Page 1

Owner's Manual

25.0 HP

ELECTRIC START

48" MOWER

AUTOMATIC

LAWN TRACTOR

Model No.

917.272261

• Safety

• Assembly

• Operation

• Maintenance

• Repair Parts

CAUTION:

Read and follow all

Safety Rules and Instructions

before operating this equip-

ment.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Visit our Craftsman website: www sears.corn/craftsman

For answers to your questions

about this product, Call:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pm, Mon - Sat

Page 2

Warranty ............................................... 2

Safety Rules ......................................... 3

Product Specifications .......................... 6

Assembly .............................................. 8

Operation ............................................ 12

Maintenance Schedule ...................... 18

LIMITED'FWOYEAR WARRANTY ON CRAFTSMAN RIDING EQUIPMENT PARTS

For two (2) years from the date of purchase, if this Craftsman Riding Equipment is

maintained, lubricated and tuned up according to the instructions in the owner's

manual, Sears will repair or replace, free of charge, any parts found to be defective in

material or workmanship. Warranty service is available free of charge by returning

your Craftsman riding equipment to your nearest Sears Service Center. In-home

warranty service is available but a trip charge will apply. This warranty applies only

while this product is in the United States.

This Warranty does not cover:

• Expendable items which become worn during normal use, such as blades, spark

plugs, air cleaners, belts and oilfilters.

• Tire replacement or repair caused by punctures from outside objects, such as nails,

thorns, stumps,or glass.

• Repairs necessary because of operator abuse, including but not limited to, damage

caused by towing objects beyond the capability of the riding equipment, impacting

objects that bend the frame or crankshaft, or over speeding the engine.

• Repairs necessary because of operator negligence, includingbut not limited to,

electrical and mechanical damage caused by improper storage, failure to use the

proper grade and amount of engine oil, failure to keep the deck clear of flammable

debris, or the failure to maintain the equipment according to the instructions

contained in the owner's manual.

• Engine (fuel system) cleaning or repairs caused by fuel determined to be contami-

nated or oxidized (stale). In general, fuel should be used within thirty (30) days of its

purchase date.

• Riding equipment used for commercial or rental purposes. A productis =used for

commercial purpose" if is used for any purpose otherthan single family household

dwellings or in usage where profitis made.

Maintenance ....................................... 18

Service and Adjustments .................... 23

Storage ............................................... 29

Troubleshooting ................................. 30

Repair Parts ........................................ 34

Parts Ordering ..................... Back Cover

LIMITED 90 DAY WARRANTY ON BA]-(-ERY

For ninety (90) days from date of purchase, it any battery included with this riding

equipment proves defective in material or workmanship and our testing determines

the battery will not hold a charge, Sears will replace the battery at no charge. War-

ranty service is available free of charge by returning your Craftsman riding equipment

to your nearest Sears Service Center. In-home warranty service isavailable but a trip

charge will apply. This warranty applies onlywhile this product is in the United States.

TO LOCATETHE NEAREST SEARS SERVICE CENTER ORTO SCHEDULE IN-

HOME WARRANTY SERVICE, SIMPLY CONTACT SEARS AT 1-800-4-MY-HOME

This Warranty gives you specific legal dghts, and you may also have other dghts

which may vary from state to state.

Sears, Roebuck and Co., [:)/817WA, Hoffman Estates, IL 60179

Page 3

IMPORTANT:This cutting machine s capable of amputatinghands and feet and

throwing objects. Failure to observe the followingsafety instructionscould result in

seriousinjury or death.

I.GENERAL OPERATION I1.SLOPE OPERATION

• Read, understand,and follow all

instructionsin the manual and on the

machine before starting.

• Only allow responsibleadults,who are

famiUar with theinstructions, tooperate

the machine.

• Clear the area of objects such as rocks,

toys,wire, etc., which couldbe picked

up and thrownby the blade.

• Be sure the area is clear of other people

before mowing. Stop machine if anyone

enters the area.

• Never carry passengers.

• Do not mowin reverse Lmlessabsolutely

necessary. Always look down and

behind before and while backing.

• Be aware ofthe mower discharge

directionand do not point it at anyone.

Do not operatethe mower without either

the entire grass catcheror the guard in

place.

• Slow down before taming.

• Never leave a rUr_ing machine

unattended. Alwaysrumoff blades, set

parkingbrake, stop engine, and remove

keys before dismounting.

Turn off blades when not mowing.

Stop engine before removing grass

catcher or uncloggingchute.

Mow orgyin daylight or good artificial

light.

Do not operate the machine whileunder

the influenceof alcoholor drugs.

Watch fortrafficwhen operatingnear or

crossing roadways.

Use extra care when loading or unload-

ingthe machineinto a trailer ortrack.

Data indic_tasthat operators, age 60

years and above, are invelved in a large

percentage of ridingmower-related

iojurles.These operatorsshould

evaluate their abilityto operate the riding

mower safely enoughto protectthem-

selves and othersfrom seriousInjury.

• Keep machine free ofgrass, leaves or

other debrisbuild-upwhich can touch

hotexhaust / engine parts and bum. Do

notallew the mower deck to plowleaves

or other debris whichcan cause build-

up to eecL_.Clean any oilor fuel

spillage before operatingor storing the

machine. Allow machineto coal before

storage.

Slopes are ama or factor related to loss-of-

control and tpover accidents,whichcan re-

ealt in severe injury or death. All slopes

require extra caution. Ifyou cannot pack up

the slope or if you feel uneasy on it, do not

mow it.

DO:

• Mow up and down slopes, not across.

• Remove obstacles such as rocks,tree

limbs, etC.

Watch for holes, ruts, or bumps. Uneven

terrain could overturnthe machine. Tall

grass can hide obstacles.

Use slaw speed. Cheese a low gear so

that you willnot have to stop orshift

while on the slope.

Followthe manufacturer'srecommenda-

tions for wheel weights or counter-

weightsto improve stablely.

Use extra care with grass catchers or

othor attachments. These can change

the stabilityofthe machine.

Keep all movement on the slopes slow

and gradual. Do not make sudden

changes in speed or direction,

Avoid starting or stopping on • slope, ti

tires lose traction, disengage the blades

and proceed siov_y straight down _e

slope.

DO NOT:

• Do not turnan slopes unless necessary,

and tben, turn slowly and gradually

downhill, if possible.

• Do notmow near drop-offs, ditches,or

embankments. The mower could

suddenlyturnover if a wheel is overthe

edge of a cliffor ditch, or if anedge

caves in.

• DOnot mow on wet grass. Reduced

traction could cause sliding.

• Do not tryto stabilize the machine by

puttingyourfoot an the ground.

• Do notuse grasscatcher an steep

slopes.

Page 4

III. CHILDREN

Tragic accidents can occur if the operator

is not alert to the presence of children.

Childrenare often attracted to the

machine and the mowing activity. Never

assume that childrenwilt remain where

you last saw them.

• Keep children out of the mowing area

and under the watchful care of another

responsible adult.

• Bealert and turn machine off ff children

enter the area.

• Before and when backing, look behind

and down for small children.

• Nevercarry children. They may fall off

and be seriously injured or _nterfere

with safe machine operation.

• Never allow children to operate the

machine,

• Use extra care when approaching blind

comers, shrubs, trees, or other objects

that may obscure vision.

IV. SERVICE

• Use extra care in handling gasoline

and otberfuels. They are flammable

and vapors are explosive.

-Use only an approved container.

-Never remove gas cap oradd fuel

with the engine running. Allow

engine to cool before refueling. Do

notsmoke,

- Never refuel the machine Indoors.

-Never store the machine or fuel

container inside where there is an

open flame, such as a water heater.

• Never run a machine inside a closed

area.

• Keep nuts and bolts, especially blade

attachment bolts, tight and keep

equipment in good condition.

• Never tamper with safety devices,

Check their proper operation regularly.

• Keep machine free of grass, leaves, or

other debds build-up. Glean oil or fuel

spillage. Allow machine to cool before

stodng.

• Stop and inspectthe equipment ifyou

strike an object. Repair, ifnecessary,

before restarting.

• Never make adjustments or repairs

with the engine running.

• Grass catcher components are subject

to wear, damage, and deterioration,

which could expose moving parts or

allow objects to be thrown. Frequently

check components and replace with

manufacturer's recommended parts,

when necessary.

• Mower blades are sharp and can cut.

Wrap the blade(s) or wear gloves, and

use extra caution when servicingthem,

• Check brake operation frequently.

Adjust and service as required.

• Besure the area is clear of other

people before mowing. Stop machine if

anyone enters the area,

• Never carry passengers or children

even with the blades off.

• Do not mow inreverse unlessabso-

lutely necessary. Always look down

and behind before and while backing.

• Never carry children. They mayfall off

and be seriously injured or interfere

with safe machine operation.

• Keep children out of the mowing area

and underthe watchful care of another

responsible adult.

0 Be alert and turn machine offIf children

enter the area.

• Before and when backing, look behind

and down for small children.

• Mow Upand down slopes (15 ° Max),

not across.

• Remove obstacles suchas rocks,tree

limbs, etc.

• Watch for holes, ruts, or bumps.

Uneven terrain could overturn the

machine. Tall grass can hide obstacles.

Page 5

• Use slow speed. Choose a low gear so

that you will not have to stop or shift

while on the slope.

• Avoid starting or stopping on a slope. If

tires lose traction, disengage the

blades and proceed slowly straight

down the slope.

• If machine stops while going uphill,

disengage blades, shift into reverse

and back down slowly.

• Do not turn on slopes unless neces-

sary, and then, turn slowly and gradu*

ally downhill, if possible.

_Look for this symbol to pointout

importantsafety precautions.It means

CAUTIONlif BECOME ALERTI!! YOUR

SAFETY IS INVOLVED.

_I, CAUTION: In order to prevent

accidental starting when setting up,

transporting, adjusting or making repairs,

always disconnect spark plug wire and

place wire where if cannot contact spark

plug.

_,CAUTION: Do not coast down a hill in

neutral, you may lose control of the

tractor.

_IbCAUTION: Tow only the attachments

that are recommendedby and comply

with specifications of the manufacturer of

your tractor. Use common sense when

towing. Operate onlyat the lowest

possiblespeed when on a slope. Too

heavy of a load, while on a slope, is

dangerous. Tires can lose traction with

the ground and cause you to lose control

of your tractor.

,_WARNING: Engine exhaust, some of

its constituents, and certainvehicle

components contain or emit chemicals

known to the State of Californiato cause

cancer and birth defects or other repro-

ductive harm.

_WARNING: Battery posts,terminals

and related accessories contain lead and

lead compounds, chemicals known to the

State of California to cause cancer and

birthdefects or other reproductive harm.

Wash hands after handling.

Page 6

PRODUCTSPECIFICATIONS

GASOLINE 3.5GALLONS

CAPACITY UNLEADED

ANDTYPE: REGULAR

OILTYPE SAE30

(ABOVE32°F)

API-SF-SJ): SAE5W-30

(BELOW32°F)

OILCAPACITY:W/FILTER:4.0PINTS

W/OFILTER:3.75PINTS

SPARKPLUG:CHAMPIONRC12YC

(GAP:.040")

GROUNDSPEEDFORWARD:0-5.5

',MPH): REVERSE: 0-2.4

FIREPRESSURE: FRONT: 14 PSI

REAR: 10PSI

_HARGING

SYSTEM: 16 AMPS @3600 RPM

3ATIE RY: AMP/HR: 30

MIN. CCA: 240

CASE SIZE: U1R

BLADE BOLT 45-55 FT. LBS,

rORQUE:

CONGRATULATIONS on your purchase

ofa newtractor. It has been designed,

engineered and manufactured to give you

the best possible dependability and

performance.

Should you experience any problem you

cannot easily remedy, please contact a

Sears or other qualified service center.

We have competent, wall-trained techni-

cians and the proper tools to service or

repairthis tractor.

Please readand retain this manual. The

instructionswill enable you to assemble

and maintain your tractor properly.

Always observe the "SAFETY RULES".

REPAIR AGREEMENT

A Repair Agreement is available on this

product. Contact your nearest Sears

storefor details.

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintain-

ing, caring for and using your tractor.

• Follow the instructionsunder "Mainte-

nance" and "Storage" sections of this

owner's manual.

• I,WARNING: This tractoris equipped

with an internal combustion engine and

should not be used on or near any

unimproved forest-covered, brush-

covered or grass-covered land unless the

engine's exhaust system is equipped with

a spark arrester meeting applicable local

or state laws (ifany). If a sparkarrester is

used, it should be maintained in effective

working order bythe operator.

In the state of Californiathe above is

required by law (Section 4442 of the

California Public Resources Code).

Other states may have similar laws.

Federal laws apply on federal lands. A

spark arrester for the muffler isavailable

through yournearest Sears service

center (See REPAIR PARTS sectionof

this manual).

Page 7

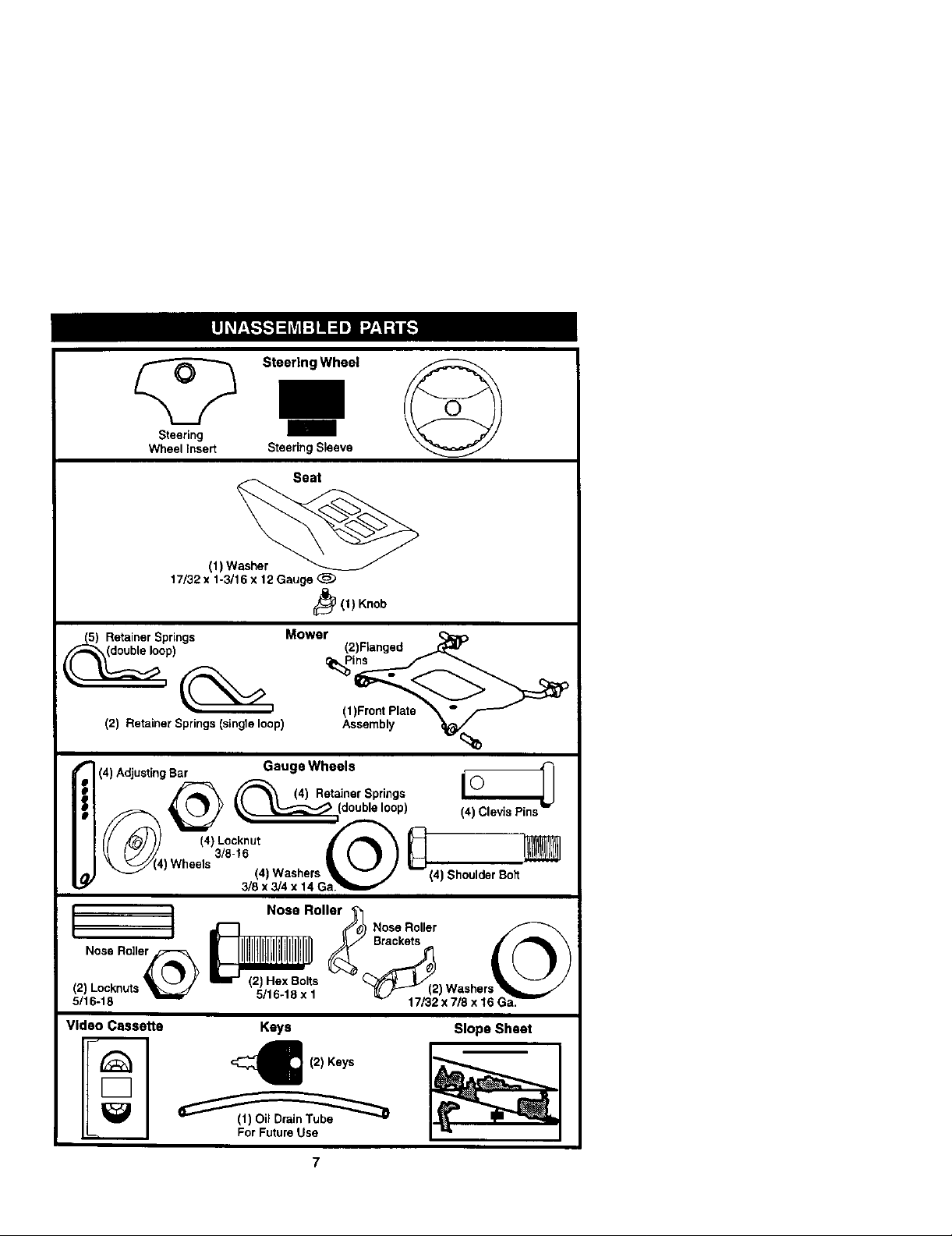

Steering

Wheel Insert Steering Sleeve

(1) W_

17/32 x 1-3/16 x 12 Gauge

Retainer Springs

)

Steering Wheel

_(1) Knob

Mower

(2)Flanged

(2) Retainer Springs (single loop)

• (4) Adjusting Bar Gauge Wheels i-O

i ,_ _ (4)Retainer Springs L_ JI

_e _ _ __(doubla loop) (4) Clevis Pins w

_.1 f T// 3/8-16 • [ • J _

,-_ 'k,__._/(4 (4) Washers _&=kJJ (4) Shoulder Bolt

-- -- Nose Roller _']

-- -- -- _'0_ Nose Roller

(4) Whee s

3/8 x 3/4 x 14 Ga.'_"

(l)FrontPlate _"

Assembly _%

)) i

=.oo"°s°Ro,,e .-IIIIIIIlllllll!l!llllllll]<=,.oxBolts B Brackets

( ) knuts _ R/IR 1R _t t _(2) Washers_._.._

5116-18 ..... "..... 17/32 x 7/8 x 16 GaW

Video CasseUa Keys Slope Sheet

[1

(2) Keys

For Future Use

7

Page 8

Your new tractor has been assembled at the factory with exception of those parts left

unassembled for shipping purposes• To ensure safe and proper operation of your

tractor all parts and hardware you assemble must be tightened securely. Use the

correct tools as necessary to insure proper tightness, Review the video cassette before

you begin.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly

easier. Standard wrench sizes you need

are listed below.

(1) 9/16" wrench (t) 3/4" Socket w/

(1) 1/2" wrench drive ratchet

(1) Utility knife (1) Pliers

(1) Tire pressure gauge

When right or left hand is mentioned in

this manual, it means, from your pointof

view, when you are in the operating

position (seated behind the steering

wheel).

TO REMOVETRACTOR FROM

CARTON

UNPACK CARTON

1. Remove all accessible loose parts

and partscartons from carton.

2. Cut, from top to bottom, along lines on

all four comers of carton, and lay

panels flat.

3. Remove mower and packing materi-

als.

4. Check for any additional loose parts

or cartons and remove.

BEFORE REMOVINGTRACTOR

FROM SKID

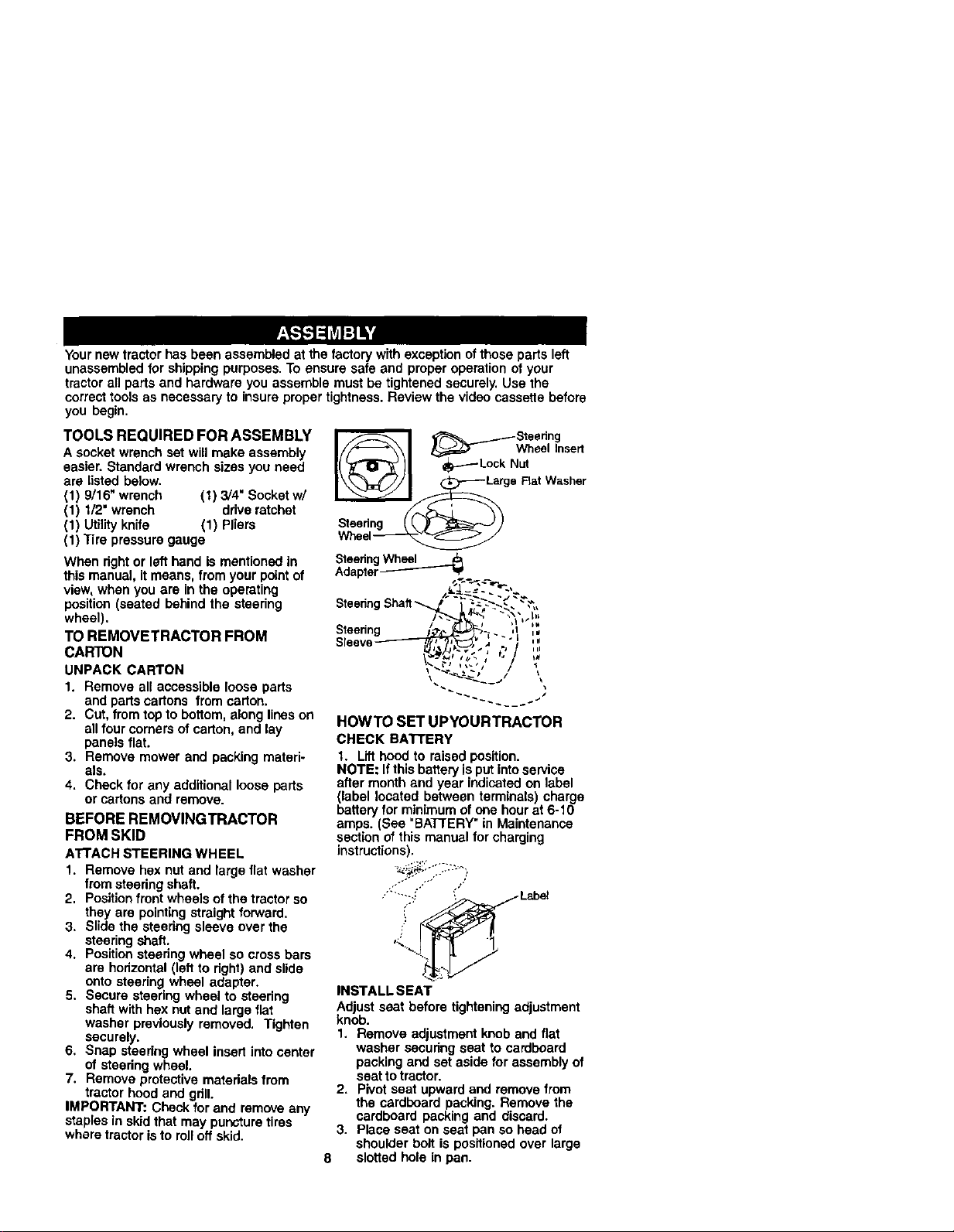

ATTACH STEERING WHEEL

1. Remove hax nut and largeflat washer

from steering shaft.

2. Positionfront wheels of the tractor so

they are pointing straight forward.

3. Slide the steadng sleeve over the

steering shaft.

4. Positionsteedng wheel so cross bars

are horizontal (left to dght) and slide

onto steering wheel adapter.

5. Secure steering wheel to steedng

shaft with hex nutand largeflat

washer previously removed. Tighten

securely.

6. Snap steering wheel insert intocenter

of steedng wheel.

7. Remove protective materials from

tractor hood and gdll.

IMPORTANT: Check for and remove any

staples in skid that may puneturetires

where tractor is to roll off skid.

I/F_'_\I t_=.,€,T WheelInsert

II

I_ I_ge Flat Washer

Steedng /_J _,)

SteeringWheel

Adapter_ v

$,eerio, :

S eeve_, ,,'t:J._ ., .') ,"

HOWTO SET UPYOURTRACTOR

CHECK BA'I-rERY

1. Lifthood to raised position.

NOTE: Ifthis batteryis putintoservice

after month and year indicated on label

(label located between terminals) charge

battery for minimum of one hour at 6-10

amps. (See "BATTERY"in Maintenance

section ofthis manual for charging

instructions).

.,........f _ Lab_

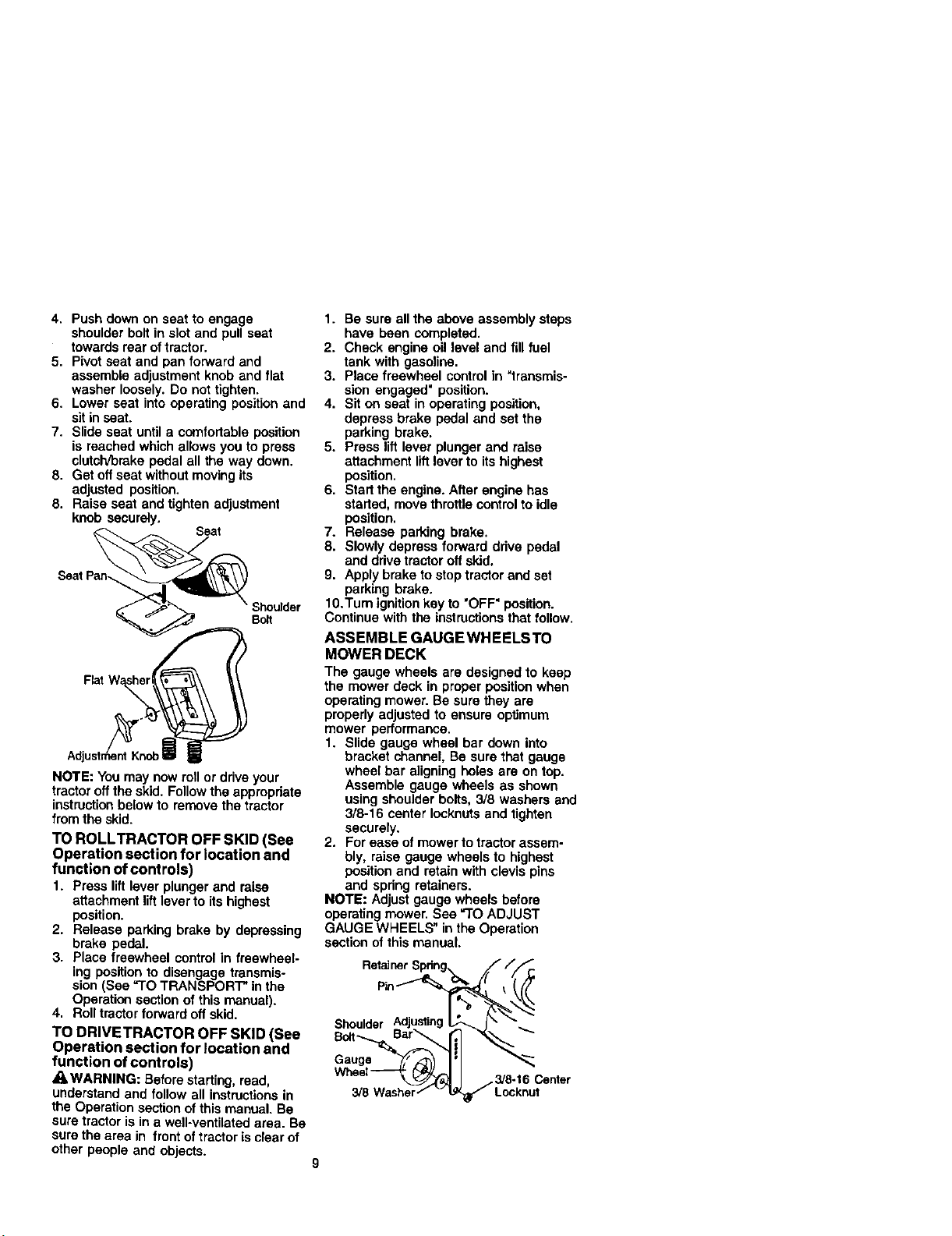

INSTALL SEAT

Adjust seat before tightening adjustment

knob.

1. Remove adjustment knob and flat

washer secudng seat to cardboard

packing and set aside for assembly of

seat to tractor.

2. Pivotseat upward and remove from

the cardboard packing. Remove the

cardboard packing and discard.

3. Place seat on seat pan so head of

shoulder bolt is positionedover large

8 slotted hole in pan.

_ s I _J III

Page 9

4. Pushdownonseattoengage

shoulderboltinslotandpullseat

towardsrearoftractor.

5. Pivot seat and pan forward and

assemble adjustment knob and flat

washer loosely. Do not tighten.

6. Lower seat into operating position and

sit in seat.

7. Slide seat until a comfodable position

is reached which allows you to press

clutch/brake pedal all the way down.

8. Get off seat without moving its

adjusted position.

8. Raise seat and tighten adjustment

knob securely.

NOTE: You may now roll or ddve your

tractor off the skid. Follow the appropdate

instructionbelow to remove the tractor

from the skid.

TO ROLLTRACTOR OFF SKID (See

Operation section for location and

function of controls)

1. Press lift lever plunger er,d raise

attachment liftlever to itshighest

position.

2. Release parklt_:3brake by depressing

brake pedal.

8. Place freewheel control in freewheel-

ing position to disengage transmis-

sion (See "TO TRANSPORT" in the

Operation section of this manual).

4. Roll tractorforward oft skid.

TO DRIVETRACTOR OFF SKID (See

Operation section for location and

function of controls)

_l, WARNING: Before starting,read,

understand and follow all instructionsin

the Operation sectionof this manual. Be

sure tractor is in a well-ventilated area. Be

sure the area in front of tractor isclear of

other people and objects.

Seat

Shoulder

Bolt

1. Be sure all the above assembly steps

have been completed.

2. Check engine oll level and fill fuel

tank with gasoline.

3. Place freewheel control In "transmis-

sion engaged" position.

4. Sit on seat in operating position,

depress brake pedal and set the

parking brake.

5. Press lif'_lever pfunger and raise

atlachment lift lever to its highest

position.

6. Start the engine. After engine has

started, move throttle controlto idle

position.

7. Release parking brake.

8. Slowly depress forward ddve pedal

and ddve tractoroff skid.

9. Apply brake to stoptractor and set

parking brake.

10.Turn ignitionkey to "OFF" position.

Continue with the instructions that follow.

ASSEMBLE GAUGEWHEELSTO

MOWER DECK

The gauge wheels are designed to keep

the mower deck in proper position when

operatingmower. Be sure they are

propedy adjured to ensure oplimam

mower performance.

1. Slide gauge wheel bar down into

bracket channel, Be sure that gauge

wheel bar aligning holes are on top.

Assemble gauge wheels as shown

using shoulder bolts, 3/8 washers and

3/8-16 center lecknuts and tighten

securely.

2. Far ease of mower to tractor assem-

bly, raise gauge wheels to highest

position and retain with clevis pins

and spdng retainers.

NOTE: Adjust gauge wheels before

operating mower, See "TO ADJUST

GAUGE WHEELS" in the Operation

section of this manual.

Shoulder

Bolt Bar--_] ._.

Wheal'_ I 13/8-t6Center

3/8 Washerj v L_ Locknut

Page 10

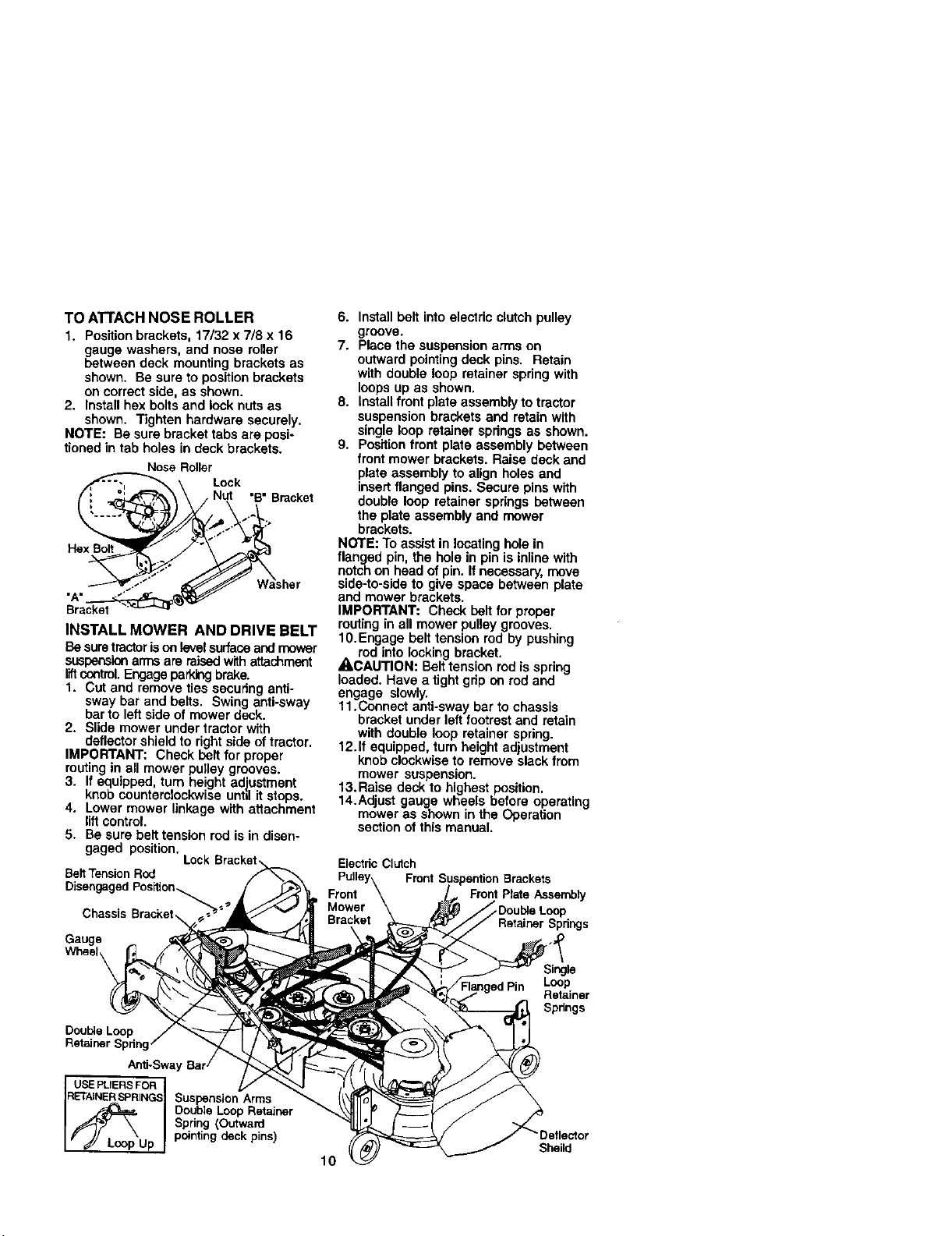

TO ATTACH NOSE ROLLER

1. Pos_ion brackets, 17132x 7/8 x 16

gauge washers, and nose roller

between deck mounting brackets as

shown. Be sure to positionbrackets

on correct side, as shown.

2. Install hex bolts and lock nuts as

shown. Tighten hardware securely.

NOTE: Be sure bracket tabs are posi-

tioned in tab holes in deck brackets.

Nose Roller

Lock

"B" Bracket

"A"

Bracket

INSTALL MOWER AND DRIVE BELT

Be suretractorison levelsurfaceand mower

suspensionarmsare _sed withattachment

codtmi. Engage parkingbrake.

1. Cut and remove ties securing anti-

sway bar and belts, Swing anti-sway

bar to left side of mower deck.

2. Slide mower under tractor with

deflectorshield to right side of tractor.

IMPORTANT: Check belt for proper

routing in all mower pulley grooves.

3. If equipped, turn height adiustment

knob counterclockwise unhl it stops.

4. Lower mower linkage with attachment

lift control.

5. Be sure belttension rod is in disen-

gaged position.

BeltTension Rod

Chassis Brackel,

Gauge

6. Installbelt into electric clutch pulley

groove.

7. Place the suspension arms on

outward pointingdeck pins. Retain

with double loop retainer springwith

loops up as shown.

8. Install front plate assembly to tractor

suspensionbrackets and retain with

single loop retainer springs as shown.

9. Positionfront plate assembly between

front mower brackets. Raise deck and

plate assembly to align holes end

insert flanged pins. Secure pins with

double loop retainer springs between

the plate assembly and mower

brackets.

NOTE: Toassist in locating hole in

flanged pin, the hole in pin is inline with

notch on head of pin. If necessary, move

side-to-side to give space between plate

and mower brackets.

IMPORTANT: Check belt for proper

routingin all mower pulley grooves.

10.Engage belttension rod by pushing

rod into locking bracket.

ACAUTION: Belt tension rodis spring

loaded. Have a tight grip on rod and

engage slowly.

11.Connect anti-sway bar to chassis

bracket under left footrest and retain

with double loop retainer spring.

12.If equipped, turn height adjustment

knob clockwiseto remove slack from

mower suspension.

13.Raise deck to highest position.

14.Adjust gauge wheels before operating

mower as shown in the Operation

section of this manual.

Electric Clutch

Pulley\ Front Suspention Brackets

Front Front Plate/_ssernbly

Mower \ _Double Loop

Bracket Relainer Springs

Single

Loop

Retainer

Spnngs

Double Loop

Retainer Spring

Anti-Sway

RETAINERSPRINGS Suspension Arms

I_L_p Double Loop Retainer

USEPLIERSFOR I

Spring (Outward

Up pointing deck pins)

Sheild

10

Page 11

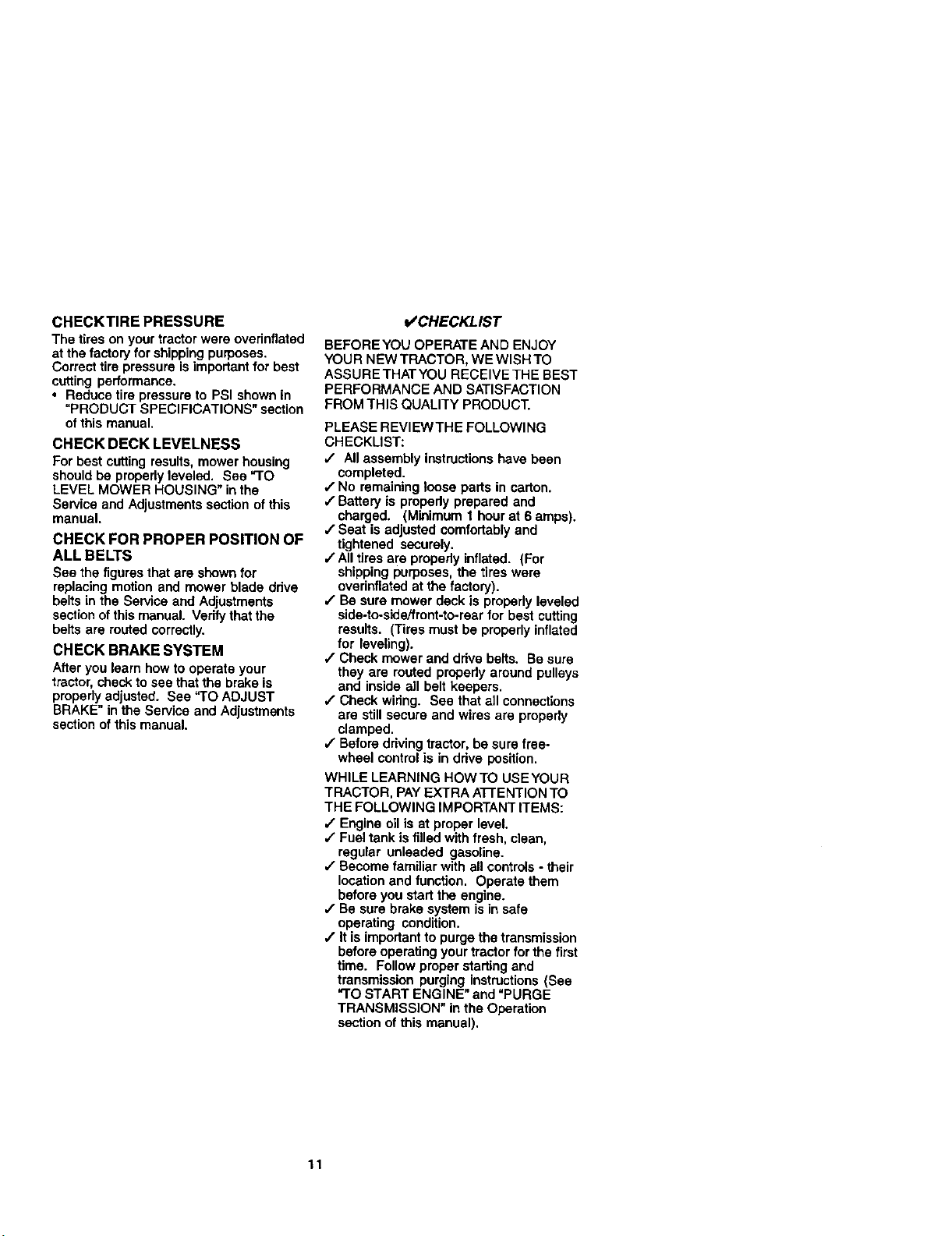

CHECKTIRE PRESSURE

The tires on your tractorwere overinltated

at the factory for shipping purposes.

Correct tire pressure is important for best

cutting performance.

• Reduce tire pressure to PSI shown in

"PRODUCT SPECIFICATIONS" section

ofthis manual.

CHECK DECK LEVELNESS

For best cuttingresults, mower housing

should be properlyleveled. See "TO

LEVEL MOWER HOUSING" inthe

Service and Adjustments section of this

manual.

CHECK FOR PROPER POSITION OF

ALL BELTS

See the figures that are shown for

replacing motion and mower blade drive

belts in the Service and Adjustments

section ofthis manual. Verifythat the

belts are routed correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your

tractor,check to see that the brake is

pmpedy adjusted. See "TO ADJUST

BRAKE" in the Service and Adjustments

section of this manual.

_CHECKLIST

BEFOREYOU OPERATE AND ENJOY

YOUR NEW TRACTOR, WE WISH TO

ASSURETHATYOU RECEIVETHE BEST

PERFORMANCE AND SATISFACTION

FROM THIS QUALITY PRODUCT.

PLEASE REVIEWTHE FOLLOWING

CHECKLIST:

/ All assembly instructionshave been

completed.

J No remaining loose parts in carton.

4" Battery is propedy prepared and

charged. (Minimum 1 hour at 6 amps).

J" Seat is adjusted comfortably and

tightened securely.

JAil tires are properly inflated. (For

shipping purposes, the tires were

overinflated at the factory).

J" Be sure mower deck is properly leveled

side-to-side/front-to-rear for best cutting

results. (Tires must be properly inflated

for leveling).

/ Check mower and drive belts. Be sure

they are routed properly around pulleys

and inside all belt keepers.

/ Check wiring. See that all connections

are still secure and wires are properly

clamped.

/ Before driving tractor, be sure free-

wheel controlis in drive position.

WHILE LEARNING HOWTO USEYOUR

TRACTOR, PAYEXTRA A'I-FENTION TO

THE FOLLOWING IMPORTANT ITEMS:

J" Engine oil is at proper level.

/ Fuel tank is filled with fresh, clean,

regular unleaded gasoline.

J"Become familiarwith all controls - their

locationand function. Operate them

before you start the engine.

,/Be sure brake system isin safe

operating condition.

,/It is importantto purge the transmission

beforeoperating your tractor forthe first

time. Followproper startingand

transmission purging instructions (See

"TO START ENGINE" and "PURGE

TRANSMISSION" in the Operation

section of this manual).

11

Page 12

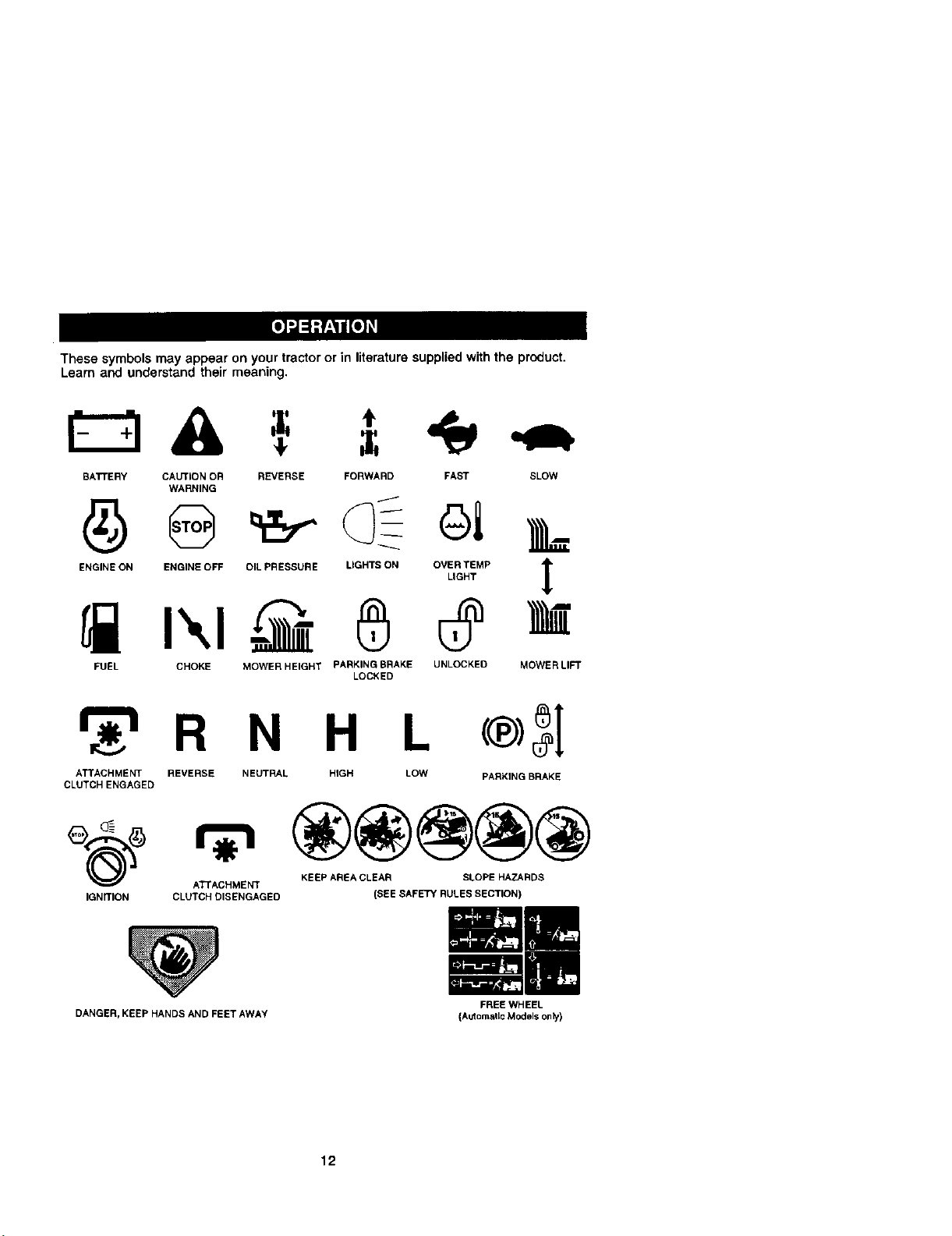

These symbols may appear on your tractor or in literature supplied withthe product.

Learn and understand their meaning,

BATTERY CAUTION OR REVERSE FORWARD FAST SLOW

ENGINE ON ENGINE OFF OIL PRESSURE LIGHTS ON OVER TEMP 1["

FUEL CHOKE MOWER HEIGHT PARKING BRAKE UNLOCKED

WARNING

LIGHT

LOCKED

R N H L

ATTACHMENT REVERSE NEUTRAL HIGH LOW

CLUTCH ENGAGED

e_) ATTACHMENT

IGNITION CLUTCH DISENGAGED

KEEP AREA CLEAR SLOPE HAZARDS

(SEE SAFETY RULESSECTION)

PARKING BRAKE

t

MOWERLI_

DANGER, KEEP HANDS AND FEET AWAY

FREE WHEEL

(AutDrasticModels only)

12

Page 13

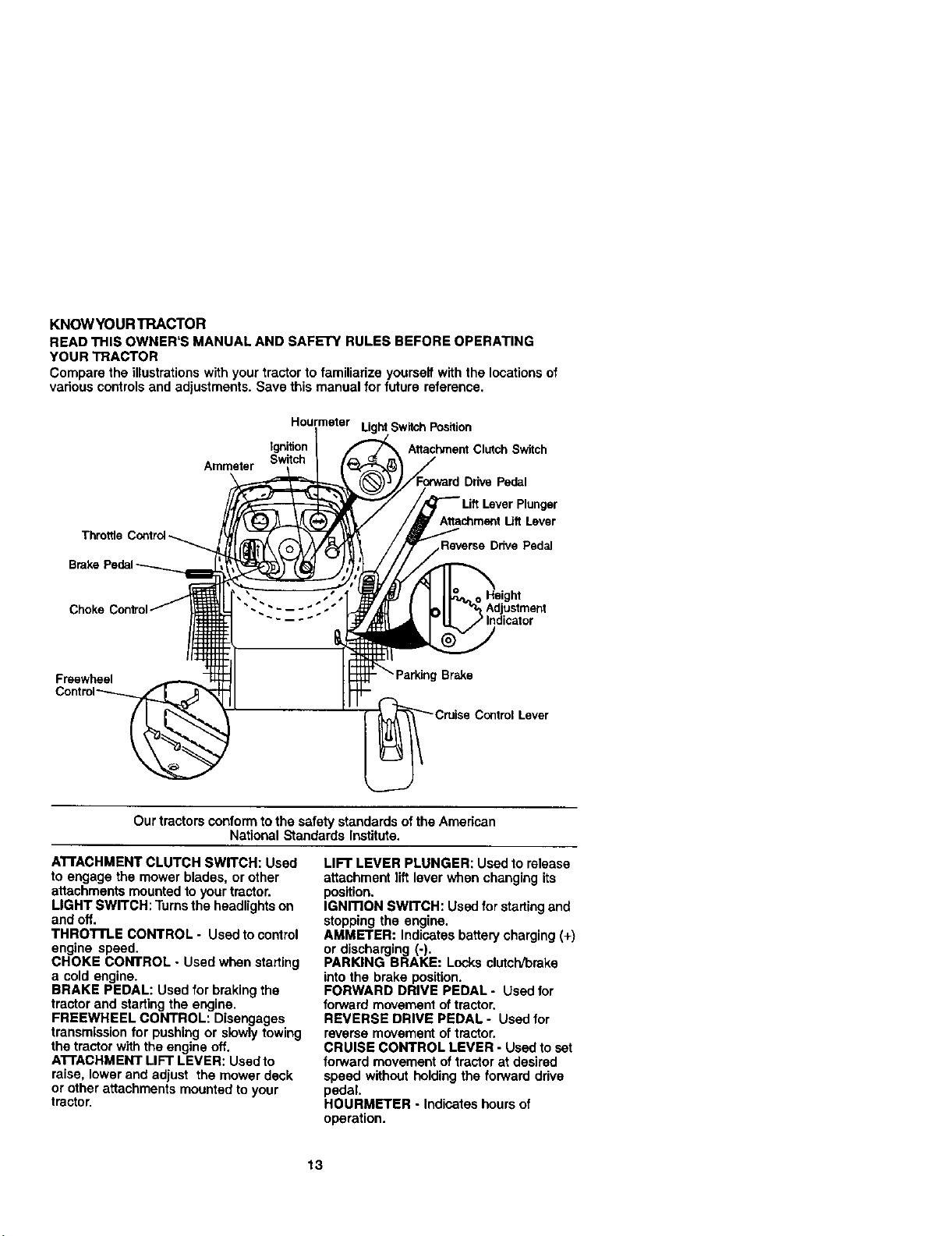

KNOW¥OURTRACTOR

READTHISOWNER'SMANUALANDSAFETYRULESBEFOREOPERATING

YOURTRACTOR

Comparetheillustrations with your tractor to familiarize yourseffwith the locationsof

various controls and adiustments. Save this manual for future reference.

Hourmeter Light Switch Position

Ignition Attachrr_nt Clutch Switch

Ammeter

Brake

Switch

Ddve Pedal

Plunger

Attachment Uft Lever

Reverse Drive Pedal

Choke C Adjustment

Freewheel

Our tractorsconform to the safety standards ofthe American

ATI'ACHMENT CLUTCH SWITCH: Used

to engage the mower blades, or other

attachments mounted to your tractor.

LIGHT SWITCH: Turnsthe headlightson

and off.

THROTI'LE CONTROL- Used to control

engine speed,

CHOKE CONTROL - Used when slatting

a cold engine.

BRAKE PEDAL: Used for braking the

tractor and startingthe engine,

FREEWHEEL CONTROL: Disengages

transmissionfor pushing or slowly towing

the tractor with the engine off.

ATrACHMENT LIFT LEVER: Used to

raise, lower and adjust the mower deck

or other attachments mounted to your

tractor,

- - -- _ _" Indicator

Brake

Contml Lever

National Standards Institute,

LIFT LEVER PLUNGER: Used to release

attachment lift lever when changing its

position.

IGNITION SWITCH: Used for startingand

stopping the engine,

AMMETER: Indicates battery charging (+)

or discharging (-),

PARKING BRAKE: Locks clutcWbrake

intothe brake position.

FORWARD DRIVE PEDAL - Used for

forward movement oftractor.

REVERSE DRIVE PEDAL o Used for

reverse movement oftractor.

CRUISE CONTROL LEVER - Usedto set

forward movement of tractor at desired

speed withoutholding the forward drive

pedal

HOURMETER - Indicates hours of

operation.

13

Page 14

Theoperationofany tractor can result inforeign objects thrown into the

eyes, which can result in severe eye damage. Always wear safety glasses I

or eye shields while operating your tractor or performing any adjustments

or repairs. We recommend a wide visionsafety mask over spectacles, or

standard safety gasses,

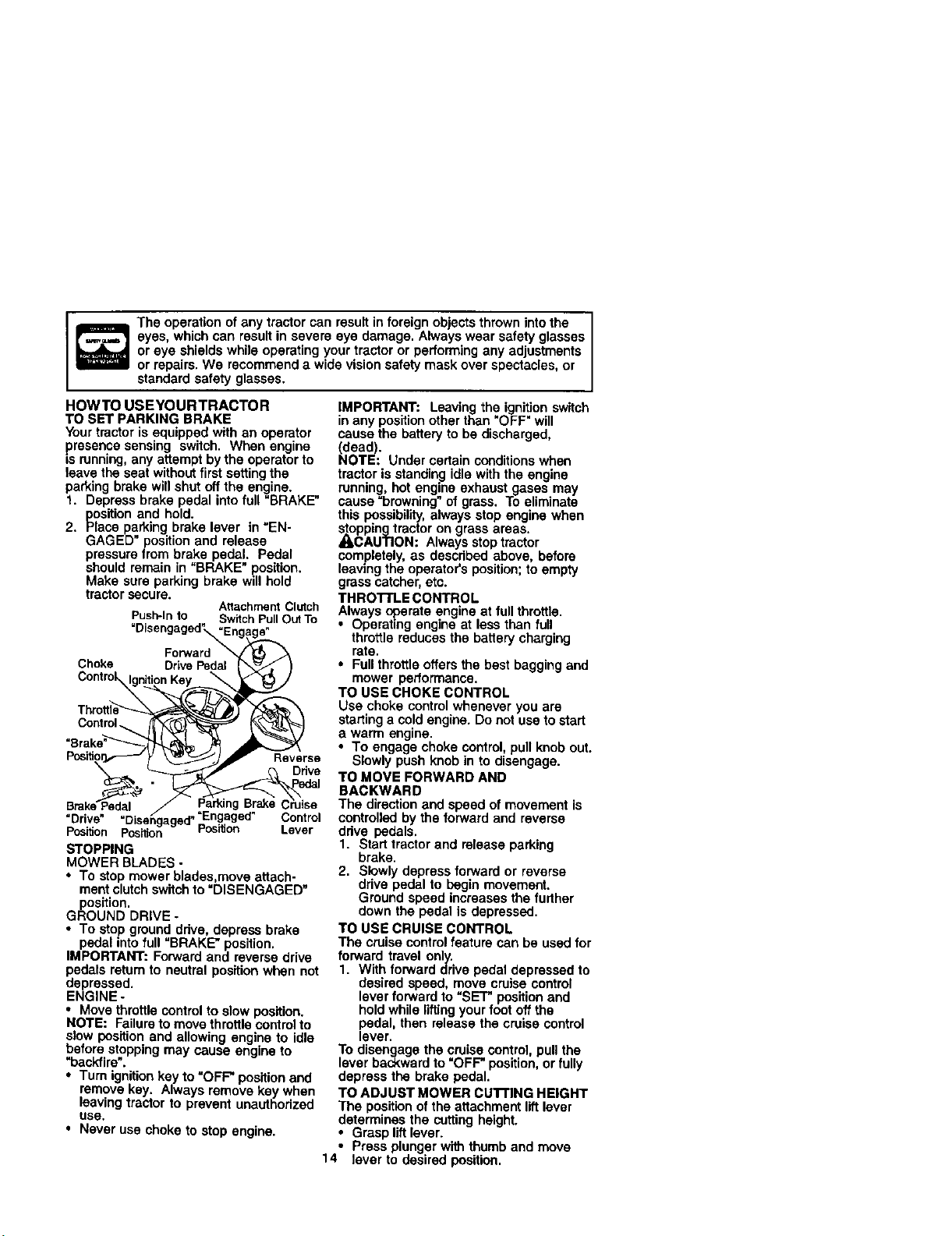

HOWTO USEYOURTRACTOR

TO SET PARKING BRAKE

Yourtractoris equipped withan operator

presence sensing switch. When engine

is running,any attempt by the operator to

leave the seat without first settingthe

parking brake willshut off the engine.

1. Depress brake pedal into full "BRAKE"

positionand hold.

2. Place parking brake lever in "EN-

GAGED" positionand release

pressurefrom brake pedal. Pedal

should remain in "BRAKE" position.

Make sure parking brake willhold

tractor secure.

Push-Into SwitchPullOutTo

=Disengaged"-_Engag_

AttachmentClutch

Control.

"Brake"__ j_

"Drive" "Dise_gagecl"_Engaged" Control

position Posff_on Posdion Lever

STOPPING

MOWER BLADES -

• To stop mower bledes,move attach-

ment clutchswitchto "DISENGAGED"

position.

GROUND DRIVE.

• To stop ground ddve, depress brake

pedal into full "BRAKE" position.

IMPORTANT: Forward and reverse drive

pedals retum to neutral positionwhen not

depressed.

ENGINE.

• Move throttle control to slow position.

NOTE: Failureto move throttle controlto

slow positionand allowing engine to idle

before stopping may cause engine to

"backfire".

• Turn ignitionkey to "OFF" positionand

remove key. Always remove key when

leaving tractor to prevent unauthodzed

use.

• Never use choketo stop engine.

IMPORTANT: Leaving the ignition switch

in any position other than "OFF" will

cause the battery to be discharged,

(dead).

NOTE: Under certain conditionswhen

tractor is standing idle with the engine

running, hot engine exhaust gases may

cause =browning" of grass, To eliminate

this possibility,always stop engine when

_Ocppingtractoron grass areas.

AUTION: Always stop tractor

completely, as described above, before

leavingthe operator's position; to empty

grass catcher, etc.

THRO'n'LE CONTROL

Always operate engine at full throttle.

• Operating engine at less than full

throttle reduces the battery charging

rate.

• Fullthrottle offers the best bagging and

mower performance.

TO USE CHOKE CONTROL

Use choke control whenever you are

starting a cold engine. Do not use to start

a warm engine.

• To engage choke control, pull knob out.

Slowly push knob in to disengage.

TO MOVE FORWARD AND

BACKWARD

The direction and speed of movement is

controlledby the forward and reverse

ddve pedals.

1. Start tractor and release parking

brake.

2. Slowly depress forward or reverse

drive pedal to begin movement.

Ground speed increases the further

down the pedal is depressed.

TO USE CRUISE CONTROL

The cruise control feature can be used for

forward travel only.

1. With forward drive pedal depressed to

desired speed, move cruisecontrol

lever forward to "SET" position and

hold while lifting your foot off the

pedal, then release the cruise control

lever.

To disengage the cruise control, pull the

lever backward to "OFF" position, or fully

depress the brake pedal.

TO ADJUST MOWER CuI"rlNG HEIGHT

The positionof the attachment lift lever

determines the cuttingheight.

• Grasp lift lever.

• Press plunger with thumb and move

14 lever to desired position.

Page 15

The cutting height range is approxi-

mately 1-1/2 to 4". The heightsare

measured from the ground to the blade

tip with the engine not running. These

heights are approximate and may vary

depending upon soil conditions, height of

grass andtypee of grass being mowed.

• The average lawn should be cut to

approximately 2-1/2 inches dudng the

cool season and to over 3 inches

during hot months. For healthier and

better looking lawns, mew often and

after moderate growth.

• For best cutting performance, grass

over 6 inches in height should be

mowed twice. Make the first cut

relatively high; the second to desired

height.

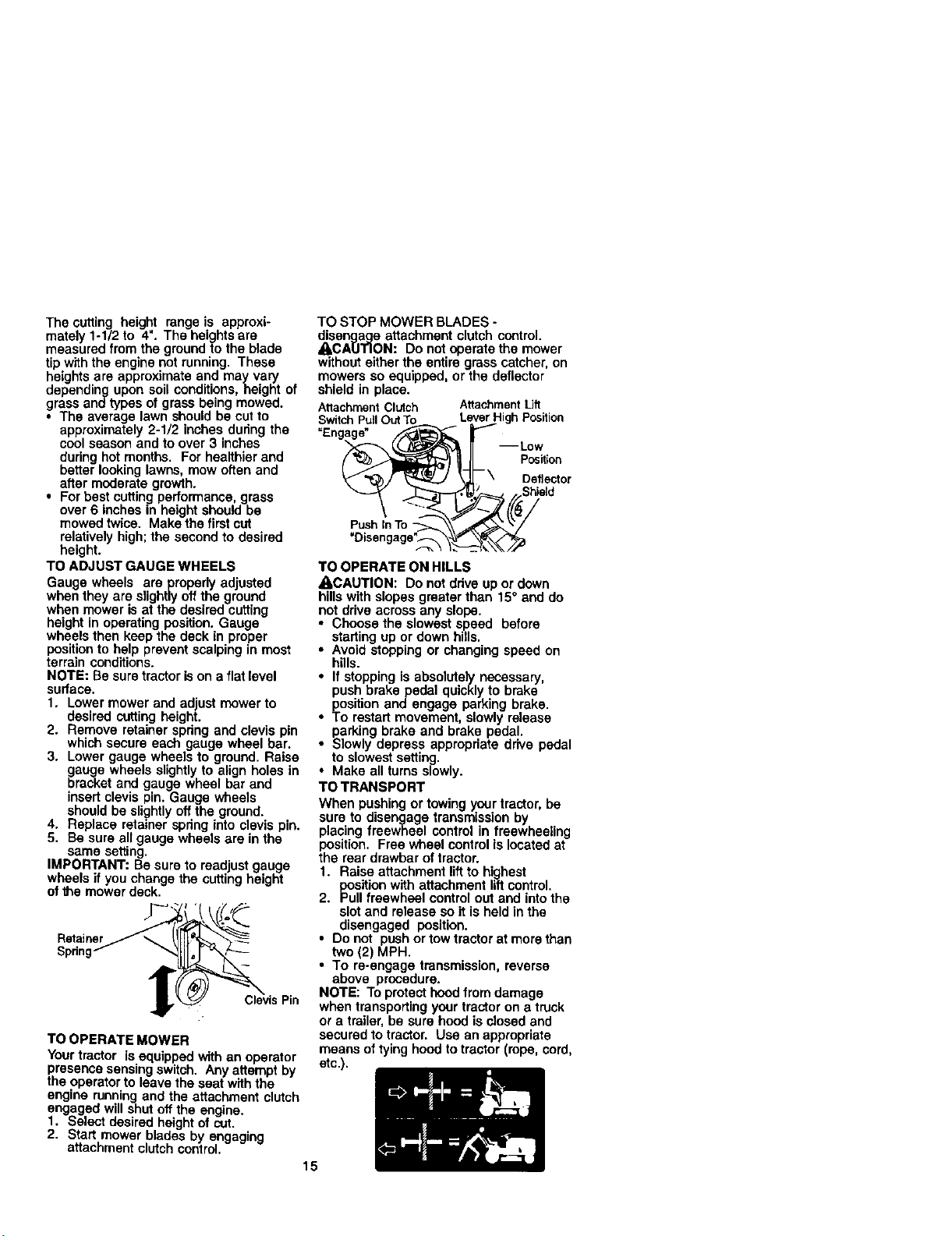

TO ADJUST GAUGE WHEELS

Gauge wheels are properly adjusted

when they are slightlyoffthe ground

when mower isat the desired cutting

height in operating position. Gauge

wheels then keep the deck in proper

position to help prevent scalping in most

terrain conditions.

NOTE: Be sure tractor is on a flat level

surface.

1. Lower mower and ad ust mower to

desired cult ng he ght.

2. Remove retainer spring and clevis pin

which secure each gauge wheel bar.

3. Lower gauge wheels to ground. Raise

_auge wheels slightlyto align holes in

racket and gauge wheel bar and

insert clevis pin. Gauge wheels

should be slightly offthe ground.

4. Replace rstamer spring into clevis pin.

5. Be sure allgauge wheels are in the

same setting.

IMPORTANT: Be sure to read ust gauge

wheels f you change the cutting height

ofthe mower deck.

Retainer

TO OPERATE MOWER

Your tractor isequipped with an operator

presence sensing switch. Any attempt by

the operator to leave the seat with the

engine running and the attachment clutch

engaged will shut off the engine.

1. Select desired height of cut.

2. Start mower blades by engaging

attachment clutch control.

TO STOP MOWER BLADES -

dieengaqe attachment clutch control.

• I,CA(.ITION: Do net operate the mower

without either the entire grass catcher, on

mowers so equipped, or the deflector

shield in place.

AttachmentClutch Attachment Lift

SwitchPull OutTo Lever HighPosition

Position

- --\ Deflector

=Enga_ _-" -- Low

/_- . Shield

TO OPERATE ON HILLS

ACAUTION: Do not drive up or down

hills with slopes greater than 15° and do

not drive across any slope.

• Choose the slowest speed before

starting up or downhills.

• Avoid stopping or changing speed on

hills.

• If stopping is absolutely necessary,

push brake pedal quicklyto brake

position and engage perking brake.

• To restart movement, slowly release

parking brake and brake pedal.

• Slowly depress appropriate drive pedal

to slowest setting.

• Make all turns slowly.

TO TRANSPORT

When pushing ortowing your tractor, be

sure to disengage transmission by

placing freewheel control in freewheeling

position. Free wheel control is located at

the rear drawbar oftractor.

1. Raise attachment liftto highest

position with attachment liftcontrol.

2. Pull freewheel control out and into the

slot and release so it is held in the

disengaged position.

• Do not pushor tow tractor at more than

two (2) MPH.

• To re-engage transmission, reverse

above procedure.

NOTE: To protect hood from damage

when transporting your tractor on a track

or a trailer, be sure hood is closed and

secured to tractor. Use an appropriate

means of tying hoodto tractor (rope, cord,

etc.).

15

Page 16

TOWINGCARTSANDOTHERATFACH-

MENTS

Towonlytheattachmentsthatare

recommendedbyandcomplywith

specificationsofthemanufacturerofyour

tractor.Usecommonsensewhentowing.

Tooheavyofaload,whileonaslope,is

dangerous.Tirescanlosetractionwith

thegroundandcauseyoutolosecontrol

ofyourtractor.

BEFORESTARTINGTHEENGINE

CHECKENGINEOILLEVEL

Theengineinyourtractorhasbeen

shipped,fromthefactory,alreadyfilled

withsummerweightoil.

1, Checkengineoilwithtractoronlevel

ground.

2. Removeoilfillcap/dipstickandwipe

clean,reinsertthedipstickandscrew

captight,waitforafewseconds,

removeandreadoillevel.Ifneces-

sery, add oil until "FULL" mark on

dipstickis reached. Do not overfill.

• For cold weather operationyou should

change oil for easier starting(See "OIL

VISCOSITY CHART" inthe Mainte-

nance section of this manual).

• To change engine oil, see the Mainte-

nance section in this manual.

ADD GASOLINE

• Fillfuel tank. Use fresh, clean, regular

unleaded gasoline with a minimum of

87 octane. (Use of leaded gasoline will

increase carbon and lead oxide

deposits and reduce valve life). Do not

mix oil with gasoline. Purchase fuel in

quantities that can be used within 30

days to assure fuel freshness.

IMPORTANT: When operating in tem-

peratures below 32°F(0°C), use fresh,

clean winter grade gasoline to help

insure good cold weather starting.

•,WARNING: -Experienceindicates that

alcohol blended fuels (called gasohol or

using ethanol or methanol) can attract

moisturewhich leads to separation and

formation of acids during storage. Acidic

gas can damage the fuel system of an

engine while in storage. To avoid engine

problems,the fuel system should be

emptied before storage of 30 days or

longer.Drain the gas tank start the

engine and let it ran untilthe fuel lines

and carburetor are empty. Use fresh fuel

nextseason. See Storage Instructions for

additional information. Never use engine

or carburetor cleaner products in the fuel

tank or permanent damage may occur.

16 temperature.

ACAUTION: Fillto bottom of gas tank

filler neck. Do not overfill.Wipe off any

spilled oil or fuel. Do not store, spill or use

gasoline near an open flame.

TO START ENGINE

When startingthe engine for the first time

or ifthe engine has run out offuel, it will

take extra cranking.time to move fuel from

the tank to the engine.

1. Be sure freewheel controlis in the

transmission engaged position.

2, Sit on seat in operating position,

depress brake pedal and set parking

brake.

3. Move attachment clutch to =DISEN-

GAGED" position.

4. Move throttle controltofast position

5. Pull choke controlout for a cold

engine start attempt. For a warm

engine start attempt the choke control

may not be needed.

NOTE: Before starting,read the warm and

cold starting pmceduras below.

6. Insert key into ignitionand turn key

clockwiseto "START" position end

release key as soon as engine starts.

Do not run starter continuouslyfor

more than fifteen seconds per minute.

If the engine does not start after

several attempts, push choke control

in, wait a few minutes and try again. If

engine stilldoes not start, pullthe

choke controlout and retry. ,

WARM WEATHER STARTING (50 F and

above)

7. When engine starts, slowlypush

choke control in until the engine

begins to runsmoothly. If the engine

starts to run roughly,pull the choke

control out slightlyfor a few seconds

and then continue to pushthe control

in slowly.

• The attachments and ground drive can

now be used. If the engine does not

accept the load, restartthe engine and

allow it to warm up for one minute

using tho choke as described above.

COLDWEATHER STARTING (50 F and

below)

7. When engine starts, slowly push

choke control in until the engine

begins to run smoothly. Continue to

push the choke controlin small steps

allowing the engine to accept small

changes =nspeed and load, untilthe

choke control is fullyin. If the engine

starts to runroughly, pullthe choke

controlout slightlyfor a few seconds

and then continue to push the control

in slowly. This may requirean engine

warm-up period from several seconds

to several minutes, depending on the

Page 17

AUTOMATICTRANSMISSION WARM UP

Before drivinq the unit in cold weather,

the transmission should be warmed up as

ictiows:

1. Besure the tractor is on level ground.

2. Release the parking brake and let the

brake slowly returnto operating

position.

3. Allow one minute for transmissionto

warm up. This can be done during the

engine warm up period.

• The attachments can be used during

the engine warm-up pedod after the

transmissionhas been warmed up and

may require the choke control be

pulled out slightly.

NOTE: if at a high altitude (above 3000

feet) or in cold temperatures (below 32 F)

the carburetor fuel mixture may need to

be adjusted for best engine pedormance.

See =TOADJUST CARBURETOR" inthe

Service and Adjustments section of this

manual.

PURGETRANSMISSION

•,CAUTION: Never engage or disengage

freewheel lever whilethe engine is

running.

To ensure proper operation and perfoh

mance, it is recommendedthat the

transmissionbe purged before operatincj

tractorfor the first time This procedurew=t

remove any trapPed air insidethe trans-

missionwhich may have developed during

shippingof your tractor.

IMPORTANT: Should yourtransmission

requireremovalfor sewice or replacement,

it shouldbe purged after rainstallation

before operatingthe tractor.

1. Place tractor safely on level surface

with engine off and parkingbrake set.

2. Disengage transmission by placing

freewheel control in freewheeling

position(See =TOTRANSPORT" in

this section of manual).

3. Sittingin the tractor seat, start engine.

After the engine is running, move

throttle controlto stow position.

Disengage parking brake.

4. Depress forward ddve pedal to full

forward position and hold for five (5)

seconds and release pedal. Depress

reverse drive pedal to full reverse

position and hold for five (5) seconds

and release pedal. Repeat this

procedure three (3) times.

NOTE: During thisprocedurethere will be

no movementof drivewheels.The air is

being removed from hydraulicdrive

system.

5. Shut- off engine and set parkk_g

brake.

6. Engage transmission by placin_

freewheel control in driving position

(See "TO TRANSPORT" inthis section

of manual).

7, Sittingin the tractor seat, start engine.

After the engine is running, move

thro_le controlto half (1/2) speed.

Disengage parking brake.

8, Drive tractorforward for approximately

five feet then backwards forfive feet.

Repeat this ddving procedure three

times.

Your tractor is now purgedand now ready

for normal operation.

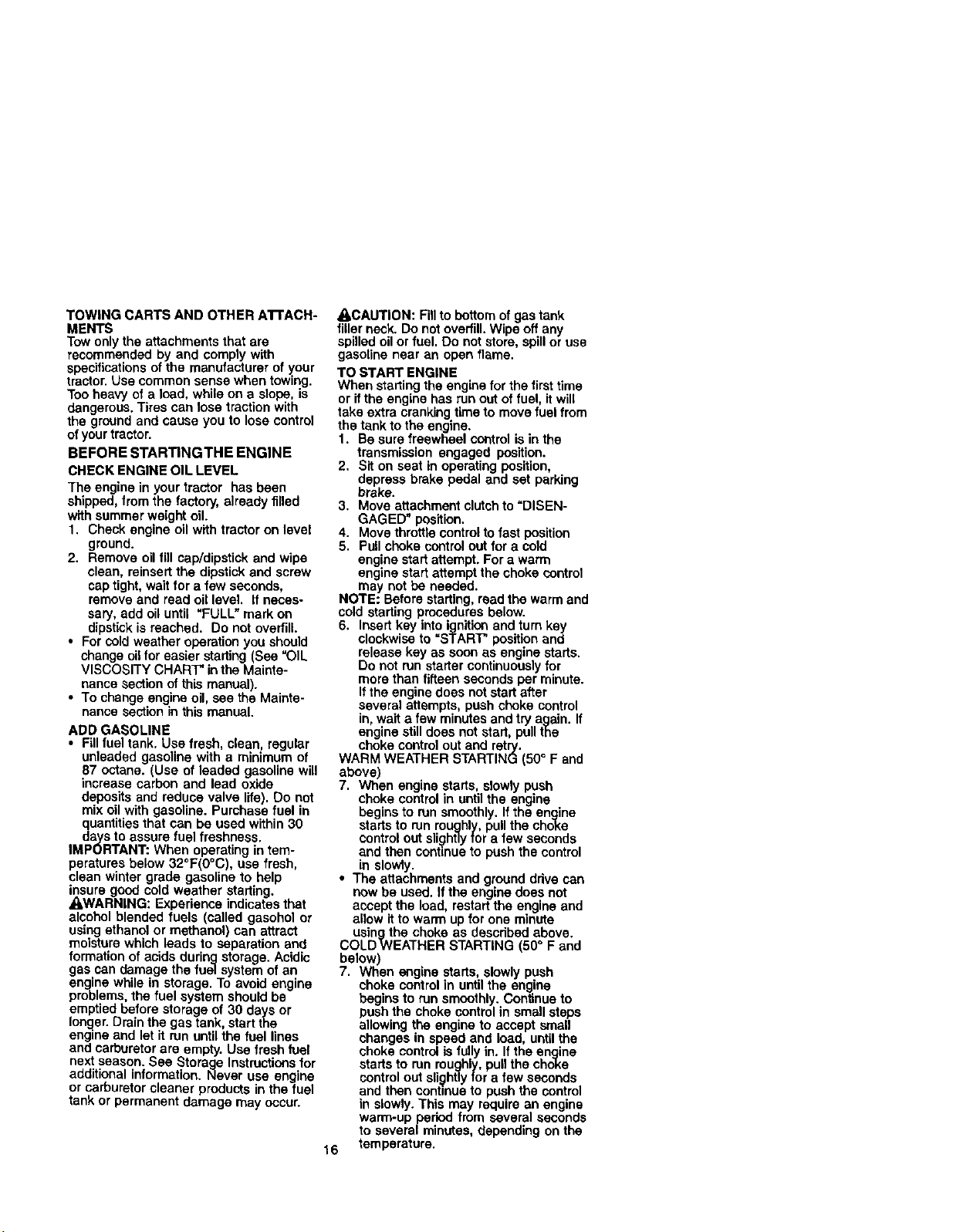

MOWINGTIPS

• Mower should be propedy leveled for

best mowing performance. See =TO

LEVEL MOWER HOUSING" in the

Service and Adjustments section of this

manual

• The left hand side of mower should be

used for trimming.

• Drive sothat clippings are discharged

onto the area that has been cut. Have

the cut area to the right of the tractor.

This will result in a more even distribu-

tion of clippingsand more uniform

cutting.

• When mowing large areas, start by

turningto the right so that clippingswill

discharge away from shrubs,fences,

driveways, etc. After one ortwo

rounds, mow in the opposite direction

making left hand turns untilfinished.

• If grass is extremely tall, it should be

mowed twice to reduce load and

possiblefire hazard from dried clip-

pings. Make firstcut relatively high;the

second to the desired height.

, Do not mow grass when it is wet. Wet

grass willplug mower and leave

undesirable clumps. Allow grass to dry

before mowing.

• Alwaysoperateenglne atfuUthrotUe

when mowing to assure better mowing

performance and proper discharge of

material. Regalate ground speed by

selecting a low enough gear to give the

mower cutting performance as well as

the quality of cut desired.

• When operating attachments, select a

ground speed that will suit the terrain

and give best performance of the

attachment being used.

17

Page 18

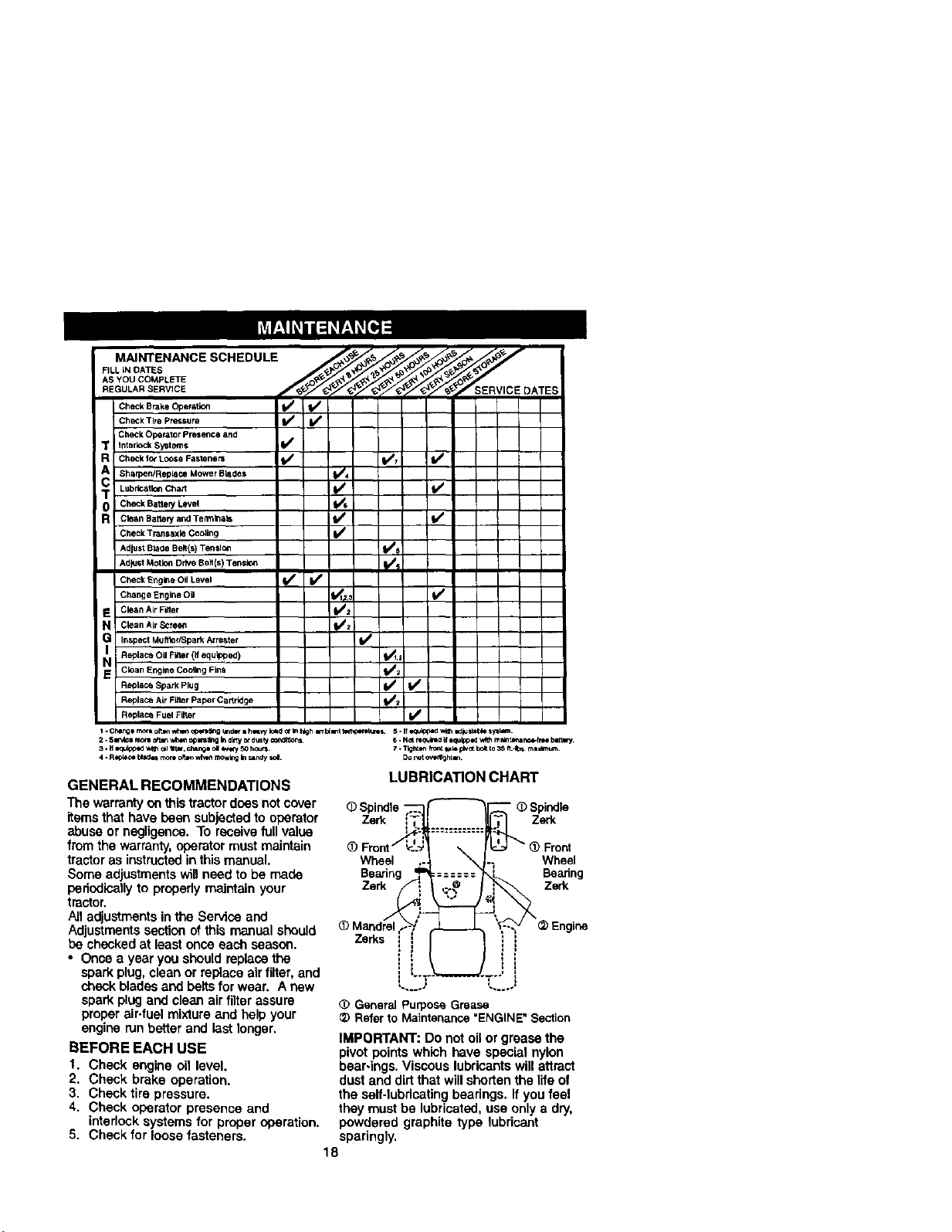

MAINTENANCESCHEDULE

FiLL iN DATES

AS YOU COMPLETE

REGULAR SERVICE SERVICE DATE

Check Brake Ope_tlen V O I_

CheCKTire pressure _ V p

CheCk Operator Presence and

interlock Systems I/

Check Ic_ LOOSeFasteners _ VsT ll_

Sha_0en!Replace Mower Blades I/4

Lubrleatlon Chart II/ fl_

Check Battery Level

Clean Batter/and Temlleala _

Check Tmnsaxle Cooling I/

Adjust Bla_e Belt(s) TenSt_ t/s

Ad_st Motion Drive Belt(s) Tensle_ _?

Cheek Engll_e Oil Level if If

Change Engine Oil I1_1_,_ V /

Clean Air Filter I/2

Clean Air Screen f/2

Inspect Muffler/Spa_ Arre_ter

Replace O!l F_er (If equipped) {1_1.;

Clean Engine Cooling Fins 11/2

Replace Spa_k Plug _ I/

ReplaCe Air Fi_terPaper Cartridge (i/_

Replace Fuel Fitter

I -Chla_g I rnc4_Dfton whqm o_ting I_nd_-i h mvy Iohd Or In I_h I_ I_t _ S - If _lpped wtffl I,d_b_e _ysb*_.

2. $o_i_1 mo_ oPm_whtn opnSng in dirty =_dus_y_n_ns 6. Not r_ln_lf *_ippe_ w_ mmts_ar_lr=_ b_

e. I1 =_:_lp_ v_ ol1111t_,d'_mgo ol _y 50 hours 7. _ghtsn trout _k* p_t bY_tto3,$_.-I_S mldn_um

4. Repro* _ad_ n'_'* olin wh*n r_ In s_roy sol Donot overd_h=*n.

GENERAL RECOMMENDATIONS

The warrantyonthis tractordoes not cover

itemsthat have been subjected to operator

abuse or negligence. To receivefull value

from the warranty, operator must maintain

tractor as instructedinthis manual.

Some adjustmentswill need to be made

pededicallyto propedymaintain your

tractor.

All adjustmentsinthe Service and

Adjustmentssection of this manual should

be checked at least once each season.

• Once a year you should replace the

spark plug, clean or replace airfilter, and

check bladesand beltsfor wear. A new

spark plug and clean air filter assure

proper air-fuel mixtureand help your

engine runbetter and last longer.

BEFORE EACH USE

1. Check engine oil level.

2. Check brake operation.

3. Check tire pressure.

4. Check operator presence and

interlock systems for proper operation.

5. Check for loose fasteners.

_) General Purpose Grease

_) Refer to Maintenance "ENGINE" Section

IMPORTANT: Do not oil or grease the

pivot points which have special nylon

bear-ings. Viscous lubricants will attract

dust and dirt that will shorten the llfe of

the self-lubricating bearings. If you feel

they must be lubricated,use only a dry,

powdered graphite type lubricant

sparingly.

18

LUBRICATION CHART

(i) Spindle ' _) Spindle

Zerk Zerk

Wheel Wheel

Bearing Bearing

Zerk Zerk

Zerks

L._.J L...o.

_) Froct

Page 19

TRACTOR

Always observe safety rules when

performing any maintenance.

BRAK_ OPERATION

If tractor requiresmore than six (6) feet

stopping distance at high speed in

highest gear, then brake must be ad-

justed. (See "[0 ADJUST BRAKE" in the

Service and Adjustments section ofthis

manual).

TIRES

• Maintain proper air pressure in all tires

(See "PRODUCT SPECIFICATIONS"

section of this manual).

• Keep tires free of gasoline, oil,or insect

control chemicals which can harm

rubber.

• Avoid stumps, stones, deep ruts,sharp

objeu-'tsand other hazards that may

cause tire damage.

NOTE: To seal tire punctures and prevent

flat tires due to slow leaks, tire sealant

may be purchasedfrom your local parts

dealer. Tire sealant also prevents tire dry

rot and corrosion.

OPERATOR PRESENCE SYSTEM

Be sure that operator presence and

intedocksystems are working properly. If

your tractor does not function as de-

scribed below, repair the problem

immediately.

• The engine should notstart unless the

brake pedal is fully depressed and

attachment clutchcontrol is in the

disengaged position.

• When the engine is running, any

attempt by the operator to leave the

seat withoutfirst setting the parking

brake should shut off the engine.

• When the engine is running and the

attachment clutch is engaged, any

attempt by the operator to leave the

seat should shut off the engine.

• The attachment clutch should never

operate unless the operator is in the

seat.

BLADE CARE

For best resultsmower blades must be

kept sharp. Replace bent or damaged

blades.

BLADE REMOVAL

1. Raise mower to highest positionto

allow access to blades.

2. Remove hex bolt, lock washer and flat

washer securing blade.

3. Install new or resharpenod blade with

trailingedge uptowards deck as

shown.

IMPORTANt': To ensure proper assembly,

center hole in blade must align with star

on mandrel assembly.

4. Reassemble hex bolt, lock washer

and fiat washer in exact order as

shown.

5. Tighten bolt securely (45-55 Ft. Lbs.

torque).

TrailingEdgeUp _ _ Mandrel

_________Star_ Assembly

Flat Washer _-_._ Center

Lock__ I_lo'e

Washer ./"_ Blade

--(Grade 8)"

*A Grade8 heattreatedboltcanbe

identifiedby sixlinesontheboffhead.

IMPORTANT: Blade bolt is grade 8 heat

treated.

TO SHARPEN BLADE

NOTE: We do rot recommend sharpen-

ing blade - but if you do, be sure the

blade is balanced.

Care should be taken to keep the blade

balanced. An unbalanced blade will

cause excessive vibration and eventual

damage to mower and engine.

• The blade can be sharpened with a file

or on a gdndingwheel. Do not attempt

to sharpen while on the mower.

• To check blade balance, you will need

a 5/6" diameter steel bolt, pin, or a cone

balancer. (When usinga cone bal-

ancer, follow the instructions supplied

with balancer.)

NOTE: Do not use a nail for balancing

blade. The lobes of the center hole may

appear to be centered, but are not.

• Slide blade on to an unthreaded

portionof the steel bolt or pin and hold

the bolt or pin parallel with the ground.

If blade is balanced, it should remain in

a horizontal position. If either end of

the blade moves downward, sharpen

the heavy end untilthe blade is

balanced.

B,ade

or Pin

19

Page 20

BA'n'ERY

Yourtractorhas a battery charging system

which is sufficient for normal use. How-

ever periodic charging of the battery with

an automotive charger will extend ts fe.

• Keep battery and terminals clean.

• Keep battery boifstight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

NOTE: The odginal equipment battery on

yourtractor is maintenance free. Do not

attempt toopen or remove caps or covers.

Adding or checking level of electrolyte is

not necessary.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirton the battery and

terminals can cause the battery to "leak"

power.

1. Remove terminal guard.

2. Disconnect BLACK battery cable first

then RED battery cable and remove

batteryfromtractor.

3. Rinse the battery with plain water and

dry.

4. Clean terminals and battery cable

ends with wire brush untilbright.

5. Coat terminals with grease or petro-

leum jelly.

6. Reinstall battery (See =REPLACING

BATTERY" in the SERVICE AND

ADJUSTMENTS section of this

manual).

V-BELTS

Check V-belts for deterioration and wear

after 100 hours of operation and replace

ifnecessary.The beltsare notadjustable.

Replace belts ifthey begin to slip from

wear.

TRANSAXLE COOLING

The transmission fan and coolingfins

should be kept clean to assure proper

cooling.

Do not attempt to clean fan or transmis-

sion while engine is runningor while the

transmissionis hot. To prevent possible

damage to seals, do not use high

pressurewater or steam to clean

transaxle.

• Inspect coolingfan to be sure fan

blades are intact and clean.

• Inspect cooling fins for dirt, grass

clippings and other matedals. To

prevent damage to seals, do not use

compressed air or high pressure

sprayer to clean cooling fins.

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory

and fluid maintenance is not required for

the life of the transaxle. Should the

transaxla ever leak or require servicing,

contact your nearest authorized service

center/department.

ENGINE

LUBRICATION

Only use high quality detergent oil rated

with API serviceclassificationSF-SJ.

Select the oil's SAE viscositygrade

according to your expected operating

temperature.

NOTE: Although multi-viscosityoils

(5W30, 10W30 etc.) improve starting in

cold weather, these multi-viscosityoils

will result in increased oil consumption

when used above 32°E Check your

engine oil level more frequently to avoid

possible engine damage from running

low on oil.

Change the oil after every 50 hoursof

operationor at least once a year if the

tractor is not used for 50 hours in one

year.

Check the crankcase oillevel before

starting the engine and after each eight

(8) hours of operation. Tighten oil fill cap/

dipstick securely each time you check the

oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oilmust meet API

service classification SF-SJ.

• Be sure tractor is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

1. Remove oilfill cap/dipstick. Be careful

notto allow dirtto enter the engine

when changing oil.

2. Remove cap from end of drain vane

and installthe drain tube onto the

fitting.

3. Unlock drain valve by pushing inward

slightly and turning counterclockwise.

4. To open, pull out on the drainvalve.

5. After oil has drained completely, dose

and lock the drain valve by pushing

inward and tuming clockwise until the

pin is in the locked position as shown.

20

Page 21

6. Remove the drain tube and replace

the cap onto to the end of the drain

valve.

7. Refill engine with oil through oil fill

dipsticktube. Pour slowly. Do not

overfill. For approximate capacity

sea "PRODUCT SPECIFICATIONS"

section of this manual.

8. Use gauge on oil fill cap/dipstick for

checking level. Be sure dipstickcap

is tightened securely for accurate

reading. Keep oilat "FULL" line on

dipstick.

Oil Drain Valve

Closed=

Cap_

CLEAN AIR SCREEN

Air screen must be kept free of dirtand

chaff to prevent engine damage from

overheating. Clean witha wire brush or

compressed air to remove dirt and

stubborndried gum fibers.

CLEAN AIR INTAKE/COOLING AREAS

To insure proper cooling, make sure the

grass screen, cooling fins, end other

external surfaces of the engine are kept

clean at all times.

Every 100 hoursof operation (more often

under extremely dusty, dirtyconditions),

remove the blower housing and other

coolingshrouds. Clean the cooling fins

and external surfaces as necessary. Make

sure the cooling shrouds are reinstalled.

NOTE: Operating the engine with a

blocked grossscreen, dirtyor plugged

coolingfins, and/or cooling shrouds

removed willcause engine damage due

to overheating.

AIR FILTER

Your engine will not runproperly using a

dirty air filler. Clean the foam pre-cleaner

after every 25 hours of operation or every

season. Service paper cartridge every

100 hours of operation or every season,

whichever occurs first.

Service air cleaner more offer under

dusty conditions.

1. Remove knobs and cover.

TO SERVICE PRE-CLEANER

2. Wash it in liquid detergent and water.

3. Squeeze it dry in a clean cloth.

4. Saturate it in engine oil. Wrap it in

clean, absorbent cloth and squeeze to

remove excess oil.

NOTE: Ifvery dirty or damaged, replace

pre-cleaner.

TO SERVICE CARTRIDGE

5. Clean cartridge by tapping gently on

flat surface. If very dirty or damaged,

replace cartridge.

6. Reinstall precleener cartridge, cover

and secure with knobs.

IMPORTANT: Petroleum solvents, such

as kerosene, are not to be used to clean

the cartridge. They may cause deteriora-

tion of the cartridge. Do not oil cartridge.

Do not use pressurized air to clean or dry

cartridge.

Foam _Cartddge

Pre-Cleaner

ENGINE OIL FILTER

Replace the engine oil filler every season

or every other oil change if the tractor is

used more than 100 hours in one year.

21

Page 22

MUFFLER

Inspectand replace corroded mufflerand

spark arrester (if equipped) as it could

create a fire hazard and/or damage.

SPARK PLUGS

Replace spark plugs at the beginning of

each mowing season or after every 100

hours ofoperation, whichever occurs first.

Spark plugtype and gap setting are

shown in "PRODUCT SPECIFICATIONS"

section ofthis manual.

IN-LINE FUEL FILTER

The fuel filter should be replaced once

each season. If fuel filter becomes

clogged, obstructingfuel flow to carbure-

tor, replacement is required.

1. With engine cool, remove filter and

plug fuel line sections.

2. Place new fuel filter in positionin fuel

line with arrow pointing towards

carburetor.

3. Be sure there are no fuel line leaks

and damps are propedy positioned.

4. Immediately wipe up any spilled

gasoline.

Clamp

FuelFilter_

CLEANING

• Clean engine, battery, seat, finish, etc.

of all foreign matter.

• Keep finished surfaces and wheels free

of all gasoline, oil, etc.

• Protect painted surfaces with automo-

tive type wax.

We do not recommend usinga garden

hose to clean your tractor unless the

electdcal system, muffler, air filter and

carburetor are covered to keep water out.

Water in engine can result in a shortened

engine life.

22

Page 23

_CAUTION: BEFORE PERFORMING ANY SERVICE OR ADJUSTMENTS:

1, Depress brake pedal fully and set parking brake•

2. Place attachment clutch in =DISENGAGED" position.

3. Turn ignition key "OFF" and removekey.

4, Make sure the blades and all moving parts have completely stopped.

5. Disconnect spark plug wire from spark plug and place wire where it cannot

come in contact with plug,

TRACTOR

TO REMOVE MOWER

1. Place attachment clutch In =DISEN-

GAGED" position,

2. If equipped, tum height adjustment

knob to lowest setting.

3. Lowermower to its lowest position.

4. Disengage belt tension md from lock

bracket.

_,CAUTION: Rod is spdng loaded. Have

a tight gdp on rod and release slowly.

5. Remove retainer spring holding anti-

swaybar to chassis bracket and

7. Remove retainer springsfrom

suspension arms at deck and disen-

gage arms from deck.

8, Raise attachment liftto its highest

position,

9. Slide mower forward and remove belt

from electric clutch pulley.

10.Slide mower outfrom under dght side

oftractor.

TO INSTALL MOWER

Follow procedure described in =INSTALL

MOWER AND DRIVE BELT" in the

Assembly section of this manual.

disengage anti-swaybar from bracket.

6. Remove four retainer spdngs from

front plate assembly and remove

plate.

Electric

Clutch Pulley

Front

Plate

BeltTension

Rod

(Disengaged_,,

Positon /7

Chassis

Suspension

Front Mower

Bracket

Retainer

Anti-Sway

Bar

(Both Sides)

Bracket

23

Page 24

TOLEVELMOWERHOUSING

Adiust the mower while tractor is parked

on level ground or driveway. Make sure

tires are properly inflated (See ROD-

UCT SPECIFICATIONS" section of this

manual). If tires are over or

undednflated, you will not propedy adjust

your mower.

SIDE-TO-SIDE ADJUSTMENT

• Raise mower to its highest position.

• At the midpointof both sides of mower,

measure height from bottom edge of

mower to ground. Distance "A* on

both sides of mower should be the

same or within 1/4" of each other.

• If adjustment is necessary, make

adjustment on one side of mower only.

• To raise one side of mower, tighten I_

link adjustment nut on that side.

• To lower one side of mower, loosen lift

link adiustment nut on that side.

NOTE: Each full turn of adjustment nut

will change mower height about 1/8".

• Recheck measurements after adjust-

ing.

BottomEdgeof BottomEdgeof

Mowerto Ground Mowerto Ground

-p

• Before making any necessary adjust-

merits, checkthat both front links are

equal in length.

• If links are not equal in length, adjust

one link to same length as otherlink.

• To lower front of mower loosen nut"E"

on both front linksan equal number of

turns.

• When distance"D" is 1/S"to 1/2" lower

at front than rear, tighten nuts "F"

against trunnionon both front links.

• To raise front of mower, loosen nut"F"

from trunnion on bothfront links.

Tighten nut "E" on both front links an

equal number of turns.

• When distance "D" is 1/8* to 112"|ower

at front than rear,tighten nut =F"against

trunnion on both front links.

• Recheck side-to-side adiustment.

o

BOTH FRONT LINKS MUST BE EQUAL

IN LENGTH

Suspen_Don

Lilt Link

Adjustment

Nut

FRONT-TO-BACK ADJUSTMENT

IMPORTANT: Deck must be level side-to-

side.If the following front-to-back adjust-

ment is necessary, be sure to adjust both

front links equally so mower will stay

level side-to-side.

To obtain the best cuttingresults,the

mower housing should be adjusted so

thatthe frontis approximately 1/8" to 1/2"

lower than the rear when the mower Is in

its highest position.

Check adjustmenton right side of tractor.

Measure distance =D" directlyin front and

behind the mandrel at bottom edge of

mower housing as shown.

Front Plate Trunnion

Assembly

TO REPLACE MOWER DRIVE BELT

MOWER DRIVE BELT REMOVAL

1. Parktractor an a level surface.

Engage parking brake.

2. Lower mower to its lowest position.

3. Disengage belt tension rodfrom lock

bracket.

ACAUTION: Rod Is spdng loaded. Have

a firm grip an rod an release slowly.

4. Remove screws from R.H. mandrel

cover and remove cover.

24

Page 25

5. Remove any dirt or grass clippings

which may have accumulated around

mandrels and entire upper deck

surface.

6. Disconnect R.H. suspensionarm from

rear deck bracket by removing

retainer spdng.

7, Carefully roll belt over the top of R.H.

mandrel pulley.

8. Remove belt from electdc clutch

pulley.

9, Remove belt from idler pulleys.

10.Check primary idler arm and two

idlers to see that they rotatefreely.

11.Be sure spring is securely hooked to

primary idler arm and spring arm.

MOWER DRIVE BELT INSTALLATION

12.Install belt in both idlers,

13.Install new belt onto electric clutch

pulley,

14.Carefully roll belt into upper groove of

R.H. mandrel pulley.

15.Carefully check belt routing making

sure belt is in the grooves correctly.

16.Reconnect R.H. suspension arm to

rear deck bracket with retainer spring,

17.Reassemble R.H. mandrel cover.

18.Engage belt tension rod by pushing

rod into locking bracket.

BeltTension R.H. Mandrel Electdc

Rod

(Disengaged Cover_ Clutch

Posen).?

4. Carefully roll belt off L.H. mandrel

pulley.

5. Remove belt from center mandrel

pulley, idler pulley, and R.H. mandrel

pulley.

6. Remove any dirt or grass which may

have accumulated around mandrels

and entire upper deck surface.

7. Check secondary idler arm and idler

pulley to see that they rotate freely.

8. Be sure springis hooked in secondary

idler arm and secondary spring arm.

9. Install new belt in lower groove of R.H.

mandrel pulley, idler pulley, and

center mandrel pulley as shown.

10.Carefully roll belt over L.H. mandrel

pulley. Make sure belt is in all

grooves properly.

11.Reinstall L.H. mandrel cover.

12.Reinstall mower to tractor (See

"INSTALL MOWER AND DRIVE

BELT" in the Assembly section of this

manual).

13. Reassemble mower drive belt (See

"TO REPLACE MOWER DRIVE BELT"

in this section of this manual).

LH. Secondary Idler Arm

_ /Secondary

SpdngArm

let Pulley Spring

Mandrel

Suspension

Arm Primary

Idler Arm

TO REPLACE MOWER BLADE DRIVE

BELT

Parkthe tractoron level surface. Engage

parking brake.

1. Remove mower drive belt (See "TO

REPLACE MOWER DRIVE BELT" in

this section of this manual).

2. Remove mower (See "TO REMOVE

MOWER" in this section of this

manual).

3. Remove screws from L.H. mandrel

cover and remove covet.

TO ADJUST BRAKE

Yourtractor is equipped with an adjust-

able brake system which is mounted on

the side ofthe transaxle.

iftractorrequires mare than six(6) feet

stoppingdistance at high speed in highest

gear on a level dry concrete or paved

surface, then brake must be adjusted.

1. Depress clutch/brake pedal and

engage parking brake.

2. Measure distance between brake

operating arm and nut"A" on brake

rod.

3. Ifdistance is other than 1-11/16",

loosen jam nut and turn nut "A" until

distance becomes 1-1f/16". Re-

tightenjam nut against nut "A".

25

Page 26

4. Roadtesttractorforproperstopping

distanceasstatedabove.Readjustif

necessary.Ifstoppingdistanceis still

greater than six (6) feet in highest

gear, further maintenance is neces-

sary. Contact your nearest autho-

rized service center/department.

With Parking Brake "Engaged"

AfTn

Do Not t :h this nut. It further brake

ad_stment is necessary cm_tact yc_r nearest

authorized service center/department

TO REPLACE MOTION DRIVE BELT

Parkthe tractor on level surface. Engage

parking brake. Forassistance, there is a

belt installation guide decal on bottom

side of left footrest.

1. Remove mower (See "I'O REMOVE

MOWER" in this section of this

manual.)

2. Disconnect clutch wire harness.

3. Remove clutch Iocator.

4. Remove belt from stationary idler and

clutching idler.

5. Pull belt slack toward rear of tractor.

Carefully remove belt upwards from

transmission input pulley and over

coolingfan blades.

6. Pull belt toward front of tractor and

remove downwards from around

electric clutch.

7. Install new belt by reversing above

procedure.

Clutch

Clutch

Clutching_

idler

Stationaryj

Idler

EIsutr_c_ !

Transmission "_....

InputPulley-- 4.___,

_-Locator

Ct_tch

Wire Hamess

TRANSMISSION REMOVAIJREPLACE-

MENT

Should your transmission require

removal for service or replacement, it

should be purged after reinstallationand

beforeoperating the tractor. See =PURGE

TRANSMISSION" in the Operation

section of this manual.

TO ADJUST STEERING WHEEL ALIGN-

MENT

If steedng wheel crossbars are not

horizontal (left to right) when wheels are

positionedstraight forward, remove

steering wheel and reassemble per

instructionsIn the Assembly sectionof

this manual.

FRONT WHEEL TOE-IN/CAMBER

The frontwheel toe-in and camber are

notadjustable on your tractor. If damage

has occurredto affect the front wheel toe-

in or camber, contactyour nearest Sears

or other qualified service center.

TO REMOVE WHEEL FOR REPAIRS

1. Blockup axle securely.

2. Remove axle cover, retaining ring and

washers t_ allow wheel removal Irear

wheel containsa square key - Do not

lose).

3. Repair tire and reassemble.

NOTE: On rear wheels only: align

grooves in rear wheel hub and axle.

Insert square key.

4, Replace washers and snap retaining

dng securely inaxle groove.

5. Replace axle cover.

NOTE: To seal tire puncturesand prevent

flat tires due to slowleaks, tire sealant

may be purchased from your local parts

dealer. Tire sealant also prevents tire dry

rotand corrosion.

(Rear Wheel Only)

26

Page 27

TOSTARTENGINEWITHAWEAK

BATTERY

A,CAUTION: Lead-acid batteries

generate explosive gases. Keep sparks,

flame and smoking materials away from

batteries. Always wear eye protection

when around batteries.

if your battery istoo weak to startthe

engine, it should be recharged. (See

"BATIERY" in the MAINTENANCE

sectionof this manual).

If "jumper cables" are used for emergency

starting,follow this procedure:

IMPORTANT: Yourtractoris equipped

with a 12 volt negative grounded system.

The othervehical must also be a 12 volt

negative grounded system. Do not use

your tractor battery to start other vehicles.

TO ATTACHJUMPER CABLES -

1. Connect each end of the RED cable to

the POSITIVE (+) terminal of each

battery,taking care notto short

against chassis.

2. Connect one end of the BLACK cable

to the NEGATIVE (-) terminal offully

charged battery.

3. Connect the other end of the BLACK

cable to good CHASSIS GROUND,

away from fuel tank and battery.

TO REMOVE CABLES,REVERSE ORDER -

1. BLACK cable first from chassis and

then from the fully charged battery.

2. RED cable last from both batteries.

=Posifi_ =Negative"

_+' /l _l_ / (-)

REPLACING BATTERY

_,CAUTION: Do not shortbattery

terminals by allowing a wrench or any

other object to contact both terminals at

the some time. Before connectingbattery,

remove metal bracelets, wristwatch

bands, rings,etc.

Positiveterminal must be connected first

to prevent sparking from accidental

grounding.

1. Lifthood to raised position.

2. Remove terminal guard.

3. Disconnect BLACK battery cable then

RED battery cable and carefully

remove battery from tractor.

4. Install new battery with terminals in

same position as old battery.

5. Reinstall terminal guard.

6. First connect RED battery cable to

positive (+) battery terminal with hex

bolt and keps nut as shown. Tighten

securely.

7. Connect BLACK grounding cable to

negative (-) battery terminal with

remaining hex bolt and keps nut.

Tighten securely

8. Close terminal access doors.

9. Close hood.

keps Nut

Terminal

Access •

Door_x I_it

_rminal _

Guard__--_ Positive(Red)

I I l -_, Cable

' I I_'_ _'_Negarlve

"_ 1/ (Black) Cable

TO REPLACE HEADLIGHT LAMP

_,CAUTION: When lit, the halogen lamps

get extremely hot. Hold lamp assembly by

the holder and do not touchthe bulb.

1. Raise hood.

2. Disconnect harness from lamp

assembly.

3. Rotate counterclockwise and pull

lamp assembly out of the hole in the

backside of the grill.

4. Insert new lamp assembly and rotate

clockwiseto lock.

5. Reconnect harness to lamp assembly.

6. Close hood.

INTERLOCKS AND RELAYS

Looseor damaged wiring may cause your

tractorto run poorly,stop running,or

preventit from starting.

• Check widng. See electrical wiring

diagram in the Repair Parts section.

TO REPLACE FUSE

Replace with 20 amp automotive-type

plug-in fuse. The fuse holder is located

behind the dash.

TO REMOVE HOOD AND GRILL AS-

SEMBLY

1. Raise hood.

2. Unsnap headlight wire connector.

3. Stand in front of tractor. Grasp hood at

sides, tilt toward engine and liftoff of

tractor.

4. To replace, reverse above procedure.

27

Page 28

Hood