Page 1

Owner’s Manual

REAR TINE TILLER WITH

DUAL ROTATING TINES

7.0 HP

17 Inch Tine Width

Model No.

This product has a low emission engine which operates

differently from previously built engines. Before you start the

engine, read and understand this Owner’s Manual.

IMPORTANT:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website:www.sears.com/craftsman

Page 2

TABLE OF CONTENTS

Warranty

Safety Rules

Product Specifications

Assembly/Pre-Operation

Operation

Maintenance Schedule

.....................................

...............................

...............

.............

....................................

...............

............

............

............

............

............

..........

2 Maintenance

2 Service and Adjustments....

4 Storage

6 Troubleshooting

8 Illustrated Parts List

14 Sears Service

.......................

................................

...................

.............

......................

.................

.................

.................

.................

.................

...Back Cover

14

16

20

21

44

WARRANTY

LIMITED TWO YEAR WARRANTY ON ORAFTSMAN TILLER

For two (2) years from date of purchase, when this Craftsman Tiller is maintained,

lubricated, and tuned up according to the operating and maintenance instructions in the

owner’s manual, Sears will repair free of charge any defect in material or workmanship.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as tines, spark plugs,

air cleaners and belts.

• Repairs necessary because of operator abuse or negligence, including bent crank

shafts and the failure to maintain the equipment according to the instructions con

tained in the owner’s manual.

• If this Craftsman Tiller is used for commercial or rental purposes, this Warranty applies

for only thirty (30) days from the date of purchase.

Warranty service is available by returning the craftsman power mower to the nearest

sears service center/department in the united states. This warranty applies only while

this product is in use in the united states.

This Warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL 60179 U.S.A.

SAFETY RULES

IMPORTANT: This cutting machine is capable of amputating hands and feet and throw

ing objects. Failure to observe the following safety instructions could result in serious

injury or death.

TRAINING

• Read the Owner’s Manual carefully. Be

thoroughly familiar with the controls and

the proper use of the equipment. Know

how to stop the unit and disengage the

controls quickly.

• Never allow children to operate the

equipment. Never allow adults to op

erate the equipment without proper

instruction.

• Keep the area of operation clear of all

persons, particularly small children, and

pets.

PREPARATION

• Thoroughly inspect the area where the

equipment is to be used and remove all

foreign objects.

Disengage all clutches and shift into

neutral before starting the engine (mo

tor).

Do not operate the equipment without

wearing adequate outer garments. Wear

footwear that will improve footing on

slippery surfaces.

Handle fuel with care; it is highly flam

mable.

Use an approved fuel container.

Never add fuel to a running engine or

hot engine.

Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors.

Replace gasoline cap securely and

clean up spilled fuel before restarting.

Page 3

• Use extension cords and receptacles

as specified by the manufacturer for all

units with electric drive motors or elec

tric starting motors.

• Never attempt to make any adjustments

while the engine (motor) is running (ex

cept where specifically recommended

by manufacturer).

OPERATION

• Do not put hands or feet near or under

rotating parts.

• Exercise extreme caution when operat

ing on or crossing gravel drives, walks,

or roads. Stay alert for hidden hazards

or traffic. Do not carry passengers.

• After striking a foreign object, stop the

engine (motor), remove the wire from

the spark plug, thoroughly inspect the

tiller for any damage, and repair the

damage before restarting and operating

the tiller.

• Exercise caution to avoid slipping or fall

ing.

• If the unit should start to vibrate ab

normally, stop the engine (motor) and

check immediately for the cause. Vibra

tion is generally a warning of trouble.

• Stop the engine (motor) when leaving

the operating position.

• Take ail possible precautions when leav

ing fhe machine unattended. Disengage

the tines, shift into neutral, and stop the

engine.

• Before cleaning, repairing, or inspecting,

shut off the engine and make certain all

moving parts have stopped. Disconnect

the spark plug wire, and keep the wire

away from the plug to prevent accidental

starting. Disconnect the cord on electric

motors.

• Do not run the engine indoors; exhaust

fumes are dangerous.

• Never operate the tiller without proper

guards, plates, or other safety protective

devices in place.

• Keep children and pets away.

• Do not overload the machine capacity

by attempting to till too deep at too fast

a rate.

• Never operate the machine at high

speeds on slippery surfaces. Look be

hind and use care when backing.

• Never allow bystanders near the unit.

• Use only attachments and accessories

approved by the manufacturer of the

tiller.

• Never operate the tiller without good vis

ibility or light.

• Be careful when tilling in hard ground.

The tines may catch in the ground and

propel the tiller forward. If this occurs,

let go of the handlebars and do not

restrain the machine.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and ac

cessories in safe working condition.

• Check shear pins, engine mounting

bolts, and other bolts at frequent inter

vals for proper tightness to be sure the

equipment is in safe working condition.

• Never store the machine with fuel in the

fuel tank inside a building where ignition

sources are present, such as hot water

and space heaters, clothes dryers, and

the like. Allow the engine to cool before

storing in any enclosure.

• Always refer to the operator’s guide

instructions for important details if the

tiller is to be stored for an extended

period.

ALook for this symbol to point out

important safety precautions. It means

CAUTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

AcAUTION: Always disconnect spark

plug wire and place wire where it cannot

contact spark plug in order to prevent acci

dental starting when setting up, transport

ing, adjusting or making repairs.

AwARNING: Engine exhaust, some of its

constituents, and certain vehicle compo

nents contain or emit chemicals known to

the State of California to cause cancer and

birth defects or other reproductive harm.

Page 4

PRODUCT SPECIFICATIONS

Gasoline 4 Quarts

Capacity: Unleaded

Regular

Oil (API-SG-SL): SAE 30 (Above 40°F)

(Capacity: 19 oz.) SAE5W-30/10W-30

(Below 40°F)

Spark Plug : Champion

(Gap: .030") RC12YC

CONGRATULATIONS on your purchase

of a Sears Tiller. It has been designed,

engineered and manufactured to give you

the best possible dependability and per

formance.

Should you experience any problems you

cannot easily remedy, please contact a

Sears or other qualified Service Center.

We have competent, well-trained techni

cians and the proper tools to service or

repair this unit.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tiller properly. Always

observe the “SAFETY RULES”.

Your new tiller has been assembled at the

factory with exception of those parts left

unassembled for shipping purposes. To

ensure safe and proper operation of your

tiller all parts and hardware you assemble

must be tightened securely. Use the cor

rect tools as necessary to insure proper

tightness.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in main

taining, caring for and using your tiller.

• Follow the instructions under the “Main

tenance” and “Storage” sections of this

Owner’s Manual.

^WARNING: This unit is equipped with

an internal combustion engine and should

not be used on or near any unimproved

forest-covered, brush-covered or grass

covered land unless the engine’s exhaust

system is equipped with a spark arrester

meeting applicable local or state laws (if

any). If a spark arrester is used, it should

be maintained in effective working order

by the operator.

In the state of California the above is

required by law (Section 4442 of the

California Public Resources Code). Other

states may have similar laws. Federal

laws apply on federal lands. A spark ar

rester for the muffler is available through

your nearest Sears service center (See

REPAIR PARTS section of this manual).

REPAIR PROTECTION AGREEMENTS

Congratulations on making a smart pur

chase. Your new Craftsman® product is

designed and manufactured for years of

dependable operation. But like all products,

it may require repair from time to time. That’s

when having a Repair Protection Agreement

can save you money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself from unexpected

hassle and expense.

Here’s what’s included in the Agreement:

• Expert service by our 12,000 profe

sional repair specialists.

• Unlimited service and no charge for

parts and labor on all covered repairs.

• Product replacement if your covered

product can’t be fixed.

• Discount of 10% from regular price of

service and service-related parts not

covered by the agreement; also, 10%

off regular price of preventive mainte

nance check.

• Fast help by phone - phone support

from a Sears technician on products

requiring in-home repair, plus conve

nient repair scheduling.

Once you purchase the Agreement, a

simple phone call is all that it takes for you

to schedule service. You can call anytime

day or night, or schedule a service ap

pointment online.

Sears has over 12,000 professional repair

specialists, who have access to over 4.5

million quality parts and accessories.

That’s the kind of professionalism you can

count on to help prolong the life of your

new purchase for years to come. Purchase

your Repair Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information

call 1-800-827-6655.

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, in

the U.S.A. call 1-800-4-MY-HOME®

Page 5

ACCESSORIES

These accessories were available when the tiller was purchased. They are also avail

able at most Sears Retail outlets and Service Centers. Most Sears Stores can order

repair parts for you when you provide the model number of your tiller.

ENGINE

SPARK PLUG MUFFLER AIR FILTER GAS CAN ENGINE OIL STABILIZER

TILLER PERFORMANCE

TILLER MAINTENANCE

BELT TINES SHEAR PIN HAIRPIN CUP

0

UNASSEMBLED PARTS

Page 6

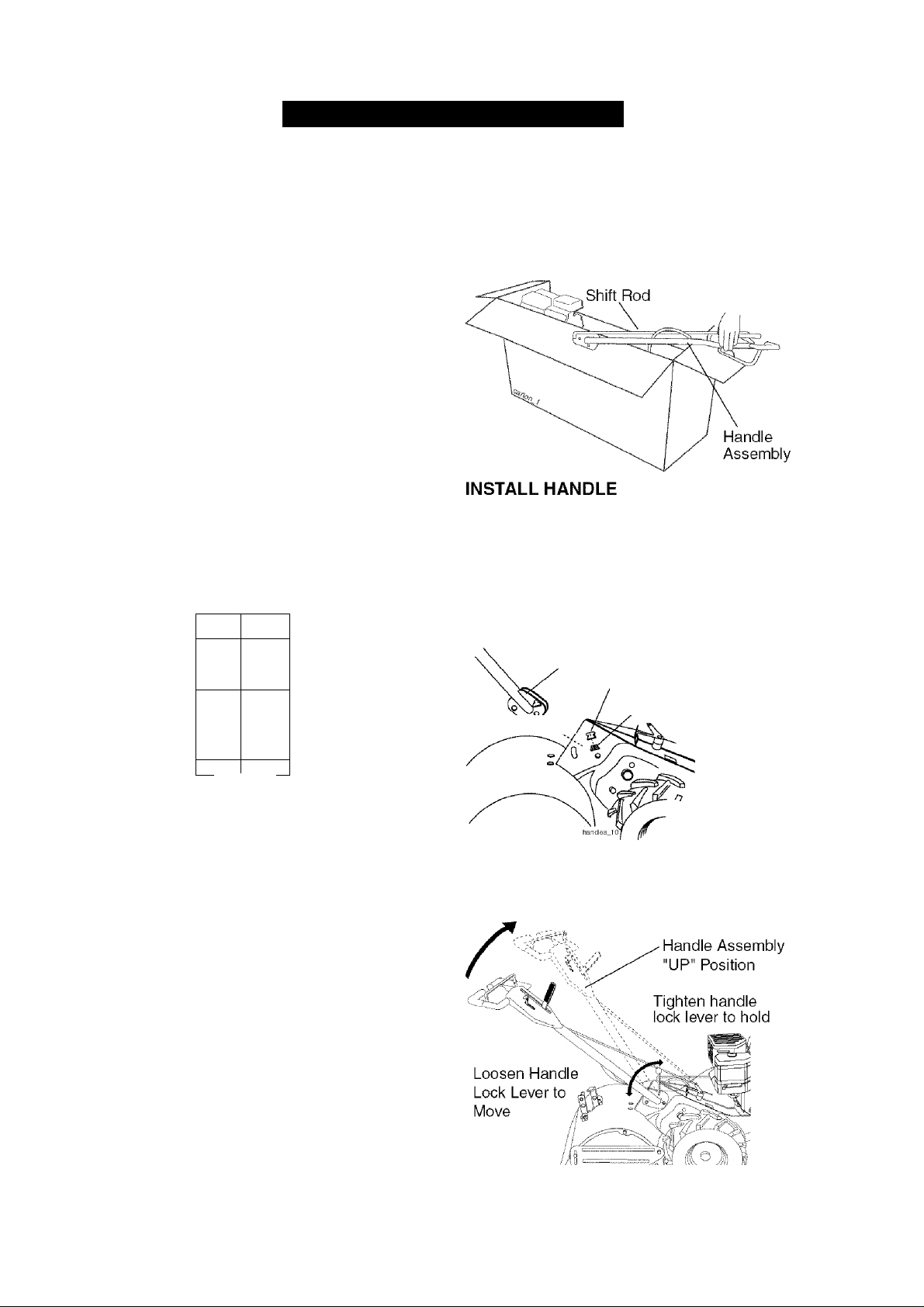

ASSEMBLY/PRE-OPERATION

Your new tiller has been assembled at the factory with the exception of those parts left

unassembled for shipping purposes. To ensure safe and proper operation of your tiller

all parts and hardware you assemble must be tightened securely. Use the correct tools

as necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(1) Utility knife

(1) Wire cutter

(1) Tire pressure gauge

(1) Screwdriver

(1) Pair of pliers

(1) 9/16" wrench

OPERATOR’S POSITION

When right or left hand is mentioned in

this manual, it means when you are in the

operating position (standing behind tiller

handles).

FRONT

a

0,

LEFT

RIGHT

1 j

1

5. Remove packing material from handle

assembly.

Insert one handle lock (with teeth fac

ing outward) in gearcase notch. (Apply

grease on smooth side of handle lock

to aid in keeping lock in place until

handle assembly is lowered into po

sition.)

VIEWED FROM R.H. SIDE OF TILLER

Handle Assembly

Gearcase Notch

Handle Lock

—J

OPERATOR’S

POSITION

UNPACKING CARTON

AcAUTION: Be careful of exposed sta

ples when handling or disposing of carton

ing material.

IMPORTANT: When unpacking and as

sembling tiller, be careful not to stretch or

kink cables.

1. While holding handle assembly, cut

cable ties securing handle assembly to

top frame. Let handle assembly rest

on tiller.

2. Remove top frame of carton.

3. Slowly ease handle assembly up and

place on top of carton.

4. Cut down right hand front and right

hand rear corners of carton. Lay side

carton wall down.

2. Grasp handle assembly. Hold in “up”

position. Be sure handle lock remains

in gearcase notch. Slide handle as

sembly into position.

Page 7

3. Rotate handle assembly down. Insert

rear carriage bolt first, with head of

bolt on L.H. side of tiller and loosely as

semble locknut.

4. Insert pivot bolt in front part of plate

and tighten.

5. Cut down left hand rear corner of car

ton. Lay rear carton wall down, which

will remove the protective cardboard

flap from leveling shield.

6. Cut down remaining corners of carton

and lay panels flat.

7. Lower the handle assembly. Tighten

nut on carriage bolt so handle moves

with some resistance. This will allow

for easier adjustment.

8. Place flat washer on threaded end of

handle lock lever.

9. Insert handle lock lever through handle

base and gearcase. Screw in handle

lock lever just enough to hold lever in

place.

10. Insert second handle lock (with teeth

inward) in the slot of the handle base

(just inside of washer).

11 .With handle assembly in lowest posi

tion, securely tighten handle lock lever

by rotating clockwise. Leaving handle

assembly in lowest position will make it

easier to remove tiller from carton.

Flat Washer

Handle Lock

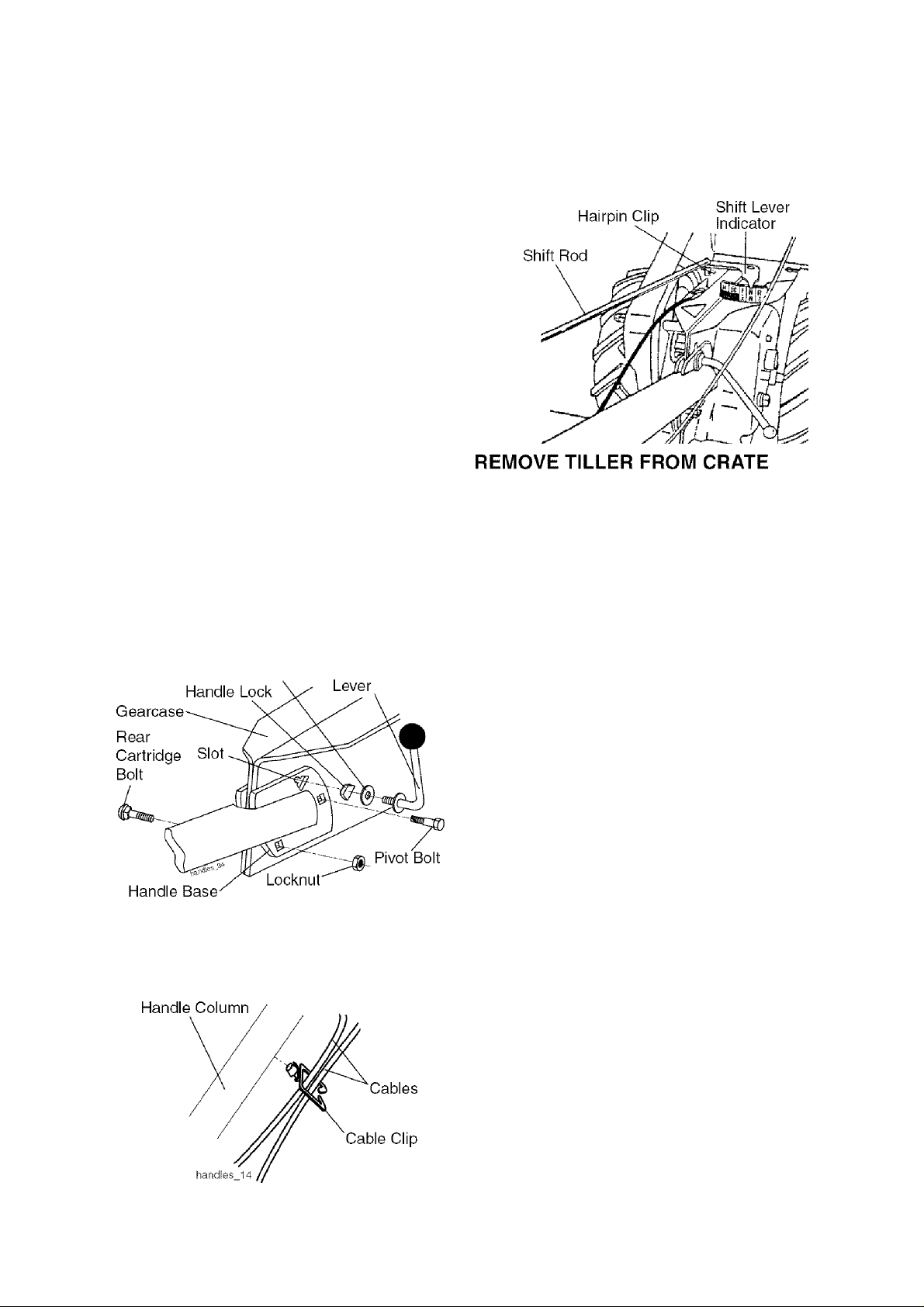

CONNECT SHIFT ROD

1. Insert end of shift rod into hole of shift

lever indicator.

2. Insert hairpin clip through hole of shift

rod to secure.

1. Adjust handle assemby to lowest

position. Be sure lock lever is tightened

securely.

2. Make sure shift lever indicator is in “N”

(neutral) position.

3. Tilt tiller forward by lifting handle. Sep

arate cardboard cover from leveling

shield.

4. Rotate tiller handle to the right and pull

tiller out of carton.

CHECK TIRE PRESSURE

The tires on your unit were overinflated at

the factory for shipping purposes. Correct

and equal tire pressure is important for

best tilling performance.

• Reduce tire pressure to 20 PSI.

INSERT CABLE CLIP

• Insert plastic cable clip into hole on the

back of handle column. Push cables

Into clip.

HANDLE HEIGHT

• Handle height may be adjusted to bet

ter suit operator. (See “TO ADJUST

HANDLE HEIGHT” in the Service and

Adjustments section of this manual).

Page 8

OPERATION

These symbols may appear on your Tiller or in literature supplied with the product.

Learn and understand their meaning.

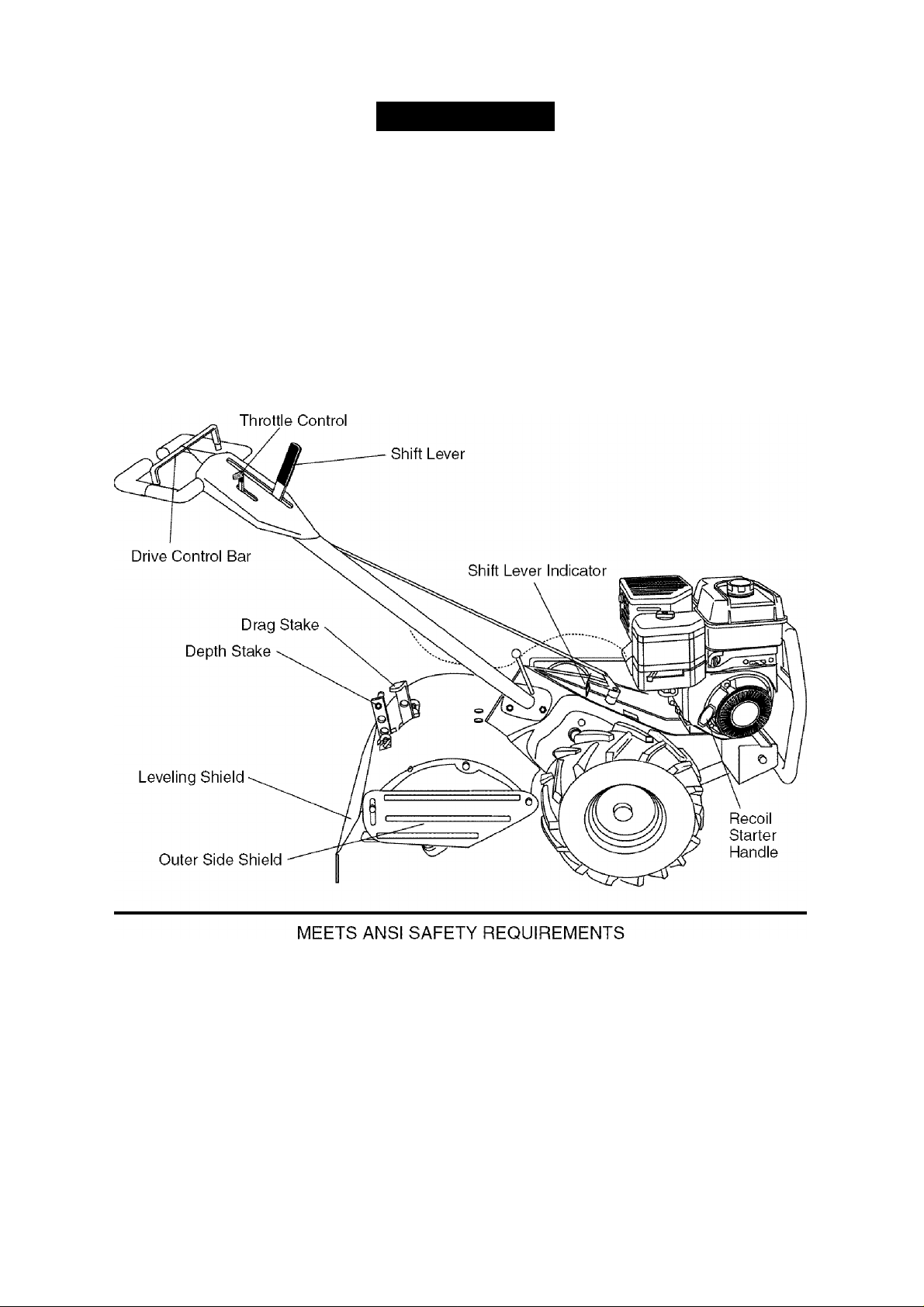

KNOW YOUR TILLER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

TILLER.

Compare the illustrations with your tiller to familiarize yourself with the location of

various controls and adjustments. Save this manual for future reference.

F

4

riLLING TILLING FORWARD NEUTRAL REVERSE OR WARNING ON OFF

" f A©

N

CAUTION ENGINE ENGINE

|\| fl ^ '

SLOW CHOKE FUEL OIL O

Our tillers conform to the safety standards of the American National Standards Institute.

DEPTH STAKE - Controls depth at which

tiller will dig.

DRAG STAKE - Controls forward speed in

forward rotating till position.

DRIVE CONTROL BAR - Used to engage

tines.

LEVELING SHIELD - Levels tilled soil.

OUTER SIDE SHIELD - Adjustable to

protect small plants from being buried.

RECOIL STARTER HANDLE - Used to

start the engine.

SHIFT LEVER - Used to shift transmission

gears.

SHIFT LEVER INDICATOR - Shows

which gear the transmission is in.

THROTTLE CONTROL - Used to control

engine speed.

8

Page 9

The operation of any tiller can result in foreign objects thrown into the eyes,

which can result in severe eye damage. Always wear safety glasses or eye

shields before starting your tiller and while tilling. We recommend standard

safety glasses or a wide vision safety mask worn over spectacles.

HOW TO USE YOUR TILLER

Know how to operate all controls before

adding fuel and oil or attempting to start

engine.

STOPPING

TINES AND DRIVE

1. Release drive control bar to stop move

ment.

2. Move shift lever to “N” (neutral) po

sition.

ENGINE

• Move throttle control to “STOP” position.

If equipped with stop switch, move

switch to “STOP” position.

NOTE: Never use choke to stop engine.

Drive Control Bar

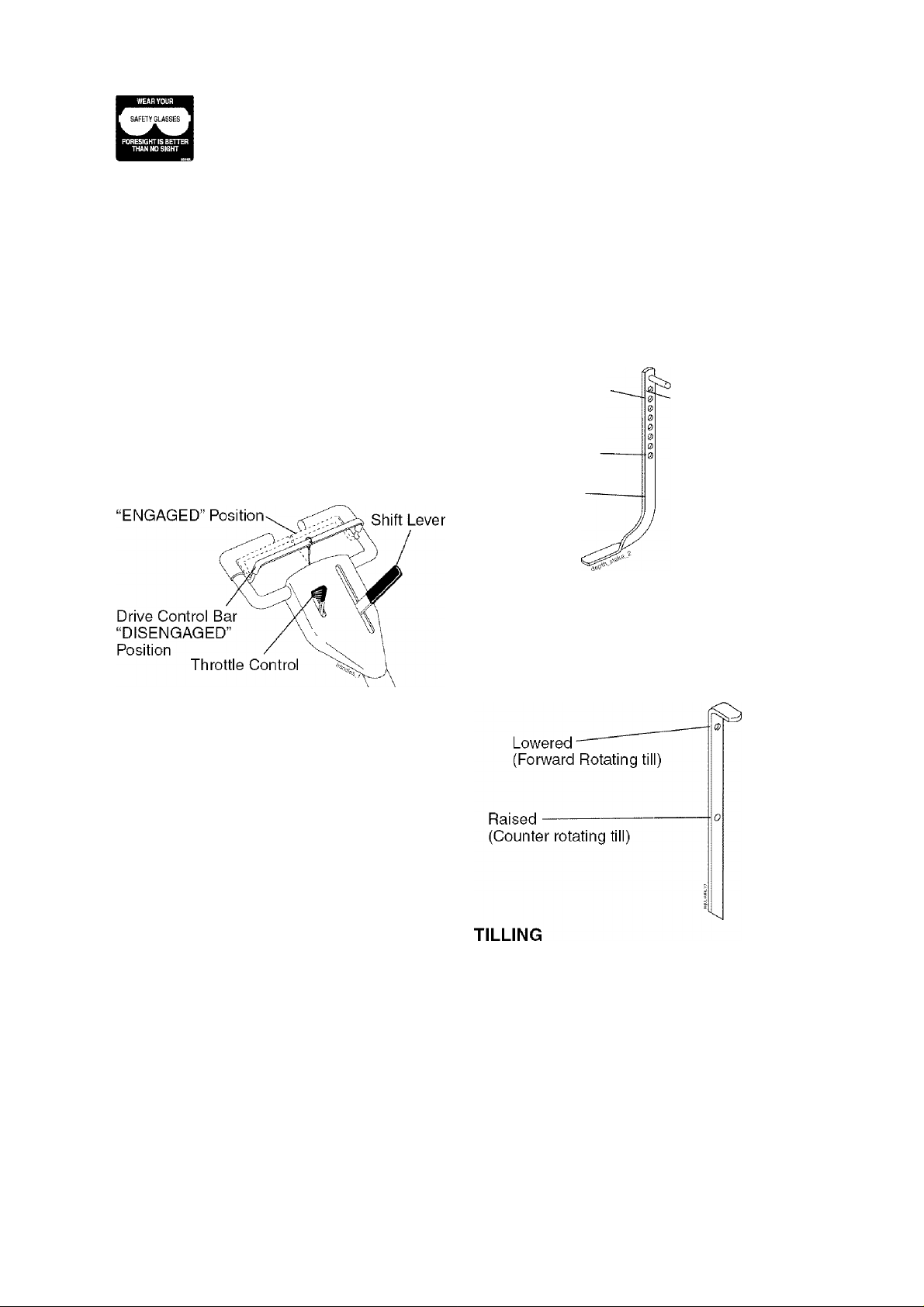

TINE OPERATION - WITH WHEEL

DRIVE

• Always release drive control bar before

moving shift lever into another position.

• Tine movement is achieved by moving

shift lever to either the counter rotating

(S) till position or the forward rotating

(g) till position and engaging drive con

trol bar.

FORWARD - WHEELS ONLY/TINES

STOPPED

• Release drive control bar and move shift

lever indicator to “F” (forward) position.

Engage drive control bar and tiller will

move forward.

REVERSE - WHEELS ONLY/TINES

STOPPED

1. DO NOT STAND DIREOTLY BEHIND

TILLER.

2. Release the drive control bar.

3. Move throttle control to “SLOW” po

sition.

4. Move shift lever indicator to “R” (re

verse) position.

5. Hold drive control bar against the

handle to start tiller movement.

HARD TO SHIFT GEARS

• Briefly engage drive control bar and re

lease or rock tiller forward and backward

until are able to shift gears.

DEPTH STAKE

The depth stake can be raised or lowered

to allow you more versatile tilling and cul

tivating, or to more easily transport your

tiller.

Shallowest Tilling

Transport Position

Deepest Tilling

Depth Stake

DRAG STAKE

The drag stake should be raised when

tilling the counter rotating (g;) till position.

The drag stake should be lowered when

tilling in the forward rotating (g) till posi

tion.

NOTE: Use the counter rotating tine drive

when tilling hard or rockey soil, virgin

ground or sod.

1. Release depth stake and drag stake

pins. Pull the depth stake up for

increased tilling depth. Raise the drag

stake. Place proper pin in hole of depth

stake or drag stake to lock in position.

2. Place shift lever indicator in counter

rotating (g) till position.

3. Hold the drive control bar against the

handle to start tilling movement. Tines

and wheels will both turn.

Page 10

4. Move throttle control to “FAST” position

for deep tilling.

IMPORTANT: Always release drive control

bar before moving shift lever into another

position.

“Locked” Position

TURNING

1. Release the drive control bar.

2. Move throttle control to “SLOW” posi

tion.

3. Place shift lever indicator In “F” (for

ward) position. Tines will not turn.

4. Lift handle to raise tines out of ground.

5. Swing the handle in the opposite

direction you wish to turn, being careful

fo keep feet and legs away from tines.

6. When you have completed your turn

around, release the drive control bar

and lower handle. Place shift lever in

(till) position and move throttle control

to desired speed. To begin tilling, hold

drive control bar against the handle.

CULTIVATING

NOTE: Use the forward rotating tine drive

when cultivating, tilling soft ground or till

ing pre-tilled soil.

1. Release the depth and drag stake pins.

Lower drag stake. Pull the depth stake

up for increased tilling depth. Place

proper pin in hole of depth stake or

drag stake to lock in position.

2. Place shift lever indicator in forward to

rotating (ii) till position.

3. Hold the drive control bar against the

handle to start tilling movement. Tines

and wheels will both turn.

4. Move throttle control “FAST” position

for deep tilling. To cultivate, throttle

control can be set at any desired

speed, depending on how fast or slow

you wish to cultivate.

IMPORTANT: Always lower the drag

stake when using the forward rotating tine

drive.

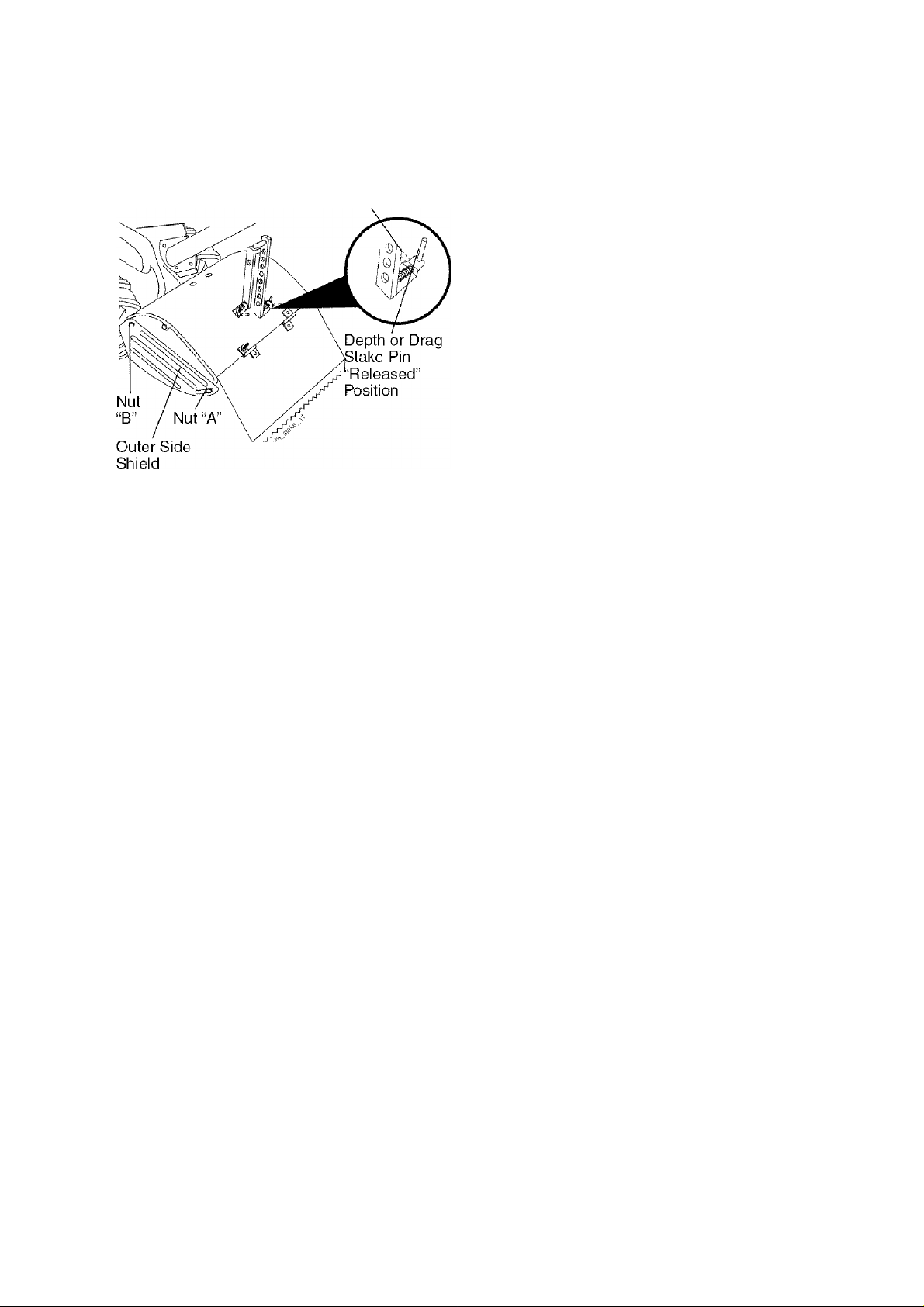

OUTER SIDE SHIELDS

The back edges of the outer side shields

are slotted so that the shields can be

raised for deep tilling and lowered for

shallow tilling to protect small plants from

being buried.

1. Loosen nut “A” in slot and nut “B”.

2. Move shield to desired position (both

sides).

3. Retighten nuts.

TO TRANSPORT

AcAUTION: Before lifting or transporting,

allow tiller engine and muffler to cool. Dis

connect spark plug wire. Drain gasoline

from fuel tank.

AROUND THE YARD

1. Release the depth stake pin. Move

the depth stake down to the top hole

for transporting the tiller. Place depth

stake pin in hole of depth stake to lock

in position. This prevents tines from

scuffing the ground.

2. Place shift lever indicator in “F” (for

ward) position for transporting.

3. Hold the drive control bar against the

handle to start tiller movement. Tines

will not turn.

4. Move throttle control to desired speed.

AROUND TOWN

1. Disconnect spark plug wire.

2. Drain fuel tank.

3. Transport in upright position to prevent

oil leakage.

BEFORE STARTING ENGINE

IMPORTANT: Be very careful not to allow

dirt to enter the engine when checking or

adding oil or fuel. Use clean oil and fuel

and store in approved, clean, covered

containers, use clean fill funnels.

CHECK ENGINE OIL LEVEL

The engine in your unit has been shipped,

from the factory, already filled with SAE 30

summer weight oil.

1. With engine level, clean area around

oil filler plug and remove plug.

2. Engine oil should be to point of over

lowing when engine is level.

• For approximate capacity see “PROD

UCT SPECIFICATIONS” on page 4

of this manual. All oil must meet A.PI.

Service Classification SG-SL.

3. Reinstall engine oil cap and tighten

10

Page 11

For cold weather operation you should

change oil for easier starting (See oil

viscosity chart in the Maintenance sec

tion of this manual).

To change engine oil, see the Mainte

nance section in this manual.

Oil Fill

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do

not overfill. Use fresh, clean, regular

unleaded gasoline with a minimum of

87 octane. (Use of leaded gasoline will

increase carbon and lead oxide deposifs and reduce valve life). Do not mix oil

with gasoline. Purchase fuel in quan

tities that can be used within 30 days to

assure fuel freshness.

ACAUTION: Fill to within 1/2 inch of top

of fuel tank to prevent spills and to allow

for fuel expansion. If gasoline is acci

dentally spilled, move machine away from

area of spill. Avoid creating any source of

ignition until gasoline vapors have disap

peared.

Wipe off any spilled oil or fuel. Do not

store, spill or use gasoline near an open

flame.

IMPORTANT: When operating in temper

atures below32°F(0°C), use fresh, clean

winter grade gasoline to help insure good

cold weather starting.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can

attract moisture which leads to separa

tion and formation of acids during storage.

Acidic gas can damage the fuel system

of an engine while in storage. To avoid

engine problems, the fuel sysfem should

be emptied before storage of 30 days

or longer. Drain the gas tank, start the

engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel

next season. See Storage Instructions for

additional information. Never use engine

or carburetor cleaner products in the fuel

tank or permanent damage may occur.

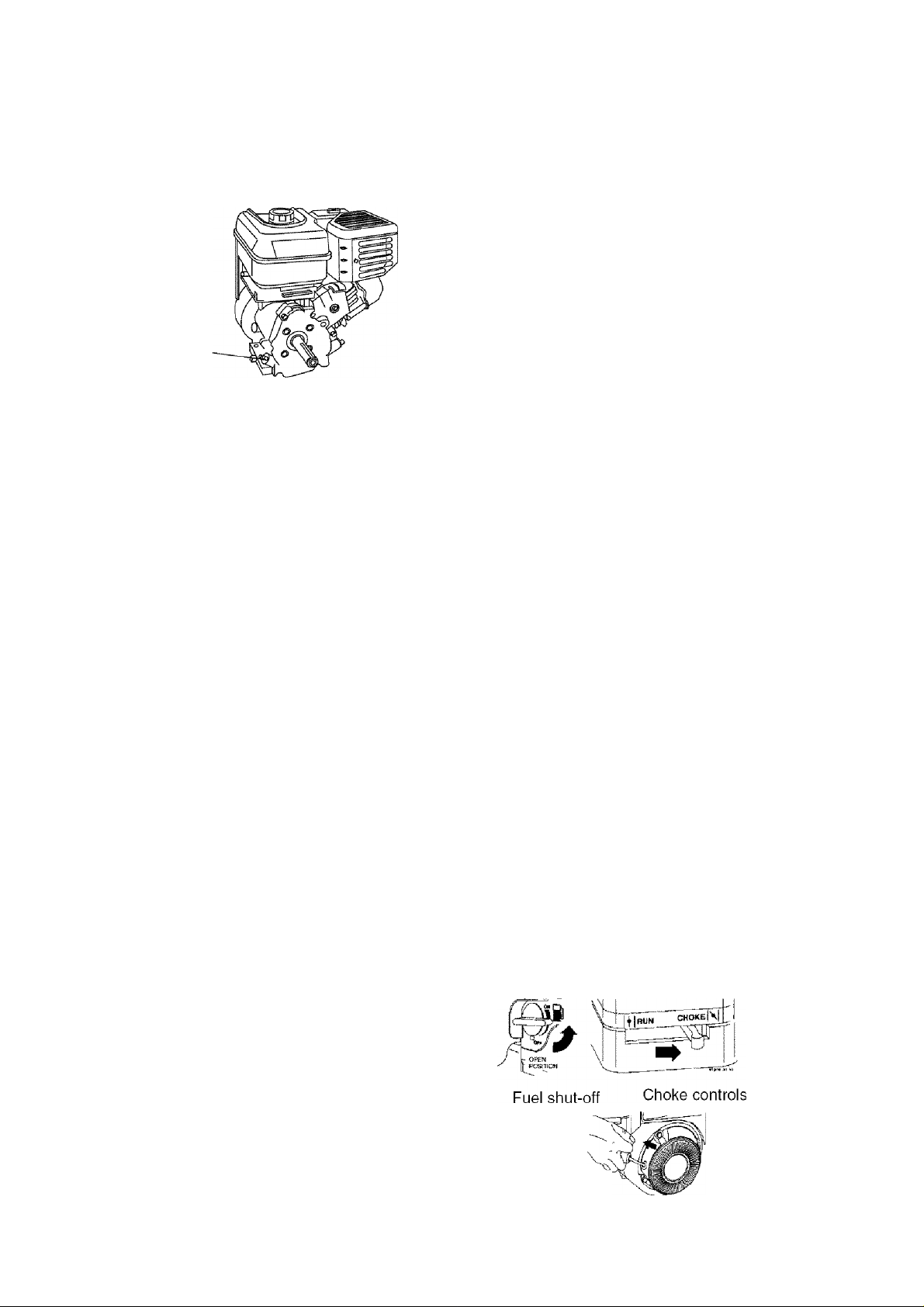

TO START ENGINE

AcAUTION: Keep tine control in “OFF”

position when starting engine.

When starting engine for the first time or if

engine has run out of fuel, it will take extra

pulls of the recoil starter to move fuel from

the tank to the engine.

1. Make sure spark plug wire is properly

connected.

2. Move shift lever indicator to “N” (neu

tral) position.

3. Place throttle control in “FAST” posi

tion.

4. Turn fuel shut-off valve 1/4 turn to open

position.

5. Push stop switch to “ON” position.

6. Move choke control to “CHOKE” posi

tion.

7. Grasp recoil starter handle with one

hand and grasp tiller handle with other

hand. Pull rope out slowly until engine

reaches start of compression cycle

(rope will pull slightly harder at this

point).

8. Pull recoil starter handle quickly. Do

not let starter handle snap back

against starter.

NOTE: If engine fires but does not start,

move choke control to half choke posi

tion. Pull recoil starter handle until engine

starts.

9. When engine starts, slowly move

choke control to “RUN” position as

engine warms up.

NOTE: A warm engine requires less

choking to start.

10. Move throttle control to desired running

position.

11 .Allow engine to warm up for a few

minutes before engaging tines.

NOTE: If at a high altitude (3000 feet) or

in cold temperatures (below 32°F), the

carburetor fuel mixture may need to be

adjusted for best engine performance.

See “TO ADJUST CARBURETOR” in the

Service and Adjustments section of this

manual.

NOTE: If engine does not start, see trou

bleshooting points.

11

Rewind starter

Page 12

TILLING HINTS

^CAUTION: Until you are accustomed

to handling your tiller, start actual field

use with throttle in slow position (mid-way

between “FAST” and “IDLE”).

• Tilling is digging into, turning over, and

breaking up packed soil before plant

ing. Loose, unpacked soil helps root

growth. Best tilling depth is 4" to 6". A

tiller will also clear the soil of unwanted

vegetation. The decomposition of this

vegetable matter enriches the soil.

Depending on the climate (rainfall and

wind), it may be advisable to till the soil

at the end of the growing season to

further condition the soil.

• Soil conditions are important for proper

tilling. Tines will not readily penetrate

dry, hard soil which may contribute to

excessive bounce and difficult handling

of your tiller. Hard soil should be mois

tened before tilling; however, extremely

wet soil will “ball-up” or clump during till

ing. Wait until the soil is less wet in order

to achieve the best results. When tilling

in the fall, remove vines and long grass

to prevent them from wrapping around

the tine shaft and slowing your tilling

operation.

• You will find tilling much easier if you

leave a row unfilled between passes.

Then go back between tilled rows.There

are two reasons for doing this. First,

wide turns are much easier to negoti

ate than about-faces. Second, the tiller

won’t be pulling itself, and you, toward

the row next to it.

• Do not lean on handle. This takes

weight off the wheels and reduces

traction. To get through a really tough

section of sod or hard ground, apply

upward pressure on handle or lower the

depth stake.

CULTIVATING

Cultivating is destroying the weeds be

tween rows to prevent them from robbing

nourishment and moisture from the plants.

At the same time, breaking up the upper

layer of soil crust will help retain moisture

in the soil. Best digging depth is 1" to 3"

(2.5-7.5 cm). Lower the outer side shields

to protect small plants from being buried.

• Cultivate up and down the rows at a

speed which will allow tines to uproot

weeds and leave the ground in rough

condition, promoting no further growth

of weeds and grass.

• Do not lean on handle, this takes weight

off the wheels, reduces traction, and

may cause the tiller to skip over the

ground.

• Always lower the drag stake when

using the forward rotating tine drive.

o o 0 0 0

o o 0 0 0

o o 0 0 0

o o 0 0 0

TINE SHEAR PINS

The tine assemblies on your tiller are

secured to the tine shaft with shear pins

(See “TINE REPLACEMENT” in the

Service and Adjustments section of this

manual).

If the tiller is unusually overloaded or

jammed, the shear pins are designed to

break before internal damage occurs to

the transmission.

• If shear pin(s) break, replace only with

those shown in the Repair Parts section

of this manual.

11

P

P

5 6 7

P

PP

12

Page 13

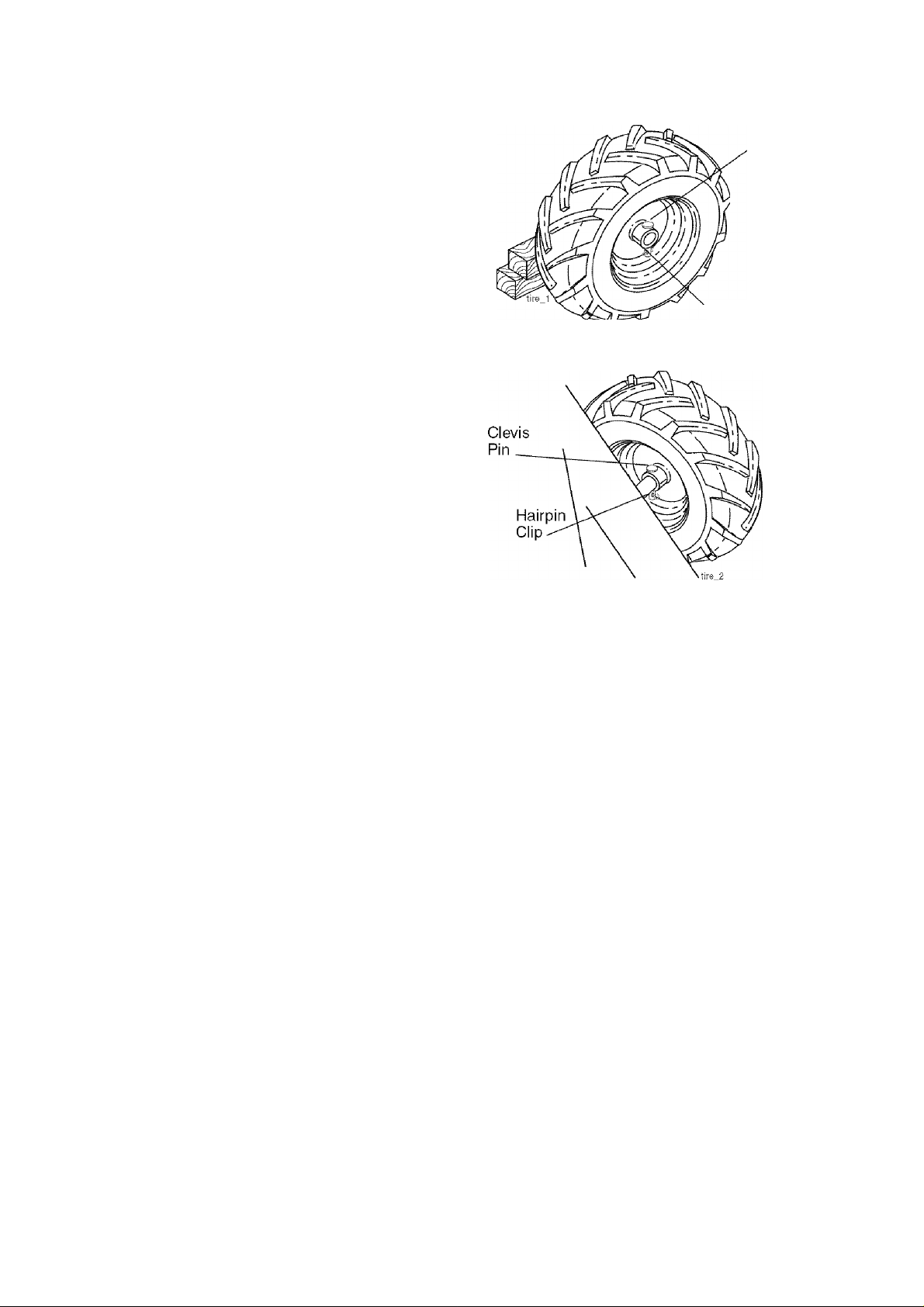

ADJUST WHEELS FOR

CULTIVATING

1. Place blocks under right hand side of

tiller and remove hairpin clip and clevis

pin from right hand wheel.

2. Move wheel outward approximately 1

inch until hole in inner wheel hub lines

up with inner hole in axle.

3. Replace clevis pin and hairpin clip on

inside of wheel and remove blocks.

4. Repeat preceding steps on left hand

side.

NOTE: In extremely rough conditions and

while cultivating, the wheels should be

moved outward on the axle for increased

stability.

OUTER VIEW OF TIRE

Clevis

Pin

Hairpin CIlip

INNER VIEW OF TIRE

13

Page 14

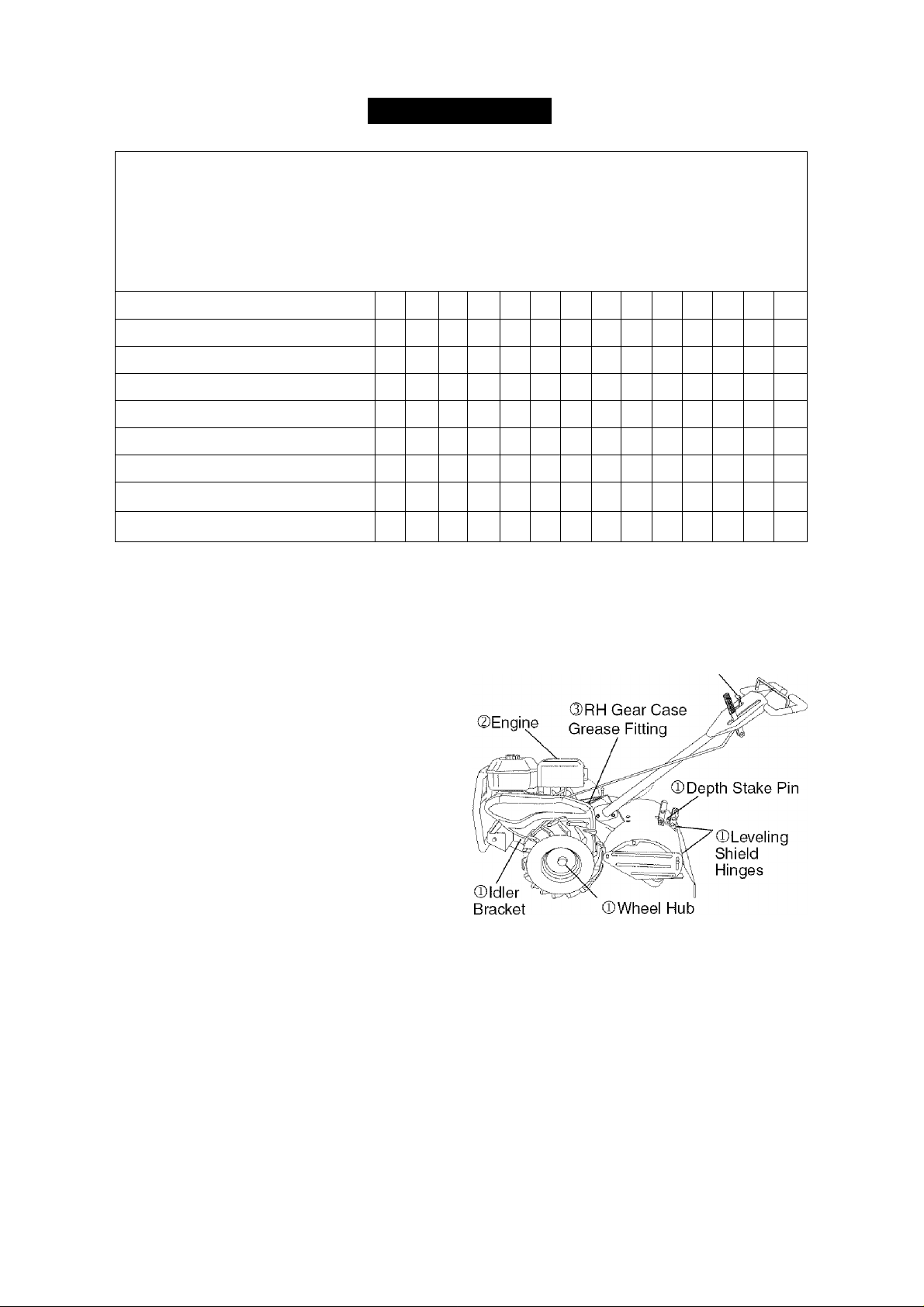

MAINTENANCE

MAINTENANCE

SCHEDULE

FILL IN DATES /

AS YOU COMPLETE /<

REGULAR SERVICE /^

Check Engine Oil Level

Change Engine Oil

Oil Pivot Points

Inspect Spark Arrester / Muffler

Inspect Air Screen

Clean or Replace Air Cleaner Cartridge

Clean Engine Cylinder Fins

Replace Spark Plug

RH Gear Case Grease Fitting (loz.)

1 - Change more often when operating under a heavy load or in high ambient temperatures.

2 - Service more often when operating in dirty or dusty conditions.

✓

✓

✓

✓

f Co /

r <o /

/ k/ / kj

/

A?/

/^/^/

'a./a /

/ /

<2

✓

✓

✓

f Cn / Cn / /

O' / O' / ^ /

✓

a/

SERVICE DATES

GENERAL RECOMMENDATIONS

The warranty on this tiller does not cover

items that have been subjected to op

erator abuse or negligence. To receive full

value from the warranty, the operator must

maintain tiller as instructed in this manual.

Some adjustments will need to be made

periodically to properly maintain your tiller.

At least once a season, check to see if

you should make any of the adjustments

described in the Service and Adjustments

section of this manual.

• Once a year you should replace the

spark plug, clean or replace air filter,

and check tines and belts for wear. A

new spark plug and clean air filter as

sure proper air-fuel mixture and help

your engine run better and last longer.

BEFORE EACH USE

1. Check engine oil level.

2. Check tine operation.

3. Check for loose fasteners.

LUBRICATION

Keep unit well lubricated (See “LUBRI

CATION CHART”) .

LUBRICATION CHART

©Throttle Control

® SAE 30 OR 10W-30 Motor Oil

@ Refer to Maintenance “ENGINE” section

0 EP #1 Grease

14

Page 15

^CAUTION: Disconnect spark plug

wire before performing any maintenance

(except carburetor adjustment) to prevent

accidental starting of engine.

Prevent fires! Keep the engine free of

grass, leaves, spilled oil, or fuel. Remove

fuel from tank before tipping unit for main

tenance. Clean muffler area of all grass,

dirt, and debris.

Do not touch hot muffler or cylinder fins as

contact may cause burns.

ENGINE

LUBRICATION

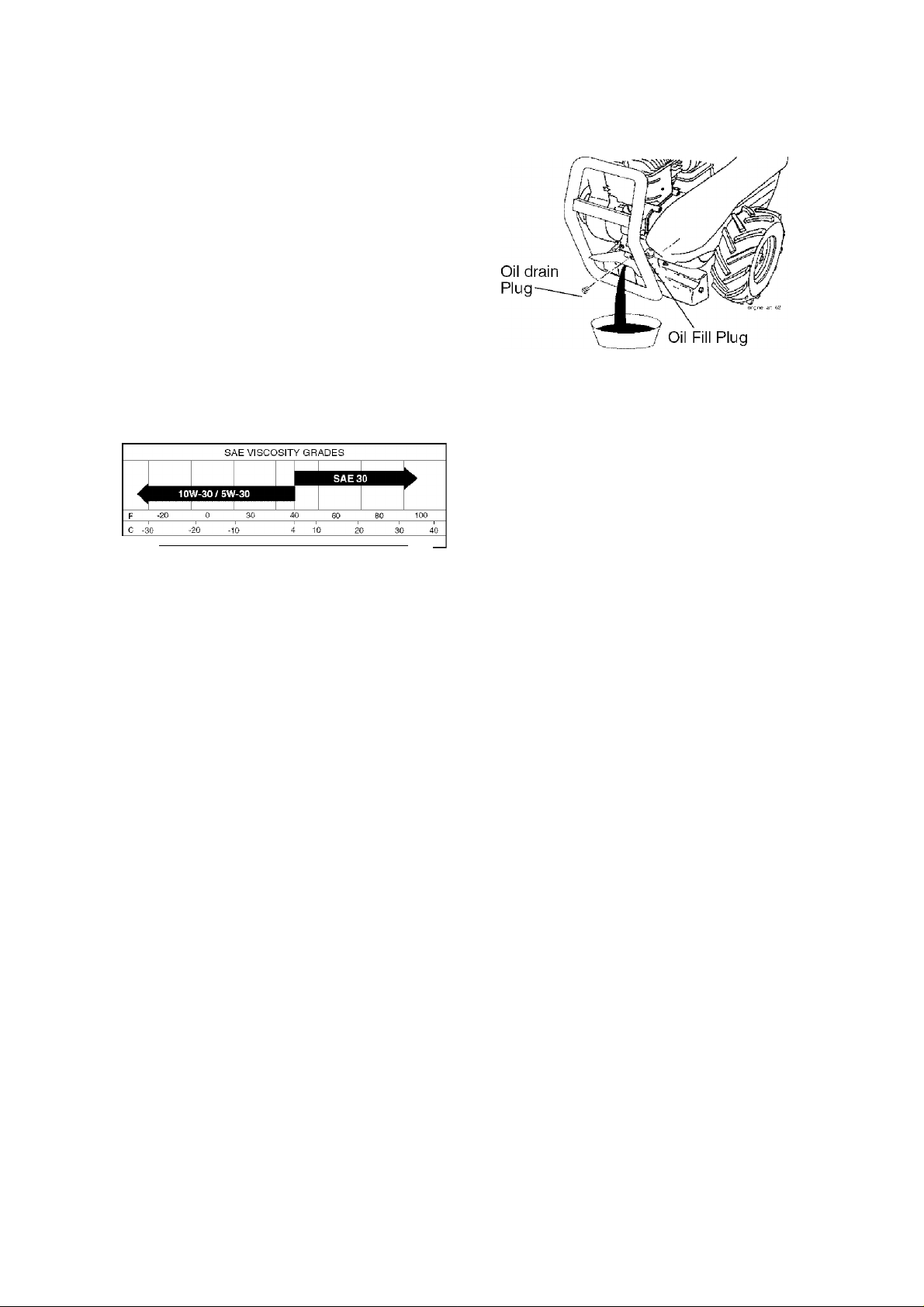

Use only high quality detergent oil rated

with API service classification SG-SL. Se

lect the oil’s SAE viscosity grade accord

ing to your expected temperature.

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

oiLvfsc_char!5_e(drt)

NOTE: Although multi-viscosity oils

(5W-30, 10W-30, etc.) improve starting

in cold weather, these multi-viscosity oils

will result in increased oil consumption

when used above 40°F (4°C). Check your

engine oil level more frequently to avoid

possible engine damage from running low

on oil.

Change the oil after every 50 hours of

operation or at least once a year if the tiller

is not used for 50 hours in one year.

Check the crankcase oil level before

starting the engine and after each five (5)

hours of continuous use. Add SAE 30 mo

tor oil or equivalent. Tighten oil filler plug

securely each time you check the oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SG-SL.

• Be sure tiller is on level surface.

• Oil will drain more freely when warm.

• Use a funnel to prevent oil spill on tiller,

and catch oil in a suitable container.

Remove drain plug.

1

For easier removal of plug use 7/16-12

Pt. socket with extension.

Tip tiller forward to drain oil.

2.

After oil has drained completely,

3.

replace oil drain plug and tighten se

curely.

Remove oil filler plug. Be careful not to

4.

allow dirt to enter the engine.

5. Refill engine with oil. See “CHECK

ENGINE OIL LEVEL” in the Operation

section of this manual.

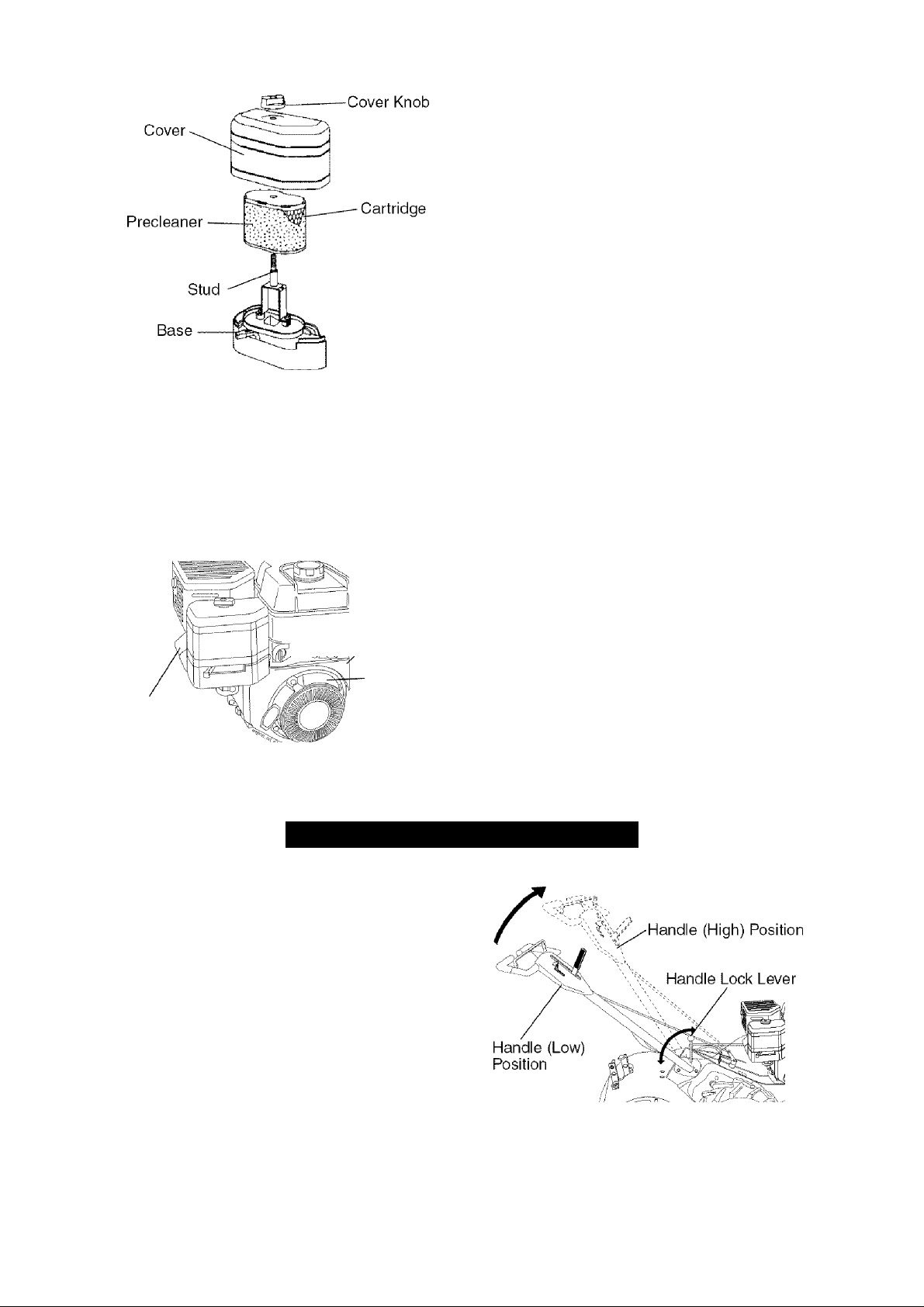

AIR FILTER

Your engine will not run properly using a

dirty air filter. Clean the foam pre-cleaner

after every 50 hours of operation or every

season. Service paper cartridge every

100 hours of operation or every season,

whichever occurs first.

Service air cleaner more often under dusty

conditions.

1. Remove knob and cover. Lift air

cleaner assembly off stud.

TO SERVICE PRE-CLEANER

2. Remove foam pre-cleaner from air

filter.

3. Wash it in liquid detergent and water.

4. Squeeze it dry in a clean cloth.

NOTE: If very dirty or damaged, replace

pre-cleaner.

5. Reinstall pre-cleaner onto air filter.

6. Reinstall cover and secure with knob.

TO SERVICE CARTRIDGE

1. Carefully remove cartridge to prevent

debris from entering carburetor. Clean

base carefully to prevent debris from

entering carburetor.

2. Remove foam pre-cleaner from air

filter.

3. Clean cartridge by tapping gently on

flat surface. If very dirty or damaged,

replace cartridge.

4. Reinstall pre-cleaner onto air filter.

5. Reinstall cover and secure with knob.

IMPORTANT: Petroleum solvents, such

as kerosene, are not to be used to clean

the cartridge. They may cause deterio

ration of the cartridge. Do not oil cartridge.

Do not use pressurized air to clean or dry

cartridge.

15

Page 16

COOLING SYSTEM

Your engine is air cooled. For proper en

gine performance and long life keep your

engine clean.

• Clean air screen frequently using a stiffbristled brush.

• Keep cylinder fins, levers, and linkage

free of dirt and chaff.

Blower

■ """"^Housing

Air Screen

Muffler

MUFFLER

Do not operate tiller without muffler. Do

not tamper with exhaust system. Dam

aged mufflers or spark arresters could

create a fire hazard. Inspect periodically

and replace if necessary. If your engine is

equipped with a spark arrester screen as

sembly, remove every 50 hours for clean

ing and inspection. Replace if damaged.

SPARK PLUG

Replace spark plugs at the beginning of

each tilling season or after every 50 hours

of use, whichever comes first. Spark plug

type and gap setting is shown in “PROD

UCT SPECIFICATIONS” on page 4 of this

manual.

TRANSMISSION

Once a season, lubricate the right hand

gear case grease fitting with 1 oz. of EP

#1 grease.

CLEANING

Do not clean your tiller when the engine

and transmission are hot. We do not rec

ommend using pressurized water (garden

hose, etc.) to clean your unit unless the

gasket area around the transmission and

the engine muffler, air filter and carburetor

are covered to keep water out. Water in

engine will shorten the useful life of your

tiller.

• Clean engine, wheels, finish, etc. of all

foreign matter.

• Keep finished surfaces and wheels free

of all gasoline, oil, etc.

• Protect painted surfaces with auto

motive type wax.

SERVICE AND ADJUSTMENTS

^CAUTION: Disconnect spark plug wire

from spark plug and place wire where it

cannot come into contact with plug.

TILLER

TO ADJUST HANDLE HEIGHT

Select handle height best suited for your

tilling conditions. Handle height will be

different when tiller digs into soil.

1. First loosen handle lock lever.

2. Handle can be positioned at different

settings between “HIGH” and “LOW”

positions.

3. Retighten handle lock lever securely

after adjusting.

16

Page 17

TIRE CARE

ACAUTION: When mounting tires, unless

beads are seated, overinflation can cause

an explosion.

• Maintain 20 pounds of tire pressure. If

tire pressures are not equal, tiller will

pull to one side.

• Keep tires free of gasoline or oil which

can damage rubber.

TO REMOVE WHEEL

1.

Place blocks under transmission to

keep tiller from tipping.

Remove hairpin clip and clevis pin from

wheel.

3.

Remove wheel and tire.

4.

Repair tire and reassemble.

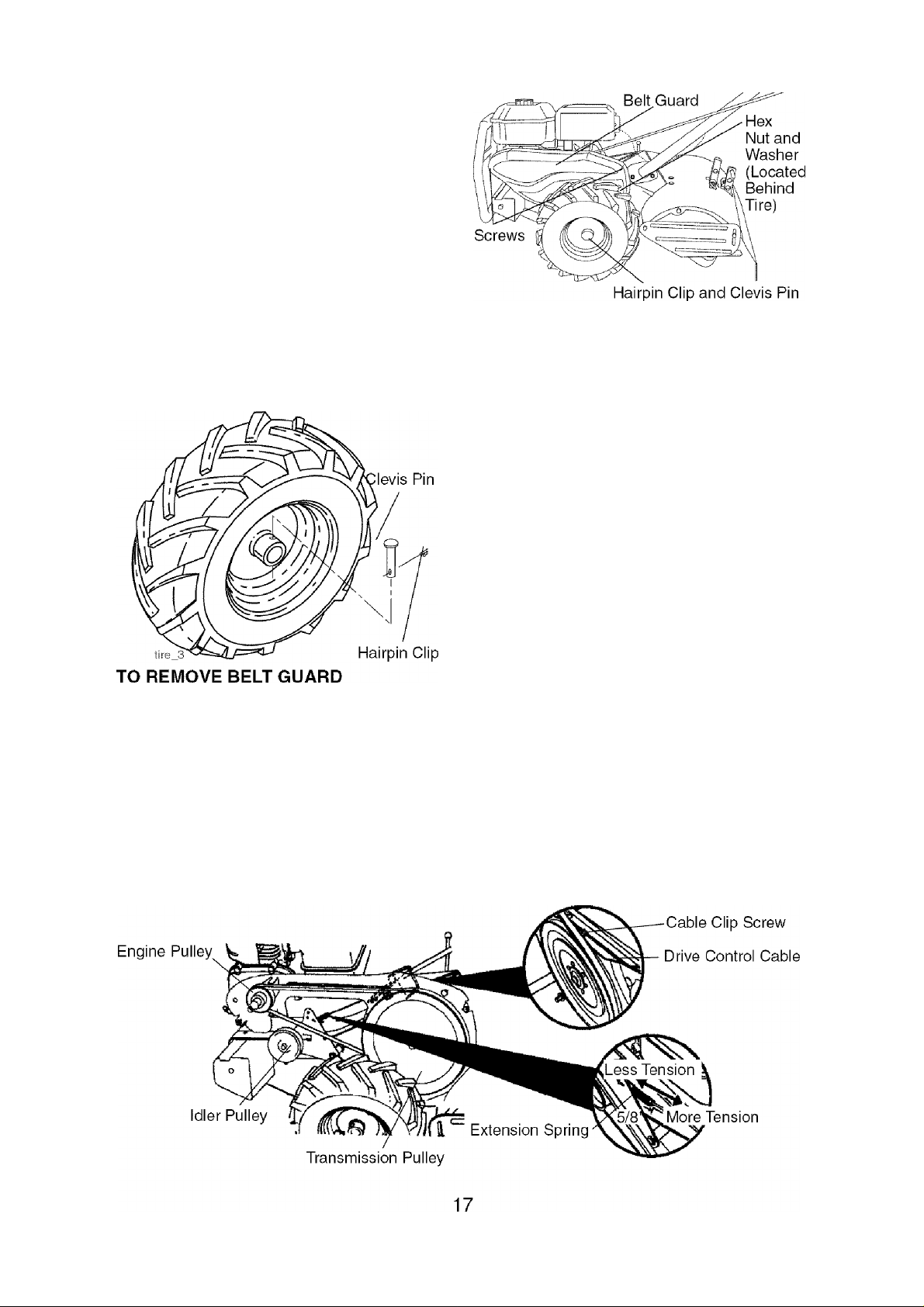

TO REPLACE GROUND DRIVE BELT

1. Remove belt guard as described in “TO

REMOVE BELT GUARD”.

2. Remove old belt by slipping off engine

pulley first then remove from trans

mission pulley.

3. Place new belt in groove of trans

mission pulley and into engine pulley.

BELT MUST BE IN GROOVE ON TOP

OF IDLER PULLEY. NOTE POSITION

OF BELT TO GUIDES.

4. Check belt adjustment as described

below.

5. Replace belt guard.

6. Reposition wheel and replace clevis

pin and hairpin clip.

NOTE: For ease of removal, remove hair

pin clip and clevis pin from left wheel. Pull

wheel out from tiller about 1 inch.

1.

Remove two (2) screws from side of

belt guard.

Remove hex nut and washer from

bottom of belt guard (located behind

wheel ^.

3.

Pull belt guard out and away from unit.

4.

Replace belt guard by reversing above

procedure.

GROUND DRIVE BELT ADJUSTMENT

For proper belt tension, the extension

spring should have about 5/8 inch stretch

when drive control bar is in “ENGAGED”

position. This tension can be attained as

follows:

1. Loosen cable clip screw securing the

drive control cable.

2. Slide cable forward for less tension and

rearward for more tension until about

5/8 inch stretch is obtained while the

drive control bar is engaged.

3. Tighten cable clip screw securely.

Page 18

TINE REPLACEMENT

^CAUTION: Tines are sharp. Wear

gloves or other protection when handling

tines.

A badiy worn tine causes your tiller to

work harder and dig more shallow. Most

important, worn tines cannot chop and

shred organic matter as effectively nor

bury it as deeply as good tines. A tine this

worn needs to be replaced.

New Tine Worn Tine

To maintain the superb tilling perfor

mance of this machine the tines should

be checked for sharpness, wear, and

bending, particularly the tines which

are next to the transmission. If the gap

between the tines exceeds 3-1/2 inches

they should be replaced or straightened

as necessary.

For tines that are slightly worn, the

bolted tine and hub assemblies can be

switched between sides to continue

tilling in the same tilling mode if tilling

in a different mode is desired then the

bolted tine and hub assemblies should

be switched back to their original side

so that the tine edge with the least wear

will be used.

Page 19

ENGINE

Maintenance, repair, or replacement of

the emission control devices and systems,

which are being done at the customers ex

pense, may be performed by any non-road

engine repair establishment or individual.

Warranty repairs must be performed by an

authorized engine manufacturer's service

outlet.

TO ADJUST THROTTLE CONTROL

CABLE

1.

The throttle control has been preset at

the factory and adjustment should not

be necessary. If adjustment is nec

essary, proceed as follows:

2.

With engine not running, move remote

throttle control lever to “FAST” position.

3.

If throttle lever on engine touches high

speed stop, no further adjustment is

necessary. If throttle lever does not

touch high speed stop, continue with

adjustment procedure.

4.

Loosen cable clamp screw.

5.

Move throttle lever up until it touches

high speed stop, and hold in this po

sition.

6.

Tighten cable clamp screw securely.

TO ADJUST CARBURETOR

The carburetor has been preset at the

factory and adjustment should not be

necessary. However, engine performance

can be affected by differences in fuel, tem

perature, altitude or load. If the carburetor

does need adjustment, contact your near

est authorized service center/department

IMPORTANT: Never tamper with the

engine governor, which is factory set

for proper engine speed. Overspeeding

the engine above the factory high speed

setting can be dangerous. If you think

the engine-governed high speed needs

adjusting, contact your nearest sears or

other qualified service center which has

the proper equipment and experience to

make any necessary adjustments.

Clamp Screw

19

Page 20

STORAGE

Immediately prepare your tiller for storage

at the end of the season or if the unit will

not be used for 30 days or more.

4&Warning: Never store the tiller with gas

oline in the tank inside a building where

fumes may reach an open flame or spark.

Allow the engine to cool before storing in

any enclosure.

TILLER

1. Clean entire tiller {See “CLEANING” in

the Maintenance section of this man

ual).

2. Inspect and replace belts, if necessary

(See belt replacement instructions in

the Service and Adjustments section of

this manual).

3. Lubricate as shown in the Maintenance

section of this manual.

4. Be sure that all nuts, bolts and screws

are securely fastened. Inspect moving

parts for damage, breakage and wear.

Replace if necessary.

5. Touch up all rusted or chipped paint

surfaces; sand lightly before painting.

ENGINE

FUEL SYSTEM

IMPORTANT: It is important to prevent

gum deposits from forming in essential

fuel system parts such as the carburetor,

fuel filter, fuel hose, or tank during storage.

Also, alcohol blended fuels (called gasohol

or using ethanol or methanol) can attract

moisture which leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an

engine while in storage.

• Empty the fuel tank by starting the en

gine and letting it run until the fuel lines

and carburetor are empty.

• Never use engine or carburetor cleaner

products in the fuel tank or permanent

damage may occur.

• Use fresh fuel next season.

NOTE: Fuel stabilizer is an acceptable

alternative in minimizing the formation of

fuel gum deposits during storage. Add

stabilizer to gasoline in fuel tank or stor

age container. Always follow the mix ratio

found on stabilizer container. Run engine

at least 10 minutes after adding stabilizer

to allow the stabilizer to reach the carbu

retor. Do not empty the gas tank and

carburetor if using fuel stabilizer.

ENGINE OIL

Drain oil (with engine warm) and replace

with clean oil. {See “ENGINE” in the Main

tenance section of this manual).

CYLINDER

1.

Remove spark plug.

2.

Pour 1 ounce (29 ml) of oil through

spark plug hole into cylinder.

Pull starter handle slowly several times

to distribute oil.

4.

Replace with new spark plug.

OTHER

• Do not store gasoline from one season

to another.

• Replace your gasoline can if your can

starts to rust. Rust and/or dirt in your

gasoline will cause problems.

• If possible, store your unit indoors and

cover it to give protection from dust and

dirt.

• Cover your unit with a suitable protective

cover that does not retain moisture. Do

not use plastic. Plastic cannot breathe

which allows condensation to form and

will cause your unit to rust.

IMPORTANT: Never cover tiller while en

gine and exhaust areas are still warm.

20

Page 21

TROUBLESHOOTING CHART:

See appropriate section in manual unless directed to Sears service center

PROBLEM CAUSE CORRECTION

Will not start 1. Out of fuel. 1. Fill fuel tank.

2. Engine not “CHOKED”

properly.

3. Engine flooded. 3. Wait several minutes before

4. Dirty air cleaner. 4. Clean or replace air cleaner

5. Water in fuel. 5. Empty fuel tank and carbure

6. Clogged fuel tank. 6. Remove fuel tank and clean.

7. Loose spark plug wire. 7. Make sure spark plug wire is

8. Bad spark plug or

improper gap.

9. Carburetor out of adjust

ment.

2. See “TO START ENGINE” in

the Operation section.

attempting to start.

cartridge.

tor, and refill tank with fresh

gasoline.

seat ed properly on plug.

8. Replace spark plug or adjust

gap.

9. Make necessary adjust

ments.

Hard to start 1. Throttle control not set

properly.

2. Dirty air cleaner. 2. Clean or replace air cleaner

3. Bad spark plug or

improper gap.

4. Stale or dirty fuel. 4. Empty fuel tank and refill with

5. Loose spark plug wire. 5. Make sure spark plug wire is

6. Carburetor out of

adjustment.

Loss of power 1. Engine is overloaded. 1. Set depth stake for shallower

2. Dirty air cleaner. 2. Clean or replace air cleaner

3. Low oil level/dirty oil. 3. Check oil level/change oil.

4. Faulty spark plug. 4. Clean and regap or change

5. Cil in fuel. 5. Empty and clean fuel tank

6. Stale or dirty fuel. 6. Empty fuel tank and refill with

7. Water in fuel. 7. Empty fuel tank and carbure

8. Clogged fuel tank. 8. Remove fuel tank and clean.

9. Spark plug wire loose. 9. Connect and tighten spark

10. Dirty engine air screen. 10. Clean engine air screen.

11. Dirty/clogged muffler. 11. Clean/replace muffler.

12. Carburetor out of

adjustment.

13. Poor compression.

21

1. Place throttle control in

“FAST” position.

cartridge.

3. Replace spark plug or adjust

gap.

fresh gasoline.

seated properly on plug.

6. Make necessary adjust

ments.

tilling.

cartridge.

spark plug.

and refill, and clean carburetor.

fresh gasoline.

tor, and refill tank with fresh

gasoline.

plug wire.

12. Make necessary adjust

ments.

13. Contact a Sears or other

qualified service center.

Page 22

TROUBLESHOOTING CHART:

See appropriate section in manual unless directed to Sears service center

PROBLEM CAUSE CORRECTION

Engine

overheats

Excessive

bounce/difficult

handling

Soil balls up or

clumps

Engine runs but

tiller won’t

move

Engine runs but

labors when

tilling

1. Low oil levei/dirty oil.

2. Dirty engine air screen.

3. Dirty engine.

4. Partially plugged muffler.

5. Improper carburetor

adjustment.

1. Ground too dry and hard.

2. Depth stake

incorrectly adjusted.

1. Ground too wet. 1. Wait for more favorable soil

1. Tine control is not

engaged.

2. V-belt not correctly

adjusted.

3. V-belt is off pulley{s).

1. Tilling too deep.

2. Throttle control not

properlyadjusted.

3. Carburetor out of adjust

ment.

1. Check oil level/change oil.

2. Clean engine air screen.

3. Clean cylinder fins, airscreen, muffler area.

4. Remove and clean muffler.

5. Adjust carburetor to richer

position.

1. Moisten ground or wait for

more favorable soil condi

tions.

2. Adjust depth stake.

conditions.

1. Engage tine control.

2. Inspect/adjust V-belt.

3. Inspect V-belt.

1. Set depth stake for shallower

tilling.

2. Check throttle control setting.

3. Make necessary adjust

ments.

Tines skip over

ground

Hard to shift into

gear

Tiller shuts off

when drive

control bar

engaged

1. Drag Stake not lowered

in forward rotating tili

mode.

2. Improper tiiling mode.

1. Gears not timed. 1. Briefly engage drive control

1. Shift lever set in between

counter rotating tili

position and forward

rotating till position.

2. Tines jammed

1. Lower Drag Stake

2. Forward rotating tine drive

should only be used for soft

ground or for soil that has

already been tilled.

bar and release or rock tiller

forward and backward until

are able to shift gears.

1. Shift to either counter rotating

till position or forward rotating

till position.

2. Clear tines.

22

Page 23

TABLA DE CONTENIDOS

Garantía............................................................23 Mantenimiento

Reglas de Seguridad

Especificaciones del producto

Montaje/Pre-Operación

Operación

Programa de Mantenimiento.................

..............................................

...........................

..............

.........................

...........23 Servicio y Ajustes

...........25 Almacenamiento

...........27 Identificación de Problemas,

...........29 Vea el Manual Inglés................ Inglés del Dueño

..........

35

........................

............................................37

.....................

.........................35

.....................

...42

GARANTIA

GARANTIA LIMITADA DE DOS ANOS PARA LA OULTIVADORA CRAFTSMAN

Por dos (2) años, a partir de la fecha de compra, cuando esta Cultivadora Craftsman se mantenga,

lubrique y afine según las instrucciones para la operación y el mantenimiento en el manual del

dueño, Sears reparará, gratis, todo defecto en el material y la mano de obra.

Esta Garantía no cubre:

• Artículos que se desgastan durante el uso normal tales como los brazos, las bujías, los filtros de

aire y las correas.

• Reparaciones necesarias debido al abuso o a la negligencia del operador, incluyéndose a los

cigüeñales doblados y a la falta de mantenimiento del equipo según las instrucciones que se

incluyen en el manual del dueño.

• Si la Cultivadora Craftsman se usa para fines de arriendo, esta garantía se aplica solamente por

treinta (30 ) treintadías a partir de la fecha de compra.

El Servicio de Garantía esta disponible al devolver la cultivadora Craftsman al centro/departamento

de servicio Sears más cercano en los estados unidos.

Esta Garantía se aplica solamente mientras el producto este en uso en los estados unidos. Esta

Garantía le otorga derechos legales específicos, y puede que también tenga otros derechos que

varían de estado a estado.

¿ti

SEARS, ROEBUCK AND CO., D/817WA, HOFFMAN ESTATES, IL60179 Ü.S.A.

REGLAS DE SEGURIDAD

IMPORTANTE: Esta Maquina cortadora es capaz de amputar las manosy los pies y de lanzar

objetos, si no se observan las instrucciones de seguridad siguientes se pueden producir lesiones

graves o la muerte.

ENTRENAMIENTO

• Lea el Manual del Dueño cuidadosamente.

Familiarícese completamente con los

controles y con el uso adecuado del equipo.

Sepa cómo parar la unidad y desenganchar

los controles rápidamente.

• Nunca permita que los niños operen el equi

po. Nunca permita que los adultos operen el

equipo sin los conocimientos adecuados.

• Mantenga el área de operación despejada de

personas, especialmente niños pequeños y

animales domésticos.

PREPARACIÓN

• Inspeccione cuidadosamente el área en

donde se va usar el equipo y remueva los

objetos extraños.

• Desenganche todos los embragues y cambie

a neutro antes de hacer arrancar el motor.

• No opere el equipo sin usar ropa exterior

adecuada. Use zapatos que mejoren el equi

librio en superficies resbalosas,

• Maneje el combustible con cuidado pues es

muy inflamable.

• Use un envase de combustible aprobado.

• Nunca añada combustible a un motor en

funcionamiento o caliente.

• Llene el estanque de combustible afuera con

mucho cuidado. Nunca llene el estanque de

combustible en un recinto cerrado.

• Vuelva a colocar la tapa del depósito de gas

olina en forma segura y limpie el combustible

derramado antes de volver a arrancar.

• Use cordones de extensión y receptáculos,

según las especificaciones del fabricante,

para todas las unidades con motores de im

pulsión o con motores de arranque eléctrico.

• Nunca trate de hacer ningún ajuste mientras

que el motor esté funcionando (excepto en

los casos específicamente recomendados

por el fabricante).

OPERACIÓN

• No ponga ni las manos ni los pies cerca o

debajo de las piezas rotatorias.

• Tenga mucho cuidado cuando opere o cruce

entradas para automóviles de ripio, senderos

o caminos. Esté alerta en lo que se refiere a

los peligros escondidos o al tráfico. No lleve

pasajeros.

23

Page 24

Después de pegarle a un objeto extraño,

pare el motor, remueva el alambre de la

bujía, inspeccione ia cuitivadora cuidadosa

mente, para verificar si hay daños, y repare

ei daño antes de volver a arrancar y operar la

cultivadora.

Tenga cuidado para evitar resbalarse o

caerse.

Si la unidad empieza a vibrar anormalmente,

pare el motor y revísela inmediatamente para

verificar la causa. La vibración normalmente

es un aviso de problemas.

Pare el motor cuando abandone la posición

de operación.

Tome todas las precauciones posibles cu

ando deje la máquina desatendida. Desen

ganche los brazos, cambie a neutro y pare el

motor.

Antes de limpiar, reparar e inspeccionar,

apague el motor y asegúrese que todas

las partes en movimiento se han detenido.

Desconecte el alambre de la bujía, y mantén

galo alejado de ésta para evitar el arranque

por accidente. Desconecte el cordón en los

motores eléctricos.

No haga funcionar el motor en recintos cer

rados; los gases de escape son peligrosos.

Nunca opere la cultivadora sin las protec

ciones, y las planchas adecuadas y sin los

demás dispositivos de seguridad en su lugar.

Mantenga a los niños y a los animales do

mésticos alejados.

No sobrecargue la capacidad de la máquina,

tratando de cultivar a mucha profundidad,

muy rápido.

Nunca opere la máquina a altas velocidades

en superficies resbalosas. Mire hacia atrás y

tenga cuidado cuando retroceda.

Nunca permita la presencia de espectadores

cerca de la unidad.

Use solamente accesorios y aditamentos

para la cultivadora aprobados por el fabri

cante.

Nunca opere la cultivadora sin buena visibili

dad o luz.

Tenga cuidado al cultivar en terreno duro.

Los brazos pueden quedarse agarrados en

el suelo e impulsar a la cultivadora hacia

adelante. Si esto sucede, suelte los mangos

y no restrinja la máquina.

MANTENiyiENTO Y ALMACENAMIEN

TO

• Mantenga los accesorios y aditamentos de

la máquina en buenas condiciones para el

funcionamiento.

• Revise las clavijas de seguro, los pernos

de montaje del motor y otros pernos, a

intervalos frecuentes, para verificar si están

apretados en forma segura y asegurarse que

el equipo esté en buenas condiciones de

funcionamiento.

• Nunca guarde la máquina con combustible

en el estanque de combustible dentro de un

edificio en donde hay fuentes de ignición

presentes, tales como calentadores de agua

o del ambiente, secadoras de ropa u otros

artefactos parecidos. Permita que se enfríe

el motor antes de guardarlo en algún lugar

cerrado.

• Siempre refiérase a las instrucciones en la

guía del operador para ver los detalles de im

portancia si la cultivadora va a ser guardada

por un período de tiempo largo.

Asusque este símbolo que señala las precau

ciones de seguridad de importancia. Quiere

decir- ¡¡¡ATENCIÓN!!! ¡¡¡ESTE ALERTO!!! SU

SEGURIDAD ESTA COMPROMETIDA.

ApRECAUCIÓN: Siempre desconecte el

alambre de la bujía y póngalo donde no pueda

entrar en contacto con la bujía, para evitar el

arranque por accidente, durante la preparación,

el transporte, el ajuste o cuando se hacen

reparaciones.

AaDVERTENCIA: El tubo de escape del

motor, algunos de sus constituyentes y algunos

componentes del vehículo contienen o despren

den productos químicos conocidos en el Estado

de California como causa de cáncer y defectos

al nacimiento u otros daños reproductivos.

24

Page 25

ESPECIFICACIONES DEL PRODUCTO

Capacidad de 4 Cuartos

gasolina: Sin plomo, regular

Aceite(API-SG-SL): SAE 30 (Sobre 40°F)

(Capacidad: 19 oz.) SAE 5w-30 SAE 10w-30

(Debajo 40°F)

Bujía : Champion RC12YC

(Abertura: 0,030")

FELICITACIONES por la compra de su Culti

vadora Sears. Ha sido diseñada, planificada y

fabricada para darle la mejor confiabilidad y el

mejor rendimiento posible.

En el caso de que se encuentre con cualquier

problema que no pueda solucionar fácilmente,

haga el favor de ponerse en contacto con un

centro de servicio Sears o con un otro centro

de servicio cualificado. Cuenta con técnicos

bien capacitados y competentes con herra

mientas adecuadas para darle servicio o para

reparar su unidad.

Haga el favor de leer y de guardar este manual.

Estas instrucciones le permitirán montar y man

tener su cultivadora en forma adecuada. Siem

pre observe las “REGLAS DE SEGURIDAD.”

RESPONSABILIDADES DEL CLIENTE

• Lea y observe las reglas de seguridad.

• Siga un programa regular de mantenimiento,

cuidado y uso de su cultivadora.

• Siga las instrucciones descritas en las sec

ciones “Mantenimiento” y “Almacenamiento”

de este Manual del Dueño.

AadVERTENCIA: Esta unidad viene equipa

da con un motor de combustión interno y no se

debe usar sobre, o cerca, de un terreno no de

sarrollado cubierto de bosques, de arbustos o

de césped, a menos que el sistema de escape

del motor venga equipado con un amortiguador

de chispas que cumpla con las leyes locales o

estatales (si existen). Si se usa un amortigua

dor de chispas, el operador debe mantenerlo

en condiciones de trabajo eficientes.

En el estado de California, la ley exige lo an

terior (Sección 4442 del “California Public Re

sources Code” [Decreto de Recursos Públicos

de California]). Otros estados pueden contar

con otras leyes parecidas. Las leyes federales

se aplican en las tierras federales. Su centro

de Servicio más cercano tiene disponible amor

tiguadores de chispas para el silenciador. (Vea

la sección de Partes de Repuesto en el manual

Inglés del dueño.)

ACUERDOS DE PROTECCION PARA LA

REPARACIÓN

Congratulaciones por su buena compra.

Su nuevo producto Craftsman® está diseñado

y fabricado para funcionar de modo fiable por

muchos años. Pero como todos los productos,

puede necesitar alguna reparación de tanto

en tanto. En este caso tener un Acuerdo de

Protección para la Reparación puede hacerles

ahorrar dinero y fastidios.

Compre ahora un Acuerdo de Protección para

la Reparación y protégese de molestias y gas

tos inesperados.

Un Acuerdo incluye los puntos siguientes:

• Servicio experto de nuestros 12.000

especialistas profesionales en la reparación.

• Servicio ilimitado sin cargo alguno para

las partes y la mano de obra sobre todas las

reparaciones garantizadas.

• Sustitución del producto si su producto

garantizado no puede ser arreglado.

• Descuento del 10% sobre el precio corriente

del servicio y de las partes relativas al

servicio no cubiertas por el acuerdo; también

el 10% menos sobre el precio corriente de

un control de mantenimiento preventivo.

• Ayuda rápida por teléfono ~ soporte

telefónico por parte de un técnico Sears

sobre productos que requieren un arreglo en

casa, y además una programación sobre los

arreglos más convenientes.

Cuando se ha comprado el Acuerdo, basta con

una llamada telefónica para programar el servi

cio. Puede llamar cuando quiera, día y noche o

fijar en línea una cita para obtener el servicio.

Sears tiene más de 12.000 especialistas

profesionales en la reparación, que tienen

acceso a más de 4.5 millones de partes y

accesorios de calidad.

Este es el tipo de profesionalidad con que

puede contar para ayudar a alargar la vida del

producto que acaba de comprar, por muchos

años. ¡Compre hoy su Acuerdo de Protección

para la Reparación!

Se aplican algunas limitaciones y exclusio

nes. Para conocer los precios y tener más

Información, llame al 1-800-827-6655.

SERVICIO DE INSTALACIÓN SEARS

Para la instalación profesional Sears de

aparatos de casa, puertas de garaje,

calentadores de agua y otros importantes

artículos para la casa, en U.S.A llamar a

1-800-4-MY-HOME®

25

Page 26

ACCESORIOS Y ADITAMENTOS

Estos accesorios estaban disponibles cuando se compró la cultivadora. También están disponibles

en la mayoría de las tiendas de Sears y en los centros de servicio. La mayoría de las tiendas Sears

también pueden ordenar partes de repuesto para usted, si les proporciona el número del modelo

de su cultivadora.

MOTOR

RENDIMIENTO DE LA CULTIVADORA

MANTENIMIENTO DE LA CULTIVADORA

CORREA BRAZOS C LA VIJ A D E S EG UR O ABRAZ AD ER A D E H OR QU ILL A

C

?

n

i

fw.

PIEZAS SIN MONTAR

Page 27

MONTAJE/PRE OPERACION

Su cultivadora nueva ha sido montada en la fábrica, con ia excepción de aquelias partes que se

dejaron sin montar por razones de envío. Para asegurarse que la cultivadora operará en forma

segura y adecuada, todas las partes y los artículos de ferretería que monte tienen que estar apre

tados en forma segura. Use las herramientas correctas, según sea necesario, para asegurarse de

que queden apretadas en forma segura.

HERRAMIENTAS NECESARIAS PARA

EL MONTAJE

Se le facilitará el montaje si cuenta con un

juego de llaves de tubo. Se han enumerado los

tamaños estándar de las llaves.

(1) Cuchillo para todo uso

(1) Cortador de alambres

(1) Destornillador

(1) Medidor de presión de las llantas

(1) Par de alicates

(1) Llave de 9/16"

POSICIÓN DEL OPERADOR

Cuando en este manual se mencionan los

términos “lado derecho” o “lado izquierdo”

se refiere a cuando usted se encuentra en la

posición de operación (parado/a detrás de los

mangos de la cultivadora).

PARTE DELANTERA

np

LADO

IZQUIERDO

11

,

LADO

DERECHO

i

Corte la esquina del lado derecho delantera

y la trasera de la caja de cartón. Tienda

en el suelo la pared lateral de la caja de

cartón.

Remueva el material de empaque del con

junto del mango.

Inserte un cierre del mango (con los dientes

mirando hacia afuera) en la muesca de la

caja de cambio. (Aplique grasa en el lado

liso del cierre del mango para ayudar a

mantenerlo en su lugar hasta que el con

junto del mango se baje a su posición.)

VISTA DESDE EL LADO DERECHO DE LA

CULTIVADORA

—)

E-

POSICIÓN DEL

OPERADOR

DESEMPAQUE DE LA CAJA DE

CARTÓN

i&PRECAUCIÓN: Tenga cuidado con las

grapas expuestas cuando maneje o deseche

los materiales de la caja de cartón.

IMPORTANTE: Cuando desempaque y monte

la cultivadora, tenga cuidado de no estirar o

enredar los cables.

1. Al mismo tiempo que se sujeta el conjunto

del mango, corte las ligaduras del cable que

aseguran el conjunto del mango al bastidor

superior y a la estaca de profundidad. Per

mita que el conjunto del mango descanse

en la cultivadora.

2. Remueva el bastidor superior de la caja de

cartón.

3. Lentamente, saque el conjunto del mango

hacia arriba y póngalo en la parte superior

de la caja de cartón.

2. Agarre el conjunto del mango. Manténgalo

en la posición “arriba.” Asegúrese que el

cierre del mango permanezca en la muesca

de la caja de cambio. Deslice el conjunto

del mango a su posición.

Conjunto del mango

posoción “Arriba”

Apriete la palanca de

cierre del mango para

... sujetarla

Suelte la palanca de

cierre del mango para

moverla

27

Page 28

3. Rote el conjunto del mango hacia abajo. In

serte el perno portador trasero primero, con

la cabeza del perno en el lado izquierdo de

la cultivadora y ponga sueltamente la tuerca

de seguridad.

4. Inserte el perno de pivote de la parte

delantera de la placa y apriete en forma

segura.

5. Corte la esquina del lado izquierdo trasera

de la caja de cartón. Tienda en el suelo la

pared trasera del cartón, la cual removerá

la solapa protectora de cartón de la defensa

de nivelación.

6. Corte las esquinas restantes del cartón y

póngalas planas.

7. Baje el conjunto de mango. Apriete la

tuerca del perno de acarreo para que el

mango pueda moverse con alguna resisten

cia. Esto facilitara el ajuste.

8. Ponga la arandela plana en el extremo

roscado de la palanca de cierre del mango.

9. Inserte la palanca de cierre del mango a

través de la base del mango y de la caja de

engranaje. Atornille la palanca de seguridad

del mango, justo lo suficiente como para

sujetar la palanca en su lugar.

10. Inserte el segundo cierre del mango (con

los dientes hacia adentro) en la ranura en

la base del mango (justo dentro de la aran

dela).

11. Con el conjunto del mango en la posición

más baja, apriete la palanca de cierre del

mango, en forma segura, rotándola en el

sentido de las manillas del reloj. Si se deja

el conjunto del mango en la posición más

baja, será más fácil remover la cultivadora

de la caja de cartón.

Caja de Cambio

Perno portador

trasero

Base del Mango

Arandela Plana

Cierre del Mango

Tuercas de Seguridad

Palanca de

Cierre del Mango

Boulon de

y®- pivot

INSERCION DE LA ABRAZADERA DEL

CABLE

• Inserte la abrazadera del cable de plástico

dentro del agujero en la parte trasera de

la columna del mango. Empuje los cables

dentro de la abrazadera.

CONEXION DE LA VARILLA DE CAMBIO

1. Inserte el extremo de la varilla de cambio

que está más alejado de la dobladura, en

el agujero del indicador de la palanca de

cambio.

2. Inserta la abrazadera de horquilla a través

del agujero de la varilla de cambio para

asegurarla con la junta de la abrazadera

sobre el lado derecho.

Abrazadera de Horquilla

Indicador de la

1 de Cambio

Varilla de Cambio,

REMOCION DE LA CULTIVADORA DE

LA CAJA

1. Ajuste el conjunto del mango a la posición

la mas baja. Asegúrese que el mango de

cierre esté bien seguro.

2. Asegúrese que el indicador de la palanca

de cambio esté en la posición neutro “N”.

3. Incline la cultivadora hacia adelante le

vantando el mango. Separe la cubierta de

cartón de la defensa de nivelación.

4. Rote el mango de la cultivadora a la dere

cha y tírela fuera de la caja de cartón.

REVISIÓN DE LA PRESIÓN DE LAS

LLANTAS

Las llantas en su unidad se inflaron demasiado

en la fábrica por razones de envío. Es impor

tante que las llantas tengan la misma presión y

que ésta sea la correcta para obtener el mejor

rendimiento en el labrado.

• Reduzca la presión de las llantas a 20 PSI.

ALTURA DEL MANGO

• Se puede ajustar la altura del mango en la

mejor forma que le acomode al operador.

(Vea “PARA AJUSTAR LA ALTURA DEL

MANGO” en la sección de Servicio y Ajustes

de este manual.)

28

Page 29

OPERACION

Estos símbolos pueden apareser sobre su cultivadora en la literature proporcionada con el pro

ducto. aprenda y comprenda sus significados.

CONOZCA SU CULTIVADORA

LEA ESTE MANUAL DEL DUEÑO Y LAS REGLAS DE SEGURIDAD ANTES DE OPERAR SU

OULTIVADORA

Compare las ilustraciones con su cultivadora para familiarizarse con la ubicación de los

diversos controles y ajustes. Guarde este manual para futura referencia.

_

LABOREO

_

n

LABOREO

F

N

4

■f

MARCHANNEUTRO

R

1-

ATTENCiÓN O MOTOR ESTRANGü

t

REVÉS

|\| (Q

LACiÓN

COM

BUSTIBLE

lA I

O

Nuestras cultivadoras cumplen con los estándares de seguridad del

American National Standards Institute,

BARRA DE CONTROL DE LA IMPULSION

- Se usa para enganchar los brazos.

CONTROL DE LA ACELERACIÓN - Controla

la velocidad del motor.

DEFENSA DE NIVELACIÓN - Nivela el suelo

labrado.

DEFENSA LATERAL EXTERIOR - Ajustable

para no enterrar las plantas pequeñas.

ESTACA DE PROFUNDIDAD - Controla la pro

fundidad a la cual excavará la cultivadora.

ESTACA DE ARRASTRE - Controla la veloci

dad de marcha hacia adelante.

INDICADOR DE LA PALANCA DE CAMBIO

- Muestra en qué cambio de engranaje se

encuentra la transmisión.

MANGO DEL ARRANCADOR DE CULA

TEO - Se usa para hacer arrancar el motor.

PALANCA DE CAMBIO - Se usa para cambiar

los engranajes de la transmisión.

29

Page 30

ANTEOJOS DE «

SEGURIDAD 1

L

U PRUEÆÎfêlA

VALE MAS QUE

FALTA DE VISION

tro de sus ojos, lo que puede producir daños graves en éstos. Siempre use anteojos

de seguridad o protecciones para los ojos antes de hacer arrancar su cultivadora o

mientras esté labrando con élla. Recomendamos gafas de seguridad o una más

cara de visión amplia de seguridad usada sobre las gafas.

COMO USAR SU CULTIVADORA

La operación de cualquier cuitivadora puede hacer que salten objetos extraños den

Sepa cómo operar todos los controles antes de

agregar combustible y aceite o antes de tratar

de hacer arrancar el motor.

PARADA

BRAZOS Y LA IMPULSIÓN

1. Suelte la barra de control de la impulsión

para parar el movimiento.

2. Mueva la palanca de cambio a la posición

de neutro (“N”).

MOTOR

• Mueva el control de la aceleración a la

posición de “PARADA” (STOP). Si equipado

con un interruptor de parada, mueva el inter

ruptor a la posición de “PARADA” (STOP).

AVISO: Nunca use la estrangulación para parar

el motor.

Barra de control de la

impulsión en la posición

“Enganchadas ^ \ .Control de la

Aceleración

5. Sujete la barra de control de la impulsión en

contra del mango para hacer arrancar en

movimiento a la cultivadora.

ES DIFÍCIL CAMBIAR LAS MARCHAS

• Enganche lentamente la barra de control de

la transmisión y suelte o bascule la cultiva

dora hacia adelante y hacia atrás hasta que

sea posible cambiar las marchas.

ESTACA DE PROFUNDIDAD

La estaca de profundidad puede levantarse o

bajarse para permitirle un labrado más versátil

o para facilitar el transporte de su cultivadora.

Labrado menos

profundo

(Cultivating)

Labrado Más

profundo

Posición de

Transporte

Estaca de profundidad

Barra de control de la

impulsión en la posición

“Disenganchada”

Palanca de

cambio

OPERACION DE LOS BRAZOS - CON

IMPULSIÓN DE RUEDAS