Craftsman 917258515 Owner’s Manual

L U 917.258515 OWNER'S MANUAL

oAssembly

Operation

Customer Responsibilities

Service and Adjustments

Repair Parts

®

For answers to your questions

about this product, Call:

1-800-659-5917

Sears Craftsman Help Line

5am - 5pro,Mon- Sat

CAUTION: Read and follow al! safety rules and instructions before operating this equipment=

FOR CONSUMER ASSISTANCE HOT LINE, CALL THIS TOLL FREE NUMBER: 1-800-659-5917

OOHT£HT$ OF H RE OK

,,a C

(1) Large Flat Washer

\

\

(2} Sheet

Meta

Screws

(i) Locknut 3/8o24

.t /_os

'Wheel

Video

Cassette

(1) _shou_derBolt 5/16oi8 (_j Hex Bu...... .-o,,_x 1

(!) Lock Washer 1/2

(___,_!_h_ _7/32

x I ,Gi! 6 x t2 Gauge

(2) Lock Washers #10

(2) Washers 3/16 x 3/4 x 16 Gauge

i% I (2) Wetd Nuts #10

(2) oc_ews #_0 x 5/8

@

(2) Nex Bolts t/4o20 x 3/4

(2) Hex Nuts 1/4o20

Boot

M_.nual Parts Bag

Parts bag contents not shown fun size

Wheel

Insert

Steednq When

(2) Keys

(2} Latch Hook

(2) Lock Washers 1/4

(2) Washers 9/32 x 5/8 x 16 Gauge

@

Slope Sheet

6

ASSE

Your new tractor has been assembled at the factory with exception of those parts Ueffunassembted for shipping purposes.

To ensure safe and proper operation of your tractor all parts and hardware you assemble must be tightened securely° Use

the correct too_s as necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(1) 5/18" wrench (1) 3/4" wrench

(2) 7/18" wrenches Tire pressure gauge

(1) !/2" wrench Utility knife

(1) 9/16" wrench (1) pMlips screwdriver

When right or left hand is mentioned in this manual, it

means when you are in the operating position (seated

behind the steering wheel).

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove alJ accessible loose parts and parts cartons

from carton (See page 8).

, Cut, from top to bottom, along lineson all four corners

of carton, and lay panels fiat°

• Check for any additional loose parts or cartons and

remove.

STEERING

WHEEL __

ADAPTER TABS

STEERING

(ASSEMBLY

POSITION)

STEERING

BUSHING

/

SHEET

METAL

SCREW

BEFORE ROLLING TRACTOR OFF SKiD

ATTACH STEERING WHEEL (See Fig. 1)

• Slide the steering bushing over the steering shaft.

• Raise steering shaft forward until screw holes in dash

line up with steering bushing. Install two (2) sheet

metal screws and tighten securely.

, Position steering boot over steering shaft.

• Place tabs of steering boot over tab slots in dash and

push down to secure.

, Slide steering wheel adapter onto upper steering shaft.

• Position front wheels of the tractor so they are pointing

straight forward.

, Position steering wheel so cross bars are horizontal

(left to right) and slide onto adapter.

• Assemble large flat washer and 3/8-24 Iocknut and

tighten securely.

o

Snap steering wheel insert into center of steering

wheel

®

Remove protective materials from tractor hood and

griH.

IMPORTANT:CHECK FOR AND REMOVE ANY STAPLES

IN SKID THAT MAY PUNCTURE TIRES WHERE TRACTOR

iS TO ROLL OFF SKID.

STEERING SHAFT

(SHIPPING POSIT!ON)

FiG. 1

TO ROLL "'_"""''

n_.,_vn OFF SKiD (See Opera-

tion section for location and function of con-

trois)

, Press liftlever plunger and raise attachment liftlever to

its highest position.

, Release parking brake by depressing clutch/brake

pedal.

• Place gearshift lever in neutral (N) position.

, Roll tractor backwards off skid.

, Remove banding holding discharge guard up against

tractor.

7

HOW TO SET UP YOUR TRACTOR

;E

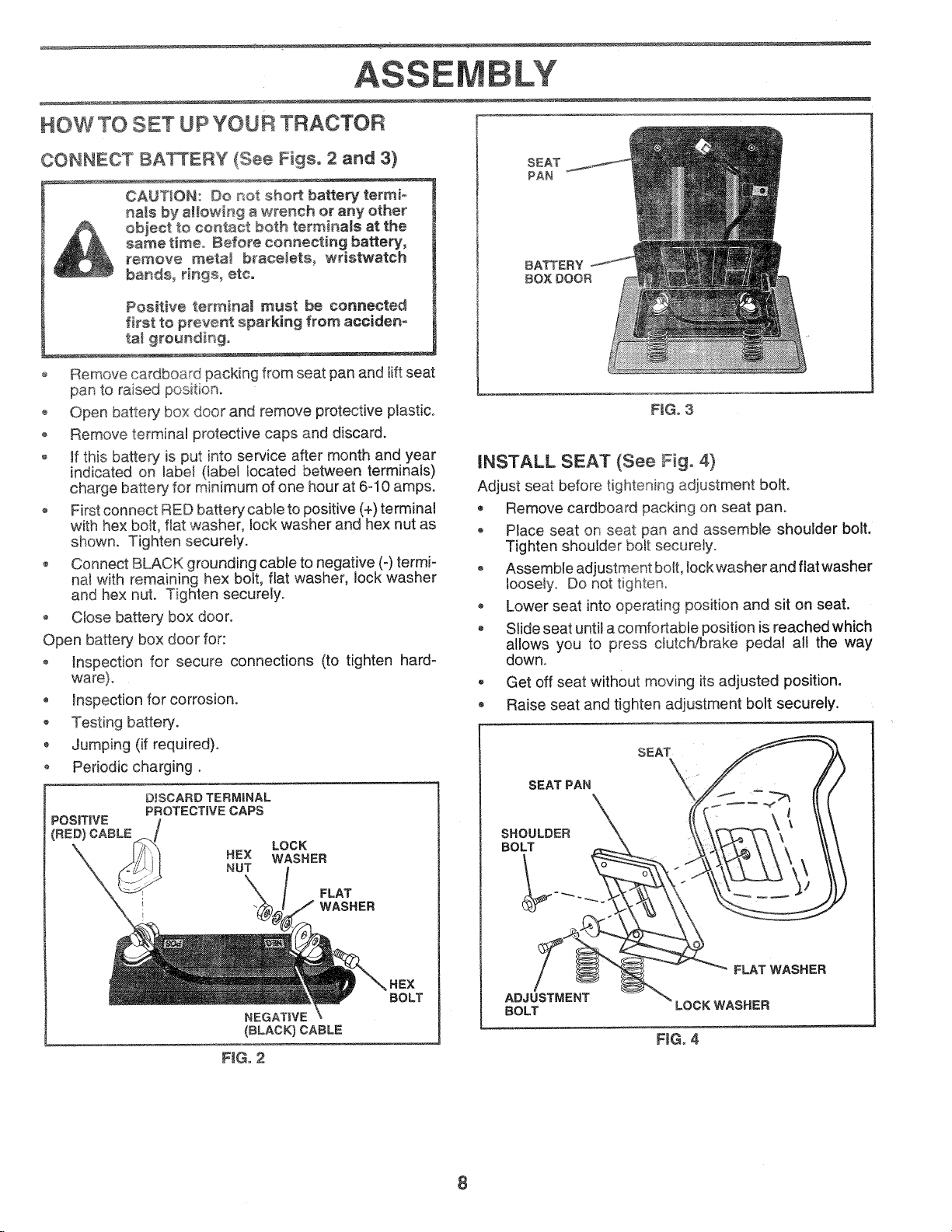

CONNECT BAKERY (See Figs. 2 and 3)

CAUTION: Do not short battery termio

hats by allowing a wrench or any other

obieet to contact both terminals at the

same time,, Before conneetin 9 battery,

remove meta_ bracelets, wristwatch

bands, rings, etco

Positive terminam must be connected

first to prevent sparking from acciden°

tat grounding°

o Remove cardboard packing from seat pan and tilt seat

pan to raised position.

o Open battery box door and remove protective ptastic.,

o Remove terminal protective caps and discard.

o if this battery is put into service after month and year

indicated on labe_ (label located between terminals)

charge battery for minimum of one hour at 6-10 amps.

First connect RED battery cable to positive (+) terminal

with hex bo_t,flat washer, lock washer and hex nut as

shown. Tighten securely.

o Connect BLACK grounding cable to negative (-) termi-

na! with remaining hex bolt, flat washer, lock washer

and hex nut. Tighten securely.

• Close battery box door.

Open battery box door for:

• Inspection for secure connections (to tighten hard-

ware).

, inspection for corrosion.

• Testing battery.

• Jumping (if required).

o Periodic charging.

D_SCARD TERMINAL

POSiTiVE

(RED) CABLE

PROTECTIVE CAPS

HEX WASHER

NUT

LOCK

FLAT

WASHER

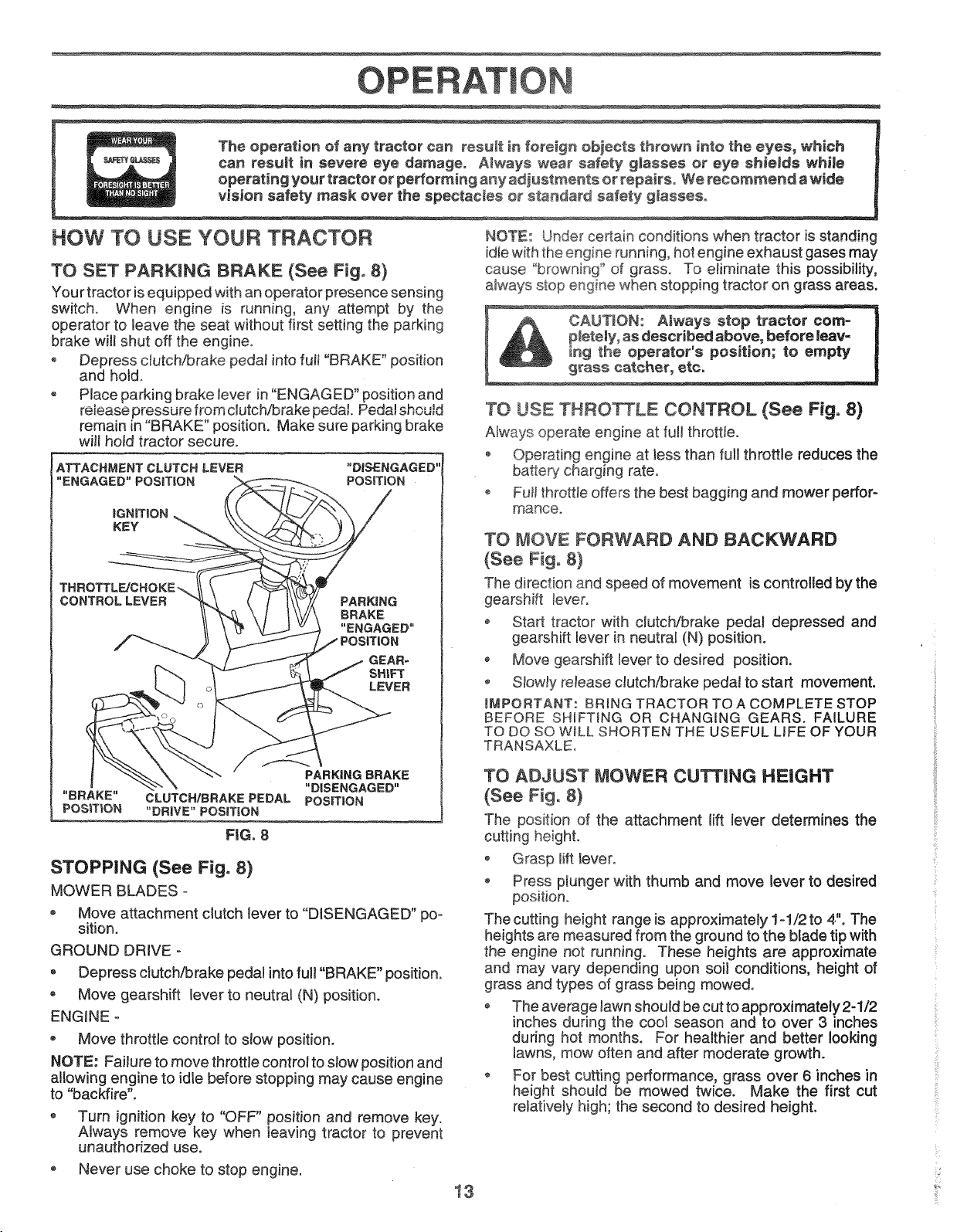

SEAT

PAN

BATTERY

BOX DOOR

FiG. 3

INSTALL SEAT (See Fig. 4)

Adjust seat before tightening adjustment bolt.

• Remove cardboard packing on seat pan.

® Place seat on seat pan and assemble shoulder bolt.

Tighten shoulder bait securely.

o Assemble adjustment bolt, lock washer and flat washer

loosely. Do not tighten.

Lower seat into operating position and sit on seat.

• Slide seat until a comfortable position is reached which

allows you to press clutch/brake pedal all the way

down.

, Get off seat without moving its adjusted position.

Raise seat and tighten adjustment bolt securely.

SEAT

SEAT PAN

SHOULDER

BOLT

NEGATIVE

(BLACK) CABLE

FiG° 2

BOLT

FLAT WASHER

ADJUSTMENT

BOLT

LOCK WASHER

FJGo4

8

LY

INSTALL t\,IULCHER PLATE

(See Figs, 5 and 6)

- Install two Jatch hooks to mulcher pBate using screw,

washer, lock washer, and weid nut as shown.

NOTE: Pre-assemble weld nut to latch hook by inserting

weld nut from the top with hook pointing down°

- Tighten hardware securelyo

® Raise and hold deflector shield in upright position.

• Place front of mulcher plate over front of mower deck

opening and slide into place, as shown.

- Hook front latch into hole on front of mower deck.

- Hook rear latch into hole on back of mower deck.

guard when a,aching muiche, plate

TO CONVERT TO BAGGING OR

DISCHARGING

Simply remove mulcher plate and store in a safe place.

Your mower is now ready for discharging or installation of

optional grass catcher accessory.

NOTE: it is not necessary to change blades. The mulcher

blades are designed for discharging and bagging also.

LATCH

NOOK

WASHER

MULCHER

PLATE

NOOK POINTS

WELD NUT

FROM THE TOP

HOOK

WELD

NUT

FiG. 5

DEFLECTOR

SHIELD

LATCH

HOOKS

FiG. 6

9

...... ASSE LY

CHECKTmREPRESSURE

The tires on your tractor were ov_rinflat_tbry for

shipping purposes. Correct tire pressure is impQrtar}t for

best cutting performance. .....

Reduce tire pressure to PSi shown in "PROE_UCT

SPECIFICATIONS" on page 3 of this manual.

CHECK DECK LEVELNESS

For best cutting results, mower housing should be properly

_eveted. See "TO LEVEL MOWER HOUSING" in the

Sewice and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

section of this manual. Verify that the belts are routed

correctly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see

that the brake is properly adjusted. See "TO ADJUST

BRAKE" in the Service and Adjustments section of this

manuai.

,/CHECKLIST

BEFORE YOU OPERATE AND ENJOY YOUR NEW

TRACTOR, WE WISH TOASSURE THAT YOU RECEIVE

THE BESTPERFORMANCEAND SATISFACTION FROM

THIS QUALITY PRODUCT.

PLEASE REVIEW THE FOLLOWING CHECKLIST:

¢" All assembly instructions have been completed.

7" No remaining toose parts in carton.

V" Battery' is properly prepared and charged. (Minimum

1 hour at 6 amps).

/ Seat is adjusted comfortably and tightened securely.

7 All tires are properly inflated. (For shipping purposes,

the tires were overinflated at the factory).

,/ Be sure mower deck is properly leveled side-to-side/

frontoto-rear for best cutting results. (Tires must be

properly inflated for leveling).

,/ Check mower and drive belts. Be sure they are routed

properly around pulleys and inside all belt keepers.

v" Check wiring. See that all connections are still secure

and wires are properly clamped.

WHILE LEARNING HOW TO USE YOUR TRACTOR, PAY

EXTRA ATTENT!ON TO THE FOLLOWING IMPORTANT

ITEMS:

,/ Engine oil is at proper level.

,/ Fuel tank is filled with fresh, clean, regular unleaded

gasoline.

,/ Become familiar with all controls - their location and

function. Operate them before you start the engine.

¢" Be sure brake system is in safe operating condition.

10

OPE 0

These symbots may appear on your tractor or in literature supplied with the product. Learn and understand their meaning.

BATTERY CAUTION OR REVERSE FORWARD FAST

WARNING

ENGINE ON ENGINE OFF OiL PRESSURE CLUTCH LIGHTS ON

FUEL CHOKE MOWER HEIGHT DIFFERENTIAL PARKING BRAKE UNLOCKED

LOCK LOCKED

OVER TEMP

L

SLOW

LIGHT

REVERSE IklI:::HTI3AI

MOWER LiFT

DANGER, KEEP HANDS AND FEET AWAY

ATTACHMENT

CLUTCH ENGAGED

HIGH

ATTACHMENT

CLUTCH DISENGAGED

11

LOW

PARKING BRAKE

IGNITION

HYDROSTATIC FREE WHEEL

(Hydro Models only)

}<NOW YOUR ....,.,......

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TRACTOR

Compare the illustrations with your tractor to familiarize yourself with the locations of various controls and adjustments. Save

this manuat for future reference.

LIGHT

SWITCH

LIFT LEVER

PLUNGER

ATTACHMENT

LIFT. LEVER

I\t

MOWER DECK

HEIGHT ADJUSTMENT

POSITIONS

GEARSHIFT

LEVER

Our tractors conform to the safety standards of the American National Standards institute.

ATTACHMENT CLUTCH LEVER: Used to engage the

mower blades, or other attachments mounted to your

tractor.

LIGHT SWITCH: Turns the headlights on and off.

THROTTLE/CHOKE CONTROL: Used for starting and

controlling engine speed.

CLUTCH/BRAKE PEDAL: Used for declutching and brak-

ing the tractor and starting the engine.

PARKING BRAKE: Locks clutch/brake pedal into the

brake position.

PARKING

BRAKE

FIG. 7

GEARSHIFT LEVER: Selects the speed and direction of

tractor.

ATTACHMENT LIFT LEVER: Used to raise, lower, and

adjust the mower deck or other attachments mounted to

your tractor.

LiFT LEVER PLUNGER: Used to release attachment lift

lever when changing its position. 4

iGNITiON SWITCH: Used for starting and stopping the

engine.

AMMETER: indicates battery charging (+) or discharging

(-),

!2

E

vision safety mask over the spectacles or standard safety, gmasseso

HOW TO USE YOUR TRACTOR

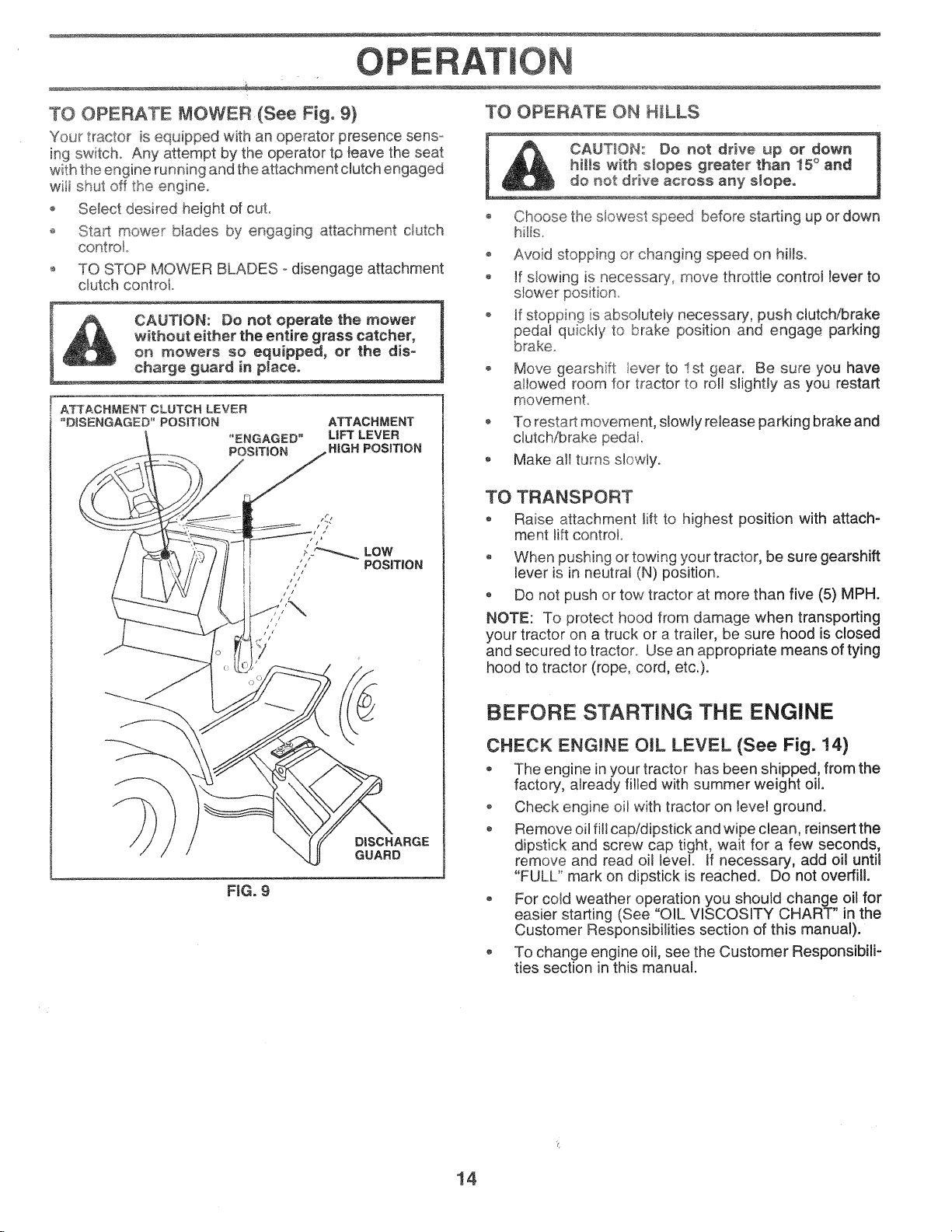

TO SET PARKING BRAKE (See Fig, 8}

Your tractor is equipped with an operator presence sensing

switch, When engine is running, any attempt by the

operator to leave the seat without first setting the parking

brake wil! shut off the engine.

• Depress clutch/brake pedal into fult "BRAKE" position

and hold.

• Place parking brake lever in "ENGAGED" position and

remain in "BRAKE" position. Make sure parking brake

wil_hold tractor secure.

ATTACHMENT CLUTCH LEVER

"ENGAGED" POSiTiON

_GNITtON

KEY

THROTTLE/CHOKE',

CONTROL LEVER

PARKING

BRAKE

"ENGAGED"

NOTE: Under certain conditions when tractor is standing

idle with the engine running, hot engine exhaust gases may

cause "browning '_of grass. To eliminate this possibility,

always stop engine when stopping tractor on grass areas.

pletely, as described above, before leav-

CAUTION: Always stop tractor corno

ing the operator's position; to empty

grass catcher, ere,

TO USE THRO_LE CONTROL (See Fig° 8)

Always operate engine at full throttle.

o Operating engine at tess than full throttle reduces the

battery charging rate.

o Fuji throttle offers the best bagging and mower perfor-

mance.

TO #OVE FORWARD AND BACKWARD

(See Fig, 8}

The direction and speed of movement is controlled by the

gearshift tever.

• Start tractor with clutch/brake pedal depressed and

gearshift lever in neutral (N) position.

, Move gearshift lever to desired position.

o Slowly release clutch/brake pedal to start movement.

_MPORTANT: BRING TRACTOR TO A COMPLETE STOP

BEFORE SHIFTING OR CHANGING GEARS. FAILURE

TO DO SO W_LL SHORTEN THE USEFUL LIFE OF YOUR

TRANSAXLEo

PARKING BRAKE

"BRAKE" CLUTCH/BRAKEPEDAL POSiTiON

POSiTiON "DRWE"POSIT!ON

FiG. 8

"DISENGAGED"

STOPPING (See Fig. 8)

MOWER BLADES -

o Move attachment clutch lever to "DISENGAGED" po-

sition.

GROUND DRIVE o

• Depress clutch/brake pedal into full "BRAKE" position.

• Move gearshift lever to neutral (N) position.

ENGINE =

• Move throttle control to slow position.

NOTE: Failure to move throttle control to slow position and

allowing engine to idle before stopping may cause engine

to "backfire".

• Turn ignition key to "OFF" position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

Never use choke to stop engine.

TO ADJUST MOWER CUTTING HEIGHT

(See Fig. 8)

The position of the attachment lift lever determines the

cutting height.

, Grasp lift lever°

• Press plunger with thumb and move lever to desired

position.

The cutting height range is approximately 1-1/2 to 4". The

heights are measured from the ground to the blade tip with

the engine not running. These heights are approximate

and may vary depending upon soil conditions, height of

grass and types of grass being mowed.

The average lawn should be cut to approximately 2-1/2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

, For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

is

TO OPERATE MOWER(See Fig, 9)

Your tractor is equipped with an operator presence sens-

ing switch. Any attempt by the operator tp leave the seat

with the engine running and the attachment clutch engaged

will shut off the engine.

o Select desired height of cut.

o Sta_t mower blades by engaging a_achment ciutch

control

TO STOP MOWER BLADES odisengage attachment

clutch control.

TO OPERATE ON H_LLS

Choose" _c_ --_

hills°

Avoid stopping or changing speed on hilts.

, If slowing is necessary, move throttle control lever to

_hes ow_,_ speed b_,ore starting up or down

F CAUTION: Do not operate the mower

without either the entire grass catcher,

_ _ on mowers so equipped, or the dis-

charge guard in pla.Ceo

ATTACHMENT CLUTCH LEVER

"DISENGAGED"' POSIT_ON

"ENGAGED"

POSiTiON

ATTACHMENT

LiFT LEVER

HiGH POSITION

rt

LOW

POSiTiON

////z

D_SCHARGE

GUARD

FiG. 9

ff stopping is absolutely necessary, push clutch/brake

pedal quickly to brake position and engage parking

brake

Move gearshift lever to 1st 9ear. Be sure you have

allowed room for tractor to roll s%hfly as you restart

movement.

To restart movement, slowly release parking brake and

clutch/brake pedat.

Make al! turns slowly.

TO TRANSPORT

Raise attachment lift to highest position with attach-

ment lift control

When pushing or towing your tractor, be sure gearshift

lever is in neutral (N) position.

o Do not push or tow tractor at more than five (5) MPH.

NOTE: To protect hood from damage when transporting

your tractor on a truck or a trailer, be sure hood is closed

and secured to tractor. Use an appropriate means of tying

hood to tractor (rope, cord, etc,).

BEFORE STARTING THE ENGINE

CHECK ENG!NE OiL LEVEL (See Fig. !4)

® The engine in your tractor has been shipped, from the

factory, already tilled with summer weight oil.

o Check engine oil with tractor on level ground.

® Remove oil fill cap/dipstick and wipe clean, reinsert the

dipstick and screw cap tight, wait for a few seconds,

remove and read oil level, if necessary, add oil until

"FULL" mark on dipstick is reached. Do not overfill.

, For cold weather operation you should change oil for

easier starting (See "OIL VISCOSITY CHART" in the

Customer Responsibilities section of this manual).

To change engine oil, see the Customer Responsibili-

ties section in this manual.

14

CUSTOMER

ESPONSIB

ES

TRACTOR

Always observe safety rules when performing any mainte°

nar_ceo

BRAKE OPERATION

if tractor requires more than six (6) feet stopping distance

at high speed in highest gear, then brake must be adjusted.

(See "TO ADJUST BRAKE" in the Service and Adjust-

ments section of this manual)o

TIRES

o Maintain proper air pressure in ali tires (See "PROD°

UCT SPEC!FICATIONS" on page 3 of this manual).

o Keep tires free of gasoline, oil, or insect controt cherni-

cats which can harm rubber.,

o Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE: To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts deater. Tire sealant also prevents tire dry rot and

corrosion.

BLADE CARE

For best results mower blades must be kept sharp. Re-

place bent or damaged blades.

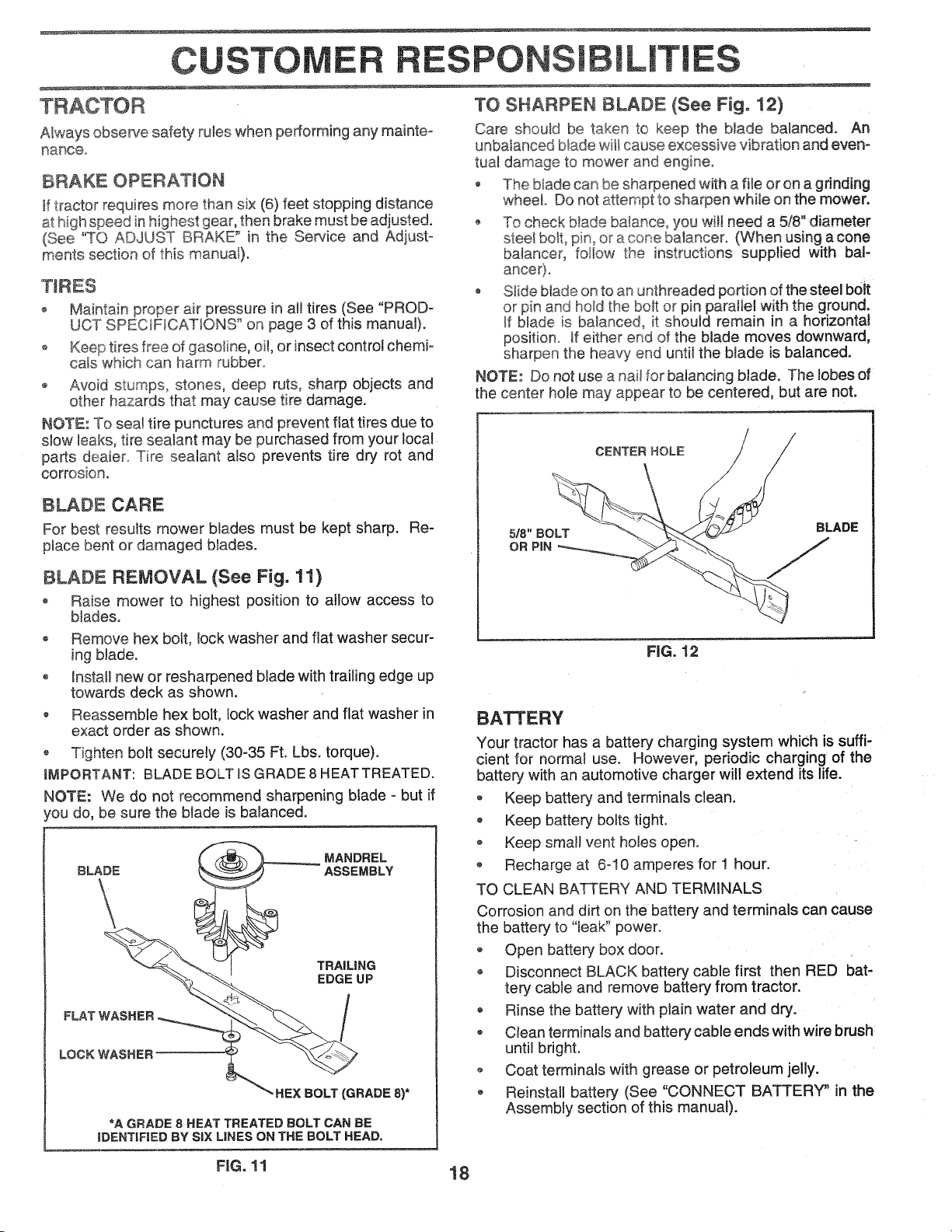

TO SHARPEN BLADE (See Fig. 12)

Care shouk_ be taken to keep the blade balanced. An

unbalanced blade will cause excessive vibration and even-

tuat damage to mower and engine°

The blade can be sharpened with afile or on a grinding

wheel Do not attempt to sharpen while on the mower.

-- To check blade balance, you wit! need a 5/8" diameter

stee_bolt, pin.°or a cone baiancer. (When using a cone

balancer, fotlow the instructions supplied with baF

o Stide blade on to an unthreaded portion of the steel b0Jt

or pin and ho_dthe bolt or pin paraJtel with the ground.

If blade is balanced, it should remain in a horizontal

position. If either end of the blade moves downward,

sharpen the heavy end until the btade is balanced.

NOTE: Donot use a nail for balancing blade. The lobes of

the center hole may appear to be centered, but are not.

CENTER HOLE

BLADE REMOVAL (See Fig. 11)

o Raise mower to highest position to allow access to

blades.

Remove hex bolt, lock washer and flat washer secur-

ing blade.

Install new or resharpened blade with trailing edge up

towards deck as shown.

Reassemble hex bolt, lock washer and flat washer in

exact order as shown.

-_ Tighten bolt securely (30-35 Ft. Lbs. torque).

iMPORTANT: BLADE BOLT IS GRADE 8 HEATTREATED.

NOTE: We do not recommend sharpening blade - but if

4ou do, be sure the blade is balanced.

TRAiLiNG

EDGE UP

LOCK WASHER

FLAT WASHER __

_" HEX BOLT (GRADE 8)*

*A GRADE 8 HEAT TREATED BOLT CAN BE

IDENTIFIED BY SIX LINES ON THE BOLT HEAD.

FIG. 12

BATTERY

Your tractor has a battery charging system which is suffi-

cient for normal use. However, periodic charging of the

batter,! with an automotive charger will extend its life.

* Keep battery and terminals clean.

Keep battery bolts tight.

Keep small vent holes open.

o Recharge at 6-10 amperes for 1 hour.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to "leak" power.

Open battery box door.

Disconnect BLACK battery cable first then RED bat-

tery cable and remove battery from tractor.

Rinse the battery with plain water and dry.

, Ciean terminals and battery cable ends with wire brush

until bright.

o Coat terminals with grease or petroleum jelly.

Reinstall battery (See "CONNECT BATTERY" in the

Assembly section of this manual).

FiG. 11 18

VoBELTS

Check V-beJts for deterioration and wear after 100 hours of

operation and replace if necessary. The belts are not

adjustable. Replace belts if they begin to s_ipfrom wear°

TRANSAXLE OOOUNG

Keep transaxte free from build-up of dirt and chaff which

can restrict cooling.

ENGINE

ES ES

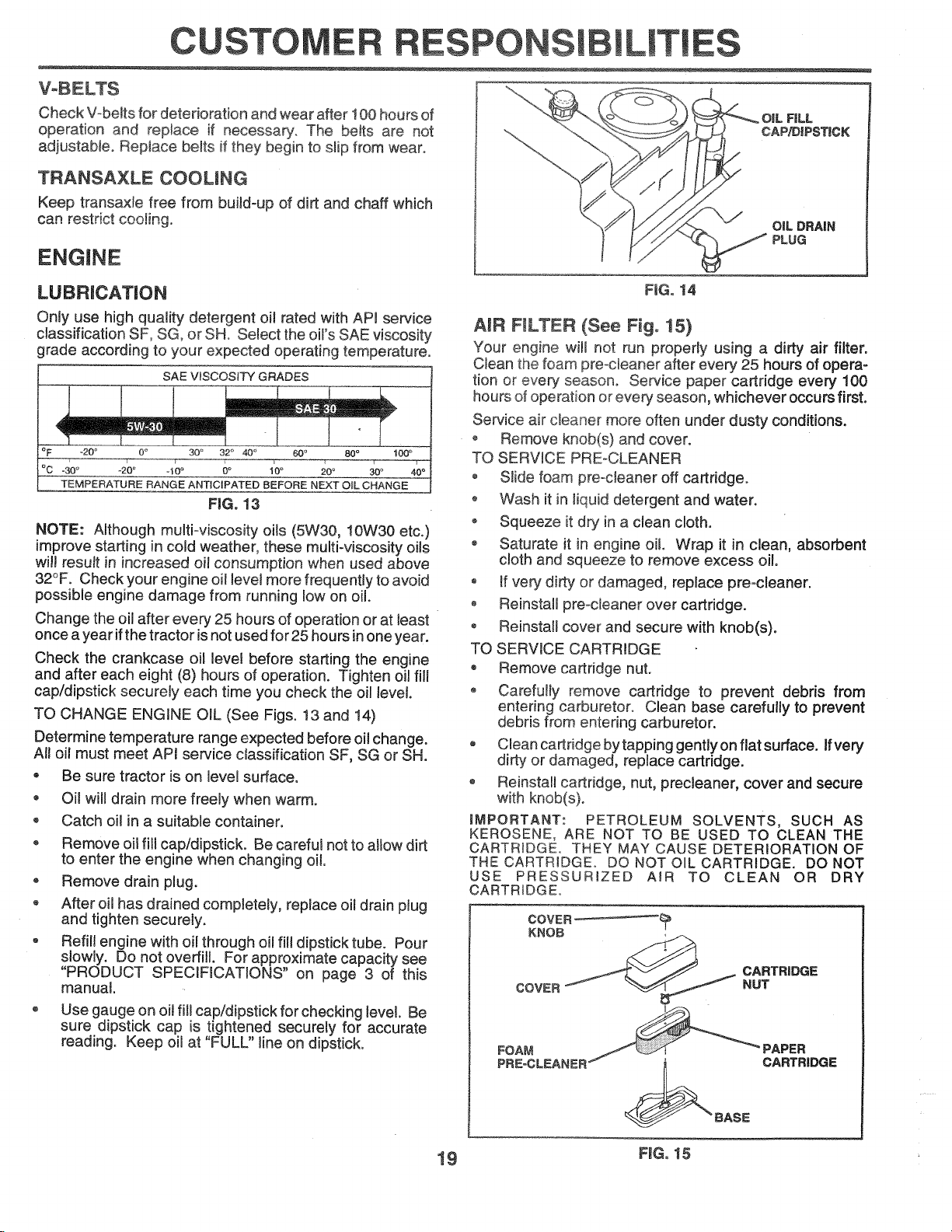

OiL F|LL

CAP/DIPSTICK

OiL DRAIN

PLUG

LUBRICATION

Only use high quality detergent oil rated with API service

classification SF, SG, or SHe Select the oil's SAE viscosity

grade according to your expected operating temperature.

SAE VISCOSITY GRADES

T

oF _20o 0,, 30° 32 ° 40 ° 60_ 80 °

_C -30 ° -20 ° d0 ° 0° iO ° ;0 o

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OiL CHANGE

FiG, 13

NOTE: Although multi-viscosity oils (5W30, 10W30 etc.)

improve starting in cold weather, these multi-viscosity oils

will result in increased oil consumption when used above

32°F. Check your engine oit level more frequently to avoid

possible engine damage from running low on oil.

Change the oil after every 25 hours of operation or at least

once a year ifthe tractor is not used for 25 hours in one year.

Check the crankcase oil level before starting the engine

and after each eight (8) hours of operation. Tighten oil fill

cap/dipstick securely each time you check the oil level

TO CHANGE ENGINE OIL (See Figs. 13 and 14)

Determine temperature range expected before oil change.

All off must meet APJ service classification SF, e_'v"or SH.

, Be sure tractor is on level surface.

o

Oil will drain more freely when warm.

®

Catch oil in a suitable container.

o

Remove oil fill cap/dipstick. Be careful not to aitow dirt

to enter the engine when changing oil.

o

Remove drain plug.

o

After oil has drained completely, replace oil drain plug

and tighten securely.

Refil! engine with oil through oil fil! dipstick tube. Pour

slowly. Do not overfill. For approximate capacity see

"PRODUCT SPECiFICATiONS" on page 3 of this

manual.

Use gauge on oil fill cap/dipstick for checking level. Be

sure dipstick cap is tightened securely for accurate

reading. Keep oil at "FULL" line on dipstick.

FiG. 14

AIR FmLTER (See Fig. 15)

Your engine wi!l not run properly using a dirty air filter.

Clean the foam preocleaner after every 25 hours of opera-

tion or every season. Service paper cartridge every 100

hours of operation or every season, whichever occurs first.

Service air cleaner more often under dusty conditions.

, Remove knob(s) and cover.

TO SERVICE PRE-CLEANER

Slide foam preocteaner off cartridge.

, Wash it in liquid detergent and water.

Squeeze it dry in a clean cloth.

o Saturate it in engine oil Wrap it in clean, absorbent

cloth and squeeze to remove excess oi!.

o tf very dirty or damaged, replace pre=cleaner.

o Reinstall pre-cieaner over cartridge.

o Reinstall cover and secure with knob(s).

TO SERVICE CARTRIDGE

* Remove cartridge nut.

o Carefully remove cartridge to prevent debris from

entering carburetor. Clean base carefully to prevent

debris from entering carburetor.

Clean cartridge bytapping gently on flat surface, ff very

dirty or damaged, replace cartridge.

Reinstall cartridge, nut, precleaner, cover and secure

with knob(s).

iMPORTANT: PETROLEUM SOLVENTS, SUCH AS

KEROSENE, ARE NOT TO BE USED TO CLEAN THE

CARTRIDGE. THEY MAY CAUSE DETERiORATiON OF

THECARTRtDGEo DO NOT OIL CARTRtDGE. DO NOT

USE PRESSURIZED AfR TO CLEAN OR DRY

CARTRIDGEo

COVER .....

KNOB

CARTRIDGE

COVER

FOAM

PREoCLEAN_ ' CARTRIDGE

NUT

_BABE

19 FiG. 15

CUSTOME PO IL!T!ES

CLEAN A_R SCREEN (See Fig, 16}

Air screen must be kept free of dirt and chaff to prevent

engine damage from overheating. Clean with a wire brush

or compressed air to remove dirt and stubborn dried gum

fibers°

ENGINE COOMNG FINS (See Fig. 16)

Remove any dust, dirt. or oi! from engine coo!ing fins to

prevent engine damage from overheating.

o Remove screws from blower housing and lift housing

and dipstick tube assembly off engine.

,_ Cover oi! fill opening to prevent entry of dirL

o Use compressed ar or stiff bristie brush to thoroughly

clean engine cooling fins.

o To reassemble, reverse above procedure.

BLOWER HOUStNG

A_R SCREEN

OiL FiLL

TUBE

ASSEMBLY

ENGINE COOMNG RNS

SCREWS

SPARK

PLUG

IN-LiNE FUEL RLTER (See Fig, 17)

The fuel filter should be replaced once each season, fffuel

filter becomes clogged, obstructing fuel flow to carburetor,

replacement is required°

o With engine cool, remove filter and plug fuel line

sections.

o Ptace new fuel filter in position in fuel line with arrow

o Be sure there are no fuet line leaks and clamps are

properly positioned°

Immediately wipe up any spilled gasoline.

FIG, 17

CLEANING

Clean engine, battery, seat, finish, etc. of all foreign

matter.

Keep finished sudaces and wheels free of al! gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean your

tractor unless the electrical system, muffler, air filter and

carburetor are covered to keep water out. Waterin engine

can result in a shortened engine life,

FiG. !6

MUFFLER

Inspect and replace corroded muffler and spark arrester (if

equipped) as it could create a fire hazard and/or damage.

SPARK PLUGS

Replace spark plugs at the beginning of each mowing

season or after every 100 hours of operation, whichever

occurs first. Spark plug type and gap setting are shown in

"PRODUCT SPECIFICATIONS" on page 3 of this manual.

20

EFIViCE A ADJ ENTS

CAUTION: gEFORE PERFORMING ANY SERVICE OR ADJUSTMENTS:

® Depress clutc_rbrake pedaJ fully and set parking brake,

* Place gearshift _ever in neutra| (N) position,

* PWaceattachment clutch in "DISENGAGED" position,

* Turn ignition key "OFF" and remove key=

, Make sure the blades and aU moving parts have completely stopped,

-= Disconnect spark plug wire from spark piug and piace wire where it cannot come _ncontact with

plug°

TO REMOVE MOWER (See Fig. 18)

Mower will be easierto remove from the right side of tractor.

* Place attachment clutch in "DISENGAGED" position.

* Move attachment lift lever forward to lower mower to its

lowest position,

* Roll belt off engine pulley.

, Disconnect clutch rod from clutch lever by removing

retainer spring.

, Disconnect anti-sway bar from chassis bracket by

removing retainer spring,

* Disconnect suspension arms from rear deck brackets

by removing retainer springs,

® Disconnect front links from deck by removing retainer

springs.

, Raise lift lever to raise suspension arms. Slide mower

out from under tractor.

iMPORTANT: iFAN ATTACHMENT OTHER THAN THE

MOWER iS TO BE MOUNTED TO THE TRACTOR,

REMOVE THE FRONT LINKS.

TO INSTALL MOWER (See Fig. 18)

- Raise attachment lift lever to its highest position.

• Slide mower undertractorwith discharge guardto right

side of tractor.

• Lower lift lever to its lowest position,

, Install mower in reverse order of removal instructions.

CLUTCH LEVER

CLUTCH

SUSPENSION ENGINE

ARMS PULLEY

SPRINGS

/

RETAINER

SPRING

ANTIoSWAYBAR

RETAINER

SPRINGS

(BOTH SIDES)

FIG. 18

SLOES)!

21

SERVICE AN A

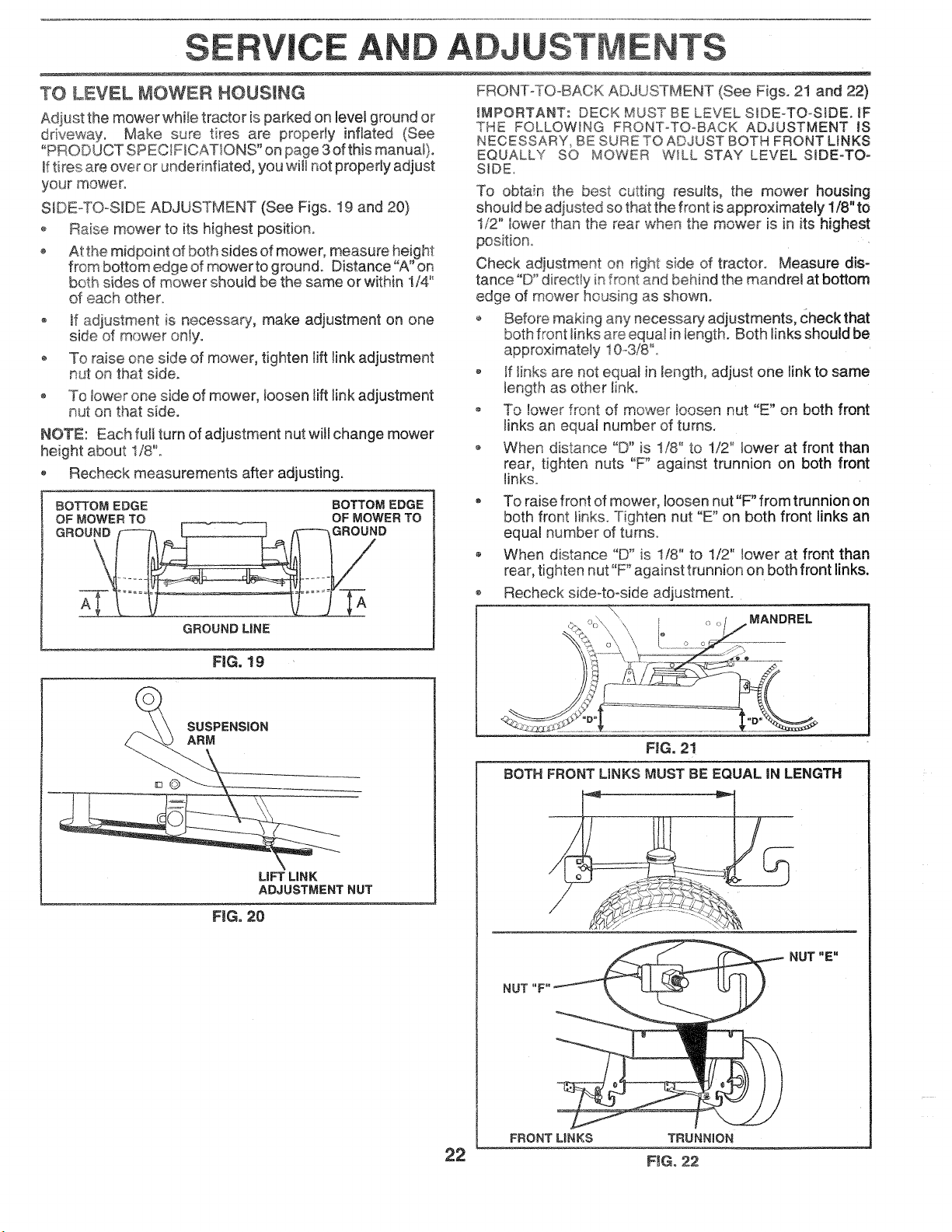

TO LEVEL MOWER HOUSING

Adiust the mower while tractor is parked on level ground or

Make sure tires are property inflated (See

"PRODUCT SPECIFICATIONS" on page 3 ofthis manuat).

tftires are over or underinfiated, you will not properly adjust

your mower.

SDEoTO-SIDE ADJUSTMENT (See Figs° I9 and 20)

o Raise mower to its highest positiono

o At the midpoint of both sides of mower, measure height

from bottom edge of mower to ground. Distance "A" on

both sides of mower should be the same or within 1/4"

of each other.

o Jfadjustment is necessary', make adjustment on one

side of mower onty.

To raise one side of mower, tighten lift link adjustment

nut on that side.

To lower one side of mower, loosen lift link adjustment

_u_ Ot_that side.

NOTE: Each fult turn of adjustment nut will change mower

height about 1/8"o

Recheck measurements after adjusting.

BOTTOM EDGE BOTTOM EDGE

OF MOWER TO OF MOWER TO

GROUND f_h [ ]/T---_,GROUND

GROUND MNE

FRONT-TO-BACK ADJUSTMENT (See Figs. 21 and 22)

_MPORTANT: DECK MUST BE LEVEL SIDEoTO-SIDE. 1F

THE FOLLOWING FRONToTO_BACK ADJUSTMENT IS

NECESSARY_ BE SURE TO ADJUST BOTH FRONT LINKS

EQUALLY SO MOWER WILL STAY LEVEL SIDE-TO-

SIDE.

To obtain the best cutting results, the mower housing

should be adjusted so that the front is approximately 1/8" to

1/2" lower than the rear when the mower is in its ,_<"_'""*,,u,,_o,

Check adjustment on right side of tractor Measure dis-

tance "D" directly in front and behind the mandrel at bottom

edge of mower ho_Jsing as shown°

o Before making any necessary adjustments, Check that

both front links are equaI in length. Both links should be

approximately 10o3/8"o

o If Iinks are not equal in tength, adjust one tink to same

length as other link.

o _r_,,,, ,_owerfront _,f_,,,,_w_,m_,__ !oosen nut "_"_on both front.

links an equat number of turns.

o When distance "D" is !/8" to 1/2" lower at front than

rear, tighten nuts "F" against trunnion on both front

links.

To raise front of mower, loosen nut"F" from trunnion on

both front links. Tighten nut "E" on both front links an

equal number of turns.

When distance "D" is 1/8" to t/2" lower at front than

rear, tighten nut "F" against trunnion on both front links.

Recheck side4o-side adjustment.

\\

I MANDREL

[]©

FiG. 19

SUSPENSION

ARM

FIG. 20

FIG. 21

BOTH FRONT LINKS MUST BE EQUAL iN LENGTH

LiFT LiNK

ADJUSTMENT NUT

NUT "E"

NUT "F"

FRONT UNKS TRUNNION

22 F_Go22

Loading...

Loading...