Owner's Manual

CRRFT$14Rli°

SNOW THROWER

11.5 Horsepower

Power-Propelled

30" Two-Stage

Model No.

917.881152

• EspaSol, p. 21

CAUTIO ."

Read and follow all

Safety Rules and Instructions

before operating this equipment

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.sears.com/craftsman

&

&

iMPORTANT

Safe Operation Practices for Walk-Behind Snow Throwers

This snow thrower is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury.

Look for this symbol to point out ira=

portant safety precautions. It means

CAUTION!!! BECOMEALERT!!! YOUR

SAFETY IS INVOLVED.

WARNING: Always disconnect spark

plug wire and place it where it cannot

contact plug in order to prevent acci=

dental starting when setting up, trans-

porting, adjusting or making repairs.

&

WARNING: Snow throwers have ex=

posed rotating parts, which can cause

severe injury from contact, or from ma=

terial thrown from the discharge chute.

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

CAUTION: Muffler and other engineparts become extremely hot during

operation and remain hot after engine

WARNING: This snow thrower is for

use on sidewalks, driveways and other

ground level surfaces. Caution should

be exercised while using on sloping sur=

faces. Do not use snow thrower on

surfaces above ground level such as

roofs of residences, garages, porches

or other such structures or buildings.

Training

1. Read, understand and follow all instructions on the

machine and in the manual(s) before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

3. Keep the area of operation clear of all persons, par-

ticularly small children.

4. Exercise caution to avoid slipping or falling, especially

when operating the snow thrower in reverse.

Preparation

1. Thoroughly inspect the area where the equipment is

to be used and remove all doormats, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting the engine (motor).

3. Do not operate the equipment without wearing adequate

winter garments. Avoid loose fitting clothing that can

get caught in moving parts. Wear footwear that will

improve footing on slippery surfaces.

4. Handle fuel with care; it is highly flammable

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors.

(d) Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground, away from your vehicle,

before filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than

from a gasoline dispenser nozzle.

_ as stopped. To avoid severe burns oncontact, stay away from these areas.

WARNING: Engine exhaust, some of

its constituents, and certain vehicle

components contain or emit chemi=

&

(f) Keep the nozzle in contact with the rim of the fuel

(g) Replace gasoline cap securely and wipe up spilled

(h) If fuel is spilled on clothing, change clothing im-

5.

Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

.

Adjust the collector housing height to clear gravel or

crushed rock surface.

7.

Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by manufacturer).

.

Always wear safety glasses or eye shields during op-

eration or while performing an adjustment or repair to

protect eyes from foreign objects that may be thrown

from the machine.

cals known to the State of California

to cause cancer and birth defects or

other reproductive harm.

tank orcontainer opening at all times, until refueling

iscomplete. Do not use a nozzle lock-open device.

fuel.

mediately.

Operation

1. Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or cross-

ing gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic.

3. After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, disconnect the

cord on electric motors, thoroughly inspect the snow

thrower for any damage, and repair the damage before

restarting and operating the snow thrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the oper-

ating position, before unclogging the collector/impeller

housing or discharge chute, and when making any

repairs, adjustments or inspections.

2

6. Whencleaning,repairingorinspectingthesnowthrower,

stoptheengineandmakecertainthecollector/impel-

ler andall movingpartshavestopped.Disconnect

thesparkplugwireandkeepthewireawayfromthe

plug.topreventsomeonefromaccidentallystartingthe

engine.

7. Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthesnowthrowerinor

outofthebuilding.Opentheoutsidedoors;exhaust

fumesaredangerous.

8. Exerciseextremecautionwhenoperatingonslopes.

9. Neveroperatethesnowthrowerwithoutproperguards,

andothersafetyprotectivedevicesinplaceandwork-

ing.

10.Neverdirectthedischargetowardpeopleor areas

wherepropertydamagecanoccur.Keepchildrenand

othersaway.

11.Donotoverloadthemachinecapacitybyattempting

toclearsnowattoofastarate.

12.Neveroperatethemachineat hightransportspeeds

onslipperysurfaces.Lookbehindandusecarewhen

operatinginreverse.

13.Disengagepowertothecollector/impellerwhensnow

throweristransportedornotinuse.

14.Useonlyattachmentsandaccessoriesapprovedby

themanufacturerofthesnowthrower(suchaswheel

weights,counterweights,orcabs).

15.Neveroperatethesnowthrowerwithoutgoodvisibility

orlight.Alwaysbesureofyourfooting,andkeepafirm

holdonthehandles.Walk;neverrun.

16.Nevertouchahotengineormuffler.

Clearing a Clogged Discharge Chute

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with

snow throwers. Never use your hand to clean out the dis-

charge chute. To clear the chute:

1. SHUT THE ENGINE OFF!

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean-out tool, not your hands.

Maintenance and Storage

1. Check shear bolts and other bolts atfrequent intervals

for proper tightness to be sure the equipment is in safe

working condition.

2. Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present such as

hot water heaters, space heaters, or clothes dryers.

Allow the engine to cool before storing in any enclosu re.

3. Always refer to operator's manual for important details

if the snow thrower is to be stored for an extended

period.

4. Maintain or replace safety and instruction labels, as

necessary.

5. Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller.

TA L OF CONTENTS

SAFETY RULES ........................................................ 2-3

PRODUCT SPECIFICATIONS ...................................... 4

CUSTOMER RESPONSIBILITIES ................................ 4

WARRANTY .................................................................. 4

ASSEMBLY / PRE-OPERATION ............................... 6-8

OPERATION ............................................................ 9=14

MAINTENANCE ..................................................... 15=16

MAINTENANCE SCHEDULE ..................................... 15

SERVICE AND ADJUSTMENTS ........................... 17-19

STO RAG E...................................................................19

TROUBLESHOOTING ................................................ 20

REPAIR PARTS ..................................................... 40-55

SEARS SERVICE ................................... BACK COVER

LIMITED 2-YEAR WARRANTY ON CRAFTSMAN SNOW THROWER

When used and maintained according to the operator's manual instructions, if this snow thrower fails due to a

defect in material or workmanship within two years from the date of purchase, call 1-800-4-MY-HOME® to arrange

for free repair.

During the first 30 days of purchase, there will be no charge to service the product in your home. For your

convenience, in-home warranty service will still be available after the first 30 days of purchase, but a trip charge

will apply. This charge will be waived if you transport the product to an authorized Craftsman drop-off location. For

the nearest authorized location, call 1-800-4-MY-HOME®.

Warranty coverage does not include:

• Expendable items that become worn during normal use, including but not limited to spark plugs, shear pins, belts.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

• Repairs necessary because of operator abuse, including but not limited to damage caused by impacting objects

that bend the frame, crankshaft or auger, or over-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to damage caused by improper

storage, failure to use the proper grade and amount of engine oil, or failure to maintain the equipment according

to the instructions contained in the operator's manual

• Engine (fuel system) cleaning or repairs necessary because of fuel determined to be contaminated or oxidized

(stale). In general, fuel should be used within 30 days of its purchase date.

• Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty applies for only 90 days if this product is used for commercial or rental purposes.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to state.

Sears, Roebuck And Co., Hoffman Estates, IL 60179

CONGRATULATIONS on your purchase of a new snow

thrower. It has been designed, engineered and manufac-

tured to give best possible dependability and performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Parts & Repair

Center. We have competent, well-trained technicians and

the proper tools to service or repair this unit.

Please read and retain this manual. The instructions will

enable you to assemble and maintain your snow thrower

properly. Always observe the "SAFETY RULES".

SERIAL NUMBER:

DATE OF PURCHASE:

THE MODELAND SERIAL NUMBERSWILL BE FOUND

ONA DECALATTACHED TO THE REAR OFTHE SNOW

THROWER HOUSING.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

PRODUCT SPECIFICATIONS

Gasoline Capacity 4.0 Quarts

and Type: Unleaded Regular only

Oil Type SAE 5W-30 or 10W-30

(API SG-SL): (0°F to +40°F /-18°O to +5°0)

Synthetic SAE 5W-30 or 10W-30

(below 0°F /-18°O)

Oil Capacity: 28 Fluid Ounces

Spark Plug: Champion RC12YC

Gap: 0.030"

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and using your snow thrower.

• Follow the instructions under "Maintenance" and "Stor-

age" sections of this owner's manual.

4

PARTS PACKE E ELY I CARTON

(1) FUEL STABiLiZER PACKET

FRESH

START

(1) POWER

CORD

(1) AUGER CONTROL ROD

(1) TRACTION DRIVE CONTROL ROD

(1) DISCHARGE CHUTE

(2) SAFETY iGNiTiON KEYS

I

I

I

I

I

L

EXTRA SHEAR BOLTS AND NUTS

2

(2) SHOULDER BOLTS

1/4-20 x 2 (AUGER SHAFT)

ROTATOR HEAD MOUNTING

(1) WASHER 3/8

CHUTE DEFLECTOR REMOTE CONTROL

(2) LOCKNUTS

1/4=20

(1) LOCKNUT 3/8

I

I

I

I

I

====_

1

(3) RETAINER

SPRINGS

I

I

I

I

I

]

(1) LOCKNUT

5/16-18

(1) CARRIAGE

BOLT 5/16=18 x 5/8

(1) LOCKNUT (1) NYLON

1/4=20 WASHER

(1) SHOULDER

BOLT 1/4=20 (1) SPRING

ASSE

Read these instructions and this manual in its entirety

before you attempt to assemble or operate your new

snow thrower. Reading the entire manual will familiar-

ize you with the unit, which will assist you in assembly,

operation and maintenance of the product.

Your new snow thrower has been assembled at the factory

with the exception of those parts left unassembled for ship-

ping purposes. All parts such as nuts, washers, bolts, etc.,

necessary to complete the assembly have been placed in

the parts bag. Toensure safe and proper operation of your

snow thrower, all parts and hardware you assemble must

be tightened securely. Use the correct tools as necessary

to ensure proper tightness.

BLY / PRE-OPERATION

REMOVE SNOW THROWER FROM CARTON

1. Remove all accessible loose parts and parts boxes

from carton.

2. Cut down all four corners of carton and lay panels flat.

3. Remove the two (2)screws securing the auger housing

to the pallet.

4. Remove all packing materials except plastic tie holding

speed control rod to lower handle.

5. Remove the two (2) plastic ties securing upper handle

to pallet.

6. Remove snow thrower from carton and check carton

thoroughly for additional loose parts.

SPEED

CONTROL

ROD_

PLASTI C TI E

UPPER

HANDLE

!

HANDLE

KNOB

LOWER

HANDLE

HOW TO SET UP YOUR SNOW THROWER

TOOL BOX (See Fig. 10)

A toolbox is provided on your snow thrower. The toolbox is

located on top ofthe belt cover. Store the extra shear bolts,

nuts and multi-wrench provided in parts bag in the toolbox.

NOTE: The multi-wrench may be used for assembly of the

chute rotator head to snow thrower and making adjustments

to the skid plates.

UNFOLD UPPER HANDLE

1. Raise upper handle tothe operating position and tighten

handle knobs securely.

iNSTALL SPEED CONTROL ROD (See Figs. 1 and 2)

1. Remove plastic tie securing rod to lower handle.

2. Insert rod intospeed control bracket and secure with

retainer spring.

SPEED

CONTROL

BRACKET

FIG. 1

SPEED CONTROL ROD

RETAINER

SPRING

SPEED

CONTROL

LEVER

FIG. 2

6

LY / E-OPERATION

iNSTALL TRACTION DRIVE CONTROL ROD

(See Figs. 3 and 4)

The traction drive control rod has the long loop on the end

of the spring as shown.

1. Slide rubber sleeve up rod and hook end of spring into

pivot bracket with loop opening down as shown.

2. With top end of rod positioned under left side of control

panel, push rod down and insert top end of rod intohole

in drive control bracket. Secure with retainer spring.

CONTROL ROD

TRACTION DRIVE !

RUBBER

SLEEVE

iNSTALL AUGER CONTROL ROD (See Figs. 5 and 6)

The auger control rod has the short loop on the end of the

spring as shown.

1. Slide rubber sleeve up rod and hook end of spring into

control arm with loop opening up as shown.

2. With top end of rod positioned under right side of control

panel, push down on rod and insertend of rod intohole

in auger control bracket. Secure with retainer spring.

iNSTALL DISCHARGE CHUTE / CHUTE ROTATOR

AUGER

CONTROL

ROD

RUBBER

SLEEVE

CONTROL

ARM

PIVOT

BRACKET

CONTROL

BRACKET

FiG, 3

DRIVE RETAINER

SPRING

FiG, 4

FiG, 5

AUGER CONTROL ROD

RETAINER

SPRING

FIG, 6

AUGER

CONTROL

LEVER

CONTROL

BRACKET

ASSE BLY/PRE-OPERATION

HEAD (See Fig. 7)

NOTE: The multi-wrench provided in your parts bag may

be used to install the chute rotator head.

1. Place discharge chute assembly on top of chute base

with discharge opening toward front of snow thrower.

2. Position chute rotator head over chute bracket. Ifneces-

sary, rotate chute assemblyto align square and pin on un-

derside of chute rotator head with holes in chute bracket.

3. With chute rotator head and chute bracket aligned,

position chute rotator head on pin and threaded stud

of mounting bracket.

4. Install 3/8 washer and Iocknut on threaded stud and

tighten securely.

CHECK TiRE PRESSURE

ALIGN CHUTE ROTATOR HEAD

WITH MOUNTING

BRACKET BEFORE

TIGHTENING

LOCKNUT

_3/8 LOCKNUT

_3/8 WASHER

iNSTALL CHUTE DEFLECTOR REMOTE CONTROL

(See Figs. 8 and 9)

1. Install remote cable bracket to discharge chute with

5/16-18 carriage bolt and 5/16-18 Iocknut as shown.

Tighten securely.

2. Install remote cable eyelet to chute deflector with

1/4-20 shoulder bolt, nylon washer and 1/4-20 Iocknut

as shown. Tighten securely.

3. Install spring hooks between hex nuts on chute rotater

head and into hole in chute deflector as shown.

1/4-20 SPRING

SHOULDER CHUTE

NYLON BETWEEN HEX

WASH ER NUTS

1/4-20 ROTATER HEAD

LOCKNUT

CABLE

EYELET

DEFLECTOR

HOOK

ON CHUTE

5/16-18

CARRIAGE

CHUTE

BRACKET

CHUTE MOUNTING

ROTATOR HEAD

ROTATOR HEAD BRACKET

FIG. 7

PIN

STUD

REMOTE

/ CABLE

/ BRACKET

5/16-18

LOCKNUT

FIG. 8

f .... ........

CHUTE DEFLECTOR

CONTROLLEVER

FIG, 9

The tires on your snow thrower were overinflated atthe fac-

tory for shipping purposes. Correct and equal tire pressure

is important for best snow throwing performance.

• Reduce tire pressure to 14-17 PSI (19-24.5 N-m).

8

OPERATI

KNOW YOUR SNOW THROWER

READ THIS OWNER'S MANUALAND ALL SAFETY RULES BEFORE OPERATING YOUR SNOWTHROWER. Compare

the illustrations with your snow thrower to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

These symbols may appear on your snow thrower or in literature supplied with the product. Learn and understand

their meaning.

I\1

DANGER ENGINE SLOW CHOKE PRIMER

OR WARNING ON

FUEL OIL FORWARD REVERSE

IGNITION KEY.

INSERT TO START

AND RUN,

PULL OUT TO STOP.

ENGINE FAST

OFF

READ AND FOLLOW ALL SAFETY INFORMATION

AND INSTRUCTIONS BEFORE USE OF THIS PRODUCT.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

SNOW

DISCHARGE

DISENGAGED

ENGAGED

TRACTION

DRIVE CONTROL

OPERATION

GASOLINE

FILLER CAP.

CON=

TROL

SAFETY

IGNITION

KEY FUEL

SHUT=OFF

VALVE

THROTTLE

/ENGINE

CONTROL

ELECTRIC AUGER

CHUTE

CLEAN=OUT TOOL

START CONTROL

BUTTON LEVER DRIVE SPEED

(AUXILIARY)

RECOIL _ONTROL LEVER

STARTER

HANDLE

CHUTE

DEFLECTOR

DISCHARGE CHUTE CONTROL LEVER

DEFLECTOR REMOTE

CONTROLLEVER

DRIVE

CONTROL

LEVER

=H TURN

TRIGGER

LIGHT

HANDLE

KNOB

TOOLBOX

NOTE: ITEMS ABOVE

ARE SHOWN IN

THEIR TYPICAL

LOCATION ON THE

ENGINE. ACTUAL

LOCATION MAYVARY

WITH THE ENGINE

ON YOUR UNIT.

O DRIFT CUTTER

AUGERS

FIG. 10

MEETS A.N.S.I. SAFETY REQUIREMENTS

Our snow throwers conform to the standards of the American National Standards Institute.

Toolbox = used to store spare shear bolts, locknuts and

wrench.

Safety ignition key = must be inserted for the engine to

start and run. Remove when snow thrower is not in use.

Electric start button = used for starting the engine.

Recoil (auxiliary) starter handle= used forstarting engine.

Primer = pumps additional fuel from the carburetor to the

cylinder for use when starting a cold engine.

Choke Control = used for starting a cold engine.

Throttle/engine control - used to select either FAST or

SLOW engine speed and to STOP the engine.

LH and RH turn triggers = used to steer the snow thrower.

Drive speed control lever = used to select forward or

reverse motion and speed of snow thrower.

Traction drive control lever = used to engage power-

propelled forward or reverse motion of snow thrower.

Auger control lever = used to engage auger motion

(throw snow).

Discharge chute control lever = used to change the

direction the snow is thrown.

Deflector remote control lever = used to change the

distance the snow is thrown.

Skid plate = used to adjust height ofscraper bar from ground.

Drift cutter = used to cut through deep snowdrifts.

10

PLATE

OPERATI

The operation of any snow thrower can result

in foreign objects thrown intothe eyes, which

can result insevere eye damage. Always wear

safety glasses or eye shields while operating

your snow thrower or performing any adjust-

ments or repairs. We recommend standard safety glasses

or a wide vision safety mask worn over spectacles.

HOW TO USE YOUR SNOW THROWER

Know how to operate all controls before adding fuel or

attempting to start the engine.

STOPPING

TRACTION DRIVE

Release traction drive control lever to stop the forward

or reverse movement of the snow thrower.

AUGER

Release the auger control lever to stop th rowing snow.

ENGINE

1. Move throttle control to "STOP" position.

2. Remove (do not turn) safety ignition key to prevent

unauthorized use.

NOTE: Never use choke to stop engine.

TO USE FUEL SHUT=OFF VALVE (See Fig. 11)

The fuel shut-off valve is located beneath the fuel tank on

the engine. Always operate the snow thrower with the fuel

shut-off valve in the OPEN position.

• To engage choke, turn knob counterclockwise. Slowly

turn knob clockwise to disengage.

I\l OLL

FIG. 13

TO CONTROL SNOW DISCHARGE (See Fig. 14)

WARNING: Snow throwers have ex=

posed rotating parts, which can cause

severe injury from contact, or from ma=

&

&

terial thrown from the discharge chute.

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

WARNING: if the discharge chute or

auger become clogged, shut=off engine

and wait for all moving partsto stop. Use

the clean=out tool, NOT YOUR HANDS,

to unclog the chute and/or auger.

OPEN

i i

I I

I.... l OFF

FIG. 11

TO USE THROTTLE CONTROL (See Fig. 12)

The throttle control is located on the engine. Always operate

the snow thrower with the engine at full throttle. Fullthrottle

offers the best snow thrower performance.

FAST

FIG. 12

TO USE CHOKE CONTROL (See Fig. 13)

The choke control is located on the engine. Use the choke

control whenever you are starting a cold engine. Do not

use to start a warm engine.

The DIRECTION inwhich snow isto be thrown is controlled

by the discharge chute control lever.

• Tochange the discharge chute position, press downward

on discharge chute control lever and move lever left

or right until chute is in desired position. Be sure lever

springs back and locks into desired position.

The DISTANCE that snow is thrown is controlled by the

position of the chute deflector. Set the deflector low to

throw snow a short distance; set the deflector higher to

throw snow farther.

Press downward on chute deflector control lever and

move lever forward to lower the deflector and decrease

the distance. Move lever back to raise the deflector

and increase the distance. Be sure lever springs back

and locks into desired position.

DISCHARGECHUTE

CONTROLLEVER

CHUTE DEFLECTOR

REMOTE CONTROLLEVER

11 FIG.14

OPERATION

TO THROW SNOW (See Fig. 15)

The auger rotation is controlled by the auger control lever

located on the right side handle.

• Squeeze auger control lever to handle to engage the

auger and throw snow.

• Release the auger control lever to stop throwing snow.

AUGER

CONTROL

LEVER

i /

FIG. 15

USING THE CLEAN=OUT TOOL (See Fig. 18)

In certain snow conditions, the discharge chute may be-

come clogged with ice and snow. Use the clean-out tool

to dislodge this blockage.

When cleaning, repairing, or inspecting, make

certain all controls are disengaged and the au=

get/impeller and all moving parts have stopped.

Disconnect the spark plug wire and keep the

wire away from the spark plug to prevent ac=

cidental starting.

TO MOVE FORWARD AND BACKWARD (See Fig. 17)

SELF-PROPELLING, forward and reverse movement of

the snow thrower, is controlled by the traction drive control

lever located on the left side handle.

• Squeeze traction drive control lever to handle to engage

the drive system.

• Release traction drive control lever to stop the forward

or reverse movement of the snow thrower.

SPEED and DIRECTION are controlled by the drive speed

control lever.

Press downward on the speed control lever and move

lever to desired position BEFORE engaging the trac-

tion drive control lever. Be sure lever springs back and

locks into desired position.

CAUTION: Do not move speed control lever

when traction drive control lever is engaged.

Damage to the snow thrower can result.

• Slower speeds are for heavier snow and faster speeds

are for light snow and transporting the snow thrower. It

is recommended that you use a slower speed until you

are familiar with the operation of the snow thrower.

NOTE: When both traction drive and auger control levers

are engaged, the traction drive control lever will lock the

auger control lever in the engaged position. This will allow

you to release your right hand from the handle and adjust

the discharge chute direction without interrupting the snow

throwing orocess.

e

Release the auger control lever and shut off the engine.

e

Removethe clean-out tool from it's mounting clip. Grasp

the tool firmly by the handle and push and twist the tool

into the discharge chute to dislodge the blockage.

After the packed snow has been dislodged, return the

clean-out tool to it's mounting clip by pushing it into the clip.

• Make sure the discharge chute is pointed in a safe di-

rection (no vehicles, buildings, people, or other objects

are in the direction of discharge) before restarting the

engine.

• Restart the engine, then squeeze the auger control

lever to the handle to clear snow from the auger hous-

ing and the discharge chute.

DISCHARGE CHUTE

TOOL

MOUNTING

TRACTION DRIVE

CONTROL LEVER

CONTROL LEVER

FIG. 17

POWER STEERING OPERATION (See Fig. 18)

Steering triggers are used to assist in steering your snow

thrower. The triggers are located on the underside of each

handle. When a trigger is squeezed, itdisengages the drive

wheel on that side of snow thrower and allows it to turn in

that direction.

• To turn left - squeeze left side trigger.

• To turn right - squeeze right side trigger.

LH TURN RH TURN

TRIGGER TRIGGER

FIG, 16 12 FIG. 18

OPERATI

TO ADJUST SKID PLATES (See Fig. 19)

NOTE: The wrench provided in your parts bag may be

used to adjust the skid plates.

Skid plates are located on each side of the auger housing

and adjust the clearance between the scraper bar and the

ground surface. Adjust skid plates evenly to proper height

for current surface conditions. For removal of snow in

normal conditions, such as a paved driveway or sidewalk,

place skid plates in the highest position (lowest scraper

clearance) to give a 5 mm clearance between the scraper

bar and the ground. Use a middle position ifthe surface

to be cleared is uneven.

NOTE: It isnot recommended to operate the snow thrower

over gravel or rocky surfaces. Objects such as gravel, rocks

or other debris, can easily be picked up and thrown by the

impeller,which can cause serious personal injury,property

damage or damage to the snow thrower.

• If snow thrower must be operated over gravel surface,

use extra caution and be sure skid plates are adjusted

to lowest (highest scraper clearance) position.

1. Shut off engine and wait for all moving parts to stop.

2. Adjust skid plates by loosening the rear 1/2" hex nut

only, then moving skid plate to desired position. Be

sure both plates are adjusted evenly. Tighten securely.

HiGH POSiTiON

(LOW GROUND

CLEARANCE)

t HOUSING

I /

I // . /

>-_-_-........ -_ _ 1/2"_HEX NUT

7

LOW POSITION (HIGH GROUND CLEARANCE)

FIG. 19

SCRAPER BAR

The scraper bar is not adjustable, but is reversible. After

considerable use it may become worn. When it has worn

almost to the edge of the housing, it can be reversed,

providing additional service before requiring replacement.

Replace a damaged or worn scraper bar.

TO USE DRIFT CUTTERS (See Fig. 20)

Use the drift cutters to cut through deep snowdrifts that are

higher than the front of the snow thrower.

• Loosen upper adjustment nut enough to allow drift

cutter to be raised to highest position and tighten nut

securely. Repeat for opposite side of snow thrower.

When not using drift cutters, loosen adjustment nut,

lower to storage position and tighten nut securely.

BEFORE STARTING THE ENGINE

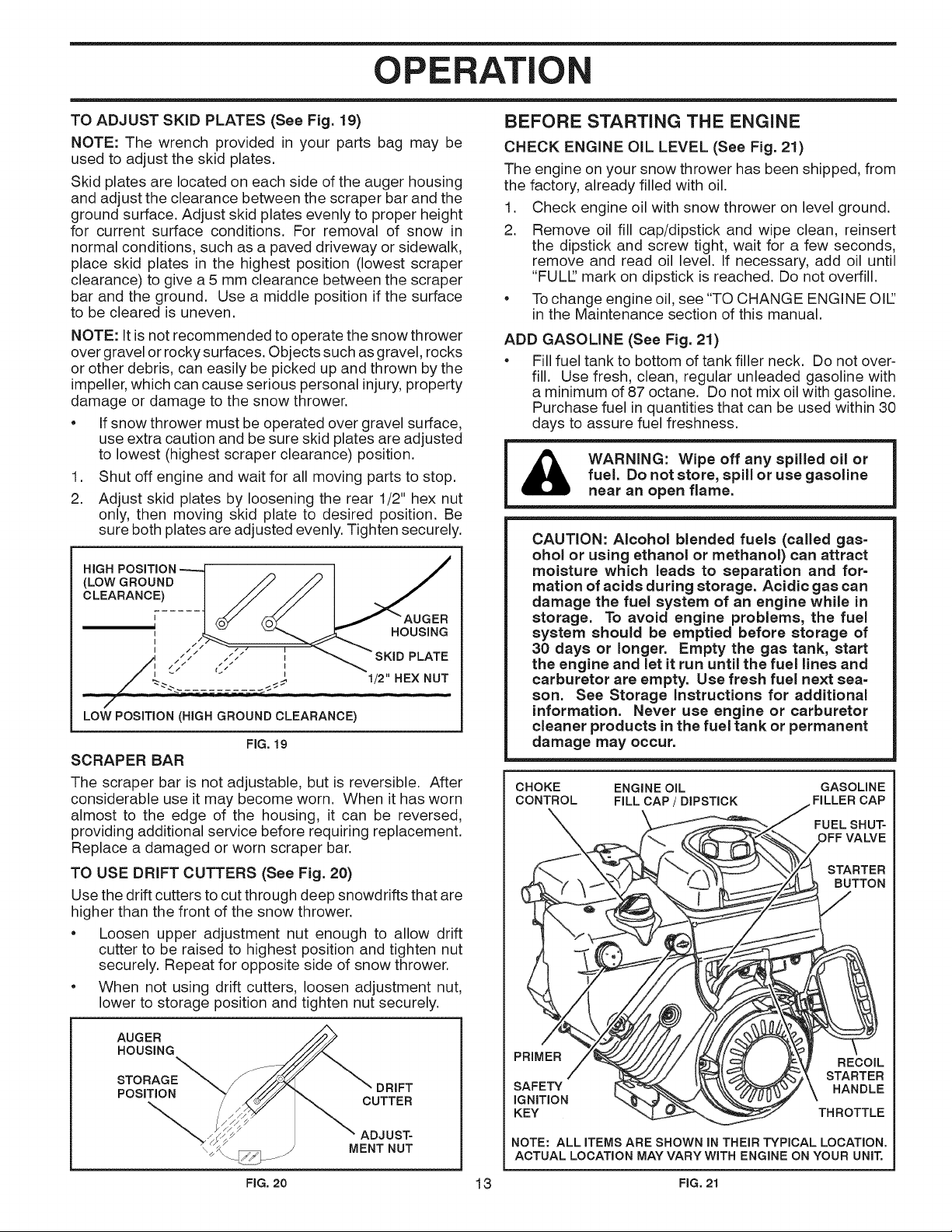

CHECK ENGINE OIL LEVEL (See Fig. 21)

The engine on your snow thrower has been shipped, from

the factory, already filled with oil.

1. Check engine oil with snow thrower on level ground.

2. Remove oil fill cap/dipstick and wipe clean, reinsert

the dipstick and screw tight, wait for a few seconds,

remove and read oil level. If necessary, add oil until

"FULl" mark on dipstick is reached. Do not overfill.

• Tochange engine oil, see "TO CHANGE ENGINE OIL'

in the Maintenance section of this manual.

ADD GASOLINE (See Fig. 21)

Fill fuel tank to bottom of tank filler neck. Do not over-

fill. Use fresh, clean, regular unleaded gasoline with

a minimum of 87 octane. Do not mix oil with gasoline.

Purchase fuel inquantities that can be used within 30

days to assure fuel freshness.

d

_JL WARNING: Wipe off any spilled oil or

CAUTION: Alcohol blended fuels (called gas-

ohol or using ethanol or methanol) can attract

moisture which leads to separation and for=

mation of acids during storage. Acidic gas can

damage the fuel system of an engine while in

storage. To avoid engine problems, the fuel

system should be emptied before storage of

30 days or longer. Empty the gas tank, start

the engine and Jet it run until the fuel lines and

carburetor are empty. Use fresh fuel next sea=

son. See Storage Instructions for additional

information. Never use engine or carburetor

cleaner products in the fuel tank or permanent

damage may occur.

CHOKE ENGINE OIL GASOLINE

CONTROL FILL CAP / DIPSTICK FILLER CAP

fuel. Do not store, spill or use gasoline

near an open flame.

FUEL SHUT-

)FF VALVE

STARTER

BUTTON

AUGER

HOUSING

PRIMER

DRIFT

CUTTER

ADJUST-

MENT NUT

FIG. 20 13 FIG. 21

SAFETY

IGNITION

KEY

NOTE: ALL ITEMS ARE SHOWN IN THEIR TYPICAL LOCATION.

ACTUAL LOCATION MAY VARY WITH ENGINE ON YOUR UNIT.

RECOIL

STARTER

HANDLE

THROTTLE

OPERATION

TO START ENGINE

Be sure fuel shut-off valve is in the OPEN position.

Your snow thrower engine is equipped with both a 120 Volt

A.C. electric starter and a recoil starter. The electric starter

is equipped with a three-wire power cord and plug and is

designed to operate on 120 Volt A.C. household current.

Be sure your house is a 120 Volt A.C. three-wire

grounded system. If you are uncertain, consult a

licensed electrician.

WARNING: Do not use the electric

starter if your house is not a 120 Volt

&

COLD START - ELECTRIC STARTER

1. Insert safety ignition key (packed seperately in parts

bag) into ignition slot until it clicks. DO NOT turn the

key. Keep the extra safety ignition key in a safe place.

2. Place throttle control in FAST position.

3. Rotate choke control to FULL position.

4. Connect the power cord to the engine.

5. Plug the other end of the power cord into a three-hole

grounded 120 Volt A.C. receptacle.

NOTE: Do not use primer when starting engine with the

electric starter.

6. Push starter button until engine starts.

IMPORTANT: Do not crank engine more than five continu-

ous seconds between each time you try to start. Wait 5 to

10 seconds between each attempt.

7. When the engine starts, release the starter button and

slowly move the choke control to the OFF position.

8. Disconnect the power cord from the receptacle first,

then from the engine.

Allow the engine to warm up for a few minutes. Engine will

not develop full power until it has reached normal operat-

ing temperature.

WARM START - ELECTRIC STARTER

Follow the steps above, keeping the choke control in the

OFF position.

COLD START - RECOIL STARTER

1. Insert safety ignition key (packed seperately in parts

bag) into ignition slot until itclicks. DO NOT turn the

key. Keep the extra safety ignition key in a safe place.

2. Place throttle control in FAST position.

3. Rotate choke control to FULL position.

4. Push the primer four (4) times if the temperature is

below 15°F/-10°C, or two (2) times if temperature is

between 15°and 50°F/-10°C and 10°C. Iftemperature

is above 50°F/10°C, priming is not necessary.

NOTE: Over priming may cause flooding, preventing the en-

gine from starting. Ifyou do flood the engine, wait a few min-

utes before attempting tostart and DO NOT push the primer.

5. Pull recoil starter handle quickly. Do not allow starter

rope to snap back.

6. When the engine starts, release the recoil starter handle

and slowly move the choke control to the OFF position.

A.C. three=wire grounded system. Serf

ous personal injury or damage to your

snow thrower could result.

Allow the engine to warm up for a few minutes. Engine will

not develop full power until it has reached normal operat-

ing temperature.

WARM START- RECOIL STARTER

Follow the steps above, keeping the choke in the OFF

position. DO NOT push the primer.

BEFORE STOPPING

Run the engine for a few minutes to help dry off any mois-

ture on the engine.

Toavoid possible freeze-up ofthe starter, proceed as follows:

ELECTRIC STARTER

1. Connect the power cord to the engine.

2. Plug the other end of the power cord into a three-hole

grounded 120 Volt A.C. receptacle.

3. While the engine is running, push starter button and

spin the starter for several seconds.

NOTE: The unusual sound made while starter isspinning

will not harm the engine or starter.

4. Disconnect the power cord from the receptacle first,

then from the engine.

RECOIL STARTER

1. While the engine isrunning, pull the recoil starter handle

with rapid, full arm strokes three or four times.

NOTE: The unusual sound made while pulling the recoil

starter handle will not harm the engine or starter.

IF RECOIL STARTER HAS FROZEN

If the recoil starter has frozen and will not turn the engine,

proceed as follows:

1. Grasp the recoil starter handle and slowly pull as much

rope out of the starter as possible.

2. Release the recoil starter handle and let it snap back

against the starter.

If the engine still fails to start, repeat the above steps or

use the electric starter.

SNOW THROWING TIPS

• Always operate the snow thrower with the engine at

full throttle. Full throttle offers the best performance.

• Go slower in deep, freezing or heavy wet snow. Use the

drive speed control, NOT the throttle, to adjust speed.

• It is easier and more efficient to remove snow imme-

diately after it falls.

• The best time to remove snow is the early morning.

At this time the snow is usually dry and has not been

exposed to the direct sun and warming temperatures.

• Slightly overlap each successive path to ensure all

snow will be removed.

• Throw snow downwind whenever possible.

• Adjust the skid plates to proper height for current snow

conditions. See "TO ADJUST SKID PLATES" in this

section of this manual.

• For extremely heavysnow, reduce the width of snow re-

moval by overlapping previous path and moving slowly.

• Keep engine clean and clear of snow during use. This

will help air flow and extend engine life.

• After snow-throwing is completed, allow engine to run

for a few minutes to melt snow and ice off the engine.

• Clean the entire snow thrower thoroughly after each

14

use and wipe dry so it is ready for next use.

&

WARNING: Do not operate snow thrower if weather conditions impair visibility. Throwing snow

during a heavy, windy snowstorm can blind you and be hazardous to the safe operation of the

snow thrower.

AI ANCE

i

MAINTENANCE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

Check for Loose Fasteners

R Clean / Inspect Snow Thrower

O

W Check / Replace V=Belts

RE Lubrication Chart

Check Engine Oil Level

E

N Change Engine Oil

Inspect Muffler

N Check / Replace Spark Plug

E

Empty Fuel Tank v'

GENERAL RECOMMENDATIONS

The warranty on this snow thrower does not cover items

that have been subjected to operator abuse or negligence.

To receive full value from the warranty, operator must

maintain snow thrower as instructed in this manual. Some

adjustments will need to be made periodically to properly

maintain your snow thrower.

At least once a season, check to see if you should make

any of the adjustments described in the Service and Ad-

justments section of this manual.

• At least once a year, you should replace the spark plug

and check belts for wear. A new spark plug will help

your engine run better and last longer.

• Follow the maintenance schedule in this manual.

NOTE: Use only Original Equipment Manufacturer (OEM)

parts to service this unit. Failure to do so can cause the

unit to malfunction and pose a risk of injury to the operator.

sc. ou-

O _ _ _ _ _ O SERVICE

LUBRICATION CHART

(_) SAE 5W=30 Motor Oil

(_) See "ENGINE" in

Maintenance section

(_ General

Purpose

Grease

@ Engine oil

BEFORE EACH USE

1. Check engine oil level.

2. Check for loose fasteners.

3. Check controls to be sure they are functioning properly.

LUBRICATION

Keep your snow thrower well lubricated

(See "LUBRICATION CHART").

SNOW THROWER

Always observe the safety rules when performing any

maintenance.

TIRES

• Maintain proper air pressure in both tires (14-17 RS.I.

/ 19-24.5 N-m).

® Auger

grease fittings

• Keep tires free of gasoline and oil, which can harm

rubber.

NOTE: To seal tire punctures and prevent flat tires due

to slow leaks, tire sealant may be purchased from your

local parts dealer. Tire sealant also prevents tire dry rot

15

and corrosion.

(_ Pivot

points

INTEN CE

V-BELTS

Check V-belts for deterioration and wear after every 50

hours of operation and replace if necessary. The belts

are not adjustable. Replace belts if they begin to slip from

wear. (See "TO REMOVE BELT COVER" in the Service

and Adjustments section of this manual).

The V-belts on your snow thrower are ofspecial construction

and should be replaced by original equipment manufacturer

(OEM) belts available from your nearest dealer. Using other

than OEM belts can cause personal injury or damage to

the snow thrower.

AUGER GEAR CASE

The gear case was filled with lubricant to the proper

level at the factory. The only time the lubricant needs

attention is if service has been performed on the gear

case.

• If lubricant is required, use only Ronex ED #1 grease.

TRACTION DRIVE SYSTEM

DO NOT lubricate the drive components inside the snow

thrower. The sprockets, hex shafts, drive disc and friction

wheel require no lubrication. The bearings and bushings

are lifetime lubricated and require no maintenance.

CAUTION: Any lubricating ofthe above compo-

nents can cause contamination of the friction

wheel and damage to the drive system of your

snow thrower.

ENGINE

LUBRICATION

Use only high quality detergent oil rated with API service

classification SG-SL. Select the oil's SAE viscosity grade

according to your expected operating temperature.

SAE ViSCOSiTY GRADES

I I

i°F -20 0 30 32 40

i°c -30 -2o 40 6 lo

TEMPERATURE RANGE ANTiCiPATED

BEFORE NEXT OiL CHANGE

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F/0°C. Check your engine oil level more frequently to

avoid possible engine damage from running low on oil.

Change the oil after every 25 hours of operation or at least

once a year if the snow thrower is not used for 25 hours

in one year.

Check the crankcase oil level before starting the engine

and after each five (5) hours of continuous use. Tighten oil

fill cap / dipstick securely each time you check the oil level.

TO CHANGE ENGINE OIL

Determine temperature range anticipated before next oil

change. All oil must meet API service classification SG-SL.

• Be sure snow thrower is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

NOTE: The left side wheel may be removed from snow

thrower for easier access to the oil drain plug and place-

ment of a suitable container. The unit tilted, resting on the

frame with the left wheel removed, will help drain any oil

trapped inside the engine. (See "TO REMOVE WHEELS"

in the Service and Adjustments section of this manual).

1. Disconnect spark plug wire from spark plug and place

wire where it cannot come in contact with plug.

2. Clean area around drain plug.

3. Remove drain plug and drain oil in a suitable container.

4. Install drain plug and tighten securely.

5. Wipe off any spilled oil from snow thrower and engine.

6. Install left wheel (if removed for draining oil). Besureto

install klick pin into proper hole in wheel axle (See "TO

REMOVE WHEELS" in the Service and Adjustments

section of this manual).

7. Remove oil fill cap/dipstick. Be careful not to allow dirt

to enter the engine.

8. Refill engine with oil through oil dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

"PRODUCT SPECIFICATIONS" section of this manual.

9. Use gauge on oil fill cap/dipstick for checking level.

Be sure dipstick cap is tightened securely for accurate

reading. Keep oil at "FULE' line on dipstick.

10. Wipe off any spilled oil.

MUFFLER

Inspect and replace corroded muffler as it could create a

fire hazard and/or damage.

SPARK PLUG

Replace spark plug at the beginning of each season or after

every 100 hours of operation, whichever occurs first. Spark

plug type and gap setting are shown in the "PRODUCT

SPECIFICATIONS" section of this manual.

CLEANING

IMPORTANT." For best performance, keep snow thrower

housing free of any dirt or trash. Clean the outside of your

snow thrower after each use.

from spark plug and place wire where

WARNING: Disconnectsparkplugwire

it cannot come in contact with plug.

e

Keep finished surfaces/wheels free of gasoline, oil, etc.

e

We do not recommend using a garden hose to clean

your snow thrower unless the electrical system, muffler

and carburetor are covered to keep water out. Water

in engine can result in shortened engine life.

16

SE iCE ADJ ENTS

WARNING: To avoid serious injury, before

performing any service or adjustments:

1. Be sure throttle is in STOP position.

2. Remove safety ignition key.

&

3. Make sure the augers and all moving

parts have completely stopped.

4. Disconnect spark plug wire from

spark plug and place wire where it

cannot come in contact with plug.

SNOW THROWER

TO ADJUST SNOW THROWER HEIGHT

See "TO ADJUST SKID PLATES" and "SCRAPER BAR"

in the Operation section of this manual.

CHUTE DEFLECTOR

The chute deflector, attached to the top of the discharge

chute, is provided to direct discharging snow away from

the operator. If the deflector becomes damaged, it should

be replaced.

never operate your snow thrower with

WARNING: To avoid serious injury,

the deflector removed or damaged.

• Tochange direction and/or distance snow isdischarged,

see "TO CONTROL SNOW DISCHARGE" in the Op-

eration section of this manual.

1. Disengage all controls and move throttle control to

STOP position. Wait for all moving parts to stop.

2. Disconnect spark plug wire from spark plug and place

wire where it cannot come in contact with plug.

3. Align holes in impeller hub with holes in impeller shaft

and install two (2) new 1/4-20 x 1-5/8" capscrew/shear

bolts. Install 1/4-20 Iocknuts and tighten securely.

CAUTION: Do not substitute. Use only original

equipment capscrew/shear bolts as supplied

with your snow thrower.

4. Connect spark plug wire to spark plug.

1/4-20 _ 1/4-20 × 1-5/8

LOCKNUT //_f - CAPSCREW /

\ f-: _J_!/ SH EAR BO LT

\ f_ _%_._ IMPELLER HUB

,/

,/

1/4-20 x 2

SHOULDER /

SHEAR BOLT

AUGER

HUB

SHEAR BOLTS (See Fig. 22)

AUGER SHEAR BOLTS

Both right and left-hand augers are secured to the auger

shaft with a shoulder/shear bolt and hex nut. Should a

foreign object or ice become lodged in the augers, the

shear bolts are designed to break, preventing damage to

any other components. If one or both augers do not turn

when auger control lever isengaged, check to see if one or

both of the bolts have sheared. To replace the shear bolts:

1. Disengage all controls and move throttle control to

STOP position. Wait for all moving parts to stop.

2. Disconnect spark plug wire from spark plug and place

wire where itcannot come in contact with plug.

3. Align hole in auger hub with hole in auger shaft and

install a new 1/4-20 x 2" shoulder/shear bolt. Install

1/4-20 lock nut and tighten securely.

CAUTION: Do not substitute. Use only original

equipment shear bolts as supplied with your

snow thrower.

4. Connect spark plug wire to spark plug.

IMPELLER SHEAR BOLTS

The impeller is secured to the impeller shaft with two (2)

capscrew/shear bolts and hex nuts. Should a foreign object

or ice become lodged in the impeller, the capscrews are

designed to break, preventing damage to any other com-

ponents. If impeller does not turn when auger control lever

isengaged, check to see if the capscrews have sheared.

To replace the capscrew/shear bolts:

1/4-20 \

',\\

HUB

FIG, 22

TO REMOVE BELT COVER (See Fig. 23)

1. Remove the two (2) screws securing belt cover to

frame.

2. Remove belt cover.

• Replace belt cover by installingcover and screws and

tighten securely.

/S _, .... BELT

_,;- , COVER

FRAME SCREWS

FIG. 23

17

AUGER

SHAFT

SERVICE A ADJ

TO REPLACE BELTS (See Fig. 24)

The auger and traction drive belts are not adjustable. If the

belts are damaged or begin to slip from wear, they should

be replaced. It is recommended that the belt(s) be replaced

by a Sears Parts & Repair Center.

NOTE: It is recommended that both the auger and traction

drive belt be replaced at the same time.

The V-belts on your snow thrower are ofspecial construction

and should be replaced by original equipment manufac-

turer (OEM) belts available from your nearest Sears Parts

& Repair Center. Using other than OEM belts can cause

)ersonal injury or damage to the snow thrower.

WARNING: Belt replacement requires

separation of the snow thrower. While

separating the auger housing from the

frame assembly, it is important that

A

FRAME

ASSEMBLY

an assistant stand in the operating

position and hold the snow thrower

handles. Serious personal injury and/

or damage to the unit could occur if the

snowthrower should fall during the belt

changing process.

AUGER

HOUSING

HINT: Insert a3/8" drive ratchet (in the "ON" position) into

the square hole in idler arm and rotate ratchet clockwise

to relieve tension.

8. With tension relieved on idler, install new traction drive

belt around pulleys and inside belt keepers.

9. Place auger belt around and inside the groove of auger

pulley only.

10. While your assistant slowly raises handles to rejoin

the auger housing and frame assembly, pull up on the

auger belt and squeeze sides together above pulley

so belt is fully seated in groove of pulley.

11. Bring snow thrower completely together and check

carefully for proper routing of belts. If auger belt has

become dislodged from the pulley (by catching the idler

arm bracket while bringing snow thrower together),

separate the snow thrower and repeat step 10. Belt

must be fully seated in pulley groove when bringing

the snow thrower together.

12. Install the two (2) hex bolts and lock washers and

tighten securely.

13. INSTALL ENGt NE PULLEY- Place belt in pulley groove

and slide pulley on crankshaft. Install flat washer, lock-

washer and bolt and tighten securely (35-40 ft. Ibs. /

41-47 N-m torque). Make sure belt isinside belt keeper.

14. INSTALL BELT COVER and two (2) screws. Tighten

securely.

15. INSTALL DISCHARGE CHUTE- See "INSTALL DIS-

CHARGE CHUTE / CHUTE ROTATER HEAD" in the

Assembly / Pre-Operation section of this manual.

HANDLES

.

REMOVE GASOLINE FROM FUELTANK- Drain gaso-

line from fuel tank into a suitable container, outdoors,

away from fire or flame. Wipe up any spilled gasoline.

.

REMOVE DISCHARGE CHUTE - Loosen Iocknut

securing chute rotator head to mounting bracket only

enough to allow chute rotator head to be raised and

discharge chute to be removed from snow thrower.

.

REMOVE BELT COVER - See "TO REMOVE BELT

COVER" in this section of this manual.

4.

REMOVE ENGINE PULLEY- Remove bolt, Iockwasher

and flat washer securing pulley to engine crankshaft.

Remove outside (auger) pulley only from crankshaft.

5.

SEPARATE SNOW THROWER - With your assistant

standing in the operating position holding the handles,

remove the two (2) bolts and lock washers holding

auger housing and frame together.

A WARNING: Asthe last bolt is removed,

.

REMOVE AUGER BELT from around pulley.

7.

RELIEVE TENSION ON TRACTION DRIVE BELT

have your assistant carefully lower the

handles down to the ground.

IDLER and remove traction drive belt from around

pulleys.

BELT

HOLE

BOLT LOCK

WASHER

18 FIG.24

TOREMOVEWHEELS(SeeFig.25)

Removetheklikpinandremovewheelfromaxle.

IMPORTANT:Wheninstalling wheel, be sure to use the

axle hole closest to the end of the shaft - do not use the

hole in the wheel hub (if equipped). Inner hole in axle and

hole inwheel hub are not used for your model snow thrower.

KLIK PiN (iNSTALL OUTER HOLE

iN OUTER HOLE

OF AXLE ONLY)

AXLE

WHEEL WHEELHUB

FIG. 25

STORAGE

NOTE: To seal punctures or prevent flat tires due to slow

leaks, tire sealant may be purchased from your local parts

dealer. Tire sealant also prevents tire dry rot and corrosion.

ENGINE

CARBURETOR

Your carburetor is not adjustable. Engine performance

should not be affected at altitudes up to 7,000 feet (2,134

meters). If your engine does not operate properly due to

suspected carburetor problems, take your snow thrower

to a Sears service centre/department.

ENGINE SPEED

Never tamper with the engine governor, which is factory set

for proper engine speed. Overspeeding the engine above

the factory high speed setting can be dangerous and will

void the warranty. If you think the engine-governed high

speed needs adjusting, contact a Sears Parts & Repair

Center, which has the proper equipment and experience

to make any necessary adjustments.

Immediately prepare your snow thrower for storage at

the end of the season or if the unit will not be used for 30

days or more.

WARNING: Never store the snow

thrower with gasoline inthe tank inside

a building where fumes may reach an

&

open flame, spark or pilot light as on

a furnace, water heater, clothes dryer

or gas appliance. Allow the engine to

cool before storing in any enclosure.

SNOW THROWER

When snow thrower is to be stored for a period of time,

clean it thoroughly, remove all dirt, grease, leaves, etc.

Store in a clean, dry area.

1. Clean entire snow thrower (See "CLEANING" in the

Maintenance section of this manual).

2. Inspect and replace belts, if necessary (See "TO RE-

PLACE BELTS" inthe Service and Adjustments section

of this manual).

.

Lubricate as shown in the Maintenance section of this

manual.

4.

Be sure that all nuts, bolts, screws, and pins aresecurely

fastened. Inspect moving parts for damage, breakage

and wear. Replace if necessary.

5.

Touch up all rusted or chipped paint surfaces; sand

lightly before painting.

ENGINE

FUEL SYSTEM

IMPORTANT: It is importantto prevent gum deposits from

forming in essential fuel system parts such as carburetor,

fuel hose, or tank during storage. Alcohol blended fuels

(called gasohol or using ethanol or methanol) can attract

moisture which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel system of

an engine while in storage.

• Empty the fuel tank by starting the engine and letting

it run until the fuel lines and carburetor are empty.

• Never use engine or carburetor cleaner products in

the fuel tank or permanent damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable alternative in mini-

mizing the formation of fuel gum deposits during storage.

Add stabilizer to gasoline in fuel tank or storage container.

Always follow the mix ratio found on stabilizer container.

Run engine at least 10 minutes after adding stabilizer to

allow the stabilizer to reach the carburetor. Do not empty

the gas tank and carburetor ifusing fuel stabilizer.

ENGINE OiL

Drain oil (with engine warm) and replace with clean engine

oil. (See "ENGINE" in the Maintenance section of this

manual).

CYLINDER

1. Remove spark plug.

2. Pour approximately one ounce (30 ml) of oil through

spark plug hole into cylinder.

3. Pull recoil starter handle slowly a few times to distribute

oil.

4. Replace with new spark plug.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• If possible, store your snow thrower indoors and cover

it to protect it from dust and dirt.

• Cover your snow thrower with a suitable protective

cover that does not retain moisture. Do not use plastic.

Plastic cannot breathe, which allows condensation to

form and will cause your snow thrower to rust.

IMPORTANT: Never cover snow thrower while engine/

exhaust area is still warm.

19

TROUBLESHOOTI G

See appropriate section in manual unless directed

CAUSEPROBLEM

Does not start

iLoss of power

1. Fuel shut-off valve (if so

equipped) inOFF position.

2. Safety ignition key

is not inserted.

3. Out of fuel.

4. Throttle in STOP position

(or ON/OFF switch is OFF).

5. Choke in OFF position.

6. Primer not depressed.

7. Engine is flooded.

8. Spark plug wire is

disconnected.

9. Bad spark plug.

10. Stale fuel.

11. Water infuel.

1. Spark plug wire loose.

2. Throwing too much snow.

3. Fuel tank cap iscovered

with ice or snow.

4. Dirty or clogged muffler.

to a Sears service centre/department.

CORRECTION

1. Turn fuel shut-off valve to OPEN position.

2. Insert safety ignition key.

3. Fill fuel tank with fresh, clean gasoline.

4. Move throttle to FAST position

(or ON/OFF switch to ON position).

5. Move to FULL position.

6. Prime as instructed in the Operation section of this manual.

7. Wait a few minutes before restarting, DO NOT prime.

8. Connect wire to spark plug.

9. Replace spark plug.

10. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

11. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

1. Reconnect spark plug wire.

2. Reduce speed and width of swath.

3. Remove ice and snow on and around fuel tank cap.

4. Clean or replace muffler.

Engine idles or

runs roughly

Excessive

vibration

Recoil starter

iis hard to pull

Loss of traction

drive / slowing

iof drive speed

Loss ofsnow

discharge or

slowing of

snow discharge

1. Choke is in FULL position.

2. Blockage in fuel line.

3. Stale fuel.

4. Water infuel.

5. Carburetor is inneed of

adjustment or overhaul.

.

Loose parts or damaged

augers or impeller.

1. Frozen recoil starter.

1. Drive belt is worn.

2. Drive belt is off of pulley.

3. Friction drive wheel is worn.

1. Auger belt is off of pulley.

2. Auger belt is worn.

3. Clogged discharge chute.

4. Augers / impeller jammed.

1. Move choke to OFF position.

2. Clean fuel line.

3. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

4. Empty fuel tank & carburetor, refill with fresh, clean gasoline.

5. Contact a Sears service centre/department.

1. Tighten all fasteners. Replace damaged parts. If vibration

remains, contact a Sears service centre/department.

1. See "IF RECOIL STARTER HAS FROZEN"

in the Operation section of this manual.

1. Check / replace drive belt.

2. Check / reinstall drive belt.

3. Contact a Sears service centre/department.

1. Check / reinstall auger belt.

2. Check / replace auger belt.

3. Clean snow chute.

4. Remove debris or foreign object from augers / impeller.

20

&

IMPORTANTE

Procedimientos de Funcionamiento Seguro Para Maquinas Quitanieves

Esta m6.quina puede amputar manos y pies y lanzar objetos.

El no observar las siguientes instrucciones de seguridad puede dar lugar a heridas graves.

Busque este simbolo que se=

_ala las precauciones de segu=

ridad de ,importancia. Quiere decir

iATENCION! iESTE ALERTO! SU

SEGURIDAD ESTA COMPROMETIDA.

ADVERTENCIA: Siempre desconecte el

alambre de la bujia y p6ngalo donde no

pueda entrar en contacto con la bujia,

para evitar el arranque pot accidente,

durante la preparacibn, el transporte, el

ajuste o cuando se hacen reparaciones.

Formacibn

1. Antes de hacerfuncionar esta unidad hay que leer,com-

prender y seguir todas las instrucciones en al m_quina

yen el manual(es). Familiarizarse completamente con

los mandos y el uso correcto de la m_.quina. Hay que

saber como parar la unidad y desconectar los mandos

r_pidamente.

2. No permitir nunca que menores de edad utilicen la

maquina. No permitir nunca que adultos sin adecuada

instrucci6n previa utilicen la maquina.

3. Mantener el area de operaci6n libre de toda persona,

especialmente nitros peque_os y animales dom@sticos.

4. Atenci6n a evitar de resbalarse o caerse especialmente

cuando se va marcha atrAs.

&

&

ADVERTENCIA: Esta m_quina quita=

nieves se puede utilizar en aceras,

vias de acceso y otras _reas a nivel

del suelo. Hay que tenet precauci6n

us_ndola sobre pendientes. No usar la

m_quina quitanieves en _reas sobre el

nivel del suelo, como techos de casas,

garajes, p6rticos u otras estructuras o

edificios similares.

ADVERTENCIA: Las m_quinas quita=

nieves tienen partes giratorias expues=

tas, que pueden causar heridas graves

pot contacto, o pot material lanzado

desde el eonducto de eyecci6n. Man=

tenet siempre el _rea de operaci6n li=

bre de toda persona, nitros pequer_os y

animales dom6sticos, incluso durante

la puesta en marcha.

PRECAUCION: El silenciador y otras

piezas del motor Ilegan a sre e×trema=

damente calientes durante la operaci6n

y siguen siendo calientes despu_s de

que el motor haya parado. Para evitar

quemaduras severas, permanezca lejos

de estas _reas.

ADVERTENCIA: El tubo de escape del

motor, algunos de sus constituyentesy

algunoscomponentes delvehiculo con=

tienen o desprenden productos quimi=

cos conocidos en el Estado de Califor=

nia como causa de c_neer y defectos al

nacimiento uotrosda_os reproductivos.

Preparaci6n

1. Inspeccionar a fondo el 6.rea donde se va a utilizar la

maquina yquitar todos los felpudos, trineos, planchas,

hilos y otros objeto ajenos.

2. Desconectar todos losembragues en la posici6n neutra

antes de poner en marcha el motor.

3. No accionar la m&quina sin Ilevar vestidos invernales

adecuados para el exterior. Evitar vestidos sueltos y

colgantes que puedan quedarse atrapados en las partes

giratorias. Calzar zapatos que mejoren la estabilidad

en &reas resbaladizas.

4. Manejar el carburante con precauci6n; es altamente

inflamable.

(a) Usar un contenedor aprobado para carburante.

(b) No aSadir nunca carburante a un motor en mar-

cha o caliente.

(c) Llenar el dep6sito de carburante al aire libre con

extrema precauci6n. No Ilenar nunca el dep6sito

de carburante al interiorde un edificio.

No Ilenar nunca contenedores dentro un veh[culo

(d)

o en un cami6n o remolque revestido con forro de

pl_stico. Posicionar siempre los contenedores en

el suelo, lejos de su veh[culo antes de Ilenarlos.

(e)

Cuando sea pr6.ctico, quitar los aparatos alimen-

tados por gas del cami6n o del remolque y abas-

tecer en el suelo. Si esto no fuera posible, enton-

ces hay que abastecer tales aparatos sobre un

remolque mediante contenedores port6.tiles, m6.s

bien que con un inyector de distribuci6n de gaso-

lina.

(f) Mantener siempre la boquilla en contacto con el

borde de la apertura del dep6sito de carburante,

hasta que el reaprovisionamiento est@completo.

No usar un dispositivo de cierre de la boquilla.

(g) Reponer el tap6n de carburante firmemente y se-

TABLA DE MATERIAS

REGLAS DE SECURIDAD .................................... 21=22

ESPECIFICACIONES DEL PRODUCTO ................... 23

GARANTIA ........................... ;...................................... 23

MONTAJE / PRE-OPERACION ............................. 25=27

OPERACION .......................................................... 28=34

MANTENIMIENTO ................................................. 34°35 21

PROGAMA DE MANTENIMIENTO ............................ 34

SERVICIO Y AJUSTES ......................................... 36=38

ALMACENAMIENTO .................................................. 38

IDENTIFICACION DE PROBLEMAS ......................... 39

PARTES DE REPUESTO ...................................... 40=55

SERVlClO SEARS ...................................... CONTRAPA

carelcarburantederramado.

(h) Sielcarburantesederramasobrevestidos,cam-

biarlosinmediatamente.

5. Paratodaslasunidadesconmotoresdemandoel6ctrico

odeencendidoelectrico,usarcablesdeprolongamiento

yrecept_culosespecificadosporelfabricante.

6. Regularlaalturadelam_quinaquitanievesparaevitar

Areasdegravillaodepedrisco.

7. Nointentarnuncahacerregulacionesmientraselmotor

est6enmarcha(exceptocuandoest_recomendado

especfficamenteporelfabricante).

8. Llevarsiempregafasdeprotecci6nom6.scaraspara

losojosdurantelautilizaci6ndelam_quinaomientras

sehagaunaregulaci6nounareparacionparaproteger

losojosdeobjetosextra_osquepuedenserlanzados

porlam_quinaquitanieves.

Funcionarniento

1. No meter las manos o los pies cerca o debajo de partes

giratorias. No acercarse nunca al Area de apertura de

eyecci6n.

2. Tener extrema cautela mientras la mAquinafuncione en

avenidas, caminos, carreteras de gravilla o los cruce.

Estar alerta por peligros escondidos o trAfico.

3. Despu@s de golpear un objeto ajeno, parar el motor,

quitar el cable de la buj[a de encendido, desconectar el

cable de los motores el6ctricos, inspeccionar a fondo

la mAquina quitanieves para detectar da_os y repara-

rlos antes de volver a encender y utilizar la mAquina

quitanieves.

4. Si la unidad empezara a vibrar de manera anormal,

parar elmotor ycontrolar inmediatamente para detectar

la causa. Las vibraciones son generalmente indicio de

problemas.

5. Parar el motor cada vez que se abandone la posici6n

de funcionamiento, antes de limpiar el alojamiento del

colector/impulsor o el conducto de eyecci6n y cuando

se hagan reparaciones, regulaciones o inspecciones.

6. Cuando se limpie, repare o inspeccione la mAquina,

cerciorarse de que todos los mandos est6n desco-

nectados y que la colector /impulsor y todas las partes

m6viles esten paradas. Desconectar el cable de la

buj[a de encendido y mantener el cable lejano de la

buj[a de encendido para prevenir puestas en marcha

accidentales.

7. No hacer funcionar el motor al interior, excepto en la

puesta en marcha y para transportar la m6.quina quita-

nieves dentro o afuera del edificio. Abrir las puertas que

dan al exterior; los gases de escape son peligrosos.

8. Tener mucho cuidado cuando se trabaja en terrenos

pendientes.

9. Nunca hacer funcionar el quitanieves sin que sus pro-

tecciones y los otros dispositivos de seguridad esten

bien colocados y funcionen.

10. No dirigir nunca la eyecci6n hacia personas o 6.reas

donde se pueden producir da_os. No permitir que los

nitros se acerquen.

11.

No sobrecargar la capacidad de la mAquina intentando

despejar nieve a una velocidad demasiado alta.

12.

No conducir la mAquina demasiado r6.pidamente sobre

superficies resbaladizas. Mirar atrAs y ser prudente

durante la marcha atrAs.

13.

Desconectar la alimentaci6n de la barrena / impulsor

cuando se transporta o no se utiliza la mAquina quita-

nieves.

14. Usar Onicamente accesorios aprobados por el con-

structor de la maquina quitanieves (como pesos para

las ruedas, contrapesos o cabinas).

15. No hacer funcionar nunca la m6.quina quitanieves sin

una buena visibilidad o iluminaci6n. Hay que estar

siempre seguros de los propios pasos y agarrarse

firmemente a la empu_adura. Caminar; nunca correr.

16. Nunca tocar un motor o un silenciador de escape

calientes.

Limpiar un conducto de descarga obturado

Elcontacto de la mano con el impulsor giratorio al interior del

conducto de descarga es la causa mas comL_nde lesiones

con las mAquinas quitanieve. Nunca usar las manos para

limpiar el conducto de descarga. Para limpiar el conducto:

1. iAPAGAR EL MOTOR!

2. Esperar 10segundos para asegurarse deque las hojas

del impulsor hayan parado de girar.

3. Usar siempre una herramienta para limpiar, nunca las

manos.

Mantenimiento y conservacibn

1. Controlar frecuentemente que el perno de cizalla y los

demAs pernos est6n adecuadamente apretados para

asegurar que la mAquina puedetrabajar con seguridad.

2. No dejar nunca la mAquina quitanieves con carburante

en su dep6sito dentro de un edificio donde hayan fuen-

tes de ignici6n, como agua caliente y calentadores de

ambiente o secadoras de ropa. Dejar enfriar el motor

antes de guardar la mAquina al interior.

3. Hacer siempre referencia a la gu[a de instrucciones

del operador para detalles importantes si se tiene que

guardar la maquina quitanieves por un largo periodo.

4. Mantener o sustituir las etiquetas de seguridad e in-

strucci6n, si fuera necesario.

5. Hacer funcionar la m_.quina quitanieves por algunos

minutos despues de lanzar nieve, para limpiar la

mAquina y prevenir el congelamiento de la colector /

impulsor.

22

GARANTiA LIMITADA DE 2 ANOS DEL LANZADOR DE NIEVE CRAFTSMAN

Siempre que se Io utilice y se Io mantenga de acuerdo a las instrucciones del manual del usuario, si este lanzador de

nieve Ilega a fallar debido a un defecto de los materiales o de fabricaci6n dentro de los dos a_os posteriores a la fecha de

compra, Ilame al 1-800-4-MY-HOME® para gestionar su reparaci6n sin cargo.

Durante los primeros 30 dias de dicho plazo, se le brindar& el servicio a domicilio sin costo. Para su conveniencia,

tambi6n podr& disponer del servicio a domicilio despu_s de los primeros 30 dias, pero se le cobrar& un vi&tico. El mismo

no ser& aplicable si usted Ileva la unidad a un centro autorizado de Craftsman. Para saber cu&l le queda m&s cerca, Ilame

al 1-800-4-MY-HOME®

La cobertura de la presente Garantia no incluye:

. Aquellos elementos perecederos que se desgastan por el uso habitual, incluidos, de manera no taxativa, las bujias, los

pernos del cortador y las correas.

. El servicio de mantenimiento est&ndar, los cambios de aceite o los afinados.

. El cambio o reparaci6n de neum&ticos pinchados por objetos extranos, tales como clavos, espinas, troncos o vidrios.

. Aquellas reparaciones que deban hacerse por problemas derivados de mal uso por parte del operador, incluidos, de

manera no taxativa, danos causados por el impacto de objetos que tuerzan el bastidor, el eje del cigOer_al o la barrena,

o bien por exigir demasiado al motor.

. Aquellas reparaciones que deban realizarse por problemas derivados de negligencia por parte del operador, incluidos,

de manera no taxativa, los daSos que se produzcan por guardarlo en condiciones inapropiadas, el no utilizar aceite de

motor del grado adecuado y en la cantidad correcta, o bien el no mantener el equipo de acuerdo alas instrucciones del

manual del usuario.

. Aquellas limpiezas o reparaciones que se le deban hacer al motor (sistema de combustible) toda vez que se determine

que el combustible estaba contaminado u oxidado (en mal estado). En general, se debe utilizar el combustible dentro

de los 30 dias posteriores a su compra.

. El deterioro y desgaste normales de las terminaciones exteriores o el reemplazo de la etiqueta del equipo.

La presente garantia ser& v&lida por solo 90 dias en caso que el equipo sea utilizado para fines comerciales o de alquiler.

La presente garantia solo ser& v&lida mientras el equipo permanezca dentro del territorio de los Estados Unidos.

La presente garantia le otorga derechos legales especificos. Puede que usted tenga tambi6n otros derechos, los cuales

varian de un estado a otro.

Sears, Roebuck and Co., Hoffrnan Estates, IL 60179

FELICITACIONES por la compra de su M_.quina Quitanieves.

Ha sido disehado, planificado y fabricado para darle la mejor

confiabilidad y et mejor rendimiento posibte.

En et caso de que se encuentre con cualquier problema que

no pueda sotucionar fa.cilmente, haga el favor de ponerse en

contacto con un Centro de Piezas y Reparaci6n Sears o con

un otro centro de servicio cualificado. Cuenta con tecnicos

bien capacitados y competentes y con las herramientas adec-

uadas para darle servicio o para reparar este unidad.

Haga el favor de leer y de guardar este manual. Estas instruc-

clones le permitir_.n montar y mantener su unidad en forma

adecuada. Siempre observe las "REGLAS DE SEGURIDAD."

NOMERO

DE SERIE:

FECHA DE COMPRA:

EL NUMERO DEL NODELO Y EL DE SERIE SE

ENCUENTRAN EN LA CALCOMAN IA ADJU NTA A LA PAR-

TE TRASERA DE LA CAJA DE LA MAQUINA QUITANIEVES.

DEBE REGISTRAR TANTO EL NUMERO DE SERIE

COME LA FECHA DE COMPRA Y MANTENGALOS EN

UN LUGAR SEGURO PARA REFENCIA EN EL FUTURO.

ESPECIFICACIONES DEL PRODUCTO

Capacidad y 4.0 Cuartos

Tipo de Gasolina: Regular sin Plomo

Tipo de Aceite SAE 5W-30 o 10W-30 (5° a -18°C)

(API SG-SL): Sintetico SAE 5W-30 o 10W-30

(Debajo -18°C)

Capacidad de Aceite: 28 Onzas

Bujia: Champion RC 12YC

Abertura: 0.030"

RESPONSABILIDADES DEL CLIENTE

• Lea y observe las reglas de seguridad.

• Siga un programa regular de mantenimiento, cuidado y uso

de su M&quina Quitanieves.

• Siga las instrucciones descritas en las secciones "Manten-

imiento" y '_Jmacenamiento" de este Manual det Due_o.

23

PARTES EMPACADAS POR SEPARADO EL LA CAJA DE CARTON

(1) CABLE DE