Craftsman 919161020 Owner’s Manual

MANUAL

MODELNO.

919.161020

CRRFTSMRN,o

PAINT TANK

IMPORTANT:

Read the Safety Guidelines and

All Instructions Carefully Before

Operating.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

MGP-161020 Rev. 1 5/4/01

DESCRIPTION

INSTALLATION

OPERATION

MAINTENANCE

PARTS LIST

TABLE OF CONTENTS

Page

WARRANTY .................................................................................................................................... 2

SAFETYGUIDELINES ...................................................................................................................... 3

WARNING CHART ....................................................................................................................... 3-4

GENERALINFORMATION ............................................................................................................... 5

Description ........................................................................................................................... 5-6

Assembly Instructions .............................................................................................................. 5

Operating Instructions .............................................................................................................. 5

Instructions for Regulator .......................................................................................................... 5

Cleaning Instructions ................................................................................................................ 6

TROUBLESHOOTING GUIDE .......................................................................................................... 7

PAINTTANK DIAGRAM ................................................................................................................... 8

PARTS REFERENCE ....................................................................................................................... 9

SERVICE NOTES ...................................................................................................................... 10-11

HOW TO ORDER REPAIR PARTS ........................................................................................ BACK COVER

FULL ONE YEAR WARRANTY ON CRAFTSMAN PAINT TANK

If this Craftsman Paint Tank fails due to a defect in material or workmanship within one year from the date of

purchase, RETURN IT TO THE NEAREST SEARS SERVICE CENTER/DEPARTMENT THROUGHOUT THE

UNITED STATES AND SEARS WILL REPAIR IT, FREE OF CHARGE.

This warranty gives you specific legal rights and you may have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

2- ENG

SAFETY GUIDELINES- DEFINITIONS

This manual contains informa-

tion that is important for you to

know and understand. This infor-

mation relatesto protecting YOUR

SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To

help you recognize this informa-

tion, we use symbols to the right.

Please read the manual and pay

attention to these sections.

IMPORTANT SAFETY INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT

IN SERIOUS INJURY AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL

WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

I _k DANGER I

URGENT SAFETY INFORMATION -A HAZARD

THATWlLLCAUS E SERIOUS INJURYOR LOSS

OF LIFE

Information for preventing damage to

equipment.

I -"LWARNING I

IM PORTANT SAFETY INFORMATION - A HAZARD

THATMIGHTCAUSE SERIOUS INJURYOR LOSS

OF LIFE.

Information that you should pay special

attention to.

• SAVE THESE INSTRUCTIONS •

I _CAUTION I

I NOTE I

• OVERPRESSURIZATION OF ATTACHMENTS •

HAZARD WHAT COULD HAPPEN HOW TO PREVENT IT

EXPLOSION OF

OBJECTS

•Attachments whose pressure rating is lower

than the adjusted pressure in the tank could

explode, resulting in serious injury or

property damage.

•Always make sure that equipment con-

nected to tank or hose outlet has a higher

pressure rating than the regulated air

pressure in the tank.

3- ENG

• TANK EXPLOSION WARNINGS •

Explosive failure of the tank, its components, or attachements to it, could result in

serious injury to self or others, or property damage from the following conditions:

HAZARD

EXPLOSION OF

TANKS

WHAT COULD HAPPEN

• Modifications to its design or construction

could weaken tank.

• Substitution of unauthorized non-standard

components could weaken tank or cause

component failure.

• Damage to the tank or its components could

weaken the tank.

• Improper cleaning or maintenance could

block air passages to the safety valve,

gauge or outlet, allowing pressure to rise

to dangerous levels, and preventing the

lowering of tank pressure.

• Tampering with the safety valve could allow

tank pressure to rise to dangerous levels.

HOW TO PREVENT IT

Assemble tank components in

accordance with service instructions. Do

not drill into tank, or weld attachments,

or alterits design in any manner.

• Use only those components furnished

with your tank, assembled in accordance

with instructions in the service literature.

• Never attempt to repair a damaged

tank. Replace it with a new one.

Following each use, clean and dry tank

and lid in accordance with maintenance

instructions. Make sure ports to safety

valve, gauge and outlet are free of hard-

ened paint or other materials which could

prevent free movement of air.

Never attempt to adjust safety valve to

change its pressure setting, or defeat its

function in any way. Operate the valve

before each use to assure that it func-

tions properly.

• Removal of the lid while the tank is under

pressure could result in the lid being propelled

violently from the tank.

• Use of reactive chemicals could attack the

the lid gasket and safety valve seal allowing

tank pressure to rise to dangerous levels.

• Halogenated hydrocarbon solvents- for

example: 1,1,1 - trichloroethane and

methylene chloride- can chemically react with

aluminum. If this reaction occurs within an

enclosed container such as this pressure feed

tank, the tank may explode.

• Overtightening clamps causing them to

weaken and fail could result in the lid being

propelled violently from the tank.

Before releasing clamp force to remove

the lid, shut off the supply of tank inlet air

and turn the regulator knob counterclock-

wise to relieve tank pressure. Check by

pulling the safety valve ring.

• Do not use reactive chemicals in your

tank such as acids, caustic solutions,

or halogenated hydrocarbon solvents.

• Do not use wrenches, pliers, or other

tools to tighten tank clamps. Use only

the torque you can apply with your hands.

If the lid gasket leaks, relieve tank pres-

sure and clean or replace the gasket.

4- ENG

GENERAL INFORMATION

DESCRIPTION

The Craftsman 21/2Gallon Paint Tank can withstand air pressure to maximum of 80 PSI. This Paint Tank is

equipped with an air regulator, gauge, safety valve, and fluid outlet. It is constructed of only the finest materials for

durability, The 21/2gallon capacity enables you to handle most any size job.

_ulu / [o]_.I

This pressure tank is not designed for highly abrasive, corrosive, or rust including materials. If used with

such materials, frequent and thorough cleaning is advised to reduce the necessity for replacement of

parts.

Assembly Instructions

1. Install the regulator assembly to the swivel adaptor

on the tank lid. Check bottom of regulator for

location of tank connection.

2. Install the lift handle in the threaded hole in center of

the tank lid. Tighten hex nut.

3. Connect the air supply hose to an air inlet fitting on

tank regulator. (Right or left side optional).

4. Attach the atomization air hose to an air outlet

fitting which is directly opposite air inlet fitting.

5. Connect material hose to the fluid outlet adaptor

located on the tank lid.

Instructions for using Air Pressure

Requlator on Paint Tank

Purpose of Pressure Regulator.

The pressure regulator on the paint tank regulates the

amount of pressure applied to the paint in the paint tank.

This controls the pressure of the paint being delivered

to the spray gun.

Recommended Paint Tank Pressures:

Internal-Mix Guns - Use higher tank pressures up to

the full amount of air pressure being delivered to the

spray gun but never in excess of 50 Ibs. air pressure at

the spray gun or paint tank.

Part of the air from the compressor or airline bypasses

the pressure regulator through the "tee" fitting and is

delivered to the spray gun. An additional pressure regu-

lator will be required between the paint tank and the

spray gun.

Operatinq The Paint Tank

You are now ready to fill the tank with material. Before

doing so be sure to thoroughly mix and strain the paint

to remove skins or undissolved particles which might

otherwise impede the flow of material through the hose

and gun.

A one gallon can of paint can be set inside the tank

instead of pouring the paint into the tank.

Place lid assembly on tank and hand tighten tank lid

clamp screws.

Shut off paint tank regulator byturning T-handle counter-

clockwise. Adjust the compressor regulator to obtain the

desired air pressure on the spray gun.

Now adjust the regulator on the paint tank to obtain the

desired pressure for the material. The higher above the

paint tank you are spraying the more pressure you will

need on the material. Normal operating pressure on

the paint tank is 25 to 30 PSI. Should you wish to re-

duce pressure, simply rotate the T-handle adjusting

screw counter-clockwise until the desired pressure set-

ting is obtained. There is no need to trigger the gun in

order to bleed off excess paint pressure.

External-Mix Guns - Use lower tank pressures. Always

start with pressure in paint tank at "zero" and increase

pressure in tank gradually until proper spray pattern is

obtained.

IMPORTANT: Before turning on air pressure, screw out

the regulator T-handle adjusting screw all the way,

counter-clockwise, to shut off the air pressure. Turn on

the air, then adjust the regulator to the required pres-

sure. (Approximately 12 Ibs. for external-mix guns.) Do

not use over 50 Ibs. working pressure in paint tank.

DO NOT USE OVER 80 PSI AIR PRESSURE

IN YOUR TANK.

5- ENG

Operatinq The Paint Tank (cont')

PRESSURE REGULATOR

(DO NOT EXCEED 80 PSI)

AIR

AIR FILTER

(RECOMMENDED,

AIR COMPRESSOR

WITH REGULATOR

NOT INCLUDED)

Cleaninq Instructions

Always shut off air pressure at source and

bleed off all pressure in Paint Tank by

gently pulling safety valve ring before

loosening thumb screw and clamps to re-

move lid.

Itis very important that the tank, material hose, and spray

gun be cleaned as soon as spray job is finished. Turn off

the main air supply to the tank. Remove all pressure from

the tank by pulling the ring on the safety valve until the

pressure bleeds down. Turn the T-handle adjusting screw

on the regulator counter-clockwise until no spring tension

is felt.

AIR REGULATOR (RECOMMENDED,

/ NOT INCLUDED)

MATERIAL HOSE

(INSIDE PAINT TANK)

J

Loosen thumb screws, tip clamps back and tip tank lid to

one side. Loosen spray gun air cap retaining ring about

three turns then turn on the air supply. Cup cloth over air

cap on the gun and pull trigger. This will force the material

back through the hose, into the tank. Empty and clean

tank and parts which come in contact with the material.

Use a suitable solvent. Pour solvent into the tank.

Replace lid and tighten the thumb screws and clamps

and spray until clean solvent appears.

6- ENG

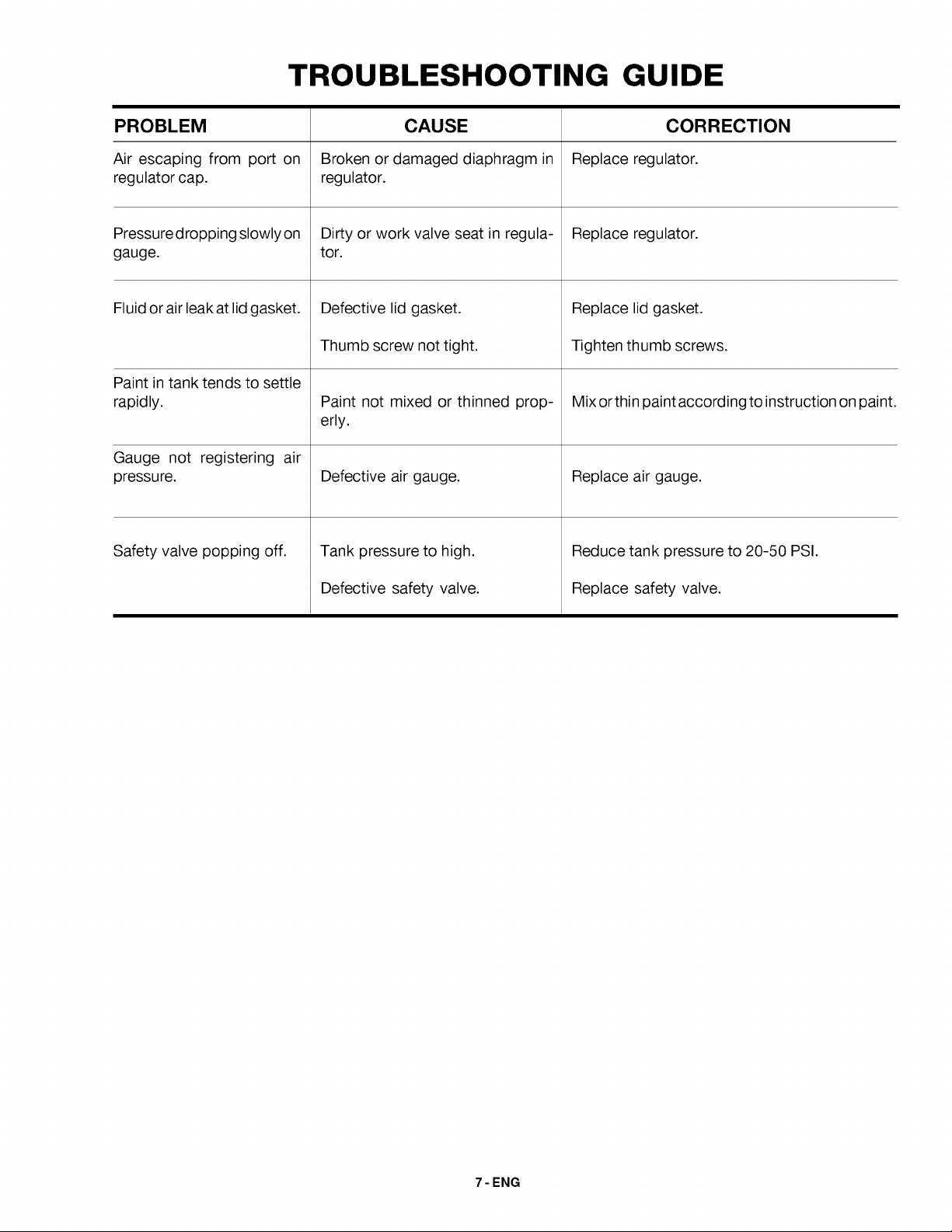

TROUBLESHOOTING GUIDE

PROBLEM

Air escaping from port on

regulator cap.

Pressure dropping slowly on

gauge.

Fluid orair leak at lid gasket.

Paint in tank tends to settle

rapidly.

Gauge not registering air

pressure.

Safety valve popping off.

CAUSE

Broken or damaged diaphragm in

regulator.

Dirty or work valve seat in regula-

tor.

Defective lid gasket.

Thumb screw not tight.

Paint not mixed or thinned prop-

erly.

Defective air gauge.

Tank pressure to high.

CORRECTION

Replace regulator.

Replace regulator.

Replace lid gasket.

Tighten thumb screws.

Mix or thin paint according to instruction on paint.

Replace air gauge.

Reduce tank pressure to 20-50 PSI.

Defective safety valve.

Replace safety valve.

7 - ENG

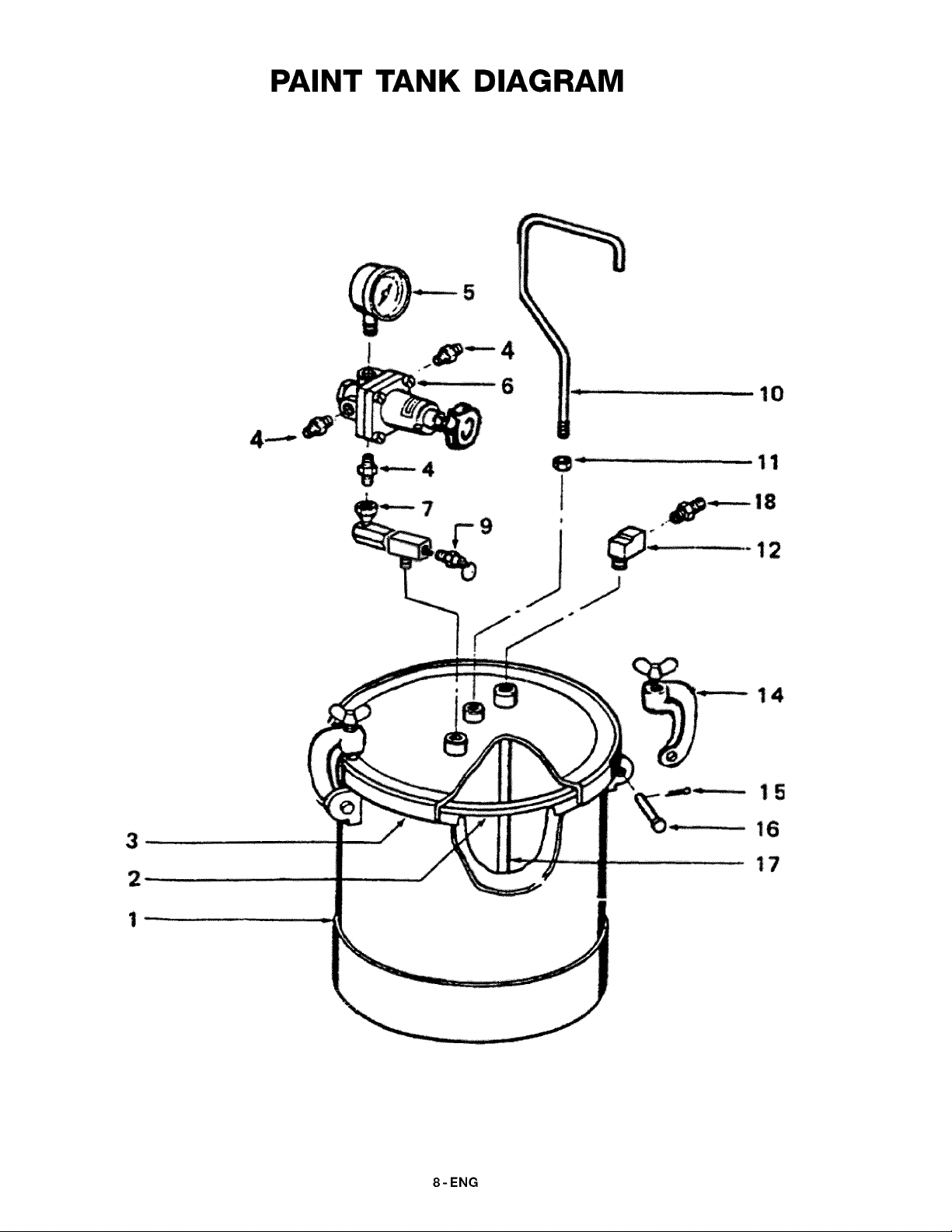

PAINT TANK DIAGRAM

............ 10

4

8_ ........"................... 11

7

!2

1

8- ENG

Loading...

Loading...