Page 1

OWNER'S MANUAL

CRQFTSMPN

V Im n r I ^ 1*1 n 11,

7.5 Horsepower

2700 PSI 3 GPM

High Pressure Washer

Model No:

919.7627Q0

h

'h

\

WARNING: Before using this

product, read this manual

and follow all Safety Rules

and Operating Instructions.

Sears, Roebuck and Co., Hoffnnan Estates, IL 60179 U.S.A.

MGP-782700 l/S/aS

Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Español

Page 2

TABLE OF CONTENTS

.........

Warranty

Safety Guidelines

Assembly

Operation

Maintenance

..................................

.....................

...

.................................

.................................

........................

.

.

.

.

Service and Adjustments.............

.

2

.........

3-5 Troubleshooting

.

........

5-7

.........

7-10 EPA Codes...

.

........

11-13

.........

14 Español

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman High Pressure Washer is main

tained and operated according to the instructions in the owner’s manual. Sears will repair, free of

charge, any defect in material and workmanship.

Storage......................

.........................................

Parts

........................

.....................

How to Order Parts

....

..........................

.

.

......

....................

.

.................16-30

...........

.

.......

.

.

................

.....31-32

Back Cover

..14

15

34-52

If your Craftsman Pressure Washer is used for commercial or rental purposes, this warranty

applies only for 90 days from the date of purchase.

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN ENGINE

For one year from the date of purchase, when this Craftsman engine is maintained and operated

according to the instructions in the owner’s manual, Sears will repair, free of charge, any defect

in material and workmanship.

If your Craftsman engine is used for commercial or rental purposes, this warranty applies only

for 90 days from the date of purchase. This warranty does not cover: Expendable items such as

spark plugs and air filters, which become worn during normal use.

Repairs necessary because of operator abuse or negligence, including damage resulting from

no water being supplied to pump or failure to maintain the equipment according to the instruc

tions contained in the owner's manual, are not covered under warranty.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HIGH PRESSURE WASHER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This, warranty gives you specific legal rights and you may also have other rights, which vary

from state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

Page 3

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols

below. Please read the manual and pay attention to these sections. SAVE THESE DEFINITIONS/INSTRUCTIONS.

A WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious iniurv.

A CAUTION indicates a potentially hazardous situation

A DANGER indicates an imminently hazardous

situation which, if not avoided, wH] result in

death or serious Iniurv.

injury-

which, if not avoided, mav result in minor or moderate

IMPORTANT SAFETY INSTRUCTIONS

AWARNING

Improper operation or maintenance of this product could result in serious injury and property damage. Read

and understand all warnings and operating instructions before using.

tO/2/97

HAZARD

A DANGER

RISK OF EXPLOSION

OR FIRE

WHAT CAN HAPPEN

Spilled gasoline and its vapors can

become ignited from cigarette

spari<s, electrical arcing, exhaust

gases, and hot engine components

such as the muffler.

Heat will expand fuel in the tank

which could result in spillage and

possible fire explosion.

Operating the pressure washer in an

explosive environment could result

in a fire.

• Materials placed against or near the

pressure washer can interfere with

its proper ventilation features

causing overheating and possible

ignition of the materials.

* Improperly stored fuel could lead to

accidental ignition. Fuel improperiy

secured could get into the hands of

children or other unqualified persons.

HOWTO PREVENT IT

Shut off engine and allow it to cool

before adding fuei to the tank.

Use care in filling tank to avoid

spilling fuel. Move pressure washer

away from fueling area before

starting engine.

Keep maximum fuel level Vz" below

top of tank to allow for expansion.

Operate and fuel equipment in well

ventilated areas free from obstruc

tions. Equip areas with fire

extinguishers suitable for gasoline

fires.

Never operate pressure washer In an

area containing dry brush or weeds.

Store fuel in container approved for

gasoline, in a secure location away

from work area.

ADANGER

RISK TO BREATHING

Breathing exhaust fumes will cause

serious injury or death.

Some cleaning fluids contain sub

stances which could cause injury to

skin, eyes, or lungs.

Operate pressure washer in a well

ventilated area. Avoid enclosed areas

such as garages, basements ,etc.

Never operate unit in a location

occupied by humans or animals.

Use only cleaning fluids specifically

recommended for high pressure

washem. Follow manufacturers

recommendations.

Page 4

IMPORTANT SAFETY INSTRUCTIONS (conrd)

HAZARD

WHAT CAN HAPPEN

HOWTO PREVENT IT

^WARNING

RISK OF UNSAFE

OPERATION

Awarning

RISK OF INJURY FROM

SPRAY

• Unsafe operation of your pressure

washer could lead to serious injury

or death to you or others.

• The spray gun/wand is a powerful

cleaning tool that could look like a

toy to a child.

Reactive force of spray will cause

gun/wand to move, and could cause

the operator to slip or fall, or

misdirect the spray, improper control

of gun/wand can result in injuries to

self and others.

* High velocity fluid spray can cause

objects to break, propelling particles

at high speed.

• Light or unsecured ot^ects can become

hazardous projectiles.

Become familiar with the operation

and controls of the pressure washer.

Keep children away from the

pressure washer at all times.

Never defeat the safety features of this

product.

Do not operate machine with missing,

broken, or unauthorized parts.

Never leave wand unattended while

unit is running.

Keep work area free of obstacles.

Stand on a stable surface and grip gun/

wand firmly. Expect the gun to kick

when triggered.

Always wear ANSI approved Z87 safety

glasses. Wear protective clothing to

protect against accidental spraying.

Never point wand at, or spray people or

animals.

Always secure trigger lock when wand

is not in service to prevent accidental

operation.

Never permanently secure trigger in pull

back (open) position.

Awarning

RISK OF

ELECTRICAL

SHOCK

Awarning

RISK OF FLUID INJECTION

Awarning

RISK OF CHEMICAL BURN

Spray directed at electrical outlets or

switches, or objects connected to an

electrical circuit, could result in a fata!

electrical shock.

• Your washer operates at fluid

pressures and velocities high enough

to penetrate human and animal flesh,

which could result in amputation or

other serious injury. Leaks caused by

loose fittings or worn or damaged

hoses can result in injection injuries.

DO NOT TREAT FLUID INJECTION AS

A SIMPLE CUT! See a physician

immediately!

* Relieve system pressure before

attempting maintenance or disassem

bly of equipment.

Use of acids, toxic or corrosive

chemicals, poisons, insecticides, or

any kind of flammable solvent with this

product could result in serious injury

or death.

Unplug any electrically operated

product before attempting to clean it.'

Direct spray away from electric outlets

and switches.

Never place hands in front of nozzle.

Direct spray away from self and others.

Make sure hose and fittings are

tightened and in good condition. Never

hold onto the hose or fittings during

operation.

Do not aliow hose to contact muffler.

Never attach or remove wand or hose

fittings while system is pressurized.

Use only hose and high pressure

accessories rated for 2000 PSI service.

To relieve system pressure, shut off

engine, turn off water supply, and pull

gun trigger until water stops flowing.

• Do not use acids, gasoline, kerosene, or

any other flammable materials in this

product. Use only household

detergents, cleaners and degreasers

recommended for use in pressure

washers.

* Wear protective clothing to protect

eyes and skin from contact with

sprayed materials.

________________

Page 5

HAZARD

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

WHAT CAN HAPPEN

HOWTO PREVENT IT

Awarning

RISK OF HOT SURFACES

Contact with hot surfaces, such as

engines exhaust components, could

result in serious bum.

• During operation, touch only the control

surfaces of the pressure washer. Keep

children away from the pressure washer

at all times. They may not be able to

recognize the hazards of this product.

IMPORTANT:

The powerful spray from your pressure washer is capable of causing damage to fragile surfaces such as: wood, glass,

automobile paint, auto stripping and trim, and delicate objects such as flowers and shrubs. Before spraying, check the

item to be cleaned to assure yourself that it is robust enough to resist damage from the force of the spray. Avoid the

use of the concentrated spray stream except for very strong surfaces like concrete and steel.

Operating unit with water supply shut off without flow of water will result in equipment damage. You should never run

this pressure washer for more than 2 minutes without pulling the trigger to allow cool water to enter the pump and the

heated (recirculated) water to exit. Running the pressure washer with water supply shut off will void your warranty.

ASSEMBLY

Carton Contents

• Main Unit pressure washer with wheels

• Handle

• High Pressure Hose

• Chemical Pickup Hose and Filter

• Bag Containing

Video Cassette

Owners’ Manual

Nozzzle Cleaning Kit and Replacement 0-Rings

~ Rubber Isolator and Mounting Hardware

• Box Containing

Gun

Wand

Engine Oi!

Handle Mounting Hardware

Tools Required for Assembly

Adjustable wrench

1/2” Socket wrench

Remove Pressure Washer from Carton

NOTE: The high pressure and chemical hose are

located at the bottom of the box.

Preparing the Pressure Washer for First Use

• Note; Included with your pressure washer is a video

tape on how to prepare your unit for operation. It is

recommended you view this tape before performing

the next steps.

1. * Insert handle onto frame,

• Slide J bolts into frame.

• Tighten knobs turning in clockwise direction.

(Tighten lutob in etocfewis«

(Krectìon to ttiTMCiatf «ntf of 4 bolt}

4 boK hot«. Thmsdod otid

goes b) botttHO hole}

• Open box from the top. Locate and remove from

box, the parts box, which includes gun, handle,

wand,oil, knobs and J bolts. Next remove the parts

bag and the handle.

• Cut carton along dotted lines.

• Remove all carton inserts.

Page 6

Remove wood plank from the frame of the unit.

2.

An adjustable wrench is required. Discard nut,

bolt and board.

3. • Mount the rubber isolator to the frame. To mount

isolator place threaded end of bolt through the

washer. Next with washer on bolt place threaded

end of bolt through the rubber isolator. Place

threaded portion of isolator through the same

hole location the wood plank was mounted to on

the pressure washer Next place lockwasher

over threaded portion of nut that has been

placed through

'Me mounting hole in the pressure

washer and use nut to tighten isolator to the

frame. Tighten nut with an adjustable wrench. All

isolator parts are supplied In parts bag.

7. • Connect high pressure hose to the quick connect

outlet on pressure washer.

QUICK CONNECT

OUTLET

NOTE: Keep hose away from engine muffler.

8. • Place assembled gun and wand on pressure

washer holder.

NUT

PRES^RE

W>^HER

FRMIE

Connect wand with nozzle extension to gun. To

4,

LOCKWASHER

r-C

^^^ISOLATOfl

BOLT—

tighten, turn knob in clockwise direction. Hand

tighten.

5. • Cut tie wrap off of high pressure hose. Unwind

high pressure hose to attach the threaded end to

the gun.

NOTE: Do not remove Telfon tape on threads.

6. • Connect chemical hose to the chemical injector

nipple on the pump.

NOTE: Your unit’s pump is shipped with a

temporary plug that must be replaced with a

breather cap. This plug is located over the pump’s

oil port. Unscrew and remove this plug. Remove

the breather cap from the bag attached to the plug

and install it in the pump’s oil port.

8NEATHER

CAP

A CAUTION; Failure to replace the plug will res

in serious pump damage.

m

Page 7

Checklist

Before going any further please review the following:

♦ Be sure you have completed assembly instruction.

• Double check all fittings to be sure they are tight.

IMPORTANT: Before any attempt to start your pres

sure washer be sure to check engine oil (See Operation

under Engine Oil, page 9.)

OPERATION

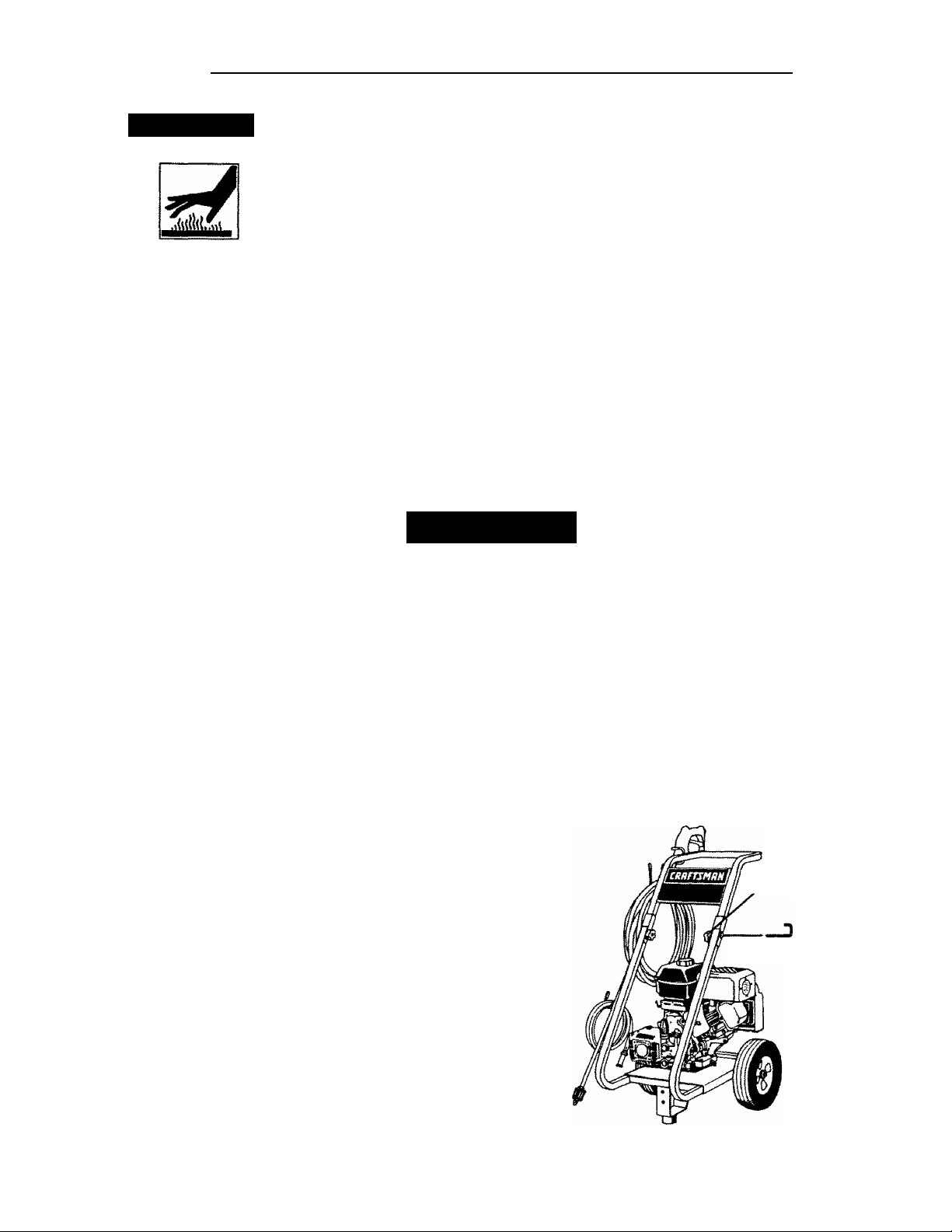

Know Your High Pressure Washer

Read this Owner^s Manual and Safety Rules before

operation of your High Pressure Washer Compare

this illustration with our pressure washer to familiarize

yourself with the location of various controls and

adjustments. Save this manual for future reference.

PUMP- Develops high pressure.

ENGINE OIL. FILL- Place where engine oil is poured.

PRESSURE REGULATOR- Allows you to adjust the

pressure of the outlet stream.

ENGINE RUN/STOP SWITCH- Sets engine in starting

mode for recoil starter — Stops running engine.

CHOKE

LEVER

RECOIL STARTER- Used for starting the engine

manually.

SPRAY GUN ASSEMBLY- Controls the application of

water onto cleaning surface with trigger device.

PUMP OIL FILL- Port where pump oil is poured and

breather cap is located.

GAS TANK/CAP- Cap is removed and unleaded

gasoline is poured.

CHEMICAL INJECTION TUBE AND FILTER- Mixes

water and detergent in outlet water flow.

HIGH PRESSURE OUTLET- Connection for high pres

sure hose.

CHOKE- Lever used for starting unit.

GUN WAND

ASSEMBLY

HANDLE

ON/OFF

PRESSURE

ENGINE OIL REGULATOR

FILL

PUMP OIL

FILL

CHEMICAL INJECTOR

TUBE & FILTER

WATER INLET

CONNECTION

THROTTLE

1

dB

HIGH PRESSURE

"^1

W*' i

SU

_

CHEMICAL

ADJUSTMENT

KNOB

Page 8

A Warning; Read Owner’s Manual. Do not attempt

to operate equipment until you have read Owners

Manualfor Safety, Operation, and Maintenance

Instructions,

Note: Included with your unit is a video cassette that

demonstrates how to operate your pressure washer.

If you have a video cassette recorder you should

view the video before operation.

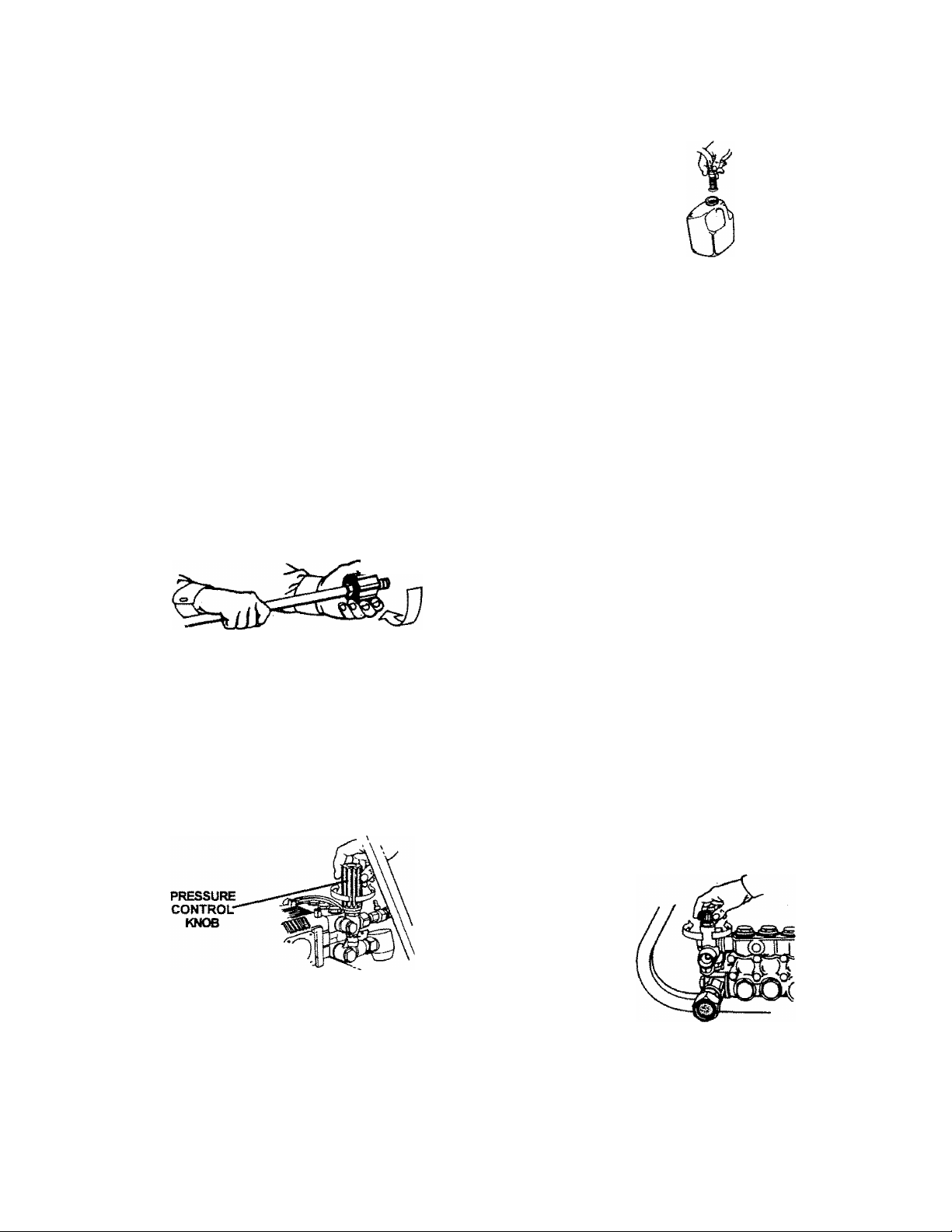

insert soap/chemical tine into your container

(soap/chemicals not included).

A Warning: Never adjust spray pattern when spray

ing. Never put hands in front of spray nozzle to

adjust spray pattern because you could be injured.

How To Use Your Pressure Washer

On the end of your spray gun is a nozzle that you can

twist from side to side. With the adjustable nozzle you

can adjust the nozzln.to either high pressure or low

pressure.

• Turn the nozzle in a counter clockwise direction to

achieve low pressure. Turn nozzle clockwise for high

pressure.

• For most effective cleaning, keep spray nozzle

between 8 and 24 inches of cleaning surface.

IMPORTANT; If you get spray nozzle too close,

especially on high pressure, you may damage the

cleaning surface.

• The pressure control knob Is located on the pump.

You can increase the pressure by turning the knob

clockwise or decrease the pressure by turning the

knob counterclockwise.

NOTE: The first step involves applying an appropriate

soap/chemical solution to penetrate and loosen grime.

The soap/chemical applied at low pressure to avoid

splashing, over spray and waste. Leave the solution

on surface for 3 to 5 minutes to allow solution to work.

NOTE: The second step involves cleaning the surface

you have prepared with the pressure washer and then

rinsing it clean.

• Turn the adjustable nozzle counter clockwise to low

pressure mode. Soap/chemicals cannot be applied

with nozzle in high pressure position.

• Review the use of the adjustable nozzle.

• Connect garden hose to water inlet (see ’To Start Your

Pressure Washer”), check that high pressure hose is

connected to spray gun and pump (see Assembly),

and start engine.

• Apply soap/chemicals to dry surface, starting

bottom and working up.

• Allow the soap/chemicals to soak in between 3-5

minutes before washing and rinsing.

• For cleaning, start at lower portion of area to be

washed and work upward, using long, even over

lapping strokes.

Your pressure washer is equipped with a chemical

injector adjustment knob. With the knob fully opened

you will get a 7 to 1 water to chemical ratio. With knob

fully closed you will get no chemical draw. Turn knob in

counterclockwise direction to achieve more chemical

draw and clockwise for less chemical draw.

NOTE: The maximum pressure for the unit is factory

adjusted. Do not attempt to adjust beyond this factory

setting.

Using Soaps/Chemicals

IMPORTANT: Use soaps and chemicals that are

designed specifically for use with pressure washers, to

apply soap/chemicals follow these steps:

• Prepare the soap/chemical as required by your job.

•

After using the pressure washer, it is recommended

the pump, chemical injector and chemical line be

flushed with clear water. To do so, simply place

chemical injector hose in water and siphon for 1 tflH

minutes.

Page 9

stopping Your Pressure Washer

Engine Oil

A CAUTION: Do not run pump without the water

supply connected and turned on. Failure to do so

will result in pump damage.

* To turn pressure washer off place the on/off switch

to the OFF position.

• Simply shutting OFF engine will not release pressure

in the system. Squeeze the trigger on the spray gun

for about 3 seconds to relieve pressure. Spray

stream wilt decrease in length.

IMPORTANT: This unit is equipped with a thermal relief

valve. If unit is allowed tp run for several minutes

without pressing the trigger on the spray gun, several

drops of water may be released through this valve to

cool the unit. The heated water will be purged from the

bottom of the pump.

Your unit has been shipped without oil in the engine.

A bottle of SAE 30 weight oil is included in the

carton. Remove oil dip stick located on the side of

engine. The oil dip stick is clearly marked with a

lines that tells you when unit has enough oil. Do not

fill above this point. Pour slowly.

NOTE: When adding oil to the engine crankcase, use

a high quality detergent oil classified “For Service SF,

SG, SH rated SAE 30 weight Use no special addi

tives. Select the oil’s viscosity grade according to

your expected operating temperatures.

SAE Vise party Gmäe«

101K-3Ü

BEFORE STARTING THE ENGINE

To operate the engine you will need to do the following.

A CAUTION: Always check engine oil level before

every start. Running engine low of oil or out of oil

could result in serious damage.

A CAUTION: Always check pump oil level before

every start. Running pump low on oil could result

in pump damage.

Adding Pump Oil

Before running the high pressure washer, check the

pump oil level by viewing the sight glass on the side of

the pump. When properly filled, the oil will be at the

half way point marked by the two triangles. Your

pressure washer pump is shipped with oil. Add oil only

if oil level is lower than the half way point on the sight

glass. Do not overfill. Use 30 weight non-detergent oil

If necessary.

A CAUTION: Do Not use engine oil that has been

shipped with your unit in your pump. Engine oil is

detergent and your pump uses a non-detergent oil

Detergent oil can cause damage to your pump.

ftTAHUMG TCMPSaATURE WnCtWTED SEFORC NEXT OtL CHWtQE

Air cooled engines run hotter than automotive engines.

The use of multi-viscosity oil such as {10W-30, etc.) in

ambient temperatures above 40“F (4*C) wilt result in

higher than normal oil consumption. If multi-viscosity

oil is used, check the oil level more frequently to

prevent any posssible engine damage due to lack of

lubrication.Use of SAE30 oil below 40“F (4*C) wilt result

in hard starting and possible engine damage due to

inadequate lubrication.

Gasoline

Your pressure washer engine is 4 cycle. Use unleaded

fuel only.

A CAUTION: Do not overfill the fuel tank. Always

allow room for fuel expansion.

A WARNING: Never fill fuel tank indoors. Never

fill fuel tank when engine Is running or hot. Do

not smoke or have open flame when filling fuel

tank.

Use clean, fresh, regular unleaded gasoline with a

minimum of 85 octane. Do not mix oil with gasoline.

If unleaded fuel is not available, leaded fuel may be

used-

Page 10

IMPORTANT: it is important to prevent gum deposits

from forming in essential fuel system parts such as the

carburetor, fuel filter hose or tank during storage. Also,

experience indicates that alcohol-blended fuels (called

gasoho! or using ethanol or methanol) can attract mois

ture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine problems,

the fuel system should be emptied before storage of 30

days or longer. Never use engine or carburetor cleaner

products in the fuel tank or permanent damage may

occur.

NOTE: Never start pressure washer without water

source turned on and connected to pressure washer.

To Start Your Pressure Washer

Make sure fuel shutoff valve is turned to the open

position.

CLOSED

OPENED

Squeeze trigger on pressure washer wand to relieve air

pressure caused by turning on the water. Water will

spew out of the gun in a thin stream. This will make it

easier to start the engine.

Engage the safety latch on the spray gun. This locks

the trigger in place and keeps you from accidentally

spraying a high pressure stream.

On the engine there is a choke/run lever. Place lever

to the choke position.

CHOKE

LEVER

• Remove gas cap

• Add unleaded gasoline, slowly, to fuel tank.

• Do not overfill.

Connect garden hose to the water inlet on the

pressure washer. Tighten by turning water inlet

counterclockwise.

Connect high pressure hose to discharge on pump.

Connect the garden hose to the water spout

and turn water supply on.

On the engine there is a throttle control lever. Place

throttle to the rabbit position. Always start engine

with throttle in the rabbit position. Place on/stop

switch to the “on" postion.

Grasp the starter grip and pull slowly until resistance

is felt, then pull firmly to start engine.

When engine starts, gradually move choke lever to

RUN position.

If engine does not start after 5 pulls, place choke

back to run position.

For hot engine starts make sure choke lever is in

the run position. Make sure fuel shut off valve is open

and throttle is in the rabbit position.

NOTE: If any leaks are present shut unit down and

tighten fittings.

10

Page 11

MAINTENANCE

OSTOMER RESPONSIBILITIES TABLE

m

MAINTENANCE TASK

PRESSURE WASHER

Check/clean mlet screen.

Check high pressure hose.

Check soap and chemical hose and filter X

Check gun and vv^nd for leaks.

Purge pump ofairand contaminants

Check pump oil

Change pump oil

ENGINE

Check oil level

Change engine oil X

Before each use

X

X

X

X

X

X

Every 25

hours or yearly

---------------

tvery 50

hours oryearty

X

Every 100

hours oryearly

roduct Specifications

é

Pressure Washer Specihcations

Pressure 2700

Flow Rate

Cleaning Units {psi x GPM)

Engine Specifications

RPM

Rated Horsepower

Spark Plug

Gasoline Capacity 4.6 Quarts

Oil SAE 30 weight

0.030” (0.76mm)

3.0 GPM

8100

3600

7.5

General Recommendations

The warranty of the high pressure washer does not

cover items that have been subjected to operator

abuse or negligence. To receive full value from the

warranty, operator must maintain high pressure

washer as instructed in this manual.

Some adjustments will need to be made periodocally to maintain your high pressure washer.

All adjustments in the Maintenance section of this

manual should be make at least once each season.

Once a year you should clean or replace the spark

plug and clean or replace the air filter and check

the gun and wand assembly for wear. A clean

spark plug and clean air filter assure proper

fuel-air mixture and help your engine run better

and last longer.

NOTE: Over time the o-rings in the gun assembly

become worn. Attached to your owners manual is a

replacememt o-ring and split backup ring.

11

Page 12

Pressure Washer Maintenance

Check and Clean Inlet Screen: Examine inlet screen

on pump inlet fitting. Clean if clogged replace if torn.

Check High Pressure Hose: High pressure hose can

develop leaks from \wear, kinking, abuse, inspect hose

each time before use. Check for cuts, leaks, abrasions

or bulging of cover, damage or movement of couplings.

If any of these conditions exist, replace hose

immediately.

Check Chemical/Soap Hose: Examine the chemical/

soap hose and clean if clogged. Hose should fit tightly

on pump fitting. Check for leaks and tears. Replace

filter or hose if either is damaged.

Check Gun and Wand: Examine hose connection to

gun making sure it is secure. Test trigger by pressing it

and making sure it springs back into place when you

release it.

Pump Oil

Pump oil level should be checked before each use.

Changing Pump OH

Oil should be changed after the first 10 hours of opera

tion. Subsequent changes after each 50 hours of opera

tion. To drain oil, simply remove oil plug with a adjust

able wrench. The oil plug is located at the bottom of the

pump. Dispose of used oil. Properly remove pump oil fill

plug. Add 30 weight non-detergent oil. Fill until oil level is

tat the mid point on the sight glass.

Pull the trigger on the gun and hold.

When the water supply is steady and constant,

disengage trigger and refasten the wand extension.

Engine Maintenance

Oil

• Oil level should be checked prior to each use

or at least every 5 hours of operation. To check oil see

Adding Engine Oil on page 9.

Changing Engine Off

For a new engine, change oil after the first 5 hours of

operation. Thereafter, change oil after every 50 hours of

operation.

Change the oil while the engine is still warm. The oil will

flow freely and carry away more impurities. Make sure

the engine is level when filling, checking, or changing oil.

Change the oil as follows:

• To keep dirt, grass clippings, etc., out of the engine,

clean the area around the drain plug and dipstick

before removing it.

• Remove the oil drain plug and dipstick. Tilt the engine

slightly towards the oil drain to obtain better drainag^

Be sure to allow ample time for complete drainage. "

Purge Pump of Air and Contaminants

To remove the air from the pump, follow these steps;

• Set up the pressure washer as described in

Assemb/y section and connect the water supply.

• Remove the wand extension from the spray gun,

• Pull the trigger on the gun and hold.

To remove the contaminants from the pump, follow

these steps;

• Set up the pressure washer as described in

ASSEMBLY section, connect the water supply.

• Remove the wand extension from the spray gun.

• Start the engine according to instructions in the

OPERATION section.

• Reinstall the drain plug. Make sure it is tightened

securely.

• Fill the crankcase with new oil of the proper type, to

the Full mark on the dipstick. Always check the level

with the dipstick before adding more oil.

12

Page 13

Reinstall the oil fill cap or plug and tighten securely.

Service Air Cleaner

NOTE; Do not use petroleum solvents, e.g., kerosene,

which will cause the cartridge to deteriorate. Do not use

pressurized air to clean cartridge. Pressurized air can

damage the cartridge.

To service air cleaner follow these steps:

1. Unscrew cover screws. Remove cover and air cleaner

assembly.

2. Remove cartridge from cover, then retainer

(if equipped) and pre-cliianer.

To service pre-cleaner, wash in liquid detergent and

water. Squeeze dry in a clean cloth. Saturate in engine

oil. Squeeze in clean, absorbent cloth to remove all

excess oil. Replace if very dirty or damaged.

To service cartridge, clean by tapping gently on a flat

surface. Do not oil cartridge. Replace if dirty or dam

aged.

TE: Do not use petroleum solvents, e.g., kerosene,

hich will cause the cartridge to deteriorate. Do not use

^^hi

pressurized a/rto clean cartridge. Pressurized air can

damage the cartiridge.

3. Reassemble pre-cleaner or retainer (if equipped.)

Place in cover with pre-cleaner mesh side toward

cartridge. Place cartridge in retainer in cover.

4. Push cover and air cleaner assembly squarely onto

base (tabs must be in slots, if equipped) and hold

firmly. Tighten cover screws securely.

Do not clean engine with a forceful spray of water

because water could contaminate fuel system. With

a brush or doth clean finger guard after every use to

prevent engine damage caused by overheating.

Before running engine, clean muffler area to remove all

combustible debris.

Clean and Replace Spark Plug

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help

your engine to start easier and run better.

Keep engine and parts clean!

13

Page 14

SERVICE AND ADJUSTMENTS

Carburetor

The carburetor of your high pressure washer is pre-set

at the factory. The carburetor should not be tampered

with, if your pressure washer is used at an altitude in

excess of 5000 feet consult with your nearest Sears

Service Center regarding high altitude set changes.

A CAUTION; Engine speed was properly adjusted

at the factory and should require no additional

adjustment. Do not attempt to change engine

speed. If you believe the engine is running too fast

or too slow, take your pressure washer to a Sears

Authorized Service Center for repair and adjustment.

A WARNING; High engine speeds are dangerous and

increase the risk of personal injury or damage to

equipment.

A CAUTION: Low engine speeds impose a heavy

load on the engine and when sufficient engine power

is not available could shorten engine life.

Nozzle Maintenance

Hi-Low Lance:

1.

Shut off the pressure washer and turn off the water

supply.

2.

Disconnect spark plug wire.

Pull trigger on gun handle to relieve any water

3-

pressure.

4.

Disconnect the wand/lance from the gun.

Rerhove the high-pressure nozzle from the lance.

5.

Remove any obstructions with the nozzle cleaning

tool provided and backflush with clean water.

6.

Direct water supply into nozzle end to backflush

loosened particles for 30 seconds.

Reassemble the nozzle to the iance using teflon tape

to prevent teaks. Tighten securely.

8.

Reconnect wand/lance to gun and turn on water

supply.

9.

Start pressure washer and place wand/lance into

high pressure setting to test.

STORAGE

This pressure washer should be stored in such a way to

protect it from freezing. Do not store this unit outdoors

or in an area where temperatures will fall below 32° F.

This can cause extensive damage to this unit.

If unit has to be stored under freezing conditions a non

toxic R.V. anti-freeze can be used to protect from

freezing.

Preparing Pressure Washer for Storage

NOTE: If you do not plan to use your unit for 30 days or

more, unit should be prepared for storage.

Engine Preparation

• First add a fuel stabilizer to the fuel tank.

• Run pressure washer for full 5 minutes to allow fuel

stabilizer to enter the fuel system.

NOTE: While doing this procedure make sure water

supply is turned on and flowing to the unit. NEVER run

unit without water supply running through pump.

• Next shut off engine and disconnect the water supply.

• Disconnect the spark plug wire and remove the spark

plug.

• Add one teaspoon of oil through the spark plug hole.

• Place rag over spark plug hole and pull the recoil a

few times to lubricate the combustion chamber.

• Replace the spark plug, but do not connect the spark

plug wire.

Pump Preparation

• Be sure engine switch is in “OFF” position and spark

plug wire has been removed from spark plug.

• Pull the trigger on the spay gun to release the

pressure in the high pressure hose. Detach high

pressure hose and garden hose from the unit.

• Pul! the recoil on the engine 4 to 6 times to discharge

remaining water in pump.

• Tip the unit on the end with the water inlet fitting

pointing upward.

• Pour approximately 1/4 cup of non-toxic R.V. anti

freeze down the fitting where the water hose attaches

to the pump.

• Set unit upright and pull starter handle on engine 4 to

6 times to circulate anti-freeze in pump until anti

freeze is discharged from the pump.

14

Page 15

TROUBLESHOOTING

i SYMPTOM

Engine won’t

start

Won’t Draw

Chemical

Pump running

normally but

pressure does

not achieve

rated values

CAUSE

1. Engine throttle is in "OFF" Position.

2. Choke lever has not been placed to

choke.

3. Pressure buildup after initial use.

1. Nozzle not in chemical draw position.

2. Chemical screen is obstructed.

3. Chemical screen not working.

4. Chemical injector orifice obstructed

or stuck.

5. Chemical injector closed.

1. Water supply resfiicted.

A

2. Nozzle is in low PSI position.

3. Nozzle incorrect or worn.

4. Pump sucking air.

5. Nozzle blocked.

SOLUTION

1. Slide throttle to "Rabbit" position.

2. Slide choke lever to choke position.

3. Depress trigger gun.

1. Place nozzle to low pressure.

2. Check chemical screen; clean if obstructed.

3. Make sure chemical screen is submerged in

chemical/water.

4. Check and clean.

5. Open chemical injector by turning adjustment

knob.

1. Check water supply and filter screen for.

blockage. Check hoses for blockage, kinks,

teaks, etc.

2. Pull nozzle at end of wand back to the high pressure

position.

3. Check and replace.

4. Check that hoses and fittings are air-tight.

5. Clean nozzle-

Fluctuating

1 Pressure

Pressure drops

after period of

normal use

Pump noisy 1. Water too hot.

Presence of

water in oil (oil

milky).

Water dripping

from pump

|i

Oil Dripping

1. Pump sucking air.

2. Garden hose inlet strainer clogged,

3. Worn Seals or Packing.

4. Inadequate water supply.

5. Fouled or dirty inlet or discharge

valves.

6. Leaky discharge hose.

1. Nozzle clogged, partially obstructed.

2. Nozzle worn.

3. Pump Valves worn, dirty or stuck.

4. Worn pump piston packing.

2. Pump sucking air.

3. Valves dirty or worn.

4. Worn bearings.

1. High humidity.

2. Piston packing and oil seal worn.

1. Thermal relief functioning normal.

2. Fittings Loose.

3. 0-rings of piston guide or retainer

worn.

4. Piston packing worn.

1. Oil sea! worn

2. Loose drain plug or worn drain plug

o-rinq.

1. Check that hoses and fittings are air tight. Purge air

from garden hose.

2. Clean. Check filter frequently.

3- Check and replace.

4. Check hose for kinks.

5. Check flow available to pump. Check for

excessive heat, 145^ F or above.

6. Clean inlet and discharge valve assemblies.

Replace if damaged.

1. Use nozzle cleaning kit to clear obstruction. (See

Nozzle Maintenance under Service Adjustment.)

2. Clean or replace.

3. Check and replace.

4. Check and replace.

1. Reduce temperature below 63° C or 145° F.

2. Check that hoses and fittings sure air tight.

3. Check, clean or replace.

4. Check and replace if necessary.

1. Change Oil.

2. Check and replace oil seals.

1. Protecting pump, if not using pressure washer for

a long period of time, shutoff engine.

2. Tighten.

3. Check and replace.

4. Check and replace.

1. Check and replace

2. Tighten drain plug or replace 0-ring. Do not overtorque.

15

Page 16

PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

3,

KEY#

1

2

3

4

5

6

7

8

9

10

11 15111

12

13

14

15

16

17

18

19

20

16532

16470

16396

16535

16371

16471

16503

P657

H100

15043

16529

T527-04

16727

PK16803

F035

P655

F464

F064

DESCRFnON

Handie

JBoli

Gun

TtrePnu^atic

Foot Rubber

Knob

Frame

0-ring Kit

Chemical Hose and Filter

Lance Hi/Low

High Pressure Hose

Decal Front Craftsman

Axle

Engine

Decal Operation

Pump

High Pressure Quick Connect

Adapter- Garden Hose

Nut Pal 5.8"

Screw Hex HDC

PARTS NOT ILLUSTRATED

MGP-762700

F078

F119

F066

FI 07

16106

F074 Flat Washer - Pump to Engine

NCT001

16776 Easy Start Valve

Owners Manual

Lockwasher. Engine to Frame

Nut Hex 5/16"- Engine to Frame

Screw 5/16"- Engine to Frame

Lockwasher- Pump to Engine

Srew, Hex- Pump to Engine

Nozzle Cleaning Tool

16

Page 17

PUMP PARTS

CRAFTSMAN 2700 PSi HIGH PRESSURE WASHER

919.762700PUMP NUMBER PK16803

17

Page 18

PUMP PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700 PUMP NUMBER PK16803

RS=.

NO.

1

2

3

4

5

6

7

8

9

10

11 AR-1260790

12

13

14 AR-880130 Oil cap

15 AR-1780050

16 AR-1780510

17

18

19

20

21

22 AR-1260091

PART

NO. DESCRiPnON

AR-960160

AR-1260162

AR-1269050 Complete valve

AR-880830

AR-620301

AR-1780130

AR-1260130

AR-1780090

AR-1780010 Pump body

AR-1266740 Cap

AR-1780550 Snap ring

AR-1780490

AR-1200430

AR-1789010 Complete cover

AR-1780040 Con rod

AR-1780060

AR-480480

0-Ring

Plug

0-Ring 6

Plug

Support ring 3

Gasket

Piston guide

Circlip

Bearing

Piston pin 3

O-Ring

Screw 6

Guiding piston 3

O-Ring 3

Spacer disc

OTY.

6

6

6

1

3

3

1

1

1

1

1

1

1

1

3

3

PART

NO.

23

24

25

27

28 AR-880530 Plug

30 AR-1260460 Seal

31

32 AR-770260 O-Ring

33 AR-1260440 Gasket

36

37

38 AR-680570

40

41

42 AR-480671

44 AR-180030

60

61

62

67 AR-820440 Grub screw

68

69

70

71

NO.

AR-1780070 Piston

AR-1260100 Piston washer

AR-1260110

AR-740290

AR-1780100 Rear piston guide

AR-1780380 Head

AR-1381550 Washer

AR-1321160

AR-1321080 Snap ring

AR-1780340 Hollow shaft 0 1

AR-1380550

AR-1780430

AR-1789200 Pump head pre-ass 1

16802

16749

16506

DESCRIPTION

Nut

O-Ring

Screw

Bearing

Seal

Screw

Gas engine flange

13ushing 1

Chemical Injector

Unloader

Thermal Relief Valve

OTY.

3

3

3

2

2

3

3

3

3

1

8

8

1

1

1

4

1

1

1

1

1

3

A*Knr 16739

Valves

Pos. Qty.

3 é

4 6

D«KIT 16745

Water Seals

Pos. Qty,

7 3

32 3

33 3

PARTS KITS

B*KIT 16746

Pistor^

Pos. Qty.

23 3

F=KIT 16749 L^KIT 16750

Bearings

Pos. Qty. Pos. Qty.

13 1 70 1

40 1

C«K!T16748

Oil Seals for

D Version

Pos. Qty,

10 1

16 1

30 3

42 1

Unloader

18

K*KIT 16802

Pos. Qty.

69 1

Page 19

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700 ENGINE NUMBER 138432-0035~A1

373©

227

10%

REF. PART

NO. NO.

1 715461

3 «710000

306

REF.

DESCRIPTION

Cylinder Assembly 10

Seal-Oil

NO.

15

17

116

116A • 710091

227

230

277

306

356

PART

NO.

710023

715000 Plug-Oil Drain

710003

•710055

710051

•710058

710004

710063

710308 Wire-Oil Sensor

DESCRIPTION

Screw-Hex

Bearing-Ball

Seai-O-Ring 616

Seal-O-Ring

Lever-Governor 725

Washer-Spacer 890

Washer-Seal

Sheild-Cylinder

REF.

NO.

373

506

614

718

1019

1062

1058

PART

NO.

710059

710090

710056

710636

710005

710102

715136

715031

715353 Sensor-Oil

273126

DESCRIPTION

Nut-Lock

Nut-Lode

Pin-Retainer

Crank-Governor

Pin-Locating

Sheild-Heat

Bracket-Support

Label Kit

Owner's Manual

«Included in Gasket Set-Part No. 715482

★ included inValve Oveitiaut Kit-Part No. 715483

Alnciuded in Carburetor Kit-Part No. 715484

★ Included in Gasket Gasket Set -Part No. 715485

19

Page 20

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

22

22A

523

116B

ENGINE NUMBER 138432-0035-AT

219

REF.

NO.

12 • 710628

17 710003

18 715463 Cover-Crankcase

2022• 710216

«Included in Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Aincluded in Carburetor Kit-Part No. 716484

-f Included in Gasket Gasket Set -Part No. 715485

PART

NO,

710032

DESCRIPTION

Gasket-Crankcase

Bearing-Ball

Seal-Oil

Sorew-Hex.

REF.

NO.

22A 710306

116B •710029

219

220 710035

PART

NO.

715341

DESCRIPTION

Screw-Hex

Sea!-0~Ring

Gear-Governor

Washer-Spacer

20

REF.

NO.

221

225 710028

523 715007 Dipstick

718 710005

PART

NO-

710027

DESCRIPTION

Cup-Govemor

Shaft-Governor Gear

Pin-Locating

Page 21

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

ENGINE NUMBER 138432-0035-A1

REF.

NO.

40A

[Included in Gasket Set-Part No. 715482

Fincluded inValve Overhaul Kit-Part No. 715483

Ainciuded in Carburetor Kit-Part No. 715484

Alnctuded in Gasket Gasket Set -Part No. 715485

PART

NO.

715444

5

7 »*710624

10

710023

13

710020 Screw-Hex

33

715445

34

715446

710011

35

40

710012

715130

DESCRIPTION

Head-Cylinder

Gasket-Cylinder Head

Screw-Hex

Valve-Exhaust

Valve-intake

Spring-Valve

Retainer-Valve

Retainer-Valve Plug 1050

ref

NO.

53A

373A 710007

PART

NO.

45 710008

53 710148

710099

337 491055

383 19374

551

715450

DESCRIPTION

Tappet-Valve 635

Stud-Carburetor 830

Mounting 868

Stud

{Muffler Mounting)

Plug-Spark 1026

Nut-Lock

Wrench-Spark 1034

Cover-Rocker

21

REF.

NO.

1022 »*710626

1029

PART

NO.

710634 Boot-Spark Plug

710016

»710019 Seal-Valve

710622 Rod-Push

710014 Arm-Rocker

710017 Guide-Push Rod

710015 Adjuster-Rocker Arm

DESCRIPTION

Stud-RodterArm

Gasket-Rocker

Cover

Page 22

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

ENGINE NUMBER 138432>0035>A1

REF. PART REF.

NO,

16 715426 Crankshaft 25

#!nduded in Gasket Set-Part No. 715482

★ Included inValve Overiiau! Kit-Part No. 715483

Ainciuded in Carburetor Kit-Part No. 715484

★ Included in Gasket Gasket Set -Part No. 715485

NO.

DESCRIPTION

Used on Type No{s).

0035, 0084

NO. NO.

26

PART

DESCRIPTION NO.

715456 Piston Assy. 27

(Standard)

715457

715448 Piston Assy.

715452

715453

715454

Piston Assy.

(.010” O.S.)

(.020" O.S.) (.020” Undersize)

Ring Set

(Standard) Rod

Ring Set

(.010" O.S.)

Ring Set

(.010” O.S.)

22

REF.

28

29 715427 Rod-Connecting

32

46

718A

1051

PART

NO. DESCRIPTION

710040

715455

715502

710041

715451

710616

710039 Ring-Retaining

Lock-Piston Pin

Pin-Piston Std.

(Standard)

Rod-Connecting

Screw-Connecting

Grear-Cam

Pin-Compression

Page 23

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

ENGINE NUMBER 138432-0035-A1

163 Co

ref

NO.

51 •*a+710060

95

98

104

105

108

117

•

•

•

PART

NO.

710672

715478

710663

710661

710674

710665

710719

122

125

715034

715473

DESCRIPTION

Gasket-Intake

Screw-Round Head

Screw-Idle Speed

Pin-Float

Valve-Needle

Valve-Choke

Jet-Main

-NOTEJet-Main

{High Attitude)

Spacer-Carburetor

Carburetor

ref

NO.

130

PART

NO,

710671 Valve-Throttle 634A

131 715480

133

715477 Float-Carburetor 634B

137

138

141

142

147

715479

• 710664

• 710676

710720 Jet-Pilot

154 710081

163 t*A+710639

620

710635

1S4

1043

PART

NO.

•

•

DESCRIPTION

Seal-Throttle Shaft

(Sold in Kit Only)

Bushing-Choke

Shaft

DESCRIPTION

Shaft-Throttle

Gasket-Float Bowl

REF.

NO.

(Sold in Kit Only) (Sold in Kit Only)

Washer

(Sold in Kit Only)

Choke Shaft Kit 955A

Nozzle-Carburetor 975

955

710667

710679

715476

Screw-Bowl

Mounting

Plug-Carburetor

Bowl-Float

Jet-Pilot

-riuic-

(High Altitude)

Nut-Hex

Gasket-Air Cleaner

Bracket-Control

•Included in Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Ainctuded in Carburetor Kit-Part No. 715484

★ Included in Gasket Gasket Set -Part No. 715485

23

Page 24

ENGINE PARTS

CRAFTSMAN 2700 PSl HIGH PRESSURE WASHER 919.762700

sa\

51^

S35

ENGINE NUMBER 138432-0035-

663^

467

REF.

NO.

11

51 ***+710060

53

129

161

•Included in Gasket Set-Part No. 715482

★ Included inValve Overtiau! Kit-Part No. 715483

Alncluded in Carburetor Kit-Part No. 715484

★ Included in Gasket Gasket Set -Part No. 715485

PART

NO.

710115

710148 Stud-Carburetor

715024

710521

DESCRIPTION

Tube-Breather

Gasket-Intake

Mounting

Screw-Governor

Speed

(High and Idle

Speed Adjustment)

Base-Air Cleaner

REF. .

NO.

202

209

232

235

354

467

535

PART

NO. DESCRIPTION

710637 Link-Mechanical

Governor

710702 Spring-Governor

710638 Spring-Link

710522

710068

280715 Knob-Control

491435

Shieid-Fue! Spray

Nut-Hex

Filter-Air

24

REF.

NO.

6208

663

967

968

969

PART

NO. DESCRIPTION

715025 Bracket-Control

710057

491588 Air Filter

495872

93473

Screw-Hex

Cover-Air Cleaner

Sorew-Hex

Page 25

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

ENGINE NUMBER 138432-0035>A1

505

53A

REF. PART

NO. NO. DESCRIPTION

53A 710099 Stud

{Muffler Mounting)

300 715508 Muffler-Exhaust

408 710307 Screw-Phillips

505 710090 Nut-Lock

•Included in Gasket Set-Part No. 715482

^Included InVaive Overhaul Kit-Part No. 715483

Aincluded in Carburetor Klt-Part No. 715464

<*>lnciuded in Gasket Gasket Set -Part No. 715485

REF. PART

NO. NO. DESCRIPTION

663 710057 Screw-Hex

673 93705 Screw-Hex

676 715230 Deflector-Muffler

737 710074 Screw-Hex

823 710248 Screw-Hex

REF. PART

NO. NO. DESCRIPTION

832 710565 Guard-Muffler

863 714319 Bracket-Muffler

883 #*710082 Gasket-Muffler

994 715491 Arrester-Spark

1075 710329 Screen-Outlet

25

Page 26

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

ENGINE NUMBER 138432-0035-A1

663A

240A

18?!^

REF.

NO.

187A 715126 Line-Fuel

PART

NO.

10

710023

180 715431

181

710490

187

715125

DESCRiPTION

SoBw-Hex

Tank-Fuel

Cap-Fuel Tank

Line-Fuel (8mm ID)

(Fuel Tank-To-Filter/

Shut-off)

(Cut to Required

Length)

(4mm ID)

(Fiiier/Shut-Off-ToCarburetor)

(Cut to Required

Length)

187A|

REF.

NO.

187B

240A

601A

PART

NO. DESCRIPTION

296004

710065

210

715027

240

298090 Filter-Fuel

710071 Fitter-Fuel

243

710070 Bowl-Filter

246

710068 Nut-Hex

354

• 710072 Seal-O-Ring

524

601 710067

710075

601A

Line-Fuel

{0.25" ID)

(Carburetof-T e-Filter)

(Cut to Required

Length)

Strainer-Fuel

Fitter-Fuel

Clamp-Hose

Clamp-Hose

18781

REF.

NO.

6018

617

663A

666

670

601B

PART

NO.

93053

•710069 Seal-O-Ring

710160

710066

710159

DESCRIPTION

Clamp-Hose

Stxew-Hex

Gauge-Fuel

Spacer-Fuel Tank

♦included in Gasket Set-Part No. 715482

^Included inValve Overtiaui Kit-Part No. 715483

Alnciuded in Carburetor Kit-Part No. 715484

+!ncluded in Gasket Gasket Set -Part No. 715485

26

Page 27

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

ENGINE NUMBER 138432-0035-A1

REF.

NO.

281

•Included tn Gasket Set-Part No. 715482

^Included inValve Overhaul Klt-Part No. 715483

Ainciuded in Carburetor Kit-Part No. 715484

^Included in Gasket Gasket Set -Part No. 715485

PART

NO. DESCRIPTION

10

710023

710646

Screw-Hex

Panel-Control

Used on Type No{s).

0035

REF.

NO.

304

305

347

PART

NO.

715465

710095

493521

REF.

DESCRIPTION

Housing-Blower 356A

Screw-Hex

Switch-Rocker

(Without Lamp) 6638 710234

27

NO.

3568

663A

670 710159

813 710083

1036 499350

1053 710305

PART

NO.

710120

710087

710160

DESCRIPTION

Wre-Stop

Wre-Stop

Screw-Hex

Screw-Hex

Spacer-Fuel Tank

Clamp

Labe! Kit-Emission

Module

Page 28

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

1054

332A

455

334*^^

ENGINE NUMBER 138432-0035

m

737 Ç

737

890A

332

ref

NO.

281A

332A 710345

•included in Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

★ .Included in Carburetor Kit-Part No. 715484

★ Included in Gasket Gasket Set -Part No. 715485

part

NO. DESCRIPTION

715429

23

120

154

332 710048

333

93836 Washer-Lock

93837

710658 Panel-Control

715464

Flywheel

Nut-Hex

Nut-Hex

Nut-Hex

Armature-Magneto

REFNO.

334

354

356C

455

475

521

526

729

737

PART

NO. DESCRIPTION

710047

710068

710324

710277

715200

710045

710089

710046

710074

Saew-Hex

Nut-Hex

Wire-Ground

Cup-Flywheel

Rectifier

Shielding-Cable

Srew-Hex

Clip-Wire

Screw-Hex

REF.

NO.

890A

892

990

1054

PART

NO.

710644

493625

392832

710349

DESCRIPTION

Bracket-Support

Key Switch

(includes Keys)

Key Set-Starter

Switch

Tie-Cable

28

Page 29

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700

737

ENGINE NUMBER 138432-0035-A1

REF.

NO.

55

56 710274

57

#lnciuded in Gasket Set-Part No. 715482

PART

NO. DESCRIPTION

715132 Housing-Rewind

Starter

Pulley-Starter

710270 Spring-Rewind

Starter

REF.

NO.

58 710275

60 490652

456 710272

459 715256 Pawl-Ratchet

★ included inValve Overhaul Kit-Part No, 715483

Alncluded in Carburetor Kit-Part No, 715484

★ included in Gasket Gasket Set -Part No. 715485

PART

NO.

REF.

DESCRIPTION

Rope-Starter 461 805956 Screw-Shoulder

(Cut to Required

Length) 608 715133 Starter-Revwnd

Grip-Starter Rope 615 805952

Plate-Pawl Friction 737 710074 Screw-Hex

29

NO.

516 806953 Spring-Pawl

PART

NO. DESCRIPTION

Ring-Rewind Starter

Page 30

ENGINE PARTS

CRAFTSMAN 2700 PSI HIGH PRESSURE WASHER 919.762700 ENGINE NUMBER 138432<0031

1033 VAtV£ OVERHAUL KTT

368^

121 CARBURETOR KTT

104.^ 1380 105$ 147f

117 %

163

634A® 6348» 142|

51 137 CD

358 GASKET SET

1168 0 524 O 3

277© “

i

1022

977 CARBURETOR GASKET SET

51 1380 163 137<^

REF.

NO.

104 A

105 A

116 • 710055 Seai-OI!

116A • 710091

116B • 710029

117 A

•Included In Gasket Set-Part No. 715482

★ Included inValve Overhaul Kit-Part No. 715483

Alncluded in Carburetor Kit-Part No. 715484

★ Included in Gasket Gasket Set -Part No. 715485

PART

NO.

710000 Seal-Oil

3 •

7 •* 710624 Gasket-Cylinder Head

12 • 710628

710215 Seal-Oi!

20 •

51«*a+710060 Gasket-Intake

710663 Pin-Float

710661

710665 Jet-Main

DESCRIPTION

Gasket-Crankcase

Valve-Needle

Seal-O-Ring

Seal-O-Ring

REF.

NO.

121

137

138

142

147 A 710675 Jet-Pilot 868 * 710019

163 6*A+710639

277 • 710004 Washer-Seal

358 715482

524 • 710072

PART

NO. DESCRIPTION

715484 Carburetor Kit 617 *710069 Seal-O-Ring

A +

A^ Washer 634B

A 710664

Gasket-Float 634A

Bowl (Sold In Kit Shaft (Sold in Kit

Only)

(Sold in Kit Only)

Nozzle-Carburetor Only)

Gasket-Air Cleaner

Gasket Set

Seal-O-Ring 1022 •*710262

30

REF.

NO.

883 •★ 710082

977

1033 715483

PART

NO.

•

•

715485 Gasket Set-

DESCRIPTION

Seal-Throttle

Only)

Bushing-Choke

Shaft (Sold in Kit

Seal-Valve

Gasket-Exhaust

Carburetor

Gasket-Rocker

Cover

l^-Valve Overhaul

Page 31

Bdggs & StrattiKi Corporation (B&S), the Caltfomia Air Resources Board (CARS)

ie interest of the environment, B&S eiigines that meet strict emisprequirements are l^)e!ed, "This engine ctmforms to 1595 -1998

ifomia emission regulations for ULGE engines and U.S. EPA

f

Ríase 1 regulations lor small non-road engines."

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE

CARS, U.S, EPA and B&S are pleased to explain die Emission

Control System Warranty on your 1996 and later utility or lawi and

garden equipment (ULGE) engine. In California, new ULGE engines

produced on or after August 1,1995 must be designed, built and

equipped to meet the State’s stringent anti-smog standards^ Else

where in me United States, new non-road, spark-ignition en^nes

certified for model year 1997 and later, must meet simfl^ standards

set forth by the U.S. EPA. 8&S must i^rant the emisión císitroi

system on your engine for the periocte of time listed below, provided

ULGE engines are warranted relative to emission aintrol parts below. If any covered part on your engine is defective, the part will be

defects for a period of two years, sul:^‘ect to provisions set forth r^iaired or r^ac^ by B&S.

As the ULGE engine owner, you are responsible fwthe performance

of tile required maintenance listed in your Operator/Owner Manud.

B&S recommends that you retain ail your rece^ (rovenng mainte

nance on your ULGE engine, tuit B&S cannot deny warranty sdely

for the lack of r^ieipis or ior your failure to ensure the performance d

all scheduled maintenance.

As the ULGE engine owner, you should however be aware that 8&S

may deny you warranty coverage if your ULGE engine or a part has

failed due to abuse, neglect, improper maintenance or unapproved

modifications.

The following are specific provisions relative to your Emission Ccmtrol Defw:to Warranty Coverage. It is in addition to the B&S engine warranty

^Bn-regulated engines found in the C^rator/Owier Manual.

arranted Parts

Coverage under this warranty extends only to the parts listed

below (the emission control systems parts) to the extent these

parts were present on the engine purchased,

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and Internal parte

• Fuel Pump

Air induction System

b.

• Air cleaner

• intake manifold

Ignition System

c.

• Spark plug(s)

• Magneto ignition system

Catalyst System

d.

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

Miscellaneous Items Used in Above Systems

e.

• Vacuum, temperature, position, time sensitive valves

• Connectors and assemblies

2.

Length of Coverage

B&S warrants to the initial owner and each subsequent purchaser

a tax

that the Warranted Parts shall be free from defects in materiais

workmanship which caused the failure erf the Warranted

rts for a period of two years from the date the engine is deliv*

?ed to a retail purchaser.

Emission Control System Warranty Statement (Owner*« Defect Warranty Rights and Obligations)

and switches

and the United State« Envtronmentat Protection Agency (U.S. EPA)

TO CERTIFIED ENGINES PURCHASED IN CALIFORNIA IN 1995

AND THEREAFTER, WHICH ARE USED IN CAUFORNIA. AND

TO CERTIFIED MODEL YEAR 1997 AND LATER ENGINES

WHICH ARE PURCHASED AND USED ELSEWHERE IN THE

UNITED STATES.

California and United States Bnlsslon Ccnttrol Defects Wanan^ SUdement

there has been no abuse, neglect or improper maintenance of your

ULGE engine.

Your emission «mtro! system includes parts ^ch as the carburetor,

air dewier, ignition sydem, muftier and catalytic converter. ^$o

induded may be connectors and other emission related assemblies.

Where a warrantee condition exists, B&S will repair your ULGE

engine at no cost to you including diagnosis, parts and labor.

Bnggs & Stratton Emission Conb'ol Defects Warranty Coverage

Owner’s Warranty Responsibilities

You are responsible for presenting your ULGE engine to an Autho

rized B&S Servbe Deafer as soon as a problem exists. The undis

puted warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days.

If you have any questior» regarding your warranty rights and

responsibilities, you should omtoct a B&S Service Representative

at 1-414-259-5262.

the emisston warranty is a defects warranty. Defects are judged on

normal ^gine performance. The warranty is not rotated to an in-use

emis^n tost.

Briggs & Stoatton Emisston Control Delects Warranty Provisions

3.

No Charge

Repair or replacement of any Warranted Part will be performed

at no charge to the owner, including diagnostic labor which leads

to the determinatiCMi that a Warranted Part is def^:tive, if the

diagnostic work is performed at an Autiiorized B&S Service

Dealer. For emissions warranty service contact ^ur nearest

Authorized B&S Servkro Dealer as listed in the “Yellow Pages"

under “Engines, Gascons," *X3asoiine Engines," “lawn

Mowers," cff similar category.

4. Qaims and Coverage Exclusions

Wairanty claims shaB be filed in aorordanœ with the provisions

of the B&S Engine Warranty Policy. Warranty covera^ sherfi be

excluded for failures of Warranted Parts which are not original

B&S parts or because of atHJse, neglect or Improper mainte

nance as set fwth in the B&S Engine Warranty Policy. B&S is not

liable to cx3ver faillies of Warranted Parts caused by the use of

add-on, non-ohginal, or modified parts.

5. Maintenance

Any Warranted Part vttitich is not scheduled fc^ replâtrent as

roquired matotonance or which is scheduled only for regular

inspection to the effect of Yepair or replace as nec^sary" shall

be warranted as to defecte for the warranty period. Any

Warranted Part which is scheduled for replacement as required

maintenance shall be wranted as to defects only for the period

of time up to the first Ktiieckited replament for that part. Any

replacement part tiiat Is equivalent in performance ^d durability

may be used in the performance of any maintenance or ropairo.

The owier is responsible for the performance of all required

maintenance, as defined in the B&S Operator/Owner Manual.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine

«împonenîs caused by the failure of any Warranted Part still

under wanranty.

31

I

■Is

L

Page 32

Briggs & Stratton welcomes warranty repair and apologizes

to you for being inconvenienced. Any Authorized Senrice

Dealer may perform warranty repaim. Most warranty repairs

are handled routinely, but sometimes requests for warranty

service may not be appropriate. For example, warranty would

not apply It engine damage occurred because of misuse, lack

of routine maintenance, shipping, handling, warehousing or

improper instaliation. Similarly, warranty is void if the serial

number of the engine has been removed or the engine has

been altered or modified.

If a customer differs with ttie decision of the ServiceOealer. an

investigation will be made to determine whe^er the warranty

applies. Ask the Service Dealer to submit a!) supporting facts to

his Distributor or the Factory for review. If tiie Distributor or the

Factory decides that Vne claim is justified, the customer will be

fully reimbursed for those items Uiat are defective. To avoid

misunderstanding which miÿrt occur between the customer

and the Dealer, listed below are some of the causes of engine

failure that the warranty does not cover.

' A

Improper maintenance:

The life of an engine depends upon the conditions under

which it operates, and the care it receives. Some ap^icatlons,

such as tillers, pumps and rotary mowers, are very often used

In dusty or dirty conditions, which can cause what appears to

be premature wear. Such wear, when caused by dirt, dust,

spark plug cleaning grit, or other abrasive material that has

entered the engine because of imprc^r maintenance, is not

covered by warranty.

This warranty covers engine related def^tive material

andi/or workmanship only, and not replacement or refund

of the equipment to which the ^gine may be mounted.

Nor does the warranty extend to repairs required

because of;

4.

Parts are ^red or broken because an engi|É|||as

operated with insufftcient or contaminated lubricaiHpil,

or an incorrect grade of lubricating oil (check oil leveraaily

or after every 8 hours of operation. Refill when necessary

^d change at recommended intervals.) Read "Owner's

Manual."

Repair or adjusbnent of associated parts or assemblies

5.

such as dutches, transmissions, remote controls, etc.,

whidi are not manufactured by Briggs & Stratton.

Damage or wear to parts caused by dirt, which entered

6.

the engine because of improper air cleaner maintenance,

re-assembly, or use of a non-original air cleaner element

or cartridge. (At recxsmmended inten/als, clean and re-oil

the Oil-Foam® element or the foam pre-cleaner, and

replace the cartridge.) Read “Owner’s Manual.”

7.

Parte damaged by overspeedtng, or overheating caused

by grass, debris, or dirt, which piugs or dogs the cooling

fins, or flywheel area, or damage caused by opemting the

engine in a confined area without sufficient ventilation.

(Clean fins on the cylinder, cylinder head and flywheel at

recommended intervals.) Read "Owner's Manual.”

Engine or equipment parts broken by excessive vibration

8.

caused by a loose er>gine mounting, loose cutter blades,

unbalanced blades or loose or unbalanced impellers,

improper attachment of equipment to engine crankshaft,

overspeeding or other abuse in operation.

A bent or broken crankshaft, caused by striking a solid

9.

object wth the cutter blade of a rotary lawn mower, or

excessive v-belt tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e., com^Mpn

chamber, valves, valve seats, valve guides, or SffiTed

starter motor windings, caused by the use of alternate

fuels such as, liquified petroleum, natural gas, altered

gasolines, etc.

ec

1. PROBLEMS CAUSED BY PARTS THAT ARE NOT

ORIGINAL BRIGGS & STRATTON PARTS.

2. Equipment conbols or installations that prevent starting,

cause unsatisfactory engine performance, or shorten

engine life. (Contact equipment manufacturer.)

3. Leaking carburetors, dogged fuel pipes, sticking valves,

or other damage, caused by using contaminated or stale

fuel. (Use dean, fresh, lead-free gasoline and Briggs &

Stratton gasoline stabilizer, Part No. 5041.)

32

Page 33

For the repair or replacement parts you need

Call 7 am - 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

' A

(1-800-473-7247)

For the location of a

Sears Parts and Repair Center In your area

Gail 24 hours a day, 7 days a week

1-800-488-1222

For Information on purchasing a Sears

Maintenance Agreement or to Inquire

about an existing Agreement

caii 9 am - 5 pm, Monday-Saturday

1 -800-827-6655

America's Repair Spectalists

Sears, Roebuck and Co., Hoffman Estates, It 60179 U.S.A.

Page 34

Loading...

Loading...