Page 1

Owner’s Manual

5.5 HORSEPOWER 22 INCH CUT

WHEELED

WEEDTRIMMER

Model No.

917.773420

Safety

Assembly

Operation

Maintenance

Español

Repair Parts

^CAUTION:

Read and follow all

Safety Rules and Instructions

before operating this equipment.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Visit our Craftsman website: www.sears.com/craftsman

Page 2

TABLE OF CONTENTS

Warranty

Safety Rules

Assembly 5

Operation

Maintenance Schedule

Maintenance

2

Product Specifications

2

Service and Adjustments

Storage

6

Troubleshooting

9

Repair Parts

9

Parts Ordering

Back Cover

WARRANTY

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN WEEDTRIMMER

For two years from date of purchase, when this Craftsman Weedtrimmer is maintained,

lubricated, and tuned up according to the operating and maintenance instructions in

the owner’s manual, Sears will repair free of charge any defect in material or workman

ship.

If this Craftsman Weedtrimmer is used for commercial or rental purposes, this warranty

applies for only 90 days from the date of purchase.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as rotating lines,

belts, air cleaners and spark plug.

• Repairs necessary because of operator abuse or negligence, including bent

crankshafts and the failure to maintain the equipment according to the instructions

contained in the owner’s manual.

9

12

14

15

30

Warranty service is available by returning the Craftsman Weedtrimmer to the nearest

Sears Service Center in the United States. This warranty applies only while this product

is in use in the United States.

This Warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

Sears, Roebuck and Co., Dept. 817 WA, Hoffman Estates, IL 60179

WARNING: This trimmer is equipped with an internal combustion engine and should

not be used on or near any unimproved forest-covered, brush-covered or grass-

covered land unless the engine’s exhaust system is equipped with a spark arrester

meeting applicable local or state laws (if any). If a spark arrester is used, it should be

maintained in effective working order by the operator.

In the state of California the above is required by law (Section 4442 of the California

Public Resources Code). Other states may have similar laws. Federal laws apply on

federal lands. A spark arrester for the muffler is available through your nearest

authorized service center/department (See REPAIR PARTS section of this manual).

Page 3

SAFETY RULES

The operation of any trimmer can result in foreign objects thrown into

the eyes, which can result in severe eye damage. Always wear safety

glasses or eye shields while operating your trimmer or performing any

adjustments or repairs. We recommend a wide vision safety mask

over spectacles or standard safety glasses. The safety goggles

provided with your trimmer may be worn over spectacles.

A

I. GENERAL OPERATION

• Read, understand, and follow all

instructions on the machine and in the

manual before starting. Be thoroughly

familiar with the controls and the proper

use of the machine before starting.

• Do not put hands or feet near or under

rotating parts.

• Keep all parts of your body away from

muffler and spinning line. A hot muffler

can cause serious burns.

• Only allow responsible individuals, who

are famiiiar with the instructions, to

operate the machine.

• Stay away from breakable objects, such

as house windows, auto glass, green

houses, etc.

• Clear the area of objects such as rocks,

toys, wire, bones, sticks, etc., which

could be picked up and thrown by the

spinning lines.

• Be sure the area is clear of other

people before trimming, particularly

small children and pets. Stop machine

if anyone enters the area.

• Wear appropriate clothing such as a

long-sleeved shirt or jacket. Also wear

long trousers or slacks. Do not wear

shorts.

• Do not wear loose clothing which could

get caught in this equipment.

• Do not operate the machine when

barefoot or wearing open sandals.

Always wear work gloves and sturdy

footwear. Leather work shoes or short

boots work well for most people. These

will protect the operator's ankles and

shins from small sticks, splinters, and

other debris, and improve traction.

• Do not pull machine backwards unless

absolutely necessary. Always look

down and behind before and while

moving backwards.

Do not operate the machine without

proper guards, plates or other safety

protective devices in place.

See manufacturer’s instructions for

proper operation and installation of

accessories. Only use accessories

approved by the manufacturer.

Never use blades, wire, or flailing

devices. This unit is designed for line

trimmer use only. Use of other accesso

ries or attachments will increase the risk

of injury.

Stop the rotating trimmer head when

crossing gravel drives, walks, or roads.

Wait for the cutting lines to stop rotating.

Stop the engine (motor) whenever you

leave the equipment and allow it to

cool, before cleaning, repairing or

inspecting the unit. Be sure the trimmer

head and all moving parts have

stopped.

Operate only in daylight or good

artificial light.

Do not operate the machine while

under the influence of alcohol or drugs.

Never operate machine in wet grass.

Always be sure of your footing: keep a

firm hold on the handle and walk; never

run.

If the equipment should start to vibrate

abnormally, stop the engine (motor)

and check immediately for the cause.

Vibration is generally a warning of

trouble.

Always wear safety goggles or safety

glasses with side shields when operat

ing machine.

Page 4

^1

SAFETY BOtES <CONT.)

A

II. SLOPE OPERATION

Slopes are a major factor related to slip

and fall accidents which can result in

severe injury. All slopes require extra

caution. If you feel uneasy on a slope, do

not trim it.

DO:

• Trim across the face of slopes; never up

and down. Exercise extreme caution

when changing direction on slopes.

• Remove obstacles such as rocks, tree

limbs, etc,

• Watch for holes, ruts, or bumps. Tall

grass can hide obstacles.

DO NOT:

• Do not trim near drop-offs, ditches or

embankments. The operator could lose

footing or balance.

• Do not trim excessively steep slopes.

• Do not trim on wet grass. Reduced

footing could cause slipping,

III. CHILDREN

Tragic accidents can occur if the operator

is not alert to the presence of children.

Children are often attracted to the machine

and the trimming activity. Never assume

that children will remain where you last

saw them.

• Keep children out of the trimming area

and under the watchful care of another

responsible adult.

• Be alert and turn machine off if children

enter the area.

• Before and while moving backwards,

look behind and down for small

children.

• Never allow children to operate the

machine.

• Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may obscure vision.

IV. SERVICE

• Use extra care in handling gasoline

and other fuels. They are flammable

and vapors are explosive.

- Use only an approved container.

- Never remove gas cap or add fuel

with the engine running. Allow

engine to cool before refueling. Do

not smoke.

- Never refuel the machine indoors.

- Never store the machine or fuel

container inside where there is an

open flame, such as a water heater.

- Move away from fueling site before

starting engine.

• Never run a machine inside a closed

area.

• Never make adjustments or repairs

with the engine (motor) running.

Disconnect the spark plug wire, and

keep the wire away from the plug to

prevent accidental starting.

• Keep nuts and bolts, especially trimmer

head and engine bolts, light and keep

equipment in good condition.

• Never tamper with safety devices.

Check their proper operation regularly.

• Keep machine free of grass, leaves, or

other debris buildup. Clean oil or fuel

spillage. Allow machine to cool before

cleaning or storing storing.

• Stop and inspect the equipment if you

strike an object. Repair, if necessary,

before restarting.

• Do not change the engine governor

setting or overspeed the engine.

• Clean and replace safety and instruc

tion decals as necessary.

Alook for this symbol to point out impor

tant safety precautions. It means CAU

TION!!! BECOME AWARE!!! YOUR

SAFETY !S INVOLVED.

^CAUTION: In order to prevent acci

dental starting when setting up, transport

ing, adjusting or making repairs, always

disconnect spark plug wire and place

wire where it cannot contact spark plug.

^WARNING: The engine exhaust from

this product contains chemicals known to

the State of California to cause cancer,

birth defects, or other reproductive harm.

Page 5

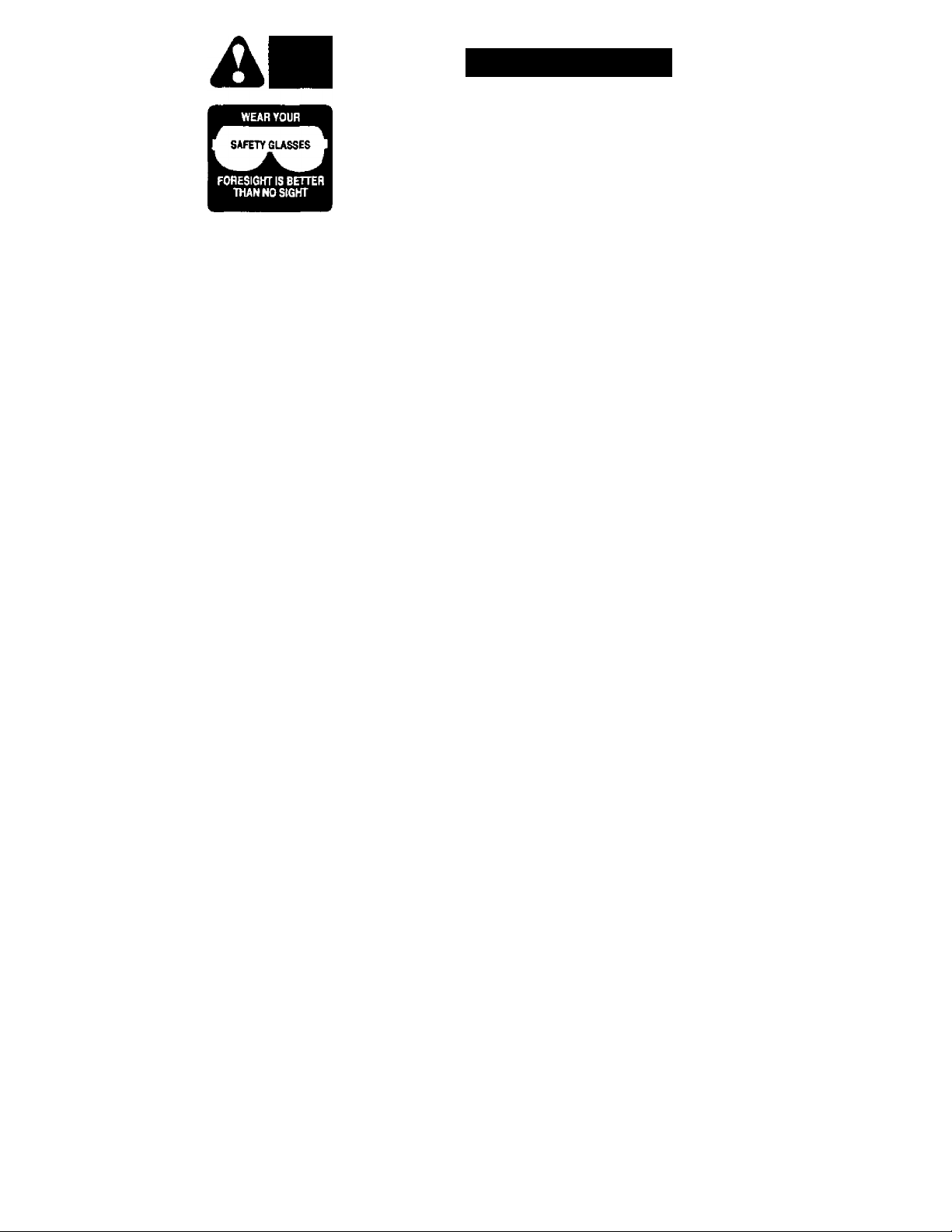

ASSEMBLY

Read these instructions and this manual in its

entirety before you attempt to assemble or

operate your new trimmer.

IMPOFITANT: This trimmer is shipped

WITHOUT OIL OR GASOLINE in the engine.

Your new trimmer has been assembled at the

factory with the exception of those parts left

unassembled for shipping purposes. All parts

such as nuts, washers, bolts, etc., necessary

to complete the assembly have been placed

in the parts bag. To ensure safe and proper

operation of your trimmer, all parts and

hardware you assemble must be tightened

securely. Use the correct tools as necessary

to ensure proper tightness.

Loose Parts Packed Separately

Safety

Goggles

20 02.

Bottle of oil

Trimmer Lines

(2) Sets

(0.155 diameter

X 18.75 inches long)

TO REMOVETRIMMER FROM CARTON

• Remove loose parts included with trimmer.

• Cut down two end corners of carton and

lay end panel down flat.

• Remove all packing materials.

• Roll trimmer out of carton and check carton

thoroughly for additional loose parts.

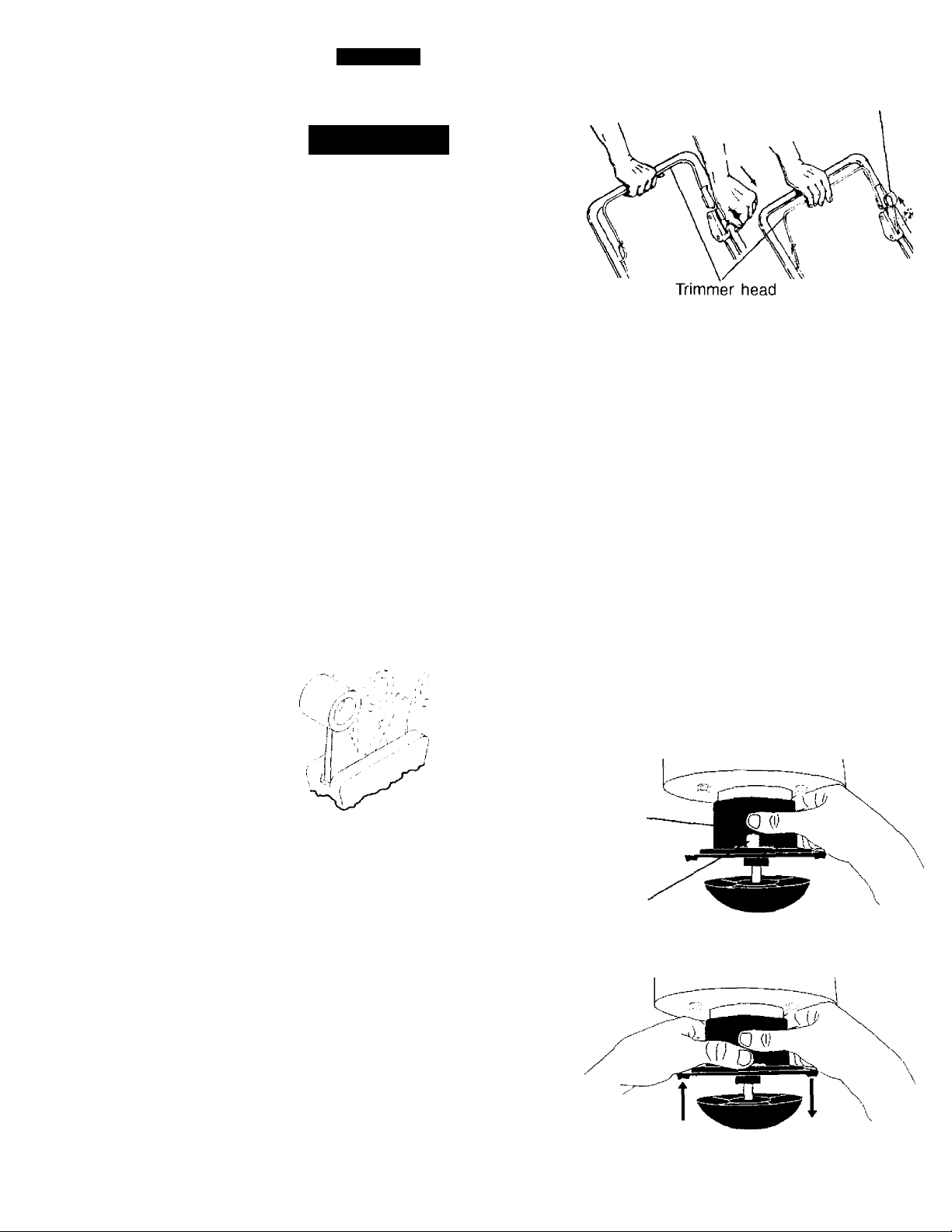

HOWTO SET UPYOURTRIMMER

TO UNFOLD HANDLE

IMPORTANT: Unfold handle carefully so as

not to pinch or damage control cables.

1. Loosen handle knob enough to allow

upper handle to be unfolded from the

shipping position.

2. Raise upper handle section into place

on lower handle and tighten handle

knob.

3. Remove handle padding holding

trimmer head control bar to upper

handle.

Your trimmer handle can be adjusted for

your trimming comfort. Refer to "Adjust

Handle" in the Service and Adjustment

section of this manual.

Handle knob

Lower handle

Upper handle

Lift up

Page 6

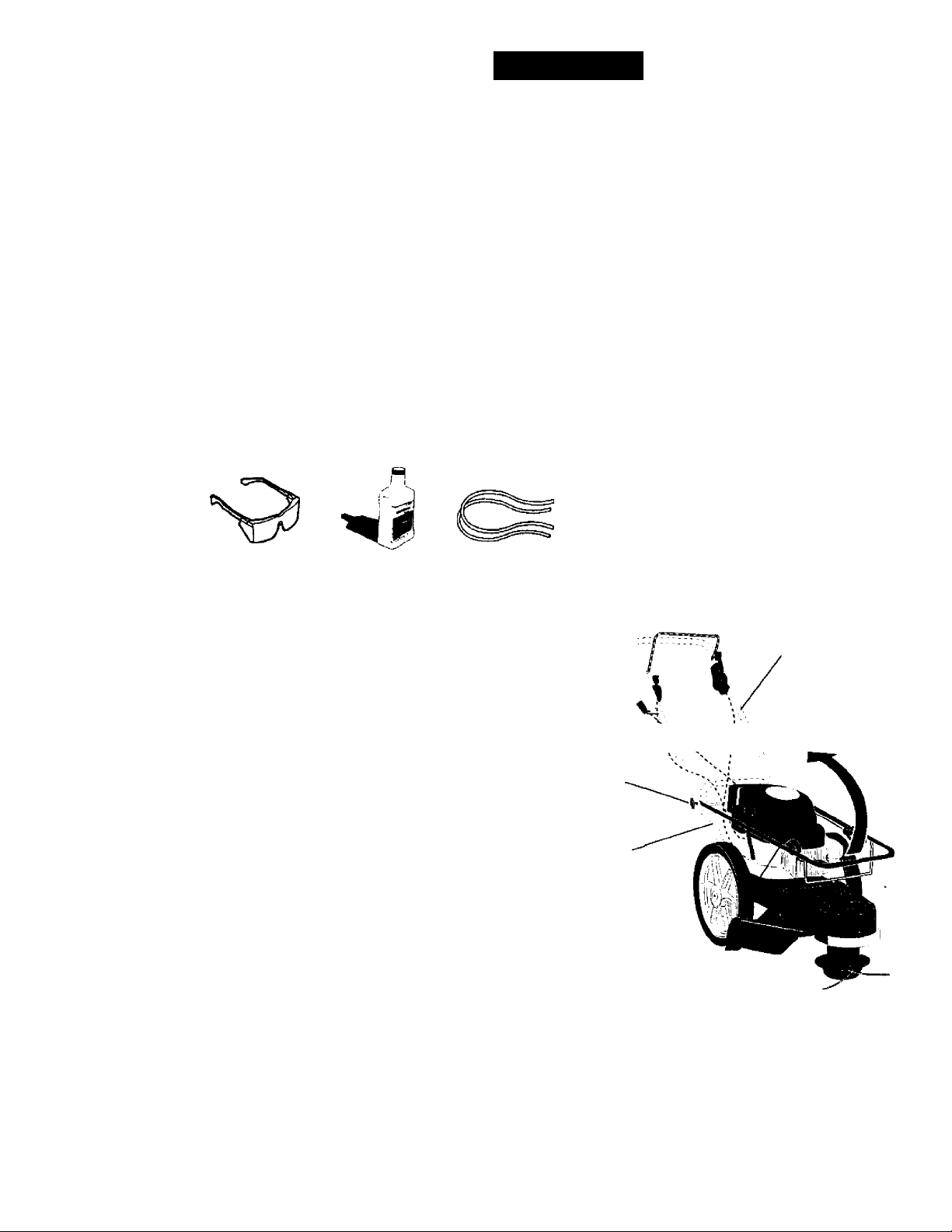

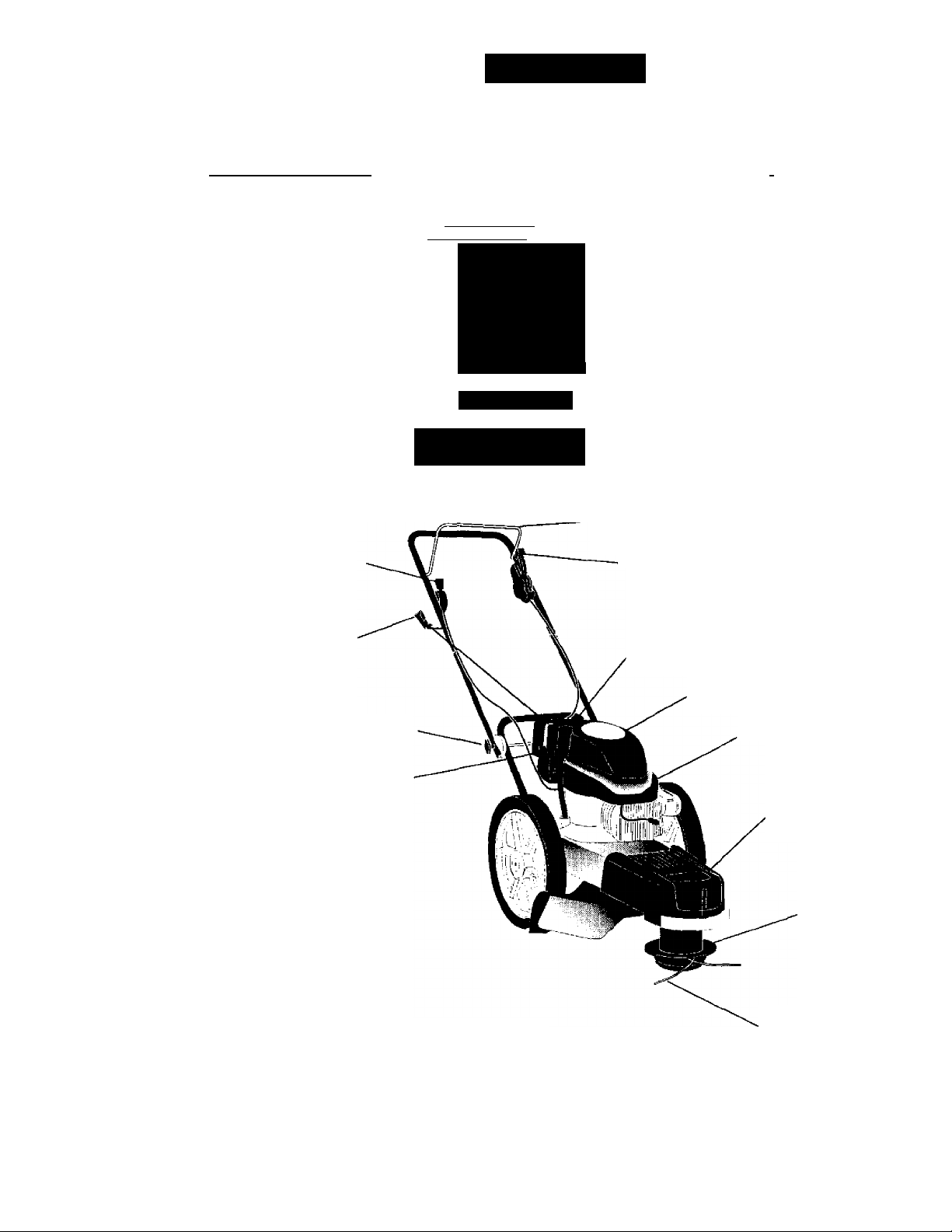

dM*ERATION

KNOW YOUR TRIMMER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

TRIMMER. Compare the illustrations with your trimmer to familiarize yourself with the location

of various controls and adjustments. Save this manual for future reference.

These symbols may appear on your trimmer or in literature supplied with the product. Learn and understand

their meaning.

A WARNING

ATOM gHKius aiHigT M imin

R£AD ANII FDUilW (ШШЧ

HAMUAL

LfAYSIGAaMAfAULOe.

РП0Р1ПААЮ.

DO KOT 0РЕНАП tfbBi CH:l№£N

OR(n>tERSAn£Af<aUND. RmOVE

OeJKm ТНДТ COUL£ К THROWN

BY THi СиТТШС UHES.

□0 NOT SetVICE 0Й ADJUST CUTTWe

HEAD Oft Crmnt M0VW6 РАШ

Un£SS ENOUU a STOPPED ANO

SPARK РЦЮ WIRE IS D^CONMEOB»

WEAR WHY APPROVED EVE

РП0ТВЯЮН WHEN орште.

00 Acnoss SLOPES NOT UP AND

DOWN.

* КШ* SAFHY DEVICES. SUCH AS GUARDS AND

oerbctors. m place and QPSWING.

• LOOK DOWN AND BEHIHO BEFORE AND WHILE

MOVING BACKWARDS.

A

CAUTION

i

FUEL OIL

Trimmer head control bar

Throttle control

Starter handle

Handle knob

Engine oil

cap w/

dipstick

Trimmer head control lever

Gasoline cap

Engine

cover

Primer

Chassis

cover

Trimmer head

IMPORTANT: This trimmer is shipped

WITHOUT OIL OR GASOLINE in the engine

Trimmer head control bar - must be held

down to the handle to engage trimmer head.

Release to stop the trimmer head.

Primer - pumps additional fuel from the

carburetor to the cylinder for use when

starting a cold engine.

Trimmer line

Throttle control - used for starting and

stopping the engine and allows you to select

either fast or slow engine speed.

Starter handle - used for starting the engine.

Trimmer head control lever - used to

engage trimmer head.

Page 7

WEAR YOUR

F SAFETT^SSES J

FORESIGHT IS BEHER

THAN NO SIGHT

The operation of any trimmer can result in

foreign objects thrown into the eyes,

which can result in severe eye damage.

Always wear safety glasses or eye shields

while operating your trimmer or perform

ing any adjustments or repairs. We

recommend a wide vision safety mask

over spectacles or standard safety

glasses. The safety goggles provided with

your trimmer may be worn over spec

tacles.

HOWTO USE YOURTRIMMER

ENGINE SPEED

The engine speed is controlled by a

throttle located on the side of the upper

handle. Fast position is for starting and

normal trimming. Slow is for light trimming

and fuel economy. Stop is for stopping the

engine.

Drive

control

lever

control bar

To engage

trimmer head

TO ADJUST TRIMMING HEIGHT

^CAUTION: Stop the engine and wait

Trimmer head

disengaged

for all moving parts to stop. Disconnect

spark plug wire from spark plug and

place wire where it cannot come in

contact with plug.

The height of cut can be set to six (6)

different positions ranging from 1-1/2

inches to 3 inches. Recommended cutting

height for the average yard is 2 inches.

1. To adjust trimming height, push in the

locking plate tab and move trimmer

head up or down to desired position.

2. Release tab and be sure head is

locked into one of the six (6) height

positions.

TRIMMER HEAD DRIVE CONTROL

Your trimmer is equipped with a trimmer

head drive control bar and lever which

requires the operator to be positioned

behind the trimmer handle to operate the

trimmer.

• Trimmer head rotation is controlled by

holding the trimmer head control bar

down to the handle and pushing the

drive control lever forward until it clicks;

then release the lever.

• Trimmer head rotation will stop when

the control bar is released.

Adjustable

Trimmer

Head

Locking

Plate Tab

Page 8

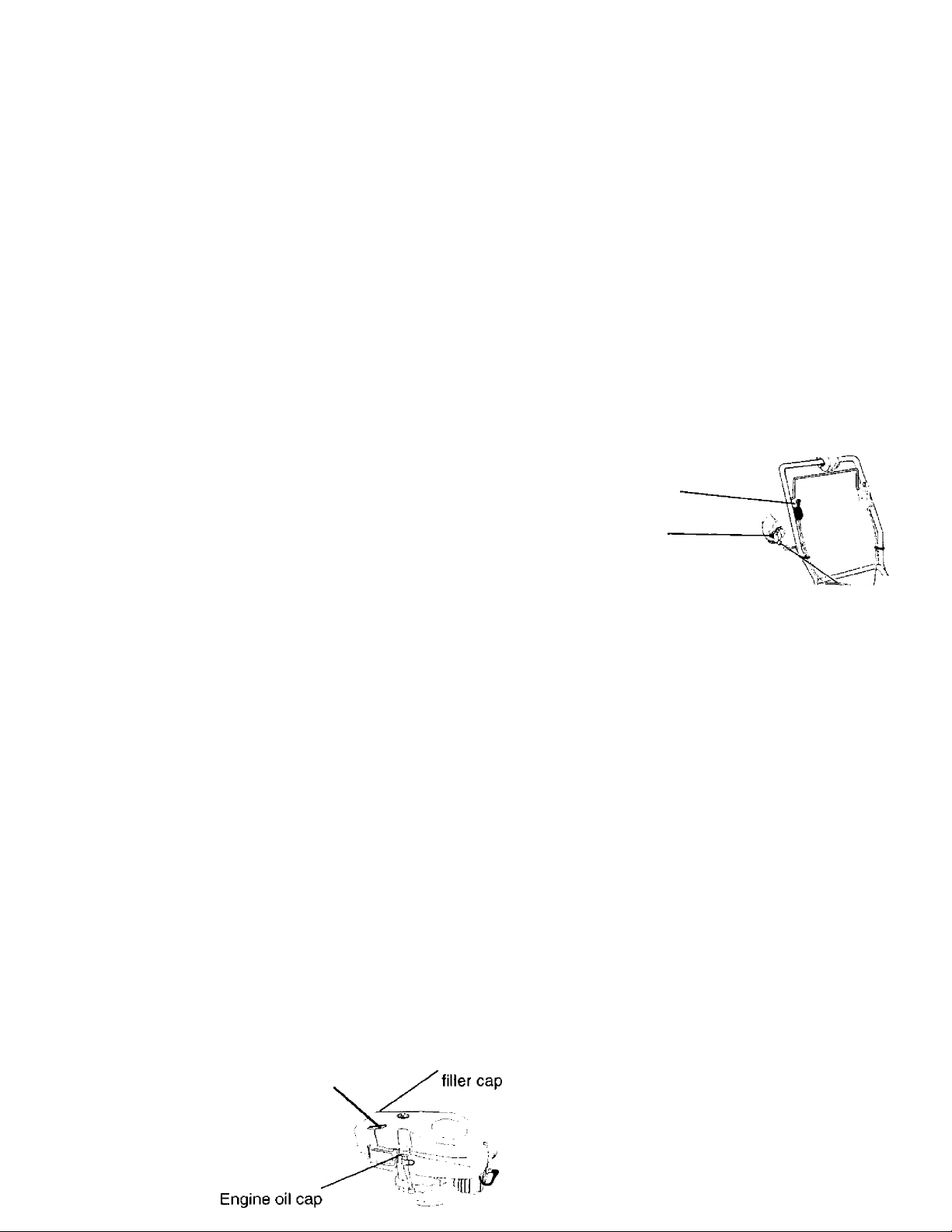

BEFORE STARTING ENGINE

ADD OIL

Your trimmer is shipped without oil in the

engine. Engine holds 20 oz. of oil. For

type and grade of oil to use, see “ENGINE”

in Maintenance section of this manual.

1. Be sure trimmer is level and area

around oil fill is clean.

2. Remove engine oil cap and fill to the

full line on the dipstick. Pour oil slowly.

Do not over fill.

NOTE; Allow oil to settle down into engine

for accurate dipstick reading. To read

proper level, tighten engine oil cap, then

remove it to read the dipstick.

3. Reinstall engine oil cap and tighten.

• Check oil level before each use. Add oil if

needed. Fill to full line on dipstick.

• Change the oil after every 25 hours of

operation or each season. You may need

to change the oil more often under dusty,

dirty conditions.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular

unleaded gasoline with a minimum of 87

octane. Do not mix oil with gasoline.

Purchase fuel in quantities that can be used

within 30 days to assure fuel freshness.

i^WARNING: Experience indicates that

alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract

moisture which leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an

engine while in storage, To avoid engine

problems, the fuel system should be

emptied before storage of 30 days or

longer. Drain the gas tank, start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel

next season. See Storage Instructions for

additional information. Never use engine

or carburetor cleaner products in the fuel

tank or permanent damage may occur.

A CAUTION: Fill to bottom of gas tank

filler neck. Do not overfill. Wipe off any

spilled oil or fuel. Do not store, spill or use

gasoline near an open flame.

Gasoline

TO START ENGINE

1. To start a cold engine, push primer three

(3) times before trying to start. Use a firm

push. This step is not usually necessary

when starting an engine which has

already run for a few minutes.

2. Move throttle control lever to fast position,

3. Flold upper handle firmly and pull starter

handle quickly. Do not allow starter rope

to snap back.

TO STOP ENGINE

• To stop engine, move throttle control lever

to stop position.

NOTE; In cooler weather it may be

necessary to repeat priming steps. In

warmer weather overpriming may cause

flooding and engine will not start. If you

do flood engine, wait a few minutes

before attempting to start and do not

repeat priming steps. /A_

Throttle

control

Starter

handle

TRIMMING TIPS

• Set the throttle control in the fast

position. If the weeds or grass are tall

and thick, operate the trimmer at a

slower walking speed.

• Frequently clean the underside of the

trimmer to remove any grass build up.

Keep top of engine around starter clear

and clean of grass clippings and chaff.

This will help engine air flow and extend

engine life. See TO REMOVE ENGINE

COVER in the Maintenance section of

this manual.

• For best results and longer lasting line,

use the ends of the line to do the cutting.

This is easily done by moving slowly

through very thick and heavy weeds.

• Use the left side of trimmer when

trimming along fences, wails, flowerbeds

and other such objects.

• If trimmer lines become too short, it will

take longer to complete the job. If

trimmer lines are worn to less than half

their original length, they should be

replaced. See TO REPLACE TRIMMER

LINE in the Maintenance section of this

manual.

• Trimmer head contact with concrete,

asphalt or other hard surfaces may

cause premature wear of the ball on

bottom of trimmer head.

8

Page 9

MAINTENANCE

Check for Loose Fasteners

Clean Trimmer

Clean Under Engine Cover

Check drive beltfpulleys

Check/Replace Trimmer Lines

Check Engine Oil Level

Change Engine Oil

Clean Air Filter

Inspect Muffler

Clean or Replace Spark Plug

Replace Air Filter Paper Cartridge

1 - Change more often when operating under a heavy load or in high ambient temperatures.

2 - Service more often when operating in dirty or dusty conditions

3 - Replace trimmer lines when they have worn to halt their originai length.

GENERAL RECOMMENDATIONS

The warranty on this trimmer does not

cover items that have been subjected to

operator abuse or negligence. To receive

full value from the warranty, operator must

maintain trimmer as instructed in this

✓

✓ ✓

✓ 2

✓ 3

✓

IMPORTANT: Do not oil or grease plastic

wheel bearings. Viscous lubricants will attract

dust and dirt that will shorten the life of the

self- lubricating bearings. If you feel they must

be lubricated, use only a dry, powdered

graphite type lubricant sparingly.

✓

✓

✓

|/l.2

✓ 2

✓

✓

1/2

manual.

Some adjustments will need to be made

periodically to properly maintain your unit.

All adjustments in the Service and

PRODUCT SPECIFICATIONS

Serial No.

Date of Purchase: .

_________________________________

Adjustments section of this manual should

be checked at least once each season.

• Once a year, replace the spark plug

and replace air filter element. A new

spark plug and clean/new air filter

element assures proper air-fuel mixture

and helps your engine run better and

last longer.

• Follow the maintenance schedule in

Gasoline Type:

Gasoline Capacity:

Oil Type:

(API-SF/SG/SH)

Oil Capacity:

Spark Plug :

(Gap: .030")

Valve Clearance:

this manual.

BEFORE EACH USE

1. Check engine oil level.

Trimmer Line Dia.: .155 inch

Trimmer Line Length: 18.75 inches

2. Check for loose fasteners.

3. Clean under engine cover.

LUBRICATION

To prolong the useful life of your trimmer,

change engine oil as recommended in

The model and serial numbers will be found on

a decal attached to the rear of the trimmer.

Record both serial number and date of

purchase in space provided above.

this section of Owner’s Manual.

Unleaded Regular

1.25 Quarts

SAE 30 (Above 32° F)

SAE 5W-30 (Below 32° F)

20 Ozs.

Champion J19LIVI

or RJ19LM

Intake: .004-.008

Exhaust: .004-.008

Page 10

TRIMMER

Always observe safety rules when perform

ing any maintenance,

TIRES

• Keep tires free of gasoline, oil, or insect

control chemicals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

TRIMMER LINE

For best results, replace trimmer lines

when they have worn to half their original

length. Use .155 inch diameter trimmer

line. Cut new trimmer line length to 18-3/4

inches. After new line is installed on

trimmer head, check all lines so they do

not vary more then one (1) inch in length.

This is important to make sure the trimmer

head is balanced and will not vibrate

abnormally.

^WARNING: Use only the specified

trimmer line. Do not use other materials

such as wire, string, rope, etc. Wire can

break off during trimming and become a

dangerous missile that can cause serious

injury.

TO REPLACE TRIMMER LINE

1.

Disconnect spark plug wire from spark

plug and place wire where it cannot

come in contact with spark plug.

Remove worn trimmer line from line

carrier plate.

3.

Fold new, cut to length, trimmer line in

half and insert folded end through

carrier plate opening to back side of

retainer clip.

4.

With folded end of line at back side of

retainer clip, pull line outward until

line is fully seated under the retainer

clip.

5.

Repeat on other side of carrier plate.

Check all lines to be sure they are the

6.

same length.

7.

Reconnect spark plug wire to spark

plug.

Trimmer

line

Carrier plate

opening

Retainer

clip

ENGINE

LUBRICATION

Use only high quality detergent oil rated

with API service classification SF, SG or

SH. Select the oil's SAE viscosity grade

according to your expected operating

temperature.

NOTE: Although multi-viscosity oils

(5W30, 10W30 etc.) improve starting in

cold weather, these multi-viscosity oils

will result in increased oil consumption

when used above 32°F. Check your

engine oil level more frequently to avoid

possible engine damage from running

low on oil.

Change the oil after every 25 hours of

operation or at least once a year if the

lawn mower is not used for 25 hours in

one year.

Check the crankcase oil level before

starting the engine and after each five (5)

hours of continuous use. Tighten oil plug

securely each time you check the oil

level.

10

Page 11

TO CHANGE ENGINE OIL

NOTE; Before tipping trimmer to drain

oil, drain fuel tank by running engine

until fuel tank is empty.

Disconnect spark plug wire from spark

1.

plug and place wire where it cannot

come in contact with spark plug.

2.

Remove engine oil cap; lay aside on a

clean surface.

Tip trimmer on its side as shown and

3.

drain oil into a suitable container.

Rock trimmer back and forth to

remove any oil trapped inside of

engine.

Wipe off any spilled oil on trimmer and

4.

on side of engine.

Fill engine with oil (See “ADD OIL" in

5.

the Operation section of this manual).

Replace engine oil cap.

6.

7.

Reconnect spark plug wire to spark

plug.

Turn

Collar

counterclockwise to

tighten

clockwise

MUFFLER

Inspect and replace corroded muffler as

it could create a fire hazard and/or

damage.

Container

AIR FILTER

Your engine will not run properly and

may be damaged by using a dirty air

filter.

Replace the air filter every year, more

often if you mow in very dusty, dirty

conditions. Do not wash air filter.

TO CHANGE AIR FILTER

1. Remove the air filter by turning

clockwise to the stop and pull away

from collar.

Remove filter from inside of cover.

2.

Clean the inside of the cover and the

3.

collar to remove any dirt accumula

tion.

Insert new filter into cover.

4.

Put air filter cover and filter into collar

5.

aligning the tab with the slot.

Push in on cover and turn counter

6.

clockwise to tighten.

SPARK PLUG

Change your spark plug each year to

make your engine start easier and run

better. Set spark plug gap at .030 inch.

CLEANING

IMPORTANT: For best performance,

keep trimmer free of built-up grass and

trash. Clean the underside of your

trimmer after each use.

^CAUTION: Disconnect spark plug wire

from spark plug and place wire where it

cannot come in contact with the spark

plug.

• Turn trimmer on its side. Make sure air

filter and carburetor are up. Clean the

underside of your trimmer by scraping

to remove build-up of grass and trash.

• Clean engine often to keep trash from

accumulating. A clogged engine runs

hotter and shortens engine life.

• Keep finished surfaces and wheels

free of all gasoline, oil,etc.

• We do not recommend using a garden

hose to clean trimmer unless the

electrical system, muffler, air filter and

carburetor are covered to keep water

out. Water in engine can result in

shortened engine life.

11

Page 12

CLEAN UNDER ENGINE COVER

Clean under engine cover before each

use, or more frequently in heavy cutting

or dirty conditions. Engine cover screen

and engine air intake screen must be

kept free of dirt and chaff to prevent

engine damage from overheating.

Knob

Engine

Be sure engine is cool before cleaning.

1. Unscrew knob on top of cover.

2. Lift cover up and away from engine.

3. Clean cover and cover screen

thoroughly.

4.

Clean top of engine and air intake

screen.

5.

Replace engine cover and tighten

knob securely. Be sure the front tabs

of engine cover are located in the

slots in engine housing.

SERVICE AND ADJUSTMENTS

A CAUTION; Before performing any

service and adjustments:

1. Stop engine.

2. Make sure the rotating lines and all

moving parts have completely

stopped.

3. Disconnect spark plug wire from spark

plug and place where it cannot come

in contact with plug.

TRIMMER

TO ADJUST TRIMMING HEIGHT

See TO ADJUST TRIMMING HEIGHT'” in the

Operation section of this manual.

TO ADJUST HANDLE

The upper handle may be adjusted to

different height positions.

• Loosen handle knob only enough to

allow the upper handle to pivot to the

desired position.

* Tighten handle knob securely.

NOTE: The handle knob and bolt may be

reversed for left handed operation.

12

Page 13

TO REMOVE/REPLACE TRIMMER HEAD

DRIVE BELT

1. Remove screw at front of chassis

cover.

2. Lift cover up and away from trimmer.

3. Turn trimmer on its side with carbure

tor and fuei cap up.

4. Remove beit from engine pulley on

crankshaft.

5. Remove belt from trimmer head pulley,

6. Remove idler assembly from chassis

and remove belt and idler from

trimmer.

7. Remove belt from idler assembly by

removing bottom belt keeper and idler

pulleys.

8. Assemble new belt, idler pulleys and

bottom belt keeper to idler bracket.

Tighten pulley bolts securely.

NOTE: Be sure belt is inside top belt

keeper on idler assembly.

9. Position belt and idler assembly in

trimmer and assemble idler to chassis.

Tighten securely.

10. Install belt around trimmer head pulley

and engine pulley.

11. Replace chassis cover and tighten

screw securely.

Always use Craftsman replacement parts

to assure proper fit and long life.

ENGINE

ENGINE SPEED

Your engine speed has been factory set.

Do not attempt to increase engine speed

or it may result in personal injury. If you

believe that the engine is running too fast

or too slow, take your unit to a Sears or

other qualified service center for repair

and/or adjustment.

CARBURETOR

Your carburetor has a nonadjustable fixed

main jet for mixture control. If your engine

does not operate properly due to sus

pected carburetor problems, take your

unit to a Sears or other qualified service

center for repair and/or adjustment.

IMPORTANT; Never tamper with the

engine governor, which is factory set for

proper engine speed. Overspeeding the

engine above the factory high speed

setting can be dangerous, if you think the

engine-governed high speed needs

adjusting, take your unit to a Sears or

other qualified service center, which has

proper equipment and experience to

make any necessary adjustments.

Top belt

keeper

Flat idler

Bottom belt

keeper

Flat idler

Trimmer

head pulley

Page 14

STORAGE

Immediately prepare your trimmer for storage

at the end of the season or if the unit will not

be used for 30 days or more.

TRIMMER

When trimmer is to be stored for a period of

time, clean it thoroughly, remove ail dirt,

grease, leaves, etc. Store ip a clean, dry area.

1. Clean entire trimmer (See "CLEANING" in

the Maintenance section of this manual).

2. Lubricate as shown in the Maintenance

section of this manual.

3. Be sure that all nuts, bolts, screws, and

pins are securely fastened. Inspect

moving parts for damage, breakage and

wear. Replace if necessary.

4. Touch up all rusted or chipped paint

surfaces; sand lightly before painting.

HANDLE

You can fold your trimmer handle for storage.

• Loosen handle knob enough to allow

upper handle to be folded forward.

IMPORTANT: When folding the handle for

storage or transportation, be sure to fold the

handle as shown or you may damage the

control cables.

Upper

handle

Handle knob

ENGINE

FUELSYSTEM

IMPORTANT: It is important to prevent gum

deposits from forming in essential fuel system

parts such as carburetor, fuel filter, fuel hose

or tank during storage. Also, experience

indicates that alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separation and

formation of acids during storage. Acidic gas

can damage the fuel system of an engine

while in storage.

1. Drain the fuel tank.

2. Start the engine and let it run until the

fuel lines and carburetor are empty.

• Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

• Use fresh fuel next season.

NOTE; Fuel stabilizer is an acceptable

alternative in minimizing the formation of fuel

gum deposits during storage. Add stabilizer

to gasoline in fuel tank or storage container.

Always follow the mix ratio found on stabilizer

container. Run engine at least 10 minutes

after adding stabilizer to allow the stabilizer to

reach the carburetor. Do not drain the gas

tank and carburetor if using fuel stabilizer.

ENGINE OIL '

Drain oil (with engine warm) and replace with

clean engine oil. (See "ENGINE" in the

Maintenance section of this manual).

CYLINDER

1. Remove spark plug.

2. Pour one ounce (29 ml) of oil through

spark plug hole into cylinder.

3. Pull starter handle slowly a few times

to distribute oil.

4. Replace with new spark plug.

OTHER

• Do not store gasoline from one season to

another.

• Replace your gasoline can if your can

starts to rust. Rust and/or dirt in your

gasoline will cause problems.

• If possible, store your unit indoors and

cover it to give protection from dust and dirt.

• Cover your unit with a suitable protective

cover that does not retain moisture. Do

not use plastic. Plastic cannot breathe

which allows condensation to form and will

cause your unit to rust.

IMPORTANT: Never cover trimmer while

engine and exhaust areas are still warm.

^CAUTION: Never store the trimmer

with gasoline in the tank inside a building

where fumes may reach an open flame or

spark. Allow the engine to cool before

storing in any enclosure.

14

Page 15

TROUBLESHOOTING

PROBLEM CAUSE

CORRECTION

Does not start

Loss of power

Excessive

Vibration

1. Dirty air filter.

2. Out of fuel.

3. Stale fuel.

4. Water in fuel.

5. Spark plug wire is

disconnected.

6. Bad spark plug.

7. Throttle control lever not

in correct position

{if equipped).

1. Dirty air filter.

2. Buildup of grass, leaves,

and trash under trimmer.

3. Too much oil in engine.

4. Walking speed too fast.

1. Lines uneven or broken.

2. Loose nuts or bolts.

3. Damaged trimmer head.

1. Clean/replace air filter.

2. Fill fuel tank.

3. Drain tank and refill with

fresh clean fuel.

4. Drain fuel tank and

carburetor and refill tank

with fresh gasoline.

5. Connect wire to plug.

6. Replace spark plug.

7. Move throttle lever to FAST

position.

1. Clean/replace air filter.

2. Clean underside of trimmer

and trimmer head.

3. Check oil level.

4. Trim at slower walking

speed.

1. Check trimmer lines.

2. Check all hardware,

including engine bolts.

3. Check/repair trimmer head.

Starter rope hard

to pull

Loss of head

drive

Hard to push

Poor trimming

performance

Trimmer head

does not

retain line

1. Bent engine crankshaft.

1. Belt not driving.

1. Handle height position not

right for you.

1. Trimmer line length is

too short.

2. Throttle control lever not

in correct position

(if equipped).

1. Trimmer line not

properly installed.

2. Broken line retainer clip.

3. Incorrect size of

trimmer line.

1. Contact a Sears or other

qualified service center.

1. Put belt on pulleys or

replace belt if broken.

1. Adjust handle height

to suit.

1. If line is worn or broken to

half original length,

replace line.

2. Move throttle lever to FAST

position. '

1. Follow instructions in

Maintenance section.

2. Replace string carrier plate

assembly.

3. Use .155 diameter

trimmer line.

15

Page 16

REPAIR PARTS

CRAFTSMAN WEED TRIMMER- - MODEL NO. 917.773420

30

Page 17

CRAFTSMAN WEED TRIMMER- - MODEL NO. 917.773420

KEY PART

NO.

10

11 170980

12 136376

13 170681

14 170682

15

16

17

18

19 171449

20 174038

21

22

23 150078

24 169823

25 57143

26 151161 Wheel 14x2

27 83923 Hex Flange Locknut 3/8-16

28

29 174034

30 174039

NO.

1

2 150406

169791

3

STD502502

4

174317

5

174274 Engine Cover Knob

6

7 174030

169821X479

8

9 150078

169797X479

170554

153638 Rope Guide

STD541025 Locknut 1/4 X 20

66426 Wire Tire

158755

172225X004 Axle Shaft Assembly

174037 Drive Control

- -

169803

- -

174041

DESCRIPTION

Engine Model No. 143.005512

(See Breakdown)

Engine Bolt 3/8-16

Engine Pulley (Includes setscrew)

Setscrew, Pulley

Engine Cover w/screen

Engine Cover Stud

LowerHandle

Screw Hx Wshd 5/16-18 x .75

UpperHandle

Handle Bolt

Handle Knob

Handle Adjuster (Inside)

Handle Adjuster (Outside)

Handle Adjust Spring

Control Bar

Throttle Control

Hex Washer Screw

Screw hex Wshd 5/16-18 x .75

Axle Spacer

Wave Washer

Decal - Warning

Decal - Engine Cover

Safety Goggles (Not Shown)

Owner's Manual

Available accessories not included with trimmer:

Z133623 Gas Can (2.5 gal.)

7133000 SAE SOW Oil (20 oz.)

71 79997 Trimmer Line (Pack of 24 strings.

31

155 dia.)

Page 18

CRAFTSMAN WEED TRIMMER- - MODEL NO. 917.773420

32

Page 19

CRAFTSMAN WEEDTRIMMER- MODEL N0.917.773420

KEY

NO.

10

11

12

13

14

15 173811

16 170552

17

18 85768

19

20 170553

21

22 STD541137

23 STD551137

24

25

26 172551

27

28

29

30

31

32

33

34

36

37

38

39 172636

40

41

43 174042

44

45

PART

NO.

1

174031X558

2

169802

3

173715

4

169790

5 172145X004

6 166042

7

173716

8 751592

9

166043

160829

155552

173717 Spacer

142748

145212

57808

169800 Skirt

149746

STD551037

169792

174549

172520

169766

174543

174581

176973

172519 Locking Plate

174544

172516 Cover, Bearing

174580

172523 Mow Ball

172342

174029

174035

174596

DESCRIPTION

Chassis Assembly

Line .155Dia X 18.75

Screw 5/16-18 X ISeif TappingBeitV

Idler Bracket

Idler Pulley V-Groove

Hex Bolt 3/8-16 X 1.25

Hex Locknut 3/8-16

Idler Pulley-Flat

Shoulder Bolt

Locknut 5/16-18

Shoulder Bolt

Flange Locknut

Return Spring

Debris Shield

Screw 1/4-20 x 1/2

Screw #10-24x3/4

Chassis Cover-Top

Screw #10-24 X 1-3/4

NUI3/8-24UNF

Lockwasher 3/8

Fla1washer3/8

Puliey - Driven

Spacer - Puiley

Bearing

Jackshaft

Cover, Bottom

Spindle Hsg. Asm. (* Includes Upper Bearing Key No. 27)

Retaining Ring 17mm External

Spring, Lock Plate

Carrier Plate Assembly

Retaining Ring 40mm Internal

Bolt, Mow Ball

Head Assembly Complete (Includes Key Nos. 22-39)

Spacer

Decal - Instruction

Decal - Chassis Cover

Bottom Belt Keeper

33

Page 20

CRAFTSMAN 4-CYCLE ENGINE MODEL NO. 143.005512

34

Page 21

CRAFTSMAN 4-CYCLE ENGINE

MODEL NO. 143.005512

KEY PART

NO. NO.

1

37266

26727

2

33734

6

36557

7

12

36775

12A

36558

12B

36694

14

28277

15

30589

34839A

16

17

31335

651018

18

19

37329

32600

20

30

37459

40027

40

40

40028

41 40025

41 40026

42 40006

42 40007

43 20381

45 36777

46 32610A

48 27241

50 37460

29914

52

39

37130

34311E

70

72

36083

27897

75

30574A

30

31

30590A

32

30591

33

30588A

650488

36

39

610961

611213

30

650815

)2

650816

¡3

00

34443B

610118

01

651007

03

04 37480

10 36230

19 36787

20 36825

25 37288

26 37289

30 6021A

35 35395

50 31672

51 31673

51A 40017

69 36783

DESCRIPTION

Cylinder (Incl. 2,20 & 150)

Dowel Pin

Breather Element

Breather Ass’y- (Incl. 6 & 12A)

Breather Tube

Breather Cover & Tube (Incl.

128)

Breather Tube Elbow

Washer

Governor Rod (Incl. 14)

Governor Lever

Governor Lever Clamp

Screw, Torx T-15, 8-32 x 19/

64"

Extension Spring

Oil Seal

Crankshaft

Piston, Pin & Ring Set (Std.)

Piston, Pin & Ring Set (.010"

OS)

Piston & Pin Ass'y. (Std.) (Incl.

43)

Piston & Pin Ass’y. (.010" OS)

(Incl. 43)

Ring Set (Std.)

Ring Set (.010" OS)

Piston Pin Retaining Ring

Connecting Rod Ass’y. (Incl.

46}

Connecting Bod Bolt

Valve Lifter

Camshaft (Exhaust MCR)(lnc.

Ref 104)

Oil Pump Ass’y.

Mounting Flange Gasket

Mounting Flange (Incl. 72 thru

83,306)

Oil Drain Plug

Oil Seal

Governor Shaft

Washer

Governor Gear Ass’y. (Incl. 81)

Governor Spool

Screw, 1/4-20 X 1-1/4"

Flywheel Key

Flywheel

Belleville Washer

Flywheel Nut

Solid State Ignition

Spark Plug Cover

Screw, Torx T-15, 10-24 x 15/

16"

Cam Bushing

Ground Wire

Cylinder Head Gasket

Cylinder Head

Exhaust Valve (Std.)

(Incl. 151)

Intake Valve (Std.) (Incl. 151)

Screw, 5/16-18 X 1-1/2"

Resistor Spark Plug (RJ19LM)

Valve Spring

Valve Spring Cap

Intake Valve Seal

Valve Cover Gasket

KEY PART

NO. NO.

172 36784

174 30200

178 29752

179 30593

182 6201

184 26756

185 36785

186 36201

200 37134

206 610973

207 36200B

209 30200

223 650451

224 36786

238 650932

239 34338

241 36919

245 36905

250 37122

260 37213A

261 30200

262 650831

275 36790A

277 650988

285 35000A

287 650926

290 34357

292 26460

298 28763

300 35586

301 36246

305 35577

306 36996

307 35499

309 650562

310 35578

313 34080

370C37318

380 640262

390 590739

400 36792B

416 36085

417 650821

900

------------

DESCRIPTION

Valve Cover

Screw, 10-24 X 9/16"

Nut & Lock Washer, 1/4-28

Retainer Clip

Screw. 1/4-28 x 7/8"

Carburetor To Intake Pipe

Gasket

Intake Pipe

Governor Link

Control Bracket (Incl. 206)

Terminal

Throttle Link

Screw, 10-24 X 9/16"

Screw, 1/4-20 x 1"

Intake Pipe Gasket

Screw, 10-32 X 49/64"

Air Cleaner Gasket

Air Cleaner Collar

Air Cleaner Filter

Air Cleaner Cover

Blower Housing

Screw, 10-24 x 9/16"

Screw, 1/4-20 X 1/2"

Muffler

Screw, 1/4-20 X 2-9/32"

Starter Cup

Screw, 8-32 x 21/64"

Fuel Line

Fuel Line Clamp

Screw, 10-32 X 35/64"

Fuel Tank (Incl. 292 & 301)

Fuel Cap

Oil Fill Tube

"0’’-Ring

"0”-Ring

Screw, 10-32 X 3/8"

Dipstick

Spacer

Primer Decal (3X)

Carburetor (Incl. 184)

Rewind Starter

Gasket Set (Incl. Items

Marked *)

Spark Arrestor Kit (Incl.

417)(Optional)

Screw, 10-32 X 1/2" (Optional)

Replacement Short Block

750837B

RPM High 3450 to 3750

RPM Low 2000 to 2300

NOTE: This engine could have been built

with 590702 starter).

NOTE: All component dimensions given in U S.

inches 1 inch = 25.4 mm

35

Page 22

CRAFTSMAN 4-CYCLE ENGINE

■^20 A

MODEL NO. 143.005512

48 36A

^ O I

25

36

Page 23

CRAFTSMAN 4-CYCLE ENGINE

PART

KEY

NO.

NO.

_

640262

631615

1

631767

2

631184 *

4

631183 *

5

640070

6

650506 ‘ Shutter Screw

7

631807 Fuel Fitting

16

17 651025

630766 Tension Spring

18

640018

20

20A 640200

631867 Float Bowl

25

631024 ‘ Float Shaft

27

28 632019

631028 * Float Bowl “0” Ring

29

631021 *

30

631022 Spring Clip

31

35 640259

36 640080

36A 632766

37 632547 *

640175 High Speed Bowl Nut

40

44 27110A * Bowl Nut Washer

47

630748

631027 * Welch Plug, Atmospheric Vent

48

632760B

60

DESCRIPTION

Carburetor (tncl. 184 of Engine Parts List)

Throttle Shaft & Lever Assembly

Throttle Return Spring

Dust Seal Washer

Dust Seal (Throttle)

Throttle Shutter

Throttle Crack Screw/ldle Speed Screw

Idle Restrictor Screw

Idle Restrictor Scrwe Cap (Black)

Float

Inlet Needle, Seat, & Clip (Incl. 31)

Primer Bulb/Retainer Ring

Main Nozzle Tube

Carburetor Tube

“0” Ring, Main Nozzle Tube

Welch Plug, idle Mixture Welt

Repair kit (Incl. Items Marked *)

MODEL NO. 143.005512

37

Page 24

CRAFTSMAN 4-CYCLE ENGINE

MODEL NO. 143.005512

11

KEY

PART

NO.

NO.

_

590702

1

590599A

2

590600 Washer

3

590696 Retainer

4

590601 Washer

5 590697

6

590698 Starter Dog

7

590699 Dog Spring

8 590700

11

590703

12

590535

13

590701 Starter Handle

O 2

0

DESCRIPTION

Recoil Starter

Spring Pin (Incl. 4)

Brake Spring

Pulley & Rewind Spring Ass'yStarter Housing Ass'y. (40 degree grommet)

Starter Rope ( 98" X 9/64" dia.)

38

Page 25

CRAFTSMAN 4-CYCLE ENGINE

MODEL NO. 143.005512

KEY

PART

NO. NO.

0

590739

3

590740

6

590616

7

590617

8

590618A

11

590638

12

590535

13

590701

14

590760

----

7

DESCRIPTION

Rewind Starter

Retainer

Starter Dog

Dog Spring

Pulley & Rewind Spring Ass'y

Starter Housing Ass’y (40

degree grommet)

Starter Rope (Length 98" x

64" dia.)

Starter Handie

Spring Ciip

9/

39

Page 26

Get it fixed, at your home or ours!

For repair of major brand appliances in your own home...

no matter who made it, no matter who sold it!

1-800-4-MY-HOME^^ Anytime, day or night

(1-800-469-4663)

www.sears.com

To bring in products such as vacuums,

lawn equipment and electronics for repair, call for

the location of your nearest Sears Parts & Repair Center.

1 *800“488“1 222 Anytime, day or night

www.sears.com

For the replacement parts, accessories and owner’s manuals

that you need to do-it-yourself, call Sears PartsDirect®'^!

1 -800-366-PART 6 a m - 11 p m CST,

(1-800-366-7278) 7 days a week

To purchase or inquire about a Sears Service Agreement:

Para pedir servicio de reparación a domicilio,

y para ordenar piezas con entrega a domicilio:

1-888-SU-HOGAR^“

(1-888-784-6427)

> Sears, Roebuck and Co.

www.sears.com/partsdirect

1-800-827-6655

7 a.m. - 5 p.m. CST, Mon. - Sat.

Au Canada pour service en français;

1-877-LE-FOYER®“

(1-877-533-6937)

HomeCentral

® Registered Trademark / ™ Trademark of Sears, Roebuck and Co.

® Marca Registrada / Marca de Fábrica de Sears, Roebuck and Co.

174041 Rev.5 06.15.00 VB/rad

Printed in U.S.A.

Loading...

Loading...