

Bezel, Headlight

Harness, Headlight (Halogen)

Nut, Cage 3/8-16

Lever, Interlock

Rod, Latch, Interlock

Rod, Arm, Interlock

Clip

Washer, Friction

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your unit and void your warranty.

27

Page 28

REPAIR PARTS SNOW THROWER - - MODEL NUMBER 944.524591

DRIVE

2

19

18

17

18

27

2

42

7

15

6

5

43

34

2_

28

28

• 39

40

35 33

Page 29

REPAIR PARTS

DRIVE

KEY PART

NO. NO.

SNOW THROWER - - MODEL NUMBER 944.524591

DESCRIPTION

1 146315

2 73800500

3 155415

4 17490508

5 180017

6 180134

7 179270

8 192616X479

9 180082

10 180065

11 187714

12 180066

13 178807

14 178619X479

15 175344

16 186951X479

17 179831

18 198176X479

19 73930500

20 178613

21 74760514

22 85179

23 180135

24 180081

25 178695

26 197763

27 178621

28 197764

29 175350X479

30 175349X479

31 72270505

32 189282

33 188909

34 175338X479

35 182504

36 191080

37 155377

38 19111507

39 10040500

40 74950512

41 12000012

42 11050500

43 179095

44 9465M

Screw, Hex Head 5/16-18 x 3/4

Nut, Lock 5/16-18

Washer, Flat

Screw, Hex Head 5/16-18 x 1/2

Bearing, Flange

Shaft, Auxiliary

Spacer, Plate

Plate, Auxiliary

Gear, Intermediate (12/58)

Gear, Pinion

Rod, Clutch

Shaft, Long, Hex

Pin, Pivot

Lever, Shifter / Wheel

Trunnion Bearing Assembly

Bracket, Pivot, Shifter

Ring, Rubber Wheel

Plate, Rubber Wheel

Nut, Lock 5/16-18

Hub, Rubber Wheel

Screw, Hex Head 5/16-18 x 7/8

Retainer, Hairpin

Spring, Bias

Gear, Axle (58 Teeth)

Pin, Pivot Lever

Plate Assembly, Drive

Shaft, Axle

Shaft, Short Hex

Lever, Shifter Plate

Bracket, Shifter Support

Bolt, Cardage 5/16-18 x 5/8

Key, Square 1/4 x 1/4 x 7/8

Bearing, Flange

Plate, Drive Mounting

Spacer, Bearing

Pulley, Traction Drive

Nut, Lock 5/16-18

Washer, Flat

Washer, Lock 5/16

Screw, Hex Head 5/16-18 x 3/4

Ring, Retaining

Washer, Lock, External Tooth 5/16

Spring, Return

Pin, Roll

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your unit and void your warranty.

29

Page 30

REPAIR PARTS SNOW THROWER - - MODEL NUMBER 944.524591

CHASSIS / ENGINE / PULLEYS

30

\

31 37

34

36

29

39

56

19

57

6 22

286 10

_ 24

26

27

15

/ \

35

/

/

J'

/

52

51

11

46

3o

Page 31

REPAIR PARTS SNOW THROWER - - MODEL NUMBER 944.524591

CHASSIS / ENGINE / PULLEYS

KEY PART KEY PART

NO. NO. DESCRIPTION NO. NO. DESCRIPTION

1 181044

2 180522

__ .

4 74780520

5 150078

6 59289

7 73930500

8 175330

9 179092

10 10040500

11 17490508

12 179259

13 85179

14 178828

15 184496

16 192306

17 179354X008

18 74780524

19 175331

20 180523

21 74610516

22 179371

23 180478

24 179157

25 62735

26 850263

27 851084

Spring, Traction Idler 28 155452

Pulley, Idler(2-1/4) 29 192213

Engine, Briggs & Stratton,

Model Number 20B414-0369-E1 30 178830

(See Breakdown) 31 17490408

Screw, Hex Head 5/16-18x 1-1/4 32 179256

Screw, Hex Washer Head 33 187853

5/16-18 x 1-1/4 34 180401

Washer, Flat 35 195767

Nut, Jam, Lock 5/16-18 36 73800500

Pin, Idler Pivot 37 178833X479

V-Belt, Traction Drive 38 187101

Washer, Lock 5/16 39 192110

Screw, HexWasher Head 40 178820

5/16-18 x 1/2 41 700279

Impeller Arm / Pad Assembly 42 179065

Retainer, Hairpin 43 179063X479

Spring, Brake 44 71210616

V-Belt, Impeller Drive 45 175324X479

Screw, Hex Head 3/8-16 x 1-1/4 46 178624X479

Arm, Idler 47 71020512

Screw, Hex Head 5/16-18 x 1-1/2 48 181156

Bushing, Idler Pivot 49 175336X615

Pulley, Idler (2-3/4) 50 187715X615

Screw, Hex Head 5/16-18 x 1 51 193364X008

Spacer, Engine Pulley 52 57079

Pulley, Engine, Traction Drive 53 192275

Pulley, Engine, Impeller Drive 54 192147

Washer, Flat 3/8 55 12000002

Washer, Lock 3/8 56 183537X479

Screw, Hex Head 3/8-24 x 1-3/8 57 11050500

58 193070

Guide, Belt

Belt Cover Assembly

(includes Toolbox Cover)

Cover, Toolbox

Screw, Hex Head 1/4-20 x 1/2

Bolt, Shoulder 5/16-18

Bellcrank Shifter

Screw, Hex Head 1/4-28 x 3/4

Arm, Auger Control

Nut, Lock 5/16-18

Bellcrank

Link, Speed Control

Trunnion, Pivot Bracket

Nut, Cage 3/8-16

Clip, Retainer

Pin, Pivot Bracket

Bracket, Bellcrank

Screw, Hex Head 3/8-16

Bracket, Pivot, Idler

Pan, Frame Bottom

Screw, Hex Head 5/16-18 x 3/4

Nut, Speed 5/16-18

Frame Assembly

Plate, Frame End

Shaft, Auger Control

Washer, Hardened

Roller

Ring, Crescent

E-Ring

Mounting Plate, Engine

Washer, Lock, External Tooth 5/16

Power Cord

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your unit and void your warranty.

31

Page 32

REPAIR PARTS

WHEELS / DECALS

SNOW THROWER - - MODEL NUMBER 944.524591

13

17

19

28

31

\

2

10

\ 12 27 •

3O

4

14 28

29

34

21

26 29

25 34

24

23

33

3

21

33

23

34

4

22 3

4

)

32

Page 33

REPAIR PARTS

WHEELS / DECALS

KEY PART

NO. NO.

SNOW THROWER - - MODEL NUMBER 944.524591

DESCRIPTION

1 196752X417

2 155443

3 192109

4 184471

7 71210616

8 185603X479

9 185602X479

10 17600406

11 17490508

12 195749

13 193506X498

14 182015

15 194944X008

16 194939X008

17 194943X008

18 181847

19 85179

20 179148X479

21 192126

22 182466

23 187622

24 194941

25 179139

26 194940

27 189282

28 174697

29 179830

30 193885

31 196753X417

32 700279

33 12000045

34 146315

Wheel Assembly, 16", Power Steering, LH

Pin, Klik 1/4

Cover, Power Steering

Screw, Hex Head #10-24 x 1/2

Capscrew, Hex Head, Flanged 3/8-16 x 1

Bracket, Steering Cable, RH

Bracket, Steering Cable, LH

Screw, Hex Head 1/4-20 x 3/8

Screw, Hex Head 5/16-18 x 1/2

Link, Steering Lever

Yoke, Steering

Pin, Steering Lever

Bellcrank

Bracket, LH Steering

Bracket, RH Steering

Pin, Steering Bellcrank

Retainer, Hairpin

Bracket, Steering

Ddver, Wheel

Ring, Wire Retainer

Lobe, Wheel

Slide, Clutch

Spring, Clutch Slide

Lobe, Axle

Key, Square 1/4 x .875

Washer, Thrust (1")

Bearing, Axle

Spring, Return, Steering Latch

Wheel Assembly, 16", Power Steering, RH

Clip, Retainer

Ring, Retaining

Screw, Hex Head, Tapping 5/16-18 x 5/8

KEY PART

NO. NO. DESCRIPTION

1 181037 Decal, Danger

2 192177 Decal, Craftsman, 9.5HP/27"

3 181035 Decal, Danger, Deflector

4 181042 Decal, Danger

5 183876 Decal, Craftsman

6 181033 Decal, Instruction

7 155798 Decal, Traction Lever

8 155800 Decal, Auger Lever

9 181039 Decal, Speed Control

10 183730 Decal, Remote Deflector

11 183907 Decal, LH Trigger

12 183905 Decal, RH Trigger

-- 199455 Owner's Manual, English

-- 199456 Owner's Manual, French

NOTE: All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT: Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your unit and void your warranty.

33

Page 34

BRIGGS & STRATTON 4-CYCLE ENGINE MODELNUMBER 20B414-0369-E1

11

1019 LABEL KIT ]

I 48SHORTBLOCK I

287 _' 842

524

725 I

1351

)329REP_CEME_ENGIN_ I

746

742_-_

24

15_

998

15

1330 REPAIRMANUAL I

718A

i___ /

22_

1095 VALVE GASKET SET

_IA_--_I

358 ENGINE GASKET SET

_o@

21

868 (_

12

1

34

Page 35

BRIGGS & STRATTON 4-CYCLE ENGINE MODELNUMBER20B414-0369-E1

1171

13,_ _ 1278_

122 51A_

383N;_