Craftsman 919155190 Owner’s Manual

Owner's Manual

ICRRFTSMRN'I

SPRAY GUN

HLVP

High Volume

Low Pressure

Model No.

919.155190

• Safety Guidelines

• Operation

• Maintenance

= Storage

= Repair Parts

CAUTION: Read the Safety Guidelines

and A+i Instructions Carefully Before

Operating.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

visit our Craftsman website: www.sears.com/craftsman

D29783 _ev_ 04/26/04

Warranty ..................... 2

Safety Guidelines - Definitions .... 2

Important Safety Instructions .... 3-4

Specifications ................. 4

Assembly ................... 5-7

Operation .................. 8-t0

Maintenance ................. 11

Troubleshooting ............ 12-13

Parts List .................... 14

Spanish .................. 15-27

How to Order Repair Parts ........

..................... back cover

r_l:1 :| :q:l _ii'

FULL ONE YEAR WARRANTY

If this spray gun faits due to a defect in material or workmanship within one

year from the date of purchase, RETURN IT TO THE NEAREST SEARS

REPAIR CENTER THROUGHOUT THE UNITED STATES AND SEARS WILL

REPAIR IT,FREE OF CHARGE. If purchased from Orchard Suppty Hardware,

return to the nearest Orchard Store and Orchard wilt repair it, free of charge.

If this spray gun is used for commercial or rental purposes, the warranty wilt

apply for ninety days from the date of purchase.

This warranty gives you specific legat rights and you may have other rights

which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

,_<l:lirii-i [itljrl] l!li_l 1{.I lll]lilllil[i]]{.l

This manual contaills [llforn_ation that is important for you to know and understated, This informatioll

relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. TOhelp you

recognize this ii_fom_ation, we use the ayrnbols below, F'lee_e read the n_eJ_ualand pay attention to

these 8eotion_,

SAFETY and PREVENTING EQUIPMENT PROBLEMS= TOhelp you recog_ize this informatiom we

use th_ syn_bols below. PFease _ead the m_nual eJhd pay attention to these sections,

_]ndicates an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury,

_]ndicates a potentially

hazardous situation

which, if not avoided, could result in

death or serious injury.

D29783 2-ENG

_[l_llndicates a potentially

which, if not avoided, _ result in

minor or moderate injury,

hazardous situation

_"_Ueed without the

safety alert symbol

indicates a potentially hazardous

situation which, if not avoided, may

result in oroloertv damaae,

= SAVE THESE INSTRUCTIONS =

_ IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USI NG THIS EQUIPMENT°

_The Following Hazards Can Occur During The Normal Use Of This Product:

Risk of explosion or fire - flammable materials

WHAT COULD HAPPEN

Risk of explosion - incompatible materials

WHAT COULD HAPPEN HOW TO PREVENT IT

The solvents 1,1,1-Trichloroethane and Methyl.-

ene Chloride can chemicaliy react with the alu-.

minum used in most spray equipment, and this

gun and cup, to produce an explosion hazard

and could result in serious injury or death,.

i ......

COULD RESULT IN SERIOUS INJURY AND PROPERTY DAMAGE,

HAZARD

HAZARD

Read the label or data sheet for the material you

intend to spray°

1. Never use any type of spray coating material

containing these sofvents

2, Never use these solvents for equipment

cleaning or flushing

3_ If in doubt as to whether a material is

compatible, contact your material supplie_

HAZARD

Risk of breathing

WHAT COULD HAPPEN ]

L I

HOW TO PREVENT IT

,_ii:i_?f_i!!i::!!i!-!'iii_i:_i.il!!!i!__i._!_!':!!_!'i:::?_:i!!!_i_!_!!!__:!!:!i:_!i!!!!i:ii!!!!f::iii::/_!i:iii_,!_!:::i!!I:?i_

HAZARD

Risk of flying objects

WHAT COULD HAPPEN

Certain parts are under pressure whenever the

gun is connected to a pressurized air lineoThese

parts may be propelled if the gun is disassembled

i!!ii!; !?i!i!!ii i!il; i! ;iiii!iiiiiiii! ,iiii: i! !i!iiiii!i:

Prolonged exposure to air spray can result in

permanent damage to hearing.

Disconnect the gun from the air line, or com_

pletely depressurize the air' line whenever the

gun is to be disassembled,

:ii.gdggieS:i6_:_las_:w_en@ra_,!n_;_::i!_.":.i:_._i.h.'.:_i!:_.i.:.:-:._!,!::_.:::_:_.!:

Always wear hearing protection when opera6ng

spray equipment..

3- ENG

HOW TO PREVENT IT

, n H,,, i, , HH,

Risk of injection

HAZARD

WHAT COULD HAPPEN

Minimum Gun Inlet Pressure

Maximum Gun Inlet Pressure

Air Connection

Fluid Connection

Paint Canister

HOW TO PREVENT tT

20 PSt

45 PSI

Standard 1/4 NPS

Standard 3/8 NPS

1 Qt- Aluminum Wide

Mouth Canister

Needle Type

Feed Type

Bleed Type

Air compressor Requirements

Stainless Steel

Siphon*

Non-bleeder

8.6 SCFM@4O PSI

* This spray gun can easily be converted to pressure feed mode to be used

with a paint tank (sold separately) when spraying heavy bodied material or on

large projects.

029783 ,1_ENG

!:_..'_.:,]=liv_1=]li'il

Contents of Carton

1- Spray Gun

1- Owners Manuat

How to Set Up

Your Craftsman spray gun is shipped

completely assembled, and set-up for

siphon feed spraying.

Prior to shipment, this gun was treated

with an anticorrosive agent. Before

using this gun flush it with a suitable

solvent (mineral sprits is a suitabte

solvent).

To Flush Spray Gun Before Use

1. Removethe matehat cup from

lid/gun assembly. NOTE: Slide

release lever to the right, rotate

lid, and remove material cup.

Cup

"Lever

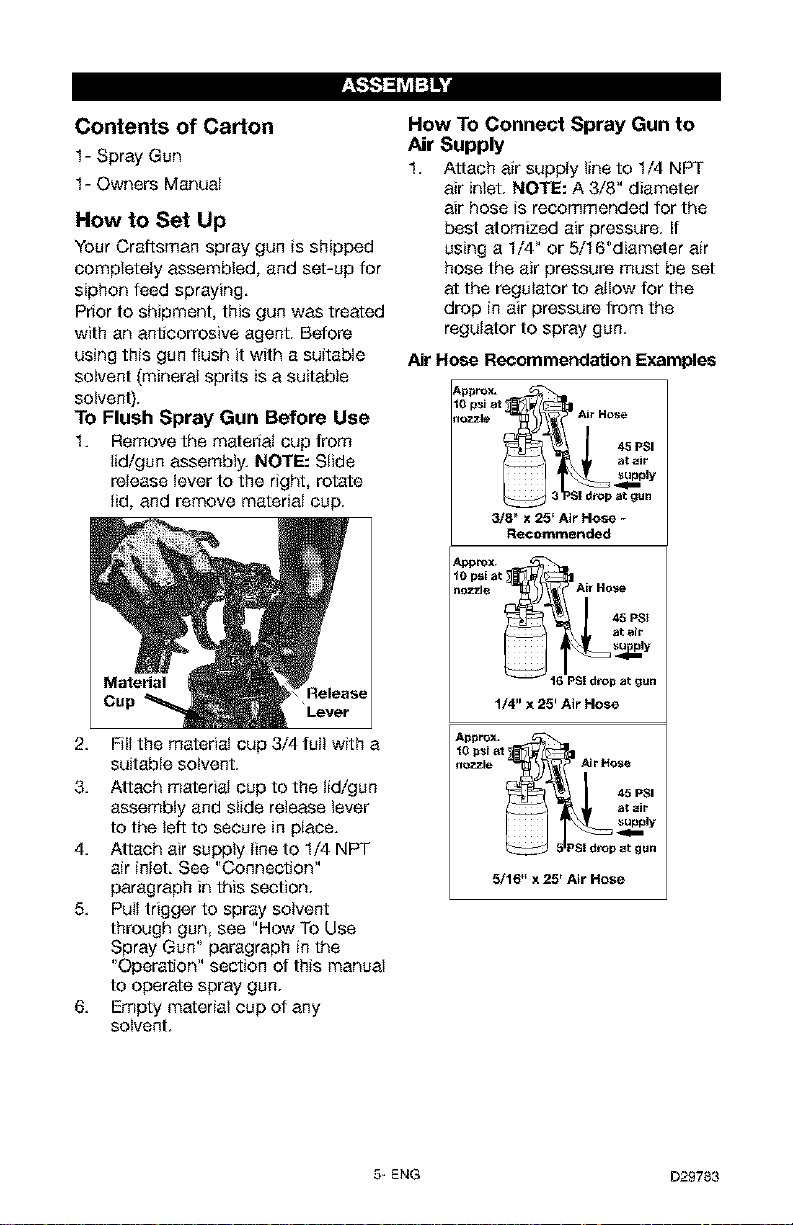

How To Connect Spray Gun to

Air Supply

t. Attach air supply line to 1/4 NPT

air inlet. NOTE: A 318" diameter

air hose is recommended for the

best atomized air pressure. If

using a 1/4" or 5/16"diameter air

hose the air pressure must be set

at the regulator to allow for the

drop in air pressure from the

regulator to spray gun.

Air Hose Recommendation Examples

lozzle Air Hose

45 PSI

lpprox.

3/8" x 25 _ Air Hose -

Recommended

10 I_i at

noz_e Air Hose

APpr°x"

1/4" x 25 _ Air Hose

at air

_ply

at gun

45 PSi

at: air

2. Fill the material cup 3/4 full with a

suitabte sotvent.

3. Aftach material cup to the lid/gun

assembly and slide release lever

to the left to secure in pIaee.

4. Aftach air suppty line to 1/4 NPT

air inlet. See "Connection"

paragraph in this section.

5. Putt trigger to spray solvent

through gun, see "How TO Use

Spray Gun" paragraph in the

"Operation" section of this manual

to operate spray gun.

6. Empty material cup of any

solvent.

10 p;i at

nozzle Air Hose

45 PSI

Approx. _i

5/16 _'x 25 _Air Hose

5-ENG [:)29783

at air

;_tgun

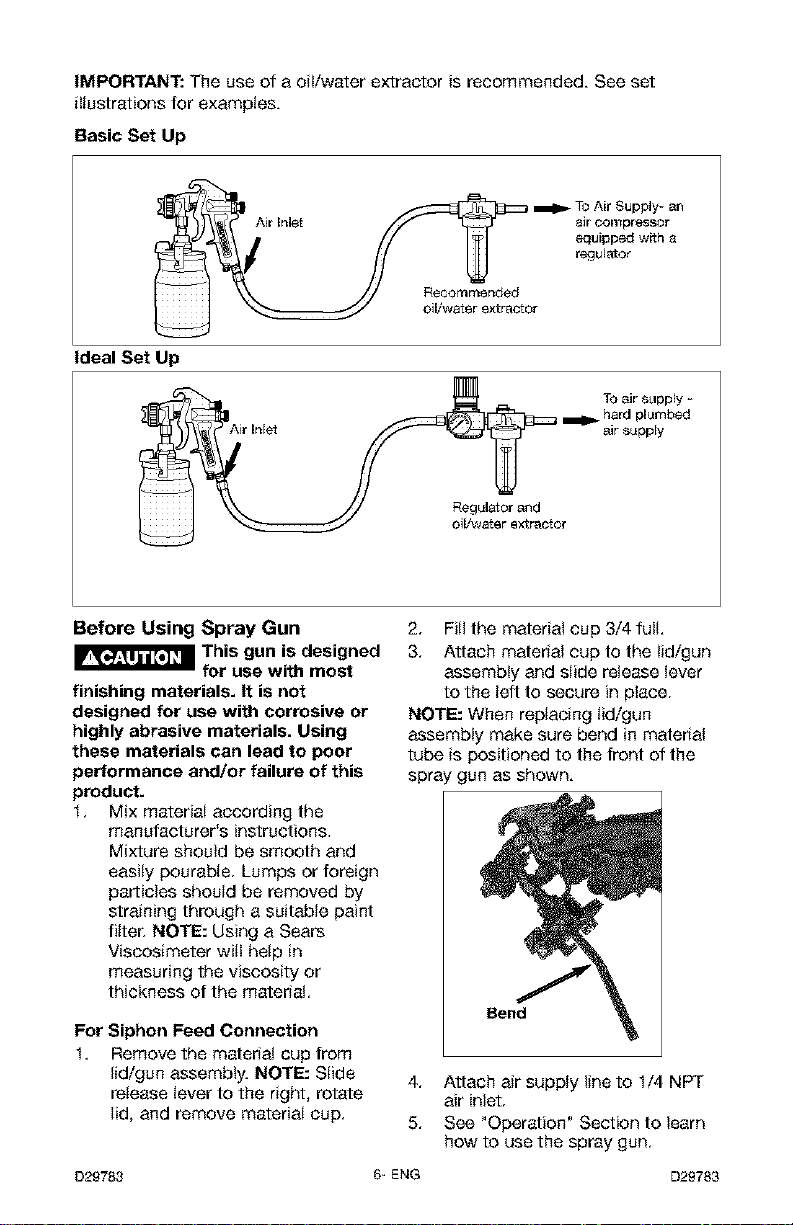

IMPORTANT: The use of a oiVwater extractor is recommended. See set

illustrations for exampIas.

Basic Set Up

Air Inlet _ir con_prsssor

_! _ _ TO Air Supply- ar_

Ideal Set Up

Before Using Spray Gun

This gun is designed

for use with most

finishing materials. It is not

designed for use with corrosive or

highly abrasive materials. Using

these materials can lead to poor

performance and/or failure of this

product.

1. Mix material according the

masufacturer's instructions.

Mixture should be smooth and

easity pourabIe. Lumps or foreign

particlas should be removed by

straining through a suitabte paint

fitter. NOTE: Using a Sears

Visceeimeter witl help in

measuring the viscosity or

thickness of the matedat.

For Siphon Feed Connection

1. Removethe matedat cup from

lid/gun assembly. NOTE: Stide

release lever to the right, rotate

tid, and remove material cup.

D29783

equipped with

regulator

R?corameeded r

TO air s_lpply -

hard plumbed

air suppFy

2, Fill the material cup 3/4 full.

3, Attach material cup to the tidigun

assembly and slide release lever

to the left to secure in ptace.

NOTE: When repiacing iidigun

assembly make sure bend in matedat

tube is positioned to the front of the

spray gun as shown.

Bend

4, Attach air supply line to 1/4 NPT

air inlet,

5, See "Operation" Section to learn

how to use the spray gun.

6- ENG

D29783

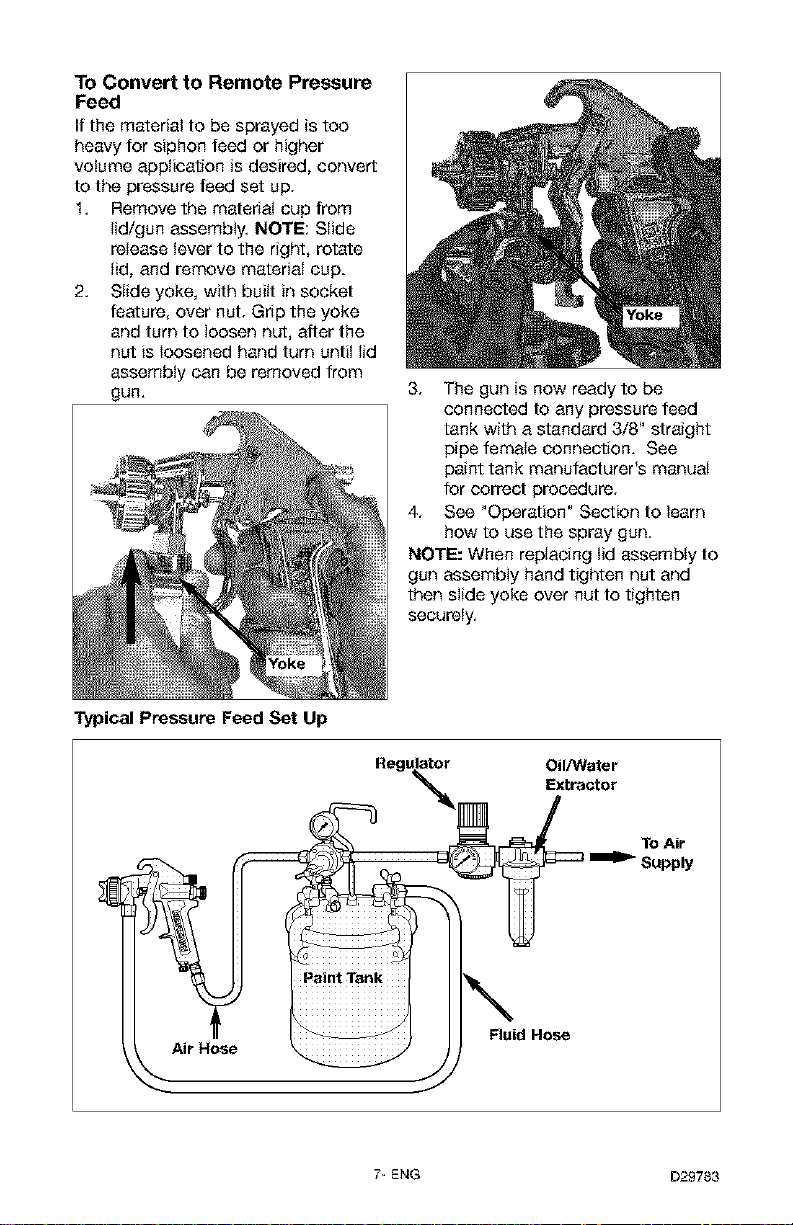

To Convert to Remote Pressure

Feed

If the material to be sprayed is too

heavy for siphon feed or higher

volume appIication is desired, convert

to the pressure feed set up,

1. Remove the material cup from

lid/gun assembly. NOTE: Stide

release lever to the right, rotate

lid, and remove material cup.

2. Siide yoke, with buiit in socket

feature, over nut. Grip the yoke

and turn to loosen nut, after the

nut is loosened hand turn untit tid

assembly can be removed from

gun.

3. The gun is now ready to be

connected to any pressure feed

tank with a standard 3/8" straight

pipe femate connection. See

paint tank manufacturer's manuat

for correct procedure.

4. See "Operation" Section to tearn

how to use the spray gun.

NOTE: When replacing lid assembly to

gun assembly hand tighten nut and

then slide yoke over nut to tighten

securely.

Typical Pressure Feed Set Up

Regu_ Oil/Water

7-ENG D29783

Extractor

To Air

Supply

Fluid Hose

Know Your Spray Gun

Machined Brass

Air Car

Hardened Steel

Fluid Tip

Release Lever

1- Quart

Siphon Feed

Material Cup

Machined Brass External Mix Cap -

The air and material are mixed after

leaving the nozzle to provide a

superior finish with thick and thin

material

Hardened Steel Fluid Tip - for long

life.

Air Cap Horns - determines a

horizontal or veriical spray pattern,

Fluid Control Knob - controts the

fluid or density of fan spray.

Pattern Control Knob - controls the

size of the pattern from a targe oblong

to small round pattern,

Air Valve Control Knob - fine tunes

the material spray with air,

1t4" NPT Air Inlet- allows the spray

gun to be connected to the air supply.

Release Lever - releases tidigun

assembly from material cup.

Yoke - with built in wrench used to

easily remove gun from material cup

without tools.

Fluid Needle Adjustment Nut

Pattern Control

__ Fluid Control

Knob

1/4" NPT Air Inlet

Air Valve

Control Knob

_ Before

disassembly or re-

moval of any part of gun or attached

components, shut off compressor,

release pressure by depressing

trigger, and disconnect power

source. NEVER assume system

pressure is zero!

_!]_ Prior to daily

operation, make

certain that all connections and fit-

tings are secure. Check hose and all

connections for a weak or worn

condition that could render system

unsafe. All replacement components

such as hose or fittings must have a

working pressure equal to or greater

than system pressure.

_TO AVOID CREATING

AN EXPLOSIVE

ATMOSPHERE, WORK ONLY IN

WELL VENTILATED AREAS.

D29783 8" ENG

F_q_,_ USE OF A FACE

MASK IS

RECOMMENDED TO PREVENT IN-

HALATION OF TOXIC MATERIAL.

Before Using Your Spray

Gun

1. Set up spray gun as described

in the "How to Set Up Spray

Gun" paragraph in the

"AssembIy" section of this

manual.

To Use Spray Gun

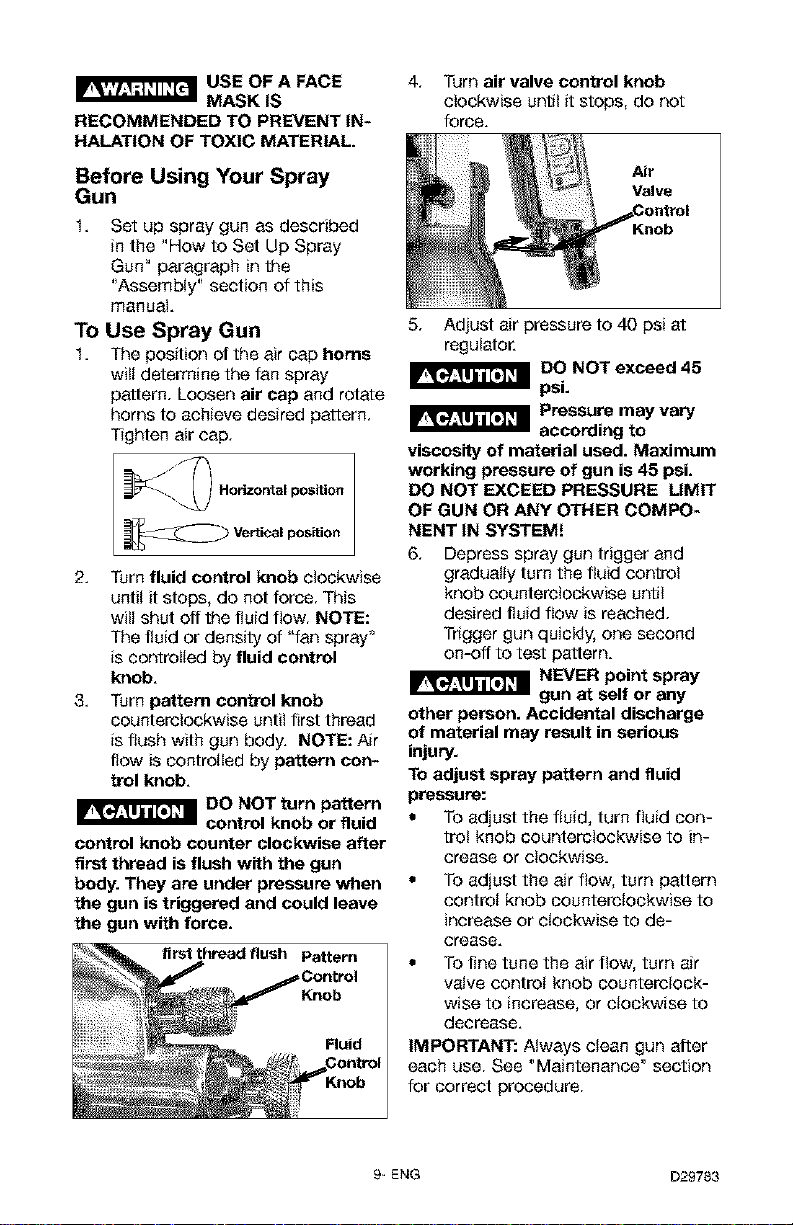

1. The position of the air cap horns

wilt determine the fan spray

pattern. Loosen air cap and rotate

horns to achieve desired pattern.

Tighten air cap.

Horizontal position

_ Vertical position

2. Turn fluid control knob clockwise

untit it stops, do not force. This

wilt shut off the fluid flow. NOTE:

The fluid or density of "fan spray"

is contretied by fluid control

knob.

3. Turn pattern control knob

counteretockwise untit first thread

is flush with gun body. NOTE: Air

flew is contreIted by pattern con-

trol knob.

_DO NOT turn pattern

control knob counter clockwise after

first thread is flush with the gun

body. They are under pressure when

the gun is triggered and could leave

the gun with force.

control knob or fluid

first thread flush Pattern

Knob

Ruid

4. Turn air valve control knob

clockwise until it stops, do not

force.

Air

Valve

5.

Adjust air pressure to 40 psi at

regulator.

_DO NOT exceed 45

I_-_ Pressure may vary

psi.

according to

viscosity of material used. Maximum

working pressure of gun is 45 psi.

DO NOT EXCEED PRESSURE LIMIT

OF GUN OR ANY OTHER COMPO-

NENT IN SYSTEM!

6. Depress spray gun trigger and

gradually turn the fluid contret

knob counterclockwise until

desired fluid flow is reached.

Tngger gun quickly, one second

on-off to test pattern.

NEVER point spray

gun at self or any

other person. Accidental discharge

of material may result in serious

injury.

To adjust spray pattern and fluid

pressure:

• TOadjust the fluid, turn fluid con-

troi knob counterclockwise to in-

crease or clockwise.

• To adjust the air flow, turn pattern

contret knob counteretockwise to

increase or clockwise to de-

crease.

• To fine tune the air flew, turn air

vatve control knob counterclock-

wise to increase, or clockwise to

decrease.

IMPORTANT: Always clean gun after

each use. See "Maintenance" section

for correct procedure.

9-ENG D29783

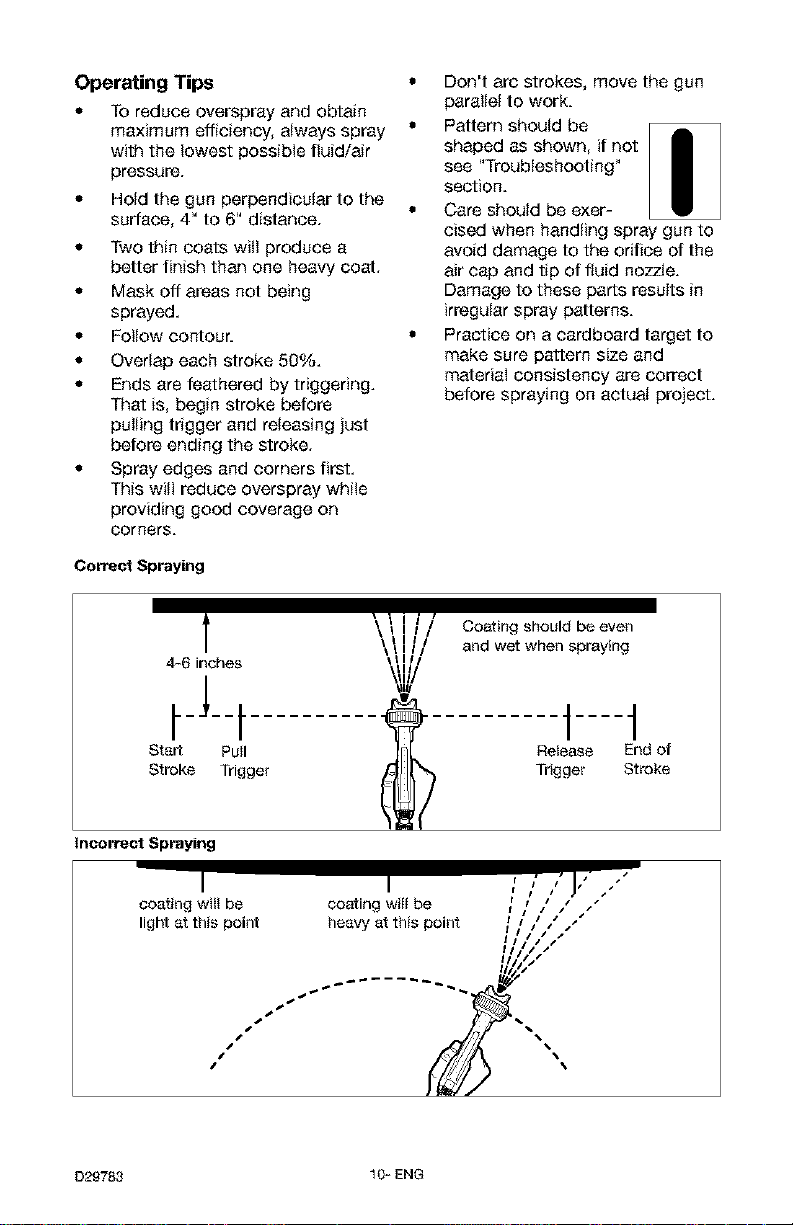

Operating Tips

To reduce overspray and obtain

maximum efficiency, always spray

with the towest possible fluid/air

pressure,

• Hold the gun perpendicular to the

surface, 4_'to 6 _'distance,

• Two thin coats witl produce a

better finish than one heavy coat,

• Mask off areas not being

sprayed.

• FoIIow contour.

• Overtap each stroke 50%.

• Ends are feathered by triggering.

That is, begin stroke before

puiiing trigger and reieasing just

before ending the stroke•

• Spray edges and corners first.

This witl reduce overspray while

providing good coverage on

corners.

Correct Spraying

Don't are strokes, move the gun

paraiieI to work.

Pattern should be

shaped as shown, if not

see "Troubleshooting"

section.

Care should be exer-

cised when handling spray gun to

avoid damage to the orifice of the

air cap and tip of fluid nozzle.

Damage to these parts results in

irregular spray patterns.

Practice on a cardboard target to

make sure pattern size and

material consistency are correct

before spraying on actual project.

t

4-6 inches

bJ--t

Start Pull

Stroke Trigger

Incorrect Spraying

I I , ,'J ,

coating wiiI be coating wiiI be _ _ / / ,"

light at this point heavy at th+spoint _] ] s /

. - - e/z/,'

,iJ S %%%

•

D29783 10+ ENG

Coating should be even

and wet when spraying

t .... t

Release End of

Trigger Stroke

r /' I I _s

Ilfl/I

II/,',"

Loading...

Loading...