Craftsman 919165613 Owner’s Manual

N004083

Owner's Manual

Permanently Lubricated

Twin V

2-Stage

Stationary

AIR COMPRESSOR

Model No.

919.165613

• Safety Guidelines

= Assembly

= Operation

° Maintenance

= Troubleshooting

= Repair Parts

CAUTION" Read the Safety Guidelines

and All Instructions Carefully Before

Operating.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: ,,Arww.sears.com/craftsman

N004083 Revo o41_4!08

W$.RRANTY ................................................ 2

SPECIFICATION CHART ..................................... 3

SAFETY GUIDELINES-DEFINITIONS ........................... 3

IMPORTANT SAFETY' INSTRUCTIONS ........................ 3-8

GLOSSARY ................................................ 9

ACCESSORIES ............................................. 9

DUTY CYCLE .............................................. 9

ASSEMBLY ............................................... I 0

INSTALLATION ......................................... 10-I 2

OPERATION ........................................... 13-I 5

MAINTENANCE ......................................... 16-18

SERVICE AND ADJUSTMENTS ............................... 18

STORAGE ................................................ 19

TROUBLESHOOTING GUIDE ............................. 20-22

REPAIR PARTS 24-27

REPAIR PROTECTION AGREEMENTS 49

HOW TO ORDER REPAIR PARTS ...................... Back Cover

FULL ONE YEAR WARRANTY AIR COMPRESSOR

If this CRAFTSMAN Air Compressor fails due to a defect in material or

workmanship within one year from the date of purchase, Sears will at

its option repair or replace it free of charge. Contact your nearest Sears

Service Center (1-800-4-MY-HOME (ib) to arrange for repair, or return the Air

Compressor to the place of purchase for replacement.

If this Air Compressor is used for commercial or rental purposes, this warranty

applies for only ninety days from the date of purchase.

This warranty gives you specific legal rights and you may have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

N004083 2- ENG

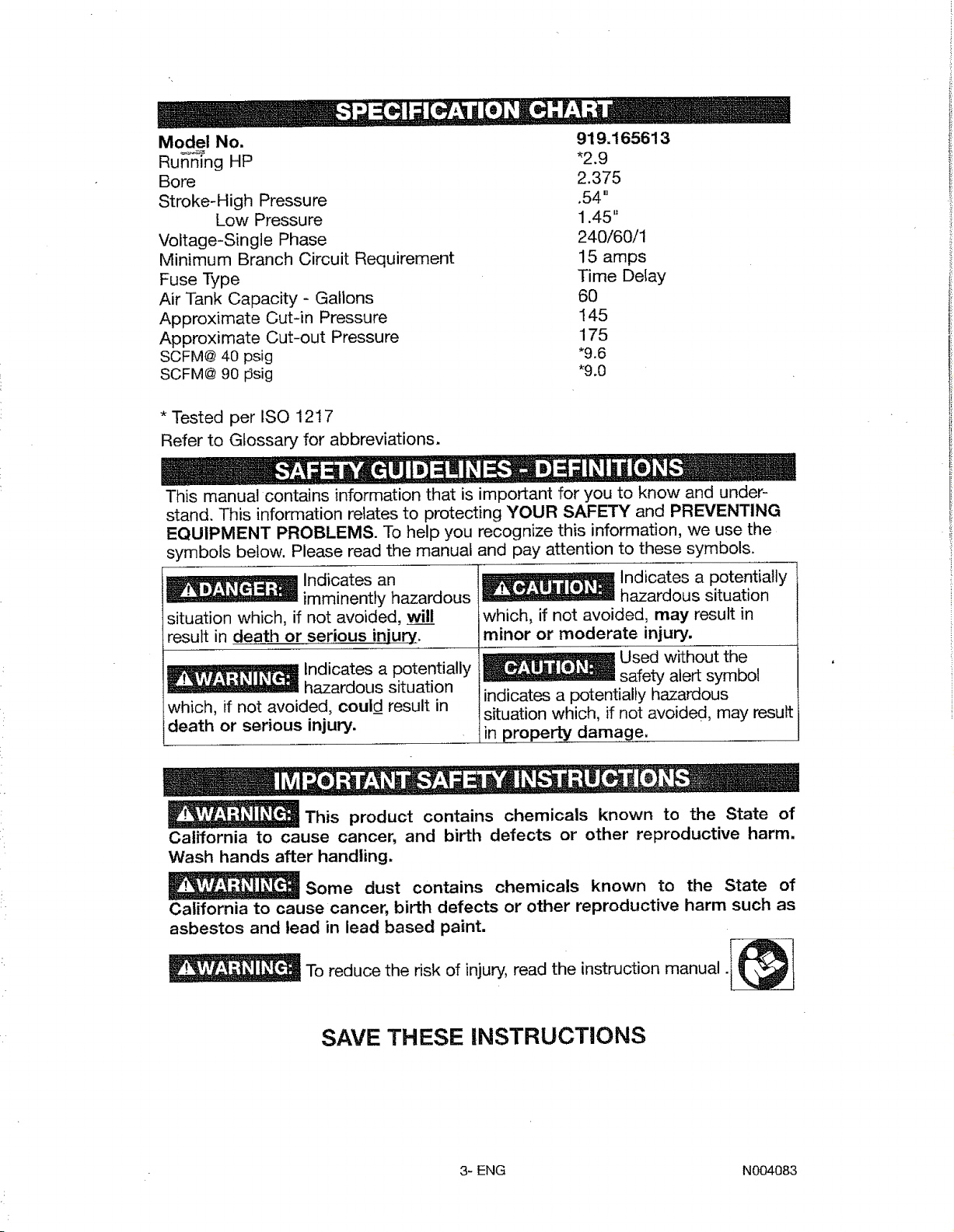

Model No.

Run'n_ng HP

Bore

Stroke-High Pressure

Low Pressure

Voltage-Single Phase

Minimum Branch Circuit Requirement

Fuse Type

Air Tank Capacity - Gallons

Approximate Cut-in Pressure

Approximate Cut-out Pressure

SCFM@ 40 psig

SCFM@ 90 #sig

* Tested per lSO 1217

Refer to Glossary for abbreviations.

This manual contains information that is important for you to know and under-

stand. This information relates to protecting YOUR SAFE'rY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

Indicates an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, could result in

death or serious injury.

m_"'Jrrma'_m_R Indicates a potentially

which, if not avoided, may result in

minor or moderate injury.

indicates a potentially hazardous

situation which, if not avoided, may result

_n properbj damage.

919.165613

*2.9

2.375

.54"

1.45"

240/60/1

15 amps

Time Delay

60

145

175

*9.6

*9.0

hazardous situation

Used without the

safety alert symbol

This product contains chemicals known to the State of

California to cause cancer, and birth defects or other reproductive harm.

Wash hands after handling.

Some dust contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm such as

asbestos and lead in lead based paint.

To reduce the risk of injury, read the instruction manual .1_L_I

SAVE THESE INSTRUCTIONS

3- ENG N004083

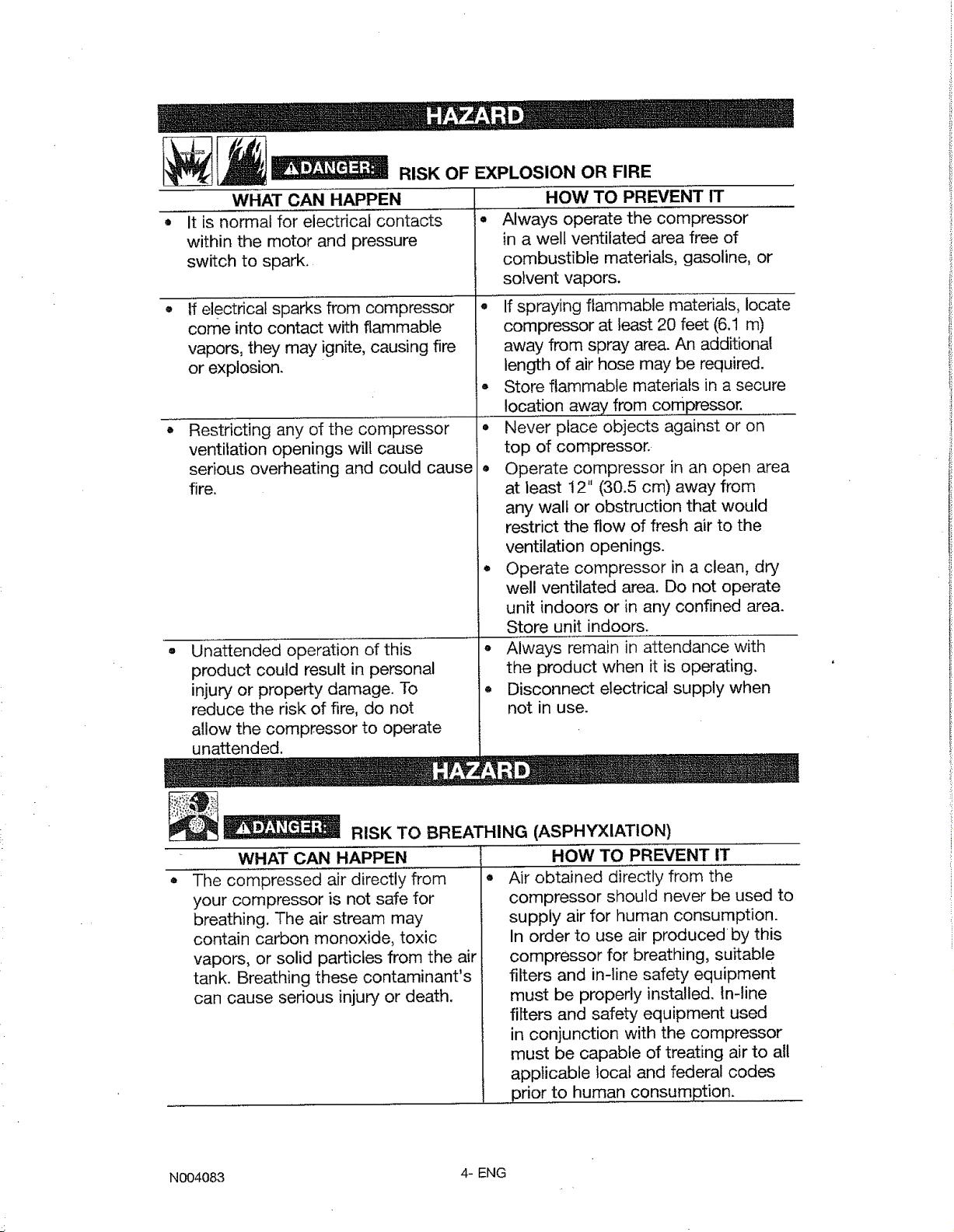

RISK OF F._XPLOSION OR FIRE

WHAT CAN HAPPEN

° It is normal for electrical contacts

within the motor and pressure

switch to spark.

HOW TO PREVENT IT

Always operate the compressor

in a well ventilated area free of

combustible materials, gasoline, or

solvent vapors.

If electrical sparks from compressor

come into contact with flammable

vapors, they may ignite, causing fire

or explosion.

Restricting any of the compressor

ventilation openings will cause

serious overheating and could cause

fire.

Unattended operation of this

product could result in personal

injury or property damage. To

reduce the risk of fire, do not

allow the compressor to operate

unattended.

° If spraying flammable materials, locate

compressor at least 20 feet (6.1 m)

away from spray area. An additional

length of air hose may be required.

o Store flammable materials in a secure

location away from compressor.

° Never place objects against or on

top of compressor.

° Operate compressor in an open area

at least 12" (30.5 cm) away from

any wall or obstruction that would

restrict the flow of fresh air to the

ventilation openings.

• Operate compressor in a clean, dry

well ventilated area. Do not operate

unit indoors or in any confined area.

Store unit indoors.

- Always remain in attendance with

the product when it is operating.

° Disconnect electrical supply when

not in use.

RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN

The compressed air directly from

° Air obtained directly from the

your compressor is not safe for

breathing. The air stream may

contain carbon monoxide, toxic

vapors, or solid particles from the air

tank. Breathing these contaminant's

can cause serious injury or death.

N004083 4- ENG

HOW TO PREVENT IT

compressor should never be used to

supply air for human consumption.

In order to use air produced by this

compressor for breathing, suitable

filters and in-line safety equipment

must be properly installed. In-line

filters and safety equipment used

in conjunction with the compressor

must be capable of treating air to all

applicable local and federal codes

prior to human consumption.

. Exposure to chemicals in dust creat-

ed by power sanding, sawing, grind-

rag, drilling, and other Construction

activities may be harmful.

• Sprayed materials such as paint,

paint solvents, paint remover, insec-

ticides, weed killers, may contain

harmful vapors and poisons.

Work in an area with good cross

ventilation. Read and follow the safe-

ty instructions provided on the label

or safety data sheets for the materi-

als you are spraying. Always use

certified safety equipment: NIOSH/

OSHA respiratory protection or prop-

erly fitting face mask designed for

use with your specific application.

__ RISK OF BURSTING

Air Tank: The air tank on your Air Compressor is designed and may be UM

coded (for units with air tanks greater than 6 inch diameter) according to ASME

Section VIII, Div. 1 rules. All pressure vessels should be inspected once every

two years. To find your state pressure vessels inspector, look under the Division

of Labor and Industries in the government section of a phone book.

The following conditions could lead to a weakening of the air tank, and result in

a violent air tank explosion:

WHAT CAN HAPPEN

= Failure to properly drain condensed

water from air tank, causing rust and

thinning of the steel air tank.

HOW TO PREVENT IT

Drain air tank daily or after each use.

if air tank develops a leak, replace it

immediately with a new air tank or

replace the entire compressor.

Modifications or attempted repairs to

the air tank.

Unauthorized modifications to the

safety valve or any other components

which control air tank pressure.

• Excessive vibration can weaken the

air tank of a stationary compressor

and cause an explosion.

Attachments & accessories:

• Exceeding the pressure rating of

air tools, spray guns, air operated

accessories, tires, and other

inflatables can cause them to

explode or fly apart, and could result

in serious injury.

Never drill into, weld, or make any

modifications to the air tank or its

attachments. Never attempt to

repair a damaged or leaking air tank.

Replace With a new air tank.

;@

The air tank is designed to withstand

specific operating pressures.

Never make adjustments or parts

substitutions to alter the factory set

operating pressures.

@

The compressor must be properly

mounted, see "Anchoring" under

Installation.

@

Follow the equipment manufacturers

recommendation and never exceed

the maximum allowable pressure

rating of attachments. Never use

compressor to inflate small low

pressure objects such as children's

toys, footballs, basketballs, etc.

5- ENG N004083

_j_ RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN

o •

Your air compressor is powered by

electricity. Like any other electrically

powered device, If it is not used

properly it may cause electric shock.

HOW TO PREVENT IT

Never operate the compressor

outdoors when it is raining or in wet

conditions.

Never operate compressor with

protective covers removed or

damaged.

° Repairs attempted by unqualified

personr{el can result in serious injury

or death by electrocution.

Any electrical wiring or repairs

required on this product should be

performed by authorized service

center personnel in accordance with

national and local electrical codes.

• Electrical Grounding: Failure to

provide adequate grounding to this

product could result in serious injury

or death from electrocution. Refer to

"Grounding Instructions" paragraph

Make certain that the electrical circuit

to which the compressor is connected

provides proper electrical grounding,

correct voltage and adequate fuse

protection.

in the Installation section.

__ RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN

The compressed air stream can

cause soft tissue damage to

exposed skin and can propel dirt,

chips, loose particles, and small

objects at high speed, resulting in

property damage or personal injury.

• Always wear certified safety

° Never point any nozzle or sprayer

HOW TO PREVENT IT

equipment: ANSI Z87.1 eye

protection (CAN!CSA Z94.3)

with side shields when using the

compressor.

toward any part of the body or at

other people or animals.

, Always turn the compressor off

and bleed pressure from the air

hose and air tank before attempting

maintenance, attaching tools or

N004083 6- ENG

RISK OF HOT SURFACES

WHAT CAN HAPPEN

• Touching exposed metal such as

the compressor head, engine head,

engine exhaust or outlet tubes, can

result in serious burns.

HOW TO PREVENT IT

+ Never touch any exposed metal

parts on compressor during or

immediately after operation.

Compressor will remain hot for

several minutes after operation.

+ Do not reach around protective

shrouds or attempt maintenance

until unit has been allowed to cool.

FROMMOVINGPA.TS

WHAT CAN HAPPEN

o o

Moving parts such as the pulley,

flywheel, and belt can cause serious

injury if they come into contact with

you or your clothing.

At-tempting to operate compressor

with damaged or missing parts or

attempting to repair compressor

with protective shrouds removed

can expose you to moving parts and

can result in serious inju_.

HOW TO PREVENT IT

Never operate the compressor

with guards or covers which are

damaged or removed.

Keep your hair, clothing, and gloves

away from moving parts. Loose

clothes, jewelry, or long hair can be

caught in moving parts.

Air vents may cover moving parts

and should be avoided as well.

Any repairs required on this product

should be performed by authorized

service center personnel

7- ENG N004083

R SKOFUNSAFE

WHAT CAN HAPPEN

o •

Unsafe operation of your air

compressor could lead to serious

injury or death to you or others.

OPERATION

HOW TO PREVENT IT

Review and understand all

instructions and warnings in this

manual.

° Become familiar with the operation

and controls of the air compressor.

• Keep operating area clear of all

persons, pets, and obstacles.

° Keep children away from the air

compressor at all times.

, Do not operate the product when

fatigued or under the influence of

alcohol or drugs. Stay alert at all

times.

° Never defeat the safety features of

this product.

° Equip area of operation with a fire

extinguisher.

° Do not operate machine with missing,

broken, or unauthorized parts.

j__ RISK OF INJURY FROM LIFTING

WHAT CAN HAPPEN I

attempting to lift too heavy an

° Serious injury can result from i"

object.

__ RISK FROM NOISE

WHAT CAN HAPPEN 1

of use, noise from this product may

• Under some conditions and duration 1=

contribute to heafinq toss.

HOW TO PREVENT IT

The compressor is too heavy to

be lifted by one person. Obtain

assistance from others before lifting.

HOW TO PREVENT IT

Always wear certified safety equipment:

ANSt S12.6 ($3.19) hearing protection.

SAVE THESE INSTRUCTIONS

N004083 8- ENG

Become familiar with these terms

before operating the unit.

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per min-

ute; a unit of measure of air delivery.

PSIG: Pounds per square inch

gauge; a unit of measure of pressure.

Code Certification: Products that

bear one or more of the following

marks: UL, CUL, ETL, CETL, have

been evatdated by OSHA certified

independent safety laboratories and

meet the applicable Underwriters

Laboratories Standards for Safety.

Cut-In Pressure: While the motor

is off, air tank pressure drops as

you continue to use your acces-

sory. When the tank pressure drops

to a certain low level the motor will

restart automatically. The low pres-

sure at which the motor automatically

restarts is called "cutqn" pressure.

Cut-Out Pressure: When an air

compressor is turned on and begins

to run, air pressure in the air tank

begins to build, it builds to a certain

high pressure before the motor auto-

matically shuts off - protecting your

air tank from pressure higher than its

capacity. The high pressure at which

the motor shuts off is called "cut-out"

pressure.

Branch Circuit: Circuit carrying elec-

tricity from electrical panel to outlet.

To Lock Out Power: Place a lock on

the line power switch so no one else

can turn on the power.

The accessories and tools are avail-

able through the current Power and

Hand Tool Catalog or full-line Sears

stores.

Accessories

• In Line Filter

• Tire Air Chuck

Quick Connector Sets (various

sizes)

o Air Pressure Regulators

• Oil Fog Lubricators

, Air Hose: 1/4", 3/8" or 1/2" I.D. in

various lengths

This air compressor pump is capable

of running continuously. However,

to prolong the life of your air com-

pressor, it is recommended that a

50%-75% average duty cycle be

Refer to the selection chart located on

the unit to select the tools this unit is

capable of powering.

The use of any

other accessory

not recommended for use with

this tool could be hazardous. Use

only accessories rated equal to

or higher than the rating of the air

compressor.

maintained; that is, the air compres-

sor pump should not run more than

30-45 minutes in any given hour.

9- ENG N004083

Contents of Carton

1 - Air Compressor

1 - Parts bag containing:

1 - Operator's Manuat

1 - Parts Manual

4- 5/8" Washers

Tools Required for Assembly

1 - 9/16" socket or open end

wrench

1 - Electric drill

Unpacking

1, Remove all packaging.

Risk of Unsafe

Opertation. it may

be necessary to brace or support

one side of the unit when removing

the pallet because the air compres-

sor will have a tendency

to tip.

2. Remove and discard the (4)

screws and washers holding the

compressor to the palfet.

,

With the help of another person

carefully remove air compressor

from pallet and place on a level

surface.

HOW TO SET UP YOUR UNIT

Location of the Air Compressor

• Locate the air compressor in a

clean, dry, and well ventilated

area.

° Located the air compressor at

least 12" (30.5 cm) away from the

wall or other obstructions that will

interfere with the flow of air.

° Locate the air compressor as

close to the main power sup-

ply as possible to avoid using

long lengths of electrical wiring.

NOTE: Long lengths of electrical

wiring could cause power toss to

the motor.

° The air filter must be kept clear of

obstructions which could reduce

air flow to the air compressor.

Anchoring of the Air Compressor

Risk of Bursting.

Excessive Vibration

can weaken the air tank and cause

an explosion, The compressor must

be properly mounted,

The air compressor MUST be bolted to

a solid, level surface.

Hardware needed:

4 - Concrete anchors

(not supplied)

4 - 3/8" Lag screw to fit concrete

anchors

(not supplied)

4 - 5/8" Washer (supplied)

shims (if needed)

!. Place the air compressor on a

solid, level surface.

2. Mark the surface using the holes

in the air compressor feet as a

template.

3. Drill holes in the surface for the

concrete anchors. Install concrete

anchors.

4. Line-up holes in surface with holes

in air compressor feet.

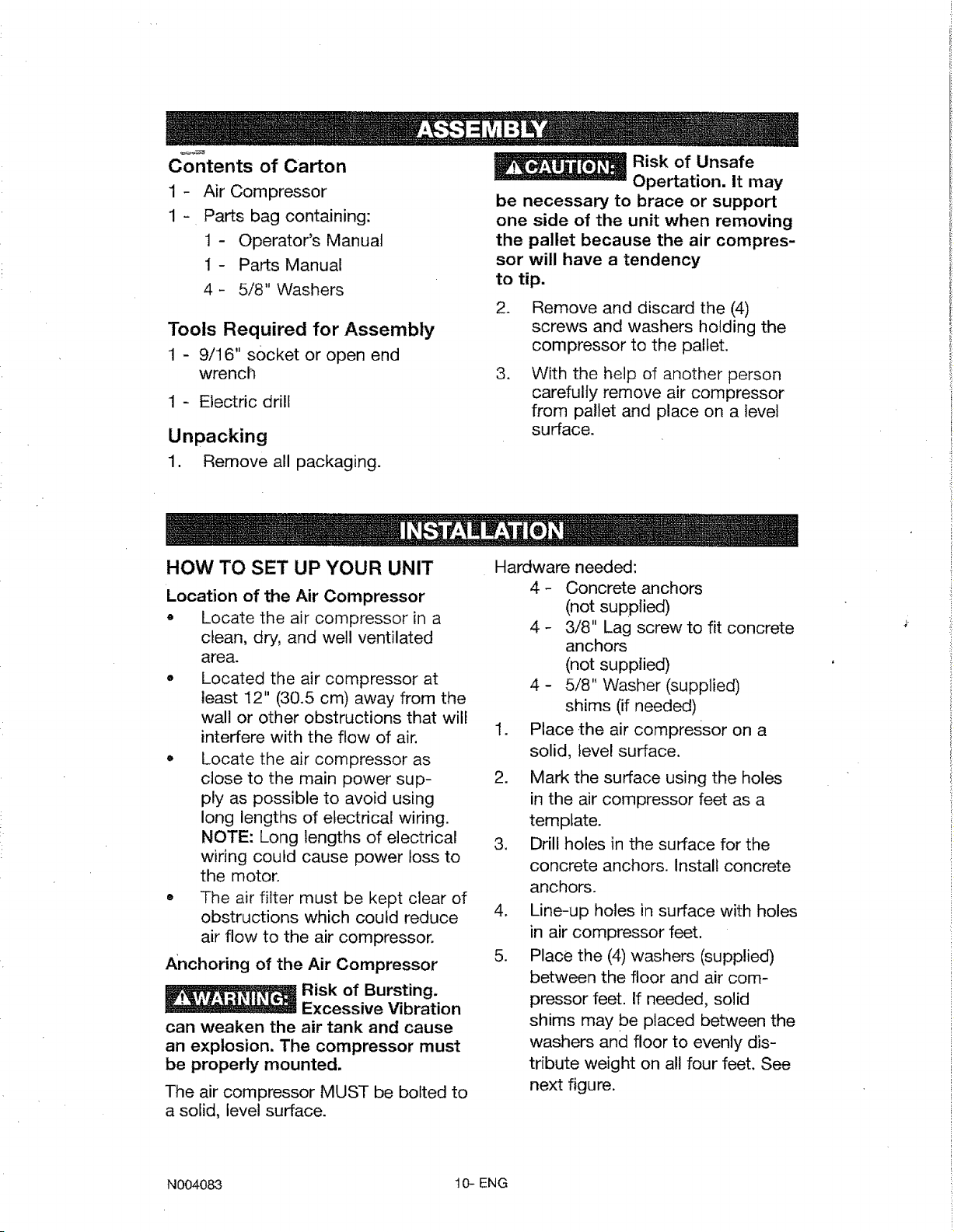

5. Place the (4) washers (supplied)

between the floor and air com-

pressor feet. If needed, solid

shims may be placed between the

washers and floor to evenly dis-

tribute weight on all four feet. See

next figure.

N004083 t0-ENG

I

.........3/8" Lag

...._ ...........Screw

,, ..............__ (not supplied)

5/8 Washer .........

(supplied) i _[-_

.... I ......

Shim Und_er _ Surf_ace Line

Washer Concrete Anchor

(not supplied) (not supplied)

_Risk of Electrical

Shock. Electrical

wiring must be located away from

hot surfaces such as manifold

assembly, compressor outlet tubes,

heads, or cylinders.

GROUNDING INSTRUCTIONS

This product should be connected to

a metallic, permanent wiring system,

of an equipment-grounding terminal

or lead on the product.

6. Place ,the (4) 3/8" lag screws

through the air compressor feet,

washers, shims, and into the

anchors.

7. Torque 3/8" lag screws to

7 - 10 ft. Ibs.

Wiring Instructions

Improper electrical

installation of this

product may void its warranty and

your fire insurance. Have circuit wiring

performed by qualified personnel

such as a licensed electricians who

is familiar with the current national

electrical code and any prevailing local

electrical codes. Une mauvaise

connexion 6tectrique de ce produit

pourrait annuler la garantie et votre

assurance contre les incendies.

A qualified electrician needs to knows

the following before wiring:

t. The amperage rating of the electri-

cal box should be adequate. Refer

to the Specification Chart for this

information.

2. The supply line should have the

same electrical characteristics

(voltage, cycle, phase) as the

motor. Refer to the motor name-

plate, on side of motor, for this

information.

NOTE: The wiring must be the same

as the motor nameplate voltage plus

or minus 10%. Refer to local codes for

recommended wire sizes, correct wire

size, and maximum wire run; undersize

wire causes high amp draw and over-

heating to the motor.

Voltage and Circuit Protection

Refer to the specification chart for the

voltage and minimum branch circuit

requirements.

Risk of Unsafe

Operation. Certain

air compressors can be operated

on a 15 amp circuit if the following

conditions are met.

1. Voltage supply to circuit must

comply with the National

Electrical Code.

2. Circuit is not used to supply any

other electrical needs.

3. Extension cords comply with

specifications.

4. Circuit is equipped with a 15 amp

circuit breaker or 15 amp time

delay fuse. NOTE: If compressor

is connected to a circuit protect-

ed by fuses, use only time delay

fuses. Time delay fuses should be

marked "D" in Canada and "T" in

the US.

if any of the above conditions cannot

be met, or if operation of the com-

pressor repeatedly causes interruption

of the power, it may be necessary to

operate it from a 20 amp circuit. It is

not necessary to change the cord set.

Air Distribution System

Risk of Bursting.

Plastic or PMC

pipe is not designed for use with

compressed air. Regardless of its

indicated pressure rating, plastic

pipe can burst from air pressure.

Use only metal pipe for air

distribution lines.

11- ENG N004083

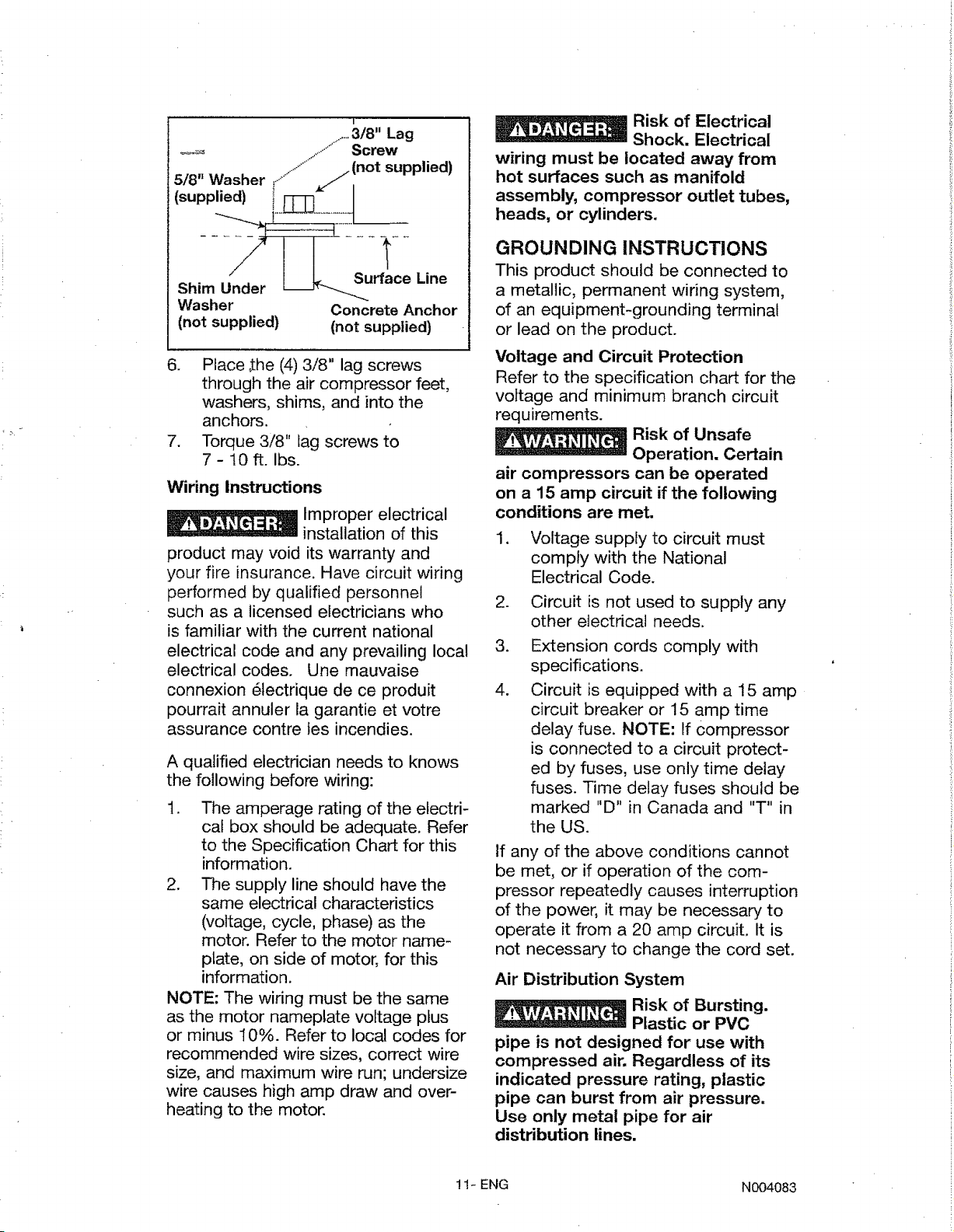

The next figure represents a typical

air distribution system. The following

a_ips to remember when setting up

the air compressor's air distribution

system.

• Use pipe that is the same size as

the air tank outlet. Piping that is

too small will restrict the flow of

air.

, If piping is over 100 feet (30.5 m)

long, use the next larger size.

,, Bur,/underground lines below

the frost line and avoid pockets

p

FEEDER LINES SLOPE ./"--"-.

where condensation can gather

and freeze. Apply pressure before

underground lines are covered to

make sure all pipe joints are free

of leaks.

A flexible coupling is recommend-

ed to be installed between the air

discharge outlet and main air dis-

tribution line to allow for Vibration.

A separate regulator is recom-

mended to control the air pres-

sure. Air pressure from the tank

is usually to high for individual air

driven tools.

r_LJ _ _ _,_ , LUBRICATOR

4

[I MOISTURE ______

t l S_LEXIBLE i__

.... AIRD,SO.AR E

TYPICAL COMPRESSED

AIR DiSTRiBUTION SYSTEM

DRAIN COCK

VALVE

N004083 12- ENG

AIR

COMPRESSOR

Know "Your Air Compressor

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with

the location of various controls and adjustments, Save this manual for future

reference.

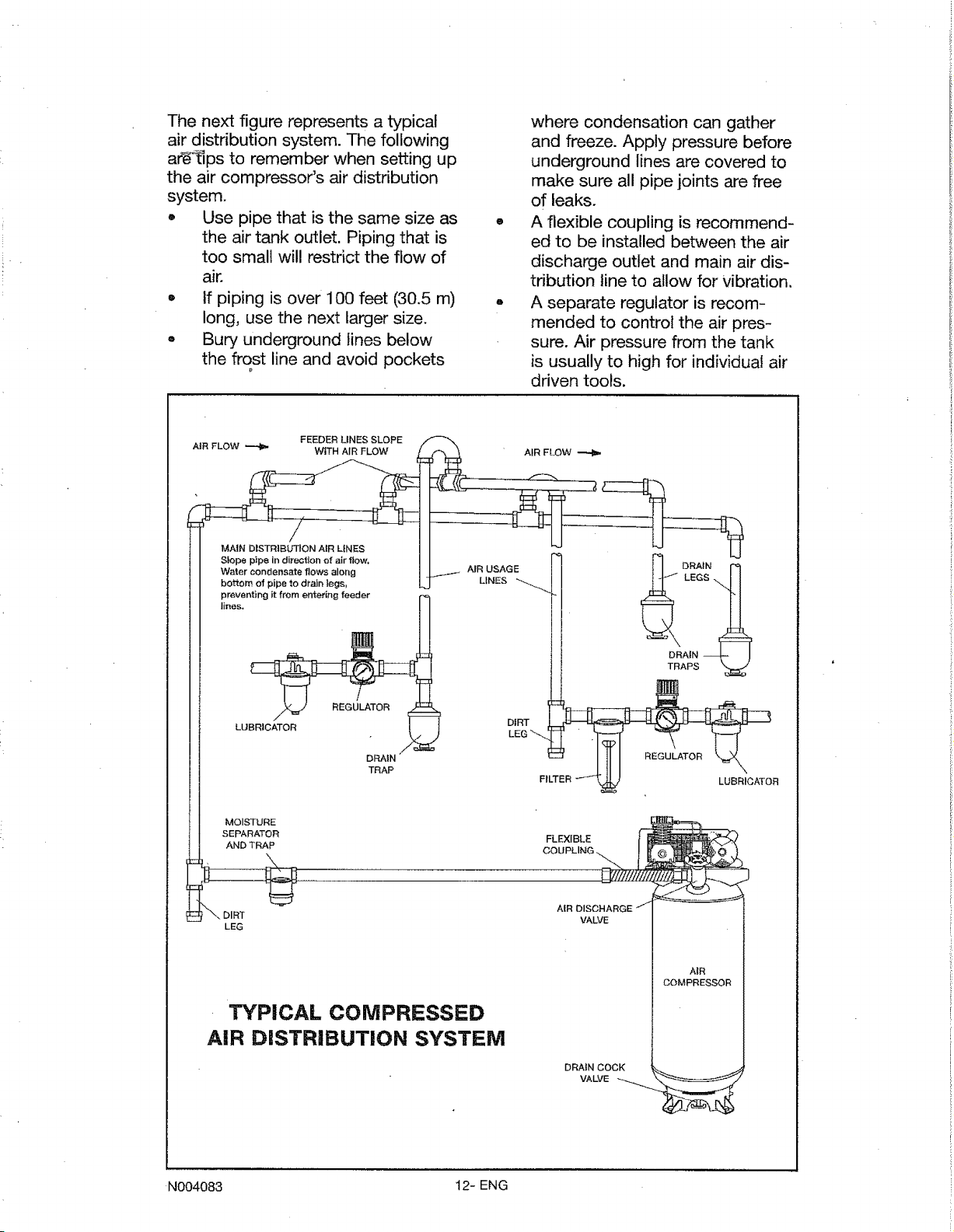

Description of Operation

Become familiar with these controls

before operating the unit.

On/Auto(I)/

off(o)

On/Auto(I)/Off(O) Switch: Turn this

switch "On!Auto(t)" to provide auto-

matic power to the pressure switch and

"Off(O)" to remove power at the end of

each use.

Pressure Switch: The pressure

switch automatically starts the motor

when the air tank pressure drops

below the factory set "cut-in" pres-

sure. tt stops the motor when the air

tank pressure reaches the factory set

"cut-out" pressure.

Safety Valve: If the pressure switch

does not shut off the air compressor

at its "cut-out" pressure setting, the

safety valve will protect against high

pressure by "popping out" at its fac-

tory set pressure (slightly higher than

the pressure switch "cut-out" setting).

Tank Pressure Gauge: The tank

pressure gauge indicates the reserve

air pressure in the tank.

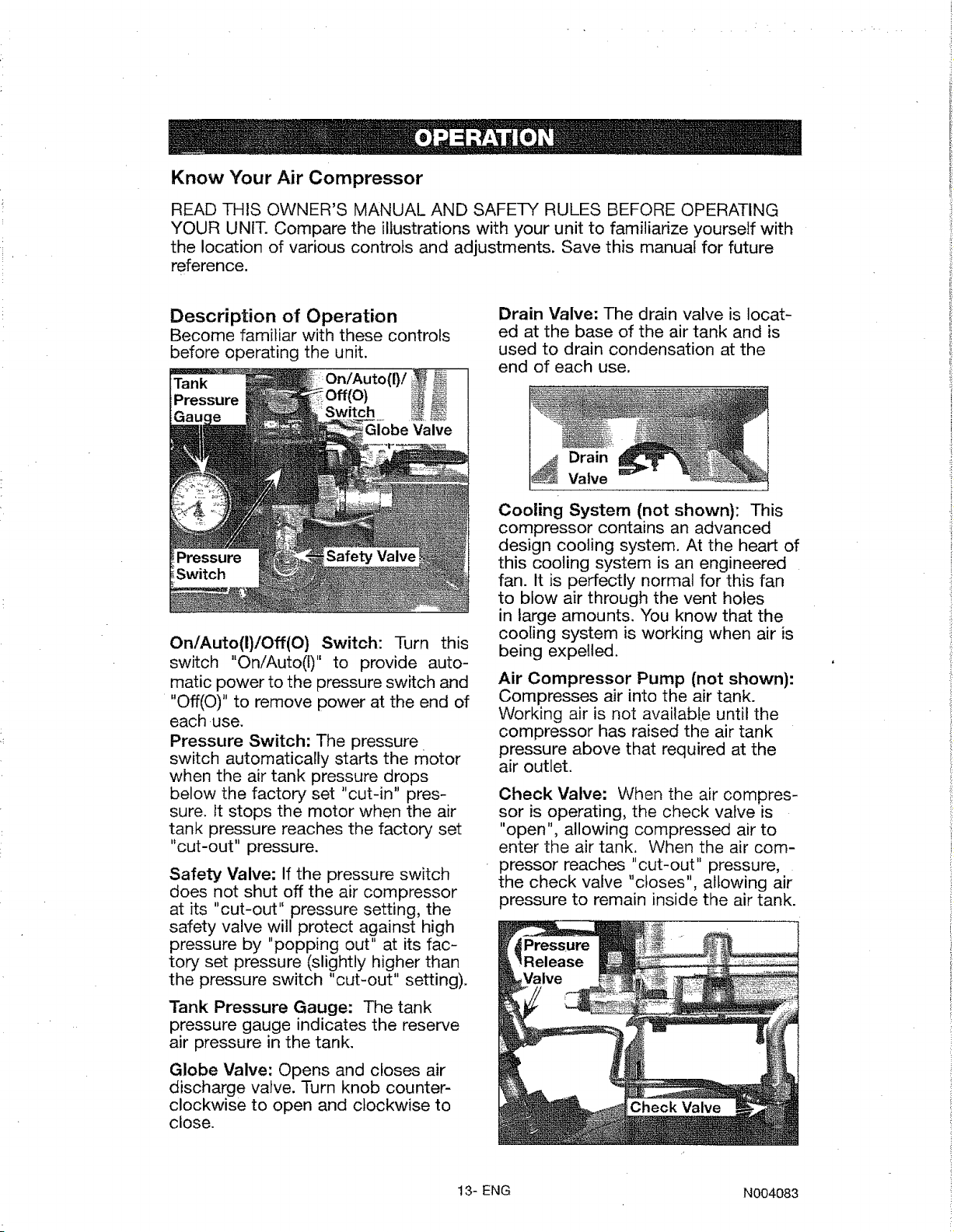

Drain Valve: The drain valve is locat-

ed at the base of the air tank and is

used to drain condensation at the

end of each use.

Drain

Valve

Cooling System (not shown): This

compressor contains an advanced

design cooling system. At the heart of

this cooling system is an engineered

fan. It is perfectly normal for this fan

to blow air through the vent holes

in large amounts. You know that the

cooling system is working when air is

being expelled.

Air Compressor Pump (not shown):

Compresses air into the air tank.

Working air is not available until the

compressor has raised the air tank

pressure above that required at the

air outlet.

Check Valve: When the air compres-

sor is operating, the check valve is

"open", allowing compressed air to

enter the air tank. When the air com-

pressor reaches "cut-out" pressure,

the check valve "closes", allowing air

pressure to remain inside the air tank.

Globe Valve: Opens and closes air

discharge valve. Turn knob counter-

clockwise to open and c!ockwise to

close.

13- ENG N004083

Pressure Release Valve: The

pressure release valve, located on

the-_de of the pressure switch, is

designed to automatically release

compressed air from the compres-

sor head and the outlet tube when

the air compressor reaches "cut-out"

pressure or is shut off. The pressure

release valve allows the motor to

restart freely. When the motor stops

running, air will be heard escaping

from this valve for a few seconds.

No air should be heard leaking when

the motor i;s running, or continuous

leaking after unit reaches "cut-out"

pressu re.

Motor Overload Protector (not

shown): The motor has an automatic

reset thermal overload protector. If

the motor overheats for any reason,

the overtoad protector will shut off the

motor. The motor must be allowed

to cool down before restarting. The

compressor wilt automatically restart

after the motor cools.

Air Intake Filter (not shown) This

filter is designed to clean air coming

into the This filter must always

be clean pump

from obstructions. See Maintenance.

ventilationand

openings free

HOW TO USE YOUR UNLIT

How to Stop:

1. Set the On/Auto/Off lever to "Off".

Before Starting

Do not operate this

unit until you read

and understand this instruction

manual for safety, operation and

maintenance instructions.

Break-in Procedure

, _,o,, of Property

Damage. Serious

damage may result if the following

break-in instructions are not

closely followed.

This procedure is required before the

air compressor is put into service and

when the check valve or a complete

compressor pump has been replaced.

1. Make sure the On/Auto/Off lever is

in the "Off" position,

2. Recheck all wiring. Make sure

wires are secure at all terminals

connections. Make sure all con-

tacts move freely and are not

obstructed.

3. Open the globe valve fully to per-

mit air to escape and prevent air

pressure build up in the air tank

during the break-in period.

4. Move the On/Auto/Off lever to

"On!Auto" position. The compres-

sor will start,

5. Run the compressor for 15 min-

utes. Make sure the globe valve

is open and there is minimal air

pressure build-up in tank.

6. Check all air line fittings and con-

nections!piping for air leaks by

applying a soap solution. Correct

if necessary. NOTE: Minor leaks

can cause the air compressor to

overwork, resulting in premature

breakdown or inadequate perfor-

mance.

7. Check for excessive vibration.

Readjust or shim air compressor

feet, if necessary.

8. After 15 minutes, close the globe

valve. The air receiver will fill to

"cut-out" pressure and the motor

will stop.

Before Each Start-Up:

1. Place On/Auto/Off lever to "Off".

2. Close the globe valve.

3. Attach hose and accessories.

NOTE: A regulator MUST be

installed when using accessories

rated at less than 175 psi.

Risk of unsafe

operation, Firmly

grasp air hose in hand when

installing or disconnecting to

prevent hose whip.

Risk of unsafe

operation. Do not

use damaged or worn accessories.

N004083 14- ENG

NOTE: The hose or accessory will

require a quick connect plug if the air

ou_Lgt is equipped with a quick con-

nect socket.

Risk of Bursting.

much air

pressure causes a hazardous risk of

bursting. Check the manufacturer's

maximum pressure rating for air

tools and accessories, The regulator

outlet pressure must never exceed

the maximum pressure rating.

How to Start:

1. Turn the On/Auto/Off lever to "On/

Auto" and allow tank pressure to

build. Motor will stop when tank

pressure reaches "cut-out" pres-

sure,

2. When the tank pressure reaches

"cut-out" pressure open the globe

valve.

IMPORTANT: When using regula-

tor and other accessories refer to the

manufacturers instructions.

Risk of unsafe

operation,

Compressed air from the unit may

contain water condensation and

oil mist. Do not spray unfiltered air

at an item that could be damaged

by moisture, Some air tools and

accessories may require filtered

air, Read the instructions for the air

tools and accessories,

if any unusual

noise or vibration

is noticed, stop the compressor

immediately and have it checked by

a trained service technician,

The compressor is ready for use.

15- ENG N004083

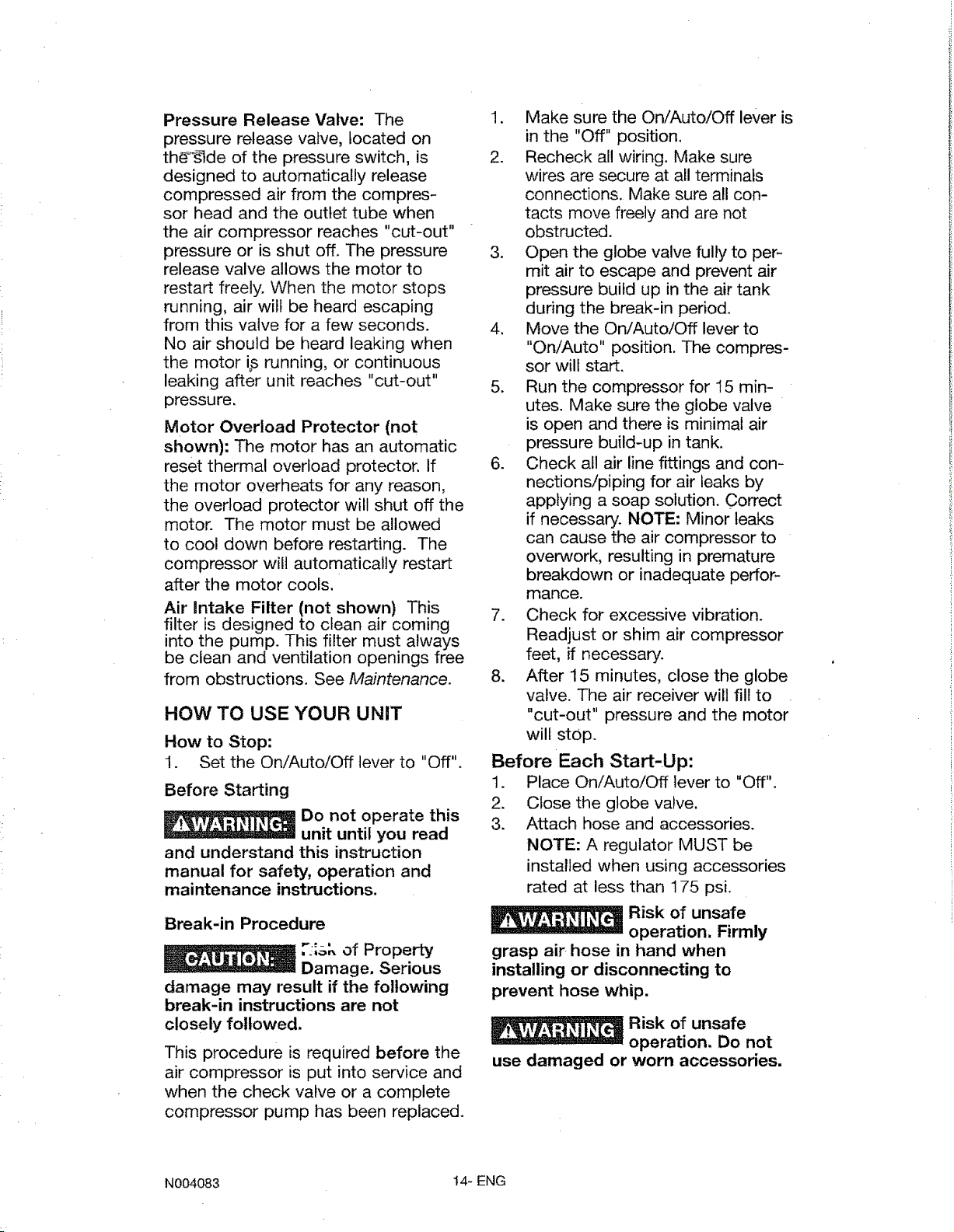

CUSTOMER RESPONSIBILITIES

Before

each use

Daily or after

each use

Every 40 hours

Yearly

Check Safety Valve

X

Drain Tank X

Air Filter

Air compressor pump

intake and exhaust

valves

Inspect air lines and X

fitt!ngs for_ leaks

j_ more frequent in dusty or humid conditions

Risk of Unsafe

Operation. Unit

cycles automatically when power

is on. When servicing, you may

be exposed to voltage sources,

wear certified safety equipment:

ANSI Z87.1 eye protection (CAN/

CSA Z94.3) with side shields.

compressed air, or moving parts.

Before servicing unit unplug or

disconnect electrical supply to

the air compressor, bleed tank

of pressure, and allow the air

compressor to cool.

To ensure efficient operation and lon-

ger life of the air compressor, a routine

TO DRAIN TANK

maintenance schedute should be pre-

pared and followed. The above routine

maintenance schedule is geared to an

air compressor in a normal working

environment operating on a daily basis.

If necessary, the schedule should be

modified to suit the conditions under

which your air compressor is used.

The modifications will depend upon

the hours of operation and the work-

ing environment. Compressors in an

extremely dirty and/or hostile environ-

ment will require a greater frequency of

all maihtenance checks.

NOTE: See Operation section for the

location of controls.

TO CHECK SAFETY VALVE

from noise. Air tanks contain high

pressure air. Keep face and other

body parts away from outlet of

drain. Use ANSI Z87.1 eye protection

(CAN!CSA Z94.3) when draining as

debris can be kicked up into face.

Use ear protection (ANSI $12.6

($3.19) hearing protection) as air flow

noise is loud when draining.

NOTE: Operation of the air compres-

sor will cause condensation to build up

in the air tank. Always drain tank on a

washable surface or in a suitable con-

tainer to prevent damaging or staining

surfaces.

Risk of Bursting.

if the safety valve

does not work properly, over-

pressurization may occur, causing

1. Set the On/Auto/Off lever to "Off".

2. Close the globe valve.

3. Remove the air toot or accessory.

air tank rupture or an explosion.

X1 ....

Risk from Flying

Objects. Always

,

Before starting compressor, pull

the ring on the safety valve to

make sure that the safety valve

operates freely. If the valve

is stuck or does not operate

smoothly, it must be replaced

with the same type of valve.

Risk of Unsafe

Operation. Risk

X

N004083 16- ENG

Loading...

Loading...