Owner's Manual

Permanently Lubricated

Tank Mounted

AiR COMPRESSOR

= Safety Guidelines

= Assembly

= Operation

= Maintenance

= Service and Adjustments

= Troubleshooting

= Repair Parts

CAUTION: Read the Safety Guidelines

and All Instructions Carefully Before

Operating.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

N01421 2 Rev,0 7/24/08

WARRANTY ................................................ 2

SPECiFiCATiON CHART ...................................... 3

SAFETY GUiDELiNES - DEFiNiTiONS ........................... 3

iMPORTANT SAFETY iNSTRUCTiONS ........................ 3-9

GLOSSARY ................................................ 9

ACCESSORIES ............................................. 9

DUTY CYCLE ............................................... 9

ASSEMBLY ............................................... 10

INSTALLATION ......................................... 10-11

OPERATION ............................................ 12-14

MAINTENANCE ......................................... 14-15

SERVICE AND ADJUSTMENTS ............................ 15-16

STORAGE ................................................ 16

TROUBLESHOOTING .................................... 17-19

REPAIR PARTS ......................................... 20-23

ESPA_IOL .............................................. 24-41

REPAIR PROTECTION AGREEMENT ........................... 43

HOW TO ORDER REPAIR PARTS ...................... back cover

ONE YEAR FULL WARRANTY

If this product fails due to a defect in material or workmanship within one year

from the date of purchase, Sears will at its option repair or replace it free of

charge. Contact Sears at 1-800-4-MY-HOME ®to arrange for repair, or return it

to the place of purchase for replacement.

If this product is used for commercial or rental purposes, this warranty applies

for only ninety days from the date of purchase.

This warranty gives you specific legal rights and you may have other rights

which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

N014212 2 - ENG

Model No. 919.152160

Running HP 0.8*

Bore 1-7/8"

Stroke 1-1/4"

Voltage-Single Phase 120V

Minimum Branch Circuit Requirement 10 amps

Fuse Type Time Delay

Air Tank Capacity 6 gallon

Approx. Cutqn 120 PSi

Approx. Cut-out 150 PSI

SCFM @40 PSIG 3.7*

SCFM @ 90 PSlG 2.6*

*Tested per ISO 1217

Refer to Glossary for abbreviations.

This manual contains information that is important for you to know and under-

stand. This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

_ Indicates an

situation which, if not avoided, will

result in death or serious inNury.

_ ndicates a potentially

which, if not avoided, could result in

death or serious injury_.

reproductive harm. Wash hands after handling.

reproductive harm such as asbestos and lead in lead based paint.

""__ understand this instruction manual for safety,

operation and maintenance instructions.

imminently hazardous

hazardous situation

This product contains chemicals known to the State of

California to cause cancer, and birth defects or other

Some dust contains chemicals known to the State

of California to cause cancer, birth defects or other

Do not operate this unit until you read and _A

_ ndicates a potentially

which, if not avoided, _ result in

minor or moderate injury.

indicates a potentially hazardous

situation which, if not avoided, may

result in property damaq#_.

hazardous situation

Used without the

safety alert symbol

SAVE THESE INSTRUCTIONS

3 - ENG N014212

' °_ _ RISK OF EXPLOSION OR FiRE

WHAT CAN HAPPEN HOW TO PREVENT iT

= It is normal for electrical contacts = Always operate the compressor in a

within the motor and pressure well ventilated area free of combus-

switch to spark, tible materials, gasoline, or solvent

vapors.

• •

If electrical sparks from compressor

come into contact with flammable

vapors, they may ignite, causing fire

or explosion.

If spraying flammable materials,

locate compressor at least 20 feet

(6.1 m) away from spray area. An

additional length of air hose may be

required.

Store flammable materials ina

secure location away from com-

pressor.

Restricting any of the compressor

ventilation openings will cause seri-

ous overheating and could cause

fire.

Never place objects against or on

top of compressor.

Operate compressor in an open

area at least 12" (30.5 cm) away

from any wall or obstruction that

would restrict the flow of fresh air to

the ventilation openings.

Operate compressor in a clean, dry

well ventilated area. Do not operate

unit indoors or in any confined area.

• Unattended operation of this prod-

uct could result in personal injury

or property damage. To reduce the

risk of fire, do not allow the com-

Always remain in attendance with

the product when it is operating.

Always turn off and unplug unit

when not in use.

pressor to operate unattended.

__ RiSK TO BREATHING (ASPHYXiATiON)

WHAT CAN HAPPEN HOW TO PREVENT iT

The compressed air directly from

your compressor is not safe for

breathing. The air stream may

contain carbon monoxide, toxic

vapors, or solid particles from the

air tank. Breathing these contami-

nants can cause serious injury or

death.

Air obtained directly from the com-

pressor should never be used to

supply air for human consumption.

In order to use air produced by this

compressor for breathing, suitable

filters and in-line safety equipment

must be properly installed. In-line

filters and safety equipment used

in conjunction with the compres-

sor must be capable of treating air

to all applicable local and federal

codes prior to human consump-

tion.

N014212 4 - ENG

Exposure to chemicals in dust cre-

ated by power sanding, sawing,

grinding, drilling, and other con-

struction activities may be harmful.

Sprayed materials such as paint,

paint solvents, paint remover, insec-

ticides, weed killers, may contain

harmful vapors and poisons.

• Work in an area with good cross

ventilation. Read and follow the

safety instructions provided on the

label or safety data sheets for the

materials you are spraying. Always

use certified safety equipment:

NIOSH/OSHA respiratory protec-

tion or properly fitting face mask

designed for use with your specific

application.

__ RISK OF BURSTING

Air Tank: The air tank on your Air Compressor is designed and may be UM coded

(for units with air tanks greater than 6" (122 mm) diameter) according to ASME

Section VIII, Div. 1 rules. All pressure vessels should be inspected once every two

years. To find your state pressure vessels inspector, look under the Division of Labor

and Industries in the government section of a phone book.

The following conditions could lead to a weakening of the air tank, and result in a

violent air tank explosion:

WHAT CAN HAPPEN

Failure to properly drain condensed

water from air tank, causing rust

and thinning of the steel air tank.

HOW TO PREVENT IT

Drain air tank daily or after each

use. If air tank develops a leak,

replace it immediately with a

new air tank or replace the entire

cornpressor.

Modifications or attempted repairs

to the air tank.

Never drill into, weld, or make any

modifications to the air tank or its

attachments. Never attempt to

repair a damaged or leaking air

tank. Replace with a new air tank.

Unauthorized modifications to • The air tank is designed to

the safety valve or any other withstand specific operating

components which control air tank pressures. Never make adjustments

pressure, or parts substitutions to alter the

factory set operating pressures.

Attachments & accessories:

• •

Exceeding the pressure rating of

air tools, spray guns, air operated

accessories, tires, and other

inflatables can cause them to

explode or fly apart, and could

result in serious injury.

Follow the equipment

manufacturers recommendation

and never exceed the maximum

allowable pressure rating of

attachments. Never use compressor

to inflate small low pressure objects

such as children's toys, footballs,

basketballs, etc.

5 - ENG N014212

Tires:

* Over inflation of tires could result in * Use a tire pressure gauge to check

serious injury and property damage, the tires pressure before each use

and while inflating tires; see the tire

sidewall for the correct tire pressure.

NOTE: Air tanks, compressors and simi-

lar equipment used to inflate tires can fill

small tires similar to these very rapidly.

Adjust pressure regulator on air supply to

no more than the rating of the tire pres-

sure. Add air in small increments and fre-

quently use the tire gauge to prevent over

inflation.

RIsKoFELECTRICALSHOCK

WHAT CAN HAPPEN HOW TO PREVENT iT

• •

Your air compressor is powered by

electricity. Like any other electrically

powered device, If it is not used

properly it may cause electric

shock.

Repairs attempted by unqualified

personnel can result in serious

injury or death by electrocution.

Electrical Grounding: Failure to

provide adequate grounding to

this product could result in serious

injury or death from electrocution.

Refer to Grounding Instructions

paragraph in the Installation

section.

Never operate the compressor

outdoors when it is raining or in wet

conditions.

Never operate compressor with

protective covers removed or

damaged.

Any electrical wiring or repairs

required on this product should be

performed by authorized service

center personnel in accordance with

national and local electrical codes.

Make certain that the electrical

circuit to which the compressor

is connected provides proper

electrical grounding, correct voltage

and adequate fuse protection.

N014212 6 - ENG

__ RiSK FROM FLYING OBJECTS

WHAT CAN HAPPEN

o

The compressed air stream can

cause soft tissue damage to

exposed skin and can propel dirt,

chips, loose particles, and small

objects at high speed, resulting in

property damage or personal injury.

= Always wear certified safety equip-

• Never point any nozzle or sprayer

HOW TO PREVENT IT

ment: ANSI Z87.1 eye protection

(CAN/CSA Z94.3) with side shields

when using the compressor.

toward any part of the body or at

other people or animals.

Always turn the compressor off

and bleed pressure from the air

hose and air tank before attempt-

ing maintenance, attaching tools or

accessories.

RiSKOFHOTSURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• • Never touch any exposed metal

Touching exposed metal such as

the compressor head, engine head,

engine exhaust or outlet tubes, can

result in serious burns.

parts on compressor during or

immediately after operation.

Compressor will remain hot for

several minutes after operation.

Do not reach around protective

shrouds or attempt maintenance

until unit has been allowed to cool.

_r_ __ R,SK FROM MOV,NG PARTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• •

Moving parts such as the pulley, fly-

wheel, and belt can cause serious

injury if they come into contact with

you or your clothing.

Attempting to operate compressor

with damaged or missing parts or

attempting to repair compressor

with protective shrouds removed

can expose you to moving parts

and can result in serious injury.

7 - ENG N014212

Never operate the compressor with

guards or covers which are dam-

aged or removed.

Keep your hair, clothing, and gloves

away from moving parts. Loose

clothes, jewelry, or long hair can be

caught in moving parts.

Air vents may cover moving parts

and should be avoided as well.

Any repairs required on this product

should be performed by authorized

service center personnel.

[__ RiSK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT iT

• Unsafe operation of your air com- • Review and understand all instruc-

pressor could lead to serious injury tions and warnings in this manual.

or death to you or others. • Become familiar with the operation

and controls of the air compressor.

Keep operating area clear of all per-

sons, pets, and obstacles.

Keep children away from the air

compressor at all times.

Do not operate the product when

fatigued or under the influence of

alcohol or drugs. Stay alert at all

times.

Never defeat the safety features of

this product.

Equip area of operation with a fire

extinguisher.

Do not operate machine with miss-

ing, broken, or unauthorized parts.

RiskOFFALLING

WHAT CAN HAPPEN HOW TO PREVENT IT

A portable compressor can fall

• • Always operate compressor in a

from a table, workbench, or roof

causing damage to the compres-

sor and could result in serious

injury or death to the operator.

stable secure position to prevent

accidental movement of the unit.

Never operate compressor on a

roof or other elevated position.

Use additional air hose to reach

high locations.

_ m D

' "" " RiSK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT IT

Under some conditions and dura- • Always wear certified safety equip-

tion of use, noise from this product ment: ANSI S12.6 (S3.19) hearing

may contribute to hearing loss. protection.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

N014212 8 - ENG

Become familiar with these terms

before operating the unit.

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per min-

ute; a unit of measure of air delivery.

PSIG: Pounds per square inch gauge;

a unit of measure of pressure.

Code Certification: Products that

bear one or more of the following

marks: UL, CUL, ETL, CETL, have

been evaluated by ©SHA certified

independent safety laboratories and

meet the applicable Underwriters

Laboratories Standards for Safety.

Cut-in Pressure: While the motor

is off, air tank pressure drops as you

continue to use your accessory. When

the tank pressure drops to a certain

low level the motor will restart auto-

matically. The low pressure at which

the motor automatically restarts is

called "cut-in" pressure.

Cut-Out Pressure: When an air com-

pressor is turned on and begins to

run, air pressure in the air tank begins

to build. It builds to a certain high

pressure before the motor automati-

cally shuts off, protecting your air tank

from pressure higher than its capacity.

The high pressure at which the motor

shuts off is called "cut-out" pressure.

Branch Circuit: Circuit carrying elec-

tricity from electrical panel to outlet.

This unit is capable of powering the following accessories. The accessories are

available through the current Power and Hand Tool Catalog or full-line Sears

stores.

Accessories

• In Line Filter

Tire Air Chuck

Quick Connector Sets

(various sizes)

Air Pressure Regulators

Oil Fog Lubricators

Air Hose: 1/4", 3/8" or 1/2" I.D. in

various lengths

Refer to the selection chart located on

the unit to select the tools this unit is

capable of powering.

_The use of any

-- other accessory

not recommended for use with

this tool could be hazardous. Use

only accessories rated equal to

or higher than the rating of the air

compressor.

This air compressor pump is capable

of running continuously. However, to

prolong the life of your air compressor,

it is recommended that a 50%-75%

average duty cycle be maintained;

that is, the air compressor pump

should not run more than 30-45

minutes in any given hour.

9 - ENG N014212

Unpacking

1. Remove unit from carton and discard all packaging.

2.

HOW TO SET UP YOUR UNiT

Location of the Air Compressor

• Locate the air compressor in a

Make sure the outlet being used

has the same configuration as the

grounded plug. DO NOT USE AN

ADAPTER. See illustration.

clean, dry and well ventilated

area.

• The air compressor should be

located at least 12" (30.5 cm)

away from the wall or other

obstructions that will interfere

with the flow of air.

= The air compressor pump and

shroud are designed to allow for

3.

proper cooling. The ventilation

openings on the compressor are

necessary to maintain proper

operating temperature. Do not

place rags or other containers on

or near these openings.

GROUNDING INSTRUCTIONS

_Risk of Electrical

Inspect the plug and cord before

each use. Do not use if there are

signs of damage.

4.

If these grounding instructions are

not completely understood, or if in

doubt as to whether the compres-

sor is properly grounded, have the

installation checked by a qualified

electrician.

Shock. In the event

of a short circuit, grounding reduces

the risk of shock by providing an

escape wire for the electric current.

This air compressor must be

properly grounded.

The portable air compressor is

equipped with a cord having a

grounding wire with an appropriate

grounding plug (see following

illustrations).

GROUNDING CAN RESULT IN

ELECTRICAL SHOCK.

Do not modify the plug provided, if

it does not fit the available outlet, a

correct outlet should be installed by

a qualified electrician.

Repairs to the cord set or plug

MUST be made by a qualified elec-

trician.

1. The cord set and plug with this

unit contains a grounding pin.

This plug MUST be used with a

grounded outlet.

iMPORTANT: The outlet being used

must be installed and grounded in

accordance with all local codes and

ordinances.

Risk of Electrical

Shock. iMPROPER

N014212 10-ENG

Extension Cords

If an extension cord must be used, be

sure it is:

• a 3-wire extension cord that has

a 3-blade grounding plug, and a

3-slot receptacle that will accept

the plug on the product

in good condition

no longer than 50 feet

14 gauge (AWG) or larger. (Wire

size increases as gauge number

decreases. 12 AWG and 10 AWG

may also be used. DO NOT USE

16 OR 18 AWG.)

-- undersized

The use of an

extension cord will cause voltage to

drop resulting in power loss to the

motor and overheating. Instead of

using an extension cord, increase

the working reach of the air hose by

attaching another length of hose to its

end. Attach additional lengths of hose

as needed.

Voltage and Circuit Protection

Refer to the specification chart for the

voltage and minimum branch circuit

requirements.

-- Certain air

Risk of Opertion.

compressors can be operated on

a 15 amp circuit if the following

conditions are met.

1. Voltage supply to circuit must

comply with the National

Electrical Code.

2. Circuit is not used to supply any

other electrical needs.

3. Extension cords comply with

specifications.

4. Circuit is equipped with a 15 amp

circuit breaker or 15 amp time

delay fuse. NOTE: If compressor

is connected to a circuit protected

by fuses, use only time delay

fuses. Time delay fuses should be

marked "D" in Canada and "T" in

the US.

If any of the above conditions cannot

be met, or if operation of the compres-

sor repeatedly causes interruption

of the power, it may be necessary to

operate it from a 20 amp circuit. It is

not necessary to change the cord set.

11 - ENG N014212

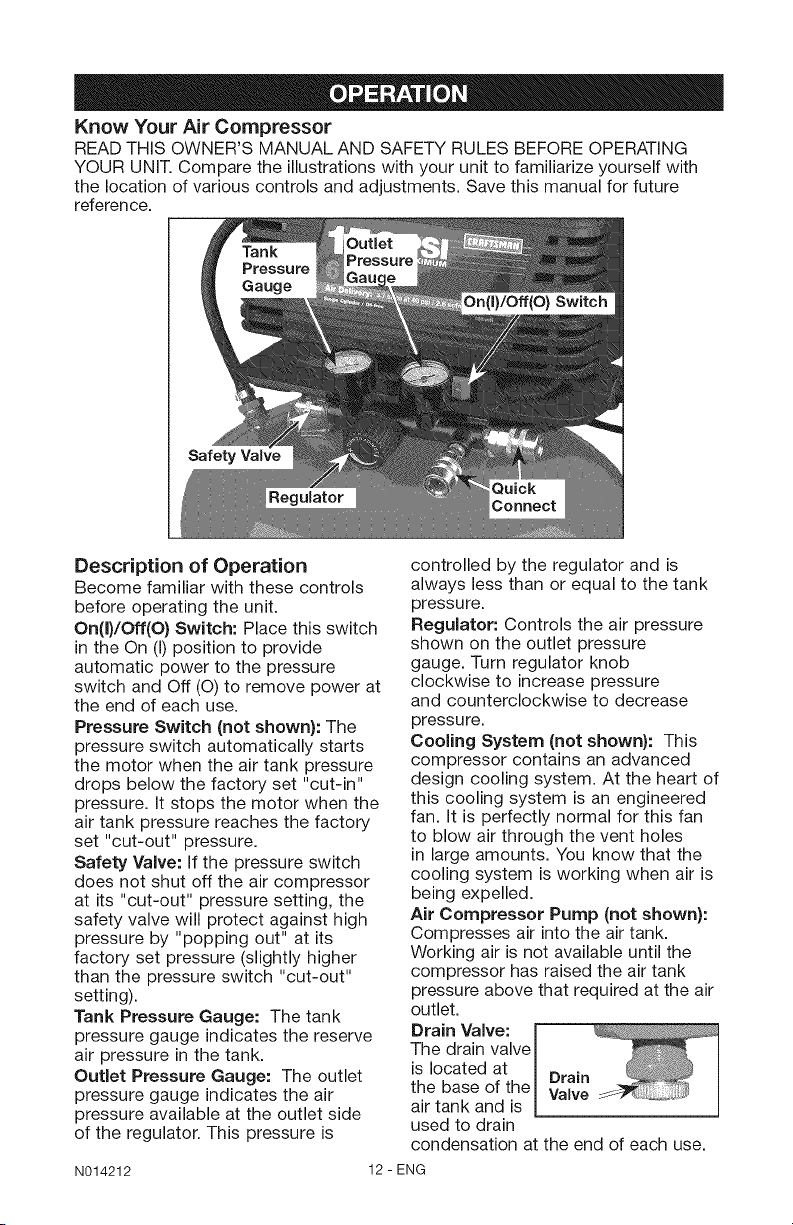

Know Your Air Compressor

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with

the location of various controls and adjustments. Save this manual for future

reference.

Safety Valve

Description of Operation

Become familiar with these controls

before operating the unit.

On(I)/Off(O) Switch: Place this switch

in the On (I) position to provide

automatic power to the pressure

switch and Off (O) to remove power at

the end of each use.

Pressure Switch (not shown): The

pressure switch automatically starts

the motor when the air tank pressure

drops below the factory set "cut-in"

pressure. It stops the motor when the

air tank pressure reaches the factory

set "cut-out" pressure.

Safety Valve: If the pressure switch

does not shut off the air compressor

at its "cut-out" pressure setting, the

safety valve will protect against high

pressure by "popping out" at its

factory set pressure (slightly higher

than the pressure switch "cut-out"

setting).

Tank Pressure Gauge: The tank

pressure gauge indicates the reserve

air pressure in the tank.

Outlet Pressure Gauge: The outlet

pressure gauge indicates the air

pressure available at the outlet side

of the regulator. This pressure is

N014212 12-ENG

controlled by the regulator and is

always less than or equal to the tank

pressure.

Regulator: Controls the air pressure

shown on the outlet pressure

gauge. Turn regulator knob

clockwise to increase pressure

and counterclockwise to decrease

pressure.

Cooling System (not shown): This

compressor contains an advanced

design cooling system. At the heart of

this cooling system is an engineered

fan. It is perfectly normal for this fan

to blow air through the vent holes

in large amounts. You know that the

cooling system is working when air is

being expelled.

Air Compressor Pump (not shown):

Compresses air into the air tank.

Working air is not available until the

compressor has raised the air tank

pressure above that required at the air

outlet.

Drain Valve:

The drain valve

is located at

the base of the Valve

Drain

air tank and is

used to drain

condensation at the end of each use.

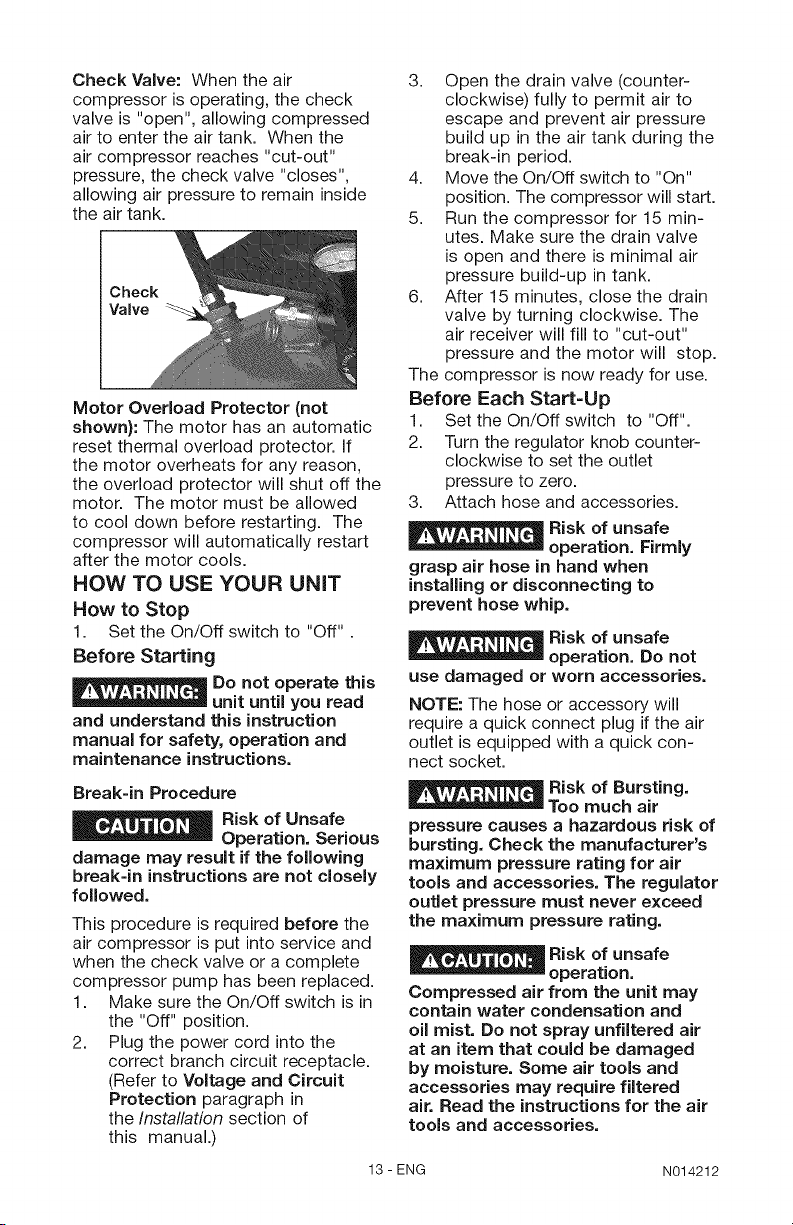

Check Valve: When the air

compressor is operating, the check

valve is "open", allowing compressed

air to enter the air tank. When the

air compressor reaches "cut-out"

pressure, the check valve "closes",

allowing air pressure to remain inside

the air tank.

Motor Overload Protector (not

shown): The motor has an automatic

reset thermal overload protector. If

the motor overheats for any reason,

the overload protector will shut off the

motor. The motor must be allowed

to cool down before restarting. The

compressor will automatically restart

after the motor cools.

NOW TO USE YOUR UNiT

How to Stop

1. Set the On/Off switch to "Off".

Before Starting

Do not operate this

and understand this instruction

manual for safety, operation and

maintenance instructions.

Break=in Procedure

-- Operation. Serious

damage may result if the following

break=in instructions are not closely

followed.

This procedure is required before the

air compressor is put into service and

when the check valve or a complete

compressor pump has been replaced.

1. Make sure the On/Off switch is in

the "Off" position.

2. Plug the power cord into the

correct branch circuit receptacle.

(Refer to Voltage and Circuit

Protection paragraph in

the Installation section of

this manual.)

unit until you read

Risk of Unsafe

3. Open the drain valve (counter-

clockwise) fully to permit air to

escape and prevent air pressure

build up in the air tank during the

break-in period.

4. Move the On/Off switch to "On"

position. The compressor will start.

5. Run the compressor for 15 min-

utes. Make sure the drain valve

is open and there is minimal air

pressure build-up in tank.

6. After 15 minutes, close the drain

valve by turning clockwise. The

air receiver will fill to "cut-out"

pressure and the motor will stop.

The compressor is now ready for use.

Before Each Start=Up

1. Set the On/Off switch to "Off".

2. Turn the regulator knob counter-

clockwise to set the outlet

pressure to zero.

3. Attach hose and accessories.

_Risk of unsafe

operation. Firmly

grasp air hose in hand when

installing or disconnecting to

prevent hose whip.

Risk of unsafe

operation. Do not

use damaged or worn accessories.

NOTE: The hose or accessory will

require a quick connect plug if the air

outlet is equipped with a quick con-

nect socket.

Risk of Bursting.

Too much air

pressure causes a hazardous risk of

bursting. Check the manufacturer's

maximum pressure rating for air

tools and accessories. The regulator

outlet pressure must never exceed

the maximum pressure rating.

Risk of unsafe

operation.

Compressed air from the unit may

contain water condensation and

oil mist. Do not spray unfiltered air

at an item that could be damaged

by moisture. Some air tools and

accessories may require filtered

air. Read the instructions for the air

tools and accessories.

13-ENG N014212

How to Start:

1. Set the On/Off switch to "On"

and allow tank pressure to build.

Motor will stop when tank pressure

reaches "cut-out" pressure.

2. Turn regulator knob clockwise to

increase pressure and stop when

desired pressure is reached.

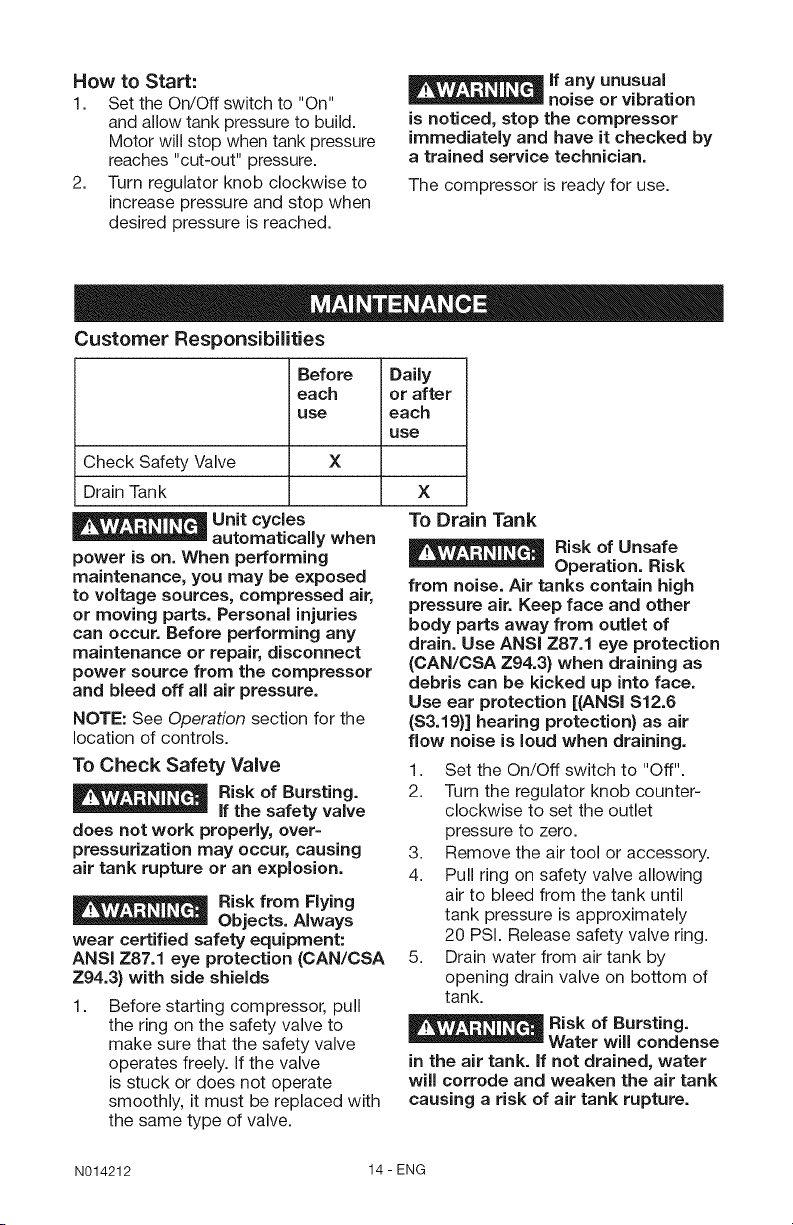

Customer Responsibilities

Before

each

use

Check Safety Valve X

Drain Tank

_Unit cycles

-- automatically when

power is on. When performing

maintenance, you may be exposed

to voltage sources, compressed air,

or moving parts. Personal injuries

can occur. Before performing any

maintenance or repair, disconnect

power source from the compressor

and bleed off all air pressure.

NOTE: See Operation section for the

location of controls.

To Check Safety Valve

_Risk of Bursting.

-- if the safety valve

does not work properly, over=

pressurization may occur, causing

air tank rupture or an explosion.

_Risk from Flying

__ Objects. Always

wear certified safety equipment:

ANSI Z87.1 eye protection (CAN/OSA

Z94.3) with side shields

1.

Before starting compressor, pull

the ring on the safety valve to

make sure that the safety valve

operates freely. If the valve

is stuck or does not operate

smoothly, it must be replaced with

the same type of valve.

lf any unusual

noise or vibration

is noticed, stop the compressor

immediately and have it checked by

a trained service technician.

The compressor is ready for use.

Daily

or after

each

use

X

To Drain Tank

Risk of Unsafe

Operation. Risk

from noise. Air tanks contain high

pressure air. Keep face and other

body parts away from outlet of

drain. Use ANSI Z87.1 eye protection

(CAN/OSA Z94.3) when draining as

debris can be kicked up into face.

Use ear protection [(ANSI S12.6

($3.19)] hearing protection) as air

flow noise is loud when draining.

1. Set the On/Off switch to "Off".

2. Turn the regulator knob counter-

clockwise to set the outlet

pressure to zero.

3. Remove the air tool or accessory.

4. Pull ring on safety valve allowing

air to bleed from the tank until

tank pressure is approximately

20 PSI. Release safety valve ring.

5. Drain water from air tank by

opening drain valve on bottom of

tank.

Risk of Bursting.

Water will condense

in the air tank. If not drained, water

will corrode and weaken the air tank

causing a risk of air tank rupture.

N014212 14 - ENG

Risk of Property

Damage. Drain

water from air tank may contain oil

and rust which can cause stains.

NOTE: If drain valve is plugged,

release all air pressure. The valve

can then be removed, cleaned, the

reinstalled.

6. After the water has been drained,

close the drain valve. The air

compressor can now be stored.

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE

PERFORMED BY TRAINED SERVICE TECHNICIAN.

Risk of Unsafe Operation. Unit cycles automatically when

power is on. When servicing, you may be exposed to

voltage sources, compressed air, or moving parts. Before servicing unit

unplug or disconnect electrical supply to the air compressor, bleed tank of

pressure, and allow the air compressor to cool.

To Replace or Clean Check

Valve

1. Release all air pressure from air

tank. See To Drain Tank in the

Maintenance section.

2. Unplug unit.

3. Remove the hose by removing

the hose clamp. NOTE: The hose

clamp is not reusable. You must

purchase a new hose clamp,

see the Parts List or purchase a

standard hose clamp at a local

hardware store.

6. Apply sealant to the check valve

threads. Reinstall the check valve

(turn clockwise).

7. Replace hose and new hose

clamp.

8. Perform the Break-in Procedure.

See Break-in Procedure in the

Operation section.

To Replace Regulator Manifold

1. Release all air pressure from air

tank. See To Drain Tank in the

Maintenance section.

2. Unplug unit.

3. Using an adjustable wrench

remove the safety valve from the

regulator manifold.

Hose

Clamp

Check

Valve

4.

Unscrew the check valve (turn

counter-clockwise) using a socket

wrench.

5.

Make sure the valve disc moves

freely inside the check valve and

the spring holds the disc in the

upper, closed position. The check

valve may be cleaned with a

solvent, such as paint and varnish

remover.

15-ENG N014212

4.

Remove the hose by removing

the hose clamp. NOTE: The hose

clamp is not reusable. You must

purchase a new hose clamp,

see the Parts List or purchase a

standard hose clamp at a local

hardware store.

Regulator

Manifold

6.

Carefully slide pump from

brackets and out of the way.

Pump

shown

moved out

of the way

Regulator

Manifold

5.

Remove pump mounting screws

securing pump (one on each side).

Pump Mounting Screw

Before you store the air compressor,

make sure you do the following:

1. Review the Maintenance section

on the preceding pages and

perform scheduled maintenance

as necessary.

2. Set the On/Off switch to "Off" and

unplug unit.

3. Turn the regulator counterclock-

wise and set the outlet pressure to

zero.

4. Remove the air tool or accessory.

5. Pull ring on safety valve allowing

air to bleed from the tank until

tank pressure is approximately

20 PSI. Release safety valve ring.

6. Drain water from air tank by

opening drain valve on bottom of

tank.

7. Using an adjustable wrench

remove the regulator manifold.

8. Apply pipe sealant to new

regulator manifold and assemble,

tighten with wrench.

9. Reapply pipe sealant to safety

valve.

10. Reassemble all components in

reverse order of removal. Make

sure to orient gauges to read

correctly and use wrenches to

tighten all components.

Risk of Bursting.

Water will condense

in the air tank. if not drained, water

will corrode and weaken the air tank

causing a risk of air tank rupture.

7. After the water has been drained,

close drain valve by turning

clockwise.

NOTE: If drain valve is plugged,

release all air pressure. The valve

can then be removed, cleaned, then

reinstalled.

8. Protect the electrical cord and

air hose from damage (such as

being stepped on or run over).

Wind them loosely around the

compressor handle.

9. Store the air compressor in a

clean and dry location.

N014212 16-ENG

Risk of Unsafe Operation. Unit cycles automatically when

power is on. When servicing, you may be exposed to

voltage sources, compressed air, or moving parts. Before servicing unit

unplug or disconnect electrical supply to the air compressor, bleed tank of

pressure, and allow the air compressor to cool.

PROBLEM

Excessive tank pressure

- safety valve pops off.

Air leaks at fittings.

Air leaks in air tank or at

air tank welds.

Air leaks between head

and valve plate.

Air leak from safety

valve.

Knocking Noise.

CAUSE CORRECTION

Pressure switch does

not shut off motor when

compressor reaches

"cut-out" pressure.

Pressure switch "cut-

out"too high.

Tube firings are nottight

enough.

Defective air tank.

Leaking seal.

Possible ddectin safety

valve.

Possible defect in safety

valve.

Move On/Off lever to

the "Off" position, if

the outfit does not shut

off contact a Trained

Service Technician.

Contact a Trained

Service Technician.

Tighten fittings where air

can be heard escaping.

Check fittings with

soapy water solution. Do

Not Overtighten.

Air tank must be

replaced. Do not repair

the leak.

Risk bursting. Do

not drill into, weld or

otherwise modify air

tank or it will weaken.

The tank can rupture

or explode.

Contact a Trained

Service Technician.

Operate safety valve

manually by pulling on

ring. If valve still leaks, it

should be replaced.

Operate safety valve

manually by pulling on

ring. If valve still leaks, it

should be replaced.

17 - ENG N014212

PROBLEM CORRECTION

Pressure reading on

the regulated pressure

gauge drops when an

accessory is used.

It is normal for "some"

pressure drop to occur.

CAUSE

If there is an excessive

amount of pressure drop

when the accessory

is used, adjust the

regulator following

the instructions in

the Description of

Operation paragraph in

the Operation Section.

NOTE: Adjust the

regulated pressure under

flow conditions (while

accessory is being

used).

Compressor is not sup-

plying enough air to

operate accessories.

Prolonged excessive use

of air.

Compressor is not large

enough for air require-

ment.

Decrease amount of air

usage.

Check the accessory

air requirement. If it is

higher than the SCFM

or pressure supplied

by your air compressor,

you need a larger

compressor.

Hole in hose.

Check and replace if

required.

Check valve restricted.

Remove and clean, or

replace.

Air leaks.

Regulator knob has con- Replace.

Damaged regulator.

Tighten fittings.

tinuous air leak.

N014212 18-ENG

PROBLEM CAUSE CORRECTION

Regulator will not shut Damaged regulator. Replace.

off air outlet.

Motor will not run. Fuse blown, circuit

breaker tripped.

Check fuse box

for blown fuse and

replace as necessary.

Reset circuit breaker.

Do not use a fuse or

circuit breaker with

higher rating than

that specified for your

particular branch circuit.

Check for proper fuse.

You should use a time

delay fuse.

Check for low voltage

problem.

Check the extension

cord.

Disconnect the other

electrical appliances

from circuit or operate

the compressor on its

own branch circuit.

Extension cord is wrong

length or gauge.

Loose electrical

connections.

Check the extension

cord.

Check wiring

connection inside

terminal box.

Faulty motor.

Have checked by

a Trained Service

Technician.

Motor overload protec-

tion switch has tripped

Refer to Motor

Overload Protection

under Operation.

If motor overload

protection trips

frequently, contact

a Trained Service

Technician.

19-ENG N014212

Air Compressor Model Number 919.152160

PARTS SHOWN FOR REFERENCE ONLY

34

36;

4

28

856

N014212

N014212 20 - ENG

Air Compressor =MODEL NUMBER 919.15216

4

t

07/31/08

Air Compressor Model Number 919.152160

ITEM PART

NO. NO. DESCRiPTiON QTY

2 D24721 Isolator Kit 3

3 91895680 Screw 3

4 SSF-621 Screw 2

5 A14877 Nipple 1

7 A17038 Drain Valve 1

8 A17987 Safety Valve 1

9 1000002226 Manifold (incl. 5, 10, 11,35) 1

10 A16182 Quick Connect Body 2

11 A17166 Gauge 1

18 A19714 Check Valve 1

19 CAC-1254 Pump Isolator 4

24 LA-3109 Drain Tank Warning Label 1

28 LA-3108 Hot Surface Label 1

31 LA-3270 Warning Label 1

32 LA-2876 Power Cord Label 1

33 1000003194 Identification Label 1

34 N014220 Nameplate 1

35 A17135 Gauge 1

36 1000002886 Rating Label 1

21 - ENG N014212

Air Compressor Model Number 919.152160

N014212 22 - ENG

Air Compressor Model Number 919.152160

iTEM PART

NO. NO. DESCRIPTION QTY

101 1000002791 Shroud (Right) 1

102 1000002792 Shroud (Left) 1

103 D25877 Head 1

104 CAC-1212 Seal 1

105 D22253 Outlet Tube 1

106 Z-D24819 Gasket Kit (Incl. 104) 1

107 Z-A08548 Valve Plate Assembly 1

108 A03865 Gasket 1

109 Z-A04615 Pump 1

110 AC-0815 Timing Belt 1

e113 SUDL-9-1 Screw 1

114 D25731 Pump Isolator 5

_115 SSF-995 Screw 4

116 Al1027 Switch 1

117 A04770 Cordset 1

118 CAC-1206-1 Hose Clamp 4

119 H-7051 Air Hose 1

120 SSF-3156 Screw 1

121 Z-D23825 Brush Motor (Ametek) 1

121 Z-D27196 Brush Motor (Gold Tuning) 1

122 N002119 Pressure Switch 1

123 A00470 Support Handle 1

124 A05239 Bracket 1

125 A10162 Air Hose 1

128 D29132 Screw 5

140 KK-4964 Connecting Rod Kit 1

141 D30324 Ring Kit 1

142 D21127 Screw 1

0143 A19123 Screw 1

846 KK-4929 Fastener Kit (Incl. 113,115,

128,143) 1

856 AC-0625 Teflon Tape(not included) 1

856 N004086 Air Hose 1

856 1000000543 BlowGun Kit 1

¢ NOTES:

113 Torque to 30-45 in.-Ibs.

115 Torque to 49-55 in.-Ibs.

143 Torque to 315-385 in.qbs.

23 - ENG N014212

GARANTIA ....................................................... 24

CUADRO DE ESPEClFICAClONES ................................... 25

DEFINICIONES DE NORMAS DE SEGURIDAD .......................... 25

IMPORTANTES INSTRUCClONES DE SEGURIDAD .................... 25-31

GLOSARIO ....................................................... 31

ACCESORIOS .................................................... 31

ClCLO DE SERVlClO .............................................. 31

ENSAMBLAGE .................................................... 32

INSTALAClON .................................................. 32-33

OPERAClON ................................................... 34-36

MANTENIMIENTO ............................................... 36-37

SERVlClOS Y REGULAClONES .................................... 37-38

ALMACENAJE .................................................... 38

GUIA DE DIAGNOSTICO DE PROBLEMAS ........................... 39-41

CONTRATOS DE PROTECClON PARA REPARAClONES .................. 43

LISTA DE PARTES ............................................... 20-23

COMO SOLIClTAR PIEZAS PARA REPARAClON ................. contratapa

GARANTJA TOTAL DE UN ANO

Siesta unidad fallase debido a defectos de materiales o de fabricaci6n dentro

del ado de su fecha de compra, Sears, a su opci6n, Io reparar& o reemplazara

sin costo alguno. Comuniquese con Sears al 1-800-4-MY-HOME ®para coordi-

nar su reparaci6n, o devuelva la unidad al lugar donde Io compr6 para que Io

cambien.

Siesta unidad se usase con fines comerciales o para alquiler, esta garantia se

aplica s61o durante los primeros noventa dias a partir de su fecha de compra

Esta garantia le otorga derechos especificos y usted podria tener otros dere-

chos que varian de un estado a otro.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

N014212 24- SP

Modelo N °

Potencia de trabajo

Diametro interior

Carrera

Voltaje-corriente manofAsica

Circuito minimo requerido

Tipo de fusible

Capacidad de aire en el tanque

Presi6n de corte de entrada

Presi6n de corte de salida

SCFM a 40 PSIG

SCFM a 90 PSIG

*Probado segun la norma ISO 1217

Refi6rase al glosario para descifrar las abreviaturas.

Este manual contiene informaci6n que es importante que usted conozca y comprenda. Esta

informaci6n se relaciona con la protecci6n de SU SEGURIDAD y LA PREVENCION DE

PROBLEMAS A SU EQUIPO. Para ayudarlo a reconocer esta informaci6n, usamos los

simbolos indicados mAs abajo. Sirvase leer el manual y prestar atenci6n a estas secciones.

_ Indica una situaci6n de

no se evita, causarA la rnuerte o lesiones peligrosa, que si no se evita, puede causar

serias, lesiones menores o moderadas.

: " situaci6n _ seguridad de alerta indica

potencialmente riesgosa, que si no se una situaci6n potencialmente riesgosa la

evita, podria causar la rnuerte o lesiones que, si no se evita, podria causar da_os

serias, en la propiedad.

riesgo inminente, que si

Indica

una

919.152160

*0,8 HP

1-7/8 pulg. (47,6 mm)

1-1/4 pulg. (31,8 mm)

120V

10A

Acci6n retardada

6 Galones (22,7 litros)

120 PSI

150 PSI

*3,7 Calibre de libras pot pulgada cuadrada

*2,6 Calibre de libras pot pulgada cuadrada

Ilndica

potencialmente

Usado sin el simbolo de

una

situaci6n

_Este producto contiene sustancias quirnicas, incluido el piorno,

cancer, defectos de nacimiento u otros problemas reproductivos. Lavese las manos

despu_s de utilizarlo.

_ amianto y el plomo de las pinturas de base plomo, reconocidas

por el Estado de California como causantes de cancer, defectos de nacimiento u

otros problemas

-- producto podrian ocasionar lesiones serias y daSos a la

propiedad. Lea y comprenda todas las advertencias e instrucciones de

funcionamiento antes de utilizar este equipo.

reconocidas por el Estado de California como causantes de

AIgunos tipos de polvo contienen sustancias quirnicas, como el

La operaci6n o el mantenimiento inadecuados deeste

I Wl

CONSERVE ESTAS INSTRUCCIONES

25 - SP N014212

RIESGO DE EXPLOSION 0 INCENDIO

_QU_ = PUEDE SUCEDER? COMO EVITARLO

• Es normal que los contactos el6ctricos • Opere siempre el compresor en un

dentro del motor y el interruptor de &rea bien ventilada libre de materiales

presi6n produzcan chispas, combustibles, gasolina o vapores de

• •

Si las chispas el6ctricas del com-

presor entran en contacto con vapores

inflamables, pueden encenderse, pro-

vocando un incendio o una explosi6n.

Restringir cualquiera de las aberturas

de ventilaci6n del compresor puede

producir un sobrecalentamiento grave

y podria provocar un incendio.

• El funcionamiento sin atenci6n de este

producto podria provocar lesiones per-

sonales o da_os a la propiedad. Para

disminuir el riesgo de incendio, no

permita que el compresor funcione sin

que alguien Io controle.

solventes.

Si se pulverizan materiales inflamables,

ubique el compresor al menos a 6,1 m

(20 pies) del Area de pulverizaci6n. Se

puede necesitar manguera adicional.

• Guarde los materiales inflamables en

lugar seguro lejos del compresor.

Nunca coloque objetos contra o sobre

el compresor.

Opere el compresor en un lugar abi-

erto con una distancia de al menos

30,5 cm (12 pulg.) a cualquier pared u

obstrucci6n que pudiera restringir el

flujo de aire fresco alas aberturas de

ventilaci6n.

Opere el compresor en un Area limpia,

seca y bien ventilada. No opere la

unidad dentro de la casa o en un Area

muy cerrada.

Permanezca siempre controlando el

producto cuando estA en funciona-

miento.

Siempre apague y desenchufe la uni-

dad cuando no est6 en uso.

m

_ RIESGO RESPIRATORIO (ASFIXlA)

&QUE PUEDE SUCEDER?

El aire comprimido que sale de su

compresor no es seguro para respi-

rarlo. El flujo de aire puede contener

mon6xido de carbono, vapores t6xi-

cos o particulas s61idas del tanque

de aire. Respirar estos contaminant-

es puede provocar lesiones graves

o la muerte.

N014212 26 - SP

i II

COMO EVITAR LO

El aire que se obtiene directamente

del compresor no se debe usar

nunca para consumo humano. Para

poder utilizar el aire producido por

este compresor para respirar, se

deben instalar correctamente filtros

y equipos en linea adecuados. Los

filtros y los equipos de seguridad en

linea que se usan junto con el com-

presor deben set capaces de tratar

el aire segQn todos los c6digos

locales y federales antes de que

sea consumido por seres humanos.

• La exposici6n a productos quimicos

en el polvo producido por las her-

ramientas electricas al lijar, aserrar,

esmerilar, taladrar y otras activi-

dades de la construcci6n puede ser

peligrosa.

Los materiales pulverizados como

pintura, solventes para pinturas,

removedor de pintura, insectici-

das y herbicidas pueden contener

vapores da_inos y venenos.

Trabaje en un _.rea con buena

ventilaci6n cruzada. Lea y siga las

instrucciones de seguridad que se

proveen en la etiqueta o en la ficha

t6cnica de los materiales que esta

utilizando. Siempre utilice equi-

pamiento de seguridad certificado:

protecci6n respiratoria aprobada

pot NIOSH!OSHA o una mascarilla

facial adecuada dise_ada para usar

para los fines que usted requiere.

" o

__ RIESGO DE EXPLOSION

Tanque de aire: El tanque de aire de su compresor de aire esta diseSado y puede

tener c6digo UM (para unidades con tanques de aire de m&s de 152 mm (6 pulgadas)

de diametro) segQn las normas de la ASME, Secci6n VIII, Div. 1. Todos los recipientes de

presi6n se deben inspeccionar cada dos aSos. Para encontrar al inspector de recipientes

de presi6n de su estado, busque en la Divisi6n Trabajo e Industrias de la secci6n guber-

namental de la guia telef6nica para obtener ayuda.

Las siguientes condiciones podrian Ilevar a un debilitamiento del tanque de aire, y provo-

car una explosi6n violenta del tanque:

_QUE PUEDE SUCEDER? COMO EVITARLO

• No drenar correctamente el agua

condensada del tanque de aire, que

provoca 6xido y adelgazamiento del

tanque de aire de acero.

• Modificaciones o intento de reparaci6n •

del tanque de aire.

• Las modificaciones no autorizadas de • El tanque esta diseSado para soportar

la v&lvula de seguridad o cualquier otro determinadas presiones de operaci6n.

componente que controle la presi6n Nunca realice ajustes ni sustituya

del tanque, piezas para cambiar las presiones de

Elementos y accesorios:

Exceder las indicaciones de presi6n

para las herramientas neum&ticas, las

pistolas pulverizadoras, los accesorios

neum&ticos, los neum&ticos y otros

articulos inflables puede hacer que

exploten o revienten, y puede provocar

lesiones graves.

Drene el tanque diariamente o luego

de cada uso. Si un tanque de aire

presenta una perdida, reemplAcelo

inmediatamente con un tanque nuevo

o reemplace todo el compresor.

Nunca perfore, suelde o haga ninguna

modificaci6n al tanque de aire o a sus

elementos. Nunca intente reparar un

tanque de aire daSado o con perdidas.

Reempl&celo con un tanque de aire

nuevo.

operaci6n fijadas en la f&brica.

o

Siga la recomendacion del fabricante

del equipo y nunca exceda el nivel

maximo de presi6n aceptable para los

elementos. Nunca utilice el compresor

para inflar objetos pequeSos de baja

presi6n, tales como juguetes de niSos,

pelotas de fQtbol o de basquetbol, etc.

27 - SP N014212

Neum_ticos:

• El inflado excesivo de los neumati-

cos podria causar lesiones graves

y da_o a la propiedad.

m _ 0

[_-_ RIESGO DE DESCARGA ELECTRICA

&QUE PUEDE SUCEDER?

• •

Su compresor de aire funciona con

electricidad. Como cualquier otro

mecanismo que funciona con electric-

idad, si no se Io utiliza correctamente

puede provocar descargas el6ctricas.

Que personal no calificado intente

realizar reparaciones puede provocar

lesiones graves o muerte pot electro-

cuci6n.

Puesta a tierra: La no colocaci6n de

la puesta a tierra adecuada para este

producto puede provocar lesiones

graves o muerte por electrocuci6n.

Consulte las Instrucciones de

Conexi6n a tierra en Instalacidn.

Utilice un medidor de presi6n de

neumAticos para controlar la presi6n

de estos antes de cada uso y mientras

los infla; observe el flanco para ver la

presi6n correcta del neumAtico.

NOTA: Los tanques de aire, los com-

presores y el equipo similar que se usa

)ara inflar neumaticos pueden Ilenar

neumb, ticos peque_os come 6stos con

mucha rapidez. Ajuste el regulador de

)resi6n en el suministro de aire a un

valor que no supere el de la presi6n

del neumatico. Agregue aire en forma

gradual y use con frecuencia el medidor

de presi6n de neum_.ticos para evitar

inflarlos.

COMO EVITAR LO

Nunca haga funcionar el compresor al

aire libre cuando esta Iloviendo o en

condiciones de humedad.

Nunca haga funcionar el compresor

sin las cubiertas de protecci6n o si

estan da_adas.

Cualquier cableado el6ctrico o las

reparaciones requeridas para este

producto deben ser realizadas por

un centro de servicio de un centro de

mantenimiento autorizado de acuerdo

con los c6digos el6ctricos nacionales

y locales.

AsegOrese de que el circuito el6ctrico

al que se conecta el compresor sumi-

nistre la conexi6n a tierra adecuada, el

voltaje adecuado y el fusible de pro-

tecci6n adecuado.

N014212 28 - SP

__ RIESGO DE OBJETOS DESPEDIDOS

&QUa: PUEDE SUCEDER?

• • Utilice siempre equipo de seguridad

La corriente de aire comprimido

puede provocar lesionesen los

tejidos blandos de la pielexpuesta

y puede impulsar suciedad, astillas,

particulas sueltas y objetos peque-

nos a gran velocidad, que pueden

producir danos en la propiedad y

lesiones personales.

__ RIESGO DE SUPERFICIES CALIENTES

&QUE PUEDE SUCEDER?

Tocar metal expuesto como el cabezal

del compresor, el cabezal del motor,

el escape del motor, o los tubos de

salida puede provocar quemaduras

graves.

• Nunca toque ninguna parte metalica

i •

COMO EVITAR LO

certificado: anteojos de seguridad

ANSI Z87.1(CAN/CSA Z94.3)con pro-

tecci6n lateral al usar el compresor.

Nunca apunte ninguna boquilla ni pul-

verizador a ninguna parte del cuerpo o

a otras personas o animales.

Apague siempre el compresor y drene

la presi6n de la manguera de aire y del

tanque de aire antes de intentar hacer

mantenimiento, conectar herramientas

o accesorios.

e

COMO EVITAR LO

expuesta del compresor durante o

inmediatamente despues de su fun-

cionamiento. El compresor continu-

ara caliente durante varios minutos

despu6s de su funcionamiento.

No toque las cubiertas protectoras ni

intente realizar mantenimiento hasta

que la unidad se haya enfriado.

RIESGOPORPIEZASM6VlLES

&QUE PUEDE SUCEDER? COMO EVITARLO

= Las piezas m6viles como la polea, el =

volante y la correa pueden provocar

lesiones graves si entran en contacto

con usted o con sus ropas.

Intentar hacer funcionar el compresor

con pares daSadas o faltantes, o

intentar reparar el compresor sin las

cubiertas protectoras puede exponerlo

a piezas m6viles Io que puede provo-

car lesiones graves.

29- SP N014212

Nunca haga funcionar el compresor

sin los protectores o cubiertas o si los

mismos estan daSados.

Mantenga el cabello, la ropa y los

guantes alejados de las piezas en

movimiento. Las ropas holgadas, las

joyas o el cabello largo pueden quedar

atrapados en las piezas m6viles.

Los orificios de ventilaci6n pueden

cubrir piezas en movimiento, pot Io

que tambi6n se deben evitar.

Cualquier reparaci6n requerida por

este producto debe ser realizada pot

un centro de servicio de un centro de

servicio autorizado.

_]_ RIESGO DE OPERACION INSEGURA

_,QUE PUEDE SUCEDER? COMO EVITARLO

• La operaci6n insegura de su com- • Revise y comprenda todas las instruc-

presor de aire podria producir lesiones ciones y advertencias de este manual.

graves o la muerte, a usted mismo o a • Familiaricese con la operaci6n y los

otras personas, controles del compresor de aire.

Mantenga el Area de operaciones libre

de personas, mascotas y obstaculos.

Mantenga a los ni_os alejados del

compresor de aire en todo momento.

No opere el producto cuando est6

cansado o bajo la influencia de alcohol

o drogas. Mant6ngase alerta en todo

momento.

Nunca anule las caracteristicas de

seguridad de este producto.

Equipe el Area de operaciones con un

extintor de incendios.

No opere la mAquina si faltan piezas,

si 6stas estan rotas o si no son las

autorizadas.

" 0

RIEsGoDECAiDAS

&QU! _ PUEDE SUCEDER?

Un compresor portatil se puede caer

de una mesa, banco o techo, provo-

cando da_os al compresor y puede

producir lesiones graves o la muerte

del operador.

m •

• Opere siempre el compresor en una

COMO EVITAR LO

posici6n estable y segura para evitar

que la unidad se mueva accidental-

mente. Nunca opere el compresor

sobre un techo u otra ubicaci6n

elevada. Utilice una manguera de aire

adicional para alcanzar las ubicaciones

elevadas.

0

' " ' " ' RESGOPORRUIDOS

&QUE PUEDE SUCEDER? COMO EVITARLO

En determinadas condiciones y segQn • Utilice siempre equipo de seguridad

el periodo de uso, el ruido provocado certificado: protecci6n auditiva ANSI

por este producto puede originar p6r- $12.6 ($3.19).

dida de audici6n.

CONSERVE ESTAS INSTRUCCIONES

PARA FUTURAS CONSULTAS

N014212 30 - SP

Familiaricese con los siguientes

terminos, antes de operar la unidad:

CFM: (Cubic feet per minute) Pies cObicos

por minuto.

SCFM: (Stardard cubic feet per minute)

Pies cObicos est&ndar por minuto; una

unidad de medida que permite medir la

cantidad de entrega de aire.

PSIG: (Pound per square inch) Libras por

pulgada cuadrada.

C6digo de certificaci6n: Los productos

que usan una o m&s de las siguientes

marcas: UL, CUL, ETL, CETL, han sido

evaluados por OSHA, laboratorios

independientes certificados en seguridad,

y reOnen los estandares suscriptos por los

laboratorios dedicados a la certificaci6n de

tanque baja al valor fijado en f&brica como

punto bajo, el motor volver& a arrancar

autom&ticamente. La presi6n baja a la cual

el motor arranca autom&ticamente, se llama

presi6n "minima de corte".

Presi6n rn_xirna de corte: Cuando un

compresor de aire se enciende y comienza

a funcionar, la presi6n de aire en el tanque

comienza a aumentar. Aumenta hasta un

valor de presi6n alto fijado en f&brica

antes de que el motor autom&ticamente se

apague protegiendo a su tanque de aire de

presiones m&s altas que su capacidad. La

presi6n alta a la cual el motor se apaga se

llama presi6n "m&xima de corte".

Rarnal: Circuito el6ctrico que transporta

electricidad desde el panel de control hasta

el tomacorriente.

la seguridad.

Presi6n minima de corte: Cuando el motor

esta apagado, la presi6n del tanque de aire

baja a medida que usted continQa usando

su accesorio. Cuando la presi6n del

Esta unidad es suficiente para abastecer de energia el6ctrica a los siguientes accesorios.

Estos se encuentran disponibles a trav6s del catAlogo para herramientas el6ctricas y man-

uales, en cualquiera de los comercios que mantiene la linea completa de SEARS.

Accesorios

• Filtro de intercalar

• Boquilla para inflar cubiertas.

Refi6rase al grafico de selecci6n ubicado

sobre la unidad, para elegir el tipo de her-

ramienta que esta unidad es capaz de

hacer funcionar.

• Juego de conexion rapida

(variasmedidas)

• Reguladores de presi6n de aire.

• Lubricadores para nieblade aceite.

• Manguera de aire:

1/4 pulg., 3/8 pulg. o 1/2 pulg. DI. en distintas

longitudes.

I___ El uso de

-- accesorios no

recornendados para utilizar con esta

herramienta puede resuRtar peligroso. Use

solamente accesorios con una capacidad

nominal igual o superior a la de la

compresor de aire.

Esta bomba compresora de aire es que oscile entre el 50% y el 75%; ello

capaz de funcionar continuamente, sin significa que la bomba compresora no

embargo para prolongar la vida Qtil de deberia trabajar m&s de 30 a 45 minutos

su compresor de aire se recomienda por hora.

mantener un ciclo promedio de servicio

31 - SP N014212

Desempaque

1. Extraiga la unidad de su caja y descarte todas las partes de embalaje.

COMO PREPARAR LA UNIDAD 2. AsegOrese que el tomacorriente tenga

la misma configuraci6n que el enchufe

Ubicaci6n del compresor de aire

• Ubicar el compresor de aire en un

lugar limpio, seco y bien ventilado.

El compresor de aire debe

colocarse alejado por Io menos

(30,5 cm) 12 pulg. de las paredes

o de cualquier otra obstrucci6n que

interfiera con el flujo de aire.

La bomba del compresor de aire y

su casco han sido dise_ados para

permitir un enfriamiento adecuado.

Las aberturas de ventilaci6n del

compresor son necesarias para el

mantenimiento de una temperatura

adecuada de funcionamiento. No

coloque trapos o contenedores,

encima, ni en las proximidades de

dichas aberturas.

INSTRUCClONES PAPA

CONEOTAR A TIERRA

_ Riesgo de choque

-- el_ctrico. Ante

la eventualidad de un cortocircuito, la

conexi6n a tierra reduce el riesgo de

electrocuci6n proveyendo un conductor

de escape para la corriente el_ctrica.

Este compresor de aire debe estar

adecuadamente conectado a tierra.

El compresor port&til de aire est& equipado

con un cable con un conductor y un

enchufe adecuado para conexi6n a tierra

(vea las siguientes ilustraciones).

1. El cable de esta unidad tiene un

enchufe de 3 espigas para conexi6n

a tierra que DEBE enchufarse en un

tomacorriente conectado a tierra.

IMPORTANTE: El tomacorriente que

que se use debe estar conectado a

tierra conforme a todos los c6digos y

ordenanzas locales.

de conexi6n a tierra. NO UTIMCE UN

ADAPTADOR. Vea la figura.

Espiga de conexi6n a tierra

3.

Inspeccione el enchufe y su cord6n

antes de cada uso. No Io use si

existieran signos de danes.

Si las instrucciones de conexi6n

4.

a tierra no fueran completamente

comprendidas, o si se estuviera ante

la duda acerca de que el compresor

estuviese adecuadamente conectado

a tierra, haga verificar la instalaci6n

por un electricista competente.

_ Riesgo de choque

el_ctrico. LA CONEXION

INADECUADA A TIERRA PUEDE

CAUSAR UNA DESCARGA ELECTRICA.

No modifique el enchufe provisto. Si no

penetrara en el tomacorriente disponible,

un electricista calificado debe instalar

uno apropiado.

La reparaci6n del cable o del enchufe

DEBE hacerla un electricista calificado.

N014212 32 - SP

Cables de e×tensi6n el_ctrica

Si - no obstante - debe utilizarse una exten-

si6n de cable, asegQrese de que:

• La extensi6n el6ctrica de 3 conduc-

totes, tenga un enchufe de conexi6n

a tierra de 3 hojas, y que exista un

receptaculo que acepte el enchufe del

producto.

• Est6 en buenas condiciones.

• No mas largo que 15,2 m (50 pies).

Sea calibre 14 (AWG) o mayor. (La

capacidad de los cables se incrementa

a medida que su nQmero ordinal dec-

rece. Tambi6n pueden usarse calibres

12 y 10 AWG. NO USE 16 NI 18

AWG).

_EI uso de cables de

__ extensi6n el6ctrica

originarA una caida de tensi6n, Io que

determinarA una p6rdida de potencia del

motor asf como su recalentamiento. En

lugar de utilizar un cable de extensi6n

el_ctrica, incremente el alcance de la

manguera de aire dentro de la zona

de trabajo, a_adi_ndole otto largo de

manguera a su extremo. Conecte los

largos adicionales de manguera de

acuerdo a su necesidad.

Protecci6n del voltaje y del circuito

Refi6rase a la cartilla de voltajes para

determinar los requisitos minimos que el

ramal del circuito requiere.

_ iesgo de Operaci6n

Insegura. Ciertos

compresores de aire pueden operearse

en un circuito de 15 A, siempre que se

cumplan las siguientes condieiones:

1. Que el voltaje suministrado al ramal

cumpla con el c6digo el6ctrico

nacional.

2. Que el circuito no sea utilizado para

alimentar ninguna otra necesidad

el6ctrica.

3. Que los cables de extensi6n cumplan

con las especificaciones.

4. Que el circuito cuente con un

disyuntor de 15 amperios o un fusible

de acci6n retardada de 15 amperios.

NOTA" Si el compresor esta

conectado a un circuito protegido per

fusibles, use s61o fusibles de acci6n

retardada. Los fusibles de acci6n

retardada deben estar marcados

con la letra "D" en Canada y "T" en

EE.UU.

Si cualquiera de las condiciones

enumeradas no pudiese cumplirse, o si

el funcionamiento del compresor causara

interrupciones reiteradas en el suministro

el6ctrico, podria set necesario operarlo

en un circuito de 20 amperios. Para ello

no sera necesario cambiar su cable de

limentaci6n.

33 - SP N014212

Conozca su compresor de aire

LEA ESTE MANUAL DEL PROPIETARIO Y SUS NORMAS DE SEGURIDAD ANTES DE

OPERAR LA UNIDAD. Compare las ilustraciones contra su unidad a fin de familiarizarse

con la ubicaci6n de los distintos controles y regulaciones. Conserve este manual para ref-

erencias futuras.

Descripci6n de operaciones

Familiaricese con estos controles antes de

operar la unidad.

Interruptor Encendido (I) Apagado (O):

Para que el interruptor de presi6n se

energice automAticamente, coloque

el interruptor en "Encendido" (I)yen

"Apagado" (O) para desenergizarlo al final

de cada uso.

Interruptor de presi6n (no rnostrado): El

interruptor de presi6n permite el arranque

autom_tico del motor cuando la presi6n del

tanque disminuye a la presi6n de arranque

regulada en fabrica. El motor se detendra

cuando la presi6n del tanque alcance la

"presi6n de corte" regulada en fabrica.

V_Jvula de seguridad: Si el interruptor

de presi6n dejara de cortar el suministro

de presi6n del compresor conforme a

los valores prefijados para la "presi6n de

corte", la valvula de seguridad proteger&

contra la presi6n elevada, "abri6ndose" a la

presi6n prefijada (ligeramente superior a la

"presi6n de corte".

Man6metro de la presi6n deJ tanque:

El man6metro que controla la presi6n del

tanque indica la reserva de presi6n del

tanque de aire.

Man6rnetro para controlar la presi6n

de salida. Este man6metro indicara la

presi6n de aire disponible a la salida del

regulador. Esta presi6n esta controlada pot

el regulador y siempre es menor o igual

que la presi6n del tanque.

Regulador: Controla la presi6n de aire

indicada en la salida del medidor de

presi6n. Gire la perilla del regulador en el

sentido del reloj para aumentar la presi6n y

contra el sentido del reloj para reducirla.

Sisterna de enfriamiento (no mostrado}:

Este compresor contiene un sistema de

enfriamiento de avanzada. El n_cleo de

este sistema de enfriamiento contiene un

ventilador diseSado especialmente. Es

normal que este ventilador sople grandes

cantidades de aire pot los orificios de

ventilaci6n. Usted sabra que el sistema

de enfriamiento funciona adecuadamente

cuando perciba que sale aire.

Bornba de cornpresi6n deJ aire (no

rnostrada}: Comprime el aire dentro del

tanque. Elaire de trabajo no se encuentra

disponible hasta que el compresor haya

alcanzado a Ilenar el tanque hasta un nivel

de presi6n pot encima del requerido para

la salida del aire.

V_ivula de

drenaje: La

v&lvula de

drenaje se

encuentra

ubicada en la

base del

tanque de aire y se usa para drenar la

condensaci6n al fin de cada uso.

N014212 34- SP

V_lvula de retenci6n: Cuando el compre-

sor de aire se encuentra funcionando, la

valvula de retenci6n esta "abierta", permi-

tiendo la entrada del aire comprimido al

tanque de aire. Cuando el nivel de presi6n

del tanque alcanza la "presi6n de corte", la

vAIvula de retenci6n "se cierra", reteniendo

la presi6n del aire dentro del tanque.

Protector de sobrecalentamiento del

motor (no mostrado): El motor tiene

un reposicionado autom&tico para la

protecci6n t6rmica. Si por cualquier raz6n

el motor se recalentara, el protector por

sobrecalentamiento Io detendr& El motor

debera dejarse enfriar antes de volver a

ponerlo en marcha. El compresor arrancar&

autom&ticamente luego que el motor se

enfrie.

COMO UTILIZAR SU UNIDAD

C6mo detenerla:

1. Apague colocando el interruptor

Encendido/Apagado en "Apagado".

Antes de poner en marcha

_No opere esta

-- unidad hasta

que haya leido y comprendido este

manual de instrucciones de seguridad,

operacibn y mantenimiento.

Procedimiento para el asentamiento

_ iesgo de Operaci6n

siguen detalladamente las instrucciones

para el asentamiento se pueden causar

daSos serios.

Este procedimiento es necesario antes

de poner en servicio al compresor de

aire, y cuando la valvula reguladora o la

bomba completa del compresor haya sido

reemplazada.

1. Cerci6rese que el interruptor

Encendido/Apagado est6 "Apagado".

2. Enchufe el cable de alimentaci6n

en el tomacorriente del ramal del

circuito correcto. (Referirse al parrafo

Protecci6n del voltaje y del

circuito en la secci6n Instalacidn de

este manual).

Insegura. Si no se

3. Abrir por completo (contra el sentido

del reloj) para dejar escapar aire y evi-

tar que la presi6n del tanque aumente

durante el periodo de asentamiento.

4. Mueva el interruptor a la posici6n de

"encendido". El compresor se pondrA

en marcha.

5. Haga funcionar el compresor durante

15 minutos. AsegOrese de que la

vAIvula de drenaje est6 abierta y que

la presi6n de aire acumulado en el

tanque sea minima.

6. Despues de 15 minutos, cerrar la v&l-

vula de drenaje girAndola en el sentido

del reloj. El tanque de aire se Ilenara

hasta alcanzar la presi6n de corte y el

motor se detendr&

Ahora el compresor esta listo para usarse.

Antes de cada puesta en marcha:

1. Apague colocando el interruptor

Encendido/Apagado en "Apagado".

2. Gire la perilla del regulador contra el

sentido del reloj para regular la pre-

si6n de la salida a cero.

3. Conecte la manguera y accesorios.

_ Riesgo.de

insegura. Sostenga la manguera

firmemente con las manos al instalarla

o desconectarla para evitar la

desconexi6n repentina de la manguera.

_ Riesgo.de

insegura. No utilice los accesorios

da_ados o usados.

NOTA: Tanto la manguera como los

accesorios requerir&n un enchufe de

conexi6n r&pida si la salida del aire esta

equipada con un acople de conexiOnrapida.

_ Riesgo de

Demasiada presi6n de aire podra ser la

causa de riesgo de explosi6n. Verifique

los valores de m_xima presi6n dados

pot el fabricante de las herramientas

neumaticas y los accesorios. La presi6n

de salida del regulador jam_s debe

exceder los valores de m_xima presi6n

especificados.

operaclon

operac|on

Explosi6n.

35 - SP N014212

_ iesgo de operacibn

insegura. El aire

comprimido de la unidad puede

contener condensaci6n de agua y

emanaci6n de aceite. No pulverice

aire no filtrado sobre un articulo que

podrfa daSarse con la humedad.

AIgunos dispositivos o herramientas

neumaticas pueden requerir aire

fiitrado. Lea las instrucciones del

dispositivo o la herramienta neum_tica.

Responsabilidades del cliente

Antes de Diariamente

cada uso o luego de

Verifique la valvula X

de seguridad

Drenaje del tanque X

_La unidad 1.

-- arranea

automaticamente cuando est_

conectada. AI hacer et mantenimiento

puede quedar expuesto a fuentes de

voltaje, de aire comprimido o a piezas

movibles que pueden causar lesiones

personales. Antes de intentar hacerle

cualquier mantenimiento, desconecte

el compresor del suministro el_ctrico y

dr_nele toda la presi6n de aire.

NOTA: Vea en la secci6n Operacidn la

ubicaci6n de los controles.

C6mo verificar la v_lvula de

seguridad

_ Riesgo de

Explosibn. Si

la valvula de seguridad no trabaja

adecuadamente, ello podra determinar

la sobrepresi6n del tanque, creando el

riesgo de su ruptura o explosi6n.

_ Riesgo de

objetos

despedidos. Utilice siempre equipo

de seguridad certificado: anteojos de

seguridad ANSI Z87.1 (CAN/CSA Z94.3)

con proteccibn lateral

cada USO

C6mo poner en marcha:

1. Coloque el interruptor Encendido/

Apagado en la posici6n de "Encendido"

y deje que se incremente la presi6n del

tanque. El motor se detendrA una vez

alcanzado el valor de presi6n "de corte"

del tanque.

2. Gire la perilla del regulador en el sentido

del reloj para aumentar la presi6n

y det6ngase al alcanzar la presi6n

deseada.

Si observa algQn

ruido o vibraci6n

inusuales, apague el compresor y contacte

a un t_cnico calificado en servicio.

Ahora el compresor est_ listo para usarse.

Antes de poner en marcha el motor,

tire del anillo de la v&lvula de seguridad

para confirmar que opera libremente.

Si la v&lvula quedase trabada o no tra-

bajara suavemente, debe reemplazarse

por el mismo tipo de v&lvula.

C6mo drenar el tanque

_ Riesgo.de

operaclon insegura.

Riesgo por ruidos. Los tanques de aire

contienen aire de alta presi6n. Mantenga

la cara y otras partes del cuerpo lejos de

la salida del drenaje. Utiliceanteojos de

seguridad ANSI Z87.1 (CAN/CSA Z94.3},

ya que al drenar se pueden desprender

residuos hacia la cara. Utilice proteccibn

auditiva ANSI S12.6 (S3.19), ya que el

ruido del flujo de aire es alto durante el

drenaje.

1. Apague colocando el interruptor

Encendido/Apagado en "Apagado".

2. Tire de la perilla del regulador y gire en

sentido contrario a las agujas de reloj

para establecer la salida de presi6n en

cero.

3. Desinstale la herramienta neum_tica o el

accesorio.

N014212 36 - SP

4. Tire del aro de la vAlvula de seguridad

dejando purgar el aire del tanque hasta

que este reduzca su presi6n aproxima-

damente a 20 PSI. Suelte el aro de la

valvula de seguridad.

5. Drene el agua contenida en el tanque

de aire, abriendo la valvula de drenaje

ubicada en la base del tanque.

_ iesgo de daSo a la

propiedad. Drene el

agua del tanque de aire puede contener

aceite y 6xido, Io que puede provocar

manchas.

6. Una vez drenada el agua, cierre la val-

vula de drenaje. Ahora puede guardar

el compresor de aire.

NOTA: Si la vAIvula de drenaje estuviese

del tanque se producira condensaci6n de

obstruida, elimine toda la presi6n de aire.

Luego puede sacarla, limpiarla y reinstalarla.

agua. Si no drena, el agua Io corroer_ y

debilitara causando un riesgo de ruptura

del tanque de aire.

TODO TIPO DE MANTENIMIENTO Y REPARACIONES NO MENCIONADOS EN ESTE

MANUAL, DEBERAN SER EFECTUADOS POR PERSONAL TECNICO ESPECIALIZADO.

_ Riesgo de Operaci6n Insegura. La unidad arranca

autornaticamente cuando est_ enchufada. AI hacer el

rnantenirniento, el operador puede quedar expuesto a fuentes de corriente y de aire

cornprimido o a piezas movibles. Antes de intentar hacer reparaciones, desconectar

el cornpresor del tornacorriente, drenar la presi6n de aire del tanque y esperar a que

el compresor se enfrie.

Para reemplazar o limpiar la v_lvula

retenci6n

1. Libere toda presi6n de aire del tanque.

Vea Drenaje del tanque en la secci6n

Mantenimiento.

2. Desenchufe el equipo.