Page 1

Owner’s Manual

CRRFTSMR№

SPRAY GUN

HLVP

High Volume

Low Pressure

Model No.

919.155190

• Safety Guidelines

• Operation

• Maintenance

• Storage

• Repair Parts

CAUTION: Read the Safety Guideiines

and Aii Instructions Carefully Before

Operating.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Oraltsman website: www.sears.oom/craftsman

D297B3 Rev- 1 04/26/04

Page 2

TABLE OF CONTENTS

Warranty ..................................

Safety Guidelines - Definitions

Important Safety Instructions ..

Specifications

Assembly

Operation

..........................

..................................

..................................

___

___

. .3-4

___

. .5-7

.8-10

Maintenance ........................

2

Troubleshooting

2

4

Parts List

Spanish

..............................

................................

How to Order Repair Parts .

........................................

....................

........

. .12-13

........

. .15-27

back cover

WARRANTY

FULL ONE YEAR WARRANTY

If this spray gun fails due to a defect in material or workmanship within one

year from the date of purchase, RETURN IT TO THE NEAREST SEARS

REPAIR CENTER THROUGHOUT THE UNITED STATES AND SEARS WILL

REPAIR IT, FREE OF CHARGE, If purchased from Orchard Supply Hardware,

return to the nearest Orchard Store and Orchard will repair it, free of charge.

If this spray gun is used for commercial or rental purposes, the warranty will

apply for ninety days from the date of purchase.

This warranty gives you specific legal rights and you may have other rights

which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, fL 60179 U.S.A.

11

14

guidelines ~ DEFINITIONS

This manuai contains informatiors that is important for you to know and ursdsrstarid. This information

relates to protecting YOUR SAFETY s^c! PREt^NTtNQ EQUiPliiENT PROBLEMS- To help you

recognize this infoniiatiors, we use the symtxrls beiow. Ple^e read the manual and pay attention to

these sections.

SAFETY and PREVffiMTtNG EQUIPMENT PROBLEMS. To heip you recognize this iiiforinatlon, we

use the symboie below. Please read the manual pay attention to these sections-

ADANGER

indicates an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

AWARNINQ

Indicates a potentially

hazardous situation

which, if not avoided, couid result in

death or serious injury.

ACAUTION

which, if not avoided, mav result in

minor Of moderate injury.

CAUTION

indicates a potentially hazardous

situation which, if not avoided, may

llndlcates a potentially

hazardous situation

■ Used without the

* safety alert symbol

result in property damage.

D29783

2- ENG

Page 3

IMPORTANT SAFETY INSTRUCTIONS

« SAVE THESE iNSTRUCTtONS «

I

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT

I

COULD RESULT IN SERIOUS INJURY AND PROPERTY DAMAGE.

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USING THIS EQUIPMENT.

AWARNING

Risk of explosion or fire - flammable materials

WHAT COULD HAPPEN

When paints or materials are sprayed, ttiey are

broken into very small particles and mixed v/rth

air. This v.'ill cause certain paints and matenals ■

to become extremely ftammabie and could

result in serious injury or death.

Risk of explosion - incompatible materials

The solvents t,1,1-Trichioroethane and Methyl

ene Chloride can chemically react with the alu

minum used in most spray equipment, and this

gun and cup, to produce an explosion hazard

and could result in serious injury or death.

Risk of breathing

The Foliowing Hazards Can Occur During The Normai Use Of This Product

HAZARD . ^ i

HAZARD ^ i

WHAT COULD HAPPEN

HAZARD

HOW TO PREVENT IT

Never spray near open flames or pilot lights in ‘

stoves or heaters. Never smoke while spraying. _

Provide ample verttilation when spraying indoors.

HOW TO PREVENT IT

Read the label or data sheet for the material you

intend to spray.

1. Never use any type of spray coating materia!

containing these solvents-

2. Never use these solvents for equipment

cleaning or flushing

3. if in doubt as to whether a material is

compatible, contact your material supplier

WHAT COULD HAPPEN

.Some paints, coatings and solvents may cause

lung damage, and burns if inhaled or allowed to

come into contact wrth skin or eyes.

WHAT COULD HAPPEN

Certain parts are under pressure whenever the

gun is connected to a pressurized air line. These

parts may be propelled If the gun is disassembled

Compressed air may propel dirt, metal shawrrgs,

etc. and possibly cause an injury.

Prolonged exposure to air spray can result in

permanent damage to hearing

3- Em

HOW TO PREVENT IT

Use a NIOSH approved mask or respirator md

protective clothing designed for use with your ■

specific application and spray materials. Some _

masks provide only limited protection against

,toxic materials and harmful paint solveni.'CDn-

suit with a Safety Expert or Industrial Hygienist if

uncertain about your equipment or .materials.

HAZARD SdSB

Risk of flying objects '' oP

HOW TO PREVENT IT

Disconnect the gun from the air fine, or com

pletely depressurize the air line v/henever the

gun is to be disassembled.

, Never point any nozzle or sprayer toward a per

son or part of the body.

Always wear ANSI 278,1 safety approved

goggles or glasses when spraying,

Always wear hearing protection when operating

spray equipment.

Page 4

Risk of injection

HAZARD . ^

WHAT COULD HAPPEN

Spray guns operate at pressures and veiocitles

high enough to penetrate human and animai

flesh, which could result iii amputation or other

senous injury. ! See a physician immediately]

Never place hands in front of nozzle.

Direct spray away from self and others.

HOW TO PREVENT IT

SPECIFICATÍONS

Minimum Gun Inlet Pressure

Maximum Gun Inlet Pressure

Air Connection

Fluid Cor’^nection

Paint Canister

Needle Type

Feed Type

Bleed Type

Air compressor Requirements

* This spray gun can easily be converted to pressure feed mode to be used

with a paint tank {sold separately) when spraying heavy bodied material or on

large projects.

20 PSI

45 PSI

Standard 1/4 NPS

Standard 3/8 NPS

1 Qt- Aluminum Wide

Mouth Canister

Stainless Steel

Siphon*

Non-bleeder

8.6 SCFM@40 PSI

D29783 4- ENG

Page 5

ASSEMBLY

Contents of Carton

1 - Spray Gun

1- Owners Manual

How to Set Up

Your Craftsman spray gun is shipped

compieteiy assembled, and set-up for

siphon feed spraying.

Prior to shipment, this gun was treated

with an anticorrosive agent. Before

using this gun flush it with a suitable

solvent (mineral sprits is a suitable

solvent).

To Flush Spray Gun Before Use

1. Remove the material cup from

iid/gun assembly. NOTE: Slide

release lever to the right, rotate

fid, and remove material cup.

Release

Lever

Fill the material cup 3/4 full with a

suitable solvent,

3. Attach material cup to the Iid/gun

assembly and slide release lever

to the left to secure in place.

4. Attach air supply line to 1/4 NPT

air inlet. See "Connection"

paragraph in this section.

5. Pull trigger to spray solvent

through gun, see "How To Use

Spray Gun" paragraph in the

"Operation" section of this manual

to operate spray gun.

6. Empty material cup of any

solvent.

How To Connect Spray Gun to

Air Supply

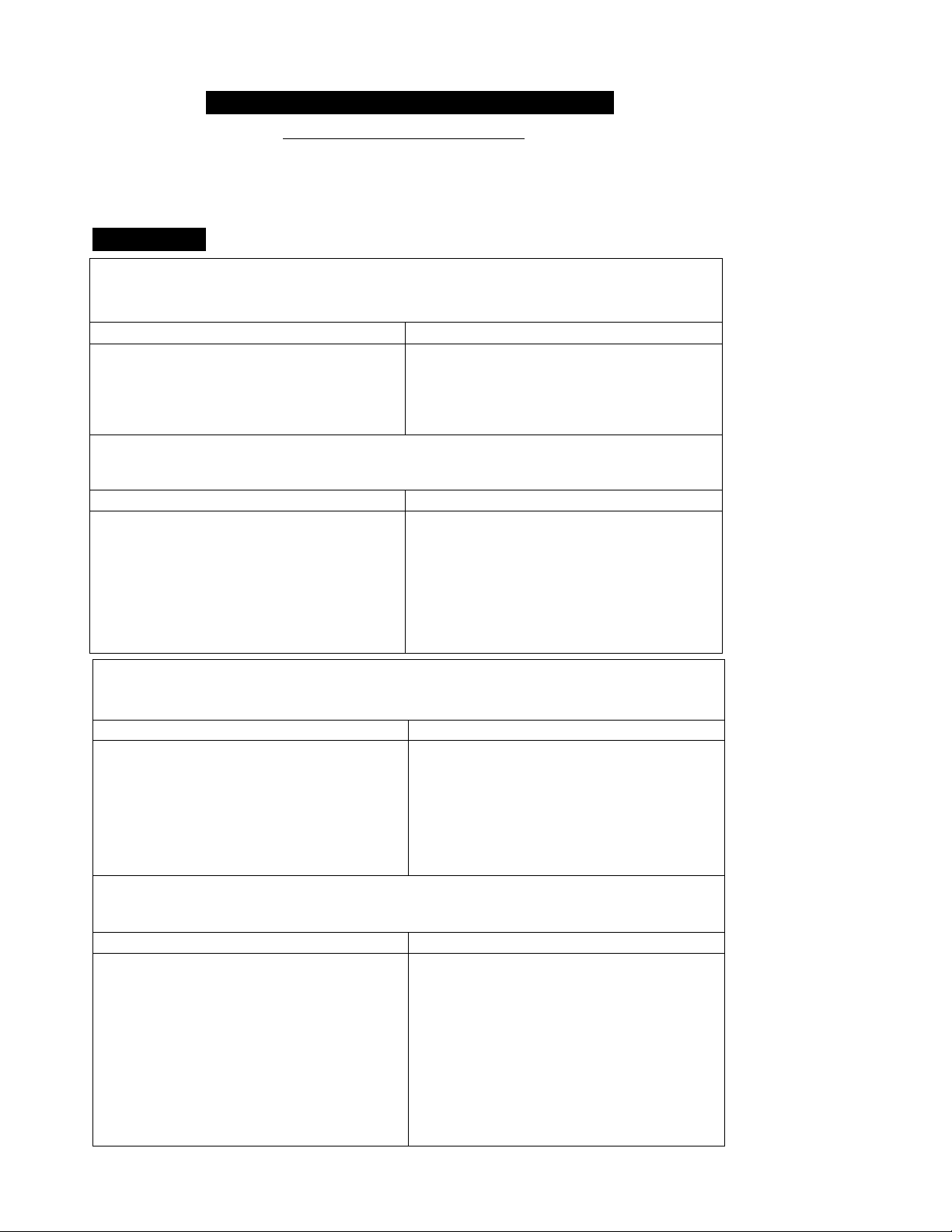

1. Attach air supply line to 1/4 NPT

air inlet. NOTE: A 3/8" diameter

air hose is recommended for the

best atomized air pressure. If

using a 1/4" or 5/16"diameter air

hose the air pressure must be set

at the regulator to allow for the

drop in air pressure from the

regulator to spray gun.

5- ENG

D297S3

Page 6

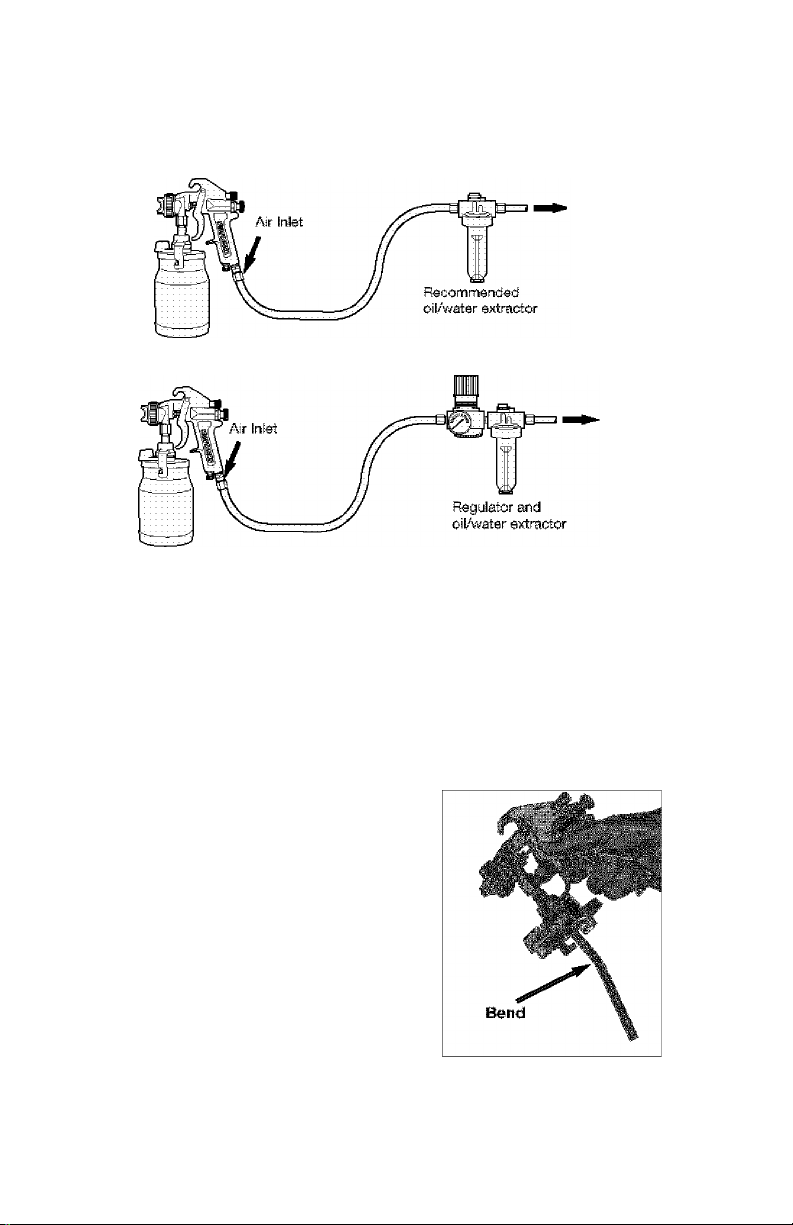

fWiPORTANT: The use Of a oil/wafer extractor is recommenOed. See set

illustrations for exampies.

Basic Set Up

. To Air Supply- ^

air compressor

ec|uipped with a

regulator

Ideal Set Up

To air supply hard plumbed

air supply

Before Using Spray Gun

ACAUTION

finishing materials- It is not

designed for use with corrosive or

highly abrasive materials. Using

these materials can lead to poor

performance and/or failure of this

product.

1, Mix materiai according the

manufacturer’s instructions.

Mixture should be smooth and

easily pourable. Lumps or foreign

particles should be removed by

straining through a suitable paint

filter, NOTE: Using a Sears

Viscosimeter will help In

measuring the viscosity or

thickness of the materiai.

For Siphon Feed Connection

1. Remove the material cup from

fid/gun assembly. NOTE: Slide

release lever to the right, rotate

fid, and remove materiai cup.

029783

This gun is designed

for use with most

2, Fill the material cup 3/4 full.

3, Attach materiai cup to the lid/gun

assembly and slide release iever

to the left to secure in place,

NOTE: When replacing lid/gun

assembly make sure bend in material

tube is positioned to the front of the

spray gun as shown.

4.

Attach air supply line to 1/4 NPT

air inlet.

See "Operation" Section to learn

5,

how to use the spray gun.

6- ENG

D29783

Page 7

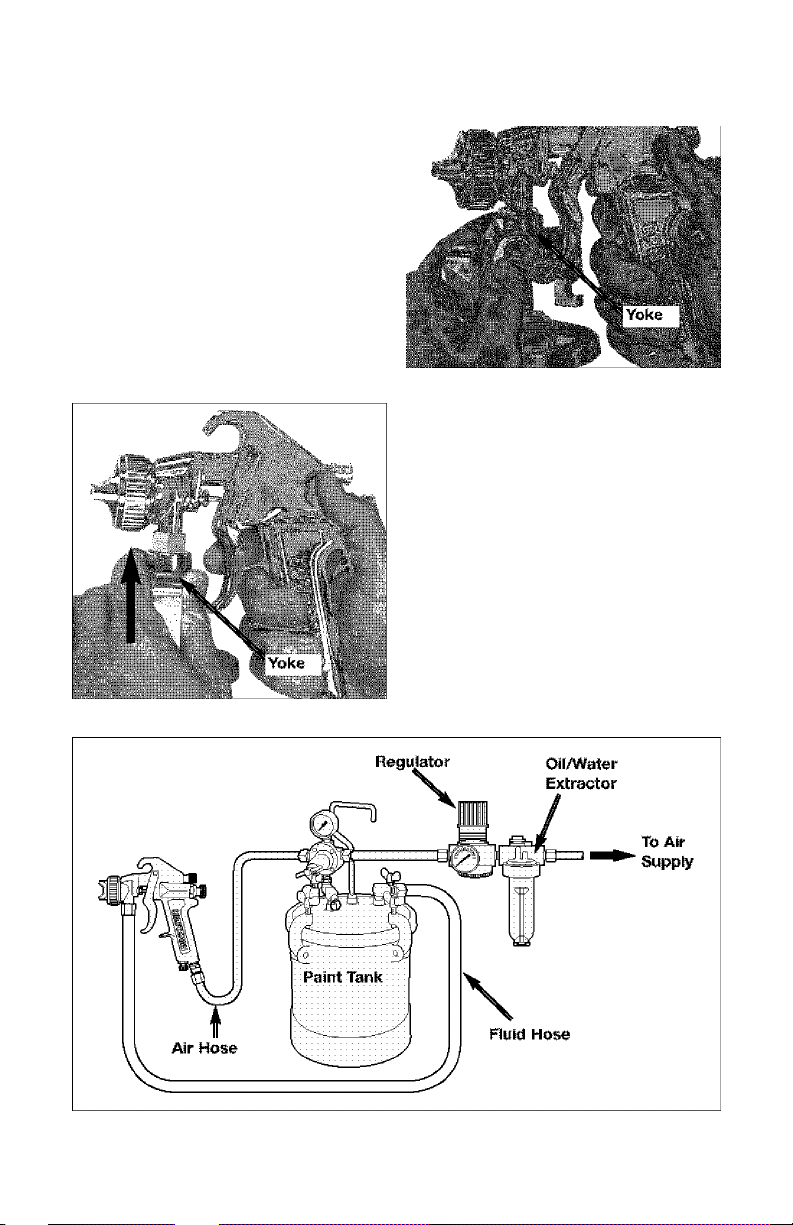

To Convert to Remote Pressure

Feed

If the material to be sprayed is too

heavy for siphon feed or higher

volume application is desired, convert

to the pressure feed set up.

1.

Remove the material cup from

fid/gun assembly. NOTE: Slide

release lever to the right, rotate

fid, and remove material cup.

2.

Slide yoke, with built in socket

feature, over nut. Grip the yoke

and turn to loosen nut, after the

nut is loosened hand turn until lid

assembly can be removed from

gun.

3. The gun is now ready to be

connected to any pressure teed

tank with a standard 3/8" straight

pipe female connection. See

paint tank manufacturer's manual

for correct procedure,

4, See "Operation" Section to learn

how to use the spray gun,

NOTE: When replacing lid assembly to

gun assembly hand tighten nut and

then slide yoke over nut to tighten

securely.

Typical Pressure Feed Set Up

7- ENG

D297S3

Page 8

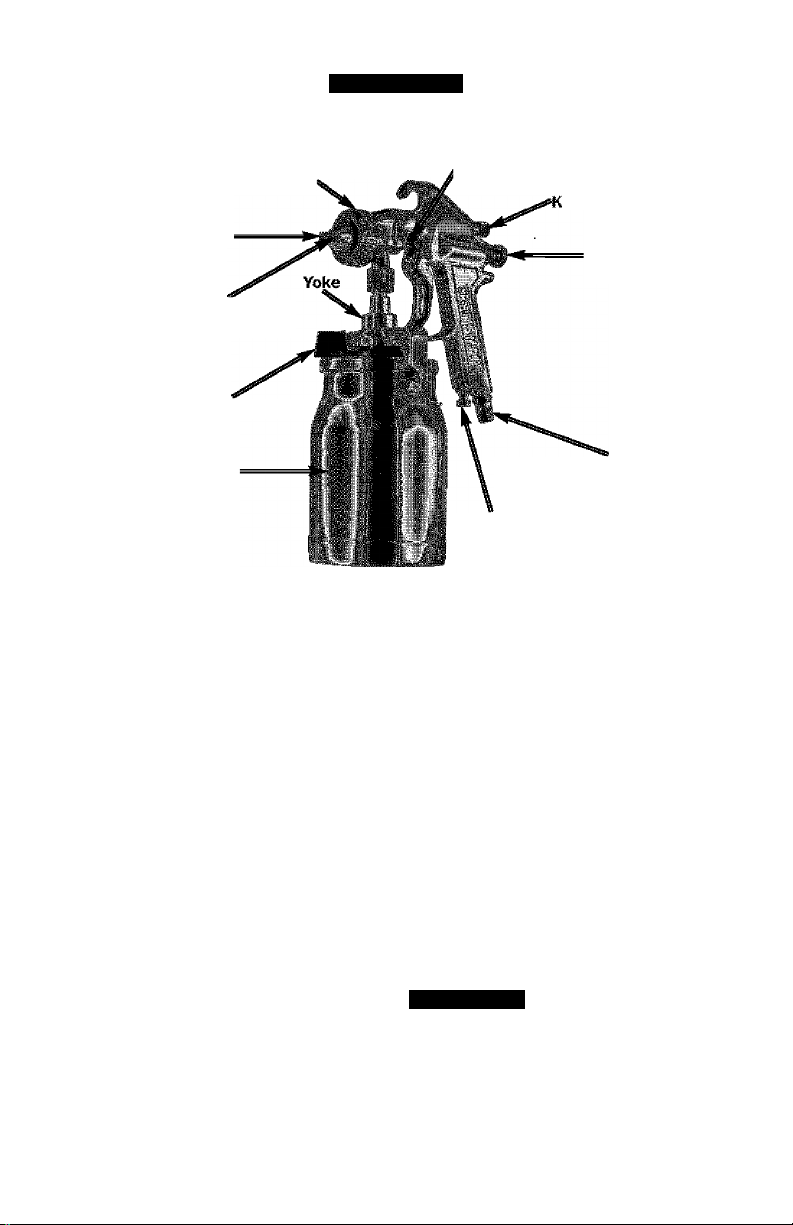

Know Your Spray Gun

OPERATION

Machined Brass

Externa! Mix CaP'

Air Cap Horns

Hardened Steel

Fluid Tip

Release Lever

1 - Quart

Siphon Feed

Material Cup

Machined Brass External Mix Cap -

The air and matersai are mixed after

¡eaving the nozzle to provide a

superior finish with thick and thin

matetial.

Hardened Steel Fluid Tip - for long

fife.

Air Cap Horns - determines a

horizontal or vertical spray pattern.

Fluid Con&ol Knob - controls the

fluid or density of fan spray.

Pattern Control Knob - controls the

size of the pattern from a large oblong

to small round pattern.

Air Valve Control Knob - fine tunes

the material spray with air.

1/4« isjp-f Inlet- allows the spray

gun to be connected to the air supply.

Release Lever - releases lid/gun

assembly from material cup.

Yoke - with built in wrench used to

easily remove gun from material cup

without tools.

Fluid Needle Adjustment Nut

Pattern Control

nob

Fluid Control

Knob

1/4" NPT Air Inlet

Air Valve

Control Knob

ACAUTION

I Before

I disassembly or re

moval of any part of gun or attached

components, shut off compressor,

release pressure by depressing

trigger, and disconnect power

source. NEVER assume system

pressure is zero!

ACAUTION

Prior to daily

operation, make

certain that all connections and fit

tings are secure. Check hose and all

connections for a weak or worn

condition that could render system

unsafe. All replacement components

such as hose or fittings must have a

working pressure equal to or greater

than system pressure.

AWARNING

TO AVOID CREATING

AN EXPLOSIVE

ATMOSPHERE, WORK ONLYfN

WELL VENTILATED AREAS.

029783

8- ENG

Page 9

AWARNING

USE OF A FACE

MASK ES

RECOMMENDED TO PREVENT ENHAU«-fON OF TOXEC MATERIAL.

Before Using Your Spray

Gun

1. Set up spray gun as described

in the "How to Set Up Spray

Gun" paragraph in the

“Assembly' section of this

manual.

To Use Spray Gun

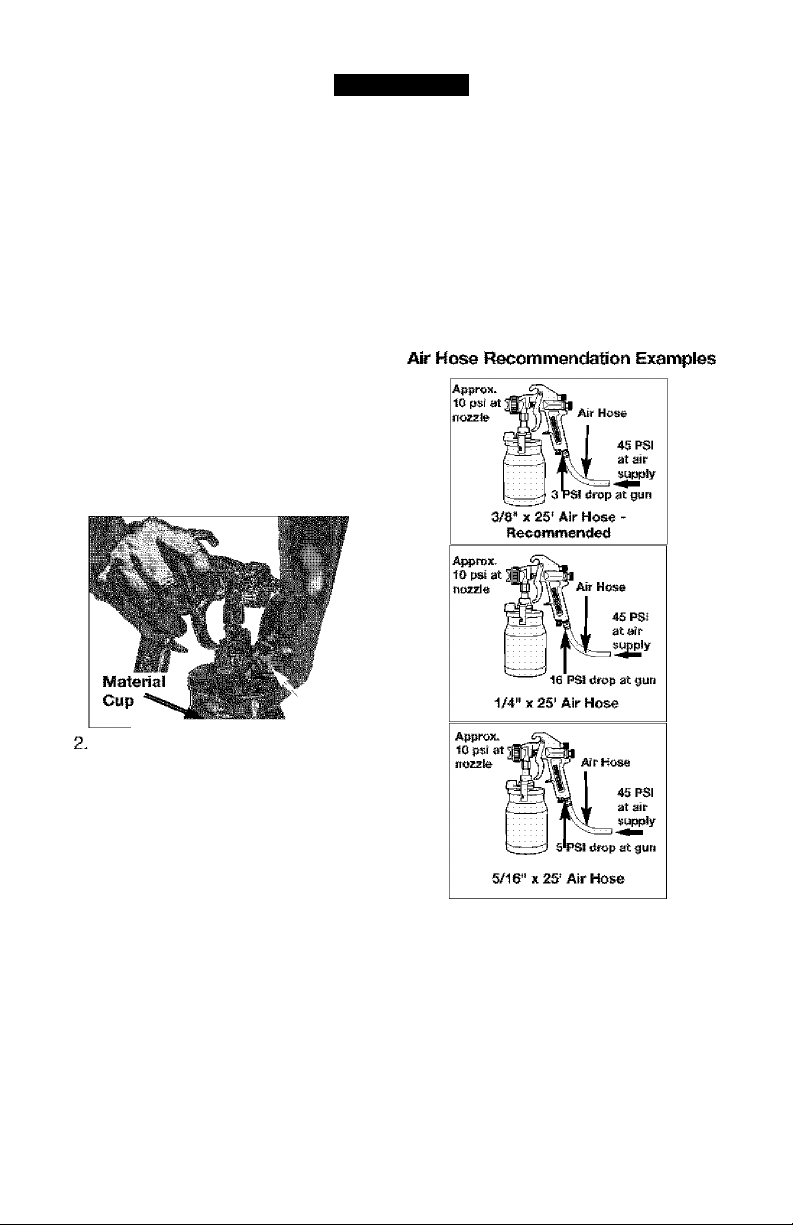

1. The position of the air cap fioms

will deteimine the fan spray

pattern. Loosen air cap and rotate

horns to achieve desired pattern.

Tighten air cap.

Horizorstal position

Vertical position

2.

Turn fEuid control knob clockwise

until it stops, do not force. This

will shut off the fluid flow. NOTE:

The fluid or density of “tan spray”

is controlled by fluid control

knob.

Turn pattern conb'ol knob

3.

counterclockwise until first thread

is flush with gun body. NOTE: Air

flow is controlled by pattern con

trol knob.

ACAUTION

control knob counter clockwise after

first thread is flush with the gun

body. They are under pressure vrtien

the gun is triggered and could leave

the gun wilb force.

'^r ^Control

DO NOT turn pattern

control knob or fluid

first thread flush pattern

Knob

Ruid

^i^sponbol

Knob

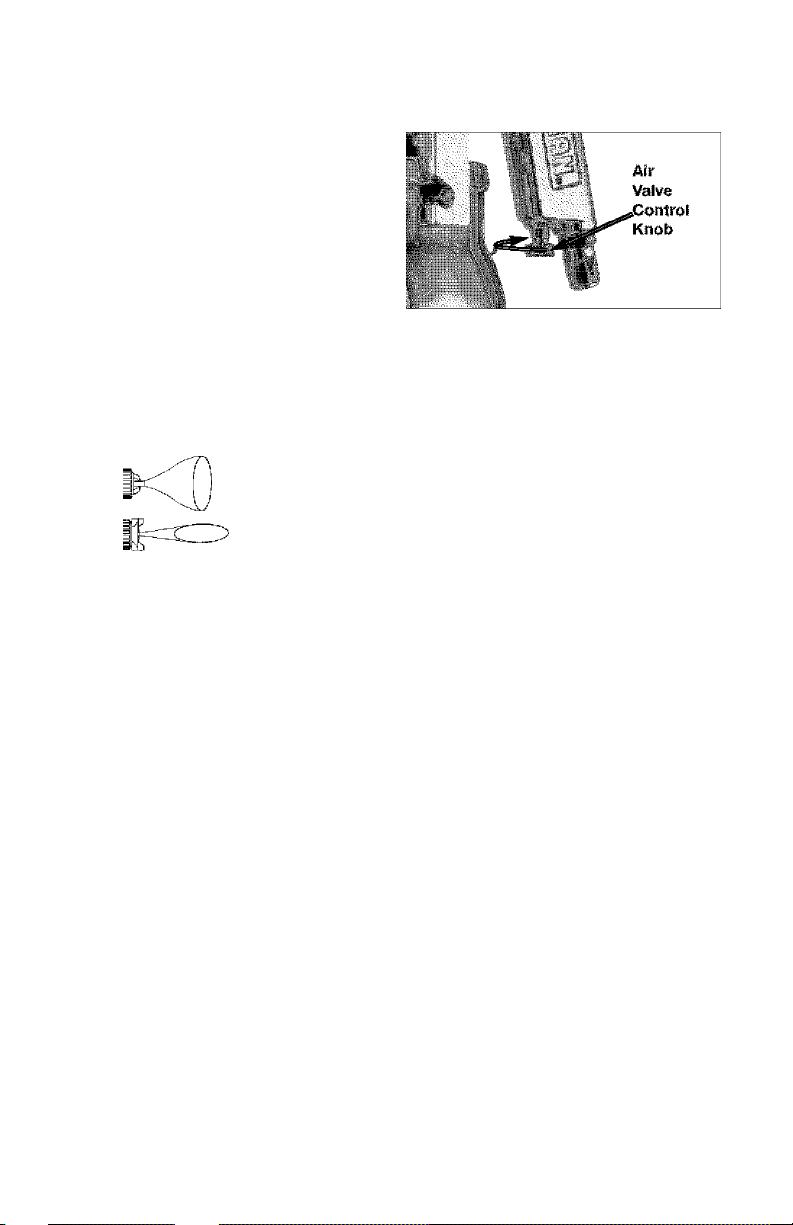

4. Turn air valvo control knob

clockwise until it stops, do not

force.

5. Adjust air pressure to 40 psi at

regulator.

ACAUTION

ACAUTION

DO NOT exceed 45

psi.

Pressure may vary

according to

viscosity of material used. Maximum

working pressure of gun is 45 psi.

DO NOT EXCEED PRESSURE LIMIT

OF GUN OR ANY OTHER COMPO

NENT IN SYSTEM!

6. Depress spray gun trigger and

gradually turn the fluid control

knob counterclockwise until

desired fluid flow is reached.

Trigger gun quickly, one second

on-off to test pattern.

ACAUTION

NEVER point Spray

gun at self or any

other person. Accidental discharge

of material may result in serious

injury.

To adjust spray pattern and fluid

presaire:

• To adjust the fluid, turn fluid con

trol knob counterciockwise to in

crease or clockwise.

• To adjust the air flow, turn pattern

control knob counterclockwise to

increase or clockwise to de

crease.

• To fine tune the air flow, turn air

valve control knob counterclock

wise to increase, or clockwise to

decrease.

IMPORTANT: Always Clean gun after

each use. See 'Maintenance" section

for correct procedure.

9- ENG

D29783

Page 10

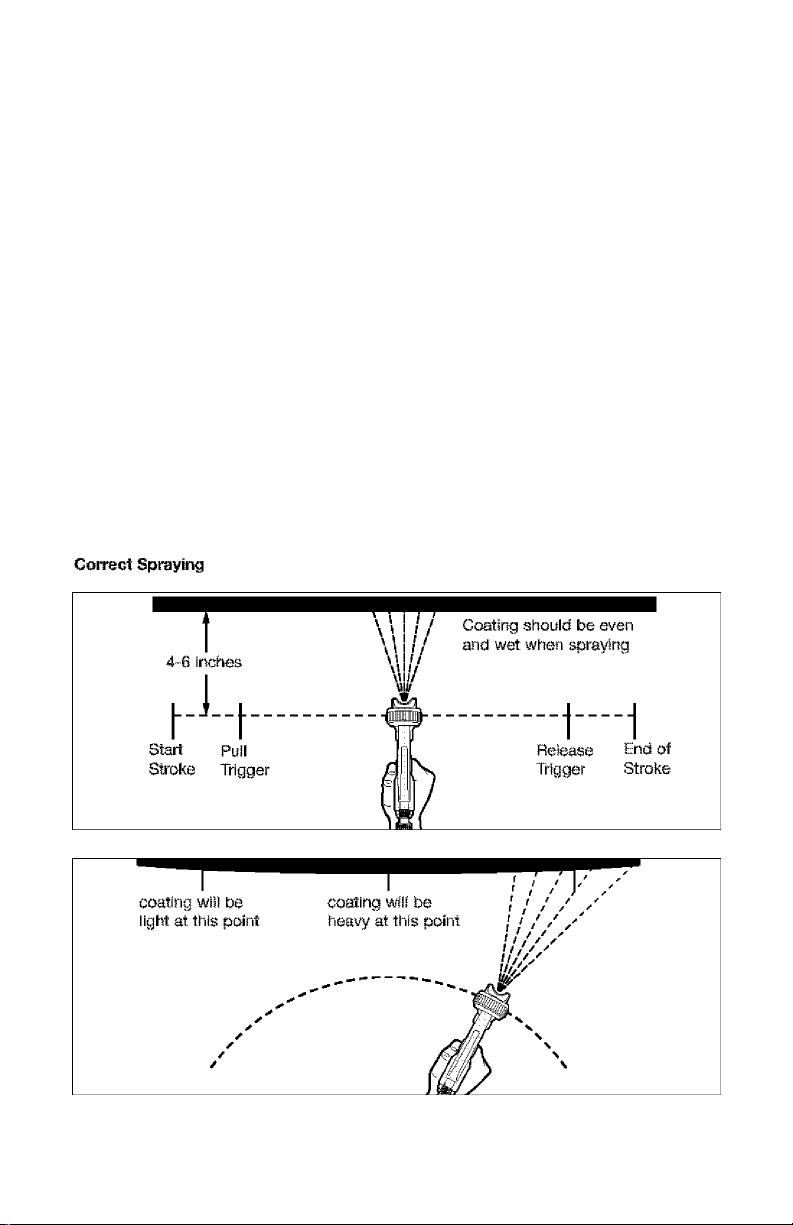

Operating Tips

• To reduce overspray and obtain

maxim um efficiency, always spray

with the lowest possible fluid/air

pressure.

• Hoid the gun perpendicular to the

surface, 4" to 6" distance.

• Two thin coats will produce a

better finish than one heavy coat.

• Mask off areas not being

sprayed.

• Follow contour.

• Overlap each stroke 50%.

• Ends are feathered by triggering.

That is, begin stroke before

pulling frigger and releasing just

before ending the stroke.

• Spray edges and corners first.

This will reduce overspray while

providing good coverage on

corners.

Don’t arc strokes, move the gun

parallel to work.

Pattern should be

shaped as shown, if not

see "Troubleshooting"

section.

Care should be exer

cised when handling spray gun to

avoid damage to the orifice of the

air cap and tip of fluid nozzle.

Damage to these parts results in

irregular spray patterns.

Practice on a cardboard target to

make sure pattern size and

material consistency are correct

before spraying on actual project.

I

incoit^ct Spraying

029783

10-ENG

Page 11

MAINTENANCE

AWARNING

DO NOT ATTEMPT

TO UNCLOG (BACK

FLUSH) SPRAY GUN BY SQUEEZING

TRIGGER WHILE HOLDING FINGER

IN FRONT OF FLUID NOZZLE.

Always axarcisa axtreme care when us-

ing any solvent or thinner. Never

clean gun near fire, flame, or any

source of heat or sparks. Properly

dispose of used cleaning materials.

DO NOT soak entire

spray gun in solvent

or thinner for a long period of time

as this will destroy lubricants and

possibly make motion uneven. NEV

ER use lye or caustic alkaline solu

tion for cleaning. Such solutions will

attack aluminum alloy parts of gun.

Cleaning

IMPORTANT: Clean gun immediately

after use. Paint and other materials

dry quickly in the small passages.

1. Turn off air supply to gun,

2. Remove the material cup from

lid/gun assembly. NOTE: Slide

release lever to the right, rotate

lid, and remove material cup.

When using the remote pressure

feed method: See manufactuier’s

manual for suggested cleaning of

remote cup or tank.

3. Empty material from material cup

and replace with a suitable

cleaning solvent (see material

container for recommended

solvent).

4. Turn air supply on and operate

trigger until all material traces have

disappeared and gun is thoroughly

clean,

5. To prevent corrosion, fiii material

cup with mineral spirits. Turn air

supply on and operate trigger until

all traces of mineral spirits have

disappeared.

IMPORTANT: Do not immerse the

gun in solvent, this will cause

damage to the packings.

NOTE: Always comply with iocai codes

when disposing of solvents,

6. Remove air cap and immerse in a

suitable solvent. Use a bristfe

brush to clean dried paint and

blow if dry with compressed air.

7. Use a wooden toothpick to dean

small dogged holes,

IMPORTANT: DO NOT use hard

objects to clean clogged holes.

TTie smallest amount of damage

may cause irregular spray

pattern.

8. Wipe gun with a solvent soaked

cloth.

IMPORTANT: Make certain air cap

and fluid nozzle are kept clean at all

times.

Lubrication

Lubrication ptocedutes must be ob

served after thoioughîy cleaning the

gun to ensure effective, high quality

performance of spray gun.

1. Lubricate working points with

straight mineral oil, or castor oil,

2, Periodically, place a few drops of

oil on tapered sections of fluid

nozzle to ensure easy operation of

air cap.

Replace nozzle set

When changing nozzle set, make sure

the complete nozzle set is exchanged.

A set includes an air cap, fluid nozzle,

and fluid needle. NOTE: Assemble

fluid nozzle before fluid needle.

11-ENG

D29783

Page 12

TROUBLESHOOTING

NOTICE: See parts list to identify parts referred to in these Troubleshooting steps.

PROBLEM

Heavy right or ieft side

pattern

)(

Heavy top or bottom

pattern

u

Heavy center pattern

«

Spilt spray pattern

I

Spitting, Irregular or

fluttering spray

CAUSE

1, Dried material is

clogging sideport "A” and

causing side-port

“B" to blow spray

towards the

clogged side.

1, Dried material at

fluid nozzie “C"

restricts air flow.

2, Loose air

nozzie.

3, Air pressure too

high

1, Too much material.

2, Materia! too thick.

1. Air pressure too high.

2. Not enough material

1. Leak at thread of fluid

nozzie.

2. Leak at fluid needle.

3. Insufficient fluid in cup.

1. Soak side-ports in thinner to

1. Remove air nozzie. Wipe fluid

2. Fast^ nozzie securely.

3. Turn pattern control knob

1. Turn fluid control knob

2. Thin materid.

1. Turn pattern controi knob

2. Turn fluid control knob counter

1. Tighten fluid nozzie.

2. Tighten the fluid needle

3. Fiii cup with fluid.

CORRECTION

dean ciog, DO NOT poke any

opening with hard objects.

tip using a cioth soaked in a

suitabie solvent or a soft brush.

dockwise to reduce air

pressure.

dockwise to decrease materia!

flow or turn pattern control

knob counter clockwise to

increase air pressure.

dockwise to reduce air

pressure.

clockwise to increase material

flow.

adjustment nut.

029783

4. Vent hole in materia! cup

cover clogged (only in

siphon feed mode).

5. Materia! cup tilted at an

excessive angle,

6. Fluid too heavy for siphon

feed.

7. Loose fluid tip or dams^ed

tip seat

12-ENG

4. Ciean veit hole.

5. Do not tilt material cup

excessively or rotate fluid tube.

6. Thin materia! or convert to

remote pressure feed mode.

7. Tighten or replace.

Page 13

PROBLEM

Unatomized or

spattered spray

CAUSE CORRECTION

1. Material too heavy.

2. Insufficient air pressure.

1. Thin material.

2. Turn pattern control knob

counter clockwise to Increase

air pressure. Turn mt valve

control knob counter clockwise

to Increase air pressure.

3. Fluid pressure too high. 3. Turn fluid control knob

clockwise to decrease fluid

flow. If using in renote

pressure feed mode decrease

fluid pressure at paint tsnk.

4. Dried material on tip of

4. Clean.

fluid nozzle or air jets of

air cap.

Inadequate air

delivery

Excessive fog

Material leaking from

fluid inlet of cup.

Material leaking from

nozzle when trigger is

released

1. Air valve control knob

partially closed.

2. Dried material in air jets

or air cap.

3. Obstaiction in air Inlet.

1. Air pressure too high for

viscosity of fluid

2. Too far from work

surface.

1. Loose cup or foreign sub

stances oiVbeiween cup

thread aid fluid inlet.

1. Dried material In tip of

nozzle.

2. Loose fluid needle

adjustment nut.

1. Turn air valve control knob

clockwise to open.

2. Clean.

3. Remove obstaiction.

1. Reduce air pressure at air

supply regulator, turn pattern

control knob clockwise, or turn

fluid control knob counter

clockwise.

2. Adjust to proper distsnce.

1. Clean and tighten.

1. Ciean

2. Tighten fluid needle «tjustment

nut.

13-ENG

D29783

Page 14

PARTS LIST

Spray Gun Model Number 919.155190

KEY

RiUlTNO

NO.

1

SQ5-0056 Brass Ring Cap

2 SG5-0057

DESCRIPTION

Air Nozzle

3 SQ5-0058 Fluid Nozzte

4

SG5-0059

5 SG5-0060

Air Reducer

Washer

6 SG5-0061 Head

7 SG5-0062 Screw

SG5-0064

8

Trigger Rn

10 SG5-0066 Snap Ring

11

SG5-0063

12 SG5-0021

SG5-0012 0-Ring

13

14

SG5-0010 Air Valve Assembly

15 SG5-0016

SG5-0024 Retaining Nut

16

17

SG5-0023

Gun Body

Fluid Needle Assembly

Spring

Spring

18 SG5-0025 Fluid Needle

Adjusting Screw

19 SG5-0020 Valve ^em Assembly

SG5-0017 0-Ring

20

21

22

029783

SG5-0018

SG5-0019

O-Ring

0-Ring

KEY

NO. PART NO

SG5-0044

23

DESCRIPTION

Adapator 1/4 NPT X 1/4 NPS

24 X

----------

X

----------

25

26 X

--------

27 X

----------

28 SG5-0009

Regulator

Screw

O-Ring

Lock Ring

Peking Retainer

29 SG5-0003 Fluid Needle Packing

30 SG5-0013 Trigger

31 4.SG5-0035

32

4.SG5-0036

4.SG5-0037 Arm

33

34

4-SGE-15 Lever Release

35 4.SG5-0039

4-

36

Screw

Nut

Lid Cannister

SG5-0040 Gasket

37 4.SG5-0041 Siphon Tube

38

4-SG5-0042

• K-0189

Ganniste"

Gasket Kit.

4.K-0190 Compiete Cup

and Lid AssempSy

X SG5-0051

14-ENG

Regulator Kit

Page 15

CONTENIDO

Qsrantla............................................ ... .15

Definiciones de normas de seguridad

instrucciones importantesde

seguridad

..........................................

Especificaciones

Ensamblaje .......................................

................................

.,. .15

.16-17

___

.18-20

Operación

Mantenimiento

Diagnóstico de problemas .

Lista de partes

17

Como solicitar repuestos .. . .contratapa

..............................

.......................

........................

............

................

................

................

21-23

24

25

14

GARANTIA

ÜN ^0 DE GARANTIA COMPLETA SOBRE LA PISTOLA ROCIADORA

Si esta pistoia rociadera fejvíera fallas de materiales o fabricación dentro del año de su fecha de

compra, DEVUÉLVALA M.CEMTRO DE REPARACSONES DE SEARS MÁS CERCMIO DENTRO DE

LOS EE.UU., Y SEAñS LA REPARARÁ SÍN CARGO ALGUNO. SI SÉ HUBIESE COMPRADO EN

UNA FERRETERÍA ORCHARD, DEVUÉLVALA A LA FERETERA ORCFIARD MÁS CERCANA, Y

ORCHARD LA REPARARÁ SIN CARGO ALGUNO.

Si esta pistoia rociadera fuera utilizada para uso comercis^ o con pre^wsito de aiquiier, la garantía

tendrá vigencia solamente por nervente días a ptrHr de le fecha de compra.

Esta garantía !e etorga derechos legales específicos y usted podría tener otros derectos que v^fan

entre los estados.

Sears, Roebuck and Co., Hoffman Estates, IL $0179 EE.UU.

definiciones de normas de seguridad

Este manual corrtiaie información que es importante que usted sepa y aitienda Esta

Infomación se reladona con la protección de SU æGURIDAD y la PREVENCfÓN DE

PROBLEMAS AL EQUIPO. Para aleudarle a identificar esta informacíén usamos ios

siguiaites símbolos. Por favor leer este manual y prestar ataición especial a estas seccíaies.

indica una situación de

no se evita causará lesiones serias o

muerte.

AADVERTENCIA

poíenciaimente riesgosa, que si no se

evita podría causar lesiones serias o

muerte.

riesgo inminente que sí

Indica una

situación

APRECAUCIÓN

peligrosa, que sí no se evitada, podría

causar lesiones menores o moderadas.

APRECAUCiÓN

alerta, indica una situación potencialmente

riesgosa que si no se evita, podría caus^

daños en la propiedad.

15- SP

Indica una situación

potencialmente

Usado sin el símbolo

de seguridad de

D297S3

Page 16

ínstrucciones importantes de seguridad

• conserve estas instrucciones «

AADVERTENCIA

ENTENDER TODAS LAS ADVERTENCIAS SEGURIDAD E INSTRUCCIONES DE OPERACIÓN

ANTES DE USAR ESTA UNIDAD.

AADVERTENCIA

Riesgo do explosión o incendio - Materiales inflamables.

¿QUE PUEDE OCURRIR?

Rie$90 de explosif ^ Metálales iecompatibies ^M||v

¿QUÉ PUEDE OCURRIR?

Loa solventes 1,1 ^ TiicEofoetanos y Cloruro

de Metiíeno pueden reaccionar químicamente

con ei aluminio que se usa en la mayona de los

equipos de pulverización en esta pistola y en

este contenedor, y pueden genersv un riesgo de

explosión.

LA OPERACIÓN INAPROPIADA DE ESTA UNIDAD RJEES CAUSAR

LESIONES SERIAS Y DAÑCS A LA PROPIEDAD. L^RY

I Los sígo/entes riesgos pueden ocurrir durante el uso normal de esíe

I

producto:

RIESGOS

ÉÉi

Jm W

~ I

¿CÓMO PREVENIRLO?

liiiíiiili

RIESOO y 1

¿CÓMO PREVENIRLO?

Leer !a etiqueta u hoja de información del material

a pulverizar.

1 .Nunca usar tipo alguno de laca protectora

puiverizabie que ccsntanga estos solventes.

2. N0 usar estos solventes para limpiar ei equipo.

3. E11 caso de duda respecto a la conipatibiíidad

del material, oontactw al proveedor del material.

RIESOO

Riesgo de inhalación

¿QUÉ PUEDE OCURRIR?

RIESGO

RiesBO de objetos en suspensión aérea

¿QUÉ PUEDE OCURRIR?

Ciertas partes están prewrizadas cuando la

pistola está conectada a una línea de aire

presurizada y pueden SE^ir disparadas si se

desarma la pistola.

La exposición prolongada al chorro de mre puede

causar lesiones permanentes ai oído.

029783

¿CÓMO PREVENIRLO?

¿CÓMO PREVENIRLO?

Desconectar la pistola de la iínea de aire, o

despnesurizwla completamente cuEVido se vaya

a desamiar la pistola.

1 • . . 1 .'-J 1 '■-! I' i ! ' i 1 1 i -h" ^"r : í" ! í

iiÌgg:|BÌÌÌgÌ'iÈlìl#fSS^

Al operw un equipo para pulverizar siempre usar

protección para ios oídos.

16- SP

Page 17

Riesgo do inyección

RIESGO

¿OUÉ PUEDE OCURRIR? |

ESPECIFtCACIONES

¿CÓMO PREVENIRLO?

Presión mínima a la entrada de ia pistola

Presión máxima a la entrada de ia pistola

Conexión de aire

Conexión de líquidos

Contenedor de pintura

Tipo de aguja

Tipo de alimentación

Tipo de purga

Requisitos dei compresor de aire

20 PSI

45 PSI

Estándar 1/4 NPS

Estándar 3/8 NPS

946m!, de aluminio con boca ancha

Acero inoxidable

Sifón*

No se purga

8.6 Pie’/min a 40 PSi

* Esta pístoia pulverszadora puede convertirse fácilmente a alimentación por presión para

usarse con un tanque de pintura (se vende por separado) cuando se pulveriza material

pesado o para proyectos grandes.

17- SP

D29783

Page 18

ENSAMBLAJE

Contenido de la caja

1 - Pistola pulverízadora

1' Manuial del propietario

Cómo aimar

La pistola puiverizadora Craflsman se

despaciia compietanente ensamblada y

preparada para pulv«-izar alimentándose

por sifón.

Esta pistola fue tratada con un

anticorrosivo antes de su despacito, por lo

que antes de usarse debe lavarse

internamente con un solvente apropiado

(destilado mineral).

Para lavar ínternatnente la pistola antes

de su uso

Contened orde

ñ de seguro i

1. Desmontar el contenedor de la tapa

en la pistola. NOTA; Deslizar ía

palanca a ia derecha, rotar la tapa y

desprender ei contenedor.

2. Llenar 3/4 partes del contenedor con

un solvente adecuado.

3. Reinstalar el contenedor en la tapa en

la pistola y deslizar la palanca a la

izquierda para asegurar el

contenedor.

4. Conectar la línea de suministro de

aire al conector de 1/4" NPT.

Referirse al párrafo "Conexión" en

esta sección.

5. Apretar el gatillo para disparar el

solvente y que pase por la pistola.

Referirse al párrafo "Como usar la

pistola puiverizadora’ en la sección

"Operación" de este manual,

6. Pulverizar iodo el solvente hasta que

se agote y evacuar cualquier residuo

del contenedor.

Como conectar la pistola puiverizadora ai suministro do aire

1. Conectar la linea de suministro de

aíre al conector de entrada de 1/4'

NPT. NOTA: Para la mejor presión de

aíre para pulverizar, se recomienda

usar una manguera de 3/8" de

diámetro. SI se usa una manguera de

aire de 1/4" ó 5/16" de diámetro, la

presión de aíre debe graduarse en el

regulador para compensar por la

caída de presión de aire entre el

regulador y la pistola puiverizadora.

Ejemplos do rocomondaciones para manguera do aire

de arre en ^ pistola 3 PSI

Manguera de air^ de

X 7,6m {25')

Caída aír^ en la pistola P$l

Mangu^^ de aire de

1/4" X 7,Sm (25‘)

Calda ce aire en la pídola P$l

Manguera de aire de

5/16”x7,Snri(25*)

029783

18™ SP

Page 19

IMPORTANTE: Se recomienda usar un extractor de aceíte/agua. Ver los ejemplos en las

ilustraciones.

Configuración básica

- A la línea de

sumifiietro de aire

(Un compresor

equipado oca un

regulador)

Configuración ideai

A la linea de

^suministro de

aire (con c^'da

fuerte de

presídn)

Antes de usar ia pistoia puiverizadora

APRECAUCIÓN

usarse con la mayoría de materiales para

acabados que no sean corrosivos o

altamente abrasivos; ya que éstos

producirfan un mai rendimiento y/o la

falla de la pistola.

1. Mezclar ^ material siguiendo las

insírucciones del fabricante. La mezcla

debe queclíT sin grumos y debe poderse

vaciar fécilmaite. Deben ^iminírse los

grumos y partículas extrañas colándose

con un filíro de pintura adecuado,

NOTA: El uso de un medidor de

vi^ostdad de Sears ayudírá medir !a

vlKioadad o espesor del matetal.

Esta pistola está

diseñada para

Para conexión con alimentación por sifón

1. Desmontar el contenedor de la

pistola. NOTA: Deslizar la palanca a

ía derecha, rotar ia tapa y desprender

el contenedor.

2. Llenar 3/4 partes del contenedor con

un solvente adecuado.

3. Reinstaiar el contenedor en la tapa en

la pistola y desilzar la palanca a ia

izquierda para asegurar el

contenedor.

NOTA: Al reinstalar la pistola, cerciorarse

que el doblez en el tubo del sifón quede

hacia el trente de !a pistola como se

muestra.

4,

Conectar ia línea de suministro de

aíre al conector de 1/4* NPT,

Para aprender a usar la pistola

puiverizadora, referirse a la sección

"Operación".

13- SP

D29783

Page 20

Para convertir a alimentación remota a presión

Sf ei material a pulverizase fuese muy

pesado para aiimentactón por sifón o se

desea aplicar una mayor cantidad de

volumen:

1.

Desmontar el contenedor de la

pistola NOTA: Deslizar la palanca

a la derecha, rotar !a tapa ^ la

pistola y despreider ei contenedor.

2.

Deslizar el yugo con e! adaptador

incorporado sobre la tuerca Agarra

el yugo y girarlo para aflojar la tuerca

y girar a mano hasta que el conjunto

de la tapa pueda sacarse de la

pistola

3. Ahora la pistola está lista para

conectarse a cualquier tanque para

ailmeníadón a presión con un niple

hembra, estándar recto de 3/8“, Para

e! procedimiento correcto, referirse al

manua! del fabricante del tanque.

4. Referirse a !a sección "Operación"

para aprender a usar la pistola

pulverízadora.

NOTA: Al reinstalar el conjunto de ía tapa

en la pistola, ajustar a mano la tuerca y

deslizar el yugo sobre la tuerca para

ajustarla firmemente.

Configuración típica alimentación remota a presión

029783

20" SP

Page 21

OPERACIÓN

Familiarización con la pistola pulverizadora

Tapa mezcladora exterior

de latón maquinado

Aletas de la

tapa de aire

Boquilla de liquido

de acero endurecido

Palanca de seguro

Contenedor de

material de a46ml

(1/4 de Gal.) con

de alimentación

por sifón

Tapa mezcladora exterior de latón

maquinado. El aire y el material se

mezclan después de salir por la boquilla

para proveer un acabado superior con

materia! grueso o fino.

Boquilla de acero endurecido para

liquido para una vida útil más larga.

Aletas de la tapa de aíre para seleccionar

entre un patrón de rociado (Abanico)

horizontal o vertical.

Perilla de control del flujo. Controla la

fluidez o densidad de! abanico de rociado.

Perilla de control del patrón de rociado

(Abanico) Controla el tamaño del patrón

de rociado o abanico desde una forma

larga ovoide hasta un un circulo pequeño.

Perilla de control la válvula de aire para

hacer el ajuste fino de la mezda de

material pulverizado con el aire.

Conector roscado de 1/4" NPT рш'а la

línea de suministro de aire.

Palanca de seguro. Suelta o asegura el

contenedor a la tapa en la pistola.

Yugo con llave incorporada que se usa

para separar el contenedor fácilmente de

la t^a en la pistola.

tuerca reguladora de

la aguja de líquido

Perilla de control de

patrón de rociado

(Abanico)

Perilla de control

del flujo

or roscado

de 1/4“ NPT para

entrada de aire

Válvula de aire

Antes de desarmar

cualquier pieza a la pistola o

componentes instalados, apagar el

compresor, despresurizar apretando el

gatillo y desconectar de la ftjente de

energía. ¡NUNCA asumir que el sistema

está despresurizado (presión cero).

APRECAUCIÓN

cerciorarse que todas ¡as conexiones y

acoples estén apretados firmemente.

Inspeccionar la manguera y todas las

conexiones para detectar si hay partes

débiles o gastadas que puedan volver ei

sistema inseguro. Todos los

componentes de repuesto como

mangueras o acoples deben tener una

capacidad de trabajo igual o mayor a ia

presión del sistema.

AADVERTENCIA

ATMÓSFERA EXPLOSIVA, TRABAJAR

SÓLO EN ÁREAS BIEN VENTILADAS.

o de sacarle

Antes de ia

operación diaria,

PARA EVITAR

CREAR UNA

21- SP

D297S3

Page 22

EZ

MASCARA PROTECTORA PARA EViTWl

INHALMt MATERIAL£S TÓXICOS.

SE RECOMi£^JDA

USAR UNA

^tes de usar la pistola

pulverizadora

í. Armarla orno se indica en el páirafo

"Armado de la pistola pulverizadora"

en la sección "Ensamblaje".

Para usar la pistola pulverizadora

1. La posición de las atetas de la tapa

de aire determina e! patrón del

abanico de rociado. Aflojar ía tapa de

aire y girar las atetas para obtener el

patrón deseado. Volver a ajustar la

tapa de aíre.

Posiciótr horizontal

Posición v^ioa!

Cortar el flujo girando la perilla de

control del flujo en ei s^tído del

reloj hasta que el flujo se detenga, sin

forzar. NOTA: La fluidez o densidad

del abanico de rociado se controla

con la perilla de control del flujo.

Girar la perilla de conbol de patrón

contra el sentido del reloj hasta que

la primera vuelta de la rosca esté a

ras con el casco de la pistola. NOTA:

El flujo de aire se controla con la

pallia de control del patrón.

APRECAUCIÓN

pabón ni la del control de fluido contra el

sentido del reloj después que ía primera

vuelta de las roscas estén a ras con el

casco de la pistola; porque están

pie^irizadas cuando se aprieta el gatillo

y podrian salir disparadas con fuerza.

No girar ia p^lla

de control del

4. Girar la perilla de ia váivuía de aire en

el sentido del reta] hasta que se

detenga, no forzarla.

Perilla de

control de

la válvula

de aire

5. Graduar el regular para una presión

de aire de 40 PSI.

APRECAUCIÓN

a la viscosidad del material utilizado. La

presión máxima de trabajo de la pistola

es 45 PSI. ¡NO EXCEDER EL LÍMITE DE

PRESIÓN DE LA PISTOLA N! DE

COMPONENTE ALGUNO DEL SISTEMA!

6. Apretar ei gatillo y gír^ gradualmente

!a perilla de control de fluido contra el

sentido del reloj hasta lograr el flujo

de líquido deseado. Probar el patrón

(abanidoj de rociado, apretar el gatillo

con una intermitencia de un segundo.

APRECAUCIÓN

pulverizadora a si mismo ni a otras

personas porque una descarga

accidental podría causar lesiones

serías.

NO exceder 45 PSI.

La presión puede

variar de acuerdo

Nunca apuntar la

pistola

Para regular el patrón de rociado y

presión de fiuido:

• Para regular la presión del líquido,

girar la perilla de control de fluido

contra el sentido del reta] para

aumentarla o en el sentido del reioj

para disminuirla.

• Para regular el flujo de aire, girar la

perliia de control del flujo de aire

contra el sentido del reioj para

aumentarla o en el sentido del reta]

para disminuirla.

• Para la regulación fina dei flujo de

aire, girar ía válvula de control de aire

contra el sentido del reioj para

aumentarlo o en el sentido del reioj

para disminuirlo.

IMPORTANTE: Siempre limpiar la pistola

después de cada uso. Referirse a la

sección “Mantenimiento“ para el

procedimiento correcto.

029783

22- SP

Page 23

Consejos prácticos:

• Para evitar pulverizar exceso y

iograr el máximo de eficiencia,

siempre pulverizar con la combinación

de presión de pintura y aire más baja

posibie.

• Sostener ia pistoia

perpendiculatmeníe a ia superficie a

una distancia de 10 a 15 cm (4" a 6")

de distancia.

• Dos capas deigadas producen un

mejor acabado que una c^a gruesa.

• Enmascarar ias áreas que no se van a

rociar.

• Seguir el contorno de ia supwticie,

• Trasiapar cada nuevo pase 50% sobre

el anterior,

• Ei movimiento del pase debe

empezarse antes de apretar ei gatilio y

el gatilio debe soltarse antes de

twminar el pase.

• PuSverizar los bordes y esquinas

primero. Esto reducirá el exceso de

pulvOTzado, asi como también

proveerá de un buen recubrimiento en

las esquinas.

Aplicación correcta:

No arquear las pasadas, mover ia

pistola en forma paralela a ia

superficie de trabajo durante toda la

pasada.

E! patrón de puíverizado

normalmente debe tener la

fotma mostrada; de io

contrario ver ia sección

"Diagnóstico de

Problemas”.

Tratar la pistola pulverizadora con

cuidado para evitar dañar ei orificio de

ia tapa de aire y de la boquília; porque

si se dañan, se producirán patrones

de pulv№zac¡ón irregulares.

Practicar sobre un cartón para

asegurarse de lograr el tamaño del

patrón de rociado (abanico) cerreto y

ia consistencia de material adecuada

antes de pintar la rociar la superficie

definitiva.

23- SP

D297S3

Page 24

MANTENIMIENTO

AADVERTENCIA

PISTOLA APRETANDO EL GATILLO Y

TAPANDO LA BOQUILLA CON EL DEDO.

APRECAUCIÓN

cuando se usen solventes o diluyentes.

Nunca limpiar o lavar la pistola cerca de

fuego, llamas ni fuentes de calor o

chispas. Desechar apropiadamente ios

materiales usados en la limpieza o

lavado.

APRECAUCIÓN

por largo Uempo porque se destruirá su

lubricación y posiblemente su

accionamiento se vuelva irregular.

NUNCA usar lejía ni soiuciones alcalinas

al limpiar (lavar) la pistola porque esas

soiuciones atacan las piezas de aleación

de aluminio.

Limpieza o Lavado

IMPORTANTE: Limpiar (lavar) la pistola

inmediatamente después de cada uso.

La pintura y otros materiales se secan

rápidamente en los pasajes pequeños.

1. Cortar e! suministro de aire a la

pistola.

2. Desconectar el contenedor de

material de la tapa en ía pistola

NOTA; Deslizar !a palanca a la

derecha, rotar la tapa en la pistola

y desprender el contenedor. Cuando

se use el método de aiimentación

remota a presión, referirse ai manual

del fabricante para las sugerencias de

limpieza (lavado) del contenedor o

tanque.

3. Vaciar eí material del contenedor y

reemplazarlo con un líquido solvente

adecuado (para el solvente apropiado,

referirse a la etiqueta del envase del

material).

4. Abrir el suministro de aire y apretar el

gatillo hasta que desaparezca toda

traza dei material y la pistoia quede

completamente limpia,

5. Para evitar la corrosión. Henar eS

contenedor con un destilado

mineral.Abrir el suministro de aire

y apretar el gatülo hasta que

desaparezca toda traza del destilado

mineral.

NO fNTENTAR

DESATORAR LA

Siempre tener

extremo cuidado

No sumergir la

pistola en solventes

IMPORTANTE; No sumergir la pistola en

el solvente porque las empaquetaduras

se dañarán.

NOTA: Siempre acatar ios códigos locales

^ desechar los solventes,

6. Sacar ia tapa y sumergirla en un

solvente adecuado. Usar una escobilla

de cerdas para limpiar la pintura seca

y soplarla con aire comprimido,

7. Usar un paüílo escarbadientes de

madera para ümpiar las obstrucciones

de ios orificios pequeños.

IMPORTANTE; No usar objetos duros

para limpiar las obstrucciones de los

orificios, porque el daño más leve puede

causar un patrón irregular de rociado.

8. Limpiar la pistola frotándola con un

paño empapado en soívente,

IMPORTANTE; Cerciorarse de manterter

siempre limpias la tapa de aire y la

boquilla para liquides.

Lubricación

Para asegurarse de mantener la calidad del

^to rendimiento de la pistola puiverizadora,

después de cada limpieza (lavado)

completo, siempre seguir el procedimiento

de íubrteación.

1. Lubricar los puntos de movimiento

con aceite minerai puro o aceite de

castor.

2. .i^licar periódicamente unas gotas de

aceite en las secetanes ahusadas de ía

boquiíia para líquidos para asegurar su

ftincionamiento ftoii de la tapa de aire.

Reemplazo del conjunto de la boquilla

Cuando se cambie eí conjunto de ía

boquilla, cerciorarse de cambiar todos sus

componentes. Eí conjunto está compuesto

por ¡a tapa de aíre, ia boquilla para líquidos

y la aguja para líquidos. NOTA: Ensamblar

la boquilla para líquidos antes que la aguja

psra líquidos.

029783

24- SP

Page 25

DIAGNÓSTICO DE PROBLEIVIAS

NOTA: Referirse a la lista de partes para identificar !as piezas a fas que se hace

PROBLEMA

Patrón grueso en el lado

izquierdo 0 derecho.

)(

Patrón grueso arriba o

abajo.

u

Patrón grueso en el

á

f

Patrón angosto en ei

ceitro.

La pistola escupe o

patrón Irregular,

tembloroso u onduiado

EN8

CAUSA

1, Material seco a

obstruyendo el ¡

orificio de salida

del lado "A"

haciendo que el l ^ )|

orificio del lado

"B” pulverice \

hacia el lado ¿

obstruido.

1, Material seco en

!a boquilla de ^

ílquidos "C" está

restringiendo el /

flujo de aire.

2, Boquillas de aire f©

suelta.

Av^

3, Presión de aire

demasiado alta

1, Demasiado material.

2. Material demasiado

espeso.

1. Demasiada presión de

are

2. Insuficiente material

1, Fuga en la rosca de la

boquilla para fluido

2, Fuga en la aguja para fluido

3. Material insuficimte en ei

contenedor.

4. Ortfiob de r^praoH^ en la

tapa d^ contenedor de

matQ-ial está obstruida (séío

ai modalidíKí de síf<^).

5. Contenedor de material

inclinado en demasiado

ángulo.

6. Liquido demasiado espeso

0 pesado para el tubo del

sifón.

7. Boquifla para fluido suelta

0 con el asiento dañado.

CORRECCIÓN

1. Sumergir las boquillas de

ambos lados en solvente ¡implo

para desatorarlas. NO usar

objetos duros para limpiar los

orificios.

1. Sacar la boquilla de aire y

limpiarla frotándola con una tela

empapada con un solvente..,

adecuado o con una escobilla

de cerdas blandas

2. Ajustar bien la tapa de la

boquiila,

3. Reducir la presión de aire

girando la perilla de control del

patrón de rociado ^ ei sentido

del reiol.

1. Reducir el flujo de líquido

girando la periila de control de

fluido en er sentido del relo o

aumentar la presión de aire

girándola tóriiia de control del

paírón (AMnicol contra el

2. Adelgazar el material.

1. Reducir la presión de aire

girando la perüia de control del

patrón de rociado (Abanico) en

eí sentido del reioj.

2. Aum«itar ei flujo de material

girando la p^ilia de control de

fluido contra el reloj

1. Ajustar la boquilla para fluido..

2. Ajustar la tuerca de ía aguja

para fluidos.

3. Reifenar el contenedor con

líquido

4. Limpiar ei orificio de respiración

5. No inclinar excesivamente o

girar el tubo de succión.

6. Adelgazar el material o cambisr

a modalidad de alimentación

remota por presión

7. Ajustar 0 cambiar.

25- SP

D29783

Page 26

PROBLEMA CAUSA

Matwal rociado no

1. Material demasiado

pulverizado o

salpicado.

2. Presión de aire

3. Presión de fluido

4. Material seco en el

Salida de aire

1. Perilla de control de ia

inadecuada.

2. Materia seco en !os

pesado o espeso

insuficiente.

demasiado alta.

orificio de la boquiiía de

fluido 0 fugas de aire por

la tapa de aire.

válvula de aire

parcialmente cerrada.

orificios de salida de are

0 la tapa de aire.

CORRECCIÓN

1. Adelgazar el material.

2. Aumentar la presión de aire

girando !a pOTila del patrón

(Abanico) contra el sentido de!

reloj. Aumentar la presión de

aire girando !a perilla de la

válvula de aire contra el

sentido del reloj,

3. Reducir e! flujo de liquido

girando la perilla de control del

flujo en el sentido del reloj. Si

se está usando con

alimentación remota a presión,

disminuir la presión del iíquido

en e! tanque de pintura.

4. Limpiar.

1, Abrir la perilla de control de !a

válvula de aíre girándola en el

sentido del reloj

2, Limpiar.

Nebulización excesiva.

Fuga de material por !a

entrada de! contenedor.

Fuga de material por la

boquilla cuando se

suelta ei gatillo.

029783

3, Obstrucción en la entrada

de aire.

1. Demasiada presión de

aire para la viscosidad

de! liquido.

2. Aplicación desde muy

lejos de ia superficie.

1. El contenedor está suelto

0 hay substancias

extrañas entre la rosca

de! contenedor y la

entrada de líquido.

1. Material seco en el orificio

de la boquilla

2. La tuerca de ajuste de la

aguja de fluidos está

suelta.

26- SP

3, Eliminar ia obstrucción.

1. Reducir la presión de aíre en el

r^ulador, girando ia perilla de

control del patrón en e! sentido

del reloj o girando !a periíia de

control de fluido contra el

seitido de! reloj.

2. Aplicar desde una distancia

adecuada.

1. Limpiar y ajustar.

1. Limpiar

2. Ajustar ia tuerca de ajuste de ia

aguja de fluidos.

Page 27

NOTES

27- SP

D29783

Page 28

NOTES

029783

28- SP

Page 29

NOTES

23- SP

D29783

Page 30

NOTES

029783

30" SP

Page 31

NOTES

31- SP

D29783

Loading...

Loading...