Craftsman 917288610, 917288611 Owner’s Manual

Operator's Manual

I'cRnFTsMn°1

LAWN' TRACTOR

26.0 HP,*54" Mower

Electric Start

Automatic Transmission

Model No.

917.28861

• Espa5ol, p. 37

I

This product has a low emission engine which operates I

differently from previously built engines. Before you start the

engine, read and understand this Owner's Manual.

IMPORTANT:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

Gasoline containing up to 10% ethanol (EIO) is acceptable for use inthis machine.

The use of any gasoline exceeding 10% ethanol (EIO) will void the product warranty.

Esta mdquina puede uUlizar gasolina con un contenido de hasta el 10% de etanol (El0).

El uso de una gasolina que supere el 10% de etanol (EIO) anulard la garantta del producto.

Sears Brands Management Corporation, Hoffman Estates IL 60179 U.S,A,

VisitourCraftsmanwebsite:www.sears.comictaftsman *As rated bytheenginemanuf=c_urer

For answers to your questions

about this product, Call:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pm, Mon- Sat

I

441273 Rev. 2

Warranty .................................................. 2

Safety Rules ............................................ 3

Product Specifications ............................. 6

Assembly/Pre-O peration ......................... 8

Operation ............................................... 13

Maintenance .......................................... 21

Service and Adjustments ....................... 26

Storage .................................................. 31

Troubleshooting ..................................... 32

Sears Service ......................... Back Cover

Maintenance Schedule .......................... 21

Craftsman Riding Equipment Warranty

CRAFTSMAN FULL WARRANTY

FOR THREE YEARS from the date of purchase, all non-expendable parts of this riding equipment

are warranted against any defects in material or workmanship. A defective non-expendable part will

receive free in-home repair or replacement if repair is impossible.

FOR FIVE YEARS from the date of purchase, the frame and front axle of this riding equipment are

warranted against any defects in material or workmanship. A defective frame or front axle will receive

free in-home repair or replacement if repair is impossible.

FOR 90 DAYS from the date of purchase, the battery (an expendable part) of this riding equipment

is warranted against any defects in material or workmanship (our testing proves that it will not hold a

charge). A defective battery will receive free in-home replacement.

ADDITIONAL LIFETIME LIMITED WARRANTY on CAST IRON FRONT AXLE (if equipped)

FOR AS LONG AS IT IS USED by the original owner after the fifth year from the date of purchase, the

cast iron front axle (if equipped) of this riding equipment is warranted against any defects in material or

workmanship. With proof of purchase, adefective cast front axle willreceive free in-home replacement.

WAR RANTY S ERVICE

For warranty coverage details to obtain free repair or replacement, call 1-800-659-5917 or visit the

web site: www.craffsman.com

[natl cases above, if part repair or replacement is impossible, the ridingequipment will be replaced

free of charge with the same or an equivalent model.

All of the above warranty coverage is void if this riding equipment is ever used while providing

commercial services or if rented to another person.

This warranty covers ONLY defects in matedal and workmanship. Warranty coverage does NOT

include:

• Expendable parts (except battery) that can wear out from normal use within the warrantyperiod,

including but not Jimited to blades, spark plugs, air cleaners, belts, and oil filters.

• Standard maintenance servicing, oil changes, or tune-ups.

• Tire replacement or repair caused by punctures from outside objects, such as nails, thorns,

stumps, or glass.

- Tire or wheel replacement or repair resulting from normal wear, accident, or improper operation or

maintenance.

• Repairs necessary because of operator abuse, including but not limited to damage caused by

towing objects beyond the capability of the riding equipment, impacting objects that bend the

frame, axle assembly or crankshaft, or ever-speeding the engine.

• Repairs necessary because of operator negligence, including but not limited to, electdcal and

mechanical damage caused by improper storage, failure to use the proper grade and amount

of engine oil, failure to keep the deck clear of flammable debris, or failure to maintain the riding

equipment according to the instructionscontained in the operator's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized

(stale). In general, fuel should be used within 30 days of its purchase date.

• Norma! deterioration and wear of the exterior finishes, or product label replacement.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

2

_DANGER: This cutting machine is capable of amputating hands and feet and

throwing objects, Failure to observe the following safety instructions could result

in serious injury or death.

_IbWARNING: Inorderto prevent acciden-

tal starting when setting up, transporting,

adjusting or making repairs, always discon-

nect spark plug wire and place wire where

it cannot contact spark plug.

_WARNING: Do not coast down a hitf in

neutral, you may lose control of the tractor.

_t, WARNING: Tow only the attachments

that are recommended by and comply with

specifications of the manufacturer of your

tractor. Use common sense when towing.

Operate only at the lowest possible speed

when on aslope. Too heavy of a load, while

on a slope, is dangerous. Tires can lose

traction with the ground and cause you to

lose control of your tractor.

_WARNING: Engine exhaust, some of

its constituents, and certain vehicle compo-

nentscontain or emit chemicals knowntothe

State ofCalifornia to cause cancer and birth

defects or other reproductive harm.

_WARNING: Battery posts, terminals and

related accessories contain lead and lead

compounds, chemicals known to the State of

California to cause cancer and birth defects

or other reproductive harm. Wash hands

after handling.

Never direct discharged material toward

anyone. Avoid discharging material

against a wall or obstruction. Material

may ricochet back toward the operator.

Stop the blades when crossing gravel

su_aces,

Do not operatemachine withoutthe en-

tire grass catcher, discharge chute, or

cther safety devices inplace andworking.

Slow down before turning.

Never leave a running machine unat-

tended. Always turn off blades, set

parking brake, stop engine, and remove

keys before dismounting.

Disengage blades when not mowing.

Shut off engine and wait for all parts to

cometo a complete stop before cleaning

the machine, removing the grass catcher,

or unclogging the discharge chute,

Operate machine only indaylightorgood

artificial light.

Do not operate the machine while under

the influence of alcohol or drugs.

Watch for traffic when operating near or

crossing roadways.

t

Useextra carewhen loading orunloading

the machine into a trailer or truck.

Alwaysweareye protection when operat-

ing machine.

Data indicates that operators, age 60

years and above, are involvedina large

I. GENERAL OPERATION

* Read, understand, and followalt instruc-

tions on the machine and in the manual

before starting.

- Do not put hands or feet near rotating

parts or under the machine. Keep clear

of the discharge opening at all times.

, Only allow responsible adults, who are

familiar with the instructions, to operate

the machine.

• Clear the area of objects such as rocks,

toys, wire, etc., which could be picked

up and thrown by the blades.

, Be sure the area is clear of bystanders

beforeoperating. Stop machine ifanyone

enters the area.

percentageof riding mower-related inju-

ries. These operators should evaluate

their ability to operate the riding mower

safely enough to protectthemselves and

others from serious injury.

Follow the manufacturer's recommen-

dation for wheel weights or counter-

weights.

Keep machine free of grass, leaves or

other debris build-upwhichcantouch hot

exhaust / engine parts and burn. Do not

allow the mower to plow leaves or other

debris which can cause build-up to oc-

cur. Clean any oil or fuel spillage before

operating or storing the machine. Allow

machine to coot before storage.

, Never carry passengers.

• Do not mow in reverse unless absolutely

necessary.Always lookdown and behind

before and while backing.

3

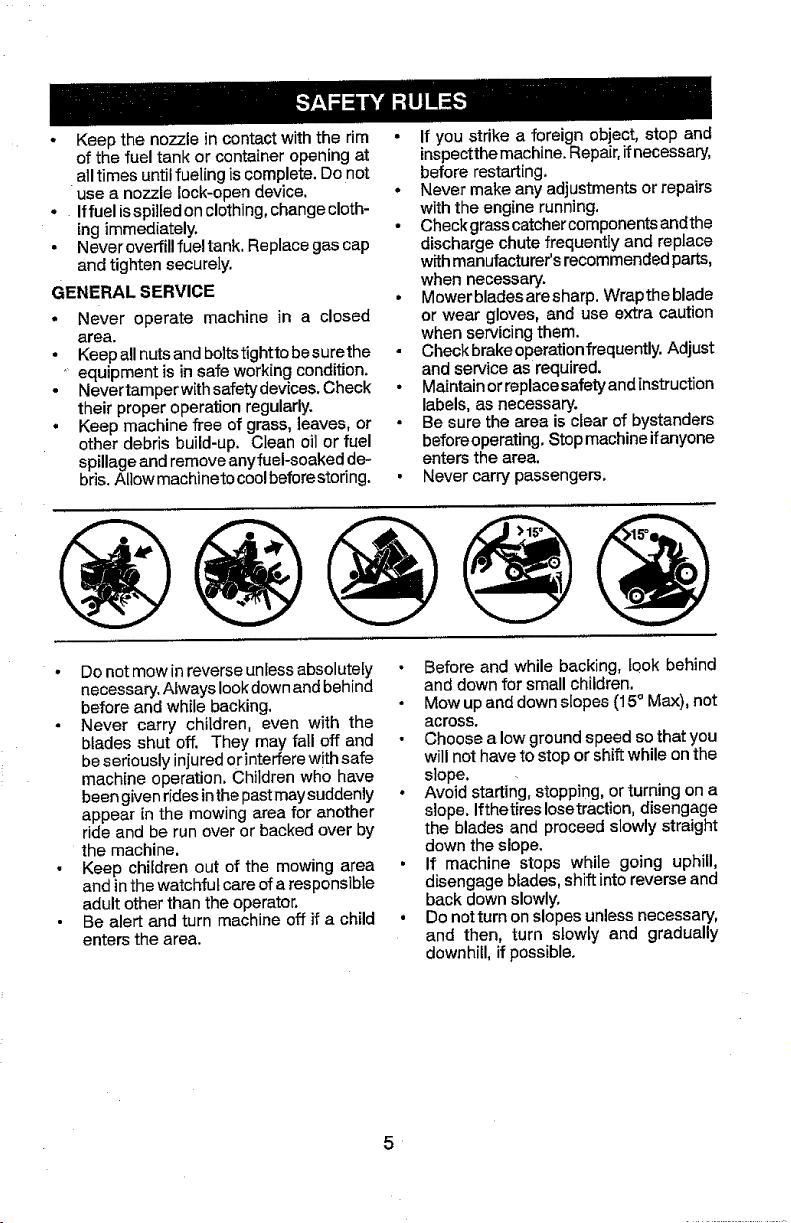

II. SLOPE OPERATION

Slopes are a major factor related to loss of

control and tip-over accidents, which can

result in severe injury or death. Operation

on all slopes requires extra caution. If you

cannot back uptheslope orifyou feel uneasy

on it, do not mow it.

° Mow up and down slopes, not across,

. Watch for holes, ruts, bumps, rocks, or

other hidden objects. Uneven terrain

could overturn the machine. Tall grass

can hide obstacles.

• Choose a tow ground speed so that you

will not have to stop or shift while on the

slope,

• Do not mowon wet grass. Tires may lose

traction.

Always keep the machine in gear when

going down slopes. Do notshift toneutral

and coast downhill.

• Avoid starting, stopping, or turning on a

slope. Ifthetires lose traction, disengage

the blades and proceed slowly straight

down the slope.

• Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction, which

could cause the machine to roll over.

• Use extra care while operating machine

with grass catchers orother attachments;

they can affect the stability of the ma-

chine. Do no use on steep slopes.

• Do not try to stabilize the machine by

putting your foot on the ground.

• Do not mow near drop-offs, ditches,

or embankments. The machine could

suddeniy roll over if a wheel is over the

edge or if the edge caves in.

II!. CHILDREN

Tragic accidents can occur if the operator

is not alert to the presence of children,

Children are often attracted to the machine

and the mowing activity. Never assume

that children will remain where you last

saw them.

• Keep children out of the mowing area

and inthe watchful care ofa responsible

adult other than the operator.

. Be alert and turn machine off if a child

enters the area.

• Before and while backing, look behind

and down for small children.

• Never carry children, even with the

blades shut off. They may fall off and

be seriously injured or interfere with safe

machine operation. Children who have

been givenrides inthe pastmaysuddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

• Never allow children to operate the ma-

chine.

• Use extra care when approaching blind

corners, shrubs, trees, or other objects

that may block your view of a child.

IV, TOWING

• Tow only with amachine that has ahitch

designed fortowing. Do not attachtowed

equipment except at the hitch point,

• Fo]lowthe manufacturer's recommenda-

tion for weight limits for towed equipment

and towing on slopes.

° Never allow children or others in or on

towed equipment.

. Onslopes, the weight ofthe towed equip-

ment may cause loss oftraction and loss

of control.

• Travel slowly and allow extra distance to

stop.

V, SERVICE

SAFE HANDLING OF GASOLINE

To avoid personal injury or property dam-

age, use extreme care in handling gasoline.

Gasoline is extremely flammable and the

vapors are explosive.

° Extinguish all cigarettes, cigars, pipes,

and other sources of ignition.

• Use oniy approved gasoline container.

• Never remove gas cap or add fuel with

the engine running. Allow engine to cool

before refueling.

• Never fuelthe machine indoors,

• Never store the machine or fuetcontainer

where there is an open flame, spark, or

pilot light such as on a water heater or

other appliances,

• Never fill containers inside a vehicle or

on a truck or trailer bed with plastic liner.

Always place containers on the ground

away from your vehicle when fit[ing.

° Remove gas-powered equipment from

the truck or trailer and refuel it on the

ground, tf this is not possible, then refuel

such equipment with a portablecontainer,

rather than from a gasoline dispenser

nozzle.

- Keep the nozzle in contact withthe rim

of the fuel tank or container opening at

all times until fueling is complete. Do not

use a nozzle lock-open device.

. Iffuelisspilledonclothing, change cloth-

ing immediately.

• Neverover{ill fueltank. Replace gas cap

and tighten securely.

GENERAL SERVICE

. Never operate machine in a closed

area.

• Keep allnuts and boltstlghtto besurethe

" equipment is in safe working condition.

. Nevertamperwith safetydevices. Check

their proper operation regularly.

• Keep machine free of grass, leaves, or

other debris build-up. Clean oil or fuel

spillage and remove anyfuel-soaked de-

bds. Allow machineto coo!before storing.

• If you strike a foreign object, stop and

inspectthe machine. Repair,ifnecessary,

before restarting.

• Never make any adjustments or repairs

with the engine running.

• Check grasscatchercomponents andthe

discharge chute frequently and replace

with manufacturer's recommended parts,

when necessary.

• Mowerbladesaresharp. Wraptheblade

or wear gloves, and use extra caution

when servicing them.

• Checkbrakeoperationfrequently. Adjust

and service as required.

• Maintain or replacesafetyandlnstruction

labels, as necessary.

• Be sure the area is clear of bystanders

beforeoperating. Stopmachineifanyone

enters the area.

• Never carry passengers.

Do not mow in reverse unless absolutely

necessary. Always lookdown andbehind

before and while backing.

Never carry children, even with the

blades shut off. They may fall off and

beseriously injured or interfere with safe

machine operation. Children who have

beengiven rides in thepast maysuddenly

appear in the mowing area for another

ride and be run over or backed over by

the machine.

Keep children out of the mowing area

and in the watchful care ofa responsible

adult other than the operator.

Be alert and turn machine off if a child

enters the area.

Before and while backing, look behind

and down for small children.

Mow up and down slopes (15° Max), not

across.

Choose a low ground speed so that you

will not have to stop or shift while on the

slope, •

Avoid starting, stopping, or turning on a

slope. Ifthetlres Iosetraction, disengage

the blades and proceed slowly straight

down the slope.

If machine stops while going uphill,

disengage blades, shiit into reverse and

back down slowly.

Do not turn on slopes unless necessary,

and then, turn slowly and gradually

downhill, if possible.

5

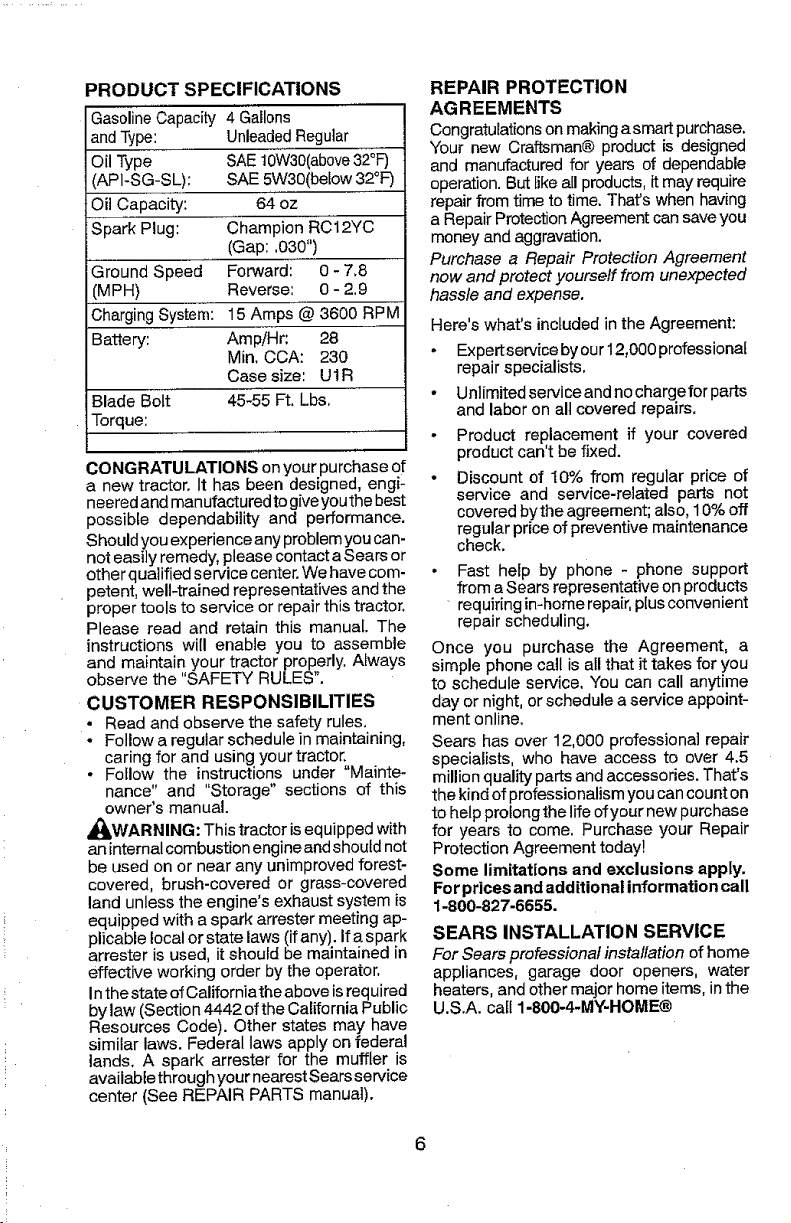

PRODUCT SPECIFICATIONS

GasolineCapacity 4 Gallons

andType: UnleadedRegular

Oil Type SAE10W30(above32°F)

AP1-SG-SL): SAE 5W30(below 32°F)

Oil Capacity: 64oz

Spark Plug: Champion RC12YC

Ground Speed Forward: 0 - 7_8

(MPH) Reverse: 0 - 2,9

ChargingSystem: 15 Amps @ 3600 RPM

Battery: Amp/Hr: 28

Blade Bolt 45-55 Ft. Lbs.

Torque:

CONGRATULATIONS onyourpurchase of

a new tractor. It has been designed, engi_-

neered and manufactured togive youthe best

possible dependability and performance.

Should you experience any problem youcan-

not easily remedy, pleasecontact a Sears or

other qualified service center.We have com-

petent,well-trained representatives andthe

proper tools to service or repair this tractor.

Please read and retain this manual. The

instructions will enable you to assemble

and maintain your tractor properly, Always

observe the "SAFETY RULES".

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules,

- Follow a regular schedule in maintaining,

caring for and using your tractor.

• Follow the instructions under "Mainte-

nance" and "Storage" sections of this

owner's manual.

_J.WAR NING: This tractor isequipped with

an internal combustion engineandshould not

be used on or near any unimproved forest-

covered, brush-covered or grass-covered

land unless the engine's exhaust system is

equipped with a spark arrester meeting ap-

plicable localor state laws (ifany). If a spark

arrester is used, itshould be maintained in

effective working order by the operator.

Inthe stateof Californiathe above is required

bylaw (Section 4442 of the California Public

Resources Code). Other states may have

similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is

available through your nearestSears service

center (See REPAIR PARTS manua]).

(Gap: .030")

Min. CCA: 230

Case size: U1R

REPAIR PROTECTION

AGREEMENTS

Congratulations on makinga smartpurchase.

Your new Craftsman® product is designed

and manufactured for years of dependable

operation.But likeall products, it may require

repairfrom time to time. That's when having

a RepairProtection Agreement can saveyou

money and aggravation.

Purchase a Repair Protection Agreement

now and protect yourself from unexpected

hassle and expense.

Here's what's includedin the Agreement:

• Expertservice byour 12,000 professional

repair specialists.

• Unlimitedserviceandnochargefor parts

and labor on all covered repairs.

• Product replacement if your covered

product can't be fixed.

• Discount of 10% from regular price of

service and service-related parts not

covered bythe agreement; also, 10% off

regular price of preventivemaintenance

check.

• Fast help by phone - phone support

from a Sears representative on products

requiring in-homerepair,plusconvenient

repair scheduling.

Once you purchase the Agreement, a

simple phone call is all that ittakes for you

to schedule service, You can call anytime

day or night, or schedule a service appoint-

ment online.

Sears has over 12,000 professiona] repair

specialists, who have access to over 4.5

million quality parts and accessories. That's

the kind of professionalism you can count on

to help prolongthe life ofyour new purchase

for years to come. Purchase your Repair

Protection Agreement today!

Some limitations and exclusions apply.

For prices and additional information call

1-800-827-6655.

SEARS INSTALLATION SERVICE

For Sears professional installation of home

appliances, garage door openers, water

heaters, and other major home items, in the

U.S.A. call 1-800-4-MY-HOME®

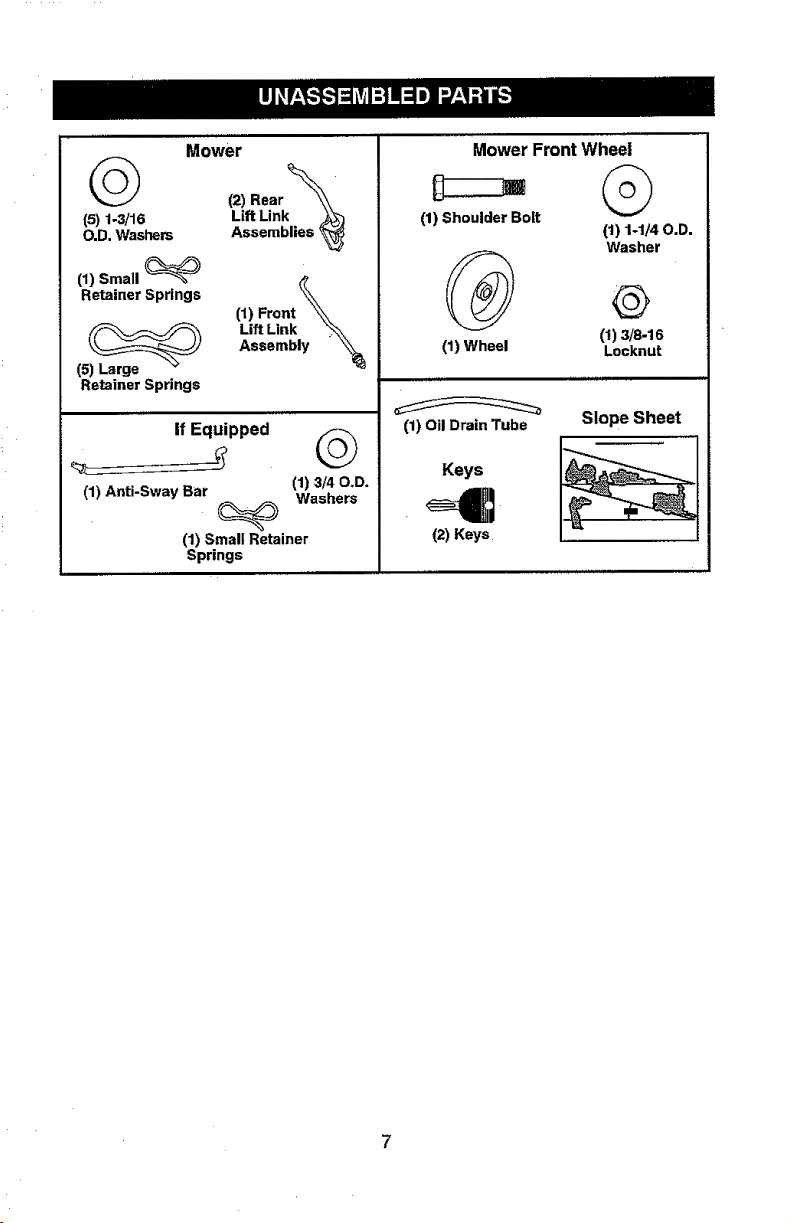

Mower

Mower Front Wheel

©

(5) 1.3/16 AssembliesO.D. Washers

(1) Small _

Retainer Springs _,

(5) Large

Retainer Springs

i , L,J, , Ji

(1) Anti-Sway Bar (1)3/40.D.

(2) Rear

Lift Link

(1) Front

Lift Link .'_\

Assembly ")_

if Equipped (_

Washers

(1) Small Retainer

Springs

(1) Shoulder Bolt

@

(1)Wheel

(1)Oil DrainTube

Keys

(2) Keys

(t) 1-1/40.D.

Washer

@

(1)3/e-16

Locknut

Slope Sheet

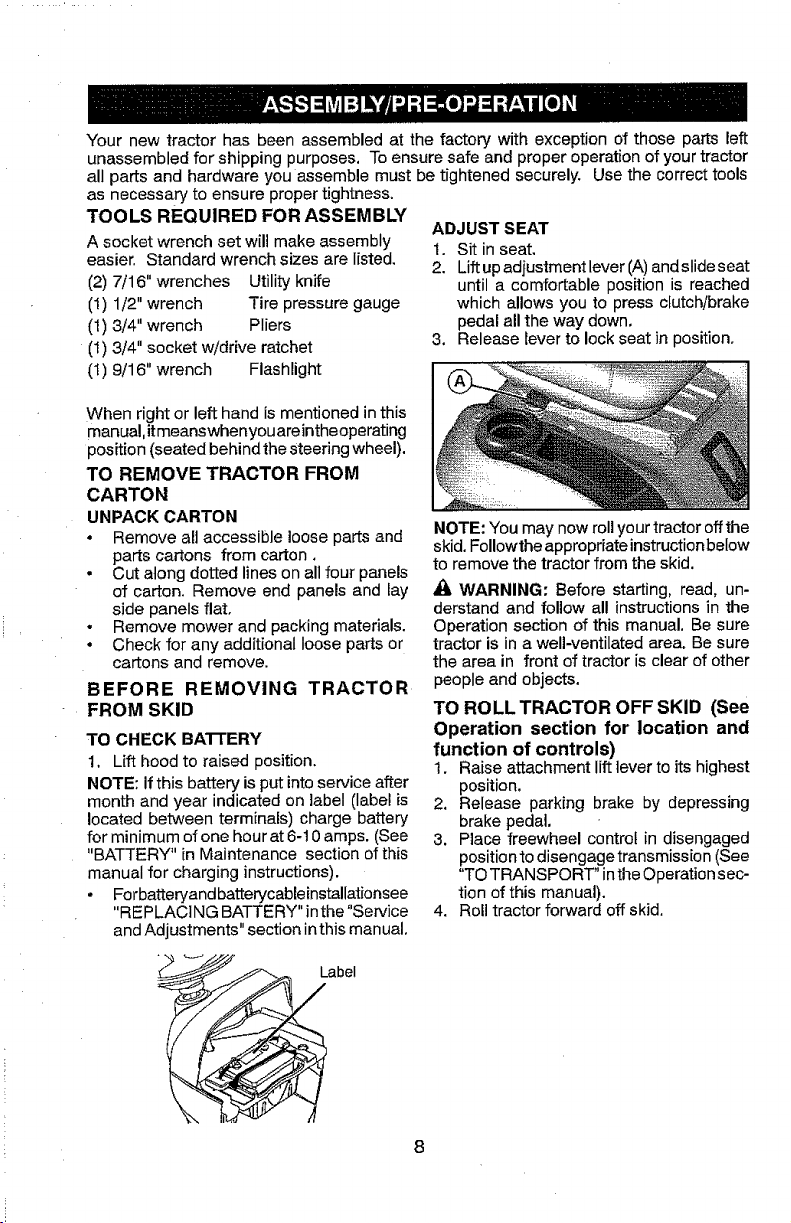

Your new tractor has been assembled at the factory with exception of those parts left

unassembled for shipping purposes, To ensure safe and proper operation of your tractor

all parts and hardware you assemble must be tightened securely. Use the correct tools

as necessary to ensure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes are listed.

(2) 7/16" wrenches Utility knife

(1) 1/2" wrench Tire pressure gauge

(1) 3/4" wrench Pliers

(1) 3/4" socket w/drive ratchet

ADJUST SEAT

1. Sit in seat.

2. Lift upadjustment lever (A) and slide seat

until a comfortable position is reached

which allows you to press clutch/brake

pedal all the way down,

3, Release lever to lock seat in position.

(I) 9/16" wrench Flashlight

When right or left hand is mentioned in this

manual,itmeanswhenyouareintheoperating

position (seated behind the steering wheel).

TO REMOVE TRACTOR FROM

CARTON

UNPACK CARTON

. Remove all accessible loose parts and

parts cartons from carton.

. Cut along dotted lines on all four panels

of carton. Remove end panels and lay

side panels flat.

• Remove mower and packing materials.

. Check for any additional loose parts or

cartons and remove.

BEFORE REMOVING TRACTOR

FROM SKID

TO CHECK BATTERY

1, Lift hood to raised position.

NOTE: If this battery is put into service after

month and year indicated on label (label is

located between terminals) charge battery

for minimum of one hour at 6-10 amps. (See

"BATTERY" in Maintenance section of this

manual for charging instructions).

• Forbatteryand batterycableinstallationsee

"REPLACING BATTERY" inthe"Service

and Adjustments" section inthis manual,

NOTE: "Youmay now roll your tractor offthe

skid.Followthe appropriate instruction below

to remove the tractor from the skid.

WARNING: Before starting, read, un-

derstand and follow all instructions in the

Operation section of this manual, Be sure

tractor is in a well-ventilated area. Be sure

the area in front of tractor is clear of other

people and objects.

TO ROLL TRACTOR OFF SKID (See

Operation section for location and

function of controls)

1. Raise attachment lift lever to its highest

position.

2, Release parking brake by depressing

brake pedal,

3, Place freewheel control in disengaged

positionto disengagetransmission (See

"TOTRANSPORT" inthe Operation sec-

tion of this manual).

4. Roll tractor forward off skid,

bel

8

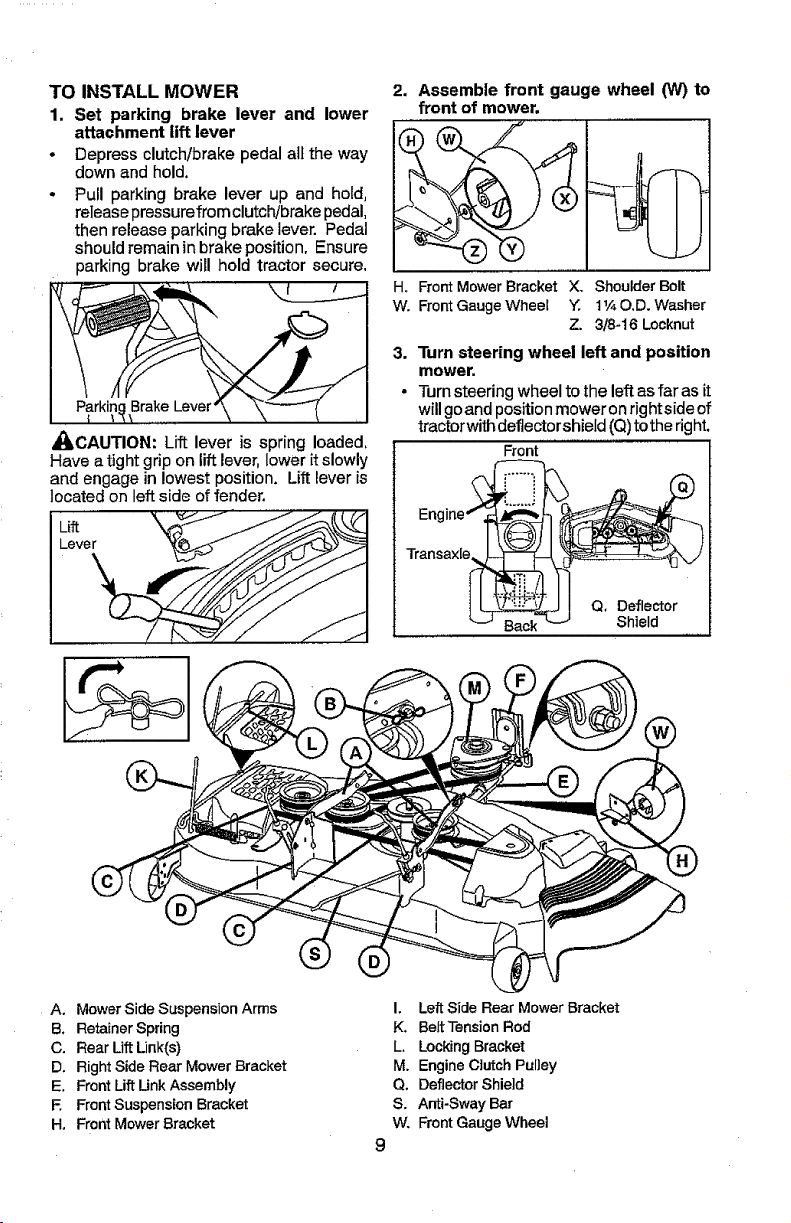

TO INSTALL MOWER

1. Set parking brake lever and lower

attachment lift lever

o Depress clutch/brake pedal aif the way

down and hold+

. Pull parking brake lever up and hold,

release pressurefrom clutch!brake pedal,

then release parking brake lever. Pedal

should remain inbrake position. Ensure

parking brake will hold tractor secure.

Brake Lever

_CAUTION: Lift lever is spring loaded.

Have a tight grip on lift lever,lower itslowly

and engage in lowest position. Lift lever is

located on left side of fender.

2. Assemble front gauge wheel (W) to

front of mower,

H. FrontMowerBracket X. ShoulderBolt

W. FrontGaugeWheel Y. 11AO.D.Washer

Z. 3/8+16Locknut

3. Turn steering wheel left and position

mower.

• Turnsteeringwheel to the leftas far as it

willgoandpositionmower onrightsideof

tractorwith deflectorshield(Q)tothe right.

Front

Q, Deflector

Shield

A. Mower Side Suspension Arms

B+ RetainerSpring

C. Rear Uft Unk(s)

D. Right Side Rear Mower Bracket

E+ Front Uft Link Assembly

E Front Suspension Bracket

H. Front Mower Bracket

I. Left Side Rear Mower Bracket

K. BeItTension Rod

L. Locking Bracket

M. Engine Clutch Pulley

Q+ Deflector Shield

S. Anti-Sway Bar

W. Front Gauge Wheel

9

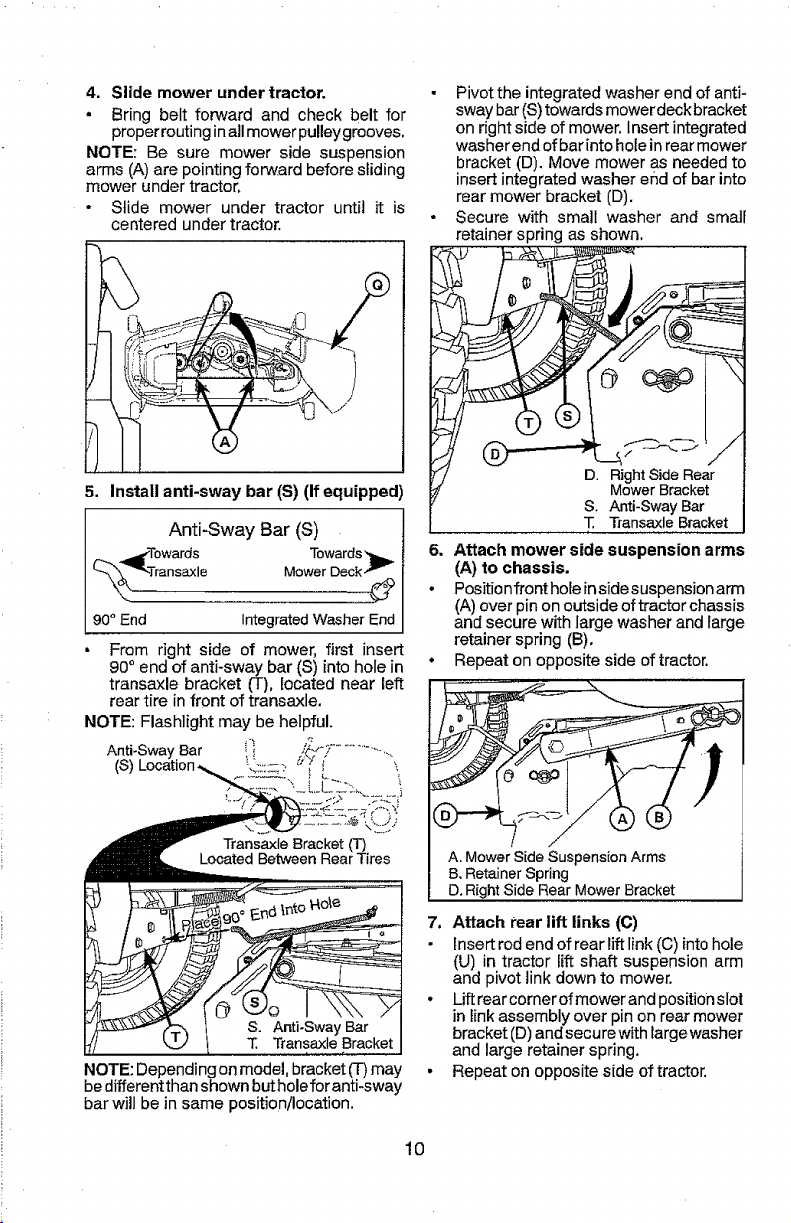

4. Slide mower under tractor.

• Bring belt forward and check belt for

properrouting in allmower pulleygrooves,

NOTE: Be sure mower side suspension

arms (A)are pointing forward before sliding

mower under tractor,

• Slide mower under tractor until it is

centered under tractor.

5. Install anti-sway bar (S) (If equipped)

Anti-Sway Bar (S)

Towards

Mower Deck

d

90" End IntegratedWasherEnd

From right side of mower, first insert

90° end of anti-sway bar (S) into hole in

transaxle bracket (T), located near left

rear tire in front of transaxle.

NOTE: Flashlight may be helpful.

Bar _.,__=............,.

Pivot the integrated washer end of anti-

sway bar(S)towards mower deckbracket

on right side of mower, Insert integrated

washer end ofbar intohole in rear mower

bracket (D). Move mower as needed to

insert integrated washer efld of bar into

rear mower bracket (D).

Secure with small washer and small

retainer spring as shown,

D. RightSideRear

Mower Bracket

S. Anti-SwayBar

T, TransaxleBracket

6. Attach mower side suspension arms

(A) to chassis.

• Positionfront holeinside suspension arm

(A)over pinon outsideoftractor chassis

andsecure withlarge washer and large

retainer spring (B).

• Repeat on oppositeside of tractor.

Transaxle Bracket

Located Between Rear Tires

T. TransaxleBracket

NOTE:Depending onmodel, bracket (T)may

bedifferentthan shown butholefor anti-sway

bar will be in same position/location.

I

A, Mower Side Suspension Arms

B,Retainer Spring

D.Right Side Rear Mower Bracket

7. Attach rear lift links (C)

Insert rodend ofrear liftlink(C) intohole

(U) in tractor lift shaft suspension arm

and pivot link down to mower.

° Liftrear corner of mower and position slot

in link assembly over pin on rear mower

bracket (D)and secure withlargewasher

and large retainer spring.

• Repeat on opposite side of tractor.

10

_ke(Sar)MowerBracket

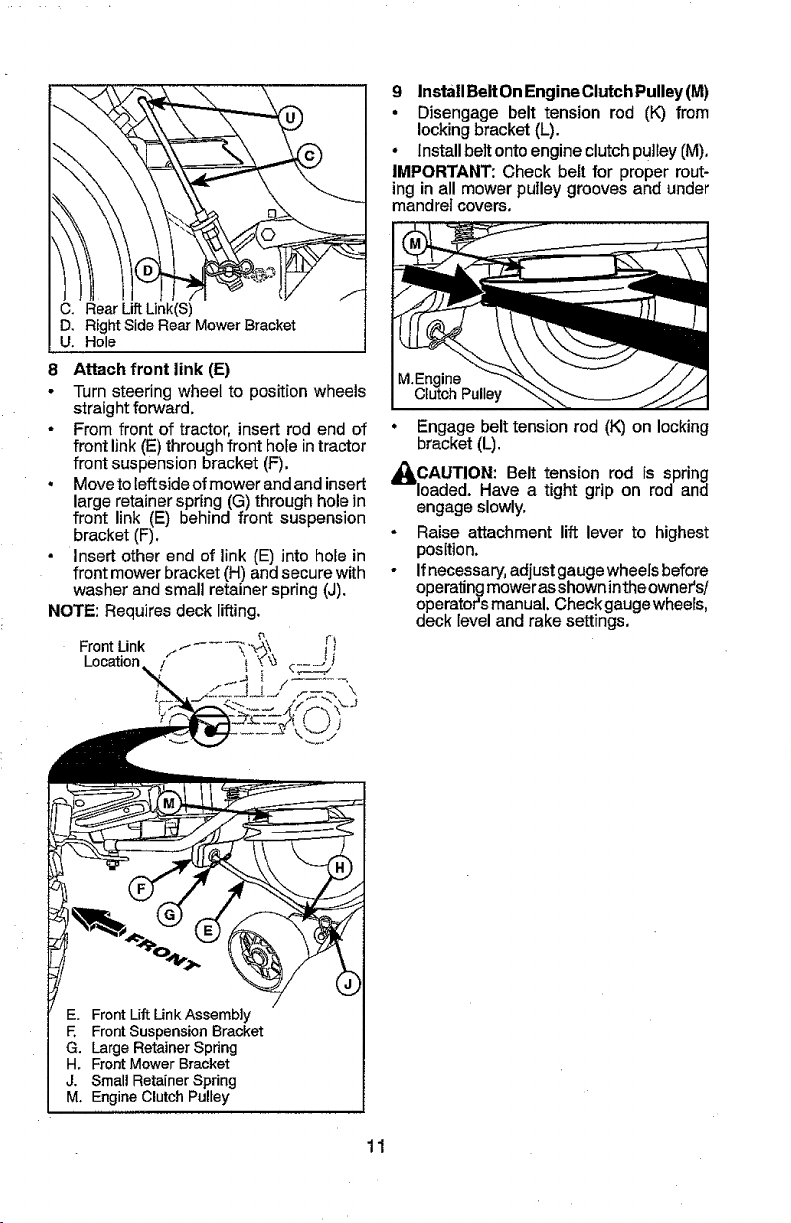

8 Attach front link (E)

• Turn steering wheel to positionwheels

straight forward.

• From front of tractor, insert rod end of

front link (E)through front hole in tractor

front suspension bracket (F).

• Move to leftsideof mower and and insert

large retainer spring (G) through hole in

front link (E) behind front suspension

bracket (F),

• Insert other end of link (E) into hole in

front mower bracket (H) and secure with

washer and small retainer spring (J).

NOTE: Requires deck lifting.

9 Install BeltOn Engine Clutch Pulley (M)

, Disengage belt tension rod (K) from

lockingbracket (L).

° Install beltontoengine clutchpulley(M),

IMPORTANT: Check belt for proper rout-

ing in all mower puIley grooves and under

mandrel covers,

Engage belt tension rod (K) on locking

bracket (L).

_ILCAUTION: Belt tension rod is spring

loaded. Have a tight grip on rod and

engage slowly,

- Raise attachment lift lever to highest

position.

• Ifnecessary,adjustgaugewheelsbefore

operatingmowerasshownintheownefs/

operator'smanual. Checkgaugewheels,

deck level and rakesettings.

E. Front Lift Link Assembly

E Front Suspension Bracket

G, Large Retainer Spring

H, Front Mower Bracket

J, Small Retainer Spring

M. Engine Clutch Pulley

11

CHECK TIRE PRESSURE

The tires on your tractor were over-inflated

atthe factory for shipping purposes. Correct

tire pressure is important for best cutting

performance.

• Reducetire pressureto PSI shown ontires.

CHECK DECK LEVELNESS

For best cutting results, mower housing

should be properly leveled. See "TO LEVEL

MOWER" in the Service and Adjustments

section of this manual.

CHECK FOR PROPER POSITION OF

ALL BELTS

See the figures that are shown for replacing

motion and mower blade drive belts in the

Service andAdjustments section ofthis man-

ual, Verify that the belts are routed correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor,

check to seethatthe brake isoperating prop-

erly. See"TO CHECKBRAKE" intheService

and Adjustments section of this manual.

CHECKLIST

Before you operate your new tractor, we

wish to assure that you receive the best

performance and satisfaction from this

Quality Product.

Please review the following checklist:

J All assembly instructions have been

completed.

J" No remaining loose parts in carton.

_' Battery is properly prepared and

charged.

J" Seat is adjusted comfortably and tight-

ened securely.

J All tires are properly inflated. (For ship-

pingpurposes, thetires were overinflated

at the factory).

J" Be sure mower deck is properly leveled

side-to-side/front-to-rear for best cutting

results. _ires must be properly inflated

for leveling).

J" Check mower and drive belts. Be sure

they are routed properly around pulleys

and inside all belt keepers.

J' Check wiring, See that all connections

are still secure and wires are properly

clamped.

!/" Before driving tractor, be sure freewheel

control is in "transmission engaged"

position (see "TO TRANSPORT" in the

Operation section of this manual).

While learning howto useyour tractor,payex-

tra attention tothe following important items:

J" Engine oil is at proper level,

J Fueltank isfilledwithfresh, clean, regular

unleaded gasoline.

-,/Become familiar with all controls, their

location and function. Operate them

before you start the engine.

Besure brake system isin safe operating

condition.

_" Be sure Operator Presence System and

Reverse Operation System (ROS) are

working properly (See the Operation and

Maintenance sections in this manual).

J' It is important to purge the transmission

before operating your tractor for the first

time. Follow proper starting andtransmis-

sionpurging instructions (See 'q-OSTART

ENGINE"and"PURGETRANSMISSION"

inthe Operation section ofthis manual),

12

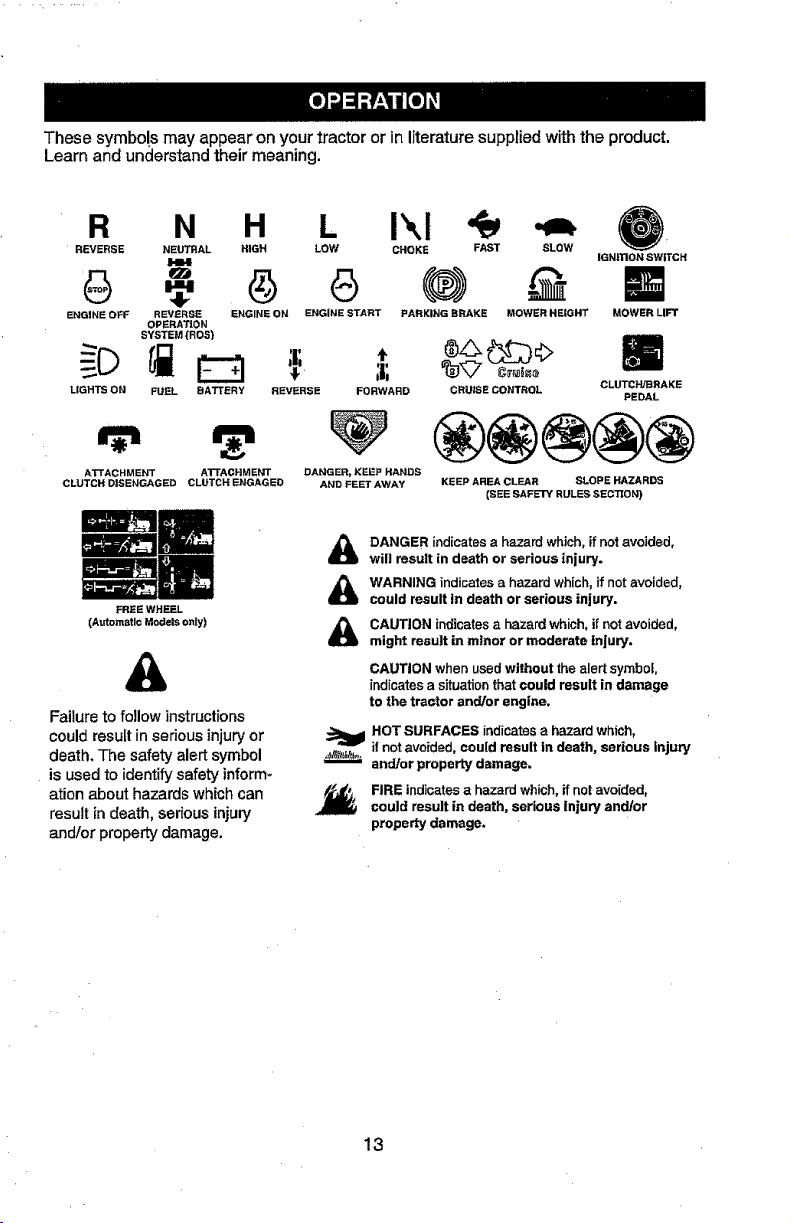

These symbols may appear on your tractor or in literature suppEiedwith the product.

Learn and understand their meaning.

R N H L

REVERSE NEUTRAL HIGH LOW

ENGINE OFF REVERSE ENGINE ON ENGINE START

LIGHTS ON FUEL BATTERY

ATrACHMENT A'rFACNMEN't"

CLUTCH DISENGAGED CLUTCH ENGAGED

OPERATION

SYSTEM (ROS)

FREE WHEEL

(Automstlo Models only)

REVERSE FORWARD

DANGER, KEEP HANDS

AND FEET AWAY

&

Failure to follow instructions

could result in serious injury or

death. The safety alert symbol

is used to identify safety inform-

ation about hazards which can

result in death, serious injury'

and/or property damage.

i\!

CHOKE FAST SLOW

PARKING BRAKE MOWER HEIGHT

CRUISE CONTROL CLUTCH/BRAKE

KEEP AREA OLFJ_R SLOPE HAZARDS

(SEE SAFE'r_ RULES SECTION)

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION when used without the alert symbot,

indicates a situation that could result in damage

to the tractor and/or engine.

HOT SURFACES indicates a hazard which,

if not avoided, could result In death, serious injury

and/or property damage.

FIRE indicates a hazard which, if not avoided,

could result in death, serious injury and/or

property damage.

IGNITION SWITCH

MOWER LIFT

PEDAL

13

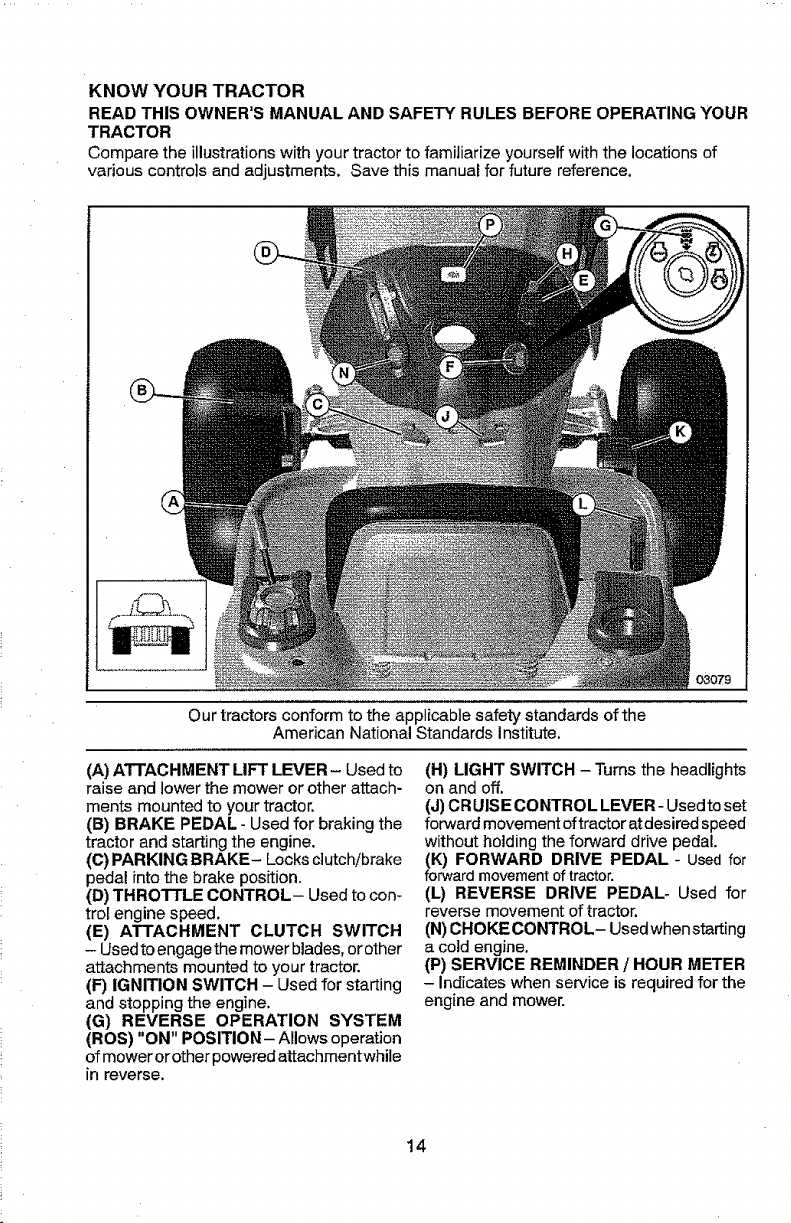

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

TRACTOR

Compare the illustrations with your tractor to familiarize yourself with the locations of

various controls and adjustments. Save this manual for future reference.

Our tractorsconform to the applicable safety standards of the

American National Standards Institute.

(A) ATTACHMENT LIFT LEVER- Usedto

raise and lower the mower or other attach-

merits mounted to your tractor.

(B) BRAKE PEDAL- Used for braking the

tractor and starting the engine.

(C) PARKING BRAKE- Locks clutch/brake

pedal into the brake position.

(D) THROTTLE CONTROL- Used to con-

trol engine speed,

(E) ATTACHMENT CLUTCH SWITCH

- Used toengagethe mower blades,or other

attachments mounted to your tractor.

(F) IGNITION SWITCH - Used for starting

and stopping the engine.

(G) REVERSE OPERATION SYSTEM

(ROS) "ON" POSITION- ALlowsoperation

of mower orother powered attachmentwhile

in reverse.

(H) LIGHT SWITCH - "liJrns the headlights

on and off.

(J) OR UISE CONTROL LEVER- Used to set

forward movement oftractor at desired speed

without holding the forward drive pedal

(K) FORWARD DRIVE PEDAL - Used for

forward movement of tractor.

(L) REVERSE DRIVE PEDAL- Used for

reverse movement of tractor.

(N) CHOKE CONTROL- Used when starting

a cold engine.

(P) SERVICE REMINDER / HOUR METER

- indicates when service is required for the

engine and mower.

14

The operation of any tractorcan result inforeign objectsthrowninto the

eyes, which can result in severe eye damage. Always wear safety glasses

or eye shields while operating your tractor or performing any adjustments

or repairs. We recommend standard safety glasses or a wide vision safety

mask worn over spectacles.

HOW TO USE YOUR TRACTOR

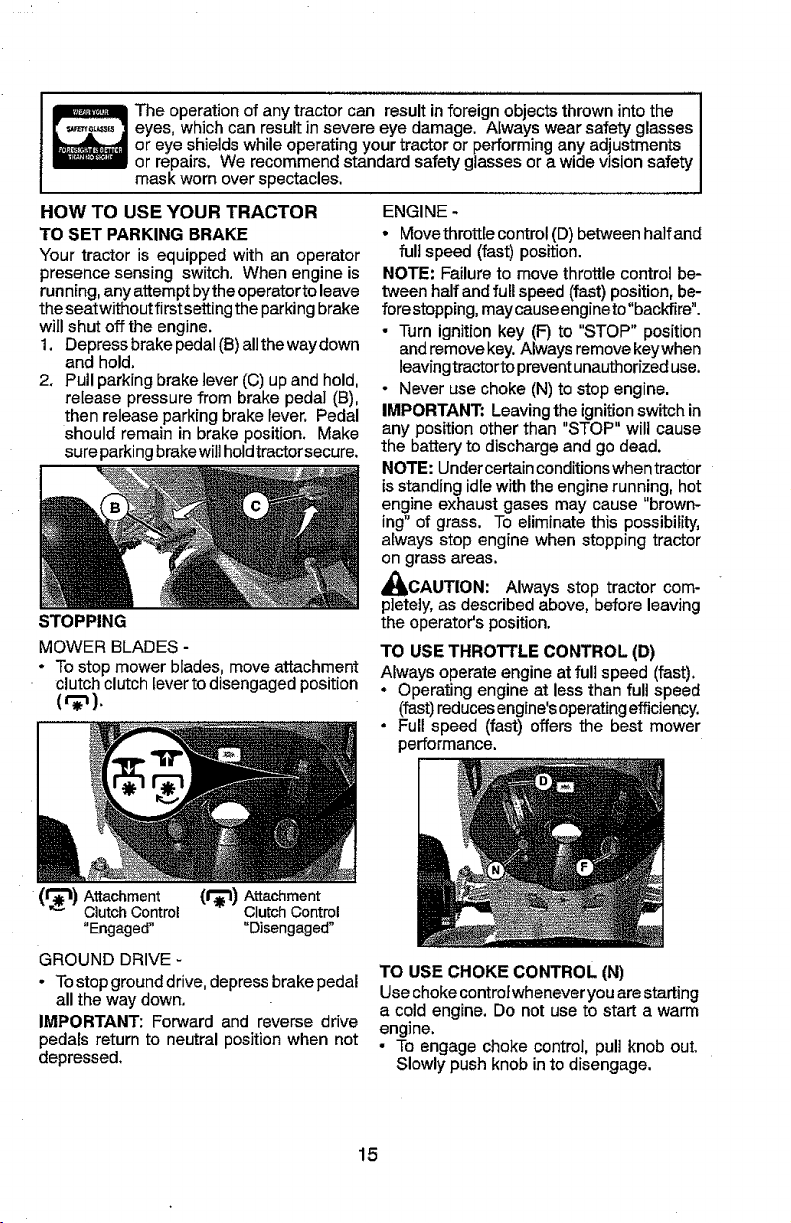

TO SET PARKING BRAKE

"Yourtractor is equipped with an operator

presence sensing switch, When engine is

running, any attempt bythe operatorto leave

the seatwithout first setting the parking brake

will shut off the engine.

1. Depress brake pedal (B)allthe waydown

and hold.

2. Pull parking brake lever (C) up and hold,

release pressure from brake pedal (B),

then release parkingbrake lever. Pedal

should remain in brake position. Make

sureparking brakewillholdtractor secure,

STOPPING

MOWER BLADES -

° To stop mower blades, move attachment

clutch clutch lever to disengaged position

(_).

ENGINE -

• Movethrottle control (D) between halfand

full speed (fast) position.

NOTE: Failure to move throttle control be-

tween half and full speed (fast) position, be-

fore stopping, may causeengine to"backfire".

• Turn ignition key (F) to "STOP" position

andremove key.Always removekeywhen

leavingtractorto prevent unauthorized use.

• Never use choke (N) to stop engine.

IMPORTANT: Leaving the ignitionswitch in

any position other than "STOP" will cause

the battery to discharge and go dead.

NOTE: Under certain conditions whentractor

isstanding idle with the engine running, hot

engine exhaust gases may cause "brown-

ing"of grass. To eliminate this possibility,

always stop engine when stopping tractor

on grass areas.

_CAUTION: Always stop tractor com-

pletely, as described above, before leaving

the operator's position.

TO USE THROI"rLE CONTROL (D)

Always operate engine at full speed (fast).

• Operating engine at lessthan full speed

(fast)reducesengine'soperatingefficiency.

• Full speed (fast) offers the best mower

performance,

(_1_1) Attachment (1"_1) Attachment

Clutch Control Clutch Control

"Engaged" "Disengaged"

GROUND DRIVE -

- To stop ground drive, depress brake pedal

all the way down,

IMPORTANT: Forward and reverse drive

pedals return to neutral position when not

depressed,

TO USE CHOKE CONTROL (N)

Use choke controlwheneveryouare starting

a cold engine. Do not use to start a warm

engine.

• To engage choke control, pull knob out.

Slowly push knob in to disengage.

15

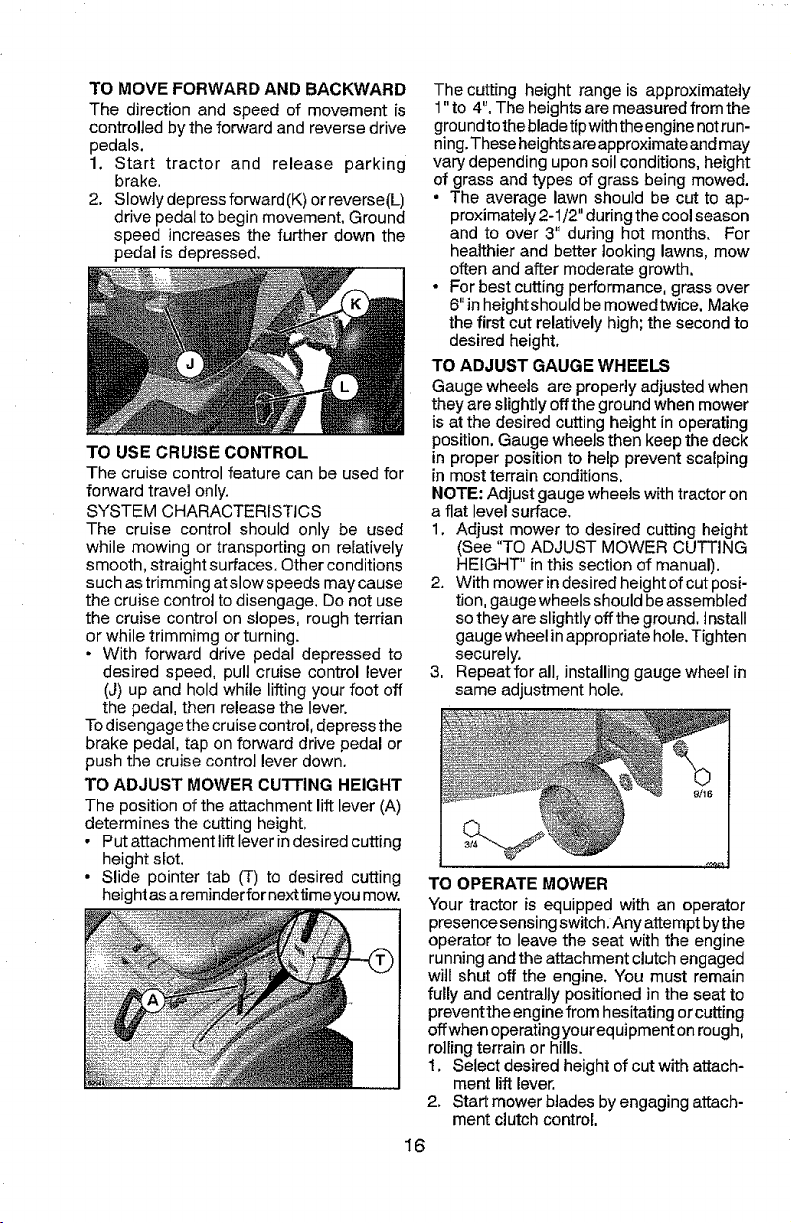

TO MOVE FORWARD AND BACKWARD

The direction and speed of movement is

controlled by the forward and reverse drive

pedals.

1, Start tractor and release parking

brake,

2. Slowly depress forward(K) or reverse(L)

drive pedal to begin movement, Ground

speed increases the further down the

pedal is depressed,

TO USE CRUISE CONTROL

The cruise control feature can be used for

forward travel only.

SYSTEM CHARACTERISTICS

The cruise control should only be used

while mowing or transporting on relatively

smooth, straight surfaces, Other conditions

such as trimming at slow speeds maycause

the cruise control to disengage. Do not use

the cruise control on slopes, rough terrian

or while trimmimg or turning.

• With forward drive pedal depressed to

desired speed, pull cruise control lever

(J) up and hold while lifting your foot off

the pedal, then release the lever.

To disengage the cruise control, depress the

brake pedal, tap on forward drive pedal or

push the cruise control lever down.

TO ADJUST MOWER CUTTING HEIGHT

The position of the attachment lift lever (A)

determines the cutting height,

• Put attachment lift lever in desired cutting

height slot.

• Slide pointer tab (T) to desired cutting

height as a reminder for next timeyou mow.

The cutting height range is approximately

1" to 4".The heights are measured from the

groundtothebladetipwith the engine notrun-

ning.These heightsareapproximate and may

vary depending upon soil conditions, height

of grass and types of grass being mowed.

• The average lawn should be cut to ap-

proximately 2-1/2" during the cool season

and to over 3" during hot months. For

healthier and better looking lawns, mow

often and after moderate growth.

• For best cutting performance, grass over

6" in heightshould bemowed twice. Make

the first cut relatively high; the second to

desired height.

TO ADJUST GAUGE WHEELS

Gauge wheels are properlyadjusted when

they are slightly offthe ground when mower

is at the desired cutting height in operating

position. Gauge wheels then keep the deck

in proper positionto help prevent scalping

in most terrain conditions.

NOTE: Adjust gauge wheels with tractor on

a flat level surface.

1. Adjust mower to desired cutting height

(See "TO ADJUST MOWER CUTTING

HEIGHT" in this section of manual).

2. With mower in desired height of cut posi-

tion. gauge wheels should beassembled

so they are slightly off the ground, Install

gauge wheel inappropriate hole. Tighten

securely.

3. Repeat for all, installing gauge wheel in

same adjustment hole.

TO OPERATE MOWER

Your tractor is equipped with an operator

presence sensing switch. Anyattempt bythe

operator to leave the seat with the engine

running and the attachment clutch engaged

wilt shut off the engine. You must remain

fully and centrally positioned in the seat to

preventthe enginefrom hesitating or cutting

offwhen operating your equipment onrough,

rolling terrain or hills.

1. Select desired height of cut with attach-

ment lift lever.

2. Start mower blades by engaging attach-

ment clutch control.

16

TO STOP MOWER BLADES

Disengage attachment clutch control.

_CAUTION: Do not operate the mower

without either the entire grass catcher, on

mowers so equipped, orthe deflector shield

iS) in place.

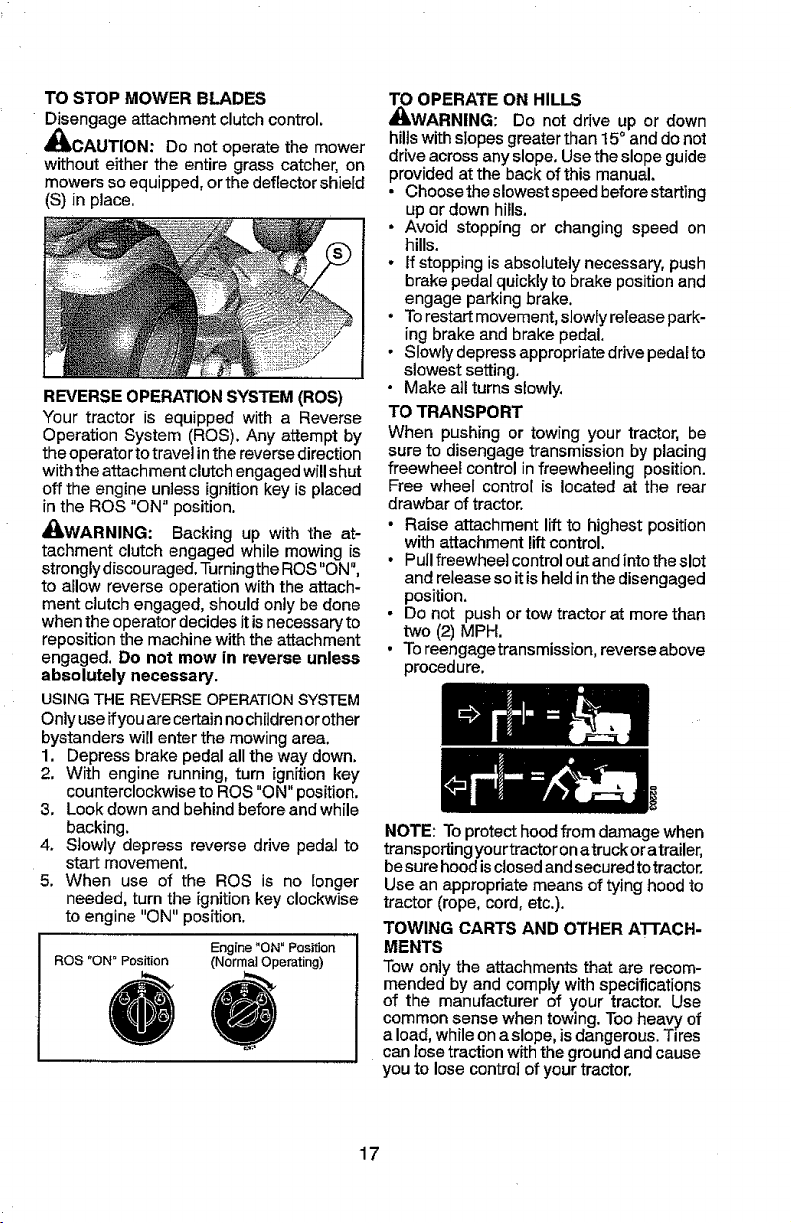

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse

Operation System (ROS). Any attempt by

the operator totravel inthe reverse direction

with the attachment clutch engaged will shut

off the engine uniess ignition key is placed

in the ROS "ON" position.

_WARNING: Backing up with the at-

tachment clutch engaged while mowing is

strongly discouraged. Turningthe ROS"ON",

to allow reverse operation with the attach-

ment clutch engaged, should only be done

when the operator decides itisnecessary to

reposition the machine with the attachment

engaged. Do not mow in reverse unless

absolutely necessary.

USINGTHE REVERSEOPERATIONSYSTEM

Only use ffyou are certain nochildren orother

bystanders willenter the mowing area.

1. Depress brake pedal all the way down.

2. With engine running, turn ignition key

counterclockwise to ROS "ON" position.

3. Look down and behind before and while

backing.

4. Slowly depress reverse drive pedal to

start movement.

5. When use of the ROS is no longer

needed, turn the ignition key clockwise

to engine "ON" position.

ROS "ON ° Posilion

Engine "ON" Position

(Normal Operating)

e

TO OPERATE ON HILLS

AI_WARNING: Do not drive up or down

hillswith slopes greater than ! 5° and do not

drive across any slope. Use the slope guide

provided at the back of this manual.

• Choose the slowest speed beforestarting

up or down hills.

• Avoid stopping or changing speed on

hills.

- If stepping is absolutely necessary, push

brake pedal quickly to brake position and

engage parking brake,

• Torestart movement, slowly release park-

ing brake and brake pedal.

• Slowly depress appropriate drive pedalto

slowest setting.

• Make a]l turns slowly.

TO TRANSPORT

When pushing or towing your tractor, be

sure to disengage transmission by placing

freewheel control in freewheeling position.

Free wheel control is located at the rear

drawbar of tractor.

• Raise attachment lift to highest position

with attachment lift control.

• Pullfreewheel controlout and into the slot

and release so it isheld inthe disengaged

position.

- Do not push or tow tractor at more than

two (2) MPH.

• To reengagetransmission, reverseabove

procedure.

NOTE: To protect hood from damage when

transporting yourtractor onatruckor atrailer,

besure hood isclosed andsecured totractor.

Use an appropriate means of tying hood to

tractor (rope, cord, etc.).

TOWING CARTS AND OTHER ATTACH-

MENTS

Tow only the attachments that are recom-

mended by and comply with specifications

of the manufacturer of your tractor. Use

common sense when towing. Too heavy of

a load, while on aslope, isdangerous. Tires

can losetraction with the ground and cause

you to lose control of your tractor.

17

SERVICE REMINDER/HOUR METER

Service reminder shows the total number

of hours the engine has run and flashes to

indicatethat the engine or mower needsser-

vicing, When service is required, the service

reminder will flash for two hours. To service

engine and mower, see the Maintenance

section of this manual.

NOTE: Service reminder runs when the

ignition key is in any position but "STOP".

For acurate reading, be sure key remains

in the "STOP" position when engine is not

running.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine inyour tractor hasbeen shipped,

from the factory, already filled with summer

weight oil.

1, Check engine oil with tractor on level

ground.

2. Unthread and remove oilfill cap/dipstick;

wipe oil off. Reinsert the dipstick into the

tube and rest oil fill cap on the tube. Do

not thread the cap ontothetube. Remove

and read oil level. If necessary, add oil

until "FULl" mark on dipstick is reached.

Do not overfill,

3. For cold weather operation you should

change oil for easier starting (See the oil

viscosity chart in the Maintenance section

of this manua D,

4. Tochange engine oil,seethe Maintenance

section in this manual.

5. Fillfuel tank to bottom of filler neck. Do

not overfill. Use fresh, clean, regular

unleaded gasoline with a minimum of

87 octane. (Use of leaded gasoline will

increase carbon and lead oxide deposits

and reduce valve life). Do not mix oil

with gasoline. Purchase fuel in quanti-

ties that can be used within 30 days to

assure fuel freshness.

CAUTION: Wipe off any spilled oil or

, Do not store, spill or use gasoline

near an open flame.

IMPORTANT: When operating in temper-

atures below 32°F(0°C), use fresh, clean

winter grade gasoline to help ensure good

cold weather starting.

CAUTION: Alcohoi blended fuels (called

gasohoI or using ethanol or methanol) can

attract moisture which leads to separation

andformation of acidsduring storage. Acidic

gas can damage thefueI system of anengine

while in storage. Toavoid engine problems,

the fuel system should be emptied before

storage of 30 days or longer. Drain the gas

tank, start the engine and tat it run until the

fuel linesand carburetor areempty. Usefresh

fuel next season. See Storage Instructions

foradditional information, Never useengine

orcarburetor cleaner products inthe fueitank

or permanent damage may occur.

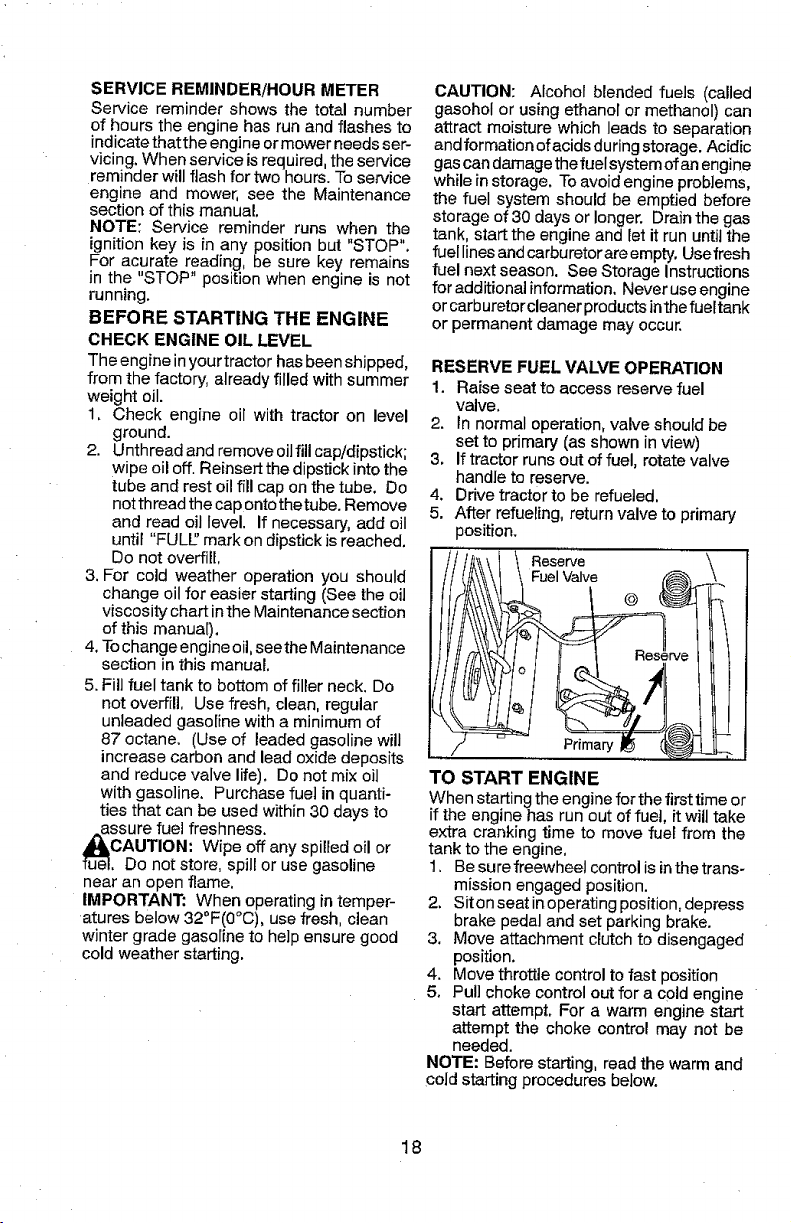

RESERVE FUEL VALVE OPERATION

1. Raise seat to access reserve fuel

valve.

2. in normal operation,valve should be

set to primary(as shown inview)

3. Iftractor runsout offuel, rotatevalve

handle to reserve.

4. Drive tractor to be refueled.

5. After refueling, return valve to primary

position.

ReseFv'e

FuelValve

@

Primary

TO START ENGINE

When starting the engine for the first time or

if the engine has run out of fuel, itwill take

extra cranking time to move fuel from the

tank to the engine,

1, Be sure freewheel control isinthe trans-

mission engaged position.

2. Siton seat inoperating position, depress

brake pedal and set parking brake.

3. Move attachment clutch to disengaged

position.

4. Move throttle control to fast position

5. Pull choke control out for a c01dengine

start attempt. For a warm engine start

attempt the choke control may not be

needed.

NOTE: Before starting, read the warm and

cold starting procedures below.

18

6. Insert key into ignition and turn key

clockwise to start position and release

key assoon as engine starts. Do not run

starter continuously formore than fifteen

seconds per minute, if the engine does

not start after several attempts, push

choke control in, wait afew minutes and

try again. If engine stiJl does not start,

puil the choke control out and retry.

WARM WEATHER STARTING

(50°F (10°C) and above)

7. When engine starts, slowJy push choke

control in until the engine begins to run

smoothly. If the engine starts to run

roughly, pulfthe choke controlout slightly

for a few seconds and then continue to

push the control in slowly.

• The attachments and ground drive

can now be used, If the engine does

not accept the load, restart the engine

and allow it to warm upfor one minute

using the choke as described above.

COLD WEATHER STARTING

(50°F (10°C) and below)

7. When engine starts, slowly push choke

contro] in until the engine begins to run

smoothly. Continue to push the choke

control insmall steps allowing the engine

to accept small changes in speed and

toad, until the choke control is fully in.

If the engine starts to run roughly, pull

the choke control out slightly for a few

seconds and then continue to push the

control in slowly. This may require an

engine warm-up period from several

seconds to several minutes, depending

on the temperature.

AUTOMATIC TRANSMISSION WARM UP

Before driving the unit in cold weather, the

transmission should be warmed up as fol-

lows:

1, Be sure the tractor is on level ground,

2. Release the parking brake and let the

brake slowly return to operating position.

3. Allow one minute for transmission to

warm up, This can be done during the

engine warm up period,

• The attachments can be used during

the engine warm-up period after the

transmission has been warmed up

and may require the choke control be

pulled out slightly.

NOTE: Ifat ahigh altitude (above 3000 feet)

or in cold temperatures (below 32°F (0°C))

the carburetor fuel mixture may need to be

adjusted for best engine performance (see

"TOADJUST CAR BURETOR"inthe Service

and Adjustments section of this manual).

PURGE TRANSMISSION

_I_CAUTION: Never engageor disengage

freewheel lever whilethe engine is running.

Toensure properoperationandperformance,

itis recommended that the transmission be

purged before operating tractor for the first

time.This procedure willremove anytrapped

air reside the transmission which may have

developed during shippingof your tractor.

IMPORTANT: Should your transmission

require removal for service or replacement,

it should bepurged after reinstallation before

operating the tractor.

1. Place tractor safely on a level surface -

that is clear of objects and open - with

engine off and parking brake set,

2. Disengage transmission by placing

freewheel control indisengaged position

(See "TO TRANSPORT" in this section

of manual).

3. Sitting in the tractor seat, start engine.

After the engine isrunning, move throttle

control to slow position. Disengage park-

ing brake.

_CAUTION: At any time, during step 4,

there may be movement of the drive wheels,

4. Depressforward drive pedalto full forward

position and holdforfive (5) seconds and

release pedal. Depress reverse drive

pedal to full reverse position and hold

for five (5) seconds and release pedal.

Repeat this procedure three (3) times.

5, Shutoff engine and set parking brake.

6. Engage transmission by placing free-

wheel control in engaged position (See

"TO TRANSPORT" in this section of

manual).

7. Sitting in the tractor seat, start engine.

After the engine is running, move throttle

control to half (1/2) speed. Disengage

parking brake.

8. Drive tractor forward for approximately

five feet then backwards for five feet,

Repeat this driving procedure three

times.

Your transmission is now purged and now

ready for normal operation.

19

MOWINGTIPS

• Tire chains cannot be used when the

mower housing is attached to tractor.

• Mower should be properlyleveled for best

mowing performance. See "TO LEVEL

MOWER HOUSING" in the Service and

Adjustments section of this manual.

• The left hand side of mower should be

used for trimming.

• Drive so that clippings are discharged onto

the area that has already been cut, Have

the cut area tothe right ofthe tractor. This

will result in a more even distribution of

clippings and more uniform cutting.

• When mowing largeareas, start byturning

tothe right so that clippings will discharge

away from shrubs, fences, driveways,

etc. After one or two rounds, mow in the

opposite direction making [eft hand turns

until finished.

f

J

• if grass is extremely tall, it should be

mowed twice to reduce load and possible

fire hazard from dried clippings, Make

first cut relatively high; the second to the

desired height.

• Do not mow grass when it is wet. Wet

grass will plug mower and leave undesir-

able c]umps. Allow grass to dry before

mowing.

• Always operate engine at full throttle

when mowing to assure better mow-

ing performance and proper discharge

of material. Regulate ground speed by

selecting a low enough speed to give the

mower cutting performance as well as the

quality of cut desired.

• When operating attachments, select a

ground speed that will suit the terrain and

give best performance of the attachment

being used.

20

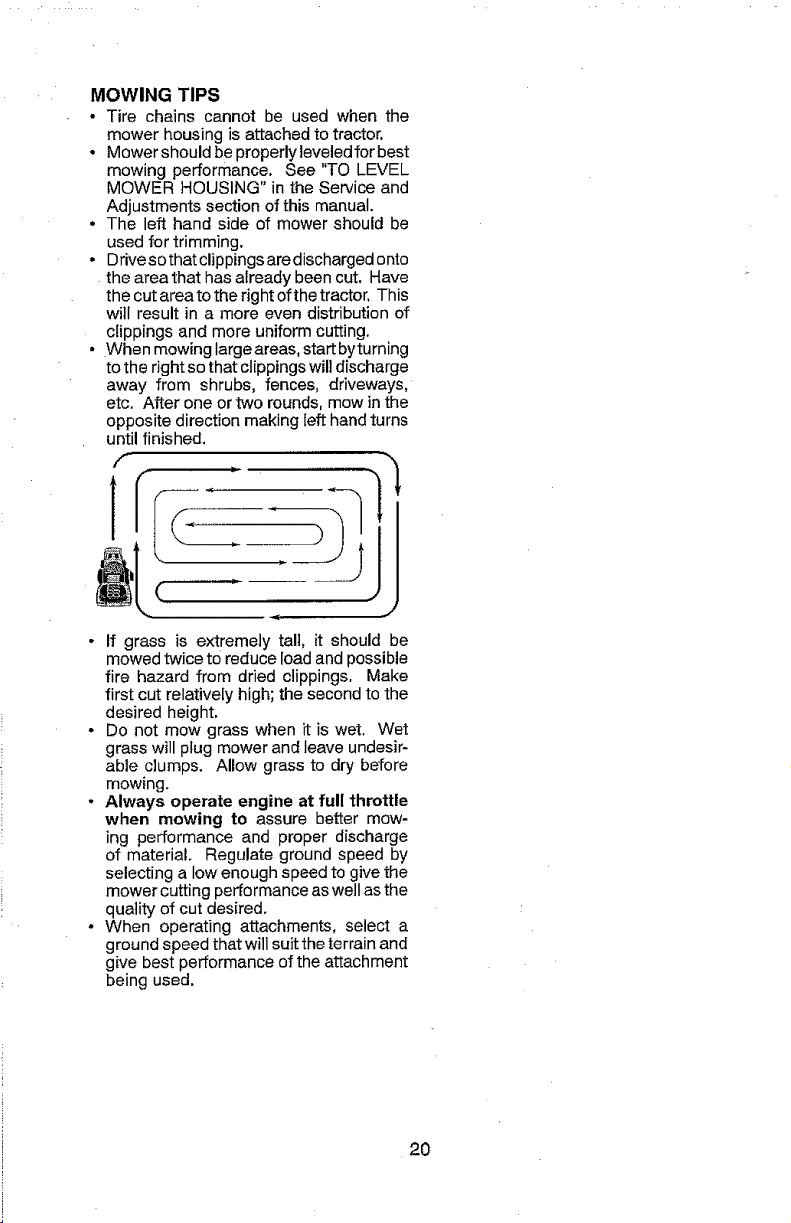

AINTENANCE BEFORE EVERY EVERY EVERY EVERY EVERY BEFORE

SCHEDULE use HOURSHOURSHOURSHOURS

Check,Brake Operation V' _'_ ' ...... ' '_ I ""

Check Tire Peessure ,,

Check Operelor Presence & ROS Systems fk/ ,

A Check for Loose Fasteners if ........

C CheekJRep_ace Mower Blades V*_ ,,.

T Lubrication Cha_t If .... V'

0 Check Battery Level .... _ ,

R CIe an Balte ry and Terminals V f

Clean Oebrie Off Steering Plate, " _ , , ,

Check Tmnsaxle Coo,_,ing V"

Check Mower Levelness V _''

Check V-Belts ,,,

Check Engine Oil Level _,,, "'_

Change Enql_ne Oil (with oil filter) V'_'._ V"

Change Engine Oi| (without oil filte,r) V'I,Z _ .......

E Clean Air Fitter J _.

F.ACH S 25 50 t00 SEASON STORAGE

V' I/" ..

G Clean AirScreen V'=

| Inspect Mull]el/Spark Arrester i_

N i Replace Oil Filter (1!equipped) _#_'=

E C ean ,Engine Coolin_ Fins V'2

Rep age Spe, rk Plug V =...... I_"

Re,place Air Filter Paper Cartridge _t_

Replace Fuel Filter ....

V

GENERAL RECOMMENDATIONS

The warranty on thistractor does not cover

itemsthat have been subjected to operator

abuse or negligence. To receive futlvalue

from the warranty, operator must maintain

tractoras instructedin this manual.

Some adjustments willneedto be made pe-

riodicallyto properly maintain your tractor.

At least once a season, check to see if

you should make any of the adjustments

described in the Service and Adjustments

section of this manual.

• At least once a year you should replace

the spark plug, clean or replace air filter,

and check blades and belts for wear. A

new spark plug and clean air filter assure

proper air-fuel mixture and help your en-

gine run better and last longer.

BEFORE EACH USE

t, Check engine oil leve!,

2. Check brake operation.

3, Check tire pressure,

4. Check operator presence and

ROS systems for proper operation,

5, Check for loose fasteners,

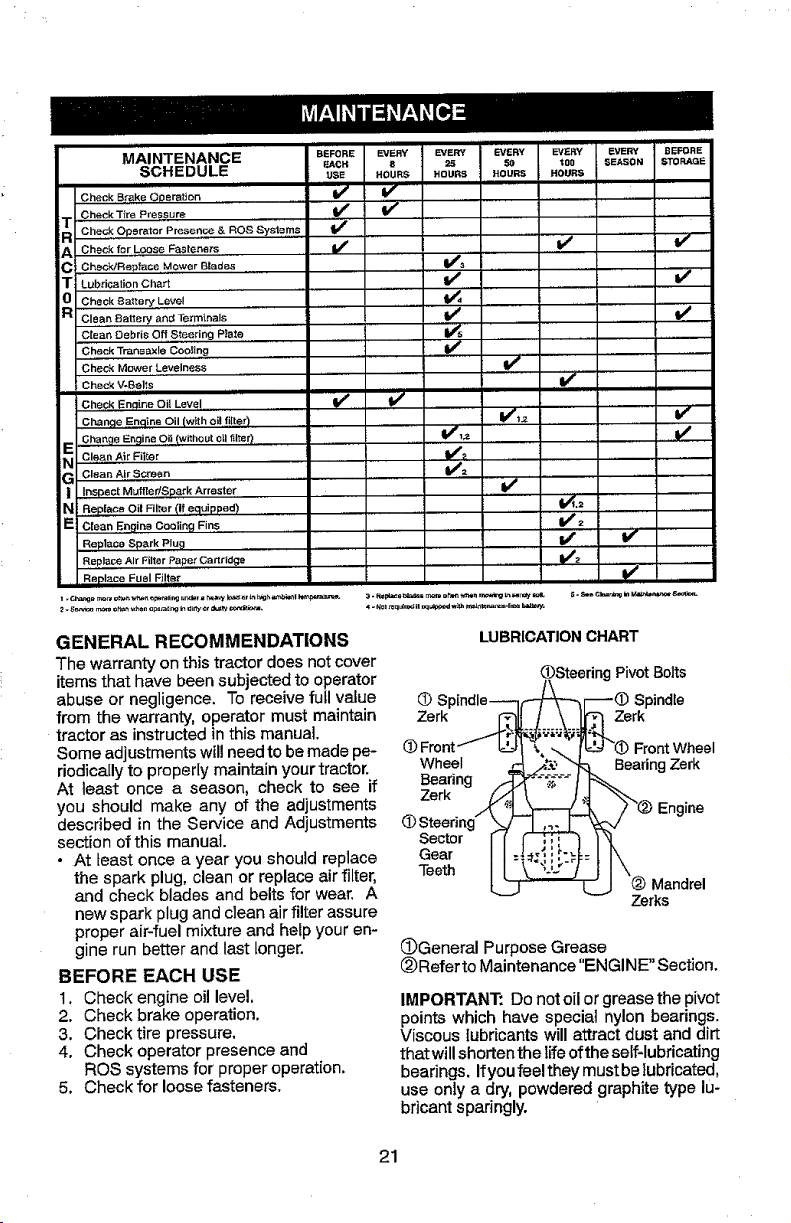

LUBRICATION CHART

(_SteeringPivotBolts

(_ Spindle----iF/_l_ Spindle

_Front I- '12_41"_.... [L..LJ"0 FrontWheel

_=____?earing Zerk

Sector [[ _.','_--_Iix{

Gear I Id_:_d.?._F:IIX

Teeth L._ _ ;": _ \_)Mandrel

OGeneral Purpose Grease

(_)Referto Maintenance"ENGINE" Section.

IMPORTANT: Do not oilor grease the pivot

points which have special nylon bearings.

Viscous lubricants will attract dust and dirt

thatwill shorten the lifeof the self-lubricating

bearings, Ifyou feel they must be lubricated,

use only a dry, powdered graphite type lu-

bricant sparingly.

21

Zerks

TRACTOR

Always observesafety ruleswhen performing

any maintenance.

BRAKE OPERATION

Iftractor requires more than five (5) feet to

stop at highest speed in highest gear on a

level, dry concrete or paved surface, then

brake must be serviced. (See "TO CHECK

BRAKE" in the Service and Adjustments

section of this manual).

TIRES

* Maintain proper air pressure in all tires

(See PSI on tires).

- Keep tires free of gasoline, oil, or insect

control chemicals which can harm rub-

ber.

° Avoid stumps, stones, deep ruts, sharp

objects and other hazards that may cause

tire damage.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant may

be purchased from your local parts dealer.

Tire sealant also prevents tire dry rot and

corrosion.

OPERATOR PRESENCE SYSTEM AND

REVERSE OPERATION SYSTEM (ROS)

Be sure operator presence and reverse

operation systems are workingproperly. If

your tractor does not function as described,

repair the problem immediately.

. The engine should not start unless the

brake pedal is futty depressed, and the

attachment clutch control is in the disen-

gaged position.

CHECK OPERATOR PRESENCE

SYSTEM

• When the engine is running, any attempt

by the operator to leave the seat without

first setting the parking brake should shut

off the engine.

• When the engine is running and the at-

tachment clutch is engaged, any attempt

by the operator to leave the seat should

shut off the engine,

. The attachment clutch should never oper-

ate unless the operator is in the seat.

ROS "ON" Position Engine "ON" Position

(Normal Operating)

CHECK REVERSE OPERATION (ROS)

SYSTEM

• When the engine isrunningwiththeignition

switch inthe engine "ON" position and the

attachment clutch engaged, any attempt

bythe operator toshift into reverse should

shut off the engine.

• Whenthe engine is runningwiththe ignition

switch in the ROS "ON" position and the

attachment clutch engaged, any attempt

bythe operator to shift into reverse should

NOT shut off the engine.

BLADE CARE

For bestresults mower blades mustbesharp.

eptace worn, bent or damaged blades.

CAUTION: Useonlya replacement blade

approved bythe manufacturer ofyourtractor.

Using a blade not approved by the manu-

facturer of your tractor is hazardous, could

damage your tractor and void your warranty.

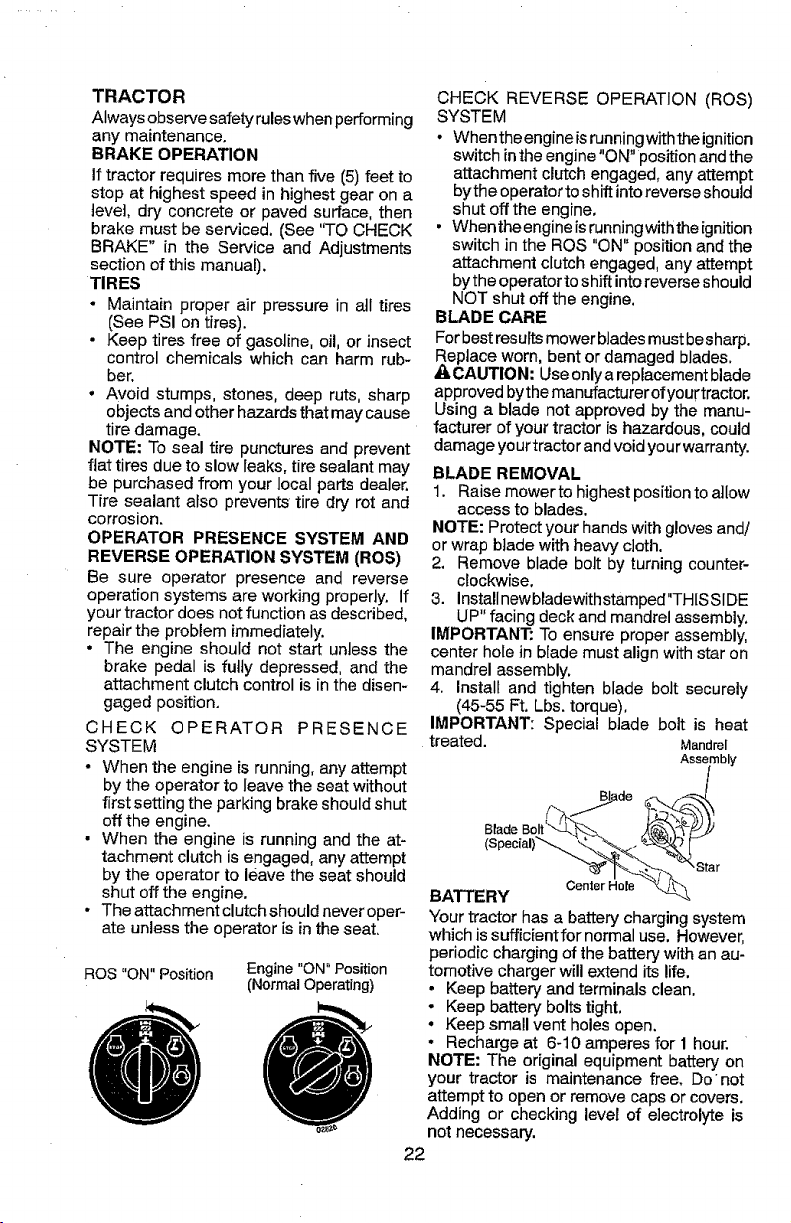

BLADE REMOVAL

1. Raise mowerto highest positiontoallow

access to blades,

NOTE: Protect your handswithgloves and/

orwrap blade withheavy cloth.

2, Remove blade bolt by turning counter-

cloct{wise,

3. InstalInewbladewithstamped"THIS SIDE

UP" facing deck and mandrel assembly,

IMPORTANT: To ensure proper assembly,

center hole in blade must align with star on

mandrel assembly.

4. Install and tighten blade bolt securely

(45-55 Ft, Lbs. torque).

IMPORTANT: Special blade bolt is heat

treated. Mandrel

Assembly

BATTERY Center _lole _,_

Your tractor has a battery charging system

which is sufficientfor normal use. However,

periodic charging of the battery with an au-

tomotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

NOTE: The original equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

22

Loading...

Loading...