Craftsman 917259570 Owner’s Manual

SE_/ARS

CRnFrZMnN

MODEL NUMBER 917.259570 OWNER'SMANUAL

• Assembly

• Operation

• Customer Responsibilities

° Service and Adjustments

• Repair Parts

CAUT|ON: Read and follow all safety rules and instructions before operating this equipment,

I

FOR CONSUMER ASSISTANCE HOT UNE, CALL THIS TOLL FREE NUMBER: 1-800-659-5917

SAFETY RULES

Safe Operation Practices for Ride-On Mowers

IMPORTANTr THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET ANDTHROWtNG OBJECTS

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH

L

GENERAL OPERATION

i

Read. understand, and tottow atl Instructions tn the manual

end on the machine before starting

Only allow responsible adults, who are familiar with the

Instruction& to operale the machine,

Clear the area el objects such as rocks, toys, wire, eta,,

which could be picked up and thrown by the blade

Be sure the area ts clear of olher people before mowing Stop

machine ]f anyone enters lhe area

Never cam/passengers

Do not mow in reverse unless absolutely necessary Always

look down and behind before and while backing,

e

Be aware of Ihe mower discharge direction and do not point

It at anyone Do not operate the mower without either lhe

enlire grass catcher or the guard in place,

Slow down before turning

Never leave e running machine unattended. Always turn off

blades,set parklng 6rake_ stopengine, and remove keys

before dismounting,

a

Turn off blades when not mowing

Stop engine before removing grass calcher or unclogging

chute

Mow onty in daylight or good artificial ltghl

Do not operate Ihe machine while under the Intluenca of

alcohol or drugs

4

Watch lot tralfic when operating near or crossing roadways

Use extra care when loading sr unloading the machine into

a Irailer or truck,

IL SLOPE OPERATION

Slepes are a major factor related to loss-of-control and

tipover accidents, which can resuff in severe injury or

death. Allslopes require extra caution. If you cannot back

up the slope or if you feel uneasy on fl, do not mow iL

DO:

• Mow up anddown slopes, not across

• Remove obstacles suchas rocks, tree limbs, etc.

•- --_._-,_.T-, ..................... _-, .................. ,- J--Grass ca char componen s ar&subiee, o.wear, damage, and

• Walctl tot r'0otes,ruts, or "bum s uneven terrain coots

....... P " . ..... delerisration, which could expose moving parts or al!ow

overturn file machine _=1stgratis can n/oe oos_aczes

• Uses!owspeed Chooseaiowgearsothalyouwiffnothave replacewIthmanufacturer'eresommendsdpads whennec-

to stop or eh ft wh e on thesl0pe essary,

• Fellow the manufacturer's resommendattons for wheal

weights or counter.,vstghteto improve atabilily

• Use extra care with grass catchers or ether attachments

Thesecan change {hestabilityofthemachlne

• Keep all movemenl on the slopes stowand gradual. Do not

make sudden changes tn speed or direction

• Avoid stadtng or stopping on a slope. If tires lose tractisn,

disengage the blades end proceed slowly stralghl downthe

slope

DO NOT:

• Do not turnon slopes unless necessary, andthen, turnstowty

end graduallydownhill It possible

• Do not mow near drop-otis, ditches, or embankments The

mower could suddenly turn over t!a wheel isover the edge

of a clltl sr dltch, ortf an edge caves In

Do not mew on wet grass Reduced traction could cause

sliding

• Do not Iry to slabitlze themachine by putting your test on the

ground,

• Do nor use grass catcher on sleep slopes

IIi. CHILDREN

Trag!e accidents can occur il Ihe operator is not aledto the

presence of children, Chftdren are often attracted to the

machine and the mowing acttvilyo Never assume that

children will remain where you rest saw them,

,, Keepchttdmnout of themowing areaand under thewalchfut

care of anolher responsible adult.

• Be alert and turn machine off ilchildren enter the area,

Before end when backing, took behind end down for small

children.

Never carry children They may fall oil and be seriously

injured ortntedere with sa[e machine operation

Never allow chiJdren to operate the machine

. Use extra care when approachingblind comers, shrubs.

tress,or other objects thatmay obscure vision,

IV_ SERVICE

• Useextracare tnhandllng gesotine and ether luels They are

Ilammable andvapors are explosive

Use onty an approved container.

Never remove gas cap or add luel with the engine

running Allow engine to cool belore refueling Do not

smoke,

Never refuel the machine indoors

Never store the machine or Iuel container inside where

there Isan open flame, such as awater healer,

° Neverrun a maehtne Inside a closed area,

Keep nuts andbolts, especiallyblade attachment bolts, t_gh[

end keep equipment ingood condition

Never tamper with safety devices, Check their proper

operation regularly,

• Keep machine free el grass, leaves, or otherdebds build.up,

Clean oil or luel spillage Allow machine to cool balers

storing

• Stop and Inspect Ihe equipment tf you slrike an object

Repair. tt necessary, balers restarting.

• Never make adjustments or repairs wilh Iheengine running

obsets to be thrown, Frequently check components and

• Mower blades ai'e sharp andcan cut Wrap the blade(s} or

wear gloves,and use extra cautionwhen servicing them

• Check brake operation hequentiy Adjust and service as

required,

A Look forthls symbol to point out important

A wire and plecewlrswhsralt cannot contact

The engine exhaust from this product contains

chemicals known to the State of California to

cause cancer, birth defects, or other reproduc-

tive harm,

safety precautions- It means

CAUTIONIH BECOME ALERTll! YOUR

SAFETY IS INVOLVED.

CAUTION; Always dfsconnent spark plug

spark plug in order to prevent accidental

starting when setting up, transporting,

adlustlng or making repairs°

WARNING

i =

n

l--

n-

UJ

U.I

14.

(1

cO

n-

O

u.

Or)

UJ

a.

0

.J

0

Z

F-

-i-

O0

0

U_

m

W

oO

0

O3

CONGRATULATIONS on your purchase of a Sears

Tractor ff has been designed, engineered and manufac-

tured to give you the best possible dependability and

pedormance

Shouid you experience any problem you cannol easiiy

remedy, please contact your nearest Sears Authorized

Service Center/Department Department, We have com-

petent, welt-tralnedtechniciansand the proper toolsto

service or repair this tractor..

Please read and retain this manual. The Instructions will

enabte you to assemble and mainlaln your tractor properly.

AIways observe the "SAFETY RULES".

MODEL

NUMBER 917 259570

SERIAL

NUMBER

DATE OF PURCHASE

TH E MODEL AND SERIAL NUMBERS WILLBE FOUND

ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

•"OR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement Is available on this prod-

uct. Contact you_ nearest Sears store tar details

CUSTOMER RESPONSIBILITIES

,, Read and ebsewe the salety rdfes

• Follow aregular schedule in maintaining, cadng for and

using your tractor.

• FoIlow the Instructions under"Customer ResponsibilF

ties" and "Storage" sections of this owner's manuaf

WARNING: This tractor is equipped wilh an internal

combu_ion engine and should not be used on or near any

unimproved foresFcovered, brush._ 'vered or grass-coy..

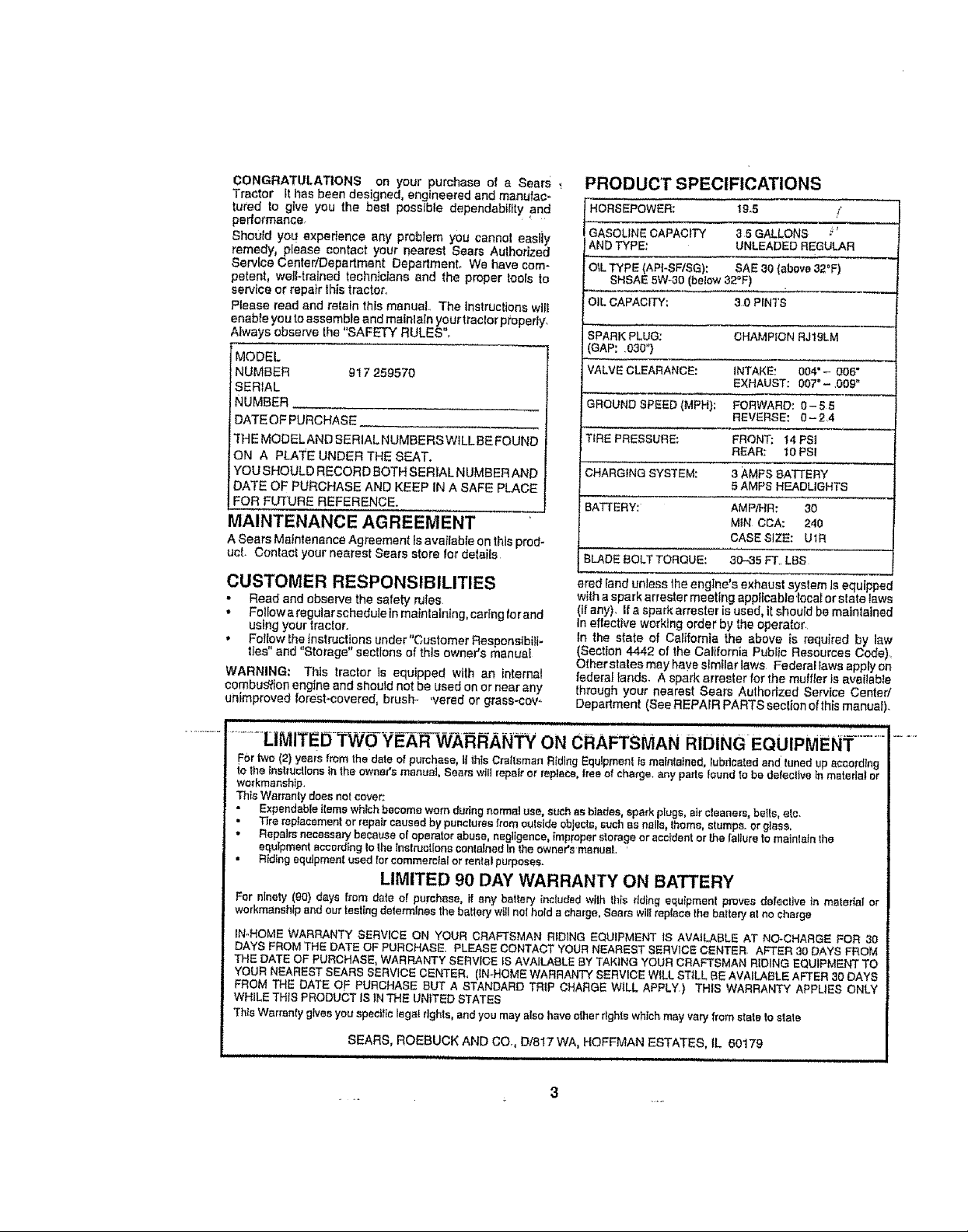

PRODUCT SPECIFICATIONS

HORSEPOWER; 19.5 /

GASOLINE DAPACITY 3 5 GALLONS "_'

AND TYPE: UNLEADED REGULAR

OILTYPE (API-SFtSG): SAE 30 (above 32DF)

SHSAE 5W-30 {below 32_'F)

[OIL CAPACITY; 3,0 PINTS

SPARK PLUG: CHAMPION RJ19LM

(GAP: 030"}

VALVE CLEARANCE: INTAKE! 004"- 006"

GROUND SPEED (MPH): FORWARD: 0- 5 5

TIRE PRESSURE: FRONT: 14 PSI

CHARGING SYSTEM: 3 AMPS SATTERY

BATTERY: AMPiHR: 30

BLADE BOLT TORQUE: 80--,35FT..LBS

eredland unless the engine's exhaust syslem Is equipped

with aspark arrestor meeting appl{cable'tocal or slate laws

(tf any). If a spark attester is used, it should be maintained

tn eflect_ve working order by the operator

In fhe state of California the above is required by law

(Section 4442 of the California Public Resources Coda).

Other states may haye similar laws Federal laws apply on

federal lands. A spark arrester for the muffler ts available

through your nearest Sears Authorized Service Center/

Department (See REPAIR PARTS seclion of this manual).

EXHAUST: 007"-,009"

REVERSE: 0-2.4

REAR; t0 PSI

5 AMP8 HEADLIGHTS

MtN CDA: 240

CASE SIZE: U1R

...............L|MITED-T-WO-YE-Ai:I-WAi-3RAN_ON CRAFTSMAN RIDING EQUIPMENT ...............

For two (2) years from the date of purchase, it this Crafisman Riding Equlpmenl tsmaintained, lubdcafed and tuned up according

to the Instructions Inthe owners manual, SearS will repair or replace, free ef charge, any partsround tobe defeclive in material or

workmanship.

This Warranty does net cover:

Expendable ileme which become worn dudng normal use, such as blades, spark plugs, air cleaners, bells, etc.

• Tirerepfacement er repair caused by punclurssfrom eulside objects,such as nails,lhems, stumps, orglass.

• Repairsnecessary because of operator abuse, negligence,tmpreper storage or accident or _nefaliure to mainlatn the

equipment according!o Ihe Instructions conlatnsd In theewneCsmanual. '

• Riding equipment used for commercial errenta! purposes.

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety (gO) days from date of pumhase, if any battery included with this riding equipment proves defective in matertat er

wmkmanshipand ourtesting determines the battery wItl nol holda cha_'ge,Sears willreplace lhe batte_' at no charge

IN-HOME WARRANTY SERVICE ON YOUR CRAFTSMAN RIDING EQUIPMENT IS AVAILABLE AT NO*CHARGE FOR 30

DAYS PROM THE DATE OF PURCHASE. PLEASE CONTACT YOUR NEAREST SERVICE CENTER. AFTER 30 DAYS FROM

THE DATE OF PURCHASE, WARRANTY SERVICE ISAVAILABLE BY TAKING YOUR CRAFTSMAN RIDING EQUIPMENT TO

YOUR NF.AREST SEARS SERVICE CENTER, (1N-HOMEWARRANTY SERVICE WILL STILL BE AVAILABLE AFTER 30 DAYS

FROM THE DATE OF PURCHASE BUT A STANDARD TRIP CHARGE WILL APPLY} THIS WARRANTY APPUES ONLY

WHILE THIS PRODUCT iS IN THE UNITED STATES

This War_nty gives you speOIle legat dghts, and you may also haveether flgh'_swhich may vary fmrn state Io state

SEARS, ROEBUCK AND CO, D/817 WA, HOFFMAN ESTATES, IL 60179

3

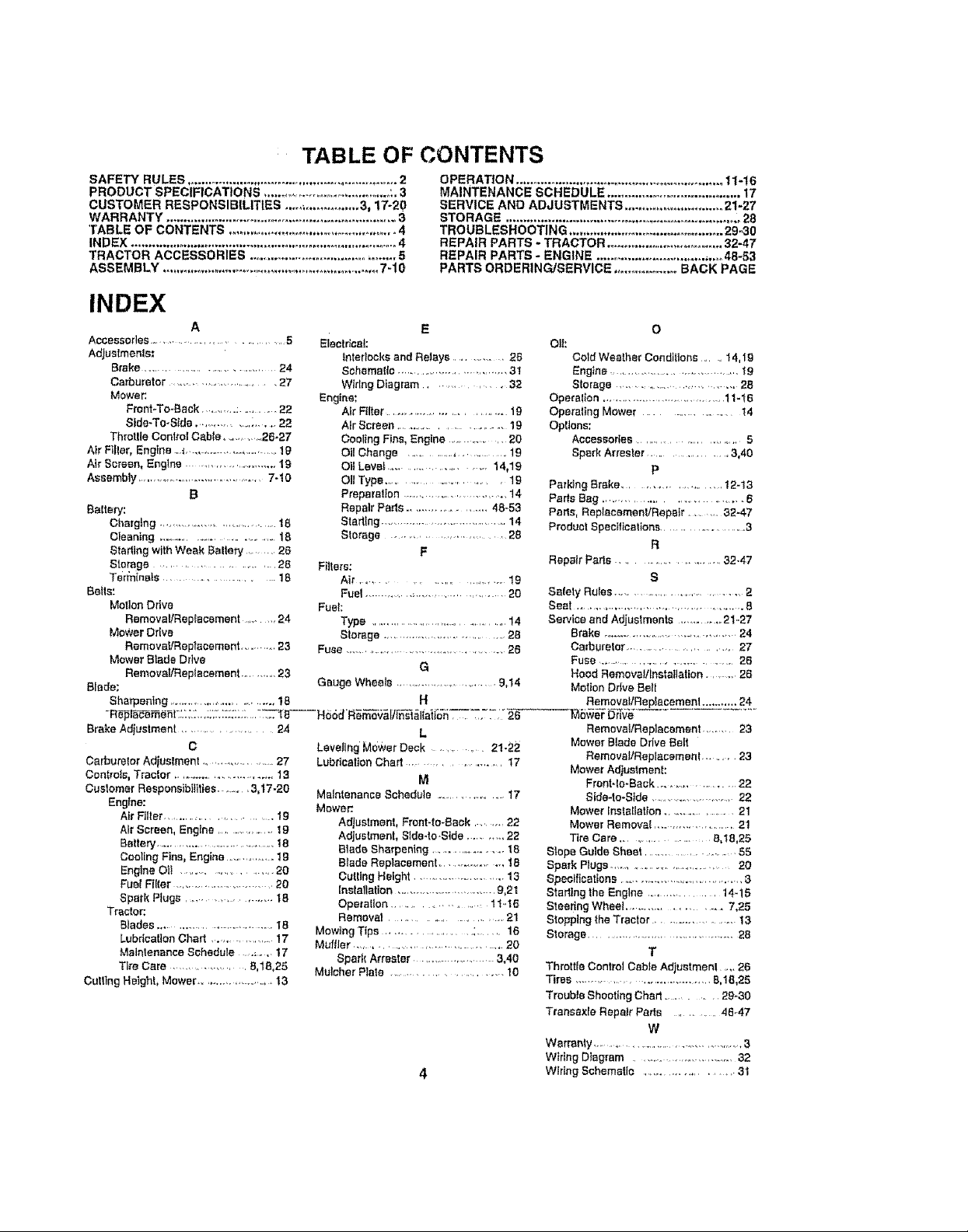

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ........................................ ',.3

CUSTOMER RESPONSIBILITIES .,°o._............... 3, 17'-20

WARRANTY ................................................................. 3

'TABLE OF CONTENTS ............................................... 4

INDEX ............................................................................ 4

TRACTOR ACCESSORIES ............................................ 5

ASSEMBLY .............................................................. 7-10

INDEX

Accessories ............................... 5

Adjuslmenls;

Brake ................................... 24

Carburetor ............................ 27

Mower:.

Front-To-Back.......... :.......... 22

Side-To-Side ..................;..... 22

Throttle Control Cable .......... 26-27

Air Filler, Engine,,_............................... lg

AirScreen, Engine ......................... lg

Assembly................................... 7-10

Battery:

Charging ...................................... 18

Cleaning ................................ 18

Stadlngwith Weak Baltery ..........28

Storage ......................28

Ter_ntnels......................... 18

Belts:

Motion Drive

Removal/Replacement ......... 24

Mower Ddve

Removef/Reptacement ........... 23

Mower Blade Drive

Removal/Replacement .......... 23

Blade;

Sha_ening ................................. 18

Brake Adjustment ......................... 24

Carburetor Adiustment .................... 27

Controls, Tractor ............................... 13

Cuslomer RespensibI!Ittes..........3,17-20

Engtne:

Air Filter .............................. ig

Air Screen, Engine .................. 19

Battery .........................................18

CoolingFins, Engine ..................19

Engine eli ..........................20

Fuel Filter ................................ 20

Bpa_'kPlugs ......................18

Trecton

Blades ............................. I 8

Lubrication Chart .. ............... 17

Maintenance Schedule . .. 17

Tire Care .......... .... B,18,25

Cutting Heighl, Mower ........................ 13

A

Electrfcet:

Interlocks and Retays ............ 2B

SchemaIIc ................................ 31

Wiring Diagram ..............32

Engine:

AirFilter............................ 19

AirScreen ....................... 19

Coating Fins, Engine ................. 20

Oil Change .............. ,............... 19

OIl Level ........................ 14,19

B

C

Oil Type............................... 19

Preparelion ..................................14

Repair Parts ................... 48-53

Starting..................................... 14

Storage ................................. 28

Filters:

Air., ................................. t9

Fuel .... .............. ..... 20

Fuel:

Type ..............................................14

Storage ...................................... 2B

Fuse ........................................ 26

Gauge Wheel8 ............................... 9,14

Leveling Mower Deck .......... 21-22

Lubdcatlon Chart ..................... 17

Maintenance Scheduta ..................... 17

Mowec

Adjustment, Front-to-Beck, • -.22

Adjustment, Side-to.Side .......... 22

Blade Sharpening ...................... 18

BIade Replacement .................. !8

Cutting Height ......................... 13

Installation .................................9,21

Opera!ion..................... 11..16

Removal ................... 21

Mowing Tips ................... :...... 16

Muffler .............. .......................... 20

Spark Arrestor ..................... 3,40

Muleher Plate ............................ 10

OPERATION ............................................................. 11-t6

MAINTENANCE SCHEDULE ...................................... 17

SERVICE AND ADJUSTMENTS ............................ 2%27

STORAGE ...................................................................... 28

TROUBLESHOOTING ............................................ 29-30

REPAIR PARTS - TRACTOR ................................... 32-47

REPAIR PARTS - ENGINE ..................................... 48-53

PARTS ORDERINGJSERVICE ................... BACK PAGE

E

F

G

H

L

M

4

eli:

Cold Weather Conditions ...... t4, tg

Engine...................................... 19

Storage .................................. 28

Operalion ........................................11=!6

Operaling Mower ..................... 14

Options,"

Accessories.............................. 5

Spark Arrestor ..................... 3,40

Parking Brake .......................... 12-13

Parts Bag ............................. 6

Paris, ReplaeamenVRepa_r....... 32-47

Product Specificatlons .............................3

Repair Parts ...................... 32-47

Solely Rules ...................... .......... 2

Seat ............................................... B

Service and Adjustments ..............21-27

Brake ............................................ 24

Carburetor ...................... 27

Fuse. ................................... 26

Hood Removal/Installation ........ 26

Motion Drive Belt

RemovallReplacement ........... 24

Removal/Replacement ......... 23

Mower Blade Drive Serf

Removal/Replacement........ 23

Mower Adjustment:

Front-to-Back ................... 22

Side-to*Side .............................22

Mower Installation ................... 21

Mower Remove{......................... 2!

TireCare ....................... B,18,25

Slope Guide Sheet ............................. .55

SparkPlugs.................................... 20

Specifications ....................................... 3

Startingthe Engine ................ 14-15

Steedng Wheel .................... 7,25

Stoppingthe Tractor ...................... I3

Storage .................................... 28

Throttle Control CableAdjustmenl ..,. 26

Tires.................................. 8,18,25

Trouble Shooting Chad ............. 29*30

Transax[e Repair Parts ......... 46-47

Wa_'ar_ty............................................... 3

Wiring Diagram ............................... 32

Wiring Schematic ....................... 31

O

P

R

S

T

W

ACCESSORIES AND ATTACHMENTS

These accessoriesend attachmentswereavailable through most Sears retatloutlets endservicecenters whenIhe tractor waspurchased

Moat Sears stores can order theseiiems for you when you provide themodel number of your Iractor_

ENGINE

SPARKPLUG GASCAN ENGINEOIL

FUELSTABILIZER

AIRFILTER

MAINTENANCE

BLADES BELTS

%

PERFORMANCE

Searscriersawide vadetyof altachments Ihaffityour Iracior Many el theseare listed below withbr{el explanations el how they canharp

you. This list was currant al thetime of pub]]car!on; however, It m_y change infuture years -,more attachments may be added, changes

may be madein these attachments, or some mayno longer be available ortit your model Contact you_"ncarest Sears stnl'e lot the

accessories and attachments that are available for your trector_

Most el theseattachments de not require additional hits]lea orconversion kfls (Ihese thatdo are indicated) and ere designed for easy

attachingand detaching

AERATOR promotes deep root growlh for a healthy lawn Ta-

pered 2.5-inch sisal spikes mounted on to-inch diameter discs

puncture holes In soil at dose intervalsto let moisture soak in

Stee_weighttray lot Increased penetration

BAGGER lets you collect grass clippings and leaves {or a

healthier, nearer looking lawn Two Permanex containers hold

30-gallon plasttcbags

BUMPER protects front end el tractorfromdamage

CARTS make hearing easy Vsdety ofsizes available, plus

accessories such as aide panei klls, tool caddy, cad cover,

protectivemat and deify

CORING AERATOR takes smatl plugs out of soil Ioa!iow mois-

ture and nutrientsto reach grass roots. 36-Inch swath 24

harder_edsteel coring tips 150 Ib capacityweight tray

EASY OIL DRAIN VALVE makes oil changes easier, faster

FRONTNOSEROLLERsanterslnfrunt :nowerdecktoraduce SPREADER/SEEDERSmakeseedlng fertfttztng,and weed ktU-

chances of "scalping" on uneven terrain_ " ]rigeasy. Broadcast spreaders am atso useful for granular de÷

GANGHtTCH lets¥ou tow2or3pull-behind attachmentsatonce,-........ ]cefs.and_s_nd_. ..........................................................

such as sweepers, dethatchers, aerators (notforusewithrollers, SWEEPERS let you co{leergrass c_lpplngsand leaves.

cartsor other heavy attachments)

GAUGE WHEELS on both sides of the mower deck reduce

chance_,of "sea{ping"on uneventerrain Formower decks not so

equipped

MULCH RAKFJDETHATCHER loosens soil and Itlpsthatch and

matted leaves to lawn audace foreasy pickup, Twenty springline

teeth_Usefulto preparebare areas for seeding. Available for front

or rear mounllng. HIGH PERFORMANCE REEL-ACTION

SPRING TINE DETHATCHER covers 36-1richwide path and

tosses thatch Intolarge hopper Mounts behind tractor

MULCHING CLOSE, OUT PLATE KIT, once tnstafled,lets you

mulch, discharge or bag clippings (bagger optional) without

changingblades. Formodels not equippedas 3-1n-tConvertible

mowers See "MOWER" in the Repair Parts section of this

manual

RAMP TOPS AND FEET tel youload and untoadtractor trom a

pickuptruck Use with2 x 8 or 2 x 10 ]umber

ROLLER for smoother Eawnsudace_ 36Jnch wide, 18-Inch

diameter warer-tightdrum holdsup to3g0 tbs.el weight, Rounded

edges prevent harm to tuff Adjustable acrsper automalicelly

cleans drbm

SNOW BLADE forsnow removafonly, f4_lnshhigh,48-1nobwide

blade clears 42-inch pathwhenangledIeftor dght. Raises,lowers

withsidelever. Adustable skids; replaceable,reversiblescraper

bar_(Use w Iht rechainsandwheel weighls andler rear drawbar

weight}

SNOWTHROWER has 40Jnch swath. Drum-type auger handles

powderyand weliheavy snow Mounts easily wilh simple pin

arrangement. Discharge chute adjustsfromtractorseet. 6-Inch

dtameter spoutdischarges snow10 to 50 feet. Lift controlledat

tractor seat. (Use with chains and wheelweights and/or rear

drawbar weight.)

SPRAYERS use 12-volt DO etecidcmotor thatconnecls to the

tractor baltery or other 12-volt source, Includes booms for

automaticsprayingandhand held wandfor spotspray{rig. Wand

has adjustable spray paftem. For applying herbicides, insecli.,

oides, lung_ctdesand liquid terltllzers

TILLER has 5hp engine and36-Inch swathtoprepareseed beds,

cultivate and compostgardehresidue. Tiller has itsownbunlJri

lilt anddepth controisystem and does NOTrequire e sleevehilch.

Fitsany lawn, yard or garden tractor,S_mplyhook upto thetractor

drawbar and go] Optional accessories convert unit for

dathatching, aerallng, hilling ..without tools

TiRE CHAINS areheavy duty; olosetyspacedexits-large crosS

linksgivesmoothride, outstanding traction.

TRACTOR CAB has heavy duty vinyl fabric over tubular steel

frame, ASS plastic top; clearplastic windshieldoffers 360 degree

visibility Hinged metal doors withcatch. Keeps operator warm

and dry Remove vinyl sides and wlndshte]ds for use as sun

protectorin summer, Optional accessories Include: tinted/

tempered soJIdsafety glass windshieldwilhhand operated wiper,

'{2-volt ambercaution ttghl for mounting on cab top

VACS Iorpowedul coltecl_onel heavy grass clippingsandleaves.

Optional wand attachment to ptck up debris tn hard-to-reach

pisces VAC/CHIPPER includesa chtpper-shredder

WEIGHT BRACKET lot drawbar forsnow removalepp_tcatEons,

Uses (I) 55 lb. weight.

WHEEL WEIGHTS for rear wheels provide needed Iractian for

snow removal or dozing heavy materials.

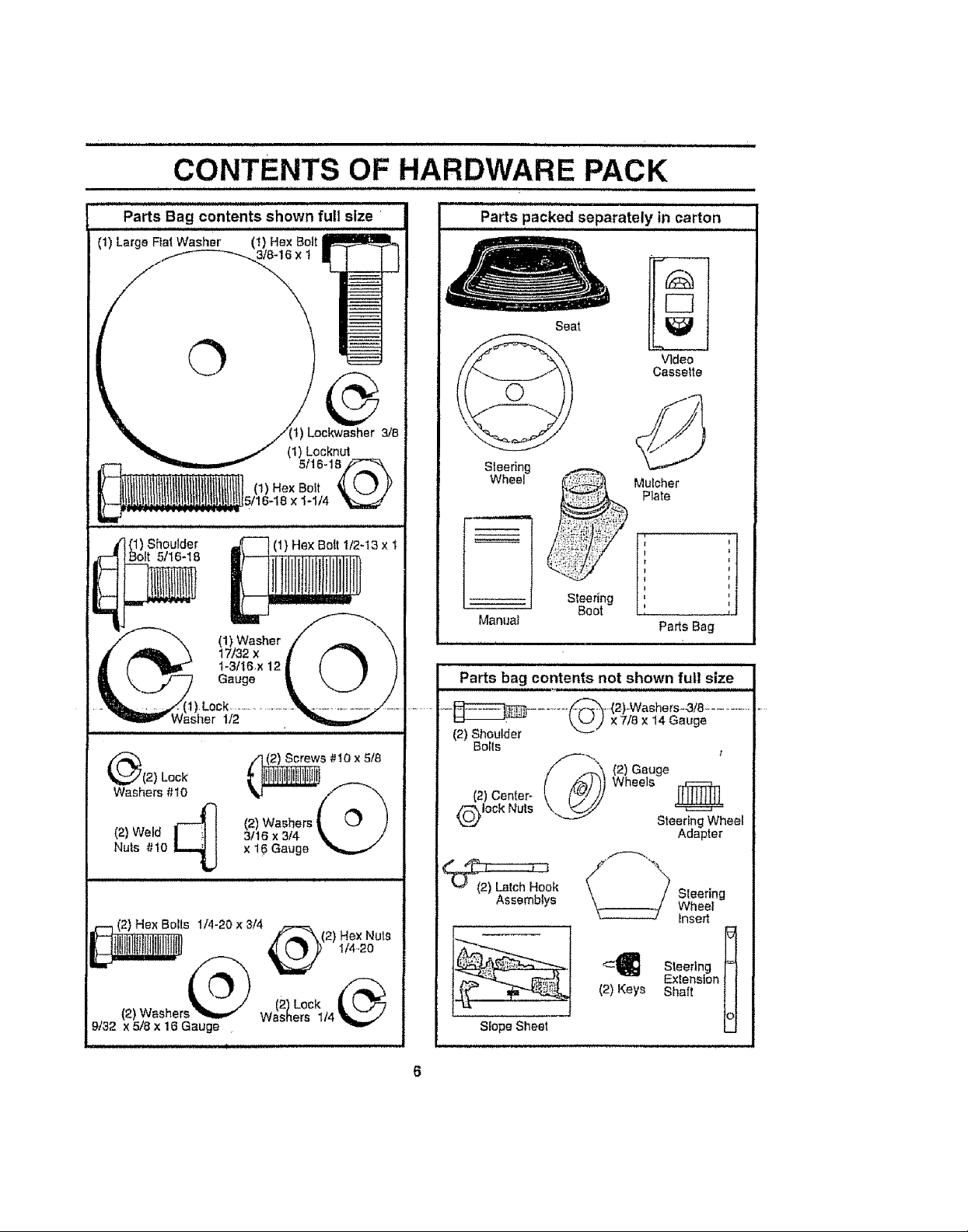

CONTENTS OF HARDWARE PACK

Parts packed separately in carton

Seat

Steedng

Wheel

i i

Video

Casselte

(1) Shoulder

Bolt 5/16-18

(1) Washer

17/32 x

1-3/16x 12

Gauge

Lock

1/2

(_(2) Lock

Washers #10

Nuts #10

(2) Weld _

(2) Hex Bolts 1/4-20 x 3/4

(1) Hex Bolt 112-13 x 1

s #10 x 5/8

(2) Washers i'i/_(_ 'XI

3118×3f4 \ /

x 16 Gauge

,,/r"_"k(2 ) Hex Nuts

Pads Bag

..{2)-Washers=3!8 .............

(2) Shoulder x 7/8 x 14 Gauge

Bolts

Wheels

(2) Center-

Qlock Nuts

Assemblys Wheel'

/f_(2) Gauge

Steertng Wheel

Adapter

k _"¢_7_ _ Steering

Insert

(2)Lock

• (2) Washer Washers 1t4

9/32 x 5/8 x 16 Gauge

Slope Sheet

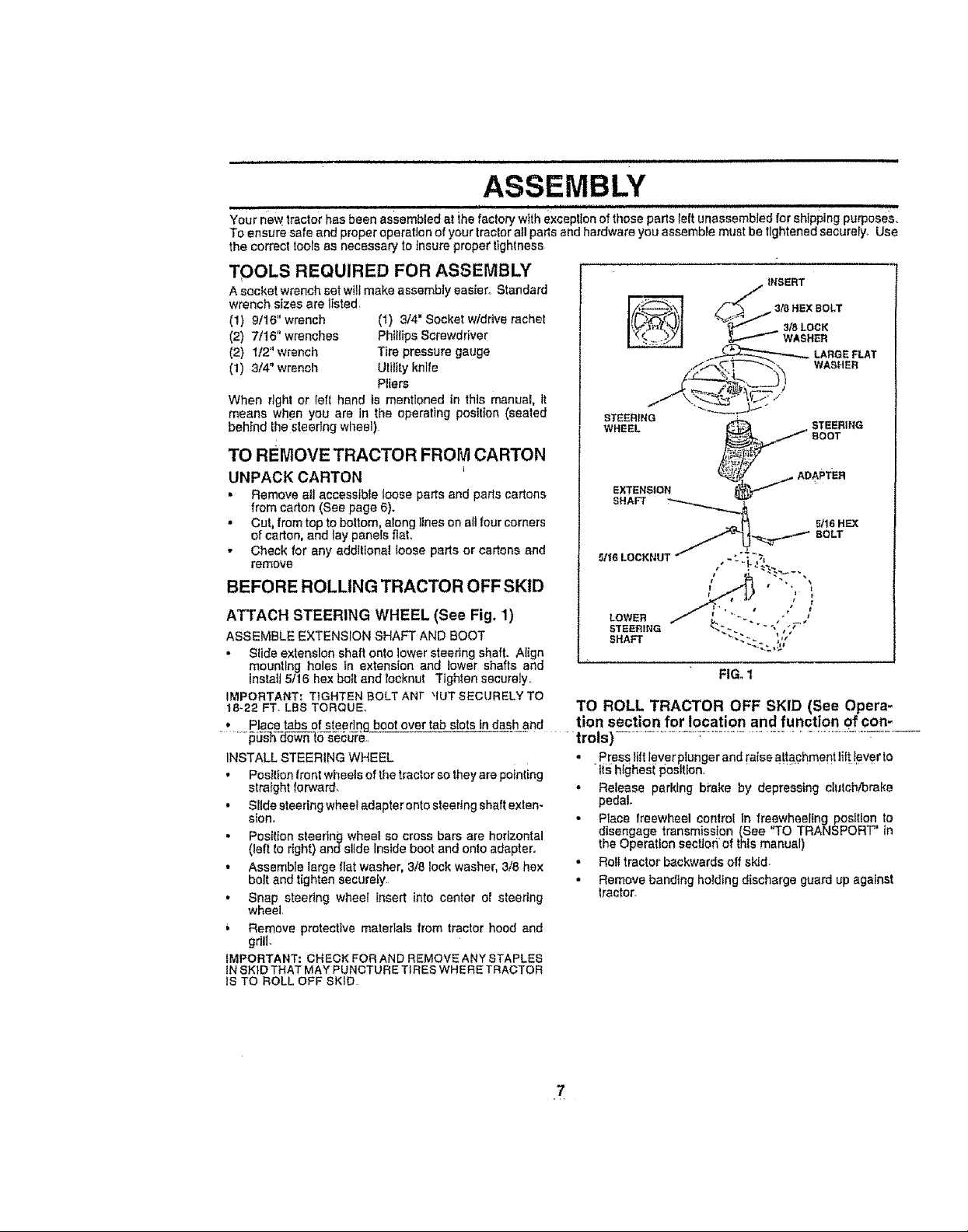

ASSEMBLY

Your new tractor has been assembled at ihe factory with exception of these parts left unassembled for shtpping purposes,

To ensure safe and proper operation of your tractor afl parts and hardware you assemble must be tightened securely. Use

the correct tools as necessary to insure proper tightness

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set wtflmake assembly easier. Standard

wrench sizes are listed,

(1) 9/16" wrench (1) 3/'4" Socket w/drive rachel

(2) 7/16" wrenches Phillips Screwdriver

(2) t12" wrench Tire pressure gauge

(1) 3/4" wrench Utility knife

When right or left hand is mentioned in this manual, it

means when you are in the operating position {sealed

behind the sleedng wheel)

i

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

,, Remove al! accessible loose parts and parts cartons

from carton (See page 6),

• Cut, from top to bottom, along lines on all four corners

of carton, and lay paneIs fiat,

- Check for any additional loose parts or cartons and

remove

BEFORE ROLLING TRACTOR OFFSKID

ATTACH STEERING WHEEL (See Fig. 1)

ASSEMBLE EXTENSION SHAFT AND BOOT

,, Slide extension shaft onto lower steedng shaft. Align

mounting holes tn extension and lower shafts and

install 5t16 hex bolt and rocknut Tighten securely,

IMPORTANT: TIGHTEN BOLT ANt _IUT SECURELY TO

t8-22 FT. LBS TORQUE.

• Placetabsof steeringbootovertabslotsindashand

..........._iJ_-_0-s_u-r_,

iNSTALL STEERING WHEEL

• Position frontwheels of the tractor so they are pointing

straight forward,

• SHde steering wheei adapter onto steedng shaft exten-

sion,

• Pes_lion steering wheel so cross bars are horizontal

(left to right) ands]_de Inside boot and onto adapter,

• Assemble large flat washer, 3/8 lock washer, 3/8 hex

bolt and tighten securely

• Snap steering wheel insert into center of steering

wheel,

Remove protective materlals from tractor hood and

gdil,

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

tN SKID THAT MAY PUNCTUR E TIRES WHERE TRACTOR

IS TO ROLL OFF SKiD

Pliers

5/16 HEX

BOLT

TO ROLL TRACTOR OFF SKID (See Opera-

tion section for location and function of con=

_'trois) ................... _...............................................-----

• Press l/It lever plunger and raise attachment lift tever to

tts highest position,, " .........

• Release parking brake by depressing clutch/brake

pedal.

• Place freewheel control In freewheeIfng position to

disengage transmission (See "TO TRANSPORT" in

the Operat{on secUoti of this manual)

• Roll tractor backwards off skid.

,, Remove banding holding discharge guard up against

tractor_

7

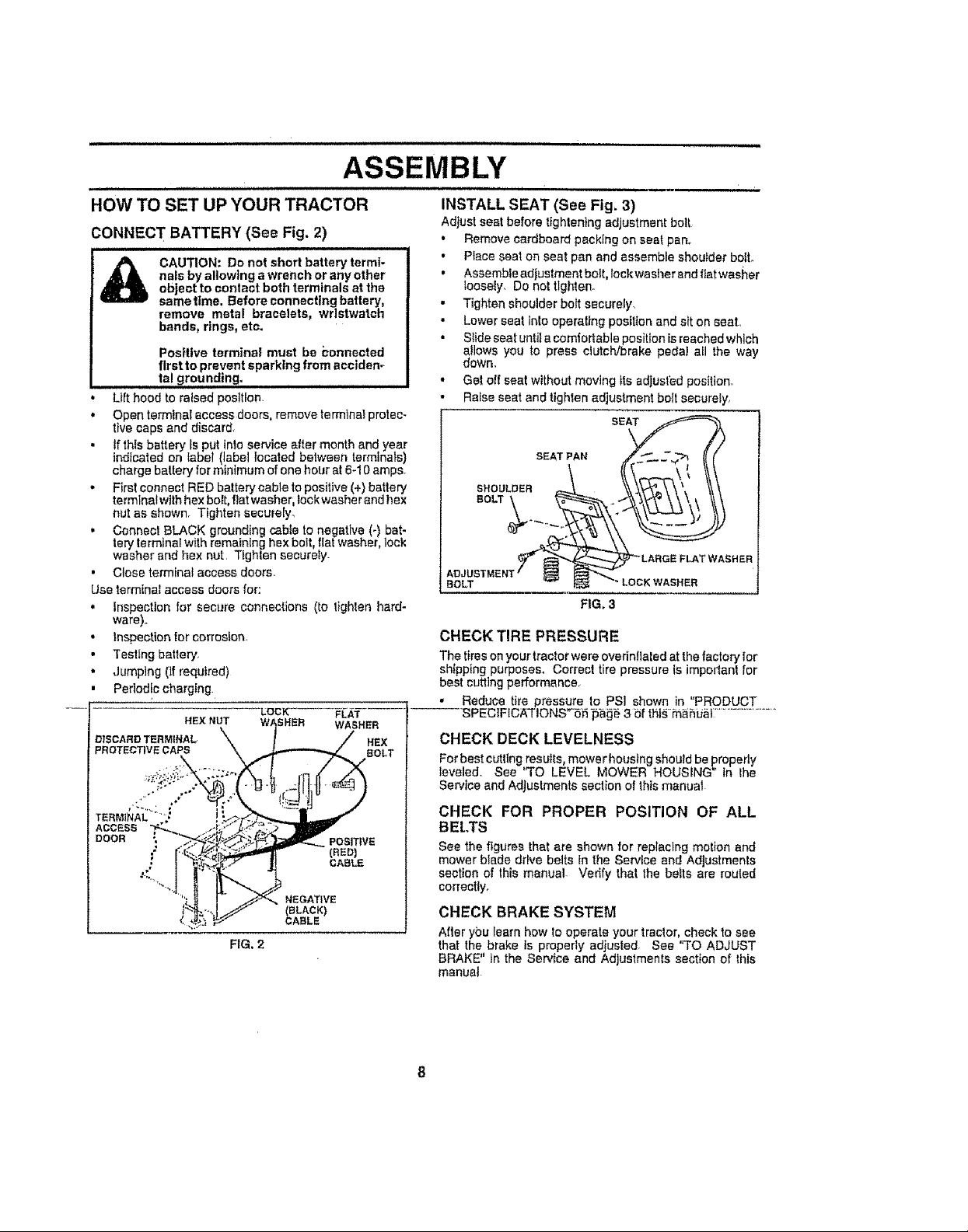

ASSEMBLY

i i ml ii ,inll,n,mnllllu i i t U

HOW TO SET UP YOUR TRACTOR

CONNECT BATTERY (See Fig. 2)

CAUTION: Do not short battery termi-

nals by allowing awrench orany other

object tocontact both terminals at the

samettme. Before connecting battery,

remove metal bracelets, wristwatch

bands, rings, etc.

Positive terminal must be 5onnected

flrstto prevent sparking from acciden_

ta! grounding,

• Lilt hood to raised position.

• Open terminal access doors, remove termlnai protec-

tive caps and discard,

If this battery Is put into service after month and year

indicated on label (label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

• First connect RED battery cable to positive (+) batlery

terminal with hex bolt, flat washer, lock washer and hex

nut as shown. Tighten securely_

, Connect BLACK grounding cable to negative (-) bat-

tary terminal with remaining hex bait, flat washer, lock

washer and hex nut. Tighten securety

• Close terminal access doors.

Use terminal access doors for:

, inspection for secure connections (to lighlan hard-

ware).

• Inspection for corrosion

• Testing battery,

• Jumping (if required)

• Periodic charging

HE}( NUT WASHER

DISCARD TERMINAL, HEX

PROTECTIVE CAPS BOLT

.- -.r

TERMINAL "

ACCESS

DOOR

=-

%

"LOCK- FLAT

NEGATIVE

(SLACK}

CABLE

FIG. 2

POSITIVE

(BED)

CABLE

illl Ill

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment bolt

* Remove cardboard packing on seat pan°

o Place seat on seat pan and assemble shoulder bolt.

, Assemble adjustment bolt, lockwasher and flat washer

loosely, Do not tlghlen_

- Tighten shoulder bolt securely.

• Lower seat inlo operating position and sit on seat,

• Slide seat until a comfortable position isreached which

a!lows you to press clutch/brake pedal aH the way

down,

• Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment bolt securely,

SEAT

SEAT PAN

SHOULDER

BOLT

BOLT

FiG. 3

CHECK TIRE PRESSURE

The tires on your tractor were ovednflaled at the factory |or

sh{pptng purposes_ Correct tire pressure is important lor

best cutting performance,

• Reduce tire pressure |o PSI shown in "PRODUCT

SPECIFICA'T!ONS'55 =p_g_ 3 5f tht_,=m_bU_[;.....................

CHECK DECK LEVELNESS

Forbest cutttngresults, mowerhoustng shoutdbeproperly

leveled. See 'TO LEVEL MOWER HOUSING in lhe

Service andAdjustments section of thismanual

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive betts in the Service and Adjustments

section of this manual- Vedfy that the belts are routed

correctly,

CHECK BRAKE SYSTEM

After ybu learn how to operate your tractor, check tosee

that the brake is properly adjusted, See "TO ADJUST

BRAKE" in the Serv{ce and Adjustmenfs section of this

manual

ASSEMBLY

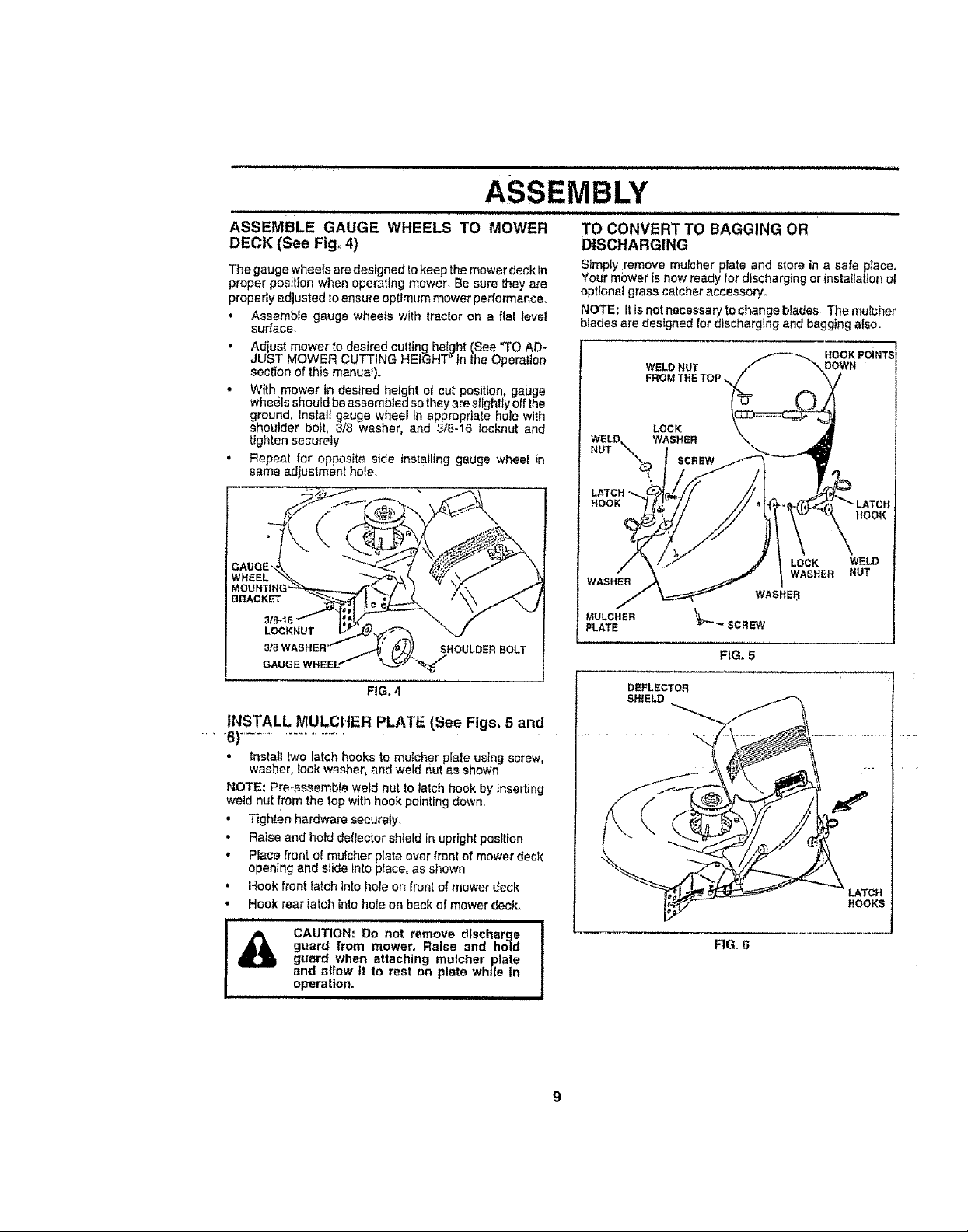

ASSEMBLE GAUGE WHEELS TO MOWER

DECK (See Fig. 4)

The gauge wheels are designed to keep the mower deck In

proper position when operating mower Be sure they are

properly adjusted to ensure optimum mower performance,

,, Assemble gauge wheels with tractor on a flai level

surlace

• Adjust mower to desired cutting height (See "TO AD-

JUST MOWER CUTTING HEIGHT in the Operaiion

section of this manua0.

• With mower in desired height of cut position, gauge

wheels should be assembled so they are slightly off lhe

ground. Instaif gauge wheel in appropriate hole with

shoulder boil, 3/8 washer, and 318-16 Iocknut and

tighten securely

• Repeat for opposite side Installing gauge wheei in

same adjustment hole

GAUGE

WHEEL

TO CONVERT TO BAGGING OR

DISCHARGING

Simply remove mulcher plate and store in a safe place,

Your mower Is now ready for discharging or installalton of

optionaI grass catcher accessory.

NOTE; It is not necessary to change blades The mulcher

blades are designed for discharging and bagging also.

WELD NUT

FROM THE TOP

LOCK WELD

WASHER

MULCHER

PLATE

FIG, 5

WASHER NUT

FIG. 4

INSTALL MULCHER PLATE {See Figs. 5 and

.....6)..........................

• fnstatl two latch hooks to muicher plate using screw

washer, lock washer, and we d nut as shown

NOTE: Pra-assemble weld nut to latch hook by inserting

weld nut from the top with hook pointing down,

,' Tighten hardware securely.

', Raise end hold deflector shield In upright position,

', Place front el mulcher prate over front ef mower deck

opening and slide into piece, as shown

, Hook front latch into hale on front ef mower deck

• Hook rear latch tnto hole on back of mower deck.

guard from mower, Raise and hold !

i ii_ll CAUTION: Do not remove discharge i

guard when attaching mulcher plate I

and allow it to rest on plate while in !

operatlon. !

DEFLECTOR

SHIELD

FIG. 6

LATCH

HOOKS

ASSEMBLY

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRA CTOR, WE WISH TO ASSURE THAT YOU RECEIVE

THEBES T PERFORMANCE AND SA TISFA CTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST."

,." All assembly instructions have been completed,

/ No remaining loose paris in cation,

v" Batteryis properly prepared and charged_ (Minimum

1 hour at 6 amps).. '

,/" Beat is adjusted comfodably and tightened securely,

€" All tires are properly Inflated. (For shipping purposes,

the tires were ovennftated at the factory),

v" Be sure mower deck is properly leveled side-to-slde/

Iront-to-rear for best cutting results. (Tires must be

properly inflated for teveting)_

v" Check mower and drive belts. Be sure they are routed

properly around pulleys and inside el! bell keepers,

/ Check wiring. Bee that all connections are stiff secure

and wires are properly clamped.

.," Before driving tractor, be sure freewheel control is in

drive position.

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA A TTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

,/ Engine oil is at proper level

7" Fuel tank is filled with fresh, clean, regular unleaded

gasoline,,

,/ Become familiar with afl controls - their location and

function, Operate them before you start the engine,

/ Be sure brake system is tn safe operating condition.

v" It is Important to purge the transmission before operat-

....... lngyourtractdrfortheflrsttim_:Fotlowproperstartlng

and transmission purging instruclions (See"TO START

ENGINE" and "PURGE TRANSMISSION" tn the Op-

eration section of thts manual),

i i

10

u,u ,un u i uuuuulnllll i i

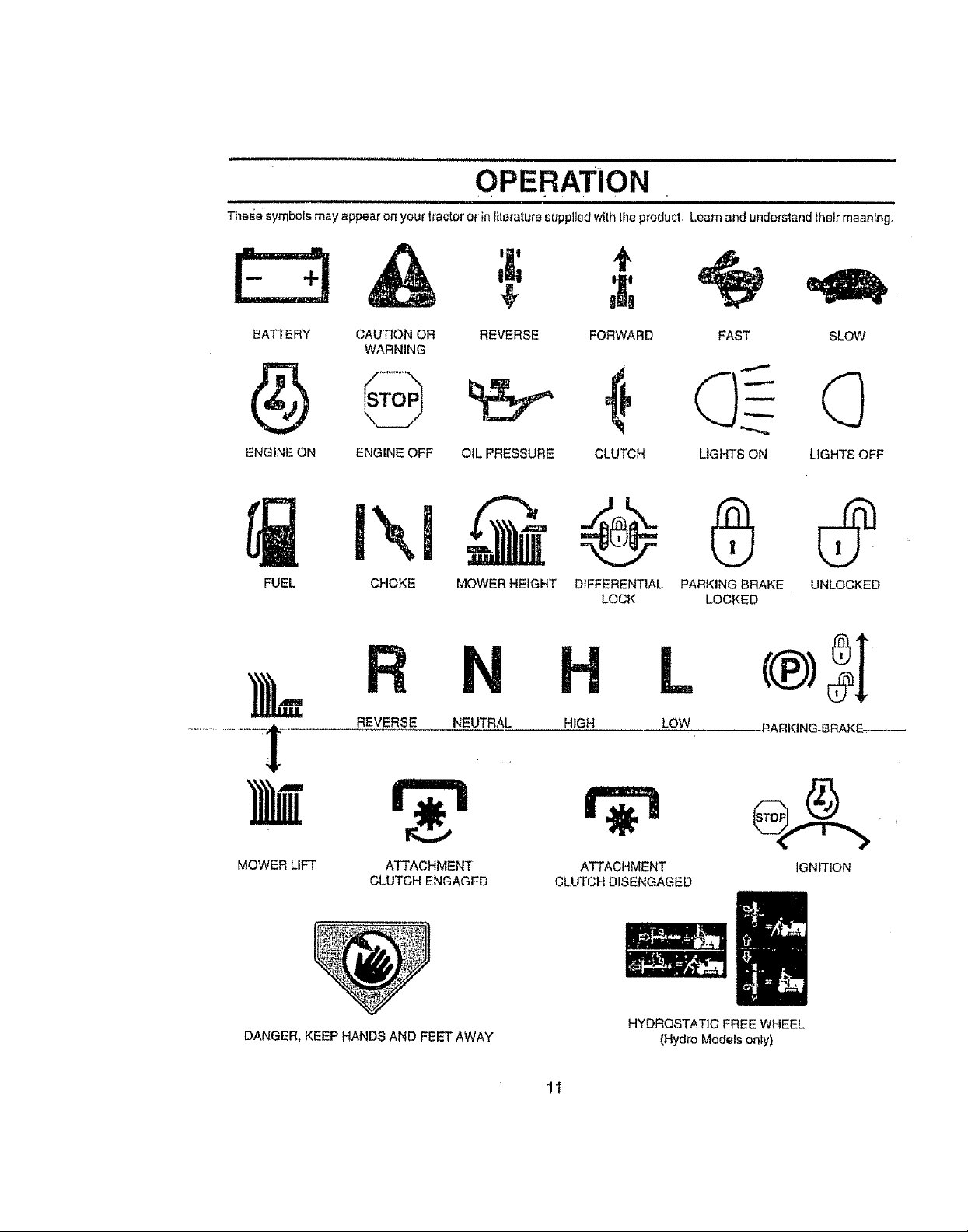

OPERATION

,ipllJ,umHn i i in i i i

These symbols may appear on your tractor or in (I1erature supplied with the product. Learn and understand their meaning,

4),

BATTERY CAUTION OR REVERSE FORWARD FAST SLOW

ENGINE ON ENGINE OFF OIL PRESSURE CLUTCH LIGHTS ON LIGHTS OFF

FUEL CHOKE MOWER HEIGHT DIFFERENTIAL PARKING BRAKE UNLOCKED

WARNING

LOCK LOCKED

REVERSE NEUTRAL HIGH

MOWER LIFT

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH ENGAGED

ATTACHMENT

CLUTCH DISENGAGED

HYDROSTAT)C FREE WHEEL

11

IGNITION

(Hydro Models only)

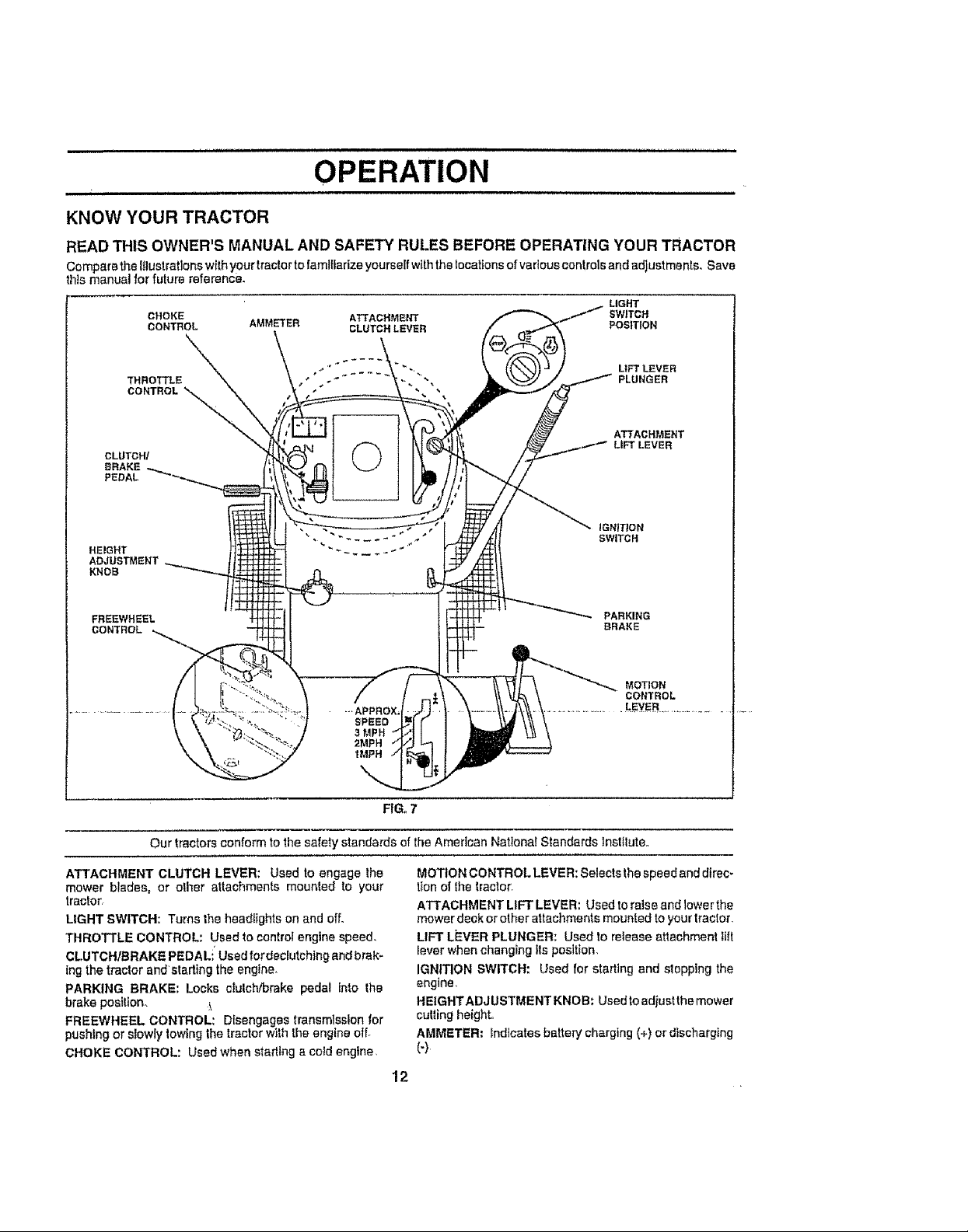

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the {tlustratlons with your tractor to famlffarize yourself with the locations of varlous controls and adjustments, Save

this manual for future reference.

LIGHT

ATTACHMENT

LtFT LEVER

THROTTLE

CONTROL _-_

CLUTCH/

PEDAL

HEIGHT

ADJUSTMENT

KNOB

CHOKE ATTACHMENT SWITCH

CONTROL AMMETER CLUTCH LEVER POSITION

©

FREEWHEEL

CONTROL

-,APPRGX,

SPEED

3 MPH

2MPH

1MPH

Our tractors conform to the safety standards of the American Nationa! Standards lnslltute.,

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor,

LIGHT SWITCH: Turnsthe headlightsonand off.

THROTTLE CONTROL: Usedto controlenginespeed,

CLUTCH/BRAKE PEDALi'Usedfordeclutehing andbrak-

ingthe tractor andstarling the engine_

PARKING BRAKE: Locks ctulch/brake pedal into the

brake posittom

FREEWHEEL CONTROL: Disengages transmissionfor

pushing or siowly towing thetractorwith the engine otL

CHOKE CONTROL: Usedwhen starting acold engine,

PARKING

BRAKE

MOTION

CONTROL

LEVER

FIG. 7

MOTION CONTROL LEVER: Selects the speed and direc-

tton of the tractor,

ATTACHMENT LIFT LEVER: Used to relse and lower the

mower deck or other attachments mounted to your tractor,

LIFT Li=VER PLUNGER: Used to release attachment ftit

lever when changing its position,

IGNITION SWITCH: Used for starting and stopping the

engine,

HEIGHTADJUSTMENT KNOB: Usedto adjustthe mower

curling height,,

AMMETER: _ndicates battery charging (+) ordischarging

(-)

12

OPERATION

In severe eye damage. Always wear safety glasses or eye shlelds while operating your tractor

l _ The operation of any tractor can result in foreign objects thrown into the eyes, which can result

11 .........

,

HOW TO USE YOUR TRACTOR

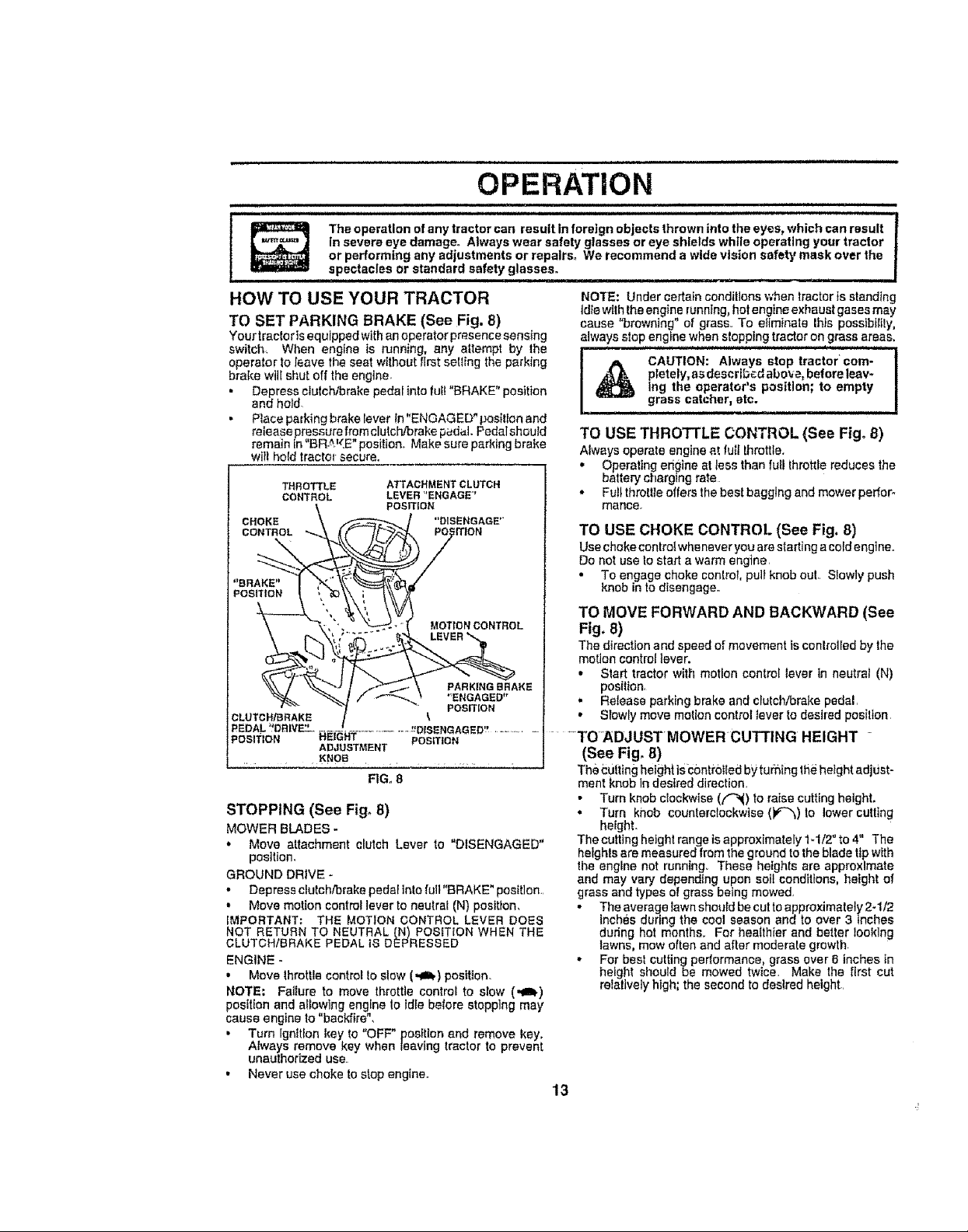

TO SET PARKING BRAKE (See Fig. 8)

Yourtractor is equipped with an operator prssenc esensing

switch, When engine ts running, any altempt by the

operator to leave the seat without first seI{ing the parking

brake wilt shut off the engine

• Depress ctulchibmke pedal intofutt "BRAKE" position

and hold

• Piece parking brake fever in"ENGAGED" position and

release pressure from clutch/brake pedal. Pedal should

remain In "BR,_KE" position. Make sure paddng brake

wiIl ho{d tractor secure.

CHOKE "'DISENGAGE"

CONTROL mON

CLUTCH_RAKE

REOAL_DRWE3-......................... _DISENGAGED!_............

POSITION HEIGHT POSITION

..... _NOe ............

STOPPING (See Fig° 8)

MOWER BLADES -

* Move attachment clutch Lever to "DISENGAGED"

position.

GROUND DRIVE -

• Depress clutch/brake pedal into full "BRAKE" position.,

. Move motion control fever to neutral (N) position.

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL IN) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED

ENGINE -

• Move throttle control to stow (,,Ill) posffion.

NOTE: Failure to move throttle control to slow (._I)

pos{tton and allowing engine to _dfe before stopping may

cause engine to "backfke",

• Turn Ignition key to "OFF" position end remove key.

Atways remove key when leaving tractor to prevent

unauthorized use

• Never use choke to stop engine.

or performing any adjustments or repairs° We recommend a wide vision safety mask over the

spectacles or Standard safety glasses.

THROTTLE ATTACHMENTCLUTCH

CONTROL LEVER _'ENGAGE"

ADJUSTMENT

POSmON

FIG_ 8

MOTFON CONTROL

PARK|NGBRAKE

"ENGAGED"

POSmON

NOTE: Under certain conditions when tractsr ts standing

Id}ewith the engine running, hot engine exhaust gases may

cause "browning" of grass,, To ei{minate Ibis possfbt{ity,

always stop engine when stopping tractor on grass areas,

pletely, as descrtb_.d abo_a, before leav-

Ing the operator's position; to empty

grass catcher, etc.

TO USE THROTTLE CONTROL (See Fig. 8)

A{ways operate engine at fu{I throttle.

- Operating origins at tess than fufl throttle reduces the

battery charging rate

• Full throttle offers the best baggtng and mower perfeF

mance.

TO USE CHOKE CONTROL (See Fig, 8)

Use choke contro{whenever you are stading acoid engine.

Do not use to start a warm engine,

• To engage choke control, pull knob out. SIowly push

knob in to disengage.

TO MOVE FORWARD AND BACKWARD (See

Fig. 8)

The direction and speed of movement ts conlrolled by the

motion control lever.

• Start tractor with motion control lever in neutral (N)

position,

. Release parking brake and clutch/brake pedal r

• Slowly move motion control fever lo desired position

......TOADJUSTMOWER CUTTING HEIGHT -

(See Fig, 8)

The cuiting heigh| iS-c0ntrotled by turning the height adjust-

ment knob in desired direction,

• Turn knob clockwise (_) to raise cutting height.

• Turn knob counterc{ockwise (P"_)to lower cutting

height.

The cutting height range tsapproximately 1.1/2" to 4" The

heights ere measured from the ground to the blade tip with

the engine not running These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average {awnshouid be cut to approximately 2-1/2

inches during the cool season and to over 3 inches

dudng hot months. For health{or and better looking

lawns, mow often and after moderale growth

• For best cuttingpedermance, grass over 6 inches In

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

13

OPERATION

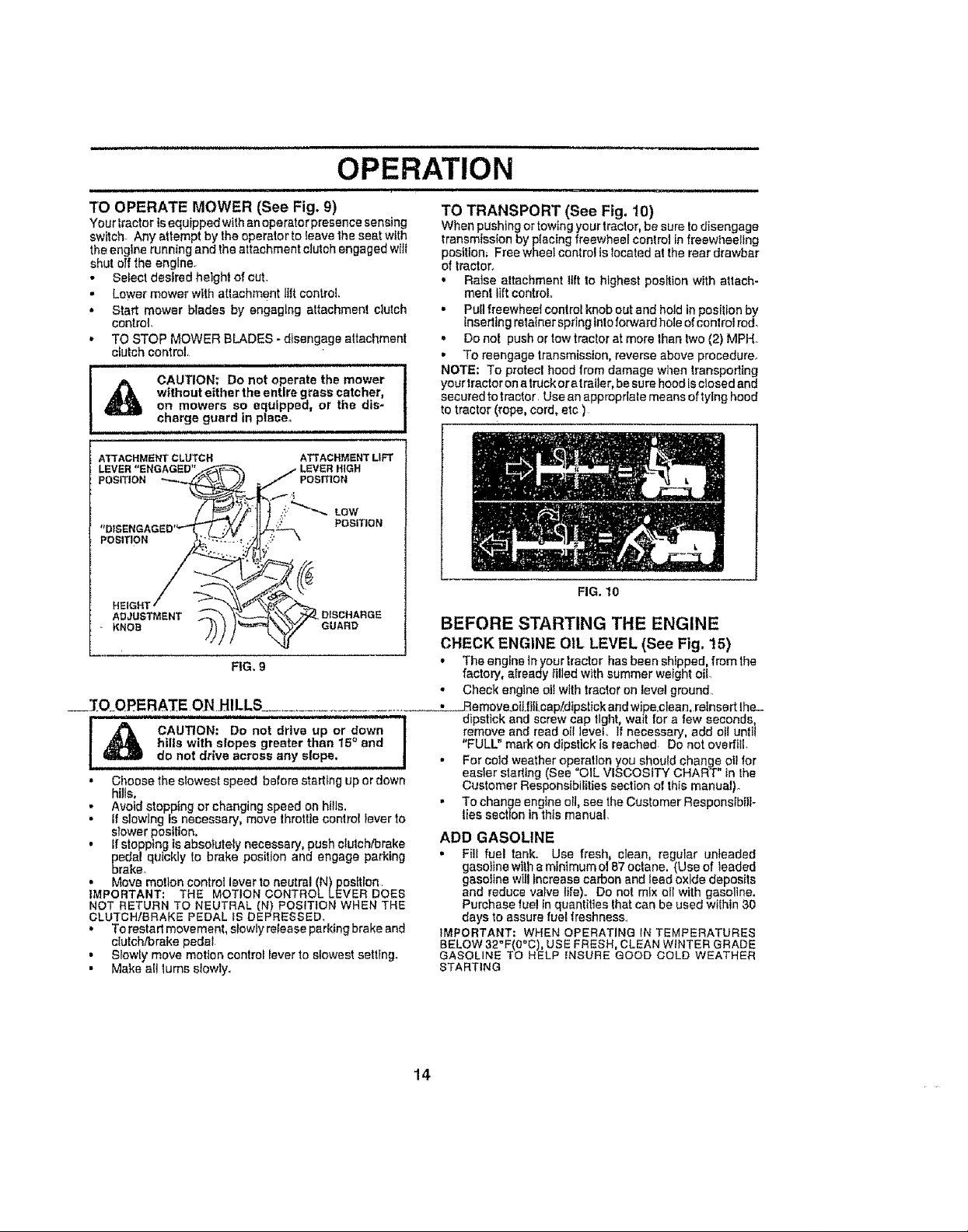

TO OPERATE MOWER (See Fig. 9)

Your tractor isequipped with an operatorpresence sensing

switch Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged witI

shut off the englne_

• Select desired height of cut.

- Lower mower with atlachment lilt control

• Start mower blades by engaging attachment clutch

control.

,* TO STOP MOWER BLADES - disengage attachment

clutch control.

without either the entire grass catcher,

CAUTION; Do not operate the mower

on mowers so equipped, or the dis-

charge guard in plaoe_

ATTACHMENTCLUTCH ATTACHMENTLIFT

LEVER"ENGAGED"

POSITION POSITION

;'_'_'_- LOW

POSITION . ;"_k

ADJUSTMENT DISCHARGE

KNOe GUARD

POSITION

TO TRANSPORT (See Fig, 10)

When pushing or towing your tractor, be sure to disengage

transmission by p(acIng freewheel control tn freewheeling

position_ Free wheel control is located at the rear drawbar

of tractor_

,, Raise altachmant lift to highest position with attach-

ment lift control

• Pull freewheel control knob out and hold in position by

Inserting retainer spring intoforward hole of conlrol rod.

,, Do not push or low tractor at more than two (2) MPH_

• To reengage transmission, reverse above procedure_

NOTE: To protect hood from damage when transpodtng

yourtractor on a truck oratrailer, be sure hood Isclosed and

secured to tractor Use an approprlale means of tying hood

to tractor (rope, cord, etc )

FIG. 10

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 15)

FIG. 9

___fO.OPERATE ONHILLS_. ....................... ___L_Remave.oII.liit.cap!d_pstick and wipe clean, relnsert lhe_

._ hills with s!opes greater than 15 ° and

! _ CAUTION: Do not drlve up or down I

" Choose the slowest speed before starting up or down

• Avoid stopping or changing speed on hills.

• If slowing is necessary, move throttle conlrot iever to

• if stopptng is absolutely necessary, push e!ulchibrake

• Move motlon control lever to neutral (N)posttlon

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED,

• To restart movement, slowly release parking brake and

• Slowly move motion control lever to slowest setting.

• Make all lums slowly.

d O no! dr!re across any slope. • For cold weather operation you should change oil for

hills,

slower position.

pedal quickly to brake position and engage parking

brake°

dutch/brake pedal

• Theenginetnyourlractor has been shippsd, fremthe

factory, already filled with summer weight oil

• Check engtne otl with tractor on level ground

dipstick and screw cap tight, wmt for a few seconds,

remove and read oil level, If necessa0f, add oil until

"FULL" mark on dipstick is reached Do not overfliL

easier stadtng (See "OIL VISCOSITY CHART" in Ihe

Customer Responsibilities section el this manual).

• To change engine ell, see the Customer Responsibili-

ties section in this manual.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded

gasoline wiih a minimum of 87 octane, (Use of teaded

gasoline will _ncreasa carbon and lead oxide deposits

and reduce valve life). Do not mix ell with gasoline.

Purchase fuel tn quantities that can be used wilhin 30

days to assure fuel freshness

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32"F(0"C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP iNSURE GOOD COLD WEATHER

STARTING

14

OPERATION

WARNtNO:Expe,enoeindtcaie ihata co ol'b e'nd

fuels (called gasohot or using ethanol or methane 0 can

attract moisture which leads to separation and formation of

acids during storage Acidic gas can damage the fuel

system of an engine while in storage To avoid engine

probfems, the fuel system shouM be emptied before stor-

age of 30 days or longer. Drain the gas tank, start the

engine and let it run until the fuel lines and carburetor are

empty, Use fresh fue_ next season See Storage Instruc-

tions for additional information. Never use engine or

carburetor cleaner products tn the fuel tank or permanent

damage may occur

fgter necko Do notoverfiiL WIpe offany I

i& CAUTION: Fill to bottom of gas tank "]

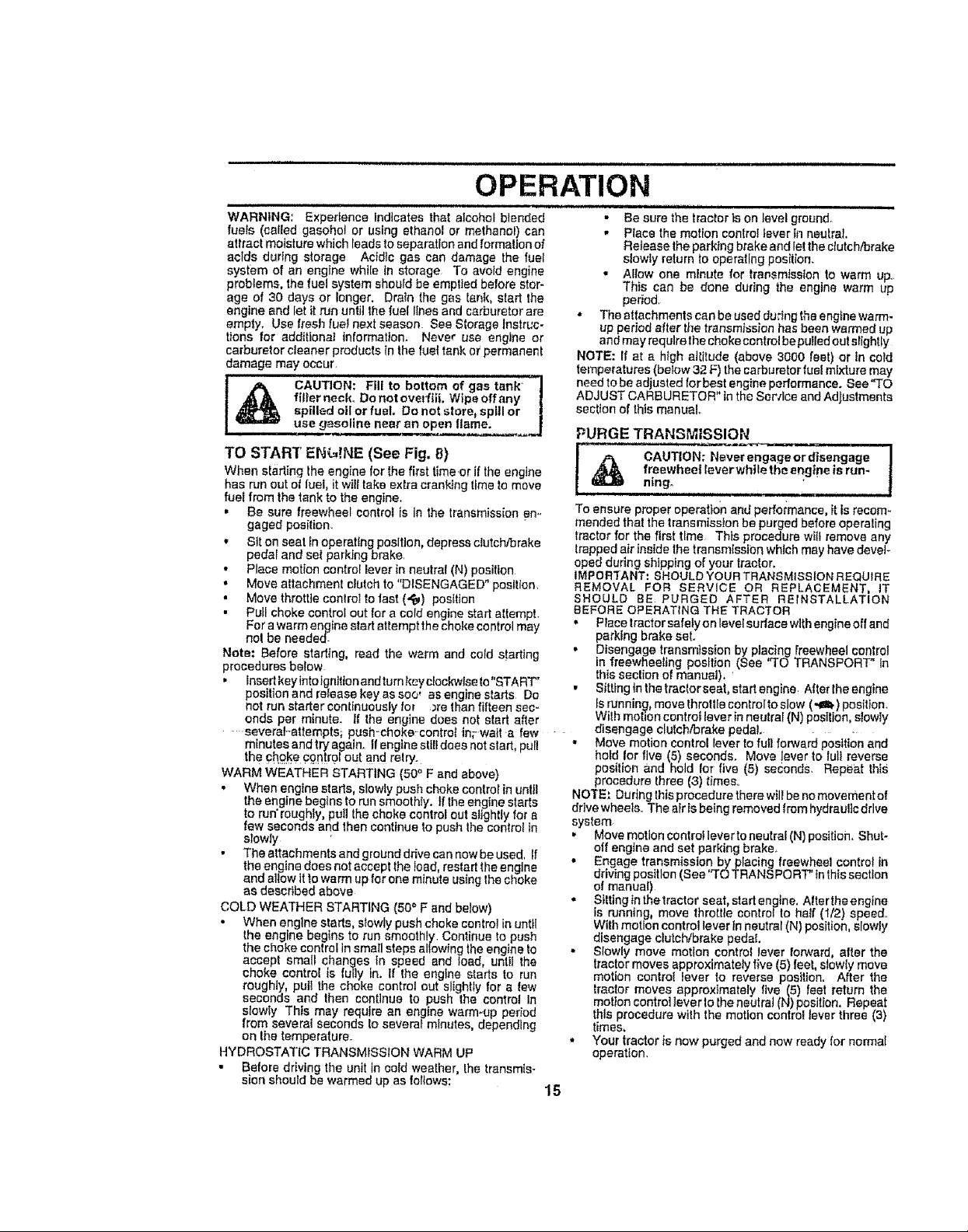

TO START ENG!NE (See Fig. 8)

When starting the engine for the first time ,or if the engine

has run out el fuel, it will take extra cranking time to move

fuel from the tank to the engine,

" Be sure freewheel control is In the transmission on-,

gaged position.

• Sit on seal in operating position, depress clutch/brake

pedal and set parking brake,

• Place motion control lever in neutral (N) position

• Move attachment clutch to "DISENGAGED" position,

• Move throttle conlrot to fast (,,_) position

• Putl choke control out for a cord engine start altempt,

For a warm engine start attempt the choke co ntrol may

not be needed.

Note: Before starting, read the worm and cold startlng

procedures below

, Insedkeylntot_ntttonandturnkeyclockwlseto"START"

position and reease key as see, as engine starts Do "

not run starter continuously for ors than fifteen sec-

ends per minute. If the engine does not start after

..... eeveraFatfempts; push=choke=controt inTwatt a few '

minutes and try again,. If engine st{Udoes not start, pul! •

the chg,ke cqr=trolout and relry.

WARM WEATHER STARTING (50" F and above)

• When engine starts, slowly push choke control in until

the engine begins to run smoothly. If theengine starts

to run'roughly, pull the choke control cut slightly for a

few seconds and then continue to push Ihe control in

slowly

• The attachments and ground drive can new be used, If

the engine does not accept the toad restart the engine "

and allow Itto warm up for one minute using the choke

as described above

COLD WEATHER STARTING (50 ° F and below)

• When engine starts, s}owly push choke control in until

the engine begins to run smoothly, Continue to push

the choke control in small steps allowing the engine to •

accept small changes in speed and toad unli! the

choke control is fully in, If the engine slarts to run

roughly, pull the choke control out slightly for a few

seconds and then continue to push the control In

slowly This may require an engine warm_up period

from several seconds 1o several minutes, depending

on the temperature° .

HYDROSTATIC TRANSMISSION WARM UP

• Before driving the unit in cold weather Ihe transmis-

sion should be warmed up as follows:

spilled oil or fuel= Do not etore_ spill or

use g.as,o!ine near an open tlome=:_.==j

• Be sure the tractor ts on level ground_

,, Place the motion control lever in neutral.

• Allow one minute for transmtsslon to warm up.

,' The attachments can be used dudng the engfne wan'n-

up period after the transmission has been warmed up

and may require Ihe choke control be pulled out slightly

NOTE: If at a Ngh aJlitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted |or best engine performance. See "TO

ADJUST CARBURETOR" tnthe Ser,,lce and Adjustments

section of this manual

..i .H.,I H.. n I I I I .

Release the parking brake and Ietthe clutch?arake

slowly return to operallng position,

This can be done during the engine warm up

period,

PURGE TRANSMISSION

_ CAUTION; Neverengageordisengage I

To ensure proper operation and performance, it is recom_

mended that the transmission be purged before operating

tractor for the first time This procedure will remove any

trapped air inside the transmission which may have devel-

oped during shtpptng of your tractor,

IMPOR3-ANT: SHOULD YOU R TRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT

SHOULD BE PURGED AFTER REINSTALLATION

BEFORE OPERATING THE TRACTOR

" Place tractor safetyon level surface with engine off and

• Disengage transmission by placing freewheel control

_vs running, move lhrotl{e controlte slew (.4R,) position.

disengage clulch/brake pedal

Move motion control lever to fulI forwarcf p0sttton and

hold lot five (5) seconds, Move lever to lull reverse

position and hold for five (5) seconds, Repeat this

procedure three (3) times.

NOTE.' During this procedure there will be no movement of

drive wheels. The air isbeing removed fromhydraulic drive

system

,, Move motion control lever to neutral (N) position, Shut-

off engine and set parking brake,

Engage transmission by placing freewheel control in

driving position (See "TO TRANS PCRT" Inthis secUon

of manuaD

Silting in thetraclor seat start engine. Atterthe engine

is running, move throttle controtto half (1/2) speed.

With motion control lever tn neutral (N) position, slowly

disengage clutch/brake pedal.

Slowly move motion control lever forWard, alter the

tractor moves approximately five (5) feet slowly move

motion control Jever to reverse position. After the

tractor moves approximately five(5) feet return the

motbn control lever to lhe neutraJ (N) position. Repeat

this procedure with the motion control lever three (3)

times,

Your tractor is now purged and now ready for normal

operatlon_

freewheel leverwhfte the engine is run-

ning, ' "

parking brake set.

in freewheeling position (See 'TO TRANSPORT" In

this section of manual). '

Sitting tn the traclor seal, start engine After the engine

ilh molten control lever in neutral (N) position, slowly

15

OPERATION

i,J,,,,,,,,,,i, i ii iii i ::::::::::::::::::::::: ii i ,,,,i ,, ,Hll

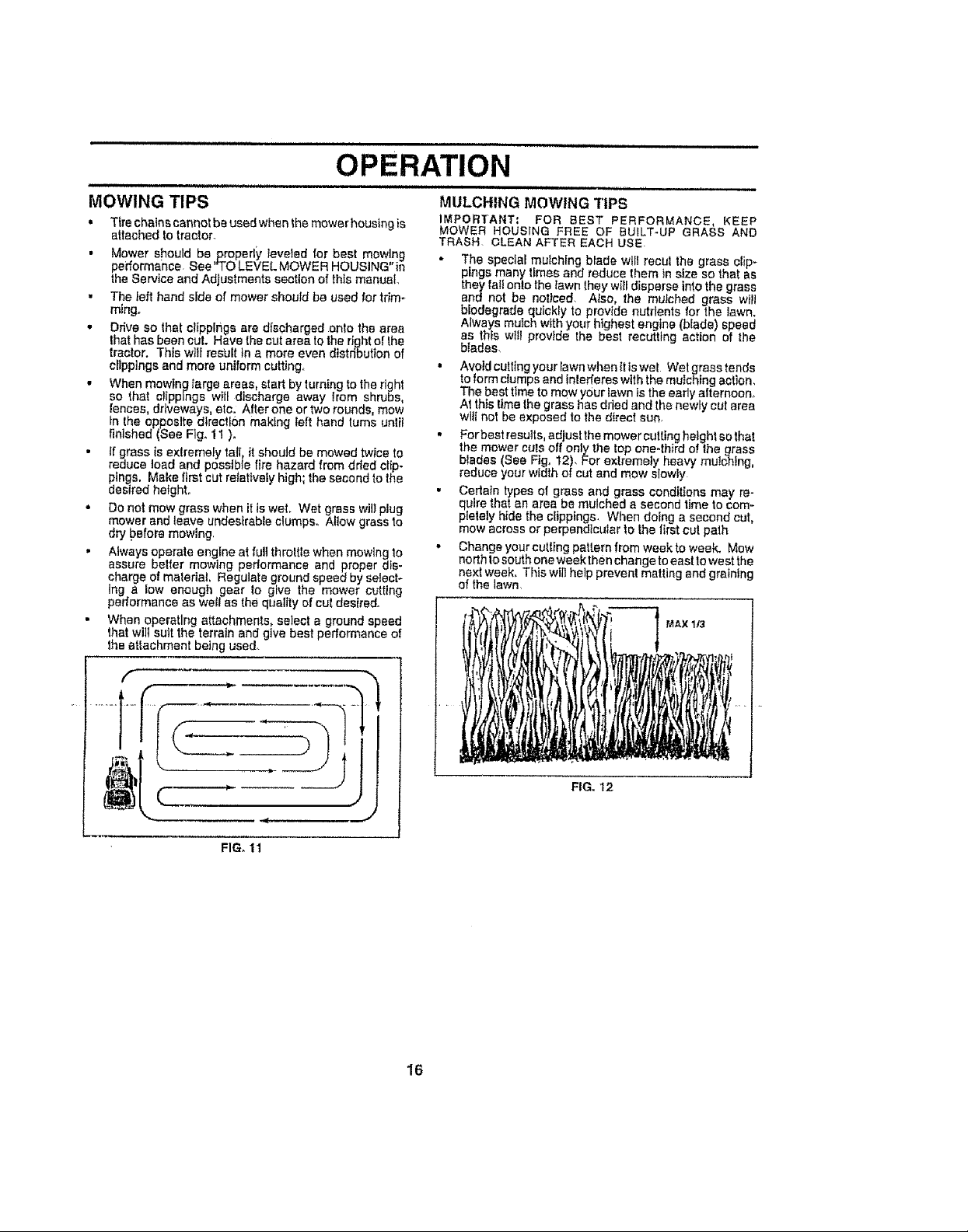

MOWING TIPS MULCHING MOWING TIPS

• Tire chains cannot be used when the mower housing is

attached to tractor.

• Mower should be propedy levered for best mowing

performance. See 'TO LEVEL MOWER HOUSING"in

the Service and Adjustments section of this manual.

• The left hand side of mower should be used for trim*

mtngo

• Ddve so that cfipplnge are dfscharged onto the area

that has been cut. Have the cut area to lhe right of Ihe

tractor. This witf result in a more even distribution of

cflppings and more uniform cutting..

• When mowing fargo areas, start by turning to the right

so that clippings will discharge away lrom shrubs,

fences, driveways, etc. After one ortwo rounds, mow

tn the opposite direction makfng left hand turns untll

finished (See Fig. 11 )o

• If grass {s extremely tall, it should be mowed twice to

reduce toad and possible fire hazard from dded clip-

pings. Make first cut relatively high; the second to the

desired hefghto ,,

• Do not mow grass when it is wet. Wet grass wii}plug

mower end leave undesirable clumps° Allow grass to

dry tpefore mowing.

• Always operate engine at full throttle when mowing to *

assure better mowing perlormance and proper dis-

charge of material, Regulate ground speed by select*

ing a low enough gear to give the mower cutting

performance as well as the quality of cutdes{i'edo

• When operating attachments, select a ground speed

that wi)l suit the terrain and give best performance of

the attachment being used_

IMPORTANT= FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF {3UfLT-UP GRASS AND

TRASH CLEAN AFTER EACH USE.

° The special muEchlng blade will recul the grass clip*

pings many times and reduce them in size so that as

they fat! onto the lawn they will disperse into the grass

and not be noticed. Also, the mulched grass will

blodegrade quickly to provide nutrients for the lawn.

Aiways mulch with your highest engine (bfade) speed

as this wtfi provide the best recurring action of the

blades.

• Avoid cutting your lawn when ttis wet Wet grass tends

to form dumps and interferes with the mulching action.

The best time to mow your lawn is the early afternoon_

At this time the grass has dried and the newly cut area

wt{{ not be exposed to the dlrecf sun.

Forbest resutts, adjust the mower cutting height so that

the mower cuts off only the top one-third of the grass

blades (See Fig. 12). For extremely heavy mutohtng

reduce your w dth of cut and mow slowly

Certain types of grass and grass conditions may re-

quire that an area be mulched a second time to com-

pletely hide the clipplngs_ When doing a second cut,

mow across or perpendicular to the iirst cut path

Change your culling pattern from week to week. Mow

north to south one week then change to east towest the

next week. This will help prevent matting and graining

of the lawn_

MAX 113

f

'_,, , , _ __=J

FIG, 11

FIG, 12

16

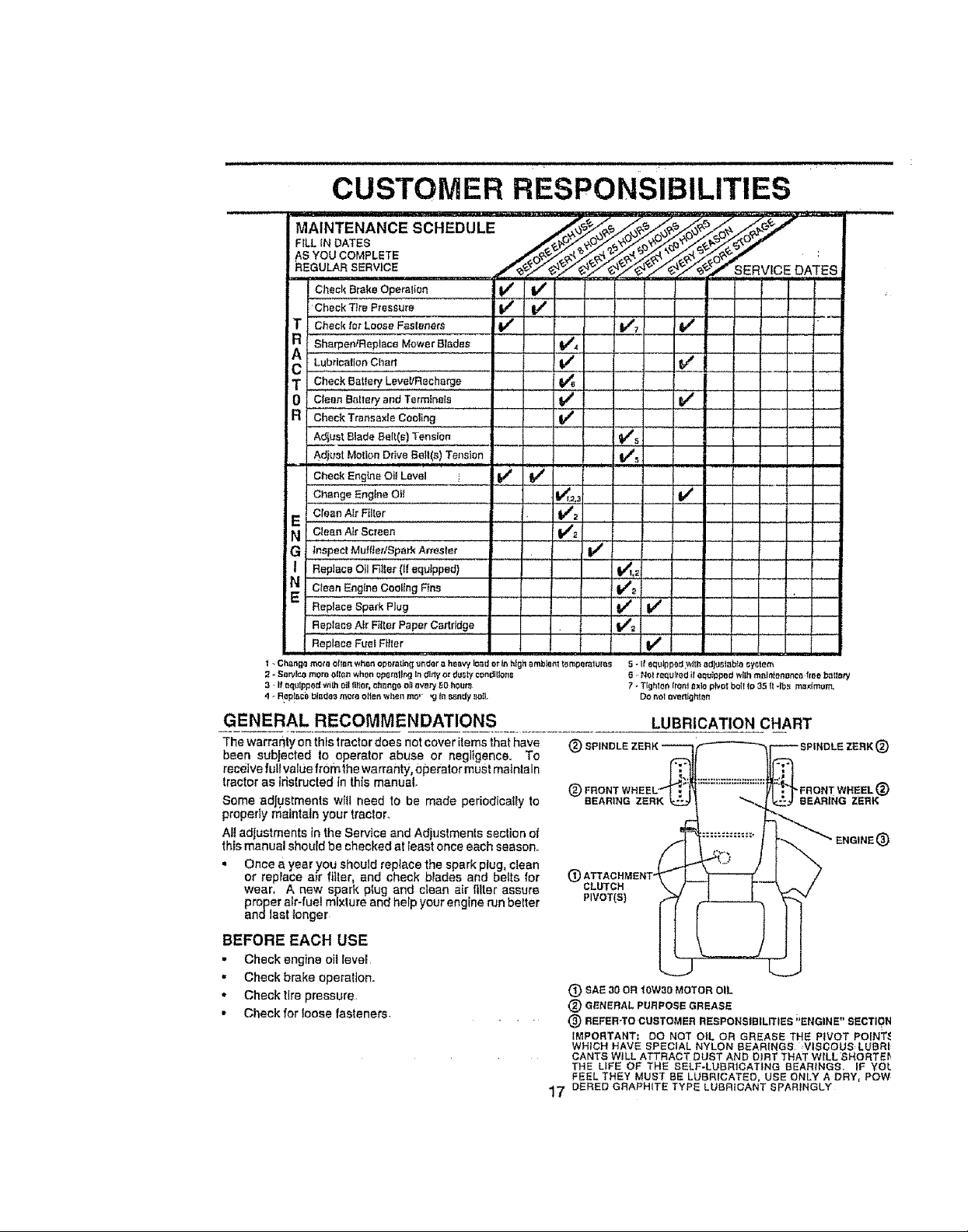

CUSTOMER RESPONSIBILITIES

l_Ch_ng_mot_oIi_r_whonoO_r_((ng_n_ora h_o_ I_d ort_h)ghamb_o_lt_r_pQ_lvr_ll

e_ S_l.Vt_morooI(_t__h_ll oper_t_r_Ir_dirtyo_d_f_Iy¢_ndiIIot_

3. I!oqulpp_dwilhoil(I)_or,_h[_eo o_owty 50hours

4 ..Rep!scebladesm_e oi|enwhentoo, ,_ fn _ndy so(L

GENERAL RECOMMENDATIONS

The warrartty on this tractor does not cover items that have ®

been subjected to operator abuse or negligence.. To

receive ful( value from the warranty, operator must maintain

tractor as (dstructed in this manual.

Some adjustments wIU need to be made periodica((y to

properly maintain your traclor.

AIt adjustments In the Service and Ad}ustmenls section of

this manual shou(d be checked at feast once each season..

,, Once a year you should replace the spark plug, clean

or replace air filter, and check blades and belts for

wear, A new spark p(ug and clean air filter assure

proper elf-fuel mixture and help your engine run better

andlast longer

BEFORE EACH USE

• Check engine oillevel

" Check brake operation.

* Checktlre pressure,

• Check for loose fasteners,

17 DERED GRAPHITE TYPE LUBRICANT SPARINGLY

LUBRICATION CHART

®

®

BEARING ZERK

®

CLUTCH

PIVOT(S}

(_ SAE 30 OR 10W30 MOTOR OIL

(_ GENERAL PURPOSE GREASE

(_ REFER'TO CUSTOMER RESPONSIB_LfflES "ENGINE" SECTION

IMPORTANT= DO NOT OIL OR GREASE THE PIVOT POINTE

WHICH HAVE SPECIAL NYLON BEARINGS VISCOUS, LUBR[

CANTS WiLL ATTRACT DUST AND DIRT THAT WILL SHORTEr'

THE L_FE OF THE SELF-LUBRICATING BEARINGS, IF YOL

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW

•FRONT WHEEL (_)

BEARING ZERK

ENGINE (_

nl i II ,,i,

CUSTOMER RESPONSIBILITIES

,U,l,i ,in i i I I

TRACTOR

Always observe safety rules when performing any mainte-

nance

BRAKE OPERATION

If tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then brake must be adjusted.

(See "TO ADJUST BRAKE" in the Service and Adjust-

ments section of this manual).

TIRES

• Maintain proper air pressure tn all tires (See "PROD.

UCT SPECIFICATIONS on page 3 of thIs manua]).

• Keep tires free of gasoline, otI, or insect control chemi-

cals which can hatm rubber.

. Avoid stumps, stones, deep ruts sharp objects and

other lazards that may cause tire damage

NOTE: To seal Itre punctures and prevent flal tires due to

slow leaks, lira sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion, "

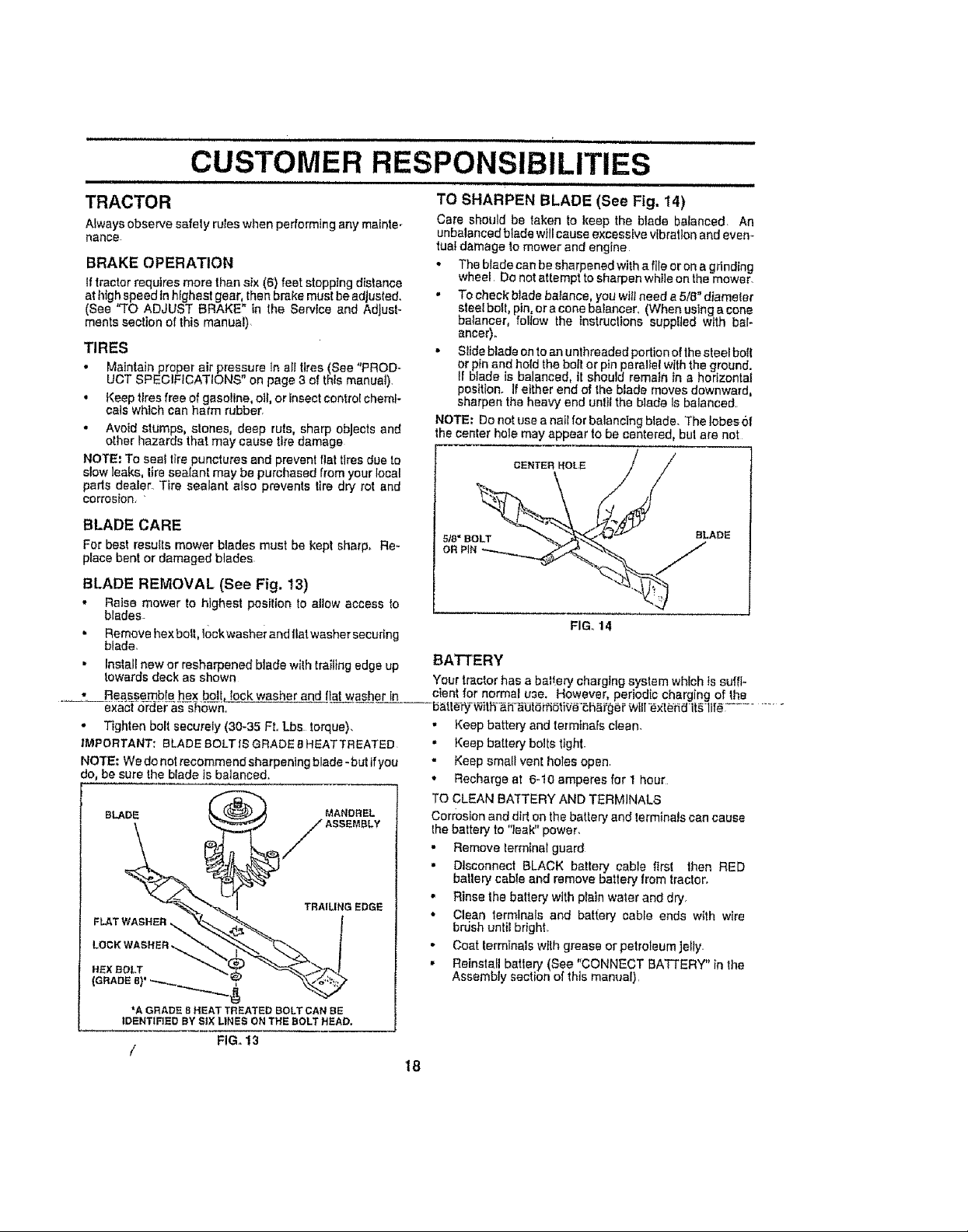

TO SHARPEN BLADE (See Fig. 14)

Care should be taken to keep the blade balanced An

unbalanced blade will cause excessive vibration and evem

tuaI damage 1o mower and engine

• The blade can be sharpened with a file or on a gdndhg

wheel. Do not attempt to sharpen while on the mower.

• To check blade balance, you wtf!need a 5/8" diameter

steel bolt, pin, or acone batancer, (When using a cone

balancer, follow the instrucltons supplied with bal-

ancer).

• Slide blade on to an unthreaded podion ofthe steel boil

or pln and hold the boff or pin parallel with the ground.

II btade is balanced, it should remain in a horizontal

position, ff either end of the blade moves downward,

sharpen the heavy end unltl the blade Is balanced

NOTE= Do not use a nail for balancing blade. The lobes ol

the center hale may appear to be centered, bul are not

OENTERHOL,E / /

BLADE CARE

For best resuIts mower blades must be kept sharp_ Re-

place bent or damaged blades

BLADE REMOVAL (See Fig. 13)

• Raise mower to highest position to altcw access to

blades_

" Remove hex bolt, lock washer andtlat washer secudng

blade.

• Inslalr new or resherpened blade with trailing edge up

towards deck as shown

. • _FI.e.as_senj_bLehex .b_J, !ock washer and flat washer In

exact order as shown,.

• Tighten bolt securety (30-35 Ft.,Lbs torque),

fMPORTANT: BLADE BOLT JSGRADE 8 HEAT TREATED

NOTE: We do not recommend sharpening blade- but tf you

do, be sure the blade is balanced.

BLADE MANDREL

TRAILING EDGE

HEX BOLT

(GRADE8}"_"_'"_-_'''_-1_

*AGRADEBHEATTREATEDBOLTCANBE

IDENTIFIEDBY SIXLINESONTHEBOLTHEAD,

/

FIG., I3

BLADE

FIG,. 14

BATTERY

Your tractor has a baPery charging syslem which is suffi-

cient for normal use. However, periodic charging of the

b_dle_°W_th-_i1_bl_,_OtiV__h_Ygei =WEllexlerid it_ lif_; ............

• Keep battery and terminals clean.

• Keep battery bolts tight.

" Keep small vent holes open

• Recharge at 6-10 amperes for 1 hour

TO CLEAN BA'fTERY AND TERMINALS

Con:oslon and dirt on the batlery and terminals can cause

the battery to '%ak" power,

• Remove terminal guard

• Disconnect BLACK battery cable first then RED

batlery cable and remove battery from tractor,

• Rinse the battery with plain water and dry,

• Clean terminals and battery cable ends with wire

brush untiebright.

• Coat terminals wllh grease or petroleum jelly,

• Reinstall batlery (See "CONNECT BATTERY" in the

Assembly section of this manual)

t8

Loading...

Loading...