Craftsman 917259566 Owner’s Manual

SEARS

I:

MODEL NU;_BER 917.259566 OWNER'S MANUAL

• Assembly

• Operation

• Customer Responsibilities

• Service and Adjustments

• Repair Parts

aFTSHaN°

For answers to your questions

about this product, Call:.

1-800-659-5917

SearsCraftsman Help Line

5 am- 5 pm, Mon- Sat

CAUTION: Read and follow all safety rules and instructions before operating this equipment.

FOR CONSUMER ASSISTANCE HOT LINE, CALL THIS TOLL FREE NUMBER: 1-800-659-5917

Safe Operation Practices for Ride-On Mowers u

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS.

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT iN SERIOUS INJURY OR DEATH.

I. GENERAL OPERATION

• Read,undemtand,and followellinstructionsinthe manual

and onthe machinebeforestarting.

• Only allow responsibleadults, who ere familiar with the

instructions,to operatethemachine.

• Clear the area of obects suchas rocks,toys,wire, etc.,

whc_ cou d bepickedup andthrownbytheblade.

• Besurethearea isclearofotherpeoplebeforemowing.Stop

machineif anyoneentersthearea.

• Nevel"carrypassengers.

• Donotmowinreverseunlessabsolutelynecessary.Always

lookdownand behind beforeandwhile backing.

• Beawareofthe mowerdischargedirectionanddo notpoint

it at anyone. Do notoperatethe mowerwithouteitherthe

entiregrasscatcherortheguardin place.

• Slowdownbefore turning.

• Neverleave arunningmachineunattended.Alwaystumoff

blades, set parkingbrake,stop engine,and remove keys

beforedismounting.

• Turnoffbladeswhen notmowing.

• Stopengine beforeremoving grasscatcheror unclogging

chute.

• Mowonly indaylightor goodartificiallight.

• Do notoperate the machine while underthe influenceof

alcoholordrugs.

• Watchfortrafficwhenoperatingnearorcrossingroedways.

• Use extracare when loadingorunloadingthemachineinto

e traileror truck.

II. SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

tipover accidents, which can result in severe injury or

death. All slopes require extra caution. Ifyou cannot back

up the slope or if you feel uneasy on it, do not mow it.

DO:

• Mowup and downslopes,notacross.

• Removeobstaclessuchas recks,tree limbs,etc.

• Watch for holes, ruts, or bumps. Uneven terrain could

overfumthe machine. Tallgrasscan hideobstacles.

• Useslowspeed. Choosea lowgearsothatyouwillnothave

tostopor shiftwhileon theslope.

• Follow the manufacturer's recommendationsfor wheel

weightsorcounterweightstoimprovestability.

• Use extra care with grass catchersor otherattachments.

These canchangethestabilityof the machine.

• Keepallmovementontheslopesslowandgradual.Do not

make suddenchangesin speedordirection.

• Avoidstartingorstoppingon a slope. Iftireslosetraction,

disengagethe bladesandproceedslowlystraightdownthe

slope.

DO NOT:

• Donottumonslopesunlessnecessary,andthen,tumslowly

and graduallydownhill,if possible.

• Do notmow near drop-offs,ditches,orembankments.The

mowercouldsuddenlyturnover ifawheel isovertheedge

of a clifforditch,or if an edgecaves in.

• Do not mowon wet grass. Reducedtractioncouldcause

sliding.

• Donottrytostabilizethemachinebyputtingyourfootonthe

ground.

• Donotusegrasscatcher onsteepslopes.

SAFETY RULES

III. CHILDREN

Tragic accidents can occur ifthe operator is notalertto the

presence of children. Children are often attracted to the

machine and the mowing activity. Never assume that

children will remain where you last saw them.

• Keepchildrenoutofthemowingareaandunderthewatchful

careofanotherresponsibleadult.

Bealertand turnmachineoftifchildrenenterthearea.

• Beforeand whenbacking,lookbehindand downforsmall

children.

• Nevercarry children. They may fall offand be seriously

injuredor interferewithsafe machineoperation.

• Neverallowchildrento operatethe machine.

• Use extra care when approachingblindcomers, shrubs,

trees,orotherobjectsthatmay obscurevision.

IV. SERVICE

• Useextracareinhandlinggasolineandotherfuels.Theyare

flammableandvaporsareexplosive.

Useonlyanapprovedcontainer.

Never remove gas cap or add fuel with the engine

running. Allowenginetocoolbeforerefueling.Do not

smoke,

Neverrefuelthemachineindoors.

Neverstorethe machineor fuelcontainerinsidewhere

there isan openflame, suchas.a waterheater.

• Neverrun a machineinsidea closedarea.

• Keepnutsandbelts,especiallybladeattachmentboltstight

andkeepequipmentingoodcondition.

• Never tamper with safety devices. Check their proper

operationragulady.

• Keepmachinefreeofgrass,leaves,orotherdebrisbuild-up.

Clean oil or fuel spillage. Allow machineto coolbefore

storing.

• Stop and inspect the equipment if you strike an object.

Repair,if necessary,before restarting.

• Nevermakeadjustmentsorrepairswiththeenginerunning.

• Grasscatchercompenantsera subjecttowear,damage,and

deterioration,which couldexpose movingparts or allow

objectsto be thrown, Frequentlycheckcomponentsand

replacewithmanufacturer'srecommendedparts,when nec-

essary.

• Mowerbladesare sharpandcancut. Wrap theblade(s)or

weargloves,anduseextra cautionwhenservicingthem.

• Checkbrake operationfrequently. Adjustand serviceas

required.

The engine exhaust from this product contains

Look for this symbol to point out important

safety precautions. It means

CAUTION!II BECOME ALERTIn YOUR

SAFETY IS INVOLVED.

CAUTION: Always disconnect spark plug

wire endplace wire where Itcannot contact

spark plug In order to prevent accidental

starting when setting up, transporting,

adjusting or making repairs.

A WARNING A

A

chemicals known to the State of California to

cause cancer, birth defects, or other reproduc-

tive harm.

2

CONGRATULATIONS on your purchase of a Sears

Tractor. It has been designed, engineeredand manufac-

tured to give you the best possible dependability and

performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service Center/Department. We have competent, well-

trainedtechniciansandthepropertoolstoserviceorrepair

this tractor.

Please read and retain this manual. The instructionswill

enableyoutoassembleand maintainyourtractorproperly.

Alwaysobservethe "SAFETY RULES".

MODEL

NUMBER 917.259566

SERIAL

NUMBER

DATEOFPURCHASE

THEMODELANOSERIALNUMBERSWILLBEFOUND

ON A PLATE UNDER THE SEAT.

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

! DATE OF PURCHASE AND KEEP IN A SAFE PLACE

I FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Sears Maintenance Agreement is available on this prod-

uct. Contact your nearest Sears store for details.

CUSTOMER RESPONSIBILITIES

Read and observe the safety rules.

Follow a regular schedule inmaintaining, caring forand

using your tractor.

• Follow the instructions under "Customer Responsibili-

ties" and =Storage" sections of this owner's manual.

WARNING: This tractor is equipped with an internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-cov-

ered land unless the engine's exhaust system is equipped

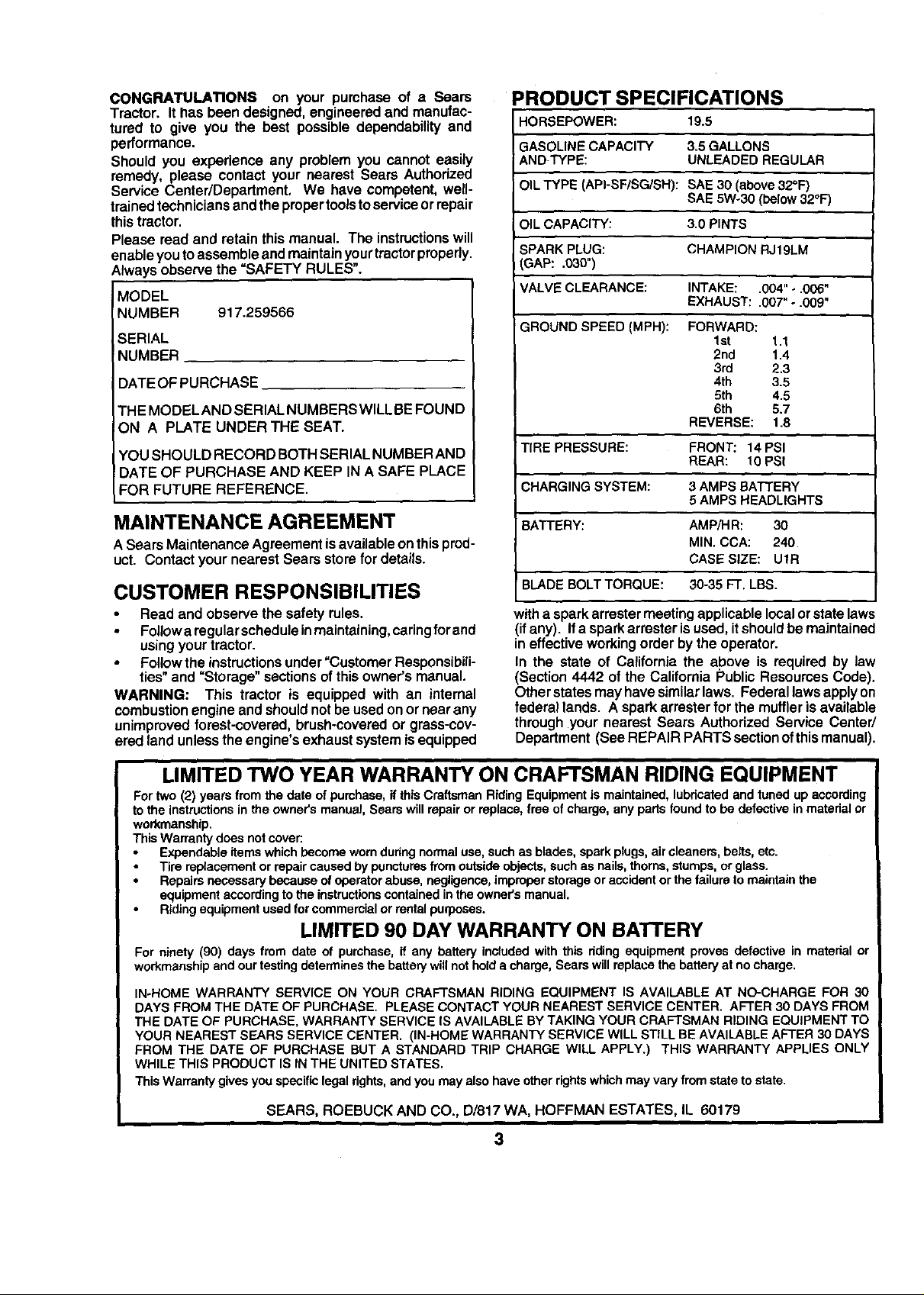

PRODUCT SPECIFICATIONS

HORSEPOWER: 19.5

GASOLINE CAPACITY 3.5 GALLONS

ANDTYPE: UNLEADED REGULAR

OIL TYPE (API-SF/SG/SH): SAE 30 (above32°1=)

OIL CAPACITY: 3.0 PINTS

I

SPARK PLUG: CHAMPION RJ19LM

GAP: .030")

VALVE CLEARANCE: INTAKE: .004"÷.006"

GROUND SPEED (MPH): FORWARD:

TIRE PRESSURE: FRONT: 14 PSI

CHARGING SYSTEM: 3 AMPS BATTERY

BATTERY: AMPiHR: 30

BLADE BOLT TORQUE: 30-35 FT. LBS.

withasparkarrastermeeting applicablelocalorstate laws

(ifany). Ifa sparkarrester isused, itshouldbe maintained

in effectiveworkingorder bythe operator.

In the state of Californiathe above is required by law

(Section4442 of the California Public ResourcesCode).

Other statesmay have similarlaws. Federal lawsapplyon

federal lands. A sparkattester for the muffler isavailable

through your nearest Sears Authorized Service Center/

Department (See REPAIR PARTS sectionofthismanual).

SAE 5Wo30 (below 32°F)

EXHAUST: .007" - .009"

1st 1.1

2nd 1.4

3rd 2.3

4th 3.5

5th 4.5

6th 5.7

REVERSE: 1.8

REAR: 10 PSI

5 AMPS HEADLIGHTS

MIN. CCA: 240

CASE SIZE: UtR

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN RIDING EQUIPMENT

For two (2) years from the date ofpurchase,if thisCraftsmanRiding Equipmentis maintained,lubricatedand tuned up according

tothe instructionsinthe owner's manual, Seam will repairor replace, free of charge, anypartsfound tobe defectivein material or

workmanship.

ThisWarranty does not cover:

Expendable itemswhichbecome worn duringnormal use,suchas blades,spark plugs,air cleaners,belts,etc.

Tire replacementor repaircausedby puncturesfromoutsideobjects,suchas nails,thorns,stumps,orglass.

Repairs necessarybecause of operatorabuse,negligence,improperstorageoraccidentorthe failuretomaintain the

equipmentaccordingto the instructionscontainedinthe owner's manual.

Ridingequipment used for commercialor rentalpurposes.

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety (90) days from date of purchase, if any battery includedwith this riding equipment proves defective in material or

workmanshipand our testingdetermines the batterywill not hold a charge, Searswill replacethe battery at no charge.

IN-HOME WARRANTY SERVICE ON YOUR CRAFTSMAN RIDING EQUIPMENT IS AVAILABLE AT NO-CHARGE FOR 30

DAYS FROM THE DATE OF PURCHASE. PLEASE CONTACT YOUR NEAREST SERVICE CENTER. AFTER 30 DAYS FROM

THE DATE OF PURCHASE, WARRANTY SERVICE IS AVAILABLEBY TAKING YOUR CRAFTSMAN RIDING EQUIPMENT TO

YOUR NEAREST SEARS SERVICE CENTER. (IN-HOME WARRANTY SERVICE WILL STILL BE AVAILABLE AFTER 30 DAYS

FROM THE DATE OF PURCHASE BUT A STANDARD TRIP CHARGE WILL APPLY.) THIS WARRANTY APPLIES ONLY

WHILE THIS PRODUCT IS IN THE UNITED STATES.

ThisWarranty gives you specificlegal rights,and you may alsohave otherrightswhichmay vary from state to state.

SEARS, ROEBUCK AND CO., D/817 WA, HOFFMAN ESTATES, IL 60179

3

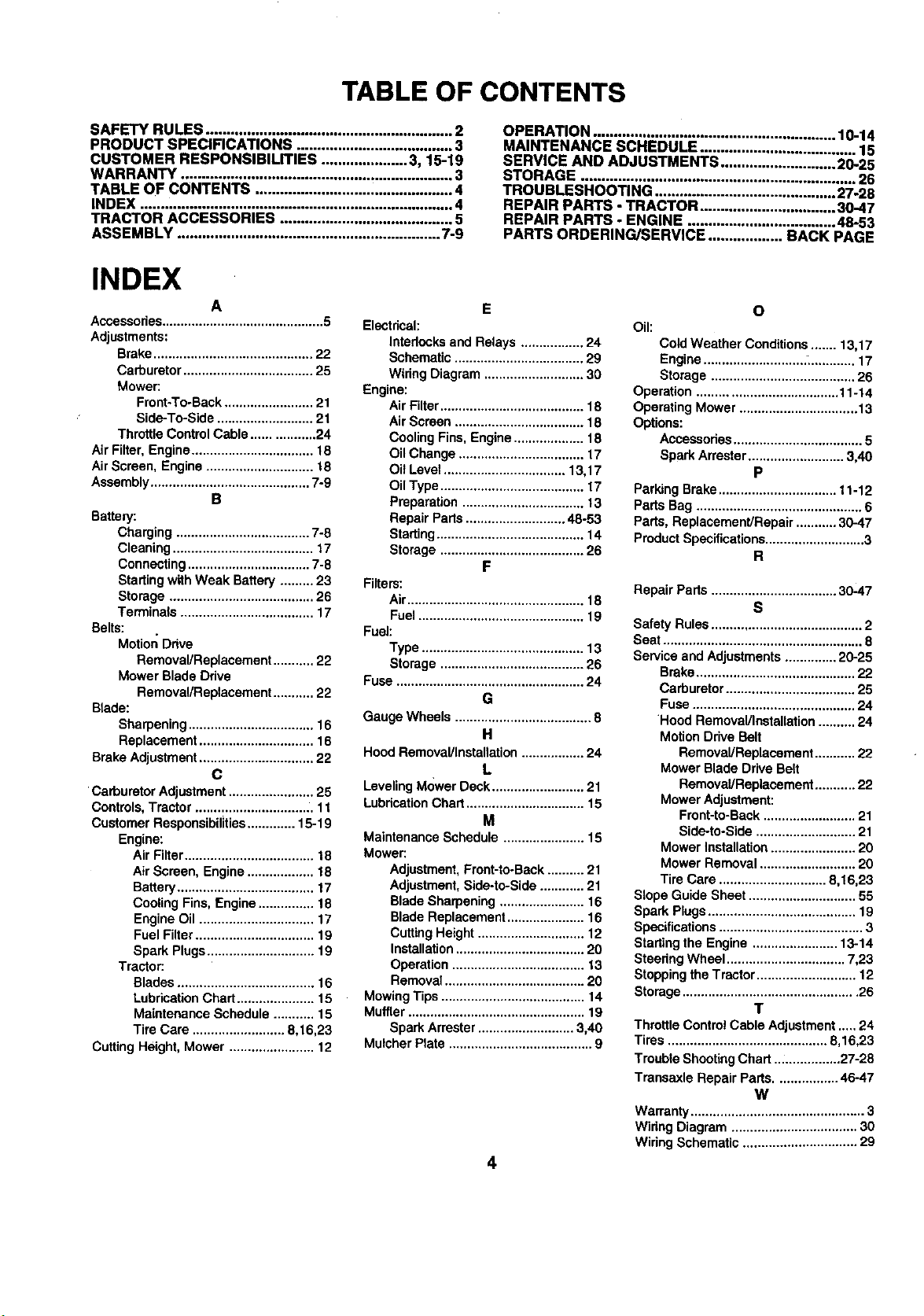

TABLE OF CONTENTS

SAFETY RULES ............................................................ 2

PRODUCT SPECIFICATIONS ...................................... 3

CUSTOMER RESPONSIBILITIES ..................... 3, 15-19

WARRANTY .................................................................. 3

TABLE OF CONTENTS ................................................ 4

INDEX ............................................................................ 4

TRACTOR ACCESSORIES .......................................... 5

ASSEMBLY ................................................................ 7-9

INDEX

A

Accessories............................................ 5

Adjustments:

Brake........................................... 22

Carburetor ................................... 25

Mower:

Front-To-Back........................ 21

Side-To-Side .......................... 21

Throttle ControlCable ................. 24

Air Filter,Engine................................. 18

AirScreen, Engine ............................. 18

Assembly........................................... 7-9

B

Battery:

Charging .................................... 7-8

Cleaning ...................................... 17

Connecting................................. 7-8

StartingwithWeak Battery ......... 23

Storage ....................................... 26

Terminals .................................... 17

Belts:

Motion Drive

Removal/Replacement ........... 22

Mower Blade Ddve

Removal/Replacement........... 22

Blade:

Sharpening.................................. 16

Replacement ............................... 16

Brake Adjustment............................... 22

C

Carburetor Adjustment....................... 25

Controls,Tractor ................................ 11

Customer Responsibilities............. 15-19

Engine:

Air Filter................................... 18

Air Screen, Engine .................. 18

Battery..................................... 17

Cooling Fins, Engine ............... 18

EngineOil ............................... 17

Fuel Filter................................ 19

Spark Plugs............................. 19

Tractor:

Blades ..................................... 16

LubricationChart..................... 15

Maintenance Schedule ........... 15

Tire Care ......................... 8,16,23

Cutting Height, Mower ....................... 12

Electrical:

Intedocksand Relays ................. 24

Schematic ................................... 29

WiringDiagram ........................... 30

Engine:

Air Filter....................................... 18

Air Screen ................................... 18

Cooling Fins, Engine ................... 18

Oil Change .................................. 17

Oit Level................................. 13,17

Oil Type ....................................... 17

Preparation................................. 13

Repair Parts........................... 48-53

Starting........................................ 14

Storage ....................................... 26

Filters:

Air................................................ 18

Fuel............................................. 19

Fuel:

Type ............................................ 13

Storage ....................................... 26

Fuse ................................................... 24

Gauge Wheels ..................................... 8

HoodRemoval/Installation................. 24

LevelingM<)werDeck......................... 21

LubdcationChart ................................ 15

MaintenanceSchedule ...................... 15

Mower:

Adjustment,Front-to-Back.......... 21

Adjustment,Side-to-Side............ 21

Blade Sharpening ....................... 16

Blade Replacement..................... 16

CuttingHeight ............................. 12

Installation................................... 20

Operation .................................... 13

Removal ...................................... 20

MowingTips ....................................... 14

Muffler................................................ 19

Spark Arrester.......................... 3,40

Mulcher Plate ....................................... 9

OPERATION ........................................................ 10-14

MAINTENANCE SCHEDULE ...................................... 15

SERVICE AND ADJUSTMENTS ............................ 2025

STORAGE ................................................................... 26

TROUBLESHOOTING ............................................ 27-28

REPAIR PARTS - TRACTOR ................................. 30-47

REPAIR PARTS - ENGINE .................................... 48-53

PARTS ORDERING/SERVICE .................. BACK PAGE

E

Oil:

Cold Weather Conditions....... 13,17

Engine........................... :_............ 17

Storage ....................................... 26

Operation ...................................... 11-14

Operating Mower ................................ 13

Options:

Accessodes................................... 5

Spark Arrester.......................... 3,40

Parking Brake................................ 11-12

Parts Bag ............................................. 6

Pads, Replacement/Repair ........... 30-47

ProductSpecifications........................... 3

F

Repair Parts .................................. 30-47

O

P

R

s

Safety Rules......................................... 2

Seat ...................................................... 8

Serviceand Adjustments.............. 20-25

Brake........................................... 22

G

H

L

M

Carburetor................................... 25

Fuse............................................ 24

Hood Removal/Installation.......... 24

MotionDrive Belt

Removal/Replacement........... 22

Mower BladeDrive Belt

Removal/Replacement........... 22

Mower Adjustment:

Frent-to-Back ......................... 21

Side-to-Side ........................... 21

Mower Installation....................... 20

Mower Removal .......................... 20

Tire Care ............................. 8,16,23

Slope Guide Sheet ............................. 55

Spark Plugs........................................ 19

Specifications....................................... 3

Startingthe Engine ....................... 13-14

Steedng Wheel ................................ 7,23

StoppingtheTractor........................... 12

Storage............................................... 26

T

ThrottleControlCable Adjustment..... 24

Tires ........................................... 8,16,23

Trouble ShootingChart .................. 27-28

Transaxle Repair Parts................. 46-47

W

Warranty............................................... 3

Widng Diagram .................................. 30

Wiring Schematic ............................... 29

4

ACCESSORIES AND ATTACHMENTS

These accessoriesand attachmentswere availablethroughmostSears retailoutletsandservicecenterswhen the tractorwaspurchased.

MostSears stores can order these items for you when youprovidethe model number of your tractor,

ENGINE

SPARKPLUG

GASCAN ENGINEOIL FUELSTABILIZER

AIRFILTER

MAINTENANCE

BLADES BELTS

%

PERFORMANCE

Sears offersa wide variety of attachmentsthatfityourtractor. Many ofthese are listedbelowwithbriefexplanationsofhowthey can help

you. This listwas current st the time of publication;however,itmay change infuture years- moreattachments may be added, changes

may be made in these attachments, orsome may nolonger be available or fit your model. Contact your nearest Sears store for the

accessories and attachments that are available for your tractor.

Mostof these attachments do not requireadditionalhitchesorconversionkits(thosethat do are indicated) and are designedfor easy

attachingand detaching.

AERATOR promotesdeep rootgrowth for a healthy lawn, Ta-

pered 2.5-inch steel spikes mountedon 10-inch diameter discs

puncture holes in soil at close intervals to let moisture soak in.

Steel weight trey for increased penetration.

BAGGER lets you collect grass clippings and leaves for a

healthier,nearer looking lawn. Two Permanex containers hold

30-gallon plastic bags.

BUMPER protectsfront end oftractor from damage.

CARTS make hauling easy. Variety of sizes available, plus

accessories such as side panel kits, tool caddy, cart cover,

protective mat and dolly.

CORING AERATOR takes small plugsoutofsoilto allowmois-

ture and nutrients to reach grass roots. 36-inch swath. 24

hardened steel coringtips. 150 lb. capacityweight tray.

EASY OIL DRAIN VALVE makes oilchanges easier, faster.

FRONT NOSE ROLLER cantersinfront ofmowerdecktoreduce

chances of =scalping" on uneven terrain.

GANG HITCH letsyoutow2 or3 pull-behindattachmentsatonce,

suchas sweepers, dethatchers, aerators(notfor usewithrollers,

carts or other heavy attachments).

GAUGE WHEELS on both sides of the mower deck reduce

chances of=scalping"onuneventerrain. Formowerdecks notso

equipped.

MULCH RAKE/DETHATCHER loosenssoiland flips thatchand

mattedleavestolawnsurfaceforeasy pickup. Twenty springtine

teeth. Usefultopreparebareareasfor seeding. Availablefor front

or rear mounting. HIGH PERFORMANCE REEL-ACTION

SPRING TINE DETHATCHER covers 36-inch wide path and

tosses thatch into large hopper. Mounts behindtractor.

MULCHING CLOSE-OUT PLATE KIT, once installed, lets you

mulch, discharge or bag clippings (bagger optional) without

changingblades. For modelsnot equippedas3-in-1 Convertible

mowers. See "MOWER in the Repair Parts section of this

manual.

RAMP TOPS AND FEET let you load and unload tractorfroma

pickuptruck. Usewith 2 x 8 or 2 x 10 lumber.

ROLLER for smoother lawn surface. 36-inch wide, 18-inch

diameter water-tightdrumholdsupto 390 Ibs.of weight,Rounded

edges prevent harm to turf. Adjustable scraper automatically

cleans drum.

SNOW BLADE forsnowremovalonly. 14-inchhigh,48-inchwide

bladeclears42-inchpath whenangledleftorfight. Raises,lowers

withsidelever. Ad ustableskids; replaceable, reversiblescraper

bar. (Use witht re cha nsandwbeelwe ghtsand/or reardrawbar

weight.)

SNOWTHROWER has 40-inchswath. Drum-typeaugerhandles

powdery and wet/heavy snow. Mounts easily with simple pin

arrangement. Dischargechuteadjustsfrom tractorseat. 6-inch

diameter spout dischargessnow 10 to 50 feet. Liffcontrolledat

tractor seat. (Use with chains and wheel weights and/or rear

drawbar weight.)

SPRAYERS use 12-voltDC electric motorthat connectsto the

tractor battery or other t2-voit source. Includes booms for

automaticsprayingandhandheldwandforspotspraying.Wand

has adjustable spray pattern. For applyingherbicides, insecti-

cides,fungicidesand liquidfertilizers.

SPREADER/SEEDERS make seeding, fertilizing, andweed kill-

ing easy. Broadcast spreaders are also usefulfor granularde-

icersand sand.

SWEEPERS letyou collectgrass clippingsand leaves.

TILLER has5hpengineand36-inch swath toprepareseed beds,

cultivateand compostgarden residue. Tiller hasits own built-in

liftanddepthcontrolsystemanddoesNOT requireasleevehitch.

Fitsanylawn,yardorgardentractor.Simplyhookuptothe tractor

drawber and go! Optional accessories convert unit for

dethatching,aerating, hilling...withouttools.

TIRE CHAINS are heavy duty;closely Spacedextra-largecross

linksgivesmooth fide, outstandingtraction.

TRACTOR CAB has heavy duty vinylfabric over tubular steel

frame, ABSplastictop;clearplasticwindshieldoffers360degree

visibility. Hinged metal doors withcatch. Keeps operatorwarm

and dry. Remove vinyl sides and windshields for use as sun

protectorin summer. Optional accessories include: tinted/

temperedsolidsafetyglasswindshieldwithhand operatedwiper;

12-voltamber caution lightfor mounting on cab top.

VACS for powerfulcollectionof heavygrassclippingsandleaves.

Optional wand attachment to pick up debris in hard-to-reach

places. VAC/CHIPPER includesa chipper-shredder.

WEIGHT BRACKET for drawbar for snow removal applications.

Uses (1) 55 Ib. weight.

WHEEL WEIGHTS for rear wheels provide needed tractionfor

snowremoval or dozing heavy materials.

5

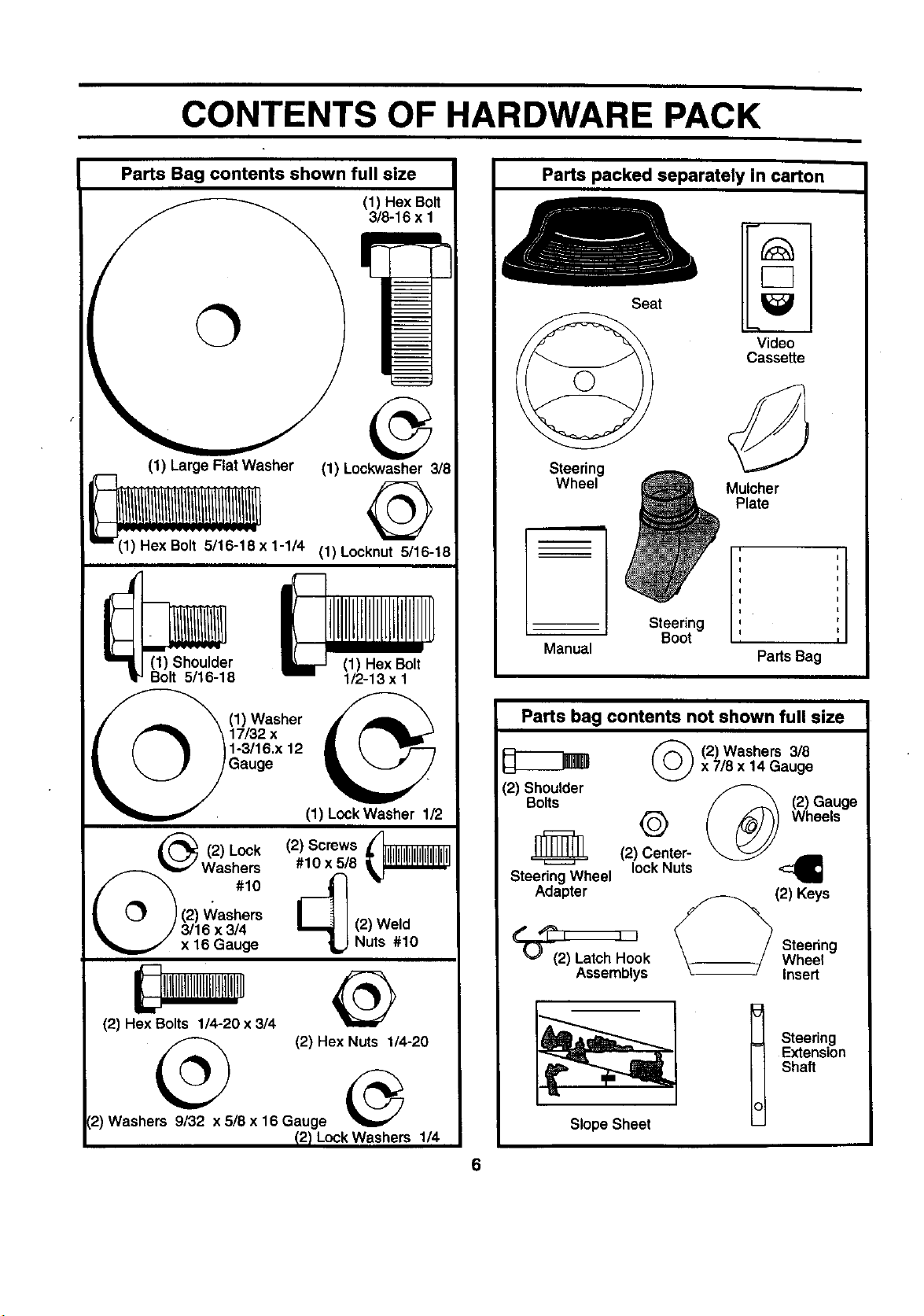

CONTENTS OF HARDWARE PACK

Parts Bag contents shown full size

(1) Hex Bolt

3/8-16 x 1

(1) Large Flat Washer (1) Lockwasher 3/8

1;:He':x:Bo;:t:5:i:16:::;:8x1-I/4(1)Locknut 5/16-18

(1) Shoulder (1) Hex Bolt

Bolt 5/16-18 1/2-13 x I

Parts packed separately in carton

Seat

Video

Cassette

Steering

Wheel

Manual

Steering

Boot

Mulcher

Plate

Parts Bag

17/32 x

1-3/16.x 12

(1) Washer _.

Gauge (1) Lock Washer 1/2

Lock

__._ (2) (2) Screws

| __J } (2) V_/ashers

_i= / 3/16 x 3/4

(2) Hex Bolts 1/4-20 x 3/4

Was%

x 16 Gauge

#10 x 5/8

(2) Hex Nuts 1/4-20

@

(2) Washers 9/32 x5/8 x 16 Gauge

12)LockWashers 1/4

Parts bag contents not shown full size

(2) Shoulder

Bolts

_ (2) Center-

Steering Wheel lockNuts

Adapter (2) Keys

Assemblys

Slope Sheet

6

(_(2) Washers 3/8

x 7/8 x 14 Gauge

Q Wheels

k

(2) Gauge

Steering

Wheel

Insert

Steering

Extension

Shaft

ASSEMBLY

Your new tractor hasbeen assembledat the factorywithexceptiono4thosepartsleft unassembledfor shippingpurposes.

To ensuresafe and properoperationofyourtractorallpartsand hardwareyou assemble mustbe tightenedsecurely. Use

the correcttoolsas necessaryto insurepropertightness.

TOOLS REQUIRED FOR ASSEMBLY

Asocketwrenchset willmake assemblyeasier. Standard

wrenchsizes are listed.

(1) 3/4" Socket w/drive rachet

(2) 7/16" wrenches PhillipsScrewdriver

(2) 1/2" wrenches Tire pressuregauge

(1) 9/16" wrench Utilityknife

When right or left hand is mentioned in this manual, it

means when you are in the operating position(seated

behindthe steeringwheel).

__3/8jE INSERT

X BOLT

LOCK WASHER

LARGE FLAT

WASHER

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessiblelooseparts and partscartons

from carton (See page 6).

Cut, from topto bottom,along linesonall four corners

of carton,and lay panels flat.

Check for any additional loose parts or cartons and

remove.

BEFORE ROLLING TRACTOR OFF SKID

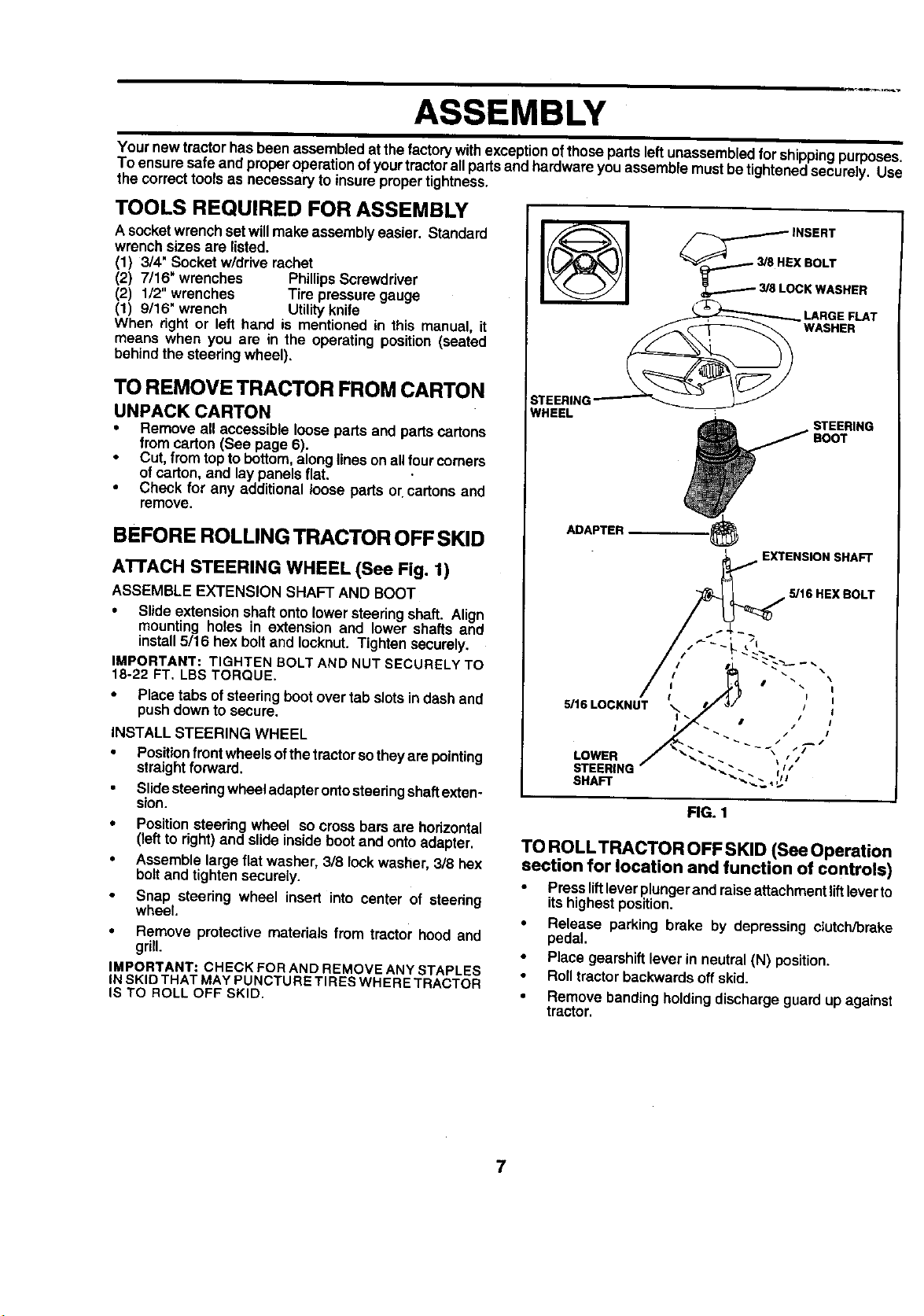

ATFACH STEERING WHEEL (See Fig. 1)

ASSEMBLE EXTENSION SHAFT AND BOOT

• Slideextension shaft onto lower steeringshaft. Align

mounting holes in extension and lower shafts and

install 5/16 hex bolt and Iocknut. Tighten securely,

IMPORTANT: TIGHTEN BOLT AND NUT SECURELY TO

18-22 FT, LBS TORQUE.

• Place tabs of steeringboot over tab slotsindash and

pushdown to secure.

INSTALL STEERING WHEEL

• Positionfront wheelsof thetractorsotheyare pointing

straightforward.

Slidesteeringwheeladapterontosteeringshaftexten-

sion.

• Positionsteering wheel so cross bars are horizontal

(leftto right)and slide insideboot and onto adapter.

• Assemblelarge flat washer, 318lookwasher, 318hex

boltand tightensecurely.

• Snap steering wheel insert into center of steering

wheel.

• Remove protective materials from tractor hood and

grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

INSKIDTHATMAYPUNCTURETIRES WHERETRACTOR

IS TO ROLL OFF SKID.

:STEERING'

WHEEL

ADAPTER_

EXTENSION SHAFT

5/16LOCKNUT

LOWER

STEERING

SHAFt"

STEERING

5/16 HEX BOLT

FIG. 1

TO ROLLTRACTOR OFF SKID (See Operation

section for location and function of controls)

• Pressliftleverplungerand raiseattachmentliftleverto

itshighestposition.

• Release parking brake by depressing clutch/brake

pedal.

• Place gearshift lever in neutral (N) position,

Roll tractor backwards off skid.

• Remove banding holding discharge guard up against

tractor.

7

ASSEMBLY

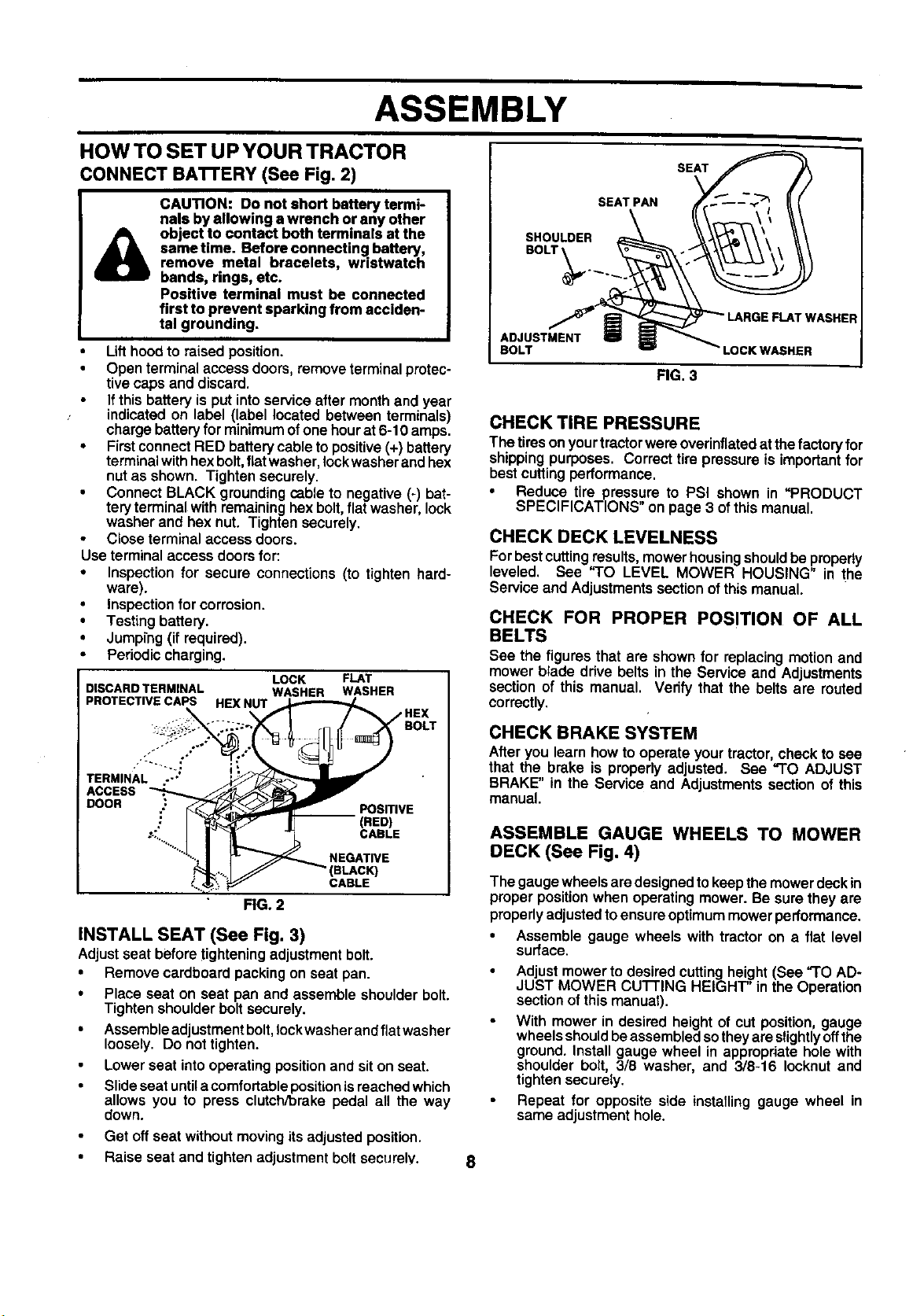

HOW TO SET UP YOUR TRACTOR

CONNECT BA'rrERY (See Fig. 2)

CAUTION: Do not short battery termi-

nals by allowing a wrench or any other

object to contact both terminals at the

same time. Before connecting battery

remove meta bracelets, wristwatch

bands, rings, etc.

Positive terminal must be connected

first to prevent sparking from acciden-

tal grounding.

Lifthoodto raised position.

Open terminalaccess doors, remove terminal protec-

tive caps and discard.

If this battery is put into service after month and year

indicated on label (label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

• First connect RED battery cable to positive (+) battery

terminal with hexbolt, flat washer, lock washer and hex

nut as shown. Tighten securely.

Connect BLACK grounding cable to negative (-) bat-

tery terminal with remaining hex bolt, flat washer, lock

washer and hex nut. Tighten securely.

Close terminal access doors.

Use terminal access doors for:

• Inspection for secure connections (to tighten hard-

ware).

• Inspection for corrosion.

• Testing battery.

• Jumping (if required).

• Pedodic charging.

DISCARD TERMINAL

PROTECTIVE CAPS HEX NUT

LOCK FLAT

WASHER WASHER

SEAT

SEAT PAN

SHOULDER

BOLT

r WASHER

ADJUSTMENT

BOLT LOCK WASNER

FIG. 3

CHECK TIRE PRESSURE

The tiresonyourtractorwere overinflatedatthe factoryfor

shippingpurposes. Correcttire pressure is importantfor

bestcuttingperformance.

Reduce tire pressure to PSI shown in "PRODUCT

SPECIFICATIONS" onpage 3 ofthis manual.

CHECK DECK LEVELNESS

Forbest cuttingresults,mowerhousingshouldbe propedy

leveled, See "TO LEVEL MOWER HOUSING" in the

Service and Adjustmentssectionofthis manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shownfor replacingmotionand

mower blade ddve belts in the Service and Adjustments

sectionof this manual. Verify that the belts are routed

correctly.

ACCESS

DOOR

FIG. 2

PosmvE

(RED)

CABLE

NEGATIVE

(BLAC_

CABLE

INSTALL SEAT (See Fig. 3)

Adjustseatbefore tighteningadjustmentbolt.

• Remove cardboard packingon seat pan.

• Place seat on seat panand assemble shoulderbolt.

Tightenshoulderboltsecurely.

• Assembleedjustment bolt, lockwasher andflatwasher

loosely. Do not tighten.

Lower seat into operating position and sit on seat.

Slide seat until acomfortable position is reached which

allows you to press clutch/brake pedal all the way

down.

Get off seat without moving its adjusted position.

• Raise seat and tighten adjustment bolt securely.

CHECK BRAKE SYSTEM

Afteryou learn how to operate your tractor, checkto see

that the brake is properlyadjusted. See "TO ADJUST

BRAKE" in the Service and Adjustmentssection of this

manual,

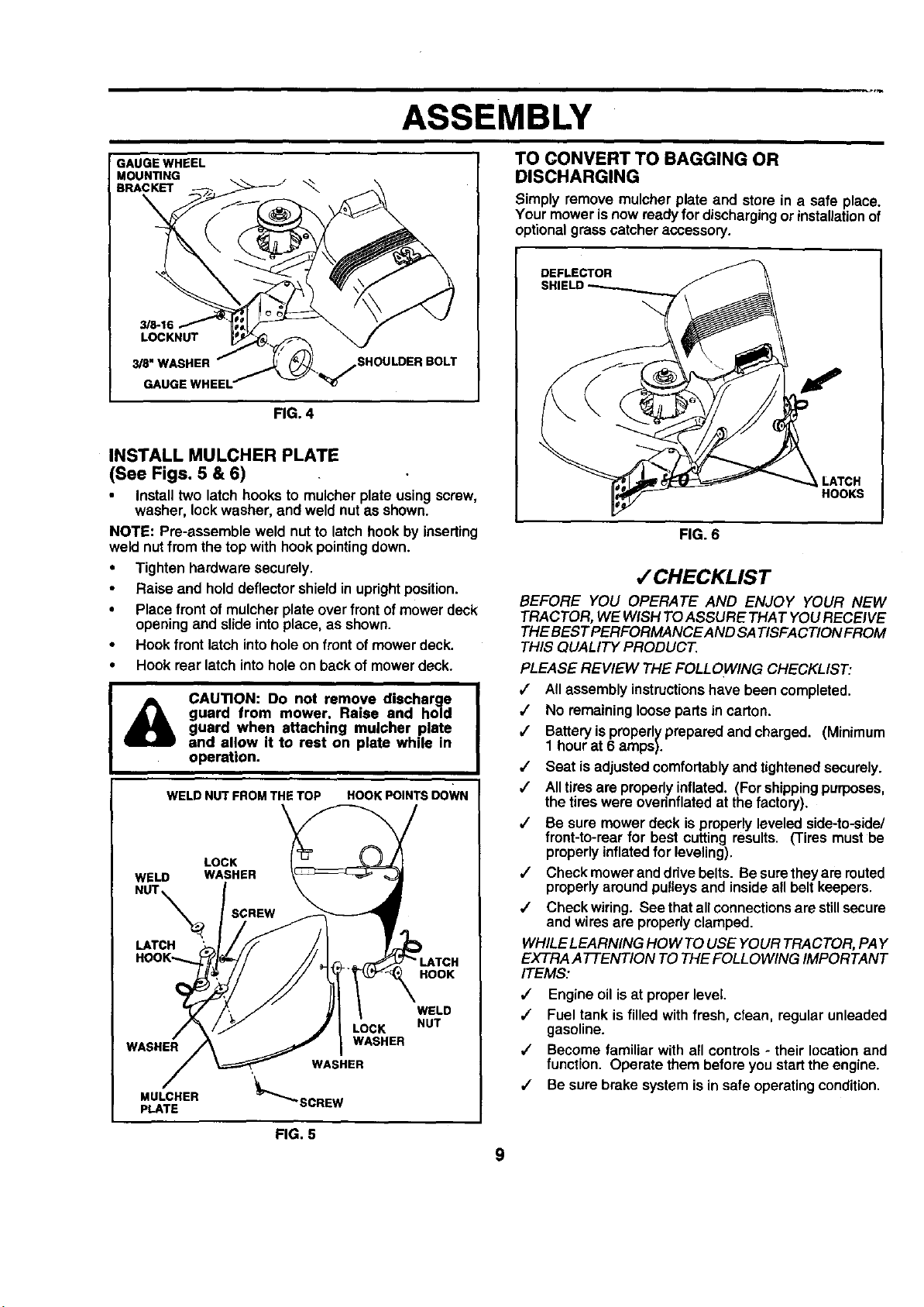

ASSEMBLE GAUGE WHEELS TO MOWER

DECK (See Fig. 4)

The gauge wheelsaredesigned to keep the mowerdeck in

proper positionwhen operatingmower. Be sure they are

properlyadjustedtoensureoptimummowerperformance.

• Assemble gauge wheels with tractor on a flat level

surface.

Adjustmowerto desired cuttingheight (See "TO AD-

JUST MOWER CU'I-]'ING HEIGHT" in the Operation

sectionofthis manual).

With mower in desired heightof cut position gauge

whee sshouldbeassembledso theyareslightlyoffthe

ground.Install gauge wheel in appropriatehole with

shoulder bolt, 3/8 washer, and 3/8-16 lecknut and

tighten securely.

Repeat for opposite side installing gauge wheel in

same adjustment hole.

ASSEMBLY

GAUGE WHEEL

MOUN_NG

BRACKET

\

3/8-16

LOCKNUT

_8"WASHER

GAUGE

_SHOULDER BOLT

FIG. 4

INSTALL MULCHER PLATE

(See Figs. 5 & 6)

Install two latch hooksto mulcher plate using screw,

washer, lockwasher, and weld nutas shown.

NOTE: Pre-assemble weld nut to latch hookby inserting

weld nut fromthe top with hookpointingdown.

• Tighten hardware securely.

• Raise and holddeflectorshieldin uprightposition.

• Place front of mulcher plateover frontof mowerdeck

opening and slide intoplace, as shown.

• Hook frontlatch intohole on frontof mower deck.

• Hook rear latch into holeon back of mower deck.

guard from mower. Raise and ho|d

CAUTION: Do not remove discharge

guard when attaching mulcher plate

and allow it to rest on plate while in

operation.

WELD NUT FROM THE TOP HOOK POINTS DOWN

WELD WASHER

NUT_ SCREW

LATCH

HOOK'--..

WASHER

MULCHER

PLATE

LOCK

'_""_SCREW

FIG. 5

WASHER

LOCK

WASHER

HOOK

WELD

NUT

TO CONVERTTO BAGGING OR

DISCHARGING

Simply remove mulcher plate and store in a safe place.

Your moweris now readyfor dischargingorinstallationof

optionalgrasscatcheraccessory.

DEFLECTOR

HOOKS

FIG. 6

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TO ASSURE THAT YOU RECEIVE

THEBEST PERFORMANCE AND SATISFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

,/ All assemblyinstructionshave been completed.

,/ No remaininglooseparts in carton.

/ Batteryisproperlyprepared and charged. (Minimum

1 hourat 6 amps).

•/ Seat is adjusted comfortablyand tightened securely.

,/ Alltiresare properlyinflated. (For shippingpurposes,

the tires were overinflatedat the factory).

,/ Be sure mower deck is properlyleveledside-to-side/

front-to-rearfor best cutting results. (Tires must be

properlyinflatedforleveling).

,/ Check mower anddrivebelts. Besuretheyare routed

properlyaround pulleysand insideall belt keepers.

,/ Check wiring. See that allconnectionsarestillsecure

and wires are properlyclamped.

WHILELEARNING HOW TOUSE YOUR TRACTOR, PAY

EXTRA ATTENTION TO THE FOLLOWING IMPORTANT

ITEMS:

•/ Engine oil is at proper level

,/ Fuel tank is filledwith fresh,clean, regular unleaded

gasoline.

,/ Become familiar with all controls- their locationand

function. Operate them before you startthe engine.

/ Be sure brake system isin safe operatingcondition.

9

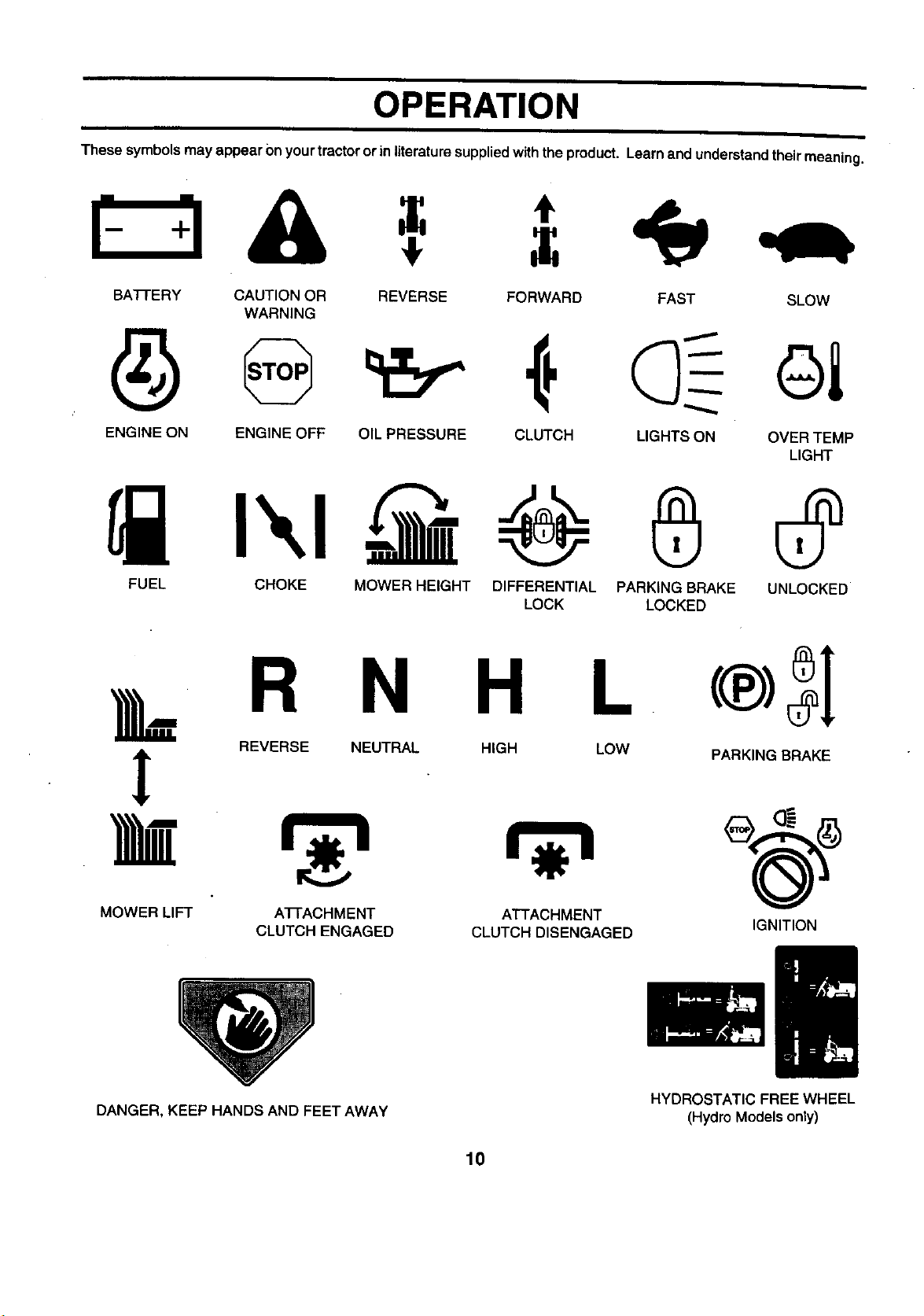

OPERATION

These symbolsmayappear Onyourtractor orinliteraturesuppliedwiththe product. Learnand understandtheirmeaning.

BATFERY CAUTION OR REVERSE FORWARD FAST SLOW

ENGINE ON ENGINE OFF OIL PRESSURE CLUTCH LIGHTS ON OVER TEMP

FUEL CHOKE MOWER HEIGHT DIFFERENTIAL PARKING BRAKE UNLOCKED

WARNING

LIGHT

LOCK LOCKED

L R N H L

i REVERSE NEUTRAL HIGH LOW PARKING BRAKE

MOWER LIFT A'I-I'ACHMENT ATTACHMENT

CLUTCH ENGAGED CLUTCH DISENGAGED

DANGER, KEEP HANDS AND FEET AWAY

10

HYDROSTATIC FREEWHEEL

(Hydro Modelsonly)

IGNITION

OPERATION

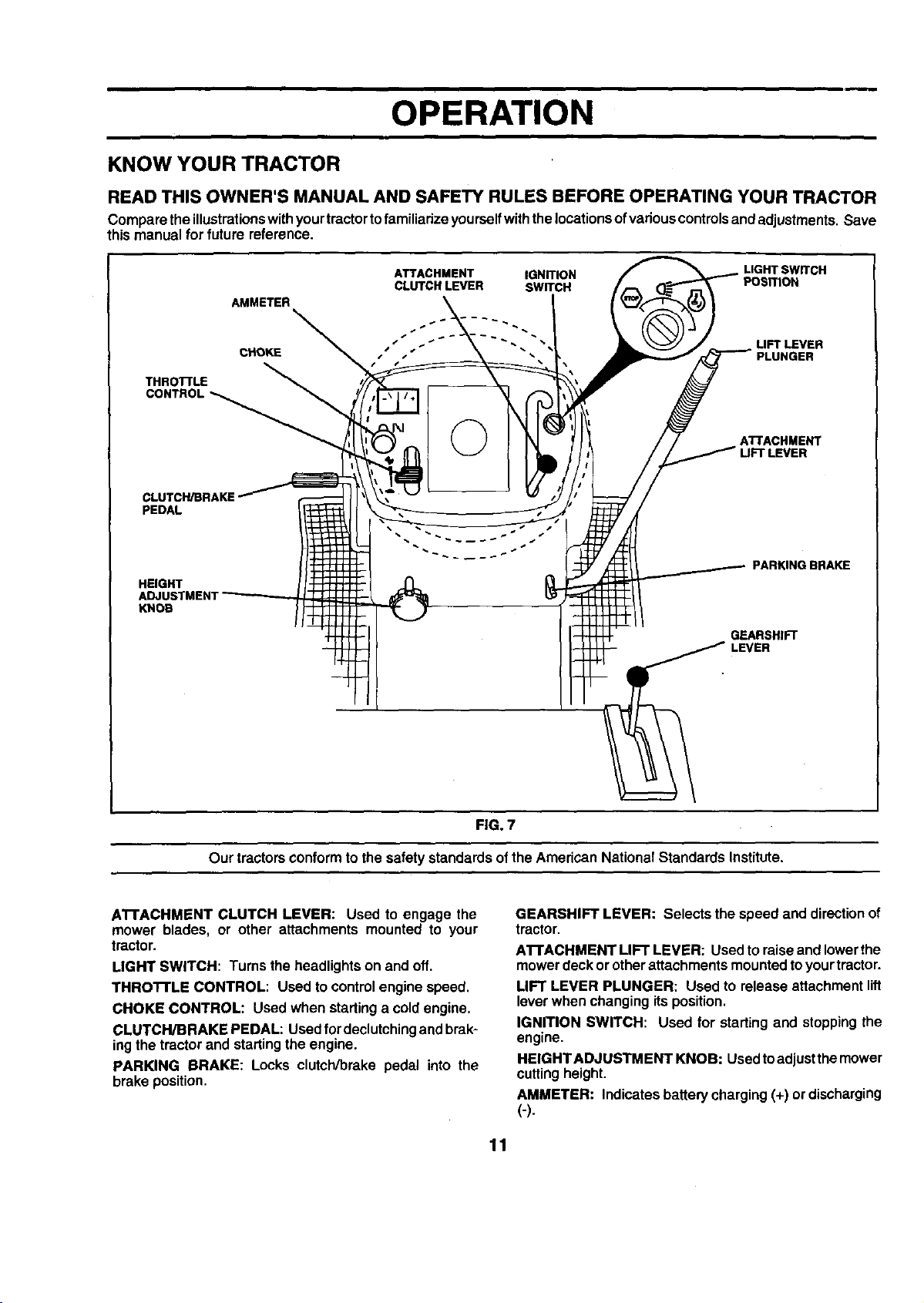

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare theillustrationswithyourtractortofamiliarizeyourselfwiththelocationsofvanouscontrolsandadjustments. Save

this manual for futurereference.

ATTACHMENT IGNITION LIGHT SWITCH

CLUTCH LEVER SWITCH POSITION

AMMETER

THROTTLE

CONTROL

CLUTCH/BRAKE

PEDAL

HEIGHT

ADJUSTMENT

KNOB

CHOKE t

©

-

LIFT LEVER

ATTACHMENT

PARKING BRAKE

GEARSHIFT

Our tractors conformtothe safetystandardsofthe American National Standards Institute.

ATFACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Tums the headlightson and off.

THROTFLE CONTROL: Used to controlengine speed.

CHOKE CONTROL: Used when startinga cold engine.

CLUTCH/BRAKE PEDAL: Usedfordeclutchingandbrak-

ingthe tractor and startingtheengine.

PARKING DRAKE: Locks clutch/brake pedal into the

brake position.

FIG. 7

GEARSHIFT LEVER: Selects the speed and directionof

tractor.

A'I-rACHMENT LIFT LEVER: Usedto raiseand lowerthe

mowerdeckor otherattachmentsmountedtoyourtractor.

LIFT LEVER PLUNGER: Used to release attachmentlift

leverwhenchanging itsposition.

IGNITION SWITCH: Used for startingand stoppingthe

engine.

HEIGHTADJUSTMENT KNOB: Usedtoadjustthemower

cuttingheight.

AMMETER: Indicatesbatterycharging(+) ordischarging

(-).

11

OPERATION

The operation of any tractor can result in foreign objects thrown into the eyes, which can

reauItIn severe eye damage. Always wear safety glasses or eye shields while operating your

tractor or performing any adjustments or repairs. We recommend s wide vision safety mask

over the spectacles or standard safety glasses.

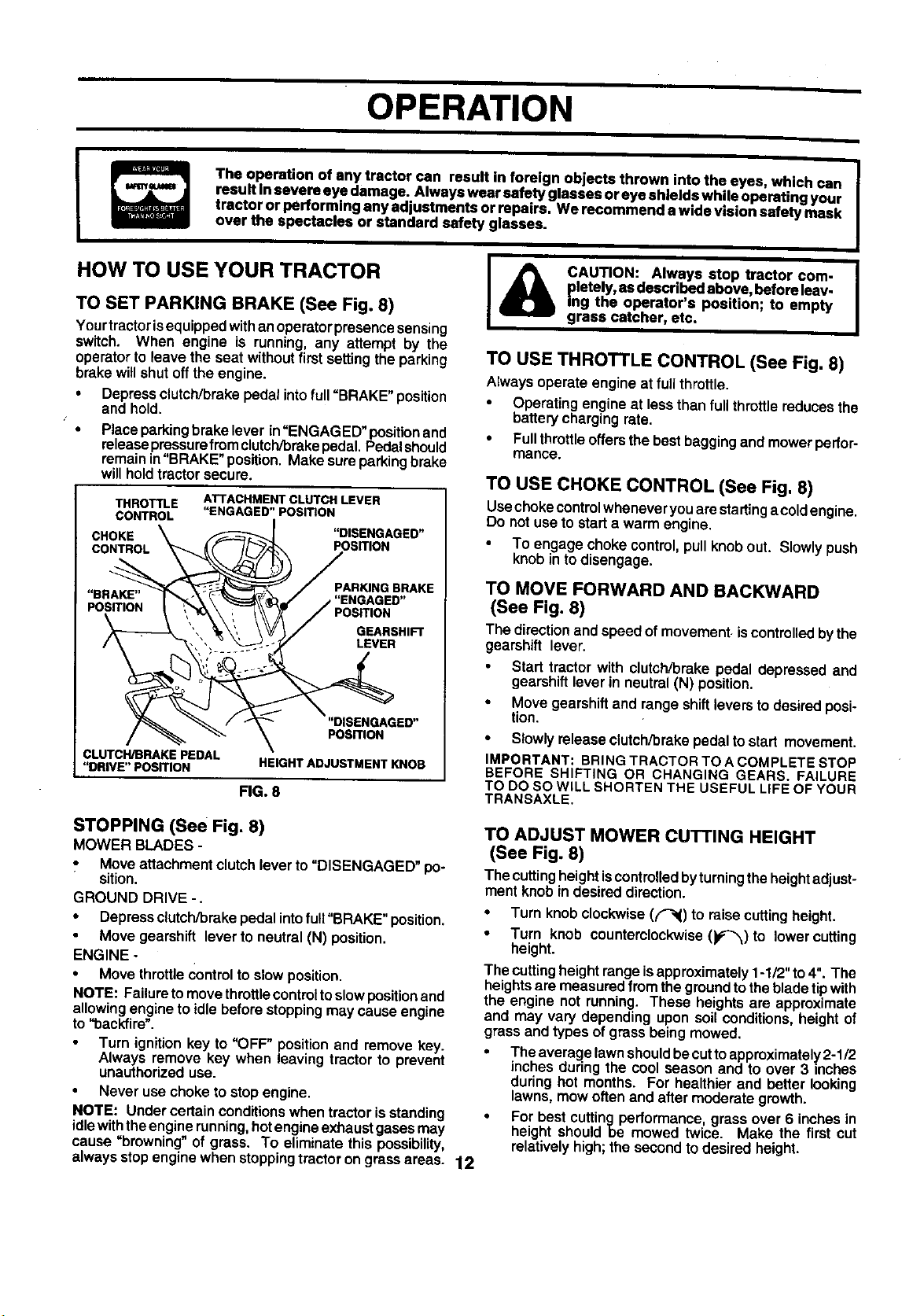

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE (See Fig. 8)

Yourtractorisequippedwithanoperatorpresencesensing

switch. When engine is running, any attempt by the

operatorto leave the seat withoutfirst setting the parking

brake willshut off the engine.

• Depressclutch/brakepedal intofull =BRAKE" position

and hold.

Placeparkingbrakelever in=ENGAGED"positionand

releasepressurefrom clutch/brakepedal.Pedalshould

remainin=BRAKE"position.Make sureparkingbrake

willholdtractorsecure.

THROTTLE

CONTROL

CHOKE "DISENGAGED"

CONTROL POSITION

ATTACHMENT CLUTCH LEVER

"ENGAGED" POSITION

pletely, asdescribed above, beforeleav-

{_ CAUTION: Always stop tractor com-

ing the operator's position; to empty

grass catcher, etc.

TO USE THROTTLE CONTROL (See Fig. 8)

Alwaysoperate engine at fullthrottle.

Operatingengineat less than fullthrottlereduces the

batterychargingrate.

• Fullthrottleoffersthe best baggingandmowerpedor-

mance.

TO USE CHOKE CONTROL (See Fig, 8)

Usechokecontrolwheneveryouarestartinga coldengine.

Do not useto start a warm engine.

• To engage choke control,pullknobout. Slowlypush

knobinto disengage.

"BRAKE"

POSITION POSITION

CLUTCH/BRAKE PEDAL

"DRIVE"POSDON

HEIGHT ADJUSTMENT KNOB

PAR_NGBRAKE

GEARSHIFT

LEVER

"DISENGAGED"

POSmON

FIG. 8

STOPPING (See Fig. 8)

MOWER BLADES -

,, Move attachmentclutch lever to=DISENGAGED" po-

sition.

GROUND DRIVE -.

• Depress clutch/brakepedal intofuit"BRAKE"position.

Move gearshift leverto neutral (N) position.

ENGINE -

• Move throttleControltoslow position.

NOTE: Failuretomovethrottlecontroltoslowposition and

allowingengine toidle beforestoppingmay cause engine

to "backfire".

Turn ignitionkey to "OFF" positionand remove key.

Always remove key when leaving tractorto prevent

unauthorizeduse.

Never usechoke to stopengine.

NOTE: Under certain conditions when tractor is standing

idlewiththeenginerunning,hotengineexhaustgasesmay

cause "browning" of grass. To eliminate this possibility,

always stopenginewhen stoppingtrector on grassareas. 12

TO MOVE FORWARD AND BACKWARD

(See Fig. 8)

The directionand speed of movement,iscontrolledby the

gearshift lever.

Start tractor with clutch/brake pedal depressed and

gearshift lever in neut_l (N) position.

• Move gearshiftand rangeshiftleversto desiredposi-

tion.

• Slowly release clutchibreke pedal to start movement.

IMPORTANT: BRING TRACTOR TO A COMPLETE STOP

BEFORE SHIFTING OR CHANGING GEARS. FAILURE

TO DO SO WILL SHORTEN THE USEFUL LIFE OF YOUR

TRANSAXLE.

TO ADJUST MOWER CUTTING HEIGHT

(See Fig. 8)

The cuttingheightiscontrolledbyturningtheheightadjust-

ment knob in desired direction.

• Turn knob clockwise(f_() to raisecuttingheight.

• Turn knob counterclockwise (_)to lower cutting

height.

The cuttingheightrangeisapproximately 1-1/2" to4". The

heights are measuredfrom the ground to the blade tip with

the engine not running. These heights are approximate

and may vary depending upon soilconditions, height of

grass and types of grass being mowed.

• The average lawn should be cut to approximately 2-1/2

inches duringthe cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

• For best cuttingpedormance grassover 6 inches in

height shouldbe mowed twice. Make the first cut

relatively high; the second to desired height.

OPERATION

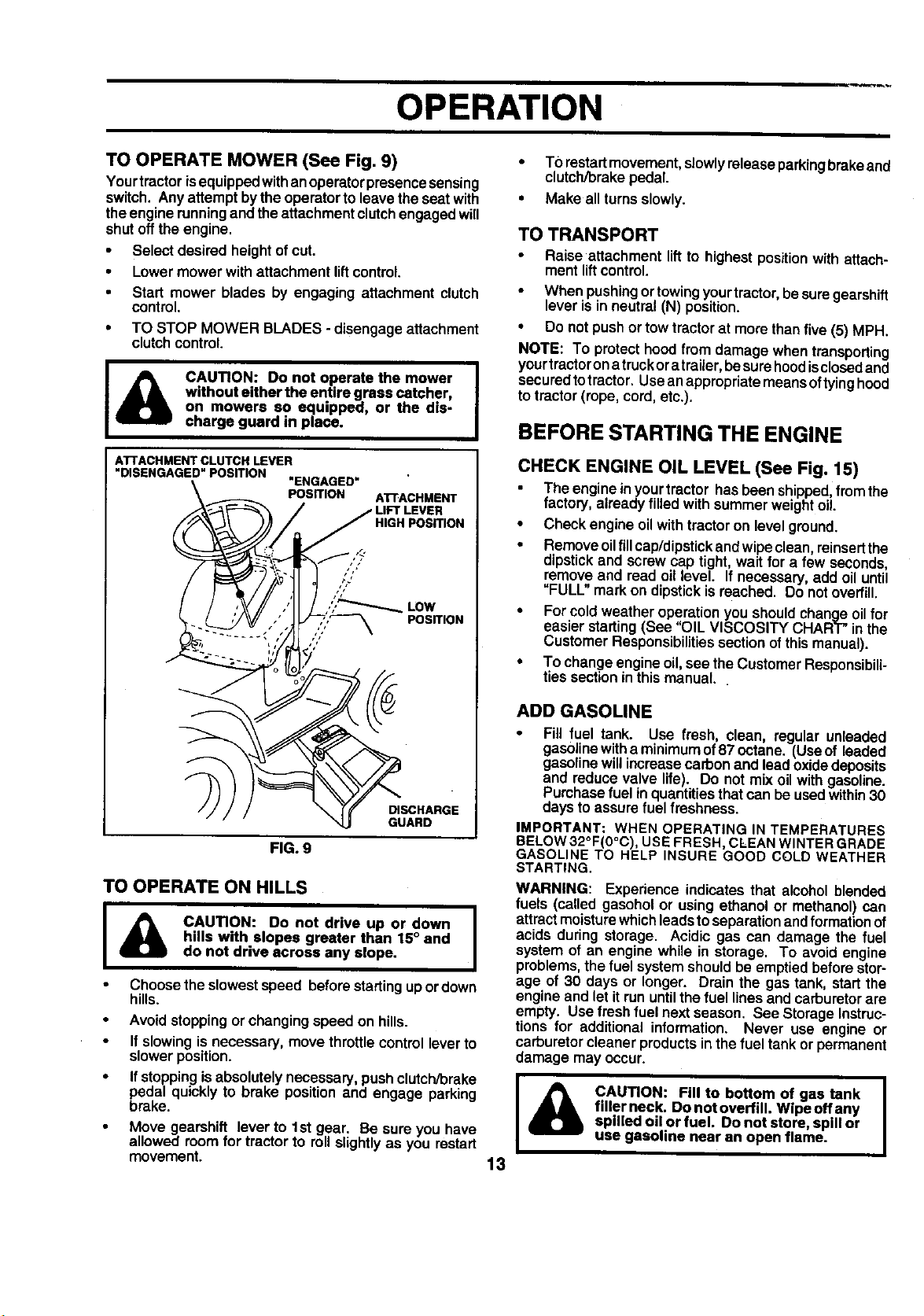

TO OPERATE MOWER (See Fig. 9)

Yourtractor isequippedwithanoperatorpresencesensing

switch. Any attemptby the operatorto leave the seat with

theengine runningand theattachmentclutchengagedwill

shut offthe engine.

• Select desired heightof cut.

• Lowermower withattachment liftcontrol.

Start mower blades by engaging attachment clutch

control.

• TO STOP MOWER BLADES - disengageattachment

clutchcontrol

without either the entire grass catcher,

on mowers so equipped, or the dis-

CAUTION: Do not operate the mower

charge guard in place.

AI"rACHMENT CLUTCH LEVER

"DISENGAGED" POSITION "ENGAGED"

_,_ / / LIFT LEVER

_\ )_ / / HIGH POSITION

POSITION ATrACHMENT

gwiTI°N

• TOrestartmovement,slowlyreleaseparkingbrakeand

clutch/brakepedal.

• Make allturns slowly.

TO TRANSPORT

• Raise attachment lift to highestpositionwith attach-

ment liftcontrol.

When pushingortowingyourtractor,besuregearshift

lever is in neutral(N) position.

• Do not push or tow tractorat more than five (5) MPH.

NOTE: To protecthoodfrom damage whentransporting

yourtractoronatruckor atrailer,besurehoodisclosedand

securedtotractor. Useanappropriatemeansoftyinghood

totractor (rope, cord,etc.).

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. 15)

The engineinyourtractor hasbeen shipped,fromthe

factory,alreadyfilledwith summerweightoil.

• Check engine oilwithtractoron level ground.

• Remove oilfillcap/dipstickandwipeclean,reinsertthe

dipstickand screw cap tight, wait for a few seconds,

remove and read oil level. If necessary, add oiluntil

"FULL"mark on dipstickis reached. Do notoverfill.

• For cold weather operationyou shouldchangeoilfor

easier starting(See "OIL VISCOSITY CHART"in the

Customer Responsibilitiessection of thismanual).

• To change engineoil,see the CustomerResponsibili-

ties sectionin thismanual.

FIG. 9

TO OPERATE ON HILLS

I _ CAUTION: Do not drive up or down I

Choose the slowestspeed before startingup ordown

hills.

Avoidstoppingorchangingspeed on hills.

Ifslowingis necessary, move throttlecontrolleverto

slowerposition.

Ifstoppingis absolutelynecessary,pushclutch/brake

pedal quickly to brake position and engage parking

brake.

Move gearshift lever to 1st gear. Be sure you have

allowed room for tractor to roll slightly as you restart

movement.

hills with slopes greater than 15° and

do not drive across any slope.

ADD GASOLINE

• Fill fuel tank. Use fresh, clean, regular unleaded

gasolinewithaminimumof87octane. (Useof leaded

gasolinewillincreasecarbon and lead oxidedeposits

and reduce valve life). Do not mix oilwith gasoline.

Purchasefuel in quantitiesthatcan be usedwithin30

daystoassure fuel freshness.

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW32°F(0°C), USEFRESH, CLEANWINTERGRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

WARNING: Experience indicates that alcohol blended

fuels (called gasehol or using ethanol or methanol) cart

attract moisturewhichleadsto separationandformation of

acids during storage. Acidic gas can damage the fuel

system of an engine while in storage. To avoid engine

problems,thefuel system shouldbe emptiedbeforestor-

age of 30 days or longer. Drain the gas tank, startthe

engineand letit run untilthefuel linesandcarburetorare

empty. Use freshfuel next season. See StorageInstruc-

tions for additional information. Never use engine or

carburetorcleaner productsinthe fuel tank or permanent

damage may occur.

CAUTION: Fill to bottom of gas tank |

filler neck. Do not overfill. Wipe off any

spilled oil or fuel. Do not store, spill or

use gasoline near an open flame.

13

I

I

OPERATION

TO START ENGINE (See Fig. 8)

When startingthe engine for the firsttime or ifthe engine

hasrunoutof fuel, it willtake extra crankingtimeto move

fuel from the tank to the engine.

• Sit on seat in operating position, depress clutch/brake

pedal and set parking brake.

• Place gear shift lever in neutral (N) position.

Move attachmentclutch to "DISENGAGED" position.

• Move throttle control to fast position

Pull choke control out for a cold engine start attempt.

For a warm engine start attempt the choke control may

not be needed.

Note: Before starting, read the warm and cold starting

procedures below.

Insertkeyinto ignitionandtum keyclockwiseto =START"

position and release key as soon asengine starts. Do

not run starter continuously for more than fifteen sec-

onds per minute. If the engine does not start after

several attempts, push choke control in, wait a few

minutes and try again. If enginestill does not start, pull

the choke control out and retry.

WARM WEATHER STARTING (50° Fand above)

• When engine starts, slowlypushchoke controlin until

the engine begins to run smoothly. If the engine starts

to run roughly, pull the choke control out slightly for a

few seconds and then continue to push the control in

slowly.

• Theattachmentsandgrounddrive can nowbe used. If

the enginedoes notacceptthe load,restart the engine

and allow itto warm upfor one minute using the choke

as described above.

COLD WE.ATHER STARTING (50° F and below)

• When engine starts,slowly push chokecontrolin until

the engine begins to run smoothly. Continue to push

thechoke controlinsmallstepsallowingthe engineto

accept small changes in speed and load, until the

choke control is fully in, If the engine starts to run

roughly,pull the choke controlout slightlyfor a few

seconds and then continue to push the control in

slowly. This may require an engine warm-up period

from several seconds to severa/minutes, depending

on the temperature.

• The attachments can beused dudng theenginewarm-

up period and may require the chokecontrol be pulled

out slightly.

NOTE: If at a high altitude (above 3000 feet) or in cold

temperatures (below 32 F) the carburetorfuelmixture may

need to be adjusted for best engine performance. See "TO

ADJUST CARBURETOR" inthe Service and Adjustments

sectionof this manual.

MOWING TIPS

• Tire chainscannot beusedwhenthemowerhousingis

attachedto tractor.

• Mower should be propedy leveled for best mowing

performance. See "TO LEVEL MOWER HOUSING" in

theService andAdjustmentssectionof thismanual.

• The left hand sideof mower should be used fortdm-

ming.

Drive so that clippingsare dischargedontothe area

thathasbeen cut. Have the cutarea to the rightofthe

tractor. This will result in a moreeven distributionof

clippingsand more uniformcutting.

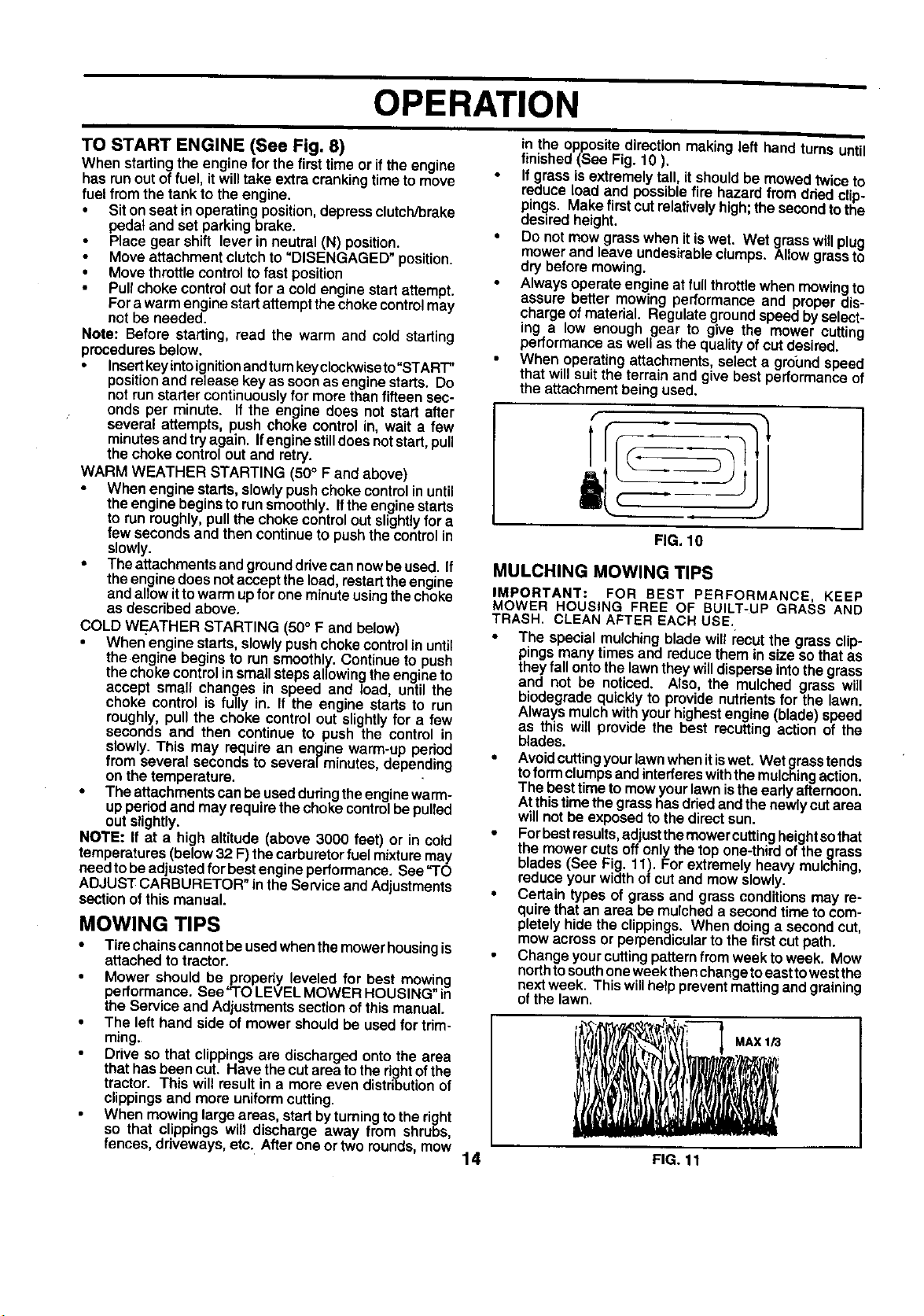

When mowing large areas, start byturning to the right

so that clippings will discharge away from shrubs,

fences, driveways, etc. After one or two rounds, mow

in the oppositedirectionmakingleft hand turnsuntil

finished (See Fig. 10 ).

If grass is extremelytall, it,should be mowed twice to

reduce load and possible Tire hazard from dded clip-

pings. Make first cutrelatively high; the second to the

desired height.

Do not mow grass when it is wet. Wet grasswillplug

mower and leave undesirable clumps. Allow grass to

dry before mowing,

Always operate engine at full throttle when mowing to

assure better mowing performance and proper dis-

charge of material. Regulate ground speed by select-

ing a low enough gear to give the mower cutting

performance as well as the quality of cut desired.

When operating attachments, select a greund speed

that will suit the terrain and give best performance of

the attachment being used.

1

FIG. 10

MULCHING MOWING TIPS

IMPORTANT: FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH. CLEAN AFTER EACH USE.

• The special mulchingblade wilt recutthe grass clip-

pingsmany times and reduce them in size so that as

theyfallontothe lawnthey willdisperseintothegrass

and not be noticed. Also, the mulched grass will

biodegradequicklyto providenutrientsfor the lawn.

Always mulchwithyour highestengine (blade)speed

as this will provide the best recuttingaction of the

blades.

• Avoidcuttingyourlawn whenitiswet. Wetgrasstends

toformclumpsandinterfereswiththemulchingaction.

The besttime tomow your lawnisthe early afternoon.

Atthistime the grasshasdriedandthe newlycut area

willnot be exposedto thedirect sun.

• Forbestresults,adjustthemower cuttingheightsothat

the mowercuts off onlythe top one-thirdofthe grass

blades(See Fig. 11). Forextremely heavy mulching,

reduceyourwidthofcut and mowslowly.

• Certain types of grass and grassconditionsmay re-

quirethatan area be mulcheda second timeto com-

pletelyhidethe clippings. When doing a secondcut,

mowacrossor perpendicularto thefirstcut path.

Change yourcuttingpatternfromweekto week. Mow

northtosouthoneweekthenchangetoeasttowestthe

next week. This willhelp preventmattingand graining

of the lawn.

.,x,o

14 FIG. 11

CUSTOMER RESPONSIBILITIES

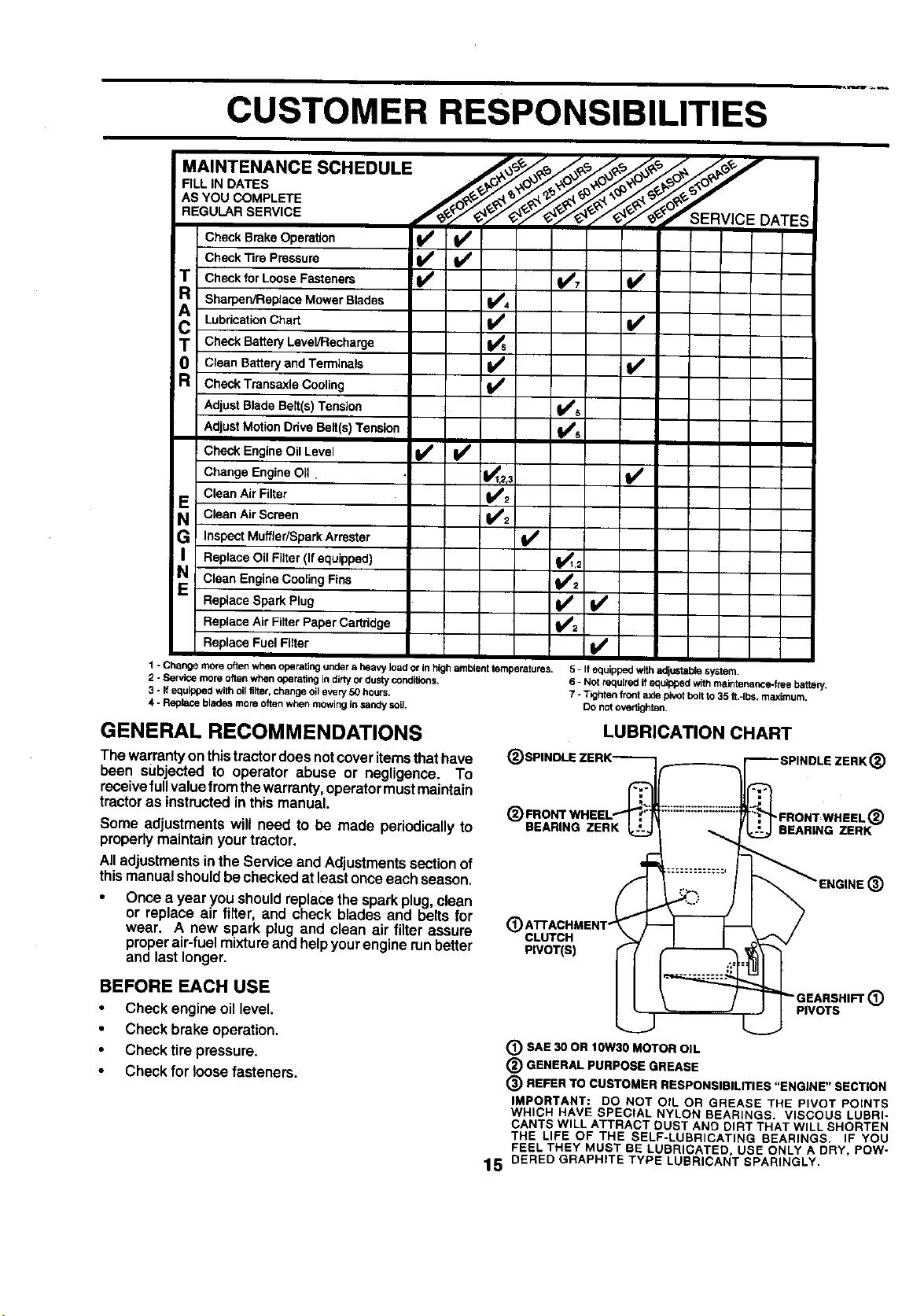

.A,NTENANCESCHEOULE

F,LL'"OATEB

REGULAR SERVICE CEDATES

Check Tire Pressure

Check Brake Operation _

T Cheek for Loose Fasteners 1_7 V'

Sharpen/Replace Mower Blades I_,=

Lubrication

TO Check Battery Level/Recharge

Clean Battery and Terminals I_

R Check Transaxle Cooling k/

Adjust Blade BeLt(s)Tension q_#'s

Adjust Motion Ddve Belt(s) Tension _Jl's

Check Engine Oil Level I1 / V w

Change Engine Oil . _1,2.3 _1_

Clean Air Filter _2

E Clean Air Screen

G Inspect Muffler/Spark Arrester I,/

I Replace Oil Filter (If equipped) 1_1,2

Chart If

1#'2

Replace Spark Plug V'

N Clean Engine Cooling Fins _i

Replace Air Filter Paper Cartridge

Replace Fuel Fitter I_

1 - Change more oftenwhen operating under a heavy loador inhighambienttemperatures.

2 - Service more oftenwhen operating indirlyordusty conditions.

3 - If equipped withoil tilter,change oil every 50 hours.

4 - Replace bladesmore oftenwhen mowingin sandy soil.

GENERAL RECOMMENDATIONS

The warrantyonthistractor doesnot coveritems thathave

been subjected to operator abuse or negligence. To

receivefullvaluefrom thewarranty,operatormust maintain

tractoras instructedinthis manual.

Some adjustments will need to be made periodically to

properlymaintain yourtractor.

Alladjustmentsinthe Service and Adjustmentssectionof

thismanualshouldbe checkedatleastonceeach season.

Once a year you shouldreplacethe sparkplug,clean

or replace air filter, and check blades and belts for

wear. A new spark plug and clean air filter assure

proper air-fuel mixture and help your engine run better

and last longer.

BEFORE EACH USE

Check engineoil level.

Check brake operation,

Check tire pressure.

Check for loosefasteners.

5 - If equipped with adjustable system,

6 - Not raquirad ifequipped with maintenance-free battery.

7 -Tighten front axle pivot boltto35 ft.-Ibs, maximum,

DOnotovedighten,

LUBRICATION CHART

_ SPINDLE ZERK (_)

(_ SPINDLE ZERK-_®FRONTWHEEL 't-- I1:::::::::::::::::::::

BEARING ZERK

CLUTCH

PIVOT(S)

(_ ATTACHMENT" !

(_) SAE 30 OR IOW30 MOTOR OIL

(_ GENERAL PURPOSE GREASE

(_) REFER TO CUSTOMER RESPONSIBILITIES "ENGINE"

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS. VISCOUS LUBRI-

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS. IF YOU

FEEL THEY MUST BE LUBRICATED, USE ONLY A DRY, POW-

lS OERED GRAPHITE TYPE LUBRICANT SPARINGLY.

;.,

SECTION

CUSTOMER RESPONSIBILITIES

TRACTOR

Alwaysobservesafety ruleswhenperformingany mainte-

nance.

BRAKE OPERATION

Iftractorrequiresmorethansix (6) feet stoppingdistance

athighspeed inhigbestgear,thenbrake mustbeadjusted.

(See 'I"O ADJUST BRAKE" in the Service and Adjust-

ments section of this manual).

TIRES

• Maintain proper air pressure in all tires (See "PROD-

UCT SPECIFICATIONS" on page 3 of this manual).

Keep tires free of gasoline, oil, or insect control chemi-

cals which can harm rubber.

,. • Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

BLADE CARE

Forbest resultsmower blades must be kept sharp, Re-

place bent or damaged blades,

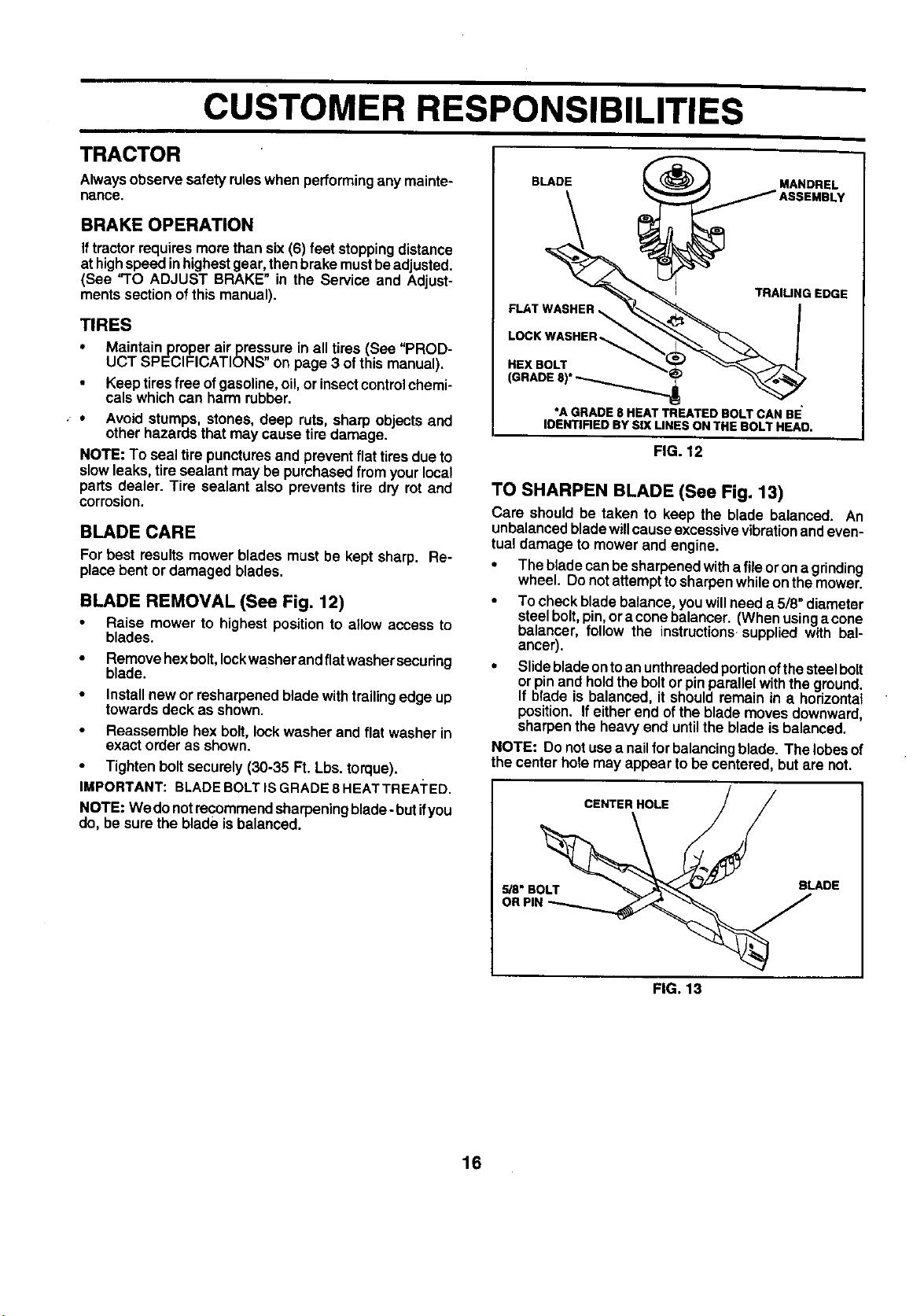

BLADE REMOVAL (See Fig. 12)

Raise mower to highest positionto a_lowaccess to

blades.

• Removehexbolt, leckwasherandflatwashersecuring

blade.

• Install newor resharpenedblade withtrailingedge up

towardsdeck as shown.

Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

• Tighten bolt securely(30-35 Ft. Lbs.torque).

IMPORTANT: BLADEBOLTIS GRADE8 HEATTREA]'ED.

NOTE: We do notrecommendsharpeningblade- but ifyou

do, be sure the blade is balanced.

BLADE _ MANDREL

IJA°SEMDLV

FLAT WASHER _ _ I

LOCKWASHER !

HEXeOLT.

TRAIUNG EDGE

GRADE,,

*A GRADE 8 HEAT TREATED BOLT CAN BE

IDENTIFIED BY SIX UNES ON THE BOLT HEAO.

FIG. 12

TO SHARPEN BLADE (See Fig. 13)

Care should be taken to keep the blade balanced. An

unbalancedbladewillcauseexcessivevibrationandeven-

tual damage to mower and engine.

• The bladecanbe sharpenedwitha fileorona grinding

wheel. Do not attempttosharpenwhileon the mower.

To checkblade balance,youwillneed a 5/8"diameter

steelbolt,pin,ora conebelancer. (When usinga cone

balancer, follow the instructions-suppliedwith bal-

ancer).

• Slidebladeontoanunthreadedportionofthesteelbolt

orpinand holdthe boltor pinparallelwiththe ground.

If blade is balanced, it shouldremain in a horizontal

position. If either end of the blade moves downward,

sharpenthe heavy end untilthe blade is balanced.

NOTE: Do notuse a nattforbalancingblade. The lobesof

the center holemay appear to be centered, butare not.

CENTER HOLE / /

16

,. ADE

OR PIN _

FIG. 13

CUSTOMER RESPONSIBILITIES

BATFERY

Yourtractorhas a batterycharging systemwhich is suffi-

cient for normal use. However, periodicchargingof the

batterywithan automotivechargerwillextend its life.

Keep battery and terminalsclean.

• Keep battery bolts tight.

Keep small vent holes open.

Recharge at 6-10 amperes for 1 hour,

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to "leak" power.

Remove terminalguard.

• DisconnectBLACK batterycable first then RED bat-

tery cable and removebattery fromtractor.

• Rinse the batterywith plainwater and dry.

• Cleanterminalsandbatterycable endswithwirebrush

untilbright.

• Coat terminalswithgrease or petroleumjelly.

• Reinstall battery (See "CONNECT BATTERY" in the

Assemblysectionof this manual).

V-BELTS

Check V-belts fordeterioration and wearafter 100 hoursof

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin to slip from wear.

TRANSAXLE COOLING

Keep transaxle free from build-upof dirt and chaffwhich

can restrictcooling,

ENGINE

NOTE: Althoughmulti-viscosity oils (5W30, lOW30 etc.)

improve startingin coldweather, these multi-viscosityoils

will resultin increased oilconsumptionwhen usedabove

32°F. Checkyour engineoillevelmore frequentlytoavoid

possibleengine damage fromrunninglowon oil.

Changethe oilafterevery25 hoursofoperationorat least

onceayear ifthetractorisnotusedfor25hoursinoneyear.

Check the crankcase oil level before startingthe engine

and after eacheight(6) hoursofoperation. Tightenoil fit_

cap/dipsticksecurely each time you check the oil level.

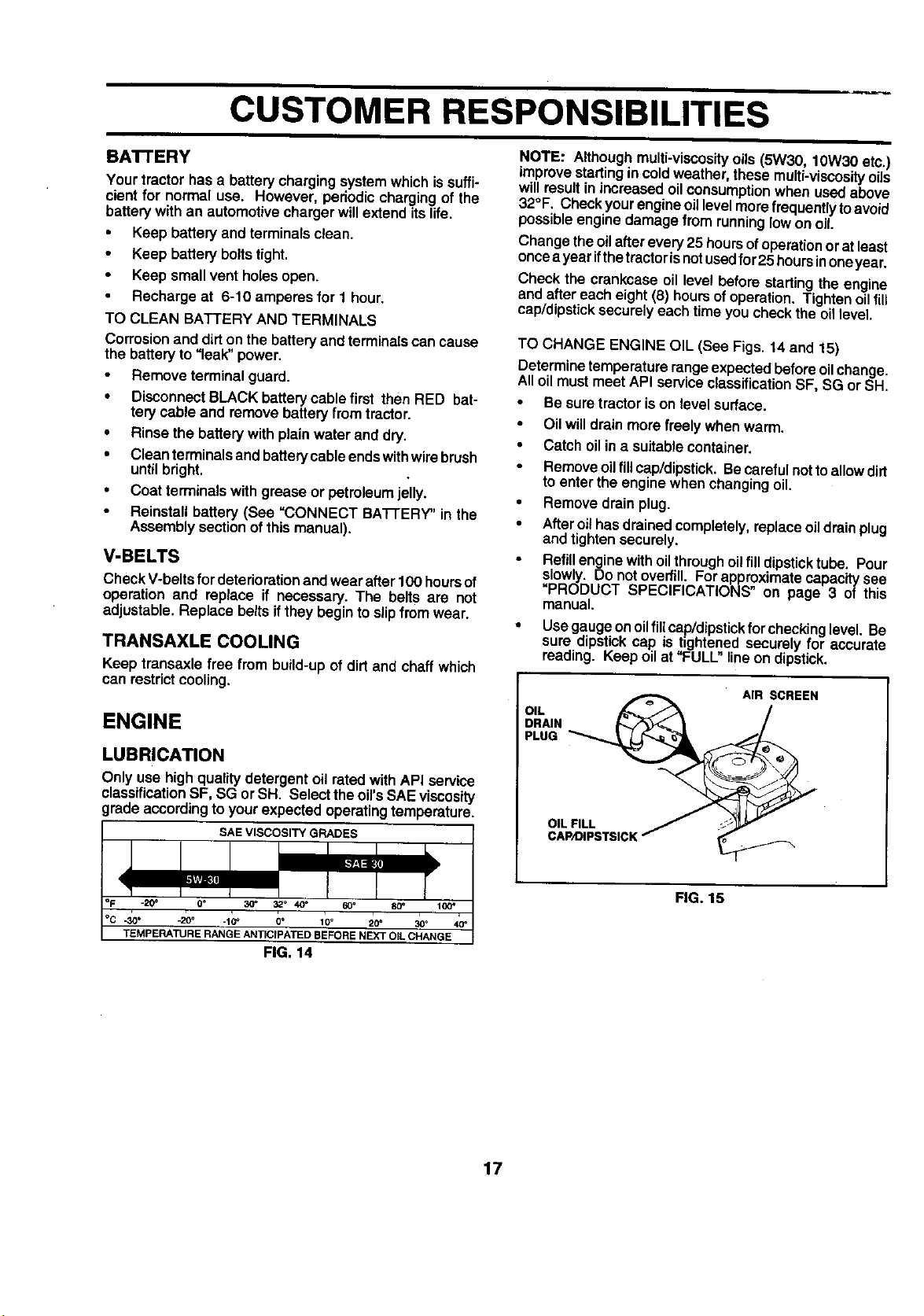

TO CHANGE ENGINE OIL (See Figs. 14 and 15)

Determine temperature range expectedbefore oilchange.

All oil must meet API service classificationSF, SG or SH.

Be sure tractor is on level surface.

• Oilwilldrain more freely when warm.

• Catch oilina suitablecontainer.

Remove oil flUcap/dipstick.Be carefulnot to allow dirt

to enter the enginewhen changingoil.

• Remove drain plug.

• Afteroilhas drained completely,replaceoildrainplug

and tightensecurely.

Refillenginewithoilthroughoilfill dipsticktube. Pour

slowly. Do notoverfill. Forapproximatecapacltysee

=PRODUCT SPECIFICATIONS" on page 3 of this

manual.

• Use gauge onoilfill cap/dipstickfor checkinglevel. Be

sure dipstickcap is tightened securely for accurate

reading. Keep oil at "FULL"lineon dipstick.

OIL _ AIR SCREEN

LUBRICATION

Only use high qualitydetergent oil rated withAPI service

classificationSF, SG or SH. Select theoil'sSAE viscosity

gradeaccordingtoyour expected operatingtemperature,

SAE VISCOSITY GRADES

_20_ 0o

.30 • -20o .10 _ 0 ° 10° 20 ° 30°

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OiL CHANGE

FIG, 14

°I s,s,cK

FIG. 15

17

Loading...

Loading...