Page 1

OWNER'S MANUAL

CRAFTSMAN

6.0 Horsepower 2350 PSI 2.2 GPM High Pressure Washer

Model No:

919.762350

WARNING: Before using this

product, read this manual

and follow ali Safety Rules

and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

16478 MGP-762350A 4/1/98

• Safety

• Assembly

• Operation

• Maintenance

• Parts List

• Español

Page 2

TABLE OF CONTENTS

Warranty

Safety Guidelines

Assembly

Operation......................................

Maintenance

.......................................

......................

..........

...........................

.................................

.................

.................

.................

.................

.................

2

3-5

5-7

7-10

11-13 EPA Codes....................................

Service and Adjustments....

Storage..........................................

Troubleshooting............................

Parts..............................................

How to Order Parts

Español.........................................

.......................

...............

......................

......................

...............

...............

...Back Cover

...............

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN HIGH PRESSURE WASHER

For one year from the date of purchase, when this Craftsman High Pressure Washer is maintained

and operated according to the instructions in the owner’s manual, Sears will repair, free of charge,

any defect in material and workmanship.

If your Craftsman Pressure Washer is used for commerical or rental purposes, this warranty

applies only for 90 days from the date of purchase.

13-14

14

15

16-27

28-29

34-51

LIMITED ONE YEAR WARRANTY ON CRAFTSMAN ENGINE

Maintenance, replacement or repair of the emission control devices and systems may be per

formed by any nonroad engine repair establishment or Individual. However, to obtain no charge

repairs under the terms and provisions of Craftsman warranty statement, any service or emission

control part repair or replacement must be performed by an factory authorized dealer.

For one year from the date of purchase, when this Craftsman engine is maintained and operated

according to the instructions in the owner’s manual. Sears will repair, free of charge, any defect in

material and workmanship.

If your Craftsman engine is used for commerical or rental purposes, this warranty applies only for

90 days from the date of purchase. This warranty does not cover; Expendable items such as

spark plugs and air filters, which become worn during normal use.

Repairs necessary because of operator abuse or negligence. Including damage resulting from no

water being supplied to pump or failure to maintain the equipment according to the instructions

contained in the owner’s manual, are not covered under warranty.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE HIGH PRESSURE WASHER TO THE

NEAREST SEARS SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This, warranty gives you specific legal rights and you may also have other rights, which vary from

state to state.

Sears, Roebuck and Co., D/817 WA, Hoffman Estates, IL 60179

Page 3

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols

below. Please read the manual and pay attention to these sections. SAVE THESE DEFINITIONS/INSTRUCTIONS.

A WARNING indicates a potentially hazardous

sitiiatton which, if not avoided, could result in

death or serious iniurv.

A CAUTION indicates a potentially hazardous situation

A DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious iniurv.

which, if not avoided, mav result in minor or moderate

iniurv.

1012197

IMPORTANT SAFETY INSTRUCTIONS

AWARNING

Improper operation or maintenance of this product could result in serious injury and property damage. Read and understand ali warnings and operating instructions before using.

HAZARD

A

DANGER

RISK OF EXPLOSION

OR FIRE

WHAT CAN HAPPEN

Spilled gasoline and its vapors can

become ignited from cigarette

sparks, electrical arcing, exhaust

gases, and hot engine components

such as the muffler.

Heat will expand fuel in the tank

which could result in spillage and

possible fire explosion.

Operating the pressure washer in an

explosive environment could result

in a fire.

Materials placed against or near the

pressure washer can interfere with

its proper ventilation features

causing overheating and possible

ignition of the materials.

Improperly stored fuel could lead to

accidental ignitton. Fuel improperly

secured could get into the hands of

children or other unqualified persons.

HOW TO PREVENT IT

Shut off engine and allow it to cool

before adding fuel to the tank.

Use care in filling tank to avoid

spilling fuel. Move pressure washer

away from fueling area before

starting engine.

Keep maximum fuel level ’/2” below

top of tank to allow for expansion.

Operate and fuel equipment in well

ventilated areas free from obstruc

tions. Equip areas with fire

extinguishers suitable for gasoline

fires.

Never operate pressure washer in an

area containing dry brush or weeds.

Store fuel in container approved for

gasoline, in a secure location away

from work area.

Adanger

RISK TO BREATHING

Breathing exhaust fumes will cause

serious injury or death.

Some cleaning fluids contain sub

stances which could cause injury to

skin, eyes, or lungs.

Operate pressure washer in a well

ventilated area. Avoid enclosed areas

such as garages, basements ,etc.

Never operate unit in a location

occupied by humans or animals.

Use only cleaning fluids specifically

recommended for high pressure

washers. Follow manufacturers

recommendations.

Page 4

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

HAZARD

AWARNING

RISK OF UNSAFE

OPERATION

WHAT CAN HAPPEN

Unsafe operation of your pressure

washer could lead to serious injury

or death to you or others.

The spray gun/wand is a powerful

cleaning tool that could look like a

toy to a child.

Reactive force of spray will cause

gun/wand to move, and could cause

the operator to slip or fail, or

misdirect the spray. Improper control

of gun/wand can result in injuries to

self and others.

HOWTO PREVENT IT

Become familiar with the operation

and controls of the pressure washer.

Keep children away from the

pressure washer at all times.

Never defeat the safety features of this

product.

Do not operate machine with missing,

broken, or unauthorized parts.

Never leave wand unattended while

unit Is running.

Keep work area free of obstacles.

Stand on a stable surface and grip gun/

wand firmly. Expect the gun to kick

when triggered.

AWARNING

RISK OF INJURY FROM

SPRAY

Awarning

RISK OF

ELECTRICAL

SHOCK

Awarning

RISK OF FLUID INJECTION

High velocity fluid spray can cause

objects to break, propelling particles

at high speed.

Light or unsecured objects can become

hazardous projectiles.

Spray directed at electrical outlets or

switches, or objects connected to an

electrical circuit, could result in a fatal

electrical shock.

Your washer operates at fluid

pressures and velocities high enough

to penetrate human and animal flesh,

which could result in amputation or

other serious injury. Leaks caused by

loose fittings or worn or damaged

hoses can result in injection injuries.

DO NOT TREAT FLUID INJECTION AS

A SIMPLE CUT! See a physician

immediately!

Relieve system pressure before

attempting maintenance or disassem

bly of equipment.

Always wear ANSI approved Z87 safety

glasses. Wear protective clothing to

protect against accidental spraying.

Never point wand at, or spray people or

animals.

Always secure trigger lock when wand

is not in service to prevent accidental

operation.

Never permanently secure trigger in pull

back (open) position.

Unplug any electrically operated

product before attempting to clean it.

Direct spray away from electric outlets

and switches.

Never place hands in front of nozzle.

Direct spray away from self and others.

Make sure hose and fittings are

tightened and in good condition. Never

hold onto the hose or fittings during

operation.

Do not allow hose to contact muffler.

Never attach or remove wand or hose

fittings while system is pressurized.

Use only hose and high pressure

accessories rated for 2000 PSI service.

To relieve system pressure, shut off

engine, turn off water supply, and pull

gun trigger until water stops flowing.

Awarning

RISK OF CHEMICAL BURN

• Use of acids, toxic or corrosive

chemicals, poisons, insecticides, or

any kind of flammable solvent with this

product could result in serious injury

or death.

Do not use acids, gasoline, kerosene, or

any other flammable materials in this

product. Use only household

detergents, cleaners and degreasers

recommended for use in pressure

washers.

Wear protective clothing to protect

eyes and skin from contact with

sprayed materials.

_________________

Page 5

IMPORTANT SAFETY INSTRUCTIONS (conyd)

HAZARD

WHAT CAN HAPPEN

HOWTO PREVENT IT

Awarning

RISK OF HOT SURFACES

international

Symbols

The powerful spray from your pressure washer is capable of causing damage to fragile surfaces such as: wood, glass,

automobile paint, auto stripping and trim, and delicate objects such as flowers and shrubs. Before spraying, check the

item to be cleaned to assure yourself that it is robust enough to resist damage from the force of the spray. Avoid the

use of the concentrated spray stream except for very strong surfaces like concrete and steel.

Operating unit with water supply shut off without flow of water will result in equipment damage. You should never run

this pressure washer for more than 2 minutes without pulling the trigger to allow cool water to enter the pump and the

heated (recirculated) water to exit. Running the pressure washer with water supply shut off will void your warranty.

• Contact with hot surfaces, such as

engines exhaust components, could

result in serious burn.

Safety Alert - Read

Owner’s Manual

O On Off (^)Stop

IMPORTANT:

During operation, touch only the control

surfaces of the pressure washer. Keep

children away from the pressure washer

at all times. They may not be able to

recognize the hazards of this product.

H5

Fuel

Shutoff

i

Fuel

N

Choke

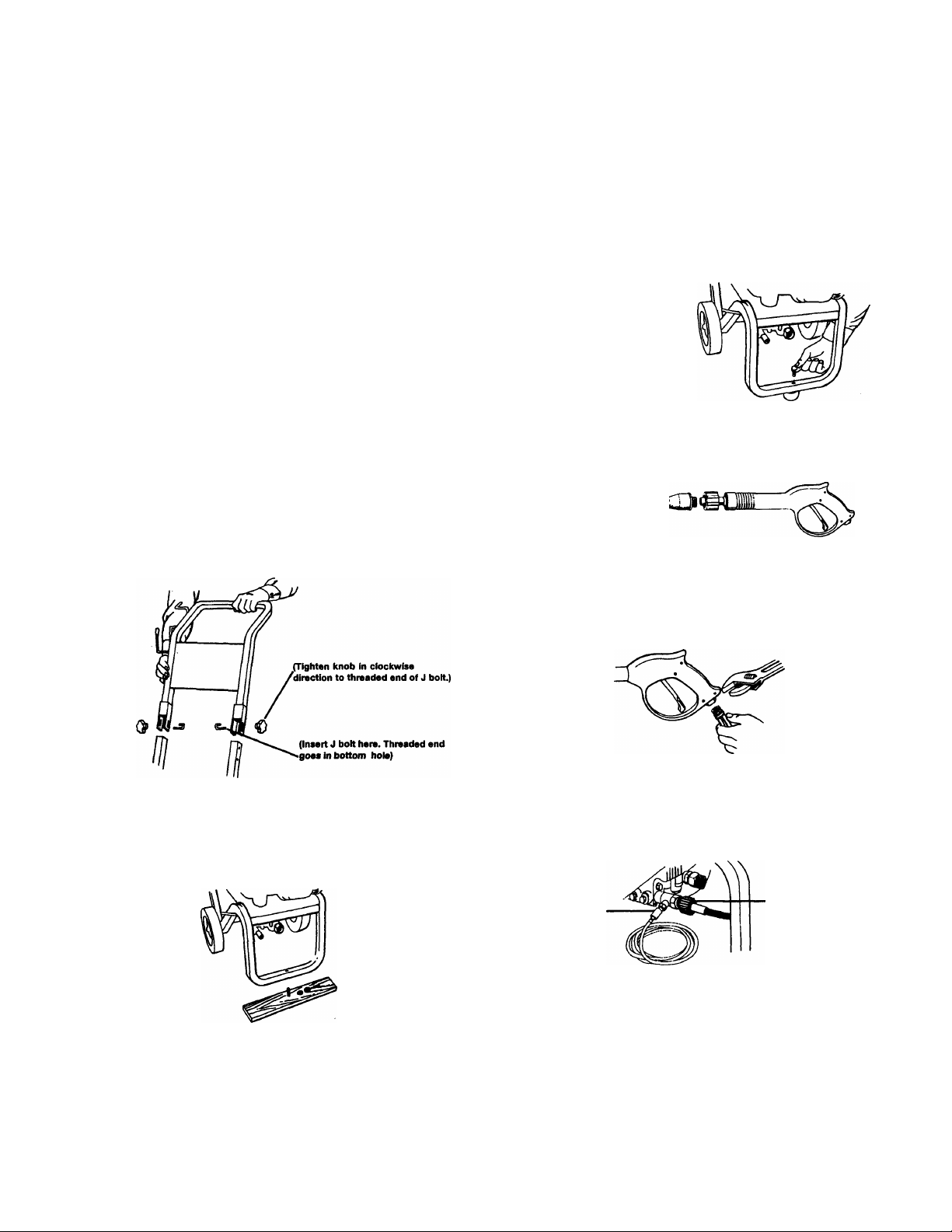

ASSEMBLY

Carton Contents

• Main Unit pressure washer with wheels

• Handle

• High Pressure Hose

• Chemical Pickup Hose and Filter

• Gun

• Wand

Main Unit pressure washer

with wheels

Handle

o

High Pressure Hose

Chemical Pickup Hose and Filter

Bag Containmg

• Video Cassette

• Owners’ Manual

• Nozzle Cleaning Kit and Replacement 0-Rings

• Engine Oil

• Rubber Isolator and Mounting Hardware

• Handle Mounting Hardware

Gun and Wand

Du O'

Video Cassette Owners’ Manual Nozzle Cleaning Kit

Handle Mounting

Hardware

Engine Oil

Replacement 0-Rings

Rubber Isolator and

Mounting Hardware

T

1

Page 6

Tools Required for Assembly

Adjustable wrench

Alien wrench 5mm (included)

Remove Pressure Washer from Carton

• Open box from the top. Locate and remove from

box, thè parts box, which includes gun, handle,

wand,oil, knobs and J bolts. Next remove the parts

bag and the handle.

• Cut carton along dotted lines.

• Remove all carton inserts.

• Roll unit through opening in Carton.

NOTE: The hose is located at the bottom of the box.

Preparing the Pressure Washer for First Use

3. • Mount the rubber isolator to the frame. To mount

isolator place threaded end of bolt through the

washer. Next with washer on bolt place threaded

end of bolt through the larger hole in bottom of the

rubber isolator. Place threaded portion of bolt

through the same hole location the wood plank

was mounted to on the pressure washer. Next

place the tee nut over the threaded portion of the

bolt and use the alien wrench provided to tighten

isolator to the frame.

PRESSURE

WASHER

FRAME

TEE NUT

\

WASHER—<S>

I

T

— ISOLATOR

A—BOLT

Note: Included with your pressure washer is a

video cassette tape on how to prepare your unit

for operation. It Is recommended you view this

tape before performing the next steps.

1. • Insert handle onto frame.

• Slide J bolts Into frame.

• Tighten knobs turning in clockwise direction.

2. • Using an adjustable wrench, remove nut from bolt

that attaches board to frame. Remove wood plank

from the frame of the imlt. Discard bolt and board.

4. • Connect wand extension to gun. To tighten, turn

knob in clockwise direction. Hand tighten.

5. • Remove tie wrap off of high pressure hose.

Unwind high pressure hose and attach the

threaded end to the gun.

6. • Connect high pressure hose to outlet on pressure

washer and hand tighten firmly. Connect

chemical pickup hose to hose barb on pump.

HIGH

CHEMICAL

HOSE

PRESSURE

HOSE

NOTE: Always keep hose away from engine muffler.

Page 7

7. • Place assembled gun and wand on pressure

washer holder.

Place pull cord into the wire bracket holder.

8.

- Pull the cord under the wire bracket to the right

of the wire loop.

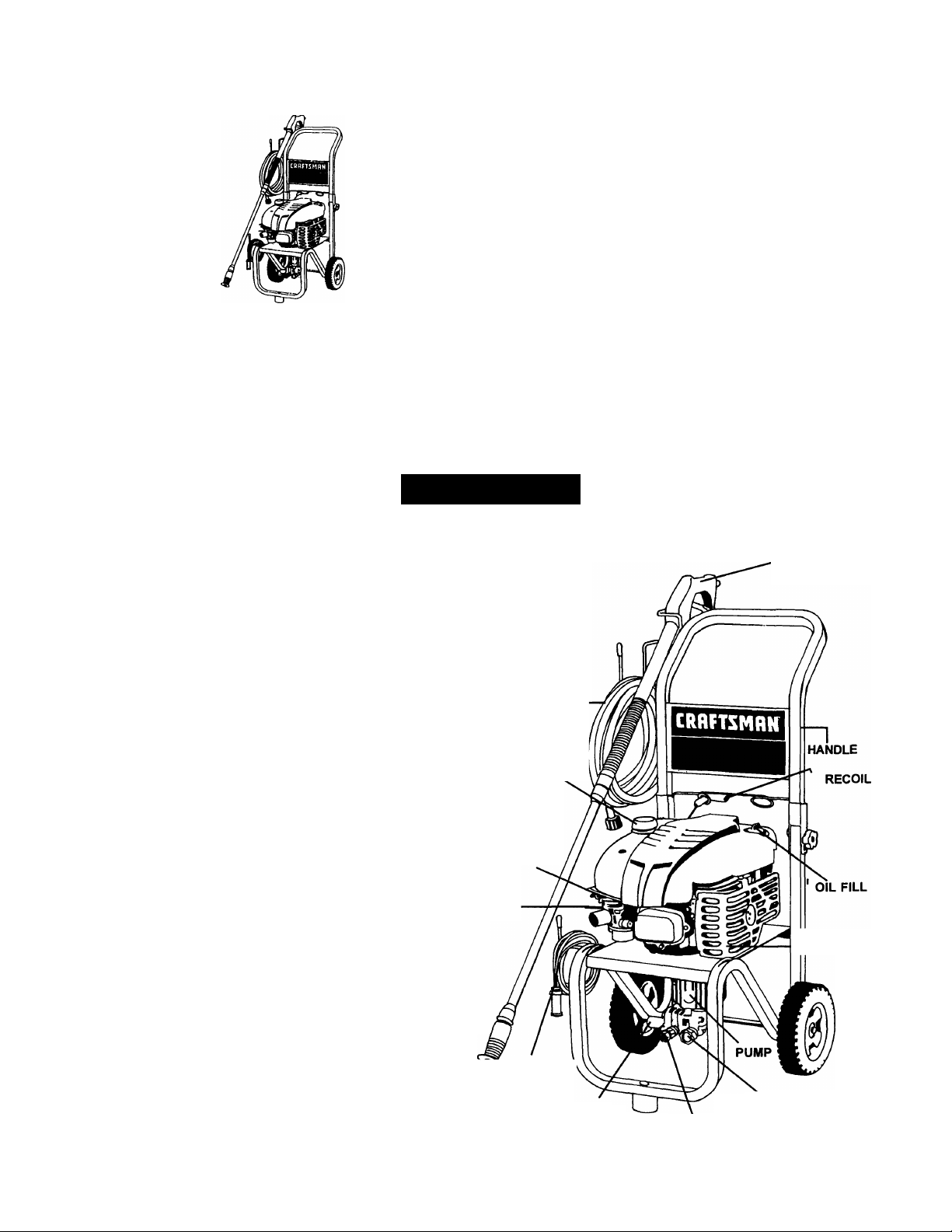

OPERATION

Know Your High Pressure Washer

Read this Owner’s Manual and Safety Rules

before operation of your High Pressure Washer

Compare this illustration with our pressure washer

to familiarize yourself with the location of various

controls and adjustments. Save this manual for

future reference.

- Lift the pull cord handle up and slide the cord to

the left sliding the cord into the wire loop.

- Next slide handle behind the wire bracket to the

left of the wire loop.

- Engine recoil will pull the cord into its final

position.

Checklist

Before going any further please review the following:

• Be sure you have completed assembly instructions.

• Double check all fittings to be sure they are tight.

IMPORTANT: Before any attempt to start your pres

sure washer be sure to check engine oil (See Operation

under Engine Oil, page 8.)

GUN WAND

ASSEMBLY

PUMP- Develops high pressure.

PRESSURE REGULATOR- Allows you to adjust the

pressure of the outlet stream.

ENGINE RUN/STOP LEVER- Sets engine in starting

mode for recoil starter — Stops running engine.

RECOIL STARTER- Used for starting the engine

manually.

SPRAY GUN ASSEMBLY- Controls the application of

water onto cleaning surface with trigger device.

OIL FILL- Port where engine oil is poured.

GAS TANK/CAP- Cap is removed and unleaded

gasoline is poured.

CHEMICAL INJECTION TUBE AND FILTER- Mixes

water and detergent in outlet water flow.

HIGH PRESSURE OUTLET- Connection for high

pressure hose.

CHOKE- Lever used for starting unit.

HIGHPRESSURE‘

HOSE

GAS CAP

RUN/STOP

CHOKE

CHEMICAL

INJECTOR

HOSE

REGULATOR

PRESSURE

-MUFFLER

WATER INLET

HIGH PRESSURE

OUTLET

Page 8

A Warning: Read Owner’s Manual. Do not attempt

to operate equipment until you have read Owners

Manual for Sal€^, Operation, and Maintenance

Instructions.

Note: Included with your unit is a video cassette that

demonstrates how to operate your pressure washer.

If you have a video cassette recorder you should

view the video before operation.

BEFORE STARTING THE ENGINE

To operate the engine you will need to do the

following.

NOTE: Your pressure washer pump is a sealed pump

you should never have to add or change the oil

A CAUTION: Always check engine oil level before

every start. Running engine low of oil or out of oil

could result in serious damage.

A Warning: Never adjust spray pattern when spray

ing. Never put hands in front of spray nozzle to

adjust spray pattern because you could be injured.

Stopping Your Pressure Washer

A CAUTION: Do not run pump without the water

supply connected and turned on. Failure to do so

will result in pump damage.

Move throttle control to the stop position to turn

pressure washer off.

THROTTLE CONTROL

• Simply shutting OFF engine will not release pressure

in the system. After engine has stopped, squeeze the

trigger on the spray gun for about 3 seconds to relieve

pressure. Spray stream will decrease in length.

IMPORTANT: This unit is equipped with a thermal relief

valve. If unit is allowed to run for several minutes

without pressing the trigger on the spray gun, several

drops of water may be released through this valve to

cool the unit. The heated water will be purged from the

bottom of the pump.

Engine Oil

Your unit has been shipped without oil In the engine.

A bottle of SAE 30 weight oil is included in the carton.

Remove oil dip stick located on top of the engine. Oil

capacity is about 20 ounces of oil. The oil dip stick is

clearly marked with a line that tells you when unit has

enough oil. To check oil, place dipstick into oil fill.

Tighten dipstick then remove.Do not fill above this

point. Pour slowly.

NOTE: When adding oil to the engine crankcase, use

a high quality detergent oil classified for Service SF,

SG, SH, rated SAE 30 weight. Use no special addi

tives. Select the oil’s viscosity grade according to your

expected operating temperatures.

colder <

Synthetic 5W-30 1

Although multi-viscosity oils (5W30,10W30, etc.)

improve starting in cold weather, these multi-viscosity

oils will result in increased oil consumption when used

above 40°F Check your engine oil level more frequently

to avoid possible damage from running low on oil. Oil

sump capacity is about 20 ounces.

----------------

40°F

------------SAE 30

> warmer

Gasoline

Your pressure washer engine is 4 cycle. Use fresh

unleaded fuel only.

BI!

^ CAUTION: Do not overfill the fuel tank. Always

allow room for fuel expansion.

WARNING: Never fill fuel tank indoors. Never

fill fuel tank when engine is running or hot. Do

not smoke or have open flame when filling fuel

tank.

Page 9

Use clean, fresh, regular unleaded gasoline with a

minimum of 85 octane. Do not mix oil with gasoline. If

unleaded fuel is unavailable leaded fuel may be used.

IMPORTANT: It is important to prevent gum deposits

from forming in essential fuel system parts such as the

carburetor, fuel filter hose or tank during storage. Also,

experience indicates that alcohol-blended fuels (called

gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before

storage of 30 days or longer. Never use engine or

carburetor cleaner products in the fuel tank or perma

nent damage may occur.

Squeeze trigger on pressure washer wand to relieve

air pressure caused by turning on the water. Water

win spew out of the gun in a thin stream. This will

make it easier to start the engine.

Engage the safety latch on the spray gun. This locks

the trigger in place and keeps you from accidentally

spraying a high pressure stream.

SAFETY

LATCH

NOTE: Never start pressure washer without water

source turned on and connected to pressure washer.

To Start Your Pressure Washer

• Remove gas cap

• Add unleaded gasoline, slowly, to fuel tank.

• Do not overfill.

Connect garden hose to the water Inlet on the

pressure washer. Tighten by turning water inlet

counter clockwise.

• On the engine there is a choke/run lever. Place lever

to the choke position.

• On the engine there is a throttle control lever. Place

throttle to the rabbit position. Always start engine

with throttle in the rabbit (high speed) position.

• Grasp the starter grip and pull slowly until resistance

is felt;, then pull firmly to start engine.

NOTE: If engine does not start right away, squeeze

the trigger on the gun to relieve water pressure

caused by turning on the water. Water will spew

out of the gun in a thin stream. This will make it

easier to pull start the engine. If more than five

pulls are required, place choke lever back to run

position.

• When engine starts, gradually move choke lever to

RUN position.

Connect high pressure hose to discharge on pump.

Connect the garden hose to the waterspout

and turn water supply on.

• For hot engine restarts, make sure throttle is in the

rabbit (High speed) position and the choke lever is in

the RUN position.

• Grasp the starter grip and pull slowly until resistance

is felt; then pull firmly to start engine.

Page 10

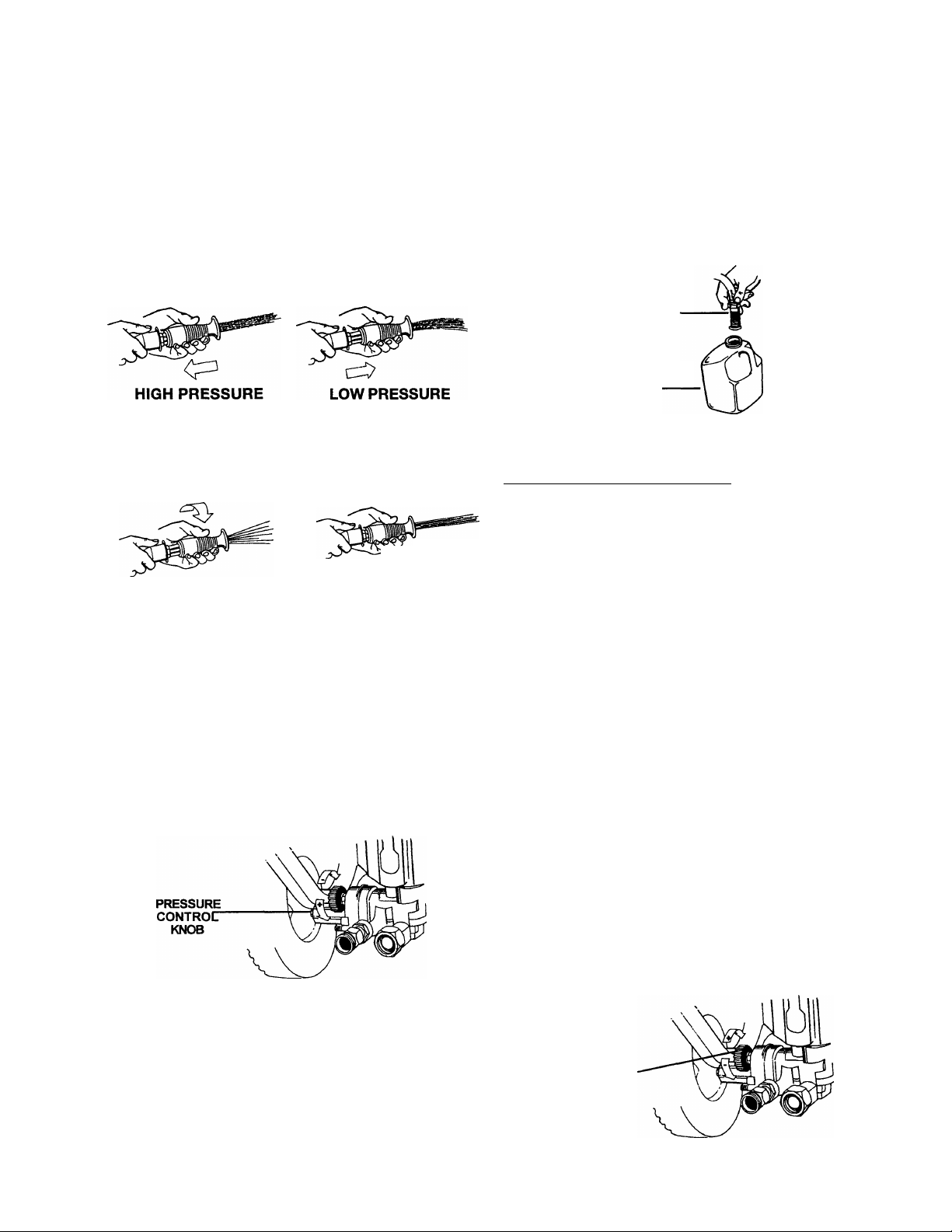

How To Use Your Pressure Washer

Using Soaps/Chemicals

On the end of your spray gun is a nozzle that you can

slide forward and backward and that you can also

twist from side to side. With the adjustable nozzle you

can adjust the spray pattern to either high pressure

or low pressure. You can also adjust the spray so it is

concentrated in a stream pattern or expanded into a fan

pattern.

• Slide the nozzle forward for low pressure. Pull nozzle

back for high pressure.

To adjust your spray pattern twist the nozzle

clockwise for fan spray or counterclockwise for

stream spray.

FAN SPRAY

STREAM SPRAY

• For most effective cleaning, keep spray nozzle

between 8 and 24 inches from cleaning surface.

IMPORTANT: If you get spray nozzle too close,

especially on high pressure, you may damage the

surface you are cleaning.

• The pressure control knob is located on the pump.

You can increase the pressure by turning the knob

clockwise or decrease the pressure by turning the

knob counterclockwise.

IMPORTANT: Use soaps and chemicals that are

designed specifically for use with pressure washers. To

apply soaps/chemicals follow these steps:

• Prepare the soap/chemical as required by your job.

• Insert soap/chemical line into your container (soap/

chemicals not included).

CHEMICAL

HOSE

CHEMICAL

JUG

NOTE: The first step involves applying an appropriate

soap/chemical solution to penetrate and loosen grime.

Apply the solution at low pressure to avoid splashing,

over spray and waste. Leave the solution on surface for

3 to 5 minutes to allow solution to work.

NOTE: The second step involves cleaning the surface

you have prepared with the pressure washer and then

rinsing it clean.

• Slide the adjustable nozzle forward to low pressure

mode. Soap/chemicals cannot be applied with nozzle

in high pressure position.

• Review the use of the adjustable nozzle.

• Connect garden hose to water inlet (see “To Start Your

Pressure Washer”). Check that high pressure hose is

connected to spray gun and pump (see Assembly),

and start engine.

• Apply soap/chemicals to dry surface, starting from the

bottom and working up.

• Allow the soap/chemicals to soak in between 3-5

minutes before washing and rinsing.

• For cleaning, start at lower portion of area to be

washed and work upward, using long, even over

lapping strokes.

• Your pressure washer is equipped with a chemical

injector adjustment knob. With the knob fully opened

you will get a maximum chemical draw. With knob

fully closed you will get no chemical draw. Turn

knob in counter clockwise direction to achieve more

chemical draw and clockwise for less chemical draw.

NOTE: The maximum pressure for the unit is set at it’s

maximum setting at the factory. Do not attempt to adjust

the pressure higher than this factory setting.

CHEMICAL

INJECTOR

ADJUSTMENT

KNOB

10

Page 11

After using the pressure washer, you should flush

the pump, chemical injector and chemical line with

MAINTENANCE

CUSTOMER RESPONSiaUTIES TABLE

MAINTENANCE TASK

PRESSURE \A№HER

Check/dean Inlet screen. X

Check high pressure hose.

Check soap and chenricai hose and filter X

Check gun and weuxI for leaks. X

Purge pump of air and contaminants

ENGINE

Check oil level

Change engine oil

Service air dearer

OeaiVrepiace spark plug

Before each use

clear water. To do so, simply place chemical injector

hose in water and siphon for 1 to 2 minutes.

Every 25

hours or yearly

X

X

X

X

Every 50

hours or yearly

X

Every 100

hours or yearly

X

Product Specifications

Pressure Washer Specifications

Pressure

Flow Rate

Cleaning Units (psi x GPM)

Engine Specifications

RPM 3600

Rated Horsepower 6.0

Spark Plug Gap

“.030” (0.76mm)

Gasoline Capacity 1.5 quarts

Oil (22 oz. capacity) SAE 30 weight

2350

2.2 GPM

5170

Generai Recommendations

The warranty of the high pressure washer does not

cover items that have been subjected to operator

abuse or negligence. To receive full value from the

warranty, operator must maintain high pressure

washer as instructed in this manual.

Some adjustments will need to be made periodocally to maintain your high pressure washer.

All adjustments in the Maintenance section of this

manual should be made at least once each season.

Once a year you should clean or replace the spark

plug, and clean or replace the air filter, and check

the gun and wand assembly for wear. A clean spark

plug and clean air filter assure proper fuel-air mixture

and help your engine run better and last longer.

Your pressure washer pump is a sealed pump, you

should never have to add or change the oil.

NOTE: Over time the o-rings in the gun assembly

become worn. Attached to your owners manual is a

replacememt o-ring and split backup o-ring.

11

Page 12

Pressure Washer Maintenance

Change Engine Oil

Check and Clean Inlet Screen: Examine inlet screen

on pump inlet fitting. Clean if clogged; replace if torn.

Check High Pressure Hose: High pressure hose can

develop leaks from wear, kinking, abuse. Inspect hose

each time before use. Check for cuts, leaks, abrasions

or bulging of cover, and damage or movement of

couplings. If any of these conditions exist, replace hose

Immediately.

Check Chenuc£ri/Soap Hose and Air Filter: Examine

the chemical/soap hose and clean if clogged. Hose

should fittightly on pump fitting. Check for leaks and

tears. Replace filter or hose if either is damaged.

Check Gun and Wand for Leaks: Examine hose

connection to gun making sure it Is secure. Test trigger

by pressing it and making sure it springs back into

place when you release it.

Purge Pump of Air and Contaminants

To remove the air from the pump, follow these steps:

• Set up the pressure washer as described in

Assembly section and connect the water supply.

• Remove the wand extension from the spray gun.

• Pull the trigger on the gun and hold.

• Change oil while engine is still warm. Preferably

drain oil from top of engine as illustrated below.

Drain oil with air cleaner side up. Oil can be drained

from engine bottom if necessary.

IMPORTANT: Before tipping engine or equipment to

drain oil, drain fuel from tank by running engine until

fuel tank is empty.

AIR CLEANER

• To drain oil from bottom of engine, remove drain

plug as illustrated below. Allow oil to drain and

replace drain plug. Remove dipstick and refill with

new oil of recommended grade. Start and run engine

at idle for 30 seconds.

OIL DRAIN

To remove the contaminants from the pump, follow

these steps:

• Set up the pressure washer as described in

ASSEMBLY section, connect the water supply.

• Remove the wand extension from the spray gun.

• Start the engine according to instructions in the

OPERATION section.

• Pull the trigger on the gun and hold.

• When the water supply is steady and constant,

disengage trigger and refasten the wand extension.

Engine Maintenance Check Oii Levei

• Oil level should be checked prior to each use

or at least every 5 hours of operation. To check oil see

Engine Oil on page 9.

Stop engine. Wait 30 seconds and re-check oil level.

If required, add oil to bring level to FULL mark on

dipstick.

12

Page 13

Service Air Cleaner

Your engine is equipped with an oval dual element.

• To service element: loosen screws and lift cover.

Then carefully remove pre-cleaner and cartridge

assembly.

• After servicing pre-cleaner and cartridge, place

pre-cleaner on cartridge.

• Install air cleaner assembly in base. Then install

cover on air cleaner and tighten screws securely to

base.

2 SCREWS

Do not clean engine with a forceful spray of

water because water could contaminate fuel system.

With a brush or cloth, clean finger guard after every

use to prevent engine damage caused by overheating.

• Before running engine, clean muffler area.

PRE-CLEANER

BASE

CARTRIDGE

Pre-Cleaner

To service pre-cleaner, wash in liquid detergent and

water. Allow to dry thoroughly before using. Do not oil

pre-cleaner. Replace if very dirty or damaged.

NOTE: Do not use petroleum solvents, e.g., kerosene,

which will cause the cartridge to deteriorate. Do not use

pressurized air to clean cartridge. Pressurized air can

damage the cartridge.

Keep engine and parts clean!

SERVICE AND ADJUSTMENTS

Carburetor

The carburetor of your high pressure washer is pre-set

at the factory. The carburetor should not be tampered

with. If your pressure washer is used at an altitude in

excess of 5000 feet consult with your nearest Sears

Service Center regarding high altitude set changes.

A CAUTION: Engine speed was properly adjusted

at the factory and should require no additional

adjustment. Do not attempt to change engine

speed. If you believe the engine is running too fast

or too slow, take your pressure washer to a Sears

Authorized Service Center for repair and adjustment.

Clean and Replace Spark Plug

Change the spark plug every 100 hours of operation or

once each year, whichever comes first. This will help

your engine to start easier and run better.

A CAUTION: Low engine speeds impose a heavy

load on the engine and when sufficient engine

power is not available could shorten engine life.

Nozzle cleaning:

If the nozzle becomes clogged with foreign materials,

such as dirt, excessive pressure may develop. If the

nozzle becomes partially clogged or restricted, the

pump pressure will pulsate. Clean the nozzle immedi

ately using the nozzle kit supplied and the following

instructions:

A WARNING: High engine speeds are dangerous and

increase the risk of personal injury or damage to

equipment.

Multi-Reg Wand/Lance:

1. Shut off the pressure washer and turn off the water

supply.

2. Disconnect spark plug wire.

13

Page 14

3. Pull trigger on gun handle to relieve any water

pressure.

4. Disconnect the wand/lance from the gun.

5. Remove the nozzle from the end of the wand with

the 2mm alien wrench provided.

6. Clean the. nozzle using the nozzte cleaner provided or

a straightened paper clip. Insert into the nozzle end

and work back and forth until obstruction is

removed.

7. Direct water supply into nozzle end to backflush

loosened particles for 30 seconds.

8. Reassemble the nozzle to the wand. Tighten

securely to prevent leaks.

STORAGE

9. Reconnect wand/lance to gun and turn on water

supply.

10. Start pressure washer and place wand/lance into

high pressure setting to test.

This pressure washer should be stored in such a way to

protect it from freezing. Do not store this unit outdoors

or in an area where temperatures will fall below 32° F.

This can cause extensive damage to this unit.

If unit has to be stored under freezing conditions a non

toxic R.V. anti-freeze can be used to protect from

freezing.

Preparing Pressure Washer for Storage

NOTE: If you do not plan to use your unit for 30 days or

more, unit should be prepared for storage.

Engine Preparation

• First add a fuel stabilizer to the fuel tank.

• Run pressure washer for a full 5 minutes to allow fuel

stabilizer to enter the fuel system.

NOTE: While doing this procedure make sure water

supply is turned on and flowing to the unit. NEVER run

unit without water supply running through pump.

• Next shut off engine and disconnect the water supply.

• Disconnect the spark plug wire and remove the spark

plug.

• Add one teaspoon of oil through the spark plug hole.

• Place rag over spark plug hole and pull the recoil a

few times to lubricate the combustion chamber.

• Replace the spark plug, but do not connect the spark

plug wire.

IMPORTANT: It is important to prevent gum deposits

form forming in essential fuel system parts such as the

carburetor, fuel filter hose or tank during storage. Also,

experience indicates that alcohol-blended fuels (called

gasohol or using ethanol or methanol) can attract mois

ture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system

of an engine while in storage. To avoid engine problems,

the fuel system should be emptied before storage of 30

days or longer. Never use engine or carburetor cleaner

products in the fuel tank or permanent damage may

occur.

Pump Preparation

• Be sure engine switch is in “OFF” position and spark

plug wire has been removed from spark plug.

• Pull the trigger on the spray gun to release the

pressure in the high pressure hose. Detach high

pressure hose and garden hose from the unit.

• Pull the recoil on the engine 4 to 6 times to discharge

remaining water in pump.

• Tip the unit on the end with the water inlet fitting

pointing upward.

• If unit will be stored where temperatures fall below

32°F, pour approximately 1/4 cup of non-toxic R.V.

anti-freeze down the fitting where the water hose

attaches to the pump.

• Set unit upright and pull starter handle on engine 4 to

6 times to circulate anti-freeze in pump until anti

freeze is discharged from the pump.

14

Page 15

TROUBLESHOOTING

SYMPTOM CAUSE

Engine won’t

start

Won’t Draw

Chemical

Pump running

normally but

pressure does

not achieve

rated values

Fluctuating

Pressure

1. Engine throttle is in ''OFF' Position.

2. Choke lever has not been placed to

choke.

3. Pressure buildup after initial use.

1. Nozzle not in chemical draw position.

2. Chemical screen is obstructed.

3. Chemical screen not working.

4. Chemical injector orifice obstructed

or stuck.

5. Chemical injector closed. 5. Open chemical injector by turning adjustment

1. Water supply restricted.

2. Nozzle is in low PSI position.

3. Nozzle incorrect or worn.

4. Pump sucking air.

5. Nozzle blocked. 5. Clean nozzle.

1. Pump sucking air.

2. Garden hose inlet strainer clogged.

3. Worn Seals or Packing.

4. Inadequate water supply.

5. Fouled or dirty inlet or discharge

valves.

6. Leaky discharge hose.

SOLUTION

1. Slide throttle to "Rabbit" position.

2. Slide choke lever to choke position.

3. Depress trigger gun.

1. Place nozzle to low pressure.

2. Check chemical screen; clean if obstructed.

3. Make sure chemical screen is submerged in

chemical/water.

4. Check and clean.

knob.

1. Check water supply and filter screen for.

blockage. Check hoses for blockage, kinks,

leaks, etc.

2. Pull nozzle at end of wand back to the high pressure

position.

3. Check and replace.

4. Check that hoses and fittings are air-tight.

1. Check that hoses and fittings are air tight. Purge air

from garden hose.

2. Clean. Check filter frequently.

3. Check and replace.

4. Check hose for kinks.

5. Check flow available to pump. Check for

excessive heat, 145° F or above.

6. Clean inlet and discharge valve assemblies.

Replace if damaged.

Pressure drops

after period of

normal use

Pump noisy

Presence of

water in oil (oil

milky).

Water dripping

from pump

Oil Dripping

1. Nozzle clogged, partially obstructed.

2. Nozzle worn.

3. Pump Valves worn, dirty or stuck.

4. Worn pump piston packing.

1. Water too hot.

2. Pump sucking air.

3. Valves dirty or worn.

4. Worn bearings.

1. High humidity.

2. Piston packing and oil seal worn.

1. Thermal relief functioning normal.

2. Fittings Loose.

3. 0-rings of piston guide or retainer

worn.

4. Piston packing worn.

1. Oil seal worn

2. Loose drain plug or worn drain plug

o-ring.

15

1. Use nozzle cleaning kit to clear obstruction. (See

Nozzle Maintenance under Service Adjustment.)

2. Clean or replace.

3. Check and replace.

4. Check and replace.

1. Reduce temperature below 63° C or 145° F.

2. Check that hoses and fittings are air tight.

3. Check, clean or replace.

4. Check and replace if necessary.

1. Change Oil.

2. Check and replace oil seals.

1. Protecting pump, if not using pressure washer for

a long period of time, shutoff engine.

2. Tighten.

3. Check and replace.

4. Check and replace.

1. Check and replace

2. Tighten drain plug or replace O-ring. Do not over torque.

Page 16

PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURi WASHER 919.762350

900

REF NO. PART NO.

1 16469

2

3

4

5

6

7 W131

8

10

11 16491

12

13 16479

14 F064

15 16470

16

18

900

20

16471

16468

16466

W137

16371

16462

H140

16467 Hose

16726

16830

PK16482

DESCRIPTION REF NO.

Handle

Knob-5/16” 22

Gun 23

Tire Semi (7x1 3/4)

Nut Pal 1/2”

Foot Rubber, Hollow

Tee Nut 5/160” X 3/4”

Frame

Hose, Chemical

Lance, Multi-Reg

Decal - Craftsman

Screw-Hex 5/16” -18 x 1 LG

J Bolt 5/16”- 18x2.5

Decal - Operation

0-Ring Kit

Engine-Referto engine breakdown (Model 121602-0206-El)

Pump

16

21

PART NO. DESCRIPTION

16829 Garden Hose Adapter 1/2

F504W 3/8” Coupling

F112 Washer

PARTS NOT ILLUSTRATED

MGP-762350A Owner’s Manual

NCT001

FI 01

FI 96

16087 Nut Flanghead-Engine to Pump

F074

16505

Nozzle Cleaning Kit

Screw, Hex-Engine to Pump

Screw, Hex-Engine to Pump

Washer Flat-Engine to Pump

Thermal Relief Valve

1

Page 17

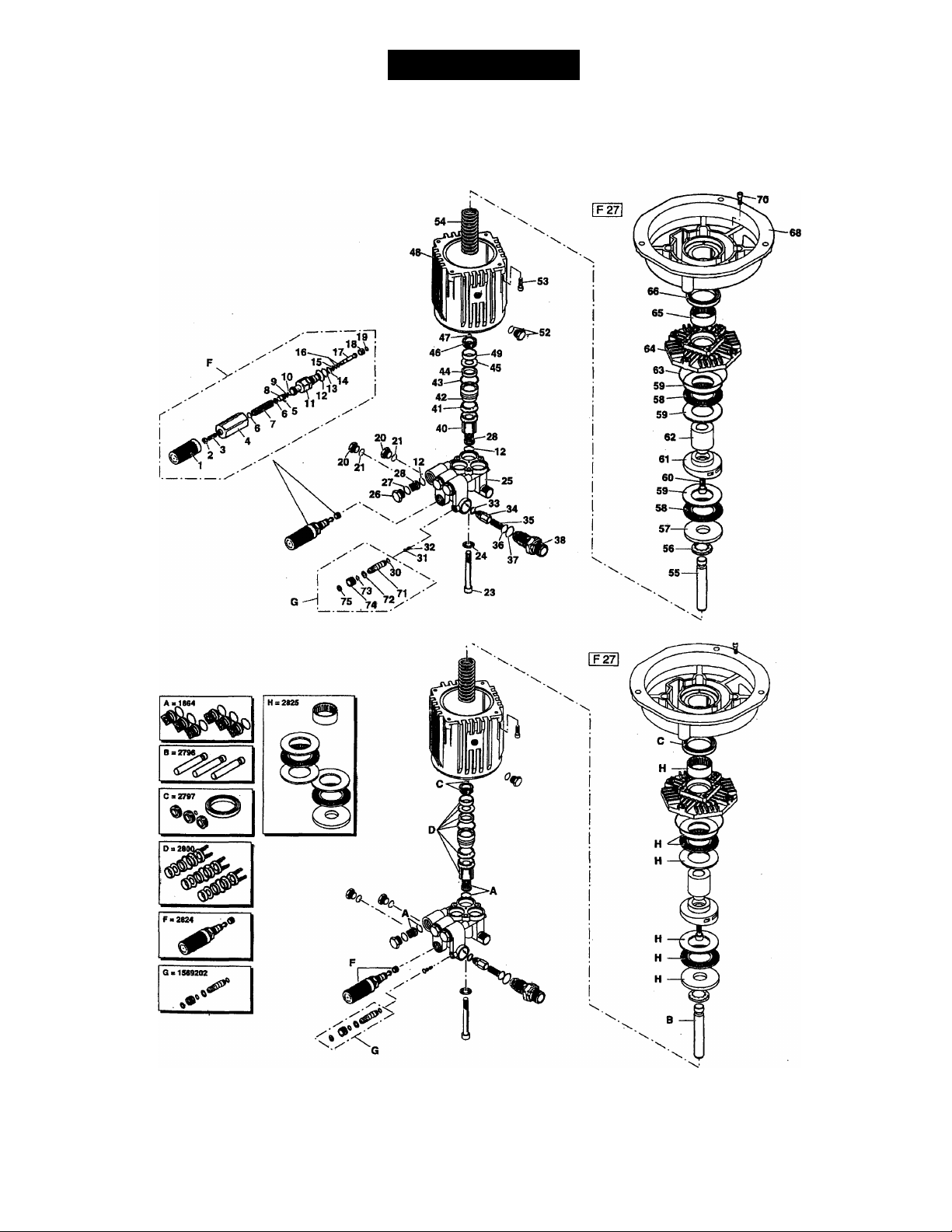

PUMP PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350

PUMP BREAKDOWN MODEL PK16482

17

Page 18

PUMP PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350

REF.

NO.

1

2

3 AR-1980470 Grub screw 1

4

5

6

7

8 AR-1080041 Upper piston 1

9 AR-1080401

10 AR-1080250 0-rang 1

11

12 AR-880830 0-Ring 7

13 AR-740290

14

15 AR-1271170 Ring

16 AR-1080190

17

18 AR-1980200 Valve seat

19 AR-1470210

20 AR-880581

21 AR-820510

23 AR-1980310

24 AR-650530

25

26

27

28 AR-1269050

30 AR-480480

31

32

33

34

35 AR-1080091

36 AR-394280

PART

NO. DESCRIPTION QTY.

AR-1322520

AR-1980300 Nut 1

AR-1980640 Handle insert

AR-1080070

AR-1980220 Plate spring

AR-1271070

AR-1980210 Piston guide 1

AR-800560

AR-1271160

AR-1980650 Pump head

AR-1260162

AR-960160

AR-1250280 Ball

AR-1560520

AR-1460430 O-Ring

AR-1540170 Jet

Knob 1

1

Pin 1 ■

1

Spring 1

Ring

0-Ring 1

0-Ring 1

0-Ring 2

Lower piston

0-Ring

Plug

0-Ring 2

Screw 3

Washer 3

Plug

O-Ring

Complete valve

O-Ring

Spring

Spring 1

O-Ring 1

1

1

1

1

1

2

1

3

3

6

1

1

1

1

1

PUMP BREAKDOWN MODEL PK16482

REF.

NO.

37 '

38

40 AR-1980190

41

42 AR-1980180 Piston guide

43 AR-770130 O-Ring

44 AR-1260440 Gasket

45 AR-1980170 Ring

46 AR-1980410 Seal

47 AR-770090 O-Ring

48 AR-1980460

49

52 AR-1980290

53 AR-180030 Screw 4

54

55 AR-1980140 Piston 3

56 AR-1980150

57 AR-1980130 Rail 1

58

59 AR-1980240 Rail 3

60 AR-850370 Screw 1

61

62 AR-1980440 Hollow shaft 1

63 AR-1980340

64 AR-1980450 Flange 1

65

66

68

70

71 AR-1560650 Hose tail 1

72 AR-800560 O-Ring 1

73 AR-480560 O-Ring 1

74 AR-1560670 Knob 1

75 AR-1560660

PART

NO.

AR-1200690

AR-1270130 Detergent injector

AR-1342761 Gasket 3

AR-1980430

AR-1980160

AR-1980250

AR-1980070

AR-1980230 Roller bearing 1

AR-480671 Seal 1

AR-1980510 El. motor flange 1

AR-1200430 Screw 4

DESCRIPTION

O-Ring

Support ring

Housing

Spacer 3

Plug

Spring 3

Ring

Cage

Wobble plate

O-Ring 1

Ring

QTY.

1

1

3

3

3

3

3

3

1

1

1

3

2

1

1

PART KITS

A=KIT 16739

Valves Pistons OH Seals Water Seals

Pos.

12 6 55 3

28

Pos. Qly.

1 1

2 1 9 1 16 2

3 1 10 1 17 1

4 1 t1 1 18

5 1 12 1 19 1 74

6 2 13

7 1 14 1

Qly.

6 47

Unloader Valve

B=KIT 16740 C=KIT 16742 D=KIT 16738

Pos.

F=KIT 16737

Pos. Qfy. Pos.

8

Qly.

1

1

15 1

Pos. Qly. Pos.

46 3 40 3

1

66 1 43

G=KIT 16741 H=KIT 16743

Chemical Injector

QV-

1 73 1

Pos.

30 1 57

71

72

75

18

Qty. Pos.

1

1

1

1

41 3

44

45 3

49 3

Qly.

3

3

Bearing

58 2

59 3

65

Qty.

1

1

Page 19

ENGINE PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

REF.

PART

NO.

NO. DESCRIPTION

1

499678 Cylinder Assembly

3 399269

5

299819

6

499643 Head-Cylinder

7

273240

8

495786

9

272481

10

94955

11

499675

13

95049

33

499642

34

499641

35

263149

40

93312

45

262679

Bushing 155

Seal-Oil 189

Gasket-Cylinder Head 305

Breather Assembly 306

Gasket-Breather 307

Screw-Hex

Tube-Breather

Screw-Hex

Valve-Exhaust

Valve-Intake

Spring-Valve

Retainer-Valve

Tappet-Valve

REF.

PART

NO.

NO.

122 281617

225325

263108

238

263131

94744

225366

94515

337

499608

354

383

19374

584

224328

585 272238

REF.

DESCRIPTION

Spacer-Carburetor

Plate-Cylinder Head

Ball-Rocker Arm

Cap-Valve 868

Screw-Hex

Sheild-Cylinder

Screw-Hex

Plug-Spark

Nut-Hex (Sold in Kit Only)

Wrench-Spark Plug

Cover-Breather Passage

Gasket-Breather Passage

NO.

635

718

830

883

993

1019 499691

1022

1023 499624 Cover-Rocker

1026 498597

1029

1034 281621

1058

19

PART

NO. DESCRIPTION

66538 Boot-Spark Plug

230192 Dowel-Sleeve

499756

498592

273348

273346

273241

225246 Arm-Rocker

273323

Stud-Rocker Arm

Seal-Valve

Gasket-Exhaust

Gasket-Plate

Label Kit

Gasket-Rocker Cover

Rod-Push

Guide-Push Rod

Owner’s Manual

Page 20

ENGINE PARTS

CRAFTSMAN 2350 PSI №GH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

REF. PART

NO. NO. DESCRIPTION

4 499619

t2 272198

15 94880

16 498615

20 399781 Seal-Oil

22 94220

Sump-Engine

Gasket-Crankcase 25

Plug-Oil Drain

Crankshaft 27 263190 Lock-Piston Pin

Note 28 499423 Pin-Piston

498612 Crankshaft 29

Used on Type No(s).

0163.

498622 Crankshaft 46 499136

Used on type No(s).

0172. 116A

Screw-Hex.

Note

94612 Screw-Hex.

(One Used in Hole

Nearest Breather)

REF. PART

NO. NO.

24

222698 Key-Flywheel

499627

26 499631

499424 Rod-Connecting

32 94669 Screw-Connecting Rod

49S737 Govemor/Oil Slinger

43

116

280393

280966

146 94388

227

498772

67072 Washer

230

DESCRIPTION

Piston Assembly

Ring Set

Gear-Cam

Seal-O-Ring

Seal-O-Ring

Key-Timing

Lever-Governor

20

REF. PART

NO.

NO.

284

94511

499621

523

525 495265 Tube-Oil Fill

562 94907 Bolt-Governor Lever

592 231082 Nut-Hex.

615 94474

616 263175 Crank-Governor

741 262598

847

498715 Dipstick/Tube

DESCRIPTION

Screw-Shoulder

Dipstick

Retainer-Governor

Gear-Timing

Assembly

Page 21

ENGINE PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

124

125A

CHOKE SYSTEM

130A 95

131

987©

1341

133

117A| 355 O

REF.

PART

NO.

NO.

51

272487 Gasket-Intake

95 94098

104 231371 Pin-Float Hinge

117

498978

124

95048 Screw-Hex. (Sold in Kit Only)

DESCRIPTION

Screw-Round Head 127

Jet-Main (Standard)

Note 131 499682

498975 Jet-Main 133 398187 Float-Carburetor

(High Altitude)

REF.

PART

NO.

NO. DESCRIPTION

125 499617 Carburetor

Plug-Welch

(Sold in Kit Only)

130 224908 Valve-Throttle 355 Washer-Seal

Shaft-Throttle (Sold in Kit Only)

134 398188

Valve-Needle

21

REF.

PART

NO.

NO. DESCRIPTION

137

163 273364 Gasket-Air Cleaner

975 493640 Bowl-Float

987

Gasket-Float Bowl

(Sold in Kit Only)

Seal-Throttle Shaft

Page 22

ENGINE PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

209

%

971^

REF.

PART

NO.

NO.

51 272487

95

94098

98 398185

104

231371

108

224783

117A 494870

124

95048 Screw-Hex.

REF.

PART

DESCRIPTION

Gasket-Intake 125A 499680

Screw-Round Head

Screw-Idle Speed

Pin-Roat Hinge

Valve-Choke

Jet-Main (Standard)

Note (Includes Seat)

497315 Jet-Main 134 398188 Gasket-Floai Bowl (Sold in Kit Only)

(High Attitude) 137 (Sold in Kit Only)

NO.

NO.

127

130A 223470

499682 Float-Carburetor

131

133 398187 Valve-Needle 975 493640

141 499681 Shaft-Choke

DESCRIPTION

Carburetor

Piug-Welch

(Sold in Kit Only) (Sold in Kit Only)

Valve-Throttel

PART

REF.

NO.

NO. DESCRIPTION

273364

163

355

633 Seal-Choke Shaft

987 Seal-Throttle Shaft

Gasket-Air Cleaner

Washer-Seal

(Sold in Kit Only)

Bowl-Float

22

Page 23

ENGINE PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

727

9101

423 1

356

REF. PART

NO. NO. DESCRIPTION

11 499675 Tube-Breather

51 272487 Gasket-Intake

163 273364 Gasket-Air Cleaner

202 261348 Link-Mechanical Gov.

209 263044 Spring-Governor

363

REF. PART

NO. NO. DESCRIPTION

263226 Spring-Gov.

Used on Type No(s).

0152.

259 224348 Bracket-Casing Clamp

445 498596 Filter-A/C Cartridge

534 95059 Screw-Slotted

620 498706 Bracket-Control

REF. PART

NO. NO. DESCRIPTION

642 281620 Cover-Air Cleaner

966 499684 Base-A/C Primer

967 273356 Filter-Pre-Cleaner

971 95103 Screw-Shoulder

976 496115 Primer-Carburetor

23

Page 24

ENGINE PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

PART

REF.

PART

NO. DESCRIPTION

NO.

37 224511 Guard-Flywheel

94904 Screw-Hex.

65

225125 Screen-Rotating

73

'94512

258

499677 Housing-Blower 356 497833 Wire-Stop

304

Screw-Slotted Hex.

REF.

NO. DESCRIPTION

NO.

305 94744 Screw-Hex.

332

94877 Nut-Flywheel

802574

333

334 94731

356A 493400

19069

363

373 94908 Nut-Hex. 1036 499343

423 93758

455 225121

474

492841 Alternator

621 396847

727

281675 Cover-Starter Drive

789 493379

Armature-Magneto

Screw-Hex.

Wire-Stop

Flywheel Puller

Screw-Hex.

Cup-Flywheel

Switch-Stop

Harness-Wiring

24

REF.

PART

NO.

NO.

851

493880

910

94510

922 262640

923 493442 Brake

935

499421

940 499679

1005 281657

DESCRIPTION

Terminal-Cable

Stud-Stator Mounting

Spring-Brake

Switch-interlock

Guard-Flywheel

Fan-Flywheel

Label Kit-Emission

Used on Type No(s).

0015, 0100, 0152,

0155.

Page 25

ENGINE PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

356

REF.

PART

NO.

NO.

153 95050 Screw-Phillips 300

187 296004 Line-Fuel 305 94744

187A 498171

188 398540 Screw-Shoulder

240 298090

284

94511

DESCRIPTION

(Cut to Required

Length) 346A

Line-Fuel

Filter-Fuel 601 93053

Screw-Shoulder

REF.

PART

NO.

NO. DESCRIPTION

498733

346

94896

95062 Screw-Hex. 883

346B 94874

346C 94786 Screw-Hex. 957 498697

REF.

PART

NO.

NO.

Muffler-Exhaust

Screw-Hex. 676 397931 Deflector-Muffler

Screw-Hex.

Screw-Hex. 921 498734 Cover-Blower Housing

Clamp-Hose

670 280512 Spacer-Fuel Tank

832

498736 Guard-Muffler

273348

972

499618 Tank-Fuel

DESCRIPTION

Gasket-Exhaust

Cap-Fuel Tank

25

Page 26

ENGINE PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

REF. PART

NO. NO. DESCRIPTION

55 497440 Housing-Rewind

Starter

56 498144 Pulley-Starter

58 280399 Rope-Starter

(Cut to Required

Length)

REF. PART

NO. NO. DESCRIPTION

60 281434 Grip-Starter Rope

65 94904 Screw-Hex.

373 94908 Nut-Hex.

456 281503 Retainer-Spring

459 281505 Plate-Paul Friction

26

REF. PART

NO. NO. DESCRIPTION

461 94943 Screw-Shoulder

608 497680 Starter-Rewind

689 263073 Spring-Friction

Page 27

ENGINE PARTS

CRAFTSMAN 2350 PSI HIGH PRESSURE WASHER 919.762350 BRIGGS ENGINE MODEL #121602-0206-El

REF. PART

NO. NO. DESCRIPTION

3 299819 Seal-oil

7 273240 Gasket-Cylinder Head

9 272481 Gasket-Breather 134

REF. PART REF.

12 272198 Gasket-Crankcase

20 399781

272487

51

104 231371 Pin-Float Hinge

116 290393 Seal-O-Ring 355

116A 280966 Seal-O-Ring

Seal-Oil 137

Gasket-Intake

121 499685 Carburetor Kit

281617 Spacer-Carburetor 585 272238

122

NO.

NO. DESCRIPTION

127

398188 Valve-Needle

273364

163

358 499686

PART

NO.

NO. DESCRIPTION

Plug-Welch

(Sold in Kit Only) (Sold in Kit Only)

(Includes Seat)

Gasket-Float Bowl

(Sold in Kit Only)

Gasket-Air Cleaner

Washer-Seal

(Sold in Kit Only)

Gasket Set

Gasket-Breather

Passage

633

868

498592 Seal-Valve

883

273348

977

499687 Gasket-Set

978

273346 Gasket

987

1022

273241

1033

499688

Seal-Choke Shaft

Gasket-Exhaust

Carburetor

Seal-Throttle Shaft

(Sold in Kit Only)

Gasket-Rocker Cover

Kit-Valve Overhaul

27

Page 28

Briggs & Stratton Corporation (B&^tbe Caiifomia Air Resources Board (CABB)

and the United Shrtes Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement (Owner’s Defect Warranty Rights and Obligations)

In the interest of the environment, B&Sengines that meet strict emis

sion requirementsare labeled, 'TNs engine conforms to 1995-1998

California emission regulations for ULGE engines and U.S. EPA

Phase I regulations for small non-road engines.”

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE

TO CERTIFIED ENGINES PURCHASED IN CALIFORNIA IN 1995

A^® THEREAFTER. WHICH ARE USED IN CALIFORNIA, AND

TO CERTIFIED MODEL YEAR 1997 AND LATER ENGINES

WHICH. ARE PURCHASED AND USED ELSEWHERE IN THE

UNITED STATES.

California and United States Emission Control Defects Warranty Statement

CARB, U.S. EPA and B&S are pleased to explain the Emission

Control System Warranty on your 1998 and later utility or lawn and

garden equipment (IX.GE) engine. In Caiifomia, new ULGE engines

produced on or after August 1,1995 must be designed, built and

equipped to meet the State’s stringent anti-smog standards^ Else

where in the Urrited States, new non-road, spark-ignition engines

certified for model year 1997 and later, must meet similar standards

set forth by the U.S. EPA. B&S must warrant the emission control

there has been no abuse, neglect or improper maintenance of your

ULGE engine.

Your emission control system includes parts such as the carburetor,

air cleaner, ignition system, muffler and catalytic converter. Also

included maybe connectors and other emission related assemblies.

Where a warrantable condition exists, B&S will repair your ULGE

engine ^ no cost to you including diagnosis, parts and labor.

system on your en^ne for the periods of time listed below, provided

Briggs & Stratton Emission Control Defects Warranty Coverage

ULGE engines are warranted relative to emission control parts below. If any covered part on your engine is defective, the part will be

defects for a period of two years, subject to provisions set forth repaired or replaced by B&S.

Owner’s Warranty Responsibilities

As the ULGE engine owner, you are responsible forthe performance

of the required maintenance listed in your Operator/Owner Manual.

B&S recommends that you retain all your receipts covering mainte

nance on your ULGE engine, but B&S cannot deny warranty solely

forthe lack of receipts orfor your failure to ensure the performance of

ail scheduled maintenance.

As the ULGE engine owner, you should however be aware that B&S

may deny you warranty coverage if your ULGE engine or a part has

failed due to abuse, neglect, improper maintenance or unapproved

modifications.

You are responsible for presenting your ULGE engine to an Autho

rized B&S Service Dealer as soon as a problem exists. The undis

puted warranty repairs should be completed in a reasonable amount

of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a B&S Service Representative

at 1-414-259-5262.

The emission warranty is a defects warranty. Defects are judged on

normal engine performance. The warranty is not related to an in-use

emission test.

Briggs & Stratton Emission Control Defects Warranty Provisions

The following are specific provisions relative to your Emission Control Defects Warranty Coverage. It is in addition to the B&S engine warranty

for non-regulated engines found in the Operator/Owner Manual.

1. Warranted Parts

Coverage under this warranty extends only to the parts listed

below (the emission control systems parts) to the extent these

parts were present on the engine purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel Pump

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

Catalyst System

d.

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

Miscellaneous Items Used in Above Systems

e.

• Vacuum, temperature, position, time sensitive valves

and switches

• Connectors and assemblies

Length of Coverage

B&S warrants to the initial owner and each subsequent purchaser

that the Warranted Parts shall be free from defects in materials

and workmanship which caused ttie failure of the Warranted

Parts for a period of two years from the date the engine is deliv

ered to a retail purchaser.

3. No Charge

Repair or replacement of any Warranted Part will be performed

at no charge to the owner, including diagnostic labor which leads

to the determination that a Warranted Part is defective, if the

diagnostic work is performed at an Authorized B&S Service

Dealer. For emissions warranty sen/ice contact your nearest

Authorized B&S Service Dealer as listed in the “Yellow Pages"

under “Engines, Gasoline,” “Gasoline Engines," “Lawn

Mowers,” or similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions

of the B&S Engine Warranty Policy. Warranty coverage shall be

exciudert for failures of Warranted Parts which are not original

B&S parts or because of abuse, neglect or improper mainte

nance as set forth in the B&S Engine Warranty Policy. B&S is not

liable to cover failures of Warranted Parts caused by the use of

add-on, non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as

required maintenance or which is scheduled only for regular

inspection to the effect of “repair or replace as necessary” shall

be warranted as to defects for the warranty period. Any

Warranted Part which is scheduled for replacement as required

maintenance shall be warranted as to defects only for the period

of time up to the first scheduled replacement for that part. Any

replacement part that is equivalent in performance and durability

may be used in the performance of any maintenance or repairs.

The owner is responsible for the performance of all required

maintenance, as defined in the B&S Operator/Owner Manual.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine

components caused by the failure of any Warranted Part still

under warranty.

28

Page 29

Briggs & StraMon welcomes warrar^ repa'rr and apologizes

to you for being inconvenienced. Any Authorized Service

Dealer may perform warranty repairs. Most warranty repairs

are handled routinely, but sometimes requests for warranty

service may not be appropriate. For example, warranty would

not apply if engine damage occurred because of misuse, lack

of routine maintenance, shippkig, handling, warehousing or

improper installation. Similarly, warranty is void if the serial

number of the engine has been removed or the engine has

been altered or modified.

If a customer differs with the decision of the ServIceHDealer, an

investigation will be made to determine whether the warranty

applies. Ask the Service Dealer to submit all supporting facts to

his Distributor or the Factory for review. If the Distributor or the

Factory decides that the claim is justified, the customer will be

fully reimbursed for those items that are defective. To avoid

misunderstanding which might occur between the customer

and the Dealer, listed below are some of the causes of engine

failure that the warranty does not cover.

Improper maintenance;

The life of an engine depends upon the conditions under

which it operates, and the care it receives. Some applications,

such as tillers, pumps and rotary mowers, are very often used

in dusty or dirty conditions, which can cause what appears to

be premature wear. Such wear, when caused by dirt, dust,

spark plug cleaning grit, or other abrasive material that has

entered the engine because of improper maintenance, is not

covered by warranty.

This warranty covers engine related defective materiai

and/or workmanship only, and not replacement or refund

of the equipment to which the engine may be mounted.

Nor does the warranty extend to repairs required

because of:

4.

Parts which are scored or broken because an engine was

operated with insufficient or contaminated lubricating oil,

or an incorrect grade of lubricating oil (check oil level daily

or after every 8 hours of operation. Refill when necessary

and change at recommended intervals.) Read “Owner’s

Manual.”

5.

Repair or adjustment of associated parts or assemblies

such as clutches, transmissions, remote controls, etc.,

which are not manufactured by Briggs & Stratton.

6.

Damage or wear to parts caused by dirt, which entered

the engine because of improper air cleaner maintenance,

re-assembly, or use of a non-original air cleaner element

or cartridge. (At recommended intervals, clean and re-oil

the Oil-Foam® element or the foam pre-cleaner, and

replace the cartridge.) Read “Owner’s Manual.”

7.

Parts damaged by overspeeding, or overheating caused

by grass, debris, or dirt, which plugs or clogs the cooling

fins, or flywheel area, or damage caused by operating the

engine in a confined area without sufficient ventilation.

(Clean fins on the cylinder, cylinder head and flywheel at

recommended intervals.) Read “Owner’s Manual.”

Engine or equipment parts broken by excessive vibration

caused by a loose engine mounting, loose cutter blades,

unbalanced blades or loose or unbalanced impellers.

Improper attachment of equipment to engine crankshaft,

overspeeding or other abuse in operation.

9.

A bent or broken crankshaft, caused by striking a solid

object with the cutter blade of a rotary lawn mower, or

excessive v-belt tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e., combustion

chamber, valves, valve seats, valve guides, or burned

starter motor windings, caused by the use of alternate

fuels such as, liquified petroleum, natural gas, altered

gasolines, etc.

1.

PROBLEMS CAUSED BY PARTS THAT ARE

ORIGINAL BRIGGS & STRATTON PARTS.

2.

Equipment controls or installations that prevent starting,

cause unsatisfactory engine performance, or shorten

engine life. (Contact equipment manufacturer.)

3.

Leaking carburetors, clogged fuel pipes, sticking valves,

or other damage, caused by using contaminated or stale

fuel. (Use clean, fresh, lead-free gasoline and Briggs &

Stratton gasoline stabilizer. Part No. 5041.)

NOT

29

Page 30

Page 31

Page 32

For the repair or replacement parts you need

Cali 7 am - 7 pm, 7 days a week

1-800-366-PART

(1-800-366-7278)

For in-home major brand repair service

Call 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247)

For the location of a

Sears Parts and Repair Center in your area

Call 24 hours a day, 7 days a week

1-800-488-1222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

call 9 am - 5 pm, Monday-Saturday

1 -800-827-6655

America's Repair Specialists

Page 33

MANUAL DEL OPERADOR

CRflFTSMRN.

Lavadora de Alta Presión

6.0 Caballos de Fuerza

2350 PSI 2.2 GPM

Modelo No.

919.762350

ADVERTENCIA: Leer este

manual y observar todas las

Precauciones de Seguridad e

Instrucciones de Operación

antes de usar este equipo.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

16478 MGP-762350A 4/16/98

TELEFONO DE AYUDA

PARA CLIENTES DE

LAVADORAS A PRESIÓN

1-800-245-5873

• Seguridad

• Ensamblaje

• Operación

• Mantenimiento

• Lista de Partes

• Español

Page 34

TABLA DE CONTENIDOS

Garantía

Pautas de Seguridad

Ensamblaje

Operación

Mantenimiento..........................

.....................................

...............

...............................

..................................

garantía limitada de un año para lavadoras craftsman de

..........

34

....35-37

....37-39

....39-43

....43-45 Cómo Ordenar Repuestos

Servicio y Regulaciones

Almacenaje

Guía para Diagnóstico de Problemas

Repuestos

....................................

......................................

.............

...........

................

......................

................

.....

ALTA PRESIÓN

Por un año a partir de la fecha de compra, y siempre que esta Lavadora Craftsman de Alta Presión se

mantenga y opere de acuerdo a las instrucciones en el Manual del Operador, Sears reparará cualquier

defecto de material o fabricación sin costo alguno.

Si esta lavadora se usa para propósitos comerciales, la garantía sólo será aplicable por 90 días a partir

de la fecha de compra. Si esta lavadora se usa para alquiler, esta garantía sólo será aplicable por 30 días

a partir de la fecha de compra.

45-46

..............

48-51

Contratapa

46

47

GARANTÍA LIMITADA DE UN AÑO DEL MOTOR CRAFTSMAN

Por un año a partir de la fecha de compra, y siempre que este motor Craftsman se mantenga y opere de

acuerdo a las instrucciones en el Manual del Operador, Sears reparará cualquier defecto de material o

fabricación sin costo alguno.

Si el motor Craftsman se usa para propósitos comerciales o de alquiler, la garantía sólo será aplicable

por 90 días a partir de la fecha de compra. Esta garantía no cubre piezas sujetas a desgaste tales como

bujías y filtros de aire, los cuales se gastan con el uso normal.

La garantía no cubre las reparaciones que se hagan necesarias debido al mal uso o negligencia de parte

del operador, incluyendo daños causados por no suministrarle agua a la bomba o no mantener el equipo

de acuerdo a las instrucciones contenidas en este manual.

SE PUEDE OBTENER SERVICIO POR GARANTÍA SI SE LLEVA LA LAVADORA DE ALTA

PRESIÓN AL CENTRO/DEPARTAMENTO DE SERVICIO DE GARANTÍA MÁS CERCANO EN

CUALQUIER LUGAR DE ESTADOS UNIDOS. Esta garantía le otorga ciertos derechos legales

específicos y usted también podría tener otros derechos que varían de un estado a otro.

Sears, Roebuck and Со., D/817 WA, Hoffman Estates, IL 60179

34

Page 35

PAUTAS DE SEGURIDAD - DEFINICIONES

Este manual contiene información que es importante que usted sepa y entienda. Esta información se relaciona con la

protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS AL EQUIPO. Para ayudarle a identificar esta información

usamos los siguientes símbolos. Por favor leer este manual y prestar atención especial a estas secciones. CONSERVAR

ESTAS DEFINICIONES/INSTRUCCIONES.

A ADVERTENCIA índica una situación

potencialmente riesgosa, la cual, si no se evita

Duede causar lesiones serías o muerte.

A PELIGRO indica una situación riesgosa

inminente que si no se evita causará lesiones

serias o muerte.

A CUIDADO indica una situación potencialmente

peligrosa que si no se evita puede causar

lesiones menores.

fO/a/97

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Aadvertencia

LA OPERACIÓN O EL MANTENIMIENTO INAPROPIADOS DE ESTA UNIDAD PUEDEN CAUSAR LESIONES SERIAS Y DAÑOS

A LA PROPIEDAD. LEER Y ENTENDER TODAS LAS ADVERTENCIAS DE SEGURIDAD E INSTRUCCIONES DE OPERACIÓN

ANTES DE USAR ESTA UNIDAD.

RIESGO

Apeligro

RIEGO DE INCENDIO O

EXPLOSIÓN

QUE PUEDE SUCEDER

La gasolina y los vapores de gasolina pueden

encenderse con las chispas de los

cigarrillos, arcos eléctricos, gases deescape

y los componentes calientes de los motores

tales como el mofle.

El calor expandirá el combustible en el

tanque lo cual puede causar un derrame y

posiblemente fuego o explosión.

Operar la unidad en un ambiente con

riesgos de explosión, puede causar un

incendio.

Los materiales colocados contra la lavadora

de presión o cerca de ésta pueden interferir

con su ventilación apropiada causando

sobrecalentamiento y posible inflamación

de los materiales.

El combustible indebidamente guardado

puede causar una ignición accidental. El

combustible indebidamente asegurado

puede caer en las manos de niños u otras

personas indebidas.

COMO PREVENIRLO

Apagar el motor y permitir que se enfríe

antes de agregar combustible al tanque.

Tener cuidado al llenar el tanque para evitar

derramar el combustible. Retirar la lavadora

de presión del área de relleno de

combustible antes de arrancar el motor.

Mantener el nivel máximo del combustible

a 1.5 cm por debajo de la tapa del tanque

de combustible para dejar sitio para la

expansión.

Operar y agregar combustible al equipo en

áreas bien ventiladas y libres de

obstrucciones. Equipar el área de operación

con extinguidor(es) adecuado(s) para

incendios de gasolina.

Nunca operar la lavadora de presión en un

área que contenga hierbas o ramas secas.

Almacenar la gasolina en envase designado

para contener gasolina y en un lugar seguro

lejos del área de trabajo.

Apeligro

RIESGO A LA RESPIRACIÓN

Inhalar los gases del escape causará

lesiones serias o muerte.

Algunos líquidos limpiadores contienen

sustancias que pueden causar daño a la piel,

los ojos o los pulmones.

35

Operar la lavadora de presión en un área

bien ventilada. Evitar áreas cerradas tales

como garajes, sótanos, etc.

Nunca operar la unidad en lugares

ocupados por personas ni animales.

Solo usar líquidos iimpiadores

especialmente recomendados para

lavadoras de alta presión. Seguir las

recomendaciones del fabricante.

Page 36

INSTRUCCIONES IMPORTANTES DE SEGURIDAD (Cont.)

RIESGO

^advertencia

RIESGO POR OPERACIÓN

INSEGURA

Aadvertencia

RIESGO DE LESIONES

POR EL CHORRO

QUE PUEDE SUCEDER

La operación o mantenimiento inadecuados

de la lavadora de presión puede causar

lesiones serias o muerte al operador o a otras

personas. . .

La pistola/tubo ^licador es una herramienta

potente de limpieza y a un niño podría

parecerte un juguete.

La fuerza reactiva del chorro hará que ei

aplicador “patee” y pueda causar cpje el

operador se resbale y caiga o dirija mal el

chorro. La pérdida de control del aplicador

puede causar lesiones al mismo operador o

a otros.

El chorro de los líquidos a alta velocidad

puede causar la rotura de algunos objetos

proyectando sus partículas a altas

velocidades.

Los objetos livianos o que no estén sujetos

se pueden convertir en proyectiles

peligrosos.

I

Familiarizarse con la operación y los controles

de la lavadora de presión.

Mantener a los niños alejados de la lavadora de

presión en todo momento.

Nunca burlar los dispositivos de seguridad de

este equipo.

No operar la máquina con piezas faltantes, rotas

o no autorizadas.

Nunca dejar desatendido el tubo aplicador

cuando la lavadora esté en operación.

Mantener el área de trabajo libre de obstáculos.

Pararse en una superficie estable y agarrar con

firmeza la pistola/tubo aplicador. Prepararse

para el retroceso de la pistola aplicadera cada

vez que se presione el gatillo.

Siempre usar anteojos de seguridad que

cumplan con la norma Z87 de ANSI. Siempre

usar ropa especial para protegerse del chorro.

Nunca apuntar el tubo aplicador ni dirigir el