Craftsman 917258670 Owner’s Manual

CRI:IFI'ZMIIN+

MODEL NUMBER 917.258670 OWNER'SMANUAL

"Assembly

' Operation

• Customer Responsibilities

• Service and Adjustments

° Repair Parts

CAUTION: Read and follow all safety rules and instructions before operating this equipment+

I[

FOR CONSUMER ASSISTANCE HOT LINE, CALL THIS TOLL FREE NUMBER; 1+800+65g.59t7

'r'll"lI'.......................i,iiilllll' "ll'll"1ii I "111'1 I i

Safe Operation Practices for Ride-On Mowers u

IMPORTANT.' THIS CUTTING MACHINE tS CAPABLE OF AMPUTATING HANDS AND FEET AND THROWING OBJECTS

FAILURE TO OBSERVE THE FOLLOWING SAFETY INSTRUCTIONS COULD RESULT IN SERIOUS INJURY OR DEATH

1° GENERAL OPERATION

,, Read, understand, end follow ell fnstruclions tn the manual

and on fhe machine before elading

Only allow responsible adults, who are famtllar wlth Ihe

instructions,Io operate the machine,

• Clear the area of objecls such as recks, toys, wire etc,

whichcould be p eked up and thrownby the blade

• Besure thearea tsclearof olherpeople beforemewing Slop

machine Banyone entersthe area

• Never carry passengers.

" Donotmow tnreverseunless absolutelynecessary Aiways

lookdown and behindbetore and while backing

Beaware ofthe mowerdischarge dlraclton enddo not point

it at anyone Do notoperate the mower wghouleither the

entlre grasscatcher orthe guard in place-

, Stowdown before turning.

,, Never leave erunning machine unattended. Always turnoff

blades, set parking 5rake, stop engine, and remove keys

before dismounting.

,. Turn off blades when not mewing

Slop engine before removing grass catcher or unclogging

chule

• Mow 0nlyIndaylight or good artificial light

, Do nol operate the machine while under the influence of

alcohoior drugs

• Watch tot traffic when operating near or crossing roadways

• Use extracare when loading or unloadingthe machlne into

a keller or truck.

IL SLOPE OPERATION

Slopes are a major factor related to loss-of-control and

ttpover accidents, whlch can result in severe Inlury or

death Al! slopes require extra caution. If you cannot back

up the slope or if you leet uneasy on It, do eel mow It.

DO:

Mow up and down slopes,not across

• Removeobstacles such as rocks, tree limbs, etc

- Welch lot holes, ruts, or bumps. Uneven terrain could

ovedum Ihe machine Taftgreas can hide obstscles,

" Useslowspeed. Choosea low gaarso that you willnot have

to stop or shift wh_e on the slope.

. Follow the manulacturar's recommendations for wheel

weightsor counlerwetghlsto improveslabtllty.

,, Use extra care with grass catchers or other atlachments

These canchange thestability ol the machine.

" Keep a_movement on theslopes slow and gradual. Do not

make suddenchanges Inspeed or direction

• Avoid stadtng or stoppingon e stops, If tires lose traction,

disengage the blades and proceed slowly strelghl down the

slope

DO NOT:

. Do notlureon slopesunlessnecessary,and then,turnslowly

andgradually downhlIl,it posstble

De notmow near drep-offs dltehea, or embankments. The

mowercouldsuddenlyturn over If e wheel isover the edge

of aoligor dilch, or ifan edge caves in,

Do not mow on wet grass, Reduced traction could cause

SAFETY RULES

Ill CHILDREN

Tragic accidents can occur If the operator ts not alert to the

presence of children Children are often attracted to the

machine and the mowing activity. Never assume that

children will remain where you last saw Ihem.

Keep eh[tdranout of themowing areaand underthe watehtu

care ofanother responsibleadult,,

• Be alert and lure machine oil ifchildrenenter the area

• Borers and when backing, look behind and down for small

children

" Never carry children They may lall oi! and be seriousy

injuredor tetedere wtlh sate machine operation

• Never allow childrento operale lhe machine

" Usa extra care when approaching blind comers shrubs,

trees,or other objectsthat may obscure vision.

IV. SERVICE

• Use extra tara In handling gassltne end olher fuefs Theyere

flammable and vapors are explosive

Use only an approved container+

Never remove gas cap or add fuel with the engine

running, Allow engine to cool before refueling Do not

smoke

Never refue_ the machine indoors

Never store the machine or fuel container Inside where

there is an open llama, such as a water heeler.

• Never tun a machtne insidea closed area

• Keep nuts and bolls, especially btade attachment bolls light

and keep equipment n good condit on

• Never tamper with safety devices Check their proper

operalion regularly

• Keep machine free ot grass tesves, or other debris build-up,

C san o or fuel spillage Mow machine to coat before

stodng

• Slop and inspect lhe equipment if you sldke an object

Repair, if necessary, before restarting.

" Never make adjustmenls or repairs wilh lhe engine running.

• GreessatchercomponenlearesubJectlowear damage and

deterioration, which could expose moving paris or allow

objects [o be thrown+ Frequenlly check components and

replace with manufaclureCs recommended parts, when nec-

essary

• Mower blades are sharp and can cut, Wrap Ihe blade(s) or

wear gloves, and use extra caution when servlclngIhem.

• Check brake operalion lrequently. Adjust and service as

,, requ_red_.........

Look for this symbol to point out important

safety precautions, It means

CAUTIONIf! BECOME ALERTIII YOUR

SAFETY IS INVOLVED.

n. ,H HHH,,n =

CAUTION: Always disconnect spark plug

wire and place wire where It cannot contact

spark plug In order to prevent acctdenlal

starting when setting up, transporting,

adjusting or making repairs.

sliding

• Denot tryto stabilize themachine by pullingyourfoot onthe

ground.

• De not usegrass catcher on sleep slopes

The engine exhaust from this product contains

chemicals known to the State of California to

cause cancer, birth defects, or other reproduc-

tive harm,

WARNING A

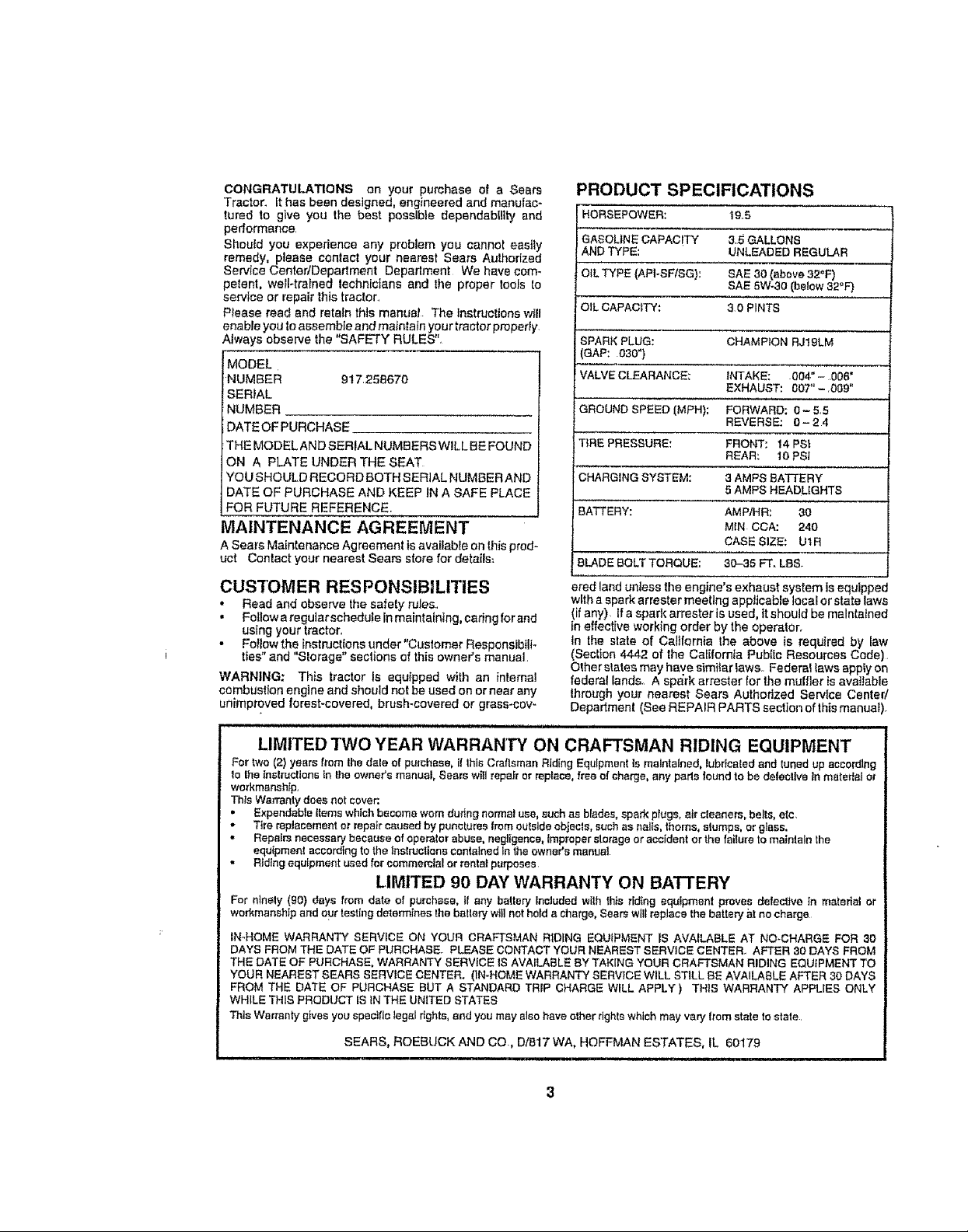

CONGRATULATIONS on your purchase of a Sears

Tractor. It has been designed, engineered and manufac-

tured to glve you the best posslbIe dependability and

performance.

Should you experience any problem you cannot easily

remedy, please contact your nearest Sears Authorized

Service CentedDepartment Department We have com-

petent, well-trained technicians and the proper tools to

service or repair this tractor_

Please read and retain this manual The Instructions will

enable you to assemble and maintain your tractor properly.

Always observe the "SAFETY RULES".

MODEL

NUMBER 917 258670

SERIAL

NUMBER

DATEOF PURCHASE

THE MODEL AND SERtAL NUMBERSWIL LBE FOUND

ON A PLATE UNDER THE SEAT

YOU SHOULD RECORD BOTH SERIAL NUMBER AND

DATE OF PURCHASE AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE.

MAINTENANCE AGREEMENT

A Seat's Maintenance Agreement is avaifab_e on this prod-

uct Contact your nearest Sears store for details:

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules..

• Follow a regularschedule Inmaintaining, ca#ng for and

using your tractor,

• Follow the instructions under "Customer ResponsibItt*

ties" and "Storage" sections of this owner's manual.

WARNING: This tractor is equipped with an internal

combustion engine and should not be used on or near any

unimproved forest-covered, brush-covered or grass-coy-

PRODUCT SPECIFICATIONS

HORSEPOWER: 19.5

GASOLINE CAPAC!TY 3.5 GALLONS

AND TYPE: UNLEADED REGULAR

OIL TYPE (APfoSFtSG}: SAE 30 (above 32'_F)

OIL CAPACITY: 3 0 PINTS

SPARK PLUG: CHAMPION RJ19LM

{GAP: O3O3

VALVE CLEARANCE: INTAKE: 004" - 006"

GROUND SPEED (MPH); FORWARD: 0- 5.5

TiRE PRESSURE: FRONT: 14 PSI

CHARGING SYSTEM: 3 AMPS BATTERY

BATTERY: AMP/HR: 30

BLADE BOLT TORQUE: 30-35 FT. LB&

ered land unless the engine's exhaust system is equipped

with a spark arrester meeting applicable local or state laws

(if any) If a spark arrestor is used, it should be maintained

in elfective working order by the operator,

In the state of Caitlornia the above is required by law

(Section 4442 of the CaIiIornta Pubtic Resources Code).

Other states may have simitar laws.. Federal taws apply on

federal lands° A spark arrester for the muffler is available

through your nearest Sears Authorized Service Center/

Department (See REPAIR PARTS section of this manual).

SAE 5W-30 (be!ow 32°F}

EXHAUST: 007"-.009"

REVERSE: 0-2 4

REAR: 10 PSI

5 AMPS HEADLIGHTS

MIN COA: 240

CASE SIZE: U1R

LIMITED TWO YEAR WARRANTY ON CRAFTSMAN RIDING EQUIPMENT

For two (2) years from the dale o! purshase, {(this Craftsman Riding Equipment Is maintained, lubricated and tuned up according

to the {nstrucltonstn the owner'smanual, Sears will repair or replace,free of charge, any pads found to be defective tn material or

workmanship,

This Warranty does not cover:.

• Expendable items whichbecome wornduring normal use, suchas blades, spark plugs, air cleaners, belts, etc.

• Tire repJacementor repaircaused by punctures from outsideobjecfe, such _s nails, thorns,stumps, or glass.

• Repairs necessary because of opereler abuse, negligence, improperstorageor accident or the failure to maintain _he

equipment accordingto the Insiructiona containedtn the owner'smanual

, Ridingequipment used forcommercialorrentalpurposes

LIMITED 90 DAY WARRANTY ON BATTERY

For ninety (90) days from date of purchase, tl any battery incJudedwilh th}s tiding equipment proves defective in materialor

workmanship and our testingdetermines _hebattery wttlnot hold a charge,Sears willreplace the battery at no charge

IN-HOME WARRANTY SERVICE ON YOUR CRAFTSMAN RIDING EQUIPMENT IS AVAILABLE AT NO-CHARGE FOR 80

DAYS FROM THE DATE OF PURCHASE. PLEASE CONTACT YOUR NEAREST SERVICE CENTER. AFTER 80 DAYS FROM

THE DATE OF PURCHASE, WARRANTY SERVICE IS AVAILABLE BY TAKING YOUR CRAFTSMAN RIDING EQU|PMENT TO

YOU R NEAREST SEARS SERVICE CENTER. (IN-HOME WARRANTY SERVICE WILL STILL BE AVAILABLE AFTER 30 DAYS

FROM THE DATE OF PURCHASE BUT A STANDARD TRIP CHARGE WILL APPLY) THIS WARRANTY APPLIES ONLY

WHILE THIS PRODUCT iS tN THE UNITED STATES

This Warrenty gives you specific ]egel rights, end you may also have other rights which may vary Item state to state.,

SEARS, ROEBUCK AND CO,, D/817 WA, HOFFMAN ESTATES, IL 60179

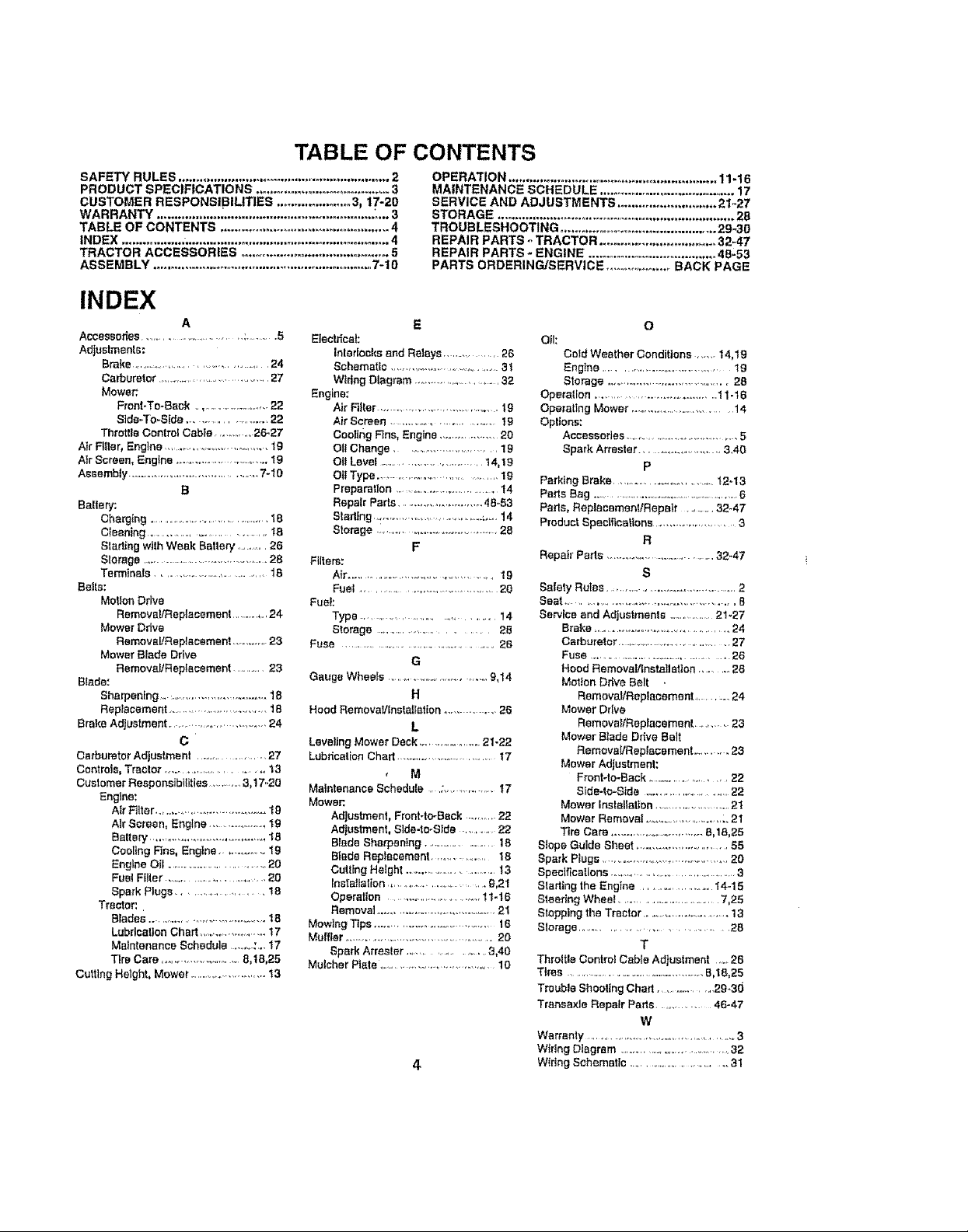

TABLE OF CONTENTS

SAFETY RULES ...................................... ...................... 2

PRODUCT SPECIFICATIONS ....................................... 3

CUSTOMER RESPONSIBILITIES ..................... 3j 17-20

WARRANTY ............................................................. L,.. 3

TABLE OF CONTENTS ................................................ 4

INDEX ............................................................................ 4

TRACTOR ACCESSORIES .......................................... 5

ASSEMBLY ................................................................ 7-10

INDEX

Accessories ................................ ;......... 5

Adjuslmenls:

Brake ................................................24

Carburetor .....................................27

Mower'..

Front*To-Back., ,.........................22

Side-To-Side ...................... 22

Throttle ControlCable ........... 26-27

Air Filler, Engine..................................19

Atr Screen, Engine .................................. 19

Aesembty......................................... 7-10

Baltery:

Charging .........................................18

CIeaning .................................. fB

Starting w]th Weak Battery .............26

Slorage..........................................28

Terminals ................................. 18

Belts:

Mo!ton Drive

RemovaVRep{asemenl............... 24

Mower Drive

RemovaVReplasement ........... 23

Mower Blade Drive

Removaf/Rep_asement .............23

Blade:

Sharpening ......................................18

Replacement.....................................18

Brake Adjustment ............................ 24

CarburetorAdjustment ..................... 27

Controls, Traclor ............................ 13

CustomerResponsibilities .............3,17-20

Engine:

Air Ftlter ........................................19

Atr Screen, Engine ...............19

Battery .................................... 18

Cooling F_ns,Engine............. lg

Engine Oil ............................... 20

Fuel Filter ................................ 20

Spark Plugs .................. 18

Tractor.

Blades ..................................... 1B

LubricationChad.........................17

Maintenance Schedule .........:., 17

Ttre Care ...... .................. 8,18,25

Cutting Helght, Mower ............................13

A

Electr;cal:

Interlocks end Relays.................. 26

Schematic ................................... 31

Wfdng Diagram ............................ 32

Engine:

Air Rilor ................................ t9

Air Screen ................................ 19

Ooot}ng Fins,Engine .................. 20

011Change ......................... 1 9

Oil Levef ................. , .......... 14,19

B

C

Oil Type ...................................... 19

Preparation ..................................14

Repatr Pads ............................46,53

Sladtng ._............................... _....14

Storage ... ................................ 28

Filters:

Air..........................................19

Fuel.....................................20

Fuel:

Type ................................14

Storage ............................... 28

Fuse ................................................... 28

Gauge WheeFs..................................... g,14

Hoed Removat/Instalfetton ..............26

Leveling Mower Deck ................... 21-22

Lubdcalion Chart ...............................17

Maintenance Schedule ;................ 17

Mower,

Adjustment, Front4o-Beck ........... 22

Adjustment, Side-to-Side .............22

Blade Sharpening..........................18

Blade Replacement ................. 18

Cutting Height .................................13

InaIaIlation ................................ g,21

Operation .............................. 11-18

RemovaJ...................................... 21

Mowing Tipe ..................................... 18

Muffler ................................................. 20

Spark Arrasler ......................... 3,40

Muteher Plate ...................................... 10

OPERATION ............................................................ 11-16

MAINTENANCE SCHEDULE ......................................... ! 7

SERVICE AND ADJUSTMENTS ............................ 21-27

STORAGE ..................................................................... 28

TROUBLESHOOTING ............................................ 29-30

REPAIR PARTS o TRACTOR ................................. 32-47

REPAIR PARTS - ENGINE ...................................... 4B-53

PARTS ORDERING!SERVICE ................... BACK PAGE

E

F

G

H

L

M

Oil:

Cold Weather Conditions ...... t4,19

Engine ................................. 19

Storage ....................................... 28

Operallon ................................. 11-t 8

Operaling Mower ................................14

OplJons:

Accessories .....................................5

Spark An'ester ..........................3.40

Parking Brake................................ t2-13

Porte Bag ..........................................................8

Pads, Replacamen_Repetr ........ 32-47

Product Bpeclftcatlons ......................... 3

Repair Pads ...................................32-47

Safety Rules ......................................... 2

Seat .......................................................8

Service and Adjuslmeols ...............21-27

Brake .......................................... 24

Carburetor .......................................27

Fuse ............................................ 28

Hood Removal/Installation....... 28

Motion Odve Belt

Removal/Replacemenf ........... 24

Mower Drive

RemovaIlRep_acement .......... 23

Mower Btade Drive Belt

ReraovaL"Replacement .........23

Mower Adjustment:

FronMo-Back ............................ 22

Side4o-Side........................... 22

Mower Installation ............................21

Mower Removal ............................L21

Tire Care .................................8,18,25

S!ope Guide Sheet ............................. 55

Spark Pluga ......................................... 20

Specifications ............................................3

Starting the Engine ....................... I4.-15

SteeringWheel .............................. 7,25

Stopping the Tractor ...........................13

Slorage................,..................28

Thraltle Oontro_Cable Adjustment ... 28

Tires..................................................... B,I8,25

Trouble ShootingChad .................. 29-30

Transexle Repair Patte ............... 46-47

Warranty ................................................3

Wiring Diagram ...................................32

Wldng Schematic ................................31

O

P

R

S

T

W

ACCESSORIES AND ATTACHMENTS

These accessoriesendattachments were available throughmost Sears retailoutlets and service centers when thetractorwas purchased.

Most Sears stores can order these itemstar you whenyou providethe modal number of your Iractor,

ENGINE

SPARKPLUQ

GAS CAN

ENGINEOIL FUELSTABILIZER AIR FILTER

PERFORMANCE

Searsoffersawide varietyof attachmentsthat f_tyourtractor Many of these arelisted belowwithbdel explanationsofhow they can help

you, Thtsftetwas currentatthe time el publication;however, itmay changetn future years - more altaehmenls may beadded, changes

may be made tn theee altachments, orsome may nolongerbe evailable or fit your medel Contsct your nearest Seare store for the

accessories and attachments that ere available for your tractor,

Most of theseeItechments do not require additional hitches or conversionkite (those thai do are Indicated) and are designed for easy

attaching and detaching

MAINTENANCE

BLADES BELTS

AERATOR promotes deep root growthfor a healthy lawn Ta.

pered 2.5-Inch steel spikes mounted on 10-inch d_ameler discs

puncture holes in soil at ctoseIntercals to let moisture soak In

Steel weight tray for Increasedpenetration

BAGGER lets you collect grass sIIppthgsand ]eaVes for a

healthier, nearer lookinglawn Two Permanex containershem

3e-gallonplasticbags

BUMPER protects front end of Iractarfrom damage,

CARTS make hauling easy Variety of sizes ava_fable, plus

accessories such as aide panel kIls, tool caddy, cart cover,

protective mat and doily

CORING AERATOR takessmelt plugsout of soil to allowmois*

lure and nutrients to reach grass mo!s 36-thch swath 24

hardenedsteel coringtips. 150 _b.capacityweighttray

EASY OIL DRAIN VALVE makes at| changeseas_er,fasler

FRONT NOSE ROLLER canters In front ofmowerdeck 1oreduce

chancesof =scalping" on uneven terrain.

GANGHITCH letsyou tow2or3 pull-behthdattachments atonce,

such as sweepers, dethetshers,aeralors(net forusewith reltere,

cads or other heavy attachmenle)

GAUGE WHEELS on both sides of the mower deck reduce

chancesof"scalpthg" on uneven terrain. Formower decks not so

equipped

MULCH RAKE/DETHATCHER loosens soil end flipsthatchand

mattedteaves tolawn sudace for easypickup. Twenty apdeg time

teeth Usefuttopreparebareareae!orseedthg. Avatlablelorfront

or rear mounting. HIGH PERFORMANCE REEL-ACTION

SPRING 'I"INE DETHATCHER covers 86_]nch wide path and

tossesthatch tnte large hopper Mounts behind tractor

MULCHING CLOSEJOUT PLATE KIT, onceInstalled, letsyou

mulch, discharge or bag ct_ppinge (bagger optional) without

changing blades. For modefs not equipped as 3.Ira1 Convertible

mowers See "MOWER" in the Repair Pads section of this

manual

RAMP TOPS AND FEET let you Ioadand unload tractor from a

pickuptnJck. Use with2 x 8 or 2 x 10 lumber

ROLLER tar smoother lawn surface° 38.,inch wide, 18-thch

dlametarwater-tightdrumholds upto3gOlbs.ofwetghL Rounded

edges prevent harm to tuff Adjustable scraper automatically

otaana drum,

SNOW BLADE forsnow removal oniy. '14-1nchhlgh, 48-Inch wide

bladaclears42qnchpathwhenangledleltordght. Raises, fcwere

withside lever. Adjustable skids; replaceable, reversible scraper

bar. (Use wl!h tirechainsand wheelweightsand/or rear draw_ar

weight ,)

SNOWTHR OWERhas40-thch swath. Drum*type auger handIes

powdery and wet/heavy snow Mounts easily with stmp_epin

arrangement D_schargechuteadjusts from tractorseat. 6-Inch

diameter spoutdischargessnow 10 to 50 feet. Liftcontrolledat

tractorseat. (Use Withchains and wheel weights end/or rear

drawbar welght)

SPRAYERS use 12-volt DC etectdc motor that connects tothe

tractor battery or ether 12-vott source. Includes booms tar

automaticspraying end hand heldwand for spot spraying, Wand

has adjustable spray I_attern, For applytng herbicides, Insecti-

cides, fungicides and liquid lediltzers.

SPREADERISEEDERS make seeding, fartitlztng,and weed kill-

tng easy. Broadcast spreaders are a{souseful forgranular de-

Icers and sand.

SWEEPERS let you collect grass clippingsand leaves

TILLER has 5 hpengine and36-Inchswath toprepare seed beds,

cultivate and compost garden residue Ttl]er has its own bulll..In

lift and depthcontrolsystem and does NOTrequireasleeve hitch.

Fits any lawn yard or gardentractor. Simply hookuptothetractor

drawbar and gel Optional accessories convert unit for

dathatchtng, aerating, hitting, without toots

TIRE CHAINS ere heavy duty; ctosely spaced extraqarge cross

links give smooth dde, outstandingtraction.

TRACTOR CAB has heavy du|y vinyl' fabdc over tubular steel

frame,ASS plastictop; _learptast|c windshield offers 360 degree

v[slblllty.Hinged metal doorswith catch. Keeps operator warm

and dry. Remove vthyl sides and wthdshiefdsfor use as sun

protector tn summer. Optional accessories Include: tinted!

tempered solid safetyglass wtedshie_dwithhandoperatedwtper,

12-voltamber caution light for mounting on cab top

VACS for powerful coltecllon ofheavy grass clippingsandleaves.

Optional wand attachment to pick up debds Inherd-to-reach

places. VAC/CHIPPER Includes a chipper-shredder.

WEIGHT BRACKET tar drawbar for snow removal appllcallenso

Uses(!) 55 lb weight

WHEEL WEIGHTS lor rear wheels provide needed traction for

snow removalor dozing heavy matedats i

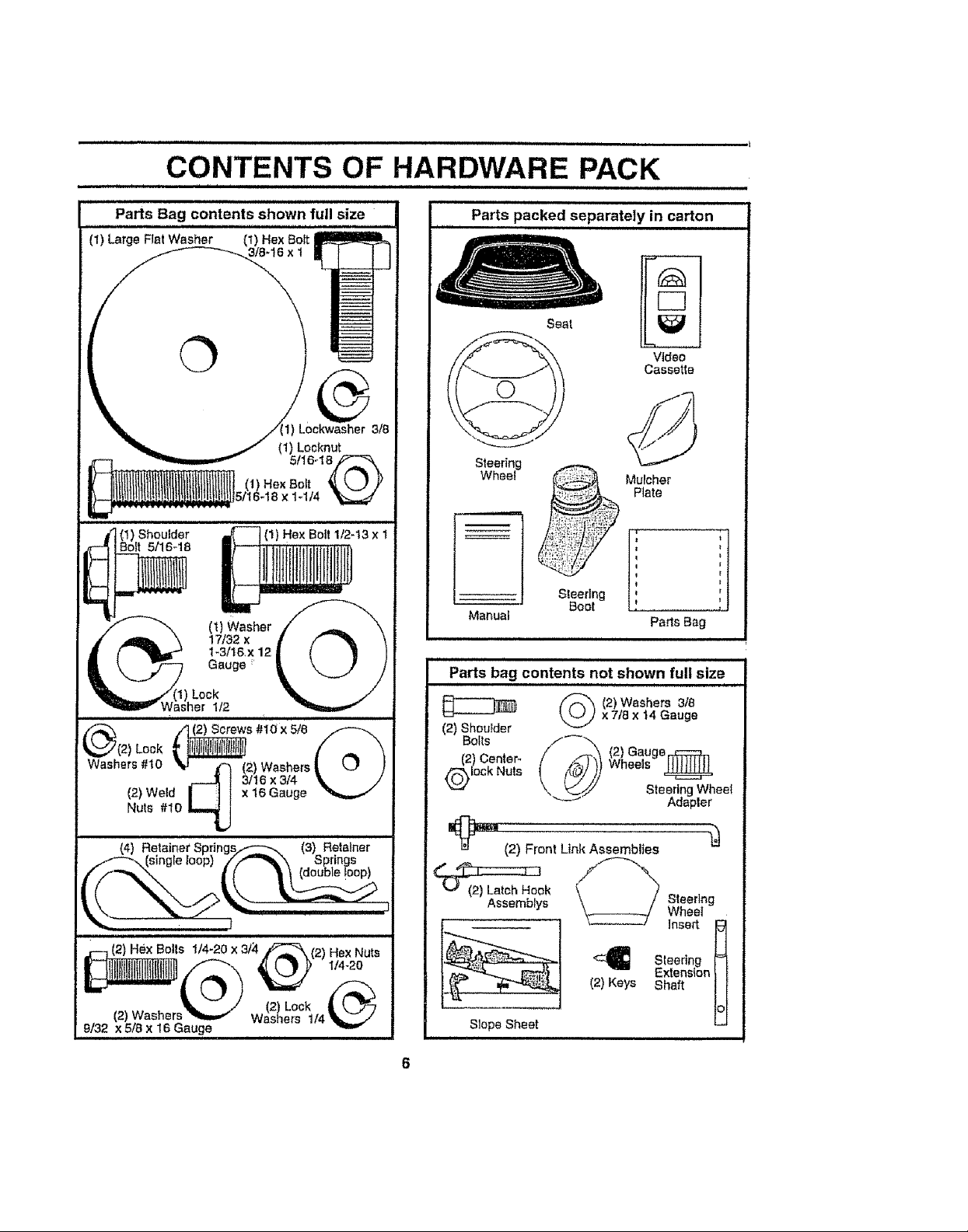

CONTENTS OF HARDWARE PACK

Parts Bag contents shown full size

(1) Large Flat Washer 1) Hex Bolt

i ,i i i

(1) Shoulder (1) Hex Beat 112-13 x 1

Bolt 5/16-18

, Lock

3t8-16 x 1

Loekwasher 3/8

(1) Locknut

(1) Hex Bolt _ \._) y

511648 X Iq14

(1) Washer

17t32 x

1-3116,x 12

Gauge

1/2

(2)Le k{: [ ,..,

Washers #10 _ t(_ (2) Washers _, _ )

(2) Weld I ] I x16Gauge

Nuts #10

(4) Retainer Spdn (3) Retainer

[single loop) Springs

I 3116 x 3t4 _ /

(double loop)

Parts packed separately in carton

Seat

Video

Cassette

Steering

Wheel Mulcher

Steering

Manual

Boot

Plate

Paris Bag

Parts bag contents not shown full size

(2) Shoulder

Bolts

(2) Center-

Iock Nuts

_(2) Front Link Assemblies

(_(2) Washers 318x 7t8 x 14 Gauge

(2) Gauge

Wheels

Steering Wheel

Adapter

(2) Hex Bolts _L'_j_ 1/4-20

9/32

i

Washer,, Washers 114_w,/

1/4-20 x 3t_, _k_(2) Hex Nuts

(2) Lock _

i in

Assemblys Steering

Slope Sheet

i i

_-_ Steering

(2) Keys Shaft

Extension

Wheel

ASSEMBLY

i u n ii i i u

Your new tractor has been assembled at the factory wtth exception of Ihose parts left unassembted for shipping pu_'poses_

T_ ensure sa_e and pro_er o_erati_n _f y_urtrac_or aI_part_ and hardware yod assembIe mus_ be _igh_ned secure_y_ Use

the correct tools as necessary to insure proper tightness,

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are Hsted

(1) 9t16" wrench (1) 3/4" Socket w/drive rachet

(2) 7t16" wrenches Phillips Screwdriver

(2) I/2" wrench Tire pressure gauge

(!) 3/4" wrench Utility knife

When right or felt hand is mentioned tn this manual, It

means when you are in Ihe operating posilion (seated

behind the steering wheel).

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton (See page 6)_

• Cut, from top to bottom, along lines on all four come.re

of carton, and ray panels flat

• Remove mower end package materials

. Check far any additional loose parts or cartons and

remove,

BEFORE ROLLINGTRACTOR OFF SKID

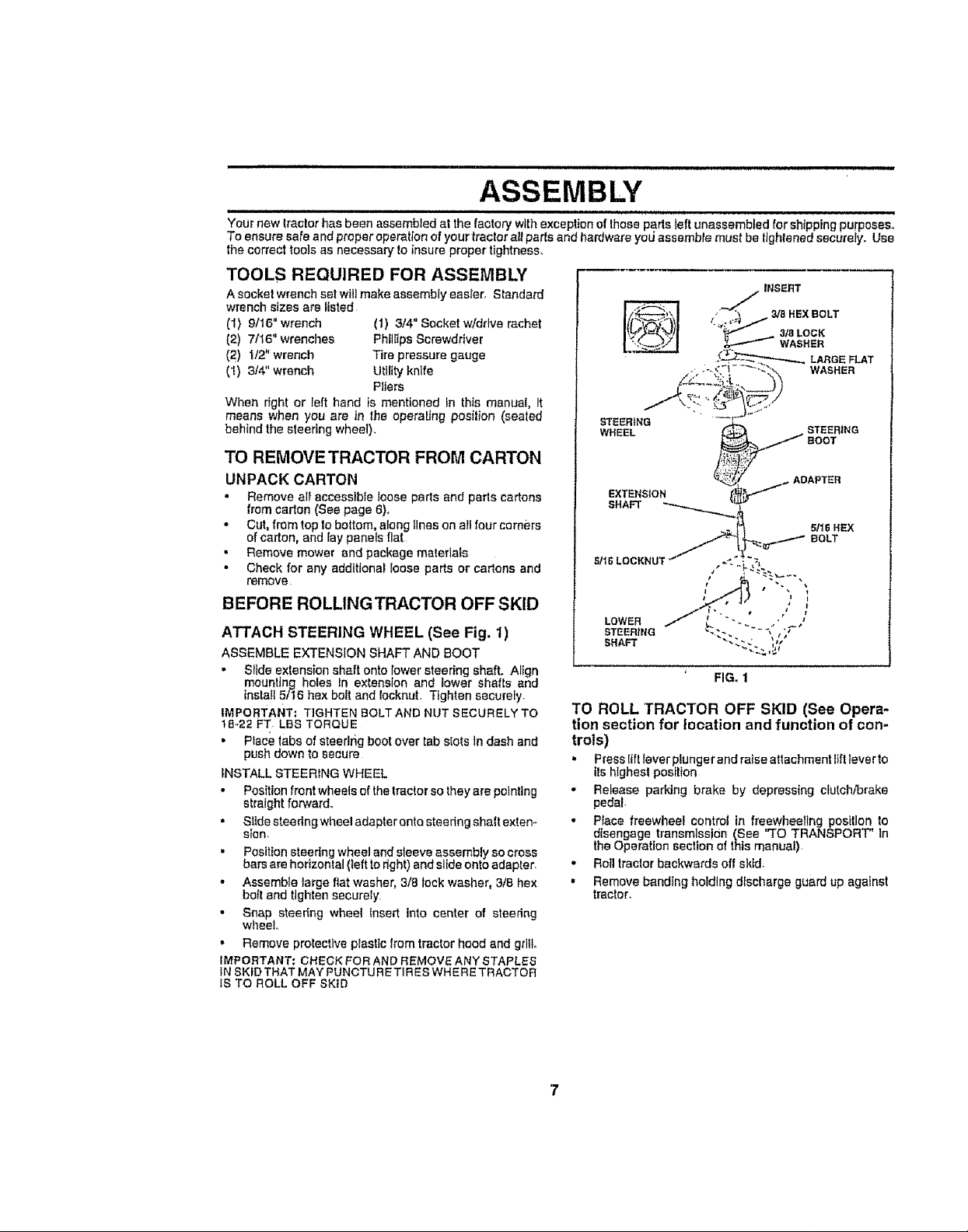

ATTACH STEERING WHEEL (See Fig. 1)

ASSEMBLE EXTENSION SHAFT AND BOOT

• Slide extension shaft onto lower steering shaft. Align

mounting holes In extension end lower shafts and

install 5/t6 hex bolt and Iocknut. Tighten securely

IMPORTANT: TIGHTEN BOLT AND NUT SECURELY TO

t8-22FT LBSTORQUE

• Place labs of steering boot over tab slots tn dash and

push down to secure

INSTALL STEERING WHEEL

• Position front wheels of the tractor so they are polnttng

straight forward.

• S!Ide steedng wheel adapter onto steering shaft exten-

sion.

• Position steering wheel and sleeve assembly so cross

bars are horizontal (lett to right) and slide onto adaple r.

• Assemble targe fiat washer, 318 lock washer, 3/8 hex

belt end tighten securely.

• Snap steering wheel Insert into center of stee_ing

wheel,

• Remove protective plastic from tractor hood and grill.

IMPORTANT: CHECK FOR AND REMOVE ANY STAPLES

{NSKID THAT MAY PUNCTURETIRES WHERE TRACTOR

tS TO ROLL OFF SKID

Pliers

5t16 HEX

BOLT

5/16 LOCKNU_

FIG. 1

TO ROLL TRACTOR OFF SKID (See Opera-

tion section for location and function of con-

trois)

• Press !ift fever plunger and ratse attachment lifHever to

its highest position

• Release parking brake by depressing clutch/brake

pedal

• PIace freewheel control in freewheeling position to

disengage transmission (See "TO TRANSPORT" tn

the Operation section of this manual)

,' Rotl tractor backwards off skid.

" Remove banding holding dlscharge guard up against

tractor,

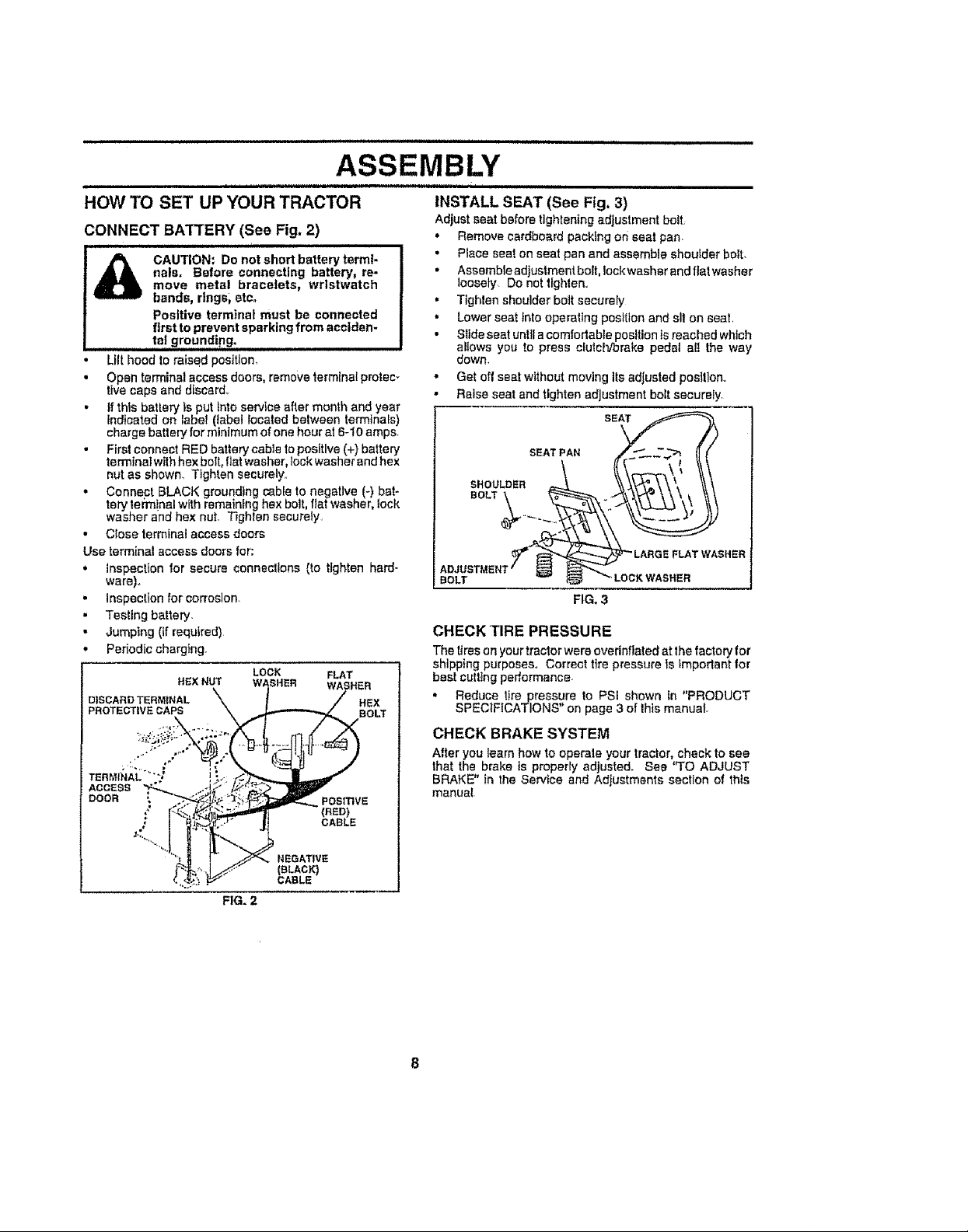

ASSEMBLY

HOW TO SET UP YOUR TRACTOR INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment boll

CONNECT BATTERY (See Fig. 2) • Removecardboardpackingon seatpan

nals, Before connecting battery, re,.

CAUTION: Do not short battery termi-

move meta! bracelets, wristwatch

bands, rings, etc.

Positive terminal must be connected

first to prevent sparking from acciden-

tal groundi_qg.

Lilt hood to raised position,

• Open terminat access doors, remove terminal protec v

tire caps and discar&

• If thts battery is put Into service after month and year

indicated on label (label located belween terminals)

charge battery for minimum of one hour at 6-t o amp&

• First connect RED battery cable lo positive (+) battery

terminalwith hex bolt, fiat washer, lock washer and hex

nut as shown_ Tighten securely..

• Connect BLACK grounding cable to negative (-) bat-

tory teh'n!nal with remaining hex bolt, liar washer, lock

washer and hex nut. Tighten securely.

, Close terminal access doors

Use terminal access doors for:

• Inspection tot secure connections (to tighten hard-

ware).

. inspection for corrosion

• Testing battery.

• Jumping (if required)

. Pedodic charging.

HEX NUT WASHER

O1SCARD TERMINAL HEX

PROTECTIVE CAPS BOLT

TERMINAL

ACCESS

DOOR

i

LOCK FLAT

CABLE

• Place seat on seat pan and assemble shoulder bolt.

• Assembte adjustment bolt, lock washer and flat washer

loosely Do not tighten..

• Tighten shoulder boit securely

• Lower seat into operating position and sit on seat.

• Slide seat until acomfortable position isreached which

allows you to press clutcl',/'orake pedal all the way

down,

- Get oft seat without moving its adjusted posltlon.

• Raise seat and tighten adjustment bolt securely

SEAT

SEAT PAN

BOLT

FIG, 3

CHECK TIRE PRESSURE

The tires on your tractor were ovednflated at the factory for

shipping purposes. Correct tire pressure Is tmpodant tor

best cutting performance.

• Reduce tire pressure to PSi shown in "PRODUCT

SPECIFICATIONS' on page 3 of !his manual.

CHECK BRAKE SYSTEM

After you learnhowto operale yourtractor,check tosee

that the brake Is properlyadjusted. Bee "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manual,

=LATWASHER

FIG. 2

NEGATIVE

(aLACK)

CABLE

ASSEMBLY

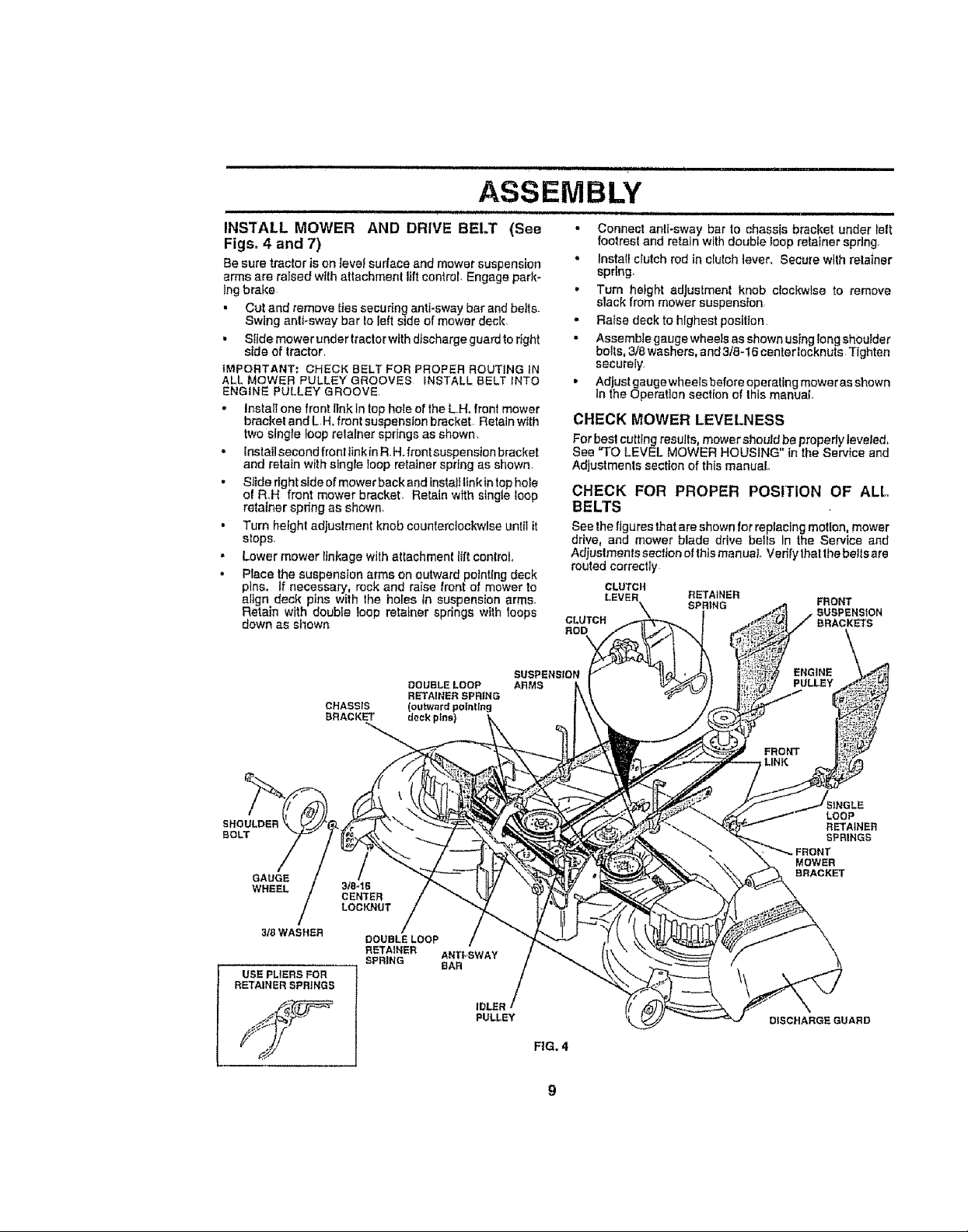

INSTALL MOWER AND DRIVE BELT (See

Figs° 4 and 7)

Be sure tractor ison leve_ surface and mower suspension

arms are raised with attachment liftcontrol Engage park-

tng brake

• Cut and remove Iias securing anti-sway bar and belts.

Swing anti-sway bar to left side of mower deck

• Slide mower under tractor with discharge guard to right

side of tractor.

IMPORTANT,' CHECK BELT FOR PROPER ROUTING IN

ALL MOWER PULLEY GROOVES INSTALL BELT INTO

ENGINE PULLEY GROOVE.

• Instal! one front link in top hole of the L.H, front mower

bracket and L H. front suspension bracket Retain with

two singre loop relatner springs as shown

• instaiI second fronl tink inR H. front suspension bracket

and retain with single loop retainer spring as shown.

SJide right side of mower back and installlink intophole

of R,H front mower bracket. Retain wfth single loop

retainer spring as shown.

• Turn height adjustment knob counterclockwise until it

stops.

• Lower mower linkage with attachment lift control

,, Place the suspension arms on outward potnting deck

pins. If necessary, rock and raise front of mower to

align deck pins with the holes in suspension arms.

Retain with double loop retainer springs with loops

down as shown

i,ll i lliNi

• Conneot anli-sway bar to chassis bracket under left

footrest and retain with double loop retainer spflng.

• Install clutch rod in ciutch lever. Secure with relainer

sprtng_

,, Turn height adjustment knob clockwise to remove

slack from mower suspension.

,' Raise deck to highest position.

• Assemble gauge whee}s as shown using !ong sh0ulder

bolts, 3/8 washers, and3tS-16 centerlocknuts Tighten

securely.

• Adjustgauge wheefs before operating mower as shown

tn the Operation section of this manual.

CHECK MOWER LEVELNESS

Forbest cutting results, mower should be properlyleveled,

See "TO LEVEL MOWER HOUSING" Inthe Service and

Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion, mower

drive, and mower blade drive belts In the Service and

Adiuslmentssec_ionofthismanua_. Verify thai the belts are

routed correctly

CLUTCH

LEVER RETAINER

CLUTCH

ROD

SPRING FRONT

SUSPENSION

SHOULDER

BOLT

3_ WASHER

USE PLIERS FOR

RETAINER SPRINGS

DOUBLE LOOP

CHASSIS (outward po{nting

BRACKET deck pins)

318-16

CENTER

LOCtGNUT

RETAINER SPRING

DOUBLE LOOP

RETAINER ANTI,,SWAY

SPRING BAR

iDLER /

PULLEY

SUSPENSION

ARMS

FIG. 4

iNGLE

LOOP

RETAINER

SPRINGS

FRONT

MOWER

BRACKET

DtSCHARGE GUARD

= ,,,,,, =,

' ' = i_= = v = == = = i=

ASSEMBLY

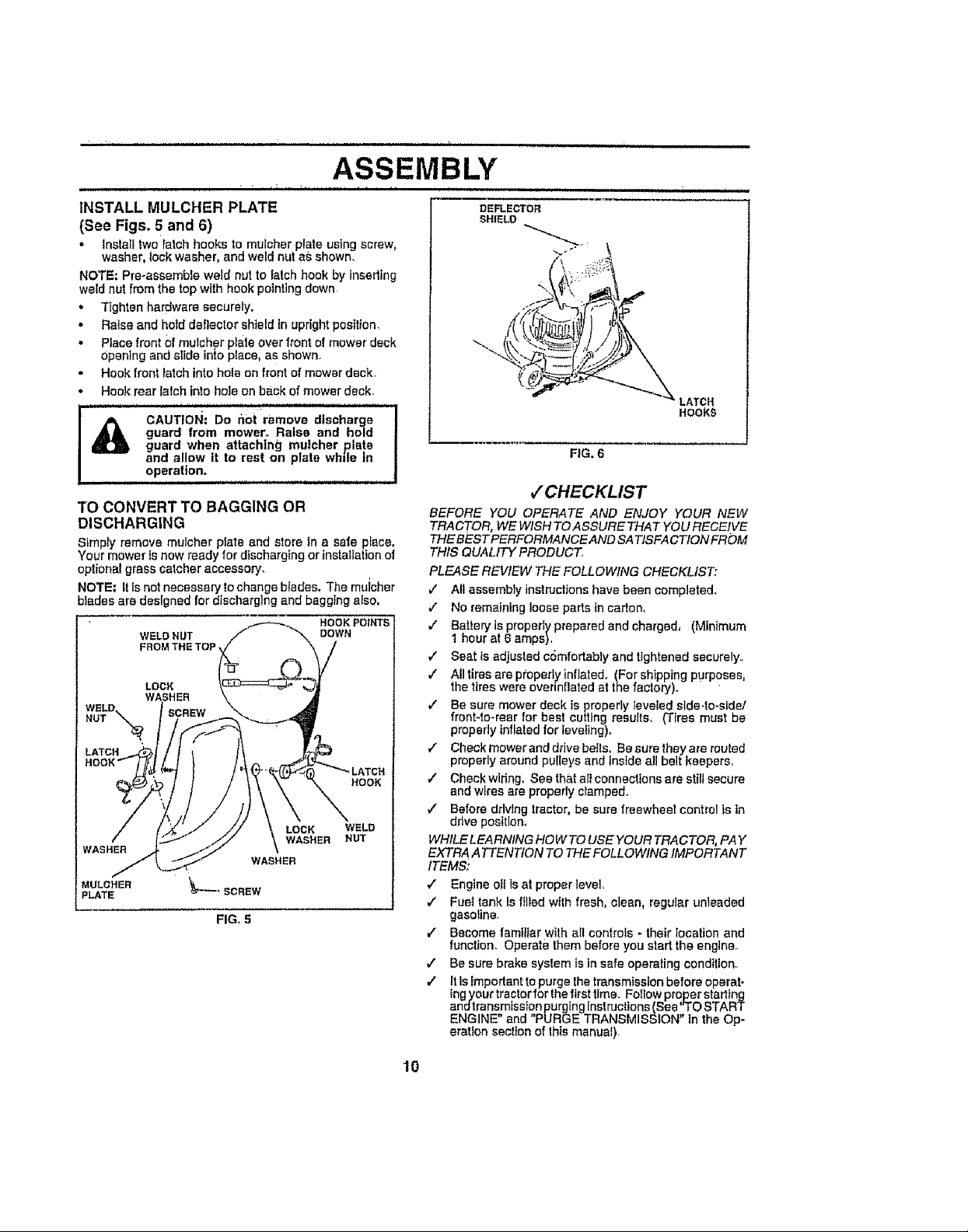

INSTALL MULCHER PLATE

(See Figs, 5 and 6)

• Install two fetch hooks to mulcher plate us{rig screw,

washer, lock washer, and weld nut as shown,

NOTE: Pro*assemble weld nut to latch hook by fnseding

weld nut from the top with hook pointing down

• T_ghten hardware securely,

• Raise and hold deflector shield in upright position,

• Place front Of mulch er plale over front of mower deck

Opening and sTida into place, as shown°

,, Hook front latch into hole on front of mower deck

• Hook rear talch into hole on back of mower deck.

guard from mower_ Raise and hold

CAUTION: Do r_0t r_move discharge

guard when attaching muloher plate

and allow it to rest on plate while in

operation.

TO CONVERT TO BAGGING OR

DISCHARGING

S_mp_yremove mulcher plate and store tn a safe place.

Your mower is now ready for discharging or installationof

optional grass catcher accessory,

NOTE: It isnot necassarytochangeblades. The muicher

blades are designedfor discharging and bagging also.

HOOK POINTS

LOCK

WASHER

DOWN

HOOK

WELD

NUT

WELD NUT

FROM THE TOP

LOCK

WELD_

NUT _ SCREW

WASHER

MULCHER

PLATE

WASHER

FIG. 5

DEFLECTOR

SHIELD

_LATCH

HOOK_

FIG. 6

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TO ASSURE THAT YOU RECEIVE

THE BEST PERFORMANCE AND SA TISFA CTION FROM

THIS QUAt.tTY PRODUCT_

PLEASE REVIEW THE FOLLOWING CHECKLIST:

,/ Alt assembly instructions have been completed.

v" No remaining loose parts in cation.

,/" Battery is properfy prepared and charged, (Minimum

1 hour at 6 stops),

/ Seat ls adjusted comfortably and tightened securely,

." All tires are properly inflaled, (For shipping purposes,

the tires were overinflated at the factory)°

/ Be sure mower deck is properly leveled side.to-side/

front-to-rear for best cutting results, (Tires must be

properly inflated for leveling).

,z Check mower and drive bells, Be sure they are rouled

properly around pulleys and inside all bait keepers,

/ Check widng, See that all connections are still secure

and wires are properly clamped.

/ Before driving &actor, be sure freewheel control is in

drive position,

WHILE L EARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA ATTENTtON TO THE FOLLOWING IMPORTANT

ITEMS;

•,/ Engine olt ls at proper level,

,/ Fuel tank ts _fed with fresh, clean, regular unleaded

gasoline,

,,z Become familiar with all controls - their Tocation and

funcltan. Operate them before you start the engine,

,/ Be sure brake system is in safe operating condition,

/ it tsimportant to purge the transmissfon before operet-

Ing your traclor for the first time. Follow proper starting

andlransmission purging instructions (See "TO START

ENGINE" and "PURGE TRANSMISSION" in the Op-

eration section of this manual).

10

,Lu! ,,,H H i= = = == i=ll= ii

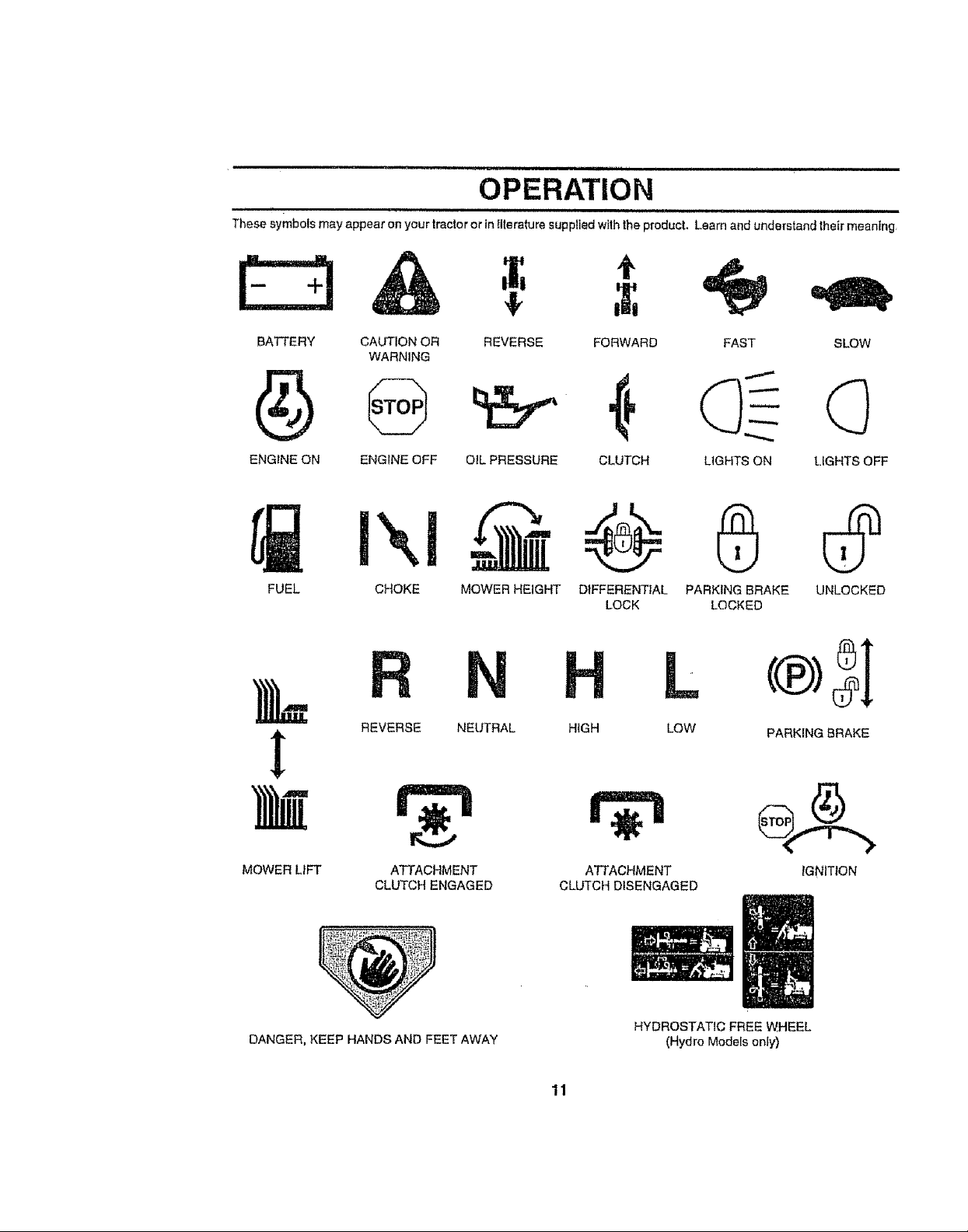

OPERATION

These symbols may appear on your tractor or in literature supplied with the product, Learn and understand their meaning

BATTERY CAUTION OR REVERSE FORWARD FAST SLOW

ENGINE ON ENGINE OFF OIL PRESSURE CLUTCH L1GHTS ON UGHTS OFF

FUEL

WARNING

CHOKE MOWER HEIGHT DIFFERENTtAL PARKING BRAKE UNLOCKED

LOCK LOCKED

L

REVERSE NEUTRAL

HIGH LOW

MOWER LIFT

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT ATTACHMENT IGNITION

CLUTCH ENGAGED CLUTCH DISENGAGED

m

HYDROSTATIC FREE WHEEL

(Hydro Models only)

11

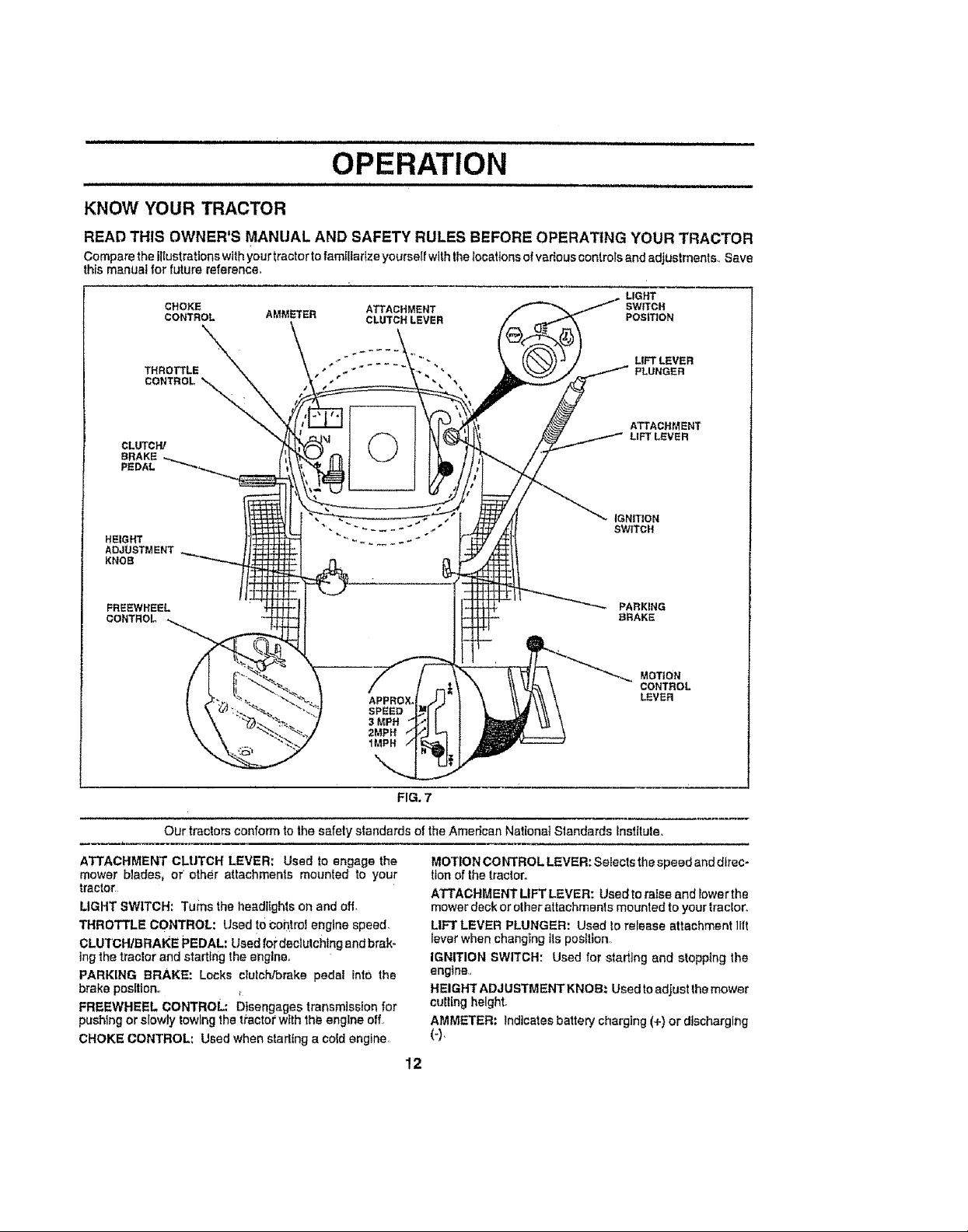

KNOW YOUR TRACTOR

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the iltustrations with your tractor to familiarize yourseff withthe locations of various controls and adjustments, Save

this manual for future reference.

CHOKE ATTACHMENT SWITCH

CONTROL AMMETER CLUTCHLEVER POSITION

LIGHT

THROTTLE

CONTROL

CLUTCW

BRAKE

PEDAL

HEIGHT

ADJUSTMENT

KNOB

FREEWHEEL

CONTROL

©

APPROX,

SPEED

3 MPH

2MPH

1MPH

FIG. 7

LIFTLEVER

PLUNGER

ATTACHMENT

LIFT LEVER

IGNITION

SW_CH

PARKING

BRAKE

MOTION

CONTROL

LEVER

OUr tractors conform to the safety standards of the Amedcan Nattonat Slandards Instltule,

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mmmted to your

tractor.

LIGHT SWITCH; Turns the headlights on and ofL

THROTTLE CONTROL; Used to control engine speed,

CLUTCHIBRAKE PEDAL: Used fordec_utchtng and brak-

ing the tractor and starting the engine,,

PARKING BRAKE: Locks c_utch/brake pedal into the

brake posit}on.,

FREEWHEEL CONTROL: Disengages transmission for

pushing or slowly towing the tractor with the engine off.,

CHOKE CONTROL; Used when starting a cold engine,

MOTION cOWrROL LEVER: SeIects the speed and direc-

tion of the tractor,

ATTACHMENT LIFT LEVER: Used to raise and lower the

mower deck or ether attachments mounted to your traclor,

LIFT LEVER PLUNGER: Used to re_ease attachment Hit

lever when changing its position,

IGNITION SWITCH: Used for staffing and stopping the

engine,

HEIGHT ADJUSTMENT KNOB_ Used toadjust the mower

cutting height,

AMMETER: Indicates battery charging (+) or dlssharglng

(-),

12

i

OPERATION

,,,,,,,,,,,,,,,,,,,,,i,,,,,,,, i,, , ,,, i, i

In severe eye damage,, Always wear safety glasses or eye shields while operating your tractor

or performing any adjustments or repairs° We recommend a wide vision safety mask over the

spectacles or standard safety glasses. ,.......

HOW TO USE YOUR TRACTOR

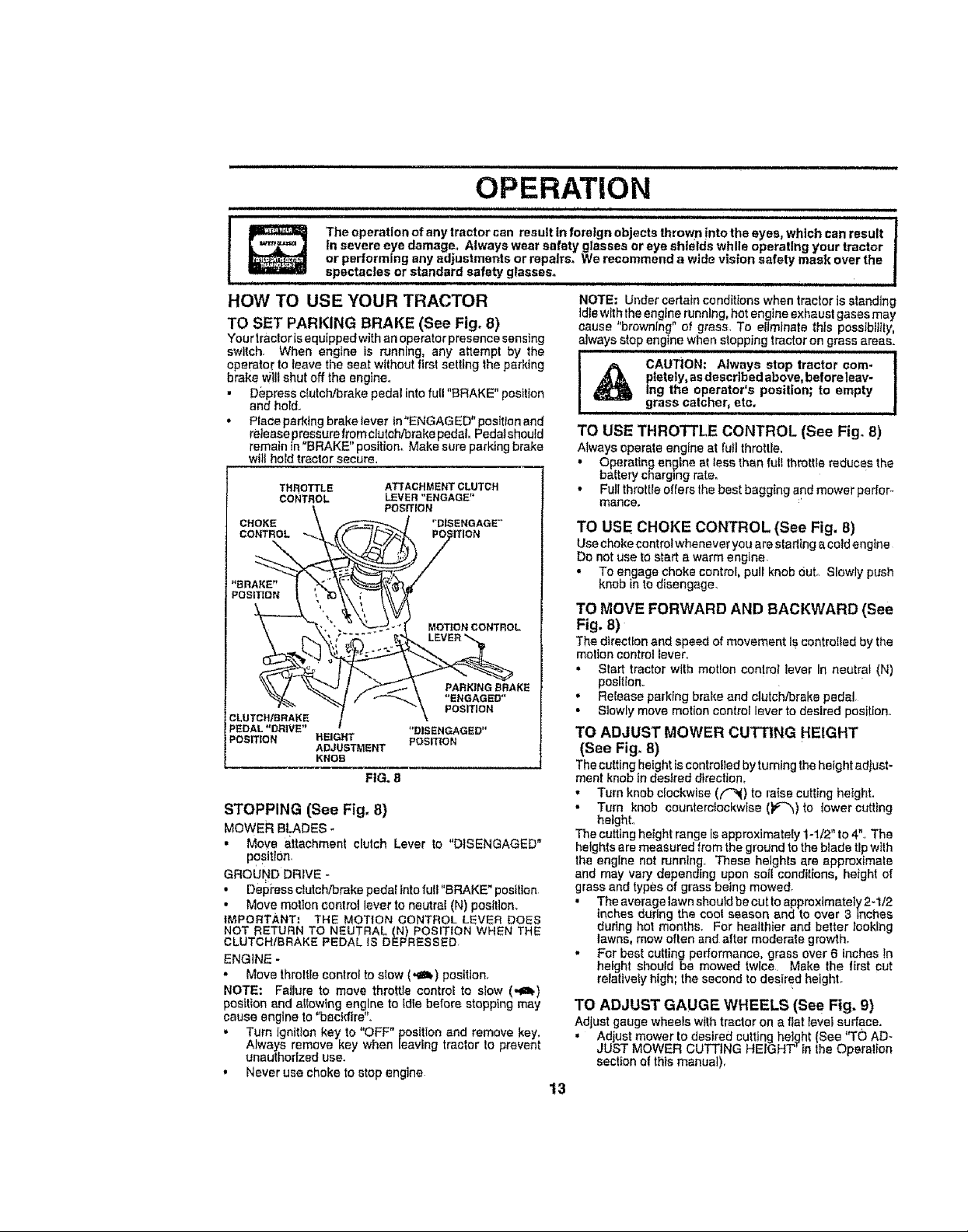

TO SET PARKING BRAKE (See Fig, 8)

Your tractor Is equipped with an operator presence sensing

switch. When engine is running, any atlempt by the

operator to leave the seat without first setting lhe parking

brake Wlil shut off the engine.

• Depress c_utch/brake pedal into full "BRAKE" position

and hold.,

• Place parking brake lever in"ENGAGED" position and

release pressure from clutch!brake pedal, Pedalshould

remain {n "BRAKE' position. Make sure parking brake

wilI hold tractor secure.

THROTTLE ATTACHMENT CLUTCH

CONTROL LEVER"ENGAGe'

CONTROL

CLUTCHfBRAKE

PEDAL"DRWE"

POSITION

HEIGHT POSITION

ADJUSTMENT

KNOB

STOPPING (See Fig, 8)

MOWER BLADES -

• Move attachment clutch Lever to "DISENGAGED"

P0sit{0n,

GROUND DRIVE -

• Dope"ass clutch/brake pedal into full "BRAKE" position

• Move motton control lover to neutral (N) position.

IMPORTANT,' THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (hi) POSITION WHEN THE

CLUTCHIBRAKE PEDAL tS DEPRESSED

ENGINE -

• Move throltle centre! to stow (,,_h.) position.

NOTE: Failure to move throttle control to slow (*_!.)

posttton and allowing engine to {die before stopplng may

cause engine to "backfire".

" Turn ignition key to "OFF" posit_on and remove key.

Always remove key when leaving tractor to prevent

unauthorfzed use.

, Never use choke to stop engine

POSfffON

FIG. 8

"DISENGAGE"CHOKE

MOTION CONTROL

PARKSNG BRAKE

"ENGAGED"

POSITION

"DISENGAGED"

,1 ii ii i

NOTE: Under certain conditions when tractor is standing

tdtewlth the engine running, hot engine exhausl gases may

cause "browning" of grass, To eliminate this possibtlffy,

always stop engine when stopping tractor on grass areas.

,,,,i J, LI

CAUTION; Always stop tractor com- !

ptetely, as described above, before leav- I

Ing the operator's position; to empty I

, , grass catcher, etc, I

TO USE THROTTLE CONTROL (See Fig° 8)

Always operate engine at fu_l throttle,

• Operating an_Ina at less than full throttle reduces the

battery charging rate.

• Full throttle offers the best bagging and mower perfor_

mance. :'

TO USE CHOKE CONTROL (See Fig. 8)

Use choke controlwhenever you are staritng acold engine

De not use to start a warm engine.

• To engage choke control, pull knob duL Slowly push

knob in to disengage.

TO MOVE FORWARD AND BACKWARD (See

Fig. 8)

The direction and speed of movement Is controlled by the

motion control lever.,

• Start tractor with motion control lever In neutral (N)

position,.

,, Release parking brake and clutch/brake pedal,

• Slowly move motion control lever to desired position..

TO ADJUST MOWER CUTTING HEIGHT

(See Fig. 8)

The cutting height is conlrofled by tuming the height adjust-

ment knob in desired direction.

• Turn knob clockwise (('_) to ra{ss cutting height.

• Turn knob counterclockwise (l#-'_)to tower cutting

height.,

The cutting height range Is approximatefy 1-1/2" to 4"., The

hetghls are measured from the ground to the blade tip wlth

the engIRe not running, "These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

• The average lawn should be cut toapproximately 2-1/2

inches during the cool season and to over 3 inches

during hot months. For healthier and belier looking

lawns, mow often and attar moderate growth.

. For best cutting performance, grass over 6 inches in

height should be mowed twice Make the first cut

relalively high; Ihe second to desired hetghL

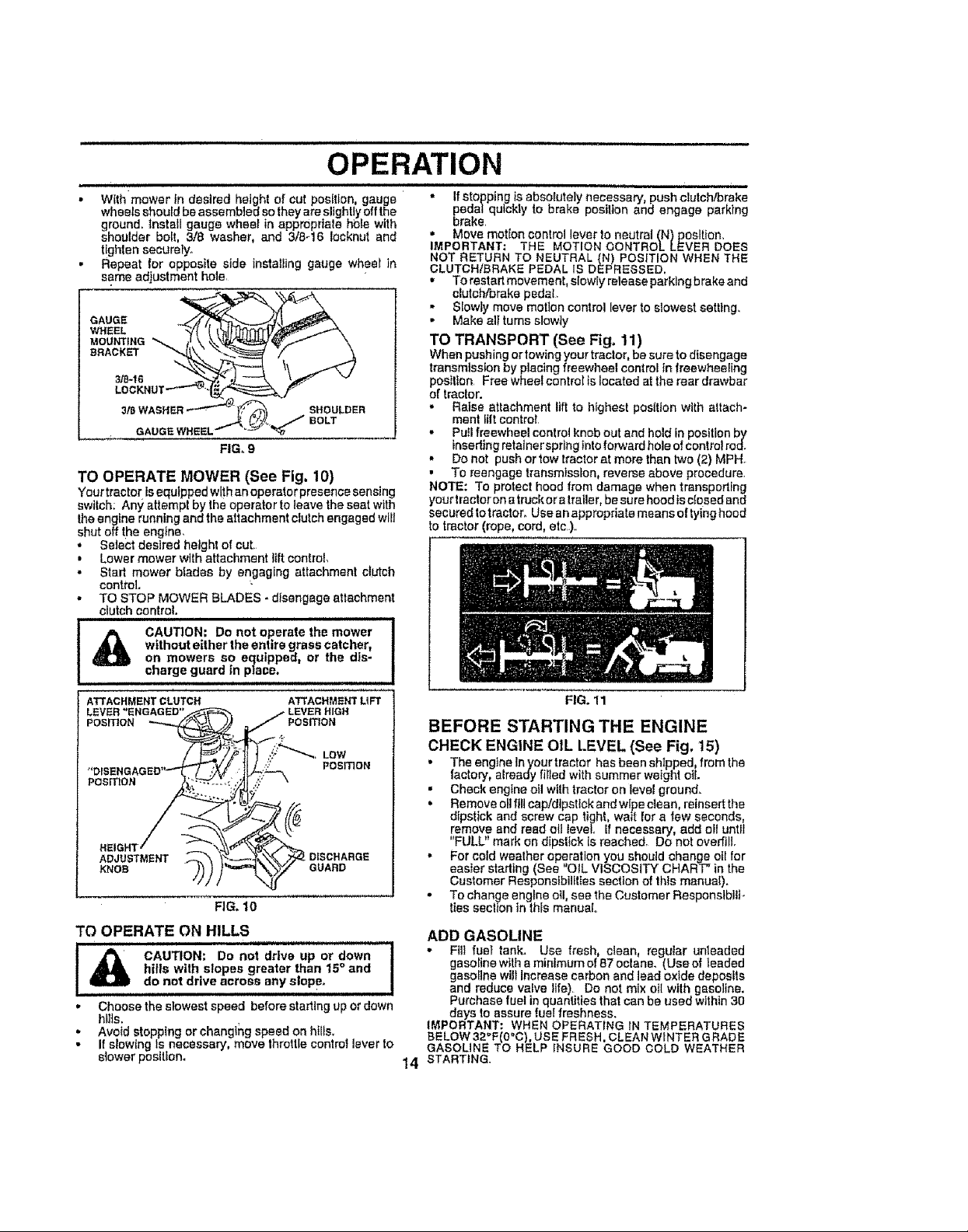

TO ADJUST GAUGE WHEELS (See Fig. 9)

Adjust gauge wheels with tractor on a fiat levst surface.

• Adjust mower to desired cutting height (See "TO AD-

JUST MOWER CUTTING HEIGHT' _nthe Operation

section of this manual),

13

,

OPERATION

• With mower In desired height of cut position, gauge

wheels should be assembled so they are slightly off the

ground, tnstall gauge wheel in apprepdate h_e with

shoulder bolt, 3/8 washer, and 3/8-16 Iocknut and

tighten secureiyo

. Repeat for opposite side installing gauge wheel In

same ad}ustment hole,

GAUGE

WHEEL

MOUNTING

BRACKET

SHOULDER

GAUGE WHEEL'

FIG. 9

BOLT

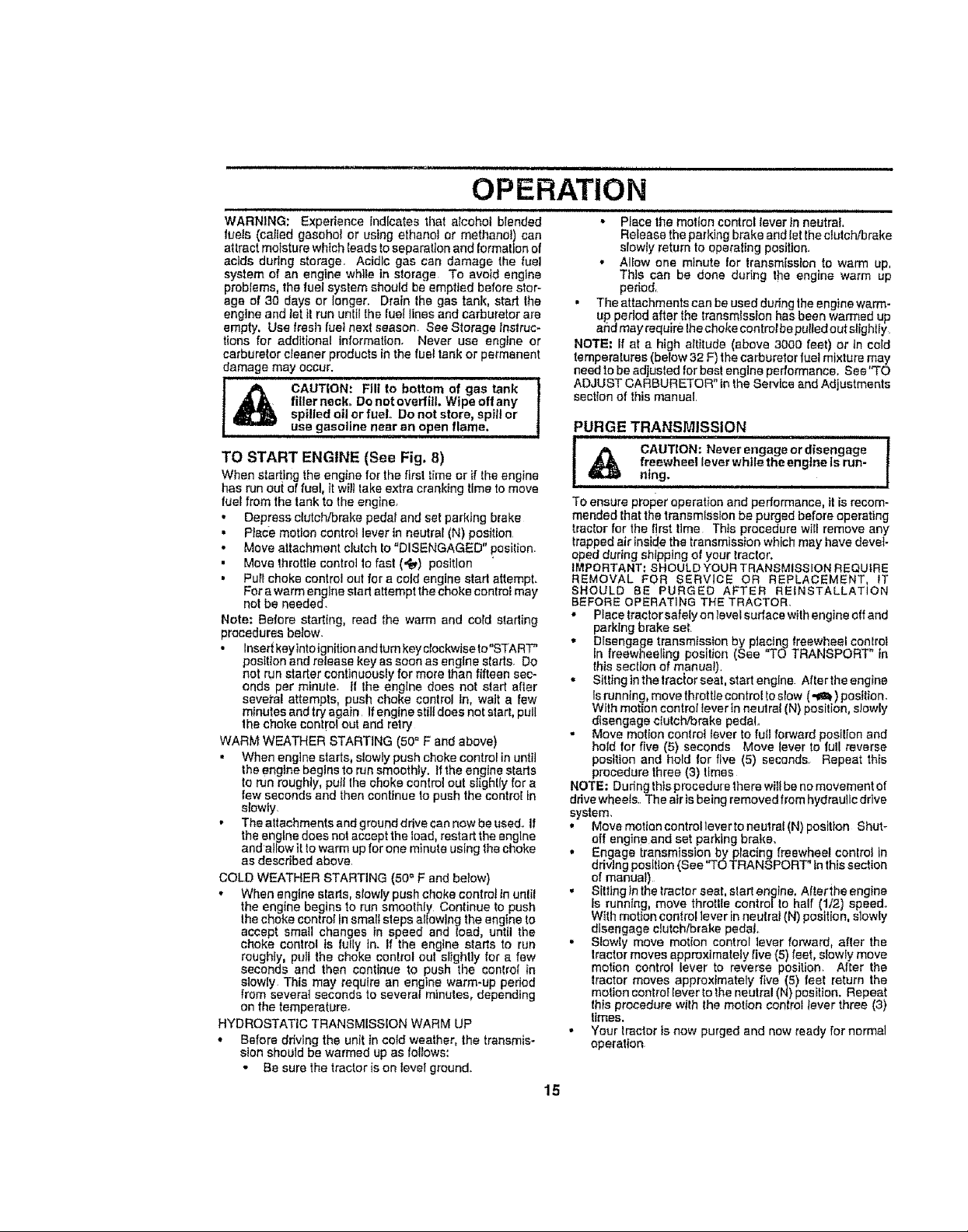

TO OPERATE MOWER (See Fig. 10)

Your tractor is equipped w!th an operatorpresence sensing

switch: Any attempt by the operator to leave the seat with

the engine running and the attachment clutch engaged will

shut off the engine,

• Select desired height of cut,

o Lower mower with attachment lift control,

• Start mower blades by engaging attachment clutch

control

• TO STOP MOWER BLADES. disengage attachment

clutch control.

=

without either the entire grass catcher_

CAUTION: Do not operate the mower

on mowers so equipped, or the dis-

i

ATTACHMENT CLUTCH ATTACHMENT L1FT

LEVER "ENGAGED"

POSITION POSITION

POSITION

TO OPERATE ON HILLS

• Avoid stopping or changing speed on hiIts,

• if s_owtng Is necessary, move throtlte control lever to

charge guard in place.

ADJUSTMENT

KNOB GUARD

FIG. 10

i i =l H,=HH

hills with slopes greater than 15 ° and I

CAUTION: Do not drive up or down I

do not drive across any slope, I

u,=,, ,u,,, ,,HL ]

Choose the slowest speed before starting up or down

hills.

slower position.

• If stopping is absolutely necessary push clutch/brake

pedalqu_ckly to brake pesilton and engage parking

brake,

• Move motion control lever to neutral (N)posltion,

IMPORTANT: THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED,

• To restart movement, slowly release parking brake and

clutch/brake pedal

Slowly move motion control lever to slowest setting,

• Make eli rums slowly

TO TRANSPORT (See Fig. 11)

When pushing or towing your tractor, be sure to disengage

transmission by placing freewheel control In freewheeling

position Free wheel control is located at the rear drawbar

of tractor.

o Raise attachment lift to highest position with attach-

ment Ittt control

- PuII freewheel control knob out and hold in position by

inserting retainersprlng intoforward hole of control rod.

', Do not push or tow tractor at more than two (2) MPH.

• To reengage transmission, reverse above procedure.

NOTE: To protect hood from damage when transporting

yourt raclor on a truckor a trailer, be sure hood is c}esed and

secured to tractor_ Use an appropriate means of tying hood

to tractor (rope, cord, etc),

FIG. 11

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL (See Fig. t5)

• The engine Inyour tractor has been shipped, from the

factory', already titled with summer weight oil.

• Check engine oil with tractor on level ground.

• Remove oil lilt cap/dipstick and wipe clean, retnsert the

dipstick and screw cap tight, wa_t for a few seconds,

remove and read oil level, If necessary add oli until

FULL mark on dipstick Is reached, Do not overfill.

• For cold wealher operation you should change oil for

easier starting (Sea OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manual),

• To change engtne oil, see the Customer Responstbtlt.

ties section in this manual

ADD GASOLINE

• Fill fuel tank. Use fresh, clean regular unleaded

gasoline w tha m n mum of 87 octane. (Use of leaded

gasoline will increase carbon and teed oxide deposits

and reduce valve life). Do not mix oil with gasoline.

Purchase fuel in quantities that can be used within 30

days to assure fuel freshness.

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW 32°F(0°C) USE FRESH, CLEAN WINTER GRADE

GASOL NE TO HELP INSURE GOOD COLD WEATHER

STARTING.

14

OPERATION

WARNING:Experienceindicatesthatalcoholblended

fuels (called gasohol or using ethanol or methanol) can

atlract molsture which {cads to separation and {ormalion of

acids during storage. Acidic gas can damage the fuel

system of an engine whlle in storage To avoid engine

problems, the fuel system should be emptied before stor-

age of 30 days or longer. Drain the gas tank, stad lhe

engine and let it run until the fuel lines and carburetor are

empty, Use fresh fue! next season. See Storage !nslruc-

lions for additional information. Never use engine or

carburetor cleaner products in the fuel tank or permanent

damage may occur.

CAUTION: Fill to bottom of gas tank

filler neck,, Do net overfill Wipe off any

lg !

TO START ENGINE (See Fig. 8)

When start!ng the engine for the first time or if the engine

has run out of fuel, it wiJt lake extra cranking time tomove

fuel from the tank to the engine.

• Depress clutch/brake pedal and set parking brake

• PFace motion contro{ lever in neutral (N) position

• Move attachment clutch _o"DISENGAGED" position

, Move lhrottle control fo fast (,_) position

, Pull choke control out for a cold engine start attempt.

For awarm engine sled attempt the choke control may

not be needed,

Note: Before starting, read the warm and cold starling

procedures below

• Insed key tntoignitionandtum key clockwiseto "START"

position and release key as soon as engine slads. Do

not run starter continuously for more than fifteen sec-

onds per minute, l{ the engine does not start after

several attempts, push choke control In. wait a few

minutes and try again If engine still does not slart, pull

the choke control out and retry

WARM WEATHER STARTING (50" F and above)

• When engine starts, slowly push choke control in until

the engine begins to run smoothly. If the engine starts

to run roughly, putl the choke control out slighliy for a

few seconds and then continue lo push the control in

slowly,

• The attachments and ground drive san now be used, if

the engine does not accept the load, restart the engine

and ailow it to warm up for one minute using the choke

as described above

COLD WEATHER STARTING (50" F and below)

• When engine alerts, slowly push choke centre! in unlil

the engine begins to run smoothly Continue to push

the choke contro! In small steps allowing the engine to

accepL small changes in speed and load, until the

choke control is fuf[y in. If the engine starts to run

roughly, pull the choke conlrol out slightly for a few

seconds and then continue to push the conlrol in

slowly This may require an engine warm-up period

from several seconds to severatmtnutes, depending

on the temperature.

HYDROSTATIC TRANSMISSION WARM UP

• Before driving the unit in cold weather, the transmis-

sion should be warmed up as tottows:

• Be sure the tractor is on level ground.

spilled oil or fuelo Do not store, spil! or

use gasoline near an open flame,

• Place the motion control lever in neutral.

Release the parking brake and let the clutch/brake

slowly return to operating position.

• Allow one minute for Iransmlsston to warm up,

Thls can be done during the engine warm up

period,

• The attachmentscan be used dudng theenginewarm-

up period after the transmission has been warmed up

and may require lhe choke control be putled out slightly

NOTE: If at a high altitude (above 3000 feet) or tn cold

temperatures (below 32 F) the carburetor fuel mixture may

need to be adjusted for besl engine pedormance, See"TO

ADJUST CARBURETOR" In the Service and Adjustments

Section of this manual

PURGE TRANSMISSION

! _ CAUTION: Neverengageordisengage

| _ freewheel lever while the engine Is run-

To ensure proper operation end performance, it is recom-

mended that the transmission be purged before operating

tractor for the f!rst time This procedure will remove any

trapped air Inside the transmission which may have devel-

oped during shipping of your tractor.

IMPORTANT: SHOULD YOUR TRANSMISSION REQUIRE

REMOVAL FOR SERVICE OR REPLACEMENT, IT

SHOULD BE PURGED AFTER REINSTALLATION

BEFORE OPERATING THE TRACTOR.

• Place tractor safely on level surface with engine off and

parking brake set.

• Disengage transmission by plating freewheelconfrol

in freewheeling position (See "TO TRANSPORT" in

this seclion of manual).

• Sitting in the tracior seal. start engine After the engine

Isrunning, move throttle control to slow (_) position.

With motion control lever in neulra{ (N) posilion, s_owly

disengage clutch'brake pedal

Move motion conlrol lever to full forward posilion and

hold for five (5) seconds Move lever to full reverse

position and hold for five (5) seconds Repeat this

procedure three (3) times

NOTE; During thlsprocedure there witibe no movement of

drive wheels. The air is being removed from hydraulic drive

system.

• Move molten control]ever to neutral (N) position Shut-

off engine and set parking brake,

. Engage transmission by placing freewheel control in

driving position (See "TOTRANSPORT" inthis section

of manual)

• Silttngin the traclor seat, start engine. Afterthe engine

Is running, move throll!e control to half (1/2) speed

With motion control lever in neutral (N) position, slowly

disengage clutch/brake pedal,

• Slowly move motion control lever forward, after the

Iractor moves approximately five (5) feet, slowly move

motion control lever to reverse position. After the

tractor moves approximately five(5) feet return the

met!on control Iever to the neutral (N) position. Repeat

this procedure with the motion control lever three (3)

limes.

• Your tractor is now purged and now ready for normal

operation.

15

OPERATION

MOWING TIPS

• Tire chains cannel be used when the mower housing Is

attached Io tractor_

• Mower should be properly leveled for best mowing

performance° Sea"TO LEVEL MOWER HOUSING" in

the Service and Adjustments section of this manual..

• The left hand sfde of mower should be used for trim-

ming.

• Drive so that clipp}ngs are discharged onto the area

that has been cut_ Have the cut area to the right of the

traclor, This will resblt in a more even distribution of

clippings and more uniform culting.r

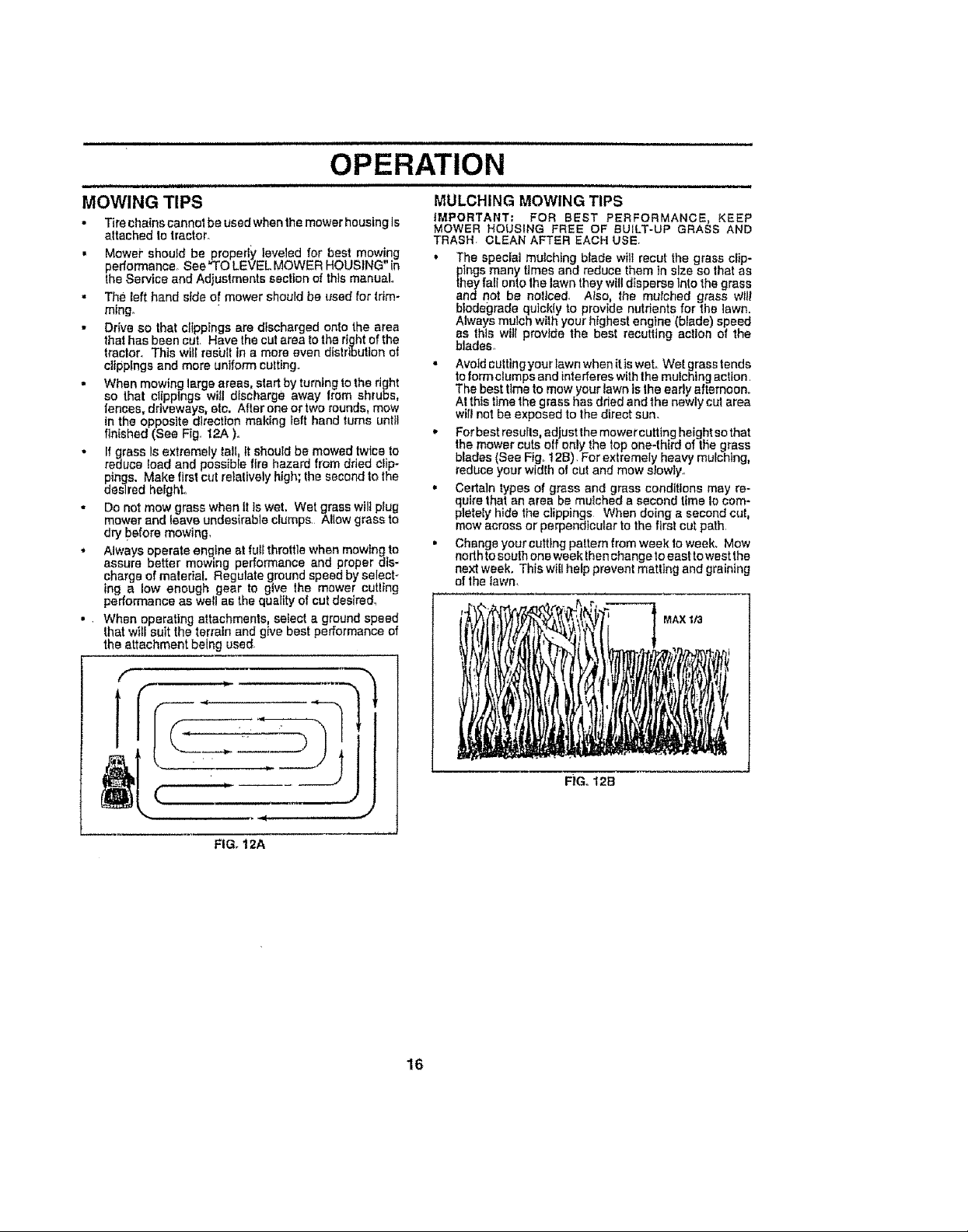

• When mowing large areas, start by turning to the right

so that clippings will discharge away Item shrubs,

fences, driveways, etc. Alter one or two rounds, mow

in the opposite direction making felt hand rums until

finished (Sea Fig. 12A ).

• If grass _sextremely tall It shou/d be mowed twice to

reduce load and possible fire hazard from dried clip-

pings. Make first cut relalivaly high; the second to the

desired hetght,.

• Do not mow grass when I! is wet. Wet grass wil; plug

mower and leave undesirable dumps. Allow grass to

dry before mowing,

• Always operate engine at furl throttle when mowing to

assure better mowing performance and proper dis-

charge of material. Regulate ground speed by select-

ing a low enough gear to give the mower cutting

performance as well as the quality of cut desired_

• . When operating attachments, select a ground speed

that will suit the terrain end give best performance of

the attachment being used.

MULCHING MOWING TIPS

IMPORTANT" FOR BEST PERFORMANCE, KEEP

MOWER HOUSING FREE OF BUILT-UP GRASS AND

TRASH. CLEAN AFTER EACH USE.

' The special mulching blade witt recut the grass clip-

pings many times and reduce them in size so that as

they falt onto Ihe lawn they wilt disperse Into the grass

and not be noticed. Also, the mutched grass WlJt

biodegrade quickly to provide nutrients for the lawn.

Always mulch with your highest engine (blade) speed

as this wit/ provide the best recutting action of the

blades.

• Avoid cutttngyour lawn when it iswet, Wet grass tends

to form clumps and interferes with the mulching action.

The best time to mow your lawn isthe early afternoon,

At this time the grass has dried and the newly cut area

wilt not be exposed to the direct sun.

,, Forbest resuIIs, adjustthe mower cutting height so that

the mower cuts off only the top one-third of the grass

blades (See Fig, 12B). For extremely heavy mulching,

reduce your width of cut and mow siowty.

,, Certain types of grass and grass conditions may re-

quire that an area be mulched a second time Io com-

pletely hide the clippings When doing a second cut,

mow across or perpendicular ta the first cut path.

, Change yourcuttlng pattern from weekto week, Mow

nodh to south one week then change to east to west the

next week, This will hefp prevent matting and graining

of the fawn,

MAX I/3

FIG, !2A

F|Go 12B

16

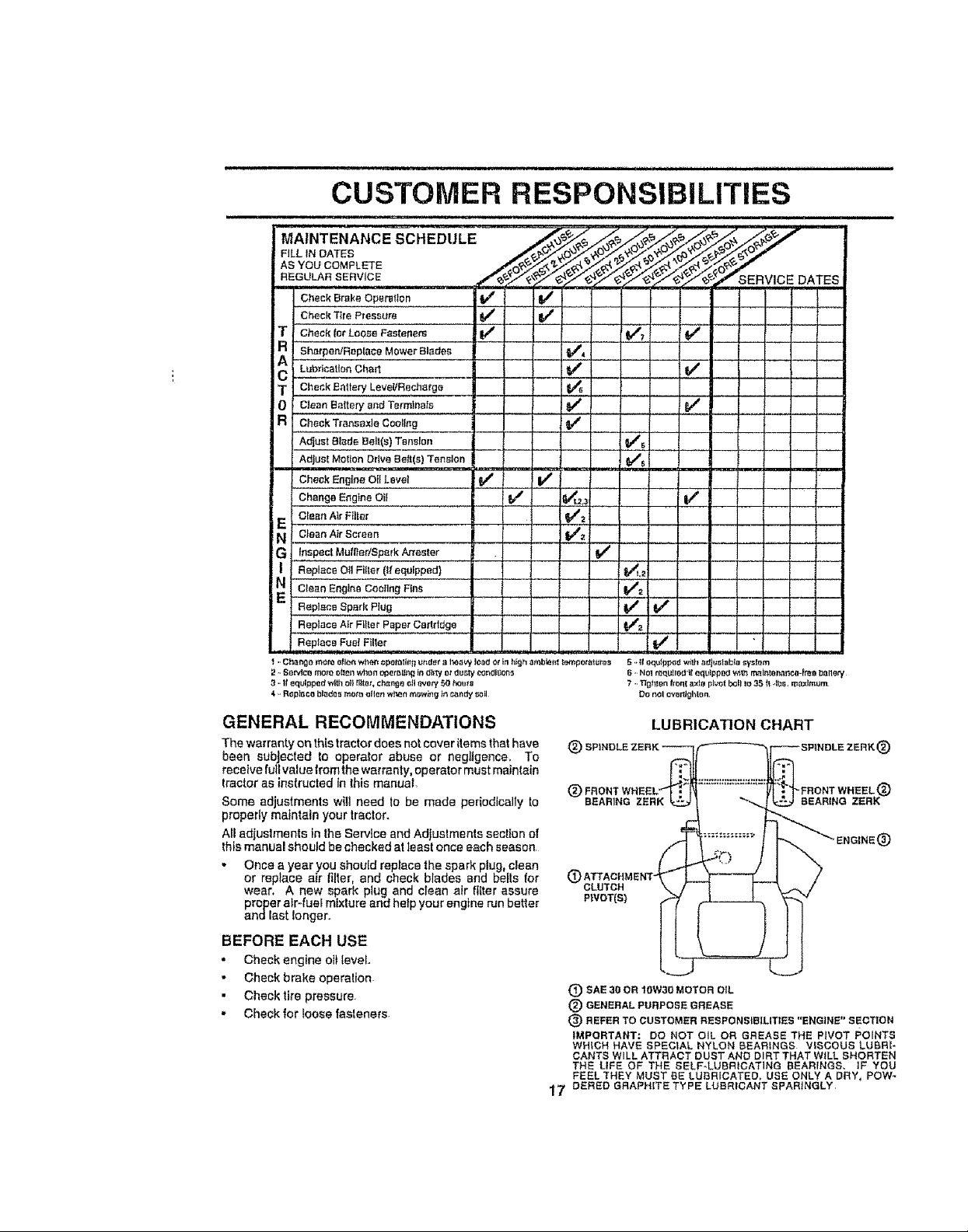

CUSTOMER RESPONSIBILITIES

AS YOU COMPLETE __:_._+_e5,.'4_;_-"0_ '_

FIEGU_ FI sERV!CE /_,_/_'TSERVIC E DATES

Check Brake Operation....... if if ..............

Check Tire PressUre _#4 If

T Check for Loose Fastene,'s If _I##_' _ I

s. ,;e.Rop,aoeMowo.R=oo V'. 1

T Check Baiter'/LeveYReeherge _

0 Clean Battery and Terminals .... _/ , , _/

R ,Check Transaxle CeoUng

Adjust Btade Belt(s) Tene_o_

Adjust Motion Drive Beit(e) Tenalon

Check Engine OIl Level

Change Engine Oil

E cIeen Air Filter

N CleenAtt Screen

G Inspect Muffter/Sperk Anester

Replace O11Filler (If equipped}

Clean Engine Cooling Fine

ReplaceSparkplug , , , ! _ I/

Replace Air FtlIe r Paper Cadddge ' ._'_

I Rep!ace Fue! F!!!er $/

I•Changemoteoflot_whell_potaIi_igunderaIteaw toader_rthighambSenlt_4q_pOt81_tt_ 5,,Ifequipped_el_jut_ioblasystem

It. Sewtcemo_eoflenwhoaopen,uteriInd_y otdusty_d_en_

e -IIequipped_h oi_II_ter,chtmgeo118,vo_50houf_

4",Rep_cobladesmore ellenwI_enm_w_g Inc_ndy_olI

=/

!v'J

T

v'

v'

6, NO1 _t_quI_d'_lequlpp_ wi_ r_'_I_tenanca4ret_l_ailery

?. TI{_f_tenfron__la pivot bell to 35,3 ¸,Ibm m_xlmurlt

De r_olo',*Bil_h[en,

GENERAL RECOMMENDATIONS

The warranty on this tractor does not cover items that have

been subjected to operator abuse or negligence. To

receive lull vafue from the warranty, ope rotor must maintain

tractor as instructed In Ibis manual.

Some adjustments wi!] need to be made periodically to

properly maintain your tractor.

All adjustments in the Service and Adjustments section of

this manual should be checked at least once each season

• Once a year you should replace the spark plug, clean

or replace air filter, and check blades and beits for

wear, A new spark pIug and clean air filter assure

proper atr-fue_ mixlure and hetp your engine run better

andlast longer..

BEFORE EACH USE

• Check engine oIt level.

• Check brake operalion

• Checktire pressure,

• Cheek for loose fasteners,

LUBRICATION CHART

1_) SPINDLE ZERK _"_ _SPINDLE ZERK (,_)

(_) FRONT WNEEL_'_! _]\ :::::::::;:::::::::::=:"".""_FRONT WHEEL (_

SEARINGZERK_ "-.-_z_ aEAR_NGZERK

"_ ENGINE@

1

(_ SAE 30 OR 10W3OMOTOR OIL

(_ GENERAL PURPOSE GREASE

(_) REFER TO CUSTOMER RESPONSIBILITIES "ENGINE" SECTION

IMPORTANT: DO NOT OIL OR GREASE THE PIVOT POINTS

WHICH HAVE SPECIAL NYLON BEARINGS VISCOUS LUBRf*

CANTS WILL ATTRACT DUST AND DIRT THAT WILL SHORTEN

THE LIFE OF THE SELF-LUBRICATING BEARINGS. tF YOU

FEEL THEY MUST BE LUBR[CATEO_ USE ONLY A DRY, POW_

17 DERED GRAPHITE TYPE LUBRICANT SPARINGLY

_ ,L HIIII I UI,LIII L U

CUSTOMER RESPONSIBILITIES

TRACTOR

A{ways observe safety rules when performing any malnte-

nBrlce,

BRAKE OPERATION

If tractor requires more than six (6)feet stopping distance

at high speed in highest gear, then brake must be adjusted.

(See 'q'O ADJUST BRAKE" in the Service and Adjust-

ments section of this manual).

TIRES

• Maintain proper air pressure in all f_res (See "PROD-

UCT SPECIFICATIONS" on page 3 of this manual).

• Keep tires free of gasoline, oil, or Insect control chemi-

cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage,

BLADE CARE

Forbest results mower blades must be kept sharp. Re-

place bent or damaged blades,,

BLADE REMOVAL (See Fig. 13)

• Raise mower to highest position to allow access to

blades.

. Remove hex bolt, {ockwasher and flat washer secudng

blade.

- Install new or rasharpened blade with trailing edge up

towards deck as shown-

. Reassemble hex boll, lock washer and flat washer in

exact order as shown.

, Tighten boil securely (30-35 Ft Lbs. torque).

IMPORTANT: BLADE BOLT IS GRADE 8HEATTREATED

NOTE: We do not recommend sharpening blade _but ifyou

do, be sure the blade is balanced

MANDREL

TRAILING EDGE

HEX BOLT

*A GRADE S HEAT TREATED BOLT CAN BE

IDENTIFIED BY SIX LtNES ON THE BOLT HEAD.

FIG. 13

TO SHARPEN BLADE (See Fig, 14)

Care should be taken to keep the blade balanced, An

unbalanced blade will cause excessive vibration and even-

tual damage to mower and engine.

. The blade can be sharpened with a file or on a grinding

wheel. Do not attempt to sharpen white on the mower.

• To check blade balance, you will need a 5tB" diameter

steel bolt, pin, or a cone balance r. (When using a cone

balancer, follow the instructions suppl{ed with bal-

enter),

,, S[fde blade on toan unthraaded portion of the stee] bolt

or pin and hold the bolt or pin parallel with the ground.

If blade Is balanced, it should remain in a horizontal

position, I( eilher end of the blade moves downward,

sharpen the heavy end until the blade isbalanced

NOTE: Do not use a nail for balancing blade. The lobes of

the center hole may appear to be centered, but are not.

CENTER HOLE

FIG. 14

BATTERY

Your tractor has a battery charging system which ts suffi-

cient for norma} use. However, perlod[c charging of the

battery with an automotive charger wilt extend its lifeo

• Keep battery and terminals c_ean,,

• Keep battery bolts tight,

• Keep small vent holes open

• Recharge at 6-10 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminal_ can cause

the battery to "leak" power.

• Remove terminal guard,

,, Disconnect BLACK battery cable first then RED

battery cable and remove battery from tractor:

• Rinse the battery with plain water and dry.

- Clean terminals and battery cable ends wlth wire

brush until bright,

• Coat terminals with grease or petroleum jelly.

• Reinstall battery (See "CONNECT BATTERY" in the

Assembly section of this manual).

I8

Loading...

Loading...