Craftsman 919175261 Owner’s Manual

SEARS

OWNERS

MANUAL

MODEL NO.

919.175261

Usted

721Y

Air

Compressor

iMPORTANT:

Read the Safety Guidelines

and Al! instructions

Carefully Before Operating

AiR COIVIPRE= OR

ASSEMBLY

0PERATION

MAINTENANCE

REPAIR PARTS

ONE STAGE

Record in the spaces provided.

(1) The model number which can be found

on the label on the front of the air tank

saddle.

(2) The code number which can be found

on the foil label on the side of the air

tank.

(3) The Manufacturer's Number (ASME

Code Compressors only} is located on

the metal data plate which is welded

onto the side of the air tank. (This data

plate is painted the same color as the

tank.)

(4} The Motor Manufacturer's name which

is located on the motor label.

(5) The Motor Mfg. number - also located

on the motor _abel.

Retain these numbers for future refer-

once,

Model No.

Code No.

Mfg. No.

Motor Mfg. Name

[ 8t9

Motor Mfg. No.

Sears, Roebuck and Coo, Chicago, IL 60684 U.S.A,

Page

WARRANTY ........................................................................... 2

SAFETY GUIDELINES ............................................................... 3

WARNING CHART ................................................................... 3

SPECZFICATION CHART ........................................................... 5

GLOSSARY ............................................................................ 5

ACCESSORIES FOR USE WITH

SEARS AIR COMPRESSORS ................................................ 5

GENERAL INFORMATION ......................................................... 6

DESCRiPTiON OF OPERATION .................................................. 6

iNSTALLATION AND 8REAKqN PROCEDURES ............................ 6

Location of Air Compressor ................................................. 6

Piping .............................................................................. 7

Lubrication and Oil ............................................................. 7

Wiring _nstructions ............................................................. 7

Wiring Diagram .................................................................. 7

8reakqn Procedures ........................................................... 8

OPERATING PROCEDURES ....................................................... 8

MAINTENANCE ...................................................................... 8

Air Compressor ................................................................. 8

Air Filter - inspection and Replacement ................................. 8

Oil - Checking and Changing ............................................... 9

Air Tank - Draining Water ................................................... g

Check Vatve- Inspection and RepJacement ............................ 9

Safety Valve inspection ...................................................... £

Motor .............................................................................. 9

Belt - Replacement ............................................................. 9

PuJte¥ and Ftywheel - Alignment .......................................... I0

TROUBLESHOOTING GUIDE ..................................................... 10

AIR COMPRESSOR DIAGRAM .................................................. 12

Parts List .......................................................................... 13

COMPRESSOR PUMP D_AGRAM ............................................... 14

Parts List .......................................................................... 15

HOW TO ORDER REPAIR PARTS ............................................... 16

FULL ONE YEAR WARRANTY

ON AiR COMPRESSORS

8fthis air compressor fai_sdue to a defect in materia_or workmanship whhin one year from the date of purchase, return

it to the nearest Sears Service Center/Department throughout the United States and Sears will repair it, free of charge.

This warrant,/gives you specific legal rights and you may have other rights that vary from state to state.

Sears, Roebuck and Co., Sears Tower, Dept. 698!731CR-2_ Chicago, _L 60684

Thismanualcontainsinformation that is important for you to kno_v and understand. This

information relates to protecting your safety and preventing equipmenlt problems. To help you

recognize this information, we use the following symbols. Please read the manuat end pay special

attention to sections headed by these symbo!so

iMPORTANT SAFETY iNFORMATiON o A

HAZARD THAT MIGHT CAUSE SERIOUS

iNJURY OR LOSS OF LIFE.

HAZARDS CAN OCCUR iF EQUIPMENT 1S NOT USED PROPERLY.

PLEASE READ THE FOLLOWING CHART.

WHAT TO

LOOK FOR WHAT COULD HAPPEN

Hot Parts

Flammable

Vapors

The compressor head and tubes get hot when

the air compressor is running, if you touch them,

you can be seriously burned.

It is normal for the motor's electrical contacts

and pressure switch contacts to spark when the

compressor starts or stops. A spark can ignite

flammable vapors from gasoline, flammable paints

or solvents, causing an explosion or fire.

Information for preventing damage to equip-

ment.

NOTE

Information that you should pay special at-

tention to.

HOW TO PREVENT IT

Never touch the air compressor head or tubes

during or immediately after operation.

Operate the compressor in well ventilated

areas that are free of gasoline, flammable paint

or solvent vapors.

if spraying a flammable material - provide

ample ventilation. Never spray in aclosed area.

There must be a flow of fresh air at all times.

Do not operate the compressor in the spray

area.

Unsuitable

Solvents

Compressed Air

The soJvents 1,1,1-Trichlorethane and Methyl-

ene Ch!oride can chemically react with amumi-

num used in paint spray guns, paint pumps, etc.

and cause an explosion. These solvents can also

react with galvanized components and cause

corrosion and weakening of parts. This does not

affect your air compressor - but it may affect the

equipment being used.

Compressed air can propel dust, dirt or tease

particles it comes in contact with.

Too much airpressure appliedto airtoo_sor

accessoriescan cause damage or riskof burst-

_ng.

if the material you intend to spray contains the

solvents listed at left (read the label or data

sheet}, do not use accessories that contain

aluminum or galvanized parts. You must either

change the material you intend to spray, or use

only stainless steel spray equipment.

Never point any nozzle or sprayer toward a

person or any partof the body.

AEways wear safety goggles or g!ssses when

using the air compressor.

Always turn the air compressor off and release

a}r pressure from hose before attaching or

removing accessories.

Check the manufacturer's maximum pressure

rating for tools and accessories. The regulator

outte_ pressure must never exceed the maxi-

mum pressure rating.

WHAT TO

LOOK FOR

WHAT COULD HAPPEN HOW TO PREVENT IT

Electricity

Moving Parts

Toxic Vapors

Your air compressor is powered by eiectricityo

Like any othar eJectricaiJy powered device, if it is

not used proper_y it can cause electrical shock.

This compressor cycles automatically when the

switch is in the "On-Auto" position, if you

attempt repair or maintenance while the com-

pressor is operating, or with the switch in the

"On-Auto" position you can expose yourself to

moving parts. These moving parts can cause

serious injury or damage if they coma into

contact with you or your cgothing.

It is normal for compressed air to contain toxic or

irritatingvapors. Such vapors are harmful if

inhaJed.

Certain materials you are spraying (like paint,

weed killer, sand or insecticide) can be harmful

if you inhate them.

Always turn off and lock out electrical power

3riot to maintenance or repair.

Wiring of the pressure switch, motor and On/

Off switch should be done by a licensed elec-

trician in accordance with national and local

codes.

Always turn off and lock out power before

repair or maintenance.

Never operate the compressor with the belt

guard removed.

Never diractJy inhale the compressed air pro-

duced by this unit.

Read labels and safety data for aHmaterials you

spray. Follow atl safety precautions.

Use a mask or respirator if there is a chance of

inhaling toxic sprayed materials. Masks and

respirators have limits and will only provide

protection against some kinds and limited

amounts of toxic material. Raad mask and

respirator instructions carefultyo Consult with a

safety expert or industrial hygienist if you are

not svre about the use of a certain mask or

respirator.

Air Tank

Vibration

Modifications to the air compressor can cause

the air tank to rupture or explode.

Changing the air tank will cause it to weaken.

The tank can rupture or explode.

If your compressor is not properiy anchored it

will vibrata. Excessive vibration can cause tank

rupture or explosion.

Do not adjust, remove or tamper with the

safety valve or pressure switch, if safety valve

or pressure switch replacement is necessary, a

_art with the same pressure rating must be

used.

Never usa a motor with a higher horsepower

rating than the one supplied.

Do not substitute a gas engine for the

motot...this compressor was not designed to

ba powered by a gasomina engine.

Never replace the compressor pump with a

different model

Never increase the compressor pump speed.

Never drill into, weld, or in any way modify the

air tank. Do not repair a leaking tank; it must be

rapmacad.

Never replace the air tank with a different

model or a larger tank.

Make sure your sir compressor is bolted to the

floor. Sea "Location of the Air Compressor" in

this manual.

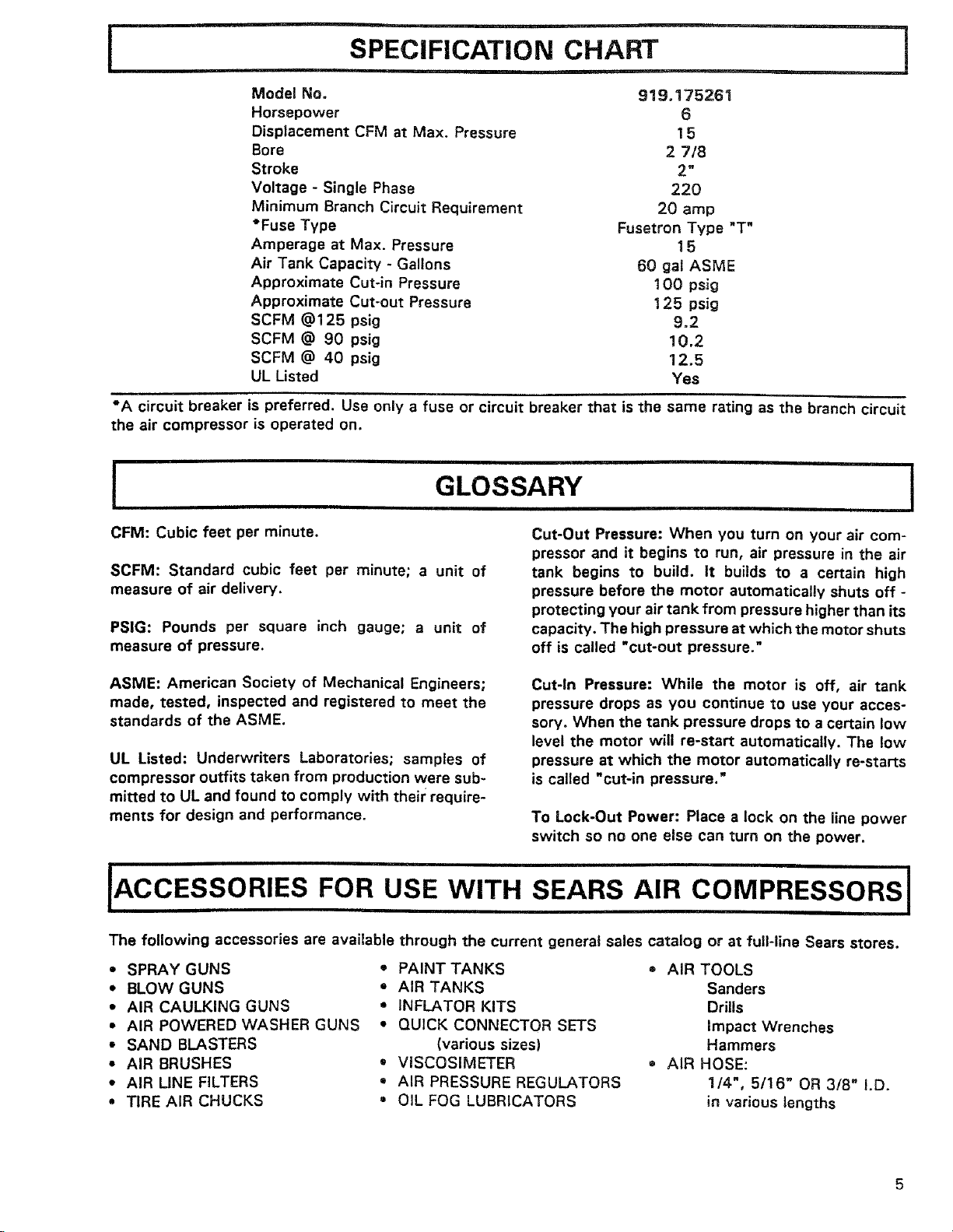

SPECIFICATION CHART J

Model No.

Horsepower

Displacement CFM at Max. Pressure

Bore

Stroke

Voltage - Single Phase

Minimum Branch Circuit Requirement

•Fuse Type

Amperage at Max. Pressure

Air Tank Capacity - Gallons

Approximate Cut-in Pressure

Approximate Cut-out Pressure

SCFM @!25 psig

SCFM @ 90 psig

SCFM @ 40 psig

UL Usted

•A circuit breaker is preferred. Use only a fuse or circuit breaker that is the same rating as the branch circuit

the air compressor is operated on.

i

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of

measure of air delivery.

PSlG: Pounds per square inch gauge; a unit of

measure of pressure.

GLOSSARY

Cut-Out Pressure: When you turn on your air com-

pressor and it begins to run, air pressure in the air

tank begins to build. It builds to a certain high

pressure before the motor automatically shuts off -

protecting your airtank from pressure higher than its

capacity. The high pressure at which the motor shuts

off is called "cut-out pressure."

919.175261

6

15

2 7/8

2"

220

20 amp

Fusetron Type "T"

15

60 gal ASME

100 psig

125 psig

9.2

10.2

12.5

Yes

I

ASME: American Society of Mechanical Engineers;

made, tested, inspected and registered to meet the

standards of the ASME.

UL Listed: Underwriters Laboratories; samples of

compressor outfits taken from production were sub-

mitted to UL and found to comply with their require-

ments for design and performance.

Cut-In Pressure: While the motor is off, air tank

pressure drops as you continue to use your acces-

sory. When the tank pressure drops to a certain low

level the motor will re-start automatically. The low

pressure at which the motor automatically re-starts

is called "cut-in pressure."

To Lock-Out Power: Place a lock on the line power

switch so no one else can turn on the power.

:ESSORIES FOR USE WITH SEARS AIR COMPRESSORS

The following accessories are available

SPRAY GUNS • PAINT TANKS • AiR TOOLS

• BLOW GUNS • AIR TANKS Sanders

• AIR CAULKING GUNS • iNFLATOR KITS Drills

• AIR POWERED WASHER GUNS • QUICK CONNECTOR SETS Impact Wrenches

• SAND BLASTERS (various sizes) Hammers

• AIR BRUSHES • VISCOSIMETER ® AiR HOSE:

• AIR LINE FILTERS • AIR PRESSURE REGULATORS 1/4", 5t16" OR 3/8" I.D.

• TIRE AIR CHUCKS = OIL FOG LUBRICATORS in various lengths

through the current general sales catalog or at full-line Sears stores.

Loading...

Loading...