Craftsman 92116472-2012 Owner’s Manual

Owner's Manual

CRRFTSMRN°

A CO PRESSOR

Oilless

Single Stage

Direct Drive, Electric

33 Gallon Vertical

Model No. 921.16472

CAUTION:

Before using this product,

read this manual and follow

all its Safety Rules and

Operating instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.craftsman.com

11/27/2012 Rev. H

Part No. 200-2798

. Safety instructions

. installation & Operation

. Maintenance & Storage

. Troubleshooting Guide

. Parts List

. Espa5ol, p. 15

. Fran_:ais, p. 24

WARRANTY.............................................................................2 SERVICEINTERVAL...............................................................8

SPECIFICATIONCHART.........................................................2 TROUBLESHOOTINGCHART................................................9

SAFETYGUIDELINES..........................................................3-4 PARTSDRAWINGSANDPARTSLISTS.........................10-14

GLOSSARYOFTERMS..........................................................4

OVERVIEW..............................................................................5

ASSEMBLY..............................................................................5

COMPRESSORCONTROLS...................................................6

MOTORRESETANDWIRING................................................6

ELECTRICALPOWERREQUIREMENTS...............................7

OPERATINGINSTRUCTIONS................................................7

MAINTENANCE.......................................................................8

CRAFTSMAN ONE YEAR FULL WARRANTY

FOR ONE YEAR from the date of purchase, this product is warranted against any defects in material

or workmanship. Defective product will receive free repair or free replacement if repair is unavailable.

For warranty coverage details to obtain repair or replacement, visit the web site: www.craftsman.com

This warranty does not cover the air filter or drive belt, which are expendable parts that can wear out

from normal use within the warranty period.

This warranty is void if this product is ever used while providing commercial services or if rented to

another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

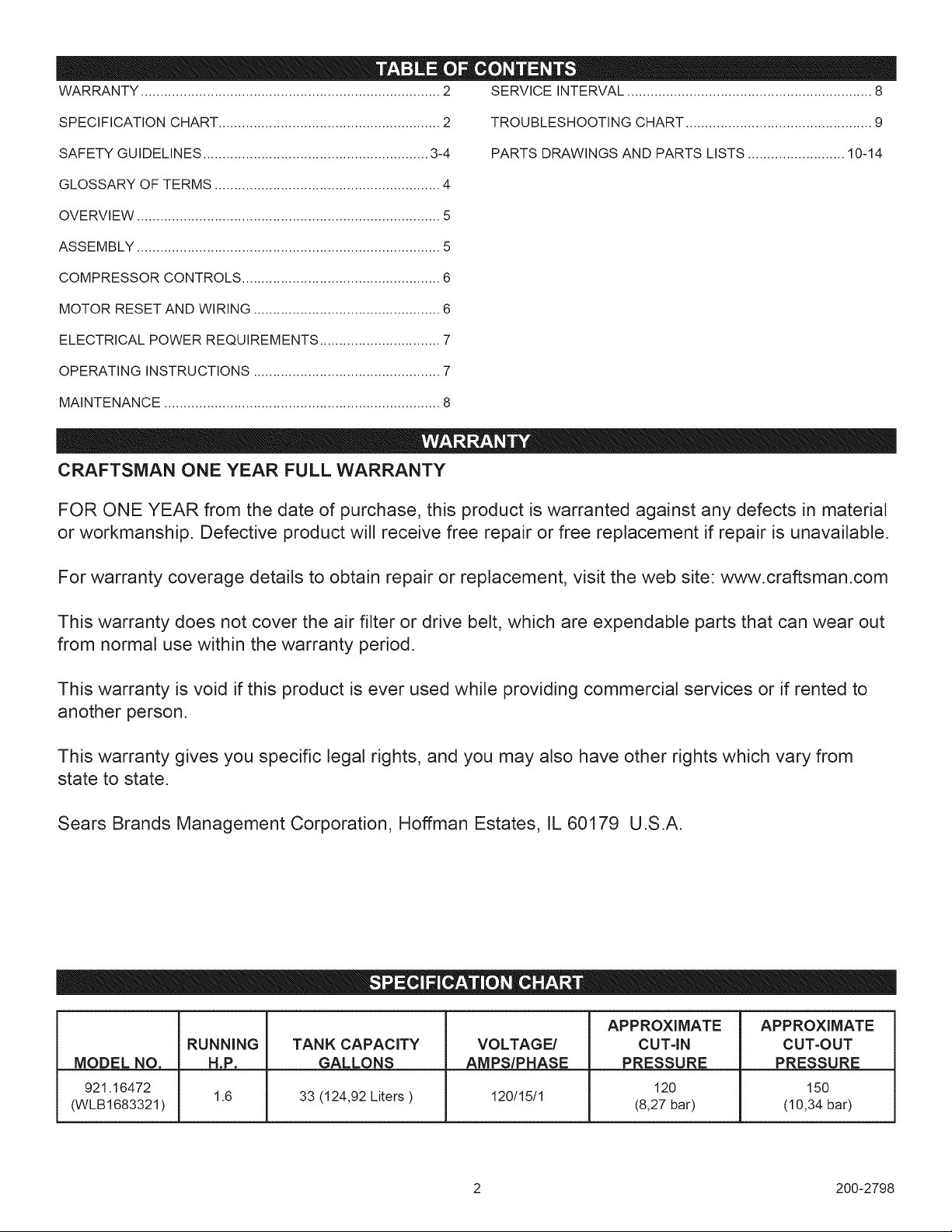

APPROXIMATE APPROXIMATE

RUNNING TANK CAPACITY VOLTAGE/ CUT-IN CUT-OUT

MODEL NO. H.P. GALLONS AMPS/PHASE PRESSURE PRESSURE

921.16472 120 150

(WLB1683321) 1.6 33 (124,92 Liters ) 120/15/1 (8,27 bar) (10,34bar)

2 200-2798

ThefollowinginformationrelatestoprotectingYOURSAFETYandPREVENTINGEQUIPMENTPROBLEMS.Tohelpyourecognize

thisinformation,weusethefollowingsymbols.Pleasereadthemanualandpayattentiontothesesections.

,_1]__! = A POTENTIAL HAZARD THAT WiLL CAUSE SERIOUS iNJURY OR LOSS OF LIFE.

,__= A POTENTIAL HAZARD THAT COULD CAUSE SERIOUS iNJURY OR LOSS OF LIFE.

_IL_ - A POTENTIAL HAZARD THAT MAY CAUSE MODERATE iNJURY OR DAMAGE TO

EQUIPMENT.

RISK OF FIRE OR EXPLOSION. Never spray flammable liquids in a confined area. It is normal for the motor and pressure switch

to produce sparks while operating. If sparks come intocontact with vapors from gasoline or other

solvents, they may ignite, causing fire or explosion. Always operate the compressor in a well-

ventilated area. Do not smoke while spraying. Do not spray where sparks or flame are present.

Keep compressor as far from spray area as possible. Store flammable materials in a secure

location away from compressor. Equip the area of operation with a fire extinguisher.

RISK OF BURSTING. Do not weld, drill or modify the air tank of this compressor. Welding or modifications on the air

_l_j _, compressor tank can severely impair tank strength and cause an extremely hazardous condition.

RISK OF ELECTRICAL SHOCK. Never use an electric air compressor outdoors when it is raining or on a wet surface, as it may

RISK OF INJURY. This unit starts automatically. ALWAYS shut off the compressor, remove the plug from the outlet,

._r and bleed all pressure from the system before servicing the compressor, and when the compressor_, is not in use. Do not use the unit with the shrouds or belt guard removed. Serious injury could

RISK OF BURSTING. Check the manufacturer's maximum pressure rating for air tools and accessories. Compressor

_l_j _, outlet pressure must be regulated so as to never exceed the maximum pressure rating of the

RISK OF BURNS. High temperatures are generated by the pump and manifold. To prevent burns or other injuries, DO

RISK TO BREATHING/ Always wear MSHNNIOSH approved, properly fitting face mask or respirator and work

INHALATION HAZARD.. in a well ventilated area when using tools that generate dust. Some dust created by power

::iiii_ili_:i_i:' of California) to cause cancer, birth defects or other reproductive harm. Some examples of these

._ chemicals are:

RISK TO BREATHING. Be certain to read all labels when you are spraying paints or toxic materials, and follow the safety

::iiii_ili_:i_i:. instructions provided on the labte or safety sheets for the materials you are spraying. Use a MSHA/

-_ NIOSH approved respirator mask if there is a chance of inhaling anything you are spraying. Read

RISK OF EYE INJURY. Always wear ANSI Z87.1 approved safety goggles when using an air compressor. Never point any

Welding or modifying the tank in any manner will void the warranty. If tank develops a leak, replace

it immediately with a new tank or replace the entire compressor.

serious injury or death from electrocution. Make certain that the electrical circuit to which the

cause an electric shock. Failure to provide adequate grounding to this product could result in

compressor is connected provides proper electrical grounding, correct voltage and adequate fuse

)rotection.

occur from contact with moving parts. Stay alert and watch what you are doing when operating the

compressor. Do not use the compressor while tired or under the influence of drugs or alcohol.

toot. Relieve all pressure through the hose before attaching or removing accessories. Never use

compressor to inflate small low pressure objects such as children's toys, footballs, basketballs, etc.

handling or servicing. Keep children away from the compressor at all times. Do not reach around

NOT touch the pump, manifold or transfer tube while the pump is running. Allow them to cool before

%otective shrouds or attempt to maintenance until unit has been allowed to cool.

sanding, grinding, drilling and other construction activities contains chemicals known (to the State

• lead from lead-based paints

• crystalline silica from bricks and cement and other masonry products

• arsenic and chromium from chemically treated lumber.

all instructions and be sure that your respirator mask will protect you. Work in an area with good

cross ventilation.

._ nozzle or sprayer toward a person, animal or any part of the body. Equipment can cause serious

RISK OF BURSTING. .Do not adjust the pressure relief valve for any reason. Doing so voids all warranties. The relief

_l_j _, valve has been pre-set at the factory for the maximum pressure of this unit. Personal injury and/or

200-2798 3

injury if the spray penetrates the skin.

property damage may result if the relief valve is tampered with.

•Do not use plastic or pvc pipe for compressed air. Use only galvanized steel pipe and fittings for

compressed air distribution lines.

RISKOFFIRE. Unattendedoperationofthiscompressorcouldresultinpersonalinjuryorpropertydamage.To

reducetheriskoffire,donotallowthecompressortooperateunattended.Alwaysdisconnect

electricalpowerbyturningthepressureswitchtooffanddrainthetankdailyoraftereachuse.

RISKTOBREATHING. Airobtaineddirectlyfromthecompressorshouldneverbeusedtosupplyairforhuman

:::iiii_ili_::i::i: consumption.Theairstreammaycontaincarbonmonoxide,toxicvapors,orsolidparticlesfrom

._ Lank.Breathing these contaminant's can cause serious injury or death. In order to use air produced

by this compressor for breathing, suitable filters and in-line safety equipment must be properly

installed. In-line filters and safety equipment must be properly installed. In-line filters and safety

equipment used in conjunction with the compressor must be capable of treating air to all applicable

local and federal codes prior to human consumption.

RISK OF INJURY Always operate the compressor in a stable secure position to prevend accidental movement of the

additional air hose to reach high locations.

unit. Never operate the compressor on a table, workbench, roof or other elevated position. Use

RISK TO HEARING. Always wear hearing protection when using an air compressor. Failure to do so may result in

hearing loss.

i_ The power cord on this product contains lead, a chemical known to the State of California to cause

NOTE: ELECTRICAL WIRING. Refer to the air compressor's serial label for the unit's voltage and amperage requirements. Ensure

A_ CALIFORNIA PROPOSITION 65 WARNING: This product contains chemicals known to the State

Drain the moisture from the tank on a daily basis. A clean, dry tank will help prevent corrosion.

Pull the tank safety valve ring daily to ensure that the valve is functioning properly, and to clear the valve of any possible obstructions.

To provide proper ventilation for cooling, the compressor must be kept a minimum of 12 inches (31 cm) from the nearest wall, in a

welt-ventilated area. Restricting any of the compressor ventilation openings will cause overheating and could cause fire, never place

objects against or on top of compressor.

Fasten the compressor down securely if transporting is necessary. Pressure must be released from the tank before transporting.

Protect the air hose and electric cord from damage and puncture. Inspect them weekly for weak or worn spots, and replace if

necessary.

To reduce the risk of electric shock, do not expose to rain. Store indoors.

Never operate the compressor if the power cord or plug are damaged. Have the unit serviced at a Sears or other qualified service

center.

cancer, and birth defects or other reproductive harm. Wash hands after handling.

Lhatall wiring is done by a licensed electrician, in accordance with the National Electrical code.

of California to cause cancer, birth defects and/or reproductive harm.

CFM: Cubic feet per minute; a unit of measure of air flow. shuts off is called "cut-out" pressure.

PSI: Pounds per square inch; a unit of measure of air pressure.

Cut-in pressure: While the motor is off, air tank pressure drops

as you continue to use your accessory. When the tank pressure

drops to factory set tow pressure point, the motor will restart

automatically. The tow pressure at which the motor automatically

restarts is called "cut-in" pressure.

Cut-out pressure: When an air compressor is turned on and

begins to run, air pressure in the air tank begins to build. It

builds to the factory set high pressure point before the motor

automatically shuts off, protecting your air tank from pressure

higher than its capacity. The high pressure at which the motor

Well-ventilated: Means of providing fresh air in exchange for

dangerous exhaust or vapors.

Dedicated circuit: An electrical circuit reserved for the exclusive

use of the air compressor.

4 200-2798

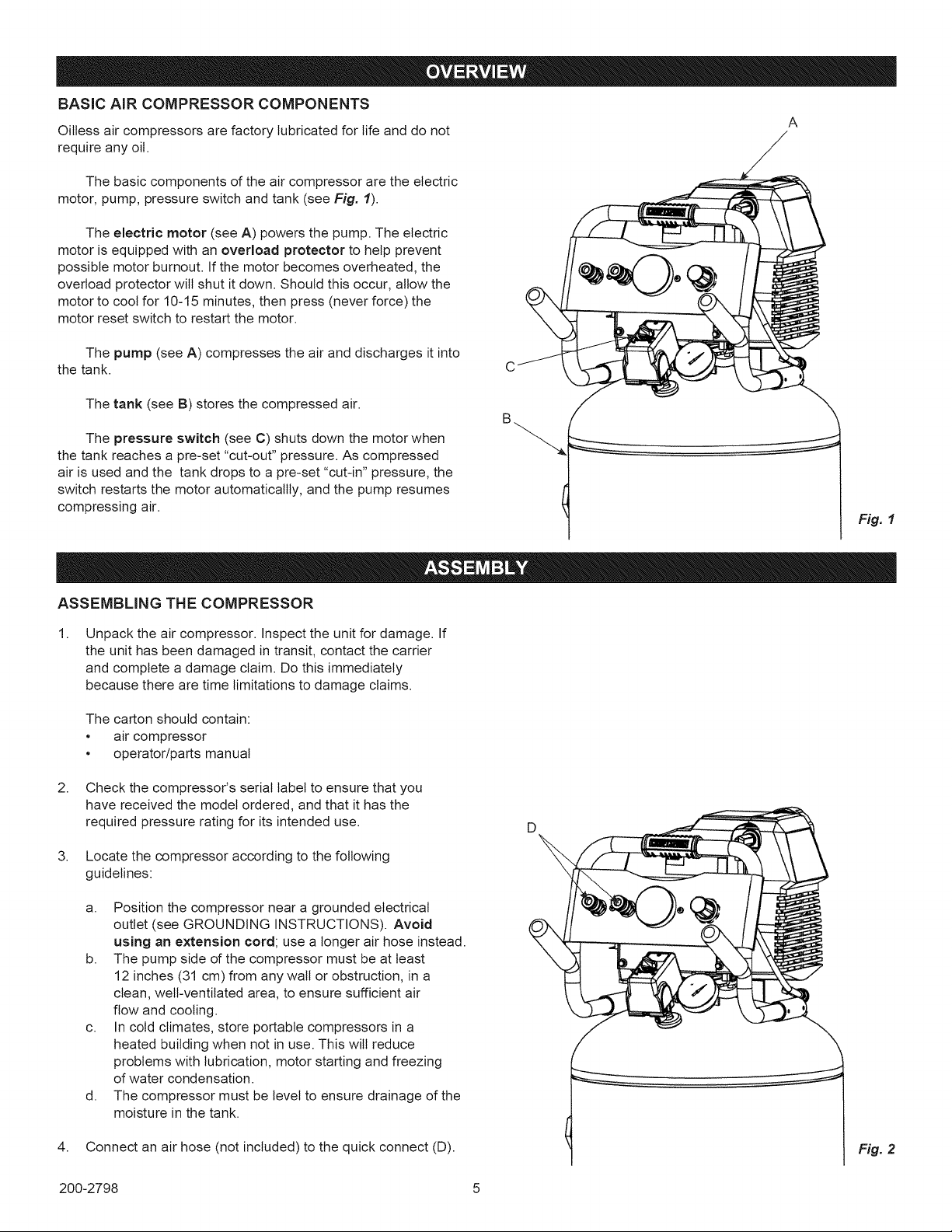

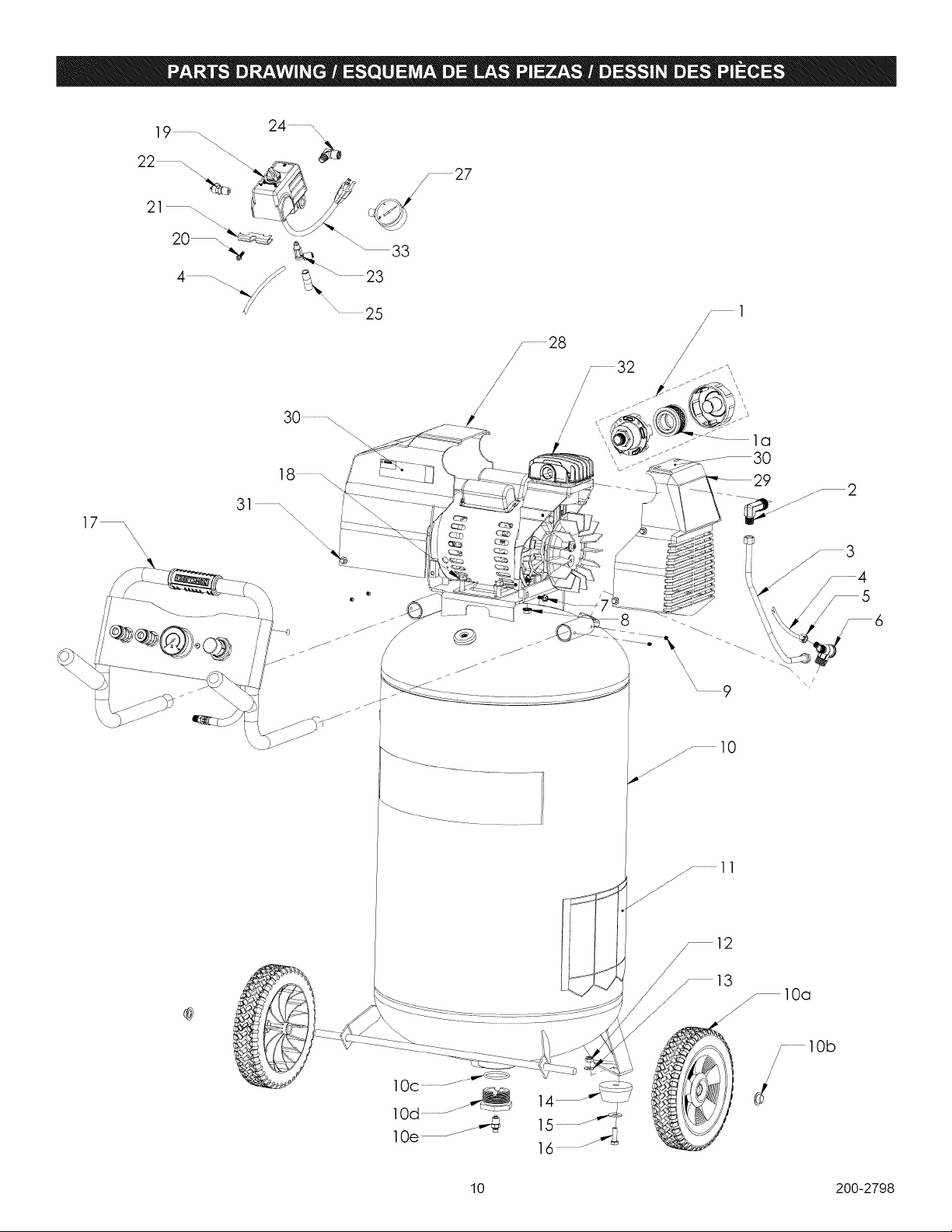

BASIC AiR COMPRESSOR COMPONENTS

Oilless air compressors are factory lubricated for life and do not A

require any oil.

The basic components of the air compressor are the electric

motor, pump, pressure switch and tank (see Fig. 1).

The electric motor (see A) powers the pump. The electric

motor is equipped with an overload protector to help prevent

possible motor burnout. If the motor becomes overheated, the

overload protector wilt shut it down. Should this occur, allow the

motor to cool for 10-15 minutes, then press (never force) the

motor reset switch to restart the motor.

The pump (see A) compresses the air and discharges it into

the tank.

The tank (see B) stores the compressed air.

The pressure switch (see C) shuts down the motor when

the tank reaches a pre-set "cut-out" pressure. As compressed

air is used and the tank drops to a pre-set "cut-in" pressure, the

switch restarts the motor automaticaltly, and the pump resumes

compressing air.

Fig. 1

ASSEMBLING THE COMPRESSOR

1,

Unpack the air compressor. Inspect the unit for damage. If

the unit has been damaged in transit, contact the carrier

and complete a damage claim. Do this immediately

because there are time limitations to damage claims.

The carton should contain:

• air compressor

• operator/parts manual

2,

Check the compressor's serial label to ensure that you

have received the model ordered, and that it has the

required pressure rating for its intended use.

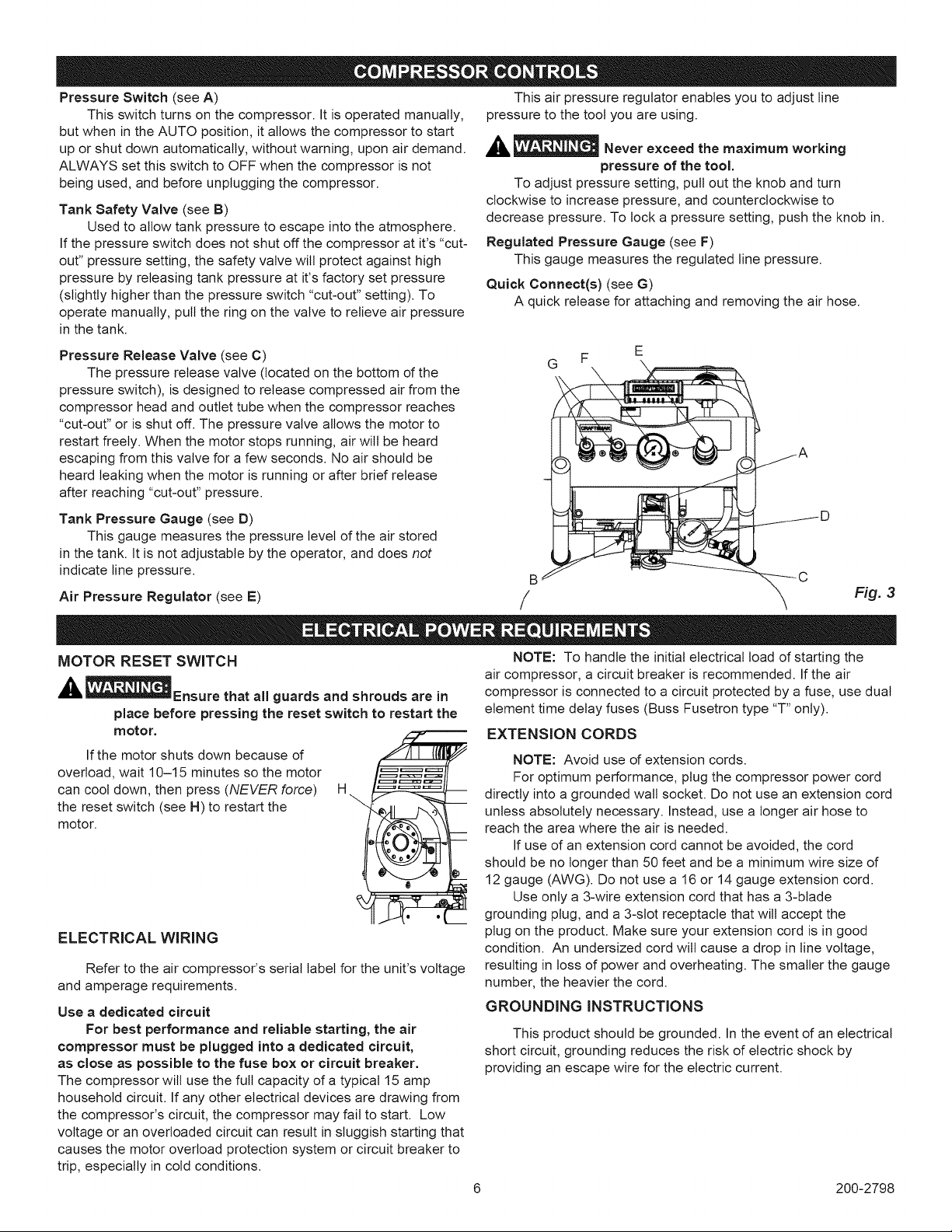

3,

Locate the compressor according to the following

guidelines:

a. Position the compressor near a grounded electrical

outlet (see GROUNDING INSTRUCTIONS). Avoid

using an extension cord; use a longer air hose instead.

b. The pump side of the compressor must be at least

12 inches (31 cm) from any wall or obstruction, in a

clean, well-ventilated area, to ensure sufficient air

flow and cooling.

c. In cold climates, store portable compressors in a

heated building when not in use. This will reduce

problems with lubrication, motor starting and freezing

of water condensation.

d. The compressor must be level to ensure drainage of the

moisture in the tank.

D

4. Connect an air hose (not included) to the quick connect (D).

200-2798 5

Fig. 2

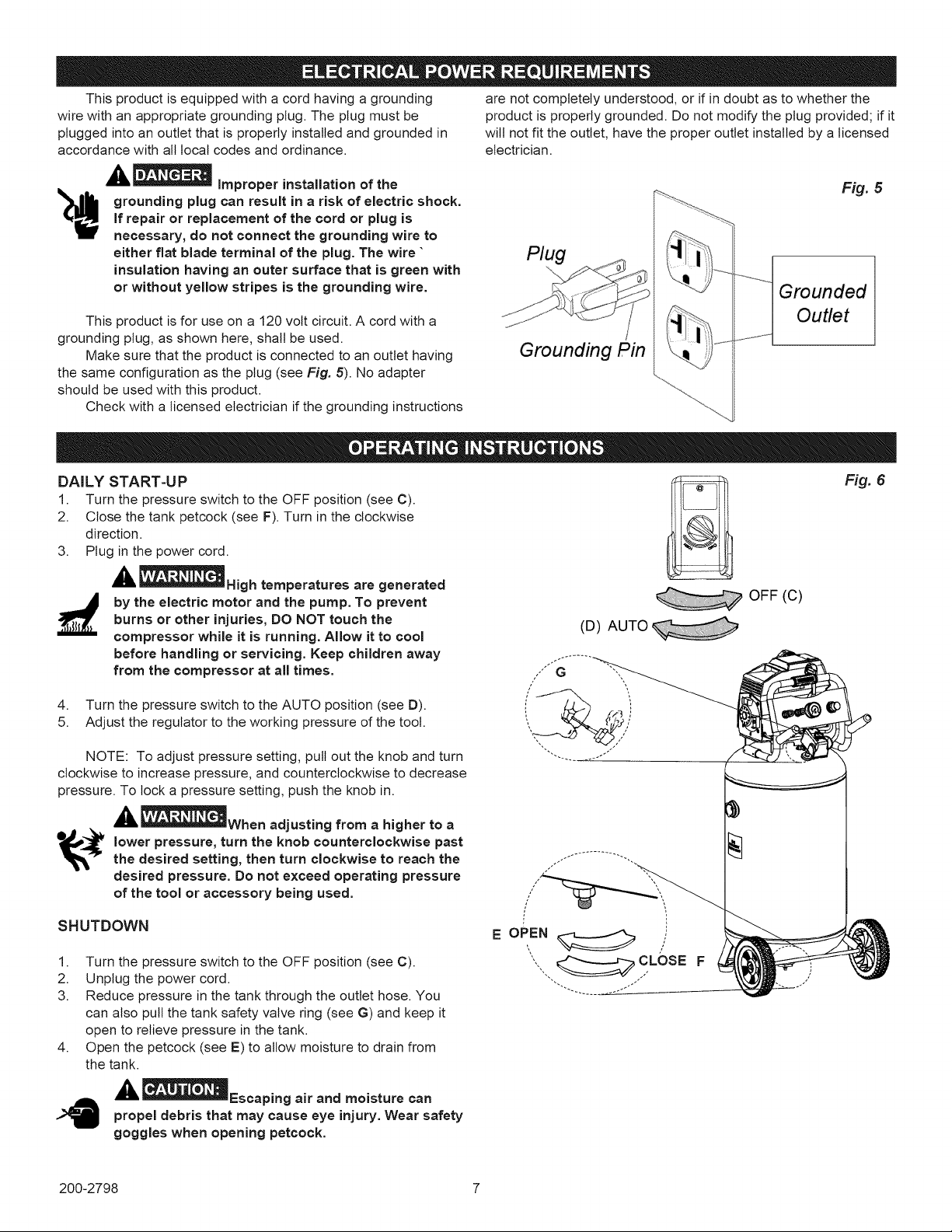

PressureSwitch(seeA)

Thisswitchturnsonthecompressor.Itisoperatedmanually,

This air pressure regulator enables you to adjust line

pressure to the tool you are using.

butwhenintheAUTOposition,itallowsthecompressortostart

uporshutdownautomatically,withoutwarning,uponairdemand.

ALWAYSsetthisswitchtoOFFwhenthecompressorisnot

beingused,andbeforeunpluggingthecompressor.

Tank Safety Valve (see B)

Used to allow tank pressure to escape into the atmosphere.

If the pressure switch does not shut off the compressor at it's "cut-

out" pressure setting, the safety valve will protect against high

pressure by releasing tank pressure at it's factory set pressure

(slightly higher than the pressure switch "cut-out" setting). To

operate manually, pull the ring on the valve to relieve air pressure

in the tank.

Pressure Release Valve (see C)

The pressure release valve (located on the bottom d the

pressure switch), is designed to release compressed air from the

compressor head and outlet tube when the compressor reaches

"cut-out" or is shut off. The pressure valve allows the motor to

restart freely. When the motor stops running, air wilt be heard

escaping from this valve for a few seconds. No air should be

heard leaking when the motor is running or after brief release

after reaching "cut-out" pressure.

Tank Pressure Gauge (see D)

This gauge measures the pressure level of the air stored

in the tank. It is not adjustable by the operator, and does not

indicate line pressure. B

Air Pressure Regulator (see E) // Fig. 3

,__ Never exceed the maximum working

pressure of the tool.

To adjust pressure setting, pull out the knob and turn

clockwise to increase pressure, and counterclockwise to

decrease pressure. To lock a pressure setting, push the knob in.

Regulated Pressure Gauge (see F)

This gauge measures the regulated line pressure.

Quick Connect(s) (see G)

A quick release for attaching and removing the air hose.

E

G

MOTOR RESET SWITCH NOTE: To handle the initial electrical toad of starting the

air compressor, a circuit breaker is recommended. If the air

'_ _Ensure that all guards and shrouds are in

place before pressing the reset switch to restart the

motor.

If the motor shuts down because of

overload, wait 10-15 minutes so the motor

can cool down, then press (NEVER force)

the reset switch (see H) to restart the

motor.

ELECTRICAL WIRING

Refer to the air compressor's serial label for the unit's voltage

and amperage requirements.

Use a dedicated circuit

For best performance and reliable starting, the air

compressor must be plugged into a dedicated circuit,

as close as possible to the fuse box or circuit breaker.

The compressor will use the full capacity of a typical 15 amp

household circuit. If any other electrical devices are drawing from

the compressor's circuit, the compressor may fail to start. Low

voltage or an overloaded circuit can result in sluggish starting that

causes the motor overload protection system or circuit breaker to

trip, especially in cold conditions.

compressor is connected to a circuit protected by a fuse, use dual

element time delay fuses (Buss Fusetron type "T" only).

EXTENSION CORDS

NOTE: Avoid use d extension cords.

For optimum performance, plug the compressor power cord

directly into a grounded wall socket. Do not use an extension cord

unless absolutely necessary. Instead, use a longer air hose to

reach the area where the air is needed.

If use of an extension cord cannot be avoided, the cord

should be no longer than 50 feet and be a minimum wire size of

12 gauge (AWG). Do not use a 16 or 14 gauge extension cord.

Use only a 3-wire extension cord that has a 3-btade

grounding plug, and a 3-stot receptacle that will accept the

plug on the product. Make sure your extension cord is in good

condition. An undersized cord will cause a drop in line voltage,

resulting in loss of power and overheating. The smaller the gauge

number, the heavier the cord.

GROUNDING INSTRUCTIONS

This product should be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current.

6 200-2798

Thisproductisequippedwithacordhavingagrounding arenotcompletelyunderstood,orifindoubtastowhetherthe

wirewithanappropriategroundingplug.Theplugmustbe productisproperlygrounded.Donotmodifytheplugprovided;ifit

pluggedintoanoutletthatisproperlyinstalledandgroundedin wiltnotfittheoutlet,havetheproperoutletinstalledbyalicensed

accordancewithalllocalcodesandordinance, electrician.

_li,_ Improper installation of the Fig. 5

If repair or replacement of the cord or plug is

grounding plug can result in a risk of electric shock.

necessary, do not connect the grounding wire to

either flat blade terminal of the plug. The wire"

insulation having an outer surface that is green with ,.

or without yellow stripes is the grounding wire. Grounded

This product is for use on a 120 volt circuit. A cord with a Outlet

grounding plug, as shown here, shall be used.

Make sure that the product is connected to an outlet having rounuln9

the same configuration as the plug (see Fig. 5). No adapter

should be used with this product.

Check with a licensed electrician if the grounding instructions .....,..

Pin

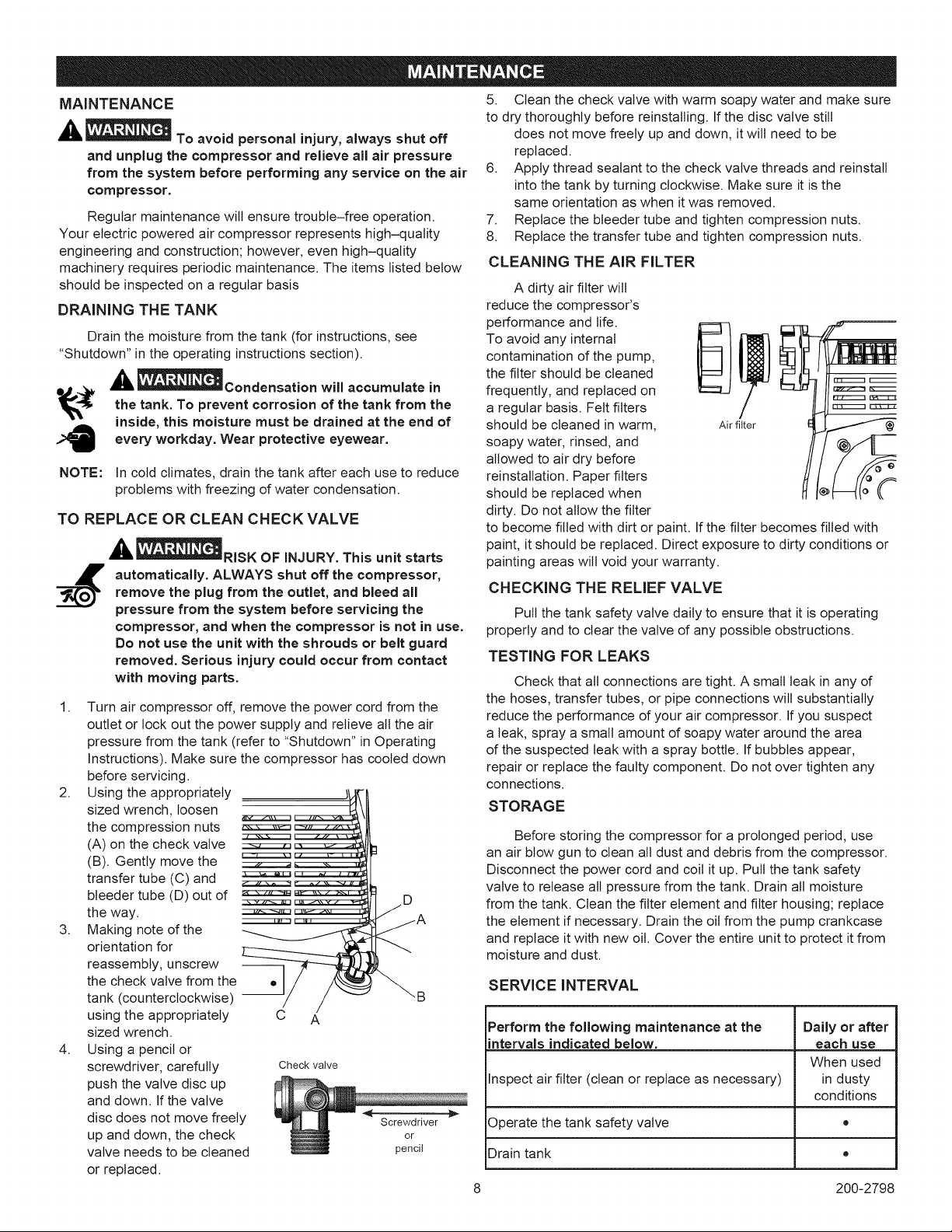

DALLY START=UP

1. Turn the pressure switch to the OFF position (see C).

2. Close the tank petcock (see F). Turn in the clockwise

direction.

3. Plug in the power cord.

_ll _High temperatures are generated

burns or other injuries, DO NOT touch the

by the electric motor and the pump. To prevent

compressor while it is running. Allow it to cool

before handling or servicing. Keep children away

from the compressor at all times.

4. Turn the pressure switch to the AUTO position (see D).

5. Adjust the regulator to the working pressure of the tool,

NOTE: To adjust pressure setting, pull out the knob and turn

clockwise to increase pressure, and counterclockwise to decrease

pressure. To lock a pressure setting, push the knob in.

_i' _When adjusting from a higher to a

._ lower pressure, turn the knob counterclockwise past

the desired setting, then turn clockwise to reach the

desired pressure. Do not exceed operating pressure

of the tool or accessory being used.

SHUTDOWN

1. Turn the pressure switch to the OFF position (see C).

2. Unplug the power cord.

3. Reduce pressure in the tank through the outlet hose. You

can also pull the tank safety valve ring (see G) and keep it

open to relieve pressure in the tank.

4. Open the petcock (see E) to allow moisture to drain from

the tank.

(D) AUTO

/ G

,," ,,

/' "i

EopE. /

", CL()SE

Fig. 6

OFF (C)

'_ _Escaping air and moisture can

propel debris that may cause eye injury. Wear safety

goggles when opening petcock.

200-2798 7

MAINTENANCE 5. Cleanthecheckvalvewithwarmsoapywaterandmakesure

to dry thoroughly before reinstalling. Ifthe disc valve still

__ To avoid personal injury, always shut off

and unplug the compressor and relieve all air pressure

from the system before performing any service on the air

compressor.

Regular maintenance will ensure trouble-free operation.

Your electric powered air compressor represents high-quality

engineering and construction; however, even high-quality

machinery requires periodic maintenance. The items listed below

should be inspected on a regular basis

DRAINING THE TANK

Drain the moisture from the tank (for instructions, see

"Shutdown" in the operating instructions section).

_" _Condensation will accumulate in

_ the tank. To prevent corrosion of the tank from the

NOTE: In cold climates, drain the tank after each use to reduce

TO REPLACE OR CLEAN CHECK VALVE

1,

2,

3,

4,

inside, this moisture must be drained at the end of

every workday. Wear protective eyewear.

problems with freezing of water condensation.

,_ _RISK OF INJURY. This unit starts

automatically. ALWAYS shut off the compressor,

remove the plug from the outlet, and bleed all

pressure from the system before servicing the

compressor, and when the compressor is not in use.

Do not use the unit with the shrouds or belt guard

removed. Serious injury could occur from contact

with moving parts.

Turn air compressor off, remove the power cord from the

outlet or lock out the power supply and relieve all the air

pressure from the tank (refer to "Shutdown" in Operating

Instructions). Make sure the compressor has cooled down

before servicing.

Using the appropriately

sized wrench, loosen

the compression nuts

(A) on the check valve

(B). Gently move the

transfer tube (C) and

bleeder tube (D) out of

the way.

Making note of the

orientation for

reassembly, unscrew

the check valve from the

tank (counterclockwise)

using the appropriately

C A

",B

sized wrench.

Using a pencil or

screwdriver, carefully

Check valve

push the valve disc up

and down. Ifthe valve

disc does not move freely

up and down, the check

valve needs to be cleaned

Screwdriver

or

pencil

or replaced.

does not move freely up and down, it will need to be

replaced.

6. Apply thread sealant to the check valve threads and reinstall

into the tank by turning clockwise. Make sure it is the

same orientation as when it was removed.

7. Replace the bleeder tube and tighten compression nuts.

8. Replace the transfer tube and tighten compression nuts.

CLEANING THE AIR FILTER

A dirty air filter will

reduce the compressor's

performance and life.

To avoid any internal

contamination of the pump,

the filter should be cleaned

frequently, and replaced on

a regular basis. Felt filters

should be cleaned in warm,

Air filter

soapy water, rinsed, and

allowed to air dry before

reinstattation. Paper filters

should be replaced when

dirty. Do not allow the filter

to become filled with dirt or paint. If the filter becomes filled with

paint, it should be replaced. Direct exposure to dirty conditions or

painting areas wilt void your warranty.

CHECKING THE RELIEF VALVE

Pull the tank safety valve daily to ensure that it is operating

properly and to clear the valve of any possible obstructions.

TESTING FOR LEAKS

Check that all connections are tight. A small leak in any of

the hoses, transfer tubes, or pipe connections will substantially

reduce the performance of your air compressor. Ifyou suspect

a leak, spray a small amount of soapy water around the area

of the suspected leak with a spray bottle. If bubbles appear,

repair or replace the faulty component. Do not over tighten any

connections.

STORAGE

Before storing the compressor for a prolonged period, use

an air blow gun to clean all dust and debris from the compressor.

Disconnect the power cord and coil it up. Pull the tank safety

valve to release all pressure from the tank. Drain all moisture

from the tank. Clean the filter element and filter housing; replace

the element if necessary. Drain the oil from the pump crankcase

and replace it with new oil. Cover the entire unit to protect it from

moisture and dust.

SERVICE INTERVAL

Perform the following maintenance at the Daily or after

intervals indicated below, each use

When used

Inspect air filter (clean or replace as necessary) in dusty

Operate the tank safety valve ,

Drain tank *

conditions

200-2798

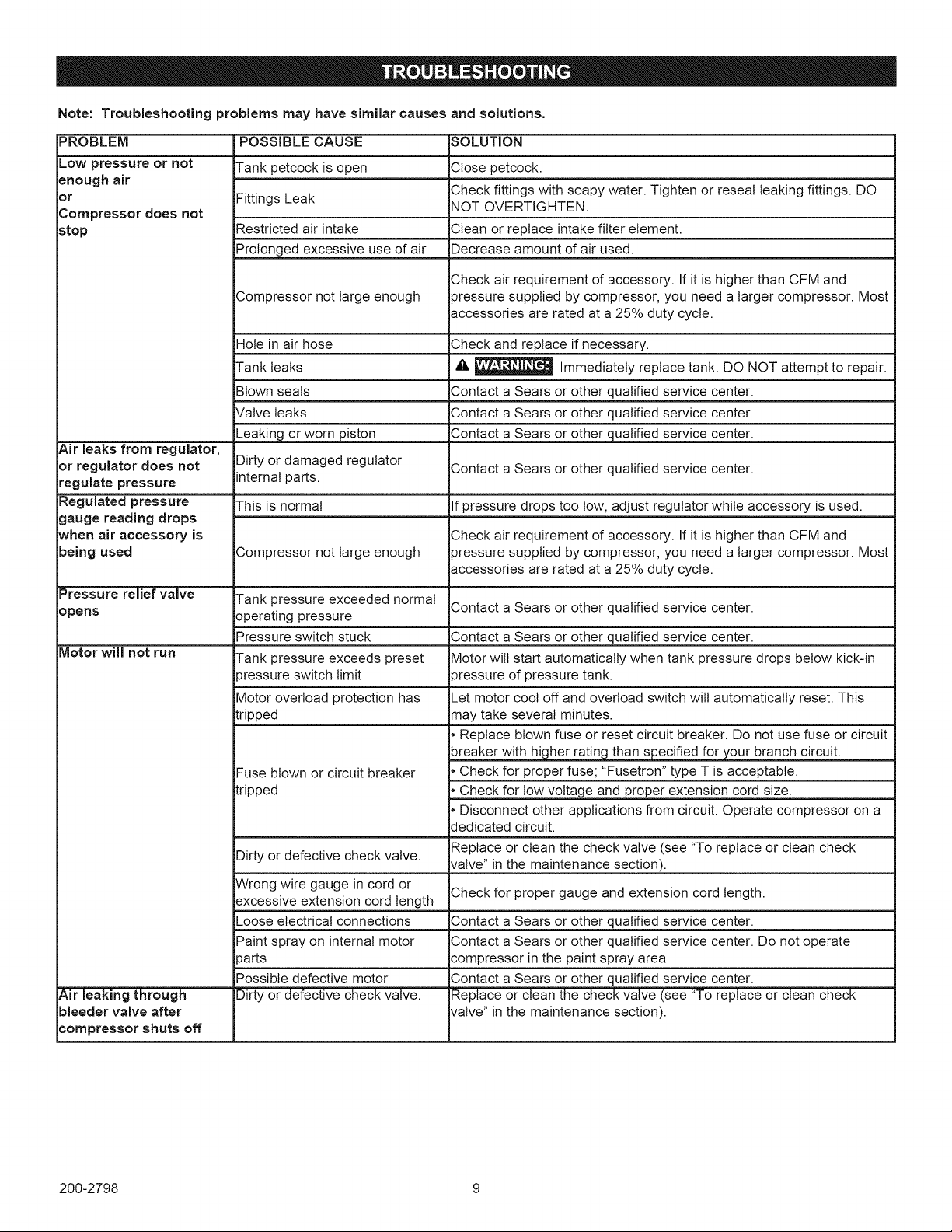

Note: Troubleshooting problems may have similar causes

PROBLEM

Low pressure or not

enough air

or

Compressor does not

stop

Air leaks from regulator,

or regulator does not

regulate pressure

Regulated pressure

gauge reading drops

when air accessory is

being used

Pressure relief valve

opens

Motor will not run

POSSIBLE CAUSE SOLUTION

Tank petcock is open Close petcock.

Fittings Leak

Restricted air intake Clean or replace intake filter element.

Prolonged excessive use of air Decrease amount of air used.

Compressor not large enough )ressure supplied by compressor, you need a larger compressor. Most

Hole in air hose Check and replace if necessary.

Tank leaks _, _ Immediately replace tank. DO NOT attempt to repair.

Blown seals Contact a Sears or other qualified service center.

Valve leaks Contact a Sears or other qualified service center.

Leaking or worn piston Contact a Sears or other qualified service center.

Dirty or damaged regulator Contact a Sears or other qualified service center.

internal parts.

This is normal If pressure drops too low, adjust regulator while accessory is used.

Compressor not large enough )ressure supplied by compressor, you need a larger compressor. Most

Tank pressure exceeded normal

operating pressure

Pressure switch stuck Contact a Sears or other qualified service center.

Tank pressure exceeds preset Motor wilt start automatically when tank pressure drops below kick-in

)ressure switch limit )ressure of pressure tank.

Motor overload protection has Let motor cool off and overload switch will automatically reset. This

tripped may take several minutes.

Fuse blown or circuit breaker • Check for proper fuse; "Fusetron" type T is acceptable.

tripped • Check for tow voltage and proper extension cord size.

and solutions.

Check fittings with soapy water. Tighten or reseal leaking fittings. DO

NOT OVERTIGHTEN.

Check air requirement of accessory. If it is higher than CFM and

accessories are rated at a 25% duty cycle.

Check air requirement of accessory. If it is higher than CFM and

accessories are rated at a 25% duty cycle.

Contact a Sears or other qualified service center.

• Replace blown fuse or reset circuit breaker. Do not use fuse or circuit

breaker with higher rating than specified for your branch circuit.

• Disconnect other applications from circuit. Operate compressor on a

dedicated circuit.

Dirty or defective check valve. Replace or clean the check valve (see "To replace or clean check

Wrong wire gauge in cord or

excessive extension cord length

Loose electrical connections Contact a Sears or other qualified service center.

Paint spray on internal motor Contact a Sears or other qualified service center. Do not operate

)arts compressor in the paint spray area

Possible defective motor Contact a Sears or other qualified service center.

Air leaking through

bleeder valve after

compressor shuts off

200-2798 9

Dirty or defective check valve. Replace or clean the check valve (see "To replace or clean check

valve" in the maintenance section).

Check for proper gauge and extension cord length.

valve" in the maintenance section).

19 ..................._\\ ,,

4 ....................

--33

17_

.....................25

/ ...................1

31

\

\\\

\,

....................10

J

@

12

_lOa

,-..................lOb

10 200-2798

Loading...

Loading...