Page 1

SEARS

CRRFTSMRN

Operator's Guide

WIRE FEED

MIG WELDER

Model No.

934.205592

CAUTION: Read and follow

all Safety Rules and

Operating Instructions before

First Use of this Product.

• WARRANTY

• INTRODUCTION

• SAFETY SUMMARY

• SPECIFICATIONS

• INSTALLATION

• OPERATION

• MAINTENANCE

• SCHEMATIC

• WIRING DIAGRAM

• REPLACEMENT PARTS

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

811-642-000 September 2001

Page 2

On Welding Gun or Cables, Welder, and Welder's Transformer

Full One Year Warranty for Craftsman

Welding Gun or Cables. For one year

from the date of purchase, when the

welding gun or cables are operated and

maintained according to the owner's

manual instructions, if the welding gun

or cables fail due to a defect in material

or workmanship, Sears will repair or

replace the welding gun or cables free of

charge. This warranty does not cover

parts consumed in normal operation,

such as contact tips, nozzles, gun liners,

and drive rollers.

Full Three Year Warranty on Craftsman

Welder For three years from the date of

purchase, when the welder is operated

and maintained according to the owner's

manual instructions, if the welder fails

due to a defect in material or

workmanship, Sears will repair or

replace the welder free of charge. This

warranty does not cover the welding

gun, cables, or normal consumable

parts.

WARRANTY SERVICE IS AVAILABLE

BY SIMPLY CONTACTING THE

NEAREST SEARS SERVICE CENTER.

This warranty applies only while this

product is in use in the United States.

This warranty gives you specific legal

rights, and you may also have other

rights which vary from state to state.

Sears Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179.

Page 3

CRAFTSMAN FULL WARRANTY ......................................................... 2

TABLE OF CONTENTS ......................................................................... 3

INTRODUCTION .................................................................................... 4

SAFETY SUMMARY ............................................................................... 5

SAFETY INFORMATION ...................................................................... 5

SHOCK HAZARDS ............................................................................. 6

FIRE HAZARDS .................................................................................. 6

FLASH HAZARDS .............................................................................. 6

FUME HAZARDS ................................................................................ 6

COMPRESSED GASSES AND EQUIPMENT HAZARDS .................. 6

BURN HAZARDS ................................................................................ 7

ADDITIONAL SAFETY INFORMATION ............................................... 7

WELDER SPECIFICATIONS .................................................................. 8

DESCRIPTION ...................................................................................... 8

WELDER OPERATING CHARACTERISTICS ...................................... 8

DUTY CYCLE ..................................................................................... 8

INTERNAL THERMAL PROTECTION .................................................. 8

WELDER INSTALLATION ..................................................................... 9

POWER SOURCE CONNECTION ....................................................... 9

POWER REQUIREMENTS ................................................................. 9

CONNECT TO POWER SOURCE ...................................................... 9

EXTENSION CORDS .......................................................................... 9

ASSEMBLING THE WELDER ............................................................... 9

UNPACKING THE WELDER ............................................................... 9

INSTALL THE GROUND CLAMP ....................................................... 9

INSTALL THE TANK TRAY AND BRACKET ........................................ 9

INSTALL THE SHIELDING GAS ....................................................... 10

CHECK THE GAS FLOW .................................................................... 11

ALIGN AND SET THE DRIVE ROLLER ............................................. 11

STANDARD DRIVE ROLLER ............................................................ 11

INSTALL THE WELDING WIRE .......................................................... 12

SET THE WIRE DRIVE TENSION ...................................................... 14

PREPARATION .................................................................................... 15

CHANGE POLARITY ........................................................................ 15

OPERATION ......................................................................................... 16

CONTROLS AND INDICATORS ......................................................... 16

MAINTENANCE .................................................................................... 17

GENERAL ........................................................................................... 17

REPLACE A GUN LINER .................................................................. 17

MAINTAINING THE CONTACT TIP .................................................. 20

MAINTAINING THE NOZZLE ........................................................... 20

TESTING FOR A SHORTED NOZZLE ............................................ 21

PREVENTIVE MAINTENANCE ......................................................... 21

TROUBLESHOOTING ........................................................................ 21

WIRING DIAGRAM ............................................................................... 23

REPLACEMENT PARTS LIST ............................................................. 24

SCHEMATIC ......................................................................................... 26

Page 4

This Welder User's Guide provides

specific information about your wire

feed welder. It is to be used together

with the Welding Instruction Guide to

provide all of the information needed to

safely and effectively use your wire

feed welder. The information in this

book applies to your specific model of

wire feed welder and gives instruction

on set-up, installation, and actual use

of the welder.

Where information is shown that does

not necessarily apply to all models or

brands of welder, it will be marked as

either optional on some welder models

or does not apply to all models.

Page 5

Every craftsman respects the tools with

which they work. They know that the

tools represent years of constantly

improved designs and developments.

The true craftsman also knows that tools

are dangerous if misused or abused.

Reading this Operator's Guide and the

Welding Instruction Guide before using

the welder will enable you to do a better,

safer job. Learn the welder's

applications and limitations as well as

the specific potential hazards peculiar to

welding.

SAFETY INFORMATION

The following safety information is

provided as guidelines to help you

operate your new welder under the

safest possible conditions. Any

equipment that uses electrical power

can be potentially dangerous to use

when safety or safe handling instructions

are not known or not followed. The

following safety information is provided

to give you the information necessary for

safe use and operation.

When a procedure step is preceded by

a WARNING, it is an indication that the

step contains a procedure that might be

injurious to a person if proper safety

precautions are not heeded.

When a procedure step is preceded by

a CAUTION, it is an indication that the

step contains a procedure that might

damage the equipment being used.

A NOTE may be used before or after a

procedure step to highlight or explain

something in that step.

READ ALL SAFETY INSTRUCTIONS

CAREFULLY before attempting to

install, operate, or service this welder.

Failure to comply with these instructions

could result In personal injury and/or

property damage.

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

Note: The followingsafety alert

symbols identify important

safety messages in this manual.

When you see one of the symbols

shown here, be alert to the possibility of

personal injury and carefully read the

message that follows.

This symbol indicates that the

possibility of electric shock

hazard exists during the

operation of the step(s) that

follow.

This symbol indicates that the

possibility of fire hazard exists

during the operation of the

step(s) that follow.

This symbol indicates that the

helmet must be worn during

the step(s) that follow to

protect against eye damage

and burns due to flash

hazard.

This symbol indicates that the

possibility of toxic gas hazard

exists during operation of the

step(s) that follow.

This symbol indicates that the

possibility of being burned by

hot slag exists during

operation of the step(s) that

follow.

This symbol indicates that the

eye protection should be worn

to protect against flying debris

in the following step(s).

This symbol indicates that the

possibility of injury or death

exists due to improper

handling and maintenance of

compressed gas cylinders or

regulators

Full explanations of the specific hazards

are shown in the WELDING

INSTRUCTION GUIDE. Make sure you

have read and understand all of the

Page 6

informationbeforeproceedingwithany

oftheinstructionscontainedinthis

user'sguide.

Publishedstandardsonsafetyare

available.Theyarelistedin

ADDITIONALSAFETYINFORMATION

attheendofthisSAFETYSUMMARY.

TheNationalElectricalCode,

OccupationalSafetyandHealthAct

regulations,localindustrialcodesand

localinspectionrequirementsalso

provideabasisforequipment

installation,use,andservice.

SHOCKHAZARDS

WARNING

ELECTRIC SHOCK CAN KILL! To

reduce the risk of death or serious

injury from shock, read, understand,

and follow the following safety

instructions. In addition, make

certain that anyone else who uses

this welding equipment, or who is a

bystander in the welding area

understands and follows these safety

instructions as well.

FIRE HAZARDS

WARNING

FIRE OR EXPLOSION CAN CAUSE

DEATH, INJURY, AND PROPERTY

DAMAGE! To reduce risk of death,

injury, or property damage from fire

or explosion, read, understand, and

follow the following safety

instructions. In addition, make

certain that anyone else that uses

this welding equipment, or is a

bystander in the welding area,

understands and follows these safety

instructions as well. REMEMBER!

Welding by nature produces sparks,

hot spatter, molten metal drops, hot

slag, and hot metal parts that can

start fires, burn skin, and damage

eyes.

6

FLASH HAZARDS

WARNING

ARC RAYS CAN INJURE EYES

AND BURN SKIN! To reduce risk of

injury from arc rays, read,

understand, and follow the following

safety instructions. In addition, make

certain that anyone else that uses

this welding equipment, or is a

bystander in the welding area,

understands and follows these safety

instructions as well.

FUME HAZARDS

WARNING

FUMES, GASSES, AND VAPORS

CAN CAUSE DISCOMFORT,

ILLNESS, AND DEATH! To reduce

risk of discomfort, illness, or death,

read, understand, and follow the

following safety instructions. In

addition, make certain that anyone

else that uses this welding equipment

or is a bystander in the welding area,

understands and follows these safety

instructions as well.

COMPRESSED GASSES AND

EQUIPMENT HAZARDS

WARNING

IMPROPER HANDLING AND

MAINTENANCE OF COMPRESSED

GAS CYLINDERS AND

REGULATORS CAN RESULT IN

SERIOUS INJURY OR DEATH! To

reduce risk of injury or death from

compressed gasses and equipment

hazards, read understand and follow

the following safety instructions. In

addition, make certain that anyone

else who uses this welding

Page 7

equipmentorabystanderinthe

weldingareaunderstandsand

followsthesesafetyinstructionsas

well.

Donotuseflammablegasseswith

MIGwelders.Onlyinertor

nonflammablegassesaresuitablefor

MIGwelding.ExamplesareCarbon

Dioxide,Argon,Helium,etc.or

mixturesofmorethanoneofthese

gasses.

BURN HAZARDS

WARNING

Hot slag can cause fires and

serious injury from burns. To

reduce the risk of discomfort or

serious injury due to burns always

wear heavy protective clothing, eye

and face protection, and gloves

designed for welding. To prevent the

risk of fires starting, use a metal plate

or some other material with a high

flash point to catch and shield

combustibles from the hot slag.

ADDITIONAL SAFETY

INFORMATION

For additional information concerning

welding safety, refer to the following

standards and comply with them as

applicable.

• ANSI Standard Z49.1 i SAFETY IN

WELDING AND CUTTING i

obtainable from the American Welding

Society, 550 NW Le Jeune Road,

Miami, FL 33126 Telephone (800)

443-9353, Fax (305) 443-7559 i

www.amweld.org or www.aws.org

• ANSI Standard Z87.1 i SAFE

PRACTICE FOR OCCUPATION AND

EDUCATIONAL EYE AND FACE

PROTECTION i obtainable from the

American National Standards Institute,

11 West 42ndSt., New York, NY 10036

Telephone (212) 642-4900, Fax (212)

398-0023 i www.ansi.org

• NFPA Standard 51B i CUTTING

AND WELDING PROCESS i

obtainable from the National Fire

Protection Association, 1

Batterymarch Park, P.O. Box 9101,

Quincy, MA 02269-9101 Telephone

(617) 770-3000, Fax (617) 770-0700

i www.nfpa.org

• CGA Pamphlet P-I i SAFE

HANDLING OF COMPRESSED

GASSES IN CYLINDERS i

obtainable from the Compressed Gas

Association, 1725 Jefferson Davis

Highway, Suite 1004, Arlington, VA

22202-4102 Telephone (703) 412-

0900 Fax (703) 412-0128 i

www.cagnet.com

• OSHA Standard 29 CFR, Part 1910,

Subpart Q., WELDING, CUTTING

AND BRAZING i obtainable from

your state OSHA office or U. S. Dept.

of Labor OSHA, Office of Public

Affairs, Room N3647, 200 Constitution

Ave. Washington, DC 20210 i

www.osha.gov

• CSA Standard W117.2 i Code for

SAFETY IN WELDING AND

CUTTING. i obtainable from

Canadian Standards Association, 178

Rexdale Blvd. Etobicoke, Ontario

M9W 1R3 i www.csa.ca

• American Welding Society Standard

A6.0. WELDING AND CUTTING

CONTAINERS WHICH HAVE HELD

COMBUSTIBLES. i obtainable from

the American Welding Society, 550

NW Le Jeune Road, Miami, FL 33126

Telephone (800) 443-9353, Fax (305)

443-7559 i www.amweld.org or

www.aws.org

Page 8

DESCRIPTION

Your new wire feed welder is designed

for maintenance and sheet metal

fabrication. The welder consists of a

single-phase power transformer,

stabilizer, rectifier, and a unique built-in

control/feeder. This MIG welder is

capable of welding with 0.024 (0.6mm)

and 0.030 (0.8mm), solid steel wire on

dc reverse polarity and with .030 inch

self-shielding flux-core wire on dc

straight polarity. Larger, 0.035 inch

(0.9mm) diameter solid steel wire, on dc

reverse polarity, and self shielding flux-

core wire on dc straight polarity may

also be used on this welder. The use of

larger diameter wire makes welding

difficult and the results cannot be

guaranteed. The manufacturer does not

recommend the use of larger diameter

wire.

Now you can weld sheet metal from 24

gauge up to 1/4 inch thick with a single

pass. You can weld thicker steel with

beveling and multiple pass techniques.

Table 1 lists your MIG welder

specifications.

Table 1. Welder Specifications

Primary (input) volts 120 Vac

Primary (inputs) Amps 25

Phase Single

Frequency 60 Hz

Secondary (output) volts 19.5

Secondary (UL output) ampsl05

Open Circuit Volts (Max.) 28 Vdc

Duty Cycle Rating 20%

WELDER OPERATING

CHARACTERISTICS

DUTY CYCLE

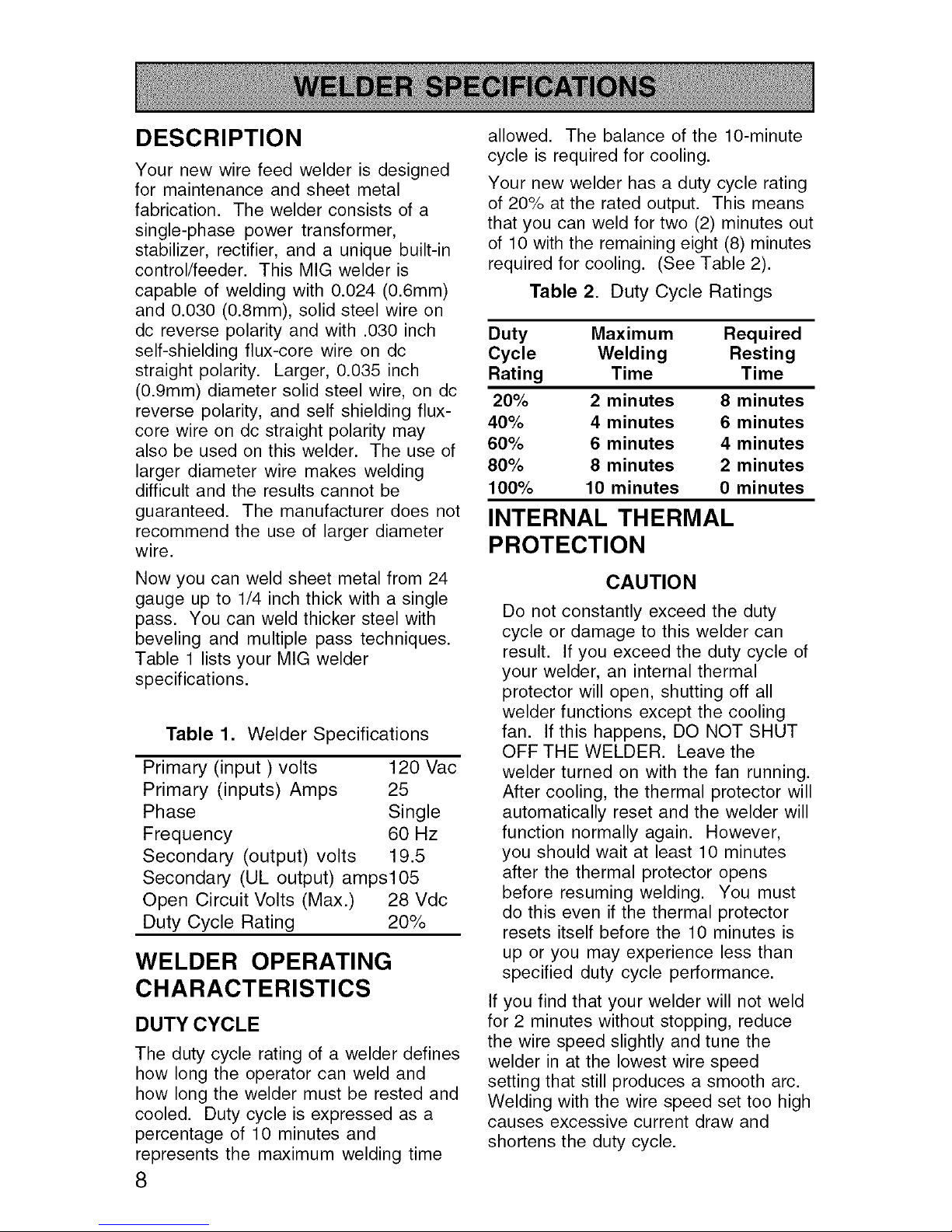

The duty cycle rating of a welder defines

how long the operator can weld and

how long the welder must be rested and

cooled. Duty cycle is expressed as a

percentage of 10 minutes and

represents the maximum welding time

8

allowed. The balance of the 10-minute

cycle is required for cooling.

Your new welder has a duty cycle rating

of 20% at the rated output. This means

that you can weld for two (2) minutes out

of 10 with the remaining eight (8) minutes

required for cooling. (See Table 2).

Table 2. Duty Cycle Ratings

Duty Maximum Required

Cycle Welding Resting

Rating Time Time

20% 2 minutes 8 minutes

40% 4 minutes 6 minutes

60% 6 minutes 4 minutes

80% 8 minutes 2 minutes

100% 10 minutes 0 minutes

INTERNAL THERMAL

PROTECTION

CAUTION

Do not constantly exceed the duty

cycle or damage to this welder can

result. If you exceed the duty cycle of

your welder, an internal thermal

protector will open, shutting off all

welder functions except the cooling

fan. If this happens, DO NOT SHUT

OFF THE WELDER. Leave the

welder turned on with the fan running.

After cooling, the thermal protector will

automatically reset and the welder will

function normally again. However,

you should wait at least 10 minutes

after the thermal protector opens

before resuming welding. You must

do this even if the thermal protector

resets itself before the 10 minutes is

up or you may experience less than

specified duty cycle performance.

If you find that your welder will not weld

for 2 minutes without stopping, reduce

the wire speed slightly and tune the

welder in at the lowest wire speed

setting that still produces a smooth arc.

Welding with the wire speed set too high

causes excessive current draw and

shortens the duty cycle.

Page 9

POWER SOURCE

CONNECTION

POWER REQUIREMENTS

This welder is designed to operate on a

properly grounded 120 Volt, 60 Hz,

single-phase alternating current (ac)

power source fused with a 20 amp time-

delayed fuse or circuit breaker. It is

recommended that a qualified electrician

verify the ACTUAL VOLTAGE at the

receptacle into which the welder will be

plugged and confirm that the receptacle

is properly fused and grounded. The

use of the proper circuit size can

eliminate nuisance circuit breaker

tripping when welding.

DO HOT OPERATE THIS WELDER if

the ACTUAL power source voltage is

less than 105 Volts ac or greater than

132 Volts ac. Contact a qualified

electrician if this problem exists.

Improper performance and/or damage to

the welder will result if operated on

inadequate or excessive power.

CONNECT TO POWER SOURCE

WARNING

High voltage danger from power

source! Consult a qualified electrician

for proper installation of receptacle at

the power source.

This welder must be grounded while in

use to protect the operator from

electrical shock. If you are not sure if

your outlet is properly grounded, have it

checked by a qualified electrician. Do

not cut off the grounding prong or alter

the plug in any way and do not use any

adapters between the welder's power

cord and the power source receptacle.

Make sure the POWER switch is OFF

then connect your welder's power cord

to a properly grounded 120 Vac, 60 Hz,

single phase, 20 amp power source.

EXTENSION CORDS

For optimum welder performance, an

extension cord should not be used

unless absolutely necessary. If

necessary, care must be taken in

selecting an extension cord appropriate

for use with your specific welder.

Select a properly grounded extension

cord that will mate directly with the ac

power source receptacle and the welder

power cord without the use of adapters.

Make certain that the extension is properly

wired and in good electrical condition.

Extension cords must be at the smallest

a #12 gauge cord. Do not use an

extension cord over 25 ft. in length.

ASSEMBLING THE

WELDER

The following procedures describe the

process required to assemble, install,

maintain, and prepare to weld with your

new wire feed welder.

UNPACKING THE WELDER

1. Remove any cartons or bags

containing parts/accessories.

2. Open the cartons or bags packed

with your welder and inspect their

contents for damage. Report any

missing or damaged items

immediately.

3. Grasp the top handle of the welder

and lift the welder out of the carton.

INSTALL THE GROUND CLAMP

Connect the ground clamp to the ground

cable (coming out the front of the

welder) according to the instructions

packaged with the ground clamp.

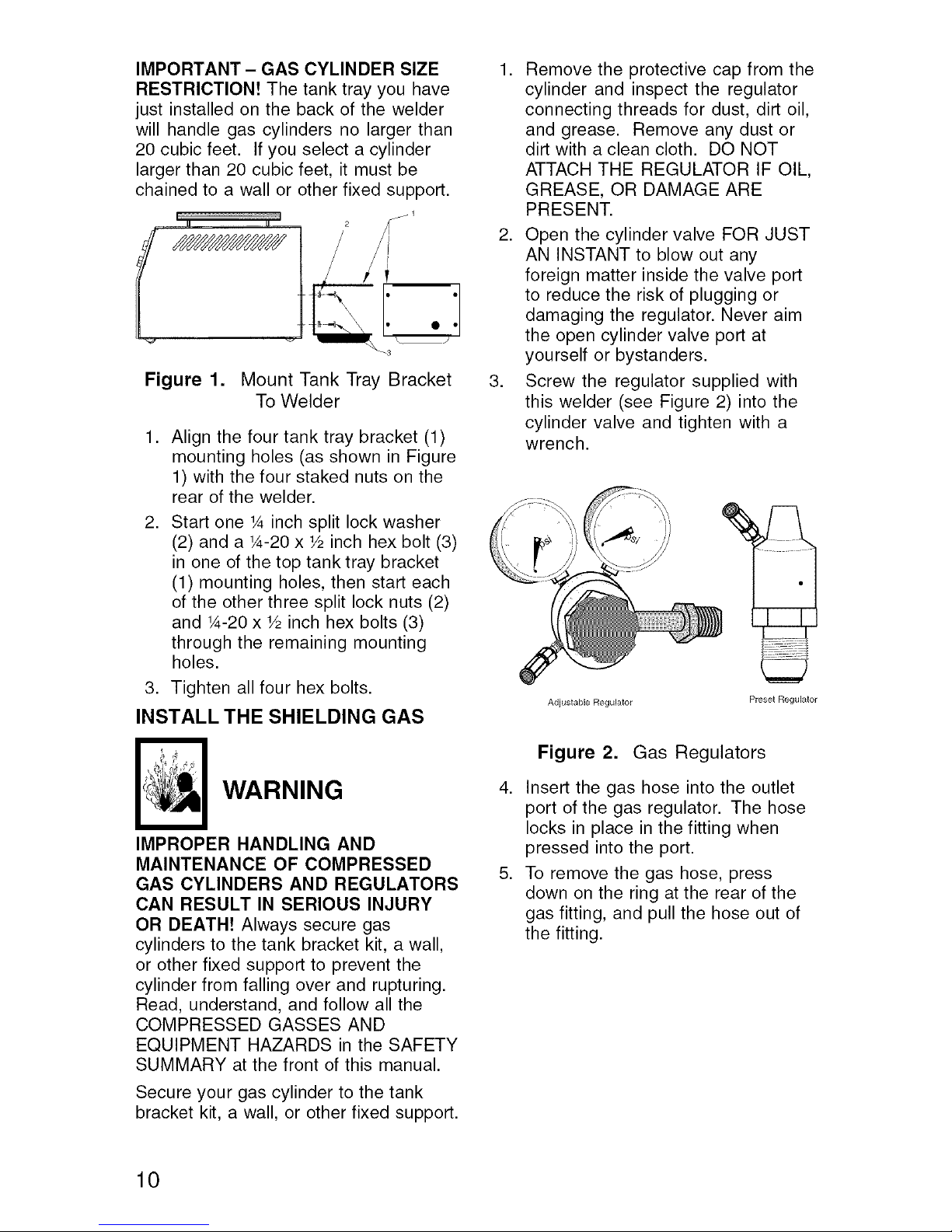

INSTALL THE TANK TRAY

AND BRACKET

The tank tray bracket is installed on the

back of the welder, see Figure 1.

Page 10

IMPORTANT - GAS CYLINDER SIZE

RESTRICTION! The tank tray you have

just installed on the back of the welder

will handle gas cylinders no larger than

20 cubic feet. If you select a cylinder

larger than 20 cubic feet, it must be

chained to a wall or other fixed support.

j 1

Figure 1. Mount Tank Tray Bracket

ToWelder

2.

Align the four tank tray bracket (1)

mounting holes (as shown in Figure

1) with the four staked nuts on the

rear of the welder.

Start one 1_inch split lock washer

(2) and a 1_-20 x _/2inch hex bolt (3)

in one of the top tank tray bracket

(1) mounting holes, then start each

of the other three split lock nuts (2)

and _-20 x 1/2inch hex bolts (3)

through the remaining mounting

holes.

3. Tighten all four hex bolts.

INSTALL THE SHIELDING GAS

WARNING

IMPROPER HANDLING AND

MAINTENANCE OF COMPRESSED

GAS CYLINDERS AND REGULATORS

CAN RESULT IN SERIOUS INJURY

OR DEATH! Always secure gas

cylinders to the tank bracket kit, a wall,

or other fixed support to prevent the

cylinder from falling over and rupturing.

Read, understand, and follow all the

COMPRESSED GASSES AND

EQUIPMENT HAZARDS in the SAFETY

SUMMARY at the front of this manual.

Secure your gas cylinder to the tank

bracket kit, a wall, or other fixed support.

1.

Remove the protective cap from the

cylinder and inspect the regulator

connecting threads for dust, dirt oil,

and grease. Remove any dust or

dirt with a clean cloth. DO NOT

ATTACH THE REGULATOR IF OIL,

GREASE, OR DAMAGE ARE

PRESENT.

2. Open the cylinder valve FOR JUST

AN INSTANT to blow out any

foreign matter inside the valve port

to reduce the risk of plugging or

damaging the regulator. Never aim

the open cylinder valve port at

yourself or bystanders.

3. Screw the regulator supplied with

this welder (see Figure 2) into the

cylinder valve and tighten with a

wrench.

Adjustable Regulator Preset Regulator

Figure 2. Gas Regulators

4. Insert the gas hose into the outlet

port of the gas regulator. The hose

locks in place in the fitting when

pressed into the port.

5. To remove the gas hose, press

down on the ring at the rear of the

gas fitting, and pull the hose out of

the fitting.

10

Page 11

CHECK THE GAS FLOW

WARNING

IMPROPER HANDLING AND

MAINTENANCE OF COMPRESSED

GAS CYLINDERS AND REGULATORS

CAN RESULT IN SERIOUS INJURY

OR DEATH! To reduce the risk of injury

or death, always stand to the side of the

cylinder opposite the regulator when

opening the cylinder valve, keeping the

cylinder valve between you and the

regulator. Never aim the open cylinder

valve port at yourself or bystanders.

Failure to comply with this warning could

result in serious personal injury.

Note: If the cylinder you have is

equipped with male regulator

connecting threads instead of

female, you will need to obtain

a special compressed gas

cylinder adapter from your gas

supplier to install between your

gas cylinder and regulator.

• The gas control function does

not require the welder to be

turned on or plugged in.

1. Slowly crack open the cylinder

valve, then turn open ALL THE

WAY.

2.

Pull the trigger on the gun to allow

the gas to flow. KEEP THE

TRIGGER PULLED. Listen and feel

for gas flowing from the end of the

welding gun. If your regulator has

no adjustment, it has been pre-set

at the factory for a flow of 20 cubic

feet per hour. If your gas regulator

has an adjustment to control the

gas flow rate, turn the adjustment

key clockwise to increase gas flow;

counterclockwise to reduce flow.

For most welding, the gas flow

should be set at 15-20 cubic feet

per hour. If no gas is heard or felt,

verify all steps involved in

connecting the gas.

3. Release the trigger.

Note: If welding outside or in a draft, it

may become necessary to set

up a windbreak to keep the

shielding gas from being blown

from the weld area.

• MAKE SURE TO TURN OFF

THE GAS CYLINDER VALVE

WHEN DONE WELDING.

ALIGN AND SET THE DRIVE

ROLLER

Before installing any welding wire into

the unit, the proper sized groove must

be placed into position on the wire drive

mechanism. Change to a neoprene

drive roller when welding with

aluminum wire.

STANDARD DRIVE ROLLER

Change the standard drive roller

according to the following steps:

1. Remove the drive tension by

unscrewing the tension adjusting

screw (ALL THE WAY in a counter-

clockwise direction). The drive

tension screw will come loose,

allowing you to pull the drive

tension arm up away from the drive

roller. Make sure to keep the screw

and the spring in place with the

drive tension arm.

2.

3.

If there is wire already installed in

the welder, roll it back onto the wire

spool by hand-turning the spool

counter-clockwise. Be careful not

to allow the wire to come out of the

rear end of the gun without holding

onto it or it will unspool itself. Put

the end of the wire into the hole on

the outside edge of the wire spool

and bend it over to hold the wire in

place. Remove the spool of wire

from the welder.

Loosen the drive roller setscrew

and pull the drive roller off the drive

shaft.

11

Page 12

Note: 6. Tighten the setscrew, while holding

the drive roller in place.

4,

5,

The drive roller has two wire

size grooves built into it. When

installing the drive roller the

number stamped on the drive

roller for the wire size you are

using should be facing away

from you. If you can read the

wire size you are using on the

drive roller, it is installed

backwards. Use only the

proper size drive roller when

using your welder.

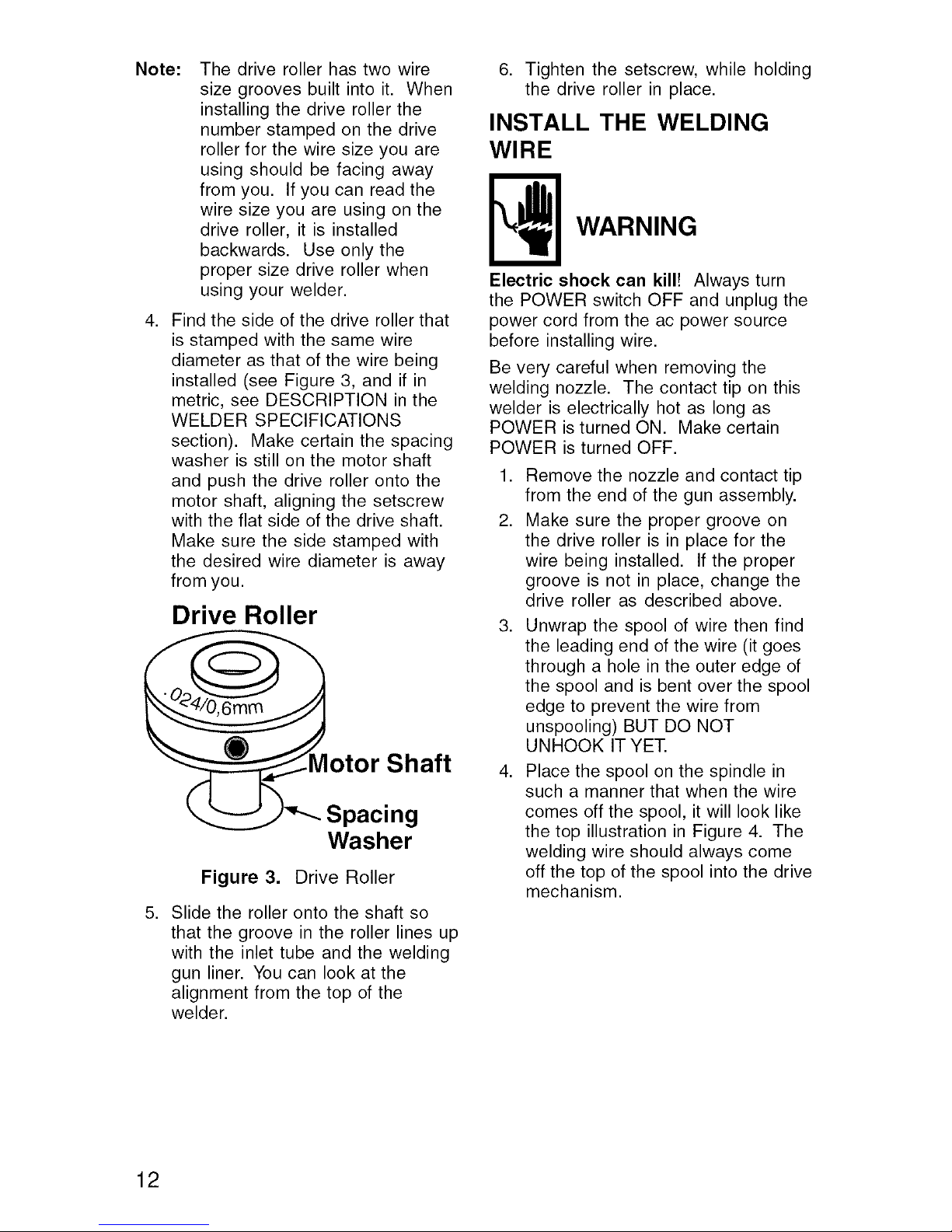

Find the side of the drive roller that

is stamped with the same wire

diameter as that of the wire being

installed (see Figure 3, and if in

metric, see DESCRIPTION in the

WELDER SPECIFICATIONS

section). Make certain the spacing

washer is still on the motor shaft

and push the drive roller onto the

motor shaft, aligning the setscrew

with the flat side of the drive shaft.

Make sure the side stamped with

the desired wire diameter is away

from you.

Drive Roller

Shaft

Washer

Figure 3. Drive Roller

Slide the roller onto the shaft so

that the groove in the roller lines up

with the inlet tube and the welding

gun liner. You can look at the

alignment from the top of the

welder.

INSTALL THE WELDING

WIRE

WARNING

Electric shock can kill! Always turn

the POWER switch OFF and unplug the

power cord from the ac power source

before installing wire.

Be very careful when removing the

welding nozzle. The contact tip on this

welder is electrically hot as long as

POWER is turned ON. Make certain

POWER is turned OFF.

1,

2.

Remove the nozzle and contact tip

from the end of the gun assembly.

Make sure the proper groove on

the drive roller is in place for the

wire being installed. If the proper

groove is not in place, change the

drive roller as described above.

3,

Unwrap the spool of wire then find

the leading end of the wire (it goes

through a hole in the outer edge of

the spool and is bent over the spool

edge to prevent the wire from

unspooling) BUT DO NOT

UNHOOK IT YET.

4,

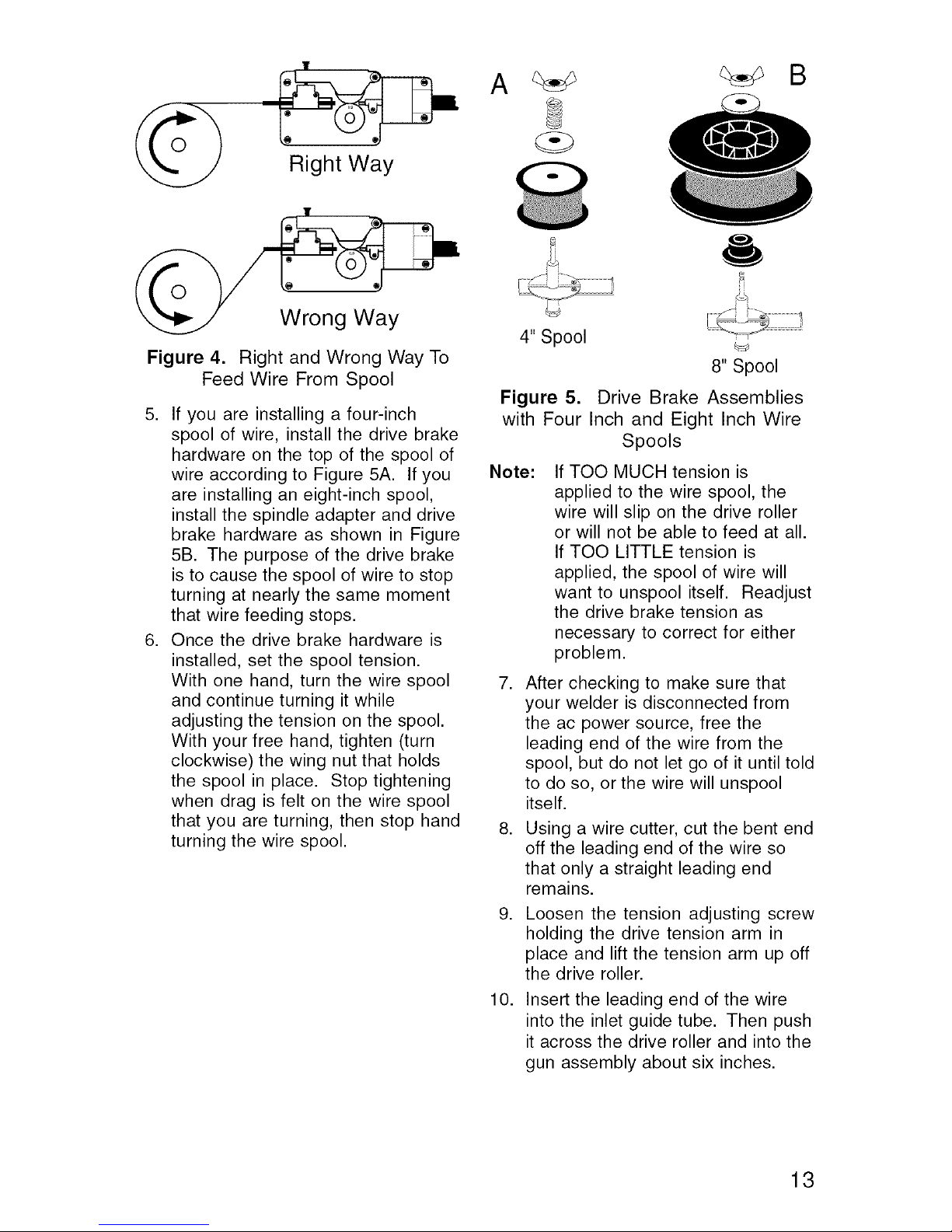

Place the spool on the spindle in

such a manner that when the wire

comes off the spool, it will look like

the top illustration in Figure 4. The

welding wire should always come

off the top of the spool into the drive

mechanism.

12

Page 13

RightWay

WrongWay

Figure 4. Right and Wrong Way To

Feed Wire From Spool

5. If you are installing a four-inch

spool of wire, install the drive brake

hardware on the top of the spool of

wire according to Figure 5A. If you Note:

are installing an eight-inch spool,

install the spindle adapter and drive

brake hardware as shown in Figure

5B. The purpose of the drive brake

is to cause the spool of wire to stop

turning at nearly the same moment

that wire feeding stops.

6. Once the drive brake hardware is

installed, set the spool tension.

With one hand, turn the wire spool 7.

and continue turning it while

adjusting the tension on the spool.

With your free hand, tighten (turn

clockwise) the wing nut that holds

the spool in place. Stop tightening

when drag is felt on the wire spool

that you are turning, then stop hand 8.

turning the wire spool.

4" Spool

8" Spool

Figure 5. Drive Brake Assemblies

with Four Inch and Eight Inch Wire

Spools

9,

10.

If TOO MUCH tension is

applied to the wire spool, the

wire will slip on the drive roller

or will not be able to feed at all.

If TOO LITTLE tension is

applied, the spool of wire will

want to unspool itself. Readjust

the drive brake tension as

necessary to correct for either

problem.

After checking to make sure that

your welder is disconnected from

the ac power source, free the

leading end of the wire from the

spool, but do not let go of it until told

to do so, or the wire will unspool

itself.

Using a wire cutter, cut the bent end

off the leading end of the wire so

that only a straight leading end

remains.

Loosen the tension adjusting screw

holding the drive tension arm in

place and lift the tension arm up off

the drive roller.

Insert the leading end of the wire

into the inlet guide tube. Then push

it across the drive roller and into the

gun assembly about six inches.

13

Page 14

CAUTION

Make certain that the welding wire is

actually going into the gun liner. Be

very sure it has not somehow been

accidentally been routed alongside

the liner or even in some other

direction. If this should happen, the

wire could feed inside the cable

casing or take a right angle and follow

the wires and gas hose inside the

welder. It could also feed back on

itself jamming up the mechanism.

11. Line the wire up in the inside groove

of the drive roller, then allow the

drive tension arm to drop onto the

drive roller.

12. Tighten (turn clockwise)the drive

tension adjusting screw until the

tension roller is applying enough

force on the wire to prevent it from

slipping out of the drive assembly.

13. Let go of the wire.

14. Connect the welder power cord to

the ac power source. Turn the

welder POWER switch ON. Set the

VOLTAGE switch to the voltage

(heat) setting recommended for the

gauge metal that is to be welded.

Refer to the label mounted on the

cover, inside the drive

compartment, for recommended

voltage (heat) settings for your

welding job. The VOLTAGE

selector controls the weld heat.

There are eight voltage (heat)

selections (numbered 1 through 8)

available on this welder.

Numbered position 1 provides the

lowest voltage (heat) and position

8 the highest voltage (heat).

15. Set the WIRE SPEED control to the

middle of the wire speed range.

16. Pull the trigger on the welding gun

to feed the wire through the gun

assembly.

17. When at least an inch of wire sticks

out past the end of the gun, release

the trigger.

18. Select a contact tip stamped with

the same diameter as the wire

being used. If stamped in metric,

see DESCRIPTION.

19. Slide the contact tip over the wire

(protruding from the end of the

gun). Thread the contact tip into

the end of the gun and hand-tighten

securely.

20. Install the nozzle on the gun

assembly. For best results, coat the

inside of the nozzle with anti-stick

spray or gel (part #4312, not

supplied).

21. Cut off the excess wire that extends

past the end of the nozzle.

SET THE WIRE DRIVE

TENSION

WARNING

To reduce the risk of arc flash, make

certain that the wire coming out of

the end of the gun does not come in

contact with the workpiece clamp or

any grounded material during the

drive tension setting process or

arcing will occur.

1,

2.

3,

Pull the trigger on the gun.

Turn the drive tension adjustment

knob clockwise, increasing the

drive tension until the wire seems

to feed smoothly without slipping.

Block the end of the nozzle by

holding it up against something

that doesn't conduct electricity,

such as a block of wood or a

concrete floor, then trigger the gun

again. The wire should slip at the

drive roller. However, if the wire

bird-nests at the drive roller,

rethread the drive system using

less drive tension and try again.

14

Page 15

4, When the drive tension is set

correctly, there should be no

slippage between the wire and the

drive roller. However, if an

obstruction occurs along the wire

feed path, the wire should then slip

on the drive roller.

PREPARATION

CHANGE POLARITY

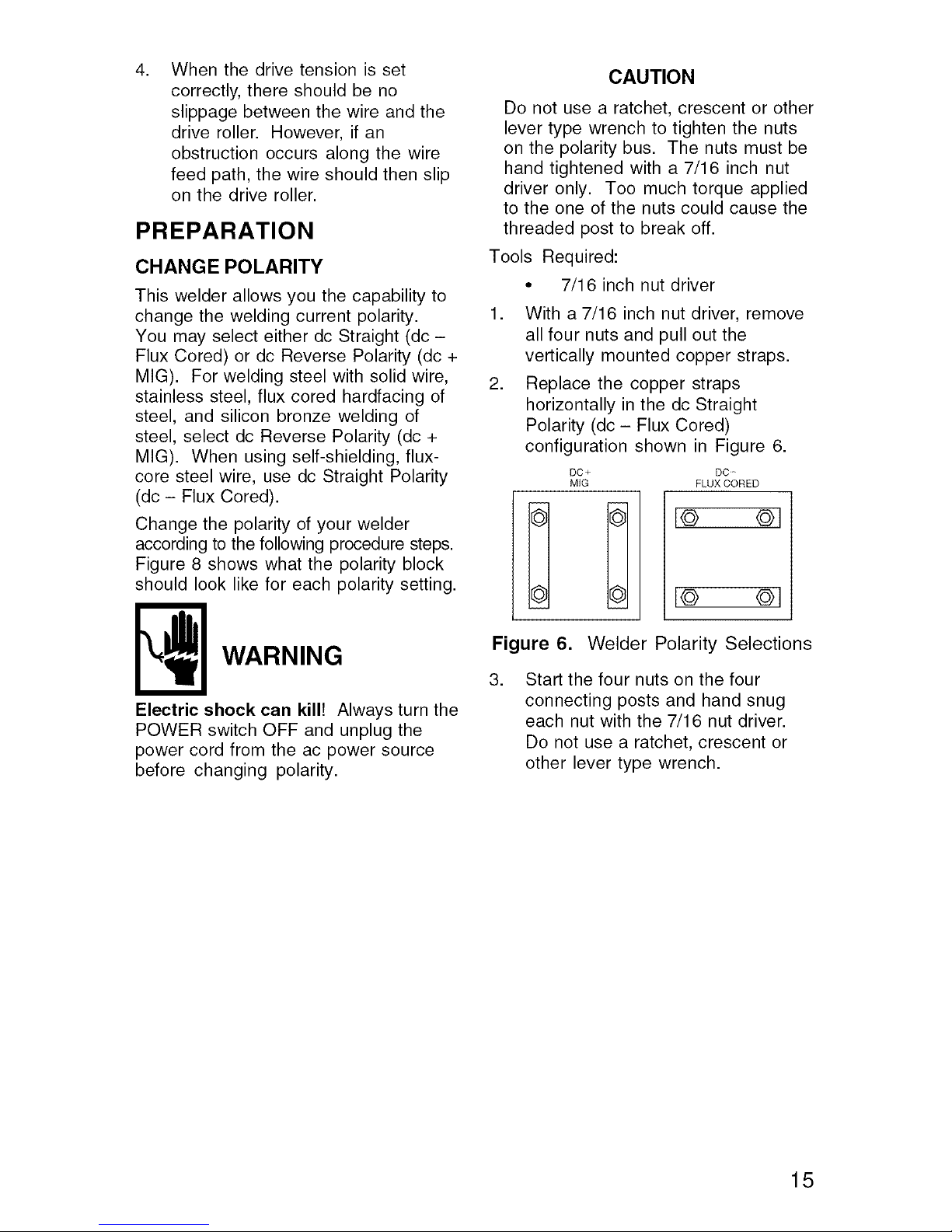

This welder allows you the capability to

change the welding current polarity.

You may select either dc Straight (dc -

Flux Cored) or dc Reverse Polarity (dc +

MIG). For welding steel with solid wire,

stainless steel, flux cored hardfacing of

steel, and silicon bronze welding of

steel, select dc Reverse Polarity (dc +

MIG). When using self-shielding, flux-

core steel wire, use dc Straight Polarity

(dc - Flux Cored).

Change the polarity of your welder

according to the following procedure steps.

Figure 8 shows what the polarity block

should look like for each polarity setting.

WARNING

Electric shock can kill! Always turn the

POWER switch OFF and unplug the

power cord from the ac power source

before changing polarity.

CAUTION

Do not use a ratchet, crescent or other

lever type wrench to tighten the nuts

on the polarity bus. The nuts must be

hand tightened with a 7/16 inch nut

driver only. Too much torque applied

to the one of the nuts could cause the

threaded post to break off.

Tools Required:

• 7/16 inch nut driver

1,

2,

With a 7/16 inch nut driver, remove

all four nuts and pull out the

vertically mounted copper straps.

Replace the copper straps

horizontally in the dc Straight

Polarity (dc - Flux Cored)

configuration shown in Figure 6.

DC+ DC

MIG FLUX CORED

Figure 6. Welder Polarity Selections

3. Start the four nuts on the four

connecting posts and hand snug

each nut with the 7/16 nut driver.

Do not use a ratchet, crescent or

other lever type wrench.

15

Page 16

Operation of this welder consists of

selecting and adjusting operating

controls for optimum voltage (welding

heat) and wire speed settings.

CONTROLS AND

INDICATORS

WARNING

Electric shock can kill! To remove

the risk of electric shock, be aware

that the VOLTAGE selector, when

OFF, does not remove power from all

internal circuitry in the welder.

POWER - This welder has a POWER

switch mounted on the front panel. The

POWER switch is used to initiate (turn

the welder ON) or extinguish (turn the

welder OFF) ac power to the welder.

VOLTAGE SELECTOR - The voltage

selector controls the welding heat. The

voltage selector provides continuous

voltage (heat) adjustment but has

reference number settings 1-8.

Number 1 is the lowest voltage (heat)

setting and number 8 the highest. Refer

to the label under the welder hood for

recommended voltage (heat) settings

for your welding job.

WIRE SPEED CONTROL - The WIRE

SPEED CONTROL adjusts the speed at

which the wire is fed out of the welding

gun. The wire speed needs to be

closely matched (tuned-in) to the rate at

which it is being melted off (see

TUNING IN THE WIRE SPEED, (in the

Welding Instruction Guide). Some

things that affect wire speed selection

are the type and diameter of the wire

being used, the heat setting selected,

and the welding position to be used.

16

Page 17

GENERAL

This welder has been engineered to give

many years of trouble-free service

providing that a few very simple steps

are taken to properly maintain it.

1. Keep the wire drive compartment lid

closed at all times unless the wire

needs to be changed or the drive

tension needs adjusting.

2. Keep all consumables (contact tips,

nozzles, and gun liner) clean and

replace when necessary. See

CONSUMABLE MAINTENANCE

AND TROUBLESHOOTING later in

this section for detailed information.

3,

4,

Replace power cord, ground cable,

ground clamp, or gun assembly

when damaged or worn.

Periodically clean dust, dirt, grease,

etc. from your welder. Every six

months or as necessary, remove

the side panels from the welder and

air-blow any dust and dirt that may

have accumulated inside the

welder.

WARNING

ELECTRIC SHOCK CAN KILL! To

reduce the risk of electric shock, always

unplug the welder from its ac power

source before removing side panels.

IT IS VERY IMPORTANT TO MAINTAIN

THE CONSUMABLES TO AVOID THE

NEED FOR PREMATURE

REPLACEMENT OF THE GUN

ASSEMBLY.

The GUN LINER is intended to provide

an unrestricted path for the welding wire

to flow through the gun assembly. Over

time it will accumulate dust, dirt, and

other debris. Replacement is necessary

when these accumulations begin to

restrict the free flow of wire through the

gun assembly.

REPLACE A GUN LINER

When removing or installing a gun liner,

care must be taken not to kink or

otherwise damage the gun liner or

replacement will be necessary. See

Figure 7 for the drive assembly and

Figure 8 for the gun assembly.

17

Page 18

Drive Drive Gun

Tension Tension Liner

Adjustment Arm

1/4" Hex

Head Screws

Inlet Guide

Tube End

Inlet

Guide

Tube

l Phillips Pan Str#in

Rehef

Head Screw Clamp

Drive

Roller

Drive

Assembly

Gun

Assembly

(Tail End)

Figure 7. Drive Assembly

Gun

Cable

Plastic

Cable Tie

Cable

Coverin(

Handle Wire

Case

Live Wire

Terminal

Contact

Gas Conductor

Gas Valve Tube Insulation

Lockwasher

Head End

Gun Liner

Tube

Gas

Diffuser Contact

(has lefthand Tip

Nozzle

Figure 8. Gun Assembly

18

Page 19

Tools Required:

° 5/16 inch open end wrench

° Crescent Wrench (6 or 8 inch)

° 9 mm open end wrench (or 3 inch

crescent)

° Phillips Screwdriver

° Straight Blade Screwdriver or 1_inch

hex driver

1,

2.

3.

Turn OFF welder POWER SWITCH.

Open the welder side panel.

Loosen the tension arm and lift it

up off the drive roller.

4. Turn the wire spool counter-

clockwise (be sure to hold onto the

wire itself while turning the spool or

the wire will unspool itself when it

becomes free of the gun liner),

removing wire from gun assembly.

5. Remove two 1_ inch hex head

screws (may also be removed with

a straight blade screwdriver) and

one pan head Phillips screw (inlet

guide tube end) from the drive

roller and lift away the strain relief

clamp that holds the tail end of the

gun in the drive assembly.

6. Leave the gun assembly (consists

of nozzle, gas diffuser, conductor

tube, handle and cable containing

gas tubing electrical cable and

liner) attached to the welder but

move the welder to a place where

the gun assembly can be laid out

straight on a table or workbench or

similar flat surface.

7,

8.

9,

Unscrew and remove the nozzle.

With a crescent wrench (six or eight

inch), turn the gas diffuser

clockwise (has left hand threads)

and remove the gas diffuser (and

contact tip together) from the

conductor tube on the end of the

gun.

Remove the four Phillips head

screws that hold the handle case

together. With the exception of the

trigger, completely remove the

contents of the handle case.

10. Cut the plastic cable tie away from

the cable covering (tubing).

Note: In the following procedure step,

it may be necessary to remove

the gas fitting from the gas

valve in order to make room to

turn out the head end of the

gun liner.

11. With a 5/16 inch open end wrench,

unscrew the head end of the liner

from the gas valve. Save the

internal star lock-washer and note

the orientation of the live wire

terminal. If you find it necessary to

remove the gas hose connector,

press down on the ring at the rear

of the gas fitting to release the gas

hose and pull out the gas hose.

Remove the gas fitting with a 9 mm

open end wrench or three inch

crescent.

12. Pull the liner out of the cable

covering (tubing) from the handle

end and push the small piece of

liner out of the conductor tube.

13. Carefully insert the new liner into

the cable taking particular care to

keep the liner straight (especially at

the terminal end) to ease its

passage through cable covering. It

may be desirable, perhaps even

necessary, to apply some silicon

grease to the outside of the new

liner so that it will slide easily

through the cable.

14. Insert the new piece of liner in the

conductor tube.

Note: If you found it necessary to

remove the gas and hose

connector at step 9, remember

to reconnect it after completing

step 12. The gas hose can be

reconnected by simply pushing

it into the back of the connector.

15. Insert the head of the gun liner

through the internal star lock

washer and the live wire terminal

(repeat the orientation noted in

step 9). With a 5/16 inch open end

wrench, screw the head end of the

new liner into the gas valve.

19

Page 20

16. Insert a new plastic cable tie in

place around the cable and tighten

it in approximately the same

location as the plastic cable tie that

was cut in step 8.

17. Return all components to the

handle casing and realign them as

they were originally.

18. With both halves of the handle

case in place, tighten the four

Philips pan head screws making

sure the trigger remains seated in

place.

19. Push the cable into the welder far

enough so that the end of the gun

liner protrudes through the inlet

guide tube end of the wire-feed

torch clamp far enough so that it is

within approximately 1/16 inch of

touching the drive roller.

20. Make sure the cable covering

(tubing) is far enough in the

machine so that it is covered by the

wire-feed torch clamp.

21. Tighten the two 1_inch hex head

screws (may also be tightened by a

straight blade screwdriver) and one

pan head Phillips screw to the

drive roller securing the gun in

place.

22. Re-install the welding wire

according to INSTALL THE

WELDING WIRE.

MAINTAINING THE CONTACT TIP

The purpose of the CONTACT TIP is to

transfer welding current to the welding

wire while allowing the wire to pass

through it smoothly.

Always use a contact tip stamped with

the same diameter as the wire it will be

used with.

If the wire burns back into the tip,

remove the tip from the gun and

clean the hole running through it

with an oxygen-acetylene torch tip

cleaner or tip drill.

2, Over time, the hole in the contact

tip will become worn by the wire

passing through it. The more worn

this hole becomes, the less efficient

is the transfer of welding current to

the wire and eventually arc

breakage and difficult arc starting

will result. Replace contact tips

when signs of wear become

apparent.

MAINTAINING THE NOZZLE

The nozzle directs the shielding gas to

the weld puddle, determines the size of

the shielding area, and prevents the

electrically hot contact tip from

contacting the work piece.

CAUTION

KEEP THE NOZZLE CLEAN! During

the welding process, spatter and slag

will build up inside the nozzle and

must be cleaned out periodically.

Failure to clean and/or replace the

nozzle in a timely fashion WILL

CAUSE DAMAGE TO THE FRONT-

END OF THE GUN ASSEMBLY.

For best results, coat the inside of a new

or freshly cleaned nozzle with anti-stick

spray or gel.

1. Stop welding and clean any

accumulated slag or spatter from

the nozzle every 5 to 10 minutes of

welding time.

2. When welding overhead, if any

molten metal drips from the weld

puddle and falls into the nozzle,

STOP WELDING IMMEDIATELY

and clean the nozzle.

3,

If the slag cannot be thoroughly

cleaned from the nozzle,

REPLACE THE NOZZLE!

Failure to keep the nozzle adequately

cleaned can result in the following

problems:

20

Page 21

A SHORTED nozzle results when

spatter buildup bridges the insulation in

the nozzle allowing welding current to

flow through it as well as the contact tip.

When shorted, a nozzle will steal

welding current from the wire whenever

it contacts the grounded work piece.

This causes erratic welds and reduced

penetration.

In addition, a shorted nozzle overheats

the end of the gun, which can DAMAGE

the front-end of the gun.

A RESTRICTED nozzle is created when

enough slag builds up in the nozzle to

affect the direction, concentration, and

or rate of the shielding gas flow. This

problem can cause porous, brittle welds

and reduce penetration.

TESTING FOR A SHORTED

NOZZLE

Arcing between the nozzle and the work

piece ALWAYS means the nozzle is

shorted, but this can be hard to detect

through the lens of a welding helmet.

The following testing method is another

way to tell if a nozzle is shorted.

With the welder unplugged from the ac

power source, touch the probes of an

ohmmeter or continuity tester to the end

of the contact tip and the outside of the

nozzle. If there is any continuity at all,

the nozzle IS shorted. Clean or replace

as needed.

PREVENTIVE MAINTENANCE

Except for internal and external

cleaning, cleaning the nozzle, and

occasionally retightening screws, there

is no periodic maintenance

recommended for your welder.

TROUBLESHOOTING

The following TROUBLESHOOTING

information is provided as a guide to

help resolve some of the more common

problems that could be encountered.

Table 3 is a troubleshooting table

provided to help you determine a

possible remedy when you are having a

problem with your welder. This table

does not provide all possible solutions,

only those possibilities considered to

likely be common faults. The table

consists of a TROUBLE or symptom, a

POSSIBLE CAUSE for that symptom,

and a POSSIBLE REMEDY for that

symptom.

21

Page 22

Table 3. Troubleshooting

TROUBLE

Dirty, porous brittle

weld

Wire feed works but

no arc

Arc works but not

feeding wire.

Nothing works

except fan

Low output or

non-penetrating weld.

Wire is birdnesting

at the drive roller

Wire burns back

to contact tip

POSSIBLE CAUSE

1. Plugged welding nozzle

2. No shielding gas

3. Wrong Type of Gas

4. Dirty or rusty welding wire

1. Bad ground or loose

connection

2. Bad connection to gun or

faulty gun

1. Faulty wire speed control

assembly

2. No tension on the drive roller

3. Faulty drive motor (very rare)

1. Faulty trigger on gun

2. Faulty transformer (rare)

3. Exceeded duty cycle; thermal

protector opened

1. Loose connection inside

machine

2. Too long or improper

extension cord

3. Wrong type or size wire

4. Poor ground connection

5. Wrong size contact tip

6. Loose gun connection or

faulty gun assembly

7. Wrong welding polarity set

8. Dirty or rusty welding wire

1. Too much tension on drive

roller

2. Gun liner worn or damaged

3. Contact tip is clogged or

damaged

4. Liner is stretched or is too

long

1. Gun liner is worn or damaged

2. Liner stretched or is too long

3. Wrong size contact tip

4. contact tip clogged or

damaged

POSSIBLE REMEDY

1. Clean or replace nozzle

2. Tank empty, flow restricted, or

regulator set too low

3. See SELECTING SHIELDING

GAS in the WELDING

INSTRUCTION GUIDE for proper

selection

4. Replace spool of wire

1. Check ground and connections

tighten as necessary

2. Check connection to gun or

replace gun

1. Replace wire speed control

assembly

2. Adjust the drive tension

3. Replace drive motor

1. Replace trigger

2. Replace transformer

3. Allow welder to cool at least 10

minutes (observe and maintain

proper duty cycle

1. Blow inside of machine out with

compressed air, clean and tighten

all connections

2. See EXTENSION CORD USE in

this manual

3. Use correct size welding wire

4. Reposition clamp and check

cable to clamp connection

5. Use correct size contact tip

6. Tighten gun or replace gun

7. Change polarity to proper for

wire being used

8. Replace spool of wire

1. Adjust the drive tension

(see INSTALLING THE WELDING

WIRE)

2. Replace gun liner

3. Replace contact tip

4. Trim liner to proper length

1. Replace gun liner

2. Trim liner for proper length

3. Use correct size contact tip

4. Replace contact tip

Ground clamp and!or Bad connection from cable to Tighten connection or replace cable

cable gets hot clamp

Gun nozzle arcs Slag buildup inside nozzle or Clean or replace nozzle as needed

to work surface nozzle is shorted

22

Page 23

w_

L)

v v

© ©

-J _j

n'_ r'n

©

©

C3

cD

©

>

o

©

I--

/ /

.___,__

_E

(_

>>

MODEL 205592

23

Page 24

@

MODEL 205592

24

Page 25

PART NO.

117-084-902

246-120-000

216-100-000

410-900-010

541-057-000

238-223-666

246-107-666

246-423-000

238-593-000

410-869-011

880-455-888

410-865-020

312-295-666

246-414-000

880-406-000

310-187-666

131-419-000

312-076-666

410-960-010

880-456-666

880-425-000

253-333-000

248-351-000

239-074-000

880-454-666

312-296-666

410-864-020

216-055-666

412-723-000

880-431-000

880-435-000

412-635-010

238-593-000

43090

43100

43480

334-440-000

334-465-000

334-495-666

059-217-040

334-468-666

334-467-000

ITEM DESCRIPTION

¥ 202082 Sears 105 amp MIG Welder

1 Potentiometer

2 Fan

3 Front Panel

4 Strain Relief

5 Cable Assembly

6 Knob

7 Switch

8 10' MIG gun

9 Control Panel

10 Transformer

11 Left Side Panel

12 Slide Latch W/Clip

13 Terminal Block

14 Wire Feed Motor

15 Steel Drive Roller

16 Tension Hardware

17 Spindle

18 Center Panel

19 Circuit Board

20 Wire Harness

21 Fitting

22 Power Cord

23 Strain Relief

24 Rectifier

25 Handle W/Hardware

26 Right Side Panel

27 Relay

28 Heatsink

29 Base

30 Thermo Breaker

31 Tank Bracket

¥ Trafimet MIG Gun (10 foot cable)

32 Contact Tip 0.024" (0,6 mm)

Contact Tip 0.030" (0,8 ram)

33 Nozzle

34 Trigger (MIG Gun)

35 Gun Cable, Complete

36 Handle (With Trigger)

37 Gas Hose

38 Liner

39 Gas Hose Quick Connector

¥ Gun Head: Gas Valve, Conductor Tube,

Conductor Tube Insulation, Gas Diffuser

40 Gas Valve

41 Conductor Tube Insulation

42 Conductor Tube

43 Gas Diffuser (MIG Gun)

1- Regulator

1- Tube Fitting for Regulator

1- Wire Spool Adapter (for 8")

1- Ground Clamp

1- Welding Face Shield

1- Not Shown In Drawing

¥ Complete Assembly

334-490-666

334-491-666

334-493-666

334-492-666

334-494-666

334-460-000

253-406-666

312-110-666

239-010-102

332-239-666

25

Page 26

28

L.)

+ _

_- -%--=

| 0 0

i_ .- n

rn

g _

cy

.2

O3

L. --_-- _ J

CJ_

YY

rn

cY _

--o d_ 5

0

c _o

z

z _o

-2

zo-_z_

MODEL 205592

Page 27

Fortherepairorreplacementpartsyouneed

delivereddirectlytoyourhome

Call 7 am - 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247)

The model number of your product is located

on the welder nameplate.

If the parts you need are not stocked locally,

your order will be electronically transmitted to

a Sears Repair Parts Distribution Center for

expedited handling.

When requesting service or ordering parts,

always give the following information:

• Product Name

* Model Number

• Part Number

. Part Description

S ARS

America's Repair Specialists

Page 28

SEARS

CRRFTSMRN

Operator's Guide

WIRE FEED

MIG WELDER

Model No.

934.205592

CAUTION: Read and follow

all Safety Rules and

Operating Instructions before

First Use of this Product.

• WARRANTY

• INTRODUCTION

• SAFETY SUMMARY

• SPECIFICATIONS

• INSTALLATION

• OPERATION

• MAINTENANCE

• SCHEMATIC

• WIRING DIAGRAM

• REPLACEMENT PARTS

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

811-642-000 September 2001

Page 29

On Welding Gun or Cables, Welder, and Welder's Transformer

Full One Year Warranty for Craftsman

Welding Gun or Cables. For one year

from the date of purchase, when the

welding gun or cables are operated and

maintained according to the owner's

manual instructions, if the welding gun

or cables fail due to a defect in material

or workmanship, Sears will repair or

replace the welding gun or cables free of

charge. This warranty does not cover

parts consumed in normal operation,

such as contact tips, nozzles, gun liners,

and drive rollers.

Full Three Year Warranty on Craftsman

Welder For three years from the date of

purchase, when the welder is operated

and maintained according to the owner's

manual instructions, if the welder fails

due to a defect in material or

workmanship, Sears will repair or

replace the welder free of charge. This

warranty does not cover the welding

gun, cables, or normal consumable

parts.

WARRANTY SERVICE IS AVAILABLE

BY SIMPLY CONTACTING THE

NEAREST SEARS SERVICE CENTER.

This warranty applies only while this

product is in use in the United States.

This warranty gives you specific legal

rights, and you may also have other

rights which vary from state to state.

Sears Roebuck and Co., Dept. 817WA,

Hoffman Estates, IL 60179.

Page 30

CRAFTSMAN FULL WARRANTY ......................................................... 2

TABLE OF CONTENTS ......................................................................... 3

INTRODUCTION .................................................................................... 4

SAFETY SUMMARY ............................................................................... 5

SAFETY INFORMATION ...................................................................... 5

SHOCK HAZARDS ............................................................................. 6

FIRE HAZARDS .................................................................................. 6

FLASH HAZARDS .............................................................................. 6

FUME HAZARDS ................................................................................ 6

COMPRESSED GASSES AND EQUIPMENT HAZARDS .................. 6

BURN HAZARDS ................................................................................ 7

ADDITIONAL SAFETY INFORMATION ............................................... 7

WELDER SPECIFICATIONS .................................................................. 8

DESCRIPTION ...................................................................................... 8

WELDER OPERATING CHARACTERISTICS ...................................... 8

DUTY CYCLE ..................................................................................... 8

INTERNAL THERMAL PROTECTION .................................................. 8

WELDER INSTALLATION ..................................................................... 9

POWER SOURCE CONNECTION ....................................................... 9

POWER REQUIREMENTS ................................................................. 9

CONNECT TO POWER SOURCE ...................................................... 9

EXTENSION CORDS .......................................................................... 9

ASSEMBLING THE WELDER ............................................................... 9

UNPACKING THE WELDER ............................................................... 9

INSTALL THE GROUND CLAMP ....................................................... 9

INSTALL THE TANK TRAY AND BRACKET ........................................ 9

INSTALL THE SHIELDING GAS ....................................................... 10

CHECK THE GAS FLOW .................................................................... 11

ALIGN AND SET THE DRIVE ROLLER ............................................. 11

STANDARD DRIVE ROLLER ............................................................ 11

INSTALL THE WELDING WIRE .......................................................... 12

SET THE WIRE DRIVE TENSION ...................................................... 14

PREPARATION .................................................................................... 15

CHANGE POLARITY ........................................................................ 15

OPERATION ......................................................................................... 16

CONTROLS AND INDICATORS ......................................................... 16

MAINTENANCE .................................................................................... 17

GENERAL ........................................................................................... 17

REPLACE A GUN LINER .................................................................. 17

MAINTAINING THE CONTACT TIP .................................................. 20

MAINTAINING THE NOZZLE ........................................................... 20

TESTING FOR A SHORTED NOZZLE ............................................ 21

PREVENTIVE MAINTENANCE ......................................................... 21

TROUBLESHOOTING ........................................................................ 21

WIRING DIAGRAM ............................................................................... 23

REPLACEMENT PARTS LIST ............................................................. 24

SCHEMATIC ......................................................................................... 26

Page 31

This Welder User's Guide provides

specific information about your wire

feed welder. It is to be used together

with the Welding Instruction Guide to

provide all of the information needed to

safely and effectively use your wire

feed welder. The information in this

book applies to your specific model of

wire feed welder and gives instruction

on set-up, installation, and actual use

of the welder.

Where information is shown that does

not necessarily apply to all models or

brands of welder, it will be marked as

either optional on some welder models

or does not apply to all models.

Page 32

Every craftsman respects the tools with

which they work. They know that the

tools represent years of constantly

improved designs and developments.

The true craftsman also knows that tools

are dangerous if misused or abused.

Reading this Operator's Guide and the

Welding Instruction Guide before using

the welder will enable you to do a better,

safer job. Learn the welder's

applications and limitations as well as

the specific potential hazards peculiar to

welding.

SAFETY INFORMATION

The following safety information is

provided as guidelines to help you

operate your new welder under the

safest possible conditions. Any

equipment that uses electrical power

can be potentially dangerous to use

when safety or safe handling instructions

are not known or not followed. The

following safety information is provided

to give you the information necessary for

safe use and operation.

When a procedure step is preceded by

a WARNING, it is an indication that the

step contains a procedure that might be

injurious to a person if proper safety

precautions are not heeded.

When a procedure step is preceded by

a CAUTION, it is an indication that the

step contains a procedure that might

damage the equipment being used.

A NOTE may be used before or after a

procedure step to highlight or explain

something in that step.

READ ALL SAFETY INSTRUCTIONS

CAREFULLY before attempting to

install, operate, or service this welder.

Failure to comply with these instructions

could result In personal injury and/or

property damage.

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

Note: The followingsafety alert

symbols identify important

safety messages in this manual.

When you see one of the symbols

shown here, be alert to the possibility of

personal injury and carefully read the

message that follows.

This symbol indicates that the

possibility of electric shock

hazard exists during the

operation of the step(s) that

follow.

This symbol indicates that the

possibility of fire hazard exists

during the operation of the

step(s) that follow.

This symbol indicates that the

helmet must be worn during

the step(s) that follow to

protect against eye damage

and burns due to flash

hazard.

This symbol indicates that the

possibility of toxic gas hazard

exists during operation of the

step(s) that follow.

This symbol indicates that the

possibility of being burned by

hot slag exists during

operation of the step(s) that

follow.

This symbol indicates that the

eye protection should be worn

to protect against flying debris

in the following step(s).

This symbol indicates that the

possibility of injury or death

exists due to improper

handling and maintenance of

compressed gas cylinders or

regulators

Full explanations of the specific hazards

are shown in the WELDING

INSTRUCTION GUIDE. Make sure you

have read and understand all of the

Page 33

informationbeforeproceedingwithany

oftheinstructionscontainedinthis

user'sguide.

Publishedstandardsonsafetyare

available.Theyarelistedin

ADDITIONALSAFETYINFORMATION

attheendofthisSAFETYSUMMARY.

TheNationalElectricalCode,

OccupationalSafetyandHealthAct

regulations,localindustrialcodesand

localinspectionrequirementsalso

provideabasisforequipment

installation,use,andservice.

SHOCKHAZARDS

WARNING

ELECTRIC SHOCK CAN KILL! To

reduce the risk of death or serious

injury from shock, read, understand,

and follow the following safety

instructions. In addition, make

certain that anyone else who uses

this welding equipment, or who is a

bystander in the welding area

understands and follows these safety

instructions as well.

FIRE HAZARDS

WARNING

FIRE OR EXPLOSION CAN CAUSE

DEATH, INJURY, AND PROPERTY

DAMAGE! To reduce risk of death,

injury, or property damage from fire

or explosion, read, understand, and

follow the following safety

instructions. In addition, make

certain that anyone else that uses

this welding equipment, or is a

bystander in the welding area,

understands and follows these safety

instructions as well. REMEMBER!

Welding by nature produces sparks,

hot spatter, molten metal drops, hot

slag, and hot metal parts that can

start fires, burn skin, and damage

eyes.

6

FLASH HAZARDS

WARNING

ARC RAYS CAN INJURE EYES

AND BURN SKIN! To reduce risk of

injury from arc rays, read,

understand, and follow the following

safety instructions. In addition, make

certain that anyone else that uses

this welding equipment, or is a

bystander in the welding area,

understands and follows these safety

instructions as well.

FUME HAZARDS

WARNING

FUMES, GASSES, AND VAPORS

CAN CAUSE DISCOMFORT,

ILLNESS, AND DEATH! To reduce

risk of discomfort, illness, or death,

read, understand, and follow the

following safety instructions. In

addition, make certain that anyone

else that uses this welding equipment

or is a bystander in the welding area,

understands and follows these safety

instructions as well.

COMPRESSED GASSES AND

EQUIPMENT HAZARDS

WARNING

IMPROPER HANDLING AND

MAINTENANCE OF COMPRESSED

GAS CYLINDERS AND

REGULATORS CAN RESULT IN

SERIOUS INJURY OR DEATH! To

reduce risk of injury or death from

compressed gasses and equipment

hazards, read understand and follow

the following safety instructions. In

addition, make certain that anyone

else who uses this welding

Page 34

equipmentorabystanderinthe

weldingareaunderstandsand

followsthesesafetyinstructionsas

well.

Donotuseflammablegasseswith

MIGwelders.Onlyinertor

nonflammablegassesaresuitablefor

MIGwelding.ExamplesareCarbon

Dioxide,Argon,Helium,etc.or

mixturesofmorethanoneofthese

gasses.

BURN HAZARDS

WARNING

Hot slag can cause fires and

serious injury from burns. To

reduce the risk of discomfort or

serious injury due to burns always

wear heavy protective clothing, eye

and face protection, and gloves

designed for welding. To prevent the

risk of fires starting, use a metal plate

or some other material with a high

flash point to catch and shield

combustibles from the hot slag.

ADDITIONAL SAFETY

INFORMATION

For additional information concerning

welding safety, refer to the following

standards and comply with them as

applicable.

• ANSI Standard Z49.1 i SAFETY IN

WELDING AND CUTTING i

obtainable from the American Welding

Society, 550 NW Le Jeune Road,

Miami, FL 33126 Telephone (800)

443-9353, Fax (305) 443-7559 i

www.amweld.org or www.aws.org

• ANSI Standard Z87.1 i SAFE

PRACTICE FOR OCCUPATION AND

EDUCATIONAL EYE AND FACE

PROTECTION i obtainable from the

American National Standards Institute,

11 West 42ndSt., New York, NY 10036

Telephone (212) 642-4900, Fax (212)

398-0023 i www.ansi.org

• NFPA Standard 51B i CUTTING

AND WELDING PROCESS i

obtainable from the National Fire

Protection Association, 1

Batterymarch Park, P.O. Box 9101,

Quincy, MA 02269-9101 Telephone

(617) 770-3000, Fax (617) 770-0700

i www.nfpa.org

• CGA Pamphlet P-I i SAFE

HANDLING OF COMPRESSED

GASSES IN CYLINDERS i

obtainable from the Compressed Gas

Association, 1725 Jefferson Davis

Highway, Suite 1004, Arlington, VA

22202-4102 Telephone (703) 412-

0900 Fax (703) 412-0128 i

www.cagnet.com

• OSHA Standard 29 CFR, Part 1910,

Subpart Q., WELDING, CUTTING

AND BRAZING i obtainable from

your state OSHA office or U. S. Dept.

of Labor OSHA, Office of Public

Affairs, Room N3647, 200 Constitution

Ave. Washington, DC 20210 i

www.osha.gov

• CSA Standard W117.2 i Code for

SAFETY IN WELDING AND

CUTTING. i obtainable from

Canadian Standards Association, 178

Rexdale Blvd. Etobicoke, Ontario

M9W 1R3 i www.csa.ca

• American Welding Society Standard

A6.0. WELDING AND CUTTING

CONTAINERS WHICH HAVE HELD

COMBUSTIBLES. i obtainable from

the American Welding Society, 550

NW Le Jeune Road, Miami, FL 33126

Telephone (800) 443-9353, Fax (305)

443-7559 i www.amweld.org or

www.aws.org

Page 35

DESCRIPTION

Your new wire feed welder is designed

for maintenance and sheet metal

fabrication. The welder consists of a

single-phase power transformer,

stabilizer, rectifier, and a unique built-in

control/feeder. This MIG welder is

capable of welding with 0.024 (0.6mm)

and 0.030 (0.8mm), solid steel wire on

dc reverse polarity and with .030 inch

self-shielding flux-core wire on dc

straight polarity. Larger, 0.035 inch

(0.9mm) diameter solid steel wire, on dc

reverse polarity, and self shielding flux-

core wire on dc straight polarity may

also be used on this welder. The use of

larger diameter wire makes welding

difficult and the results cannot be

guaranteed. The manufacturer does not

recommend the use of larger diameter

wire.

Now you can weld sheet metal from 24

gauge up to 1/4 inch thick with a single

pass. You can weld thicker steel with

beveling and multiple pass techniques.

Table 1 lists your MIG welder

specifications.

Table 1. Welder Specifications

Primary (input) volts 120 Vac

Primary (inputs) Amps 25

Phase Single

Frequency 60 Hz

Secondary (output) volts 19.5

Secondary (UL output) ampsl05

Open Circuit Volts (Max.) 28 Vdc

Duty Cycle Rating 20%

WELDER OPERATING

CHARACTERISTICS

DUTY CYCLE

The duty cycle rating of a welder defines

how long the operator can weld and

how long the welder must be rested and

cooled. Duty cycle is expressed as a

percentage of 10 minutes and

represents the maximum welding time

8

allowed. The balance of the 10-minute

cycle is required for cooling.

Your new welder has a duty cycle rating

of 20% at the rated output. This means

that you can weld for two (2) minutes out

of 10 with the remaining eight (8) minutes

required for cooling. (See Table 2).

Table 2. Duty Cycle Ratings

Duty Maximum Required

Cycle Welding Resting

Rating Time Time

20% 2 minutes 8 minutes

40% 4 minutes 6 minutes

60% 6 minutes 4 minutes

80% 8 minutes 2 minutes

100% 10 minutes 0 minutes

INTERNAL THERMAL

PROTECTION

CAUTION

Do not constantly exceed the duty

cycle or damage to this welder can

result. If you exceed the duty cycle of

your welder, an internal thermal

protector will open, shutting off all

welder functions except the cooling

fan. If this happens, DO NOT SHUT