Craftsman 917259150 Owner’s Manual

CRAFTXMnN°

25915

Instruction manual

Please read these instructions

carefully and make sure you

understand them before using this

ma_hin_

1

Safety specifications.

Sicherheitsbestimmungen.

Consignes de securitY.

2

3

4

6

7

Assembly.

7usammenbau.

Montage.

Functional description.

Funktionsbeschreibung.

Description du fonctionnement. __

Procedure before start.

MaBnahmen vor dem Anlassen.

Avant de demarrer.

Driving.

Betrieb.

Conduite.

Maintenance, adjustment.

Instandhaltung, Einstellung.

Entretien, reglages.

Faulttracing.

StSrungssuche.

Recherche des pannes.

8

Storage.

Aufbewahrung.

Rangement.

We reserve the right to changes without prior notice.

2

Safe Operation Practices for Ride-On Mowers

IMPORTANT: THIS CUTTING MACHINE IS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS.

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH.

1. Safety Rules

O I. Training

Read the instructions carefully. Be familiar with the

controls and the proper use of the equipment.

Never allow children or people unfamiliar with the ins-

tructions to use the lawnmower. Local regulations may

restrict the age of the operator.

Never mow while people, especially children, or pets are

nearby.

Keep in mind that the operator or user is responsible for

accidents or hazards occurring to other people or their

property.

All drivers should seek and obtain professional and

practical instruction. Such instruction should empha-

size:

- the need for care and concentration when working

with ride-on machines;

- control of a ride-on machine sliding on a slope will

not be regained by the application of the brake.

The main reasons for loss of control are:

a) insufficient wheel grip;

b) being driven too fast;

c) inadequate braking;

d) the type of machine is unsuitable for its task;

e) lack of awareness of the effect of ground

conditions,especially slopes;

f) incorrect hitching and load distribution.

II. Preparation

While mowing, always wear substantial footwear and

long trousers. Do not operate the equipment when

barefoot or wearing open sandals.

Thoroughly inspect the area where the equipment is to

be used and remove all objects which may be thrown by

the machine.

WARNING - Petrol is highly flammable.

- Store fuel in containers specifically designed for this

purpose.

- Refuel outdoors only and do not smoke while refu-

eling.

- Add fuel before starting the engine. Never remove

the cap of the fuel tank or add petrol while the engine

is running or when the engine is hot.

If petrol is spilled, do not attempt to start the engine

but move the machine away from the area of spillage

and avoid creating any source of ignition until petrol

vapors have dissipated.

- Replace all fuel tanks and container caps securely.

Replace faulty silencers.

Before using, always visually inspect to see that the

blades, blade bolts and cutter assembly are not worn or

damaged. Replace worn or damaged blades and bolts

in sets to preserve balance.

On multi-bladed machines, take care as rotating one

blade can cause other blades to rotate.

III. Operation

Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

Mow only in daylight or in good artificial bight.

Before attempting to start the engine, disengage all blade

attachment clutches and shift into neutral.

Do not use on slopes of more than 10°.

Rememberthere is no such thing as a "safe" slope. Travel

on grass slopes requires particular care. To guard

against overturning;

- do not stop or start suddenly when going up or

downhill;

- engage clutch slowly, always keep machine ingear,

especially when traveling downhill;

- machine speeds should be kept low on slopes and

during tight turns;

- stay alert for humps and hollows and other hidden

hazards;

- never mow across the face of the slope, unless the

lawnmower is designed for this purpose.

Use care when pulling loads or using heavy equipment.

Use only approved drawbar hitch points.

Limit loads to those you can safely control.

Do not turn sharply. Use care when reversing.

- Use counterweight(s) or wheel weights when sug-

gested in the instruction handbook.

Watch out for traffic when crossing or near roadways.

Stop the blades from rotating before crossing surfaces

other than grass.

When using any attachments, never direct discharge of

material toward bystanders nor allow anyone near the

machine while in operation.

Never operate the lawnmower with defective guards,

shields or without safety protective devices in place.

Do not change the engine governor settings or overspeed

the engine. Operating the engine at excessive speed

may increase the hazard of personal injury.

Before leaving the operator's position:

- disengage the power take-off and lower the attach-

ments;

- change into neutral and set the parking brake;

- stop the engine and remove the key.

Disengage drive to attachments, stop the engine, and

disconnect the spark plug wire(s) or remove the ignition

key

- before cleaning blockages or unclogging chute;

- before checking, cleaning or working on the

lawnmower;

- afterstrikingaforeignobject. Inspectthelawnmower

for damage and make repairs before restarting and

operating the equipment;

- if the machine starts to vibrate abnormally (check

immediately).

Disengage drive to attachments when transporting or not

in use.

Stop the engine and disengage drive to attachment

- before refueling;

- before removing the grass catcher;

- before making height adjustment unless adjust-

ment can be made from the operator's position.

Reduce the throttle setting during engine run-out and, if

the engine is provided with a shut-off valve, turn the fuel

off at the conclusion of mowing.

3

IV. Maintenance and Storage

Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

Never store the equipment with petrol in the tank inside

a building where fumes may reach an open flame or

spark.

Allow the engine to cool before storing in any enclosure.

To reduce the fire hazard, keep the engine, silencer,

battery compartment and petrol storage area free of

grass, leaves, or excessive grease.

Check the grass catcher frequently for wear or deteriora-

tion.

Replace worn or damaged parts for safety.

If the fuel tank has to be drained, this should be done

outdoors.

On multi-bladed machines, take care as rotating one

blade can cause other blades to rotate.

When machine is to be parked, stored or left unattended,

lower the cutting means unless a positive mechanical

lock is used.

CAUTION: Always disconnect spark wire and

place wire where it cannot contact spark plug in

order to prevent accidental starting when setting up,

transporting, adjusting or making repairs.

plug

4

_) These symbols may appear on your tractor or in the literature supplied with the product. Learn and understand their meaning.

R N H L "_ (]_ Q

REVERSE NEUTRAL HIGH LOW FAST SLOW LIGHTS ON UGHTS OFF

ENGINE ON ENGINE OFF PARKING BRAKE LOCKED UNLOCKED .PARKING BRAKE BA'i-rERY

I

CLUTCH CHOKE FUEL OIL PRESSURE DIFFERENTIAL LOCK REVERSE FORWARD

IGNITION ATTACHMENT ATI*ACHMENT CAUTION MOWER HEIGHT BEWARE OF

CLUTCH ENGAGED CLUTCH DISENGAGED THROWN OBJECTS

15

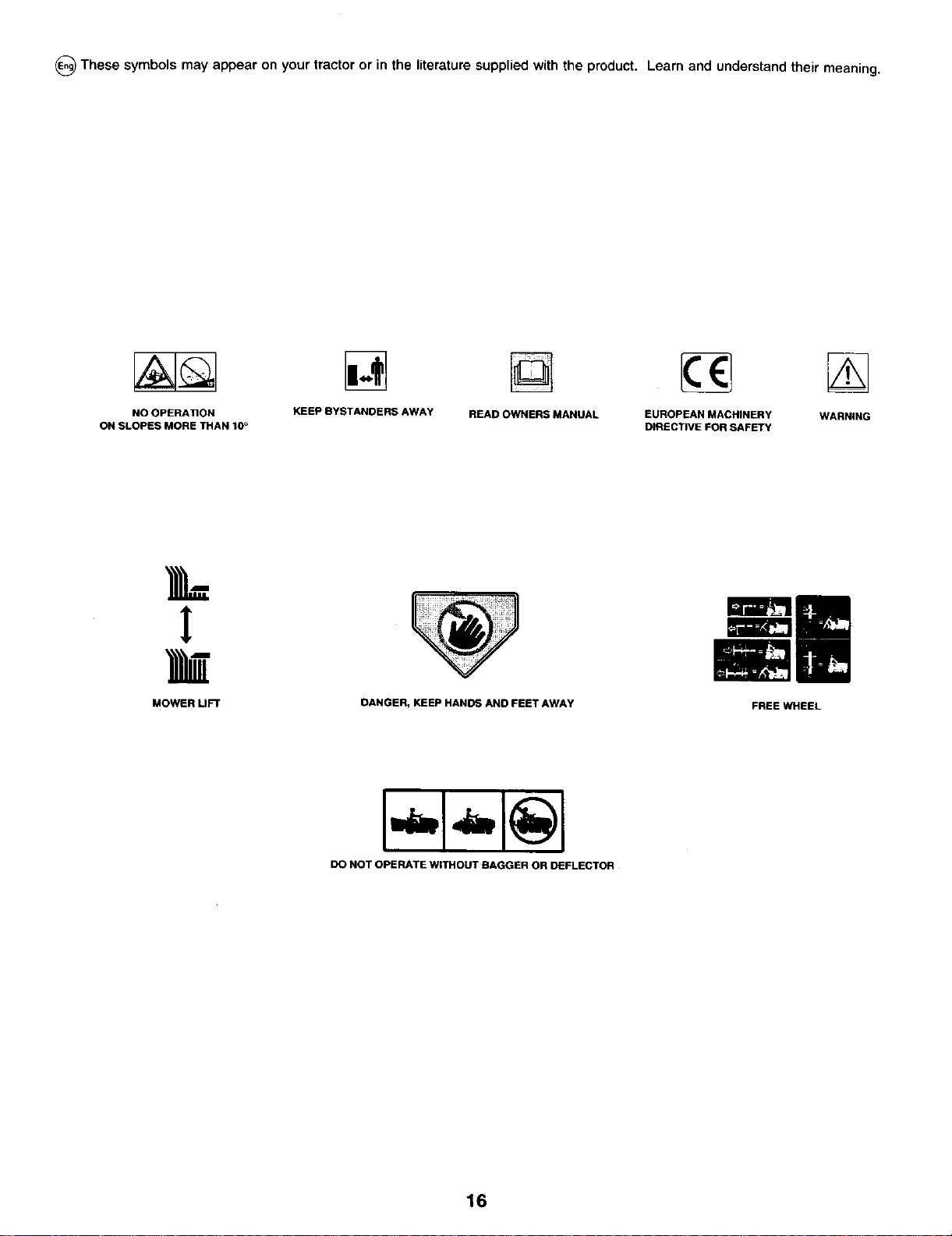

_) These symbols may appear on your tractor or in the literature supplied with the product. Learn and understand their meaning.

NO OPERATION KEEP BYSTANDERS AWAY READ OWNERS MANUAL EUROPEAN MACHINERY WARNING

ON SLOPES MORE THAN 10° DIRECTIVE FOR SAFETY

L

MOWER LIFT

DANGER, KEEP HANDS AND FEET AWAY

DO NOT OPERATE WITHOUT BAGGER OR DEFLECTOR

FREE WHEEL

16

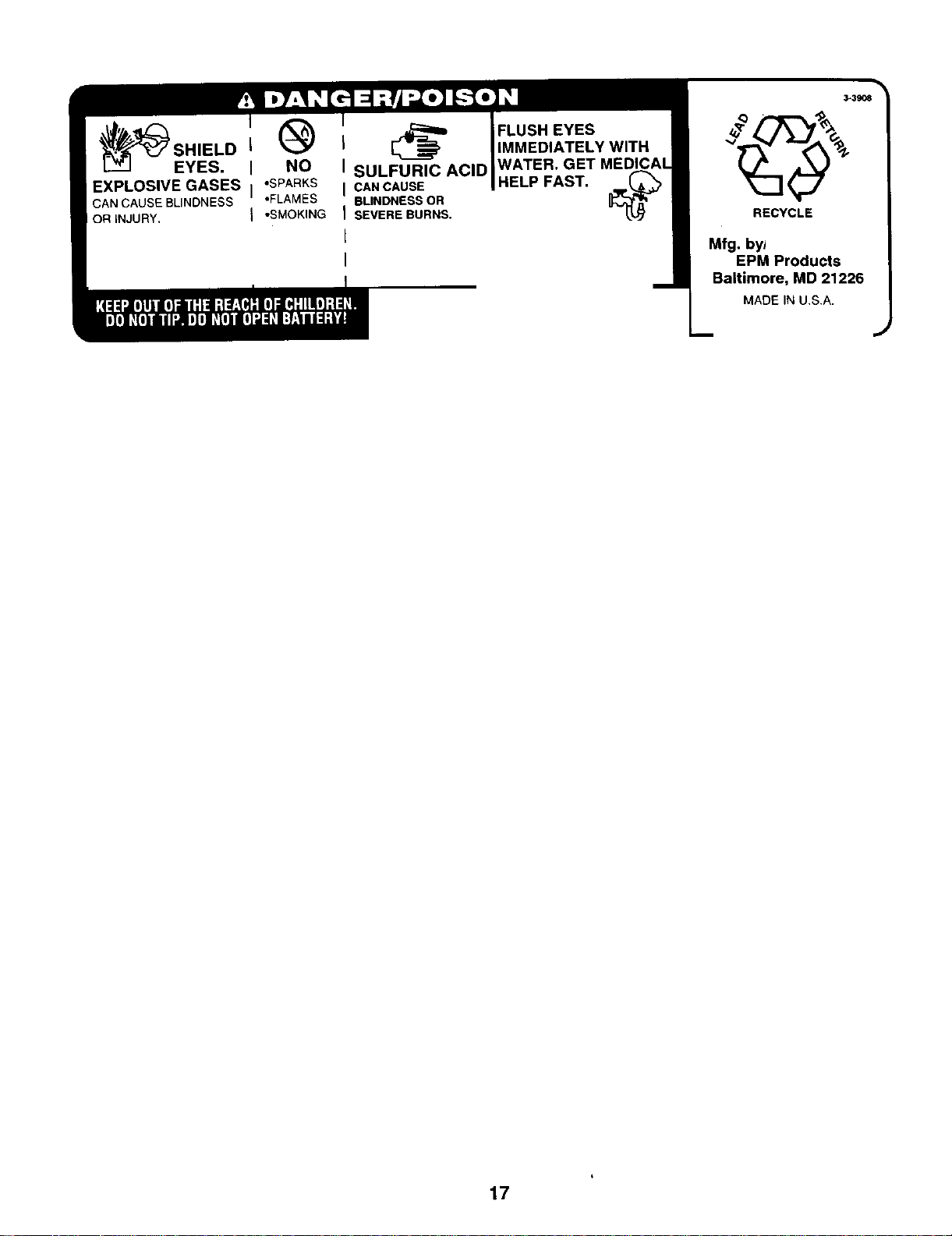

EXPLOSIVE GASES I -SPARKS

CAN CAUSE BLINDNESS .FLAMES

OR LNJURY, I -SMOKING

[_ FLUSH EYESIMMEDIATELY WITH

SULFURIC ACID WATER. (_

;ANCAUSE HELP FAST. ,,_(_

BLINDNESS OR

SEVERE BURNS.

RECYCLE

Mfg. byJ

EPM Products

Baltimore, MD 21226

MADE IN U,S.A.

17

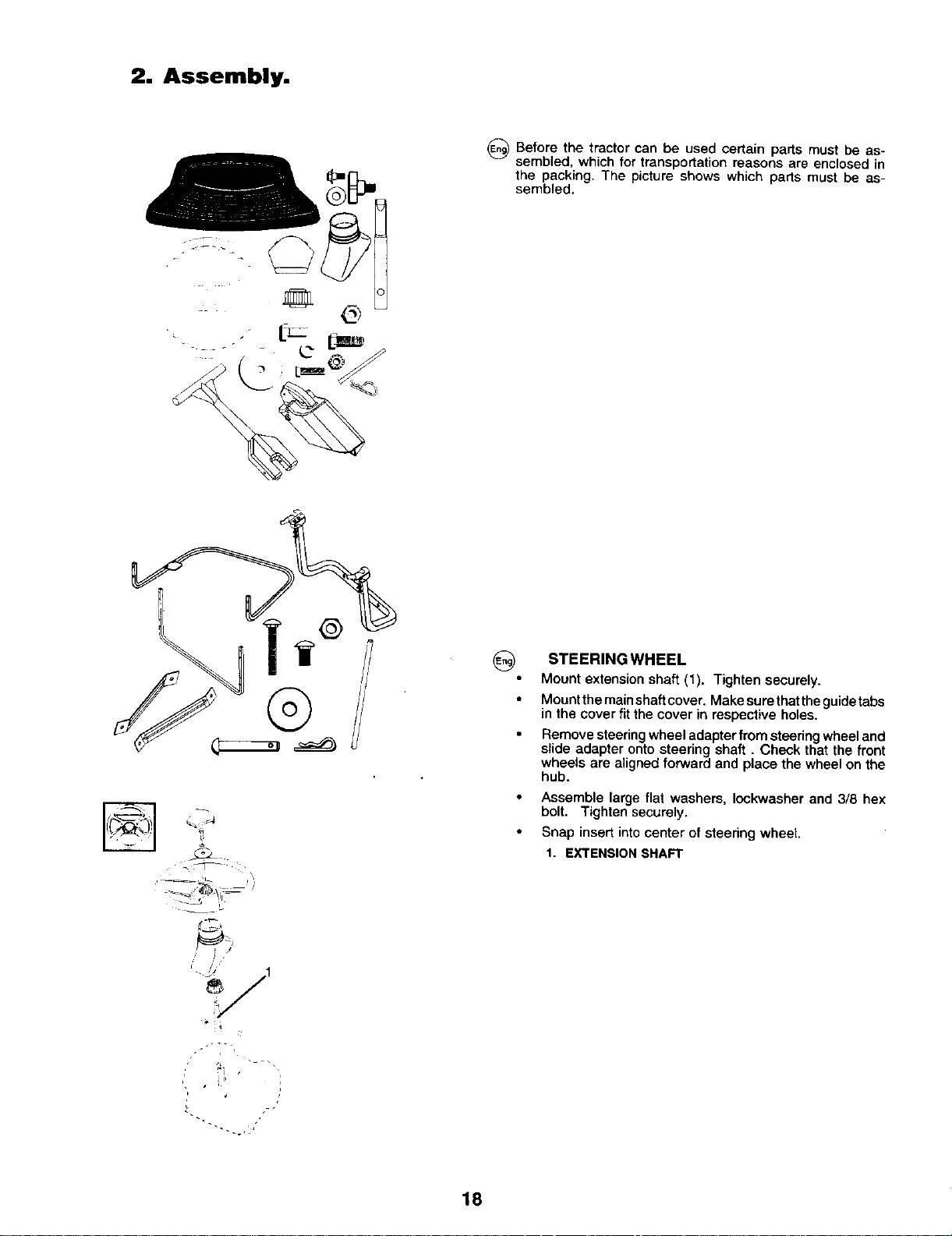

2. Assembly.

@

_) Before the tractor can be used certain parts must be as-

sembled, which for transportation reasons are enclosed in

the packing. The picture shows which parts must be as-

sembled.

__ _,_1-_,i-

] s

i /

/J t

t_

,' • i P

_j

i t

0

STEERING WHEEL

Mount extension shaft (1). Tighten securely.

Mount the main shaft cover. Make sure that theguidetabs

in the cover fit the cover in respective holes.

Remove steering wheel adapter from steering wheel and

slide adapter onto steering shaft. Check that the front

wheels are aligned forward and place the wheel on the

hub.

Assemble large flat washers, Iockwasher and 3/8 hex

bolt. Tighten securely.

Snap insert into center of steering wheel.

1. EXTENSION SHAFT

18

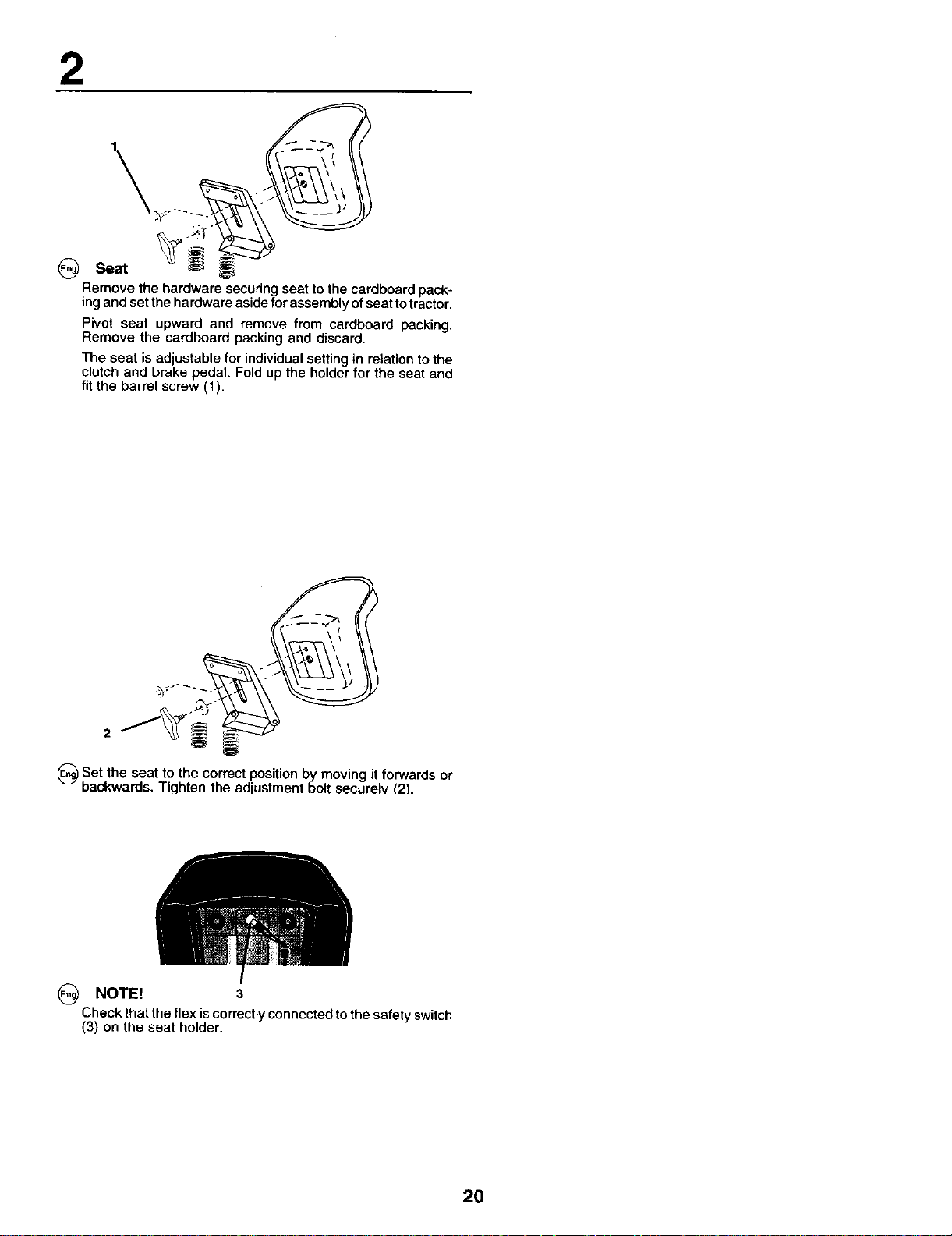

2

@

Remove the hardware securing seat to the cardboard pack-

ing and set the hardwara aside for assembly of seat to tractor.

Pivot seat upward and remove from cardboard packing.

Remove the cardboard packing and discard.

The seat is adjustable for individual setting in relation to the

clutch and brake pedal, Fold up the holder for the seat and

fit the barrel screw (t).

2

_)Set the to the correct it forwards

backwards, Tiqhten the adiustment bolt securelv _2_.

(_ NOTE! 3

Check that the flex is correctly connected to the safety switch

(3) on the seat holder.

seat

position by moving

or

20

2

O

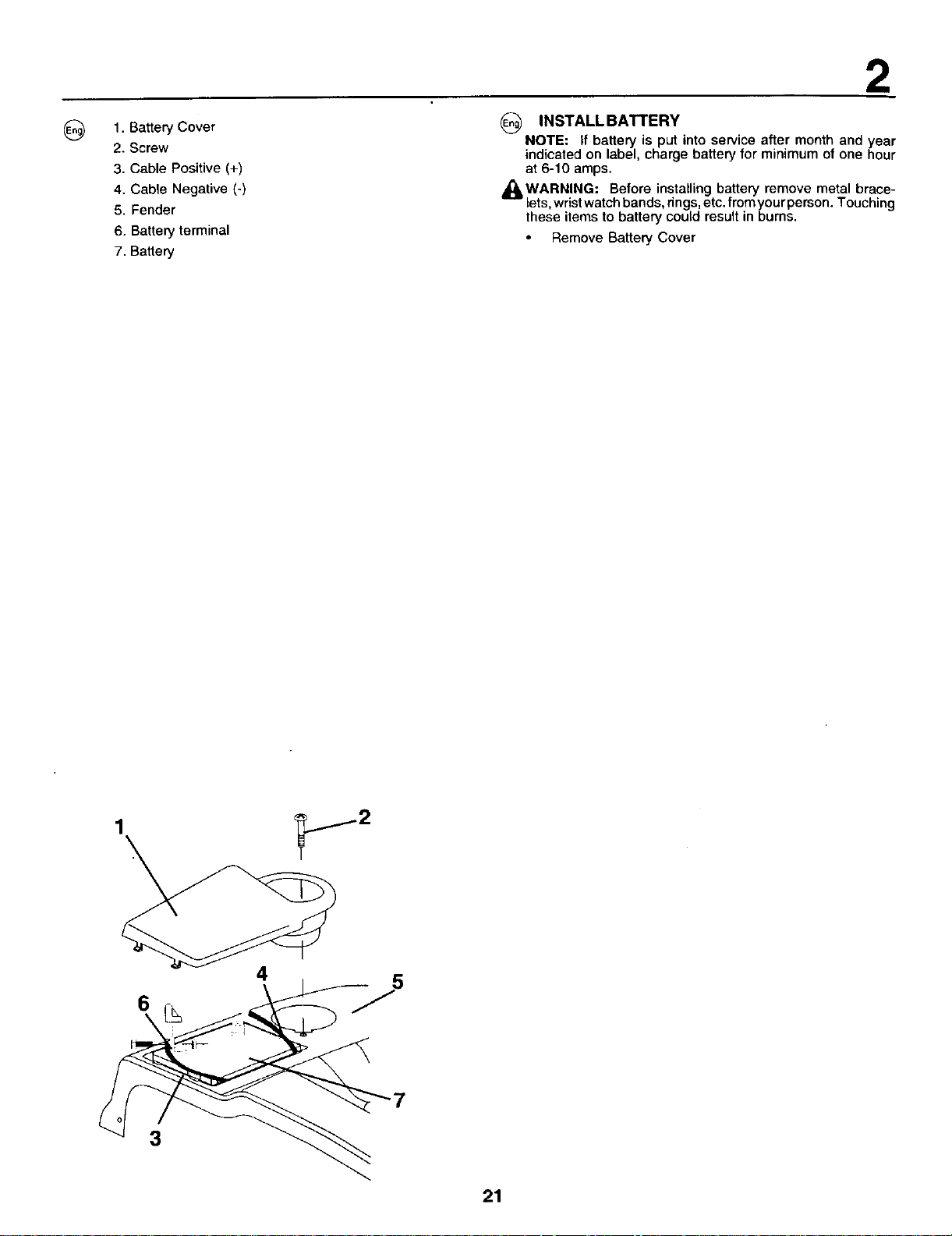

1. Battery Cover

2. Screw

3. Cable Positive (+)

4. Cable Negative (-)

5. Fender

6. Battery terminal

7. Battery

(_) INSTALL BATTERY

NOTE: If battery is put into service after month and year

indicated on label, charge battery for minimum of one hour

at 6-10 amps.

_q_,WARNING: Before installing battery remove metal brace-

lets,wristwatch bands, dngs, etc.from yourperson. Touching

these items to battery could result in burns.

Remove Battery Cover

1

4

0 F'

3

21

2

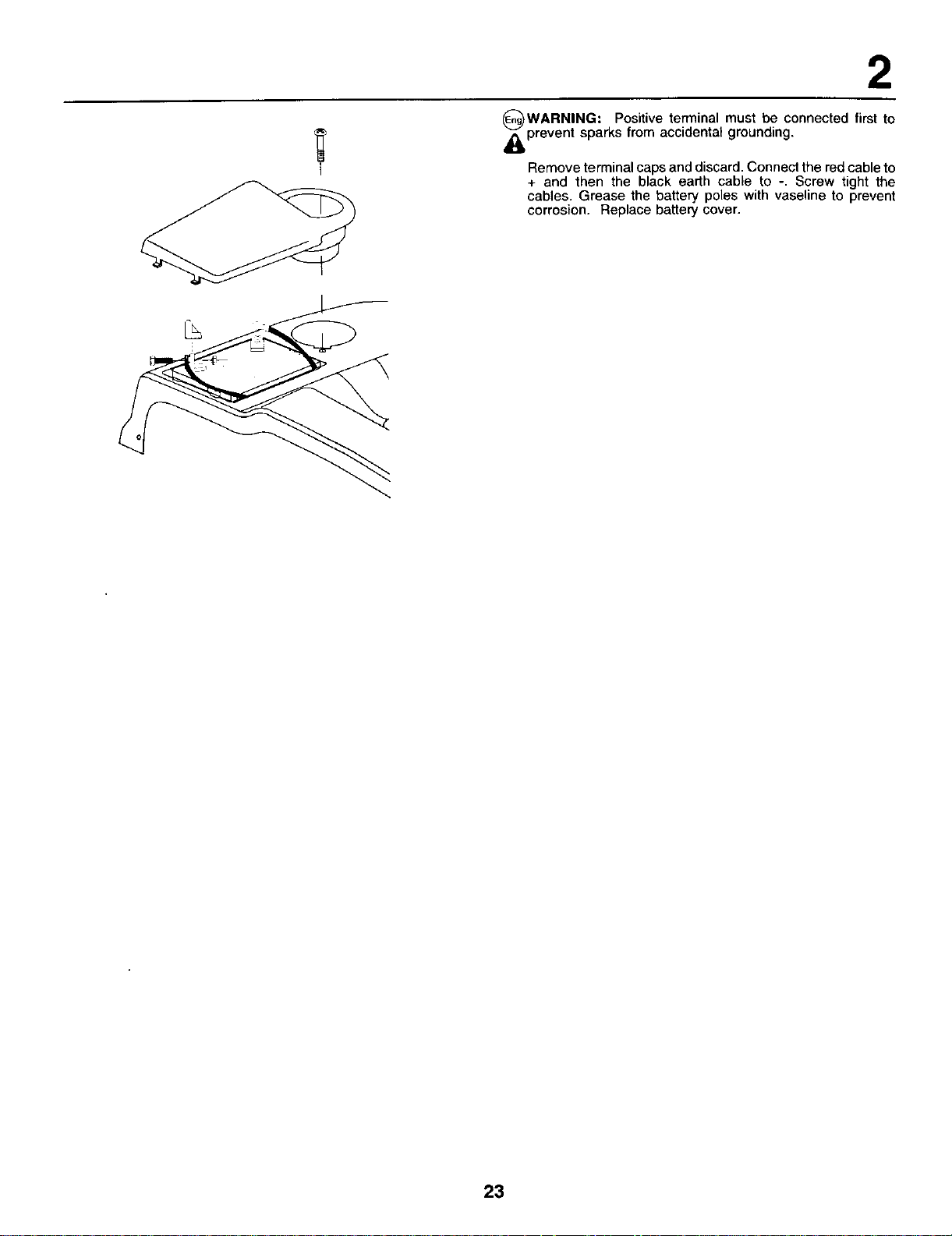

OWARNING: Positive terminal must be connected first to

_prevent sparks from accidental grounding.

Remove terminal caps and discard, Connect the red cable to

+ and then the black earth cable to -, Screw tight the

cables. Grease the battery poles with vaseline to prevent

corrosion. Replace battery cover.

23

2

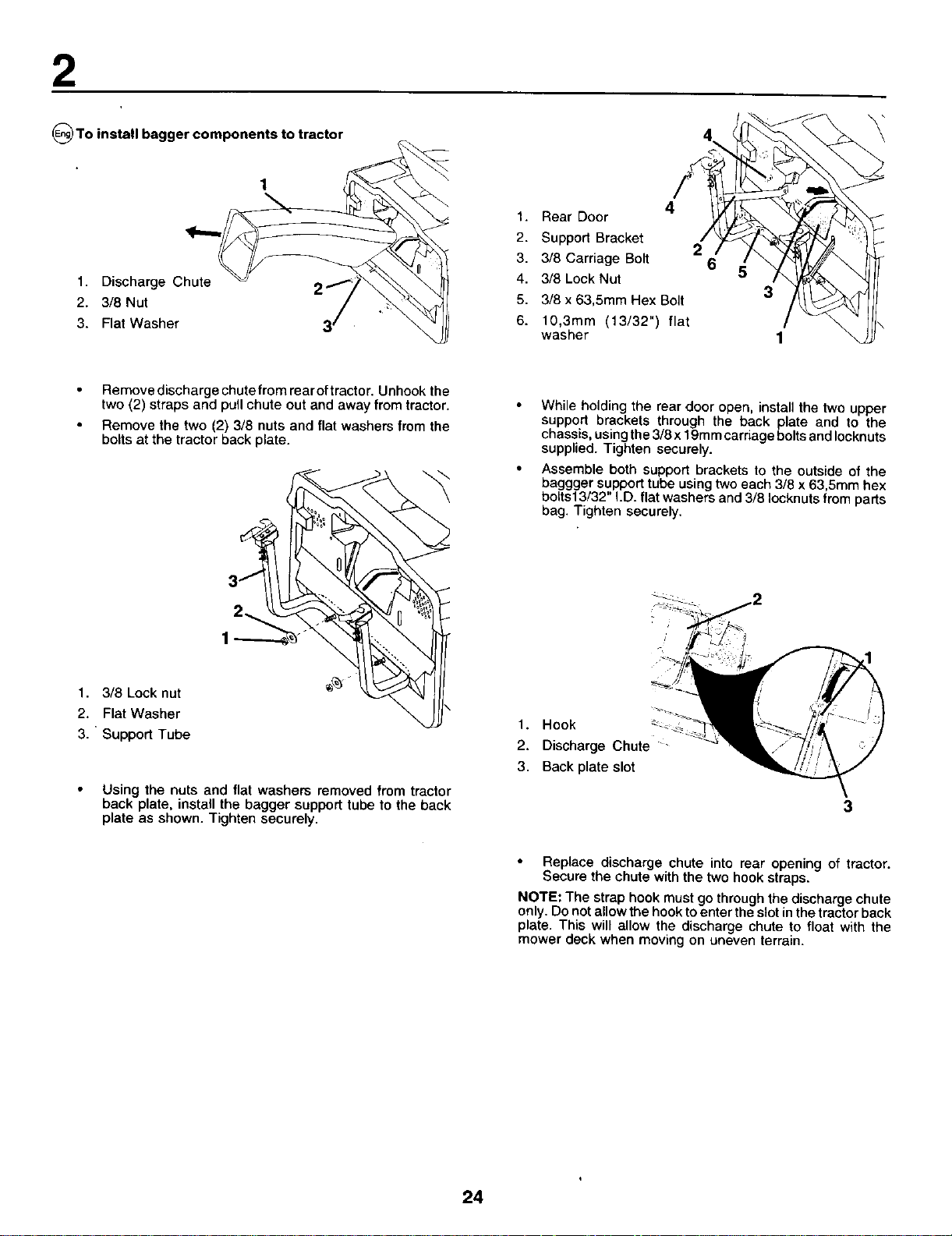

O To install bagger components to tractor

1

1. Discharge Chute

2. 3/8 Nut

3. Flat Washer

Remove discharge chute from rear oftractor. Unhook the

two (2) straps and pull chute out and away from tractor.

Remove the two (2) 3/8 nuts and flat washers from the

bolts at the tractor back plate.

1. Rear Door

2. Support Bracket

3. 3/8 Carriage Bolt 6

4. 3/8 Lock Nut

5. 3!8 x 63,5mm Hex Bolt 3

6. 10,3mm (13/32") flat

washer 1

While holding the rear door open, install the two upper

support brackets through the back plate and to the

chassis, using the 3/8 x 19mm carriage bolts and Iocknuts

supplied. Tighten securely.

Assemble both support brackets to the outside of the

baggger support tube using two each 3/8 x 63,5mm hex

bolts13/32" I.D. flat washers and 3/8 Iocknuts from parts

bag. Tighten securely.

4

2

31

2_

1. 3/8 Lock nut

2. Flat Washer

3. Support Tube

Using the nuts and flat washers removed from tractor

back plate, install the bagger support tube to the back

plate as shown. Tighten securely.

1. Hook

2. Discharge Chute -

3. Back plate slot

3

Replace discharge chute into rear opening of tractor.

Secure the chute with the two hook straps.

NOTE: The strap hook must go through the discharge chute

only. Do not allow the hook to enter the slot in the tractor back

plate. This will allow the discharge chute to float with the

mower deck when moving on uneven terrain.

24

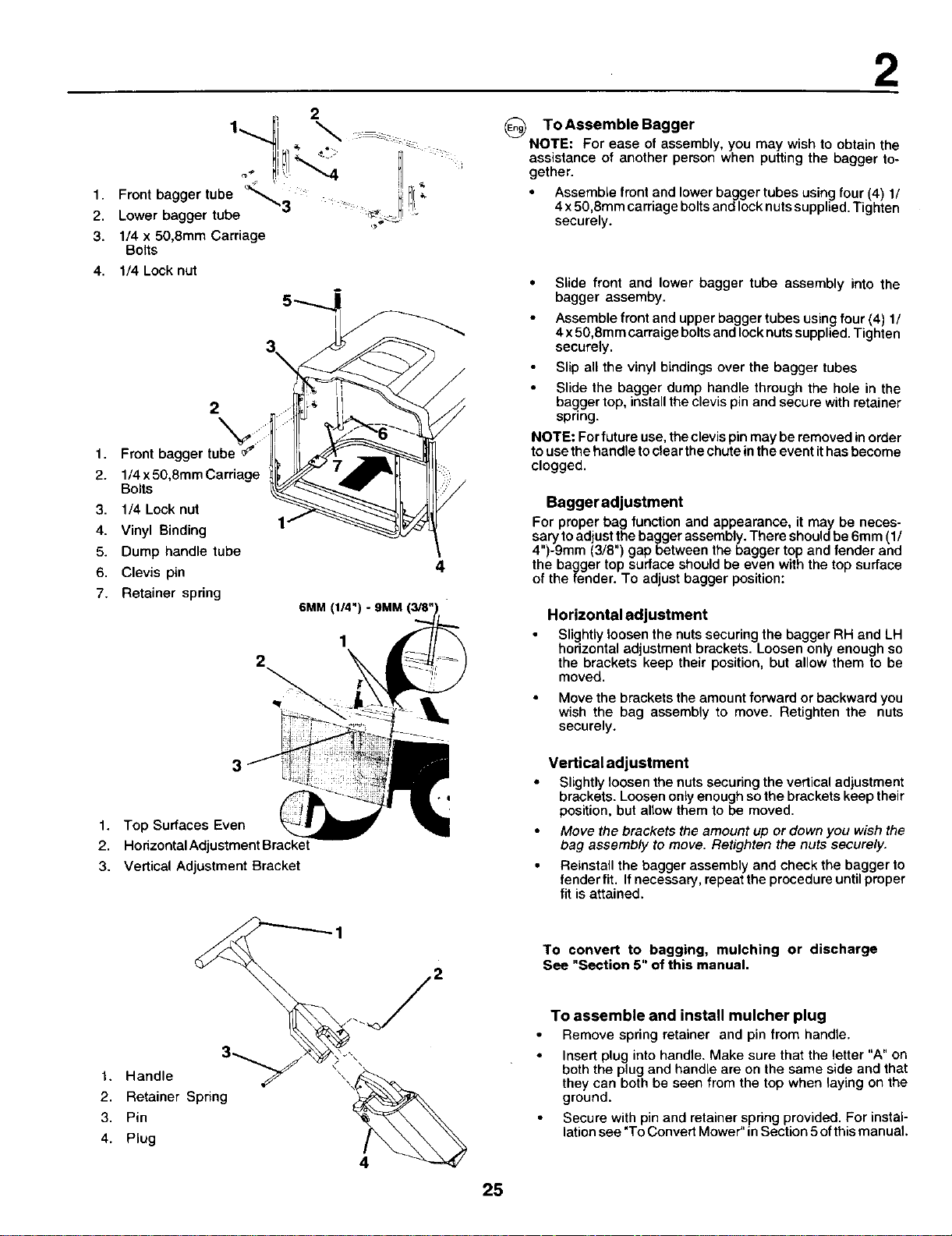

1. Front bagger tube _3

2. Lower bagger tube

3. 1/4 x 50,8mm Carriage

Bolts

4. 1/4 Lock nut

2

1,

2. 1/4x 50,8mm Carriage

Bolts

3. 1/4 Lock nut

4. Vinyl Binding

5. Dump handle tube

6. Clevis pin

7. Retainer spring

2

To Assemble Bagger

NOTE: For ease of assembly, you may wish to obtain the

assistance of another person when putting the bagger to-

gether.

Assemble front and lower bagger tubes using four (4) 1/

4 x 50,8ram carriage boltsand lock nutssupplied. Tighten

securely.

• Slide front and lower bagger tube assembly into the

bagger assemby.

Assemble front and upper bagger tubes using four (4) 1/

4x 50,8mm carraige bolts and lock nutssupplied. Tighten

3\

1

6MM

2

securely.

Slip all the vinyl bindings over the bagger tubes

Slide the bagger dump handle through the hole in the

bagger top, install the clevis pin and secure with retainer

spring.

NOTE= For future use, the clevis pin may be removed in order

to use the handle to clear the chute in the event ithas become

clogged.

Bagger adjustment

For proper bag function and appearance, it may be neces-

sary to adjust the bagger assembly. There should be 6mm (1/

4")-9mm (3/8") gap between the bagger top and fender and

the bagger top surface should be even with the top surface

of the fender. To adjust bagger position:

Horizontal adjustment

Slightly loosen the nuts securing the bagger RH and LH

hodzontal adjustment brackets. Loosen only enough so

the brackets keep their position, but allow them to be

moved.

Move the brackets the amount forward or backward you

wish the bag assembly to move. Retighten the nuts

securely.

3

1. Top Surfaces Even

2.

3. Vertical Adjustment Bracket

3

t. Handle

2. Retainer Spring

3. Pin

4. Plug

Vertical adjustment

Slightly loosen the nuts securing the vertical adjustment

brackets. Loosen only enough so the brackets keep their

position, but allow them to be moved.

Move the brackets the amount up or down you wish the

bag assembly to move. Retighten the nuts securely.

Reinstall the bagger assembly and check the bagger to

fender fit. If necessary, repeat the procedure until proper

fit is attained.

To convert to bagging, mulching or discharge

See "Section 5" of this manual.

To assemble and install mulcher plug

Remove spring retainer and pin from handle.

Insert plug into handle. Make sure that the letter "A" on

both the plug and handle are on the same side and that

they can both be seen from the top when laying on the

ground.

Secure with pin and retainer spring provided. For instal-

lation see "To Convert Mower" in Section 5 of this manual.

4

25

3. Functional description.

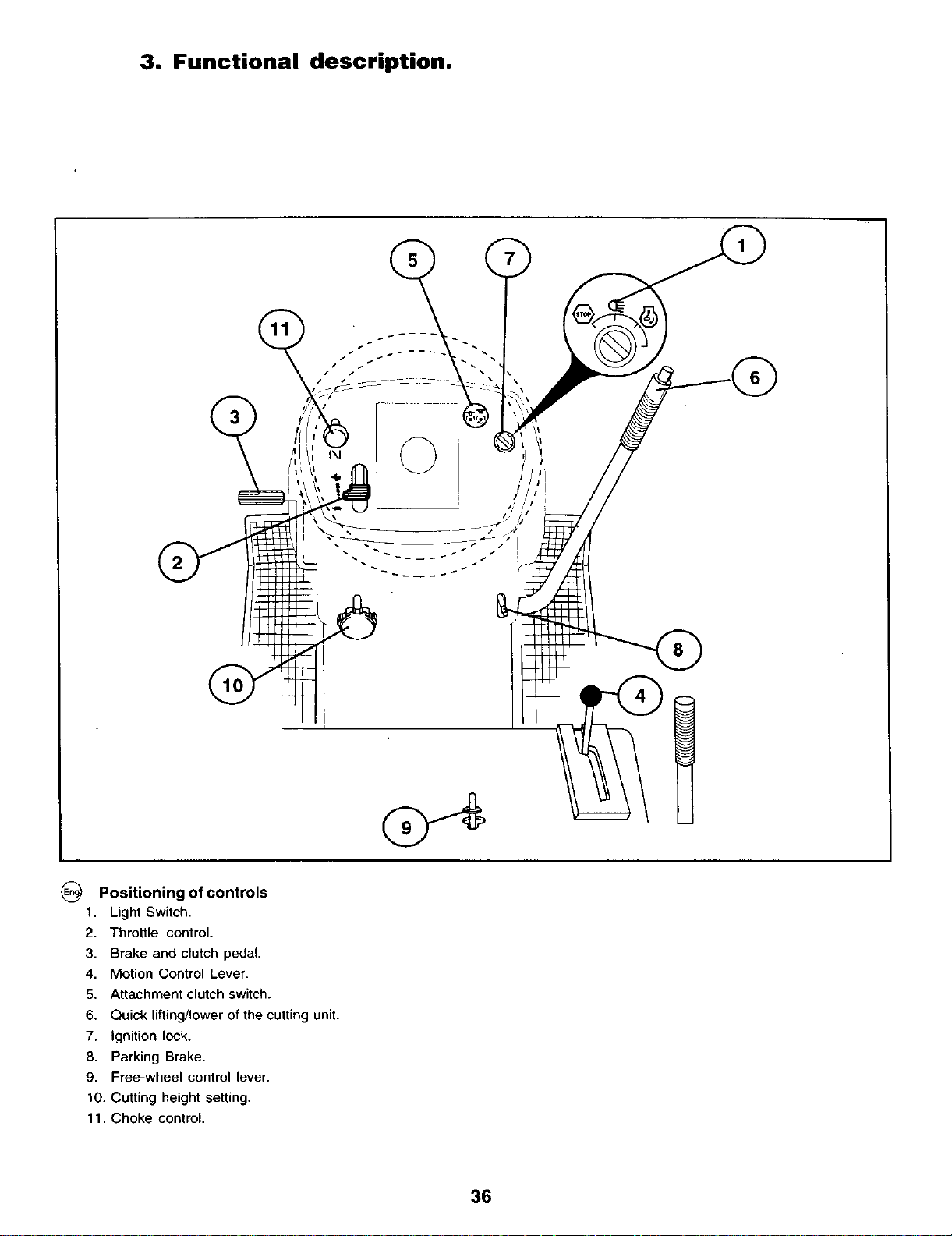

Positioning of controls

1. Light Switch.

2. Throttle control.

3. Brake and clutch pedal,

4, Motion Control Lever.

5, Attachment clutch switch.

6. Quick lifting/lower of the cutting unit.

7. ignition lock.

8. Parking Brake.

9, Free-wheel control lever.

10. Cutting height setting,

11, Choke control,

i

36

3

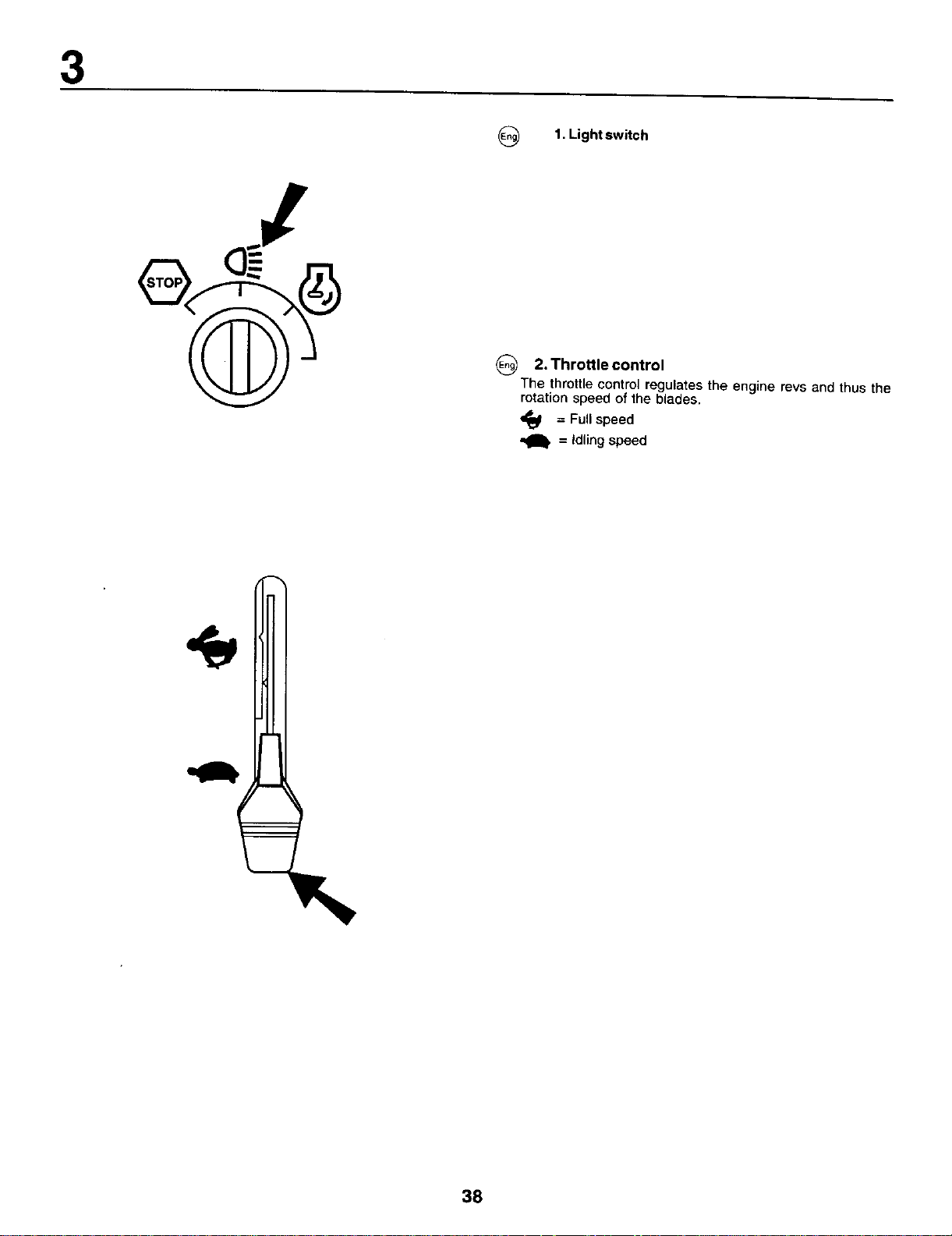

1. Light switch

2. Throttle control

The throttle control regulates the engine revs and thus the

rotation speed of the blades.

_1 = Full speed

= Idling speed

38

Loading...

Loading...