Craftsman 93420105 Owner’s Manual

. EAR$

OWNERS

MANUAL

811-309-000

MANUAL

MODEL No.

934.20105

CAUTION:

Read Rules for

Safe Operation

and Instructions

Carefully

WIRE FEED

MIG WELDER

Operation

Repair Parts

811-309-000

SEARS ROEBUCK AND CO., CHICAGO, IL 60684 U.S.A.

Table of Contents

IMPORTANT SAFETY INSTRUCTIONS 1

SHOCK HAZARDS ......................... 1

FLASH HAZARDS ......................... 2

FIRE HAZARDS ........................... 2

FUME HAZARDS .................... ...... 3

COMPRESSED GASSES AND EQUIPMENT HAZ-

ARDS ................................... 3

ADDITIONAL SAFETY INFORMATION ......... 4

PRODUCT DESCRIPTION 5

SPECIFICATIONS ......................... 5

WELDER CONTROLS AND THEIR FUNCTIONS. 5

DUTY CYCLE ............................. 5

INTERNAL THERMAL PROTECTION .......... 5

ASSEMBLY AND INSTALLATION 6

UNPACKING YOUR WELDER ................ 6

INSTALL THE GROUND CLAMP .............. 6

INSTALL WELDING GUN ASSEMBLY .......... 7

PROVIDE REQUIRED POWER ............... 7

Power Requirements ....................... 7

Connect Welder to Power Source ............. 8

Extension Cord Use ........................ 8

INSTALL TANK TRAY AND BRACKET .......... 8

SELECT SHIELDING GAS ................... 9

Gas Selection For Steel Welding With Steel Wire. 9

Gas Selection for Aluminum Welding .......... 9

Gas Selection for Stainless Steel Welding ...... 9

Gas Selection for Steel Welding

with Silicon-Bronze Wire .................... 10

INSTALL THE SHIELDING GAS ............... 10

CHECKING GAS FLOW ..................... 11

SELECT WELDING CURRENT POLARITY ...... 11

SELECT THE WELDING WIRE ............... 11

Selecting the Type of Wire ................... 11

SELECT THE SPOOL SIZE .................. 12

Wire Spool Storage ........................ 13

Select the Wire Diameter .................... 13

INSTALL THE WELDING WIRE ............... 13

Changing the Drive Roller ................... 13

INSTALLING ALUMINUM WIRE .............. 16

PREPARING TO WELD 17

PREPARING A SAFE WELDING WORK AREA.. 17

PREPARING THE WORK PIECE ............. 17

ALUMINUM WELDING PREPARATION ........ 18

CONNECT WELDER GROUND .............. 18

OPERATION 19

GETTING TO KNOW YOUR NEW WELDER .... 19

SETTING THE CONTROLS ................. 19

HOLDING THE GUN ....................... 20

Position of the Gun to the Work Piece ......... 20

Distance from the Work Piece ............... 21

LAYING A BEAD .......................... 21

CLEANING THE WELD BEAD ............... 21

WELDING TECHNIQUES 22

TRAVELING WITH THE GUN ................ 22

TYPES OF WELD BEADS .................. 22

WELDING POSITIONS ..................... 23

MULTIPLE PASS WELDING ................. 24

SPECIAL WELDING METHODS 25

SPOT WELDING .......................... 25

SPOT WELDING INSTRUCTIONS ............ 25

MAINTENANCE AND TROU-

BLESHOOTING 26

GENERAL MAINTENANCE ....... .......... 26

CONSUMABLE MAINTENANCE AND TROU-

BLESHOOTING .......................... 26

TESTING FOR A SHORTED NO72'LE ......... 27

TROUBLESHOOTING ...................... 27

REPLACEMENT PARTS LIST 33

WARRANTY 34

IMPORTANT SAFETY INSTRUCTIONS Page 1

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS! DO NOT OPERATE YOUR WELDER UNTIL

YOU HAVE READ AND UNDERSTAND THESE INSTRUCTIONS

(welding rod or welding wire). Any metal parts on

the electrode holder or MIG gun.

ELECTRIC SHOCK CAN KILL!

I_:_l ARC RAYS CAN INJURE EYES AND

BURN SKIN!

FIRE OR EXPLOSION CAN CAUSE

DEATH, INJURY, AND PROPERTY DAMAGE!

FUMES, GASSES, AND VAPORS CAN

CAUSE DISCOMFORT, ILLNESS, AND DEATH!

IMPROPER HANDLING AND MAIN-

TENANCE OF COMPRESSED GAS CYLIN-

DERS AND REGULATORS CAN RESULT IN

SERIOUS INJURY OR DEATH!

NEVER weld in a damp area or come in contact

with a moist or wet surface when welding.

NEVER attempt to weld if any part of clothing or

body is wet.

NEVER allow the welding equipment to come in

contact with water or moisture.

NEVER drag welding cables (or MIG gun assem-

bly) or weld powercord through or allow them to

come into contact with water or moisture.

NEVER touch welder, attempt to turn welder on or

off, or attempt to plug welder into powersource if

any part of body or clothing is wet or damp, or if

standing in or in physical contact of any kind with

water or moisture.

NEVER connect welder ground clamp to or weld

on electrical conduit.

NEVER alter powercord or powercord plug in any

way.

IMPORTANT! DO NOT ATTEMPT OPERATION

of this welding equipment until reading and under-

standing the following safety instructions to reduce

risk of DEATH, INJURY, AND PROPERTY DAM-

AGE.

SHOCK HAZARDS

ELECTRIC SHOCK CAN KILL! To reduce risk of

death from electric shock, read, understand, and

follow the following safety insructions. In Addition,

make certain that anyone who uses this welding

equipment or is a bystander in the welding area

understands and follows these safety instructions

as well.

NEVER Stand, Sit, Lie, Lean On, Touch, or come

into physical contact in any way with any part of the

welding current circuit including:

the work piece or any conductive material in con-

tact with it. The ground clamp. The electrode

NEVER attempt to plug welder into powersource if

ground prong on powercord plug is bent over,

broken off, or missing.

NEVER allow welder to be connected to power-

source or attempt to weld if welder, welding cables

(or MIG gun assembly), welding site, or welder

powercord are exposed to rain, snow, sleet, mist,

fog or other forms of atmospheric precipitation or

mist or spray off an ocean or other body of water.

NEVER carry coiled welding cables around shoul-

ders, or any other part of the body, when they are

plugged into the welder.

NEVER modify any wiring, ground connections,

switches, or fuses in this welding equipment.

ALWAYS wear welding gloves to help insulate

hands from welding circuit.

IMPORTANTSAFETYINSTRUCTIONSPage2

ALWAYSkeep containers of water or other liquids

far enough away from welder and work area so that

ifspilled, the liquid could not possibly come incontact

with the welder, welding cables (or MIG gun assem-

bly), welder powercord, the workpiece being welded,

or any other part of the electrical welding circuit.

ALWAYS replace any cracked or damaged parts

that are insulated or act as insulators such as

welding cables (or MIG gun assembly), or power-

cord IMMEDIATELY.

FLASH HAZARDS

ARC RAYS CAN INJURE EYES AND BURN

SKIN! To reduce risk of injury from arc rays, read

understand and follow the following safety insrtuc-

tions. In addition, make certain that anyone else

that uses this welding equipment, or is a bystander

in the welding area, understands and follows these

safety instructions as well

NEVER look at an electric arc without proper pro-

tection. A welding arc is extremely bright and in-

tense and, with inadequate or no eye protection,

the retina can be burned, leaving a permanent

dark spot in the field of vision. A shield or helmet

with a number 10 shade filter lens (minimum) must

be used.

the inside of your helmet or shield, then into your

eyes. If a reflective background exists in your weld-

ing area, either remove itor cover it with something

nonflammable and non-reflective. Reflective arc

rays can also cause skin burn in addition to eye

injury.

FIRE HAZARDS

FIRE OR EXPLOSION CAN CAUSE DEATH, IN-

JURY, AND PROPERTY DAMAGE! To reduce

risk of death, injury, or property damage from fire

or explosion, read, understand, and follow the fol-

lowing safety insrtuctions. In addition, make cer-

tain that anyone else that uses this welding

equipment, or is a bystander in the welding area,

understands and follows theses safety instructions

as well. REMEMBERI Arc welding by nature pro-

duces sparks, hot spatter, molten metal drops, hot

slag, and hot metal parts which can start fires, burn

skin and damage eyes.

NEVER wear gloves or other clothingthat contain

oil,grease, or other flammable substances.

NEVER wear flammable hair preparations.

NEVER strike a welding arc until all bystanders

and you (the welder) have welding shields and/or

helmets inplace.

NEVER wear a cracked or broken helmet and

replace any cracked or broken filter lenses IMME-

DIATELY.

ALWAYS provide bystanders with shields or hel-

mets fitted with a number 10 shade filter lens.

ALWAYS wear protective clothing. The intense

light of the welding arc can bum the skin in much

the same way as the sun, even through light-

weight clothing. Wear dark clothing of heavy mate-

rial. The shirt worn should be long sleeved and the

collar kept buttoned to protect chest and neck.

ALWAYS protect against REFLECTED ARC

RAYS. Arc rays can be reflected off shiny surfaces

such as a glossy painted surface, aluminum, stain-

less steel, and glass. It is possible for your eyes to

be injured by reflected arc rays even when wearing

a protective helmet or shield. If welding with a

reflective surface behind you, arc rays can

"bounce off" the surface, then off the filter tens on

NEVER weld in an area until it has been checked

and cleared of combustable and/or flammable ma-

terials. BE AWARE that sparks and slag can fly 35

feet and can pass through small cracks and open-

ings. If work and combustibles cannot be sepa-

rated by a minimum of 35 feet, protect against

ignition with suitable, snug-fitting, fire resistant

covers or shields.

NEVER weld on walls until checking for and remov-

ing combustibles touching the wall on the other side.

NEVER weld, cut, or perform other hot work on

used barrels, drums, tanks, or other containers

that contained a flammable or toxic substance.

The techniques for removing flammable sub-

stances and vapors, to make a used container safe

for welding or cutting, are quite complex and re-

quire special education and training.

NEVER strike an arc on a compressed gas or air

cylinder or other pressure vessel. Doing so will

create a brittle area that can result in a violent

rupture immediately or at a later time as a result of

rough handling.

IMPORTANT SAFETY INSTRUCTIONS Page)3

NEVER weld or cut in an area where the air may

contain flammable dust (such as grain dust), gas,

or liquid vapors (such as gasoline).

NEVER handle hot metal, such as the workpiece

or welding wire, with bare hands.

ALWAYS wear leather gloves, heavy long sleeve

shirt, cuffless trousers, high-topped shoes, helmet,

and cap. As necessary, use additional protective

clothing such as leather jacket or sleeves, fire

resistant leggings, or apron. Hot sparks or metal

can lodge in rolled up sleeves, trouser cuffs, or

pockets. Sleeves and collars should be kept but-

toned and pockets eliminated from the front.

ALWAYS have fire extinguishing equipment handy

for instant use! A portable chemical fire extin-

quisher, type ABC, is recommended.

ALWAYS wear ear plugs when welding overhead

to prevent spatter or stag from falling into ear.

ALWAYS make sure welding area has a good,

solid, safe floor, preferably concrete or masonry,

not tiled, carpeted, or made of anyother flammable

material.

ALWAYS protect flammable walls, ceilings, and

floors with heat resistant covers or shields.

ALWAYS check welding area to make sure it is

free of sparks, glowing metal or slag, and flames

before leaving the welding area.

FUME HAZARDS

FUMES, GASSES, AND VAPORS CAN CAUSE

DISCOMFORT, ILLNESS, AND DEATH! To re-

duce risk of discomfort, illness, or death, read,

understand, and follow the following safety instruc-

tions. In addition, make certain that anyone else

that uses this welding equipment or is a bystander

in the welding area, understands and follows these

safety instructions as well.

nized steel, unless the coating is removed, the

area is well ventilated, or the operator and _all'

bystanders wear air-supplied respirators.

NEVER weld, cut, or heat lead, zinc, cadmium,

mercury, beryllium, or similar metals without seek-

ing professional advise and inspection of the ven-

tilation of the welding area. These metals produce

EXTREMELY TOXIC fumes which can cause dis-

comfort, illness, and death.

NEVER weld or cut in areas that are near chlorin-

ated solvents. Vapors from chlorinated hydrocar-

bons, such as trichlorbethylene and

perchloroethylene, can be decomposed by the

heat of an electric arc or its ultraviolet radiation to

form PHOSGENE, a HIGHLY TOXIC gas, along

with other lung and eye-irritating gasses. Do not

weld or cut where these solvent vapors can be

drawn into the work area or where the ultraviolet

radiation can penetrate to areas containing even

very small amounts of these vapors.

NEVER weld in a confined area unless it is being

ventilated or the operator (and anyone else in the

area) is wearing an air-supplied respirator.

NEVER bring gas cylindersinto or allow gas leaks

in a confined space. Leaked gas can rapidly re-

duce oxygen concentration levels in a confined

space.

ALWAYS shut off shielding gas supply at its source

before leaving a confined area and check to make

sure that the area is safe before reentering it.

ALWAYS stop welding if you develop momentary

eye, nose, or throat irritation as this indicates in-

adequate ventilation. Stop work and take neces-

sary steps to improve ventilation in the welding

area. Do not resume welding ifphysical discomfort

persists.

COMPRESSED GASSES AND

EQUIPMENT HAZARDS

NEVER weld in an area until it has been checked

for adequate ventilation as described in ANSI

standard #Z49.1. If ventilation is not adequate to

exchange all fumes and gasses generated during

the welding process with fresh air, do not weld

unless you (the welder) and all bystanders are

wearing air-supplied respirators.

NEVER heat metals coated with or containing ma-

terials that produce toxic fumes, such as galva-

IMPROPER HANDLING AND MAINTENANCE

OF COMPRESSED GAS CYLINDERS AND

REGULATORS CAN RESULT IN SERIOUS IN-

JURY OR DEATH! To reduce risk or injury or death

from compressed gasses and equipment hazards,

read, understand, and follow the following safety

instructions. In addition, make certain that anyone

else who uses this welding equipment or is a

bystander in the welding area understands and

follows these safety instructions as well.

IMPORTANT SAFETY INSTRUCTIONS Page 4

NEVER use flammable gasses with MIG welders.

Only inert or non-flammable gasses are suitable

for MIG welding. Examples are Carbon Dioxide,

Argon, Helium, etc. or mixtures of more than one

of these gasses.

NEVER attempt to mix gasses or refill a cylinder

yourself.

NEVER expose cylinders to excessive heat,

sparks, slag, and flame, etc. Cylinders exposed to

temperatures above 130 degrees F. will require

water spray cooling.

NEVER expose cylinders to electricity of any kind.

NEVER use cylinder or its contents for anything

other than its intended use. Do not use as a sup-

port or roller.

NEVER locate cylinders in passageways or work

areas where they may be struck.

ALWAYS protect cylinder, especially valve, from

bumps, falls, falling objects, and weather.

ALWAYS make sure cylinder cap is securely in

place, on the cylinder, whenever cylinderis moved.

ALWAYS remove faulty regulator from service im-

mediately for repair (first close cylinder valve) if

any of the following occur: Gas leaks extemally,

delivery pressure continues to rise with down

stream valve closed, and/or gauge pointer does

not move off the stop pin when pressurized or fails

to return to the stop pin after pressure is released.

ADDITIONAL SAFETY

INFORMATION

For additional information concerning welding

safety, refer to the following standards and comply

with as applicable.

NEVER lift cylinders off the ground by their valves

or caps or with chains, slings, or magnets.

NEVER use a wrench or hammer to open a cylin-

der valve that cannot be opened by hand. Notify

your supplier.

NEVER modify or exchange gas cylinder fittings.

NEVER deface or altar name, number, or other

markings on a cylinder. It is illegal and hazardous.

NEVER use cylinders without the name of the gas

marked on the cylinder. Do not rely on cylinder

color to identify the content.

NEVER connect a regulator to a cylinder contain-

ing gas otherthan that for which the regulator was

designed.

NEVER attempt to make regulator repairs. Send

faulty regulators for repair to manufacturer's des-

ignated repair center.

1. ANSI Standard Z49.1 -- SAFETY IN WELDING

AND CUTTING ---obtainable from the American

Welding Society, 2051 N.W. 7th St., Miami, FL

33125 Telephone (305) 443-9353

2. ANSI Standard Z87.1 -- SAFE PRACTICE

FOR OCCUPATION AND EDUCATIONAL EYE

AND FACE PROTECTION -- obtainable from

the American National Standards Institute, 1430

Broadway, New York, NY 10018

3. NFPA Standard 51B -- CUTTING AND WELD-

ING PROCESSES -- obtainable from the Na-

tional Fire Protection Association, 470 Atlantic

Ave., Boston, MA 02210

4. CGA Pamphlet P-1 --SAFE HANDLING OF

COMPRESSED GASSES IN CYLINDERS

obtainable from the Compressed Gas Associa-

tion, 500 5th Ave., New York, NY 10036

NEVER attempt to lubricate regulator.

ALWAYS handle cylinders carefully to prevent

leaks and damage to their wails, valves, or safety

devices.

ALWAYS secure cylinders with a steel chain so

that they cannot be knocked over.

5. OSHA Standard 29 CFR, Part 1910, Subpart Q,

WELDING, CU'I-I'ING AND BRAZING -- ob-

tainable from your state OSHA office.

6. CSA Standard W177.2 -- Code for SAFETY IN

WELDING AND CUTTING -- obtainable from

Canadian Standards Association, 178 Rexdale

Blvd., Rexdate, Ontario, Canada M9W 1R3

PRODUCT DESCRIPTION Page. 5

PRODUCT DESCRIPTION

Your new Metal Inert Gas (MIG) wire feed welder

is designed for maintenance, and sheetmetal fab-

rication. The welder consists of a single-phase

power transformer, stabilizer, rectifier, and a

unique built-in control/feeder. This MIG welder is

capable of welding with .024" and .030" solid steel,

or stainless steel wires and .030" aluminum (spec

#5356 alloy) wire on DC positive polarity and with

.030", self-shielding flux-core wire on DC negative

polarity.

NOTE; When using .035 Flux Core wire your duty

cycle may be shorter than 20%.

Now you can weld 20 gauge sheet metal up to

3/16" with a single pass. Welds 114" steel with

beveling and multiple pass.

SPECIFICATIONS

Primary (input) volts .............................. 120 VAC

Primary (input) Amps ....................................... 18

Phase ....................................................... Single

Frequency ................................................ 60 Hz

Kilovolt Amps ................................................ 2.2

Secendary (output) volts ............................... 18

Secondary (output) amps ............................. 75

Duty Cycle Rating: ..................................... 20%

Open Circuit Volts (Max.) ...................... 31 VDC

WIRE SPEED - This control adjusts the speed at

which the wire is fed out of the gun. The wire speed

needs to be closely matched ("tuned-in") to the

rate at which it is being melted off. Some things

that affect wire speed selection are the type and

diameter of the wire being used, the heat setting

selected, and the welding position to be used.

DUTY CYCLE

The duty cycle rating of a welder tells the operator

how long he or she can weld and how long the

welder must rest-to cool. tt is expressed as a

percentage of 10 minutes (the industry recognized

cycle time) and represents the maximum welding

time allowed, with the balance of the 10-minute

cycle required for cooling (see chart below).

Your new welder has a duty cycle rating of 20%.

You can weld for 2 minutes out of 10, with the

remaining 8 minutes required for cooling.

Duty Cycle

Rating

Maximum Required

Welding Time Resting Time

WELDER CONTROLS AND THEIR

FUNCTIONS

POWER SWITCH- Has three settings: LOW, OFF,

and HIGH. Setting the switch to OFF shuts the

welder off. When set to LOW, the welder can

produce up to 45 amps of welding current. When

set on HIGH, up to 75 amps of welding current will

be available. NOTE: The actual amperage will

vary depending on wire speed, length of the arc

held when welding, the type of wire being used,

and the ACTUAL voltage available at the wall

receptacle.

ELECTRIC SHOCK CAN KILL! To reduce risk of

electric shock, be aware that having the POWER

SWITCH in the OFF position does not remove

power from all intemal circuitry of the welder.

20% 2 Minutes 8 Minutes

40% 4 Minutes 6 Minutes

60% 6 Minutes 4 Minutes

80% 8 Minutes 2 Minutes

100% 10 Minutes 0 Minutes

INTERNAL THERMAL PROTECTION

If you exceed the duty cycle of your welder, and

internal thermal protector will open and shut off ai!

welder functions. After cooling, the thermal protec-

tor will automatically reset and the welder wilt func-

tion normally again.

DO NOT CONSTANTLY EXCEED THE DUTY

CYCLE OR DAMAGE TO THIS WELDER CAN

RESULT!

ASSEMBLYANDINSTALLATIONPage6

ASSEMBLY AND INSTALLATION

ELECTRIC SHOCK CAN KILL! To re-

duce risk of electric shock, DO NOT PLUG

WELDER IN TO AC POWER SOURCE UNTIL

TOLD TO DO SO later in this manual.

4. Lay out the parts and compare tofollowing illus-

trations to familiarize yourself with the parts and

what they are called. This will help you when

reading the manual.

5. Grasp the top handle of the welder and lift the

welder out of the carton.

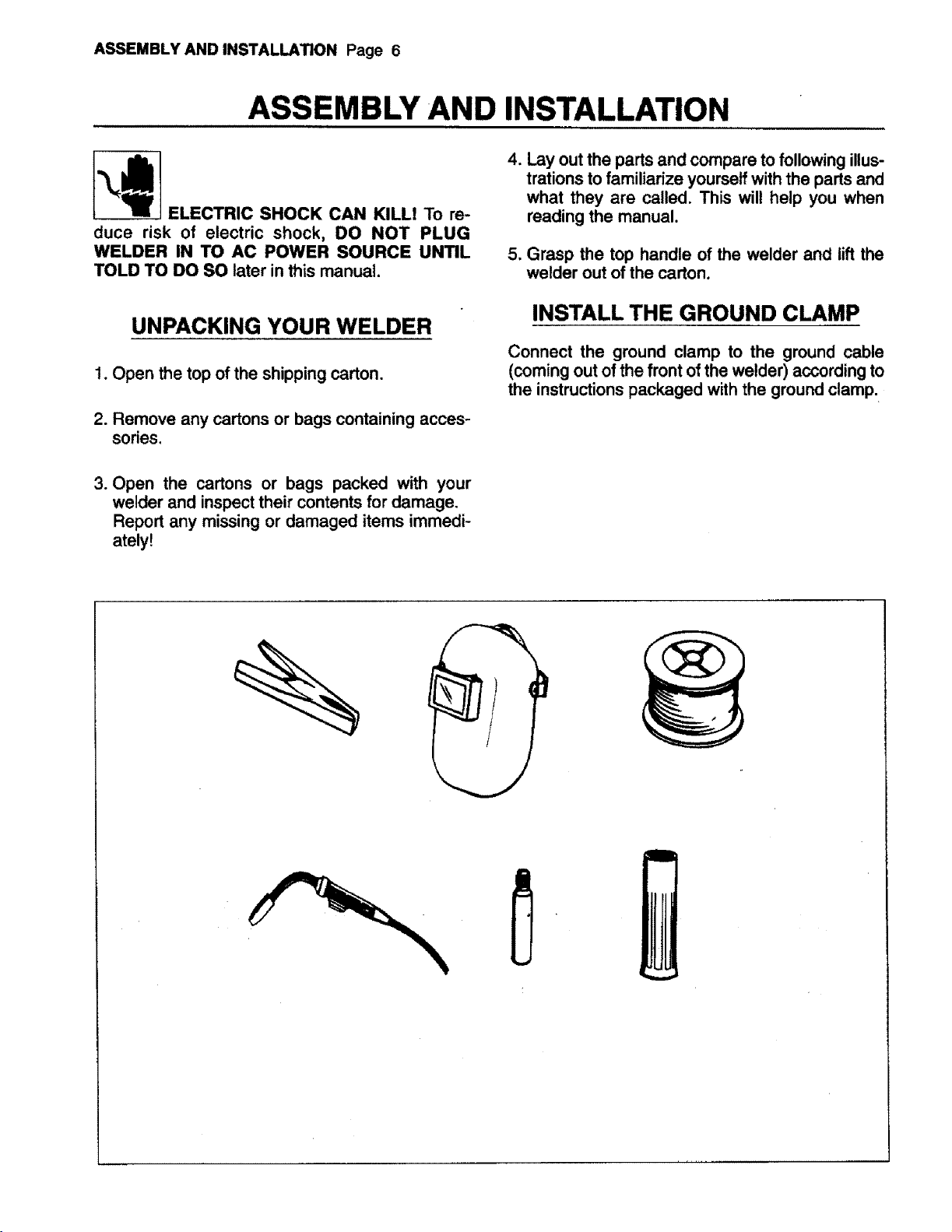

UNPACKING YOUR WELDER

1. Open the top of the shipping carton.

2. Remove any cartons or bags containing acces-

sories.

3. Open the cartons or bags packed with your

welder and inspecttheir contents for damage.

Report any missing or damaged items immedi-

ately!

INSTALL THE GROUND CLAMP

Connect the ground clamp to the ground cable

(coming out of the front of the welder) according to

the instructions packaged with the ground clamp.

O

O O

000

0 0

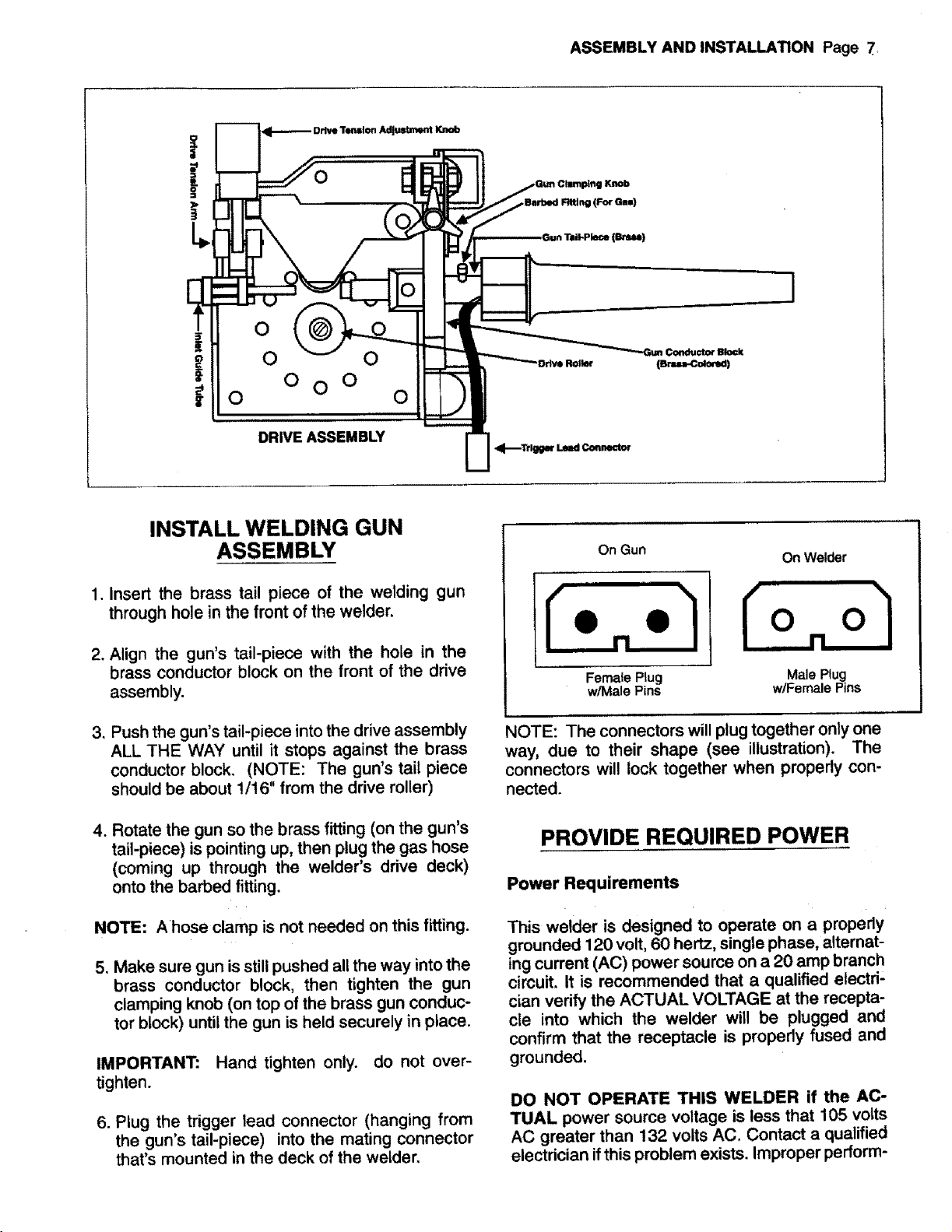

DRIVE ASSEMBLY

ASSEMBLY AND INSTALLATION Page 7

Knob

INSTALL WELDING GUN

ASSEMBLY

1. Insert the brass tail piece of the welding gun

through hole in the frontof the welder.

2. Align the gun's tail-piece with the hole in the

brass conductor block on the front of the drive

assembly.

3, Push the gun's tail-piece into the drive assembly

ALL THE WAY until it stops against the brass

conductor block. (NOTE: The gun's tail piece

should be about 1/16" from the drive roller)

4. Rotate the gun so the brass fitting (on the gun's

tail-piece) is pointing up, then plug the gas hose

(coming up through the welder's drive deck)

onto the barbed fitting.

NOTE: Ahose clamp is not needed on this fitting.

5. Make sure gun is still pushed all the way into the

brass conductor block, then tighten the gun

clamping knob (on top of the brass gun conduc-

tor block) until the gun is held securely in place.

IMPORTANT: Hand tighten only. do not over-

tighten.

6. Plug the trigger lead connector (hanging from

the gun's tail-piece) into the mating connector

that's mounted in the deck of the welder.

On Gun

Female Plug

w/Male Pins

NOTE: The connectors will plug together only one

way, due to their shape (see illustration). The

connectors will lock together when properly con-

nected.

On Welder

PROVIDE REQUIRED POWER

Power Requirements

This welder is designed to operate on a properly

grounded 120 volt, 60 hertz, single phase, alternat-

ing current (AC) power source on a 20 amp branch

circuit. It is recommended that a qualified electri-

cian verify the ACTUAL VOLTAGE at the recepta-

cle into which the welder will be plugged and

confirm that the receptacle is properly fused and

grounded.

DO NOT OPERATE THIS WELDER if the AC-

TUAL power source voltage is less that 105 volts

AC greater than 132 volts AC. Contact a qualified

electrician ifthis problem exists. Improper perform-

ASSEMBLY AND INSTALLATION Page 8

ance and/or damage to the welder will result if

operated on inadequate orexcessive power.

ELECRIC SHOCK CAN KILL! FIRE CAN KILL,

INJURE, AND CAUSE PROPERTY DAMAGE! To

reduce the risk of electric shock and fire, connect

only to properly grounded and fused outlets.

NEVER ALTER the AC powercord or powercord

plug provided on the welder. NEVER ALTER and

extension cord or extension cord plugs.

Connect Welder to Power Source

1, DO NOT ALTER the AC power cord or power-

cord plug on the welder. Doing so may VOID

THE WARRANTY. If the welder's AC powercord

plug does not mate with your existing recepta-

cle, have an appropriate receptacle installed by

a qualified electrician in accordance with the

National Electrical Code and local codes and

ordinances. Do not use any adapters between

the welder's AC powercord plug and AC power

source receptacle.

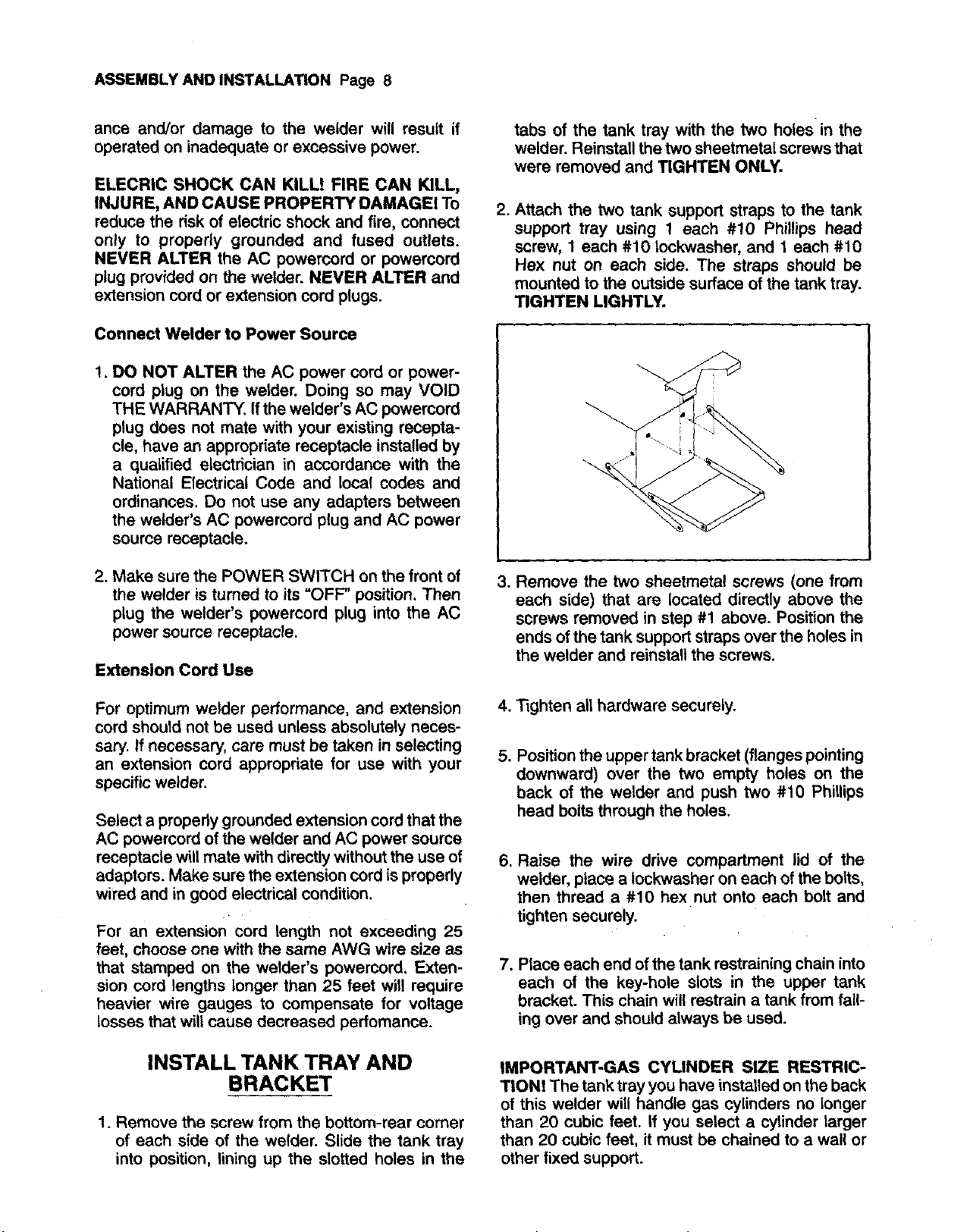

tabs of the tank tray with the two holes in the

welder. Reinstall the two sheetmetal screws that

were removed and TIGHTEN ONLY.

.

Attach the two tank support straps to the tank

support tray using 1 each #10 Phillips head

screw, 1 each #10 Iockwasher, and 1 each #10

Hex nut on each side. The straps should be

mounted to the outside surface of the tank tray.

TIGHTEN LIGHTLY.

2. Make sure the POWER SWITCH on the front of

the welder is turned to its "OFF" position. Then

plug the welder's powercord plug into the AC

power source receptacle.

Extension Cord Use

For optimum welder performance, and extension

cord should not be used unless absolutely neces-

san/. If necessary, care must be taken in selecting

an extension cord appropriate for use with your

specific welder.

Select a property grounded extension cord that the

AC powercord of the welder and AC power source

receptacle will mate with directly without the use of

adaptors. Make sure the extension cord is properly

wired and in good electrical condition.

For an extension cord length not exceeding 25

feet, choose one with the same AWG wire size as

that stamped on the welder's powercord, Exten-

sion cord lengths longer than 25 feet will require

heavier wire gauges to compensate for voltage

losses that will cause decreased perfomance.

3,

Remove the two sheetmetal screws (one from

each side) that are located directly above the

screws removed in step #1 above. Position the

ends of the tank support straps over the holes in

the welder and reinstall the screws.

4. Tighten all hardware securely.

.

Position the upper tank bracket (flanges pointing

downward) over the two empty holes on the

back of the welder and push two #10 Phillips

head bolts through the holes.

6. Raise the wire drive compartment lid of the

welder, place a Iockwasher on each of the bolts,

then thread a #10 hex nut onto each bolt and

tighten securely.

7,

Place each end of the tank restraining chain into

each of the key-hole slots in the upper tank

bracket. This chain will restrain a tank from fall-

ing over and should always be used.

INSTALL TANK TRAY AND

BRACKET

1. Remove the screw from the bottom-rear comer

of each side of the welder. Slide the tank tray

into position, lining up the slotted holes in the

IMPORTANT-GAS CYUNDER SIZE RESTRIC-

TION! The tank tray you have installed on the back

of this welder will handle gas cylinders no longer

than 20 cubic feet. If you select a cylinder larger

than 20 cubic feet, it must be chained to a wall or

other fixed support.

SELECT SHIELDING GAS

ASSEMBLYANDINSTALLATIONPage9

The shielding gas plays an extremely important

role in the MIG welding process. As with most

welding processes, itis critical that the molten weld

puddle be "shielded" from the atmosphere. Inade-

quate shielding will result in porous, brittle welds.

Notonly isshieldingthe weld important, butselect-

ing the proper gas to shield with isof equal impor-

tance. Generally, the shielding gas selected is

dependent upon the type and thickness of metal

being welded. Selecting the wrong gas for the

metal to be welded can result in porosity, brittle-

ness, and/or undesirable penetration of the weld.

Although there are many gasses and mixtures

available for MIG welding, the following recom-

mendations are based on the electrical output

characteristicsand metal-thickness welding capa-

bilitiesof this specific MIG welder.

GAS SELECTION FOR STEEL WELDING WITH

STEEL WIRE

Gas Selection For Aluminum Gas Welding

100% ARGON

Our only recommendation for shielding an alumP

num weld is pure Argon. Do not attempt to use the

Argon/Carbon Dioxide mixture (recommended for

steel) when welding aluminum.

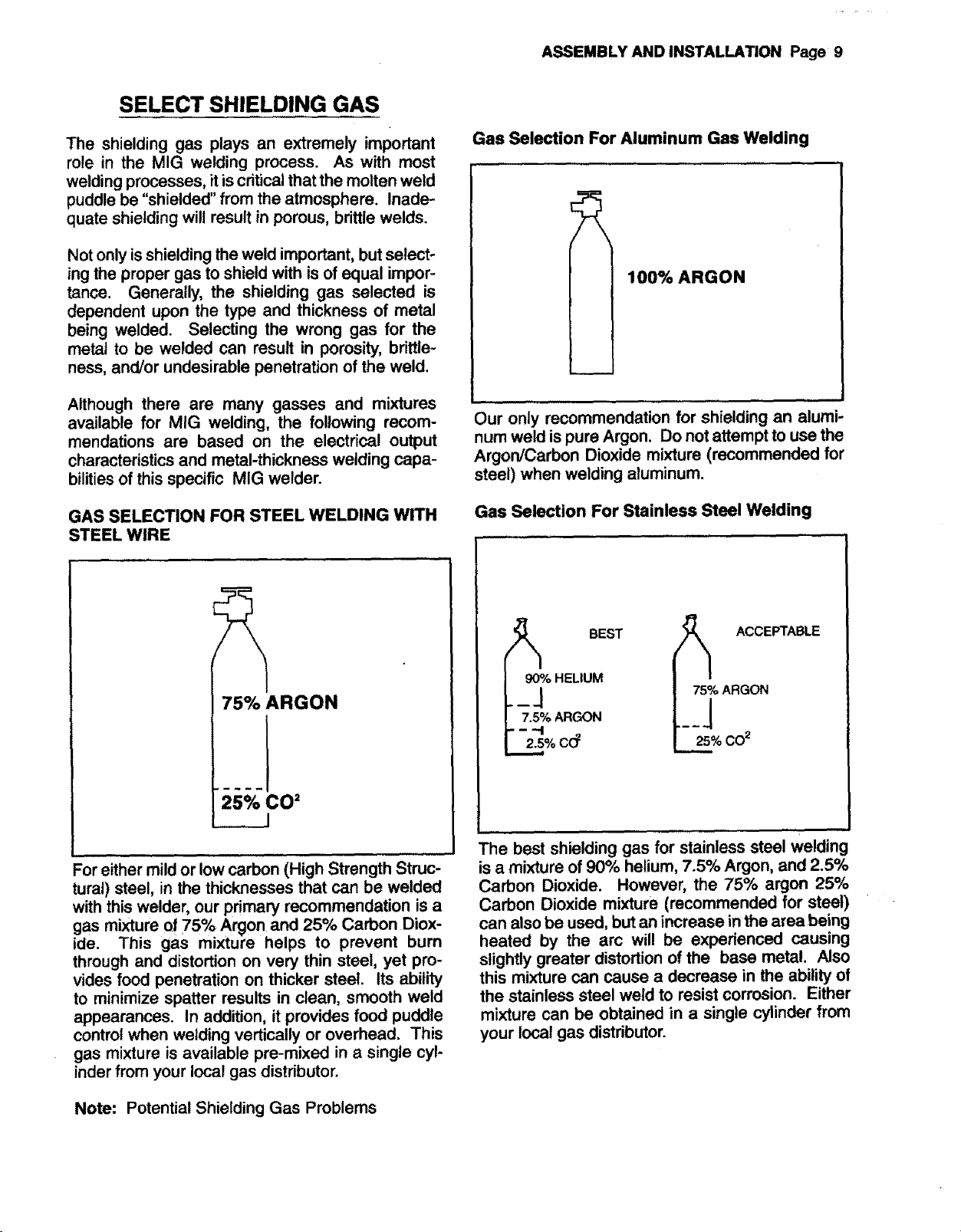

Gas Selection For Stainless Steel Welding

75% ARGON

25% CO=

_J

For either mild or low carbon (High Strength Struc-

tural) steel, in the thicknesses that can be welded

with this welder, our primary recommendation is a

gas mixture of 75% Argon and 25% Carbon Diox-

ide. This gas mixture helps to prevent burn

through and distortion on very thin steel, yet pro-

vides food penetration on thicker steel. Its ability

to minimize spatter results in clean, smooth weld

appearances. In addition, it provides food puddle

control when welding vertically or overhead. This

gas mixture is available pre-mixed in a single cyl-

inder from your local gas distributor.

_o/o BEST

HELIUM

F "_"_''%ARGON

_% c(:f

The best shielding gas for stainless steel welding

is a mixture of 90% helium, 7.5% Argon, and 2.5%

Carbon Dioxide. However, the 75% argon 25%

Carbon Dioxide mixture (recommended for steel)

can also be used, but an increase in the area being

heated by the arc will be experienced causing

slightly greater distortion of the base metal. Also

this mixture can cause a decrease in the ability of

the stainless steel weld to resist corrosion. Either

mixture can be obtained in a single cylinder from

your local gas distributor.

_o/, ° ACCEPTABLE

ARGON

r - -2_% co 2

Note: Potential Shielding Gas Problems

Loading...

Loading...