Page 1

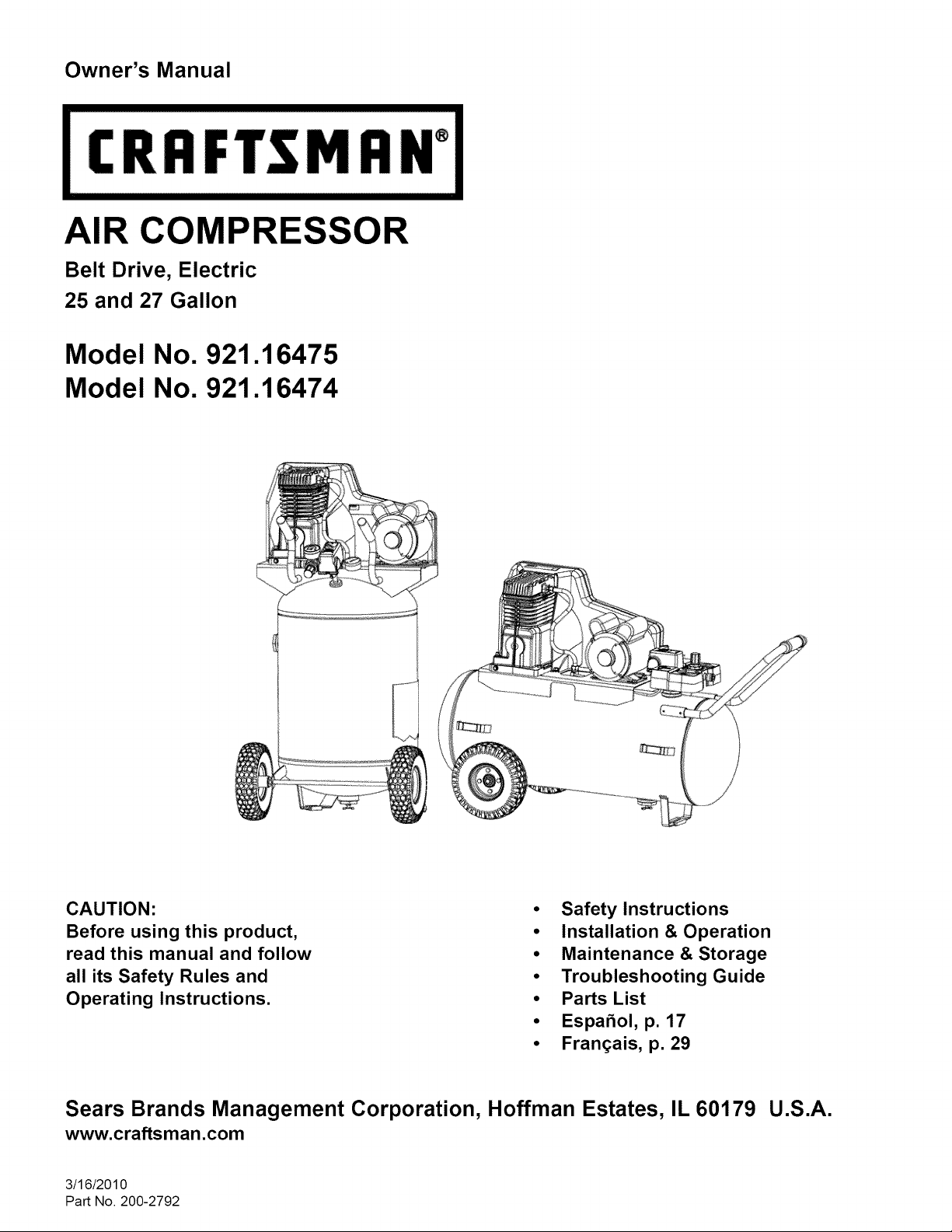

Owner's Manual

AIR COMPRESSOR

Belt Drive, Electric

25 and 27 Gallon

Model No. 921.16475

Model No. 921.16474

®

CAUTION:

Before using this product,

read this manual and follow

all its Safety Rules and

Operating Instructions.

• Safety Instructions

• Installation & Operation

• Maintenance & Storage

• Troubleshooting Guide

• Parts List

• Espa_ol, p. 17

• Fran_:ais, p. 29

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.craftsman.com

3/16/2010

Part No. 200-2792

Page 2

i_:_:]|: Co]_[a_o]_/ i :__/ l_'_

WARRANTY ....................................... 2

SPECIFICATION CHART ............................ 2

SAFETY GUIDELINES ............................. 3-4

GLOSSARY OF TERMS ............................. 4

OVERVIEW ....................................... 5

Basic Air Compressor Components ................. 5

ASSEMBLY ....................................... 5

COMPRESSOR CONTROLS ......................... 6

MOTOR RESET AND WIRING ........................ 6

ELECTRICAL POWER REQUIREMENTS ............... 7

Electrical Wiring ................................ 7

Extension Cords ................................ 7

Grounding Instructions ........................... 7

OPERATING INSTRUCTIONS ........................ 8

Break-in of the Pump ............................ 8

Daily Startup ................................... 8

Shutdown ..................................... 8

MAINTENANCE .................................... 9

Draining the Tank ............................... 9

Checking the Oil ................................ 9

Changing the Oil ................................ 9

Belt Tension and Pulley Alignment ............... 9-10

Replacing or Cleaning the Check Valve ............. 10

Cleaning the Air Filter ........................... 11

Checking the Relief Valve ........................ 11

Testing for Leaks .............................. 11

Storage ...................................... 11

SERVICE INTERVAL ............................... 11

TROU BLESHOOTI NG CHART ....................... 12

PARTS DRAWINGS AND PARTS LISTS ............. 13-17

kv,vh._t_t_F:_blk"4

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted against any defects in material or workmanship.

Defective product will receive free repair or free replacement if repair is unavailable.

For warranty coverage details to obtain repair or replacement, visit the web site: www.craftsman.com

This warranty does not cover the air filter or drive belt, which are expendable parts that can wear out from normal use

within the warranty period.

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

[,,,___o] _I[_

RUNNING TANK CAPACITY VOLTAGE/ KICK-IN KICK-OUT

MODEL NO. H.P. GALLONS AMPS/PHASE PRESSURE PRESSURE

921.16474 120 150

(WLB1982713) 1.9 Vert. 27 (102) 115/15/1 (8,27 bar) (10,34 bar)

921.16475 120 150

(WPB1982513) (8,27 bar) (10,34bar)

1.9 Horiz. 25 (94,6) 115/15/1

2 200-2792

Page 3

ThefollowinginformationrelatestoprotectingYOURSAFETYandPREVENTINGEQUIPMENTPROBLEMS.Tohelpyourecognize

thisinformation,weusethefollowingsymbols.Pleasereadthemanualandpayattentiontothesesections.

__ - A POTENTIAL HAZARD THAT WILL CAUSE SERIOUS INJURY OR LOSS OF LIFE.

_L_- A POTENTIAL HAZARD THAT COULD CAUSE SERIOUS INJURY OR LOSS OF LIFE.

__ - A POTENTIAL HAZARD THAT MAY CAUSE MODERATE INJURY OR DAMAGE TO

EQUIPMENT.

RISK OF FIRE OR EXPLOSION.

RISK OF BURSTING.

RISK OF ELECTRICAL SHOCK.

RISK OF INJURY.

r

RISK OF BURSTING.

RISK OF BURNS.

Never spray flammable liquids in a confined area. It is normal for the motor and pressure switch to

produce sparks while operating. If sparks come into contact with vapors from gasoline or other

solvents, they may ignite, causing fire or explosion. Always operate the compressor in a

well-ventilated area. Do not smoke while spraying. Do not spray where sparks or flame are

)resent. Keep compressor as far from spray area as possible.

Do not weld, drill or modify the air tank of this compressor. Welding or modifications on the air

compressor tank can severely impair tank strength and cause an extremely hazardous condition.

Welding or modifying the tank in any manner will void the warranty.

Never use an electric air compressor outdoors when it is raining or on a wet surface, as it may

cause an electric shock.

This unit starts automatically. ALWAYS shut off the compressor, remove the plug from the outlet,

and bleed all pressure from the system before servicing the compressor, and when the compressor

is not in use. Do not use the unit with the shrouds or belt guard removed. Serious injury could occur

from contact with moving parts.

Check the manufacturer's maximum pressure rating for air tools and accessories. Compressor

outlet pressure must be regulated so as to never exceed the maximum pressure rating of the tool.

Relieve all pressure through the hose before attaching or removing accessories.

High temperatures are generated by the pump and manifold. To prevent burns or other injuries, DO

NOT touch the pump, manifold or transfer tube while the pump is running. Allow them to cool

before handling or servicing. Keep children away from the compressor at all times.

RISK TO BREATHING.

RISK OF EYE INJURY.

RISK OF BURSTING.

RISK OF BURSTING.

200-2792 3

Be certain to read all labels when you are spraying paints or toxic materials, and follow the safety

instructions. Use a respirator mask if there is a chance of inhaling anything you are spraying. Read

all instructions and be sure that your respirator mask wilt protect you. Never directly inhale the

compressed air produced by a compressor. It is not suitable for breathing purposes.

Always wear ANSI Z87.1 approved safety goggles when using an air compressor. Never point any

nozzle or sprayer toward a person or any part of the body. Equipment can cause serious injury

if the spray penetrates the skin.

Do not adjust the relief valve for any reason. Doing so voids all warranties. The relief valve has

been pre-set at the factory for the maximum pressure of this unit. Personal injury and/or property

damage may result if the relief valve is tampered with.

Do not use plastic or pvc pipe for compressed air. Use only galvanized steel pipe and fittings for

compressed air distribution lines.

Page 4

kvlv/-'1r,,1_II_[-e"]

RISK TO HEARING.

Always wear hearing protection when using an air compressor. Failure to do so may result in

hearing loss.

The power cord on this product contains lead, a chemical known to the State of California to cause

cancer, and birth defects or other reproductive harm. Wash hands after handling.

NOTE: ELECTRICAL WIRING.

Drain the moisture from the tank on a daily basis. A clean, dry tank will help prevent corrosion.

Pull the pressure relief valve ring daily to ensure that the valve is functioning properly, and to clear the valve of any possible

obstructions.

To provide proper ventilation for cooling, the compressor must be kept a minimum of 12 inches (31 cm) from the nearest wall, in a

vvell-ventilated area.

Fasten the compressor down securely if transporting is necessary. Pressure must be released from the tank before transporting.

Protect the air hose and electric cord from damage and puncture. Inspect them weekly for weak or worn spots, and replace if

necessary.

To reduce the risk of electric shock, do not expose to rain. Store indoors.

Never operate the compressor ifthe power cord or plug are damaged. Have the unit serviced at a Sears or other qualified service

center.

Refer to the air compressor's serial label for the unit's voltage and amperage requirements. Ensure

[hat all wiring is done by a licensed electrician, in accordance with the National Electrical code.

CFM

Cubic feet per minute; a unit of measure of air flow.

PSI

Pounds per square inch; a unit of measure of air pressure.

Kick-in pressure

Factory set low pressure point that starts the compressor to repressurize the tank to a higher pressure.

Kick-out pressure

Factory set high pressure point that stops the compressor from increasing the pressure in the tank above a certain level.

Well-ventilated

A means of providing fresh air in exchange for dangerous exhaust or vapors.

Dedicated circuit

An electrical circuit reserved for the exclusive use of the air compressor.

4 200-2792

Page 5

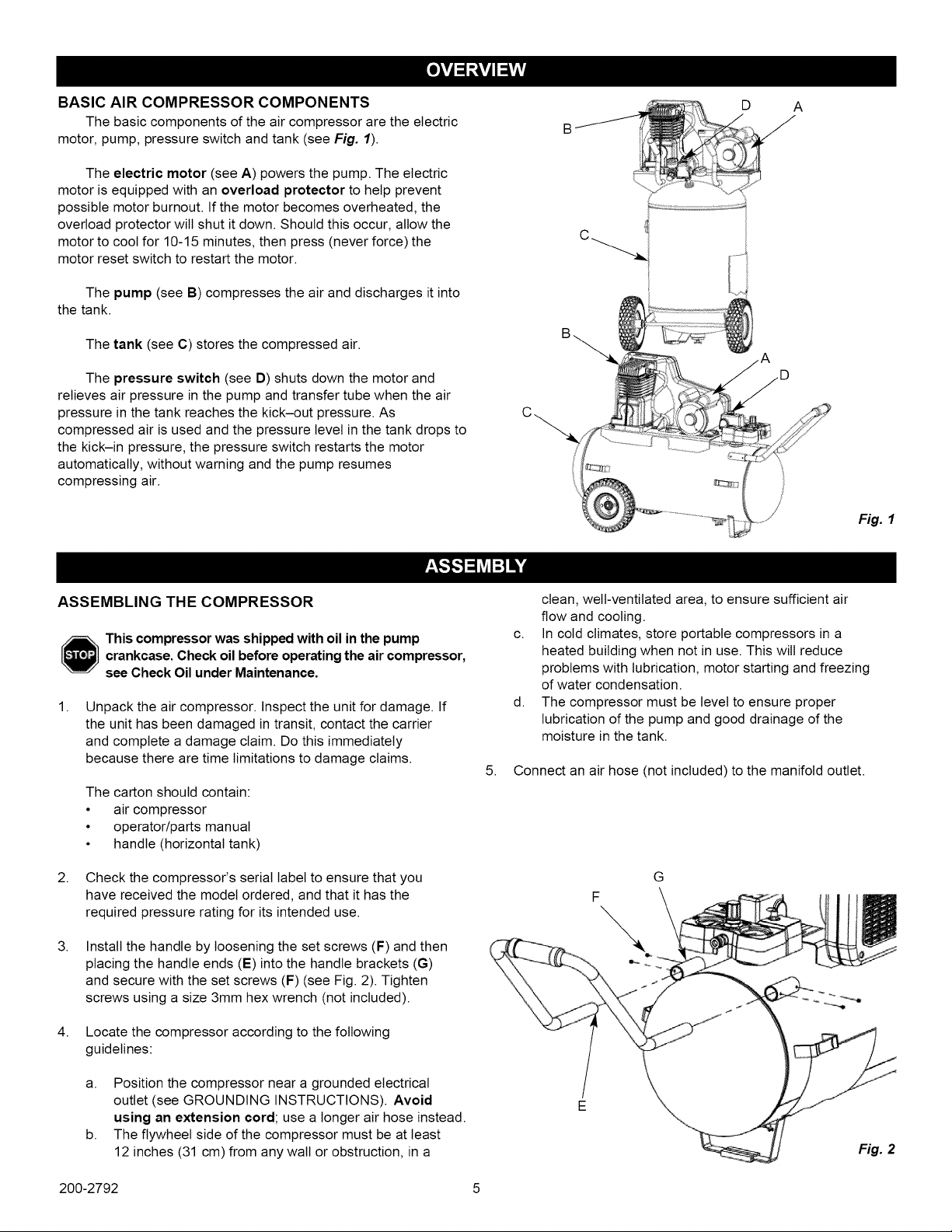

BASIC AIR COMPRESSOR COMPONENTS

The basic components of the air compressor are the electric

motor, pump, pressure switch and tank (see Fig. 1).

The electric motor (see A) powers the pump. The electric

motor is equipped with an overload protector to help prevent

possible motor burnout. If the motor becomes overheated, the

overload protector will shut itdown. Should this occur, allow the

motor to cool for 10-15 minutes, then press (never force) the

motor reset switch to restart the motor.

The pump (see B) compresses the air and discharges it into

the tank.

The tank (see C) stores the compressed air.

The pressure switch (see D) shuts down the motor and

relieves air pressure in the pump and transfer tube when the air

pressure in the tank reaches the kick-out pressure. As

compressed air is used and the pressure level in the tank drops to

the kick-in pressure, the pressure switch restarts the motor

automatically, without warning and the pump resumes

compressing air.

B i ,

i

A

D

Fig. 1

ASSEMBLING THE COMPRESSOR

This compressor was shipped with oil in the pump

crankcase. Check oil before operating the air compressor,

see Check Oil under Maintenance.

1.

Unpack the air compressor. Inspect the unit for damage. If

the unit has been damaged in transit, contact the carrier

and complete a damage claim. Do this immediately

because there are time limitations to damage claims.

The carton should contain:

• air compressor

• operator/parts manual

• handle (horizontal tank)

2. Check the compressor's serial label to ensure that you

have received the model ordered, and that it has the

required pressure rating for its intended use.

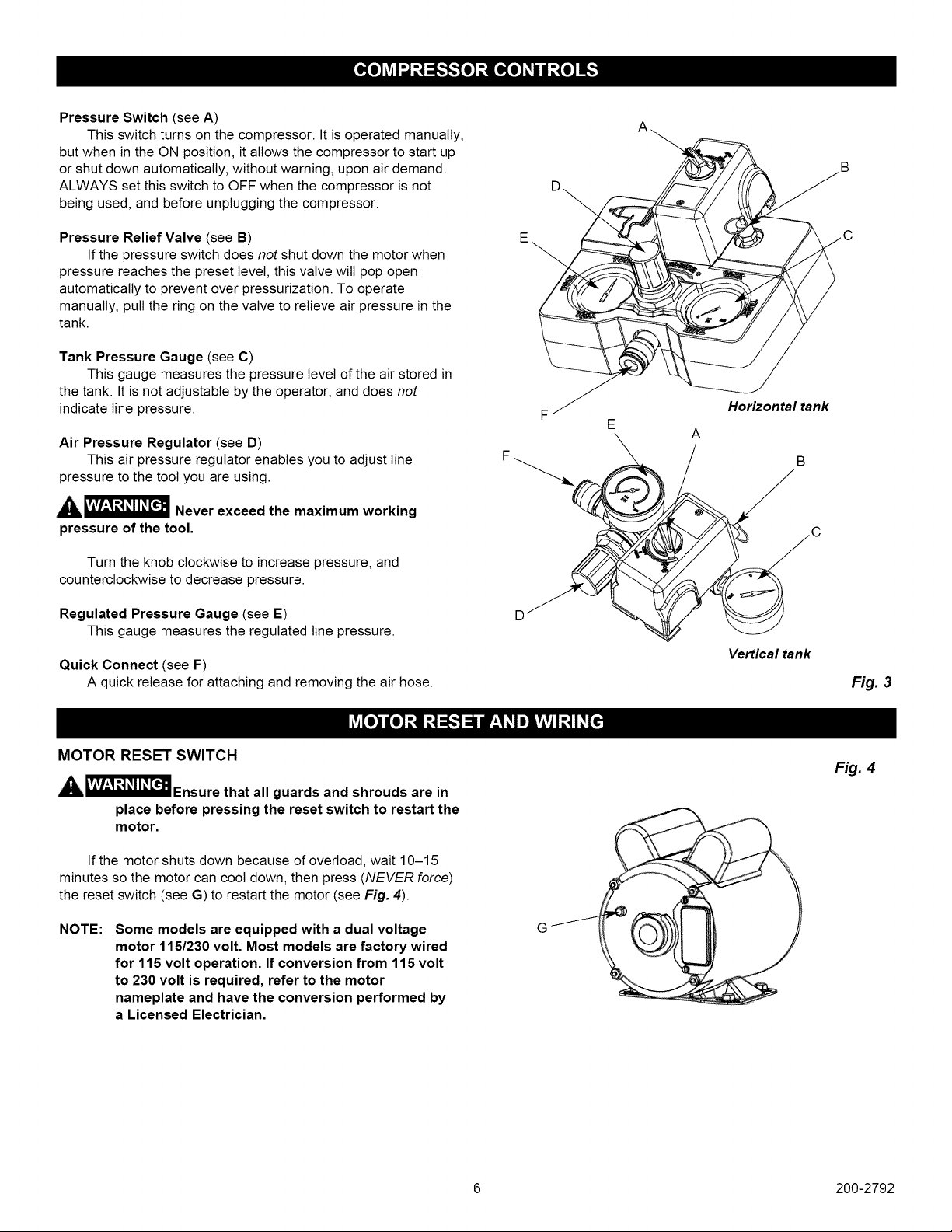

3.

Install the handle by loosening the set screws (F) and then

placing the handle ends (E) into the handle brackets (G)

and secure with the set screws (F) (see Fig. 2). Tighten

screws using a size 3mm hex wrench (not included).

4. Locate the compressor according to the following

guidelines:

clean, well-ventilated area, to ensure sufficient air

flow and cooling.

c. In cold climates, store portable compressors in a

heated building when not in use. This wilt reduce

problems with lubrication, motor starting and freezing

of water condensation.

d. The compressor must be level to ensure proper

lubrication of the pump and good drainage of the

moisture in the tank.

5. Connect an air hose (not included) to the manifold outlet.

G

F

\

a. Position the compressor near a grounded electrical

outlet (see GROUNDING INSTRUCTIONS). Avoid

using an extension cord; use a longer air hose instead.

b. The flywheel side of the compressor must be at least

12 inches (31 cm) from any wall or obstruction, in a

200-2792 5

E

Fig. 2

Page 6

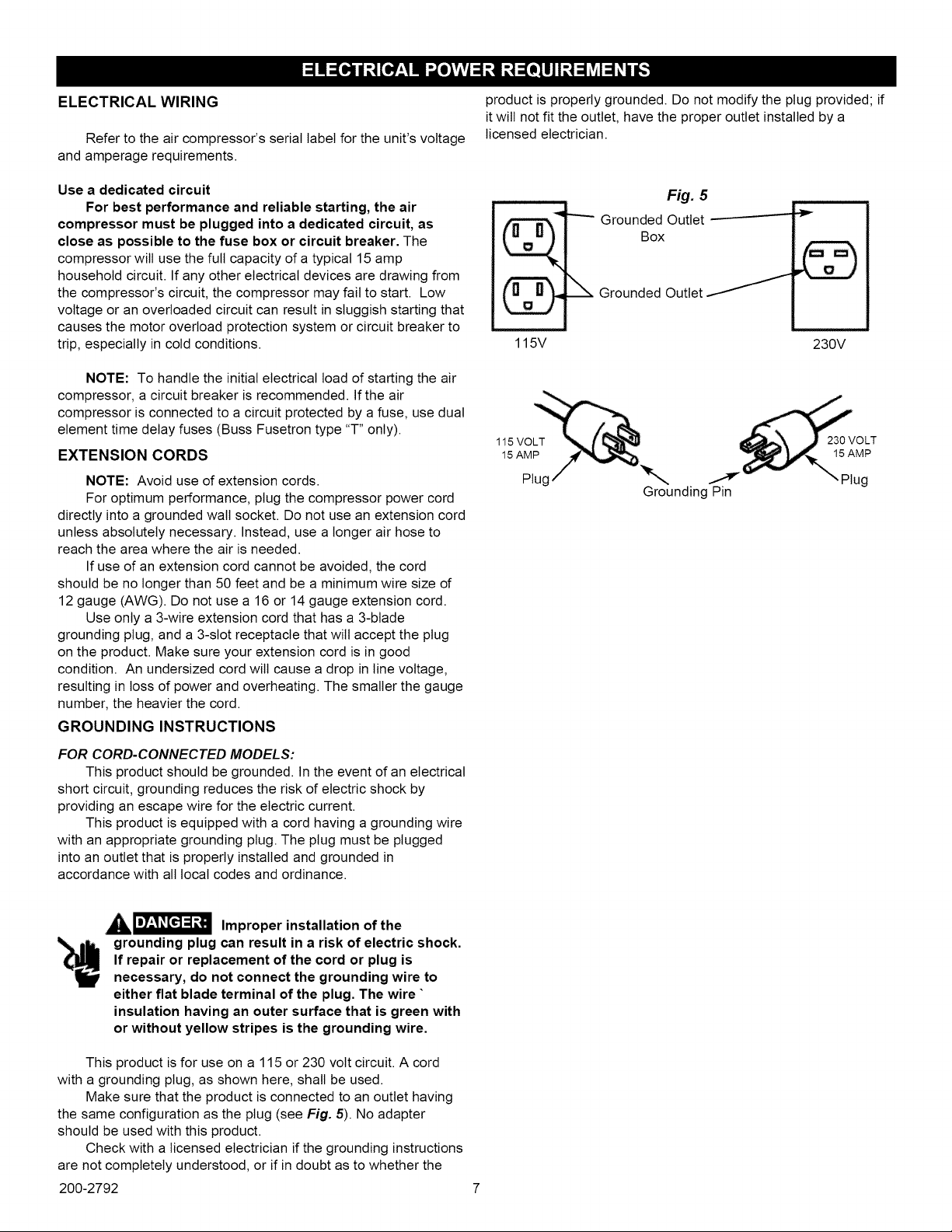

Pressure Switch (see A)

This switch turns on the compressor. It is operated manually,

but when in the ON position, it allows the compressor to start up

or shut down automatically, without warning, upon air demand.

ALWAYS set this switch to OFF when the compressor is not

being used, and before unplugging the compressor.

Pressure Relief Valve (see B)

If the pressure switch does not shut down the motor when

pressure reaches the preset level, this valve wilt pop open

automatically to prevent over pressurization. To operate

manually, pull the ring on the valve to relieve air pressure in the

tank.

Tank Pressure Gauge (see C)

This gauge measures the pressure level of the air stored in

the tank. It is not adjustable by the operator, and does not

indicate line pressure.

Air Pressure Regulator (see D)

This air pressure regulator enables you to adjust line

pressure to the tool you are using.

__ Never exceed the maximum working

pressure of the tool.

Turn the knob clockwise to increase pressure, and

counterclockwise to decrease pressure.

B

Horizontal tank

A

B

Regulated Pressure Gauge (see E)

This gauge measures the regulated line pressure.

Quick Connect (see F)

A quick release for attaching and removing the air hose.

MOTOR RESET SWITCH

__Ensure that all guards and shrouds are in

place before pressing the reset switch to restart the

motor.

If the motor shuts down because of overload, wait 10-15

minutes so the motor can cool down, then press (NEVER force)

the reset switch (see G) to restart the motor (see Fig. 4)

NOTE:

Some models are equipped with a dual voltage

motor 115/230 volt. Most models are factory wired

for 115 volt operation. If conversion from 115 volt

to 230 volt is required, refer to the motor

nameplate and have the conversion performed by

a Licensed Electrician.

Vertical tank

Fig. 3

Fig. 4

G

6 200-2792

Page 7

ELECTRICAL WIRING

Refer to the air compressor's serial label for the unit's voltage

and amperage requirements.

product is properly grounded. Do not modify the plug provided; if

it will not fit the outlet, have the proper outlet installed by a

licensed electrician.

Use a dedicated circuit

For best performance and reliable starting, the air

compressor must be plugged into a dedicated circuit, as

close as possible to the fuse box or circuit breaker. The

compressor will use the full capacity of a typical 15 amp

household circuit. If any other electrical devices are drawing from

the compressor's circuit, the compressor may fail to start. Low

voltage or an overloaded circuit can result in sluggish starting that

causes the motor overload protection system or circuit breaker to

trip, especially in cold conditions.

NOTE: To handle the initial electrical toad of starting the air

compressor, a circuit breaker is recommended. If the air

compressor is connected to a circuit protected by a fuse, use dual

element time delay fuses (Buss Fusetron type "T" only).

EXTENSION CORDS

NOTE: Avoid use of extension cords.

For optimum performance, plug the compressor power cord

directly into a grounded walt socket. Do not use an extension cord

unless absolutely necessary. Instead, use a longer air hose to

reach the area where the air is needed.

If use of an extension cord cannot be avoided, the cord

should be no longer than 50 feet and be a minimum wire size of

12 gauge (AWG). Do not use a 16 or 14 gauge extension cord.

Use only a 3-wire extension cord that has a 3-blade

grounding plug, and a 3-slot receptacle that wilt accept the plug

on the product. Make sure your extension cord is in good

condition. An undersized cord will cause a drop in line voltage,

resulting in loss of power and overheating. The smaller the gauge

number, the heavier the cord.

GROUNDING INSTRUCTIONS

115V

115 VOLT

15 AMP

Plug

Fig. 5

""- Grounded Outlet

Box

_ Grounded Outlet

230V

,,...

Grounding Pin

FOR CORD-CONNECTED MODELS:

This product should be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current.

This product is equipped with a cord having a grounding wire

with an appropriate grounding plug. The plug must be plugged

into an outlet that is properly installed and grounded in

accordance with all local codes and ordinance.

IL_ Improper installation of the

grounding plug can result in a risk of electric shock.

If repair or replacement of the cord or plug is

necessary, do not connect the grounding wire to

either fiat blade terminal of the plug. The wire"

insulation having an outer surface that is green with

or without yellow stripes is the grounding wire.

This product is for use on a 115 or 230 volt circuit. A cord

with a grounding plug, as shown here, shall be used.

Make sure that the product is connected to an outlet having

the same configuration as the plug (see Fig. 5). No adapter

should be used with this product.

Check with a licensed electrician if the grounding instructions

are not completely understood, or if in doubt as to whether the

200-2792

Page 8

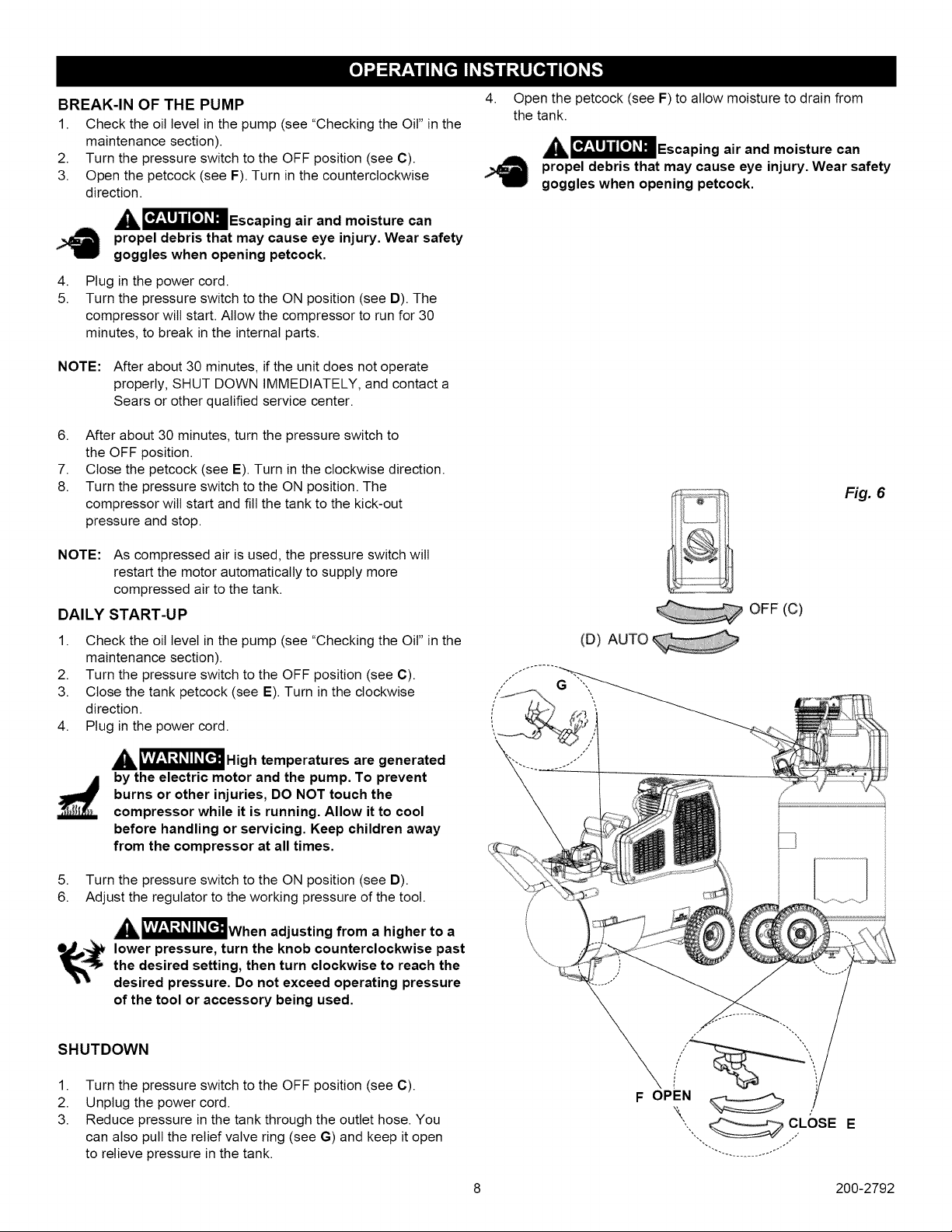

BREAK-INOFTHEPUMP

1. Checktheoillevelinthepump(see"CheckingtheOil"inthe

maintenancesection).

2. TurnthepressureswitchtotheOFFposition(seeC).

3. Openthepetcock(seeF).Turninthecounterclockwise

direction.

__Escaping air and moisture can

propel debris that may cause eye injury, Wear safety

goggles when opening petcock,

4.

Plug in the power cord.

5.

Turn the pressure switch to the ON position (see D). The

compressor will start. Allow the compressor to run for 30

minutes, to break in the internal parts.

NOTE: After about 30 minutes, if the unit does not operate

properly, SHUT DOWN IMMEDIATELY, and contact a

Sears or other qualified service center.

6. After about 30 minutes, turn the pressure switch to

the OFF position.

7. Close the petcock (see E). Turn in the clockwise direction.

8. Turn the pressure switch to the ON position. The

compressor wilt start and fill the tank to the kick-out

pressure and stop.

4.

Open the petcock (see F) to allow moisture to drain from

the tank.

__Escaping air and moisture can

propel debris that may cause eye injury. Wear safety

goggles when opening petcock.

Fig. 6

NOTE: As compressed air is used, the pressure switch will

restart the motor automatically to supply more

compressed air to the tank.

DAILY START-UP

1. Check the oil level in the pump (see "Checking the Oil" in the

maintenance section).

2. Turn the pressure switch to the OFF position (see C).

3. Close the tank petcock (see E). Turn in the clockwise

direction.

4. Plug in the power cord.

__ High temperatures are generated

by the electric motor and the pump. To prevent

burns or other injuries, DO NOT touch the

compressor while it is running. Allow it to cool

before handling or servicing. Keep children away

from the compressor at all times.

5. Turn the pressure switch to the ON position (see D).

6. Adjust the regulator to the working pressure of the tool.

__When adjusting from a higher to a

lower pressure, turn the knob counterclockwise past

the desired setting, then turn clockwise to reach the

desired pressure. Do not exceed operating pressure

of the tool or accessory being used.

OFF (C)

(D) AUTO

SHUTDOWN

1. Turn the pressure switch to the OFF position (see C).

2. Unplug the power cord.

3. Reduce pressure in the tank through the outlet hose. You

can also pull the relief valve ring (see G) and keep it open

to relieve pressure in the tank.

F OPEN

\ CLOSE E

8 200-2792

./

Page 9

MAINTENANCE

ADJUSTING DRIVE BELT TENSION

__ To avoid personal injury, always shut off

and unplug the compressor and relieve all air pressure

from the system before performing any service on the air

compressor.

Regular maintenance will ensure trouble-free operation.

Your electric powered air compressor represents high-quality

engineering and construction; however, even high-quality

machinery requires periodic maintenance. The items listed below

should be inspected on a regular basis

DRAINING THE TANK

,__Condensation will accumulate in

the tank. To prevent corrosion of the tank from the

inside, this moisture must be drained at the end of

every workday. Be sure to wear protective eyewear.

Relieve the air pressure in the system and open the

petcock on the bottom of the tank to drain.

CHECKING THE OIL

To check the oil level in the pump, unscrew the dipstick

and wipe off oil. Screw the dipstick all the way in and then

unscrew. The pump oil level should be between between add

(see C) and full (see B). Replace the dipstick. Do not overfill

or underfill.

NOTE: Use synthetic, non-detergent air compressor oil.

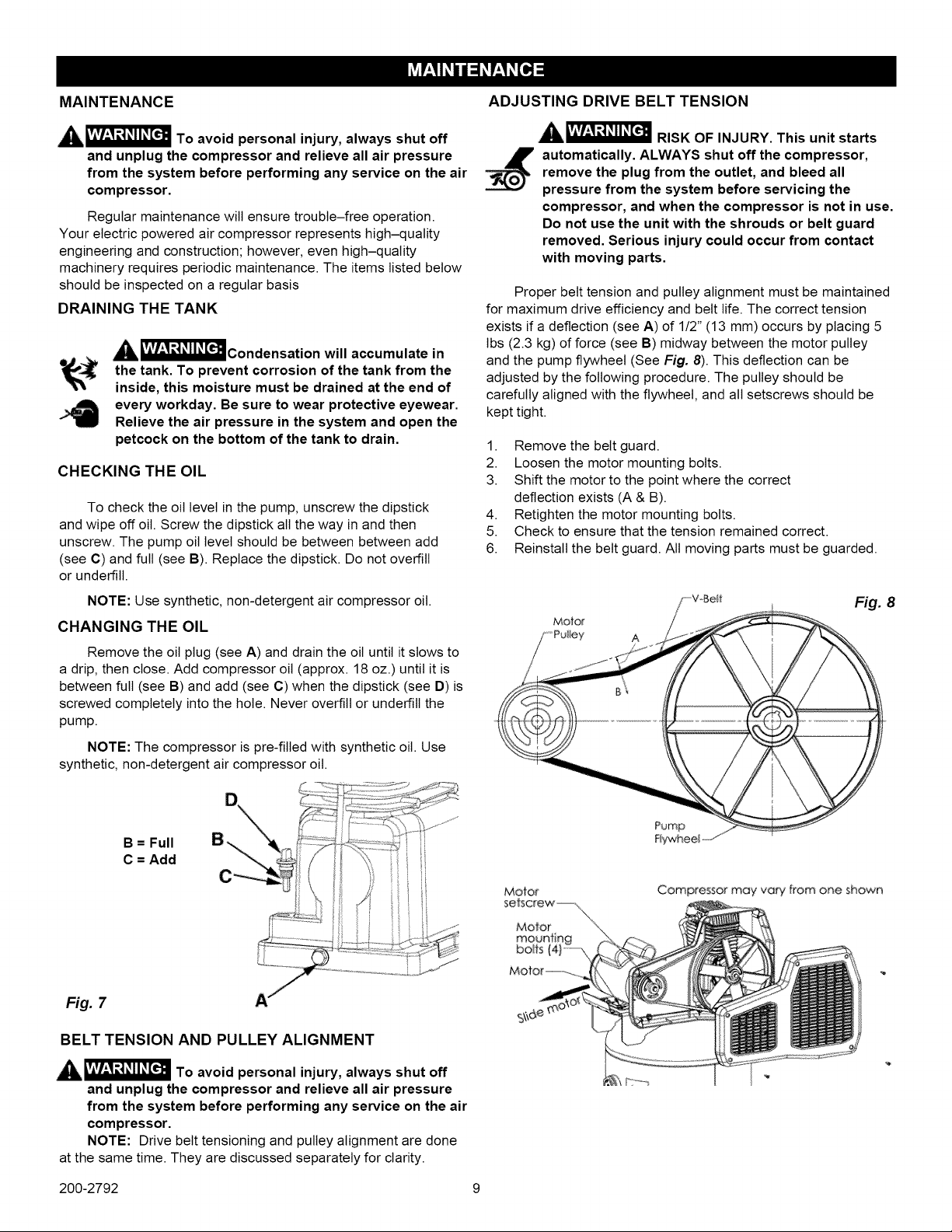

CHANGING THE OIL

Remove the oil plug (see A) and drain the oil until it slows to

a drip, then close. Add compressor oil (approx. 18 oz.) until it is

between full (see B) and add (see C) when the dipstick (see D) is

screwed completely into the hole. Never overfill or underfill the

pump.

NOTE: The compressor is pre-fitted with synthetic oil. Use

synthetic, non-detergent air compressor oil.

__ RISK OF INJURY. This unit starts

automatically. ALWAYS shut off the compressor,

remove the plug from the outlet, and bleed all

pressure from the system before servicing the

compressor, and when the compressor is not in use.

Do not use the unit with the shrouds or belt guard

removed. Serious injury could occur from contact

with moving parts.

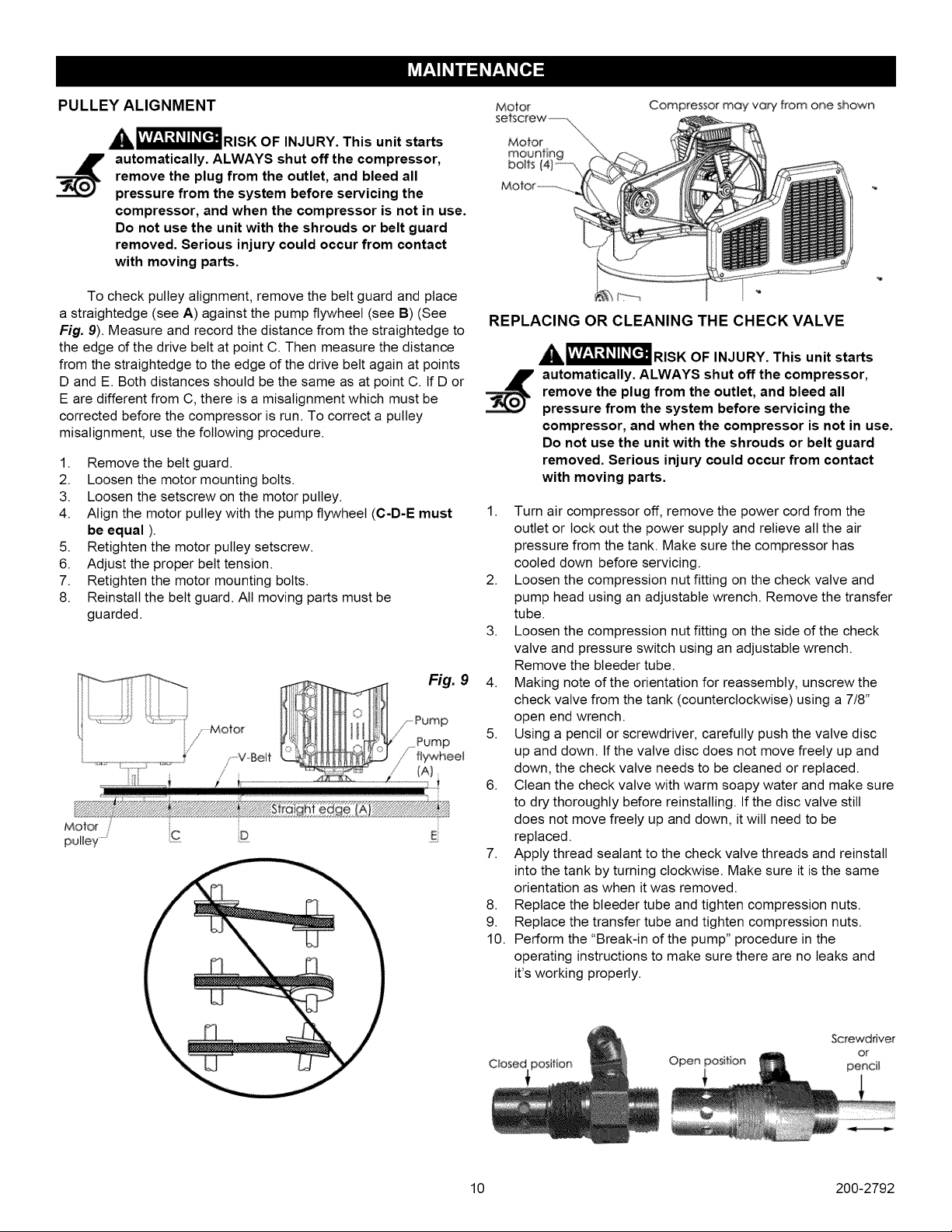

Proper belt tension and pulley alignment must be maintained

for maximum drive efficiency and belt life. The correct tension

exists if a deflection (see A) of 112" (13 mm) occurs by placing 5

lbs (2.3 kg) of force (see B) midway between the motor pulley

and the pump flywheel (See Fig. 8). This deflection can be

adjusted by the following procedure. The pulley should be

carefully aligned with the flywheel, and all setscrews should be

kept tight.

1. Remove the belt guard.

2. Loosen the motor mounting bolts.

3. Shift the motor to the point where the correct

deflection exists (A & B).

4. Retighten the motor mounting bolts.

5. Check to ensure that the tension remained correct.

6. Reinstall the belt guard. All moving parts must be guarded.

Fig. 8

Motor

B = Full

C = Add

Fig. 7 A

BELT TENSION AND PULLEY ALIGNMENT

__ To avoid personal injury, always shut off

and unplug the compressor and relieve all air pressure

from the system before performing any service on the air

compressor.

NOTE: Drive belt tensioning and pulley alignment are done

at the same time. They are discussed separately for clarity.

200-2792 9

Motor

Motor

bolls

Pump

F_ywhee_

Compressor may vory from one shown

Page 10

PULLEY ALIGNMENT

Motor

Compressor may yaw from one shown

,_IL_RISK OF INJURY. This unit starts

automatically. ALWAYS shut off the compressor,

remove the plug from the outlet, and bleed all

pressure from the system before servicing the

compressor, and when the compressor is not in use.

Do not use the unit with the shrouds or belt guard

removed. Serious injury could occur from contact

with moving parts.

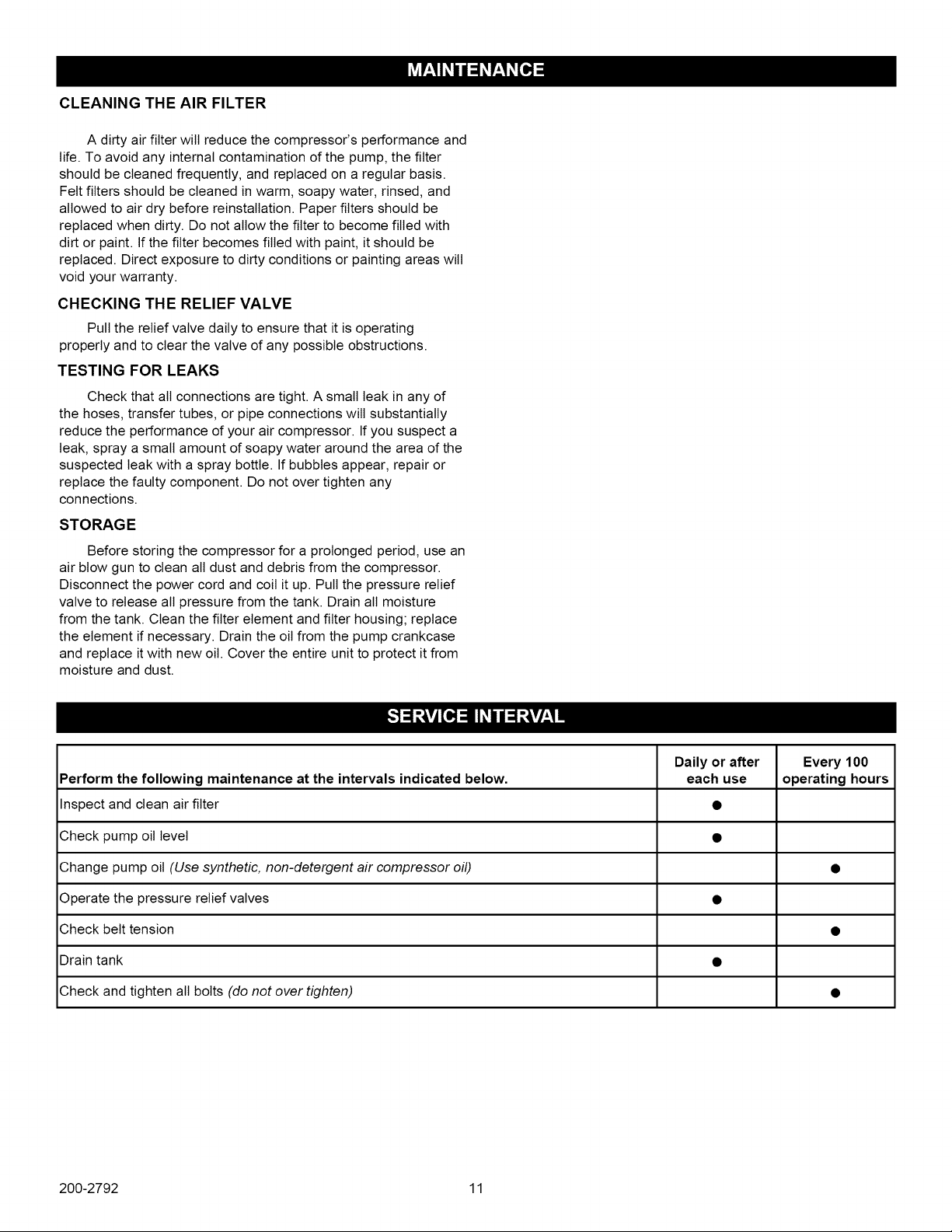

To check pulley alignment, remove the belt guard and place

a straightedge (see A) against the pump flywheel (see B) (See

Fig. 9). Measure and record the distance from the straightedge to

the edge of the drive belt at point C. Then measure the distance

from the straightedge to the edge of the drive belt again at points

D and E. Both distances should be the same as at point C. If D or

E are different from C, there is a misalignment which must be

corrected before the compressor is run. To correct a pulley

misalignment, use the following procedure.

1. Remove the belt guard.

2. Loosen the motor mounting bolts.

3. Loosen the setscrew on the motor pulley.

4. Align the motor pulley with the pump flywheel (C-D-E must

be equal ).

5. Retighten the motor pulley setscrew.

6. Adjust the proper belt tension.

7. Retighten the motor mounting bolts.

8. Reinstall the belt guard. All moving parts must be

guarded.

Motor'

C

Motor

bolts

REPLACING OR CLEANING THE CHECK VALVE

__RISK OF INJURY. This unit starts

automatically. ALWAYS shut off the compressor,

remove the plug from the outlet, and bleed all

pressure from the system before servicing the

compressor, and when the compressor is not in use.

Do not use the unit with the shrouds or belt guard

removed. Serious injury could occur from contact

with moving parts.

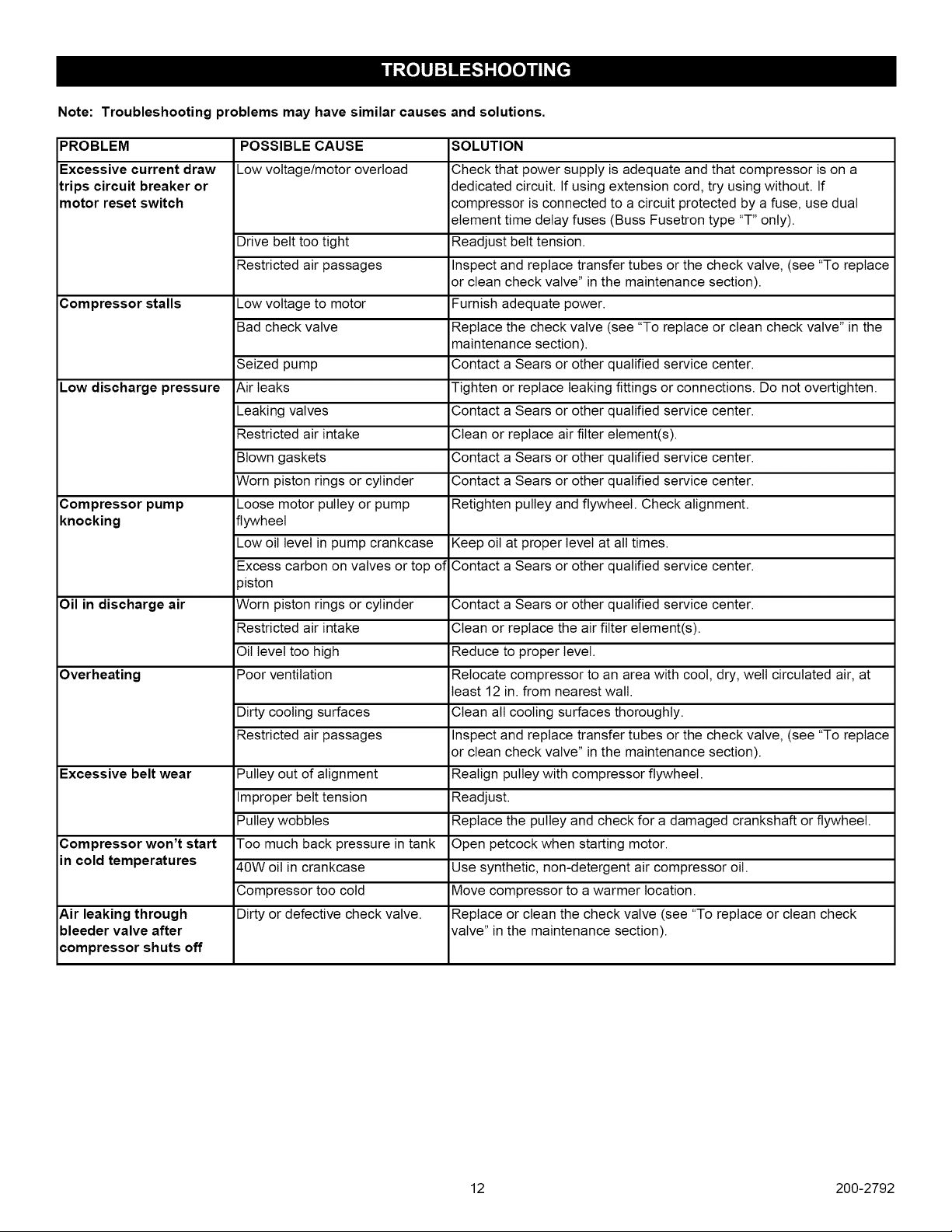

1. Turn air compressor off, remove the power cord from the

outlet or lock out the power supply and relieve all the air

pressure from the tank. Make sure the compressor has

cooled down before servicing.

2. Loosen the compression nut fitting on the check valve and

pump head using an adjustable wrench. Remove the transfer

tube.

3. Loosen the compression nut fitting on the side of the check

valve and pressure switch using an adjustable wrench.

Remove the bleeder tube.

4. Making note of the orientation for reassembly, unscrew the

check valve from the tank (counterclockwise) using a 7/8"

open end wrench.

5. Using a pencil or screwdriver, carefully push the valve disc

up and down. If the valve disc does not move freely up and

down, the check valve needs to be cleaned or replaced.

6. Clean the check valve with warm soapy water and make sure

to dry thoroughly before reinstalling. If the disc valve still

does not move freely up and down, it will need to be

replaced.

7. Apply thread sealant to the check valve threads and reinstall

into the tank by turning clockwise. Make sure it is the same

orientation as when it was removed.

8. Replace the bleeder tube and tighten compression nuts.

9. Replace the transfer tube and tighten compression nuts.

10. Perform the "Break-in of the pump" procedure in the

operating instructions to make sure there are no leaks and

it's working properly.

Screwdriver

C_oselposition

Open position

ot

penc_i

10 200-2792

Page 11

CLEANING THE AIR FILTER

A dirty air filter wilt reduce the compressor's performance and

life. To avoid any internal contamination of the pump, the filter

should be cleaned frequently, and replaced on a regular basis.

Felt filters should be cleaned in warm, soapy water, rinsed, and

allowed to air dry before reinstaltation. Paper filters should be

replaced when dirty. Do not allow the filter to become filled with

dirt or paint. If the filter becomes filled with paint, it should be

replaced. Direct exposure to dirty conditions or painting areas will

void your warranty.

CHECKING THE RELIEF VALVE

Pull the relief valve daily to ensure that it is operating

properly and to clear the valve of any possible obstructions,

TESTING FOR LEAKS

Check that all connections are tight. A small leak in any of

the hoses, transfer tubes, or pipe connections wilt substantially

reduce the performance of your air compressor. If you suspect a

leak, spray a small amount of soapy water around the area of the

suspected leak with a spray bottle. If bubbles appear, repair or

replace the faulty component. Do not over tighten any

connections.

STORAGE

Before storing the compressor for a prolonged period, use an

air blow gun to clean all dust and debris from the compressor.

Disconnect the power cord and coil it up. Pull the pressure relief

valve to release all pressure from the tank. Drain all moisture

from the tank. Clean the filter element and filter housing; replace

the element if necessary. Drain the oil from the pump crankcase

and replace it with new oil. Cover the entire unit to protect it from

moisture and dust.

Daily or after Every 100

Perform the following maintenance at the intervals indicated below, each use operating hours

Inspect and clean air filter •

Check pump oil level •

Change pump oil (Use synthetic, non-detergent air compressor oil) •

Operate the pressure relief valves •

Check belt tension •

Drain tank •

Check and tighten all bolts (do not over tighten) •

200-2792 11

Page 12

Note: Troubleshooting problems may have similar causes and solutions.

PROBLEM POSSIBLE CAUSE SOLUTION

Excessive current draw Low voltage/motor overload Check that power supply is adequate and that compressor is on a

trips circuit breaker or dedicated circuit. If using extension cord, try using without. If

motor reset switch compressor is connected to a circuit protected by a fuse, use dual

element time delay fuses (Buss Fusetron type "T" only).

Drive belt too tight Readjust belt tension.

Restricted air passages Inspect and replace transfer tubes or the check valve, (see "To replace

or clean check valve" in the maintenance section).

Compressor stalls Low voltage to motor Furnish adequate power.

Bad check valve Replace the check valve (see "To replace or clean check valve" in the

maintenance section).

Seized pump Contact a Sears or other qualified service center.

Low discharge pressure Air leaks Tighten or replace leaking fittings or connections. Do not overtighten.

Leaking valves Contact a Sears or other qualified service center.

Restricted air intake Clean or replace air filter element(s).

Blown gaskets Contact a Sears or other qualified service center.

Worn piston rings or cylinder Contact a Sears or other qualified service center.

Compressor pump Loose motor pulley or pump Retighten pulley and flywheel. Check alignment.

knocking flywheel

Low oil level in pump crankcase Keep oil at proper level at all times.

Excess carbon on valves or top of Contact a Sears or other qualified service center.

3iston

Oil in discharge air Worn piston rings or cylinder Contact a Sears or other qualified service center.

Restricted air intake Clean or replace the air filter element(s).

Oil level too high Reduce to proper level.

Overheating Poor ventilation Relocate compressor to an area with cool, dry, well circulated air, at

Dirty cooling surfaces Clean all cooling surfaces thoroughly.

Restricted air passages Inspect and replace transfer tubes or the check valve, (see "To replace

Excessive belt wear Pulley out of alignment Realign pulley with compressor flywheel.

Improper belt tension Readjust.

Pulley wobbles Replace the pulley and check for a damaged crankshaft or flywheel.

Compressor won't start Too much back pressure in tank Open petcock when starting motor.

in cold temperatures 40W oil in crankcase Use synthetic, non-detergent air compressor oil.

Compressor too cold Move compressor to a warmer location.

Air leaking through Dirty or defective check valve. Replace or clean the check valve (see "To replace or clean check

bleeder valve after valve" in the maintenance section).

compressor shuts off

least 12 in. from nearest wall.

or clean check valve" in the maintenance section).

12 200-2792

Page 13

Vertical tank (27 Gal)

El tanque vertical

R6servoir vertical

Horizontal tank (25 Gal)

El tanque horizontal

R6servoir horizontal

-6 1_

10

Item Part No. Qty

Articulo NQm / P Cant

Article No / P Qte Description

1 034-0228 1 Switch, pressure (includes #ems 9-11)

2 019-0270 1 Regulator

3 N/A 1 Plug, 1/8"X 5/16" (27 gal vert)

or N/A 1 Plug, 1/4" (25 gal horiz)

4 032-0025 1 Gauge, 300# 1/4" bottom connect (27gal vert)

or 032-0118 1 Gauge, 300 PSI 1/8" RH connect (25 gal horiz)

5 032-0092 1 Gauge 300 PSI, 2" Dia Face (27gal vert)

or 032-0119 1 Gauge, 300 PSI 1/8" LH Connect (25 gal horiz)

6 N/A 1 Nipple 1/4" X 1 1/2" (27 gal vert)

or N/A 1 Nipple, 1/4"x2" (25galhoriz)

7 036-0031 1 Quick connect coupler

8 136-0104 1 Valve, ASME

9 136-0090 1 Valve, bleeder

10 071-0033 1 Strain relief

11 061-0216 1 Screw

12 N/A 1 Street Elbow, 1/4"-90 ° (25 gal horiz)

13 142-0235 1 Control panel cover (25 gal horiz)

*N/A - These are standard parts available at your local hardware store.

*N/A - Estas son piezas est#ndares disponibles en su ferreteria local.

*N/A - Ces pi#ces sont des pi#ces standard disponibles en quincaillerie.

200-2792 13

Descripci6n

Man6metro (incluye los

articulos 9-11)

Regulador

Enchufe

Enchufe

Man6metro

Man6metro

Man6metro

Man6metro

Niple

Niple

Acoplador especial

Valvula

Valvula

Aliviador de esfuerzo

Tornillo

Te

Cubierta

Description

Interrupteur (inclut les

#l#ments 9-11)

Regulateur

Prise

Prise

Manometre

Manometre

Manometre

Manometre

Manchon filete

Manchon filete

Raccord rapide

Soupape

Soupape

Soulagement de traction

Vis

Piece en t

Couverture

Page 14

1

13F

14

_J3B

17

i3

200-2792

Page 15

Item Part No. Qty

Articulo Num / P Cant

Article No / P Qte Description

1 125-0151 1 belt guard, outer

2 N/A 5 Screw, #10-14

3 146-0016 1 Key

4 006-0009 1 Pulley

5 007-0013 1 V-Belt, 4L-510

6 N/A 2 Setscrew, 5/16"-18

7 098-2856 1 Label, warning

8 N/A 5 Bolt, 5/16-18 x 112"

9 125-0152 1 belt guard, inner

10 160-0264 1 Motor (seecapacitor table below)

11 026-0233 1 Cord, interconnect

12 N/A 4 Bolt, 5/16 x 112"

13 153-0173 1 Tank assembly (27gallon vert)

or 153-0172 1 Tank assembly (25 gallon horiz)

13A 095-0038 2 Wheel

13B 033-0001 2 Hubcap 112"

13C 094-0029 2 Pad (vert.)

or 094-0031 1 Pad (horiz.)

13D 513-0002 1 O-Ring 1-1/2

13E 512-0035 1 Bushing, 1-1/2 NPSM x 1/4 NPT

13F 072-0001 1 Petcock

14 098-3870 1 Label, warning

15 145-0394 1 Tube, bleeder 114" x 12.25"

16 026-0030 1 Cord, power

17 See page 13 1 Manifold assembly

18 093-0031 1 Handle grip (vert.)

19 N/A 4 Bolt, 5/16 x 1 114"

20 See pages 16 & 1 Pump assembly

17

21 064-0056 1 Elbow, 90° brass

22 031-0060 1 Check Valve, 112"x 112" (horiz.)

or 031-0037 1 Check Valve, 112"x 318" (vert.)

23 058-0016 2 Nut, 112"O.D. tube (horiz.)

or 058-0007 2 Nut, 318" O.D. tube (vert.)

24 145-0623 1 Tube, transfer (horiz.)

or 145-0636 1 Tube, transfer (vert.)

25 068-0063 1 Connector, 114"X 112"(horiz.)

or 068-0092 1 Connector, 114"X 318" (vert.)

26 N/A 1 Nipple, 114"x 2-1/2" (vert.)

or N/A 1 Nipple, 114"x 2" (horiz.)

27 N/A 4 Setscrew, M6 x 6mm (horiz.)

28 112-0198 1 Handle assy (horiz-includes grip)

*N/A - These are standard parts available at your local hardware store.

*N/A - Estas son piezas estandares disponibles en su ferreteria local.

*N/A - Ces pi_ces sont des pi_ces standard disponibles en quincaillerie.

Descripcion

Protector

Tornillo

Chaveta

Polea

Correa

Tornillo fajador

Amonestadora escritura de la etu

Perno

Protector

Motor

Cord6n

Perno

Conjunto de tanque

Conjunto de tanque

Rueda

Tapacubo

Almohadilla

Almohadilla

Anillo t6rico

Buje

Llave de desagee

Amonestadora escritura de la etu

Tubo

Cord6n

Conjunto de mQItipte

Empufiadura

Perno

Conjunto de bomba

Codo

Valvula

Valvula

Tuerca

Tuerca

Tubo

Tubo

Conector

Conector

Niple

Niple

Tornillo fajador

Empufiadura

Description

Garant

Vis

Cle

Poulie

Courroie

Vis d'arr6t

D'avertissement etiquette

Boulon

Garant

Moteur

C&ble

Boulon

Ensemble du reservoir

Ensemble du reservoir

Roue

Chapeau de moyeu

Tampon

Tampon

Joint torique

Bague

Robinet de purge

D'avertissement etiquette

Tube

C&ble

Ensemble du collecteur

Poignee

Boulon

Ensemble du pompe

Coude

Soupape

Soupape

Ecrou

Ecrou

Tube

Tube

Connecteur

Connecteur

Manchon filete

Manchon filete

Vis d'arr6t

Poignee

Start capacitor

La condensador de arranque

Le condensateur de

d6marrage

A.O. Smith motor 166-0143 166-0144

capacitors A.O. Smith p/n - 16622936 A.O. Smith p/n - 628318-313

GE motor capacitors 166-0148 166-0149

GE p/n - 52A 103967P1 GE p/n - 976B399ASP3

Better motor 166-0180 166-0181

capacitors Better p/n - 0901080 Better p/n - 0901040

200-2792

Start capacitor cover

La tapa de arranque la

condensador

Le couvercle de d_marrage

du condensador

166-0145

A.O. Smith p/n - 174588-004

166-0150

GE p/n - 111B291AAP3

166-0182

Better p/n - 0104045

15

Run capacitor

La condensador de

funcionar

Le condensateur de march

Run capacitor cover

La tapa de funcionar la

condensador

Le couvercle de marche du

condensateur

166-0146

A.O. Smith p/n - 17821153

166-0151

GE p/n - 111B276ACP8

166-0182

Better p/n - 0104045

Page 16

130 Pump Assy

24

® ®®

® @® ® ]

Head Bolt Torque Sequence

Secuencia De Los Demos

Del Cabeza

Sequence De Serrage Des

Boulons A Tate

Sequence #'s 1, 2, 3, 4, 5, 6, 7

&8

Torque to 220-300 Ibs-in

# De Secuencia 1, 2, 3, 4, 5, 6,

7y8

Torsi6n hasta 24,6 - 33,9 N-m

Sequence De Serrage Des

Boulons 1,2, 3, 4, 5, 6, 7 et 8

serrez _ un couple compris entre

24,6 a 33,9 N°m

Pump Specifications

Weight-39 Ibs.

Oil Capacity (approx.)-18 oz.

Min. RPM-700

Max, RPM-1200

Max. Ambient Temp-104°F (40°C)

Torque to 150-250 Ibs-in

Torsi6n hasta 17- 28,3 N-m

Serrez _ un couple compris entre 150

250 pouces par livre

8

\\

\

'1

t2

Torque to 160-200 Ibs-in

Torsi6n hasta 18, 1 - 22,6 N°m

Serrez a un couple compris entre

160 a 200 pouces par livre

13

Io.I

Carrier Bolt Sequence

Torque to 170-230 Ibs-in

Secuencia De Los Pemos

Del Transportador

Torsi6n hasta 19,2 - 26 N-m

Sequence De Serrage Du

Boulons Porteur 1, 2, 3, ET 4

serrez _ un couple compris

entre 170 _ 230 pouces par

livre

Torque to 30-50 Ibs-in

Torsi6n hasta 2,7 - 5,7 N.m

Serrez a un couple compris

entre 30 a 50 pouces par livre

16 200-2792

Page 17

130 Pump Assy

Item Part No.

Articulo Nem / P

Article No/P

1 059-0144

2 054-0112

3 048-0065

4 047-0091

5 051-0043

6 046-0149

045-0053

8 N/A

9 N/A

10 060-0053

11 044-0064

12 046-0161

13 053-0041

14 051-0013

15 049-0050

16 046-0263

17 077-0148

18 061-0113

19 061-0112

20 056-0019

21 043-0142

Qty Description

Cant

@6

8 Screw, 5/16-18 x 2.50" lg

1 Ring set

2 Piston assembly

2 Rod, 130 pump

1 Bearing

1 Gasket

Carrier, includes items 5 & 12

4 Screw, 5/16-18 x 1" lg

1 Screw, 5/16-18 x 1.0" lg

1 Washer

1 Flywheel, 12" A width

1 Seal

1 Crankshaft, 130 pump

1 Bearing

1 Crankcase, includes #em 14

1 Gasket

1 Base

14 Screw, #10-24 x 1/2

1 Plug, 5/16-18

1 Dipstick

Plate, assy, includes 21a-21b

21a 046-0152 1 Gasket

21b 046-0151 1 Gasket

22 042-0103 1 Head

23 118-0023 1 Sc_en

24 019-0052 1 Filter, _lt

Descripci6n

Tornillo

Juego de anillos

Conjunto de pist6n

Varilla

Cojinete

Empaquetadura

Portador, incluye los articulos 5 y

12

Tornillo

Tornillo

Arandela

Volante, A

Sello

CigOe_al

Cojinete

Carter, incluye los articulos 14

Empaquetadura

Base

Tornillo

Tap6n

Varilla de aceite

Conjunto de placa, incluye los

articulos 21a-21b

Empaquetadura

Empaquetadura

Cabezal

Malla

Filtro

Description

Vis

Jeu d'anneaux

Ensemble du piston

Tige

Roulement

Joint

Support, inclut les #l#ments 5 et

12

Vis

Vis

Rondelle

Volant-moteur, A

Joint

Vilebrequin

Roulement

Carter, inclut les #l#ments 14

Joint

Base

Vis

Bouchon

Jauge de niveau

Ensemble du plaque, inclut les

#l#ments 21a-21b

Joint

Joint

T6te

Crepine

Filtre

*N/A - These are standard parts available at your local hardware store.

*N/A - Estas son piezas estandares disponibles en su ferreteria local.

*N/A - Ces pi_ces sont des pi_ces standard disponibles en quincaillerie.

Available Service Kits

046-0159 1 Gaskets, complete set (includes

items 6, 16, 21a and 21b)

165-0083 1 Overhaul kit, ncludes ring and

gasket sets, valve plate

assembly and filter element

040-0429 1 Pump assembly includes items

1-24 excluding 9-10 and 11

Juntas, conjunto completo

incluye los artfculos 6, 16, 21a

/21b)

Juego de acondicionamiento,

incluye conjuntos de anillo y

junta, conjunto de la placa de

la valvula y elemento del filtro

Ensamblaje de la bomba

(incluye los artfculos 1-24

excepto 9-10 y 11)

Joints, jeu complet (inclut les

el6ments 6, 16, 21a et 21b)

Jeu de pi_ces de reparation,

comprend des jeux de bagues et

dejoints, I'assemblage de la

plaque et de joints, I'assemblage

de la plaque de la soupape et

I'el6ment du filtre

Pompe (inclut les el6ments 1-24

I'exclusion de 9-10 et 11)

200-2792 17

Page 18

GARANTIA....................................... 18

CUADRODEESPECIFICACIONES................... 18

PAUTASDESEGURIDAD........................ 19-20

GLOSARIODETERMINOS......................... 20

RESUMENGENERAL.............................. 21

Componentesbasicosdelcompresordeaire......... 21

MONTAJE....................................... 21

CONTROLESDELCOMPRESOR.................... 22

RESTABLECIMIENTOYCABLEADODELMOTOR...... 22

REQUERIMIENTOSDEALIMENTACIONEL#CTRICA....23

Cableadoeiectrico............................. 23

Verificaci6n del nivel de aceite .................... 25

Cambio de aceite .............................. 25

Tensi6n de ta correa y alineaci6n de ta polea ...... 25-26

Substituyendo o timpiando la valvulade cheque ....... 26

Limpieza del fittro de aire ........................ 27

Revisi6n de la vatvula de alivio .................... 27

Detecci6n de fugas ............................. 27

Almacenamiento ............................... 27

INTERVALOS DE SERVICIO ........................ 27

CUADRO DE DETECCION DE FALLOS ................ 28

ESQUEMA DE LA PIEZAS Y LISTA DE LAS PIEZAS . . .13-17

Cordonesprolongadores........................ 23

Instruccionesdeconexi6natierra................. 23

INSTRUCCIONESOPERATIVAS..................... 24

Marchainicialdelbomba........................ 24

Arranquediario................................ 24

Parada...................................... 24

MANTENIMIENTO................................. 25

DesagQedeltanque............................ 25

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted against any defects in material or workmanship.

Defective product will receive free repair or free replacement if repair is unavailable.

For warranty coverage details to obtain repair or replacement, visit the web site: www.craftsman.com

This warranty does not cover the air filter or drive belt, which are expendable parts that can wear out from normal use

within the warranty period.

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

RUNNING

H.P. CAPACIDAD DEL VOLTAJE PRESION DE PRESION DE

MODELO (CV) TANQUE - LITROS AMP/FASE CONEXION DESCONEXION

921.16474 120 150

(WLB1982713) 1.9 Vert. 27 (102) 115/15/1 (8,27 bar) (10,34 bar)

921.16475 120 150

(WPB1982513) (8,27 bar) (10,34bar)

1.9 Horiz. 25 (94,6) 115/15/1

18 200-2792

Page 19

Lainformaci6nquesigueserefierealaprotecci6ndeSUSEGURIDADytaPREVENCIONDEPROBLEMASDELEQUIPO.Como

ayudaparareconocerestainformaci6n,usamoslossiguientessimbolos.Leaporfavorelmanualypresteatenci6naestassecciones.

A _1--==_"_J'__ UN POSIBLE RIESGO QUE CAUSARA LESIONES GRAVES O LA PleRDIDA DE LA VIDA.

___ V-'Im_vj=lt,t/=l_[@]P'-'l - UN RIESGO POTENCIAL QUE PODRIA PROVOCAR GRAVES LESIONES O MUERTE.

__ I'-.]t,_l=[@}'-'_.l[_[I]_ll - UN RIESGO POTENCIAL QUE PODRIA PROVOCAR LESIONES LEVES O DANAR EL

EQUIPO.

RIESGO DE INCENDIO O

EXPLOSION.

RIESGO DE EXPLOSION.

RIESGO DE DESCARGA ELECTRICA.

RIESGO DE LESIONES.

I1'

RIESGO DE EXPLOSION.

RIESGO DE QUEMADURAS.

RIESGO PARA LA RESPIRACION.

RIESGO DE LESIONES OCULARES.

Nunca rocie liquidos inflamables en un area conflnada. Es normal que el motor y el

interruptor de presi6n produzcan chispas al estar en funcionamiento. Si tas chispas entran

an contacto con los vapores de la gasolina o con otros disolventes, estos podrian

encenderse, causando un incendio o una explosi6n. Siempre opere el compresor en un

lugar bien ventitado. No fume al rociar. No rocie donde existan chispas o llama. Mantenga el

compresor tan lejos del lugar de rociado como sea posible.

No suelde, no perfore ni modifique el tanque del aire de este compresor. La soldadura o las

modificaciones en el tanque del compresor de aire podrian deteriorar gravemente la

resistencia del tanque y causar una condici6n extremadamente peligrosa. Soldar o modificar

el tanque de cualquier manera anulara la garantia.

Nunca utitice un compresor electrico de aire en el exterior cuando este ttoviendo ni 1o

coloque sobre una superficie mojada, ya que esto podria causar descargas electricas.

Esta unidad arranca automaticamente. SIEMPRE apague el compresor, quite el enchufe del

[omacorrientes, y purgue toda la presi6n del sistema antes de realizar el servicio al

compresor y cuando el compresor no este en uso. No utilice la unidad sin las cubiertas o sin

el protector de la correa ya que podria sufrir lesiones por el contacto con las piezas m6viles.

Veriflque ta presi6n nominal maxima sugerida por el fabricante para las herramientas y los

accesorios neumaticos. La presi6n de salida del compresor se debe regular de tal manera

que nunca se exceda la presi6n nominal maxima de la herramienta. Antes de conectar o

retirar accesorios, alivie toda presi6n del tubo.

La bomba y el mQltipte producen altas temperaturas. Para prevenir quemaduras u otro tipo

de heridas, NO TOQUE la bomba, el mQltiple ni el tubo de transferencia mientras ta bomba

se esta funcionando. Permita que se enfrie antes de manipulartos o realizar el servicio

necesario. Mantenga a los niSos alejados del compresor en todo momento.

AsegQrese de leer todas tas etiquetas cuando este rociando pinturas o materiales t6xicos, y

siga las instrucciones de seguridad. Use una careta respiratoria si existe la posibitidad de

inhalar algQn producto al rociar. Lea todas tas instrucciones y asegQrese de que su careta

respiratoria le proteja. Nunca inhale directamente el aire comprimido producido por un

compresor. No es adecuado para respirarly.

Cuando utitice un compresor de aire siempre use gafas de seguridad aprobadas segQn ANSI

787.1. Nunca dirija la boquitta ni el rociador hacia una persona ni hacia alguna parte del

cuerpo. El equipo puede causar una lesi6n grave si el rocio penetra en la piel.

RIESGO DE EXPLOSION.

RIESGO DE EXPLOSION.

200-2792 19

No ajuste ta valvula de alivio. En caso contrario, se anularan todas tas garantias. La vatvula

de alivio fue ajustada de fabrica para que ta unidad funcione a su presi6n maxima. Si se

altera la valvula podria ocurrir un accidente con lesiones a personas o da_os a la propiedad.

No use tuberia de plastico ni de PVC para el sistema de aire comprimido. Use s6to tuberia y

conectores de acero galvanizado para las lineas de distribuci6n de aire comprimido.

Page 20

RIESGO AL SENTIDO DEL OiDO.

Siempre use protectores auditivos cuando use un compresor de aire. Si no 1ohace podria

sufrir perdida de la audiciSn.

El cable de energia de este producto contiene plomo, un elemento quimico que segQn el

Estado de California puede producir cancer y malformaciones de nacimiento u otros

)roblemas de reproducci6n. Lavese las manes despues de utilizarlo.

NOTA: CABLEADO ELECTRICO.

Refierase al r6tulo del nQmero de serie del compresor de aire para conocer los

requerimientos de voltaje y amperaje de la unidad. Cerci6rese de que todo el cableado 1o

instala un electicista capacitado, de conformidad con el C6digo Electrico Nacional.

1-2z_i;[o,Y_,ILI[o,][o]_ii

Elimine la humedad del tanque todos los dias. Un tanque limpio y seco ayudara a evitar la corrosi6n.

Tire del anitto de ta vatvula de alivio de la presi6n todos los dias para asegurarse de que la valvula este funcionando adecuadamente

para eliminar cualquier obstrucci6n en la valvula.

A fin de lograr una ventitaci6n adecuada para el enfriamiento, el compresor debe mantenerse a un minimo de 31 cm (12 pulgadas) de

la pared mas cercana, en una zona bien ventilada.

Sujete el compresor muy bien si es necesario su transporte. Debe liberarse la presi6n del tanque antes de su transporte.

Proteja la manguera de aire y el conducto electrico contra dafios y pinchaduras. InspecciSnelos todas las semanas para comprobar

ue no existen zonas debites o desgastadas, y reemptacelos si fuera necesario.

Para reducir el riesgo de choque electrico, proteja la unidad de la Iluvia. Almacene en el interior.

Nunca funcione el compresor si se dafia el cable electrico o el enchufe. Tenga la unidad mantenida en el Sears o el otro centro de

servicio calificado.

I/rain

Litros por minuto; una unidad de la medida de flujo de aire.

Bar

Es una unidad de medida de la presi6n del aire.

Presion de conexion

Punto de presi6n baja fijado en fabrica que arranca el motor de la bomba para volver a presurizar el tanque de aire a una presi6n mas

elevada.

Presion de desconexion

Punto de presi6n alta fijado en fabrica que impide que el motor de la bomba aumente la presi6n en el tanque por encima de un cierto

nivel.

Bien ventilado

Un medio de proveer aire fresco para contrarrestar el escape de gases o los vapores peligrosos.

Circuito dedicado

Un circuito electrico reservado para uso exclusivo del compresor de aire.

20 200-2792

Page 21

COMPONENTESBASICOS DEL COMPRESOR DE AIRE

Los componentes basicos del compresor de aire son el

motor electrico, la bomba, el interruptor de presi6n y el tanque

(Fig. 1).

El motor electrico (vea A) acciona la bomba. El motor

electrico esta equipado con un protector contra sobrecarga

para ayudar a evitar el quemado posible del motor. Si el motor

llegara a sobrecalentarse, el protector contra sobrecarga Io

apagara. En caso de ocurrir esto, permita que el motor se enfrie

durante 10 a 15 minutos y tuego presione (nunca fuerce) el

interruptor de restablecimiento del motor para volver a arrancar el

motor.

La bomba (vea B) comprime el aire y 1odescarga hacia el

tanque.

El tanque (vea C) almacena el aire comprimido.

El interruptor de presi6n (vea D) apaga el motor y alivia la

presi6n del aire en la bomba y el tubo de transferencia cuando

la presi6n del aire en el tanque alcanza el timite establecido en

fabrica. AI ir usandose el aire comprimido y bajar el nivel de

presi6n en el tanque hasta llegar al nivel preestablecido, el

interruptor de presi6n vuelve a arrancar el motor y la bomba

continua comprimiendo el aire.

a i ,

i

A

D

Fig. 1

MONTAJE DEL COMPRESOR

Este compresor rue enviado con aceite en el carter del

motor de la bomba. Compruebe el aceite antes de

funcionar el compresor de aire, vea el aceite del cheque

bajo mantenimiento.

1,

Desembale el compresor de aire. Inspeccione ta unidad

para verificar que no sufri6 dafios. Si ta unidad ha sido

dafiada durante el transporte, comuniquese con la

empresa transportadora y complete una rectamaci6n por

dafios. Haga esto de inmediato porque existen

limitaciones de tiempo respecto alas reclamaciones por

dafios.

La caja debe contener los elementos siguientes:

• compresor de aire

• operador/piezas manuales

• manija (el tanque horizontal)

2,

Verifique el r6tulo del nQmero de serie del compresor para

asegurarse de que haya recibido el modelo que pidi6

y que el mismo tenga la presi6n nominal requerida para el

uso deseado.

3,

Instale la manija aflojando los tornittos de presi6n (f) y

entonces ta colocaci6n de ta manija termina (e) en el (G) de

los soportes de ta manija y asegure con los tornittos de

presi6n (f) (vease fig. 2). Apriete los torniltos usando una

lave de maleficio del tamafio 3mm (no incluida).

4. Ubique el compresor de acuerdo con las pautas

siguientes:

electrico conectado a tierra (consulte

INSTRUCCIONES DE PUESTA A TIERRA).

Evite el uso de una cuerda de extension; es

preferible usar una manguera de aire mas targa.

b. El tado del volante del compresor se debe encontrar

cuando menos a 31 cm (12 pulgadas) de cualquier

pared u obstaculo, en un area limpia y bien ventilada,

a fin de asegurar el flujo del aire y el

enfriamiento adecuados.

c. En ctimas frios, almacene el compresor portatit en un

edificio con calefacci6n. Esto reducira problemas de

lubricaci6n, arranque del motor y congelamiento del

agua de condensaci6n.

d. El compresor debe estar nivelado para asegurar una

buena lubricaci6n de ta bombay un buen drenaje del

agua condensada en el tanque receptor.

5,

Conecte una manguera de aire (no incluida) con el

enchufe mul'tiple.

F G

\

I

E

a. Ubique el compresor cerca de un tomacorriente

200-2792 21

Fig. 2

Page 22

Interruptorde presion (vea A)

Este interruptor enciende el compresor. Se opera

manualmente, pero cuando esta en la posici6n ON, permite que

el compresor arranque o se pare automaticamente, sin aviso,

segen la demanda de aire. SIEMPRE coloque este interruptor en

la posici6n OFF cuando el compresor no este en uso y antes de

desconectarlo.

Valvula de alivio de presion (vea B)

Si el interruptor de presi6n no apaga el motor cuando ta

presi6n alcanza el nivel de desconexi6n, esta valvula se abrira

automaticamente para evitar una sobrepresi6n. Para accionarta

manualmente, tire del anillo en la valvula de alivio de la presi6n

del aire en el tanque.

Manometro del tanque (vea C)

Este man6metro mide la presi6n del aire almacenado en el

tanque. No es ajustable por el operador y no indica la presi6n de

la linea.

Regulador de presion de aire (vea D)

El regulador de presi6n de aire permite ajustar ta presi6n en

la linea que conecta la herramienta que se esta usando.

__Nunca sobrepase el indice maximo de

presion de la herramienta.

B

El tanque horizontal

A

B

Gire la peritta a la derecha para aumentar la presi6n, y a la

izquierda para disminuirla.

Manometro regulado (vea E)

Este man6metro mide la la linea presi6n regulada de salida.

Conector de acoplamiento rapido (vea F)

Permite conectar y desconectar rapidamente la manguera de

aire.

INTERRUPTOR DE RESTABLECIMIENTO DEL MOTOR

__Asegurese de que todos los

protectores y cubiertas esten colocados en su lugar

antes de presionar el interruptor de restablecimiento

para volver a arrancar el motor.

Si el motor se apaga debido a una sobrecarga, espere entre

10 y 15 minutos para que el motor pueda enfriarse y tuego

presione (NUNCA fuerce) el interruptor de restablecimiento (vea

G) para volver a arrancar el motor (Fig. 4).

NOTA:

Algunos modelos estan equipados con un motor

de voltaje doble de 115/230 voltios. La mayoria de

los motores se conectan en la fabrica para que

funcionen a 115 voltios. Si la conversion a partir

de 115 voltios a 230 voltios se requiere, refiera a

la placa de identificacion del motor y haga que la

conversion sea terminada por un electricista

licenciado.

El tanque vertical

Fig. 3

Fig. 4

G

22 200-2792

Page 23

CABLEADO EL#CTRICO

Consulte el r6tulo del nQmero de serie del compresor de aire

para ver los requerimientos de voltaje y amperaje de la unidad.

Use un circuito exclusivo

Para el mejor rendimiento y un arranque confiable, el

compresor de aire debe conectarse en un circuito exclusivo,

tan cerca como sea posible de la caja de fusibles o del

cortacircuito. El compresor utitizara ta capacidad maxima de un

circuito de 15 amperios de una casa normal. Si hay otros equipos

electricos que esten consumiendo energia del circuito al cual esta

conectado el compresor, es posible que este no arranque. Un

voltaje bajo o un circuito sobrecargado puede causar un arranque

lento que causara que salte el interruptor de reposicionamiento

del motor o el cortacircuito, especialmente en condiciones de

baja temperatura.

NOTA: Para manejar la carga electrica inicial de

encender el compresor de aire, un disyuntor se recomienda.

Si el compresor de aire esta conectado con un circuito

protegido por un fusible, utilice los fusibles de retraso de

tiempo del elemento dual (tipo "T" de Buss Fusetron

solamente).

CORDONES PROLONGADORES

NOTA: Evite el uso de cordones prolongadores.

Para obtener un rendimiento 6ptimo, enchufe el cord6n

electrico del compresor directamente en un tomacorriente de

pared conectado a tierra. No use un cord6n prolongador a menos

que sea absotutamente necesario.

Como alternativa, intente utilizar una manguera de aire mas

larga para llegar a la zona donde se requiere aire, el cable no

debe tener una longitud mayor que 9.1 m (50 pies) y un alambre

con calibre minimo de 12 (AWG). No use cables de extensi6n de

calibre 14 ni 16.

Use solamente un cord6n de 3 alambres que tenga un

enchufe de 3 patas y un receptaculo de 3 ranuras que permita el

enchufe del producto. AsegQrese de que su cord6n prolongador

este en buenas condiciones. Un cord6n demasiado pequeSo

causara una caida en el voltaje de la linea, causando una perdida

en la energia y un sobrecalentamiento. Cuanto mas pequeSo sea

el nQmero de calibre, tanto mas pesado sera el cord6n.

INSTRUCCIONES DE CONEXlON A TIERRA

PARA MODELOS CONECTADOS CON CORDON:

Este producto debe conectarse a tierra. En el caso de un

cortocircuito electrico, ta conexi6n a tierra reduce el riesgo de

choque electrico pues ofrece un escape para la corriente

electrica.

Este producto esta equipado con un cord6n que tiene un

alambre de conexi6n a tierra con su enchufe correspondiente. El

enchufe debe conectarse en un tomacorriente que este bien

instalado y conectado a tierra de acuerdo con todos los c6digos y

ordenanzas locales.

Este producto se debe usar en un circuito de 115 6 230

voltios. Se debera usar un enchufe con un terminal conectado a

tierra, tal como el mostrado aqui.

AsegQrese de que el producto este conectado a un

tomacorriente que tenga la misma configuraci6n que el enchufe

( Fig. 5). No debe usarse ningQn adaptador con este producto.

Consulte con un electricista capacitado si no comprende

completamente las instrucciones de conexi6n a tierra, o si tiene

dudas con respecto a si el producto esta correctamente

conectado a tierra. No modifique el enchufe provisto; si no encaja

en el tomacorriente, haga que un electricista capacitado instale

un tomacorriente adecuado.

Fig. 5

Caja de tomacorriente/

puesta a tierra

Tomacorriente puesta /

a tierra

115 VOLTIOS

15 AMPERIOS

230 VOLTIOS

15 AMPERIOS

Pasador de

Tap6n

,puesta a tierra Tap6n

__ La instalacion incorrecta del

enchufe de conexion a tierra puede causar un riesgo

de descarga electrica. Si es la reparacion o el

reemplazo de la cuerda o del enchufe necesario, no

conecte el alambre que pone a tierra con cualquier

terminal piano de la lamina del enchufe. El alambre

de conexion a tierra tiene aislamiento de color verde

con rayas amarillas o sin elias.

200-2792 23

Page 24

IMIARCHAINIClAL DE LA BOIMIBA

1. Compruebe el nivel de aceite en la bomba (vease ta

"comprobaci6n del aceite" en secci6n del mantenimiento).

2. Cotoque el conmutador activado por presi6n en la posici6n

APAGADO. (vea C).

3. Abra la llave de descompresi6n (vea F). Hagalo girar hacia

la izquierda.

__ El aire y la humedad que

escapan del tanque pueden arrojar desechos que

podrian causarle daSo en los ojos. AI abrir la Ilave

de descompresion use gafas de seguridad.

4.

Enchufe el cord6n electrico.

5.

Cotoque el conmutador activado por presi6n en la posici6n

ENCENDIDO (vea D). El compresor arrancar& Permita el

funcionamiento del compresor durante 30 minutos, a fin de

suavizar los componentes internos.

herramienta o del accesorio que este usando.

PARADA

1. Coloque el conmutador activado por presi6n en la posici6n

APAGADO (vea C).

2. Desenchufe el cord6n electrico.

3. Reduzca la presi6n en el tanque a traves de ta manguera

de salida. Tambien puede tirar del anitto de ta vatvula de

alivio (vea G) y mantenerla abierta para aliviar la presi6n

en el tanque

4. Abra la ltave de descompresi6n (vea F) para permitir que

la humedad salga del tanque.

A_

_UI==='=I"L_r-'''L'_L'J_NEI aire y la humedad que

escapan del tanque pueden arrojar desechos que

podrian causarle daSo en los ojos. AI abrir la Ilave

de descompresion use galas de seguridad.

NOTA:

6. Despues de aproximadamente 30 minutos, cotoque el

7. Cierre ta Ilave de descompresi6n. (vea E).

8. Coloque el conmutador activado por presi6n en la posici6n

NOTA: Mientras que se utiliza el aire comprimido, el interruptor

ARRANQUE DIARIO

1. Compruebe el nivel de aceite en la bomba (vease ta

2. Cotoque el conmutador activado por presi6n en la posici6n

3. Cierre ta ltave de descompresi6n del tanque (vea E).

4. Enchufe el cord6n electrico.

Despues de cerca de 30 minutos, si ta unidad no

funciona correctamente, CIERRE INMEDIATAMENTE, y

entre en contacto con a Sears u otro calific6 el centro de

servicio.

conmutador activado por presi6n en la posici6n

APAGADO.

(ENCENDIDO). Hagalo girar hacia la derecha. Et

compresor comenzara a funcionar, llenara el tanque hasta

la presi6n de desconexi6n y dejara de funcionar.

de presi6n recomience el motor automaticamente para

suministrar mas aire comprimido al tanque.

"comprobaci6n del aceite" en secci6n del mantenimiento).

APAGADO (vea C).

Hagalo girar hacia la derecha.

_IL_ El motor electrico y la

bomba producen altas temperaturas. Para evitar

quemaduras y otras lesiones, NO toque el

compresor durante su funcionamiento. Permita que

se enfrie antes de manipular o realizar el servicio.

Mantenga a los nihos alejados del compresor en

todo momento.

Fig. 6

OFF (C)

(D) AUTO

5. Cotoque el conmutador activado por presi6n en la posici6n

ENCENDIDO (vea D).

6. Ajuste el regulador a la presi6n de funcionamiento de la

herramienta.

__AI efectuar un ajuste desde

la izquierda hasta que sobrepase el ajuste deseado,

una presion mas alta a una mas baja, gire la perilla a

despues gire a la derecha hasta alcanzar la presion

deseada. No exceda la presion de operacion de la

24

ABIERTO

"%"\, SE CIERRAN E

200-2792

Page 25

MANTENIMIENTO

de servicio en el compresor de aire.

__ Para evitar lesiones personales,

siempre apague y desenchufe el compresor y alivie toda

la presion de aire del sistema antes de realizar algun tipo

de servicio en el compresor de aire.

El mantenimiento regular asegurara una operaci6n sin

problemas. Su compresor de aire con alimentaci6n electrica

representa 1omejor en ingenieria y construcci6n; sin embargo,

a0n la maquinaria de mejor calidad requiere un mantenimiento

peri6dico. Los elementos enumerados a continuaci6n deben

inspeccionarse de manera regular.

DESAGOE DEL TANQUE

_ La condensacion se

acumulara en el tanque. Para evitar la corrosion del

tanque desde el interior, esta humedad debe ser

drenada al final de cada dia de trabajo. Asegurese

de utilizar proteccion ocular. Alivie la presion de aire

en el sistema y abra la Ilave de descompresion que

se encuentra en el rondo del tanque para drenar.

VERIFICACION DEL NIVEL DE ACEITE

Para revisar el nivel de aceite en la bomba, destornille la

varilla de medici6n de aceite y limpie ta varitta. Atornitte

completamente ta varitta de medici6n y despues destornillela. El

nivel de aceite de ta bomba debe estar entre las marcas

ranuradas superior e inferior (vea B y C).

NOTA: Use aceite sintetico no-detergente para el

compressor de aire.

CAMBIO DE ACEITE

Quite el tap6n de aceite (vea A) y deje salir el aceite hasta

que empiece a gotear, tuego vuelva a porter el tap6n. Afiada

aceite para compresor (532 ml) hasta que se encuentre entre las

marcas Lleno (vea B) y Agregar (vea C) cuando ta varitla de

aceite (vea D) se haya introducido completamente en el orificio.

Nunca se debe poner demasiado ni muy poco aceite en la

bomba.

NOTA: Et ajuste de ta tensi6n de la correa de transmisi6n y

la alineaci6n de ta potea se realizan al mismo tiempo. Se explican

por separado para mayor claridad.

AJUSTE DE LA TENSION DE LA CORREA

^A _ Esta unidad arranca

automaticamente. SIEMPRE apague el compresor,

quite el enchufe del tomacorrientes, y purgue toda la

presion del sistema antes de realizar el servicio al

compresor y cuando el compresor no este en uso.

No utilice la unidad sin las cubiertas o sin el

protector de la correa ya que podria sufrir lesiones

por el contacto con las piezas moviles.

Se debe mantenerse ta tensi6n correcta de ta correa y ta

alineaci6n adecuada de la polea para obtener una maxima

eficiencia de accionamiento y vida 0tit de ta correa. La tensi6n es

correcta si ocurre una deflexi6n (vea A) de 13 mm (1/2") al

colocar 2,3 kg (5 tb) de fuerza (vea B) en el medio entre la potea

del motor y el volante del compresor (Fig. 8). Esta deflexi6n

puede ajustarse mediante el procedimiento siguiente. La polea

debe alinearse cuidadosamente con el volante y todos los

tornillos de fijaci6n deben mantenerse ajustados.

1. Retire el protector de ta correa.

2. Afloje los pernos de montaje del motor.

3. Desplace el motor hasta el punto en el cual exista la

deflexi6n correcta (A y B).

4. Vuelva a ajustar los pernos de montaje del motor.

5. Verifique para asegurarse de que la tensi6n se mantuvo

correcta.

6. Vuelva a instalar el protector de ta correa. Todas tas

piezas m6vites deben estar protegidas.

Fig. 8

Polea

motor A

NOTA: El compresor se prellena con aceite sintetico. Utitice

el aceite sintetico, no detergente del compresor de aire.

B = Lleno

C = Agregor

Fig. 7 A:

TENSION DE LA CORREA Y ALINEACION DE LA

POLEA

__ Para evitar lesiones personales,

siempre apague y desenchufe el compresor y alivie toda

la presion de aire del sistema antes de realizar algun tipo

200-2792 25

Rueda volante

de la bomba

El compreso_

puede variar a

partir de] uno

demostrado

Page 26

ALINEACION DE LA POLEA

Motor Compressor may vary from one shown

_llL_Esta unidad arranca

automaticamente. SIEMPRE apague el compresor,

quite el enchufe del tomacorrientes, y purgue toda la

presion del sistema antes de realizar el servicio al

compresor y cuando el compresor no este en uso.

No utilice la unidad sin las cubiertas o sin el

protector de la correa ya que podria sufrir lesiones

por el contacto con las piezas moviles.

Para veriflcar ta alineaci6n de ta polea, retire el protector de

la correa y cotoque una regta (vea A) contra el volante de ta

bomba (vea B) (Fig. 9). Mida y registre ta distancia desde ta regla

al borde de la correa de transmisi6n en el punto C. Luego mida la

distancia desde la regla al borde de ta correa de transmisi6n

nuevamente en los puntos D y E. Ambas distancias deben ser

iguales a la del punto C. Si D o E resultan distintas de C, existe

una mala alineaci6n que debe ser corregida antes de hacer

funcionar el compresor. Para corregir una mala alineaci6n de la

pole& aplique el procedimiento siguiente.

1. Retire el protector de ta correa.

2. Afloje los pernos de montaje del motor.

3. Afloje el tornillo de fijaci6n de la polea del motor.

4. Alinee la polea del motor con el volante de la bomba

(C-D-E debe ser igual).

5. Vuelva a ajustar el tornillo de fijaci6n de la polea del

motor.

6. Ajuste la tensi6n correcta de ta correa.

7. Vuelva a ajustar los pernos de montaje del motor.

8. Vuelva a instalar el protector de ta correa. Todas tas

piezas m6vites deben quedar protegidas.

_ Fig. 9

...........................i ................... Bomba

[ ............ Motor Rueda

. vo_anfe

i .... . V Bet Be a

.............................:::i:::[::::!....................... ..... bomb a {AI

Borde recto (A/ _;!_y_:4_f;_i

Polea !IC

del

motor

Motor

boits

SUBSTITUYENDO O LIMPIANDO LA VALVULA DE

CHEQUE

_Esta unidad arranca

automaticamente. SIEMPRE apague el compresor,

quite el enchufe del tomacorrientes, y purgue toda la

presion del sistema antes de realizar el servicio al

compresor y cuando el compresor no este en uso.

No utilice la unidad sin las cubiertas o sin el

protector de la correa ya que podria sufrir lesiones

por el contacto con las piezas moviles.

1. Apague el compresor de aire, quite el cable electrico de

enchufe o trabe hacia fuera la fuente de alimentaci6n y

releve todo el aire presi6n del tanque. Cerci6rese de que el

compresor tenga refrescado abajo antes de mantener.

2. Afloje ta guarnici6n de ta tuerca de ta compresi6n en la

valvula de cheque y bombee ta cabeza usando una Ilave

ajustable. Quite la transferencia tubo.

3. Afloje ta guarnici6n de ta tuerca de ta compresi6n en el

lado del cheque vatvula e interruptor de presi6n usando una

llave ajustable. Quite el tubo del sangrador.

4. Anotando la orientaci6n para el nuevo ensamble, desatornitte

vatvula de cheque del tanque (a la izquierda) usando un 718"

ltave de extremo abierto.

5. Usando un lapiz o un destornittador, empuje cuidadosamente

el disco de ta valvula arriba y abajo de. Si el disco de ta

valvula no se mueve libremente para arriba y abajo, la

vatvula de cheque necesita ser limpiada o ser substituida.

6. Limpie la vatvula de cheque con agua jabonosa caliente y

cerci6rese de para secarse a fondo antes de reinstalar. Si

todavia la vatvula de disco no se mueve tibremente hacia

arriba y hacia abajo, 6t necesitara ser substituido.

7. Aptique el seltante del hito de rosca a los hitos de rosca de ta

valvula de cheque y reinstatelo en el tanque dando vuelta a

la derecha. Cerci6rese de que sea igual orientaci6n como

cuando fue quitada.

8. Substituya el tubo del sangrador y apriete las tuercas de la

compresi6n.

9. Substituya el tubo de transferencia y apriete las tuercas de la

compresi6n.

10. Realice "robo el procedimiento de ta bomba" en las

instrucciones de manejo de cerciorarse de alli no son

ninguJ n escape y esta trabajando correctamente.

Posid6n cerrada Pos_d6n abierta Destomillador

26 200-2792

Page 27

LIMPIEZA DEL FILTRO DE AIRE

Un fittro de aire sucio reducira el rendimiento y la vida Qtitdel

compresor. Para evitar cualquier contaminaci6n interna de la

bomba del compresor, el fittro debe timpiarse frecuentemente y

reemplazarse de manera regular. Los filtros de fieltro deben

limpiarse en agua jabonosa tibia. No permita que los filtros se

llenen de suciedad ni pintura. Si el filtro se ttena de pintura,

debera reemplazarse. La exposici6n directa a condiciones de

suciedad y zonas en las que esten pintando anularan su

garantia.

REVISION DE LA VALVULA DE ALIVIO

Tire de la vatvula de alivio todos los dias para asegurarse de

que este operando correctamente y para eliminar cualquier

obstrucci6n posible de la misma,

DETECCION DE FUGAS

Compruebe que todas tas conexiones esten ajustadas. Una

pequeSa fuga en cualquiera de las mangueras, tubos de

transferencia o tuberia reducira de manera substancial el

rendimiento de su compresor de aire. Si sospecha la existencia

de una fuga, rocie una pequeSa cantidad de agua jabonosa

alrededor de ta zona con una botelta rociadora. Si aparecen

burbujas, selle y ajuste nuevamente la conexi6n. No ajuste

demasiado.

ALMACENAMIENTO

Antes de almacenar el compresor durante periodos

prolongados, use un soplete de aire para limpiar todo el polvo y

suciedad del compresor. Desconecte el cord6n electrico,

enroltandolo. Tire de ta valvula de alivio de ta presi6n para liberar

toda la presi6n del tanque. Etimine toda la humedad del tanque.

Limpie los elementos y el alojamiento del fittro; reemplacelos si

fuera necesario. Drene el aceite del carter de la bombay

reemplacelo con aceite nuevo. Cubra toda la unidad para

protegerla de la humedad y del polvo.

Diario o despues Cada 100 horas

Realice el mantenimiento siguiente a los intervalos indicados a continuacion, de cada uso de operacion