MG-UMCTAN

CRRFTSMRN

PERMANENTLY LUBRICATED

TANK MOUNTED

AIR COMPRESSOR

. SAFETY GUIDELINES

• ASSEMBLY

" OPERATION

" MAINTENANCE

• TROUBLESHOOTING

... IMPORTANT:

Read the Safety Guidelines and

All Instructions Carefully Before

Operating,

• REPAIR PARTS

TABLE OF CONTENTS

Page

SAFETY, GUIDELINES .................................................................................................................... 3

WARBLING CHART ................................................................................................................. 3

GLO_.ARY q

ACCESSORIES FOR USE WITH SEARS AIR COMPRESSORS ..................................... 5

GENERAL INFORMATION ................................................................................................... 5

DESCR!PTJON OFOPERATION ............................................................................................... 6

ASSEMBLY .......................................................................................................................... 7

!NSTALLA-FIO N AND BREAK-IN: PROCEDURES ............................................................................ _. 7

Lccation of Air Compressor ..................................................................................................... 7

Lubrication and Oil .................................................................................................................. 7

E'.,..tensionCords ........................................................................................................... :............ 7

Vo',;:ageand Circuit Protection .......................................................... :.......... ......................... 7

Groqnding Instructions ......................... :...................................................................................... 8

Brea_<,4qProcedure ................................................................................................................. 8

OPER.s:q:!NGPROCEDURES ............ 9

MAiNTZNAHCE ........................................................................................................................ I0

Ci,': ;k',,'ak.e-RepPacement .................................................................................................... 10

Sak;>_v\ialve- Inspection 10

S_cY_9_ .............................................................................................. 10

THC;L_ZL[FS'-i(::OTtNG GUIDE ............................................................................................... 1!

HOW [O OF;f)ER REPAIR PARTS !4

\4vAF_RZ _.__,y

................................. 14

SAFETY GUIDELINES

This manual contains in{ormation

that is important for you to know

and undeE.tand. This informatim_

relatestoproteding YOUR SAFETY

and PREVENTING EQUIPMENT

PROBLE[VIS. To he.!p you recog-

nize this in tof'matlo!_, we use sym-

bo}s to the right Please read the

manuai and p_-yattenhon to these

sections

IMPORTANT SAFETY iNSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS

INJURY AND PROPERTY DAMAGE, READ AND UNDERSTAND ALL WARN,_HGS AND OPERATING

[ .........

HAZARD

RISK OF BURSTING

INSTRUCTIONS BEFORE USING THiS EQUIPMENT.

- DEFINITIONS

URGENT SAFETY INFORMATION - A H_ARD

THAT WILL CAUSE SERIOUS INJURY OR LOSS

OF LIFE.

[ _,,=WAR_

IMPORTANT SAFETY INFORMATION - A

HAZARD THA[ MIGHT CAUSE SERIOUS

iNJURY OR L,?,,SSOF LIFE.

- SAVE T_HESE INSTRUCTIONS o

WHAT CAN HAPPEN

Air Tank

• IH_EFOLLOW IN_GjCONDLTLONS_C_OU_LD

lead to a we_kep,ing of the tank, a_d

R:_ESU_T= IN A 2_LO_L,ENT TANK

EXPLOSION:

inforrnatior_for preventing dam_.ge to

equipment

_nformation that you should pay special

atte_tion to

[.c,u'.o. ]

HOW TO PREVENT IT

L............

RISK OF ELECTRIC

SHOCK

1. FAILURE TO PROPERLY DRA_N

condensed _._.&-f_E_RFROM THE

C___:_ .... :AN K. u_us_nt__ust and thinning o_

the tank steel

2. MODIFICATIONS or attempted

repairs TO TH_ TANK.

3. Unau[ho_ized MODLFtQATiON_

SAF_7_y_',[?z'E,__\R any Q'TH_R

;]pL_;'L &P'G COL}d i<_::;U_[ i{'_ se_'_cl, is }n_ucy.

electricity. Like any other electricaJiy

powered device, |E it Js NOT___U.<_.D

PROPERLY it MAY CA[;SE ELECTRICAL_

SHOCK.

ELECTRIICAL GR O_UNDtNG: FAILURE TO

_ROVI DE ADEQUAT_E_G_BOUN D4NG TO

THIS PRODU_QT COU.LD RESULT LN_N

SERIOUS INJURY OR DEATH FROM

ELECTROCUTION. S_DI.LN_

}_NS.T.,RUCTI O_JF___E_PLIPABLE,

_:R_._! T_jL@_,_DA_!__# R=_/.LFT E..R.EACH

USE. ff tank develo_;.,s _ leak, repiace i_

..., a ..... ; }_..rs,ew

_ompr_ssJ _,dlt.

NE'.y..ER dri{i into, weld, or __AK$_NY

_.&QDtF[QATI_ON_S TO ZH_ TAfLK or its

attachmen;s. Never attempt to repair a

damaged or Ieaking tank. Reptace with a

new tank

The tank is designed te withstand specffic

operating pressure,s. N_ER M&KE.

__ _STITt!]'_RI4_S 1tO alter the .EAQ__G_

SEI operatff_9 pRESS Uj&_S.

Fol!:',_: the eq,ui_m,ent manufLtcbJ_:rs

r(-._r_olRn-h*_lld_iti©Q _!l_ _\,'_!" exceed tl_e

[Y;_XiPIurI_ ;.]tib.:,3}::,iO id_.sstJre rat_q(j .'J{

LQ_'_: P_gS_LR!_ Qt.!J__C_FS SUf;L_i A-_

Qbjj_DREN:_/iR___L$_ FQQJL.B&Lk,S,

Any ELECTRICAL WiRiNG OR REPAJR._

required to this product SHOU .!=____BE

EE R._FO_R_M_F-D6_YAL_._

P_RSONNEL:. OR. a LICENSED

ELECTRtCtA____NN,in accordance with national

and local electrical codes.

MAKE O___ERTAI,L_Nthat the ELECTRICAL

IR_ to which the compressor is

connected pROVIDES PROP_

EL_CTR!CAL._GROU NDING_, O_

VOLTAGE, A_JD ADE_Q_UATE FUSE

PROTECIION

Never operate the compressor outdoors

when it is raining.

GLOSSARY

CFM: Cubic feet pet minute°

SCFM" Standardcubi,; feet o_r minute: aunit of measure of air

PSIG: Founds per SqLam nc- gauge; aunit of measure of

.C4%_L,Te.

ASME: Americ_-;n S(:,ciety of Mechan ca! Engineers; made

tested, inspect(;d and ieg_s1eredto meet the standards of the

ASME

U.L. Listed: Th is product is Listed by Underwriters Laborato-

ties, inc. (UL). Samples of this product have been evaluated by

uLand meet applicabte LILStandardsforSafety.

ACCESSORIES FOR USE WITH SEARS

AIR COMPRESSORS

Cut-in Pressure: Whitethe motor isoil, airtank pressure drops

asyou continue to use yOLIraccessory. When the tan k pressu re

dropsto acertain low level the motor will restart automatically.

]-he low pressure at which _hemotor automatically re-starts +s

ca!}ed "cut-in pressure,"

C_t+Out Pressure: When you turn on your air compressor and

it begins to run. air pressure in the air tank begins to buiid. It

builds to scertain high pressqre before the motor autornaticai!y

shuts off- protecting y0urair tar.,kifore pressure higherthan its

capacity. The high pressureat whichthe motorshuts off iscalled

"cut+out pressure."

+SPP_&YGUNS

,BLOWGUNS

-AtRCAULKING GUNS

+AiR BRUSHES

• AIR LINE FILTERS

•TIREAIR CHUCKS

*PAtNTTANKS

_AIR TAN KS

..:'+FL,ATr)R_KITS

+,DLIICK CONNECTOR SETS

0,'_,!ious sizes)

GENERAL INFORMATION

o_: I _:_-;',',::.¢,, ._.... o, a,qair uu; ;+_resso_ cr.,tt consisting of

_,:.-_.ec+,,iin_,_':,s!nqi_:-+s[age a_; com.p++essor pump _u-d air

tank. +nciuded or9 wheels regulator, gauges, and handle.

T [ _ r

+Ch:S+3.ifCOIT;tDr_}ssor requires P,o oi!. Now you can enjoy all

tbo b(_:_cfils 0[ having an air compressor without ever

having to purchase, add or change oil.

YOth_&ipcompressoroan be used for operating paint spray

guns, air tools, air brushes, or inflating tires and plastic

+A.,!RPRESSURE ,_r^ +.i ,,_r_,

+OIL FOG LUBRICATORS

=AIRTOQLS:

Drills- Intermittent Use

lmpactWrenche_+ _r,,tennRtentUse

+AIR HOSE:

1/4", 5/16" or3/8" I.DI

in various lengths

NAILER/STAPLERS

+DRAIN CLEANER

toy's, spraying weed k; ,e,-% ' ....... ._..:-_ ai+

pr essdre regui_Lcr is rs;Llu!;_,'_for +7_01:._(:,fi! ;_ :i_i::F_licat,O:"s.

An air filter which removes moisture and dirt from corn- .-

pressed air should be used where applicable.

These accessories can be p_rchased from most Sears

stores or from the Sears Power Toot Catalog.

l_+, _"-++:++.++!_ZJ_ _LJi"+t;,,_

HAZARD

RISK OF

ELECTRICAL SHOCK

{cont'd)

WHAT CAN HAPPEI',i [ HOW TO P_V$.NT2 L

I

_.-;::_,P,_£ONNEL CAN..R__E_$._L3___LfJ____':-._?.LQi_J_ 1 R_QU!REF) ON TH!S PRODUCT _LL) £E

_JURY_O.R.DEAT_HBY EL._I"BLk<LiT?.'_'!,., ( _pf)"LF;:);_.4ED6Y _L!ZlJORi_Z_D__.$__Vj.C.___OZ£_:

TF;R_P_R._',Si'_N_!_ ;;q ACCORDANCE '¢.;'!TH

NATK_Hi:',[ AND LO':::i:tL _f,ECTRICAt. CODES.

t

t

[£.ECTR!CAL. GR,OUND)NG: r-_.,_,l._ , ....... _._

I

t

S_SI< FROM ................... _..........-' " '""..... _-":" _ "

FLYi;",!G OBJECTS -_,';:....._: _i(L-...'-".,_ ,-:. ......., .

"j:2:'.2'_,S::_!_2_:_J:i3d'.'.'/ ;:R / ,:;'(, T!-ih _3Q,.')Y- "-:?i iUY'

2: L '(,,',2 . : "f t ),r:?<i "$%U: :";+'i W:;_:._,¢'f't_:;:'_ ¢)_:_1 ,_ ';_,,

.D_:rTA!_I-<_.'_.,.2_.:_):::'.})J._ ;:,i : :_:3L;EiS:3,:_;RIES.

EFtJ-ii_:D_ Lirait-'v C,;! f_:_,DM /',< BREATHIi',,;GI

DEY !CE CC,NNt':CY[::_{) _ 0 i Hi:: C: ")v*'a_qES%?-ff'* !

vg.N'D_LATJp.._ HE,;,_::,,',ND Ge_kl,_o_wTb._ I

$&EETY, IN_S3"n_.[CTJ_'Q_-_PROVIDED ON "iH_.'

LABEL C'F", SAFETY _st-_,..... ,I;-, SHEETS _EOR_'[)--/E

t4K?S_d,_7_Z4A. .i_ ?£y_3.0LO__Q.j3_3RAT OR_ DE

SIGNED FOlq ' ,qf ',,J_TFi YOL)R SPECIF!C

APP]. [C,"_,Tit:"N

:', _ _.,:,.., , h., .-, Mi'\INTEH,'_.;';CL:.

eoo_ chess-i

RISK FROM

L

RiSK OF _3URNS

", ...... ':" OPERATE COMPRESSOR IN A

$.T..A.BL_i._]k:'._C__R_E...__P.f)_.LTJON t (3 PREV[:!NY

_.;C!_,'_..,,:A_ MOVEMENT ,D,c IHE UNIT. NEVER

OPERATE COMPRESSOR ON A ROOF OR

OTHER E LE.VATED pO$LTION.. USE ADDI-

' TION_:L, AiR HOSE TO REACH HiGH LOCA_

T tON%

ALW,_YS Zk!t3_N._,_.E_E THE COM___PRESS___OOR.

OU_),,SJ'.. ,.B_£O{IE PERFORMING MAINTE-

N A N C_5 QB_,_:;'d_?j ,:i'__C,._.,t 0 CLk_ __&N_D_Ap_.C.ES-

SQRm_.

,.[:._,'_ OR DAMAG,- r F: T!-'& Y ::-L '._ =" _- r::H;')h. TH(S :_'i-4CD_:K"_ NEVER OPERATE TI(E

,,,.,.,'J,.;:.CTWlTH YOt _OFt VOt)R C: (:,:" ;,:' ... £:,_,,_I._.._!_528_SL..?,_'__W_i:LGU_,)IDS OR COVEF_,'7;

,,-_TTEMPTING TO OPERATE ©P, ::T:i:'D!_ /',4'4. p,..,-.+,t_.,o...,-.,,:,;E,:'Uq-!!,-D ©N Tt !IS PROBUCT

(:_p}_PRESSOR WITH PROTECTIV2 .:f..i:{i._:,":_-,!,_:_.. SHOULd ii._ P!':_,_-Of_MEB BY cuTH-_5]_]_:_-_

}:'gS Tb__&ND__ ELEOTRICAk _.SHO'Cg,

T'DUCHING EXPOSED_METAL Si_CH _,S T_IF_ NEVER "(OUCH ANY EXPOSED METAL PARTS

COF.:IPF1ESSOR HEAD OR QUTLb:I TIE'-': !].,':._t_,j O_N._CO).,1_!_:.Z$:-._"JIR. !St;[qli,iG OR (MMEDi/_TELY

__ULTIN_OU__B__RNS, AFTER OrZ'b.P,,_:'-;'i!C_N. COMPRESSOR WILl.

Wi4K', ! ,,-",RL-DA,',;.,k'SE", OR R:_aOVED.

B_,E__AI_N_.HiOiT FOR SEVERAl. M;NUTES AFTER

OPERA7 [OF,'.

AirCompressorPump:Tocompressair,thepistonmovesup

anddowninthe cylinder. On the downstroke, air is drawn in

through the air intake valves. The exhaust valves remain

closed, On the upstroke of the piston, airiscompressed. The

intake valves close andcompressed air isforcedoutthrough the

exhaust vaives, through the outlet tube, through the check

valve and into the air tank. Working air is not available until

the corn pressor has raised the air tank pressure above that

required at the air outlet,

Check Valve: When the aircompressor isoperating, the check

valve is "open". altowing compressed air to enterthe airtank.

Whenthe aircompressorreaches"cut-out" pressure, thecheck

valve "closes", allowing air pressure to remain inside the air

tank.

Pressure Release Valve: The pressure t_leasevalve located on

the side of the pressure switch, is designed to automatically

releasecompressed airfrom the comp_essorhead and the outlet

tube widen the aircompressor reaches"cut_out" pressure or is

sh[-t.,_ff, if tile airis riot released, the motor will not be able to

staR. The pressure release valve allows the motor to restart

freely, wnen the motorstops runr;ing, airwill be hear(,'escaping

from _?:evaive for afewseconds. No.si!-si;ould be leaking when

the rr,o',or is running.

Pr_ssu_'e Switch: The pressure sv,;itchautomaticaily starts the

motor wi_en {he air tank pressure dnups below the factory set

"c_tqn' orsssu,_e, tlstopsthe mc.tc_¢.'hen the air tank pressure

rea;'_.....r_s_. _,-,_-"fa _'[nr_ "_.set;'cut-out '_,,_"essure

SafetyValve: tfthe pressure switch does notshutoffthe air

compressor at its cut-out pressure setting, the safetyvatve will

protect the tank against high pressure by "popping out" at its

factory, set p_essure(slightly higherthan the pressure switch cut-

out setting}.

Regulator: The air pressure coming from the air tank is

controlled bythe regulator. Tur n the regulator knob clockwise

to increase pressureand counter-ctockwisetodecrease pres-

sure. To avoid minor readjustment after making a change in

pressure setting, always approach the desired pressure from a

lower pressure, When reducing from a higher toa lower setting,

first reduce to some pressure less than that desired, then bring

uptothedesired pressure. Depending onthe airrequirements

of each particular accessory, the outlet regulated air pressure

may have to be adjusted while operating the accessory.

OutLet Pressure Gauge: The outlet pressure gauge indicates

theair pressure available attheoutlet side oftheregulator-This

pressure iscontrolled bythe regulator and isalways less orequa!

tothe ta,nk pressure. See,Operating Procedures".

Tank Pressure Gauge: The tank pressure 9auge indicates the

resen_e-zir pressure in the tank.

Coo!in9 System: ihis co_,npressor cont_4ns an advancedde-

sign coo!irg system. At the heart of this cooiing system is an

er',_.kzse.*ed fan. It isperfectly normal for this fan to blow air

_,h_ough the,:ent hoies in large amounts. You know that the

cooli_ _gsystem is working when air is being expelled.

TOOLS NEEDED FOR ASSEMBLY

...., ................ __:_::_,'_"open end wrench or socket totighten handle screws

• a .w _u secket or open end w_ench for a_acI _,ngthe ,#f _.__,s

InstallingWheels, Handles, Molded

FootBumi:_

THE WHEELS AND HANDLE DO NOT PRO-

V_DE ADEQUATE CLEARANCE, STAB1UTY

L;_ :_. : , L RT FOR PULUNG THE UNiT UP

AND D©WN S]rAtRS OR STEPS. THE UNIT

f4UST F_ELIFTED, OR PUSHED UP A RAMP,

ASSEMBLY

_: "_'"- ,_,1.... s are

: _:.,,,_l sec__rely.fhe outfit wiil sit level ifth?, _,;

properly installed.

it will be necessary to brace or support

one side of the outfit when installing the

wheels because the compressor will have

a tendency to .tip o_er.

Attacl; tb.,Phand!P, tothe cornpresso_ saddle by inserting

the har;,ite :aside the compressor sadd!e aRd Iin!ng up

the L_o!th,:.%;_:I:_-_e,_:_ch side. insialfthet..:_.oscrews, or_eori

each sid,}, Tif]_ht_:nsecurely.

INSTALLAT ON AND BREAK-IN PROCEDURES

Location of the Air Compressor

__ocatet¢iLsi; C'C,, f,_r_:_sso,in a c,_arL c;_/ a'ld wel! ventilated

area. The ak coh:pre:;sor should be i_..'.atedat ;east ! 2" away

from the Wall or o[her obstructions that wiil interfere with the

........ ,_Lt,:._.0ot_LJRipa_!,_.,b;iro_d ai e,Je_lgFied

t,_-a!!_w for prop<._r.'..'::'oi!rig. Th 3ve,.'-.ti!a[ic.'nopen ,rigs on t:]e

,;Oral.:r,._sse_'_o :-;_-_c_ssa,-,,to mair-_13]__b."oper operating _ern-

r,_;ra_ure. E',>iq,:;Lpb,,e rq0s c:rO_b£;copt-_iR,_-s c;n or r,ear

theseop.er_;:_{;_.

Lubrication and Oil

,::ie_r i,_r;d d_/unde=s;C_:: o fa;r tan kleg opposite whee!s.

i_-__ove the F;ot,_-_:i_ve..m-ip[rc;m the adhesive backed

m:;.i,J_cdfoot bL'm.:',:_m. A.tt_a,.ththe _oot bL!m_'ers tothe

bc!::om of leq ,3r;ear.l_ e;_,J.Hr:esu flrr_ ,y :=_korqace.

If an ex_er_sion cord mJ_t _._ L=ed, be sure iI is:

a %w'.re extensioq cord tl;at has a.:,-,.,i._ci8g, o,.,_=d=ag

pl.; ._.,a._da 3 =Ict r.:,,.,_,........=t!}_t w_!l._.cceptthe plug o[]

the p_oduct

,i ......

:', ;,o Ir_.nger thar_ 50 f_et:

- t2 gauge (AWG) or _a_'ger. _,Wire size increases as

gauge number decreases. 10 AWG and 8 AWG may

a_.o be used. DO NOT USE t 4 OR 16 AWG.)

This unit needs no lubrication or oiling.

Extension Cords

Use extra air hose instead of an extension cord to avoid voltage

drop and power !ossto the motor, and to prevent overheating.

Voltage and Circuit Protection

Refer to your Parts List Manual for the voltage and circuit

protection requirements of your compressor. Use only a

fuse or circuit breaker that is the same rating asthe branch

circuit the air compressor is operated on. If the compressor

is connected to

a circuit protected by fuses, use only dual element time

delay fuses, as noted in that Service Bulletin.

•..:tot_pre-'e:or 'qodeis can batopsmt{:d on a15an siscircuff ii:

i. Vtq,%},:-'-su Dpty to circ ui! !s no_n-_aL

,'. t:!i_c_;t_::.ra_tusedtosupp!y;.Ln,.._th_re,_t.[ ,.,a ,_?eq.s

}. i';:>,;:e::x310 }CO!'dS .'.}orr_priv,;; t : ::pec]i[Ca Iioqs.

4. Cirr:.uitlsequipped_._4f!_a iSam[:,('kcd[br_sks_o; i_!n'nF;

i_i_' d.'-;:',,.;yfuse.

ifany ol ff_eabove cor,ditior, s c':_nn,,:_L:ereel or if r:,peratior;: i

[l_-_c'-,[r;i:,resso_'; epeatedly cai:_ses;¢,terrupti,.:,T_of th® power, it

may be r,scessaB_ to operate it fror._ a >_:0amp circuit. It is not

necessa ry tochange the cord set.

}[ ',ep._ir;!, 2,.:..::'.r::_or ph;g, ;no .q_rour,cii'_gv,,ve _p,ust be kept

sc.'parats fr_:,i-_!he ctirrsnt- carryh_g v@_s. Ne,-"erconnect lf'a

grour_ding w;re _oa fiat blade ph._gtermir_ _i:T_ie grounding

,,_ -/.,,._, _ot4._:,on_.v,.t,_ _.,u_e,.,:,r,a_.....:, :_]!een-withal

without ye!k_w s_:ripes.

or ,!:,-;,.JcU::-t_:_s[,s whether the,¢;0[_:prssscris pr_3:,er!yg_ound.

ed ',i i_:,n-.?:_:;:_:;i_q-sito,_checked t;!.8qt_:-'.dif;_:,ddeciitcian.

I' 5 AMP F'k_g

_ Out_et

(_rourlded

1/t

/

Out!et

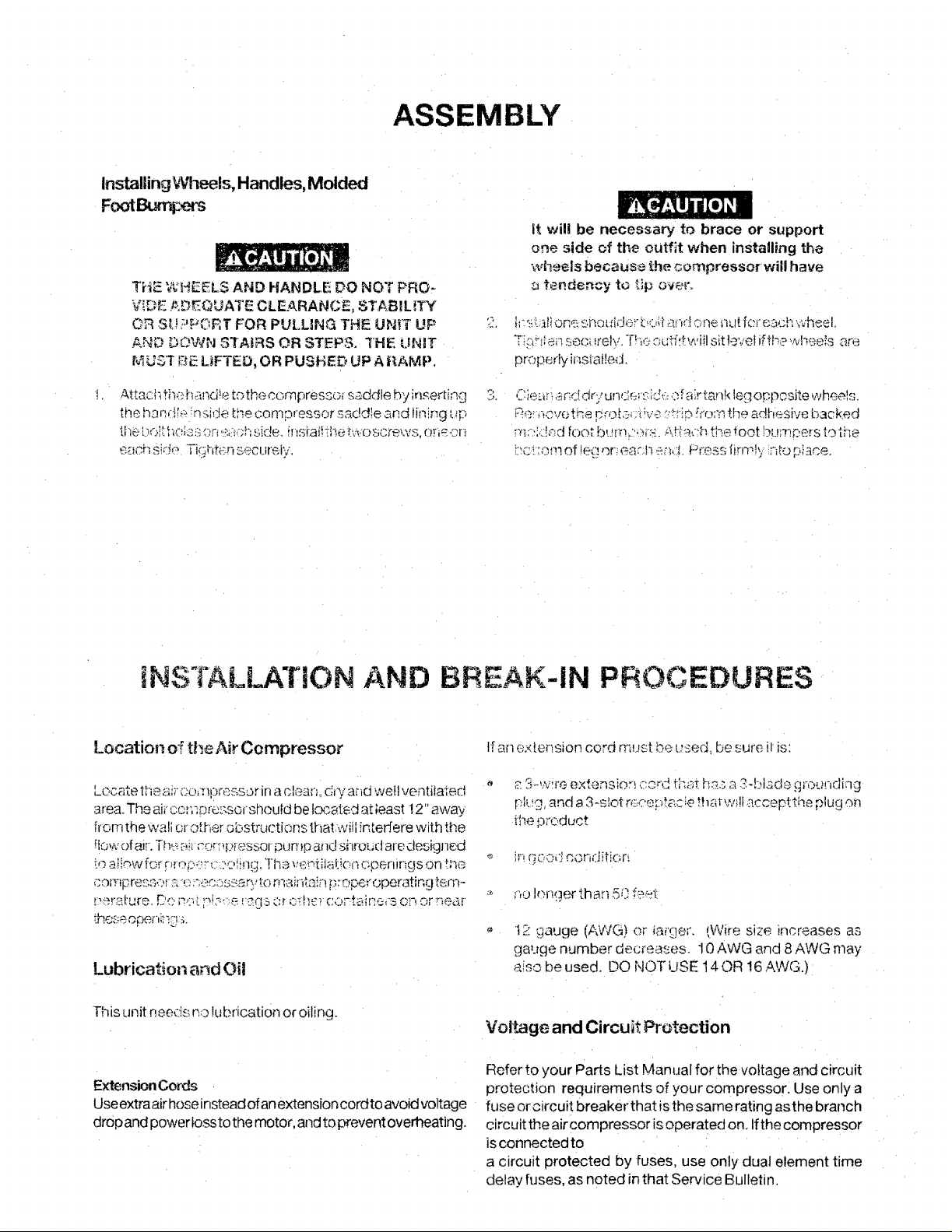

GROUNDING INSTRUCTIONS

R_S_k OR ELECTR|CAL 5t_©CK. !n the

ew€4°4of a short circuit, grounding reduces

the risk of shock by pro'ddin_ an escape

v_ire fo[" the electric current, This air corn-

presser must be proped'y g{our'_ded.

The podab!e awcompressor iseau sped with a cord ha.vir;g

.:!rcuaduq9 wwe with an app_ epriategrounding plug Thu

pk:r;!rriu _i [')eused with an outlet that has been installed a'nd

!$oundsd _ilaccordance wi lhal' Iota} codes and ordinances.

Fi_eoudet must have the same co_ffiguration as the plug.

DO NO"[ US_ AN ADAPTER TO DEFEAT THE

_b4::OU;,4;}tiiG FEATURE OF THE PLUG.

iMPROPER GROUNDING CAN RESULT IN

ELECTRICAL SHOCK.

"bo not modify the plug that has been

provided, If it does not fit the available

outlet, the correct outlet should be in-

stalled by a qualified electrican.

B ,eak4n Procedure

Ssrious d2u'nage may restttt if the following

M"-_:_k-- :_Mstructions a,'e not c.k,_se!y followed.

This _,_c,c_?d"_a :srequ;red or]lyonce, beforethe aircompressor

f< r'L t, ,[ "_S-__-_,"_,

1. S?-_tlY' "? eSsL!reswitci_ OFF/t_U'TO }ever in the

"OFF" bc r-:,tiof

._:':_.;qthe p.t._wercord h_tothe correct bra,%:h cu'cuit

T{._t'}A_)r ;!C!.2

3 rum _i-.er,%]uiator clockwise, openhqg it fully, to

orevent air pressure build-up in thetank.

4. _. o,etr e__.,f.F/AUTO e,_erto"AtjTO" Thecom-

pressor will start.

5. Ran thecomk_ressorfor 15rninures. Make surethe

regulator is open andthere is notank pressure build-

up.

6. After 15 minutes, close the regulator byturning it

,u,:.,',_nterclockwise. The air-tank _,_Aitfill to cut-out

pressure and then the motor wilt stop.

Refer.o Op..rudng Procedures .

OPERATING PROCEDURES

Before attaching air hose or accessories, make sure the

OFF/AUTO lever is set to "OFF" and the air regulator is

closed.

2. Attach hose and accessories.

TOO MUCH AIR PRESSURE CREATES A

HAZARDOUS RISK OF BURSTING. CARE-

FULLY FOLLOW STEPS 3 AN D 5 EACH TIME

THE COMPRESSOR IS USED,

Compressed air from the outfit may contain

water condensation, Do not spray unfiltered

air at an item. that ceuld be damaged. Some air

operated tools or devices may req uire filtered

air. Read the insth'uetions for the a_r too! or

device,

5,

Check the manL,facturer's m_xir,num pressure rating forair

tools-:..'_ldaccesscr :es -[he reguTatoroutiet pressure t; =us1

;,ever exceec;t he:#L&;4ii_;.JR"ipressure lating, t; your

compress@ is not suppiied wfh aregulator with gauge,

i,_stal;one befi_re using accessories°

,

Alwaysoperatethe aircompresso_inwetFventilatedareas;

freeof gasotine or other solvent vapors.

Do not operate the compressor nearthe spray area.

Whenyouarefinished:

7. Set the "OFF/AUTO" lever to "OFF".

.

Turn the regulator counterclockwise and set the outlet

pressuretozero.

9.

Remove the airtoolor accessory.

10.

Open the regulatorand allow the airto slowly bleed from

the tank. Close the regulator when tank pressure is

approximate y 20 psi

11. Drainwaterfromairtank.

WAIER WiLL COIqD'ZNS£ tN }_HEAIR TANK, iF

NO-[ DRAINED, WATER WILL CORROD_ AND

W_AKEN THE AiR TANK CAUSING A R!SK OF

.:kIRTANK RUPTURE°

_%";thtapkL)ressurea':appr:;x2,'ta;eb2Or;._i,ope- the@a ncoc <

ordraiA va!ve.

_O"i'[f:

,.:_es.,:,_'re. The valve c;:_n tber_ be removed,

,;

...... u ,_wat..r, ,--,,..,x._.[,, ,.:._:,_:.,.I ,.'.k%e,dmii_cock or

t !',-blr_"'_!v9. [1! :38it'_:ONIo: .:,!_:_:__":7;a:iDb;:vbe Stored.

TROUBLESHOOTING GUIDE

PERFORMING REPAil-3S MAY EXPOSE VOLTA("=_E" SOURCES, MOVING PARTS OR COM-

PRESSED AJl_ SOURCES. PERSONAL _JURY MAY O_:CUR. PRIOR !'O AT_EMPTI?_G ANY

REPAIRS, U_PLUG THE COMPRESSOR AND BLEK_ OFF TANK A!R PR_.SSURE.

_×cez:si'Je_ar:kp,:_1-':.!:,-.-:_,:__::!y-iajve

Pr ¢'S:._U:_:_sWJigi: r.J'.:,eSriot shdt .)If iT,etor

popsoff.

P:ess:._r9 switch 'k:LiDo:.lt ''too _:igh,

Air :oaks at fitlings, j

Alrlea_satDressu,_sw t_-_ etease j

valve.

Air teaks ip air tapi.: o.r al 3_rt_:,_l_, D._:fe,2_b,,_:ai¢i-,_.n_

w6_ds.

lui:e _ttfin,:_.<are not ;:ight eaot;gh.

i

Defective pressure switch releaseva_ve

Defective flapper valve in manifold,

Check V_/e so.atdamage,d.

i',1evethepresso'es,,dtoh leverto the"OFF >'position iftb,e

ot_t a_ar;'t shL_loff, _:r_dtheelectdc_!coF_:acts are w;dd...-_d

[ogeth_:t, r_plac_lh_:!t_.t-est_u:s swii'd'_.

:::1-t'_ur:'_the eLf,-ere__'..;:,:t-:::_.rdc_ Centertc c'h_ckand adiu_,

Tightep, fittings where air can be heard escaping. Ci_eck

fittings with soapy water soiution. DQ NOT QVER-

T}GHTEN

Removeand rep_acethereleasevaive.

Checkte seeifthe pin inthet_ttom of the p_essureretease

_aive is stuck, If itdoes not rnovefree y, replacethevalve.

A defective flapper va}ve resu}ts it.,aconstant air leak _the

pressurereiease vak_ewhenthere ispressurein the tank and

the compressor is shut off. Remove and clean or replace

v,,3_ie.

k_spectand replaceupper ma nifcld assemb!y.

Airtank mustbe rep:aced. Do not repairtheleak,

OO NOT D_!I.L =N"l'O _....... D OR O, H,-.RWk_E

MODIFY A_T, _A_. C._:_ _T WILL WEAKEN.

i THE TAFi_ CAN _t_.UPTUFI_. OR EXPLODE°

•', ...... : ..... i : _.......... _ %_,:_uN:_._zJsc:e'.',_to_,tLI(:3._R}_,iado.,::.s_iots_opi_=:,,

/. e .}:% ..bL_,,L:.-':: .... r_. • - _ _R_ ;i;': _:(-L:'_

is@to. :

_,r>..u_rt:.:: 'or some ;:re.z.sure,:J:,?;:.i.u I!lhere}sanex(:eE_:ivealr, ounlotpressuredrop_d_entile

p_e.>o_...... ,=g_auged.o_ _ ,J.,._r. , _ "'_..... _"",' ......... - 9:__[,'r. accessory }susted,?;_jUst't;'iGt'6q{_ ,l,_torfoilowklgti_e ;ns[:uc-

c_:ssors is d._;ad, tic;/?SOl_page 6.

NOTE

Adjust the reguteted pressure u_der flov¢ c,onditi,oi_s

lwhile accascry _sbeing used).

MAINTENANCE

UNIT CYCLES AUTOMATICALLY WHEN POWER IS ON. WHEN [_OING {qA|NTENANCE, YOU MAY BE EXPOSED TO

VOLTAGE SOURCES, COMPRESSED AJR OR MOVING PARTS. PERSONAL INJURIES CAN OCCUR. BEFORE PER-

FORMING PNY MAINTENANCE OR REPAIR, UNPLUG THE COMPRESSOR AND SLEED OFF ALL AtR PRESSURE.

ALL MAINTENANCE AND REPAIR OPERATI©NS NOT LISTED MUST BE OONE BY

_UALIFiED SER_ t_,E _ERSONNEL,

Ch,ckVa_ve - Replacement Safe_ Vaive- _nspection

_¢_ore servicing:

_,epJug or disconnect e_ectrJcal supply to

co!_!pressor,

_leed tank of pressure,

Allow compressor to cool

,: .....,.......:_,._,,e,..otto r .rTut5i-,i move the ¢,_ti,:.;__Lbe!dbt!T÷

s de.

3. Unsc_e,,','thecheckvalve(turncounte_ciockwise)ts n_;a

soc;.';--.t'wench,

4 ;;. :,._;i._ti ".a_the valve diz;s ,! o:,'es healy fnsS!,=[he oh6 ::k

,-,,-....,_.i!._,_-,......,"_'=_ .".h,_.,._,"I. do,_.>'_'_>rq'._V,b-_;........81R8Ted '_.,'J,h 8soi'._ei_'

;,._,:.'q{_.9fx;.;ntand y?.rnisi'_r :x7%',ver.

H the safety valve does not work properly,

_,ver-pressurization may occur_ causing air

1_:-_r_krupture or an exp!osion, Before start-

i_g compressor, pull _he ring on the safety

_,.-'_v,_et_) make sure that the safety valve

op_uaLes freely, if the valve i,,_stuck or does

ao_: operate smoothly, it m_sf. be replaced

_,:_:;_.d__he same type of valve,

!3e-f..}re yc,b-:store.the air compressor, n_ake sure you do the

folk, :vJc._;:

* i:i<:,,i<:, ff,_:::"[._,t:-:_i!st,f:{_nce"sl id "{}i.),_r&tiq{_P_ocedLires"

_<-.;t.: :: -._d period;r: i-,:ai:_tena;_c<:,__:.,"_,__:cess_O,. Be swc.

to:r:i#d,:,, v_::!,or,_ron_the air !ap.k.

2. !broo=(::?!:r:._eiectrJc7! cord ;;_nd::_;rhose from damage

?.;_:c',_:-__-"b_-.ingstepped 0n or £;,7o;_elf Wind ttTernloose!,,,

&r@._'c!!!7<_com,pressoriTaRdle.

S_-or__b,_ai_compressor iri aclean and @7/_ocati0n.

Ah !st_k iY_:_n_safety valve.

Rossible defect insafetyvalve.

C p_,.;ate safety valve mano_,tty by pul_ln_}on ring. lfvalve

-ti_leaks it should be replaced.

Kno,,. kk _gNoise Def__as_ti_echeck_atve.

_mp, _ss,Trisno_suppl}4ng enough

Pi_olonged excessive use of air.

airto '._i:_rateaccessories.

Compresso_ is not large enough for a}_

requirement.

Restricted air intake fitter.

Hole in hose.

• Ch÷_k vaJverestrictecl.

_'-'ir _eaks.

_,_r,Jn. !-L'._eUown circu,tbreakertrippe_. , f ..-_ ..... ,_. -H .... -_ -.-<_ ,_-

_.em,::ve and clean, or_eplace.

i2'.-:_-:re.a_::eamountof air usage.

Cl:._c <t" eaccessoni _ir req Jirement. !fit ish;gher thanthe

_.:_:_-M or oressL_re supplied by your _{i,_ccmpressor, ynu

".,_:_:_f a _r_er com_essor

C_,£,,:?ncr replace air intake filter. Do not operate the av

c::.n presso:, inthe pak_t spray area.

:g, :.,:'!:and _eplaceifrequired.

!:;,'_ _,Oveand clean, orreplace.

.: iTtennttilTgS. (SeeAir L eaksSection ofTroublesb, ooting

t L ii,.j_,.;

r_÷.):.:..,chocLlitbreaker. Do not use a i:_.;s_o; ('ircuit breaker

:, ,;:! 7gherrating thanthat specified _e_yourpart}cular

_-"q_ ";-'h CJrc uit

.-'.:*:;:'c, rprof_er _use You sbou',d i-:,s,[..:.::71!_*QuickActin9

. } _ :i(fl:;r low Vo;tc_d_eDrot_ienl.

,-, :.•:.-'.'_',:_r!Teextensionc,_rd.

:cor,r_._tttTe othereteotrical applisnces _-om circuit or

: _-.<,_ihe6orl_!)ress.o.'offi:so.wrff:_ran,dtc_cuit.

t::..Z_-_nsion cord is wion 9 ier_.:jt;,o, gaL_.y:

Luose eiectricaiconri_tiorls.

- .,}_e_e.,_te;76[of7cL}rd

* iqq conr_e,cticP, iP,s_deterniinai box.

': .... ,s

FaLsitymotor. .- '_ :becke.qatloca!Sea_sSan.,iceCt,.qter.

•P._:_::i:;t. '_.:oh co_:iinuous airleak. E.',_tyor damaged _egulatc_rh:terPal p£:.,t_ _ rep[ac.e _egutator, o_hsbs,rnai pa.__.s.

Reguls,'._. ,_,il _ot shut off at air

SERVICE NOTES

OWNER'S

PERMANENTLY LUBRICATED

TANK MOUNTED

MANUAL

When requesting service or ordering

pa_ts, always provide t!_e following

information:

• Mode_ Number

• Part Number

Part Description

, Name of Item

AIR COMPRESSOR

For the repair or replacement parts you need

Call 7 am - 7 pro, 7 days a week

1 -800-366-PART

(1-800-366-7278)

For in-t_ome major brand repair service

Cal! 24 hours a day, 7 days a week

1-800-4-REPAIR

(1-800-473-7247}

For the location of a

Sears Parts and Repair Center in your area

FULL ONE YEAR

WARRANTY

AIR COMPRESSOR

If this a_rcompressor fails due to a defect

irl material or workmanship within one year

from the date of purchase. RETURN IT TO

THE NEAREST SEARS REPAIR CENTER

THROUGHOUT THE UNITED STATESAND

SEARSWILL REPAIR fT,FREEOFCHARGE.

IF PURCHASED FROM ORCHARD SUP-

PLY HARDWARE, RETURNTO THE NEAR-

EST ORCHARD STORE AND ORCHARD

WILL REPAIR IT, FREE OF CHARGE.

Call 24 hours a day, 7 days a week

1 800-488-1 222

For information on purchasing a Sears

Maintenance Agreement or to inquire

about an existing Agreement

call 9 am - 5 pro, Monday-Saturday

1-800-8.27-6655

If this air compressor _s used for commer-

cial or rental purposes, the warranty wi!l

apply for ninety days from the date of

purchase.

This warranty gives you specific legal rights

and you may have other rights which vary

from state to state.

SF.AR$

America's Rel_il _i_tall sis

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

SEARS

MANUAL DEL

OPERADOR

I:RRFTSMR_

COMPRESOR DE AIRE

DE LUBRICAC!ON

PERMANENTE MONTADO

EN EL TANQUE

= PAUTAS DE SEGURiOAD

ENSAMBLAJE

OPERAC:I{_N

_' MANT_IIMIENTO

TABLA DE CONTENIDOS

Pagina

PAUTAS DE SEGURIDAD .................................................................................................... 3

TABLA DE ADVERTENCIAS .................................................................. ...::.............................. 3

GLOSARIO .................................................................................................................. 5

ACCESORIOS PARA USAR EN COMPRESORES DE AIRE DE SEARS ..................................... _.

INFORMAL, tON GENERAL ....................................................................................... 5

DESCRtPCt0N D__LA OP_.RA,., ..,,,t ....................................................................................... 6

ENSAMBLAJE .......................................................................................................................... 7

PROCEDIMtENTOS PARA _ iNSTALACION Y ASENTi\MiENTO ............................................... 7

Ubicaci&q def Cor_-'.presor de Ake .............................................................................................. 7

Lubdcaci6n y Aceite .............................................................................................................. 7

Cordones de E×tens_0n ............................................................................................... 7

Voltaje y Protecci6n del Circuito ........................................................................................ 7

lnstrucciones para Conexi0n aTierra ...................................................................................... 8

Procedimiento de Asentamiento ............................................................................................. 8

PROCEDtMIENTOS PARA LA OPERACfON ................................................................................. 9

MANTENtMIENTO ................................................................................................................. 10

Valvula de Retenci6n - Reemp!azo ..................................................................................... t0

Vaivula de Seguddad - !nspecc!on ........................................................................................ t0

Almacenamiento .................................................................................................................. 10

GUiA DE DtAGNOSTICO DE PROBLEMAS ................................................................................. ! 1

COMO ORDENAR REPUESTOS ............... ' .................................................................................... 14

GARANT[A ........................................................ ,....................................................................... t4

PAUTAS DE SEGURIDAD - DEFINICIONES

Este manual r.;ontiene informacion

que es irnportante que usted sopa

y en[ientta. Esta informacion se

relaciona con la proteccion de SU

SEGURIDAD y la PREVENCI(]N

DE PROBLEMAS AL EQUIPO.

Para ayudarIe a identificar esta

info_macion usamos los siguien[es

sfmboios. Per favor leer este

manua; y prestar atenci6n especial

a estas secciones,

_NFORMACtON DE SEGURtDAD URGENTE -

UN RIESGO QUE CAUSARA LIESIONES

PERSONALES SERIAS O LA PI_RDIDA DE VtDA.

|NFORMAC!0N DE SEGURIDAD IMPORTANTE

- UN RIESGO QUE PUEDE CAUSAR LESIONES

PERSONALES SEll]AS O LA PERDIDA DE VIDA.

[,_ PELIGRO ]

[_ ADVERTENClA 1!

[& CUIDADO ]

Informaci6n para evitar daises at equipo

[ii NOTA ]

Information a la que debe prestar

atenci6n especial

iNSTRUCCiONES iMPORTANTES DE SEGURIOAD

" C__Q!!S_SRVAEE$_ASI_N_TRUGGJ_ONE_,

f_JE$60 OE CHOQUE

EL#2CTR!::;O

_,M_D/£!GA(:!.gN_'::-::ne c_utorizadas!t_

SF.GUFI_OAB O a cualqufer OTRO

COMPONEf,ITE _ !,J_7___Q_{).__.PJ_ I___tLJ,._4

PRESt(')N de! ;3nqt:,s,

ADITAMENTOS Y A CCESORIOS

EXCEDER LA G_,PACtOAO DE PRESTON tie

LAS HERFtAt'_!IENTAS NEUMAT!CA',_,

pistolas rociadoras, accesorios pare aire.

fias",tas, y OTROS AF)TIOULOS INFLABLES

P_U2DE_bIHACERLO£ EXPLO'TAR O_SALIR

DISPARADO_.._AU S,AN OO LESIONES_

SERtAS.

"gj_C__O__,._t&_6E_SP_-L_!qT;..Ai[_.f_£,opera con

electricidad Come cuak.:_td.,<;roho disposi[i_,o

C,gNEXI6N A TIERFiA; EL NO HAOER

ADECU..,',,DAM__TNT£ LA CONEXi0N A

TI_IRA DE ESTA UN_DAQ_.pU__EEOECAUSAR

LE#!O_TgS_ SgRIA_SLQ MUERTE D_gIDO A

Iiy3TRU_CCj ON E$ _Oi.C_Ot24_IX}_#lA T1ERRA_

APLk,A#LE,,.

..... CL"_'.,_A.

[:=1 ....

_AS_i_fi_ZA__S_nia te;'sr ' ......... - ..........

PRES!Oft_S de ,r ...... lo27_;<.L!v_._+A,z __ ,_

Siempre observar I% recoftleRdacioqes L_'_"_-:

fabric_nt9 de! equipo y nunca exc_,,,ie_-la p_'esi0h

maxima especificada pars un adJtamen[o. NUN_'{_

NIN#_& 9ELOTAS DE FOTBOL_

cual est-_ conectado e! compresoq ES-f£

_:_._t;_--_'C,.T,¢IDO._A_._ZLERRA EN FO_M:_

&2_B:Q_f_I.Ai_.)__L.__:__£]3__VEA EL _'OLTAJ_

COFiF_EG_'O Y _r_NGA . P_LQT_C_j.t_N

. _ RIESGO

L__A__ES EFECTUAD.D_AS POR _rO___D_D.O_C_ABLE,ADOO REPARACIO__N QUE ESTA

P.ERSONAL_ADO PUEDEN C_.A_A__.&B LiNIDAD REQUIERA DEBE_REALIZA_

LES!ONE,,_,_LEB_IAS O MUERTE DEBIDO, A =PERSONAL =QALtFICADO DE _ERVICIO

___. ACATAN DO LOS CODtGOS ELI_CTRICOS

&DEC UAD_MENT__ LA CONEX|ON _ATIERRA DE AL CUAL ESTA C©NECTADO F_LCOMPRESOR,

LA_I)NIDAD_P_t__Er3E_C_SARLESIONESSE_A_S E.qTE CONEOTADO A TIERRA ENi!ORM&

LA'5 LNNSTSU_CClO__4ESDE CONEXIQN A TIERRA _Y_._e_N_3A F'_OT_£-'C,_!0N AP_#_.U..=&AA._M._._O_!#N];E

DANAR EL TEJiDO HUMANO BLANDO DE LA PIEL D5 GEGURIDAD ,}ON Pi:K)TECTORES LATERA.LES

EXPUES/A Y PUEDE !_M.P2J_kLSA.___R_TIEIRRA, Qu£.C_UM._LJ_'j_Qt)0__(.___NORM._=&__=NSIZ6_7_..j

PART_C!,JLA._ Y OBJETOS _c:_ r: ,<.

.... f ,::.iv. _:NOc SUELTOS

A "' '"'r" ' _" _ _!!J;_K_:'A'_"iNT_P' i _ ,_:J..A ,, A C .... ROCf-_9OR

MiITER_ALIS O L.ES!ONES Pi'-RSONALES. Hi .:_./Wx!M,:U.E!S.

"{;aj

QUE PUEDE SUCEDER COMO EVITARLO

NACIONALES Y LOCALES.

4_,_3........ _,,..ES _LTA-3, C_[JSANDO DAtqO'.:; i_ .,-. !.}-,':L

.... _.'' P."FH _-T. (}:U,?_?FO,_q_,'q._._._P_F.LS,.'71NA_3

S![::i,_tPRE A%_ _ £:%',.,,._MR_tkSOR v ALIVlAR

Li',_£B#:s!O__ D[i LA _.i,,'4_& r__2,V,a,_ _J"[___S DE

iNTE NT!_,R fP,_L, L: f,,IAN TE NIMIE_,,ITO O

._.'£-;_÷

>;P_J

RESGO A LA

. . :.,, COMPRESOR iNO E&S__AtjB_Z&P.&BA__RES£!:RA_r C Qi_'_IRR_LS__[:i, YA SEA DIRECTAMENTE O A

_=SPIRACtO,,, EL CH'ORR© DE AIRE PUEDE CONTr:NER Tq@¢¢S D_ U_-,;_' <-,_,_-,o._-rW: Pi_,RA RESPiRAR

r MONOX_DO DE CARBONO. VAPORES TOXtCOS. CC'NECT_,DO )d. COMPRZSOR.

I;'";':O''':_"/&" 3_. 0 PAtqT,CLILAS 80LiDAS.

i)_i# :"::./;" LAS SUBSTANCfAS PULVr-RJZADAS TALES _.&.B_A_.J_.[L.E_j)_J_REA2Bj_N_VENTILA_A _

_':;:1" REMOVEDORES D_ PINTt)RA, INSECT!CIDAS, .................SEGLIR!I3ADF,_R,j_,-.,,',-r_{._,_,,> Ebl LAS i{ t'IQ!.JCTAS Y

RIESQO DE CAI©AS LN C_LO)_P,.Rf!##[L£O£_b.I;!;_.RL!_L',I..{;A_B'3-_2 ! S :Tfi,P'--'-i::!:.:.-'__82,'_;_L,fL.L'_:&O.___,:_B£/,:_:AB_{S__ii__O.N_A_

--" j D8 UNA MESA, B,'\N:30 {)k'_T_qAg.e,JO O TE_., _O, _:(a_l:,.:_t-!__:t:_._}L.'LtAi-Tt_Y k:StA3U} .,'-'ARA{-v'tT,_R_:_-'t_-

• , i g_.'i_'_£'-._-:'J._At'4 DO'._'L.___"........DAi'IO::,:-___L"AI._i':':_.,=_a-.&,'.,/_/__R_SO_ _[Lhs'.__" ,'.,_...._i !'_;_}_:,i) -":_. _:__K',,,s ACCK.F;:TLLMENTE.

EL AtRE COMP_tMIDO PRODUC ,90 POR EL N_-_!_i"_-_-L..L. _ " " =_

COMO PINTURAS, SOLVENTES DE PINTURA, LEE£ Y _.C.Z!_ ..... iNSTRUCCIONES rOE

H_RB{CIDAS, ETC., CONTiENE_ VAPORES -.,.,,_o ...... _ _" _ !'"

i" du i

..... _HA-,-;_ _- A!F!E PROVENIENTE DEL

"4 `0 i_': D.:',It')S nE .bEv_.R u,.D DEL

N!#8.'d!_/g_L4._,_Y L:!,S*Z_AC:OPA£A LA t,_LA£Ag.[_

i£:3,"ECIF]CA

,,.: . , : ,.q ::_{:,.L::i a'. L; .-.',!'-T:':::- :_ {_LiViAFI LA

O /,L; ;;£,;.91x <:!_

, 4<' ,,_,

_.;.1 _.z_,..kd.C.O__jO:,,,O,,. :_'.._!--_ 2- .>.'±a..'=_!:2._£_..;2 ' = ;L , it' :-'' ,,;;a i; _[::L[_'::[Z_S:j:)::_,:id.9£TL

.................................................. ]:.:,. , :z.,'z

.C)}'_}}b.kE'iizF:,;5. _.E2'),._ ffI:')S!I3L"_:" Y TdE'.,r-'.=_3',./i

............................................... L'2£2,ZC7£._.LLL1L-]£.'7- _ {T;_.£ ___ ..................................................... ;.............................................................................. ..................... I

i

I

GLOSARIO

CFMi Pies cL_bicos por minuto.

SCFM: Pies c6bicos est,3ndar por minuto; una unid_d de

medida det aire producido,

PSIG: Libras por Ougada cuadrada e[das en 91pm?,.r,6n=e!ro

una unidad de medida de presi6n.

ASME: Amer_caiqSocisty of Mec,hanicai Eng__:e_:..!S-__,-{Med

Americaaa de !ngenieros Mecaniccs}: _,c=:;_: _:;...<:.'c'.,:'..

inspeccionado y regislrado para cumplir con _o.:;es,__::_&:_res

de ASME.

Registrado pot U.L.: Este producto ester.P,e?'s:,',_:dc.F,o:

Underwritem Labora_.odes, Inc. (UL). UL eva!t.',_muost._s {ie

equipos en producci6n y encontro que cun"piiar con !as

normas de segundad de UL

ACCESOR ,...,: %RA USAR CON LOS

COMPRESOR. S DE AtRE DE SEARS

,' PISTOLAS PULVERIZADORAS

I, PtSTOL&S SOPLADORAS

• PISTOLAS DE AIRE APLICADORAS DE

MASILLA

• CEP!LLOSDEAIRE

• FtLTROS PARA L1NEAS DE AIRE

• MANDR1LES NEUM,_TtCOS PARA LLAN]I_S

• TANQUES DE PINTURA

• TANQUESDEAtRE

• EQUIPOS tNFLADORES

• JUEGOS DE CONEXION RAPtDA

(Vados tamahos)

PRESK)N DE ARRANQUE: Cuando elmotor est& apagado,

la presi6n de aire va disminuyendo conforme se contin6a

usando et accesodo. Cuando la presion del tanque cae a

cierto bajo nivet, etmotor arranca automaticamente E£4 baia

preskSna la cual el motor- a_ranca automNicamente, s_ !!area

"presion de arranque".

PRESIf_N DE CORTE: Cuando se arranca el co!:Tpret!or de

_i_:ey o_pieza 8fur Y.;io!_ai.2!8 re gel tro de! tar que .SL'T'_en;";_

a acumutarse hasta cid}i:) nJvetde presi(:,n en 81L',_#,:_ir_-ic_gr

se a,oagaau_omaticsms;;_e para proteger el tanque de;8ire .L'.'8

presiones que exceden su capacidad, La presi0n alts_a la ct _al

ei ;aotor se apaga so i!ama "presi6n de co4eL

• REGULADORES DE PRESION DE AIRE

• LUBRICADORCZS PULMERtZADQRES

• F_£RRAMIEN_.S ,"qi_UM.-4,T!CAS:

Taladros - Uso interrnitente

Uaves de impscto-2 Uso Intermitente

,, MANGUERA N_L£q_,TiCA

1/4", 5/16"o 3/8" Diam. Int.

De vadas longitudes

• Cb_,VADORESiE NGAAPADQ RES

LIMPIADOR DE DRENAJES

INFORMACiON GENERAL

Usted ha con'prado una unidad comp,,_esom d_ air-_de _._,-_

c;lindro, consistente eo.una bomba compres-o_-ar}_ono_£spica

de un solo ci!i_dro, un tanque de ai;e, ruedss r,-ii!Li,.a,:Jer,

medidores y asa

Es_e corr:pn_,,scrge aire no requiem ac_i[e, AJ_c_'_as,,}pu<ie

gozar de _os los beneficios que brinda tenet un <;emp,_ssoF

de aire sin tenet que comprar, acjegar o c.3rnbi,_r c4"ei!e.

El corr,lpresel de aire puede usarse p,:_i'aops_a,' 'i_qsb_)i::x_

puivedzadoras de pir_ura, i_errarr,_ientashe'...;'_S_ic/_s,c<L_:,F}cs

de aire, irfflar lia:K::_s y juguetes de pl4sticr_, mciar

herbk'idas a insecUcids.s etc, Se _equiere ur_r;:,{iu!edor

d:_ .:'.i_epara la _r_aycr{a de !as aplicacioneso

CuLr.q!t]O tU_Se F}8. ;OL:L_2i'['. _,9 'Je}_'_. US-.]r Uil tr_qs{_:i .; _:.4_o_ ,Je

aire independien _e',-qt_e.our:_bine las funciones de _e,_!u!sc:,!:,n

de {,Jreyio e!iminaci6r_ tie i_umedad y suciedad.

Estos accesodos pued.sr;cornprarse en lamayoria de Ti_;ndas

Sea_so pot msdio dei C_:iSiogo de Herrsmient,.:_s Ti;ectdcad

I,,"leum-Aicas",(secle.:__-s,

DESCRIPCION DE LA OPERACION

ii i i rill. i

Bomba del Compresor de Aire: Para comprimir aire. elpist6n

se mueve de arriba a abafo en el cilindro. En la carrera hacia

abalo, e!aire ingresa por las valvulas de admisi6n. La vatvula

de sa]ida permanece cerrada. Cuando el pistbn corre hacia

arriba, el aire se comprime. Las vaJvulas de admision se cierran

y et aire comprimido es forzado a salir por lavalvuta de salida

atrav6s d_'ftubo de salida por la v_,tvulade retencion y entra al

t_nque de aire. El aire no esta disponibte para trabajar hasta

que elcompresor eleve la presion en et tanque pot encima de 1o

requerido en el punto de salida de aim.

V_lvula de Retenci6n: Cuando et compresor de aim est.5

operando, la v_lvula est& abierta, perrnitiendo que el aire

compdmido entre altanque. Cl_qdo etcompresor de aire !legue

a ta "presi6n de corte", la v&lvuta de retenci6n se "cierra".

haciendo que el aire se quede dentro del tanque de aire.

V_ilvula de Alivio de Presi6n: La v_lvula de alMo de presi6n

que seencuentra atlado del inte_uptor de presidn, es-ladisefiada

para dejar escapar automaticamente el aire comprimido de!

cabezal de_compresor y det tubo de satida cuando el compresor

de a_realcance la presion de "corte" o se apague. Si et aire no

sale, e! motor tratara de arrancar pero sin Iograrlo. La vatvula

de alivio de presion le permite al motor volver a arrancar

libremente. Cuando el motor deja de funcionar, se escucha

escapar aire de la v&wula por algunos segunclos. No deben

escucharse fugas de aire cuando atmotor este flJrlcionando.

lnt_rruptor de Presi6n: El intemJptor de presi6n hace ar_,a,ncar

e!motor automaticamente cuando !a presion baja del nivel de

presi6n de "arranque" fijado en ia f&brica. Tambien apaga el

motor cuando la presidn de! tanque de aire sube hasta el nivel

de "corte" fijado en !a fa.brica.

iii i ...............

V_ilvuladeSeguridad: Si elinterruptOrde presi6n noapaga

el€ompresor de aireen lapresiondecorteprefijada,lav&tvula

de seguridad protegera el tanque contra la alta presion

activandose alapresi6n prefijadaen fabrica(ligeramentemas

alta que lapresi6n de corte fijada).

Regulador: La presion de aire proveniente det tanque de aire

est& controlada por el regulador. Girar la perifla en el sentido

del relol para aumen_ar tapresi6n y cont_'ael sentido del reioi

para reducir la presi6n. Para evitar reajus_s menores despu6s

de hacer cambios en tapresi6n fijada, siempre Ilegar a una

presi6n supedor a ladeseada desde un nivel inferior de presi6n.

Cuando se reduce la presi6n, siempre bajada mas abaio del

nivel deseado y luego subirla hasta el nivel que se desee.

Dependiendo det requerimiento de presi6n de cada accesorio

en particular, lapresi6n de salida debera ajustarse mientras se

opera el accesorio.

Medidor de Presi6n de Salida: Ei regulador de presion indica

la presi6n en la salida del regulador. Esta pcesi6n ia controla

el regulador ysiempre esmenor o !gt:ata la presi6n del tarTque.

Ver los Proced_m_entos de Operac_on.

Medidor de Presi6n det Tanque: Ei medidor de pre.sion del

tanque indica lapresi6n dentro dei r_a_-_quede reserca.

Sistema de En_amiento: Este compresor [iene un sisterna

de enfriamiento avanzado. En eln_]cleo de este sistema de

e__,iamiento hay un ven.ilador eo_e :iat,nente dioerhado. Es

parf, ectarnente nor-real q_e el ventdador bore grandes

cantidades de aire por los orificios de ventilacidn. Se sabe

que el sistema de enfriamiento esta funcionando cuando

expete aire.

HERRAMIENTAS NECESARIAS

PARA EL ENSAMBLAJE

* UnaflaredadooIlavedebocade 9/16" parafijar laspJedas. _ Una llave dado o tlave de boca de 3/8"'para ajustar los

tomiltos del asa.

ENSAMBLAJE

Instalacion de Ruedas, Asas, Patas de Caucho

moldeado para Apoyo.

LAS RUEDAS Y EL ASA NO PROVEEN

SUFICIENTE ESPACIO L|BRE, ESTABILIDAD NI

SOPORTE PARA SUBIR Y BAJAR ESCALERAS O

ESCALONES RODANDO LA UN|DAD. LA UNIDAD

DEBE LEVANTARSE O RODARSE POR UNA

RAMPA,

Fijarelasa os iamon'rLtr_de! complesor el__,F.ui.f_,ndo!ohaste

que !osorifictos p;._raoemes queden alir',,e:_dc,s a cada '. : -

nstR_r osd,--sE_.:rrlosi.Irtoa cada lade g#!stf_rfilrr;em.anto.

AI instalar las ruedas, tapas de ruedas y pie

de caucho, sera necesario fijar o sujetar un

lado dei equipo, porque el compresor tiende a

voltearse.

0

instalar un pem,otoDe y una tuerca en cada meda y aiLtsta_Ia

firmemente. Et equipo se nivelaM si las _uedas se ir,stai-:_r,

apropiadamente.

O.

Lirnpiar y secar [a parte inferior de !apata de! tanq_ !c que

es@,opuesta aias _u::_tas.Retirar ei papet ptok,.cior :Ld !::.We

ai_toadhes;vo de ia 'baitL_u-_d,_f_-a','"",, _: >- ' i-,.... _',

firrneme,qte pare Fiiaren posicion.

PROOEDtMIENTOS PARA LA If ,..TALAO!0N"S

ASEN3"}! ,M tENTO

Ubicaci6n de! Oomp_esor de Aire

Ubicar el comp_ esor de aire en un area t_n_.,=...... ca y bien

veni_ilada. E!compresor de aire debe ubicarse per !o menos a

12" (30 cm) de !a pared o cualquier obstrucciSq qHe pueda

intofferir con .elDa]o de aire. E!cabezal y la c,ubie4a de la

borT%a de! compmsor de aire est_ disefiadc)s pare pem)itir ei

enfrian]ienLo aprepiado. Las abertt.lla,"s de _'=a_',.,t._.i,¢xc,toD_"' _ e_',."_ _..Id

compmsor son n÷cesanas pare mantener ia tEn_pe{abjra de

operaci0n a@_cu:!da I_ocok)car tropes ni oti'Os c.ont÷w_or,as

:-'.:;b_9r:;c!rede,_i:::,Je es_as;.lbsrtura.'-'..

u__lt,a.:,., ,......._.-, :_,_,_t._.,,tfubricaci6

P_ra etita_'14,:;F_c _ _e _4:,!t_ie pd_,rddac e pc.t{x Us d _ T',(20i ?

cord<}r!de e;-(l'÷_tsk::;n.

S_se hate necesafio usa_oun cord6n de e£ensi6n:

Utilizer solo cordoqes de extensfon de 3 alarnb_es. ,_nchu?a

con espiga para conexion a tierra, y un tOIT!aCC!Ti::r_:};L]Ue

Qua no tenaa l"n_sde 15 nVS0 pies de ar.en

,. a, bFe ! ' ._ _ fr!as grueso U- r o,.:_-

n!syor c:u_::_iire r,,_e__orsea su notate. _:tm::i_: ::.;:-,.!,.._,:., ,.;

CALIBRES i J _il !"6 i_,_v.=./

\."o;_je y P;"o_ecci6n de_ CL,_ui_o

i;:ara IOSre.qi;erii'_:!eril3s d:_ protecci@s de '1o{:;_i:;:: [_.4.i:?:,1_

<I;;i:?.orf!pre,qJqefeHn:b _dManc._jdo L.ista,Jef:]_.sp,,r<_:,'c,:::,:.) :::r

?;{:,IC, Lffl flJSibi-.:_ L._,i ',L:_;!_';. LO! d8 CirL_ f!_..; de., ! . .; ,_. '::! :U:;_T_i::;

:_u_._et,sirccito e:_9; c;'_:a!esi:-aope_'a!i,:_o$i co_r/_,be;vA:;;.-_8'.s

Si ei c,ampresor de ai:e ,_staconectado a ur] cfrcu% _._+'ch;_._fq,:}o

per fusib!es, usherOnicamente hisib_es de reta¢cl,,:_d.s do:de

o;dmento, taJcome se indies en el Boiet[n de S_wvicio.

Referirse a la Lista de Partes en el Manual det compresor.

Ciertos modelos de compresores de aire pueden operar en

circuitos de 15 Amp. si es que:

1, El Suministro de vottaje at circuito es normal.

Si no_seentienden estas instrucciones completamente, o si se

tienen dudas en cuanto a qua el compresor este conectado a

tierra apropiadamente, hacdr vefifiCar la instalacion por un

electricista calificado.

ilL!i::

2. El circuito no se usa para suministrar electricidad a otros

equipos, artefactos, luces, etc.

3. Los c0rdones de extension cumplen con las

especificaciones. ..

4. Elcircuito esta equipado con un interruptor de circuito de

t5 Amp. o un fusible de retardo de 15 Amp.

Si no puede cumplirse alguna de las condiciones mencionadas

arriba, o si fa operaci6n del compresor causa interrupciones

repetidas de energia, puc--_eset necesario operar etcompresor

en un circuito de20/_mp. No es necesa;io cambiar el ju,_o de

cab,_s.

BNSTRUCC|ONES PARA LA

CONEXi6N A TIERRA

RIESGO DE CHOQUE ELECTRICO En caso de

cortocircuito, la conexion a tierra reduce e!

riesgo de choque electrico facilitando ur_

atambre de escape para !a corriente. IEsLe

ceJ_presor de ah'a debe coneciarse a t_e_ta

aprop,_adamenLe,

E!ccmpm$cl de abe po,!;£titesta eq_.tio_,do con un co_J6R que

t!¢qe bn atarnbre pare conects, atieP,a y un enchufe adrscur:ldo

para tierra. El enchufe debe conecLarse a un tomacomente

instatado a [ierrs de acuerdo con los c6digos y ordenanzas

locales. Et tomacotriente debe tener la misma configuraci6n

que el enchufe.

NO USA_ ADAPTADORES PARA BURLAR LA

CONEXION A TIERRA.

LA CONEXt6N INADEGUA.OA A TIEP_RA PUCD.,"_"

R.,.,S_.]i_R EN CHOQUiE EL[_:CTRtCO

r _ ii Wjll L

Alambre

Enchufe de t5 Amp

TOrT_aC.Or_'i_T_t _ COil

COr_e_i_i] _ _e_la

Tomacotriefl[e,

@

\ .

/

/

Espla_ _,ar3

Tier_a

Procedimiento para el Asentamiento

S; no se ob.se,_van ias instruccio_es para e_

ase_itamie_to abajo indbcadas, se p_ieden

_ausar s_-io_ da_oS.

be r_qutere seg_ _eoLe,procedural _. Los61ouna vez, antes de

poner el compresor de aJreen se_vicio.

t. Fijar la patanquiLa "OFF/AUTO" (Apagado!Automatico)

del interruptor de presi6n en ia posici6n de "OFF"

(Apagado).

2. Conectar el cordon de extensi6n en ai tomacordente

adoc_.kado.

3. Girar el regu;ado[ en el sentido del reioj abrierldoio

comptebamenLe p?,ra evitar que s,Jacumu!e presiOn de aire

dentn3 det tanque,

iL Mov_:_i i_', p_ia,._qaita do Or_:iAUTO a "AUTO". El

.r.:©Ripie_...,.r_:_tr'Sn¢.._._-_.

;_i. []8i_i_'.Jrick:,it_,',re:,':or_:_9'=rt .''''_ _: "_;Y _,_: _ " '- _-_ "_

(TiU3 _:':i;';SL:id:_.:;dJ_, "&:i,_:,'_:L:!i}di _.07 i:,L !": }'I,"" 1: ,,'Y.;;_; :'!Li, :i" !('i _

@

_111S}3(:!U_:':_:_!C::;.;_C_':)J:'__',._Si':_i ! (!(.' O: ;ii:,,] ]1 :'i _',,.;._i'_'................o,-_r _ %;,J._.s

PROCEDIMIENTOS

PARA OPERAR

1. Antes de conectar la manguera de aire o accesorios.

asegurarse que la palanquita "OFF/AUTO" este en la

posicion de "OFF" yque etregulador de aire este cerrado.

2. Conectarla mangueraylosaccesodos.

EL EXCESO DE PRESION DE AIRE GENERA

RIESGOS DE EXPLOSION. SEGUIR

CUIDADOSAMENTE LOS PASOS 3 Y 5 CADA VEZ

QUE SE USE EL COMPRESOR:

El ait, e Comprimido proveniente del eqnkJo

puede teneF condensaci_n de agua, No _oc!a.'

en mate_._les qL;_ puedan daSars_ c_n a;T.;

sin filtre_, A}_unas herramientas y accesoriL, s

neum&ticos pueden requerir aire fiit_aeo. Le_

ias i_st_co;o._es de las herraraientss y

accesorios :_eum_ticos.

& V÷dficar los ranges ae toresior_ maxlq'a p_',ra ;.:_s

herranqientas y _ccesor_os neumAticos_ L_),s,ql;d_;_,:-jei

regulador d9 presion nunca debe exce,uer la p_-,._s;cn

maxima. Si el compresor no estdviese Qro_is._o de _n

regu!ador c(_r_medidor, instalar uno ar;[es de L_:-'.?,,__:::S

aoce,_rio5.

6; Siempre operar el compresor de aire en areas bien ventiladas,

tibres de vapores de gasolina y de otros solventes.

No operar et compresor cerca del area de pulvedzaci6n.

A! Terminar=

7. Mover la palanquita de "OFF/AUTO" a la posici6n de"OFF"

(Apagado).

8. G}rar etregulador contra el sentido del relo} y fi}ar_apres_6n

en cero.

9.. Retirar laherramienta neumatica o accesorio.

10. Abrir el regulador y permitir que se drene ef sire del tanq_e

tentamente. Cemar e'._,egul_..dorc_3ndo lapresicn del ,_s.nqu<_

e's_:een aproximadameo,_e 20 PS!.

1i. D;-enar ei_gua de{ ai_9d£_;tanque.

EL AGUA DEL AtRE SE CONDENSARA L*;E_,I'I°S{;>

DE_L TANQUE DE A_E Y SI NO SE DR_r;/_, £-

AGUA OORROER_o v £EBILITAR,_ EL TANQt_ O_

A!!RE CAUSANDO b_ RIESGO DE RUPTURA.

P_;..'°o,drenar la hurnedad _,brir la v_Ivula de satida c de d_en_i,-_.

cur., la p, _ o _u_l ta, ...._,. _ ap ux rr,adame, t_ ..... _.

4. Cotocar I-:__Oa[_P.qLIIt3 de "OFF/AUTO" en "AUT_-_;,"

permitir t:iue e! tanque acumule presl6n El mc_o: _:-_.

de[entire, cuando ia oreslon ;fegue a{nivei de pres_Sp d÷

cor[e.

5, Abrirel regu]ador girandolo en el sentido del reini. Fij_r ei

regulador a ia presion correcta. Ahora el compresor esta

listo para usarse.

NOTA

Si la v,_lvuta 6,__;_:_;ida se abaca, sotta_ .'.ed_, i::_

presi0n de rare. £;_smontar la valvu_a, li.mp_ada

!2 DesDu#-s de dren_ _; _gua, cen-ar la !lave de s3hd_Jo ',l_._,e

de d_naie. Ahor:_ t_!,,.._4,'- _._,eguardarel comprescr

MANTENi IIENTO

LA UNIDAD ENTRA EN FUNCIONAMIENTO AUTOMATICAMEN_E CUANDO ESTA ACTIVADA EN "ON". AL DARLE

MANTENIMIENTO, EL OPERADOR PUEDE QUEDAR EXPUESTO IA LAS FUENTES DE VOLTAJE, PARTES MOVIBLES O

AIRE COMPRIMIDO, PUEDEN OCURRIR DAI_tOS PERSONALES. ANTES DE INTENTAR HACER REPARACIONES O

CUALQUIER TIPO DE MANTENIMIENTO, DESCONECTAR EL COMPRESOR Y ALIVIAR TODA LA PRESJ(_N DE AIRE;

TODOS LOS TRABAJOS DE MANTENIMIENTO Y REPARArCII3N QUE NO SE INDICAN AQUI DEBEN SER

Valvula de Retencibn - Reemplazo

Antes de dar servicio:

* Descon_ctar el compresor o cortar el

suministro electrico.

* Dr3nar la presi6n dei tanque.

* Esperar a qu_ se enfHe eJ con3presor.

1. Dejaresc_l_r todoelairedeltanqueydesconectare!equipo.

EFECTUADOS POR PERSONAL CALIFICADO DE SERVICIO.

Valvula de Seguridad -Inspecci6n

Si la valvula de seguridad no funciona

apropiadamente, e! tanque puede sob._ecargarse

de presi6n y romperse o reventar. Antes de

arrancar el compresor, haiar ef ani!io de la

v&lvula de se_ju_idad papa asege_arse que la

• atvu|a opere _iibremente.. S_ _a v&lvu|,3 se attaca

o no opera con suavidad_ ree_r,,pl_zarla co_ otra

de| mismo tipo.

2. Af!oiar las tuerca inferior ymover el tubo de saiida _ un

costadc.

3_

Desenrcscar ta v,_!vula de retenci0n (contra el sentido dei

reloj) usando una Ilave de dado.

4.

V_,riBca_rque e! disco de la v#',vula se mueva iibremep,_e

dentro de tav_[vLiia(:;.9_'e(encion yqde e{resorte rnal_,tepq8

8Jdisco e_,.i3 posicior_ ce;rada s;.li)er!or. L8 vStdb'ia CJ_:?

re_enc_Onp_J_de li_ _,*,;::.:_'secon tin sol'_',c_te, tsf corqo uc_

¢emoved,:srde pir_tu;ss y bamices.

5. Ap icark_ set!ador a I.__,osca ,:_e...... v ._lade, <.,.n .... ].

Reinstaisr ta vS_vu!ade r .t:, _ion

e _n_--_, (girar en et sentido"o'

reloi).

6. Volver a poner el tc:bo de sa;ida v aiustar ia t_erca ;nM ;,::,_

,_mt_cenaje

Aseguracse de hace_' io siguiente aptes de almacenar e{

com_resor de aire:

!a Oper_ci0n' :, _qc.e_!,e€ r;_,ar_t_mimie;.:9 r_t_,::esah".

ASe%Jrarse de ::i_gn3y,._t;.!guade! sips;%,._ ._,ehub!cse

acumuiado en el tar_qu_ de ,]i,?

2. _-#o[eqere!cor,_on nl_ ,._ov iR:3r_o{.i,?ian,'L::dm_{,cadieda¢_os

{tales como pisar/os o pass: po_-encimaL Enrollar!os

Guardar el compresor de aJ_een ur_!ugar seco ylimpio.

GUJA DE DIAG E PROBLEMAS

AL RACER EL MANTENIMtENTO PUEDEN QUEDAR I_XPUESTAS LAS FUENTES DE VOLTAJE, PARTES

MOVIBLES O FUENTES DE AIRE COMPRIMIDO. PUI_DEN CAUSAR DANO_ PERSONALES. ANTES DE

INTENTAR HACER REPARACIONES, DESCONECTAR EL COMPRESOR Y AL!V!AR LA PRESION DEL

AIRE DEE TANQUE.

PROBLEMA CAUSA iSOLUC!0N

PresJ6n excesiva el! et tanque. Et inter,,u,_io_ de _:,,-esi3,;_,r_o a!_flga _el Mover fa palunq,.,i}a de! interrupto, de p,'e:_i_a a fa

La valvuta de pr_sl,.?_"saFta motor cuand." k-_:_n:_si_ _icabza el i posic;d_n de _OFF". Si esto no apaga et mot;;r Ios

nive! de "corse" con[actos electr;cos se han fundtdo y peg-3do.

reemplazar el interrupter de presion.

I'_qLJV alto oa_aaue ve!ifiqt_e, ajus_eo ree:npla.s_-_e; .: :._,. ;:_o!:

Fuqadeaire_o_ iosacoples, i Los acc,,o_e_-_' ' :t..:.:, ".:

sLf : eateme.q,--., .;:s18__:...:._. escaDa, inspecc_oaar los acopies ce_ _as so,, _cio.

Fugas de aire po_ el intetr uptor " [nterr Jptor de or,e_o,_ ::!ei_va_\,,_lade Retirar y repa;ar ta valvuia de alivio,

de presi6n de I.-_valvtl!a de

alivio o desfogue.

Fugas de aire per las costuras

del tanque de aire.

Vatvula de rete_cion defectuosa.

Et asiento de _ , ...... :_, .

esta da_ado, i

Tanque de '. .... _-,"* _" !

u_ eslJ2,n to Rlustar los ........ _"_,c..._,s:.__lo,qde se escuc!;,_%.z_,,%e a,:s,

i d;_agua labo_osa. _'.,;OSOBREAJUST,'_,R.

lnspeccionar si es que ta claviia en la part÷ inferior

de la valvuta de alivio de presion est;J atracada. Si

no se mueve libremente, reemplazar la v&ivula.

Una valvula de retencion defectucsa produce

constantes ragas de aire per la v&l'vL:laUe a;_v;oda

presion cuando hay presi6n en ei :anq_Je y el

compresor esta apagado. Retira_" ¢ !impi-_r o

reemptazar Is va.lvula.

Inspeccionar y _eemptazar el ensambiaj:_ dot m_itipi_

superior.

Se debe reemplazar e! tanque de aire. No r,_.pamrla

fuga.

NO PERFORAR, SOLDAR, ;_,i_

_N FORMA ALGUNA POROi;;!.- S{--'_.

[_.a. Drosior_ e!] !_i _' ' .4#}

• f}_) f.,iQ C,[ _,

;egub_cor cq? ._c,.l _.,., 5_

coQecta un accesoric,.

O EXPLOTAR.

n< ._+"',-.-;._-,_. fie Iapagina 6,

HO '._'A

Ajus[ar is .ocesi6n regu_ads ba_:o

condiciones de flujo _[_,',it_tras se usa

el accasorio }.

GUiA DE DIAGNOSTICO

DE PROBLEMAS (ContinuaciSn)

PROBLEMA

Fuga de aire por ta vaivula de

seguridad.

CAUSA

Posibfe defecto en

seguridad,

la valvufa de

SOLUCION

Operar la valvula de seguridad manuatmente bajando

el anitlo. Si ta fuga persiste, reemplazar ta vafvuta.

1

Sonido de g01pes. . .........

El compresor no provee

suficiente aire para operar los

accesodos.

........................ T-2-T ",................. .....................] ;_..................7...........................................

_, mot,), ao f ....... , ....

• -, _,_t ._v,:, , tus_b!e .,:olado, el _nterrmpto,-Ide Veuf_ca,"s; e! h;s_;_.:,eita,,'o_adoen la,taj::_,::.'_tusibles

Valvula de retencion defectuosa.

Excesivo uso prolongado del aire 1

E!compresor no es io suficientem_nte

grande para tas necesidades de airt_.

Restricci6n de aire en el fittro de

entrada.

H,Aeco 8_1 tamanguera.

La valvula de retenclOn

restringida.

Fugas cla aim..

, t.cs t _ODk._a.b,,la Guia da r)i;_gn6st;r-o _-_'_..... = , -",

c_'olecci,c]ndeso[:;ec2rcmh,_ ssltaao._ y re,_m[,!,_7_r;,_._,;e.< it.a_:_mdo FW',p.',,,oi,-_,/arel

eSta

Desmontar, limpiar o reemplazar.

Disminuir la cantidad de aire en uso.

Verificar el requerimiento de aire del accesorio. Si

es mayor que elSCFM oque tapresi6n suministrada

pot el compresor de aire. se necesita uncompresor

ma_sgrande.

Limpiar o cambiar el filtro de entrada da aire. No

operar el compresor dentro del area de p r tado

Verificar Vreemptazar si fuese necesa,,io_

Desmontar, lirnpia_ o reempi-szar.

interruptor de ci,q;uito. No usar ur_ rinsible ni

interruptor de circuito de mayo€ capaoidad que el

especific_dc para esa _sn",a!dei circu;to.

Fuga de aire continua pot la

per;lla del regulador. El

regulador de isresion no cierra

la satida de aire.

Verifica; clue _tlfu:_fb!o sea adecuado. P,_;_d,i"que sa

est& tlsar, do un fusible de ,__cc:ioorgp,d_

vo ta _

nspe(:db'_a.;- e cord0-t de e:4ensi6_

Des,:-o,m_x:b_r los otros artefactos el.tc_ricos

en urt in ,.._lp,o_,lo de cirrui_:,t.

El cordSr_ de ext_nsk{:.n dei calibre o

largo raquwocado.

Cone×ior_es eI@ctricas sue;',las.

Motor defectuoso, i mas cerc¢_:o.

............ ........... i ................................

Partes iptemasdel re_!"].:lorsucias c Limpi_r r.)rg_.,mp!a_ar el r_.,gulador o l-._spartes

dadadas, intemas,

lnspeccic:nar elcord6n de extensisn.

Ins.pecciof _arfa coaaxidr' de los alamb as ciept{o de

la caja da terminales.

' Hacer nct, occ.ionar e_tel Oentro de £m.-,,<%.,Sears

_.,aiu....-et,:.c_a__, hay pi'c:o._er,._:.de

NOTAS DE SERVICIO

MANUAL

CRRFTSMRN,°

COMPRESOR DE A/RE

DE LUBRICA CI( N

DEL

OPERADOR

AI ord_.__a_repuestos siempre dar

la siguiente informaci6n:

• NL:!mero de Modelo

• NL]mero det Repuesto

• Descripcr6n del Repuesto

• Nombre del item

COMPRESOR DE AIRE CON

GARANTiA COMPLETA DE

UN AI_iO

Si esie compresor de aire falla debido a

defectos de material o fabricacion, durante

un periodo de un a_o a partir de la fecha de

compra, DEVOLVERLO AL CENTRO/

DEPARTAMENTO DE SERVlClO DE SEARS

MAS CERCANQ EN CUALQUtER PARTE DE

ESTADOS UNIDOS Y SEARS LO REPARAR/_

SIN COSTO ALGUNO, SI ESTE

COMPRESOR DE AIRE FUE COMPRADO

DE ORCHARD SUPPLY HARDWARE

DEVOLVERLO AL ORCHARD SUPPLY

HARDWARE MAS CERCANO EN

CUALQUIER PARTE DE ESTADOS UNIDOS

Y ORCHARD SUPPLY HARDWARE LO

REPARARA SIN COSTO ALGUNO.

Si el compresor se usa pare fines comerciales

o pare alquFler, la garat]tia solo cubrira los

primeros 90 dias posteriores ala fecha de

compra.

Esta gara_tia le otorga ciertos derechos

legales especificos y usted puede tener otros

derechos que varian de un estado a otto,

PERMANENTE MONTADO

EN EL TANQUE

Para solicitar servi¢io de reparaci6n o

repuestos que usted necesite, ilamar

de 7 am a 7 pm, los 7 d_as de Ja sernana at

1-800-366-PART

(1-800-366-7278}

Para se_vicio de reparaci_n en su domicilio

de electrodom_sticos de las torincipales

marcas, Ilamar ias 24 bores del die,

los 7 dies de la semana al

1 -8OO-,4- R E PAl R

(1-800-473-7247)

Pare la ubicacion de| Centro de

Repuestos y Reparaci<_n de Sears

en su ,_rea, Ilamar tas 24 heras

de| dies, los 7 dias de la samana al

1-800-,488-1222

Pare informacibn sobre la compra de un

Contrato de Mantenimiento de Sears

o para averiguar sobre aJg_n Contrato

existente, llamar de 9 am a 5 pro,

de Lunes a Sabado at

1-800-827-6655

Loading...

Loading...