Craftsman 921165730 Owner’s Manual

Owner's ManuaJ

I *'1

AIR CO[_PRESSOR

33-gallon

t.7 HP

OHoFree, UMC

Mode! No. 92! .165730

CAUTION:

Before using this prOduCt, read this

manual and follow aU its Safety

Ru{es and Operating Instructions.

Sears Brand Management Corporation, Hof_man Estates, _L 60179

U,S,A.

www,sear$,oom/oroftsman

0_!2/20_ 3

Part #_0, E1063£9

* Safety Instructions

o _nstaHation & Operation

Maintenance & Storage

o Troubleshooting Guide

o Parts List

o EspaSol, p. 24

Page

Warranty ......................................... see below

Safety Symbols ............................................. 3

Important Safety Instructions & Guidelines ....................... 3

Specifications ............................................. 9

Glossary .................................................. 9

Duty Cycle .............................................. 10

Overview ................................................ 11

Assembly ............................................. !2-13

Installation ............................................ 14-t5

Operating Procedures ...................................... 16

Maintenance ............................................. 17

Storage ................................................ 17

Troubleshooting Guide .................................. 18-!g

Parts List ............................................. 20-22

Spanish ................................................ 24

Serv}ce Number .................................... back cover

ONE YEAR FULL WARRANTY ON CRAFTSMAN

AiR COMPRESSOR

_f this Craftsman Air Compressor fai_s due to manufacturer's defects

in material or workmanship within one year of the date of purchase,

RETURN IT TO THE NEAREST SEARS STORE OR SERVICE CENTER/N

THE UNITED STATES and it will be replaced or repaired (at our option),

free of charge.

If this Air Compressor is used for commercial or rental purposes, _his

warranty applies for only 90 days from the date of purchase. This warranty

gives you specific legal rights and you may atso have other rights which

vary from state to state.

Sears Brand Management Corporation, Hoffman Estates, ]L 60179

U.S.A,

2- ENG

This manual contains information that is important for you to know and understand.

This information re_ates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

lndicates an imminently _ indicates a potentially

avoided, wilJ result in death or serious avoided, may result in minor or

infury, moderate injury.

ion which, if not hazardous situation which, if not

indicates apotentiafly _ indicates a practice

hazardous situation which, if not not related to personal injury which,

avoided, could resutt in death or if not avoided, may result in properby

serious iniaR/, damage,

_This product contains chemicals known to the State of California

to cause cancer, and birth defects or other reproductive harm. Wash hands after

handling.

_Some dust contains chemicals known to the State of California

to cause cancer, birth defects or other reproductive harm such as asbestos and

lead in lead based painL

TO reduce the risk of ini_[y, read the inst(uction manual _

SAVE THESE INSTRUCTIONS

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN

It is normal for electrical

contacts within the motor and

pressuf_ switch to spark_

If electrical sparks from

compressor come into contact

with flammable vapors, they may

ignite, causing fire or explosion.

HOW TO PREVENT IT

Always operate the compressor

in a well ventilated area free

of combustible materials,

gasoline, or solvent vapors.

if spraying flammable materials,

locate compressor at least

20' (6,1 re) away from spray

area. An additional length of

air hose may be required.

Store fiammab!a materials

in a secure Iocation away

from compressor.

3_ ENG

Restricting any of the corn _

presser ventilation openings

will cause serious overheat°

ing and could cause fire,

o Unattended operation of this prod_

uct could resutt in personal injuPy

or property damage, To reduce the

risk of fire, do not a_low flqe corn _

presser to operate unattended.

RiSK TO BREATHING (ASPHYX|ATION}

WHAT CAN HAPPEN

The comoressed air directly from

your comore.£sor is not safe for

breathing. The air stream may

con[ain carbon monoxide, toxic

vapors, or solid #articles from the air

tank. Breathing these contaminants

can cause serious iniun/ or death.

Exposure to chemicals in dust

created by power sanding,

sawing, grindinG, driIfing,

and other construction

actMbes may _e harmful.

Sprayed materials such as aaint,

paint solvents, paint remover.

insecticides, weeo killers, ma,_

contain harmful vapors and ooisons.

Never place objects against

or on top of compressor.

Operate compressor in an open

area at least 12" (30,5 cm} away

from any wall or obstruction that

would restrict the flow d fresh

air to the ventilation openings.

Operate compressor in a

clean, dry wel_ventilated area,

Do not operate unit in any

confined area, Store indoors;

Always remain in attendance with

the product when it is operating.

AIwaya turn off and unplug

unit when not in use.

HOW TO PREVENT IT

Never use air obtained direct}y

from the compressor to supply

air for human consumption. The

compressor is not equipped with

suitabte filters and in-line safety

equipment for human consurr ation.

Work in an area w_m gooo cross

ventilation. Read and foflow

the safety instructions providec

on the labe or safety data

sheets for the materials you are

spraying. A_ways use certified

safety equipment: NiOSHiOSHA

respiratory protection or propeny

fitting face mask designed for use

L _y_ULSj_e__c.i_f_!P__P_._ n- ......

4- ENG

__ RISK OF BURST|NG

Air Tank; On February 26, 2002, the U.S. Consumer Product Safety Commission

pubJished Release # 02-108 concerning air compressor tank safety:

Air comoressor receiver tanks co not have an infinite life. Tank tife is deoendent

upon several factors some of which include operating conditions, ambient condF

_ons, proper installations, field modifications, and the level of maintenance, The

exact effect of these factors on air receiver life is difficult to oredtct

if proper _aintenance eroceaures are not followed, interna_ corrosion to _ne

inner wall of the air receiver tank can cause the a_rtank tr_ unexpectedly rupture

allowing pressurized air to suddenly and forcefully escape, posing risk of injury to

consumers°

Your compressor air tank must be removed from servfce by'the end of the year

ShOWnon your tank warning label

The following conditions could toad to a weakening of the air tank and result in a

violent air tank explosion:

WHAT CAN HAPPEN

Failure to properly drain condensed

water from air tank. causing rust

and thinning of the steel air tank.

Modifications or attempted

repairs to the air tank.

I HOW TO PREVENT IT

if air tank devebes a leak. replace

it immediately with a new air tank

or replace the entire compressor.

_a_o y

modifications to the air tank or its

attachments. Never attempt to

io rain air tank daily or after each use.

repair a damaged or leaking air

tank. Replace with a new air tank.

Unauthorized modifications

to the safety vatve or any

other components which

control air taek pressure;

specific operating pressures.

Never make adjustments or

'The air tank is designed to withstand

parts substitutions to alter the

factory set operating pressures.

Attachments &accessories:

Exceeding the pressure rat-

ing of air tooB, spray guns, air

operated accessories, tires,

and other inSatables can cause

them to explode or fly apart, and

could result in serious injury.

Follow the equipment manufacturers

recommendation and never exceed

the maximum allowable pressure

rating of attachments, Never use

compressor to inflate small low

pressure objects s_ch as children's

toys, footbals, basketbails, etc,

5- ENG

_¢ _ RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN

Your compressor is powered by

electricity. Like any other electrically

Dowered device, if it is not used

properly it may cause electric shock.

Repairs attempted by unqualified

personnel can result in serious

injury or death by electrocution.

, Electrical Grounding; Failure to

provide adequate :Irounding to this

oroduct could result inserious injury

or oealh from electrocution. Refer to

Grounding Instructions paragraph

in the Installation section.

HOW TO PREVENT IT

Never operate the compressor

outdoors when it _s raining

or in wet conditions.

Never operate compressor

with protectwe covers

removea or oamageo.

Any eiezstdsal wiring or reoalrs

required on this product should be

performed by authorized set€ice

cen_er personnel in accordance with

national ann local electrical cooes.

Make certain that the electrical

circuit to which the compressor

is connected provides proper

electrical ground}ng, correct voltage

and adequate fuse protection.

WHAT CAN HAPPEN

The compressed air stream can

cause soft tissue damage to

exposed skin and can propel dirt,

chips, bose panicles, and small

objects at high speed, resulting in

property damage or personal {njury,

HOW TO PREVENT IT

Always wear certified safety

equipment_ ANSI Z87;1 eye

protection (CAN/CSA Z94_3)

with side shietds when

using the compressor.

Never point any nozzle or sprayer

toward any part of the body or

at other people or animats.

Alwa$rs turn the compressor

off and bleed pressure from

the air hose and air tank before

attempting maintenance,

attaching tools or accessories.

6_ ENG

WHAT CAN HAPPEN

RiSK OF HOT SURFACES

Touching e×posed metal such

as the compressor head, engine

head, engine exhaust or outlet

tubes, can result in serious burns.

HOW TO PREVENT IT

Never touch any exposed metal

parts on compressor during or

immediately after operation.

Compressor witl remain hot for

several minutes after operation.

Do not reach around protective

shrouds or attempt maintenance

until unit has been allowed to cool

WHAT CAN HAPPEN

Moving parts such as the pulley,

flywheel, and be!t can cause

serious injury if they come into

contact with you or your clothing.

o A[tempting to operate compressor

with damaged or missing parts or

attempting to repair compressor

with protective Shrouds removed

can expose you to moving parts

.........and can resg!t!n serious injury.

MOVING PARTS

HOW TO PREVENT _T

Never operate the compressor

with guards or covers which

ere damaged or removed,

Keep your hair, clothing, and

gI0ves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts_

Air vents may cover moving parts

and should be avoided as well

Any repairs requi_ed on this product

should be performed by authorized

service center personnel.

7 ENG

RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN

Unsafe operation of your

compressor could lead to serious

injury or death to you or others.

HOW TO PREVENT IT

Review and understand ail

instructions and warnings

in this manual.

Become familiar with the operation

and controls of tile air compressor.

Keep operating area ctear of ail

persons, pets, arid obstacles.

Keep children away'from the

air compressor at all times.

Do not operate the product

when fatigued or under the

influence of alcohol or drugs.

Stay alert at all times,

Never defeat the safety fea-

tures of this product.

Equip area of operation

with a fire extinguisher.

Do not operate machine

with missing, broken, or

WHAT CAN HAPPEN L HOW TO PREVENT IT

OF FALLING

from a table, workbench, or roof stable secure position to prevent

causing damage to the compressor accidental movement of the unit.

and could result in serious injuc_ Never operate compressor on a

or death to the operator, roof or other elevated position. Use

A portable Compressor can falt [_' Ak_ayS operate compressor in a

additiona! air hose tO reach high

locations.

8- ENG

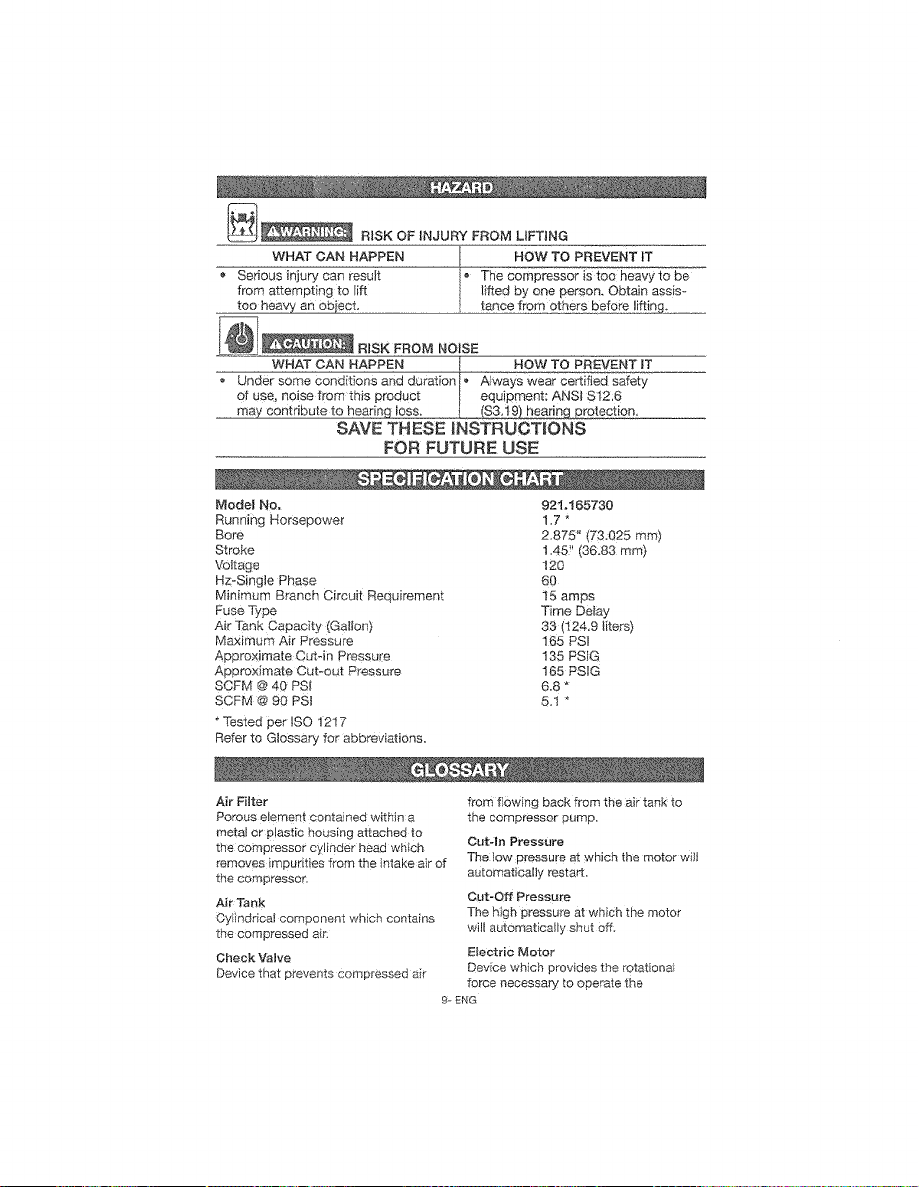

RiSK OF INJURY FROM LIFTING

WHAT CAN HAPPEN I HOW TO PREVENT IT

from attempting to lift lifted by one person. Obtain assis-

Serious injury can result _ The compressor is too heavy to be

too heavy an 0biect. tahoe from others before lifting:_..=.

WHAT CAN HAPPEN HOW TO PREVENT iT

RtSK FROM NOISE

Under some conditions and duration Always wear certified safety

of use, noise from this product equipment: ANSI $12:6

may contribute to hearing loss, (S&

SAVE THESE ItNSTRUGTIONS

FOR FUTURE USE

Model No, 92% f 65730

Runnir_g Horsepower 1.7 "

Bore 2.875* (73 Q25 ram)

Stroke 1,451' (3&83 mrn}

Vokage t20

Hz-Single Phase 60

Minimum Branch Circuit Requirement 15 amps

Fuse Type Time De_ay

Air Tank Capacity (Gallon} 33 (124.9 liters)

Maximum Air Pressure 165 PSI

Approximate Cutqn Pressure 135 PSIG

Approximate Cut_out Pressure 165 PSIG

SCFM @40 PSI 6.8 *

SCFM @ 90 PS_ 5,1 *

• Tested per tSO 1217

Refer to Glossary for abbreviations.

Air Filter

Porous e!emerlt contained within e

mete{ or plastic housing attached ta

the compressor cyllnder head which

removes impurities from the intake air of

the compressor,

Air Tank

CylindrioaJ component wMch contains

the compressed air.

Cheek Valve

Device that preve_ts compressed air

from flowing back from the air tank to

the compressor pump,

Outqn Pressure

The low pressure at which the motor wi;}

automatically restart.

Cut-Off Pressare

The high pressure at which the motor

will automatically shut off

Electric Motor

Device which provides the rotational

force necessary to operate the

9- ENG

compressorDump.

NPT[NationalPipeThread)

Asealthreadtapemustbeusedto

erovBaealeak-freesealorpipe[nreaaea

connections,

PressureRegulatorKnob

Regulatestheoutgoingpressurefrom

[neaftoutlettothetool._tisPossibleto

Bncreaseordecreaseteepressurea[me

outletbyadjustingthiscontrolknob.

PressureSwitch

Automaticallycontrolstheon/off

cyclingofthecompressor,itstopsthe

comoressorwhenthecut-offuressure.

7thetankisreachedandstartsthe

comuressorwhentheairpressurearops

belowthecutdnpressure.Thearessure

switchwillnotautomaticallys_aRanu

CONtrolthecompressorunlesstee

manualAUTO/OffSwitchi£inthe

AUTOposition.

Pump

Producesthecompressesairwitha

reciprocaungpistoncontainedwithinthe

cylinder.

RegulatorPressureGauge

Displaysthecurrentlineeressure.Line

Dressureisadiustedbyrotatinglhe

pressureregulatorknob,

PressureReliefValve

Preventsairaressure in the air tank from

rising over a oredetermined twsit,

SCFM (Standard Cubic Feet Per Minute)

A unit of measure of air deliver_,

Tank Pressure Gauge

Indicates the aressure in the air tank,

Thermal Overload Switch

Automatically shuts off the compressor

if the temoerature of the eJectric motor

exceeds a predetermined limit.

PSI(PoundsPerSquareInch)

Measurementofthepressureexerted

bytheforceoftheair.TheactualPS!is

measuredbyapressuregaugeonthe

compressor.

This air compressor pump is capable of running continuously. However, to p_otoeg

the _ife of yoLir air compressor, it is recommended that a 50% W5% average duty

cycIe be maintained; that is; the air compressor pump should not run more than 30-

45 minutes in any given hour,

Accessories for this unit are available at the store the unit was purchased,

The use of any other accessory not recommended for use with this tool could

be hazardous, Use o_ly accessories rated equal to or higher than the rating of

the air compressor.

10-ENG

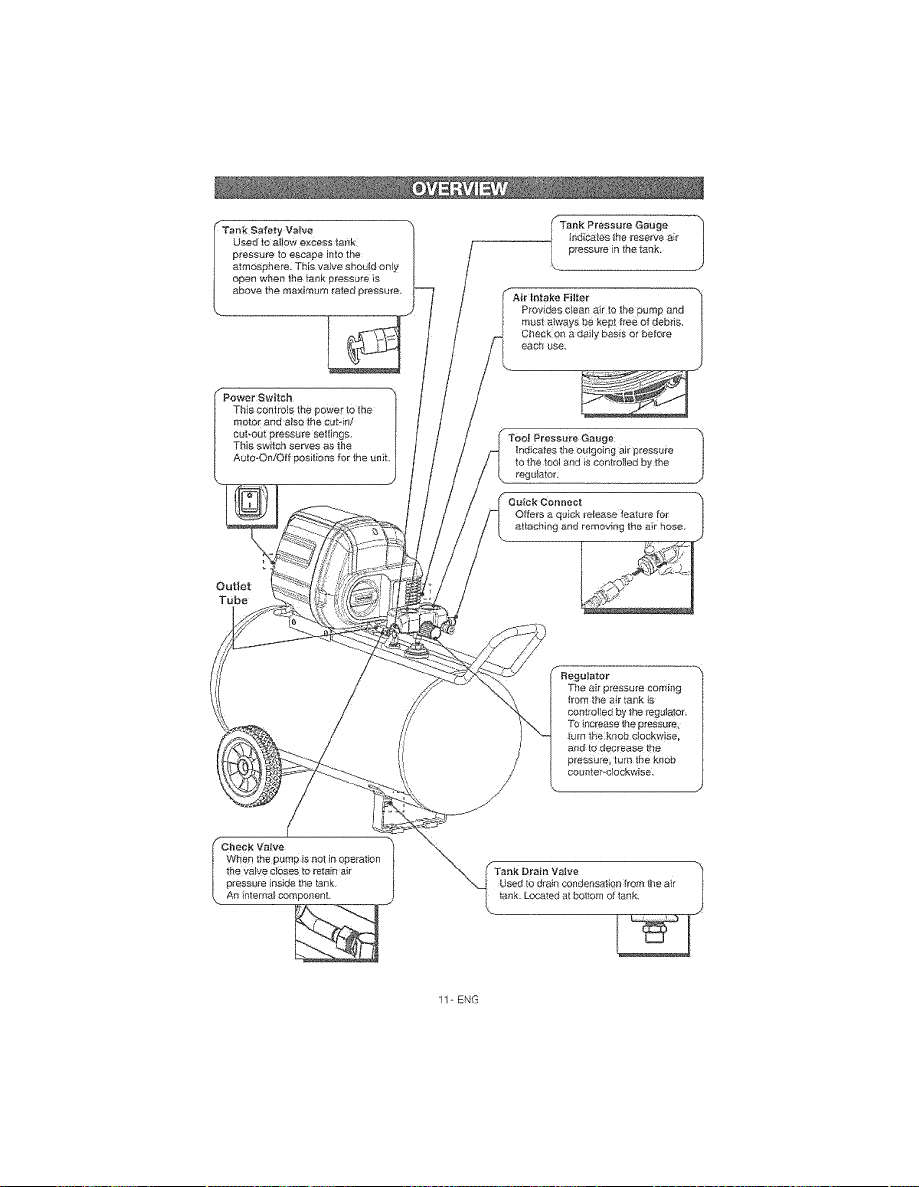

Valve

Used to 8_!OW excess t_nk

p_essure to escape intothe

_tmosphere This valve should only

open when the tank pressure is

above the rns_:iraum rate¢_ ptessure_

This ¢eet role the power to the

motor and a_so _he ct4-in/

c_t.o_t pressure settings,

Th_s switsh serves as _he

Auto_O[1/Off positioRs for _he unit

ir_d[cAtes the rsserve air

I Tank Pressure Gauge -I

p_essure in the t_k.

Pressure Gauge

Indicates the outgoing air pressure

to the tool and is contro;ied by the

regulator;

Offers & qt_ick _s[ease feature fe_

attaching and removing the air hose.

ulster

The ak' pressure sorak_g

irom the air tank is

sestrolfed by the regu_ator_

'To increase the pressure;

ium tRe knob elockw!se,

and to decrease the

pressure turn the knob

couhter-clockwise_

_Tank Drain Val_e

_j_ Used to dra_s condensation from the air

i tank. Located a_ bottom of tank;

11- ENG

ASSEMBLING THE COMPRESSOR

The air corneressor should Re turner[ off. unplugged from me Dower source, me

air b_ed from the tank and the unit allowed time to cool before any maintenance

is performed. Personal in unes could occur from moving parrs, electrical sources,

compressed air or hot surfaces. The quick CoRRect aes_rnbly must Be a_tached

before use. Failure to assemble correctly could result in eak:s and possible injury,

If unsure of assembfy instructions or you experience difficulty in the assembly u_ease

ca_r/our local service department for further info-mabon.

UneacK me air comnressor Inseect the unit for damage, if the unit has been

damaged in transit contact the carrier are complete a damage claim. Do this i

mmediately because there are time limitations to damage claims

2.

Check me comaressor'e seria label to ensure that you have received the model

oroerec and that it has the requires pressure raung for its intended use.

3,

Locate the compressor according to the foflowing guidelines:

a. Position the compressor near a grounded e!ectdcal outIet.

b, The compressor must be at least 12 inches (3I cm} from any wall or

Obstruction, in a clean welt-ventilated area, to ensure sufficient air flow and

cooling.

c, In cold climates, store portable compressors in a heated building when

act in use. This will reduce problems with motor starting and freezing of

water condensation.

d. Remove the compressor from the carton and place it on the floor or a hard,

level surface The compressor must be level to ensure proper drainage of

the moisture in the tank.

12- ENG

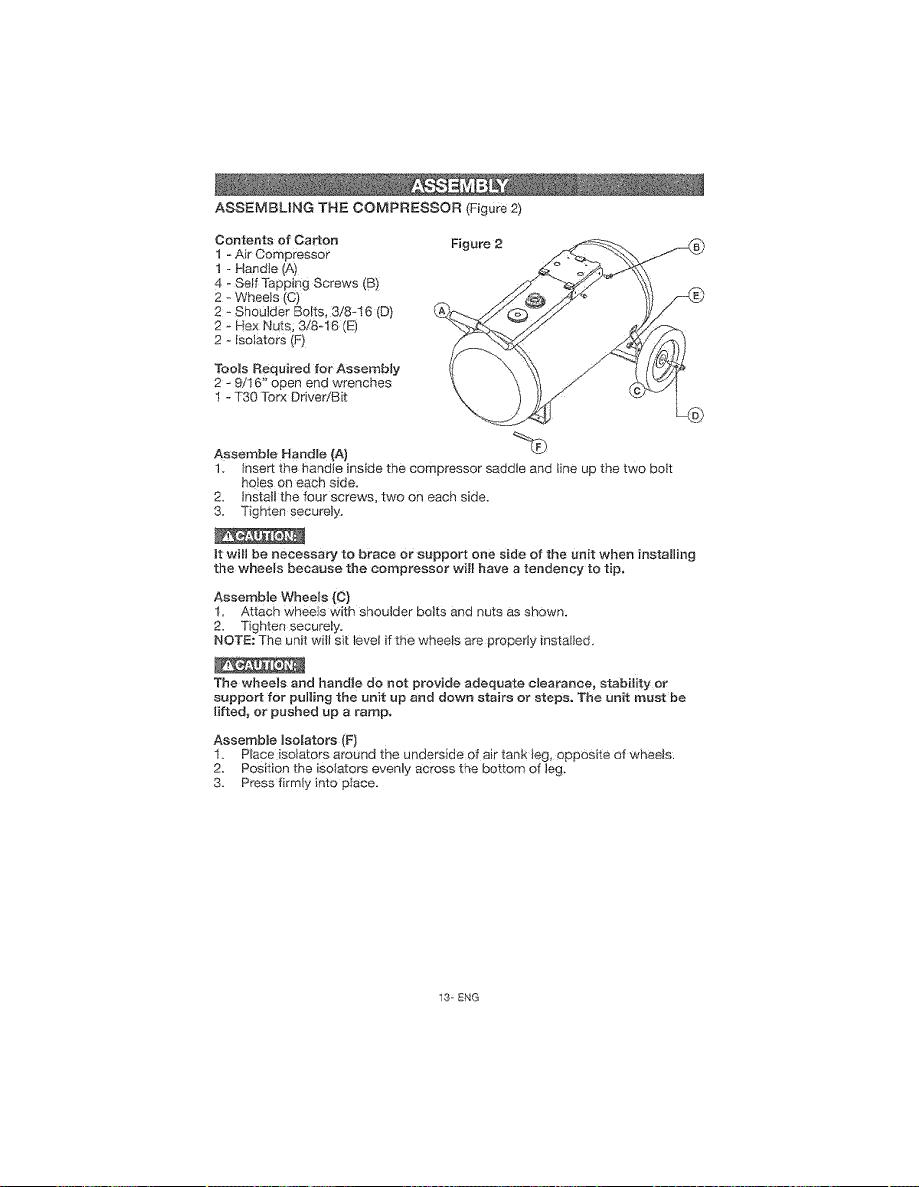

ASSEMBLING THE COMPRESSOR (Figure 2)

Contents of Car_on

1 - Air Compressor

1 - Handle (A)

4 - Seff Tapping Screws ([3)

2 - Wheels (C)

2- Shoulder Bolts, 3/8-16 (D)

2 - Hex Nuts; 3/8-16 (E)

Figure 2

2 __so_ators (F)

Tools Required for Assembly

2 - 9/16" open end wrenches

1 - T30 Torx Driver/Bit

Assemble Handle (A)

1. Insert the handle inside the compressor saddle and line up the two bo{t

holes on each side.

2 _nstall the four screws, two on each side.

3. Tighten securely.

It will be necessary to brace or support one side of the unit when insta[IMg

the wheefs because the compressor will have a tendency to tip,

Assemble Wheels (C)

1, Attach wheels with shoulder bolts and nuts asshown.

2, Tighten secureJy.

NOTE: The unit will sit level if the wheels are proper_y installed

The wheels and handle do not provide adequate clearance, stability or

support for pulling the unit up and down stairs or steps. The unit must be

Iifted, or pushed up a ramp,

Assemble _so[ators (F)

1. P_ace isolators around the underside of air tank ieg, opposite of wheels:

2. Position the isolators evenly across the bottom of leg,

3. Press firmly into place.

13- ENG

GETTING STARTED

Location of the Air Compressor

The air compressor should aJways be located in a clean, dry and welt ventilated

environment. The unit should have at minimum, 12 inches of space on each side,

The air filter intake should be free of any debris or obstructions. Check the air filter

on a daily basis to make sure it is clean and in working order.

Risk Of Fire Or E×plosioa

This product incorporates snap action switch contacts and a universal eiectdo

meter which tend to produce arcs end soarking aria therefore should not

oe exposed _o flammable liquids or vapors. This oroduct is net intended for

instal{orion or use in a corrlmerciat garage or shoo environment.

Greut_ding instructions

This sroeuc{ must be grounoee, n the event of an electrical short circuit

grounding reduces the risk of electric shock by providing an escaee wwe for

the electric current_ This product is eeuipped with a cord hav;ng a grounding

wire with an appropriate grounding plug The pDug must be pJugged into an

outlet that is oroeefl_ fnstalled and grounded in accordance with all toca_ codes

one ordinances. Check with s qualified electrician or service personnel if these

instructions are not completely understood or ff in doubt as to whether the tool

is propeny grounded.

_mproper installation of the grounding Dug Nill result

in e risk of electric shock, f repair or replacement

of the cord or plug Is necessary, do not connect the

grounding wire to either flat blade terrains. The wire

with insulation having an outer surface that is green with or without yellow

stripes is the grounding wire. Check with a eudifJed electrician or servlcemar

if the groune_ng instructions are not comp/eteP, understood, or if in doubt as _o

whether the eroduct is property grounded. Do not modify the plug proweee: it it

w_tl not fix tee outlet, have the oroper outlet installed by a qualified electrician.

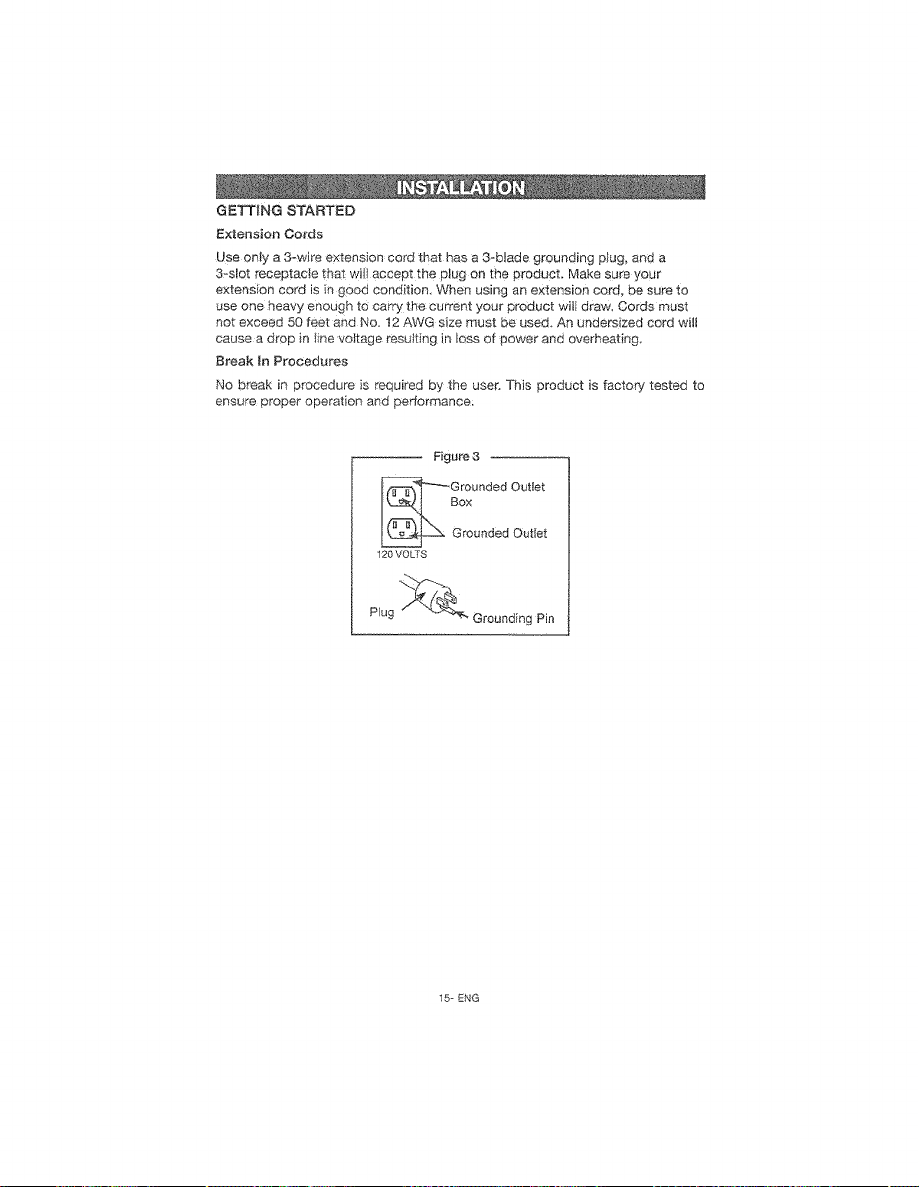

This product _s for use on a nominal 120-V circuit and has a grounding plug

eimi[ar to tne e_ug illustrated in (Figure 3), Only connect the product to an outlet

having the same configuration as the plug. Do not use an adapter with this

proeuc[.

14_ ENG

GETT|NG STARTED

E×tensian Cords

Use only a 3-wire extension cord that has a 3-Made grounding plug, and a

3-slot receptacle that will accept the pJug on the product. Make sure your

extension cord is in good condition, When using an extension cord, be sure to

use one heavy enough to carry the current your product wilt draw. Cords must

not exceed 50 feet and No, 12 AWG size must be used, An undersized cord will

cause a drop in fine vo_tage resulting in less of power and overheating,

Break _n Procedures

No break in procedure is required by the user, This product is factor,/tested to

ensure proper operation and performance:

-- Figure8

Grounded Outlet

Box

120 VOLTS

Plug Grounding Pin

Grounded Outlet

15-_NG

Loading...

Loading...