Page 1

-r-

OWNERS

MANUAL

MODEL NO.

919.762000

CRAFTSMAN.

6HP 2000 PSI2 GPM

HIGH PRESSURE POWER WASHER

WARNING

Read Owner's Manual. Do not operate equipment until you have read Owners Manual for Safety. Operation, and Maintenance Instructions.

•This product is not equipped with a spark arresting muffler. If the product will be used around flammable materials, or

on land covered with materials such as agricultural crops, forest, brush, grass, or other similar items, then an approved

spark arrester must be installed and is legally required in the state of California It is a violation of California statutes

section 130050 and/or sections 4442 and 4443 of the California Public Resources Code, unless the engine is equipped

with a spark arrester, as defined in section 4442, and maintained in effective working order. Spark arresters are also

required on some U.S. Forest service land and may also be legally required under other statutes and ordinances.

Engine exhaust from this product contains chemicals known, in certain quantities, to cause cancer, birth defects or

other reproductive harm.

1S256 «18.782000 7/1/07

Searis, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Page 2

Safety Guidelines

TABLE OF CONTENTS

...................

" r -

« -

i-'- - -. :^.'i

4-

.....

3-4

!•

Operating Instructions

^^^)ntents ■••■■•■■■■■■■•••■•••■•■•■■>>••>■••■

Assembly Instructions

Prestart instructions

........................

........................

.........................

Starting Instructions.............................

High Pressure Instructions

Usings Soap/Chemicais

Nozzle Cleaning

....................................

.......

..........

.......................

^Proul^le ^}h^)^)ting

Pump Breakdown

Parts List

...............................................

Pressure Washer Breakdown

.................................

..............

S

......

...........

6

.................

...........

■••••«■■■■•a 8

................

•■■••■■•■■■a 8

...........

.

..............

...................

6

7

8

9

10

12

Parts List

Warranty/Repair/Replacement Parts.

aaaaaaa aa aa aa a aaaa a 13

aa Back Cover

ini,'-' - ..

-T-'-'i,

-rji, . - ■

Page 3

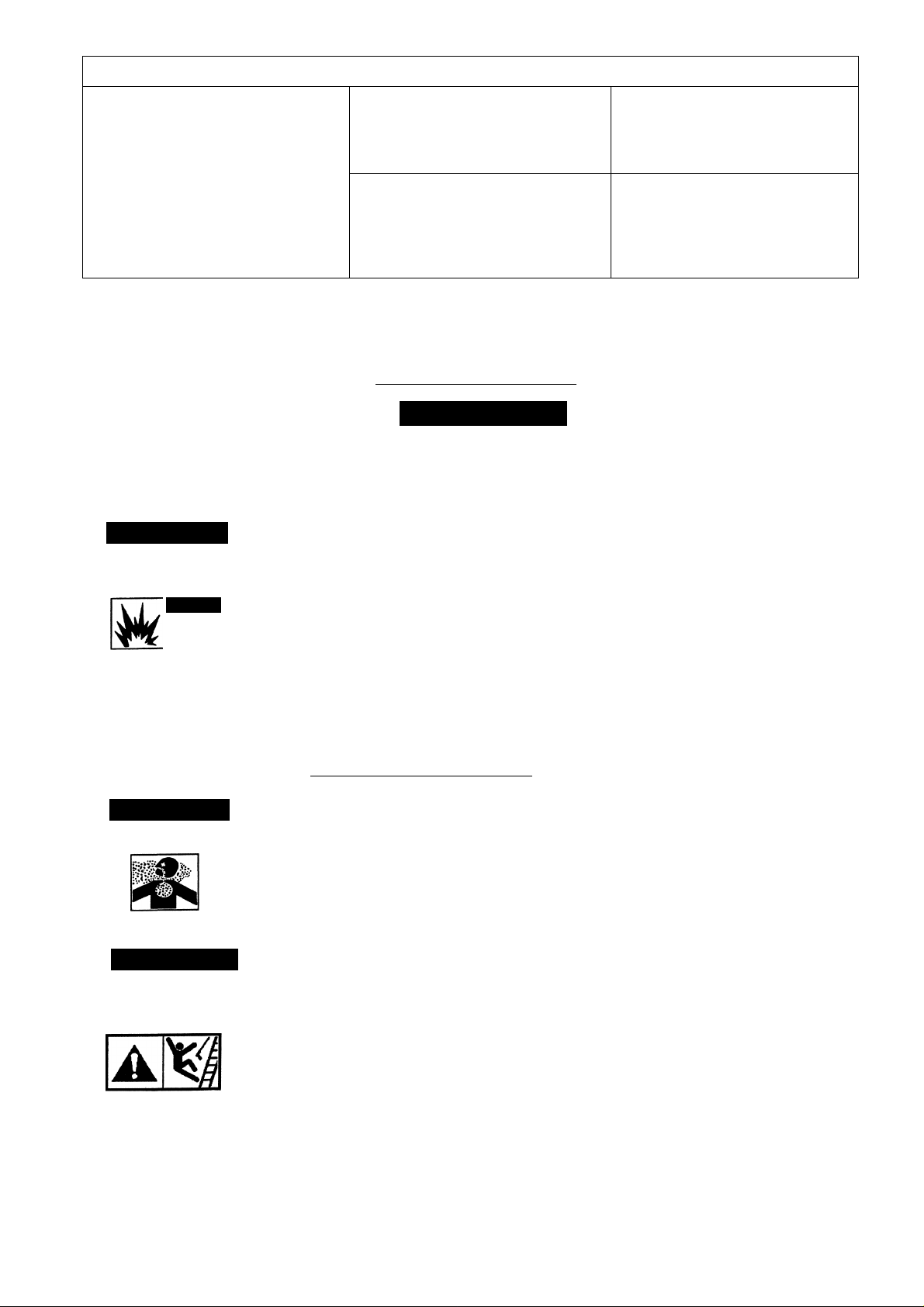

SAFETY <

QUIDELINES - DEFI

NITIONS

This manual contains information

that is important for you to know

and understand. This information

relates to protecting YOUR

SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help

you recognize this information, we

use the symbols to the right. Please

read the manual and pay attention

to these sections.

Iadangeri

URGENT SAFETY INFORMATION - A

HAZARD THAT WILL CAUSE SERI

OUS INJURY OR LOSS OF LIFE.

1A WARNING 1

IMPORTANT SAFETY INFORMATION - A

HAZARD THAT MIGHT CAUSE SERIOUS

INJURY OR LOSS OF LIFE.

Information that you should pay

special attention to.

Information for preventing damage

to equipment.

Ia cautioni

1 NOTE 1

IMPORTANT SAFETY

INSTRUCTIONS

• SAVE THESE INSTRUCTIONS »

AWARNING

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS INJURY AND PROPERTY

DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING

ha2:ard

Adanger

RISK OF EXPLOSION

OR FIRE

WHAT CAN HAPPEN

Spilled gasoline and it’s vapors can

become ignited from cigarette sparks,

electrical arcing, exhaust gases, and

hot engine components such as the

muffler.

Heat will expand fuel in the tank which

could result in spillage.

Operating the pressure washer in an

explosive environment could result in a

fire.

Materials placed against or near the

pressure washer can interfere with its

proper ventilation features causing

overheating and possible ignition of

the materials.

Improperly stored fuel could lead to

accidental ignition. Fuel improperly

secured could get into the hands of

children or other unqualified persons.

Shut off engine and allow it to cool

before adding fuel to the tank.

Use care in filling tank to avoid spilling

fuel. Move pressure washer away from

fueling area before starting engine.

Keep maximum fuel level W' below top

of tank to allow for expansion.

Operate and fuel equipment in well

ventilated areas free from obstructions.

Equip areas with fire extinguishers

suitable for gasoline fires.

Never operate pressure washer in an

area containing dry brush or weeds.

Store fuel in container approved for

gasoline, in a secure location away

from woric area.

HOW TO PREVENT IT

Adanger

RISK TO BREATHING

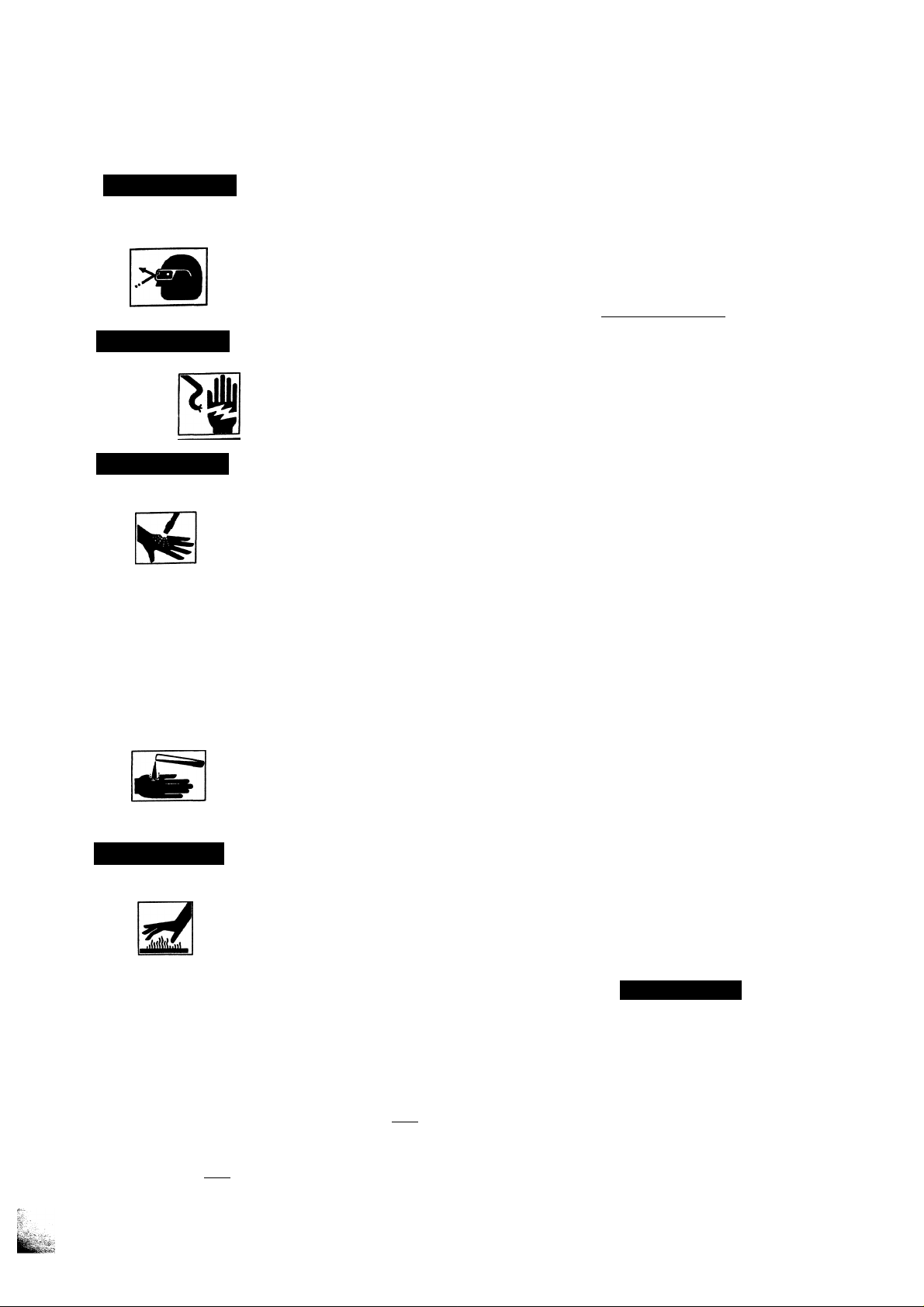

AWARNING

RISK OF UNSAFE

OPERATION

Breathing exhaust fumes will cause

serious injury or death.

Some cleaning fluids contain sub

stances which could cause injury to

skin, eyes, or lungs.

Unsafe operation of your pressure

washer could lead to serious injury or

death to you or others.

The spray gun/wand is a powerful

cleaning tool that could look like a toy

to a child.

Reactive force of spray will cause gun/

wand to move, and could cause the

operator to slip or fall, or misdirect the

spray. Improper control of gun/wand

can result in injuries to self and others.

Operate pressure washer in a well

ventilated area. Avoid enclosed areas

such as garages, basements ,etc.

Never operate unit in a location

occupied by humans or animals.

Use only cleaning fluids specifically

recommended for high pressure

washers. Follow manufacturers

recommendations.

Become familiar with the operation and

controls of the pressure washer.

Keep children away from the pressure

washer at all times.

Never defeat the safety features of this

product.

Do not operate machine with missing,

broken, or unauthorized parts.

Never leave wand unattended while

unit is running.

Keep work area free of obstacles.

Stand on a stable surface and grip gun/

wand firmly. Expect the gun to kick

when triggered.

Page 4

r-

IMPORtANT SAFETY INSTRUCTIONS (cont’d)

HAZARD

AWARNING

RISK OF INilURY FROM

SPRAY

AWARNING

RISK OF

ELECTRICAL

SHOCK

Awarning

RISK TO FLUID INJECTION

WHAT CAN HAPPEN

High velocity fluid spray can cause

objects to break, propelling particles at

high speed.

Light or unsecured objects can become

hazardous projectiles.

Spray directed at electrical outlets or

switches, or objects connected to an

electrical circuit, could result in a fatal

electrical shock.

• Your washer operates at fluid pressures

and velocities high enough to penetrate

human and animal flesh, which could

result in amputation or other serious

injury. Leaks caused by loose fittings or

worn or damaged hoses can result

in injection injuries. DO NOT TREAT

FLUID INJECTION AS A SIMPLE CUT!

See a physician immediately!

• Relieve system pressure before attempt

ing maintenance or disassembly of

equipment.

HOW TO PREVENT IT

Always we^ ANSI approved Z87 safety

glasses. Wear protective clothing to

protect against accidental spraying.

Never point wand at, or spray people or

animals.

Always secure trigger lock when wand is

not in service to prevent accidental

operation.

Never permanently secure trigger in pull

back (open) position.

Unplug any electrically operated product

before attempting to clean it. Direct spray

away from electric outlets and switches.

Never place hands in front of nozzle.

Direct spray away from self and others.

Make sure hose and fittings are tightened

and in good condition. Never hold onto

the hose or fittings during operation.

Do not allow hose to contact muffler.

Never attach or remove wand or hose

fittings while system is pressurized.

Use only hose and high pressure

accessories rated for 2000 PSI service.

To relieve system pressure, shut off

engine, turn off water supply, and pull gun

trigger until water stops flowing.

__________________

Use of acids, toxic or corrosive

chemicals, poisons, insecticides, or any

RISK OF CHEMICAL BURN

Awarning

kind of flammable solvent with this

product could result in serious injury or

death.

Contact with hot surfaces, such as

engines exhaust components, could

result in serious bum.

RISK OF HOT SURFACES

GLOSSARY

PSI: Unit of measure, pounds per square inch.

FLOW RATE: This is the amount of water that passes

through your wand. (Usually measured in G.P.M.,

gallons per minute).

PRESSURE WASHER PUMP: Delivers high water

pressure. Pressure washer pump is shipped with oil.

No oil should be added to this pump.

Engine: Gasoline powered engine drives pump.

Engine is shipped with oil. See Manufacturers Owner's

Manual for oil recommendations.

Do not use acids, gasoline, kerosene, or

any other flammable materials in this

product. Use only household detergents,

cleaners and degreasers recommended

for use in pressure washers.

Wear protective clothing to protect

eyes and skin from contact with sprayed

materials.

During operation, touch only the control

surfaces of the pressure washer. Keep

children away from the pressure washer

at all times. They may not be able to

recognize the hazards of this product.

ACAUTION

Operating unit with water suppiy shut-off

without flow of water will result in

equipment damage.

BYPASS MODE: This pertains to the time that the

pressure washer is running without the trigger on the

gun engaged to spray. You should never run this

pressure washer for more than 2 minutes without

pulling the trigger to allow cool waterto enterthe pump

and the heated (recirculated) waterto exit. Running the

pressure washer with water supply shut-off would void

your warranty.

Page 5

ACAUTiON

THE POWERFUL SPRAY FROM YOUR PRESSURE WASHER IS CAPABLE OF CAUSING

DAMAGE TO FRAGILE SURFACES SUCH AS; WOOD, GLASS, AUTOMOBILE PAINT,

AUTO STRIPPING AND TRIM, AND DELICATE OBJECTS SUCH AS FLOWERS AND

SHRUBS. BEFORE SPRAYING, CHECK THE ITEM TO BE CLEANED TO ASSURE

YOURSELF THAT IT IS ROBUST ENOUGH TO RESIST DAMAGE FROM THE FORCE OF

THE SPRAY. AVOID THE USE OF THE CONCENTRATED SPRAY STREAM EXCEPT FOR

VERY STRONG SURFACES LIKE CONCRETE AND STEEL.

OPERATING UNIT WITH WATER SUPPLY SHUT-OFF WITHOUT FLOW OF WATER

WILL RESULT IN EQUIPMENT DAMAGE. YOU SHOULD NEVER RUN THIS PRESSURE

WASHER FOR MORE THAN 2 MINUTES WITHOUT PULLING THE TRIGGER TO

ALLOW COOL WATER TO ENTER THE PUMP AND THE HEATED (RECIRCULATED)

WATER TO EXIT. RUNNING THE PRESSURE WASHER WITH WATER SUPPLY SHUT

OFF WOULD VOID YOUR WARRANTY.

Everything Below is Detailed

in this Manual — Please See

Reference Pages Noted Below

lASSEMBLY

^JiNsmucnoNS

I Reference Below Right)

Connect Handle to Frame

• Connect Wand to Gun

Attach High Pressure Hose

Attach Water Source (Garden

Hose)

PRESTART INSTRUCTIONS

ijrencgPage 5)

ill Gas tank

j # Check Engine Oil

S T^lifn Water Source On

^• Check for Leaks

OPERATING INSTRUCTIONS

Quick Reference Guide

¡STARTING

Imstruciions

(Reference Page 5)

1 SLIDETHROTTLECONTROL

TO RUN POSITION

2 PUSH PRIMER BULB 3TIMES-WAIT

2SECONDS BETWEEN EACH PUSH

3 PULLSTART

(NOTE: If engine doesn't

start right away, trigger

gun to depressurize the unit)

HELPLINE;

\-stryy

Page 6

BOX CONTENTS

STEP#1

STEP #2

Handle

Hose

ASSEMBLY INSTRUCTIONS

Connect Handle

to Frame

Pi

HkikJfelj

Gun

Chemical Hose

Tighten

Knob

by Turning

STEP#3

STEP#4

Connect Wand

to Gun

Attach High

Pressure Hose

ater

ce

(Garden Hose)

Discharge Fitting

Front Vbw

Garden

Hose

QpgneQtign

Page 7

PRESTART INSTRUCTIONS

STEP#1

Fill Gas Tank

phlyl

STEP#2

Check

Engine

Oil

• Be sure the engine is in a level position.

• Remove the oil filler cap.

• To check oil level, check to ensure oil is to full

mark on the dipstick.

• If the level is low, add oil to the full mark with

30 weight detergent oil.

• Reinstall the oil filler cap/dipstick.

30 Weight

Oil

STEP#3

Turn Water

Source On

STEP#4

Check for Leaks

Leaking from Water Inlet Source

Does Not Affect Performance

if; leRKS’ ora!

onQ CliQCK Ql

RAOT TlOni

r mnlaM

- mm

WII llliil

o-ringi

M

11*10^'-'

IMPORTANT: Running the engine with a low oil level can cause engine damage.

STARTING INSTRUCTIONS

m 1

u 0

Damaifie ^ Pump.

TO RUN POSITION

2 PUSH PRIMER BULB

3 TIMES-WAIT 2 SECOND

BETWEEN EACH PUSH

3 PULLSTART

(NOTE: If engine doesn't

start right away, trigger gun

/>^\

( X M 1

iTN.

1—1

m

\±i

SPECIFICATIONS:

Model 919.762000

Operating Pressure 2000 PSI • Gallons Per Minute — 2GPM

• Engine: 6.0 HP Craftsman • Pump: Wobble Plate Oil Bath

• Chemical Injection - Under L ;« ■,(<r

Hose:V4”x25’ • Gun: Trigger Control

• Wheels: Two 8” Semi-Pneumatic

Page 8

HIGH PRESSURE INSTRUCTIONS

Push Nozzle Forward

for Low Pressure

Pull Back Nozzle

for High Pressure

1. The power washer spray pattern may be adjusted by rotating the nozzle head, clockwise or

counterclockwise.

2. For the narrowest spray pattern (greatest cleaning impact), rotate nozzle head counterclockwise.

3. For widest spray pattern (greatest cleaning coverage), rotate nozzle head clockwise.

OPEN (3/8" GAP)

to Draw Chemical

This Pressure

Washer is Preset at

the Factory to

Achieve Majdmum

Pressure at Fuii

Throttie

CLOSED (1/8" GAP)

for High Pressure

0° Degree Narrow

Spray Pattern Greatest

Cleaning Impact Turn

Counterclockwise

60° Degree Wide

Spray Pattern Great

est Cleaning Coverage

Turn Clockwise

USING SOAP/CHEMICALS

Excessive soap concentration does not necessarily improve cleaning

power.

NOTE: Follow chemical manufacturer’s label & safety directions!

For chemical recommendations specific to your application, contact your local

janitorial supply or chemical manufacturer.

A

Use EX-CELL 5000 (Formulated for EX-CELL Pressure Washers) Or Contact Your Local Janitorial

or Chemical Supplier for Recommendations for Your Specific Application.

NOZZLE CLEANING

1. Remove wand from gun by unscrewing at coupler.

2. Open the adjustable nozzle atthe end of the wand to the 0 position by

turning counterclockwise. (See Diagram 1). This will allow maximum

accessibility to clean the nozzle. Be carehji not to damage metal

spray fins.

3. insert the nozzle cleaning wire or straightened paper clip into the

nozzle orifice. Move gently in and out to clear blockage from nozzle.

(See Diagram 2).

Diagram 1

Nozzle Fins Open

4. Flush water through the nozzle backwards with garden hose.

5.

8

Diagram 2

Insert Cleaning Tool

Page 9

■

TROUBLE

SHOOTING

SYMPTOM

Engine won’t start

Won’t Draw

Chemical

Pump running

normally but

pressure does

not achieve

rated values.

Fluctuating

Pressure

CAUSE

Engine throttle is in "OFF" Position

Primer bulb hasn't been pushed

Pressure build up after initial use

Nozzle not in chemical draw position

Chemical screen is obstructed

Chemical screen not working

Chemical injector orifice obstructed or stuck

Water supply restricted

Nozzle is in low PSI position

Nozzle incon’ect or worn

Pump sucking air

Nozzle blocked

Pump sucking air

Garden hose inlet strainer clogged

Worn Seals or Packing.

Inadequate water supply.

Fouled or dirty inlet or discharge valves.

Leaky discharge hose.

SOLUTION

Slide throttle to “Run" position.

Push primer bulb 3 times, waiting 2 seconds between

pushes.

Depress triqaer qun

Push nozzle forward at end of wand.

Check chemical screen, clear) of obstructed.

Make sure chemical screen is submerged in chemical/

water

Check and clean

Check water supply and filter screen for blockage. Check

hoses for blockage, kinks, leaks, etc..

Pull nozzle at end of wand back to the high pressure

position.

Check and replace.

Check that hoses and fitting are air tight.

Clean nozzle.

Check that hoses and fittings are airtight. Purge air from garden

hose.

Clean. Checkfilterfrequently.

Check and replace

Check flow available to pump. Check for excessive heat 145^ F

Clean inlet and discharge valve assemblies. Replace if damaged.

Pressure drops

after period of

normal use

Pump noisy

Presence of

water in oil (Oil

milky) Water

dripping

from Dumo

Water dripping

from

pump

Oil Dripping

Nozzle clogged, partially obstructed

Nozzle worn

Valves worn, dirty or stuck

Worn piston packing

Water too hot

Pump sucking air

Valves dirty or worn

Worn bearings

High humidity

Piston packing and oii seal worn

Fittings Loose

0-rings of piston guide or retainer worn

Piston packing worn

Oil seal worn

Loose drain plug or worn drain plug o-ring.

Clean or replace.

Check and replace.

Check, clean or replace.

Check and replace.

Reduce temperature below 63° C or 145° F.

Check that hoses and fittings are air tight.

Check, clean or replace.

Check and replace if necessary.

Change Oil.

Check and replace oil seals.

Tighten

Check and replace.

Check and replace.

Check and replace

Tighten drain plug or replace O-ring. Do not over torque.

9

Page 10

I

о

<

111

cc

Э

Q.

Page 11

SERVICE KITS

KEY# DESCRIPTION

16286 OIL SEAL KIT

16287 PLUNGERKIT

16288 WOBBLE PLATE/

BEARING KIT

16289 INLET EXTENSION KIT

16290 OUTLET EXTENSION KIT

16304 PACKING KIT

16305 VALVE KIT

16306 UNLOADERCHECK

16307 INJECTORREPAIR

16308 UNLOADERSET

REF.

COMPONENTS

3 VENTED VALVE

0-RING [117]

10

0-RING [80]

16

0-RING [114]

18

19

OILSIGHT GLASS

OIL SEAL

63

OIL FILL CAP

69

F^NG

58

PISTON

59

SPRING

60

11

BEARING DISC

12

NEEDLE BEARING

WOBBLE PLATE

13

CAP

14

15 BE/VRINGDISC

CONNECTION RING

20

NUT

INLETEXTENSION

21

UNDER CAP

23

WASHER

77

O-RING[140]

78

GASKETW/FILTER

80

UNDERPLUG

43

aRING[14X2]

78

CX/TUETEX7ENSICX^

81

aRING[2093]

65

0-RING

67

0-RING [22X14X1,5]

76

0-RING[2050]

25

VALVE

26

0-RING[12X2]

68

WASHER

79

37 NO RETURN VALVE

SPRING

38

INJECTORNOZZLE

39

aRING[8X2]

40

0-RING [2037]

41

IMECnONNIPPLE

42

0-RING [5X2]

75

CHEMICALSPRING

31

BALL STAINLESS 16302

32

STEEL

0-RING [2031]

35

O-RING [2015]

62

VALVE SEAT PLATE

46

VALVE SEAT

47

BALL STAINLESS

52

STEEL

O-RING [2037]

41

KEY# DESCRIPTION

16309

16310

16311

15955

UNLOADERSTEM

MANIFOLD ASSEMBLY

HEAD,BRASS PUMP

MANIFOLD

COMPLETE PUMP ASSY.

REF.

COMPONENTS

22

O-RING [2050]

24

O-RING [108]

33

O-RING [2025]

48

BACK-RING FORO-RING [lOi

49

O-RING [2056]

50

BY-PAS VALVE BODY

53

BY-PAS PISTON

54

BACK-RING FOR O-RING [20:

55

SPACER

56

PRESSUREREG. SCREW

57

PRESSUREREG.NUT

82

PW

22

O-RING [2050]

24

O-RING [108]

27

O-RING [15X2]

28

MANIFOLD

30

SCREW

31

CHEMICALSPRING

32

BALL STAINLESS STEEL

33

O-RING [2025]

34

CHEMICAL DOSING BODY

35

O-RING [2031]

36

CHEMICAL DOSING SCREW

37

NO RETURN VALVE

38

spmm

39

INJECTORNOZZLE

40

O-RING [8X2]

41

O-RING [2037]

INJECnONNI№LE

42

44

SCREWTCEL [M5X3012K]

45

BYPASS PIN

46

VALVE SEAT PLATE

47

VALVE SEA

48

BACK-RING [FORO-RING 1C

49

O-RING [2056]

50

BY-PASS VALVE BODY

51

PLUG

52

BALLSTAINLESS STEEL

53

BY-PAS PISTON

54

BACK-RING [FOR O-RING 2i

55

SPACER

56

PRESSUREREG. SCREW

57

PRESSUREREG. NUT

62

O-RING [2015]

75

O-RING [5X2]

82

PIN[M2X10]

73

28

11

Page 12

PRESSURE WASHER BREAKDOWN

90 89

12

Page 13

PARTS LIST

KEY#

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

PART NUMBER

16272

C042

15226

W137

16303

15223

15231

15972

16273

16257

ADI 87

H040

WA100

15227

HI 28

16270

Not Illustrated

16256

DESCRIPTION

Handle

Knob, 5/16

Tire, Semi, 8x13/4

Nut, Pal, 1/2

Label, Hot Surface

Foot, 2x1

Hose, Chemical

Cap, 5/16

Frame

Label, Craftsman

Label, Warning

Hose, 1/4x25 ft.

Wand, Rotary

Lance, Multi-Reg.

Gun, 1/4 Male

Oil, 27 oz., 30 Wt.

Owners Manual

13

Page 14

OWNERS

MANUAL

CRAFTSMRN.

6HP 2000 PSI2 GPM

HIGH PRESSURE POWER WASHER

For the repair or replacement parts you need

Call 7 am - 7 pm, 7 days a week

MODEL NO.

919.762000

When requesting service or ordering

parts, aiways provide the following

information:

• Model Number

• Part Number

• Part Description

• Name of Item

1-800-366-PART

(1-800-366-7278)

For in-home major brand repair service

Call 24 hours a da% 7 days a week

1-800-4-REPAIR

(1-800-473-7247)

For the location of a

SearsPaitsand RepairCenterfeiyourarea

Call 24 hours a day, 7 days a week

1-800-488-1222

FULL ONE YEAR WARRANTY

AIR COMPRESSOR

If this aircompressorfails due to a defect in

material or workmanship within one year

from the date of purchase, RETURN IT TO

THE NEAREST SEARS REPAIR CENTER

THROUGHOUTTHE UNITED STATES AND

SEARS WILL REPAIR IT, FREE OF

CHARGE.

If this air compressor is used for commercial

or rental purposes, the warranty will apply

for ninety days from the date of purchase.

This wanantygivesyou specific legal rights

and you may have other rights which vary

from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

call 9 am - 5 pm, Monday-Saturday

1-800-827-6655

America's Repafa’ Spedaliats

Loading...

Loading...