Craftsman 917292460 Owner’s Manual

OWNER'S

MANUAL

MODEL NO.

917.292460

Caution:

Read and follow

all Safety Rules

and inst_uctions

Before Operating

This Equipment

MAN°

5.5 HP

26 ! CH TiNE WIDTH

FRONTTI ETILLER

WITH VE E

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

= Repair Parts

Sears_ Roebuck and Co., Hoffman Estates, iL 60179 U.S.A.

Safe Operation Practices for Walk-Behind Powered Rotary THEers

SAFETY RULES

TRAINING

Read the Owner's Manual carefully. Be thoroughly

familiar with the controls and the proper use of the

equipment, Know how to stop the unit and disengage

the controls quickly.

o Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

Keep the area of operation clear of all persons, particu-

larly small children, and pets.

o Thoroughly inspect the area where the equipment isto

be used and remove alt foreign objects.

* Disengage all clutches and shift into neutral before

starting the engine (motor).

, Do not operate the equipment without wearing ad-

equate outer garments. Wear footwear that witi im-

prove footing on slippery surfaces.

, Handle fuel with care; it is highly flammable.

, Use an approved fue! container.

o Never add fuel to a running engine or hot engine.

, Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

° Replace gasoline cap securely and dean up spilled

fuel before restarting.

, Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

, Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

recommended by manufacturer).

OPERATION

, Do not put hands or feet near or under rotating parts.

o Exercise extreme caution when operating on or cross-

ing gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic. Do not carry passengers.

• After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly in-

spect the tiller for any damage, and repair the damage

before restarting and operating the tiller.

Exercise caution to avoid stipping or falling.

o If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of troubie.

, Stop the engine (motor) when leaving the operating

position.

• Take all possible precautions when leaving the ma-

chine unattended. Disengage the tines, shift into

neutral, and stop the engine.

o Before cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have stopped.

Disconnect the spark piug wire, and keep the wire

away from the plug to prevent accidental starting.

Disconnect the cord on electric motors.

, Do not run the engine indoors; exhaust fumes are

dangerous.

o Never operate the tiller without proper guards, plates,

or other safety protective devices in ptace.

o Keep children and pets away.

o Do not overload the machine capacity by attempting to

till too deep at too fast a rate.

o Never operate the machine at high speeds on stippery

surfaces. Look behind and use care when backing.

o q'4ever allow bystanders near the unit.

Use only attachments and accessories approved by

the manufacturer of the tiller (such as wheel weights,

counterweights, cabs, and the like).

° Never operate the tiller without good visibility or light.

Be careful when tilling in hard ground. The tines may

catch in the ground and propel the tiIler forward. If this

occurs, let go of the handlebars and do not restrain the

machine.

MAINTENANCE AND STORAGE

o Keep machine, attachments, and accessories in safe

working condition,

o Check shear pins, engine mounting bolts, and other

bolts at frequent intervals for proper tightness to be

sure the equipment is in safe working condition.

• Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such as

hot water and space heaters, ctothes dryers, and the

like. Allow the engine to coo! before storing in any

enclosure.

Always refer to the operator's guide instructions for

important details if the tiller is to be stored for an

extended per!od.

IMPORTANT -

CAUTIONS, IMPORTANTS, AND NOTES ARE A MEANS

OF ATTRACTING ATTENTION TO IMPORTANT OR

CRITICAL INFORMATION IN THIS MANUAL.

ttVIPORTANT: USED TO ALERT YOU THAT THEREtSA

POSSIBILITY OF DAMAGING THIS EQUIPMENT.

NOTE: Gives essential information that wili aid you to

better understand, incorporate, or execute a particular set

of instructions.

Look for this symbol to point out im-

portant safety precautions. It means

CAUTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark

plug wire and place wire where it can-

not contact spark plug in order to pre-

vent accidental starting when setting

up, transporting, adjusting or making

repairs.

& WARNING

The engine exhaust from this product con-

tains chemicals known to the State of Califor-

nia to cause cancer, birth defects, or other

reproductive harm.

2

CONGRATULATIONS on your purchase of a Sears Tilter.

it has been designed, engineered and manufactured to

give you the best possible dependability and performance.

Should you experience any problems you cannot easity

remedy, please contact your nearest authorized Sears

Service Center/Department. We have competent, well-

trained technicians and the proper tools to service or repair

this unit.

Please read and retain this-manual. 'The instructions will

enable you to assemble and maintain your tiller properly.

Always observe the "SAFETY RULES".

MODEL

NUMBER 4317:292460

PRODUCT SPECIFICATIONS

HORSEPOWER: 5.5 HP

DISPLACEMENT: t3 cu. in.

GASOLINE CAPACITY: 3 Quarts

Unleaded Regular

OiL (API-SFiSG): SAE 30 (Above 32°F)

(CAPACITY: 20 oz.) SAE 5W-30 (Below 32°F)

SPARK PLUG: Champion RJ19LM

(GAP: .030") (STD36t458)

SERIAL

NUMBER

DATE OF

PURCHASE

THE MODEL AND SERIAL NUMBERS WILL BE

FOUND ON THE MODEL PLATE ATTACHED TO

THE RIGHT HAND ENGINE BRACKET.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

uct. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

- Read and observe the safety rules.

• Follow a regular schedule inmaintaining, caring for and

YOU SHOULD RECORD BOTH SERIAL NUMBER

AND DATE OF PURCHASE AND KEEP IN A SAFE

PLACE FOR FUTURE REFERENCE.

using your tiller.

Follow the instructions under the "Customer

Responsibilities" and"Storage" sections ofthis Owner's

Manual.

IMPORTANT: THIS UNIT IS EQUIPPED WITH AN INTERNAL COMBUSTION ENGINE AND SHOULD NOT BE USED ON

OR NEAR ANY UNIMPROVED FOREST-COVERED, BRUSH-COVERED OR GRASS COVERED LAND UNLESS THE

ENGINE'S EXHAUST SYSTEM IS EQUIPPED WiTH A SPARK ARRESTER MEETING APPLICABLE LOCAL OR STATE

LAWS (iFANY). iFASPARKARRESTER tS USED, IT SHOULD BE MAINTAINED IN EFFECTIVE WORKING ORDER BY

THE OPERATOR.

IN THE STATE OF CALIFORNIA THE ABOVE IS REQUIRED BY LAW (SECTION 4442 OF THE CALIFORNIA PUBLIC

RESOURCES CODE). OTHER STATES MAY HAVE SIMILAR LAWS. FEDERAL LAWS APPLY ON FEDERAL LANDS.

SEE YOUR SEARS AUTHORIZED SERVICE CENTER FOR SPARK ARRESTER. REFER TO THE REPAIR PARTS

SECTION QF THIS MANUAL FOR PART NUMBER.

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN TILLER

For two (2) years from date of purchase, when this Craftsman TiIter is maintained, lubricated, and tuned up

according to the operating and maintenance instructions in the owner's manual, Sears wiIt repair free of charge any

defect in material or workmanship.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as tines, spark plugs, air cleaners and belts.

o Repairs necessary because of operator abuse or negligence, including bent crankshafts and the failure to

maintain the equipment according to the instructions contained in the owner's manual.

• If this Craftsman Tiller is used for commercial or rental purposes, this Warranty applies for only thirty (30) days

from the date of purchase.

WARRANTY SERVICE IS AVAILABLE BY RETURNING THE CRAFTSMAN TILLER TO THE NEAREST SEARS

SERVICE CENTER/DEPARTMENT IN THE UNITED STATES. THIS.WARRANTY APPLIES ONLY WHILE THIS

PRODUCT iS iN USE tN THE UNITED STATES.

This Warranty gives you specific }egal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO., Di817WA, HOFFMAN ESTATES, IL 60179

TABLE OF CONTENTS

SAFETY RULES ........................................................... 2

CUSTOMER RESPONSiBILITiES ..................... 3, 12-I 4

PRODUCT SPECIFICATIONS ...................................... 3

WARRANTY .................................................................. 3

ACCESSORIES ............................................................. 5

ASSEMBLY ................................................................ 6-7

OPERATION ............................................................. 8-11

iNDEX

A

Accessories ..................................... 5

Adjustments:

Carburetor .............................. t7

Depth Stake .............................. 9

Handle Height ......................... 14

Tines .................................. 14-15

V-Beit ...................................... 16

Wheels ...................................... 9

Air Cleaner .................................... 13

B

Belt, V-:

Belt Guard .............................. 17

Repair Parts ............................ 2t

V-Belt Replacement ................ 16

C

Cooling System ............................. 13

Controls:

Choke ....................................... 8

Throttle ..................................... 8

Tines ......................................... 8

Cultivating ..................................... 11

Customer Responsibilities:

Air Cleaner .............................. 13

Cooling System ...................... 13

Finish ...................................... !4

Maintenance Schedule ........... 12

Muffler ..................................... 14

Oil Change .............................. 13

Spark Plug .............................. t4

Transmission .......................... 14

D

Depth Stake:

Adjustment ................................ 9

Repair Parts ............................ 22

E

Engine:

Air Cleaner .............................. 13

Cooling System ...................... 13

Fuel Type ................................ 10

Lubrication .............................. 13

Oil Level .................................. 10

Oil Type ............................. 10,13

Engine Cont.:

Repair Parts ....................... 26-30

Spark Plug .............................. 14

Starting ................................... 10

Stopping ................................... 9

Storage ................................... 18

Winter Operation .................... 13

Fuel:

Filling Tank ............................. 10

Storage ................................... 18

Type ........................................ I 0

Finish:

Maintenance ........................... 14

Handle:

Height Adjustment .................. t4

Repair Parts ............................ 20

Lubrication:

Lubrication Chart ................... 12

Engine .................................... 13

Muffler:

Maintenance ........................... t4

Spark Arrester .......................... 3

Oil:

Level ....................................... 10

Type ................................... 10,13

Operation:

Cultivating ............................... 11

Fill Fuel Tank .......................... I0

Starting Engine .......................... 10

Stopping Tines & Engine .......... 9

Tilling ........................................ 9

Tilling Hints ............................. 11

Tine Operation .......................... 9

Transporting Tiller ................... 10

Winter Operation .................... I3

MAINTENANCE SCHEDULE ...................................... 12

SERVICE & ADJUSTMENTS ................................. !4-17

STORAGE ................................................................... 18

TROUBLESHOOTING ................................................. t9

REPAIR PARTS-TILLER ........................................ 20-25

REPAIR PARTS-ENGINE ...................................... 26-30

SERVICE/PARTS ORDERING .................... Back Cover

R

Repair Parts

Tiller ................................... 20-24

Engine ............................... 26-30

Rules for Safe Operation ................. 2

S

Service & Adjustments:

F

H

L

M

O

Carburetor .............................. 17

Handle Height ......................... 14

Tines .................................. t4-I5

V-Belt ...................................... 16

Wheels ...................................... 9

SenJice:

Repair Parts ....................... 20-30

Service Record ....................... t 2

Spark Plug:

Gap ........................................... 3

Maintenance ........................... 14

Storage:

Fuel System ............................ 18

Tiller ........................................ 18

T

Tilling .......................................... 9,11

Tines:

Arrangement ...................... t4-15

Operation .................................. 9

Repair Parts ............................ 23

Replacement .......................... I5

Transmission:

Maintenance ........................... 14

Repair Parts ............................ 24

Troubleshooting ............................ 19

Transporting .................................. 10

W

Warranty .......................................... 3

Wheels:

Adjustments .............................. 9

Repair Parts ............................ 22

4

ACCESSORIES

These accessories were available when the tiller was purchased. They are also available at most Sears Retail

outlets, Catalog and Service Centers. Most Sears Stores can order repair parts for you when you provide the modef

number of your tiller,

ENGINE

SPARK PLUG MUFFLER AiR FILTER

TILLER MAINTENANCE

BELT T_NES

!

!

i_ ,- _.

GAS CAN ENGINE OiL

! i\

S ........J

Lj' __)

CLEVIS PiN

_J

STABILIZER

; I

S L.

i! J

HAiRPiN CLIP

5

ASSEM LY

Your new tiller has been assembled at the factory with exception of those parts left unassembbd for shipping purposes. To

ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened secure{y. Use the

correct tools as necessary to insure proper tightness. . ._

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(1) Utility knife

(1) Screwdriver

(1) Pair of pliers

(2) 1/2" wrenches

CONTENTS OF HARDWARE PACK

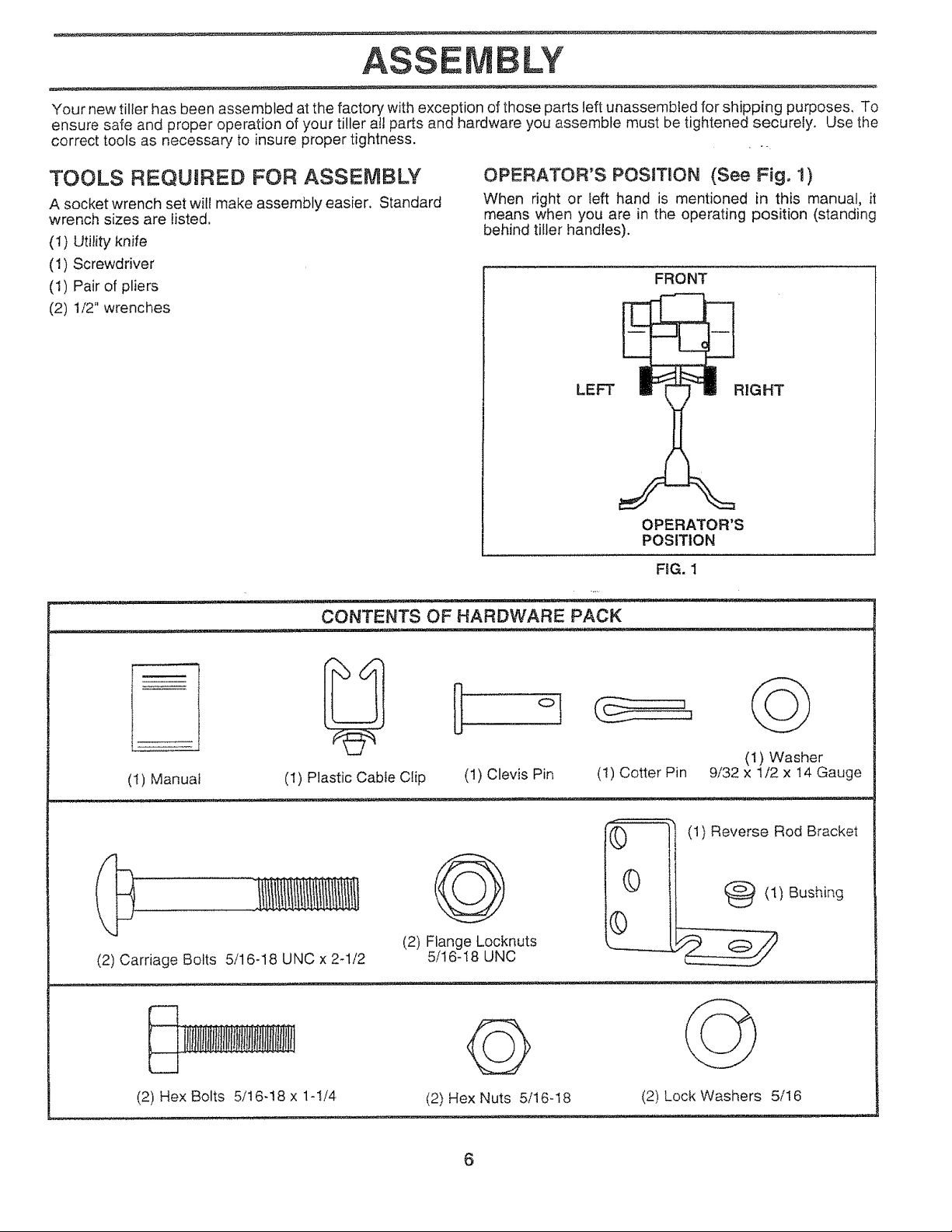

OPERATOR'S POSITION (See Fig. 1)

When right or left hand is mentioned in this manual, it

means when you are in the operating position (standing

behind tiller handles).

FRONT

LEFT

j

OPERATOR'S

POSITION

FroG. 1

(I) Manual

(2) Carriage Bolts 5/16-18 UNC x 2-1/2

(2) Hex Bolts

5/16-18 x 1-!/4

(1) Plastic Cable Clip (1) Clevis Pin

(2) Flange Locknuts

5/16-I8 UNC

Q

(2) Hex Nuts 5/t6-18

6

..... I (_

(!) Cotter Pin

(1) Reverse Rod Bracket

©

®

(2) Lock Washers 5/16

(1) Washer

9/32 x 1/2 x 14 Gauge

@(t) Bushing

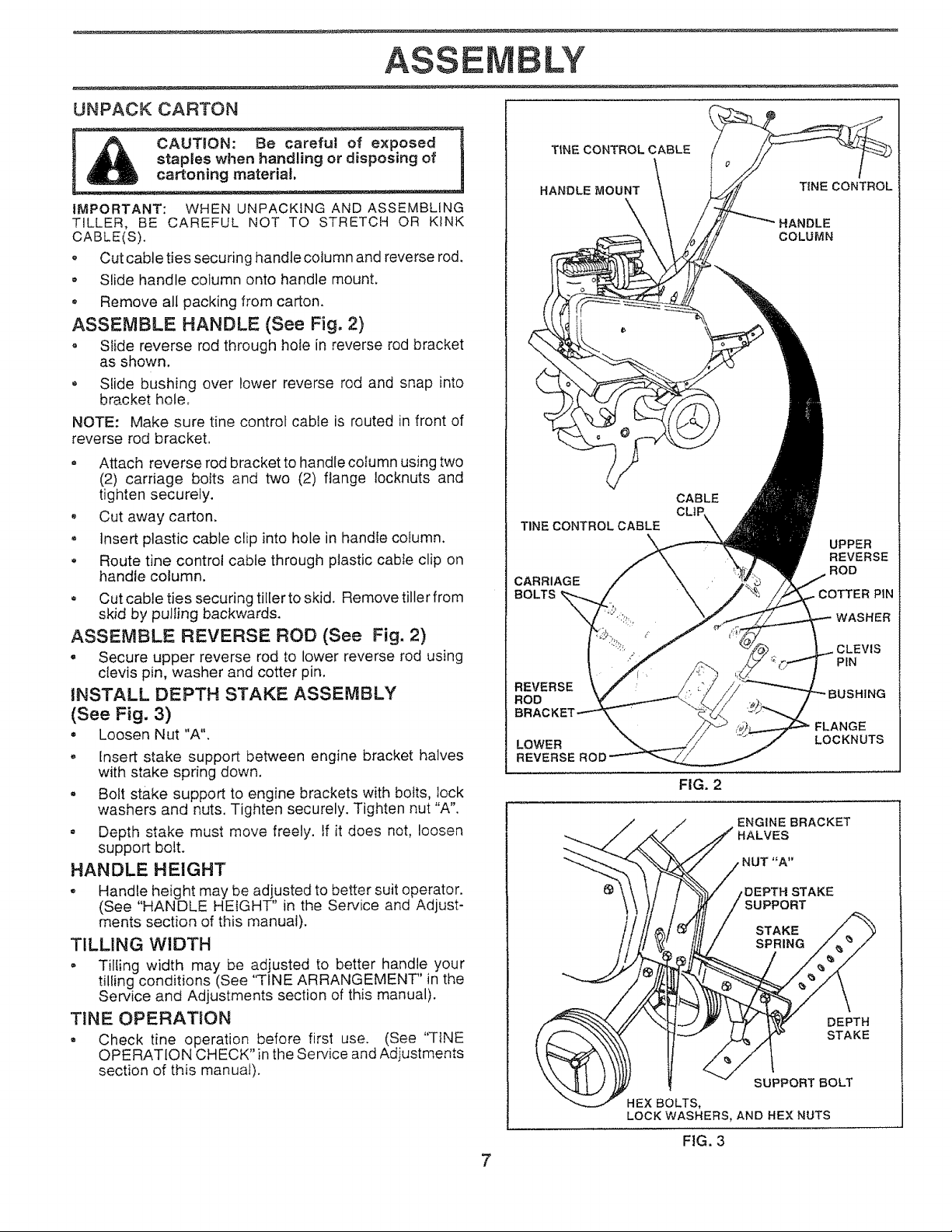

UNPACK CARTON

ASSE LY

CAUTION: Be carefut of exposed

staples when handling or disposing of

cartoning material.

IMPORTANT: WHEN UNPACKING AND ASSEMBLING

TILLER, BE CAREFUL NOT TO STRETCH OR KINK

CABLE(S).

° Cut cable ties securing handle column and reverse rod,

, Slide handle column onto handle mount,

* Remove all packing from carton.

ASSEMBLE HANDLE (See Fig. 2)

, Stide reverse rod through hole in reverse rod bracket

as shown,

= Slide bushing over lower reverse rod and snap into

bracket hole,

NOTE: Make sure tine control cable is routed in front of

reverse rod bracket.

= Attach reverse rod bracket to handle column using two

(2) carriage bolts and two (2) flange locknuts and

tighten securely.

• Cut away carton.

Insert plastic cable clip into hole in handle column.

Route tine control cable through plastic cable clip on

handle column.

- Cutcable ties securing tiller to skid. Remove tiller from

skid by pulling backwards.

ASSEMBLE REVERSE ROD (See Fig. 2)

• Secure upper reverse rod to lower reverse rod using

clevis pin, washer and cotter pin.

INSTALL DEPTH STAKE ASSEMBLY

(See Fig. 3)

= Loosen Nut "A".

Insert stake support between engine bracket halves

with stake spring down.

Bolt stake support to engine brackets with bolts, lock

washers and nuts. Tighten securely. Tighten nut "A".

• Depth stake must move freely, tf it does not, loosen

support bolt.

HANDLE HEIGHT

• Handle height may be adjusted to better suit operator.

(See "HANDLE HEIGHT" in the Service and Adjust-

ments section of this manual),

TILLING WIDTH

- Tilling width may be adjusted to better handle your

tilling conditions (See "TINE ARRANGEMENT" in the

Service and Adjustments section of this manual).

TINE OPERATION

® Check fine operation before first use, (See "TtNE

OPERATION CHECK" in the Service and Adjustments

section of this manual).

T|NE CONTROL CABLE

HANDLE MOUNT

TINE CONTROL CABLE

CARRIAGE

BOLTS

REVERSE

ROD

LOWER

REVERSE ROD

7

TINE CONTROL

DLE

COLUMN

CABLE

UPPER

REVERSE

ROD

COTTER PIN

CLEVIS

PIN

FLANGE

LOCKNUTS

FIG. 2

ENGINE BRACKET

HALVES

STAKE

SUPPORT

DEPTH

STAKE

SUPPORT BOLT

HEX BOLTS,

LOCK WASHERS, AND HEX NUTS

FIG. 3

OPERAT!O

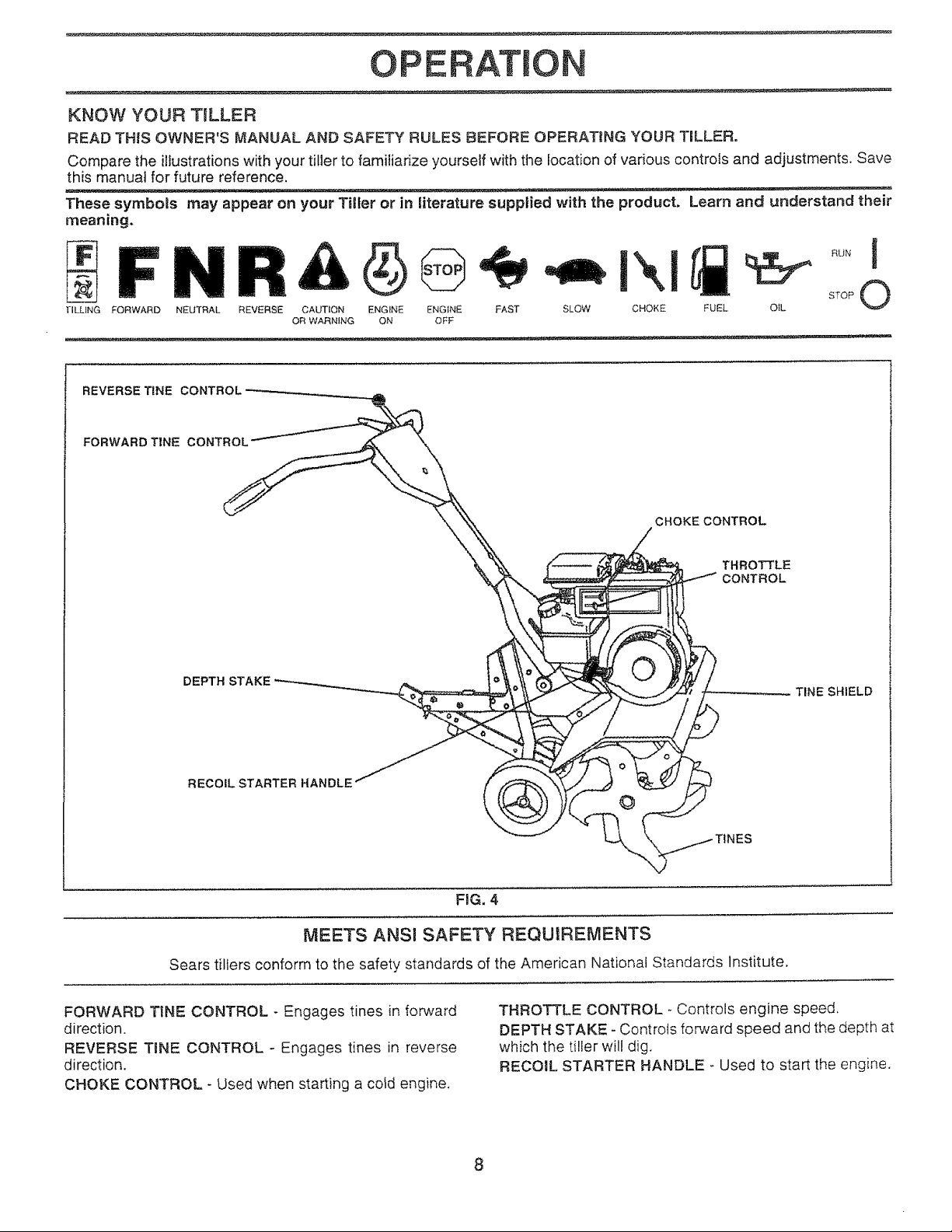

KNOW YOUR TILLER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER.

Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

These symbols may appear on your Tiller or in literature supplied with the product. Learn and understand their

I l;

TILLING FORWARD NEUTRAL REVERSE CAUTION ENGINE ENGINE FAST SLOW CHOKE FUEL OtL

REVERSE TINE CONTROL

FORWARD TINE CONTROL

OR WARNING ON OFF

CHOKECONTROL

THROTTLE

CONTROL

DEPTH

RECOIL STARTER HANDLE

O

FIG, 4

MEETS ANSI SAFETY REQUIREMENTS

Sears tilters conform to the safety standards of the American National Standards Institute.

TINE SHIELD

FORWARD TINE CONTROL - Engages tines in forward

direction.

REVERSE TINE CONTROL - Engages tines in reverse

direction.

CHOKE CONTROL - Used when starting a cold engine.

THROTTLE CONTROL - Controls engine speed,

DEPTH STAKE - Controls forward speed and the depth at

which the tiller will dig.

RECOIL STARTER HANDLE - Used to start the engine.

8

OPERATION

The operation of any tiller can resu|t in foreign objects thrown into the eyes, which can

resuJt in severe eye damage. Always wear safety gmasses or eye shields before starting

your tiller and while tilling. We recommend a wide vision safety mask over the spectacles

or standard safety glasses,

HOW TO USE YOUR TILLER

STOPPING (See Fig. 5)

TINES

= Retease forward tine control to stop forward move-

ment.

• Release reverse tine control to stop reverse move-

ment.

ENGINE

° Move throttle control to "STOP" position.

• Never use choke to stop engine.

REVERSE TINE CONTROL FORWARD TINE CONTROL

"OFF" (UP) POSITION

FORWARD TINE CONTROL

"ON" (DOWN) POSITION

TILLING

The speed and depth of tilling is regulated by the position

of the depth stake and wheet height.

The depth stake should always be below the wheels for

digging. It serves as a brake to slow the tiller's forward

motion to enable the tines to penetrate the ground. Also,

the more the depth stake is lowered into the ground the

deeper the tines will dig.

DEPTH STAKE (See Fig. 6)

Adjust depth stake by removing the hairpin clip and clevis

pin. Change depth stake to desired position. Replace the

clevis pin and hairpin clip.

• For normal tilling, set depth stake at the second or third

hole from the top.

WHEELS (See Fig. 6)

Adjust wheels by"removing the hairpin clip and ctevis pin.

Change wheel position. Replace the hairpin clip and clevis

pin.

For normal tilling, set wheels at the second orthird hole

from the top.

HAIRPIN CLIP

AND CLEVIS PIN

CHOKE

CONTROL_ CONTROL

FIG. 5

TINE OPERATION (See Fig. 5)

FORWARD

, Squeeze forward tine contro_ to handle.

REVERSE

- With forward fine control in "OFF" (up) position, pult

back and hold reverse fine control

"WHEEL

FIG. 6

DEPTH

STAKE

HAIRPIN CLIP

AND CLEVIS PIN

9

OPERATION

TRANSPORTUNG YOUR TILLER

cAuT,o.- Bofo o

ing, altow tiller engine and muffler to t

cool. Disconnect spark plug wire. Drain

gasoline from fuel tank.

AROUND THE YARD

- Tip depth stake forward until it is held by the stake

spring.

o Push tiller handles down, raising tines off the ground.

® Push or pull tiller to desired location.

AROUND TOWN

- Disconnect spark plug wire.

° Drain fuel tank.

,, Transport in upright position to prevent oil leakage.

BEFORE STARTING ENGINE

IMPORTANT: BE VERY CAREFUL NOT TO ALLOW DIRT

TO ENTER THE ENGINE WHEN CHECKING OR ADDING

OIL OR FUEL. USE CLEAN OIL AND FUEL AND STORE

IN APPROVED, CLEAN, COVERED CONTAINERS. USE

CLEAN FILL FUNNELS.

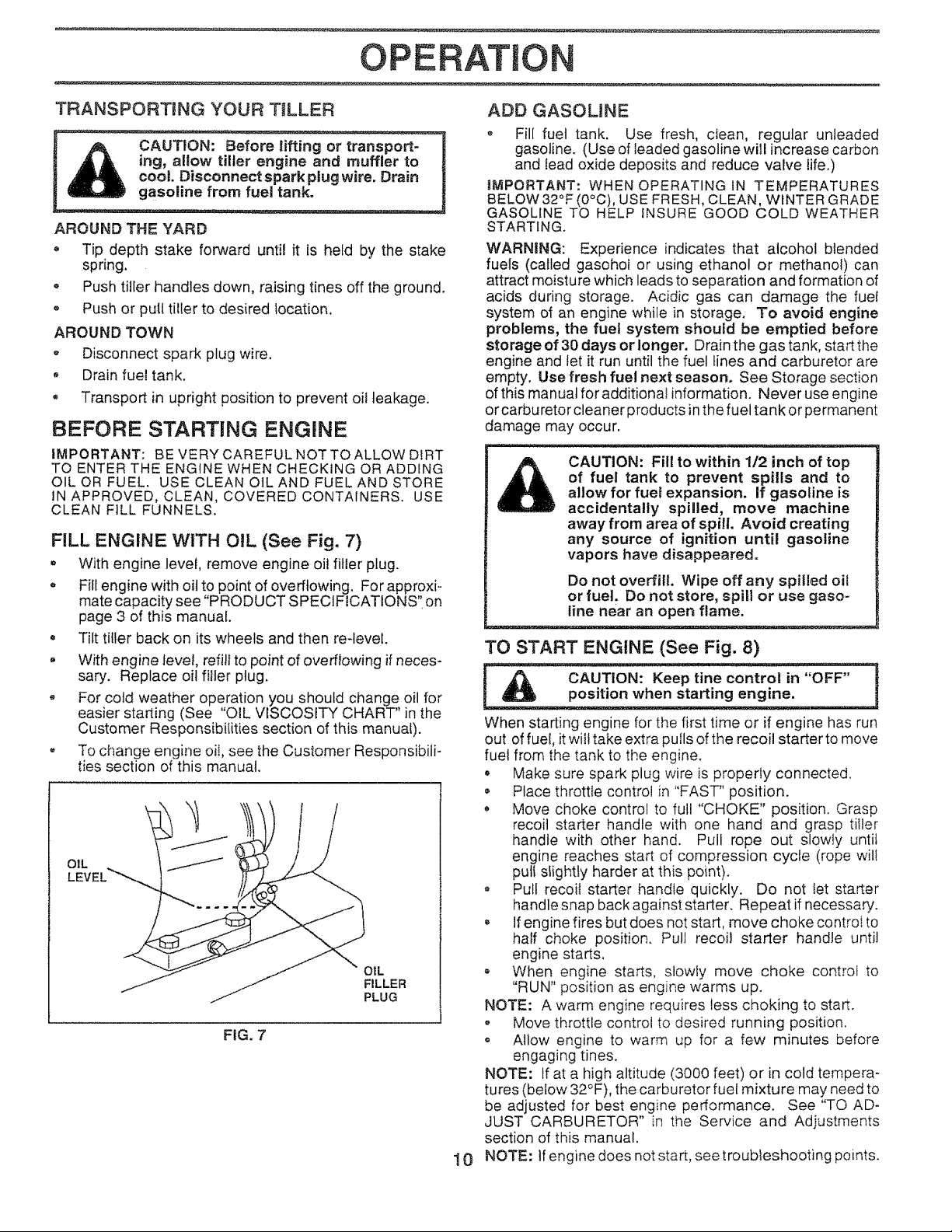

FiLL ENGINE WITH OIL (See Fig. 7)

o With engine level, remove engine oil filler plug.

Fill engine with oil to point of overflowing. For approxi-

mate capacity see "PRODUCT SPECIFICATIONS" on

page 3 of this manual.

, Tilt tiller back on its wheels and then re-level.

• With engine level, refill to point of overflowing if neces-

sary. Replace oil fitter plug.

, For cold weather operation you should change oil for

easier starting (See "OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manual).

° To change engine oiI, see the Customer Responsibili-

ties section of this manual.

OIL

OIL

FILLER

PLUG

FiG. 7

ADD GASOLINE

Fill fuel tank. Use fresh, clean, regular unleaded

gasoline. (Use of leaded gasoline will increase carbon

and Iead oxide deposits and reduce valve life.)

IMPORTANT: WHEN OPERATING iN TEMPERATURES

BELOW 32°F (0°C), USE FRESH, CLEAN, WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

WARNING: Experience indicates that alcohot blended

fuels (called gasohoi or using ethanol or methanol) can

attract moisture which leads to separation and formation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems, the fuel system should be emptied before

storage of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty. Use fresh fuel next season. See Storage section

of this manual for additional information. Never use engine

or carburetor cleaner products in the fuel tank or permanent

damage may occur.

of fuel tank to prevent spills and to

allow for fuet expansion, if gasoline is

CAUTION: Fill to within 1/2 inch of top

accidentally spilled, move machine

away from area of spill. Avoid creating

any source of ignition until gasoline

vapors have disappeared.

Do not overfill. Wipe off any spilled oil

or fuel. Do not store, spill or use gaso-

line near an open flame.

TO START ENGINE (See Fig. 8)

When starting engine for the first time or if engine has run

out offuel, it wilt take extra pulls of the recoil starter to move

fuel from the tank to the engine.

, Make sure spark plug wire is properly connected.

Place throttle control in "FAST" position.

Move choke control to full "CHOKE" position. Grasp

recoil starter handle with one hand and grasp tiIler

handle with other hand. Pull rope out slowty until

engine reaches start of compression cycle (rope wilt

putt slightly harder at this point).

Pull recoil starter handle quickly. Do not tet starter

handle snap back against starter. Repeat if necessary.

Ifengine fires but does not start, move choke control to

half choke position. Pull recoil starter handle until

engine starts,

- When engine starts, slowly move choke controi to

"RUN" position as engine warms up.

NOTE: A warm engine requires less choking to start.

Move throttle control to desired running position.

° Allow engine to warm up for a few minutes before

engaging tines.

NOTE: tf at a high altitude (3000 feet) or in cold tempera-

tures (below 32°F), the carburetor fuel mixture may need to

be adjusted for best engine performance. See "TO AD-

JUST CARBURETOR" in the Service and Adjustments

section of this manual.

NOTE: tfengine does not start, see troubleshooting points.

10

Loading...

Loading...